Patents

Literature

153results about How to "Improve automation production efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

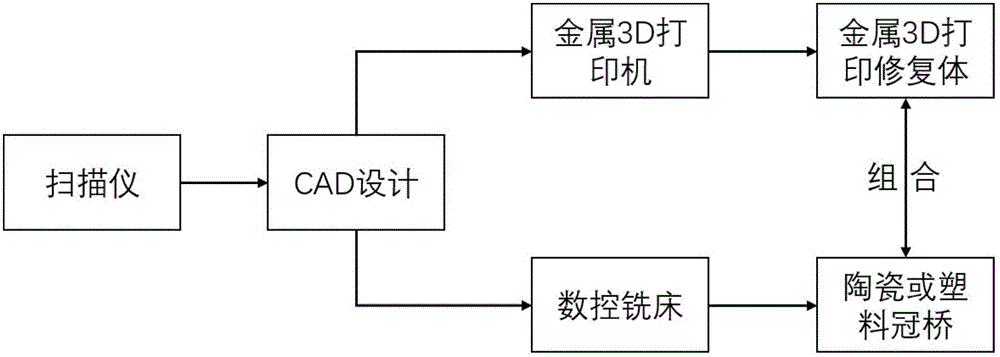

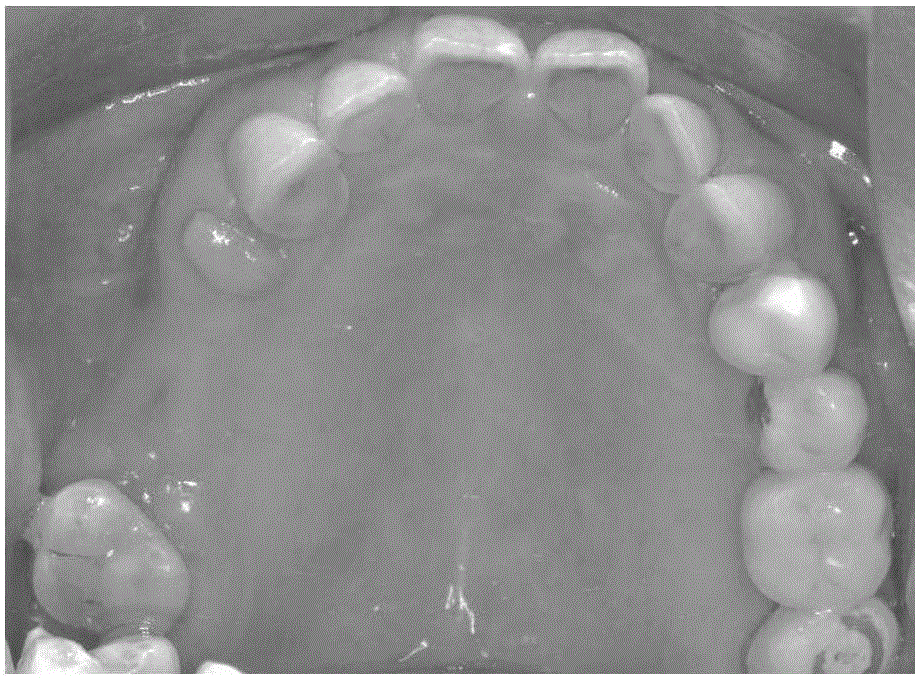

Dental prosthesis CAD/CAM/SLM-3D printing compound method

ActiveCN106264762AImprove product qualityImprove stabilityArtificial teeth3D printingNumerical controlMeasuring instrument

The invention discloses a novel dental prosthesis CAD / CAM / SLM-3D printing compound method. The method comprises the steps that a CAD / CAM / SLM-3D printing compound system which is composed of an optical scanning measuring instrument or a contact type scanning measuring instrument, computer-aided design software of a dental prosthesis, a miniaturized metal 3D printer and a numerical control milling machine is adopted to prepare a metal prosthesis, an existing dental CAD / CAM system is combined with a metal 3D printing technology, respective numerical control machining methods are organically combined, and the effect is extremely achieved. The automated production efficiency of the dental metal prosthesis, especially the complex dental metal prosthesis is greatly improved, traditional cumbersome processes for manually making a dental prosthesis are omitted, the making quality and stability of the prosthesis are improved, the purpose of rapid, accurate and personalized making is achieved, and the urgent needs of patients missing teeth are well met.

Owner:维视医疗信息科技山东有限公司

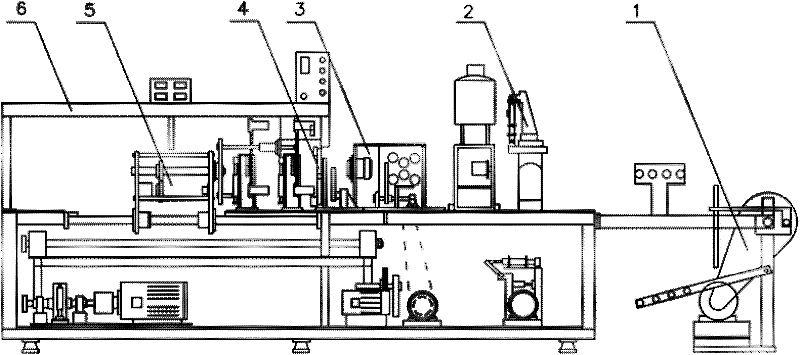

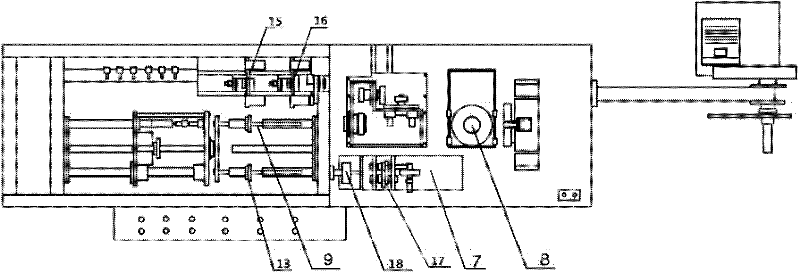

Double-rod shrinking machine and method for shrinking casing by using same

InactiveCN102550638AHigh degree of automationImprove automation production efficiencySausage casingsAutomationPulp and paper industry

The invention relates to a double-rod shrinking machine and a method for shrinking a casing by using the same. The double-rod shrinking machine comprises a frame and a casing conveying transmission mechanism, a shirking mechanism, a cutting knife mechanism, a rotating disk mechanism and a casing withdrawing mechanism, which are installed on the frame, wherein, the casing conveying transmission mechanism is used for introducing a casing to be shrunk into the shirking mechanism, the rotating disk mechanism is used for introducing a shrunk casing out from the shirking mechanism and conveying the casing cut by the cutting knife mechanism into the casing withdrawing mechanism, the shirking mechanism is used for shrinking the casing, the cutting knife mechanism is used for cutting the shrunk casing and the casing withdrawing mechanism is used for compressing the cut and shrunk casing and withdrawing the compressed casing from the rotating disk mechanism. According to the invention, the casing can be spirally folded, cutting and shrinking of the casing are realized, and the degree of automation in production is improved; and more importantly, rapid automatic sausage filling is made feasible, automatic production efficiency is substantially improved, and market demands are met.

Owner:GUANGXI SHENGUAN COLLAGEN BIOLOGICAL GRP CO LTD

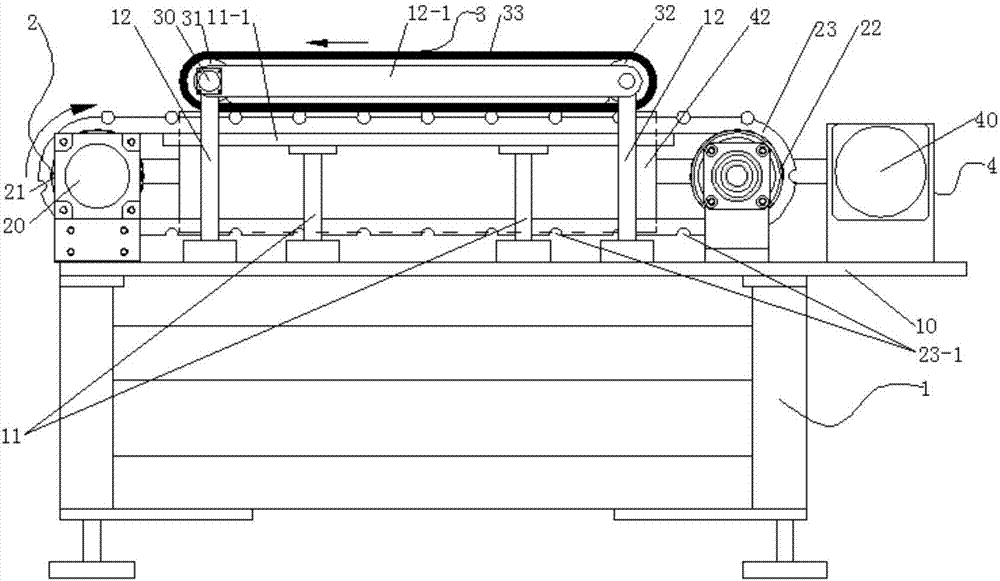

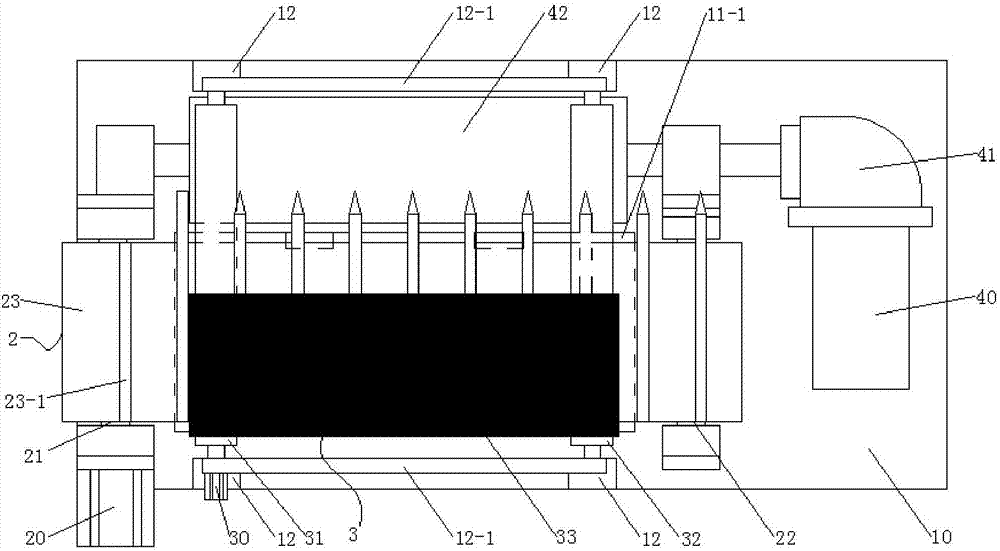

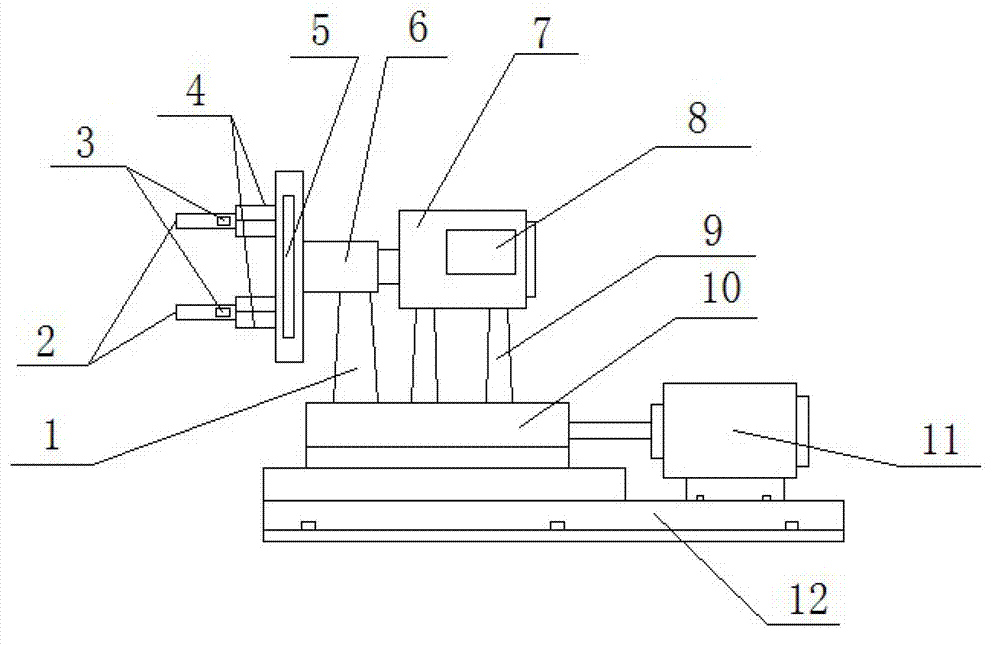

Pencil production polishing device

InactiveCN107225473AImprove automation production efficiencyEnables high-volume grinding operationsEdge grinding machinesGrinding carriagesReducerEngineering

