Patents

Literature

74results about How to "Avoid displacement deviation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

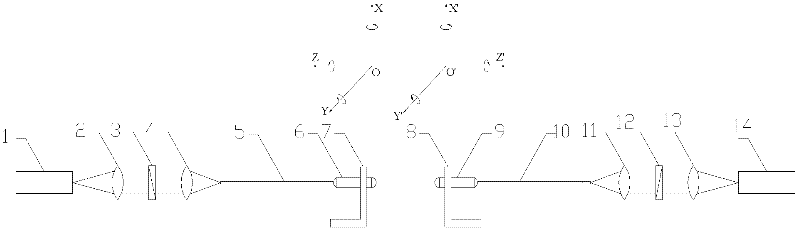

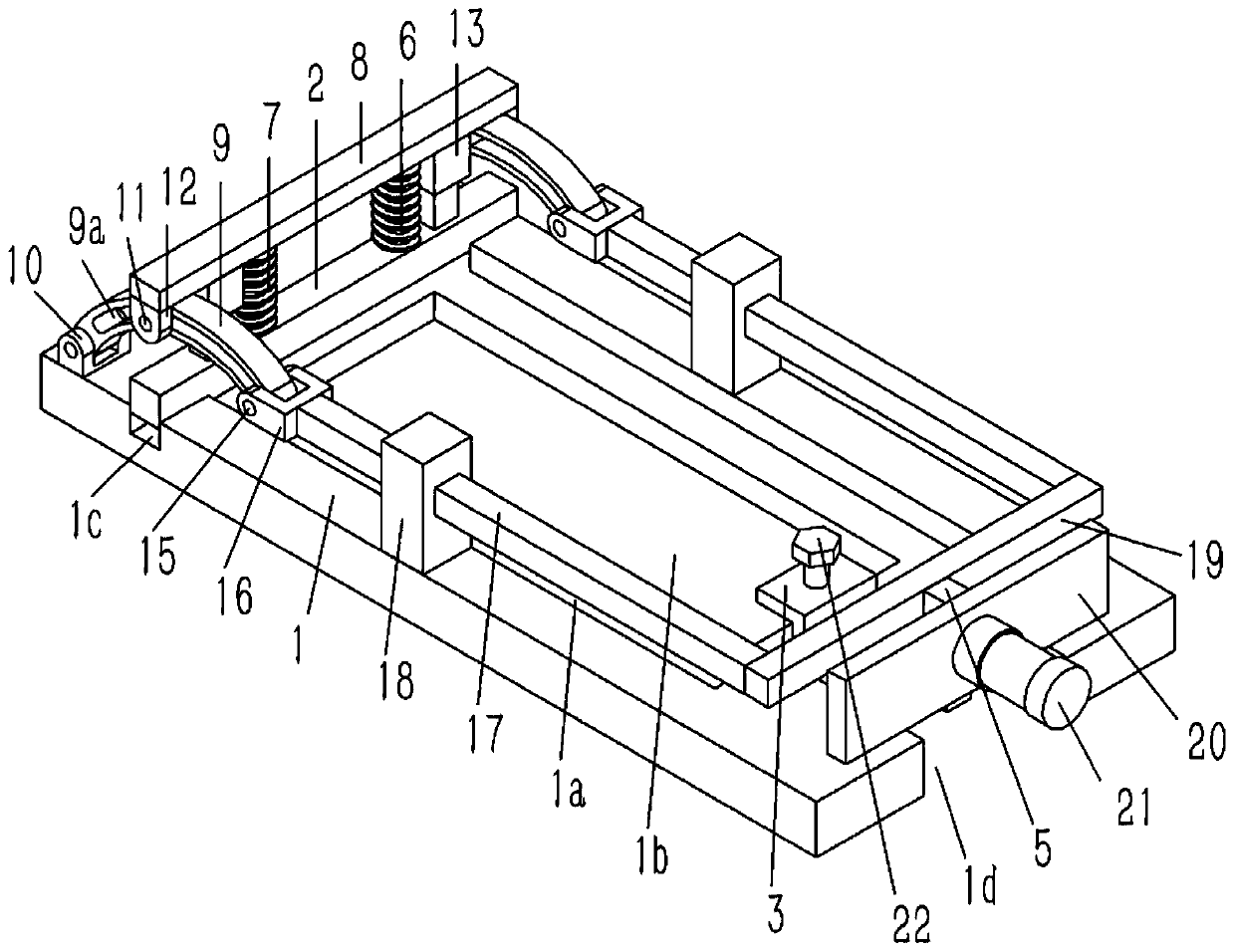

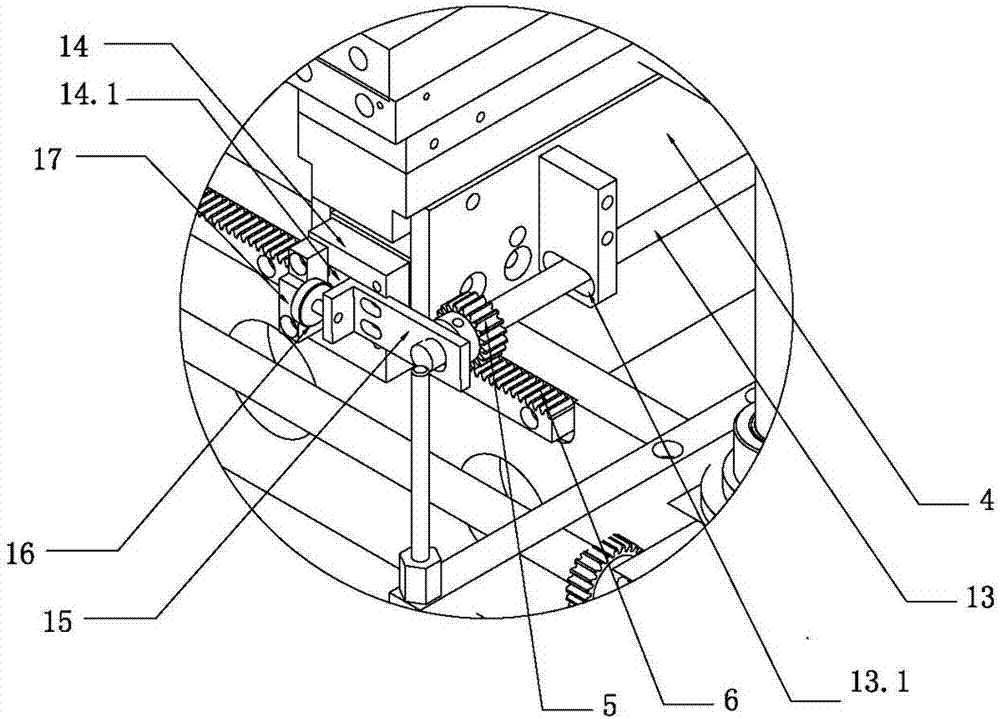

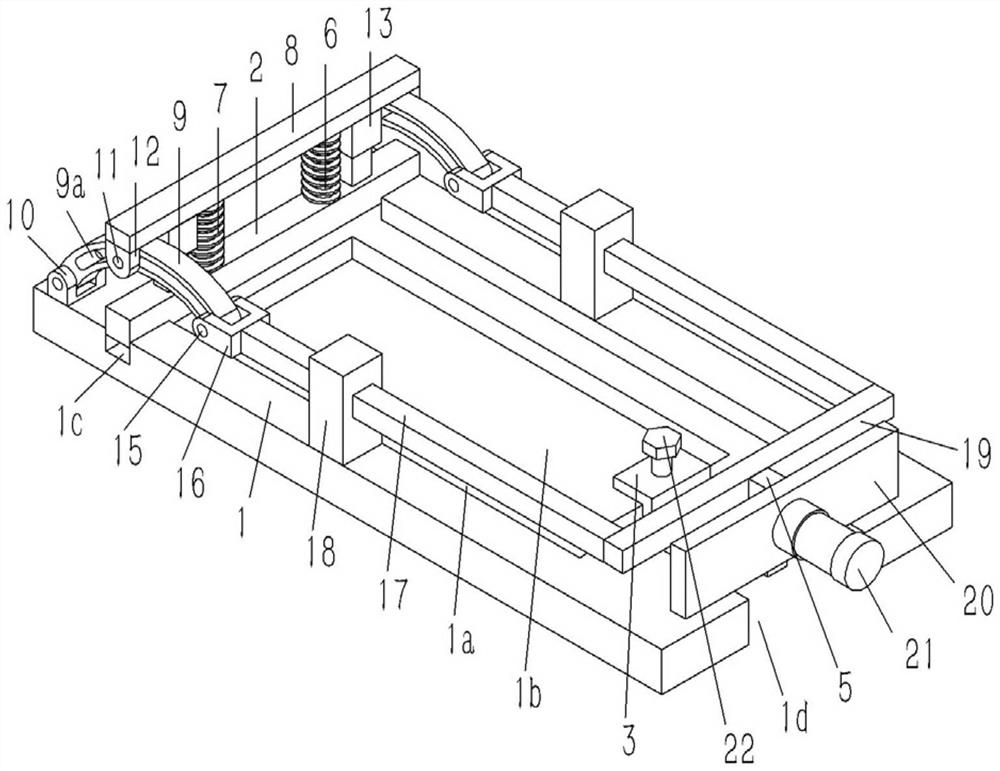

Space adjustment mechanism for aligning polarization-maintaining fiber collimators, device and alignment method thereof

InactiveCN102338917AReduce in quantityReduce dependenceCoupling light guidesPhotometry using electric radiation detectorsFiberOptical power

The invention provides a space adjustment mechanism for aligning polarization-maintaining fiber collimators, which comprises a sliding substrate, two sets of mechanical adjusting parts which are the same in structure and a set of physical reference datum parts. The invention also provides an alignment device adopting the space adjustment mechanism and a method for aligning two polarization-maintaining fiber collimators by using the set of devices. The space adjustment mechanism for aligning the polarization-maintaining fiber collimators also comprises a linearly polarized light generator, a fiber connection network and an optical parameter measurement unit. The beneficial effects are achieved by adopting the content of the invention: a physical reference datum is provided, so that initialspace position alignment is simple and easy to implement; the number of mechanical movement parts is reduced by adopting a fiber optical path; online measurement is realized on optical power and polarization extinction ratio; the displacement deviation caused by eccentric adjustment is avoided; the optical power fluctuations caused by the rotation movements of the polarization-maintaining fiber collimators are reduced; by the alignment method, the adjustment efficiency is improved, and the dependence on the skill of an operator is reduced; and the shaft running phenomenon when polarization alignment is carried out is avoided by adopting the polarization-maintaining fiber optical path through a method for measuring the polarization extinction ratio.

