cleaning robot

A technology for cleaning robots and bodies, applied to machine parts, manual sweeping machines, vacuum cleaners, etc., can solve problems such as failure to successfully remove garbage particles, obstruction of garbage, and impact on cleaning efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

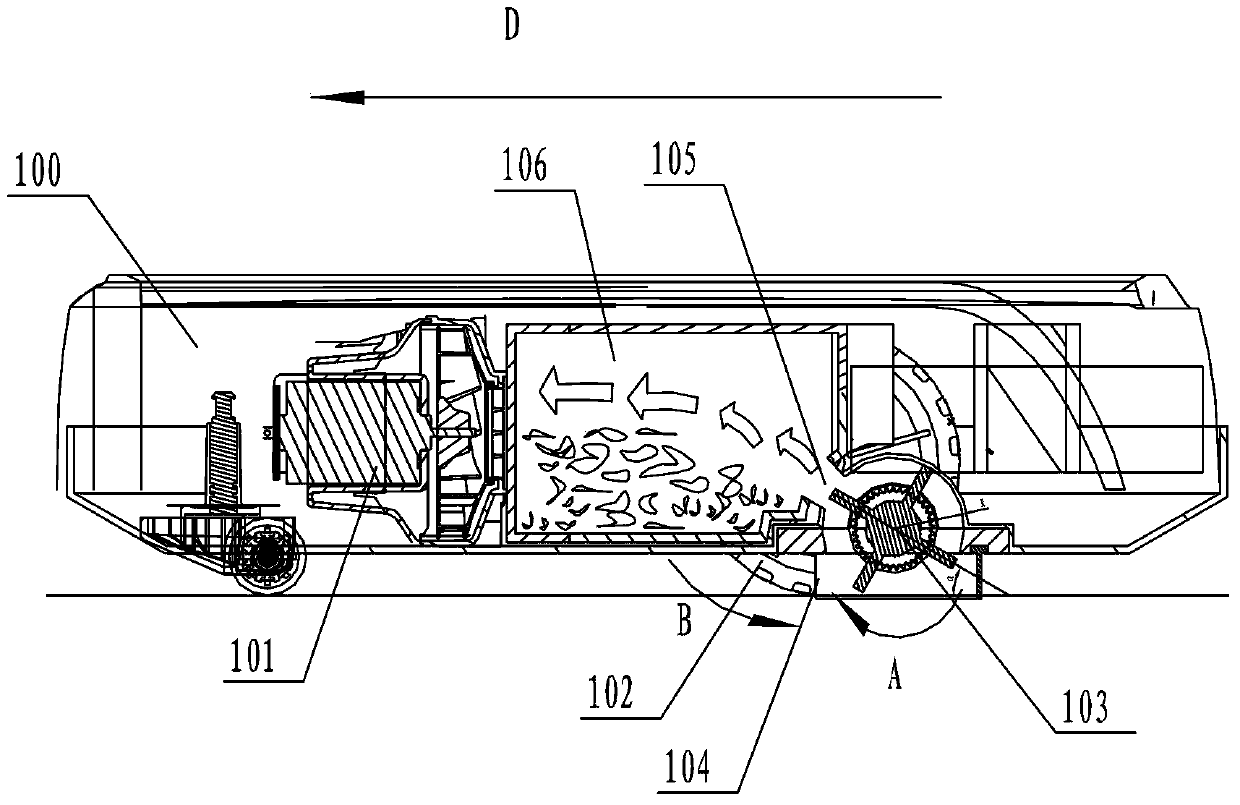

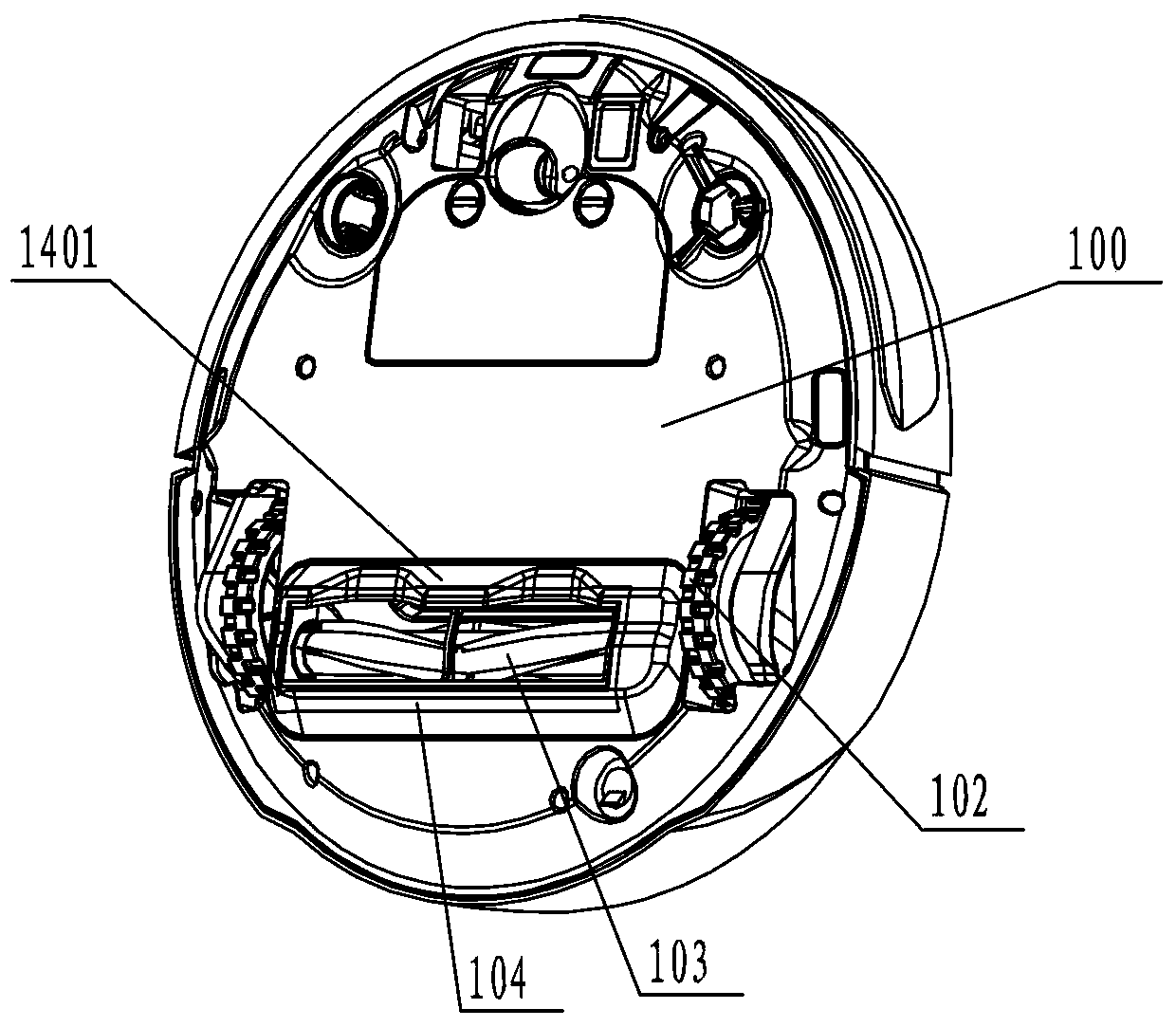

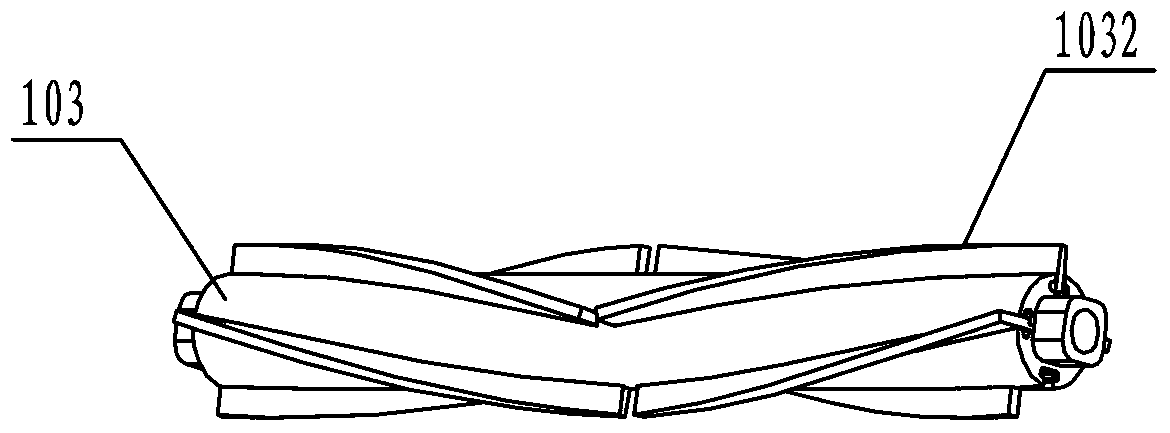

[0020] figure 1 It is a schematic cross-sectional view of the overall structure of the cleaning robot of the present invention; figure 2 It is a schematic diagram of the bottom structure of the cleaning robot of the present invention. Such as figure 1 and combine figure 2 As shown, the present invention provides a cleaning robot, including a body 100 and a dust collection chamber 106, a dust suction motor 101 and a dust collection channel 105 are arranged in the body, and a drive wheel 102, a rolling brush 103 and a suction wheel are arranged at the bottom of the body. Dust port 104 , the roller brush 103 is arranged at the dust suction port 104 . The dust is cleaned by the roller brush 103 , and is collected into the dust collection chamber 106 by the dust suction port 104 through the dust collection channel 105 under the suction effect of the dust collection motor 101 . Assuming that the moving direction of the cleaning robot during the cleaning operation is forward, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com