Owner:许莲丽

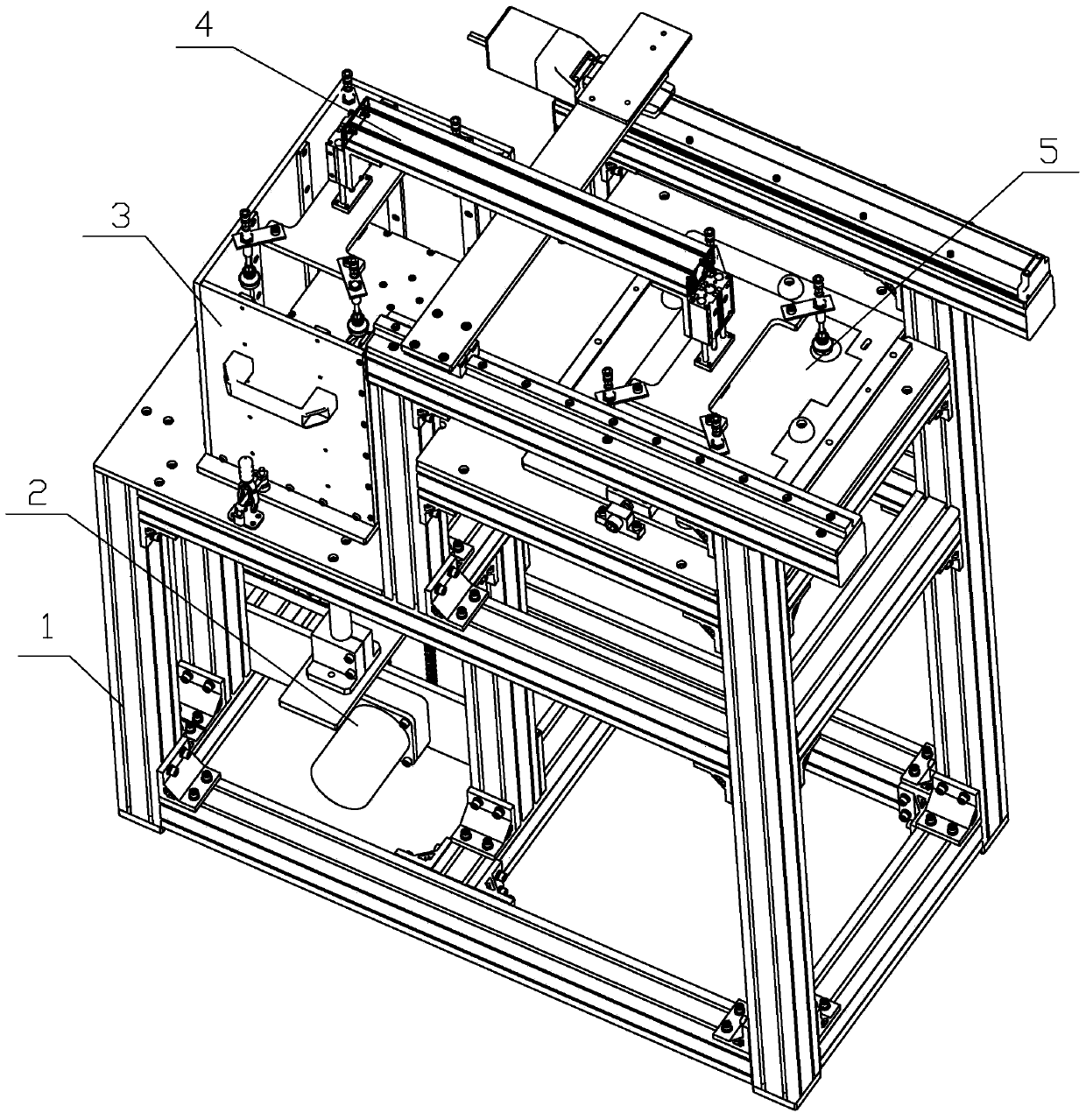

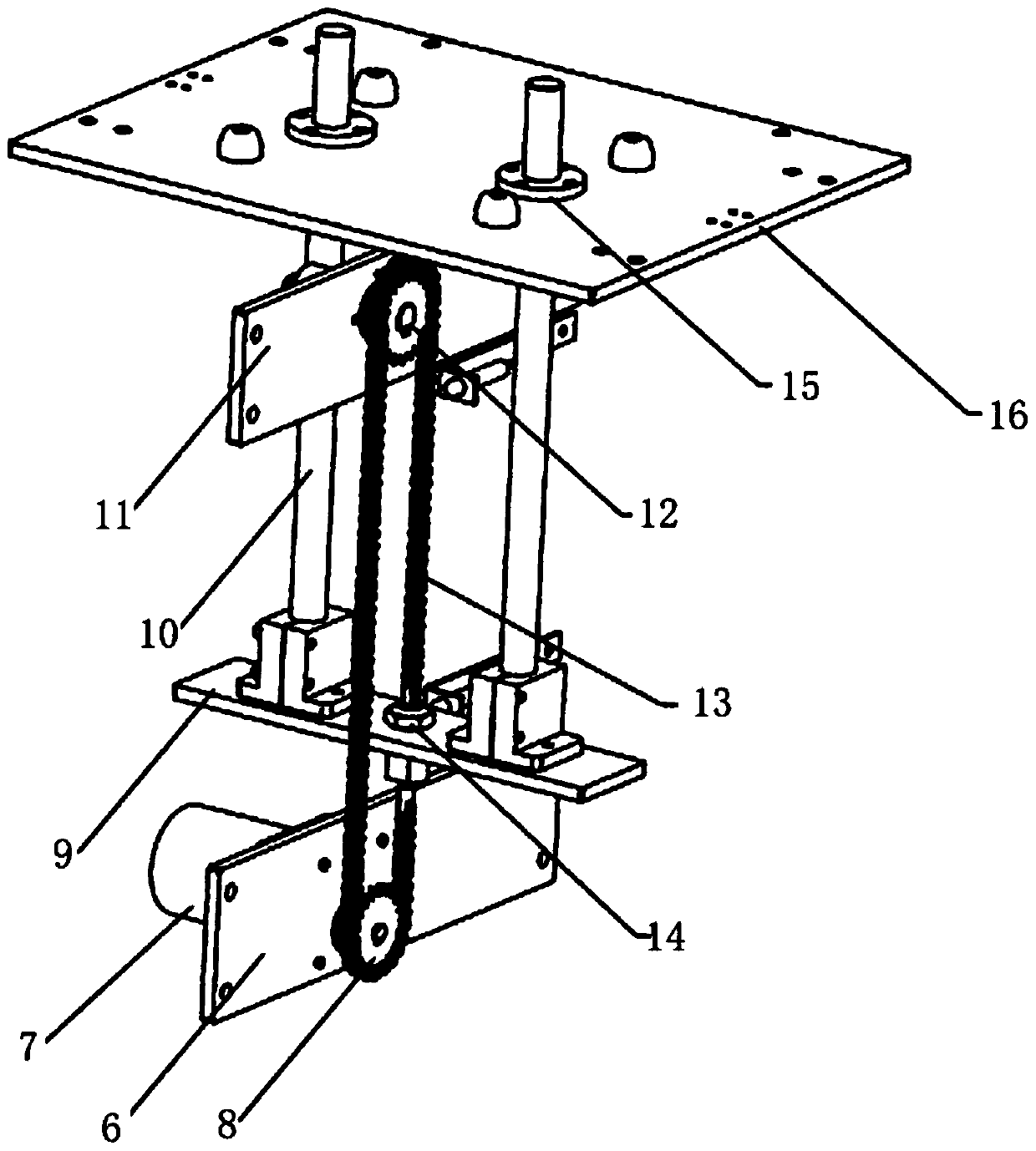

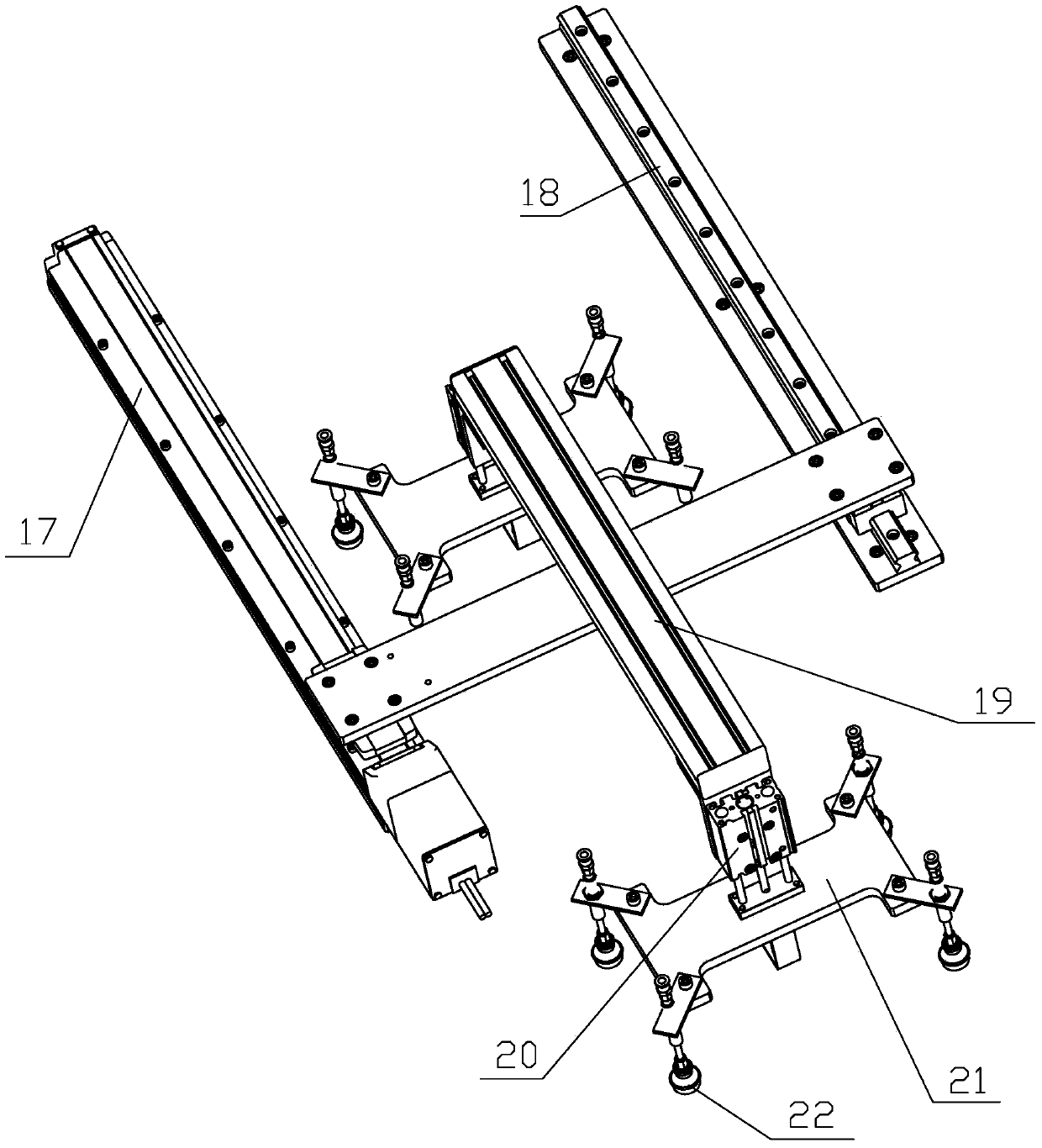

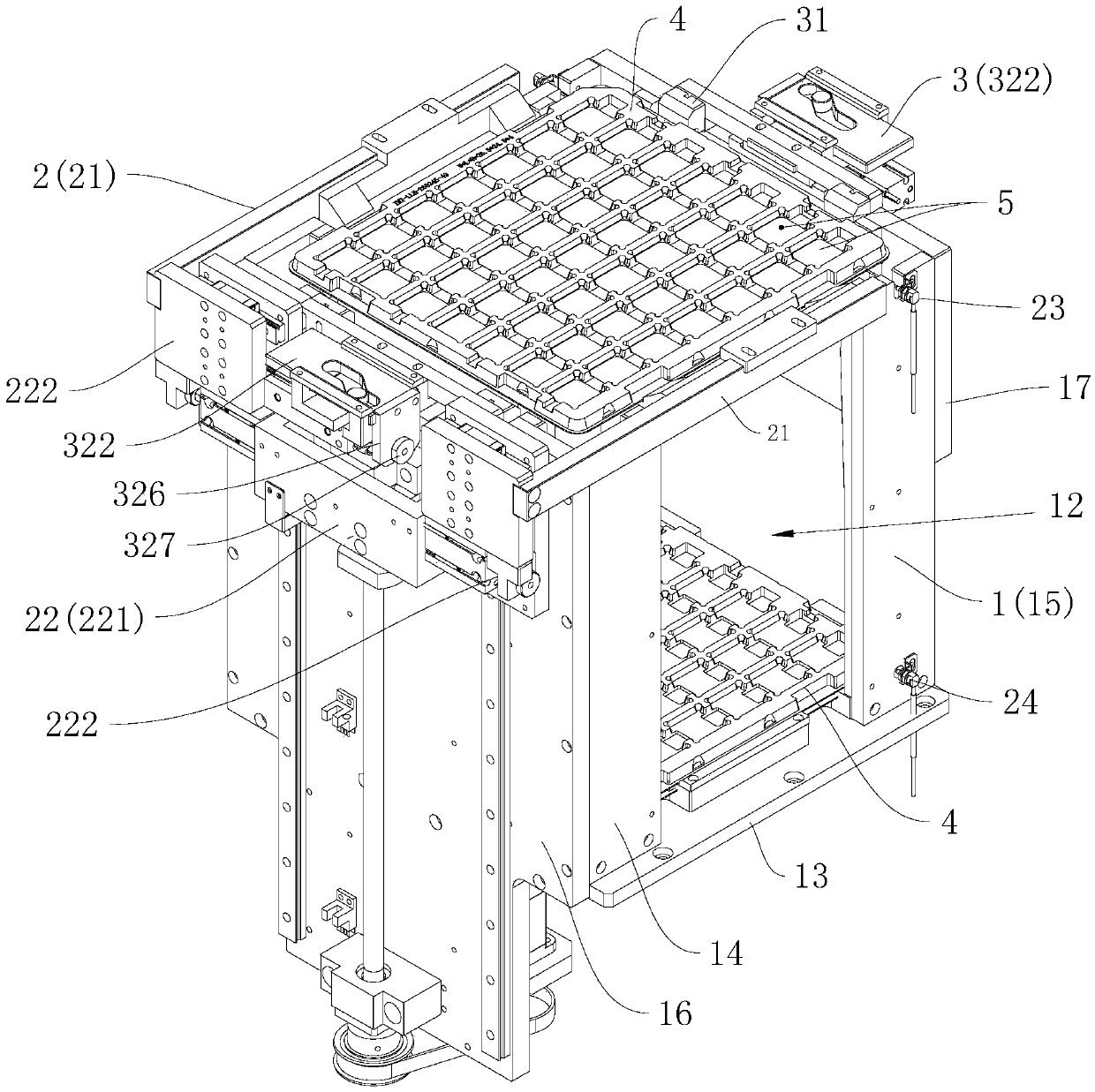

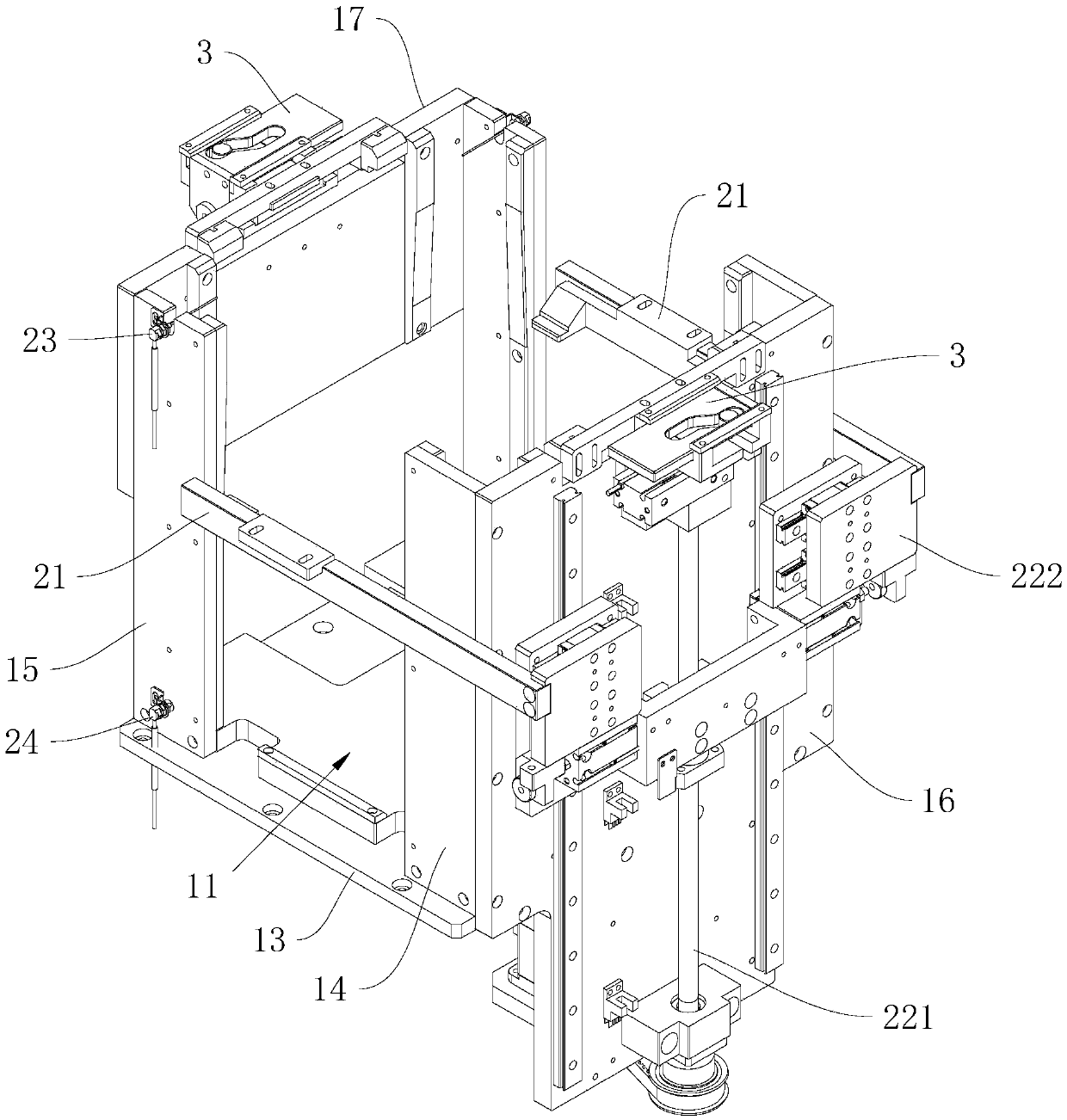

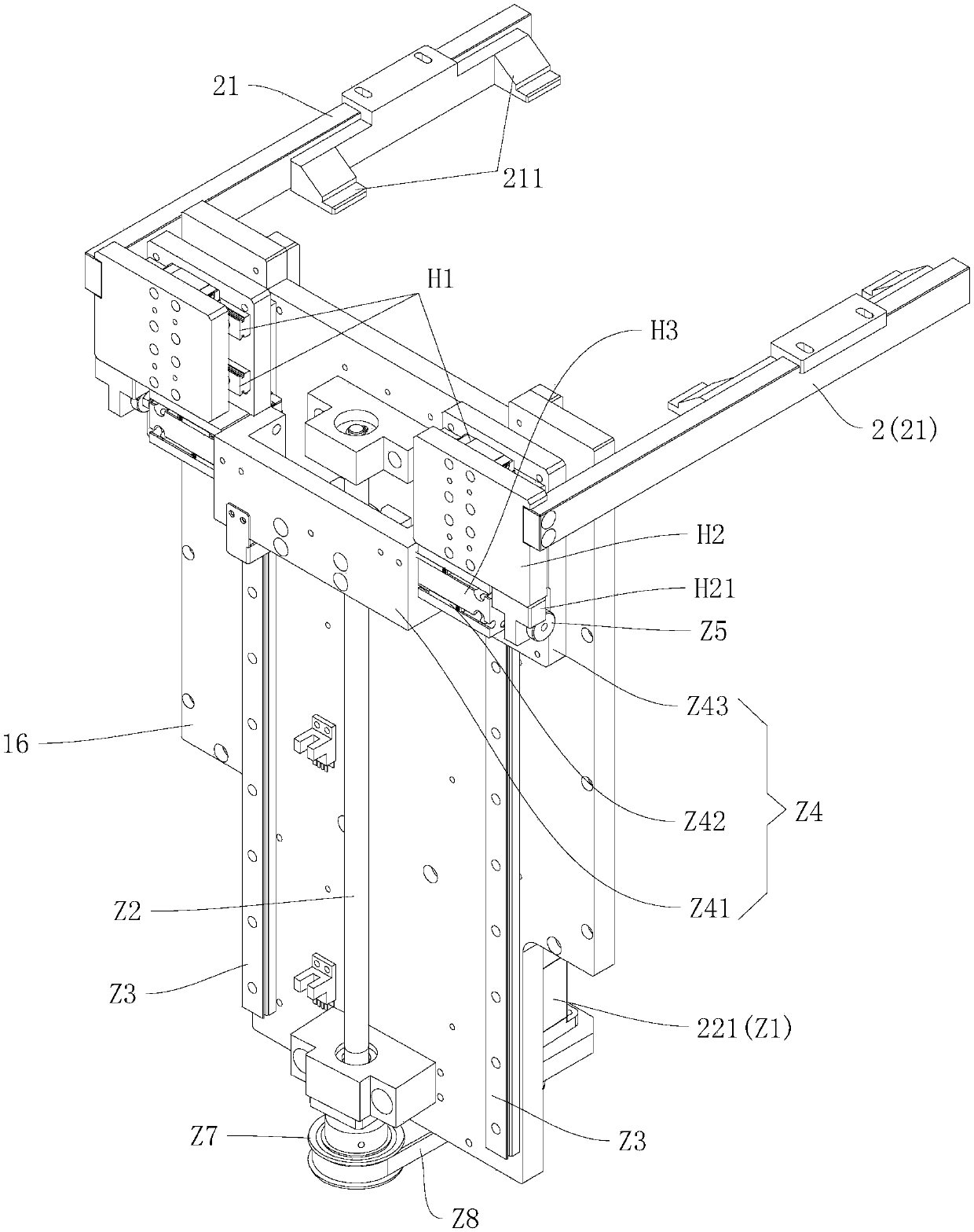

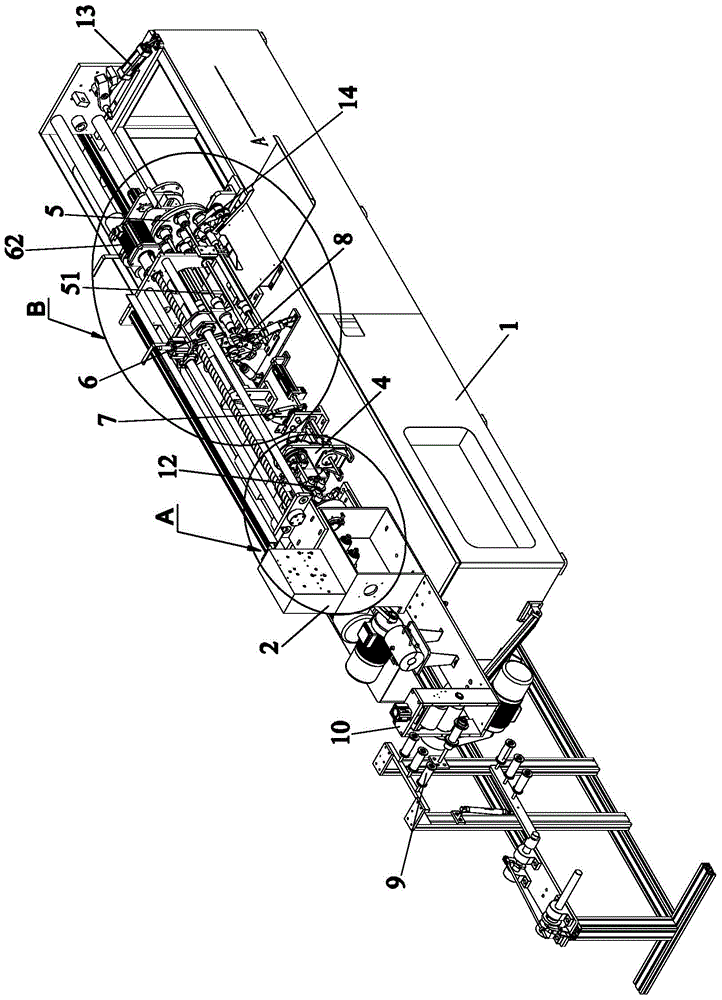

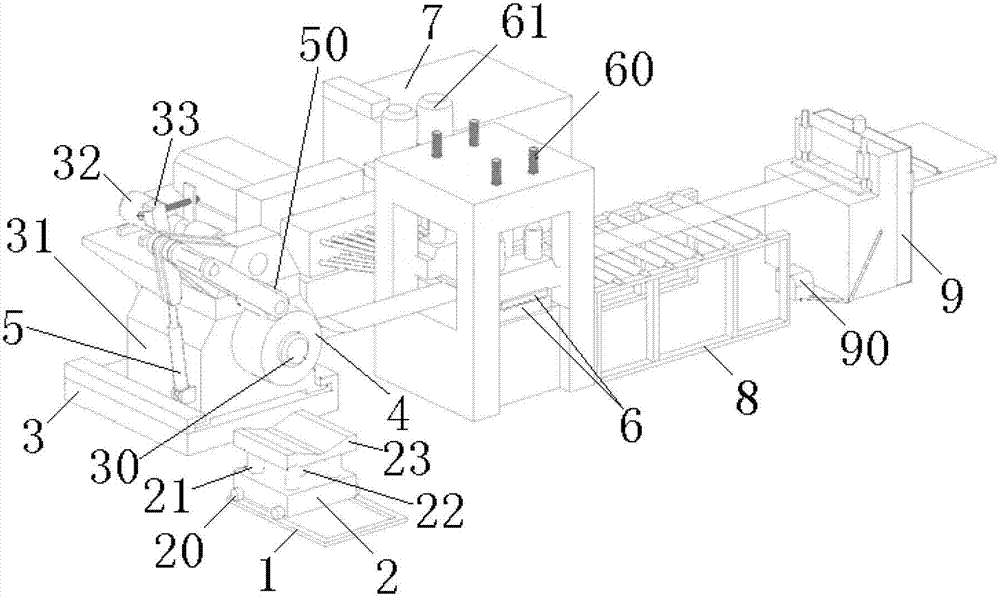

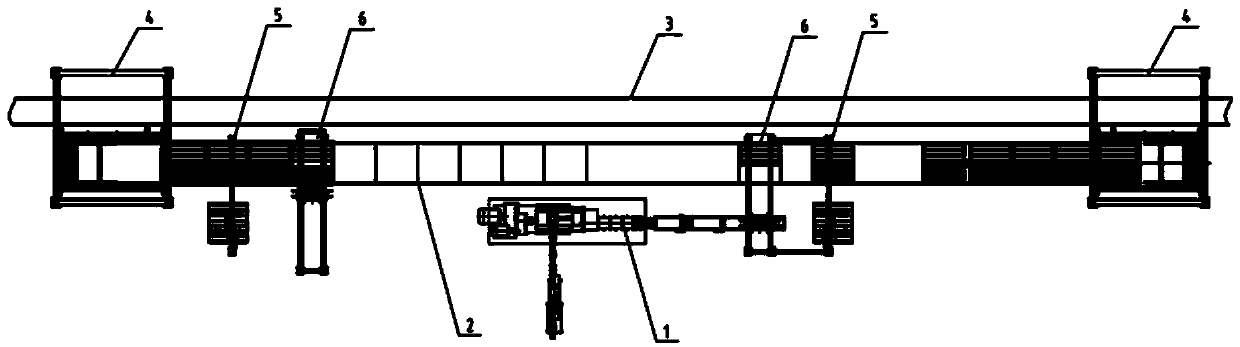

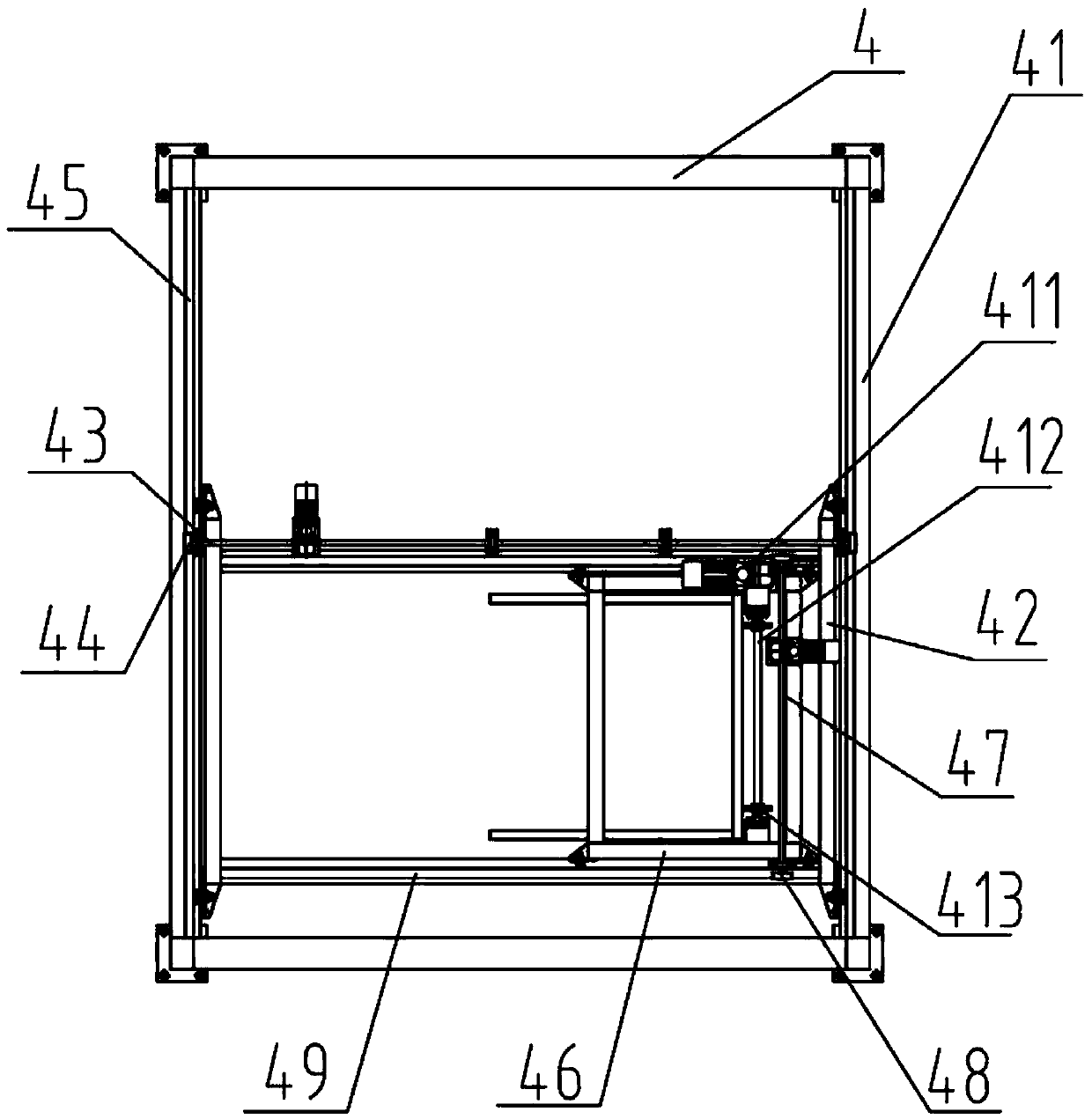

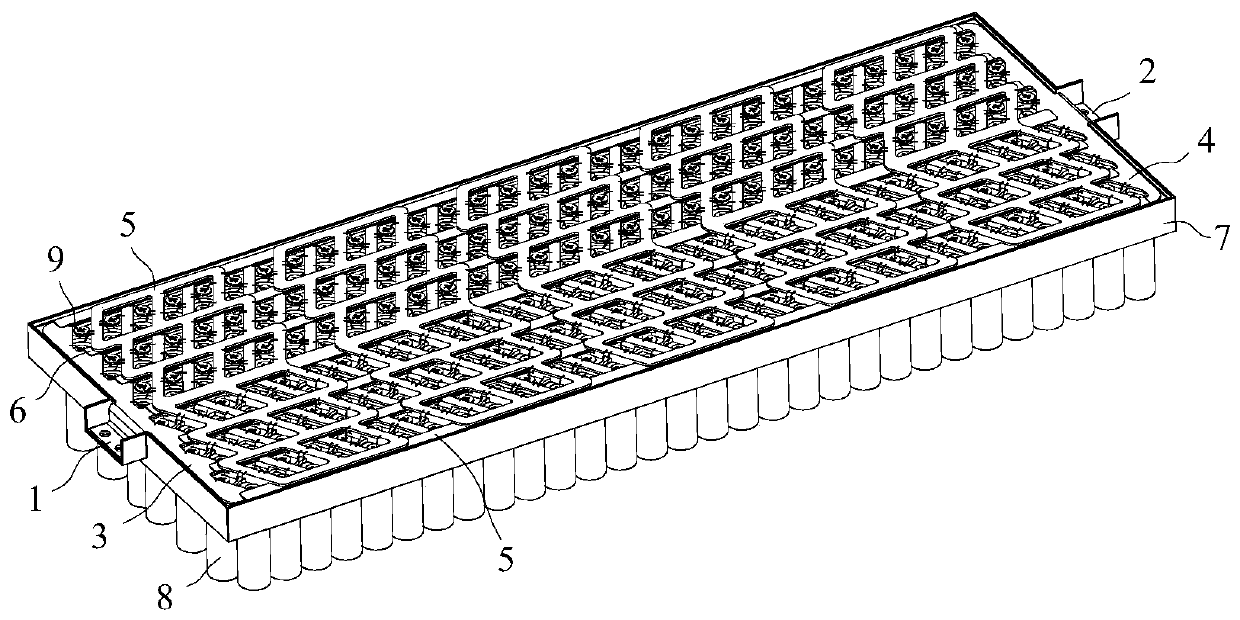

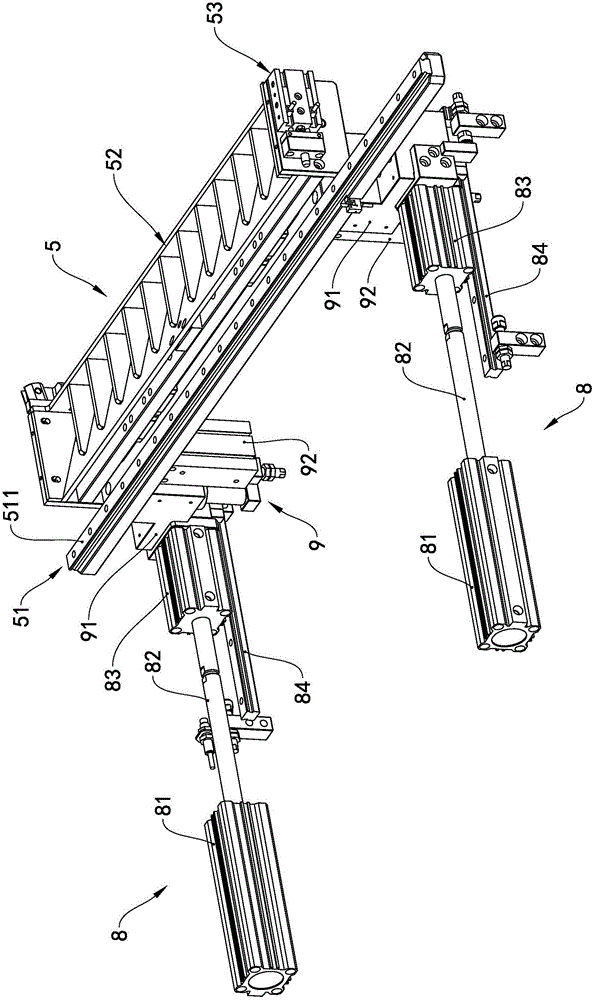

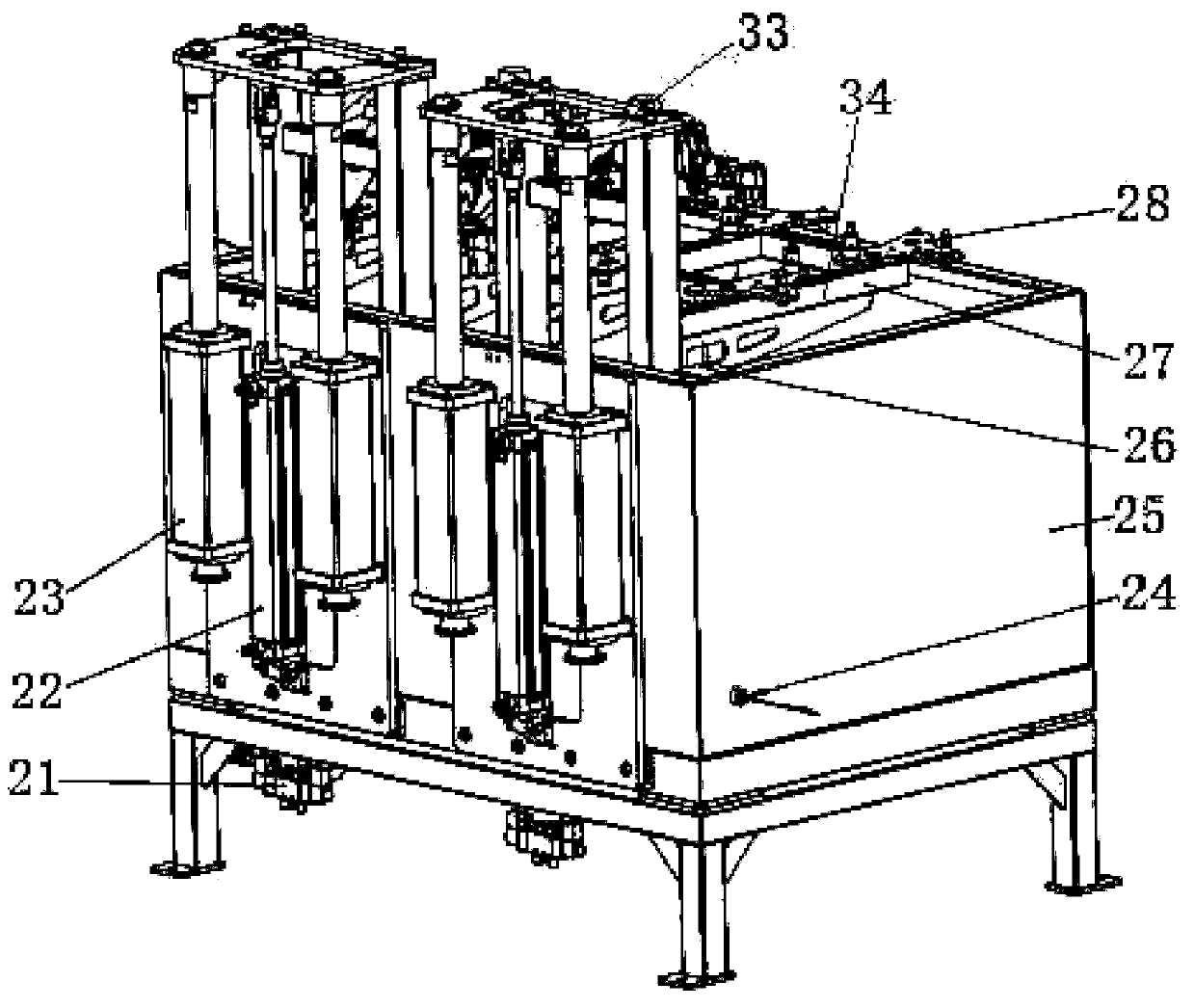

Automatic feeding device of power lithium battery pole pieces

InactiveCN103803300APrecise feeding positionImprove automation production efficiencyConveyor partsPole pieceEngineering

