Patents

Literature

528 results about "Dioctyl terephthalate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Dioctyl terephthalate (bis(2-ethylhexyl) benzene-1,4-dicarboxylate or Di(2-ethylhexyl) terephthalate), commonly abbreviated DOTP or DEHT, is an organic compound with the formula C₆H₄(CO₂C₈H₁₇)₂. It is a non-phthalate plasticizer, being the diester of terephthalic acid and the branched-chain 2-ethylhexanol. This colorless viscous liquid used for softening PVC plastics is known for chemical similarity to general purpose phthalates such as DEHP and DINP, but without any negative regulatory pressure. It possesses very good plasticizing properties and may be used as a direct replacement for DEHP and DINP in many applications.

Insulating and environment-friendly PVC modified material and preparation method thereof

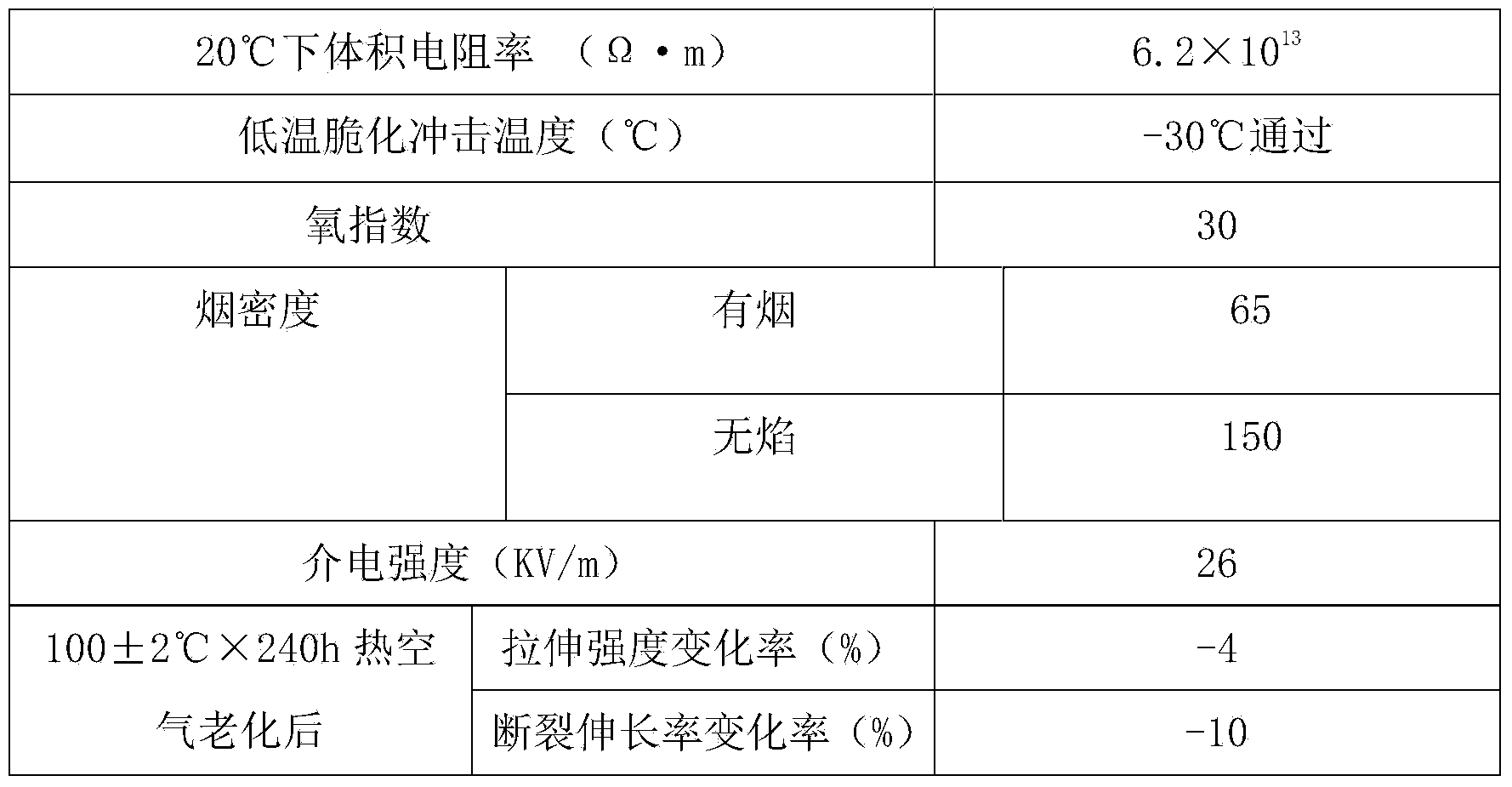

The invention relates to the technical field of PVC modified materials and particularly relates to an insulating and environment-friendly PVC modified material and a preparation method thereof. The insulating and environment-friendly PVC modified material contains the following raw materials: 80-120 parts of PVC resin, 40-60 parts of bulking agent, 40-60 parts of plasticizer, 10-15 parts of insulation modifier, 3-7 parts of heat stabilizer and 0.5-1.5 parts of lubricant, wherein the plasticizer is a mixture prepared from dioctyl terephthalate and tri-n-butyl citrate which are in the weight ratio of (5-7): 1; the insulation modifier is a mixture prepared from kaolin, titanium white and glass micro-beads which are in the weight ratio of (2-4): (1.5-2.5): 1, and the particle size of the glass micro-beads is smaller than 20 microns. According to the modified material prepared by the preparation method, all properties exceed the national standards, the insulating property is good, the resistivity reaches up to 5.1*10<14> omega, and the modified material is environment-friendly; the preparation method disclosed by the invention is simple in process, convenient in operation and control, stable in quality and high in production efficiency and can be applied to large-scale industrial production.

Owner:广东祺龙科技有限公司

Environment-friendly cold-resistant polyvinyl chloride cable material and preparation method thereof

InactiveCN102653618AImprove performanceHeat resistantPlastic/resin/waxes insulatorsAntioxidantDioctyl terephthalate

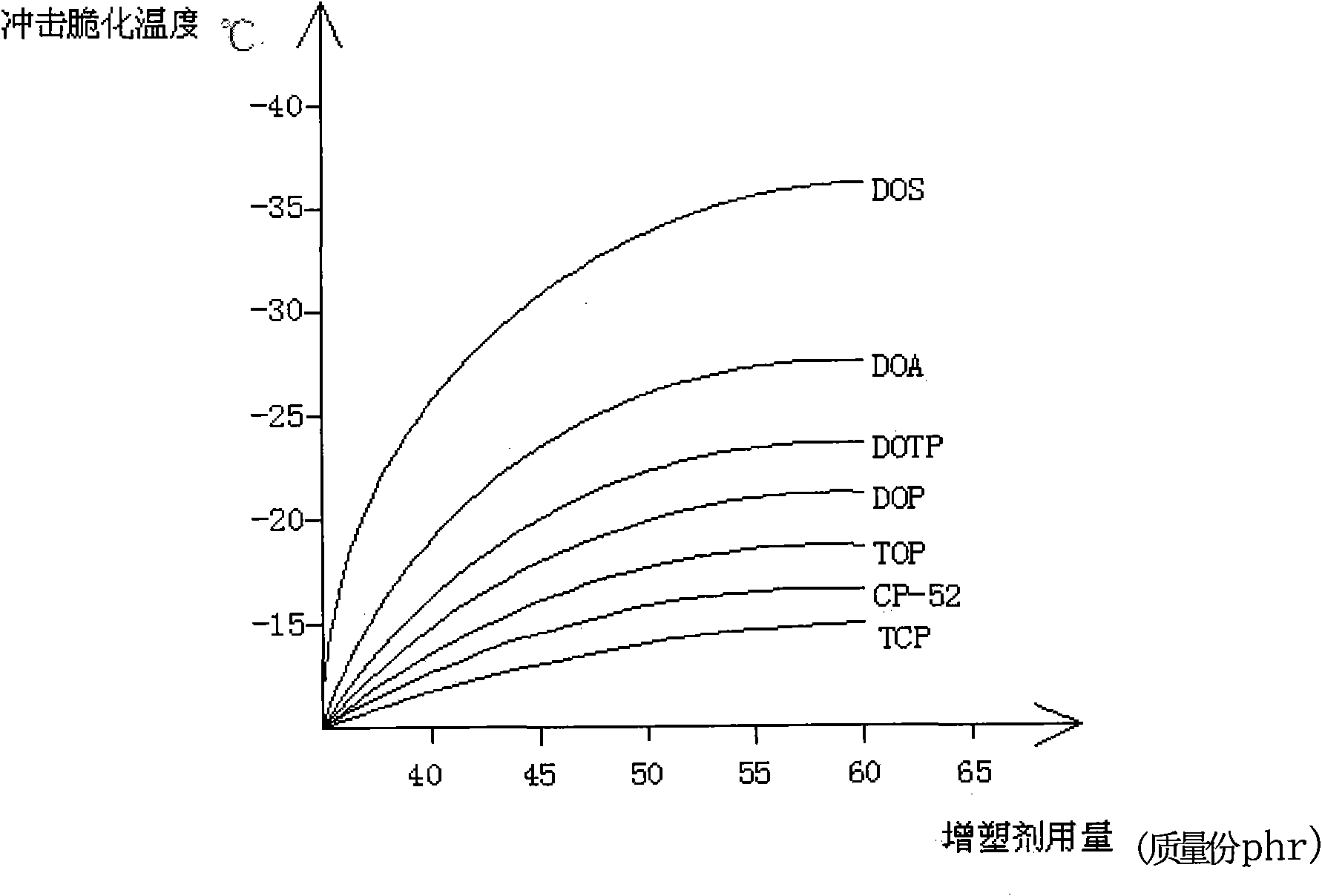

The invention provides an environment-friendly cold-resistant polyvinyl chloride cable material and a preparation method thereof. The environment-friendly cold-resistant polyvinyl chloride cable material is prepared from the following raw materials in percentage by mass: 40-60% of polyvinyl chloride, 5-25% of dioctyl terephthalate, 5-25% of dioctyl adipate, 1-10% of chlorinated polyethylene, 5-25% of light activated calcium carbonate, 1-3% of lubricant, 2-8% of Ca-Zn composite stabilizer, 0.1-1% of antioxidant and 0.1-4% of pigment. The environment-friendly cold-resistant polyvinyl chloride cable material is mainly compounded from dioctyl terephthalate and dioctyl adipate. The cable material can be normally used in a low-temperature environment of -40 to -65 DEG C, has favorable shock resistance under low-temperature conditions, does not contain ortho-benzoic ether compounds, and is environment-friendly, thereby solving the problem that the existing polyvinyl chloride cable material is not environment-friendly and has poor shock resistance under low-temperature conditions.

Owner:QINGDAO HAIER NEW MATERIAL R&D CO LTD +1

Mould-proof mothproof non-woven fabric and preparation method thereof

InactiveCN103696142AHigh tensile strengthImprove adhesionSynthetic resin layered productsNon-woven fabricsPentachlorophenolJojoba oil

The invention provides a mould-proof mothproof non-woven fabric, which comprises a top surface layer, a back surface layer, and a fiber cotton layer sandwiched between the top surface layer and the back surface layer, wherein the top surface layer and the back surface layer are made of non-woven fabric materials; the non-woven fabric is prepared by the following active ingredients in parts by weight through adopting a melt-blowing method: 100 parts of isotactic polypropylene, 2-3 parts of molybdenum disulfide, 1-2 parts of copper sulfate, 1-2 parts of jojoba oil, 1-2 parts of pentachlorophenol, 3-4 parts of zinc stearate, 1-2 parts of antioxidant 168, 12-15 parts of dioctyl terephthalate, 10-12 parts of rice hulls, 2-3 parts of bamboo charcoals, 2-3 parts of coptidis rhizome, 1-2 parts of cogongrass rhizome, 1-2 parts of rust-coloured crotalaria herb with root, and 4-5 parts of auxiliaries. The non-woven fabric has the mould-proof mothproof properties, as well as aromatic fragrance and health-care function, can adsorb harmful gas and peculiar smell, is heat-resistant, corrosion-resistant, non-toxic and odorless, large in tensile strength, good in binding power and free from dust and chips.

Owner:MAANSHAN HUBIN NONWOVEN CLOTH TECH

Preparation method of environmentally-friendly disposable polyvinyl chloride glove

The invention relates to a preparation method of an environmentally-friendly disposable polyvinyl chloride (PVC) glove, belonging to the fields of synthesis, application and processing shaping of high polymer materials. PVC paste resin is used as a raw material, a non-phthalic acid ester plasticizer, a non-heavy metal heat stabilizer and the like are used as the additives of an environmentally-friendly formula, and a calcium / zinc composite is used as the heat stabilizer to prepare the environmentally-friendly disposable PVC medical or civilian glove, wherein the plasticizer can be triisooctyl trimellitate (TOTM), dioctyl terephthalate (DOTP), biological oil-based ester, vegetable oil-based ester, fatty acid triglyceride, epoxy fatty acid ester or citrate ternary ester compounds. The invention provides the method for preparing the non-toxic and environmentally-friendly disposable PVC glove; and the prepared glove successfully passes the international SGS detection and the main properties of the product are obviously better than those of the similar PVC products in the market.

Owner:无锡神宇塑胶制品有限公司

Production method of dioctyl terephthalate

InactiveCN102701984AImprove product qualityImprove quality rateOrganic compound preparationCarboxylic acid esters preparationAlcoholDioctyl terephthalate

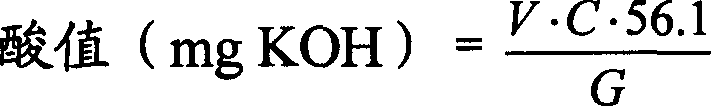

The invention provides a production method of dioctyl terephthalate. The production method comprises the steps 1) of feeding fine terephthalic acid and 2-ethyl hexyl alcohol into an esterfying reaction kettle by the weight ratio of 1 to 1-1.8, heating while stirring, adding catalyst when the temperature is increased to 170-210 DEG C, controlling the esterfying temperature within the range of 190-200 DEG C, reacting for 7-13h, and stopping esterfying when the acid value is less than 0.3mg KOH / g; and 2) of transferring the mixture into a neutralizing refining kettle after the temperature of the mixture is reduced below 100 DEG C, neutralizing and rinsing by water at 80-100 DEG C, removing superfluous reaction alcohol, separating water phase, adding a porous absorbing material, stirring, separating solid from liquid, so as to obtain a high-quality pure DOPT (dioctyl terephthalate) product, wherein the catalyst is reusable; the production method has the characteristics of low product pollution, high quality, and high product purity.

Owner:ANHUI XIANGFENG NEW MATERIALS

Irradiation crosslinking low-smoke halogen-free flame-retardant polyolefin cable material for photovoltaic cables

The invention provides an irradiation crosslinking low-smoke halogen-free flame-retardant polyolefin cable material for photovoltaic cables. The cable material is prepared from the following raw materials in parts by weight: 40-50 parts of polyethylene (PE), 30-40 parts of polyvinyl chloride resin, 20-30 parts of CSM2305, 10-12 parts of ethylene-acrylate copolymer, 10-15 parts of epichlorohydrin rubber T3100, 5-10 parts of epoxidized soybean oil, 2-3 parts of carbonyl iron powder, 10-12 parts of high abrasion carbon black N330, 5-10 parts of light calcium carbonate, 1-2 parts of zinc oxide, 5-10 parts of wollastonite powder, 4-5 parts of vermiculite, 1-2 parts of polytetrafluoroethylene micro powder, 1-2 parts of graphite, 1-2 parts of nano boron carbide, 2-3 parts of ferric oxide, 0.1-0.2 part of UV-O, 0.1-0.2 part of UV-53, 0.1-0.2 part of flame retardant TBC, 10-12 parts of aluminium hypophosphite, 5-8 parts of decabromodiphenyl ether, 8-10 parts of dioctyl terephthalate, 6-8 parts of trioctyl trimellitate, 8-10 parts of triethyl citrate, 1-2 parts of calcium stearate, 0.2-0.4 part of stearic acid, 0.1-0.2 part of oxidized polyethlene wax, 0.2-0.3 part of ethylene bis stearamide, 0.1-0.2 part of DCP, and 12-15 parts of modified filler. The cable material has the characteristics of high flame retardance, high ultraviolet resistance and high ageing resistance, and meanwhile, has a good mechanical property, and is environment-friendly.

