Patents

Literature

78results about How to "Shrink well" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

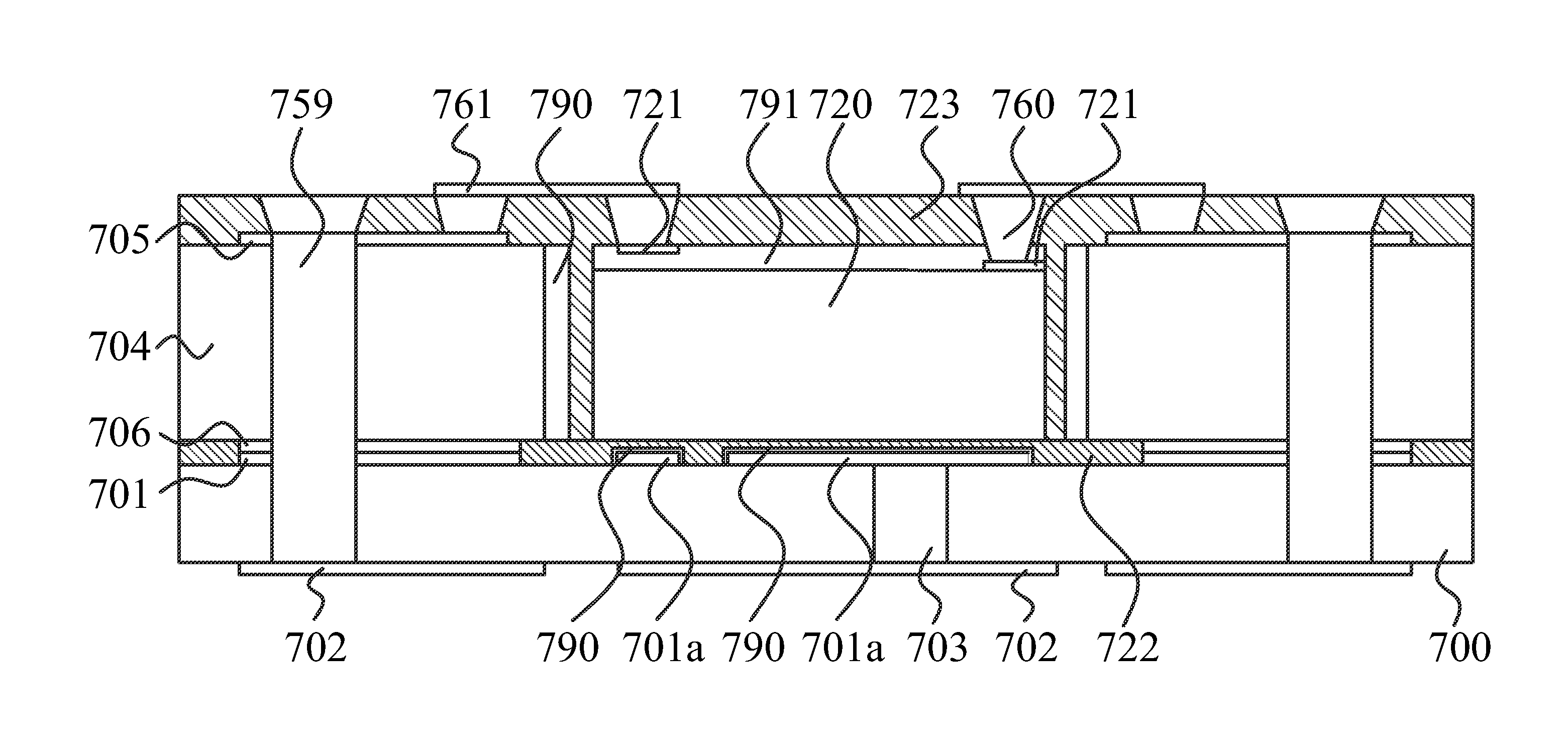

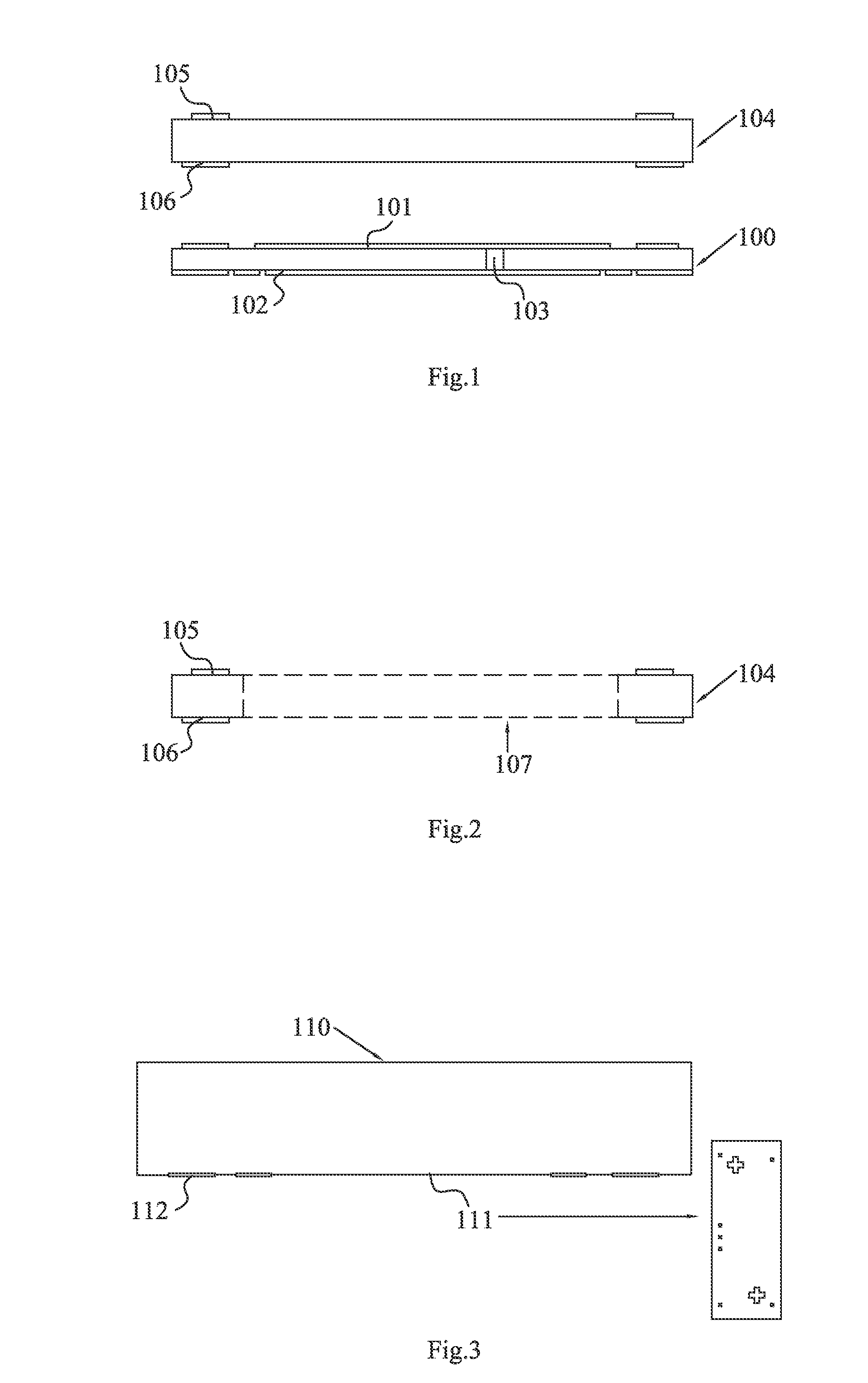

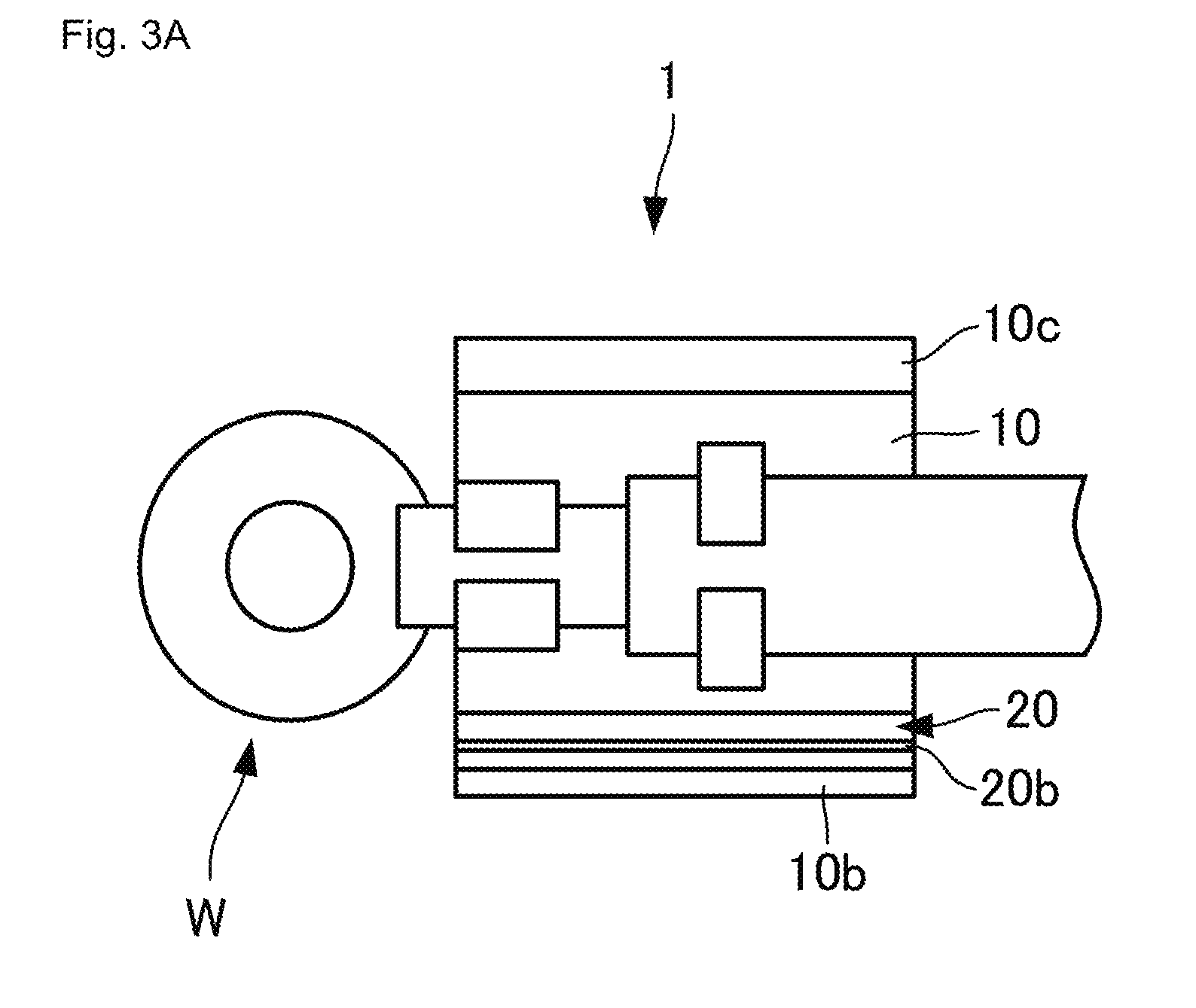

Semiconductor Device Package Structure and Method for the Same

InactiveUS20100301474A1Shrink wellShrinkage sizeSemiconductor/solid-state device detailsSolid-state devicesRedistribution layerPunching

The present invention discloses a semiconductor device package and the method for the same. The method includes preparing a first substrate and a second substrate; opening a die opening window through the second substrate by using laser or punching; preparing an adhesion material; attaching the first substrate to the second substrate by the adhesion material; aligning a die by using the aligning mark of the die metal pad and attaching the die onto the die metal pad with force by the adhesion material; forming a first dielectric layer on top surfaces of the second substrate and the die and pushing the first dielectric layer into gap between the side wall of the die and the side wall of the die opening window under vacuum condition; opening a plurality of via openings in the first dielectric layer; and forming a redistribution layer in the plurality of via openings and on the first dielectric layer.