The invention discloses an automatic feeding device of power lithium battery pole pieces, and belongs to feeding devices. The automatic feeding device structurally comprises a section bar support, a jacking mechanism, a pole piece work bin, a carrying mechanical hand and a secondary positioning system, wherein the jacking mechanism, the pole piece work bin, the carrying mechanical hand and the secondary positioning system are respectively arranged on the section bar support, the jacking mechanism is arranged on the lower portion of the pole piece work bin, the secondary positioning system is arranged at the rear of the pole piece work bin, and the carrying mechanical hand is arranged at the position, between the pole piece work bin and the secondary positioning system, of the section bar support. Compared with the prior art, the automatic feeding device of the power lithium battery pole pieces has advantages, thereby having excellent popularization and application value.

Owner:SHANDONG ATAW IND ROBOT TECH

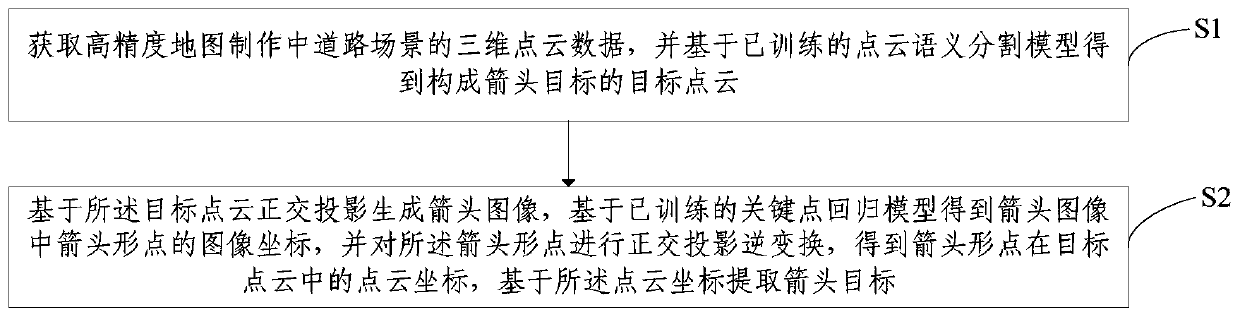

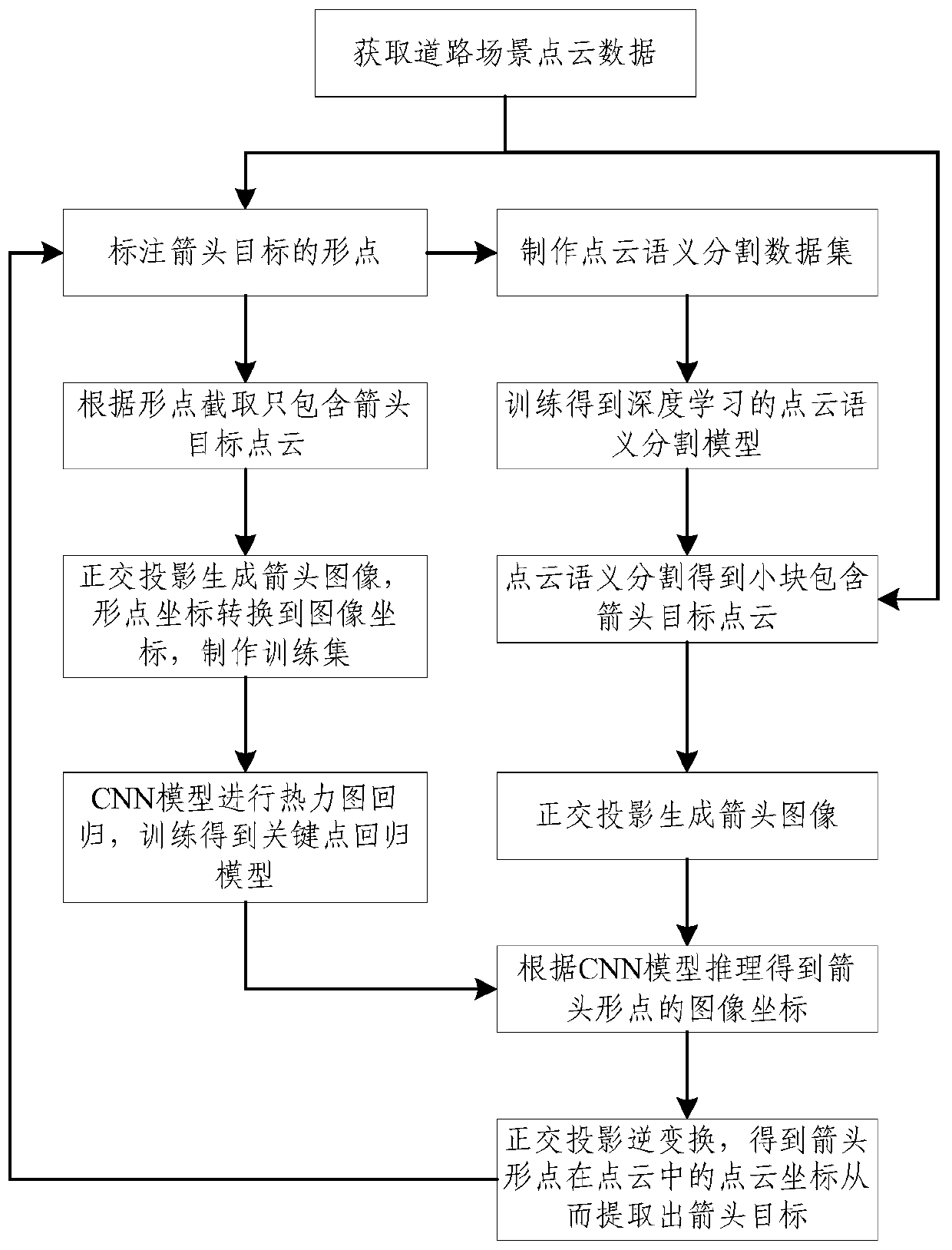

Method and device for automatically extracting arrow type marking lines in high-precision map manufacturing

ActiveCN109858374AGuaranteed accuracyHigh precisionCharacter and pattern recognitionCrucial pointPoint cloud

The embodiment of the invention provides a method and a device for automatically extracting arrow marked lines in high-precision map manufacturing. The method comprises: using three-dimensional pointcloud data as input, automatically extracting arrow target shape points from end to end, effectively extract the arrow target shape points by using an image key point regression method, and ensure that the arrow extraction precision meets the high-precision map manufacturing requirement; using point cloud semantic segmentation to obtain high-level semantic relation scene understanding, and improving algorithm robustness. The accuracy of arrow type marking line extraction and the automatic manufacturing efficiency of a high-precision map can be effectively improved, and the workload of manual marking is reduced.

Owner:WUHAN ZHONGHAITING DATA TECH CO LTD

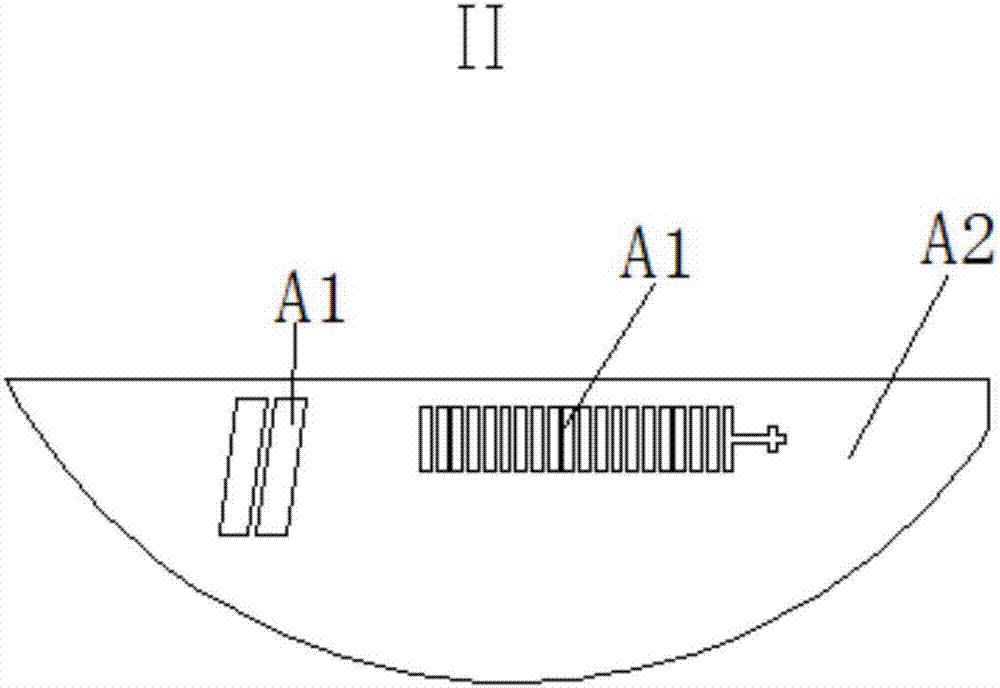

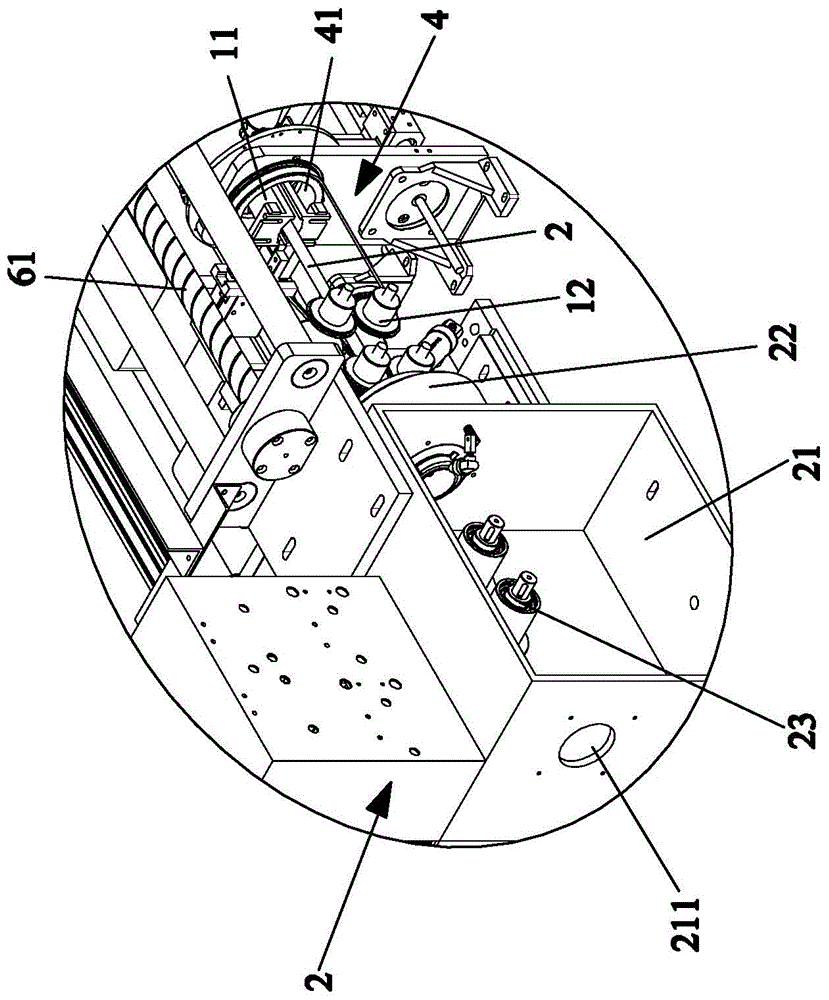

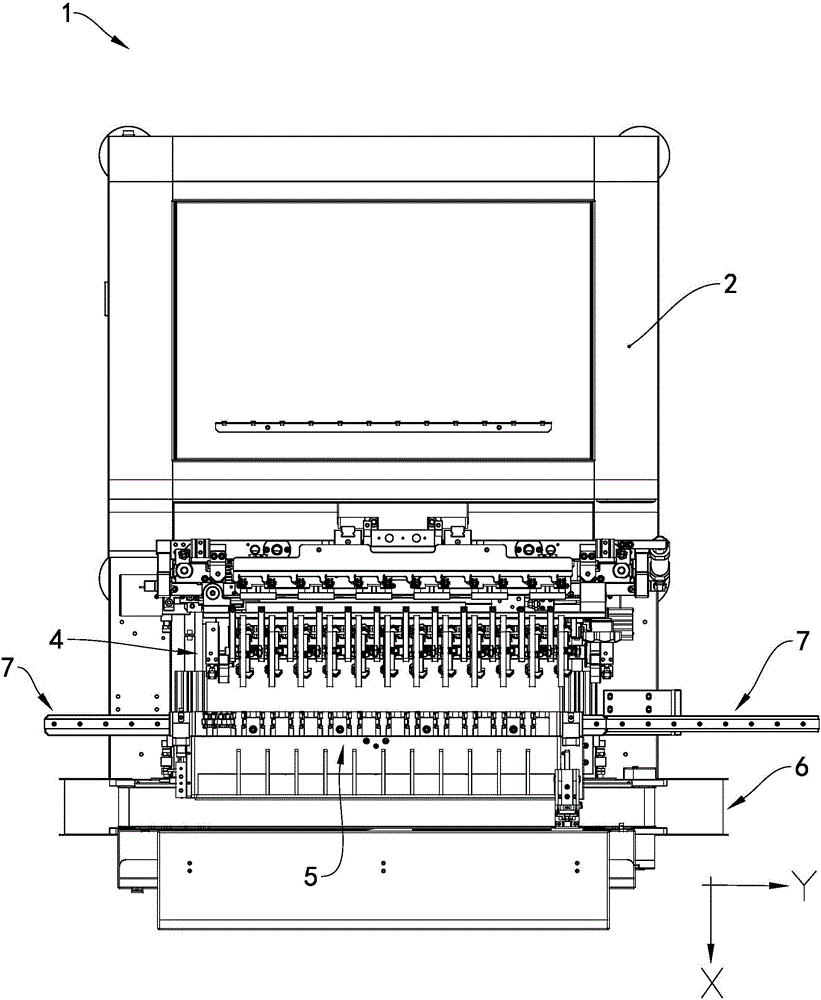

Automatic alignment lighting device for flexible OLED panel and FPC

PendingCN107478871ARealize alignment crimpingAvoid technical problems with excessive offsetsMeasurement instrument housingEngineeringConnection control

The present invention discloses an automatic alignment lighting device for a flexible OLED (Organic Light-Emitting Diode) panel and a FPC (Flexible Printed Circuit). The device comprises a location connection unit, an alignment control unit and a light test unit. The location connection unit comprises a flexible OLED panel vacuum sucker and a FPC location crimping tool, and when the flexible OLED panel vacuum sucker absorbs a flexible OLED panel, the deviation values of the displacement offsets of PINs on the flexible OLED panel are not larger than 5% of the widths of the PINs; the alignment control unit comprises a CCD lens, an automatic alignment platform, a control box and a device operation desk; and the flexible OLED panel vacuum sucker is connected with the automatic alignment platform, the CCD lens is arranged between the flexible OLED panel vacuum sucker and the FPC location crimping tool, the detection operation desk is electrically connected with the control box, and the control box is electrically connected with the automatic alignment platform, the CCD lens and the FPC location crimping tool. The automatic alignment lighting device for the flexible OLED panel and the FPC are simple in structure and convenient to use, can rapidly and accurately realize alignment crimping of PINs of the flexible OLED panel and the PINs of the FPC.

Owner:WUHAN JINGCE ELECTRONICS GRP CO LTD

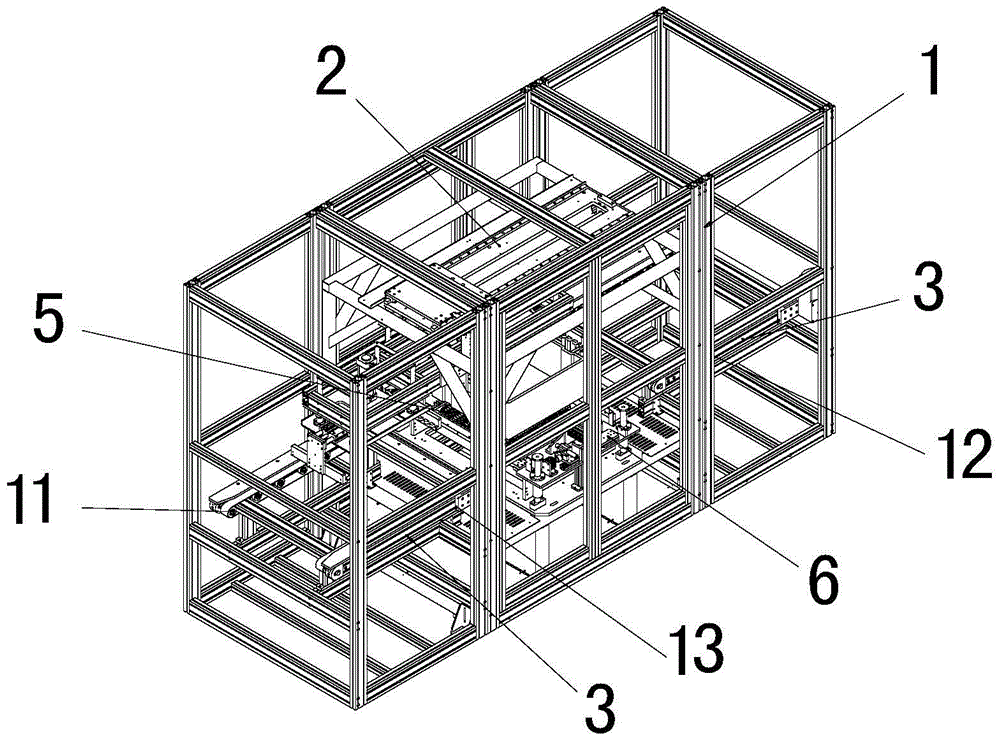

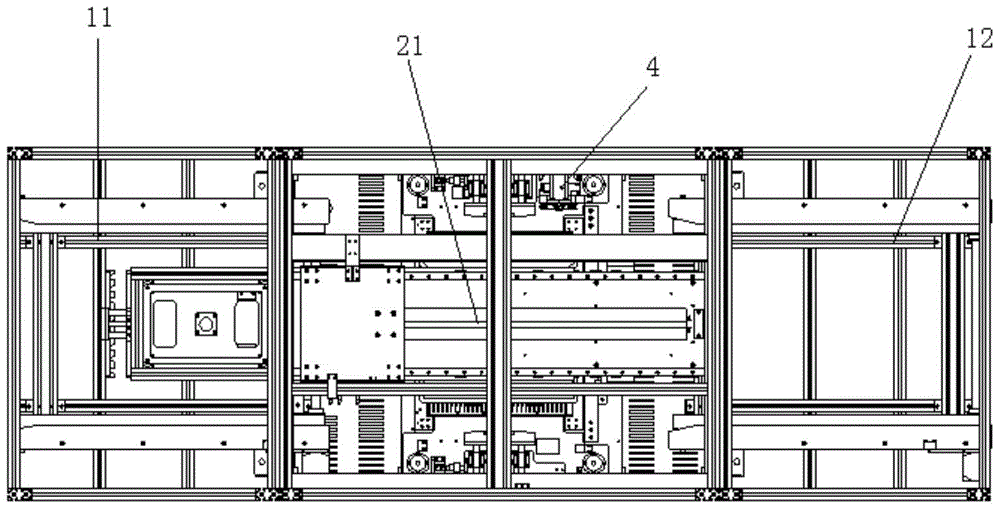

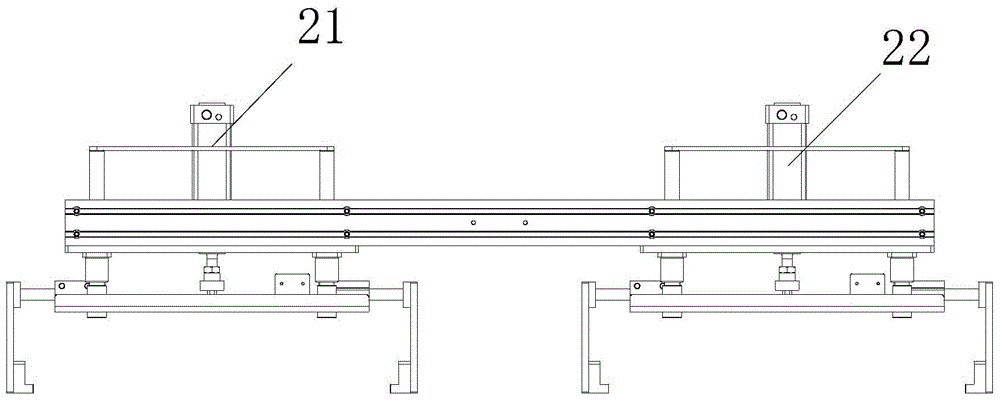

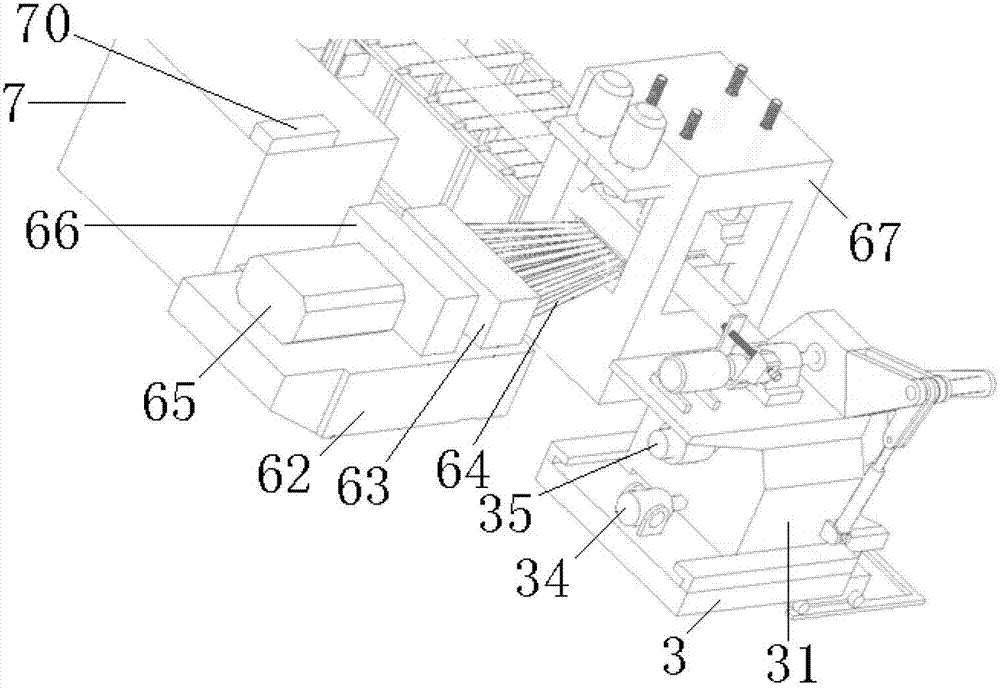

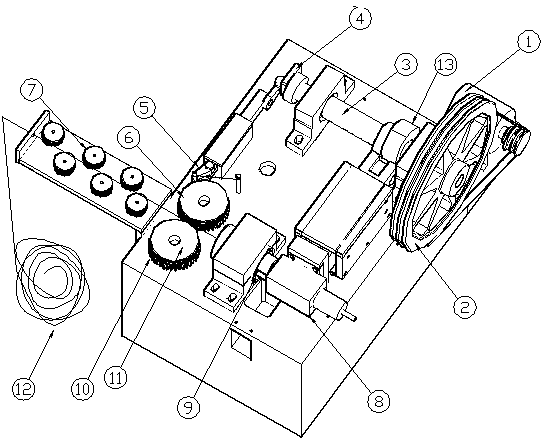

Soft package lithium ion battery open circuit voltage internal resistance measurement equipment