Owner:温州市粤来电子加速器应用有限公司

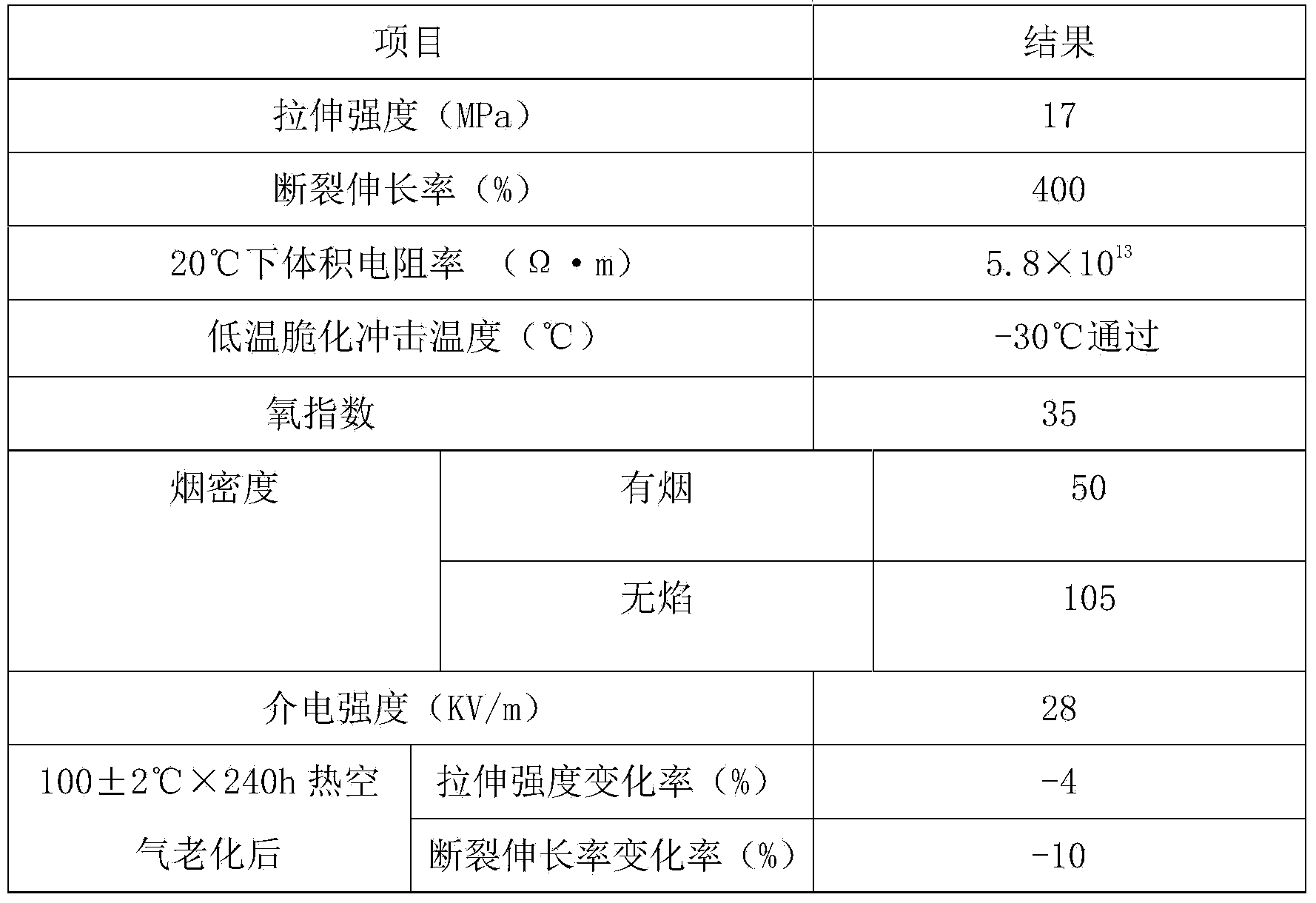

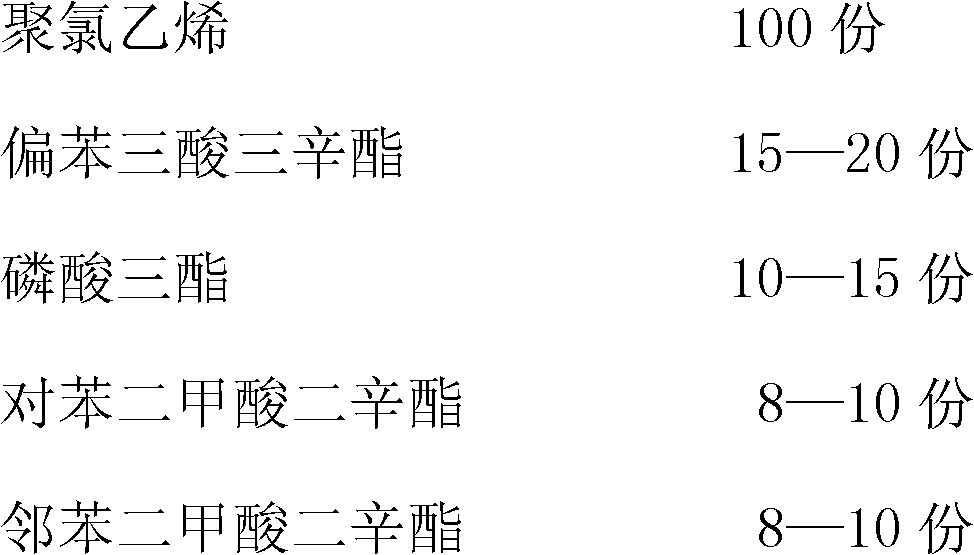

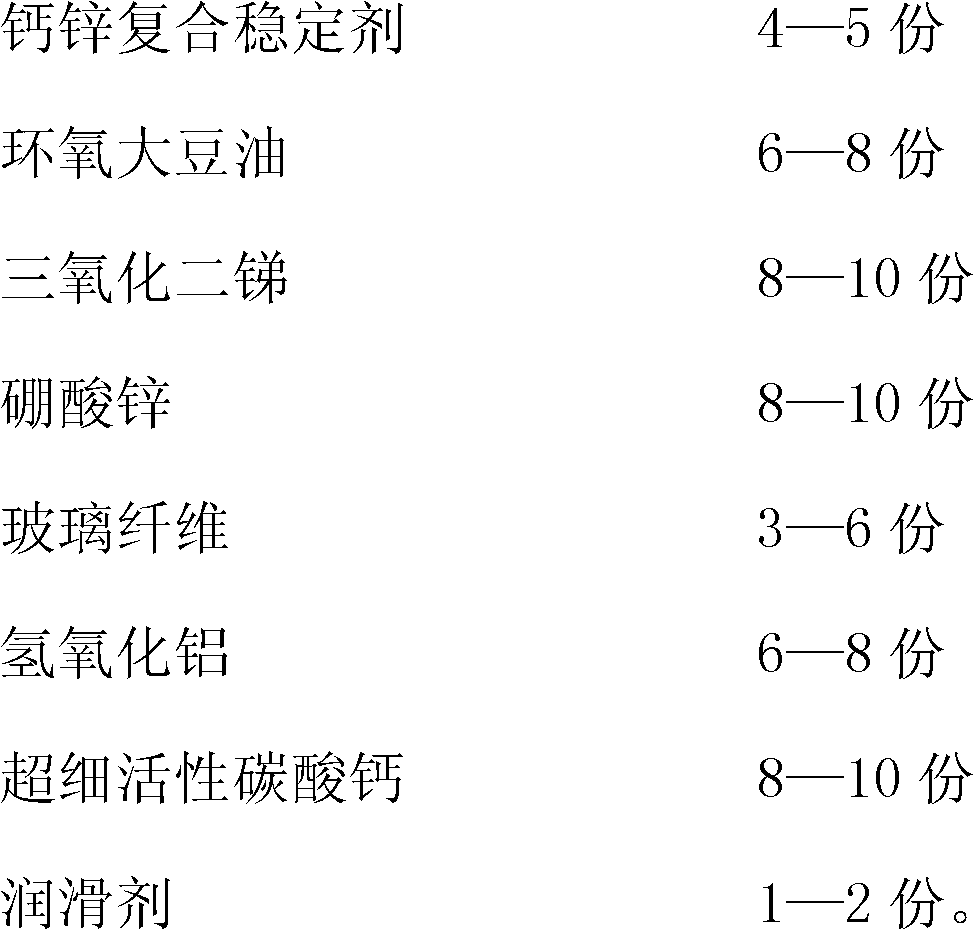

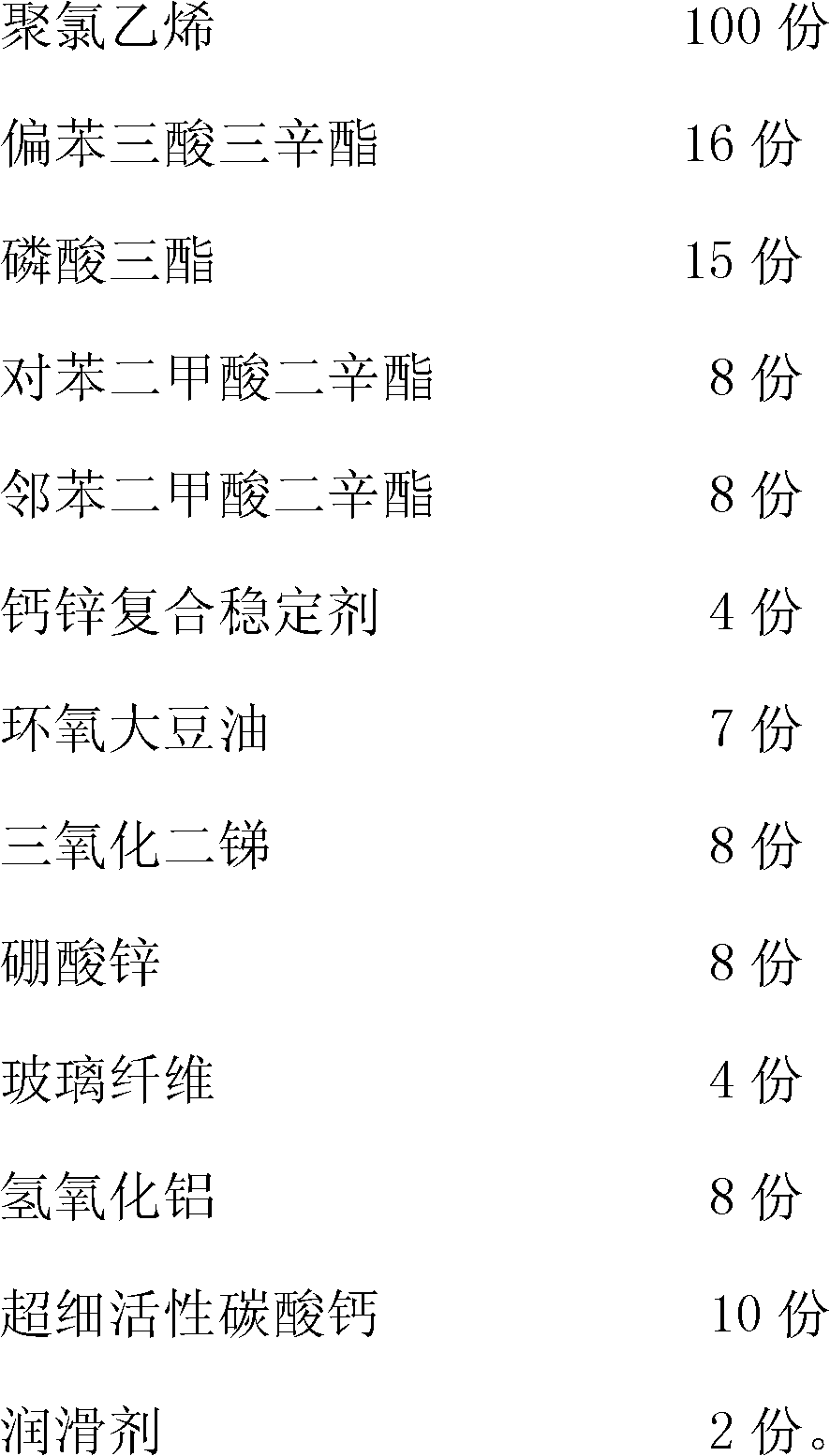

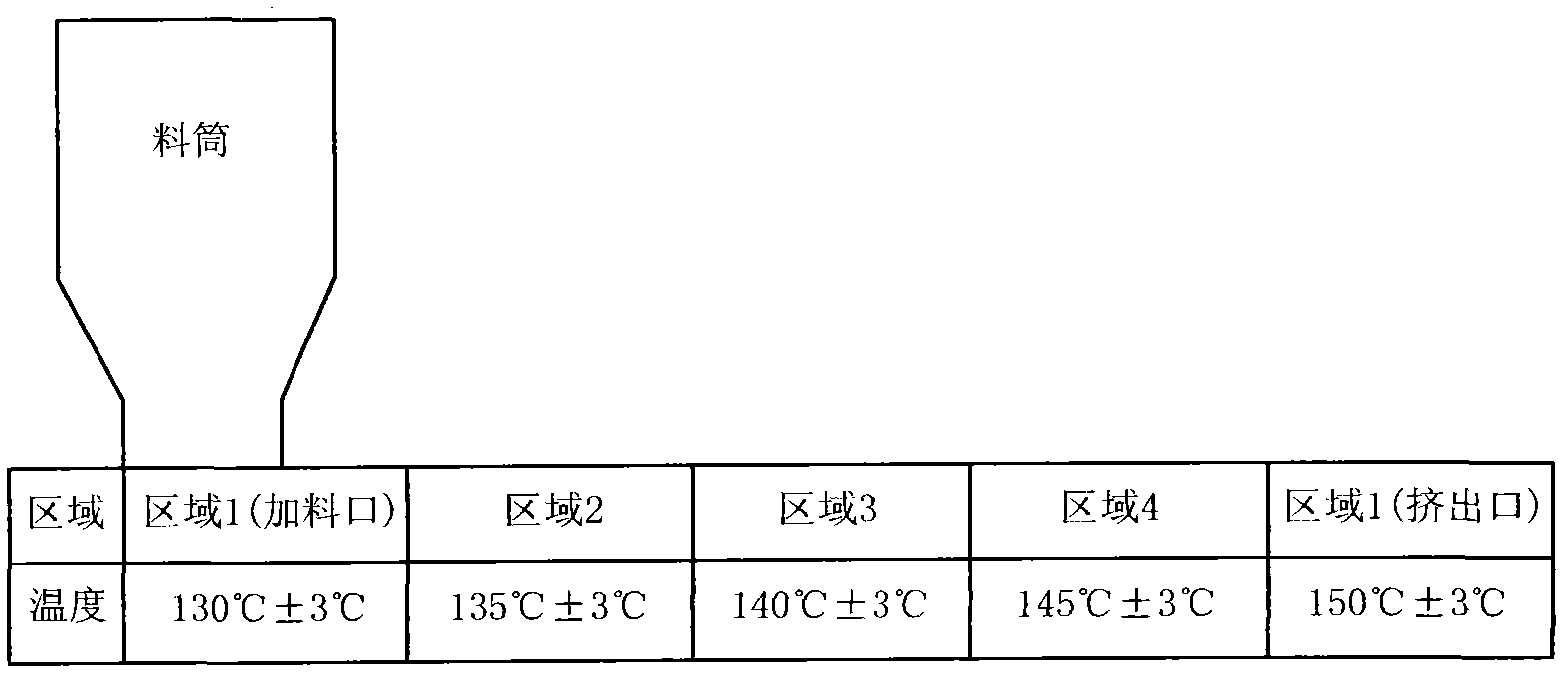

Polyvinyl chloride cable sheath material for CMR-grade high-flame-retardant environment-friendly coaxial cable

InactiveCN102161805AGood physical and mechanical propertiesEnvironmental protection is goodInsulated cablesInsulated conductorsAluminium hydroxideEngineering

The invention relates to a polyvinyl chloride cable sheath material for a CMR-grade high-flame-retardant environment-friendly coaxial cable, which is mainly prepared from the following components in parts by weight: 100 parts of polyvinyl chloride, 15-20 parts of trioctyl trimellitate, 10-15 parts of triphosphate, 8-10 parts of dioctyl terephthalate, 8-10 parts of dioctyl phthalate, 4-5 parts of calcium / zinc composite stabilizer, 6-8 parts of epoxy soybean oil, 8-10 parts of antimony trioxide, 8-10 parts of zinc borate, 3-6 parts of glass fiber, 6-8 parts of aluminum hydroxide, 8-10 parts of ultrafine activated calcium carbonate and 1-2 parts of lubricant. The sheath provided by the invention has the advantages of high strength, favorable shell forming property and durability in the burning process, excellent flame retardancy and environmental protection, and especially can satisfy the design requirements for CMR-grade high-flame-retardant fine coaxial cables.

Owner:LINAN PUFA CABLE MATERIAL

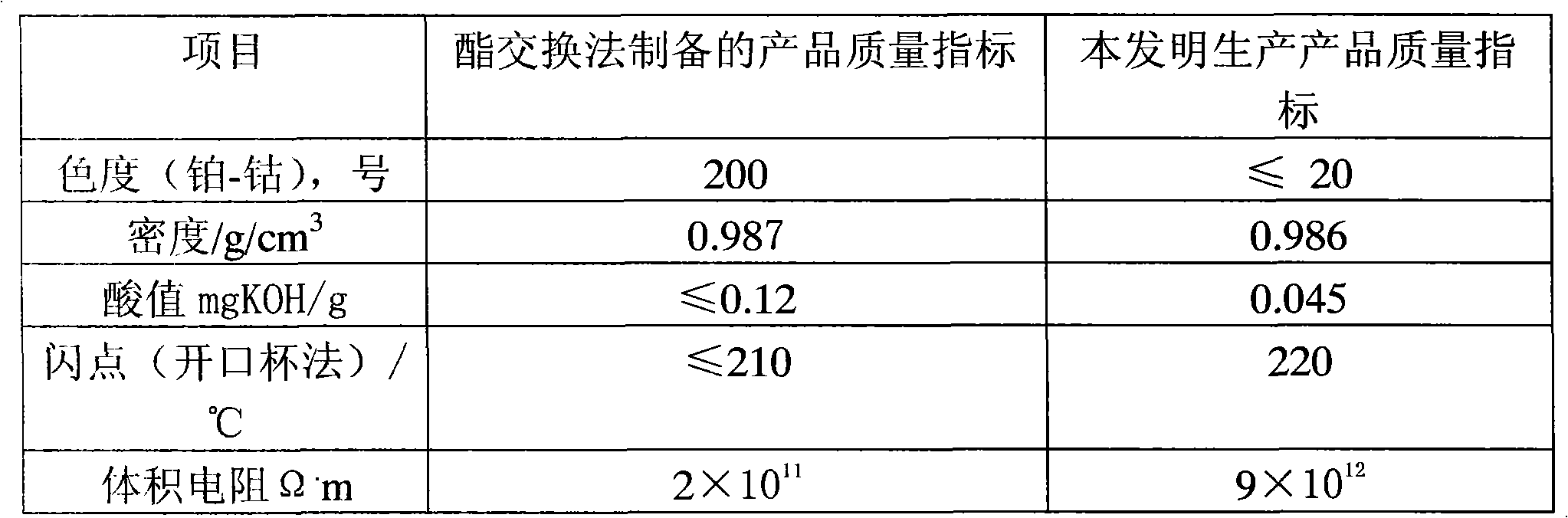

Method for producing dioctyl terephthalate

InactiveCN101139293AQuick responseImprove product qualityOrganic compound preparationCarboxylic acid esters preparationAlcoholFiltration

The present invention discloses a production method of the terephthalic dioctyl ester wherein the terephthalic acid and the isooctyl are put into the reactor; the catalyst is added for the esterification; the esterified water and the left alcohol are distilled from the materials; the porous material with the functions of adsorption and decolorization are added; the mixture is stirred and the product can be got after the filtration. The present invention has the little waste emission and the high-ester product.

