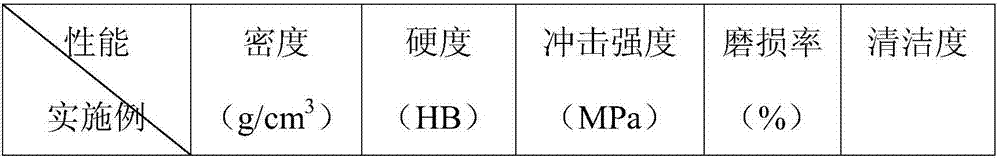

Patents

Literature

329 results about "Manganese sulfide" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

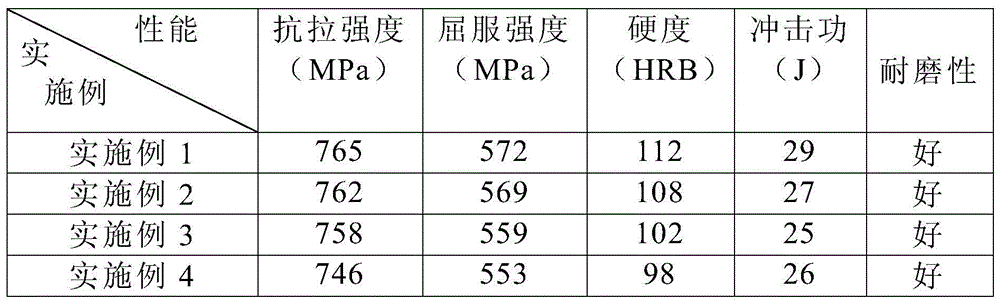

Preparation method of powder-metallurgy refrigeration compressor valve sheet

ActiveCN102380613AHigh forming densityImprove production continuityTurbinesOther manufacturing equipments/toolsRefrigeration compressorAlloy

The invention relates to a preparation method of a powder-metallurgy refrigeration compressor valve sheet. The preparation method is characterized by comprising the following steps of: mixing iron powder, high-alloy main powder, graphite powder, manganese sulfide powder and zinc stearate powder according to certain proportion, leading the weight percentage of all elements in the total components to be as follows: 0.5-2.0% of carbon, 3.0-6.5% of cobalt, 2.5-4.5% of chromium, 2.5-4.5% of molybdenum, 0.5-2.0% of nickel, 0.2-1.0% of vanadium, less than 3% of impurities and the balance of iron; using a mold to press and form the mixture to obtain a powder-metallurgy green blank; putting the green blank in a sintering furnace to sinter for more than 5 minutes with the sintering temperature being 1150-1250 DEG C; carrying out repressing and finishing on the sintered blank; carrying out quenching and annealing under the protective atmosphere; and carrying out grinding on the valve sheet. In the preparation method, the problems of the adding mode and effective alloying of the powder-metallurgy high alloy are solved, and higher forming density needed by the powder-metallurgy valve sheet material under higher alloy content is realized, so that the powder-metallurgy refrigeration compressor valve sheet achieves the needed wear resistance. The prepared powder-metallurgy refrigeration compressor valve sheet has the advantages of low material cost, high material utilization ratio and suitability for large-batch production.

Owner:NBTM NEW MATERIALS GRP

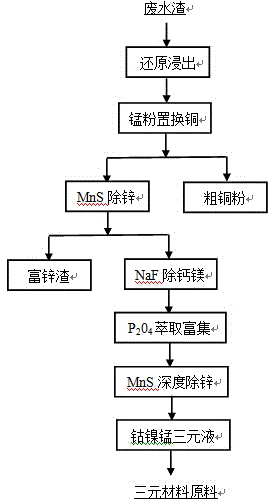

Cobalt nickel metallurgy wastewater sludge recycling method

ActiveCN104480317AEmission reductionHigh recovery rateProcess efficiency improvementSludgeAcid dissolution

The invention provides a cobalt nickel metallurgy wastewater sludge recycling method, and belongs to the field of waste recycling. The method comprises the following steps: carrying out acid dissolution reduction on cobalt nickel metallurgy wastewater sludge to leach out valuable metals in the wastewater sludge, displacing copper by using manganese powder to recover copper, precipitating zinc by using manganese sulfide to recover zinc, using a fluoride to remove calcium and magnesium from the obtained zinc removed solution, carrying out advanced impurity removal and cobalt nickel manganese enrichment by using a P2O4 extractant, and carrying out advanced impurity removal on the obtained solution rich in cobalt, nickel and manganese by using manganese sulfide to obtain a solution for preparing an NCM ternary precursor. The method allows nickel, cobalt, manganese, zinc, copper and other metals to be completely recovered and the obtained cobalt, nickel and manganese solution to be used to prepare the NCM ternary precursor as a raw material, avoids cobalt, nickel and manganese separation, and also has the advantages of simple process, substantial improvement of the metal recovery rate, low cost, harmlessness to environment, and industrialization prospect.

Owner:SHAOXING KEQIAO DRAINING

Preparation method and product of cobalt manganese sulfide electrocatalyst

InactiveCN107855128ARaw materials are cheap and easy to getEasy to preparePhysical/chemical process catalystsElectrodesVulcanizationOxygen

The invention relates to a cobalt manganese sulfide electrocatalyst and a preparation method thereof. The preparation method comprises the following steps that 1, cobalt salt, manganese salt and ureaare weighed, the weighed cobalt salt, manganese salt and urea are dissolved in water, stirring is conducted, and evenly mixed solution is obtained; 2, the solution and carrier are placed into a reactor together to undergo a hydrothermal reaction, and supported cobalt manganese carbonate is obtained; 3, the supported cobalt manganese carbonate is put into aqueous solution containing vulcanizing agent to undergo a vulcanization reaction, and supported cobalt manganese sulfide is obtained. The cobalt manganese sulfide electrocatalyst and the preparation method have the following advantages that the adopted raw materials are cheap and easy to obtain, the preparation method is simple, operation is easy and convenient, and the cost is low; the manganese element is introduced into cobalt, binarycobalt manganese sulfide is prepared, meanwhile carbon paper, carbon cloth, foam nickel, foam copper, titanium mesh or stainless steel mesh are combined and used as substrate, the two-in-one structureof catalyst and electrode is directly formed, testing is convenient, and the catalyst is endowed with excellent electrochemical catalysis hydrogen evolution or oxygen evolution performance by means of the synergistic effect of cobalt manganese sulfide and the substrate.

Owner:JIANGHAN UNIVERSITY

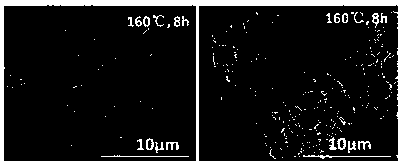

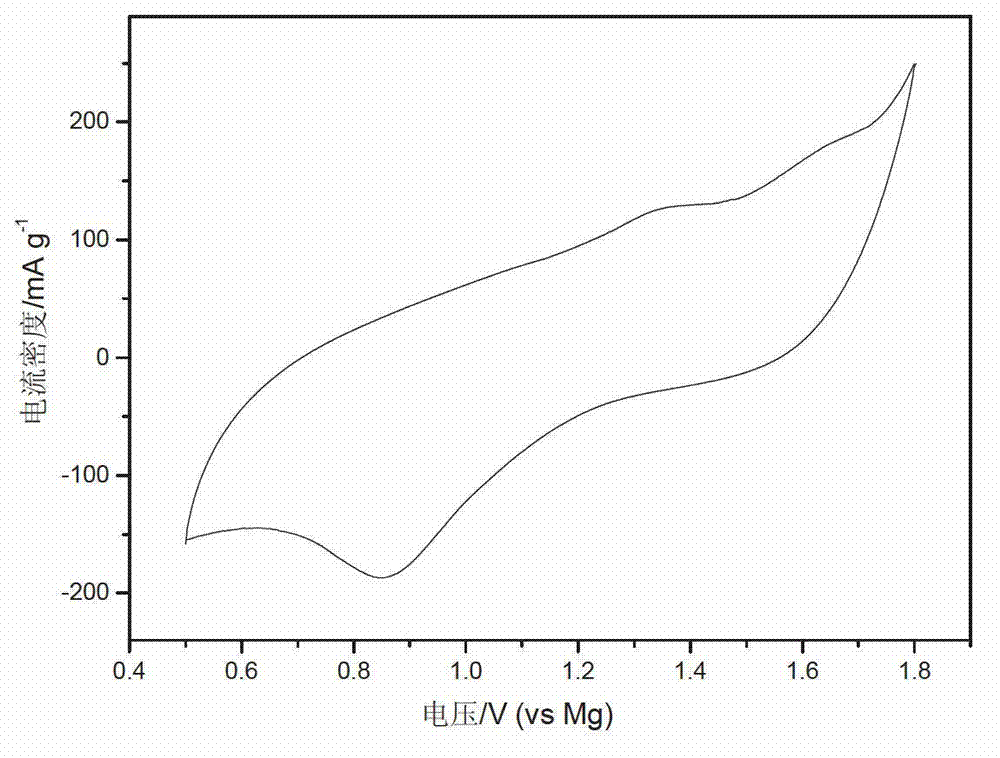

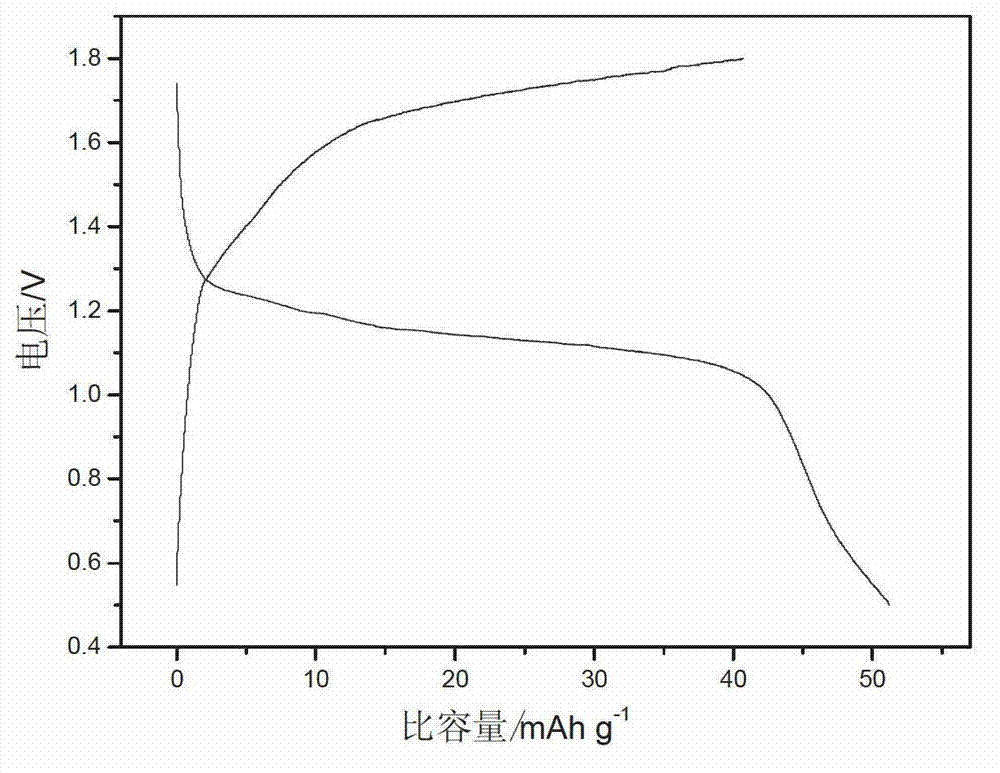

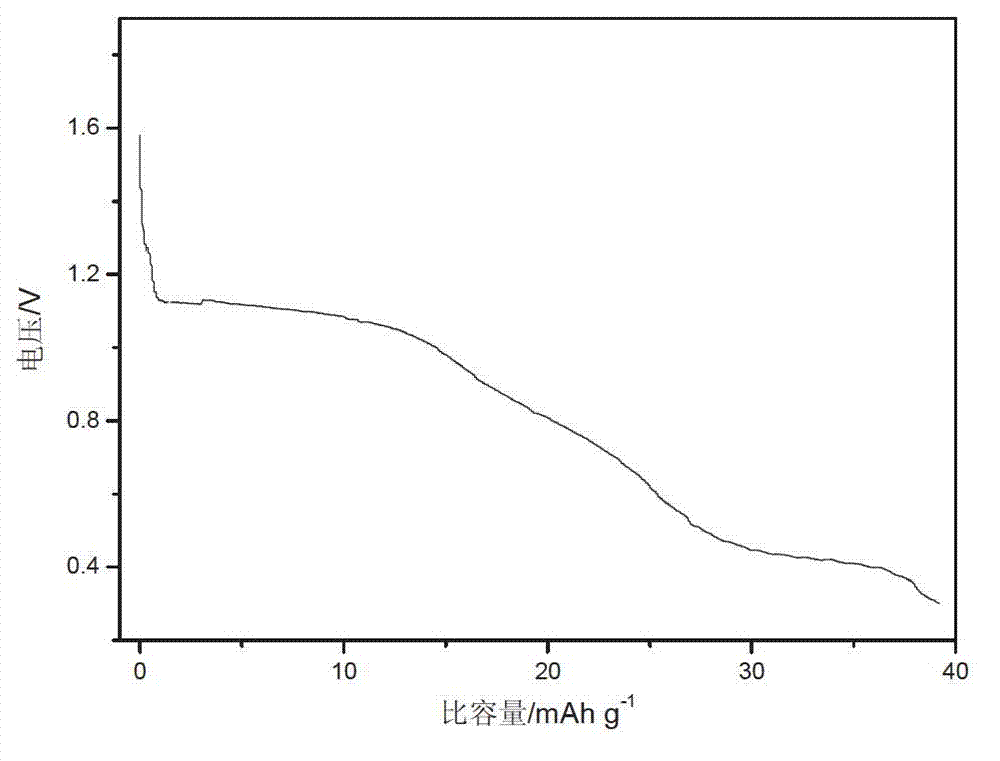

Application method of binary metal sulfides in chargeable magnesium battery

InactiveCN102969501AUnderstand the purposeLearn about featuresCell electrodesFinal product manufactureNickel sulfideCobalt sulfide

The invention discloses an application method of binary metal sulfides in a chargeable magnesium battery. The binary metal sulfides comprise nickel sulfide, manganese sulfide, cobalt sulfide, ferric sulfide, tin sulfide, tungsten sulfide, zinc sulfide, vanadic sulfide and the like. The preparation method for preparing the chargeable magnesium battery with the binary metal sulfides as an anode material specifically comprises the steps of: grinding the binary metal sulfides; adding a conductive agent and a bonding agent into the binary metal sulfides, and agitating uniformly and coating on a current collector; placing the current collector in an oven to dry, punching into a pole piece by a punch, tabletting and placing into a vacuum oven to dry so as to obtain the anode material; and using magnesium as a cathode, adding an electrolyte and assembling the chargeable magnesium battery. The chargeable magnesium battery prepared by the method provided by the invention has the advantages of simpleness in preparation, abundance in materials, low cost, and easiness in mass production. The chargeable magnesium battery has a great advantage as a large energy storing battery and has a good application prospect as a green energy resource.

Owner:SHANGHAI JIAO TONG UNIV

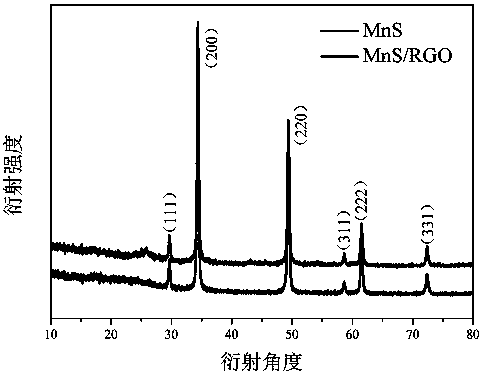

Preparation method of manganese sulfide/graphene nano composite material, negative electrode of lithium ion battery and lithium ion battery

ActiveCN106159239AEvenly distributedImprove performanceMaterial nanotechnologyCell electrodesNano compositesGraphene nanocomposites

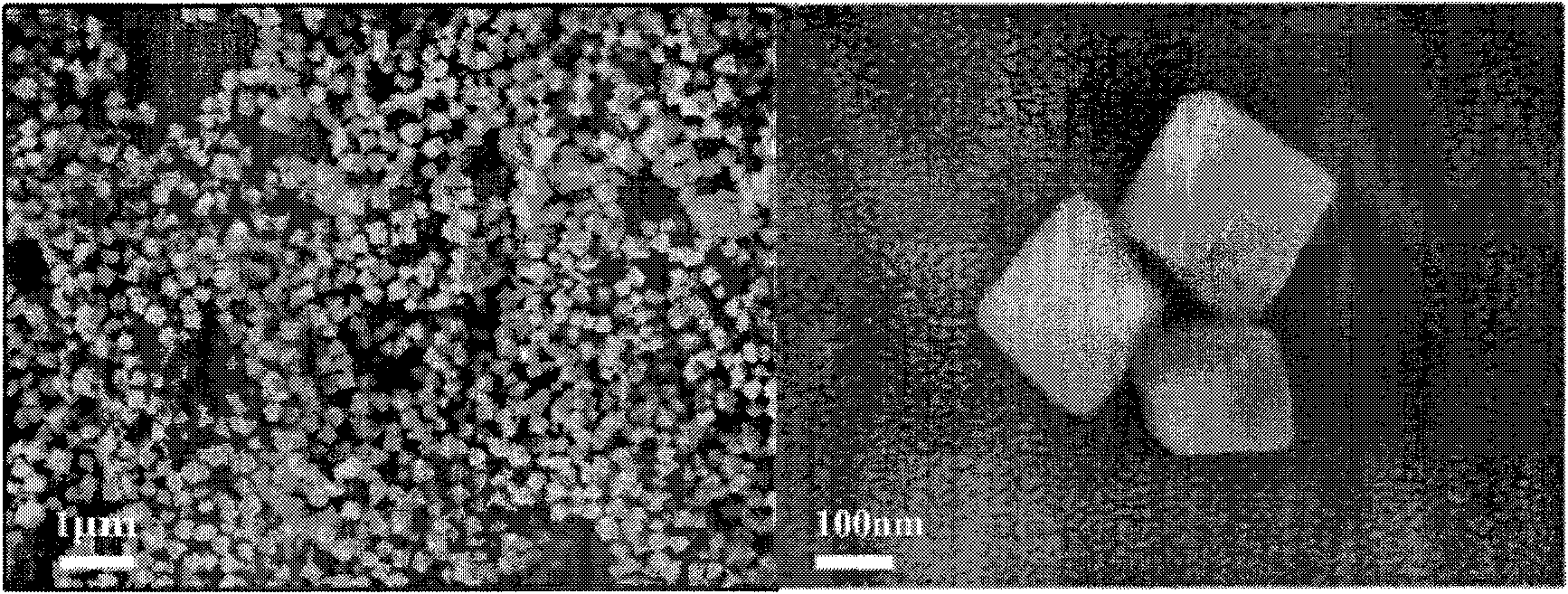

The invention discloses a preparation method of a manganese sulfide / graphene nano composite material, a negative electrode of a lithium ion battery and the lithium ion battery. The preparation method comprises the steps of a hydrothermal procedure and a compounding procedure. By virtue of the preparation method, in-situ growth of manganese sulfide is directly carried out on the surface of graphene; after washing and drying steps are carried out, the manganese sulfide / graphene nano composite material is obtained; the disadvantages such as poor stability caused by volume change are overcome through compounding of the manganese sulfide and three-dimensional reduced graphene oxide are overcome and the conductivity is enhanced, so that the properties of the lithium ion battery are improved; the material is applied to a negative electrode material of the lithium ion battery and has the advantages of good circulating stability, high specific energy density and the like.

