Patents

Literature

703results about "Tree debarking" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

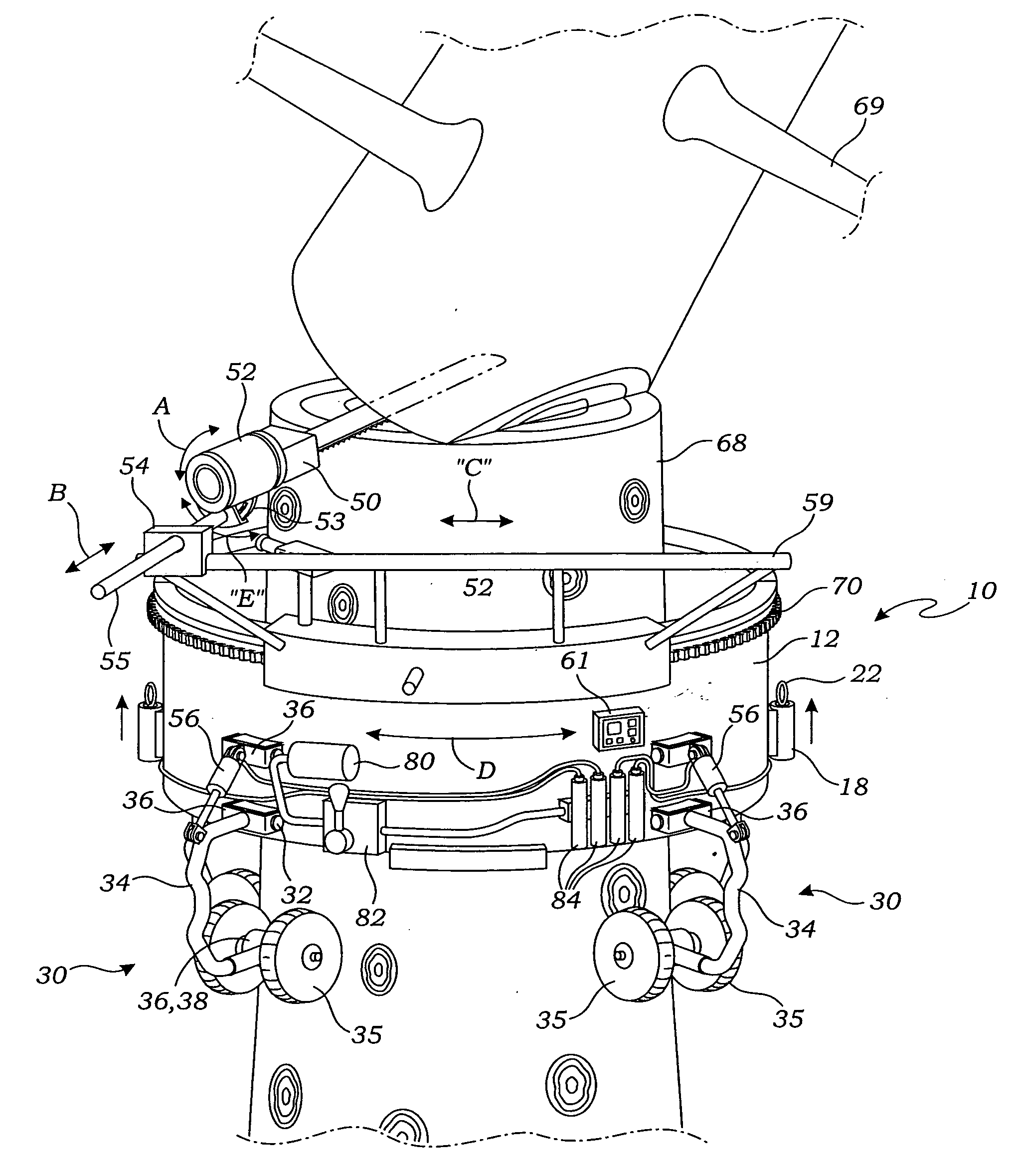

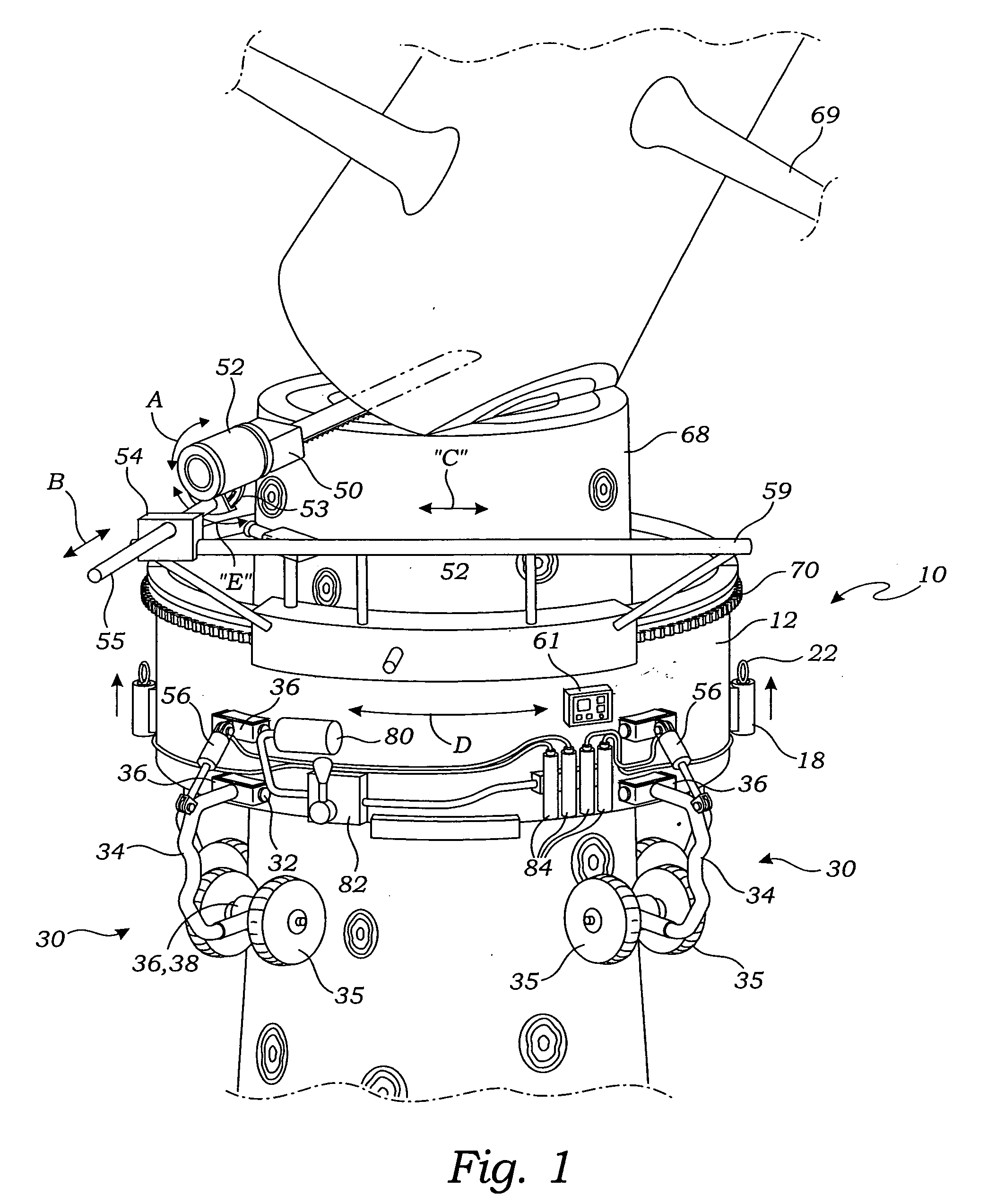

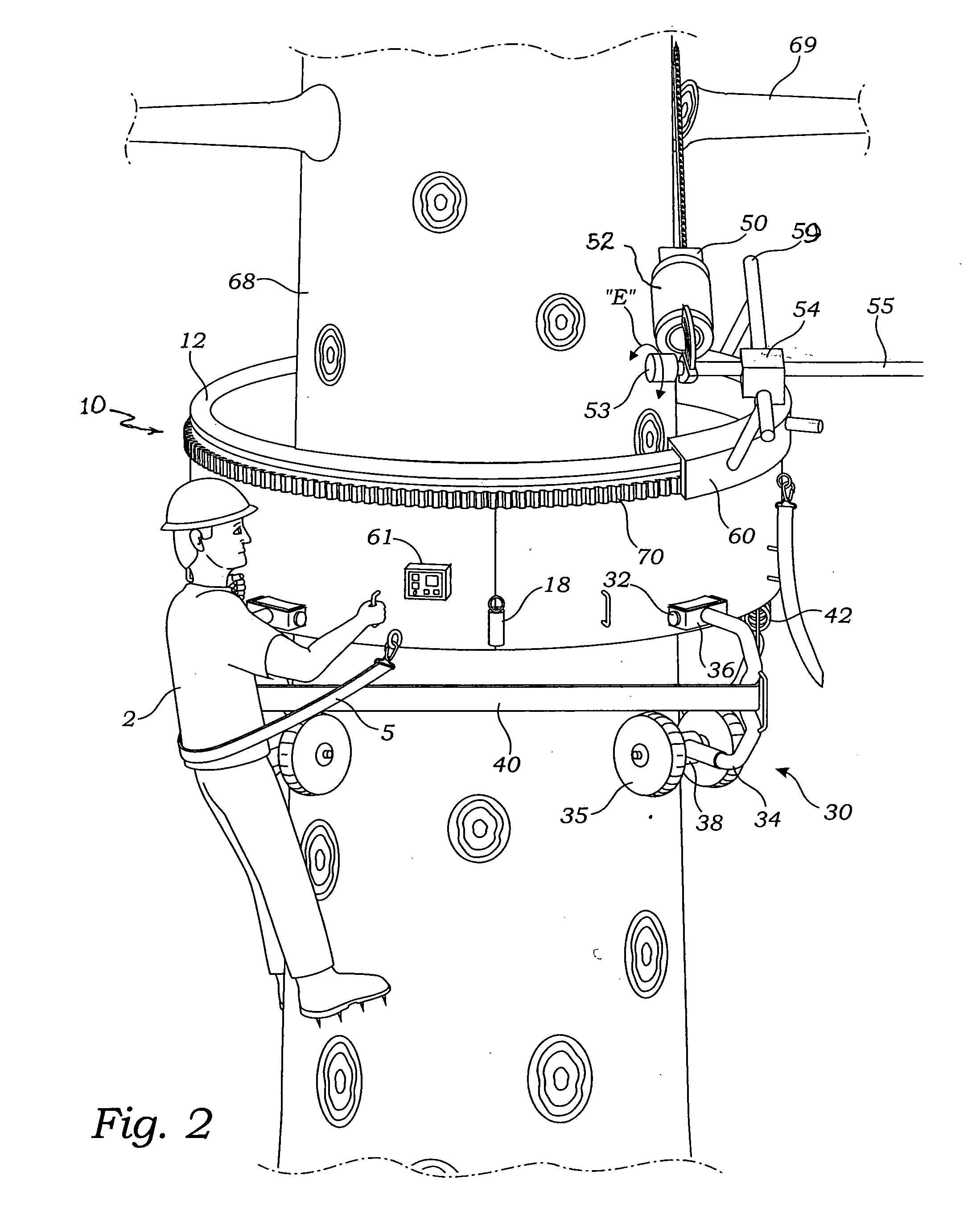

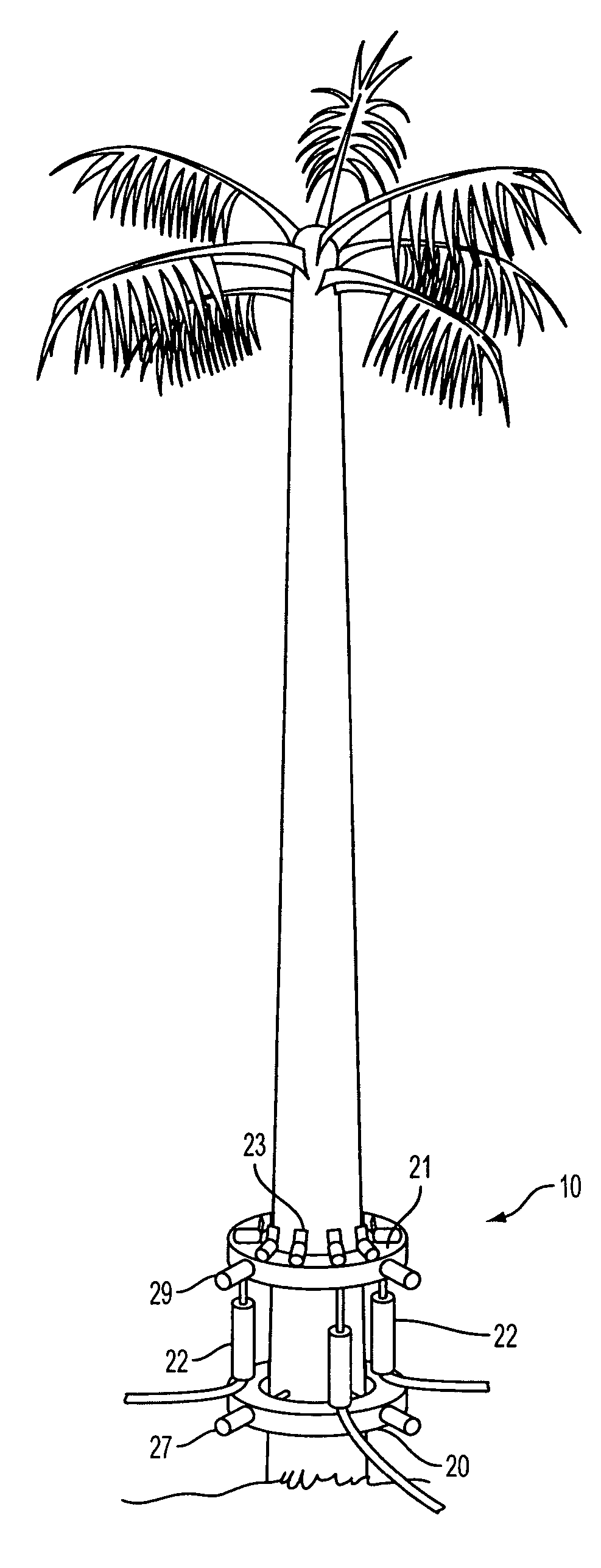

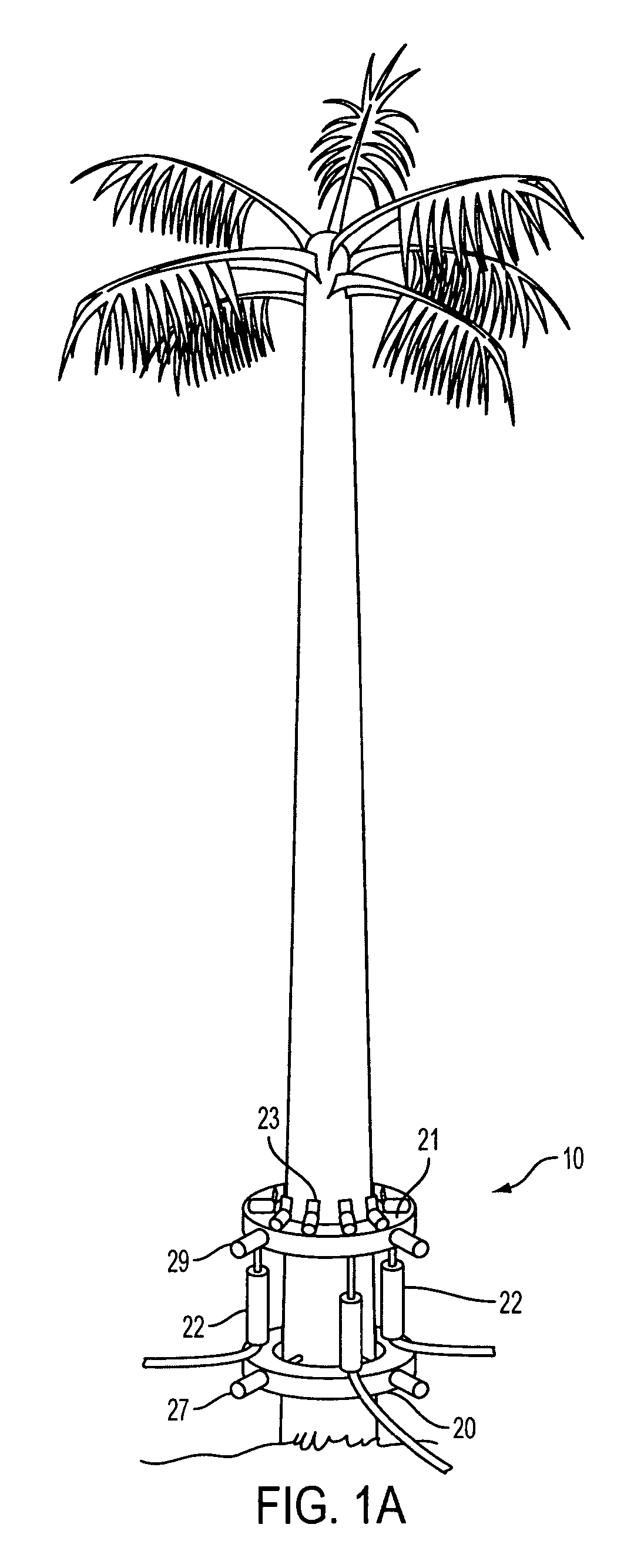

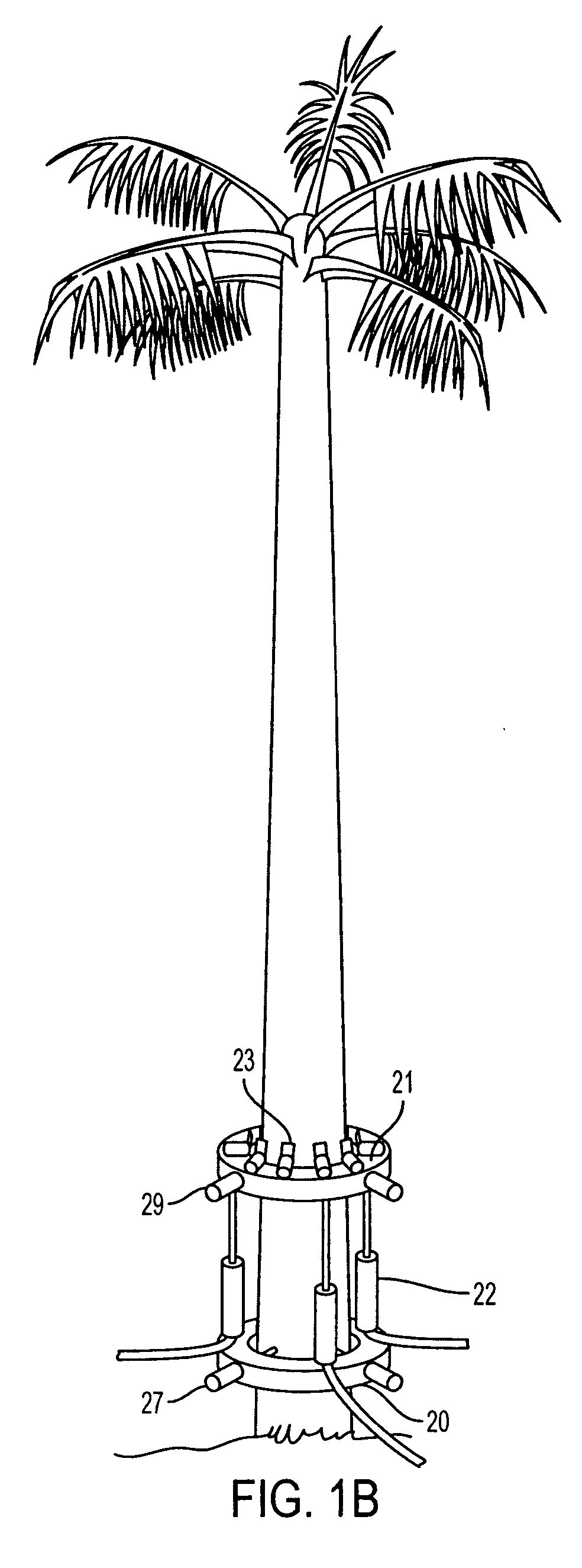

Tree climbing and cutting apparatus

InactiveUS20070181217A1Reliably repeatedUniform appearanceTree debarkingForestryClassical mechanicsEngineering

A split support ring having two halves joined by a hinge is mounted about a tree. A trolley is mounted on the support ring and movable horizontally in all positions over 360 angular degrees. A plurality of wheel assemblies are paced around the support ring and depend downwardly providing wheels angularly positionable into contact with the tree for supporting and moving the support ring vertically on the tree. A tension device in contact with the wheel assemblies causes the wheels to gain traction against the tree. A saw is mounted on the trolley, the saw engaged so as to move in mutually orthogonal directions for positioning the saw as needed in cutting into the tree and its branches or fronds.

Owner:AHDOOT NED

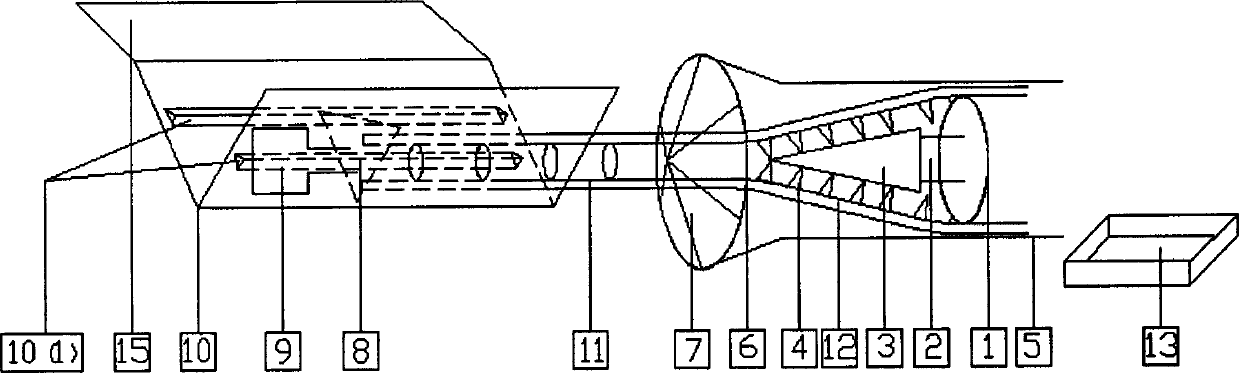

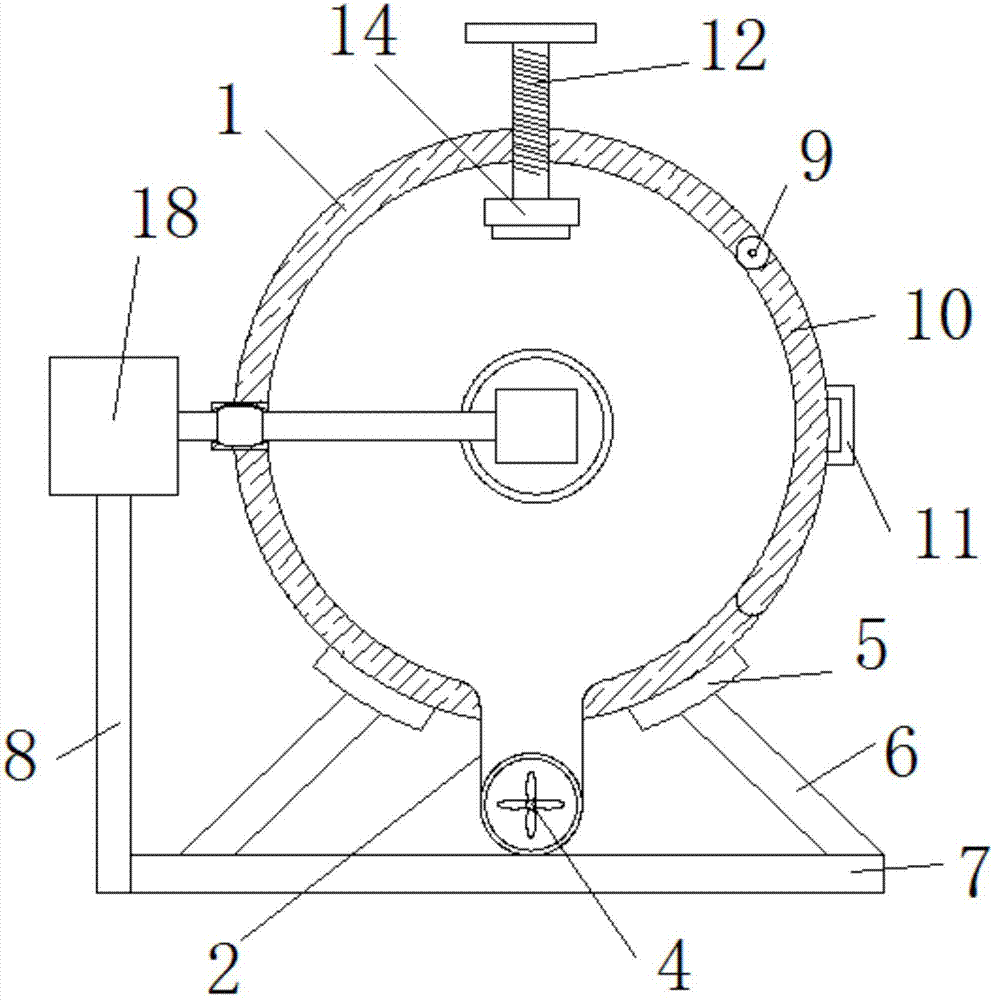

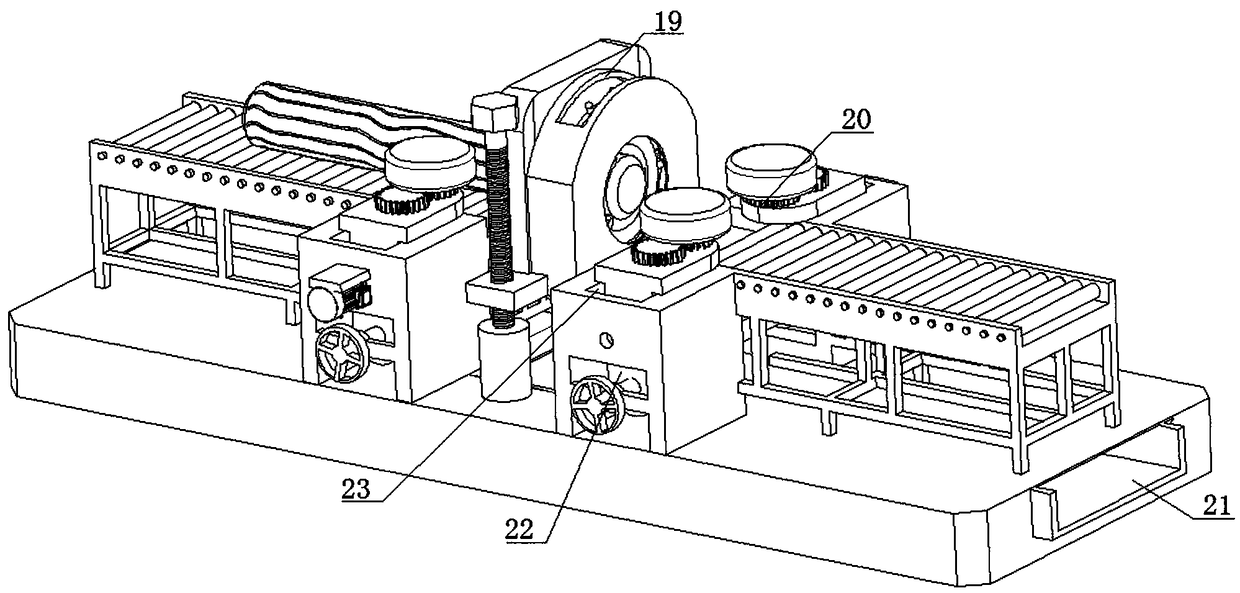

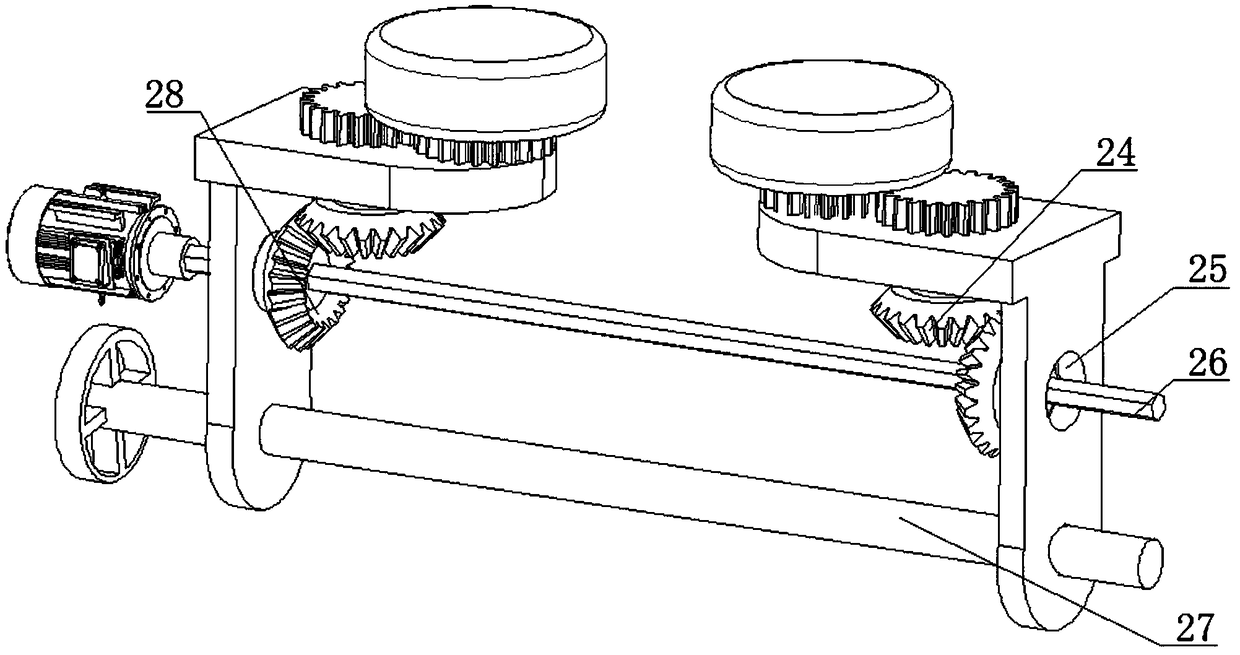

Slitting and bamboo joint removing integrated machine for bamboo billet cylinder

InactiveCN103009446AOutstanding innovationEasy to operateTree debarkingCane mechanical workingCircular coneEngineering

As a traditional bamboo joint removing method is low in degree of mechanization and production efficiency, and consumes time and labor, the invention discloses a slitting and bamboo joint removing integrated machine for a bamboo billet cylinder, which aims to improve the production efficiency of bamboo processing, belongs to the technical field of processing machinery of bamboo products, and comprises a circular cutter, a solid cylinder, a solid circular cone, an outer cylinder, outer cylinder inner plates, an annular cutterhead, a cutter, a movable baffle plate, a power device, a fixing device, a receiving device, a feeding device and other devices that all form a complete machine. The slitting and bamboo joint removing integrated machine for the bamboo billet cylinder is a novel bamboo joint removing machine for the bamboo billet cylinder, and slits the bamboo billet cylinder and removes bamboo joints at the same time, so as to achieve the purposes of labor conservation and production time conservation, and meet the processing requirement for batch production at the same time.

