Patents

Literature

147 results about "Liquid Petrolatum" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Liquid petrolatum. A mixture of liquid hydrocarbons obtained from petroleum. This mixture is used as a vehicle for medicinal substances for local applications. Light petrolatum is employed as a topical spray, whereas heavy petrolatum was once used internally to treat constipation.

Hot-melt pressure-sensitive adhesive type matrix for medical use and its preparation

InactiveCN1800289AImprove anti-agingOxidative decomposition is goodSurgical adhesivesFilm/foil adhesivesPetroleum resinThermoplastic elastomer

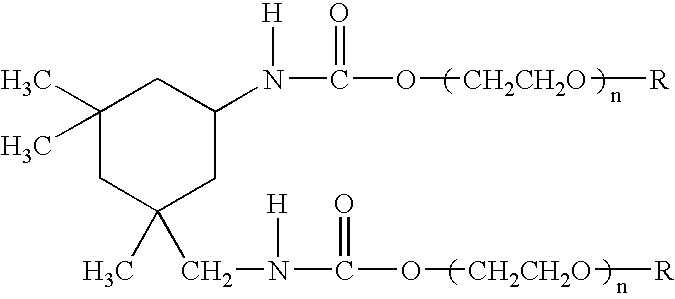

The invention relates to a medical used hot melt pressure-sensitive adhesive type base material and its preparing method which provides a hot melt pressure-sensitive adhesive and an adhesive used paste preparation. The main element of the hot melt pressure-sensitive adhesive is styrenic thermoplastic elastomer SIS (phenylethene -isoprene -phenylethene three block copolymers) with adhesive resin (such as petroleum resin, terpenes polymer, polyisobutylene), flexing oil (such as liquid petrolatum) and aging retarder (such as propyl gallate, BZ) and so on.

Owner:SHANGHAI ARIBA ELECTRIC

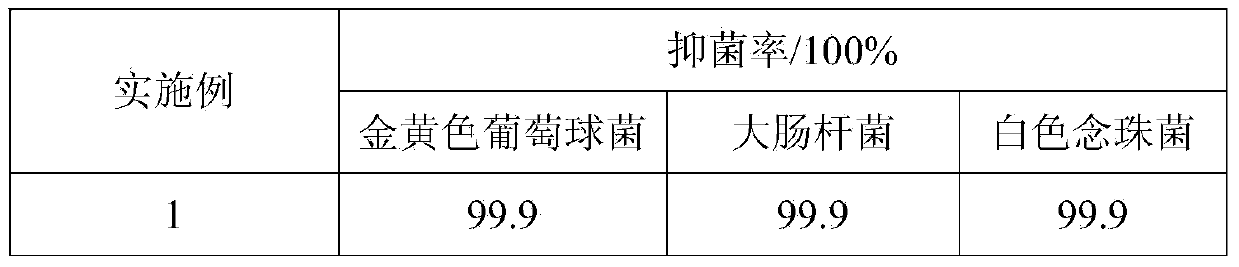

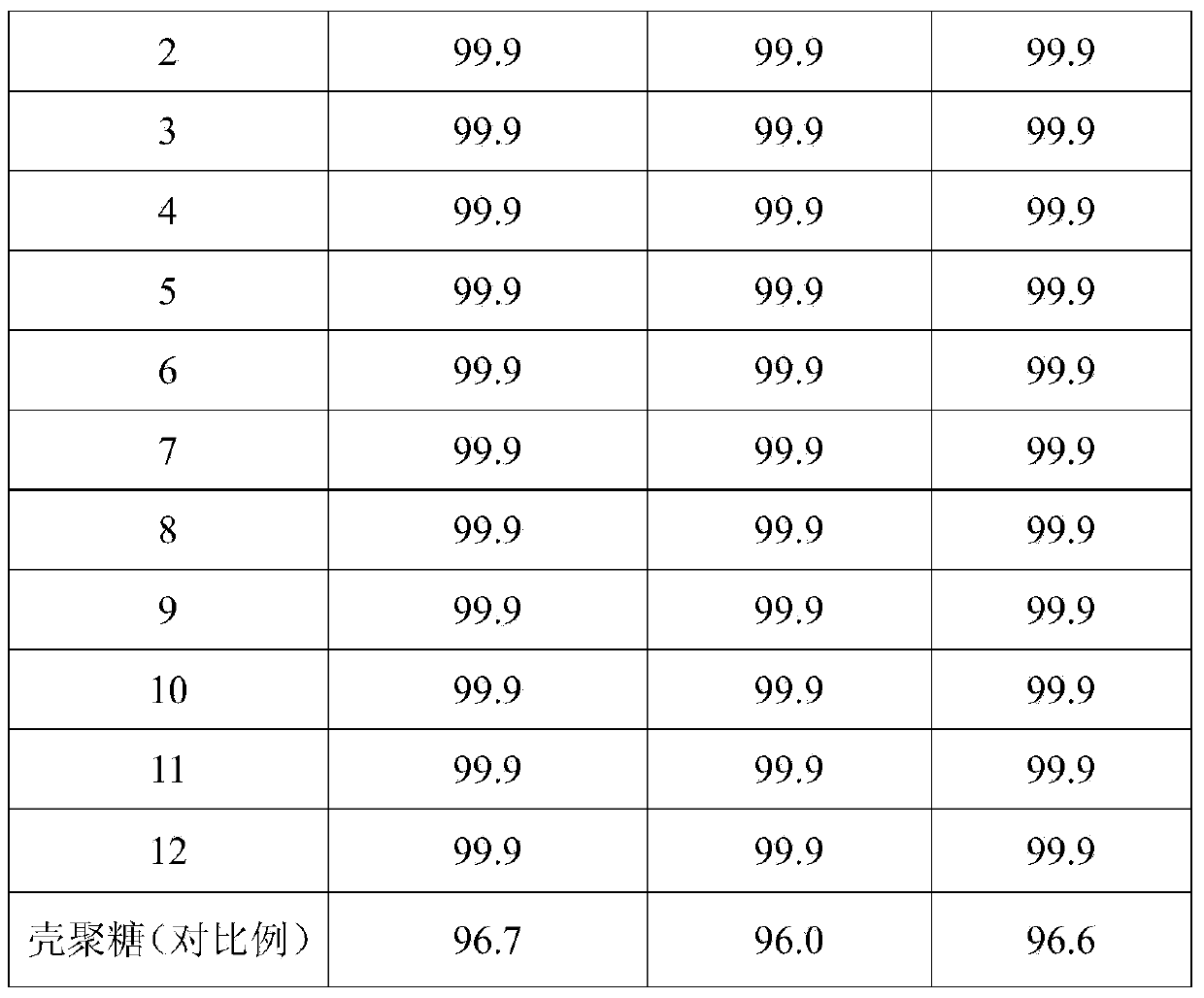

Nano-TiO2 loaded chitosan compound and preparation method thereof

ActiveCN103726319AImprove antibacterial propertiesHigh antibacterial activityFibre treatmentOil phaseMicro spheres

The invention discloses a nano-TiO2 loaded chitosan compound and a preparation method thereof. The preparation method comprises the following steps: mixing chitosan and a nano-TiO2 solution into water to obtain an aqueous phase mixture; taking petroleum ether / liquid petrolatum as an oil phase mixture; preparing nano-TiO2 loaded chitosan anti-bacterial micro-spheres according to the suspension-cross-linking technology. As the natural antibacterial agent chitosan is taken as a wall material, a metal ion-type antibacterial agent TiO2 is taken as a core material, and the compound antibacterial agent is prepared according to the suspension-cross-linking technology, the performance and the application range of the antibacterial agent can be greatly improved through the synergistic effect and advantage complementation of chitosan and TiO2. Furthermore, after being compounded, the novel antibacterial agent is high in performance, relatively wide in anti-bacterial range, and high in stability.

Owner:科凯精细化工(上海)有限公司

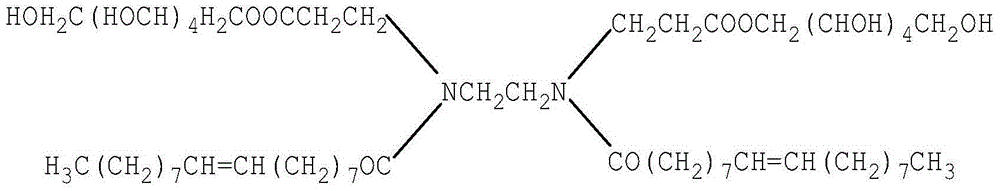

Emollient compositions with polyethylene beads

InactiveUS6432421B1Effective compositionNovel methodCosmetic preparationsPowder deliveryParticulatesOctyl palmitate

An emollient composition comprising at least 5-30% by weight polyethylene, 0-60% by weight petrolatum, and 0-50% octyl palmitate. These emollient compositions may be used as emollient carriers for various materials, such as fragrances and pigments or dyes, to be externally applied to the skin. These emollient compositions may be formed into particulate shapes, such as spheres, for subsequent use in cosmetic products.

Owner:INT FLORA TECH

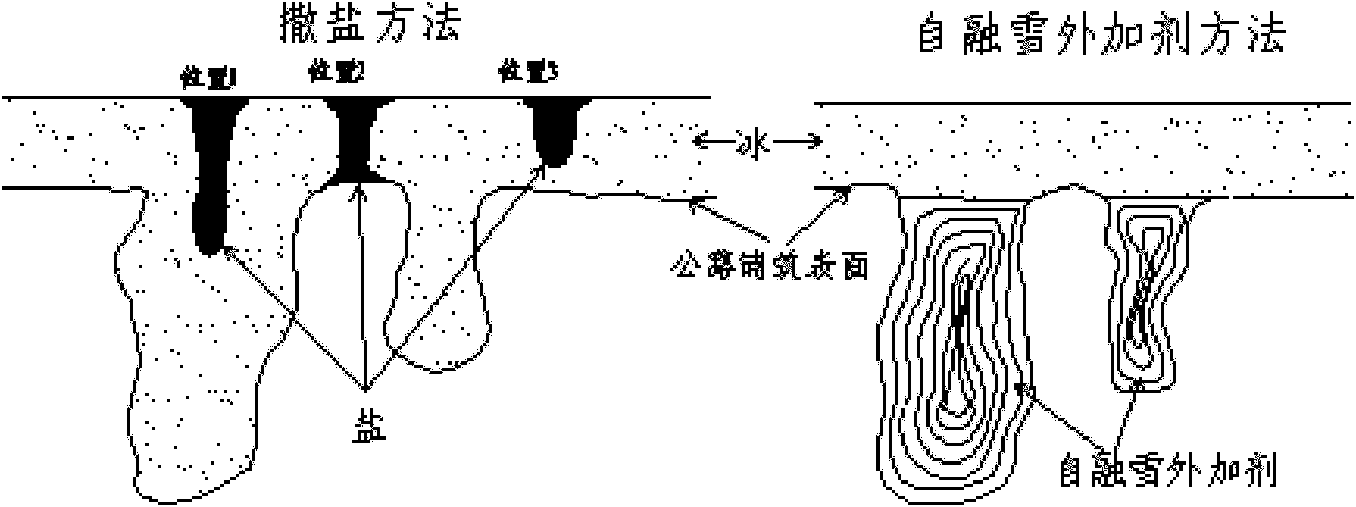

Environmental-protection self-snow-melting asphalt pavement admixture and preparation method thereof

InactiveCN102092978ADoes not affect indicatorsAdapt to mechanized construction technologySnow meltingRoad surface

The invention relates to an environmental-protection self-snow-melting asphalt pavement admixture and a preparation method thereof. The environmental-protection self-snow-melting asphalt pavement admixture is prepared from a component A, a component B and a component C, wherein the component A is solid particles formed by K<+> or Na<+> or Ca<2+> or Mg<2+>, and NO<3-> or SO4<2+> or CH3COO<-> or PO4<3-> or Cl<->; the component B is glycerin or silicone oil or tung oil or vaseline or lanolin; and the component C is NaOH powder or Na2CO3 powder or ore powder. The preparation method comprises the following steps: mixing the component A and the component B, so that the surface of the component A is evenly coated with a layer of component B, and the component C is attached onto the surface of the component A through the component B to form coating particles; and screening, and cooling to obtain the environmental-protection self-snow-melting asphalt pavement admixture. When in use, the admixture is added into the asphalt mixture to be used on the asphalt pavement, thereby reducing the snow melting by salt sprinkling, solving the problems of environment pollution and waste of resources when the snow melting agent is used, effectively preventing the pavement from icing for a long time, lowering the pavement maintenance cost in winter, keeping the roads clear in snowy days, and reducing the incidence rate of traffic accidents.

