Patents

Literature

100results about How to "Thoroughly peeled" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

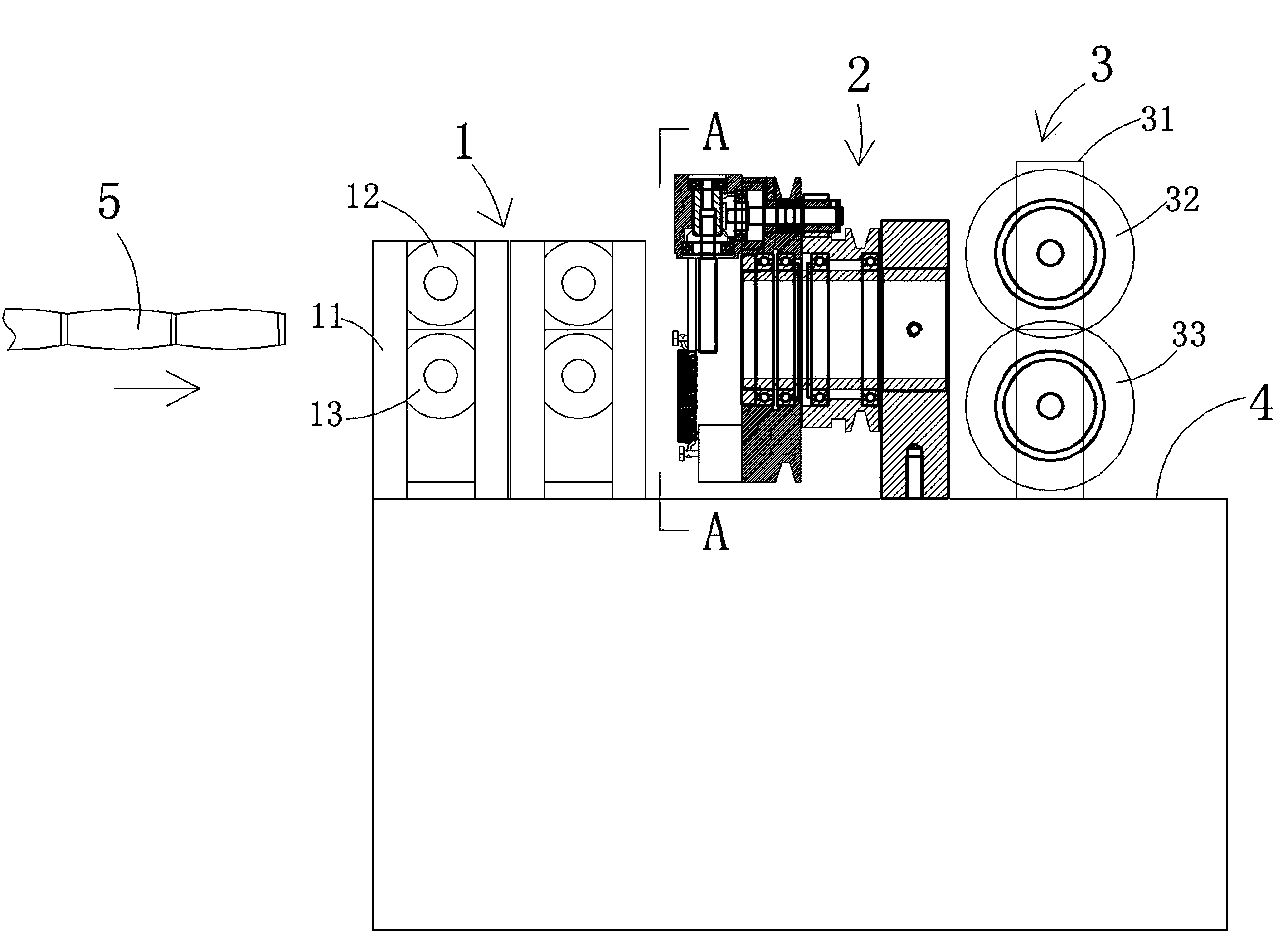

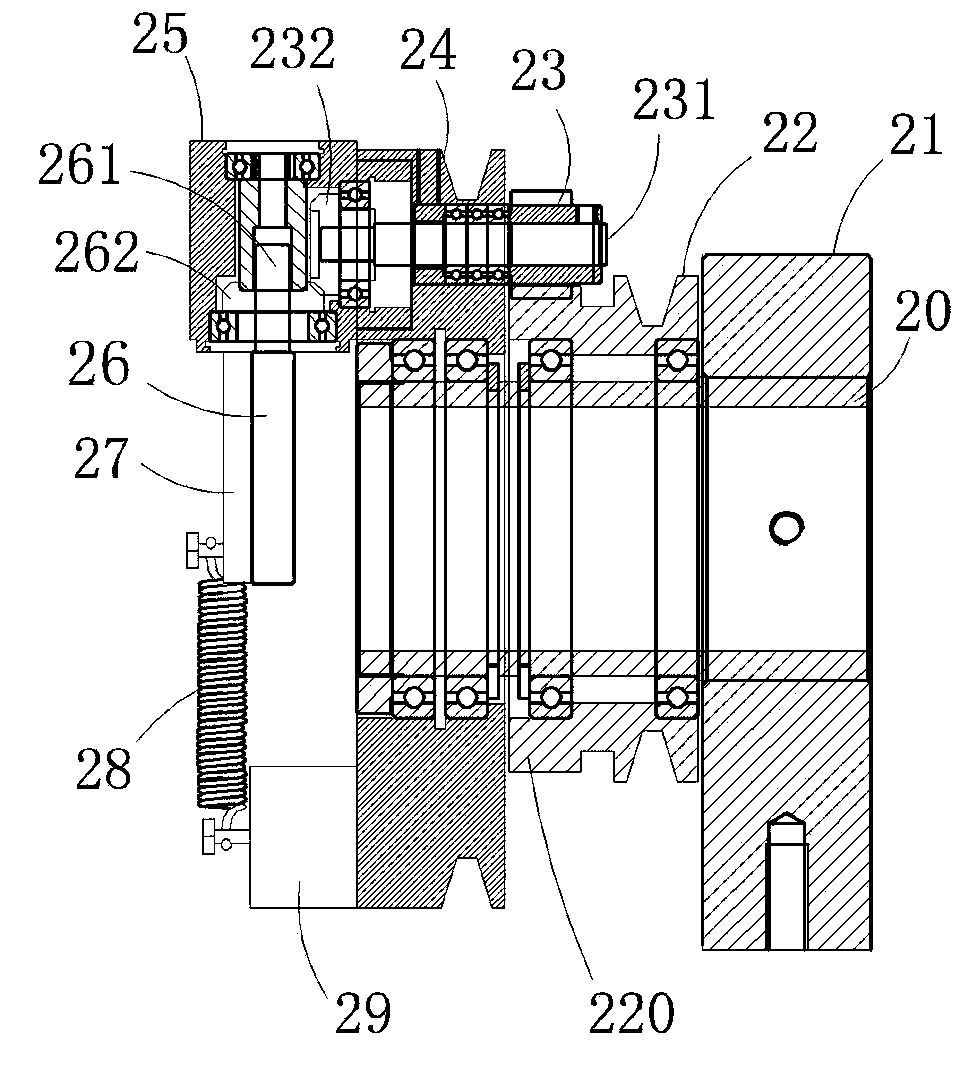

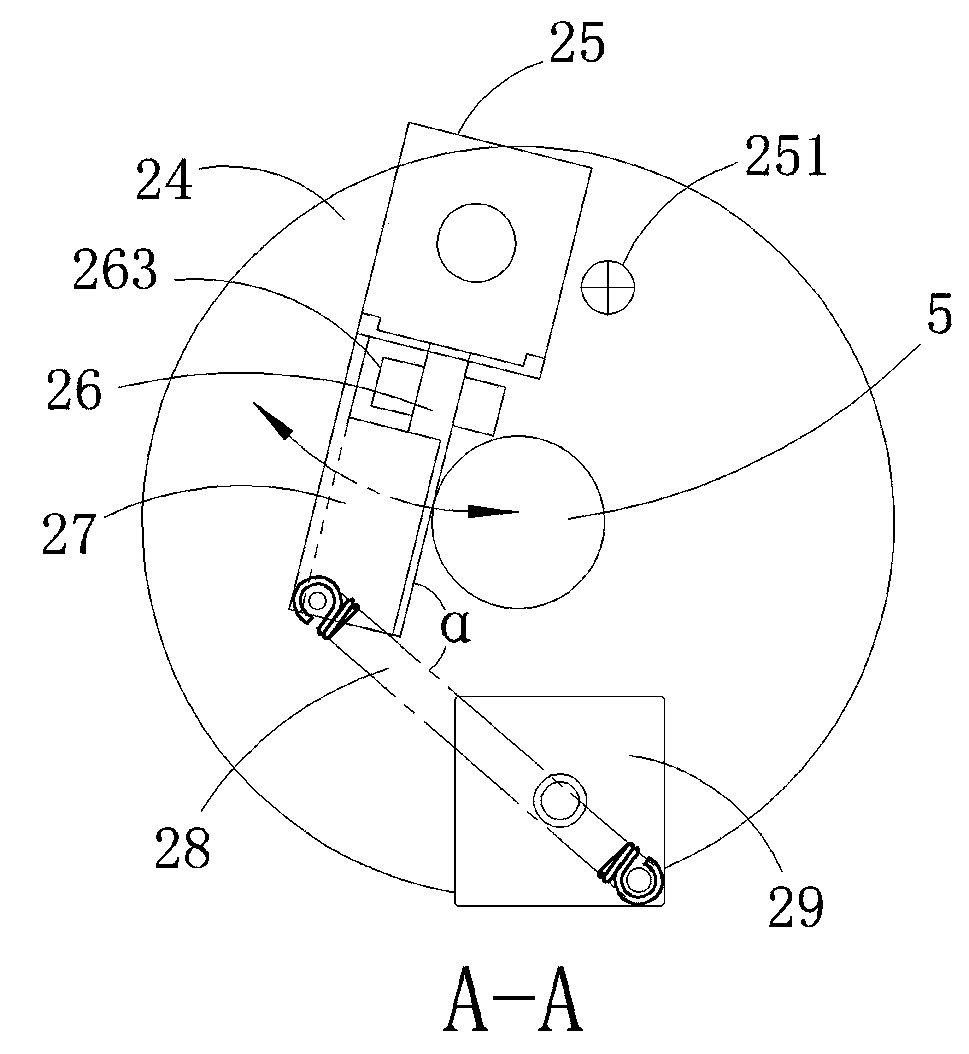

Peeling machine for sugarcanes

The invention relates to a peeling machine for sugarcanes different in thickness. The peeling machine for the sugarcanes comprises a peeling mechanism and is characterized in that the peeling mechanism comprises a cylindrical spiral milling cutter, a cutter base and a main belt plate. The spiral milling cutter is installed on the cutter base through a cutter shaft in a rotatable mode. The cutter base is installed on one side of the main belt plate in a rotatable mode, the main belt plate is installed on a shaft sleeve in a rotatable mode, and the shaft sleeve is fixedly installed on a shaft sleeve base. An auxiliary peeling piece is fixedly connected to the cutter base, the auxiliary peeling piece and the spiral milling cutter are arranged side by side, the milling cutter is used in cooperation with the auxiliary peeling piece for peeling, the cutter base makes the milling cutter close to the shaft center of the shaft sleeve through a torsion component, and the milling cutter and the main belt plate are driven by a power source to rotate. The peeling machine has the advantages of being stable in structure, convenient to use, thorough in peeling and capable of peeling the sugarcanes different in thickness.

