Patents

Literature

750results about How to "Avoid frequent replacement" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

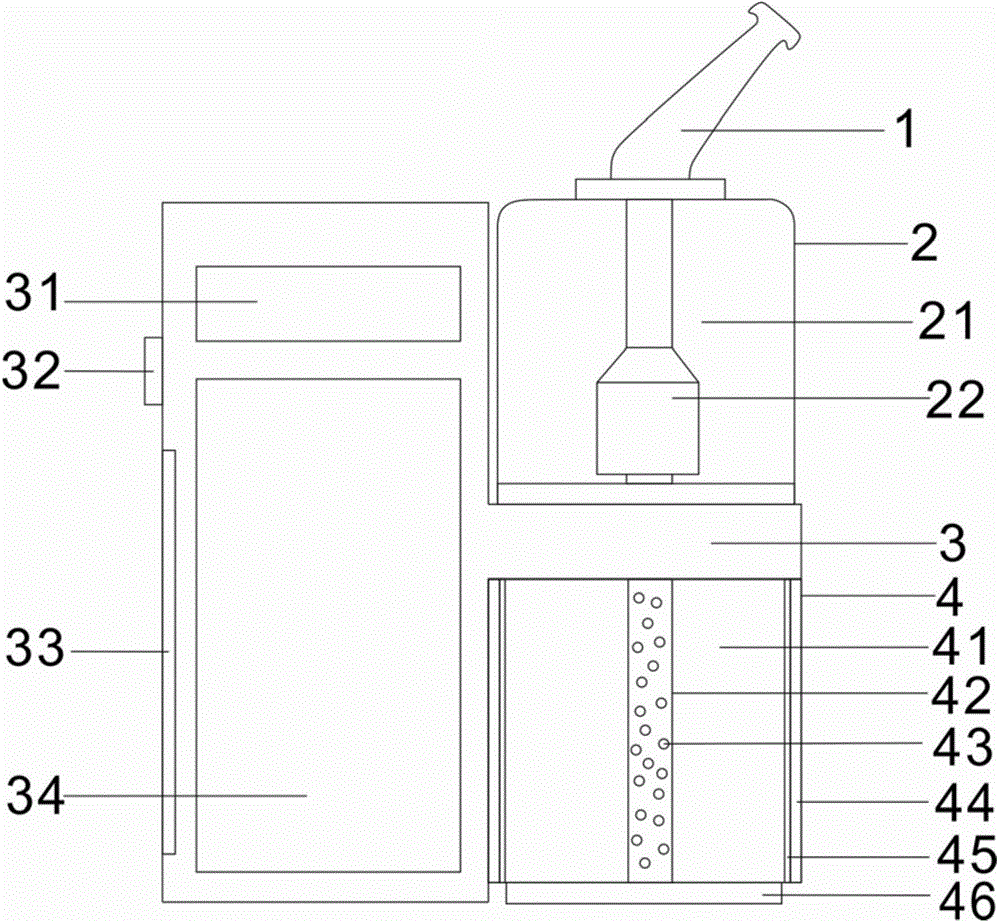

Mixed type electronic cigarette appliance

InactiveCN104886776AMake up for the defect of poor tasteEnhance sensory experienceTobacco devicesEngineeringElectronic cigarette

The invention discloses a mixed type electronic cigarette appliance. The mixed type electronic cigarette appliance comprises a suction nozzle, an atomizer and an electronic cigarette body which are connected together, and the middle of the suction nozzle, the middle of the atomizer and the middle of the electronic cigarette body are closely communicated. A liquid storage cavity and a heating element are arranged in the atomizer. A PCB control circuit board on the electronic cigarette body is connected with a switch, a battery and the heating element in the atomizer, wherein the switch and the battery are arranged on the PCB control circuit board. The electronic cigarette body further comprises a cut tobacco heating cavity which is internally provided with a cut tobacco storage bin. A center steam pipe communicated with the heating element is arranged in the middle of the cut tobacco bin. Small holes are formed in the center steam pipe. A heating piece connected with the PCB control circuit board is arranged on the inner wall of the cut tobacco heating cavity outside the cut tobacco bin. A sealing cap is arranged at the bottom of the cut tobacco storage bin, and an air hole communicated with the center steam pipe, the heating element and the suction nozzle is formed in the middle of the sealing cap. The electronic cigarette appliance can atomize tobacco juice and heat cut tobacco at the same time, and the difference between an electronic cigarette and a traditional cigarette and the difference in unique tobacco juice of the electronic cigarette smoking taste is greatly reduced.

Owner:CHINA TOBACCO GUANGXI IND

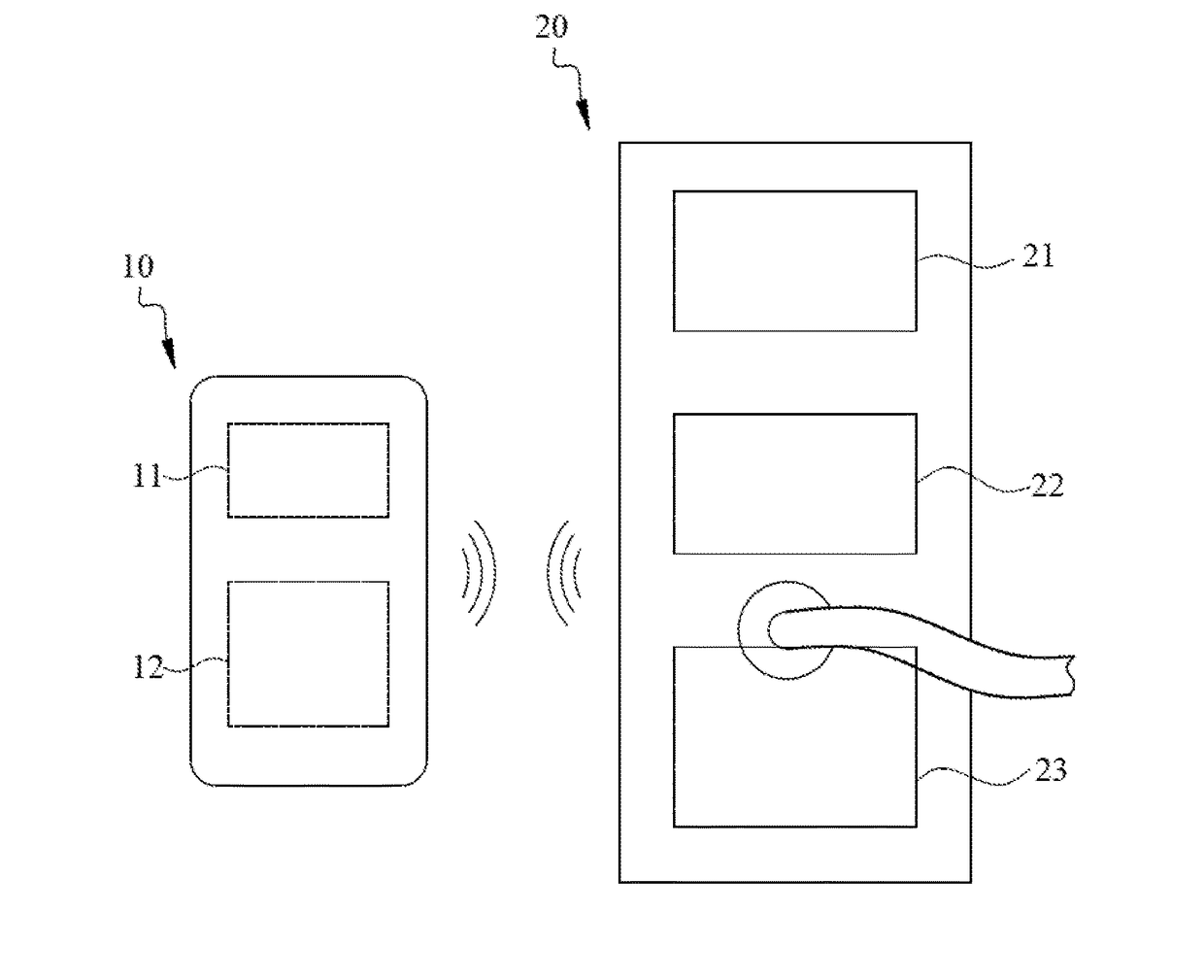

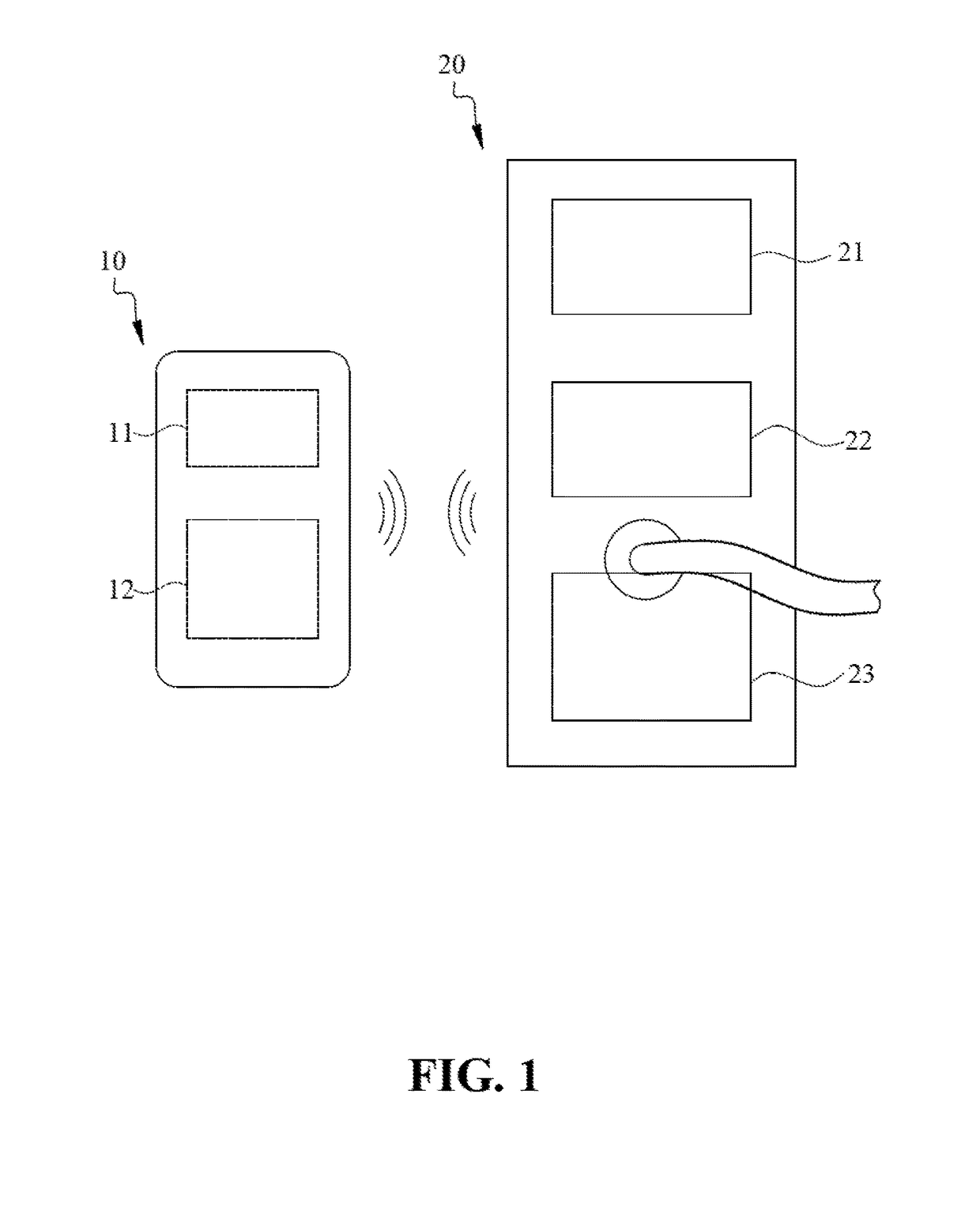

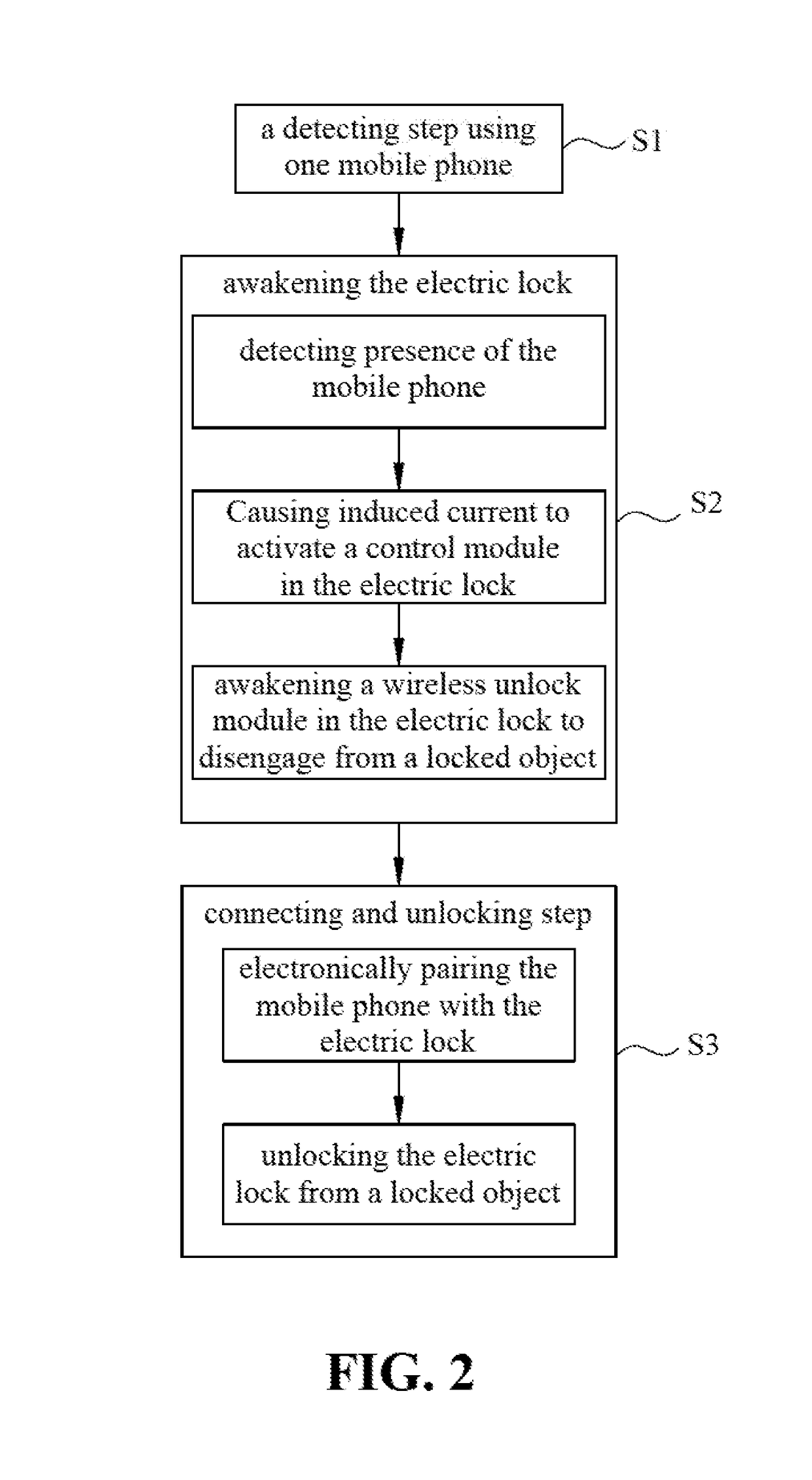

Electric lock adapted to be activated by a mobile phone and method thereof

InactiveUS20170243420A1Save battery powerLarge powerNon-mechanical controlsIndividual entry/exit registersElectrical batteryWireless communication protocol

Provided is an electric lock adapted to be activated by a mobile phone. The mobile phone includes a wireless connection module and a battery unit for supplying power to the wireless connection module and the electric lock includes a detection device, a control module and a wireless unlock module, wherein the detection device and the wireless unlock module are connected electrically to the control module and the wireless unlock module is configured to couple with the wireless connection module of the mobile phone via a wireless communication protocol such that once the wireless connection module of the mobile phone and the wireless unlock module of the electric lock are paired with each other, the mobile phone is capable of converting without touching awakening the wireless unlock module in order to unlock the electric lock relative to a locked object.

Owner:WFE TECH CORP

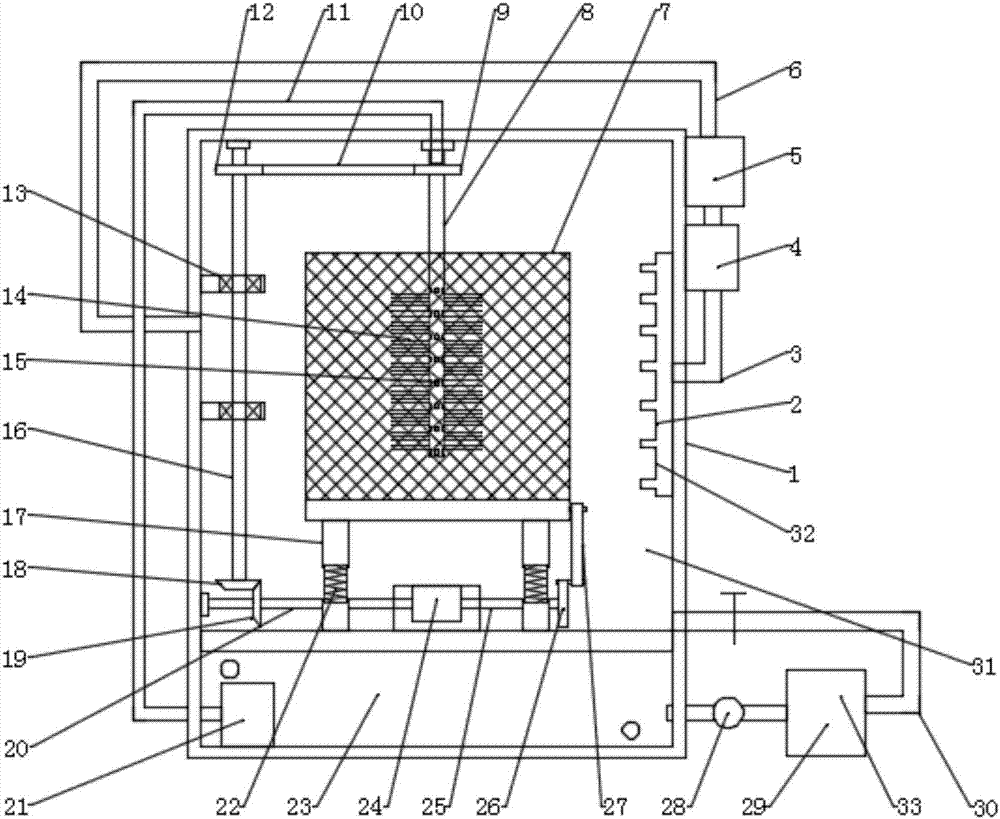

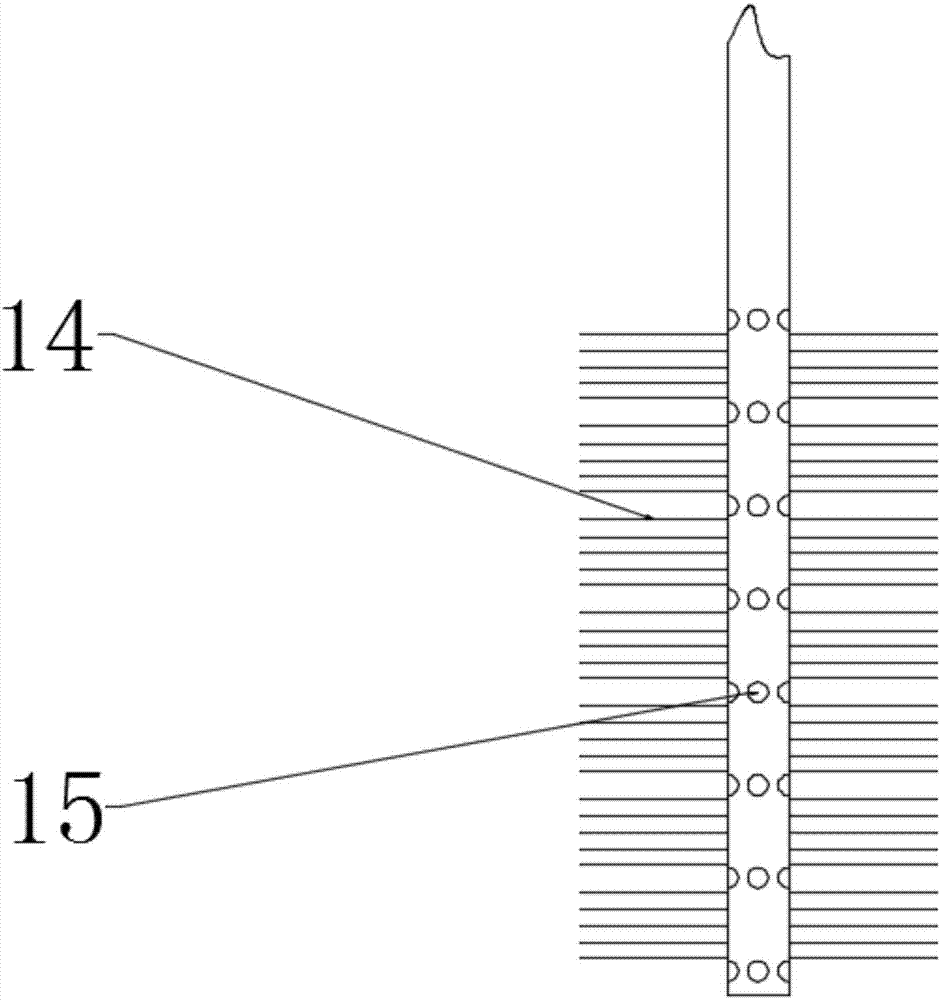

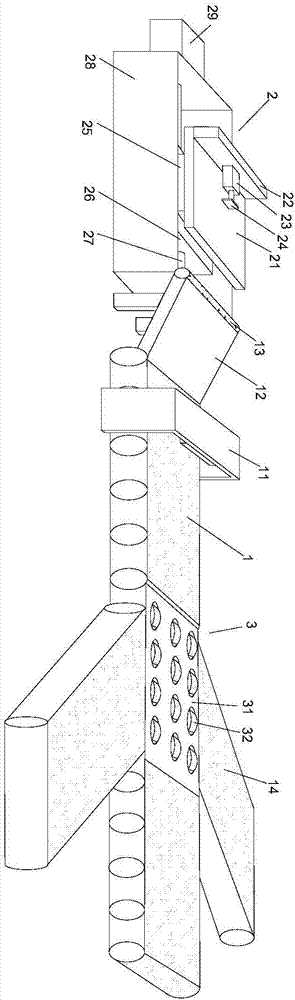

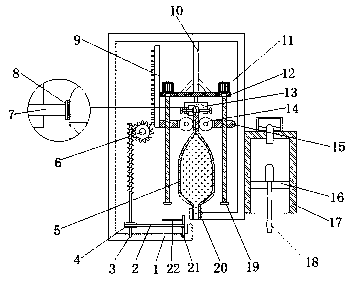

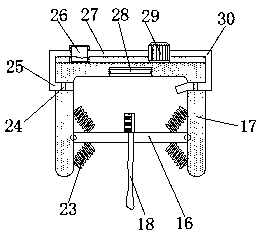

Efficient medial instrument cleaning device

InactiveCN107243480AAvoid wastingAvoid frequent replacementDrying gas arrangementsCleaning using toolsEngineeringScrub brushes