Owner:GUANGXI UNIV

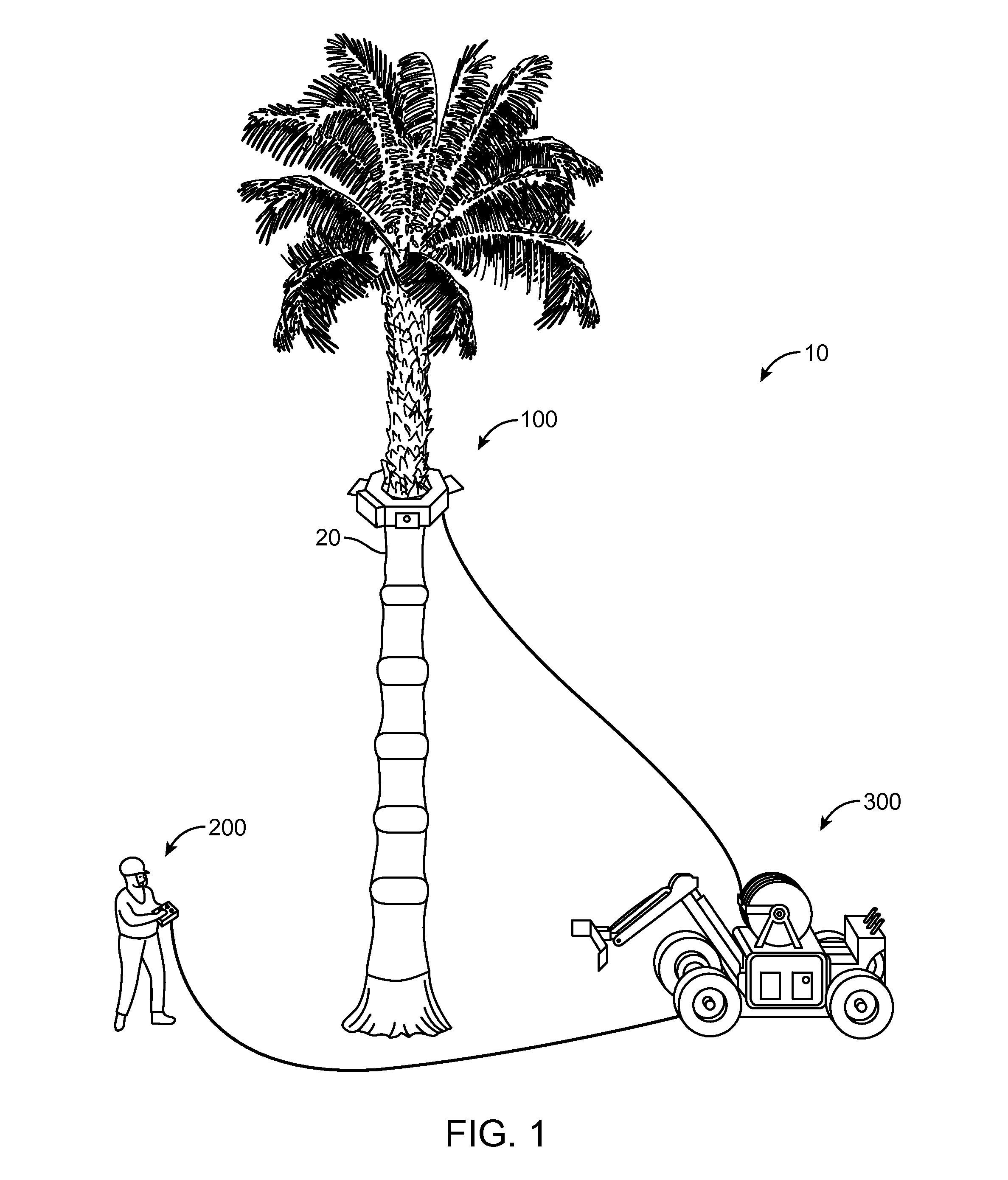

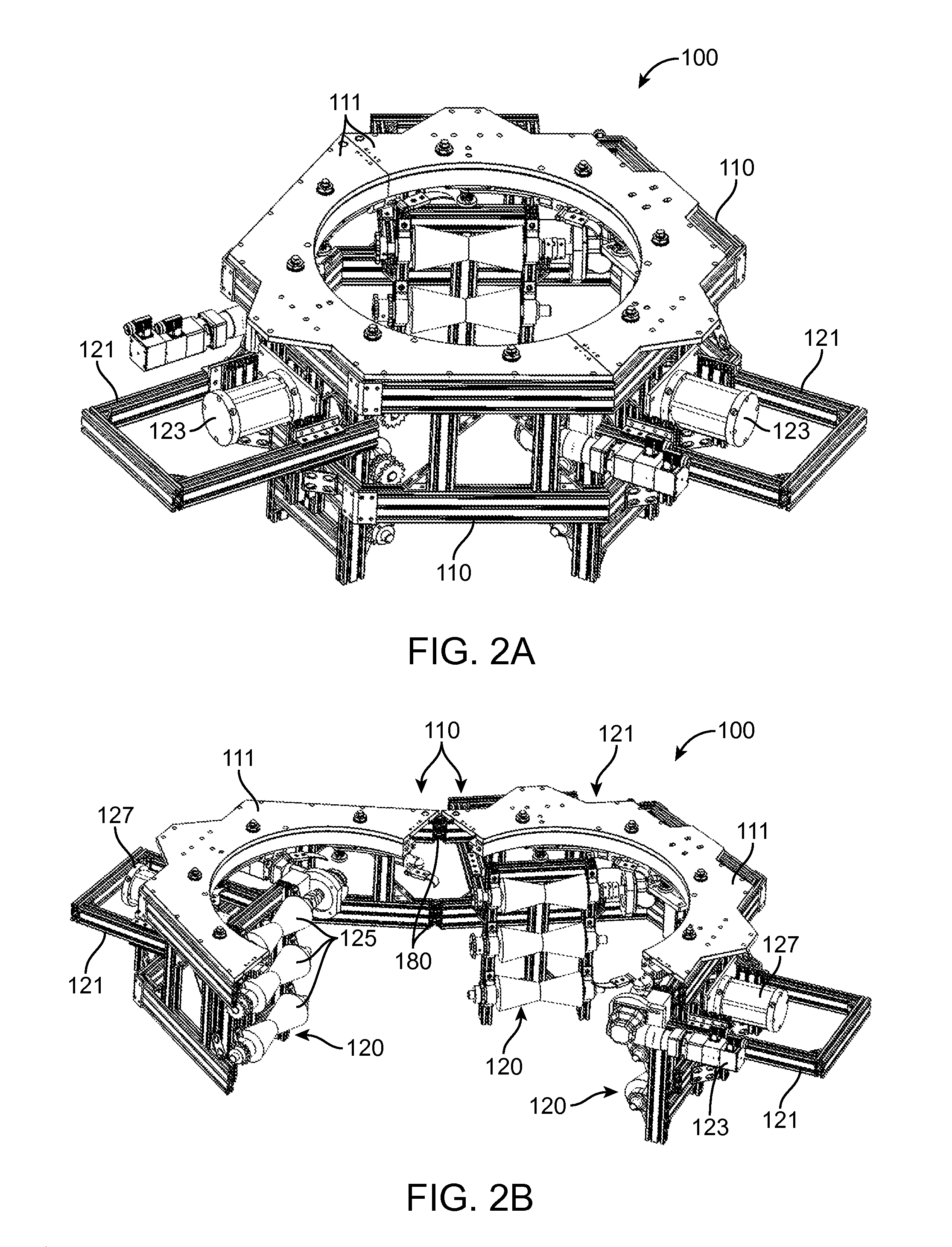

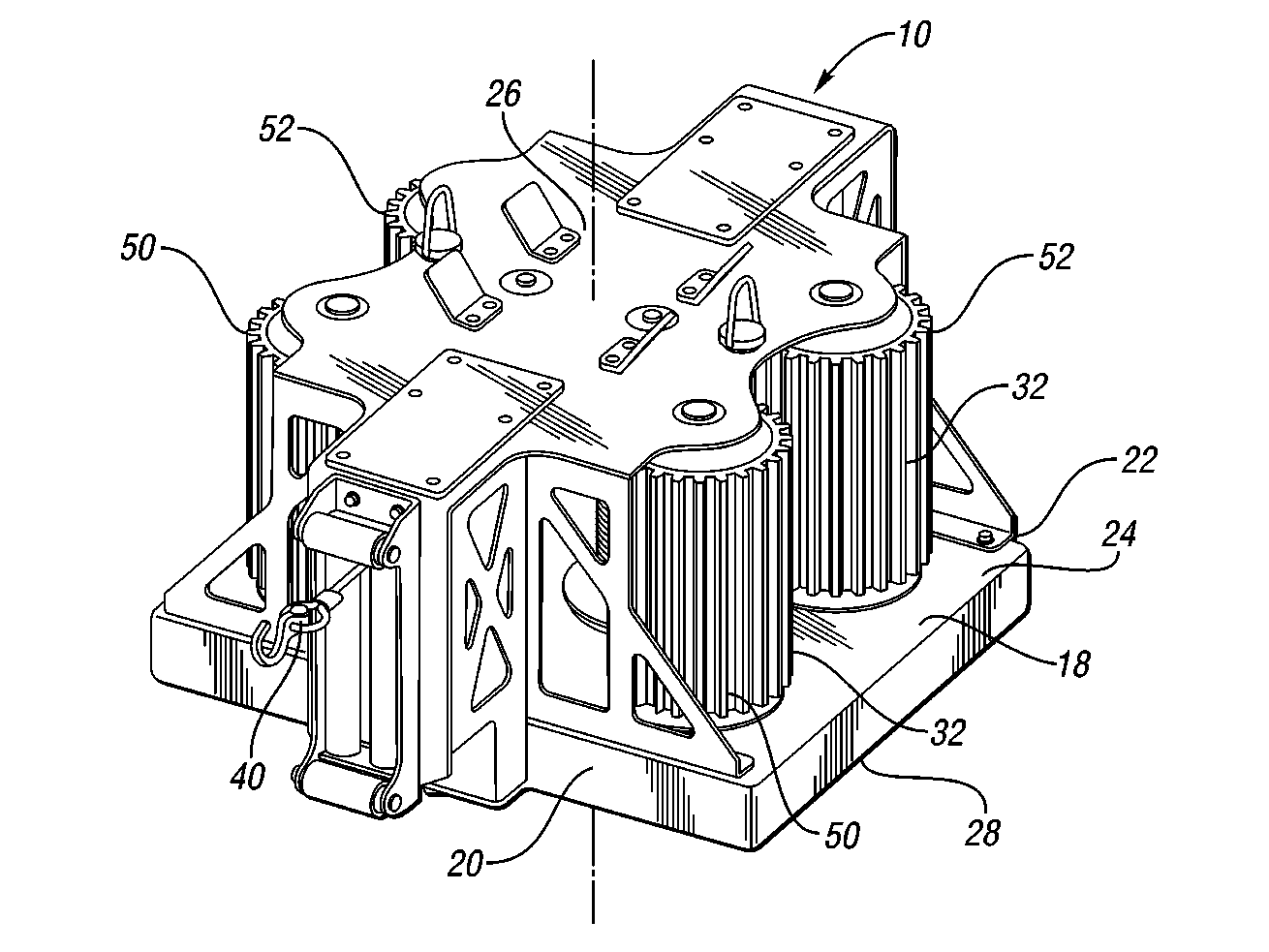

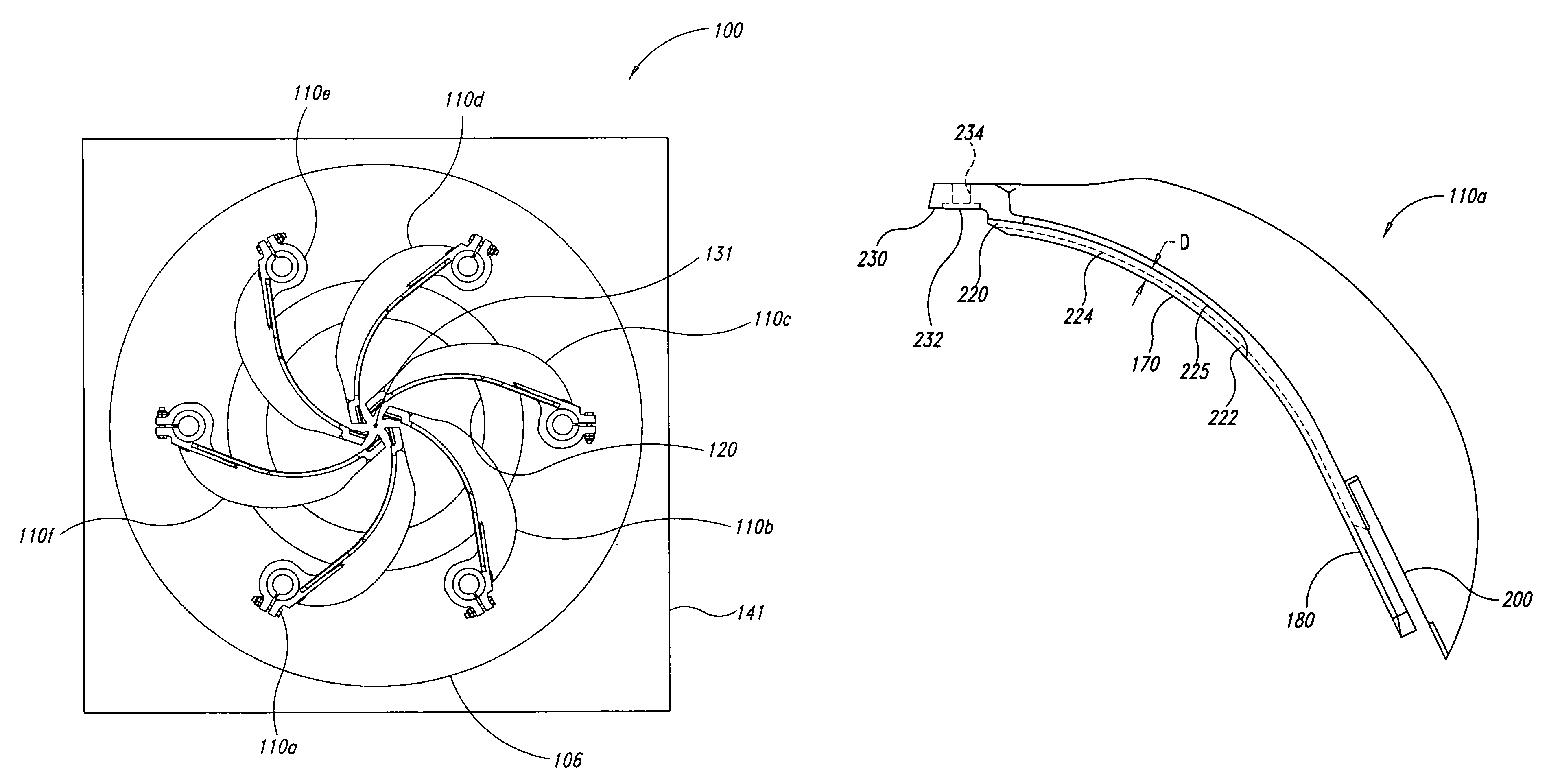

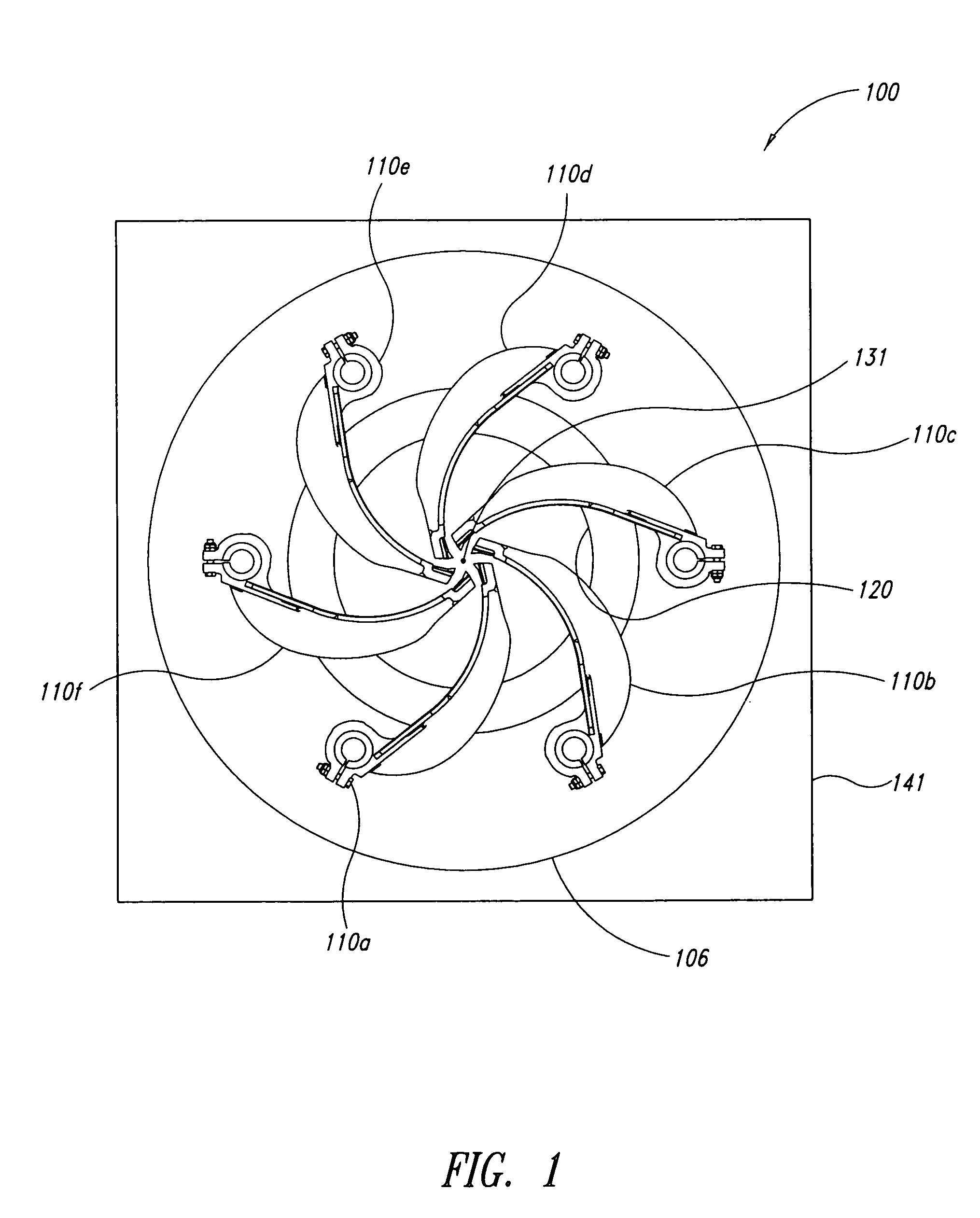

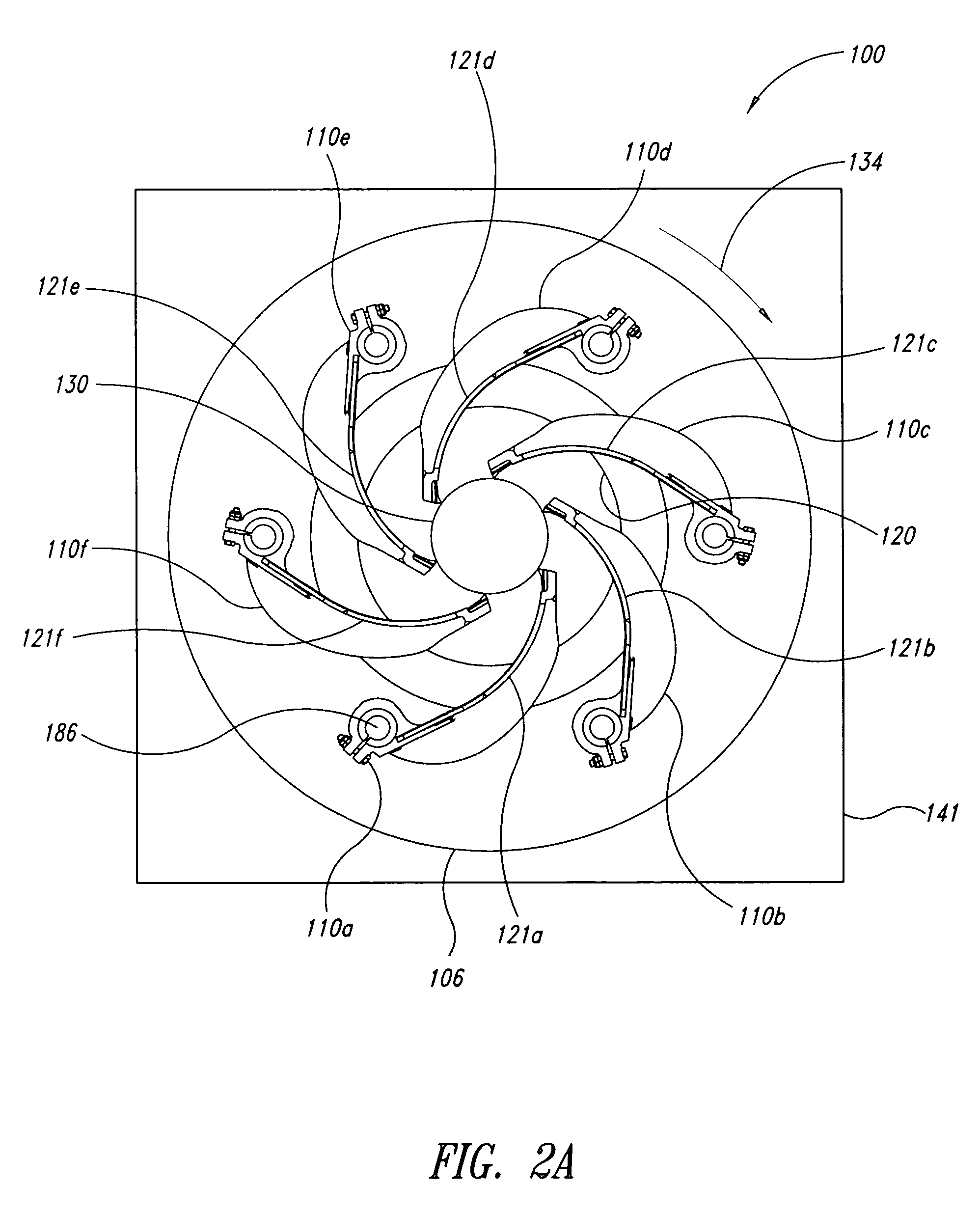

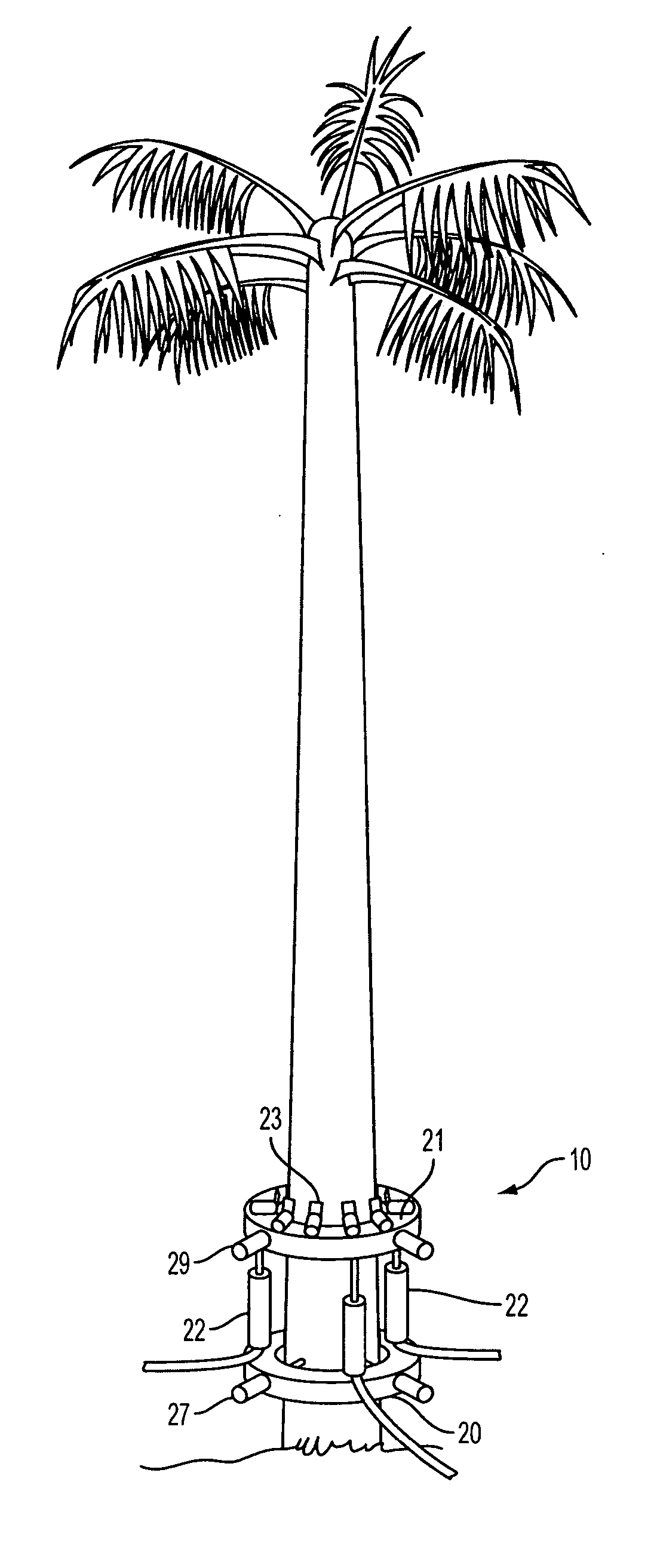

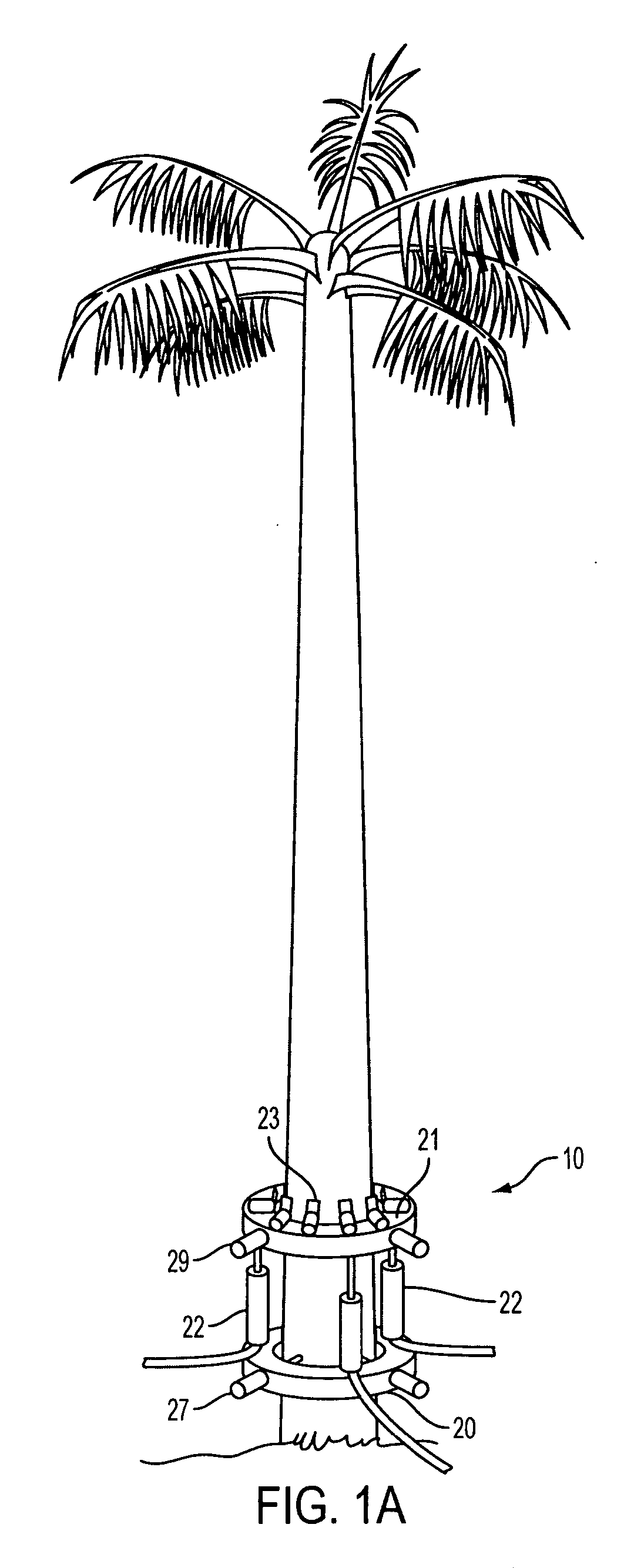

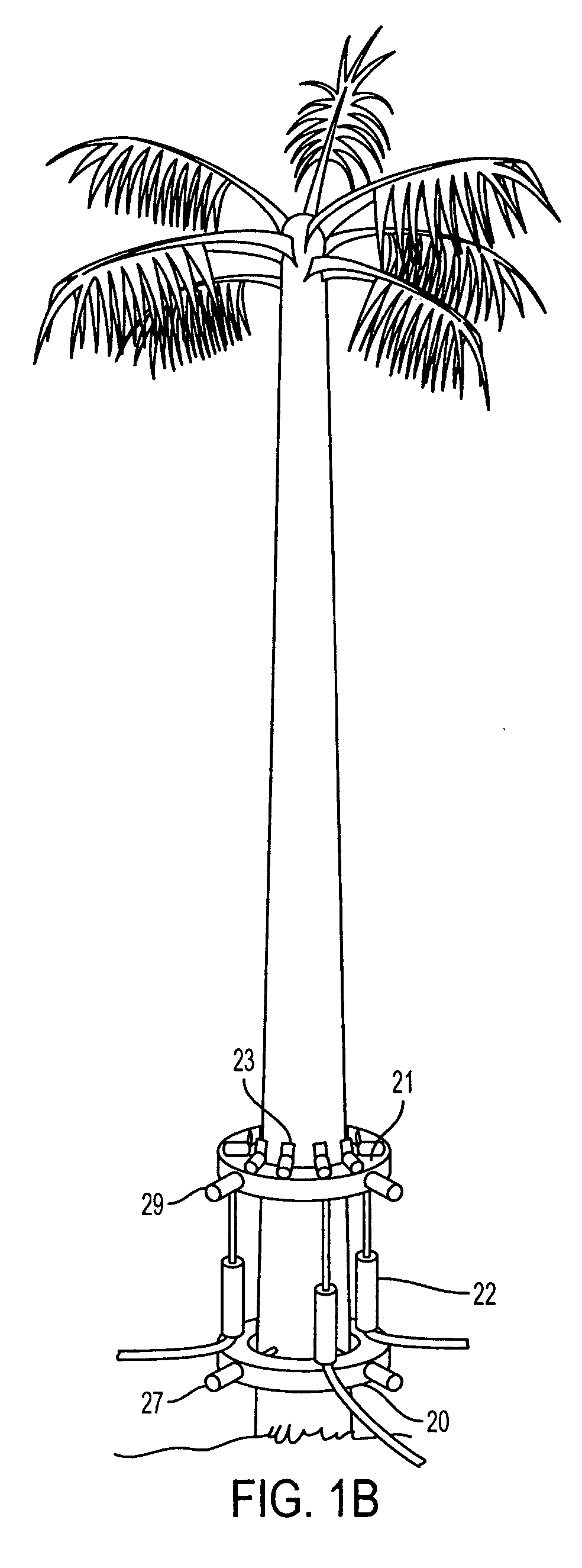

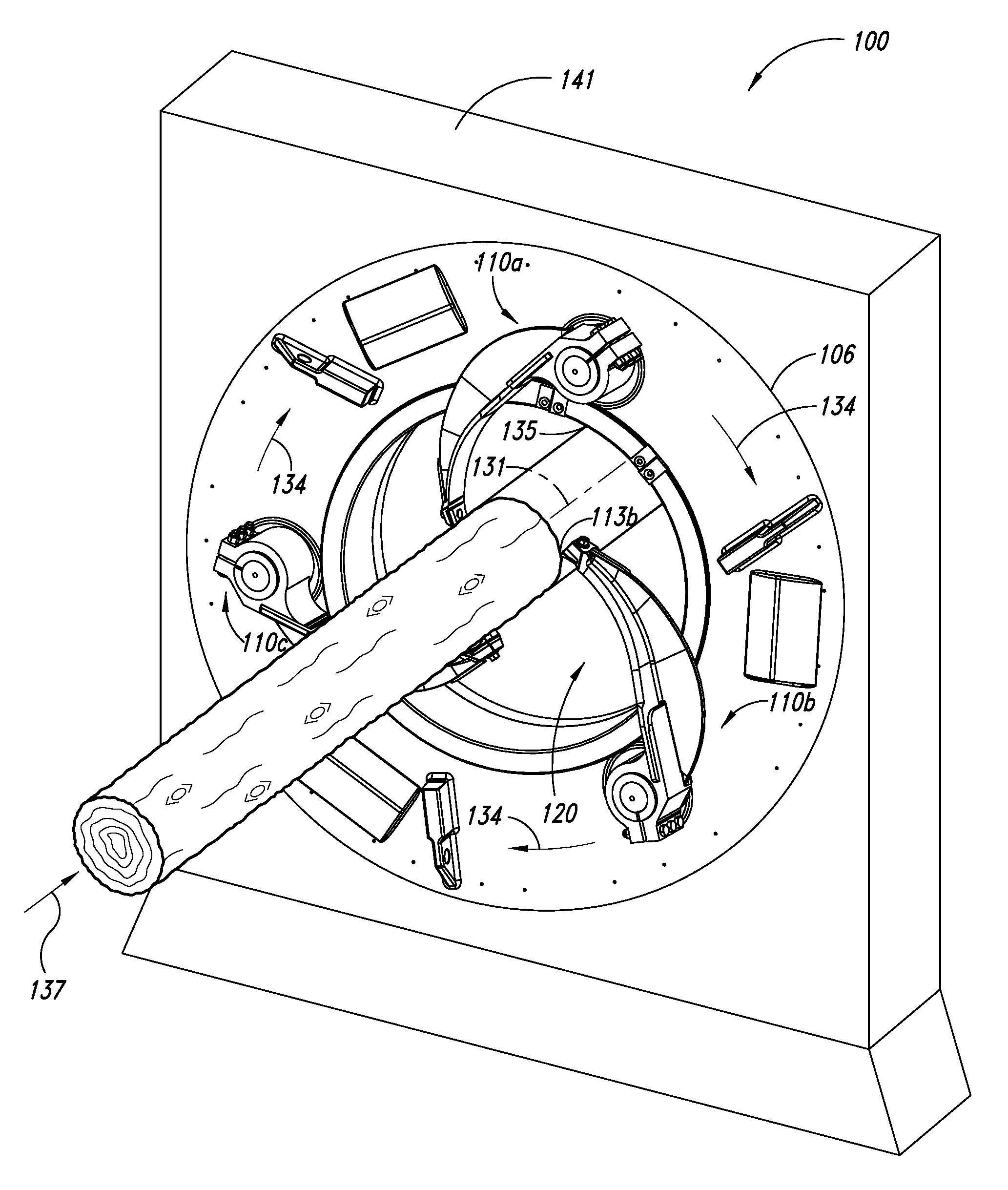

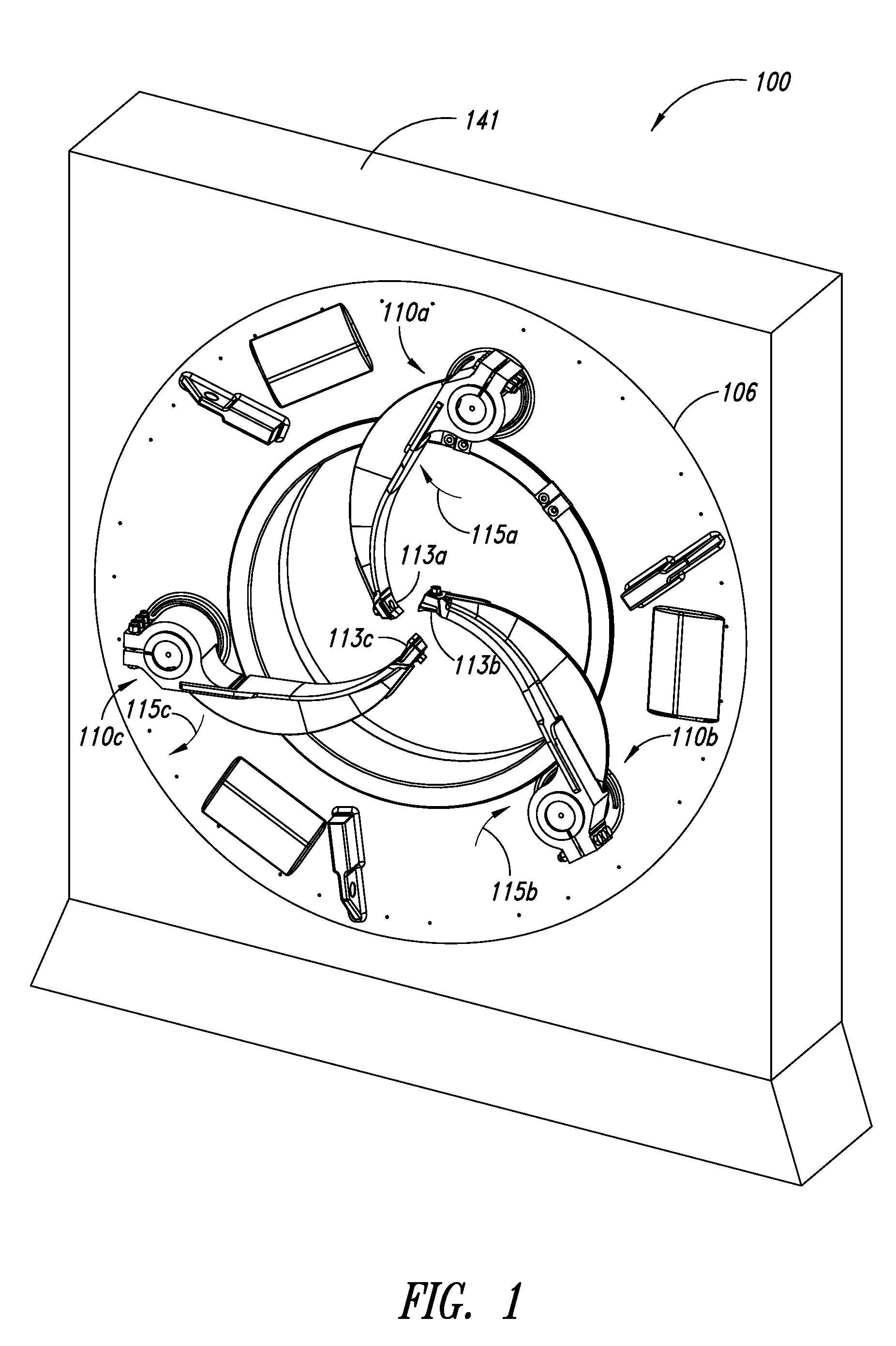

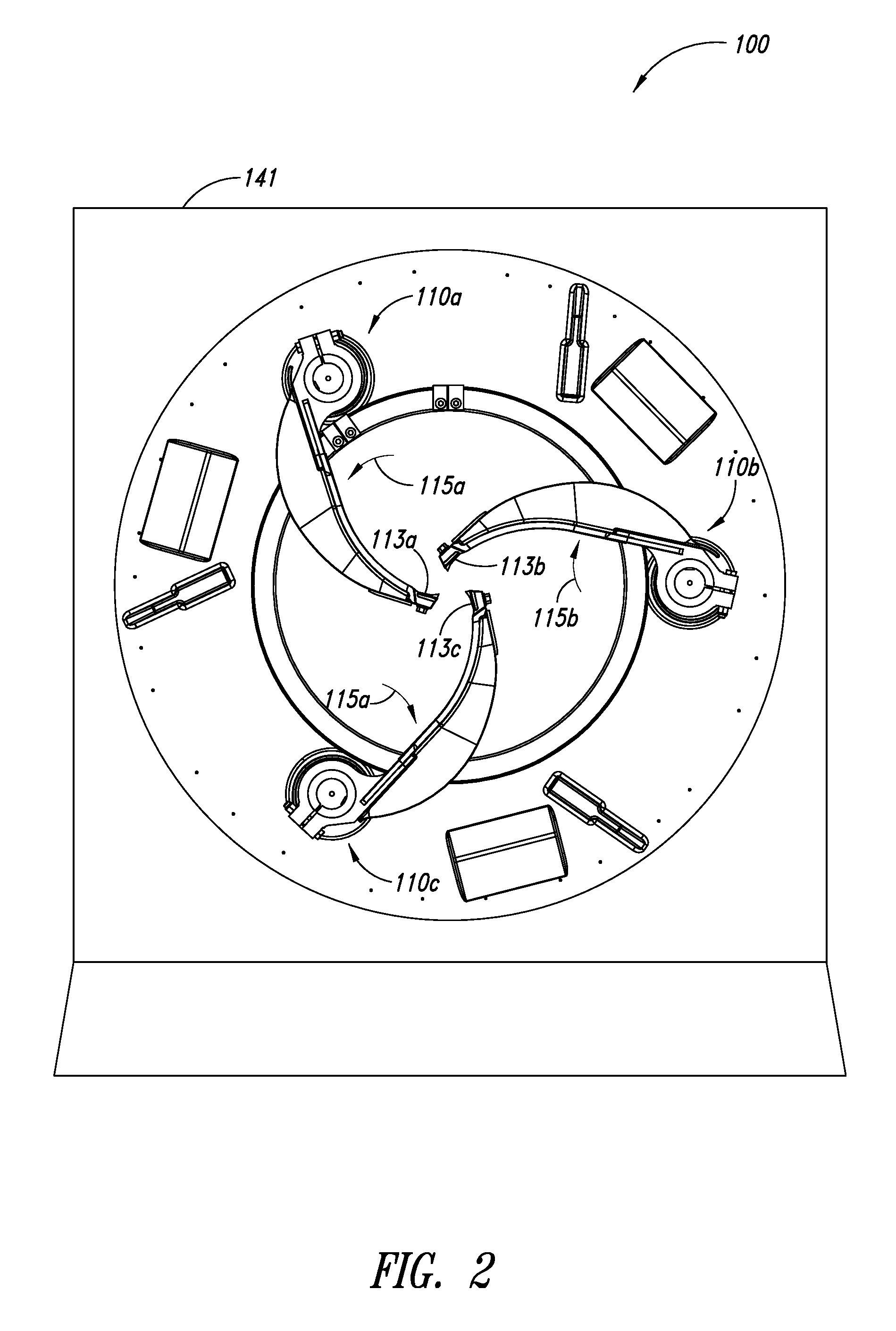

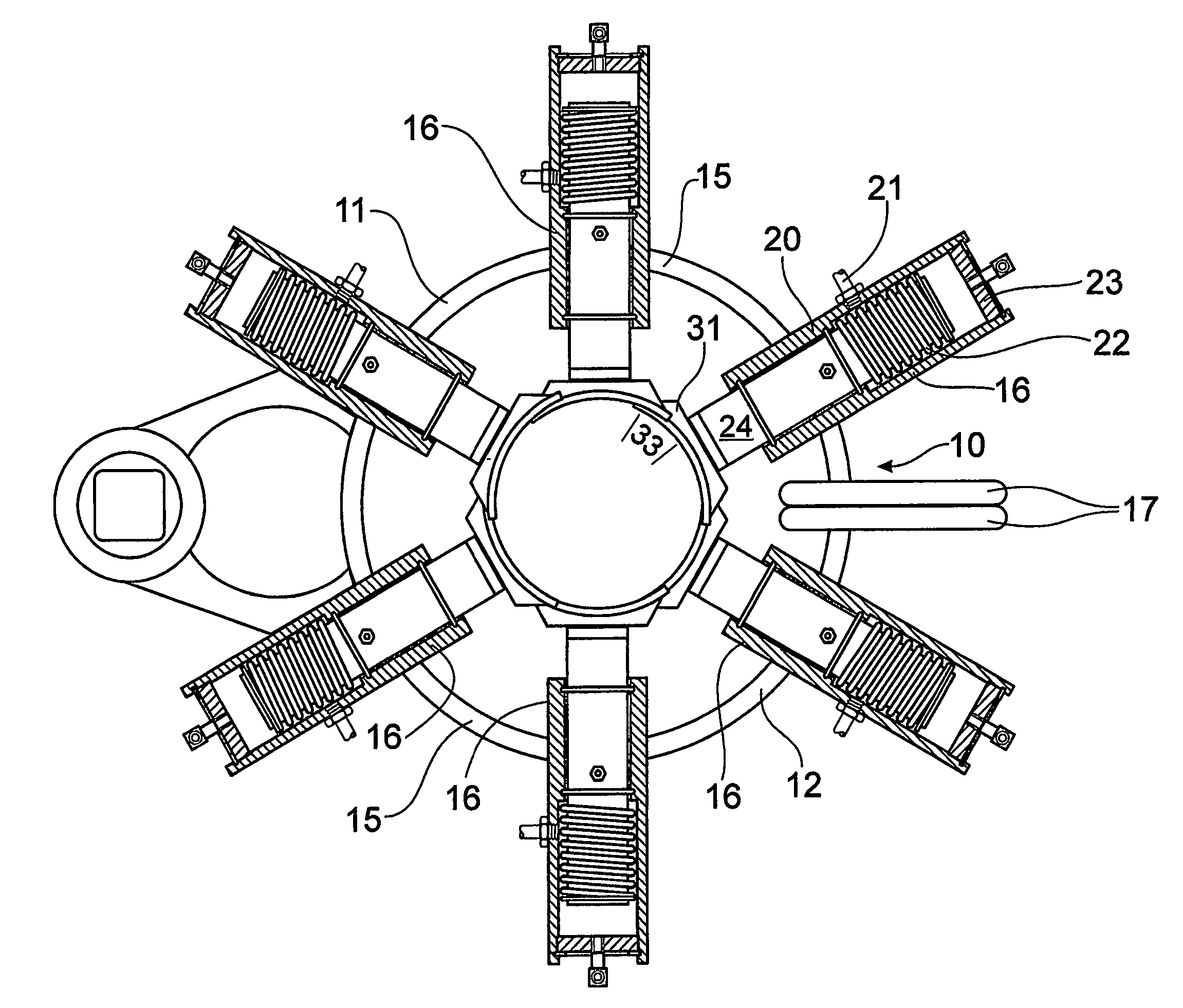

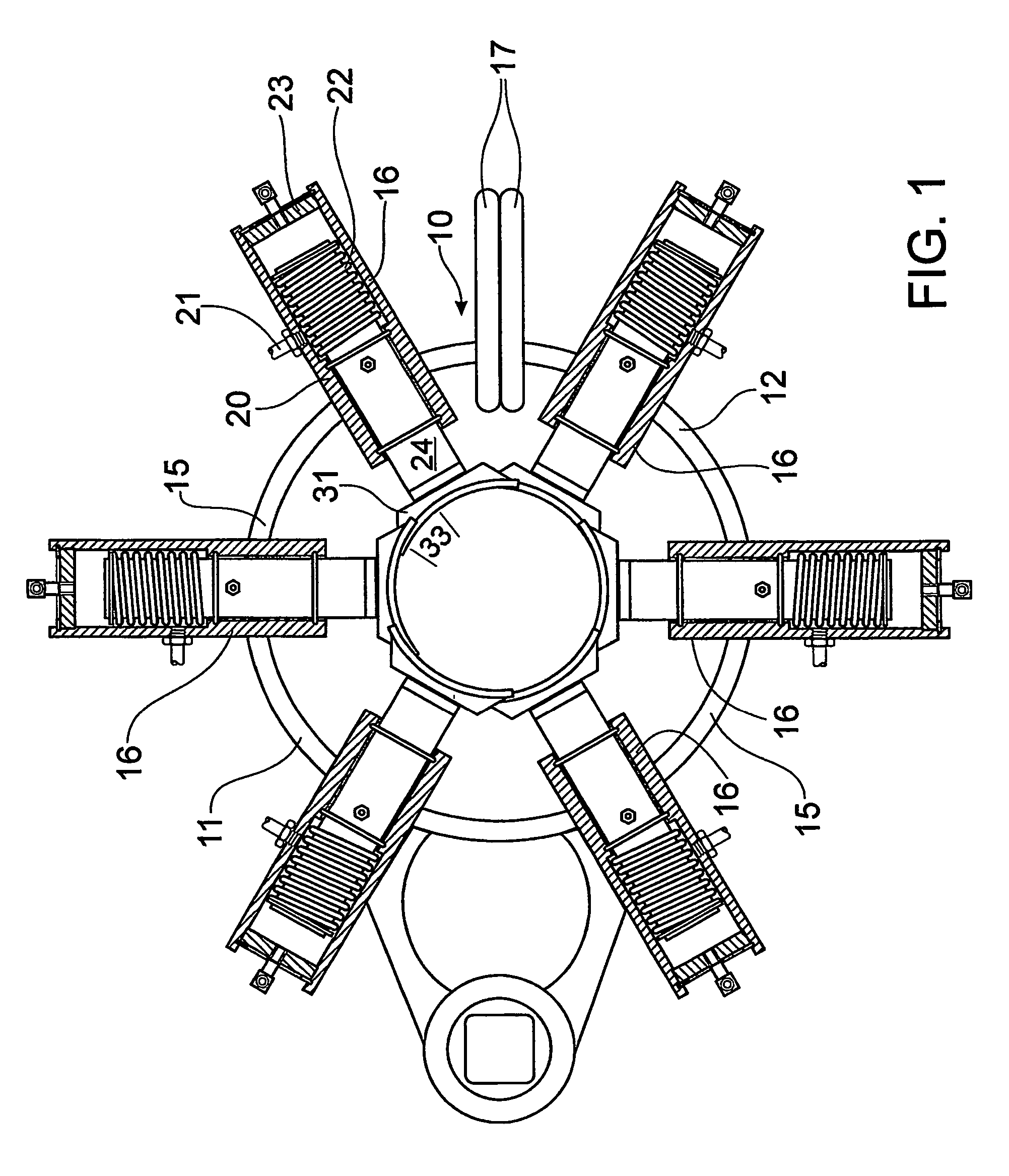

Multi-axis controlled self-climbing tree trimmer

A multi-axis controlled self-climbing tree trimmer used for shaping and severing peripheral growth from a tree is provided herein. The trimmer typically includes a structural segment hinged together to form a rigid chassis that surrounds a tree trunk climbing segment and a trimming portion. The climbing portion is retained within the structural segment in the form of a number of inward-extending carriages containing one or more rollers for gripping the tree trunk during climbing, and the trimming portion may include a rotatable split ring gear containing centrifugally rotating trimming blade members and / or a cutting tool on a positionable arm. When rotated, the blade members unlatch and pivot, into the trunk of the tree to effect controlled trimming. The system may utilize a multi-axis control system that uses linear interpolation, circular interpolation and coordination of all axes to enable the trimmer to follow an XYZ contour selected by a user.