Owner:ANHUI NORMAL UNIV

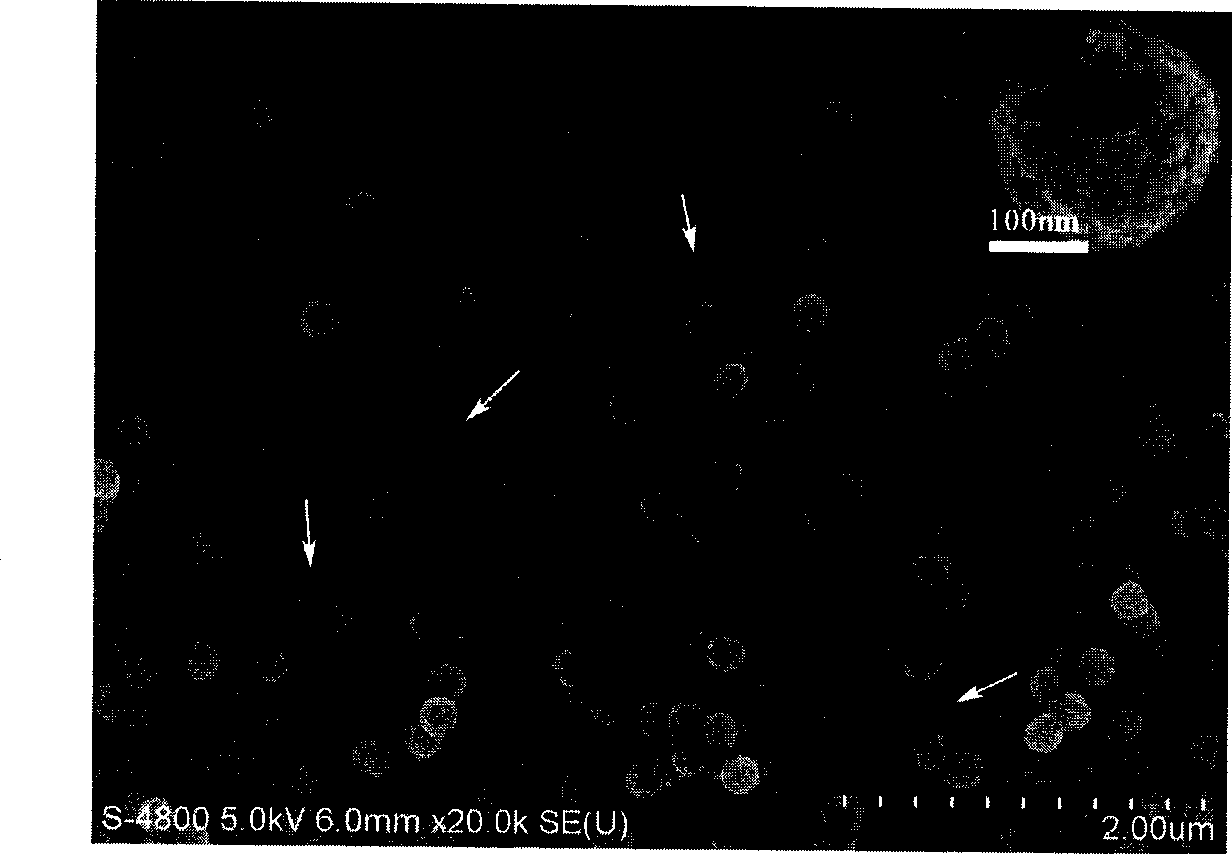

One-step template-free method for preparing a great amount of monodisperse ZnS hollow nanospheres

The invention relates to a one-step template-free method for preparing a great amount of monodisperse ZnS hollow nanospheres. The method comprises the following steps: the zinc acetate is dissolved in distilled water; thiourea is added to the solution and stirred in the solution at the room temperature until the solution is clear; the obtained solution is transferred to a stainless steel reaction vessel with a polytetrafluoroethylene lining for sealing, then the reaction vessel is heated to the reaction temperature and kept at the reaction temperature for 1 to 48 hours, and the thiourea is decomposed and reacts with the zinc acetate to generate deposition; and after the reaction, the reaction vessel is cooled to the room temperature, then the clear solution on the upper layer is removed, and the obtained deposition is washed with the distilled water and dried in a vacuum drying oven at 30-100 DEG C to obtain the monodisperse ZnS hollow nanospheres. By adopting the method, the monodisperse ZnS hollow nanospheres with radius of 200 nm and with casing layers assembled by nano-particles can be prepared at a large scale. The method is simple and environment-friendly, needs lower temperature and no template and additive agent and takes the water as the solvent. The method can prepare other transition metal oxide hollow nanospheres, such as manganese sulfide, cadmium sulfide, and the like.

Owner:WUHAN UNIV OF TECH

400-MPa-grade fine-grain hot rolled steel bar and manufacturing process thereof

ActiveCN110042303AImprove performanceHigh strengthProcess efficiency improvementManganese sulfideRebar

The invention discloses a 400-MPa-grade fine-grain hot rolled steel bar and a manufacturing process thereof, and belongs to the field of hot-rolled steel bar production. The steel bar comprises the following components in percentage by mass: 0.20-0.25% of C, 0.3-0.8% of Si, 1.2-1.6% of Mn, 0.01-0.04% of P, 0.01-0.04% of S, 0.005-0.03% of Ti, 0.001-0.08 % of Cr, 0.0001-0.008% of V, 0.0001-0.008% ofNb, 0.0001-0.008% of Al, 0.01-0.02% of O, 0.003-0.01% of N, and the balance Fe and inevitable impurities; and the steel bar further comprises manganese silicate inclusions, titanium oxide manganese sulfide multiphase inclusions, manganese sulfide inclusions, and other inevitable inclusions. The manufacturing process comprises the following steps of smelting molten steel, heating a continuous casting billet, and rolling a steel bar. According to the process, by combining optimization of the components and the inclusions with smelting continuous casting and rolling improvement as well as the inclusion induced fine grain strengthening mechanism, the strength of the steel bar is improved, the addition of precious alloy elements is reduced, and low-cost and high-quality production of the hot-rolled steel bar is achieved.

Owner:NORTHEASTERN UNIV

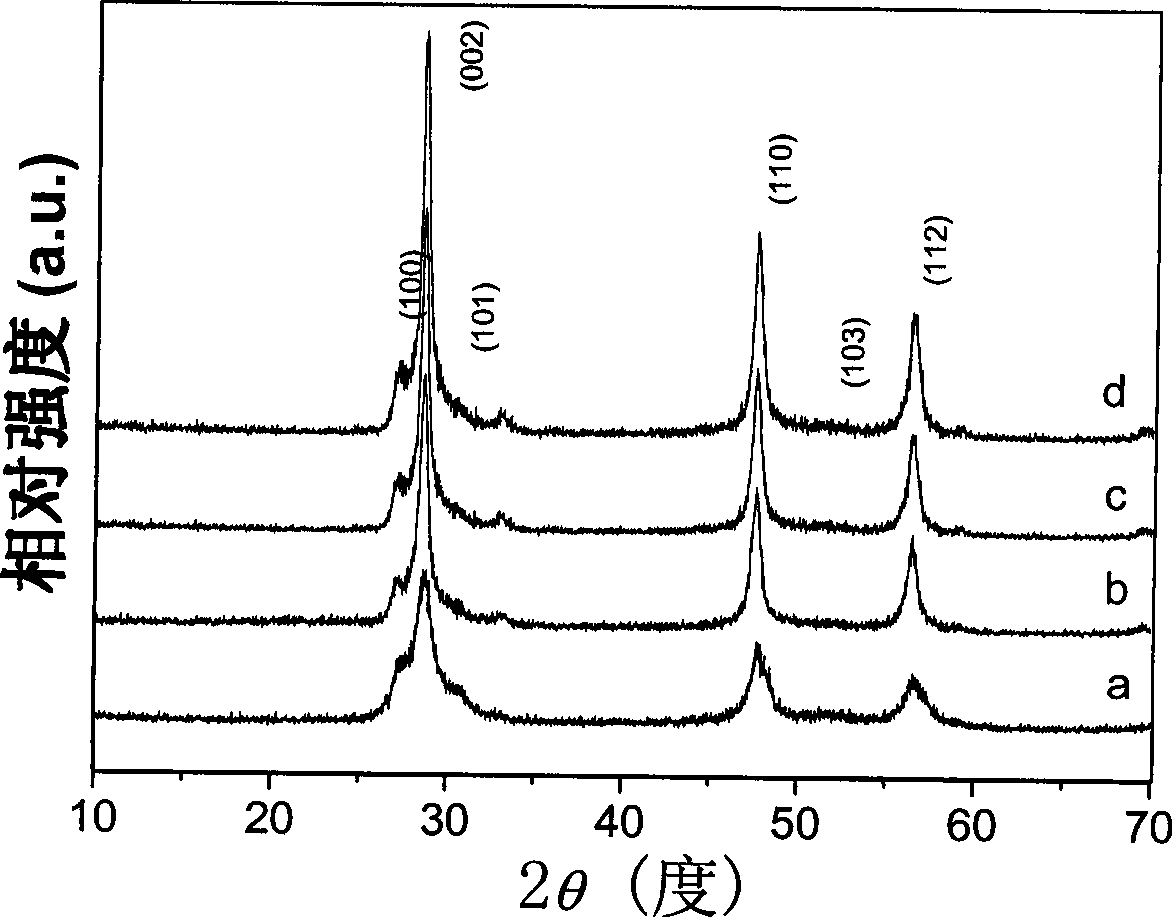

Preparation method of manganese sulfide nano material

InactiveCN101555040AChange crystal formChange shapeNanostructure manufactureManganese compoundsManganese sulfideFree cooling

The invention relates to a preparation method of manganese sulfide nano material, belonging to the inorganic nano material field. The preparation method comprises the following steps of: step 1. preparing solution a and solution b, wherein, solution a: dissolving manganese chloride in pure water, adding a modifying agent, stirring and forming solution a, solution b: dissolving sodium sulfide in pure water and forming solution b; step 2. mixing solution a and solution b in the step 1 according to the molar ratio of the manganese chloride and the sodium sulfide of 2:3; stirring, transferring the mixed solution into a high-pressure kettle containing a polyfluortetraethylene liner, reacting for 6 to 12 hours under the temperature of 120 to 180 DEG C, and naturally cooling; and step 3. washing the products obtained in the step 2 after cooling, drying thereby obtaining the manganese sulfide nano material. The method has simple and convenient operation, high yield and uniform and controllable crystal types and appearance of products and the like.

Owner:SHANGHAI JIAO TONG UNIV

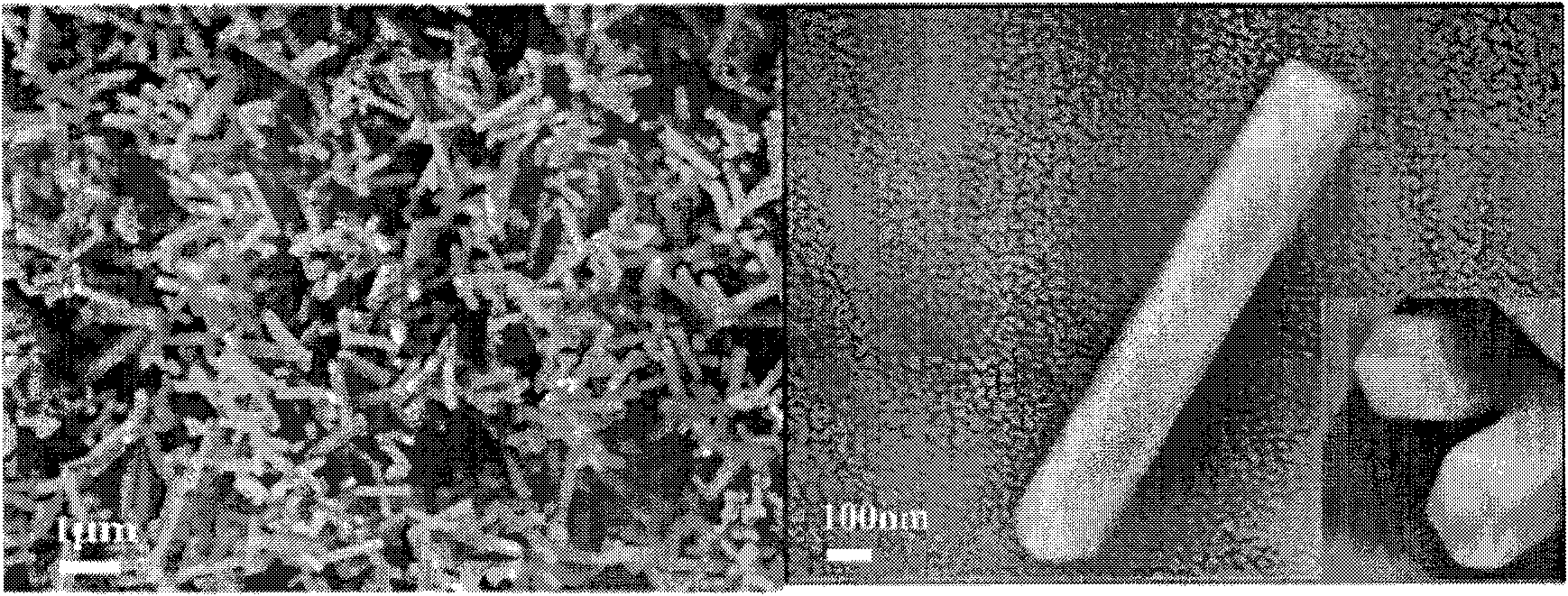

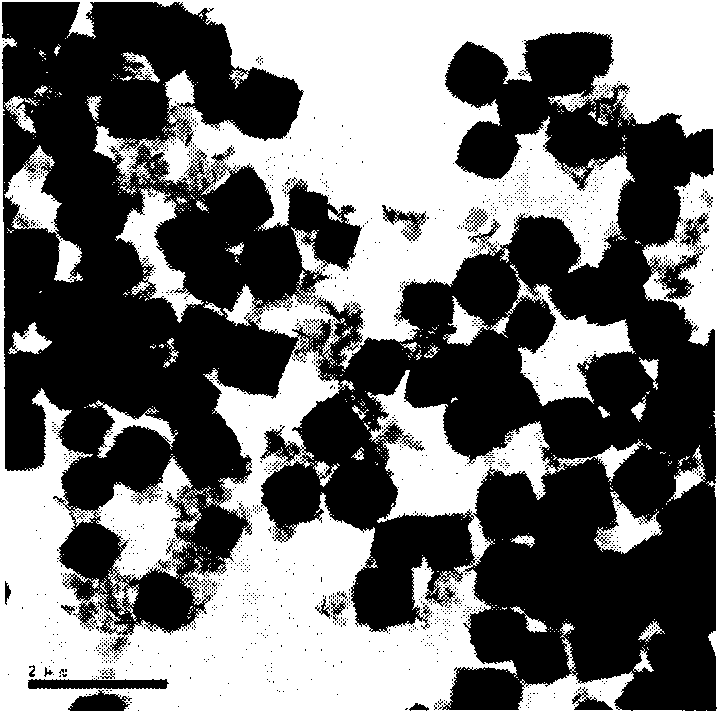

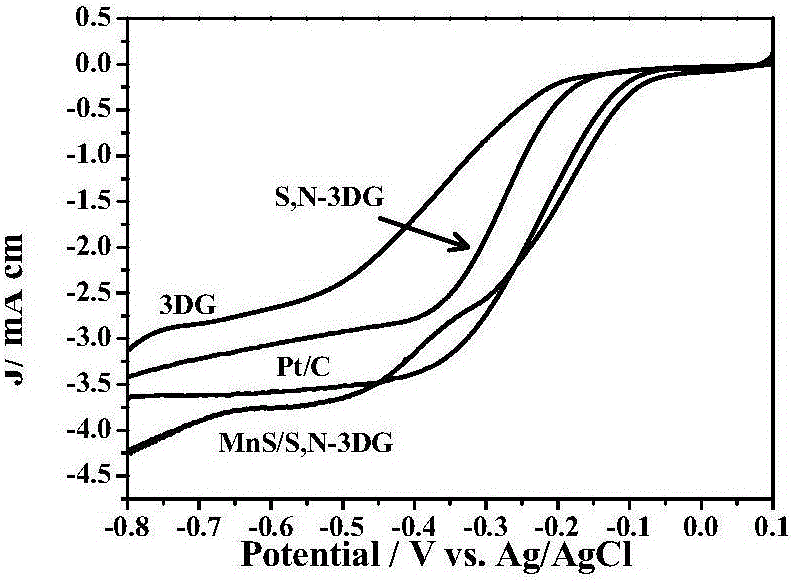

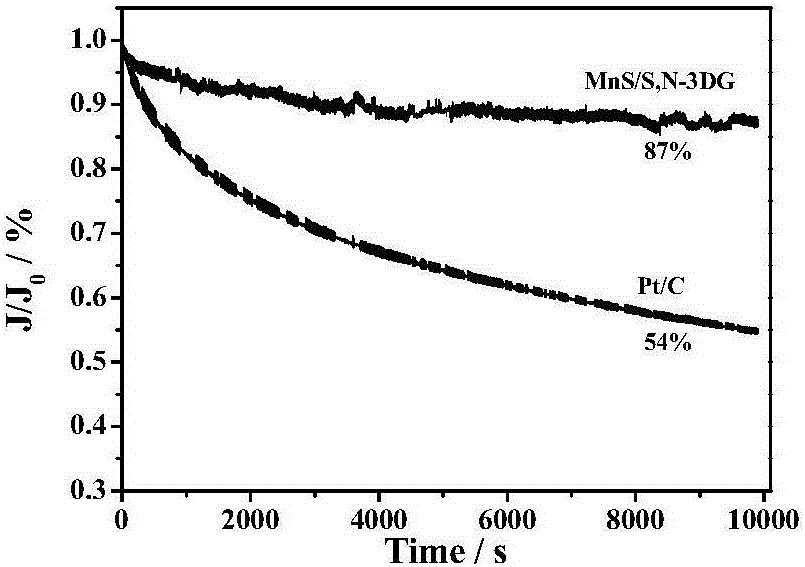

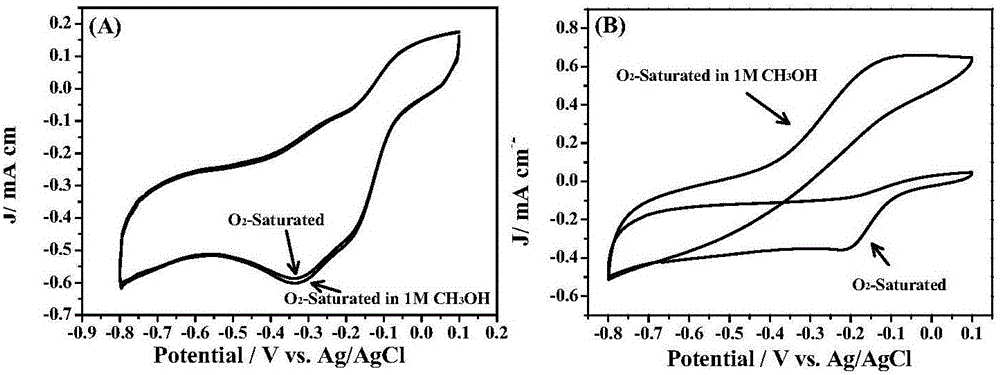

Preparation of sulfur and nitrogen co-doped three-dimensional graphene/manganese sulfide composite material and application of composite material in electrocatalytic reduction of oxygen

ActiveCN106000439AEasy to prepareHigh catalytic activityPhysical/chemical process catalystsCell electrodesSulfurManganese sulfide

The invention relates to preparation of a sulfur and nitrogen co-doped three-dimensional graphene / manganese sulfide (MnS / S,N-3DG) composite material and an application of the composite material in electrocatalytic reduction of oxygen. The preparation includes the following steps: preparing a MnS / S,N-3DG composite material, modifying a glassy carbon electrode surface with the MnS / S,N-3DG composite material, and testing the reduction electrocatalytic activity of the material on oxygen. The preparation has the beneficial effects that the sample and feasible way is adopted for preparation of the MnS / S,N-3DG composite material. Along with the introduction of nitrogen atoms, sulfur atoms and manganese sulfide, the composite material shows excellent oxygen reduction electrocatalytic activity. The stability and methanol resistance of the material are better than those of a commercial Pt / C catalyst.

