Patents

Literature

847results about How to "Achieve extrusion" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

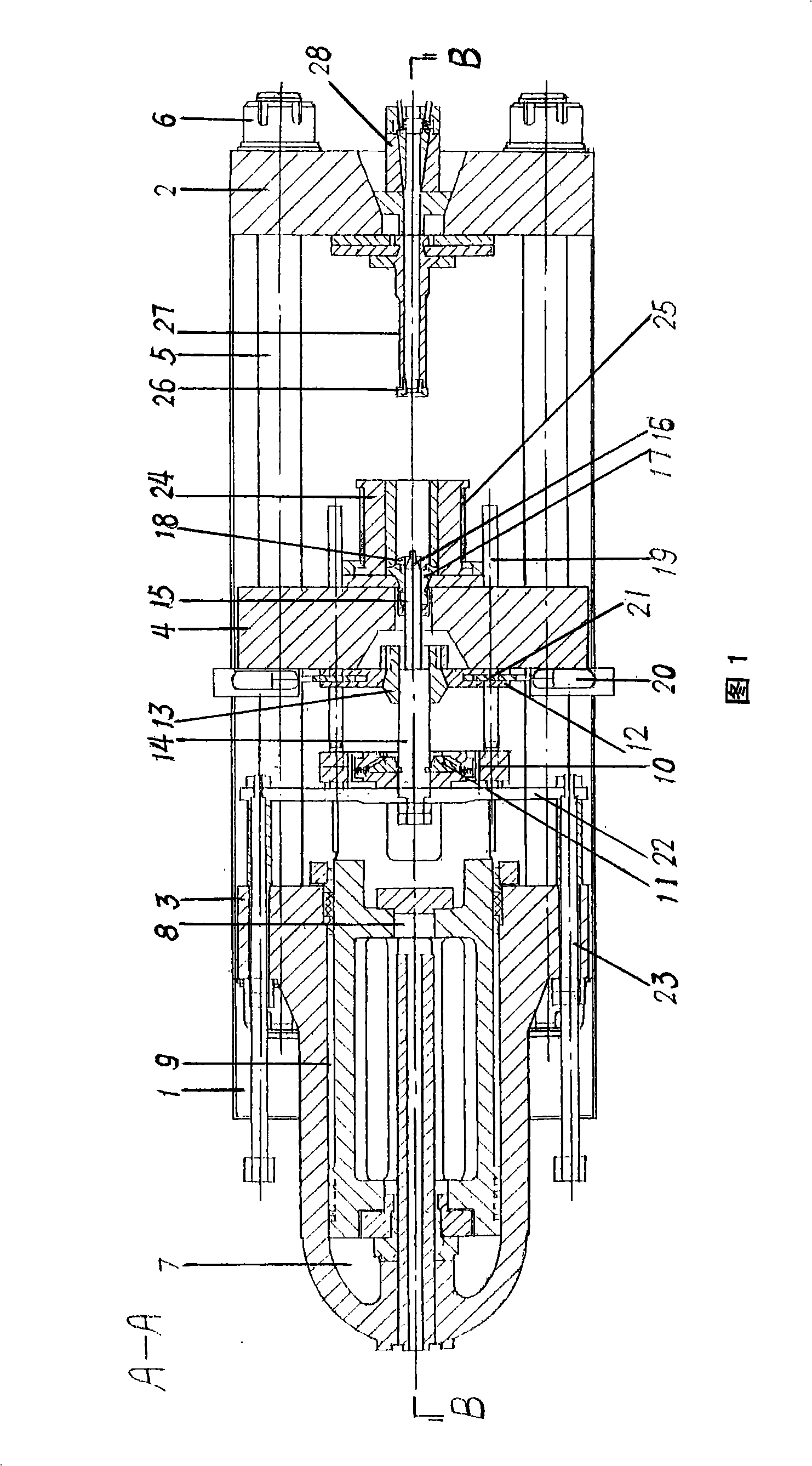

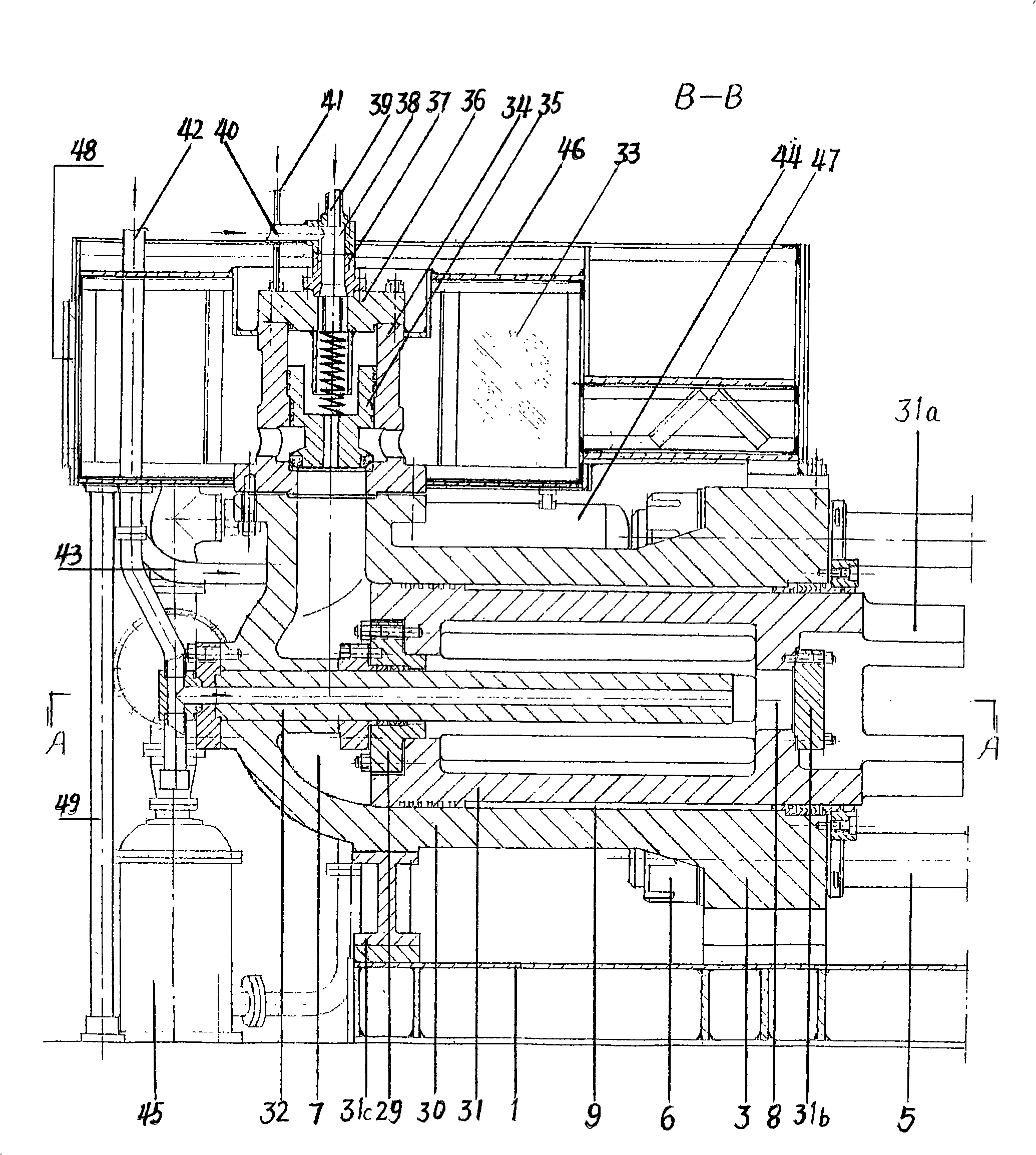

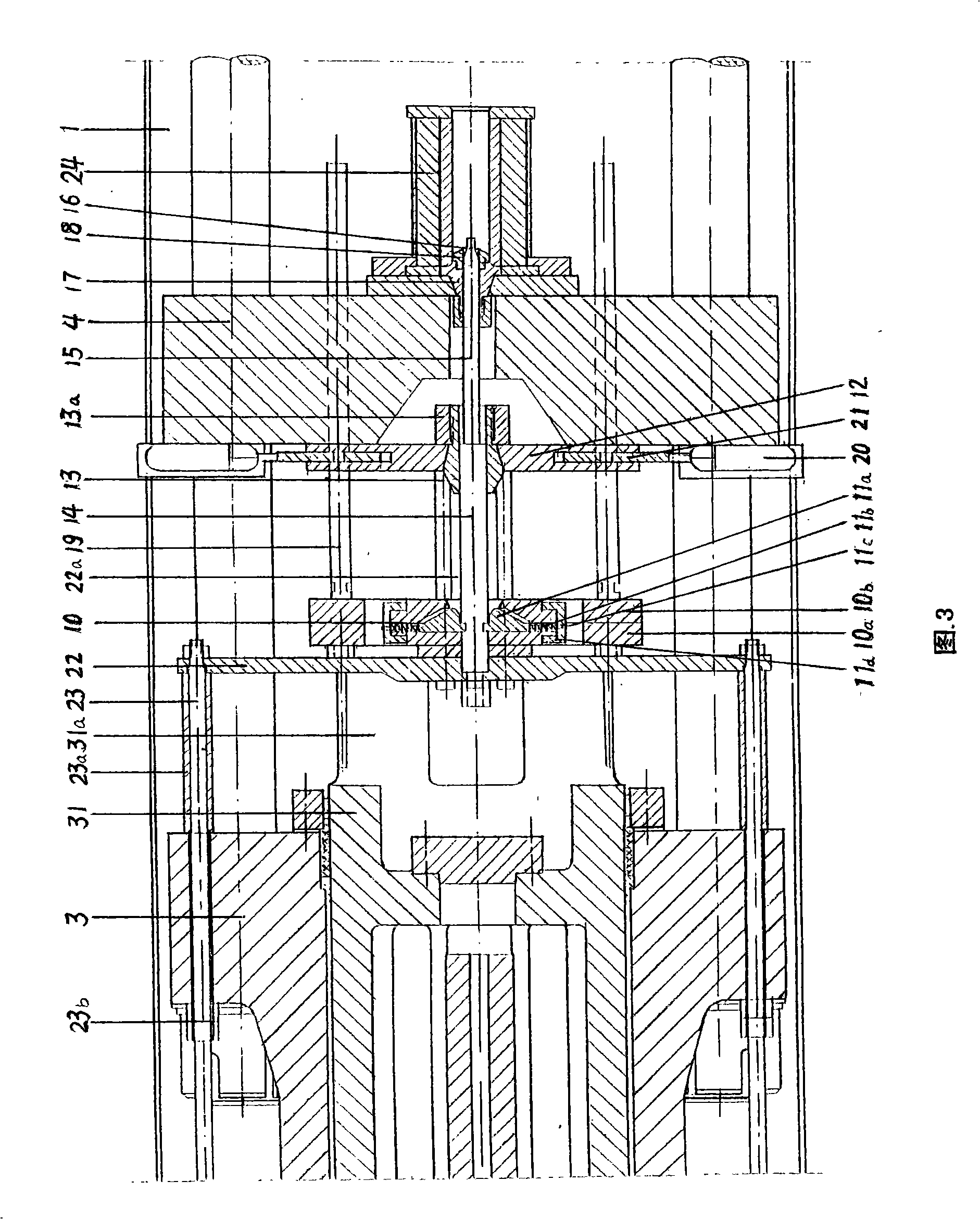

Alloyed steel horizontal type indirect extrusion machine

The invention discloses a horizontal reverse alloy steel extrusion machine, which belongs to the novel technical field of seamless steel pipe and relates to a seamless steel pipe manufacturing facility. The purpose is to settle the problems of complex process, inefficiency, high energy consumption and pollution of the environment with the prior domestic cold drawing techniques of small-bore seamless alloy steel tube. The machine consists of a rigid framework, a liquid-filled combined hydraulic cylinder and a die assembly, wherein, the rigid framework consists of an anterior fixed beam, a posterior fixed beam and an intermediate moving beam on the frame, which are connected in series by a four tensile columns; the liquid-filled combined hydraulic cylinder has a compact structure and is capable of executing the operations of die displacement, material feeding, perforation, extrusion and die removal; the die assembly consists of a perforation and extrusion and automatic switching system, a hot extrusion / molding system and a die removal and disengaging and residual extrusion and cutting system. The machine is capable of achieving once-and-for-all heating and once-and-for-all molding to directly produce finished products of small-bore seamless alloy steel pipes. Compared with forward extrusion, the deviations of the displacement of the piercing mandril and the dies are small, and no friction occurs between the billets and the internal wall of the container, thereby the machine can directly adopt continuous casting billets to extrude small-bore pipes, and has the advantages of simple process, high quality, high efficiency, low energy consumption, etc.

Owner:周家镳

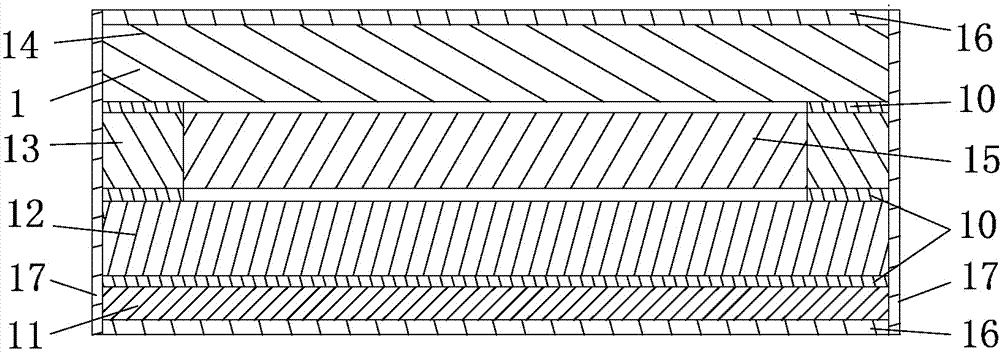

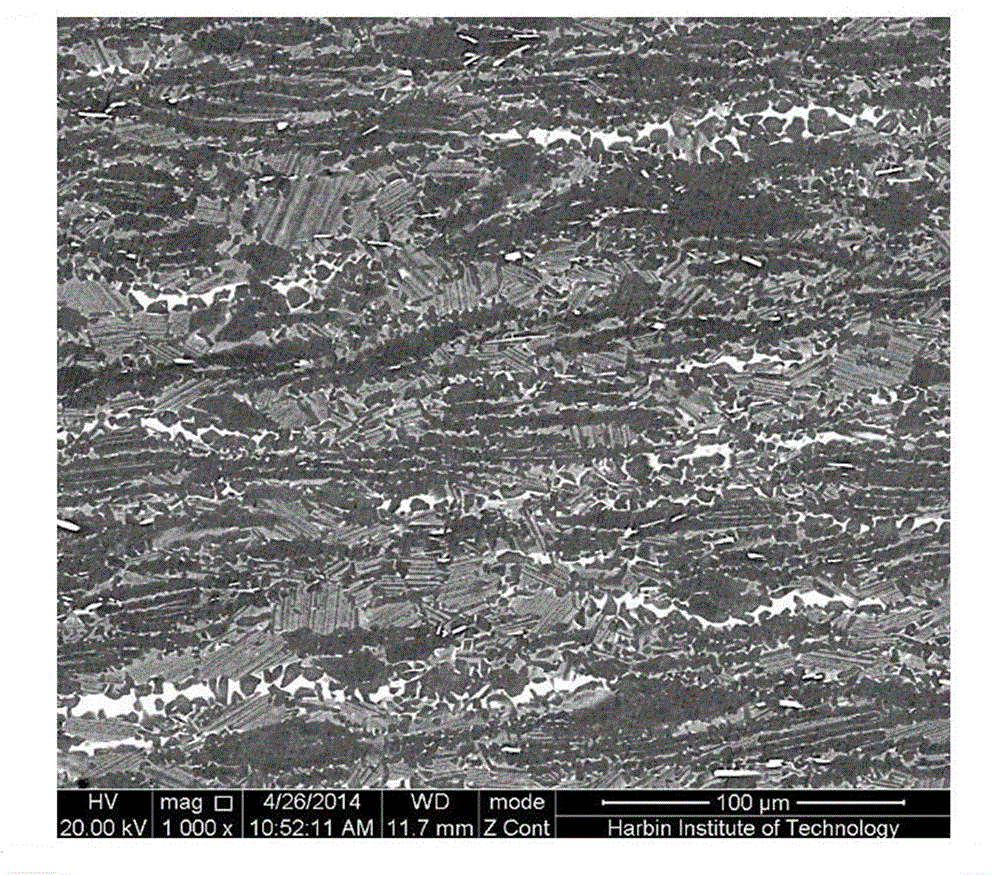

Integrated fully-sealed liquid crystal screen and manufacturing process for same

ActiveCN104679339AScreen thickness is light and thinGood solid fluidityNon-linear opticsInput/output processes for data processingLiquid-crystal displayGlass cover

The invention discloses manufacturing process for an integrated fully-sealed liquid crystal screen. Components which are sequentially arranged are laminated into a whole through a solid ultraviolet flexible adhesive, wherein the components comprise screen protecting glass, a liquid crystal screen set, a support frame and a rear glass cover plate, wherein edge lighting type backlight module is nested in the support frame. The integrated fully-sealed touch and display screen manufactured by the process is waterproof, damp-proof and ultrathin, all gaps of the screen protecting glass or the touch screen set, a liquid crystal display screen set and the side lighting type backlight module are eliminated, image definition is improved, and brightness can be reduced to achieve a remarkable energy-saving effect.