Owner:天津峻烽科技有限公司

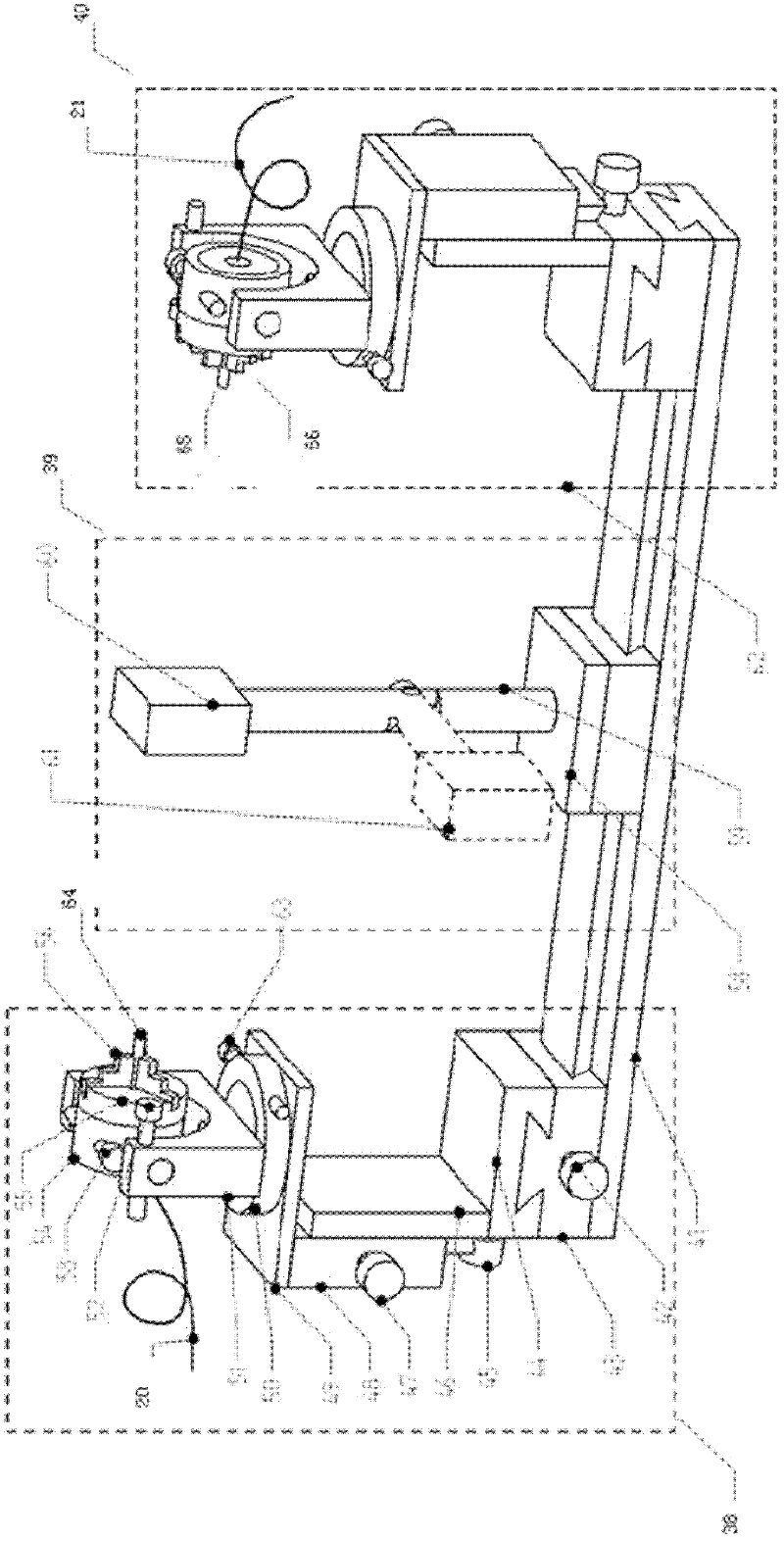

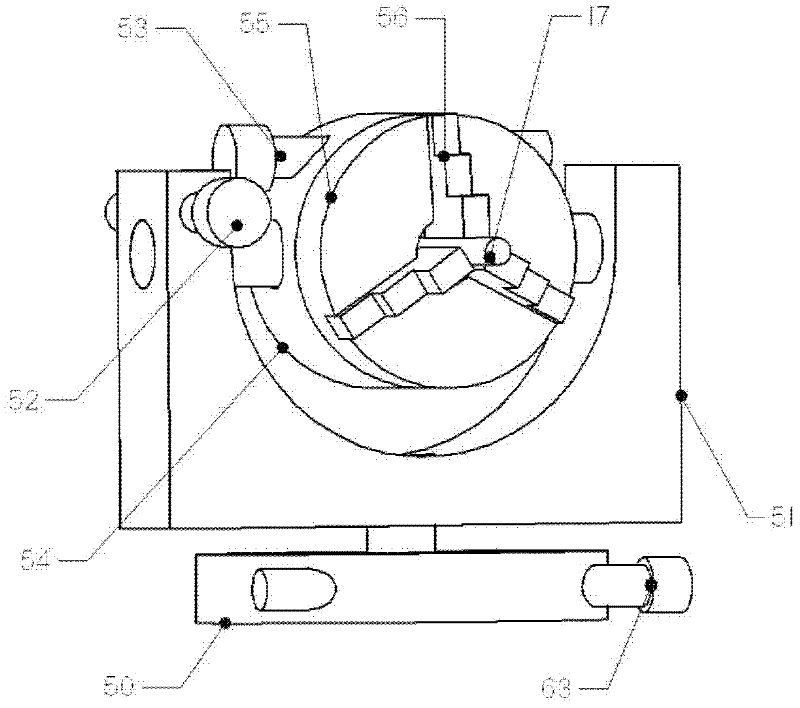

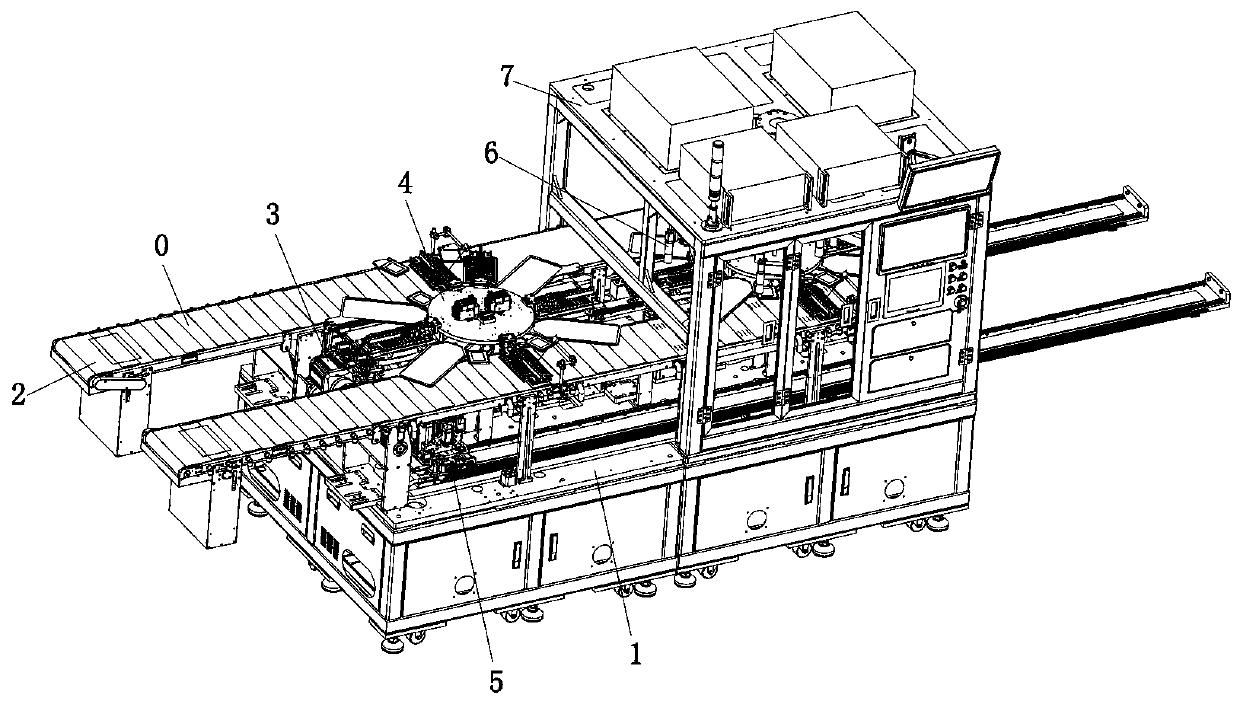

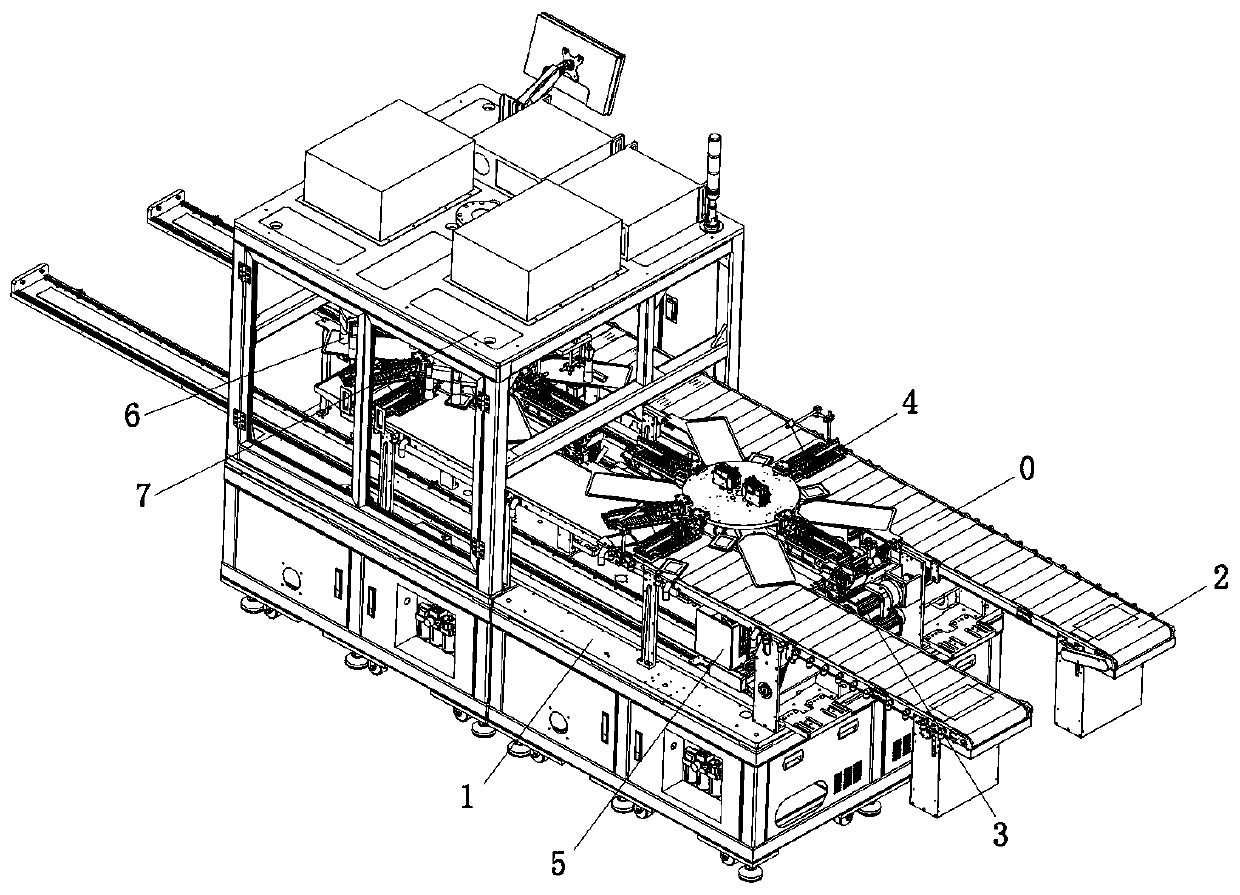

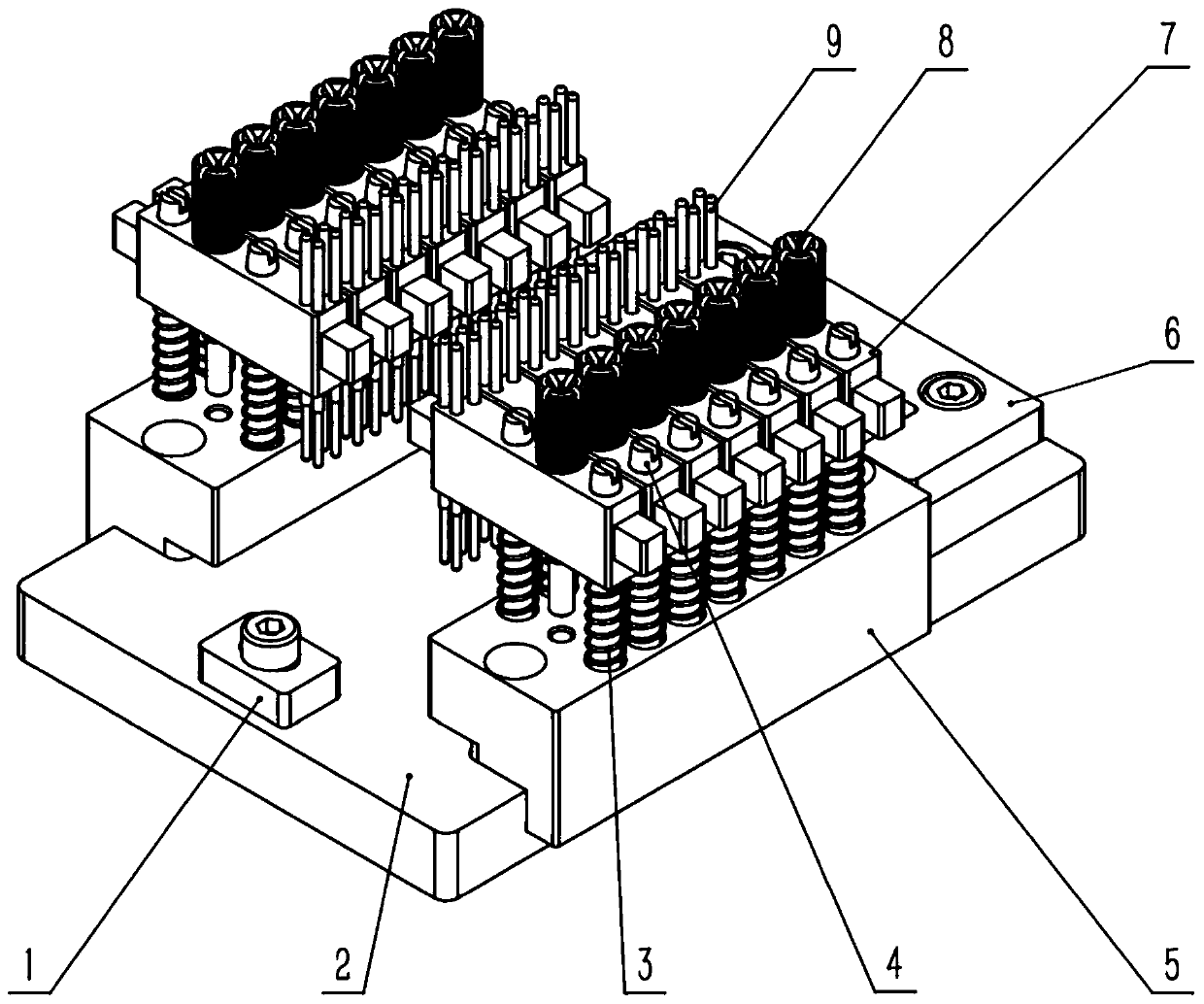

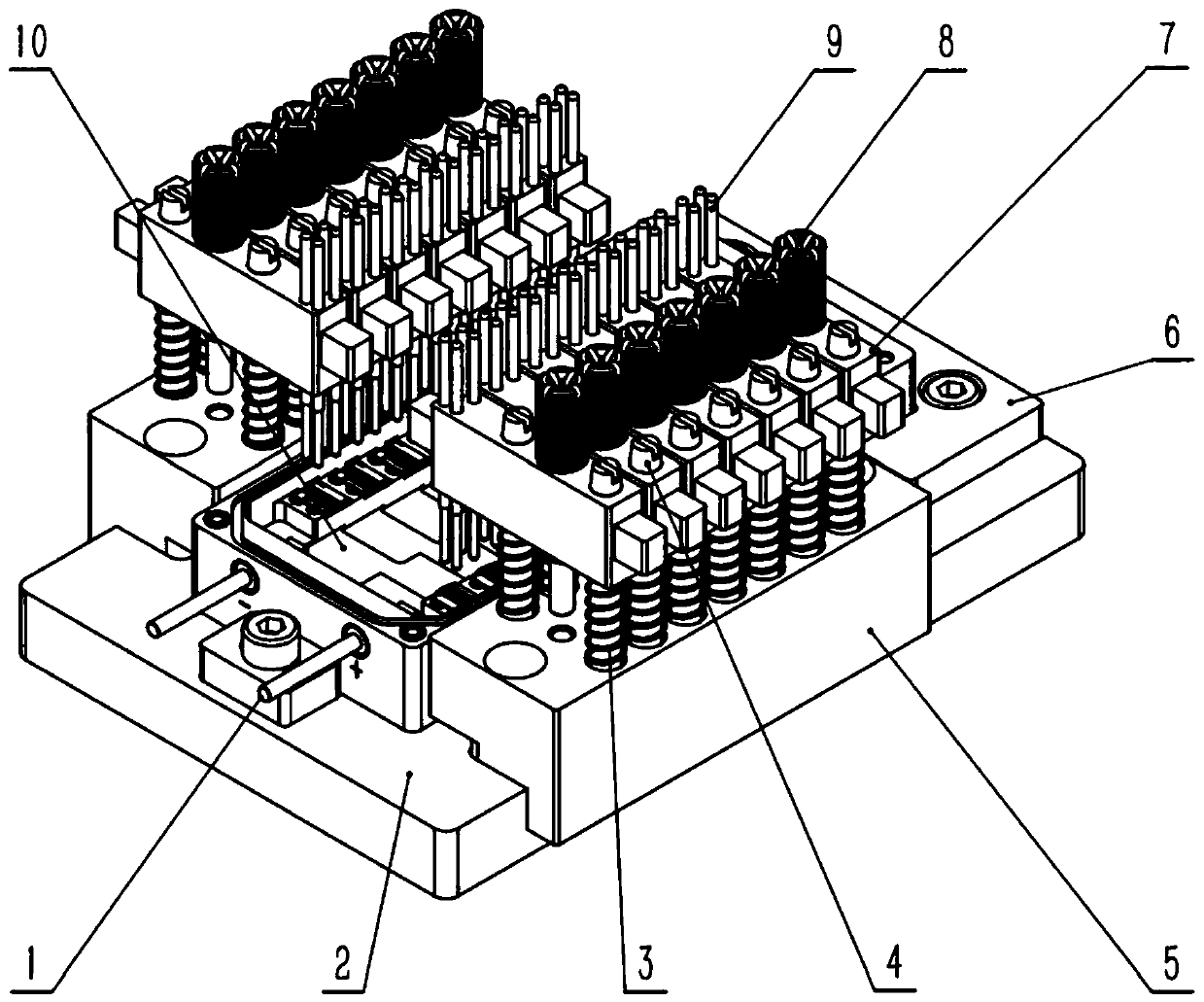

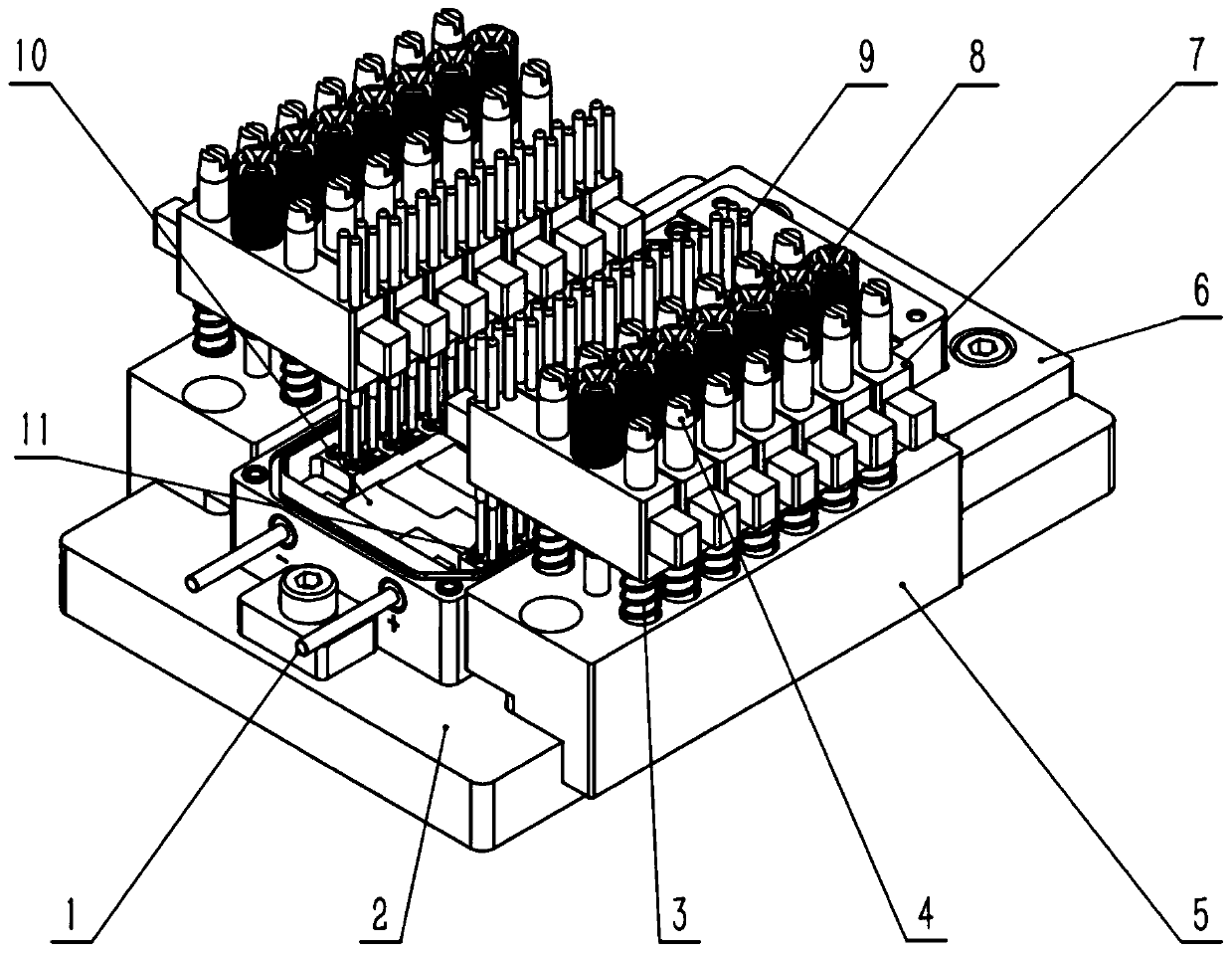

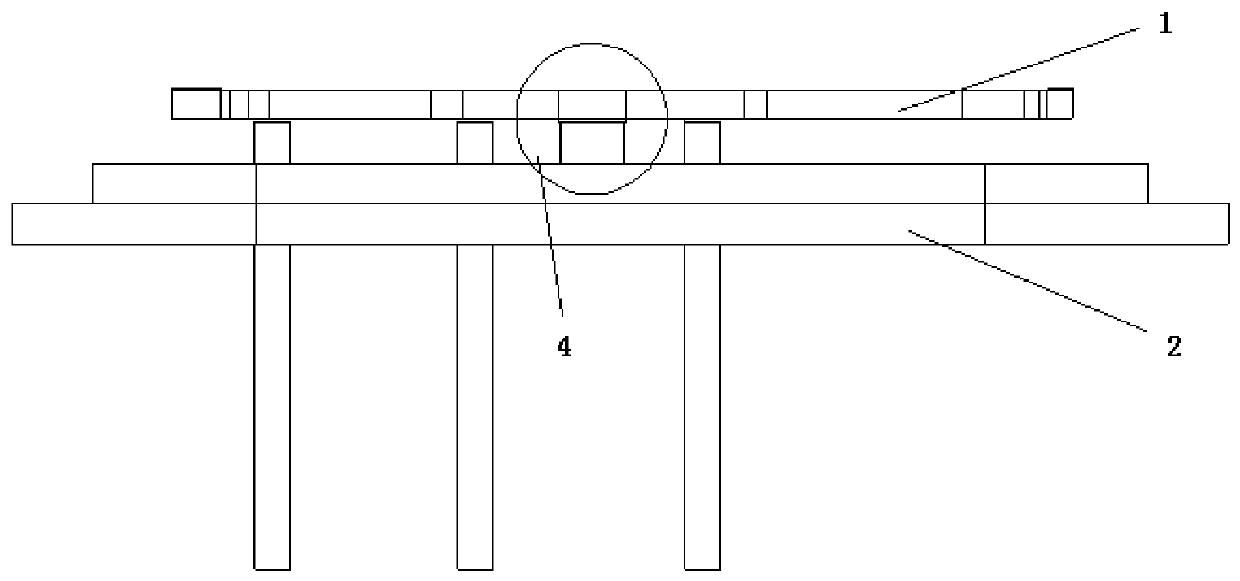

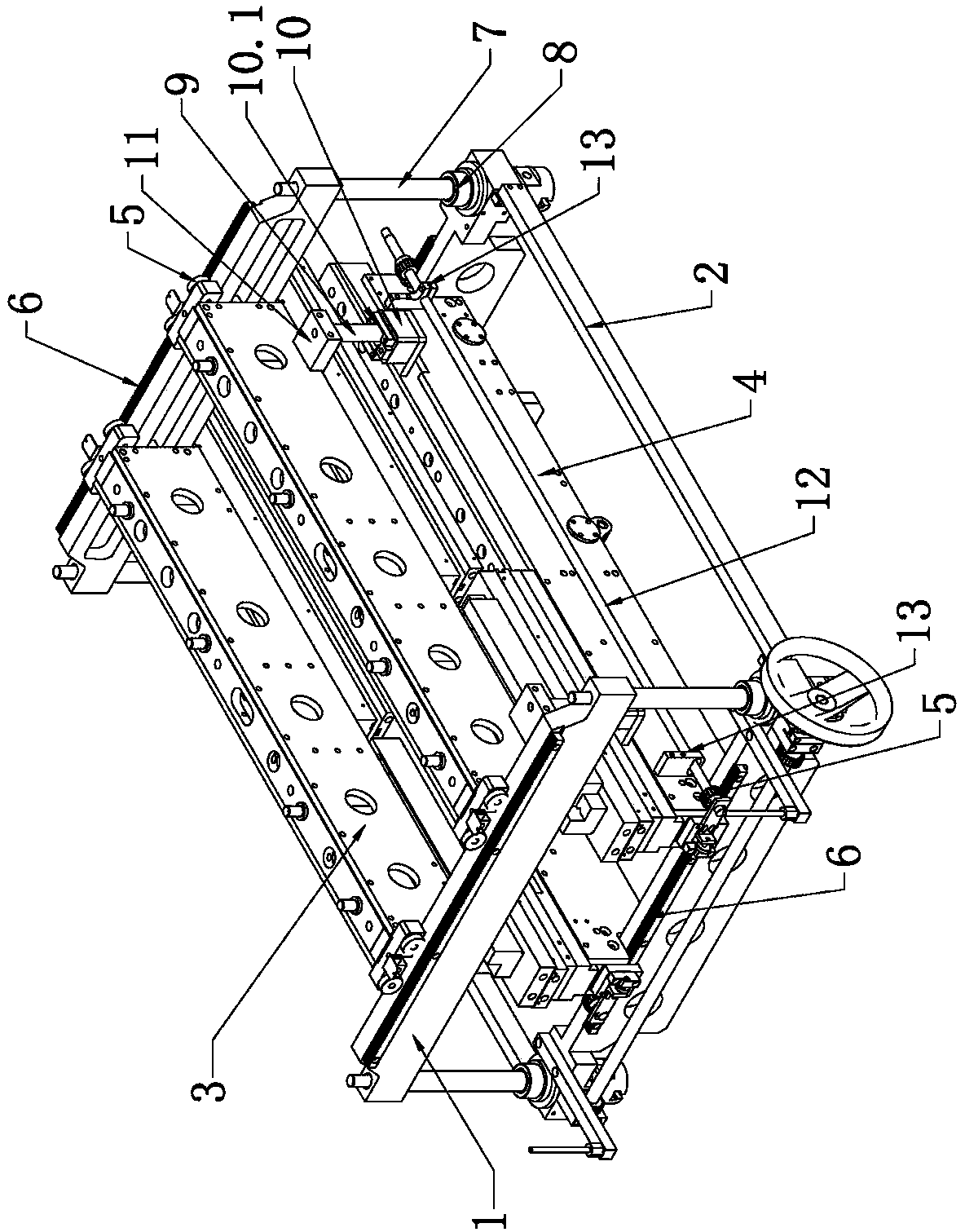

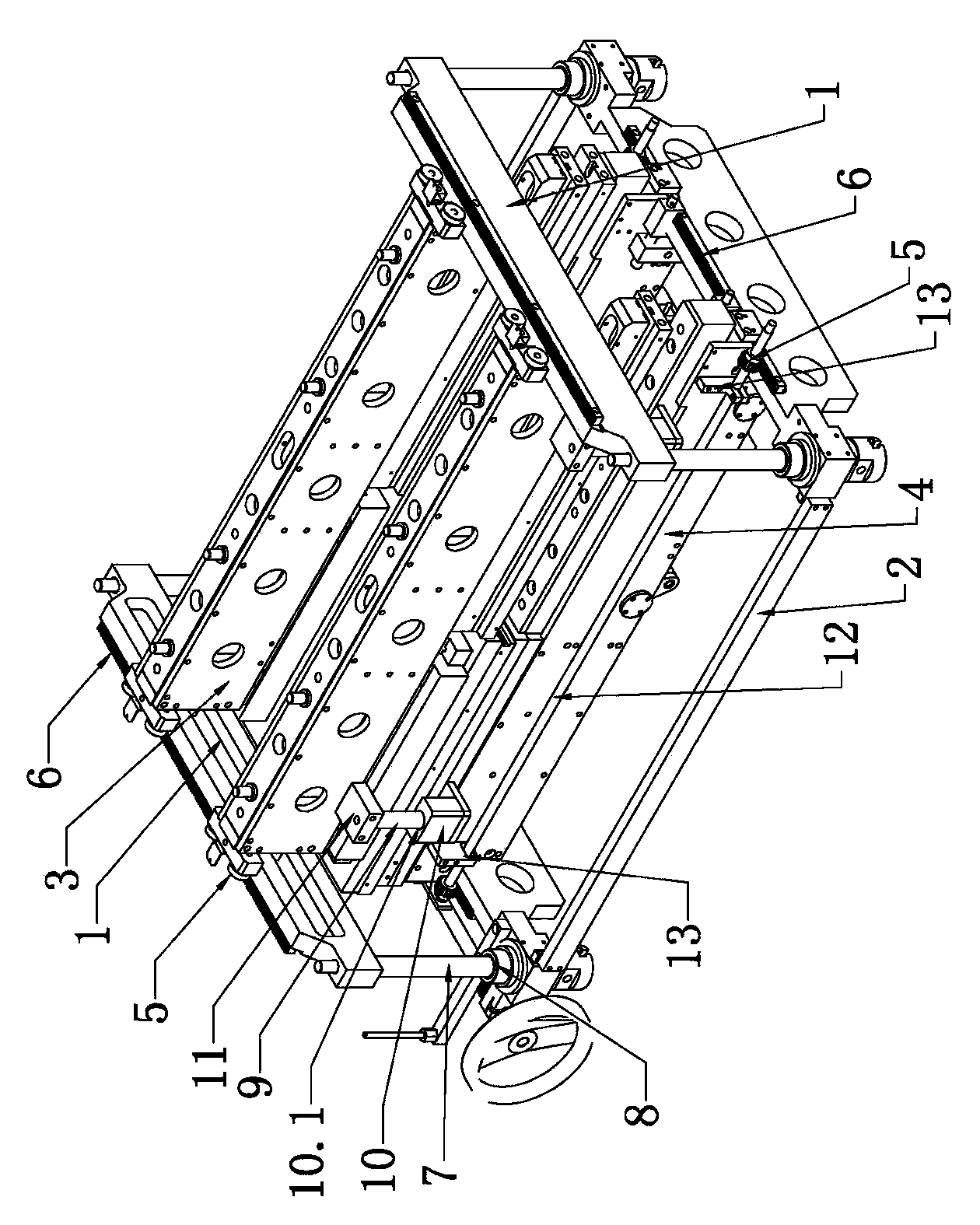

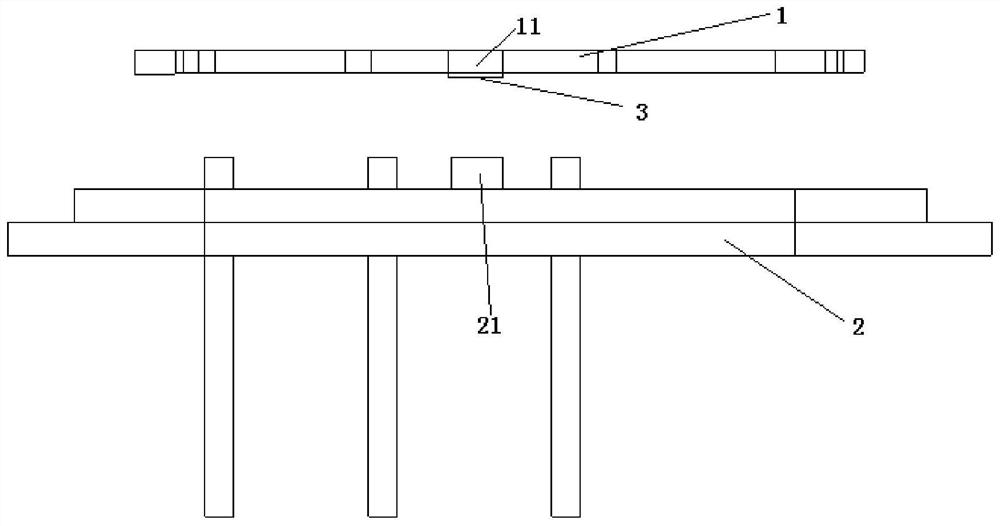

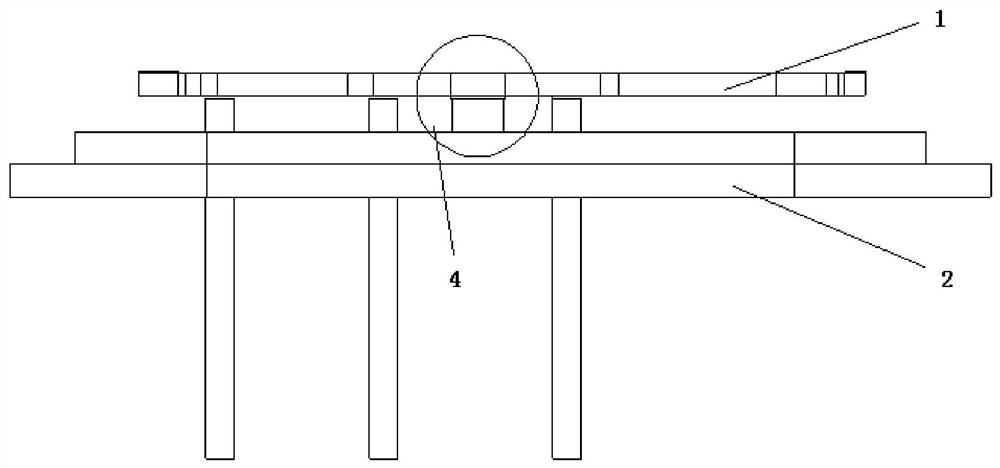

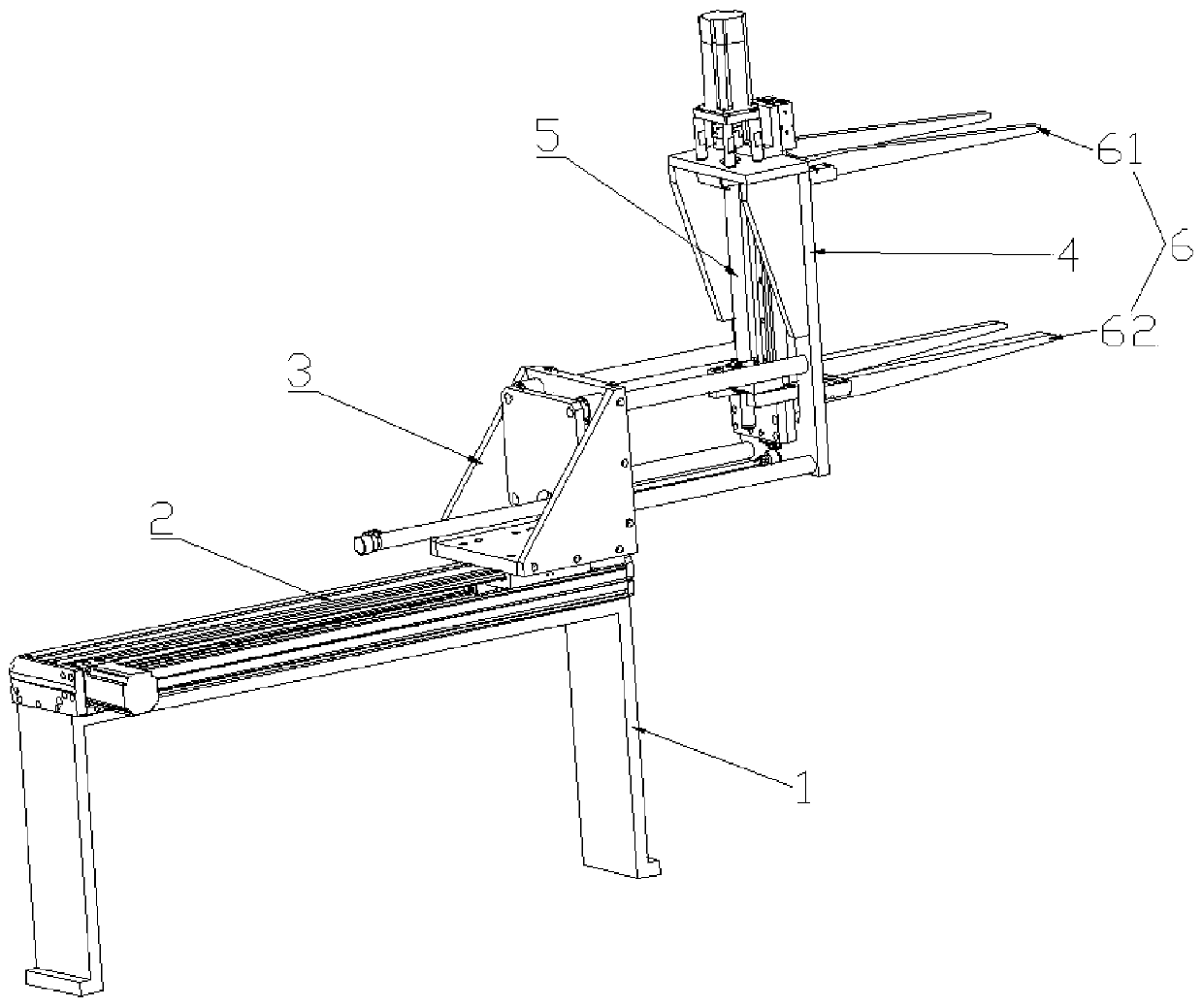

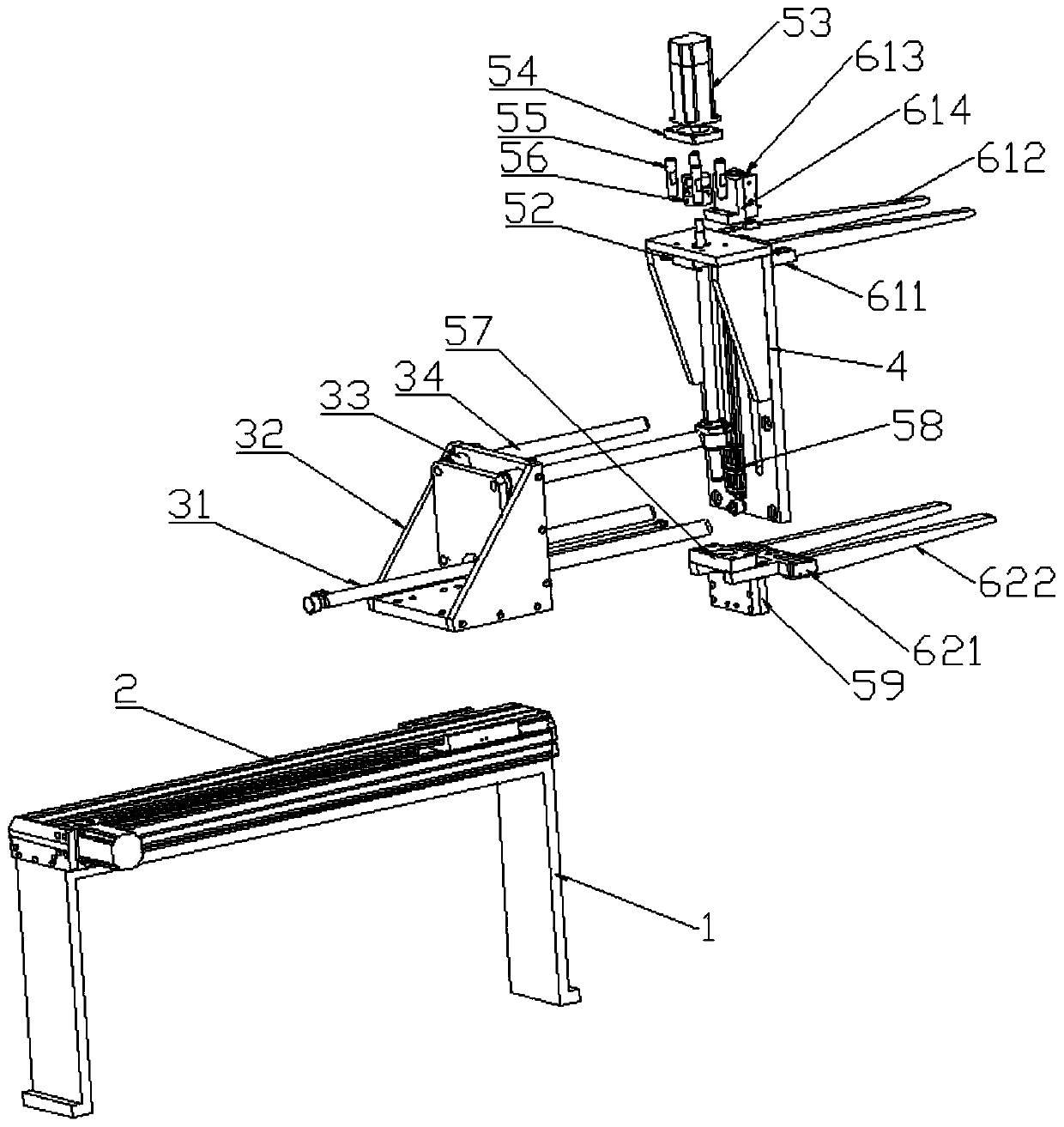

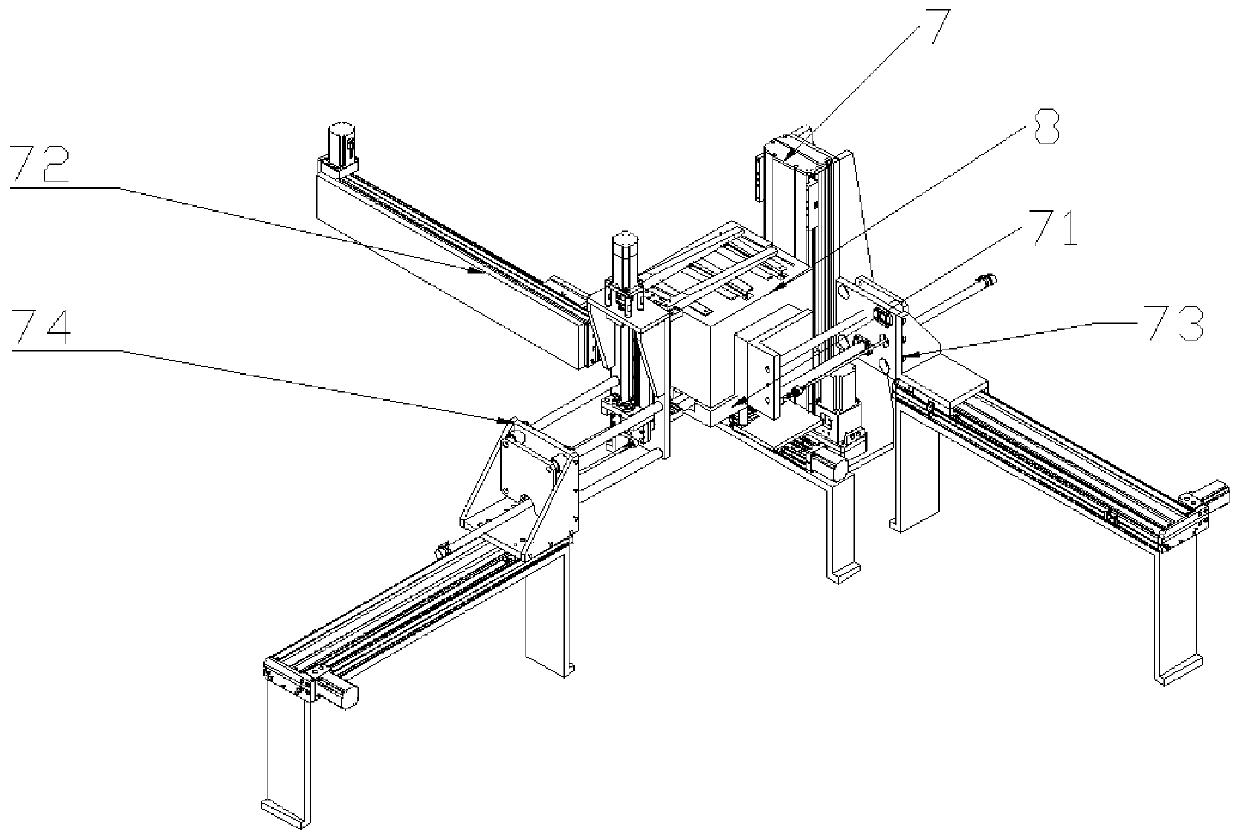

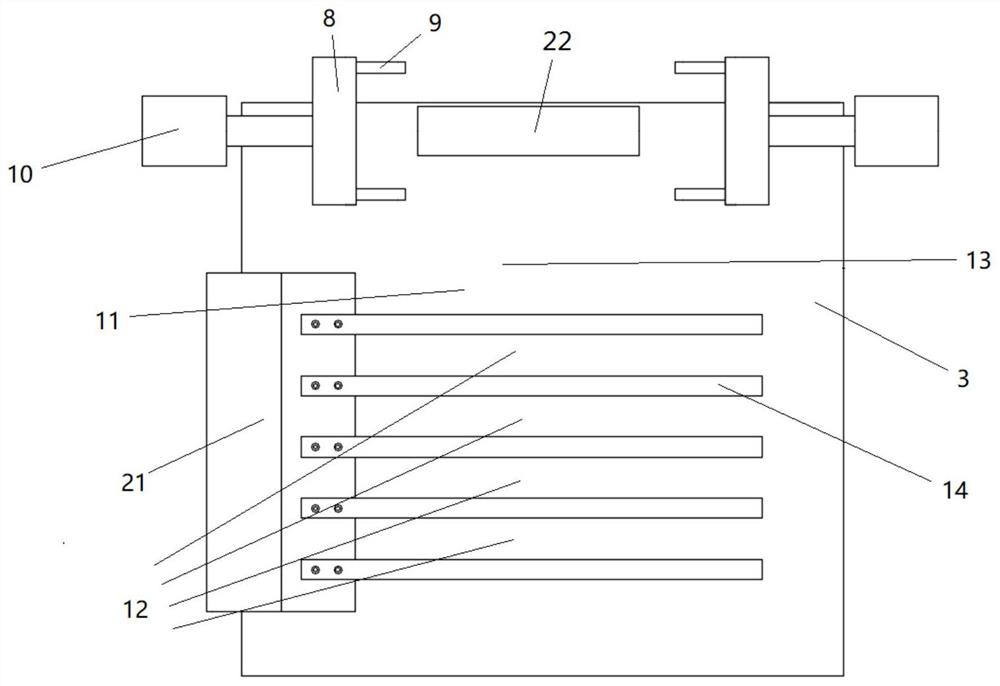

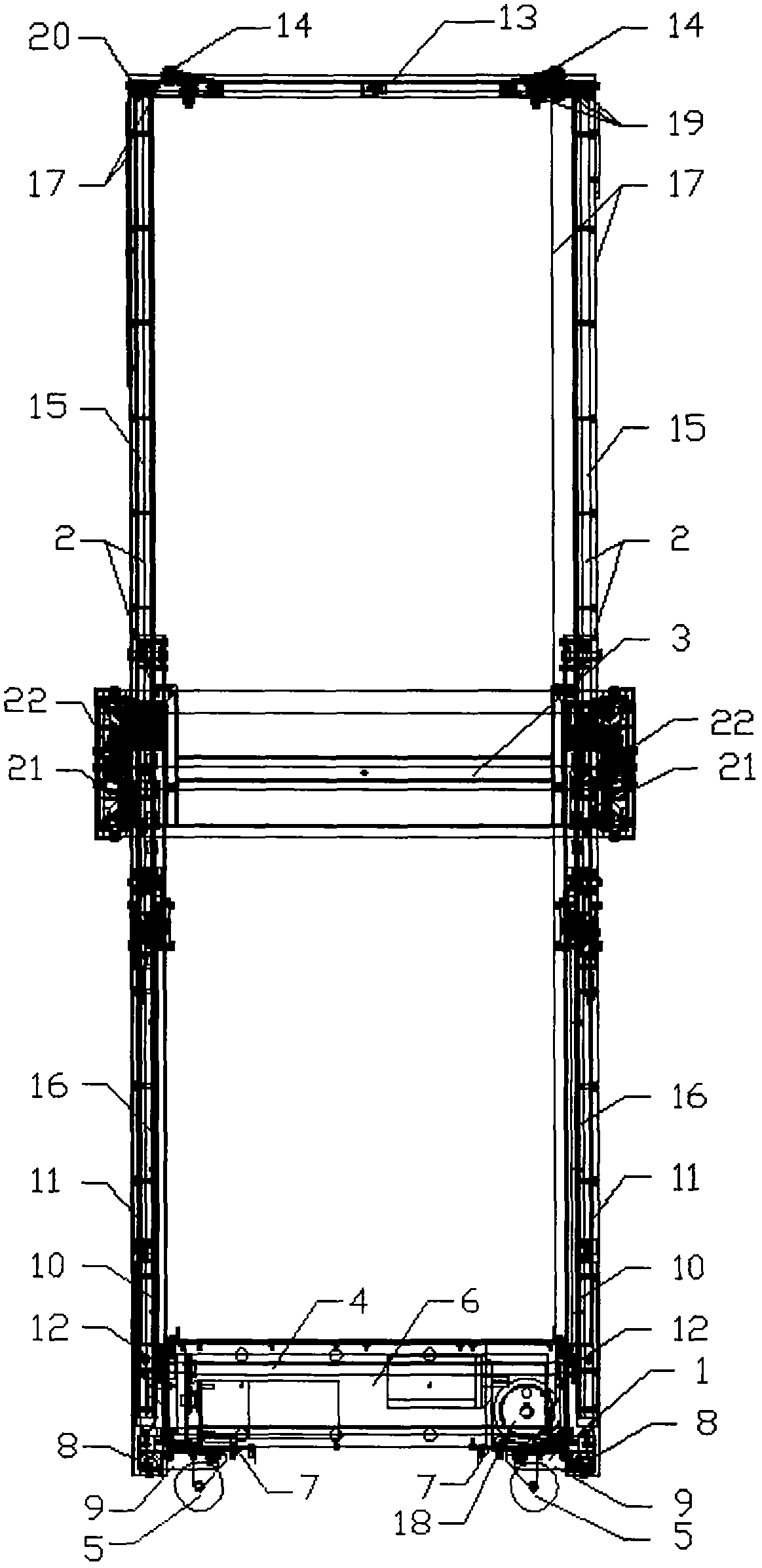

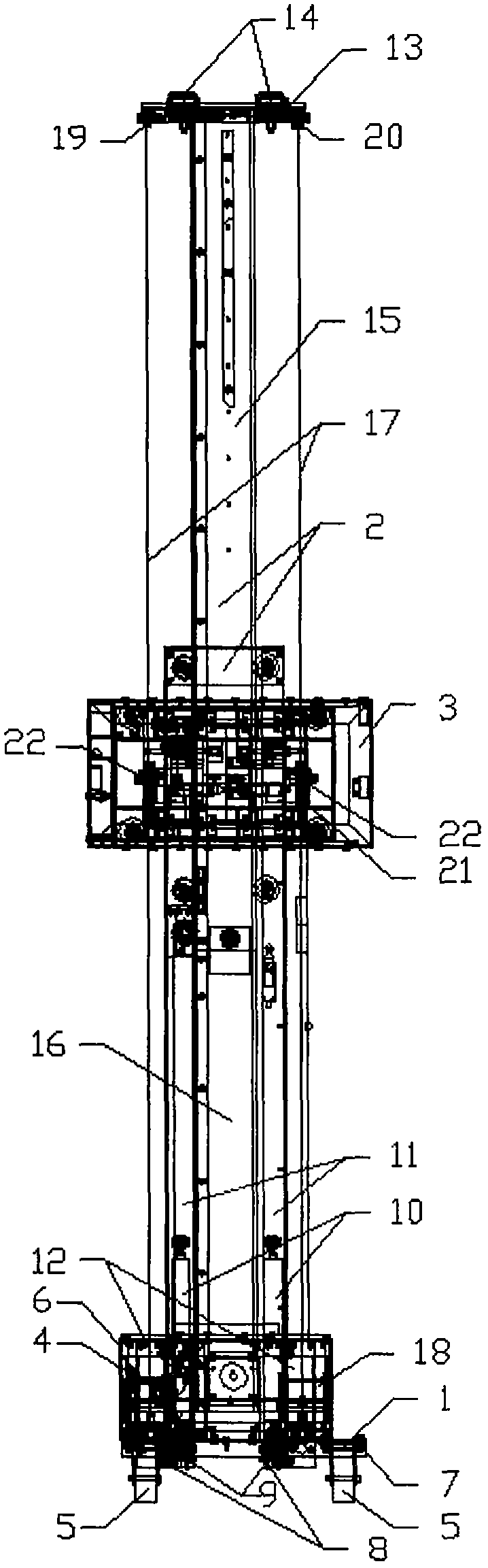

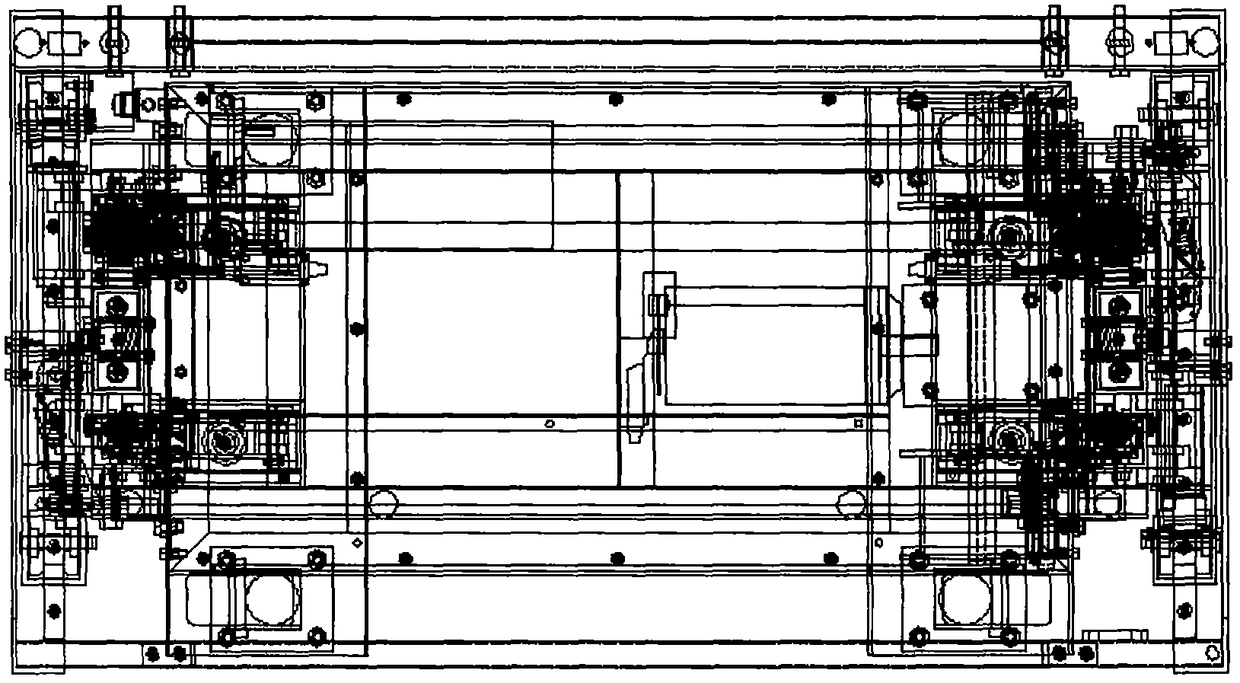

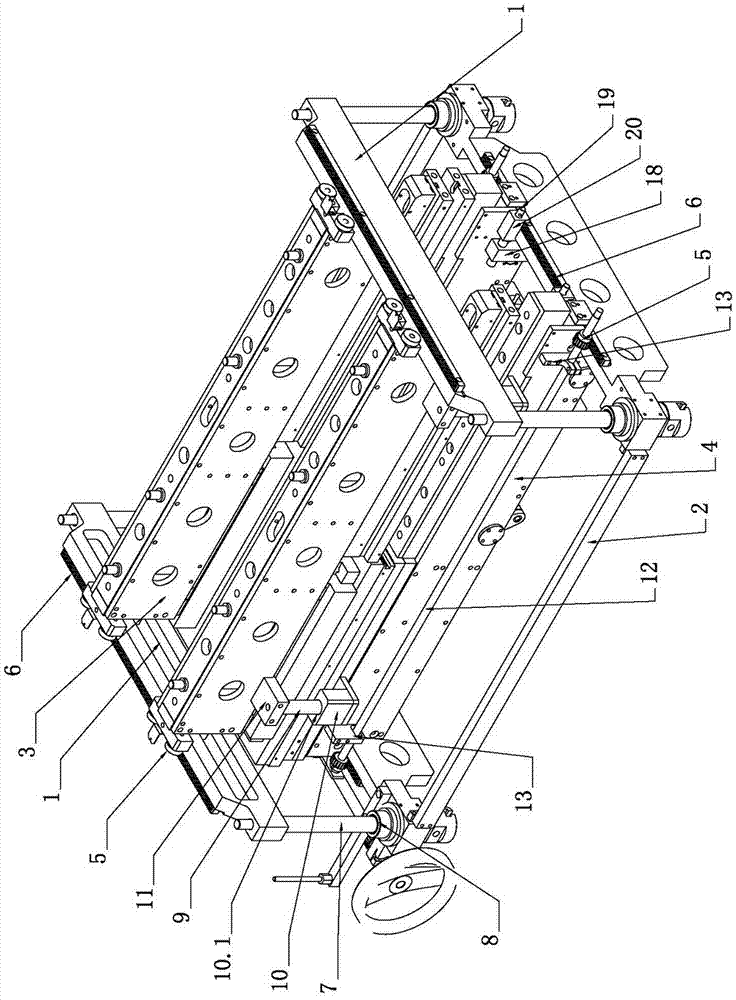

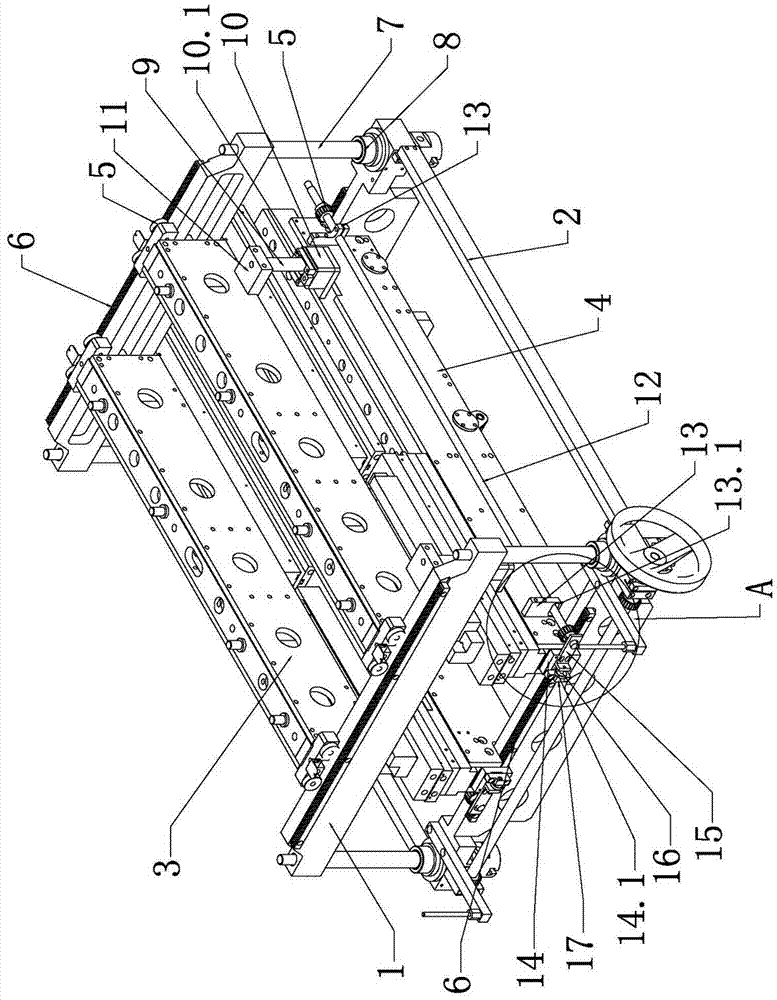

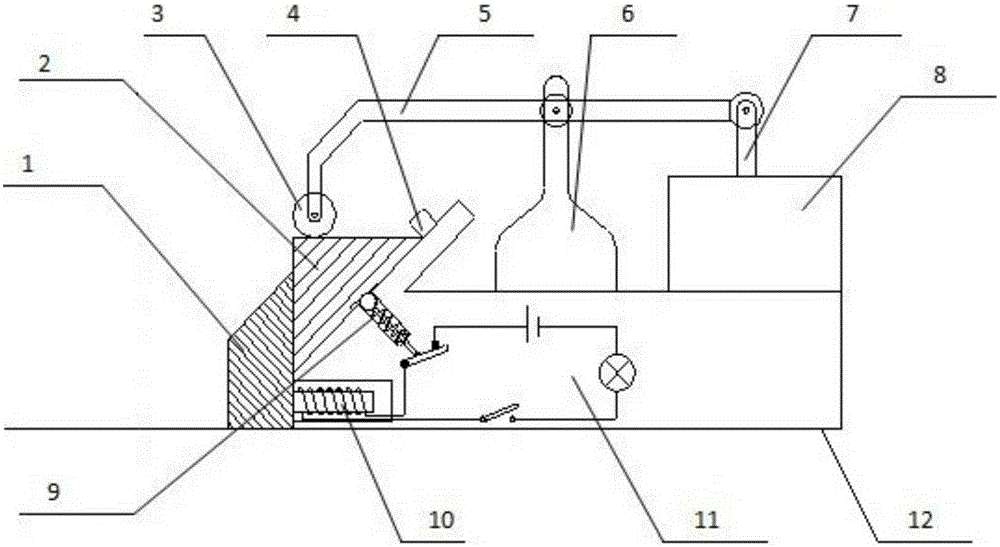

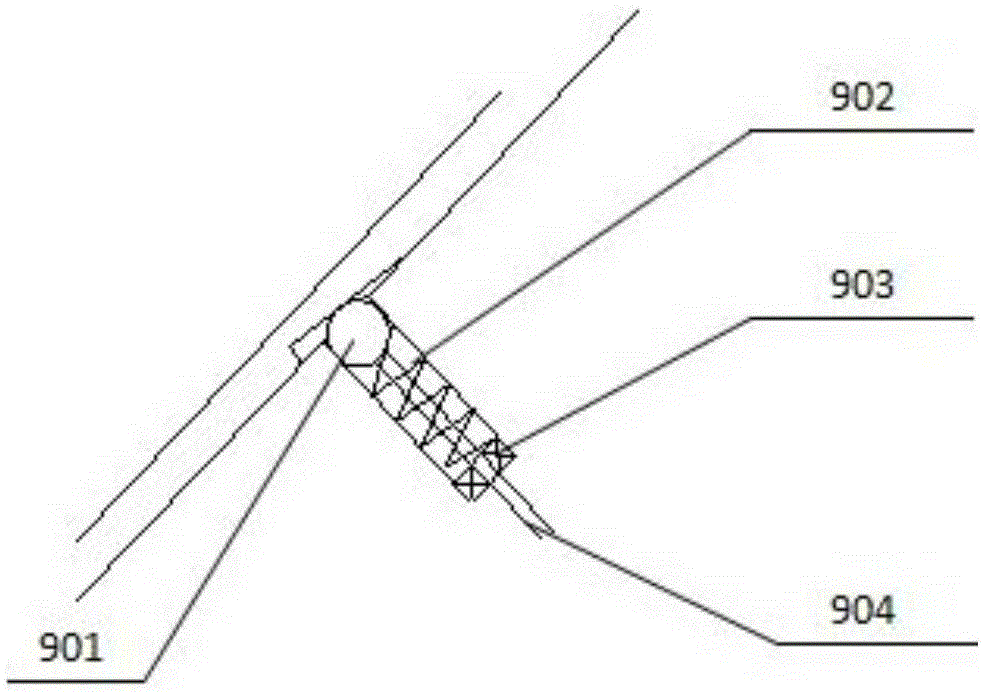

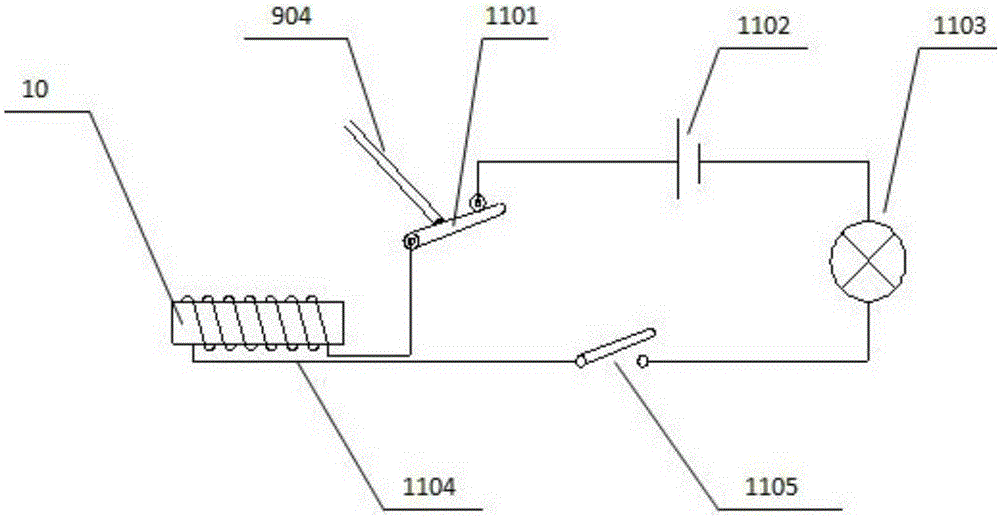

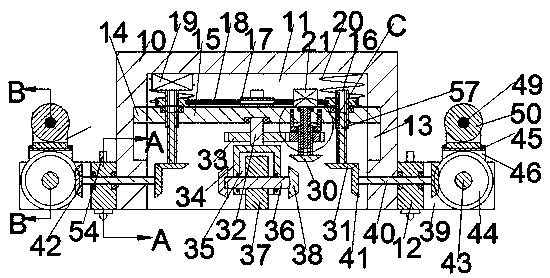

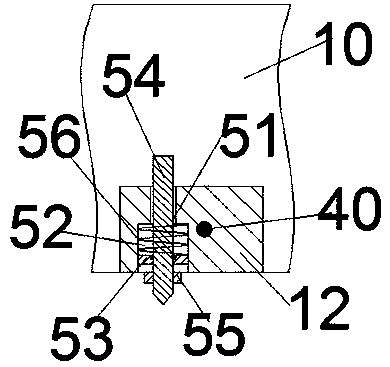

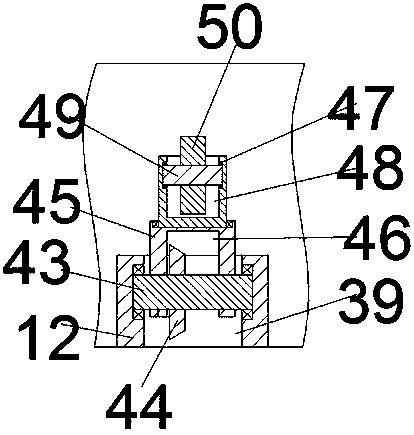

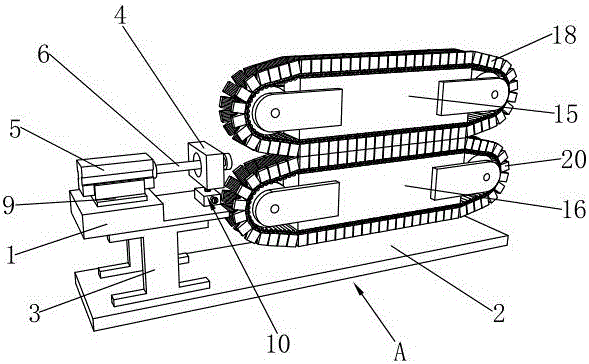

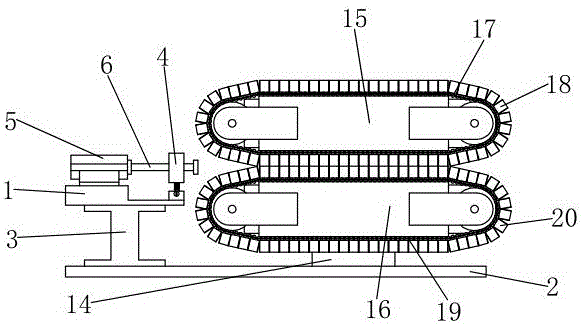

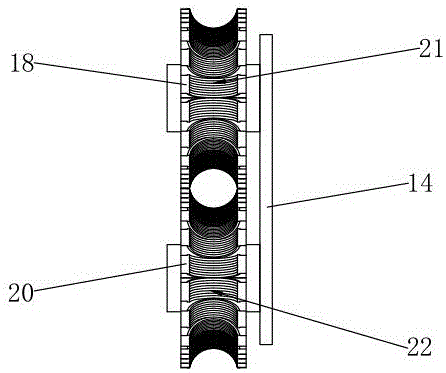

Turret type automatic lamination production line and lamination process thereof

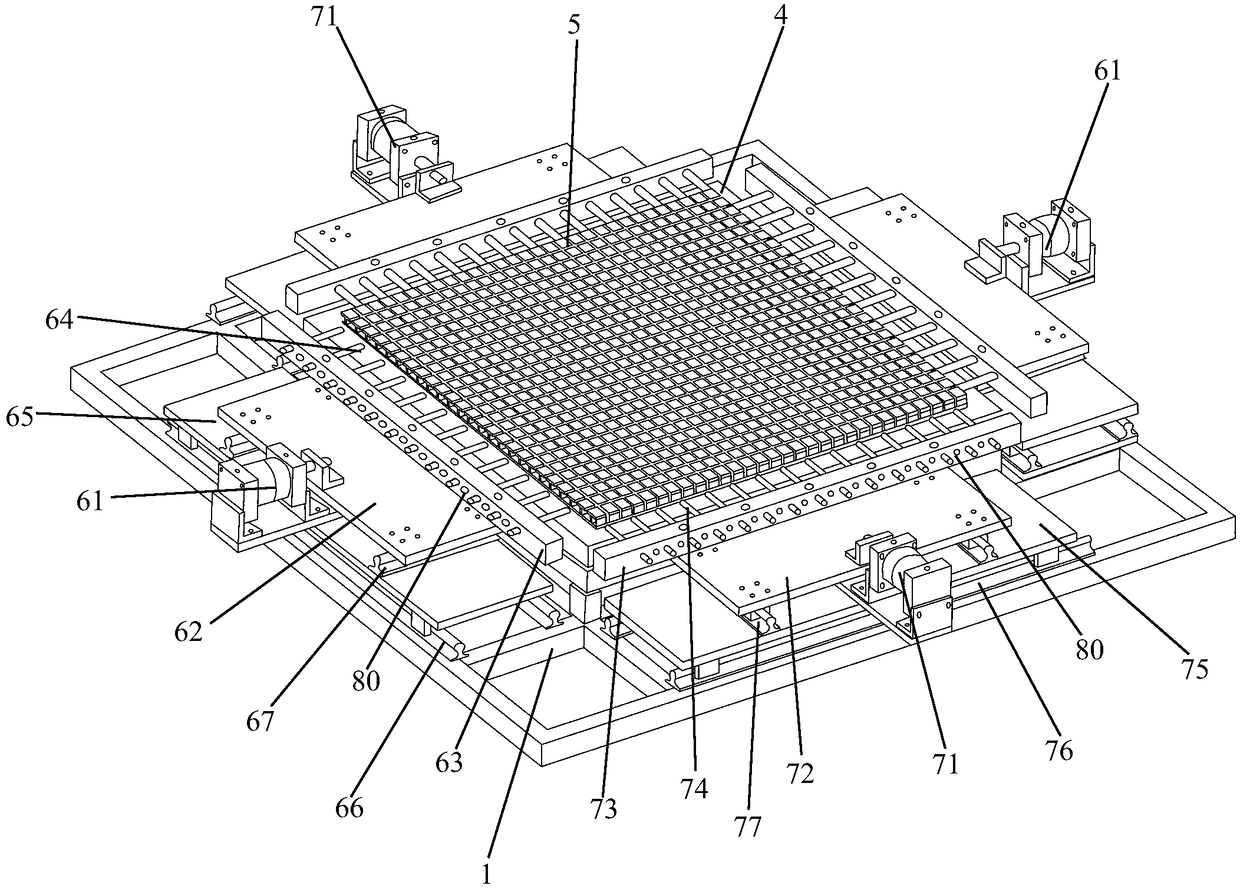

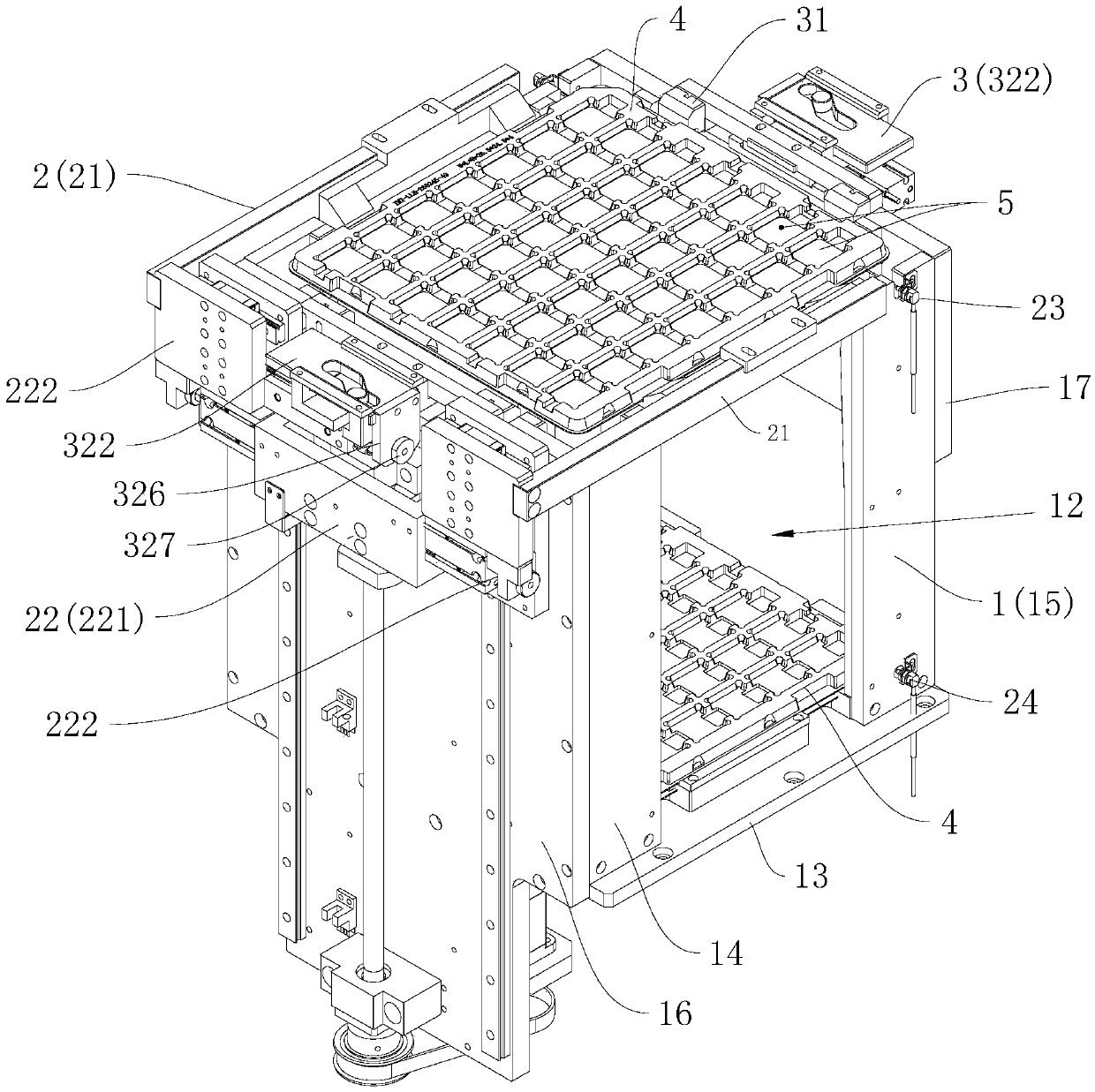

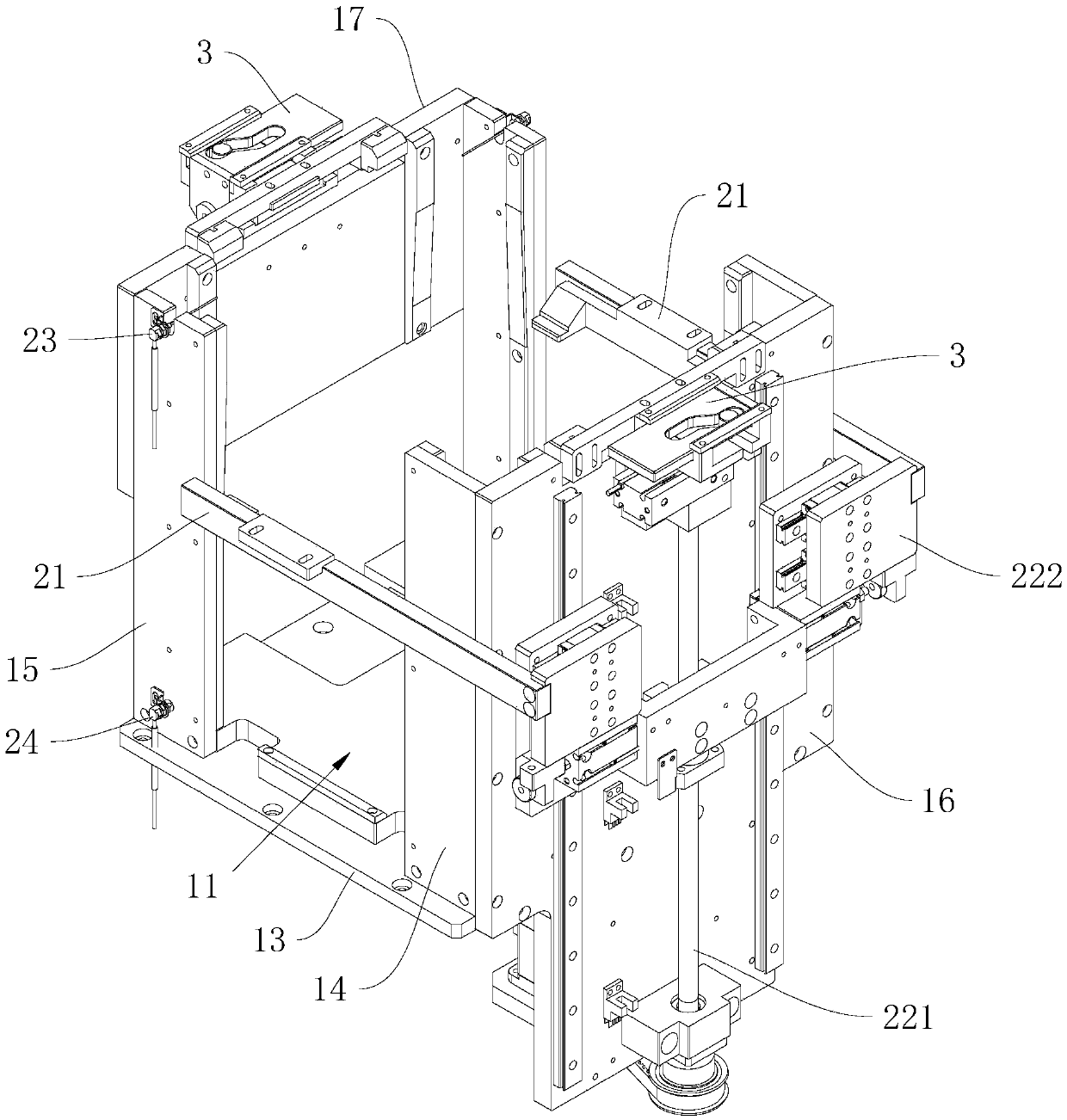

PendingCN110350253AAvoid displacement deviationImprove lamination efficiencyFinal product manufactureLi-accumulatorsProduction lineEngineering

