Method and device for removing wood side plate tegument

A side board and xylem technology, applied in the field of removing wood side board bark and its device, can solve the problems of inability to peel off the bark and low efficiency, and achieve the effects of solving wood shortage, fast peeling and protecting forest trees

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

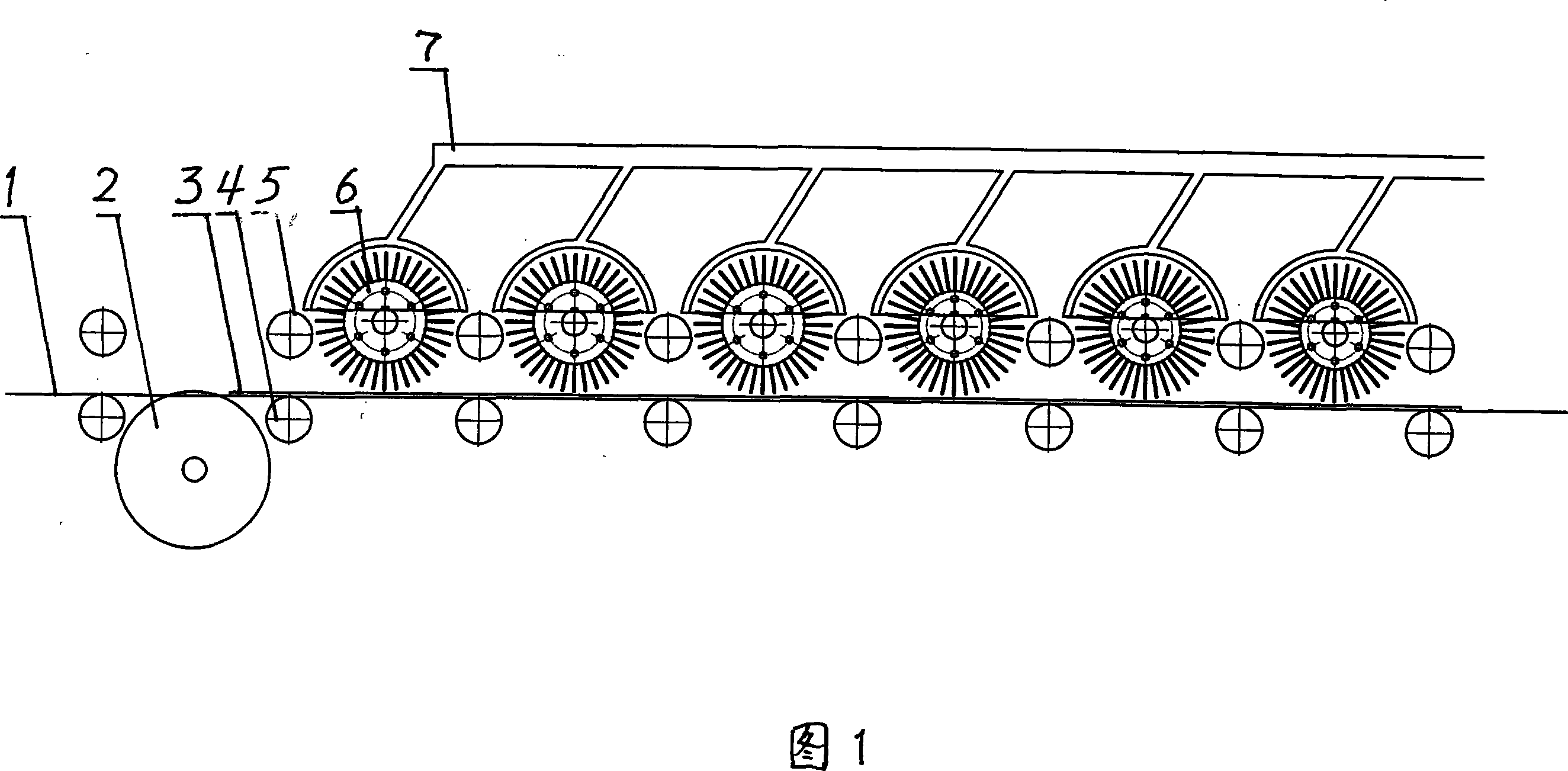

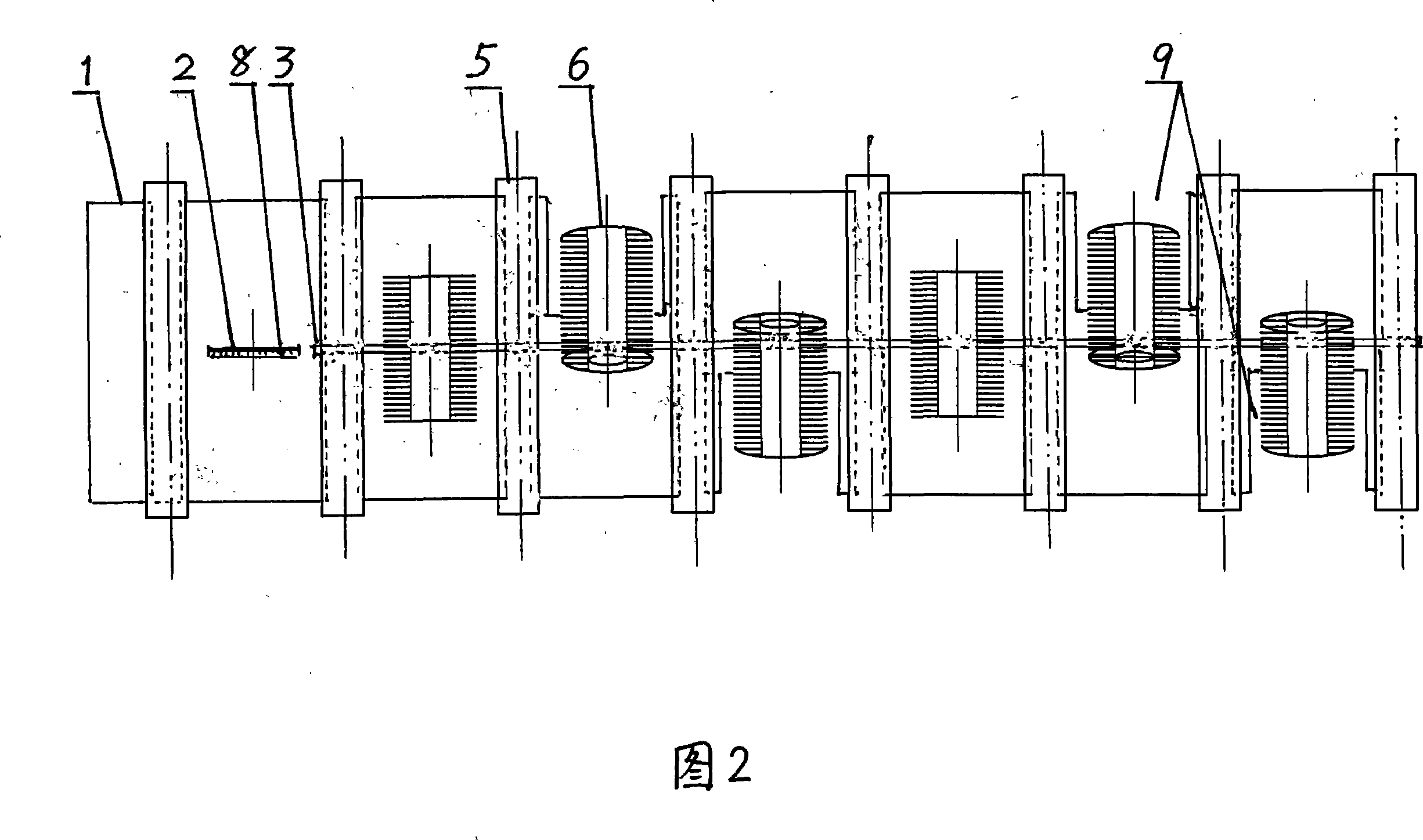

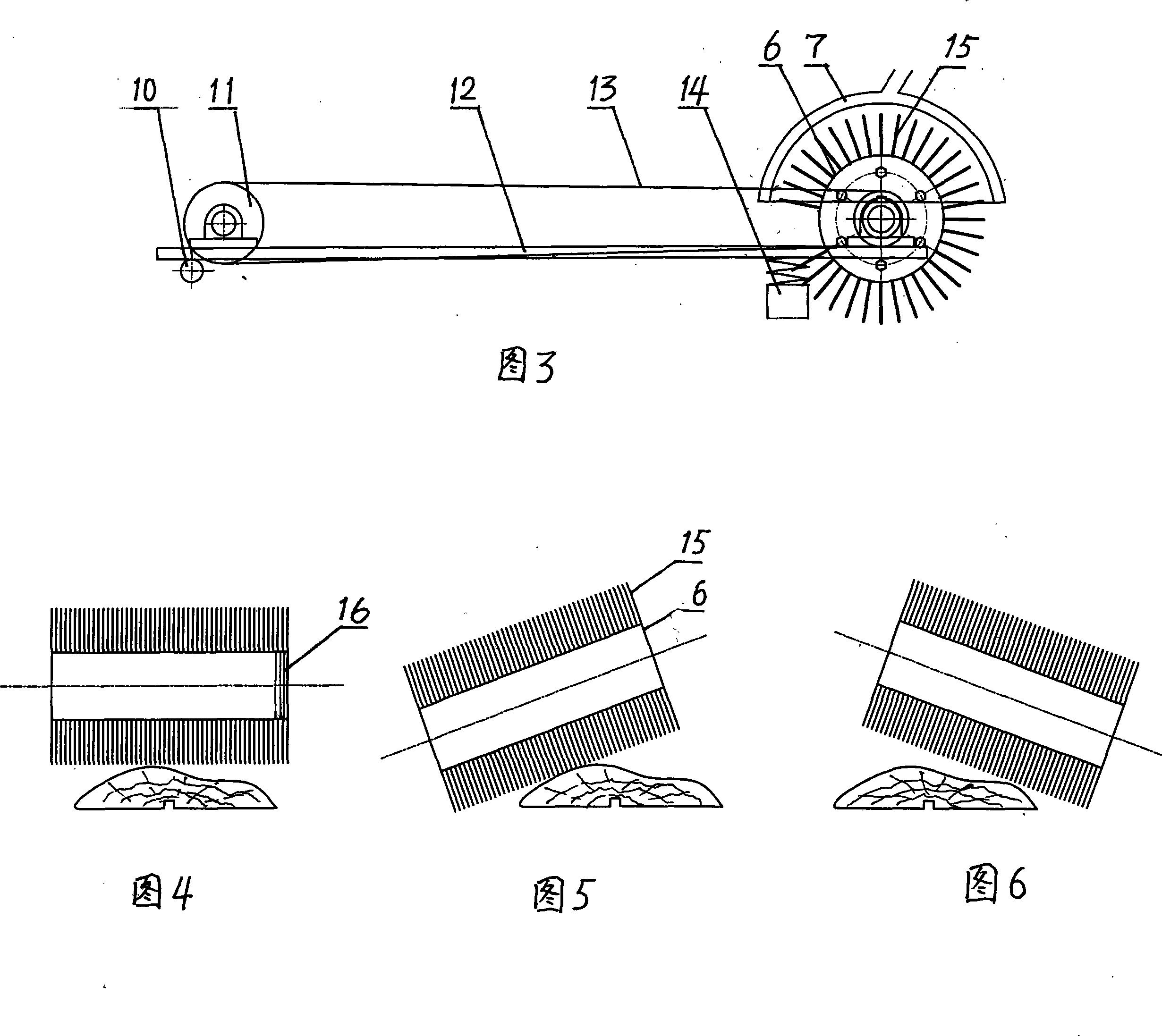

[0015] The present invention at first carries out sorting and pretreatment to the peeling of wood edge board, splits hard knots, pulls out iron nails, selects the thickness of xylem greater than 8mm, vertically puts on the workbench 1 with the plane down, on the upper feed roller 5 and Under the combined action of the lower feed roller 4, the side board is fed longitudinally, and a positioning groove with a longitudinal width of 3 mm and a depth of 5 mm is opened on the plane of the side board through the slotting saw 2, and as the side board continues to move forward, the positioning The groove is stuck on the positioning rail 3, and the side board will not move to the left or to the right. At the same time, the swing rod 12 descends along the axis 10 to contact the side board, and is fixed at a suitable height by the buffer positioner 14, and the motor 11 is started. The belt 13 drives the flexible strip knife group roller 6 to rotate rapidly, and the rollers in the three sta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com