Owner:KING DRAGON INT

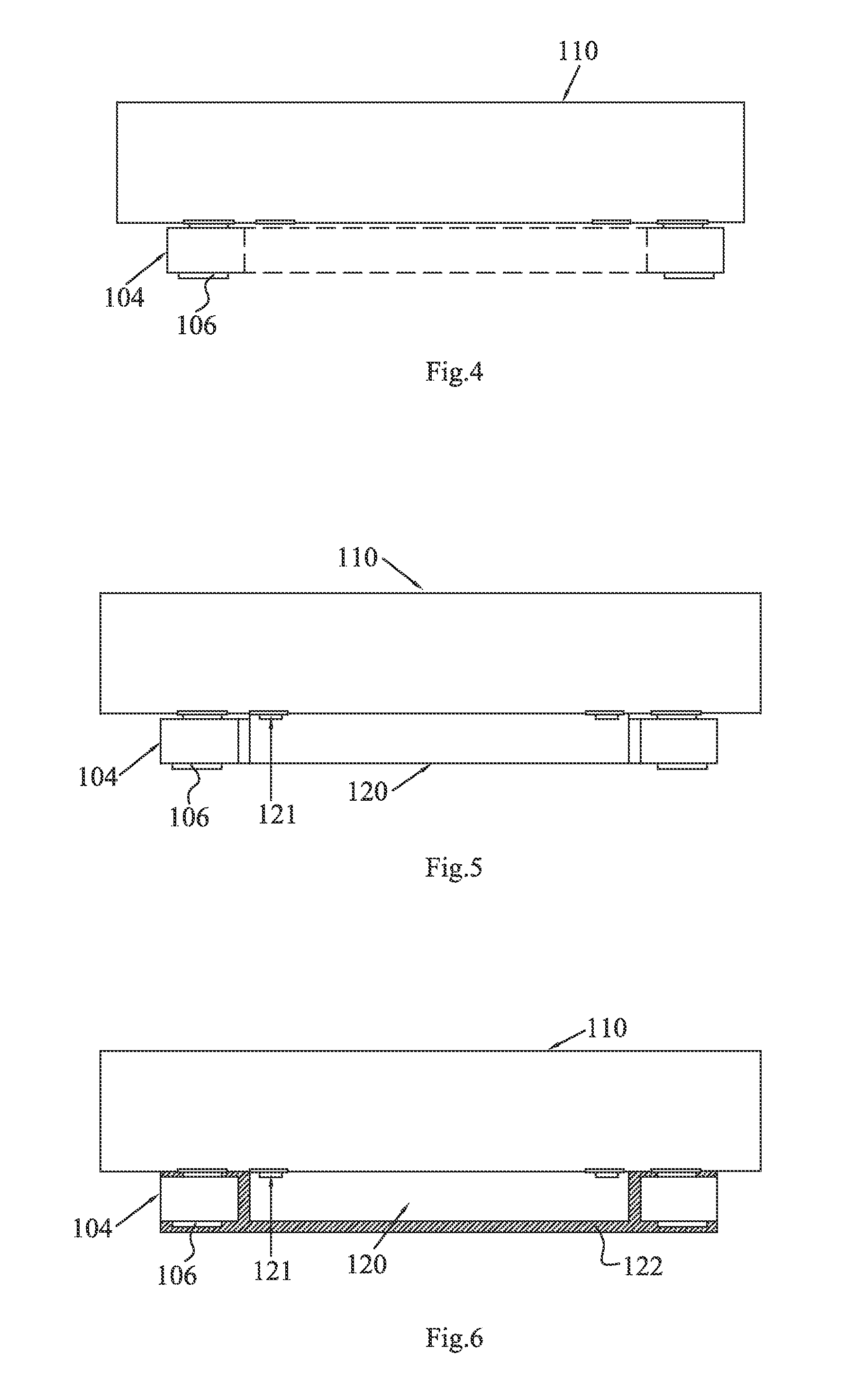

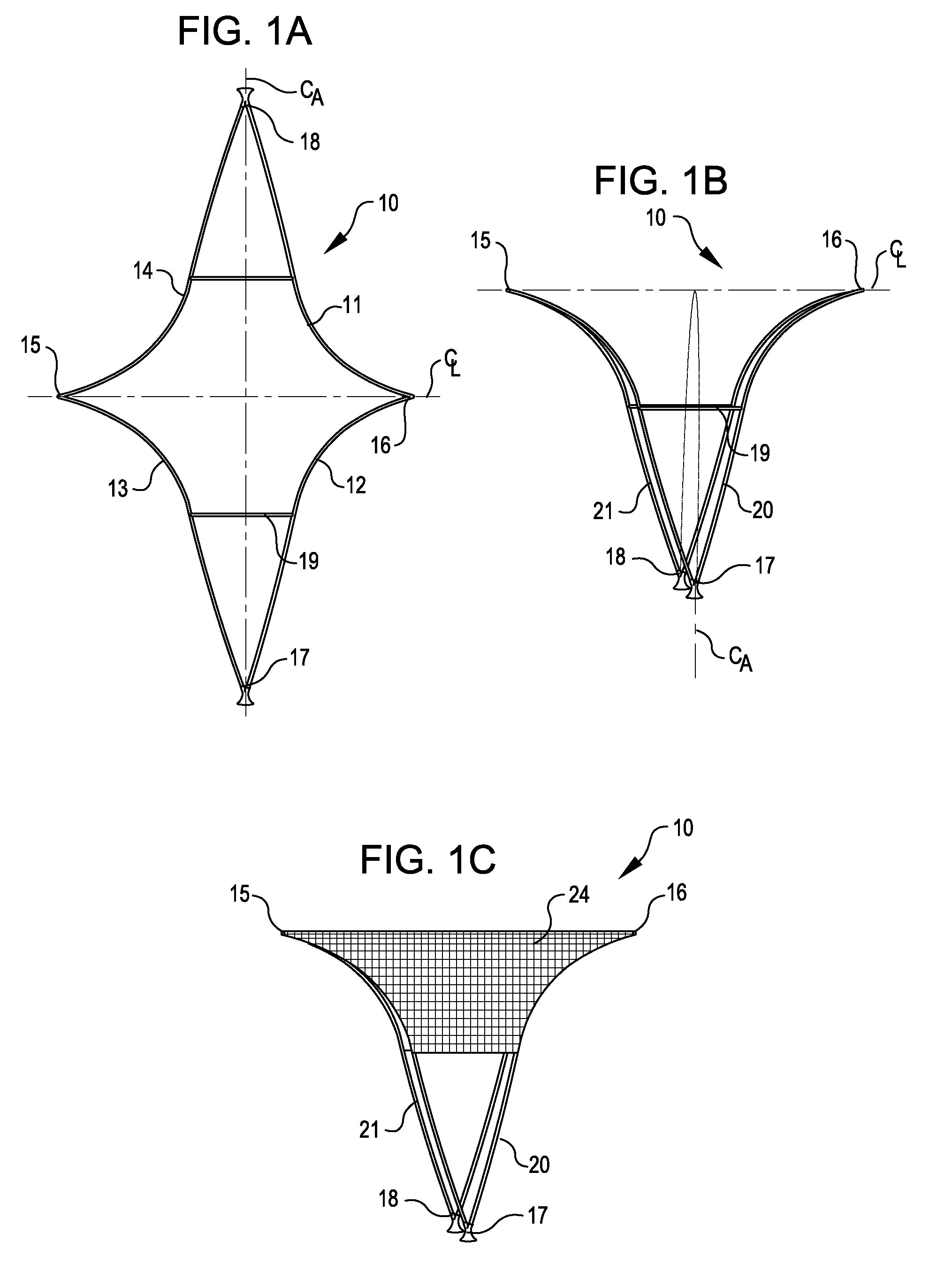

Systems and methods for supporting or occluding a physiological opening or cavity

ActiveUS20100094335A1Promote re-endothelializationPromote tissue growthStentsDilatorsImplanted deviceEngineering

Implantable devices for placement at a cavity or opening such as an aneurysm are disclosed. The implantable devices, in a deployed condition, have a generally inverted U-shaped profile with a curved or angled framework support structure sized and configured for placement in proximity to tissue surrounding the opening and anchoring legs extending proximally from the framework structure sized and configured to contact the wall of a neighboring lumen at opposed locations. Occlusive and semi-occlusive membranes may be associated with the framework support structure and deployed over the opening to provide exclusion of the opening and flow diversion. Proximal anchoring segments providing additional lumen wall surface area contact for the implantable device following deployment may be incorporated.

Owner:PULSAR VASCULAR

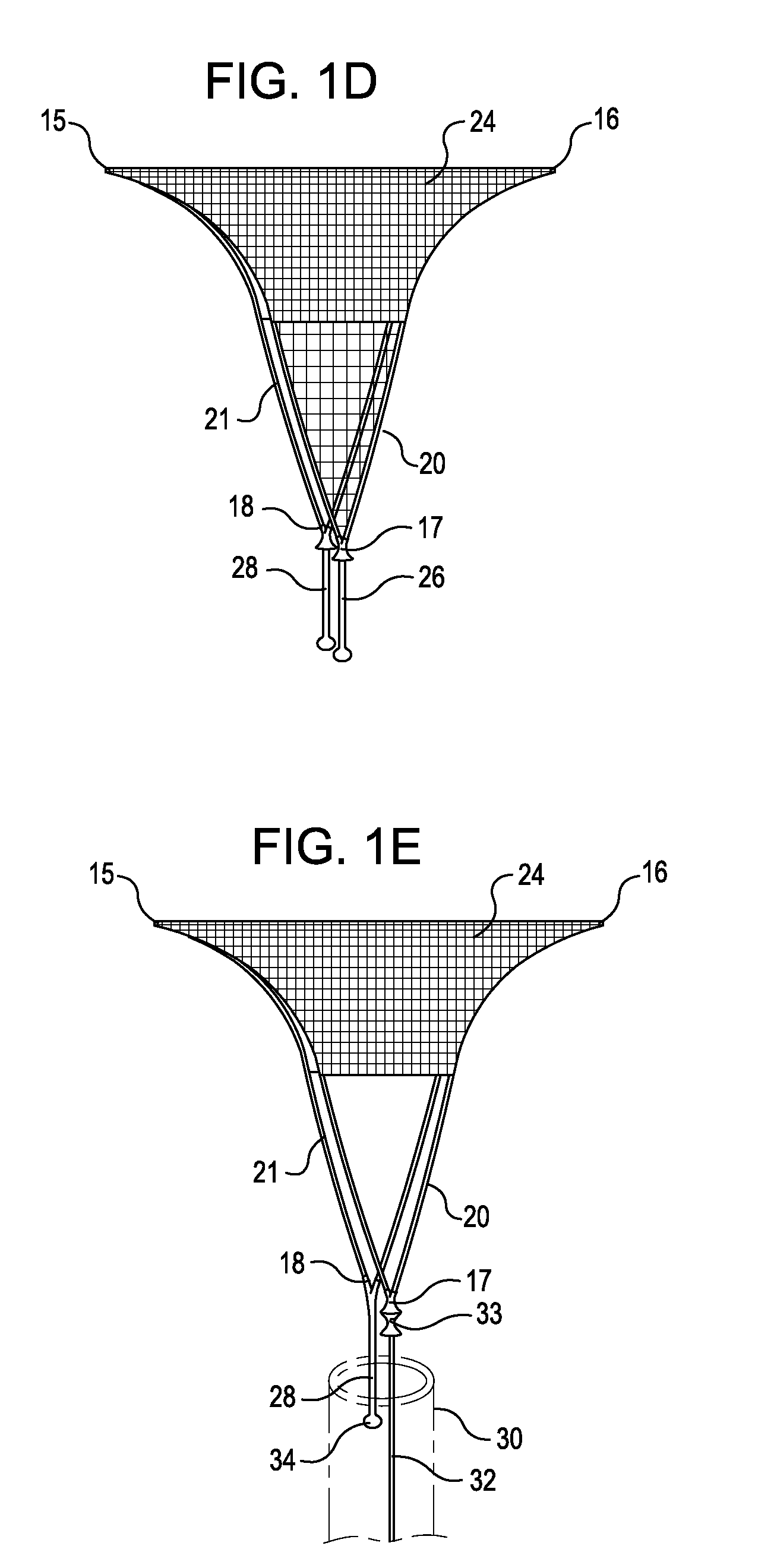

One-step method production process of ultra-low contract terylene industry fiber

ActiveCN101407942AGuaranteed uniformityLow Dry Heat ShrinkageMelt spinning methodsFilament-forming treatmentSolid phasesMelt spinning

The invention discloses a one-step production technology of ultra-low shrinkage terylene industrial fibers, which comprises the steps as follows: A. the preparation of high-viscosity chips: the high-viscosity chips with the viscosity of 0.99 plus or minus 0.015 are obtained by the solid phase polymerization of low-viscosity chips; B. melt spinning: the high-viscosity chips are extruded by melting by a screw extruder in a spinning manifold, spun by a spinning component, and shaped by lateral blowing cooling, and pump oiling is carried out by adopting an ester leveling agent with the kinematic viscosity of 20 to 60mm<2> / s at the temperature of 30 DEG C, and the oiling rate is 0.6 plus or minus 0.15 percent; C. heat setting by drawing: heat setting by drawing is carried out firstly by a pre-tension roller, and sequentially by two groups of drawing rollers and three groups of hot rollers for shaping; and D. shaping by winding: products can be obtained by winding by a winding head after the obtained fibers pass through a main network device. In the invention, not only the technology has high production efficiency, but also the dry heat shrinkage value of the obtained ultra-low shrinkage terylene industrial fibers is low and has high strength and excellent combination property.

Owner:ZHEJIANG UNIFULL IND FIBER

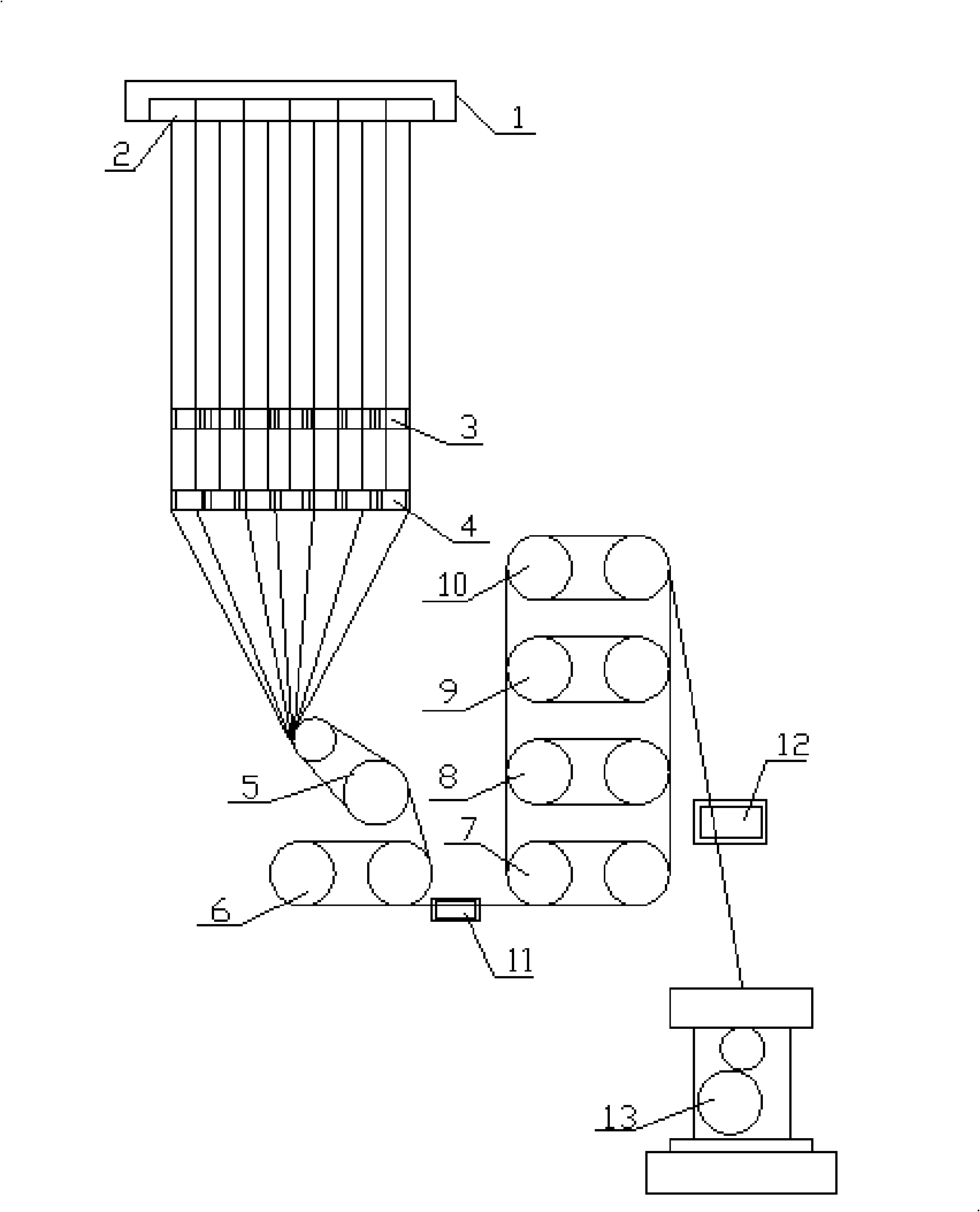

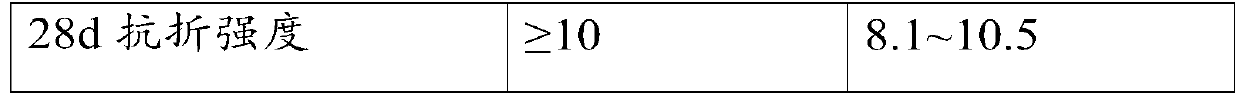

Quick-hardening anti-cracking cement-based self-leveling mortar powder, slurry, mortar and preparation method thereof

PendingCN109836106AImprove initial fluidityNo significant decrease in fluidity after 20 minutesAcid corrosionSlurry

The invention provides quick-hardening anti-cracking cement-based self-leveling mortar powder, slurry, mortar and a preparation method, and relates to the field of building materials. The mortar powder comprises the following raw materials in percentage by weight: 30%-50% of quick-cementing and -hardening high-belite sulphoaluminate cement, 46.19%-51.97% of a fine aggregate, 0.15%-0.3% of a waterreducing agent, 0%-0.04% of a thickening agent, 0.05%-0.2% of a defoaming agent, 0.5%-3.5% of latex powder, 0.075%-0.25% of a retarder and 0.15%-0.3% of a coagulation accelerator. The self-leveling mortar has the excellent properties of acid corrosion resistance, small shrinkage, high tensile bonding strength, high setting and hardening speed and the like, and is suitable for self-leveling floors,industrial floors, civil floors, artistic floors and the like in an acid salt environment.

Owner:TANGSHAN POLAR BEAR BUILDING MATERIAL

Polyolefin Series Heat-Shrinkable Film, Molded Product and Heat-Shrinkable Laminated Label Employing the Film, and Container

ActiveUS20080311320A1Good heat shrinkabilityLow naturalWrappers shrinkageShrinkage connectionsPolymer sciencePolyolefin

The present invention provides a polyolefin series heat-shrinkable film comprising a mixed resin mainly containing a polyolefin series resin (A), polylactic acid series resin (B), and a resin (C) facilitating compatibility with the resin (A) and the resin (B), or comprising at least one layer made of the mixed resin, wherein mass ratio of the resin (A) to the resin (B) is (A) / (B)=99 / 1 to 70 / 30; heat shrinkage ratio of the film at least in one direction when dipped in hot water at 80° C. for 10 seconds is 20% or more; and natural shrinkage ratio of the film when stored at 40° C. under 50% RH environment for 7 days is less than 10%. This polyolefin series heat-shrinkable film exhibits excellent heat-shrinkable property and shrink finishing quality, and inhibits natural shrinkage. This invention also provides a polyolefin series heat-shrinkable label and container on which the heat-shrinkable label is fitted.