Owner:CHANGZHOU UNIV

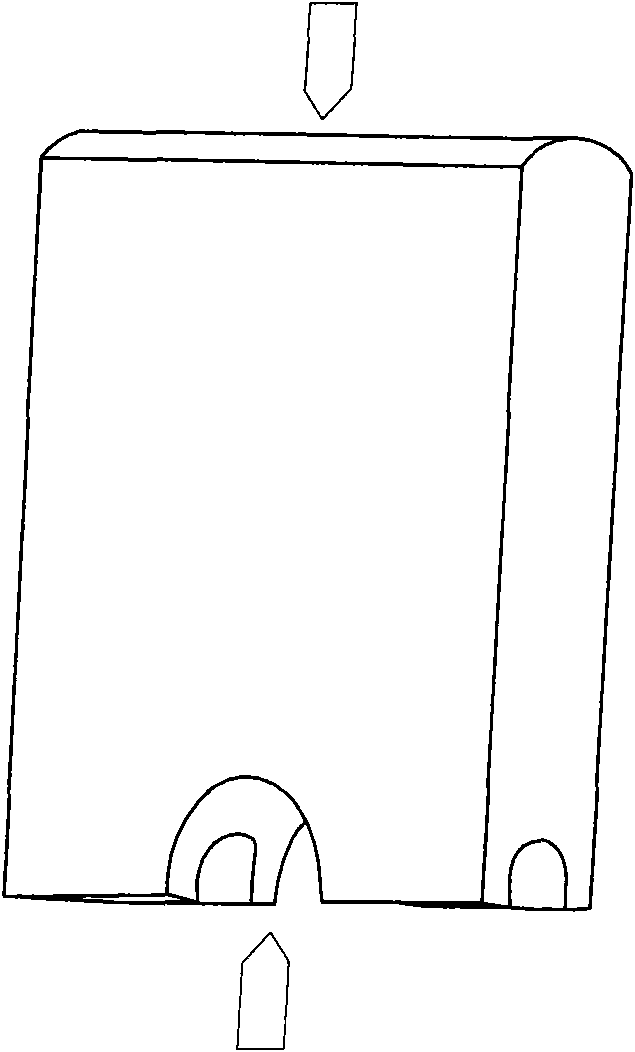

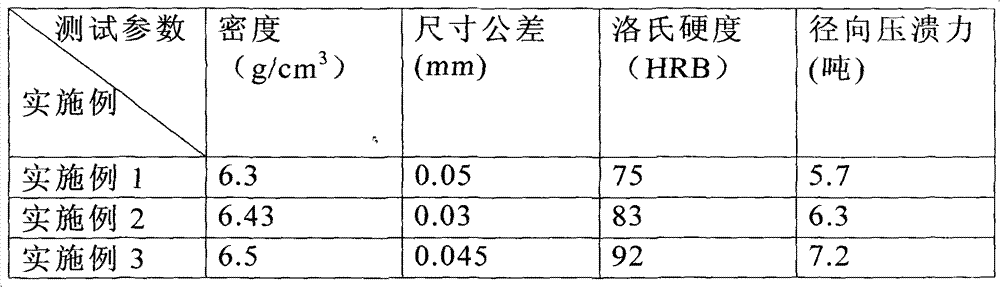

Guider of damper and preparation method of guider

The invention provides a guider of a damper, belonging to the field of automobile accessories and solving the problem of low density of the conventional guider of the damper. The guider of the damper comprises the following components in parts by weight: 40-60 parts of reducing iron powder, 0.2-0.5 part of electrolytic copper powder, 0.1-0.3 part of graphite, 0.25-0.35 part of lubricant and 0.15-0.25 part of manganese sulfide. The invention also provides a preparation method of the guider of the damper. By means of rationally selecting ingredients for preparing the guider of the damper and utilizing a powder metallurgy method, the cost can be reduced, the product density can be improved, the dimensional tolerance of a product can be reduced, and the hardness of the product can be improved. Further, the dimensional tolerance of the product is reduced by using shaping, and the product density is further improved through water atomization steam treatment, so that the product density of the guider of the damper can reach 6.3-6.5 g / cm<3>.

Owner:宁波拓发汽车零部件有限公司

Iron-based mixed powder for powder metallurgy and sintered body

InactiveUS7300490B2Improve machinabilitySolve the real problemTransportation and packagingMetal-working apparatusCalcium biphosphateApatite