Owner:OPTON (SHUNCHANG) OPTICS CO LTD

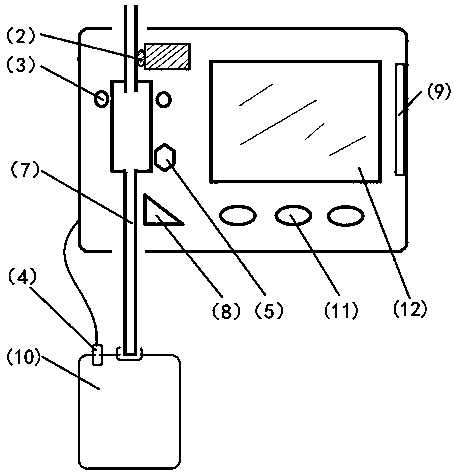

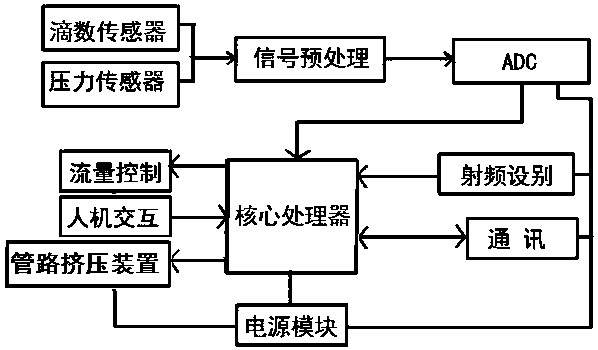

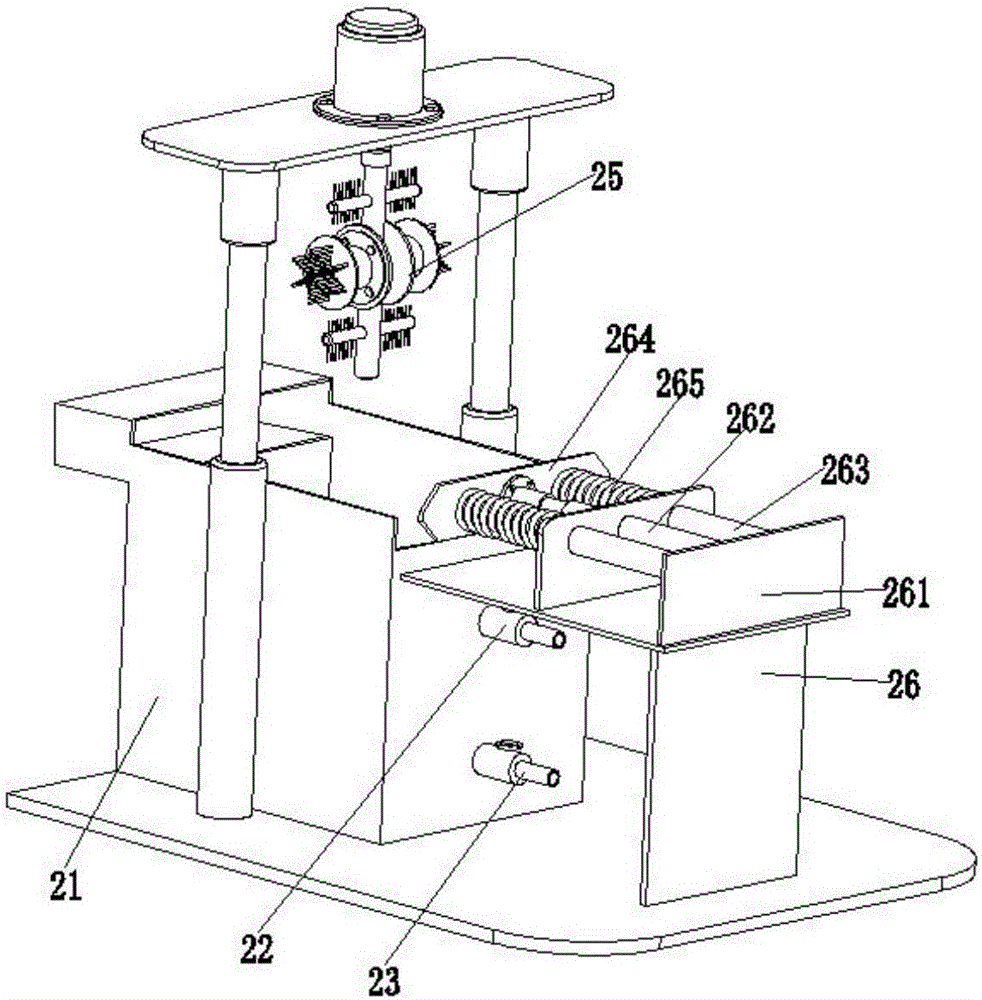

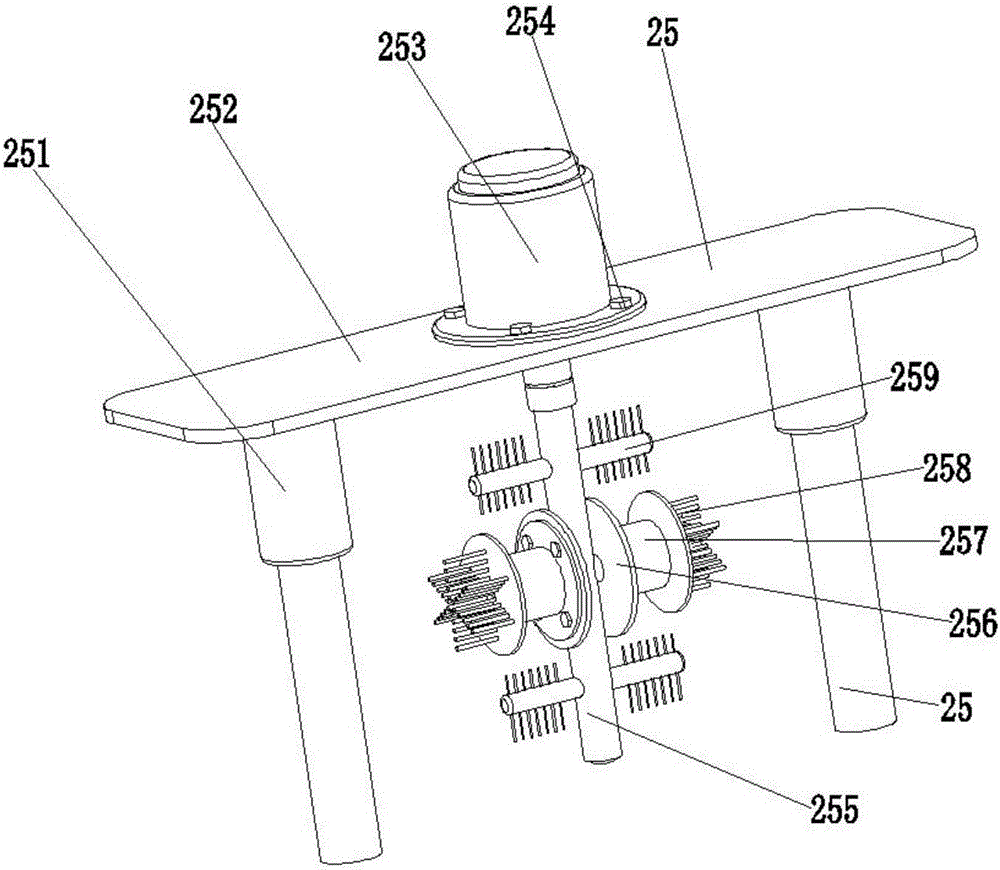

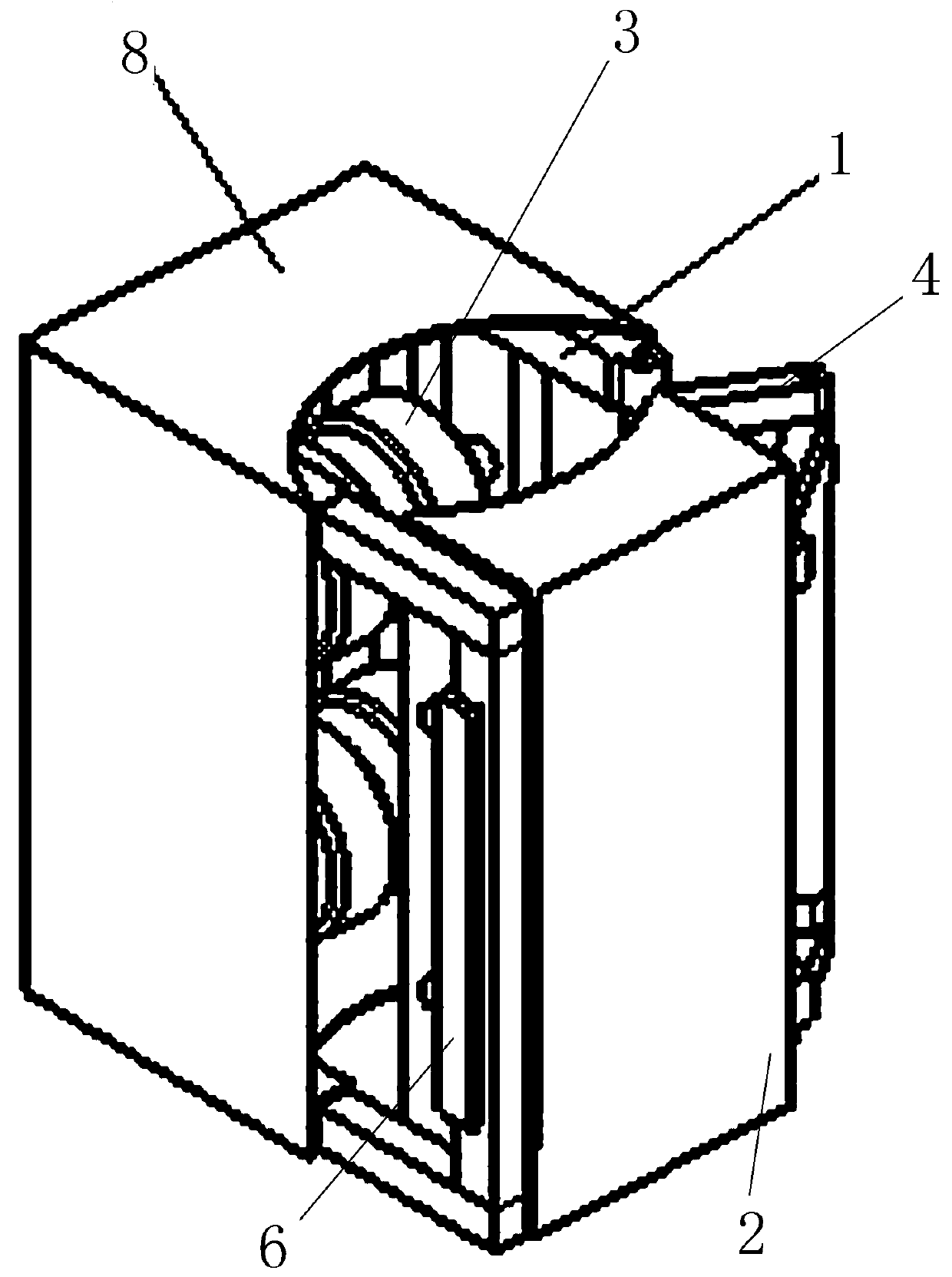

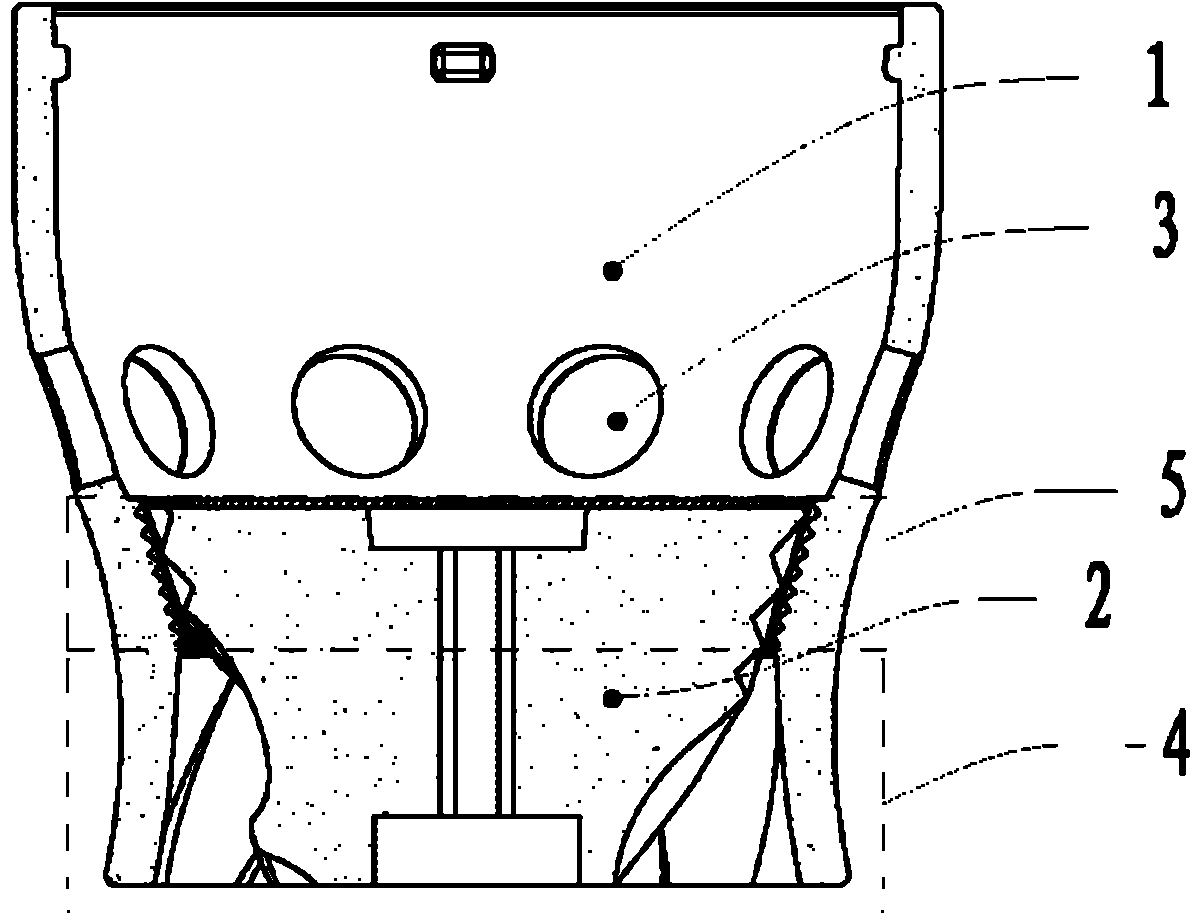

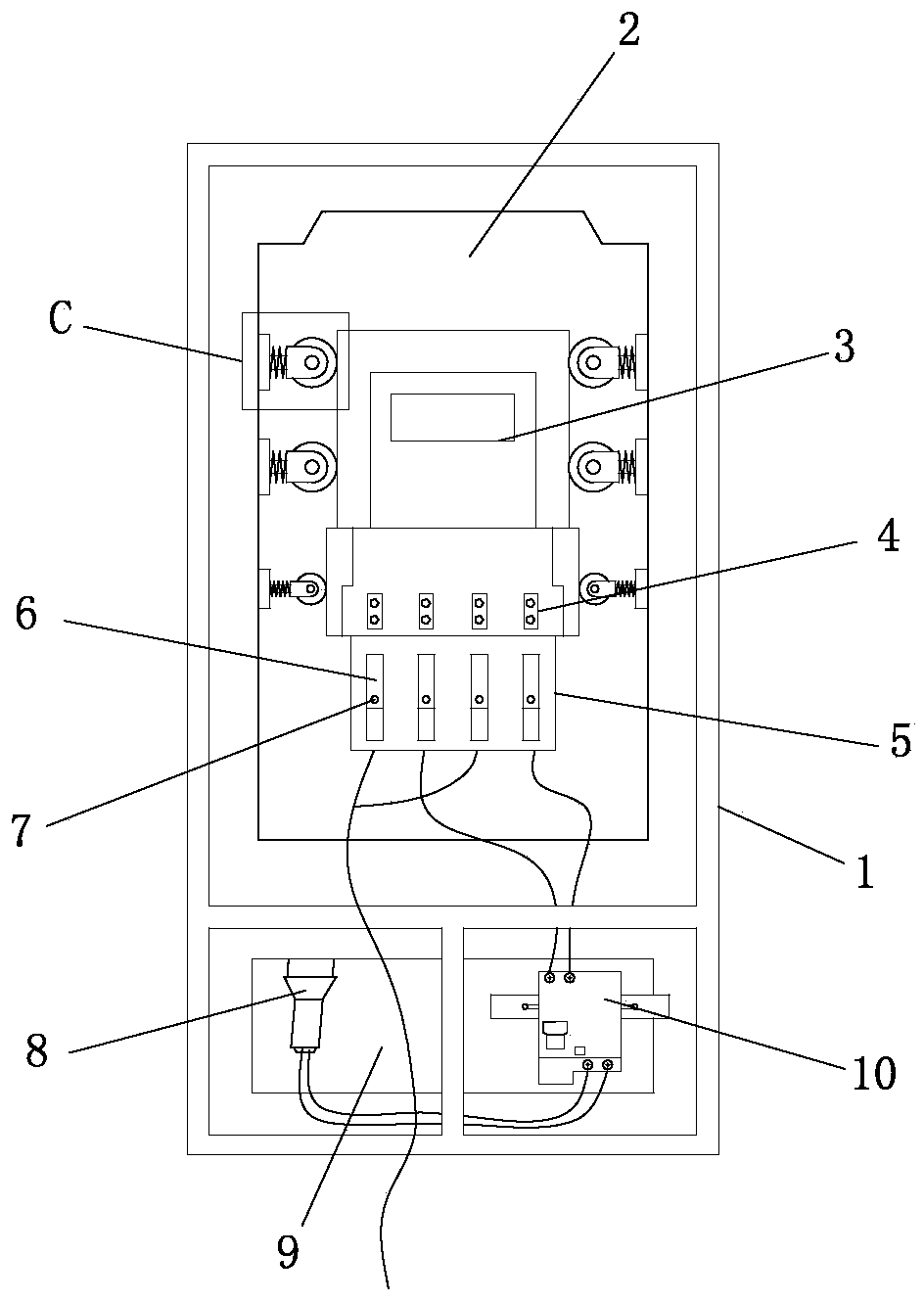

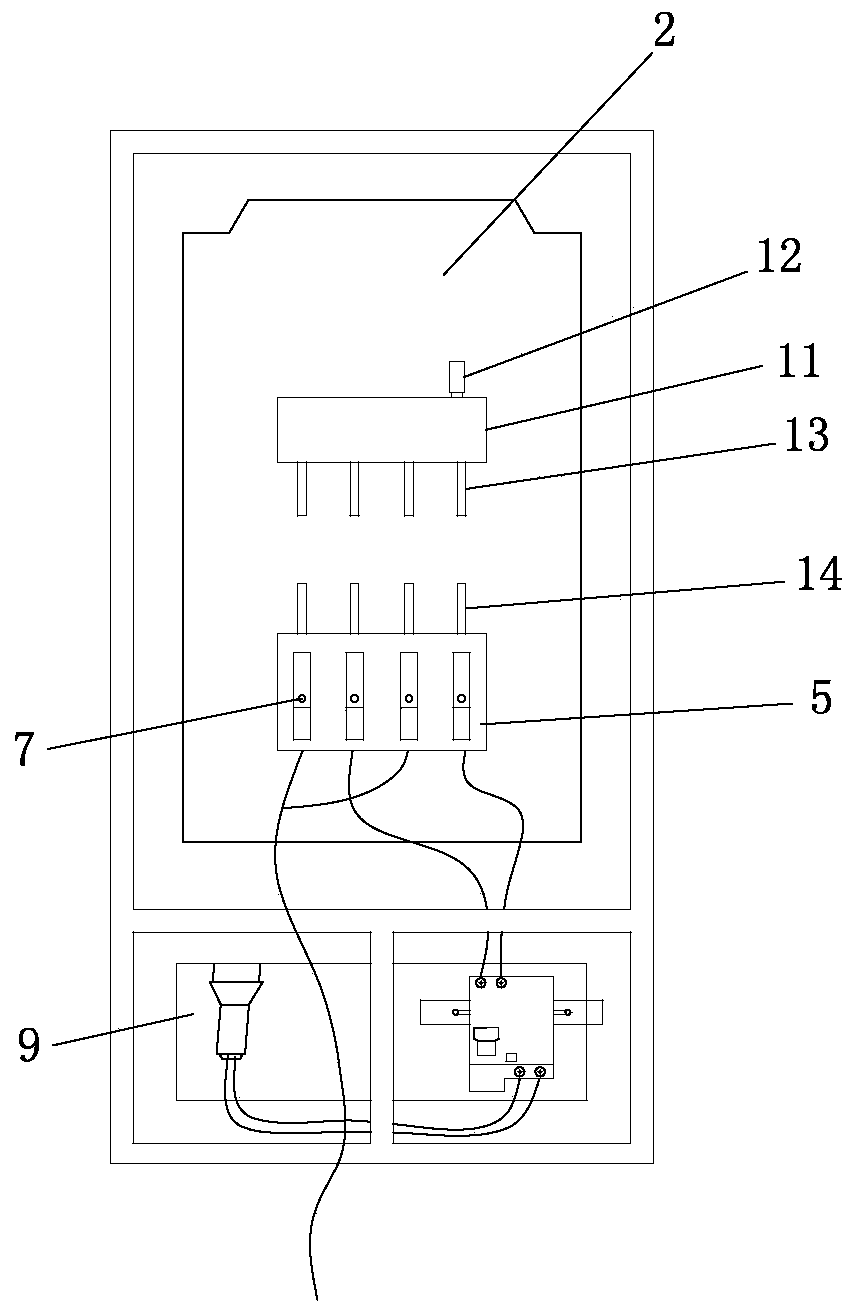

Intelligent control and monitoring system for thoracic / coeliac drainage

InactiveCN107670130AAchieve extrusionFast bindingMedical devicesIntravenous devicesAbdominal cavityMonitoring system

An intelligent control and monitoring system for thoracic / coeliac drainage is composed of a core processor (1), a flow control device (2), a drop counting sensor (3), a pressure sensor (4), a coloridentification sensor (5), a communication module (6), a pipeline squeezing device (8), a radio frequency identification device (9) and a human-computer interaction interface (11). The intelligentcontrol and monitoring system for the thoracic / coeliac drainage not only greatly enhances the safety of the thoracic / coeliac drainage, but also greatly reduces the work strength of nursing and improves the effectiveness of hospital information management.