Owner:郭立耀 +2

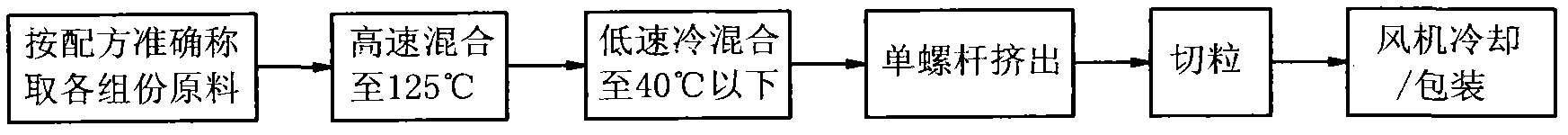

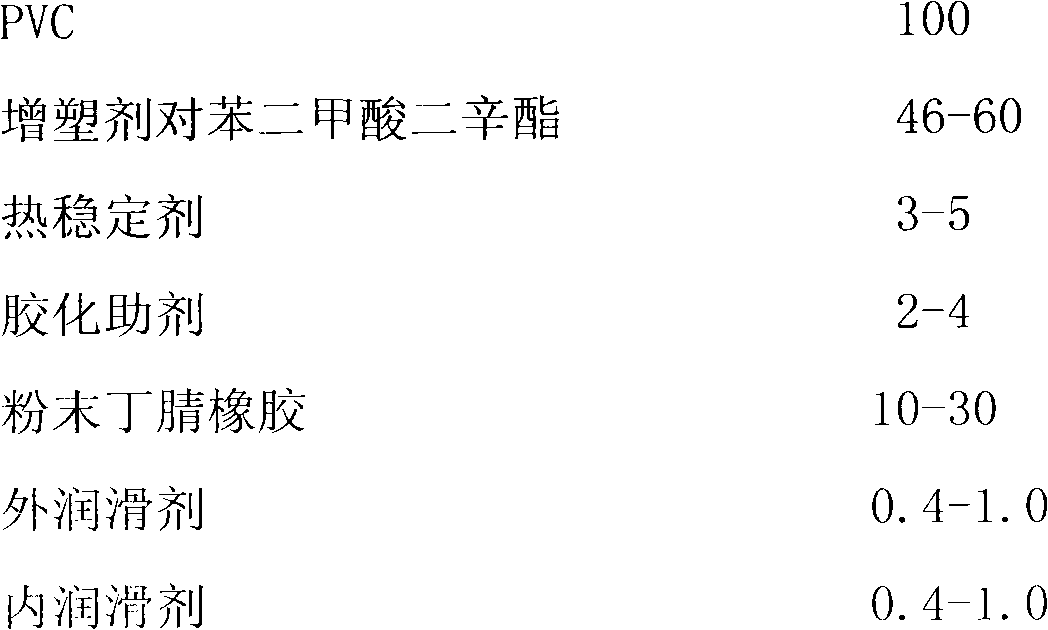

Low-volatile-separation PVC (Polyvinyl Chloride) particle composition and preparation method and application thereof

ActiveCN102660089AGuaranteed performanceLow Volatility MigrationOther chemical processesNitrile rubberLow speed

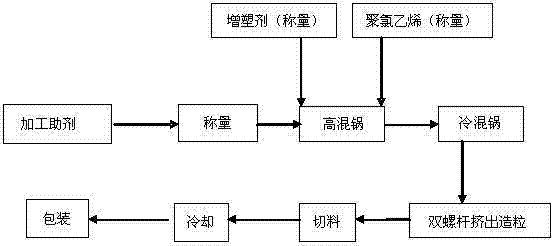

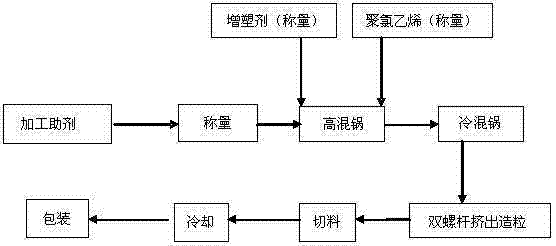

The invention provides a low-volatile-separation PVC (Polyvinyl Chloride) particle composition and a preparation method and an application thereof. Based on every 100 parts by weight of PVC, the composition comprises the following components in parts by weight: 46-60 parts of dioctyl terephthalate serving as a PVC100 plasticizing agent, 3-5 parts of a thermal stabilizer, 2-4 parts of a gelatinizing aid, 10-30 parts of powder nitrile rubber, 0.4-1.0 part of an external lubricant and 0.4-1.0 part of an internal lubricant. The preparation method comprises the following steps of: weighing component raw materials according to a formula; mixing at a high speed to 125 DEG C; performing cold mixing at a low speed to a temperature below 40 DEG C; extruding with a single screw; pelletizing; and cooling and packaging with a fan. The low-volatile-separation PVC particle composition is suitable for manufacturing an automobile sealing strip which requires low volatile separation of a plasticizing agent.

Owner:NINGBO TAIYONG AUTOMOTIVE PARTS

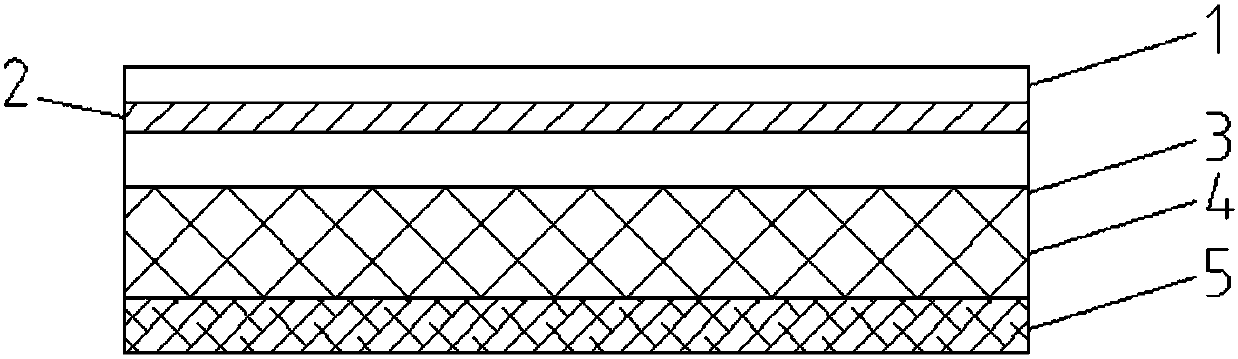

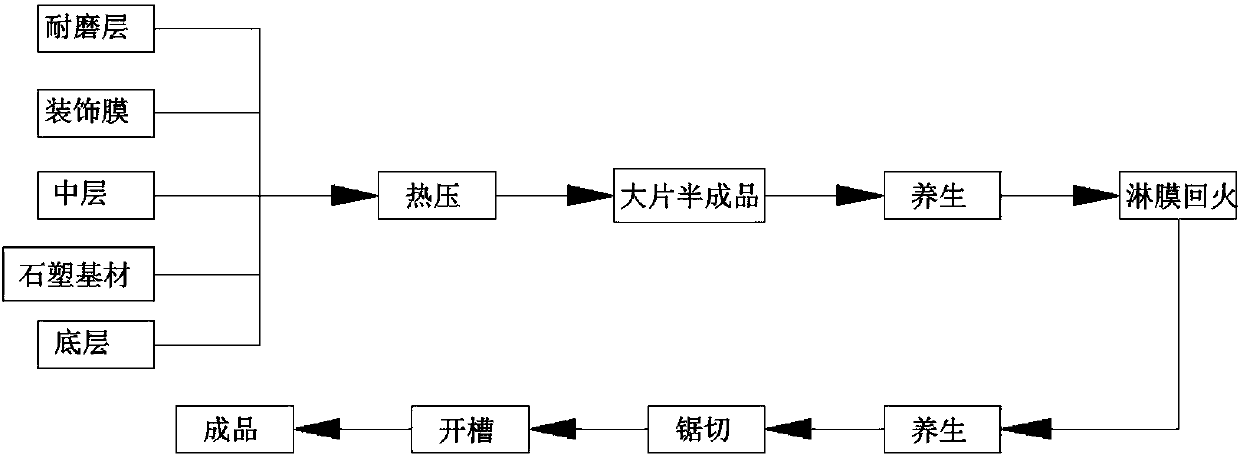

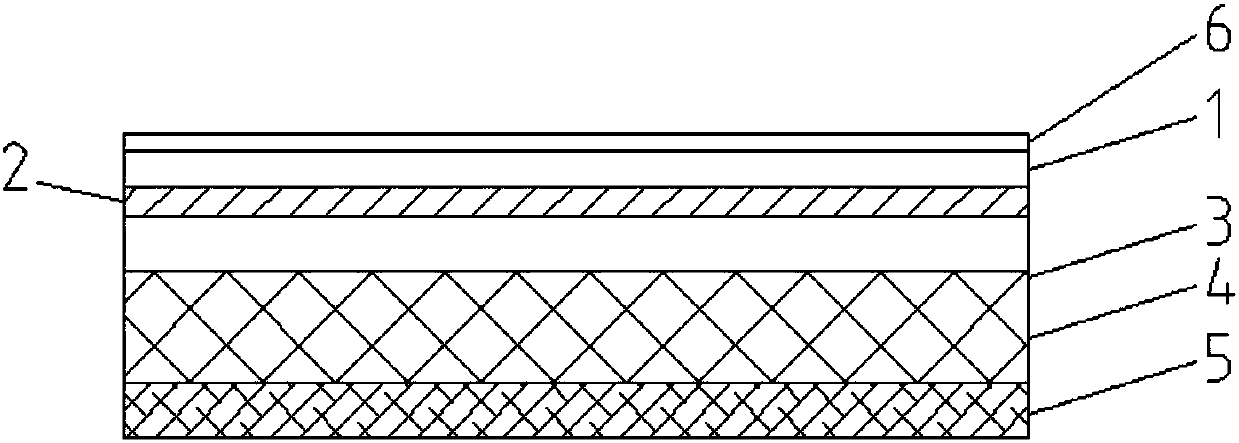

PVC stone-plastic floor and production method thereof

PendingCN107627687AMaintain Embossing FidelityKeep three-dimensionalSynthetic resin layered productsWear resistantDioctyl terephthalate

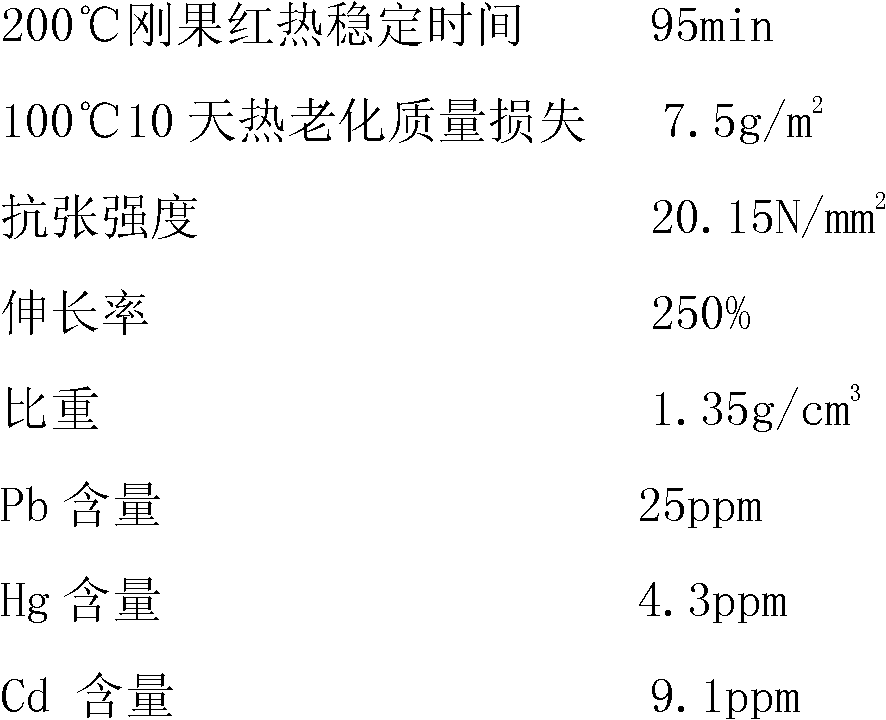

The invention relates to the technical field of floors, in particular to a PVC stone-plastic floor and a production method thereof. The PVC stone-plastic floor is formed by a wear-resistant layer, a decoration layer and a base layer through hot pressing composition, wherein the base layer is formed by a middle layer, a stone-plastic base material layer and a bottom layer through hot pressing composition, the middle layer is close to the decoration layer, the stone-plastic base material layer is located in the middle, and the bottom layer is at the bottom of the whole PVC stone-plastic floor; the middle layer comprises components in percentage by mass as follows: 12%-17% of PVC resin, 7%-11% of dioctyl terephthalate, 0.1%-0.3% of a stabilizer, 70%-80% of calcium carbonate and 0.05%-0.1% ofcarbon black; the bottom layer comprises components in percentage by mass as follows: 30%-40% of PVC resin, 7%-15% of dioctyl terephthalate, 0.3%-1.0% of a stabilizer, 50%-70% of calcium carbonate and0.02% of carbon black.

Owner:浙江海象新材料股份有限公司

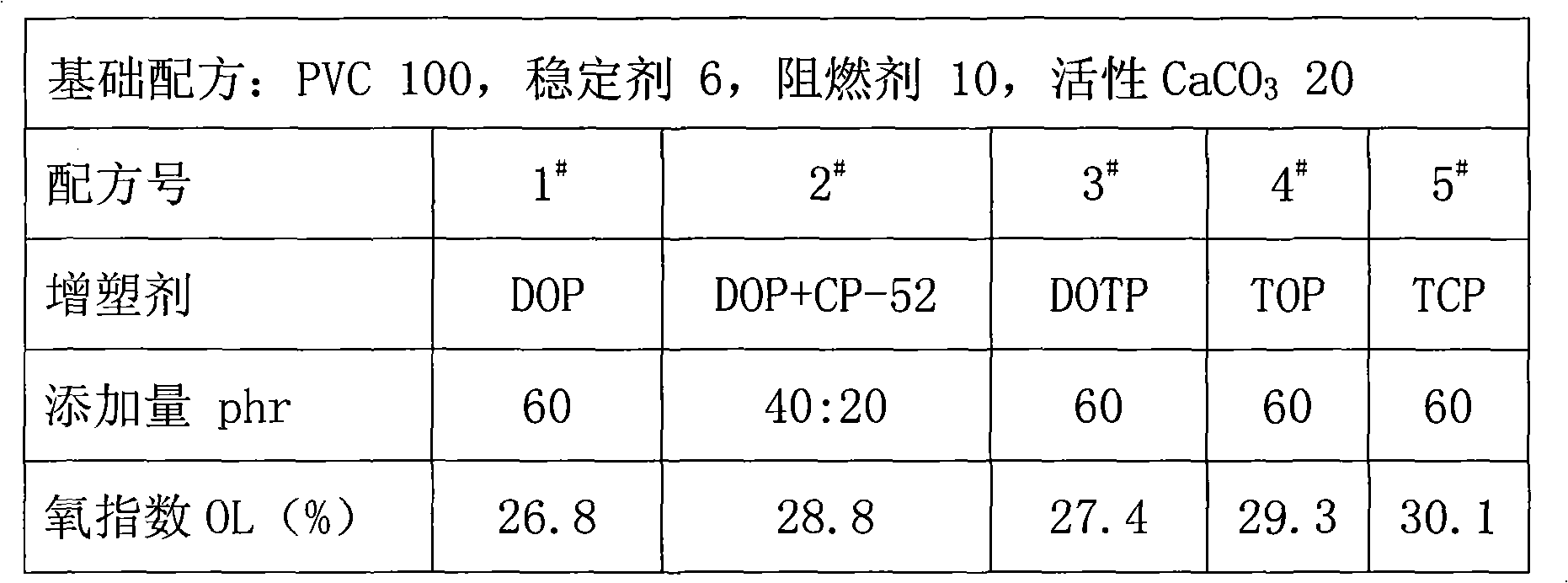

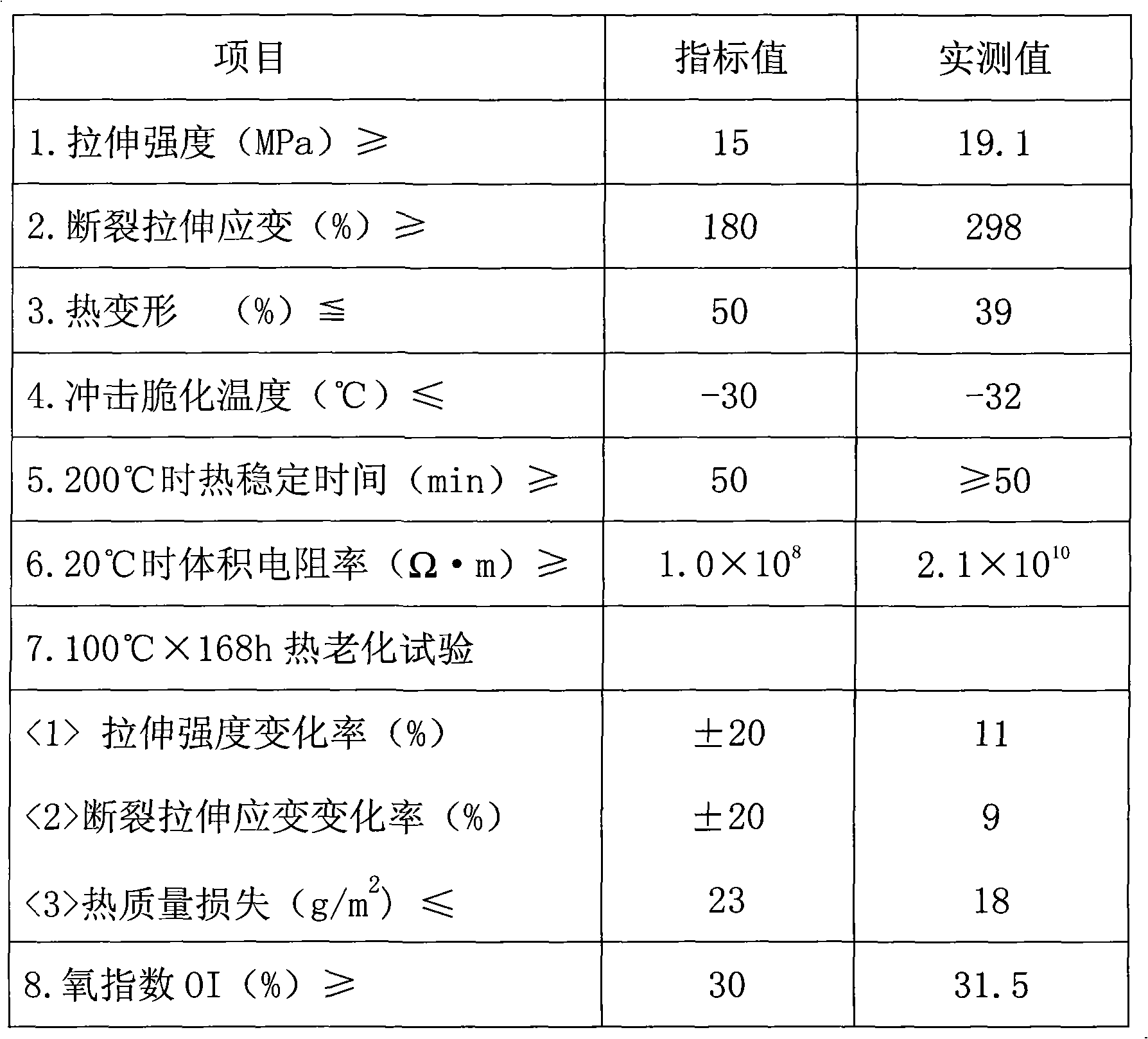

Cold-resistance and flame-retardant level PVC (polyvinyl chloride) cable material

The invention mainly discloses a cold-resistance and flame-retardant level PVC (polyvinyl chloride) cable material. The cold-resistance and flame-retardant level PVC cable material is characterized by adopting 100 parts by weight of PVC as the standard and comprising the other following components in parts by weight: 20-22 parts of dioctyl phthalate, 16-18 parts of dioctyl terephthalate,4-6 parts of trioctyl phosphate, 4-8 parts of dioctyl sebacate, 12 parts of 52 chlorcosane, 6-7 parts of heat stabilizer, 8-10 parts of antimonous oxide, 6-8 parts of CP-70, and 16-20 parts of active CaCO3. The cold-resistance and flame-retardant level PVC cable material has the advantages that different from the common-level cable material, firstly, the mechanical performance and the ageing performance meet the requirements of GB / T8S15-2008; secondly, the low-temperature impact embrittlement performance is less than 50% in fracture at the temperature of below minus 36 DEG C; and thirdly the requirement for the oxygen index (OI) in the flame-retardant performance is more than 30%.