Owner:CHANGAN UNIV

Method for manufacturing automobile connecting rod through powder metallurgy

InactiveCN103223487AEnhance the effect of mixing and pressingHigh bulk densityTurbinesOther manufacturing equipments/toolsPolyethylene vinyl acetateCadmium Cation

The invention discloses a method for manufacturing an automobile connecting rod through powder metallurgy. The method comprises the following step: the automobile connecting rod is manufactured by the following raw materials in percentage by weight: 0.4-0.6 percent of nickel, 0.4-0.6 percent of graphite, 0.6-0.8 percent of zinc oxide powder, 0.4-0.6 percent of cadmium, 0.3-0.4 percent of zinc stearate, 1-2 percent of performance additive, 4-6 percent of copper and the balance of iron. According to the invention, through the added performance additive, superfine powder is provided in the mixed material, and the superfine powder can be filled in the gaps of large particles, so that apparent density of the mixture is improved; the superfine powder is mainly formed by nano-silicon dioxide and calcium stearate, and through additives including a silane coupling agent and the like, a novel performance additive is obtained, various physical properties about wear resistance and the like of the product are further improved, and as polyethylene vinyl acetate and liquid petrolatum are taken as lubricants to be added into the performance additive, the effect of the performance additive during mixing and pressing is enhanced, the blank pressing strength of a powder metallurgy structural piece under equal pressing pressure is greatly improved, combination form and pore shape of raw material particles are changed, and the problem about crack generation is solved from the root cause.

Owner:XUZHOU DALT MECHANICAL EQUIP MFG CO LTD

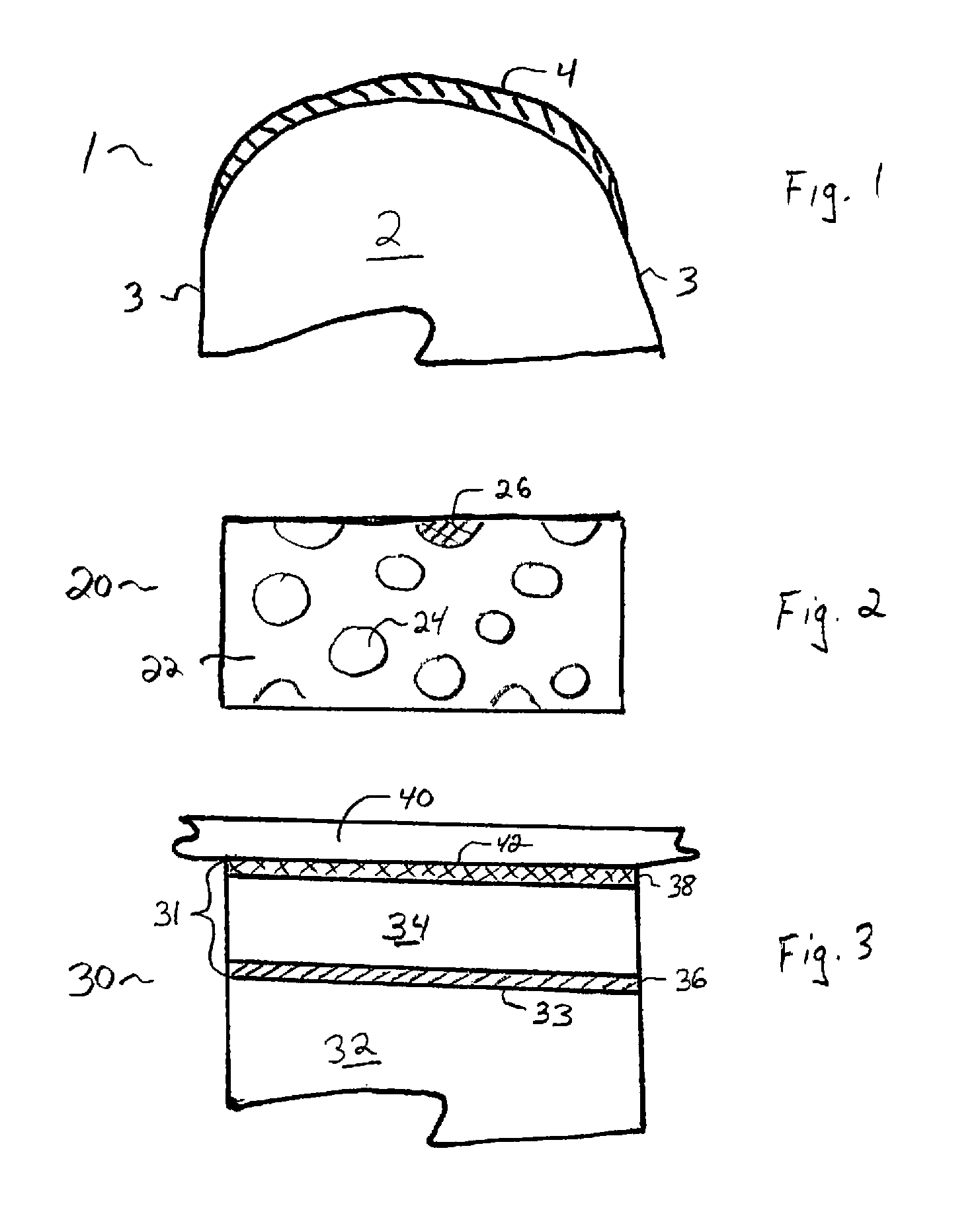

Compositions and Methods for the Treatment of Wounds and Scar Tissue

InactiveUS20080317830A1Promote healingReduce fine lineHeavy metal active ingredientsBiocideFine lineWrinkle skin

Compositions for the treatment of wounds and / or scars are described herein. The compositions contain between 1 and up to 30% by weight, more preferably between 1 and 20%, most preferably between about 5 and 10% by weight particles, such as titanium dioxide or a similar material in a pharmaceutically acceptable base or carrier, such as petrolatum. The compositions are less greasy than petrolatum alone, and thus are more aesthetically pleasing. The compositions exhibit occlusive properties comparable to petrolatum. The compositions are absorbed into the skin, unlike petrolatum, and exhibit significant wound healing characteristics not observed with petrolatum alone. In one embodiment, the pharmaceutically acceptable base is petrolatum and the particles are titanium dioxide. The compositions can be used to treat complex, hard to heal wounds, such as diabetic ulcers; pressure sores, such as bed sores; lacerations; bite wounds; burns; penetrating wounds; surgical wounds, etc. The composition can also be used to promote normal healing of scar tissue. The compositions can also be used for the topical delivery of one or more active agent. The compositions can be used to reduce fine lines and wrinkles, and to rehydrate skin or to treat dry skin.

Owner:LIOLABS

Preparation method for flower and volcanic mud cream

InactiveCN102512343ARelieve fatigueRelieve pressureCosmetic preparationsToilet preparationsDiseaseSide effect

A preparation method for a flower and volcanic mud cream is disclosed, comprising the following steps of: taking raw materials composed of 50% of volcanic mud, 30% of flower powder, 10% of beewax and 10% of medicinal Vaseline; uniformly mixing; heating to 40-50 DEG C; and dissolving and then preparing the mud cream. The mud cream contains lots of nutrient ingredients such as mineral substances, trace elements and amino acids needed by human skin, and is especially suitable for being used for the skin of the whole body. The mud cream has a unique curative effect on skin diseases such as skin colour darkness, skin cracking and skin pruritus. The mud cream has no irritation, no injury and no toxic and side effects on skin after being used. The mud cream is a skin-care product with the functions of maintaining, prevention, treating and whitening.

Owner:罗芸

Method for manufacturing eccentric wheel through powder metallurgy

ActiveCN103223489AEnhance the effect of mixing and pressingHigh bulk densityCranksEccentricsPolyethylene vinyl acetateMixed materials

The invention discloses a method for manufacturing an eccentric wheel through powder metallurgy. The method comprises the following step: the eccentric wheel is manufactured by the following raw materials in percentage by weight: 0.2-0.4 percent of nickel, 0.4-0.6 percent of molybdenum, 0.6-0.8 percent of tin, 0.3-0.5 percent of aluminium oxide powder, 0.8-1 percent of graphite powder, 0.4-0.6 percent of petroleum wax, 4-6 percent of copper, 1-2 percent of performance additive and the balance of iron. According to the invention, through the added performance additive, superfine powder is provided in the mixed material, and the superfine powder can be filled in the gaps of large particles, so that apparent density of the mixture is improved; the superfine powder is mainly formed by nano-zinc oxide powder and calcium stearate, and through additives including a silane coupling agent and the like, a novel performance additive is obtained, and various physical properties about wear resistance and the like of the product are further improved, and as polyethylene vinyl acetate and liquid petrolatum are taken as lubricants to be added into the performance additive, the effect of the performance additive during mixing and pressing is enhanced, the blank pressing strength of a powder metallurgy structural piece under equal pressing pressure is greatly improved, combination form and pore shape of raw material particles are changed, and the problem about crack generation is solved from the root cause.

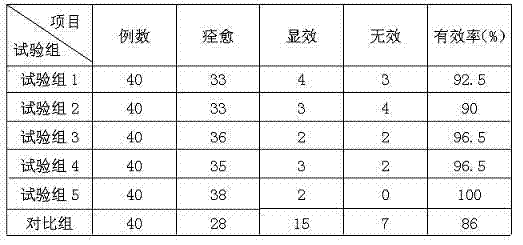

Preparation of shaolin plaster for rheumatism and wound and quality control method

The invention relates to a preparation and quality control method of a Shaolin rheumatism trauma paste. The original production process of the Shaolin rheumatism trauma paste has the problems that (1) power consumption of plastication is great; (2) temperature rises quickly in the plastication, which results in easy aging and loss of cohesive force; (3) the menthol, menthyl salicylate and borneol in the prescription are once tried for soaking rubber to carry out the plastication, which leads to excessive loss of the components in finished products; when petrolatum is used for replacing the components to soak the rubber for carrying out the plastication, serious problem of oil permeation occurs in the finished products; (4) the relative density of the extract of medical material specified by the standards can not be controlled. The invention aims at providing the preparation and quality control method of the Shaolin rheumatism trauma paste, proposing a reasonable prescription of base materials and a production technique to ensure that finished products have clean and smooth appearance and good cohesive force and reducing the loss of active components of the finished products, particularly the volatile components such as menthol, menthyl salicylate and borneol. The quality standards essentially comprises thin layer identification of angelica, forsythia fruit, rhubarb root, root of common peony and resina draconis, limit tests on adhesion ability and aconitine and determination of the content of menthol, menthyl salicylate and borneol of the products by gas chromatography.

Owner:张会林

Microfluidic chip electrode for electrochemical detection and method for manufacturing microfluidic chip

This invention relates to a microfluidic chip electrode for electrochemical detection and method for manufacturing microfluidic chip, which comprises the following steps: (1) coating sheet vaseline layer on position of detection electrode joining piece on conductive film of the glass, cutting metal strip with width as the electrode, and putting the strip with vaseline on its bottom on former position of detection electrode joining piece; (2) putting the glass into HCl solution to etch and remove the metal strip; (3) clearing the vaseline coating. This invention is convenient and low cost.