Owner:JFE STEEL CORP

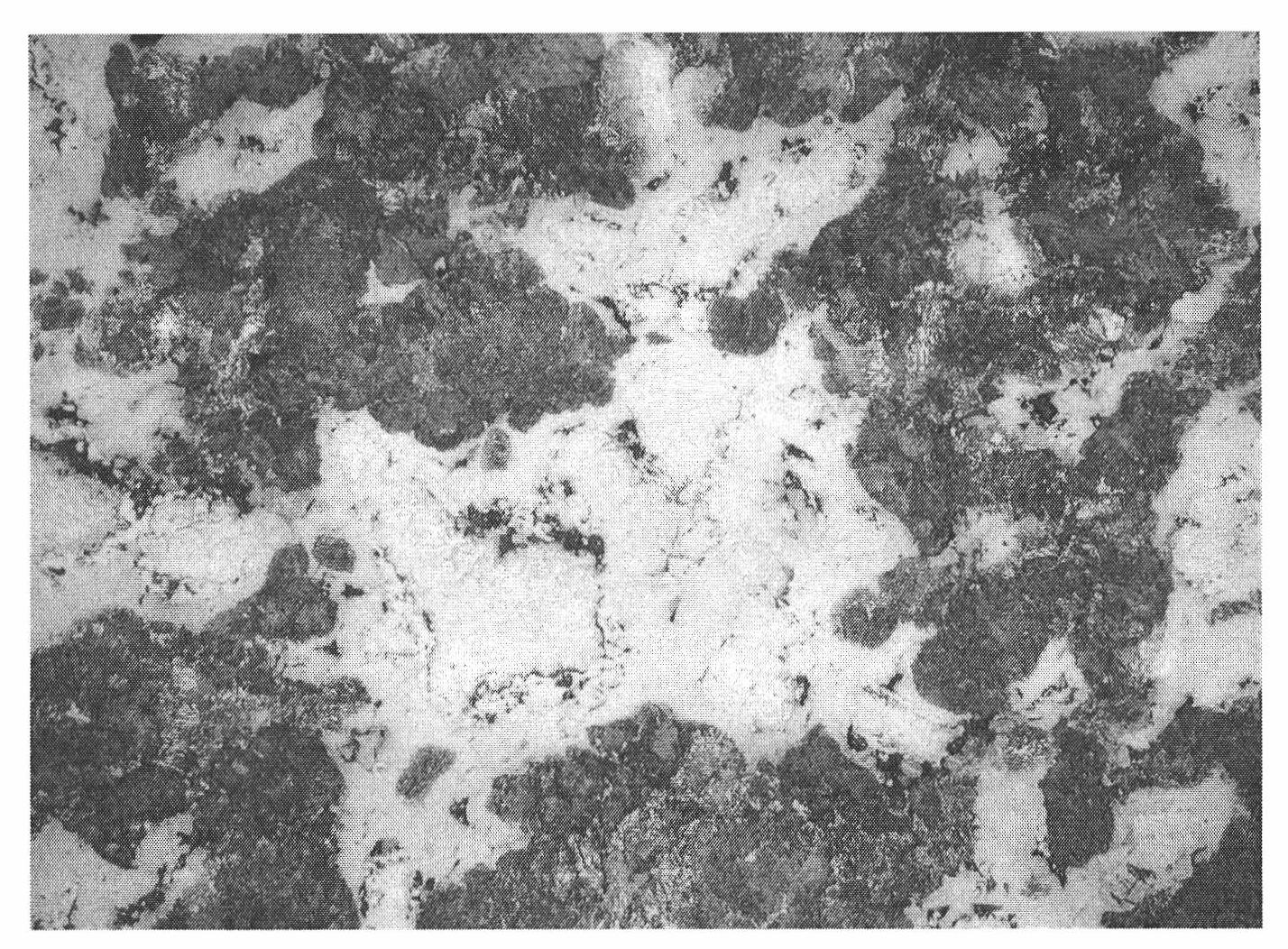

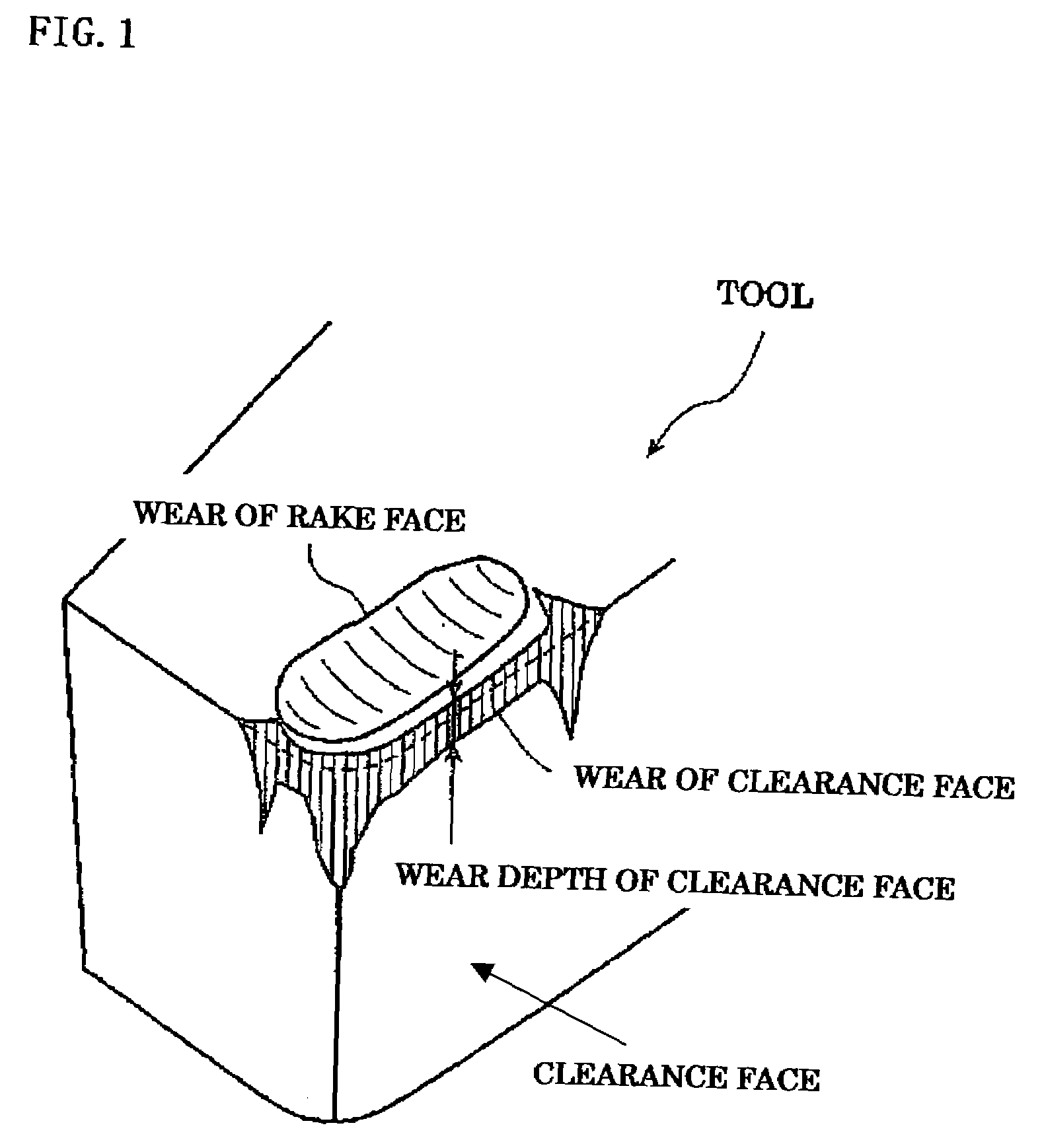

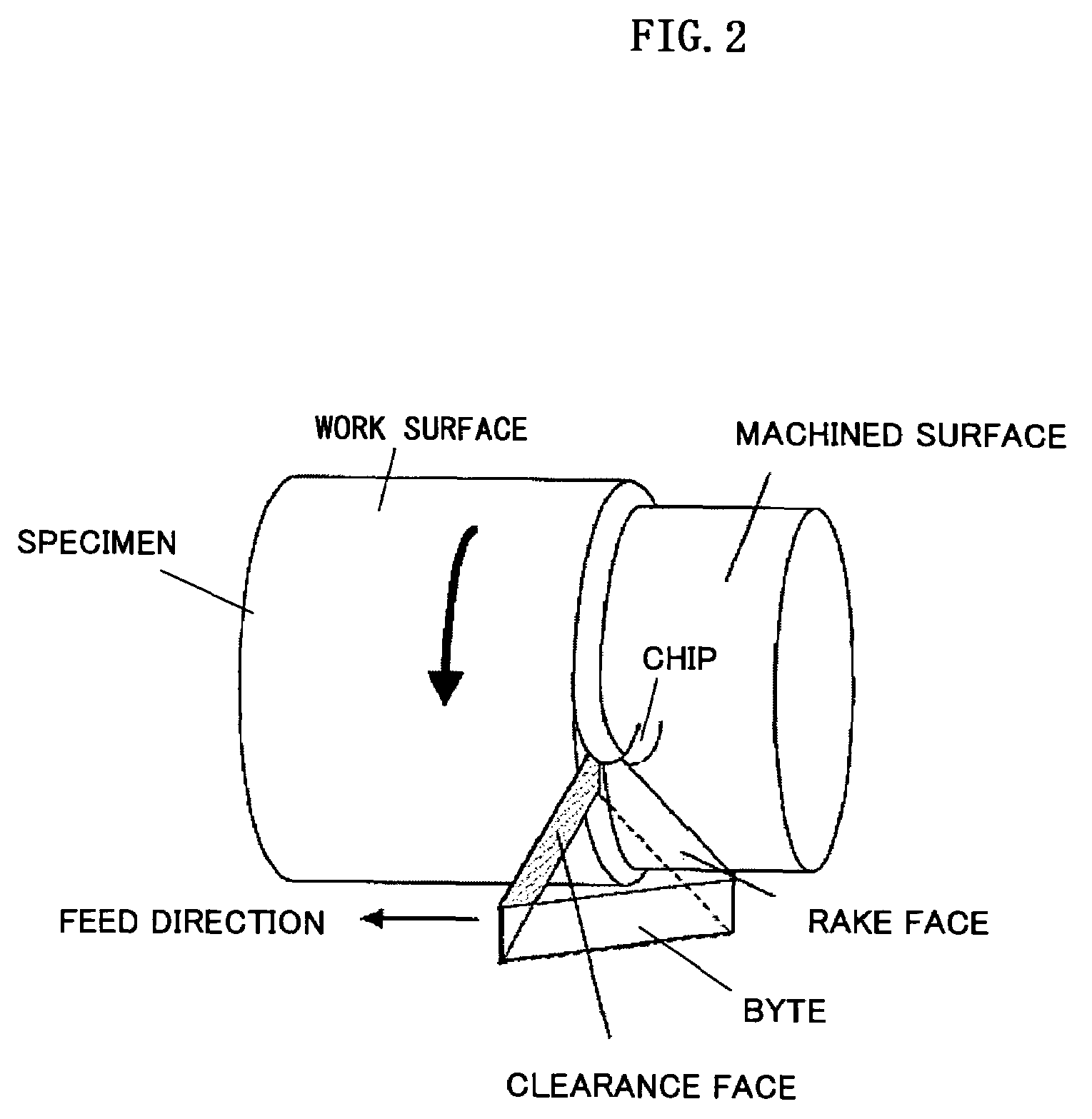

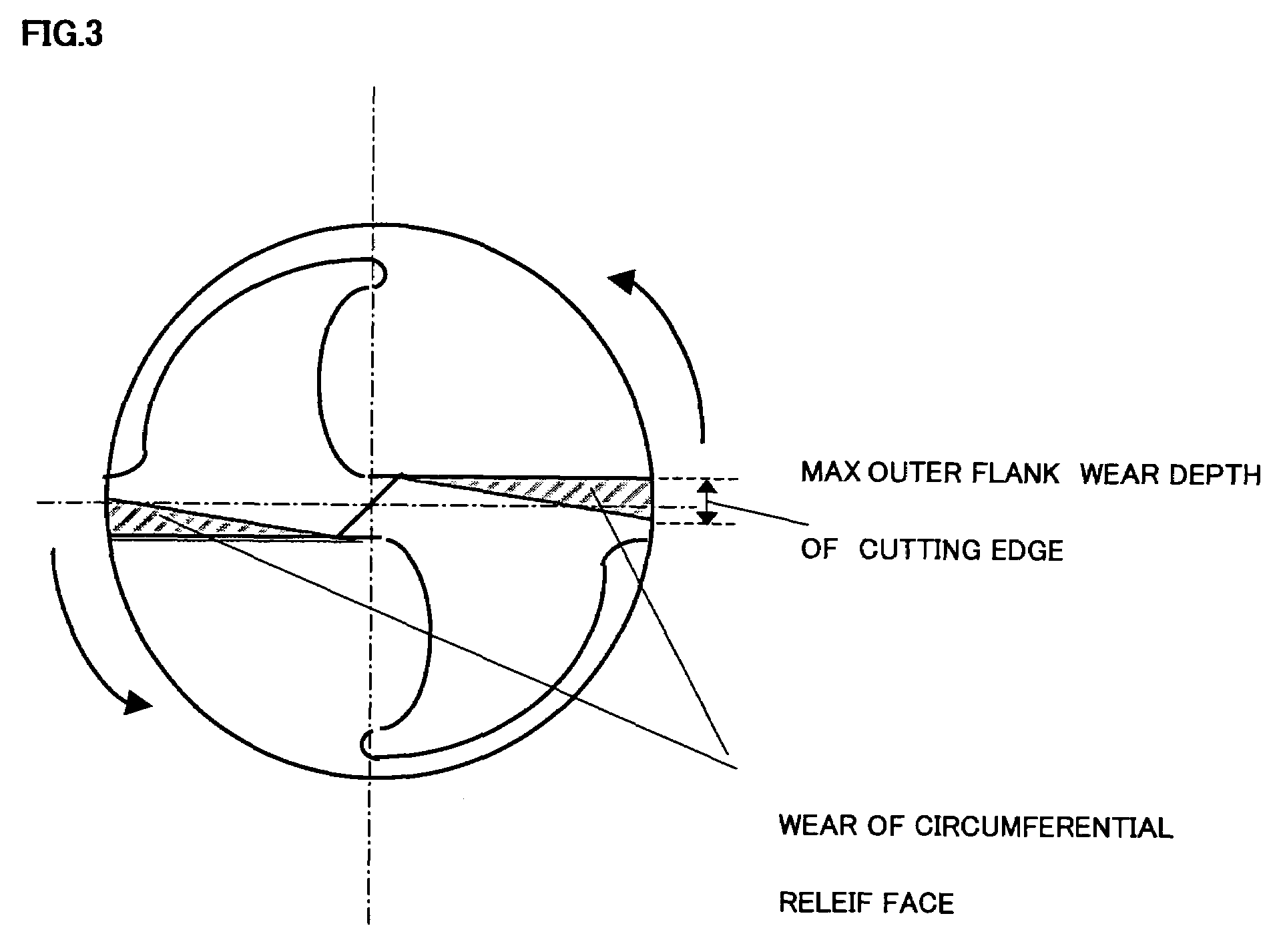

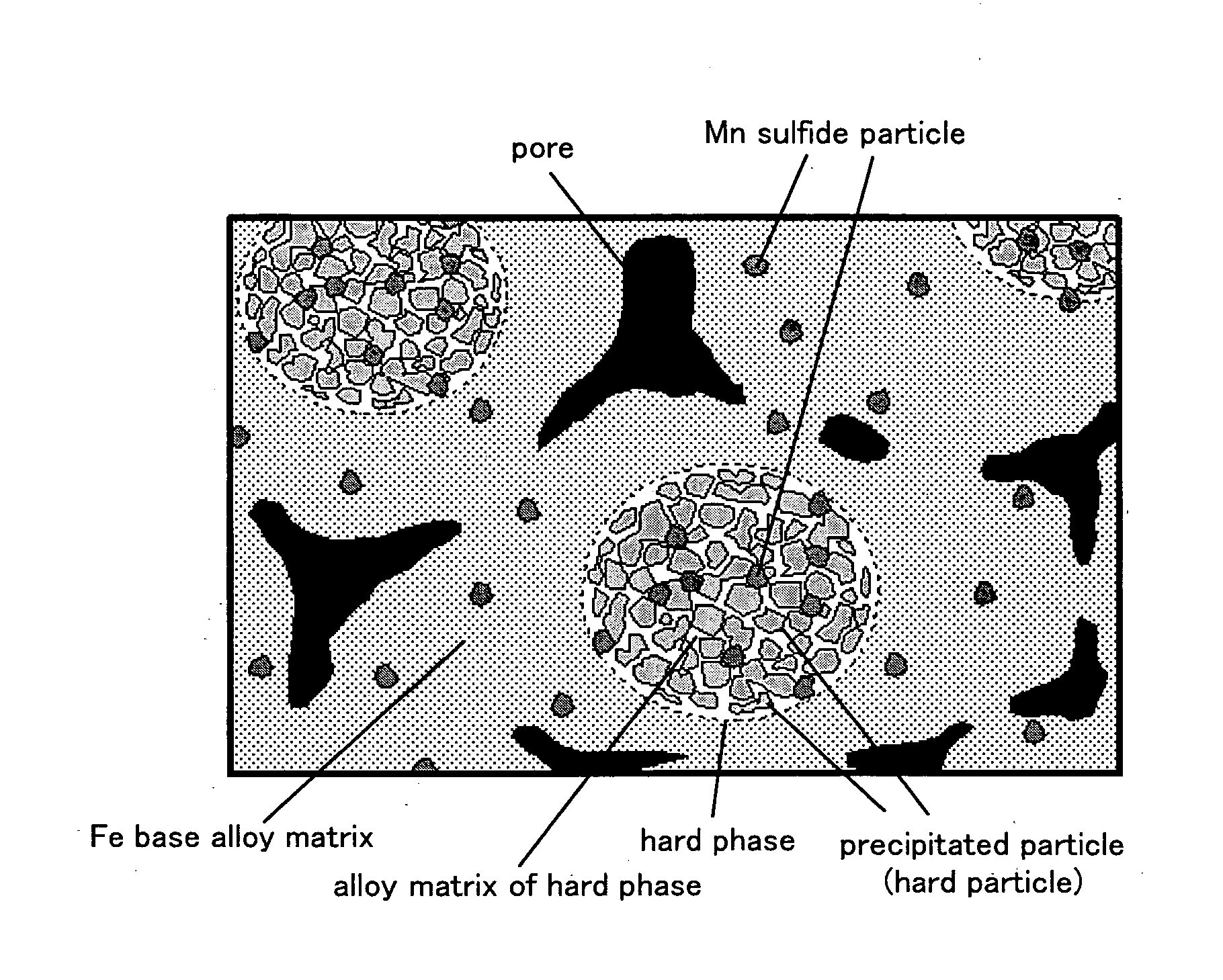

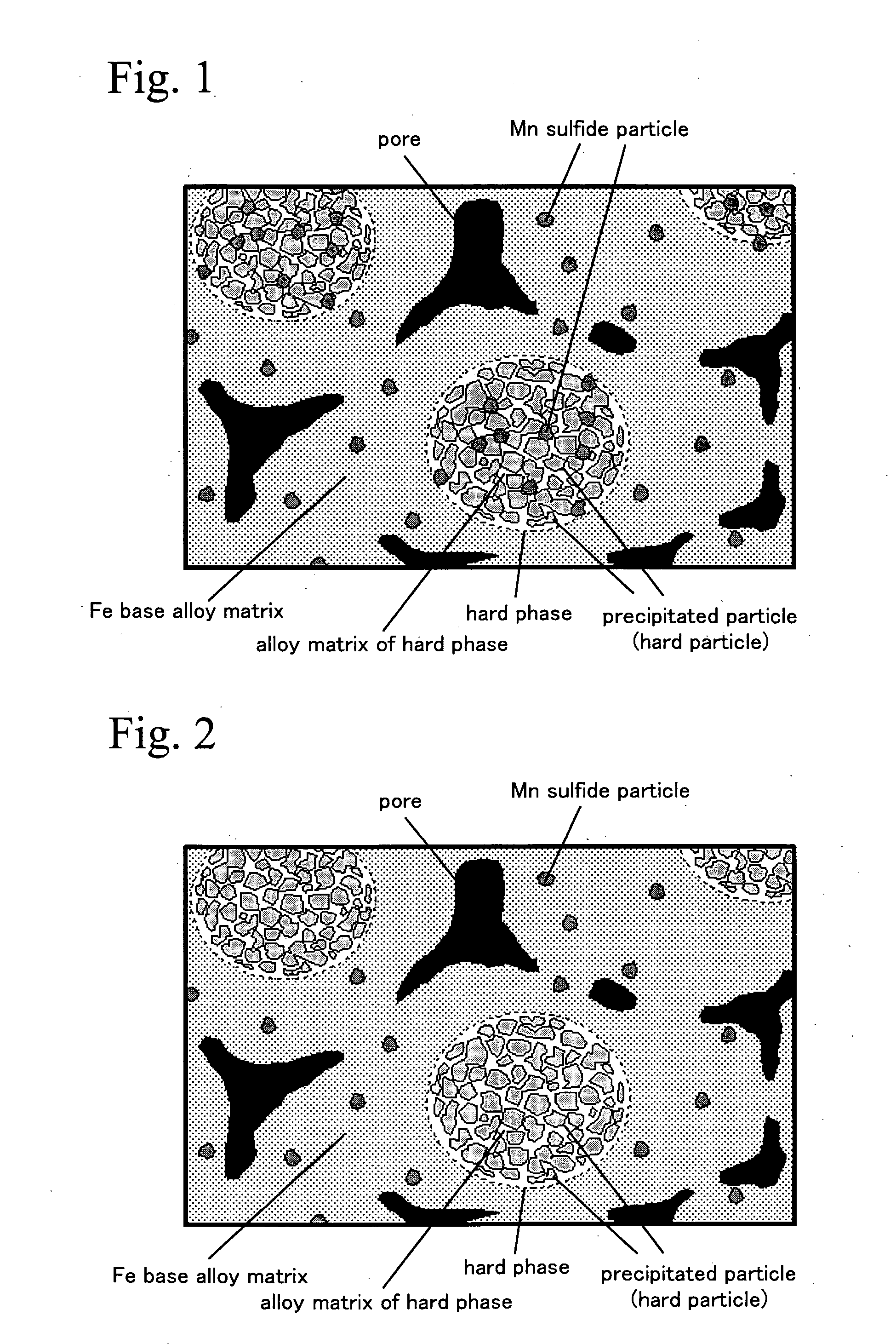

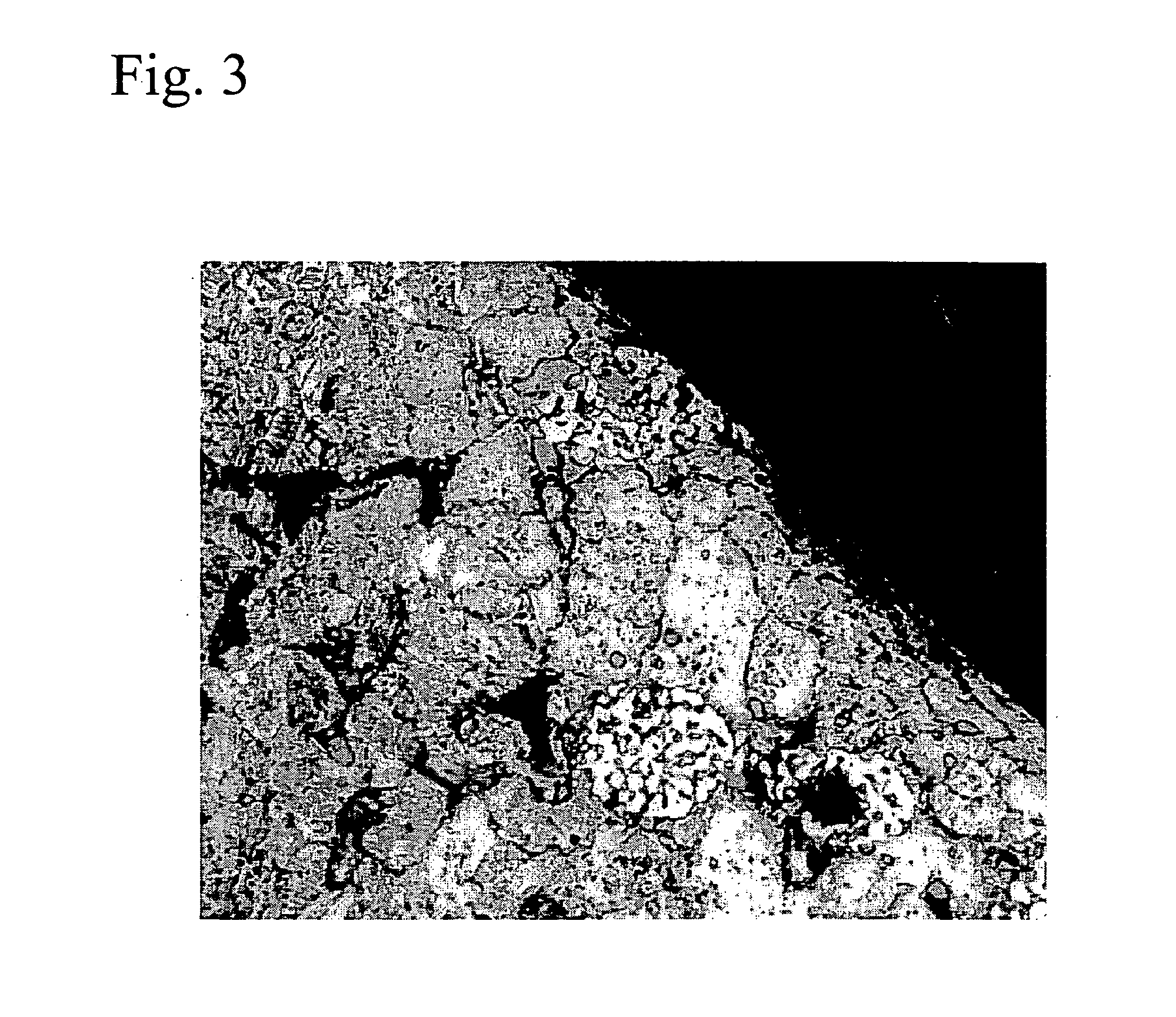

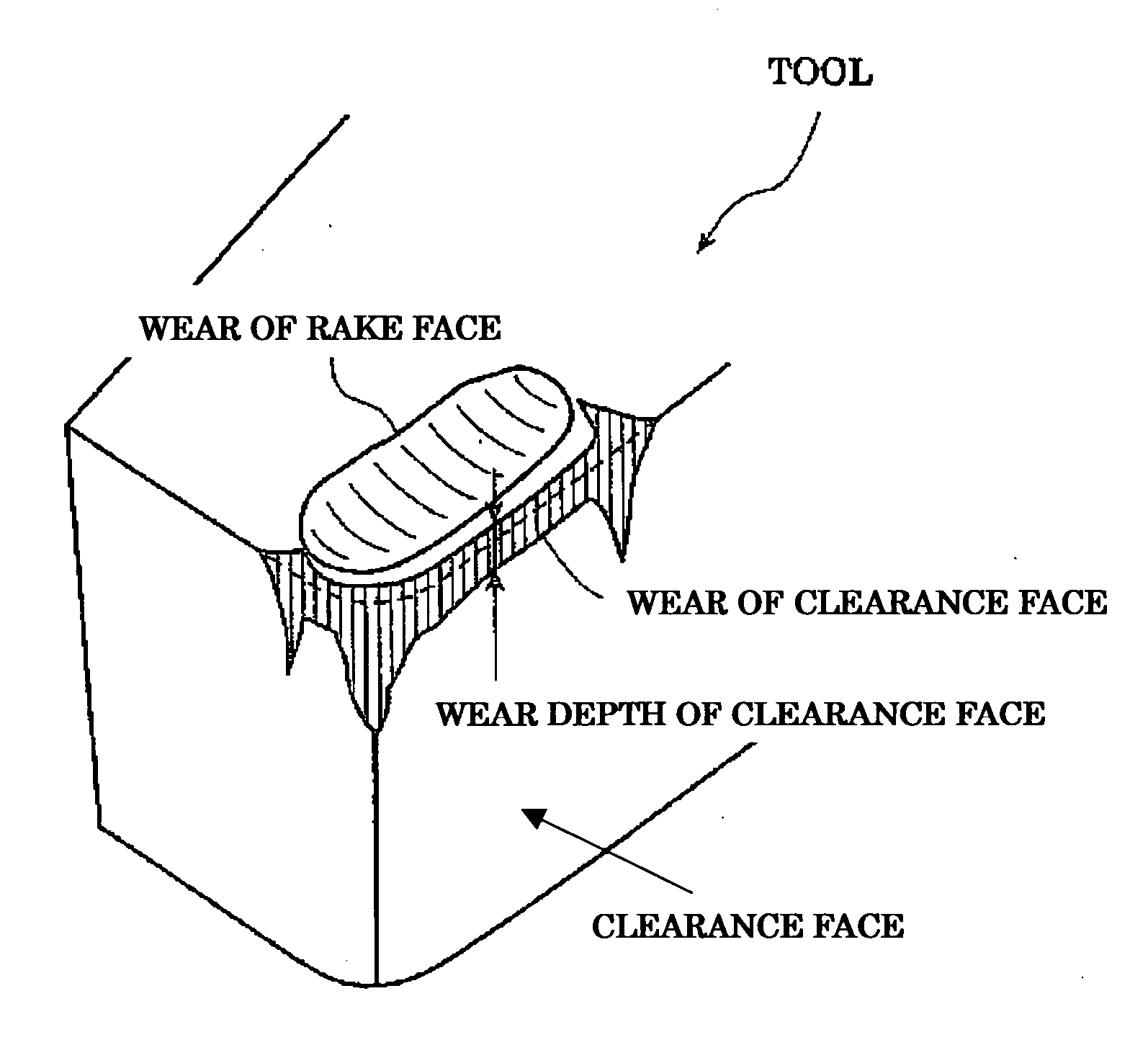

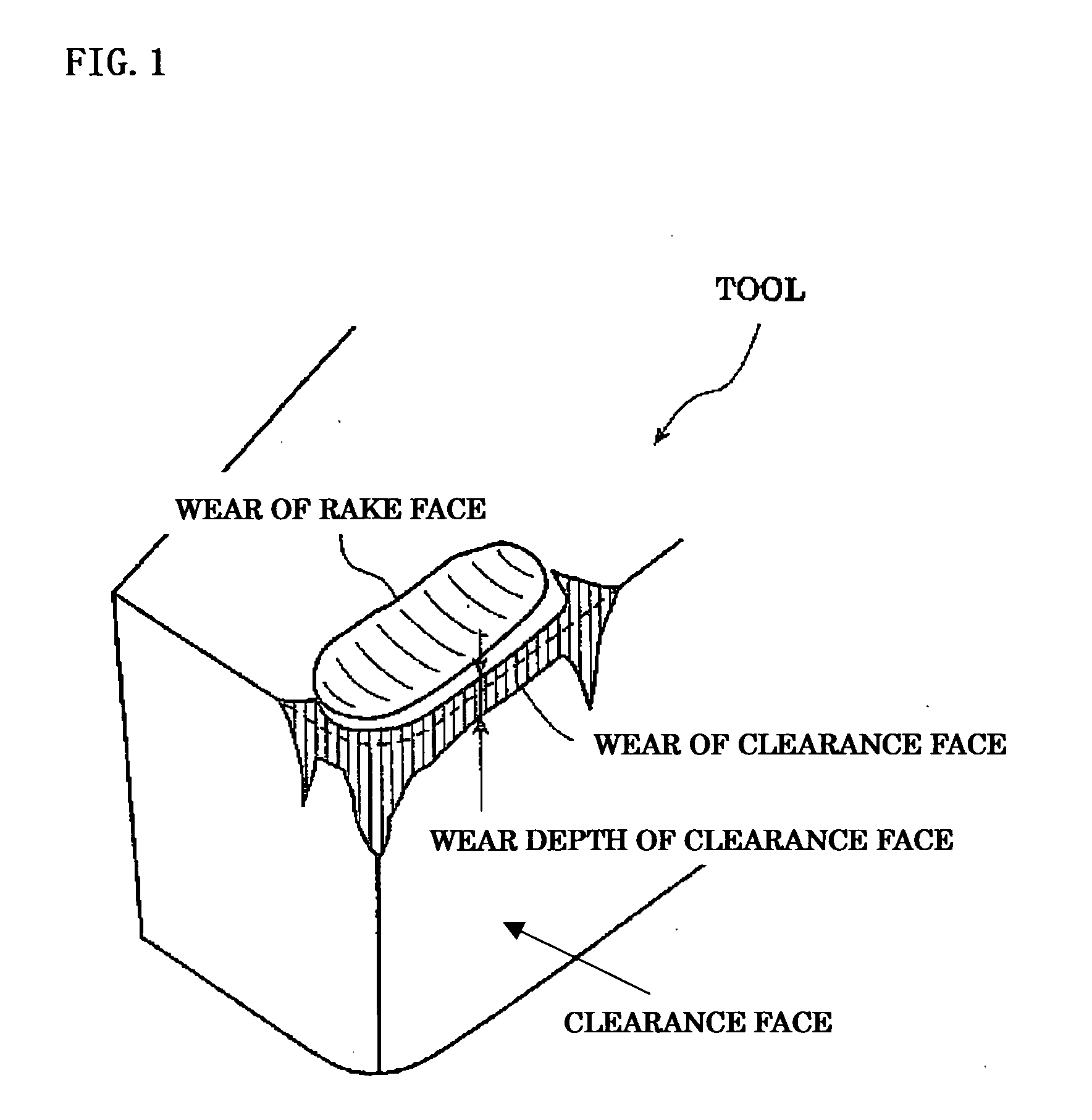

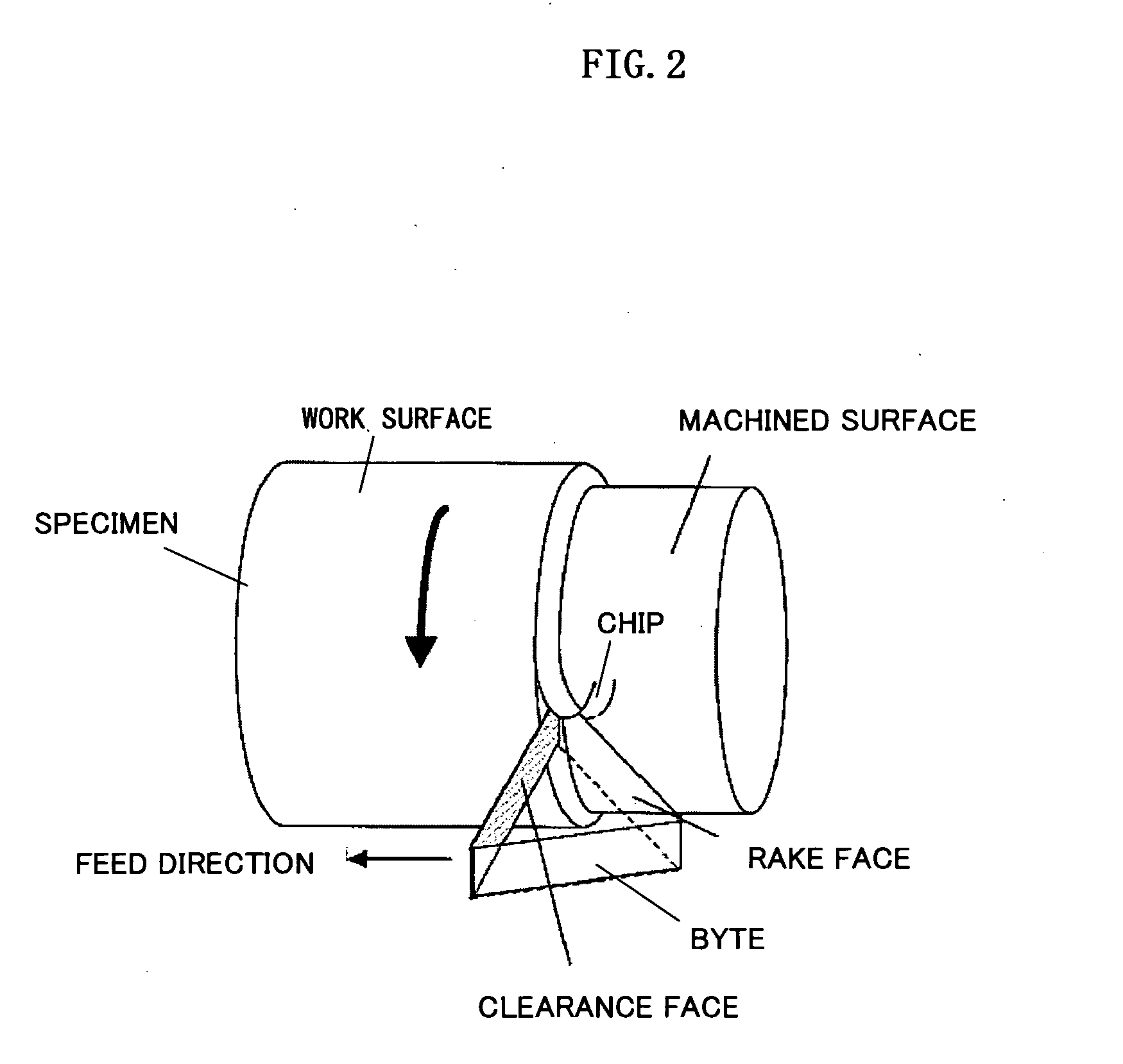

Wear resistant sintered member and production method therefor

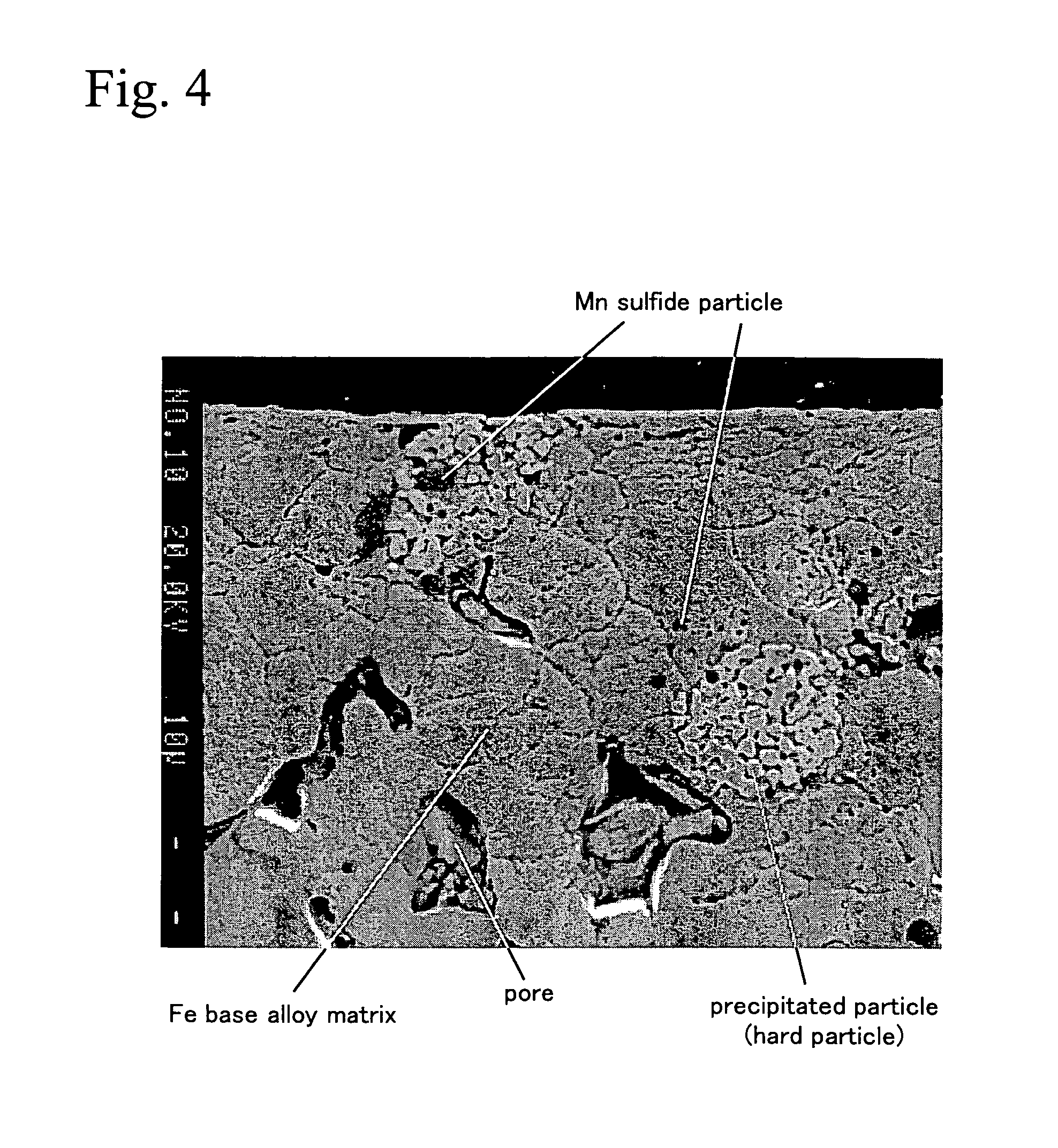

ActiveUS20060219054A1Improve machinabilityImprove wear resistanceTransportation and packagingMetal-working apparatusWear resistantManganese sulfide