Owner:RUGAO ZHONGRU CHEM

Method for preparing environment-friendly plasticizer by recycling waste resources

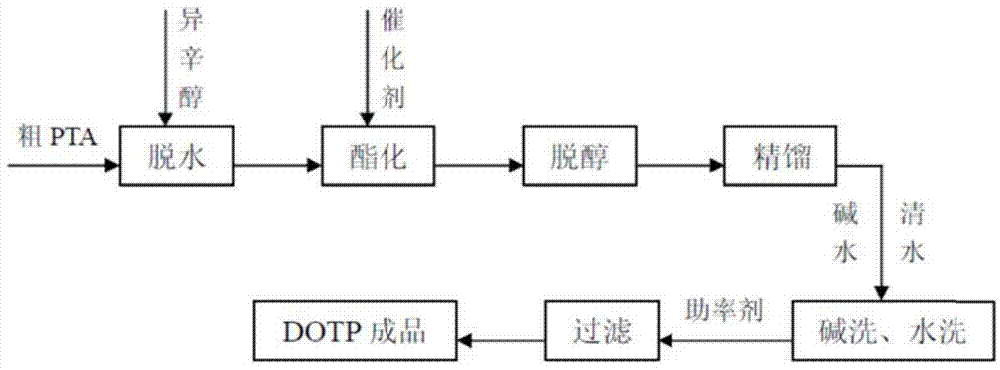

ActiveCN104496819AImprove qualityAvoid wastingOrganic compound preparationCarboxylic acid esters preparationFiltrationOctanol

The invention relates to a method for preparing an environment-friendly plasticizer by recycling waste resources. The method comprises the following steps of transferring alkali-reduction wastewater containing sodium terephthalate into an acid precipitation tank with a stirring device and adding sulfuric acid to further precipitate terephthalic acid (PTA) solids; carrying out plate-frame filtration on the mixed solution to obtain a crude PTA material; adding the recovered crude PTA material into an esterification reactor with an alcohol-water separation device, adding iso-octanol, heating and dehydrating, adding tetrabutyl titanate as a catalyst and carrying out esterification reaction; after water is no longer produced, stopping reaction and dealcoholizing to obtain a crude DOTP (Dioctyl Terephthalate) product; rectifying the prepared crude DOTP product in a packing-type rectifying tower to obtain a rectified product, adding the rectified product into a neutralization reaction kettle, adding sodium hydroxide lye, stirring and washing with alkali; standing, precipitating and discharging the aqueous solution in the lower layer, adding hot water, stirring and washing with water, standing, precipitating and discharging the moisture in the lower layer, carrying out temperature-raising dehydration, adding an inorganic filter aid and filtering to obtain the pure DOTP product. By the method, the recycling of the waste resources is achieved.

Owner:INST OF CHEM IND OF FOREST PROD CHINESE ACAD OF FORESTRY

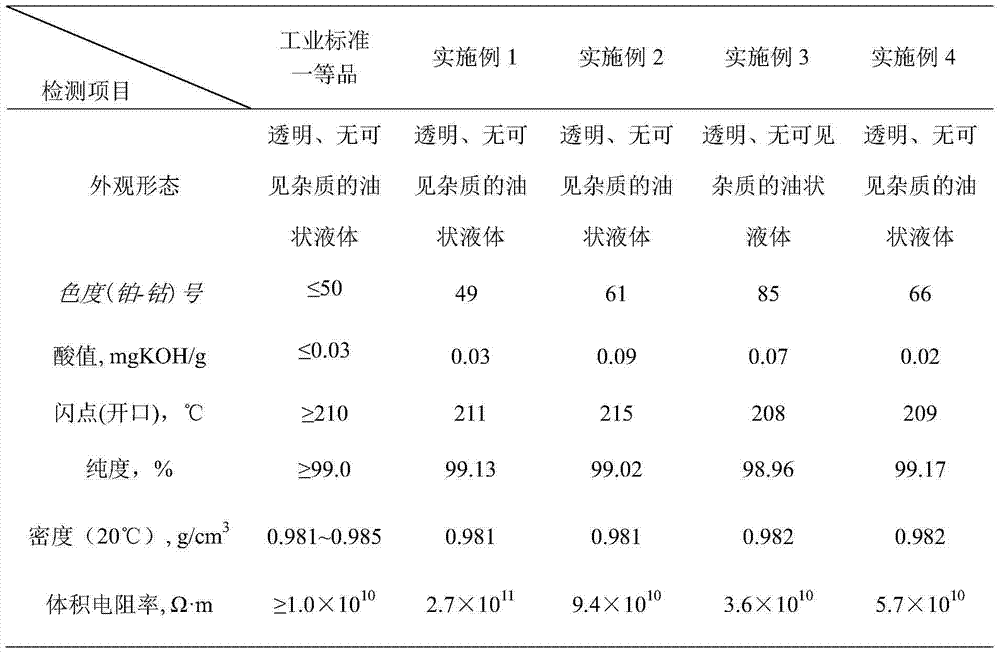

Dioctyl phthalate production line and DOTP production method

ActiveCN102952019ASave operating timeReduce dosageOrganic compound preparationCarboxylic acid esters preparationState of artAlcohol content

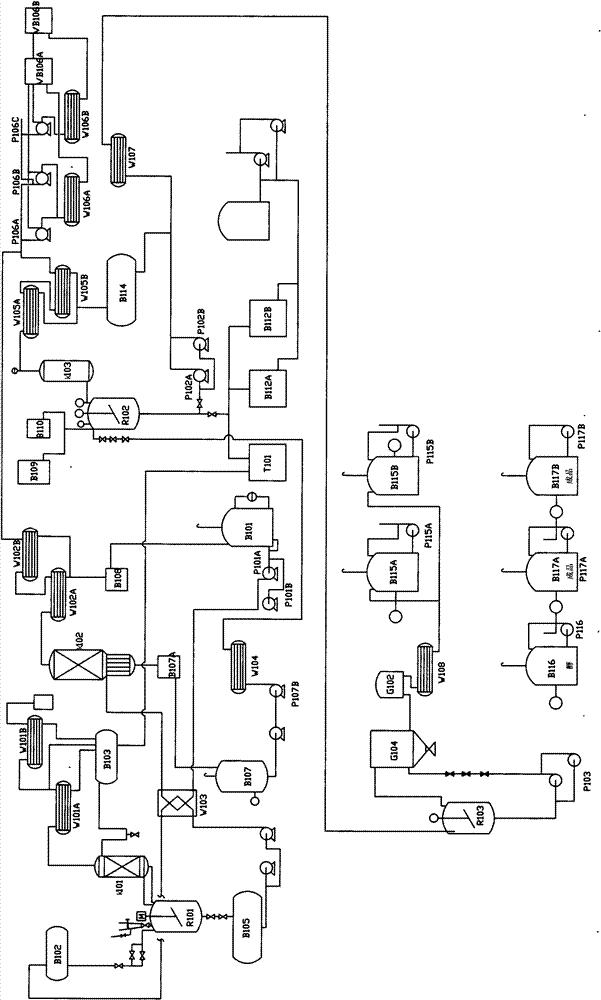

The invention relates to a dioctyl phthalate production line and a DOTP production method. Existing DOTP production methods have the defects of long esterification reaction time, large catalyst dosage, high octanol content in product, and slightly yellow color. The invention provides a dioctyl phthalate production line comprising an esterification system, a dealcoholization system, a neutralization / washing system, a stripping system, a filtering and decolorizing system, and a sewage purification and recovery system. All the systems are modified. The invention also relates to a DOTP production method, comprising a plurality of steps such as esterification, dealcoholization, neutralization / washing, stripping, filtering and decolorizing, sewage purification and recovery, and the like. All the steps are different from those of prior arts. When DOTP is produced with the method provided by the invention, the esterification reaction can be achieved in 4-5 hours; a catalyst dosage is low; the product is clean and colorless; alcohol content in finished product can be reduced to 20ppm; and quality is greatly improved. The production line and the method can be used for producing dioctyl terephthalate, dioctyl orthophthalate, and dioctyl isophthalate.