The invention discloses a turret type automatic lamination production line and a lamination process thereof. The turret type automatic lamination production line comprises a rack, feeding vacuum pullbodies, lamination mechanisms, turret mechanisms, material discharging mechanical arms and CCD mechanisms; two feeding vacuum pull bodies are provided; the two feeding vacuum pull bodies are parallelly arranged on the rack at intervals; two turret mechanisms are provided; the two turret mechanisms are arranged at two lamination stations respectively; four lamination mechanisms are provided; two groups of lamination mechanisms are arranged to two sides of the two turret mechanisms respectively, wherein each group of lamination mechanisms includes two lamination mechanisms; two material discharging mechanical arms are provided; the two material discharging mechanical arms are sequentially arranged below the two feeding vacuum pull bodies respectively; two CCD mechanisms are provided; and thetwo CCD mechanisms are arranged above the two lamination stations respectively. With the turret type automatic lamination production line and the lamination process thereof of the invention adopted,the sequential alternating lamination of the two lamination mechanisms is realized in the same rotation cycle, so that lamination efficiency is improved; the continuous lamination of a platform is realized, and the problem of movement interference during material discharging is avoided; and pole sheets are pressed uninterruptedly, so that the displacement deviation of the pole sheets is effectively avoided.

Owner:SHENZHEN XING GRAIN AUTOMATION CO LTD

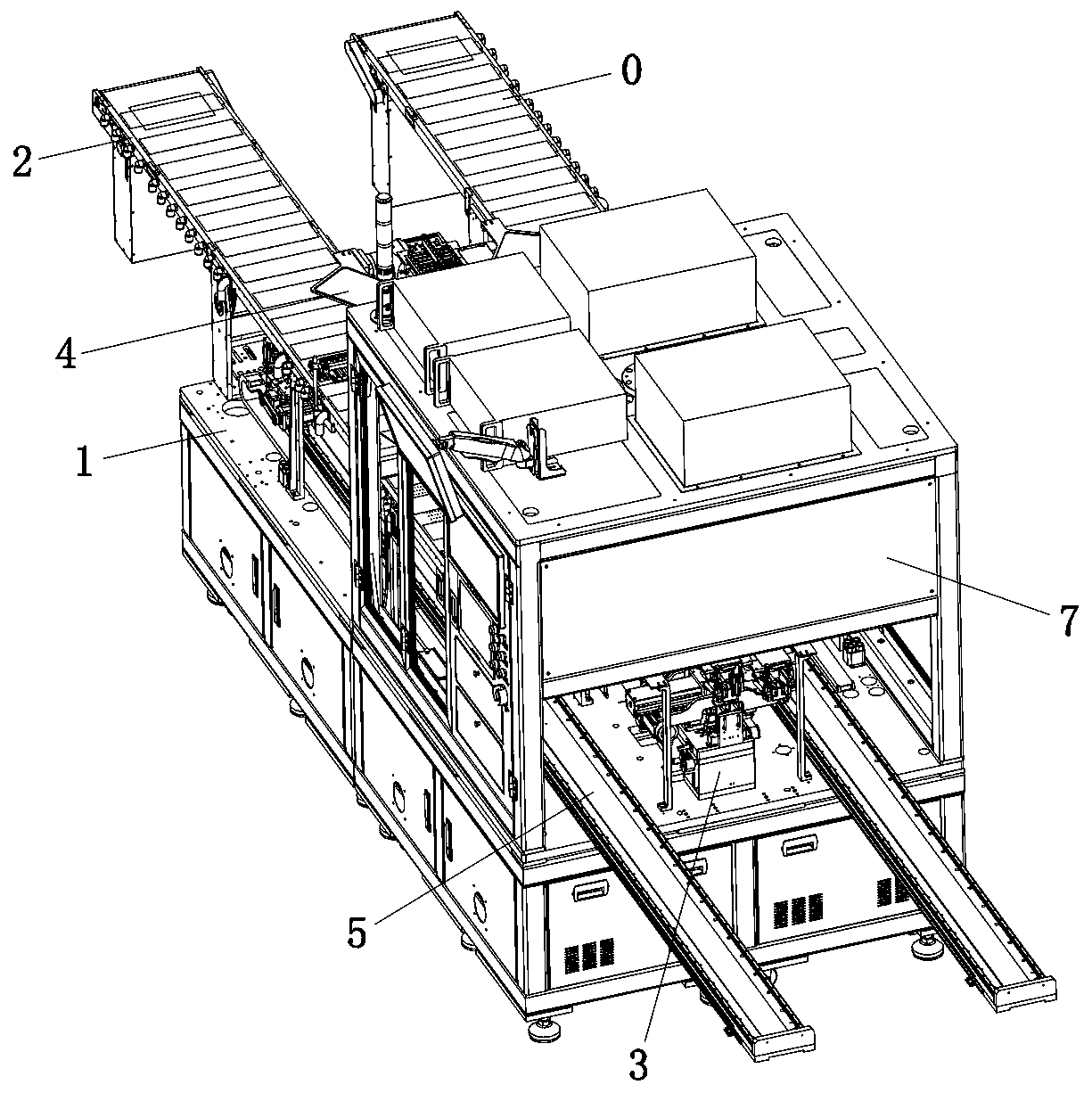

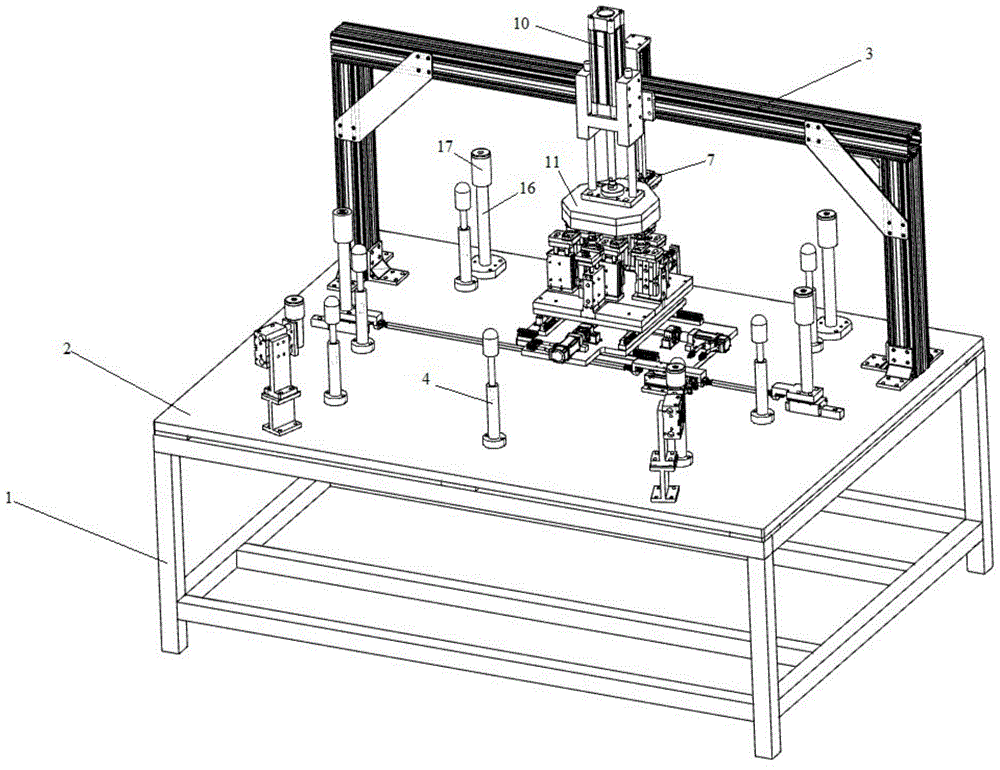

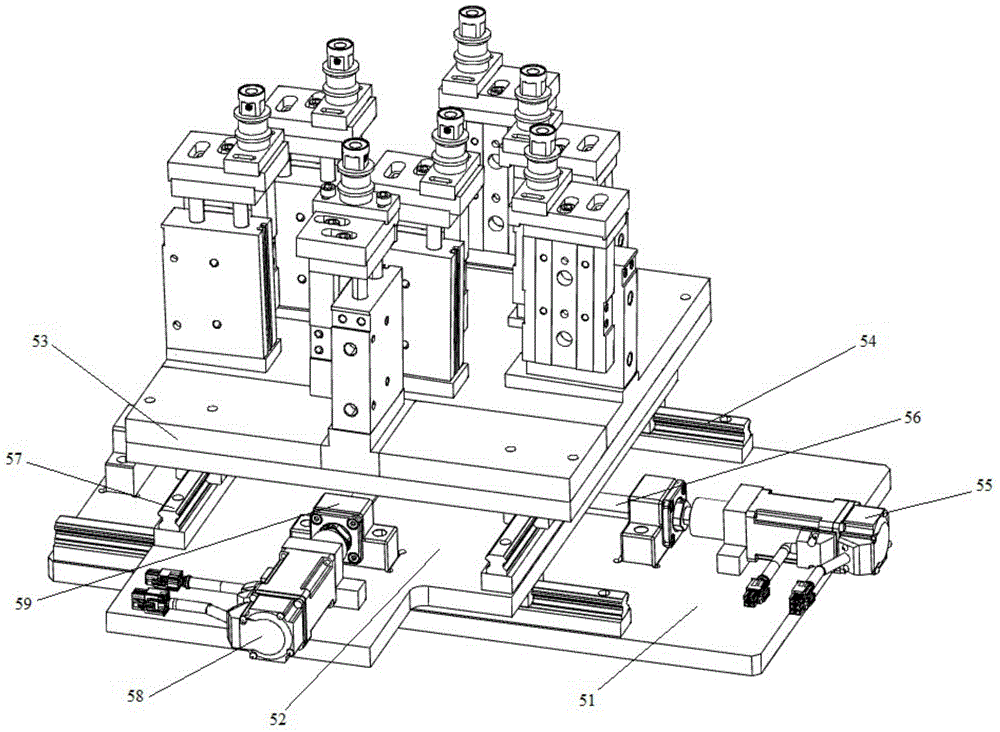

Multi-accessory high-precision automatic positioning and adhering equipment

The invention relates to multi-accessory high-precision automatic positioning and adhering equipment. The equipment comprises a rack, a working table, a fixing mechanism, a clamping mechanism and a limiting mechanism. A gantry support and multiple supporting pillars used for supporting a windshield are arranged on the working table, an electrical cabinet and a computer are further arranged on the rack, the equipment further comprises a pressing mechanism arranged on the gantry support, a positioning servo mechanism arranged on the working table and a shooting mechanism, the pressing mechanism, the positioning servo mechanism and the shooting mechanism are connected with the electrical cabinet through a circuit, and multiple pneumatic pressing mechanisms are arranged on the positioning servo mechanism and arranged on the working table movably through the positioning servo mechanism. Compared with the prior art, the structural arrangement is compact, module work division is clear, all the mechanisms cooperate with one another, in this way, windshield metal nails can be automatically positioned and adhere in a high-precision mode, positioning precision is high, adhering is firm, and production efficiency is effectively improved.