Owner:RUIAN RUIHONG AUTOMATION TECH

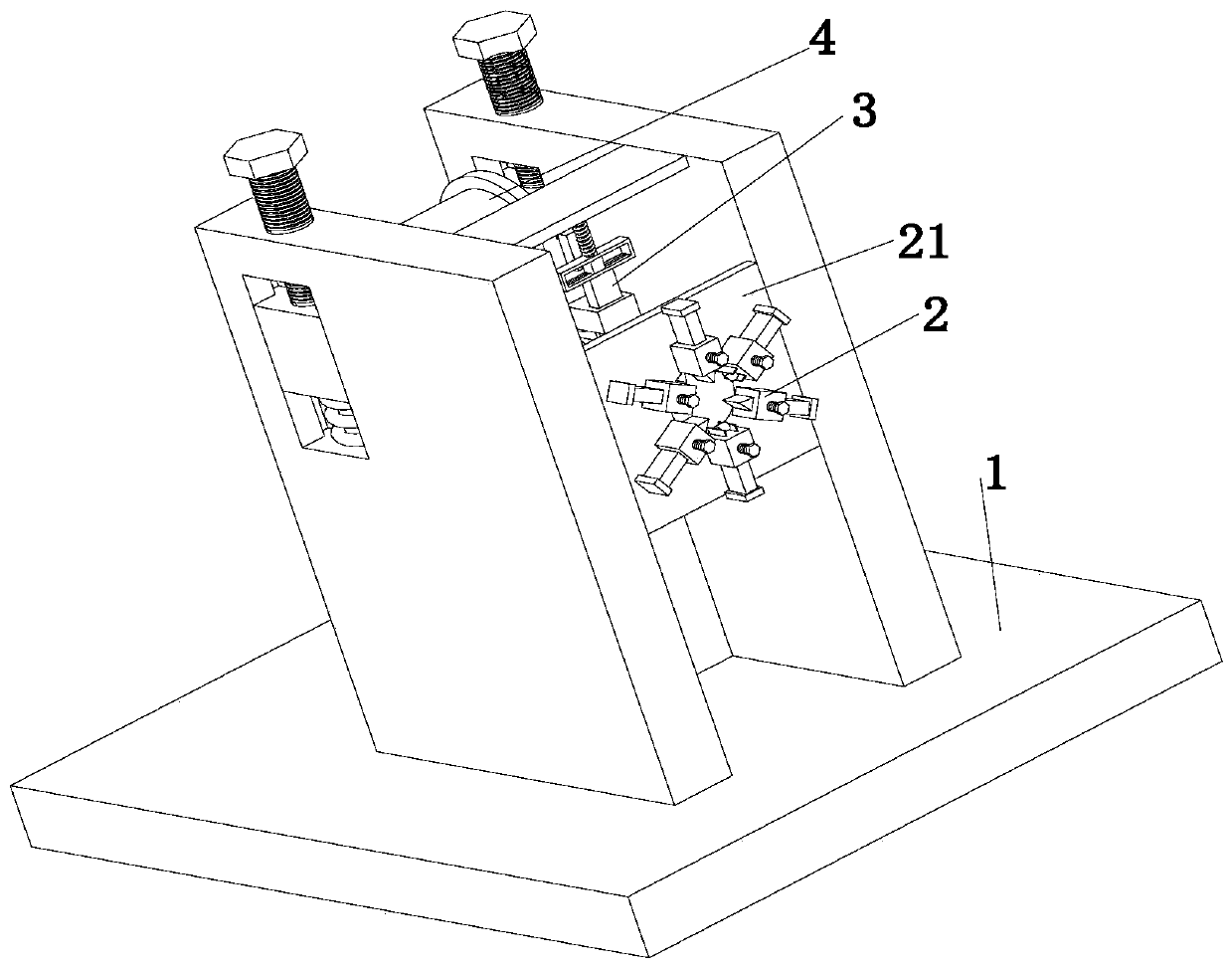

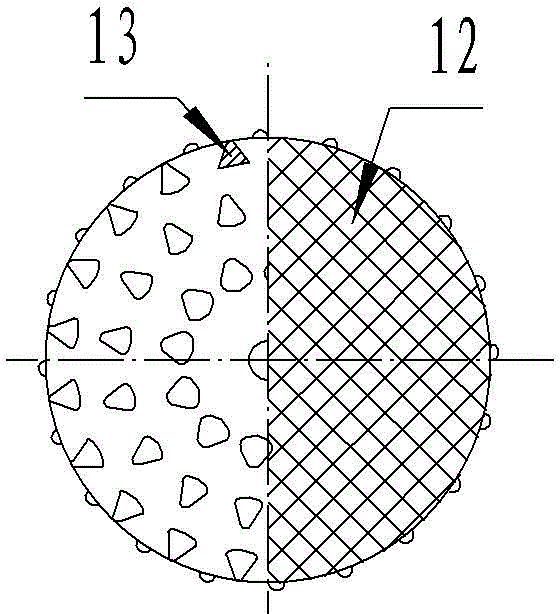

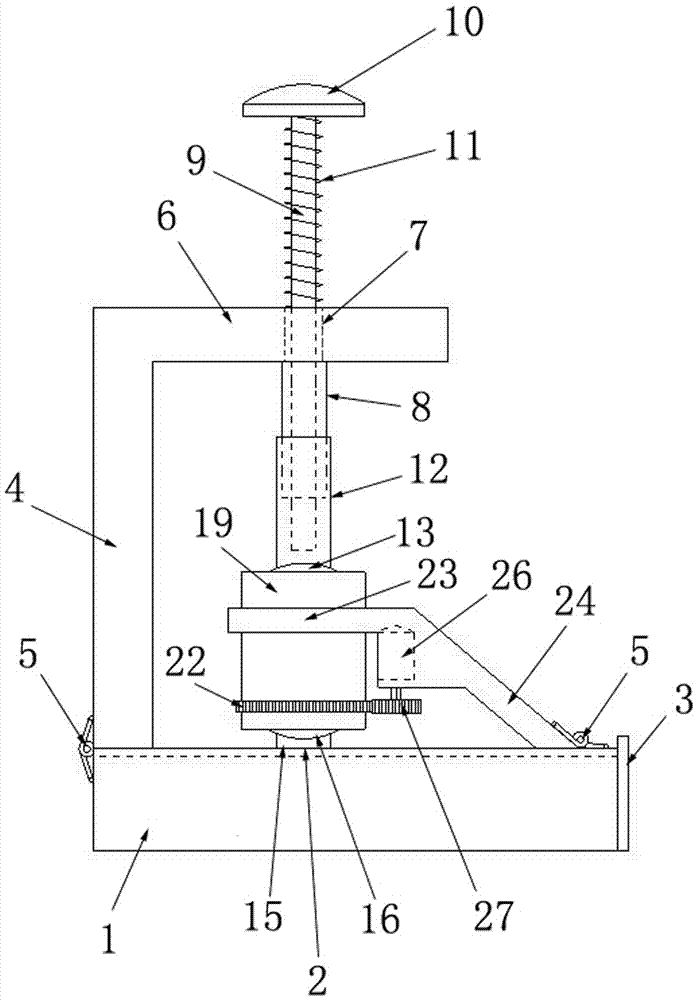

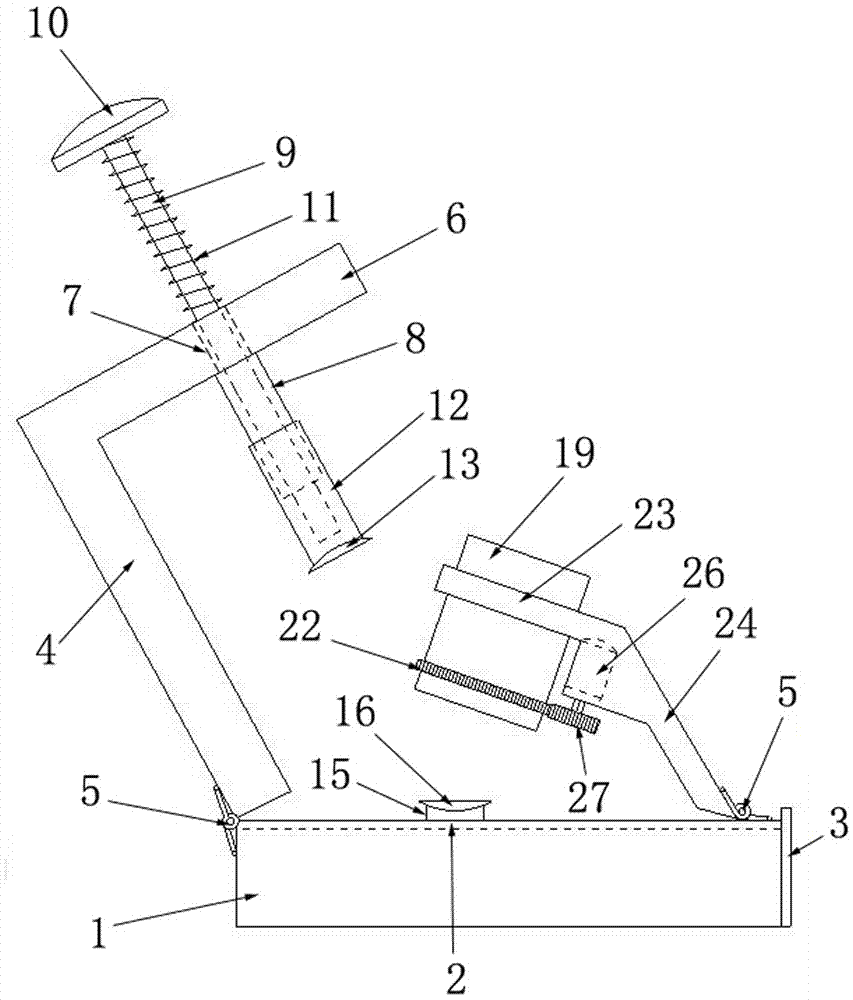

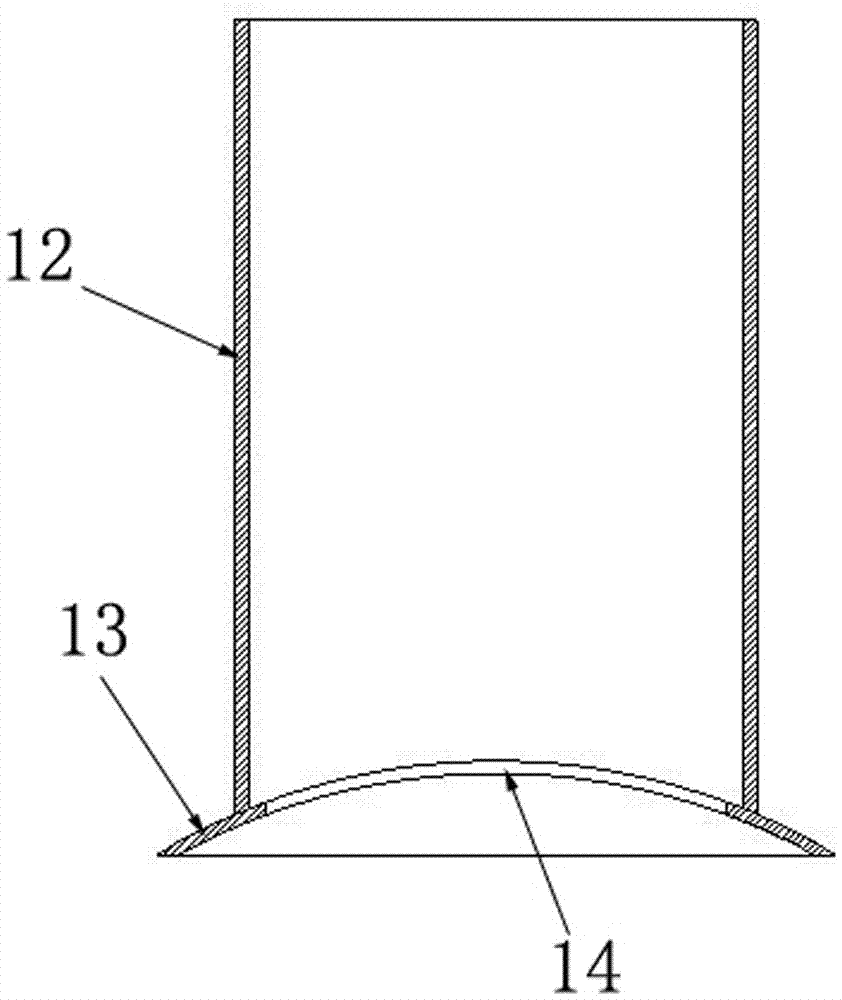

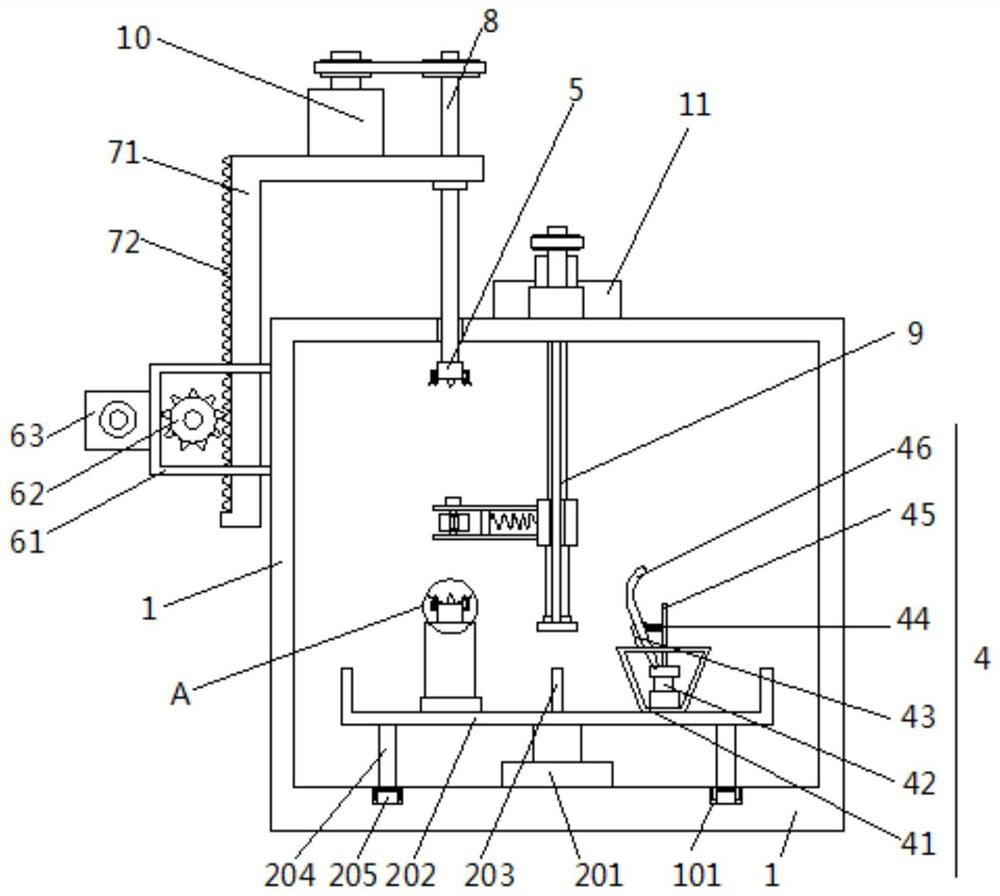

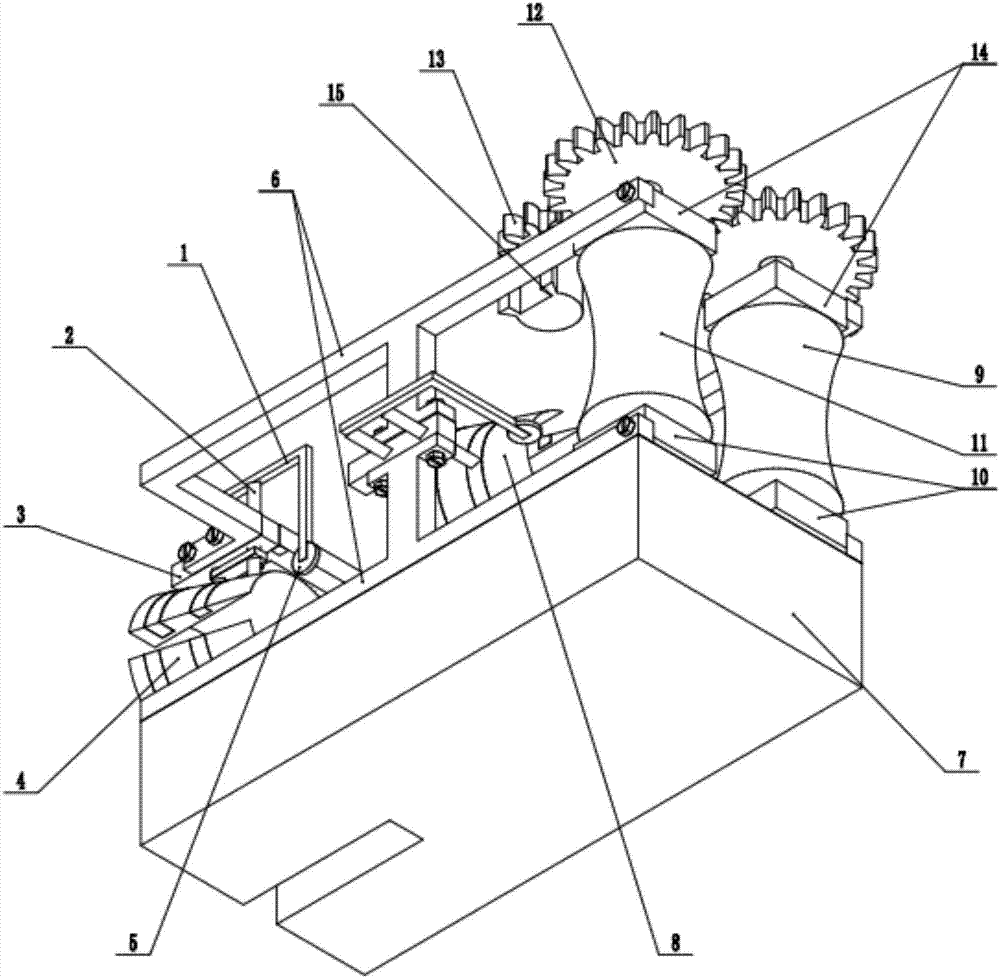

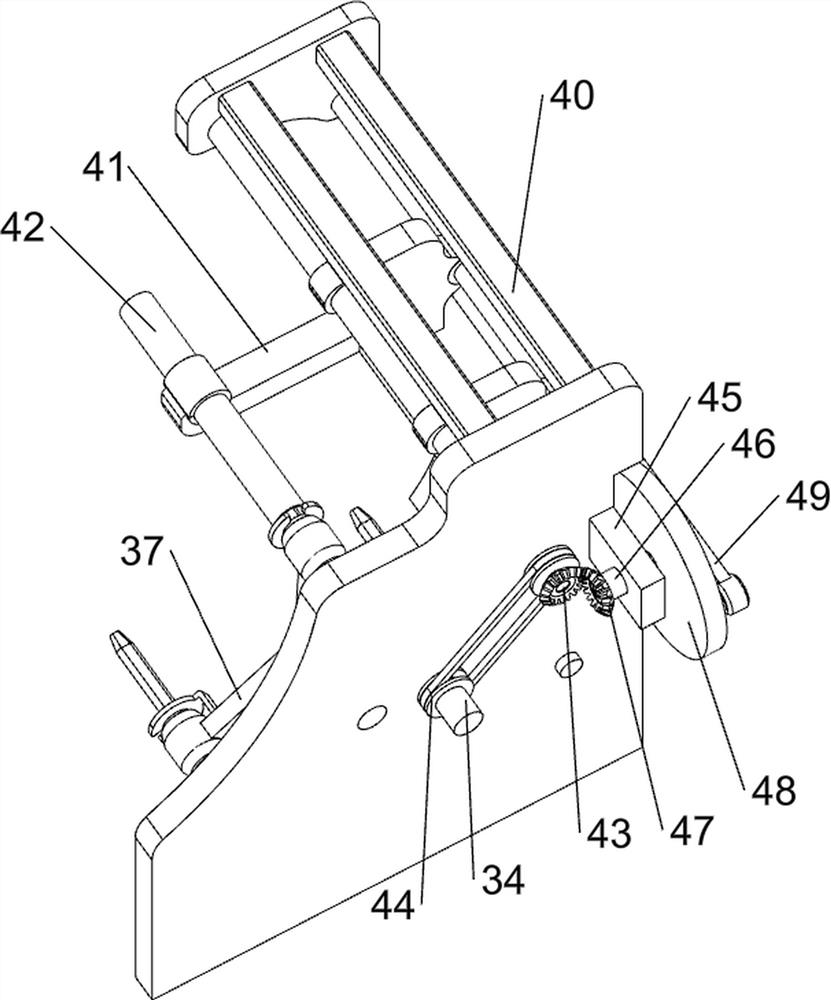

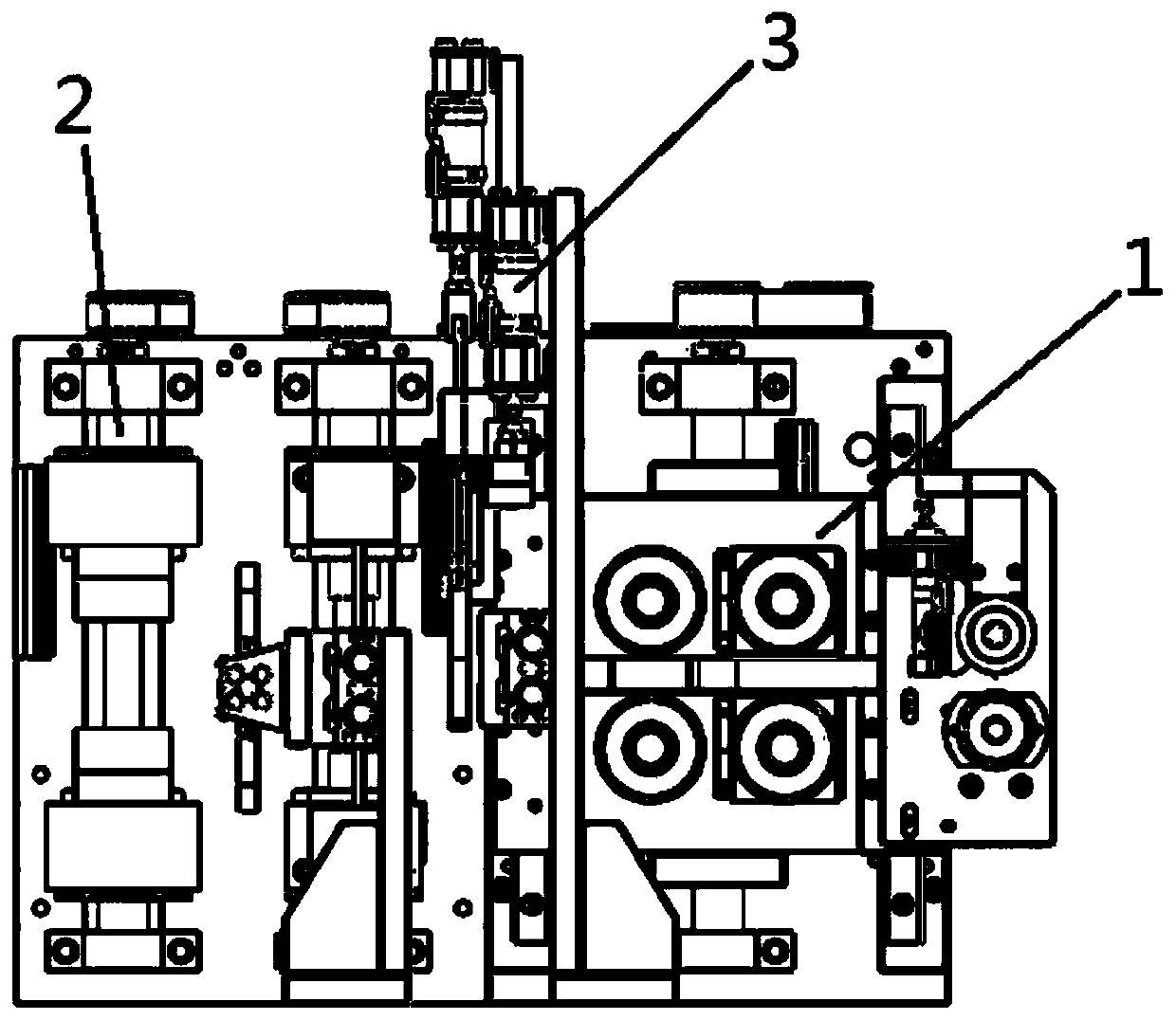

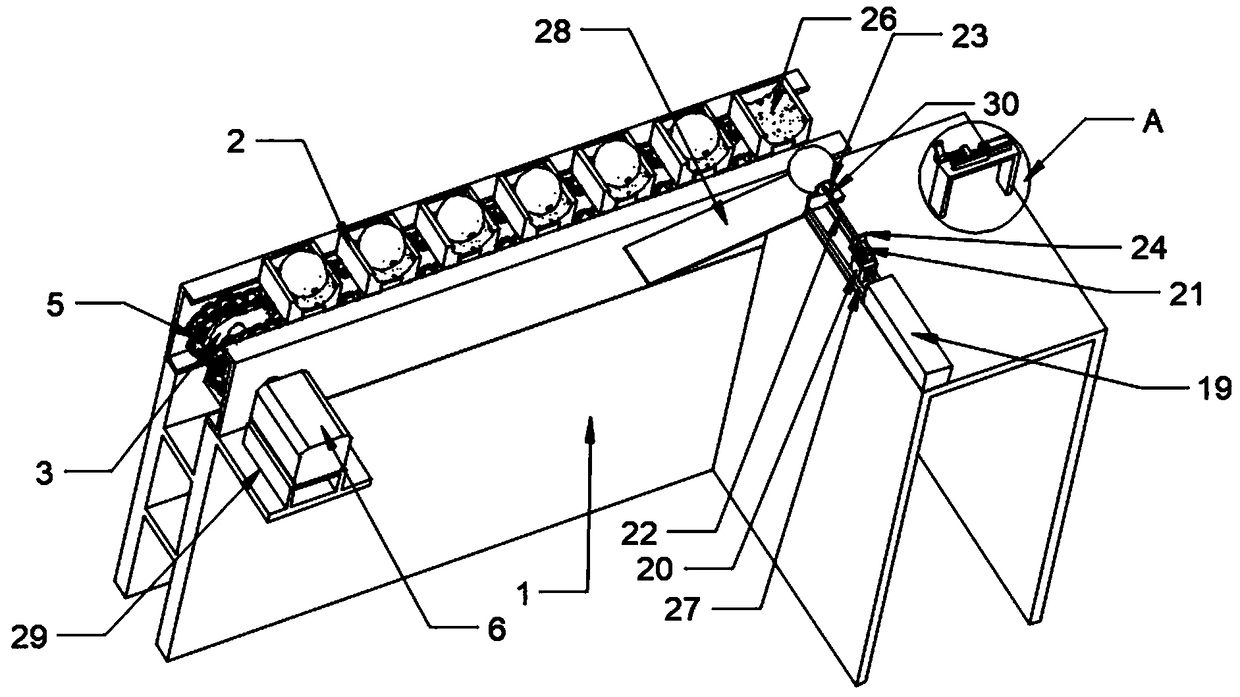

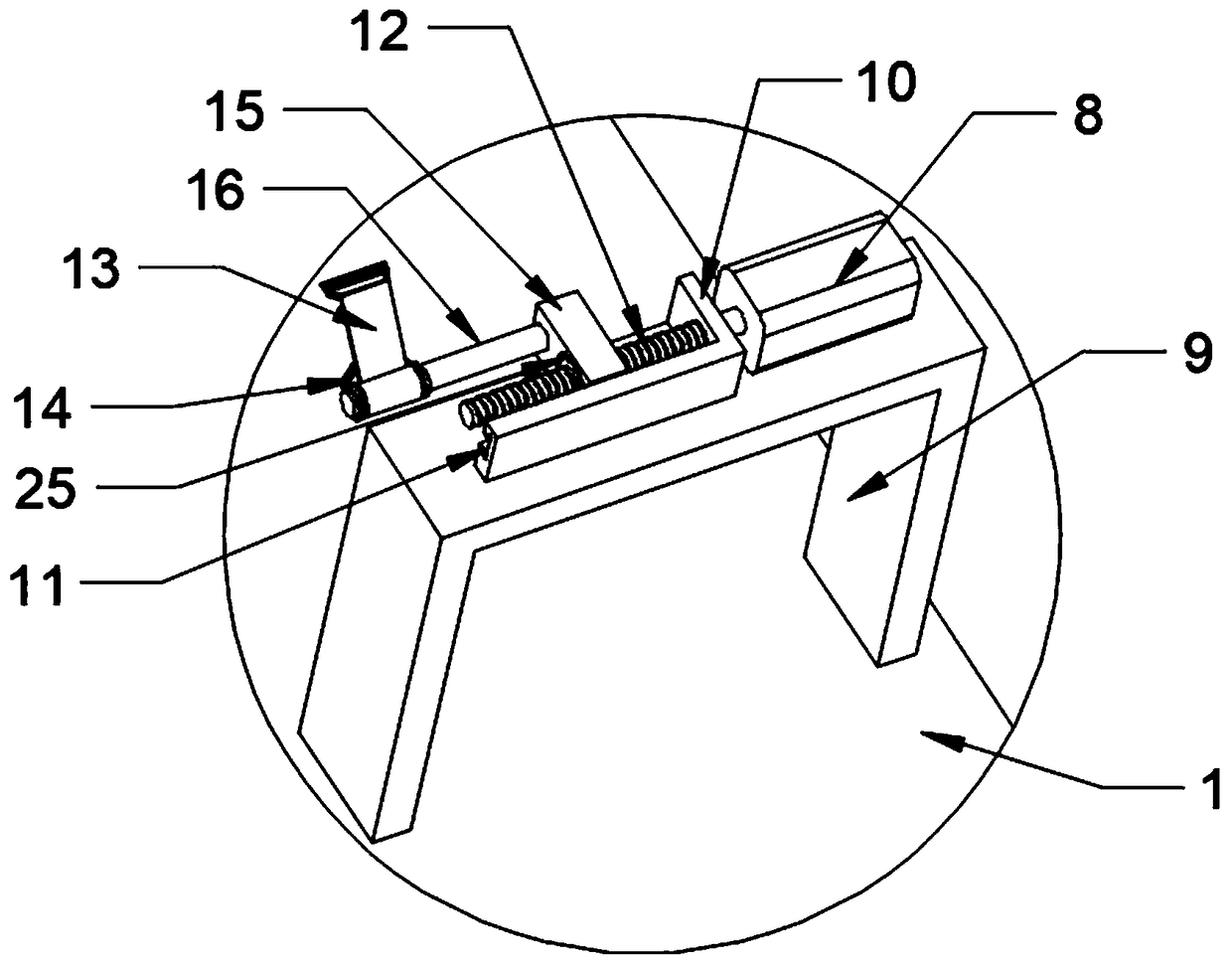

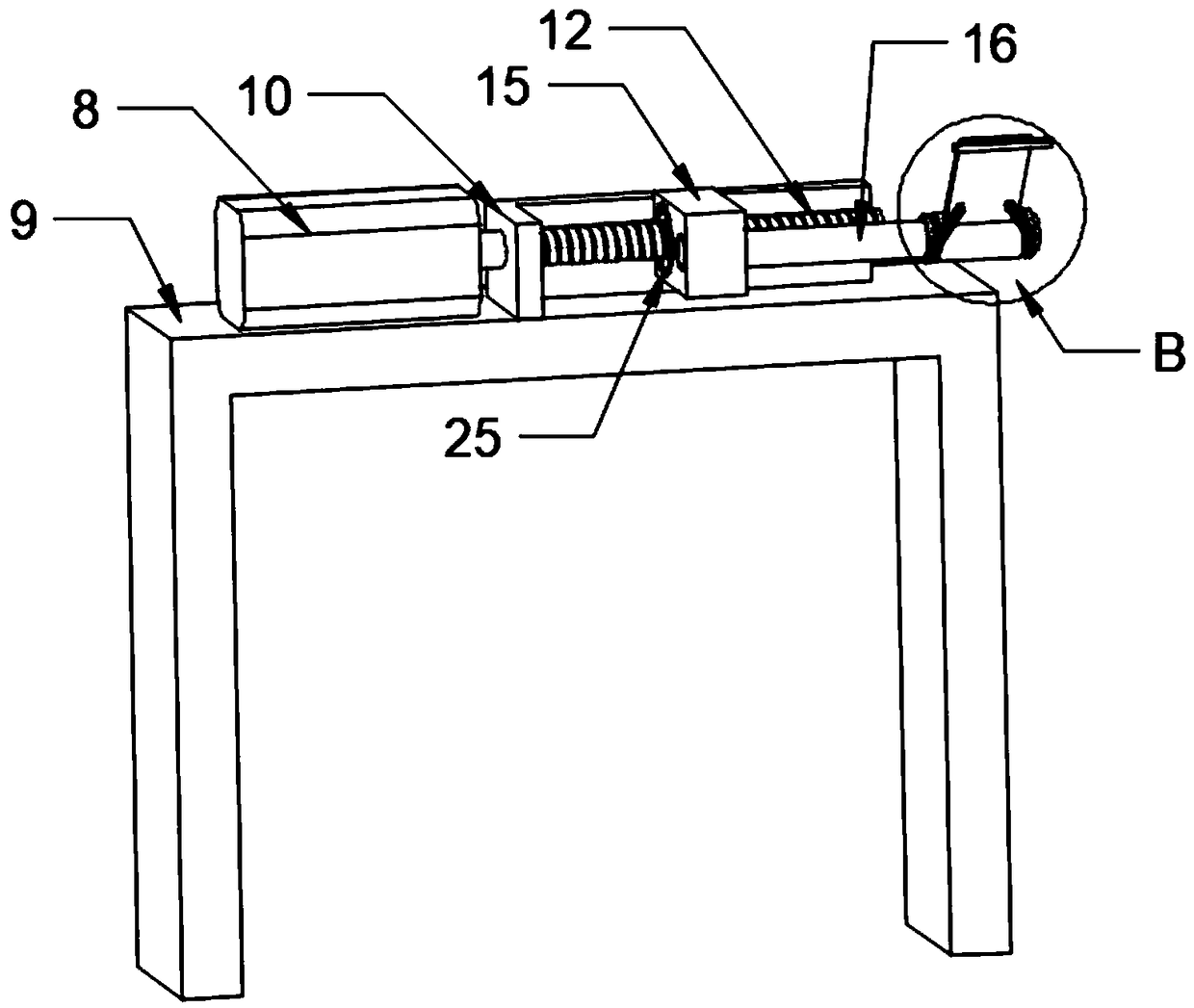

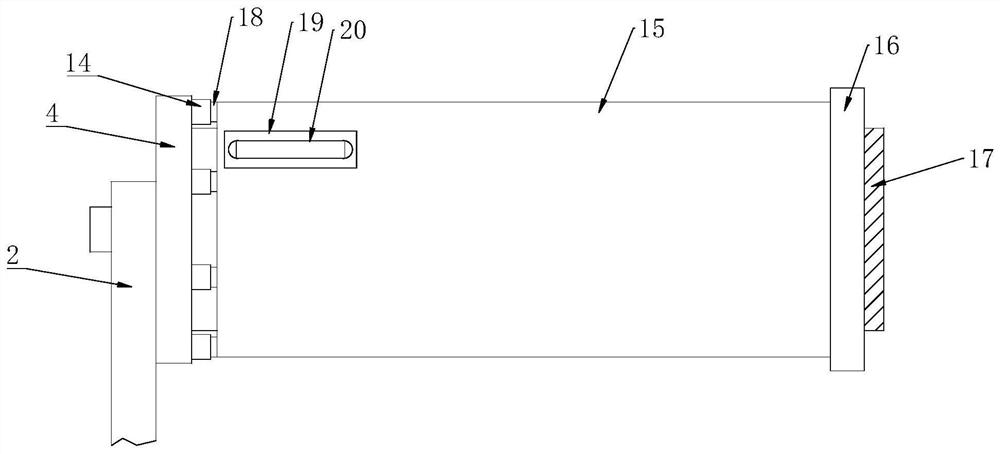

Semi-automatic peeling and slicing device for luffa acutangula roxb

InactiveCN109434918AThoroughly peeledImprove work efficiencyVegetable peelingMetal working apparatusHydraulic cylinderSemi automatic

The invention discloses a semi-automatic peeling and slicing device for luffa acutangula roxb. The semi-automatic peeling and slicing device comprises a machine frame, a feeding mechanism, a peeling mechanism, a slicing mechanism, a control panel and a material box. The feeding mechanism is mounted at the left end of a machine frame mounting plate, and the peeling mechanism and the slicing mechanism are sequentially mounted on the rear side of the feeding mechanism. The feeding mechanism comprises a material placing seat and a hydraulic cylinder A, wherein the material placing seat is a cubicbody, an arc material placing groove is formed in the upper end face of the material placing seat, and the center of the hydraulic cylinder A and the center of the material placing groove are consistent. The slicing mechanism is fixed on the peeling mechanism, and the material box is mounted below the slicing mechanism. The control panel is provided with keys to specially control movement of all hydraulic cylinders. By adopting the structure, luffa acutangula roxb is placed into the material placing groove of the material placing seat, the keys on the control panel are pressed, the hydraulic cylinder A pushes the