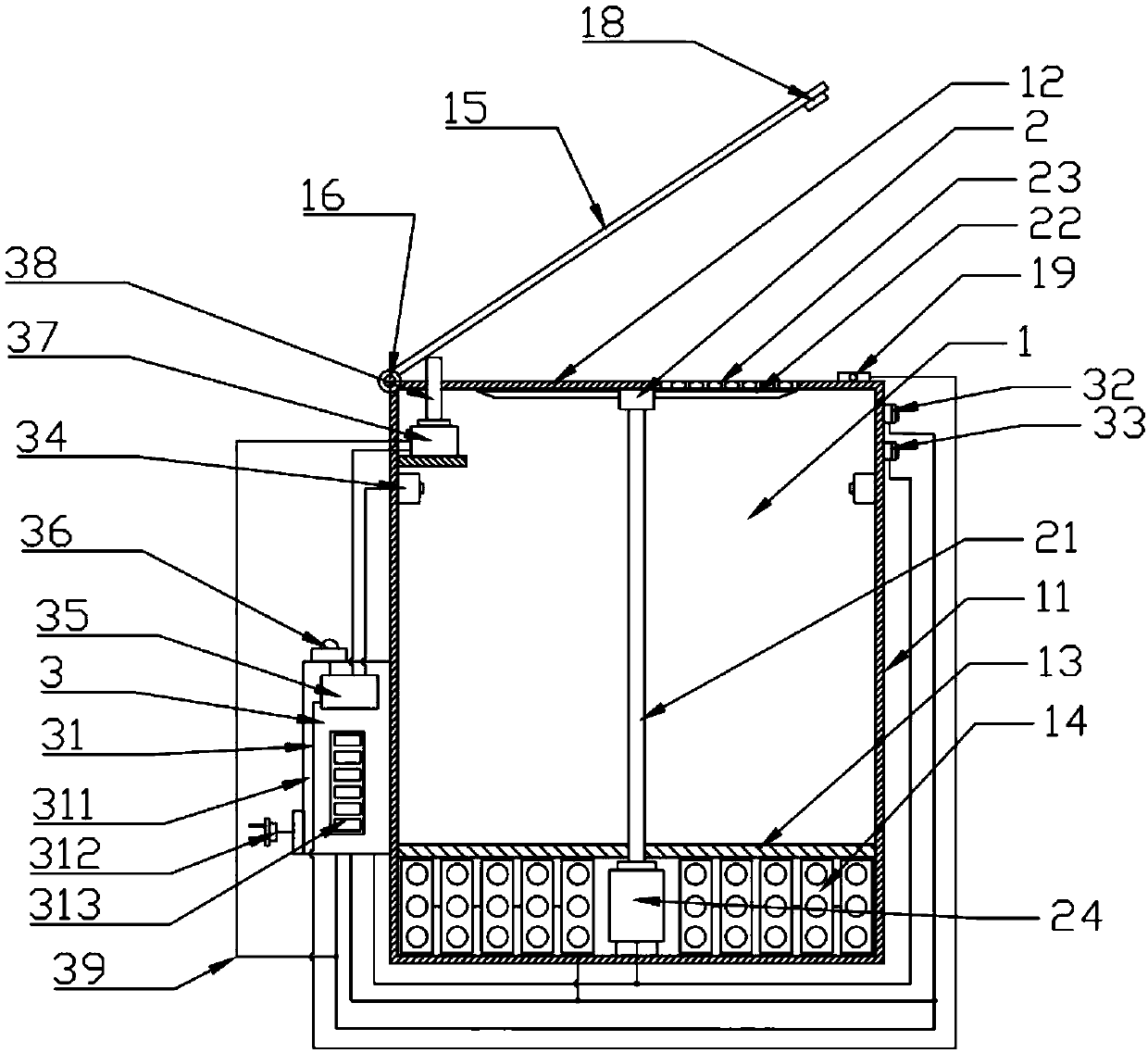

The invention discloses an efficient medial instrument cleaning device. The efficient medial instrument cleaning device comprises a box body, a cleaning cavity, a cleaning liquid cavity, a cleaning frame, a dual-shaft motor, a first belt wheel, a belt, a second belt wheel, a hollow pipe, spraying holes, a brush, a first water pipe, a water pump, a circulating device and a drying device; the device is provided with the dual-shaft motor, a disc and a connecting rod, through cooperation of above components, the cleaning frame is driven to shake continuously, medical instruments in the cleaning frame are continuously turned over, and are more sufficiently in contact with cleaning liquid, cleaning efficiency is improved, a first bevel wheel, a second bevel wheel, a rotating shaft, the first belt wheel, the belt, the second belt wheel and the hollow pipe are arranged, the brush continuously brushes medical instruments, stubborn stains on the surfaces of the medical instruments are removed, cleaning efficiency is improved, meanwhile, the spraying holes spray cleaning liquid from inside to outside, the cleaning liquid can sufficiently clean the all medical instruments, the blots are flushed out of the cleaning frame, and thorough cleaning can be further ensured.

Owner:童贤波

Logistics sorting device

The invention discloses a logistics sorting device. The logistics sorting device comprises a controlling system, a main conveyor belt, code scanning devices, an auxiliary conveyor belt, a weighing mechanism and a sorting mechanism; the code scanning devices are arranged above the main conveyor belt and are fixed on ground on the front side and rear side of the main conveyor belt; an inclined slideway is fixedly connected with the left side of the main conveyor belt, and a convey assisting roller is fixedly connected to the top end of the inclined slideway; the weighing mechanism is arranged on the left side of the convey assisting roller; the weighing mechanism comprises a tray, an air cylinder supporting seat, an air cylinder, a pushing plate, a weight sensor, a sliding block, a lead screw, a weighing mechanism casing and a first motor; the sorting mechanism is arranged on the right side of the main conveyor belt; and the sorting mechanism comprises a sorting mechanism casing, guiding wheels, a second motor, a guiding wheel supporting seat and a third motor. According to the logistics sorting device, input of labor cost can be reduced, sorting and transporting of logistics can be accurately achieved through a controlling system, efficiency is high, and error is not easy to occur.