Owner:MITSUBISHI CHEM CORP

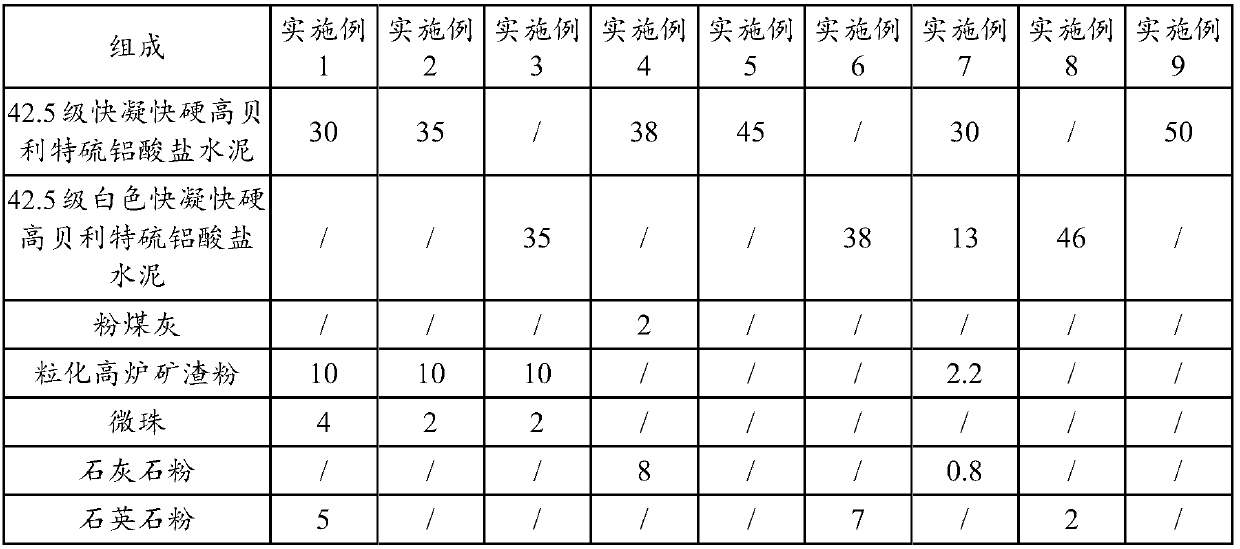

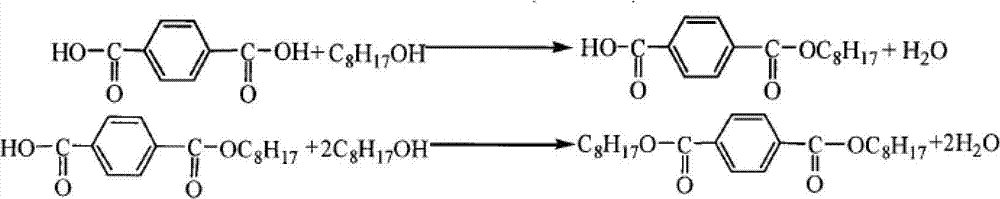

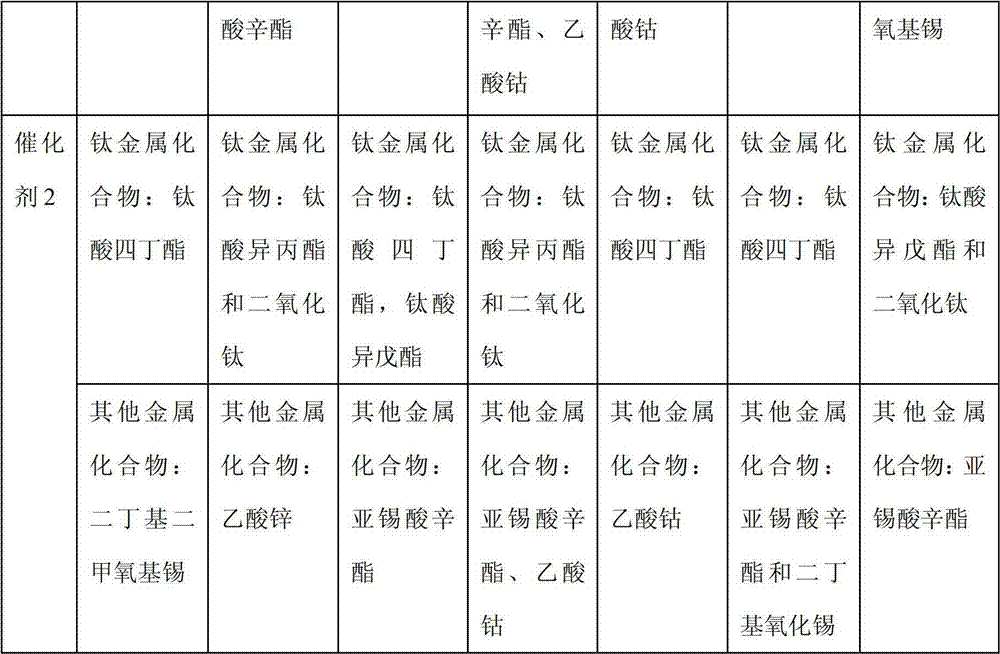

Preparation method of dioctyl terephthalate and used catalyst

InactiveCN102824929AIncrease contact areaShrink wellOrganic compound preparationOrganic-compounds/hydrides/coordination-complexes catalystsDibutyltin oxideTitanium metal

The invention provides a catalyst for use in synthesis of dioctyl terephthalate and a method for preparing dioctyl terephthalate by applying the catalyst. The catalyst consists of a catalyst 1 and a catalyst 2, wherein the catalyst 1 consists of an ionic liquid and a metal compound; the catalyst 2 consists of a titanium metal compound and other metal compound; the positive ion of the ionic liquid are an imidazole ion or a benzimidazole ion; the negative ion of the ionic liquid is a bisulfate ion; or the positive ion of the ionic liquid is a benzimidazole ion or an imidazole ion with one or two sulfonic acid radicals; the titanium metal compound is selected from at least one compound of tetrabutyl titanate, isopentyl ester titanate, isopropyl titanate or titanium dioxide; and the other compound is selected from at least one compound of dibutyldimethoxytin, dibutyltin oxide, monooctyl ester stannite, zinc acetate and cobalt acetate. Due to the adoption of the technical scheme provided by the invention, the cost can be reduced, the reaction speed is increased, energy consumption is lowered, and the quality of an obtained product is high.

Owner:FOSHAN GAOMING XIONGYE CHEM

Powder metallurgy manufacturing method for valve flap of check valve

The invention discloses a powder metallurgy manufacturing method for a valve flap of a check valve. The powder metallurgy manufacturing method comprises the following steps of: a, selecting the following powder raw materials in percentage by weight to form the valve flap through powder metallurgy one-time pressing: balance of iron-base powder, 0.7 percent of carbon, 0.9 percent of molybdenum, 1.1 percent of aluminum, 0.9 percent of magnesium, 0.3 percent of tree ash and 0.8 percent of zinc stearate; and b, placing the valve flap product obtained by sintering and forming into engine oil of No. 20-30 to soak for 2-3 hours, and performing water atomization steam treatment at the temperature of 550-650 DEG C for 3-5 hours. The valve flap is a powder metallurgy material which is mainly made of alloy steel powder and has the characteristics of capabilities of improving the strength, the corrosion resistance and the wear resistance of metal components and reducing the manufacturing cost.

Owner:ANHUI PUYUAN SEPARATION MACHINERY MFG CO LTD

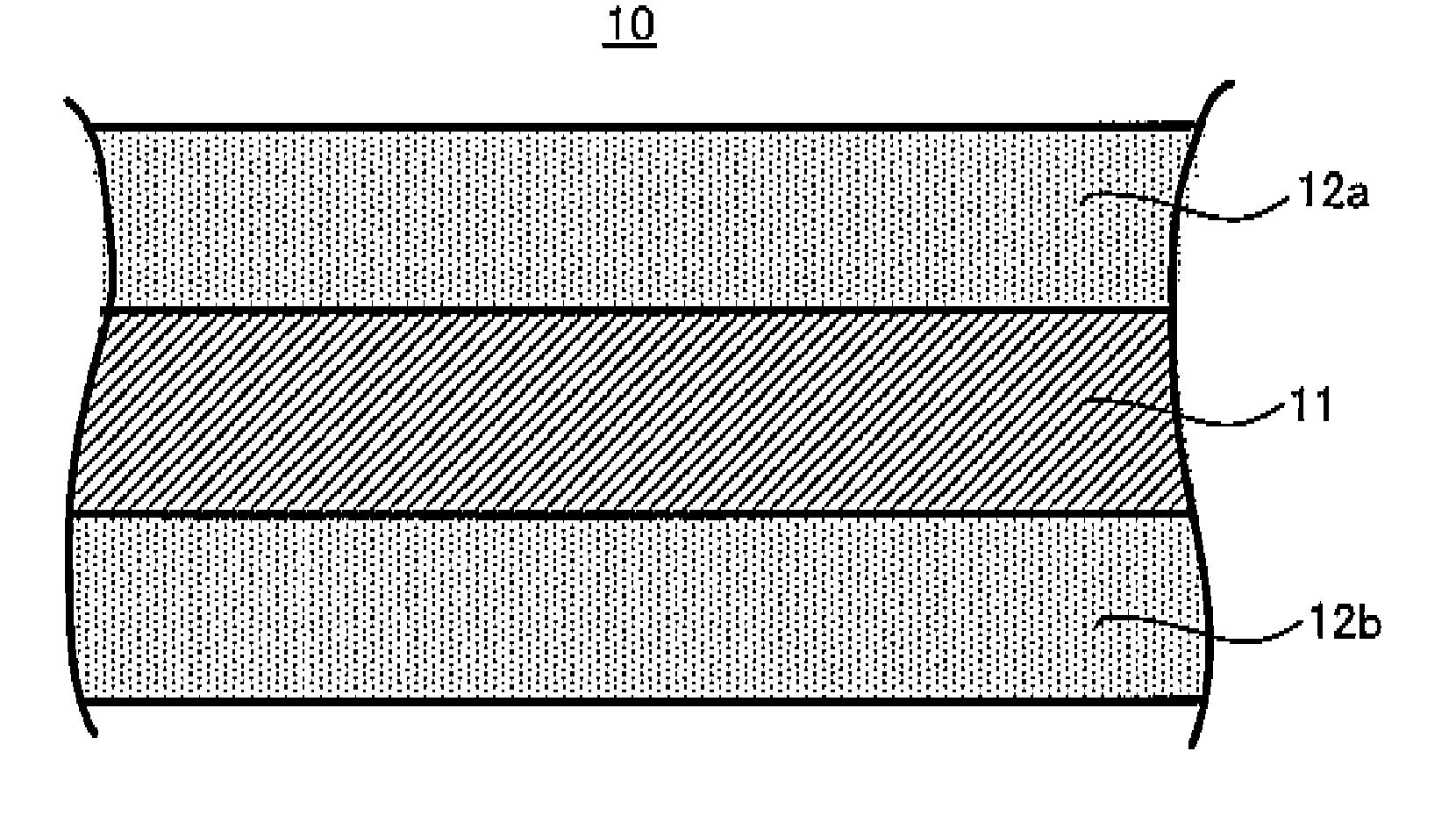

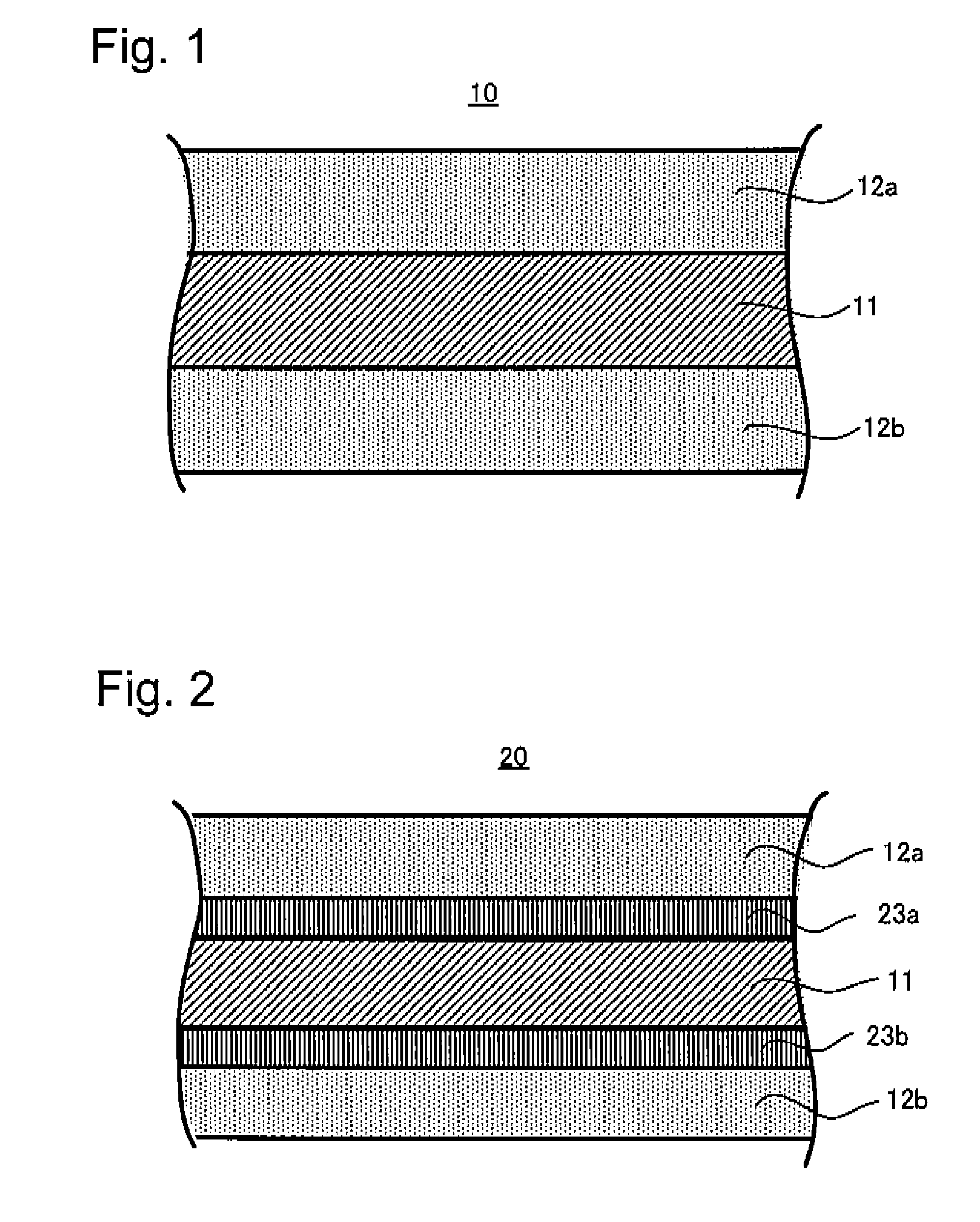

Polyolefin series heat-shrinkable film, molded product and heat-shrinkable laminated label employing the film, and container

ActiveUS8137773B2Good heat shrinkabilityLow naturalWrappers shrinkageSynthetic resin layered productsPolyolefinThermal water

The present invention provides a polyolefin series heat-shrinkable film comprising a mixed resin mainly containing a polyolefin series resin (A), polylactic acid series resin (B), and a resin (C) facilitating compatibility with the resin (A) and the resin (B), or comprising at least one layer made of the mixed resin, wherein mass ratio of the resin (A) to the resin (B) is (A) / (B)=99 / 1 to 70 / 30; heat shrinkage ratio of the film at least in one direction when dipped in hot water at 80° C. for 10 seconds is 20% or more; and natural shrinkage ratio of the film when stored at 40° C. under 50% RH environment for 7 days is less than 10%. This polyolefin series heat-shrinkable film exhibits excellent heat-shrinkable property and shrink finishing quality, and inhibits natural shrinkage. This invention also provides a polyolefin series heat-shrinkable label and container on which the heat-shrinkable label is fitted.

Owner:MITSUBISHI CHEM CORP

Heat-shrinkable laminated film, molded product and heat shrinkable label and container, employing the film

InactiveUS20090202758A1Improve suppression propertiesQuality improvementStampsWrappers shrinkagePolymer scienceDynamic viscoelasticity

The present invention provides a heat-shrinkable laminated film having at least three layers including: a (I) layer; and two (II) layers respectively disposed on each surface of the (I) layer, the (I) layer being composed by a layer containing at least one polyolefin series resin as a main component and the (II) layer being composed by a layer containing at least one polylactic acid series resin as a main component, and the storage elastic modulus (E′) of the laminated film at 80° C. being 10 MPa or more and 1,000 MPa or less when dynamic viscoelasticity about a direction orthogonal to the film's main shrinking direction is measured under a condition of vibrational frequency at 10 Hz, strain at 0.1%. The film of the invention exhibits excellent shrink finishing quality, heat-shrinkage property at low temperature, and small natural shrinkage; thereby suitably used for shrinkable packing, shrinkable banding packing, shrinkable label and the like.