luffa acutangula roxb to move forwards, the peeling mechanism removes peel, the slicing mechanism obliquely slices the peeled luffa acutangula roxb, and then the sliced luffa acutangula roxb falls into the material box. The device can feed semi-automatically and peel and slice automatically, through two times of peeling, peeling is more complete, and the heat receiving area isenlarged through oblique slicing.

Owner:GUIGANG HOUSHUN INFORMATION TECH CO LTD

Wire and cable recovery processing equipment and recovery processing method

ActiveCN110676771ALow efficiencyEasy to operateApparatus for removing/armouring cablesBilateral symmetryElectric cables

The invention relates to wire and cable recovery processing equipment, which comprises a bottom plate, a stripping device, a cutting device and a cleaning device. Supporting plates are installed on the bottom plate in a bilateral symmetry mode. The stripping device is installed between the front inner walls of the supporting plates. The cutting device is installed between the middle inner walls ofthe supporting plates. The cleaning device is arranged between the rear inner walls of the supporting plates. The wire and cable recovery processing equipment can solve the following problems of theexisting recycled wires and cables during stripping of cable insulating layers: firstly, at present, the insulating layers of the cables are stripped by manually operating wire stripping pliers, and various types of wire stripping pliers need to be used when stripping wires with different diameters, so that the efficiency is low; the cable needs to be controlled by one hand when the cable is stripped by using a cutter, and hands are easily injured if an operator carelessly strips the cable during operation; and secondly, a traditional stripping machine cannot strip a relatively long cable andsome cable cannot be stripped off, so that the cable needs to be stripped off again by using the wire stripping pliers manually, and time is wasted.

