Method and device for transverse feeding removing wood side plate tegument

A technology of horizontal feeding and side boards, which is applied in the direction of bark, wood processing equipment, manufacturing tools, etc., can solve the problems of low efficiency, bark cannot be peeled off, and damage to xylem, etc., to achieve fast peeling and solve wood shortages , the effect of protecting forests

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

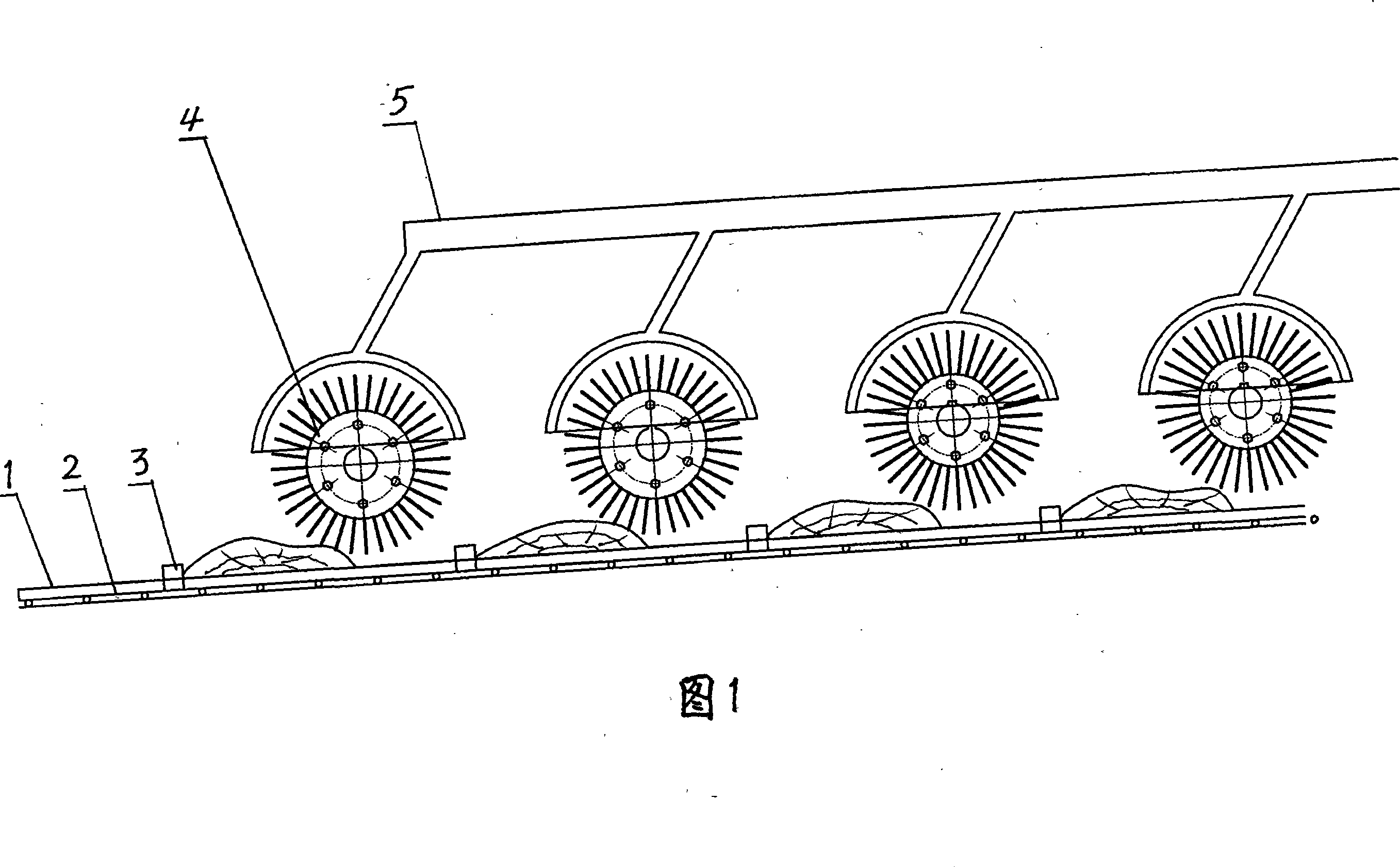

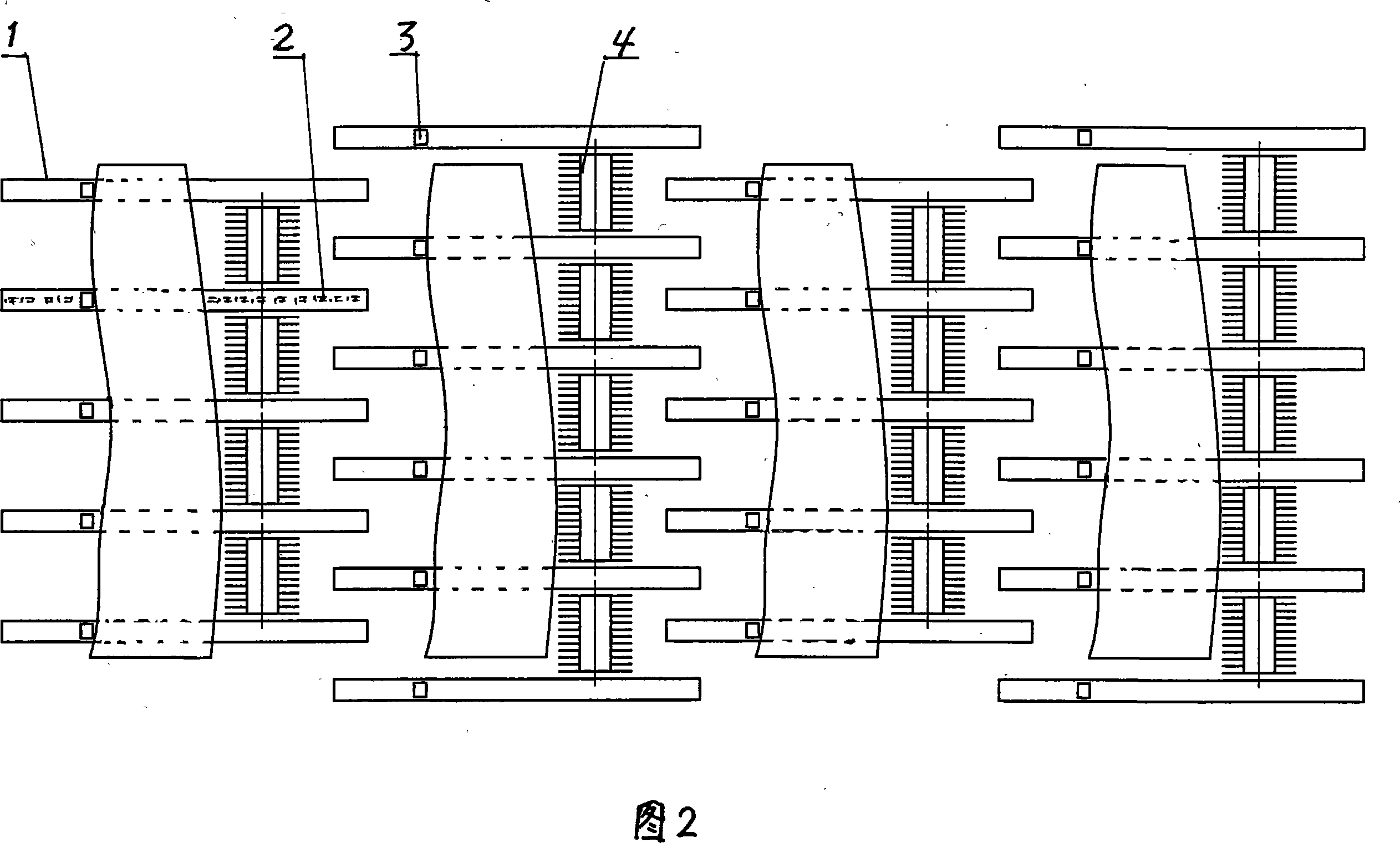

