Shaft entering and withdrawing dual-purpose device for plastic packaging motor rotor

A technology of plastic-encapsulated motors and dual-purpose devices, which is applied in electromechanical devices, manufacturing motor generators, and adjusting/balancing rotors. It can solve problems such as difficulty in installing bearings, crushing fingers, and enlarged shaft heads, so as to avoid replacement equipment, improve production efficiency, and avoid finger crushing effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

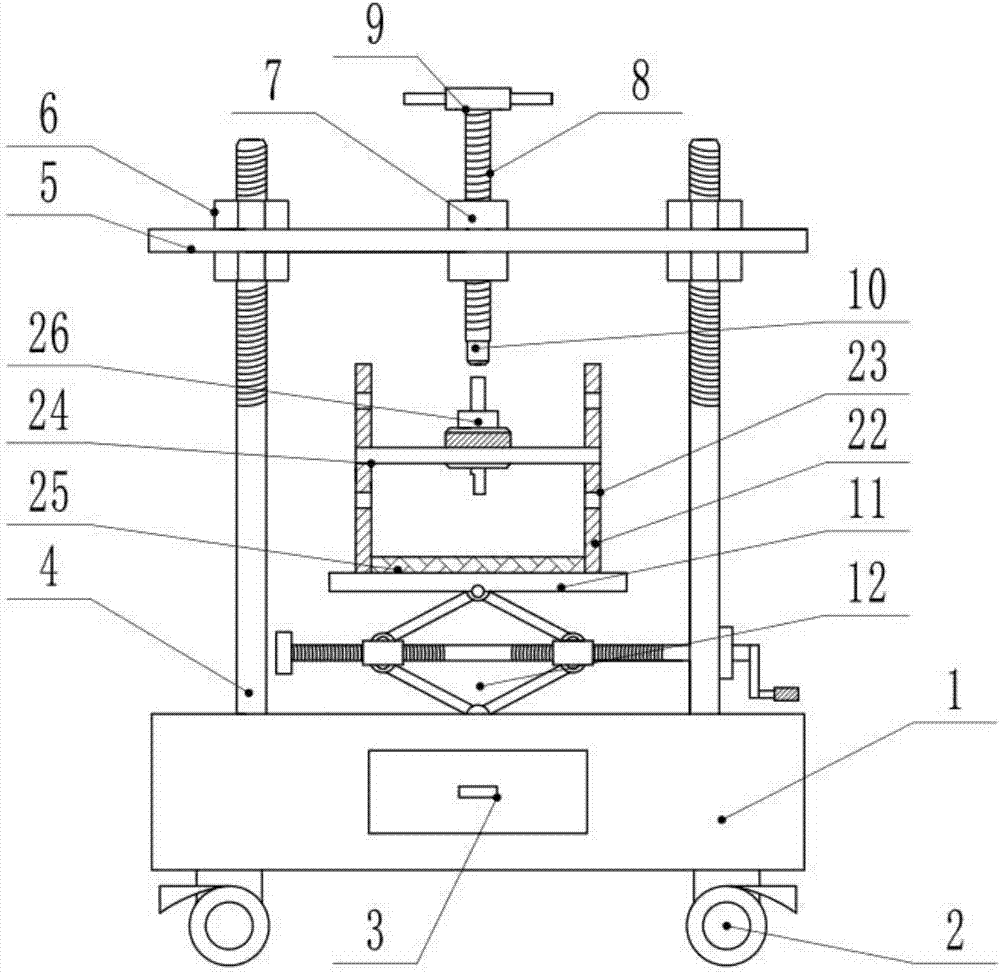

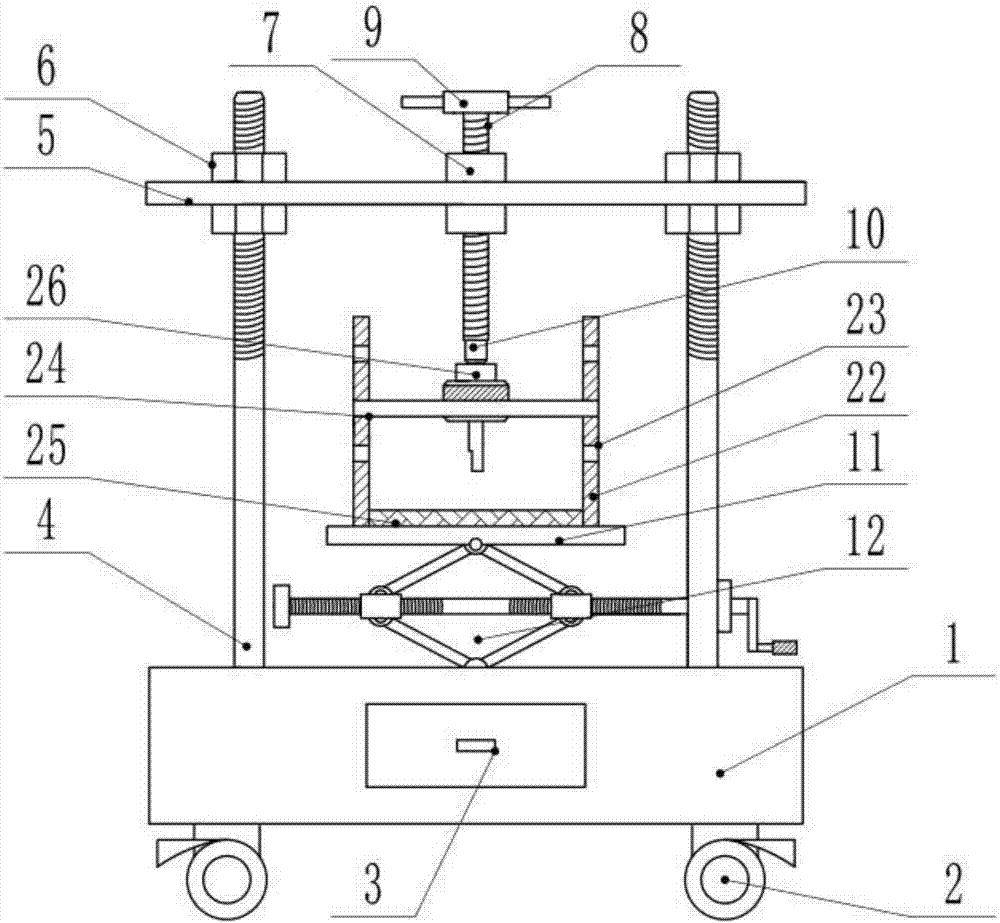

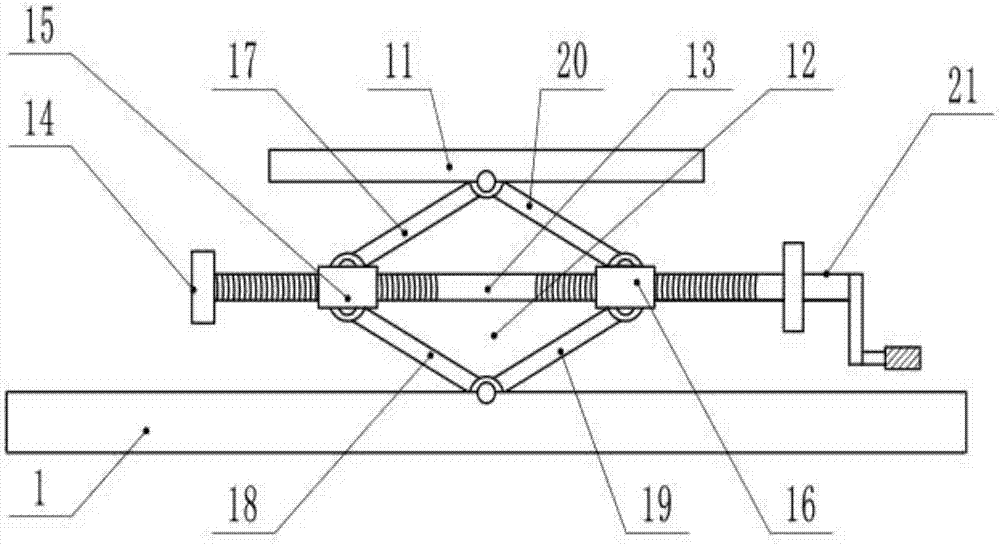

[0021] The technical scheme of this patent is described in further detail below in conjunction with specific embodiments

[0022] see Figure 1-4 , a dual-purpose device for entering and withdrawing the shaft of a plastic-encapsulated motor rotor, including a machine platform 1, a tool box 3, an adjusting screw 4, a support plate 5, a screw A8, a rotating handle 9, an extrusion head 10, a lifting platform 11, a lifting Device 12, fixed frame 22 and pressure nozzle 26, universal wheels 2 are fixedly installed on the lower side of the machine table 1, and there are at least four sets of universal wheels 2, and limited locking devices are installed on the universal wheels 2 to prevent the device from Movement occurs during work; the inside of the machine table 1 is a hollow structure, and a tool box 3 is slidably installed inside the machine table 1 through a chute. Adjusting screw 4 is fixedly installed, at least four groups of adjusting screw 4 are arranged, and the upper and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com