Owner:XIAN INT UNIV

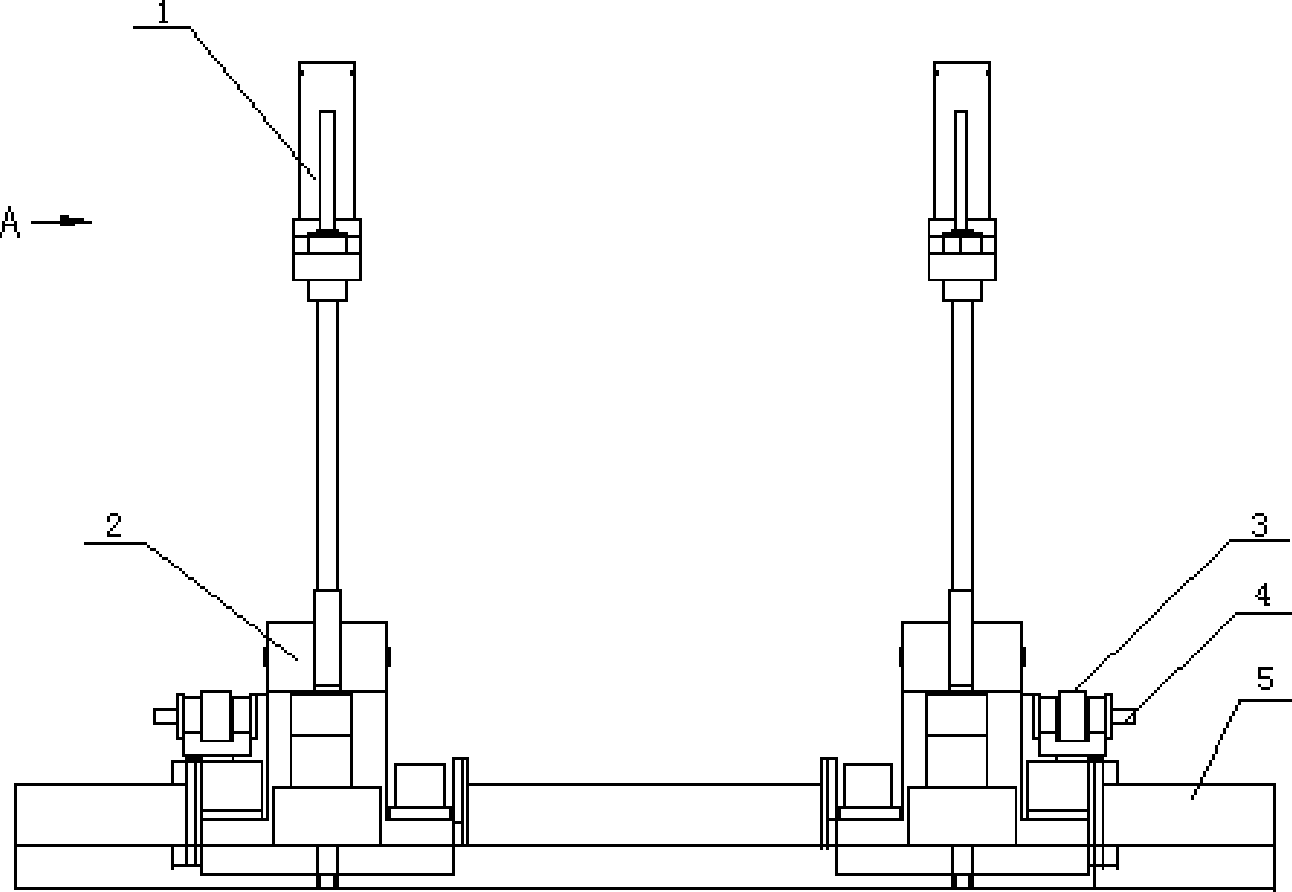

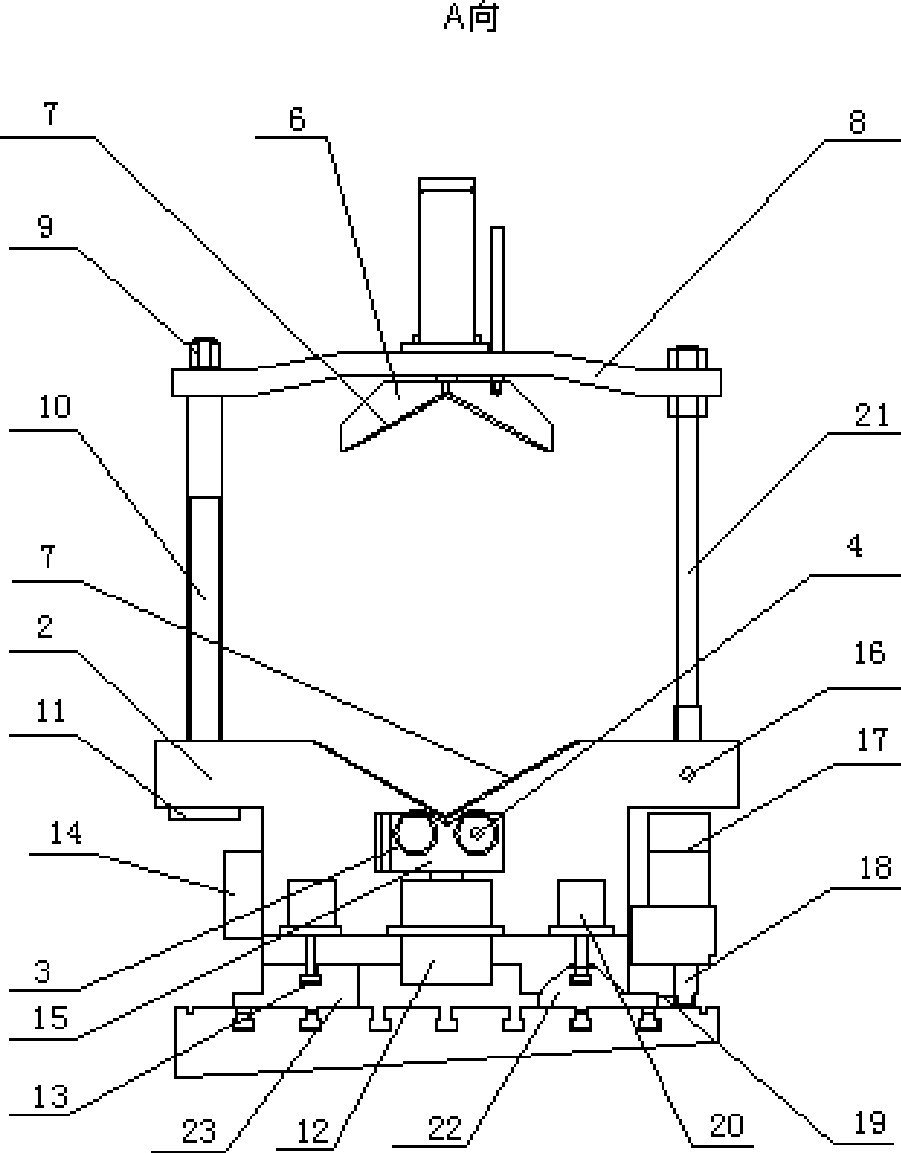

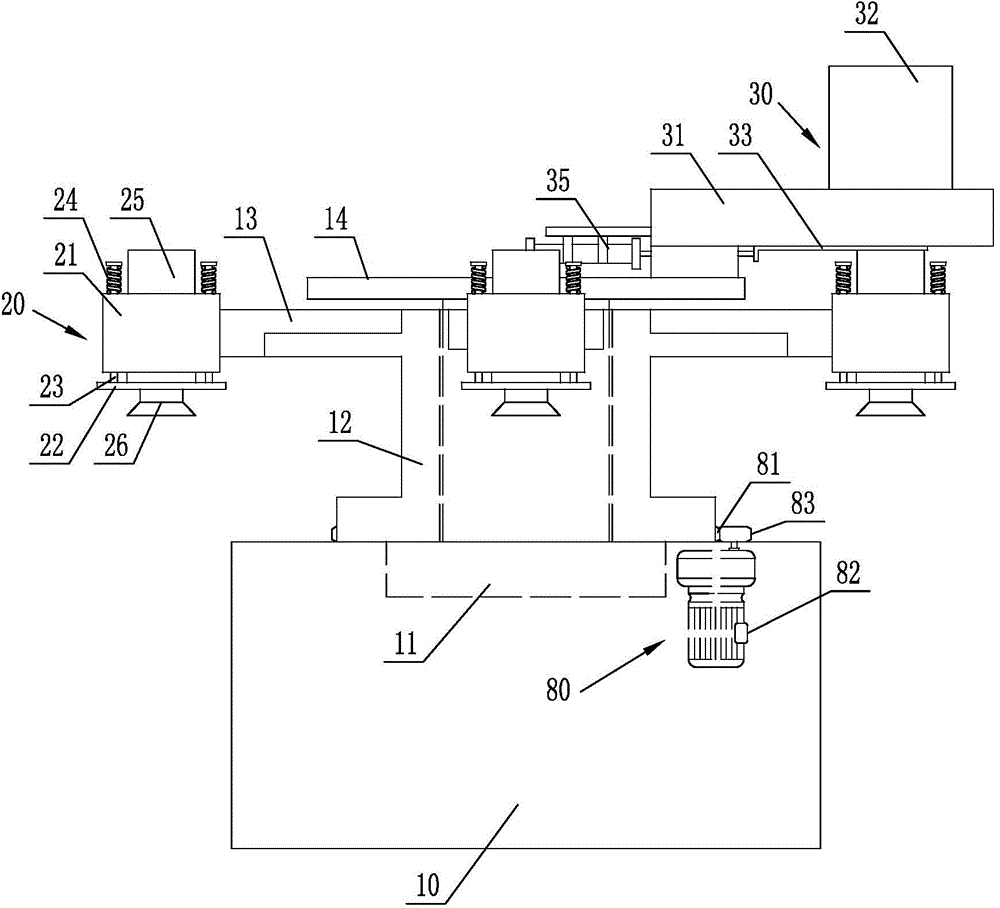

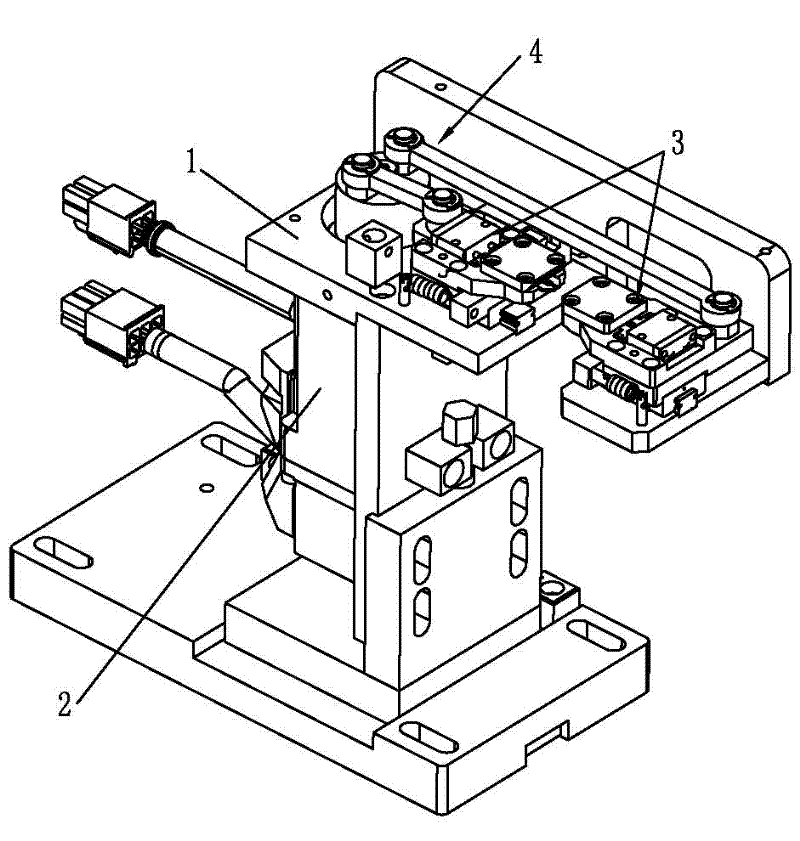

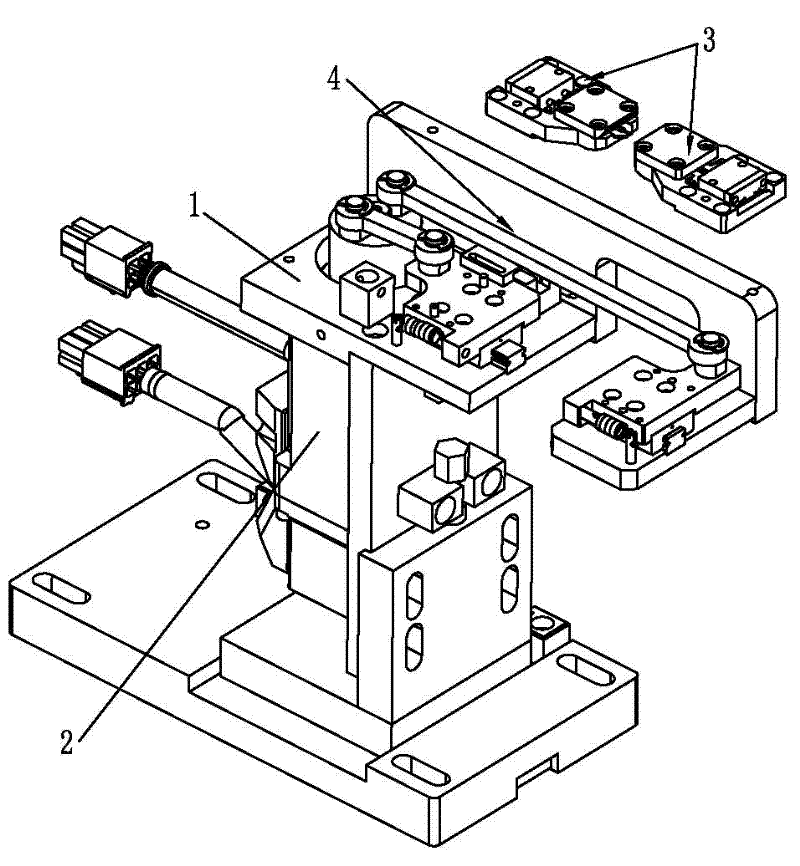

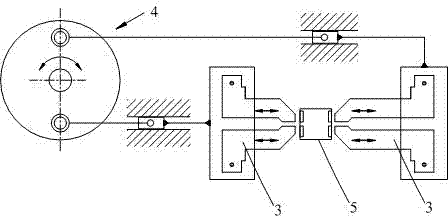

Full automatic hydraulically operated fixture device

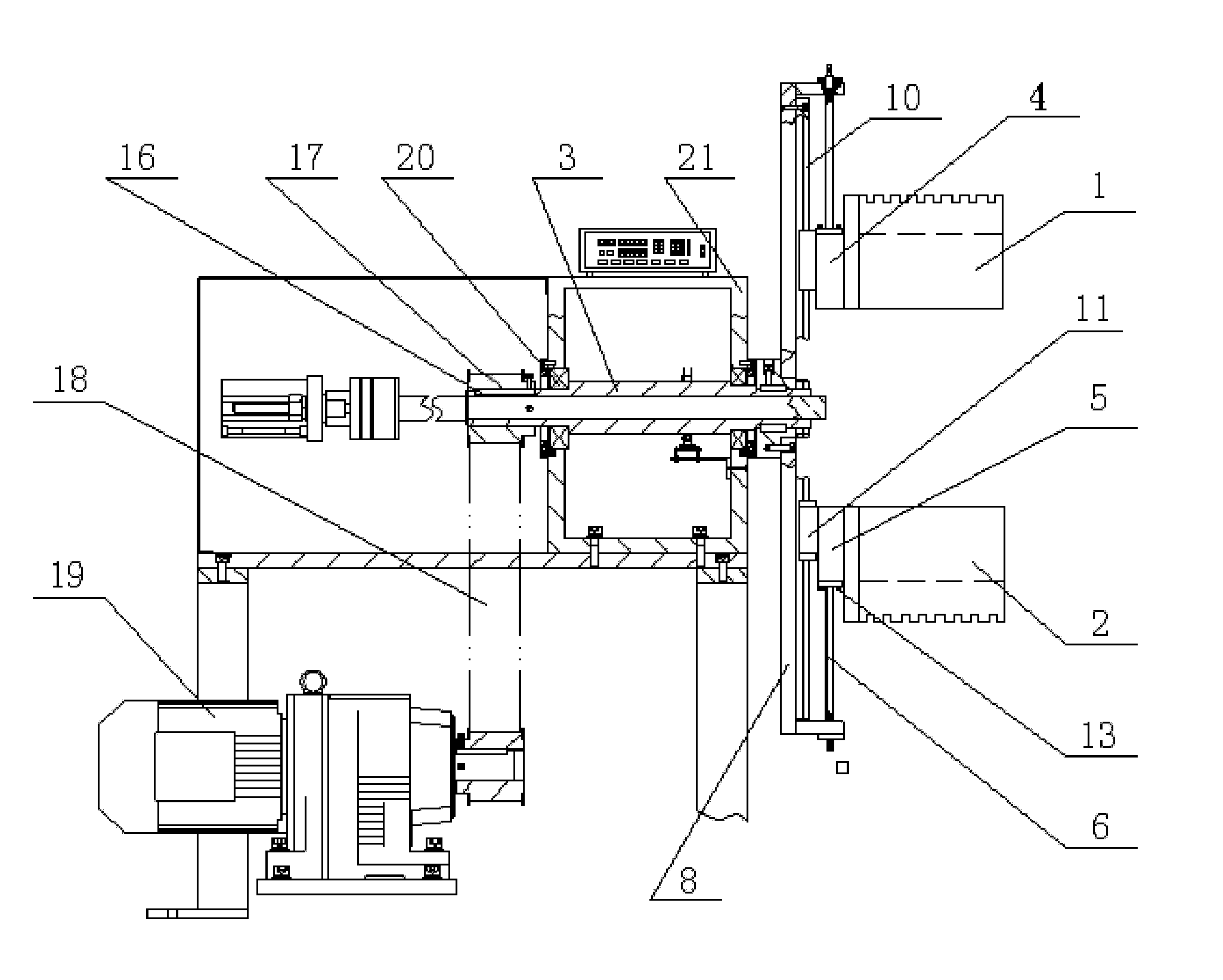

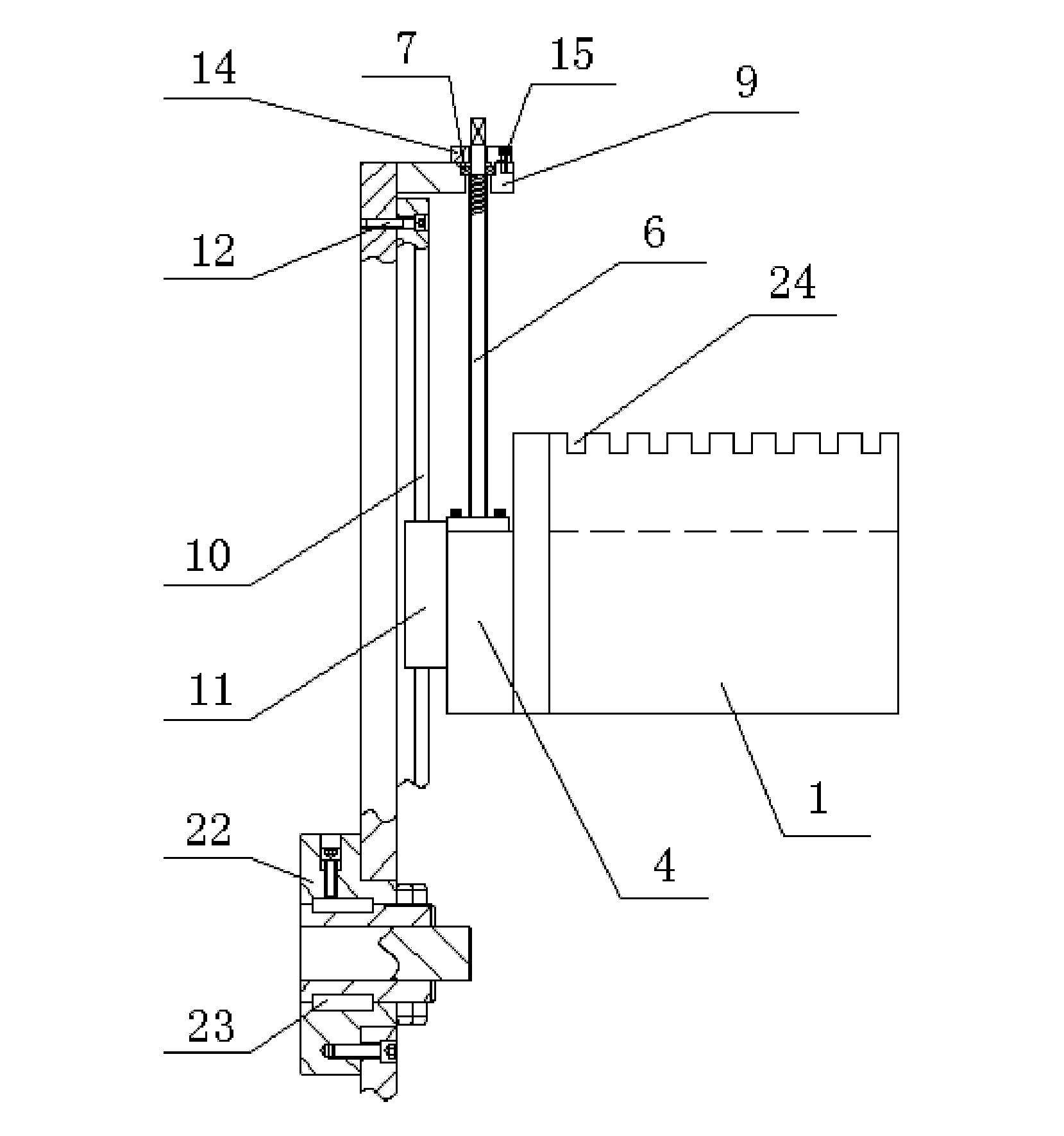

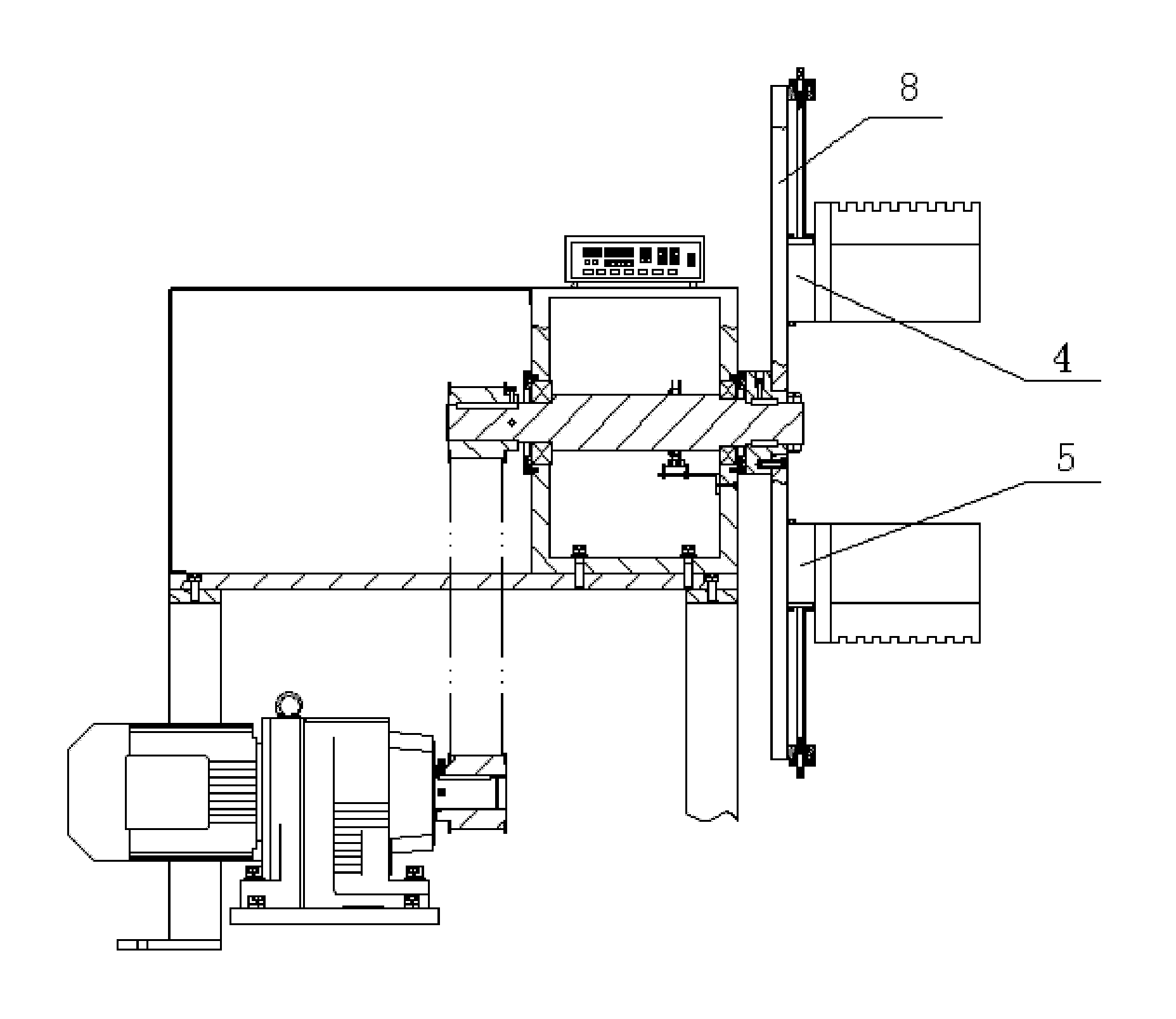

InactiveCN101376216AReduce labor intensityIncrease productivityPositioning apparatusMetal-working holdersEngineeringAutomation

The invention relates to a fixture, in particular to a full automatic hydraulic fixture device used for a milling machine or a boring machine, which comprises at least two fixture bodies for clamping parts on a working table, a clamping mechanism arranged above a base through a support, and a guide rail fixed on a working table top. The base of each fixture body is arranged on the guide rail; and a moving mechanism for moving the base along the guide rail and a hydraulic locking mechanism for fixing the base on the guide rail are arranged on the base. The full automatic hydraulic fixture device has the advantages of wide clamping range, high mounting and positioning precision, and high automation degree, thereby greatly reducing labor intensity of operators and improving production efficiency, is particularly suitable for high strength cutting of shaft parts, and is widely applied to the manufacturing fields of various processing such as the milling of a flat head, the milling of a circular arc at the root part of the flat head, the milling of a key slot, the processing of a wabbler of a supporting roll, the beveling of a flat surface and the wabbler, the drilling and the rigid tapping processing to complete the processing of shaft parts with different diameters and different lengths through a milling machine or a boring machine.

Owner:GUILIN MACHINE TOOL

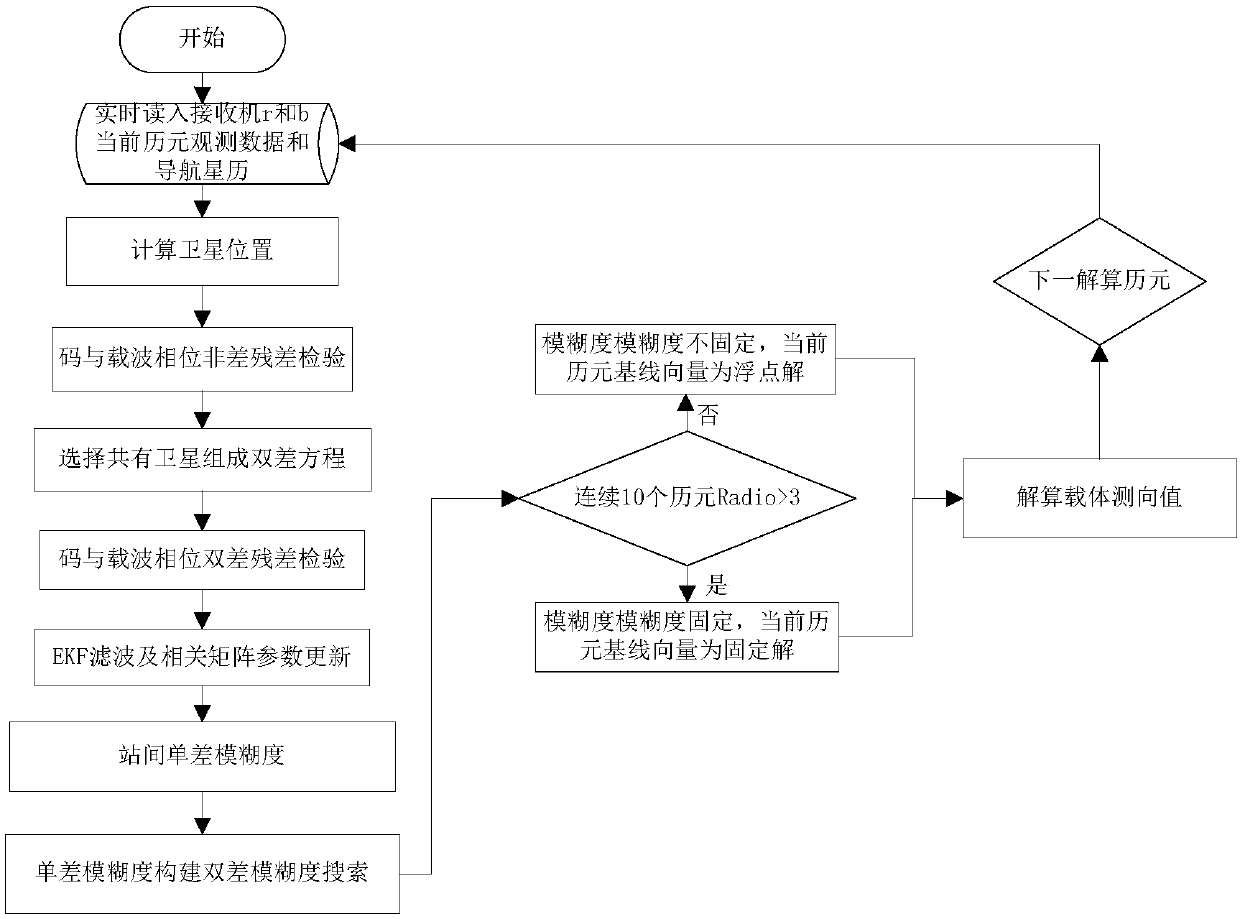

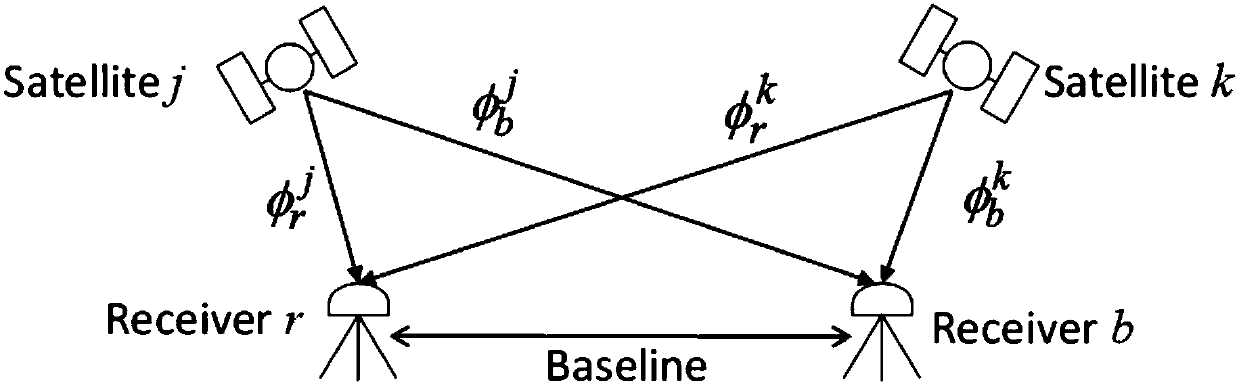

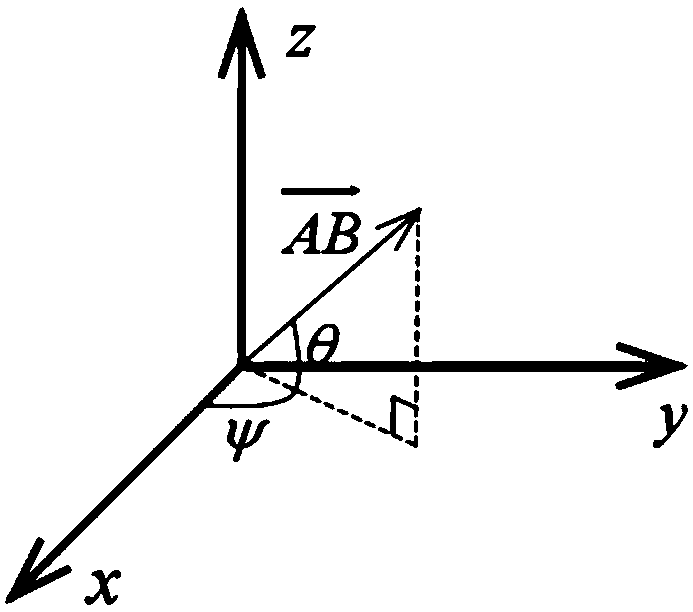

Method for real-time direction finding of base station antenna ultrashort baseline GNSS double antenna

InactiveCN109613585AEliminate errorsGuaranteed reliabilitySatellite radio beaconingDouble differenceAmbiguity

The invention discloses a method for real-time direction finding of a base station antenna ultrashort baseline GNSS double antenna. The two-dimensional pose of a carrier can be determined by measuringa vector fixed on the carrier. The vector that reflects the two-dimensional pose of the carrier can be formed when the antennas of two receivers are mounted on a rigid carrier. And the heading angleof the carrier can be calculated by accurately determining the direction and distance of the two ends of the vector in space. According to the method for the real-time direction finding of the base station antenna ultrashort baseline GNSS double antenna, the common errors of the satellite and the receiver are eliminated by constructing a double difference model to perform a global solution on thebaseline vector. The problem of the frequent replacement of a reference star is avoided by firstly solving the single-difference ambiguity between fixed stations. The reliability of the baseline vector is ensured by using the EKF solution. The single epoch can be guaranteed to be solved, the real-time performance is effectively ensured, and in particular, various errors in the observation of the low-cost positioning module and the antenna in the absolute positioning are prevented from affecting the receiver antenna and making the high-precision position difficult to obtain.

