Vinyl monomer-modified polyester resin and anti-shrinking agent, and preparation methods thereof

A vinyl monomer and modified polyester technology, applied in the field of vinyl monomer modified polyester resin, low shrinkage agent and preparation, can solve poor stability, weak thickening ability, low shrinkage agent coloring performance To achieve the effect of widening the selection range, improving colorability, excellent mechanical properties and moisture resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

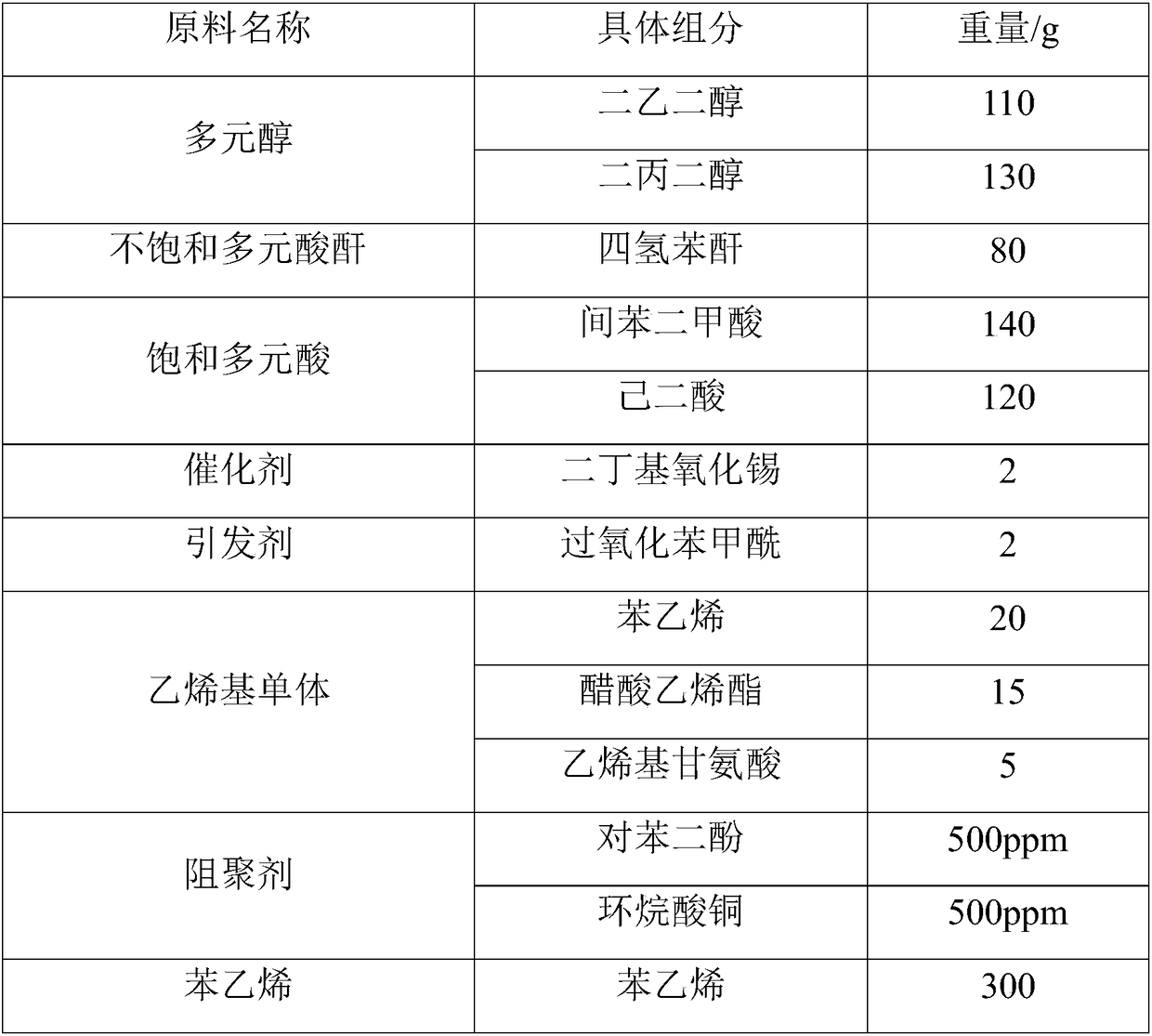

[0050] A vinyl monomer-modified polyester resin and a low-shrinkage agent are prepared according to the following raw material formula and preparation method.

