Method used for producing 1, 4-cyclohexanedimethanol

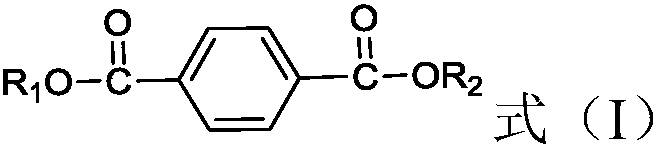

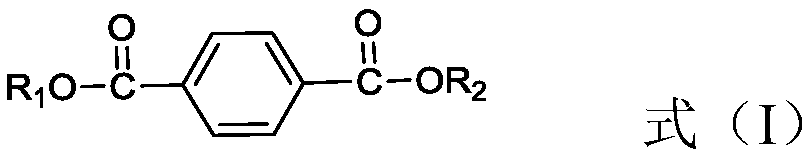

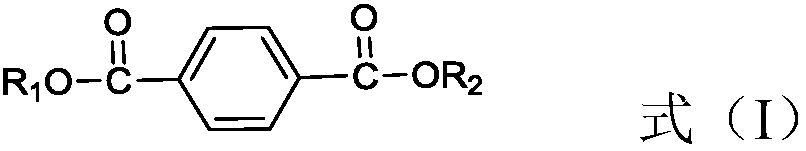

A technology of cyclohexanedimethanol and cyclohexanedicarboxylate, which is applied in the field of producing 1,4-cyclohexanedimethanol, can solve the problems of low solubility and high melting point of dimethyl terephthalate, and achieve The effect of low raw material residue, good product quality, and reduced hydrogen consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] Primary hydrogenation unit: Dioctyl terephthalate and H 2 Pass through the fixed bed reactor together from bottom to top (the catalyst packed in it is Pd-Rh / Al 2 o 3 (0.3% by weight Pd, 0.3% by weight Rh), the catalyst in H 2 Atmosphere, reduction and activation at 150°C for 6 hours) for hydrogenation reaction, a micro-nanoporous membrane (the average diameter of nanopores is 20nm, and the average diameter of micropores is 800μm) is set in front of the fixed-bed reactor, and hydrogen passes through the micro-nanoporous membrane , highly dispersed or dissolved in dioctyl terephthalate. The hydrogenation reaction conditions are: temperature is 110°C, pressure is 3MPa, H 2 The molar ratio to dioctyl terephthalate is 10, and the weight space velocity of dioctyl terephthalate is 0.9h -1 . According to calculation, the conversion rate of dioctyl terephthalate at the outlet of the primary hydrogenation unit is 99.9%, and the selectivity of dioctyl 1,4-cyclohexanedicarboxy...

Embodiment 2

[0045] Primary hydrogenation unit: Dibutyl terephthalate and H 2 Pass through the fixed bed reactor together (the loaded catalyst is Ru / SiO 2 (2.3% by weight Ru), the catalyst in H 2 atmosphere, reduction and activation at 120°C for 10 hours) for hydrogenation reaction, the hydrogenation reaction conditions are: temperature is 60°C, pressure is 10MPa, H 2 The molar ratio to dibutyl terephthalate is 3.5, and the weight space velocity of dibutyl terephthalate is 1.3h -1 . It is calculated that the conversion rate of dibutyl terephthalate at the outlet of the primary hydrogenation unit is 99.8%, and the selectivity of dibutyl 1,4-cyclohexanedicarboxylate is 100%.

[0046] Secondary hydrogenation unit: the primary hydrogenation product containing dibutyl 1,4-cyclohexanedicarboxylate obtained from the primary hydrogenation unit and H 2 Pass through the fixed bed reactor together (the loaded catalyst is CuO-MnO 2 -ZrO 2 (60% by weight CuO, 35% by weight MnO 2 , 5% by weight Z...

Embodiment 3

[0049] Primary hydrogenation unit: Dioctyl terephthalate and H 2 Pass through fixed bed reactor together (the catalyst of packing is Rh-Pd / C (0.3% by weight Rh, 0.2% by weight of Pd), described catalyst is in H 2 atmosphere, reduction and activation at 180°C for 5 hours) for hydrogenation reaction, the reaction conditions are: temperature 160°C, pressure 0.1MPa, H 2 The molar ratio to dioctyl terephthalate is 100, and the weight space velocity of dioctyl terephthalate is 3h -1 . According to calculation, the conversion rate of dioctyl terephthalate at the outlet of the primary hydrogenation reactor is 99.6%, and the selectivity of dioctyl 1,4-cyclohexanedicarboxylate is 99.1%.

[0050] Secondary hydrogenation unit: the primary hydrogenation product containing dioctyl 1,4-cyclohexanedicarboxylate obtained from the primary hydrogenation unit and H 2 Pass through the fixed bed reactor together (the loaded catalyst is CuO-ZnO-Al 2 o 3 (42% by weight CuO, 38% by weight ZnO, 20...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com