Owner:张炜海

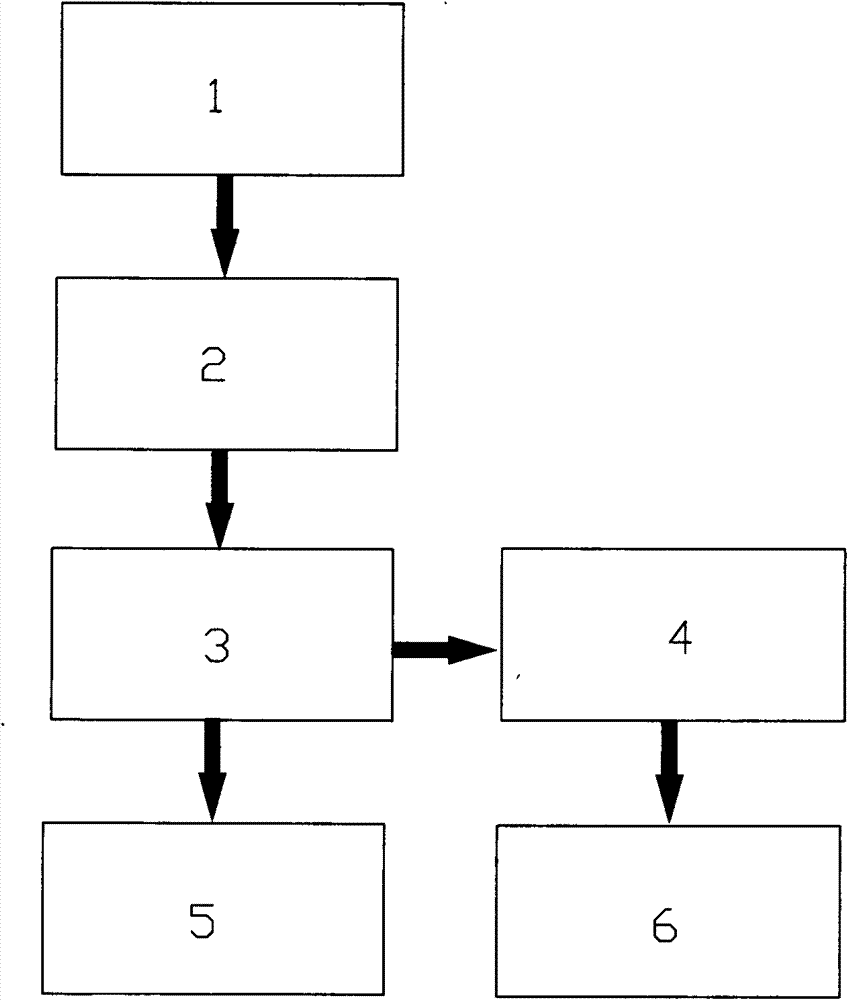

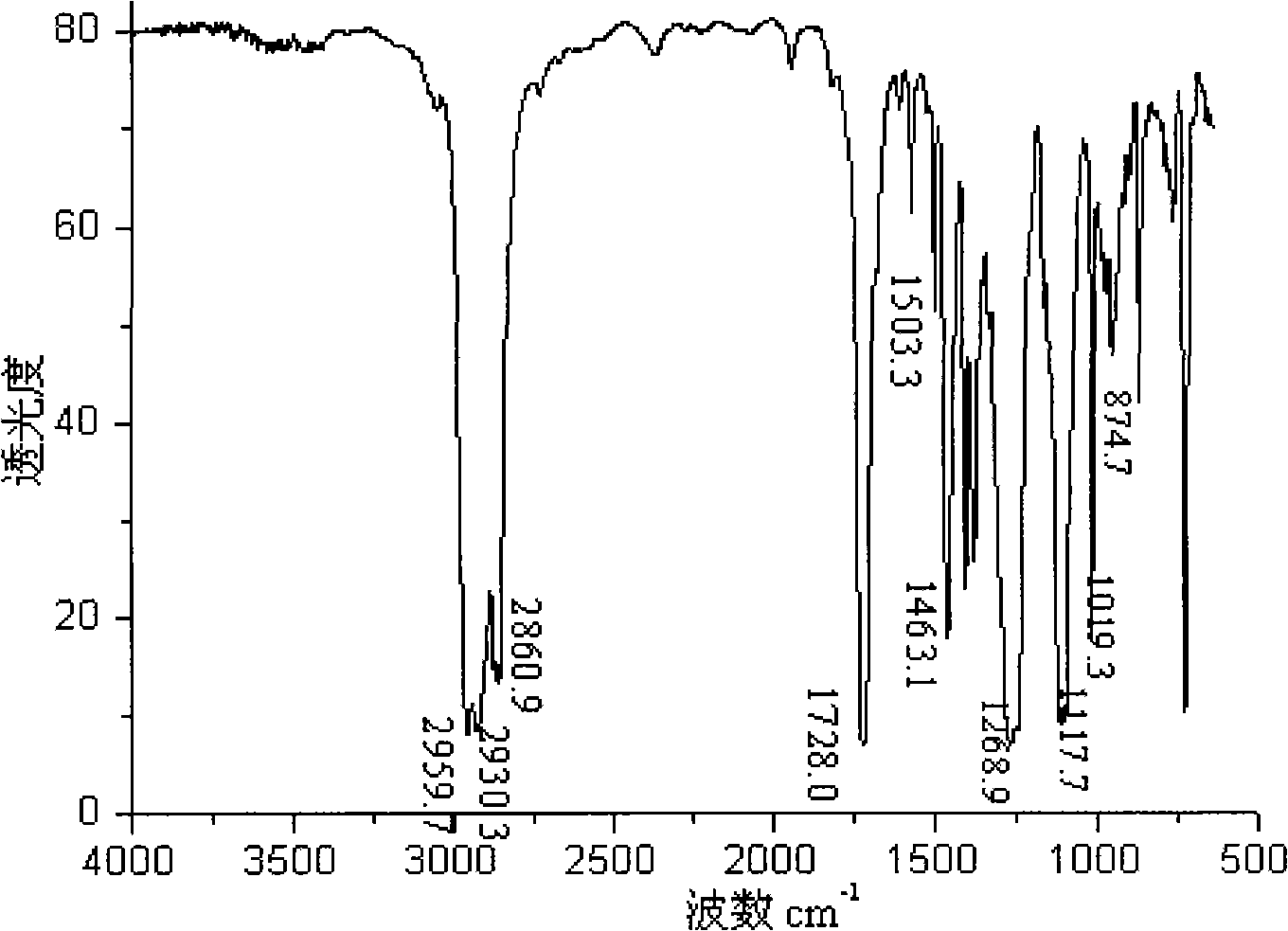

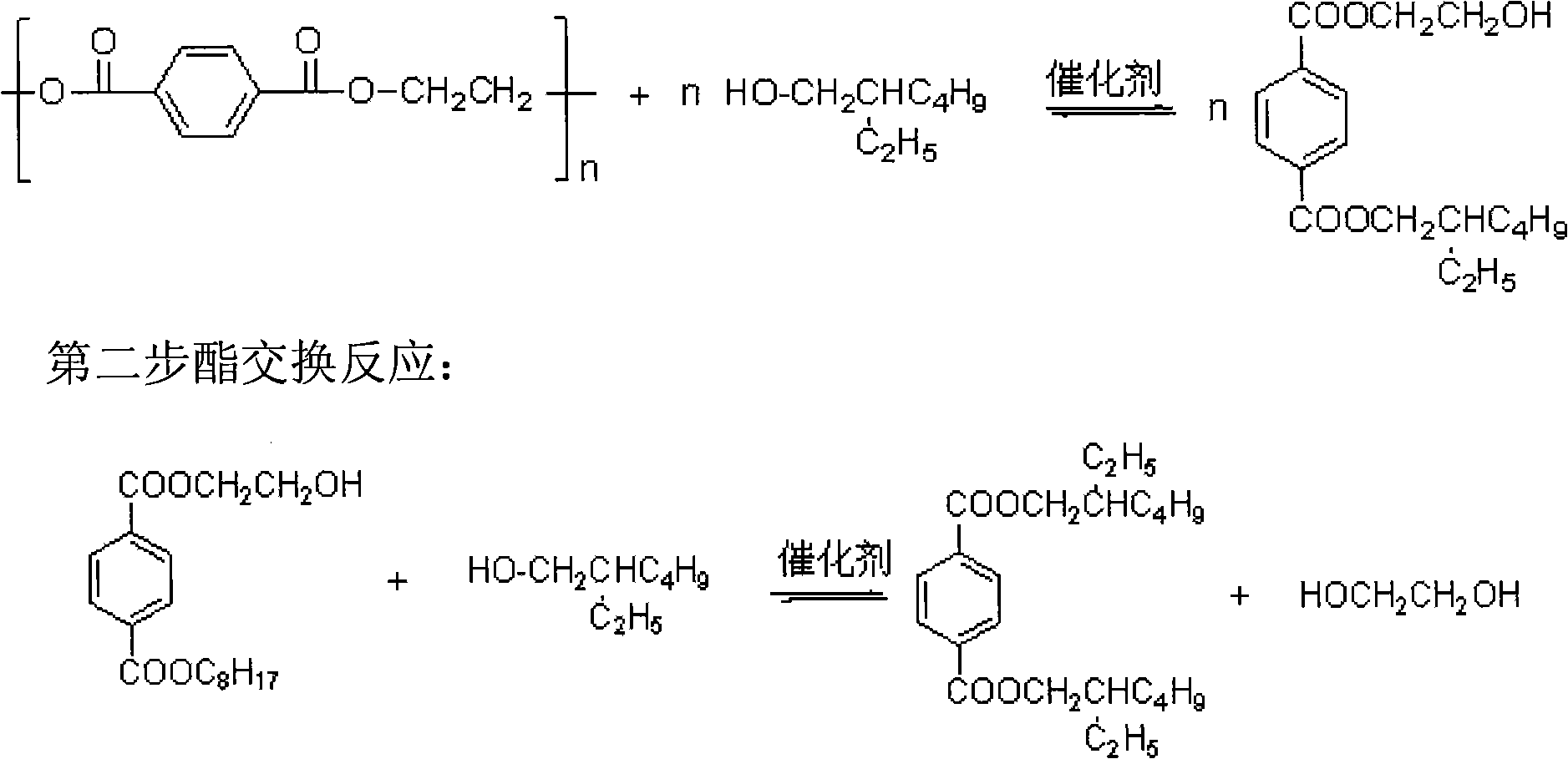

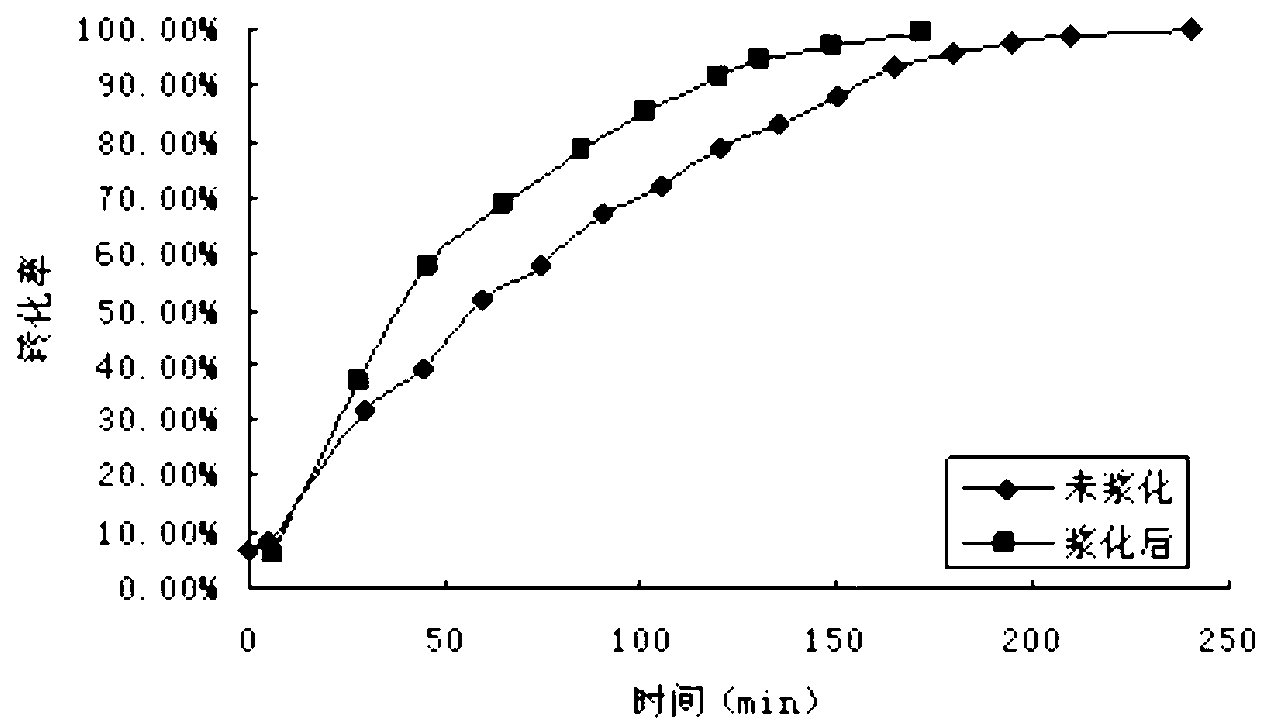

Method for synthesizing PVC plasticiser by reclaiming waste polyester

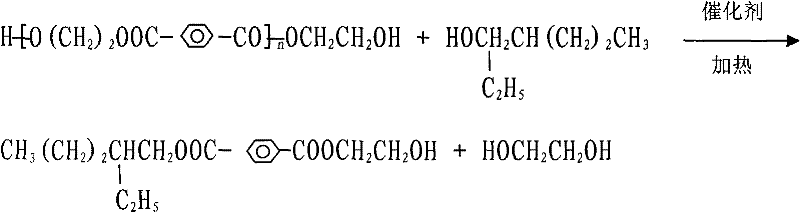

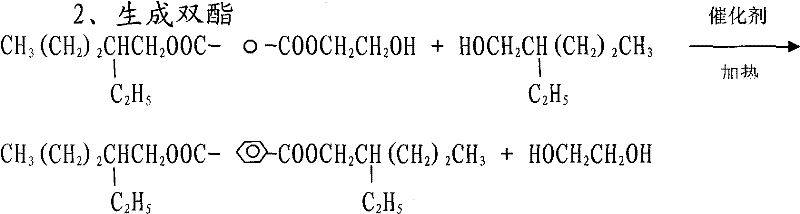

InactiveCN101302158AShort reaction timeShort processPreparation by ester-hydroxy reactionOrganic compound preparationPolyesterFiber

The invention discloses a method for synthesizing PVC plasticizer DOTP by waste polyester resource utilization, which belongs to the plasticizer technical field. The method comprises the following steps that: 1. under the existence of catalyst, waste polyester scraps are heated with 2-ethyl hexanol to carry out the degradation reaction; 2. glycol produced by the reaction and the 2-ethyl hexanol are coboiled and condensed, and then the glycol is removed through water scrubbing and is reclaimed; 3. reactant coarse ester is orderly subject to aqueous alkali and water for washing, an aqueous layer and an organic layer are separated; the organic layer is added with adsorbent, then the unreacted 2-ethyl hexanol is steamed out, and the plasticizer product dioctyl terephthalate (DOTP) is obtained after the filtration. The raw material of the invention, namely waste polyester can be polyester fiber, waste terylene cloth, leftover materials, waste polyester bottles, and polyester films and so on; the removal method of the catalyst adopts a water scrubbing filtration mode, the catalyst is simultaneously removed during neutralization, water scrubbing and filtration processes, and no additional process operation needs to be added for the removal of the catalyst, so the method has short process flow and low production cost.

Owner:JIANGNAN UNIV

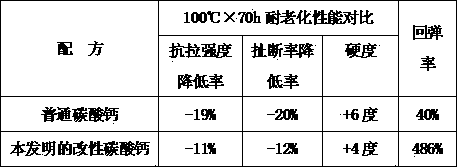

Modified calcium carbonate for wear-resistant rubber shoe soles and preparation method thereof

ActiveCN103408801AUniform particle sizeLarge specific surface areaSolesPigment treatment with macromolecular organic compoundsDispersityRubber material

The invention provides a modified calcium carbonate for wear-resistant rubber shoe soles, which is prepared from the following raw materials in parts by weight: 95-100 parts of ground calcium carbonate, 0.2-0.3 part of stearyl alcohol based polyethenoxy ether, 0.3-0.4 part of polyoxyethylene sorbitan fatty acid ester, 0.1-0.4 part of PE (polyethylene) wax, 0.5-0.8 part of triphenyl phosphite, 0.5-1 part of teflon micropowder, 0.1-0.3 part of ananti-aging agent 4020, 1-2 parts of ABS (acrylonitrile-butadiene-styrene) high rubber powder, 0.2-0.5 part of high-wear-resistance carbon black, 0.1-0.2 part of zirconium fluoride, 1-2 parts of dioctyl terephthalate (DOTP), 0.5-0.6 part of polyvinyl alcohol and 1-2 parts of a titanate coupling agent TMC-TTS. The preparation method comprises the following steps: drying calcium carbonate, proportionally and sequentially adding the other raw materials in batches, thoroughly mixing in a high-speed stirrer, drying and grinding. The modified calcium carbonate provided by the invention has the advantages of favorable dispersity and favorable wear resistance, and can lower the cost and enhance the working properties and wear resistance of shoe rubber when being used in shoe sole rubber materials.

Owner:QINGYANG COUNTY YONGCHENG CALCIUM IND

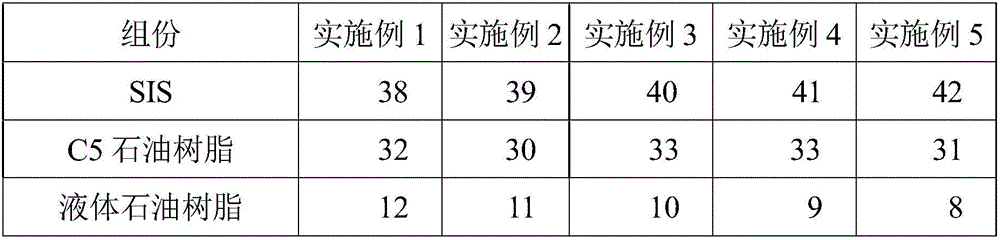

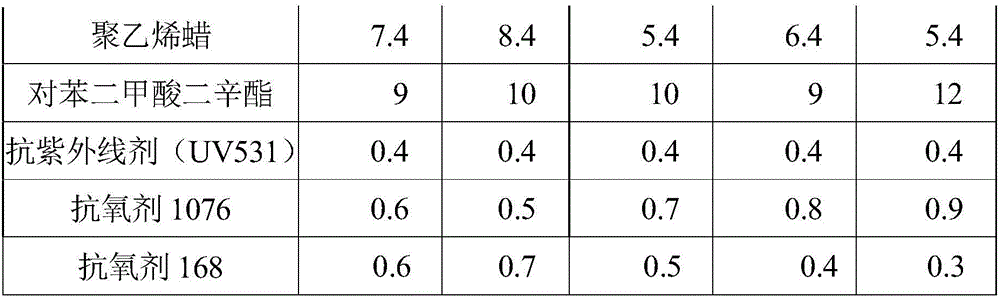

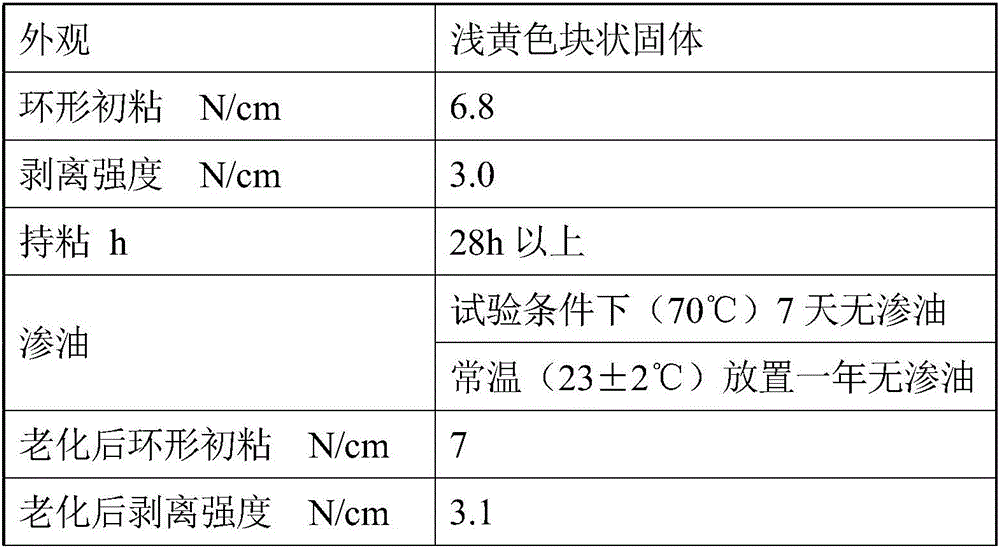

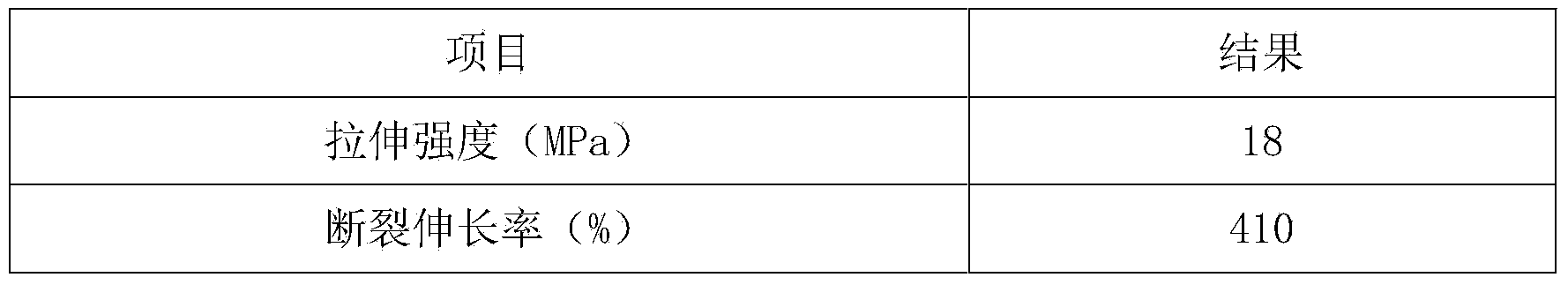

Removable hot-melt pressure-sensitive adhesive and preparation method

ActiveCN106318292AExcellent adhesionImprove retentionNon-macromolecular adhesive additivesFilm/foil adhesivesEnvironmental resistanceUltraviolet

The invention relates to a removable hot-melt pressure-sensitive adhesive and belongs to the technical field of adhesives. The pressure-sensitive adhesive is prepared from raw materials in parts by mass as follows: 35-45 parts of matrix resin, namely, a styrene-isoprene-styrene triblock copolymer, 30-40 parts of a tackifier, namely, C5 petroleum resin, 8-13 parts of a softener, namely, dioctyl terephthalate, 3-8 parts of a peel strength modifier, namely, polyethylene wax, 7-15 parts of a viscosity modifier, namely, liquid petroleum resin, 0.6-1.4 parts of an antioxidant and 0.4 parts of an ultraviolet absorbent. An adhesive tape prepared from the pressure-sensitive adhesive can be peeled and pasted repeatedly, and the adhesive cannot be transferred after the pressure-sensitive adhesive is pasted with paper, PE films, PP films and the like. The pressure-sensitive adhesive meets the environmental protection requirement of European Union REACH and RoHS on the basis of detection of specialized agencies and can completely meet the requirement of production of sealing labels, labels and removable adhesive bags.

Owner:河北方大新材料股份有限公司

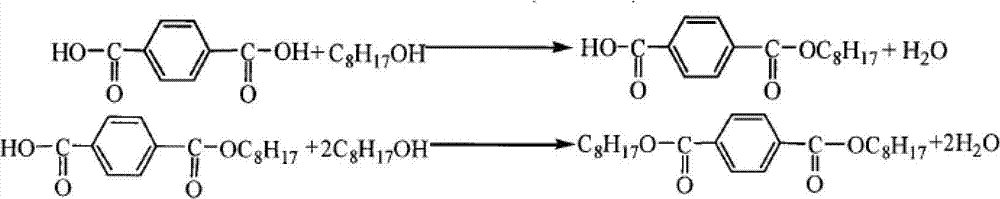

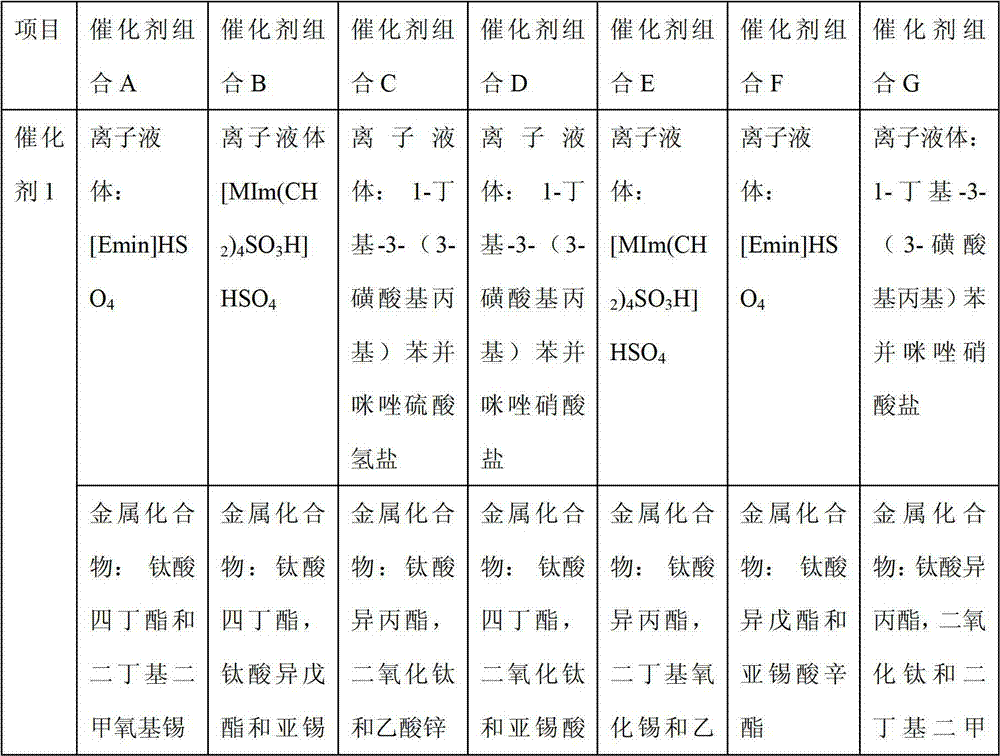

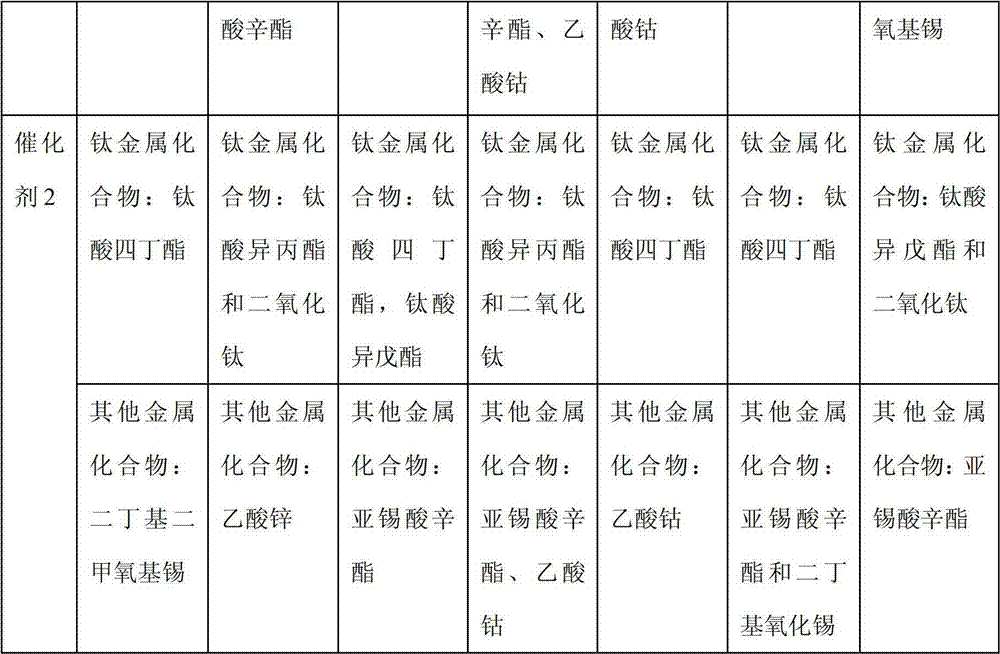

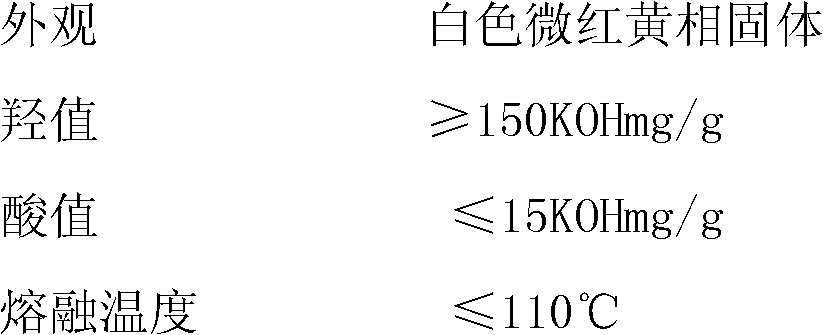

Preparation method of dioctyl terephthalate and used catalyst

InactiveCN102824929AIncrease contact areaShrink wellOrganic compound preparationOrganic-compounds/hydrides/coordination-complexes catalystsDibutyltin oxideTitanium metal

The invention provides a catalyst for use in synthesis of dioctyl terephthalate and a method for preparing dioctyl terephthalate by applying the catalyst. The catalyst consists of a catalyst 1 and a catalyst 2, wherein the catalyst 1 consists of an ionic liquid and a metal compound; the catalyst 2 consists of a titanium metal compound and other metal compound; the positive ion of the ionic liquid are an imidazole ion or a benzimidazole ion; the negative ion of the ionic liquid is a bisulfate ion; or the positive ion of the ionic liquid is a benzimidazole ion or an imidazole ion with one or two sulfonic acid radicals; the titanium metal compound is selected from at least one compound of tetrabutyl titanate, isopentyl ester titanate, isopropyl titanate or titanium dioxide; and the other compound is selected from at least one compound of dibutyldimethoxytin, dibutyltin oxide, monooctyl ester stannite, zinc acetate and cobalt acetate. Due to the adoption of the technical scheme provided by the invention, the cost can be reduced, the reaction speed is increased, energy consumption is lowered, and the quality of an obtained product is high.