Owner:FUZHOU UNIV

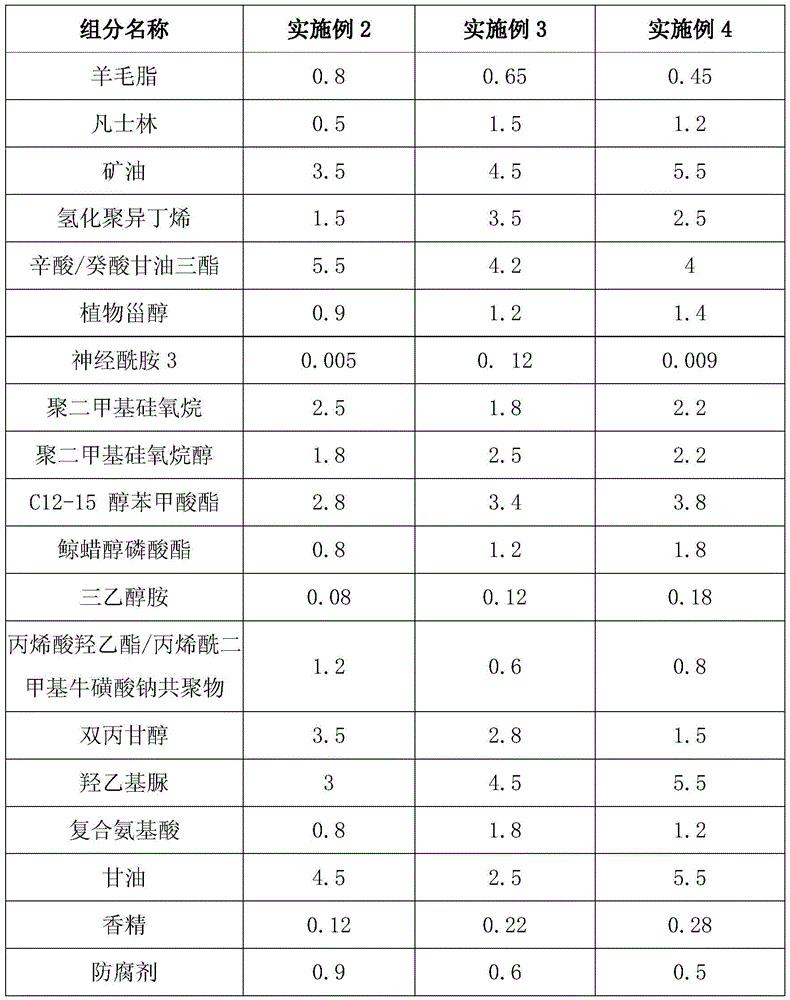

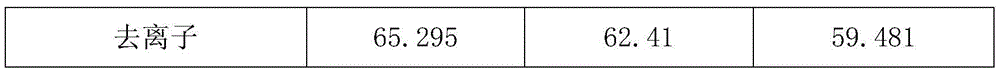

Wash-resisting hand cream and preparing method thereof

ActiveCN105596234AImprove wash resistanceIncrease contentCosmetic preparationsToilet preparationsAdditive ingredientGlycerol

The invention discloses a wash-resisting hand cream. The hand cream comprises wool fat, vaseline, mineral oil, hydrogenated polyisobutene, caprylic / capric triglyceride, phytosterol, ceramide 3, polydimethylsiloxane, dimethiconol, C12-15 alcohol benzoate, cetyl phosphate, triethanolamine, hydroxyethyl acrylate / acrylyl dimethyl sodium taurate copolymer, dipropylene glycol, hydroxyethylurea, compound amino acid, glycerol, essence, preservative and deionized water. Cetyl phosphate with high water resistance and a structure similar to that of skin is adopted for the wash-resisting hand cream, a wash-resisting protection film is formed after cetyl phosphate is matched with vaseline and mineral oil which are high in closure property, other nourishing ingredients not prone to migration under washing and various moisturizing and water reserving ingredients are also adopted, and then the functions of highly nourishing, moisturizing, repairing, anti-chapping and hand skin smoothing are realized and the content of the nourishing ingredients can still be high after multiple times of washing.

Owner:广州蜜妆生物科技有限公司

Method for manufacturing motorcycle crank shaft through powder metallurgy

InactiveCN103223490AEnhance the effect of mixing and pressingHigh bulk densityTurbinesOther manufacturing equipments/toolsPolyethylene vinyl acetateParaffin wax

The invention discloses a method for manufacturing a motorcycle crank shaft through powder metallurgy. The method comprises the following step: the motorcycle crank shaft is manufactured by the following raw materials in percentage by weight: 0.4-0.6 percent of nickel, 0.4-0.6 percent of manganese sulfide powder, 0.4-0.6 percent of aluminium, 0.4-0.6 percent of manganese, 0.3-0.4 percent of zinc stearate, 1-2 percent of performance additive, 21-25 percent of copper and the balance of iron. According to the invention, through the added performance additive, superfine powder is provided in the mixed material, and the superfine powder can be filled in the gaps of large particles, so that apparent density of the mixture is improved; the superfine powder is mainly formed by nano-silicon dioxide and calcium stearate, and through additives including a silane coupling agent and the like, a novel performance additive is obtained, and various physical properties about wear resistance and the like of the product are further improved, and as polyethylene vinyl acetate and liquid petrolatum are taken as lubricants to be added into the performance additive, the effect of the performance additive during mixing and pressing is enhanced, the blank pressing strength of a powder metallurgy structural piece under equal pressing pressure is greatly improved, combination form and pore shape of raw material particles are changed, and the problem about crack generation is solved from the root cause.

Owner:江门速龙机车制造有限公司

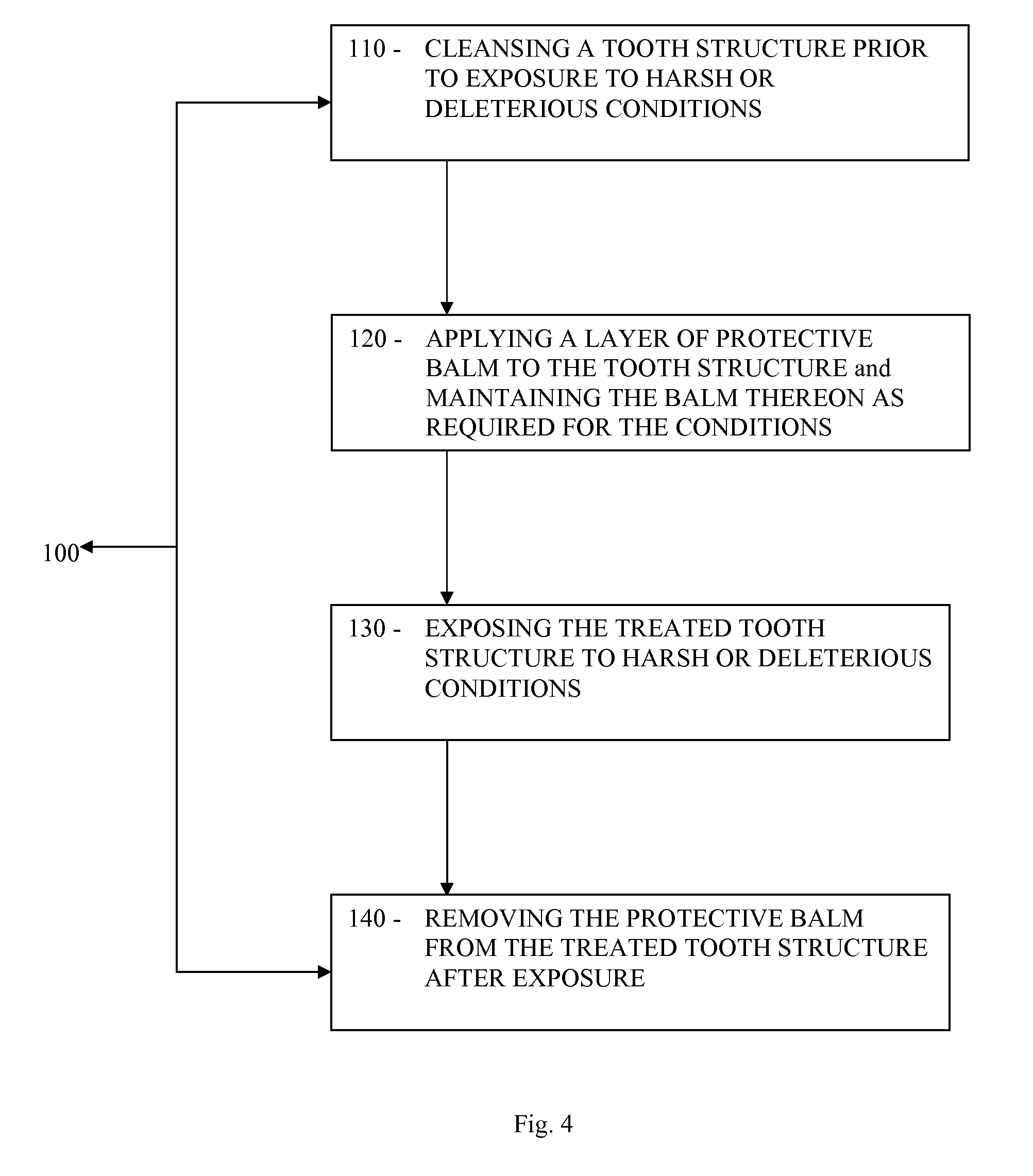

Dental balm and method of prevention of damage to teeth

InactiveUS20060239938A1Good for dental healthAvoid damageCosmetic preparationsToilet preparationsWhite petrolatumWater insoluble

A dental balm composition prevents damage to teeth which are prone to prolonged exposure to air or other drying conditions and which are therefore susceptible to tooth decay. The dental balm composition is comprised of an active decay preventing agent such as fluoride ion dispersed in a water insoluble adhesive and protective balm base such as petrolatum along with optional thickeners, flavorants and the like. The method of damage prevention requires the application of the balm, such as by swab or finger, to the outer surfaces of the subject's front teeth prior to vigorous physical activity, exercise, prolonged episodes of mouth breathing, or other drying conditions such as after tooth whitening procedures.

Owner:PERECHOCKY JOSEPH

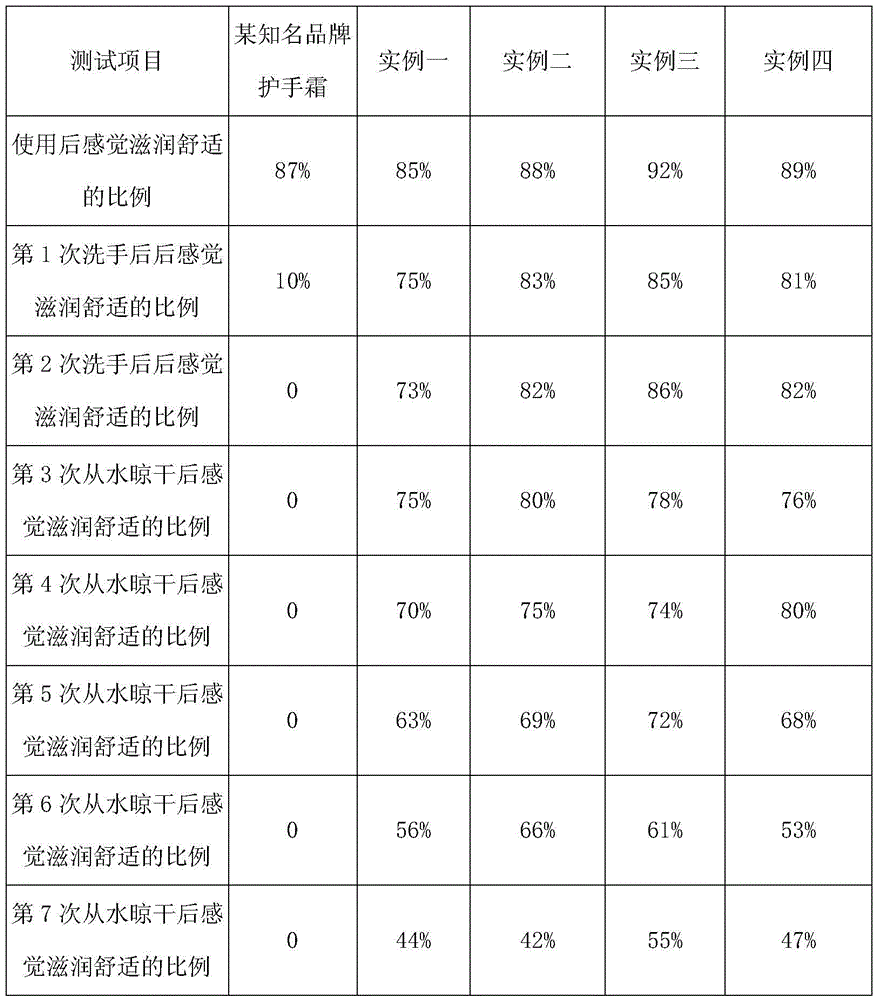

Easily-emulsified compound oil phase for emulsion explosive and preparation method