Owner:NAT TIME SERVICE CENT CHINESE ACAD OF SCI

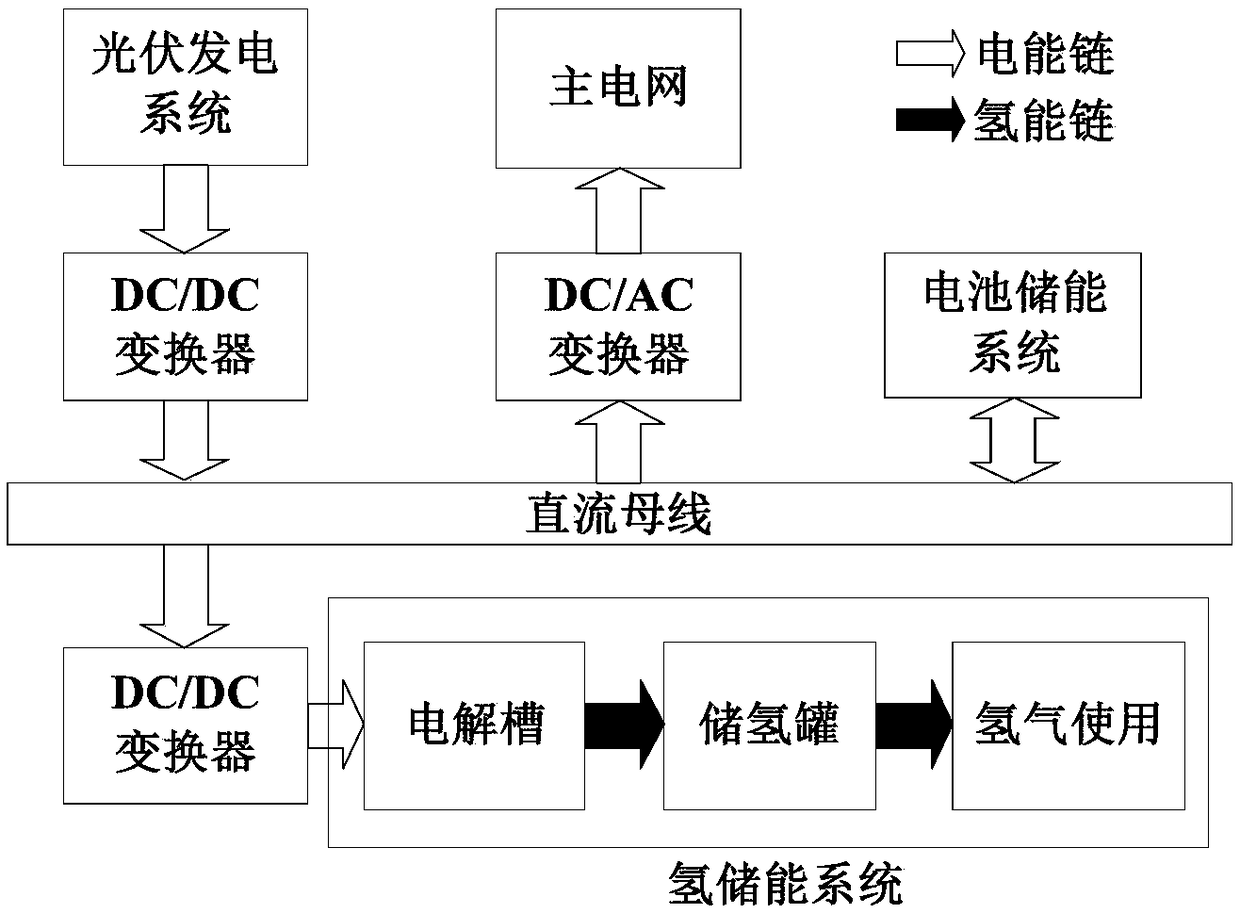

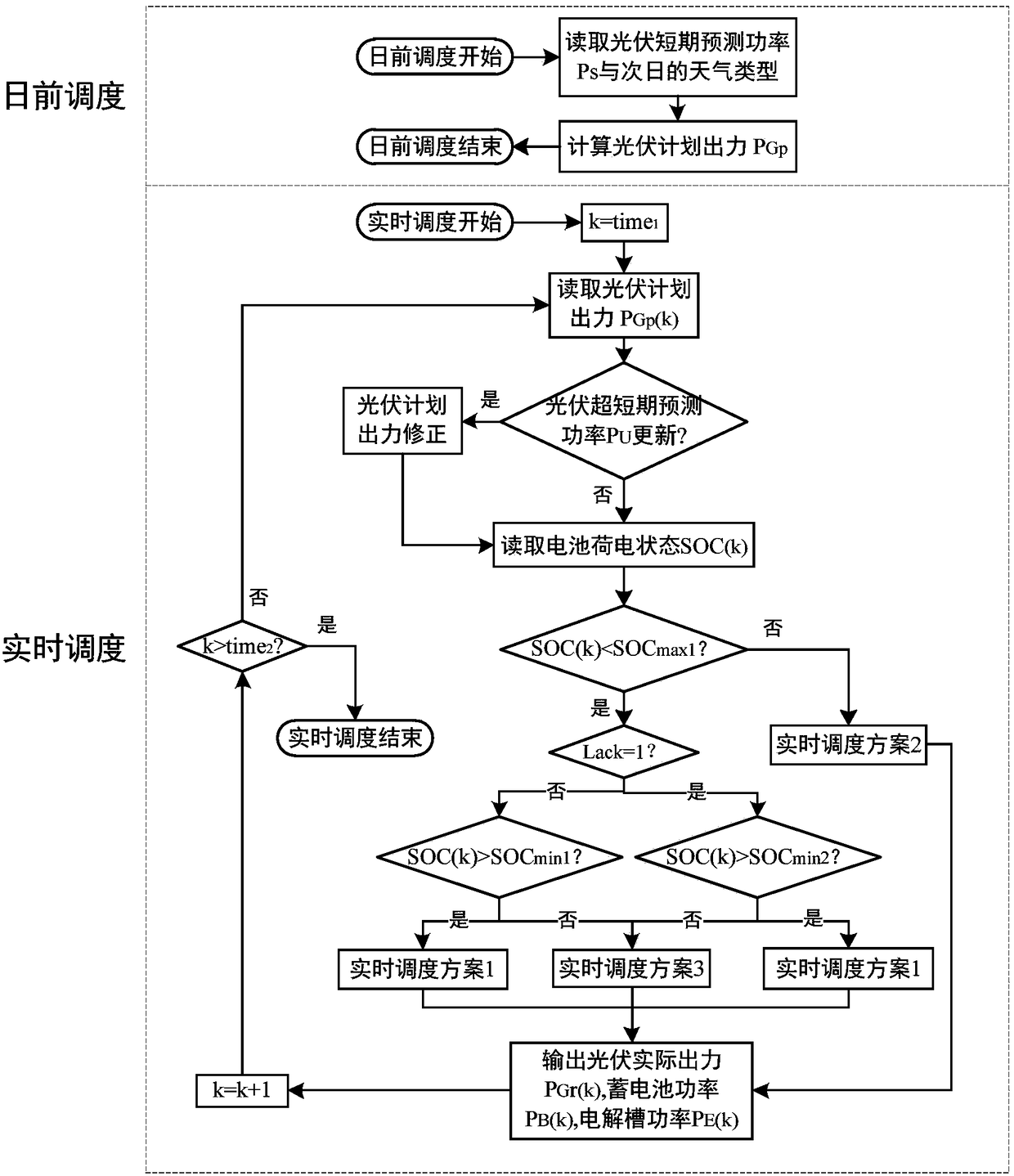

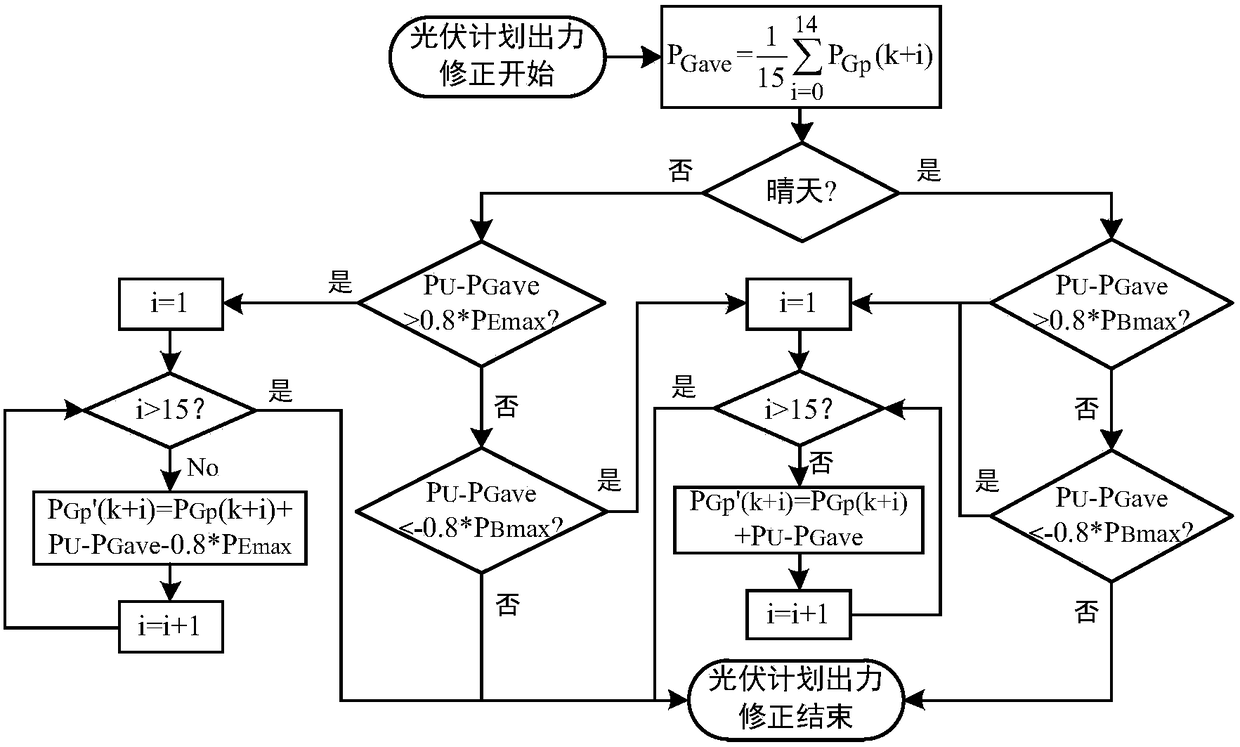

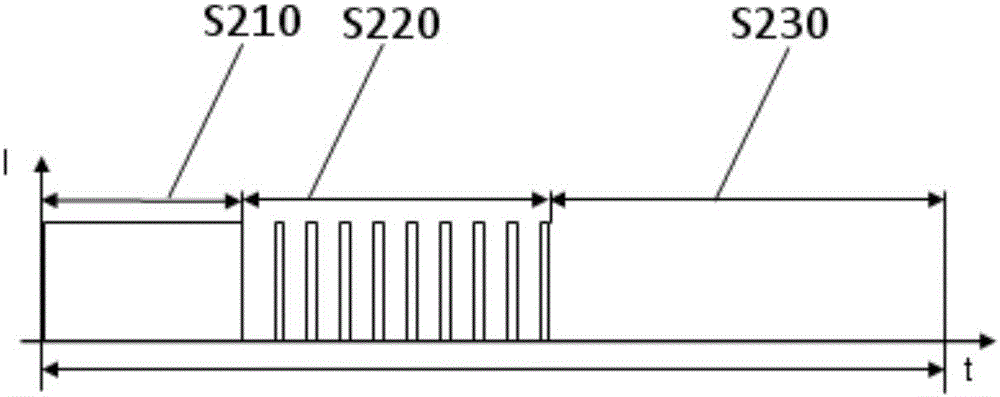

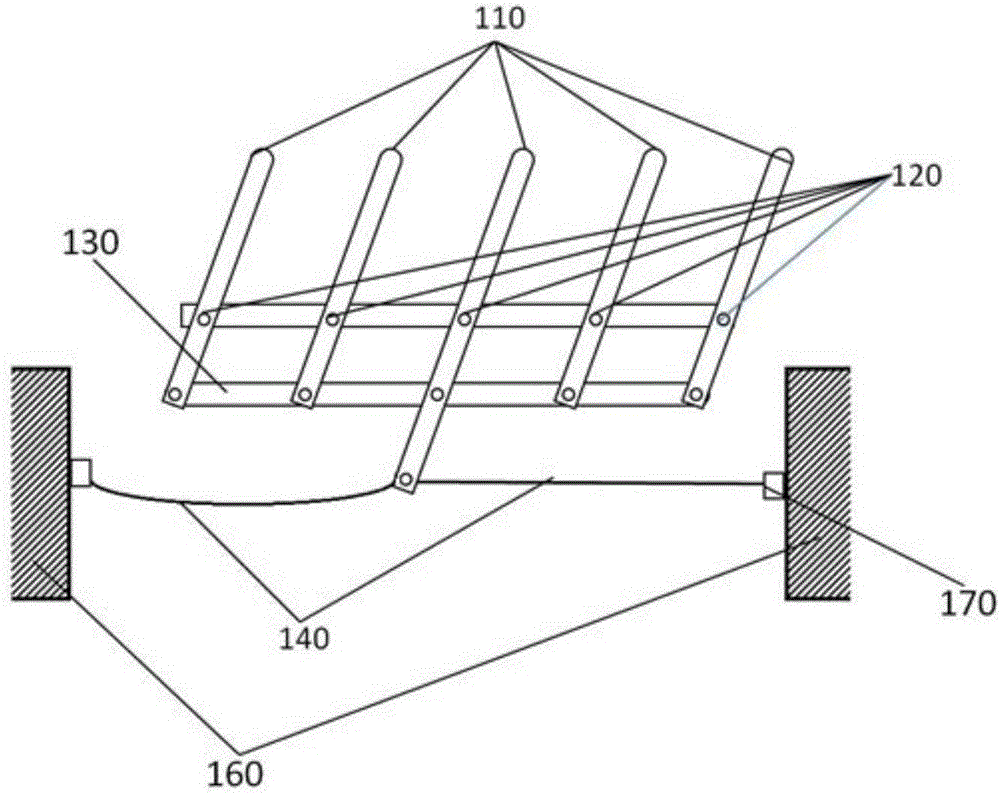

Scheduling method for tracking photovoltaic planned output by using battery storage energy and hydrogen storage energy

ActiveCN108599245AAvoid frequent replacementExtended service lifeSingle network parallel feeding arrangementsEnergy storageElectric power systemFrequency modulation

The invention discloses a scheduling method for tracking a photovoltaic planned output by using a battery storage energy and a hydrogen storage energy. The scheduling method comprises the steps of making an output plan of a next day based on a short-term photovoltaic prediction power, and making different day-ahead scheduling schemes according to magnitudes and fluctuation violent degrees of prediction errors of photovoltaic powers in a sunny day and a non-sunny day; correcting a day-ahead photovoltaic planned output by using an ultrashort-term photovoltaic prediction power; and then, selecting an appropriate real-time scheduling scheme according to a state of charge of a storage battery, and calculating an actual output of a photovoltaic power generation system as well as input powers ofthe storage battery and an electrolytic bath to output to a central control unit of the photovoltaic power generation system, thereby performing real-time scheduling on each power generation electricmodule in the system. The impact on the power system is reduced, the frequency modulation pressures of water and thermal generation units are alleviated, an energy storage battery is guaranteed to work in a low-load state beneficial to prolonging the service life, the frequent change of the energy storage battery due to premature failure is prevented, and the total cost in a whole life cycle of the system is reduced.

Owner:XI AN JIAOTONG UNIV +1

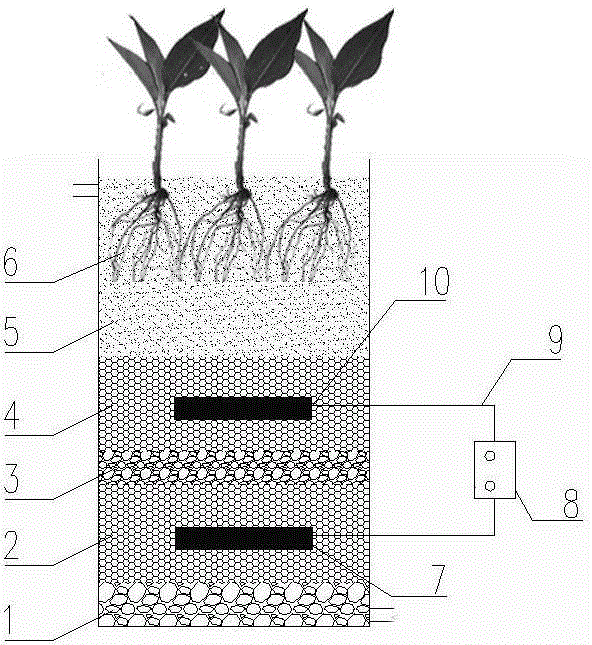

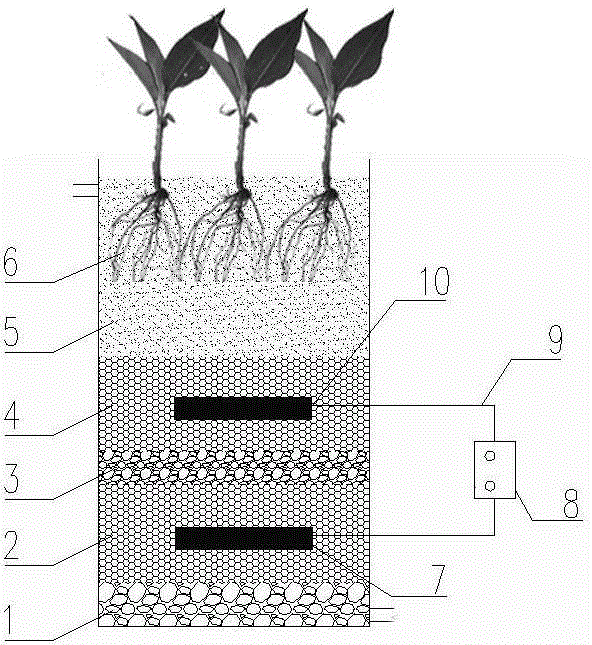

Enhanced denitrification method and device for coupled microorganism electrolytic tank of downstream vertical flow artificial wetland

ActiveCN105217796AImprove removal efficiencyImprove total nitrogen removal effectTreatment with aerobic and anaerobic processesSustainable biological treatmentWastewaterWater flow

The invention discloses an enhanced denitrification method and device for a coupled microorganism electrolytic tank of a downstream vertical flow artificial wetland. The enhanced denitrification method comprises the following steps: (A) water is uniformly distributed on the top of a system, and waste water firstly flows into an upper non-conductive filler layer; (B) waste water flows into an anodic conductive filler layer, and unoxidized organic matters are removed in the anodic conductive filler layer; (C) then waste water flows into a non-conductive filler isolating layer which is a separator between a cathodic conductive filler layer and the anodic conductive filler layer; (D) waste water flows into the cathodic conductive filler layer to generate an autotrophic denitrification process; and (E) waste water is drained through a bottom draining pipe. The anodic conductive filler layer is connected with the bottom communication filler layer and the non-conductive filler isolating layer, respectively, the anodic conductive filler layer is connected with the non-conductive filler isolating layer and the upper non-conductive filler layer, respectively, and cathodic and anodic collector electrodes are respectively placed in the cathodic conductive filler layer and the anodic conductive filler layer. The enhanced denitrification method has the beneficial effects that the operation is simple, and the removal efficacy of the downstream vertical flow artificial wetland to low-carbon and high-nitrogen wastewater is substantially improved.

Owner:INST OF AQUATIC LIFE ACAD SINICA

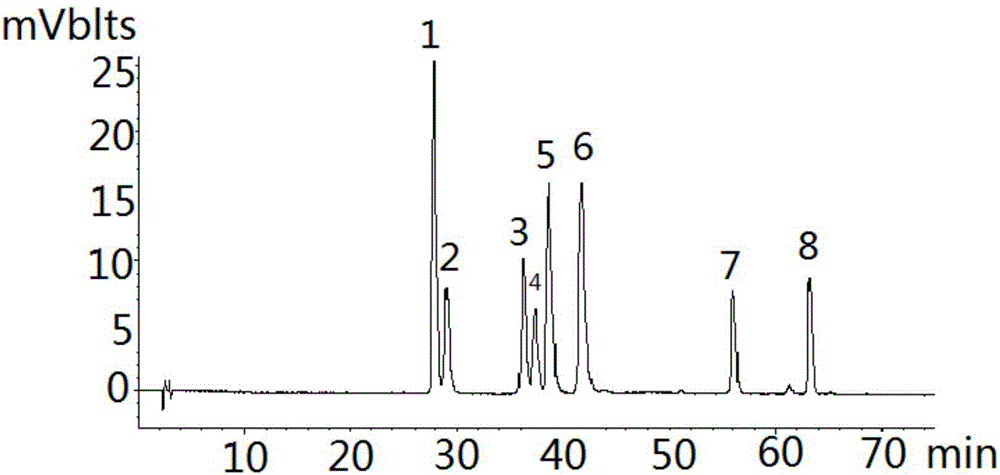

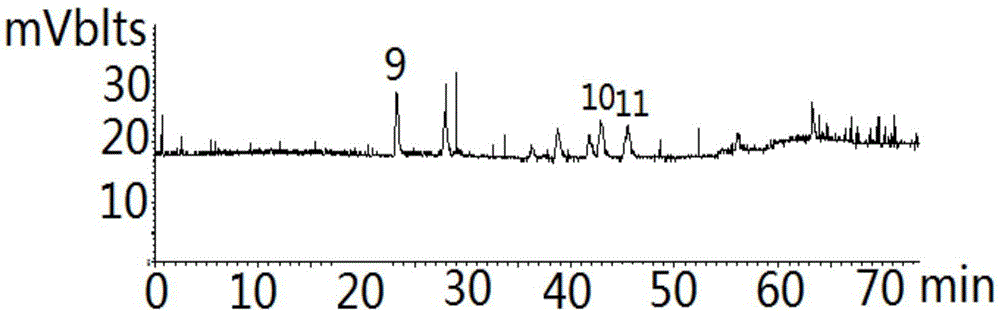

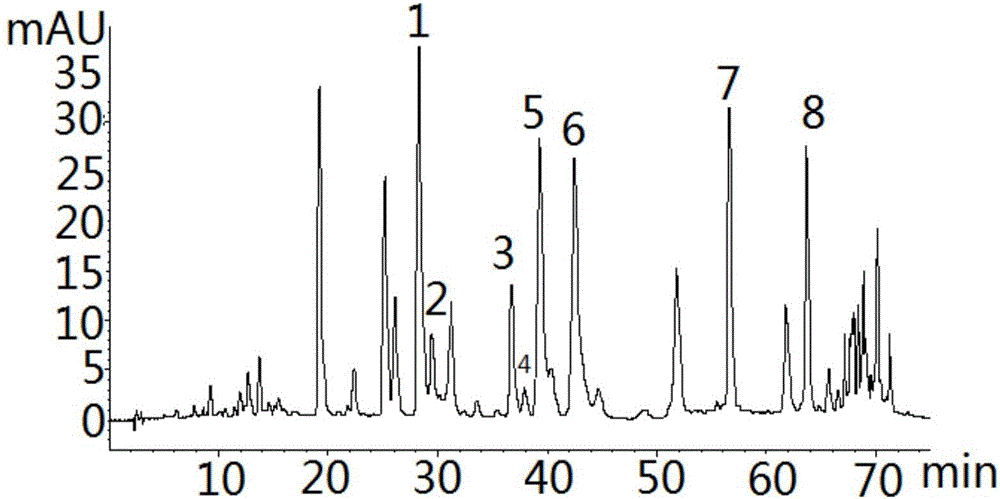

Detecting method for measuring content of flavonoid compounds and terpene lactone compounds in ginkgo leaf extract or preparations of ginkgo leaf extract at same time

ActiveCN105891355AAvoid frequent replacementImprove work efficiencyComponent separationGinkgo leaf extractAnalysis method

The invention relates to the field of medicine detection, in particular to a high-performance liquid chromatography detecting method for measuring the content of flavonoid compounds and terpene lactone compounds in ginkgo leaves (or ginkgo leaf extract) or preparations of the ginkgo leaves at the same time. The HPLC-DAD-ELSD method is set up, the method can measure the eight flavonoid compounds and three terpene lactone compounds in the ginkgo leaves (or the leaf extract) or preparations of the ginkgo leaves at the same time, the measurement result is analyzed, and a new analysis method and a basis are provided for quality control over the ginkgo leaf extract and the preparations of the ginkgo leaf extract.

Owner:HEBEI SHINEWAY PHARMA +2

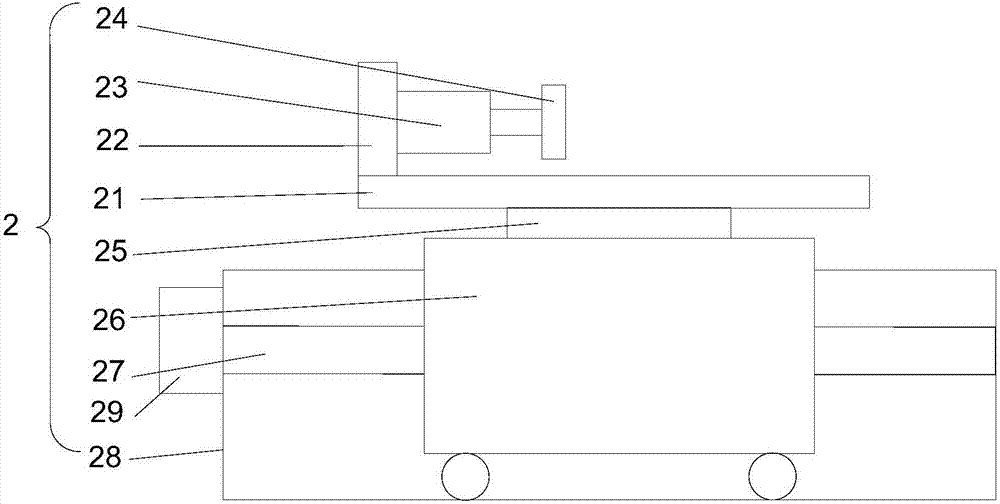

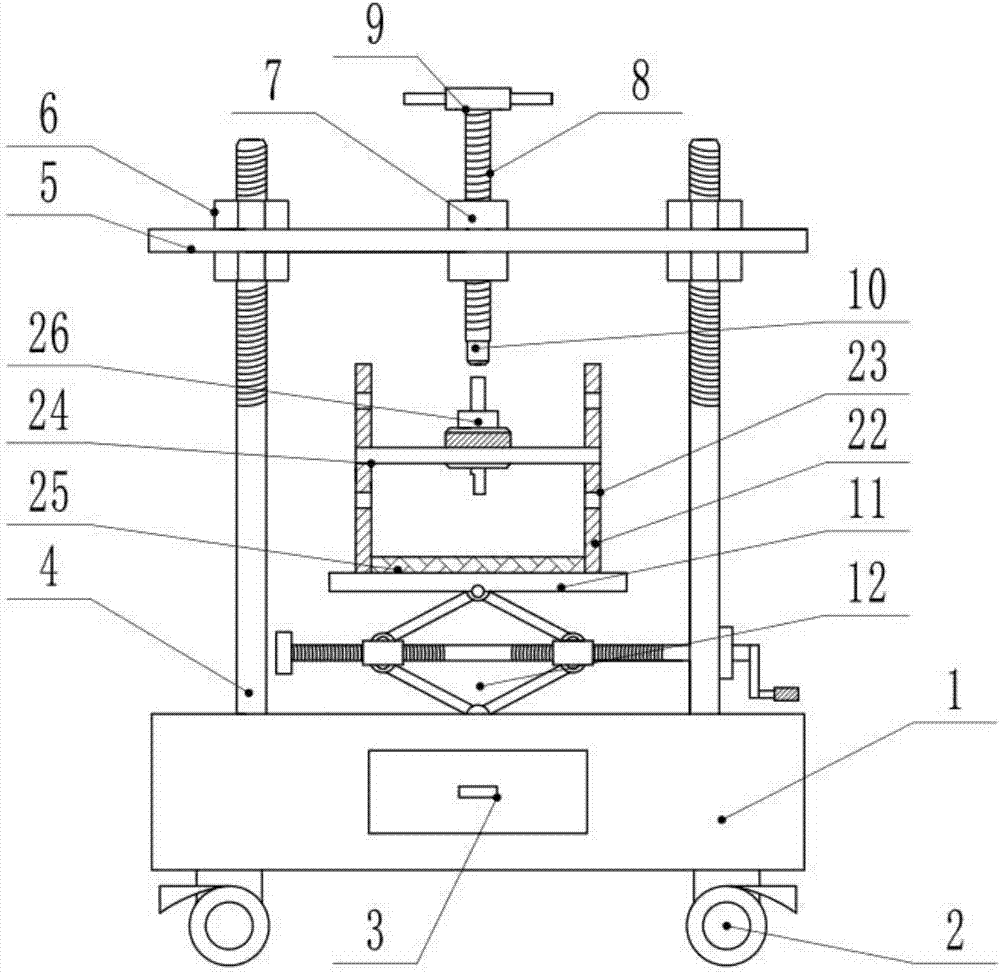

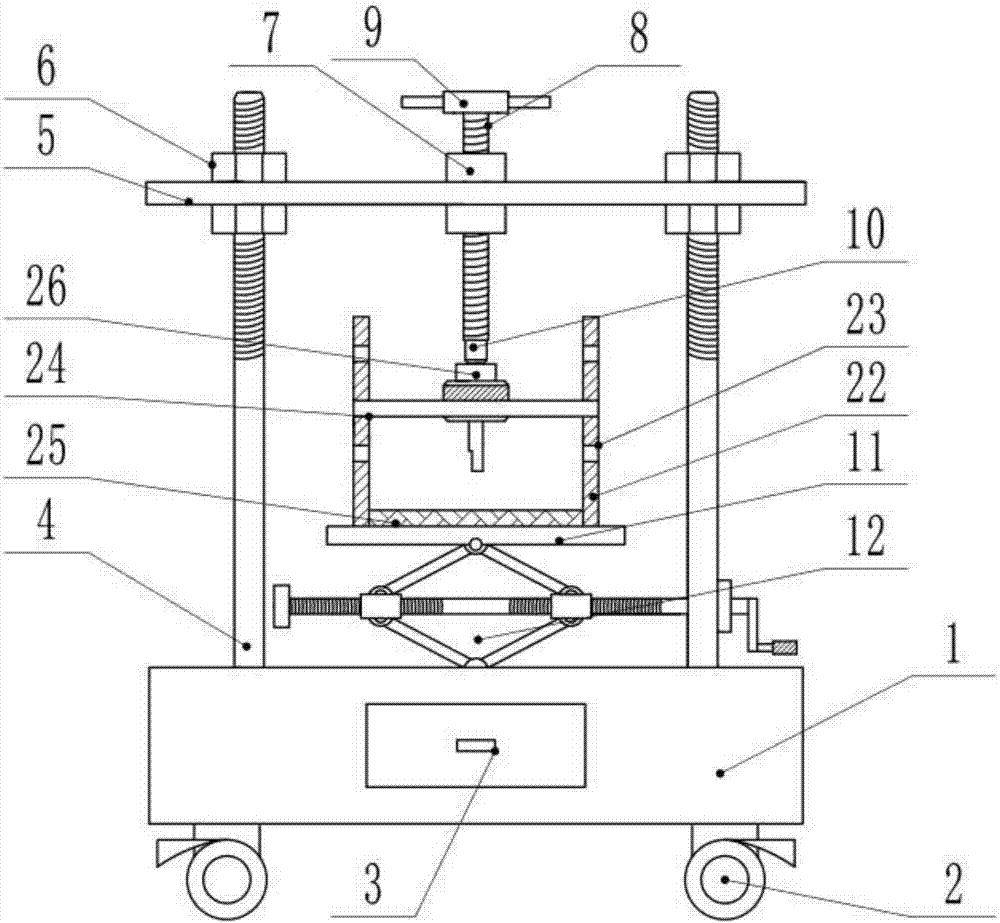

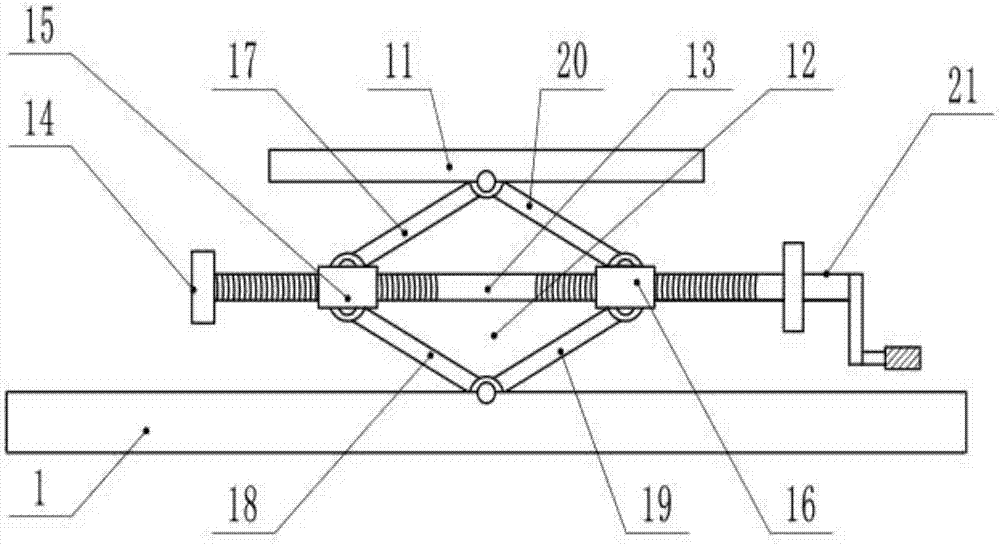

Shaft entering and withdrawing dual-purpose device for plastic packaging motor rotor

InactiveCN107104563AAvoid frequent replacementPrevent crushingCentering/balancing rotorsPlastic packagingIndustrial engineering

The invention discloses a shaft entering and withdrawing dual-purpose device for a plastic packaging motor rotor. The shaft entering and withdrawing dual-purpose device comprises a machine table, a tool box, an adjustment screw rod, a supporting plate, a lead screw A, a rotary handle, an extrusion head, a lifting platform, a lifting device, a fixed frame and a pressure nozzle; a lead screw sleeve is fixedly arranged at a central position of the supporting plate; the lead screw A is in screw connection inside the lead screw sleeve; the rotary handle is fixedly arranged at an upper end of the lead screw A, and the extrusion head is fixedly arranged at a lower end of the lead screw A; the lifting device is fixedly arranged on the machine table; a plurality of groups of limiting grooves are formed at two sides of the fixed frame; and limiting plates are arranged on the limiting groove in an insertion manner. According to the device, under the condition of not replacing equipment, the shaft entering and withdrawing work are performed, and the repair personnel is prevented from frequently replacing the equipment; and meanwhile, through the rotary handle, the lead screw moves downward to implement extrusion on a rotating shaft, so compared with manual shaft withdrawing, the device is more time-saving and labor-saving; and the lifting platform is provided such that the repair personnel can perform the shaft entering and withdrawing work on different lengths of the rotating shafts conveniently.