Owner:FOSHAN GAOMING XIONGYE CHEM

High-fluidity PVC (polyvinyl chloride) sheath material

InactiveCN103289222AGuaranteed environmental performanceLow costInsulated cablesInsulated conductorsDioctyl terephthalateZinc

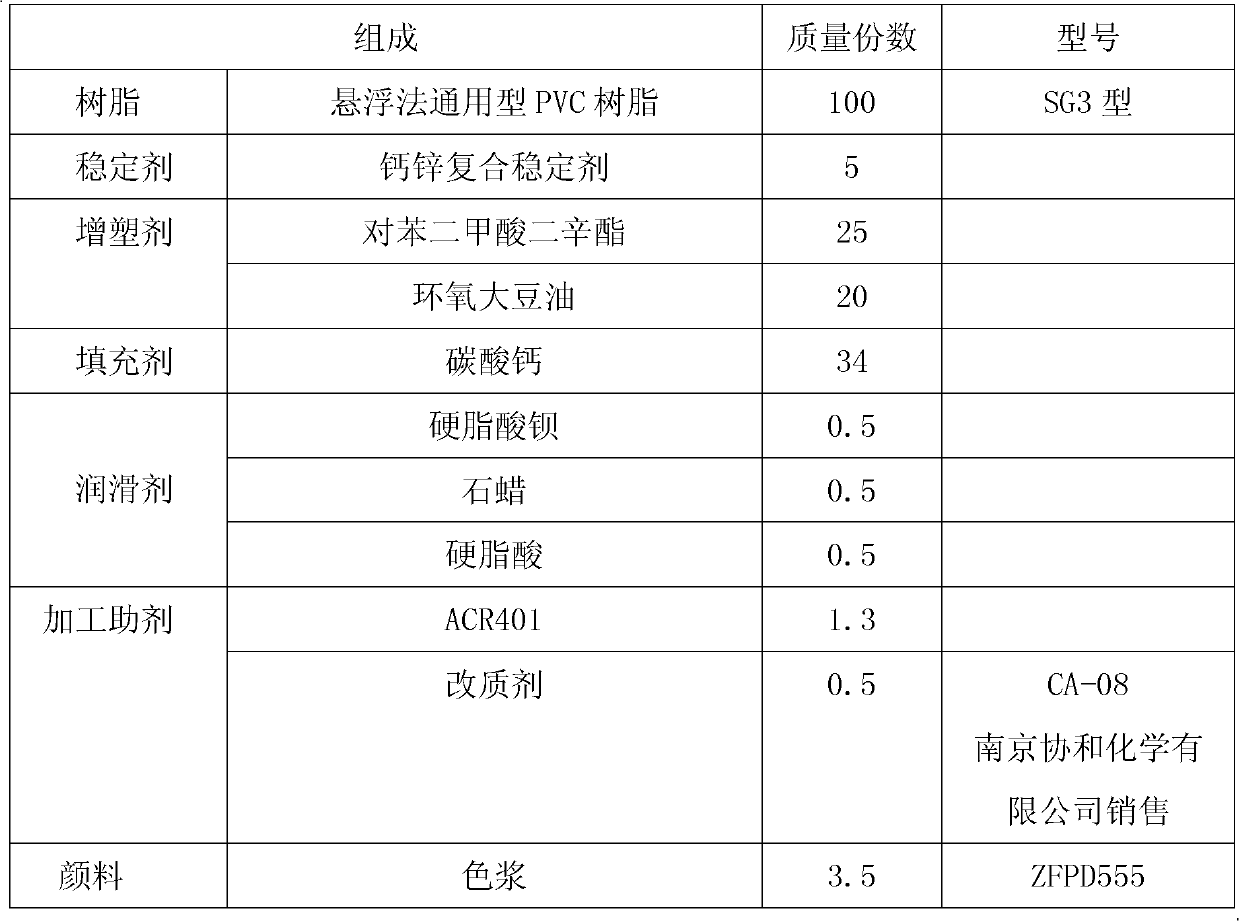

The invention relates to a high-fluidity PVC (polyvinyl chloride) sheath material which consists of the following components: 100 parts of PVC resin, 5-10 parts of calcium-zinc composite stabilizer, 45-55 parts of plasticizer, 30-60 parts of filler, 1.5-3 parts of lubricant, 1.5-2.5 parts of processing aid and 3.5-4.5 parts of pigment. According to the high-fluidity PVC sheath material provided by the invention, the environmental protection performance is guaranteed by the calcium-zinc composite stabilizer, the processing fluidity is improved by combining functional modifiers CA-08 and ACR 401, and the formula cost is reduced through the co-plasticization of low-cost epoxidized soybean oil and dioctyl terephthalate. The environmental protection performance of the PVC sheath material meets the requirements of the ROHS standard, and the general performance meets the HI-90 type index requirements in GB / T 8815-2008 of the standard Flexible PVC Plastics for Wires and Cables.

Owner:FAR EAST CABLE +2

Elastic waterproof sealant, preparation method thereof, and roof waterproof structure formed by eastic waterproof sealant

ActiveCN103555255ANo pollution in the processBonding is versatileNon-macromolecular adhesive additivesBuild-up roofsDioctyl terephthalateUltraviolet

The invention discloses an elastic waterproof sealant comprising 15-25 parts of alpha-dimethoxysilane-terminated polyether resin, 20-30 parts of gamma-trimethoxysilane-terminated polyether resin, 5-10parts of dioctyl terephthalate, 40-55 parts of nano-calcium carbonate, 0.1-5 parts of fumed silica, 0.5-5 parts of titanium dioxide, 0.1-1 part of carbon black, 0.1-0.5 parts of an ultraviolet absorber, 0.1-0.5 parts of a light stabilizer, 0.5-1 parts of a dehydrating agent, 0.5-1 parts of an adhesion promoter. The invention also discloses a preparation method of the elastic waterproof sealant, and a roof waterproof structure formed by the elastic waterproof sealant. The elastic waterproof sealant has the advantages that: the elastic waterproof sealant is harmless to human; a roof waterproofstructure formed by the elastic waterproof sealant can form a completely closed waterproof layer; construction is simple, and waterproof effect is excellent.

Owner:JIANGSU CUMT DAZHENG SURFACE ENG TECH

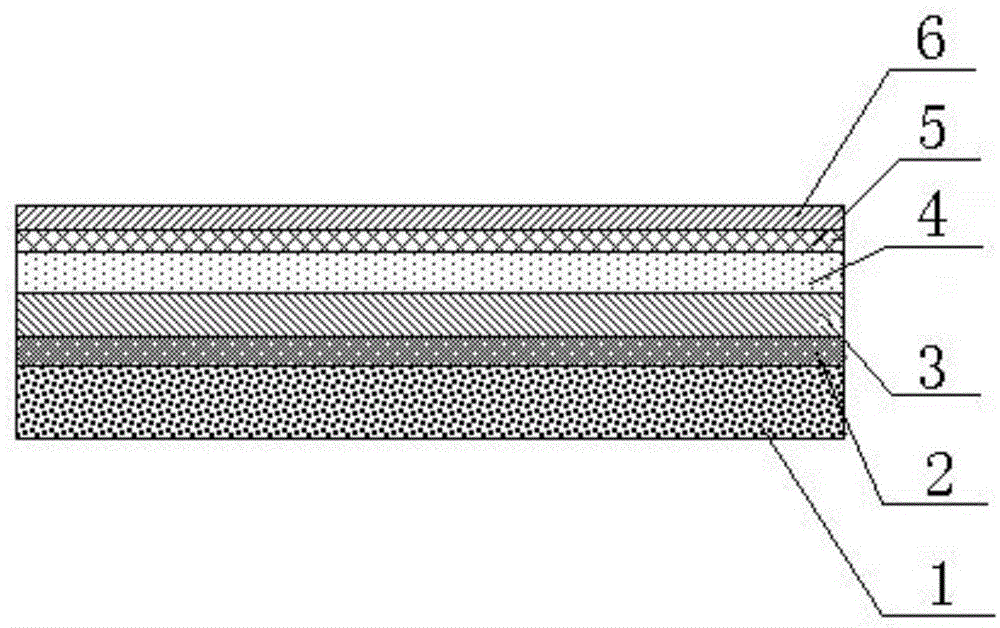

Color fiber alkali decremental waste water treating and recovering process

InactiveCN1935703AReduce CODcr valueHigh purityOrganic chemistryWater/sewage treatment bu osmosis/dialysisFiberDimethyl terephthalate

The invention discloses a process of recovering terephatalic acid from colored alkali reduction waste water, processing two waste water streams thick and thin coming from alkali reduction process by qualities, firstly decolorizing by decolorizing agent, then integrating acid precipitation with diaphragm process to recover erephatalic acid from the waste water, thus making CODcr of waste water reduced by 50-70% for the convenience of follow-up biochemcial and physical chemcial treaments, where the purity of the recovered terephatalic acid is up to above 90%, able to act as chemcial raw material for preparing dimethyl terephthalate, and dioctyl terephthalate. And it can be applied to chemcial production, controlling pollution, improving environment, saving energy sources, reducing cost, and obtaining good economic and environmental benefits.

Owner:ZHEJIANG UNIV

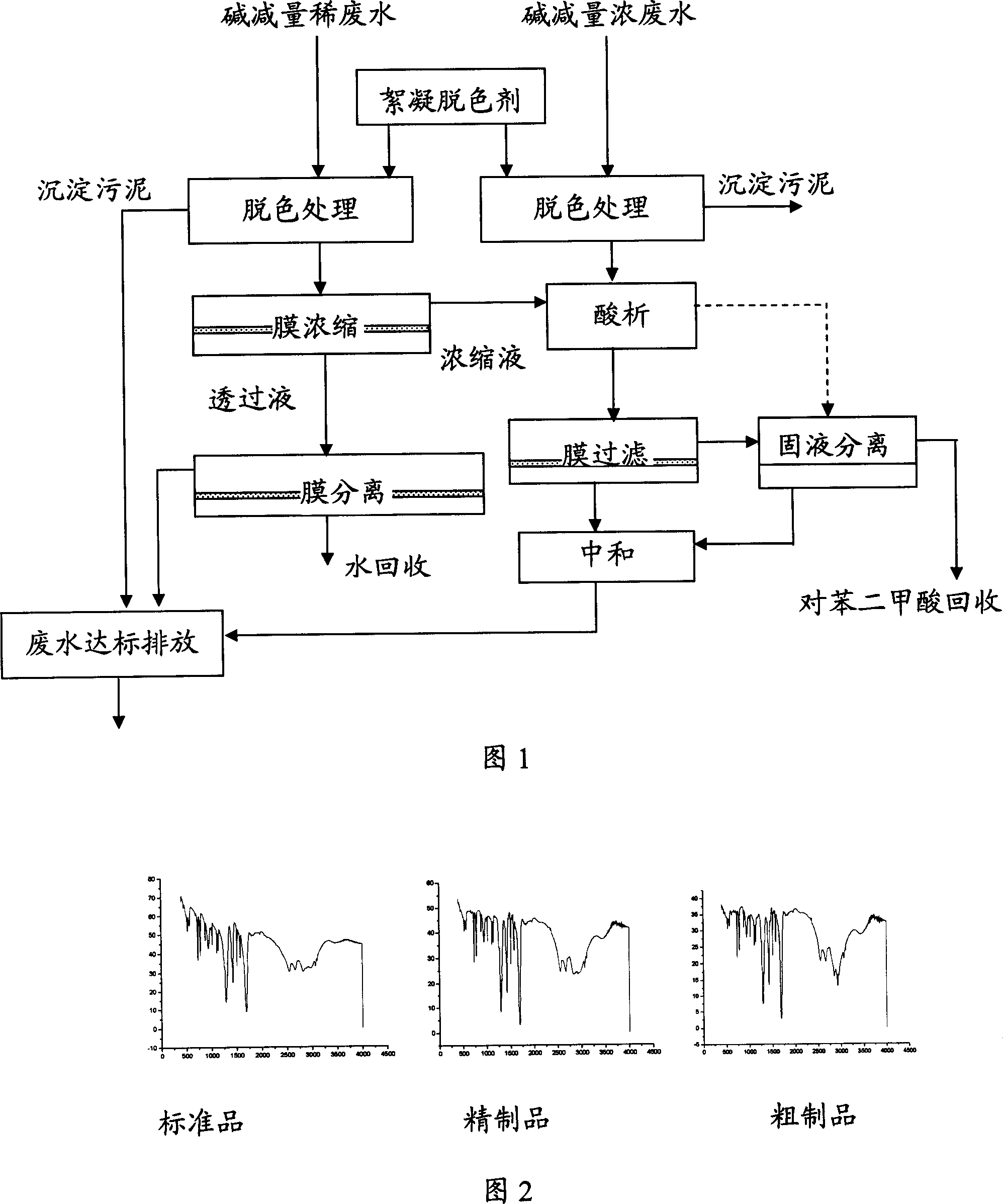

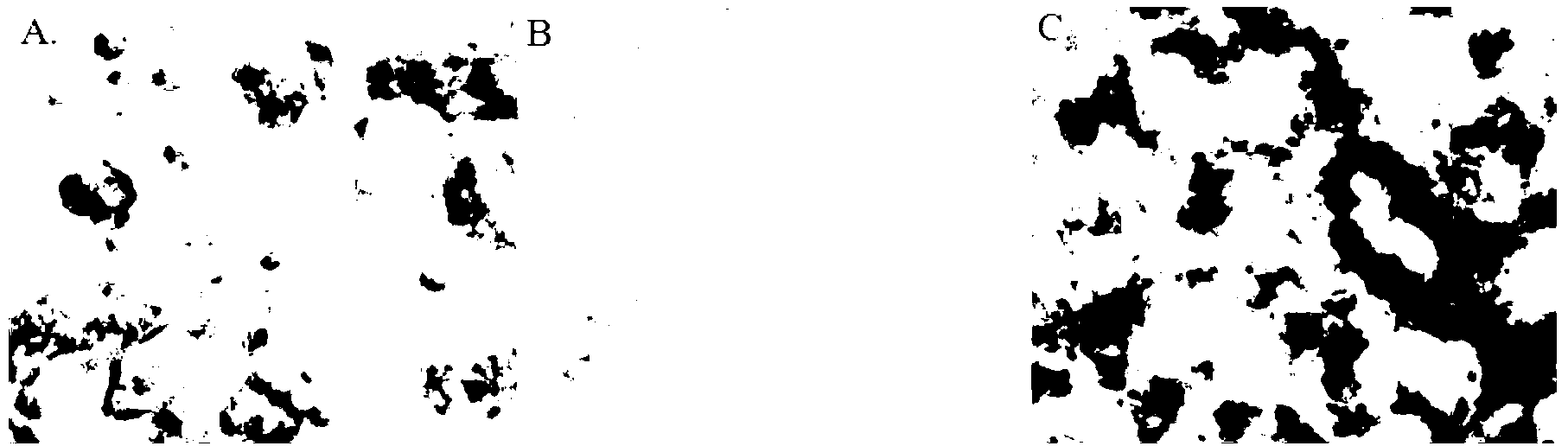

Process of recycling terephthalic acid to produce DOTP (dioctyl terephthalate) by using polyester alkaline to reduce wastewater

InactiveCN104230714AExcellent ester contentSolve the problem that the color is difficult to meet the downstream use standardPreparation from carboxylic acid saltsOrganic compound preparationBenzeneActivated carbon

The invention discloses a process of recycling terephthalic acid to produce DOTP (dioctyl terephthalate) by using polyester alkaline to reduce wastewater. The process comprises the following process steps: adding terephthalic acid reclaimed materials and isooctyl alcohol into a reaction kettle in a certain proportion, stirring and heating, adding a catalyst and activated carbon when water yield is obviously reduced, continuously stirring and heating the mixture, controlling the temperature of the mixture to 190-230 DEG C, carrying out dealcoholization in vacuum after reaction is ended, heating to 265-285 DEG C and distilling under reduced pressure under -0.09MPa to -0.1MPa to obtain raw ester, adding H2O2 in a certain proportion to discolor; and finally, absorbing impurities by use of activated carbon and kaolin and carrying out filter-pressing to obtain a nearly colorless DOTP finished product. According to the process, the raw materials can adopt untreated alkaline which is low in purity and chromaticity to reduce wastewater to recycle the terephthalic acid, so that a complex pretreatment process is avoided, the terephthalic acid reclaimed materials are utilized to the greatest extent, and the high ester content and the low colour and luster of the DOTP product are guaranteed while the efficiency is high and the energy consumption is low.

