Patents

Literature

515results about How to "Achieve smash" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

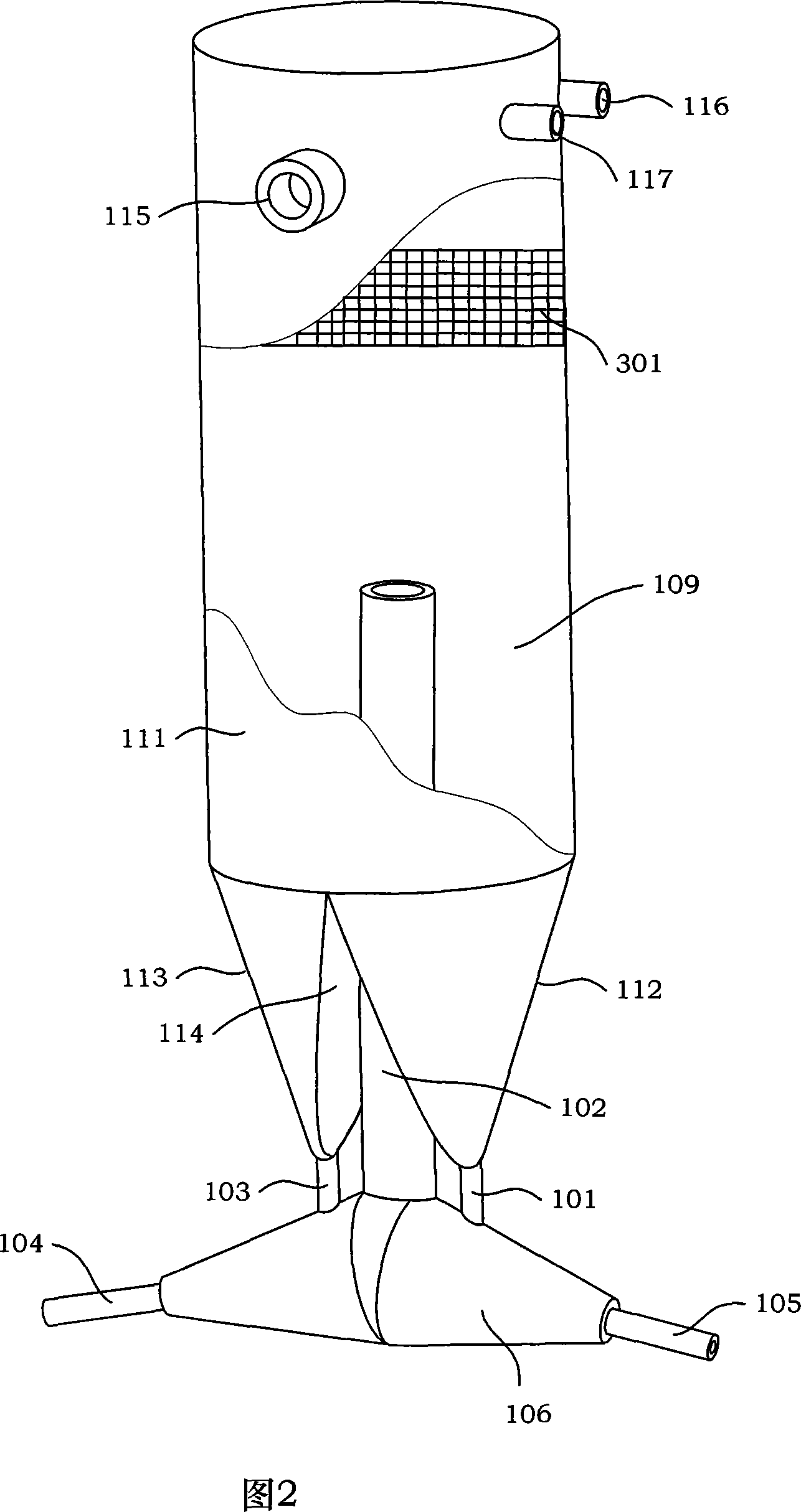

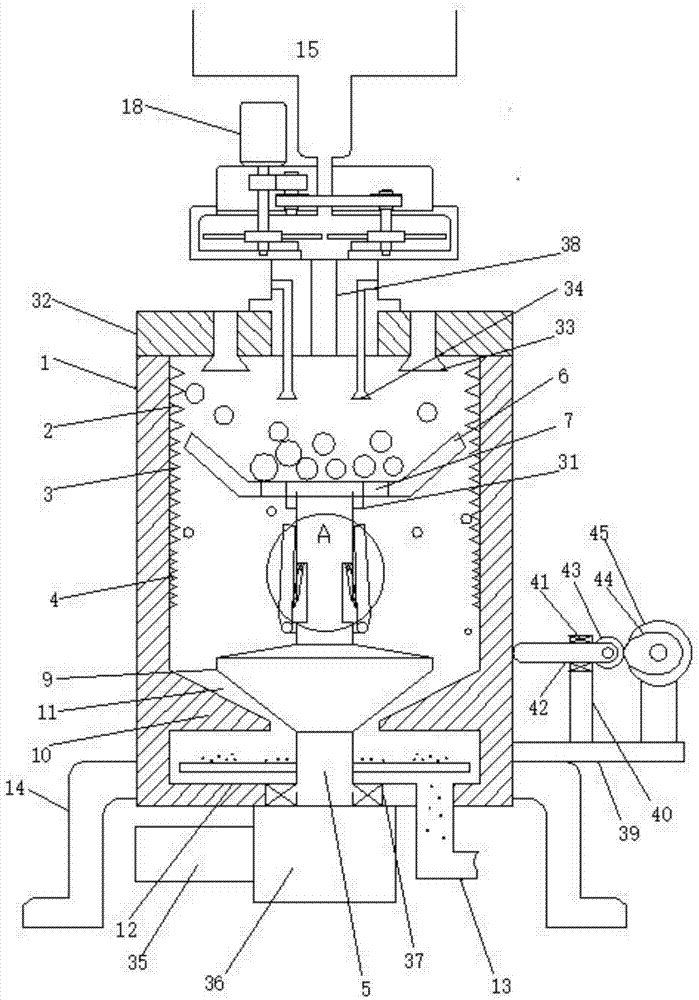

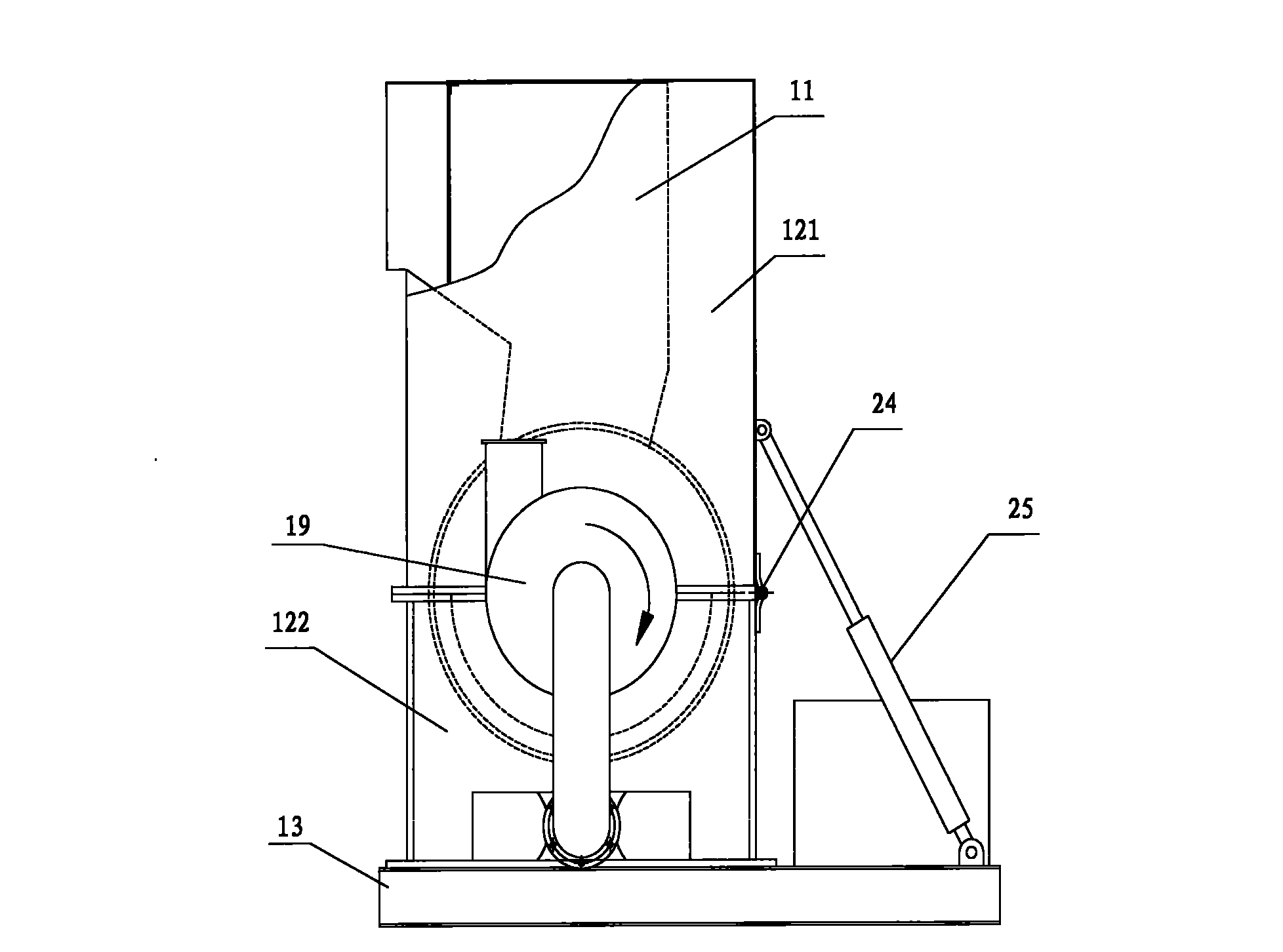

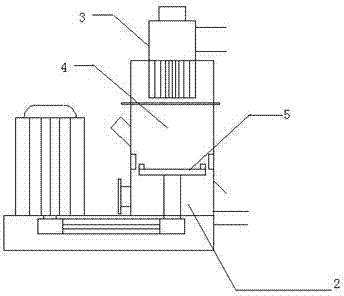

Technique and equipment for preparing Nano granules in high purity by using method of comminution by gas stream

InactiveCN101049580AEasy accessGood for collision smashingDispersed particle filtrationGrain treatmentsNanoparticleEngineering

An apparatus for preparing high-purity nanoparticles by airflow pulverizing method is composed of an air source system, a pulverizing system consisting of left and right reflux pipes and flow-up pipe to form a circulating loop of material, and air-solid separating system. Its process features that the raw material is carried by two supersonic jets for mutual and cyclic collision to obtain nanoparticles.

Owner:BEIHANG UNIV

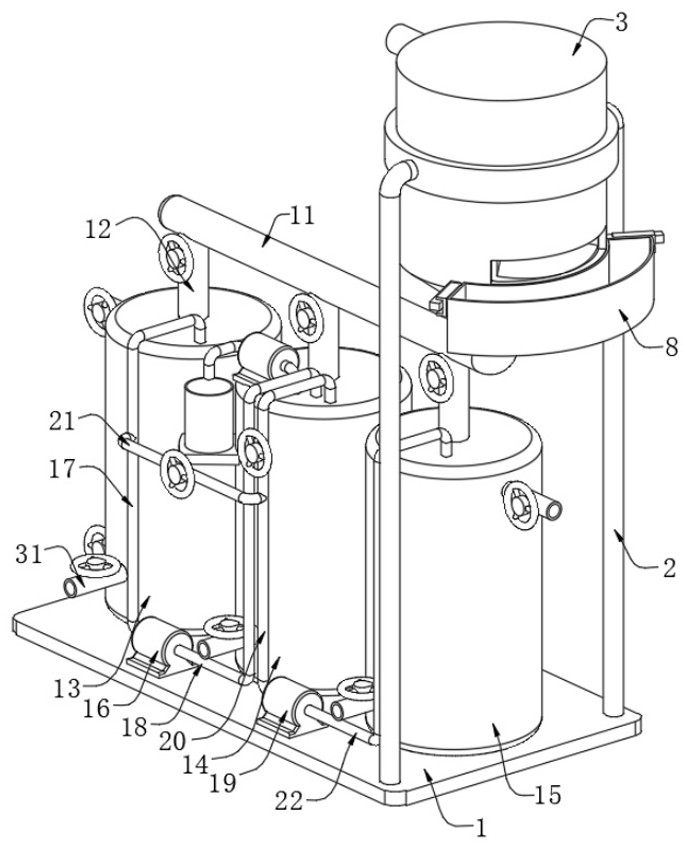

Oily sludge treatment system and treatment method thereof

PendingCN106746420AGood processing effectEasy to handleWaste water treatment from quariesSievingWater storageSludge

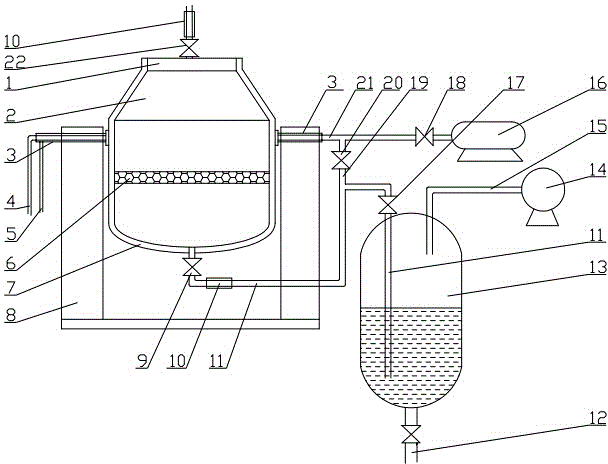

The invention discloses an oily sludge treatment system and a treatment method thereof. The treatment system comprises crushing equipment, a vibrating screen, a precipitation device, an ejector, a high-speed crushing device, a water storage device and separation device for separating oil, water and sludge, wherein the crushing equipment is used for primarily crushing oily sludge and is provided with an oil slick space and a first oil slick outlet which can be opened and closed; the vibration screen is located at the upper part of the precipitation device; the precipitation device is used for precipitating the screened oily sludge; the high-speed crushing device is used for crushing the oily sludge into fine particles; the precipitation device is sequentially connected with the ejector, the high-speed crushing device and the separation equipment; a water outlet of the water storage device is connected with a water inlet of the ejector. The treatment system can be applicable to dewatering of various oily sludges, meanwhile, the oil rate of the oily sludge can be reduced to below 3%, oil can be recovered to the maximal extent and secondary pollution of wastewater is not generated.

Owner:仇霞霞

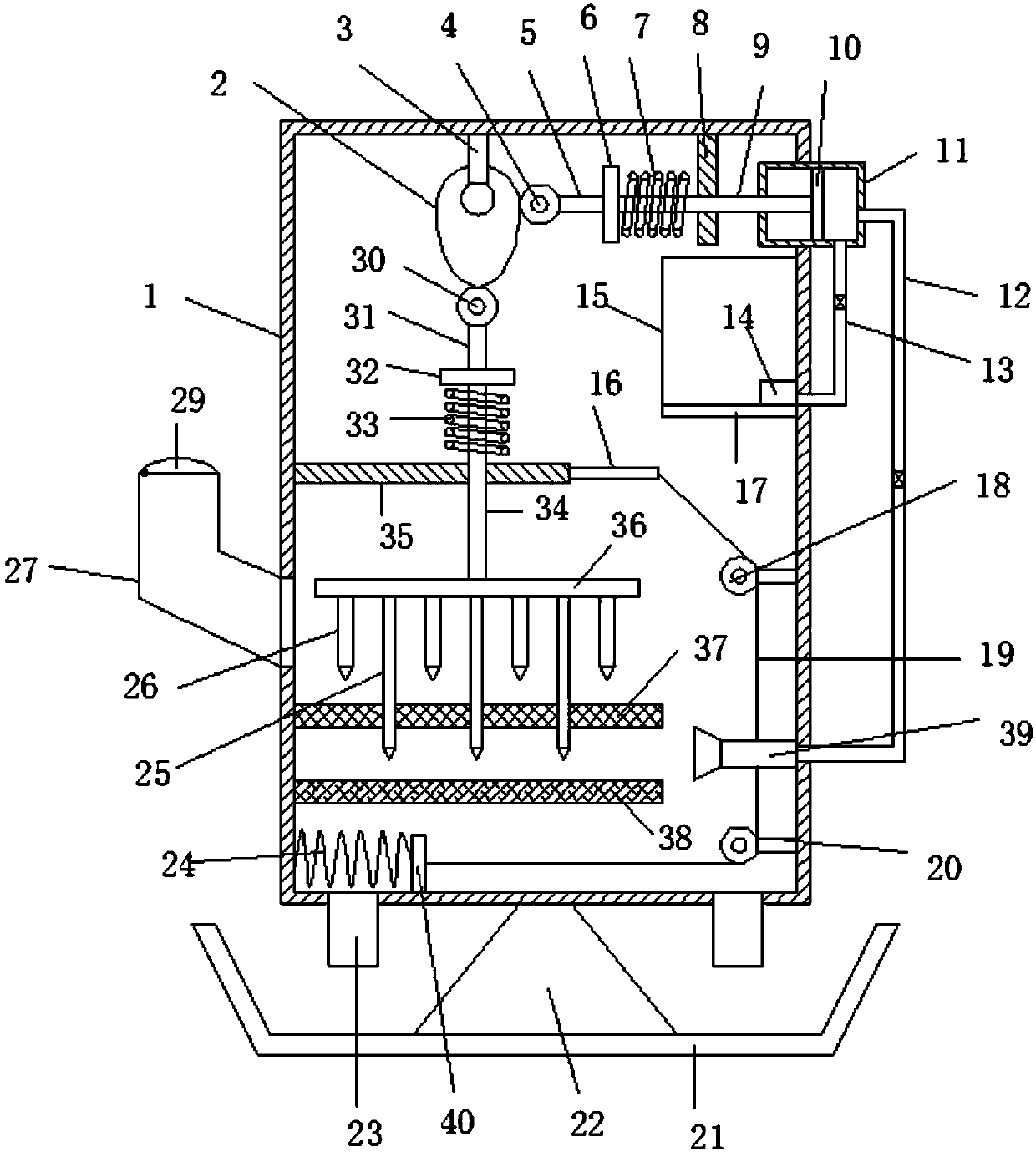

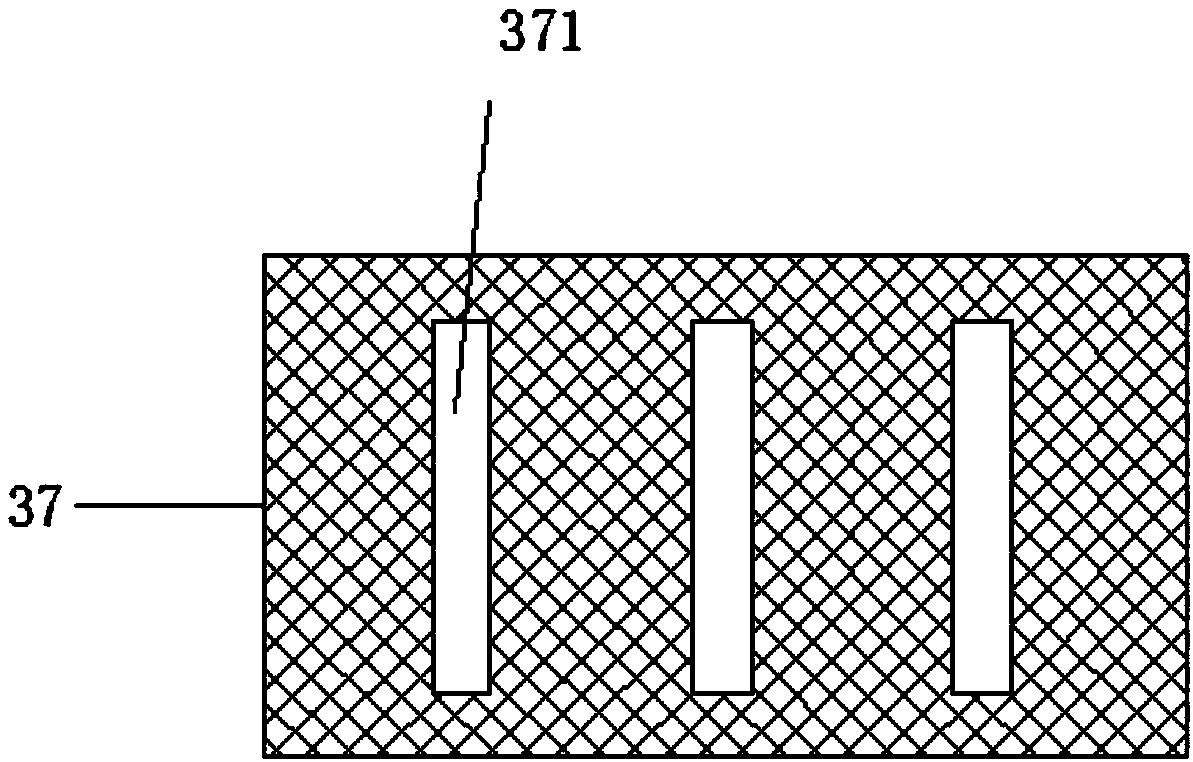

Dedicated environment-friendly soil treatment and remediation device for municipal engineering gardens

InactiveCN107583950AReasonable structureInnovative designContaminated soil reclamationGrain treatmentsSoil treatmentPollution soil

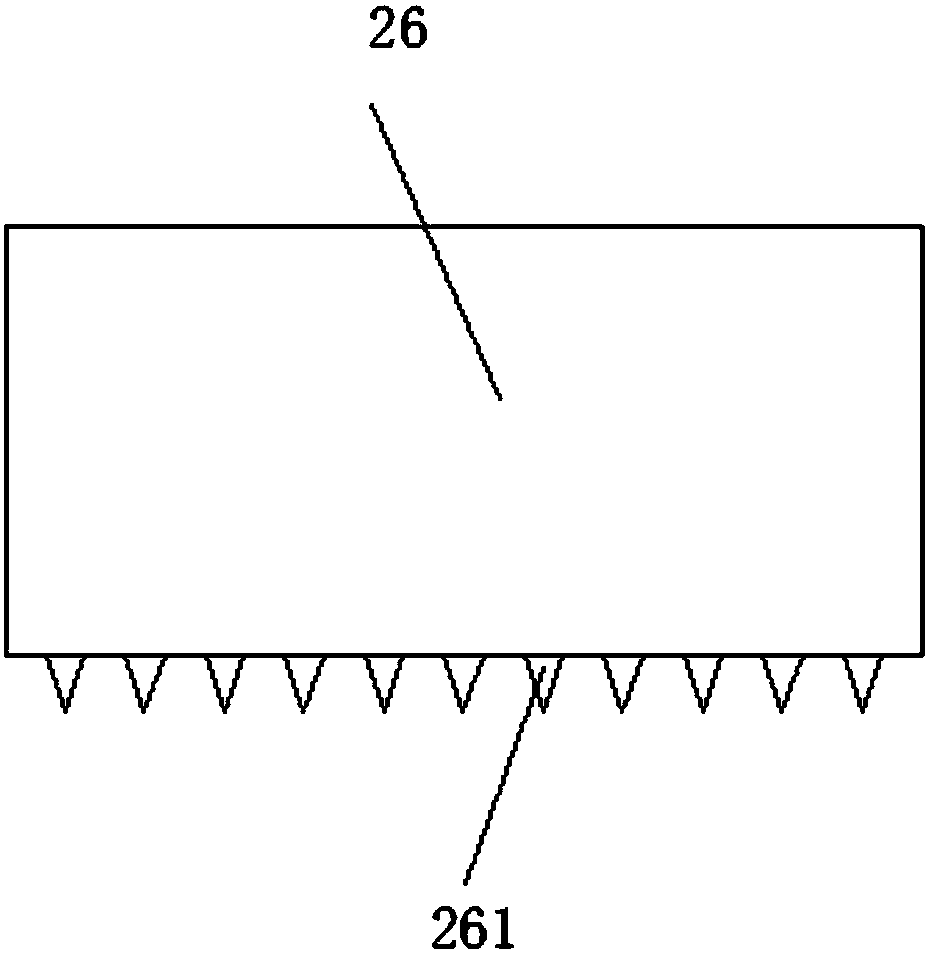

The invention discloses a dedicated environment-friendly soil treatment and remediation device for municipal engineering gardens. The dedicated environment-friendly soil treatment and remediation device comprises a remediation box, wherein a fixed frame is arranged at the upper end of an inner wall of the remediation box, a rotary cam is arranged in the middle of the lower end of the fixed frame,the lower end of the rotary cam is in contact with a first idler wheel, a first limit rod is connected to the lower end of the first idler wheel, a first limit plate is arranged in the middle of the lower end of the first limit rod, a first movable rod is arranged in the middle of the lower end of the first limit plate, a lifting plate is connected to the tail end of the first movable rod, long smashing plates and short smashing plates are evenly arranged at the lower end of the lifting plate, the right end of the rotary cam is in contact with a second idler wheel, a second limit rod is arranged in the middle of the right end of the second idler wheel, a second limit plate is arranged at the right end of the second limit rod, a second movable rod is arranged in the middle of the right endof the second limit plate, and a piston plate is arranged at the right end of the second movable rod. The dedicated environment-friendly soil treatment and remediation device achieves smashing, chemical spraying and remediating effects on polluted soil, improves a remediation effect on garden soil and meets a requirement in remediating the soil in large scale.

Owner:刘彬

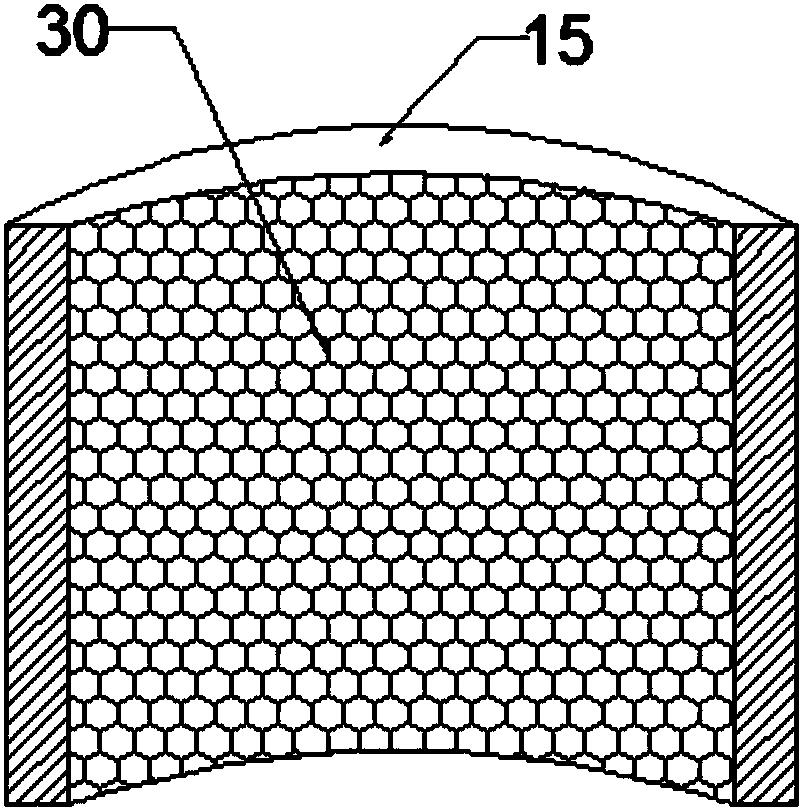

Solid-liquid separation device and method for producing Hopcalite

ActiveCN104689637AReasonable structureRealize solid-liquid separationFiltration circuitsMetal/metal-oxides/metal-hydroxide catalystsAir compressionVapor–liquid separator

The invention discloses a solid-liquid separation device and a method for producing Hopcalite, relating to the field of solid-liquid separation devices of chemical reaction products and catalyst preparation. The device comprises a sealed tank, wherein a feed opening is formed in the top of the sealed tank, a filtering layer is arranged at the lower middle part in the sealed tank, a rotating shaft is arranged on the outer side of the sealed tank, and the rotating shaft is a hollow shaft and is connected with a power overturning device; the upper side of the filtering layer in the sealed tank is connected with an air compressor through the rotating shaft and an air compression pipeline; a drain valve and a drain pipeline are arranged at the bottom of the sealed tank, the other end of the drain pipeline is connected with a gas-liquid separator, the top of the gas-liquid separator is connected with a vacuum pump through a vacuum pipeline, and a liquid outlet is formed in the bottom of the gas-liquid separator; the air compression pipeline is connected with the drain pipeline through a pipeline, and valves, liquid inlet valves and air compression valves are respectively arranged on the pipeline, the drain pipeline and the air compression pipeline. The device is good in solid-liquid separation effect and is high in production efficiency; when the device is used for producing Hopcalite, the cost is low, the production cycle is short, potassium sulfate and sodium sulfate can be respectively recovered, and thus the potassium sulfate and the sodium sulfate can be recycled.