Owner:VANDYPALM

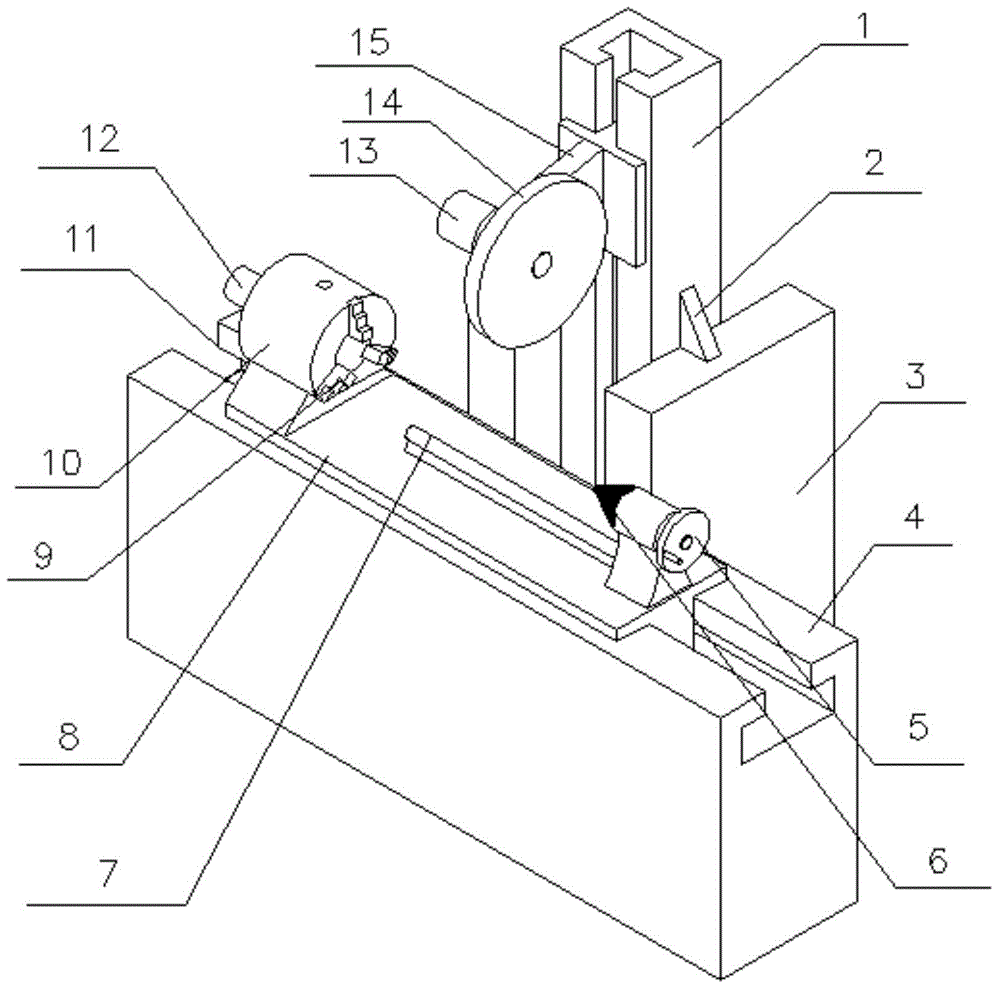

Tree barking device

InactiveCN104015237AImprove work efficiencyRevolution surface grinding machinesTree debarkingEngineeringGrinding wheel

The invention discloses a tree barking device and belongs to the field of agricultural machines. The tree barking device consists of a grinding wheel guide rail, a reinforcing rib, a grinding wheel guide rail supporting seat, a mechanical main body, a rotary disc, a tip, a tail frame guide rail, a working platform, angle-iron type clamps, a chuck, a working platform guide rail, a main shaft motor, a grinding wheel motor, a grinding wheel and a grinding wheel frame. The tree barking device is characterized in that the grinding wheel guide rail and the grinding wheel guide rail supporting seat are fixedly connected together by the reinforcing rib; the grinding wheel guide rail supporting seat and the mechanical main body are fixedly connected together; the mechanical main body is provided with the working platform guide rail; the working platform is arranged on the working platform guide rail; the tail frame guide rail is fixed on the working platform and is provided with the tip; the rotary disc is arranged behind the tip; the chuck is fixed on the working platform and is provided with the angle-iron type clamps; the main shaft motor is connected together with the chuck; the grinding wheel is arranged on the grinding wheel frame; the grinding wheel and the grinding wheel motor are distributed at the two sides of the grinding wheel frame which is arranged on the grinding wheel guide rail. The tree barking device disclosed by the invention has the beneficial effect of barking off trees automatically.

Owner:张超

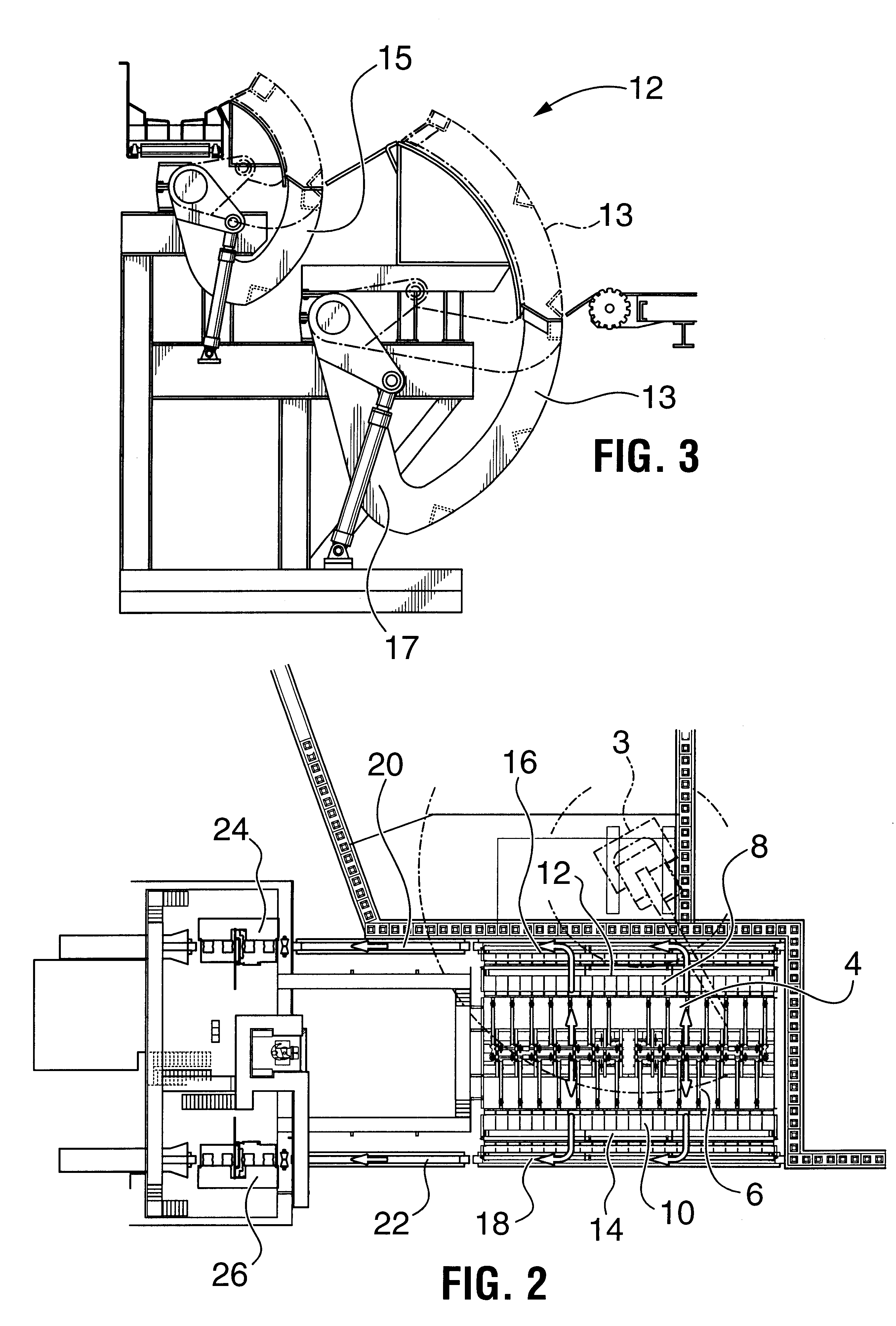

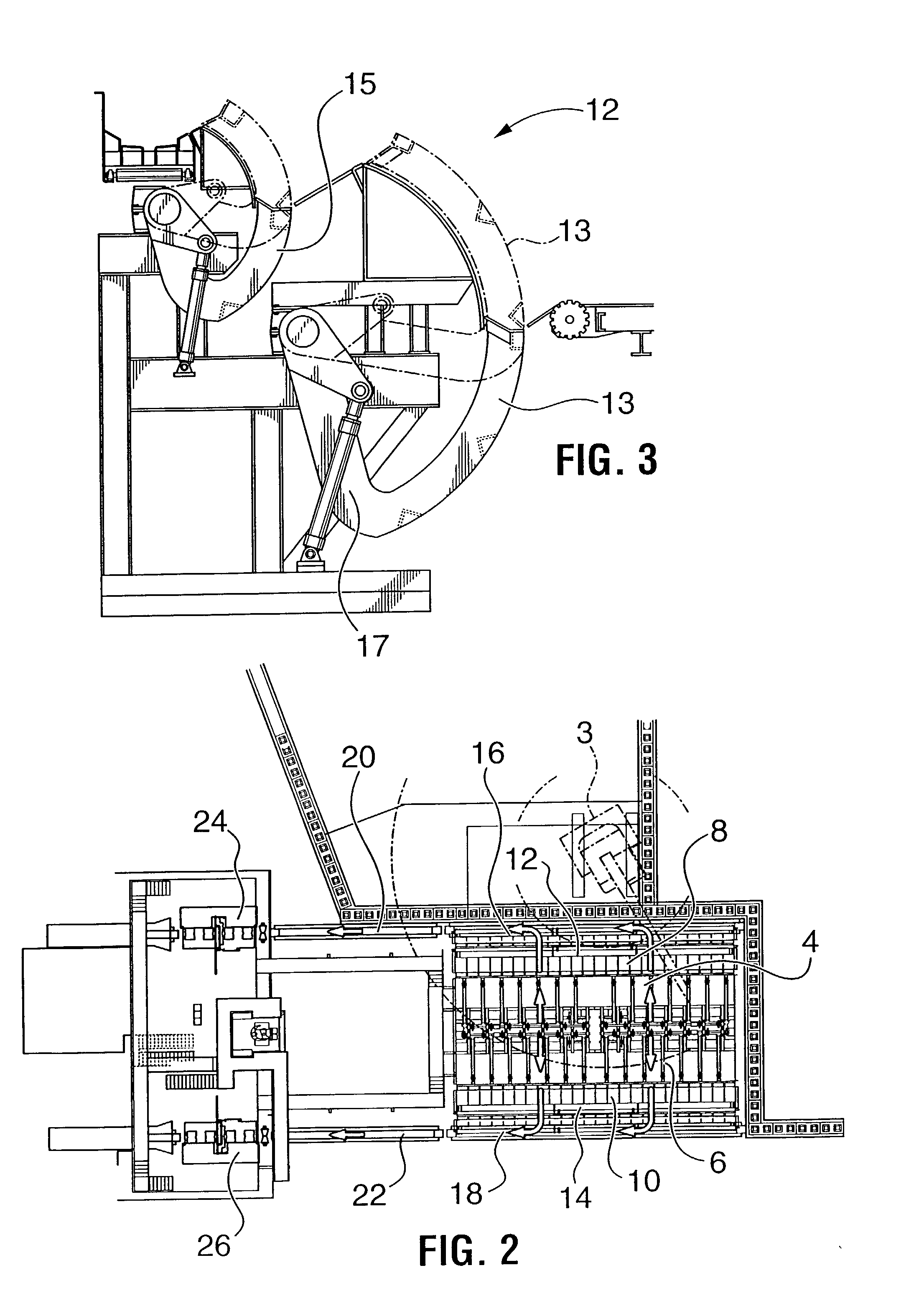

Method and apparatus for singulating, debarking, scanning and automatically sawing and sorting logs into lengths

InactiveUS6539993B1Reduce stepsMinimize travelMulti-purpose machinesAdjusting equipmentComputer hardwareAlgorithm

Owner:WEYERHAEUSER CO

Barking Device and Barking Tool

ActiveUS20070261762A1Designing can be facilitatedExtra stepTree debarkingMulti-purpose machinesEngineeringMechanical engineering

Owner:IGGESUND TOOLS

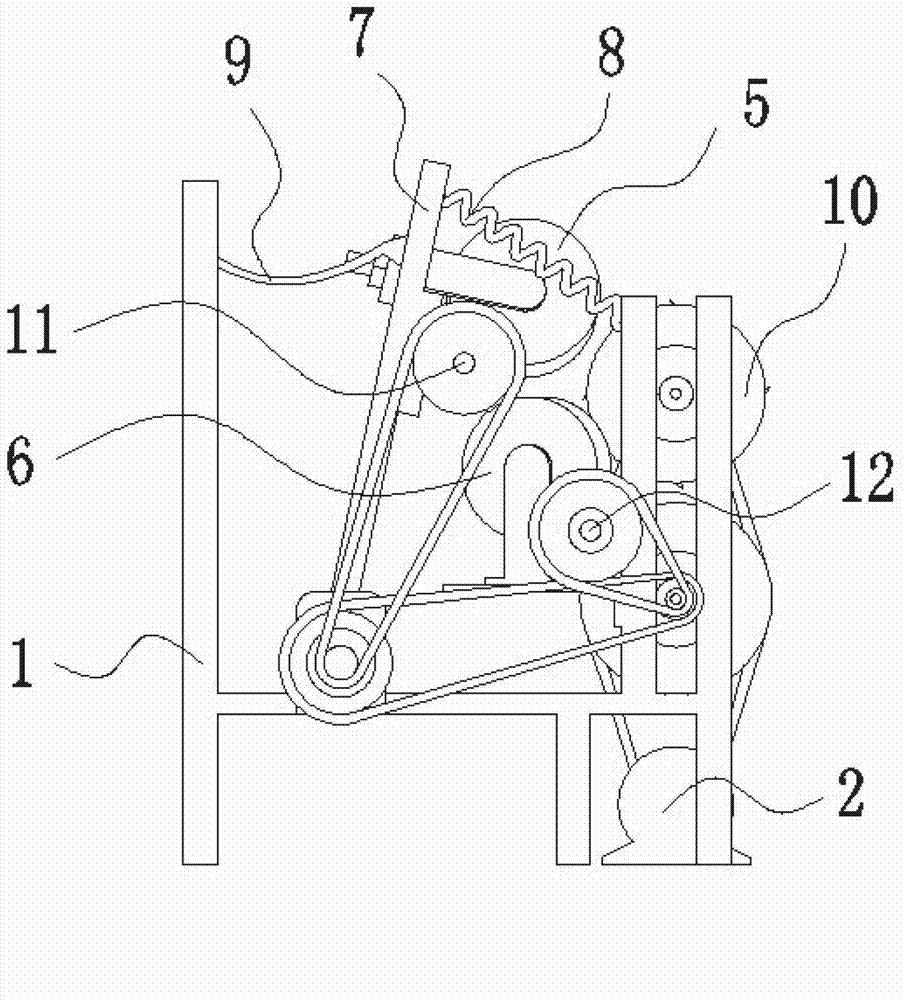

Barking device

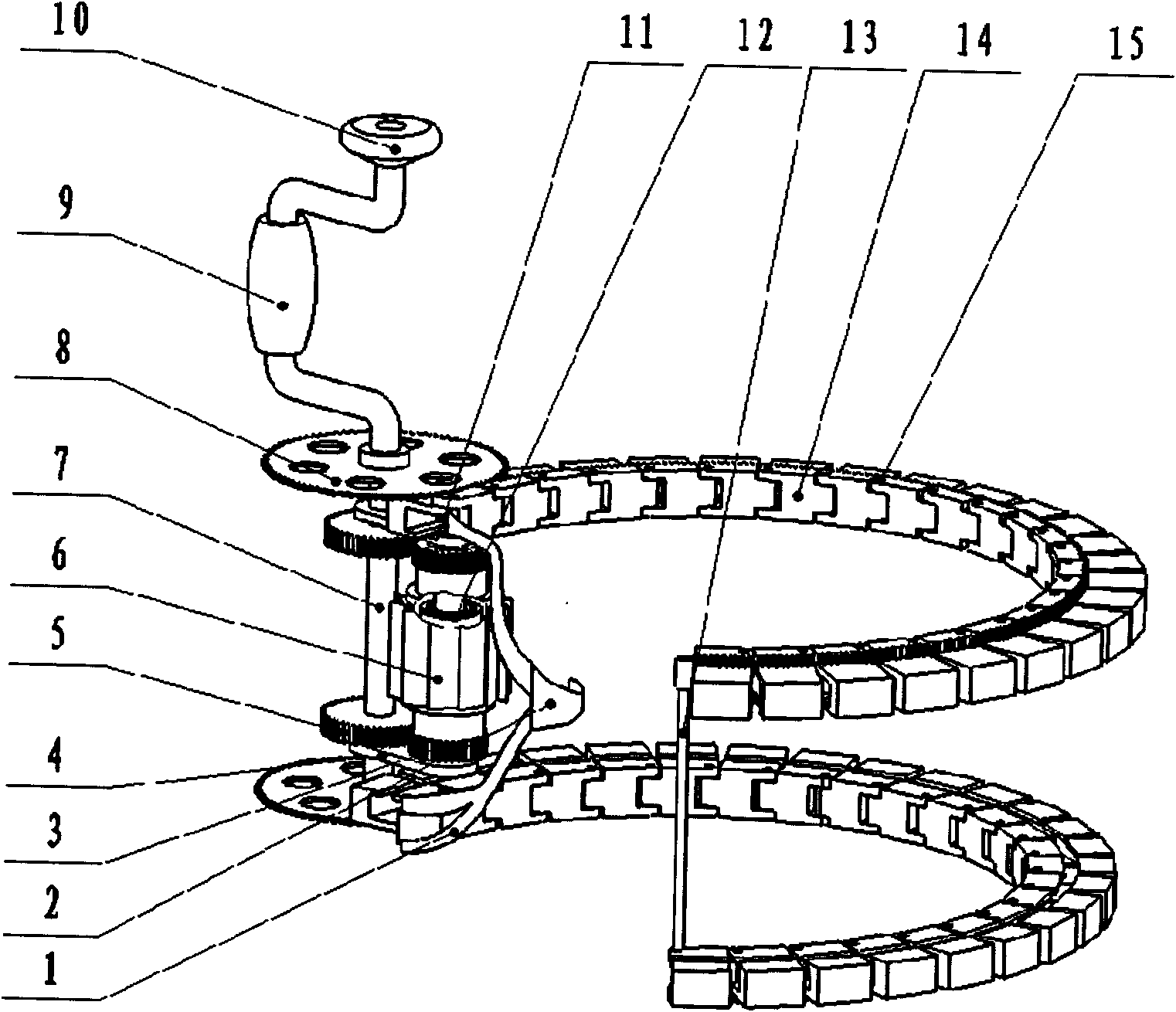

The invention relates to a barking device which is characterized by comprising an elastic cord, an iron hook, pinions, fixed plates, gearwheels, a barking wheel, a crankshaft, chain wheels, a rotary handle, a fixed handle, a mandrel, bearings, a draw rod, adhesion blocks and connecting shafts, wherein, the fixed handle, the rotary handle, the chain wheels, the fixed plates and the gearwheels are installed on the crankshaft; the fixed handle, the rotary handle and the two fixed plates are connected with the crankshaft in a sliding manner, and the chain wheels and the gearwheels are fixedly connected with the crankshaft; the bearings are installed in the barking wheel, and the two pinions are fixedly arranged at both ends of the barking wheel and respectively meshed with the two gearwheels fixed to the crankshaft; the mandrel is connected with the crankshaft through the fixed plates, and the fixed plates are in a slip connection with the mandrel; every two adhesion blocks are connected with each other through the connecting shafts to constitute a guide rail which can be bent freely; the guide rail is connected with the draw rod on one end through the elastic cord and the iron hook on the other end, and is wound and fixed to a tree trunk; grooves on both ends of the mandrel are embedded in the grooves on the adhesion blocks; and teeth on each adhesion block are meshed with teeth on the chain wheel.

Owner:NANTONG LIPEI FLUID VALVE IND CO LTD

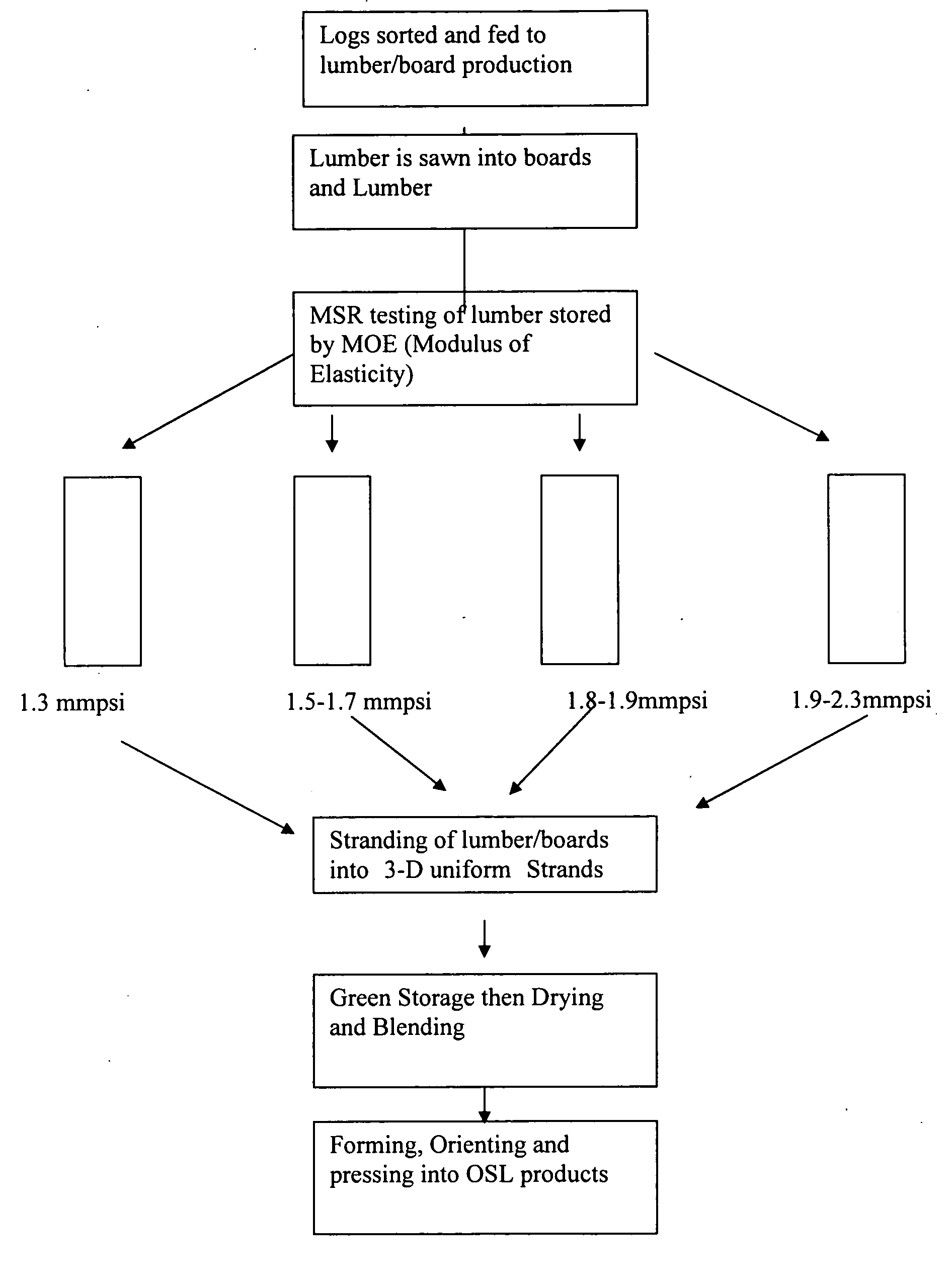

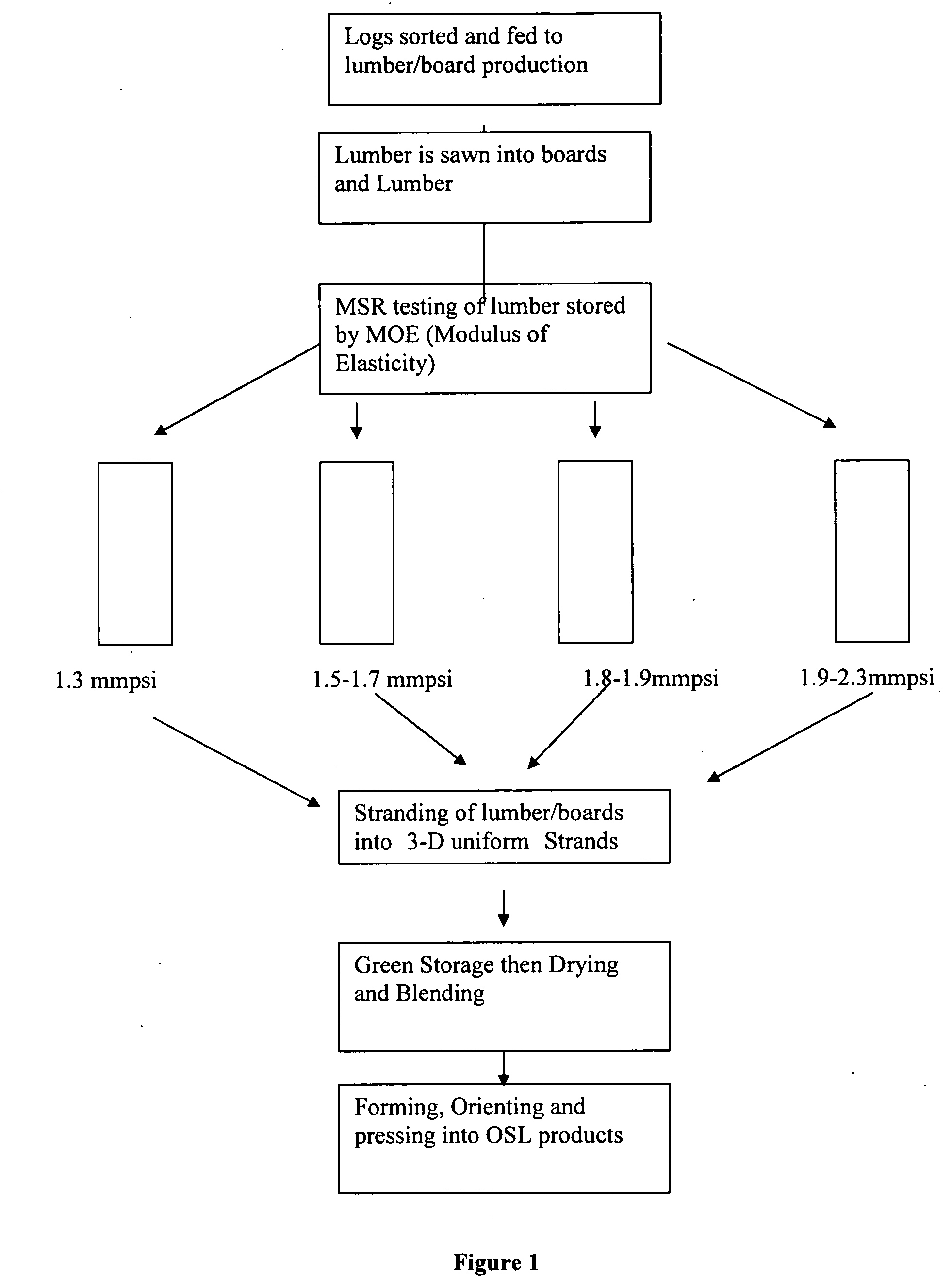

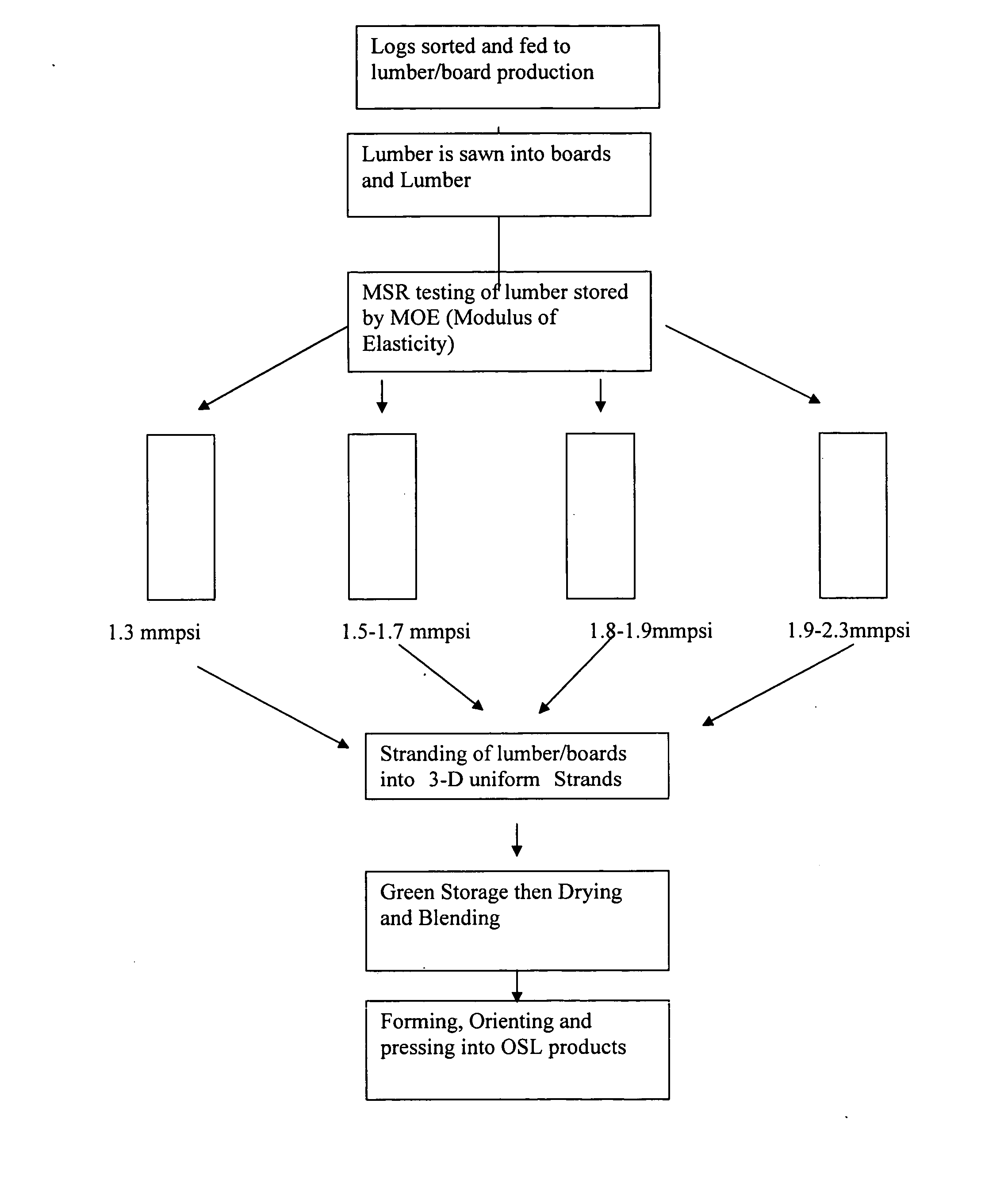

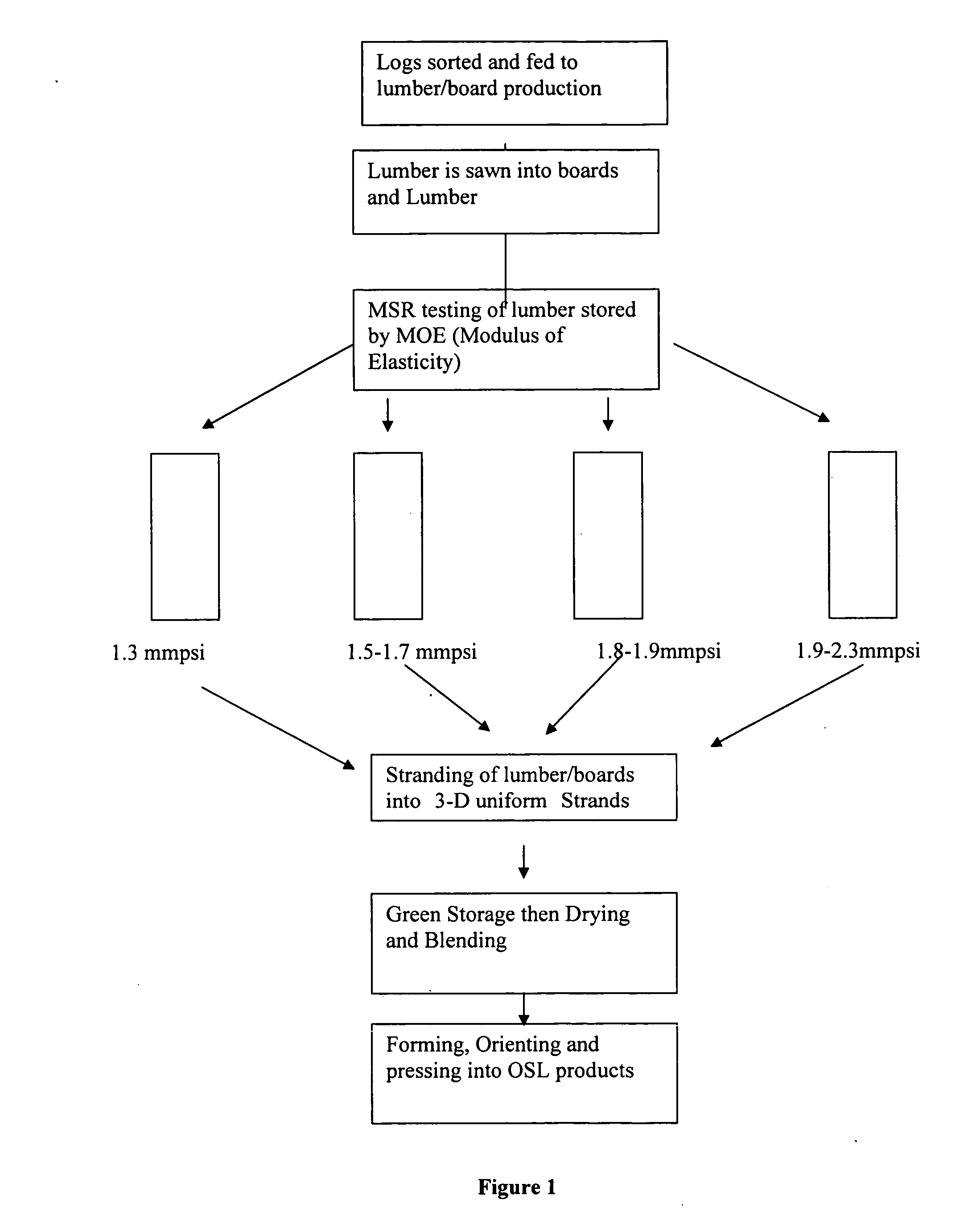

Methods for making improved strand wood products and products made thereby

An overall method of making engineered strand wood products in relation to a number of different possible criteria is provided. Such a method may involve any combination of different screening procedures to determine the best wood sources from which individual strands may be prepared. Such screening procedures may include initial determinations of certain physical characteristics of individual logs, further or initial determinations of certain physical characteristics of portions of sawn logs, further or initial determinations of certain physical characteristics of individual strands, and any combinations thereof. Additionally, after the initial physical characteristic sorting is completed, optionally the wood may be cut into uniformly sized and shaped strands for incorporation within a target strand product. Still further, such strands, in substantially uniform size and shape, as well as substantially uniform physical characteristics, may then be incorporated into a target strand product in specific predetermined configurations. Such various possible combinations of screening procedures and / or selective stranding processes results in strand products (boards, lumber, and the like) of improved properties over previously made strand products. Thus, encompassed within this invention are processes involving each of these procedures either individually or in combination with other sequential processes for the production of desired strand products.