Owner:MITSUBISHI PLASTICS INC

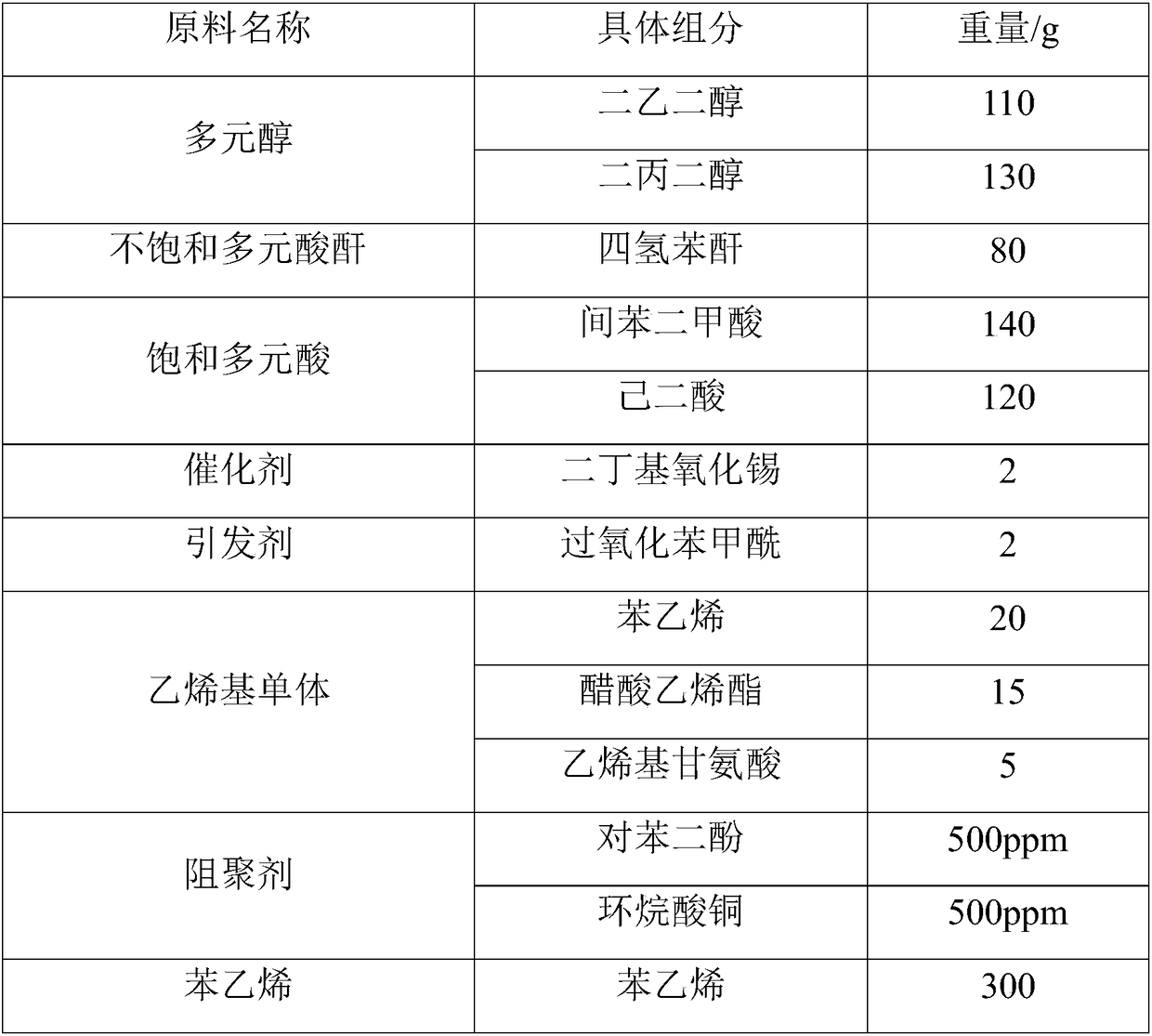

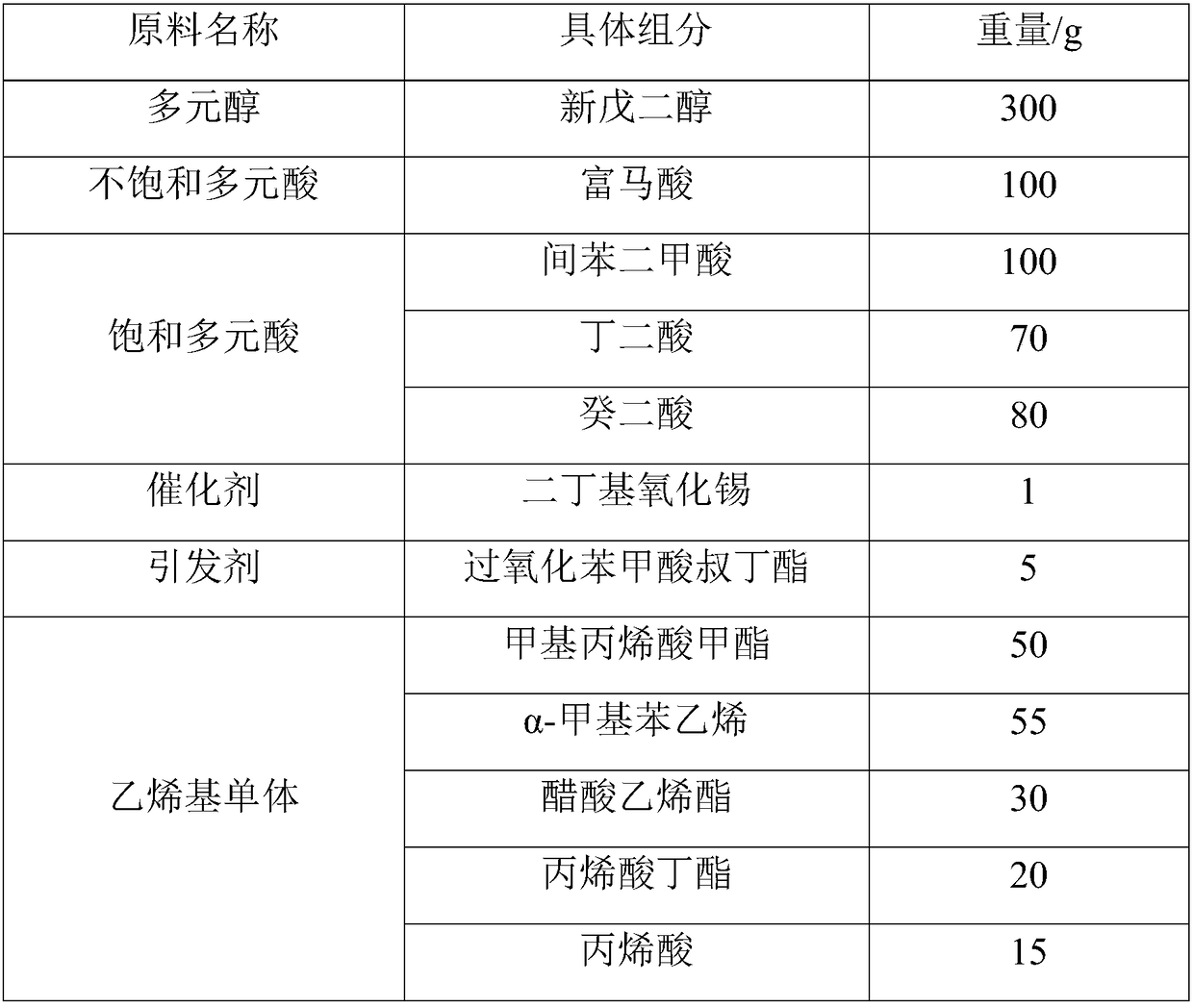

Vinyl monomer-modified polyester resin and anti-shrinking agent, and preparation methods thereof

The invention discloses vinyl monomer-modified polyester resin and an anti-shrinking agent, and preparation methods thereof. A preparation method for the vinyl monomer-modified polyester resin comprises the following steps: subjecting polyol, saturated polyatomic acid or acid anhydride and unsaturated polyatomic acid or acid anhydride to polymerization under the action of a catalyst so as to obtain unsaturated polyester resin; and reacting vinyl monomer with the unsaturated polyester resin under the action of an initiator. The preparation method for the anti-shrinking agent comprises a step ofmixing the vinyl monomer-modified polyester resin, styrene and a polymerization inhibitor. The anti-shrinking agent prepared from the vinyl monomer-modified polyester resin has excellent low shrinkage, toughness, mechanical strength and waterproofness, can substantially improve the stainability of products, overcomes the problem of color bleeding of products, and allows products to have A-grade surface effect; moreover, the anti-shrinking agent has excellent thickening capability and can coordinate with a variety of resin to realize effective thickening so as to allow the resin to reach SMC / BMC construction viscosity.

Owner:CHANGZHOU HUAKE POLYMERS

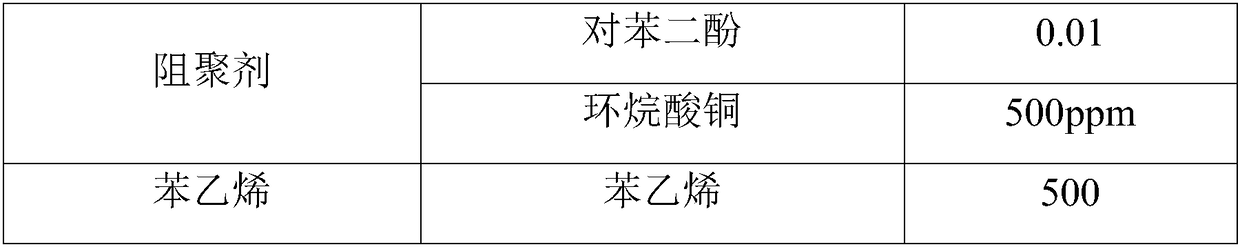

Method for producing permanent ferrite magnet with less shrinkage

InactiveCN108101529AFast sinteringShorten the timeInorganic material magnetismInductances/transformers/magnets manufactureSlurryFilter press

The invention discloses a method for producing a permanent ferrite magnet with less shrinkage. The method comprises following steps: step 1), a main component is added to a ball mill and ground for 4-6 h, and slurry is obtained, wherein the main components comprise constituents in percentage by mass as follows: 10.8%-11.5% of SrCO3, 3.2%-3.7% of La2O3, 1.1%-1.4% of Co2O3 and the balance of Fe2O3,and the sum of all main components in percentage by mass is 100%; step 2), the slurry obtained in the step 1) is stirred with a wet method firstly and subjected to primary mixed grinding, obtained slurry is subjected to filter pressing by a filter press to be dewatered, and water content of the slurry is enabled to be 35%-38%; step 3), the slurry obtained in the step 2) is pumped into a rotary kiln for pre-sintering and subjected to a solid-phase reaction at the temperature of 1230-1260 DEG C, and a permanent ferrite magnet pre-sintered material is obtained; step 4), after the permanent ferrite magnet pre-sintered material obtained in the step 3) is subjected to ball milling to be coarse powder, the coarse powder and additives are mixed uniformly, a mixture is put in the ball mill for secondary fine grinding, and a dispersing agent and an emulsifier are added during secondary ball milling; step 5), fine slurry obtained in the step 4) is subjected to wet press molding, a magnetic shoe blank is obtained and sintered, and the permanent ferrite magnet is obtained.

Owner:HENGDIAN GRP DMEGC MAGNETICS CO LTD

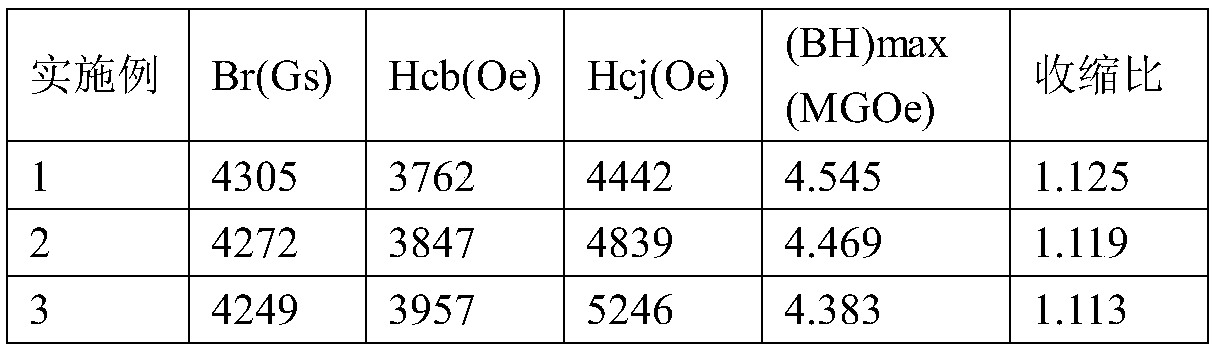

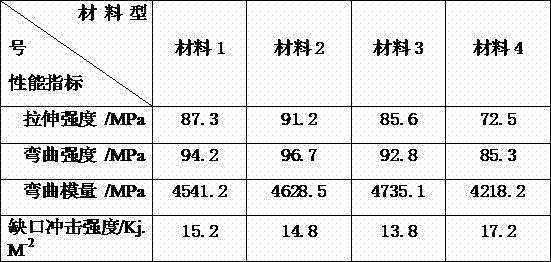

High-temperature-resistant and low-shrinkage polyarylester fiber master batch/polypropylene composite material and preparation method thereof

InactiveCN104693597AHigh impact strengthIncreased flexural modulusPolypropylene compositesLow shrinkage

The invention discloses a high-temperature-resistant and low-shrinkage polyarylester fiber master batch / polypropylene composite material and a preparation method thereof. The polyarylester fiber master batch / polypropylene composite material is prepared by the steps of rapidly and uniformly mixing the following components in parts by weight: 40-60 parts of polypropylene, 20-40 parts of polyarylester fiber master batches, 15-30 parts of a mineral filling agent, 1-3 parts of a compatilizer, 5-15 parts of a flexibilizer, 0.3-0.6 part of an antioxidant and 0.5-1.2 parts of a lubricant, and extruding and granulating by virtue of an extruder. The polyarylester fiber master batch / polypropylene composite material has the advantages of high temperature resistance, low shrinkage and high impact strength and bending modulus and can be widely applied to the fields of electrics, electrons and automobiles and other protection fields.

Owner:HEFEI GENIUS NEW MATERIALS

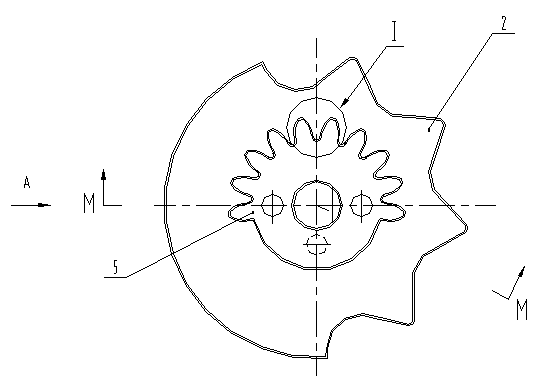

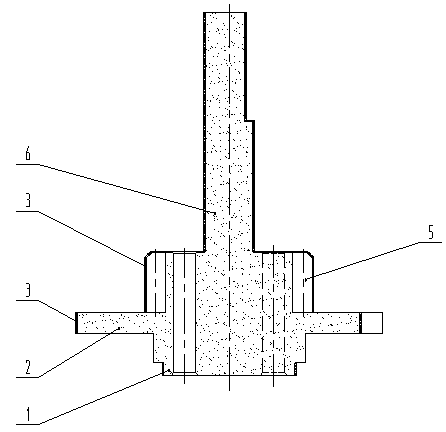

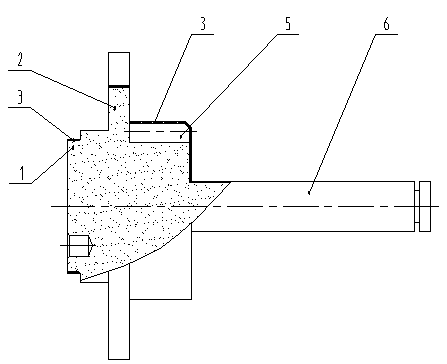

High performance motorcycle engine powder metallurgy gear cam and manufacturing method thereof

InactiveCN103821904AReduce stress concentrationIncrease profitCamsPortable liftingStress concentrationWear resistant

The invention discloses a high performance motorcycle engine powder metallurgy gear cam. The high performance motorcycle engine powder metallurgy gear cam comprising a body made by powder metallurgy for entire structure comprises a bearing journal, a shaft gear, a drive gear mounting journal and drive gears which are located in the same axle and which are arrayed sequentially. The tooth roots of adjacent drive gears are in fillet transition. The outer wall of the bearing journal, the outer wall of the shift gear, the outer wall of the drive gear mounting journal and the outer walls of the drive gears are provided with wear resistant composite layers. According to a preferable technical scheme, the wear resistant composite layers are rare earth compound composite layers. The invention further discloses a manufacturing method of the high performance motorcycle engine powder metallurgy gear cam. The method includes blending, mixing, pressing, sintering, heating, hot forging, finishing and chemical infiltrating procedures. Material utilization rate is high, strength, fatigue resistance and other mechanical properties of the motorcycle engine gear cam can be guaranteed, wear resistance can be guaranteed, and the problem of stress concentration of the tooth roots of the drive gears can be solved.