ActiveCN105044620AImprove automation production efficiencyIncrease productivityElectrical testingLogistics managementElectrical battery

The invention discloses soft package lithium ion battery open circuit voltage internal resistance measurement equipment. The equipment comprises a rack, conveyor assemblies, a transplanting manipulator assembly, a needle plate assembly, a rotating disk mechanism assembly, a tray positioning assembly, a battery OCV / IR measurement instrument and a control mechanism, wherein the conveyor assemblies are arranged on front and rear ends of the rack and are connected to a preposition logistics line and a postposition logistics line respectively; the transplanting manipulator assembly is used for grabbing a battery tray; the needle plate assembly is closely contacted with a battery pole ear; the rotating disk mechanism assembly is used to adjust a battery tray position according to different types of batteries; the tray positioning assembly is installed between the front and the rear conveyor assemblies and is located below the needle plate assembly; the battery OCV / IR measurement instrument is used to collect voltage and current signals of each battery and update signal data to a PC; and the control mechanism is arranged in the PC outside the rack. The control mechanism is used for controlling motion of the conveyor assemblies, the transplanting manipulator assembly, the needle plate assembly, the rotating disk mechanism assembly, the tray positioning assembly and the battery OCV / IR measurement instrument. The needle plate assembly is electrically connected to the battery OCV / IR measurement instrument through a conductive beam.

Owner:ZHEJIANG HANGKE TECH

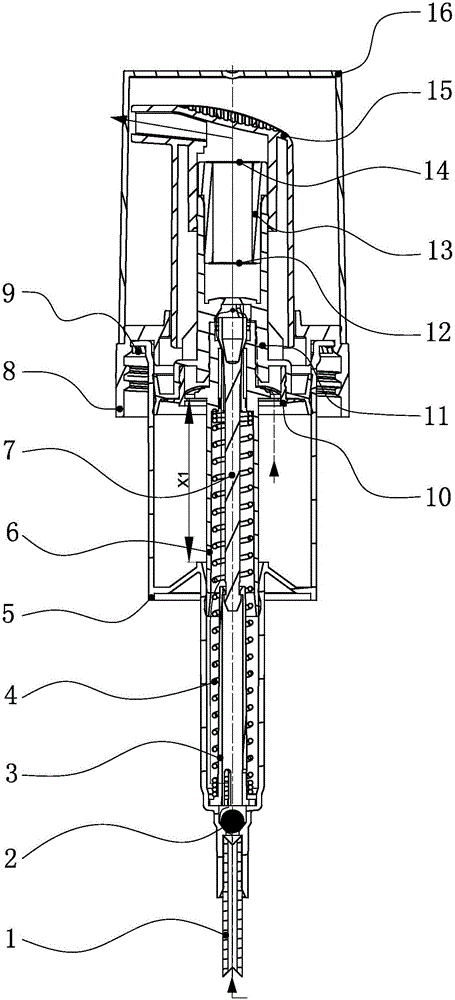

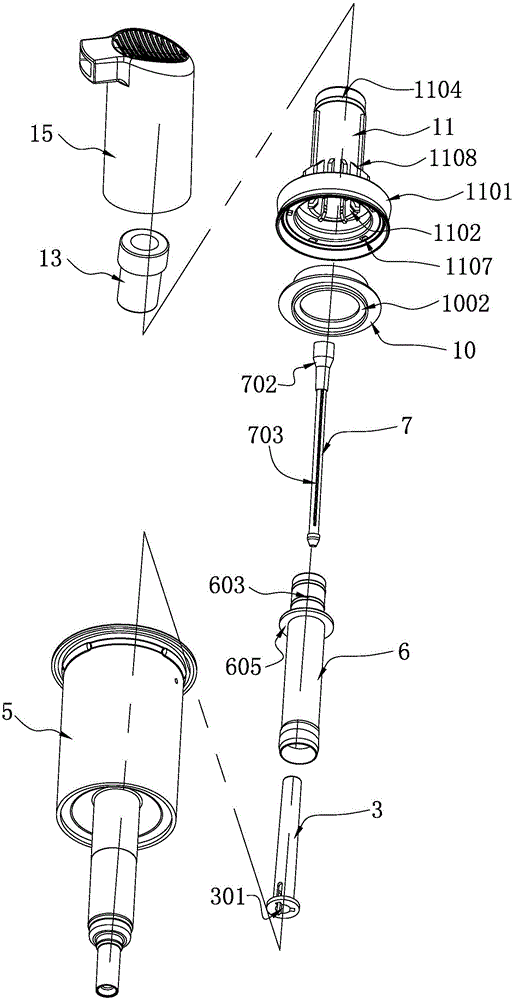

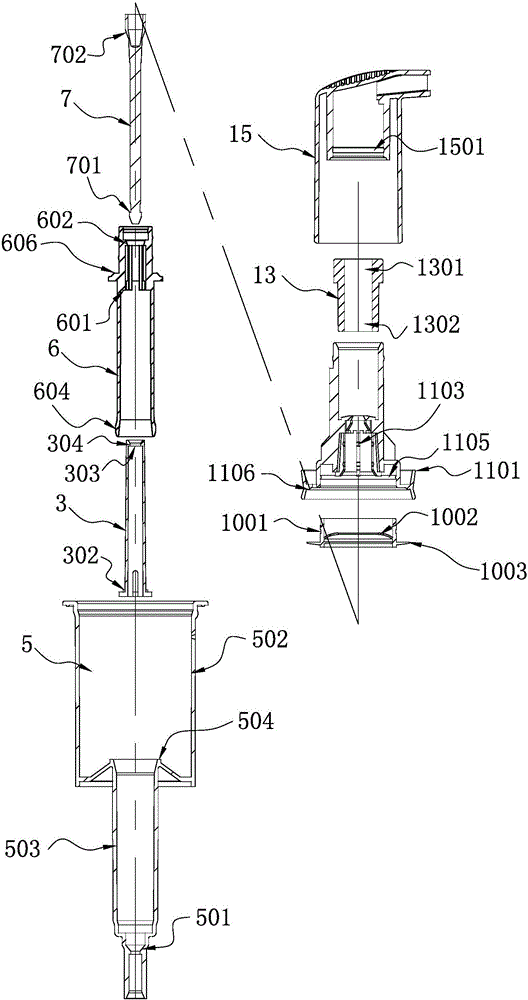

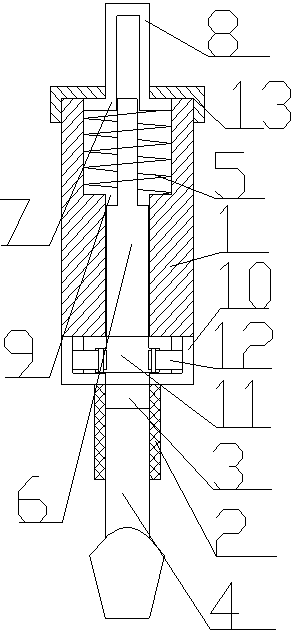

Press-type foam pump and discharge rate control method thereof

ActiveCN105923253AMeet the requirements of ejection volumeImprove interoperabilityClosuresSingle-unit apparatusEngineeringDischarge rate

The invention relates to a press-type foam pump and a discharge rate control method thereof and aims to solve the technical problems that conventional like products are inconvenient in discharge rate changing and controlling, and need to be further improved in structural design. The press-type foam pump is mainly characterized in that an outwardly protruding convex clasp ring and a tapered limit opening are respectively formed at the nesting parts between a valve rod and a pump body, downward movement of a piston driven by a duckbill is the stroke that a limit ring at the external diameter of the valve rod moves downwards to be propped against the limit opening of the pump body, the limit opening of the pump body is provided with a cylindrical glue site protruding toward the interior of the pump body, and the cylindrical glue site is subjected to integral injection molding with the limit opening and the pump body. Therefore, the discharge rate of the foam pump is changed only by changing the structure of the limit opening in the pump body on the basis of not changing the integral structure of the foam pump, that is, the discharge rate of the foam pump is controlled by controlling the downward movement of the piston via the length of the cylindrical glue site. Accordingly, sharing of product parts and the university of automatic assembly equipment are effectively improved, the production efficiency is improved, energy consumption is reduced, and the production cost is lowered.

Owner:ZHEJIANG Z&Z IND CO LTD

Double-nut tightening device with automatic counting function

InactiveCN103028936AImprove automation production efficiencyMetal working apparatusProduction lineBall screw

The invention relates to a double-nut tightening device with an automatic counting function. The double-nut tightening device comprises a connecting shaft support frame, a double-tightening head, a moment strain gage, a first servo motor, a double-tightening head clearance adjustment device, a connecting shaft, a second servo motor, a counting display screen, a second servo motor support frame, a guide rail mobile table, a third servo motor, a base, a linear guideway and a ball screw. The double-nut tightening device with the automatic counting function has the beneficial effects that two nuts can be tightened simultaneously in an automatic production line, the tightened nuts are ensured to meet the technical requirements according to a set moment numerical value, and the automatic production efficiency is improved.

Owner:葛双好

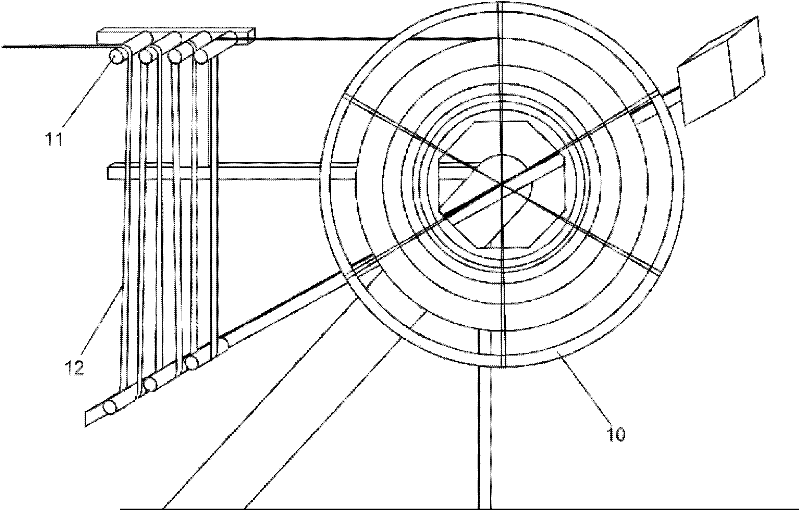

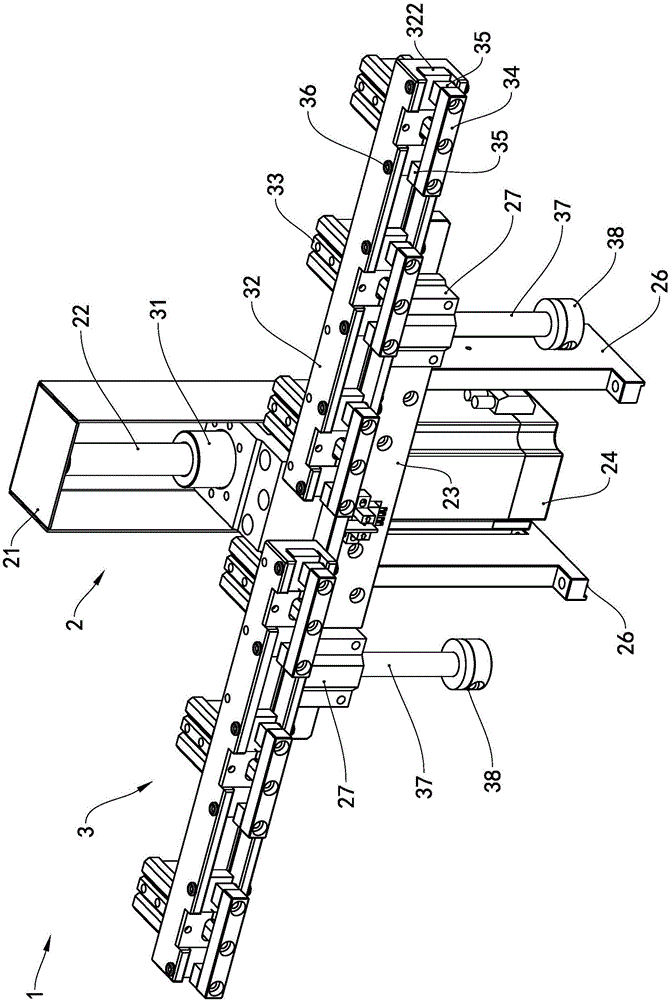

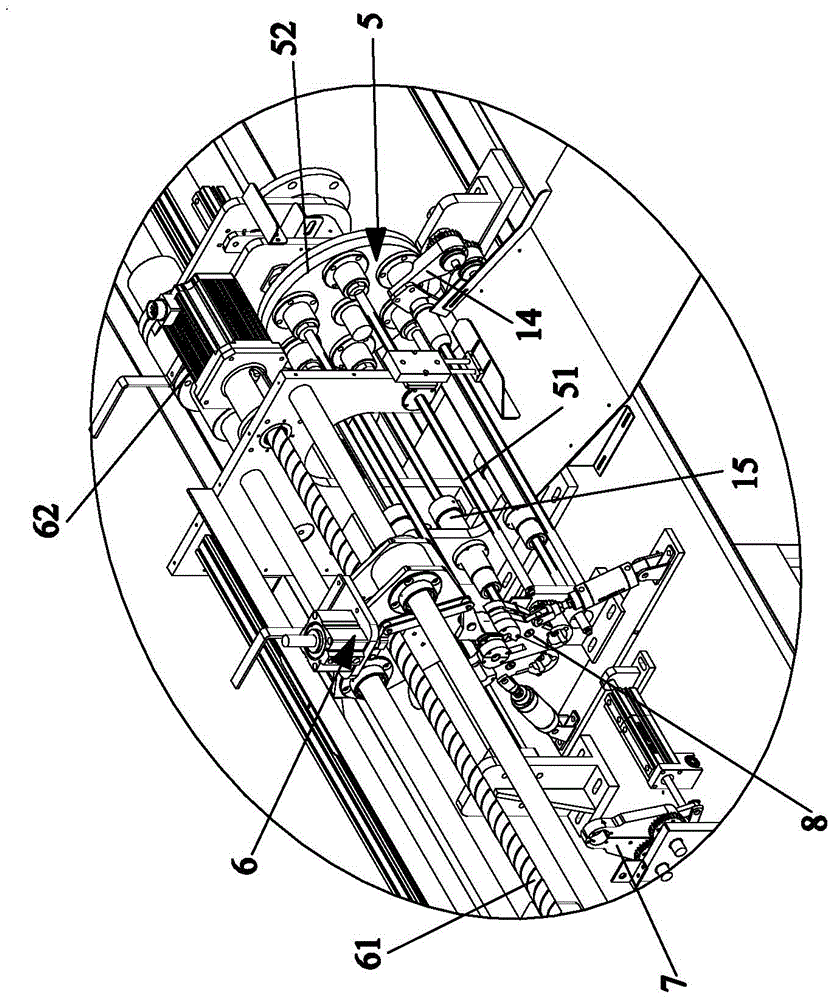

Servo-controlled winding tension attenuation apparatus, winding machine and control method therefor

ActiveCN106531436AGuaranteed stabilitySimple structureInductances/transformers/magnets manufactureWinding machineEngineering

The invention provides a servo-controlled winding tension attenuation apparatus, a winding machine and a control method therefor. The tension attenuation apparatus comprises a wire conveying mechanism and a wire pressing mechanism, wherein the wire conveying mechanism comprises a servo motor; the servo motor controls the wire pressing mechanism to move up and down; the wire pressing mechanism comprises a moving plate, a pressing block assembly and a front air cylinder and a back air cylinder; guiding holes are formed in the moving plate; the guiding holes are used for guiding varnished wires or insulating wires; and the front air cylinder and the back air cylinder drive the pressing block assembly to press the varnished wires or insulating wires tightly. The servo motor controls the wire pressing mechanism to move up and down, and the front air cylinder and the back air cylinder drive the pressing block assembly to press the varnished wires or insulating wires tightly, so that the magnitude of the tension of the varnished wires or insulating wires can be adjusted in order to satisfy process requirements of enabling the varnished wires or insulating wires to wind workpiece pins, and enabling the varnished wires or insulating wires to pass through framework wire-passing grooves; therefore, the magnitude of the tension of the varnished wires or insulating wires can be adjusted in the pin winding process in the fully automatic production; and in addition, the tension attenuation apparatus is simple in structure, and capable of improving the production efficiency and the product yield.

Owner:珠海市艾森工匠科技有限公司

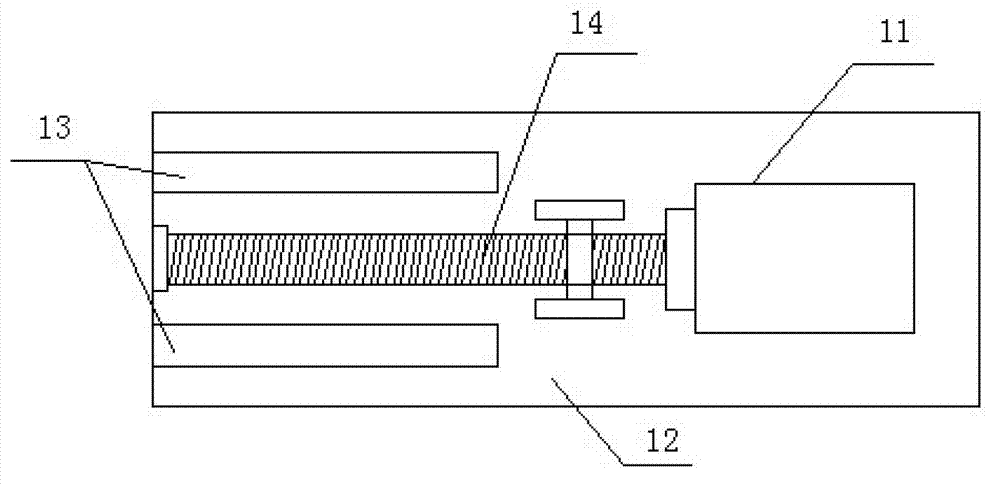

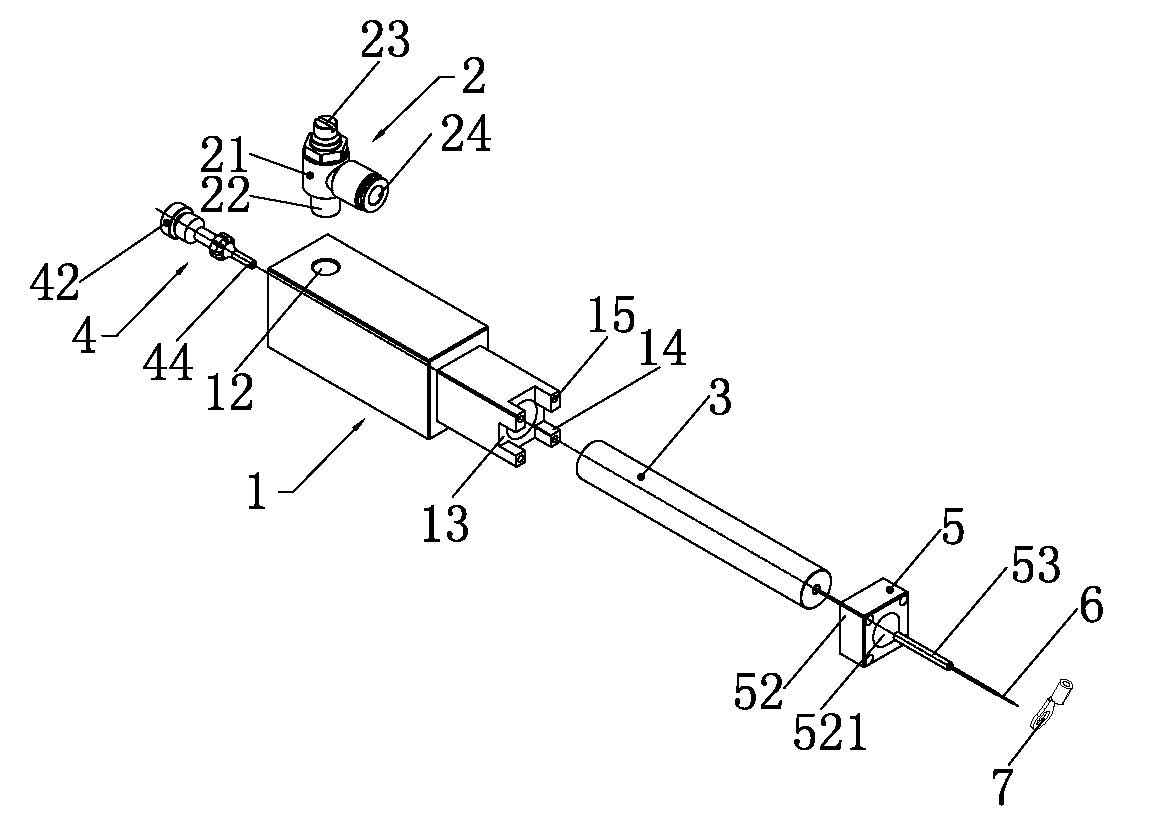

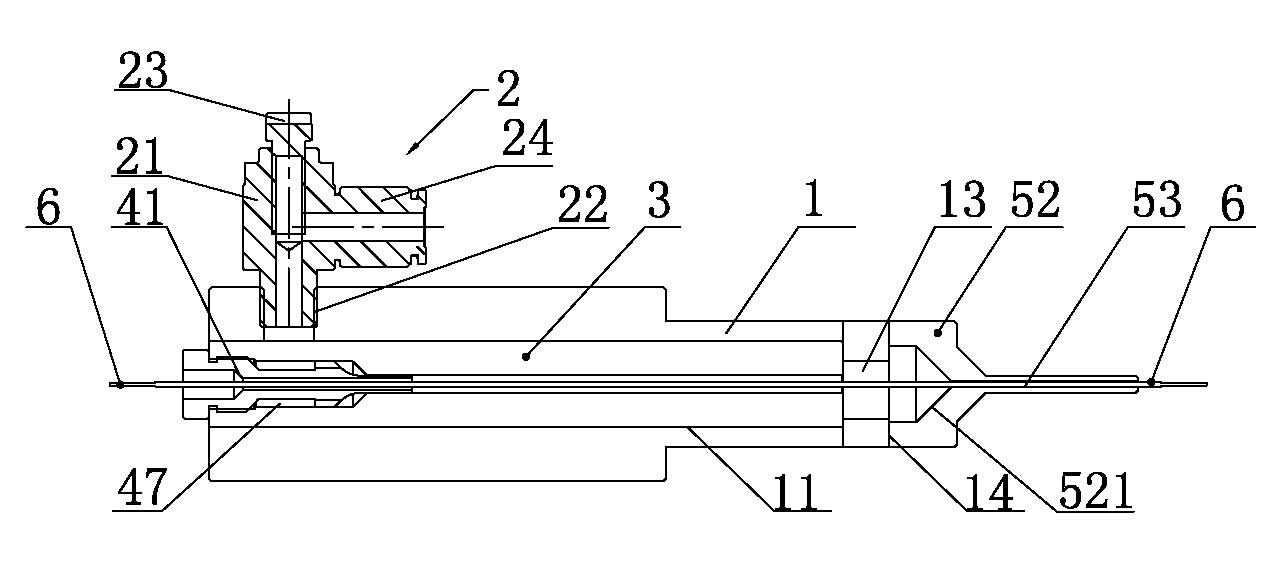

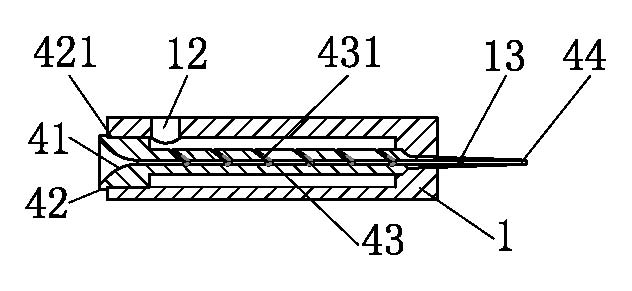

Automatic wire rod guiding and threading device and wire rod guiding and conveying method

InactiveCN102658344AReduce labor intensityImprove automation production efficiencyWire rodCompressed air

The invention relates to an automatic wire rod guiding and threading device and a wire rod guiding and conveying method. The device comprises a base, a through hole, a penetrating hole, an air leaking part, a wire rod guiding mechanism, an air source connector, a guide pipe and an air source flow guiding mechanism, wherein the through hole is formed on the base along an axis in a penetrating manner; the penetrating hole is formed at the part of the base along the radial direction, which is close to an inlet end, and is vertically penetrated with the through hole; the air leaking part is arranged the tail end of the through hole; the wire rod guiding mechanism is connected with an outlet end of the base in a sealing manner and is used for guiding a wire rod to stretch to the outside; the air source connector is connected with the base through the penetrating hole of the base in the sealing manner; the guide pipe is inserted in the through hole of the base and is located at the rear section of the penetrating hole of the base and is provided with a wire hole; and the air source flow guiding mechanism is sleeved in the through hole at the inlet end of the base and is communicated with the penetrating hole of the base. The method comprises the following steps that: the wire rod is conveyed into an inlet of the air source flow guiding mechanism; an air flow which is rushed forwards is generated by compressed air through air cavities in the air source connector and the base to enable the wire rod to be forwards conveyed along the guide pipe; and the wire rod is introduced into a needle pipe with a smaller introducing diameter through a tapered guiding hole of a wire rod guiding pipe; and the air flow is discharged from the air leaking part, and the wire rod is accurately transferred to an appointed position to be butted with a wiring terminal hole.