Owner:HUBER ENGINEERED WOODS

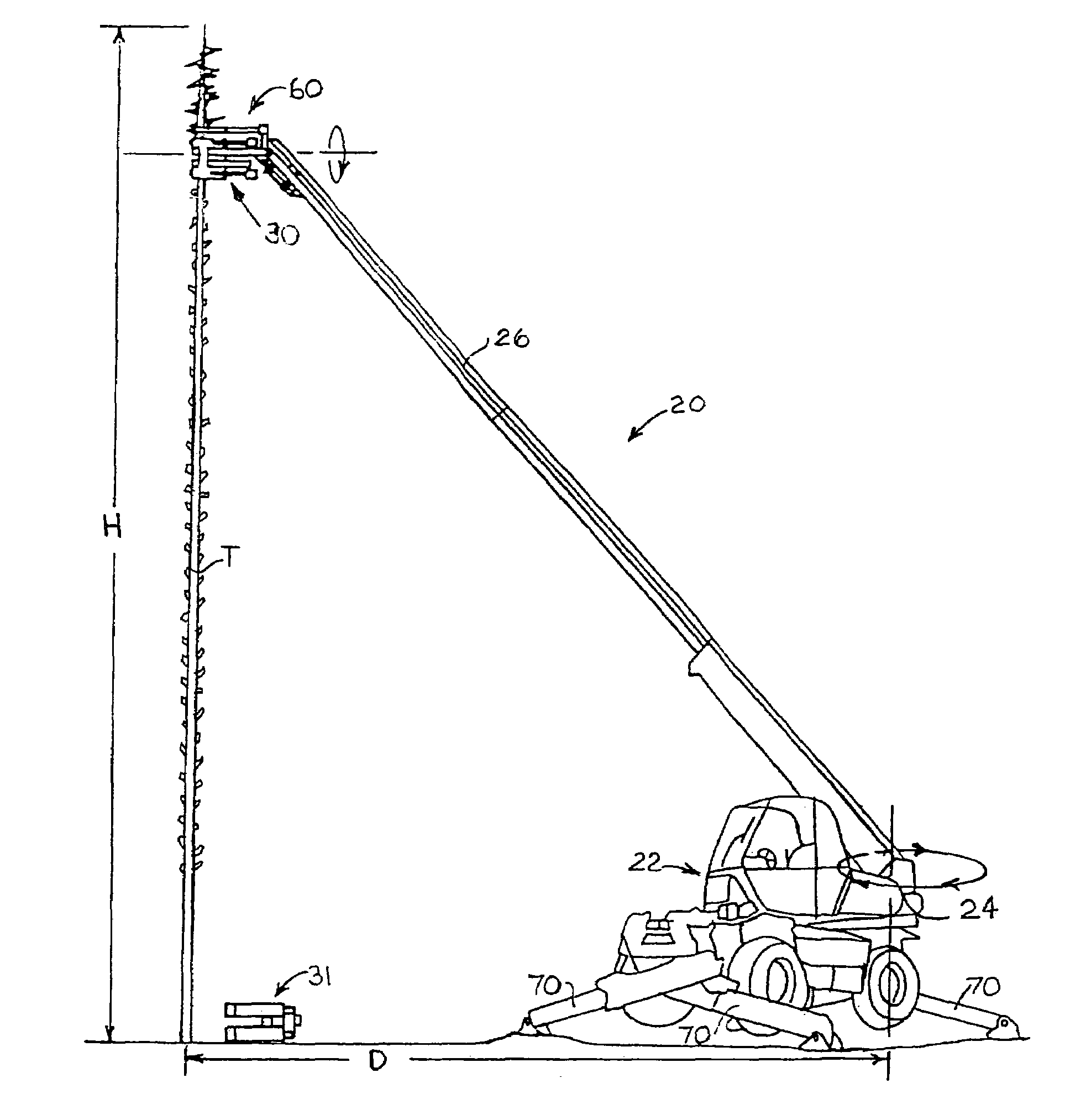

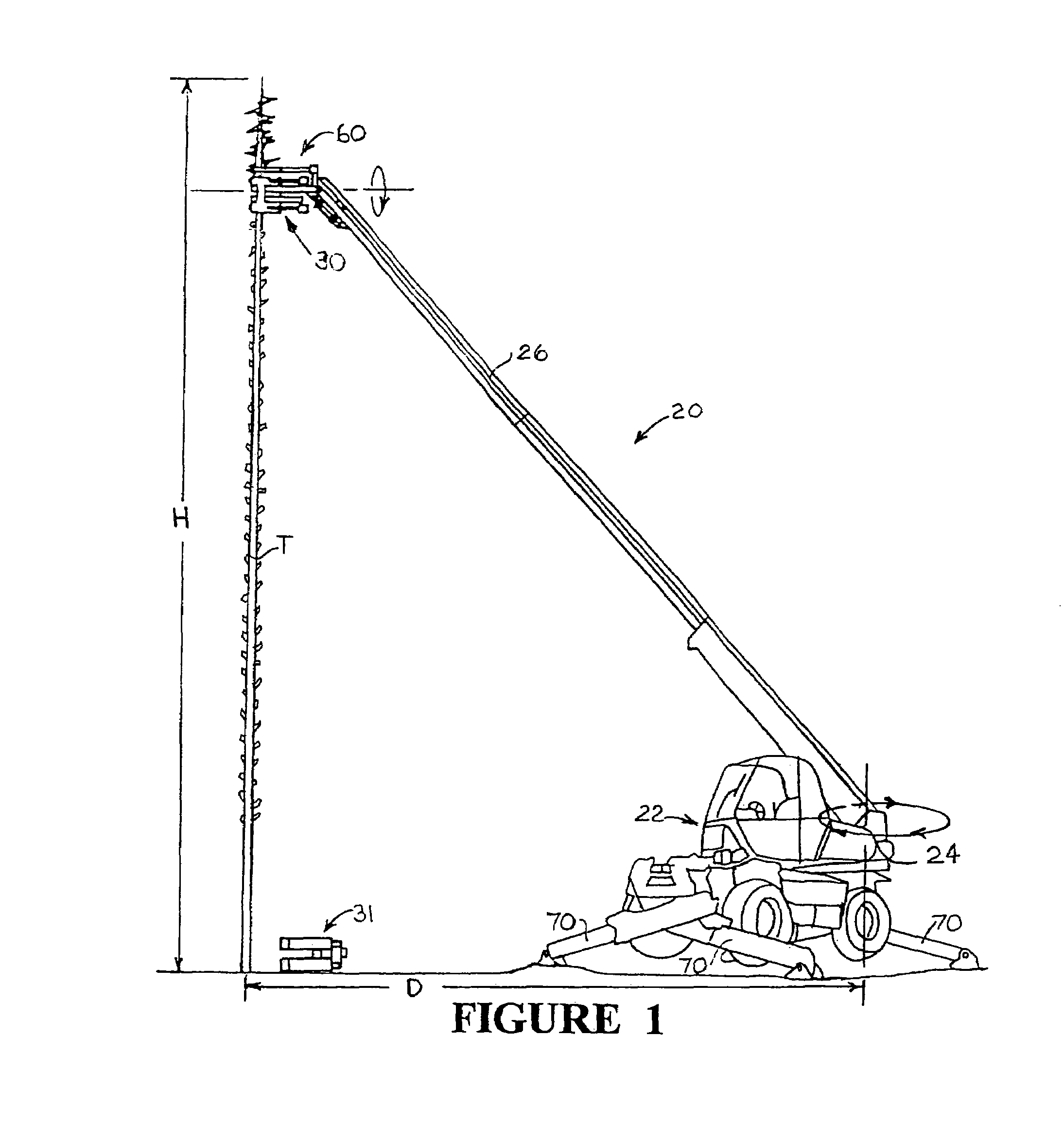

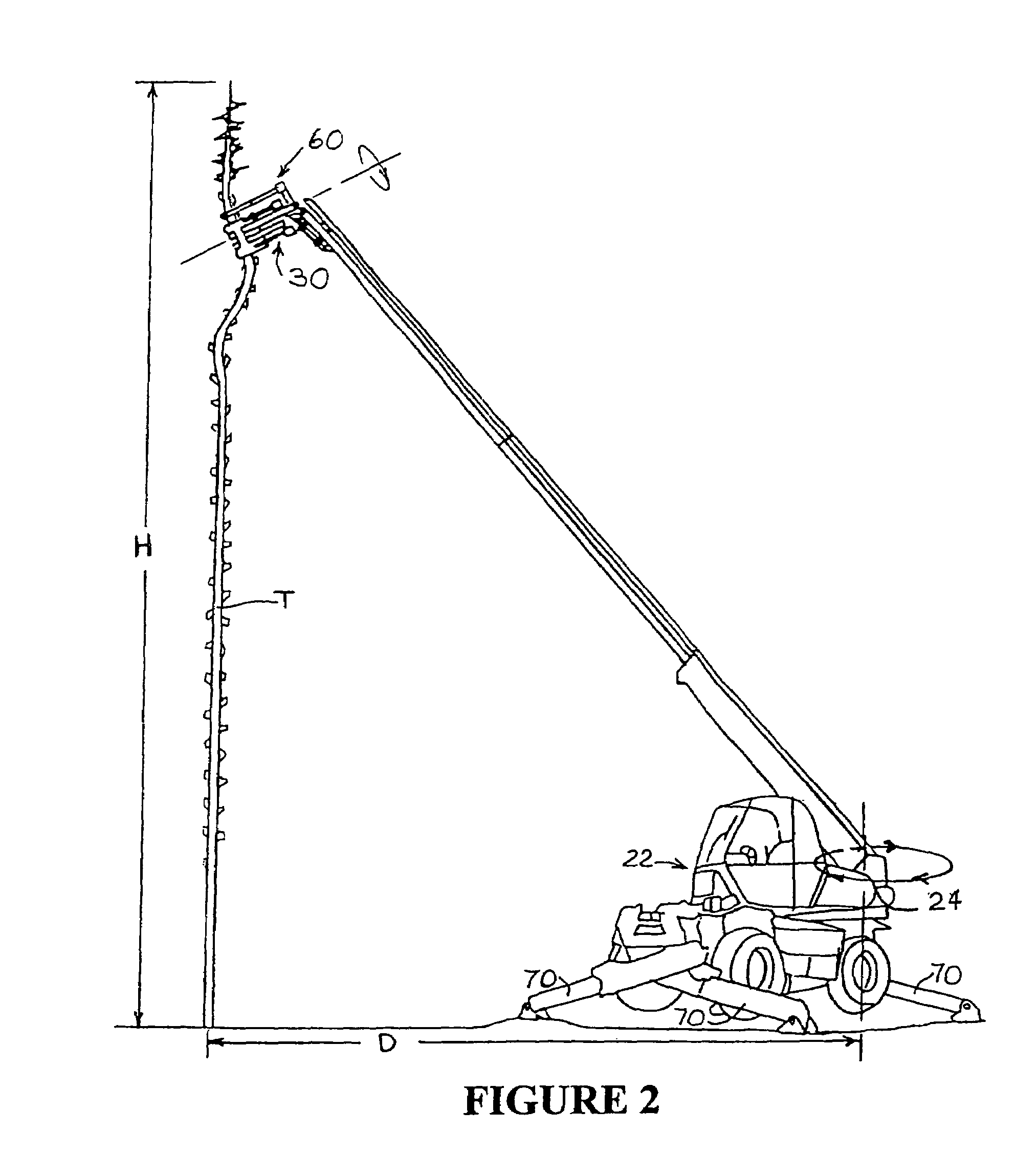

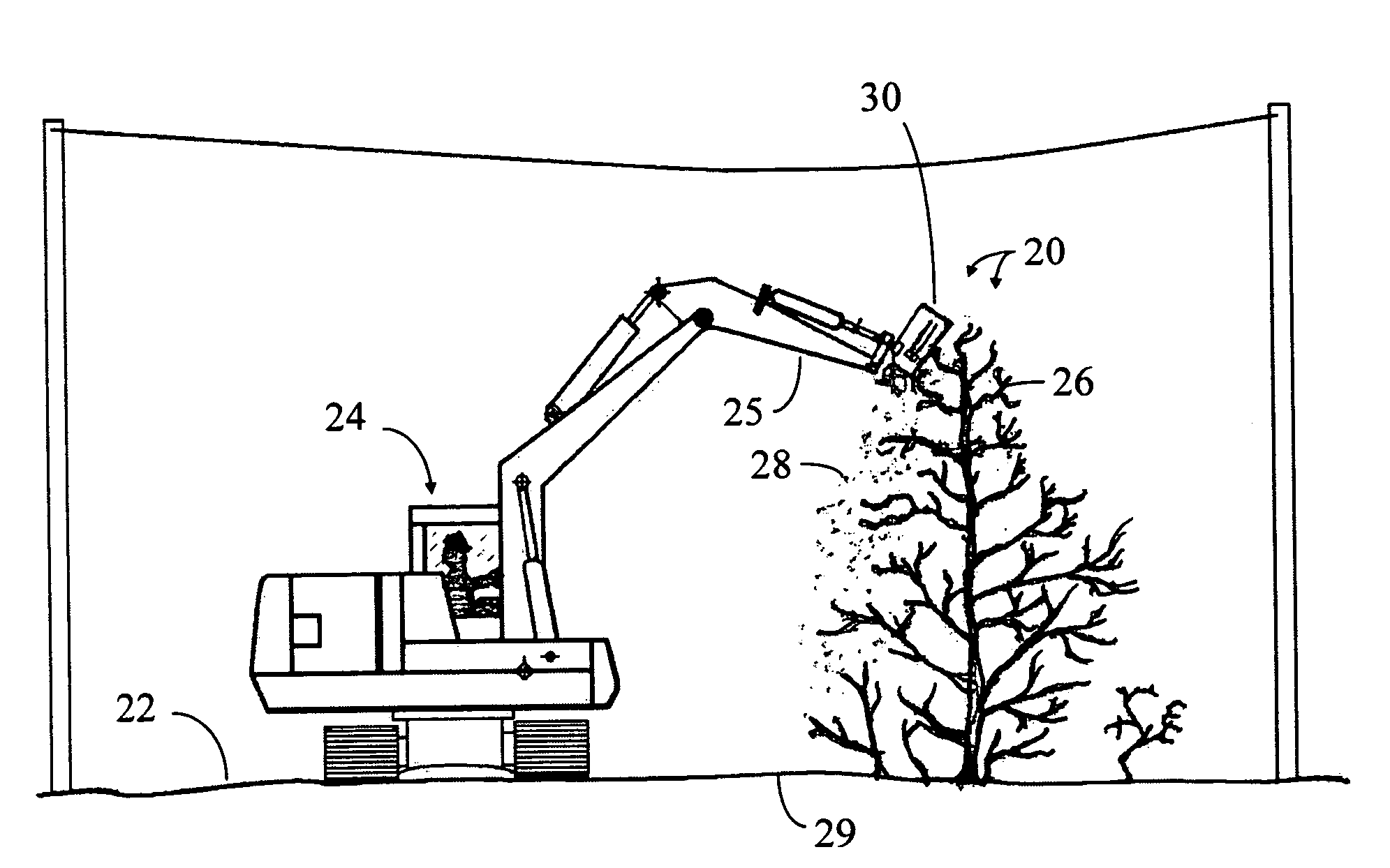

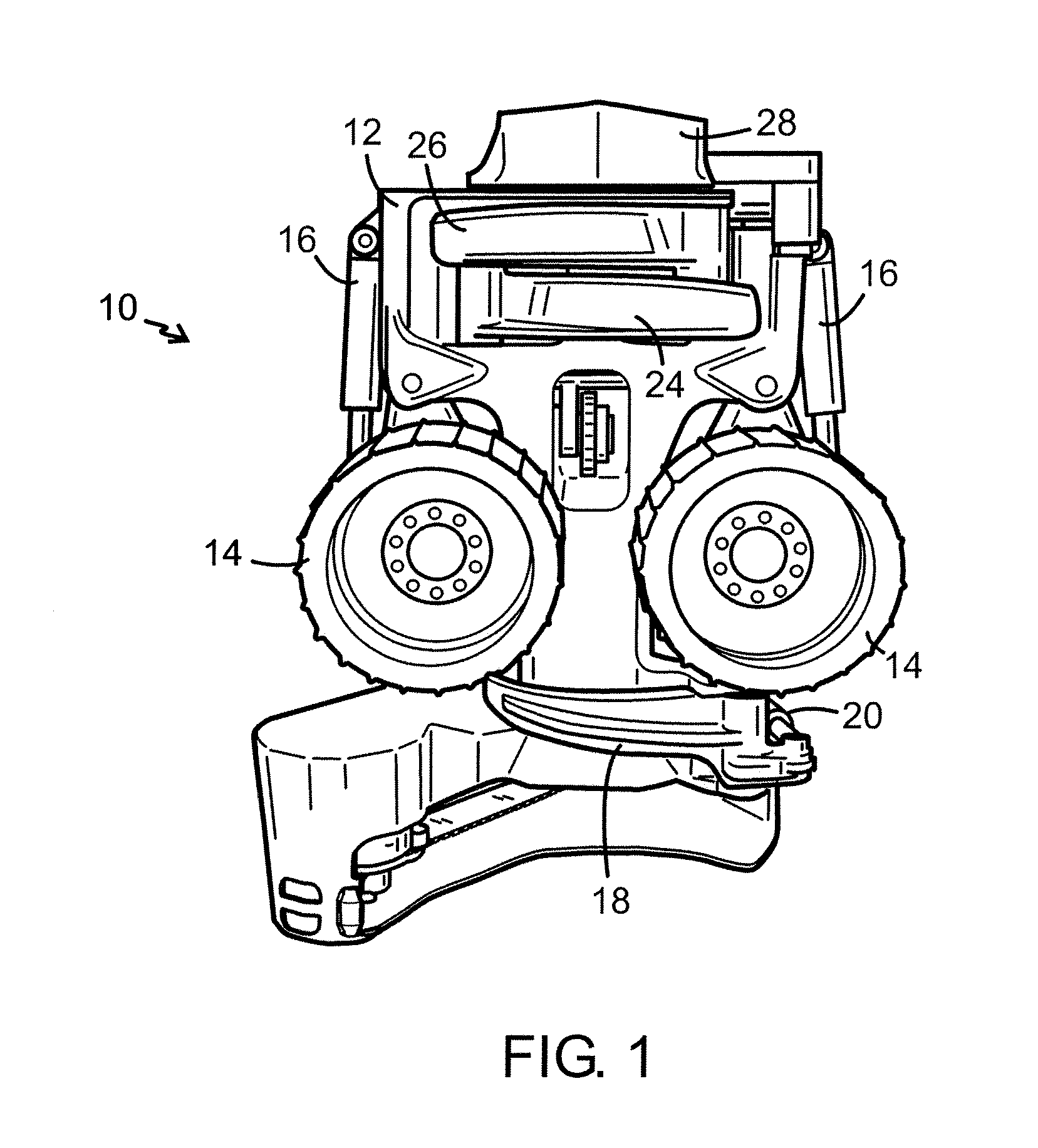

Tree harvesting apparatus and method which enable a cut top or other cut portion of a tree to be weighed before being dropped or lowered to the ground

InactiveUS7086435B1Safely weighedJam is detectedMulti-purpose machinesTree debarkingIndustrial areaFree falling

A tree harvesting apparatus and method is particularly adapted for use in crowded housing and industrial areas where there is concern for relatively heavy cut tree portions causing damage when allowed to free fall to the ground. The tree harvesting apparatus and method enables a cut portion of a tree such as a tree top to be weighed after being cut but before it is lowered or allowed to free fall to the ground dependent on its weight. A camera mounted on the harvesting apparatus enables the cutting and weighing operation to be observed by an operator on the ground. The tree harvesting apparatus mounts on the outer end of a boom which in turn mounts on a turntable which can rotate 360°, thus making the apparatus and method useful for harvesting a plurality of trees from one location of the apparatus.

Owner:BIG BEAVER WOOD COMPANY INC THE

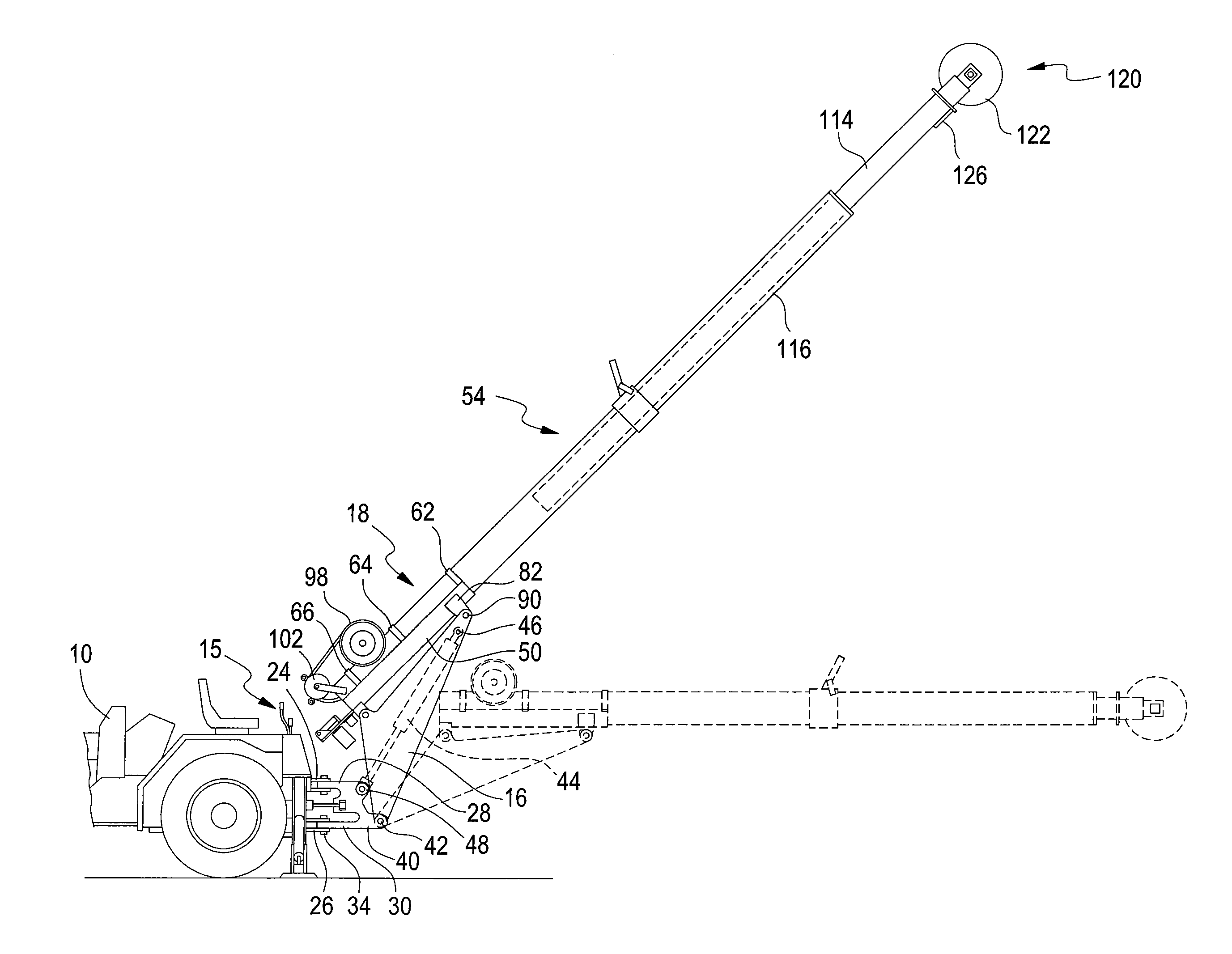

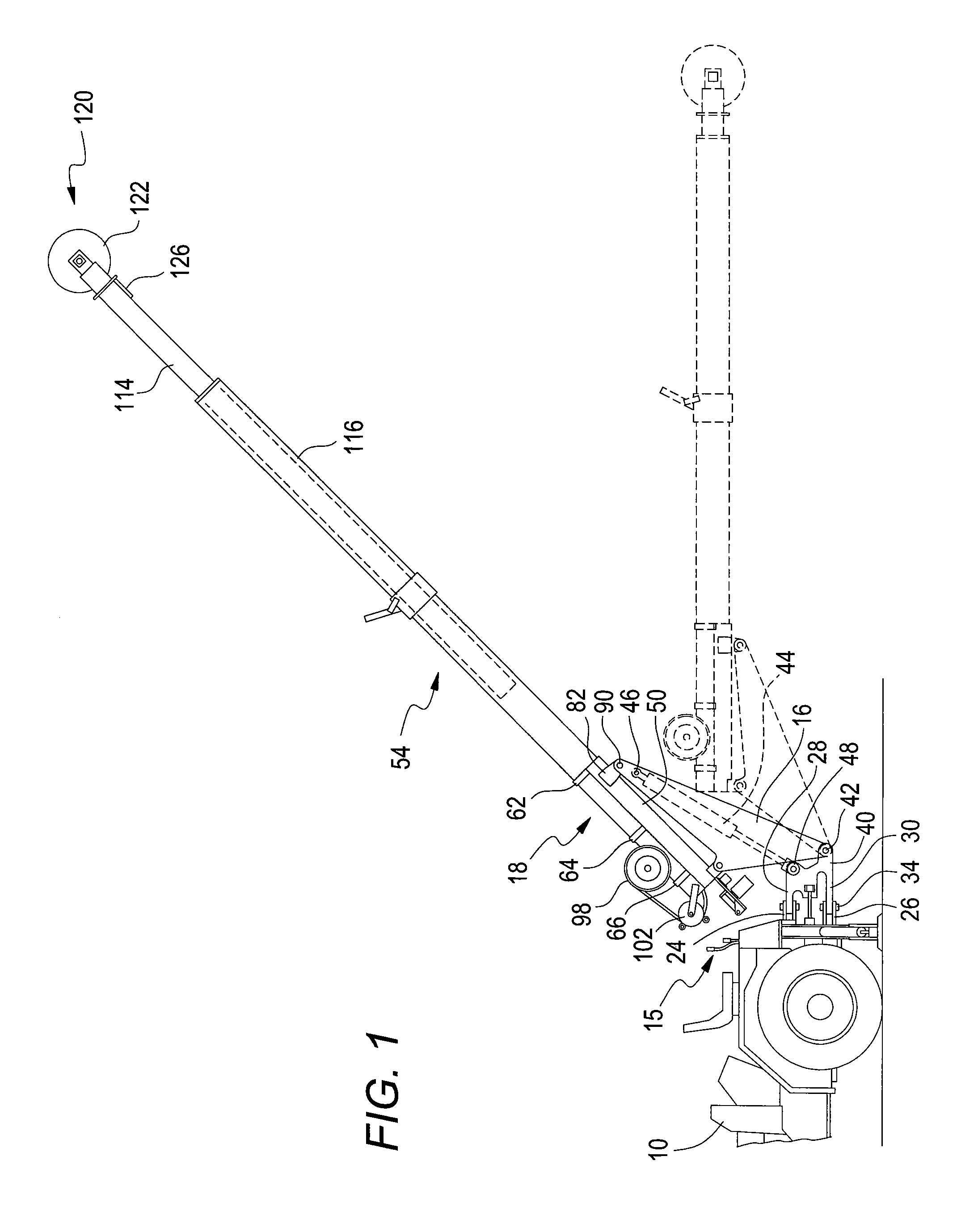

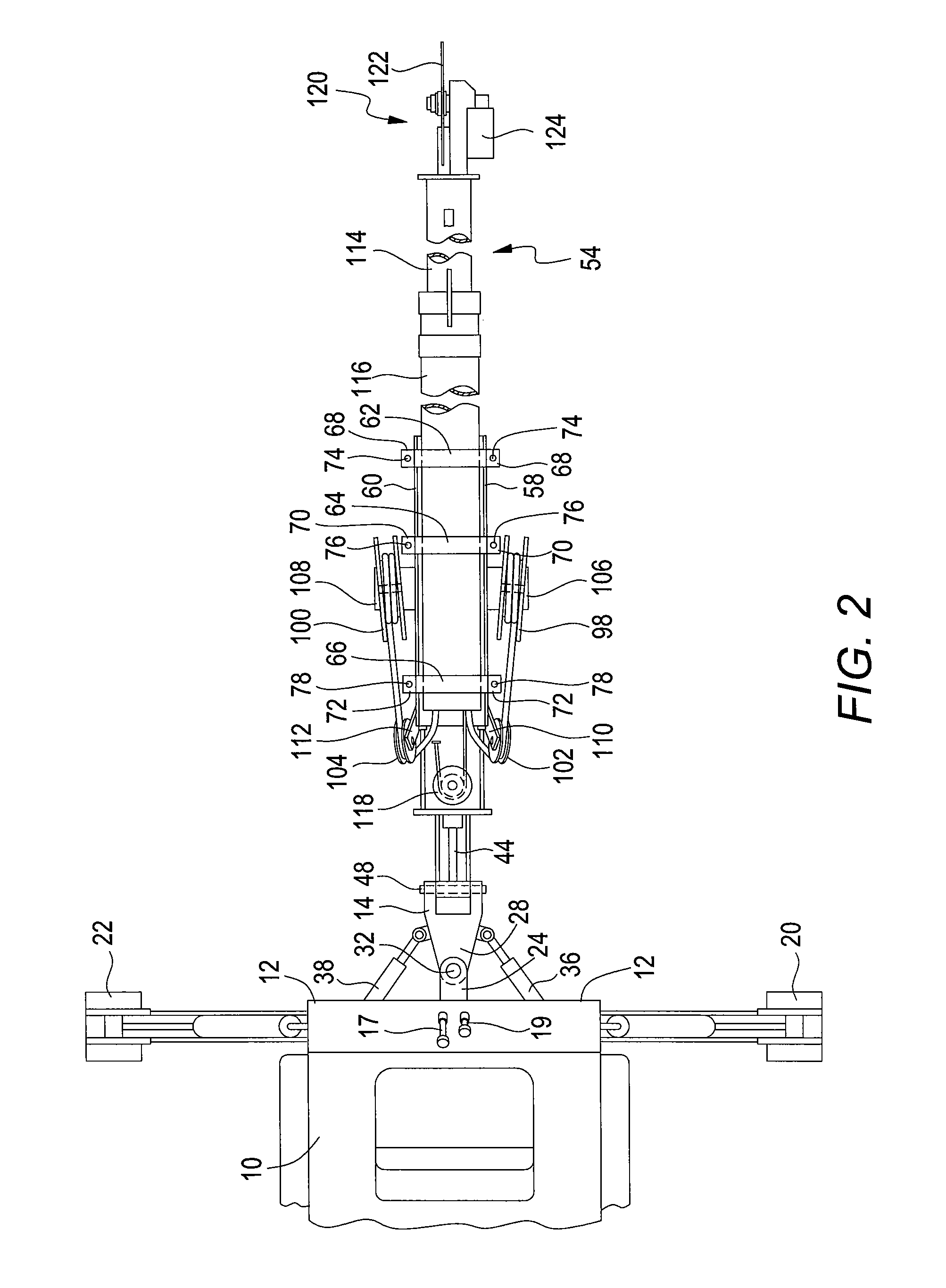

Tree trimmer

InactiveUS7367368B2Linear movement is impededMetal sawing devicesTree debarkingVegetationHorizontal axis