Owner:XIAN WINZISS MEDICAL GRP CO LTD

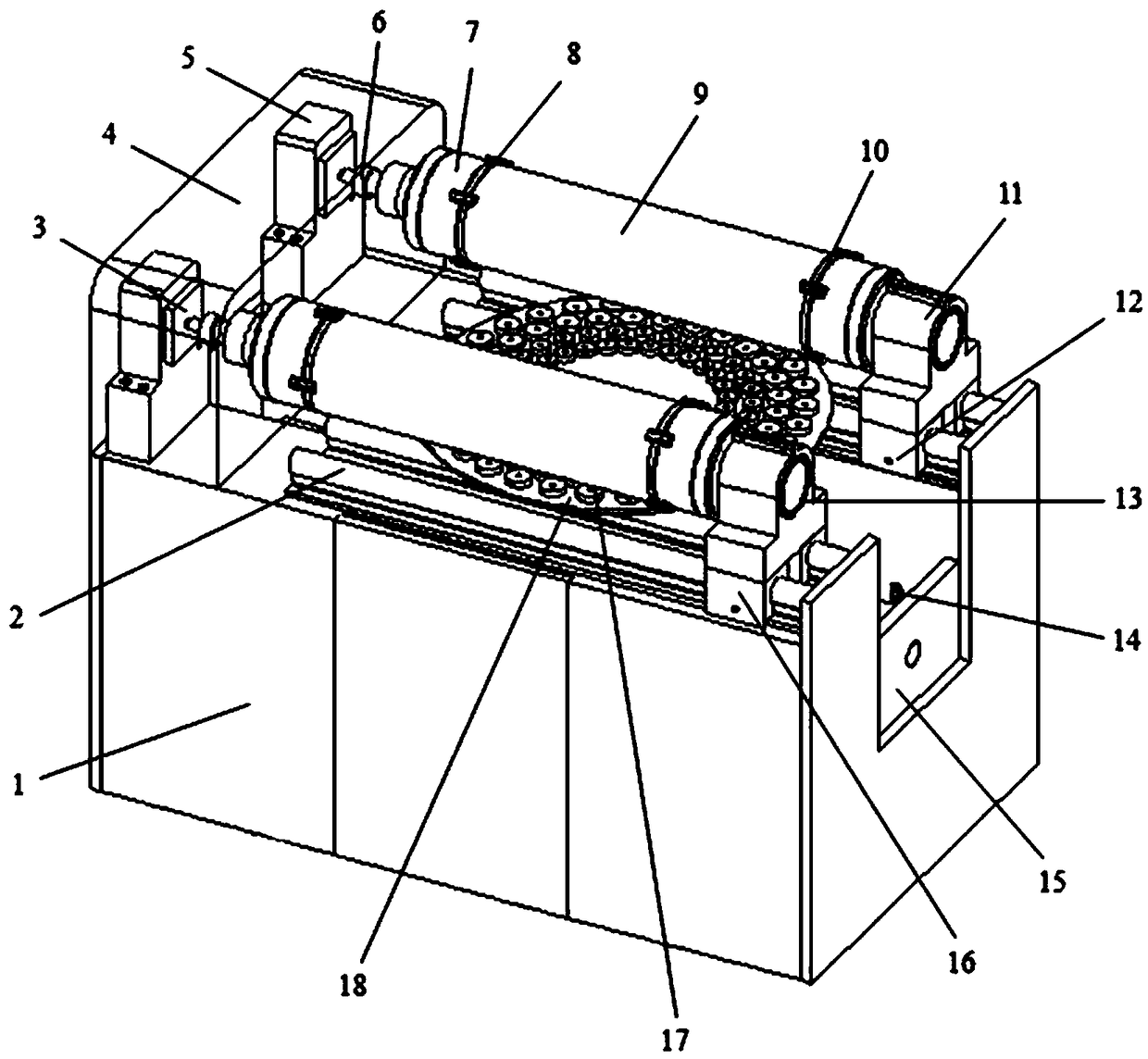

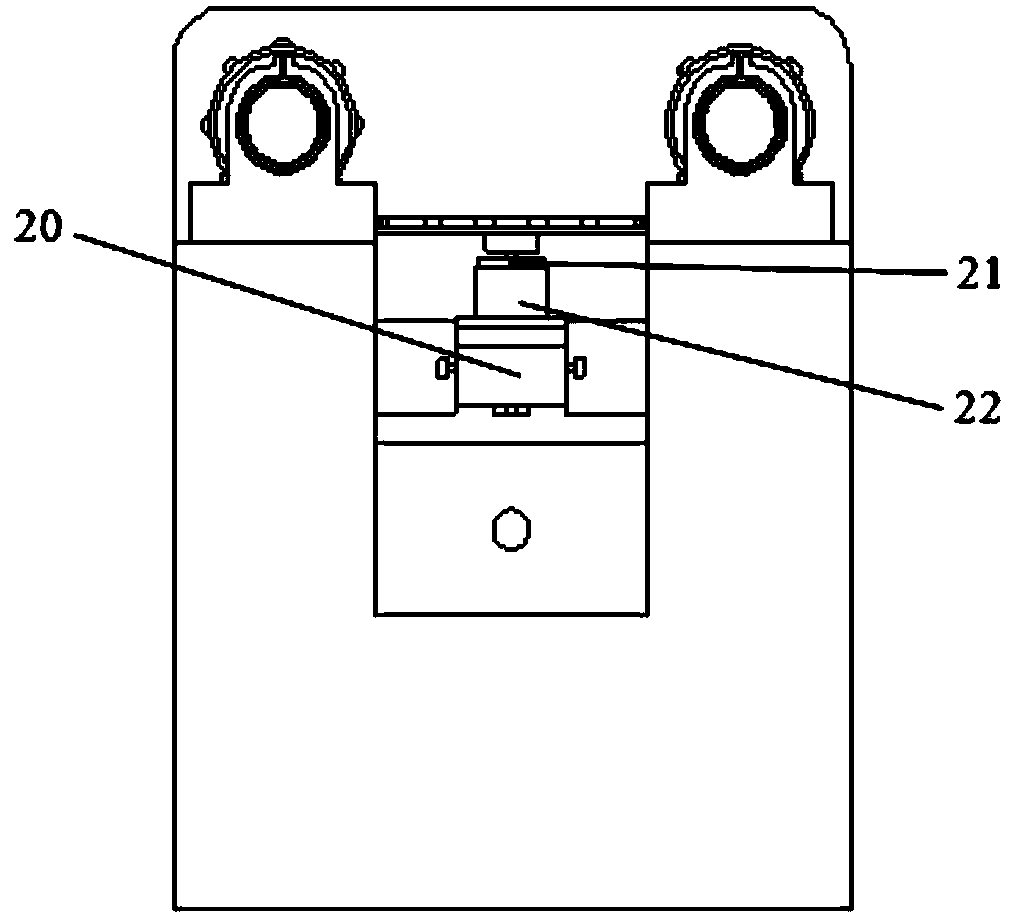

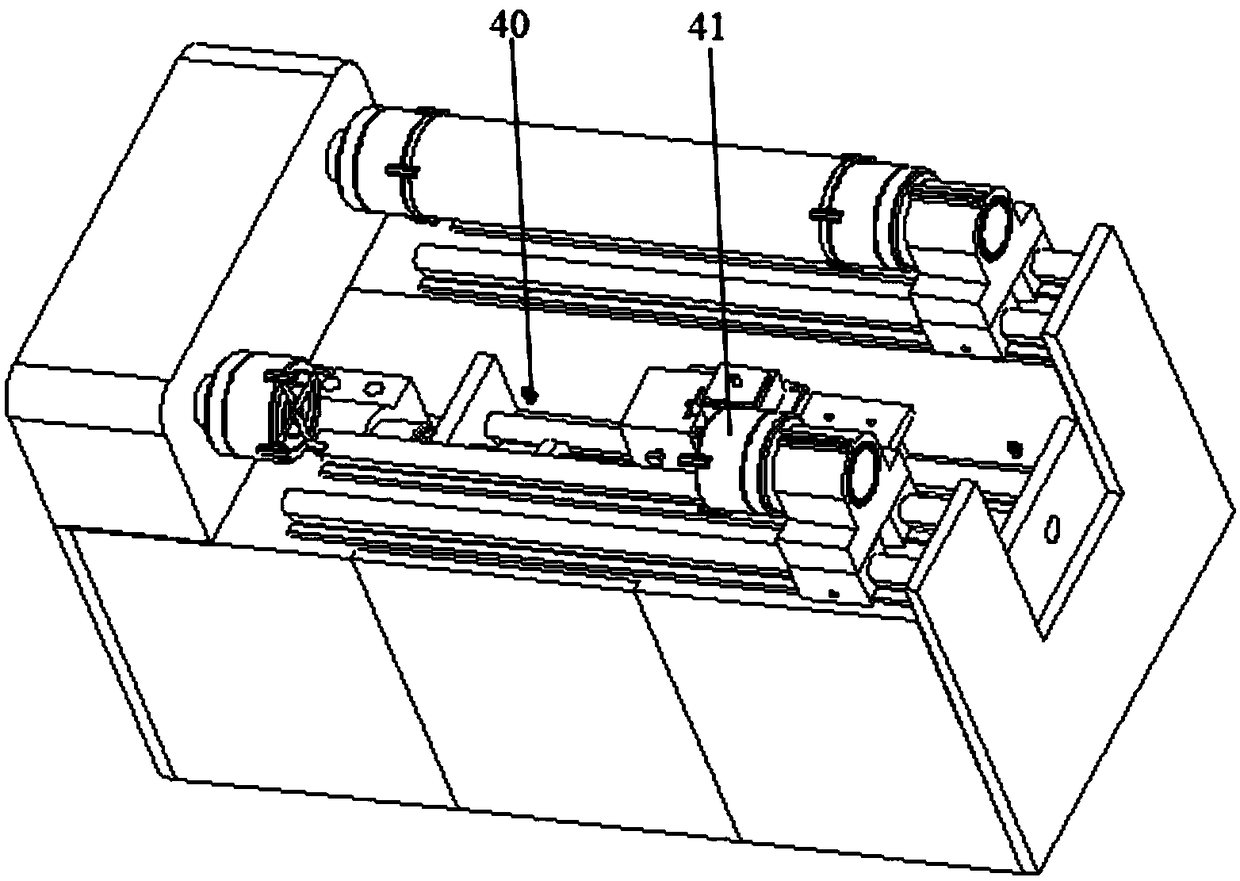

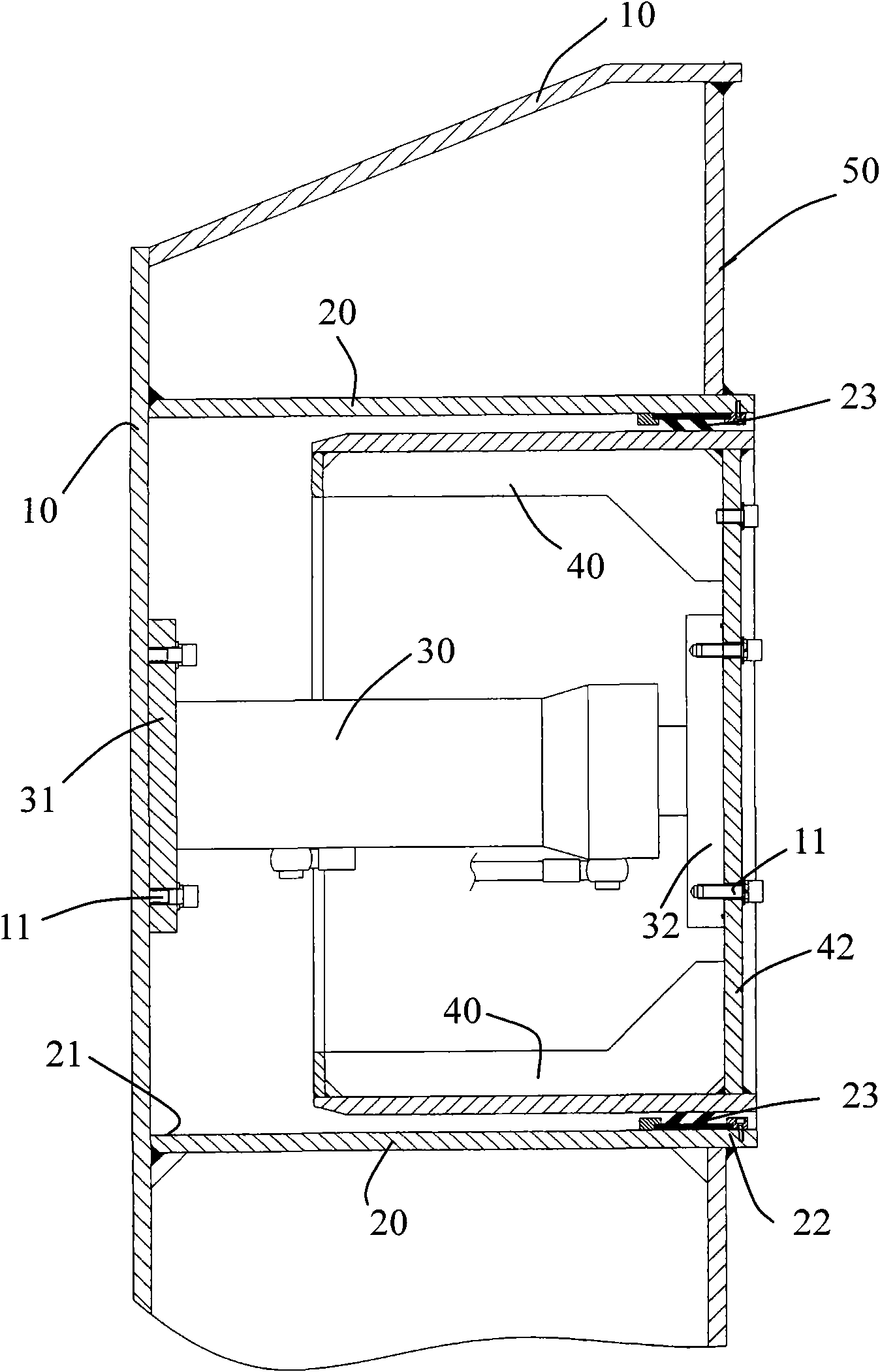

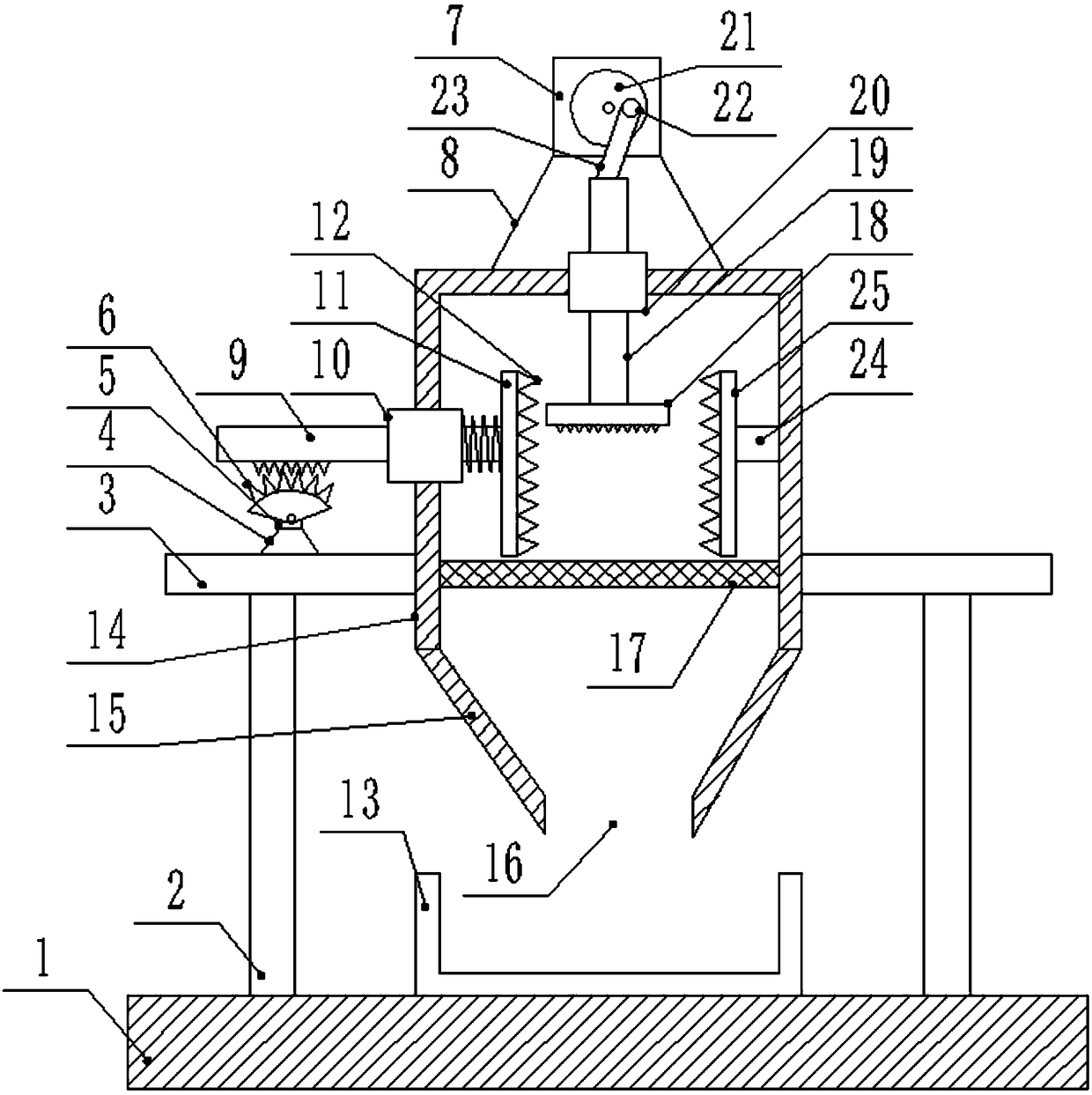

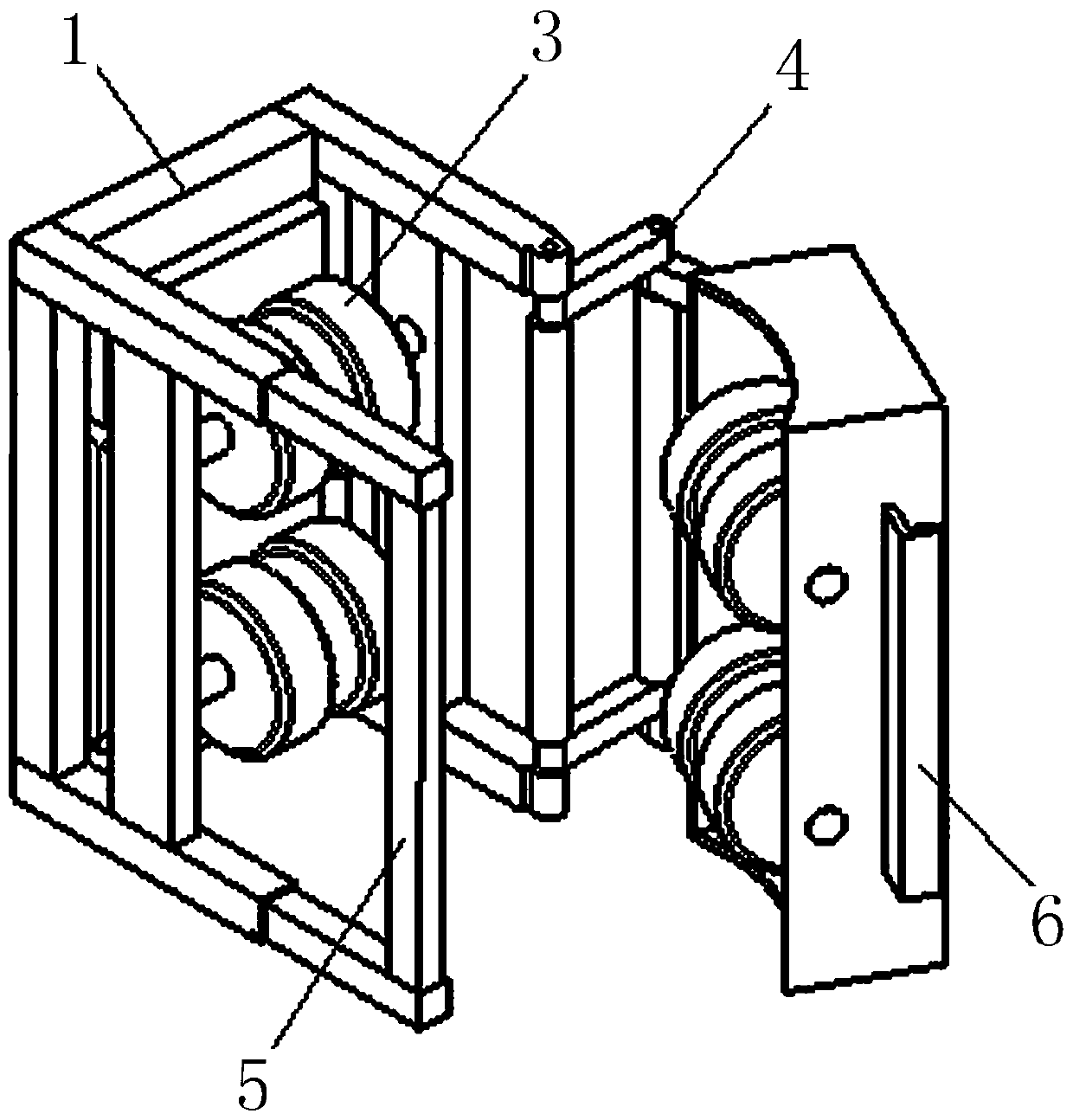

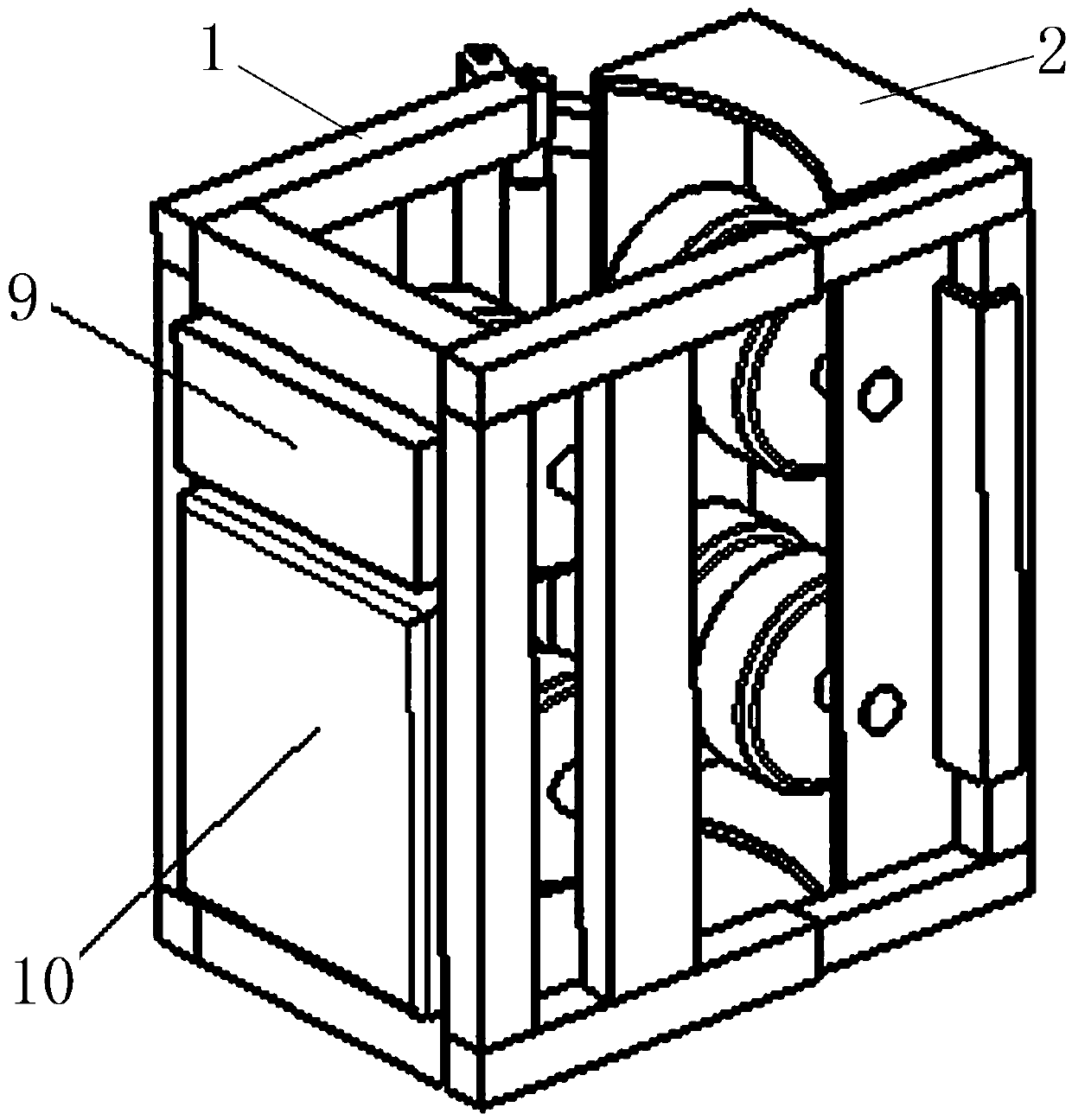

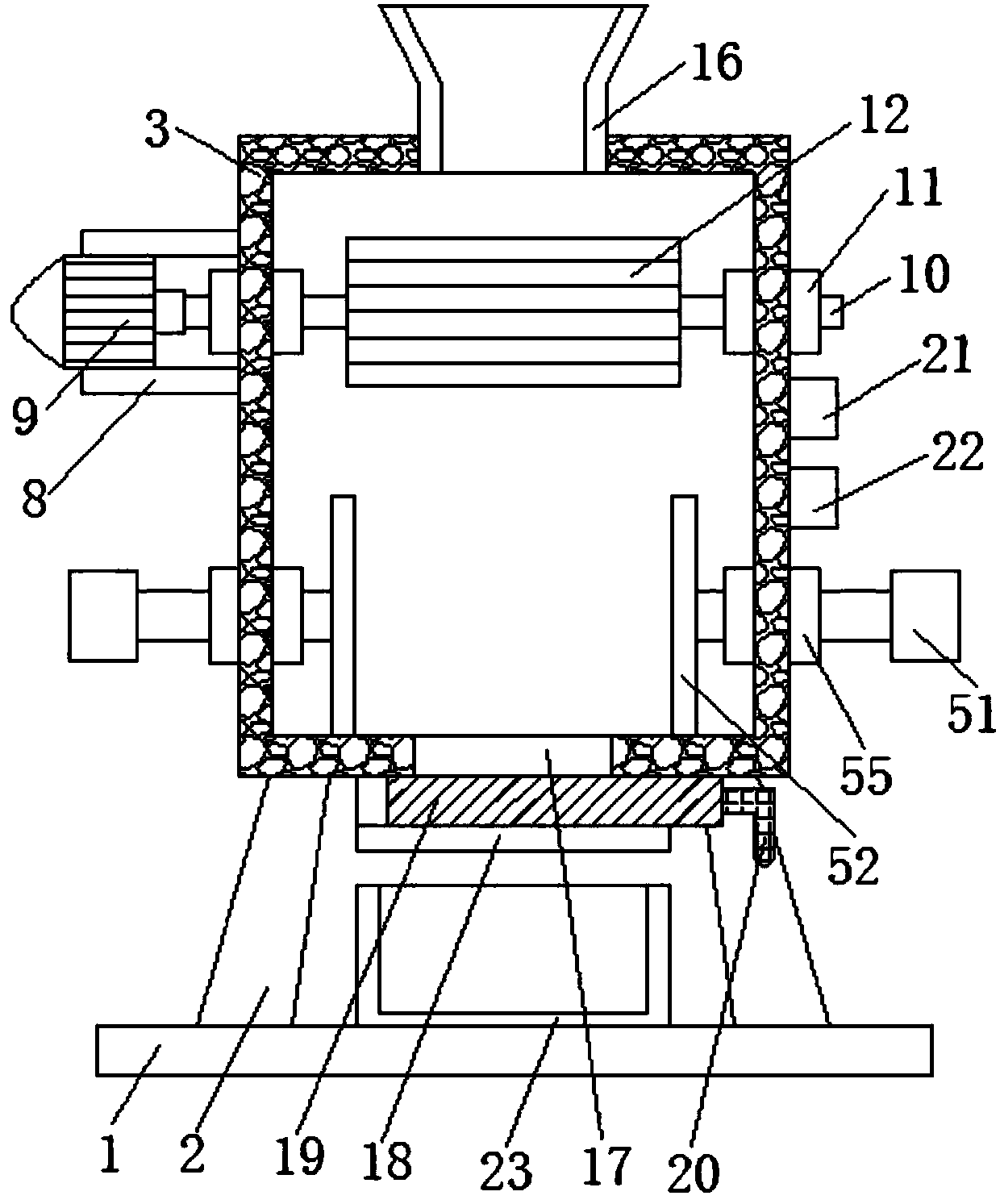

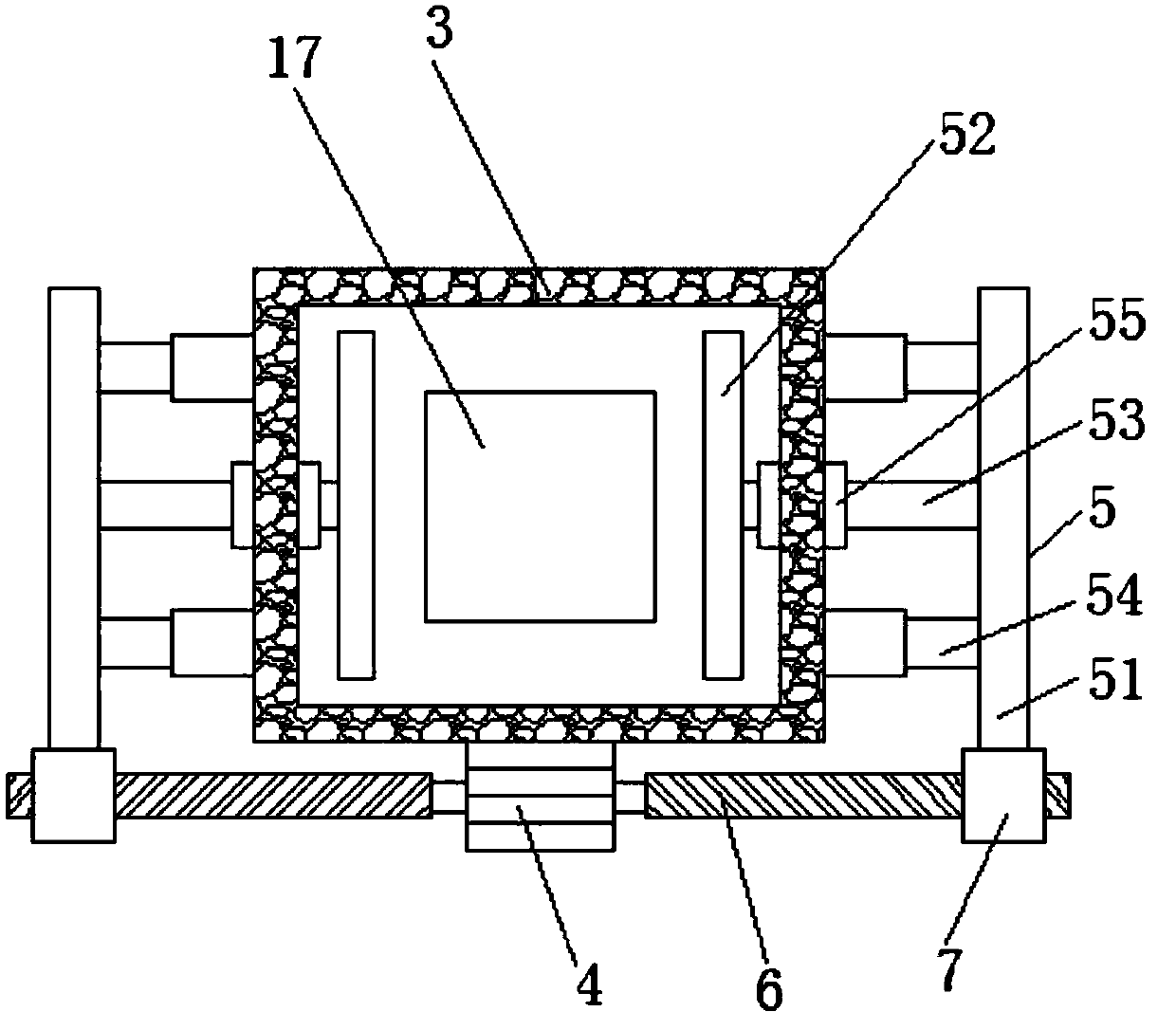

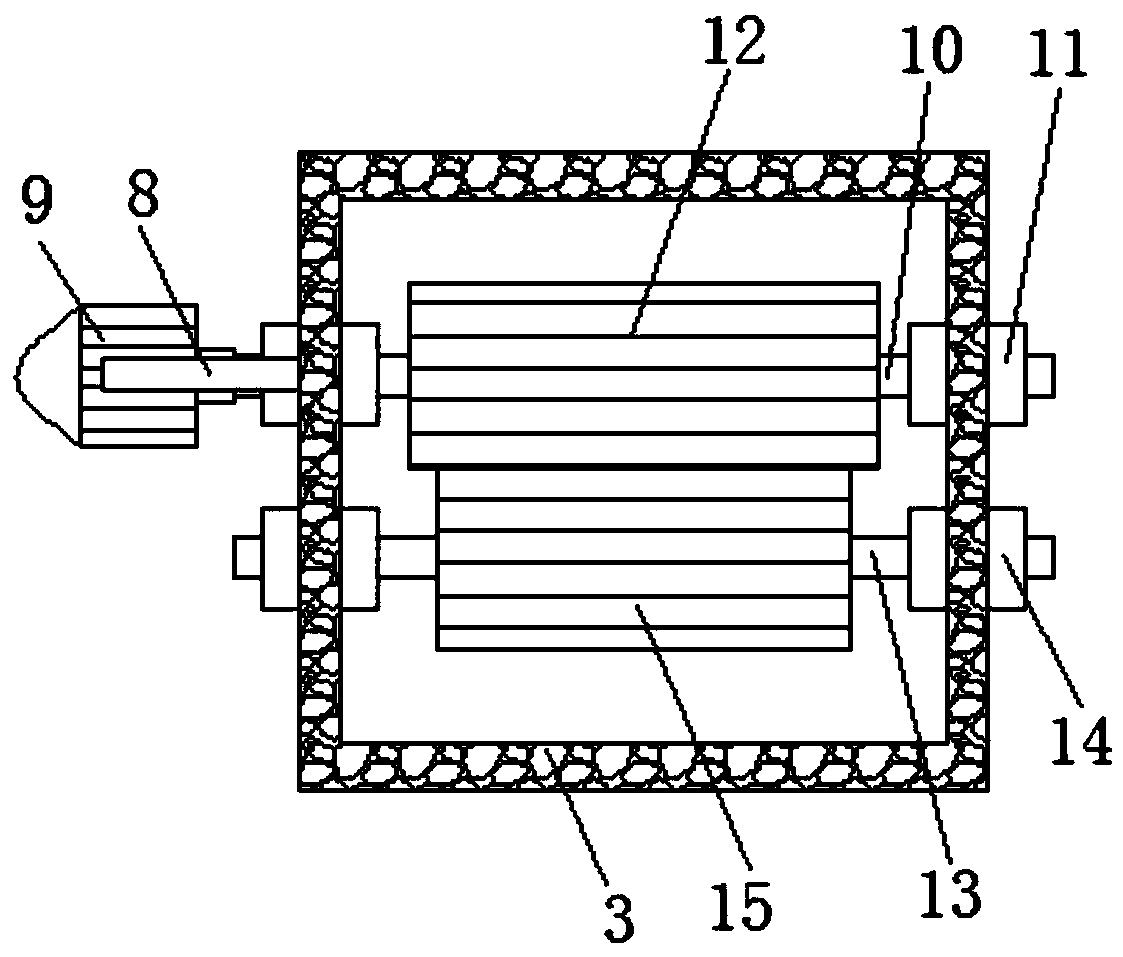

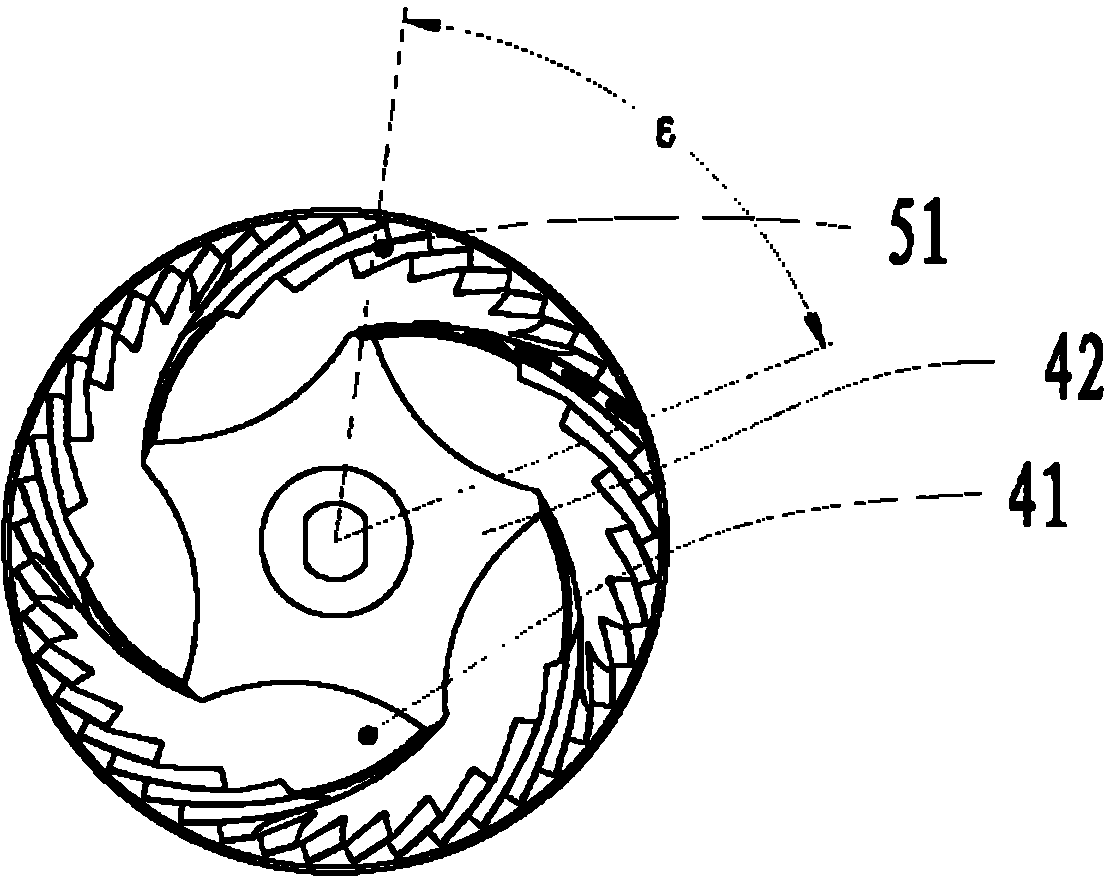

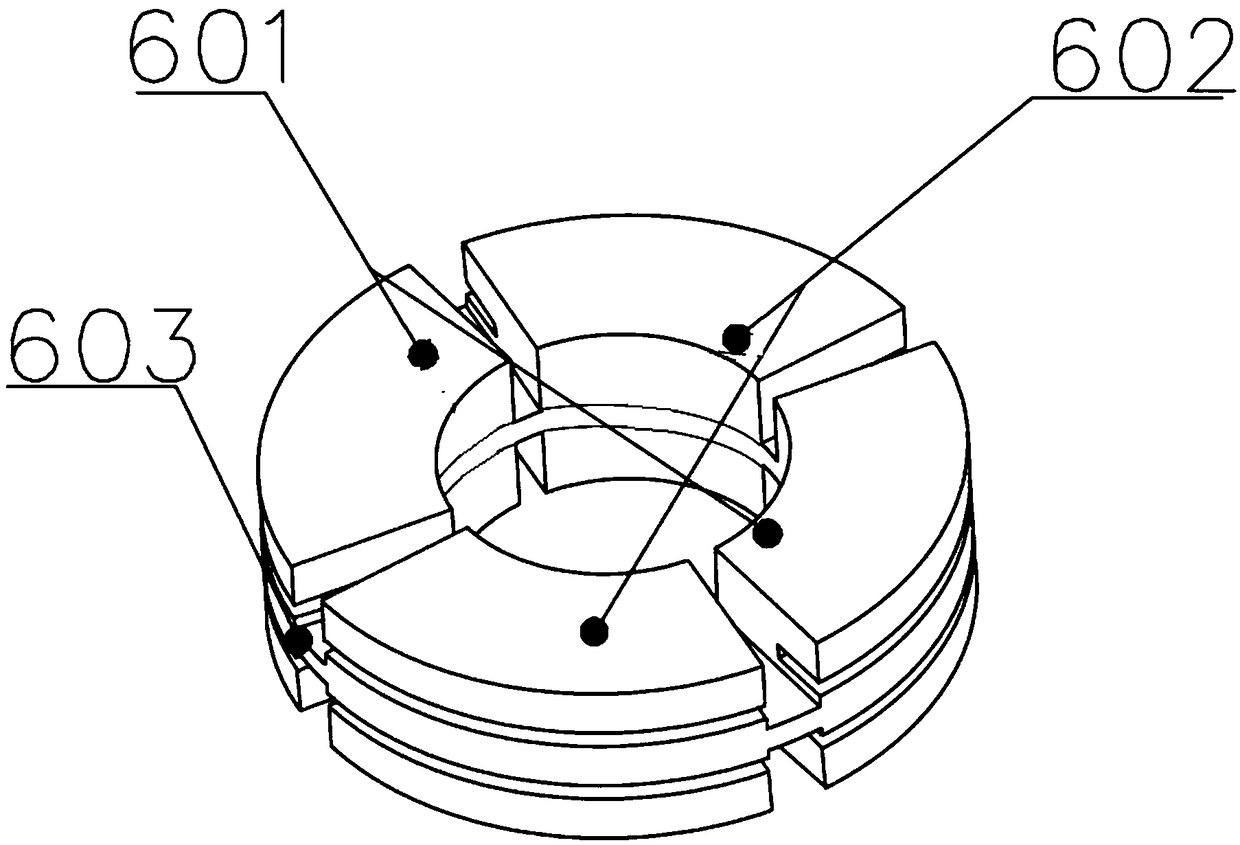

Device and method for magnetically grinding inner surfaces of large-diameter long and straight pipes

PendingCN108857605AHigh degree of automationImprove processing efficiencyEdge grinding machinesPolishing machinesMotor driveMachining

The invention relates to a device and a method for magnetically grinding the inner surfaces of large-diameter long and straight pipes. The device comprises a bed, spindle motors, couplings, a magneticpole disc, a motor driving slide rail device and a hoisting device. Two ends of each pipe fitting can be sealed by pipe fitting plugs and are fixed by the aid of four-jaw chucks, the four-jaw chuck at one end of each pipe fitting is connected with the corresponding spindle motor by the corresponding coupling, the four-jaw chuck at the other end of each pipe fitting is connected with a support seat by bearings, support seat slide rails are fixed onto the bed, and the support seats are slidably connected with the support seat slide rails by support seat sliders; the motor driving slide rail device is arranged at the bottom of the bed, and the magnetic pole disc is connected with the motor driving slide rail device by the hoisting device, can be lifted under the control of the hoisting device and can axially move along the pipe fittings under the control of the motor driving slide rail device. The device and the method have the advantages that finish machining can be carried out on the inner surfaces of the pipe fittings by the aid of magnetic grinding processes, and carbon deposits, oil stain and rust stain which are accumulated at grooves inside the pipe fittings can be effectivelyremoved by the aid of the device and the method.