Owner:邯郸市同俊达矿山设备股份有限公司

Novel method for producing ethanol through steam explosion of cereal starchy material

InactiveCN102002516AEmission reductionReduce energy consumptionBiofuelsFermentationSteam pressureFermentation

The invention belongs to the technical field of bio-ethanol production, in particular relating to a novel method for producing ethanol through the steam explosion of a cereal starchy material, which comprises the following steps: pre-treating the cereal starchy material; carrying out the steam explosion for 0.00875 to 1s under the steam pressure of 1-4kPa, and the pressure time is kept for 2-120s; and collecting the exploded material; and then carrying out saccharification and fermentation to produce the ethanol. The novel method for producing the ethanol through the steam explosion of the cereal starchy material is applied, so that the process automation is improved, the production cost of products is reduced by 10-30%, the production resources and space can also be saved, thereby playing important roles in the energy saving and emission reduction as well as the improved economic efficiency.

Owner:HENAN AGRICULTURAL UNIVERSITY +1

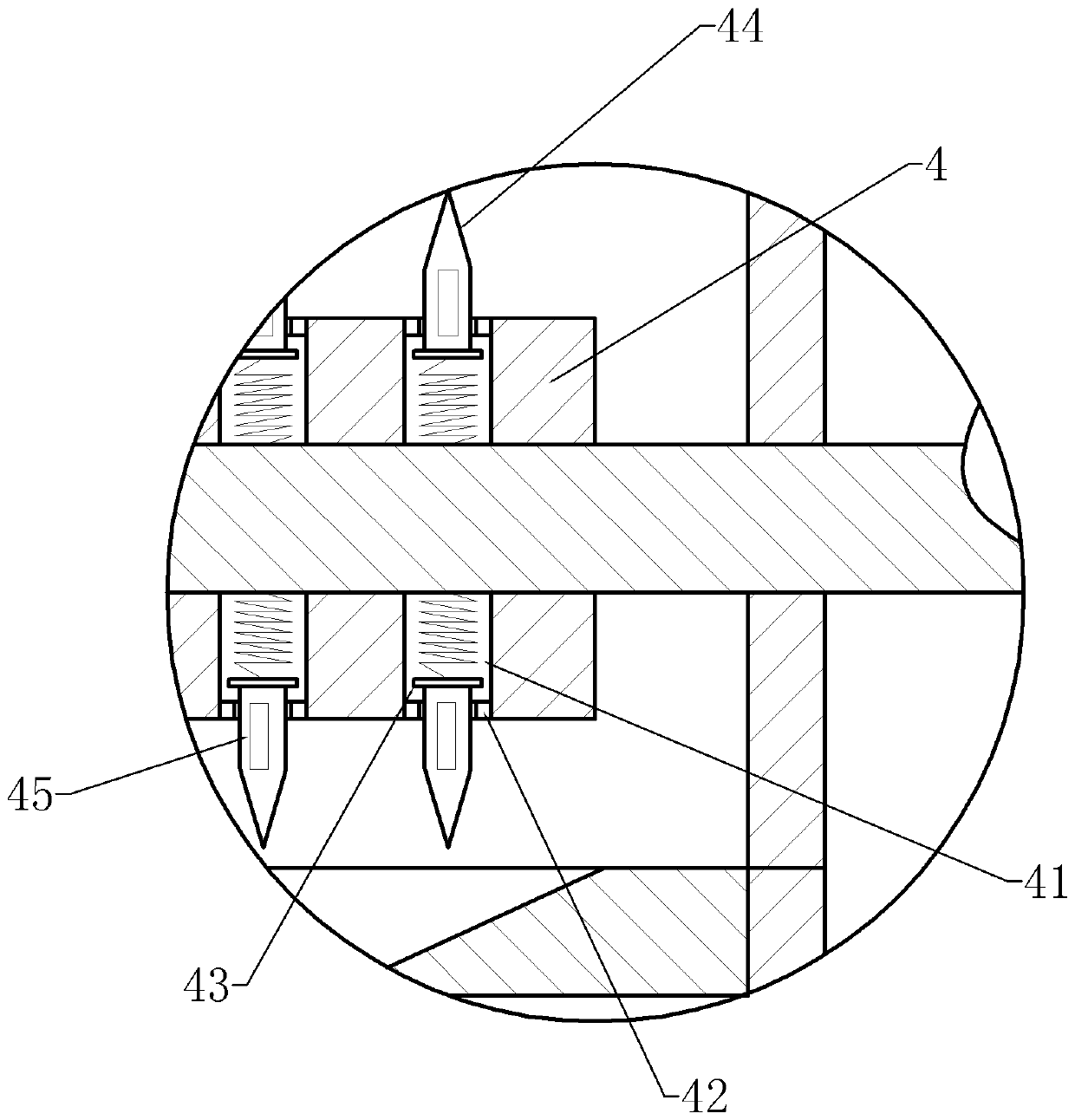

Uniform crushing device for rubber

The invention belongs to the technical field of crushing machinery, and discloses a uniform crushing device for rubber. The uniform crushing device for rubber comprises a machine body, wherein a firstcrushing bucket, a second crushing bucket and a receiving bucket are arranged in the machine body, a first rotary shaft and a second rotary shaft are rotationally connected in the first crushing bucket, and a crushing roll knife is arranged on each of the first rotary shaft and the second rotary shaft; a third rotary shaft is rotationally connected in the second crushing bucket, and vertical to the first rotary shaft; a sleeve is arranged on the third rotary shaft, a plurality of through holes are formed in the sidewall of the sleeve, and a first shearing knife and a spring are arranged in each through hole; two material-stopping plates are further arranged in the second crushing bucket, a compression spring is arranged between each of the two material-stopping plates and the second crushing bucket, and a second shearing knife is arranged on each material-stopping plate; and a strip-shaped magnet is arranged in each of the first shearing knife and the second shearing knife. The uniform crushing device for rubber solves the problems that the crushed rubber particles are non-uniform in particle size, and the rubber particles with large particle sizes need to be crushed again, so that the crushing time is long, in the prior art.

Owner:CHONGQING WEIXING RUBBER

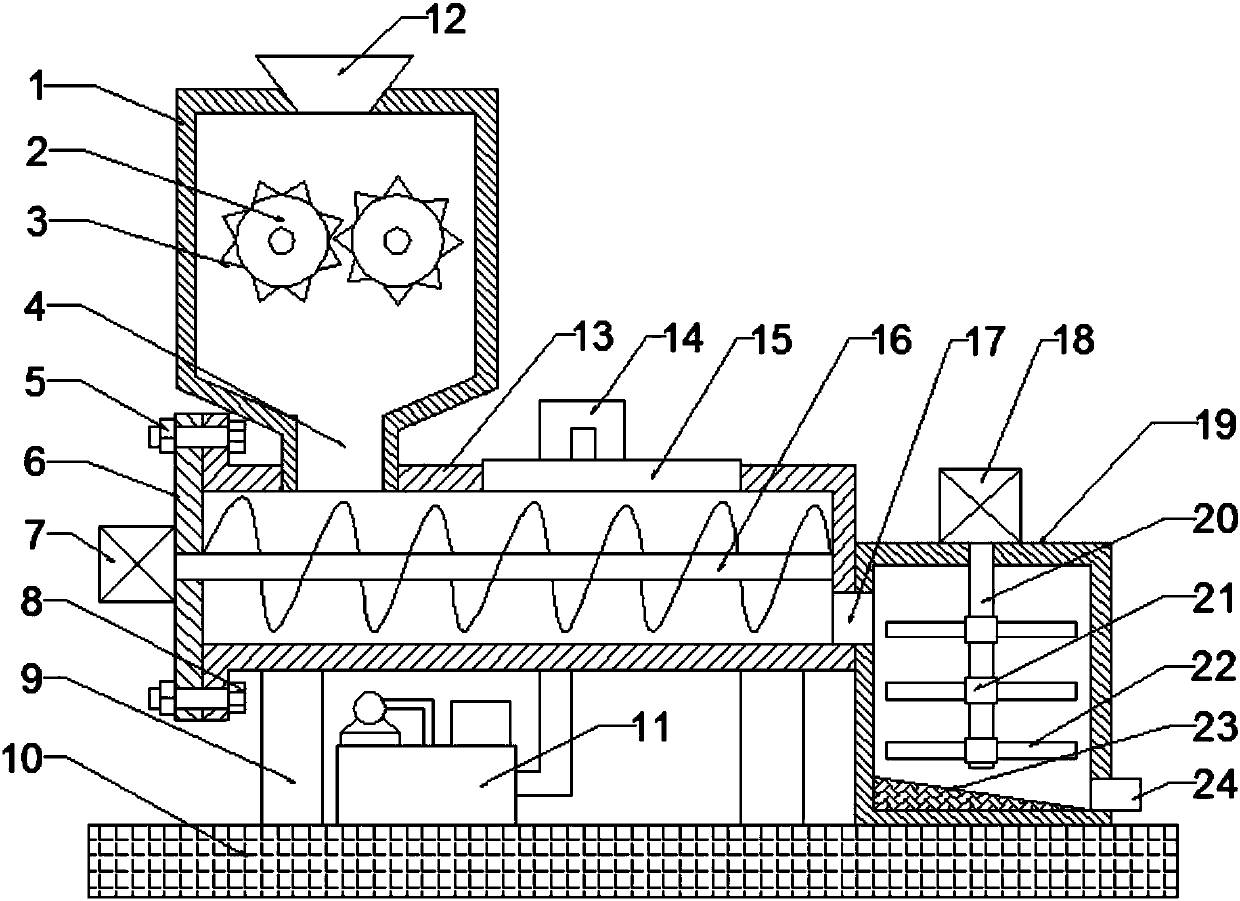

Iron removal type medicinal material processing device capable of crushing and drying

InactiveCN107626421AGuarantee processing qualityEasy to crushDrying gas arrangementsDrying chambers/containersIron removalPulp and paper industry

The invention discloses an iron removal type medicinal material processing device capable of crushing and drying, and belongs to the field of medicinal material processing equipment. The processing device comprises a crushing device, a discharging cylinder and an iron removing device; the discharging cylinder is fixedly arranged on the upper part of a base through supporting columns; a crushing box is fixedly arranged on the left side of the top end of the discharging cylinder, and the crushing box communicates with the discharging cylinder through a discharging pipe; crushing rotary wheels are arranged below a feed hopper in the crushing box, crushing teeth are arranged on the crushing rotary wheels, and the crushing rotary wheels are connected with an external driving device through crushing rotary shafts; and a spiral rod is horizontally arranged on a center line in the discharging cylinder, and the left end of the spiral rod penetrates through the discharging cylinder and is connected with a first motor. According to the iron removal type medicinal material processing device, raw material of the medicinal materials is crushed, processing efficiency is improved, drying treatmentis carried out after crushing, an iron removal tank is arranged so that scrap iron in the medicinal material can be removed conveniently, processing quality of the medicinal materials is guaranteed,and a good effect is achieved for subsequent medicinal material treatment.