Owner:TRIM ALL EQUIP

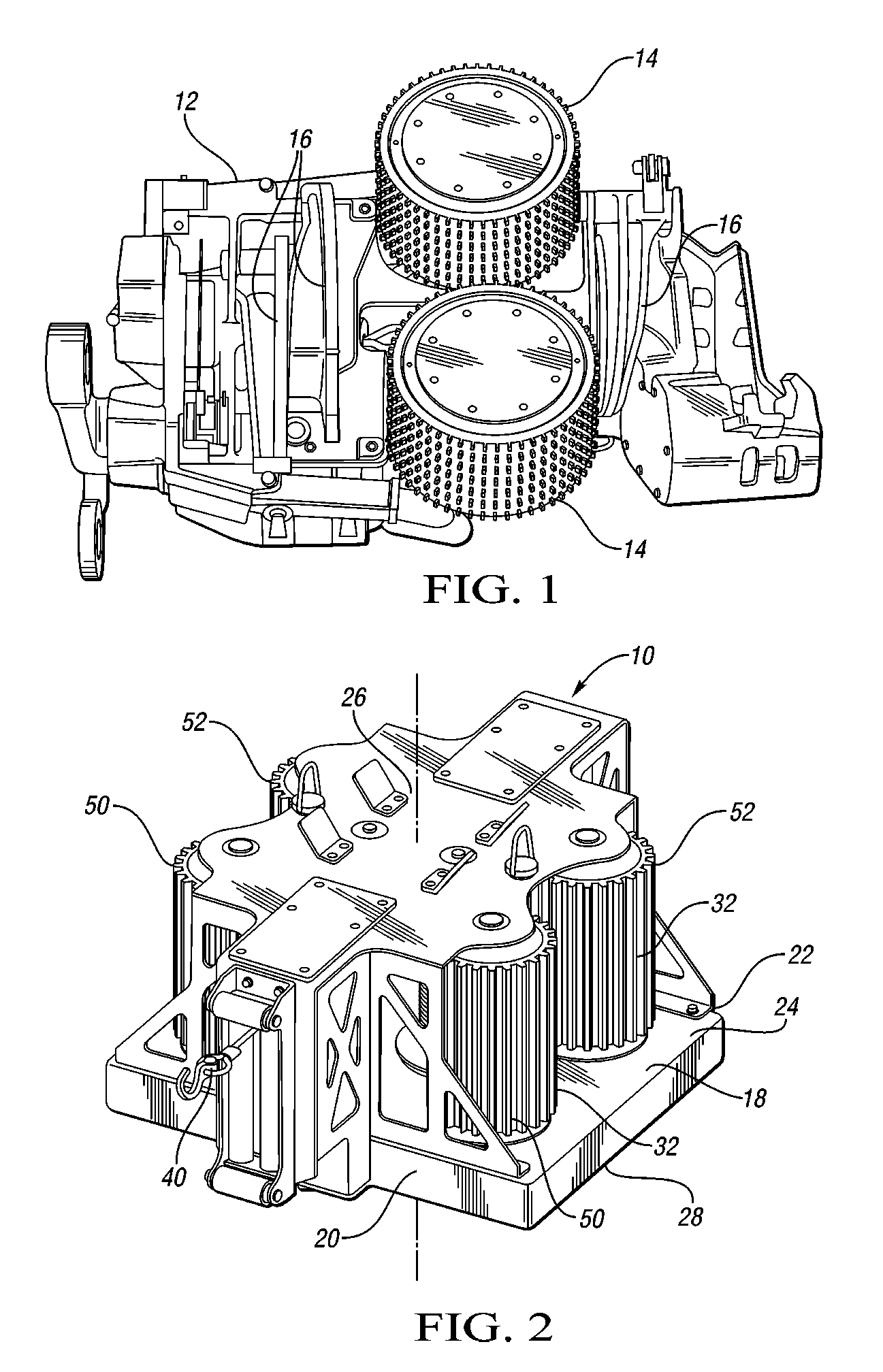

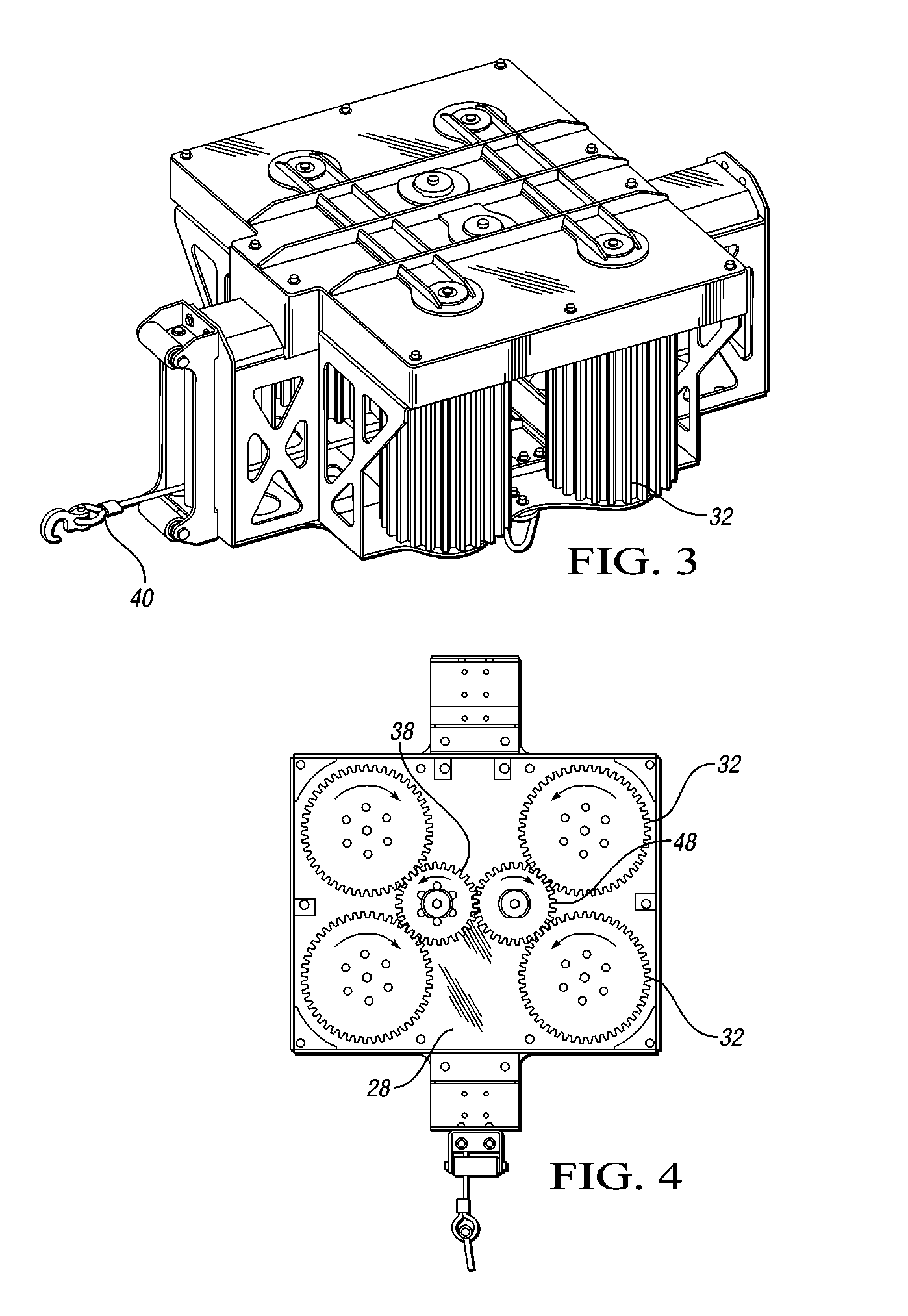

Forestry winch system

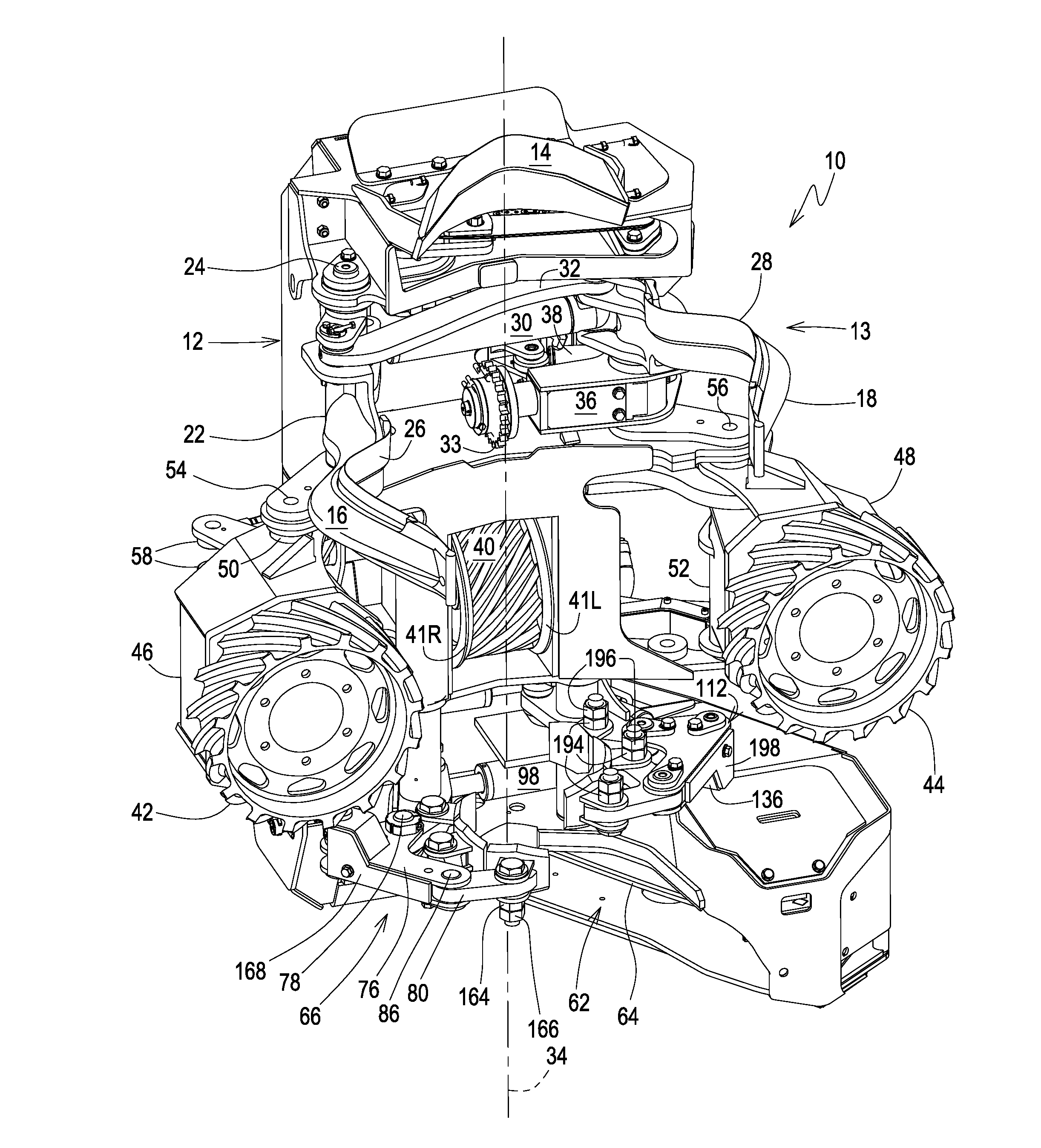

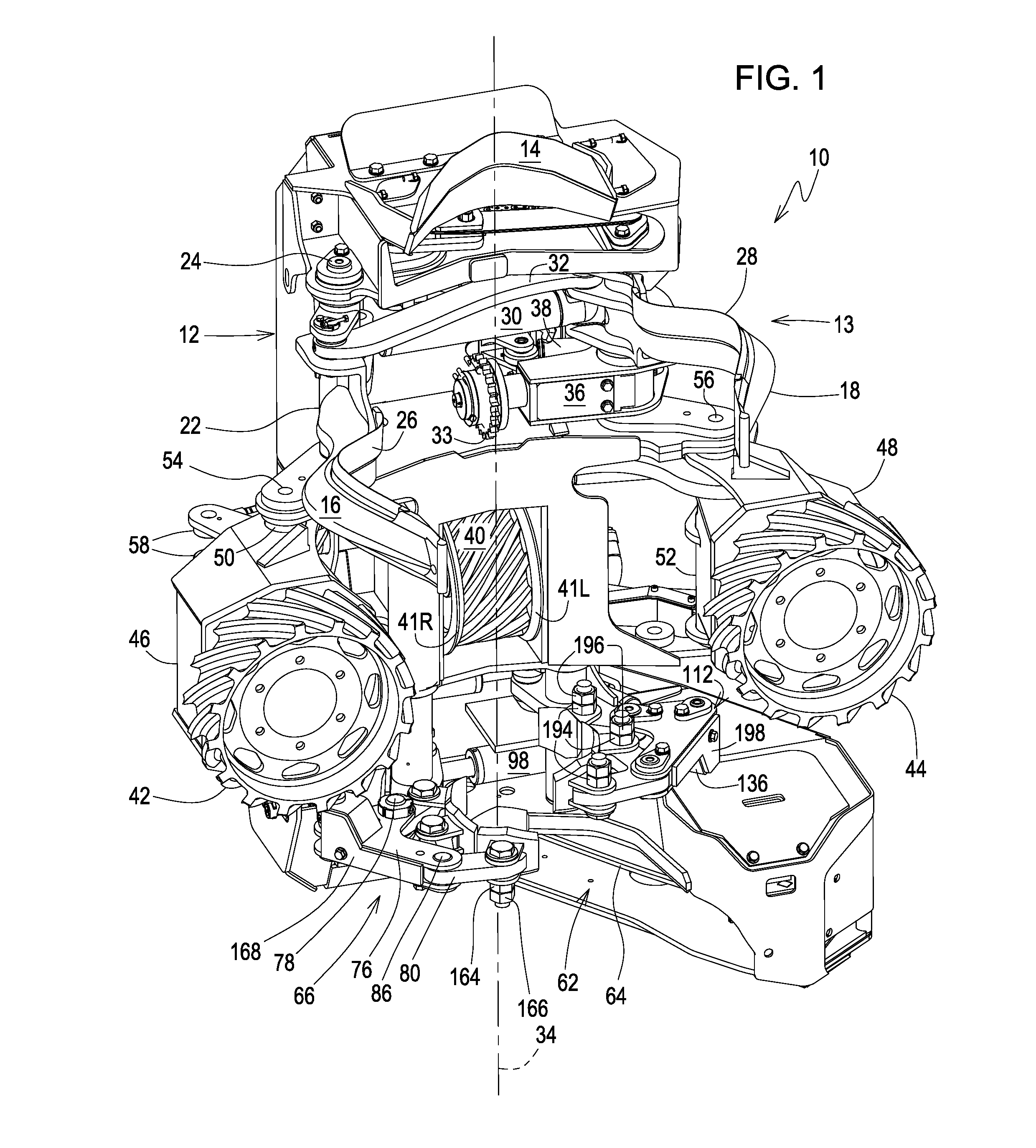

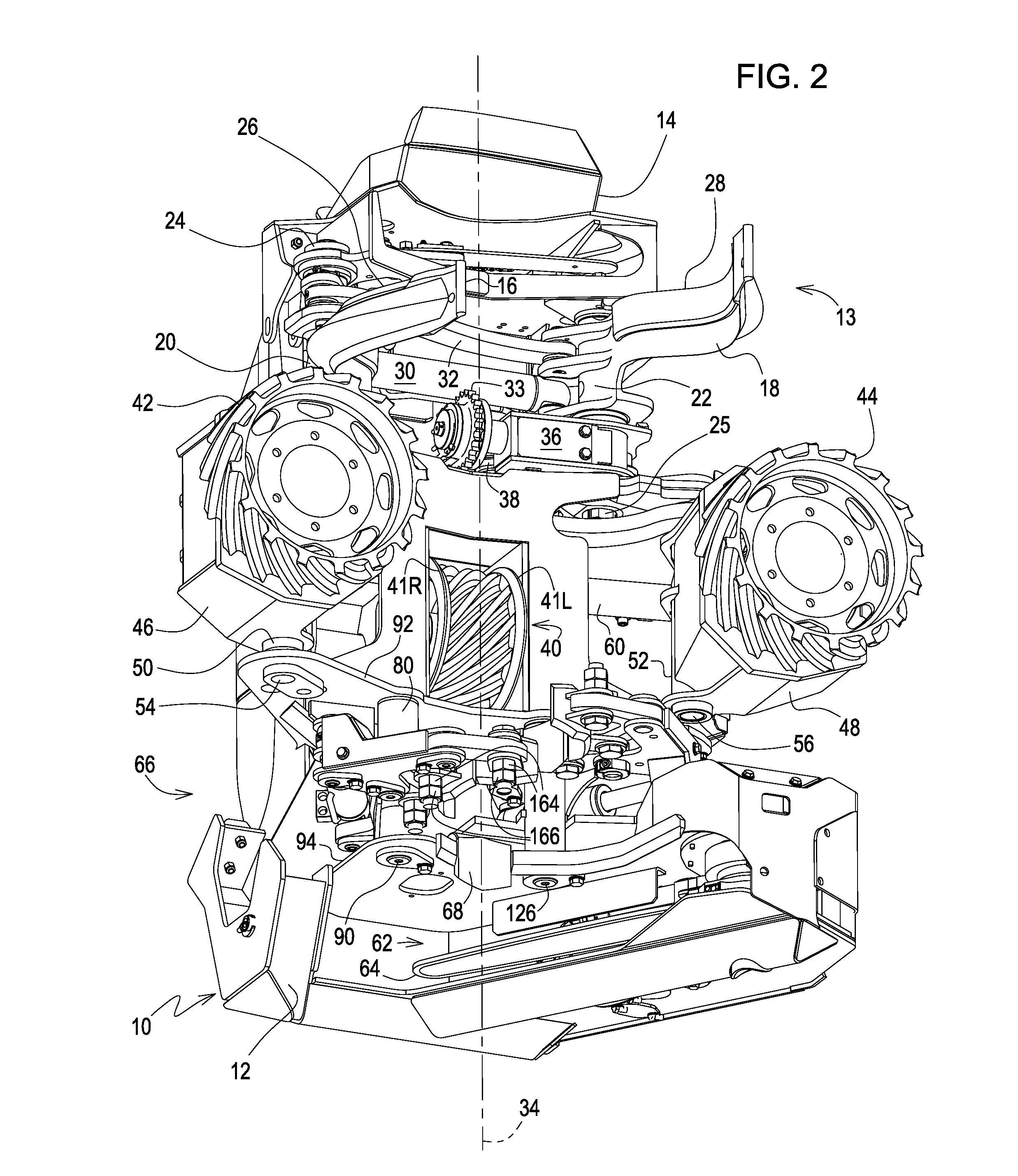

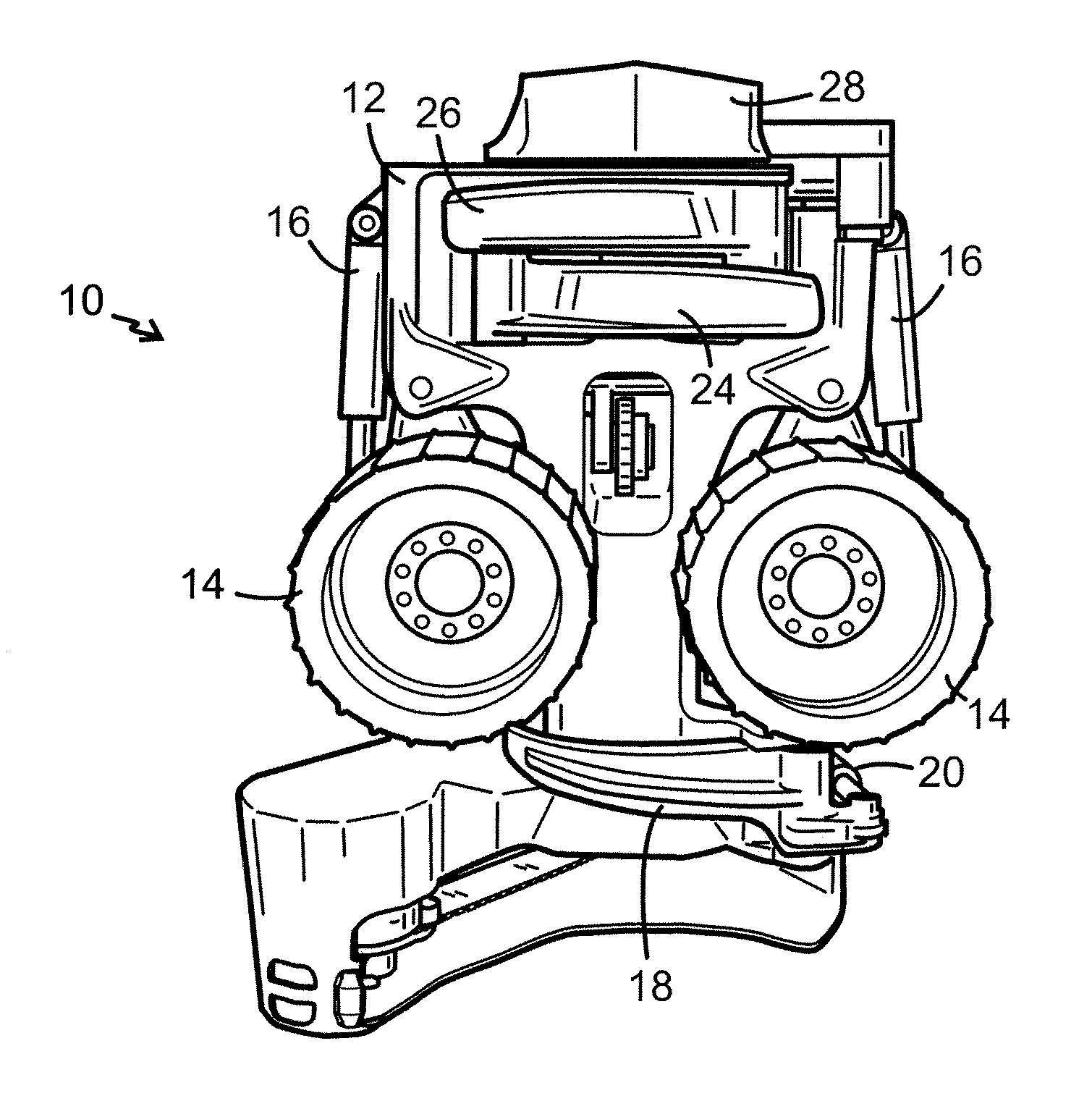

ActiveUS20140341696A1Tree debarkingSemiconductor/solid-state device manufacturingEngineeringVertical axis

A winch system 10 coupled to a processor energy source 12 having multiple processor driving rollers 14. The processor 12 provides energy to the winch system 10. The winch system has a body 18 with a front face 20, a back face 22, lateral sides 24, a top 26, a bottom 28 and an imaginary vertical axis A-A. Multiple driven winch drive rollers 32 are supported by the body 18 so that they are rotatable about axes that are parallel to the vertical axis in response to the multiple processor driving rollers. A winch drum 36 is attached to the body 18. A drum gear 38 influences the speed and direction of winch drum rotation. Attached to the winch drum is a cable 40 having a proximal end 42 region and a distal end region that is detachably attachable to an object 46 to be retrieved by the winch system. The cable extends outwardly from the front 20 or back faces 22 of the body 18.

Owner:GSE TECH

Tree trimming apparatus

“A tree trimming device that automatically climbs a tree or other vertical member and shears limbs or debris as it climbs has an anchor structure with substantially horizontal clamps, a cutting assembly with substantially horizontal clamps, vertical connecting pistons, and a cutting blade assembly.”

Owner:SMITH GEORGE E +1

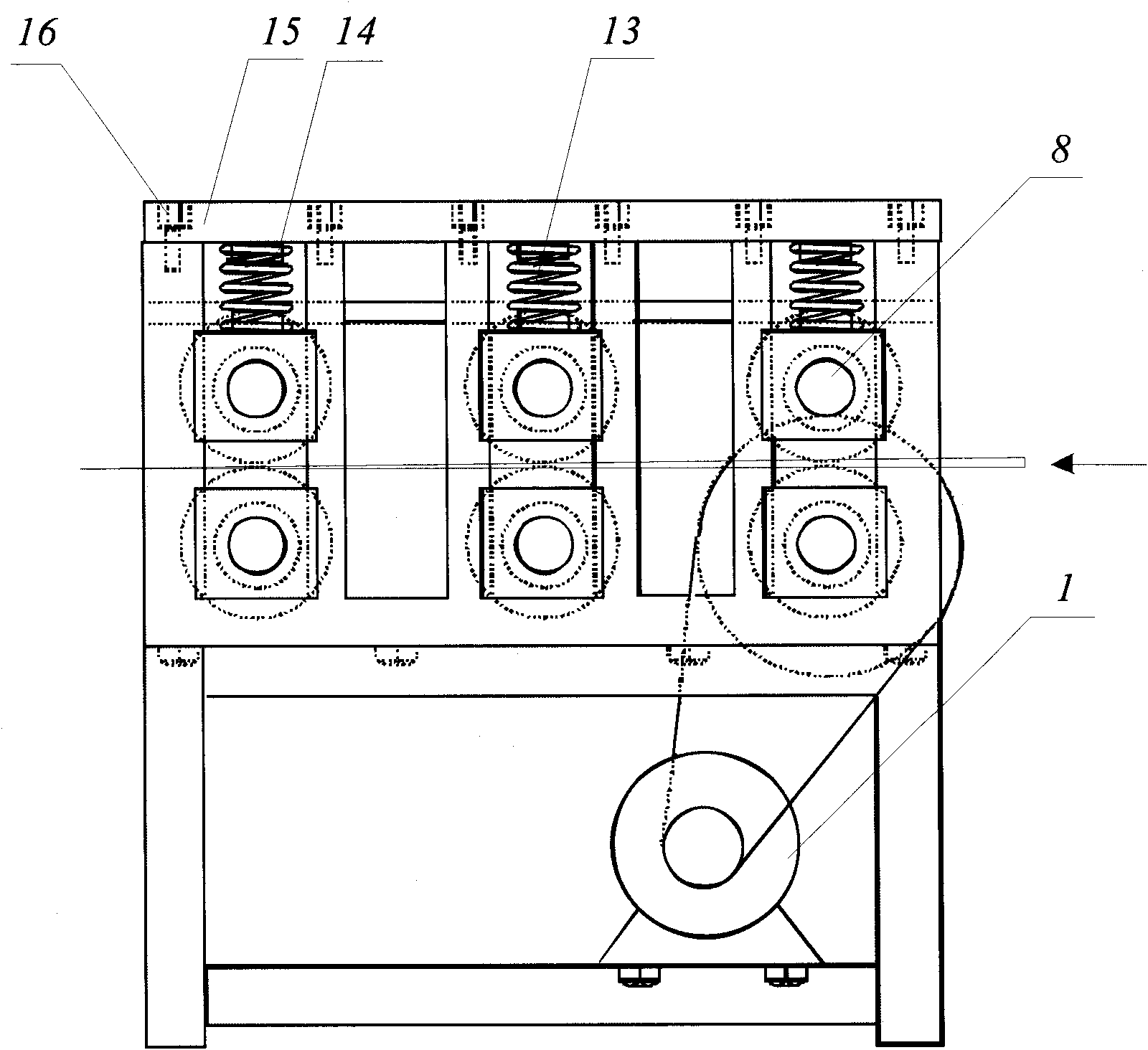

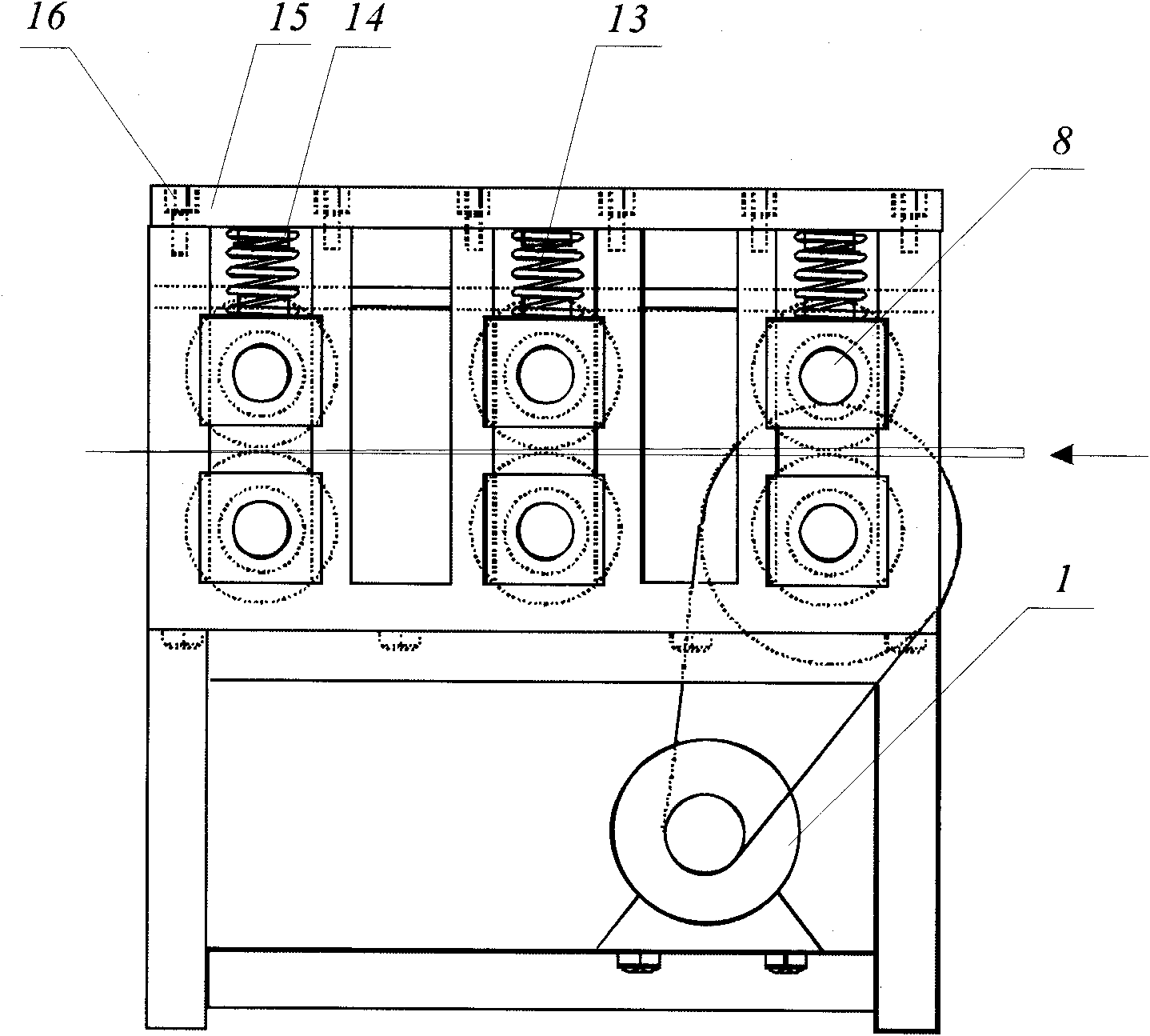

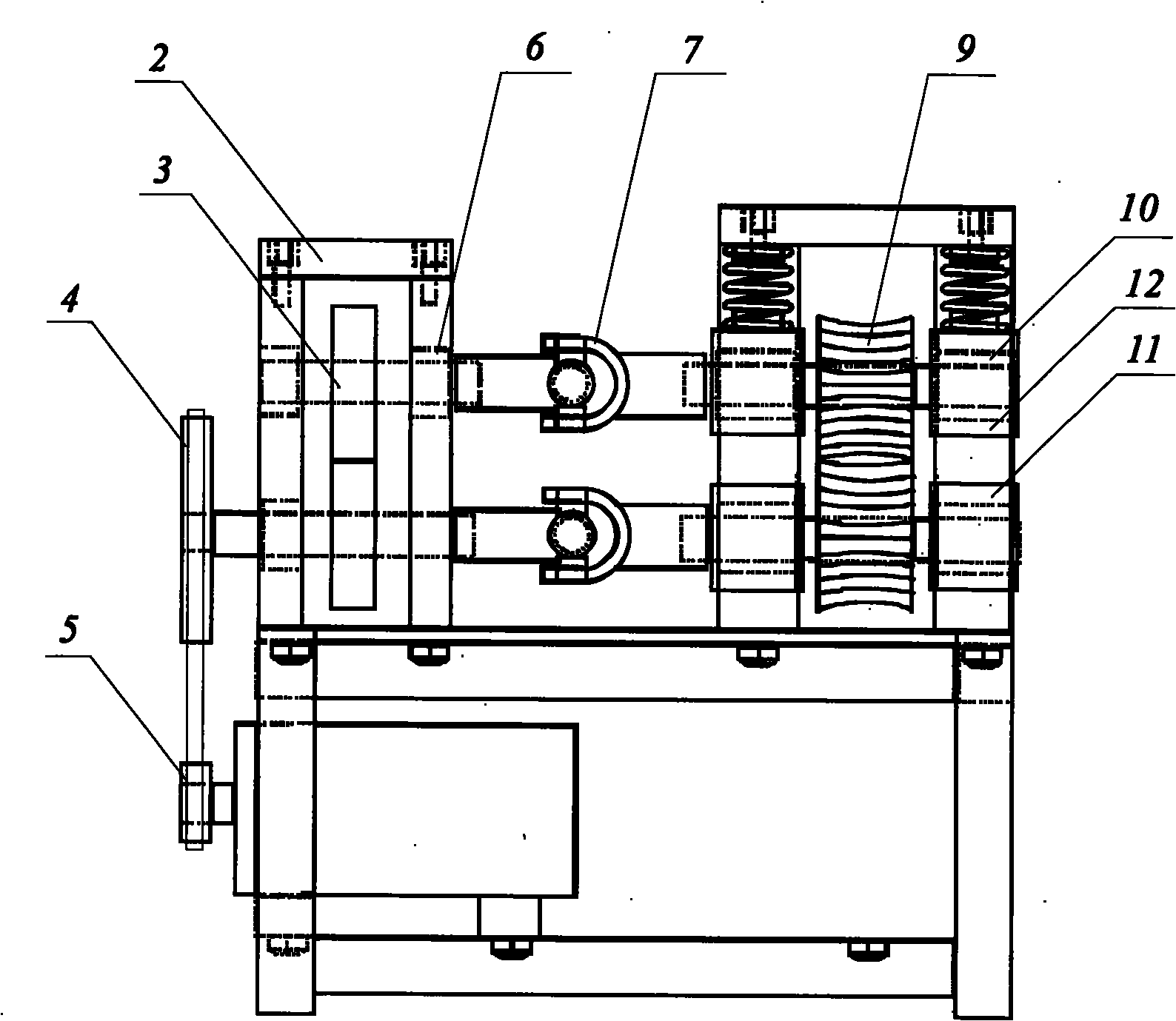

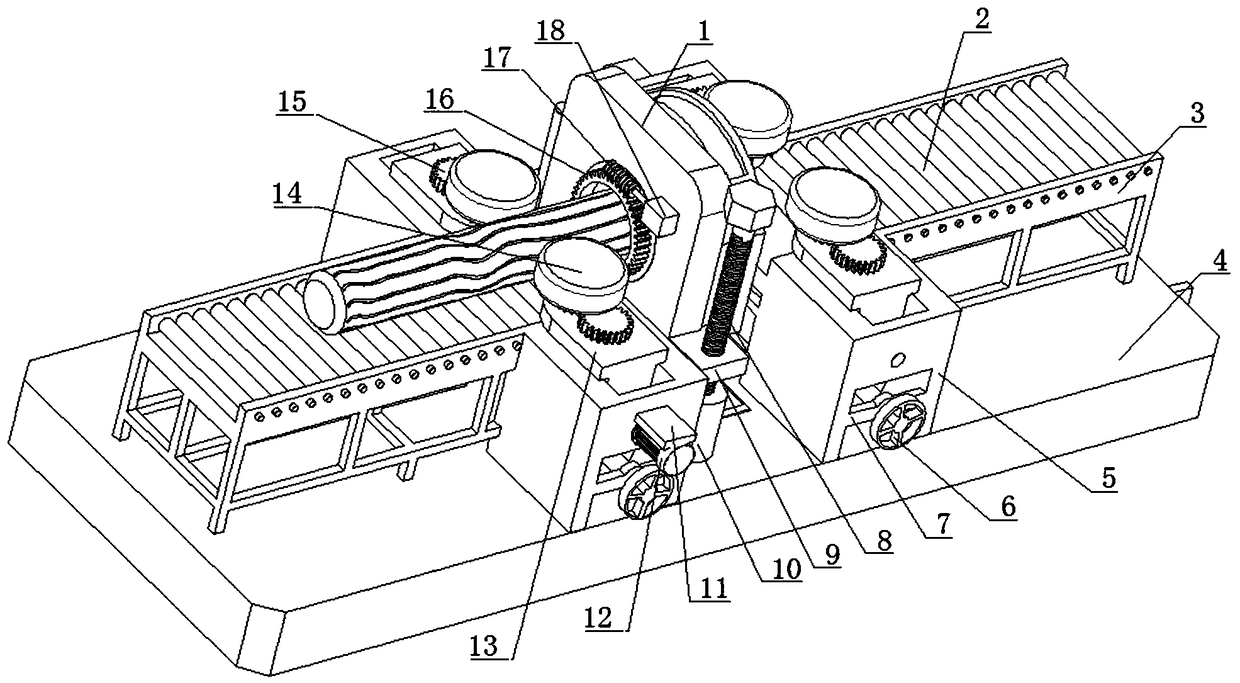

Mulberry branch peeler

The invention discloses a mulberry branch peeler, which comprises a reducer driven by a motor. The reducer is a one-input six-output reduction gearbox; three pairs of output shafts of the reducer are respectively connected with three pairs of pair roller shafts through six universal couplers; the surfaces of the pair rollers are provided with the same crescent gears; two ends of the pair roller shafts are provided with ball bearings which are fixed in bearing bushes, wherein lower roller bearing bushes are fixed on the roller rack, while upper roller bearing bushes can move up and down in roller rack sliding grooves along with the extending and retracting of springs; and compression springs are arranged on the sliding bearing bushes, and are fixedly positioned by upper and lower positioning pins. The mulberry branch peeler has the advantages of reasonable and simple structure and high peeling efficiency, and is suitable for peeling annual or biennial mulberry branches.

Owner:SUZHOU UNIV

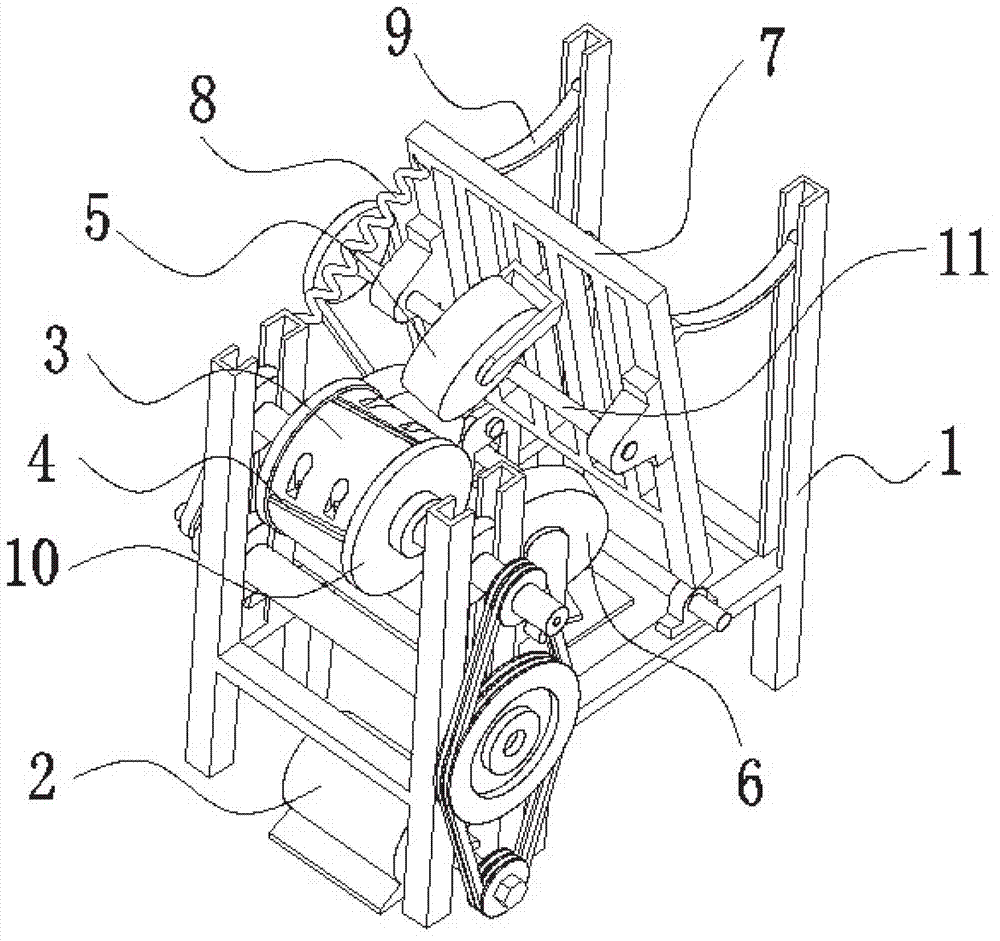

Tree peeling machine

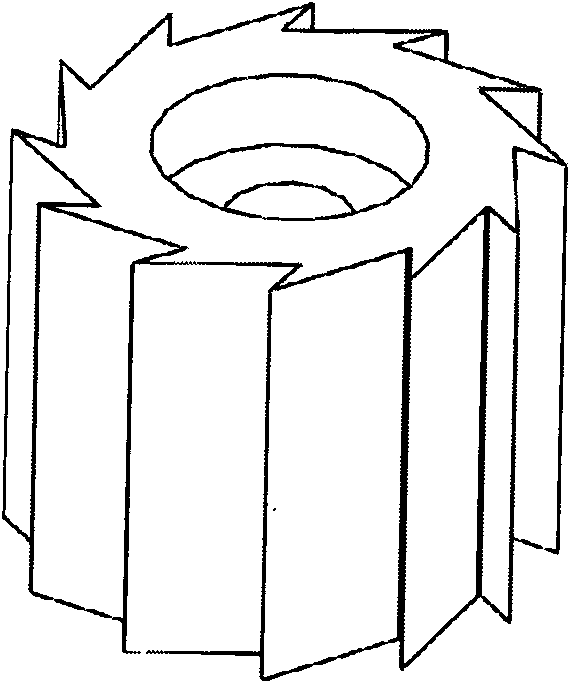

InactiveCN102950634ARealize automatic feedingSimple structureTree debarkingEngineeringMaterial resources

The invention discloses a tree peeling machine which comprises a frame, a driving device, a cutter disk, an upper feed wheel and lower feed wheels, wherein cutter blades are arranged on the outer circumference of the cutter disk which is driven to rotate by the driving device; wood is clamped by the cutter disk, the upper feed wheel and the lower feed wheels; an axial line of the upper feed wheel or the lower feed wheels is not parallel to an axial line of the cutter disk; both the upper feed wheel and the lower feed wheels are driven to rotate by the driving device; and the direction of a horizontal component of the upper feed wheel and the lower feed wheels on the wood is coincident with the feed direction. According to the tree peeling machine disclosed by the invention, automatic feed can be realized in the cutting process, and an automatic pressing mechanism can be matched with a feed device, so that the wood can be clamped by the feed device all the time when the diameter of the wood is changed. The processing device has a simple structure and can be conveniently operated, manpower and material resources are saved, and the processing cost is saved.