Owner:上海蓓奕化工有限公司 +1

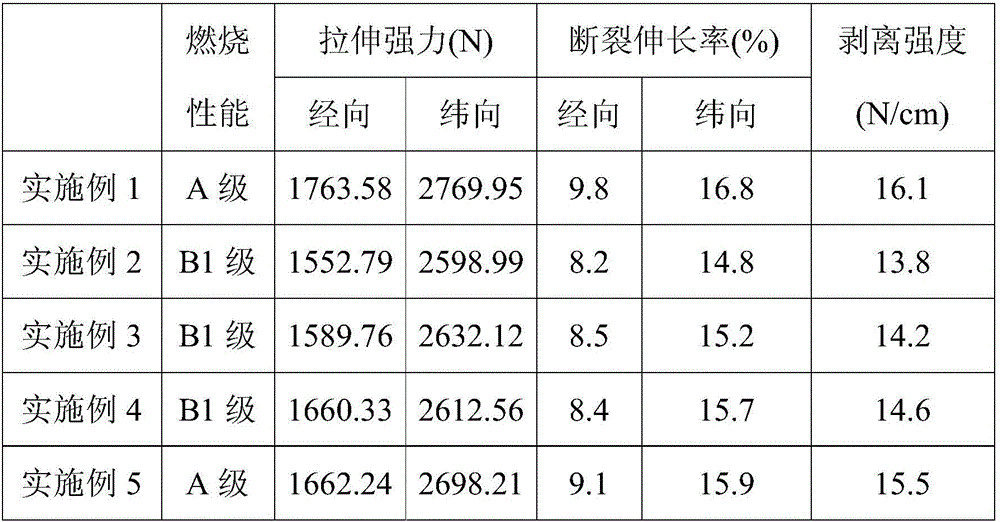

Long-lasting anti-fouling membranous-structure composite canopy material

ActiveCN106003931AIncreased static contact angleNot easy to penetrateSynthetic resin layered productsCoatingsPolyesterFiber

The invention relates to a long-lasting anti-fouling membranous-structure composite canopy material comprising a base membrane, base cloth and a surface membrane which are arranged sequentially from bottom to top, wherein a polyvinylidene fluoride coating is arranged on the surface membrane and is subjected to mirror face embossing treatment; the surface membrane as well as the base membrane is prepared from the following raw materials in parts by weight: 100 parts of polyvinyl chloride (PVC) resin powder, 50 to 70 parts of a dioctyl terephthalate plasticizer, 5 to 25 parts of calcium carbonate powder, 1 to 5 parts of a flame retardant, 1 to 4 parts of a smoke suppressant, 1 to 6 parts of a barium-zinc stabilizer and 1 to 5 parts of a titanium pigment; the base cloth is 1000D*1000D polyester fiber woven cloth. Raw materials such as PVC resin powder, the plasticizer, calcium carbonate, the stabilizer and the flame retardant are mixed, plasticizing and calendaring are carried out to obtain soft membranes, then the soft membranes are compounded with the 1000D*1000D polyester fiber woven cloth, and embossing is carried out after surface treatment of polyvinylidene fluoride, so that the long-lasting anti-fouling membranous-structure composite canopy material is a membranous-structure composite canopy material being long-lasting in fouling resistance, efficient in fire retardancy, and high in strength.

Owner:浙江明士达股份有限公司

Environment-friendly cold-resistant polyvinyl chloride cable material

InactiveCN103509293AStrong impact resistanceSolve environmental problemsWear resistantDecabromodiphenyl ether

The invention provides an environment-friendly cold-resistant polyvinyl chloride cable material. The polyvinyl chloride cable material is prepared with the following components and raw materials by weight: 60-70 parts of polyvinyl chloride, 10-15 parts of polysiloxane, 8-10 parts of silicon rubber, 12-15 parts of dioctyl terephthalate, 5-10 parts of triethylene glycol di-2-ethylhexoate (triglycol dioctate), 3-5 parts of epoxy triglyceride, 8-10 parts of tributyl acetocitrate, 1-2 parts of cobalt naphthenate, 0.2-0.3 part of ethyl silicon oil, 2-5 parts of chlorinated polyethylene, 10-15 parts of aluminum hydroxide, 5-6 parts of triphenyl phosphate, 4-6 parts of decabromodiphenyl ether, 8-10 parts of light activated calcium carbonate, 5-8 parts of bentonite, 1-2 parts of zinc oxide, 1-2 parts of titanium dioxide, 5-6 parts of cinerite, 6-8 parts of highly wear-resistant carbon black, 2-3 parts of Ca-Zn compound stabilizer, 0.1-1 part of antioxidant 1076, 0.1-0.3 part of dicumyl peroxide (DCP), 0.2-0.3 part of butyl stearate, 1-2 parts of barium stearate, 0.1-0.5 part of zinc stearate, and 8-10 parts of modified filler. The cable material is of good shock resistance at low temperature and environment-protection property, thereby solving the problem that the existing polyvinyl chloride cable material is not environment-friendly, and bad in the shock resistance at low temperature.

Owner:东莞虎塑塑胶科技有限公司

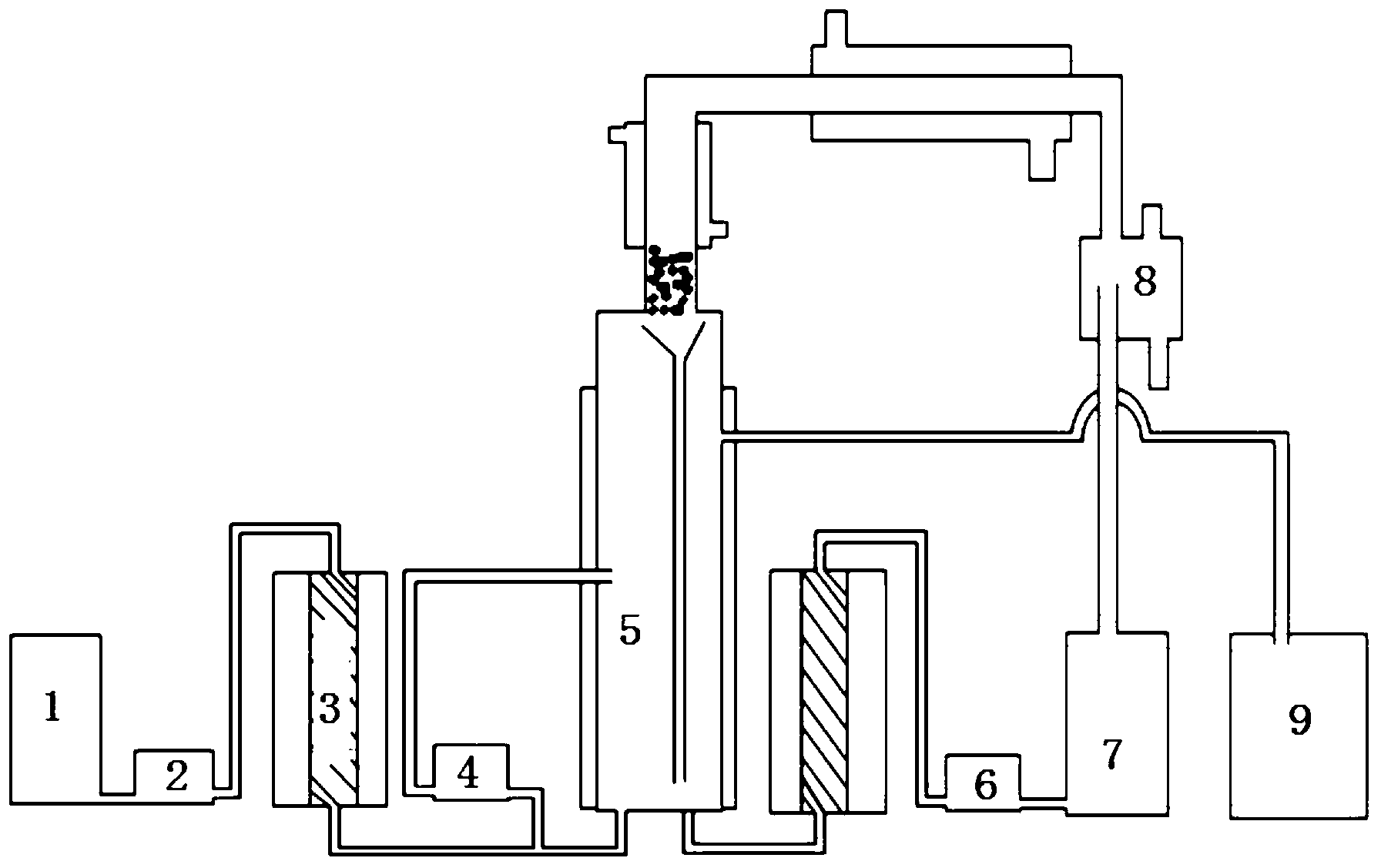

Continuous preparation process for environment-friendly plasticizer and device used in process

InactiveCN103242164ASmall granularityIncrease return flowOrganic compound preparationCarboxylic acid esters preparationIsooctyl alcoholAlcohol

The invention relates to a continuous preparation process for an environment-friendly plasticizer and a device used in the process. The process comprises the following steps of: enabling solid terephthalic acid and isooctyl alcohol which serve as raw materials to react in the existence of an esterification catalyst and an antioxidant for continuously preparing dioctyl terephthalate (DOTP); pulpifying the solid terephthalic acid in the isooctyl alcohol until the particle size of the solid terephthalic acid reaches 5 to 20 mu m; adding the isooctyl alcohol so as to adjust the mole ratio of alcohol to acid in pulp liquid as 2:1 to 4:1; adding into a slurry tank, preheating, and entering a reaction kettle from the bottom; reacting with the preheated isooctyl alcohol which enters from the bottom of the reaction kettle in the reaction kettle in the existence of the esterification catalyst and / or the antioxidant; reacting until an acid value decreases to be below 2, and continuously feeding the raw materials namely the solid terephthalic acid and the isooctyl alcohol; and adding the DOTP which is generated in reaction from the upper part of the reaction kettle to a product tank, condensing the isooctyl alcohol which does not completely reacts and the generated steam through a condenser on the top of the reaction kettle, separating through an oil water separator, and entering an octyl alcohol tank for recirculation.

Owner:INST OF CHEM IND OF FOREST PROD CHINESE ACAD OF FORESTRY

Yoga mat and manufacturing method thereof

ActiveCN105498148AEnhanced Surface IndiaSolve the problem of poor color fastnessShock absorber matsPolyesterDioctyl terephthalate

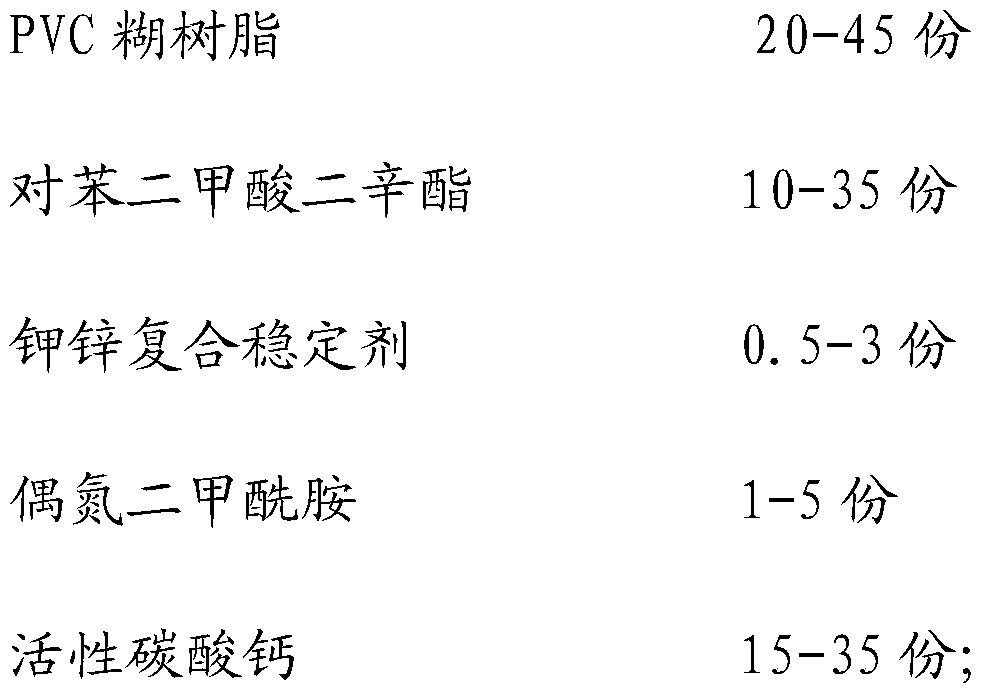

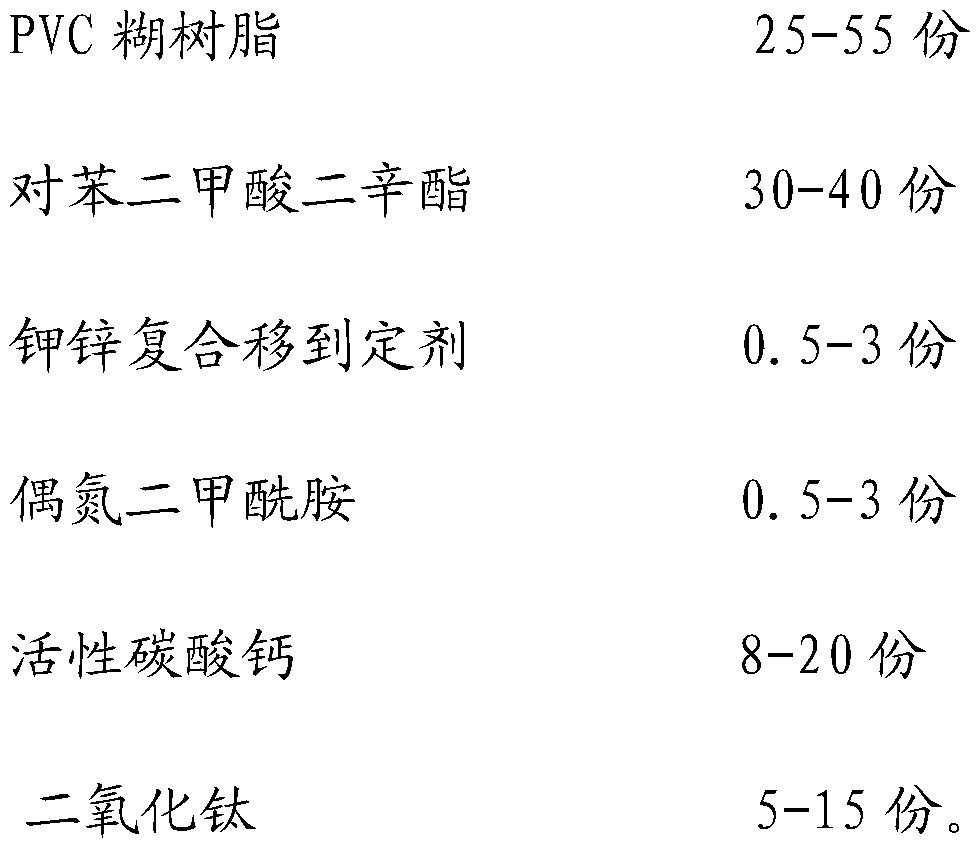

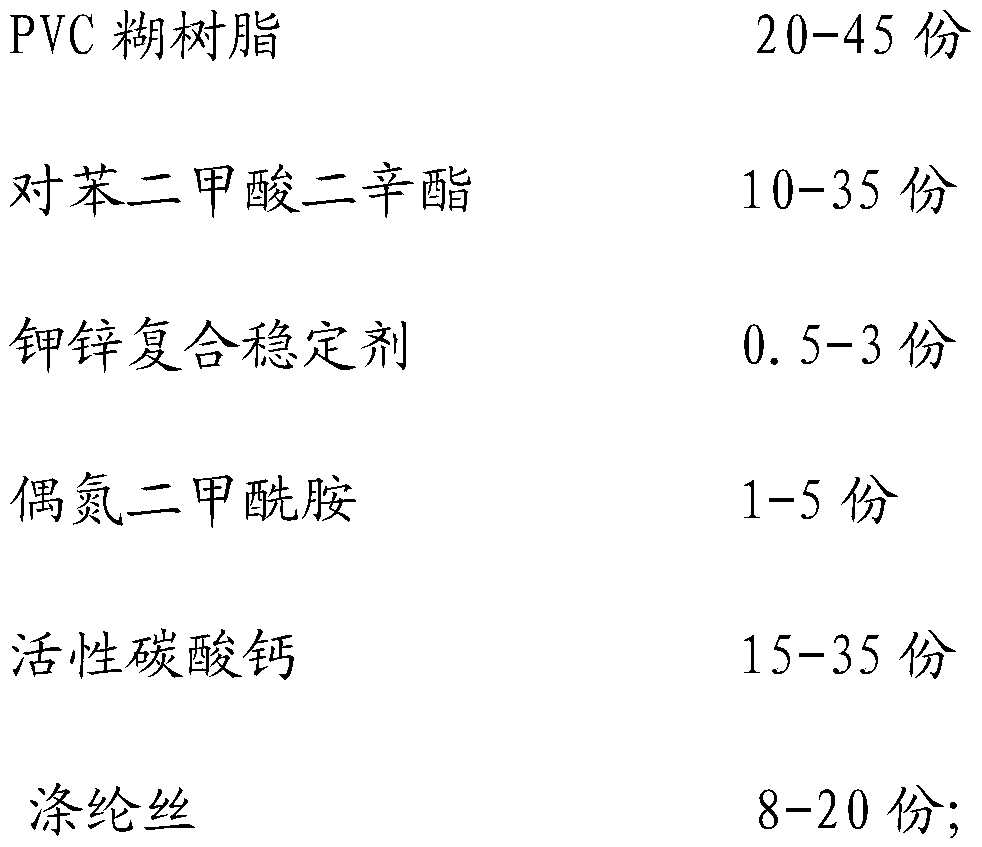

The invention discloses a yoga mat and a manufacturing method thereof. The yoga mat comprises a lining cloth layer, a foaming layer compounded on the lining cloth layer, and a wearing layer compounded on the foaming layer, wherein the lining cloth layer is a layer of lining cloth, and the lining cloth is formed by weaving polyester silk; the foaming layer is prepared by foaming the following components in parts by weight: 20-45 parts of polyvinyl chloride (PVC) paste resin, 10-35 parts of dioctyl terephthalate, 0.5-3 parts of potassium-zinc complex stabilizer, 1-5 parts of azodicarbonamide and 15-35 parts of activated calcium carbonate; the wearing layer is prepared by foaming the following components in parts by weight: 25-55 parts of PVC paste resin, 30-40 parts of dioctyl terephthalate, 0.5-3 parts of potassium-zinc complex stabilizer, 0.5-3 parts of azodicarbonamide, 8-20 parts of activated calcium carbonate and 5-15 parts of titanium dioxide. According to the yoga mat, the wearing layer is additionally arranged, so that the problem that the color fastness of patterns on the surface of the conventional yoga mat is poor can be solved; furthermore, the traditional silk-screen method or intaglio printing method is replaced by a heat transfer method, so that the pattern content and colors on the surface of the product are richer.