Owner:FUYAO GRP SHANGHAI AUTOMOBILE GLASS CO LTD

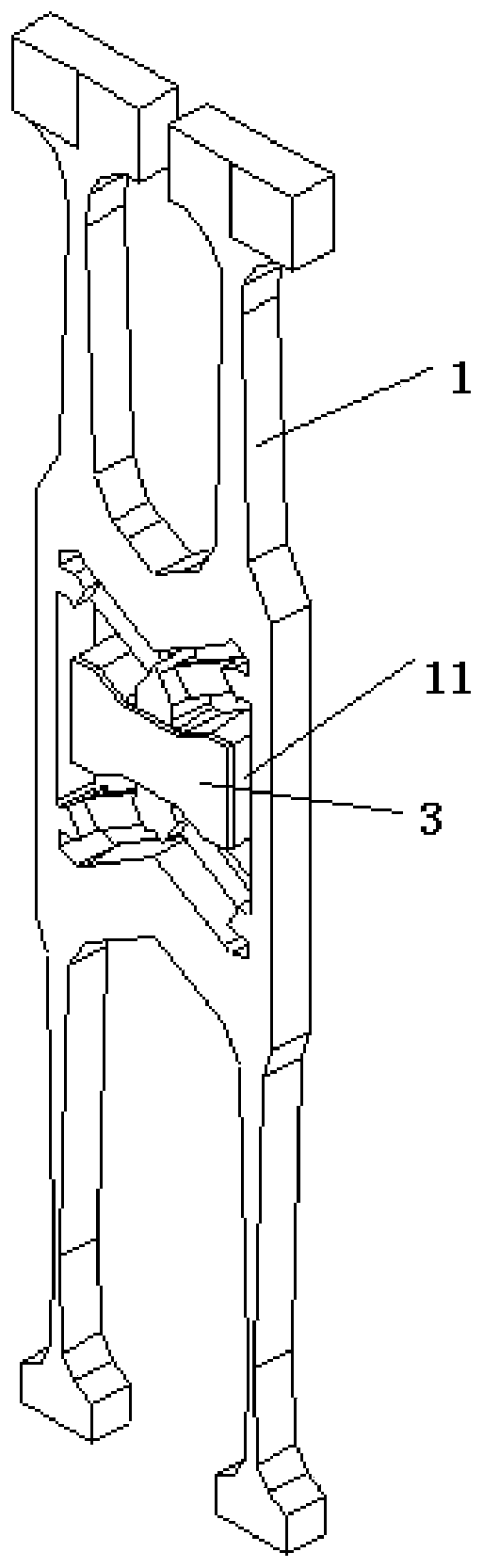

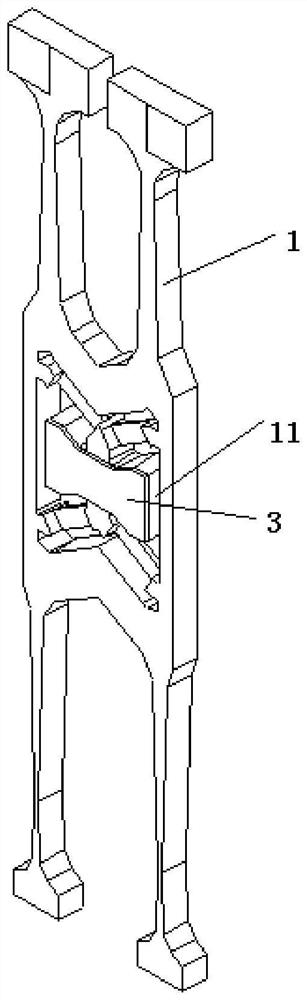

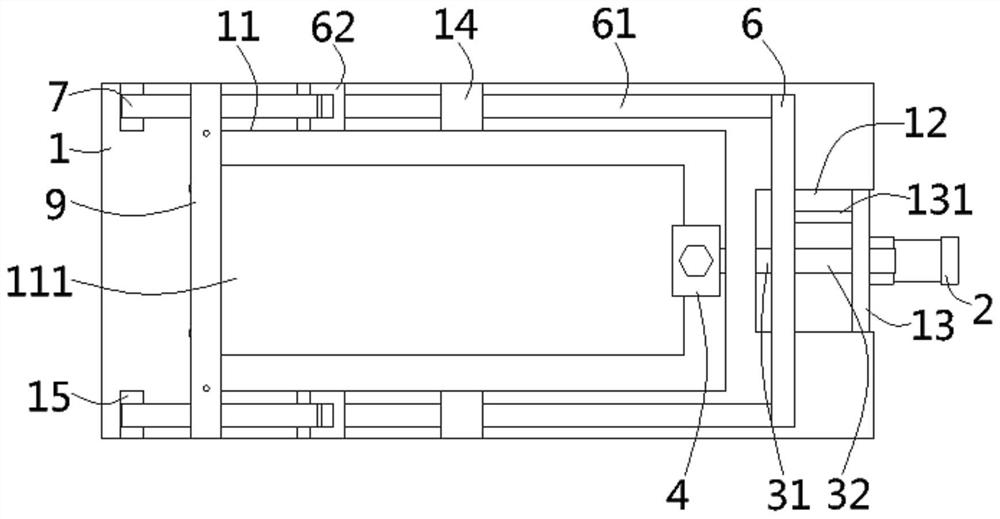

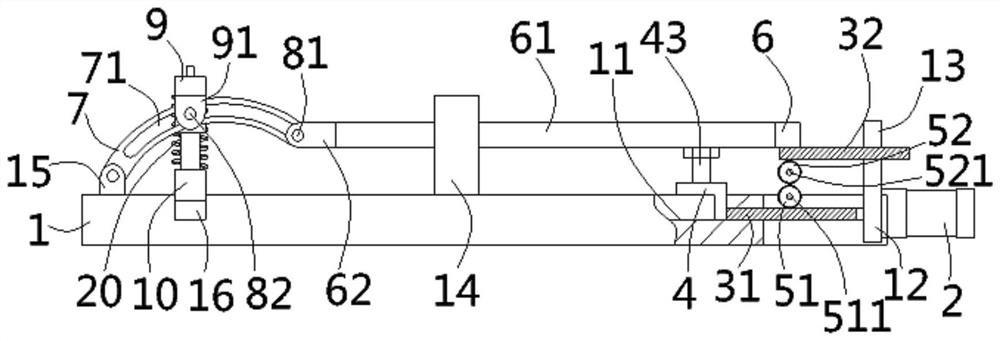

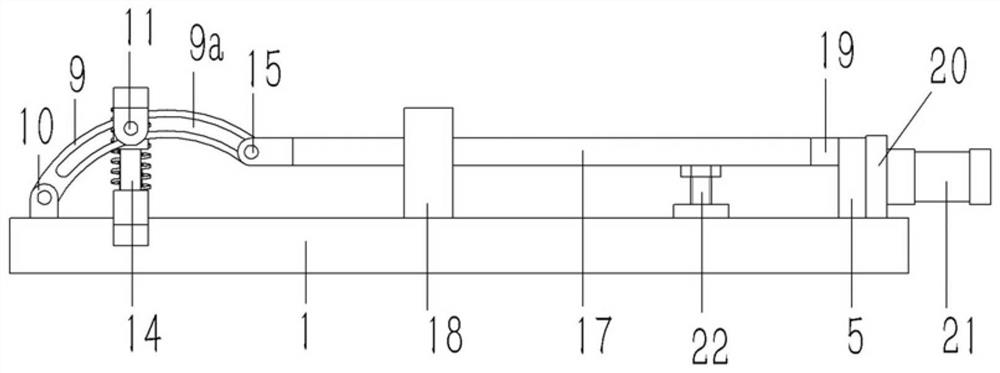

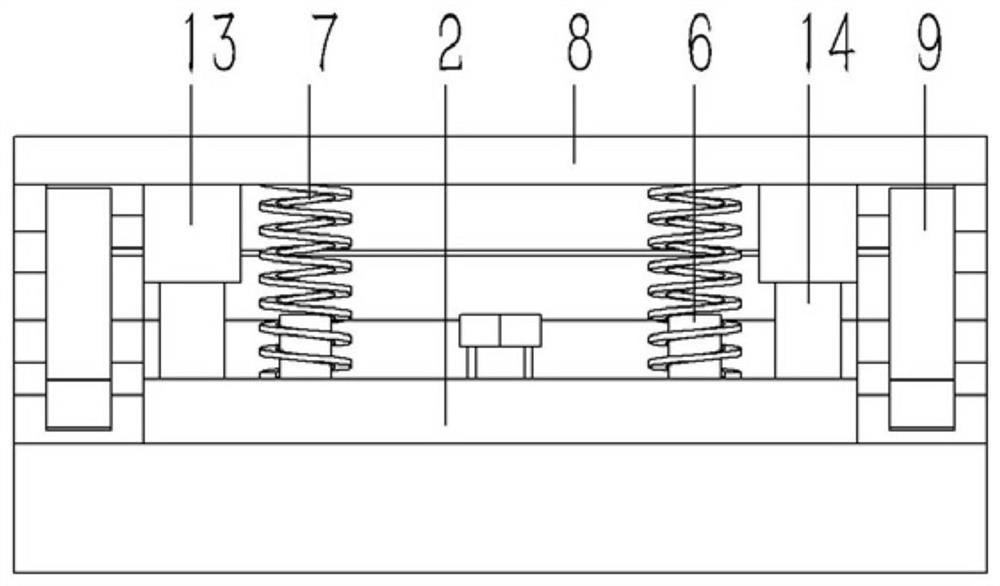

COS welding fixture for semiconductor laser

PendingCN110961846AAvoid displacement deviationRealize package soldering processWelding/cutting auxillary devicesAuxillary welding devicesEngineeringCantilever

The invention discloses a COS welding fixture for a semiconductor laser, and belongs to the technical field of COS welding. The COS welding fixture comprises a bearing and positioning assembly and atleast one cantilever spring probe assembly; the bearing and positioning assembly is used for bearing and positioning a tube shell base; the cantilever spring probe assembly comprises at least one positioning rod, pressure springs in one-to-one correspondence with the positioning rods, at least one spring probe, a cantilever support and a locking piece; the positioning rod is arranged on the bearing and positioning assembly, and is sleeved with the pressure spring; the pressure spring is compressed between the bearing and positioning assembly and the cantilever support; the positioning rod passes through the cantilever support; the locking piece is used for limiting the cantilever support at a position with a certain distance from the bearing and positioning assembly; the spring probe is arranged on the cantilever support and used for pressing the COS on the welding flux arranged on the tube shell base. The COS welding fixture for the semiconductor laser can effectively prevent COS fromgenerating displacement deviation in the welding process and improve COS positioning accuracy.

Owner:INST OF APPLIED ELECTRONICS CHINA ACAD OF ENG PHYSICS

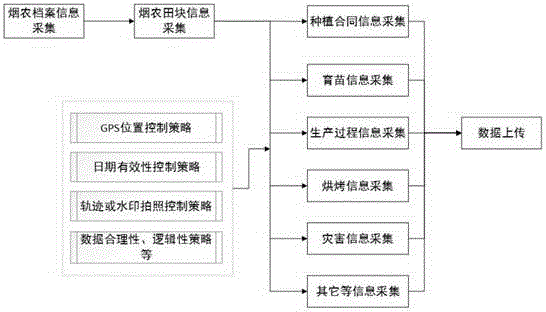

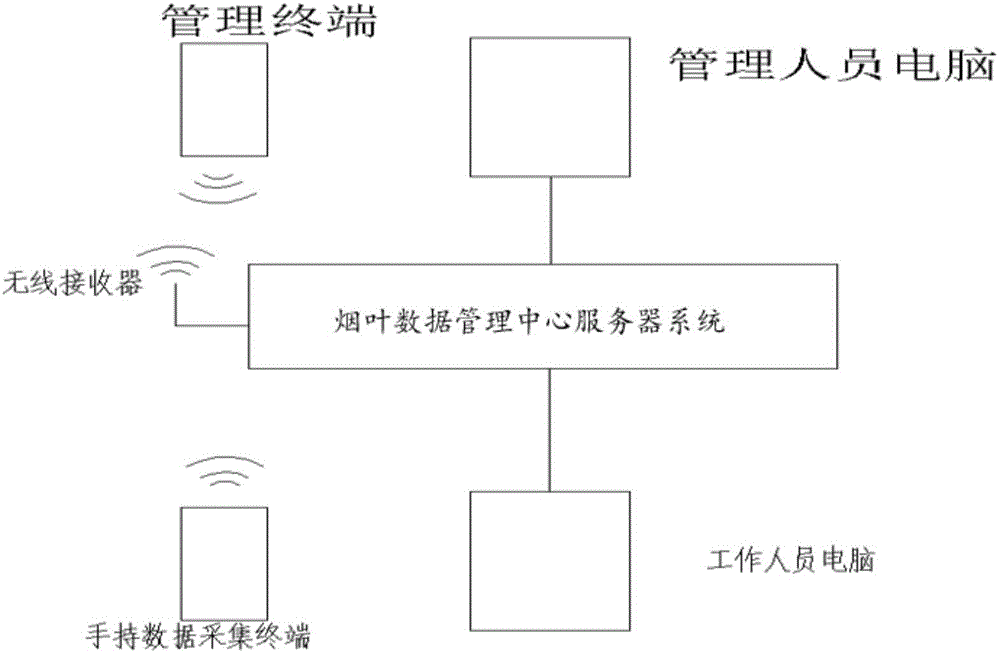

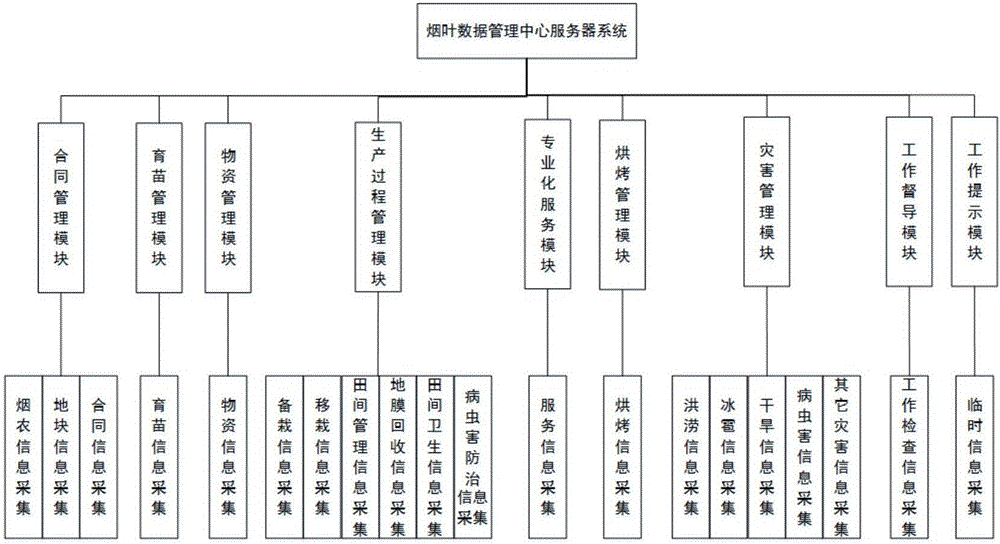

System for accurately collecting mountainous area tobacco production information data and data collection method

InactiveCN106779397AImprove transmission efficiencyRealize automatic collectionOffice automationResourcesData connectionData acquisition

The invention discloses a system for accurately collecting mountainous area tobacco production information data and a data collection method. The tobacco production information system comprises a tobacco data management center server system, a handheld data collection terminal and a management terminal, wherein the handheld data collection terminal is connected with the tobacco data management center server system in a wireless interaction mode, or the handheld data collection terminal is connected with the tobacco data management center server system in a wired interaction mode after being connected with a computer through a data connecting line. In this way, it can be ensured that data input each time is site practical operation; data is displayed from a macrocosmic view to a microcosmic view, step-by-step drilling of data at any level of subordinate departments is realized, the current situation that only production data at a lower level can be known is changed, the problem of difficult and complicated tobacco field data collection can be effectively solved, and meanwhile data entry authenticity is guaranteed.

Owner:中国烟草总公司贵州省公司

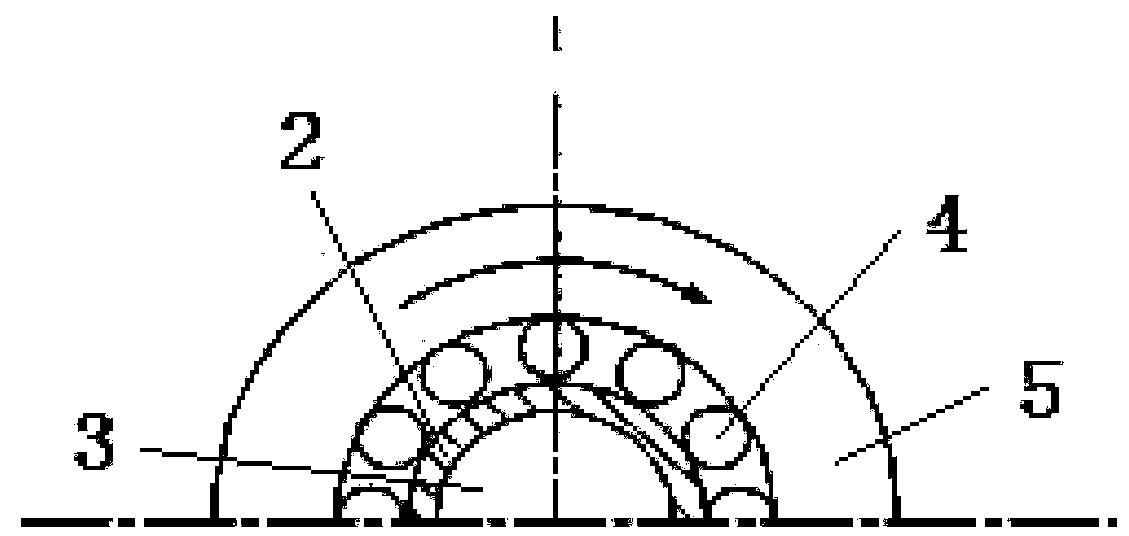

Large-scale mechanical automatic three-dimensional integral square knitting device

The invention discloses a large-scale mechanical automatic three-dimensional integral square knitting device, which comprises a frame, a shell, a spindle, a square chassis, a guide rail, a transversedriving mechanism and a longitudinal driving mechanism. A plurality of guide rails are arranged side by side in the square chassis, and the guide rails are uniformly provided with several grooves in the longitudinal direction; several grooves are arranged side by side in the horizontal direction of the guide rail to form a sliding groove for the spindle to slide; the spindles are arranged in a rowto slide in the sliding groove; the spindles are ellipsoidal and the length is greater than the width of the groove; both ends of the guide rail are connected with the longitudinal driving mechanism;the longitudinal driving mechanism drives the guide rail to move in the longitudinal direction of the guide rail; the transverse driving mechanism drives the spindle to move in the sliding groove. According to the large-scale mechanical automatic three-dimensional integral square knitting device, the spindle clamping phenomenon is not easy to occur in the manufacturing process of three-dimensional knitted fabric, the spindle and the guide rail are controlled to move in the weaving space by full automation, the yarn can form the three-dimensional knitted fabric at the knitted surface so as toachieve the mechanization and automation of the three-dimensional knitting machine and achieve the goal of improving the production efficiency of the product.

Owner:李典森

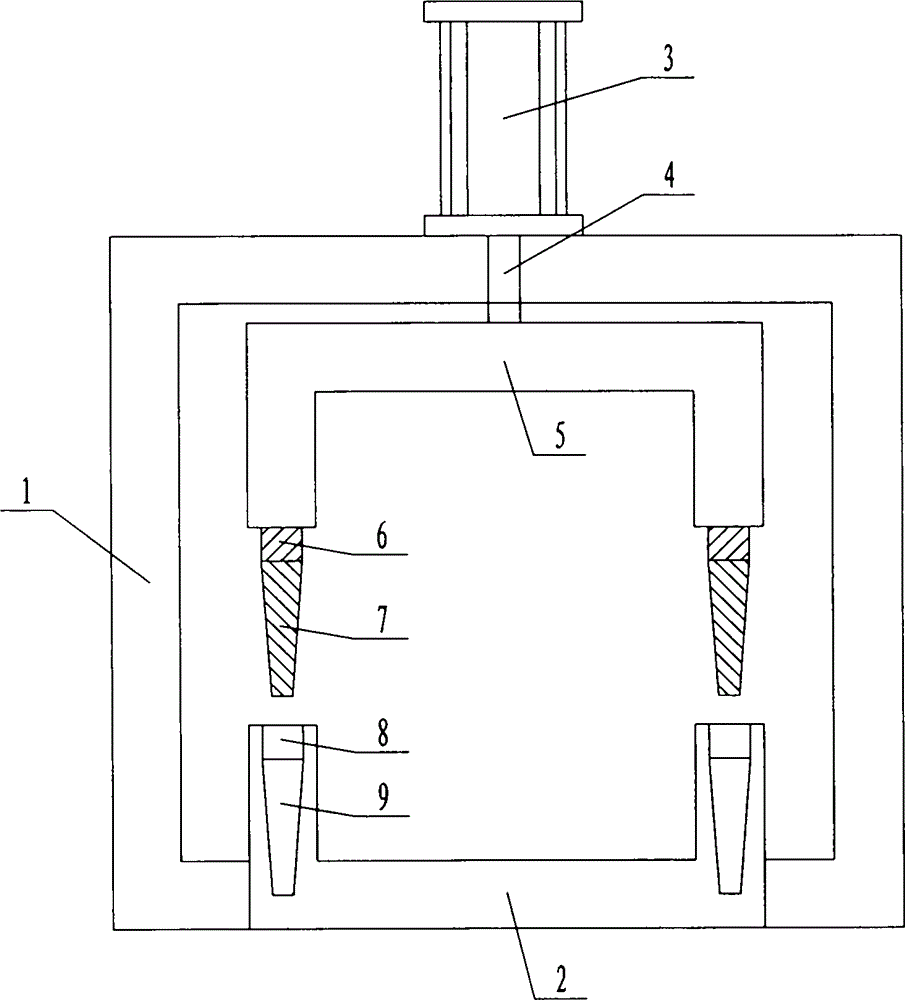

Tray automatic feeding device

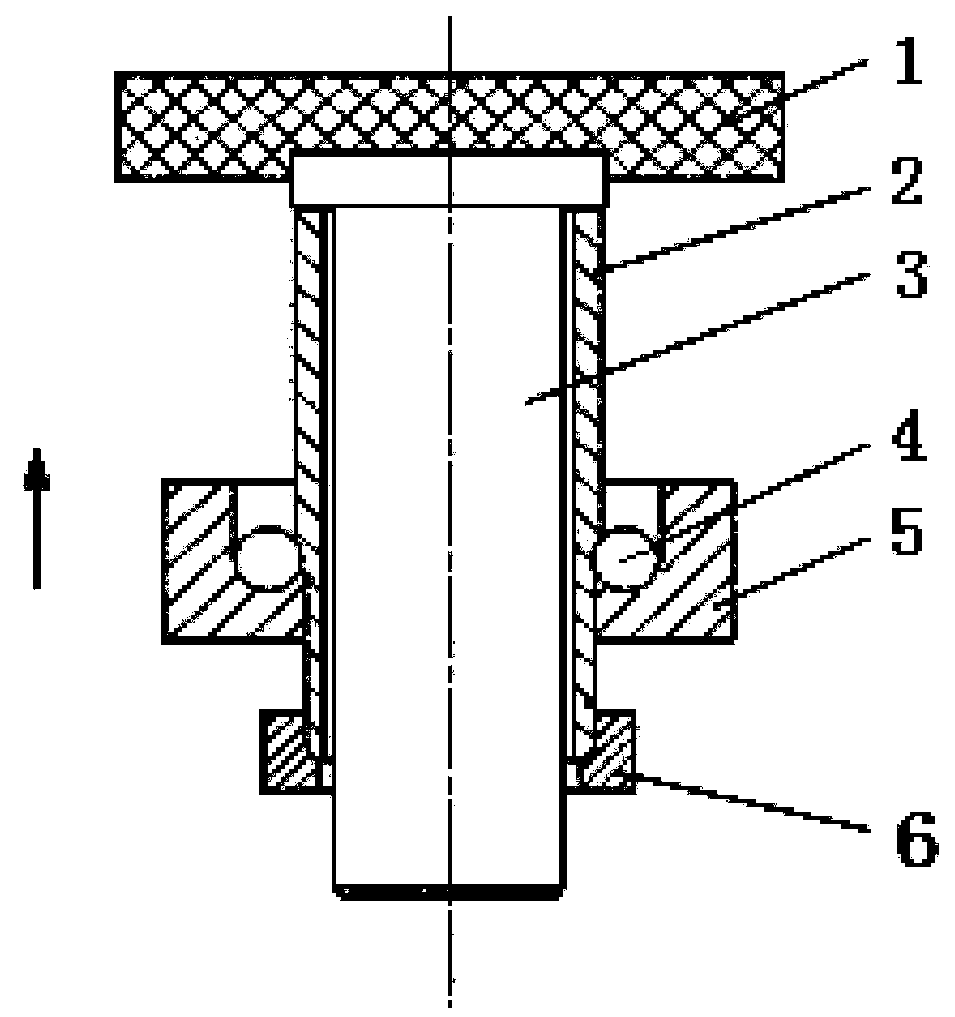

ActiveCN109592424AAvoid displacement deviationAvoid uninterrupted reloadingConveyorsDe-stacking articlesEngineeringMechanical engineering

The invention discloses a tray automatic feeding device comprising a box assembly, a feeding mechanism and a discharge auxiliary mechanism. The box assembly comprises a holding space for stacking trays. The top of the box assembly is provided with a discharge outlet. The lower section of the lateral part of the box assembly is provided with a feeding inlet. The feeding mechanism comprises a lifting support and a first driving assembly for driving the lifting support. The discharge auxiliary mechanism comprises a tray pressing block and a second driving assembly for driving the tray pressing block. Empty trays are taken away immediately from the discharge outlet in the top of the box assembly, a user puts products with the trays into the holding space from the feeding inlet in the lateral part of the box assembly at intervals in the production process, continuous production can be ensured, and production cost is reduced. The multiple trays are taken automatically by the feeding mechanism, empty trays are sucked away automatically by a sucker of the next procedure, and automatic production efficiency is improved. The tray pressing block abuts against the tray of the uppermost layer,and displacement deviation of trays in the sucking process of the sucker of the next procedure can be avoided.

Owner:深圳市大族锂电智能装备有限公司

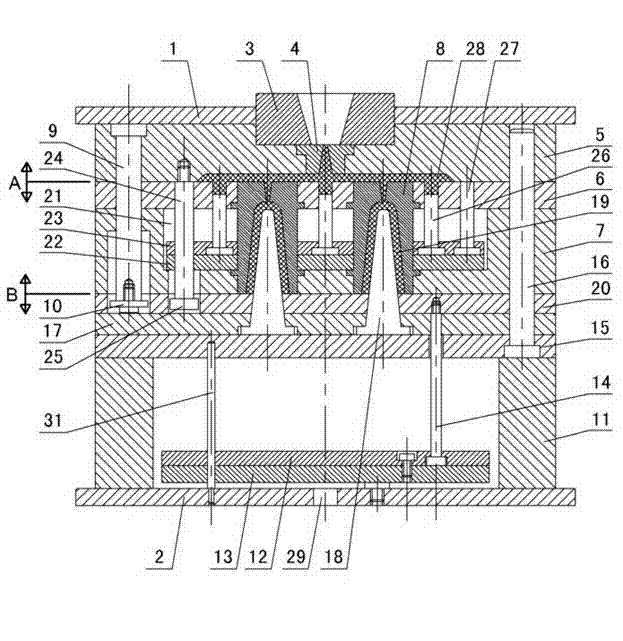

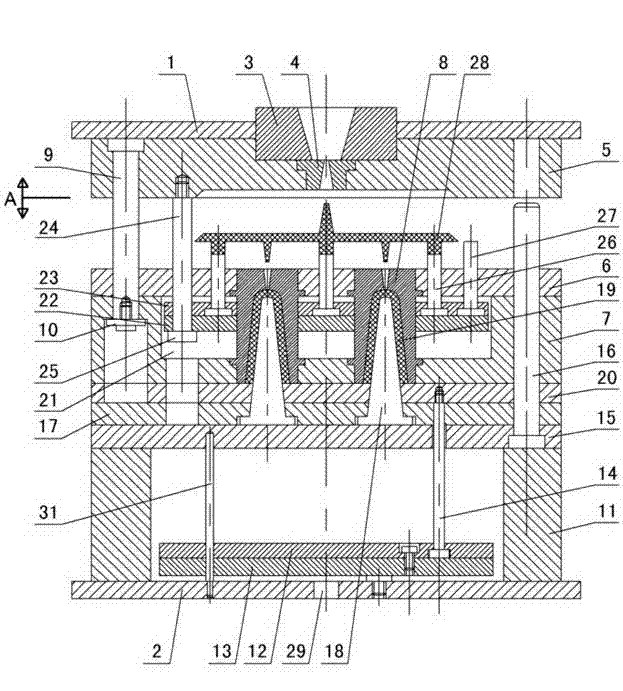

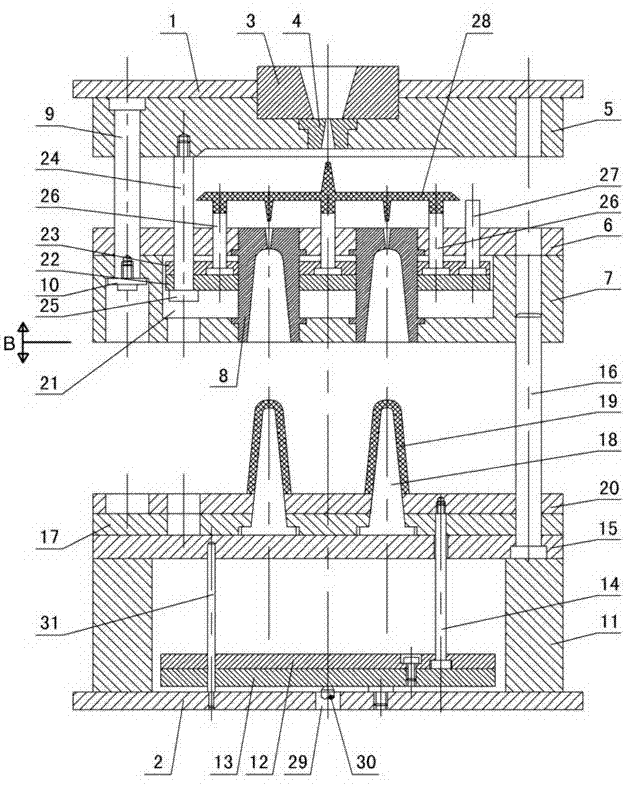

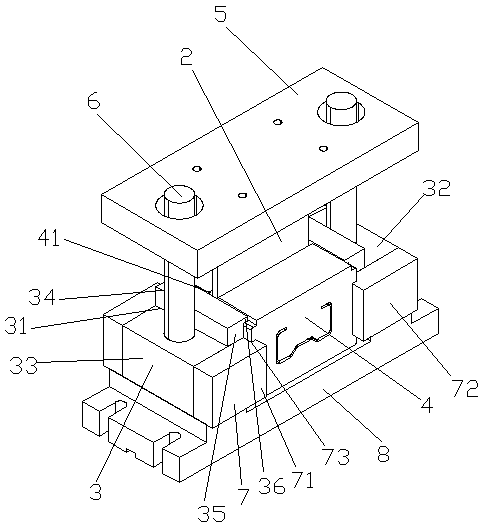

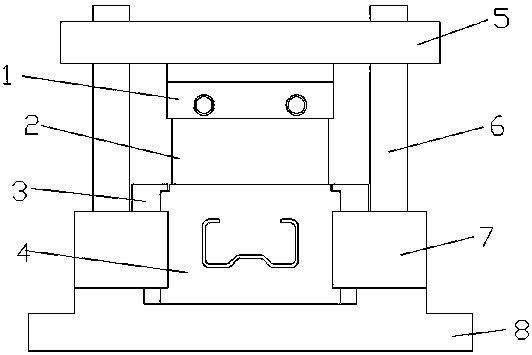

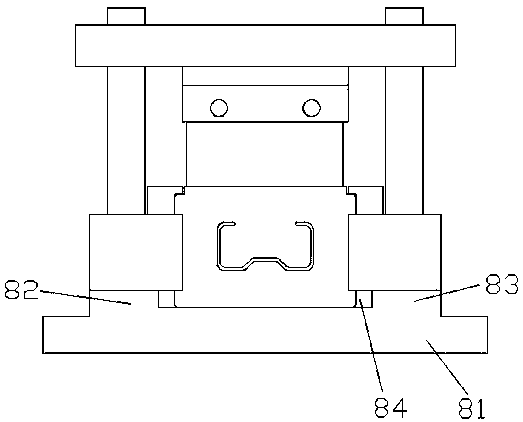

Mechanism for snapping pin-point gate through stationary mold push plate for injection mold

The invention discloses a mechanism for snapping a pin-point gate through a stationary mold push plate for an injection mold, wherein the mechanism comprises an upper compound plate and a lower compound plate, a runner plate is connected below the upper compound plate, a mold cavity fixing plate is connected below the runner plate, a mold cavity plate is connected below the mold cavity fixing plate, a mold cavity embedding block is fixed between the mold cavity plate and the mold cavity fixing plate, a fixed distance guide post is arranged below the upper compound plate, a baffle is installed below the fixed distance guide post to be matched with the mold cavity plate, an upper thimble plate and a lower thimble plate are arranged between mold pins installed on the lower compound plate, a discharging push rod is installed between the upper thimble plate and the lower thimble plate, a punch hole is formed in the lower compound plate, an injector mandril passes through the punch hole to contact with the lower thimble plate, a plastic element is arranged between a mold core embedding block and the mold cavity embedding block fixed in the mold cavity fixing plate installed on a supporting plate, a discharging plate is arranged on the mold cavity fixing plate to be fixed with the discharging push rod, the mechanism is characterized in that a mold push plate and a stationary mold push plate fixing plate are arranged in a hollow cavity processed in the mold cavity plate, the disk-shaped large end of a fixed distance pull rod installed below the runner plate is in contact with the stationary mold push plate, a waste material mandril and a waste material jacking out a resetting rod are fixed in the stationary mold push plate fixing plate, and the waste material mandril is in contact with the waste material.