Owner:SUZHOU WUZHONG DISTRICT GUANGFU XIANGXUE NURSERY GARDEN

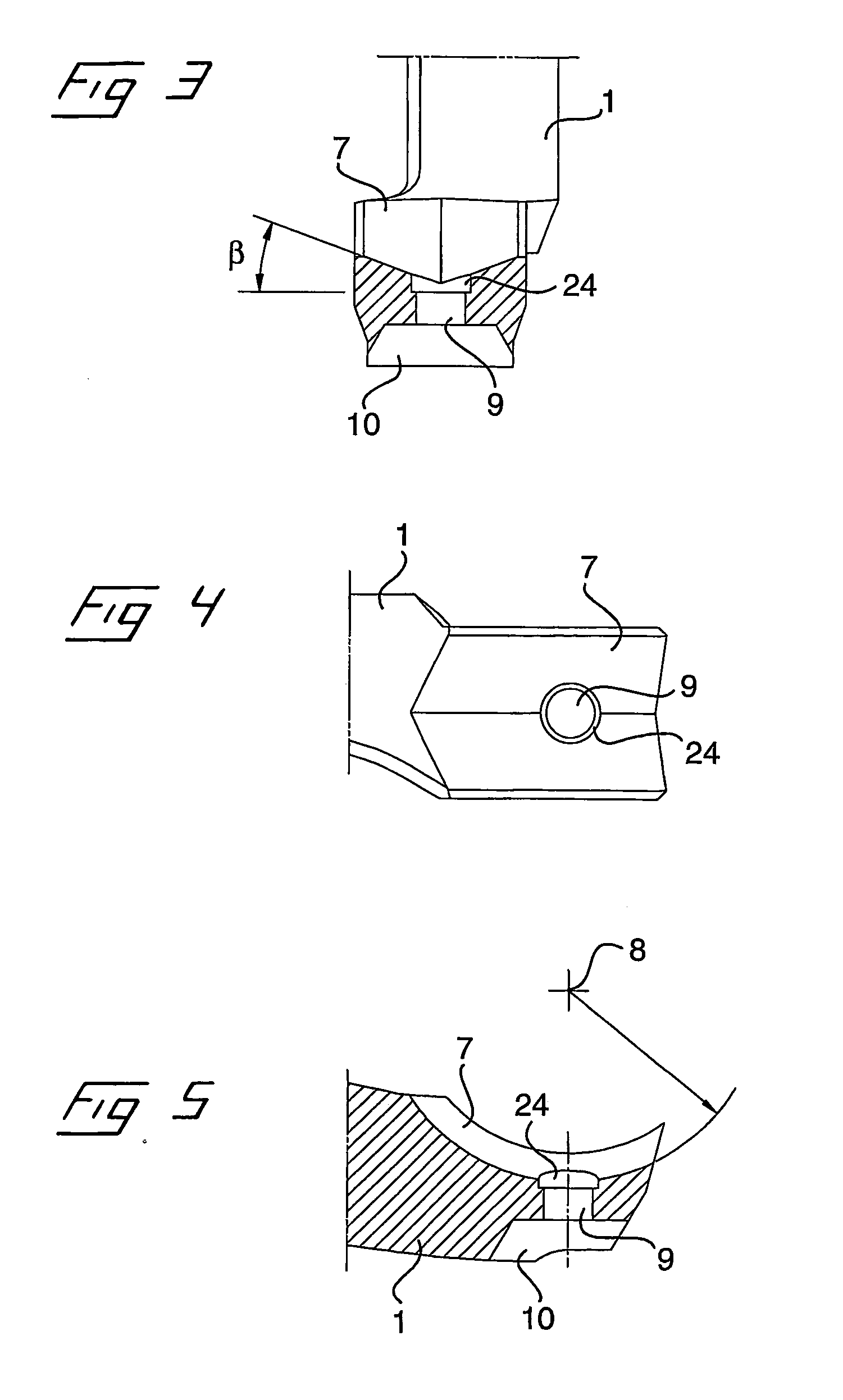

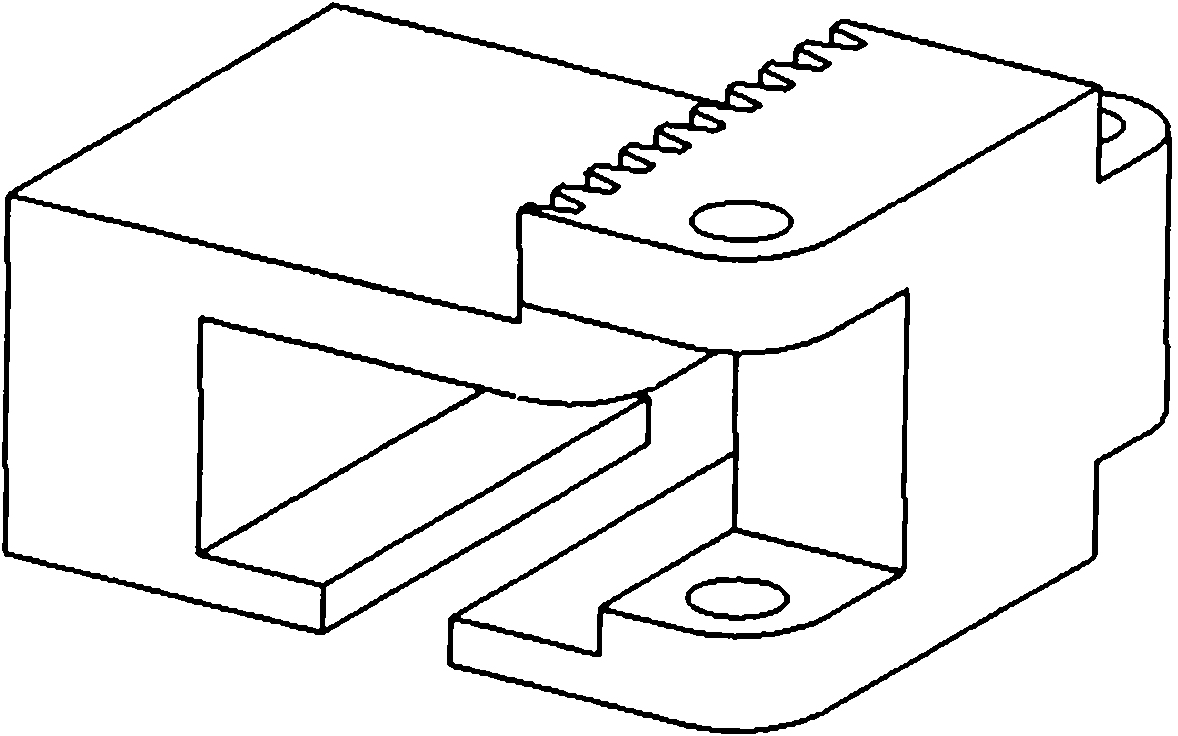

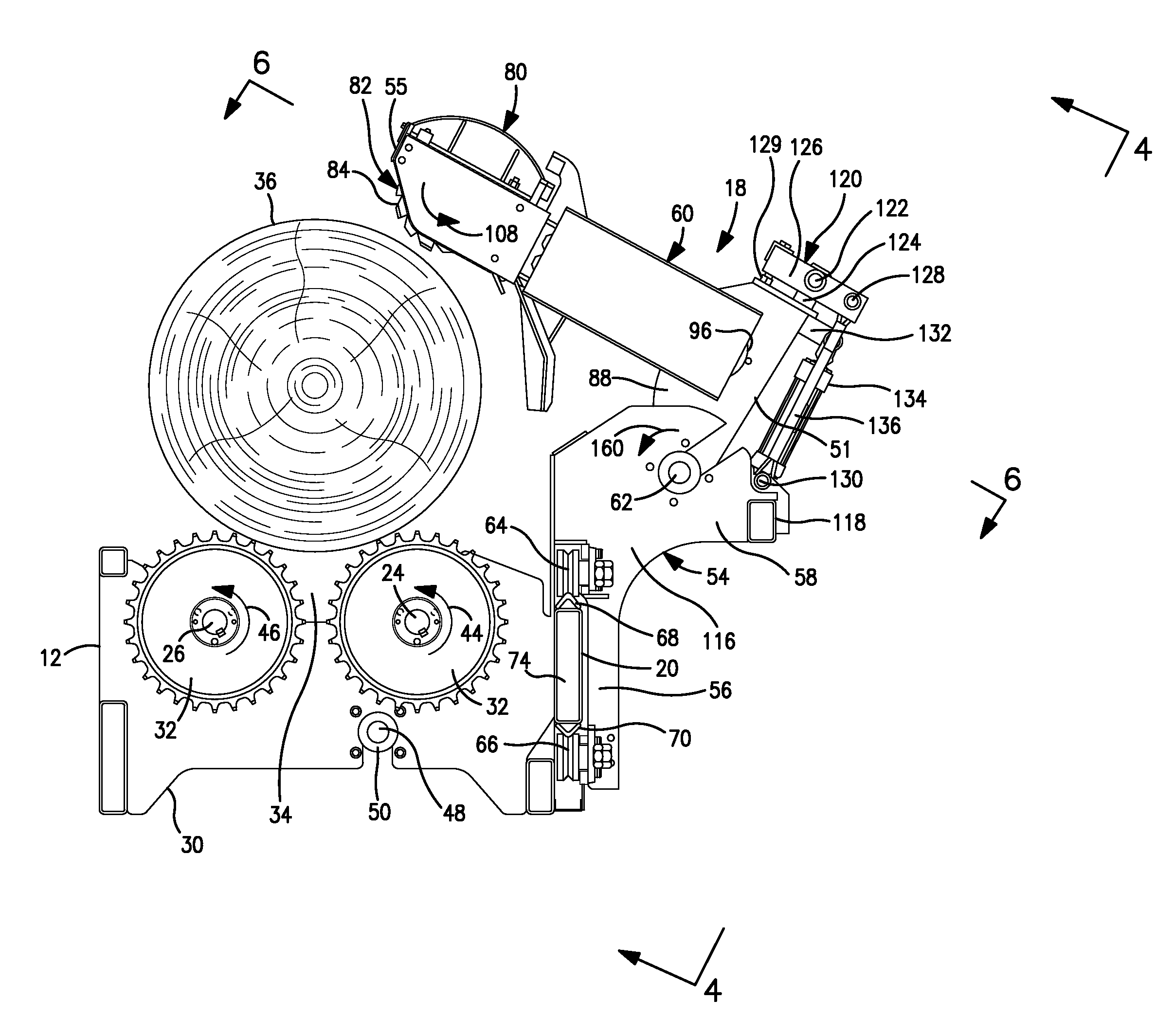

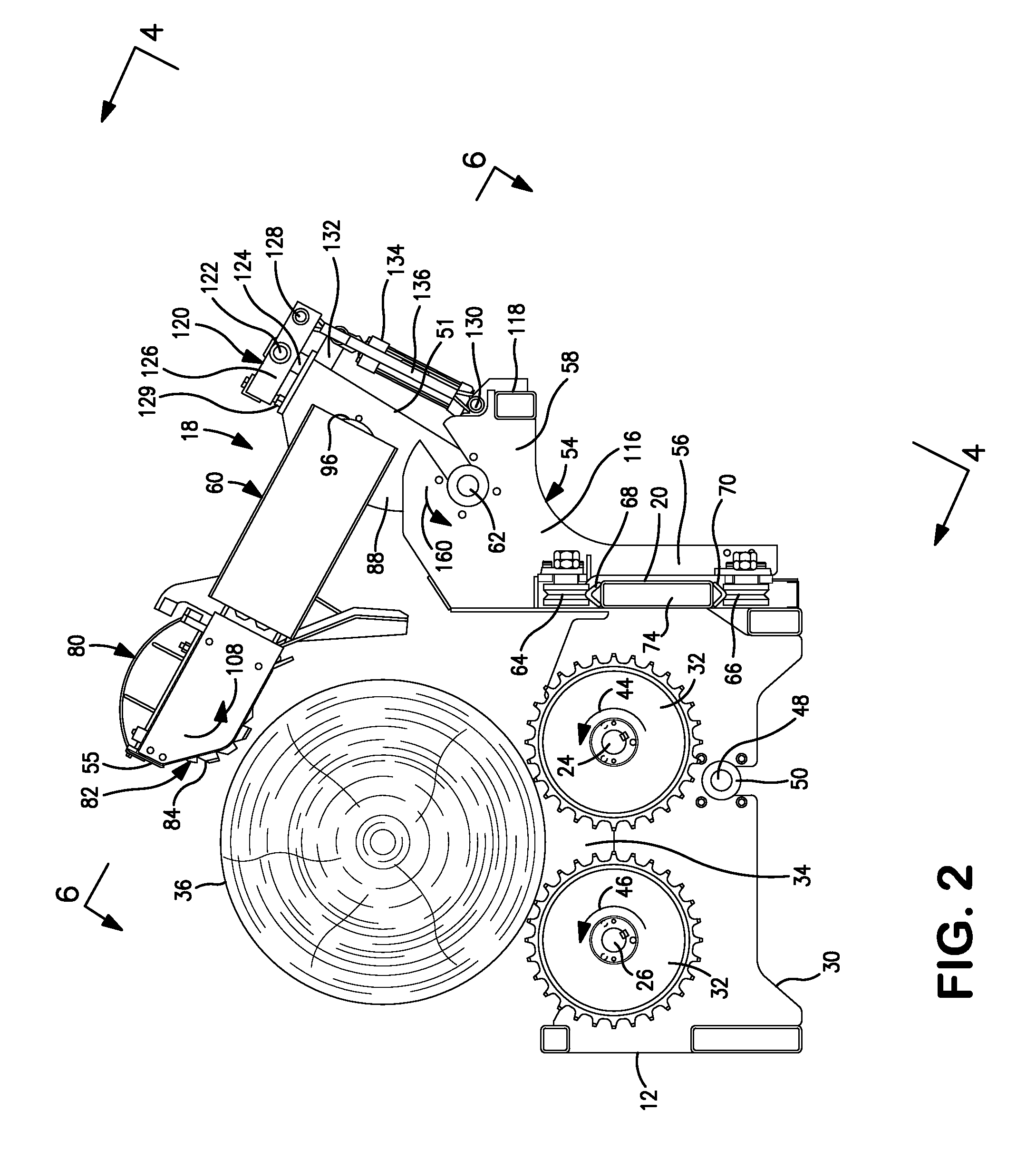

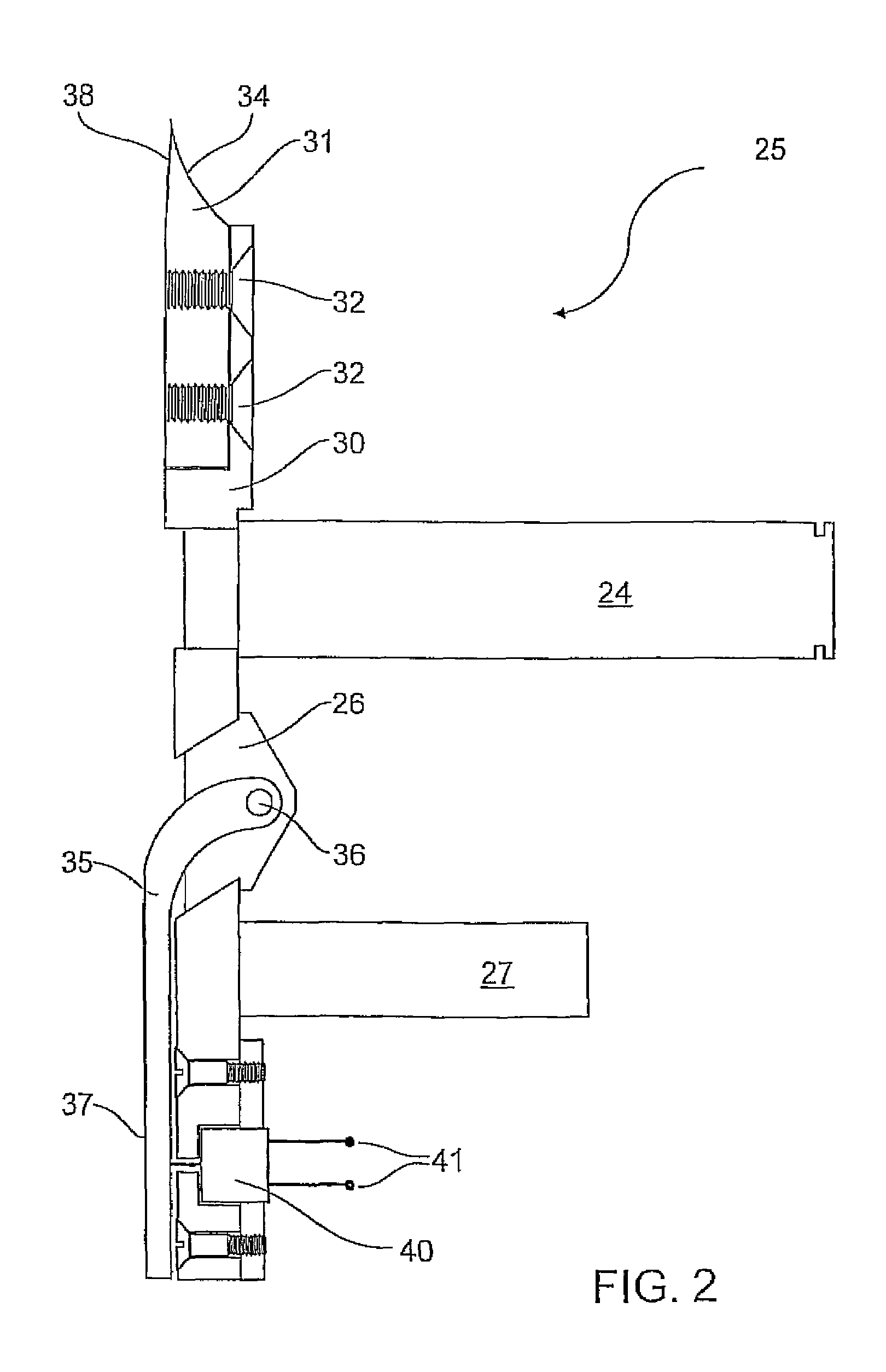

Swing arm assembly with replaceable insert for use with a debarker apparatus

Apparatuses, systems, and methods for debarking logs are shown and described. The disclosed embodiments can be used for quickly and conveniently replacing contact surfaces, such as leading edges, of swing arm assemblies. Some disclosed embodiments include a swing arm assembly having a replaceable insert that defines a leading edge for engaging logs moving along a processing line. The insert can be made of a wear resistant material for a prolonged life. A worn insert can be replaced with another insert to ensure proper functioning of the debarker.

Owner:NICHOLSON MFG

Bark stripping device for wood

InactiveCN106965284AReduce scrap rateAchieve utilizationTree debarkingBark-zones/chip/dust/waste removalWood grainEngineering

The invention discloses a wood peeling device, which comprises a shell, a sliding sleeve rod, a first rod and a fixed ring. Two pipelines, a fan is installed in one end of the second pipeline, a support bracket is fixedly connected to the bottom of the housing, a diagonal rod is fixedly connected to the bottom of the support bracket, and a support seat is fixedly welded to the lower end of the diagonal rod , one end of the support seat is vertically installed with a support rod, the front of the housing is horizontally equipped with a rotating shaft, the rotating shaft is connected to the door body in rotation, the door handle is fixedly installed on the door body, and the top of the housing The middle thread is connected with an adjusting bolt, the upper end of the adjusting bolt is fixedly connected with a rotating handle, and the lower end of the adjusting bolt is rotatably connected with a knife seat, and a blade is welded below the knife seat. The invention can accurately peel the bark according to the thickness and length of the wood without damaging the grain of the wood.

Owner:WUXI JIAN AUTOMATION TECH CO LTD

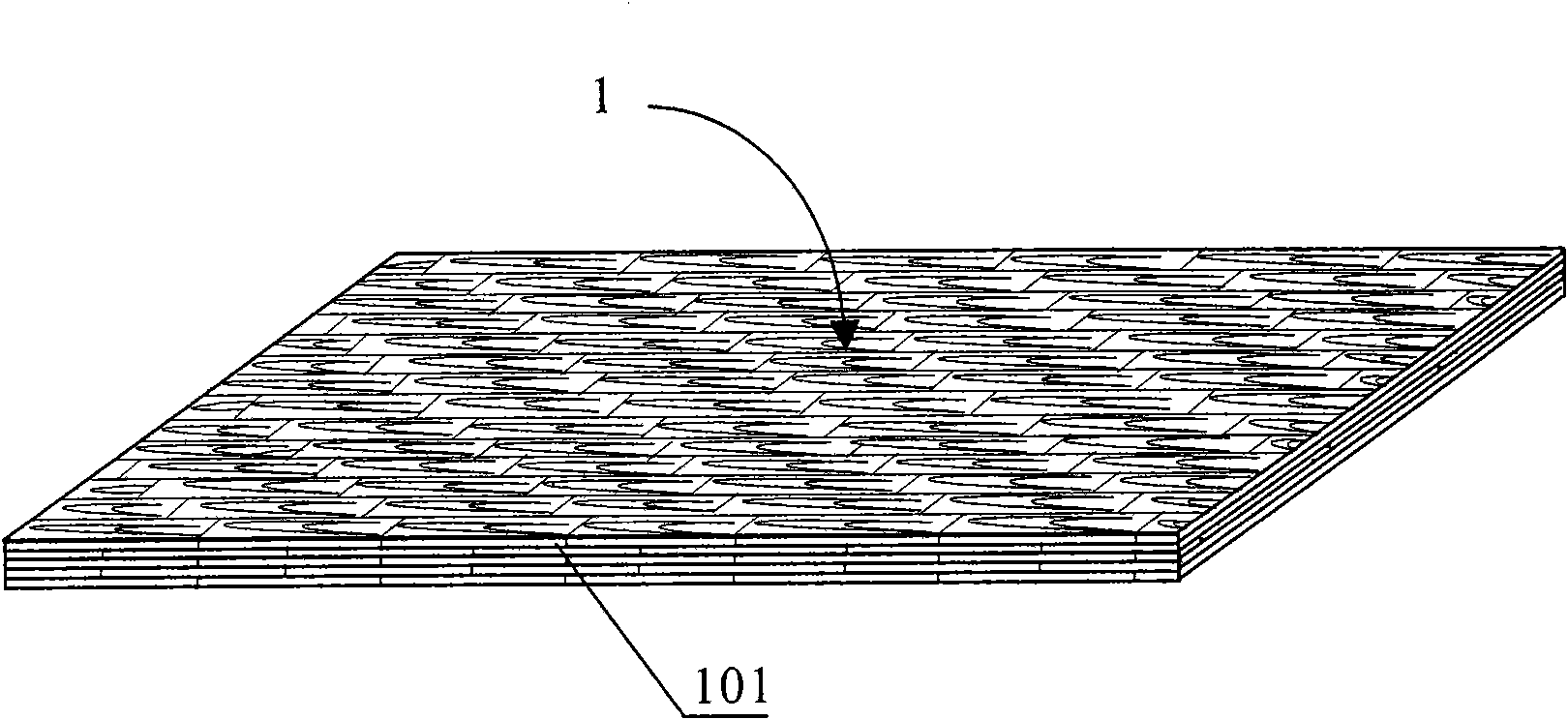

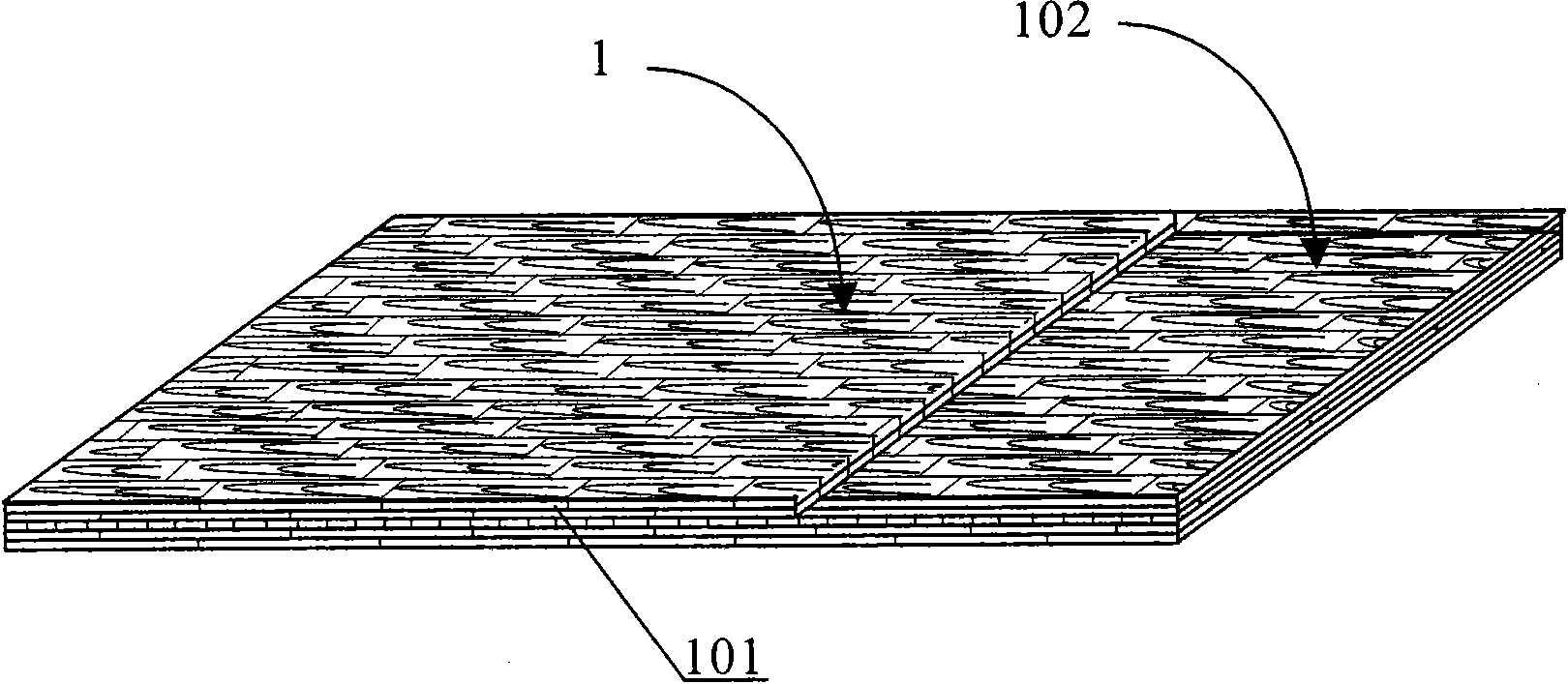

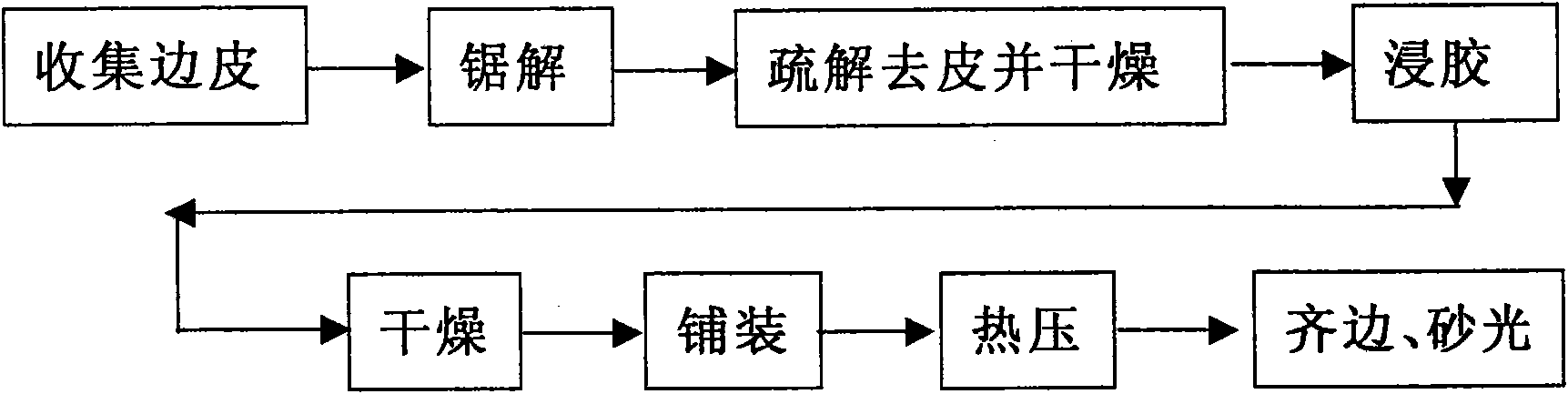

High-performance wood restructuring laminated wood and manufacturing method thereof

InactiveCN101579879AHigh strengthImprove performanceTree debarkingDomestic articlesHeat pressMoisture

The invention discloses a high-performance wood restructuring laminated wood and a manufacturing method thereof. Massive remainders, namely wood slabs, produced in wood processing are taken as raw materials to manufacture high-density high-strength laminated boards and squared timbers used for structure and decoration by wood restructuring technology; wherein the waste remainders of the wood processing are sawed, discongested and peeled and dried to form edgings with certain specifications; then the edgings are levelly paved in multilayer, and heat pressing and post treatment are carried out to manufacture laminated boards and squared timbers. The processing technological processes are as follows: sawing the remainders, namely the wood slabs of the wood processing to be edgings with certain width and length, discongesting and peeling, and drying to certain moisture content; carrying out gumming and secondary drying on the dried edgings, then paving the edgings in a concave groove to form blanks; then pushing the blanks in the concave groove to a die on a thermocompressor for heat pressing, forming blank flat squared timbers, and then trimming and sanding to manufacture the finished product.

Owner:INST OF WOOD INDUDTRY CHINESE ACAD OF FORESTRY

Tree trimming apparatus

A tree trimming device that automatically climbs a tree or other vertical member and shears limbs or debris as it climbs has an anchor structure, a cutting assembly, vertical connecting pistons, and a cutting blade assembly. The anchor structure and the cutting assembly may be attached by vertical connecting pistons. The device climbs vertical members by clamping the anchor structure to the tree or other vertical member, then extending the vertical connecting pistons, which forces the cutting assembly to move up the vertical member, shearing limbs or other debris as it moves. Once the vertical connecting pistons are extended, the cutting assembly may be clamped to the tree, and the vertical connecting pistons may be retracted, thus pulling the anchor structure up the vertical member towards the cutting assembly. The process may be repeated until the vertical member is trimmed to the desired height. The process may be reversed to lower the device back to the ground.