Owner:CHANGSHA WUDAO IND DESIGN CO LTD

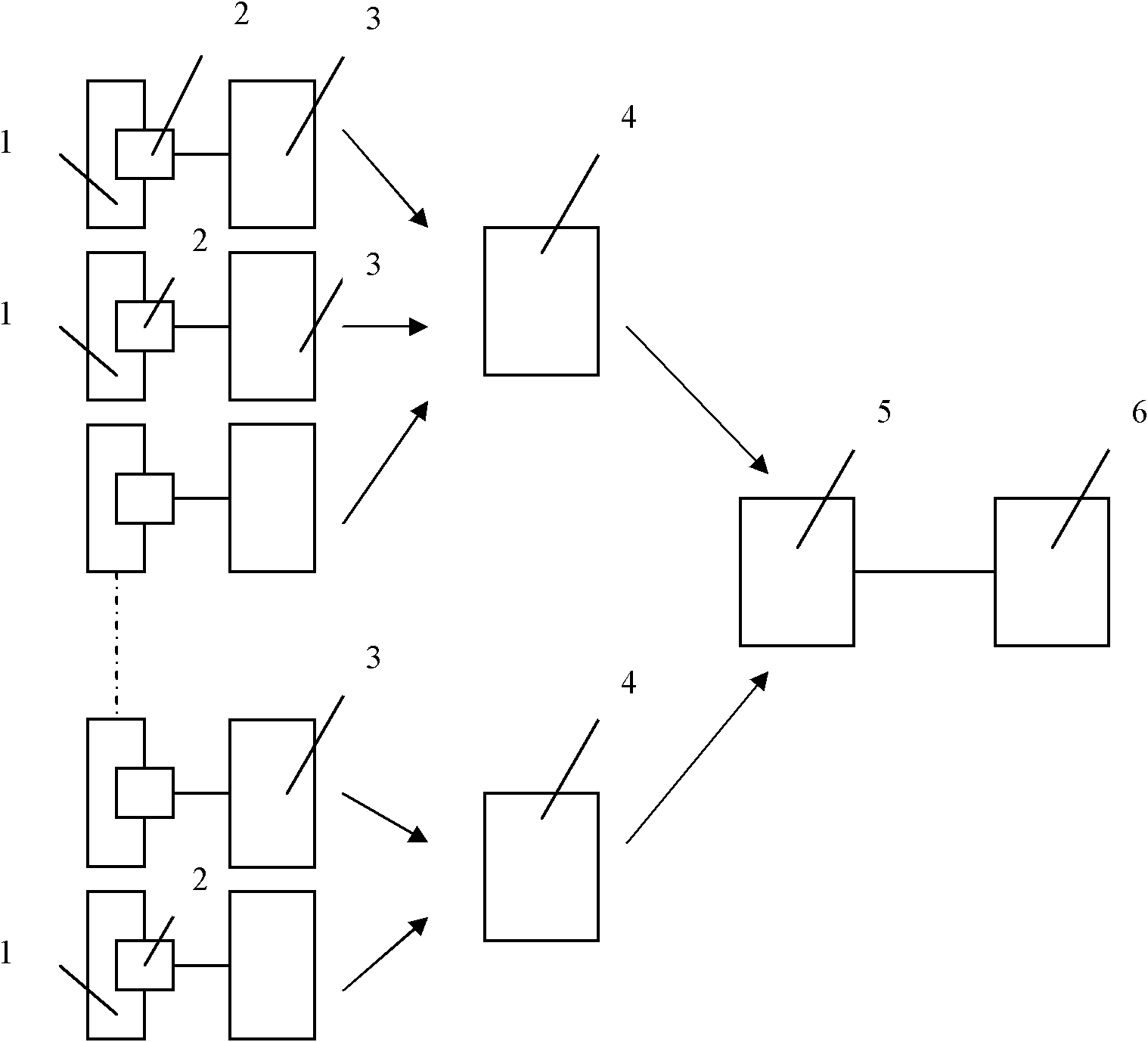

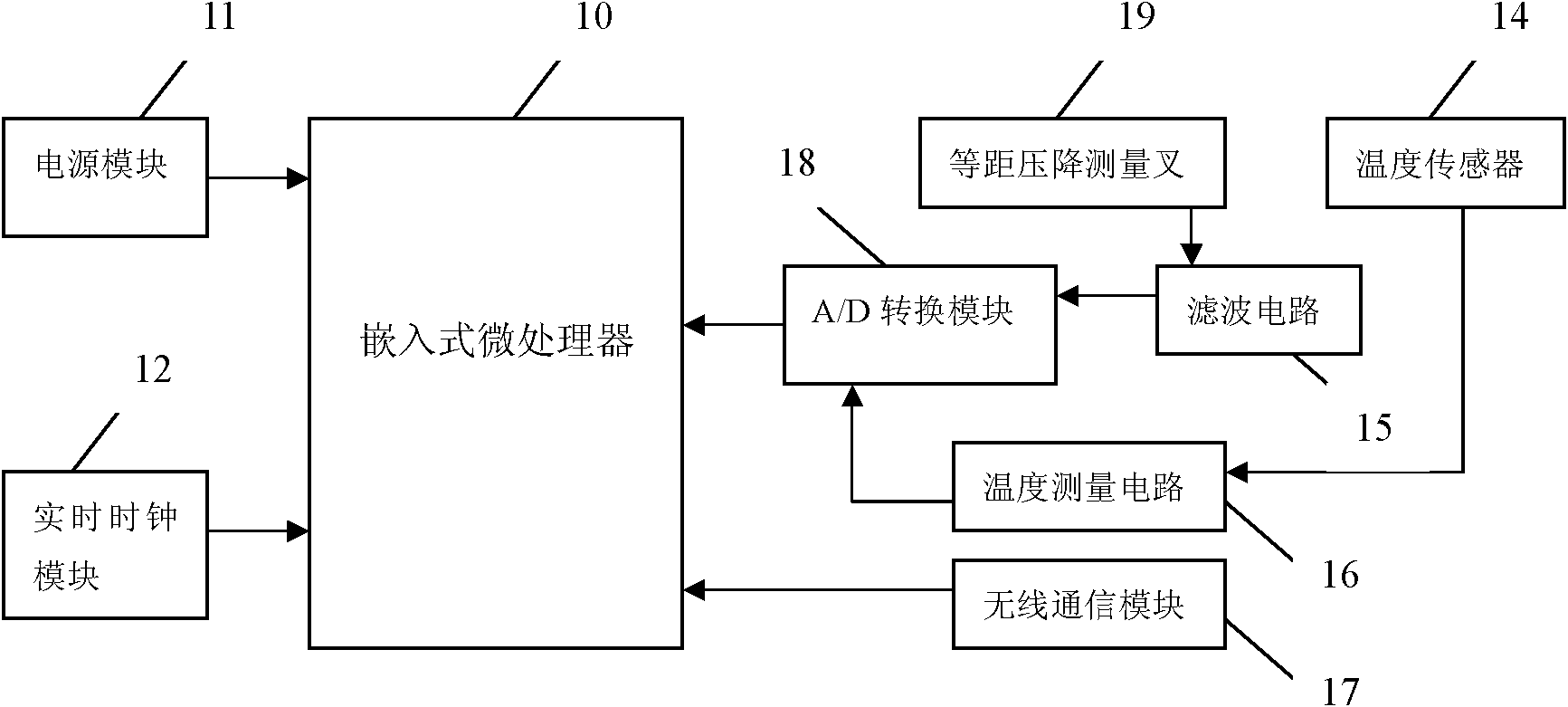

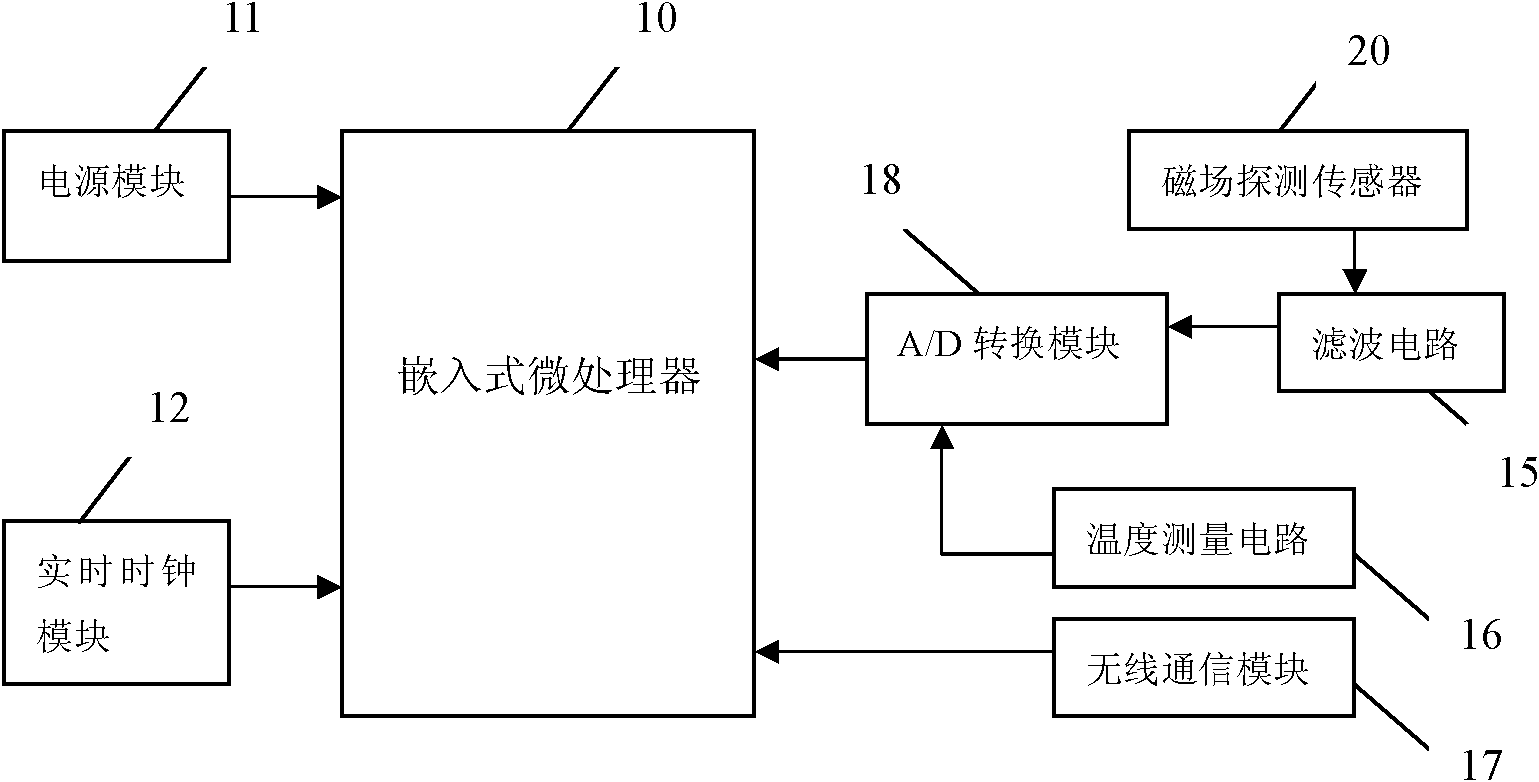

Online monitoring system for current distribution of aluminum electrolytic tank

The invention discloses an online monitoring system for the current distribution of an aluminum electrolytic tank, belonging to the technical field of aluminum electrolysis. The online monitoring system for the current distribution of the aluminum electrolytic tank comprises at least one measuring device comprising an isometric pressure drop measurement fork or a magnetic field detection sensor, the isometric pressure drop measurement fork is used for measuring the isometric pressure drop value of an anode guide rod or a cathode steel bar of the aluminum electrolytic tank to be tested, the magnetic field detection sensor converts the magnetic induction intensity around the anode guide rod or the cathode steel bar into a proportional voltage value according to a Hall principle, and the measuring device is sequentially connected with a data processing device, a wireless network and an upper computer. The invention satisfies the measurement requirements under high-temperature high-dust environment with high magnetic field intensity, has high system flexibility, is favorable to far-distance signal transmission and can simultaneously monitor a plurality of aluminum electrolytic tanks.

Owner:NORTH CHINA UNIVERSITY OF TECHNOLOGY

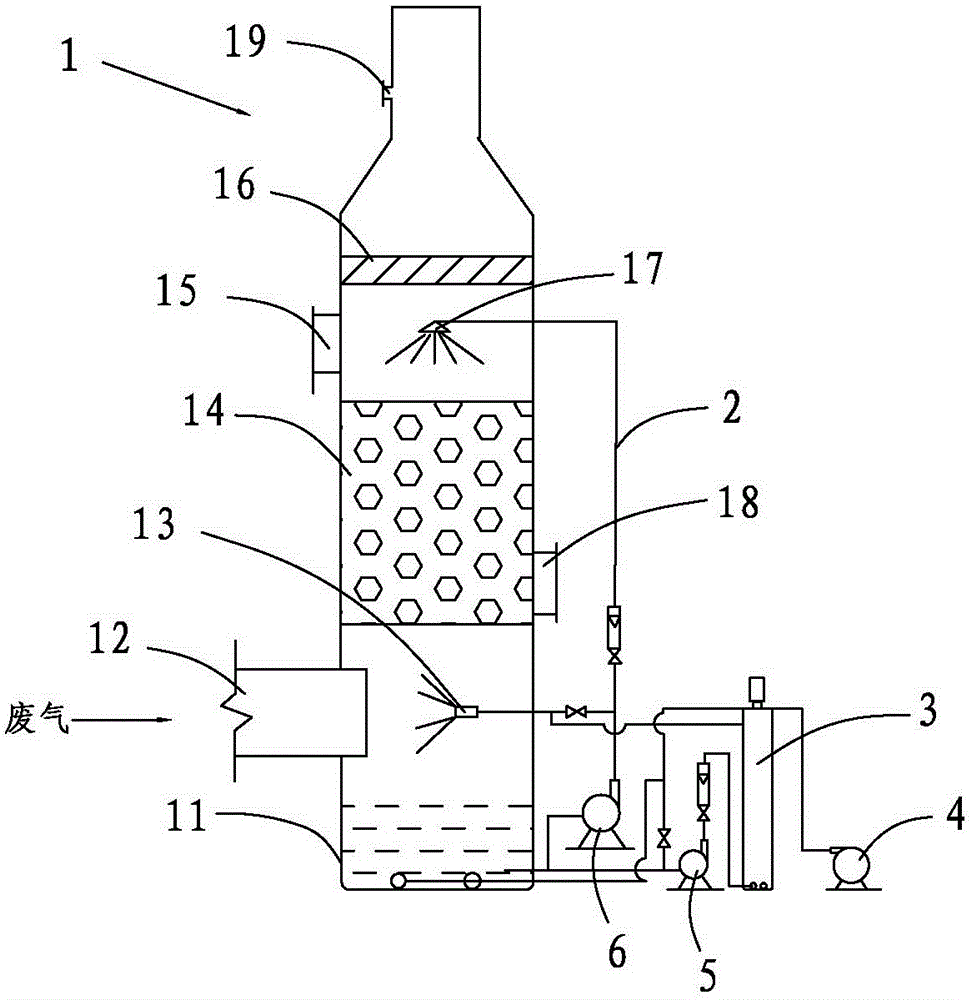

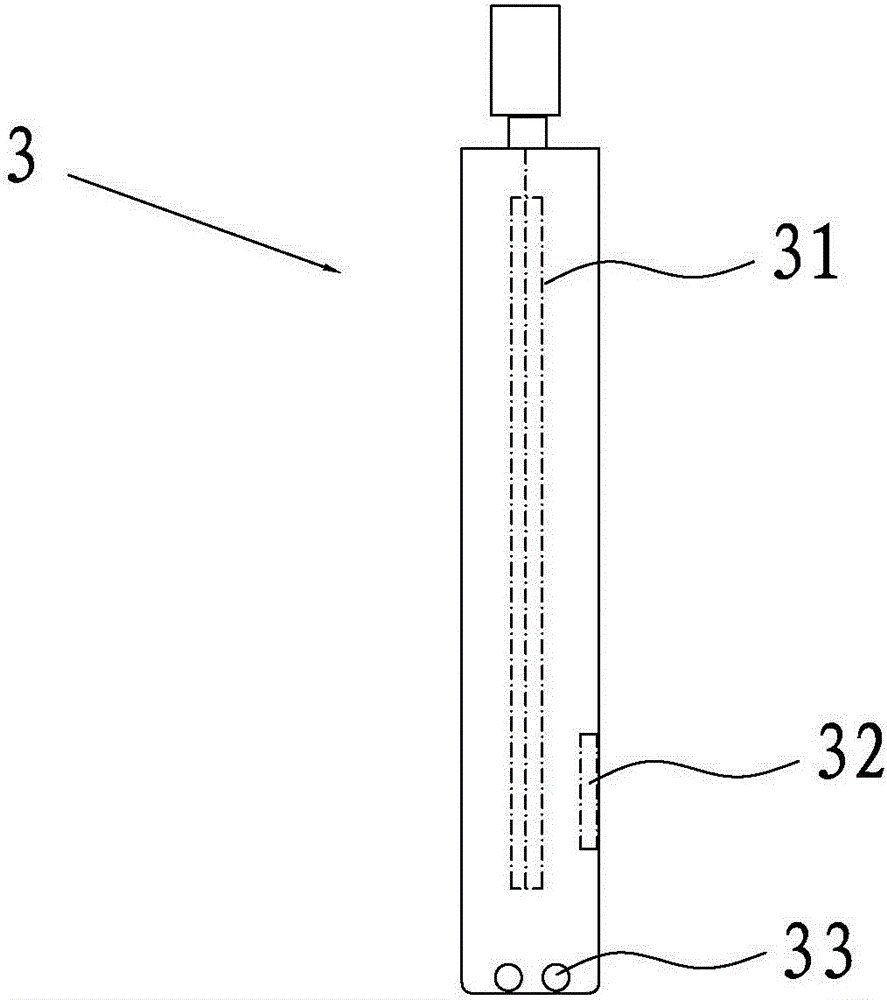

Waste gas processing device and waste gas processing method

ActiveCN105126534AExtended service lifeAvoid frequent replacementDispersed particle separationDemisterProcess engineering

The invention relates to the technical field of waste gas processing, and specifically relates to a waste gas processing device and a waste gas processing method. The waste gas processing device comprises an absorbing tower, a gas-liquid mixing device, a delivering device, a UV oxidizing device, and a releasing device which is connected to the UV oxidizing device. The absorbing tower is provided with a liquid containing part, a gas inlet, a filling material layer, a final nozzle, and a demister from bottom to top in sequence. The final nozzle is communicated with the liquid outlet of the delivering device, the liquid inlet of the gas-liquid mixing device is communicated with the liquid containing part, the liquid outlet of the gas-liquid mixing device is communicated with the UV oxidizing device, and the gas outlet of the UV oxidizing device is communicated with the liquid containing part. The waste gas processing method utilizes the provided waste gas processing device. According to the processing method, the adsorption, catalytic oxidation, and spraying are effectively integrated together to strengthen the waste gas processing effect, moreover, different absorbing liquids that can effectively absorb the waste gas is provided according to the waste gas generated by different types of factories; the waste processing method is flexible and has a wide application range, furthermore, the purification efficiency is improved, the operation is simple and convenient, and the investment cost and operation cost are low.