ActiveCN103951534AReasonable matchReduce interfacial tensionNon-explosive/non-thermic compositionsMicrocrystalline waxEmulsion explosive

The invention relates to an easily-emulsified compound oil phase for emulsion explosives and a preparation method. The compound oil phase comprises the following substances by mass: 4-10 parts of paraffin, 2-8 parts of microcrystalline wax, 3-20 parts of beeswax, 5-15 parts of machine oil, 10-20 parts of Vaseline, 0-10 parts of asphalt, 0-8 parts of rosin, 0-15 parts of octadecylamine, and 20-55 parts of a water-in-oil emulsifier, wherein the water-in-oil emulsifier is bisoleamide bissorbic acrylate ethanediamine. The preparation method of the compound oil phase comprises steps of melting, blending, curing and cartonning. Compared with the prior art, the oil phase material of the invention matches the emulsifier more reasonably, which significantly reduces the interfacial tension between the compound oil phase and an ammonium nitrate aqueous solution. When the emulsification effect is identical, the rotating speed of an emulsifying machine is decreased greatly, and the emulsification time is shortened; When the productivity is the same, the pressure of a static mixer pipeline is decreased significantly. Substrates prepared by the compound oil phase have storage time of up to 24 months; the explosive storage time is up to 18 months; and the explosion performance of explosives meets the national standard GB / T18095-2000.

Owner:CHINA COAL TECH & ENG GRP HUAIBEIBLASTING TECHN RES INST

Protective Dental Balm and Method

InactiveUS20080112902A1Good for dental healthAvoid damageCosmetic preparationsToilet preparationsWhite petrolatumWater insoluble

A dental balm composition and method prevents damage to teeth which are prone to prolonged exposure to air or other drying conditions and which are therefore susceptible to tooth decay. The dental balm composition and uses an active decay preventing agent such as fluoride ion, xylitol or glycerin dispersed in a water insoluble adhesive and protective balm base such as petrolatum along with optional thickeners, flavorants and the like. The method of damage prevention applies the balm, such as by swab or finger, to the exposed surfaces of the subject's front teeth prior to vigorous physical activity, exercise, prolonged episodes of mouth breathing, or other harsh or deleterious conditions including drying conditions during strenuous periods of exercise or tooth whitening procedures.

Owner:PERECHOCKY JOSEPH

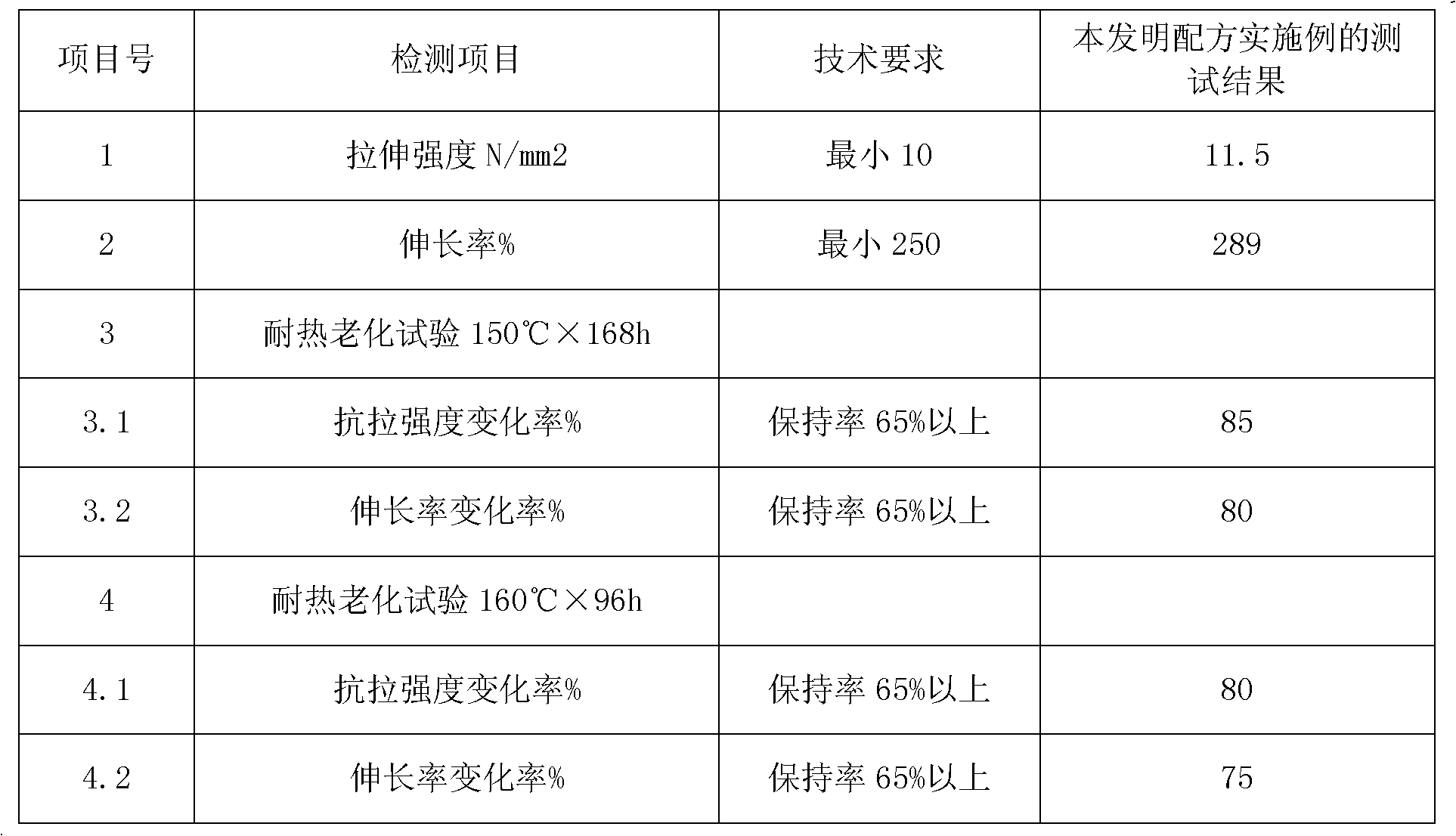

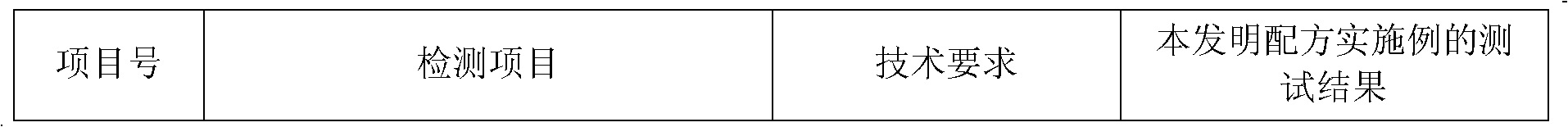

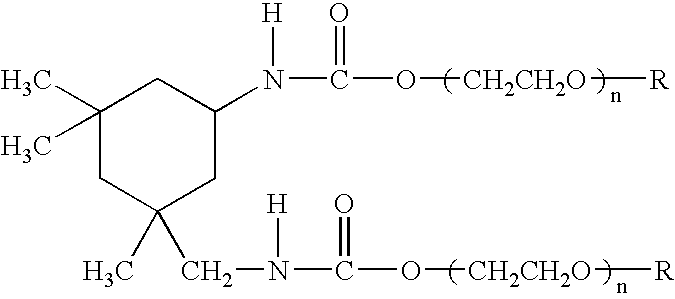

Ethylene-propylene-diene monomer composition

The invention relates to an ethylene-propylene-diene monomer composition. The ethylene-propylene-diene monomer composition comprises the following components in parts by weight: 100 parts of ethylene-propylene-diene monomer, 100 to 160 parts of fast extrusion N 550, 10 to 40 parts of liquid petrolatum, 3 to 5 parts of magnesium oxide, 1 to 2 parts of antiager RD, 1 to 2 parts of antiager MB, 2 to 4 parts of polyethylene glycol, 1 to 5 parts of assistant crosslinker and 2 to 10 parts of bis (tert-butyl isopropyl peroxide) benzene. In the invention, a peroxide curing agent is utilized, a -C-C-bond can be formed on products in the cross-linking process, the bond energy is high, the heat and chemical stability is high, and the products have excellent heat oxygen heat aging resistant performance. The ethylene-propylene-diene monomer formula ensures that the retention rate of the tensile property (brute force and pull-apart extension) is more than 65% under the conditions of high temperature heat aging, therefore, the advantage of the formula on the heat aging resistant performance of the ethylene-propylene-diene monomer is better reflected.

Owner:TIANJIN PENGYI GRP CO LTD

Sore ulcer treating ointment and its prepn

InactiveCN1403097AEasy accessImprove absorption rateInanimate material medical ingredientsMammal material medical ingredientsDiseaseWhite petrolatum

The present invention discloses one kind of sore ulcer treating ointment and its preparation process. The medicine is prepared with liquid paraffin, calamine, borneol, pearl, borax and other six kinds of Chinese medicinal materials and through crushing, mixing and other steps. The present invention has simple preparation process, low cost and high treating effect on pus pocket, boil, carbuncle, ulcer, insect bite and other skin diseases.