Owner:SMITH GEORGE E +1

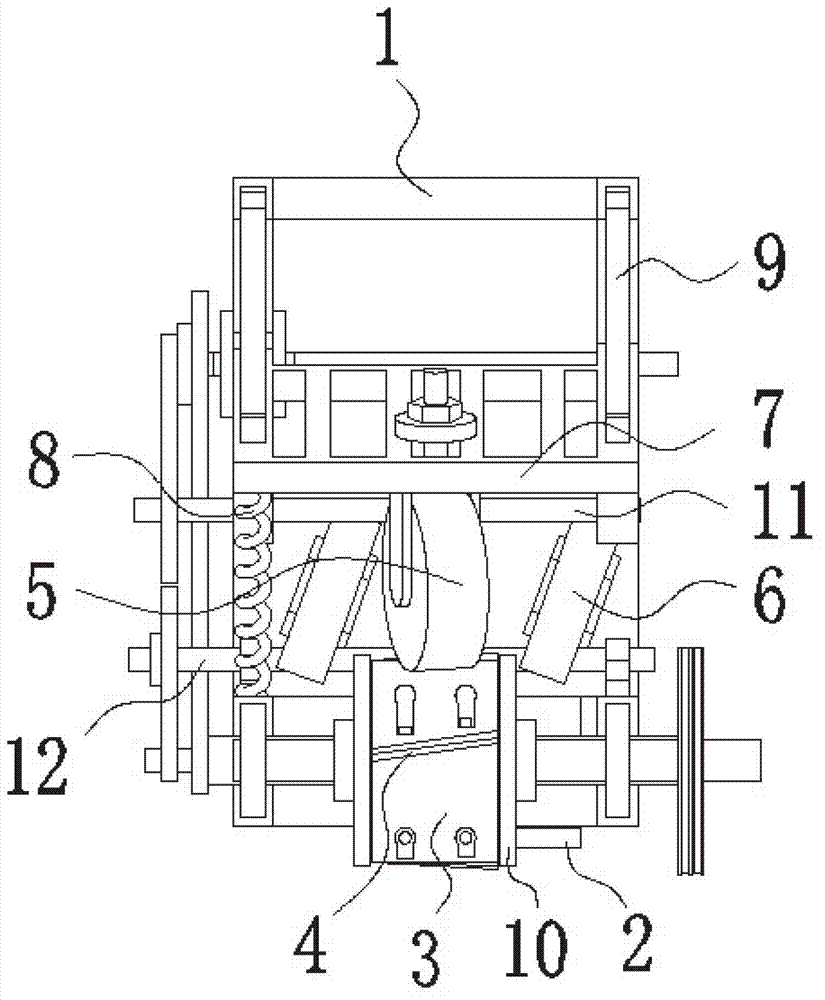

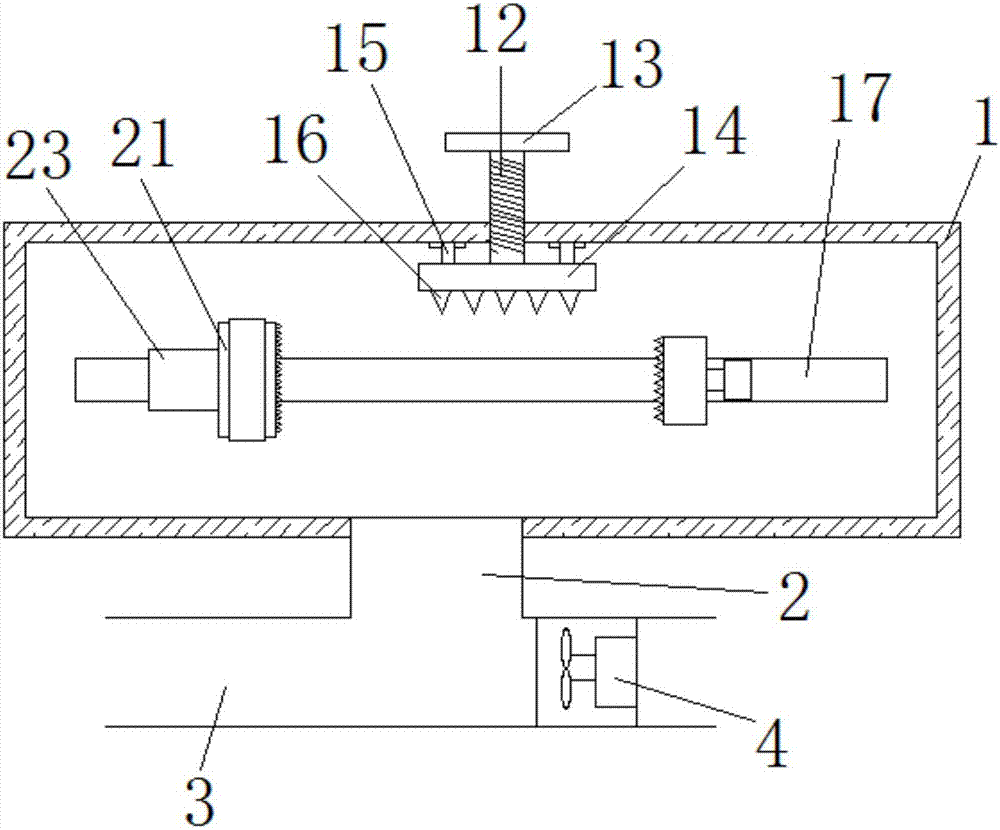

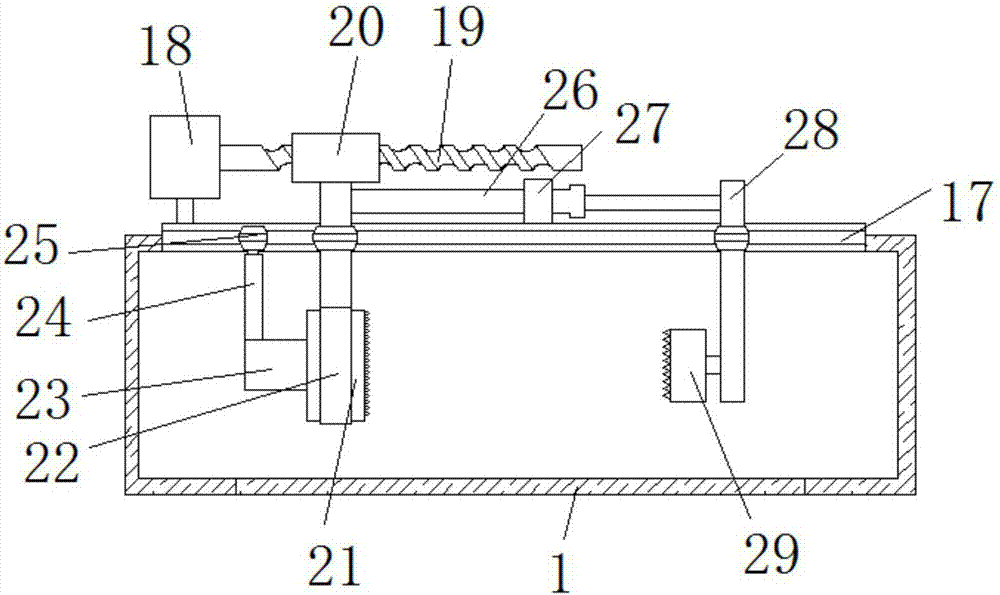

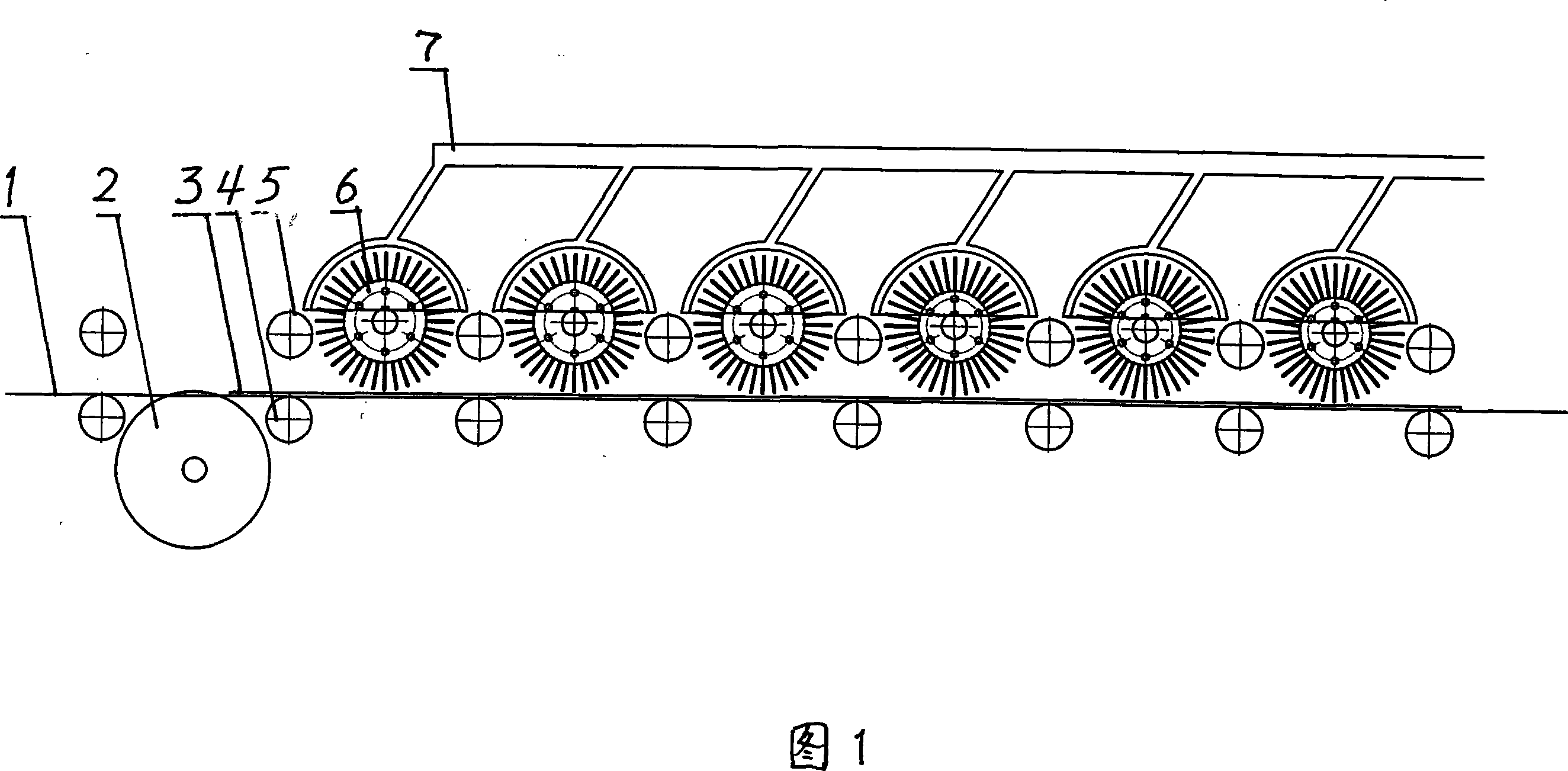

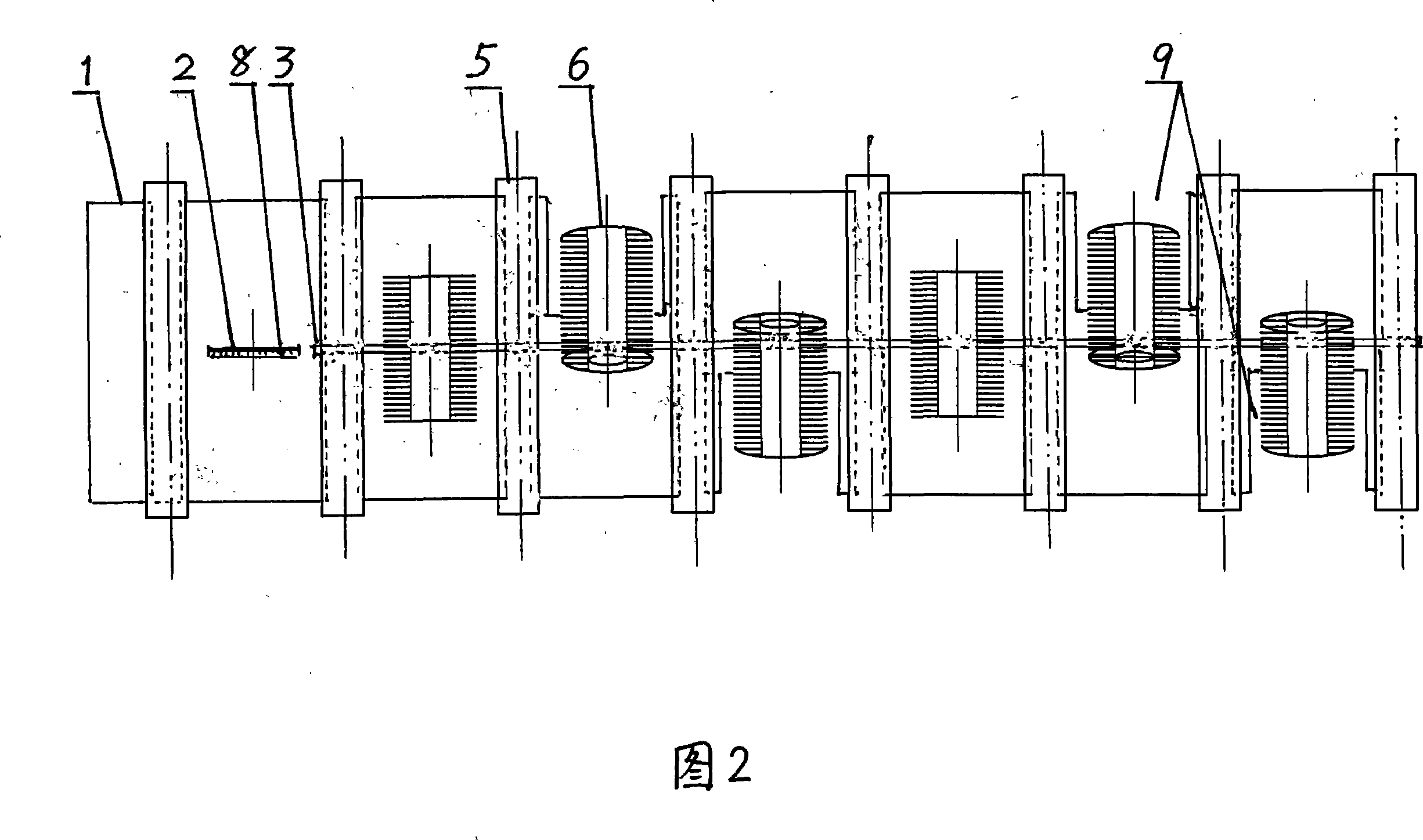

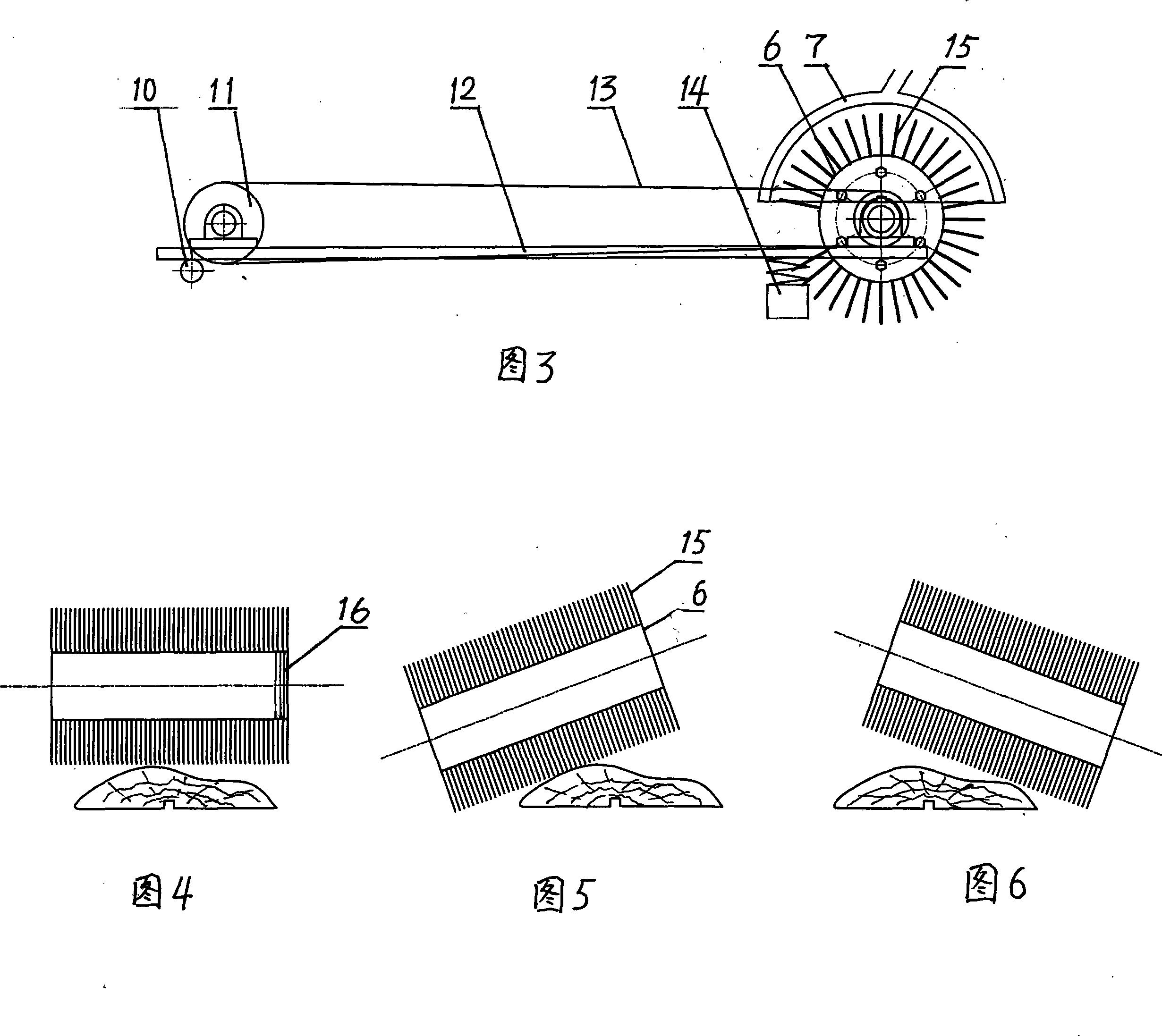

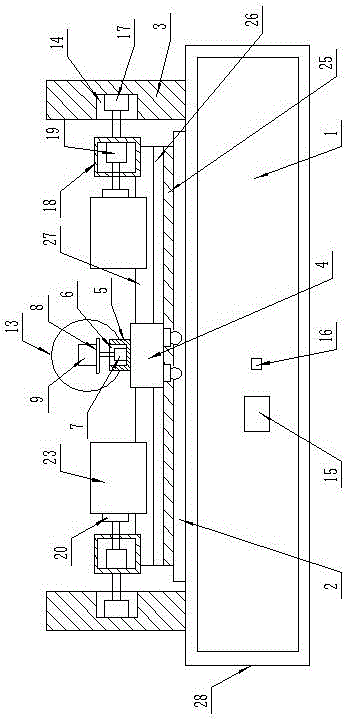

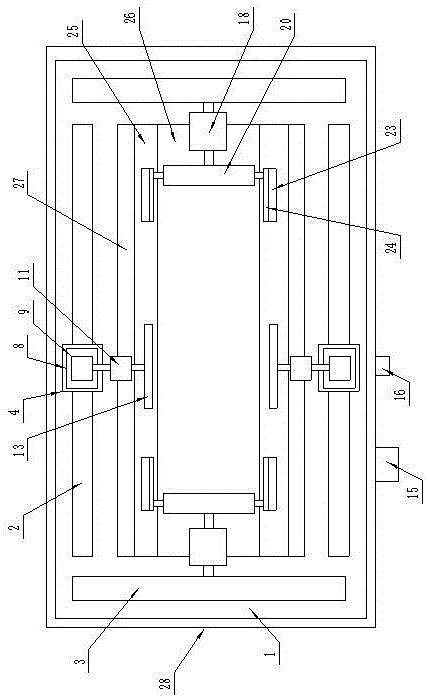

Method and device for removing wood side plate tegument

InactiveCN101209561ADifficulties in resolving shortagesQuick peelTree debarkingThick plateBiomedical engineering

The invention provides a method and a device used for removing the skin of a wood-edge plate, consisting of a power, a transmission part, a frame, a workbench (1), feeding mechanisms (5, 4) and a cutter. A slotting saw (2) is arranged on the lower left of the workbench; a saw kerf (8) and a positioning track (9) are arranged in the centre of the workbench in longitudinal direction; the positioning track (9) is provided with flexible strip cutter rollers (6) in horizontal state, left inclined state and right inclined state; a dust hood (7) is arranged above the roller (6). The device is specially used for removing the skin of a wood-edge plate; classification and pre-disposal are carried out to the edge plate in advance when the skin is being removed; the excessively thin plate is not processed and the skin of the plate with non-uniform thickness is removed by section on which the thin plate is cut and the thick plate is preserved; the whole skin of a thicker plate with is removed; coarse and hard knurr is cleaved by the saw and iron nails are pulled out. By adopting the device to remove the skin of a wood-edge plate, the invention has the advantages of sufficiently taking the wood-edge plate as the raw material of integration material, solving the lack of raw wood, removing the skin quickly, cleanly and thoroughly and not damaging the xylem.

Owner:ZHEJIANG FORESTRY UNIVERSITY

Tree trunk skin removing machine and skin removing method

The invention discloses a tree trunk skin removing machine and a skin removing method, relates to the field of tree trunk skin removing equipment, in particular to the tree trunk skin removing machine. The tree trunk skin removing machine comprises a T-shaped bottom plate. The tree trunk skin removing machine is characterized in that a supporting shaft is fixed to one end of the upper side of theT-shaped bottom plate, the upper side of the supporting shaft is hinged to one end of a U-shaped rod, and a first top block is in threaded connection with the other end of the U-shaped rod. The two opposite ends of the upper side of the T-shaped bottom plate are separately and fixedly connected with two ends of a cross rod of a T-shaped groove rod through an L-shaped bracket, a T-shaped sliding rail is arranged on the cross rod of the T-shaped groove rod, a first T-shaped sliding block is arranged in the T-shaped sliding rail, a first cylinder rod is fixed to the middle of one side of the first T-shaped sliding block, and the first cylinder rod penetrates through the T-shaped sliding rail, a first sliding groove at the lower end of a straight groove rod and a clamping groove at the upper end of an H-shaped groove rod. The tree trunk skin removing machine can realize the skin removing of tree trunks and smashing of tree skins.

Owner:张小汴 +1

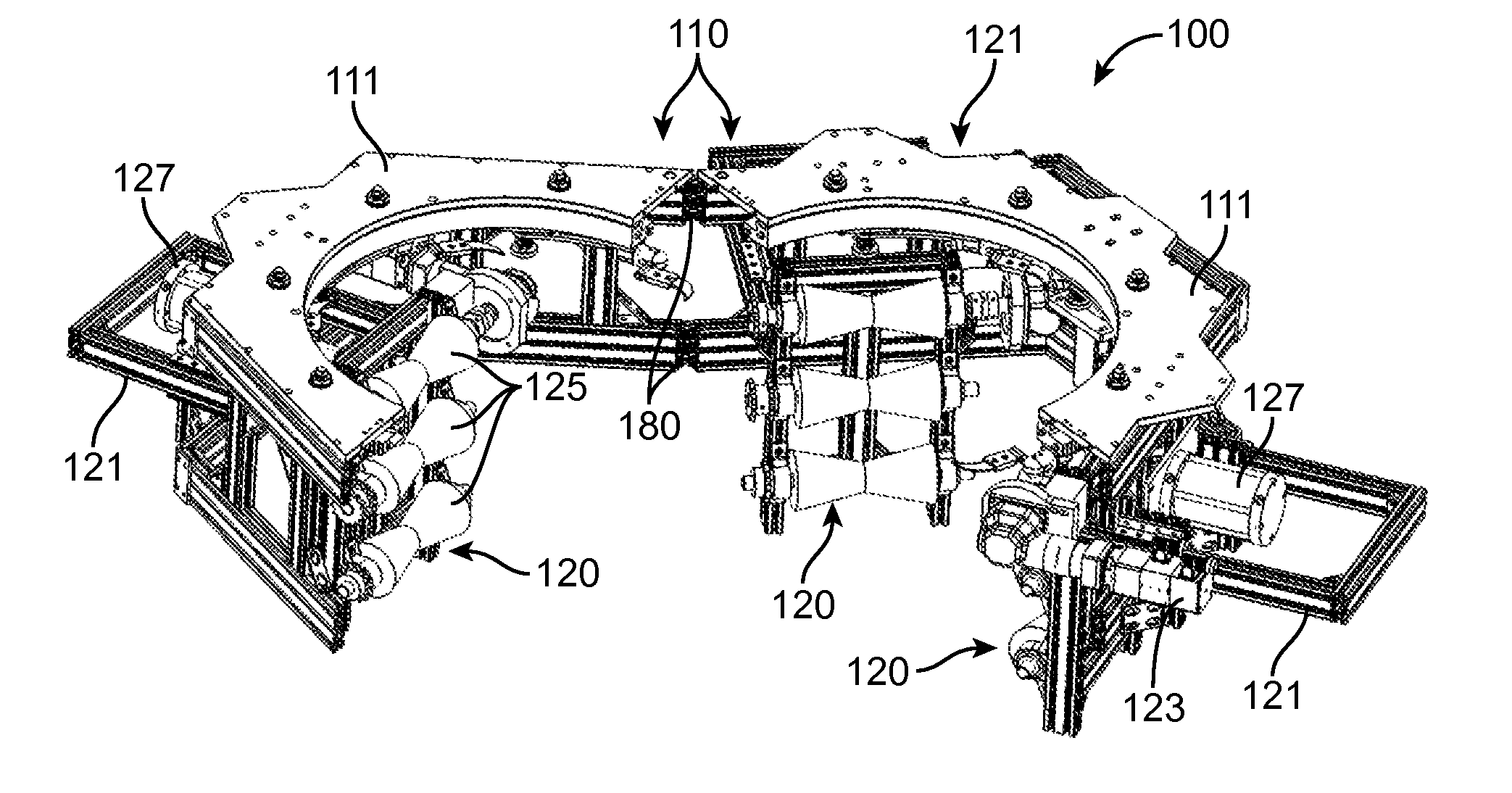

Debarker systems with adjustable rings

ActiveUS20120305137A1Allow flexibilityPressure in the actuation devices can be decreased or increasedTree debarkingAir cellEngineering

Apparatuses, systems, and methods for debarking logs are shown and described. The disclosed embodiments can be easily adjusted to process different logs. Air-cell rings provide for a wide range of force gradients to process both large and small diameter logs. The rings include force gradient adjustment mechanisms configurable to provide different force gradients to process logs.

Owner:NICHOLSON MFG

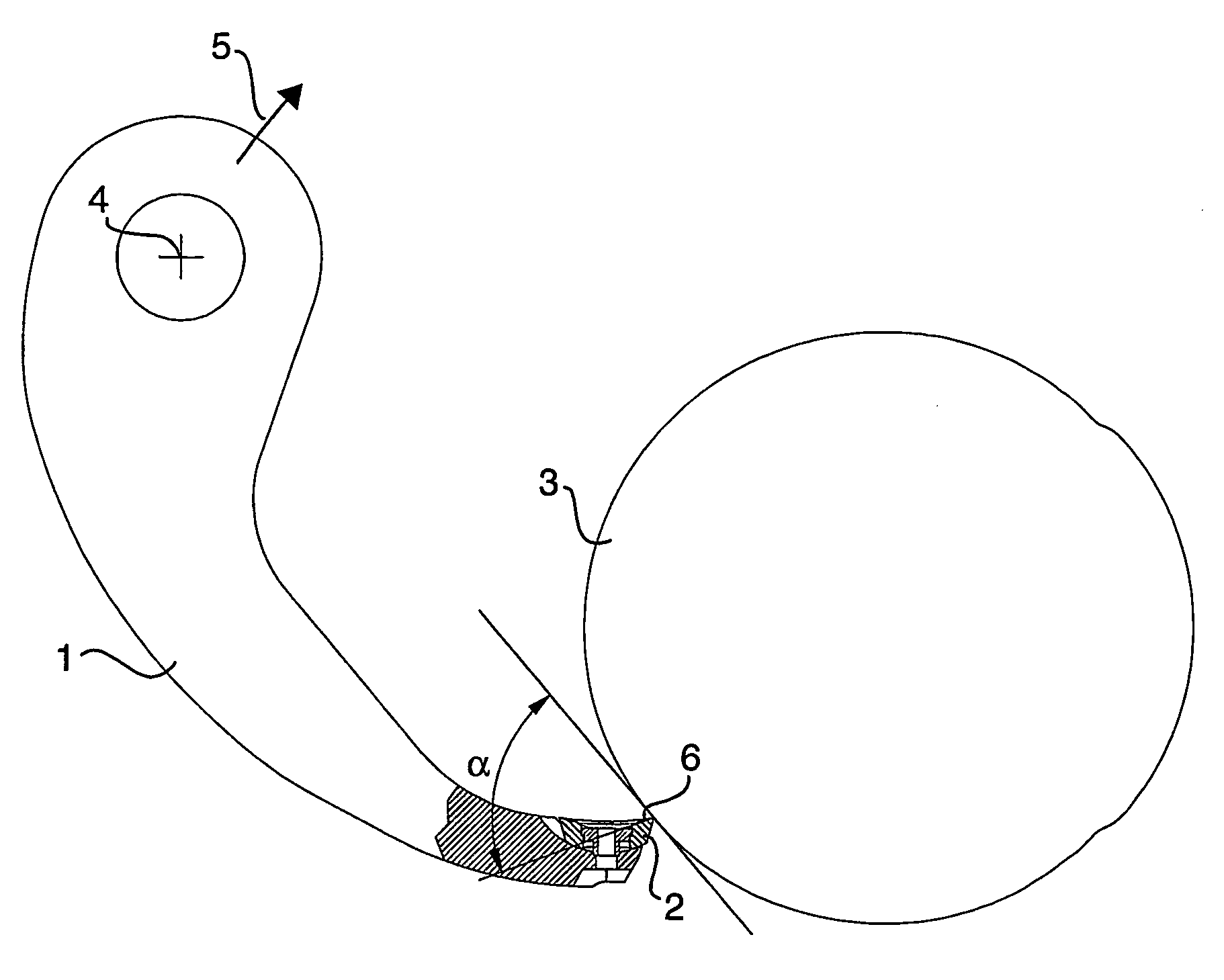

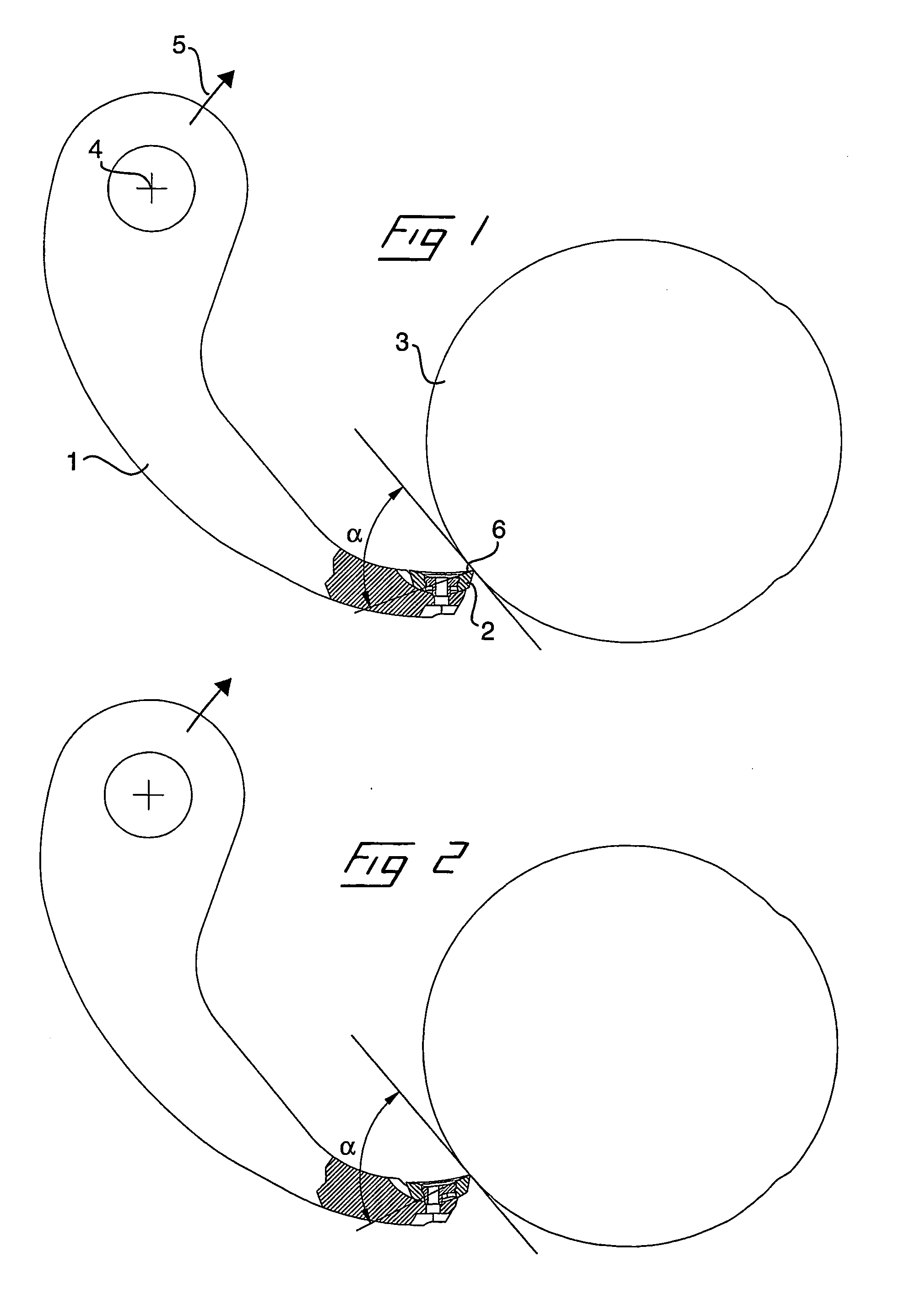

Debarking blade arrangement

A debarking blade arrangement is carried by a frame of a tree harvesting head and includes a fixed knife segment that cooperates with three articulated knife segments carried by each of right- and left-hand, articulated debarking arm assemblies which are disposed on opposite sides of a tree stem feed axis. Each arm assembly includes a rear arm section that carries a first knife segment, an intermediate arm section and a front arm section that carries second and third knife segments and is yieldably biased toward the intermediate arm section so as to dispose the second and third knife segments for engagement with a tree stem. A hydraulically-powered arrangement is coupled to each arm assembly for selectively pivoting the entire assembly about a fixed axis and for pivoting the intermediate and front arm sections relative to the rear arm section for keeping the knife segments in debarking engagement with the stem.

Owner:DEERE & CO

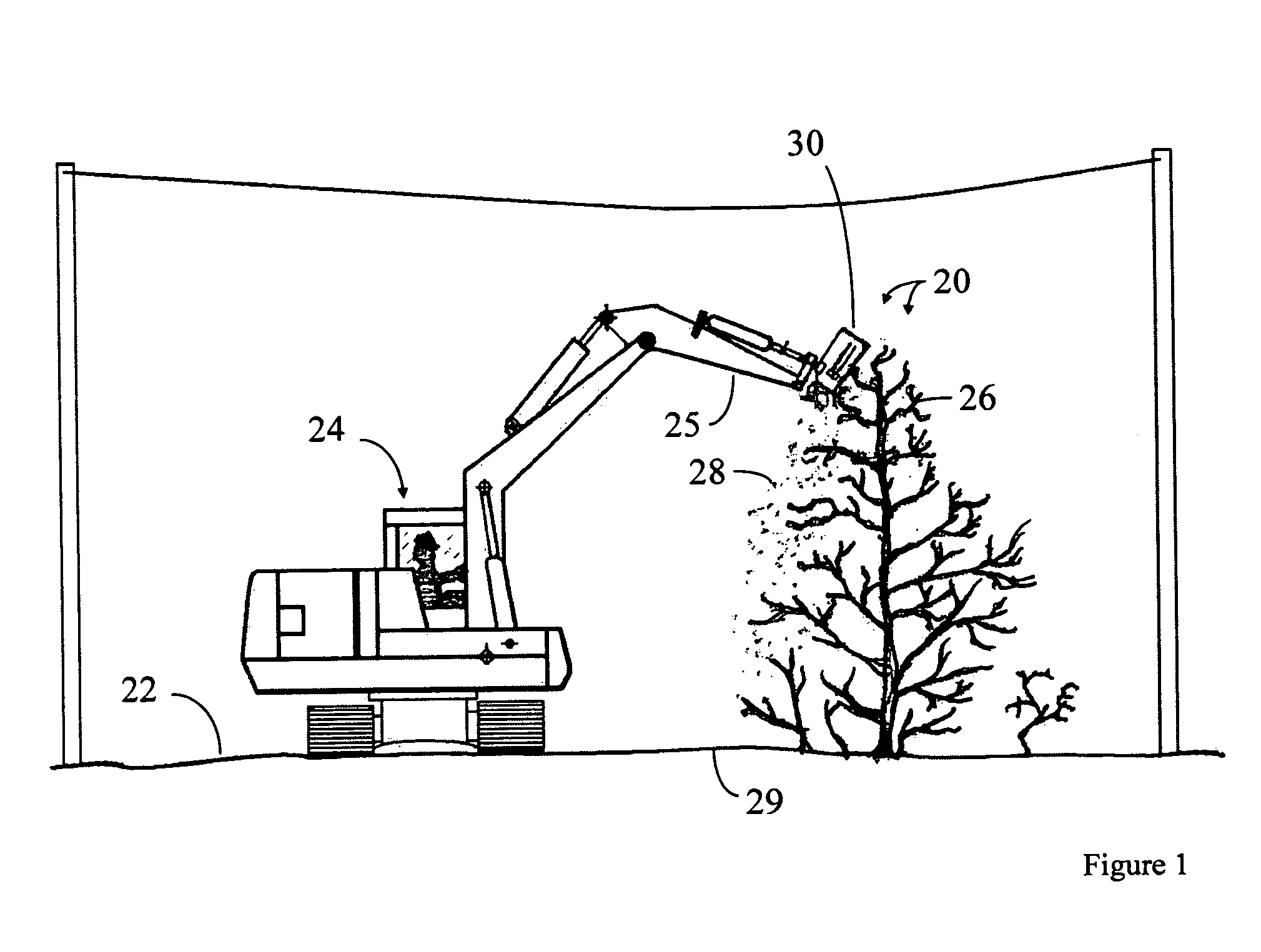

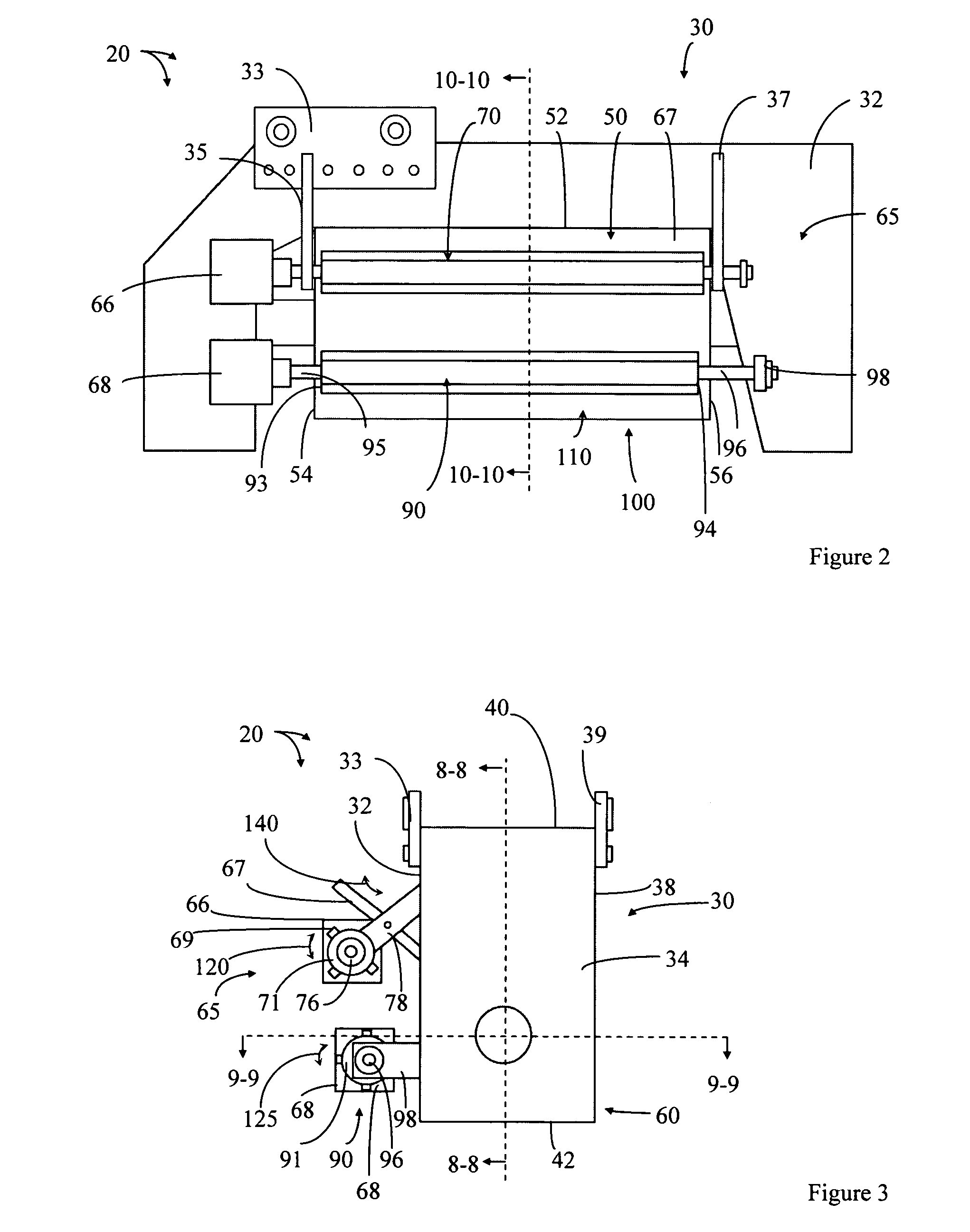

Brush cutter

InactiveUS7373960B1Maintain visual clarityPromoting safety of operatorTree debarkingMulti-purpose machinesEngineeringRotating drum

The invention provides a brush cutter and chipper that attaches to the end of an articulating arm or boom on equipment. The cutter may utilize existing hydraulic power and controls. The cutter includes a housing with external feed assembly that feeds material through a gate to an internal cutting assembly. The feed assembly has a tensioned upper roller that may move arcuately and a stationary lower roller. The rollers preferably rotate oppositely and each has peripheral cleats to facilitate feeding. The housing mounts an internal rotating drum that may be rotationally linked with the rollers. The drum has a cutting surface, which may be a peripherally wound toothed chain, that cuts entering materials smaller pieces. The drum rotates against the bottom side of the fed material to insure that the material is cut into small pieces. The small pieces exit through a chute at the bottom of the housing.

Owner:WESTBROOK MARK KEVIN +1

Methods for making improved strand wood products and products made thereby

An overall method of making engineered strand wood products in relation to a number of different possible criteria is provided. Such a method may involve any combination of different screening procedures to determine the best wood sources from which individual strands may be prepared. Such screening procedures may include initial determinations of certain physical characteristics of individual logs, further or initial determinations of certain physical characteristics of portions of sawn logs, further or initial determinations of certain physical characteristics of individual strands, and any combinations thereof. Additionally, after the initial physical characteristic sorting is completed, optionally the wood may be cut into uniformly sized and shaped strands for incorporation within a target strand product. Still further, such strands, in substantially uniform size and shape, as well as substantially uniform physical characteristics, may then be incorporated into a target strand product in specific predetermined configurations. Such various possible combinations of screening procedures and / or selective stranding processes results in strand products (boards, lumber, and the like) of improved properties over previously made strand products. Thus, encompassed within this invention are processes involving each of these procedures either individually or in combination with other sequential processes for the production of desired strand products.

Owner:HUBER ENGINEERED WOODS

Log debarking machine and method

InactiveUS7243693B1Quality improvementExtend your lifeTree debarkingEngineeringMechanical engineering

Owner:MELLOTT MFG

Log peeling device

ActiveCN106272823AMaintain personal safetyEasy to operateTree debarkingLinear motorMains electricity

The invention discloses a log peeling device which comprises a workbench. A set of sliding rails are arranged on the upper surface of the workbench. Vertical mounting boards are arranged on the upper surface of the workbench and located on the two sides of the set of sliding rails. Each sliding rail is provided with an electric cart, and a mounting block is arranged on the upper surface of each electric cart. A first circular groove is formed in the upper surface of each mounting block. A first linear motor with the upward telescopic end is arranged in each first circular groove. A controller is arranged on one side surface of the workbench. An electric supply joint is arranged on one side of the controller. The power wiring terminal of the controller is connected with the electric supply joint through a wire. The input end of the controller is connected with the electric carts, the first linear motors, the second linear motors and a rotary motor through wires. The log peeling device has the beneficial effects that automatic turning and cutting processing modes are achieved, the working efficiency is high, personal safety of workers is maintained, and the log peeling device is convenient to use and high in novelty.