Owner:CHANGSHA KEYUE ENTERPRISE MANAGEMENT CONSULTING CO LTD

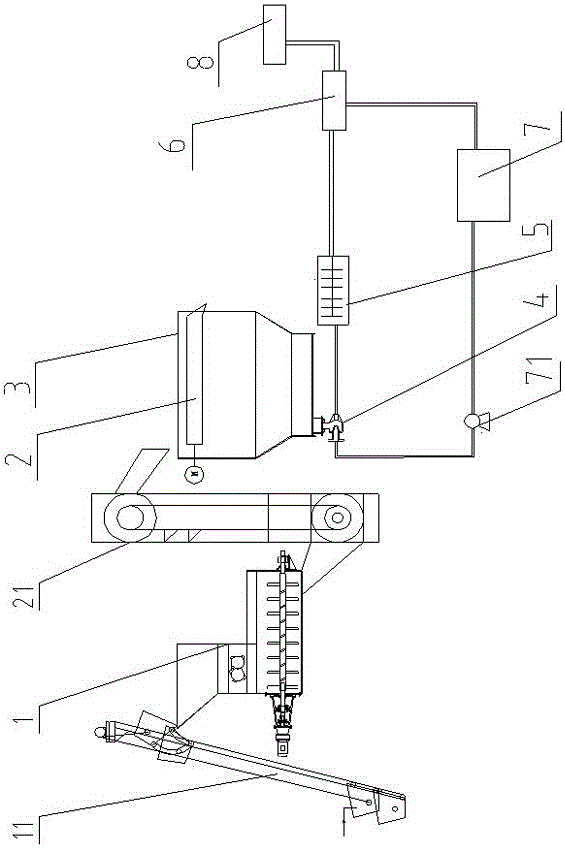

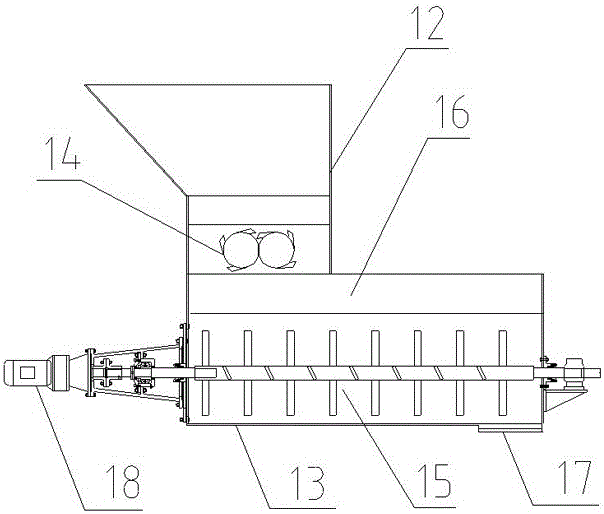

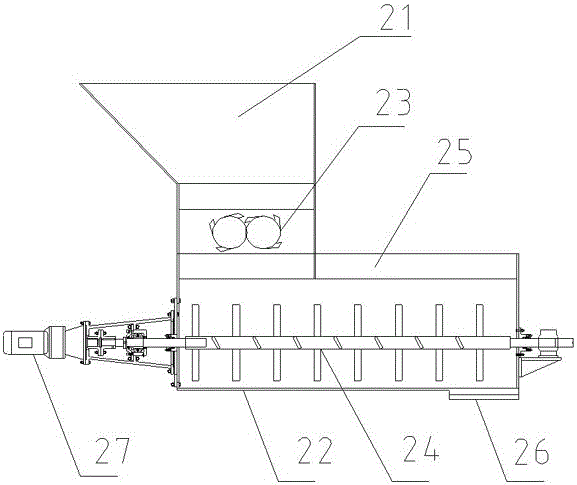

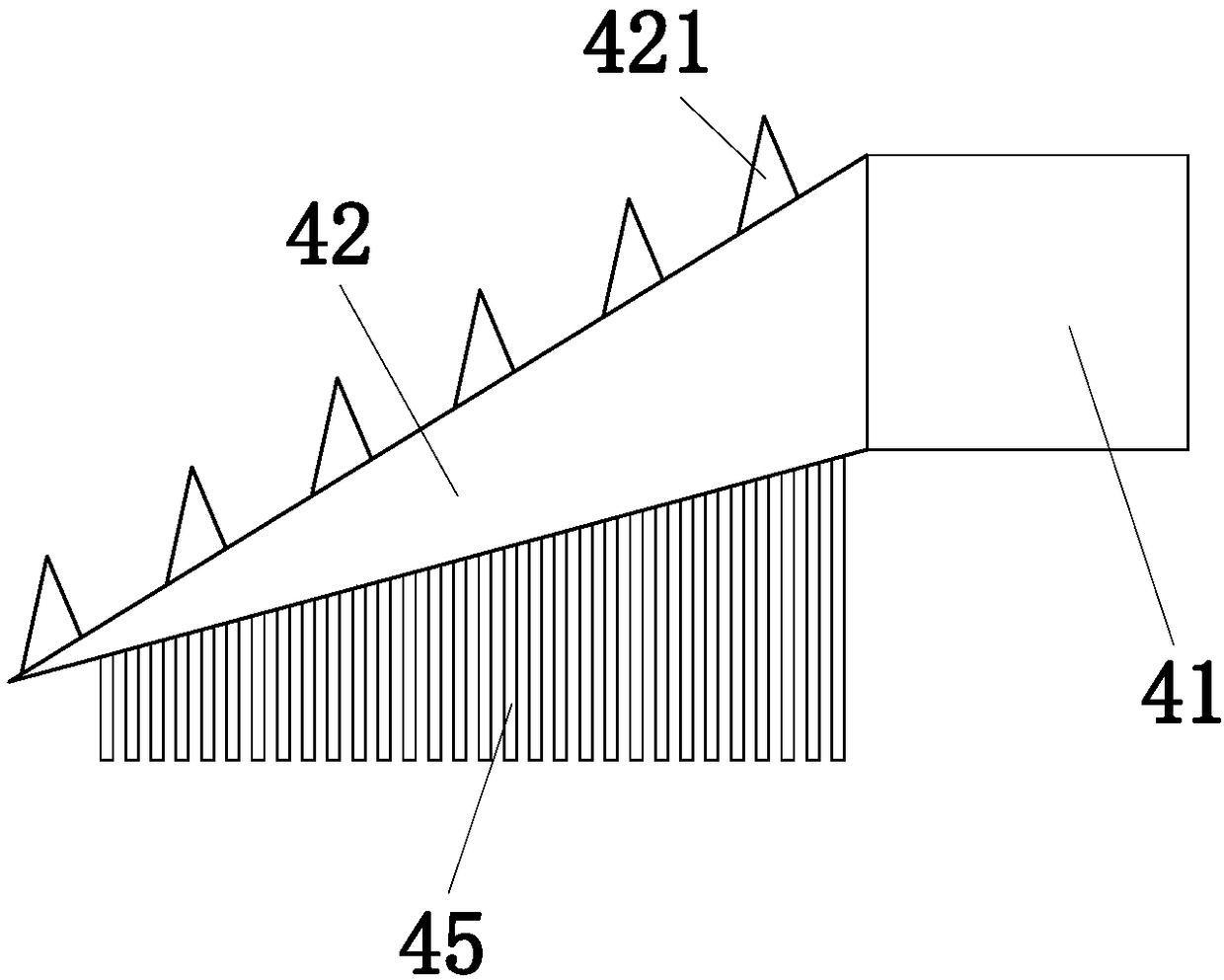

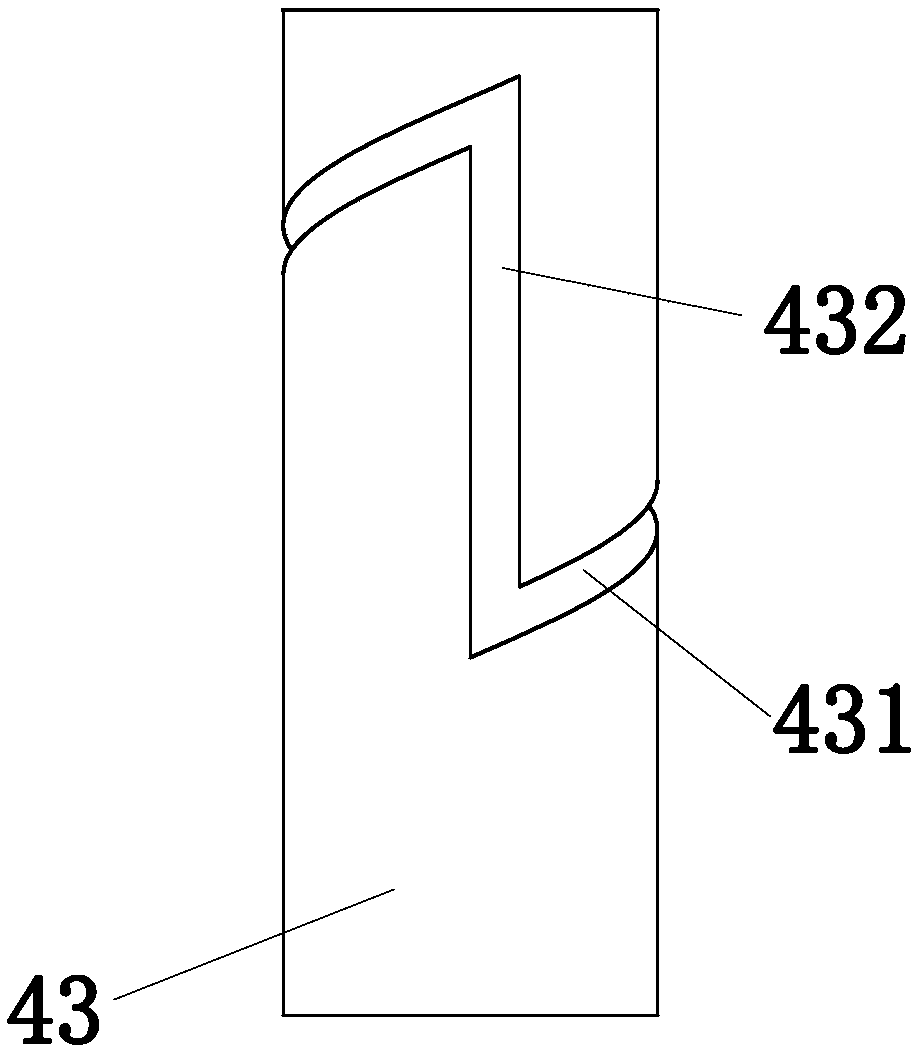

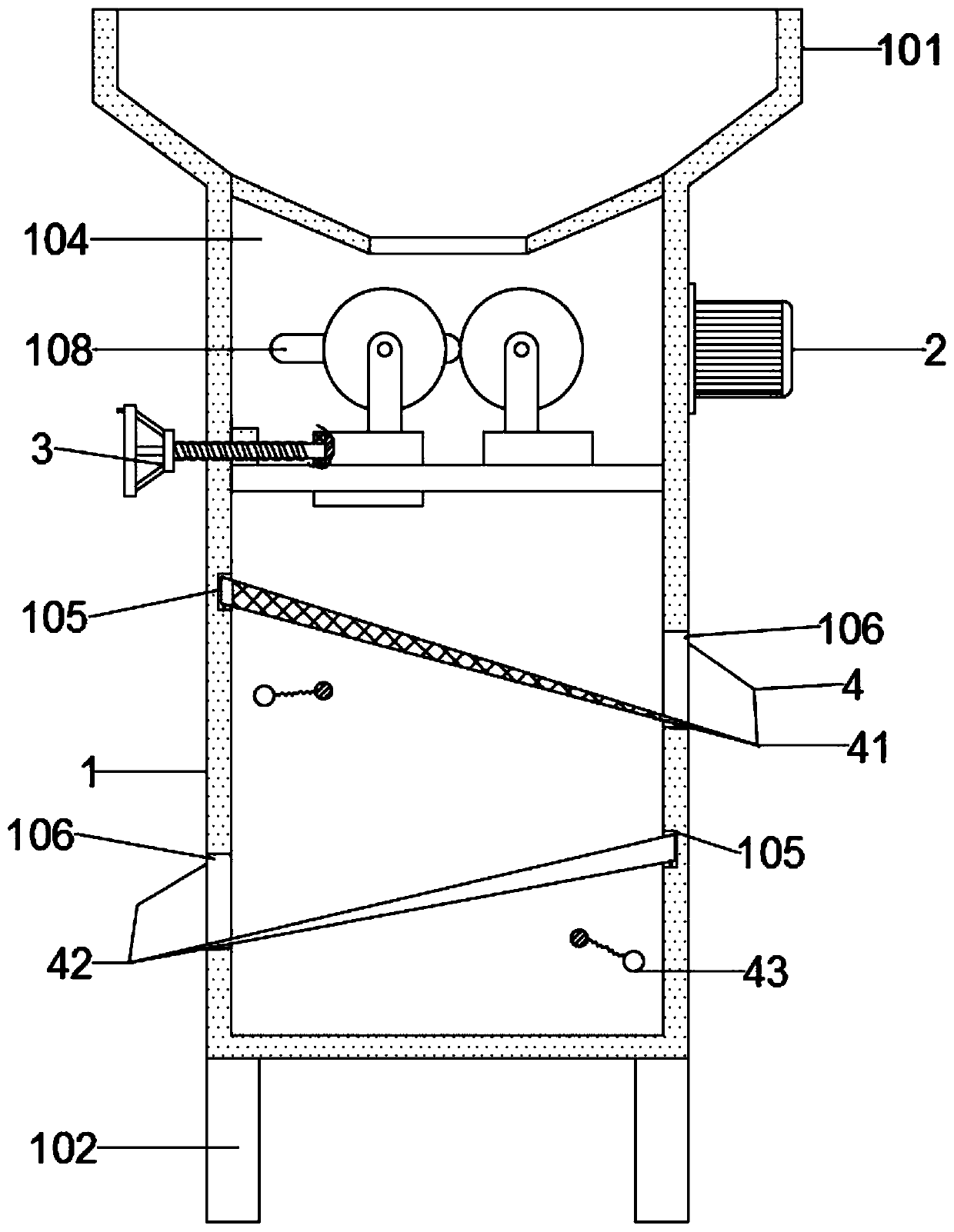

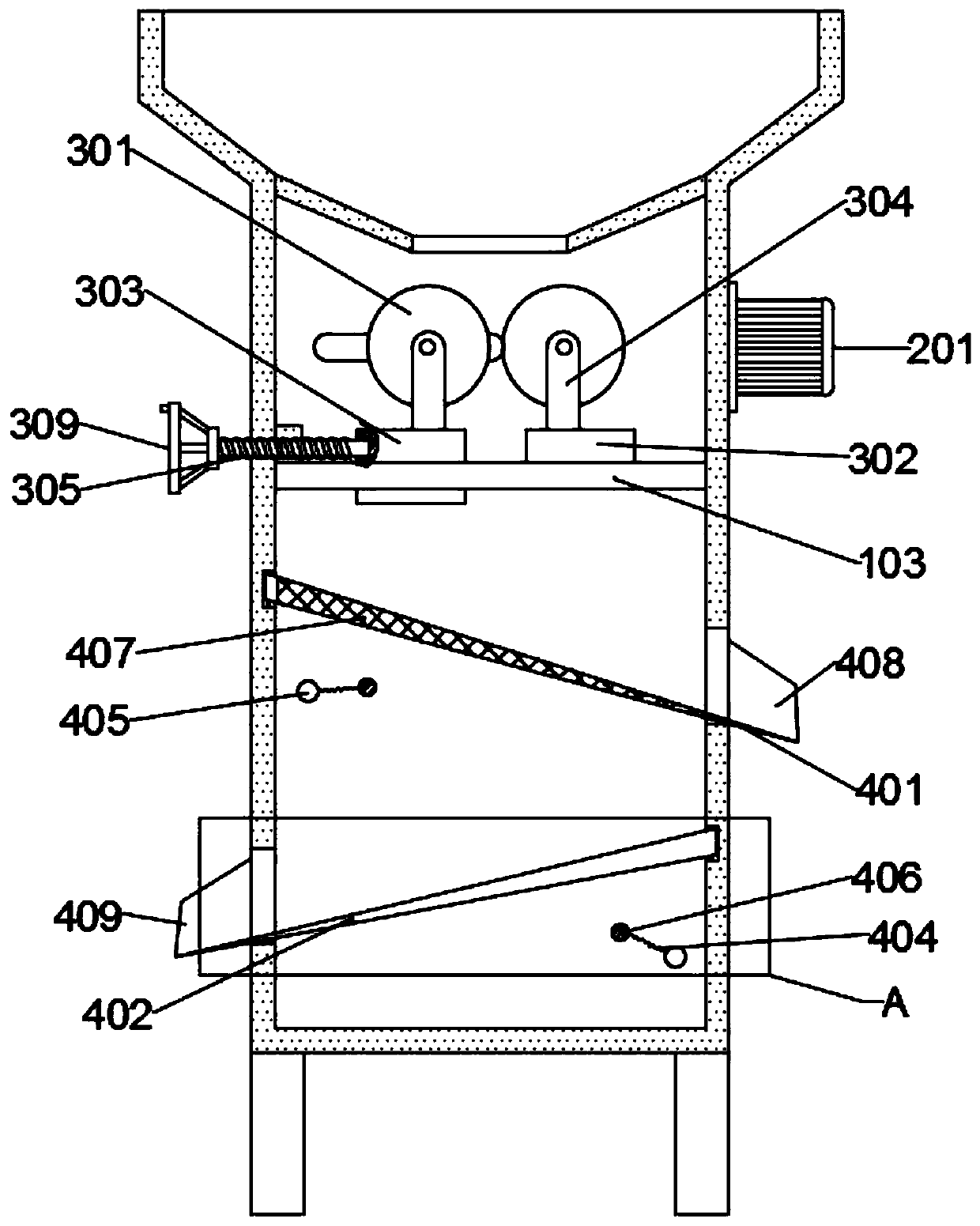

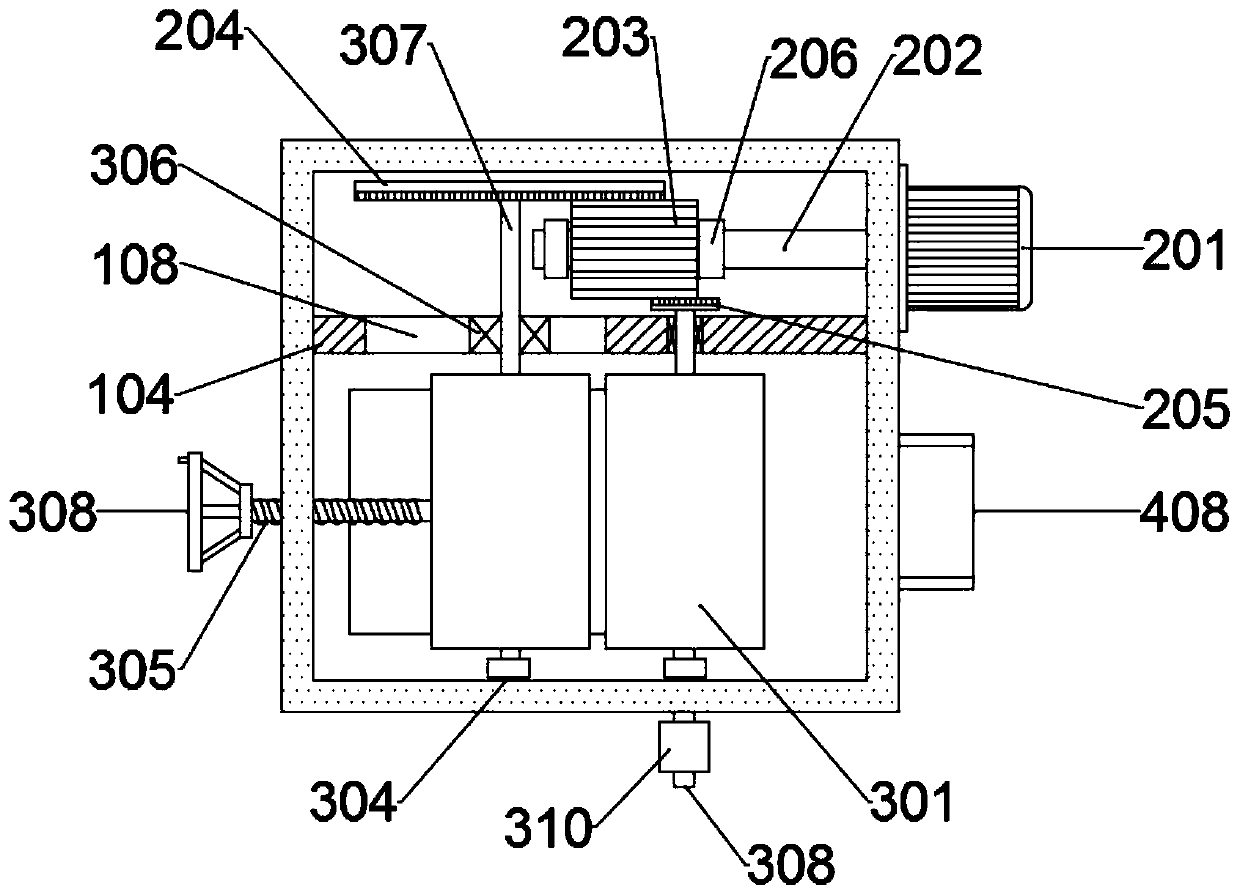

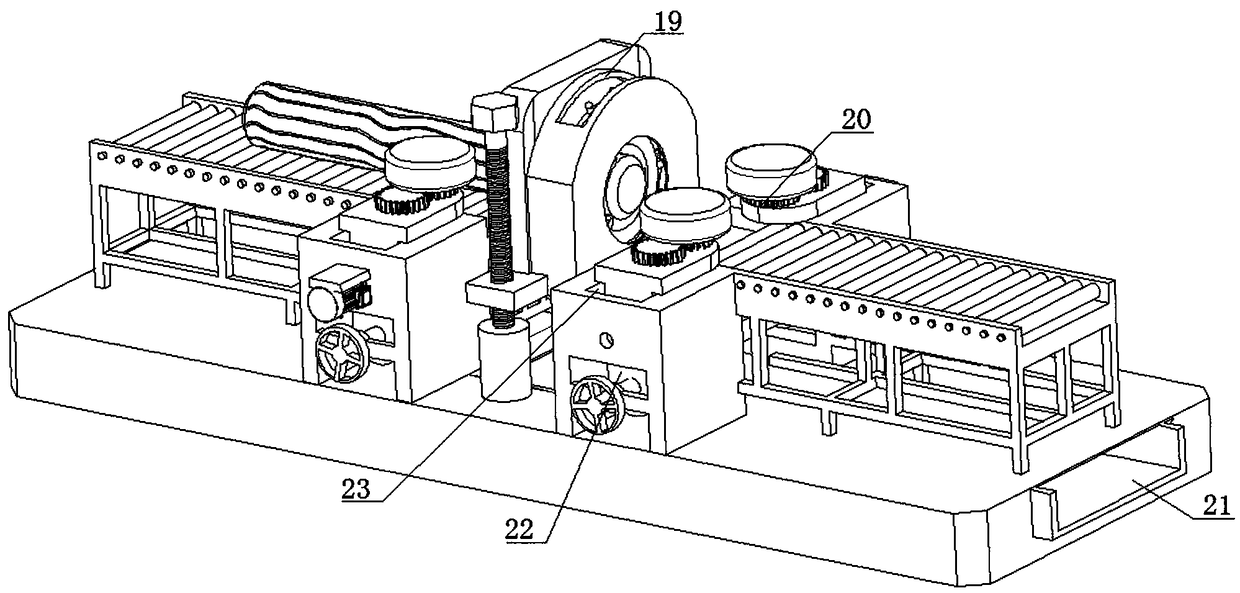

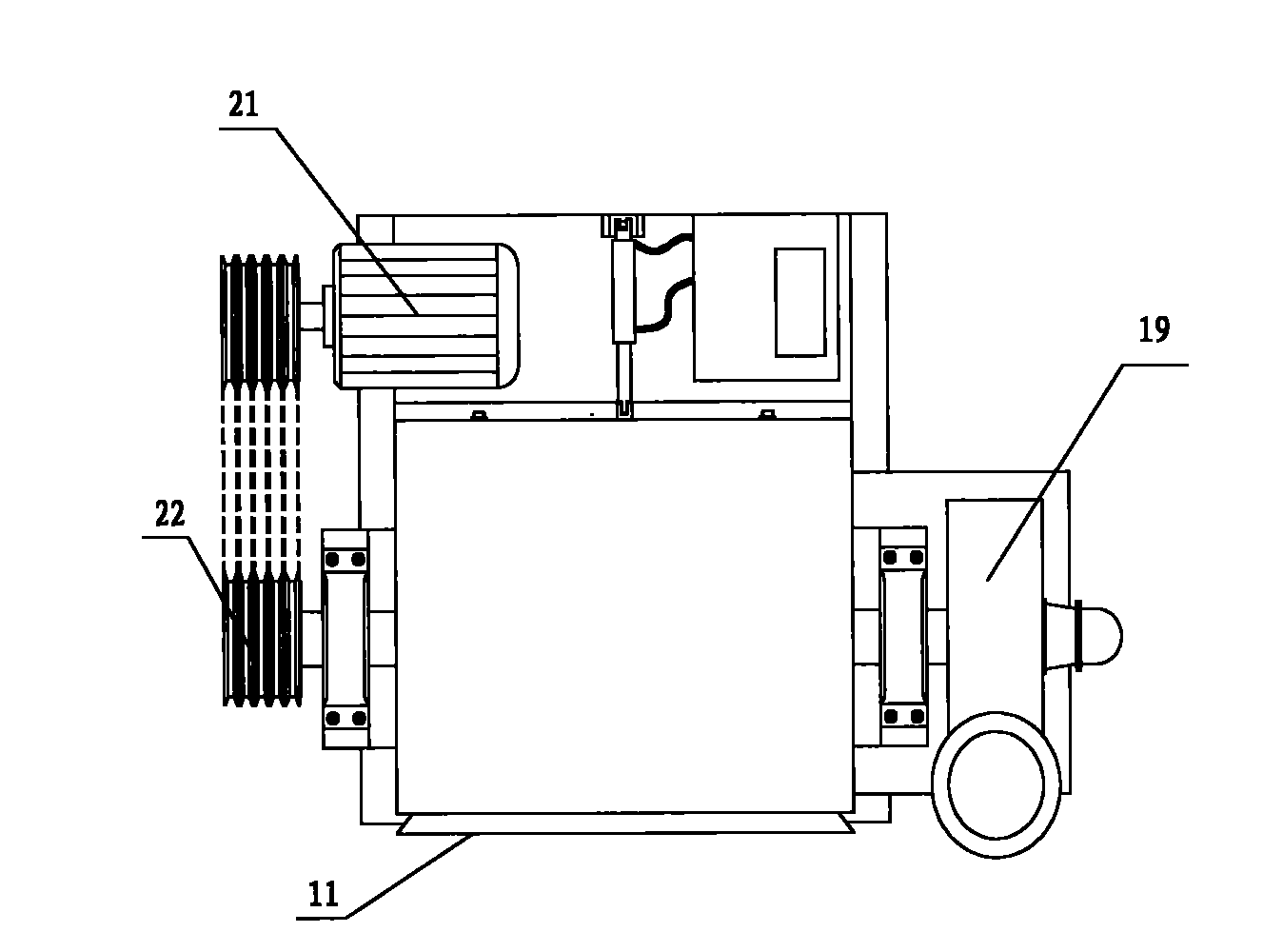

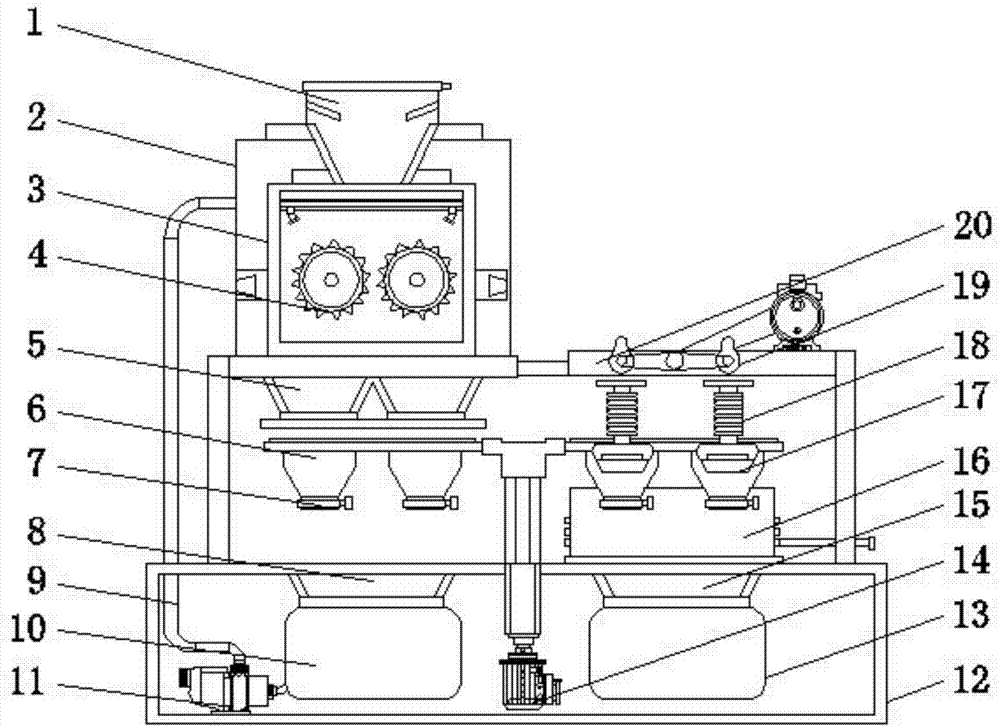

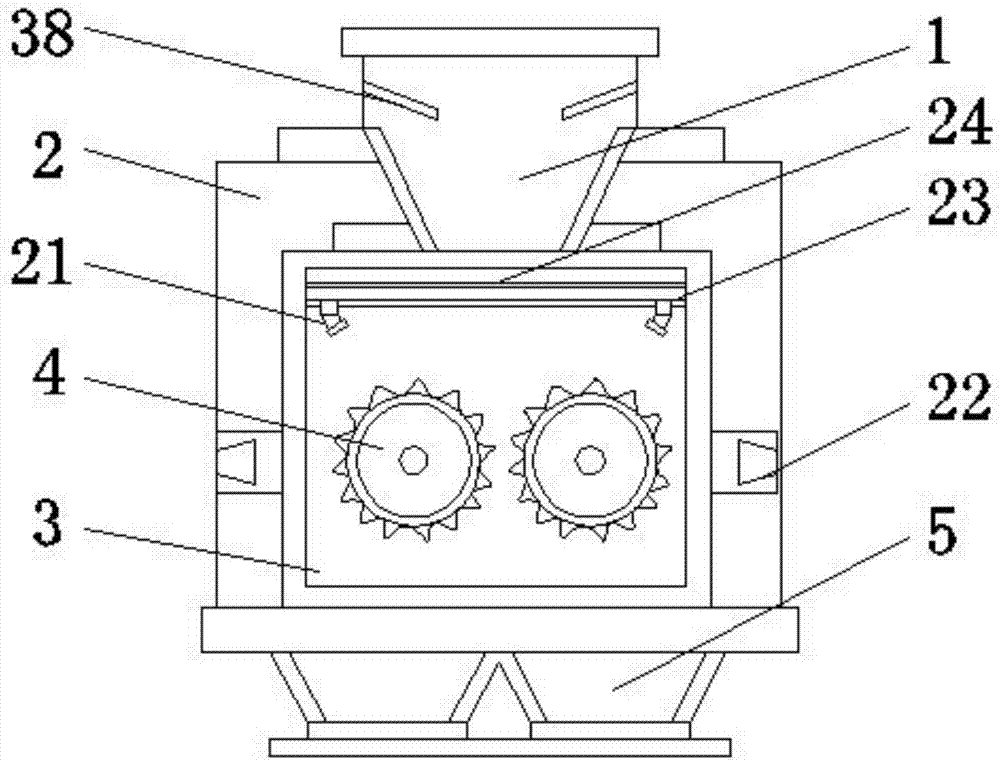

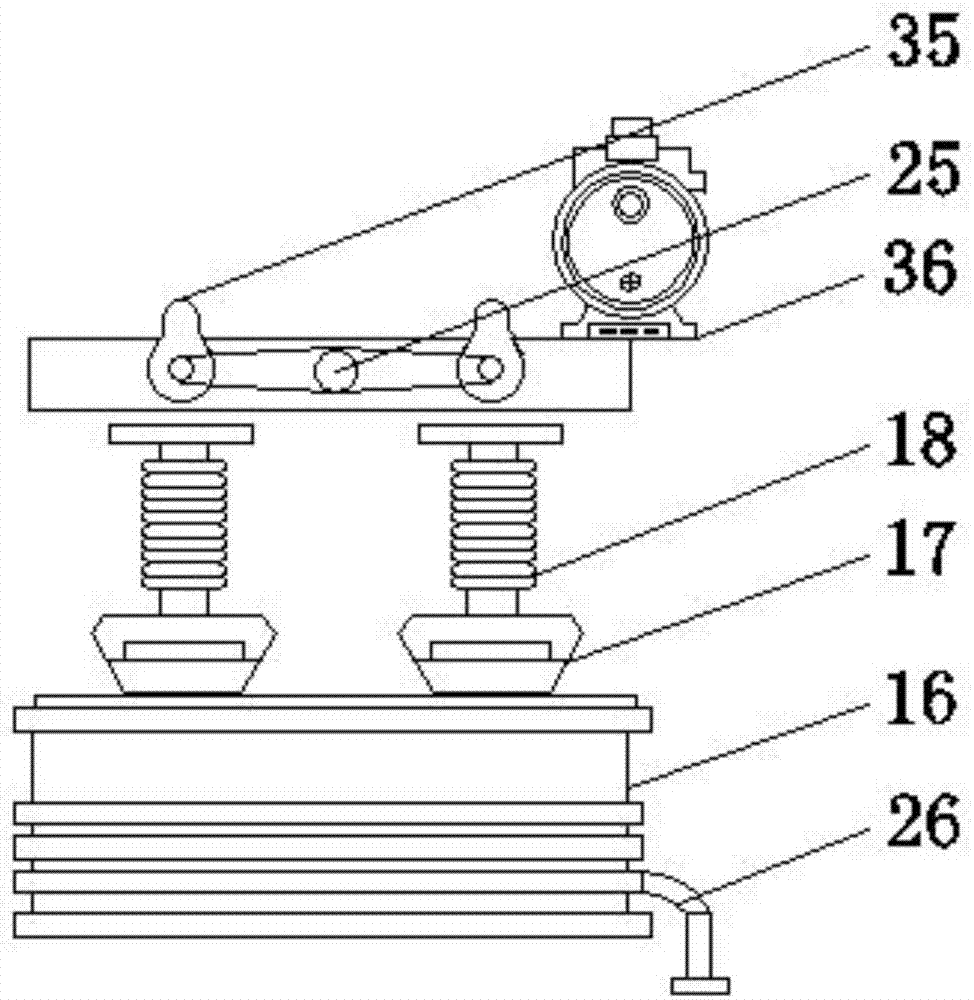

Treatment system, crushing equipment and treatment method for oily sludge

PendingCN106630515AEasy to washStir wellWaste water treatment from quariesSievingSludgeHigh pressure water

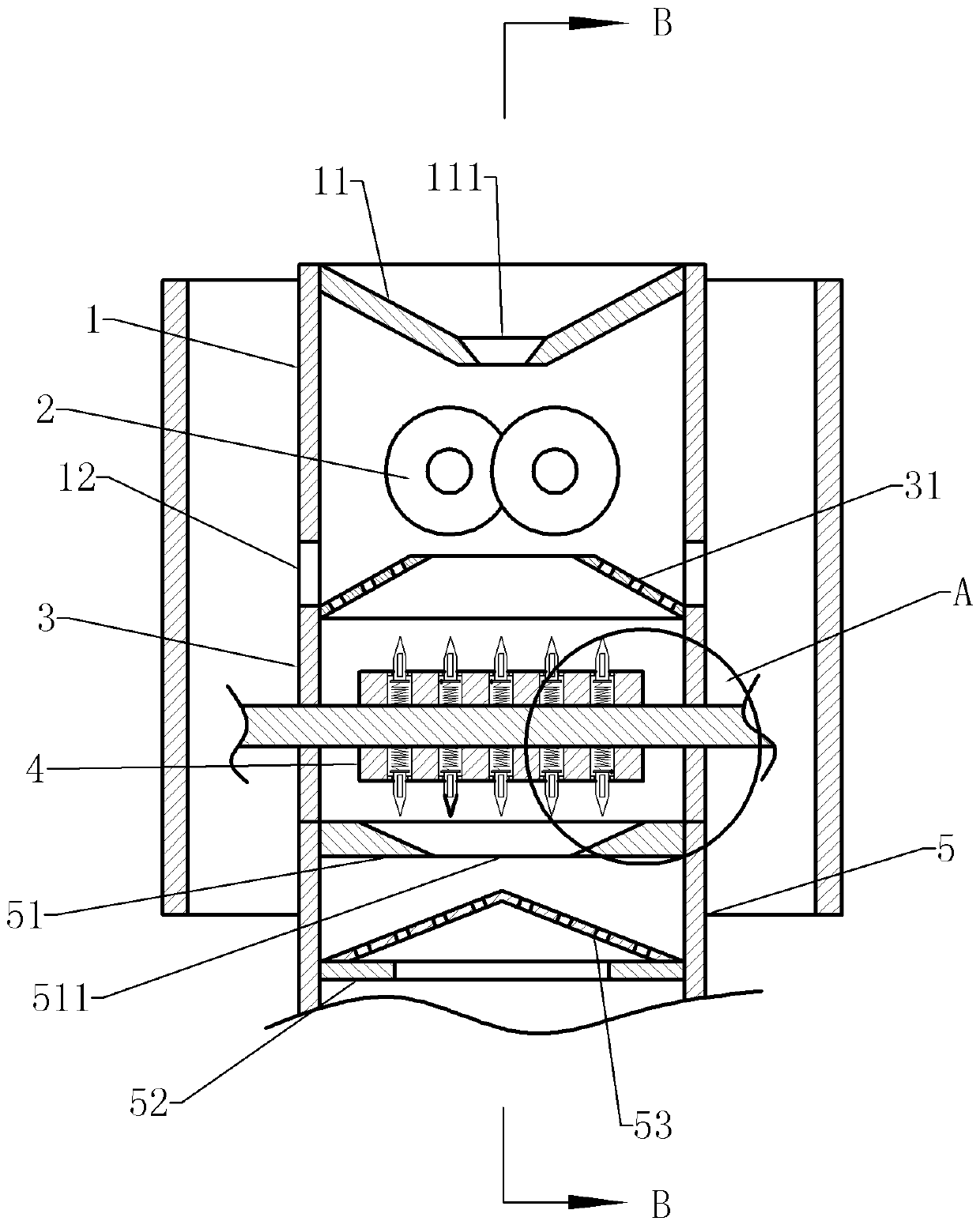

The invention discloses a treatment system, crushing equipment and a treatment method for oily sludge. The equipment comprises an inlet cylinder body, a crushing cylinder body, a double-roller type shredding mechanism, a rotating shaft type crushing mechanism, a high-pressure water spraying device and a first oil scraping device, wherein the lower part of the inlet cylinder body is connected with the crushing cylinder body; the high-pressure water spraying device is arranged above or inside the inlet cylinder body; the double-roller type shredding mechanism is arranged in the inlet cylinder body; the crushing cylinder body is provided with an oil slick space above the rotating shaft type crushing mechanism; the first oil scraping device is arranged in the oil slick space; a first oil slick draining outlet which can be opened and closed is formed in an end opposite to the first oil scraping device; an oily sludge discharging outlet is formed in the bottom of the crushing cylinder body. The oily sludge treatment equipment disclosed by the invention is formed by combining multistage crushing, multistage oil removal, high-efficiency oil binding or extraction, can be suitable for the oily sludge with different oil contents, and is particularly suitable for the oily sludge with lower oil content or serious emulsification.

Owner:仇霞霞

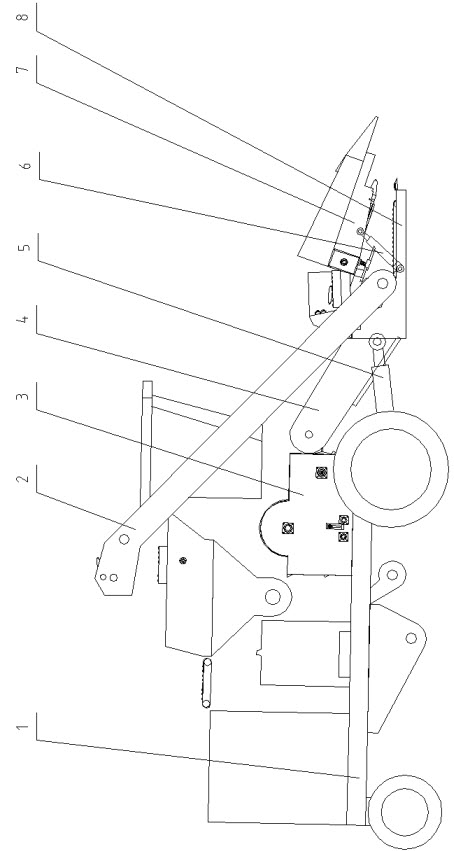

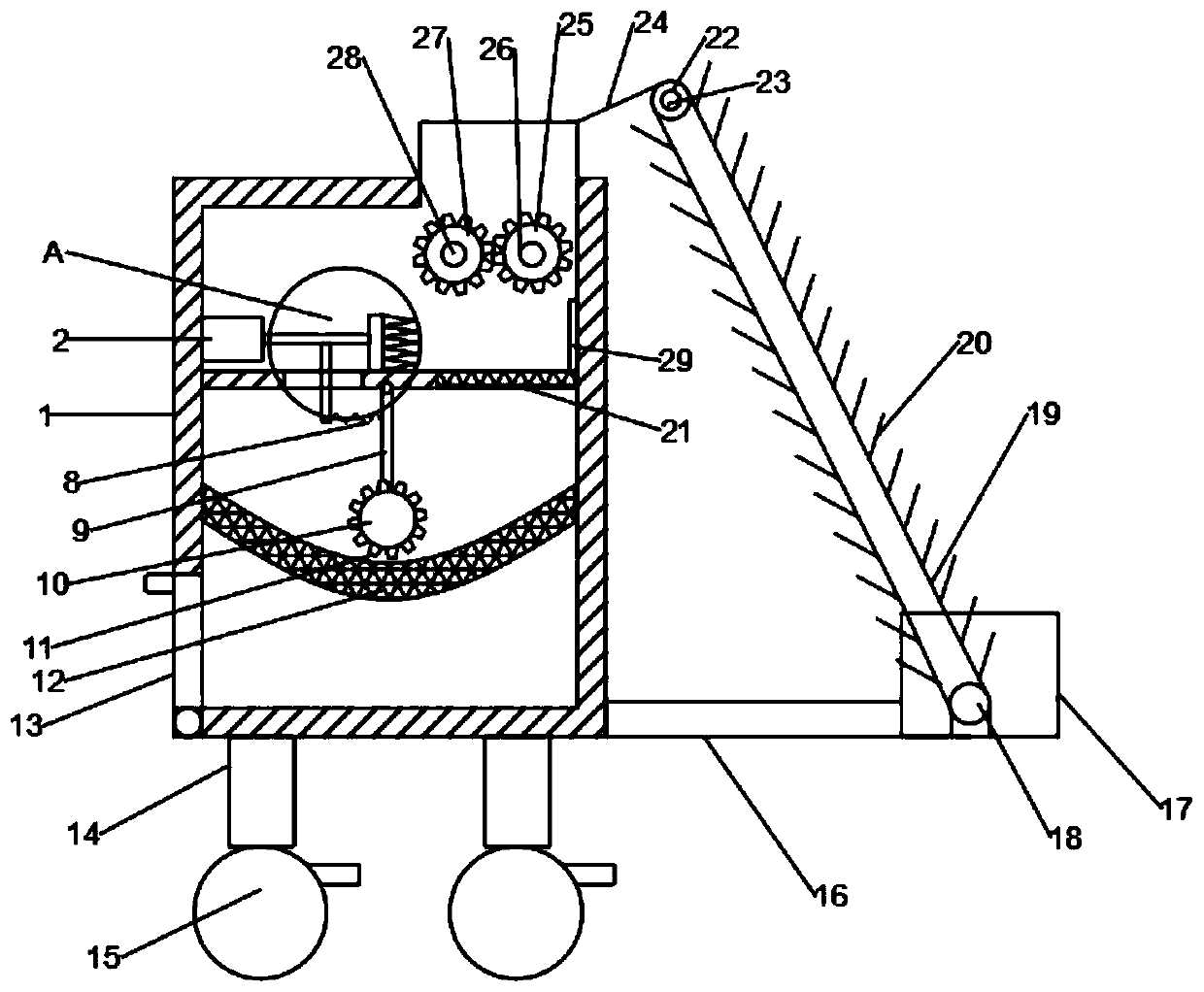

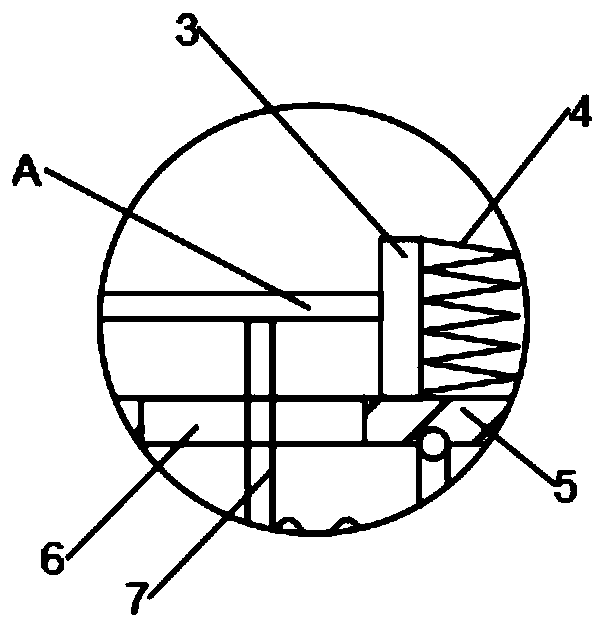

Multifunctional corn harvester

The invention relates to a multifunctional corn harvester which comprises a vehicle, a longitudinal elevator and a header, wherein the longitudinal elevator is installed on the vehicle, the header is installed at the front part of the vehicle and consists of an upper layer header and a lower layer header, the upper layer header consists of a poking grain device assembly and a transverse corn conveyor, and the lower layer header is a straw collection and transmission device and consists of a stem and root cutting knife, a straw conveyor, a stirring cage and a straw conveyor. The harvester realizes corn ear harvest, also satisfies the needs of diversified straw treatments and adopts double layer header arrangement on the whole structure, wherein the upper layer fulfills a function of ear plucking, and the lower layer fulfills the functions of cutting and conveying straws. The harvester can also be provided with a straw smashing device to realize grain cleaning and smashing, realize ensilage cutting by changing a cutter type smasher and fulfill the function of straw pavement by opening a lower bottom plate of the straw conveyor. The corn harvester with the structure harvests both ears and stems, thereby realizing harvest without losing grains and also realizing straw diversified treatments.