[0051] The formula is:

[0052]

[0053] The preparation method steps are as follows:

[0054] (1) Add polyhydric alcohol into the reaction kettle with heating device and stirring device, feed nitrogen, start stirring, heat up to 100°C until the material melts, then add saturated polybasic acid or acid anhydride, unsaturated polybasic acid or acid anhydride in sequence And the esterification catalyst, continue to heat up the water outlet under the protection of nitrogen, the distillation head temperature is 90 °C, the reaction temperature is 200 °C, and the acid value is 8 mgKOH / g;

[0055] (2) Then lower the temperature to 110°C, add a mixed solution of vinyl monomer (styrene, vinyl acetate, vinylglycine) and initiator dropwise to the reaction kettle, add dropwise for 1 hour, and keep warm at 110°C for 4h, Prompt...

Embodiment 2

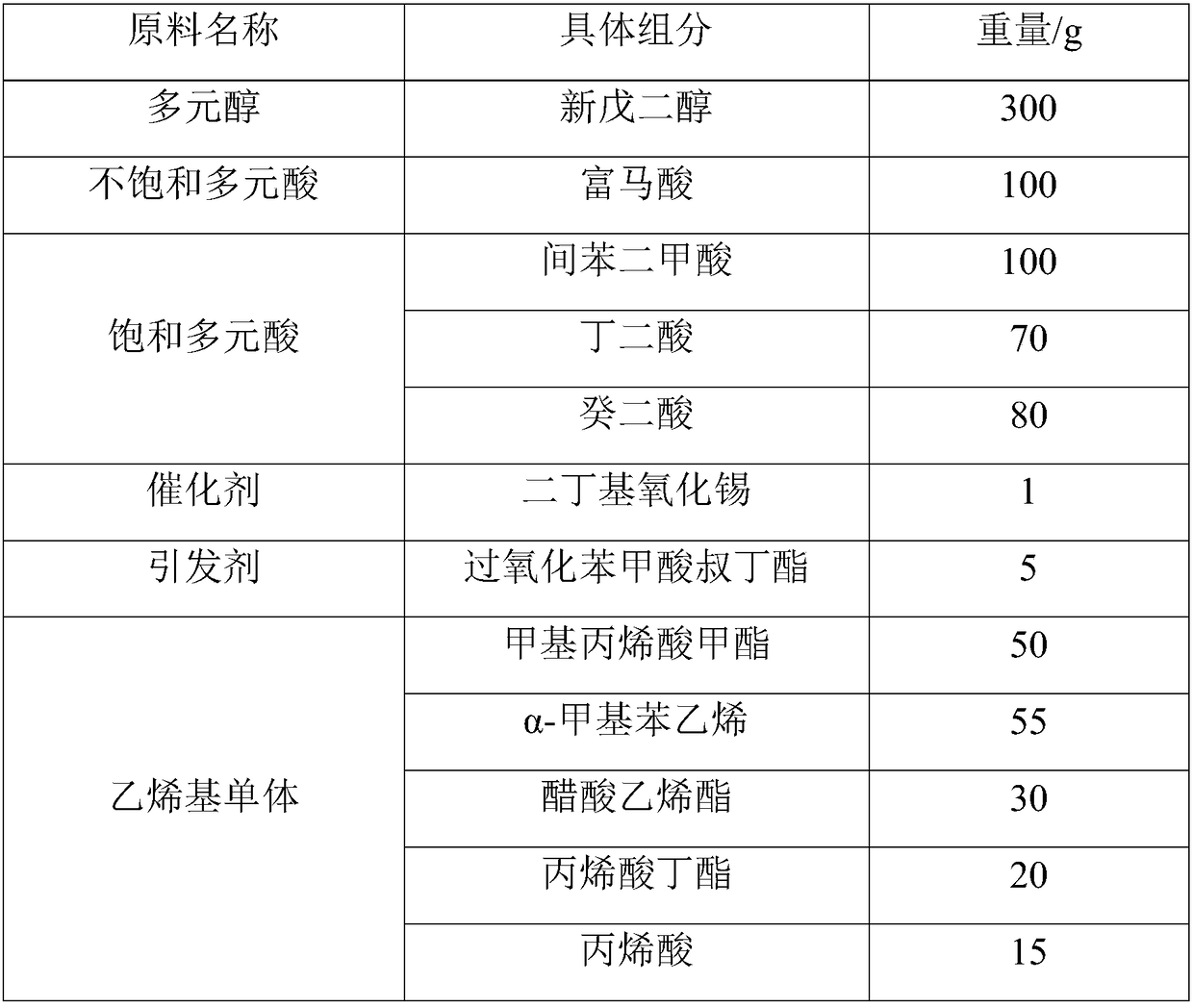

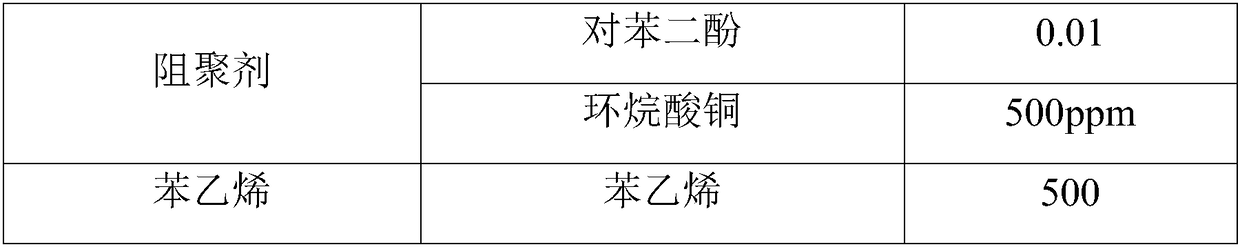

[0058] A vinyl monomer-modified polyester resin and a low-shrinkage agent are prepared according to the following raw material formula and preparation method.

[0059] The formula is:

[0060]

[0061]

[0062] The preparation method steps are as follows:

[0063] (1) Add polyhydric alcohol into the reaction kettle with heating device and stirring device, feed nitrogen, heat up and heat until the material in the kettle melts, start stirring, add saturated polybasic acid or acid anhydride, unsaturated polybasic acid or acid anhydride and Esterification catalyst, continue to heat up the water outlet under the protection of nitrogen, the head temperature is 100°C, the reaction temperature is 230°C, and the acid value is 6mgKOH / g;

[0064] (2) Then lower the temperature to 140°C, add a mixture of vinyl monomers (methyl methacrylate, α-methylstyrene, vinyl acetate, butyl acrylate, methacrylic acid) and initiators dropwise into the reactor The solution was added dropwise for...

Embodiment 3

[0067] A vinyl monomer-modified polyester resin and a low-shrinkage agent are prepared according to the following raw material formula and preparation method.

[0068] The formula is:

[0069]

[0070]

[0071] The preparation method steps are as follows:

[0072] (1) Add polyhydric alcohol into the reaction kettle with heating device and stirring device, feed nitrogen, heat up and heat until the material in the kettle melts, start stirring, add saturated polybasic acid or acid anhydride, unsaturated polybasic acid or acid anhydride and Esterification catalyst, continue to heat up the water outlet under the protection of nitrogen, the distillation head temperature is 95°C, the reaction temperature is 140°C, and the acid value is 7mgKOH / g;

[0073] (2) Then the temperature was lowered to 90°C, and the mixed solution of vinyl monomer and initiator was added dropwise to the reaction kettle for 2 hours, and kept at 90°C for 4 hours to obtain 1035g of vinyl monomer modified ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

| shrinkage | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com