Soil pulverizer capable of performing one-time soil pulverizing

A technology of soil crusher and soil, which is applied in the direction of soil crushing machine, agricultural machinery and implements, etc. It can solve the problems of high energy consumption of the soil crushing method, and achieve energy saving, low energy consumption, and easy movement Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

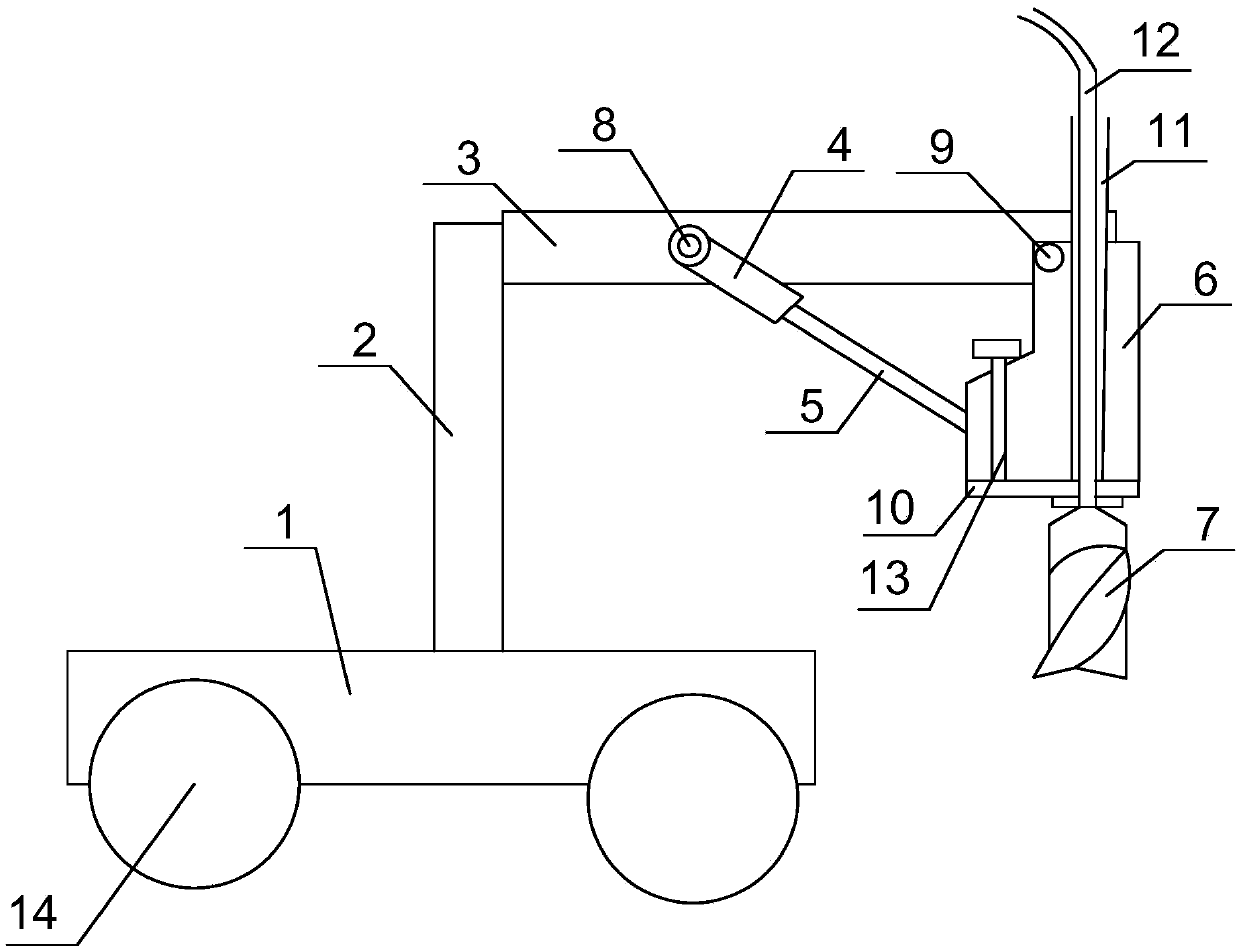

[0022] Such as figure 1 As shown in the present invention, the soil crusher capable of crushing soil at one time includes a base 1 placed horizontally, a support plate 2 perpendicular to the base 1 is provided above the base 1, and a soil crushing cutter is provided on the support plate 2 , the broken soil cutter includes a horizontal plate 3, an oil cylinder 4, a movable rod 5, a knife seat 6, a cutter head 7, a power unit for controlling the rotation of the cutter head 7, the horizontal plate 3 is vertically connected with the support plate 2, and the horizontal plate 3 There is a fixed shaft 8 on the top, the oil cylinder 4 is connected to the fixed shaft 8, one end of the movable rod 5 is connected to the oil cylinder 4, and the other end of the movable rod 5 is connected to the knife seat 6, and the knife seat 6 is located on the oil cylinder 4 away from the support plate 2 On one side, the top of the oil cylinder 4 is rotationally connected with the horizontal plate 3 th...

Embodiment 2

[0025] Based on Embodiment 1, a cutter body 10 is connected between the cutter head 7 and the cutter seat 6, the cutter body 10 is provided with a bearing for fixing the cutter head 7, and the top of the cutter body 10 is connected with a vertically inserted tool holder 6 inside. A cylindrical tube 11, the top of the cutter head 7 is connected with a flexible steel wire shaft 12, the flexible steel wire shaft 12 passes upward through the cylindrical tube 11 and is connected to the power device that controls the rotation of the cutter head 7, and the flexible steel wire shaft 12 is connected to the inside of the cylindrical tube 11. cut. The cutter body 10 is connected to the cutter body 6 through an adjusting bolt 13 , and the adjusting bolt 13 is inserted downward on the cutter holder 6 to connect with the cutter body 10 .

[0026] In the present invention, the flexible steel wire shaft is the power transmission device between the cutter head and the power device. The power t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com