Owner:TIANJIN BISHENG INTELLIGENT TECH DEV

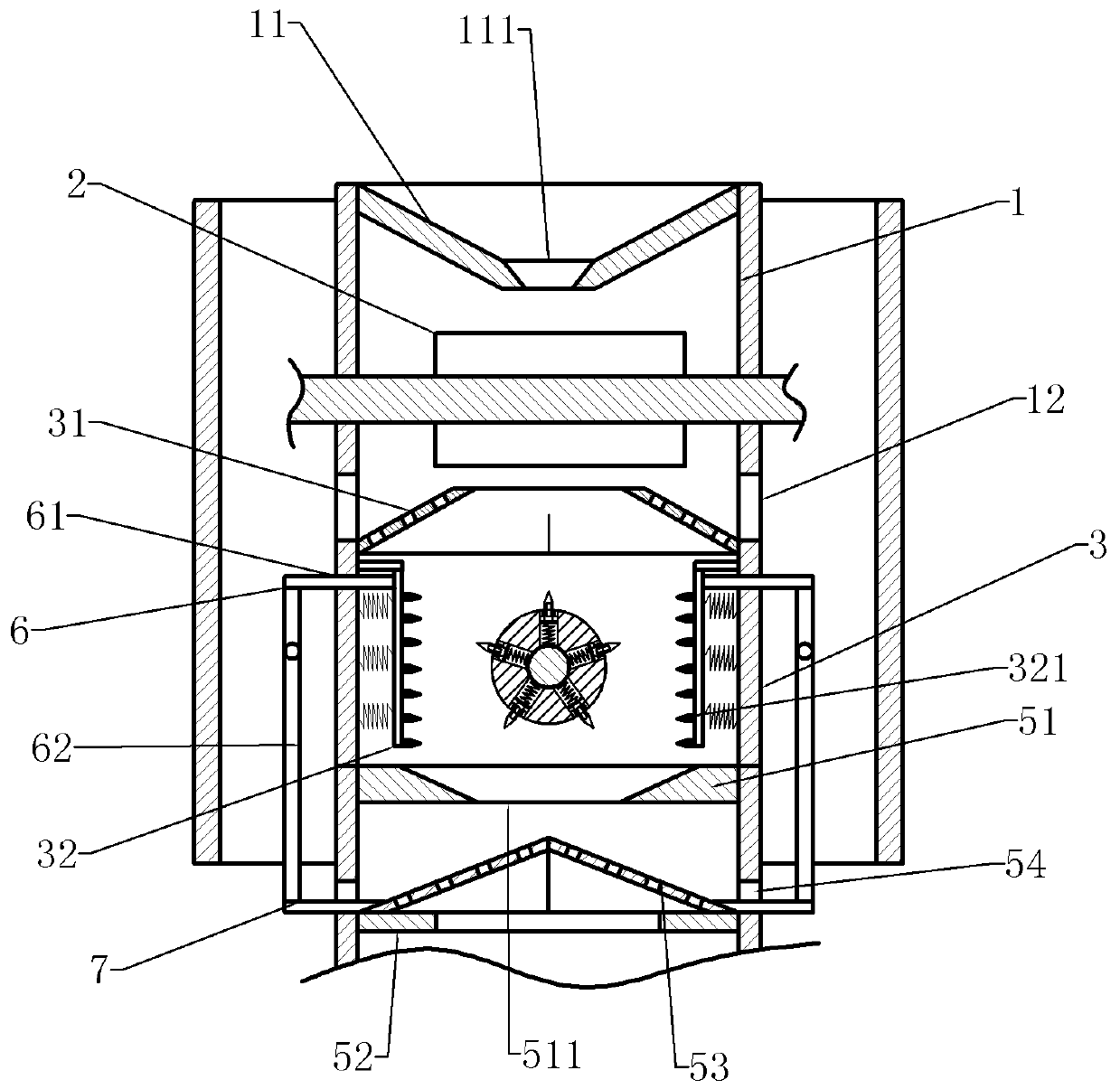

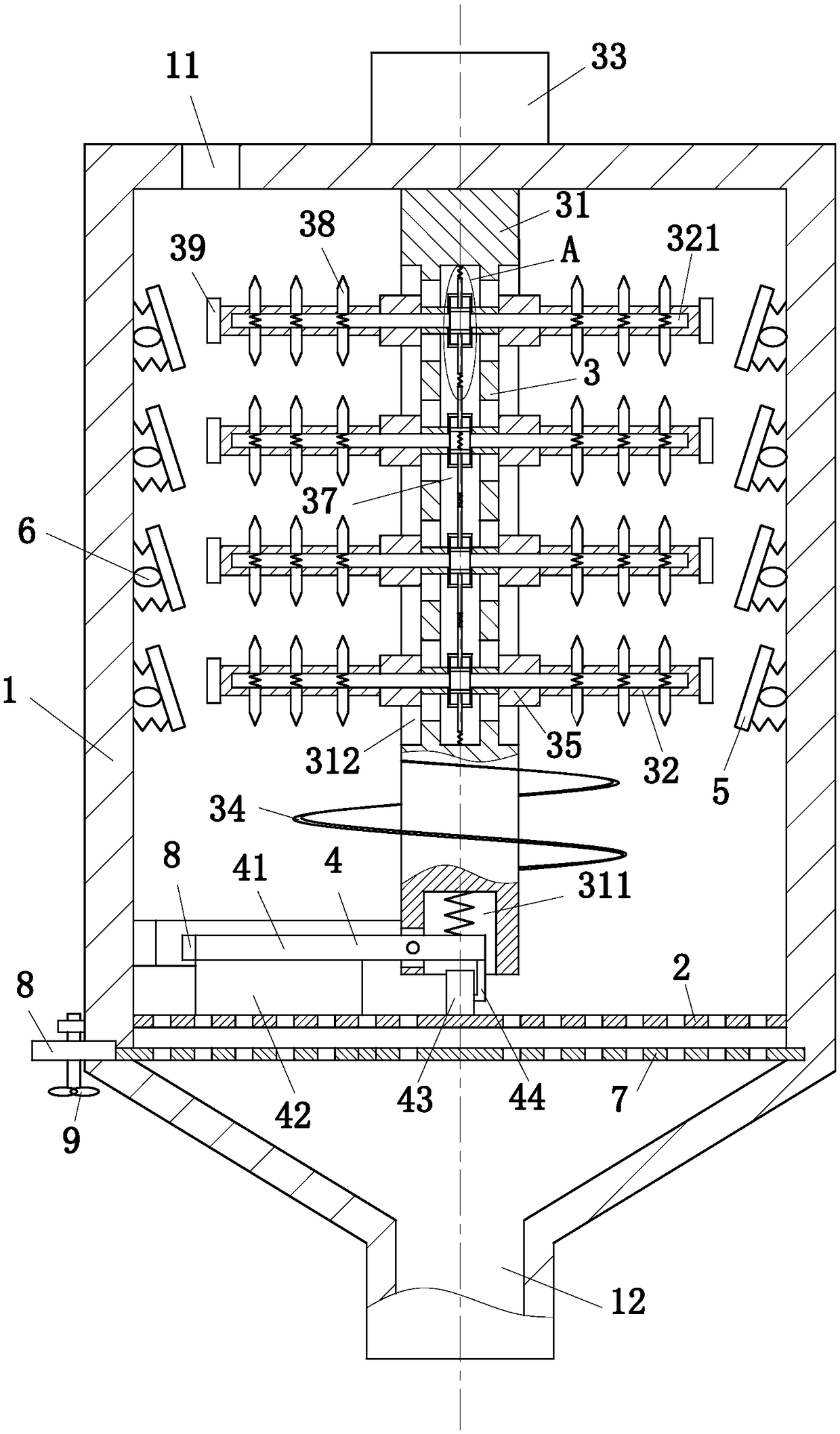

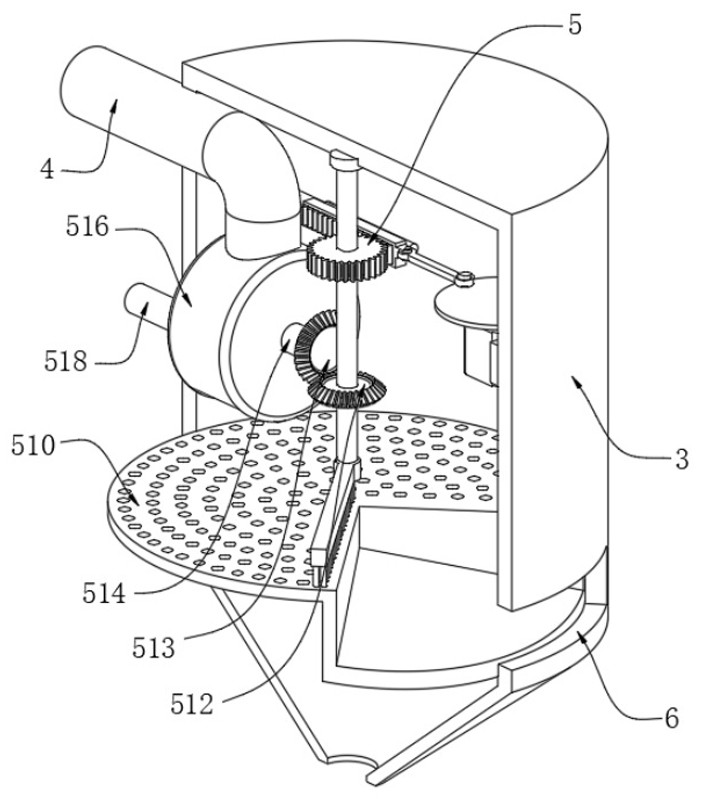

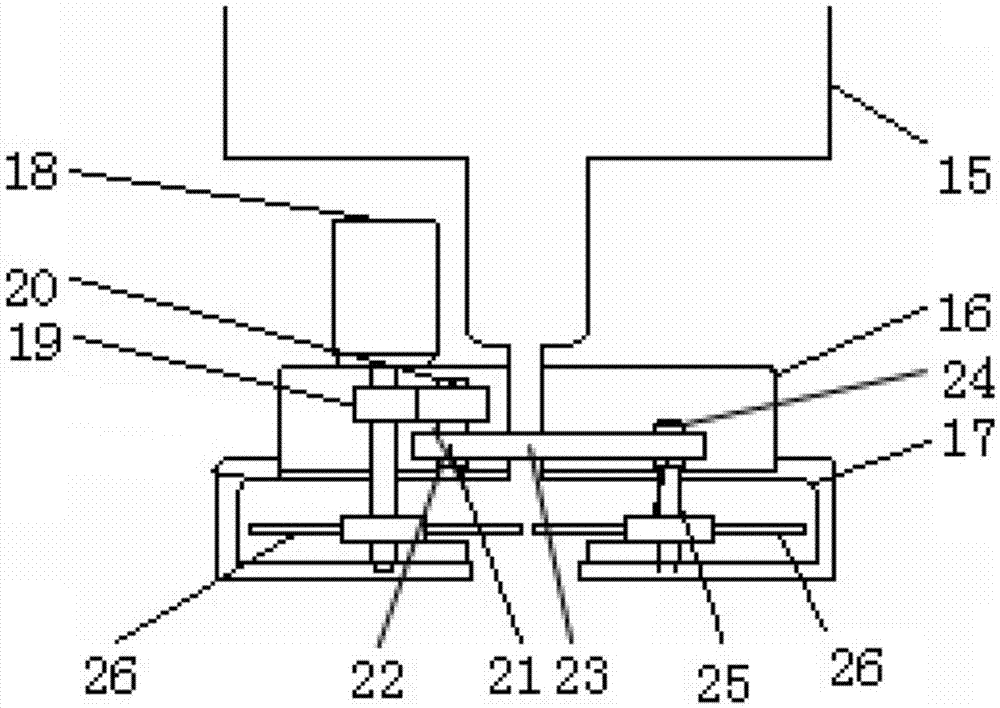

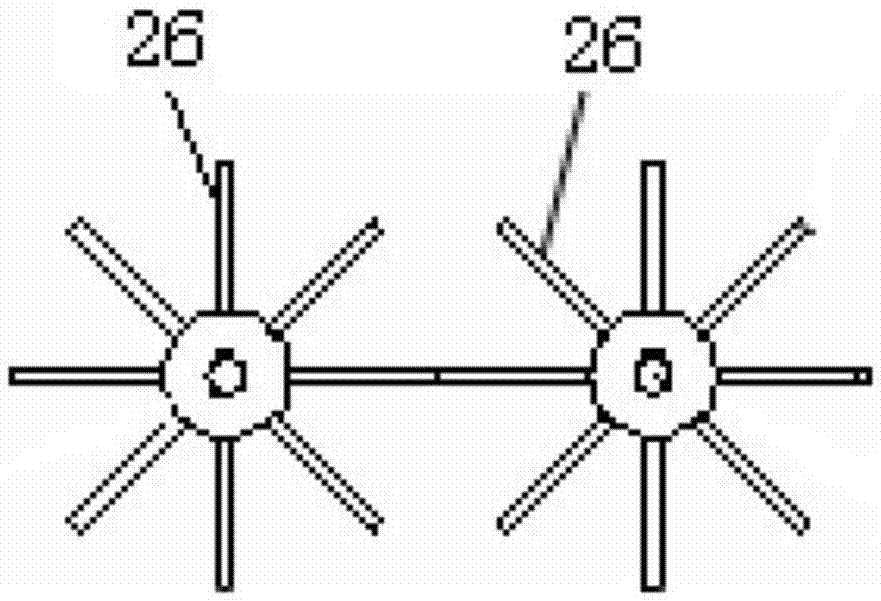

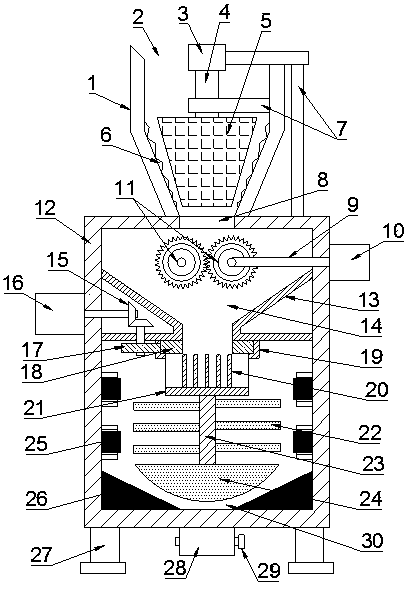

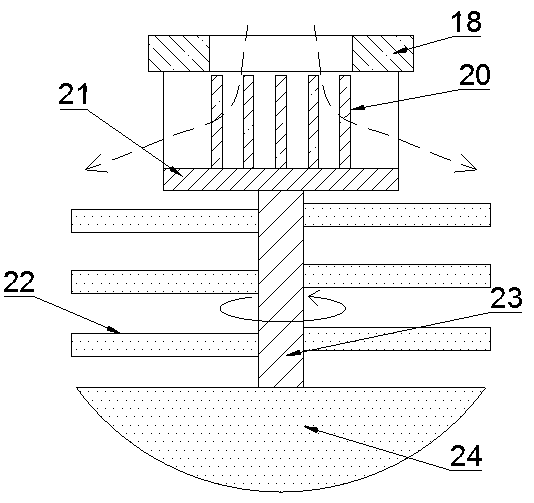

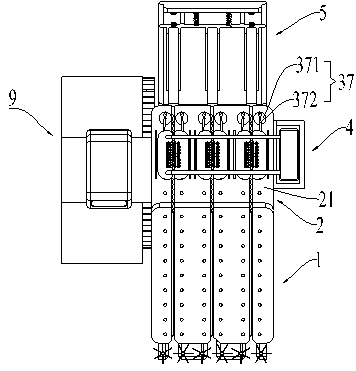

Rare earth ore fine-processing device and control system thereof

ActiveCN109277170AGuaranteed withdrawalImprove the effectCocoaGrain treatmentsEngineeringControl system

The invention belongs to the technical field of rare earth production, and particularly relates to a rare earth ore fine-processing device and a control system thereof. The rare earth ore fine-processing device comprises a box body, a filtering plate, a crushing unit and a turning unit, wherein the filtering plate is mounted at the bottom of the box body and used for filtering crushed rare earth ore; the crushing unit comprises a rotating shaft, crushing rods and a motor; the rotating shaft is vertically mounted in the box body; the crushing rods are horizontally mounted on the rotating shaftand used for crushing the rare earth ore inside the box body; the motor is used for driving the rotating shaft to turn; the turning unit is positioned at the bottom of the box body; and through the cooperation between the turning unit and the crushing unit, the rare earth ore which is incompletely crushed can be raised and crushed again, thereby guaranteeing the rare earth ore crushing uniformityand the rare earth ore utilization ratio. By the adoption of the rare earth ore fine-processing device provided by the invention, the comprehensive crushing of rare earth can be achieved and the sufficient extraction of a rare-earth raw material can be guaranteed.