Owner:UNIV OF SCI & TECH LIAONING

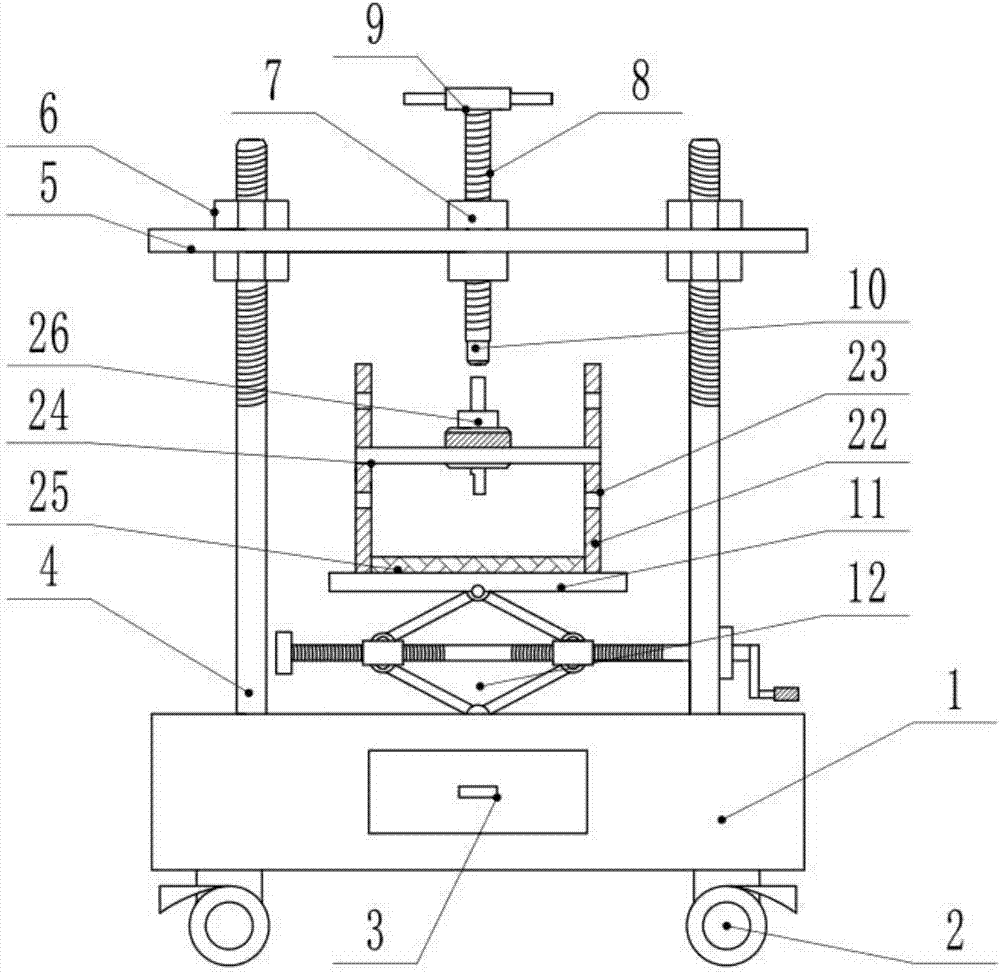

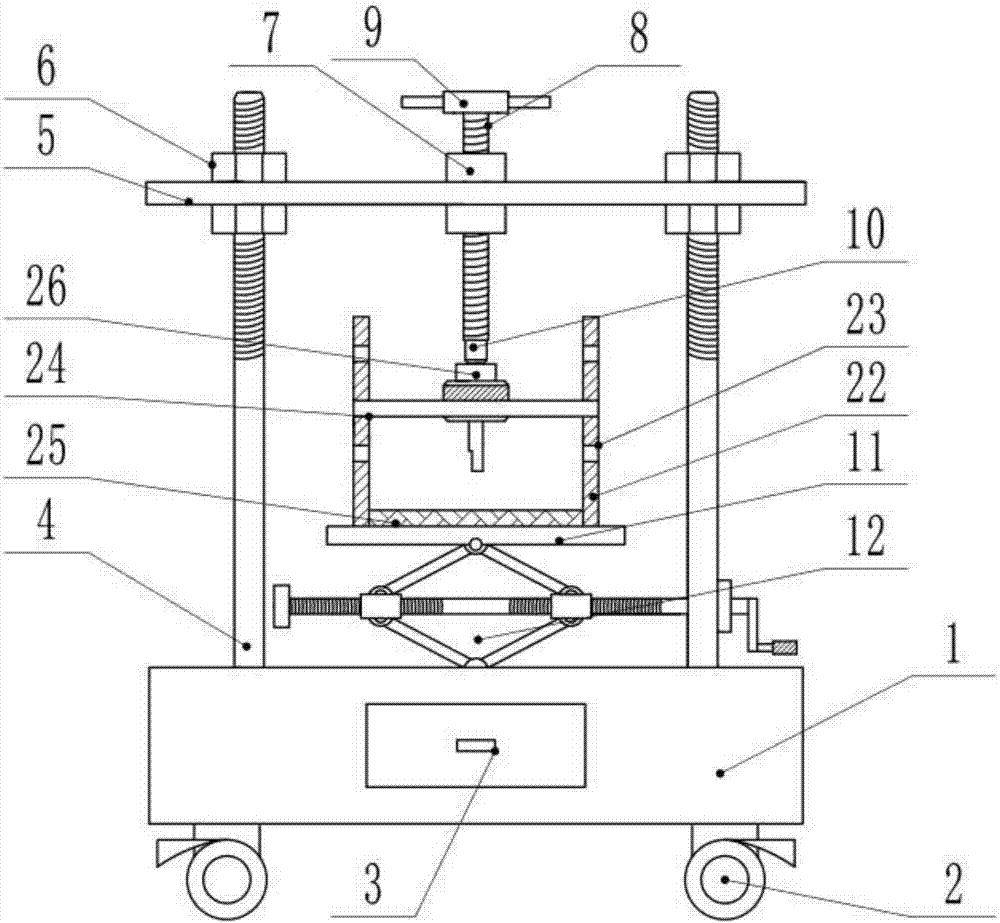

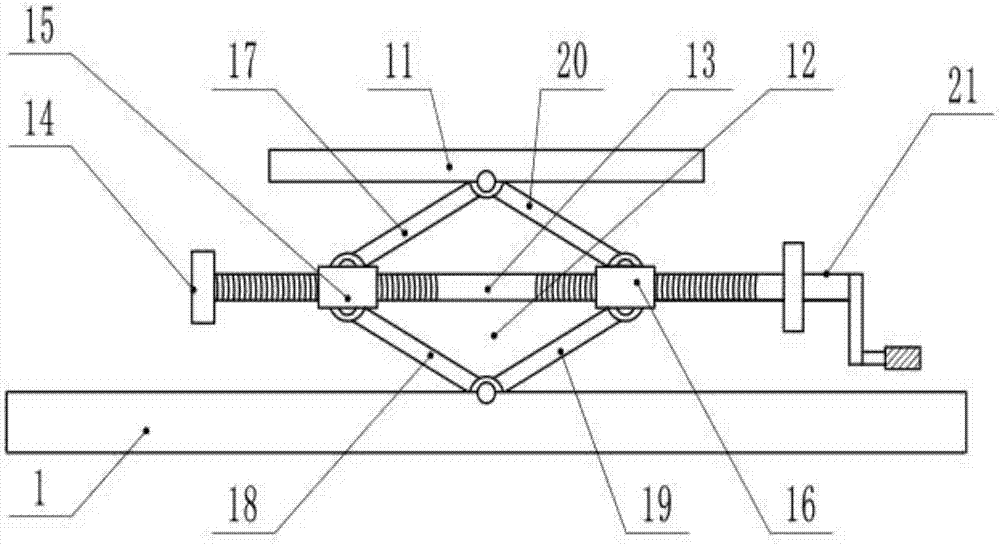

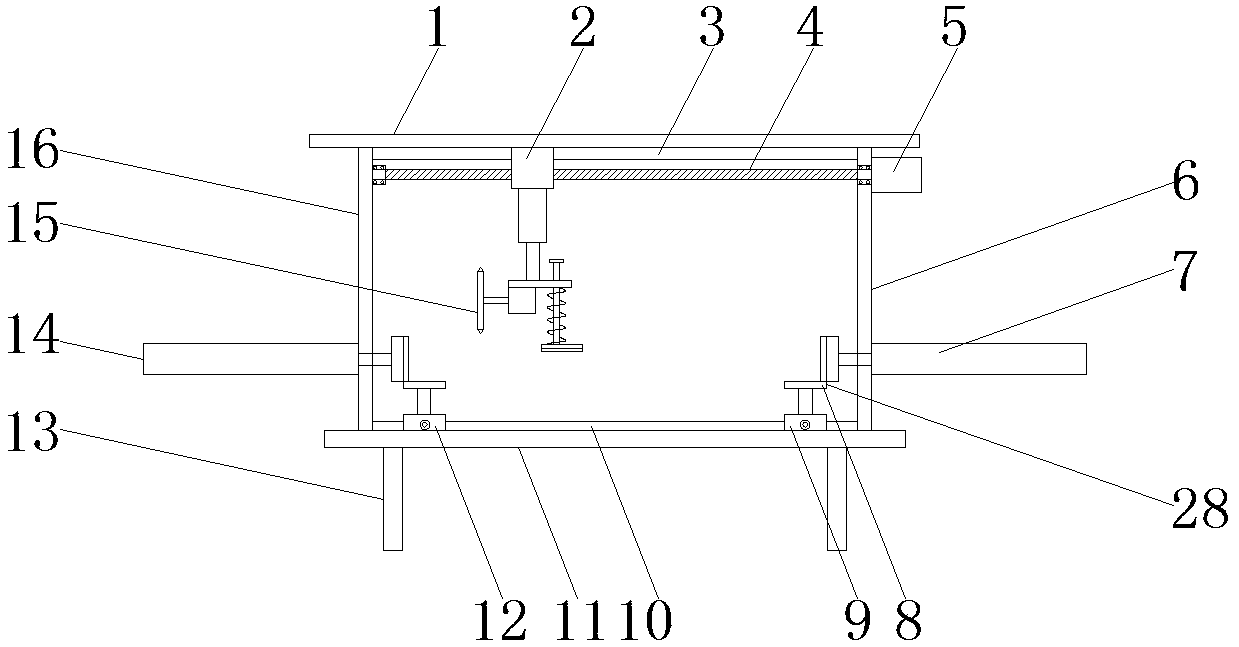

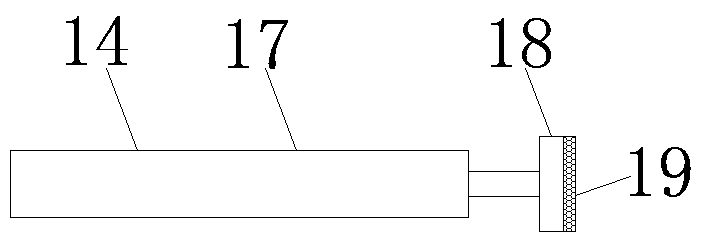

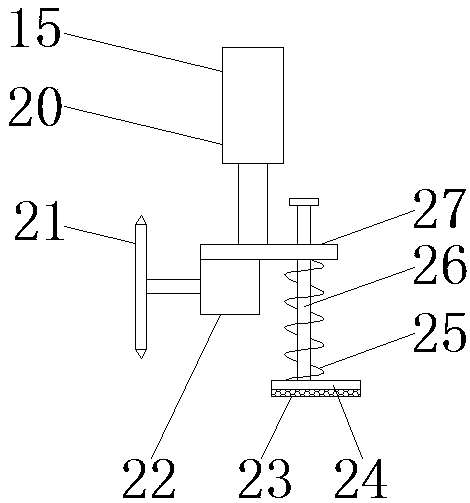

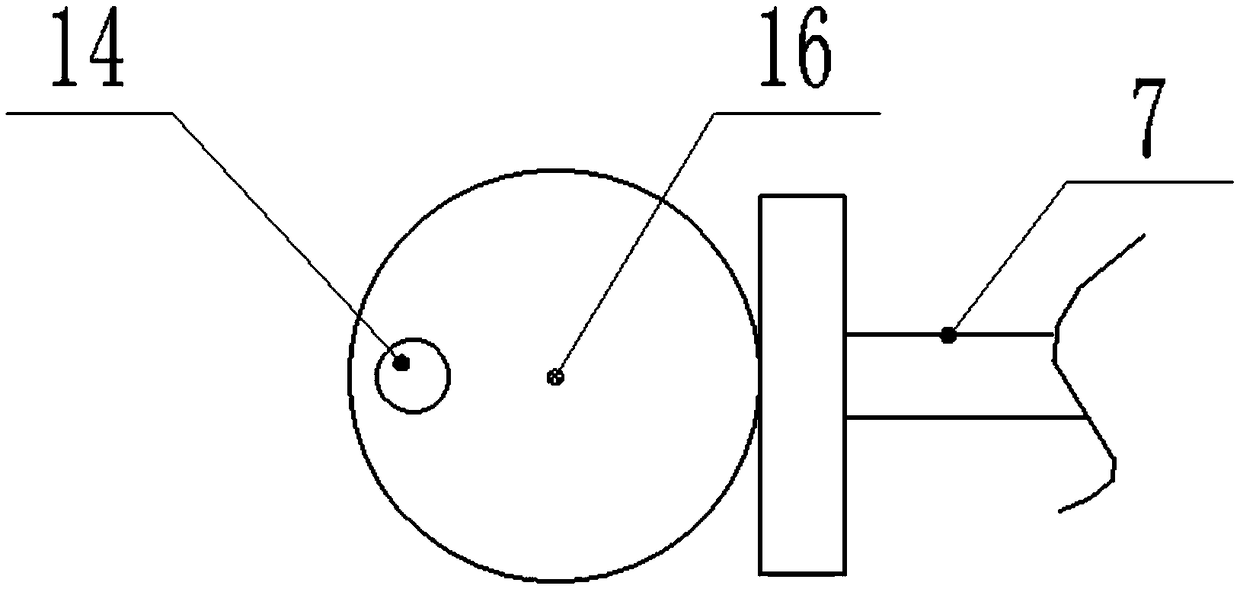

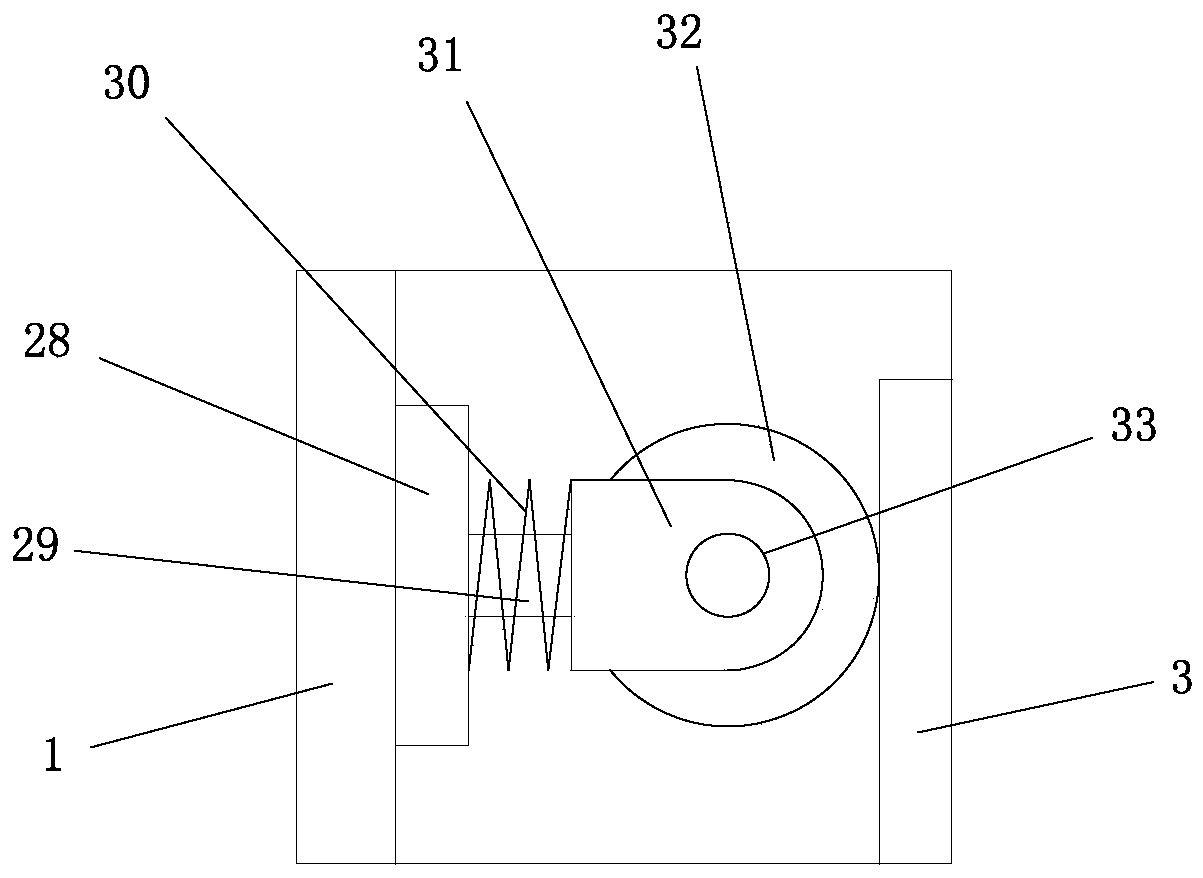

Shaft entering and withdrawing dual-purpose device for plastic packaging motor rotor

InactiveCN107104563AAvoid frequent replacementPrevent crushingCentering/balancing rotorsPlastic packagingIndustrial engineering

The invention discloses a shaft entering and withdrawing dual-purpose device for a plastic packaging motor rotor. The shaft entering and withdrawing dual-purpose device comprises a machine table, a tool box, an adjustment screw rod, a supporting plate, a lead screw A, a rotary handle, an extrusion head, a lifting platform, a lifting device, a fixed frame and a pressure nozzle; a lead screw sleeve is fixedly arranged at a central position of the supporting plate; the lead screw A is in screw connection inside the lead screw sleeve; the rotary handle is fixedly arranged at an upper end of the lead screw A, and the extrusion head is fixedly arranged at a lower end of the lead screw A; the lifting device is fixedly arranged on the machine table; a plurality of groups of limiting grooves are formed at two sides of the fixed frame; and limiting plates are arranged on the limiting groove in an insertion manner. According to the device, under the condition of not replacing equipment, the shaft entering and withdrawing work are performed, and the repair personnel is prevented from frequently replacing the equipment; and meanwhile, through the rotary handle, the lead screw moves downward to implement extrusion on a rotating shaft, so compared with manual shaft withdrawing, the device is more time-saving and labor-saving; and the lifting platform is provided such that the repair personnel can perform the shaft entering and withdrawing work on different lengths of the rotating shafts conveniently.

Owner:CHANGSHA WUDAO IND DESIGN CO LTD

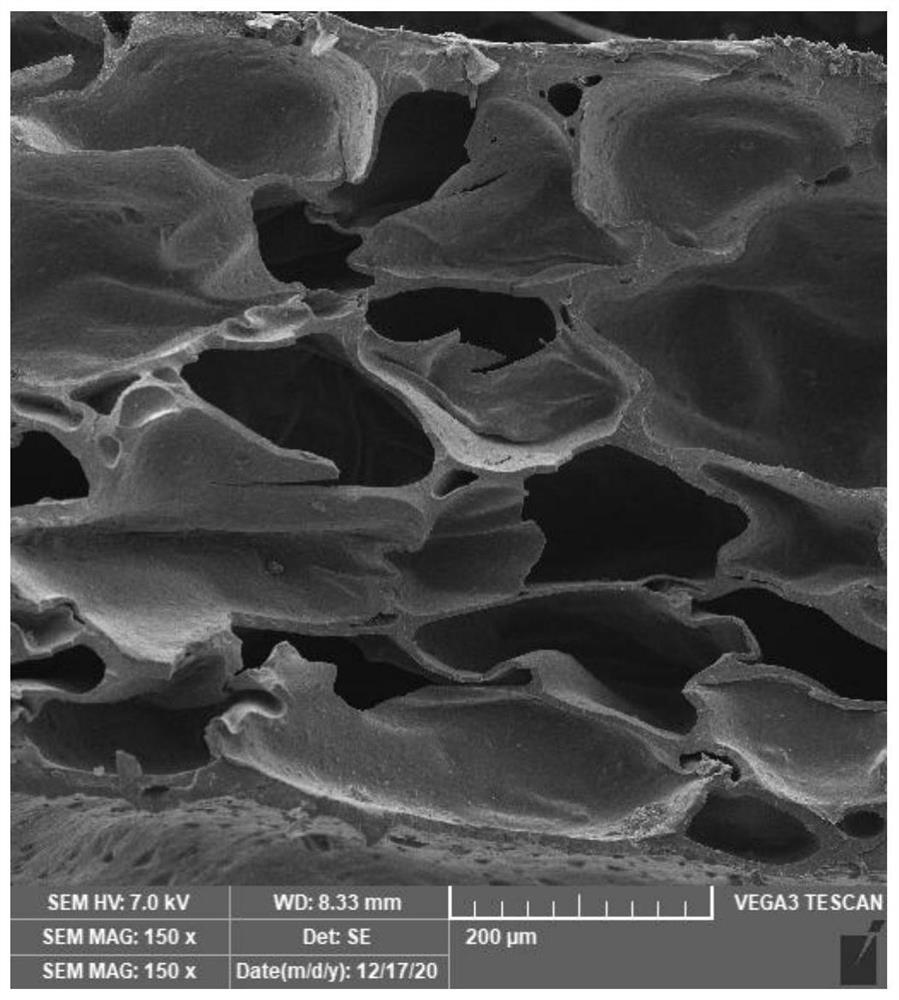

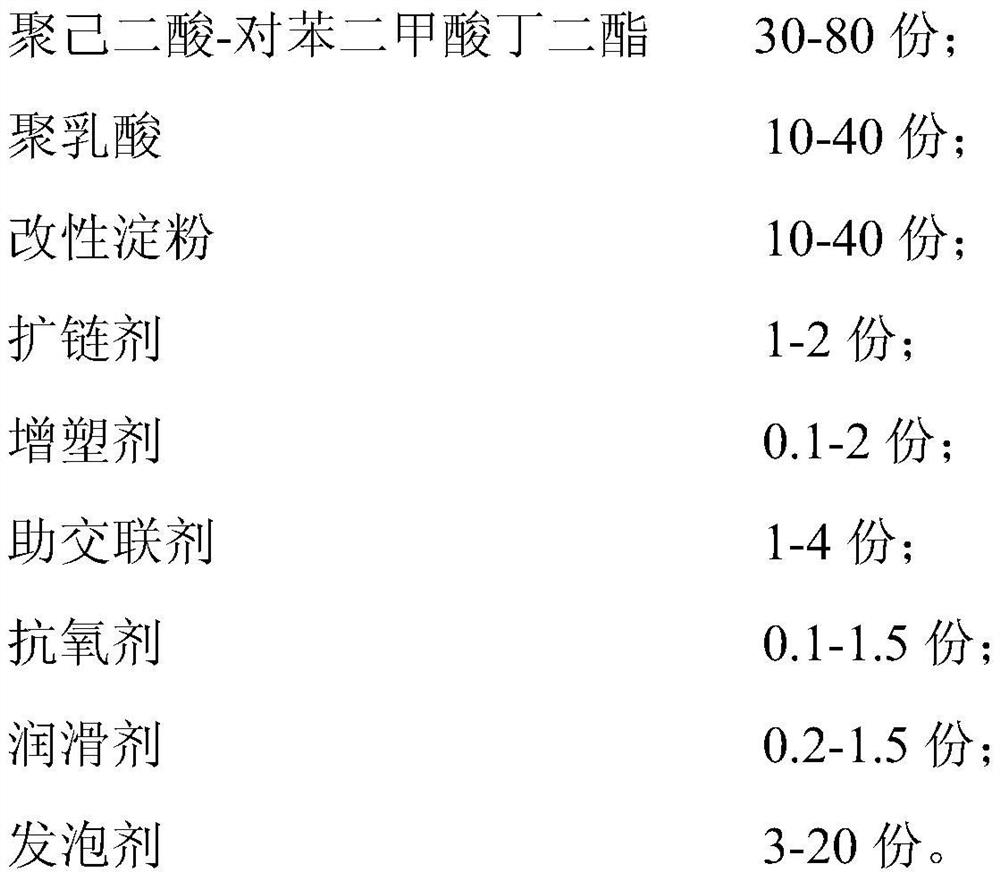

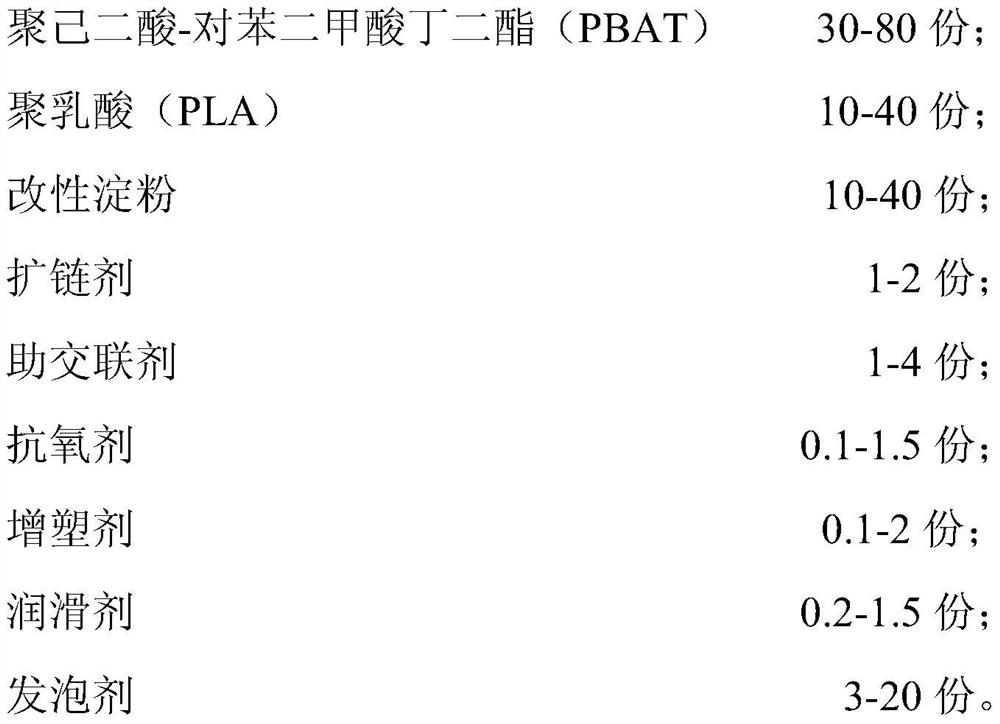

Degradable foaming material and preparation method thereof

The invention relates to the technical field of foaming materials, and discloses a degradable foaming material and a preparation method thereof. The degradable foaming material is prepared from, by mass, 30-80 parts of poly(butylene adipate-co-terephthalate); 10-40 parts of polylactic acid; 10-40 parts of modified starch; 1-2 parts of a chain extender; 0.1-2 parts of a plasticizer; 1-4 parts of an assistant crosslinker; 0.1-1.5 parts of an antioxidant; 0.1-1.5 parts of a lubricant and 3-20 parts of a foaming agent. By blending and modifying PLA through PBAT, on one hand, the melting point of PLA can be remarkably reduced, the melt extrusion temperature during subsequent coiled material extrusion is further reduced, decomposition of a chemical foaming agent is inhibited, and decomposition of the foaming agent is completely controlled in the foaming stage of a high-temperature foaming furnace; and on the other hand, the advantages and disadvantages of PBAT and PLA materials are combined, and the degradable foaming material with excellent ductility, tensile strength and comprehensive performance is obtained.

Owner:ZHEJIANG UNIV OF TECH

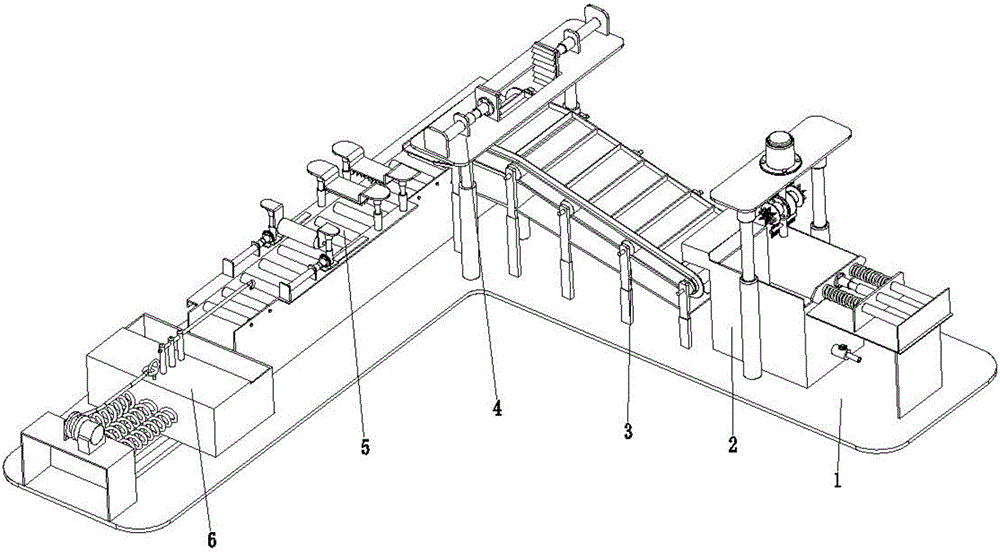

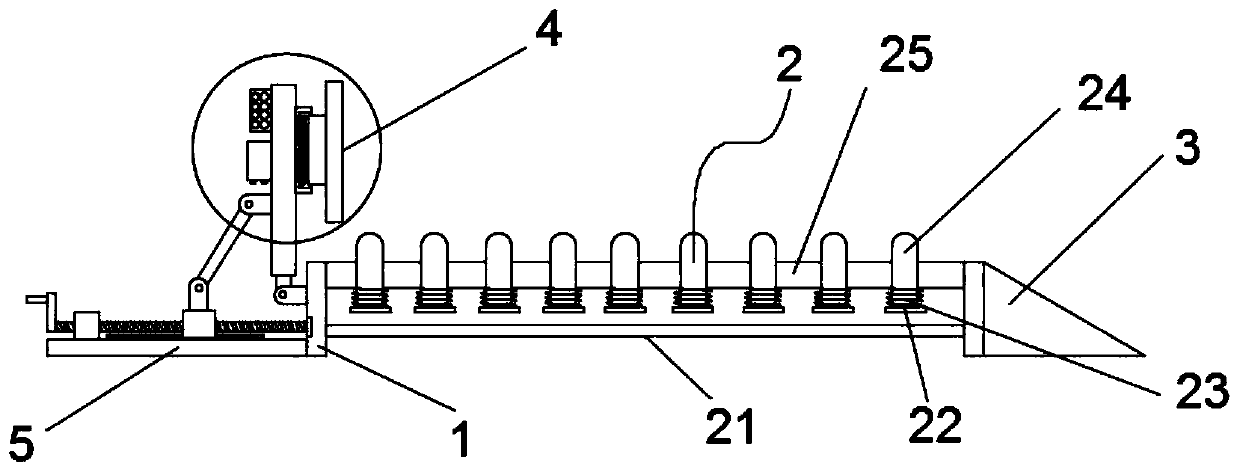

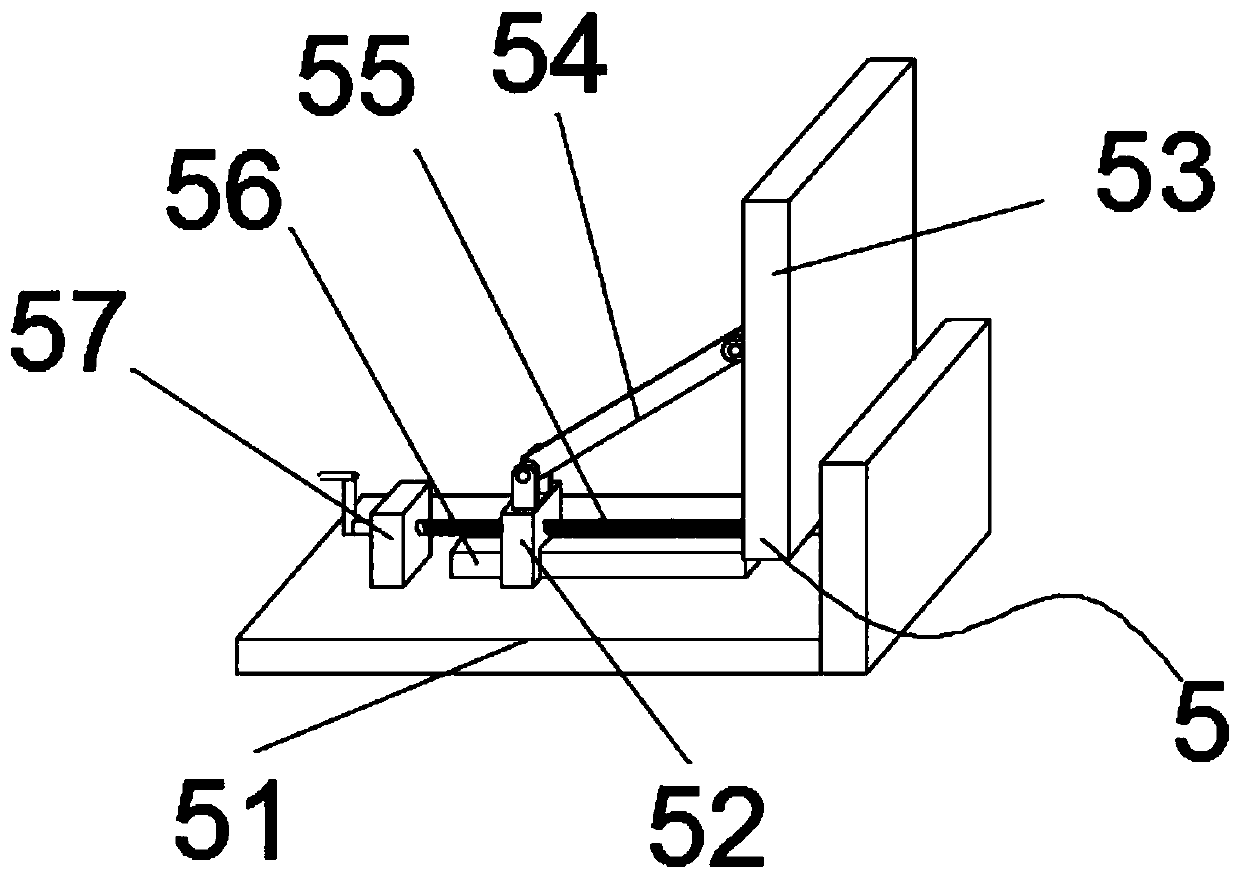

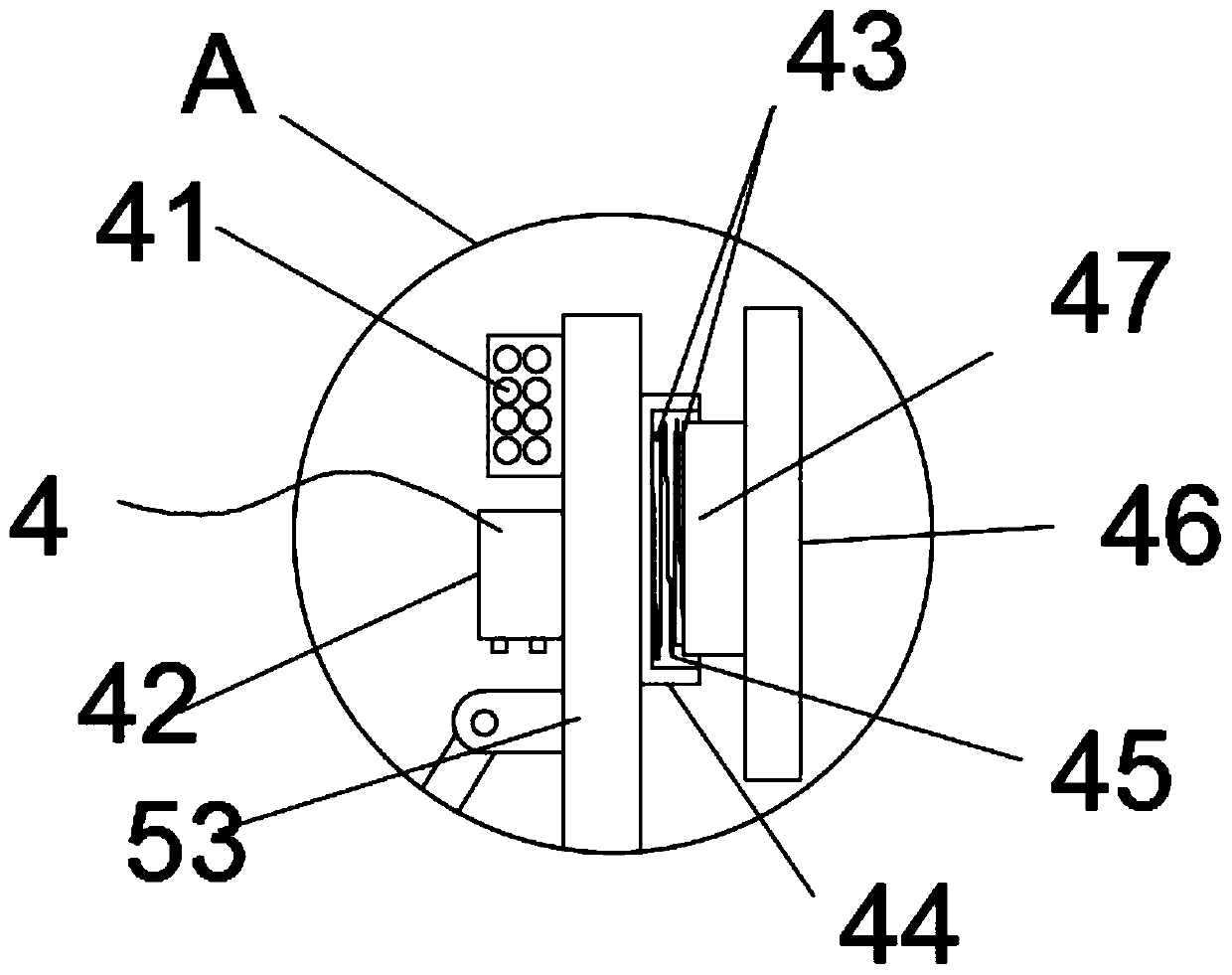

Environment-friendly recycling treatment system for waste plastic bottles

ActiveCN106608004AAvoid pollutionProtect the ecologyPlastic recyclingMechanical material recoveryPollutionMechanization

The invention relates to an environment-friendly recycling treatment system for waste plastic bottles. The environment-friendly recycling treatment system comprises a base plate, a cleaning and feeding device, a conveying device, a squeezing device, a crushing device and a storage device. The base plate is of an L-shaped structure. The cleaning and feeding device is located at the front side end of the base plate. The conveying device is located right on the rear portion of the cleaning and feeding device, and the conveying device and the cleaning and feeding device are located on the same straight line. The squeezing device is located at an outlet in the rear side of the conveying device. The crushing device and the conveying device are vertically arranged, and the crushing device is fixedly connected with the base plate. The storage device is installed at the left side of the crushing device. By means of the environment-friendly recycling treatment system, the waste plastic bottles can be cleaned, pushed, fed, conveyed, squeezed, crushed and stored, and the whole recycling treatment of the waste plastic bottles is realized; moreover, the treatment process is high in degree of mechanization, a large number of labor force is saved, and treatment efficiency is improved; and meanwhile, pollution to the environment by the waste plastic bottles is avoided, and the environment and ecology are protected.