Owner:徐州博创建设发展集团有限公司

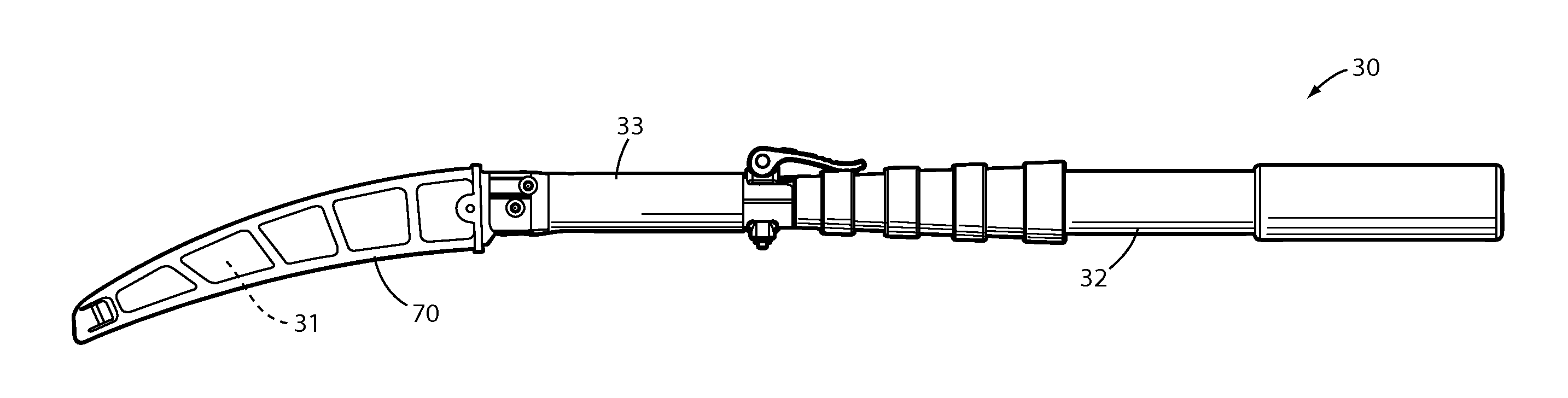

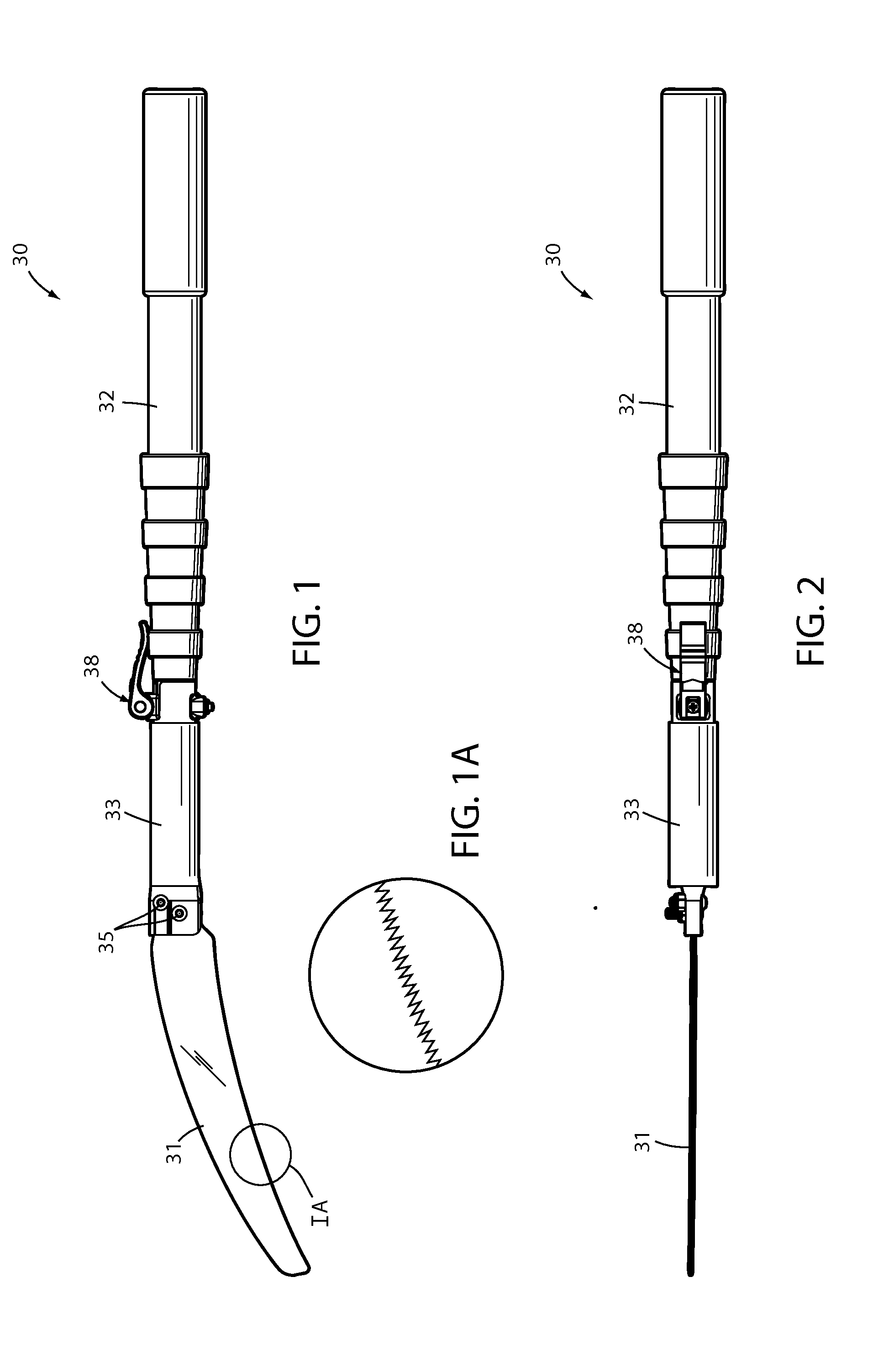

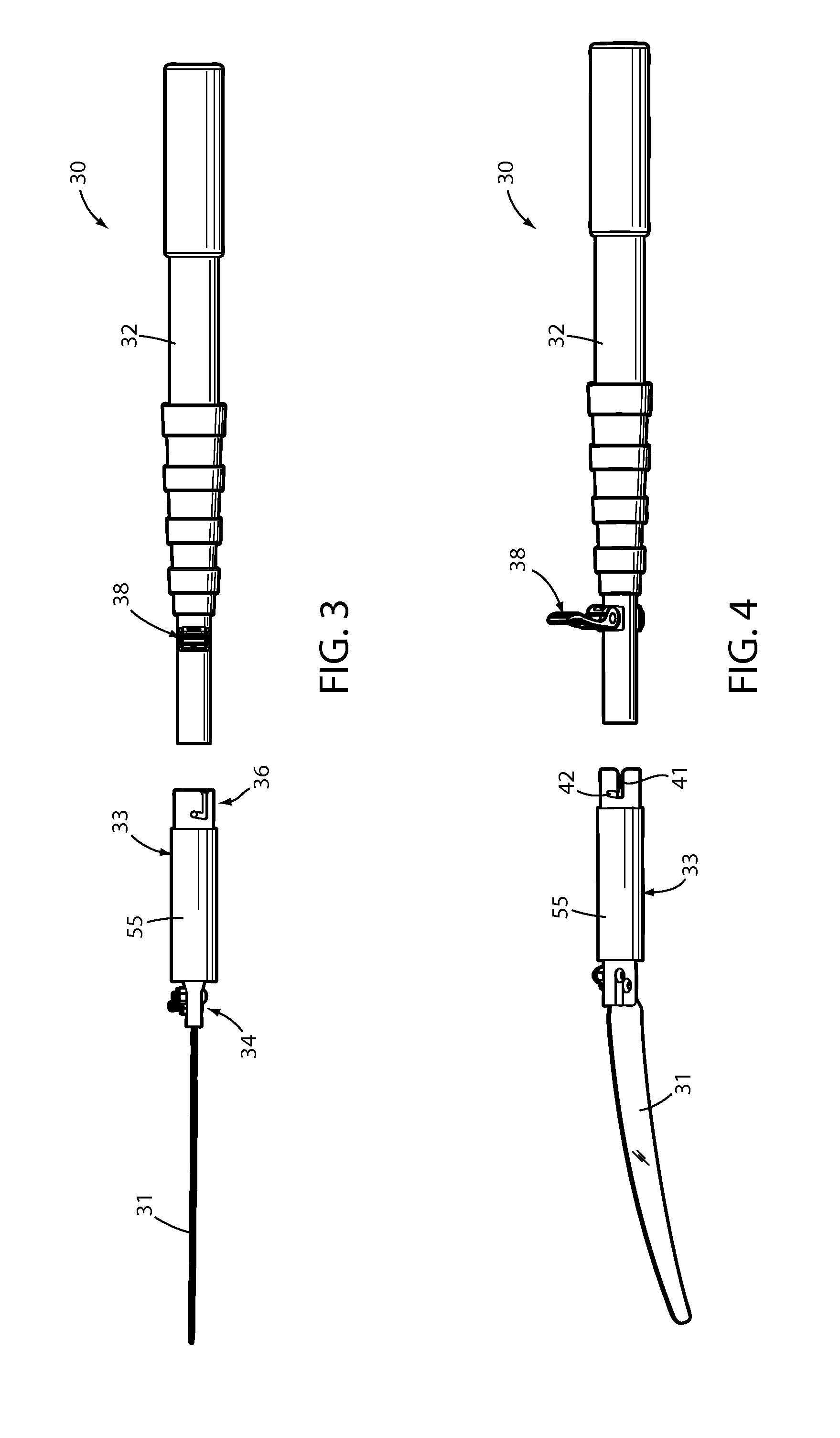

Light pole saw

A pole saw apparatus includes a saw blade, a pole, and a tubular adapter connecting the saw blade to the pole. The adapter includes an obround blade-receiving end that stably telescopingly engage sides of the blade-receiving end, with bolts fixing the blade on the adapter. The adapter also includes a pole-engaging end that is cylindrically shaped to telescopingly engage the anchoring end of the pole. A friction clamp includes a transverse shaft extending through the pole, the shaft being shaped to slide into longitudinal slots in the pole-engaging end of the adapter and then rotate into circumferential slots where it is not longitudinally removable. A rotatable cam handle on the clamp is manipulated to create circumferential friction to hold (or release) the adapter on the pole. The blade, adapter and pole align along a common centerline for robust and balanced use.

Owner:WICKED LLC +1

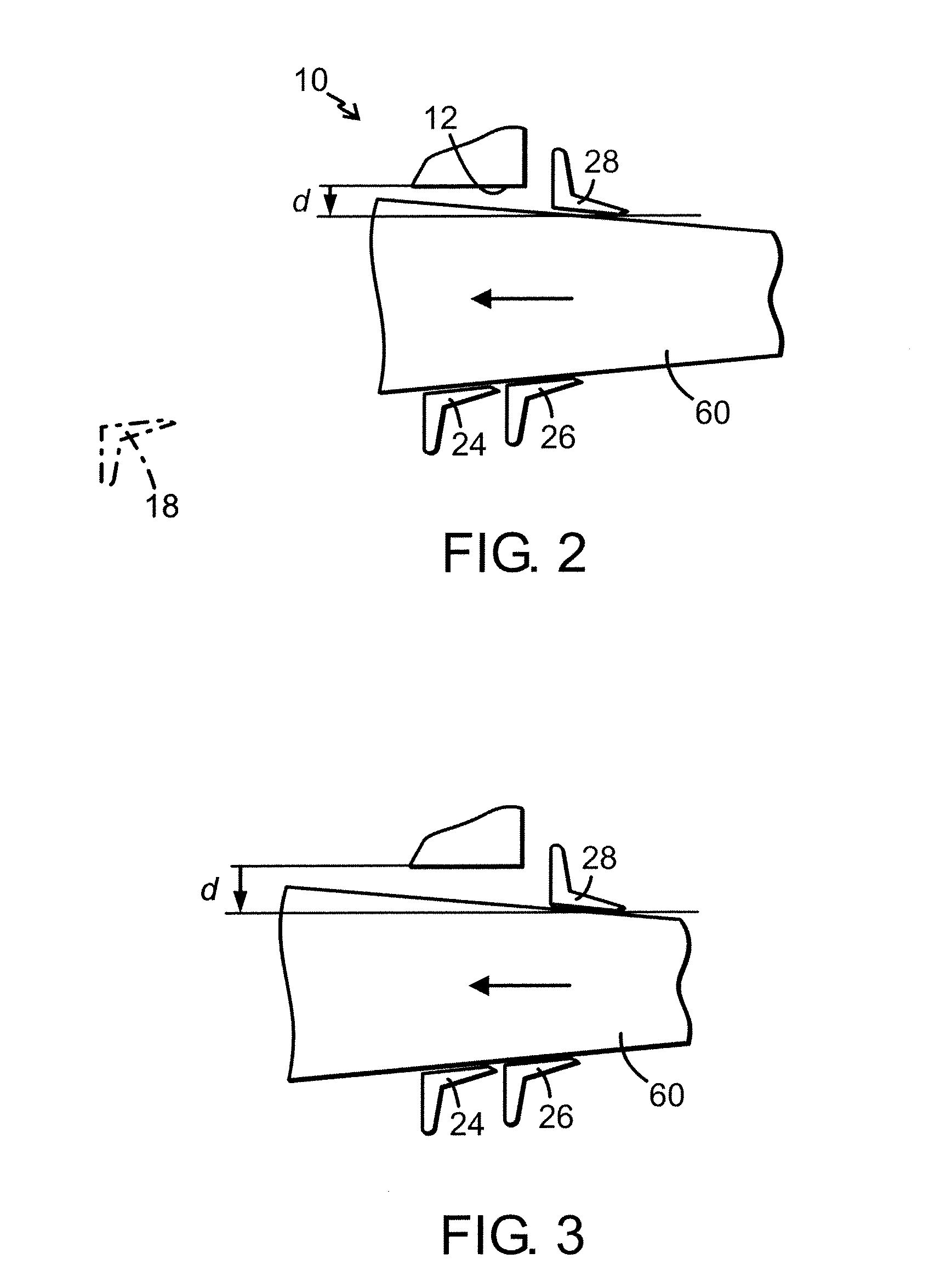

Tree delimbing method and device

Method and device for delimbing a tree trunk (60) in a compliant gripping state defined by a set of limbing knives (18, 24, 26, 28) enclosing the trunk. The limbing knives are repeatedly adjusted through a control unit (46) for adaption of the gripping state to a varying thickness of the trunk when the trunk is advanced between the knives for the delimbing of the trunk. The invention comprises entering a desired compliance (D1) of the gripping state in the control unit (46), detecting an actual compliance (d) of the gripping state, and performing each adjustment of the limbing knives via the control unit until the actual compliance (d) corresponds to the desired compliance (D1).

Owner:LOG MAX

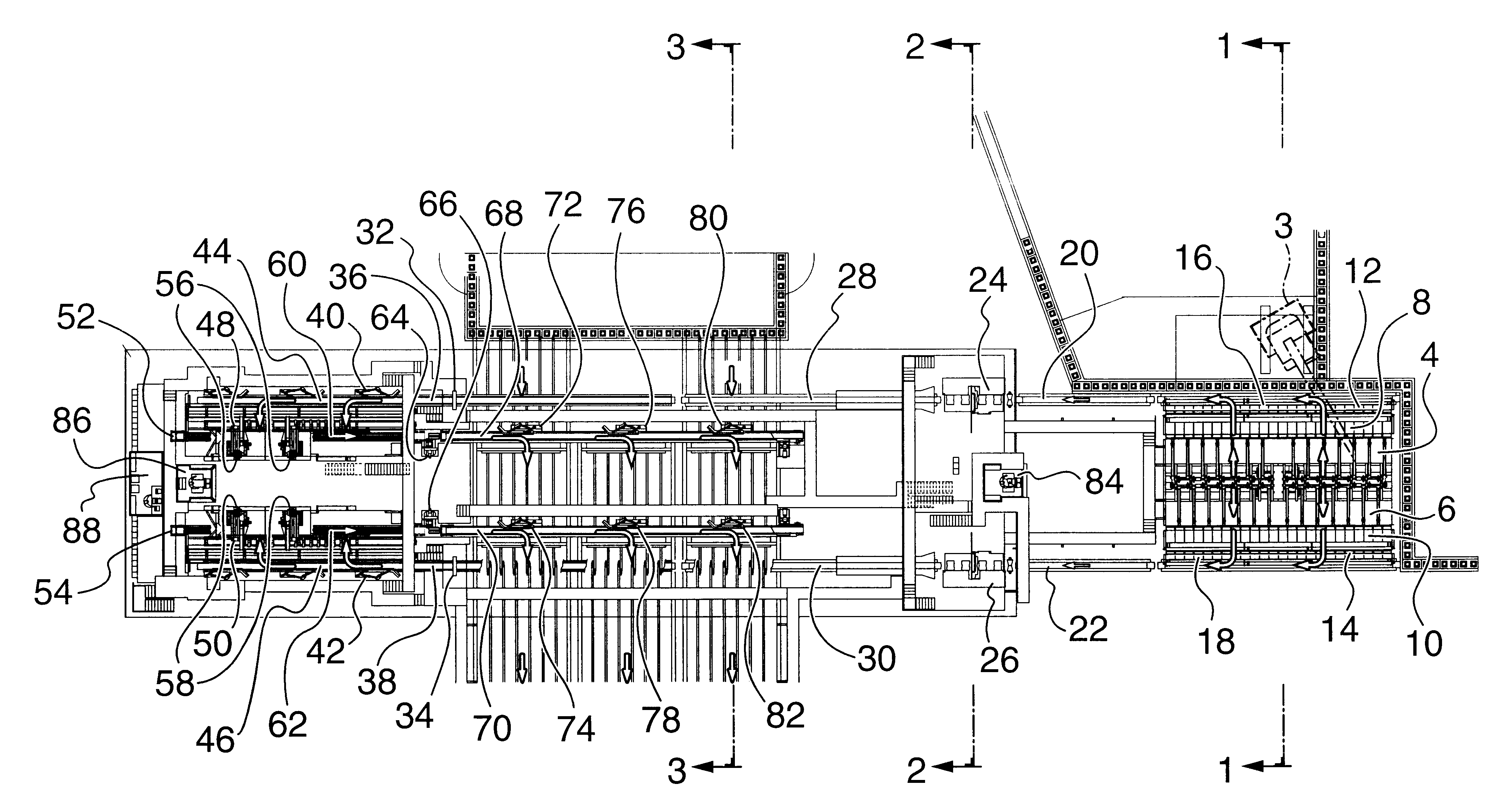

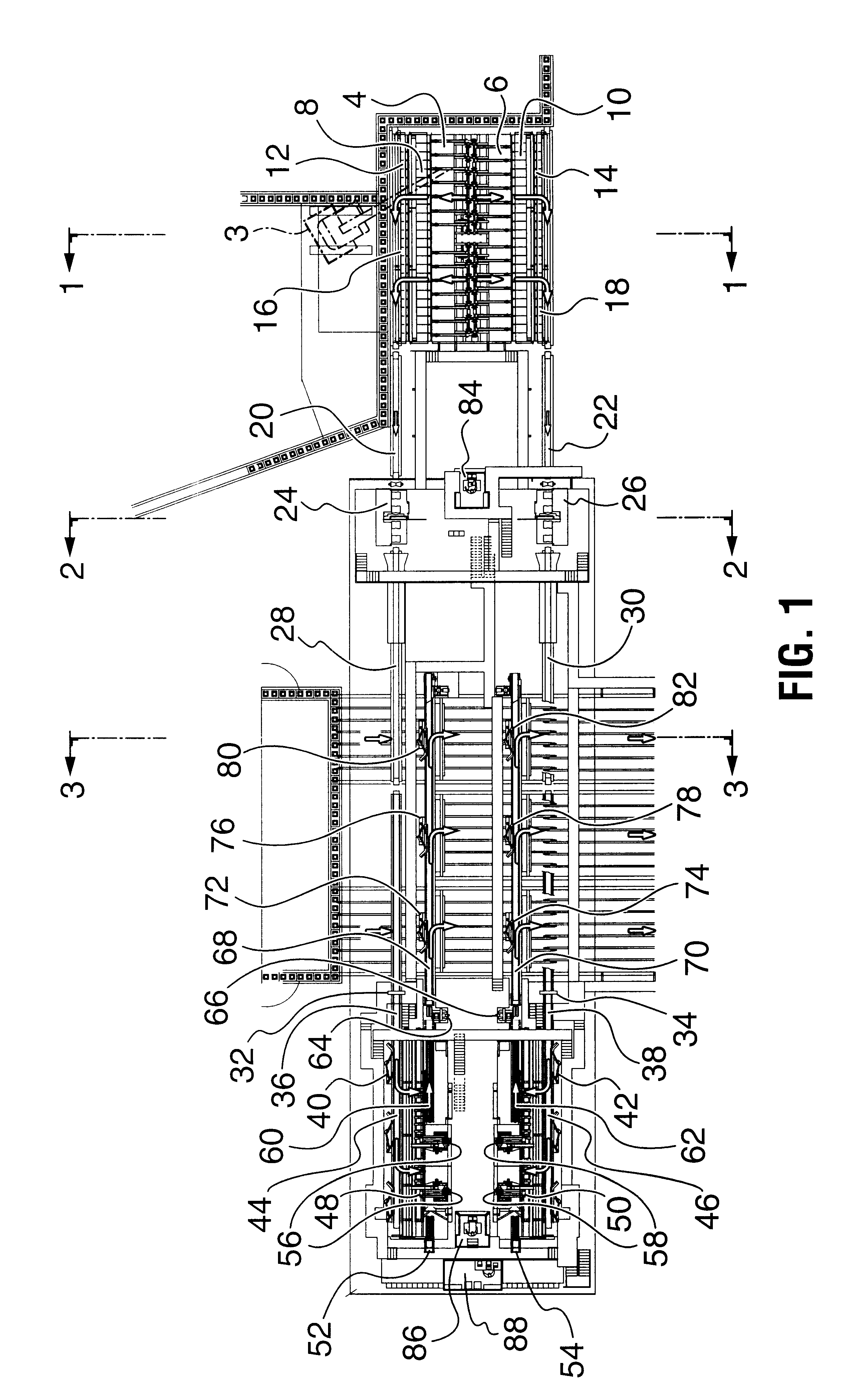

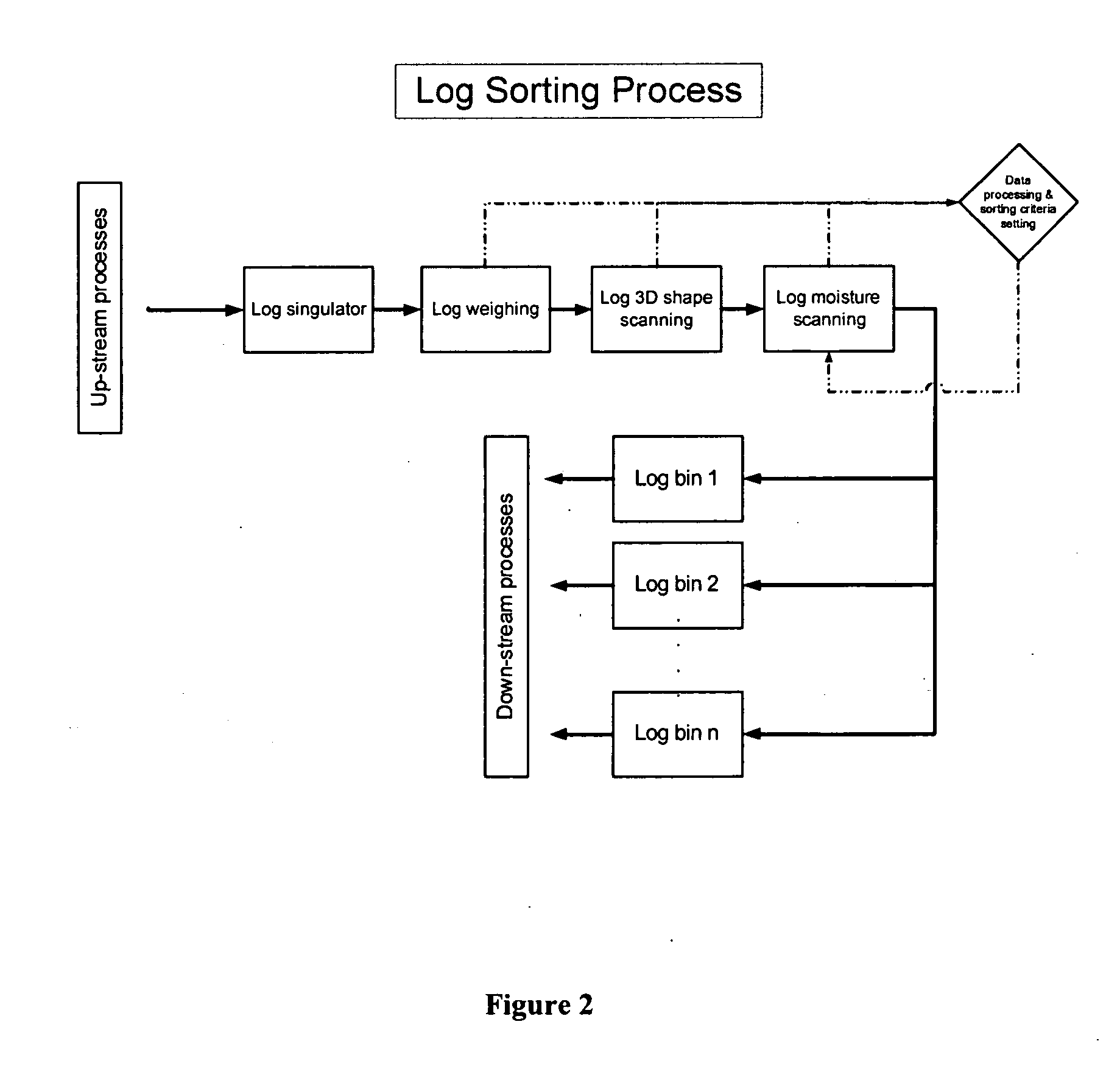

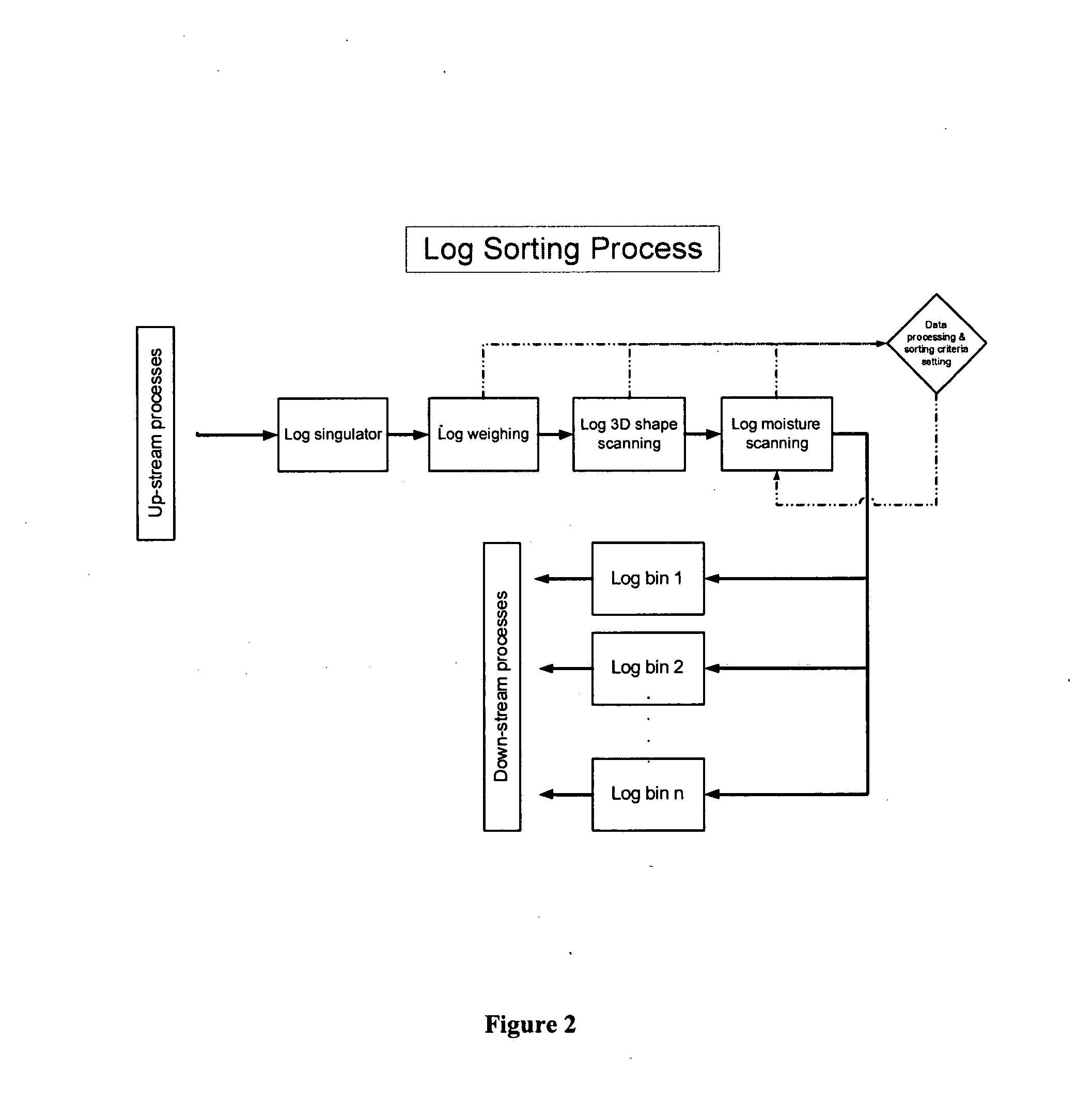

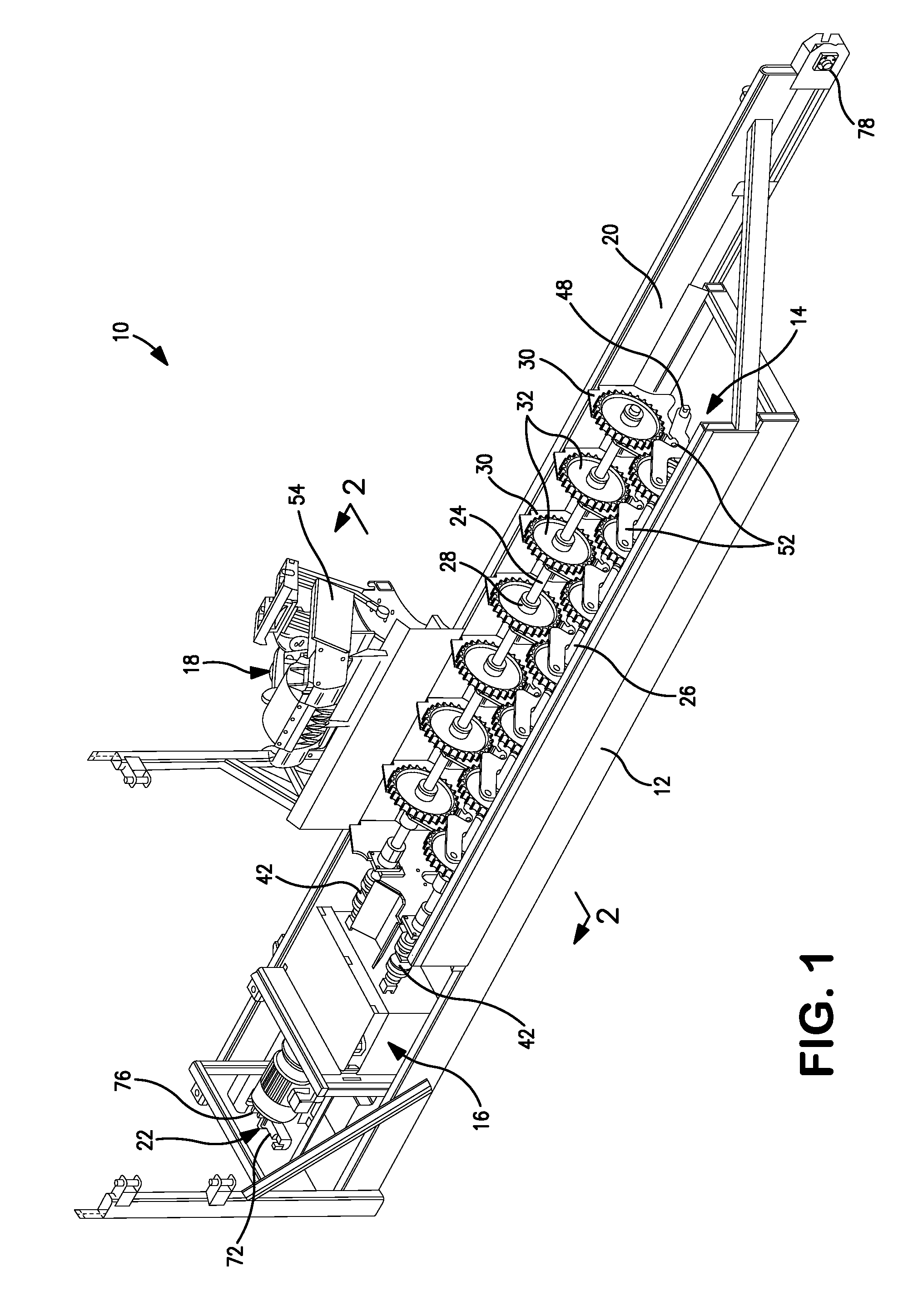

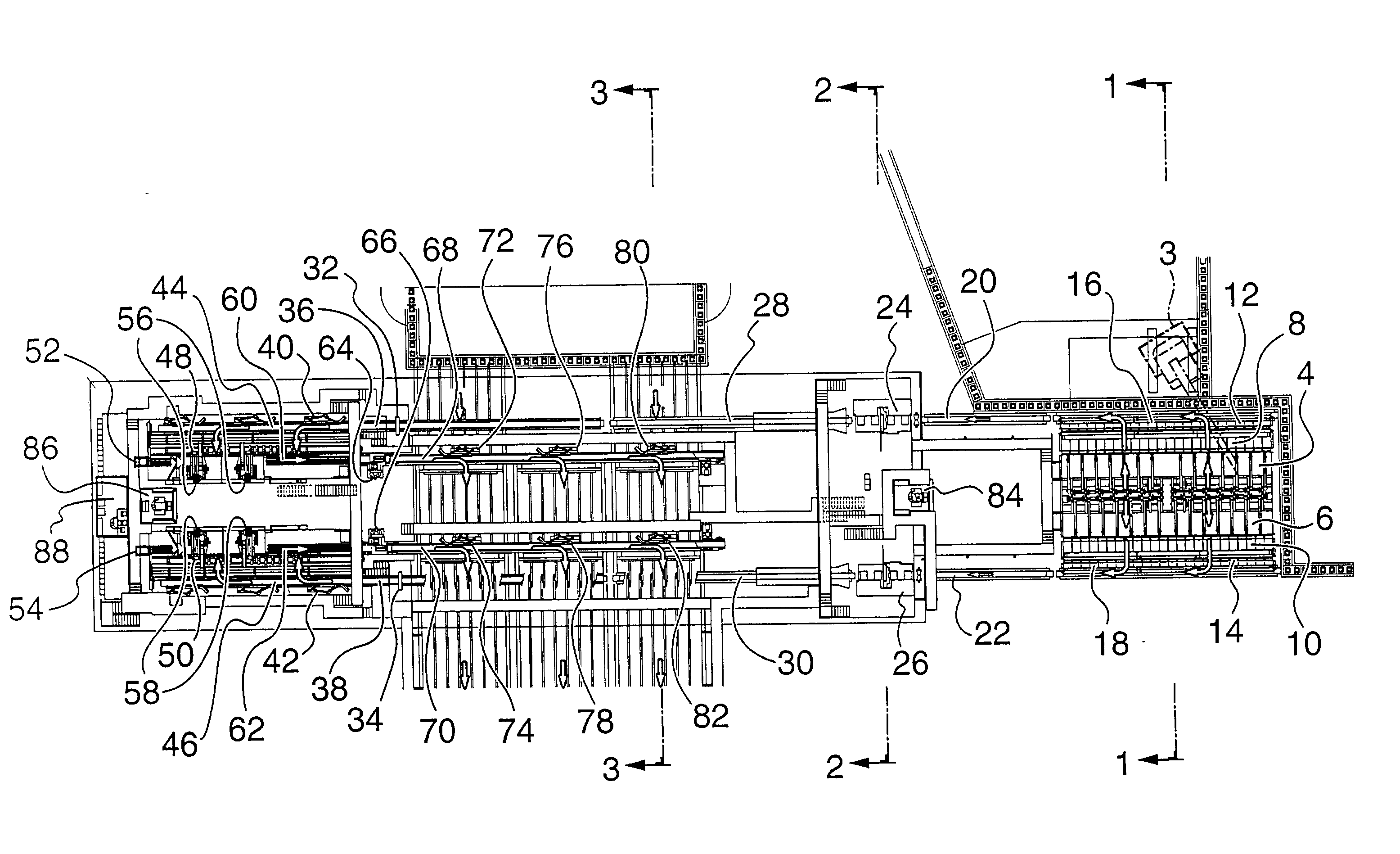

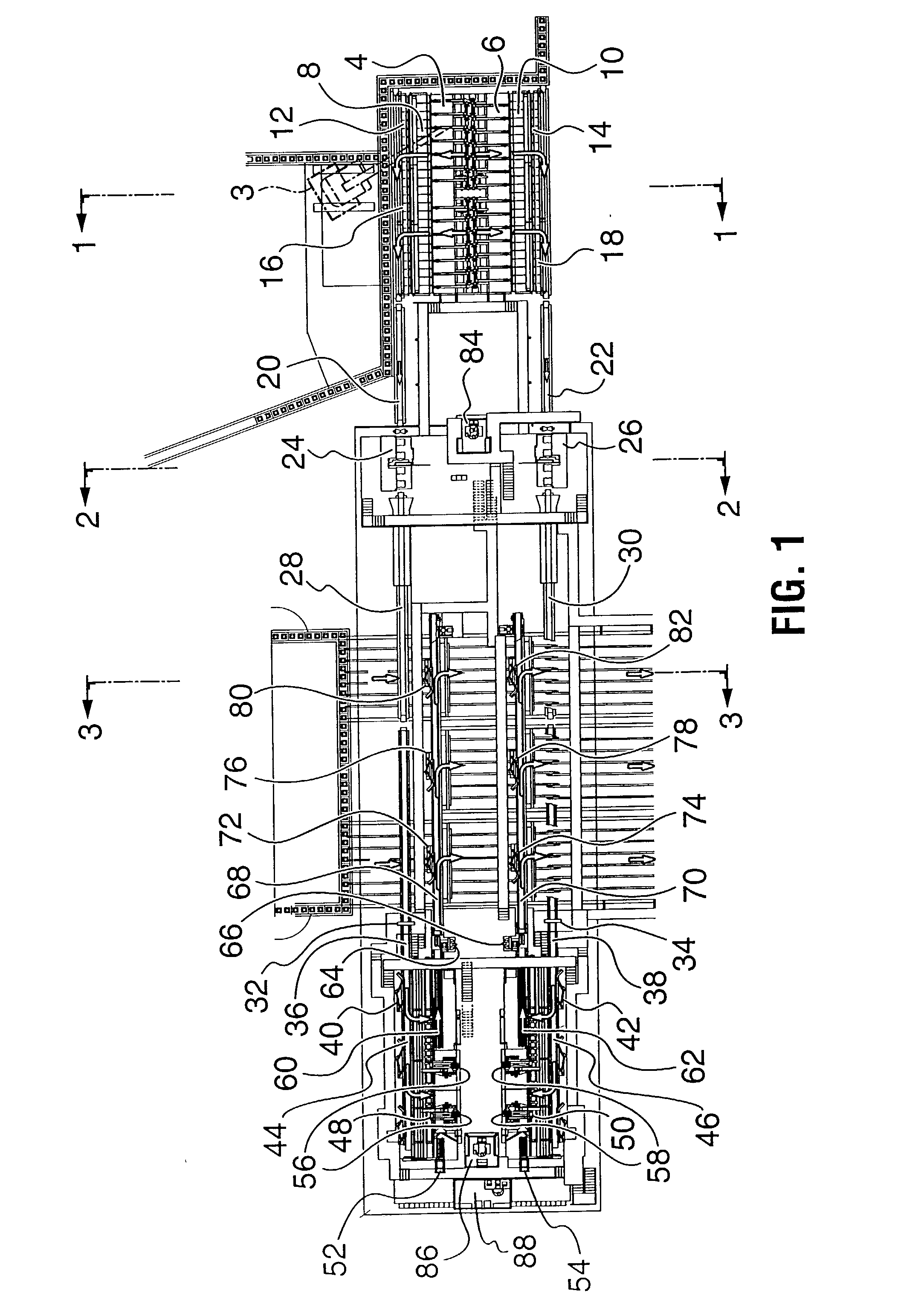

Method and apparatus for singulating, debarking, scanning and automatically sawing and sorting logs into lengths

InactiveUS20030029519A1Reduce stepsMinimize travelAdjusting equipmentFeeding apparatusFiberEngineering

A log handling and cutting system which cuts logs into lengths, and allows for maximum use of fiber. The system includes equipment for singulating the logs, optimally removing the bark from the logs, scanning the true log image, cutting the logs to length, and sorting the cut logs arranged in a sequence of coupled operations. The logs are singulated using a dual quadrant singulation system to provide maximum singulation reliability, thereby allowing a single operator to attend to this process. Once singulated, the logs are fed automatically into a debarker where the diameter and volume are scanned and debarker-operating parameters are set for optimum bark removal. The log is then scanned, tree length, using a unique scanning system, which determines the true image of the log. This enables the determination by computer of the optimum bucking solution of the log as well as a proper sorting of the optimum random lengths. The saws are adjusted in response to the computer solution and the log is positioned by a positioner according to a computer generated reference datum. This results in the log being positioned for cutting to the optimum random lengths. A command signal is sent from the computer to the log sorting system, which tracks the position of the random lengths and allows them to be sorted to the appropriate sort storage bin.

Owner:WEYERHAEUSER CO

Tree pruning apparatus

Owner:AUST PACIFIC FOREST MANAGEMENT

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com