Owner:GANZHOU FORTUNE ELECTRONICS

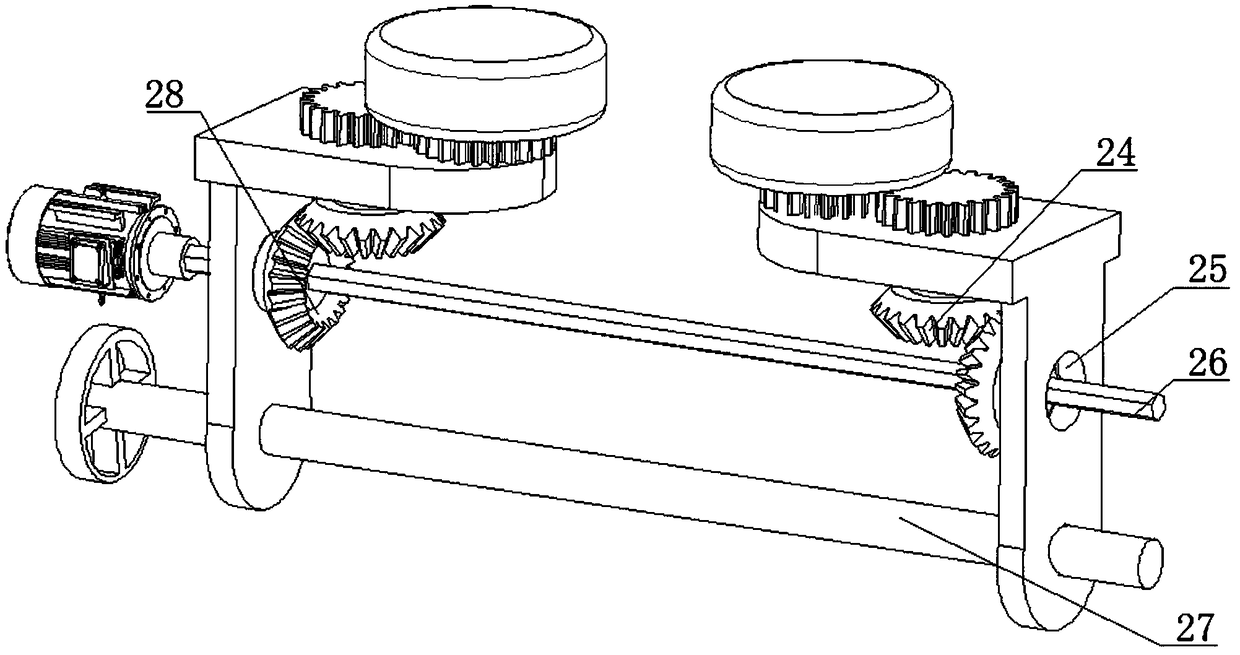

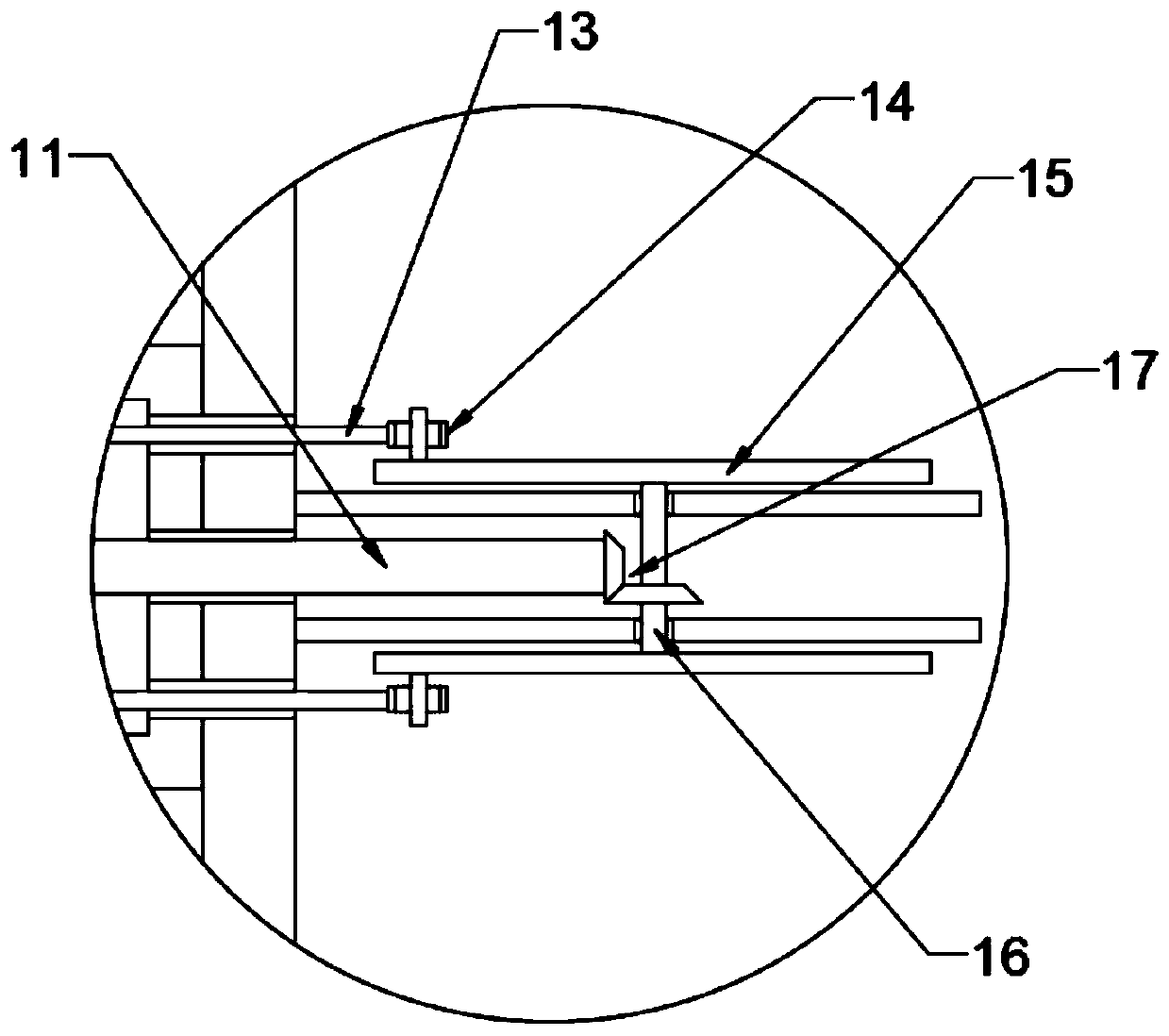

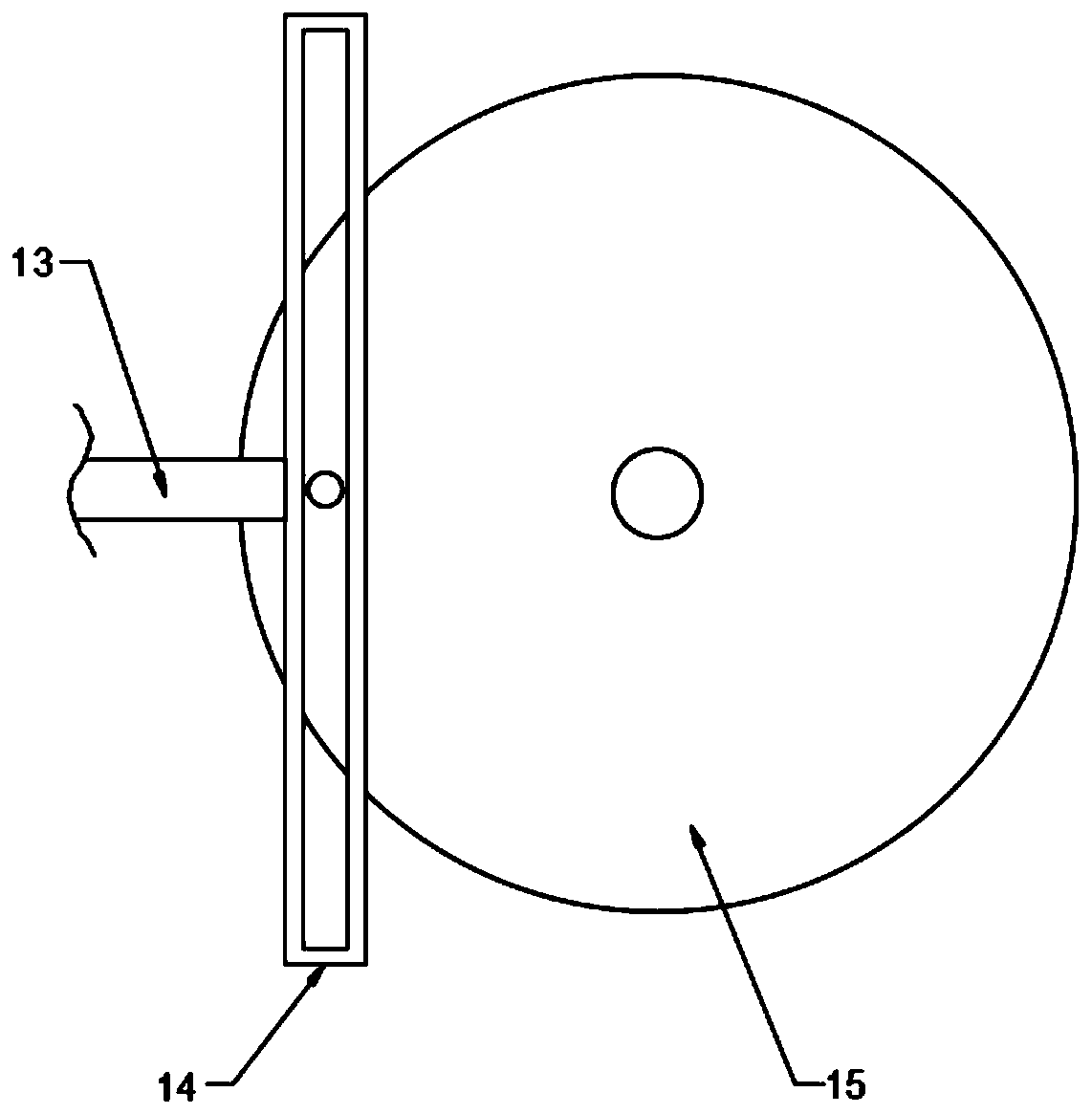

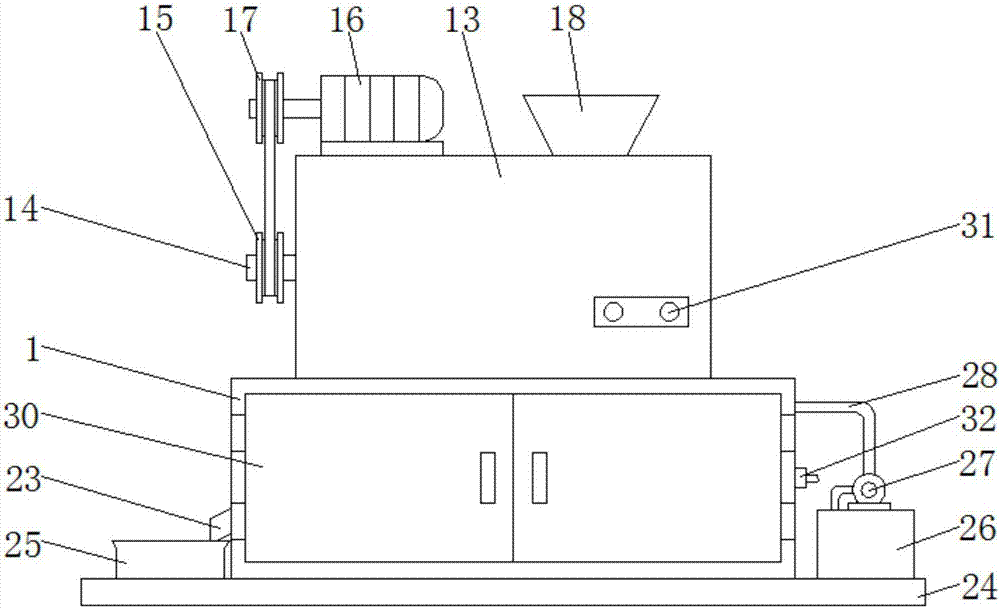

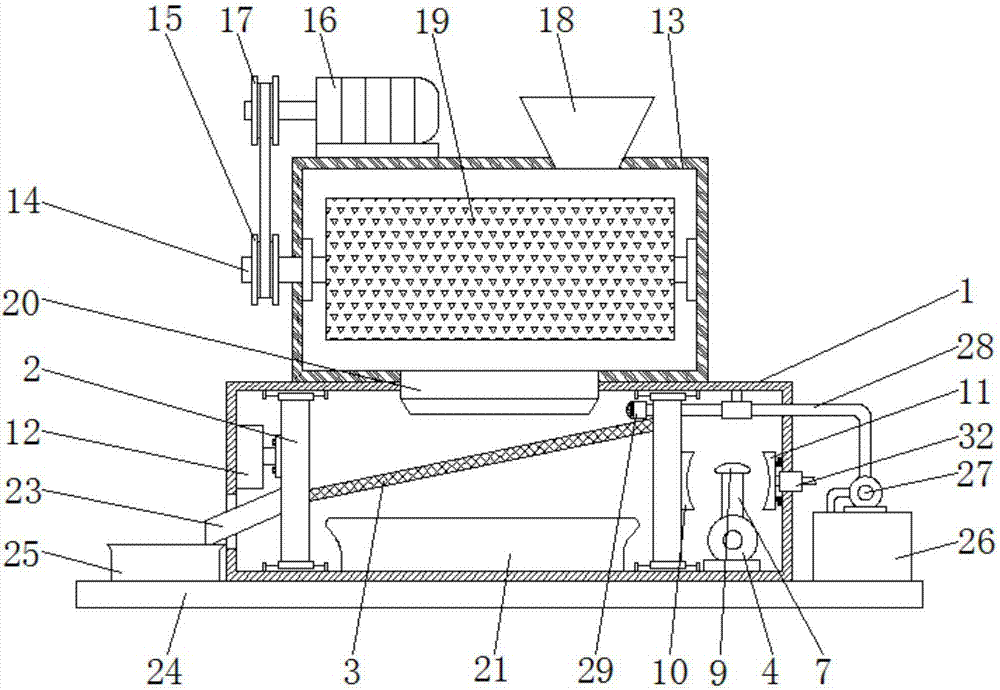

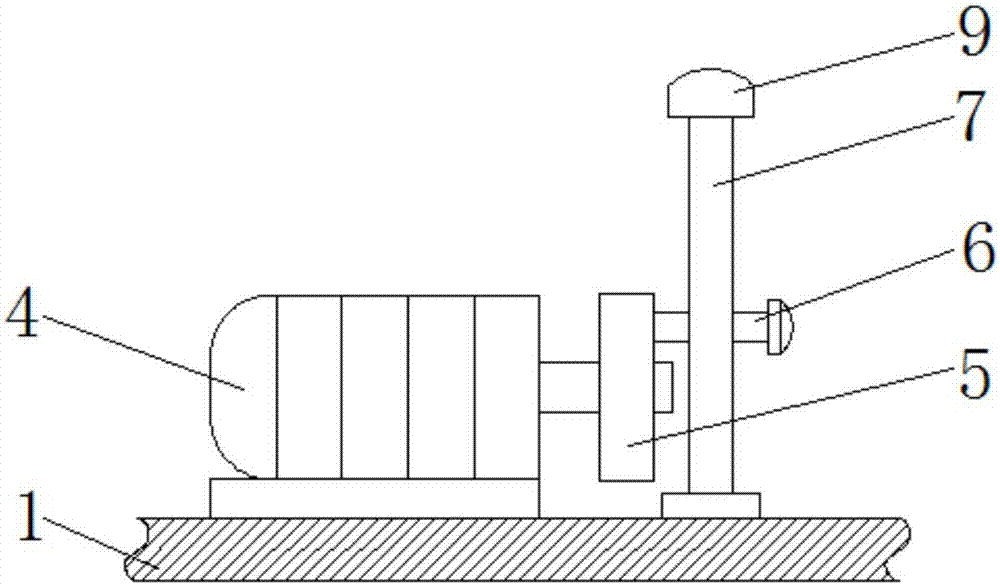

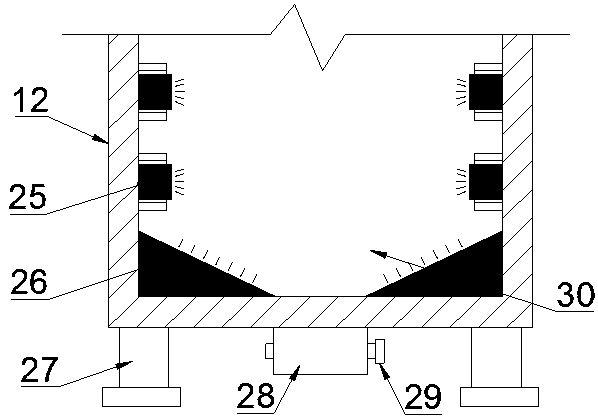

Space-adjustable smashing device for micro powder production

The invention relates to the technical field of smashing devices for micro powder production, in particular to a space-adjustable smashing device for micro powder production. The device is simple in structure, convenient to use, low in production cost and suitable for smashing treatment in the micro powder production process. Through rotation of a motor, rotation of two sets of smashing rollers can be achieved, micro powder smashing is achieved, through manual rotation of a hand rotation disc, adjusting of the gap between the two sets of smashing rollers is achieved, micro powder smashing is achieved, the hand rotating disc is manually rotated by the manual work, adjusting of the gap between the two sets of smashing rollers can be achieved, different powder required in the different needscan be produced, and the application range is wide. The smashed micro powder falls on a screening plate from falling holes, the micro powder smaller than the diameter of screening meshes falls on a guide plate, and slides out of a second discharging hopper connected with the guide plate, and the micro powder larger than the diameter of the screening meshes directly slides out of a first discharging hopper connected with the screen plate for subsequent machining. A gear shaft rotates to drive a vibration ball to continuously beat the screening plate and the guide plate, falling of the micro powder is promoted, and the screening efficiency is improved.

Owner:连云港市沃鑫高新材料有限公司

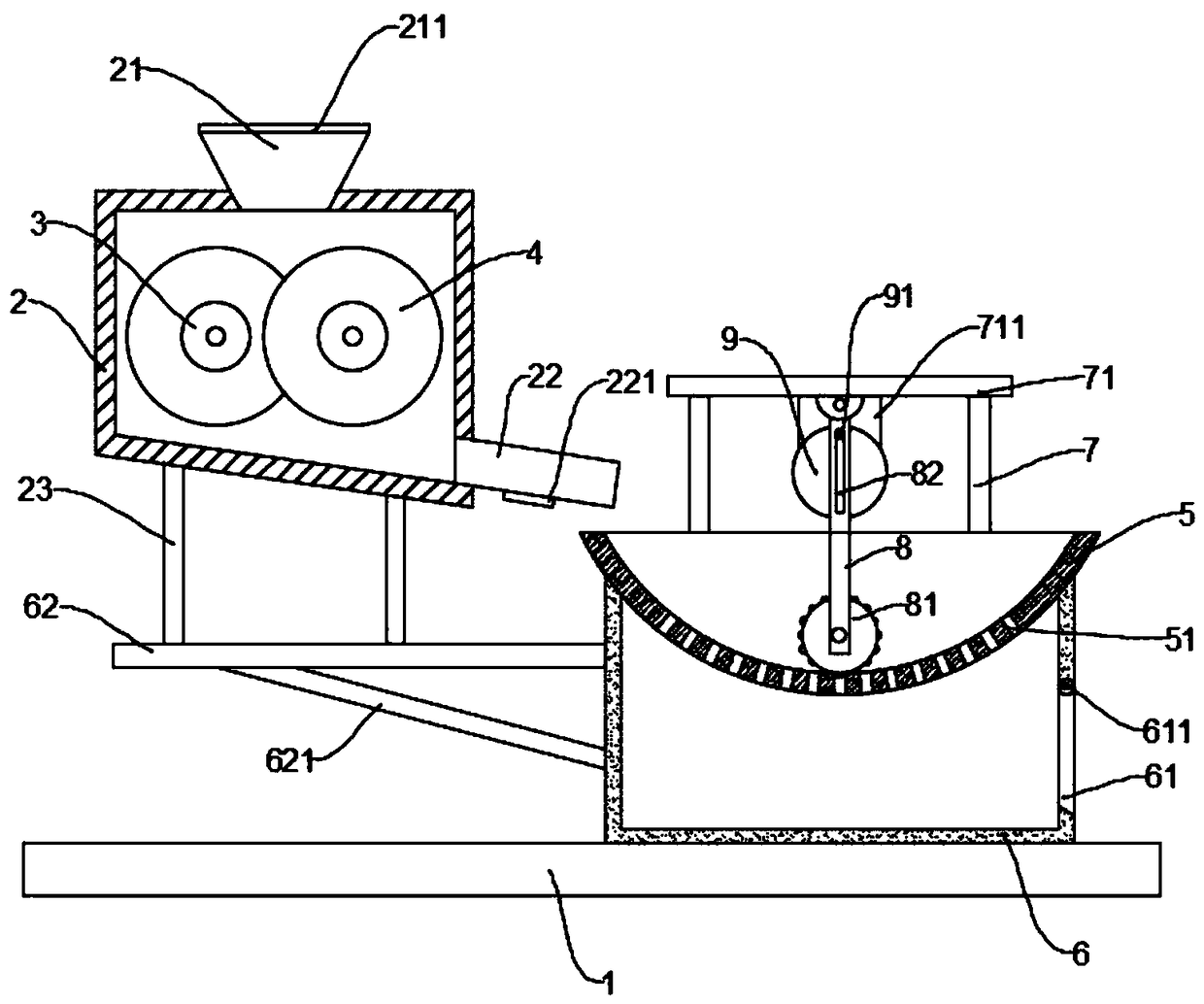

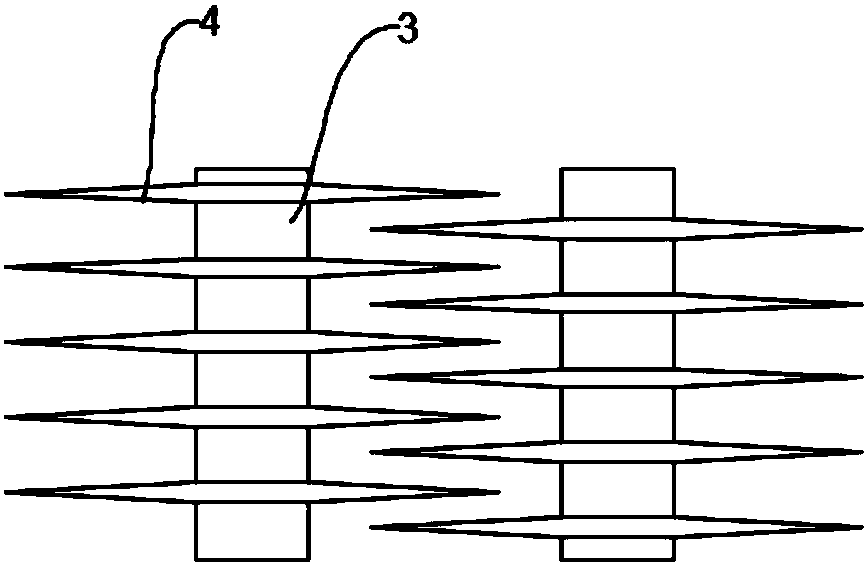

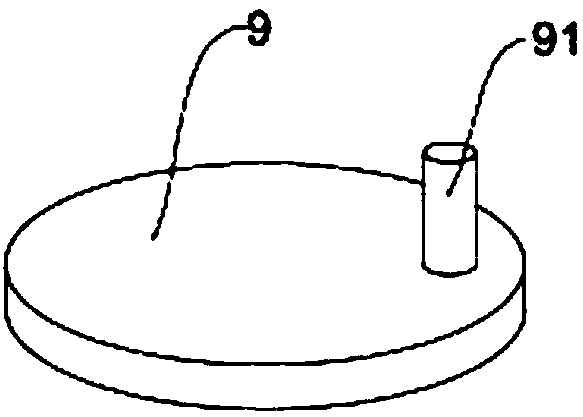

Garbage disposal device for improving disposal fragmentation degree

InactiveCN108201966AIncrease the degree of fragmentationEasy to handle workGrain treatmentsEngineeringMechanical engineering

The invention discloses a garbage disposal device for improving the disposal fragmentation degree. The device comprises a base, a smashing box and a receiving frame, wherein the smashing box and the receiving frame are arranged on the base from left to right. A grinding bowl is fixed to the top of the receiving frame. Garbage is smashed and then ground, so that the garbage fragmentation degree isgreatly improved, and convenience is brought to garbage disposal work. Annular blades on smashing rollers on the two sides are staggered, the gap between the annular blades on the two sides is gradually reduced from top to bottom, accordingly, gradual smashing for garbage is achieved, and the smashing effect is ensured. By means of cooperated use of a disc and swing, a grinding roller rolls back and forth on an inner cavity face of the grinding bowl for repeated grinding, and the grinding effect is ensured; and meanwhile due to the fact that the rotating radius of a swing rod is the same as the curvature radius of the bottom face of an inner cavity of the grinding bowl, the grinding roller is always kept to be in fit with the bottom face of the inner wall of the grinding bowl in the swingprocess, and therefore grinding uniformity is ensured.

Owner:SHENZHEN CHENGHONG ENTERPRISE MANAGEMENT CO LTD

Manufacturing device for automobile brake pad

InactiveCN106964423AImprove work efficiencyEasy to collectSievingRotary stirring mixersSilicon oxideMillstone

The invention relates to a manufacturing device, in particular to a manufacturing device for an automobile brake pad. The invention aims to solve the technical problem of providing the manufacturing device for the automobile brake pad, through the manufacturing device, silicon oxide powder and silicon nitride can be subjected to crushing and mixing at the same time. In order to solve the above technical problem, the manufacturing device for an automobile brake pad, provided by the invention, comprises a mixing box, a first baffle, first connecting rods, a cylindrical filter screen frame, a first bearing support, a first rotating rod, a stirring rod, a rotating mechanism, a second rotating rod and the like, wherein the first baffle is connected to the bottom of the mixing box in a rotating manner; the mixing box is in bolt connection to the right part of the first baffle plate; and the first connecting rods are respectively connected to the left side and the right side of the upper part in the mixing box. According to the manufacturing device disclosed by the invention, firstly, the rotating mechanism is arranged, so that the silicon oxide powder and the silicon nitride are crushed by the reciprocating rotation of a cylindrical millstone driven by the rotating mechanism.

Owner:来安县华鹏摩擦材料厂

Tree trunk skin removing machine and skin removing method

The invention discloses a tree trunk skin removing machine and a skin removing method, relates to the field of tree trunk skin removing equipment, in particular to the tree trunk skin removing machine. The tree trunk skin removing machine comprises a T-shaped bottom plate. The tree trunk skin removing machine is characterized in that a supporting shaft is fixed to one end of the upper side of theT-shaped bottom plate, the upper side of the supporting shaft is hinged to one end of a U-shaped rod, and a first top block is in threaded connection with the other end of the U-shaped rod. The two opposite ends of the upper side of the T-shaped bottom plate are separately and fixedly connected with two ends of a cross rod of a T-shaped groove rod through an L-shaped bracket, a T-shaped sliding rail is arranged on the cross rod of the T-shaped groove rod, a first T-shaped sliding block is arranged in the T-shaped sliding rail, a first cylinder rod is fixed to the middle of one side of the first T-shaped sliding block, and the first cylinder rod penetrates through the T-shaped sliding rail, a first sliding groove at the lower end of a straight groove rod and a clamping groove at the upper end of an H-shaped groove rod. The tree trunk skin removing machine can realize the skin removing of tree trunks and smashing of tree skins.

Owner:张小汴 +1

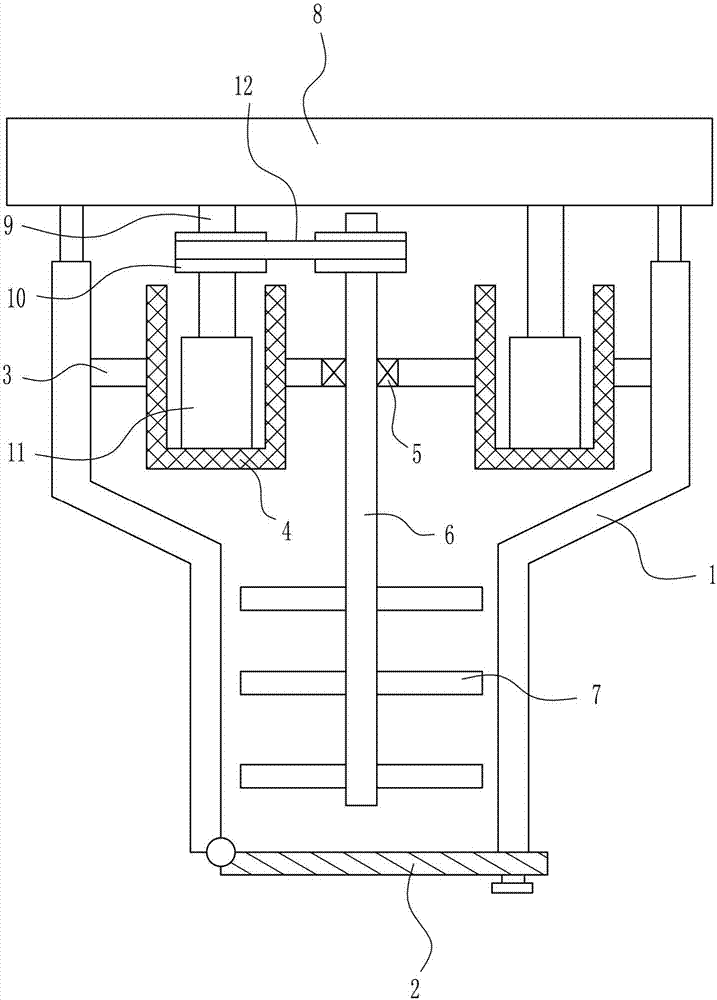

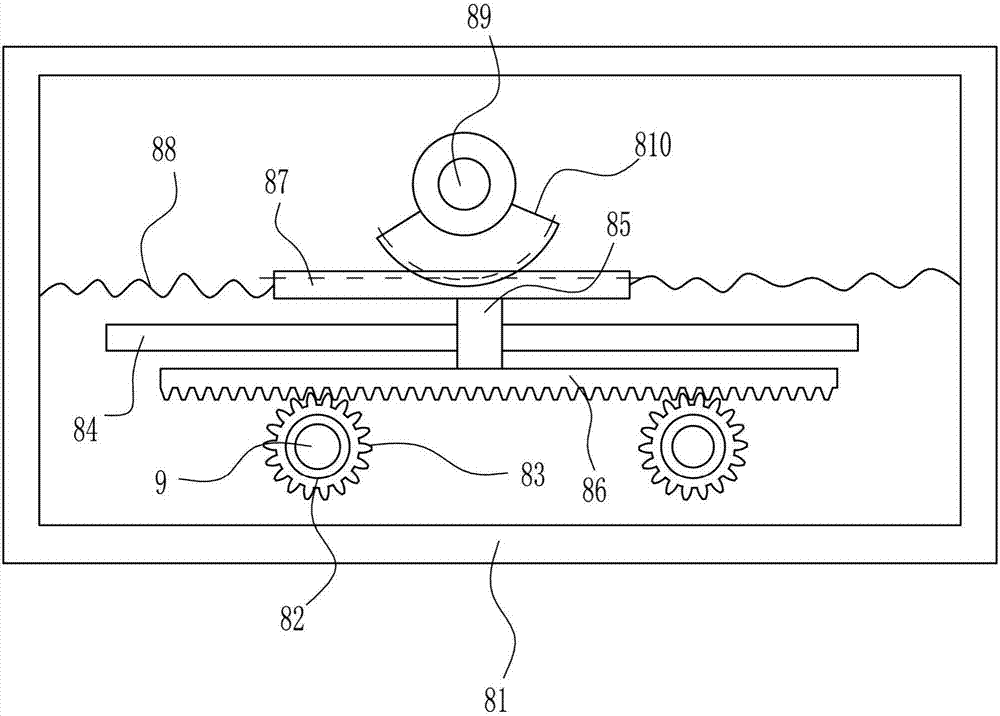

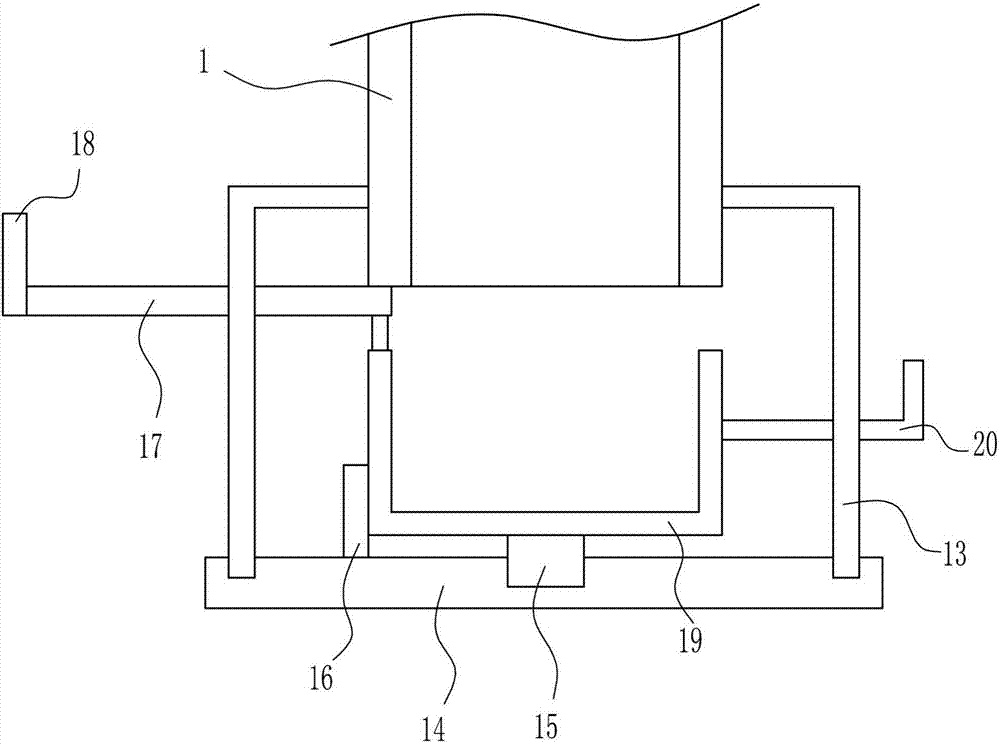

Full-automatic wastewater integrated multi-stage treatment equipment

ActiveCN113173675AInvalid processing workImprove processing efficiencyFatty/oily/floating substances removal devicesWater/sewage treatment by irradiationProcess engineeringSewage

The invention discloses full-automatic wastewater integrated multistage treatment equipment, and belongs to the technical field of wastewater treatment. The full-automatic wastewater integrated multistage treatment equipment comprises a bottom plate, a primary treatment box is installed on the bottom plate through a supporting frame, a water inlet pipe is installed at the top of the primary treatment box, and a smashing and filtering assembly is installed in the primary treatment box; and the bottom of the primary treatment box is funnel-shaped and is connected with a shunt pipe. The equipment can be used in a combined mode according to the type of sewage, multiple times of invalid treatment of part of the sewage is avoided, the sewage treatment efficiency is improved, impurities in the wastewater can be smashed and filtered, cleaning work can be achieved, continuous wastewater treatment is facilitated, and recycling and utilization of oil stains in the wastewater are achieved; a ultraviolet disinfection lamp can perform secondary disinfection and sterilization on the wastewater, and finally, the electric heating tube is used for heating the wastewater, so that germs in the wastewater are inactivated at high temperature, and the efficient disinfection and sterilization effect is achieved.