Owner:TAIZHOU KAIHUA AUTOMOBILE MOULD CO LTD

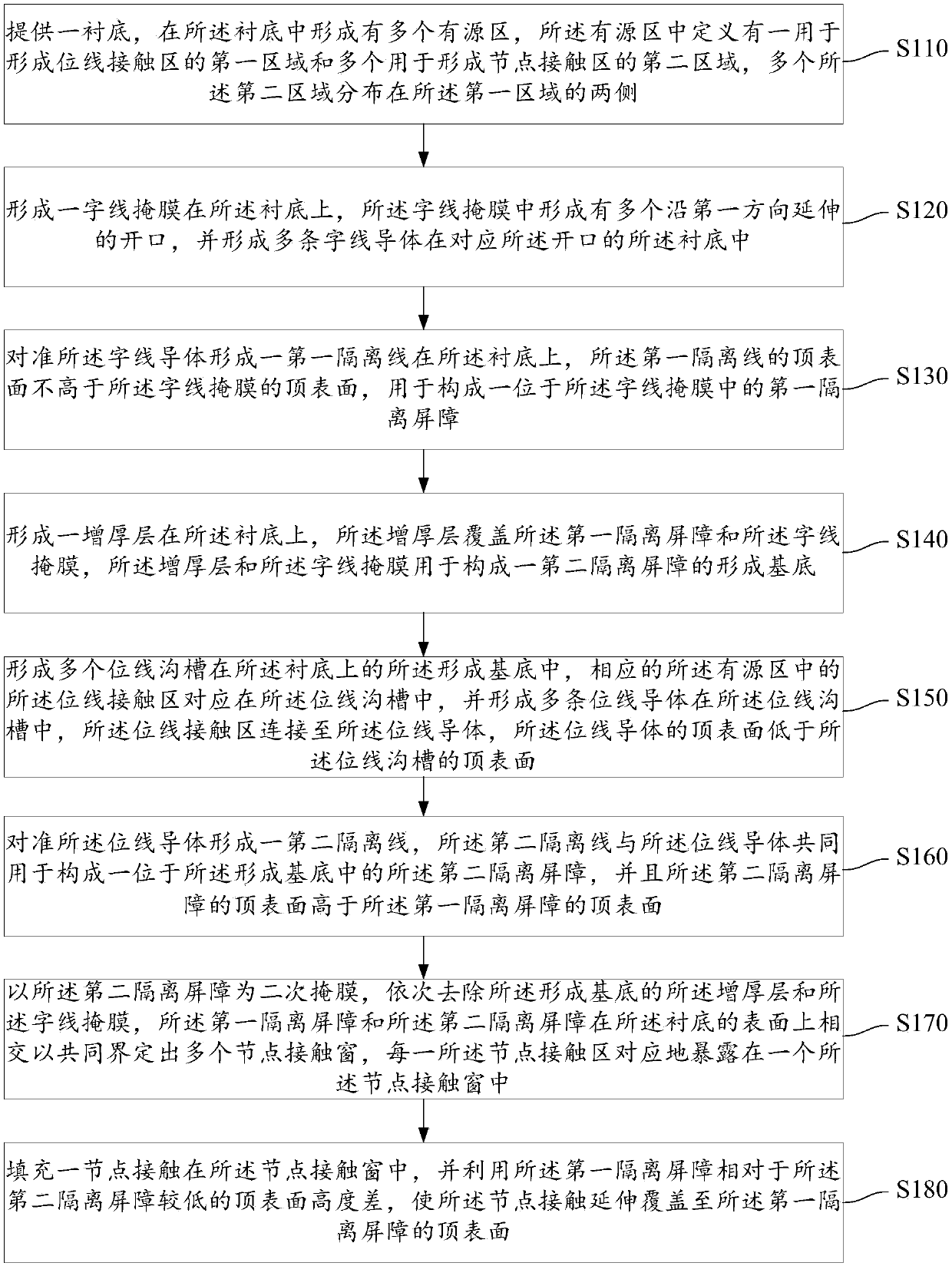

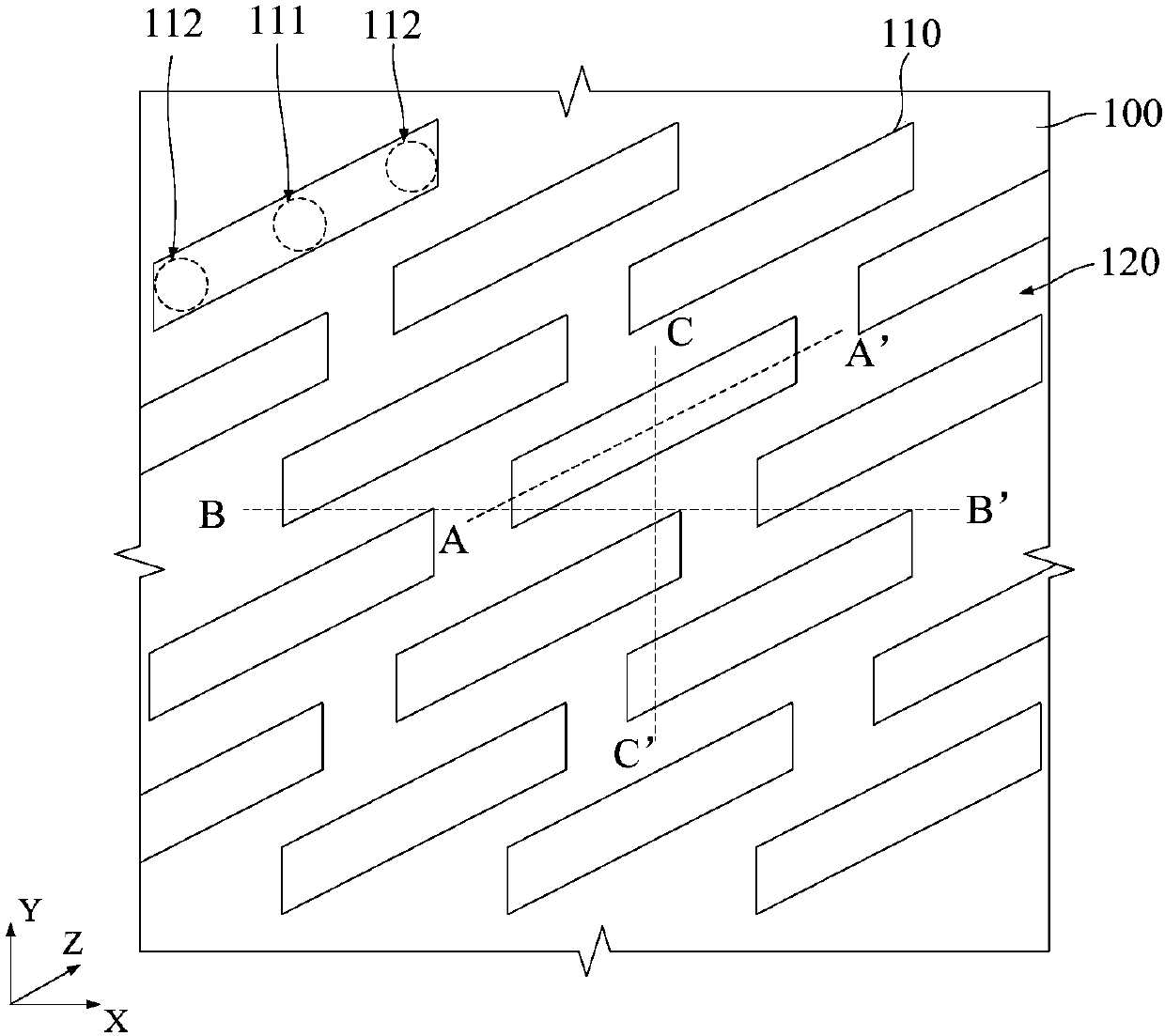

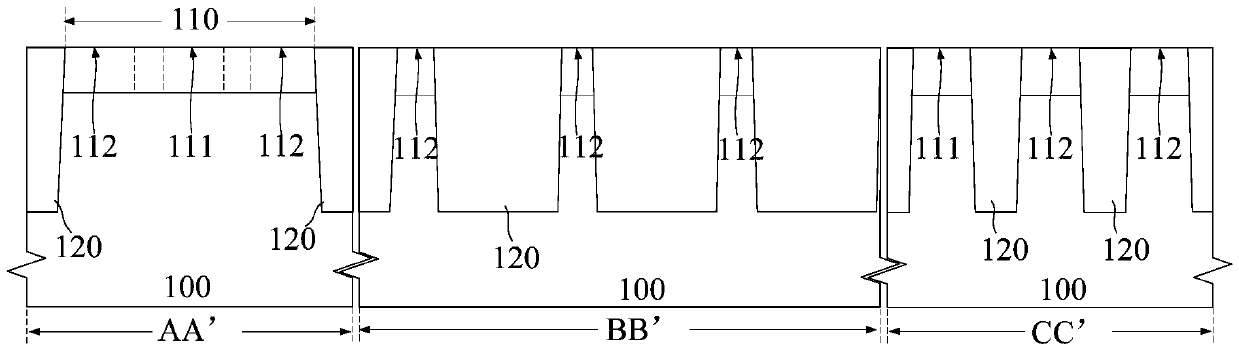

Storage, forming method thereof and semiconductor device

ActiveCN107611133AIncrease densityAvoid displacement deviationSolid-state devicesSemiconductor devicesPhotolithographyPower semiconductor device

The invention provides a storage, a forming method thereof and a semiconductor device. A word line mask which defines a word line conductor is used for forming a first isolation barrier in an autocollimation manner, and a thickening layer is formed so as to increase the thickness of a forming substrate of a second isolation barrier so that the top surface of the second isolation barrier in the forming substrate can be higher than the top surface of the first isolation barrier. Therefore, not only can the crossed first isolation barrier and second isolation barrier be used for defining a node contact window, and accordingly, the problem of displacement deviation caused by the photolithography technique can be eliminated; but also the lower top surface of the first isolation barrier is usedso as to realize extension of the top in contact with the nodes and adjust the arrangement manner of a plurality of nodes on the contact surface of the nodes and a capacitor, and the arrangement density of the capacitor can be further optimized.

Owner:CHANGXIN MEMORY TECH INC

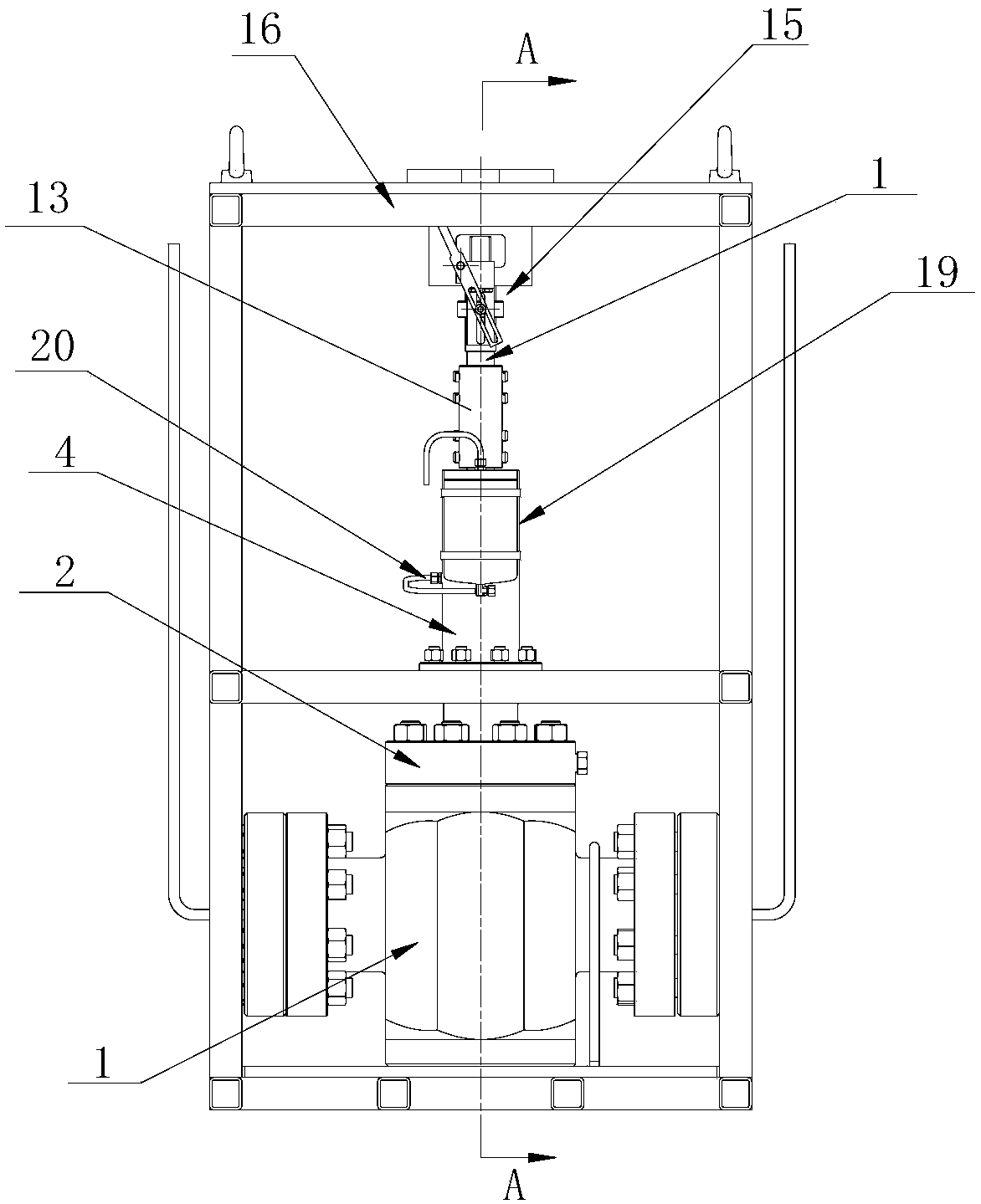

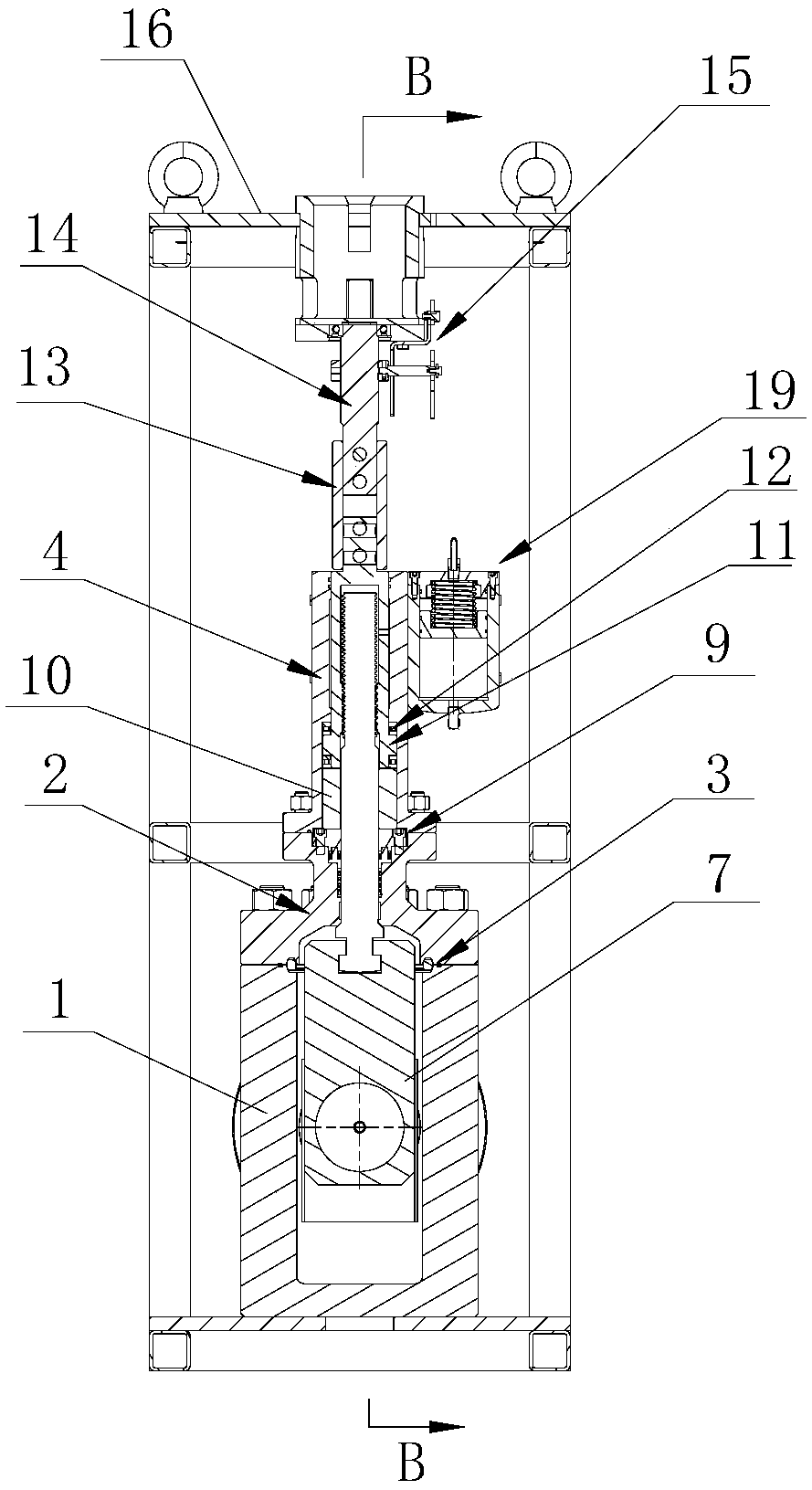

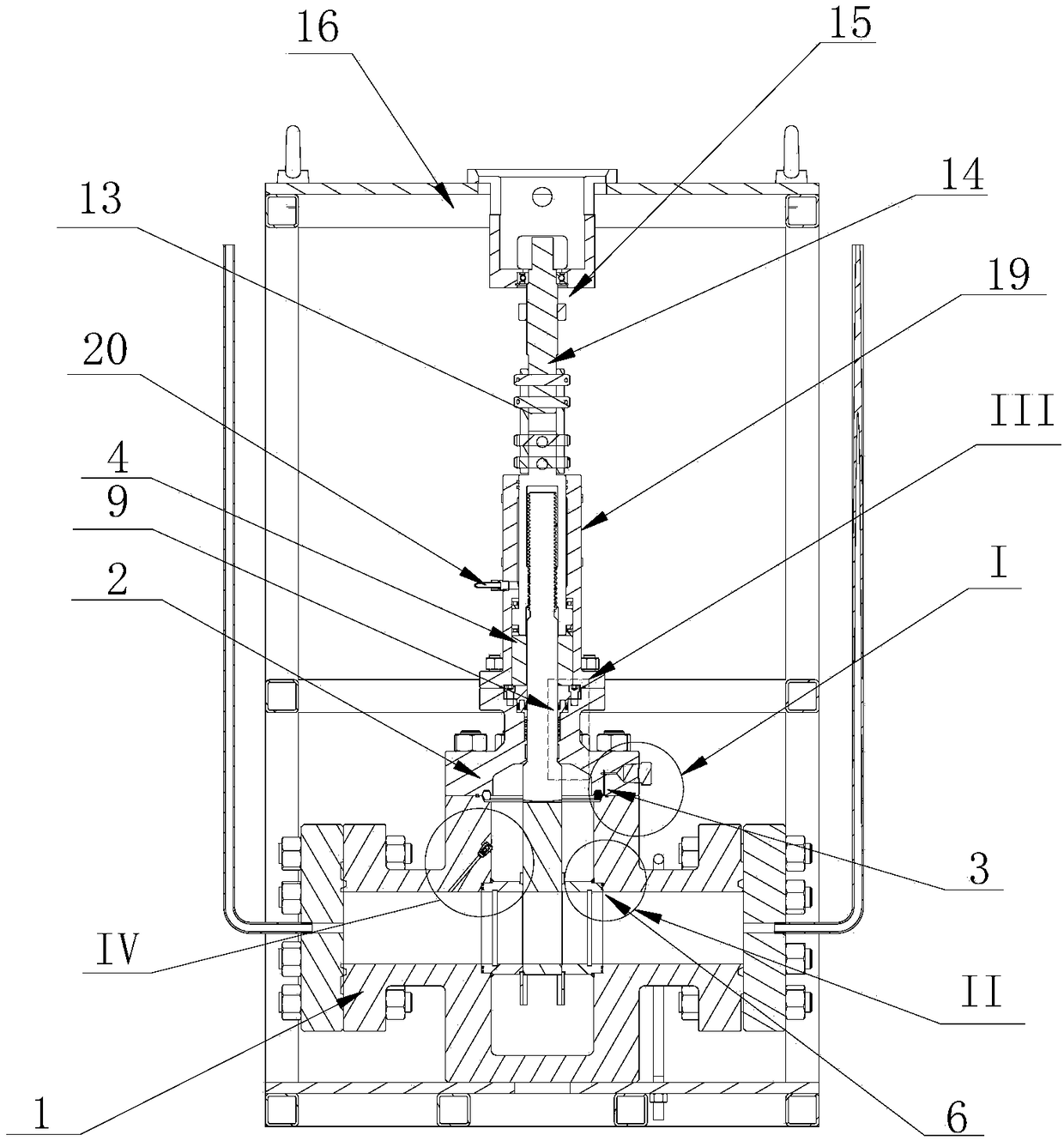

Underwater flat gate valve for sea bottom christmas tree

PendingCN108443524AReduce processing cumbersome proceduresRealize online replacement and maintenanceSlide valveValve housingsCorrosionRelief valve

The invention relates to an underwater flat gate valve for a sea bottom christmas tree. The underwater flat gate valve comprises a valve body, a valve cover, a gate plate, a support and a valve seat.A first sealing structure is arranged between the valve body and the valve cover. A second sealing structure is arranged between the valve seat and the valve body. A third sealing structure is arranged between the valve cover and a valve rod. A gasket ring and a valve rod nut are mounted in the support, and the valve rod stretches out of the valve cover to penetrate the gasket ring to be in threaded connection with the valve rod nut. The upper end of the valve rod nut is connected with a drive sleeve, the drive sleeve is connected with an upper valve rod, and the upper valve rod is connected with a valve position indication mechanism. The upper valve rod is connected with an ROV connector through a supporting bearing. A pre-pressing disc spring for providing initial specific pressure is mounted on the valve seat. A pressure relief channel extending in the upstream direction is arranged in the valve body, and a one-way pressure relief valve is mounted on an inner channel of a valve cavity of the valve body. A gate plate guide mechanism is detachably mounted at the symmetric positions of the middle of the valve seat. The underwater flat gate valve has the advantages that sealing performance is good, and the functions of gate plate guide and start and stop compensation are achieved; and meanwhile, for gate plate and valve seat hardening treatment, the corrosion resisting strengthis improved, corrosion resistance is high, and the service life is long.

Owner:天津祥嘉流体控制系统有限公司

3D-printing femoral-condyle five-in-one integration osteotomy device and forming method thereof

PendingCN108784782AIt has the characteristics of not easy to deform under forceFit tightlySurgery3d printFemoral osteotomy

The invention provides a 3D-printing femoral-condyle five-in-one integration osteotomy device and a forming method thereof, and relates to the technical field of medical apparatuses and instruments. For solving the technical problem that errors are easy to generate in existing total knee replacement femoral-condyle osteotomy, the 3D-printing femoral-condyle five-in-one integration osteotomy devicecomprises a femoral osteotomy device model matched with the affected-side femoral condyle of a patient, the femoral osteotomy device model is provided with a femoral-condyle front fitting face, a femoral-medial-condyle fitting face and a femoral-lateral-condyle fitting face, and the femoral-condyle front fitting face is used for fixed with the femoral condyle; the femoral osteotomy device model is subjected to stress and is not front to deformation, and is formed in a 3D-printing mode. Two osteotomy processes can be merged into one process, femoral-condyle osteotomy is completed one time, theusing quantity of osteotomy guiding plates is decreased, and deviations are reduced.