Owner:TAIZHOU KECHENG AUTOMOBILE PARTS

Dual-component water-based bright colorized tile decorative crack-sealer

The invention discloses a dual-component water-based bright colorized tile decorative crack-sealer. The decorative crack-sealer is prepared from an ingredient A and an ingredient B by mixing according to a weight ratio of 1: 1-2. The ingredient A comprises, by weight, 70-90 parts of epoxy resin, 5-20 parts of an emulsifier, 0.5-2 parts of a rheology modifier, 3-20 parts of a flexible additive and 2-4 parts of a surfactant. The ingredient B comprises, by weight, 50-90 parts of a curing agent, 10-30 parts of pigments with different colors and fillers, 4-30 parts of deionized water, 4-10 parts of a brightening agent, 0.1-1.5 parts of a dispersant, 1-5 parts of a crack-resistant agent, 0.1-2 parts of a thickening agent, 0.1-1.5 parts of a dispersant, 0.25-2 parts of an antifoaming agent, 0.5-2 parts of a leveling agent, 1-5 parts of an anti-settling agent and 2-6 parts of an anti-sagging agent. The decorative crack-sealer has high brightness and high hardness, does not mildew, blacken, shrink, collapse, sag and fall, can resist water, oil stain, acid, alkali, etch, scrubbing and water immersion, has good adhesion and has excellent aesthetic feeling.

Owner:SHANGHAI YOUJIN COMPOSITE NEW MATERIAL CO LTD

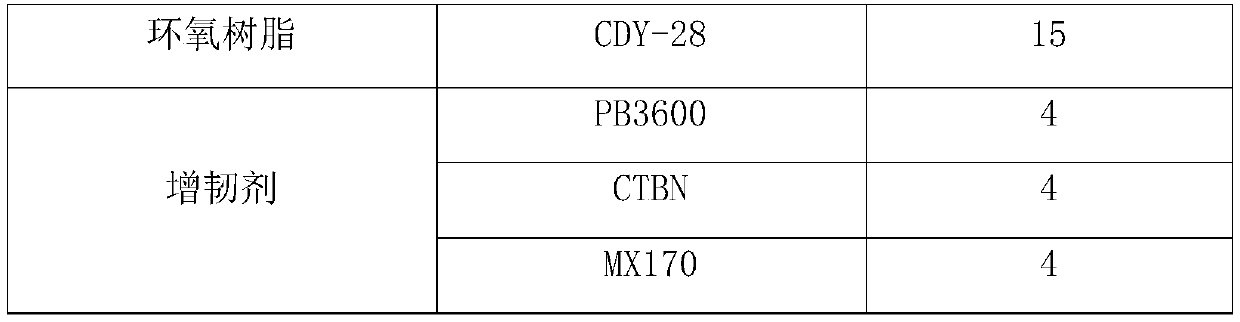

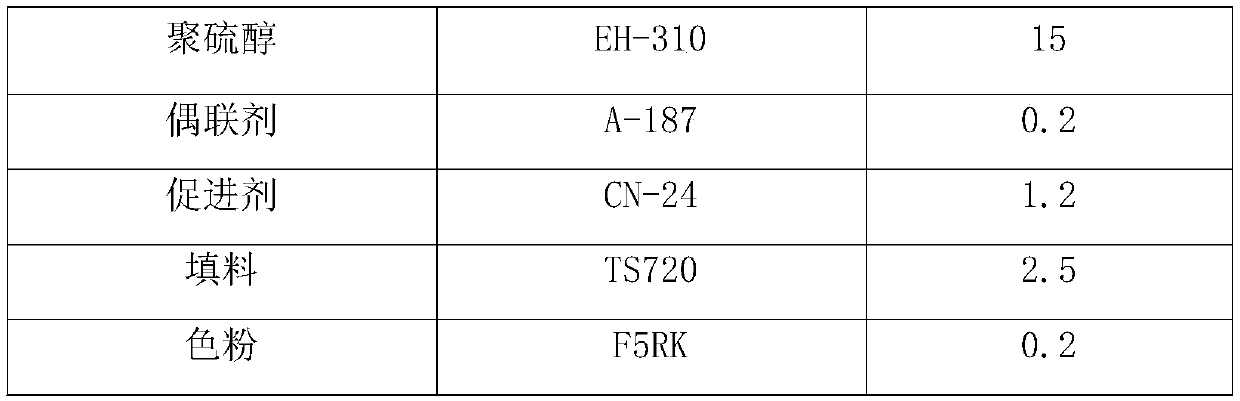

Epoxy adhesive with low-temperature rapid curing

InactiveCN110184011AFast curingSolve the problem that the curing rate is less than 95%Non-macromolecular adhesive additivesEpoxy resin adhesivesThiolWater boil

The invention discloses an epoxy adhesive with low-temperature rapid curing. The epoxy adhesive comprises the following components in parts by weight: 30-40 parts of an epoxy resin, 20-30 parts of a toughening agent, 20-30 parts of a thiol curing agent and 5-10 parts of an aid. Thiol is selected, the problem of stability in an operation period is finally solved through PE1 of Showa Denko, by adjusting amounts of the thiol and a promoter, problems that curing is implemented at a velocity of 95 DEG C / 3 minutes and the curing rate is less than 95% can be solved, the primary adhesiveness is greater than 30MPa, and the retention rate of the adhesiveness is 50% in 16 hours of water boiling at 121 DEG C in a sealed manner.

Owner:上海本诺电子材料有限公司

Acne-removing skin-protection face pack

InactiveCN101427991AShrink wellObvious crustingCosmetic preparationsToilet preparationsNatural productBletilla striata

The invention discloses pox removing and skin caring facial mask which is formed by blending and evenly stirring all ingredients. The facial mask is characterized in that the facial mask comprises ingredients by the following mass ratio: 80 to 120 parts of mung bean powder, 40 to 60 parts of dahurian angelica powder, 80 to 120 parts of white indian bread, 40 to 60 parts of hyacinth bletilla powder, 20 to 40 parts of pearl powder, 10 to 20 parts of glycyrrhiza powder, 20 to 50 parts of milk and 100 parts of egg white. The facial mask is a purely natural product which has good pox removing effect, the effect of preventing poxes and the function of skin moistening and whitening, thereby being very suitable for people suffering from poxes to apply on the faces in summer.

Owner:熊丽

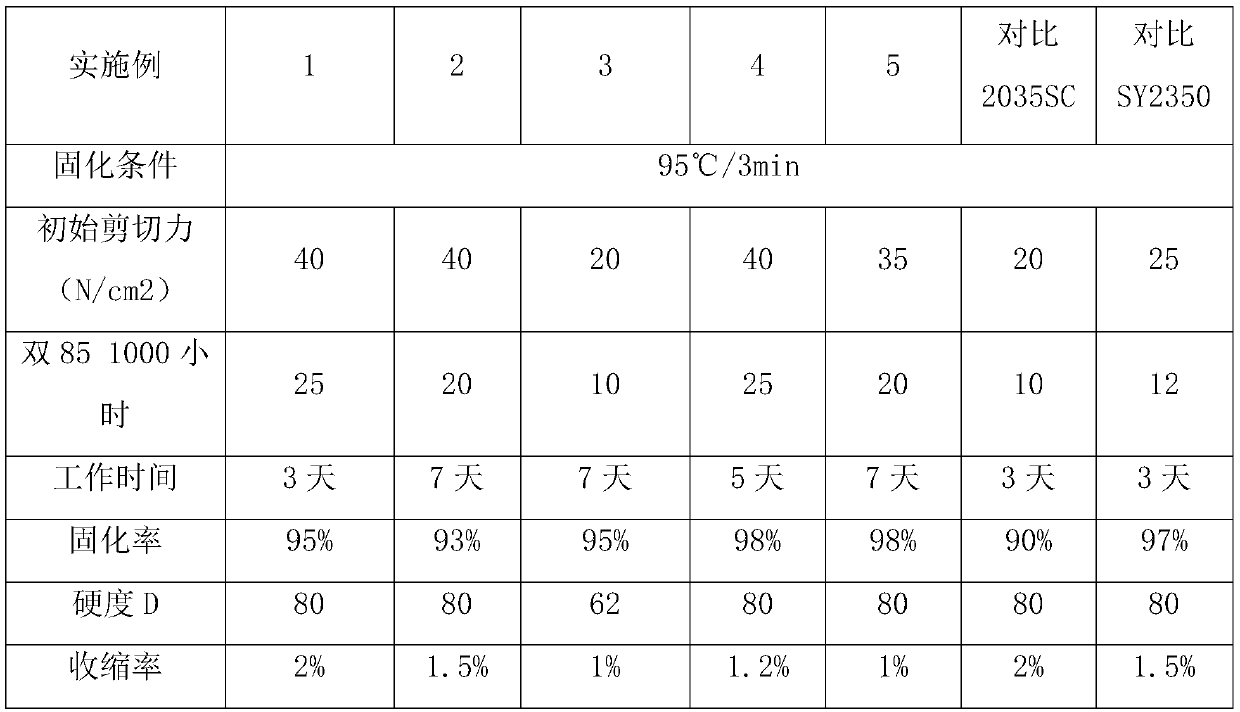

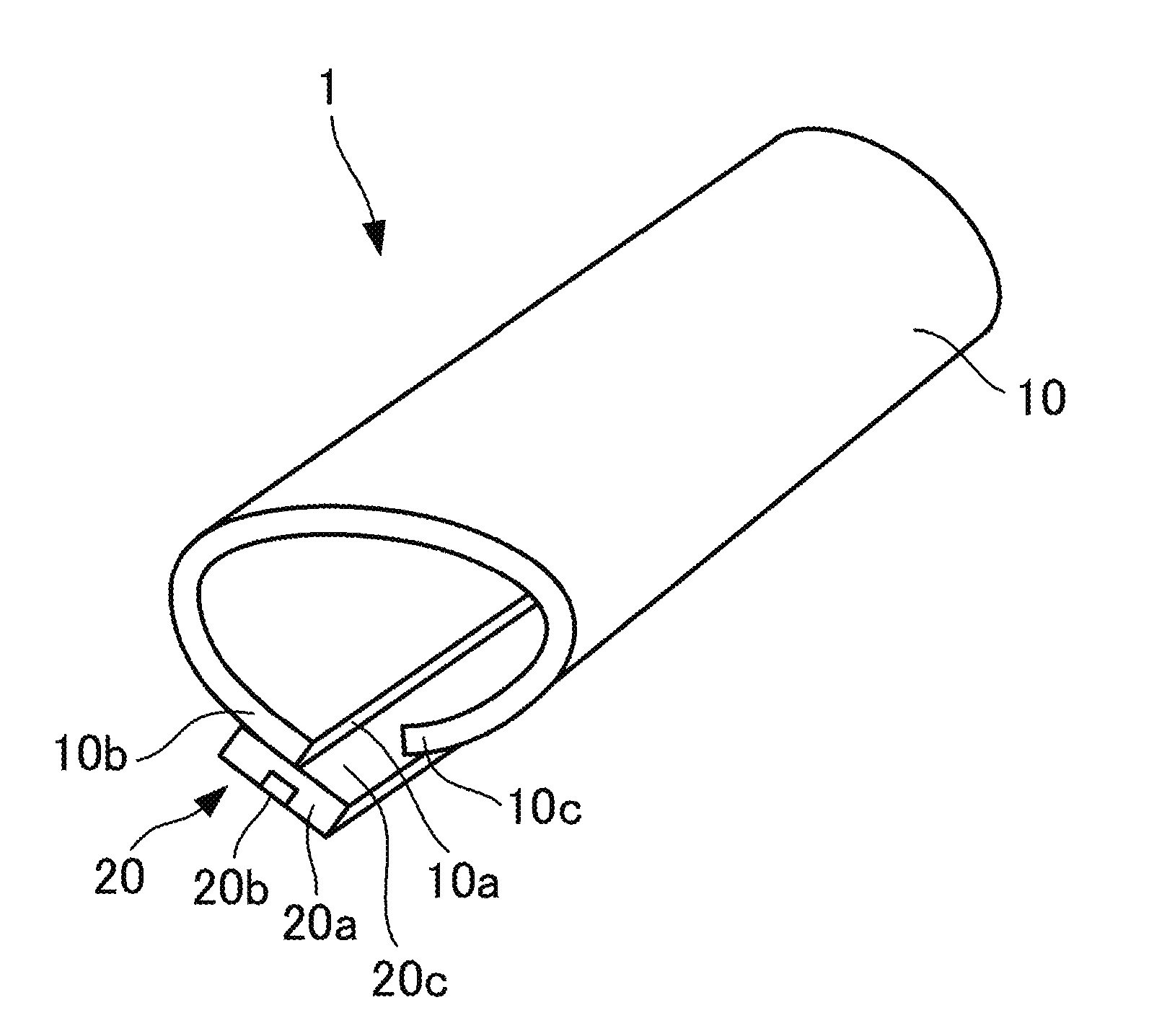

Heat-shrinkable slitted tube

InactiveUS20160268794A1Shrink wellLow costConnections effected by permanent deformationCable junctionsHeat resistanceEngineering

A heat-shrinkable slitted tube includes a tube main body capable of bending into a tube shape and which shrinks due to application of heat; and a heat-resistant tape which, in a closed state where the tube main body is deformed so as to close a slit extending in a length direction, fastens together areas proximate to two end portions of the tube main body so as to maintain the closed state. In the heat-shrinkable slitted tube, in a case where, by affixing the heat-resistant tape to the tube main body such that one of the end portions is positioned at a short-direction center portion of an indicator of the heat-resistant tape, the other end portion is brought together with the end portion to achieve the closed state, the heat-resistant tape is affixed so as to intervene between the areas proximate to the two end portions.