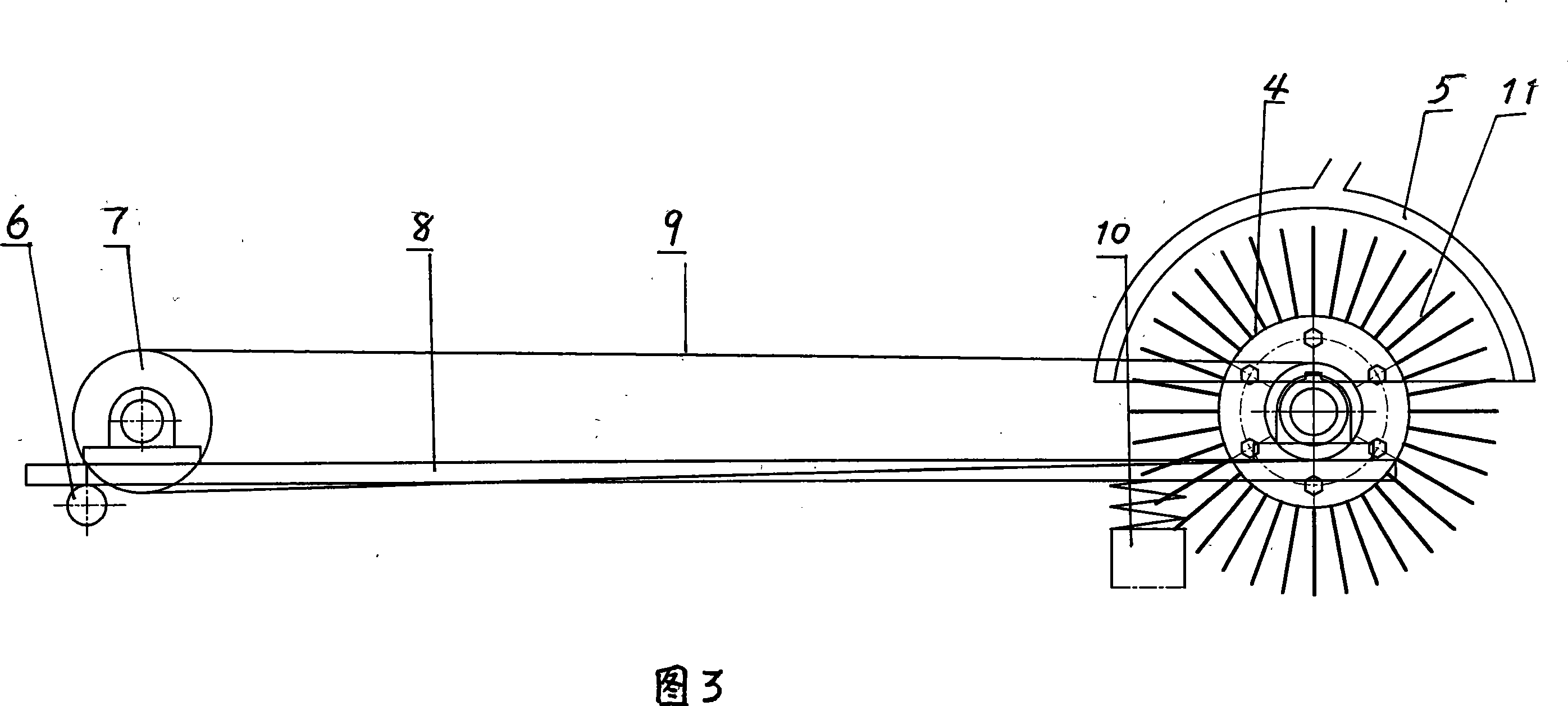

[0014] In the present invention, the peeling of the wooden side boards is firstly pretreated, the hard knots are split, the iron nails are pulled out, the wooden side boards are cut into lengths matching the width of the device, and the plane is placed on the workbench horizontally downwards, and the motor , chain 2, and vertebral plate 3, the side plate is fed laterally, and at the same time, the swing frame 8 descends along the axis 6 to contact the side plate, and is set at a suitable height by the buffer positioner 10, and the motor 7 is driven through The belt 9 drives the roller 4 of the flexible strip knife group to rotate quickly, and each flat roller with spring pressing function is connected to the aforementioned connection method to rotate rapidly respectively. The lower peeling blind area can be peeled under the rollers installed in the second stage, and the side plate continues to move forward. After passing through the third and fourth stages, the surface of the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com