Owner:华能(泰安)光电科技有限公司

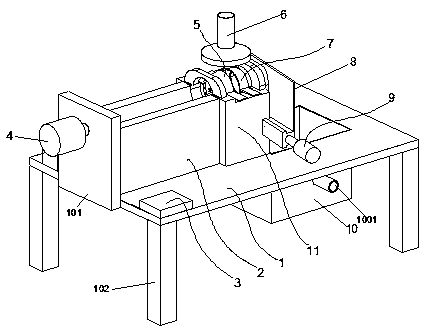

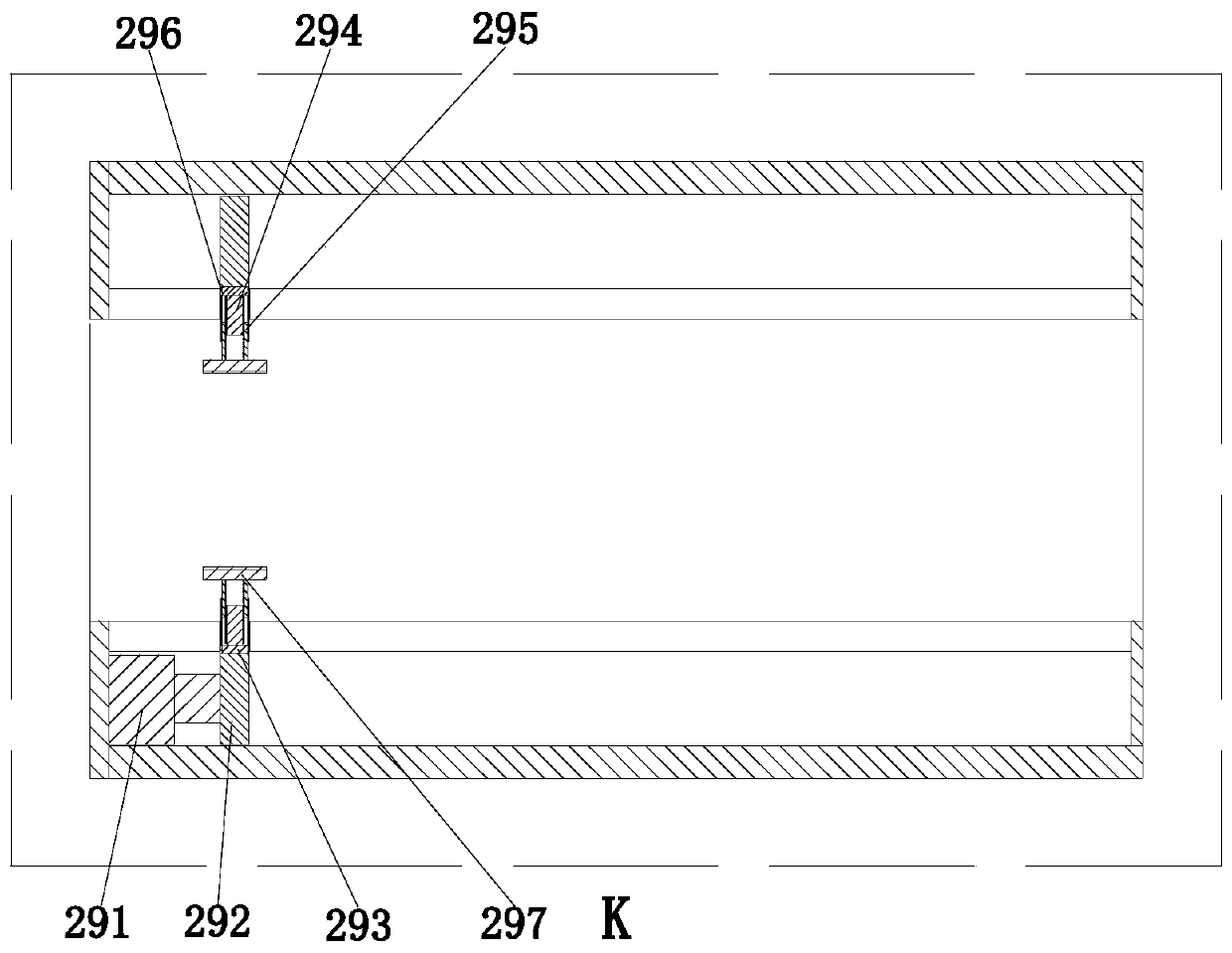

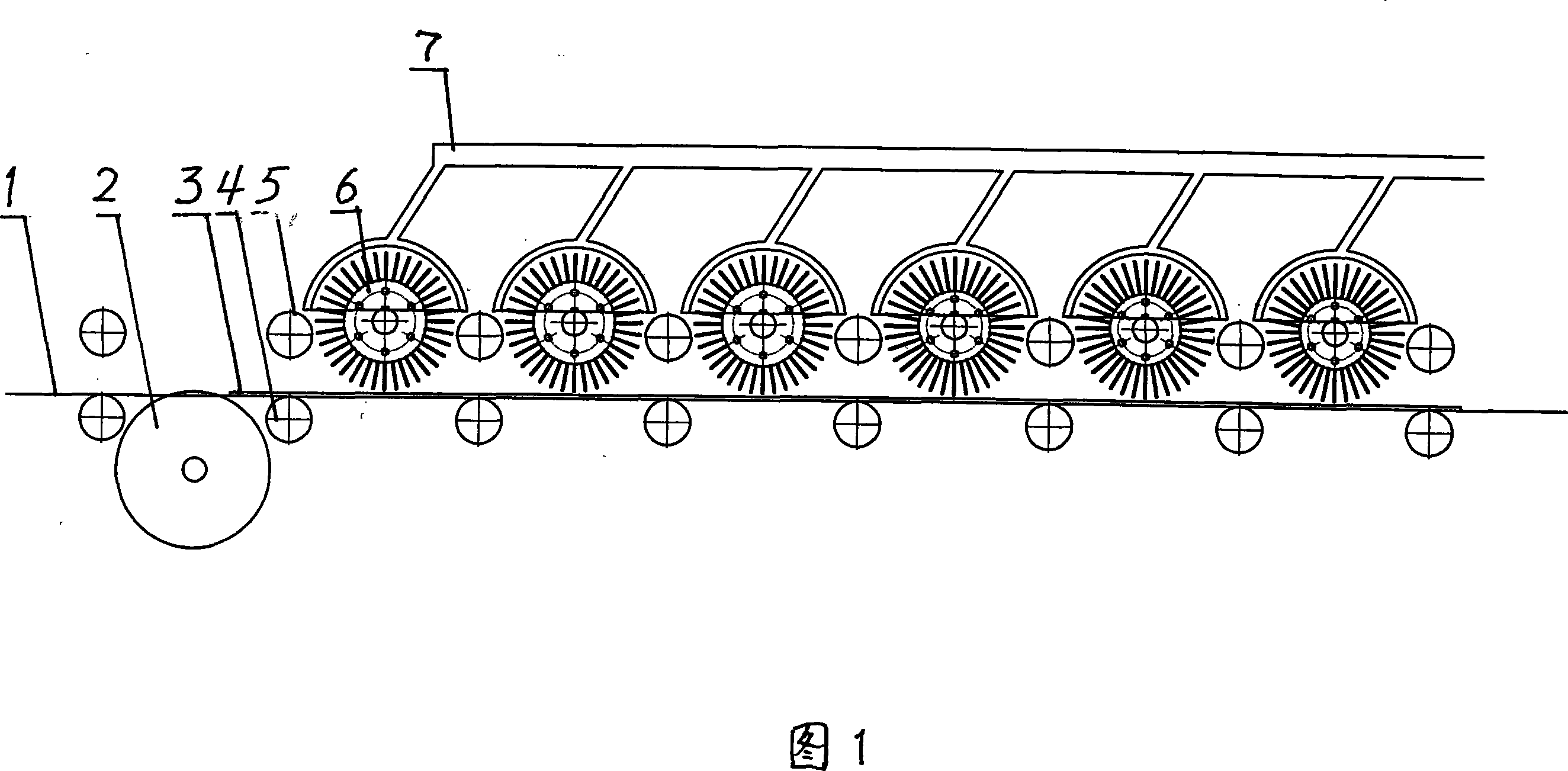

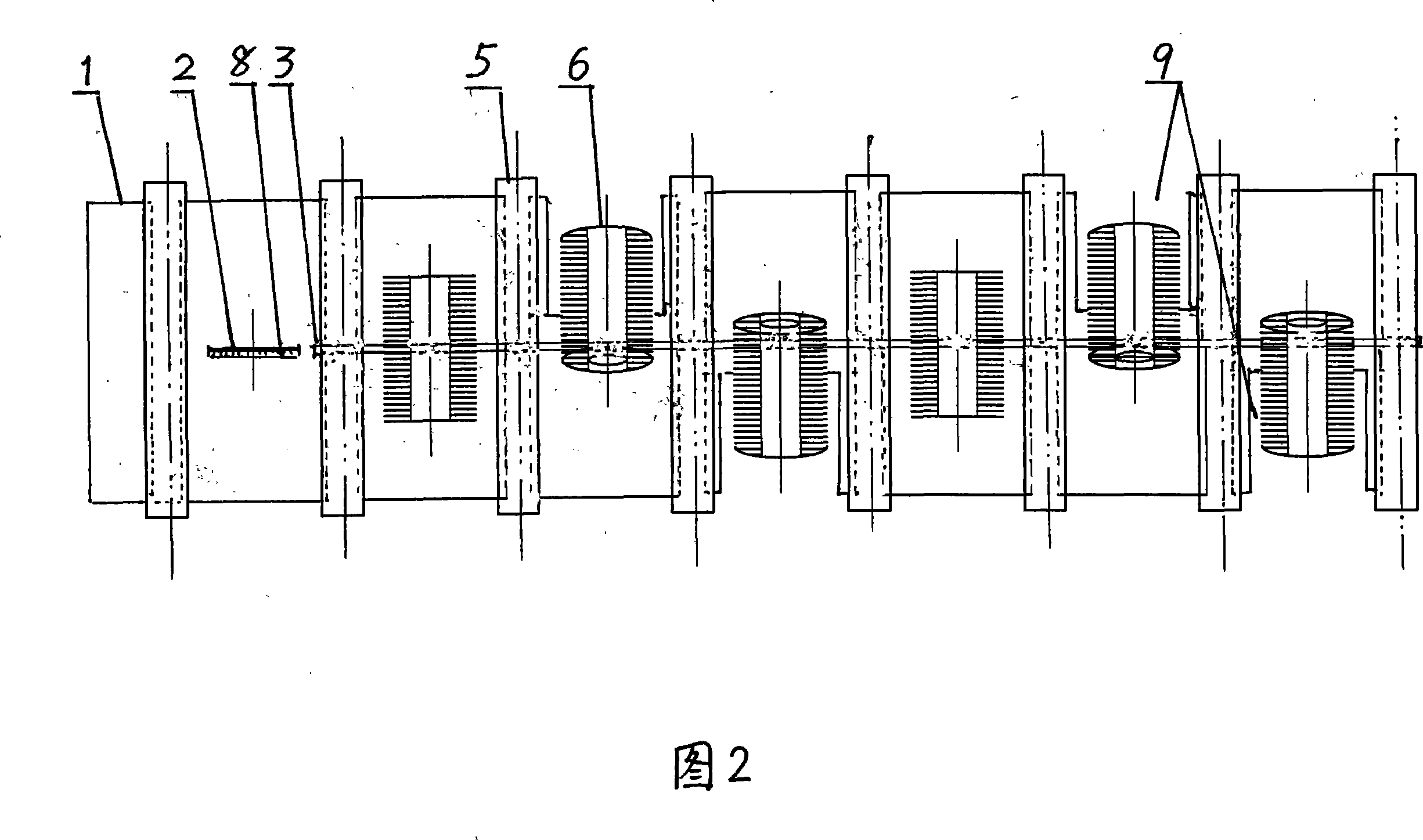

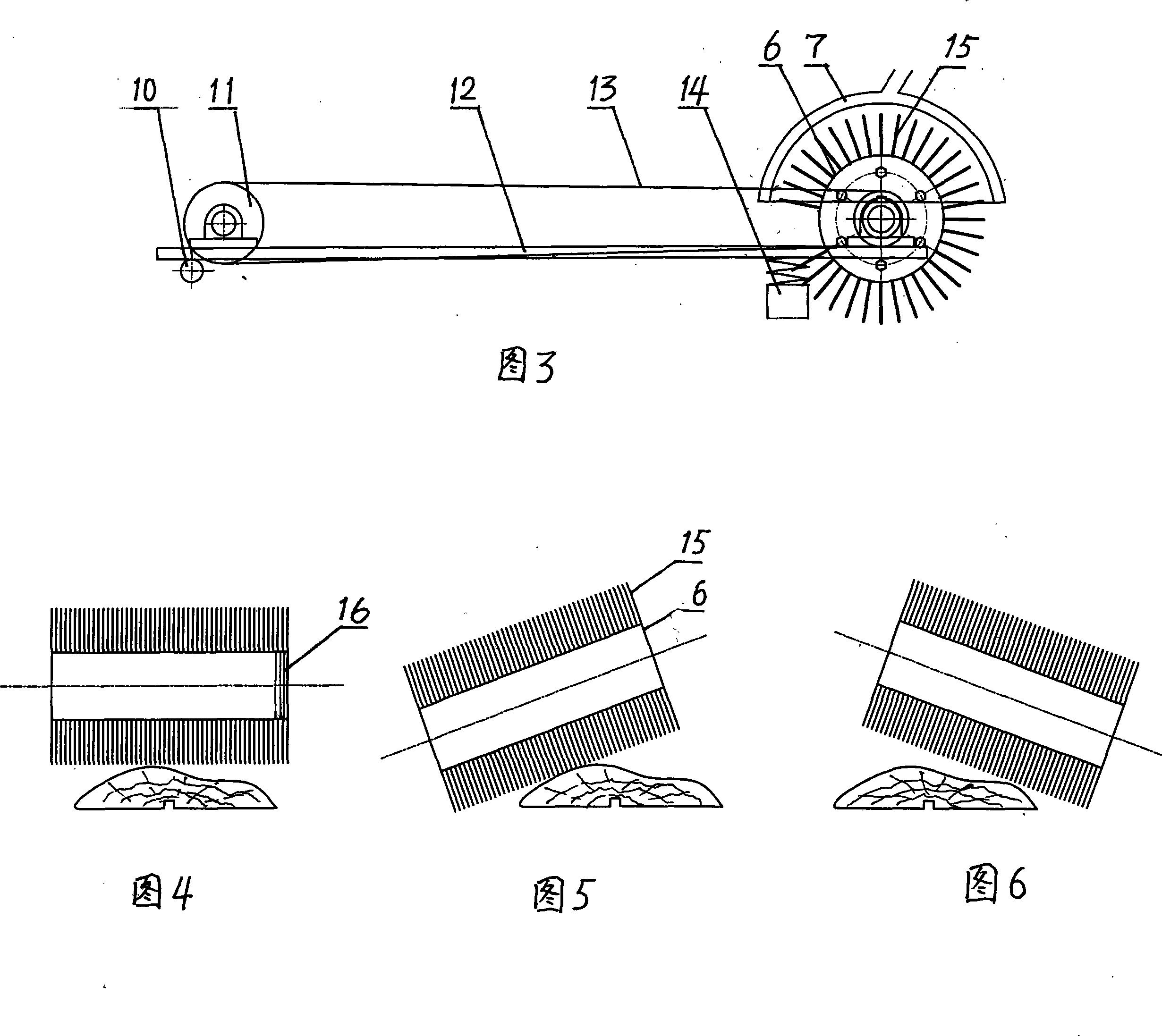

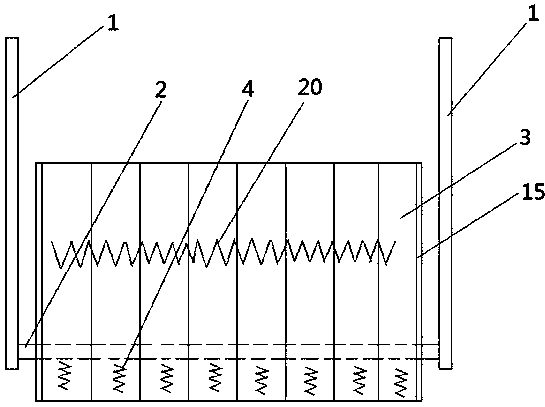

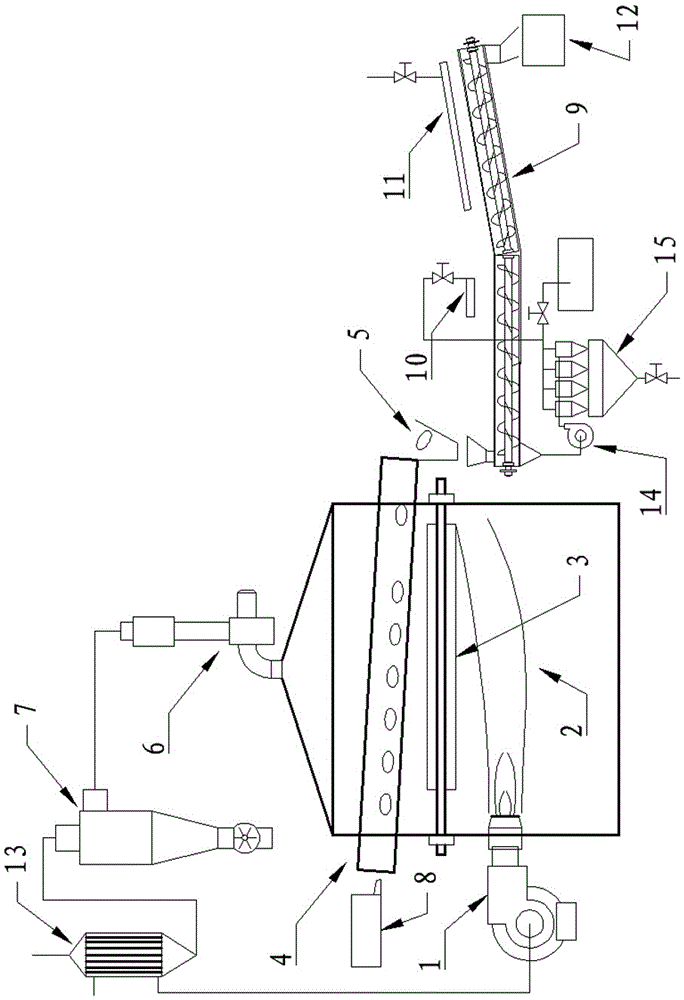

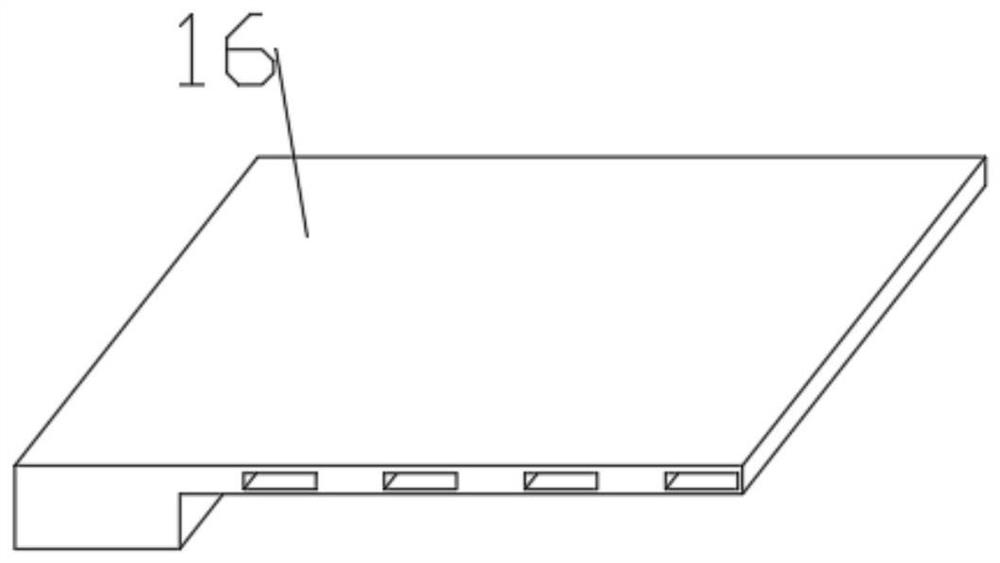

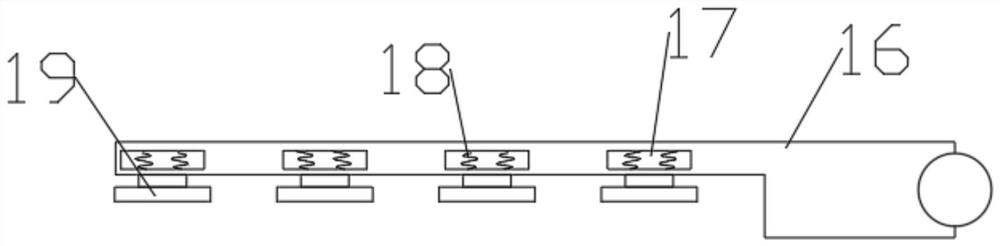

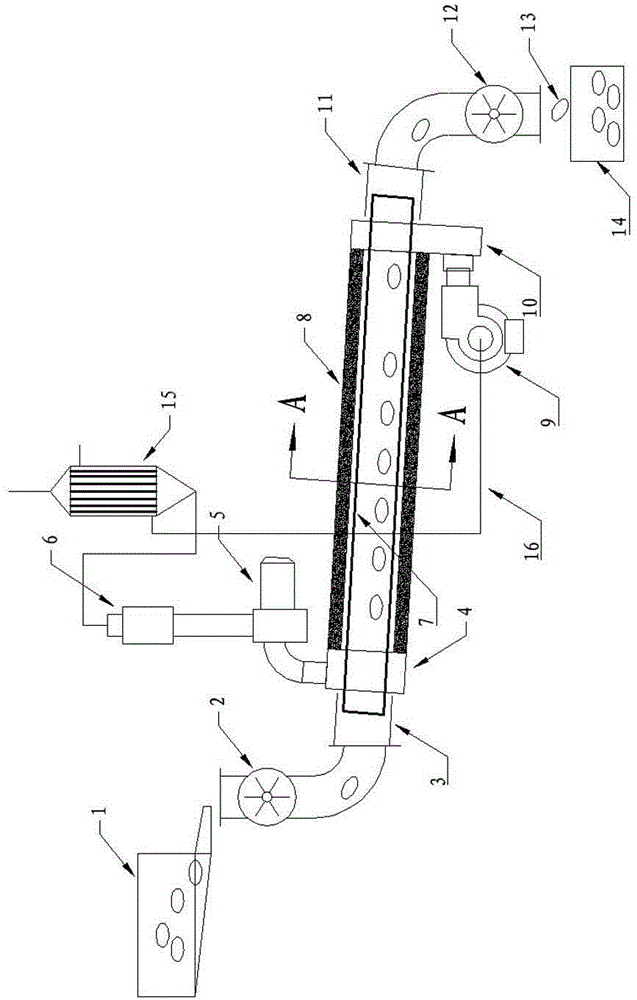

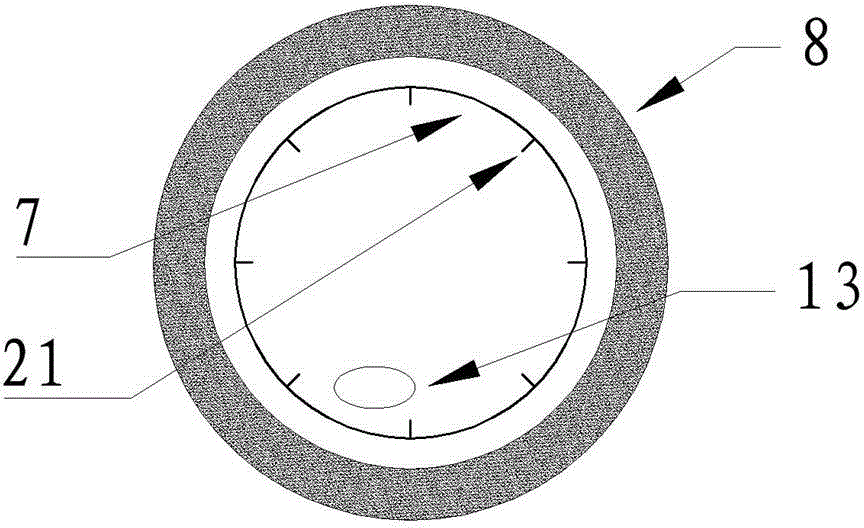

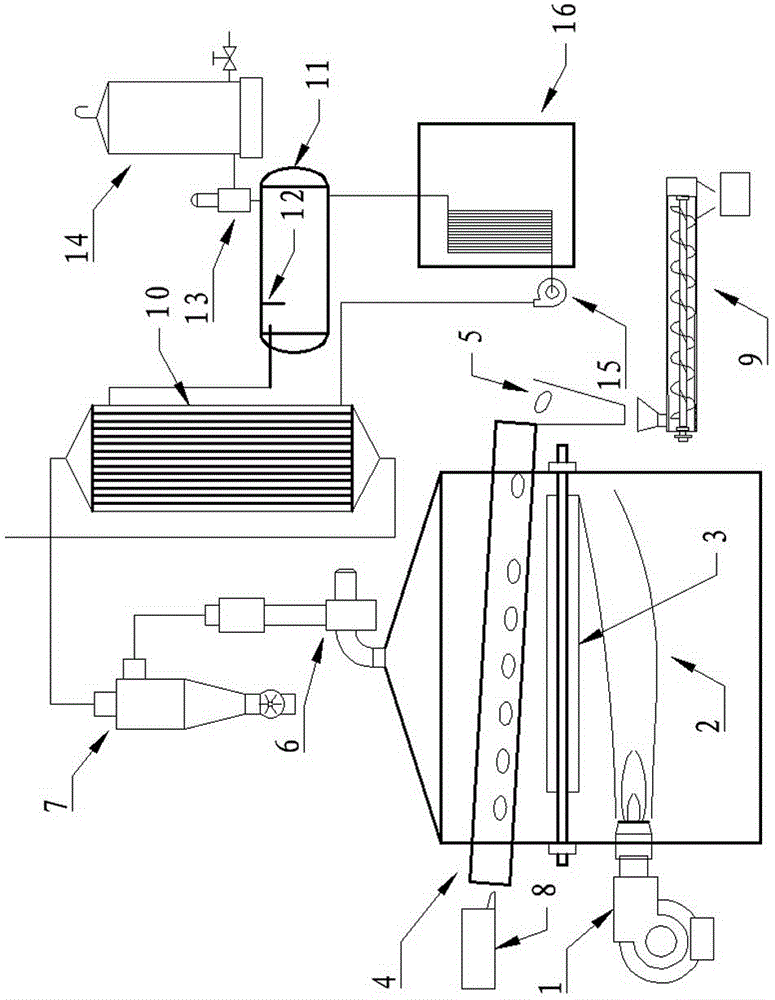

Method and device for removing wood side plate tegument

InactiveCN101209561ADifficulties in resolving shortagesQuick peelTree debarkingThick plateBiomedical engineering

The invention provides a method and a device used for removing the skin of a wood-edge plate, consisting of a power, a transmission part, a frame, a workbench (1), feeding mechanisms (5, 4) and a cutter. A slotting saw (2) is arranged on the lower left of the workbench; a saw kerf (8) and a positioning track (9) are arranged in the centre of the workbench in longitudinal direction; the positioning track (9) is provided with flexible strip cutter rollers (6) in horizontal state, left inclined state and right inclined state; a dust hood (7) is arranged above the roller (6). The device is specially used for removing the skin of a wood-edge plate; classification and pre-disposal are carried out to the edge plate in advance when the skin is being removed; the excessively thin plate is not processed and the skin of the plate with non-uniform thickness is removed by section on which the thin plate is cut and the thick plate is preserved; the whole skin of a thicker plate with is removed; coarse and hard knurr is cleaved by the saw and iron nails are pulled out. By adopting the device to remove the skin of a wood-edge plate, the invention has the advantages of sufficiently taking the wood-edge plate as the raw material of integration material, solving the lack of raw wood, removing the skin quickly, cleanly and thoroughly and not damaging the xylem.

Owner:ZHEJIANG FORESTRY UNIVERSITY

Automatic potato peeling processing device

The invention relates to the technical field of automated machinery, in particular to an automatic potato peeling processing device. The automatic potato peeling processing device comprises an outer box body, a rotating rod and a blade holder, wherein a sliding groove is fixedly connected to the top of the right side wall of the outer box body; a first reciprocating motor is arranged on the sliding groove; a push rod is fixedly connected to the lower end of a second reciprocating motor; the rotating rod is inserted into a threaded cylinder; an arc-shaped fixing frame is fixedly connected to one surface of the inner side of an electric air cylinder; a first supporting spring and a second fixing rod are inserted into a first fixing rod; the four corners of an outward end face of the blade holder are fixedly connected with four second supporting springs, and a first movable baffle is hinged to the lower end of the arc-shaped fixing frame through a spring hinge. According to the automaticpotato peeling processing device, the structural design is reasonable; blades can be freely adjusted to tightly fit the surface of a potato under the action of the second supporting springs, so that the problem of small application range of existing potato peeling devices is solved. The thrust generated by the second reciprocating motor can ensure that the potato is fully scraped by the blade, sothat peeling of the potato is more thorough.