Owner:MAYINGLONG PHARMA GROUP

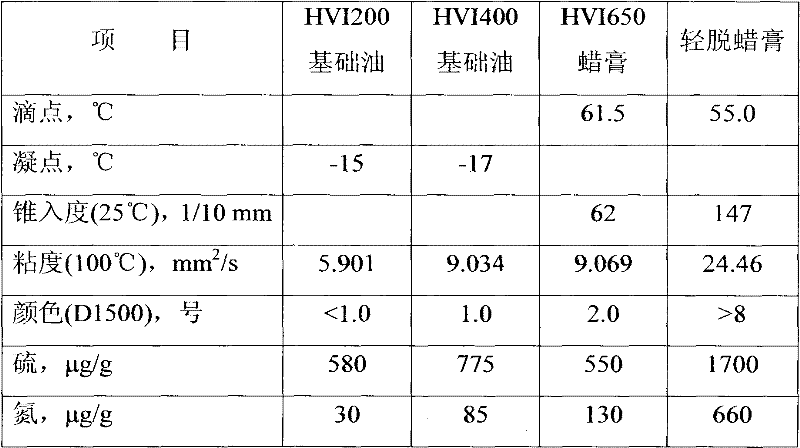

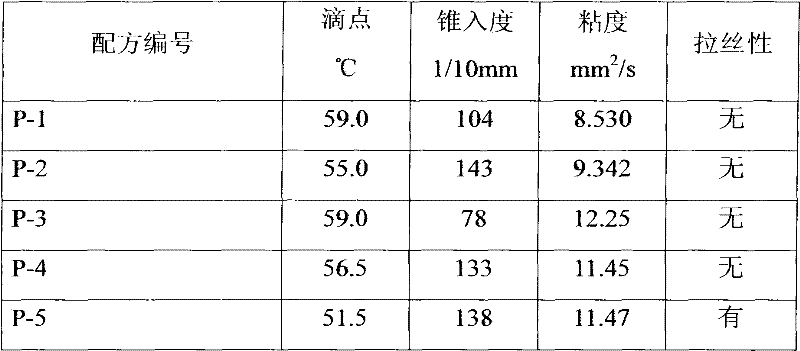

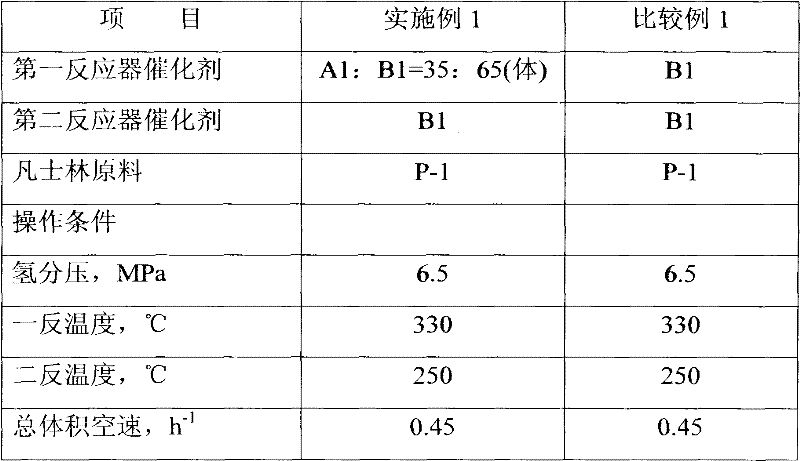

Production method of vaseline

The invention discloses a production method of vaseline. The method comprises the following steps: 1, blending HVI650 cerate, reduced pressure distillate oil base oil and selective reduced pressure residual oil light removal cerate which are treated as raw materials; 2, hydrotreating the obtained blended mixture through first-stage series hydrofinishing with a fixed bed; and 3, allowing the blended mixture to go through a first reactor and a second reactor under hydrofinishing conditions, wherein the first reactor is filled with a hydroisomerizing catalyst and a hydrofinishing catalyst, and the second reactor is filled with a hydrofinishing catalyst. The method of the invention allows high quality vaseline products to be obtained by treating raw materials which cannot be vaseline raw materials in the prior art as the vaseline raw materials, blending the raw materials with a proper process and hydrogenating the raw materials, so the vaseline raw material source is enlarged, the HVI650 cerate utilization approach is widened, and economic benefits are improved.

Owner:CHINA PETROLEUM & CHEM CORP +1

Herbal cream or oil for the treatment hemorroids and wounds

This (Patent) protection covers the process for preparing cream for wounds and internal and external hemorrhoids which consists of making herbal-oil extract in three different ways.Vaseline and lanolin are added to this herbal-oil extract and all is mixed and heated to +40° C. for duration of about 20-30 minutes, when honey is added continuously mixing, up to +35° C., when pollen powder is added with mixing until the mass is homogenized, after which dissolved propolis is added, mixing the mass until it cools of to 25° C. and until the mass is fully homogenized.To repeat, the herbal-oil extract is made in such way when mix of various herbs in several ways is extracted with ethanol, then mix with olive oil, then alcohol evaporates leaving herbal-oil extract, which is used for preparing medicaments for wounds and hemorrhoids and any other topical use.