Owner:SUMITOMO WIRING SYST LTD

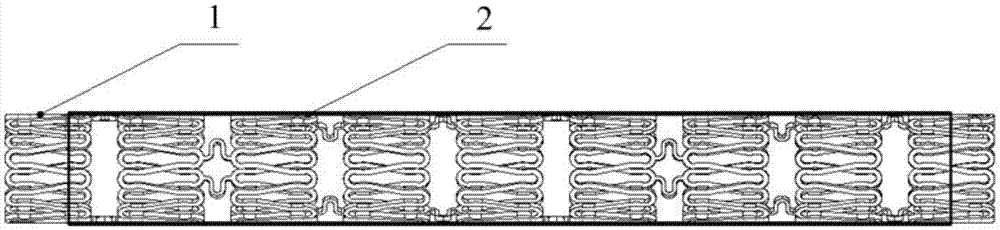

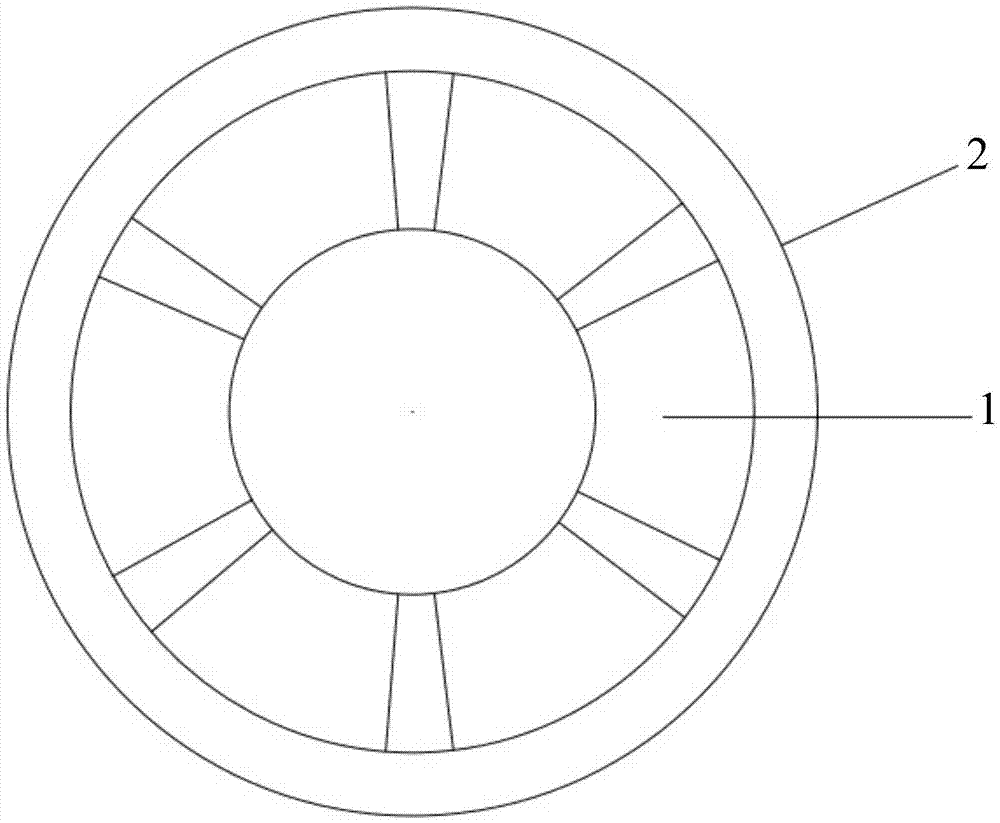

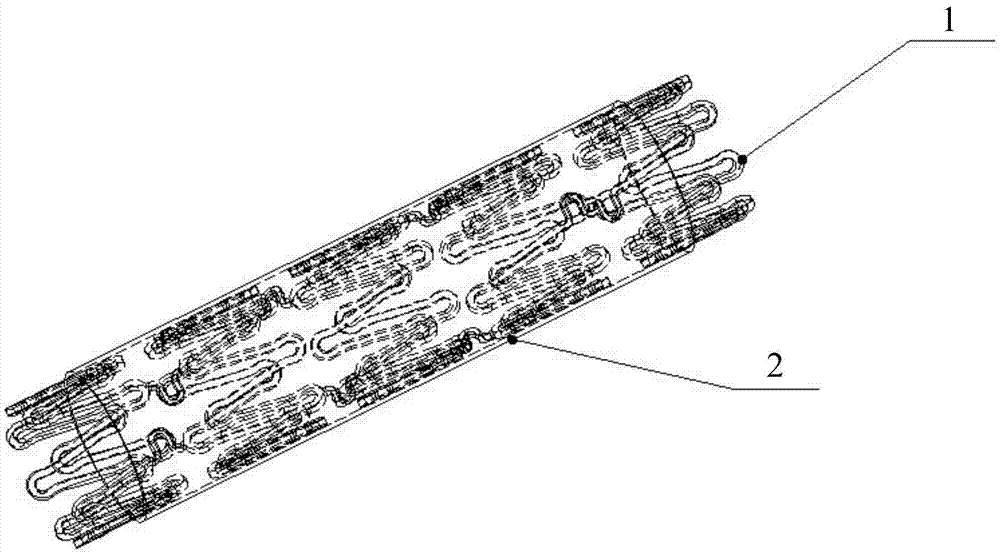

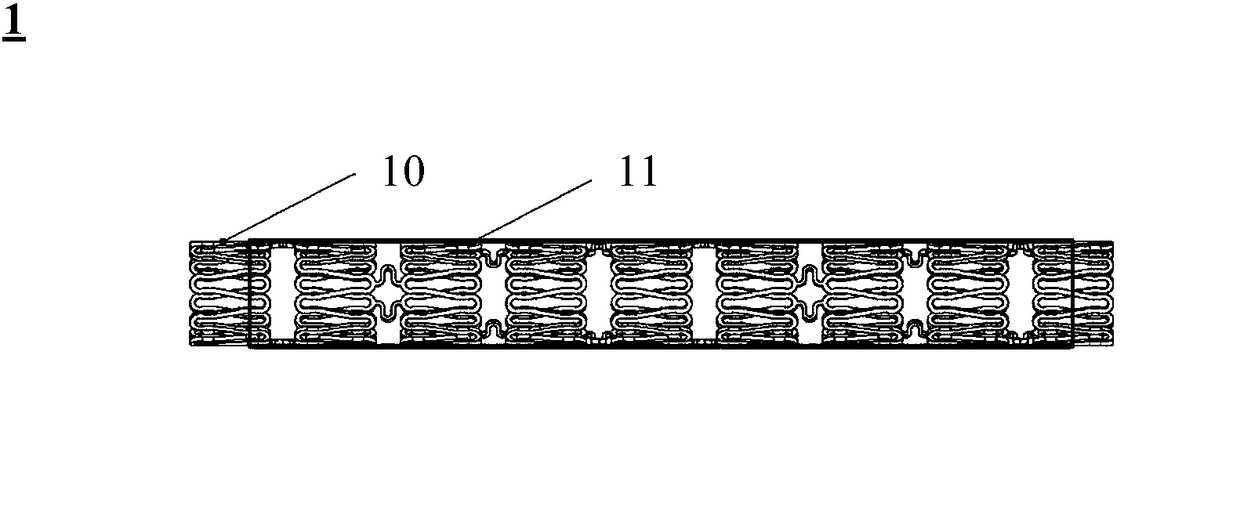

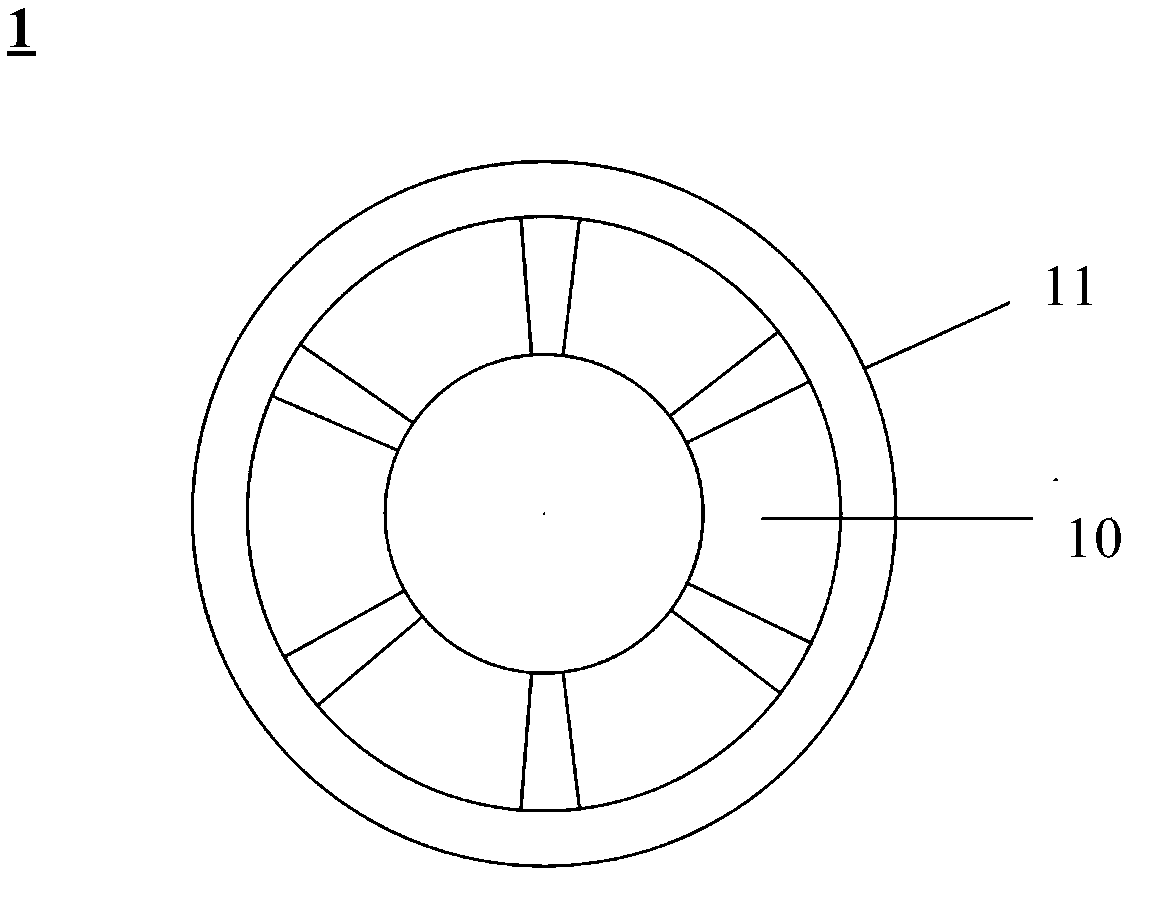

Covered stent and preparation method thereof

The invention provides a covered stent and a preparation method thereof. The covered stent comprises a stent body and a covered pipe material which sleeves the stent body, wherein the covered pipe material is in a retracted state and is fitted to an outer surface of the stent body; the covered pipe material can be tightly fitted to the surface of the stent without the need of additional sewing and spinning processes and the like; one covered pipe material can be applicable to stents with different specifications, so that the applicability of the covered stent is improved; only one layer of the stent and one layer of the covered pipe material are adopted, so that the outer diameter size of the covered stent is small and the trafficability and smoothness of the covered stent are improved. The invention further provides the preparation method of the covered stent; the stent body, which is sleeved with the covered pipe material, is put into a medium with pre-set temperature, and the covered pipe material is retracted and fitted to the outer surface of the stent body, so that the covered stent can be prepared before surgeries; multi-specification goods preparation is not needed, and the cost of clinical goods preparation is low.

Owner:SHANGHAI MICROPORT MEDICAL (GROUP) CO LTD

Liquid dressing for treating hemorrhoids, and preparation method thereof

The invention relates to a liquid dressing for treating hemorrhoids, and a preparation method thereof. The liquid dressing is prepared from the following components: alginate, modified chitosan, allantoin, tetracaine hydrochloride, glycerinum, hyaluronic acid, human collagen, growth factor, polyethylene glycol, didecyl dimethyl ammonium chloride, phmg, N-isopropyl acrylamide, and the like. The dressing is used for improving bleeding pain, porta hepatis fall-swell and other syndromes caused by internal hemorrhoid, external hemorrhoid, mixed hemorrhoid, anal fissure, anal fistula surgery, promoting hemorrhoid reduction, preventing hemorrhoid prolapse, relieving the syndromes of prolapsed and hemorrhoids congestion and the like, and performing treatment and anti-bacterial nursing of porta hepatis diseases of hemorrhoids and the like.

Owner:广西达庆生物科技有限公司

Medical biological hydrogel functional dressing for hemorrhoid and preparation method thereof

ActiveCN105169456APromote repairGood regeneration performanceOrganic active ingredientsAbsorbent padsIrritationPolyhexamethylene guanidine

The invention relates to the technical field of medical dressing, and specifically relates to a medical biological hydrogel functional dressing for hemorrhoid and a preparation method thereof. The dressing is composed of the following raw materials: glycerin, chitosan quaternary ammonium salt, Chinese lobelia extract, scutellariae barbatae extract, sedum verticallatum extract, smilax glabra extract, stephanotis extract, rabdosia rubescens extract, mint extract, polyhexamethylene guanidine, and the balance being purified water. The dressing other than the auxiliary materials is made of pure traditional Chinese herbals, thus has little irritation, does not have any side or toxic effect, is safe to use, and has the advantages of good permeability and curative effect, fully-exerted effect, long-lasting effect, and difficult relapse. The dressing can be applied to anus to relieve the symptoms of internal hemorrhoid, external hemorrhoid, and mixed hemorrhoid, and symptoms caused by anal fissure / anal fistula surgery such as bleeding, aches, anal pendant expansion, etc. The dressing can also promote hemorrhoid shrinkage, prevent hemorrhoid prolapse, and relieve hyperemia and edema of hemorrhoid mucous membrane, and is capable of being applied to antibacterial nursing of anus diseases such as hemorrhoid.

Owner:DONGGUAN DAQING MEDICAL DEVICES CO LTD +2

Modified PP (Polypropylene) material and application thereof

The invention discloses a modified PP (Polypropylene) material. The modified PP material is prepared from the following raw materials in parts by weight: 63-67 parts of recycled PP material, 23-27 parts of glass fiber, 4-6 parts of calcium carbonate and 4-6 parts of high-pressure PE (Poly Ethylene). In the scheme, the recycling of the PP material is realized by recycling and modifying the PP material, so as to avoid the problems of environmental pollution and resource waste caused by direct discarding or burning of the PP material, meanwhile the modified PP material has excellent strength, deformation, shrinkage, smooth surface, heat resistance and the like, and can be used as a raw material for the production of different products.