Owner:YIKANG TECH CO LTD

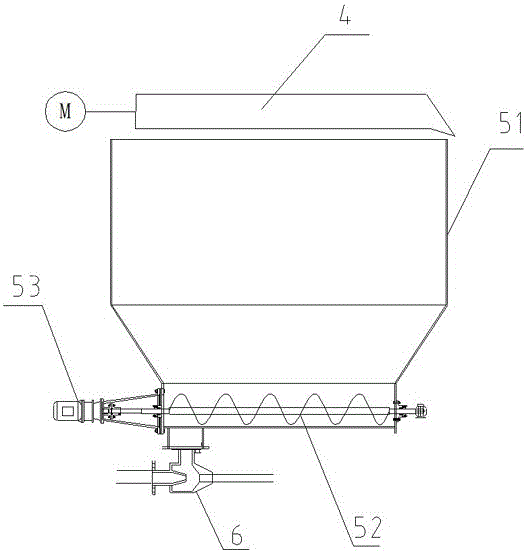

Three-level centrifugal corn grinder preventing feed from being bridged and grinding method

The invention provides a three-level centrifugal corn grinder preventing feed from being bridged and a grinding method. The corn grinder comprises a conveying mechanism, and is characterized in that the conveying mechanism is communicated with a grinding barrel, and first-level grinding teeth, second-level grinding teeth and third-level grinding teeth are sequentially arranged on the inner wall of the grinding barrel from top to bottom; a main shaft is arranged in the grinding barrel, first-level rotating supporting plates are arranged on the top of the main shaft and provided with first-level powder falling ports, air cylinder installing grooves are formed in the middle of the main shaft, and second-level grinding mechanisms are arranged in the air cylinder installing grooves; an upper cone grinder is arranged on the lower side of the main shaft, a lower cone grinder used in cooperation with the upper cone grinder is arranged on the side wall of the grinding barrel, and a conical grinding cavity is formed between the upper cone grinder and the lower cone grinder; and powder scraping pulp is arranged on the lower side of the lower cone grinder, a powder discharging pipeline is arranged at the bottom of the grinding barrel, and ground feet are arranged on the outer wall of the grinding barrel.

Owner:WEIFANG UNIV OF SCI & TECH

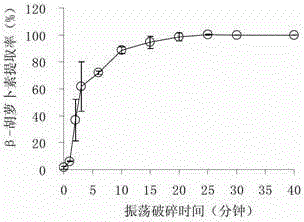

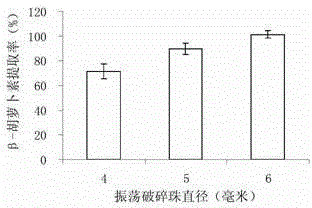

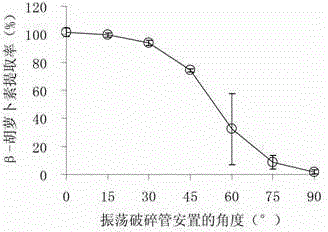

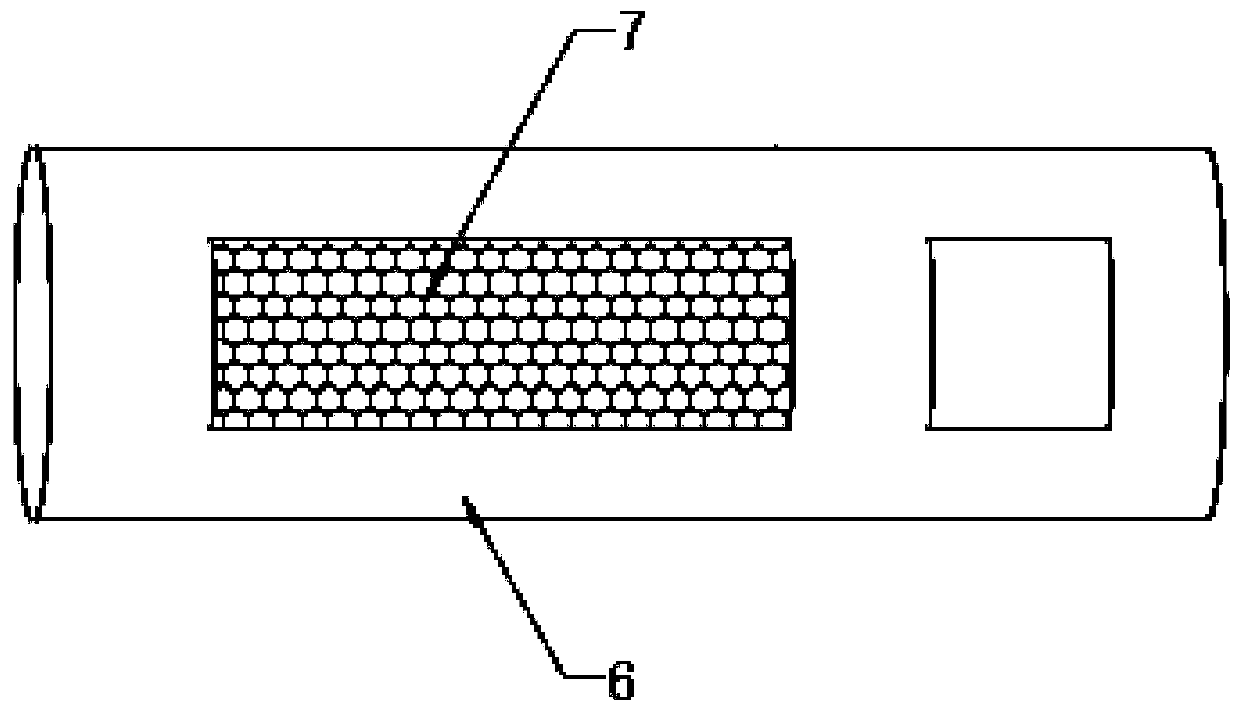

High-throughput method for extracting carotene in biological sample

InactiveCN102914462AEasy to operateAvoid poisoningPreparing sample for investigationProcess optimizationMicroorganism

The invention relates to a high-throughput method for extracting carotene in a biological sample. The method comprises the following steps of: providing oscillating and crushing power through a mechanical oscillator fixed with an oscillating and crushing tube rack, filling the biological sample, an oscillating and crushing ball and an organic solvent in the oscillating and crushing tube, and locking the sealed oscillating and crushing tube on the oscillator tube rack; and realizing grinding crushing of tissues or cells of the biological sample and dissolving and extracting of a carotene sample by utilizing collision friction of the oscillating and crushing ball and osmosis dissolution of the organic solvent in a tube at a certain oscillating rotating speed or frequency. Compared with the prior art, the method has the advantages of sample treatment flux, simple process, high working efficiency, low experimental system error, fewer required samples and solvents, low labor intensity, insulation of solvent volatilization and the like; and according to the method, the sample treatment flux and the carotene extraction efficiency can be effectively improved in the process of industrial microorganism, animal and plant high-quality variety breeding and process optimization.

Owner:SHANGHAI RES INST OF CHEM IND

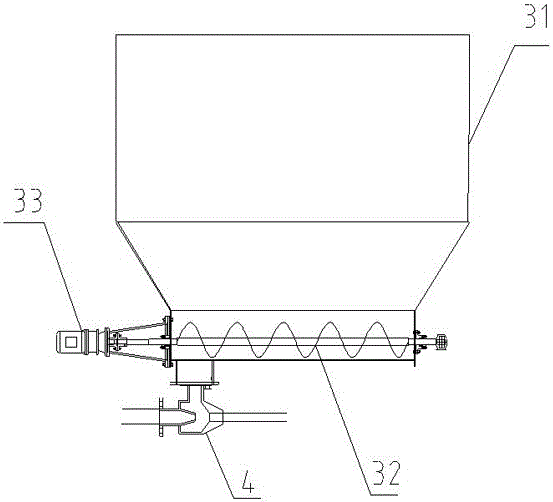

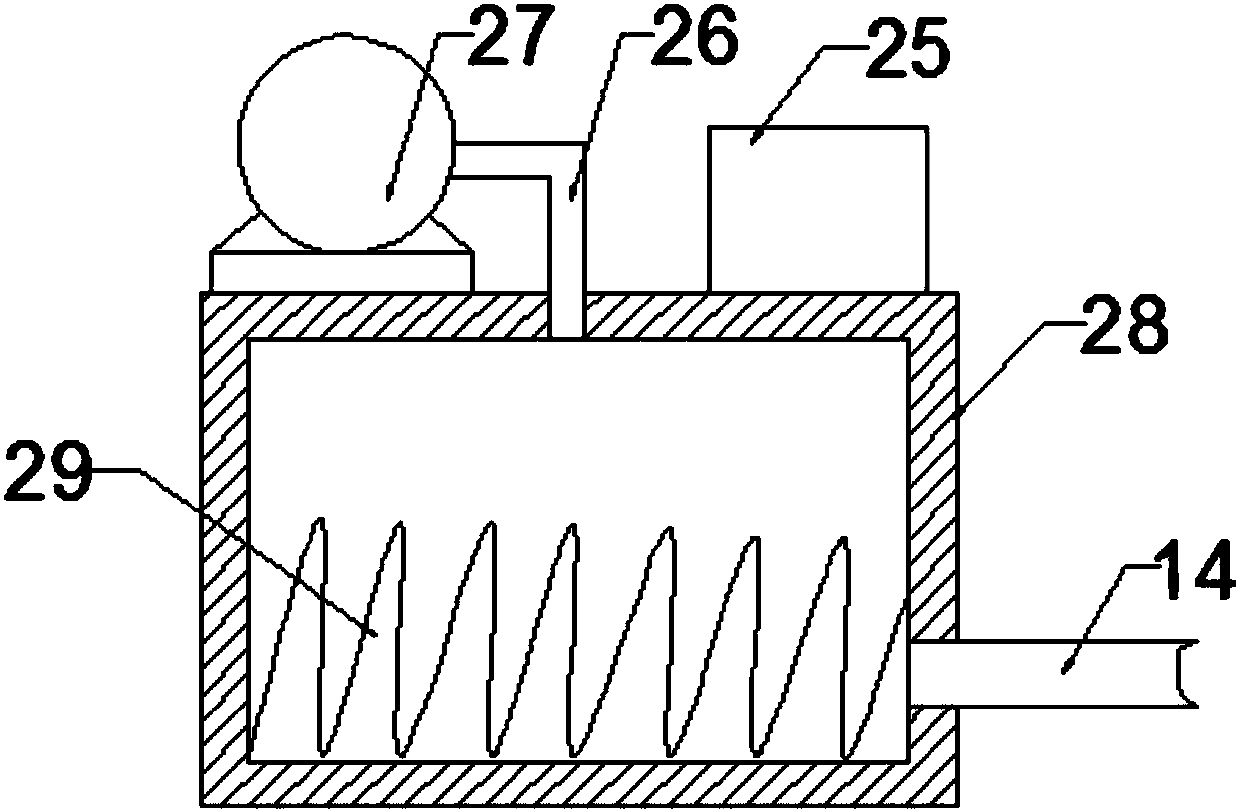

Kitchen waste pretreatment device

InactiveCN110524932ARealize extrusion dehydrationAchieve smashDrying solid materials without heatDrying gas arrangementsWater leakageSpiral blade

The invention discloses a kitchen waste pretreatment device. The kitchen waste pretreatment device comprises a shell, a dehydration barrel is arranged in the shell, and a water leakage net is embeddedat the lower portion of the dehydration barrel. A spiral blade roller is arranged in the dehydration barrel, an extrusion plate is arranged at the right side of the spiral blade roller and is connected with a reciprocating mechanism, the right side of the dehydration barrel communicates with a discharging pipe, and the discharging pipe communicates with a drying cylinder. Through the arrangementof the dehydration barrel, the water leakage net, the water collection cover and the extrusion plate connected with the reciprocating mechanism, the extrusion and dehydration of the kitchen waste is achieved, and the dehydration efficiency is improved. By arranging a hollow rotating shaft provided with the air spraying heads, the kitchen waste is rapidly and evenly dried, and the drying efficiencyis improved. By arranging the extrusion holes and the crushing cutters, the kitchen waste is further crushed, and the follow-up processing and transportation are facilitated.

Owner:唐红艳

Crushing and screening integrated mine stone crusher

InactiveCN107138224AConvenient crushing workEasy to filter jobsSievingUsing liquid separation agentScreening effectCrushed stone

The invention discloses a crushing and screening integrated mine rock crusher, which comprises a screening box, a support plate is slidably connected between the top and bottom of the inner wall of the screening box, and a screen is fixedly connected between the two support plates. The bottom of the inner wall of the screening box and one side of the support plate are fixedly connected with a shaking motor, the outer surface of the output end of the shaking motor is covered with a turntable, and the side of the turntable away from the shaking motor is fixedly connected with a sliding rod. The bottom of the inner wall and one side of the shaking motor are rotatably connected to a swing plate through a connecting block. The invention relates to the technical field of mining crushing equipment. The crushing and screening integrated mine stone crusher greatly enhances the screening effect, and avoids the accumulation of crushed stones on the screen, which will cause the screen to be blocked, thus ensuring that the stone crusher can perform normal operation. Crushing and screening greatly facilitate people's ore crushing and screening work.

Owner:LIAONING TECHNICAL UNIVERSITY

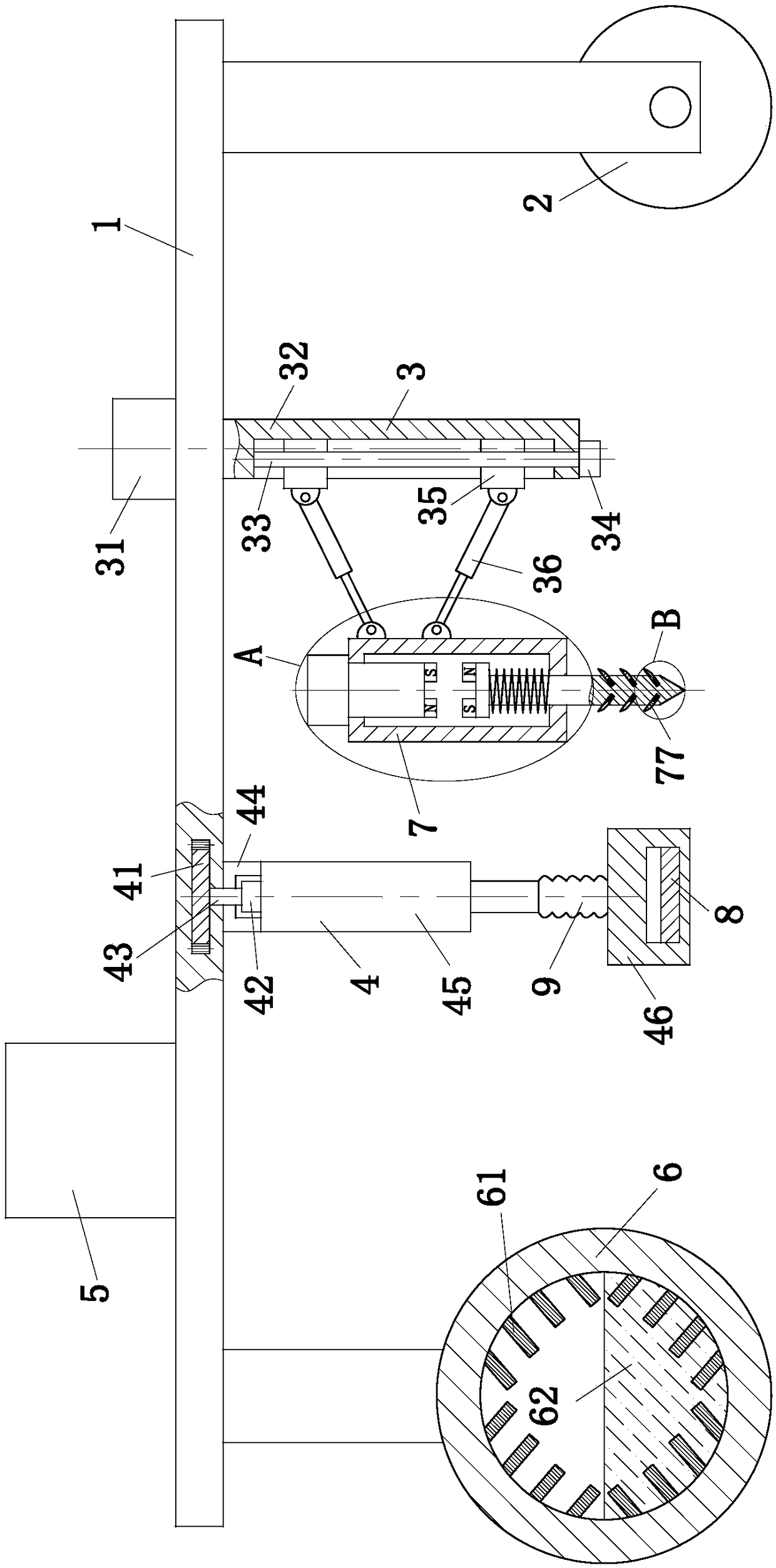

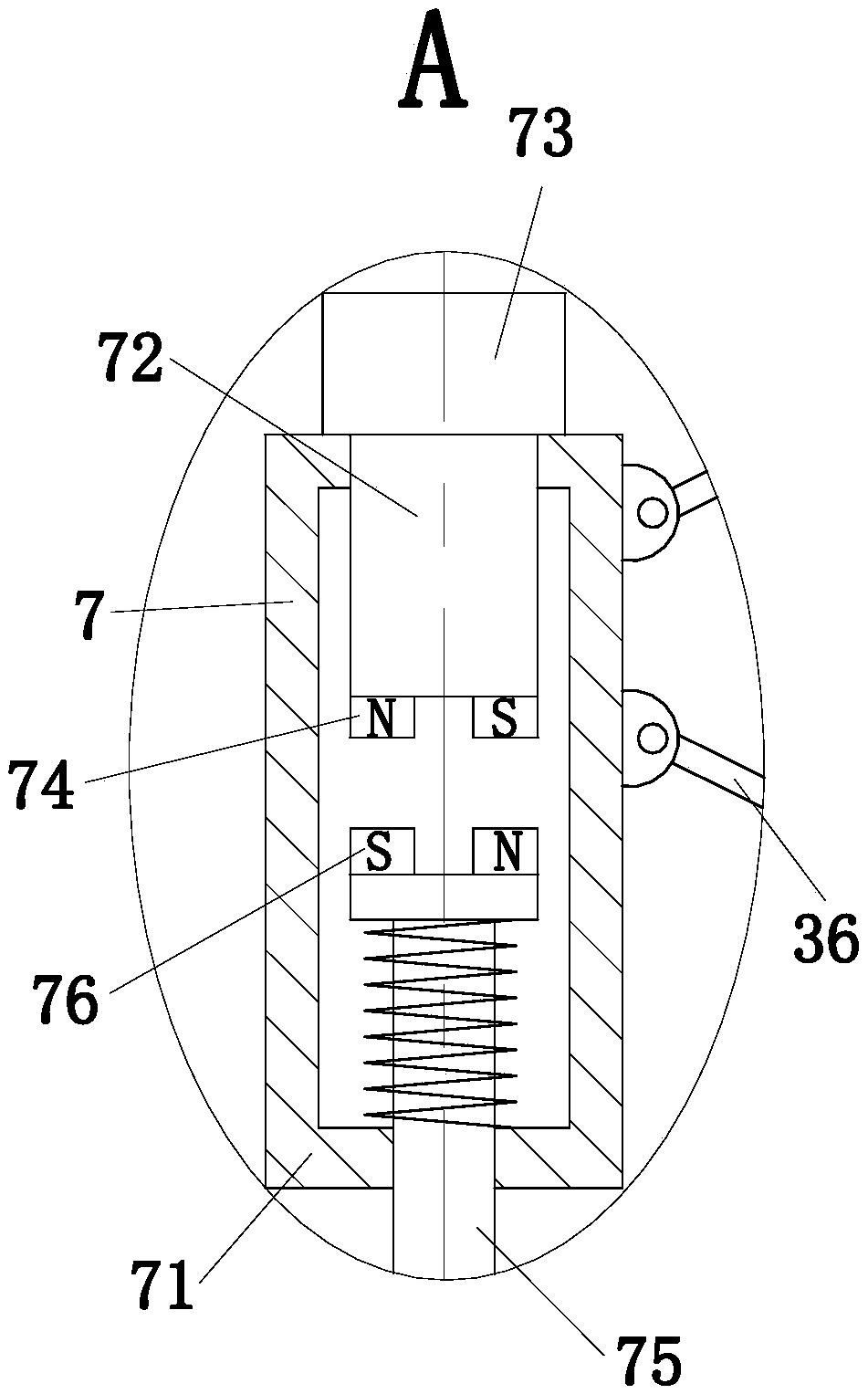

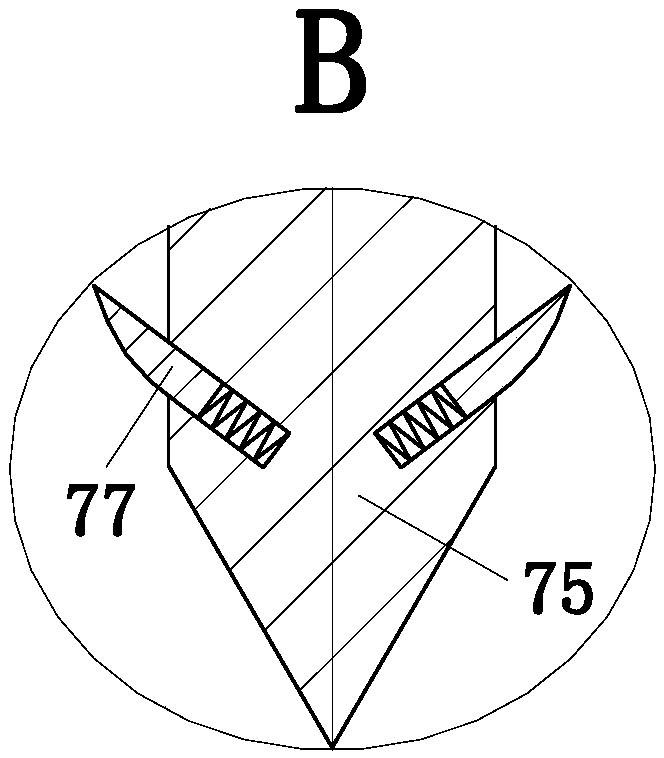

Road repairing device

The invention belongs to the technical field of pavement repairing devices, Specifically, the invention relates to a road repairing device, comprising a frame, a traveling wheel, a puncture unit, a crushing unit, a stuffing box and a rolling roller, wherein the puncture unit is installed on the frame, and the puncture unit is used for knocking the edge of the damaged pavement to determine the range of the damaged pavement, and simultaneously avoiding damage to the intact pavement during the repairing process; The crushing unit is installed on the vehicle frame, the crushing unit is located behind the puncture unit, and the crushing unit is used for completely crushing the damaged road surface knocked by the puncture unit; The stuffing box is used for adding asphalt to the pavement to be repaired after being crushed by the crushing unit according to the actual needs and repairing the pavement again; The rolling roller is installed under the vehicle frame, the rolling roller is located behind the stuffing box, and the rolling roller is used for rolling the pavement and repairing the pavement. The invention greatly improves the repairing efficiency, and at the same time, the crushed asphalt is heated and reused, thereby reducing the cost.

Owner:南京天方市政工程有限公司

Environment-friendly garbage smashing device

The invention discloses an environment-friendly garbage smashing device, and relates to the technical field of environmental technology. The problem that an existing device is not thorough in smashing is solved. The device comprises a device main body, a hydraulic cylinder, a first filter plate, a storage box body, a feeding conveying belt and a second motor; a feeding box is arranged on the right side of the top of the device main body, the upper end of the right side of the feeding box is connected with a driving wheel through a sliding plate, the driving wheel is arranged on a first motor, the driving wheel is connected with a driven wheel through a feeding conveying belt, the second motor is arranged in the feeding box, the rear end of the second motor is fixedly connected with the inner surface of the rear wall of the device main body, a bearing plate is arranged in the device main body, the garbage can be effectively smashed, the smashing effect is good, triple smashing is achieved, the problem that garbage needs to be lifted to the high position to be put into a garbage box, and fatigue is generated is avoided, and the device is suitable for popularization.

Owner:北京瑞仕邦精细化工技术有限公司

Lithium battery negative electrode smashing and demagnetizing device convenient to clean

InactiveCN109449526AAchieve smashAchieving stirringWaste accumulators reclaimingMagnetic separationDemagnetizing deviceElectrode material

The invention discloses a lithium battery negative electrode smashing and demagnetizing device convenient to clean. The device comprises a feeding and smashing mechanism, a crushing assembly, a rotating material pushing mechanism, a negative electrode smashing box body and a demagnetizing assembly arranged in the negative electrode smashing box body; the feeding and smashing mechanism is installedon the top of the negative electrode smashing box body, a material guiding hopper is welded to the inner wall of the negative electrode smashing box body and divides the interior of the negative electrode smashing box body into a smashing cavity and a demagnetizing cavity, and the demagnetizing assembly is installed in the portion, in the demagnetizing cavity, of the negative electrode smashing box body; and the feeding and smashing mechanism smashes lithium battery negative electrodes, the crushing assembly crushes the lithium battery negative electrodes, lithium battery negative electrode materials dropping into the demagnetizing cavity are stirred in the rotating material pushing mechanism, fully demagnetized by magnetic rings and magnetic blocks and discharged by a discharge pipe. Smashing, crushing, stirring, demagnetizing and discharging operations of the lithium battery negative electrodes are achieved, the operations are convenient and fast, and the smashing and demagnetizingeffects are good.

Owner:枣庄领创新能源科技有限公司

Smashing device for chemical raw materials

The invention provides a smashing device for chemical raw materials. The smashing device comprises a smashing case divided into an upper case body and a lower case body through a horizontally-arranged partition plate. The lower case body is a storage case. Smashing equipment is arranged in the upper case body. The smashing device comprises a fixed plate fixedly arranged on the partition plate. A through hole is formed in the center of the fixed plate. A smashing block is arranged on one side of the fixed plate. First smashing teeth are arranged at one end of the smashing block. A connecting rod is arranged at the other end of the smashing block and penetrates through the through hole of the fixed plate to be connected with a pushing plate. The inner side of the pushing plate is fixedly connected with the fixed plate through upper and lower springs. A cam is arranged on the outer side, between the pushing plate and the side wall of the upper case body, of the pushing plate and connected with a motor arranged on the partition plate through a connecting shaft. The smashing device for the chemical raw materials is energy saving, small in occupied space and suitable for being used in various places such as factory job shops and chemical laboratories.

