Method for producing different consistency vaselines

A production method, Vaseline technology, applied in the field of flexible production, can solve the problems of only considering the removal effect of impurities, and achieve the effects of shortening the production process, simplifying the production method, and saving equipment investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The petrolatum hydrorefining method of the present invention can use a single vacuum residue light dewaxing paste or its blend as the petrolatum hydrorefining raw material. The components that can be blended with the vacuum residue light dewaxing paste include vacuum distillate base oil, vacuum distillate dewaxing oil and solvent refined oil.

[0013] The petrolatum hydrorefining method of the present invention adopts two fixed-bed reactors, or one reactor is connected in series with two catalyst beds. The catalyst can be any petroleum wax product hydrorefining catalyst, including W-Ni Type hydrorefining catalyst and Mo-Ni type hydrorefining catalyst. The two reactors can be filled with the same catalyst or different catalysts.

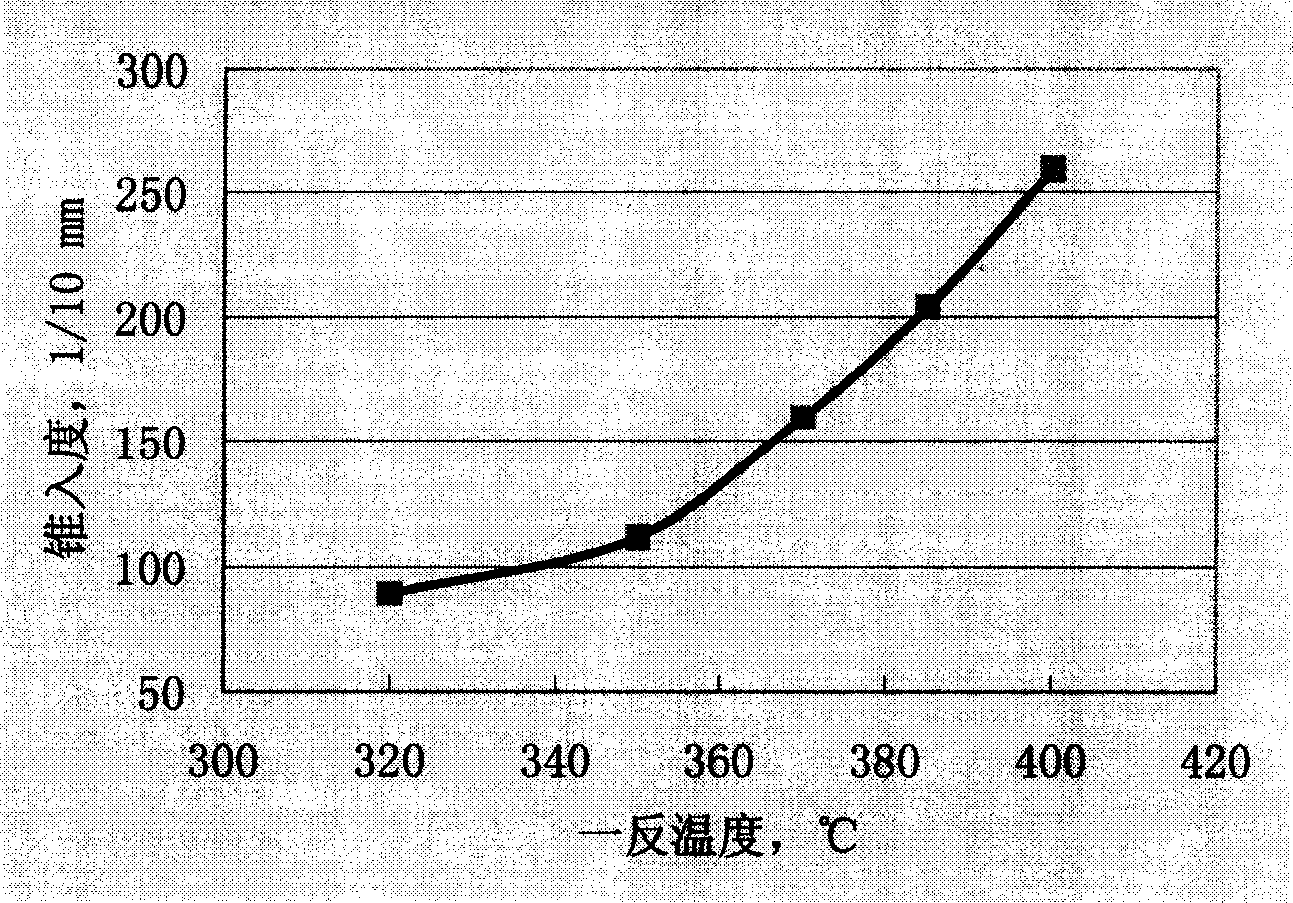

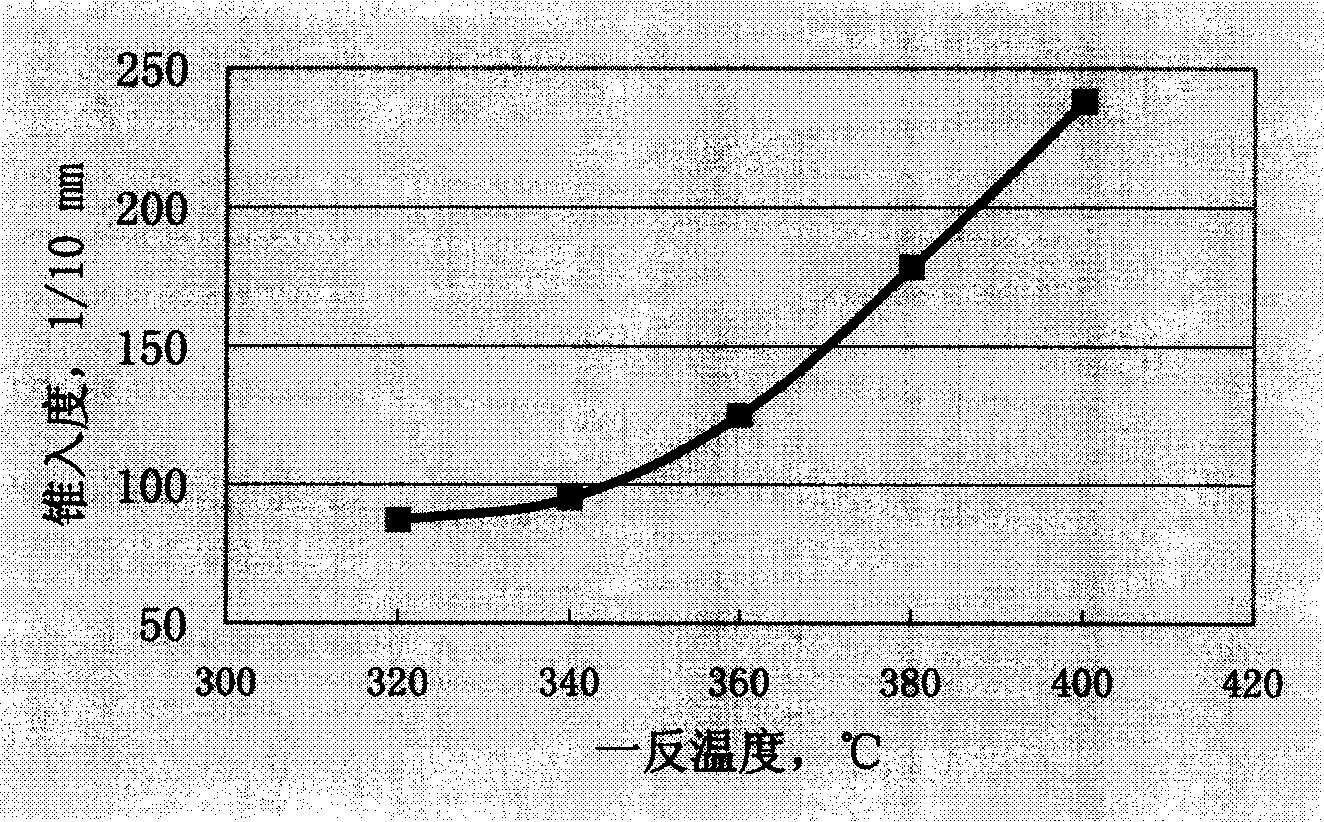

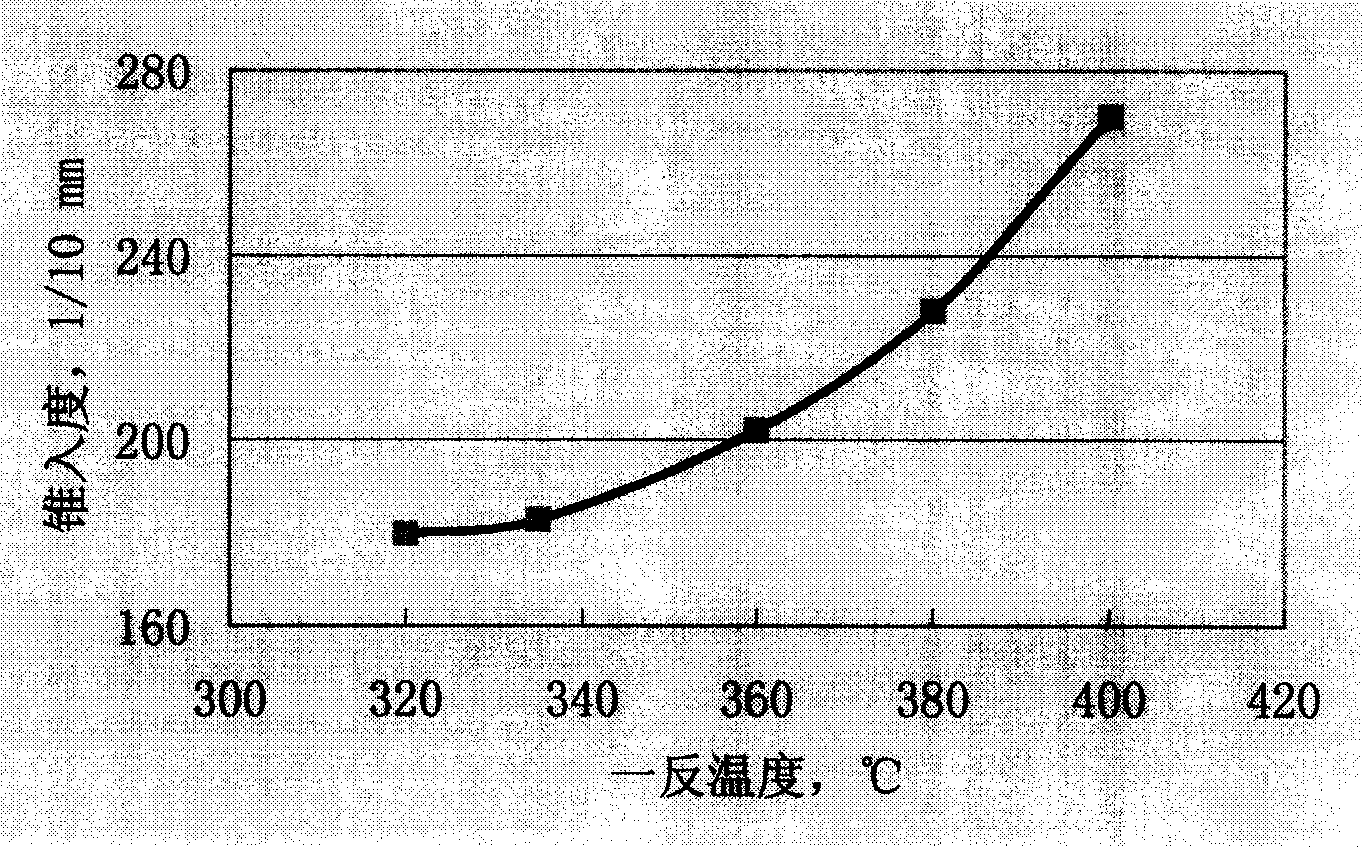

[0014] Different raw materials and catalysts generally need to draw different product penetration curves corresponding to the temperature of the first reactor, but the curves obtained from typical raw materials and catalysts are representative and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com