Owner:THE SECOND AFFILIATED HOSPITAL ARMY MEDICAL UNIV +1

Connecting structure, connecting method and application of quartz tuning fork and base

ActiveCN111256673AImprove temperature stabilityResolving Temperature MismatchesSpeed measurement using gyroscopic effectsGyroscopes/turn-sensitive devicesEpoxyGyroscope

The invention discloses a connecting structure of a quartz tuning fork and a base. The connecting structure comprises an island, a boss and a plurality of metal film layers arranged between the islandand the boss and used for connecting the island and the boss, the island is arranged in the center of the quartz tuning fork, and the boss is arranged on the surface of the base. The invention further provides a connecting method for the connecting structure of the quartz tuning fork and the base and application of the connecting structure in quartz tuning fork gyroscopes. The quartz tuning forkand the base are connected by adopting a micro-assembly process, the inevitable problems of temperature mismatching and gas release of the quartz tuning fork and the base based on an epoxy resin adhesive process are fundamentally solved based on the properties of materials, the full-temperature performance and the temperature stability of the quartz gyroscope can be effectively improved, and the strength and the reliability of the connecting structure are guaranteed; meanwhile, the MEMS technology is adopted and can be compatible with traditional automatic bonding equipment, and the micron-scale micro-assembly precision is guaranteed through specific micro-assembly technological parameters.

Owner:BEIJING CHENJING ELECTRONICS

Clamping tool for PCB processing

ActiveCN111347278AAvoid displacement deviationWork clamping meansPositioning apparatusEngineeringStructural engineering

The invention discloses a clamping tool for PCB processing. The clamping tool comprises a clamping platform, wherein a rectangular concave table is formed on the upper end face of the clamping platform, a rectangular slot penetrating the lower end face o f the clamping platform is formed in the bottom face of the concave table, a longitudinal groove communicating with the concave table is formed in the upper end face of the left side of the clamping platform, a rectangular notch is formed in the middle of the right side of the clamping platform, a longitudinal batten is inserted into the longitudinal groove of the clamping platform, and an L-shaped push block is inserted into the right side of the concave table of the clamping platform; and a push rod is fixed on the right end face of thepush block, and is inserted into a right side wall of the concave table, and the right end of the push rod is inserted into the notch of the clamping platform.

Owner:江门市浩远科技有限公司

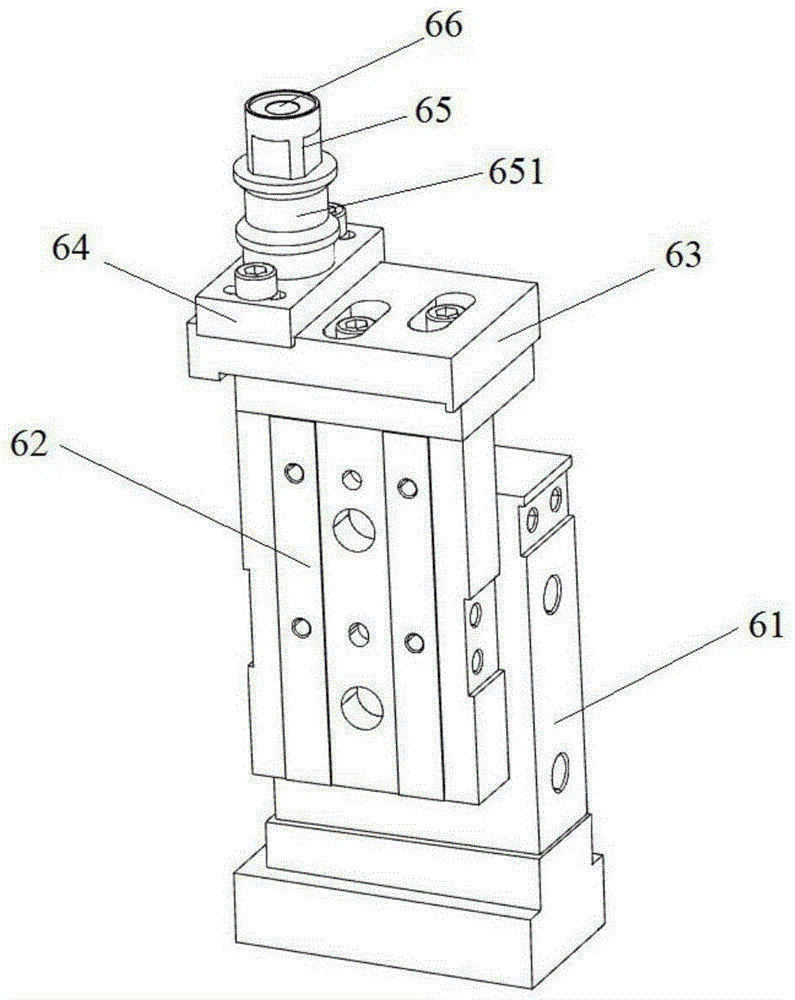

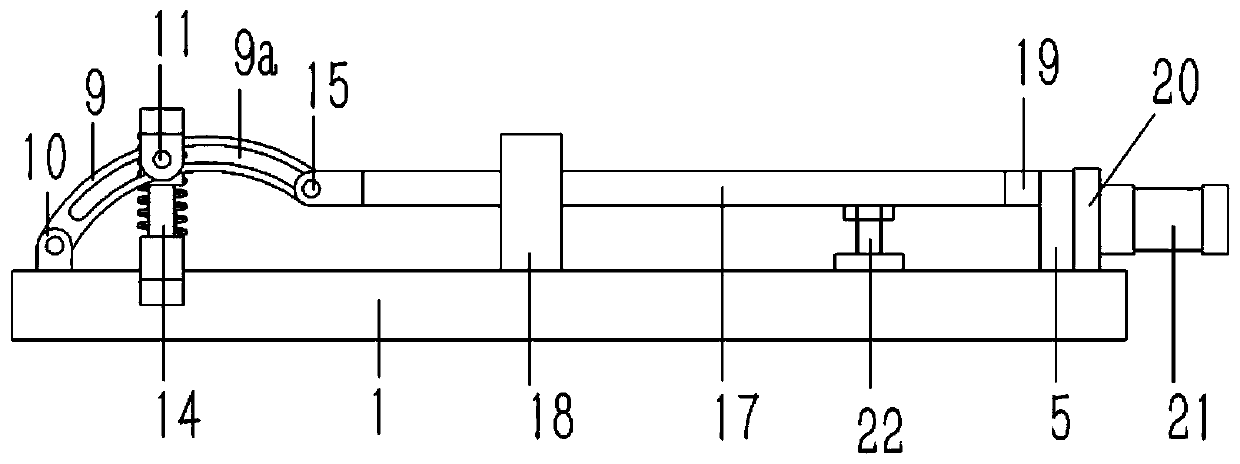

On-line cutter

PendingCN107737989AAvoid displacement deviationAccurate and reliable positioningShearing machinesShearing toolsEngineeringClassical mechanics

The invention relates to a cutter, in particular to an on-line cutter, and belongs to the technical field of cutting-off devices. The on-line cutter comprises an upper template (5), a lower template (8), a dynamic cutter body (2) and a static cutter body (4). The static cutter body (4) is arranged on the lower template (8), the static cutter body (4) is positioned through a fixed guiding plate (3)and a baffle (7) arranged on the two sides of the static cutter body (4), and the dynamic cutter body (2) is arranged above the static cutter body (4); and the dynamic cutter body (2) is arranged atthe bottom of the upper template (5), the two ends of the upper template (5) arranged on two guiding columns (6) in a penetrating and sleeving mode correspondingly, and the lower ends of the two guiding columns (6) are correspondingly arranged on the fixed guiding plate (3). According to the on-line cutter, positioning is accurate, the dynamic cutter body and the static cutter body are arranged upand down, the dynamic cutter body is driven by hydraulic equipment, the cutting-off quality is good, and the efficiency is high.

Owner:江苏凌云恒晋汽车零部件有限公司

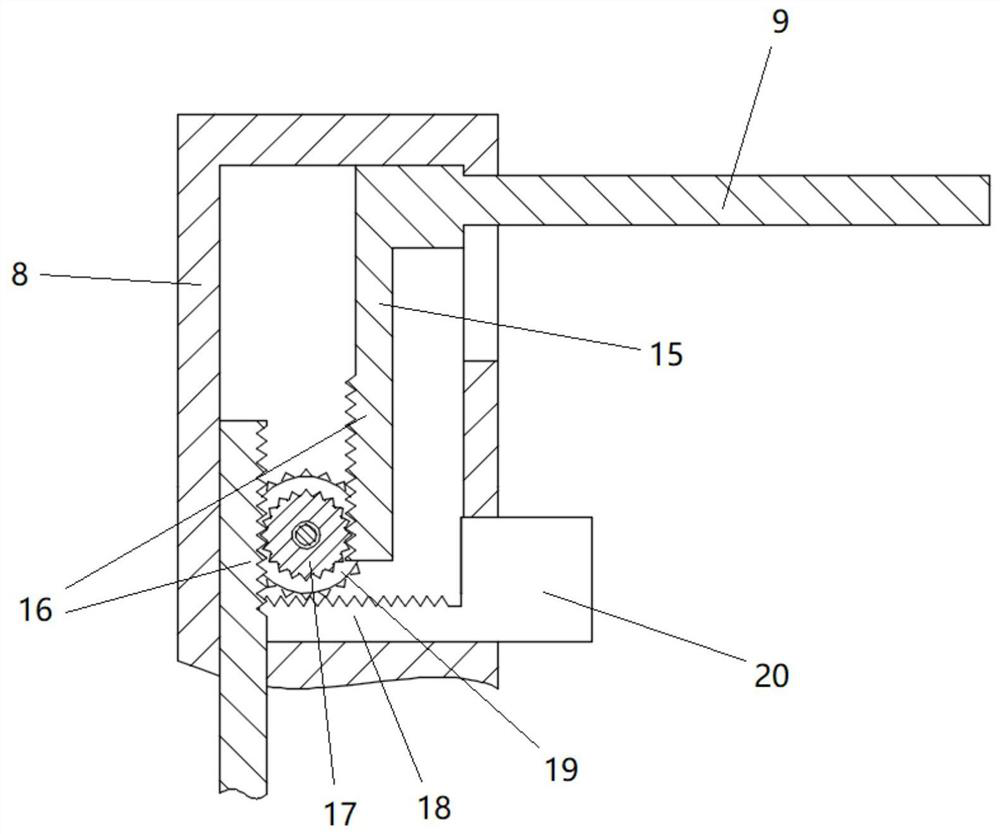

Positioning die

InactiveCN104924663AAvoid displacement deviationMeet production needsPressesElectric energyPrimary energy

The invention discloses a positioning die. The positioning die comprises a support. The support is provided with a seat, a hand-cranking ratchet wheel, a pedal ratchet wheel, a transmission shaft and an electricity generating shaft of an electricity generating device. The transmission shaft is provided with a first transmission wheel, a second transmission wheel and a third transmission wheel. The electricity generating shaft on the electricity generating device is provided with a transmission belt wheel. The hand-cranking ratchet wheel is connected with the first transmission wheel through a first transmission chain. The pedal ratchet wheel is connected with the second transmission wheel through a second transmission chain. The third transmission wheel is connected with the transmission belt wheel through a transmission belt. The positioning die has the advantages that physical ability consumed by body building of people can be converted into electric energy, primary energy is saved, the electricity generating device generates electricity and is free of pollution, the positioning die is simple in structure and convenient to use, and the delight in building the body is provided for people.

Owner:盐城市建龙机电设备制造有限公司

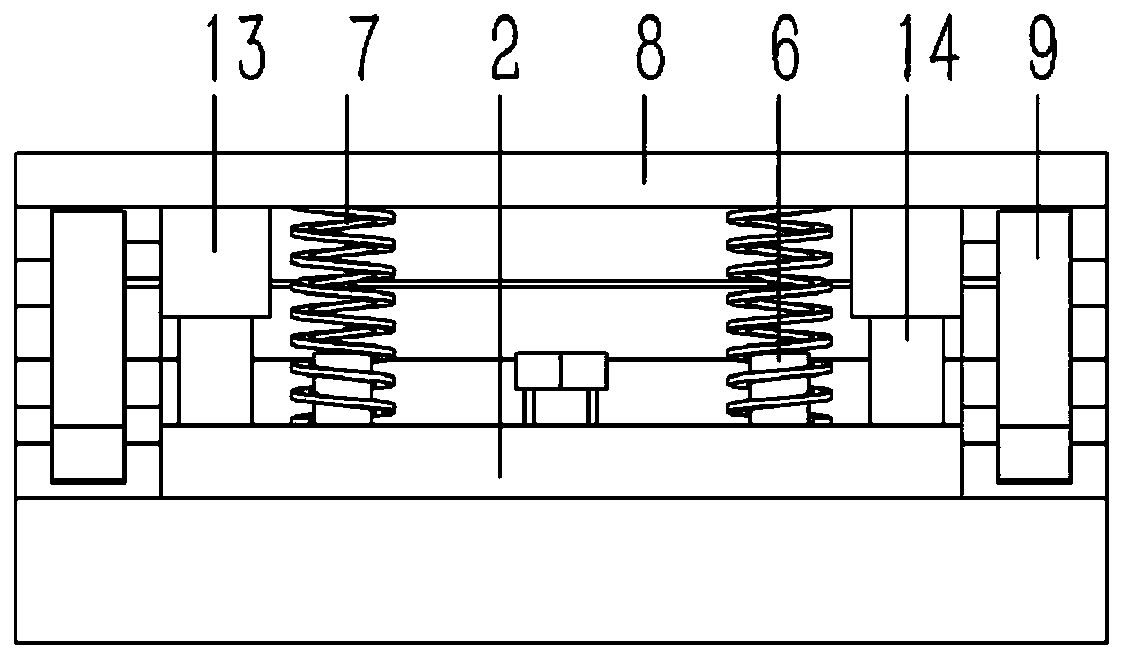

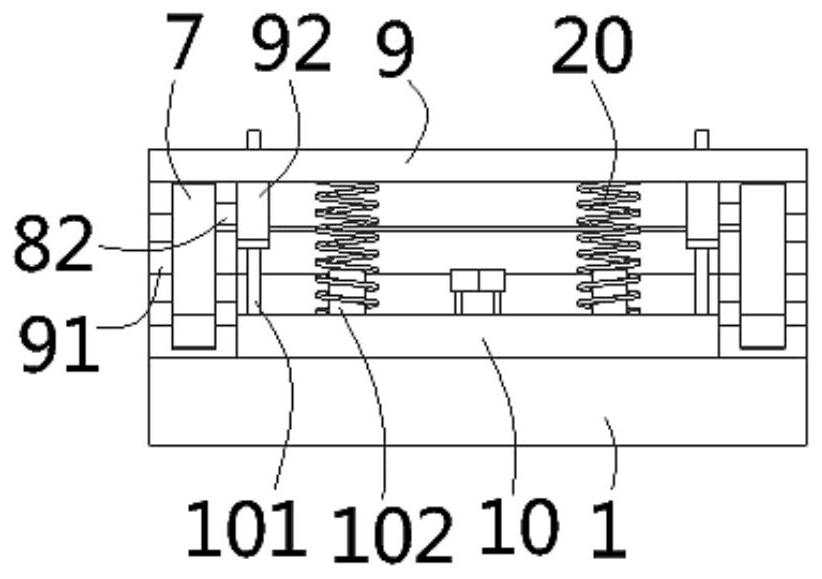

Bag making machine longitudinal sealing device with integrated movable and static hot press plates

ActiveCN104070704AAvoid displacement deviationDisplacement deviation will notBox making operationsPaper-makingEngineeringMechanical engineering

The invention relates to a bag making machine longitudinal sealing device with integrated movable and static hot press plates. The bag making machine longitudinal sealing device comprises an upper machine frame, a lower machine frame, the movable hot press plate, the static hot press plate, a roll gear, a rack, machine frame guide columns, springs, gear rods and gear rod fixing blocks. The bag making machine longitudinal sealing device is characterized in that hot press plate guide columns, hot press plate guide blocks and hot press plate fixing blocks are further included, the hot press plate fixing blocks are fixedly arranged at the two ends of the movable hot press plate, the hot press plate guide blocks corresponding to the hot press plate fixing blocks are arranged on the static hot press plate, guide column holes are formed in the hot press plate guide blocks, one end of each hot press plate guide column is fixedly connected with the corresponding hot press plate fixing block, and the other end of each hot press plate guide column is arranged in the guide column hole of the corresponding hot press plate guide block. The bag making machine longitudinal sealing device has the advantage of being capable of preventing movement of the movable hot press plate and the corresponding to the static hot press plate.

Owner:江阴市汇通包装机械有限公司

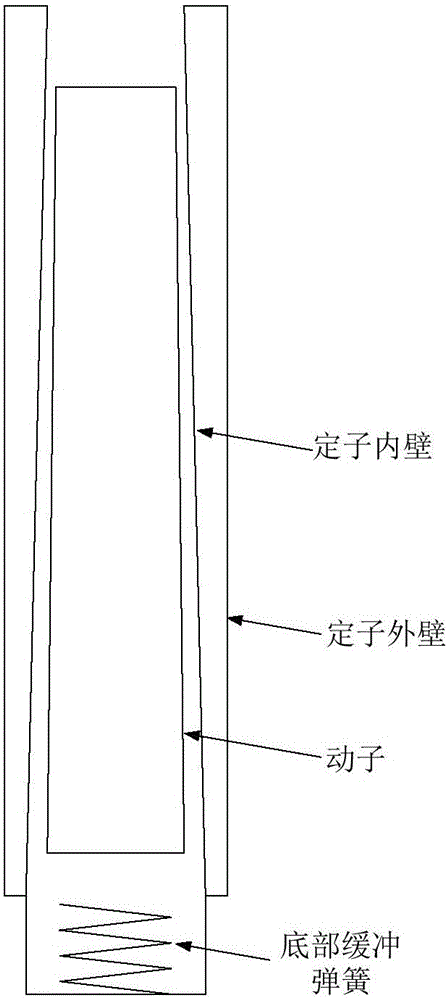

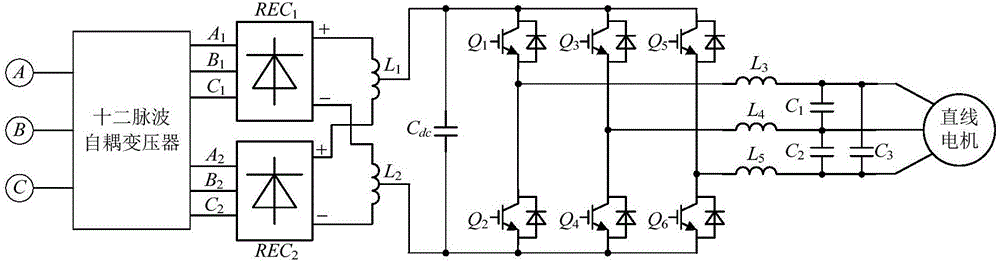

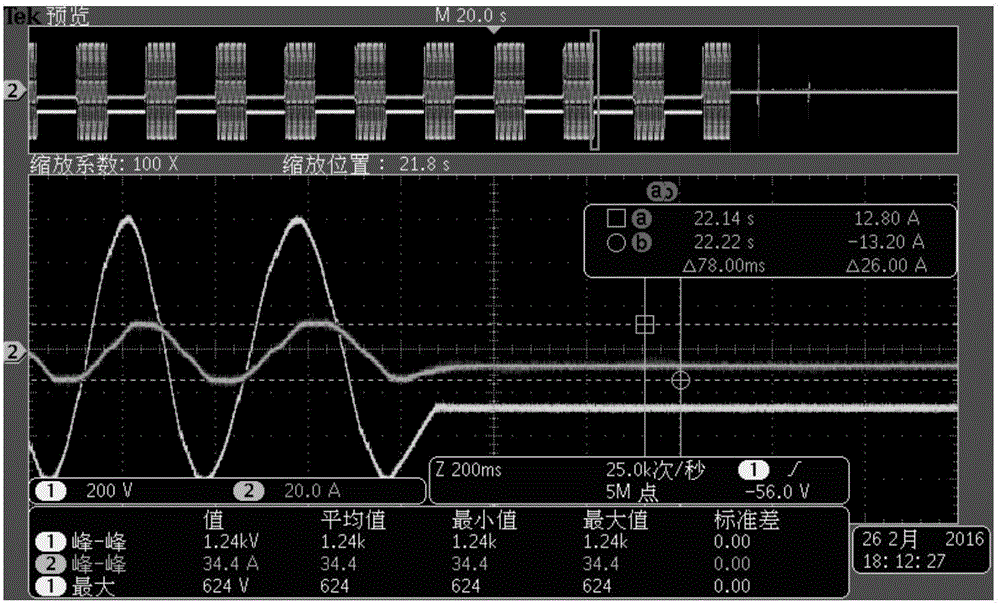

Control method for preventing submersible linear motor from bumping

The invention discloses a control method for preventing a submersible linear motor from bumping. The submersible linear motor comprises a stator and a mover, wherein the stator is provided with an upper limit device and a lower limit device, the mover does reciprocating motion between the upper limit device and the lower limit device, and a motion period and a waiting period are alternately carried out in a motion process. The method is characterized by comprising steps that the displacement information is acquired on the basis of a voltage of the submersible linear motor, and a driving voltage of a driving motor is changed on the basis of the displacement information. The method is advantaged in that jig frequency stepless adjustment on the submersible linear motor can be realized, electricity consumption for keeping the position of the mover generally does not increase, and thereby jig frequency stepless adjustment is realized on the condition that the position of the mover is kept unchanged.

Owner:NO 719 RES INST CHINA SHIPBUILDING IND

A connection structure, connection method and application of a quartz tuning fork and a base

ActiveCN111256673BImprove temperature stabilityResolving Temperature MismatchesSpeed measurement using gyroscopic effectsGyroscopes/turn-sensitive devicesEpoxyGyroscope

The invention discloses a connection structure between a quartz tuning fork and a base, which includes an isolated island, a boss and a multi-layer metal film layer arranged between the two for connecting the two with each other, the isolated island is arranged at the center of the quartz tuning fork, and the The boss is arranged on the surface of the base. The present invention also provides a connection method of the above-mentioned quartz tuning fork and base connection structure and an application in the quartz tuning fork gyroscope. The invention uses a micro-assembly process to connect the quartz tuning fork and the base. Based on the properties of the material, it fundamentally solves the inevitable temperature mismatch and gas release between the quartz tuning fork and the base based on the epoxy resin bonding process, and can effectively improve The full-temperature performance and temperature stability of the quartz gyroscope ensure the strength and reliability of the connection structure. At the same time, the use of MEMS technology can be compatible with traditional automatic bonding equipment, and the micron-level micro-assembly accuracy is guaranteed through specific micro-assembly process parameters.

Owner:BEIJING CHENJING ELECTRONICS

Clamping and limiting device for PCB

ActiveCN111836471APress to achieveAvoid displacementPrinted circuit manufactureGear wheelRack and pinion

Owner:台州市路桥聚鑫电子有限公司

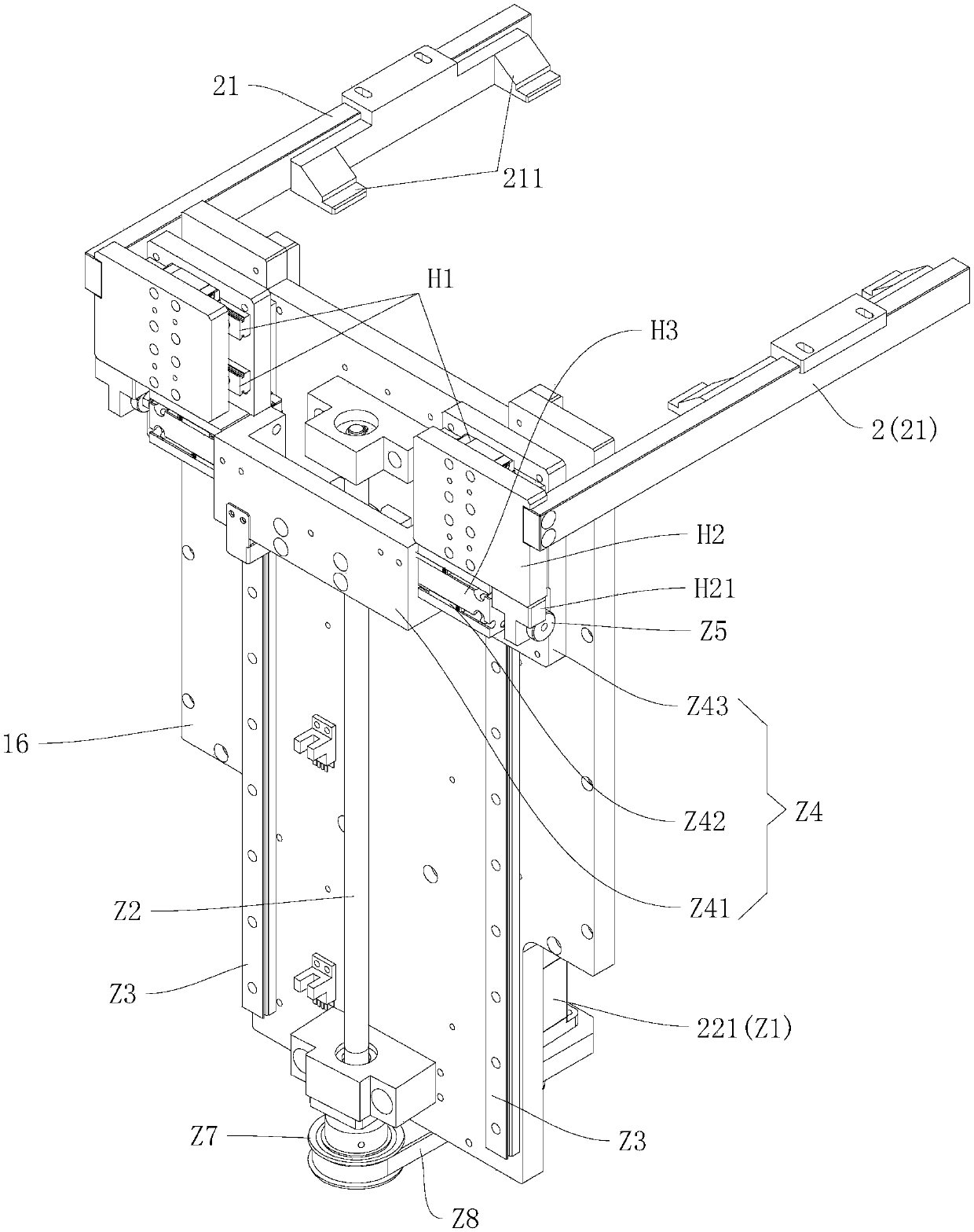

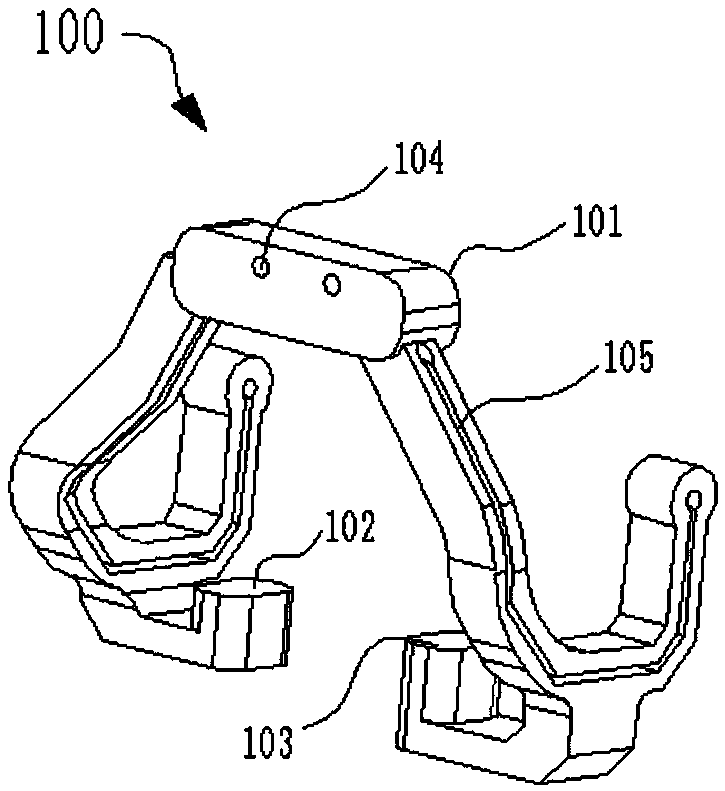

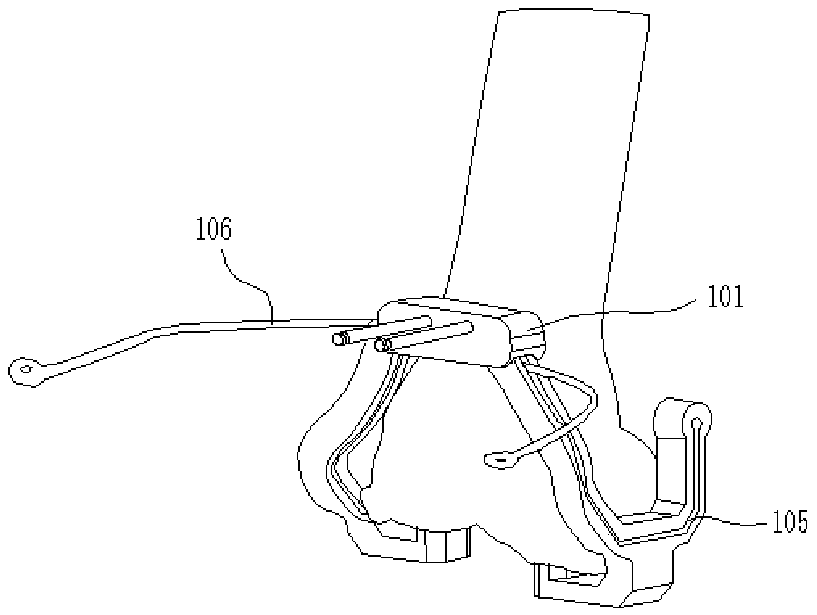

Cell taking manipulator

InactiveCN110103246APrevent free fallAvoid displacement deviationProgramme-controlled manipulatorGripping headsManipulator