Owner:深圳恒高自动技术有限公司

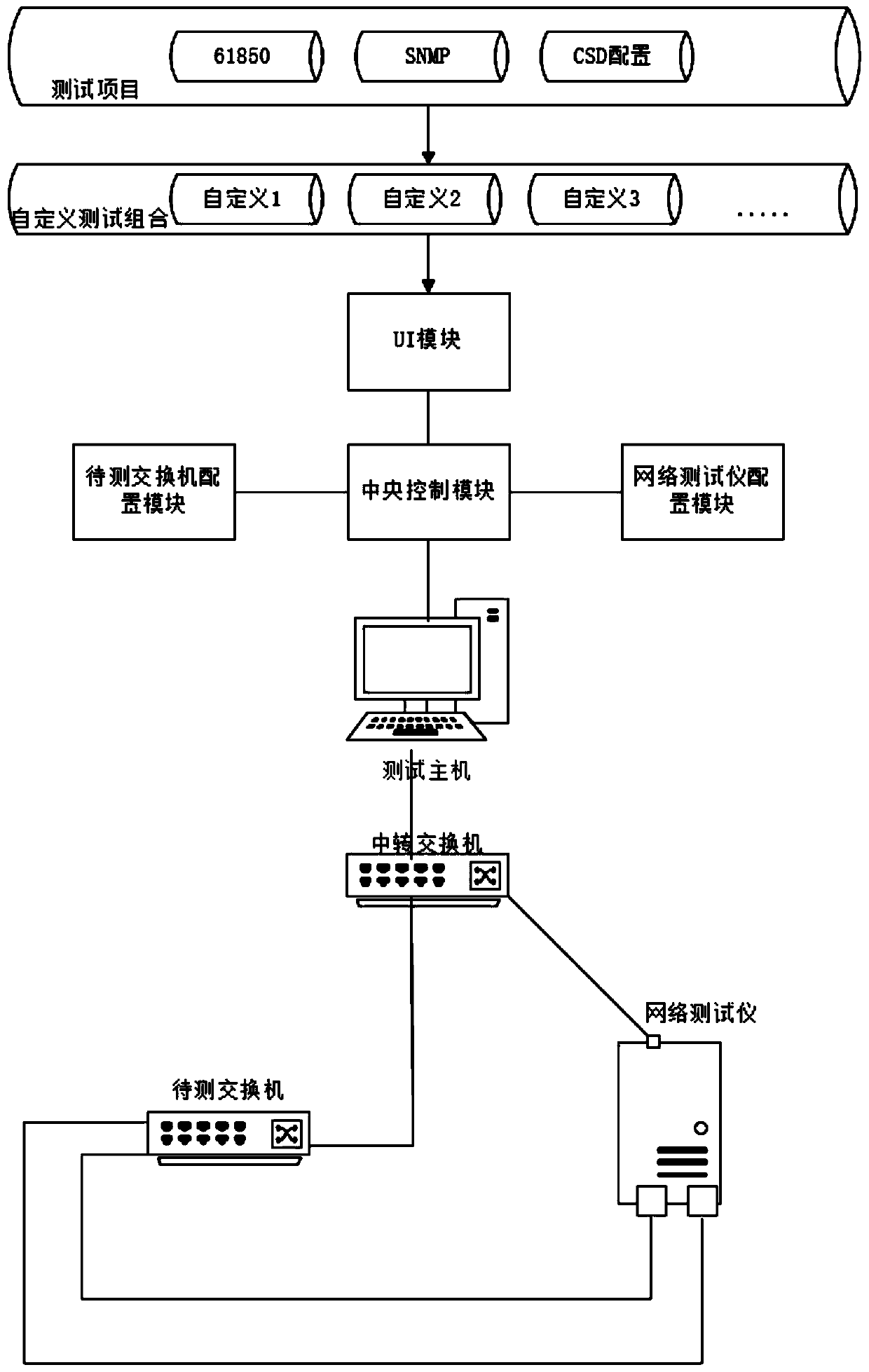

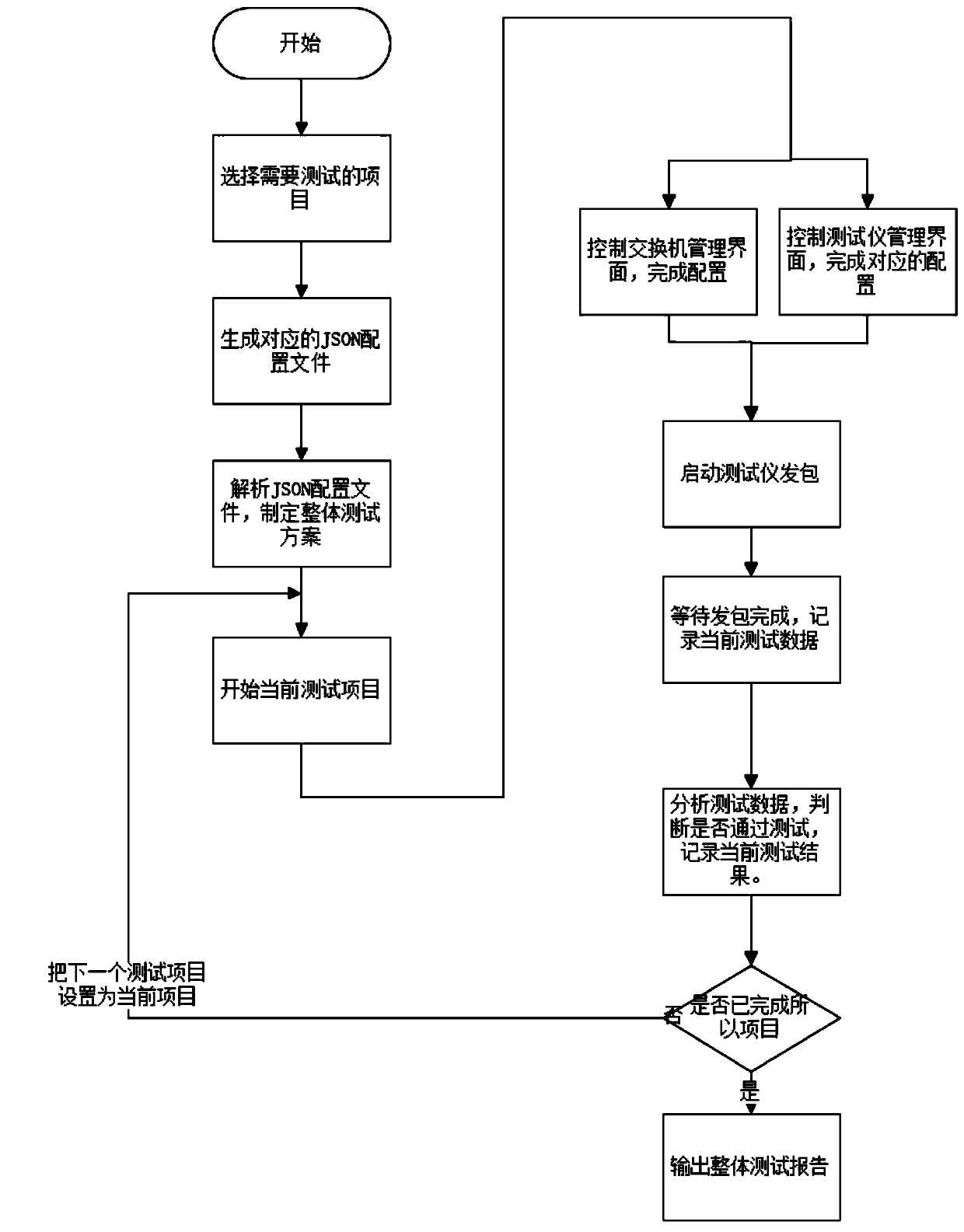

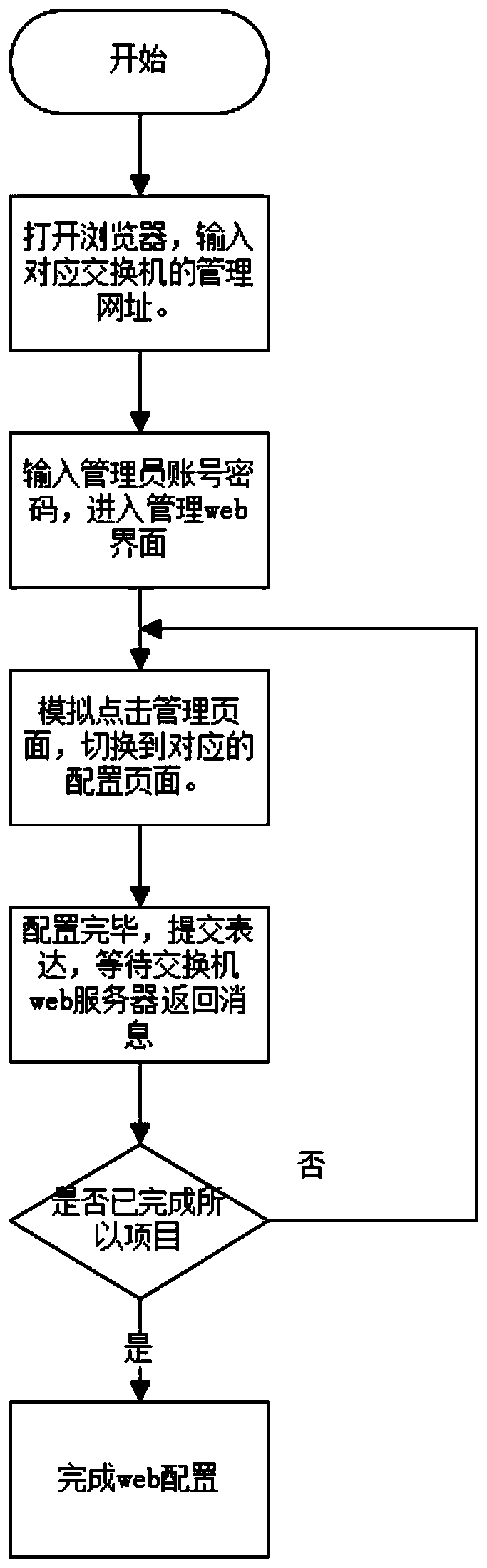

Production automation test method of industrial Ethernet switch

ActiveCN110493079AImprove automation production efficiencySimplify commissioningData switching networksIndustrial EthernetUser input

The invention provides a production automation test method of an industrial Ethernet switch. The production automation test method comprises the following steps: step 1, a user selects test items: IEC61850 standard, SNMP and CSD configuration; step 2, a human-computer interaction UI module receives a test item input by a user, generates a corresponding JSON configuration file and transmits the JSON configuration file to a central control module; step 3, the central control module analyzes the JSON configuration file and formulates a test scheme; step 4, the test host orderly executes project tests, and respectively configures a switch and / or a network tester according to the current test project; step 5, information interaction between the test host and the switch or between the network tester and the switch is performed to generate test data, and a return result is sent to the central control module; step 6, the central control module analyzes the test data and records a test result;and step 7, after the overall test is finished, an overall test report is output. The production efficiency of the switch can be improved.

Owner:长园深瑞继保自动化有限公司

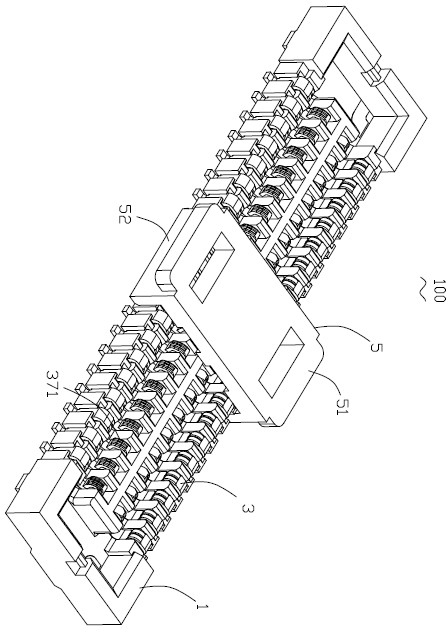

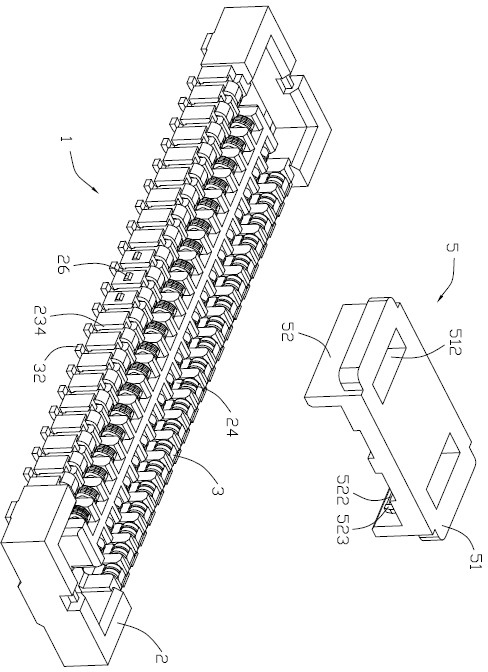

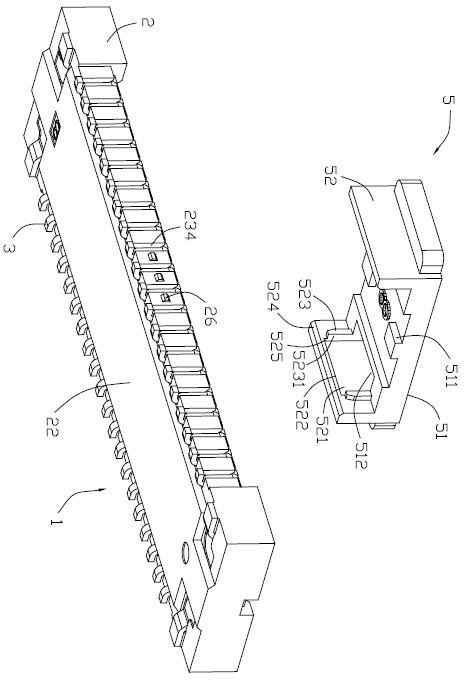

Electric connector

InactiveCN102683934AImprove automation production efficiencyPrevent being pinched and deformedCoupling device detailsEngineeringMechanical engineering

Owner:KUNSHAN JIAHUA ELECTRONICS

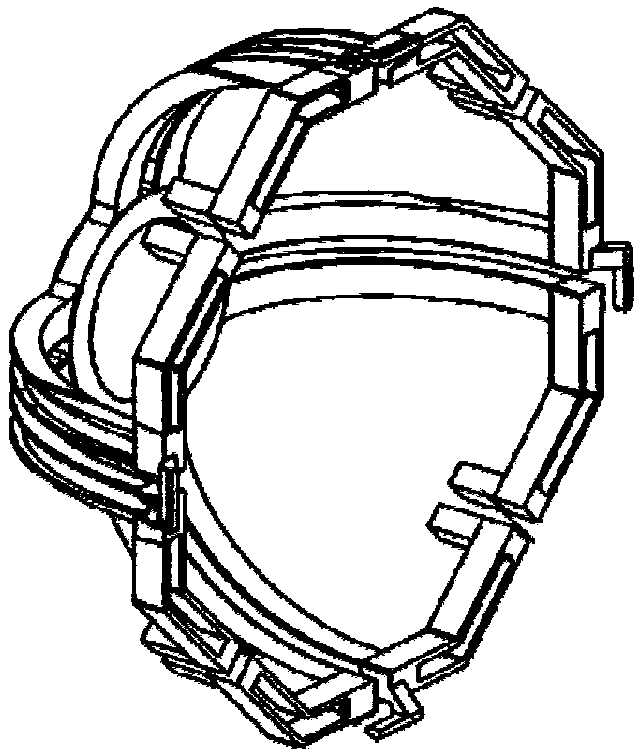

Low-frequency antenna oscillator and base station antenna

InactiveCN108717997AStable structureReduce production complexityAntenna supports/mountingsRadiating elements structural formsStructural deformationElectricity

The invention belongs to the technical field of mobile communication antenna equipment, and discloses a low-frequency antenna oscillator and a base station antenna. The low-frequency antenna oscillator comprises an oscillator PCB board, Balun PCB boards and a feeding PCB board; two pairs of dipoles are arranged on the oscillator PCB board, and the oscillator PCB board is used for forming a radiation face; each pair of dipoles comprises two opposed dipoles and polarization directions of the two dipoles are perpendicular mutually; each dipole comprises two radiation arms; four Balun PCB boards are provided in total; a parallel line Balun is arranged on each Balun PCB board; each parallel line Balun is used for carrying out feeding on one dipole; two feeding lines are arranged on the feedingPCB board; each Balun PCB board is respectively connected with the oscillator PCB board and the feeding PCB board; and the base station antenna comprises a feeding network, a signal input port and thelow-frequency antenna oscillator. The invention solves problems of relatively serious structural deformation, large oscillator size, heavy weight and complex assembling and welding of an antenna oscillator in the prior art.

Owner:WUHAN HONGXIN TECH DEV CO LTD

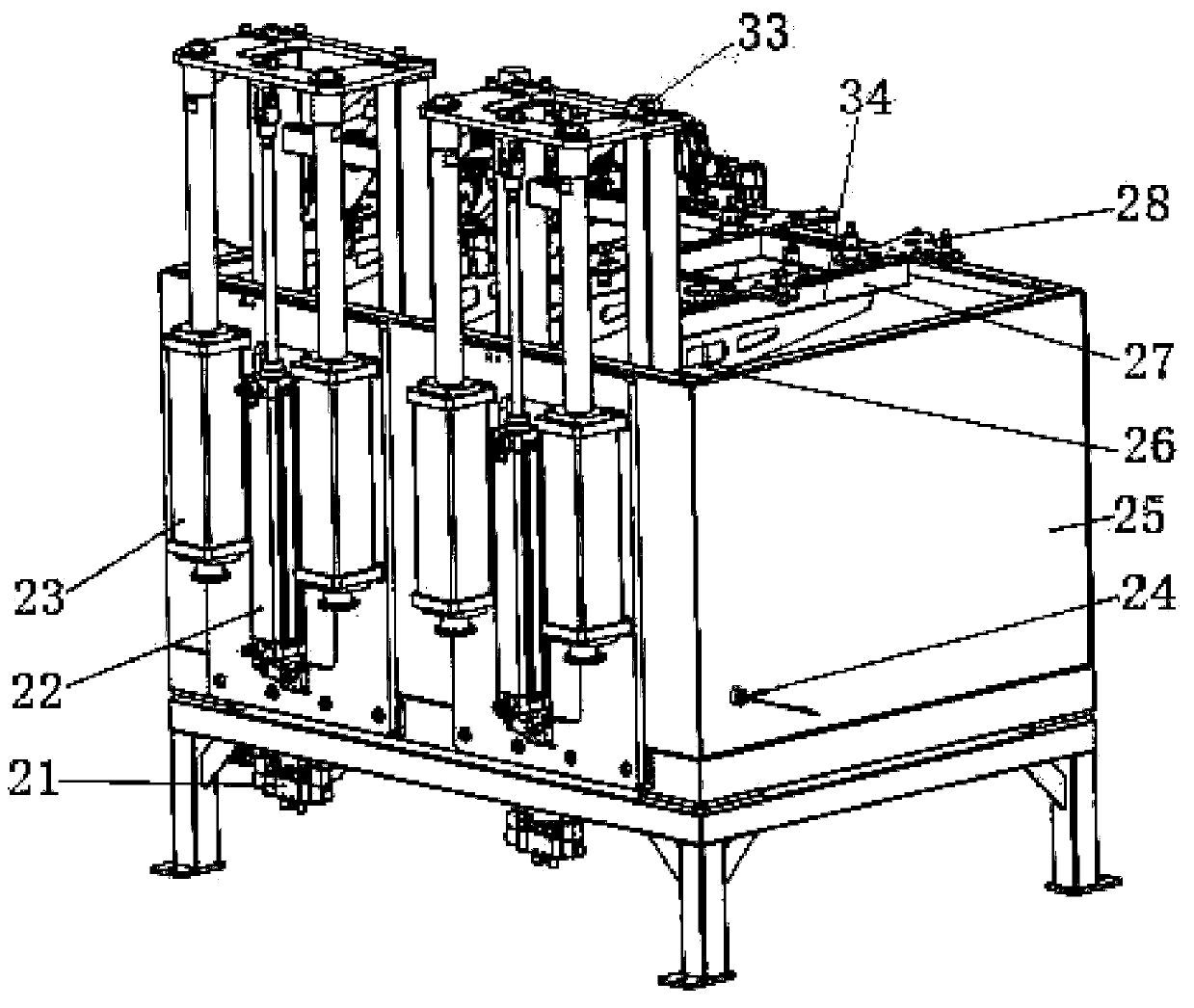

Tray automatic feeding device

ActiveCN109592424AAvoid displacement deviationAvoid uninterrupted reloadingConveyorsDe-stacking articlesEngineeringMechanical engineering

The invention discloses a tray automatic feeding device comprising a box assembly, a feeding mechanism and a discharge auxiliary mechanism. The box assembly comprises a holding space for stacking trays. The top of the box assembly is provided with a discharge outlet. The lower section of the lateral part of the box assembly is provided with a feeding inlet. The feeding mechanism comprises a lifting support and a first driving assembly for driving the lifting support. The discharge auxiliary mechanism comprises a tray pressing block and a second driving assembly for driving the tray pressing block. Empty trays are taken away immediately from the discharge outlet in the top of the box assembly, a user puts products with the trays into the holding space from the feeding inlet in the lateral part of the box assembly at intervals in the production process, continuous production can be ensured, and production cost is reduced. The multiple trays are taken automatically by the feeding mechanism, empty trays are sucked away automatically by a sucker of the next procedure, and automatic production efficiency is improved. The tray pressing block abuts against the tray of the uppermost layer,and displacement deviation of trays in the sucking process of the sucker of the next procedure can be avoided.