Owner:同信生态环境科技有限公司

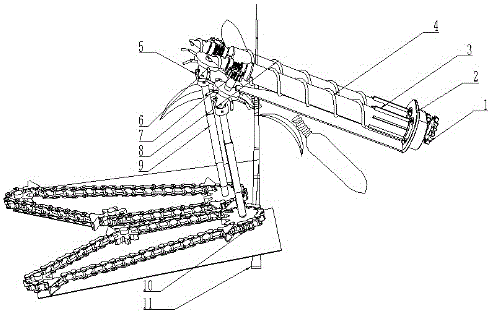

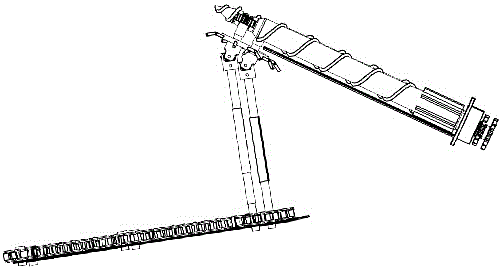

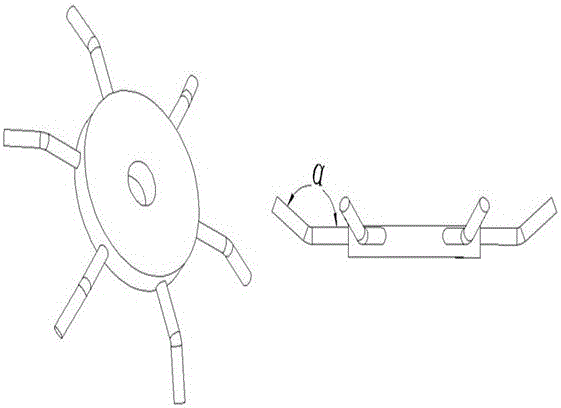

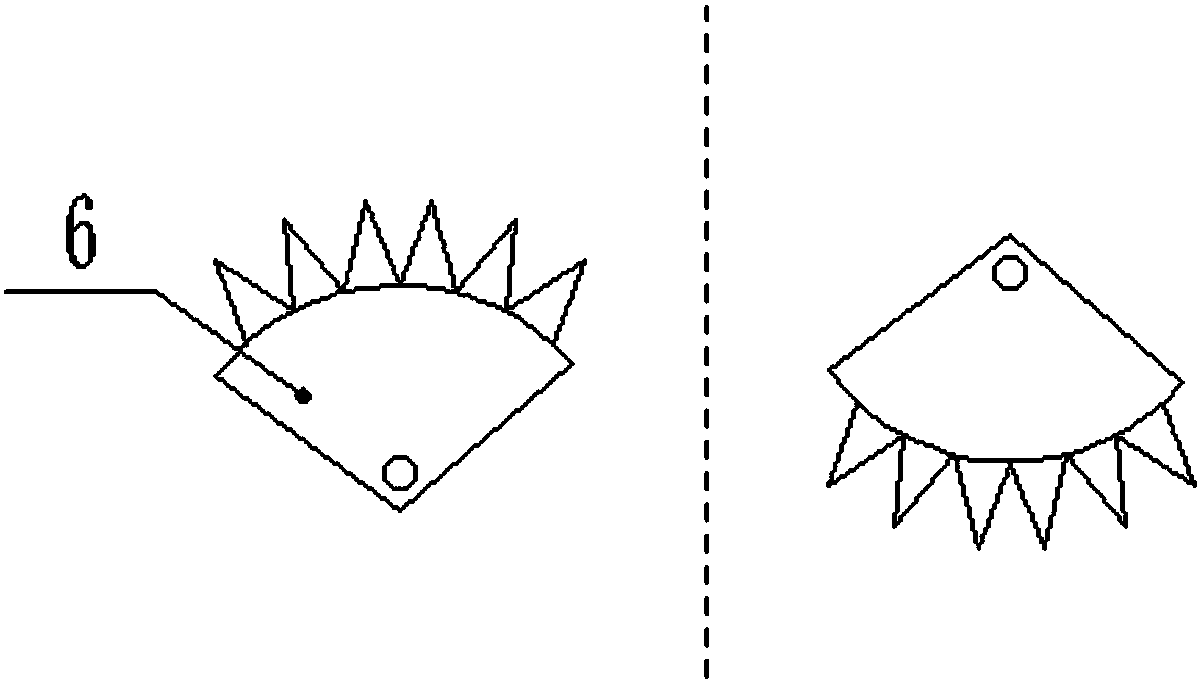

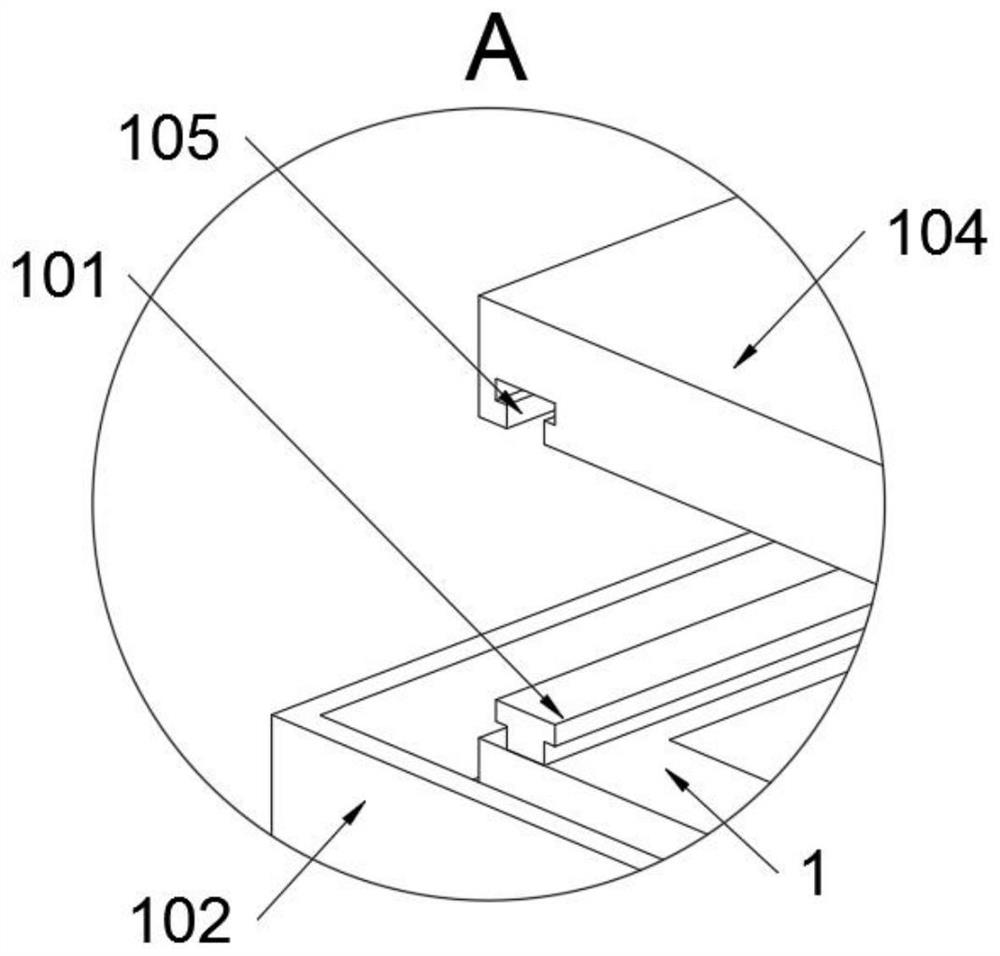

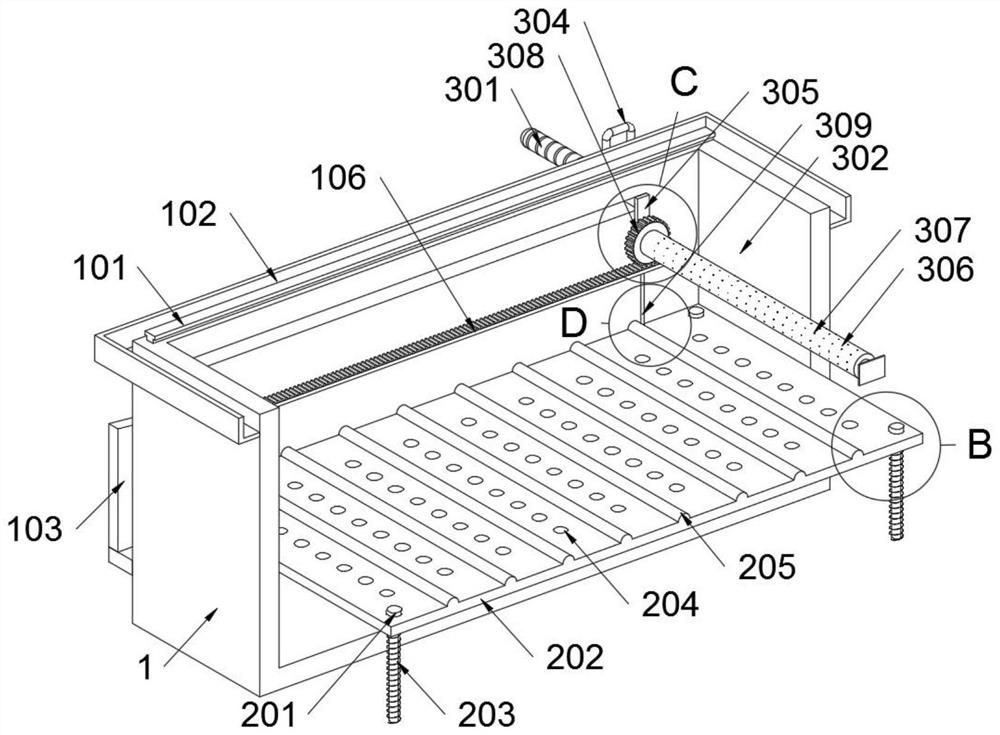

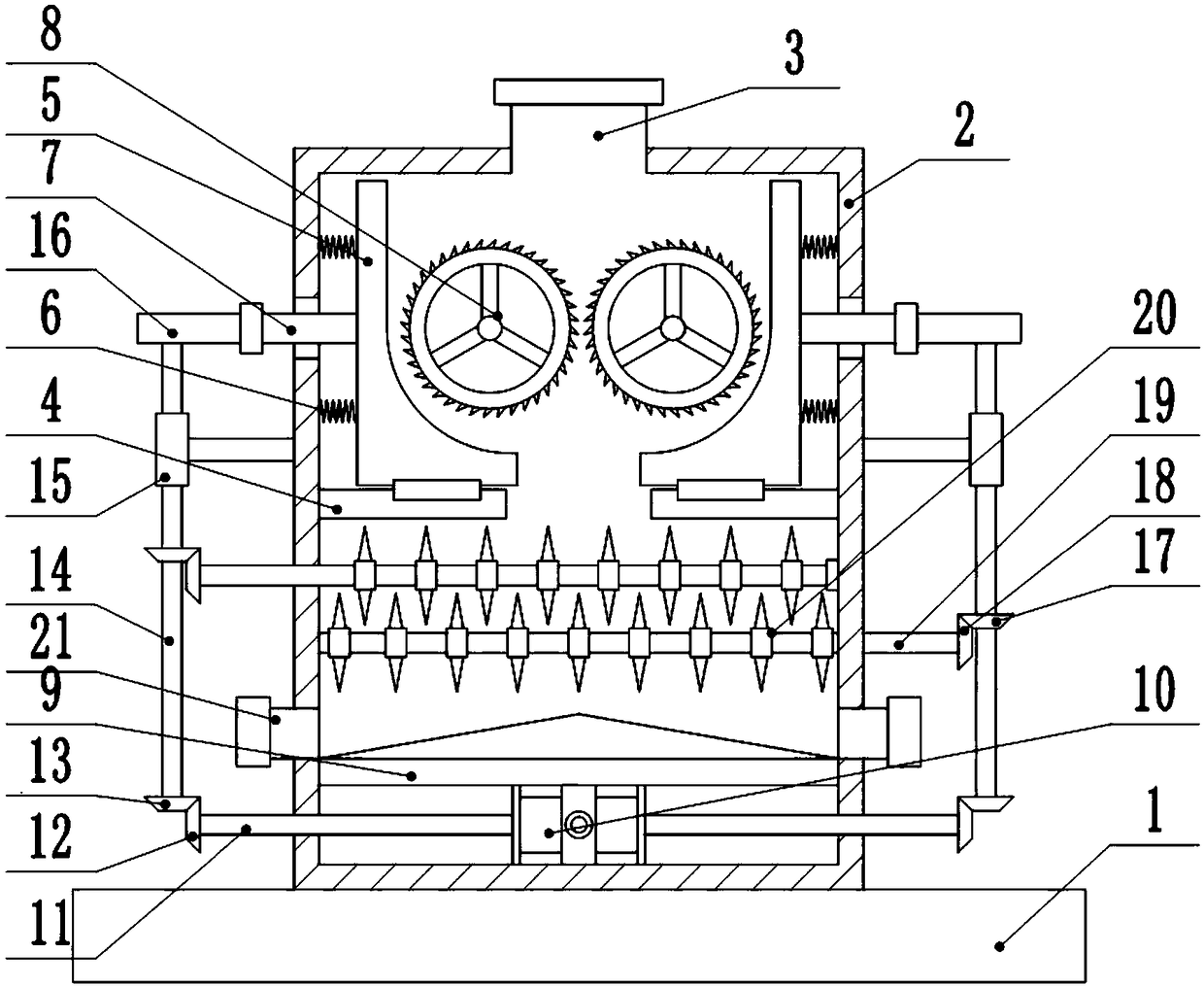

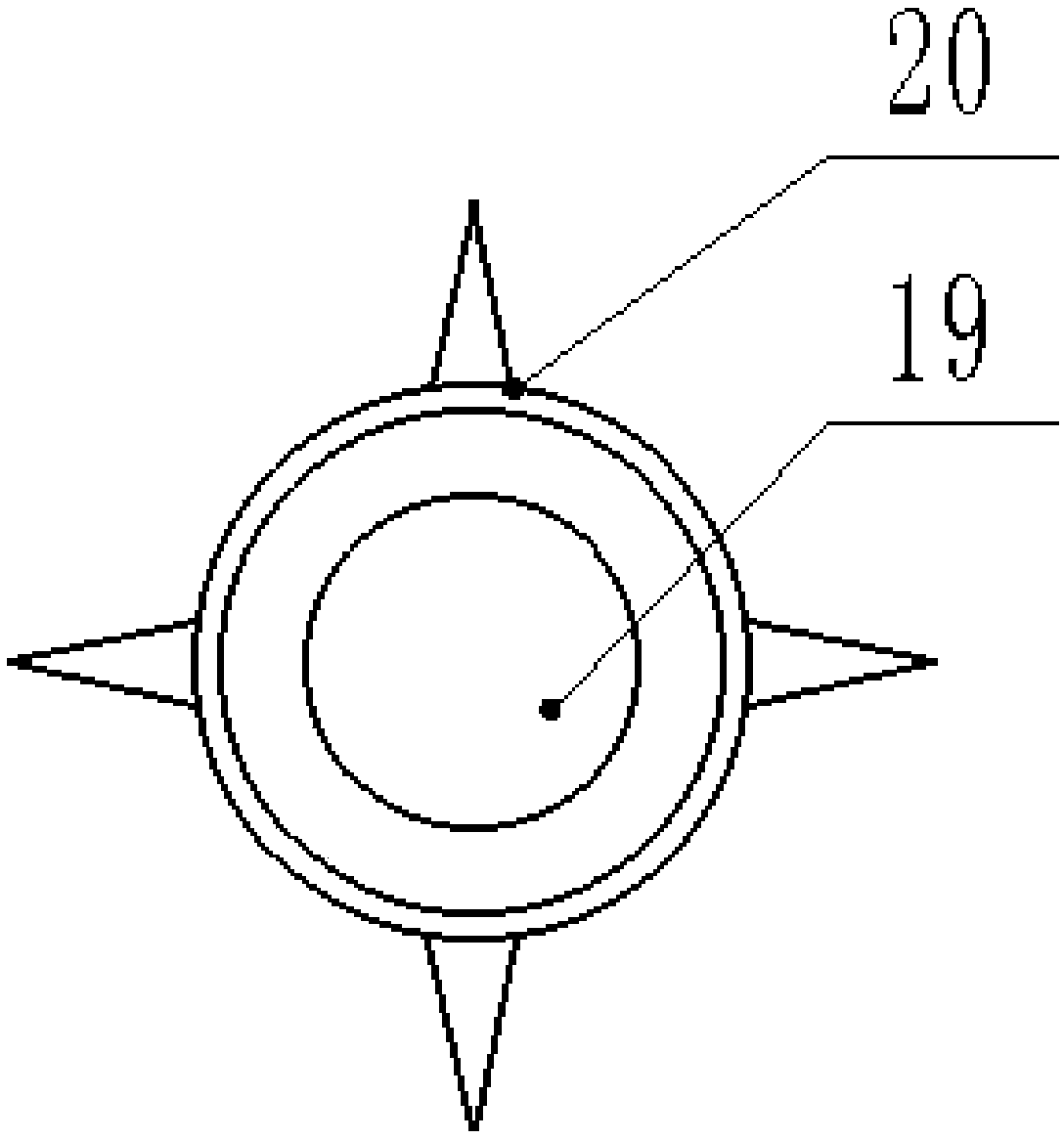

Floatable driving plate and grain pulling chain combined roller plate type corncob breaking-off mechanism

InactiveCN105684639ASimple transmissionEasy feedingHarvestersUniversal jointAgricultural engineering

The invention provides a floatable driving plate and grain pulling chain combined roller plate type corncob breaking-off mechanism, relates to a corncob picking device installed on a corn harvesting machine and belongs to the technical field of corn harvesting machinery. The floatable driving plate and grain pulling chain combined roller plate type corncob breaking-off mechanism comprises a transmission gear, a box body, corncob blocking plates, short stem-pulling delivery rollers, universal joints, driving plates, worms and gears, long stem-pulling delivery rollers, floating rods and grain pulling chains and is characterized in that the floatable driving plate and grain pulling chain combined roller plate type corncob breaking-off mechanism comprises a pair of long stem-pulling delivery rollers, a pair of the short stem-pulling delivery rollers and a pair of corncob blocking plates arranged under the delivery rollers, the driving plates are respectively located at the front ends of the long stem-pulling delivery rollers and the front ends of the short stem-pulling delivery rollers and are connected and driven by using the worms and gears, the grain pulling chains are located under the driving plates and are connected with the universal joints through the floating rods, the driving plates and the grain pulling chains guide corn plants to be accurately fed the position between the two stem-pulling delivery rollers through the combined clamping effect.

Owner:SHANDONG UNIV OF TECH

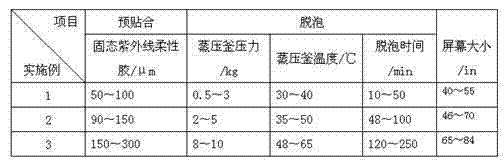

High specific gravity tungsten alloy material and preparation method thereof

The invention relates to a high specific weight tungsten alloy material and a preparation method thereof, and relates to a tungsten alloy material and a preparation method thereof. The invention solves the problems of poor plasticity, low strength, small deflection, large residual force of the prior high specific weight tungsten alloy product, and large equipment tonnage required, long demoulding time, tightly hermetical die and high cost in the method. The high specific weight tungsten alloy material is prepared by tungsten powder, nickel powder, iron powder and cobalt powder. The preparation method comprises the following steps: firstly, preparation of mixed powder A; secondly, preparation of a blank; thirdly, sintering of the blank; fourthly, preparation of mixed powder B; fifthly, preparation of a lubricating medium; and sixthly, acquisition of the high specific weight tungsten alloy material by placing the blank and the lubricating medium into the die for extrusion forming. The high specific weight tungsten alloy material has good plasticity, large strength, large deflection and small residual force. The preparation method is simple, has small equipment tonnage required, short demoulding time and low cost, and has no strict requirement on the die.

Owner:于洋

Low-temperature flue gas denitration catalyst forming process

ActiveCN104174442AHigh activityBroad application prospectsOrganic-compounds/hydrides/coordination-complexes catalystsDispersed particle separationIonStearic acid

The invention relates to a low-temperature flue gas denitration catalyst forming process. The low-temperature flue gas denitration catalyst forming process comprises the following steps of adding ammonium metavanadate powder and kapok in deionized water, stirring to form white suspension liquid, then adding monoethanolamine, and heating until the ammonium metavanadate powder is wholly dissolved to form a solution 1; dropwise adding a lactic acid solution in a mixed liquid of silica sol and alumina sol to form a solution 2; adding titanium dioxide, sesbania powder, PEO, CMC, stearic acid and fiber, stirring and uniformly mixing to obtain milk white mixed powder; adding the solution 1, the solution 2 and the deionized water in the mixed powder, and stirring to obtain a wet material mass; and carrying out extrusion moulding on the wet material mass by an extruder, and drying and calcining to obtain the catalyst. With the adoption of the low-temperature flue gas denitration catalyst forming process, as active ingredients of a traditional vanadium-tungsten-titanium catalyst system are hardly modified, and the production process is changed to certain extent, the activity is obviously improved, strip and honeycomb type catalysts are extruded by slightly regulating a formula, and the low-temperature flue gas denitration catalyst forming process can be widely applied to industrial furnaces used for waste incineration and the like with low temperature and complex flue gas conditions and flue gas denitration of a coal-fired power plant in low-temperature arrangement.

Owner:TSINGHUA UNIV +1

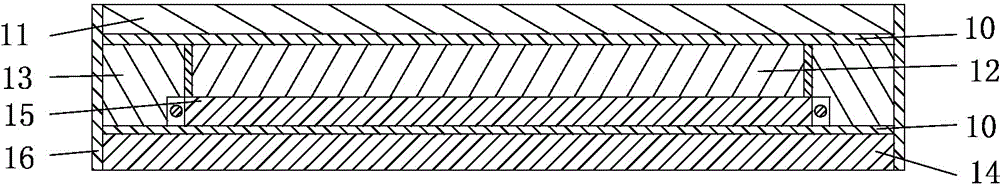

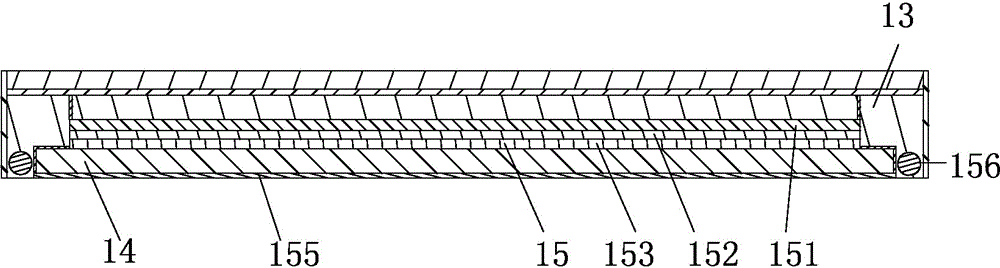

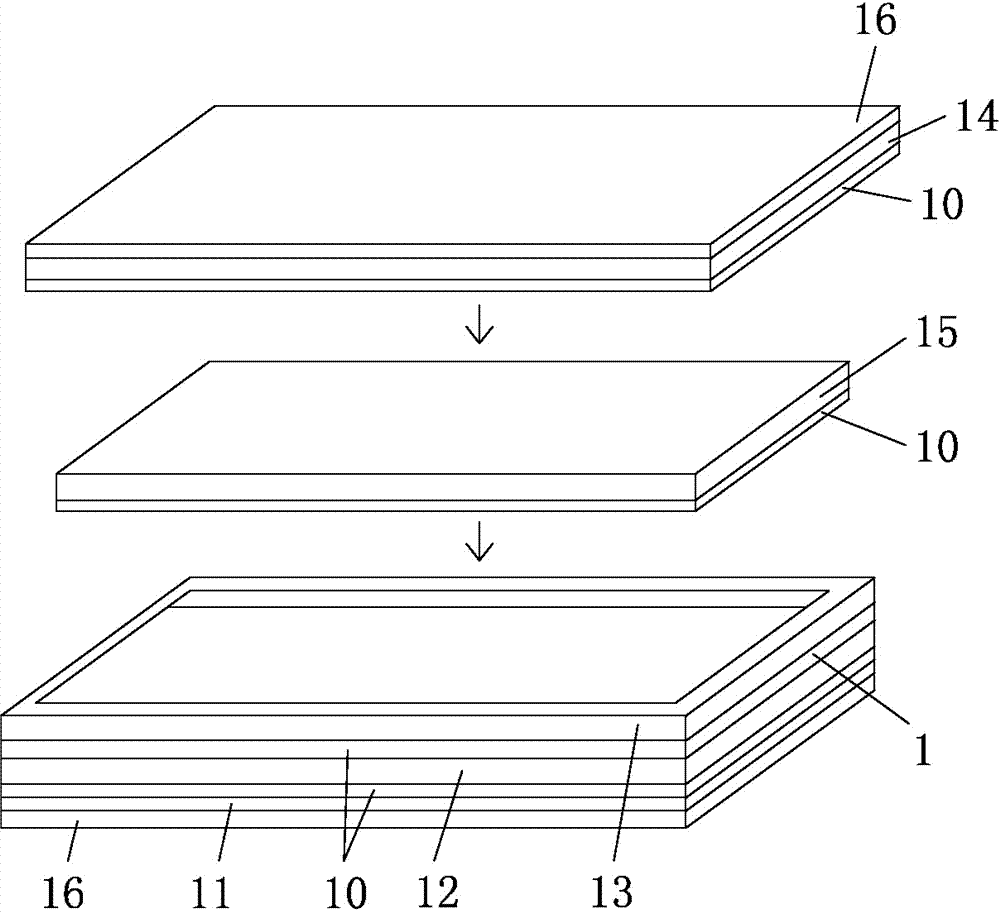

Fully-sealed touch control integrated liquid crystal screen and manufacturing process thereof

InactiveCN104503630AGood solid fluidityAchieve extrusionNon-linear opticsInput/output processes for data processingGlass coverUltraviolet

The invention discloses a manufacturing process of a fully-sealed touch control integrated liquid crystal screen. According to the manufacturing process, components which are arranged in sequence are glued to each other to form the fully-sealed touch control integrated liquid crystal screen through solid ultraviolet flexible glue; the components include a touch screen set, a liquid crystal screen set, an organic glass frame and a glass cover plate, wherein a backlight module is embedded among the liquid crystal screen set, the organic glass frame and the glass cover plate. According to transparent gluing bodies produced through the novel technology, bubbles cannot be easily generated, and the novel glued touch control display backlight integrated screen with features that the distances between every two adjacent gluing bodies are equal, the thickness difference and the unevenness difference do not exist, no stiffness phenomenon exists, and glue overflowing cannot easily happen can be manufactured.

Owner:OPTON (SHUNCHANG) OPTICS CO LTD

Method for preparing TiAl alloy plate without canning

The invention discloses a method for preparing a TiAl alloy plate without canning in order to solve the problems that an existing ingot metallurgy canning and rolling the TiAl alloy plate is complicated in process, high in machining cost and low in raw material utilization rate, and a TiAl alloy bar prepared through a powder metallurgy method is easy to introduce impurities and is high in cost. The method comprises the specific steps of 1, weighing all raw material ingredients; 2, preparing a casting ingot through induction skull melting of a water-cooling copper crucible and melted model precision casting; 3, carrying out blank pre-treatment; 4, carrying out a first plate extrusion stage; 5, carrying out a second plate extrusion stage, thus obtaining the TiAl alloy plate. According to the method for preparing the TiAl alloy plate without canning, disclosed by the invention, the surface of the obtained plate is smooth and has no cracks, and the TiAl alloy plate is uniformly organized, is small in crystal grain and has excellent mechanical performance.

Owner:TAIYUAN UNIV OF TECH

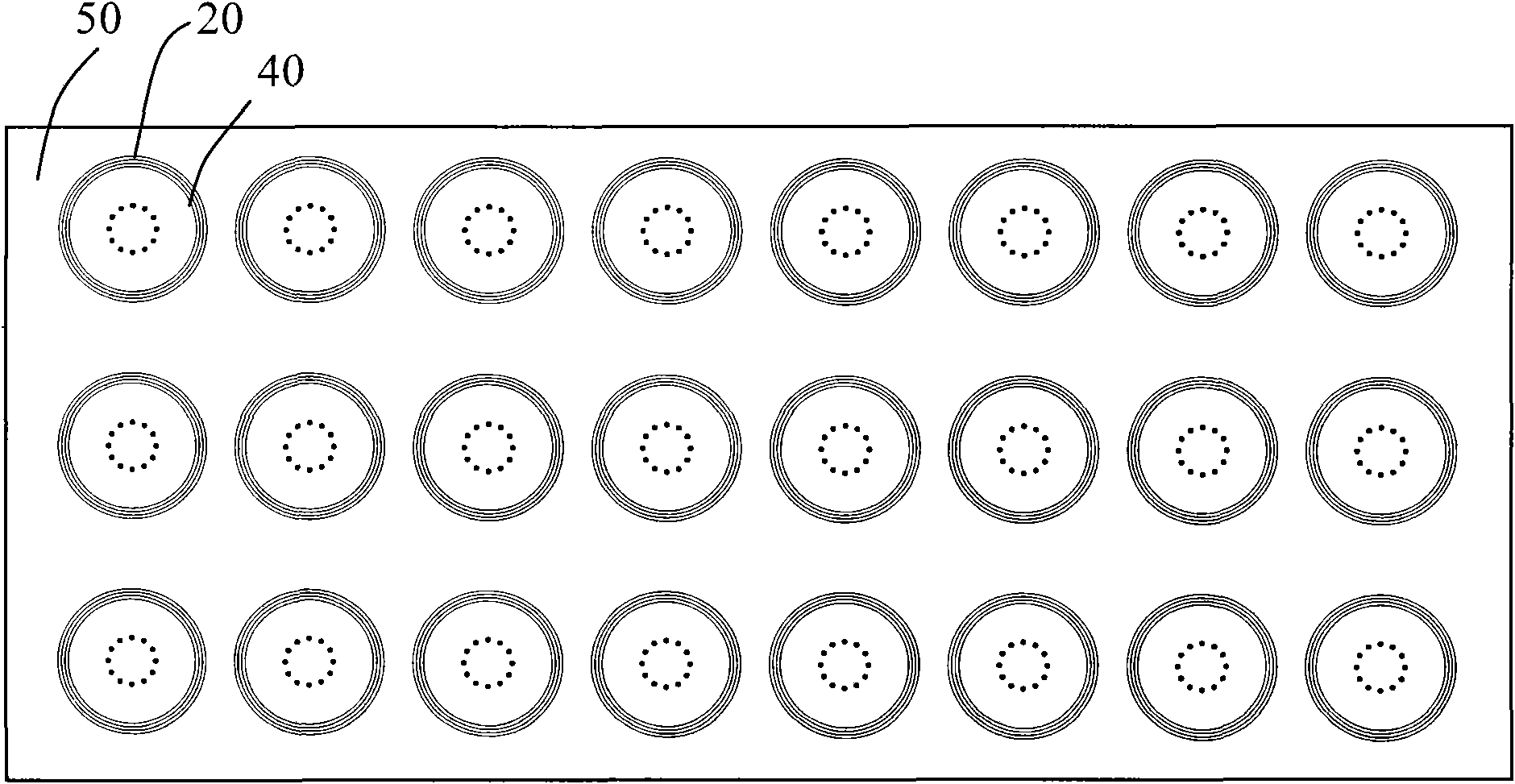

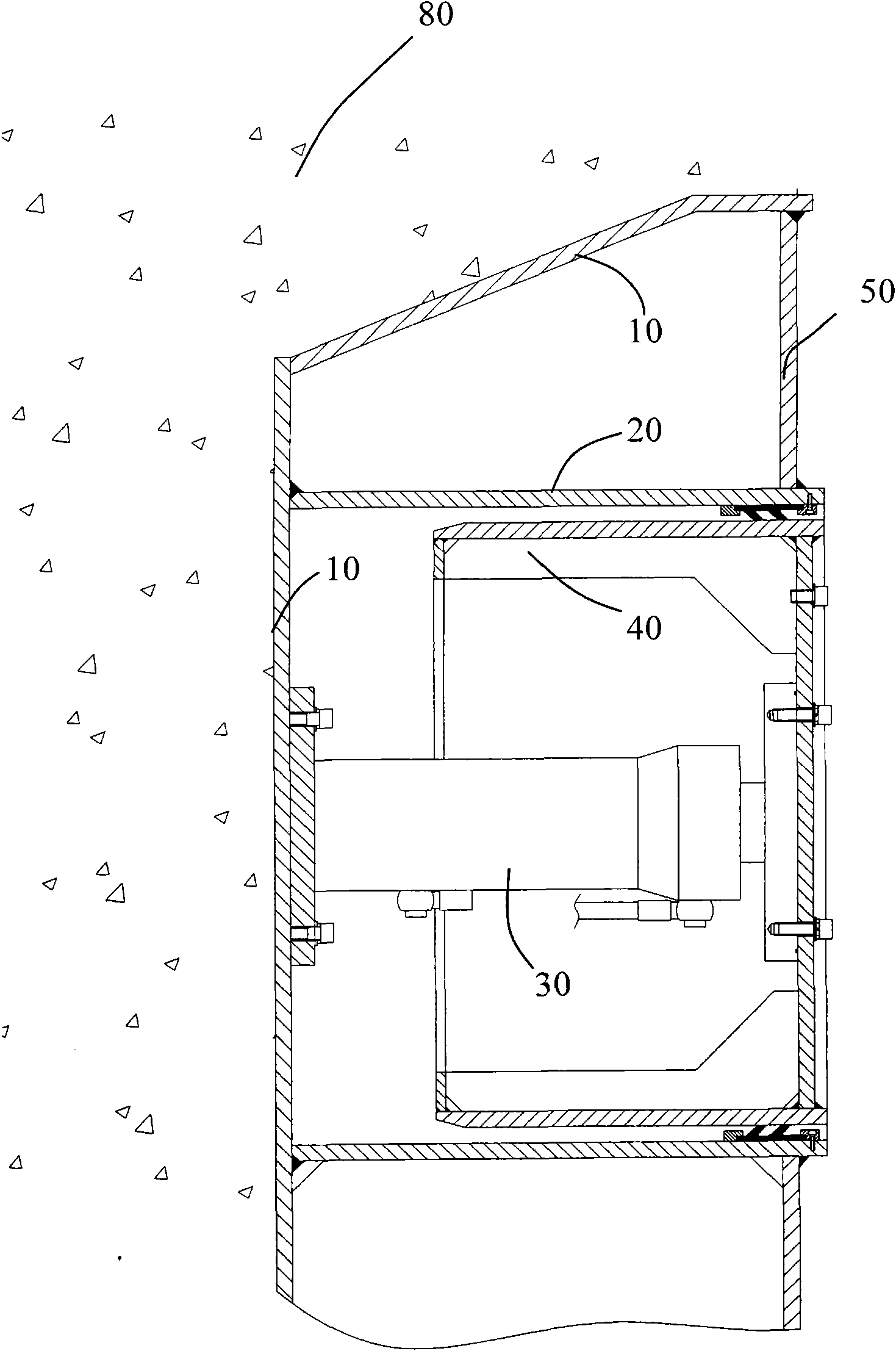

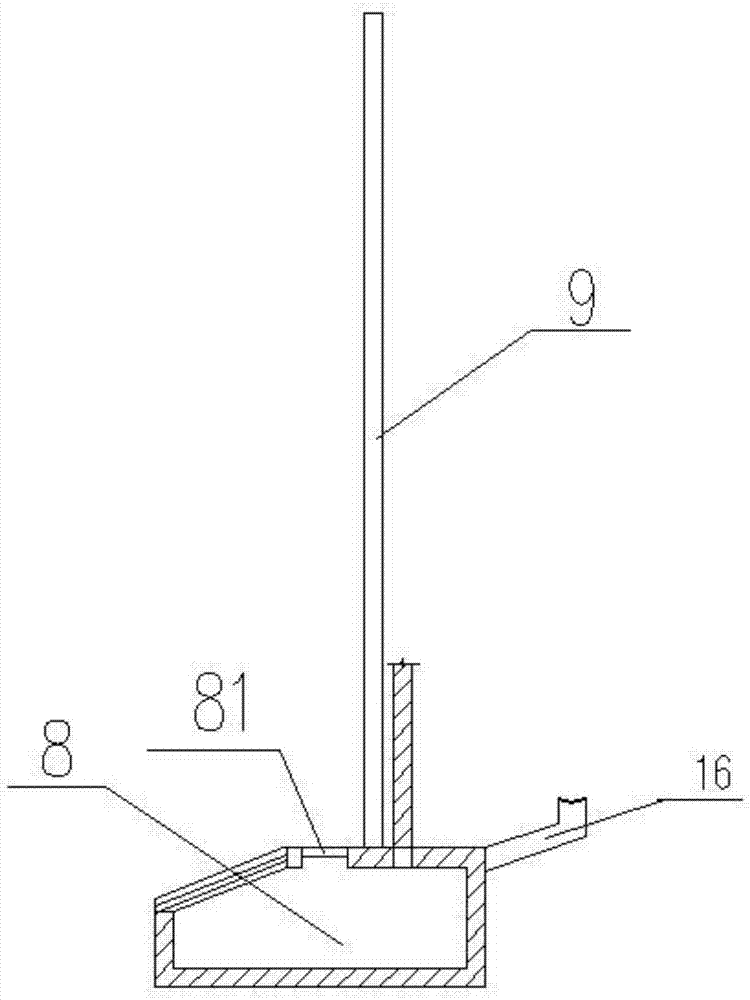

Side hydraulic loading system for simulation test bed

ActiveCN101629872AAchieve extrusionMaterial strength using tensile/compressive forcesStructural/machines measurementHydraulic cylinderSheet steel

The invention discloses a side hydraulic loading system for a simulation test bed. The system comprises a side wall embedded steel plate, a plurality of fixed buckets which are uniformly distributed in parallel, a plurality of hydraulic cylinders, a plurality of loading cylindrical buckets and a closing plate, wherein, the side wall embedded steel plate is embedded in a concrete casting side wall; the inner ends of the fixed buckets are fixed on the side wall embedded steel plate; the hydraulic cylinders are respectively coaxially and telescopically arranged in the corresponding fixed buckets, and the inner ends are fixedly connected with the side wall embedded steel plate; the loading cylindrical buckets are respectively coaxially arranged in the corresponding fixed buckets and are respectively sheathed outside the corresponding hydraulic cylinders, the outer ends are fixedly connected with the outer ends of the hydraulic cylinders, and the loading cylindrical buckets driven by the hydraulic cylinders can freely telescopically move in the fixed buckets; and the closing plate connects the top end and the bottom end of the side wall embedded steel plate with the outer ends of the fixed buckets into a whole. Driven by the hydraulic cylinders, the lateral hydraulic loading device of the invention drives the loading cylindrical buckets to extrude the soil bodies, thereby simulating the pressure thereof; and the driving pressure of the hydraulic cylinders can be adjusted to simulate the pressure of different soil bodies.