Owner:LUAN CITY JIEMEI RECYCLED MATERIAL RECYCLING

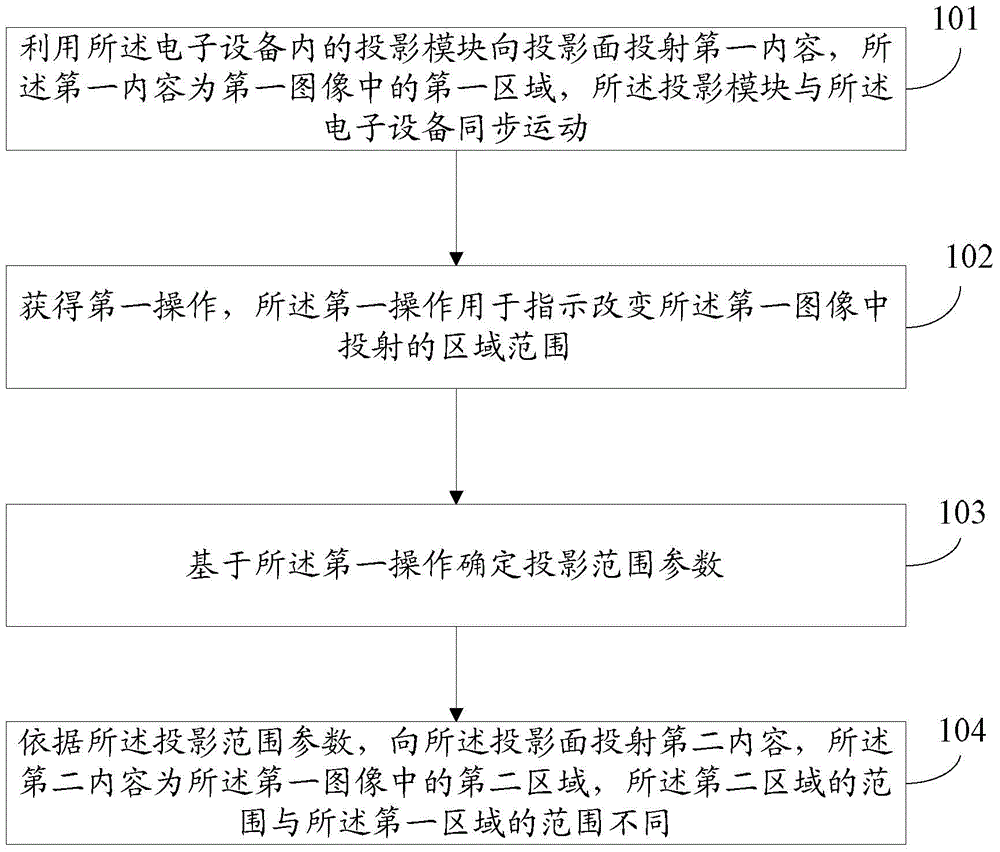

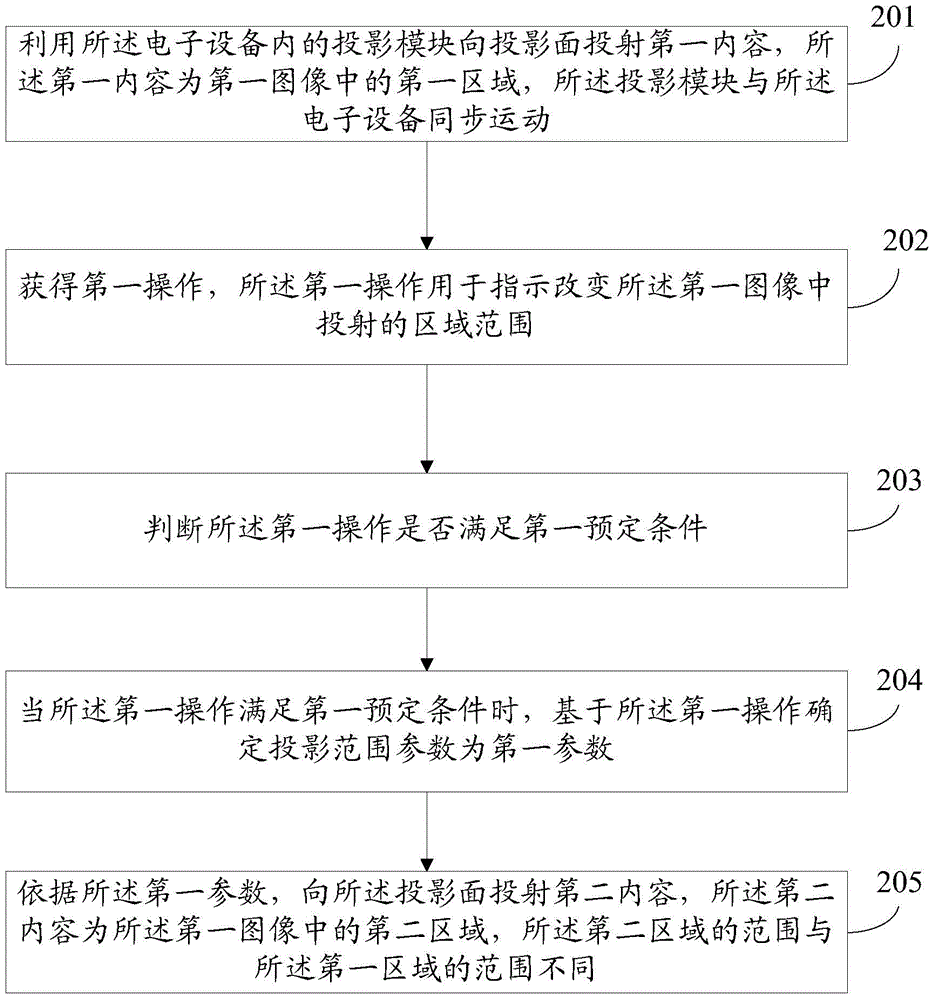

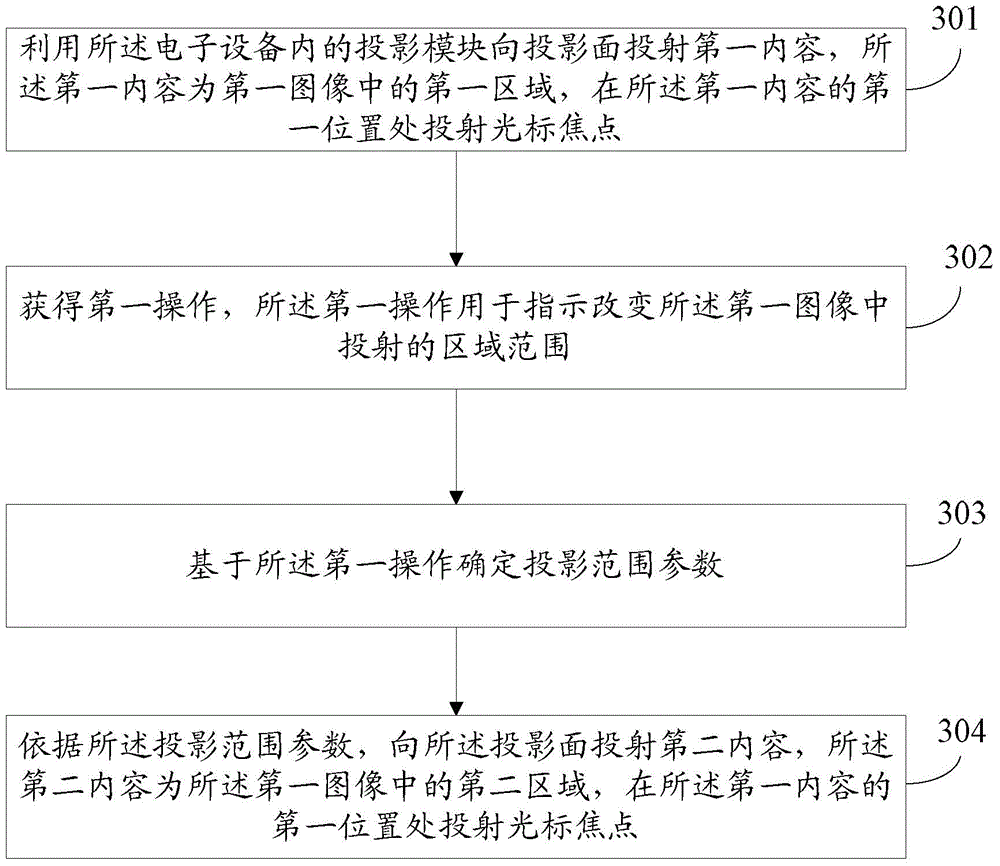

Interaction method and electronic equipment

ActiveCN106293037AEasy to zoom inShrink wellInput/output for user-computer interactionGraph readingProjection planeHuman–computer interaction

The invention discloses an interaction method and electronic equipment. The interaction method includes the steps that first content is projected to a projection plane through a projection module in the electronic equipment, the first content is a first region in a first image, and the projection module and the electronic equipment move synchronously; first operation is obtained, and the first operation is used for indicating that the region range projected in the first image is changed; projection range parameters are determined based on the first operation; second content is projected to the projection plane according to the projection range parameters, the second content is a second region in the first image, and the range of the second region is different from that of the first region.

Owner:LENOVO (BEIJING) CO LTD

Medical hemorrhoids biological hydrogel functional dressing and preparation method thereof

ActiveCN105056288APromote growthPromote healingAbsorbent padsBandagesDiseasePolyhexamethylene guanidine

The invention relates to the technical field of skin nursing, in particular to medical hemorrhoids biological hydrogel functional dressing and a preparation method thereof. The medical hemorrhoids biological hydrogel functional dressing comprises, by weight, 8-12% of chitosan quaternary ammonium salt, 0.1-0.2% of polyhexamethylene guanidine, 0.15-0.23% of alums, 12-18% of glycerinum, 0.08-0.12% of anise oil, 0.2-0.4% of allantoin, 0.3-0.6% of coenzyme Q 10, 0.15-0.25% of ceramide, 0.3-0.65% of mint and the balance purified water. The medical hemorrhoids biological hydrogel functional dressing can be used for repairing and relieving bleeding, pain, anal pendant expansion and other symptoms caused after inner hemorrhoid, external hemorrhoid, mixed hemorrhoid, anal fissure and anal fistula surgeries, promoting hemorrhoid shrinkage, and preventing hemorrhoid prolapse and relieving hemorrhoid mucosa hyperemia edema and other symptoms, can also be used for nursing for treatment of hemorrhoids and other anus diseases, and is convenient to use.

Owner:DONGGUAN DAQING MEDICAL DEVICES CO LTD +2

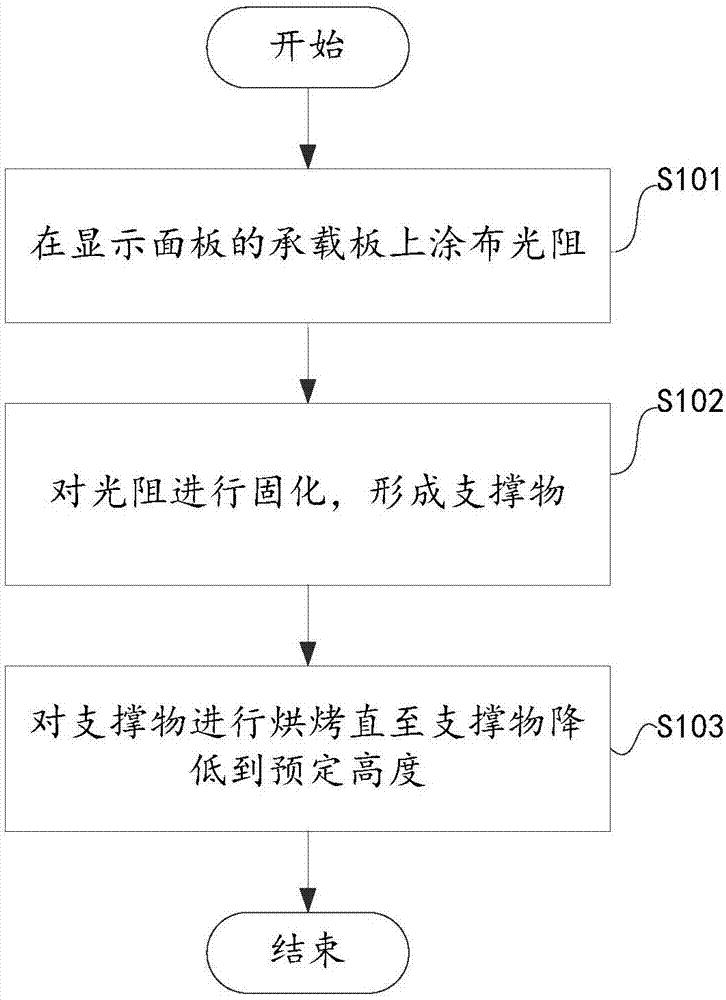

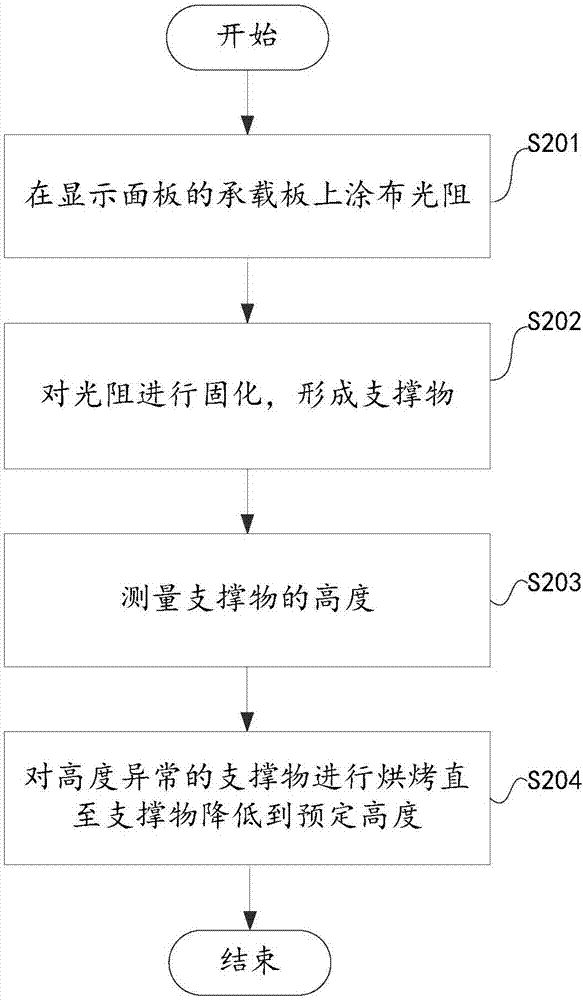

Display panel manufacturing process and baking device for display panel

InactiveCN107045215AShow normalyLower the altitudeNon-linear opticsEngineeringUltimate tensile strength

The invention discloses a display panel manufacturing process and a baking device for a display panel. The display panel manufacturing process includes the following steps: coating a transmitting substrate of the display panel with a light resistor; performing patterning and solidifying on the light resistor to form a supporting body; and baking the supporting body till the supporting body descends to a preset height. Micro adjustment and repairing of the supporting body can be achieved by baking the support body, local high structures of the supporting body can be avoided, the bad phenomenon that the display panel is white and uneven can be prevented, and the display panel can achieve normal display. The supporting body is locally baked, the baking intensity and the baking time is easy to control during baking, the supporting body can be controlled accurately, and an optimal shrinkage of the supporting body can be achieved.

Owner:HKC CORP LTD +1

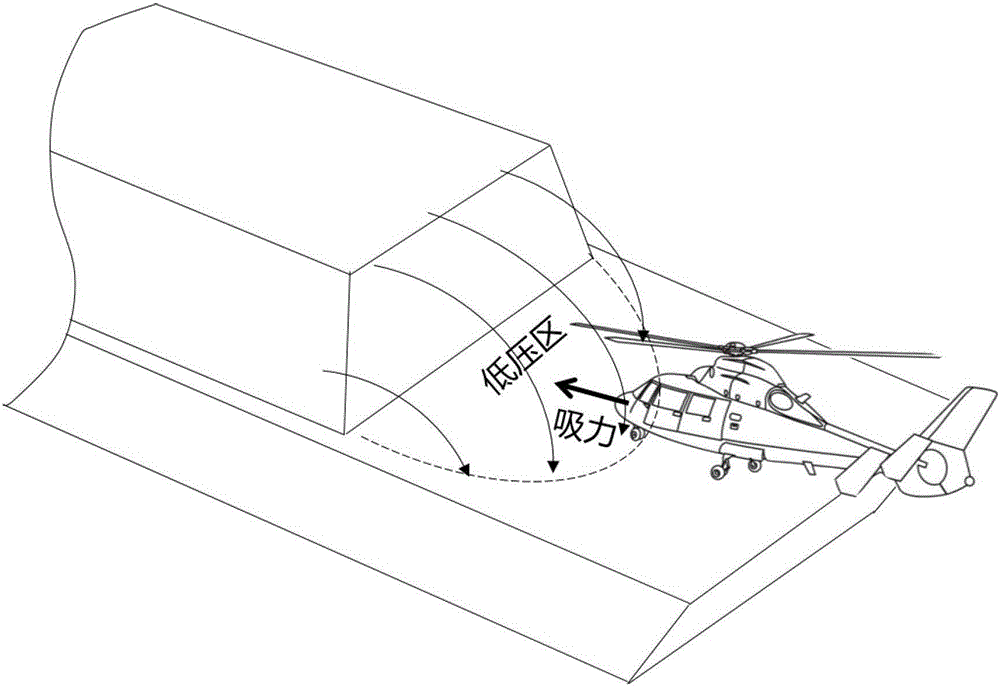

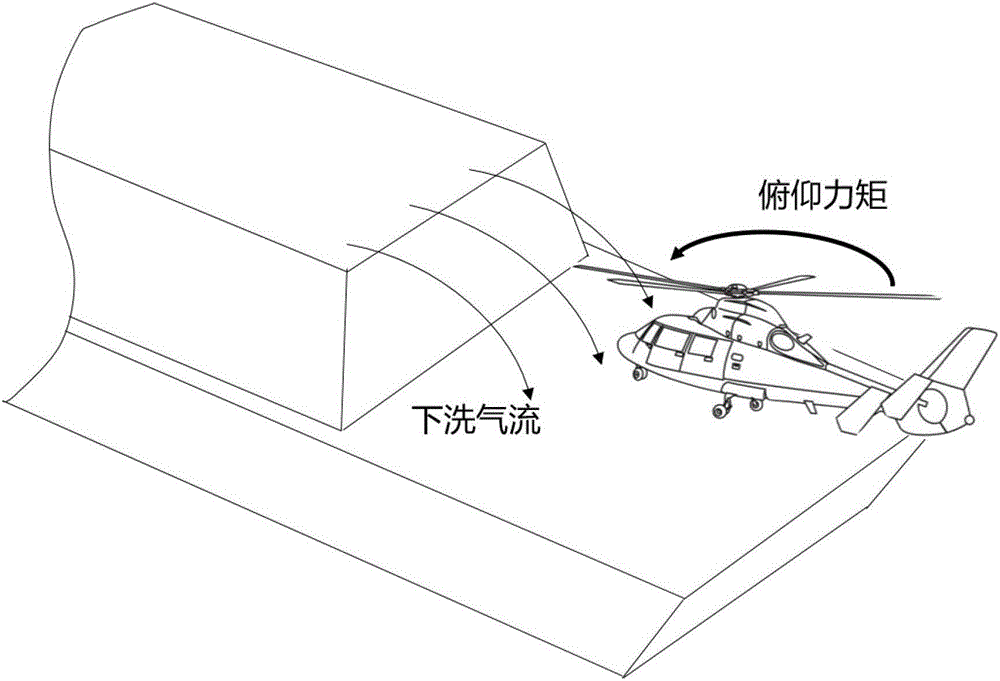

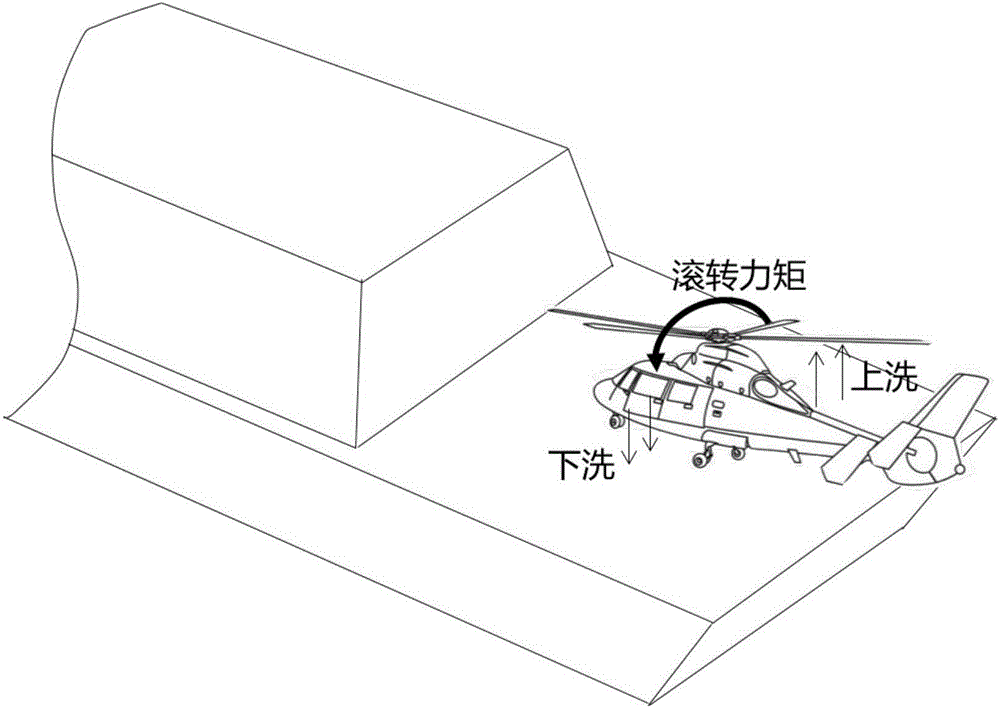

Driving flow control system and method of ship tail flight deck flow field

ActiveCN106828846AImprove flow field structureReduce instabilityAircraft carriersGround installationsMarine engineeringControl system