Owner:MIKALACKI SVETISLAV +1

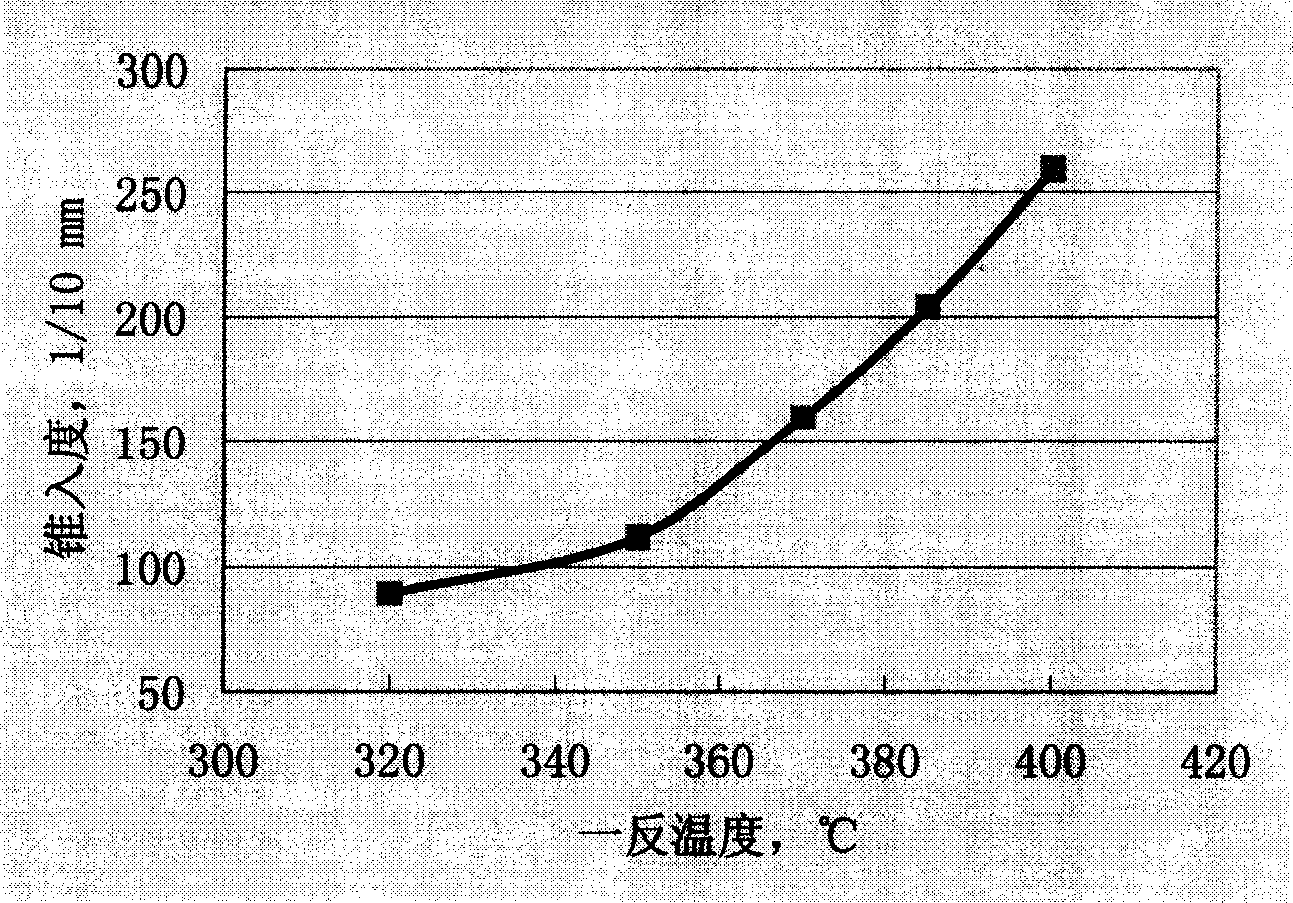

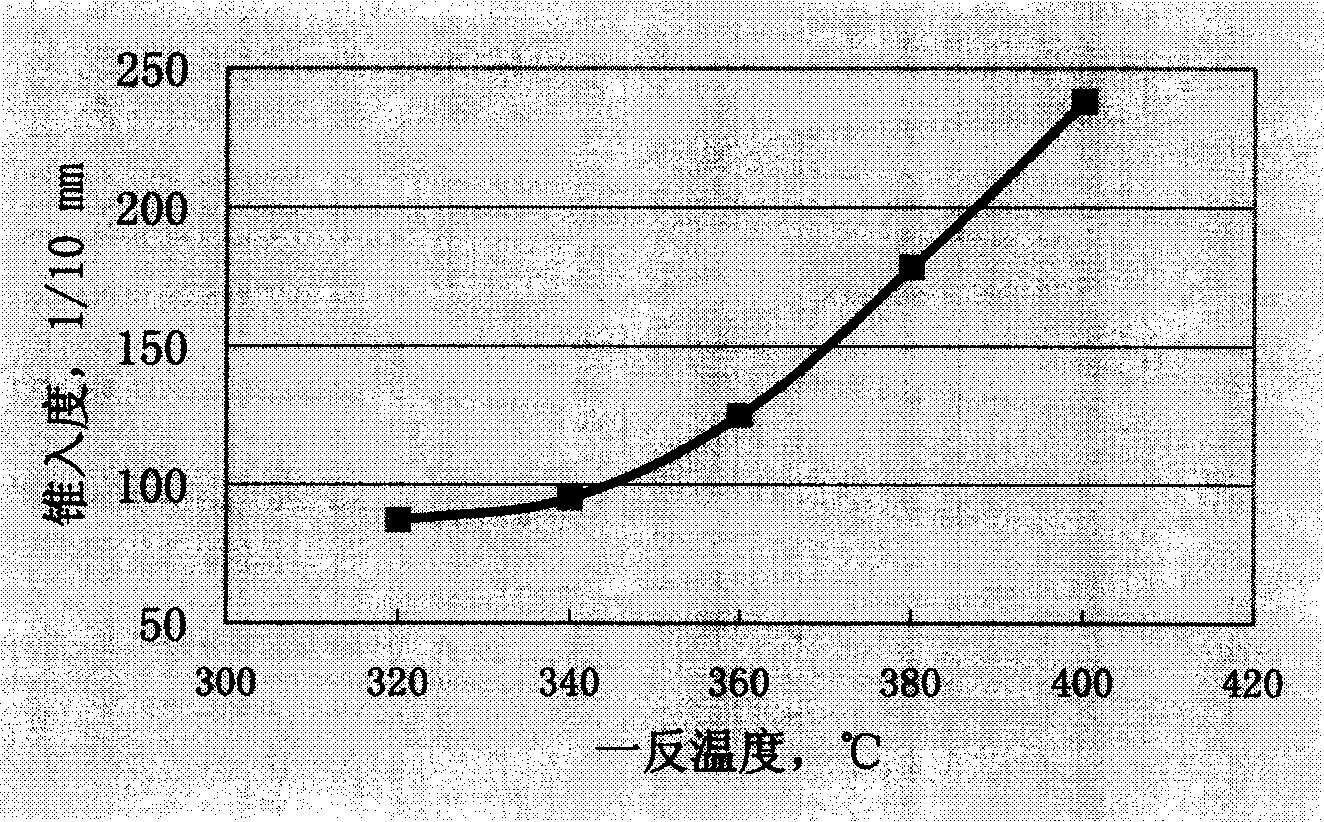

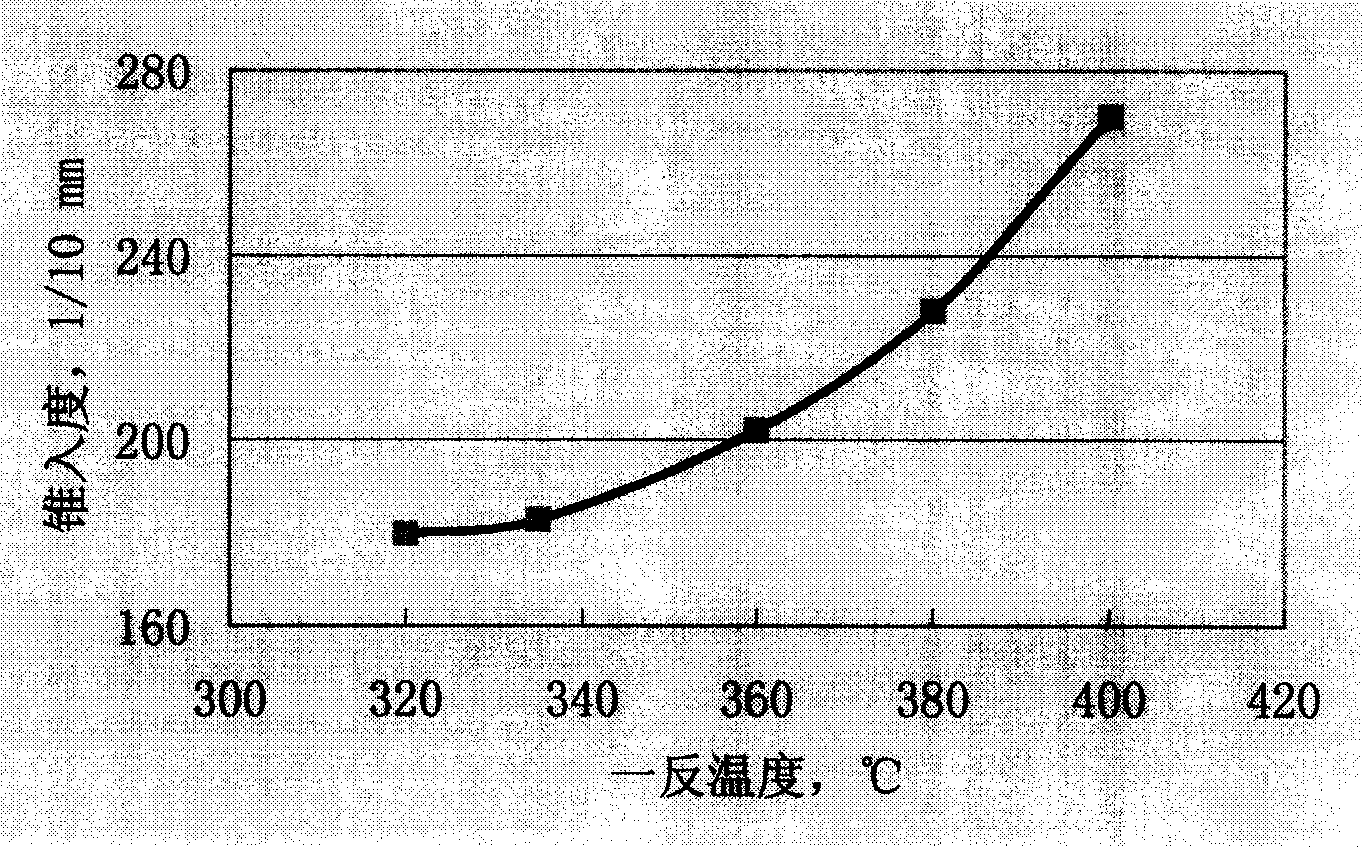

Method for producing different consistency vaselines

ActiveCN1611579AEasy to produceAvoid frequent replacementAerosol deliveryOintment deliveryWaxVaseline

This invention opens one manufacturing method of geoline of different consistencies, especially one hydrofining method to produce geoline of different consistencies, with single component short residue cerate or its concoction as the materials. Characteristics of this method is that pricking degrees of hydrogenation materials can be changed by suitable degradation reaction. Any hydrofining catalyst of petroleum wax can be used in this method. This method solves the problem existing in current techology that different features of materials have to be prepared to produce geoline of different consistencies and can be flexibly and conveniently applied to produce products of different consistencies. Geoline produced by this method can be applied in medicine and cosmetics.

Owner:CHINA PETROLEUM & CHEM CORP +1

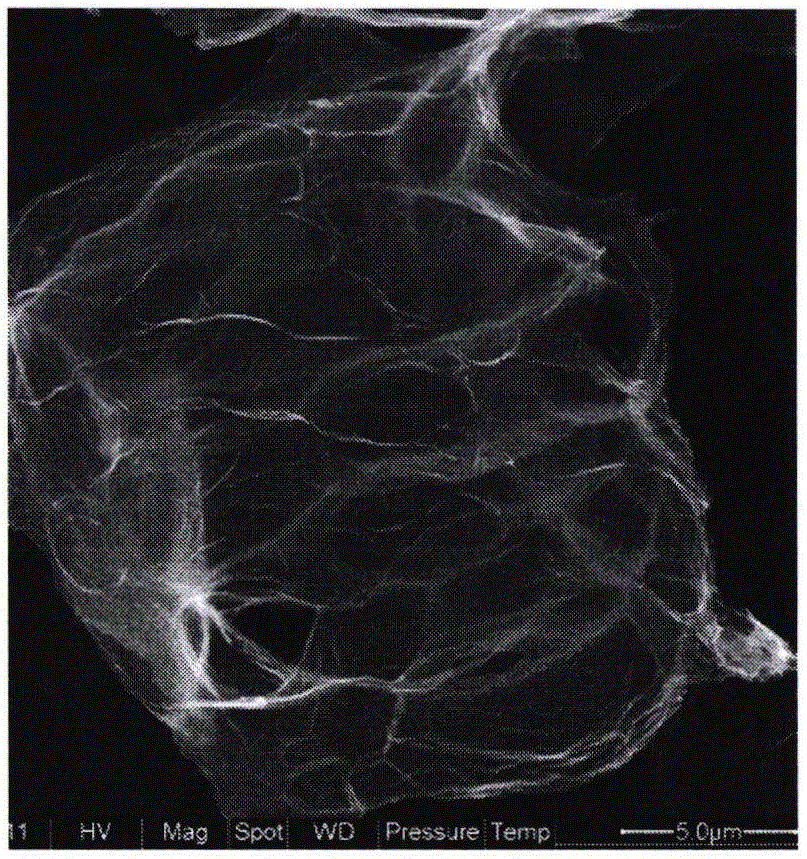

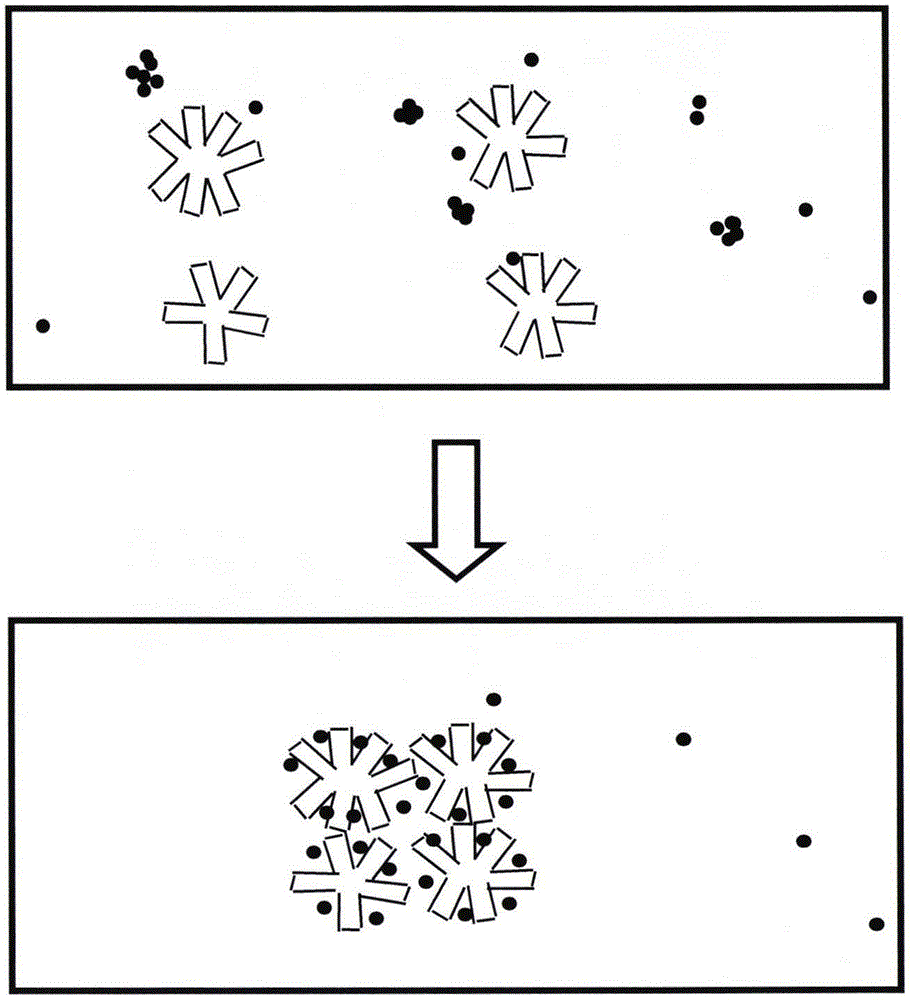

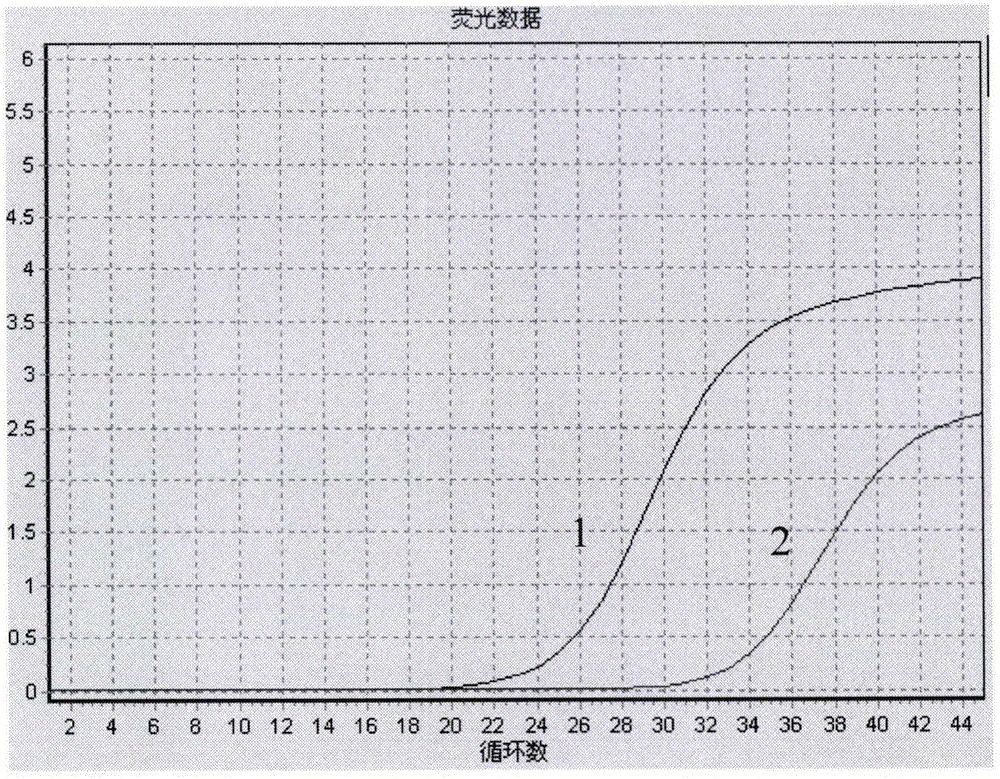

Graphene accelerated PCR (polymerase chain reaction) technology

InactiveCN105420364AAvoid pollutionSolve pollutionMicrobiological testing/measurementBiotechnologyGraphene

The invention provides a graphene accelerated PCR (polymerase chain reaction) technology, in particular an integrated novel modified PCR technology integrating a novel material graphene and PCR and being capable of accelerating nucleic acid amplification, and aims to increase contact between nucleic acid molecules, accelerate PCR process and reduce nonspecific amplification in a PCR system by utilizing the characteristics of adsorption and high-specific surface of graphene. The graphene accelerated PCR technology relates to the field of nucleic acid amplification in molecular biology and molecular tests, is a theoretical innovation integrating the novel material graphene and PCR detection, and can be used for increasing the contact probability of nucleic acid molecules by utilizing the characteristics of adsorption and high-specific surface of graphene, integrating a PCR to slowly release one or various ingredients, combining mineral oil or liquid petrolatum to seal and isolate the external environment, and solving the problem of false positivity caused by over-long reaction time of the PCR and increase of nonspecific amplification due to over-long reaction time of the PCR.