Owner:上海盾构设计试验研究中心有限公司 +2

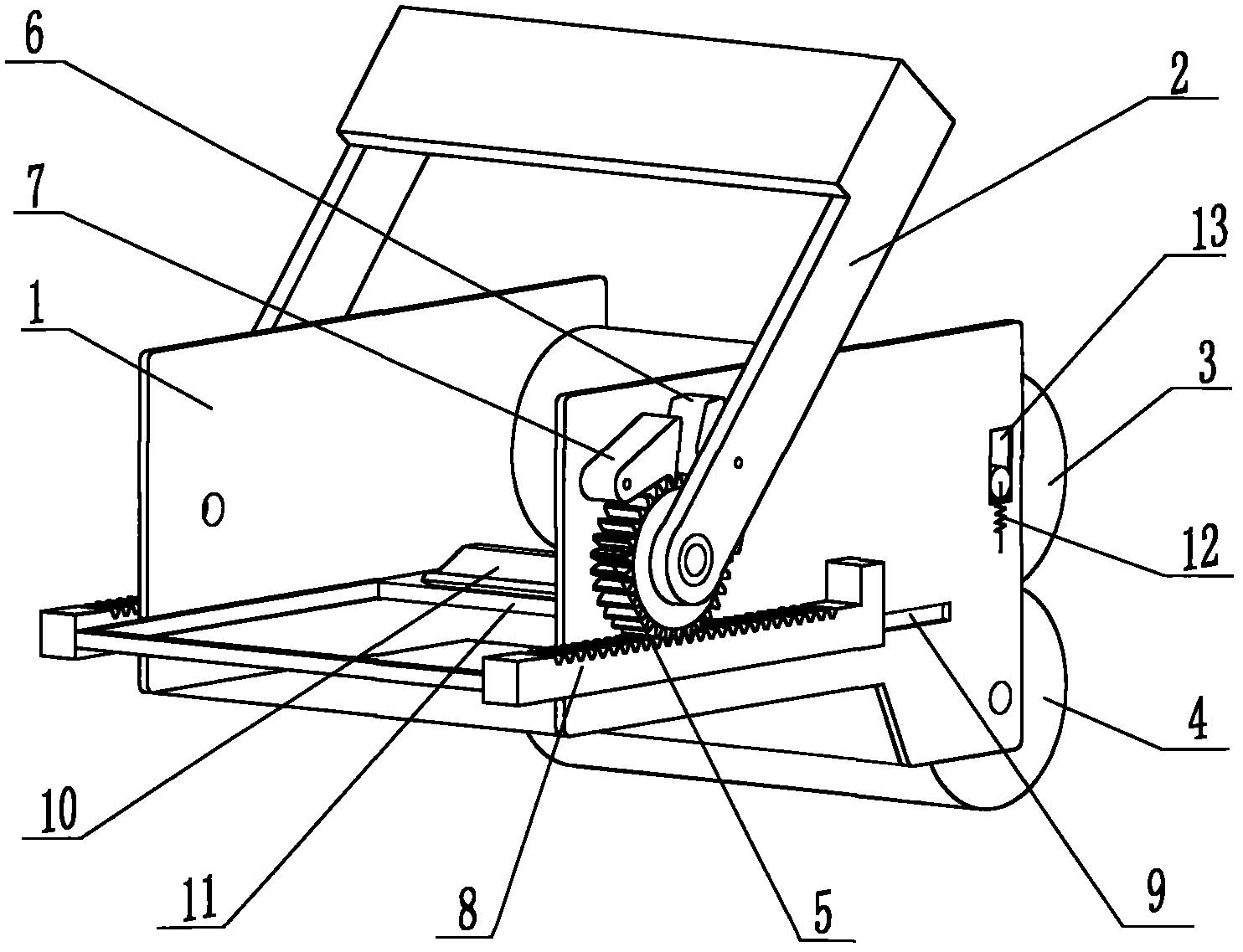

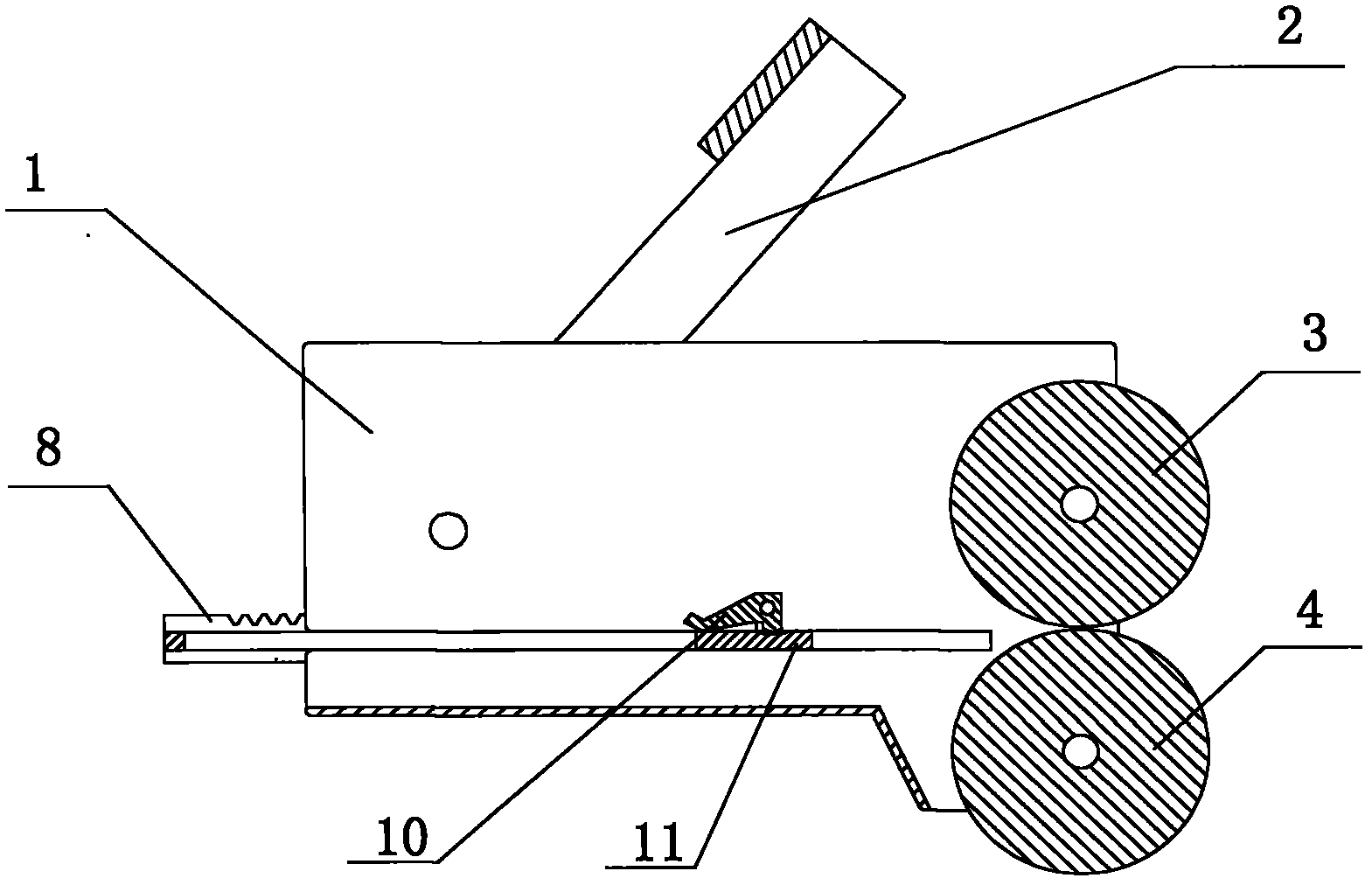

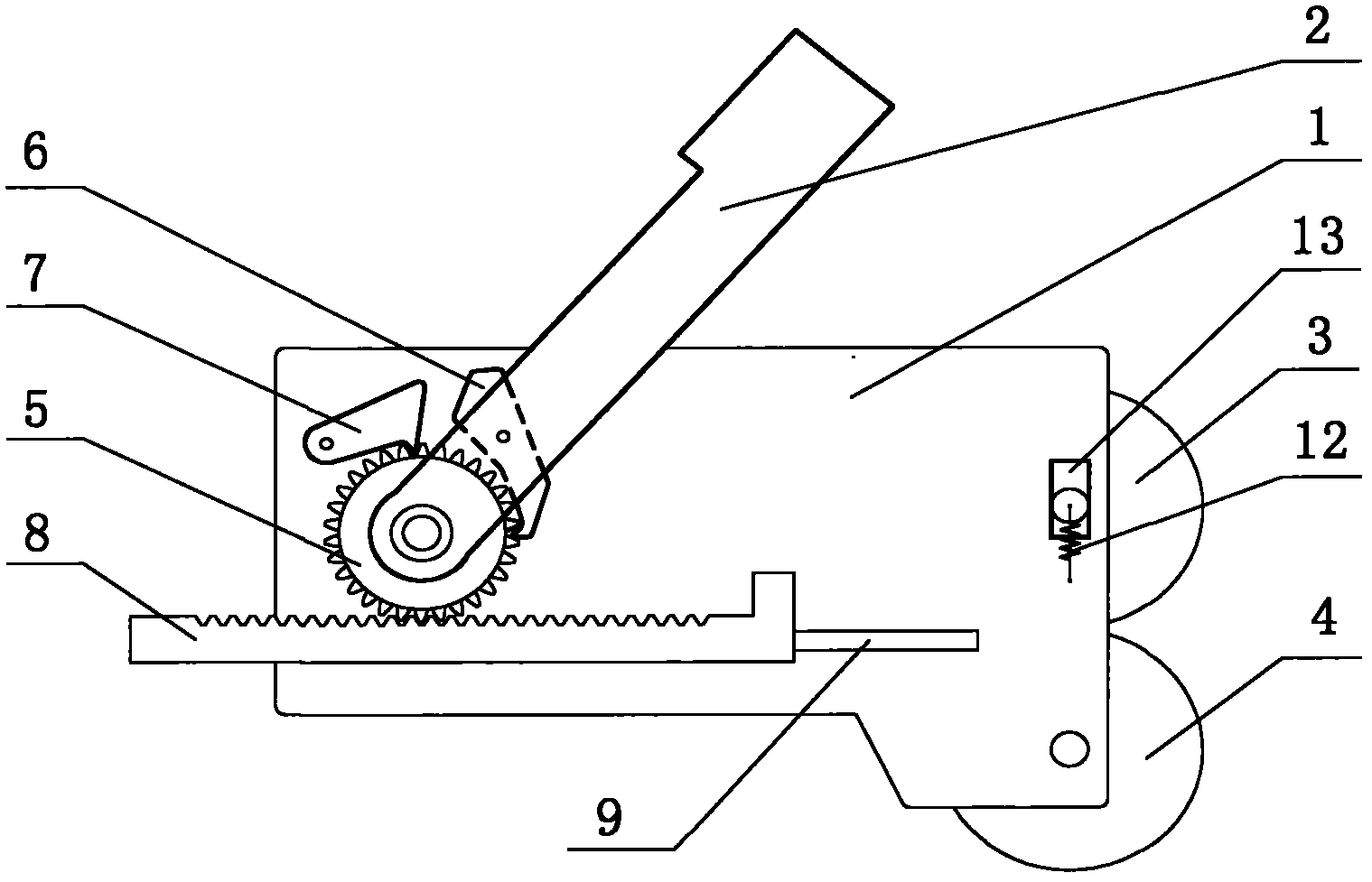

Toothpaste squeezing device

InactiveCN102490949AAchieve extrusionControl the amount of extrusionArticle unpackingGear wheelToothpaste

The invention relates to a toothpaste squeezing device, and aims to provide a toothpaste squeezing device which is easy and convenient to operate, saves labor and can control the squeezing amount of toothpaste effectively and reduce waste. The toothpaste squeezing device comprises a support, a squeezing mechanism, a draw-off mechanism and a clamping mechanism, wherein the squeezing mechanism consists of two rollers which are parallel up and down in the axial direction and a spring, and the two rollers are closed by the spring; the draw-off mechanism consists of a handle, a gear, a rack, a propelling ratchet wheel and a backstop ratchet wheel; a sliding chute in which the rack can slip is formed on the support; the gear is meshed with the rack; the propelling ratchet wheel is matched with the handle to push the gear to rotate; the backstop limits the reversing rotation of the gear; and the clamping mechanism consists of a clamp and a clamping plate, is fixedly connected with the rack of the draw-off mechanism and slips with the rack. The toothpaste squeezing device has a novel structure, can be hold and operated by one hand, is easy, convenient, labor-saving and convenient to carry, and can control the squeezing amount of the toothpaste effectively, overcome the defect that the toothpaste is left on the tail part of a toothpaste tube, save resources effectively and avoid waste.

Owner:郝士冲

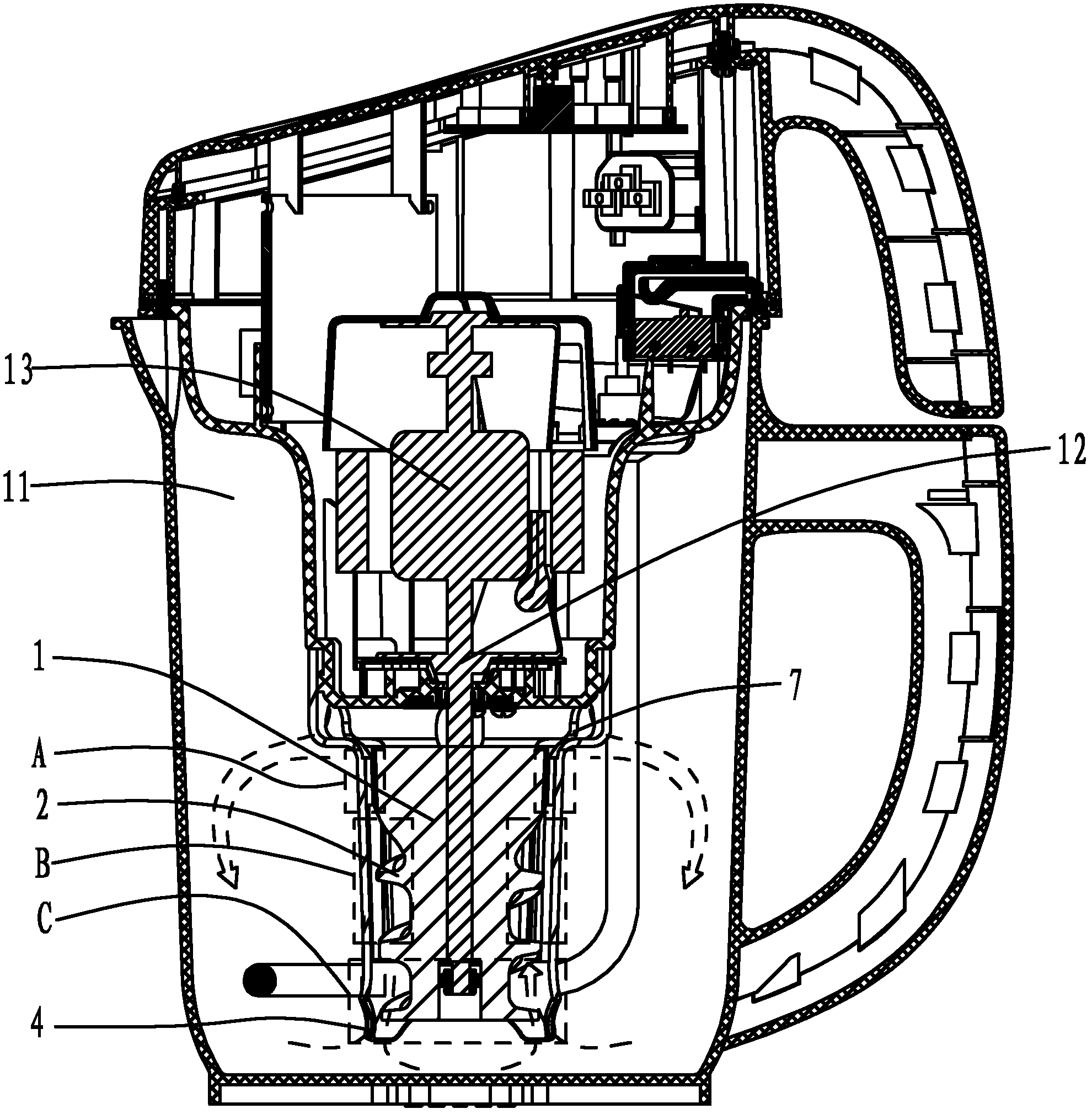

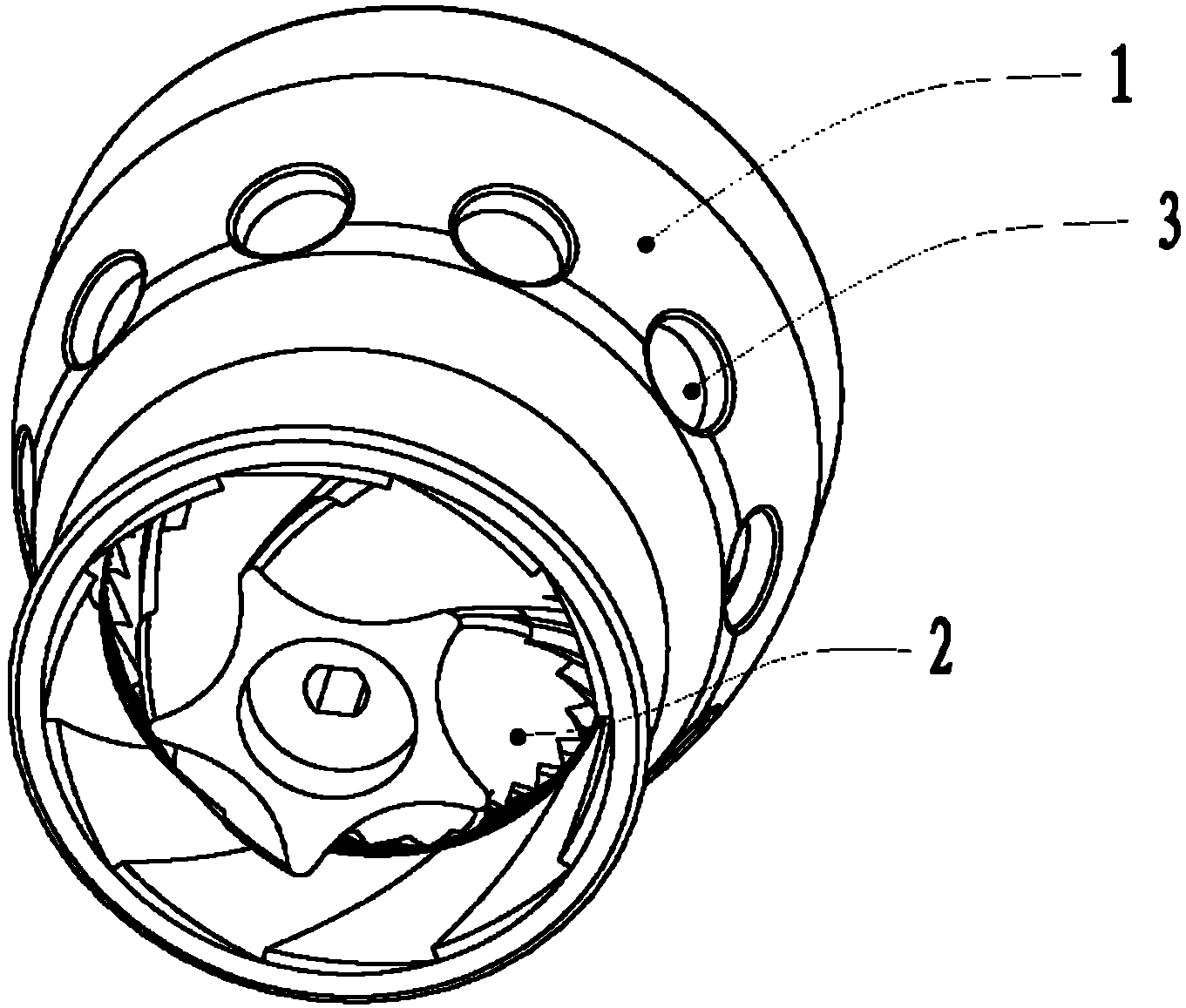

Soybean milk machine

ActiveCN102188157AAchieve mechanical mass productionEasy to cleanBeverage vesselsMilk substitutesWear resistantEddy current

The invention belongs to the field of small kitchen appliances, and particularly relates to a soybean milk machine. The soybean milk machine comprises a movable grinding head arranged on a motor shaft, wherein the movable grinding head comprises a liquid flow driving device which is provided with at least one screw tooth, and a movable grinding tooth arranged at the upper end of the liquid flow driving device; and the liquid flow driving device has a rough shape of a cylinder or rod or inverted cone. When a material is prepared, the movable grinding head rotates at a high speed in a static grinding material guiding cavity to form driven liquid flow so as to produce rotary suction eddy current, and the material is rotatablely sucked into the liquid flow driving device, is coarsely ground and further is subjected to fine grinding by using the movable grinding tooth. The gap gradually becomes smaller from the bottom to top, and the grinding process in which the coarse material is ground into the fine material is realized at the same time. A grinding mechanism of the soybean milk machine has a good grinding effect, and the grinding head is easy to process and is wear-resistant.

