Grinding mechanism for bean juice maker

A technology of a grinding mechanism and a soymilk machine, which is used in milk substitutes, beverage preparation devices, household appliances, etc., can solve the problems of unfavorable coarse to fine pulverization, difficult to clean, and difficult to achieve fine pulverization of soybean milk particles, and achieves easy processing and easy processing. cleaning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

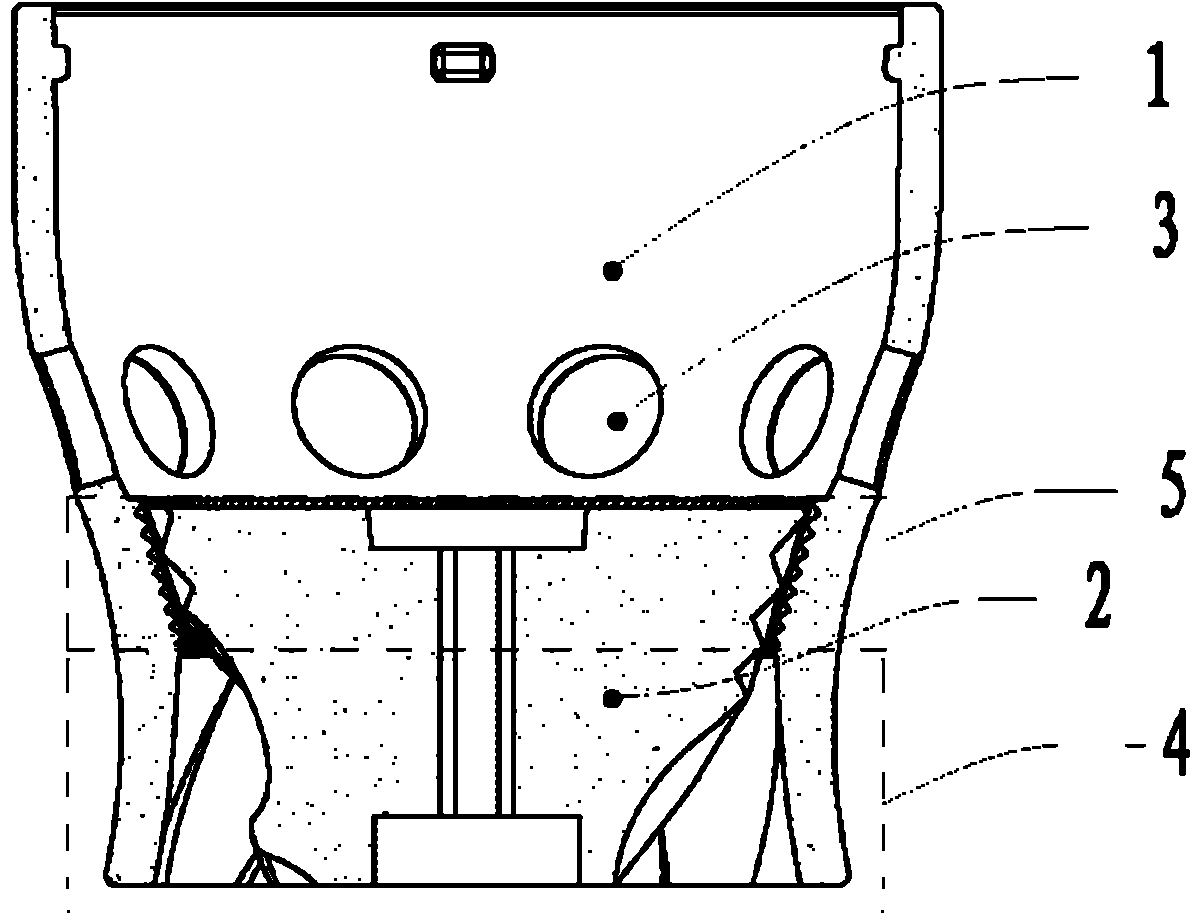

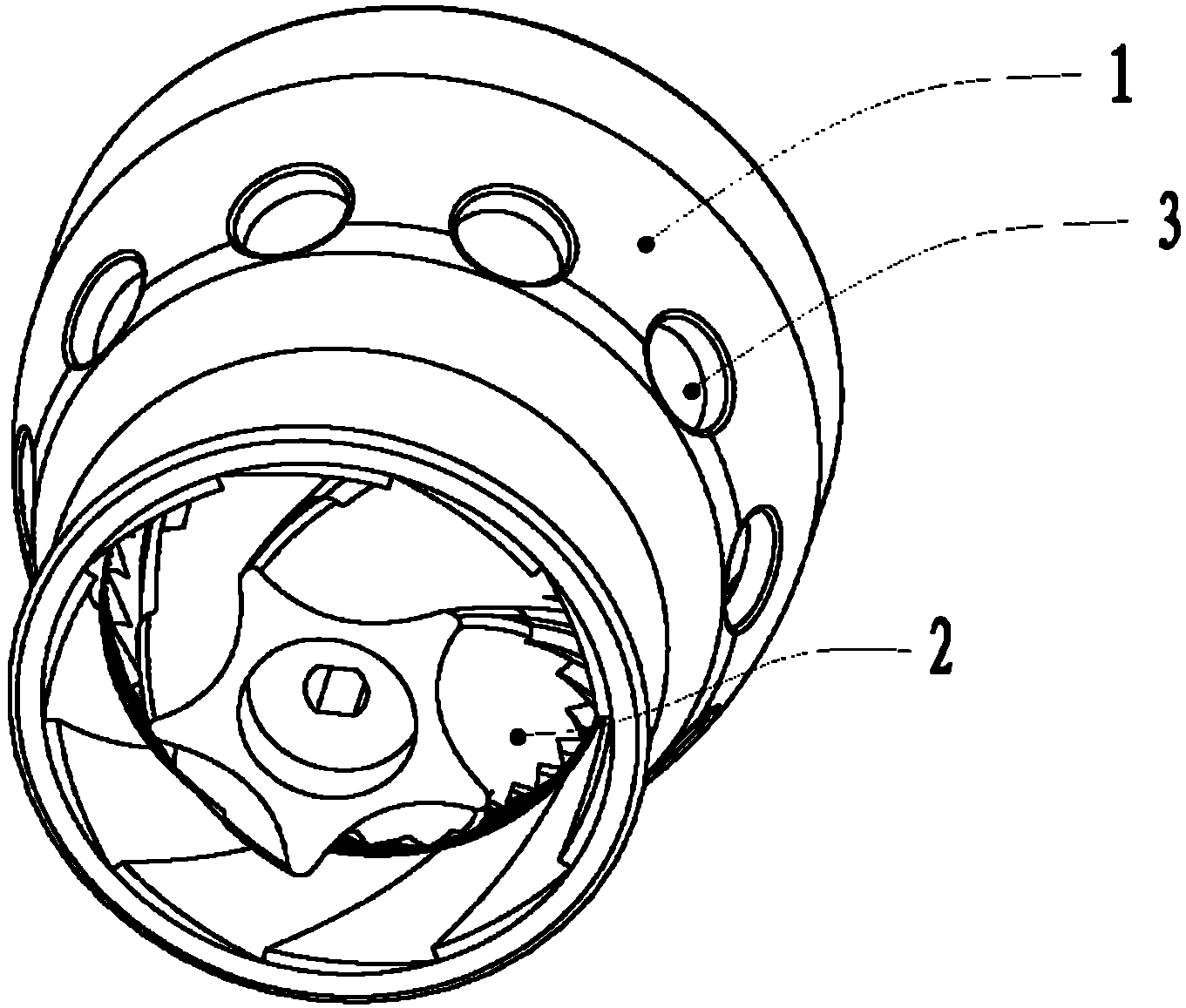

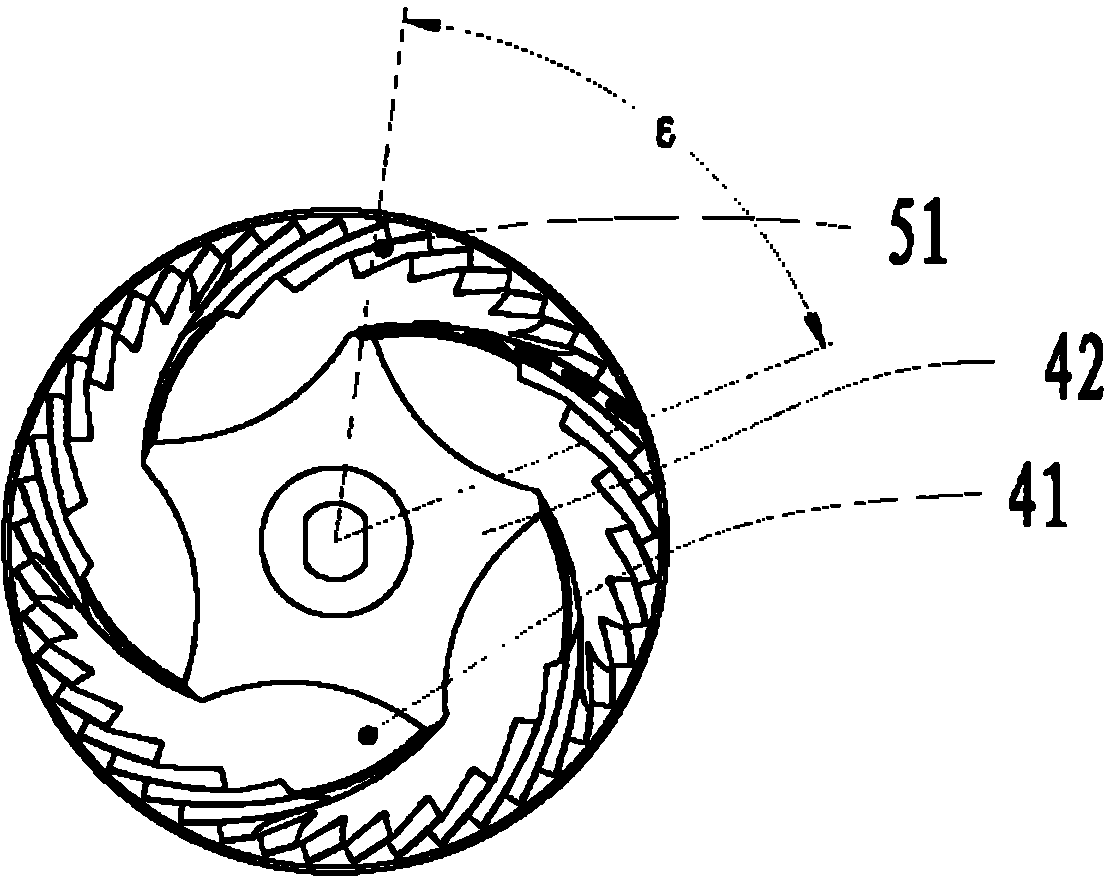

[0061] See attached Figure 1~14 , a soybean milk machine grinding mechanism, including a static grinding assembly containing a static grinding head 1 and a dynamic grinding head 2 arranged in the static grinding assembly and matched with the static grinding assembly, the side wall of the static grinding assembly is provided with a flow guide hole 3. The fitting gap between the static grinding assembly including the static grinding head 1 and the moving grinding head 2 forms the spin suction part 4 and the grinding part 5 from bottom to top, the spin suction part 4 gradually becomes smaller from bottom to top, and the grinding part 5 Place it vertically above the whirling part 4.

[0062] When making materials, the materials are sucked up by the spin suction part 4 and enter the grinding part 5 for grinding and pulverization. At this time, the gap gradually becomes smaller from bottom to top, realizing the grinding process of materials from coarse to fine.

[0063] The movin...

Embodiment 2

[0085] Such as Figure 15~17 As shown, the material guide teeth of this embodiment are different from those of Embodiment 1, and have the same technical effects as Embodiment 1 in other places, so details will not be repeated here.

[0086] In this embodiment, an impeller is arranged under the material guide teeth, and the impeller is roughly in the shape of a sheet.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com