Owner:邓杰帆

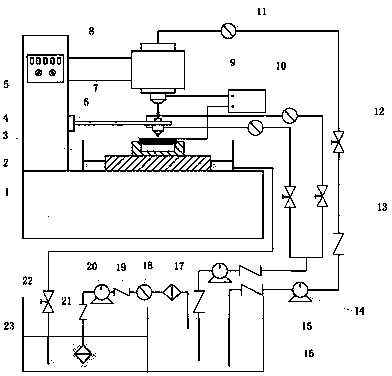

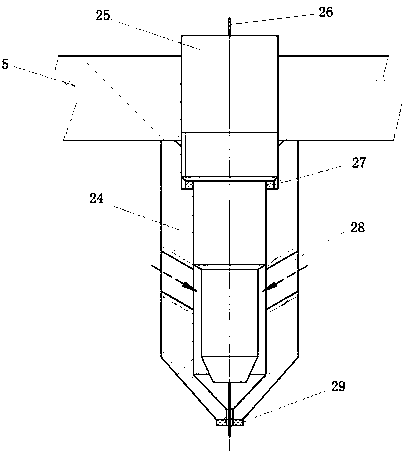

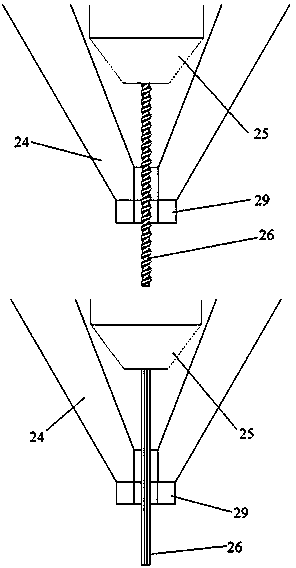

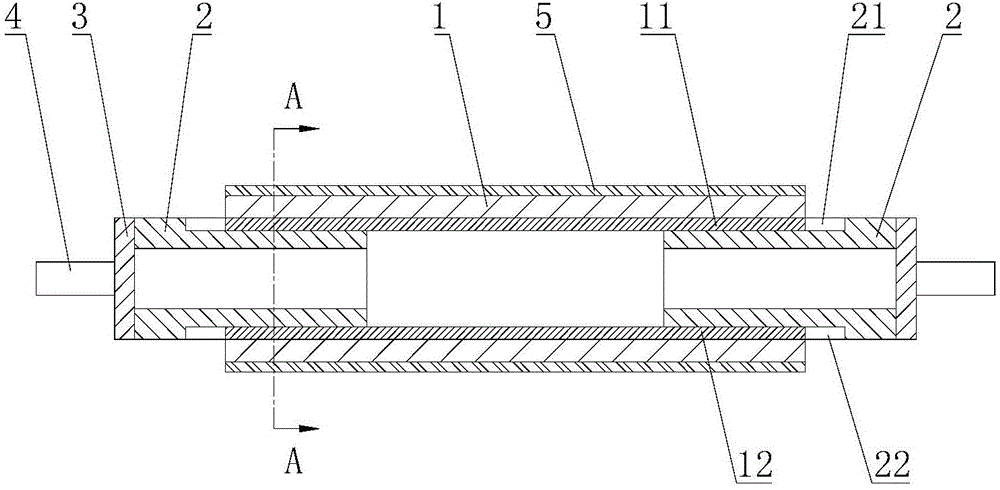

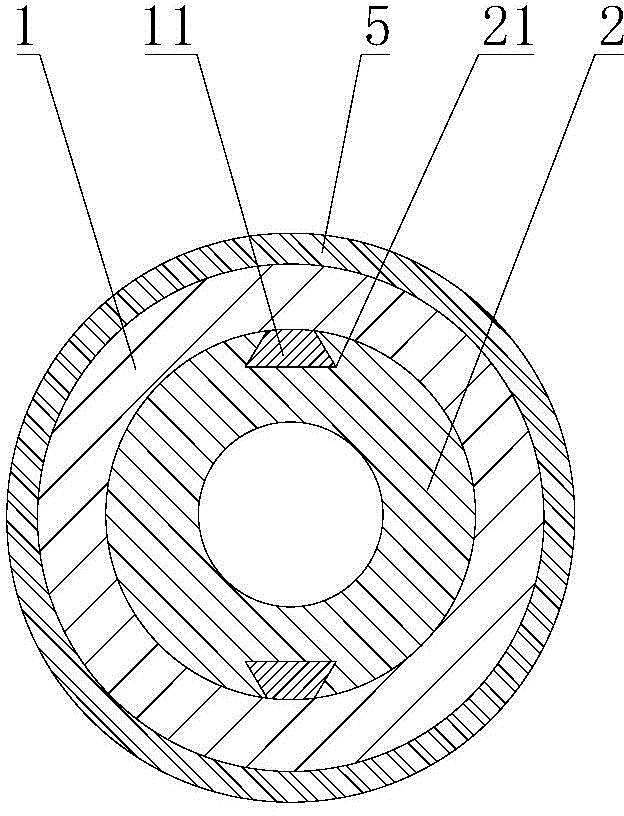

Micro-hole electric discharge and electrolytic combined machining multi-channel symmetrical flushing device and method

ActiveCN103386521AMeet the requirements of the flow fieldAvoid frequent replacementElectric dischargeElectrolysis

The invention provides a micro-hole electric discharge and electrolytic combined machining multi-channel symmetrical flushing device and a micro-hole electric discharge and electrolytic combined machining multi-channel symmetrical flushing method, and belongs to the technical field of electromachining. The device comprises a tool electrode, a clamping and guiding device, a diversion device and a solution sealing device; during electric discharge machining, a working solution flows from the inside of the tool electrode into a machining area at a high speed, the electric discharge perforation machining is realized; during electrolytic machining, the working solution flows into the machining area along the outer wall of the tool electrode through the diversion device, and electrolytic reaming machining is realized. Two flushing methods of the working solution are realized, and requirements of electric discharge machining and electrolytic machining on a flow field are respectively met, the two machining methods can be realized under the condition of the same machine tool, the same station and the same tool electrode, errors caused by frequently changing tool clamps can be avoided, the operation is simplified, and the machining efficiency and quality are improved. In addition, the solution sealing device and the diversion device are used for realizing small-gap large-flow flushing, the stability of the flow field is ensured and the hole forming effect is improved.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

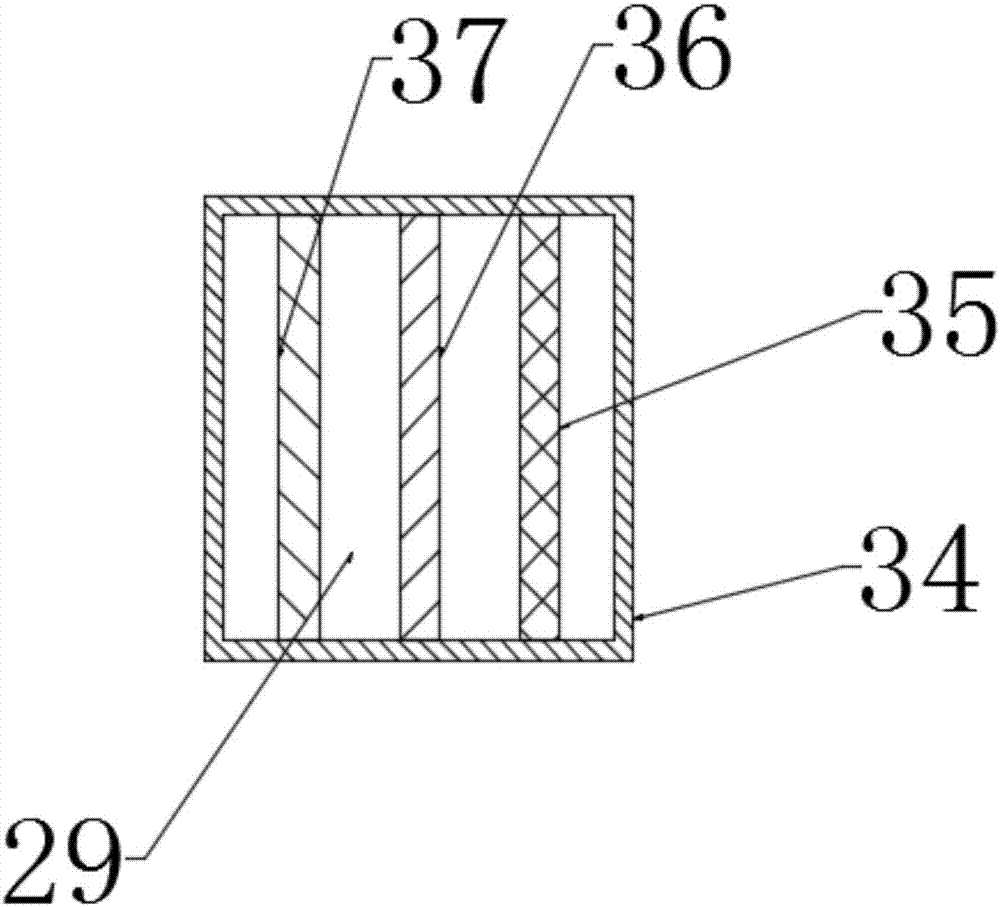

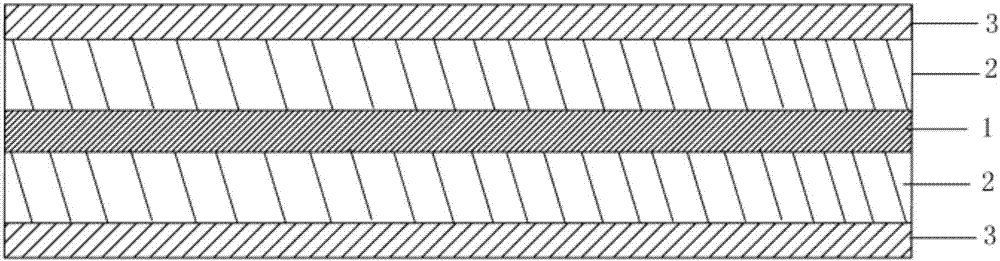

High-tenacity waterproof coiled material and preparation method

InactiveCN106881927AImprove toughnessImprove waterproof performanceSynthetic resin layered productsLaminationGlass fiberPolymer modified

The invention discloses a high-toughness waterproof coiled material and a preparation method thereof, belonging to the field of waterproof coiled materials. The waterproof coiled material includes: a substrate layer, the upper and lower surfaces of the substrate layer are respectively provided with self-adhesive waterproof layers, and the surfaces of the self-adhesive waterproof layers are respectively provided with isolation protection layers. Wherein, the base material layer is an alkaline glass fiber felt layer, the self-adhesive waterproof layer is a polymer modified asphalt, and the isolation protection layer is a PE film. The preparation steps include: (1) preparation of graphene / natural rubber nanocomposite material; (2) preparation of polymer modified asphalt; (3) preparation of waterproof coiled material. The waterproof coiled material of the present invention not only has good waterproof and anti-corrosion effects, but also greatly improves the toughness of the waterproof coiled material, and the existence of graphene makes the waterproof coiled material have better environmental stability, greatly extending the waterproof coiled material. service life and has a good application prospect.

Owner:HEFEI ZHONGKE FUHUA NEW MATERIAL

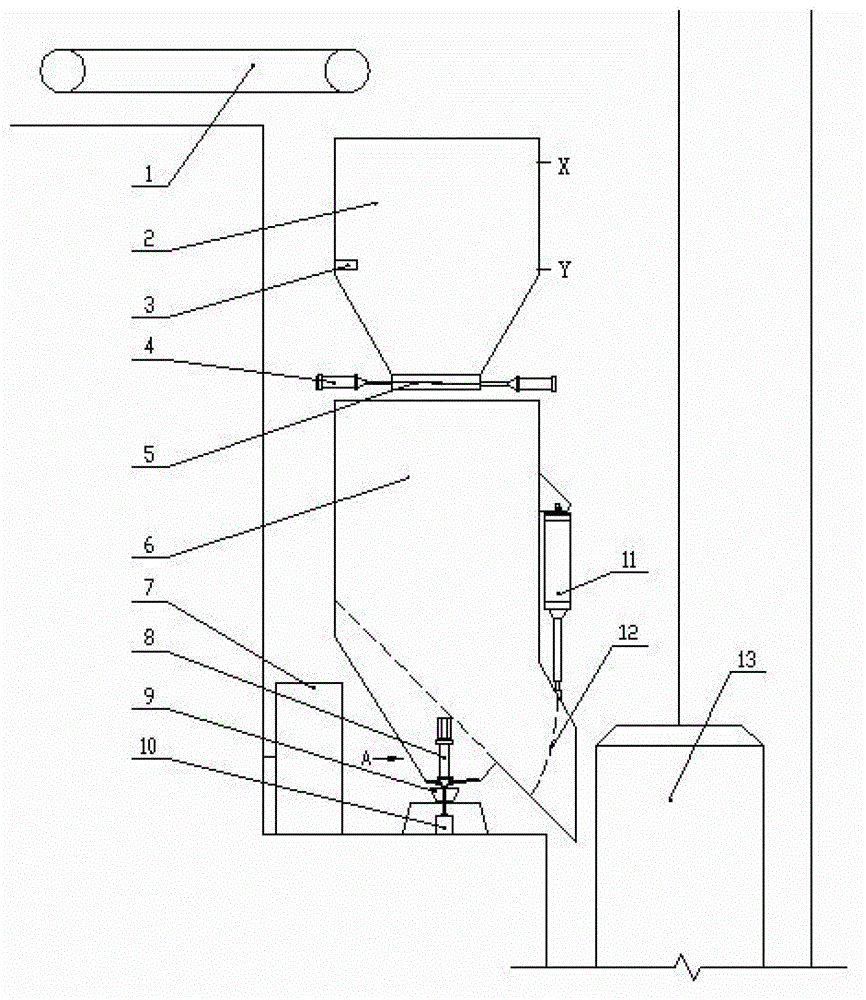

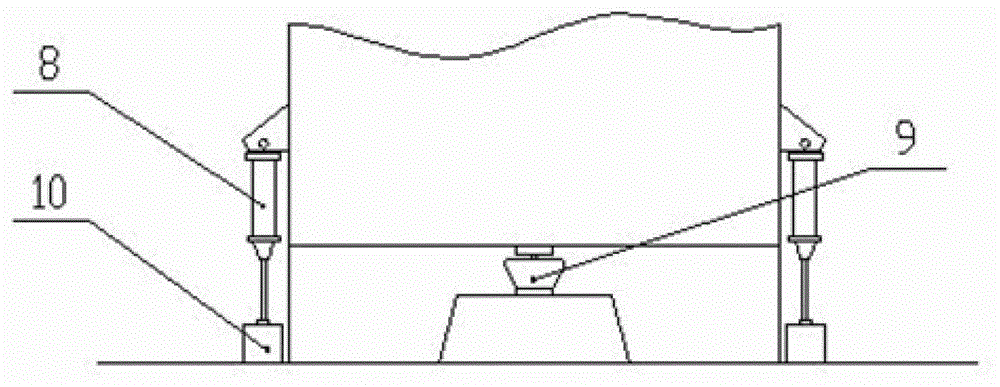

Improved skip weight-fixed loading equipment

ActiveCN102910459AReduce distractionsAvoid frequent replacementLoading/unloadingElectricityHydraulic pump

The invention discloses improved skip weight-fixed loading equipment, which belongs to the technical field of weighing. A sector gate is mounted at an discharge port of a weight-fixing hopper; a weighing sensor is mounted at the bottom of the weight-fixing hopper; an sector gate oil cylinder is welded on the side wall of the weight-fixing hopper; the sector gate is connected with the sector gate oil cylinder; a coal level meter is mounted in a surge bunker; the discharge port of the surge bunker is positioned at the bottom of the bunker; a flat gate is mounted at the discharge port and is connected with a flat gate oil cylinder; the surge bunker is positioned right above the weight-fixing hopper; counterweight lifting oil cylinders are mounted below the two side walls of the weight-fixing hopper respectively; the oil paths of the flat gate oil cylinder, the counterweight lifting oil cylinders and the sector gate oil cylinder are connected with a hydraulic pump station; the coal lever meter, the weighing sensor, a belt conveyor and the hydraulic pump station are electrically connected with a controller in a lifting control chamber. The improved skip weight-fixed loading equipment has the advantages of high coal loading precision, strong reliability, avoidance of frequent exchange of the weighing sensor and reduction in maintenance cost.

Owner:XUZHOU WUYANG TECH

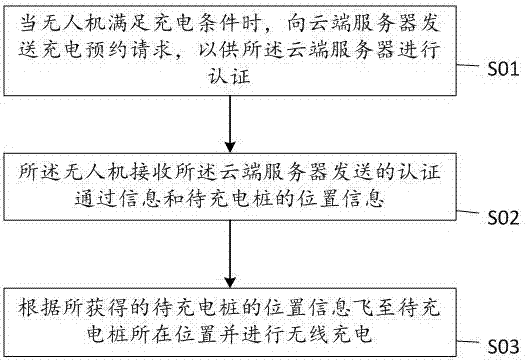

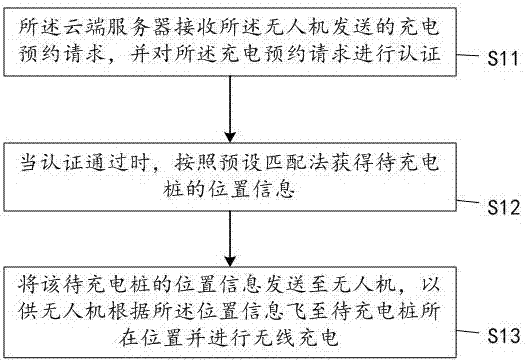

Unmanned aerial vehicle, cloud server and wireless charging system and method

InactiveCN108001684AAvoid frequent replacementImprove battery lifeCharging stationsRadio transmissionUncrewed vehicleInductive charging

The invention relates to the technical field of unmanned aerial vehicles, in particular to an unmanned aerial vehicle, a cloud server and a wireless charging system and method. The wireless charging method comprises the following steps that when the unmanned aerial vehicle meets a charging condition, a charging reservation request is sent to the cloud server for authentication of the cloud server;the unmanned aerial vehicle receives authentication pass information sent by the cloud server and position information of a to-be-charged pile; and the unmanned aerial vehicle flies to the position where the to-be-charged pile is according to the obtained the position information of the to-be-charged pile and conducts wireless charging. According to the wireless charging method, when the unmannedaerial vehicle meets the charging condition, the unmanned aerial vehicle is matched with the best charged pile automatically by the cloud server, and the unmanned aerial vehicle flies to the chargedpile for wireless charging; and unified deployment and planning are achieved by the cloud server in the whole process, manual control is not needed, and meanwhile, the trouble of manual charging is eliminated, so that the cruising ability of the unmanned aerial vehicle is improved.

Owner:SHANGHAI TOPXGUN ROBOT CO LTD

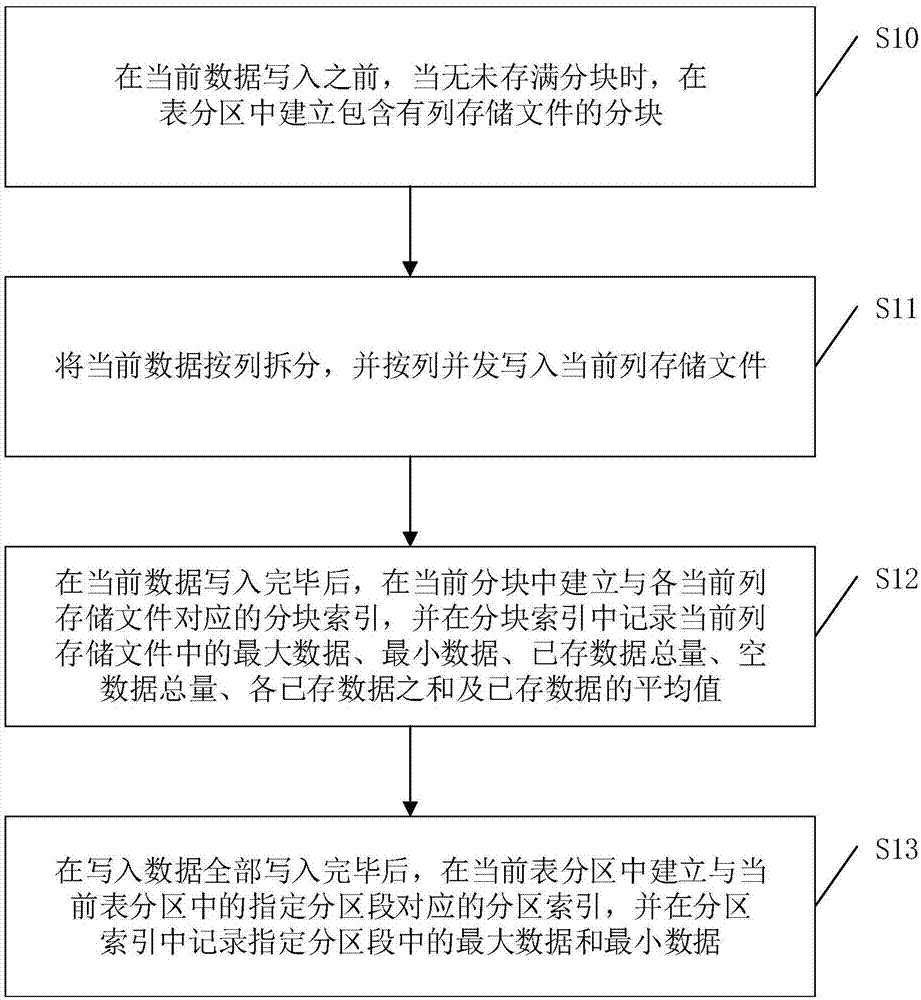

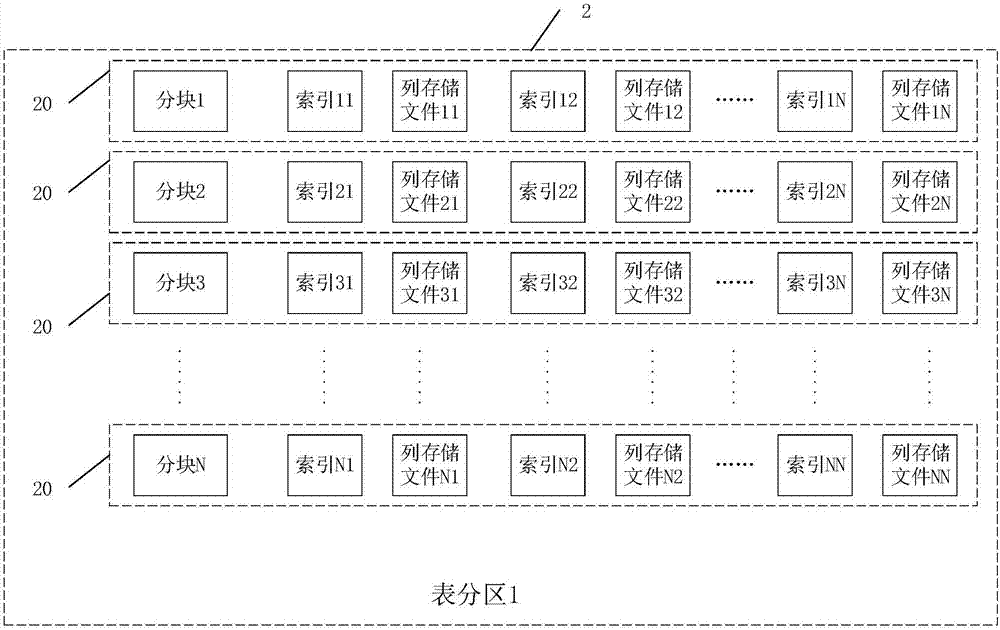

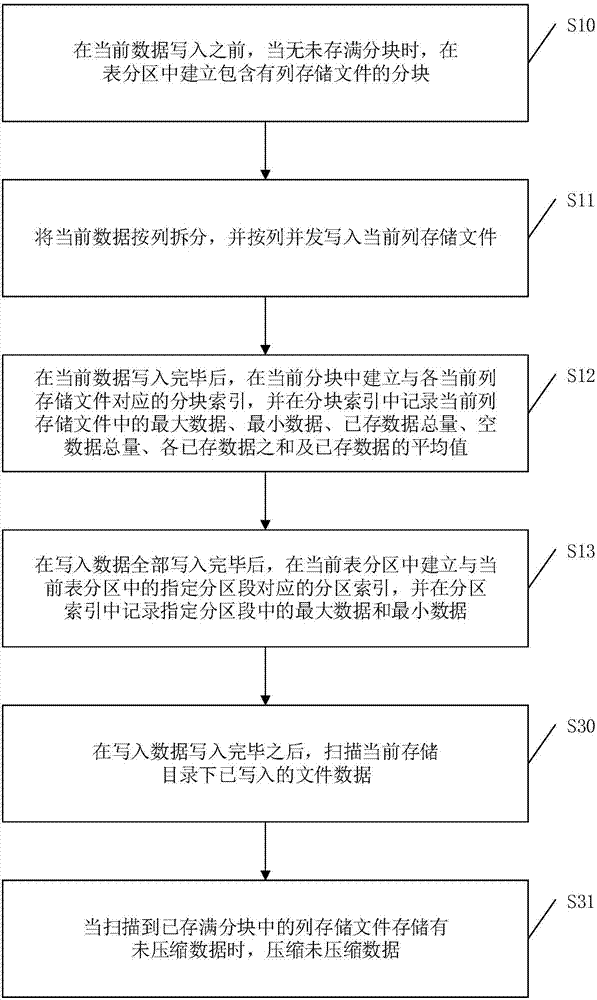

Data storage method and device

ActiveCN107577436AImprove query speedNarrow your searchInput/output to record carriersSpecial data processing applicationsData queryData store

The invention discloses a data storage method. Due to the fact that only maximum data and minimum data in a designated partition section of a table partition are stored in a partition index and the maximum data, minimum data, the total quantity of stored data, only the total quantity of empty data, the sum of stored data and the mean value of the stored data in column-stored files are stored in ablocking index during data storage, both the storage space occupied by the partition index and the storage space occupied by the blocking index are very small, the partition index and the blocking index can be also basically stored in a memory even during massive data storage, and frequent memory replacement caused by huge indexing files is avoided. Therefore, by adopting the data storage method,the partition index and the blocking index can be completely stored in the memory during massive data storage, and the data query speed can be improved. In addition, the invention also discloses a data storage device having the above advantages.

Owner:HANGZHOU SHIQU INFORMATION TECH CO LTD

Toothpaste squeezing device with good safety performance

ActiveCN109124436AAvoid infectionImprove securityHolders and dispensersUnpacking by expelling contentsCouplingToothpaste

The invention belongs to the technical field of toiletries, especially the toothpaste squeezing device with good safety performance. In order to solve the problems of the inconvenience of operation ofthe toothpaste extruder used in hotels, and the problem that the health and safety of toothpaste in hotels cannot be guaranteed, the following scheme is proposed, including a main body and a connecting tube, the top inner wall of the main body is provided with a connecting rod, and the other side of the connecting rod is provided with a mounting plate, both sides of the top outer wall of the mounting plate are provided with reinforcing rods, and the other side of the reinforcing rod is fixed with the connecting rod by screws, the two ends of the top outer wall of the mounting plate are provided with a stepping motor, the output shaft of the stepping motor is connected with a first screw rod through a coupling, and the one side outer wall of the two first screw rods is connected with the same moving plate through screws. The invention can automatically squeeze toothpaste through two squeeze rollers, can effectively disinfect and sterilize the stored toothbrush, and greatly improves thehygiene safety of the toothbrush.