Owner:甄城

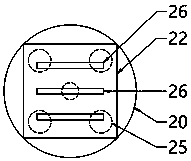

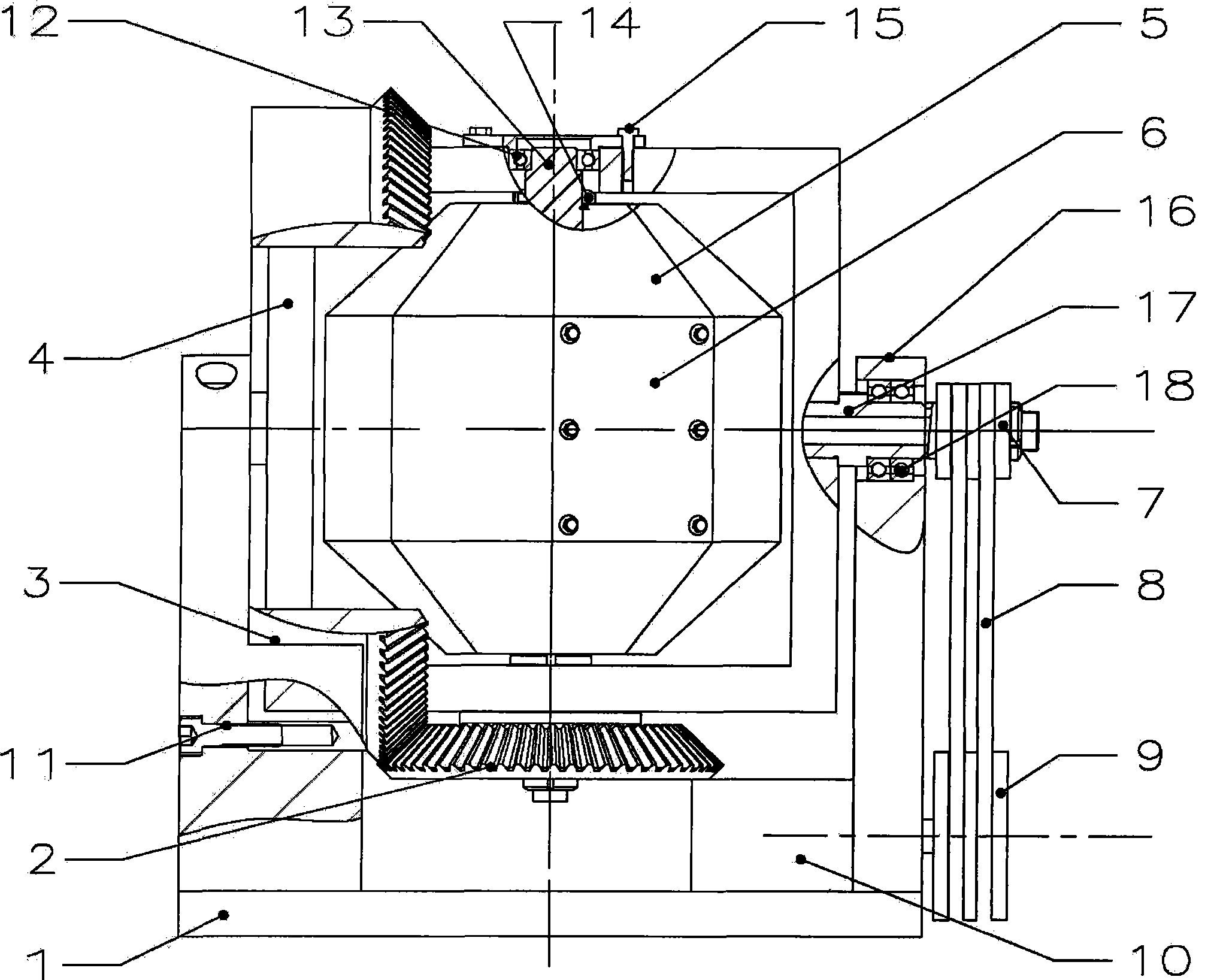

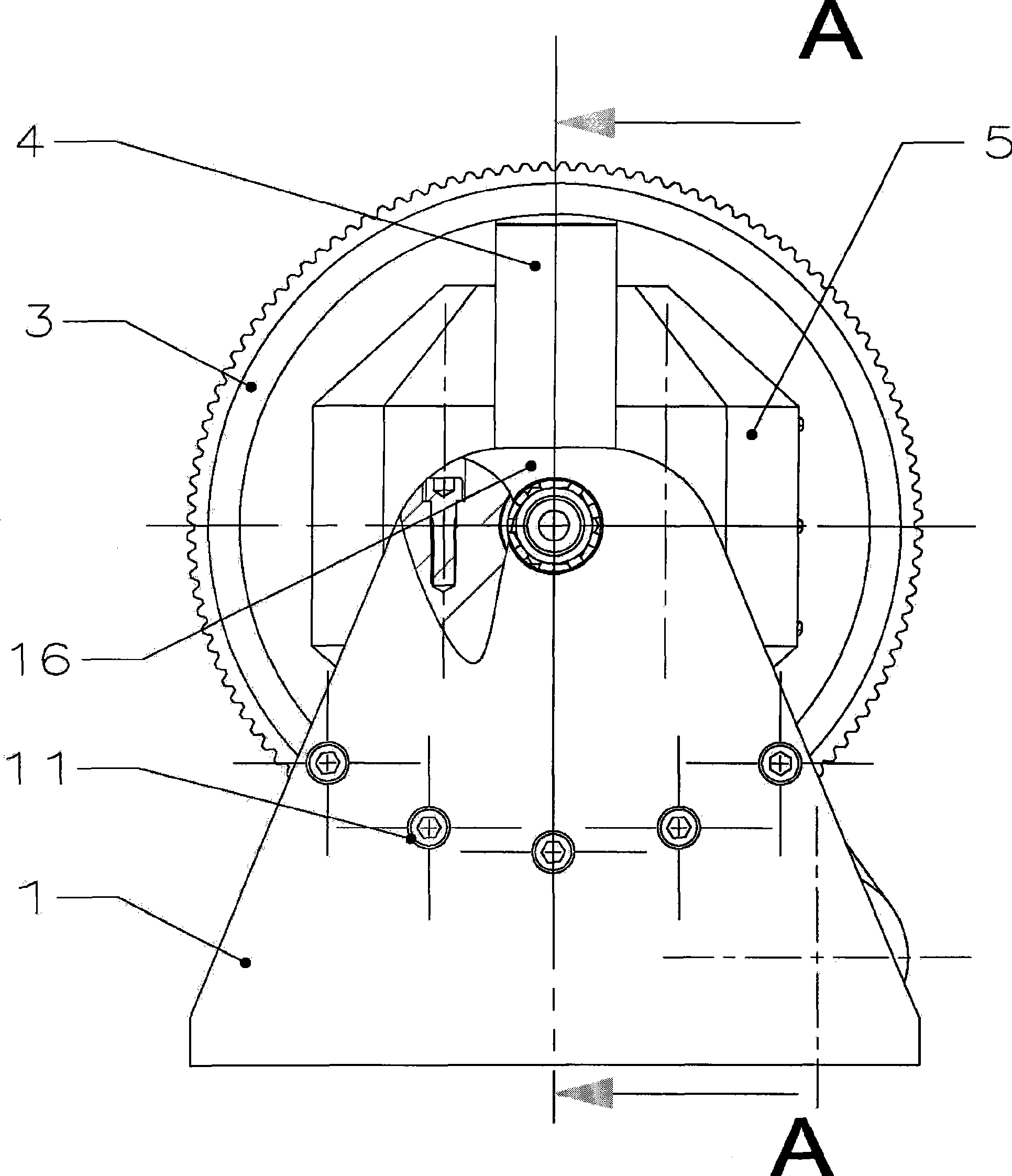

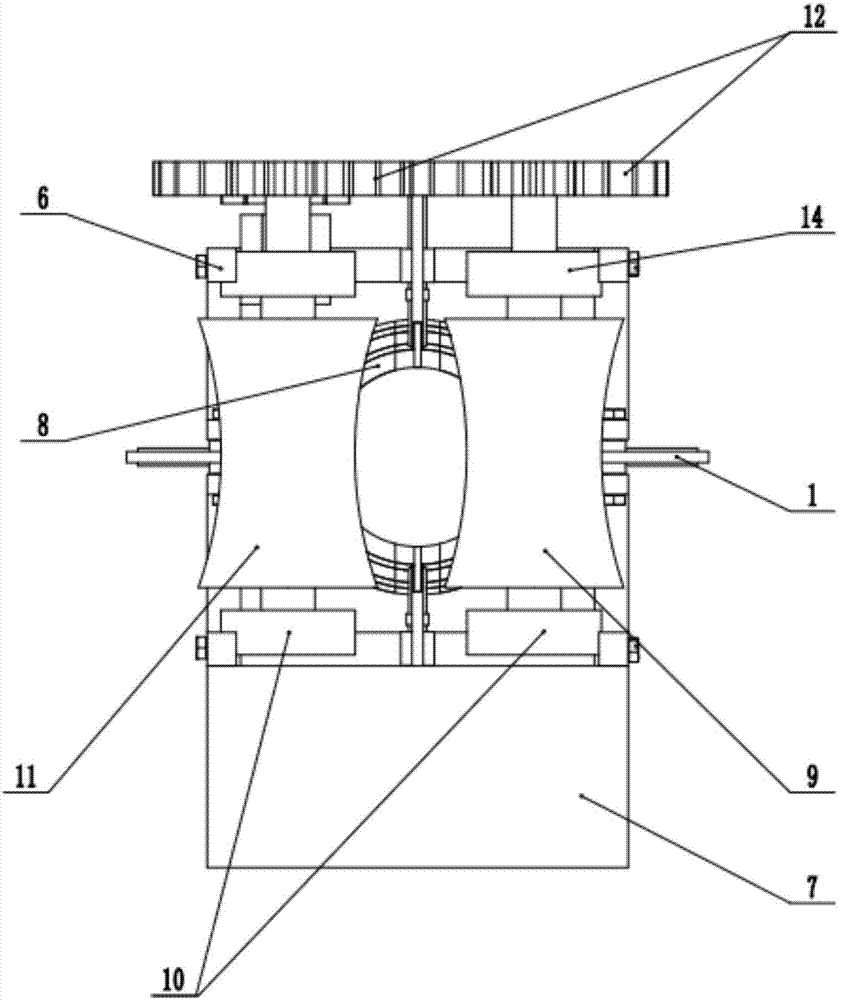

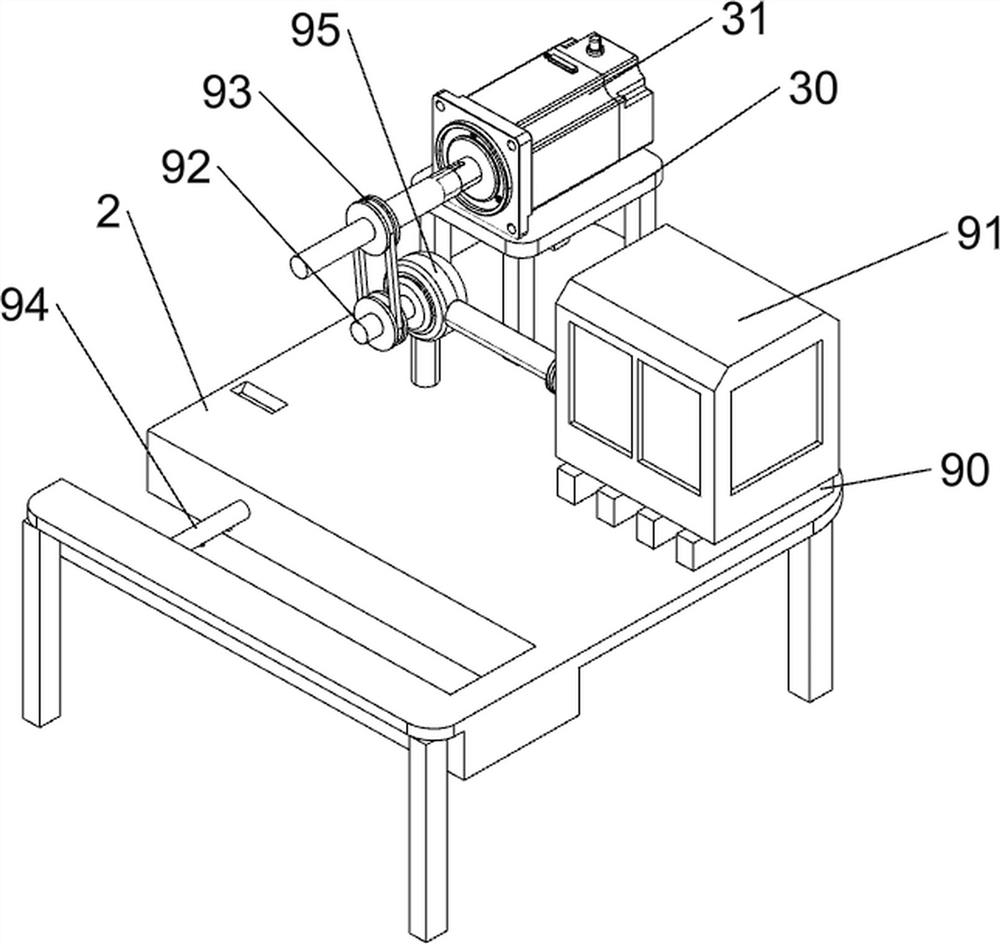

Automatic peeling machine of potato

Disclosed is an automatic potato peeler, belonging to food processing machinery. The potato peeler comprises a pedestal which is a U-shaped metal piece. A gear transmission mechanism, a silo mechanism and a belt transmission mechanism are fixedly arranged on the pedestal. The gear transmission mechanism is composed of a big bevel gear and a small bevel gear which is meshed with the big bevel gear. The belt transmission mechanism comprises an electromotor which is connected with a big belt wheel, and the big belt wheel is connected with a small belt wheel through a transmission belt. The electromotor is fixed on the pedestal. The automatic potato peeler is characterized in that the silo mechanism is arranged at the middle part of the pedestal, and the gear transmission mechanism and the belt transmission mechanism are arranged at two sides of the silo mechanism. The silo mechanism is composed of a bearing frame and a silo. The bearing frame is connected with the pedestal and the silo is connected with the bearing frame through a shaft. A silo port and a silo port cover are arranged on the silo and abrasive is arranged inside the silo. The automatic potato peeler has the good effects that the automatic potato peeler can totally peel the potato without secondary processing; the automatic potato peeler is particularly suitable for rootstalk fruit with unsmooth surfaces; and the automatic potato peeler is small in waste and high in peeling efficiency and preserves the nutrition of the fruit to the largest extent.

Owner:ZHONGBEI UNIV

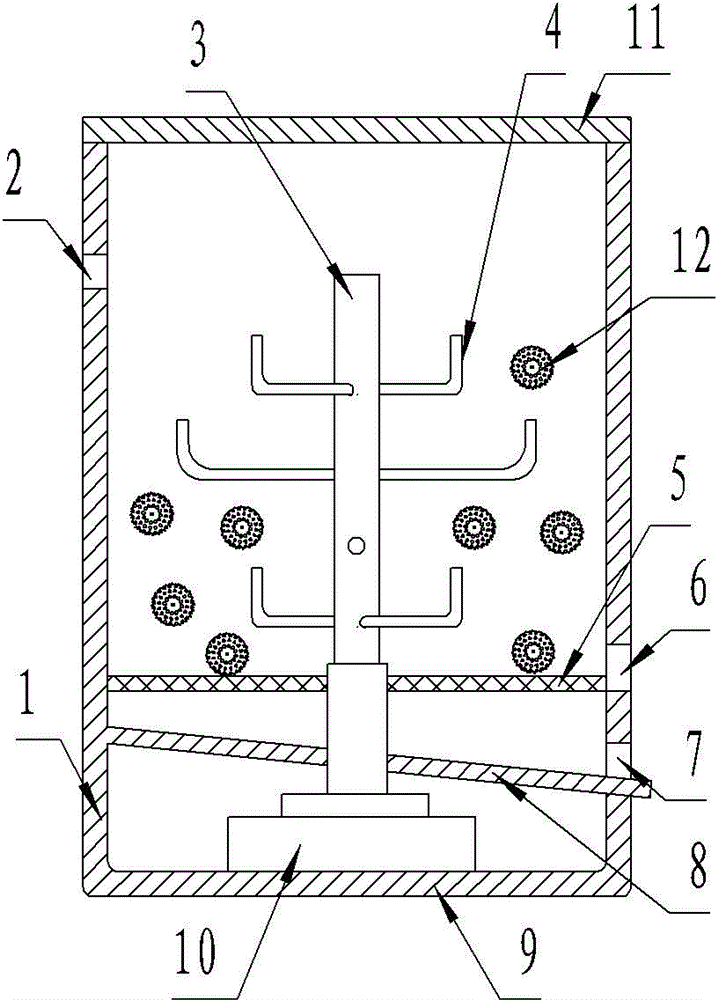

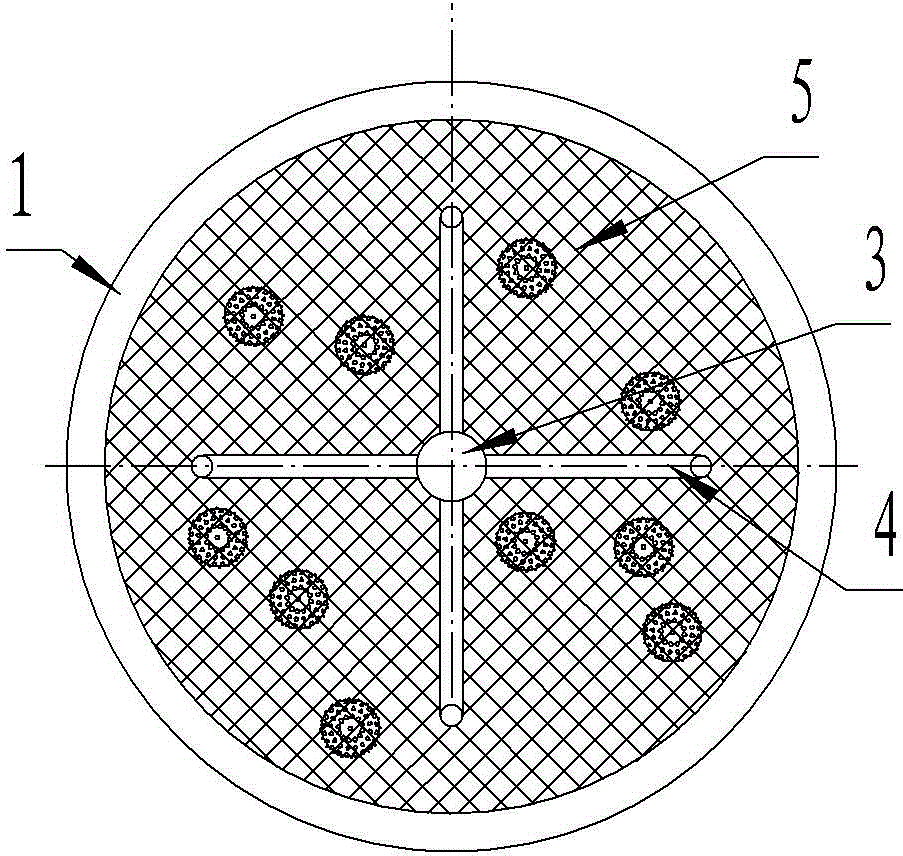

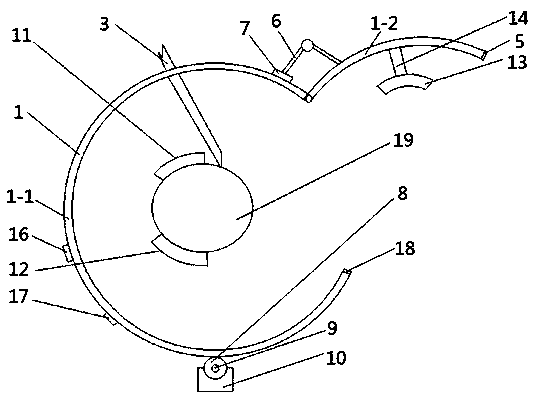

Water chestnut peeling machine

ActiveCN104473305AThoroughly peeledImprove peeling efficiencyVegetable peelingWater ChestnutsPower output

The invention discloses a water chestnut peeling machine comprising a cylinder. The cylinder is provided with an upper bottom and a lower bottom. A horizontal motor is arranged between the upper bottom and the lower bottom. A power output shaft of the horizontal motor extends upward to penetrate the upper bottom to be connected with a vertical shaft. The vertical shaft is driven by the power output shaft and uniformly provided with multi-row stirring bar sets. Each stirring bar set comprises at least two stirring bars which are radially mounted on the vertical shaft. The tails of the stirring bars bend downward. A screen is arranged between the lowest stirring bar set and the upper bottom which is obliquely arranged. A slagging outlet and a discharging outlet are formed in the wall of the cylinder. A plurality of flexibly peeling balls with metal protrusions are arranged upon the upper bottom in the cylinder. By the use of the water chestnut peeing machine, the problems that the conventional water chestnut peeling is difficult and low in efficiency and deep-processed product development of the water chestnuts is limited can be solved.