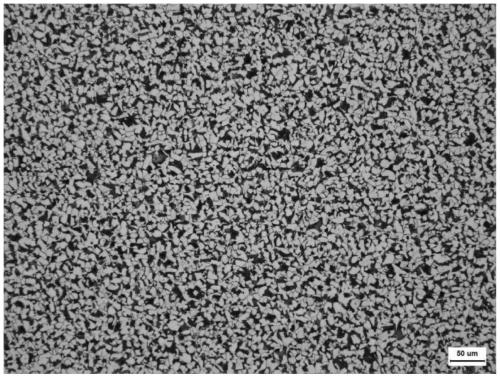

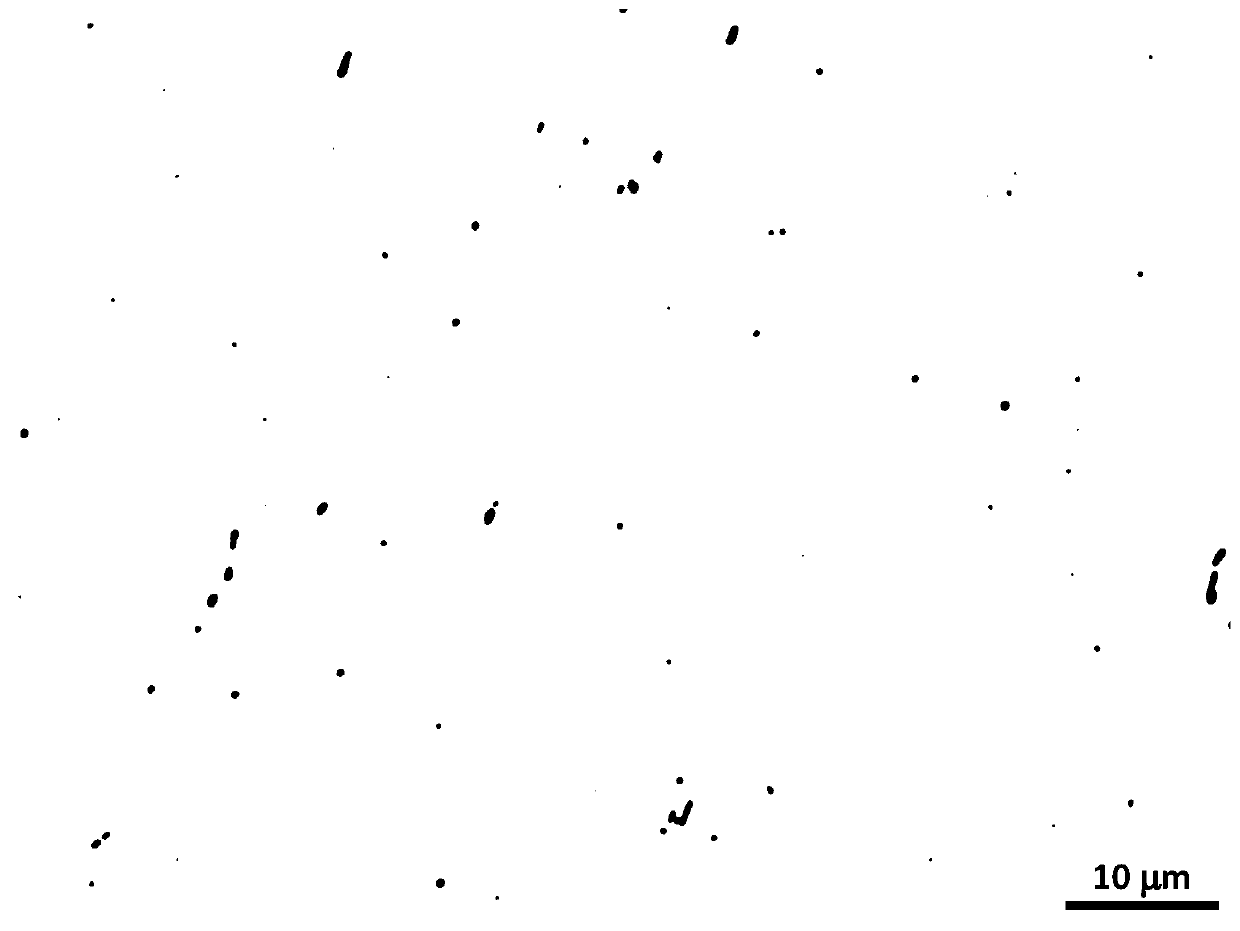

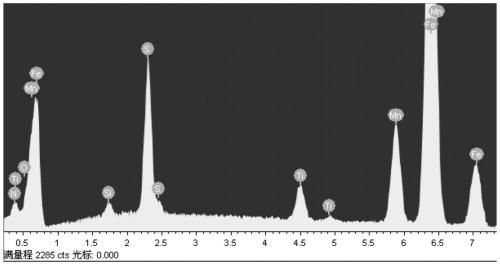

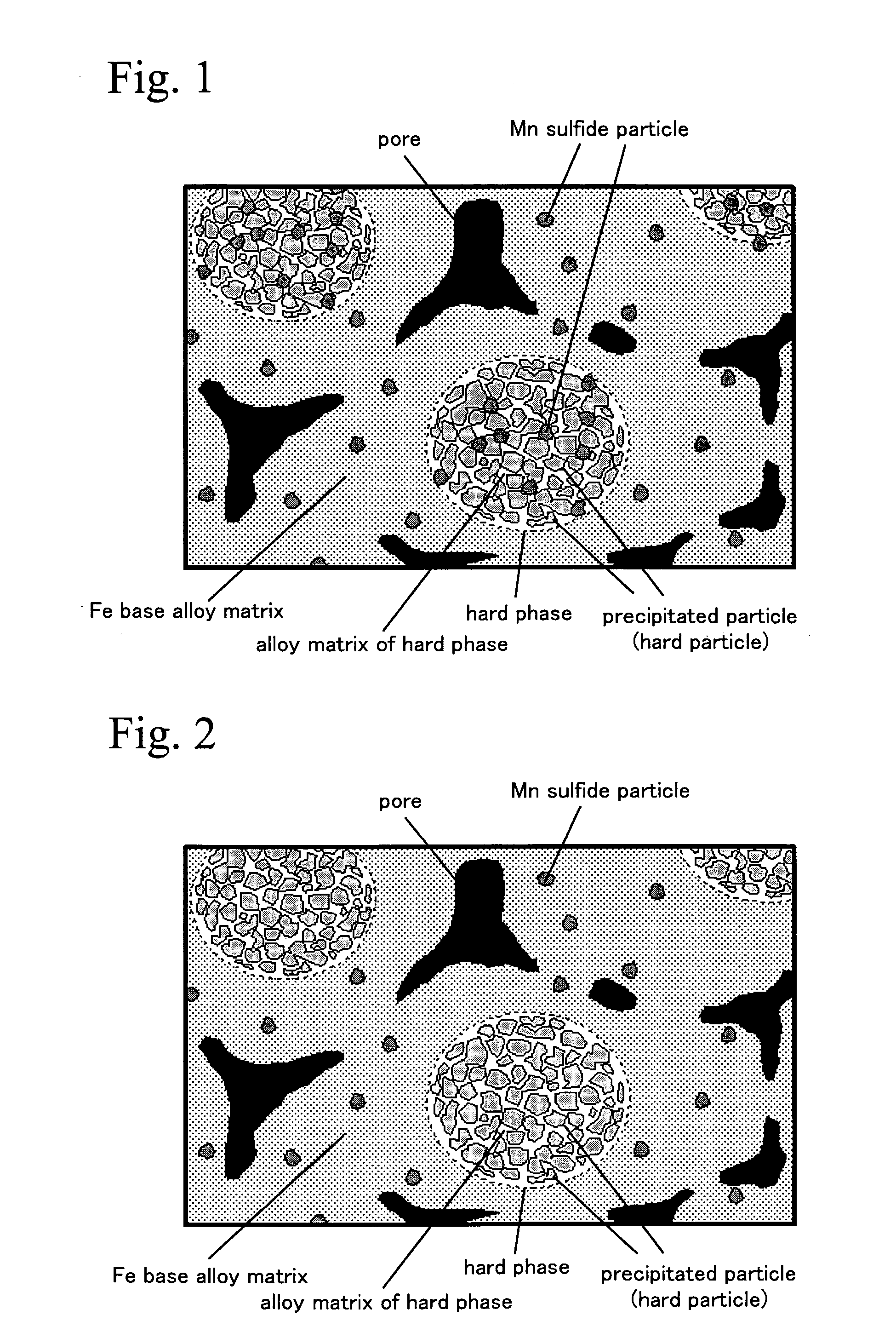

A wear resistant sintered member comprising an Fe base alloy matrix and a hard phase dispersed in the Fe base alloy matrix and having an alloy matrix and hard particles precipitated and dispersed in the alloy matrix. Manganese sulfide particles having particle size of 10 μm or less are uniformly dispersed in crystal grains of the overall Fe base alloy matrix, and manganese sulfide particles having particle size of 10 μm or less are dispersed in the alloy matrix of the hard phase.