Owner:HANGZHOU YUJIN TECH CO LTD

Method and apparatus for intensifying denitrification in coupling microorganism electrolytic tank of upstream vertical flow artificial wetland

ActiveCN105236584AImprove removal efficiencyImprove total nitrogen removal effectWater contaminantsTreatment with aerobic and anaerobic processesMicroorganismNitrate nitrogen

The invention discloses a method and apparatus for intensifying denitrification in a coupling microorganism electrolytic tank of an upstream vertical flow artificial wetland. The method comprises the following steps: A, uniformly distributing water at the bottom of a system, raising waste water in a pushing flow manner along a bottom non-conducting filler layer firstly; B, enabling the waste water to flow in an anode conducting filler layer; C, then enabling the waste water to flow in a non-conducting filler isolated layer which is a separator between a cathode conducting filler layer and the anode conducting filler layer; D, enabling the waste water to flow in the cathode conducting filler layer, and carrying out autotrophic denitrification removal on nitrate nitrogen; and E, enabling the waste water to flow out of a drain pipe in the upper non-conducting filler layer. The anode conducting filler layer is connected with the non-conducting filler isolated layer and the bottom non-conducting filler layer respectively, the cathode conducting filler layer is connected with the upper non-conducting filler layer and the non-conducting filler isolated layer respectively, and a cathode collector and an anode collector are placed in the cathode conducting filler layer and the anode conducting filler layer respectively. The operation is simple, and the removal capability of the upstream vertical flow artificial wetland for the waste water containing low carbon and high nitrate nitrogen is greatly improved.

Owner:INST OF AQUATIC LIFE ACAD SINICA

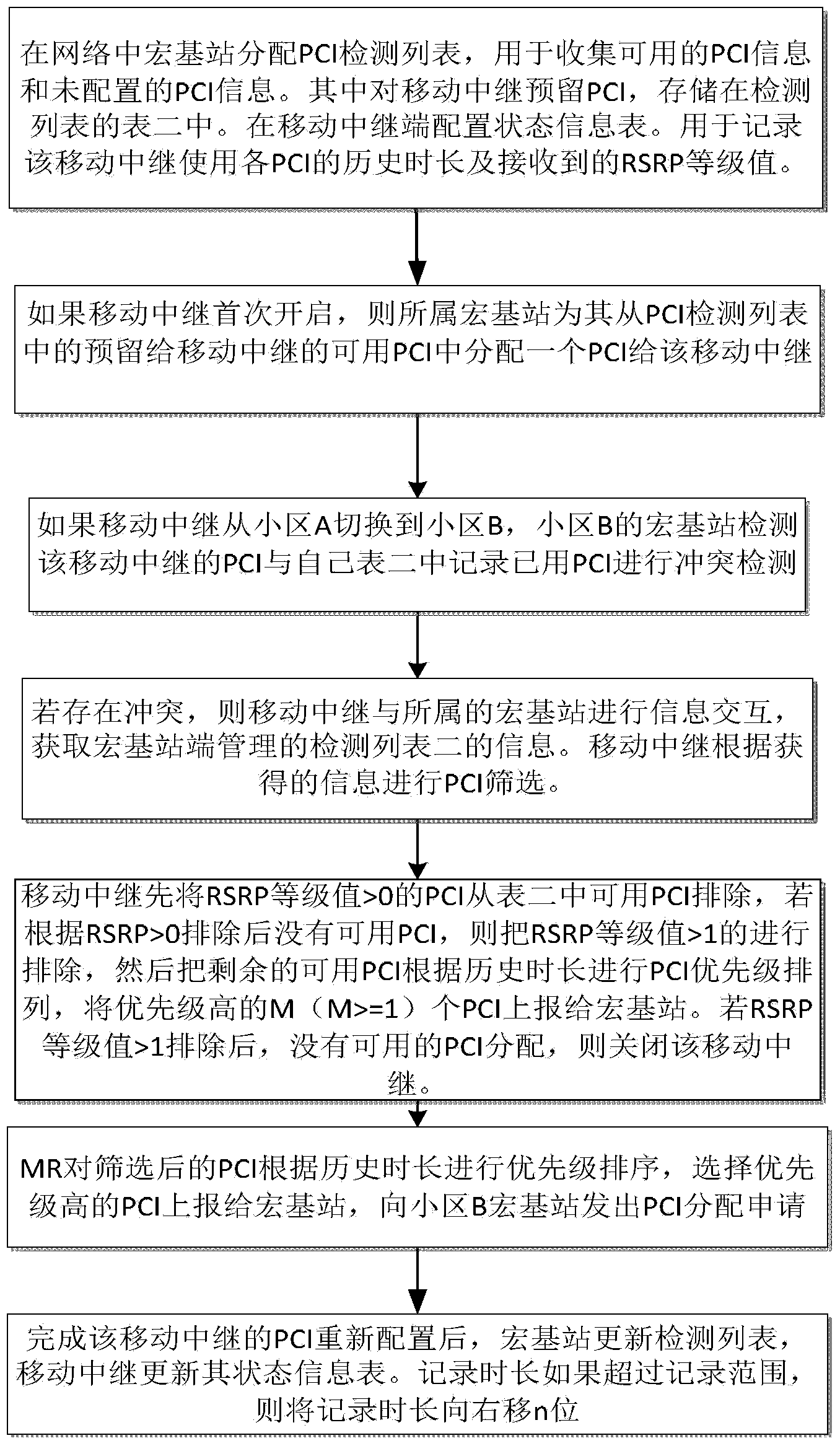

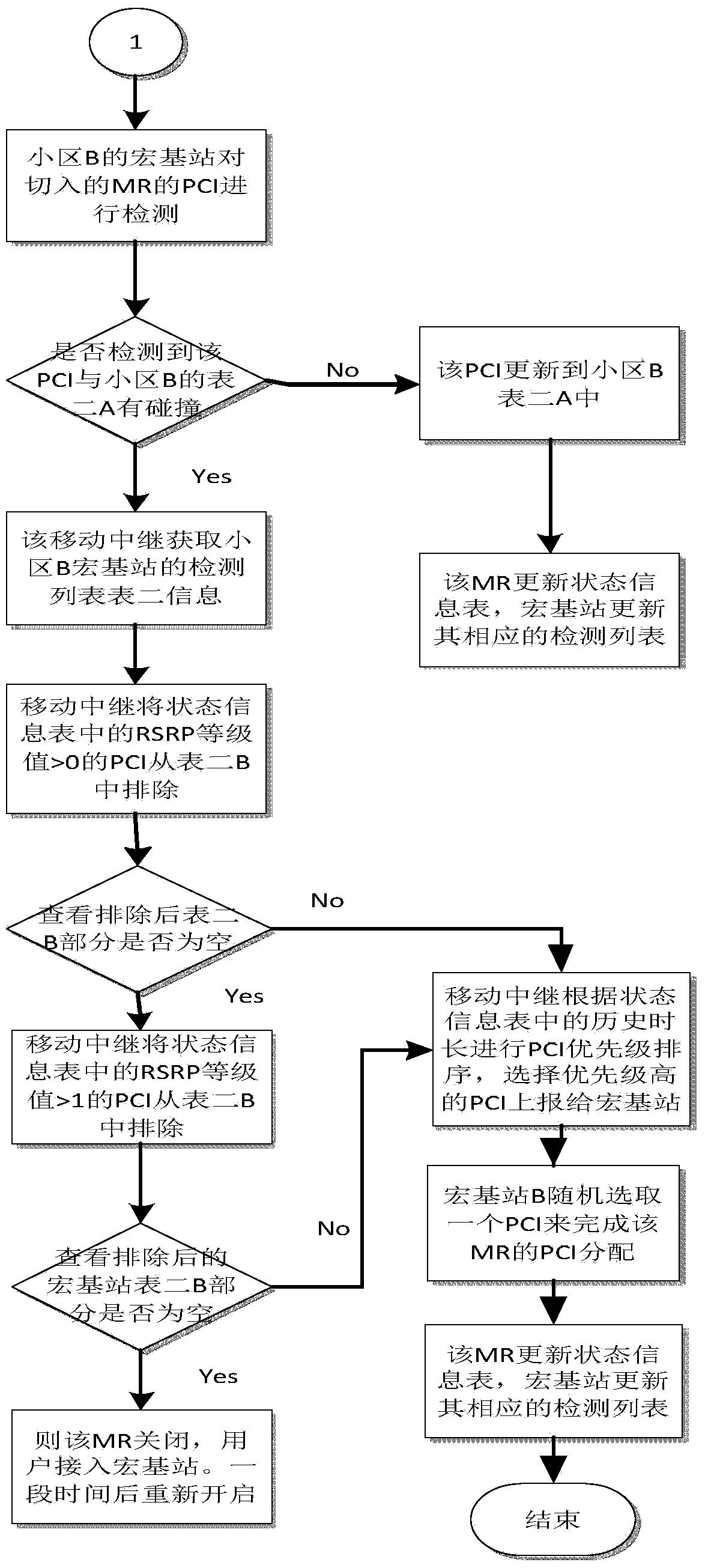

PCI (physical cell identification) allocation method suitable for low-speed MR (mobile relay)

The invention relates to a PCI allocation method suitable for a low-speed MR, and belongs to the field of wireless communication. The method comprises the steps as follows: a PCI allocation detection list is configured and maintained at a macro base station terminal of each cell, and a state information list is configured and maintained at each MR terminal simultaneously; the MR determines an access cell B according to cell selection norm and performs signaling interaction with a macro base station of the target cell B, so that the cell switching is finished; the macro base station of the cell B performs matching search on PCI of the MR and a PCI allocation detection list managed by the macro base station of the cell B, and whether collision exists is detected; the MR performs PCI screening by utilizing the obtained allocation detection list managed by the macro base station of the cell B and the state information list, and performs priority ranking; M (M is equal to 1) PCIs with highest priority ranking are selected to be reported to the macro base station of the cell B; the PCIs are reallocated for the MR by the macro base station of the cell B according to the PCIs reported by the MR; and the MR and the macro base station of the cell B perform information updating correspondingly. With the adoption of the PCI allocation method suitable for the low-speed MR, the problems of PCI collision and confusion caused when the MR moves in multiple cells at a lower speed can be effectively solved, and the replacement times of the PCIs are reduced.

Owner:TSINGHUA UNIV

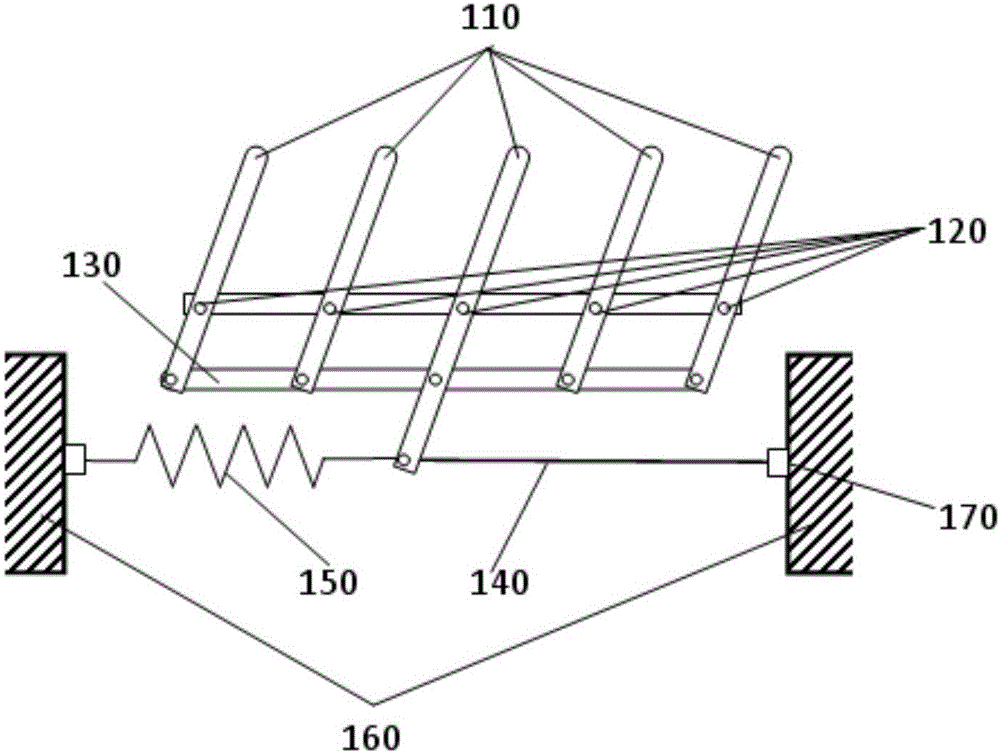

Vehicle-mounted air condition air sweeping device driven by electric control shape memory alloy

InactiveCN105946515AReduce volumeNo electromagnetic interferenceAir-treating devicesVehicle heating/cooling devicesMicrocontrollerMicrocomputer

The invention discloses a vehicle-mounted air condition air sweeping device driven by an electric control shape memory alloy. The vehicle-mounted air condition air sweeping device is composed of a drive part, a control part, a transmission part and an execution mechanism. The drive part adopts the shape memory alloy as a drive element, the shape memory alloy shrinks when electrified to be heated and is lengthened when cooled, and output of displacement and force of a driver is achieved. The control part is composed of a sensor, a single-chip microcomputer and a manual control key, the current on a shape memory alloy wire is controlled, and therefore the temperature of the shape memory alloy wire is controlled. The transmission part is mainly composed of a clutch device or a reset device. The execution mechanism is vehicle-mounted air conditioner air sweeping blades. The vehicle-mounted air condition air sweeping device has the beneficial effects of being small in size, simple in structure, convenient to install, easy to achieve, free of electromagnetic interference, good in periodical control effect and the like.

Owner:JILIN UNIV

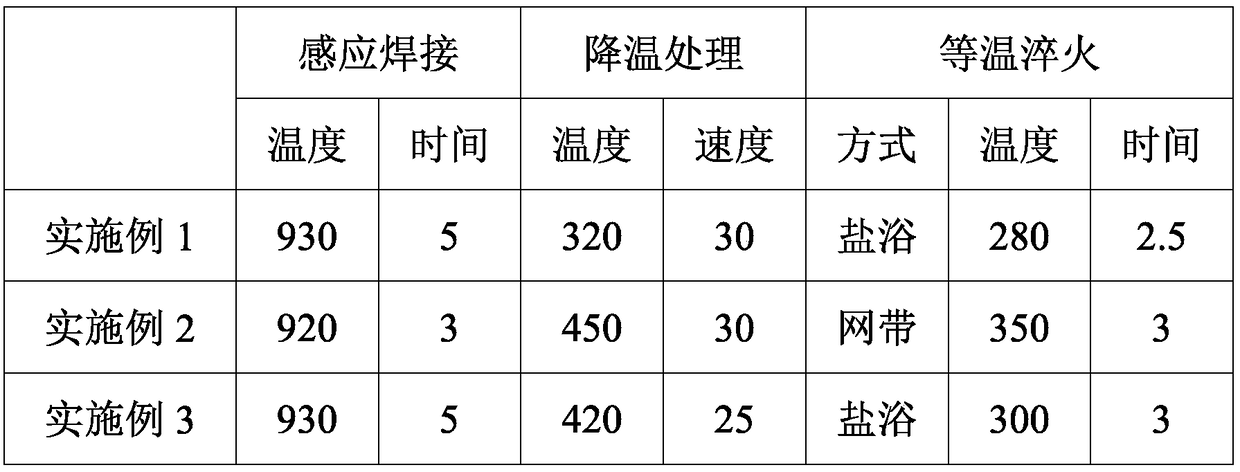

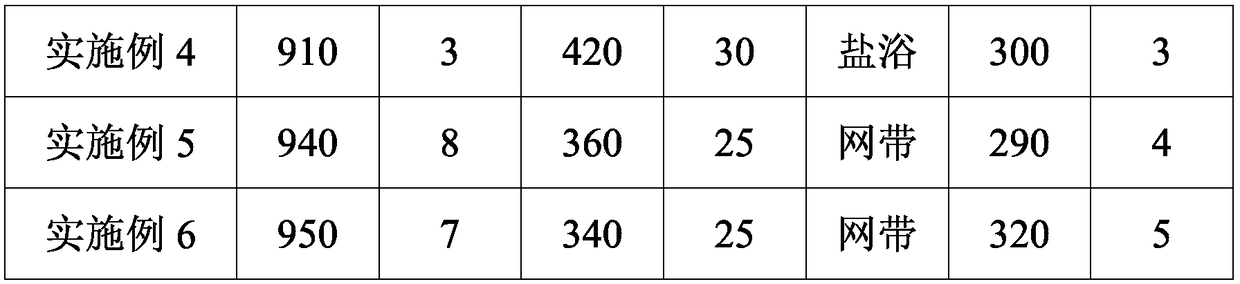

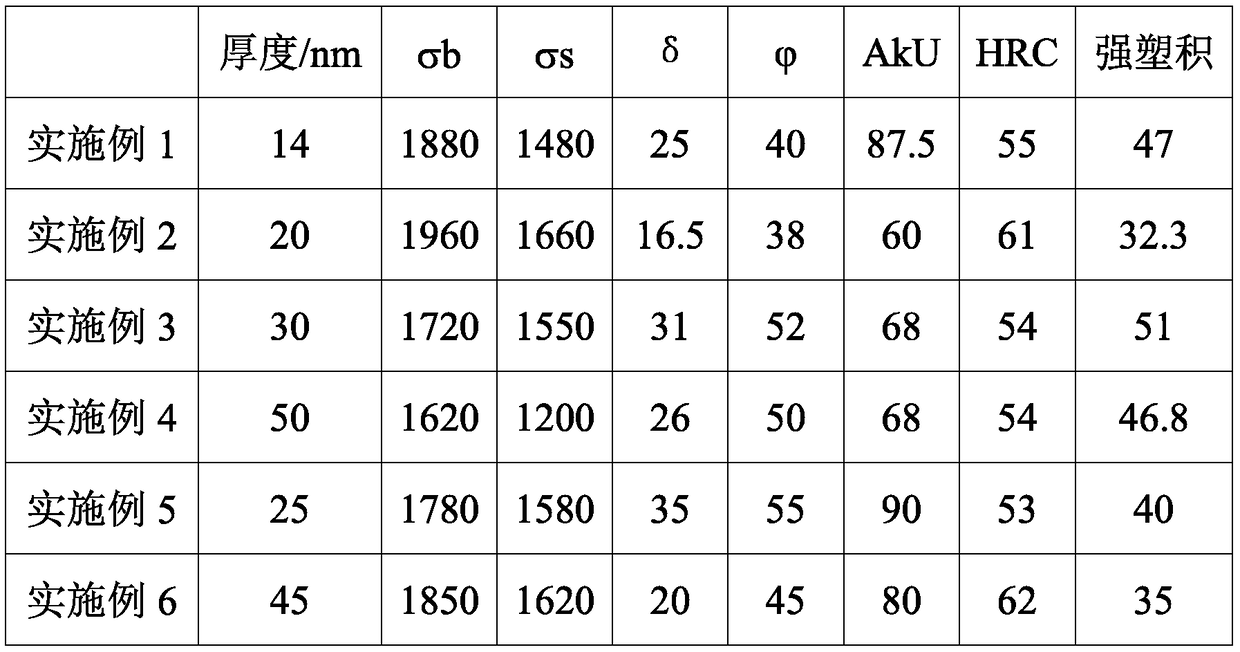

High performance cutting pick and manufacturing method thereof

InactiveCN108977631AOptimize chemical compositionHigh hardnessFurnace typesHeat treatment furnacesRaw materialMicrostructure

The invention provides a high performance cutting pick and a manufacturing method thereof, the high performance cutting pick comprises a tooth tip and a tooth body. The tooth body is high-strength, high-toughness and high-wear-resistance steel. The chemical components are as following by weight percent, 0.30 to 0.40 of C, 2.30 to 2.50 of Si, 2.20 to 2. 60 of Mn, 0.80 to 1.50 of Cr, 0.35 to 0.45 ofMo, 0.01 to 0.1 of Re, 0.02 to 0.04 of Nb, less than 0.01 of S, less than 0.01 of P, and the rest of Fe. After raw materials are refined and cast to obtain steel ingots or subjected to continuous casting to obtain continuous casting billets, after being rolled into round steel, cutting and annealing are conducted, and finally a cutting pick body is obtained by cold forging. The tooth tip is prepared from cemented carbide and welded to the tooth body by medium frequency induction heating. After cooling, austempering treatment is conducted, and finally discharging and air-cooling to room temperature are conducted. The finally obtained tooth body has tensile strength sigma b of 1700 to 2000MPa, yield strength sigma s of 1100 to 1520MPa, elongation delta of 16 to 35%, section shrinkage phi of45 to 55%, impact work Aku of 55 to 90 J, hardness HRC of 53 to 62, and strong plastic product of 32 to 51 GPa.%. The microstructure of the tooth body is a nano-carbide-free bainite-martensitic multiphase organization, and the thickness of a substructure slat is 10 to 50 nm.