The invention discloses a driving flow control method of a ship tail flight deck flow field. The driving flow control method of the ship tail flight deck flow field is characterized in that the wind speed and the wind angle of a ship are detected by a wind speed and direction sensor; when a ship-based helicopter takes off or lands, a flow control actuating element is driven by a control unit to generate a control airflow according to the detected wind speed and wind angle, a flow state of a main flow is changed, the ranged of a vortex region is reduced, a high upwash airflow or a downwash airflow is restrained to form, a rolling moment and a yawing moment of the ship-based helicopter during ship landing are weakened, and a flow field structure above a ship tail flight deck is improved. The driving flow control method of the ship tail flight deck flow field is applied to ship types such as a marine surveillance ship with a hangar and a destroyer, a complex flow field above a deck can be controlled, and uniformity of the flow field is improved.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

Valve rod powder metallurgy manufacturing method for check valve

ActiveCN103008642AHigh densityChange the amount addedTurbinesOther manufacturing equipments/toolsPowder metallurgyManganese sulfide

Owner:ANHUI PUYUAN SEPARATION MACHINERY MFG CO LTD

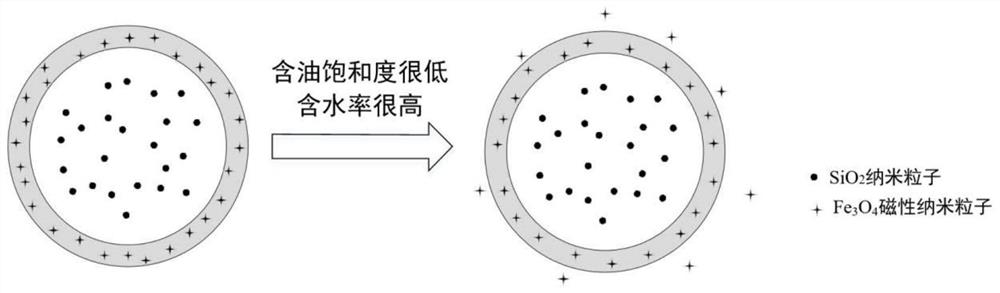

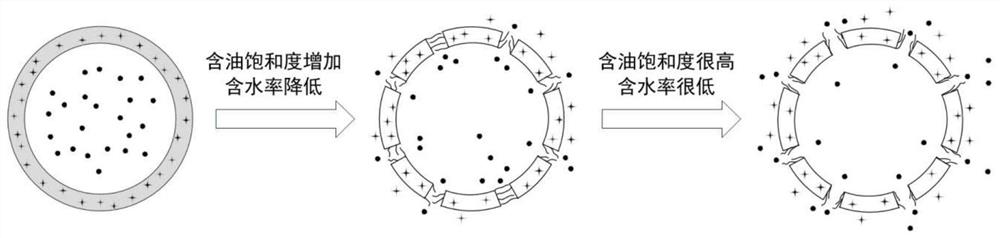

Preparation method and application of intelligent controlled-release targeting nanometer oil-displacing agent microcapsule

InactiveCN112538145AReduce lossReduce clumpingDrilling compositionMicroballoon preparationControlled releaseMagnetite Nanoparticles

The invention provides a preparation method and application of an intelligent controlled-release targeting a nanometer oil-displacing agent microcapsule. The preparation method comprises the followingsteps: embedding magnetic nanoparticles in the capsule wall of a polymer microcapsule, and conducting targeting positioning on a nanometer oil-displacing agent by using an external magnetic field; and realizing controlled-release of the nanometer oil-displacing agent through the extension-contraction characteristic of a specific polymer grafted chain in a membrane hole, wherein when oil saturation is very low and a water content is very high, a macromolecular chain in a membrane is in an extension state, so the membrane hole is closed, and the release of the nanometer oil-displacing agent inthe microcapsule is limited; when the oil saturation is increased, the macromolecular chain in the membrane is gradually changed into a shrinkage state, so membrane hole is opened; and the higher theoil saturation is, the more obvious the molecular chain shrinkage is, a release open channel for the nanometer oil displacement agent in the micro-capsule is formed, the nanometer oil displacement agent is gradually released outwards, and the purpose of targeted oil displacement is achieved.

Owner:SOUTHWEST PETROLEUM UNIV

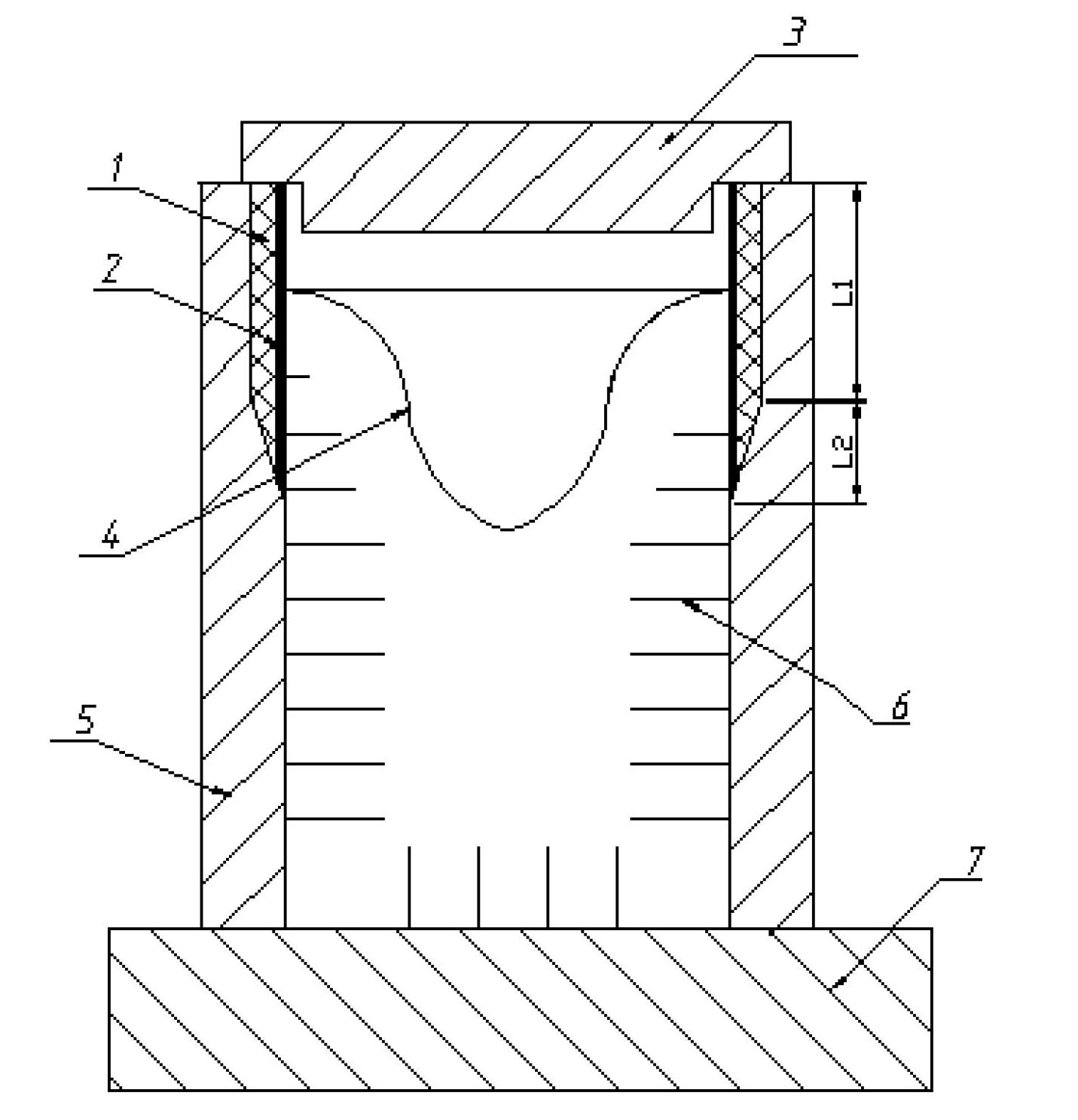

Invisible riser for ingot casting and heat-preservation method thereof

InactiveCN102649150AShrink wellImprove insulation effectFoundry mouldsFoundry coresInsulation layerIngot casting

The invention relates to an invisible riser for pouring in ingot casting and a heat-preservation method; and the invisible riser inlaid at the inner wall of a casting film is also provided with an electric heating heat-preservation cover, a traditional special riser and a method of a heat-preservation material are replaced, and substantial riser-free pouring is realized. The device of the method comprises a permanent heat-insulation layer (1) with high-temperature resistance, which forms a whole with the casting film, a protective layer (2) which has high-temperature resistance and scouring resistance and is not stuck with steel (or other metal) and the electric heating heat-preservation cover (3). The method has the advantages that the operation is simple, the qualification rate of ingot casting is high, the quality of ingot casting is good, the environment is good and the like.

Owner:王召祥

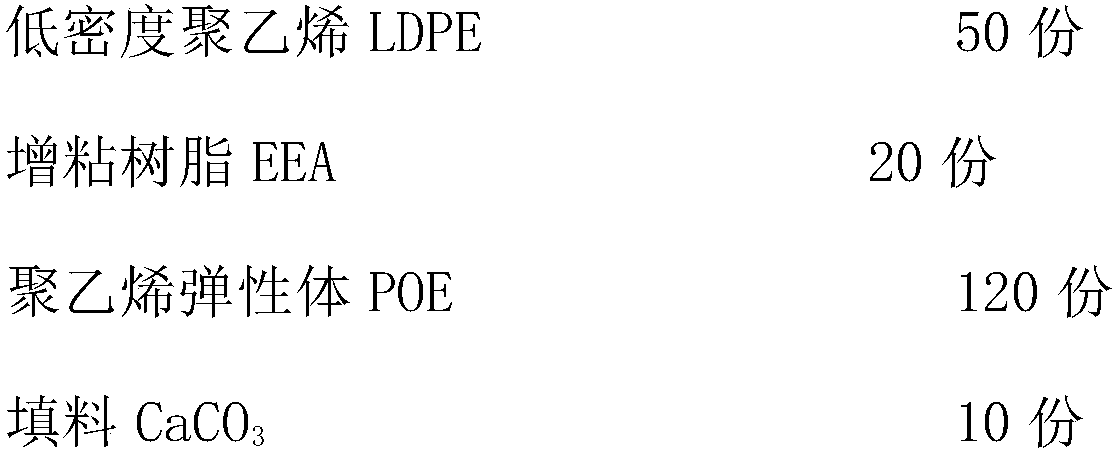

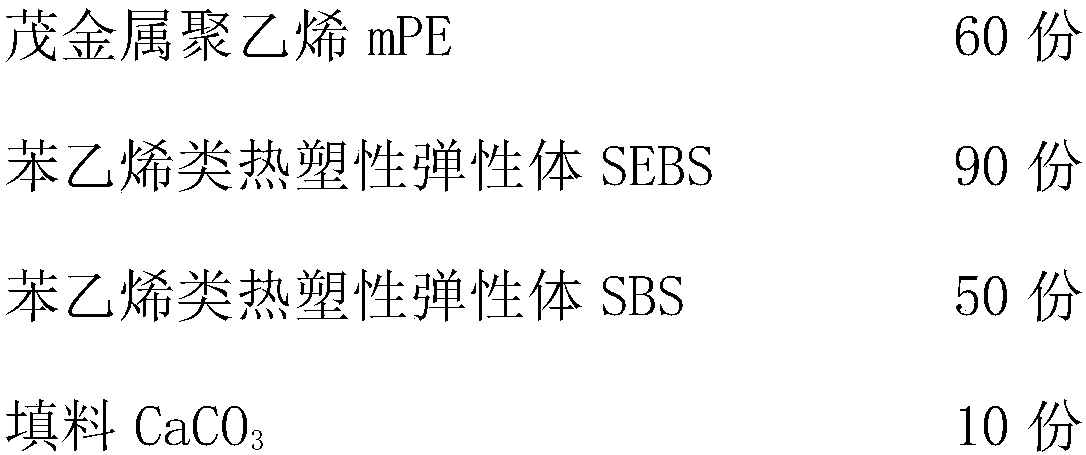

Polyolefin elastomer peritoneal dialysis drainage bag cover cap capable of being thermoplastically processed and preparation method of polyolefin elastomer peritoneal dialysis drainage bag cover cap

InactiveCN108102201AEcologicallyMeet environmental protection requirementsElastomerPeritoneal dialysis

The invention discloses a polyolefin elastomer peritoneal dialysis drainage bag cover cap capable of being thermoplastically processed and a preparation method of the polyolefin elastomer peritoneal dialysis drainage bag cover cap. The preparation method concretely comprises the following steps of adding tackifying resin, a thermoplastic elastomer and a filler in polyolefin, and performing open milling, internal mixing or extrusion to obtain a polyolefin elastomer medical cover cap material capable of being thermoplastically processed. The material can be used for being applied to medical packaging after being prepared into a finished product through processes of extrusion, injection molding and the like. Compared with a soft polyvinyl chloride (SPVC) medical cover cap material which is widely used at present, the material cannot cause any pollution to a medical content, does not generate any peculiar smell and cannot obviously shrink at the sterilization temperature.

Owner:深圳恒方大高分子材料科技有限公司 +2

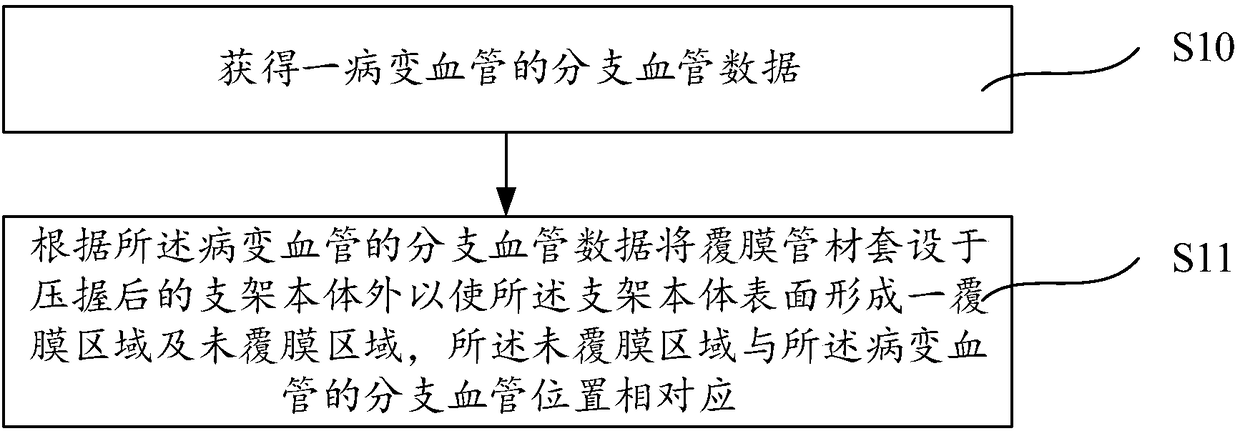

Covered stent and manufacturing method thereof

The invention provides a covered stent and a making method thereof. The covered stent comprises a stent body and a covering membrane attached outside the stent body, thus, the covered stent can have a smaller appearance, and therefore the flexibility of the covered stent is improved; in addition, the surface of the stent body is not completely covered with the covering membrane, and therefore the covered stent does not block branch vessels. Furthermore, the covering membrane is made of biodegradable polymer materials, therefore, endothelialization of the covered stent can be promoted, arterial aneurysm is activated to shrink, formation of thrombus in the covered stent is avoided, blocking of the branch vessels is avoided, and blood flow reserve of a patient is increased. Further, the making method of the covered stent is simple, the covered stent can be made before an operation according to different clinic requirements, therefore, the covered stent can better adapt to the condition of the patient, and the product preparation cost of a hospital is reduced.

Owner:SHANGHAI MICROPORT MEDICAL (GROUP) CO LTD +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com