Owner:RESONAC CORP

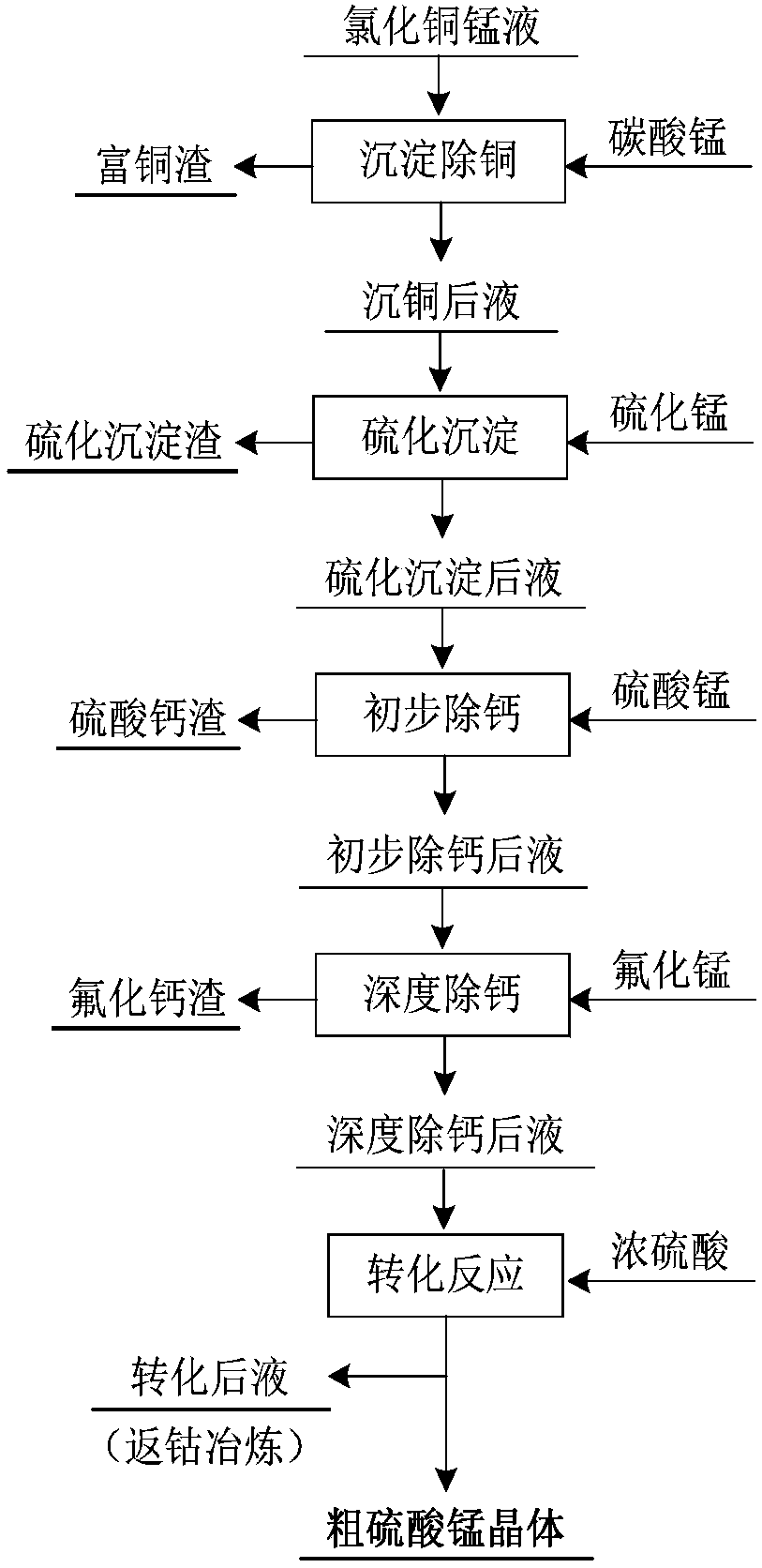

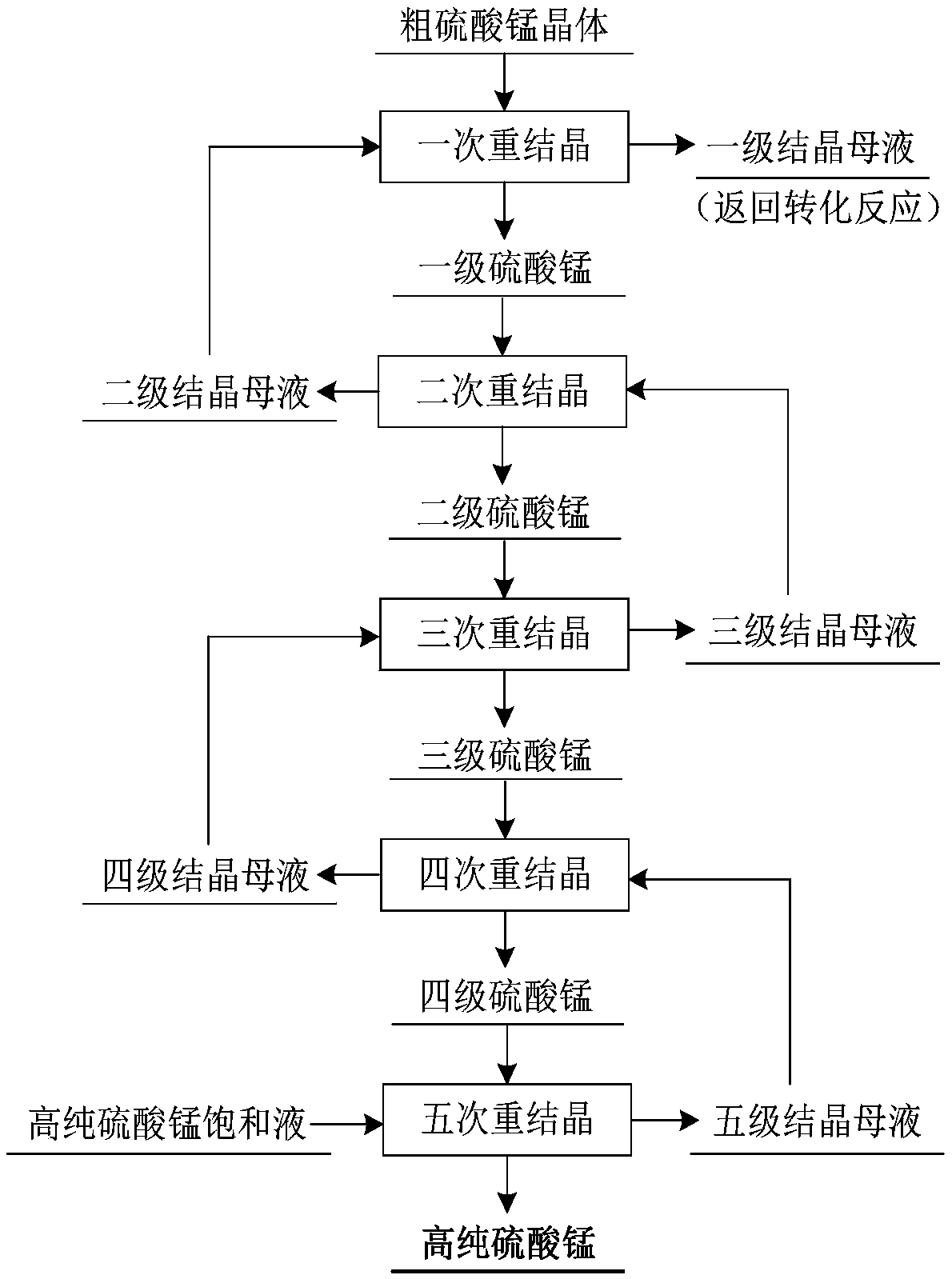

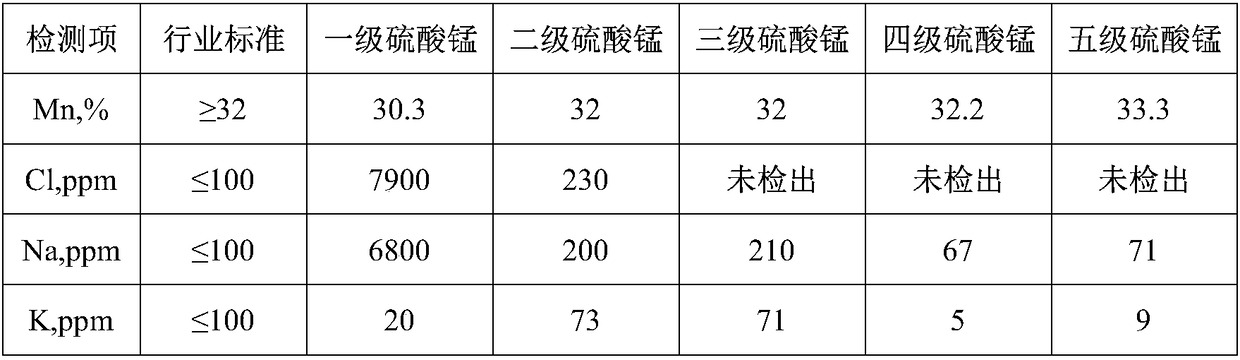

Method for preparing battery-grade manganese sulfate by using copper chloride manganese liquid

InactiveCN108585051ARealize deep decalcificationLow costManganese sulfatesWater dischargeDissolution

The invention discloses a method for preparing battery-grade manganese sulfate by using a copper chloride manganese liquid. The method comprises the steps that the copper chloride manganese liquid reacts with concentrated sulfuric acid to synthesize a coarse manganese sulfate crystal after neutralizing and precipitating copper ions through manganese carbonate, precipitating heavy metal ions through manganese sulfide, preliminarily precipitating calcium ions through manganese sulfate and deeply precipitating calcium ions through active manganese fluoride in sequence; and the coarse manganese sulfate crystal is recrystallized to obtain a battery-grade manganese sulfate crystal. The method for preparing the battery-grade manganese sulfate by using the copper chloride manganese liquid has theadvantages that the whole process adopts manganese-containing materials to remove and recover cuprum, zinc, calcium and other components in the copper chloride manganese liquid, and a five-stage countercurrent series recrystallization purification technology is combined, so that the quality of manganese sulfate is greatly improved, and the high-efficiency utilization of manganese resources and thewhole-process no-waste-water discharge are ensured; concentrated sulfuric acid is directly adopted to achieve the precipitation and conversion of manganese chloride to synthesize the coarse manganesesulfate, and the complex process for synthesizing the manganese sulfate by firstly extracting manganese ions then reversely extracting sulfuric acid or firstly precipitating manganese ions through carbonate then synthesizing the manganese sulfate through sulfuric acid dissolution is avoided.

Owner:CENT SOUTH UNIV

Guider of automobile shock absorber and manufacturing method thereof

The invention relates to a guider of an automobile shock absorber and a manufacturingmethod thereof, and belongs to the field of automobile spare parts. The guider of the automobile shock absorber is formed by hot-pressing and sintering alloy powder, ceramic powder, pore-foaming agents and binders, wherein the mass ratio of the alloy powder, the ceramic powder, the pore-foaming agents and the binders is 100 to 40-90 to 0.3-1 to 1-5; the alloy powder is composed of, by weight, 2-8% of reduction copper powder, 2-8% of graphite powder, 0.3-2% of phosphorization iron powder, 0.5-3% of manganese sulfide, 3-12% of chromium powder, 0.5-3% of nickel powder and the balance iron powder. The invention further provides the manufacturingmethod of the guider of the automobile shock absorber. According to the manufacturing method, material for manufacturingthe guider of the automobile shock absorber is reasonably selected, the alloy powder and the ceramic powder are selected for manufacturing porous material, multi-stage high-temperature sintering and low-temperature tempering are adopted after forming, and therefore the weightof the guider of the automobile shock absorber is lowered, the comprehensive property of the guider is improved, the mechanical property of the guider is excellent, the strength, the rigidity, the wear resistance and the high temperature resistance of the guider are good, the cost is low, the use efficiency of the guider is improved, and the service life of the guider is prolonged.

Owner:NINGBO QUNXING POWDER METALLURGY

Iron-based mixed powder for powder metallurgy and sintered body

InactiveUS20060065072A1Improve machinabilitySolve the real problemTransportation and packagingMetal-working apparatusApatiteAlloy

The invention provides an iron-based mixed powder for powder metallurgy enabling the iron-based mixed powder to improve the machinability, without being accompanied by degrading the mechanical property of a sintered body. In order to obtain the purpose of the invention, the iron-based mixed powder comprises a mixture of an iron-based powder, a powder for an alloy, a powder for machinability improvement, while further adding lubricant. And, (1) the powder for machinability improvement comprises a manganese sulfide powder, and at least one selected from the group consisting of a calcium phosphate powder and a hydroxy apatite powder, or, (2) the powder for machinability improvement has an average particle diameter of 1 to 60 micrometers and is at least one selected from the group consisting of manganese sulfide powder and calcium fluoride powder.

Owner:JFE STEEL CORP

Ultrahigh-strength steel hot-rolled base plate and manufacturing method thereof

ActiveCN108531810AUniform tissueIncrease the compression ratioProcess efficiency improvementChemical compositionManganese sulfide

The invention provides an ultrahigh-strength steel hot-rolled base plate and a manufacturing method thereof. The designed ultrahigh-strength steel base plate has strict requirements for chemical components, the plate shape and the like, and thus, the four links of component design, smelting, rolling and plate cutting are strictly controlled. Firstly, the contents of C, Si, Mn, P, S, Mo, V, Cr, Ni,Cu, Nb and B are properly controlled; secondly, a continuous rolling method, a cooling process, a comprehensive, microalloying method, a solution strengthening method, a tissue strengthening method and the like are design to obtain a uniform complex-phase tissue containing ferrite, nodular troostite and a small quantity of bainite, and meanwhile, the dimension precision, surface quality and plateshape of a hot-rolled plate coil are controlled; thirdly, the content of S and the content of P are minimized through ultra-pure smelting, so that the tenacity is improved by reducing the inclusion of manganese sulfide; fourthly, an LF and RH duplex process is adopted to strictly control the content of H in steel; and fifthly, the internal quality of a steel billet is strictly controlled though electromagnetic stirring and slight pressing processes.

Owner:MAANSHAN IRON & STEEL CO LTD

Method for preparing powder metallurgy of valve seat

ActiveCN103252498AEnhance the effect of mixing and pressingHigh bulk densityPolyethylene vinyl acetateAdditive ingredient

The invention discloses a method for preparing powder metallurgy of a valve seat. The method includes: the valve seat is made of following raw materials, by weight, 0.4-0.6% of nickel, 0.2-0.3% of carbon, 0.2-0.4% of manganese sulfide, 0.2-0.3% of vanadium, 0.6-0.8% of graphite powder, 0.1-0.2% of chrome, 0.3-0.4% of silicon, 1-2% of performance additive, 10-20% of copper, and the balance iron; via adding the performance additive, superfine powder is provided in the mixed raw materials and can fill in seams among large granules, so that density of the mixed materials is improved; main ingredients of the superfine powder include nano potassium feldspar powder and calcium stearate, and the novel performance additive is obtained via agent like silane coupling agent, physical properties like abrasion performance of prepared products is further improved; and polyethylene vinyl acetate and liquid paraffin serving as lubricating agent are added in the performance additive, so that effect of the performance additive under mixed compression is strengthened, the strength of compaction of power metallurgy structural members is greatly improved under same compression force, combining shape and hole shape of the raw material granules is changed, and problem about generation of crack is solved basically.

Owner:浙江同力重型机械制造有限公司

Wear resistant sintered member

ActiveUS7575619B2Improve wear resistanceImprove machinabilityTransportation and packagingMetal-working apparatusManganese sulfideWear resistant

Owner:RESONAC CORPORATION

Automobile power steering pump powder metallurgy inner and outer rotor formula and preparation technology

The invention discloses an automobile power steering pump powder metallurgy inner and outer rotor formula and preparation technology. The formula comprises the following components, by weight percentage, 92-95% of atomized iron powder, 0.6-1.2% of colloidal graphite, 1-5% of electrolytic copper, 0.5-3% of nickel powder, 0.5-3% of molybdenum powder, 0.1-0.6% of manganese sulfide, 0.1-0.6% of sulfur, 0.3-0.7% of micronized waxes, and 5-30ml / 100kg of spindle oil. The preparation technology comprises the following steps of ingredient preparing, powder mixing, compression molding, sintering and alloying, shaping and correcting, machining, steam treating and the like. Utilization ratio of materials is improved effectively, the surface roughness reaches 0.8-1.6Mum, the service life, accuracy class, safety performance of the power steering pump are improved effectively, and production cost is reduced.

Owner:ANHUI HENGJUN POWDER METALLURGY TECH

Automobile shock absorber piston and production technique thereof

The invention relates to an automobile shock absorber piston and a production technique thereof. The automobile shock absorber piston comprises 480 to 500 parts of iron powder, 2 to 4 parts of carbon powder, 2.2 to 2.8 parts of zinc stearate, 4 to 6 parts of copper powder, 1.2 to 1.8 parts of manganese sulfide and 0.065 to 0.075 parts of 5# white oil by weight. The production technique includes steps of material mixing, pressing, sintering, oil immersion, finishing, cleaning and blackening. The automobile shock absorber piston prepared by the production technique according to the proportions is high in intensity and hardness, and accordingly the wearing resistance thereof is improved. One-step forming process and one-step finishing process are used for pressing the automobile shock absorber piston, the problem that the other processes need subsequent finish machining is reduced, and accordingly the production efficiency is improved.

Owner:YANGZHOU TIANJIAN MACHINERY MFR

Method for manufacturing motorcycle crank shaft through powder metallurgy

InactiveCN103223490AEnhance the effect of mixing and pressingHigh bulk densityTurbinesOther manufacturing equipments/toolsPolyethylene vinyl acetateParaffin wax

The invention discloses a method for manufacturing a motorcycle crank shaft through powder metallurgy. The method comprises the following step: the motorcycle crank shaft is manufactured by the following raw materials in percentage by weight: 0.4-0.6 percent of nickel, 0.4-0.6 percent of manganese sulfide powder, 0.4-0.6 percent of aluminium, 0.4-0.6 percent of manganese, 0.3-0.4 percent of zinc stearate, 1-2 percent of performance additive, 21-25 percent of copper and the balance of iron. According to the invention, through the added performance additive, superfine powder is provided in the mixed material, and the superfine powder can be filled in the gaps of large particles, so that apparent density of the mixture is improved; the superfine powder is mainly formed by nano-silicon dioxide and calcium stearate, and through additives including a silane coupling agent and the like, a novel performance additive is obtained, and various physical properties about wear resistance and the like of the product are further improved, and as polyethylene vinyl acetate and liquid petrolatum are taken as lubricants to be added into the performance additive, the effect of the performance additive during mixing and pressing is enhanced, the blank pressing strength of a powder metallurgy structural piece under equal pressing pressure is greatly improved, combination form and pore shape of raw material particles are changed, and the problem about crack generation is solved from the root cause.