Owner:钦州市钦南区金窝工业园管理委员会

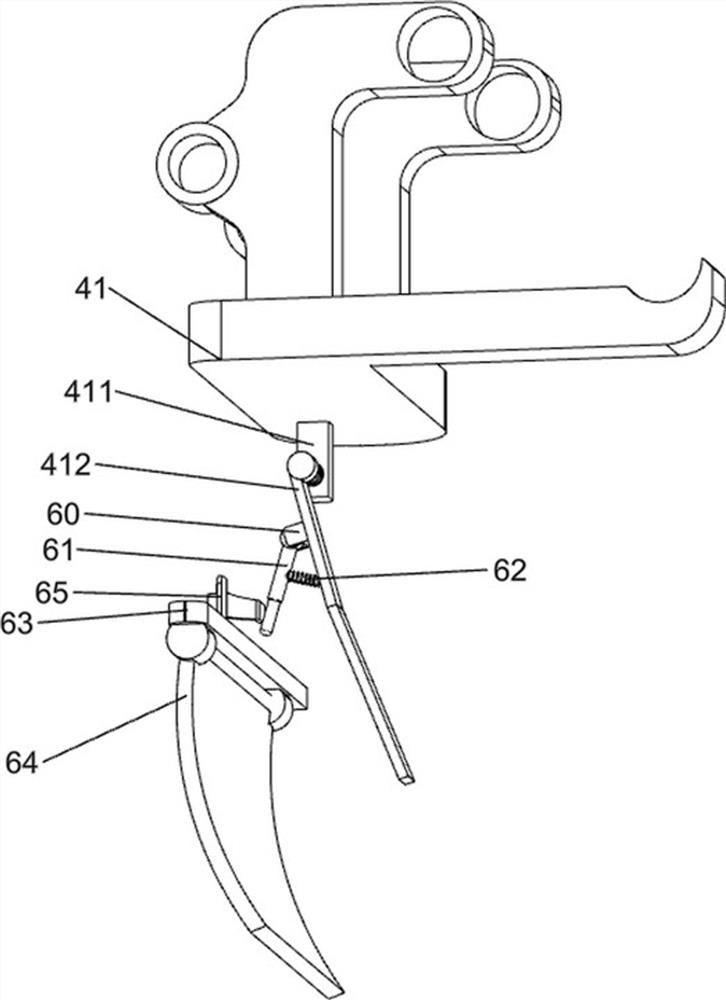

Portable fresh red date peeling and stone removing machine

PendingCN107114807AInnovative designSimple structureFruit stoningVegetable peelingElectric machineBristle

The invention discloses a portable fresh red date peeling and stone removing machine. The machine includes a base, a support beam, a stone removing rod, an upper fixture, a lower fixture, a peeling tube and a connecting arm; the support beam is hinged to the base; the upper fixture and the lower fixture are oppositely mounted on the support beam and the base; the stone removing rod is mounted on the support beam and inserted in the upper fixture; bristles are arranged in the peeling tube; the peeling tube is mounted on the connecting arm through a bearing; the other end of the connecting arm is hinged to the base; a motor is mounted in the connection arm; an output end of the motor is connected with the peeling tube in an engaged mode through gears. The machine has the advantages of being novel in design, simple in structure, small and exquisite, convenient to carry, convenient to operate and low in cost, and has the functions of peeling and removing stones. The inner wall of the peeling tube is covered with the bristles, through the constant rotation of the peeling tube, and the bristles constantly brush peels of red dates so as to achieve the function of peeling, the peeling is thorough and the efficiency is high. To achieve the stone removing function, impact stone removing is conducted on red date stones by using the stone removing rod, the stone removing precision is accurate and the efficiency is very high.

Owner:RES INST OF AGRO PROD PROCESSING SHANXI ACADEMY OF AGRI SCI

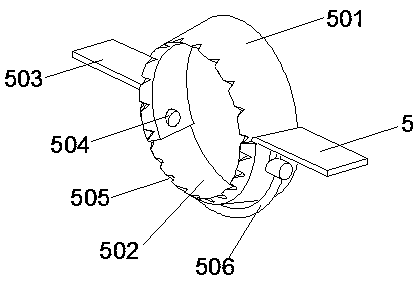

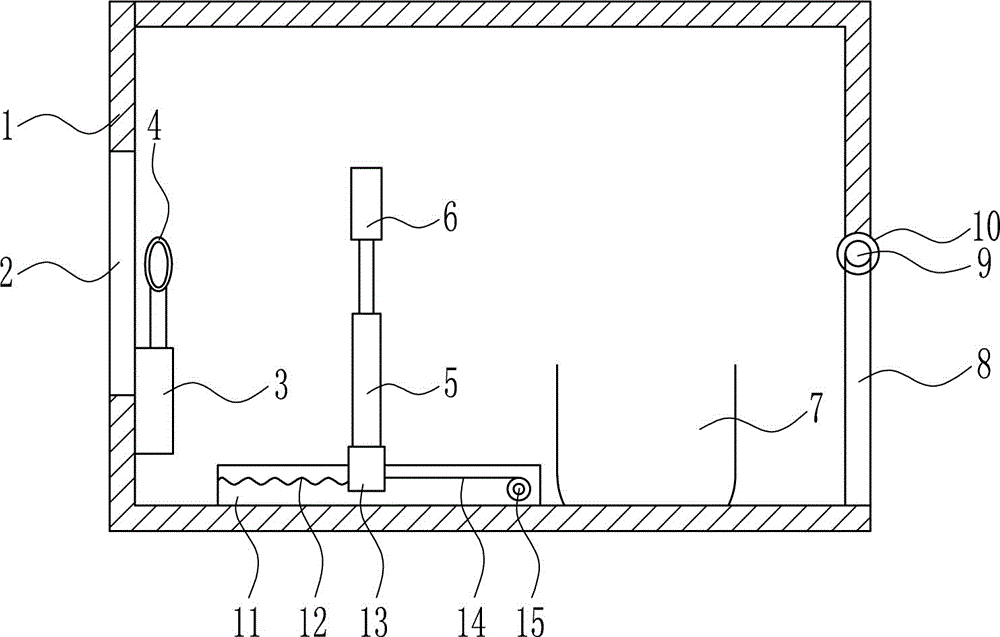

Cable fast peeling device for electronic communication

InactiveCN106340832AFast peelingThoroughly peeledApparatus for removing/armouring cablesElectronic communicationMaterial resources

The invention relates to a cable fast peeling device, and particularly relates to a cable fast peeling device for electronic communication. The technical problem to be solved is to provide a cable fast peeling device for electronic communication, and the device has the advantages of fast peeling speed, thorough peeling and a simple peeling process. In order to provide the cable fast peeling device for electronic communication, the device comprises a box body, an electric push rod I, a guide sleeve I, an electric push rod II, a peeling device, a collection groove, a baffle plate, a rotation shaft, a motor, a sliding rail, a spring I, a slide block, a pull wire, and an electric reel. The middle of the left wall of the box body is provided with a straight hole. The electric push rod I is arranged under the left wall in the box body. The upper end of the electric rod I is connected to the guide sleeve I. The bottom in the box body is provided with the collection groove and the slide rail which is at the left side of the collection groove. The slide rail is provided with the slide block. According to the device, the effects of the fast peeling speed, thorough peeling, and the simple peeling process are achieved, and a lot of manpower and material resources are saved.

Owner:湖北喵喵智能物联网科技有限公司

Red date sesame paste and preparation process thereof

InactiveCN103766709AThoroughly peeledSolves bitter tasteSugar food ingredientsFood ingredient as taste affecting agentFlavorSlurry

The invention discloses a preparation process for a red date sesame paste. The process includes: soaking red dates in an acidic aqueous solution, then conducting high pressure steam treatment, beating and separation to obtain a date slurry and data residue; heating, stirring and separating the data residue to obtain a secondary date slurry, combining the date slurries, adding embedding materials, and carrying out concentration and drying to obtain red date powder; mixing the red date powder, rice meal, coarse grain powder and black sesame powder, and conducting sterilization, thus obtaining the red date sesame paste. The invention also discloses the red date sesame paste prepared by the process. According to the invention, by means of acidic water solution soaking for peeling and embedding material adding, the astringent taste of the red date product can be effectively eliminated. The prepared red date sesame paste has rich nutrition, heavy flavor, and fragrant and sweet taste.

Owner:李雄骥

Peeling and gourd ladle taking integrated device for pumpkin processing

ActiveCN111642967ANot easy to dropTo achieve the effect of peelingPeelersAgricultural engineeringStructural engineering

The invention provides a peeling and gourd ladle taking integrated device for pumpkin processing. The device comprises a box body in a front and back side penetrating arrangement, an annular chute isformed in the outer side of the bottom center of the box body; a rotary collecting device is horizontally and rotationally connected to the center of the bottom of the box; a supporting shaft and a ladle removing device are horizontally and rotationally connected to the two sides of the center of the top of a horizontal collecting device correspondingly; a servo motor is fixedly mounted at the topof a lifting assembly; a rotating shaft is vertically and rotationally connected to the side, close to the center of the box, of the lifting assembly; a notch groove is longitudinally formed in the center of the top of the box, rolling grooves are formed in the left and right sides of the notch groove; a lifting device is mounted at the upper end of the notch groove; and a vertical plate is fixedly connected to the position, located on the rear side of the notch groove, of the top of the box body, a first electric push rod is fixedly connected to the side, close to the center of the box body,of the vertical plate, and the other end of the first electric push rod is fixedly connected with the lifting device. The invention provides the peeling and gourd ladle taking integrated device for pumpkin processing to solve the problem of low efficiency of peeling and gourd ladle taking of the pumpkin processing.

Owner:新疆海川三新食品有限公司

Garlic peeling machine

The invention discloses a garlic peeling machine, comprising a stander and a drive motor. An inclined cylinder-shaped casing body is arranged on the stander, a rotation inner cylinder is arranged in the casing body, the rotation inner cylinder is fixed in the cylinder-shaped casing body by a shaft collar, the outer wall of the rotation inner cylinder is provided with an outer gear ring matched with a drive gear, an opening of the upper end of the rotation inner cylinder is a feeding and skin-discharging port, an opening of the lower end is a garlic outlet, the garlic outlet is provided with a skin-blowing wind pipe, and a wind outlet of the skin-blowing wind pipe points to the feeding and skin-discharging port. In the garlic peeling machine, garlic is peeled by a way of streamlined production. And the garlic peeling machine has the advantages of being high in work efficiency, large in output in a unit time and simple in structure.

Owner:LIAONING FUBEN FOOD

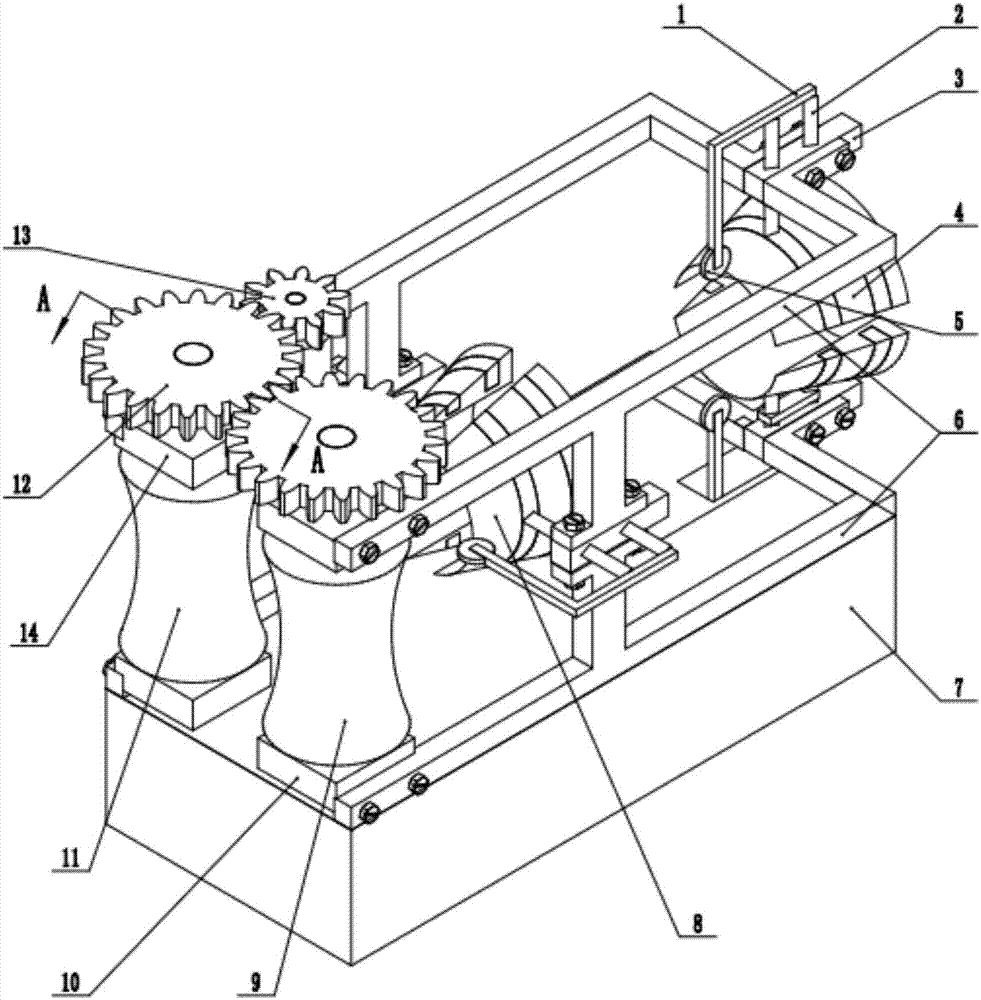

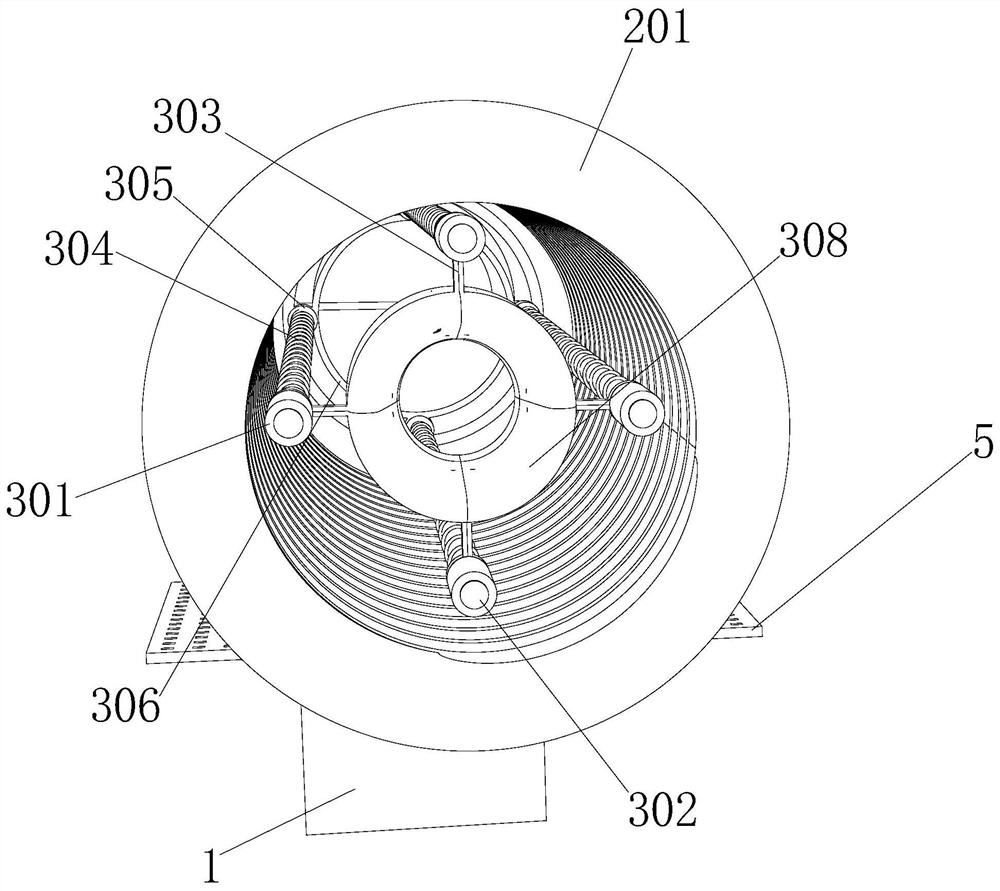

Sugarcane peeling device

ActiveCN107087966APeeling saves effortThoroughly peeledPeelersMechanical engineeringEnergy consumption

The invention relates to a sugarcane peeling device, and belongs to the technical field of food processing. The sugarcane peeling device is composed of a datum frame, a knife rest, a knife rest fixing rod, a first cutter, a datum wheel, a rack, a base, a second cutter, a first feeding roller, a lower bearing pedestal, a second feeding roller, a driving gear, a driven gear, an upper bearing pedestal and a driving machine. The knife rest is composed of a fitting knife rest, a catch spring plate, a spring and a sliding rod, and the first feeding roller is composed of a roller soft core, a roller outer covering shell and a rotating shaft. The sugarcane peeling device has the advantages of being high in efficiency, small in energy consumption, easy to operate and small in noise, and the peeled sugarcane has not residual peel or extrusion damage and is attractive in appearance and good in mouthfeel.

