Online electret receiving device of non-woven fabric

A technology of non-woven fabrics and receiving devices, applied in textiles and papermaking, complete sets of equipment for producing artificial threads, filament/thread forming, etc., can solve the problem of large volume, high manpower and material resources, and occupying a large amount of equipment and production sites, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

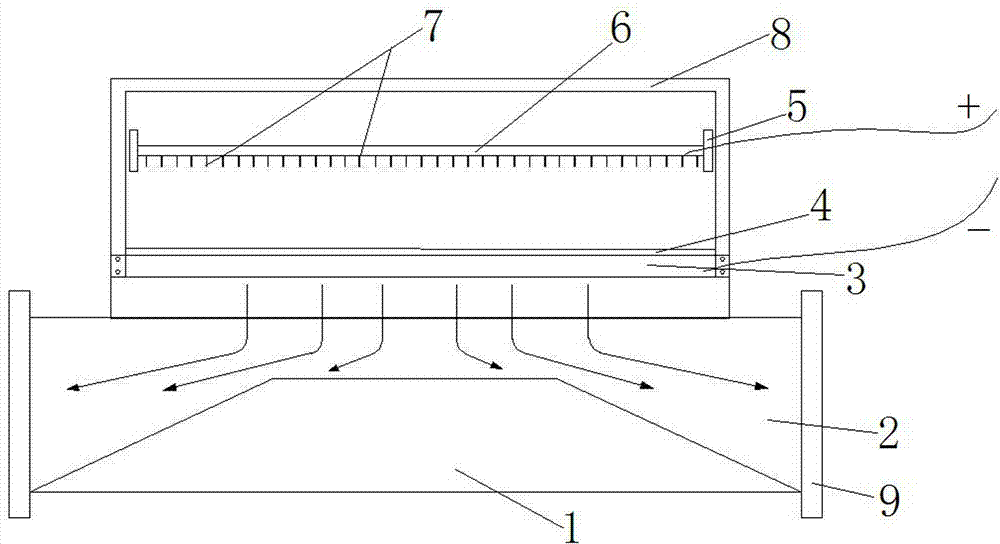

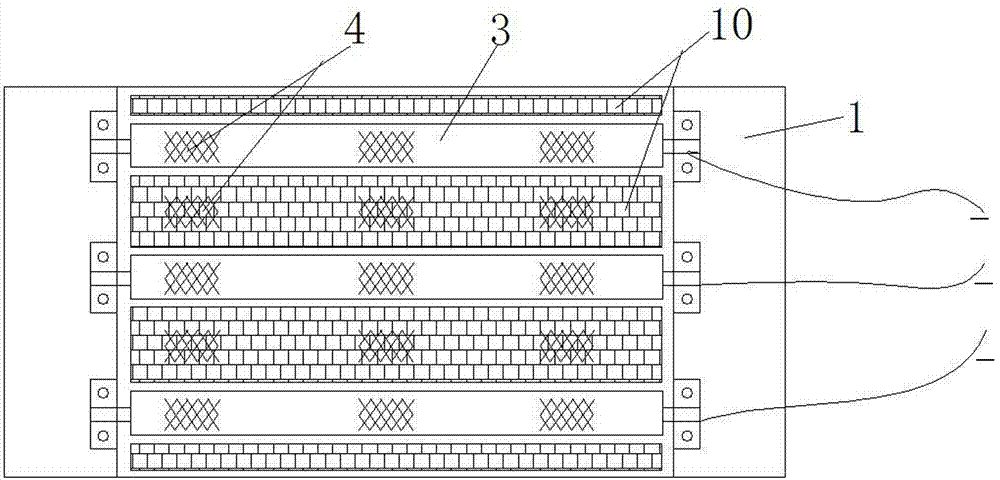

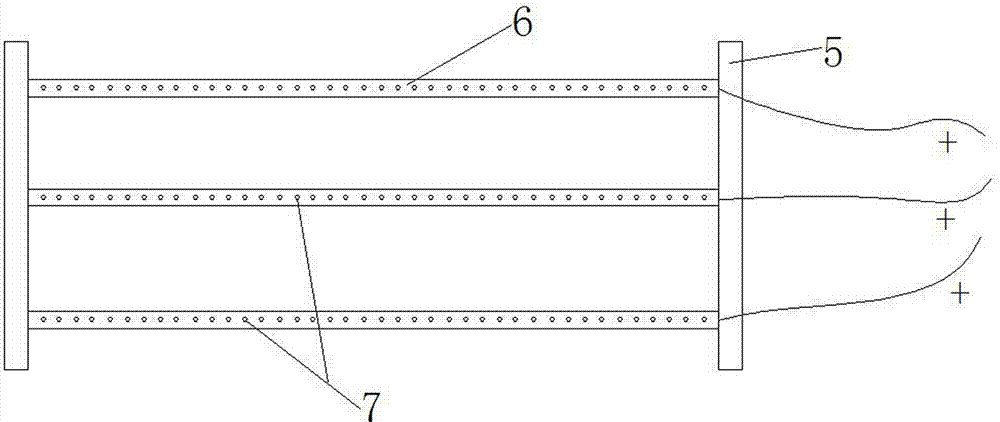

[0015] Refer to attached Figure 1~3 , an on-line electret receiving device for nonwoven fabrics includes an insulating box body 1, an insulating cover plate 8, several static grounding rollers 3, an insulating air intake network plate 10, a nylon mesh curtain 4, an electret plate mounting bracket 5 and several pieces Electret plate6. An air channel 2 is arranged in the insulating box 1, and connecting flanges 9 are arranged on both sides of the insulating box 1 for connecting the induced draft fan. A number of electrostatic grounding rollers 3 are installed on the upper part of the insulating box 1. The electrostatic grounding rollers 3 are connected to the negative pole of the matching high-voltage electrostatic generator. Between the electrostatic grounding rollers 3, an insulating air intake grid plate 10 is laid. A nylon mesh curtain 4 is provided on the upper part of the roller 3 and the insulating air intake grid plate 10 for receiving nonwoven fabric.

[0016] An ele...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com