Owner:TIANJIN GST CHEM TECH

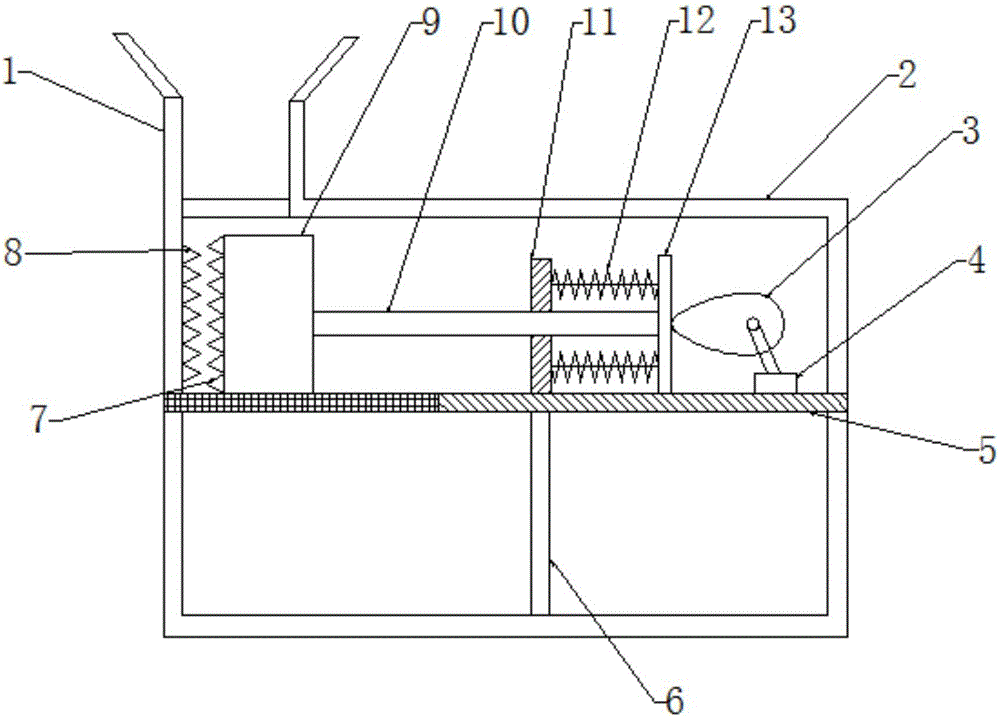

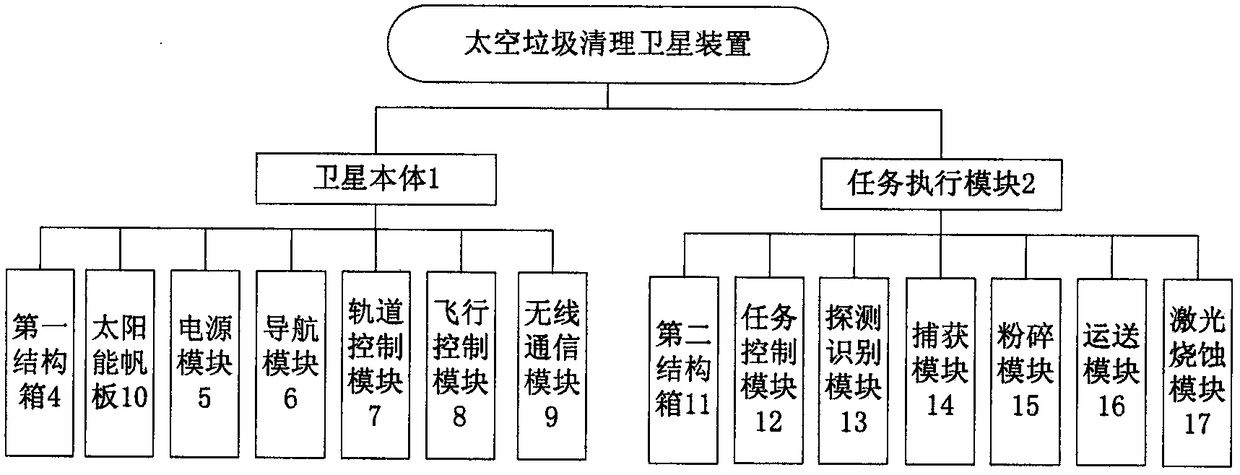

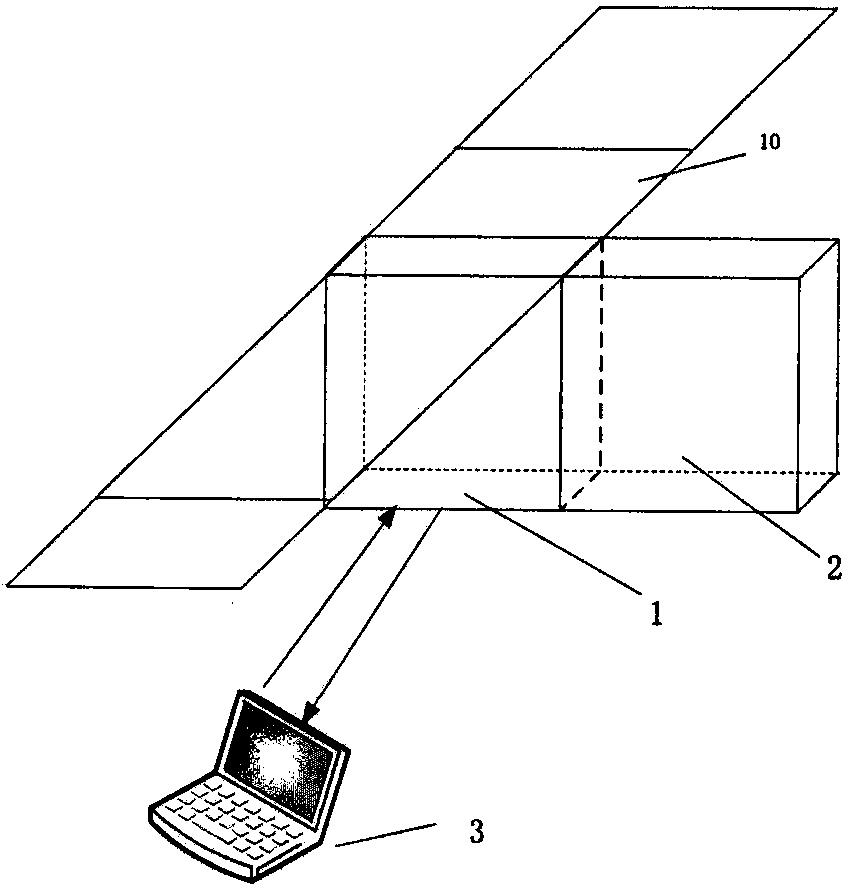

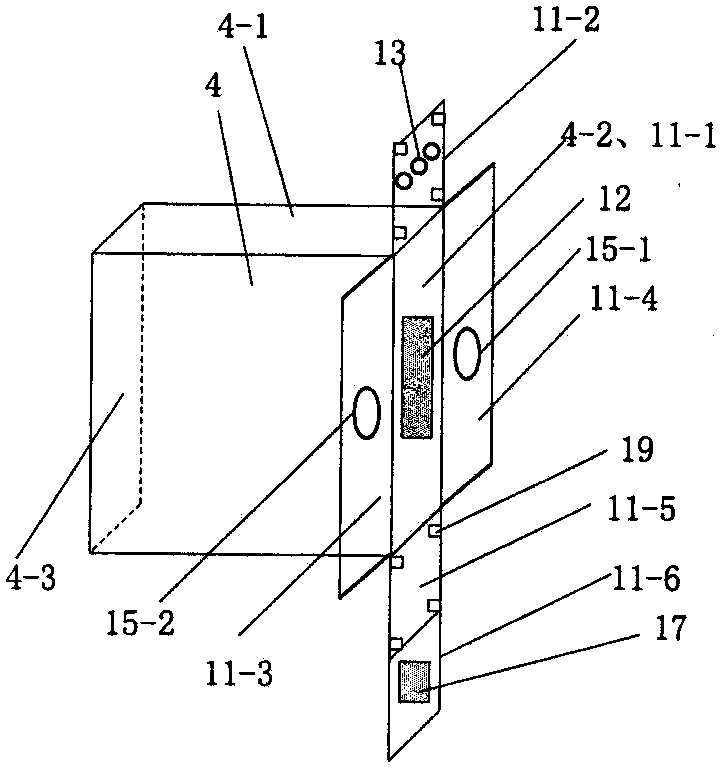

Space junk removal satellite device

PendingCN108082537ALess catchSmall sizeArtificial satellitesSpacecraft guiding apparatusEngineeringConductive materials

The invention discloses a space junk removal satellite device which comprises a satellite body and a task execution module. The satellite body comprises a first structure box, a power module, a navigation module, an orbit control module, a flight control module, a wireless communication module and a solar cell array, the power module, the navigation module, the orbit control module, the flight control module and the wireless communication module are arranged in the first structure box, the first structure box is a cube, and all the faces of the box are fixed through mechanical structures; andthe task execution module comprises a second structure box, a task control module, a detection recognition module, a capture module, a smashing module, a transporting module and a laser ablation module, the task control module, the detection recognition module, the capture module, the smashing module, the transporting module and the laser ablation module are arranged in the second structure box, the second structure box is a cube, the left side face of the second structure box is a fixed face mechanically locked to the satellite body, and the remaining five faces are each of a deformable structure and can be unfolded and folded within the range from -60 degrees to 60 degrees. The device can capture and remove small-size space junk, and the space junk containing a conductive material can beablated through the laser ablation module and then secondarily used to supply energy to the laser ablation module.

Owner:LANZHOU JIAOTONG UNIV

Grinder

InactiveCN101797528AAchieve smashEasy to recycleSolid waste disposalGrain treatmentsKnife bladesPrinted circuit board

The invention relates to a grinder. The grinder comprises a feed hopper and a grinding cavity communicated with the feed hopper, wherein the grinding cavity is fixed on a device base, the inside of the grinding cavity is provided with a main shaft, the main shaft is provided with a rotating cutter linked with the main shaft; the grinder also comprises a cavity communicated with the grinding cavity, a screen is arranged between the cavity and the grinding cavity; and the cavity is communicated with a feeding fan through a pipeline, and the pipeline is communicated with a discharge hole. The grinder provided by the invention is used to efficiently grind materials to be grinded such as the waste printed-circuit board of waste electrical appliances and facilitate subsequent recovery and utilization.

Owner:HUNAN VARY TECH

Gypsum raw material stirring apparatus for medical orthopedics department

ActiveCN108704565AEasy to operateImprove processing efficiencyRotary stirring mixersTransportation and packagingGypsumPower control

The invention relates to the technical field of medical instruments, in particular to a gypsum raw material stirring apparatus for medical orthopedics department. The left ends of two supporting rodsare fixedly connected with a transverse plate, the left end of the transverse plate is fixedly connected with a vertical plate, the left ends of a lower rod and an upper rod are fixedly connected witha motor seat, and the lower rod is fixedly connected to the upper end of the vertical plate; and the upper ends of the two supporting rods are fixedly connected with a disc seat, and two U-shaped sliding seats are symmetrically fixedly connected to the front end and the rear end of the disc seat. By adopting the gypsum raw material stirring apparatus, a gypsum raw material can be smashed, the smashed gypsum raw material can be stirred, so that the smashing and the stirring can be synchronously performed, the operation is simple, and the processing efficiency is high; and the smashed gypsum raw material falls into the stirring apparatus, when the gypsum raw material reaches a given weight, a hinge rod drives a power apparatus to be separated from a smashing apparatus by virtue of a power control member, so that the smashing apparatus is automatically stopped discharging without power, and the gypsum raw material can be distributed according to the equal weight.