The invention relates to a cell taking manipulator. The cell taking manipulator comprises a bracket, a horizontal moving component, a lifting component and clamping jaw components, wherein the horizontal moving component is arranged on the bracket, the lifting component is connected with the horizontal moving component by virtue of a lifting bracket, the clamping jaw components are connected withthe lifting component, the clamping jaw components include an upper clamping jaw component and a lower clamping jaw component, the upper clamping jaw component is arranged on the lifting bracket in asliding mode, and the lower clamping jaw component is in transmission connection with the lifting component. The lower clamping jaw component is driven to lift by the lifting component, the upper clamping jaw component slides on the lifting bracket, so that the clamping and loosening matching of an upper clamping jaw and a lower clamping jaw is realized, positive and negative pole pieces are disengaged from a jig layer by layer when the jig is pulled away, the lower clamping jaw moves upwards so as to support the positive and negative pole pieces layer by layer, so that the pole pieces are prevented from freely falling, the displacement deviation of the positive and negative pole pieces is prevented from being generated, the precision of cells is effectively increased, and finally, the superimposed pole pieces are clamped by the lower clamping jaw together with the upper clamping jaw and are moved to the next station.

Owner:陈保成

Punching device for chain pin

InactiveCN111687451AEnsure consistencyAvoid mistakesLarge fixed membersMetal working apparatusClassical mechanicsChain link

The invention discloses a punching device for a chain pin. The punching device comprises a punching assembly and a conveying assembly, wherein the conveying assembly comprises a base plate, a push plate used for pushing the pin, a power assembly and a frame body used for supporting the power assembly.

Owner:杭州传智自动化科技有限公司

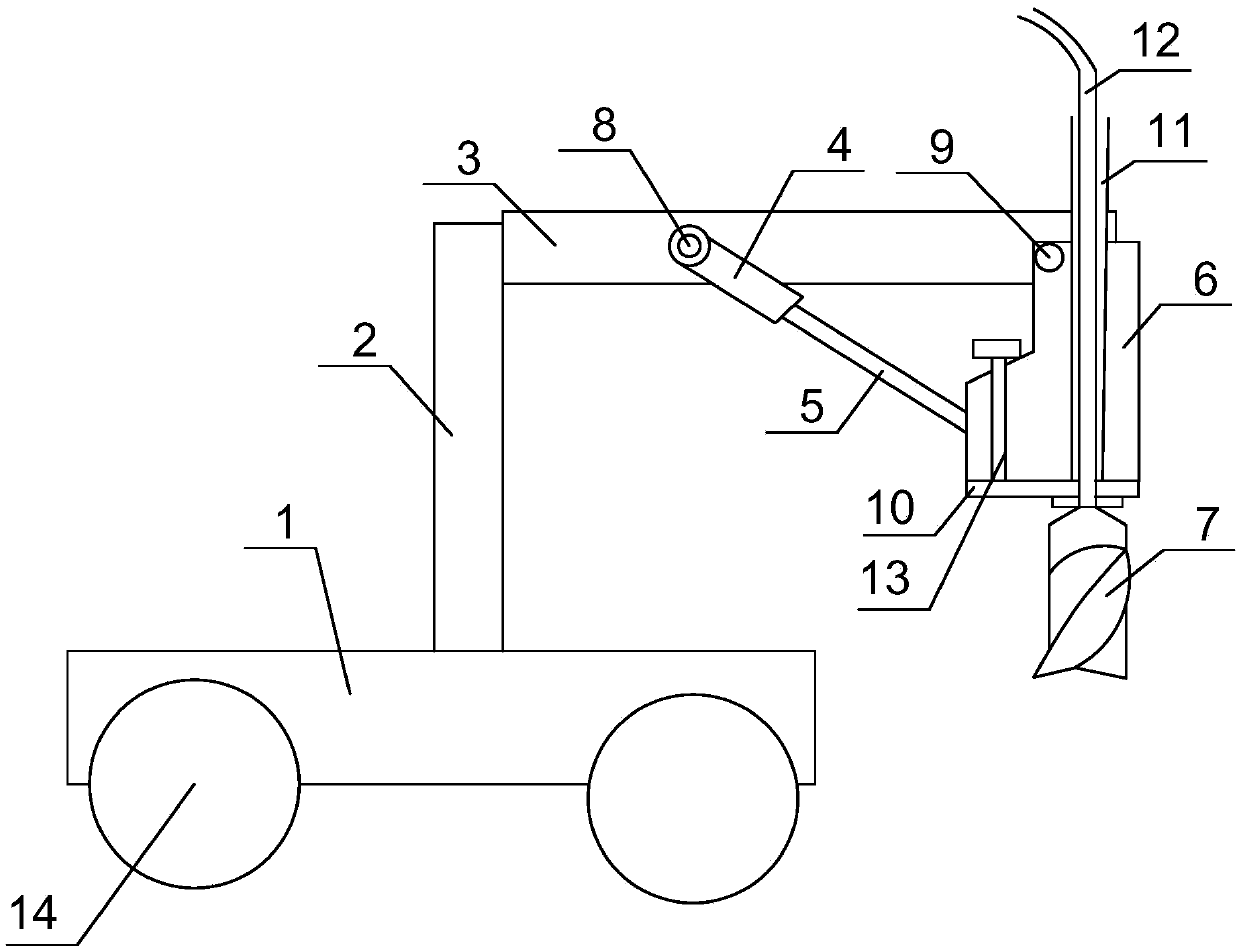

Multi-function indoor construction hanging machine

InactiveCN108442654AAvoid displacement deviationMeet construction needsBuilding material handlingSupporting systemAngle grinder

The invention relates to a multi-function indoor construction hanging machine, comprising a main machine, hanging pieces, a railway and the like. The multi-function indoor construction hanging machineis characterized in that the main machine has a walking levelling function, a stand bar supporting system of the main machine can be lengthened and stretched so that the main machine can be supportedbetween the ground and a ceiling, and can move along the railway; under the driving control of a power distribution system, a lifting rack system moves up and down with the stand bar as a guiding rail and the lifting rack system can also move forward and backward horizontally; by hanging a hopper, a plastering machine head, a feeding groove, a hanging machine head, a counterweight and other hanging pieces and hanging a spraying head, a grooving machine, a polishing machine, an angle grinder and other small equipment on the lifting rack, lifting of concrete, building blocks, mortar and other materials in secondary structure construction is finished, and inner wall plastering, putty spraying, paint spraying, grooving, polishing, cleaning and other decoration construction are finished. The multi-function indoor construction hanging machine has the advantages that adaptation is high, operation is convenient, the main machine is regarded as the basic equipment, different equipment can be hung, function extension can be achieved, and multi-usage of one machine is achieved.

Owner:刘满仓

Preparation method of high-quality large diameter extremely thin-walled seamless titanium tube

ActiveCN109396240AAvoid displacement deviationHigh dimensional accuracyShaping toolsSurface roughnessTitanium

The invention discloses a preparation method of a high-quality large diameter extremely thin-walled seamless titanium tube. The preparation method comprises the steps that a titanium tube is subjectedto multi-pass spinning by a vertical ball spinning machine to obtain the seamless titanium tube. The external diameter of the seamless titanium tube is 100mm-300mm, the ratio of wall thickness and the external diameter is not more than 0.001, the dimensional tolerance of the external diameter is + / -0.02mm, the tolerance of the wall thickness is + / -0.01mm, the straightness accuracy is less than 0.5mm / m, and the internal and external surface roughness of the seamless titanium tube Ra is less than 0.2[mu]m. According to the preparation method of the high-quality large diameter extremely thin-walled seamless titanium tube, by controlling the deviation of the external diameter of a core rod of the vertical ball spinning machine and the internal diameter of a spinning tube blank, and accordingto the thickness of the spinning tube blank, a ball bite angle is designed reasonably, then multi-pass spinning is carried out by controlling the thinning ratio and feed rate in the spinning process,dimensional accuracy and surface quality of the seamless titanium tube are improved, the seamless titanium tube with good surface quality, high dimensional accuracy and good plasticity is obtained, and the preparation method is suitable for the production of the various extremely thin-walled seamless titanium tubes with the cold spinning deformability.

Owner:NORTHWEST INSTITUTE FOR NON-FERROUS METAL RESEARCH

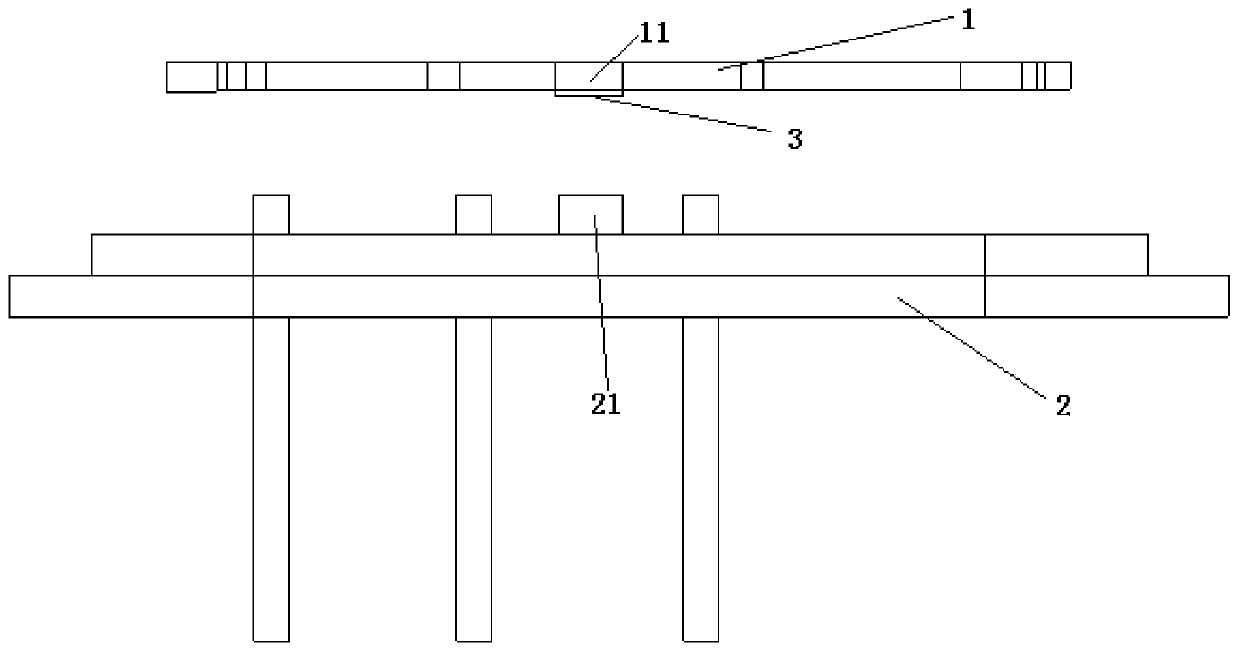

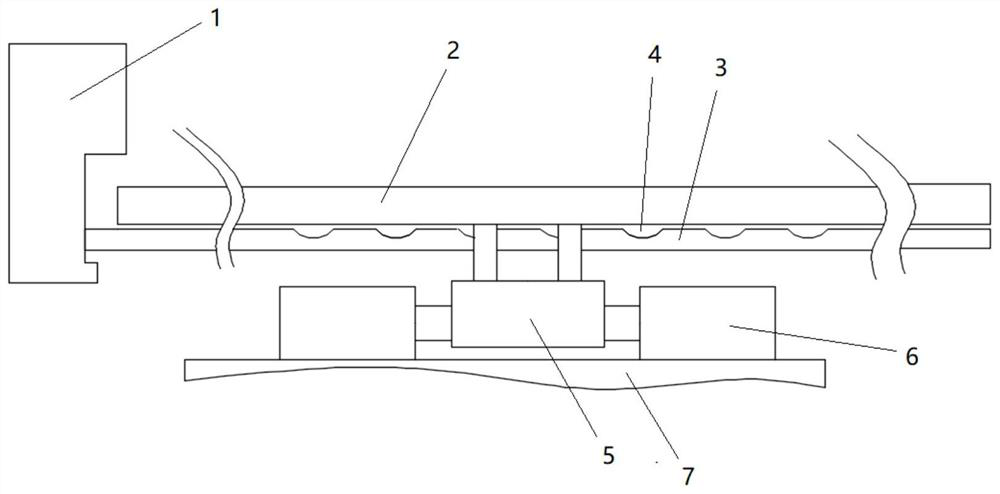

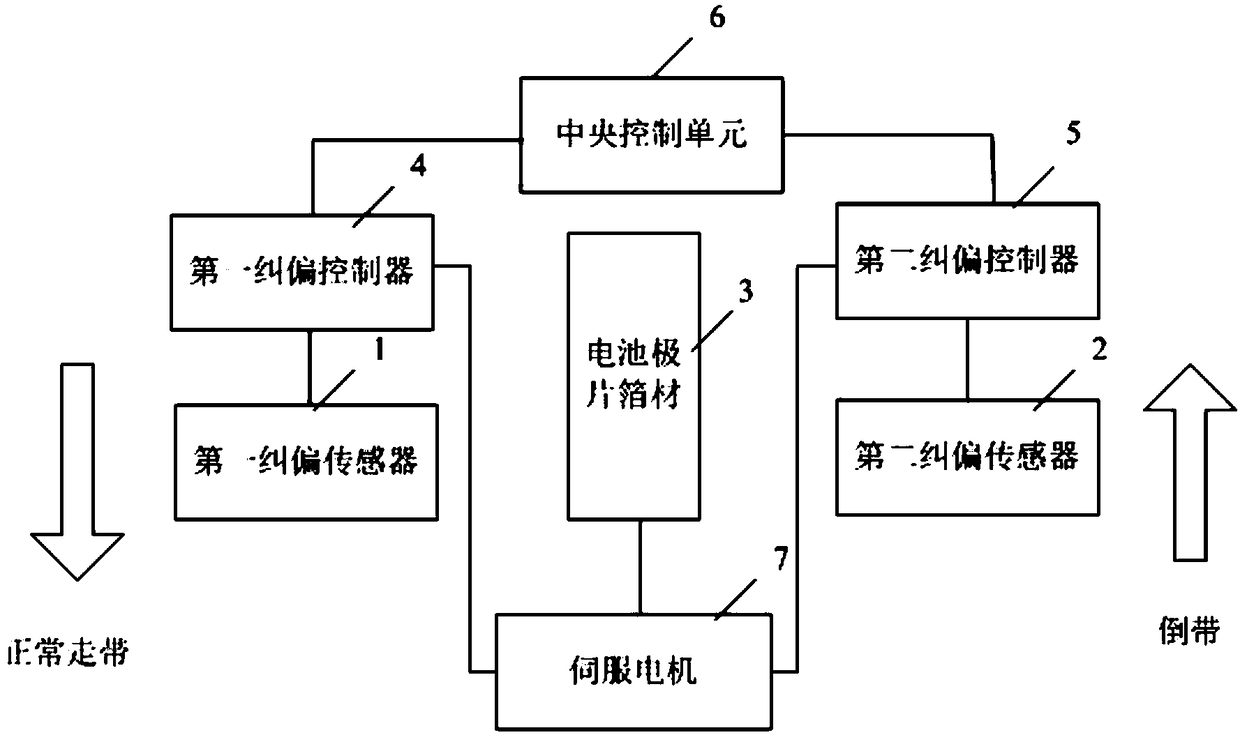

Novel deviation rectifying device of battery pole piece slurry coating machine

InactiveCN108525958AGuaranteed winding accuracyAvoid displacement deviationLiquid surface applicatorsNon-aqueous electrolyte accumulator electrodesSlurry coatingControl unit

The invention discloses a novel deviation rectifying device of a battery pole piece slurry coating machine. The novel deviation rectifying device comprises a first deviation rectifying sensor (1) anda second deviation rectifying sensor (2), wherein the first deviation rectifying sensor (1) and the second deviation rectifying sensor (2) are respectively located at left and right sides of a batterypole piece foil (3) which is conveyed in the longitudinal direction; a first deviation rectifying controller (4) is connected with the first deviation rectifying sensor (1); a second deviation rectifying controller (5) is connected with the second deviation rectifying sensor (2); a central control unit (6) is connected with the first deviation rectifying controller (4) and the second deviation rectifying controller (5) respectively; a servo motor (7) is connected with the first deviation rectifying controller (4) and the second deviation rectifying controller (5) respectively. The novel deviation rectifying device can be used for carrying out automatic deviation rectification on a battery pole piece in a rewinding process; the winding precision in the rewinding process can be ensured anddisplacement deviation of the battery pole piece is avoided, so that a wrinkling problem of the battery pole piece is avoided.

Owner:TIANJIN LISHEN BATTERY

Soil pulverizer capable of performing one-time soil pulverizing

InactiveCN107801430ASolve the problem of high energy consumptionSmall crushed areaClod-crushersEngineeringEnergy consumption

The invention discloses a soil pulverizer capable of performing one-time soil pulverizing. The soil pulverizer capable of performing one-time soil pulverizing comprises a base which is arranged horizontally, wherein a support plate vertical to the base is arranged on the base, a soil-pulverizing cutter is arranged on the support plate, and the soil-pulverizing cutter comprises a horizontal plate,an oil cylinder, a mobile rod, a cutter holder, a cutter head and a power device which is used for controlling the rotation of the cutter head; the horizontal plate is vertically connected with the support plate, a fixed shaft is arranged on the horizontal plate, and the oil cylinder is connected with the fixed shaft; one end of the mobile rod is connected to the oil cylinder, the other end of themobile rod is connected to the cutter holder, and the cutter holder is arranged on the side, away from the support plate, of the oil cylinder; the top of the oil cylinder is rotatably connected withthe horizontal plate through a mobile shaft, the cutter head is connected to the bottom of the cutter holder, and the power device which is used for controlling the rotation of the cutter head is alsoconnected to the upper part of the cutter head. According to the soil pulverizer capable of performing one-time soil pulverizing, by means of the cutter head for soil pulverizing, since soil of a small region is pulverized by the cutter head, only the soil in the specific region is pulverized, so that energy consumption is reduced and less than that of a traditional pulverizing method, and the efficiency is high.

Owner:CHENGDU HONGDE YONGXING BREEDING CO LTD

Adjustable bag making machine longitudinal sealing device with movable hot pressing plates and static hot pressing plates integrated

ActiveCN104118140AAvoid displacement deviationAdjustable positionBox making operationsPaper-makingFixed SlideHot press

The invention relates to an adjustable bag making machine longitudinal sealing device with movable hot pressing plates and static hot pressing plates integrated. The adjustable bag making machine longitudinal sealing device comprises an upper rack, a lower rack, the movable hot pressing plates, the static hot pressing plates, rolling gears, gear racks, rack guide columns, springs, gear rods and gear rod fixing blocks. The adjustable bag making machine longitudinal sealing device is characterized by further comprising hot pressing plate guide columns, hot pressing plate guide blocks, hot pressing plate fixing blocks, adjusting fixing blocks, adjusting sliding blocks, adjusting bolts I, bolt fixing blocks, bolt adjusting blocks, adjusting bolts II and bolt fixing sliding blocks. The adjustable bag making machine longitudinal sealing device has the advantages that displacement between the movable hot pressing plates and the corresponding static hot pressing plates can be greatly reduced, the static hot pressing plates can be finely adjusted, and the positions of the movable hot pressing plates and the static hot pressing plates can be adjusted fast and conveniently without shutdown.

Owner:江阴市汇通包装机械有限公司

Connecting-rod type part large end lateral clamping device with linkage resetting function

ActiveCN105171600AImprove processing efficiencyNo offsetGrinding drivesHoning machinesEngineeringFailure causes

The invention relates to a connecting-rod type part large end lateral clamping device with a linkage resetting function. The lateral clamping device comprises a power driving mechanism, a metal positioning piece, a base, a pressing block, a movable switch mechanism and an electromagnetic attraction mechanism. A vertical contact face and an inclined contact face are arranged on the base. The vertical contact face is provided with a first through hole and can make contact with the metal positioning piece. The inclined contact face is provided with a second through hole. The pressing block is arranged on the inclined contact face and abuts against the metal positioning piece. The power driving mechanism is connected with the pressing block. One end of the movable switch mechanism is arranged in the second through hole and makes contact with the pressing block, and the other end of the movable switch mechanism is connected with the electromagnetic attraction mechanism. The electromagnetic attraction mechanism is arranged in the second through hole and can make contact with the metal positioning piece. Compared with the prior art, the purposes of stable and effective clamping, timely and rapid releasing and clamping of large-end holes can be achieved, and it is guaranteed that honing failures caused by deviation of the large-end holes are avoided. The lateral clamping device has the advantages of being simple in structure, convenient to operate, practical, capable of improving the production efficiency and work reliability and the like.

Owner:SHANGHAI UNIV OF ENG SCI

Manipulator moving device

ActiveCN111331573AWith lifting functionAvoid displacement deviationManipulatorClassical mechanicsManipulator

The invention discloses a manipulator moving device. The manipulator moving device comprises a box body and a power groove formed in the bottom end face of the box body, the power groove is internallyprovided with a moving steering device, first rising and falling blocks are fixedly arranged on the front end face, the rear end face, the left end face and the right end face of the box body, risingand falling devices are arranged on the first rising and falling blocks, the moving steering device comprises limiting grooves formed in the left side end wall and the right side end wall of the power groove, and limiting blocks are arranged on the limiting grooves in a sliding fit mode. The moving action is provided for a manipulator and a mechanical arm, the device is internally provided with amoving mechanism to meet the moving and steering demands of the device, the device further has a lifting function which is mainly used for meeting the stability of the manipulator and the mechanicalarm during working, thus the displacement deviation caused by vibration during working is avoided, and meanwhile, the device is further provided with a positioning mechanism so that the lifting and falling actions can be realized at the predetermined position to facilitate fixing.

Owner:常州翼展电器设备有限公司

A clamping tool for PCB board processing

ActiveCN111347278BAvoid displacement deviationWork clamping meansPositioning apparatusEngineeringMechanical engineering

The invention discloses a clamping tool for PCB board processing, comprising a clamping platform, a rectangular concave platform is formed on the upper end surface of the clamping platform, and a rectangular slot hole penetrating through the lower end surface of the clamping platform is formed on the bottom surface of the concave platform. , the upper end surface on the left side of the clamping platform is formed with a longitudinal groove connected with the concave platform, the middle part of the right side of the clamping platform is formed with a rectangular notch, and the longitudinal groove of the clamping platform is inserted with a longitudinal bead, An L-shaped push block is inserted on the right side of the concave table of the clamping platform, and a push rod is fixed on the right end surface of the push block. in the notch of the platform.

Owner:江门市浩远科技有限公司

Corrugated pipe forming device

InactiveCN106825167AAvoid displacement deviationPlay the role of axial positioningEconomic benefitsElectrical and Electronics engineering

The invention discloses a bellows forming device, which comprises a forming workbench and a supporting base plate. The forming workbench is arranged on the supporting base plate. A driving mechanism and a positioning seat are respectively arranged on the forming workbench. The driving mechanism is located on one side of the positioning seat. An adjustment mechanism is provided between the positioning seat and the forming workbench, a support frame is provided on the support base plate, a first transmission mechanism and a second transmission mechanism are respectively provided on the support frame, and a first transmission roller group is provided on the first transmission mechanism. The first transmission roller set is provided with an upper pressure roller, and two adjacent upper pressure rollers are connected end to end. The second transmission mechanism is provided with a second transmission roller set, and the second transmission roller set is provided with a lower pressure roller. The two lower pressure rollers are connected end to end, and the upper pressure roller is in contact with the lower pressure roller. The invention has stable molding, good molding effect, high product quality, long service life, automatic safety, high production efficiency, simple structure, low manufacturing cost and remarkable economic benefits.

Owner:全南县智护力工业产品设计有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com