Owner:鄂尔多斯市神东天隆矿山机械有限责任公司 +1

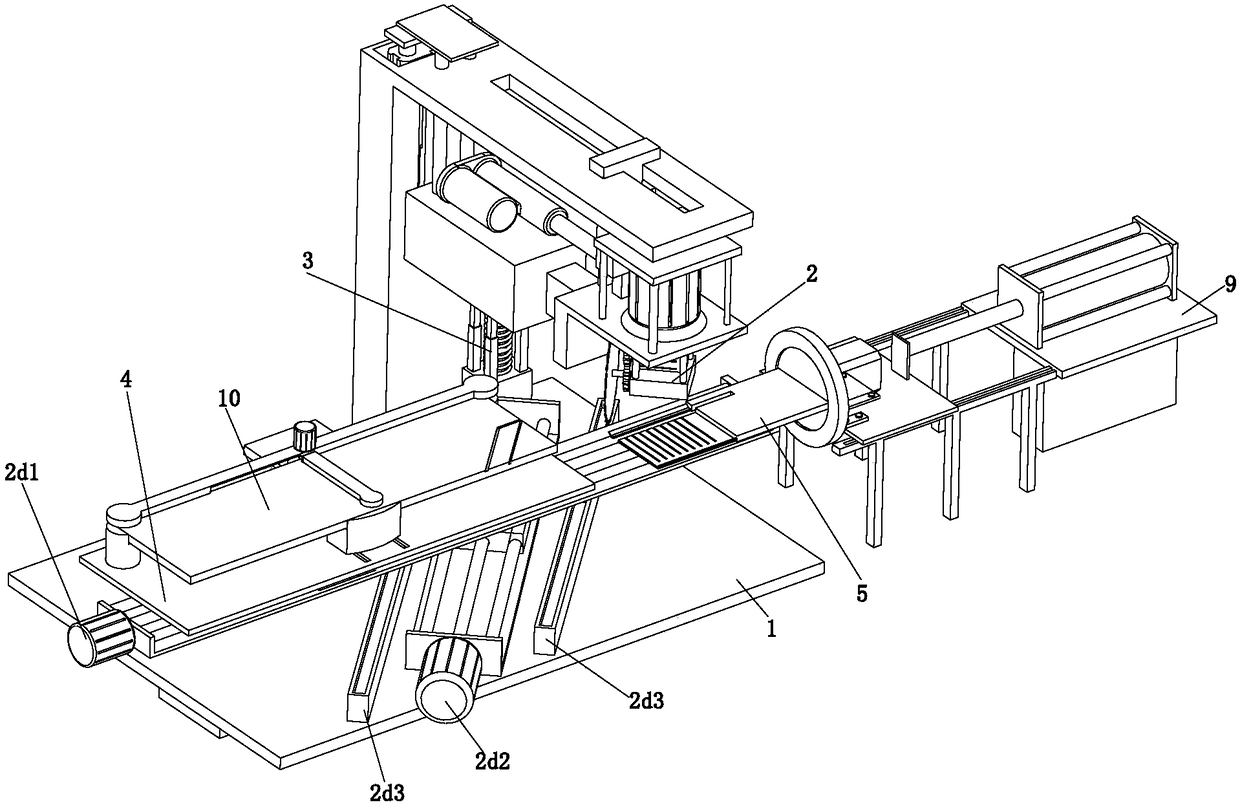

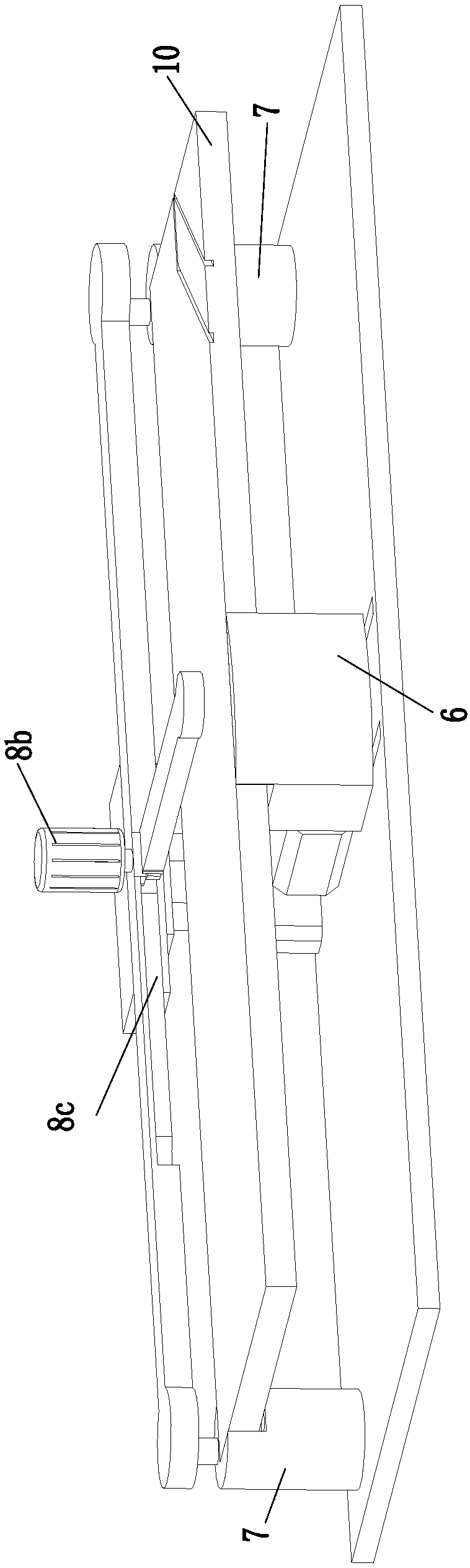

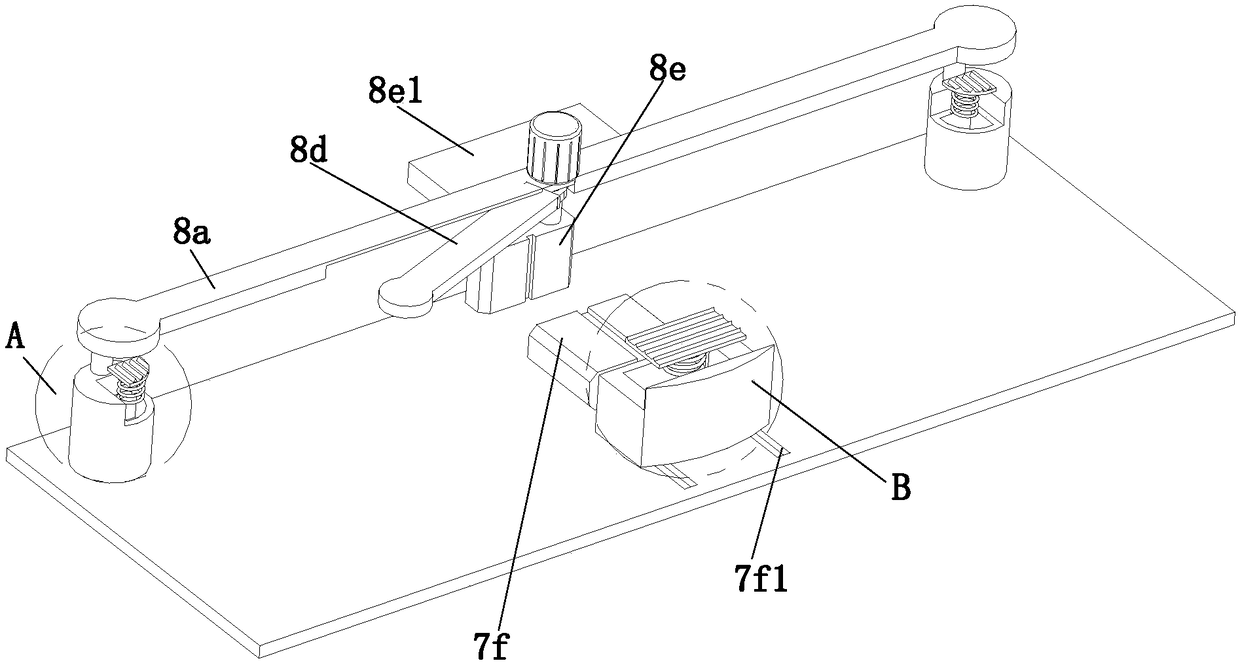

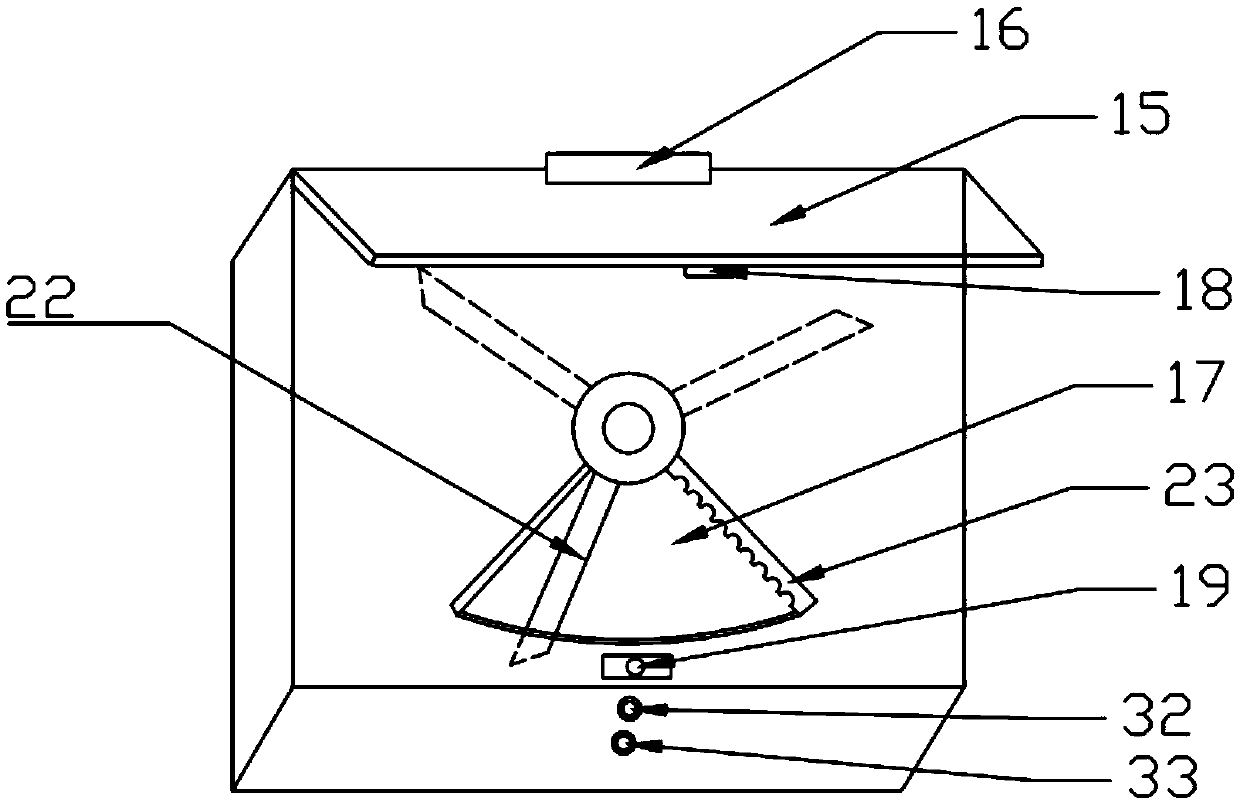

Single-cutter and 135-degree and 45-degree cutting type notching machine

The invention relates to the field of wood notching, and particularly relates to a single-cutter and 135-degree and 45-degree cutting type notching machine. The machine comprises a cutting platform, apositioning excluding mechanism and a notching mechanism, wherein the cutting platform is provided with a rectangular working plane; the notching mechanism comprises a bearing column, and a notchingpart which is positioned at the front end of the bearing column; a guide part is arranged on the cutting platform and is matched with the notching part to cut the end part of wood by 135 degrees or 45degrees; the bearing column is vertically arranged at one side of the cutting platform; a top plate which extends to the other side of the cutting platform is integrally formed on the top part of thebearing column; a bearing part is arranged below the front end of the top plate; the notching part is positioned on the top part of the bearing part; an angle adjusting motor is arranged above the bearing part and used for driving the bearing part to rotate. According to the machine, single notching sawblade can be operated to flexibly notch by 135 degrees and 45 degrees; the quantity of cuttersis decreased, so that the problem of frequent replacing of a plurality of cutters subjected to fictional loss can be avoided.

Owner:ANHUI NORMAL UNIV

Adjustable fabric winding drum

Owner:WUXI QIAOYANG MACHINERY MFG

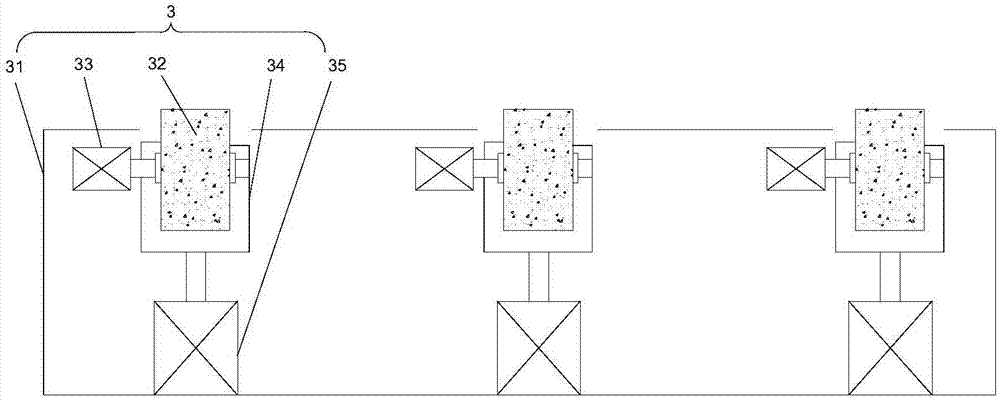

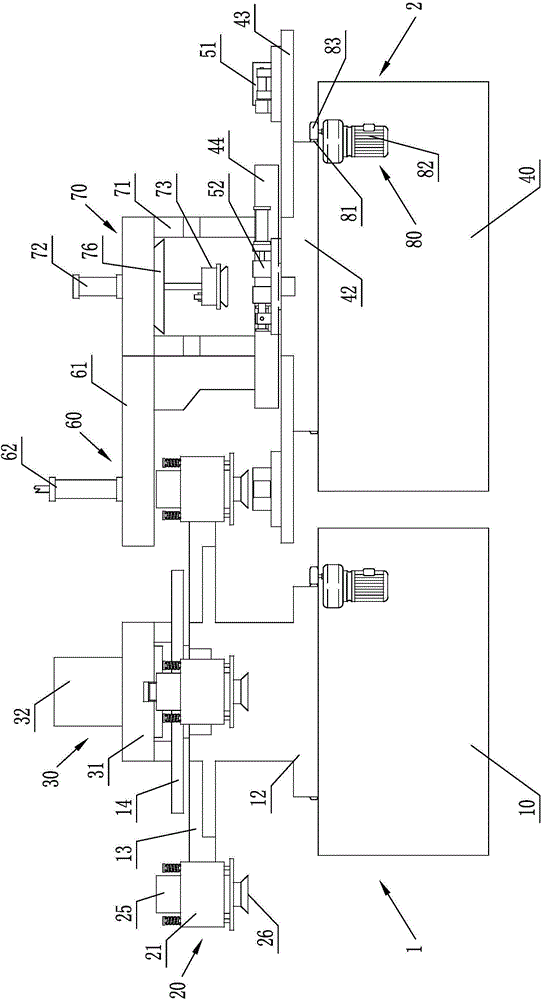

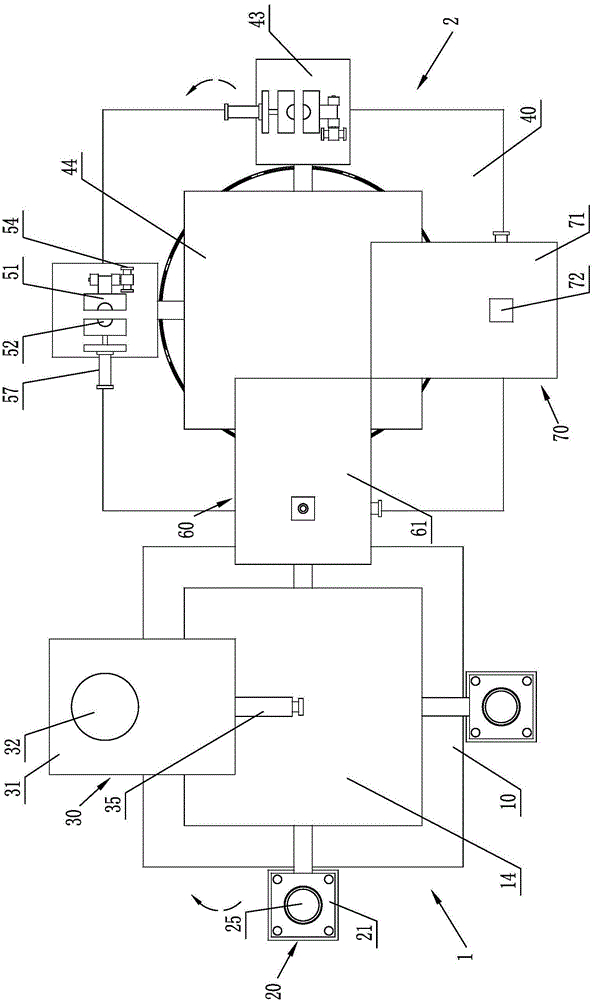

Multi-combined-station automatic core making center

The invention discloses a multi-combined-station automatic core making center. The automatic core making center comprises a sand jetting rotary working device and a core model rotary working device, wherein the sand jetting rotary working device comprises a sand jetting rotary seat; a plurality of sand jetting worktables are arranged on the peripheral side above the sand jetting rotary seat; a sand jetting mechanism is arranged on each sand jetting worktable; a sand storage mechanism is supported on the top of the sand jetting supporting seat; the core model rotary working device comprises a core model rotary seat; a plurality of core model worktables with the amount which corresponds to the amount of the sand jetting worktables are arranged on the peripheral side of the core model rotary seat; a core jetting mold matched with the sand jetting mechanism is arranged on each core model worktable; and a sand blowing mechanism is supported on the upper side of the core model supporting seat. By utilizing the automatic core making center, the production of sand cores of a plurality of models can be performed at the same time, the sand receiving, sand jetting, fixing and core pulling processes can be performed at the same time, and meanwhile, the sand cores are effectively prevented from falling during the sand pulling process.

Owner:刘晓桐

Chip detector for SMD (Surface Mounted Device) LED (Light-Emitting Diode) chip light spitting machine

InactiveCN102360062ASimple structureAvoid frequent replacementMeasurement instrument housingLamps testingSurface mountingMaterials science

The invention discloses a chip detector for an SMD (Surface Mounted Device) LED (Light-Emitting Diode) chip light spitting machine. The chip detector comprises a support plate; a drive source is arranged at one side of the support plate while an elastic probe assembly and a synchronous drive mechanism are arranged at the other end of the support plate; one end of the synchronous drive mechanism is connected with the drive source while the other end of the synchronous drive mechanism is connected with the elastic probe assembly; the synchronous drive mechanism is driven by the drive source; and the elastic probe assembly is driven to contact or leave a chip to be detected under the action of the synchronous drive mechanism. The chip detector disclosed by the invention is a chip detector based on chip fixture and probe movement; compared with the prior art, the chip detector has the characteristics of simple structure, easiness for implementation and capability of avoiding frequent change of a probe and ensuring the detecting precision; and the service life of the probe is more than 30 times to that of the probe of a needle structure in the prior art.

Owner:广东志成华科光电设备有限公司

Winding mould mechanism for winding machine

InactiveCN102684411AAvoid frequent replacementReduce investmentManufacturing dynamo-electric machinesPhysicsWinding machine

The invention discloses a winding mould mechanism for a winding machine. The winding mould mechanism comprises an upper mould and a lower mould which are in central symmetry about a rotating spindle. The winding mould mechanism is characterized in that the upper mould is mounted on an upper base, the lower mould is mounted on a lower base, the outside of each base is connected with an adjusting screw rod in a threaded manner, the outer end of each adjusting screw rod is connected with a screw rod mounting seat positioned on a rotary table of the winding machine through a bearing, the upper base and the lower base are respectively slidably connected on the rotary table of the winding machine through a guide mechanism, and the extension direction of each adjusting screw rod and the guide mechanism is perpendicular to the rotating shaft. The adjusting screw rods are connected with the upper base and the lower base positioned at the bottoms of the upper mould and the lower mould respectively in a threaded manner, so that the distance between the upper mould and the lower mould is adjusted, the requirements of various stator coils on winding are met, and the utilization rate of the winding machine is increased.

Owner:NIDE MECHANICAL EQUIP

Mercury-free catalyst for preparation of VCM (vinyl chloride monomer) through acetylene hydrochlorination and using method

InactiveCN104549522ASolve the lack of activityImprove stabilityMolecular sieve catalystsPreparation by halogen halide additionActive componentCompound (substance)

The invention discloses a mercury-free catalyst for preparation of a VCM (vinyl chloride monomer) through acetylene hydrochlorination and a using method. The mercury-free catalyst comprises chemical components in percentage by mass as follows: not higher than 0.1% of an active component, 0.1-20% of an additive, not higher than 10% of a stabilizer and the balance of a carrier, wherein the active component is a precious metal. Compared with the prior art, the mercury-free catalyst has the obvious advantages as follows: the high-activity precious metal is used as the active component, insufficient activity of base metals is avoided, and the basic requirement of industrial application is met; the content of the precious metal is not higher than 0.1%, the cost is substantially reduced, and the possibility of large-scale investment application is provided; the catalyst is excellent in stability, frequent replacement can be avoided, and the operability of industrial application is realized.

Owner:阳永荣

Magnetic fixed medical sharps box and using method thereof

InactiveCN109533730ASave spaceAvoid frequent replacementSurgical furnitureRefuse receptaclesMagnetic tension forceMotor drive

The invention discloses a magnetic fixed medical sharps box and a using method thereof. The magnetic fixed medical sharps box comprises a collection box, a shearing mechanism and a control system, wherein an electromagnet group is arranged at the inner bottom of the collection box; the shearing mechanism comprises a rotating shaft, a cutter blade, a cutter head and a rotor motor; the cutter bladeand the cutter head are arranged on an opening of the top of the collection box; the rotor motor and the cutter blade are arranged on the rotating shaft; a metal plate is arranged on a cover of the collection box; a top electromagnet is arranged at the corresponding position of the top of the box; when a start button on the control system is pressed down, the electromagnet group is charged, a stepper motor drives a push rod to open the cover of the collection box, sharps are put in the box, a cutting-off button on the control system is pressed down, the rotor motor drives the cutter blade to cut off a flexible pipe, and the sharps are tightly absorbed at the bottom of the box under the action of the magnetic force of the electromagnet group. When the collection box is almost full of the sharps, the box cover can also be automatically locked and is prevented from falling out. The magnetic fixed medical sharps box avoids the accidental injury caused by the direct contact between medicalpersonnel and discarded sharps, and is convenient and safe to operate.

Owner:XIEHE HOSPITAL ATTACHED TO TONGJI MEDICAL COLLEGE HUAZHONG SCI & TECH UNIV

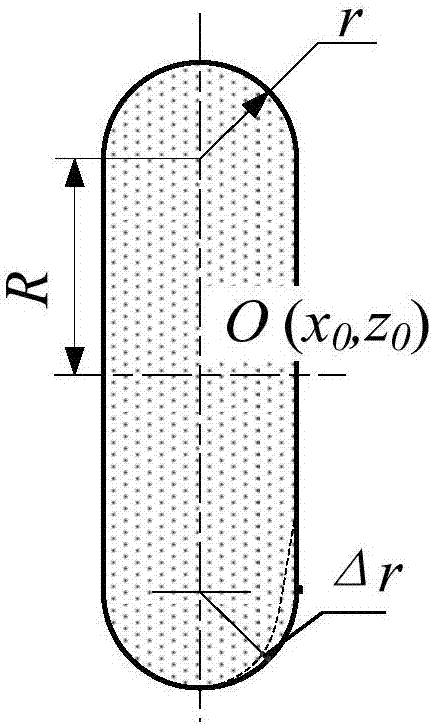

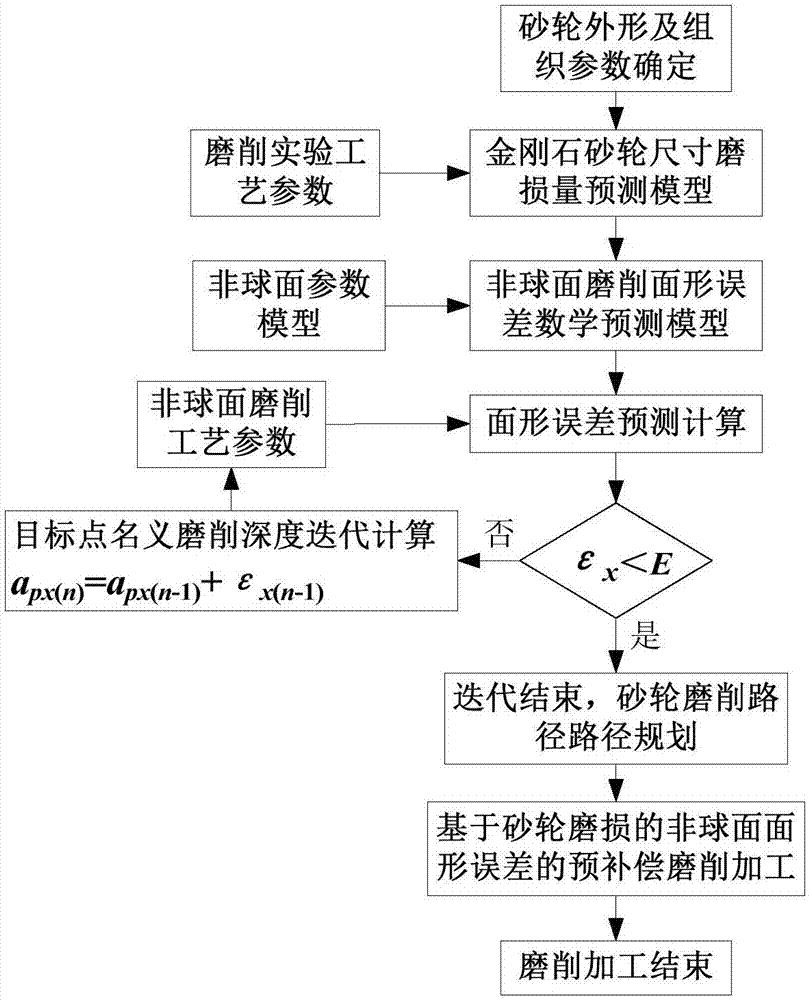

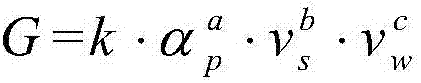

Large-caliber reflection mirror iterative precompensation grinding method based on grinding wheel wear prediction

ActiveCN107378687AExtended service lifeHigh precisionOptical surface grinding machinesTarget surfaceNumerical control

The invention relates to a large-caliber reflection mirror iterative precompensation grinding method, in particular to a large-caliber reflection mirror iterative precompensation grinding method based on grinding wheel wear prediction. In order to solve the problems that in the prior art, under the fixed nominal grinding depth, the target surface figure accuracy is achieved through repeated replacement of a grinding wheel for repeated grinding, consequently, the grinding wheel losses are serious, the surface figure accuracy is poor, and wear efficiency is low, the method comprises the steps of building a predication model of the grinding wheel grinding ratio G about the grinding parameter, secondly, building a radial size wear amount predication model at the grinding wheel wear point in the grinding process, thirdly, building a non-spherical-face surface-shape error predication model, fourthly, through the iterative precompensation method, calculating wear surface-shaped error values of all points on a non-spherical-face generatrix until the requirements are met and fifthly, recording nominal grinding depth final predication values of all contact points in the iterative process, and carrying out numerical control grinding machining programming and subsequent machining. The method is used for the technical field of grinding machining of an optical non-spherical-face reflection mirror.

Owner:HARBIN UNIV OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com