Owner:徐州彭耀家具厂

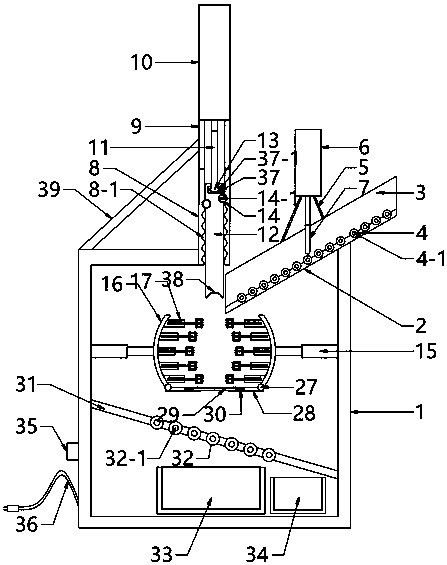

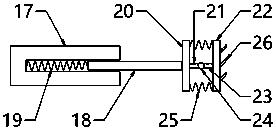

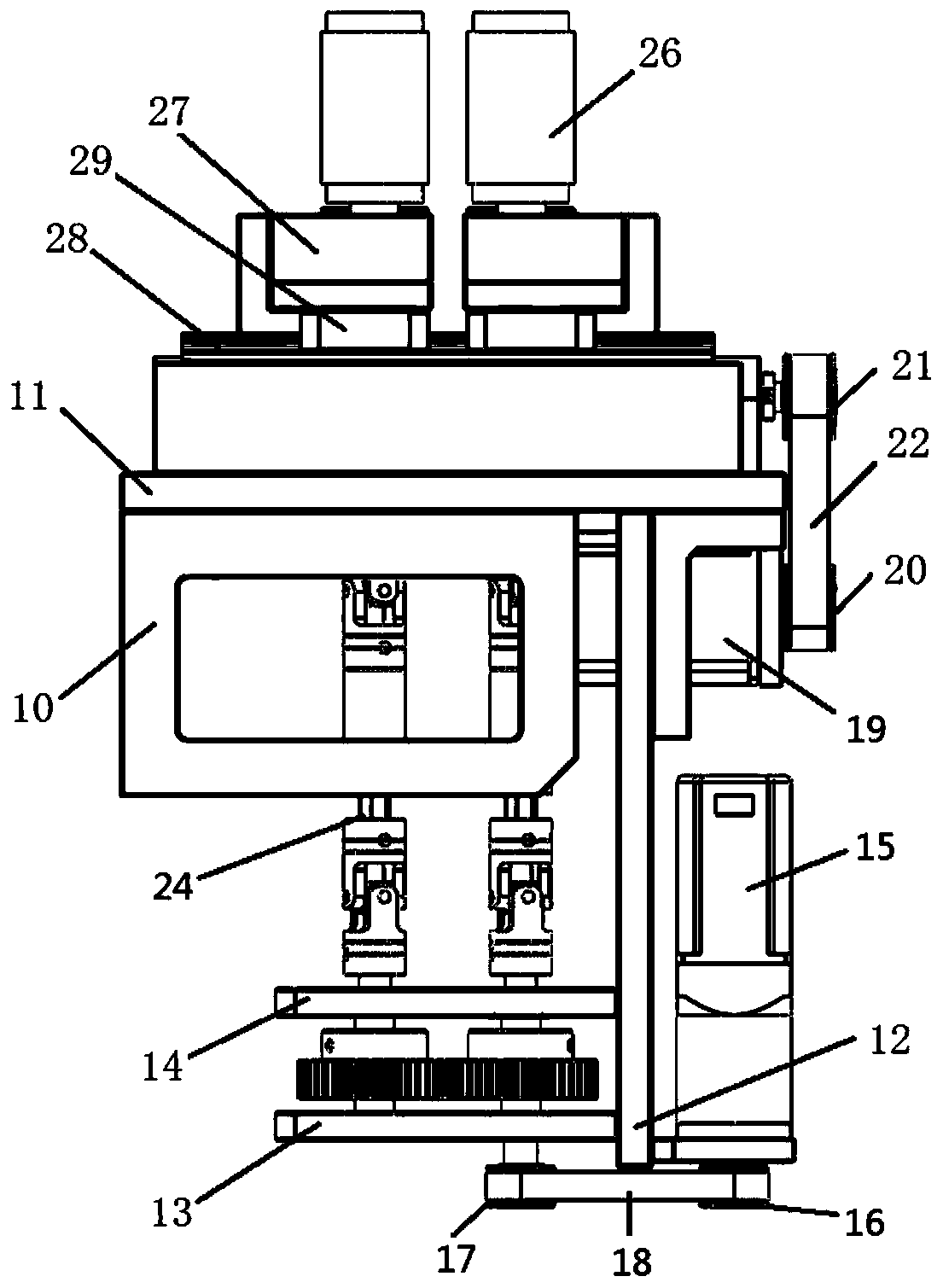

Apple processing equipment for food production

PendingCN112586750AImprove work efficiencyThoroughly peeledFruit stoningVegetable peelingProcess engineeringIndustrial engineering

The invention relates to processing equipment, in particular to apple processing equipment for food production. The apple processing equipment for food production which can be used for automatically peeling and coring apples and has the high working efficiency is provided. The invention provides the apple processing equipment for food production, and the apple processing equipment for food production comprises a bottom plate, a work table, a turntable mechanism, a sliding mechanism and a storage box, wherein the work table is arranged at the top of the bottom plate; the turntable mechanism isarranged at the upper part of the work table; the sliding mechanism is arranged between the upper part of the work table and the turntable mechanism; and the storage box for collecting water for cleaning apples is arranged in the middle of one side of the top of the bottom plate. Through the cooperation of the turntable mechanism and the sliding mechanism, conveying and coring operations can be automatically performed on the apples, people do not need to manually core the apples, and the working efficiency of people is improved; through a reset mechanism, a cutter can peel the apples more thoroughly, and convenience is brought to the work of people; and through a slicing assembly, the peeled apples can be automatically sliced.

Owner:湖南金玖农商现代农业有限公司

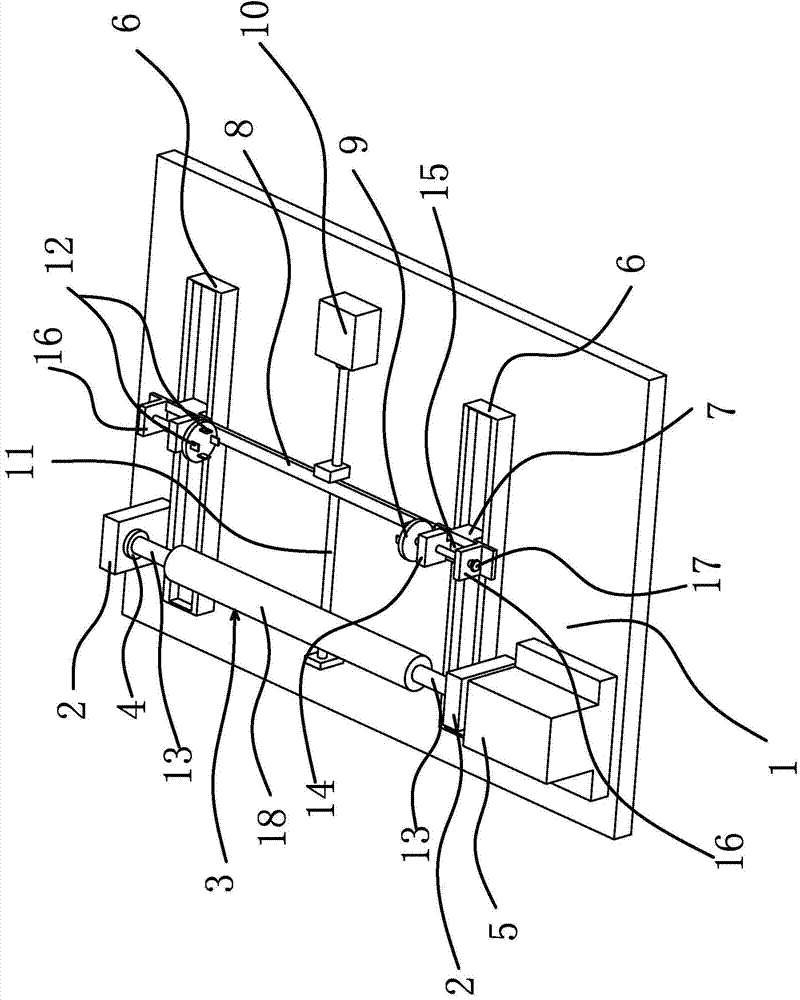

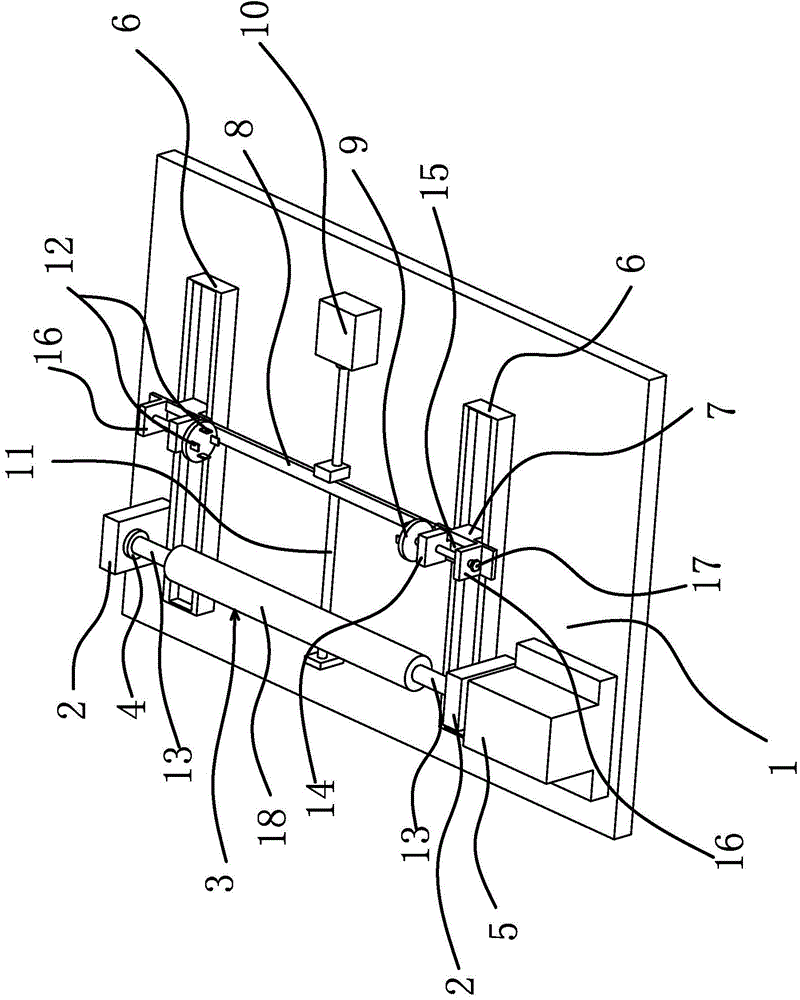

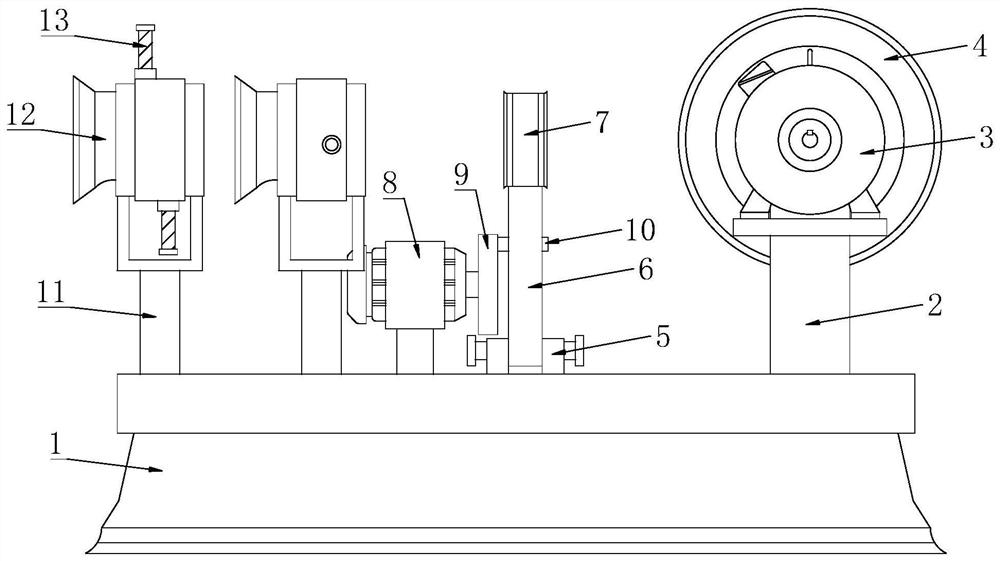

Chinese yam peel-removing method

The invention provides a Chinese yam peel-removing method and belongs to the technical field of machinery. In order to solve the technical problems of high time consumption and the like when a current Chinese yam peel remover is used for removing peel of Chinese yam. The Chinese yam peel-removing method comprises the following steps: a, fixing the two ends of the Chinese yam to a rotary plate of the Chinese yam peel remover though a positioning mechanism on the Chinese yam peel remover; b, operating a motor I to rotate a roller barrel; c, moving a slide base towards the roller barrel in a slide rail length direction by moving the fixed rod, and driving the Chinese yam fixed on the rotary plate to move towards the roller barrel until the side wall of the Chinese yam and the side wall of the roller barrel are clung; d, operating the rotary plate to drive the Chinese yam to rotate until the rotary roller barrel grinds the peel on the side wall of the Chinese yam. The Chinese yam peel-removing method can be used for reducing waste during peel removal of Chinese yam.