Owner:深圳市大族锂电智能装备有限公司

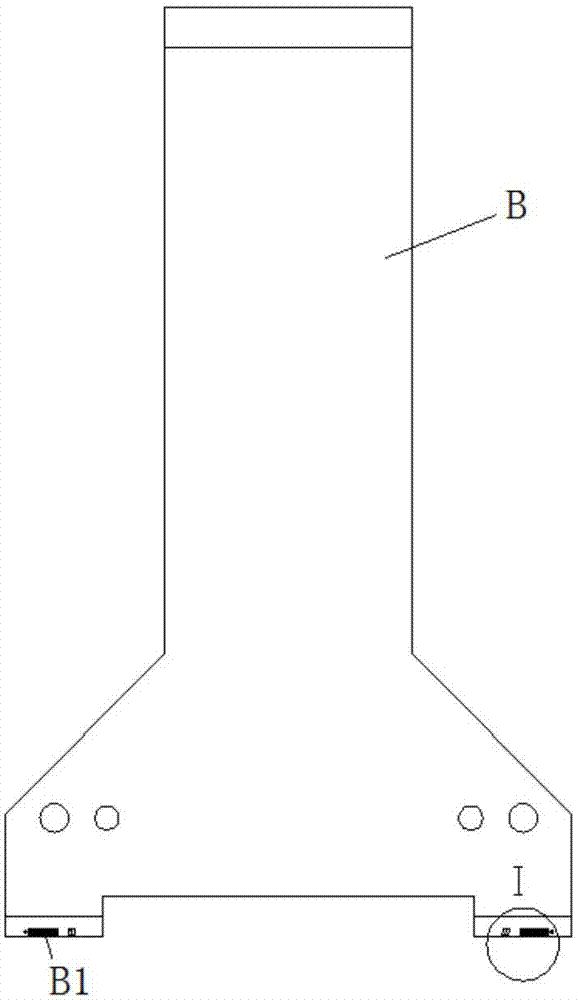

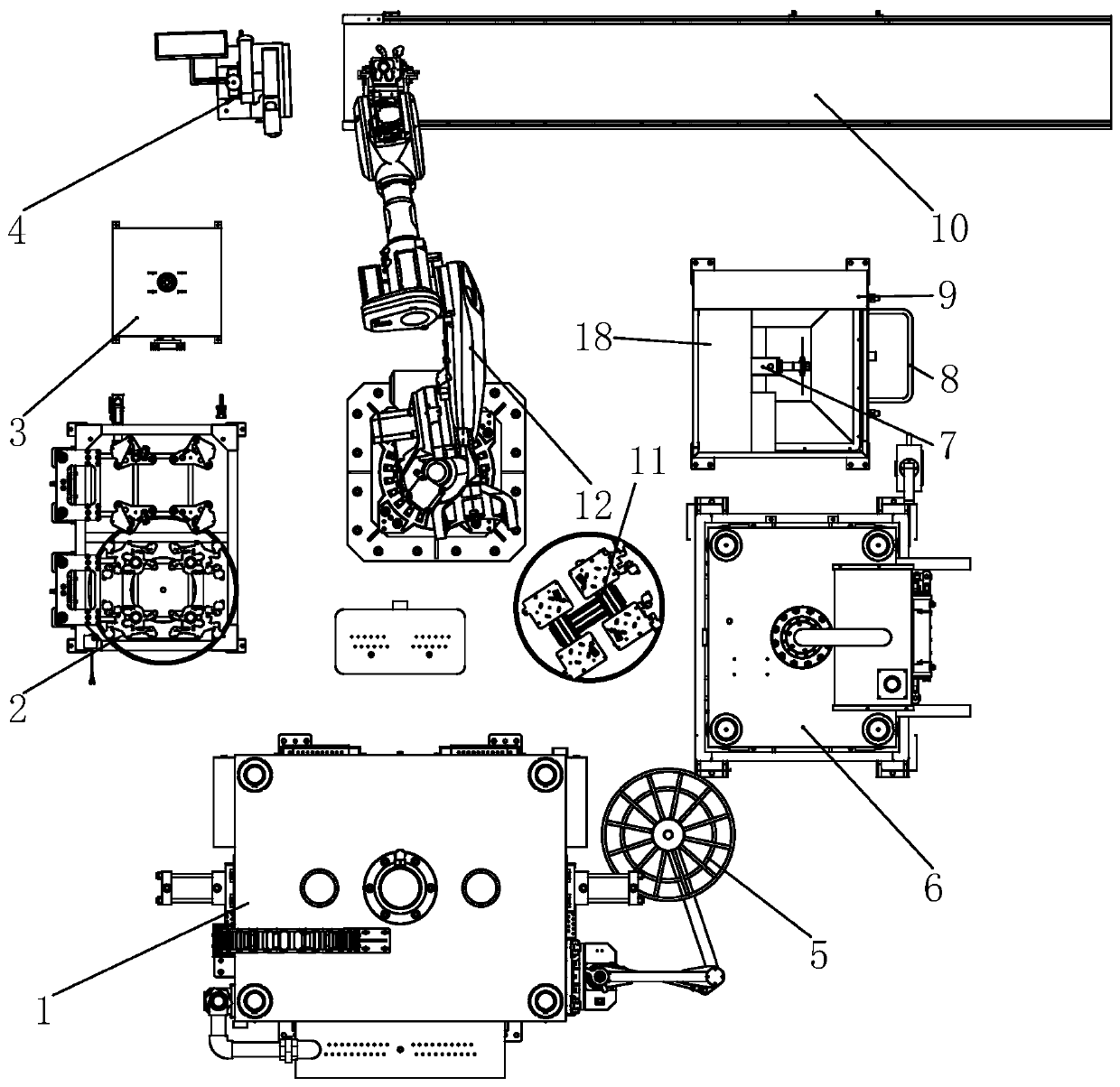

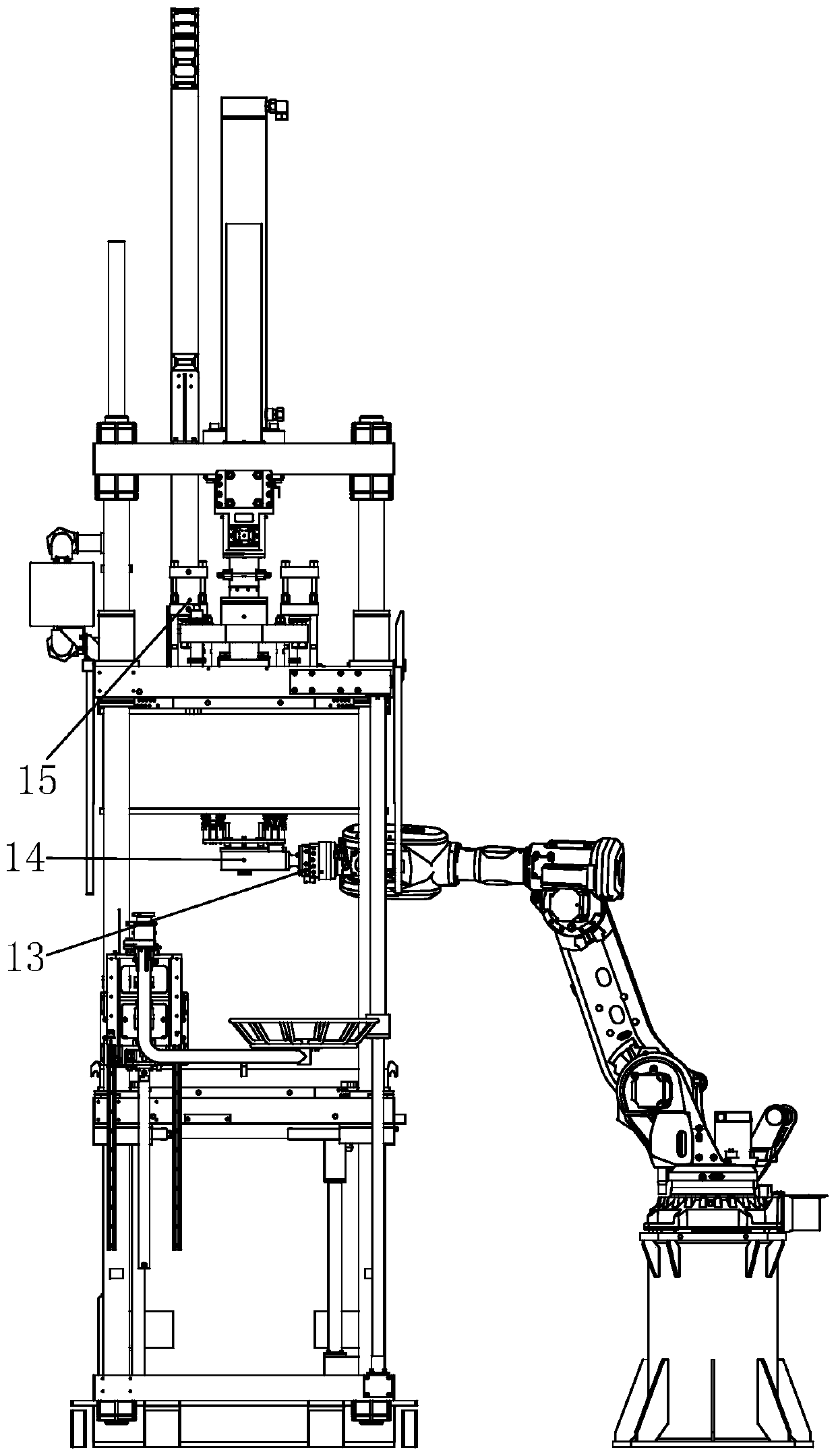

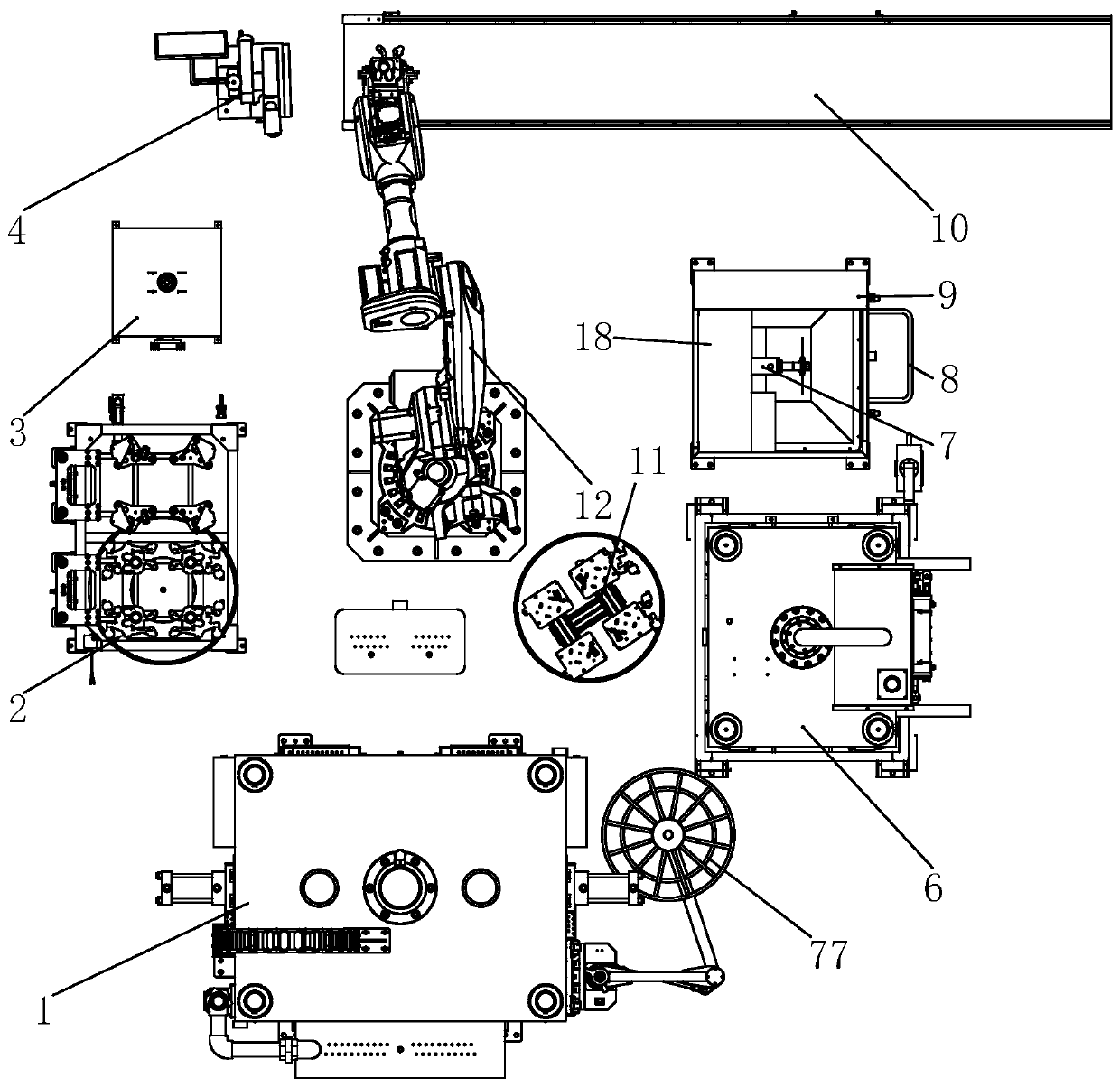

Metal part casting automation system

The invention relates to a metal part casting automation system. The metal part casting automation system comprises a casting machine, a robot, a casting cooling unit, a tool warehouse, a casting grabbing tool and a casting conveying unit. The casting cooling unit comprises a water tank and a casting positioning mechanism arranged on the water tank. The casting positioning mechanism comprises a bracket guide mechanism, a bracket driving mechanism and a soaking bracket, wherein the soaking bracket is arranged on the water tank. The bracket driving mechanism drives the soaking bracket to do linear movement in the vertical direction and immerse into the water tank. A plurality of sets of casting grabbing tools are arranged in the tool warehouse and comprise connecting arms, trays, tray driving mechanisms, tray guide mechanisms and clamping jaw driving mechanisms, wherein the connecting arms are arranged on a mechanical arm of the robot, and the trays are installed on the connecting arms.The tray driving mechanisms drive the trays to move in the guiding directions of the tray guiding mechanisms. The clamping jaw driving mechanisms are arranged on the top surfaces of the trays. The metal part casting automation system is reasonable in layout, high in universality and automation degree, simple and easy to use.

Owner:青岛航大新材料技术有限公司 +1

Multi-rod shrinking machine

InactiveCN104909004ASimple structureLow costPackagingSausage casing shirringButt jointPulp and paper industry

The invention discloses a multi-rod shrinking machine which comprises a frame, a shrinking mechanism, a shrinking rod, a cutting mechanism, a multi-rod receiving mechanism, a moving clamp, a first rod supporting clamp and a second rod supporting clamp, wherein the shrinking mechanism, the shrinking rod, the cutting mechanism, the multi-rod receiving mechanism, the moving clamp, the first rod supporting clamp and the second rod supporting clamp are mounted on the frame. The moving clamp is used for moving shrinking materials, and the first rod supporting clamp and the second rod supporting clamp are used for clamping the shrinking rod. The two ends of the shrinking rod are provided with a first air inlet and a first air outlet respectively. The first air inlet and the first air outlet are communicated with a first inner cavity. The two ends of each receiving rod are provided with a second air inlet and a second air outlet respectively. The second air inlet and the second air outlet are communicated with a second inner cavity. The second air inlet is connected with an inflation pump. When the receiving rod is in butt joint with the shrinking rod, air is conveyed to the shrinking rod from the receiving rod, and therefore the inflation process is completed. The mode that through a traditional technology, inflation is completed through a vacuum pump is replaced, the structure is simple, cost is effectively lowered, automatic production efficiency is improved, and market popularization is facilitated.

Owner:莫少难

Continuous type stirring device

PendingCN107261919ARealize flow operationImprove automation production efficiencyRotary stirring mixersTransportation and packagingImpellerAssembly line

The invention discloses a continuous type stirring device. The continuous type stirring device comprises a shell body, a rotor, a stirring impeller and a dialing impeller, wherein the shell body serves as a stator, and the rotor, the stirring impeller and the dialing impeller synchronously rotate in the shell body; and the shell body has a material inlet in the top and a lateral material outlet which is formed in the bottom and is over against the dialing impeller, the stirring impeller is arranged below the rotor, and the dialing impeller is arranged below the stirring impeller. According to the continuous type stirring device disclosed by the invention, charging and discharging can be carried out uninterruptedly, assembly line operation of continuously stirring materials is achieved, and thus, the efficiency of automated production is greatly increased; and large-sized space equipment is not required, so that the production cost is reduced.

Owner:广东友为实业有限公司

Shearing apparatus of metal sheet

ActiveCN102814657AEasy to operateLower skill requirementsOther manufacturing equipments/toolsElectrical controlEngineering

The invention discloses a shearing apparatus of a metal sheet. The shearing apparatus of the metal sheet comprises a shearing mechanism and a metal sheet roll, and further comprises an uncoiling mechanism, a straightening mechanism, a hydraulic power system and an electrical control system, wherein the metal sheet roll is sleeved on a collapsible curling head of the uncoiling mechanism, the curled metal sheet penetrates between two rows of straightening rollers of the straightening mechanism and then is arranged below a shearing cutter in the shearing mechanism. According to the shearing apparatus of the metal sheet, the shearing operation of the metal sheet is simple, the processes of uncoiling, strengthening and shearing to the metal sheet can be finished at one time, the automatic production efficiency is high, required operation workers are less, the skill requirement of automatic production on the workers is low, the applicable personnel range is wide, the distance between a positioning staff gauge and the shearing cutter is adjustable, the shearing requirements of metal sheets in different lengths can be satisfied, and the production efficiency is greatly improved.

Owner:ANHUI CHUJIANG TECHCAL NEW MATERIAL CO LTD

Hinge pin cutting mechanism

The invention discloses a hinge pin cutting mechanism, which comprises a bracket, a transmission main shaft, a spring, a cam, a push rod, a static cutting module, a movable cutting module and a blanking hole, wherein the bracket is provided with the transmission main shaft; the transmission main shaft is provided with the cam; the push rod is arranged vertical to the transmission main shaft; the cam is connected with the push rod; the movable cutting module is arranged at the front end of the push rod; the static cutting module and the movable cutting module are arranged in parallel; the blanking hole is formed below the movable cutting module. Through the way, the hinge pin cutting mechanism disclosed by the invention has the advantages of high reliability, compact structure, high adaptability, high automatic production efficiency, stable product quality, adjustable product size and the like; meanwhile, the hinge pin cutting mechanism has a wide market prospect in the field of chain transmission manufacturing equipment.