Owner:广州市优伟家居用品有限公司

Transparent and environment-friendly PVC modified material and preparation method thereof

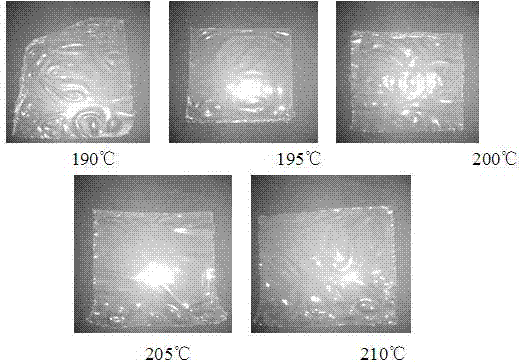

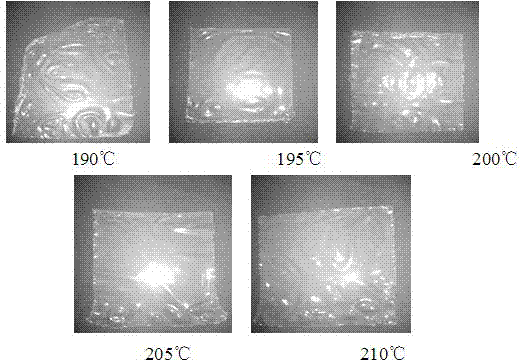

The invention relates to the technical field of PVC (polyvinyl chloride) modified materials, in particular to a transparent and environment-friendly PVC modified material and a preparation method thereof. The modified material PVC resin comprises the following raw materials by weight: 80-120 parts of PVC resin, 60-100 parts of a plasticizer, 1-3 parts of a heat stabilizer, and 0.5-1.5 parts of a lubricant. The plasticizer is a mixture of dioctyl terephthalate and diisononyl cyclohexane-1, 2-dicarboxylate in a weight ratio of 2-4:1. The heat stabilizer is a mixture composed of (RCOO)2Ba and (RCOO)2Zn in a mole ratio of 1.4-2.2:1, wherein R is alkyl of C8-C24 or alkenyl of C6-C24. The material provided by the invention has high transparency, high light transmittance up to 93-95%, and is environment-friendly. The preparation method involved in the invention has the characteristics of simple process, convenient operation control, stable quality and high production efficiency, and can be used for large scale industrialized production.

Owner:广东祺龙科技有限公司

Method for synthesizing dioctyl terephthalate through esterification

ActiveCN102001948AEasy to recycleIncrease reaction rateOrganic compound preparationCarboxylic acid esters preparationDioctyl terephthalateChloride

The invention discloses a method for synthesizing dioctyl terephthalate through esterification, which is characterized by taking terephthalic acid and 2-ethylhexanol as raw materials, and synthesizing dioctyl terephthalate through esterification by using a chloride butyl pyridine stannous chloride ionic liquid as a catalyst. The synthesis method of the invention has the characteristics of quick response speed, high conversion rate, reusable catalyst, no pollution and environmental protection.

Owner:HUAQIAO UNIVERSITY

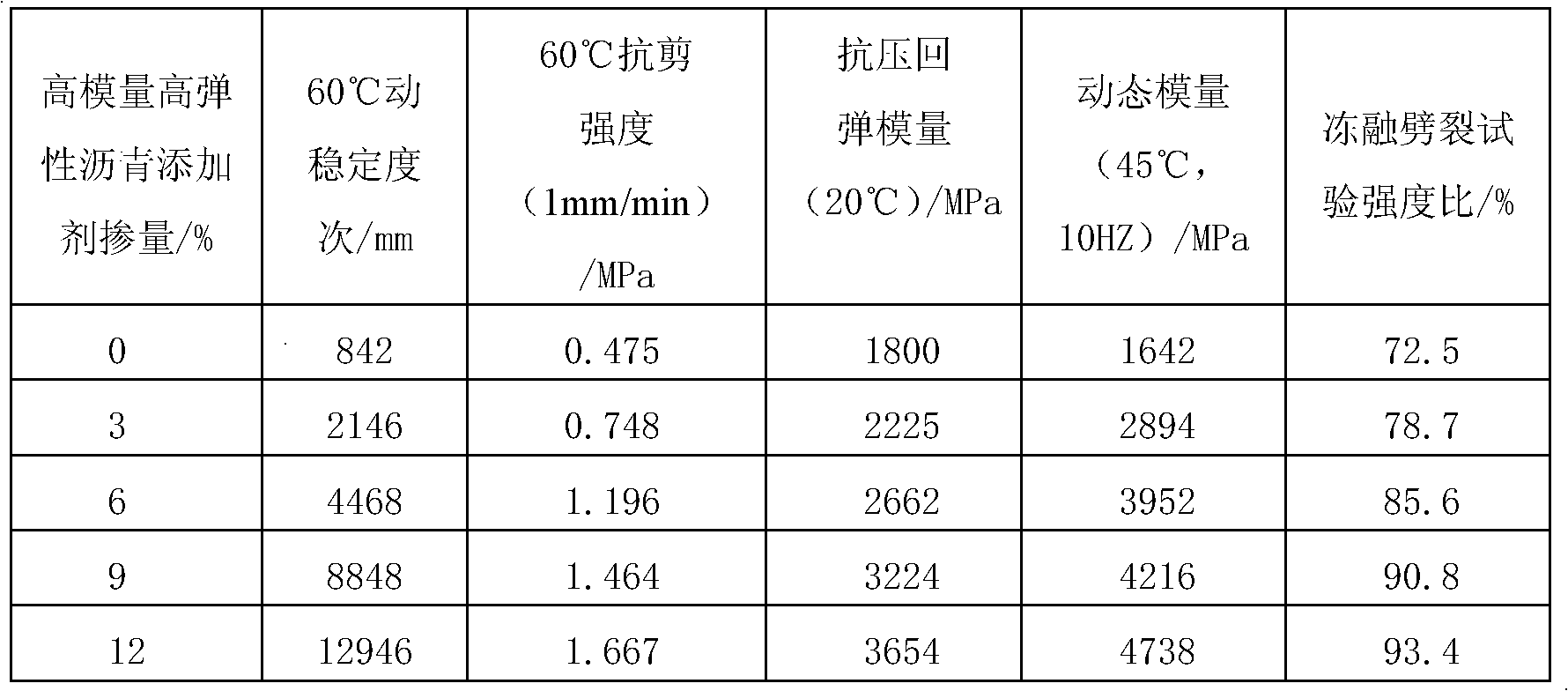

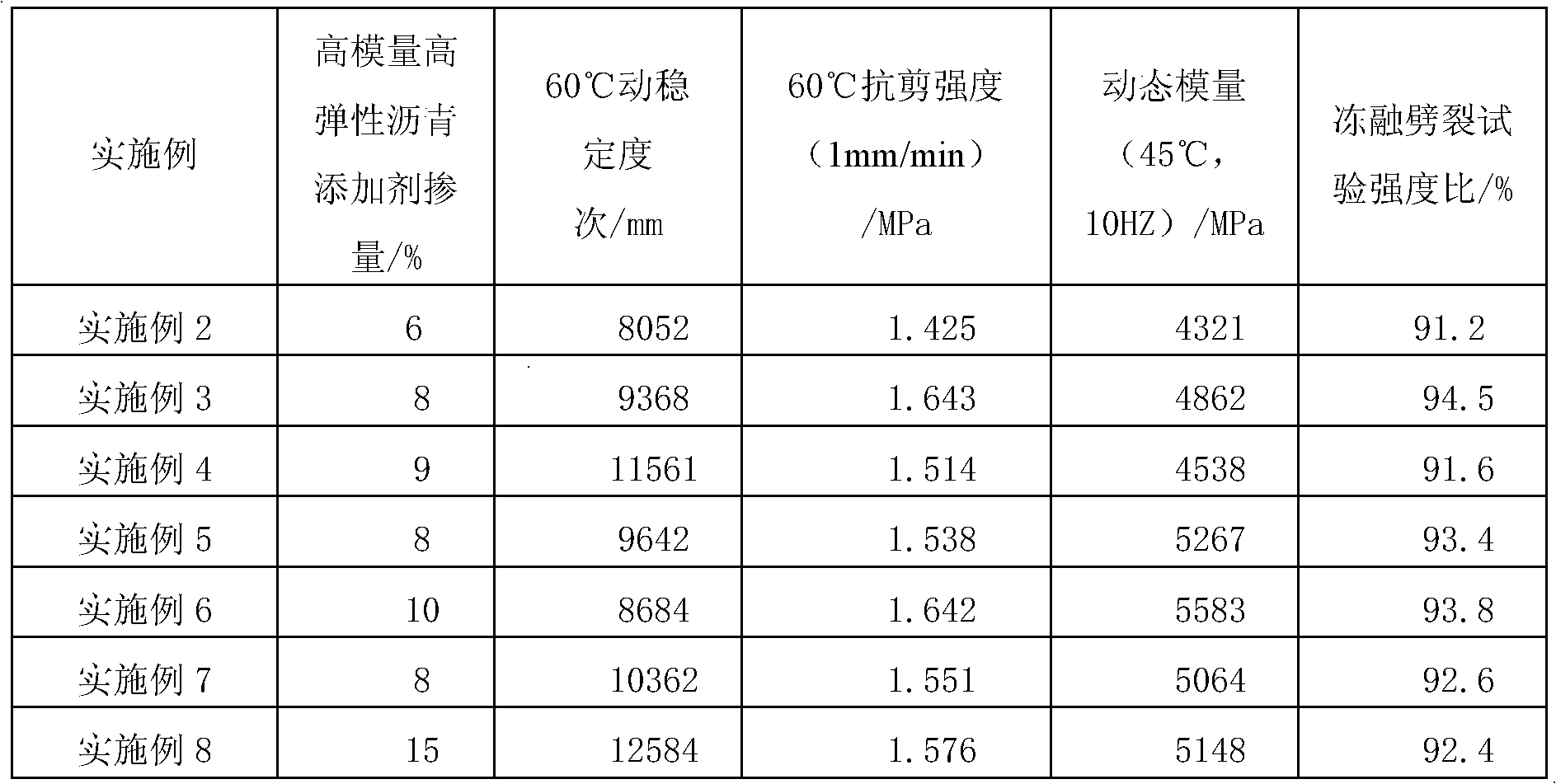

High-modulus and high-elasticity asphalt additive, preparation method thereof and application thereof

ActiveCN102199360ASolve the problem of difficult meltingImproves rutting resistanceBuilding insulationsLow-density polyethylenePolymer science

The invention discloses a high-modulus and high-elasticity asphalt additive, a preparation method thereof and application thereof. The high-modulus and high-elasticity asphalt additive comprises the following components in part by mass: 100 parts of polymer resin, 40 to 60 parts of filler and 20 to 40 parts of softener, wherein the polymer resin is a mixture of low-density polyethylene, high-density polyethylene and polycarbonate in a mass ratio of (1-1):(0.1-2):(0.05-0.5); the softener is dioctyl terephthalate; and a promoter is dibenzyl dithiocarbamate zinc. The preparation method comprisesthe following steps of: mixing the polymer resin and the filler uniformly at the temperature of between 145 and 170 DEG C; and adding the softener, an ultraviolet light screening agent and the promoter into a material obtained in the step a, and mixing uniformly at the temperature of between 180 and 195 DEG C and granulating, wherein the mixing amount can be selected according to different road sections. By the high-modulus and high-elasticity asphalt additive, the wheel rutting resistant performance, low-temperature performance and shear-resistant performance are better improved.

Owner:JIANGSU SOBUTE NEW MATERIALS +2

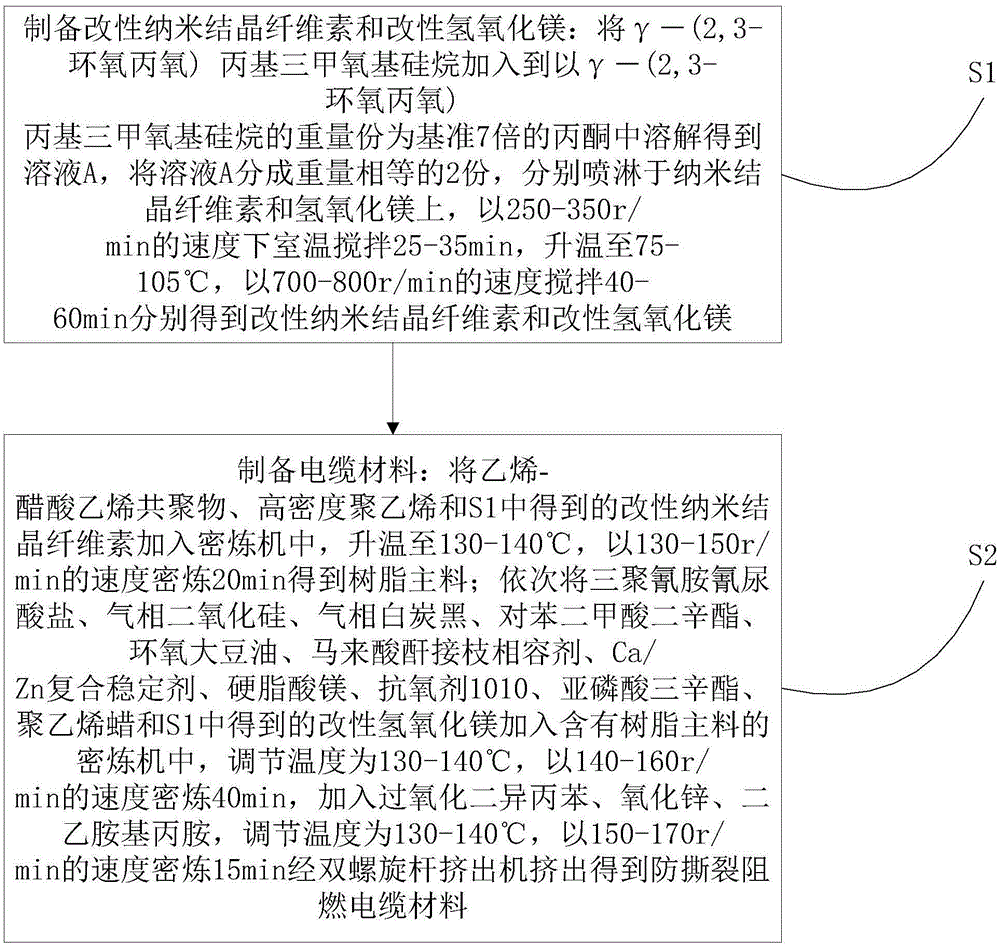

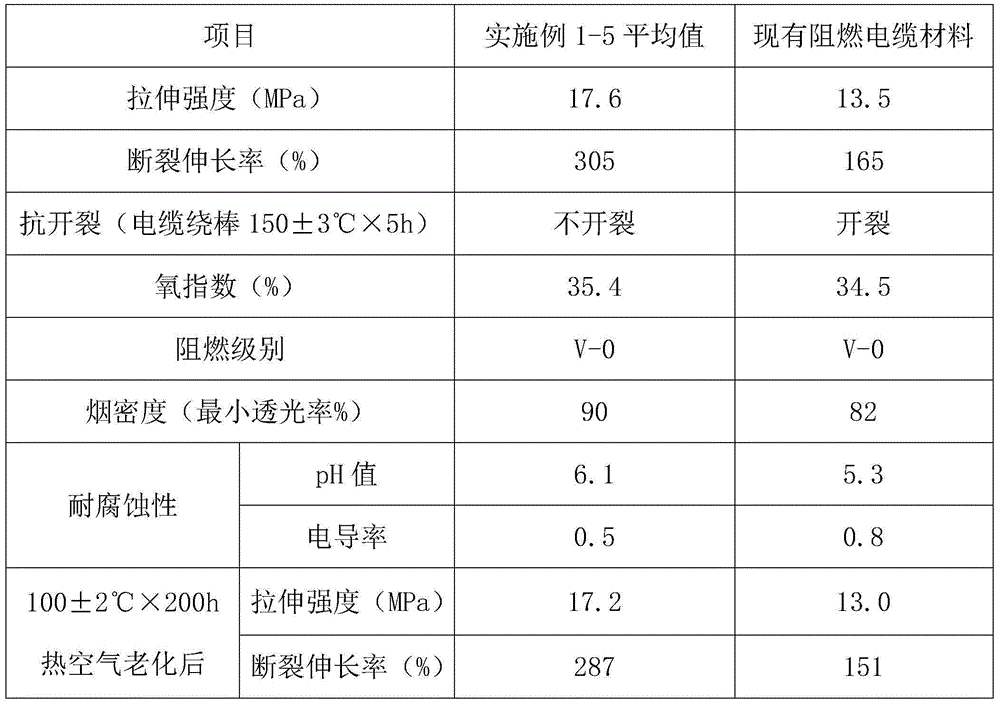

Anti-tearing flame-retardant cable material and method for manufacturing same

InactiveCN105153529AHigh grafting rateImprove adsorption capacityPlastic/resin/waxes insulatorsPhosphorous acidGas phase

The invention discloses an anti-tearing flame-retardant cable material. The anti-tearing flame-retardant cable material comprises, by weight, 70-80 parts of ethylene-vinyl acetate copolymers, 20-30 parts of high-density polyethylene, 30-50 parts of gas-phase white carbon black, 10-15 parts of nano crystalline cellulose, 3-4 parts of gamma-(2, 3-trimethoxysilyl) propyl methacrylate, 40-50 parts of magnesium hydroxide, 1-3 parts of melamine cyanurate, 3.5-4.5 parts of gas-phase silicon dioxide, 15-30 parts of dioctyl terephthalate, 15-30 parts of epoxy soybean oil, 0.4-1 part of dicumyl peroxide, 0.5-1.5 parts of zinc oxide, 0.5-1.5 parts of diethylin propylamine, 5-10 parts of maleic anhydride grafting compatilizer, 2-4 parts of Ca / Zn compound stabilizers, 1-2 parts of magnesium stearate, 0.1-0.3 part of antioxidants 1010, 0.1-0.2 part of trioctylphosphine phosphorous acid ester and 1-3 parts of polyethylene wax. The invention further discloses a method for manufacturing the anti-tearing flame-retardant cable material.

Owner:无为县茂林电缆材料有限公司

Method for producing dioctyl terephthalate from polyester waste

InactiveCN102241592AAvoid disadvantagesWide variety of sourcesPreparation by ester-hydroxy reactionHydroxy compound separation/purificationPolyesterIndustrial waste water

The invention provides a method for producing dioctyl terephthalate from PET (Polyester) waste, belonging to the technical field of plasticizers. The method is implemented by the following steps of: coarsely crushing PET waste, cleaning and drying to obtain a clean PET material; adding the clean PET material and industrial octanol into a reaction kettle in a certain ratio and undergoing an ester exchange reaction under the action of a catalyst; returning the industrial octanol into the reaction kettle by dealcoholization for recycling to obtain crude dioctyl terephthalate; and adding a decoloring agent and a filter aid, fully stirring and filtering with a filter press to obtain finished dioctyl terephthalate. In the method, PET waste is taken as a raw material, the raw material is readily available, a new measure is provided for the recycling of the PET waste, and the requirement for recycling economy is met; and alkali neutralizing and water washing procedures are eliminated in the process flow, the defect of the production of a large amount of industrial waste water in the reaction process existing in the prior art is overcome, the production process is simple and the cost is low.

Owner:WUDI YONGXIN BIO ENG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com