Owner:BEIJING LEAGENE BIOTECH CO LTD

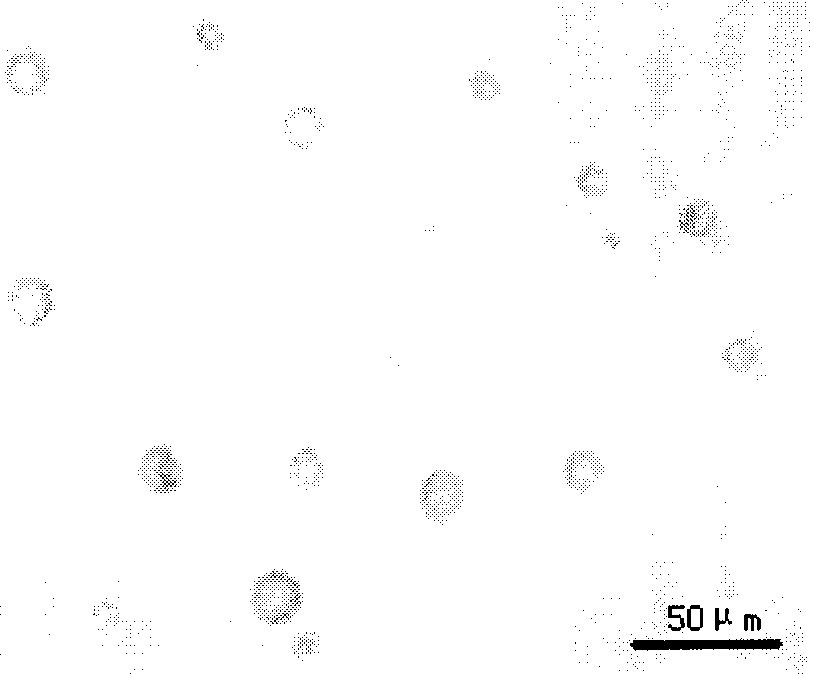

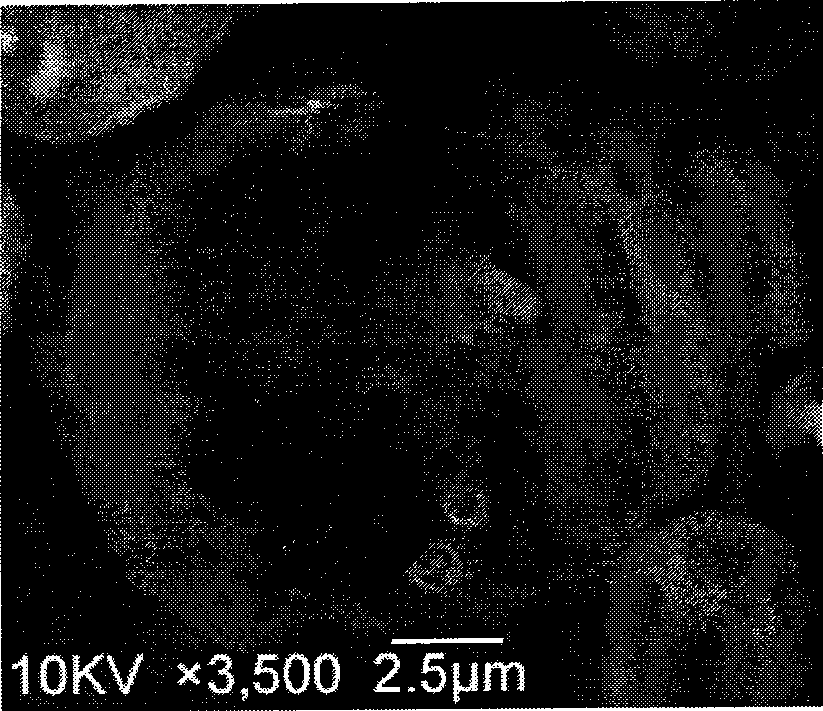

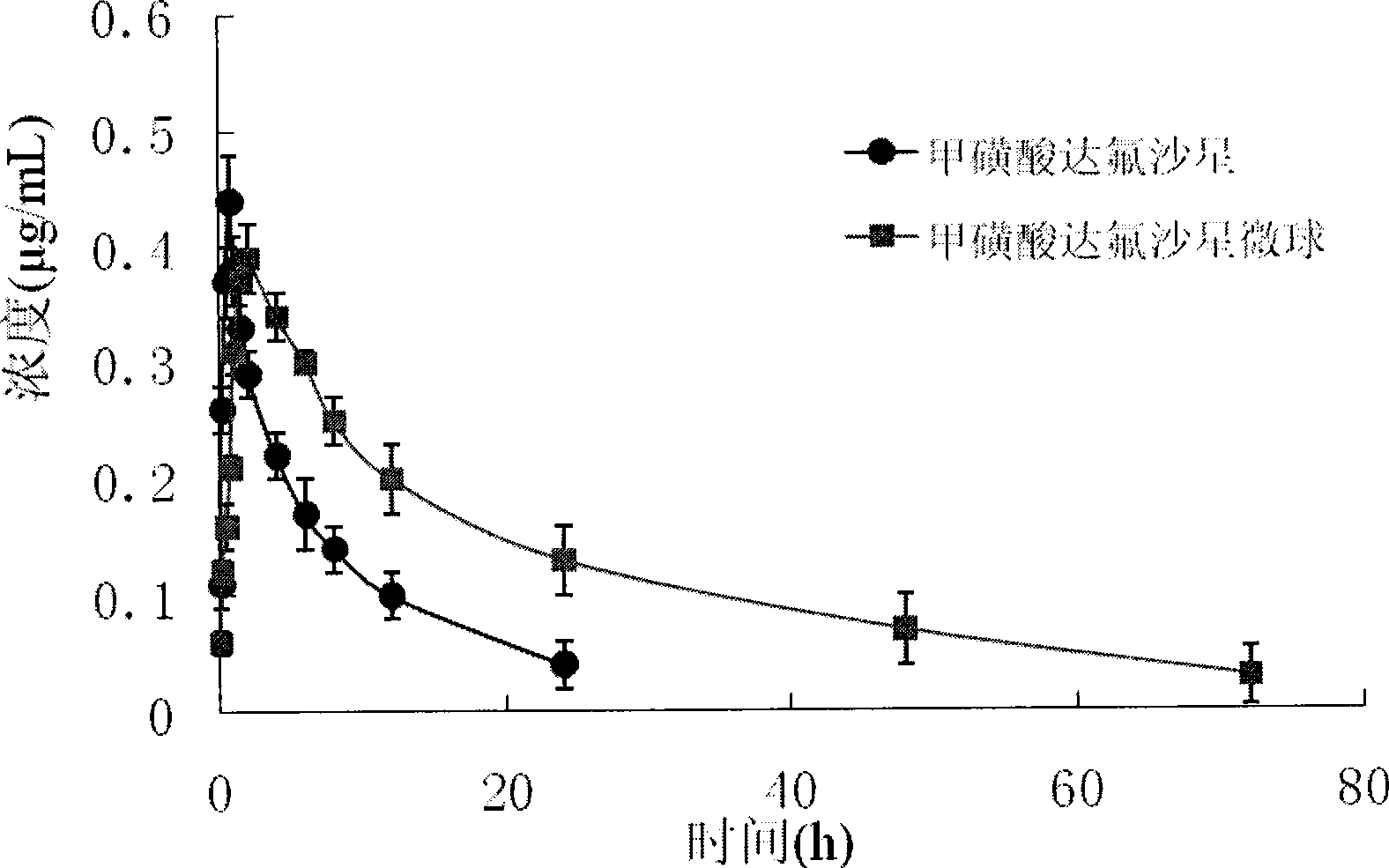

Danofloxacin mesylate microsphere formulation for livestock and poultry and preparation method thereof

ActiveCN101411689ALong elimination half-lifeHigh affinityAntibacterial agentsOrganic active ingredientsCross-linkIntramuscular injection

The invention relates to a danofloxacin mesylate microsphere preparation, which is prepared by the following steps: adding gelatin, or gelatin and polyglycol, or gelatin and polyglycol as well as xanthan gum into water, and adding danofloxacin mesylate for dissolution to obtain a water phase; adding an emulsifying agent into liquid petrolatum to mix evenly to obtain an oil phase; and adding the water phase into the oil phase, emulsifying, cross linking and solidifying the mixed phases and removing supernatant to obtain the danofloxacin mesylate microsphere preparation for livestock and birds. The preparation adopts an emulsifying and condensing method to wrap the danofloxacin mesylate in microspheres, can release slowly after using the microspheres for intramuscular injection, and prolong elimination half-life of medicament in vivo. The preparation technology has the advantages of simple operation, low requirements on preparation equipment and conditions, round shape of the obtained microspheres, and good dispersing property in water solution; and can prolong effective acting time of the medicament in vivo after intramuscular injection for pigs.

Owner:武汉回盛生物科技股份有限公司

Petrolatum Composition

A petrolatum composition comprises from 10 to 60 wt % of a wax having an average number of carbon atoms per molecule of between 25 and 70, and having between 5 and 50 wt % branched paraffins in which the branches are selected from methyl and ethyl branches; from 10 to 60 wt % of a linear paraffin having an average number of carbon atoms per molecule of between 10 and 20; and optionally, a low melt wax. The petrolatum composition has a drop melt point of from 35° C. to 80° C.

Owner:SASOL CHEM IND LTD

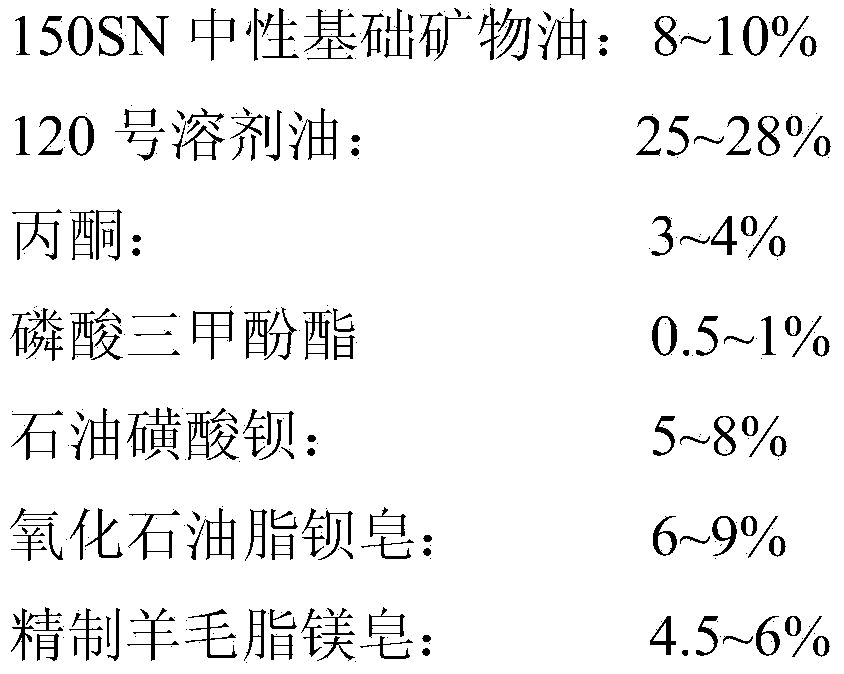

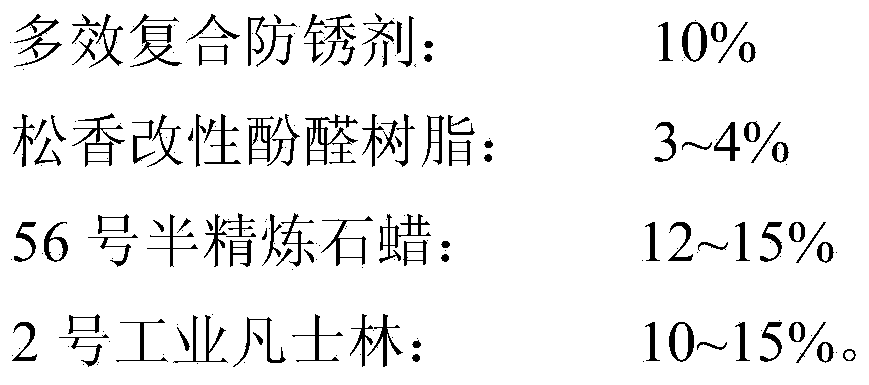

Brown high-build quick-drying antirust oil applicable to diesel engines of ships and warships and preparation method thereof