Owner:SUZHOU SHUNGE INTELLIGENT TECH

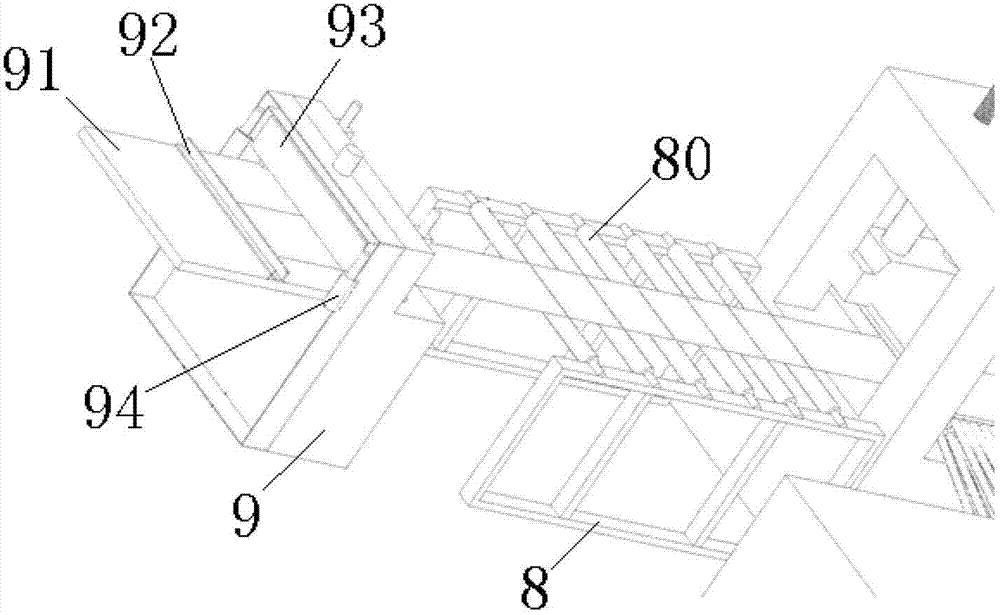

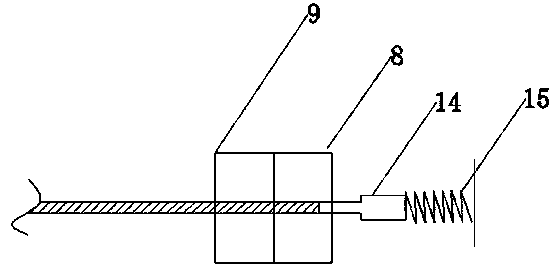

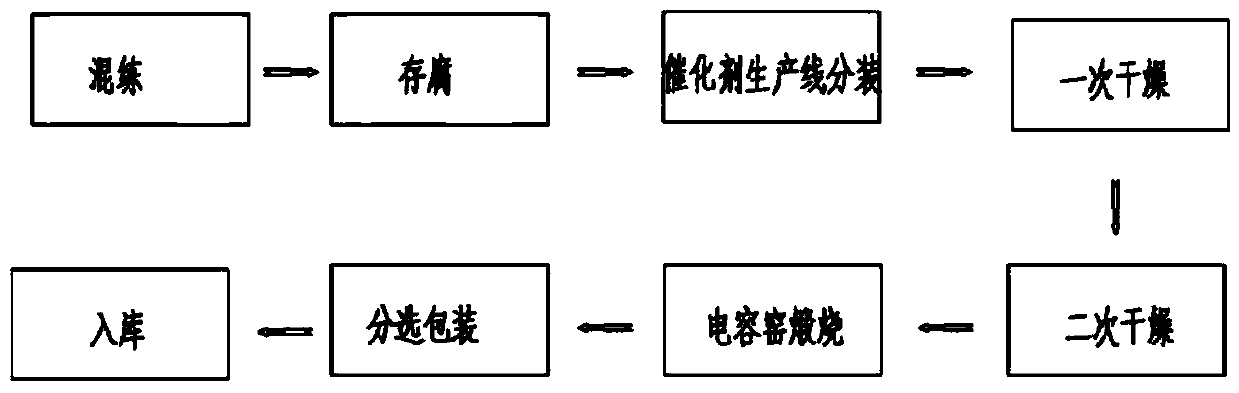

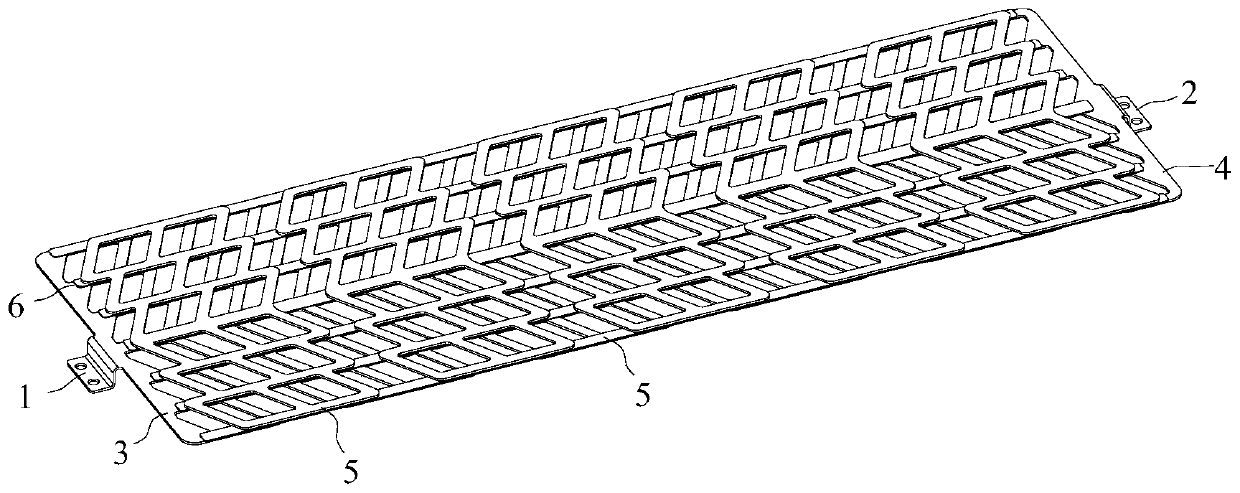

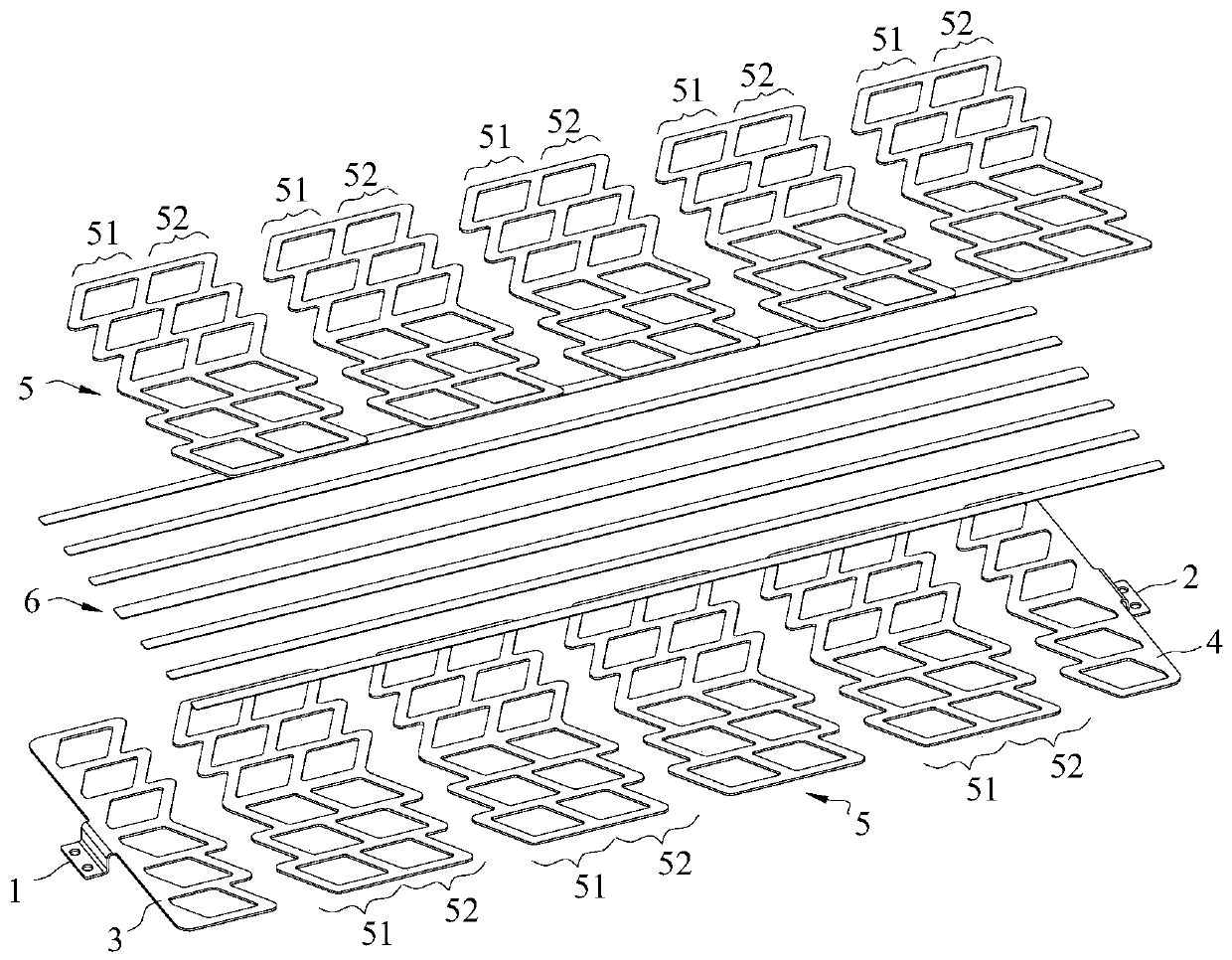

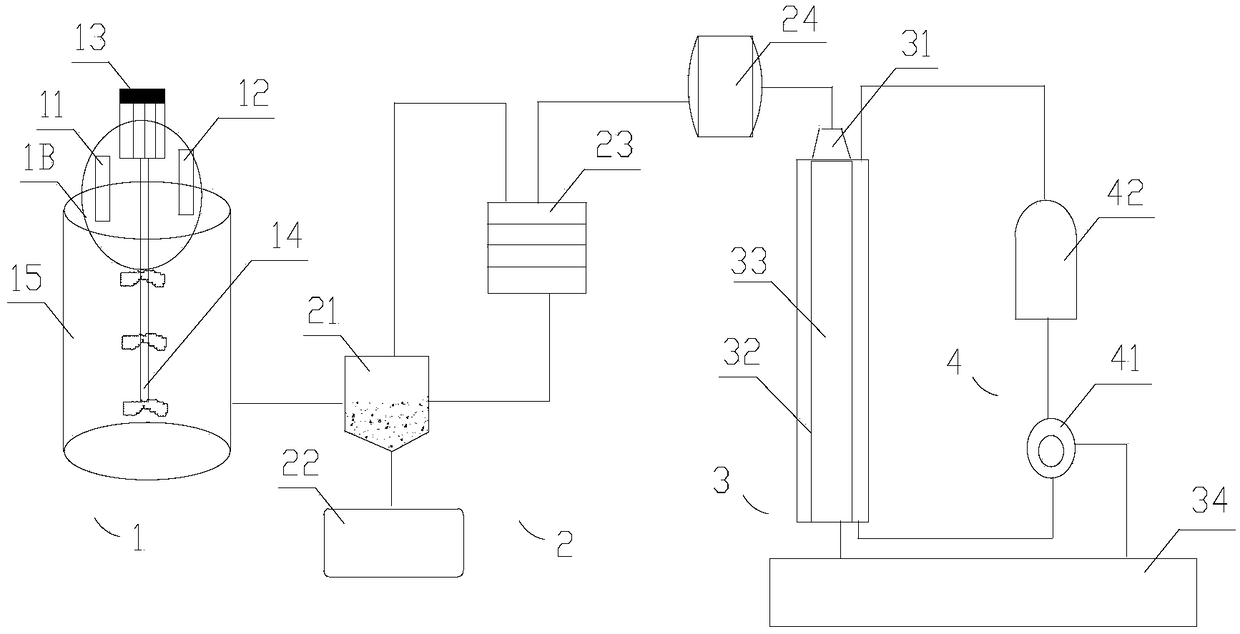

SCR catalyst production system

InactiveCN104190476AImprove automation production efficiencySmall amount of deformationDrying gas arrangementsCatalyst activation/preparationCapacitanceConveyor belt

The invention discloses an SCR catalyst production system which comprises a mixer, a storage room, an automatic production line, a primary drying kiln, a secondary drying kiln, a capacitance kiln and the like, wherein the production line mainly comprises a product conveying line, a tray loading and unloading system, an upper cover loading and unloading system and a catalyst loading and unloading system; the primary drying kiln comprises a primary drying kiln body, a product conveying system, a gas circulation control system, a temperature control system and a humidity control system; the secondary drying kiln comprises a kiln body, a steam pipeline, a frequency conversion control axial flow fan, a humidity control system and a kiln vehicle guide rail; and the capacitance kiln comprises a kiln body, a conveyor belt and a moisture removal system. A catalyst blank production line is automatically assembled, and the automatic production efficiency is greatly improved. According to the production process generated by the unique structure of the drying kilns, the product deformation is reduced, and the rejection rate is reduced. The products are conveyed in the capacitance kiln by adopting ceramic roller rods, the production system is stable in structure, difficult to deform and high in firing yield and achieves heating of heating wires.

Owner:江苏宇达环保科技股份有限公司

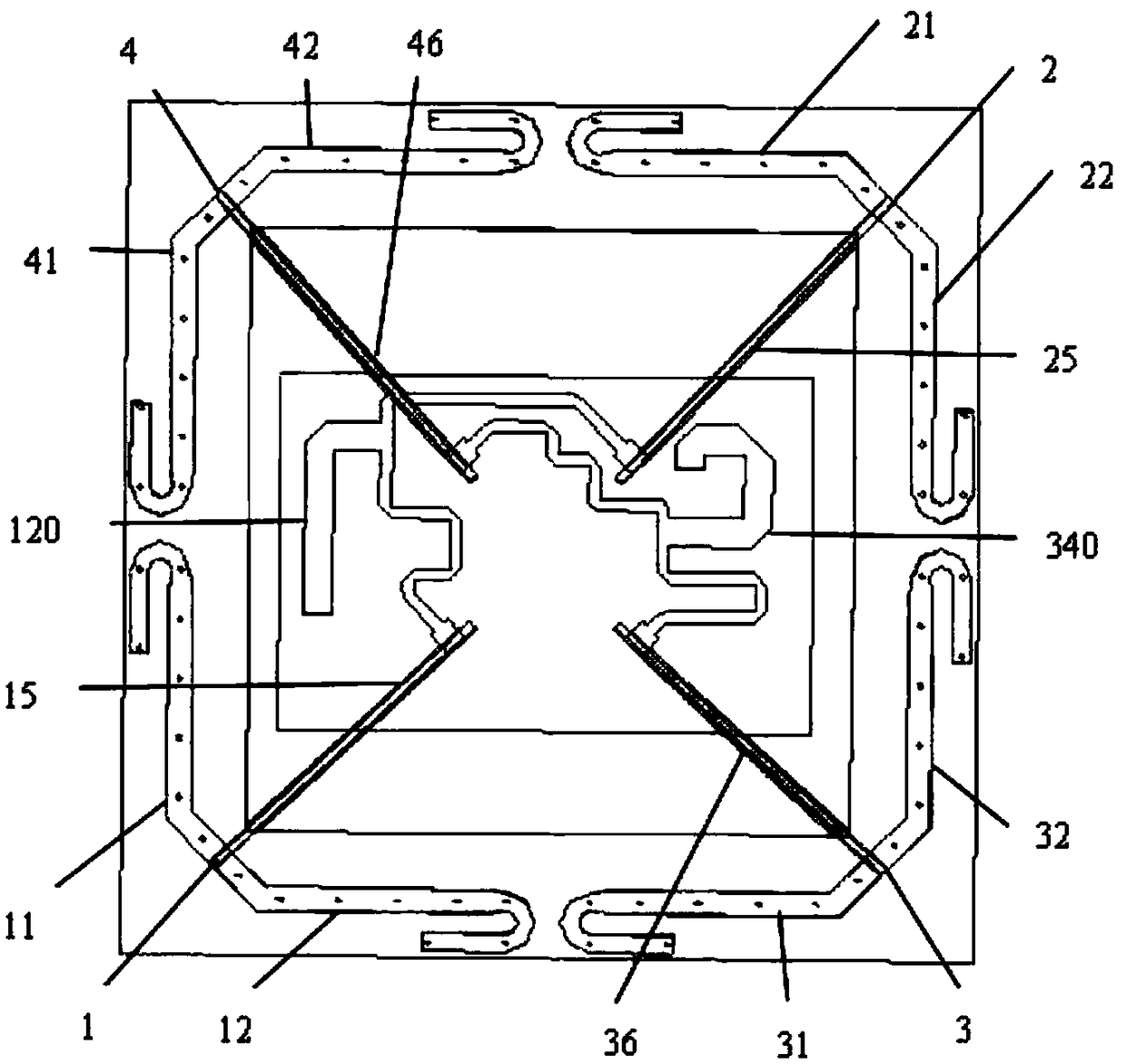

Busbar structure and cell module

PendingCN109860495AEnsure insulation safetyRealize one-sided confluenceCell component detailsBusbarEngineering

The invention discloses a busbar structure and a cell module. The busbar structure comprises: a positive output pole; a negative output pole; a positive output pole busbar connected with the positiveoutput pole; a negative pole busbar connected with the negative output pole; and a plurality of intermediate busbars having a cell anode connection portion and a cell cathode connection portion, wherein the cell anode connection portion of the first intermediate busbar and the positive output pole busbar are insulated from each other and are distributed in a stack mode, and the cell cathode connection portion of the last intermediate busbar and the negative pole busbar are insulated from each other and are distributed in a stack mode. The cell module comprises a module holding member providedwith a cell matching structure; the cell array comprises a plurality of monomer cells which have cathodes facing the module holding member and are matched with the cell matching structure. The busbarstructure is arranged on the module holding member, the monomer cells of the cell array are connected through the busbar structure to form the cell module. The product process can be effectively simplified, the production process is reduced, and the production cost is saved.

Owner:GUANGZHOU XIAOPENG MOTORS TECH CO LTD

Manual and rapid screwdriver

The invention discloses a manual and rapid screwdriver which comprises a handle, a sleeve, a magnet, a replaceable screwdriver head, a ratchet wheel mechanism, a spring, a threaded rod, a connecting rod and a button. The ratchet wheel mechanism is arranged at the front end of the handle, the sleeve is arranged in front of a ratchet wheel, the magnet is arranged in the sleeve, the replaceable screwdriver head is connected in the sleeve in a sleeved mode, a threaded rod hole is formed in the axis direction of the handle, the threaded rod is arranged in the threaded hole, the front end of the threaded rod is connected with the ratchet wheel mechanism, the spring is arranged on the threaded rod in a sleeved mode, the connecting rod is arranged on the threaded rod in a sleeved mode, and the button is arranged at the tail end of the connecting rod. Due to the mode, the manual and rapid screwdriver has the advantages of being high in reliability, compact in structure, good in adaptability, high in automatic production efficiency, easy and convenient to operate, high in product precision and the like and meanwhile having wide market prospects in the field of die devices.

Owner:SUZHOU DODRON MACHINERY MFG

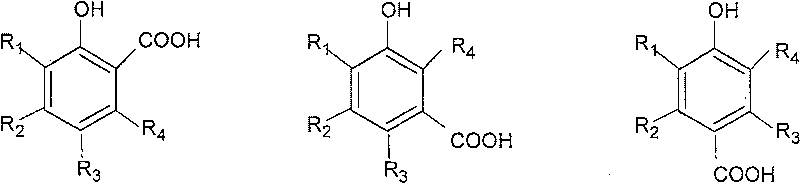

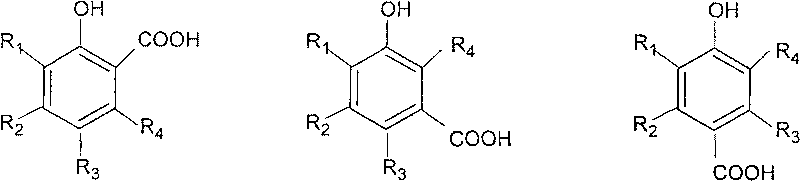

Photocureable etching-resistant printing ink

InactiveCN1693382AThere is no problem of insolubilityThere is no problem of difficult film removalPhotomechanical apparatusInksSolubilityDiluent

An optically solidified ink resisting to etching for PCB features that it contains the resin soluble in the aqueous solution of alkali and photosensitive diluent, and its solidified film has linear molecular structure easy to dissolve in the aqueous solution of alkali.

Owner:RONGDA PRINTING INK HUIZHOU

Device for preparing lithium hydroxide micro-nano powder

PendingCN109502611ASolve carbonizationSimple processMaterial nanotechnologyLithium oxides/hydroxidesMicro nanoLithium hydroxide

The invention provides a device for preparing lithium hydroxide micro-nano powder. The device is characterized by comprising a reaction system, a concentration regulation and control system, a spraying and drying system and a gas circulating system, wherein the reaction system comprises a feeding opening A, a feeding opening B, a motor, a stirrer and a reaction container; the concentration regulation and control system comprises a settling tank, a calcium carbonate storage tank, a filter and an evaporation concentrator; the spraying and drying system comprises an atomizer, an induction coil, an atomization drying cavity and a lithium hydroxide powder collection chamber; the gas circulating system comprises a gas filter and a nitrogen gas generator. By adopting the device for preparing thelithium hydroxide micro-nano powder provided by the invention, the problems that the average powder granularity is difficultly thinned in an existing lithium hydroxide preparation process and moistureabsorption and carbonization are easy to occur in a preparation process are effectively solved; the device has the advantages of simple technology, high efficiency, low production cost, greenness andno pollution and can be used for preparing the lithium hydroxide micro-nano powder in a large scale.

Owner:湖南众德新材料科技有限公司

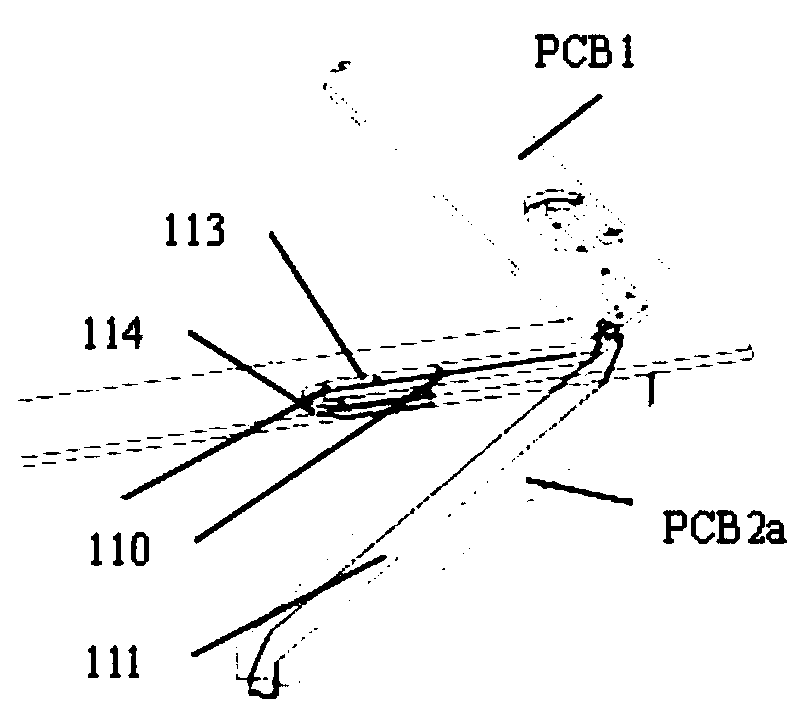

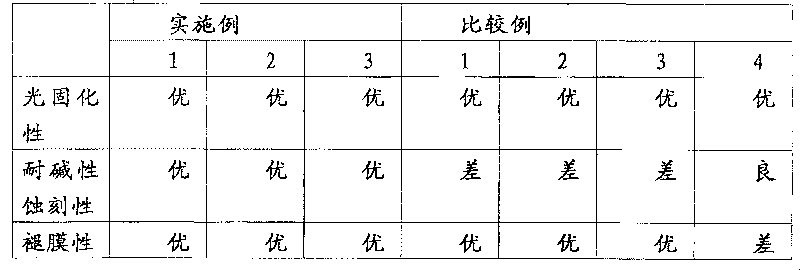

UV solidified alkali resistant etching ink composition and uses thereof

ActiveCN101220224BImprove automation production efficiencyEasy to fadePhotomechanical apparatusInksSolubilityPrinting ink

Owner:深圳市容大感光科技股份有限公司

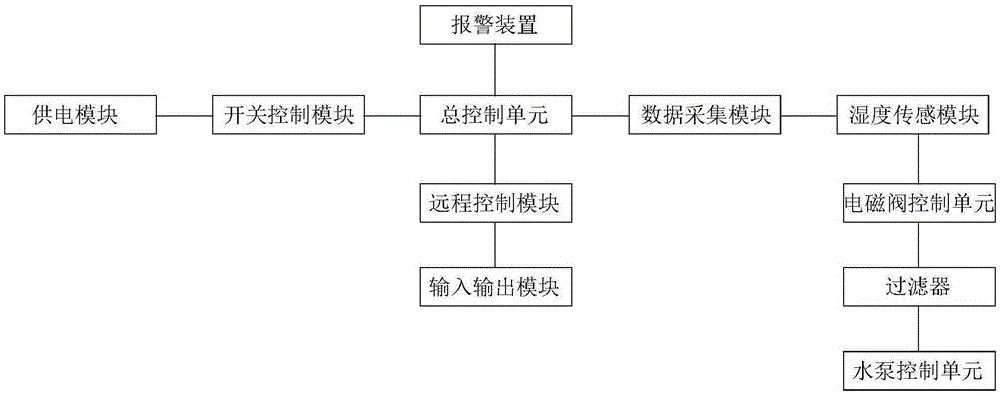

Remote control irrigation system

InactiveCN105379610AReduce labor costsImprove automation production efficiencyWatering devicesCultivating equipmentsAgricultural engineeringIrrigation

The invention discloses a remote control irrigation system. The remote control irrigation system comprises a master control unit, a data acquisition module, a humidity sensing module, an electromagnetic valve control unit, a water pump control unit, a remote control module, an input / output module, a switch control module and a power supply module, the master control unit is in telecommunication connection with the data acquisition module, the data acquisition module is in telecommunication connection with the humidity sensing module, the humidity sensing module is in telecommunication connection with the electromagnetic valve control unit, the electromagnetic valve control unit is connected with the water pump control unit, the master control unit is further in telecommunication connection with the remote control module, the remote control module is in telecommunication connection with the input / output module, the switch control module is connected with the master control unit, and the power supply module is connected with the master control unit.