Owner:江门速龙机车制造有限公司

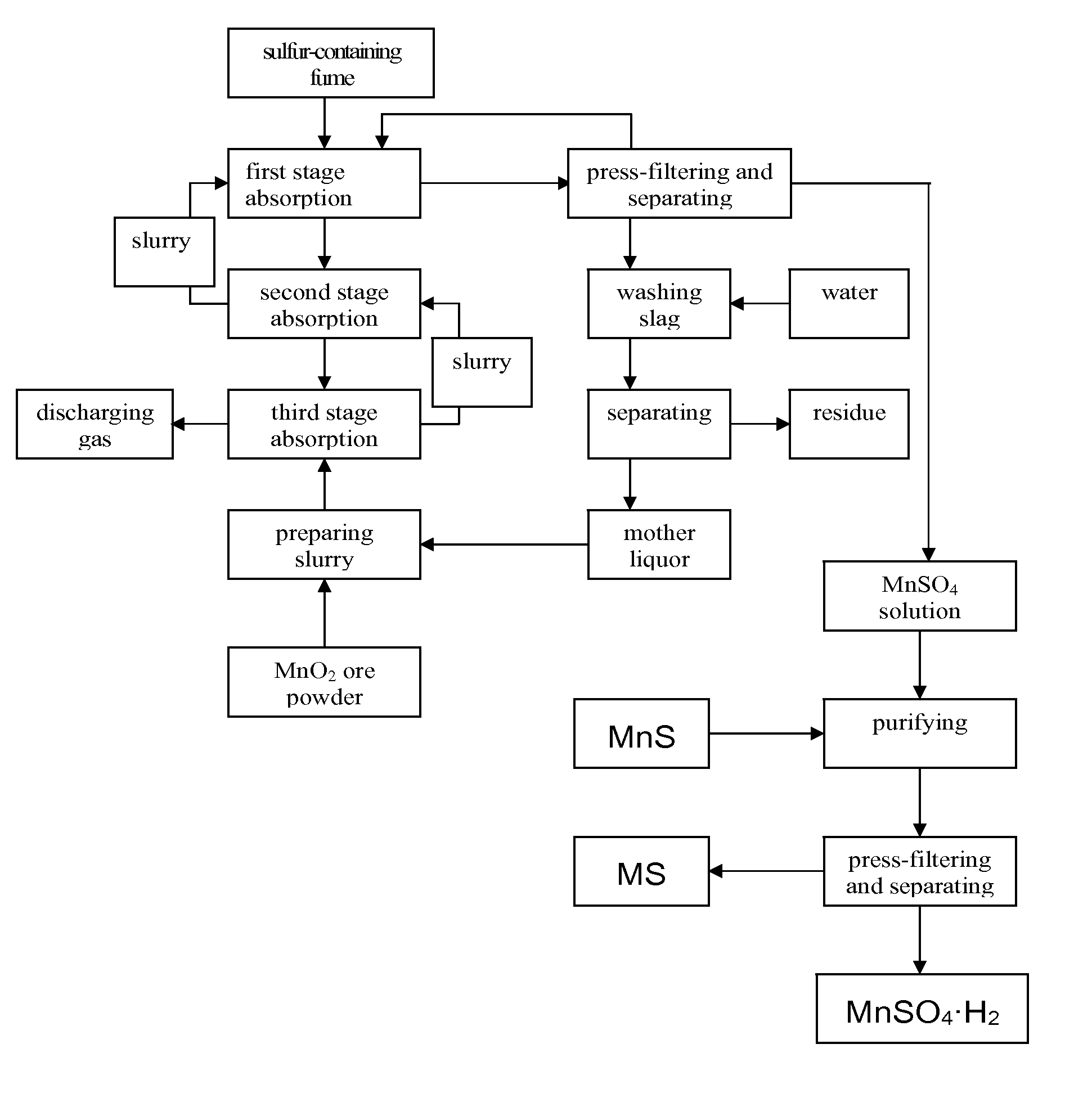

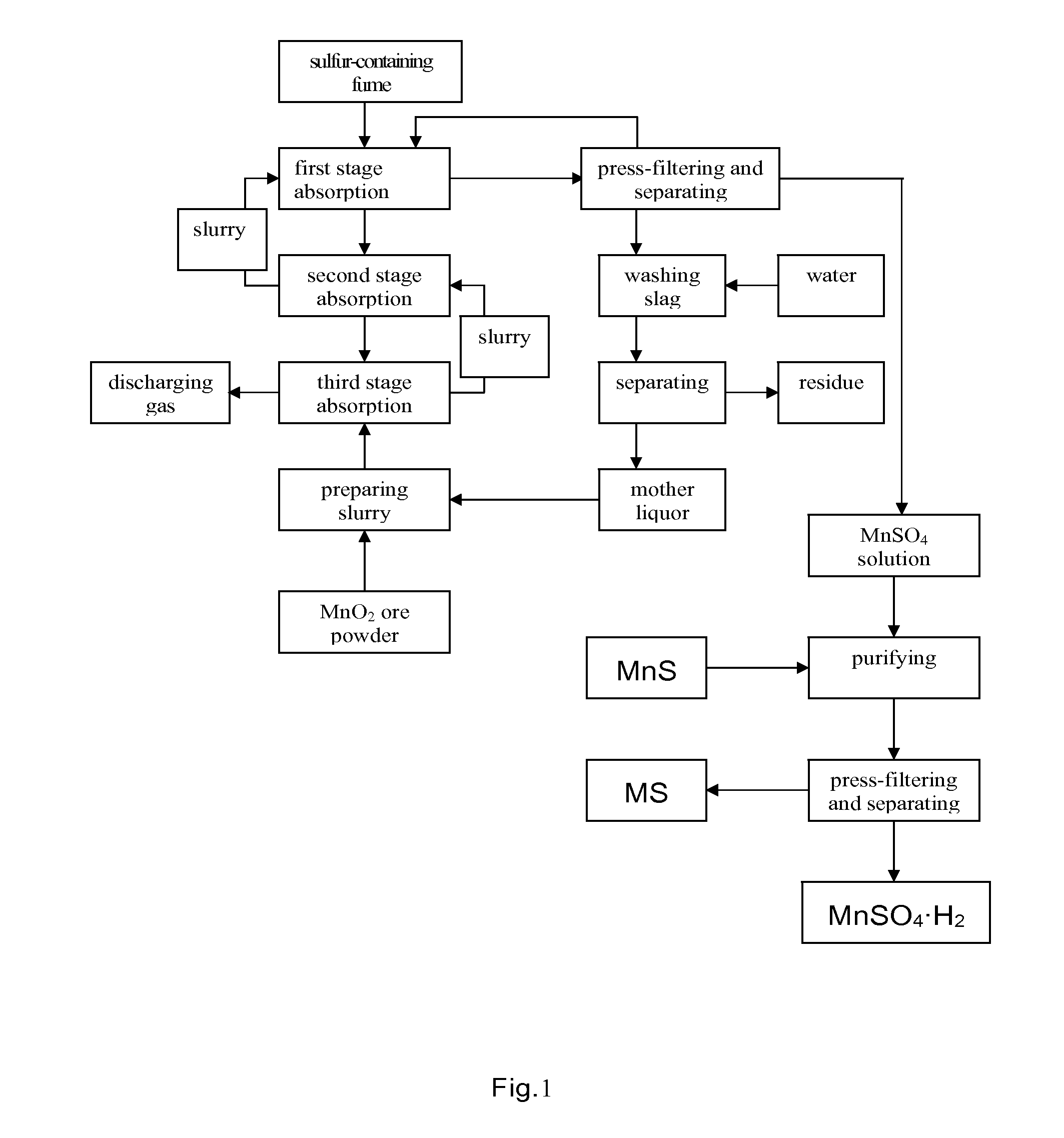

Method for preparing manganese sulfate monohydrate by desulfurizing fume with middle-low grade manganese dioxide ore

InactiveUS20120328495A1Low costImprove efficiencyDispersed particle separationManganese sulfatesSlurrySulfur containing

A method for preparing manganese sulfate monohydrate by desulfurizing fume with middle-low grade manganese dioxide ore, which includes: preparing a slurry by using middle-low grade manganese dioxide ore powder, putting sulfur-containing fume in an absorbing device and controlling gas velocity and gas-liquid ratio, and then adding manganese dioxide slurry and controlling the slurry to backwards flow relative to the sulfur-containing fume, discharging the desulfurized fume from the absorbing device, pressure-filtering and separating the slurry discharged from the absorbing device, recycling the mother liquor to the absorbing device, and continuing the recycling operation until the manganese sulfate in the mother liquor is >=200 g / l, the obtained filter cake at 60-70° C., adjusting pH value of the clear solution obtained to 2-4, adding manganese sulfide under agitation at 25-95° C., and removing impurities, continuing agitating, pressure-filtering and separating, vaporizing the obtained clear filtrate, and obtaining manganese sulfate monohydrate after drying in the air stream.

Owner:GUIZHOU REDSTAR DEVING

Composite microbial preparation for controlling black and odorous water body of rivers as well as preparation method, application and preparation method of composite microbial preparation

The invention discloses a composite microbial preparation for controlling a black and odorous water body of rivers as well as a preparation method, application and a preparation method of the composite microbial preparation, belonging to the field of biological treatment of sewage. The preparation method of the composite microbial preparation comprises the followings steps: (1) cutting willows into cuboids; (2) preparing a mixed solution; (3) taking out pyrolyzed willow blocks in the step (1) from a furnace, adding the pyrolyzed willow blocks into the solution obtained in the step (2) before the temperature is decreased to 85 DEG C; (4) selecting a biogas digester in a pig farm, weighing biogas slurry from the biogas digester, stirring, mixing, and feeding Bacillus subtillis and Candida albicans into the biogas slurry; and (5) feeding the loaded pyrolyzed willow blocks obtained in the step (1) into the biogas slurry, so as to obtain the composite microbial preparation. The composite microbial preparation is good in stability and is capable of eliminating blackness and odor of the water body and strongly absorbing substances including hydrogen sulfide, iron, manganese sulfide and the like in sewage, the preparation work is simple, the quality of treated water completely meets the national discharge standard, and secondary pollution is avoided.

Owner:SHENZHEN GELINWO ENVIRONMENT PROTECTION TECH DEV CO LTD

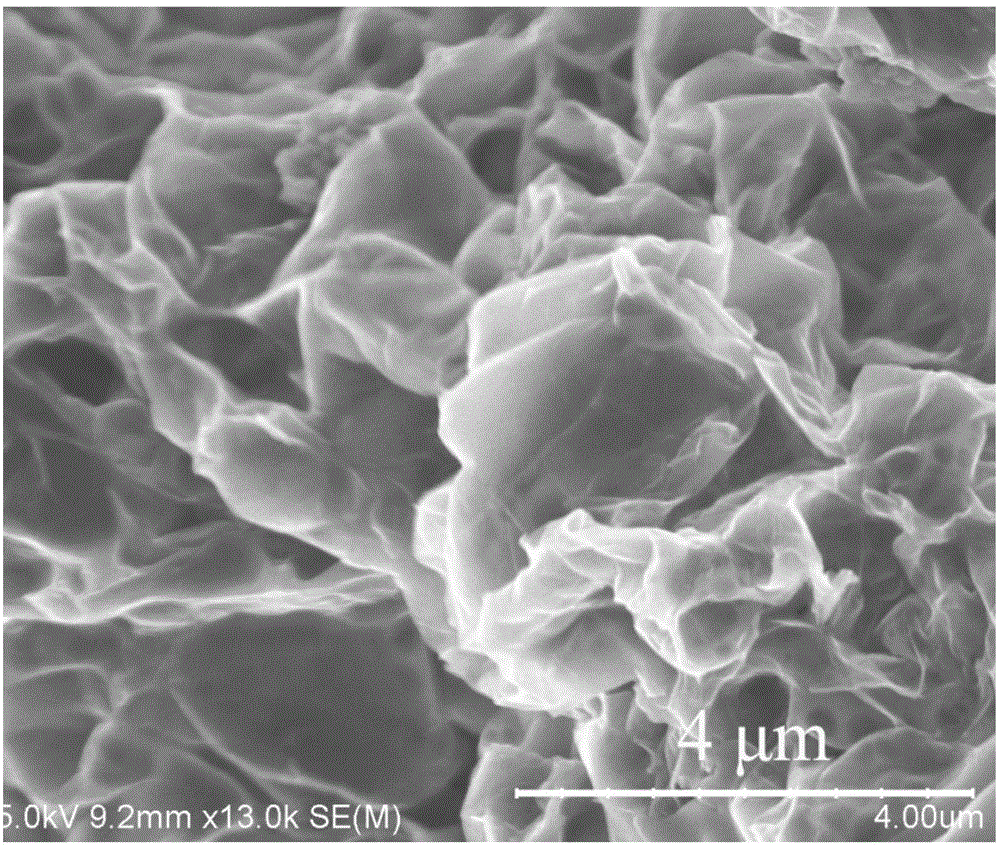

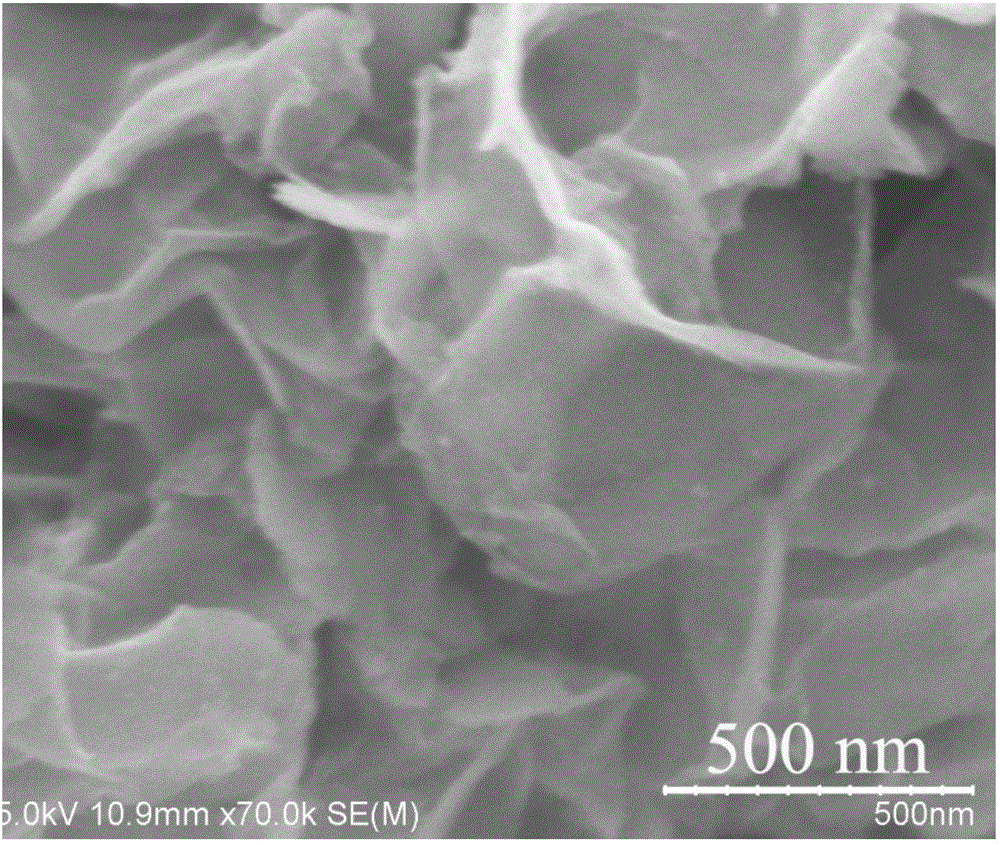

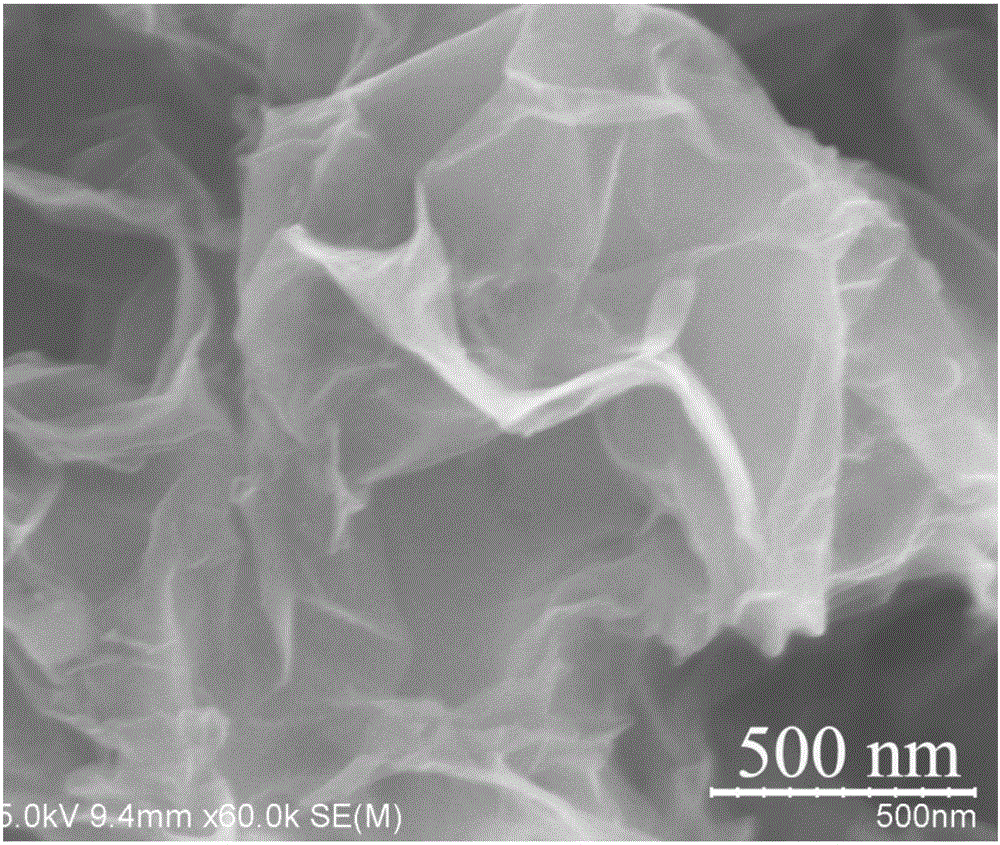

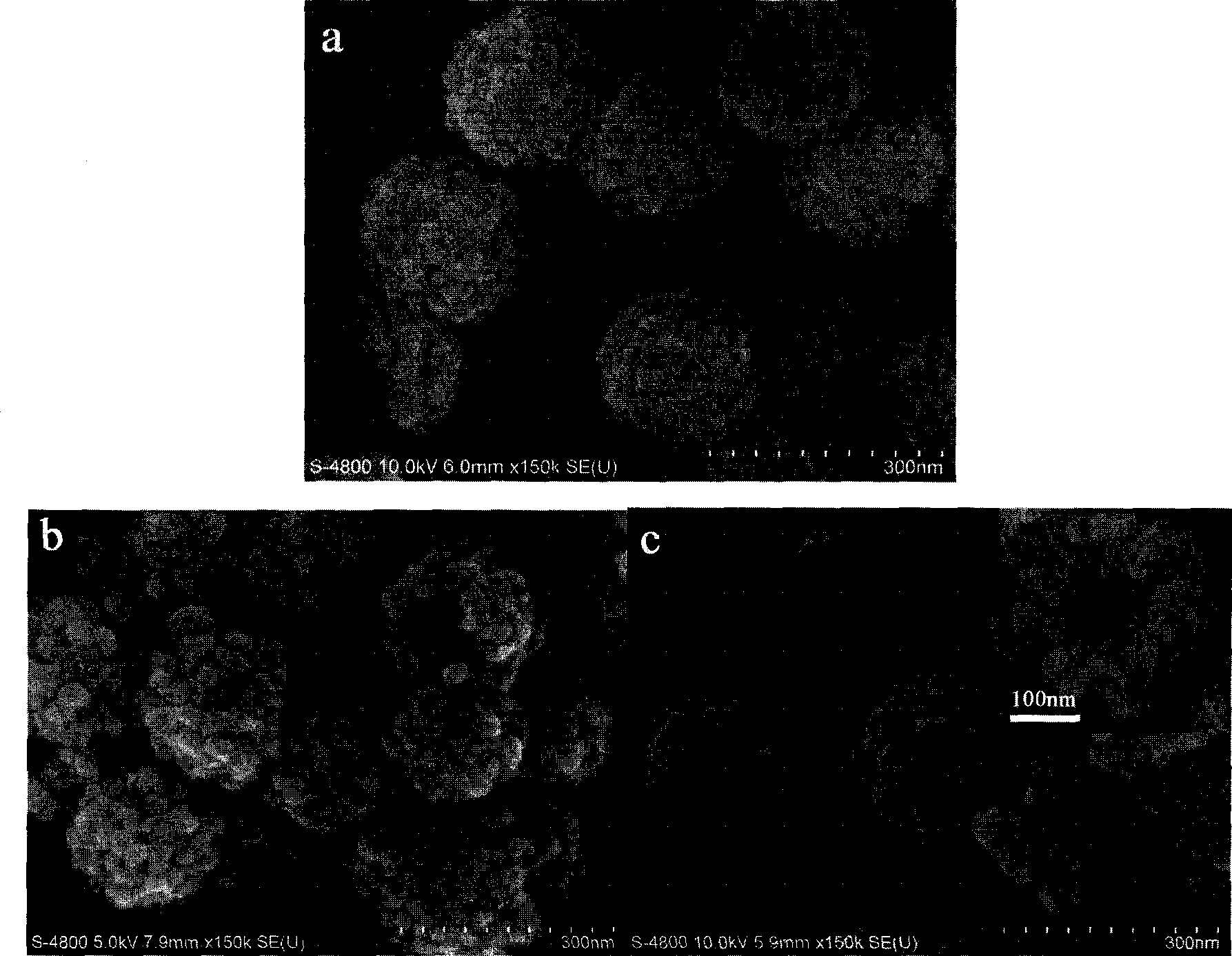

Method for preparing porous manganese sulfide and graphene composite material

InactiveCN108365185ASimple preparation processLow costCell electrodesSecondary cellsConvex structureMicrosphere

The invention relates to a porous manganese sulfide and graphene composite material used as a lithium battery negative electrode material, and a preparation method thereof. The method mainly comprisesthe following steps: forming a uniform mixed solution by using a suitable manganese source, a suitable sulfur source and graphene oxide, performing a reaction by using a hydrothermal technology, andperforming calcination to improve the crystallinity of the composite material in order to finally obtain the porous manganese sulfide and graphene composite material. The composite material prepared in the invention has a good electrical conductivity and a good structural stability, the surface of a manganese sulfide microsphere has a concave-convex structure, the internal of the manganese sulfidemicrosphere has a micro-porous structure, the micro-porous structure reduces the transmission path of lithium ions, and the concave-convex structure provides many sites and a large specific surface area to store the lithium ions and achieve sufficient contact with an electrolyte. The introduction of graphene provides a buffer space for the volume change in the charge and discharge process, so thecycle stability of the composite material is improved. The composite material prepared in the invention can be used for producing a lithium ion battery, and can improve the performances of the lithium ion battery.