Owner:ZHEJIANG SHAOXING SUPOR DOMESTIC ELECTRICAL APPLIANCE CO LTD

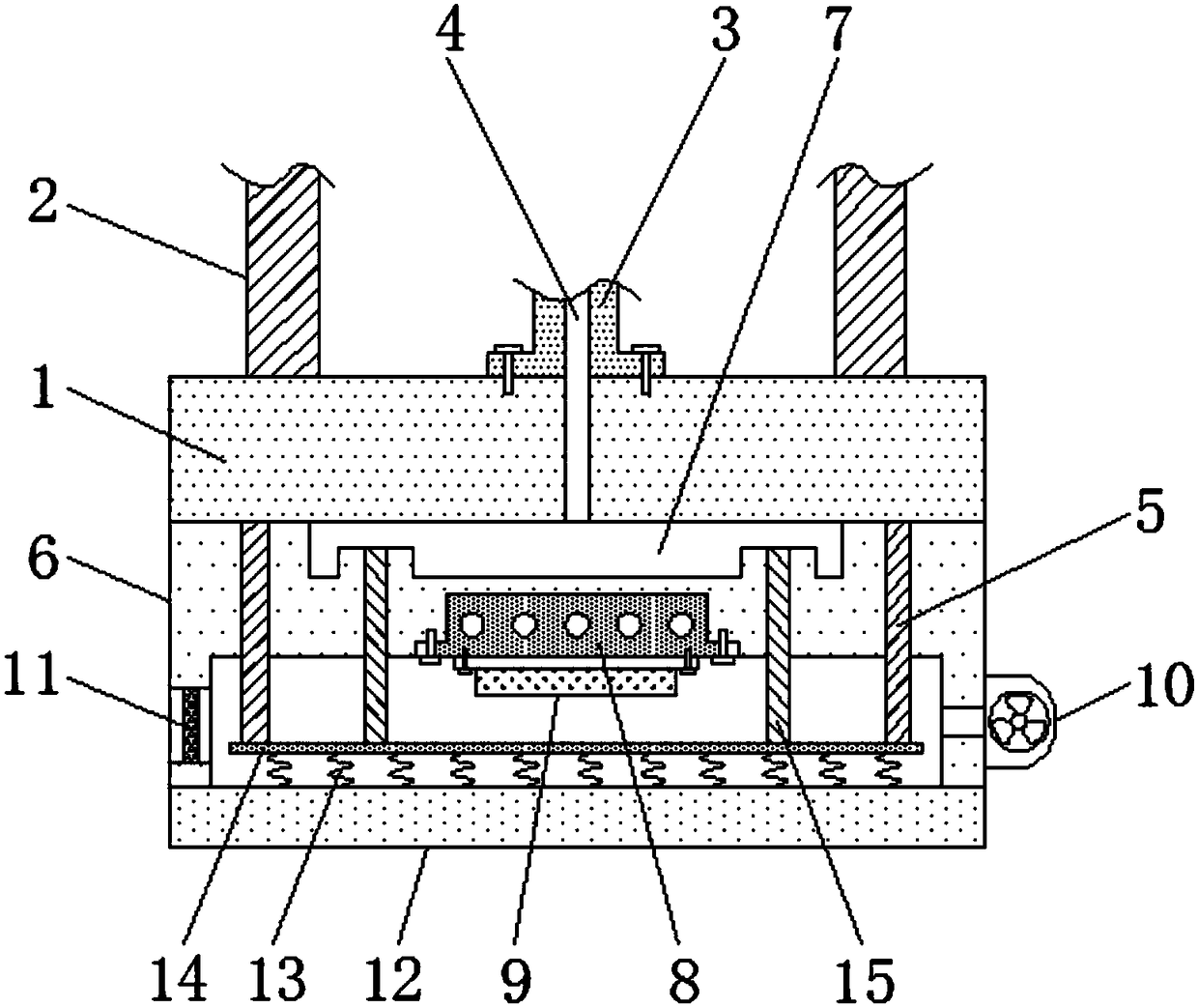

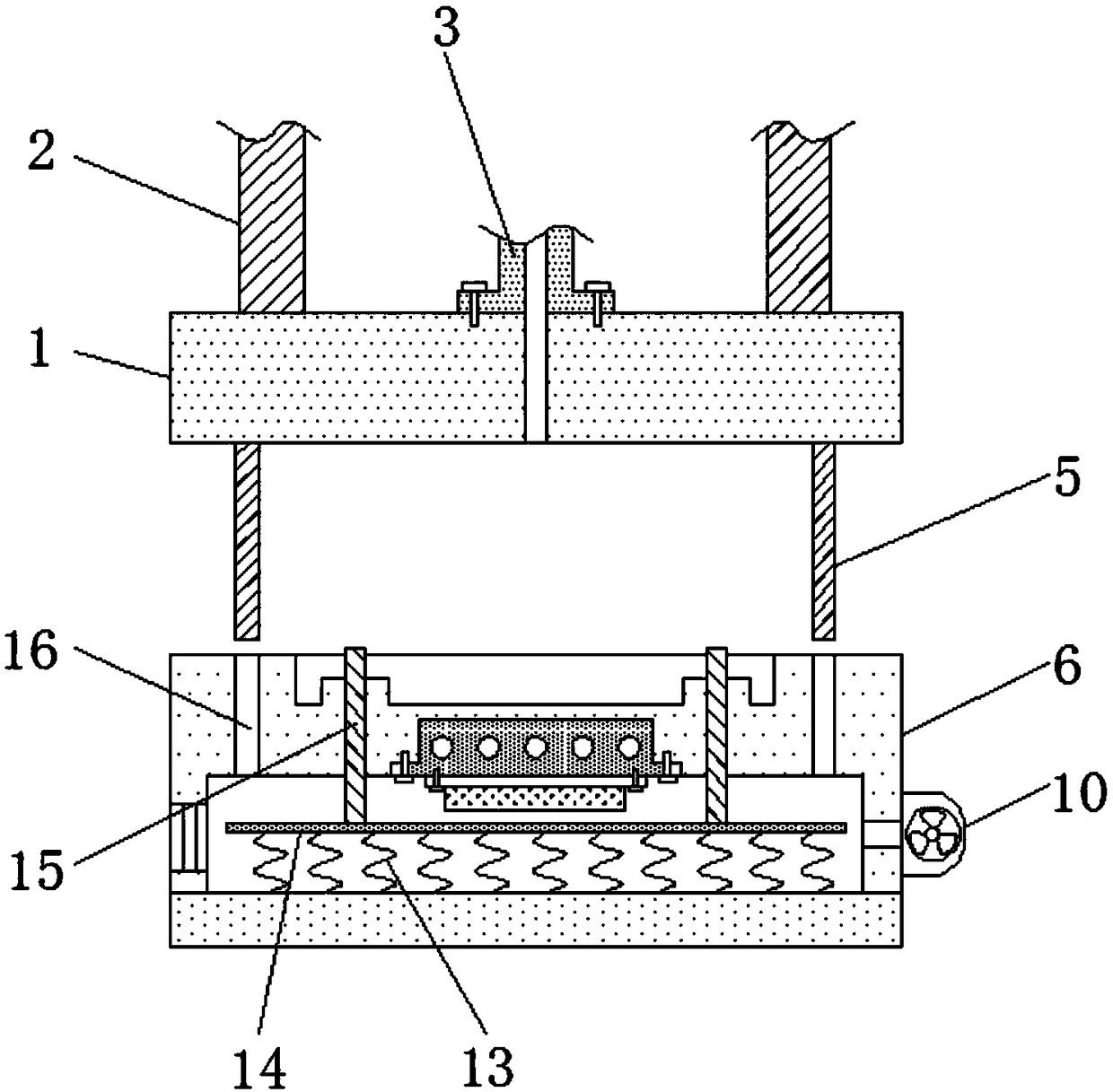

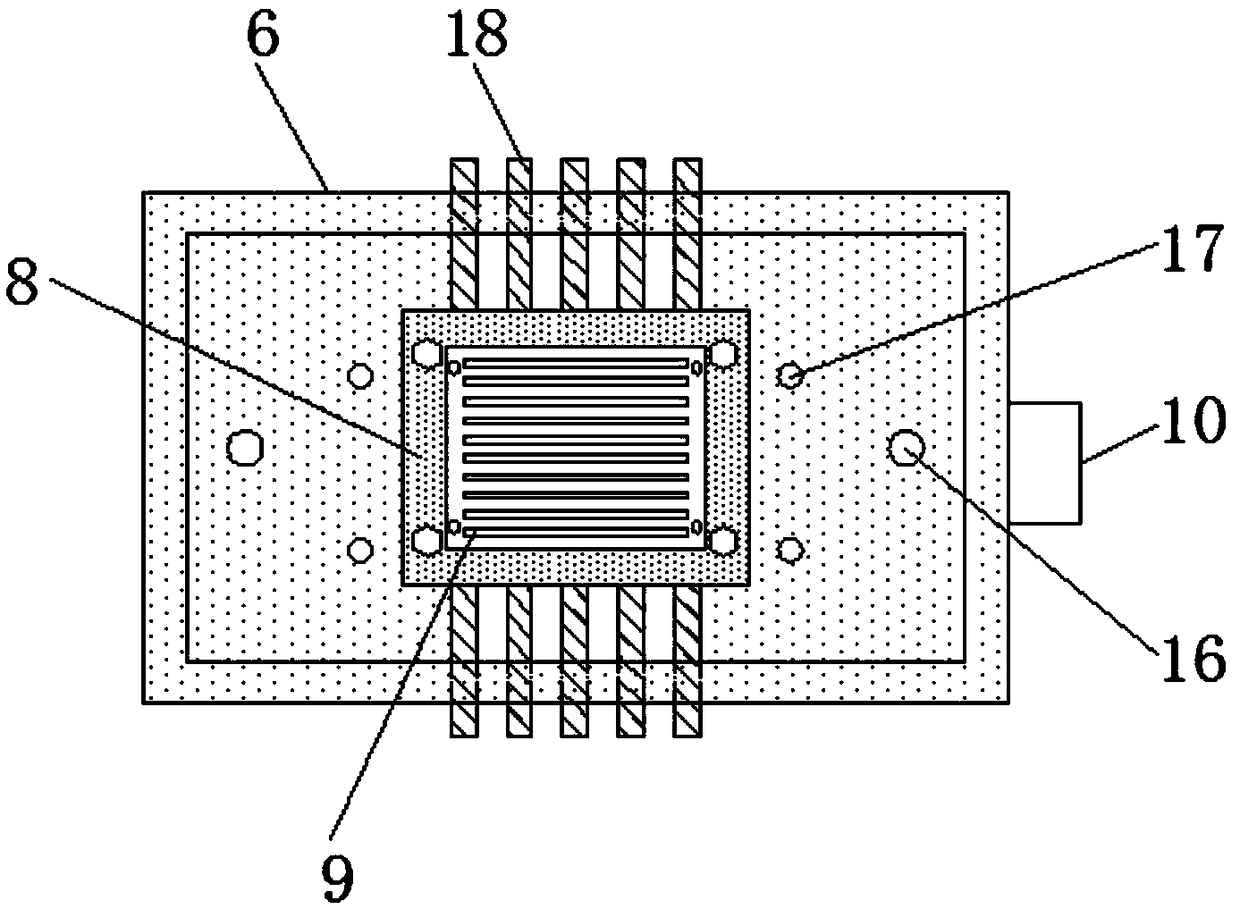

Injection mold capable of achieving fast cooling and demolding

The invention discloses an injection mold capable of achieving fast cooling and demolding. The injection mold comprises an upper mold body, a lower mold body and a base; pressing rods are connected tothe two sides of the upper end of the upper mold body correspondingly; injection molding flow channels are pre-reserved inside the upper mold body and an injection molding head; the lower mold body is located at the lower end of the upper mold body; a heat conducting plate is disposed inside the lower end of the lower mold body; fins are connected to the lower end surface of the heat conducting plate; a fan is mounted at the right end of the outer side of the lower mold body; the base is located at the lower end of the lower mold body; demolding rods are disposed on the two sides of the upperend of a connecting plate correspondingly and penetrate through the lower mold body through second guiding holes; connecting pipes are connected to the front side and the rear side of the heat conducting plate correspondingly; and a heat dissipation flow channel is pre-reserved inside the heat conducting plate. By means of the injection mold capable of achieving fast cooling and demolding, duringinjection molding of plastic products, fast cooling and demolding of the plastic products can be achieved, the manufacturing time of the plastic products can be shortened, and the economic benefits are improved.

Owner:杨传平

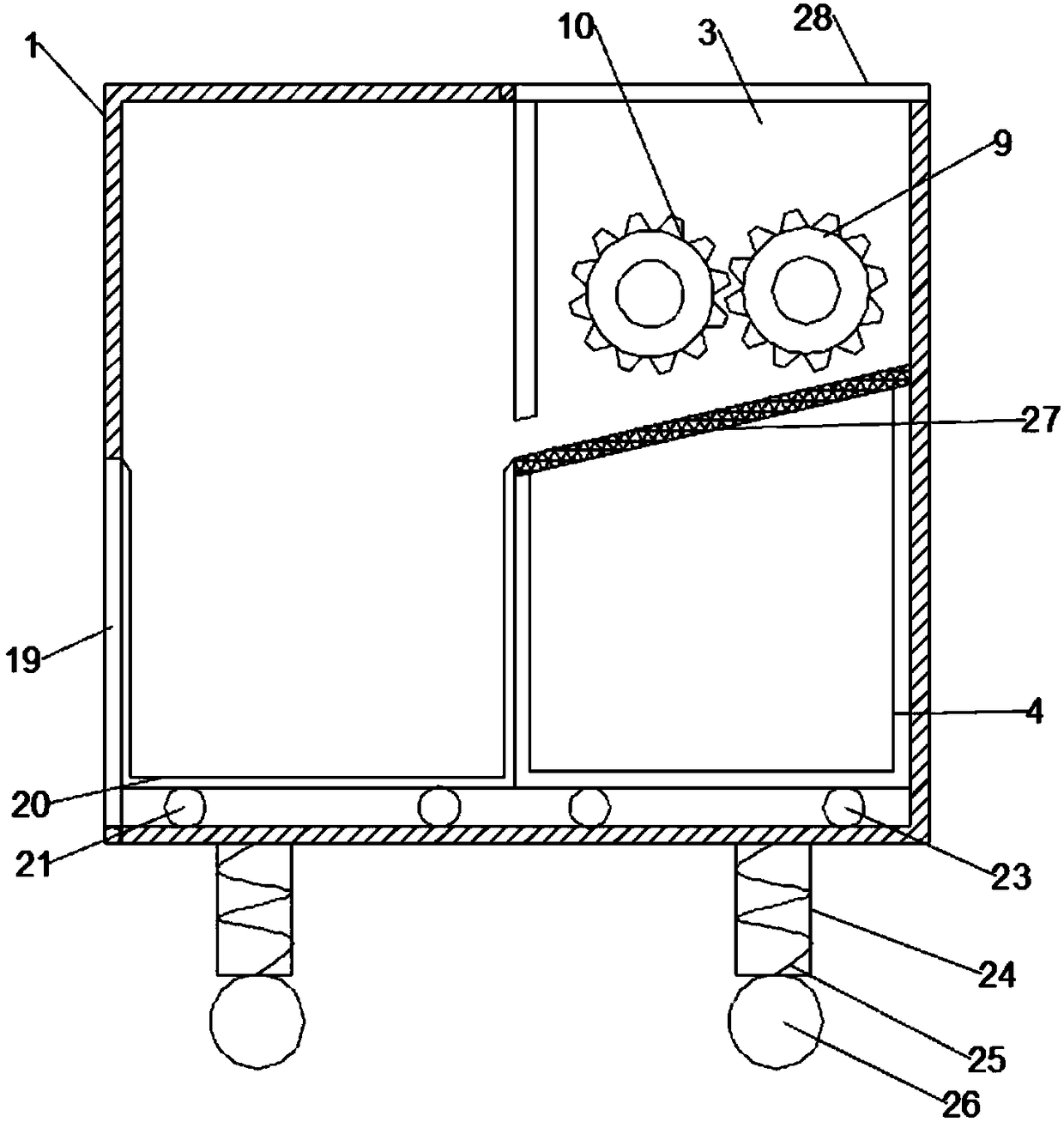

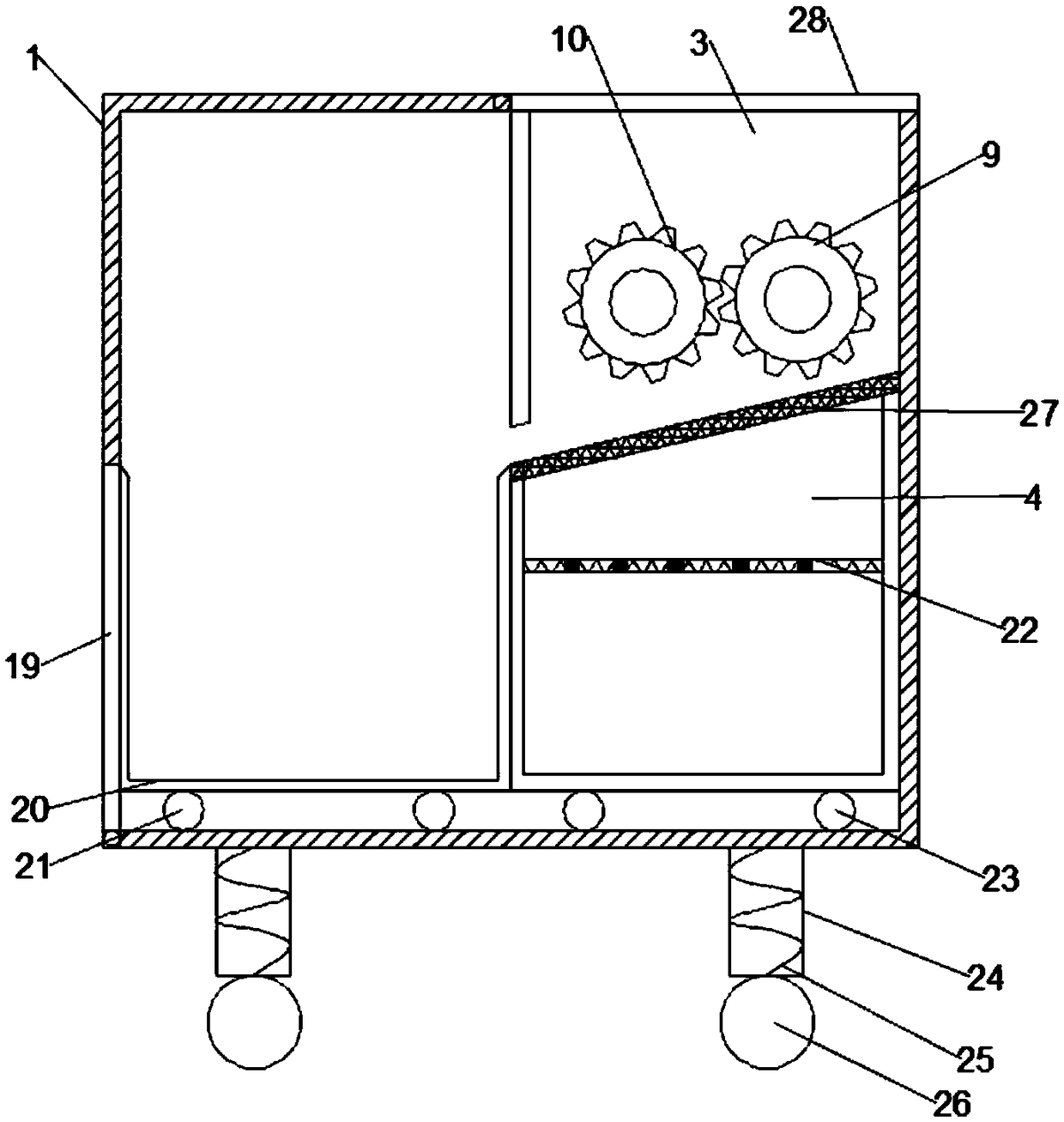

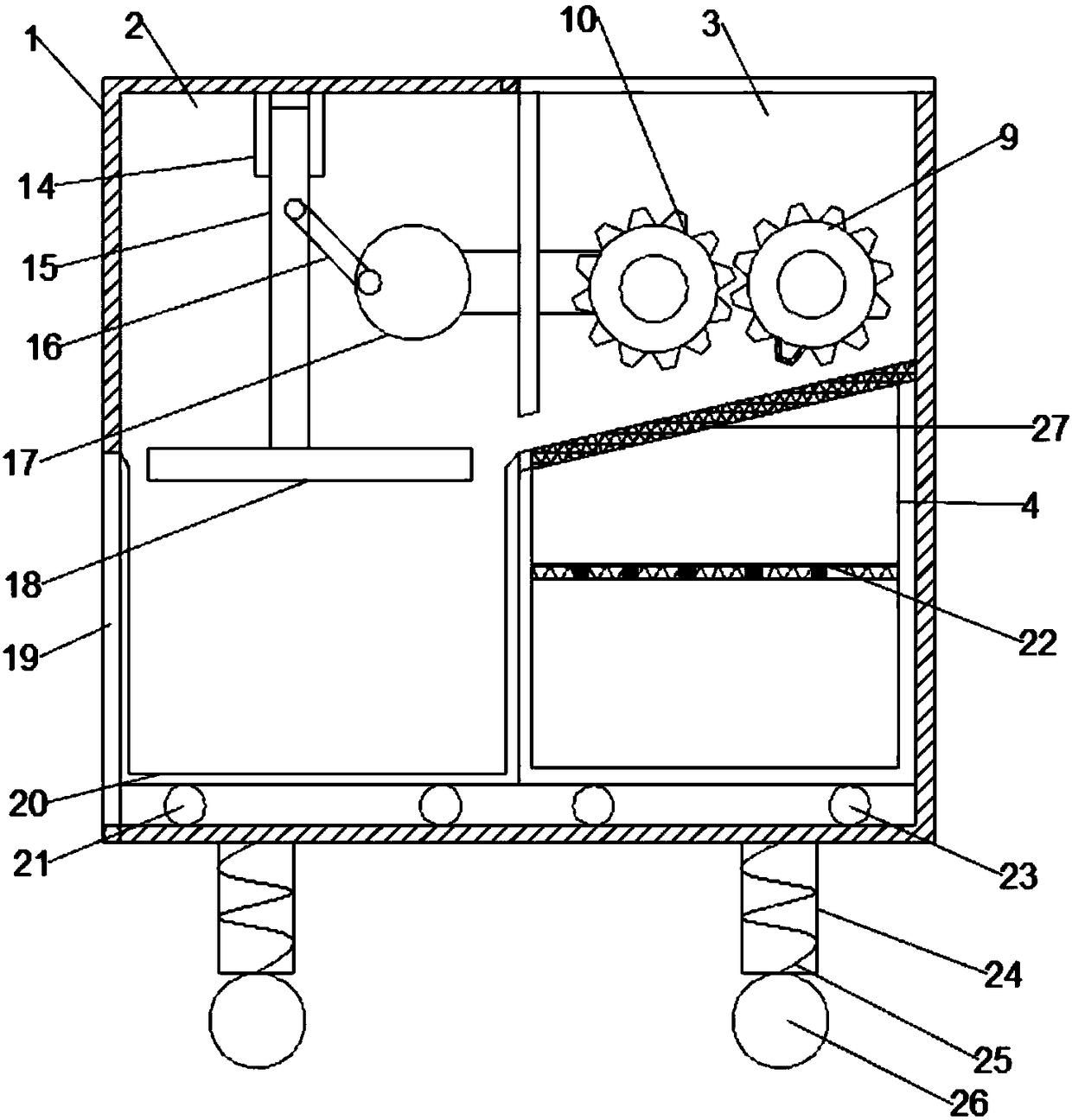

Round wheel pressing automatic-controlled environmental-protection kitchen garbage treatment device

InactiveCN109078954ASave resourcesReduce pollutionSolid waste disposalTransportation and packagingAutomatic controlEngineering

The invention discloses a round wheel pressing automatic-controlled environmental-protection kitchen garbage treatment device. The device comprises a base; brackets are fixedly connected to the left and right sides above the base; two brackets are provided; a connecting rod is fixedly connected to the upper ends of the two brackets; a garbage treatment box is fixedly mounted at the middle part ofthe connecting rod; baffle plates are fixedly connected to the lower ends of box bodies on the left and right sides of the garbage treatment box; two baffle plates are provided; water outlets are formed in the lower ends of the two baffle plates; a waste water tank is formed right under the water outlets; water filter plates are fixedly connected under the box bodies on the left and right sides inthe garbage treatment box; first fixed slide blocks are fixedly connected to the middle parts of the box bodies on the left and right sides of the garbage treatment box; a second fixed slide block isfixedly connected to the middle part of the box body on the upper side of the garbage treatment box; a push rod is in contact connection in the middle of the second fixed slide block in the verticaldirection; and a second extrusion plate is fixedly connected to the lower end of the push rod. The device can realize reutilization of kitchen garbage to save resources and to reduce environmental pollution.

Owner:黄剑鹏

Material cutting and cutting plate device for circuit plate processing

PendingCN108748339AAchieve supportAchieve extrusionNon-rotating vibration suppressionMetal working apparatusEngineeringFriction force

The invention discloses a material cutting and cutting plate device for circuit plate processing. The device comprises a first air cylinder, a second air cylinder, a second anti-skid pad, a pressing plate, a cutting blade, a bottom plate and a top plate; the second air cylinder is used for driving a piston rod to extend so as to push the pressing plate to move downwards to be in contact with the top of the plate, so that the purpose of fixing the position of the plate is further achieved; the friction force between the bottom of the pressing plate and the top of the plate is increased by arranging the second anti-skid pad, the effect of fixing the position of the plate is further improved, and the effect of cutting the plate is further guaranteed; the second air cylinder further drives thepiston rod to extend, so that the cutting blade is further pushed to move downwards to be in contact with the top of the plate and a damping spring is extruded; and through the rotation of a cuttingmotor, the cutting blade is driven to rotate so as to cut the plate, so that the purpose of cutting the plate is achieved, and the operation is simple.

Owner:湖北荣宝电子科技有限公司

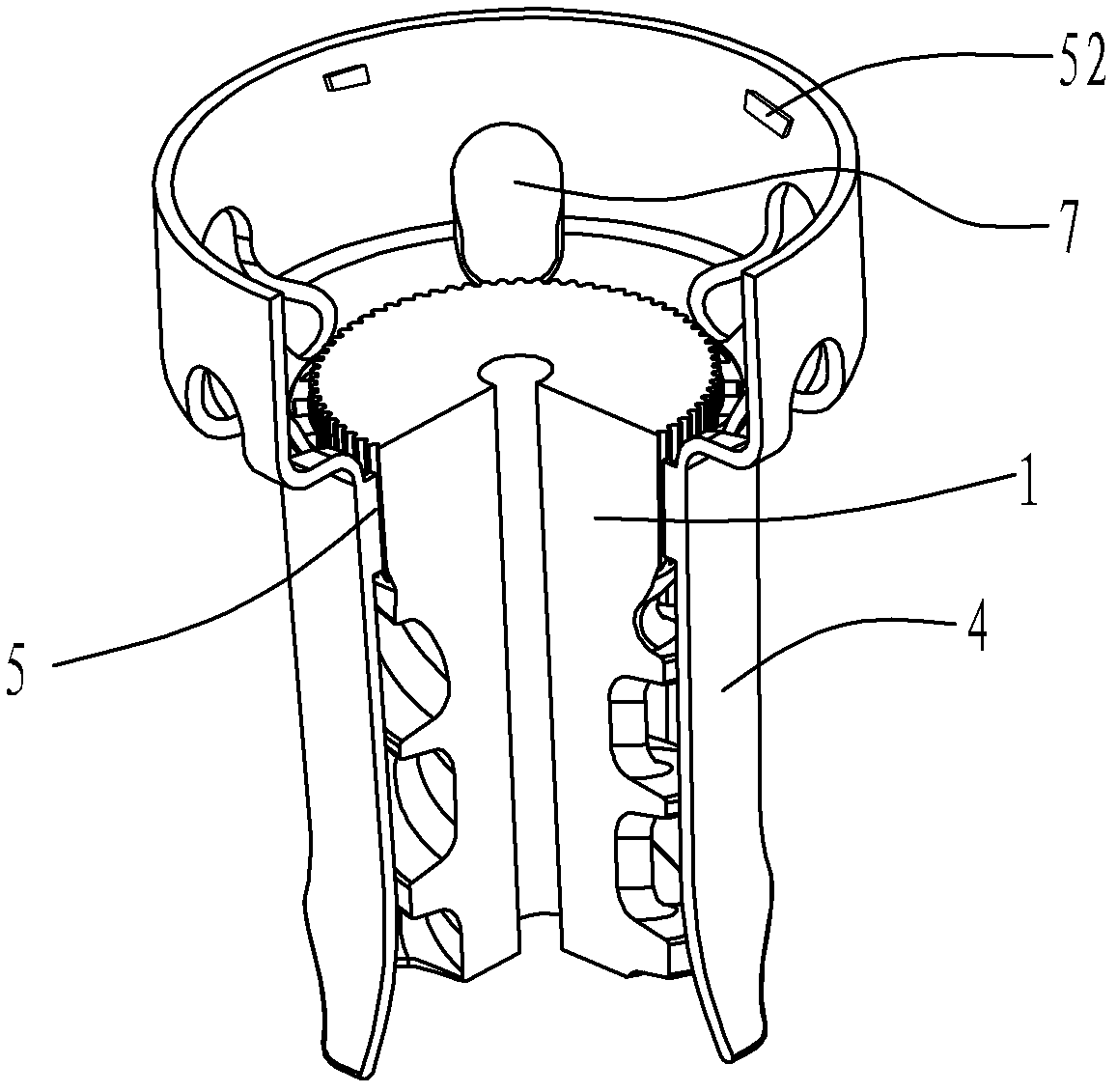

Pole-climbing robot

The invention relates to a pole-climbing robot. The pole-climbing robot comprises a first frame body and a second frame body. Walking wheel mechanisms are arranged on the first frame body and the second frame body. The two sides of the walking wheel mechanism of one of the two frame bodies is correspondingly connected with the two sides of the other walking wheel mechanism of the other walking wheel mechanism through two connecting structures respectively. In this way, the walking wheel mechanisms on the two frame bodies are oppositely arranged. An accommodating space for a pole-climbing bodyto penetrate through is formed between the two walking wheel mechanisms. One of the two connecting structures is a flexible connecting structure, and the other connecting structure is a detachable connecting structure. At least one of the side edges of the two sides of the walking wheel mechanisms of the two frame bodies is provided with an active contraction mechanism for adjusting the length ofthe side edge. When the length of one side is adjusted through the active contraction mechanism, the contraction deformation amount can be compensated through the arrangement of the flexible connection structure. The whole adjusting process is simple, convenient, safe and reliable. The power consumption is low in the crawling process, and the pole-climbing robot is very practical.