ActiveCN103540393AStrong adhesionImprove corrosion resistanceLubricant compositionParaffin waxLanolin

The invention discloses brown high-build quick-drying antirust oil applicable to diesel engines of ships and warships and a preparation method thereof. The black high-build quick-drying antirust oil applicable to the diesel engines of the ships and warships is prepared from 150SN neutral basic mineral oil, No.120 solvent oil, acetone, tricresyl phosphate, barium petroleum sulfonate, barium soap of petroleum ester oxide, refined lanolin magnesium soap, a multi-effect compound antirust agent, rosin modified phenolic resin, No.56 semi-refined paraffin wax and No.2 industrial Vaseline. The brown high-build quick-drying antirust oil can form a semi-hard membrane-like protective coating with strong compactness, good adhesive force and naturally quick-drying property on the surface of a material, is resistant to atmospheric corrosion and has excellent moisture resistance and salt mist resistance, and the rustproof life can be more than three years; the antirust effect is good, and the antirust quality technical requirement of a user on products in processes of production, manufacturing, transportation, storage and the like can be completely met.

Owner:广东中诚表面防护材料检验研究院有限公司

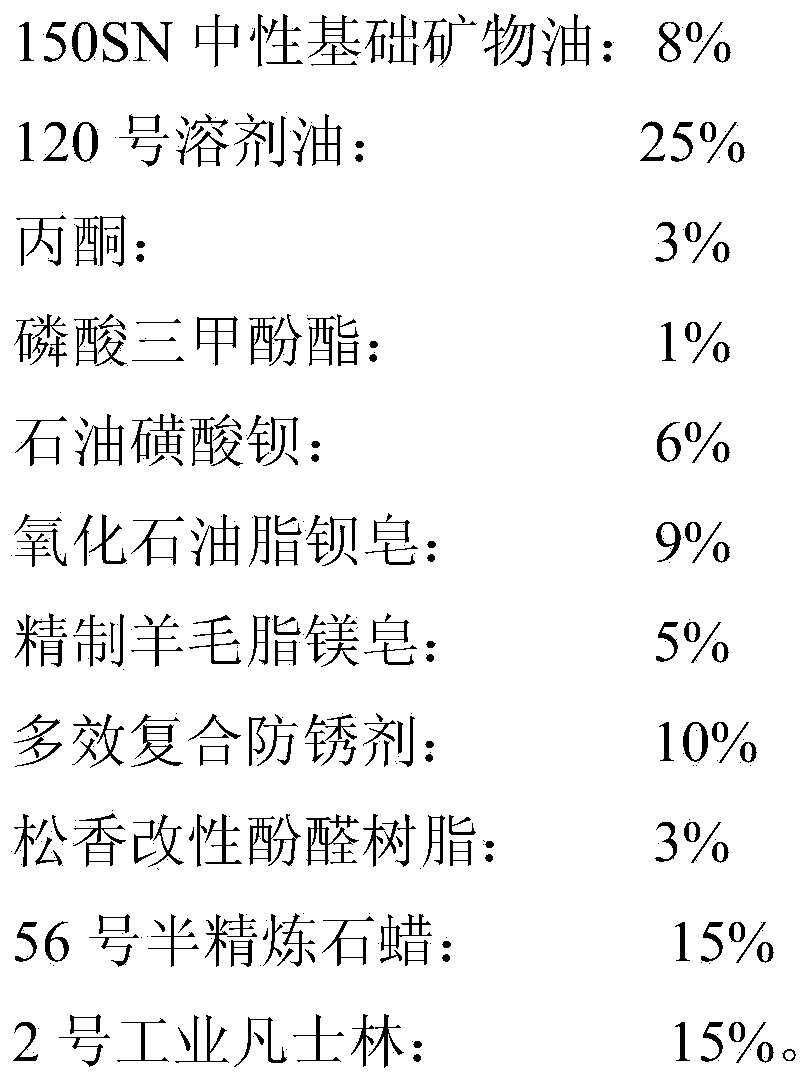

Paraffin sizing material for electronic cloth of low solid content

The invention relates to a paraffin wax impregnating compound with low solid content used by an electronic cloth. The compositions by weight percentage of the paraffin wax impregnating compound are: 1.2 to 1.5 percent of paraffin wax, 0.8 to 1.5 percent of engine oil, 0.8 to 1.5 percent of vaseline, 0.6 to 0.8 percent of emulsifying agent, 0.1 to 0.15 percent of cationic film, 2.5 to 3.8 percent of fixing agent, the balance being water. Moreover, epoxy resin can be also added into the compositions and occupies 0.3 to 0.5 percent of the total weight. The invention reduces the amount of oil substances such as the paraffin wax, the vaseline, the engine oil and so on in the compositions of the impregnating compound and adds the cationic film with a certain proportion. Glass fiber yarns the surface of which is coated by the impregnating compound are soft and have good weaving performance and low combustible content. According to actual detection, the combustible content of the glass fiber yarns produced by the formula is between 0.75 and 0.85 percent and reduces by 15 to 25 percent compared with 1 percent of combustible content of the prior paraffin wax yarns, and the production cost is reduced.

Owner:山东兴国大成特种纤维科技有限公司

Moisturizing skin ointment - composition consisting of polymyxin B Sulfate, bacitracin zinc, neomycin (the combination of which totals 1 ounce), hydrocortisone acetate (1 ounce) and white petrolatum (13 ounces)

This invention relates to a moisturizing skin ointment composition consisting of polymyxin B Sulfate, bacitracin zinc, neomycin (the combination of which totals 1 ounce), hydrocortisone acetate (1 ounce) and white petrolatum (13 ounces). When combined and water evaporated, an external ointment that penetrates the skin and alleviates dry skin conditions, itching and minor scrapes and scratches is created. The properties of the antibiotic products help to promote healing of minor scrapes and scratches as well as preventing the spread of dry skin conditions. The properties of the hydrocortisone aids in the alleviation of itching associated with dry skin. Because this ointment penetrates the dermis almost immediately, the moisturizing properties of petrolatum allows the full benefit of the antibiotic products and hydrocortison to remain on / in the skin through several washings thereby alleviating the need to reapply several times a day.

Owner:MEEKS JOYCE ANN

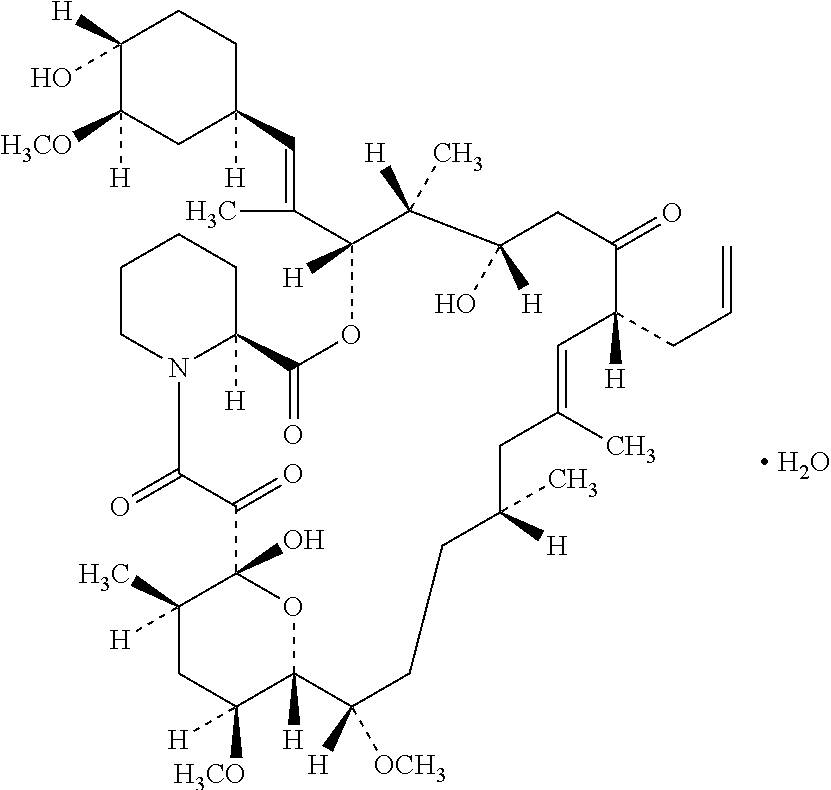

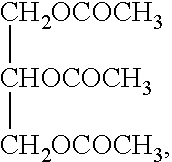

Tacrolimus preparation for external applications

InactiveUS20110212988A1Low dermal irritationImprove stabilityBiocideOintment deliveryExternal applicationMedicine

The present invention provides tacrolimus containing ointment having low dermal irritation and excellent stability. It was found that an ointment comprising triacetin as a solubilizer for tacrolimus may sufficiently solubilize tacrolimus, has low dermal irritation and excellent stability. Preferably, the ointment of the present invention is an o / o type (oil-in-oil type) ointment in which tacrolimus-solubilized triacetin droplets are dispersed in an ointment base, preferably a mixture of beeswax and petrolatum.

Owner:TAKATA SEIYAKU

Rubber tree tapping face coldness-proof coating agent and method for producing same

The invention discloses a rubber tree cut cold-proof coating-packing agent and manufacturing method, which consists of 35-50% rubber seed oil and 50-65% vaseline, wherein the vaseline is heated to 45-55 deg.c to add rubber seed oil according to certain proportion, which is cooled to indoor temperature after blending evenly. The invention can coat and pack rubber tree with temperature not less than 10 deg.c, which protects cutting surface from flowing rubber and accelerates bark recombination and regeneration.

Owner:肖余保

Paste plaster for treating psoriasis and preparation method thereof

InactiveCN102406658ASpread the bloodNo adverse reactionHydroxy compound active ingredientsAerosol deliveryDiseaseWhite petrolatum

The invention discloses a paste plaster for treating psoriasis. The paste plaster comprises the following raw materials in parts by weight: 20-28 parts of white alum, 21-27 parts of mirabilite, 20-28 parts of sulphur, 4-7 parts of borneol, 200-300 parts of vaseline and 80-120 parts of paraffin. The paste plaster for treating psoriasis is prepared according to the following steps: a, weighting theraw materials in parts by weight; b, grinding white alum, mirabilite, sulphur and borneol into fine powder, and screening by a 100-meshed screen for later use; and c, putting the mixture obtained in the step b in a mortar for uniform stirring, adding vaseline to blend uniformly, and then adding liquid paraffin to regulate uniformly. The components are mutually matched to dispel disease mainly, and relieve wind heat, relieve dampness and turbidity, activate collaterals, harmonize qi and blood to realize metabolism, clarify skin, smooth blood vessel and remove stasis to promote tissue regeneration. The paste plaster plays effects mainly by using local skin administration, and has no adverse effect when in use. The paste plaster can take effect after being used once to twice by a patient with mild symptom generally, skin can gradually become soft and thin, the symptom can be relieved within 10-25 days and skin is gradually improved to be normal; and patients with long course of disease and serious symptoms can be recovered in 1-2 months usually.

Owner:丁荣松

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com