Owner:温保军

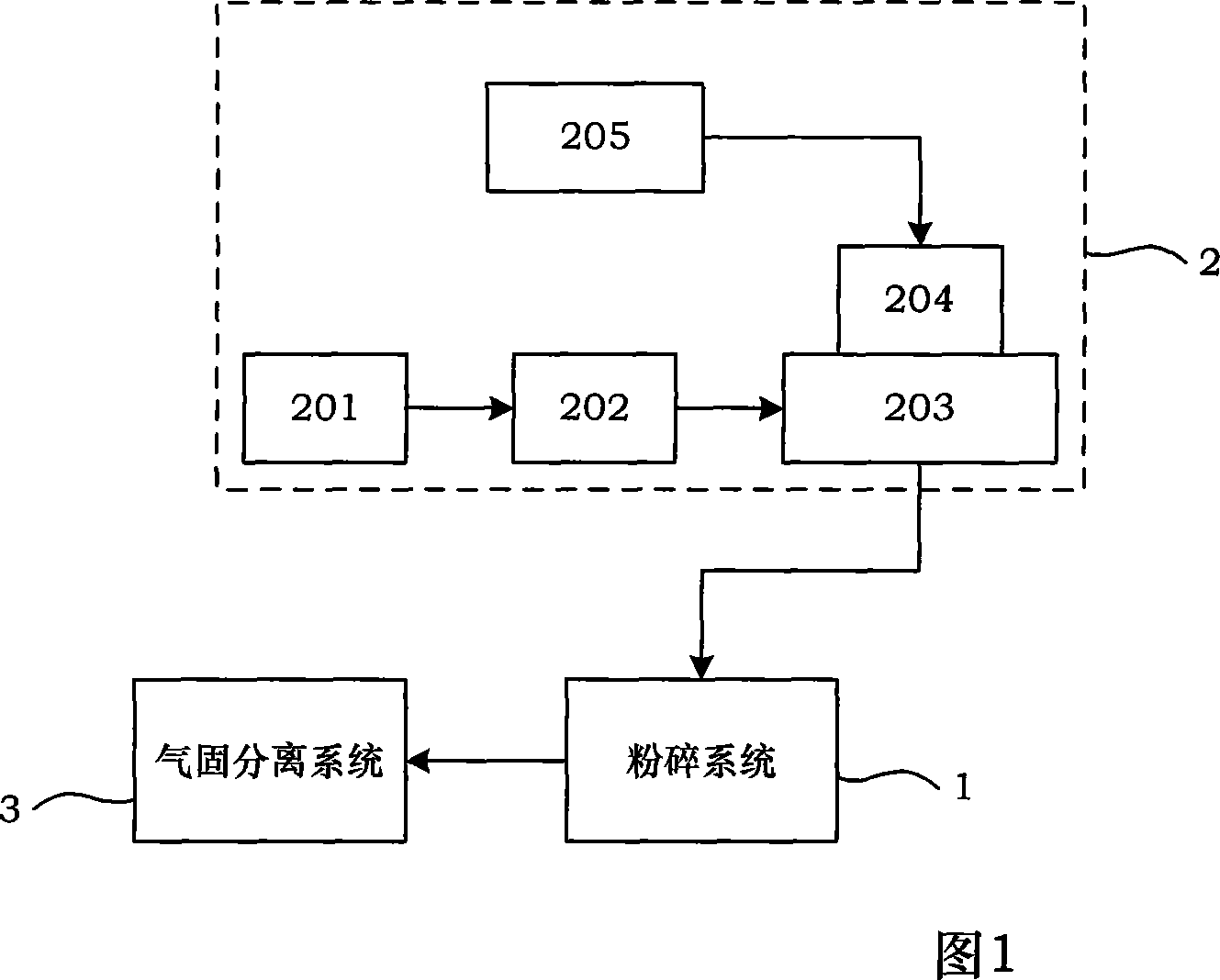

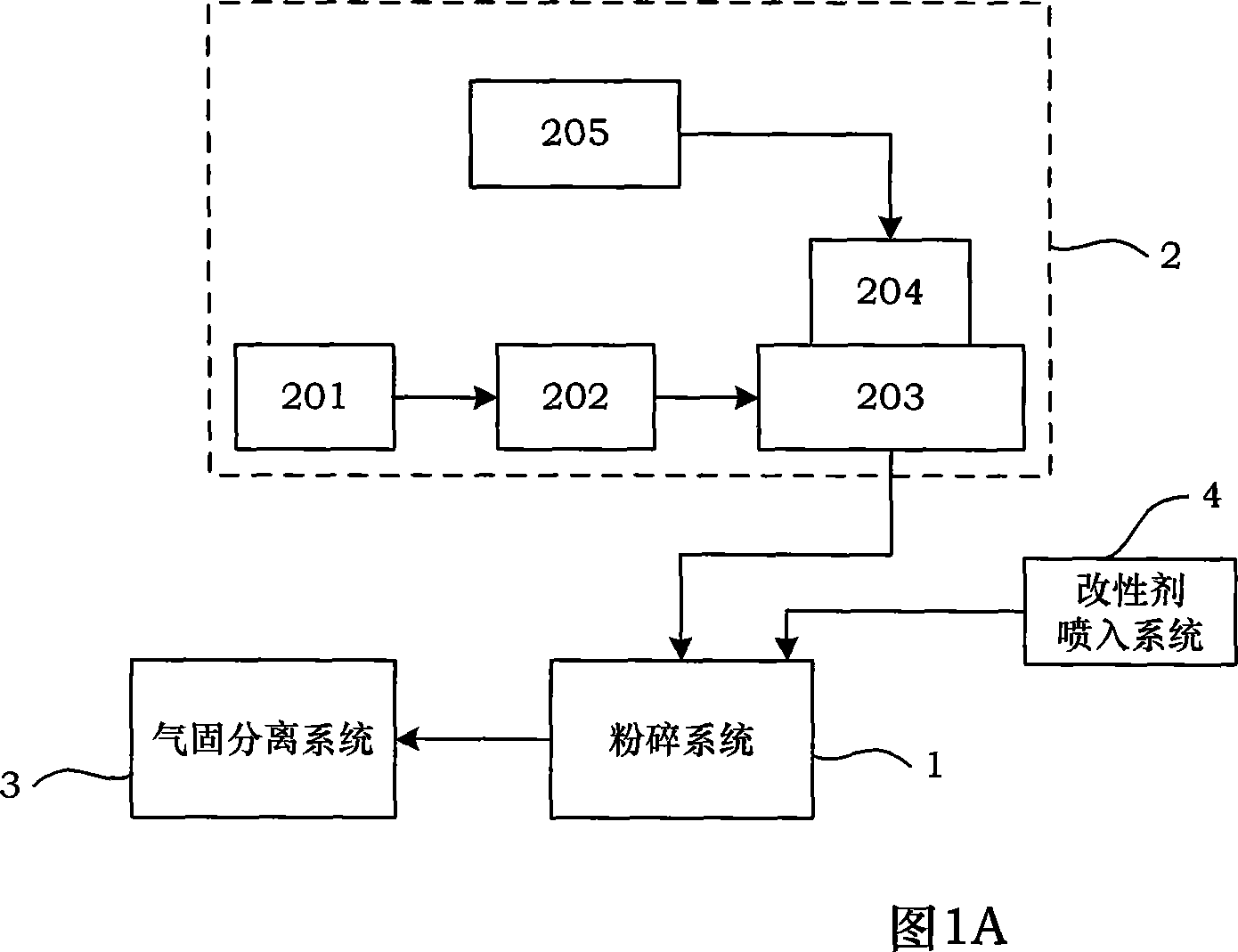

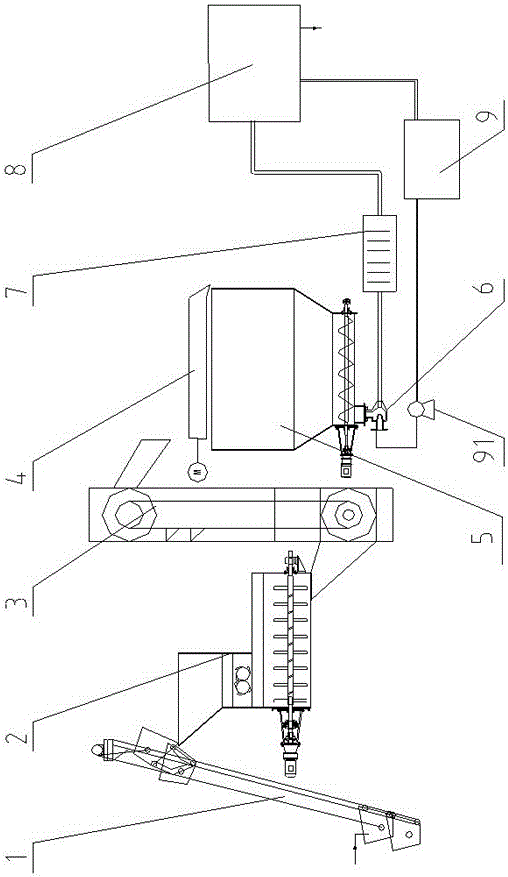

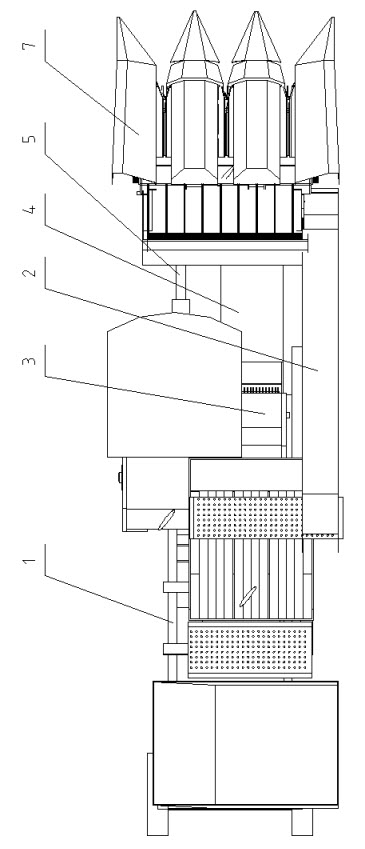

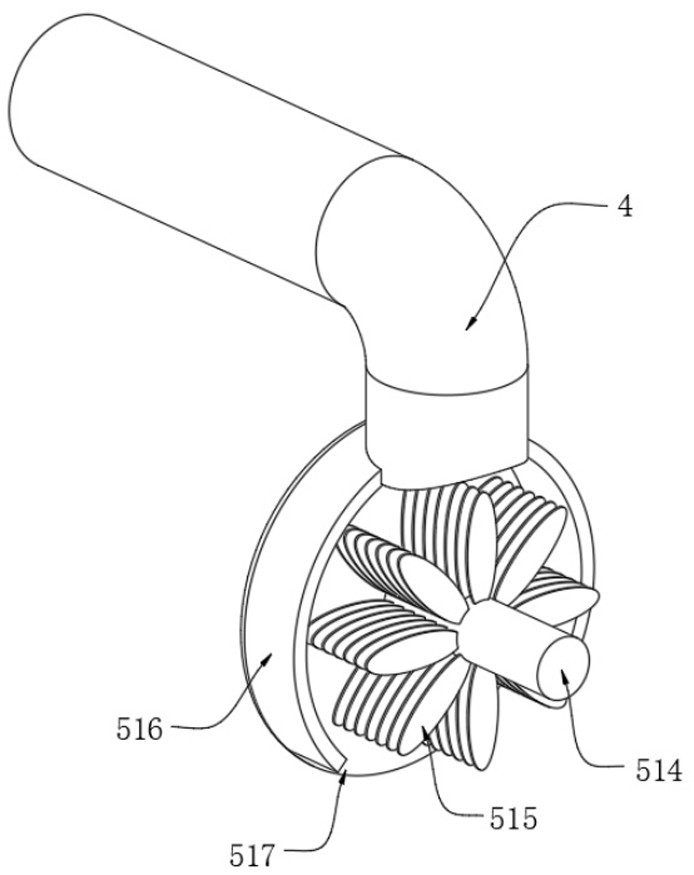

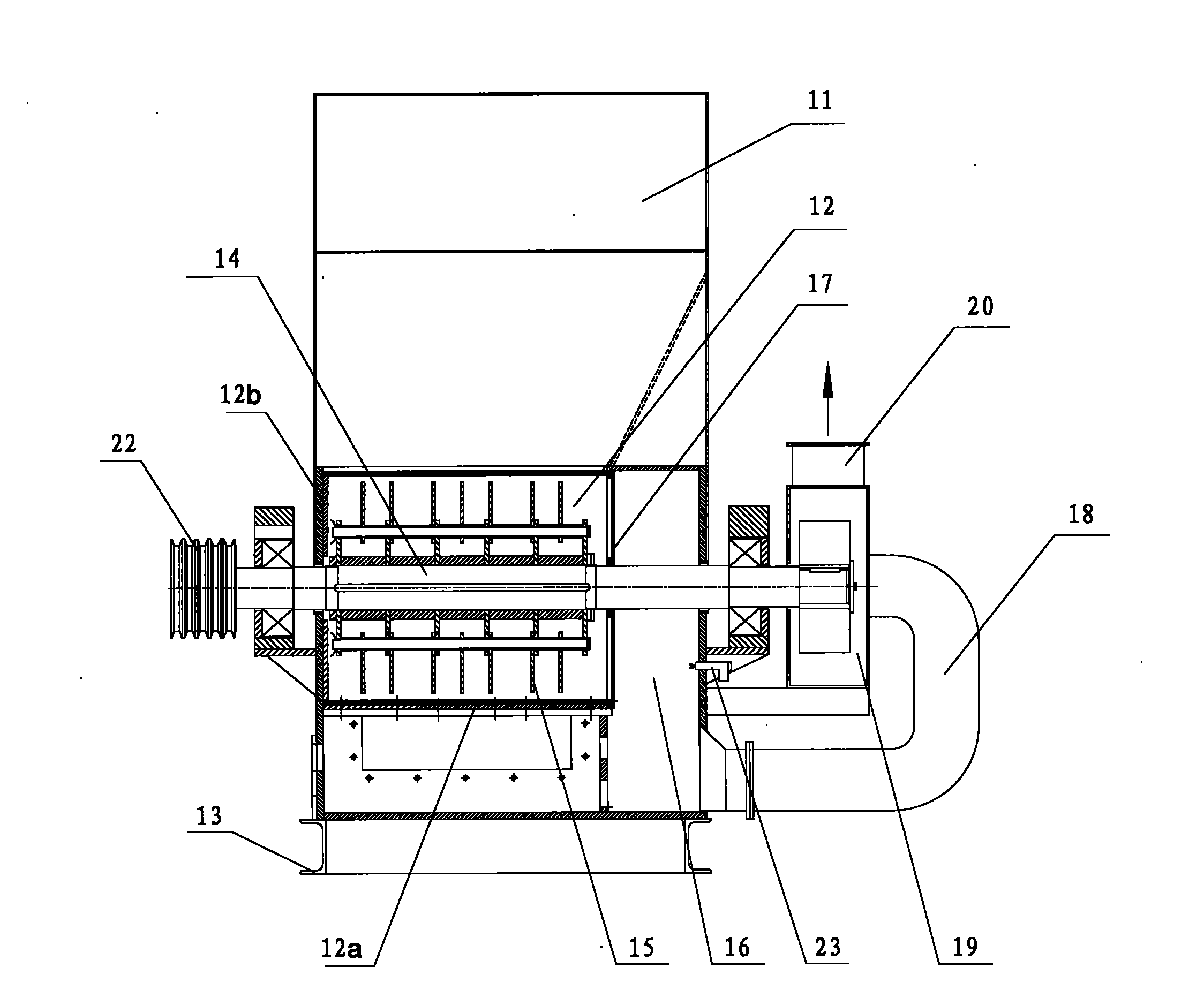

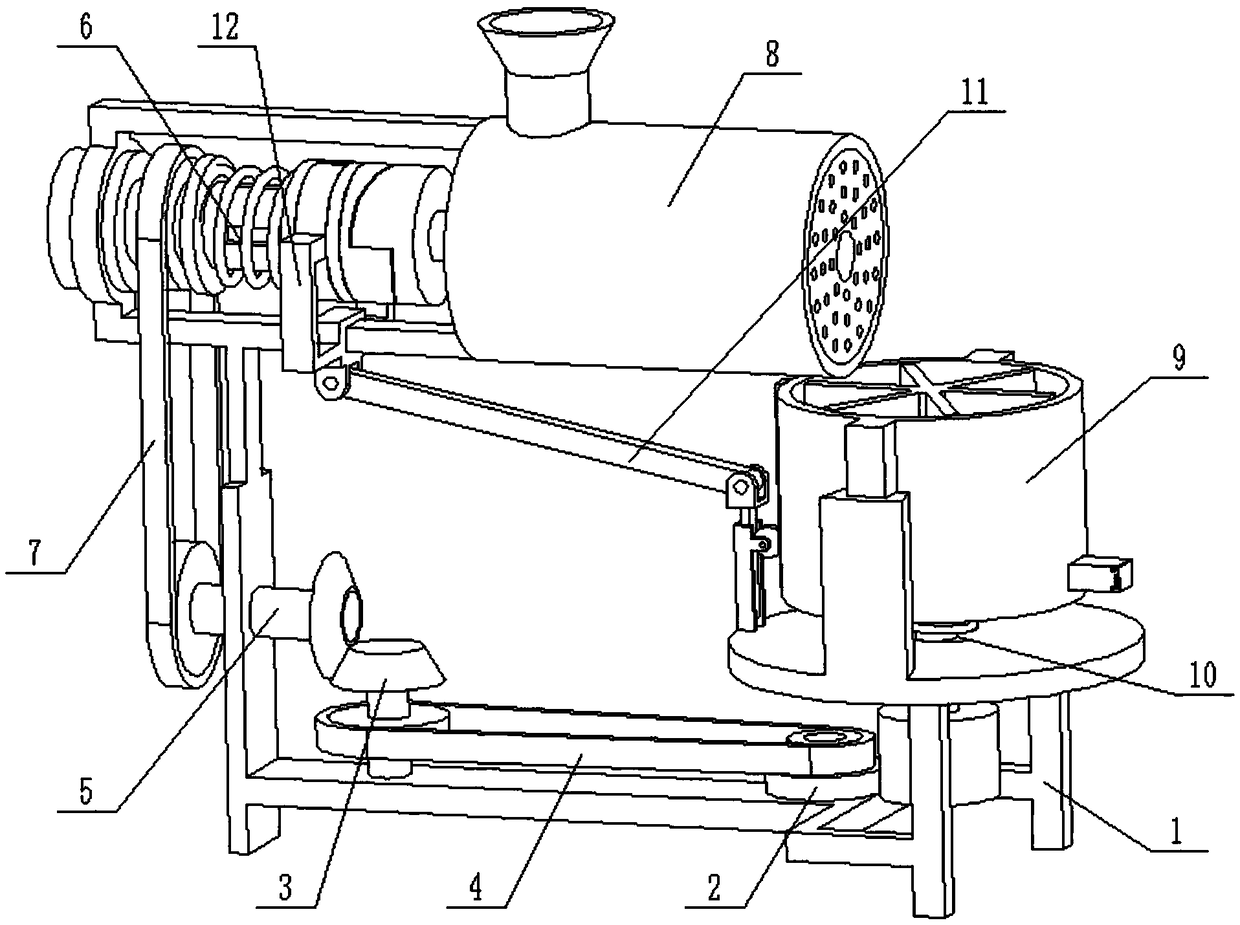

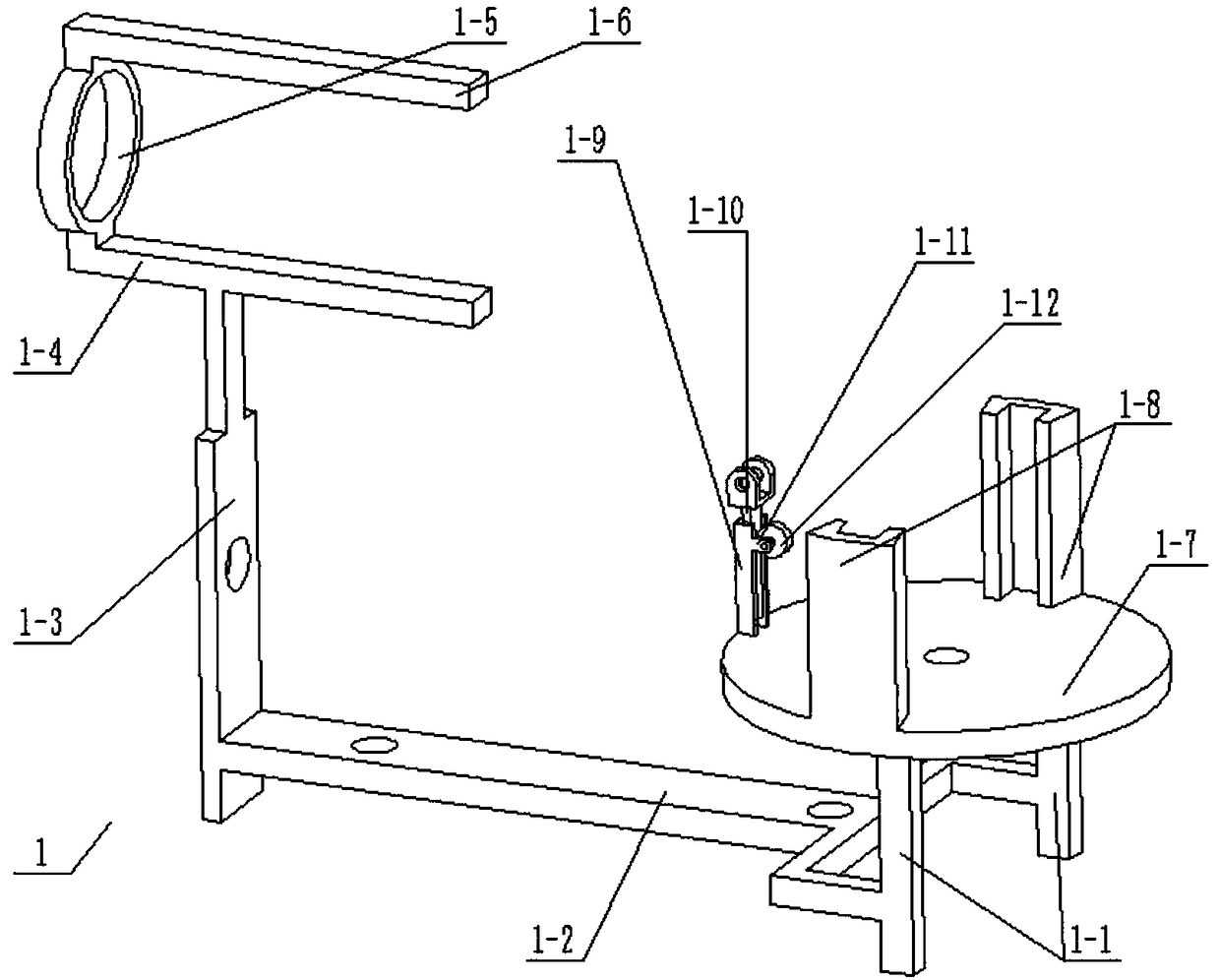

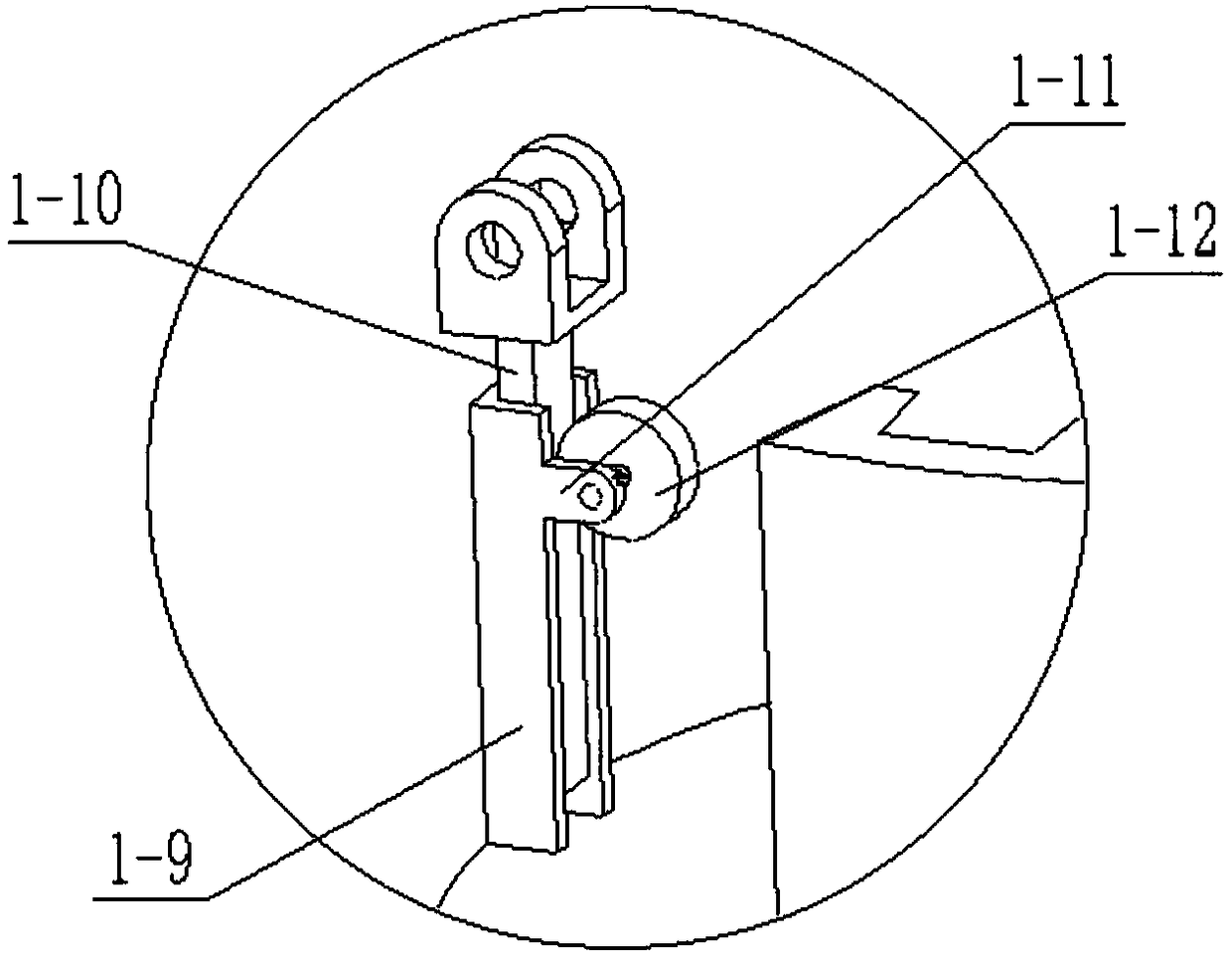

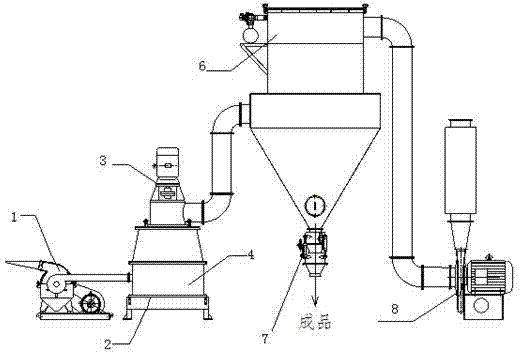

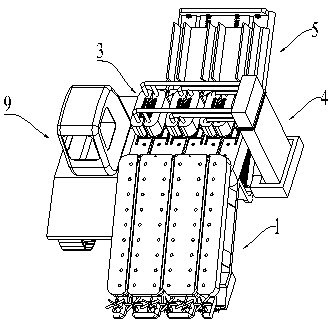

Device and method for preparation of biomass ultrafine powder

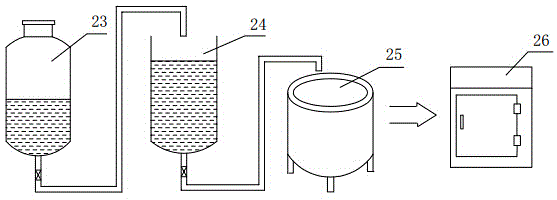

InactiveCN103285987ALow densityAchieve smashGas current separationGrain treatmentsEngineeringCrusher

The purpose of the present invention is to provide a device and a method for preparation of a biomass ultrafine powder. The device for preparation of the biomass ultrafine powder comprises a coarse crusher, a biomass-specialized ultrafine crusher, a pulse bag deduster, a double-plate baiting valve and an induced draught fan. The coarse crusher and the biomass-specialized ultrafine crusher are connected through a pipeline. The biomass-specialized ultrafine crusher is provided respectively with, from bottom to top, a crushing chamber and a grader. The biomass-specialized ultrafine crusher and the grader are configured into an integral structure, and crushing and grading can be continuous and synchronous. The beneficial effects of the invention are that: fed materials are crushed into powders with non-uniform particle sizes by a millstone of the crushing chamber, the powders with non-uniform particle sizes are graded into a qualified fine powder and an unqualified coarse powder by the grader, the unqualified coarse powder falls back to the crushing chamber for continued crushing, the qualified fine powder enters into the pulse bag deduster from the grader through the pipeline, and the irregular crystal powder is obtained through colleting by the double-plate baiting valve, so simple and convenient screening can be realized; at the same time, the biomass-specialized ultrafine crusher and the grader are configured into an integral structure, so that crushing and grading can be continuous and synchronous; and dust-containing exhaust gases are discharged by use of the induced draft fan, and the pollution of the environment can be greatly reduced.

Owner:MULTIENERGY GRP

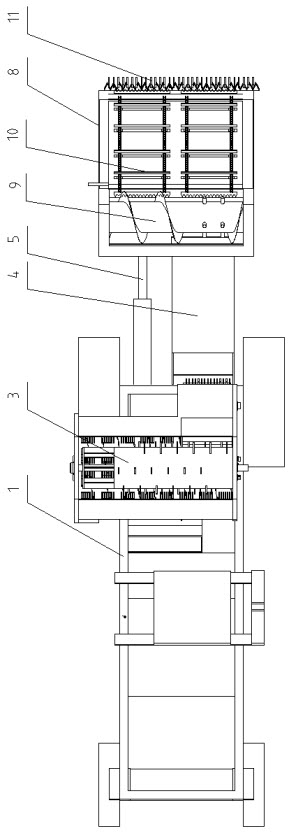

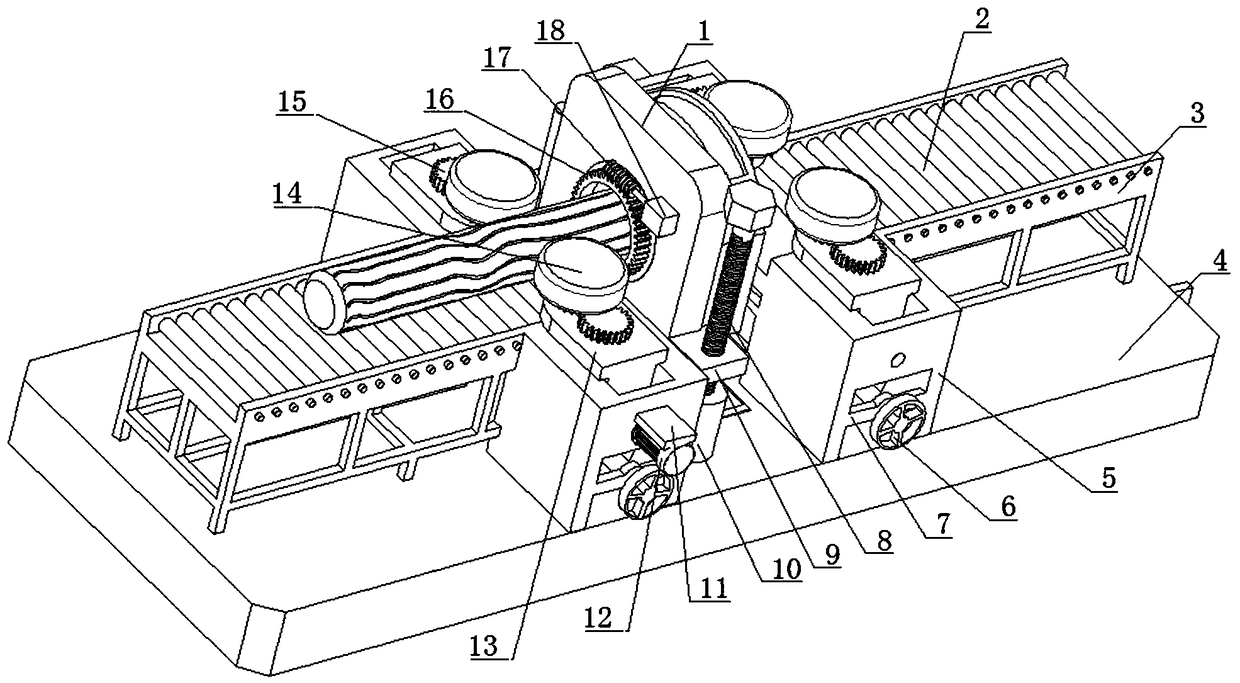

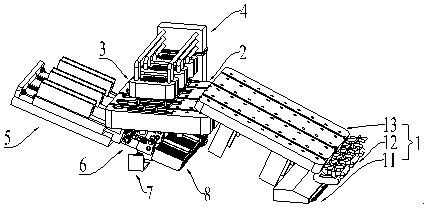

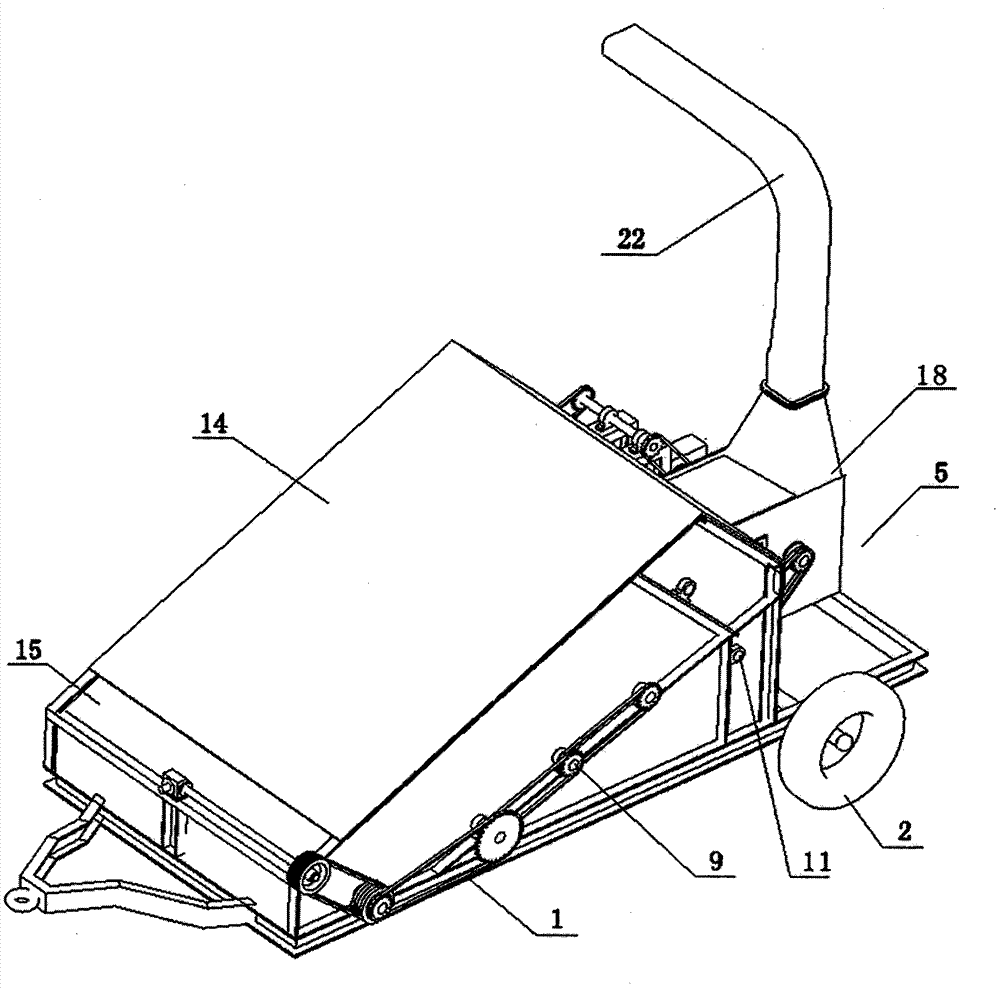

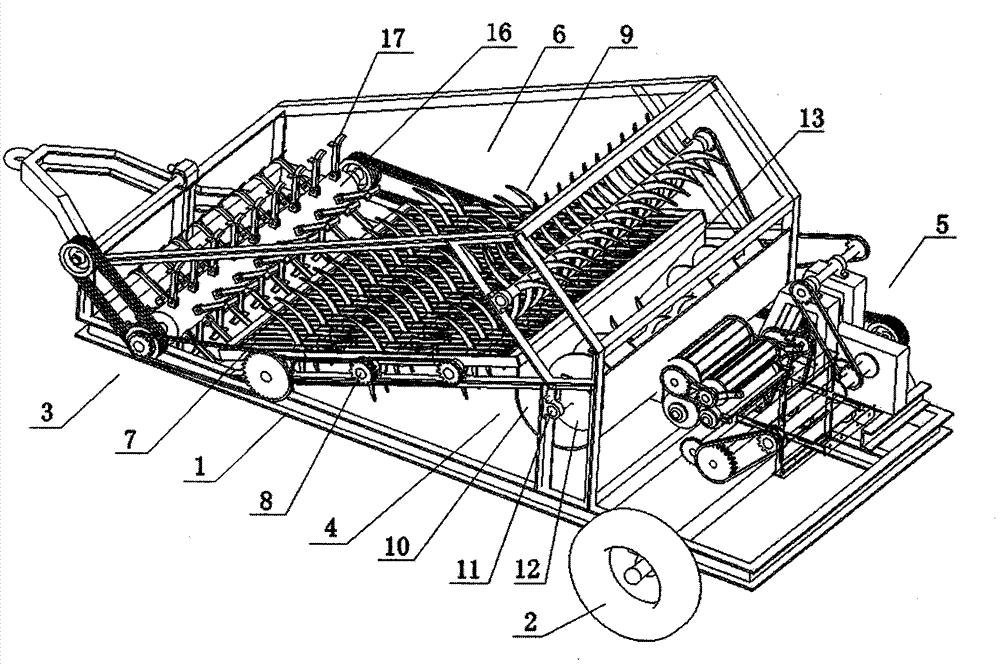

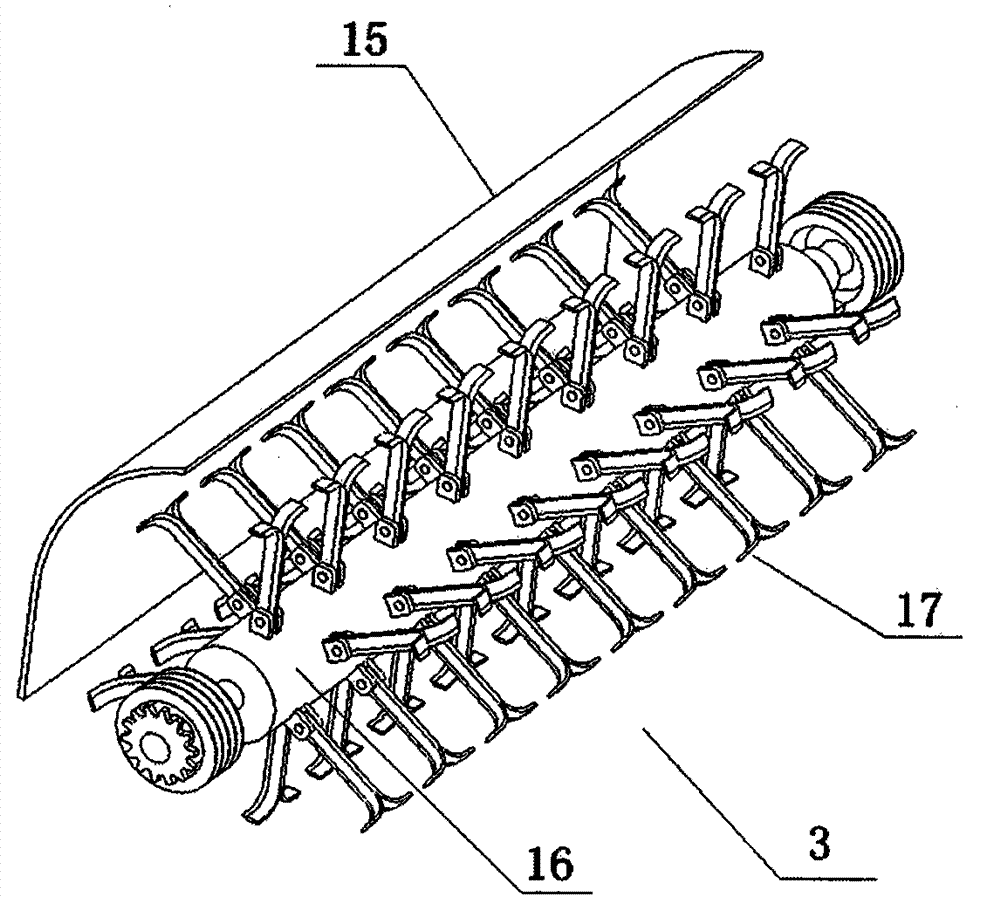

Fully automated kenaf harvesting integrated machine

ActiveCN108064545AAchieve smashGuaranteed safe and reliable useMowersThreshersFiberComputer engineering

The invention relates to a fully automated kenaf harvesting integrated machine comprising a harvesting device, a second clamping and conveying device, a branch and leaf treatment device, a residue discharge device, a feeding device, a kenaf stem-fiber separation device, a collecting and bundling device, a smashing device and a transport vehicle. The harvesting device, the second clamping and conveying device, the branch and leaf treatment device, the residue discharge device, the feeding device, the kenaf stem-fiber separation device, the collecting and bundling device and the smashing deviceare arranged on the transport vehicle. The fully automated kenaf harvesting integrated machine completes kenaf harvesting, branch and leaf removal and kenaf stem-fiber separation, the kenaf stem-fiberseparation treatment is completed automatically in the whole process, kenaf stem-fibers are bundled after the kenaf stem-fiber separation, the treatment efficiency is high, the treatment automation can be achieved, follow-up processes are reduced, and the cost is reduced. Through the compact layout of the overall machine, operations by workers are facilitated, and the fully automated kenaf harvesting integrated machine is complete in function, saves labor and is environmentally friendly.

Owner:振林建设集团股份有限公司

Automatic pounding machine for pharmaceutical preparation technology of traditional Chinese medicine pseudo-ginseng promoting blood circulation and removing blood stasis

InactiveCN107335505AMashed to achieveThe masher is realized by installing crushingHollow article cleaningGrain treatmentsTransverse grooveRemove blood

The invention relates to an automatic pounding machine for promoting blood circulation and removing blood stasis traditional Chinese medicine Panax notoginseng pharmaceutical process, which includes a crushing tank, a smashing tank, a base and a steel frame seat. A first fixed horizontal plate is horizontally installed inside the steel frame seat on one side of the water tank, and a second fixed horizontal plate is horizontally installed inside the steel frame seat on the side of the mounting piece close to the collection tank. The first fixed horizontal plate and the second fixed horizontal plate The bottom ends of the horizontal plates are provided with two crushing grooves, and two tamping hammers are installed inside the steel frame seat at the position of the second fixed horizontal plate. , and the interior of the installation groove is provided with a crushing groove. The present invention installs a crushing groove, an installation groove, a crushing wheel and a second driving motor, and the second driving motor drives the crushing wheel to rotate to pre-pulverize the notoginseng medicinal material, so that the crushed notoginseng medicinal material is divided into smaller blocks and then crushed. Mashing is beneficial to the mashing work.

Owner:陈书芳

Stalk pickup and chopping machine

InactiveCN104322205AThrown in placeImprove cutting efficiencyLoadersMowersEngineeringMechanical engineering

The invention discloses a stalk pickup and chopping machine. A frame is sequentially provided with a cutting pickup device, a conveying screen, a feeder and a chopping thrower from front to back; the conveying screen comprises a soil screening grate; 2-5 grass poking shafts driven by a transmission mechanism are arranged below the soil screening grate; a grass poking shaft driven by the transmission mechanism is arranged on the back part on the soil screening grate; each grass poking shaft is fixedly provided with a plurality of grass poking wheels; each grass poking wheel is provided with 2 to 4 arc grass poking claws; the feeder comprises a feeding trough; a feeding shaft driven by the transmission mechanism is arranged in the feeding trough; two ends of the feeding shaft are provided with spiral sheets which rotate in opposite directions and gather materials towards the middle; the middle of the feeding shaft is provided with a plurality of feeding claws. The stalk pickup and chopping machine is simple and compact in structure and low in cost, can realize pickup and crushing or harvesting and crushing combined work, the obtained crushed stalks do not have dust, and the working efficiency is high.

Owner:李海龙

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com