Owner:临颍县爬杆机器人有限公司

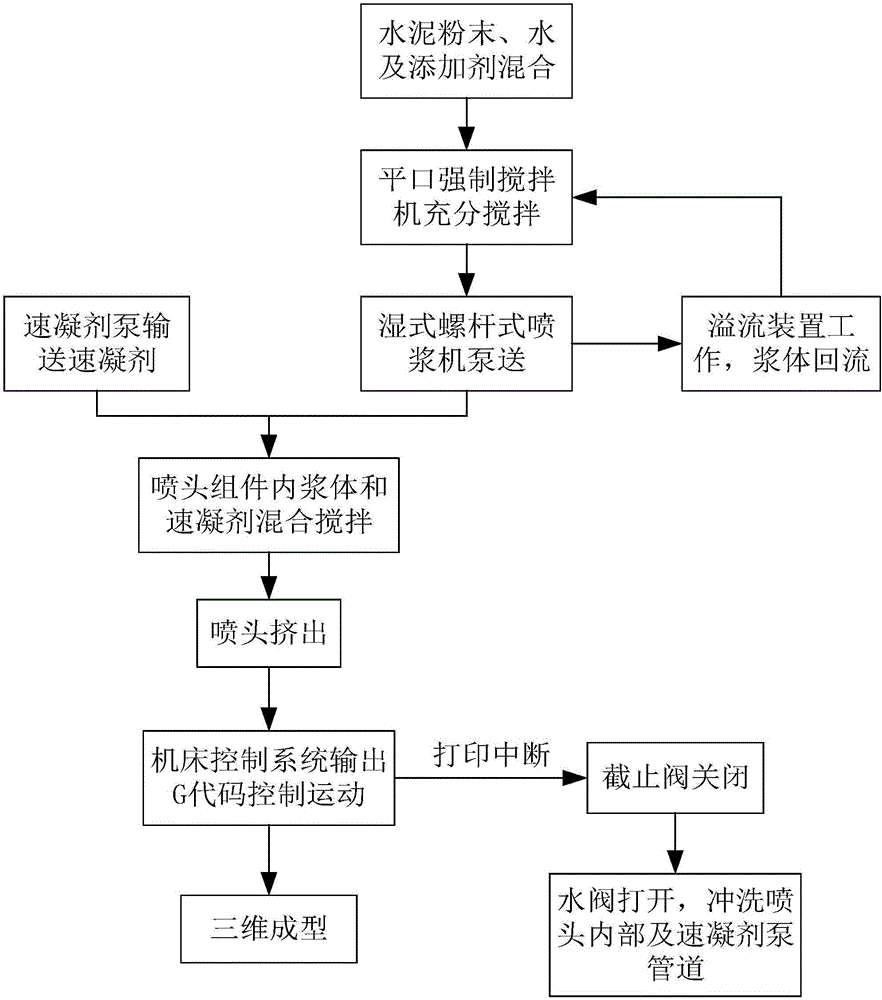

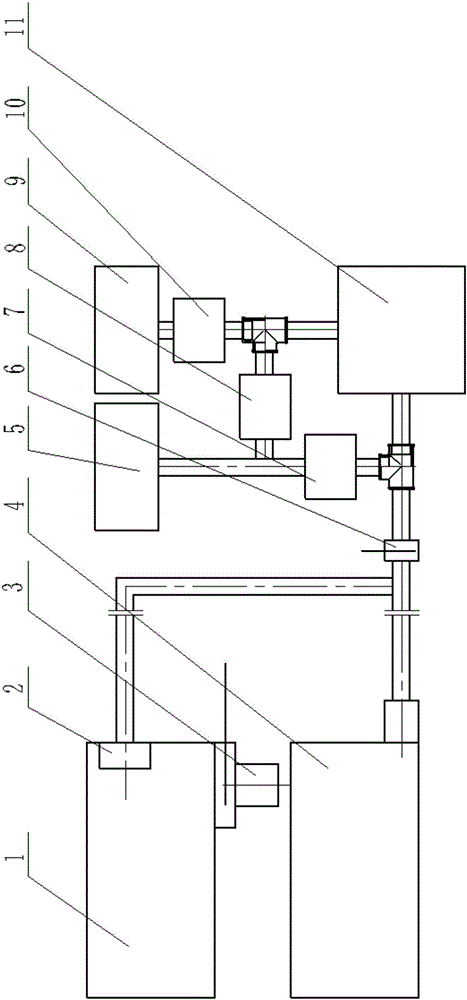

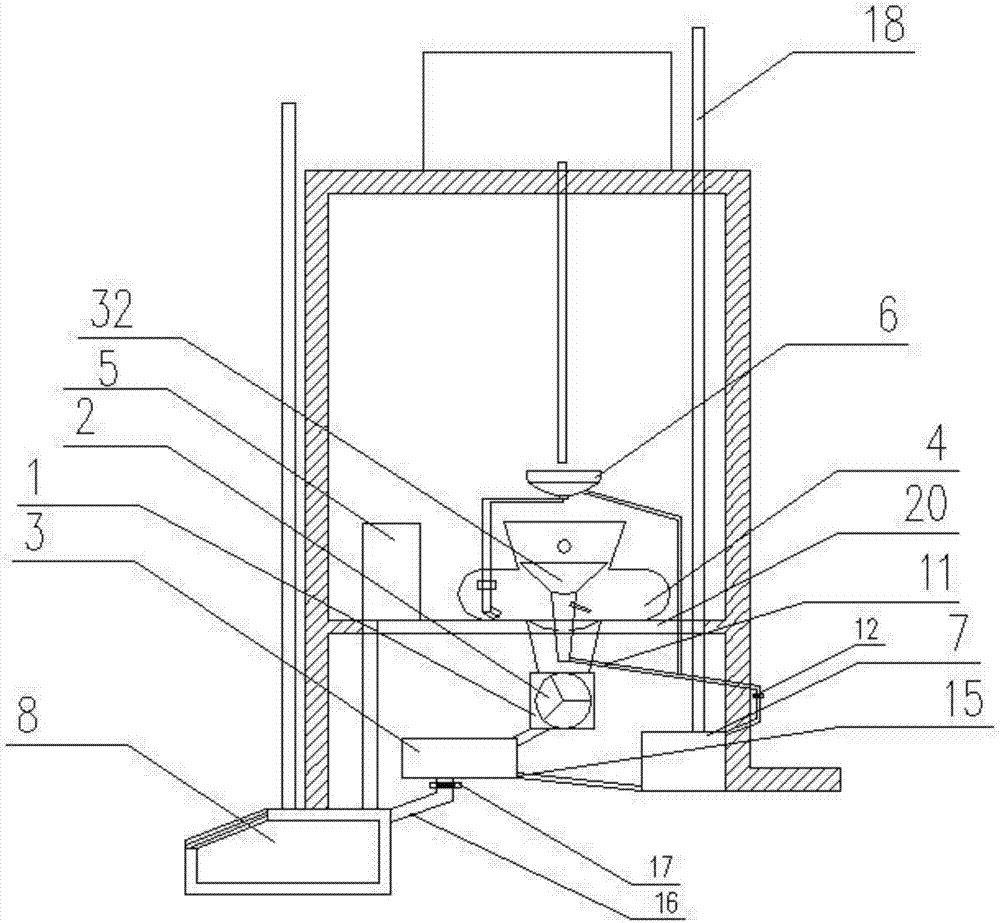

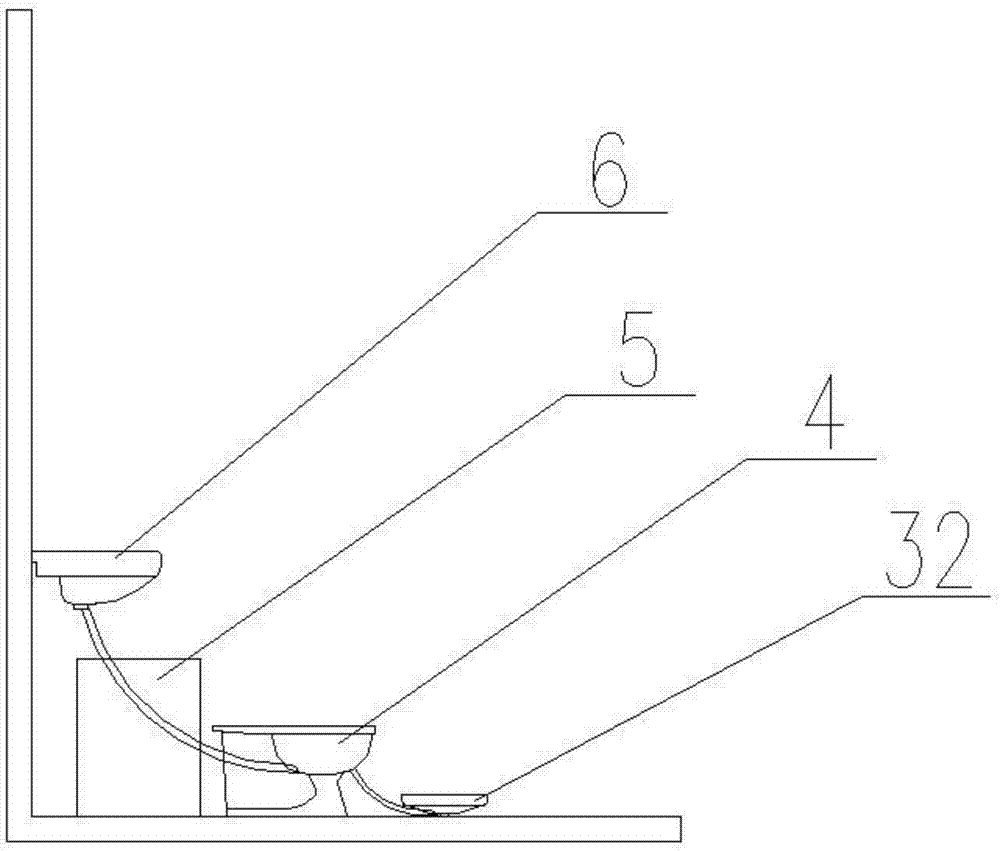

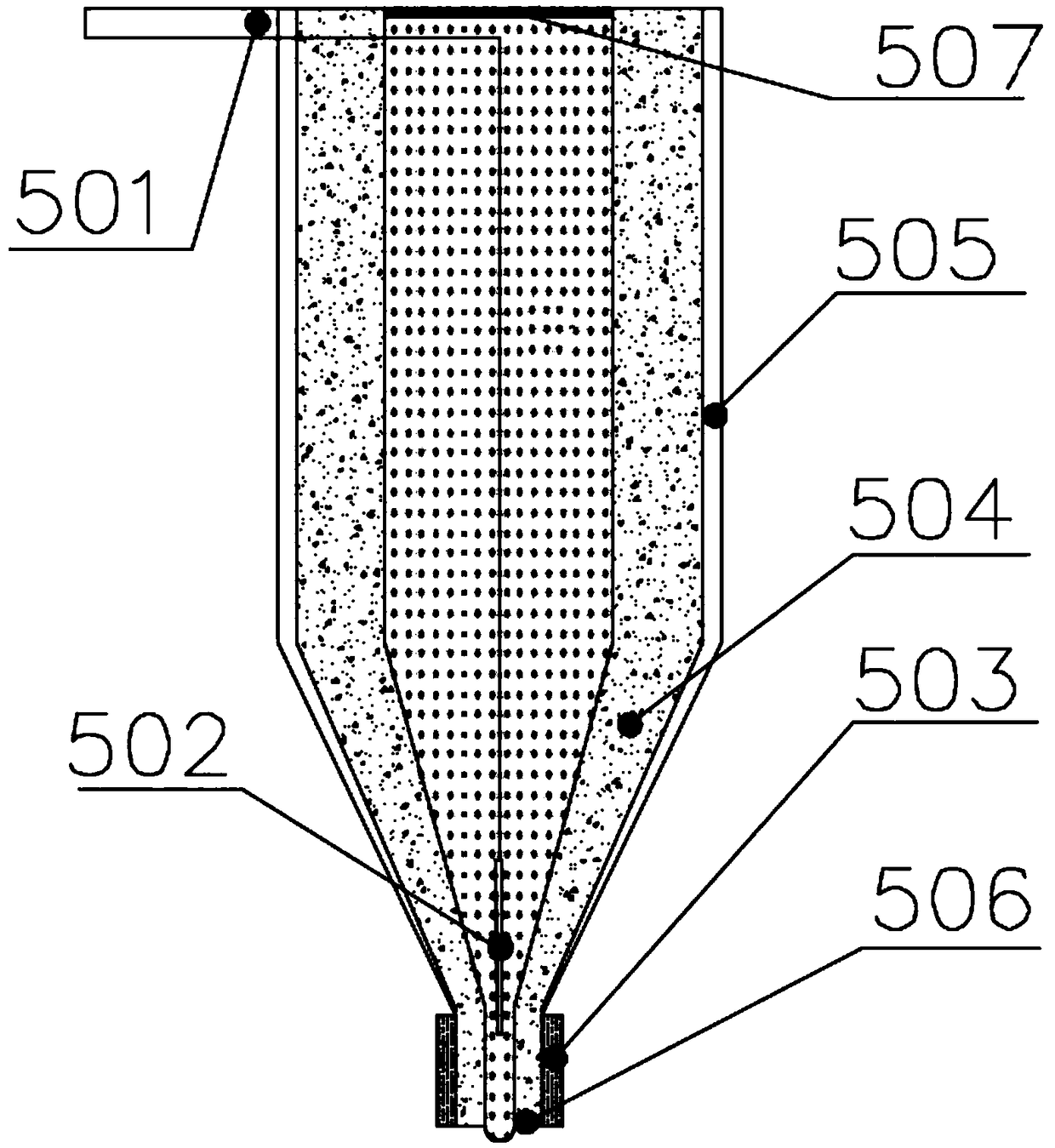

Concrete 3D printing process

ActiveCN106827168AAvoid cloggingEffective controlAdditive manufacturing apparatusCeramic shaping apparatusEngineeringHigh pressure water

The invention relates to a concrete 3D printing process. The process mainly comprises the steps of stirring and delivery of concrete grout, addition of liquid accelerators, addition and stirring of accelerators, cleaning of the interior of a spray head assembly during interruption of printing, recovery of concrete grout and extrusion forming, wherein the concrete grout is stirred in plain opening concrete forced mixer; the concrete grout is pumped out and delivered through a wet type screw-type grout spraying machine; the accelerators are added and stirred through screw rods in an accelerator pump and the spray head assembly; cleaning of the interior of the spray head assembly during interruption of printing is realized through a high-pressure water pump and a stop valve together. By means of the concrete 3D printing process, the concrete grout can be effectively extruded to realize 3D printing; the situation which may occur in the 3D printing process are fully considered and dealt with; and a new method is proposed for application of 3D printing in the building field.

Owner:NANJING UNIV OF TECH +1

Rural water-saving and odorless ecological toilet for separation and collection of faeces and urine

InactiveCN107296561AImprove fertilityGuaranteed nutritionBathroom accessoriesSpecial buildingEngineeringFermentation

The invention discloses a rural water-saving and odorless ecological toilet for separation and collection of faeces and urine. The rural water-saving and odorless ecological toilet for separation and collection of the faeces and urine comprises a faeces pool and a tank body, wherein a bottom plate is arranged in the tank body, and the tank body is divided into an upper part and a lower part through the bottom plate; a toilet bowl is arranged at the upper part of the interior of the tank body, and the faeces pool is arranged below the outside of the tank body; the toilet bowl is communicated with the faeces pool, and the faeces pool is also connected with a dry faeces chamber; the dry faeces chamber is internally provided with a drying device, and the faeces pool is internally provided with a faeces processing device; a rainwater box and a control device are arranged on the top of the outer surface of the tank body, and a solar battery panel is arranged on the control device. Since a bio-fermentation chamber, a liquid fertilizer pool and a dry faeces pool are connected with the faeces pool, every time a toilet user finishes an excrement, separation of the faeces and the urine is conducted firstly, then the faeces in the faces pool is subjected to bio-degradation and temperature-raising dehydration, and solid faeces are processed into faeces blocks or granules which are then stored in the dry faeces pool for weathering and drying; the emitting amount of odor of the faeces after dehydration is greatly reduced, so that the surrounding environment is protected.

Owner:CHINA MCC17 GRP

Rapid waste recycling device of 3D printer

InactiveCN107599411ASpeed up the recycling processShorten the timeAdditive manufacturing apparatusManufacturing recycling3d printerWaste recycling

The invention discloses a rapid waste recycling device of a 3D printer. The rapid waste recycling device of the 3D printer comprises a base plate. The upper surface of the base plate is fixedly connected with a shell through supporting legs. The front face of the shell is fixedly connected with a double-shaft motor. Two output shafts of the double-shaft motor are both fixedly connected with threaded columns. The outer surfaces of the two threaded columns are both connected with nuts in a threaded manner. The back faces of the two nuts are both fixedly connected with squeezing devices. Each squeezing device comprises a connection rod. According to the rapid waste recycling device of the 3D printer, crushed waste falls to the lower surface of the inner wall of the shell, the double-shaft motor is made to rotate forwards, so that the nuts drive squeezing plates to move inwards through the connection rods and sliding rods, the two squeezing plates are close to each other, so that the crushed waste is squeezed, workers do not need to convey the crushed waste to other places for squeezing, so that the waste recycling process is accelerated, the time of the workers is saved, and the production efficiency of an enterprise is improved.

Owner:CHENGDU CHUANGNIAN TECH CO LTD

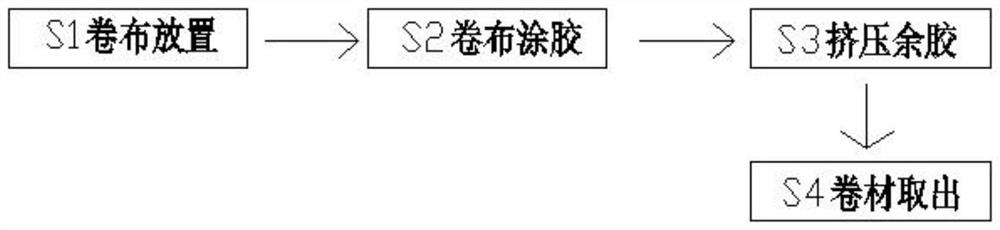

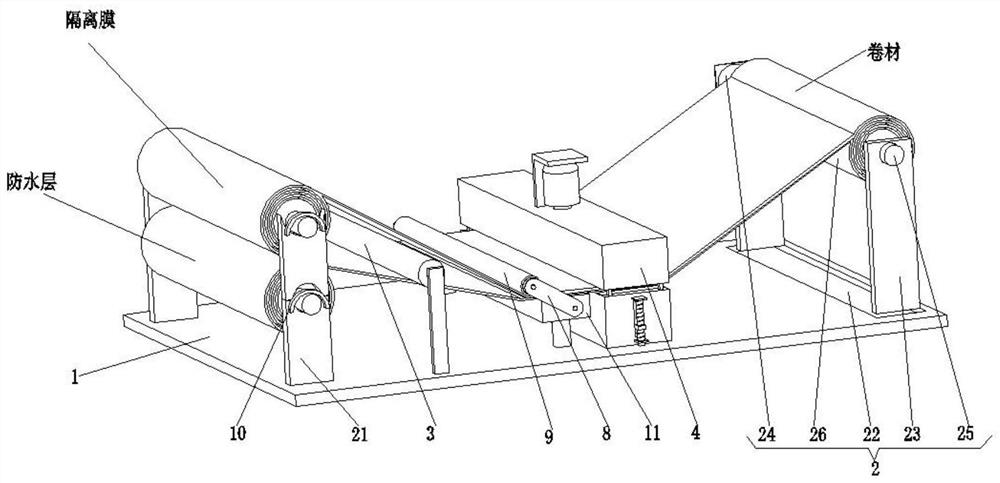

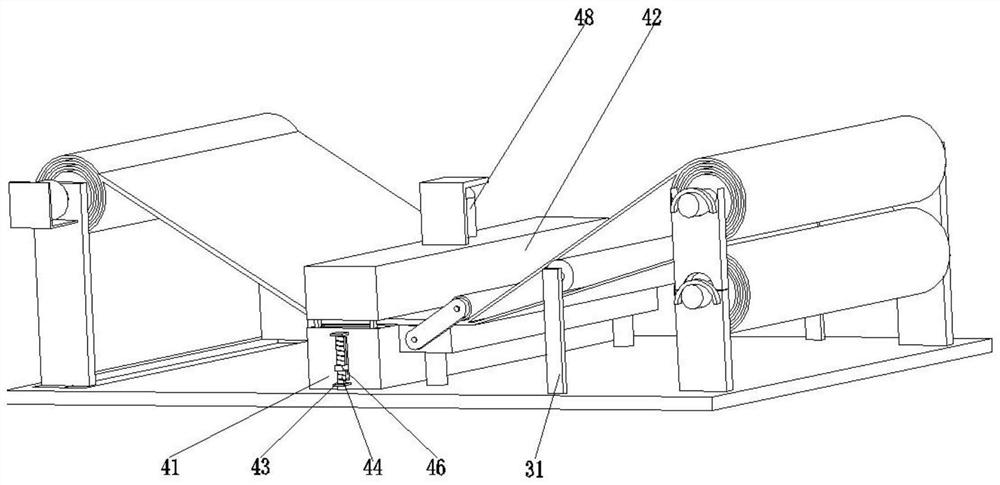

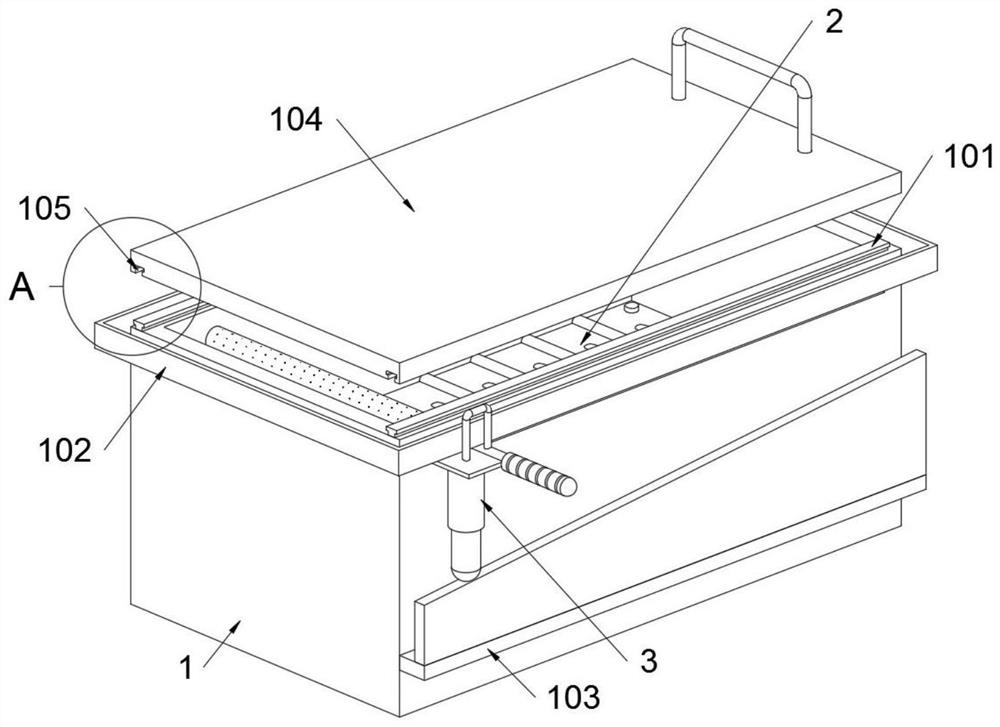

Production method of polyvinyl chloride waterproof coiled material

PendingCN112937061ARealize unloadingAchieve bondingLiquid surface applicatorsLaminationElectric machinePolyvinyl chloride

The invention relates to a production method of a polyvinyl chloride waterproof coiled material. A pasting device is used in the method and comprises a base, a winding and unwinding device, a gluing device, a laminating device and an alignment table. According to the winding and unwinding device, by starting a driving motor, the output end of the driving motor drives a material winding rotating shaft to rotate, and rotation of the material winding rotating shaft drives a material winding roller to rotate, thus achieving unwinding, adhesion and winding of a separation film roll and a waterproof layer roll. According to the laminating device, after an extrusion motor is started, the output end of the extrusion motor drives a center shaft to rotate, the center shaft drives a gear to rotate when rotating, and therefore, two extrusion rollers do repeated opposite movement and relative movement along the middle part of the laminated coiled material, so that bubbles and redundant glue in the laminated waterproof coiled material can be extruded out.

Owner:刘宝琴

Linkage type liquid dead-corner-free cleaning device for medical disinfection instruments

ActiveCN112775083AAchieve extrusionRealize water jet cleaningCleaning using liquidsMedical equipmentReciprocating motion

The invention provides a linkage type liquid dead-corner-free cleaning device for medical disinfection instruments, relates to the technical field of medical equipment, and solves the problems that jet cleaning and rotary cleaning cannot be realized through structural improvement and organic combination of jet cleaning and rotary cleaning cannot be realized through structural improvement. The linkage type liquid dead-corner-free cleaning device for the medical disinfection instruments comprises a box body, wherein a placing structure is arranged in the box body, and a cleaning structure is slidably connected to the box body. Due to the fact that the head ends of poke rods make contact with the top end face of a placing plate and the poke rods form a protruding extrusion structure, when a handle moves, reciprocating motion of the placing plate can be synchronously achieved, and then jet spraying at cleaning holes is achieved. Fourthly, bulges are welded on the placing plate in a rectangular array shape, the bulges are of semi-cylindrical structures, and the bulges welded in the rectangular array shape jointly form an auxiliary supporting structure of medical supplies, so that gaps can be reserved between the medical supplies and the cleaning holes.

Owner:TIANJIN YUPING INSTR TECH CO LTD

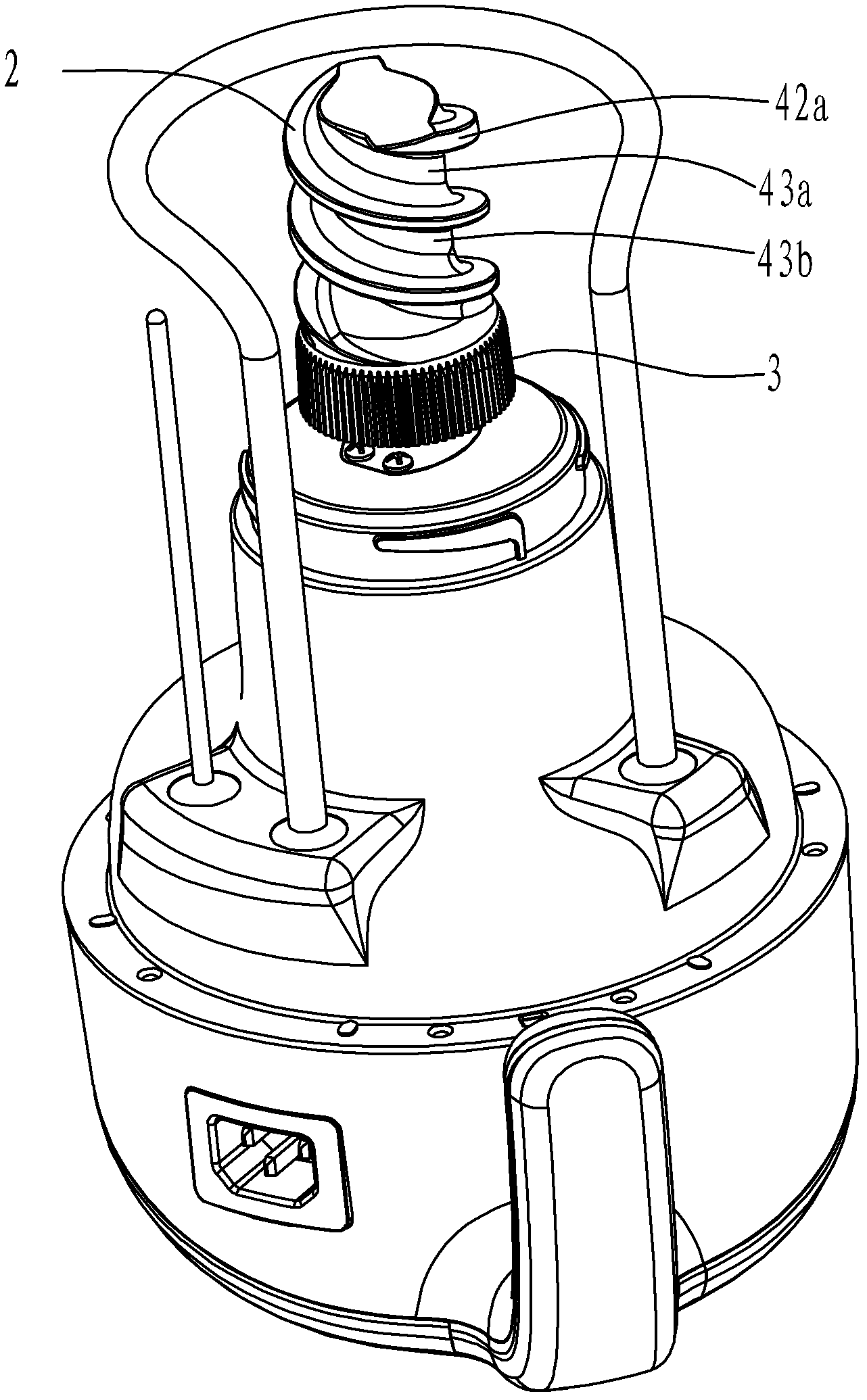

Grinding mechanism for bean juice maker

InactiveCN102204791AAchieve smashAchieve mechanical mass productionBeverage vesselsMilk substitutesMechanical engineeringGrinding process

The invention belongs to the field of small kitchen appliances and relates to a bean juice maker, and in particular to a grinding mechanism for the bean juice maker. The grinding mechanism comprises a static grinding assembly comprising a static grinding head and a movable grinding head which is arranged in the static grinding assembly and is matched with the static grinding assembly, the side wall of the static grinding assembly is provided with guide holes, and the grinding mechanism is characterized in that a clearance is gradually reduced from bottom to top when the static grinding assembly is matched with the movable grinding head, thus a rotary sucking part and a grinding part are formed, and the grinding part is longitudinally arranged above the rotary sucking part. When material is prepared, the material is sucked by the rotary sucking part and is fed into the grinding part to be ground and smashed. The clearance is simultaneously gradually reduced from bottom to top, thus a coarse to fine grinding process on the material is realized. The grinding mechanism for the bean juice maker in the invention has good grinding effect, and the grinding head is easy to process and is resistant to abrasion.

Owner:ZHEJIANG SHAOXING SUPOR DOMESTIC ELECTRICAL APPLIANCE CO LTD

Vehicle slipping preventing device for parking lot

InactiveCN111042609APrevent rollingEnsure safetyAlarmsElectric/electromagnetic audible signallingControl theoryVehicle safety

The invention discloses a vehicle slipping preventing device for a parking lot and relates to the technical field of parking lot management. The vehicle slipping preventing device comprises a supportframe, an antiskid structure, a slope plate, an alarm structure and a slipping preventing structure, wherein the antiskid structure is mounted on the top side of the support frame, the slope plate isarranged at one end of the support frame, and the slipping preventing structure is arranged at the other end of the support frame. By arrangement of the antiskid structure and the slipping preventingstructure, a handle is rotated according to the gradient of a slope to drive a screw rod to rotate to drive a slider to move along a guide rail, so that the included angle between a baffle and a support plate is changed; a vehicle is blocked by the baffle, vehicle slipping can be avoided timely, and the safety of the vehicle and surrounding vehicles can be guaranteed; and during parking of the vehicle, as the vehicle is parked on the slope, wheels are located on the top side of an upper cross beam, during movement of the vehicle, ends of a plurality of rubber columns are tangent to outer sidesof the wheels under the action of telescopic springs, the road gripping force of the wheels is increased, slipping on rainy days is avoided, and the vehicle safety is protected.

Owner:陕西铭泊停车服务有限公司

Municipal garbage treating device

InactiveCN109174900APrevent proliferationPlay a role of buffer protectionSolid waste disposalTransportation and packagingSolid particleEngineering

The invention discloses a municipal garbage treating device. The device comprises a device main body, a pulverizing area, a first collecting vehicle and a second collecting vehicle, wherein a motor isfixedly connected on the inner surface, which is below the top of the device main body, of the rear wall of the pulverizing area; a second pulverizing roller is fixedly connected at the front end ofan output shaft of the motor; a first pulverizing roller meshed with the second pulverizing roller is arranged at the right side of the second pulverizing roller; a first isolating plate is arranged below the pulverizing area; the first collecting vehicle is placed below the first isolating plate; the second collecting vehicle is arranged at the left side of the first collecting vehicle; and a first driving wheel which is fixedly connected on the output shaft of the motor and arranged at the rear side of the second pulverizing roller is connected with a second driving wheel via a conveyor belt. The device disclosed by the invention has the advantages that the device has a simple structure and various functions; garbage in the second collecting vehicle can be squeezed to separate solid particles from liquid; primary treatment is carried out on the liquid; and the device is convenient to move.

Owner:YANCHENG BILLION CONNAUGHT MACHINERY CO LTD

Magnetic disk crushing device for electronic component production

InactiveCN108636502AAchieve extrusionPlay the role of crushing and pressurizingGrain treatmentsInterference fitGear wheel

The invention discloses a magnetic disk crushing device for electronic component production. The magnetic disk crushing device for electronic component production comprises a base, a crushing box, crushing rolls, a cam and crushing knives, wherein a slide way is fixedly installed on the inner walls of the left side and the right side in the crushing box through a screw separately; an extrusion plate is slidably installed on each slide way; a first spring is connected between the outer side of each extrusion plate and the inner wall of the crushing box; an ejection rod is welded to the outer side of each extrusion plate; a plurality of groups of crushing rolls are further installed in the crushing box; and a plurality of groups of crushing knives are installed on a crushing shaft in a manner of interference fit. A first bevel gear is connected with a second bevel gear in an engagement manner, so that a cam starts to rotate, the cam intermittently drives the extrusion plates to move towards the inner side to realize intermittent extrusion for the extrusion plates, and meanwhile, the role of crushing pressurization is played in combination with the action of the crushing rolls, so that the crushing effect is greatly improved; and meanwhile, secondary crushing for a magnetic disk can further be indirectly driven, the crushing effect for the magnetic disk is greatly improved throughthe secondary crushing for the magnetic disk, and the case that primary crushing is insufficient is avoided.

Owner:广西川嘉科技有限公司

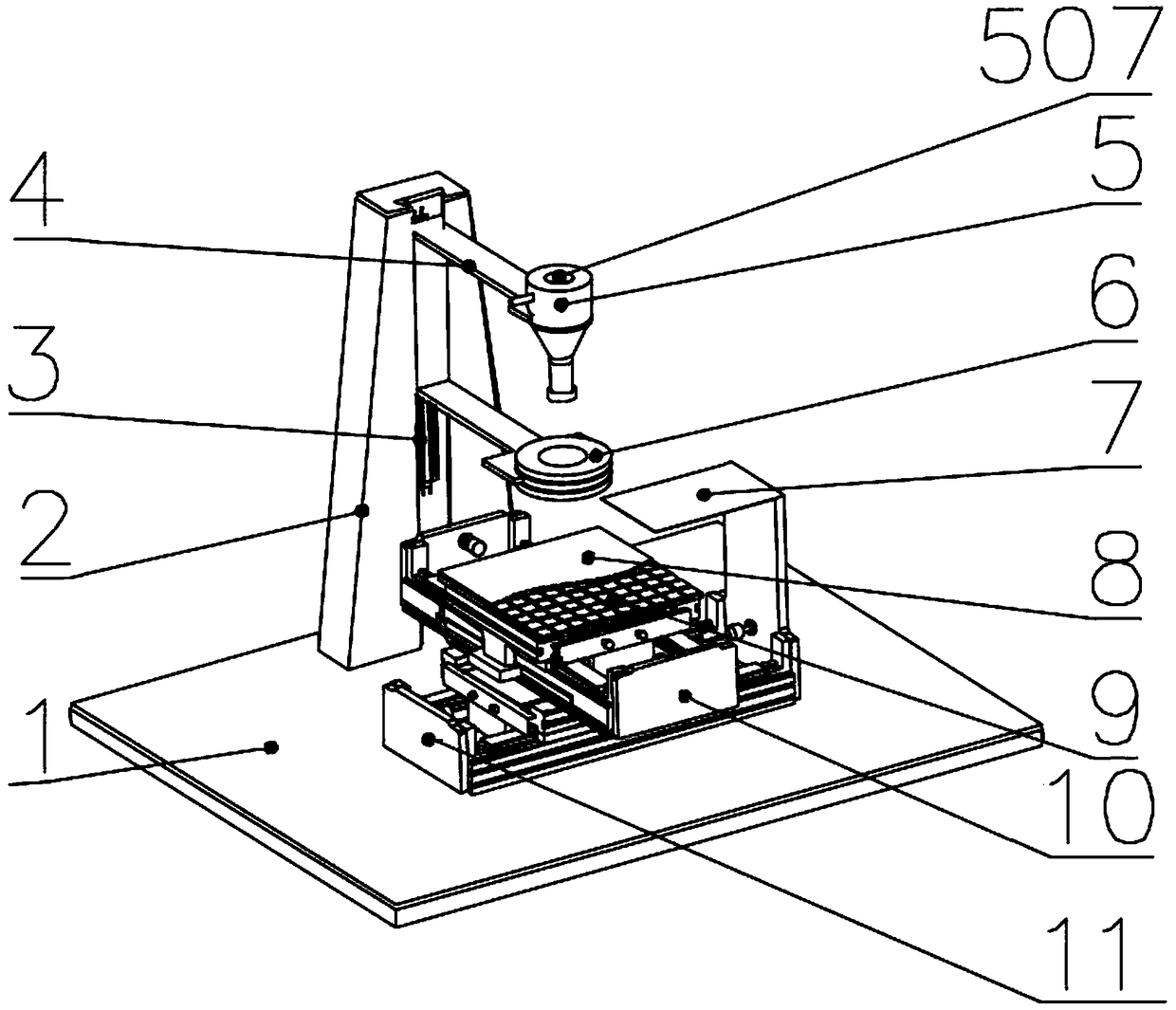

Additive manufacturing device and method for micro-system three-dimensional structure

PendingCN109049674AEnabling Additive ManufacturingAchieve extrusionAdditive manufacturing apparatus3D object support structuresElectrode arrayHigh frequency

The invention relates to an additive manufacturing device and method for a micro-system three-dimensional structure, and belongs to the field of additive manufacturing. A high-viscosity microdroplet extrusion nozzle is fixed to a guide upright column through a supporting frame, an X-axis moving device is fixed to a base, a Y-axis moving device is fixed to the X-axis moving device, a deflection electric field electrode is installed on the guide upright column through a Z-axis moving device, a dielectric layer adheres to an electrode array, the electrode array is fixed to the Y-axis moving device, and a polarization module is fixed to the base and above the dielectric layer. According to the device and method, a layered manufacturing technology is utilized, the technical characteristic thatliquid material droplets solidify and are formed under a pulsed electric field, and the precise control over additive manufacturing is realized by using a pulsed electric field separation technology.Accurate jetting of the micron-scale droplets is achieved by adjusting voltage parameters so as to achieve high-viscosity liquid high-frequency jetting.

Owner:JILIN UNIV

Uninterruptible power ammeter replacement device

InactiveCN110108911AEasy to replaceShorten the timeTime integral measurementEngineeringElectricity meter

The invention provides an uninterruptible power ammeter replacement device, which comprises a box. The box is internally provided with a first insulating mounting board and a second insulating mounting board; a detachable ammeter is mounted on the first insulating mounting board; an ammeter adapter matched with the detachable ammeter is also mounted on the first mounting board; multiple drainage bases are mounted on the ammeter adapter; the drainage base is provided with multiple first electrified jacks; a safety switch is mounted on the second insulating mounting board; and a lighting lamp isconnected to the safety switch. According to the uninterruptible power ammeter replacement device disclosed in the invention, ammeter replacement is facilitated, the ammeter replacement time is shortened, manual cost for ammeter replacement is reduced, and the ammeter can be prevented from being damaged in the case of ammeter replacement.

Owner:NINGHAI COUNTY POWER SUPPLY BUREAU

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com