Owner:SHANGHAI UNIV

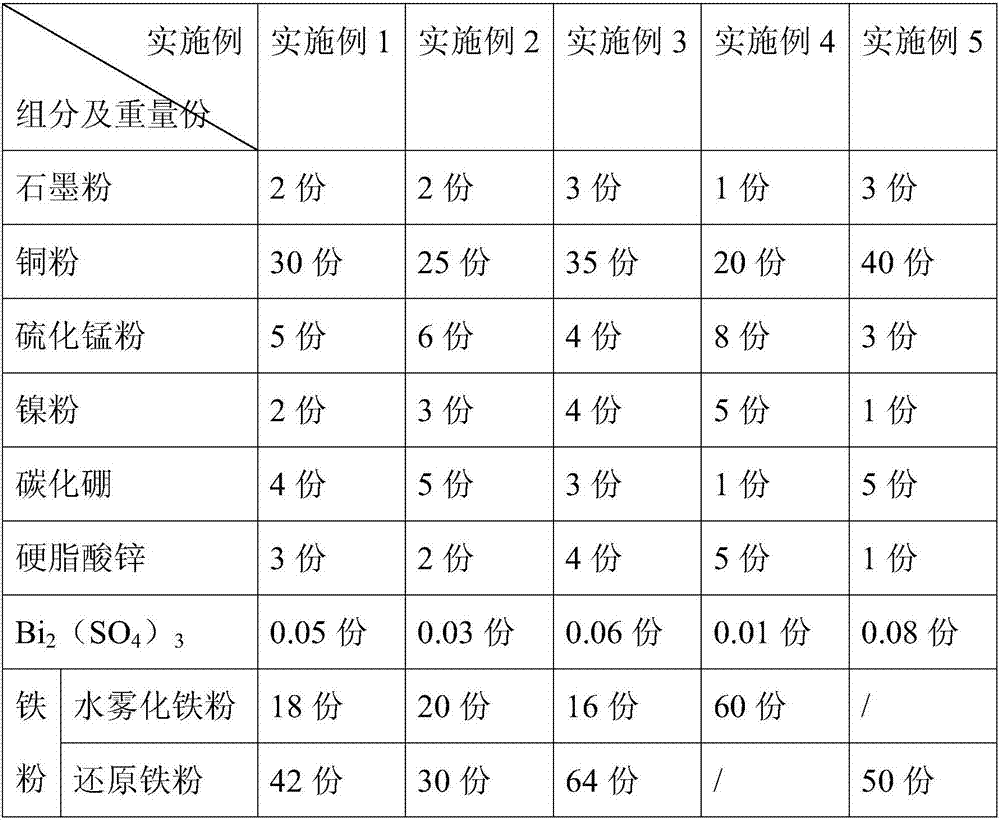

Shock absorber guiding device

ActiveCN107470632AExtended service lifeHigh strengthSpringsTransportation and packagingIron powderManganese sulfide

The invention relates to a shock absorber guiding device and belongs to the technical field of powder metallurgy. The shock absorber guiding device comprises the following components including, by weight, 1-3 parts of graphite powder, 20-40 parts of copper powder, 3-8 parts of manganese sulfide powder, 1-5 parts of nickel powder, 0.01-0.08 part of Bi2(SO4)3 powder, 1-5 parts of boron carbide, 1-5 parts of zinc stearate and 40-80 parts of iron powder. By means of the shock absorber guiding device, due to the fact that raw materials of the shock absorber guiding device are reasonable matched, a protection agent is sprayed during secondary pressing forming and secondary pressing and shaping is conducted under large pressure, the shock absorber guiding device can have extremely good strength, hardness and wear resistance, the density of the manufactured guiding device is larger than 6.7 g / cm<3>, the surface hardness is larger than 90 HB, the strength is larger than 700 MPa, cleanliness reaches the 8th level, and therefore the service life of the shock absorber guiding device is greatly prolonged.

Owner:宁波金钟粉末冶金有限公司

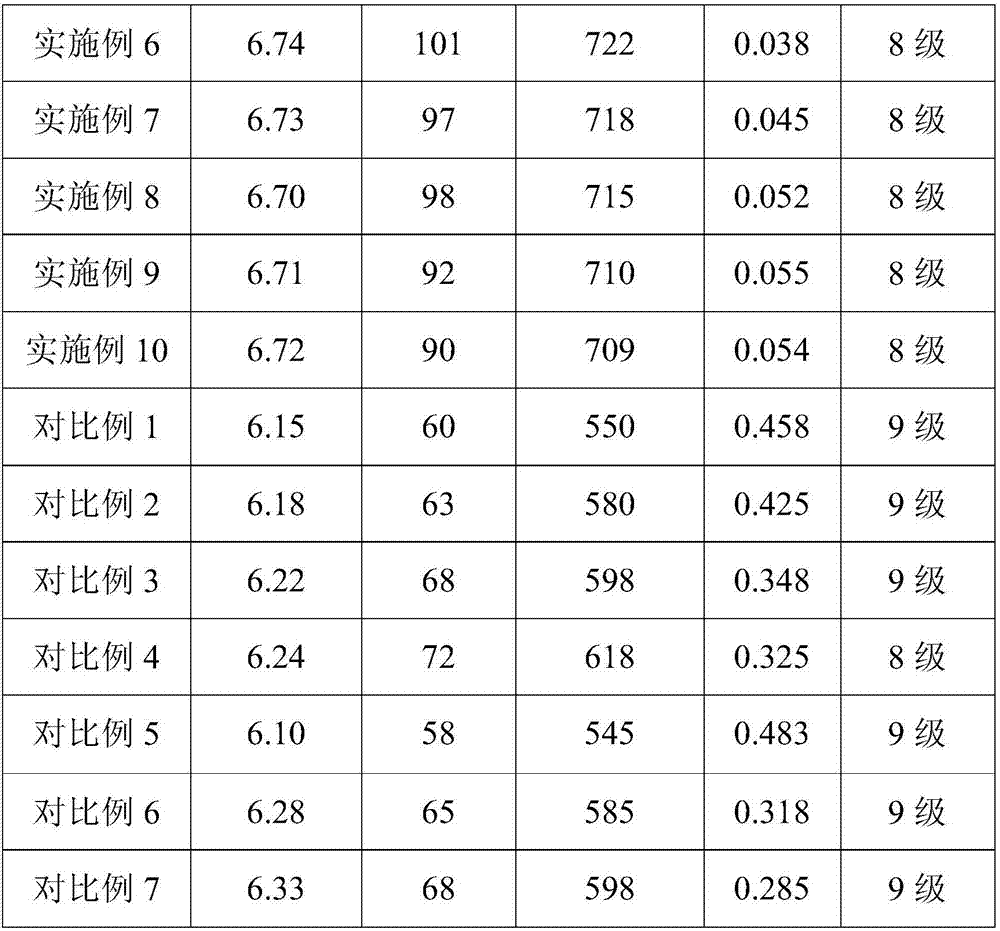

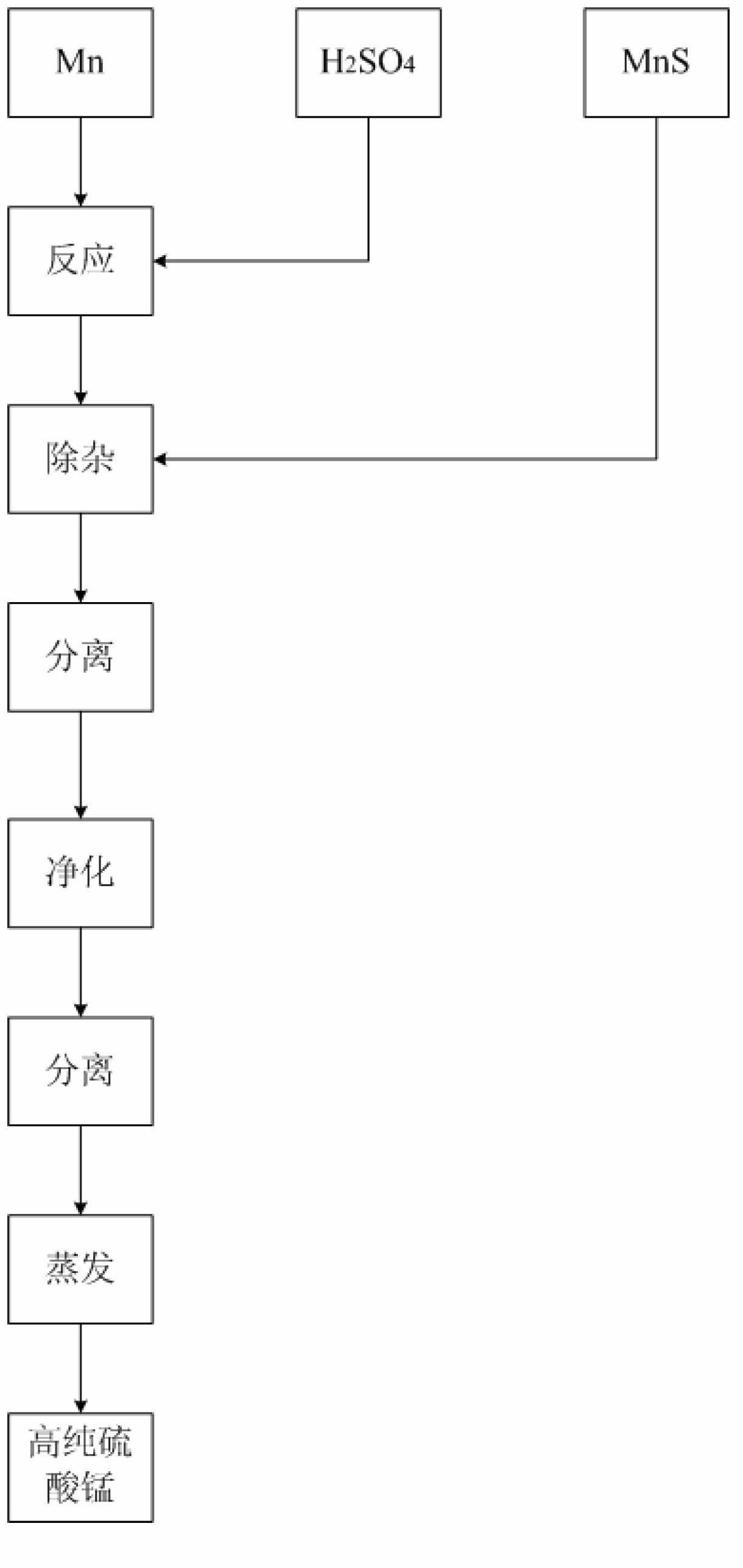

Preparation method of manganese sulfate and manganese sulfate product prepared by same

ActiveCN102674467ASolve technical problems with long process flowOptimize and simplify the preparation processManganese sulfatesSulfateManganese sulfide

The invention relates to a preparation method of manganese sulfate and a manganese sulfate product prepared by the same. The method comprises the following steps: A. adding metal manganese into deionized water, and slowly adding sulfuric acid into the mixture to react until the pH value reaches 3.5-4.0, thereby obtaining a solution; B. adding excessive manganese sulfide relative to impurity content into the solution obtained in the step A, stirring to react at 70-100 DEG C for 4-6 hours, and carrying out solid-liquid separation; C. adding excessive hydrogen peroxide into the solution obtained by the solid-liquid separation in the step B, uniformly stirring, heating to a boiling state, and carrying out solid-liquid separation; and D. evaporating the solution obtained by solid-liquid separation in the step C to obtain the manganese sulfate. The preparation method provided by the invention optimizes and simplifies the preparation technique of high-purity manganese sulfate. The high-purity manganese sulfate product prepared by the method provided by the invention contains fewer impurities, and especially the content of potassium, sodium and other impurities which are difficult to remove is nearly down to 10ppm.

Owner:GUIZHOU REDSTAR DEVING +1

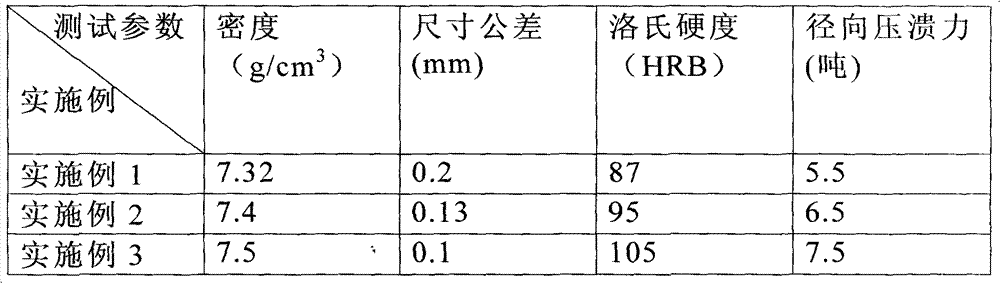

Damper compression valve and preparation method thereof

The invention provides a damper compression valve, belongs to the field of automobile parts, and is used for solving the problem that the existing damper compression valve is low in density. The damper compression valve provided by the invention comprises the following components in parts by weight: 50-80 parts of reduced iron powder, 7.5-10 parts of electrolytic copper powder, 0.2-0.5 part of colloidal graphite, 0.25-0.35 part of lubricant and 0.25-0.35 part of manganese sulfide. The invention also provides a preparation method of the damper compression valve. Through rationally selecting the ingredients for preparing the damper compression valve and utilizing a powder metallurgy method, the cost is reduced, the density of a product is improved, the size tolerance of the product is lessened, and the hardness of the product is improved. Furthermore, the size tolerance of the product is further lessened through reshaping; and the density of the product is further improved through water atomizing steam treatment, and the density of the damper compression valve can reach up to 7.32-7.5g / cm<3>.

Owner:宁波拓发汽车零部件有限公司

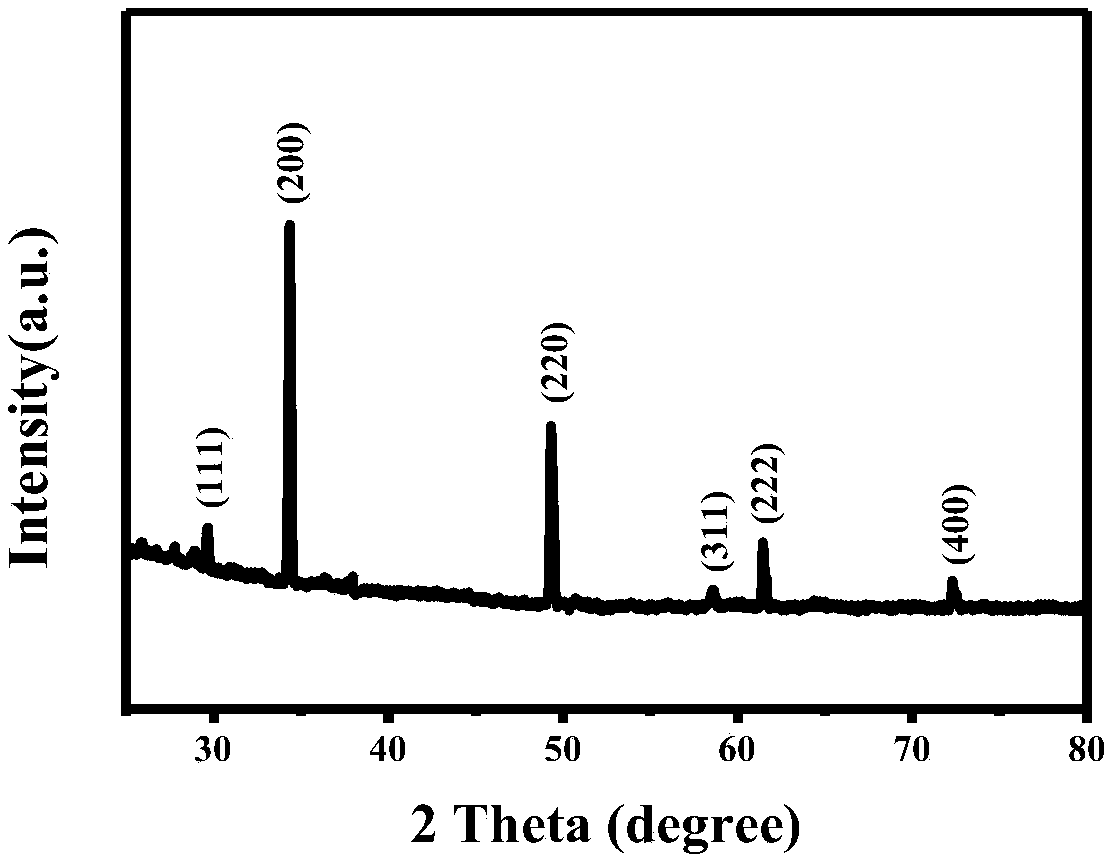

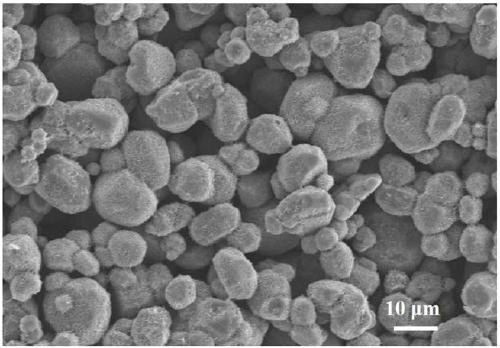

Preparation method of manganese sulfide

InactiveCN109626437ASimple preparation processSimple processManganese compoundsMANGANESE ACETATEChemical synthesis

The invention belongs to the technical field of chemical synthesis, and particularly relates to a preparation method of manganese sulfide. The method comprises the steps that (1), manganese acetate isdissolved in a solvent; (2), a sulfur source is added and stirred uniformly to conduct hydrothermal reaction; (3), solid and liquid are separated to obtain separated solid, and a product manganese sulfide is obtained after the solid is washed and dried. The method has the advantages that a preparation technology is simple, reaction conditions are mild, and the prepared manganese sulfide has goodmorphology and high purity.

Owner:JIANGSU UNIV OF TECH

Method for preparing manganese sulfate, ferrous sulfate and calcium sulfate from manganese ore tailings

InactiveCN102115204AHigh yieldTake advantage ofSolid waste disposalCalcium/strontium/barium sulfatesSolubilitySulfide

The invention provides a method for preparing manganese sulfate, ferrous sulfate and calcium sulfate from manganese ore tailings. The manganese ore tailings are pulverized to powders of 80 meshes to 100 meshes, the powders react with an excessive amount of dilute hydrochloric acid, and the reaction product is filtered to produce a filtrate; an excessive amount of sodium sulfide is added to the filtrate, and the reaction liquid is filtered to produce a filter cake containing manganese sulfide, ferrous sulfide and calcium sulfide; the filter cake containing manganese sulfide, ferrous sulfide and calcium sulfide reacts with a sulfuric acid solution, the reaction product is filtered to produce a filter cake of calcium sulfate and a filtrate containing manganese sulfate and ferrous sulfate, and the filtrate containing manganese sulfate and ferrous sulfate is distilled under a reduced pressure to produce a saturated solution; the saturated solution is cooled at different temperatures according to the difference in solubility between manganese sulfate and ferrous sulfate at different temperatures, so as to produce manganese sulfate crystals and ferrous sulfate crystals respectively; the crystallization product is filtered and dried to obtain a manganese sulfate product and a ferrous sulfate product respectively; and the filter cake of calcium sulfate is washed, dried and pulverized to obtain a calcium sulfate product.

Owner:谢善情

Method for manufacturing butterfly valve rod by powder metallurgy

ActiveCN102773482AImprove production continuityIncrease profitFurnace typesProcess efficiency improvementNiobiumPolyamide

The invention discloses a method for manufacturing a butterfly valve rod by powder metallurgy. The method includes steps of a, preparing a mixed material: using atomized iron powders as base materials, and mixing the atomized iron powders with other components of, by weight, 4%-6% of scrap iron powders, 3.5%-4.0% of nickel powders, 4%-6% of tool steel powders, 1.2%-1.3% of manganese sulfide powders, 0.5%-0.7% of molybdenum disulfide powders, 1.7%-1.9% of aluminum powders, 0.2%-0.4% of tungsten powders, 0.02%-0.03% of niobium powders, 1.1%-1.4% of graphite, 1.0%-1.5% of polyamide wax micro powders and 1.2%-1.8% of stearic acid; and b, performing pressing molding: feeding the evenly mixed powder metallurgy material to a press machine, and performing the pressing molding by means of a mold to form the butterfly valve rod. The method for manufacturing the butterfly valve rod by the powder metallurgy is high in production continuity, high in material utilization, suitable for volume-producing and capable of reducing costs, and the performance of the butterfly valve rod can meet requirements of normal use.

Owner:ANHUI FANCHANG COUNTY WANNAN VALVE CASTING

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com