Owner:CHONGQING XUANNU BIOTECH

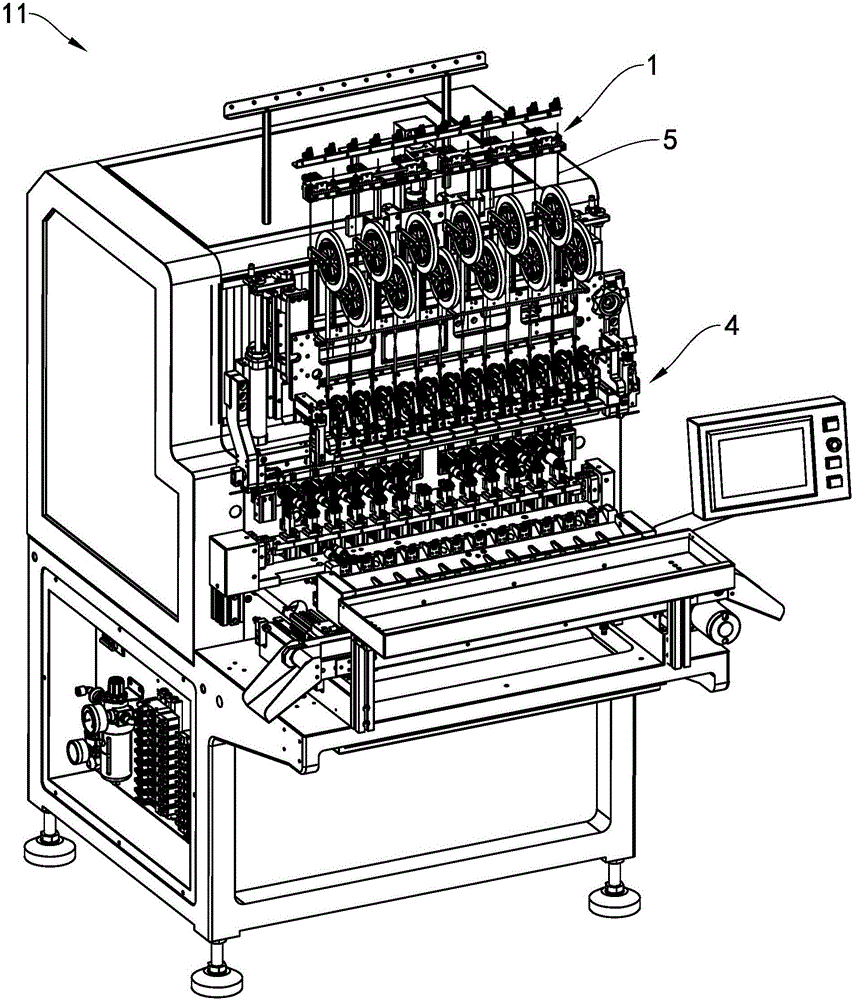

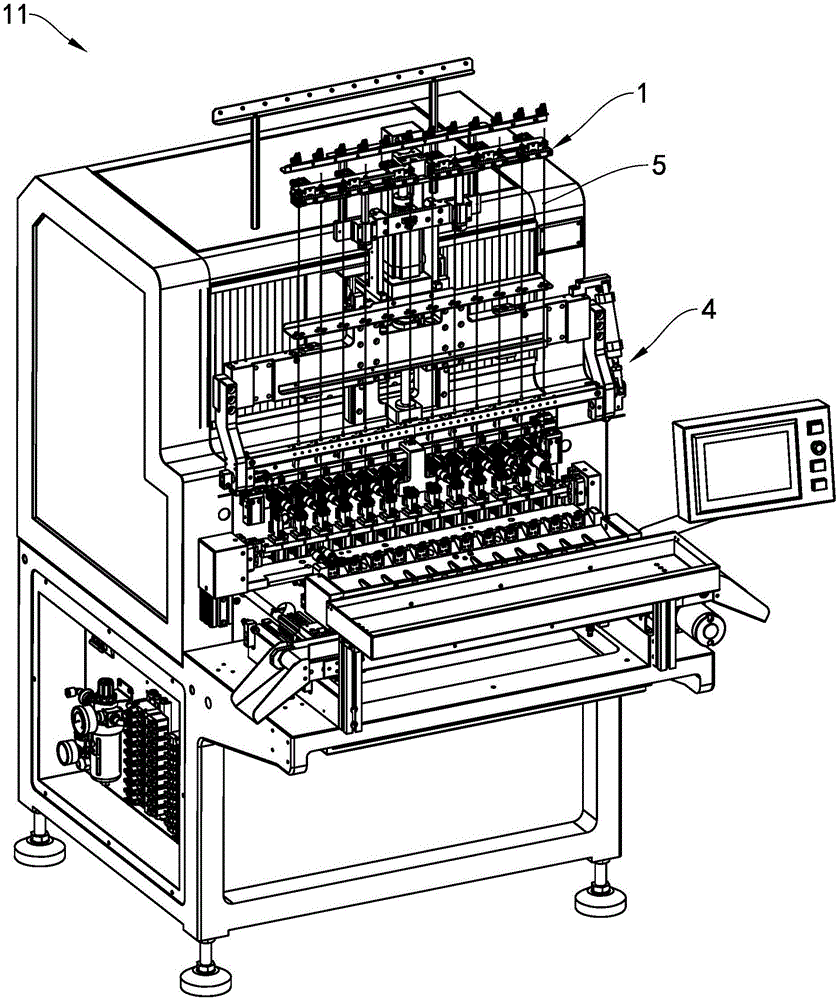

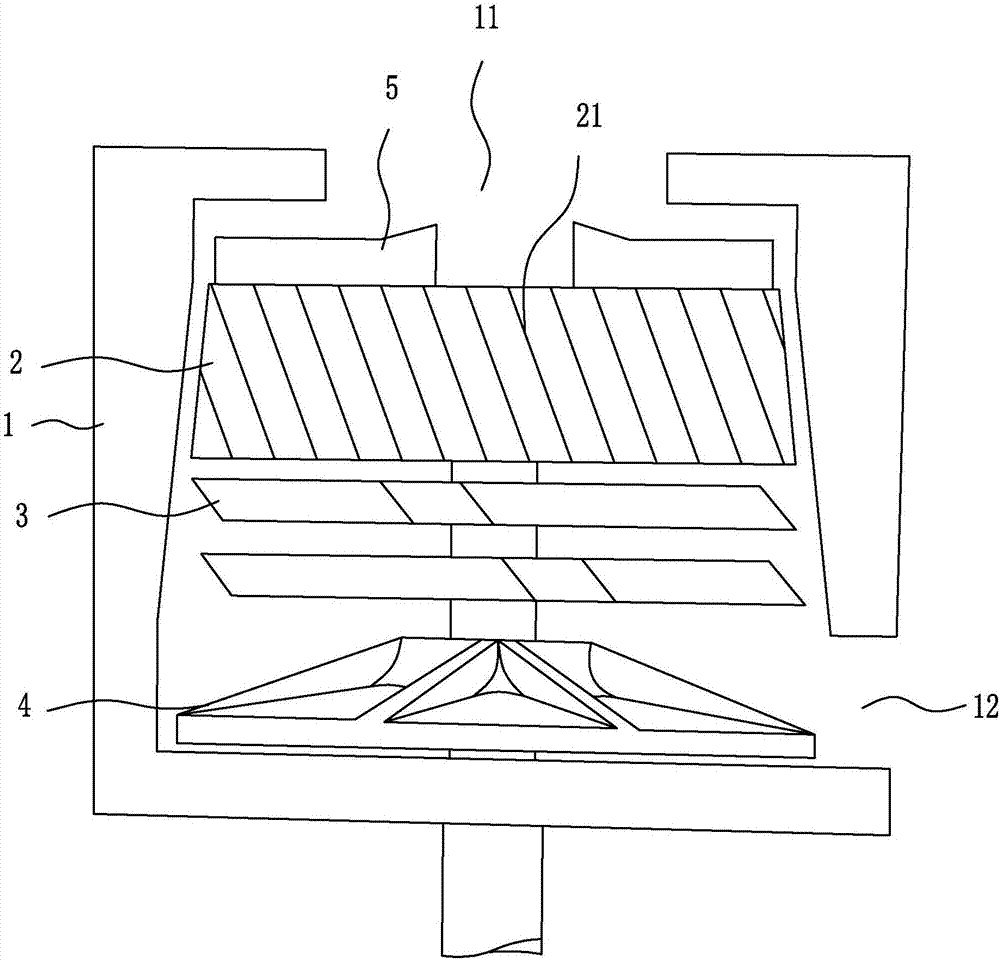

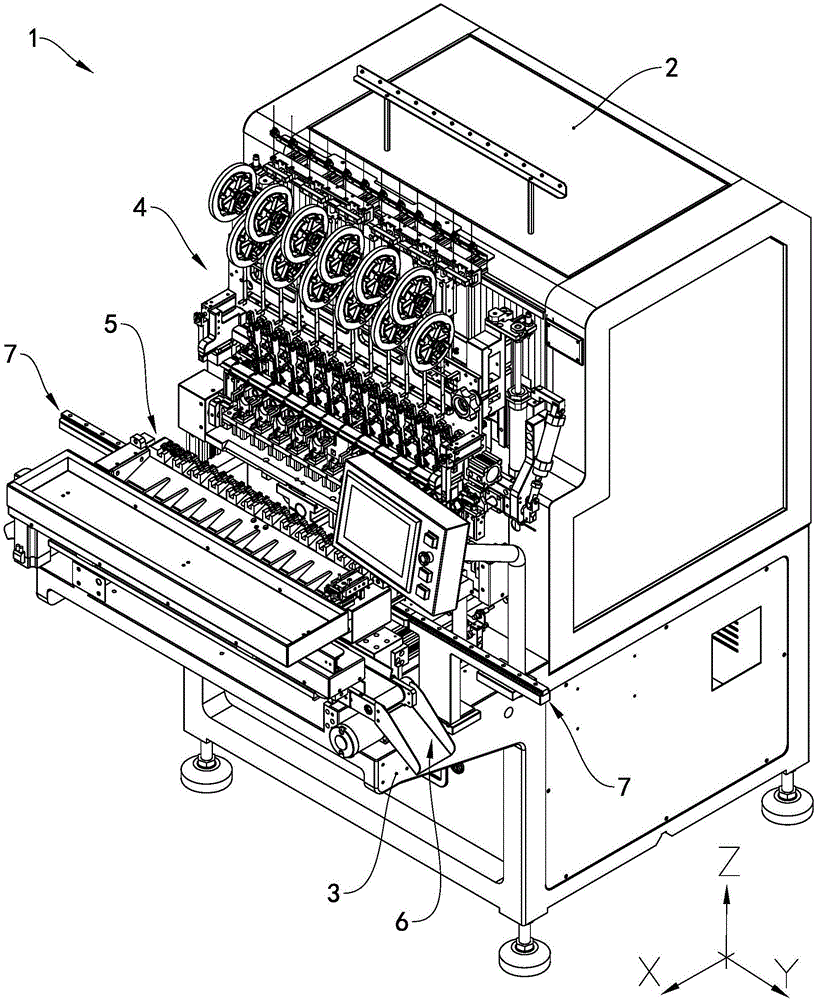

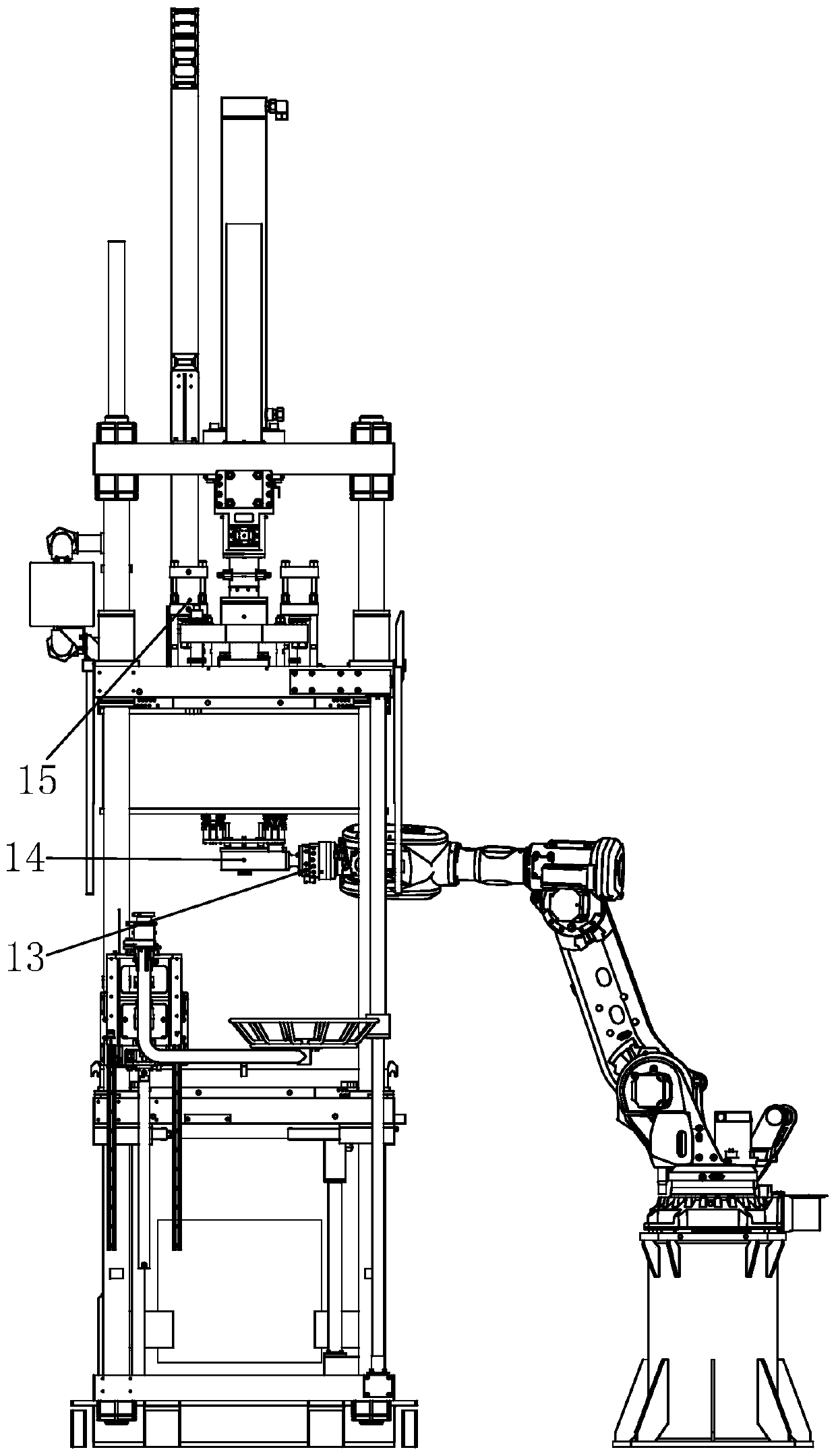

Wire winding machine, wire winding machine production line and production method

ActiveCN106384663ASimple structureImprove stabilityInductances/transformers/magnets manufactureConveyor partsWinding machineProduction line

The invention provides a wire winding machine, a wire winding machine production line and a production method. The wire winding machine production line comprises a feeding machine, a wire winding machine and a post-processing machine, wherein the wire winding machine is connected between the feeding machine and the post-processing machine; the wire winding machine comprises a wire winding mechanism, an X-axis moving mechanism, a Z-axis moving mechanism and a feeding device; the Z-axis moving mechanism is used for controlling the feeding device to move; the X-axis moving mechanism is used for controlling the Z-axis moving mechanism and the feeding device to move; the feeding device comprises a movable guide rail, a first workpiece clamp and a Y-axis moving mechanism; the Y-axis moving mechanism controls the first workpiece clamp to move on the movable guide rail; and the first workpiece clamp is used for a clamping a to-be-processed workpiece and taking out the processed workpiece. The production line is used for producing by increasing or reducing number of wire winding machines according to the coil model and the winding number alteration, so that the mode of alternating the production line is simplified, the debugging difficulty is reduced, the production efficiency is improved, and the production cost is reduced.

Owner:珠海市艾森工匠科技有限公司

Automatic casting system

The invention discloses an automatic casting system which comprises a casting machine, a robot, a casting cooling unit, a tool magazine, a plurality of casting grabbing tools and a casting conveying unit. A receiving device is arranged on a casting machine rack and comprises a sliding rack, a receiving guiding mechanism, a large rotary arm, a pull rod, a receiving bracket an d a receiving plate; the casting cooling unit comprises a water tank and a casting positioning mechanism; the casting positioning mechanism comprises an immersing bracket guiding mechanism, an immersing bracket driving mechanism and an immersing bracket; the immersing bracket driving mechanism drives the immersing bracket to be immersed into the water tank; the casting grabbing tools are placed in the tool magazine andeach casting grabbing tool comprises a connecting arm, a tray, a tray driving mechanism, a tray guiding mechanism and a chuck driving mechanism; the connecting arm is mounted on a manipulator of therobot, and the tray is mounted on the connecting arm; the tray driving mechanism drives the tray to move; and the chuck driving mechanism is mounted on the tray. The automatic casting system is reasonable in layout, high in universality, high in automatic degree and simple and easy to use.

Owner:青岛航大新材料技术有限公司 +1

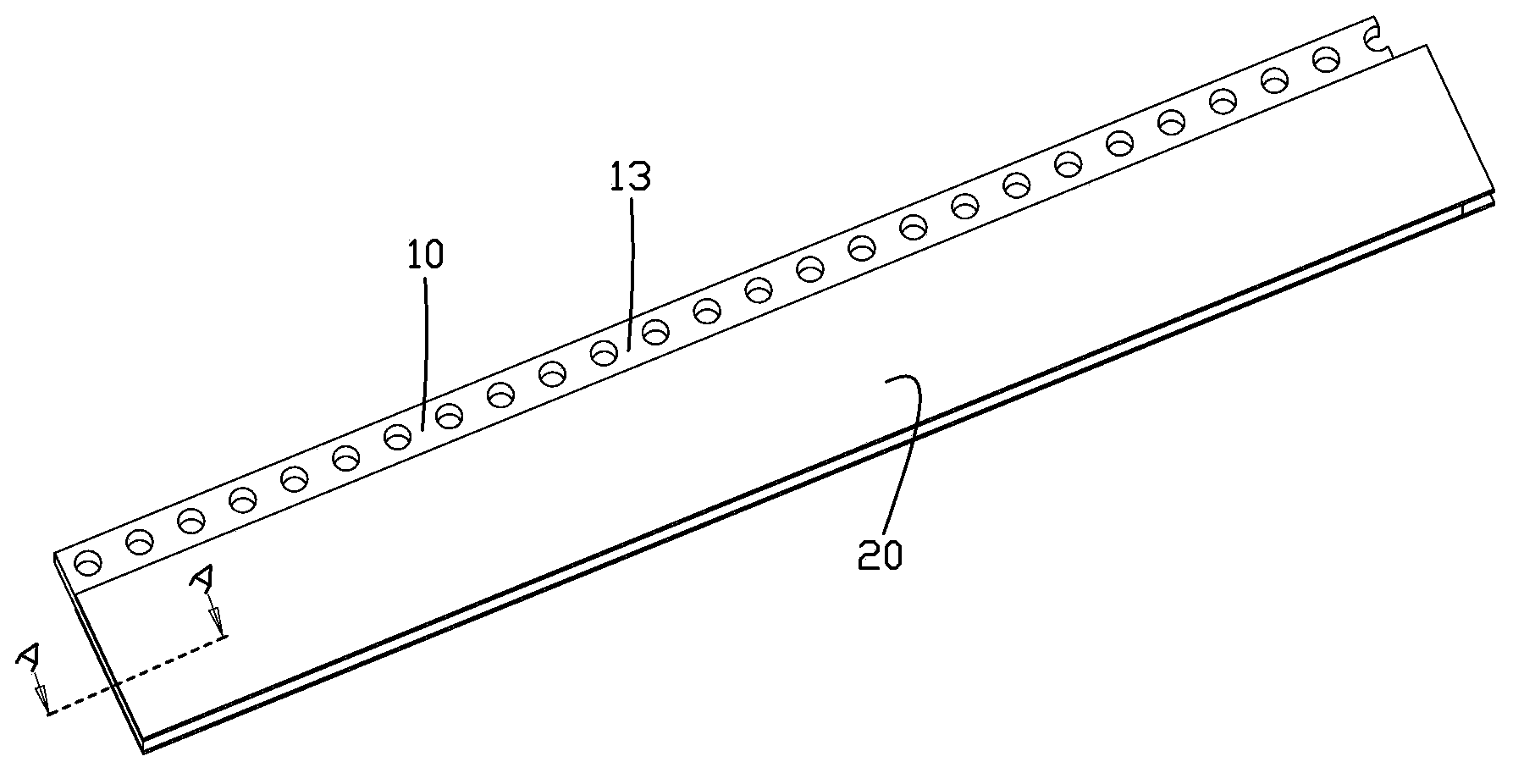

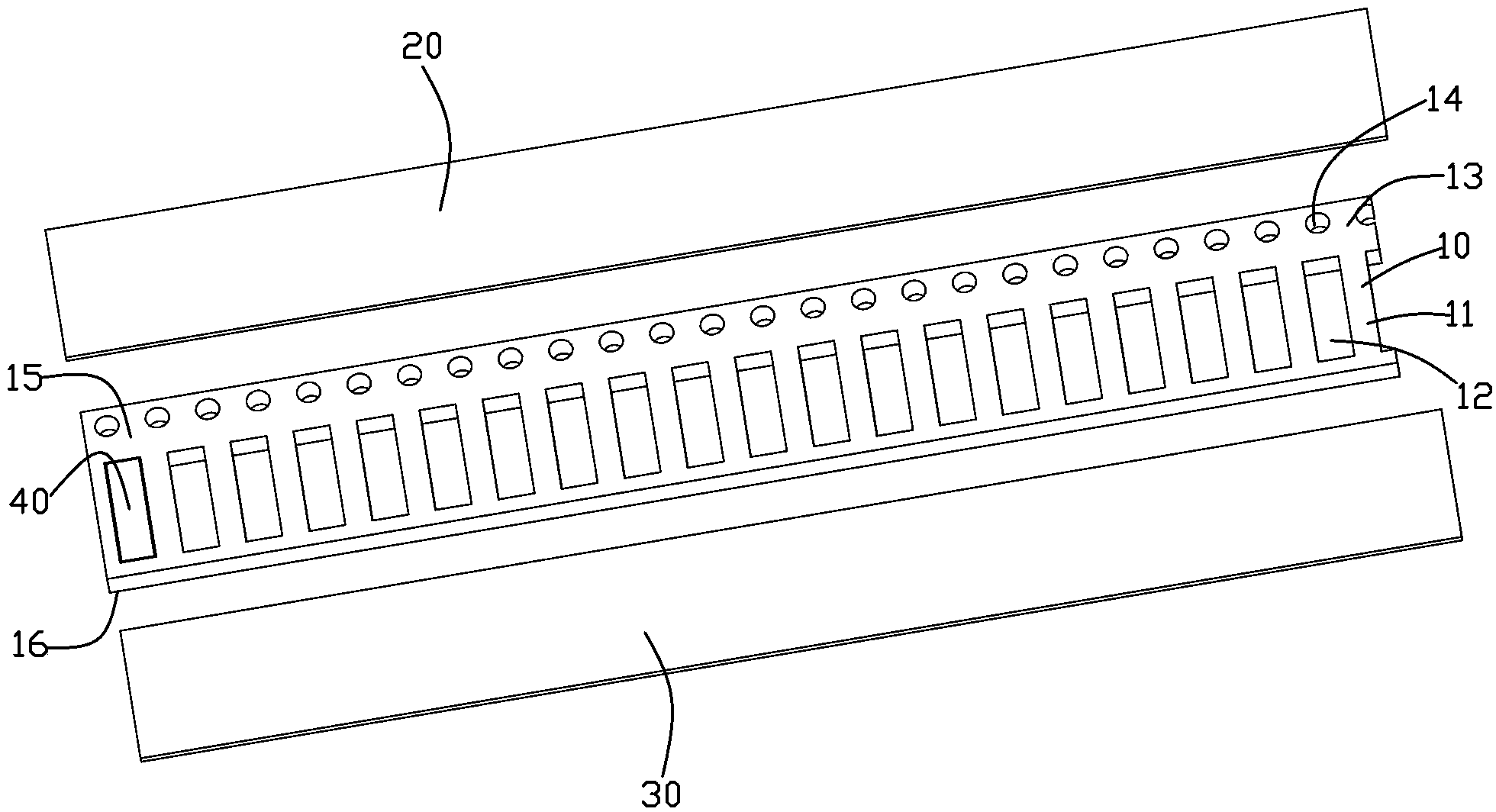

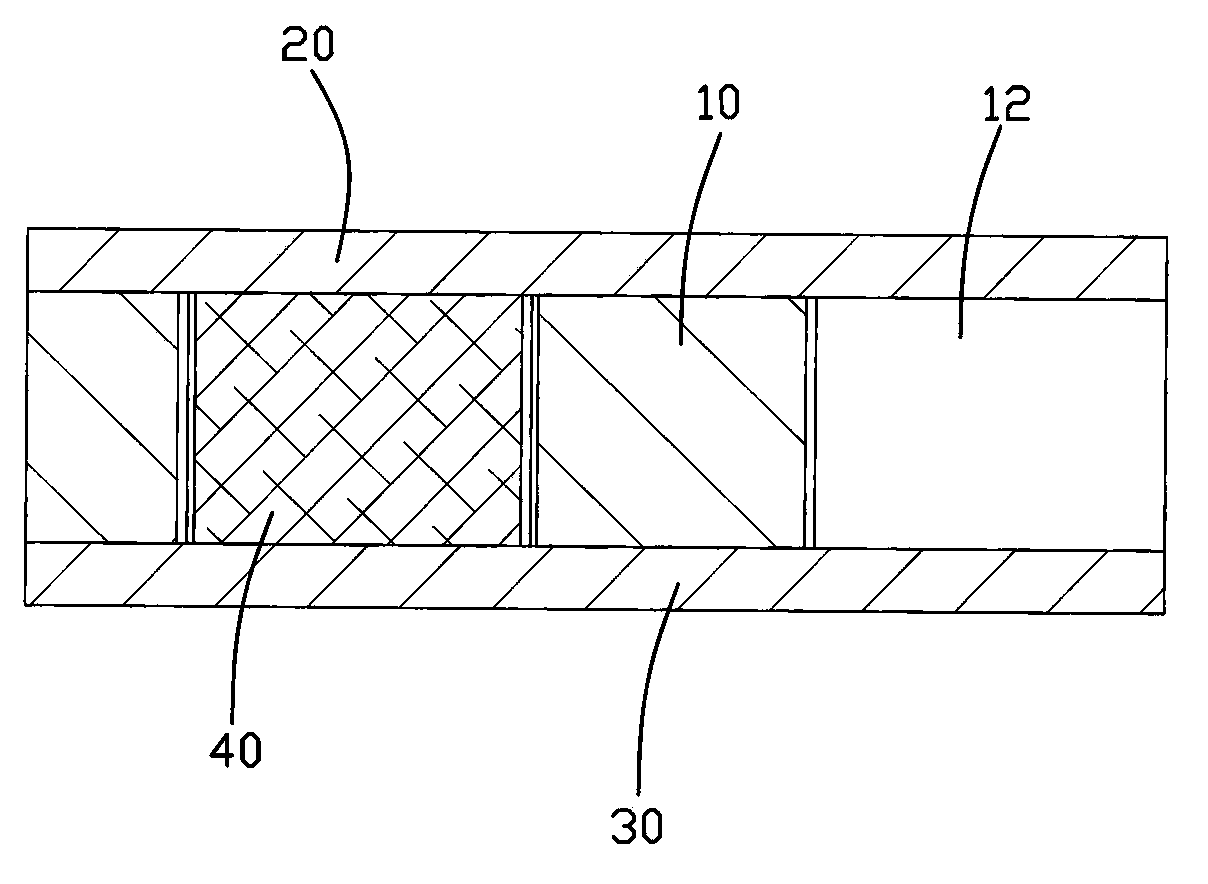

Package for thin type products and packing method thereof

InactiveCN104071452AAvoid the defect of R angleImprove automation production efficiencyPackagingEngineeringElectrical and Electronics engineering

A package for thin type products comprises a carrier band, an upper cover band and a lower cover band. The carrier band comprises a base part and a fixed part formed on one side of the base part. The base part is provided with a plurality of packing grooves penetrating the base part in the vertical direction and used for packing the thin type products, the lower cover band covers the bottom surface of the carrier band so as to cover the packing grooves from above, and the upper cover band covers the top surface of the carrier band so as to cover the packing grooves from below. The package for the thin type products can greatly improve automatic production efficiency and product yield.

Owner:SHENZHEN EVERWIN PRECISION TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com