Owner:南通东湖国际商务服务有限公司

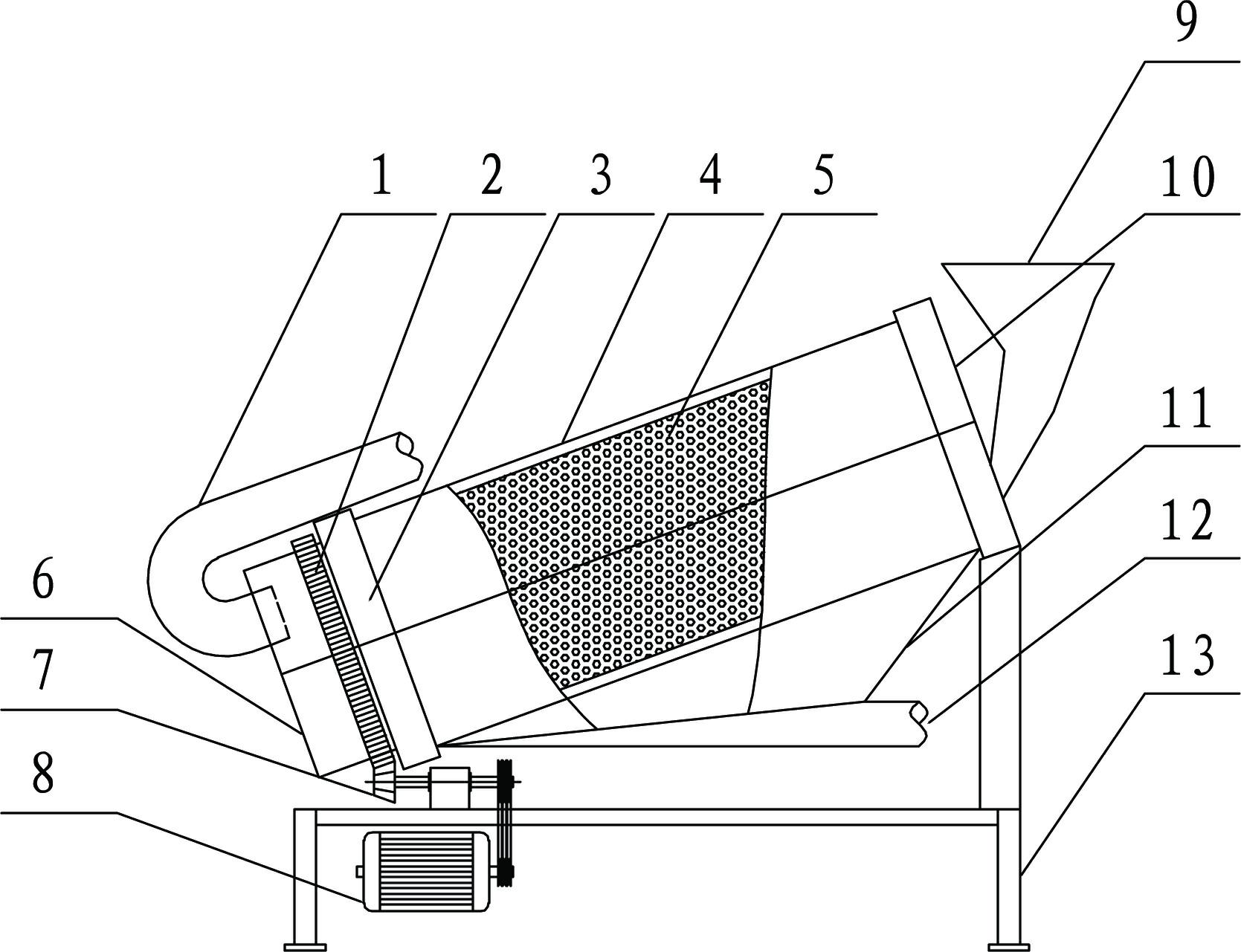

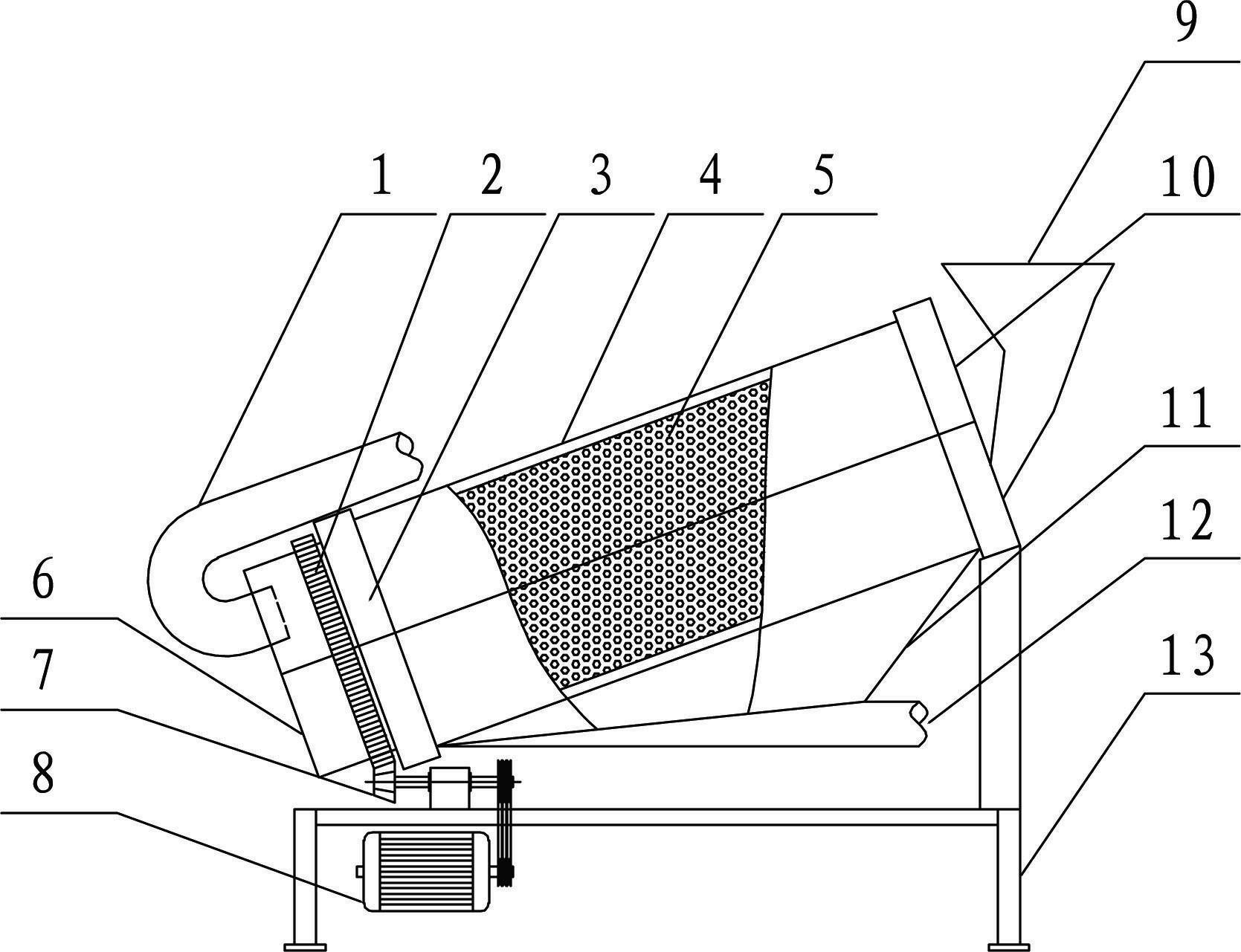

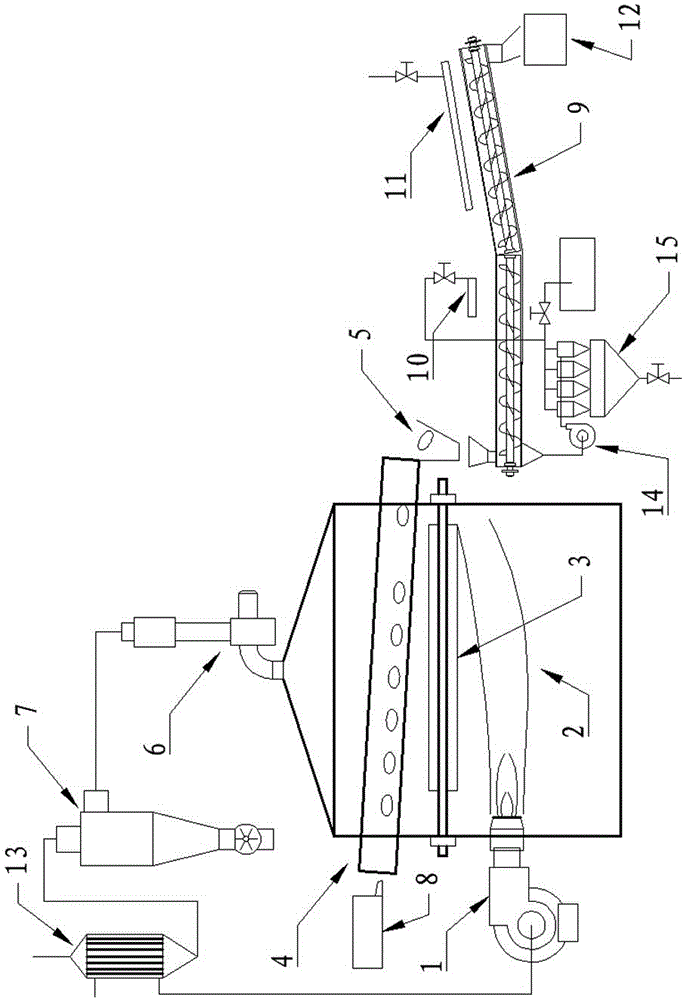

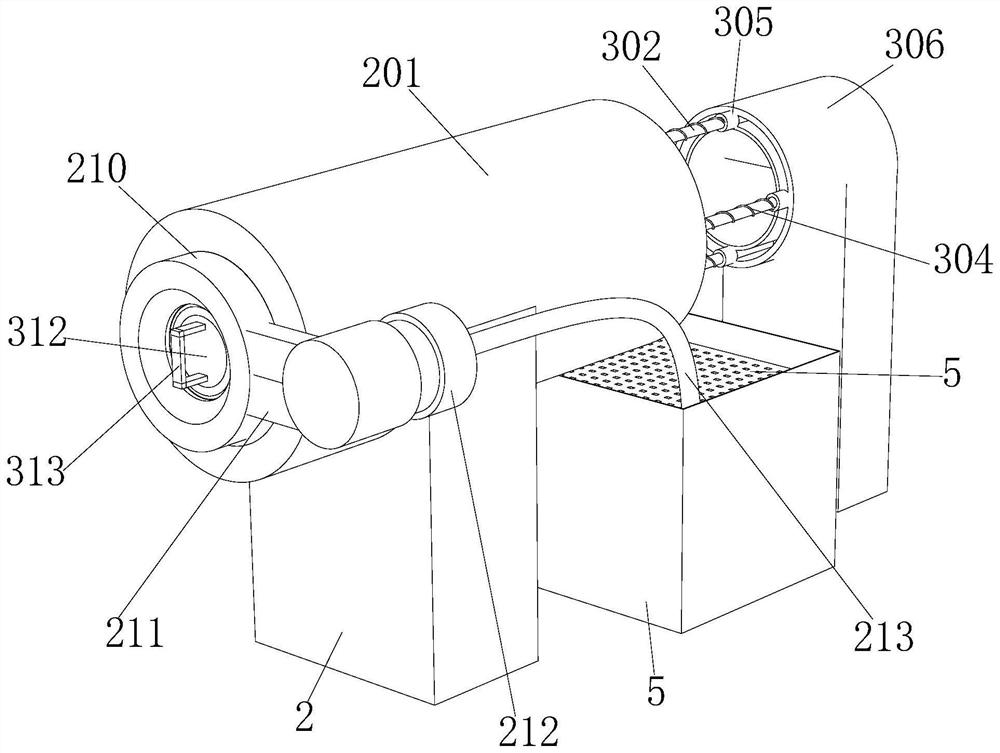

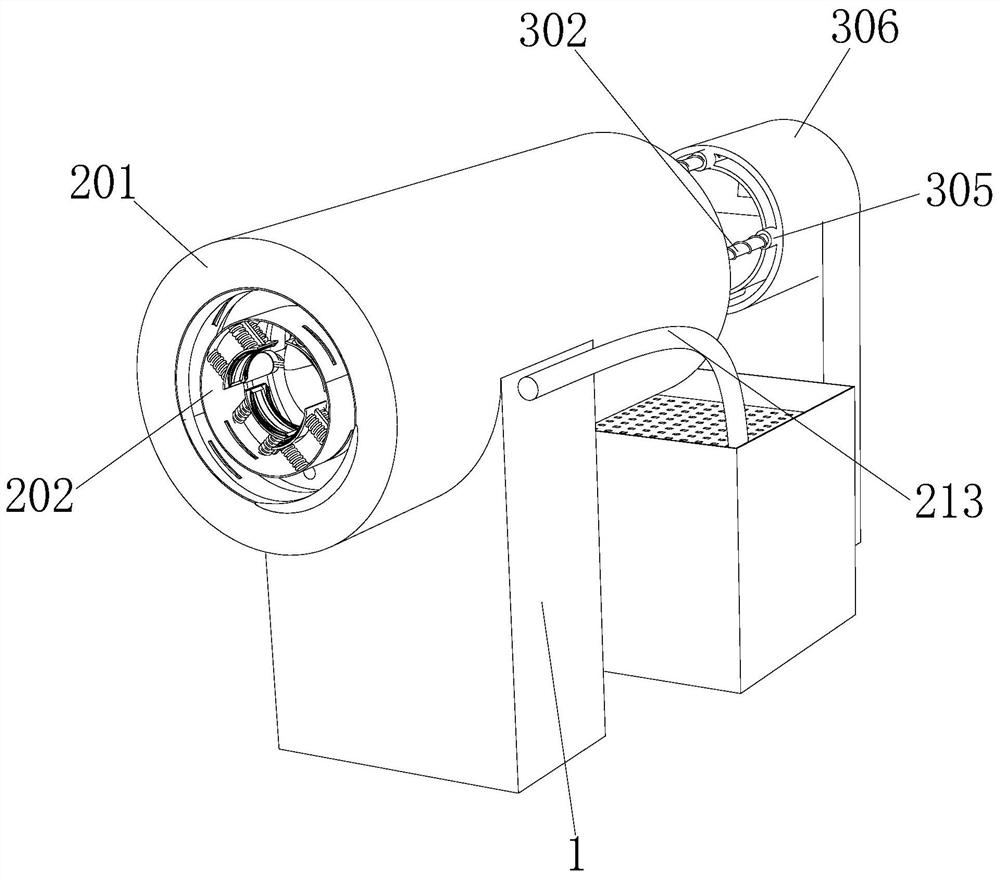

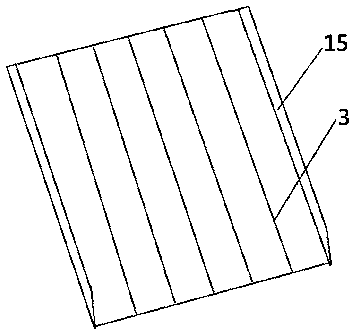

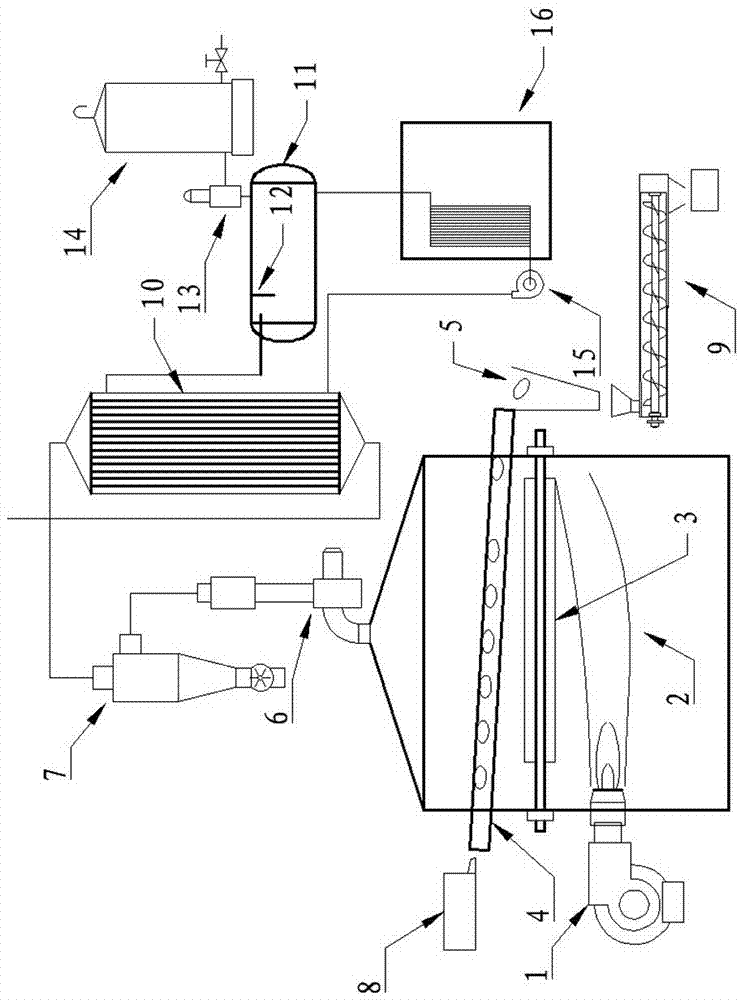

Drum screen type fire peeling device for mangos

ActiveCN104799414ASimple peelingReduce energy consumptionVegetable peelingEngineeringMechanical engineering

The invention discloses a drum screen type fire peeling device for mangos. A long-paddle flame stirrer is arranged between a drum screen and combustor flame, wherein the drum screen, the long-paddle flame stirrer and a combustor form a firing and carbonizing part; the inclination angle and rotation speed of the drum screen are adjustable; a heat insulation and preservation layer which is thick enough is arranged in an external surrounding structure to form a baking chamber; a vibratory feeding hopper is arranged at the feeding end of the drum screen; the discharging end of the drum screen is connected with a brush stranding cage; a left section of the brush stranding cage is a parallel structure and comprises a coarse screen which is communicated with a buffering tank and a regeneration water sprayer through a water pump and a cyclone separator component; the regeneration water sprayer is used for spraying the left section of the brush stranding cage; a running water sprayer is arranged above the right section of the brush stranding cage and is used for spraying the right section of the brush stranding cage; the discharging end of the brush stranding cage is connected with a finished product tank. According to the drum screen type fire peeling device for mangos, the drum screen is used for conveying and stirring materials and cooperates with a powerful stirring manner to carry out fire peeling; no noxious residue is left after the mangos are washed; the drum screen type fire peeling device for mangos is capable of easily, thoroughly and uniformly peeling, conveniently adjusting the processing scale and continuously peeling.

Owner:JISHOU UNIVERSITY

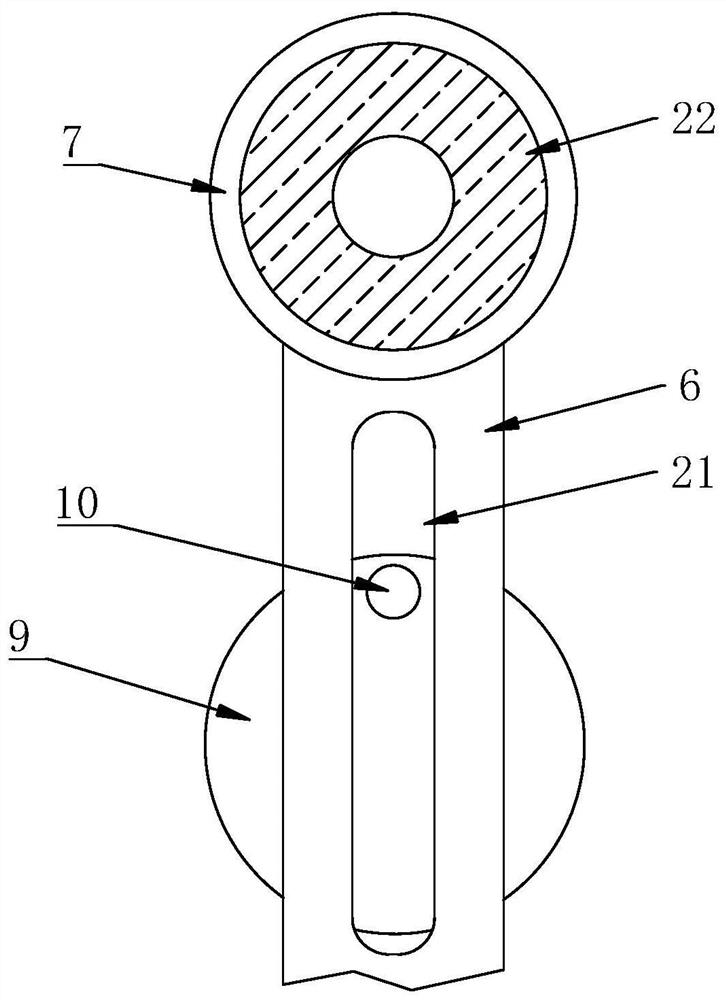

Green walnut peeling machine

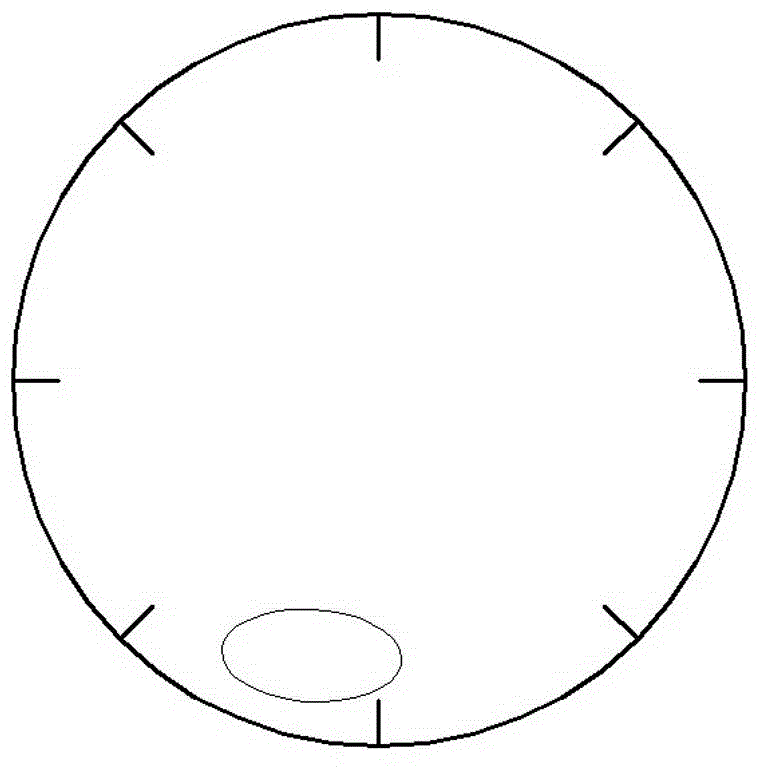

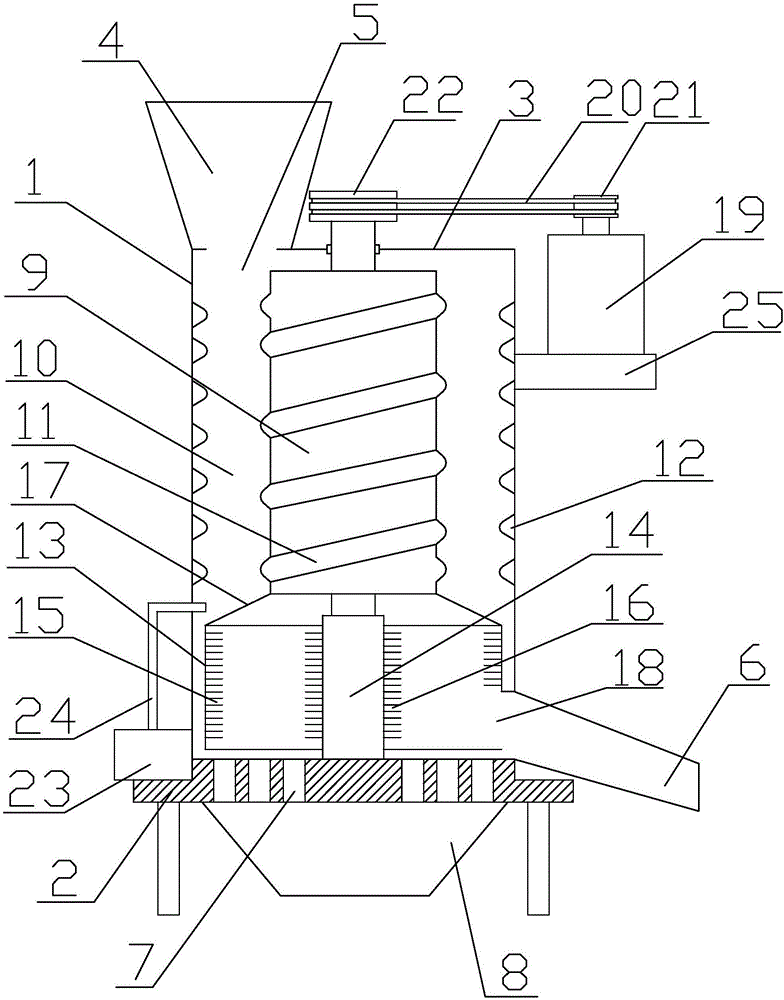

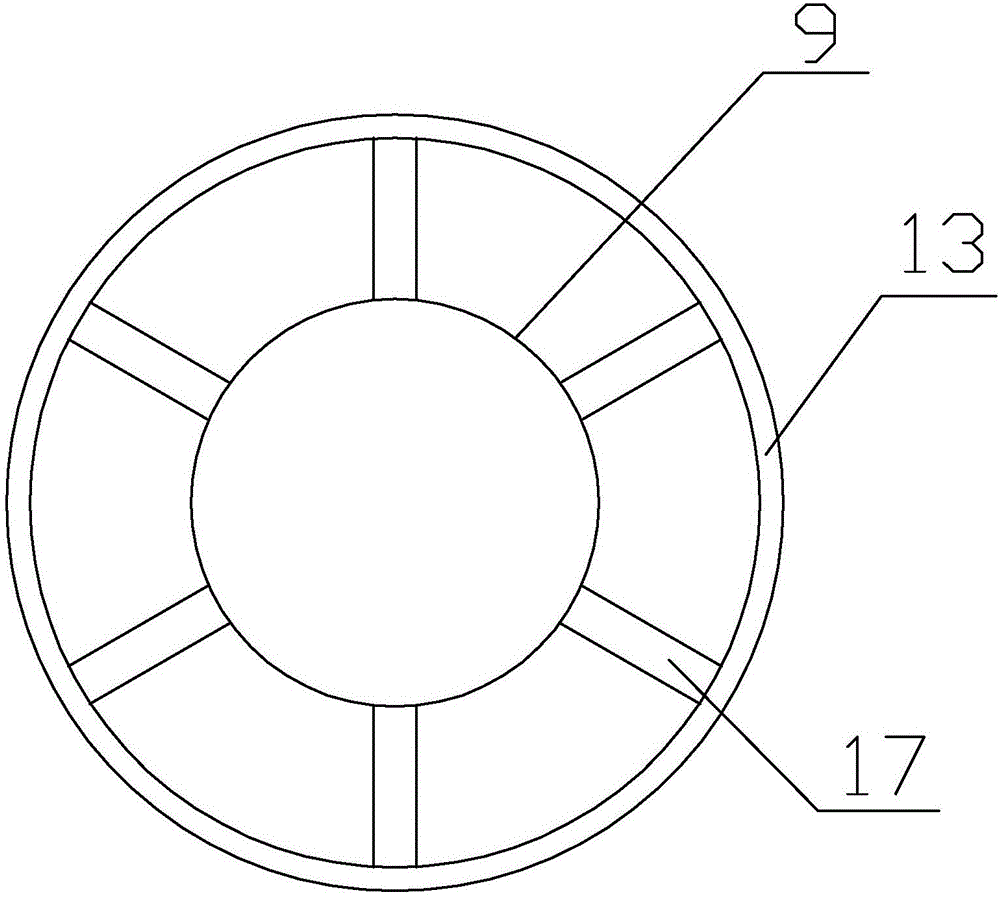

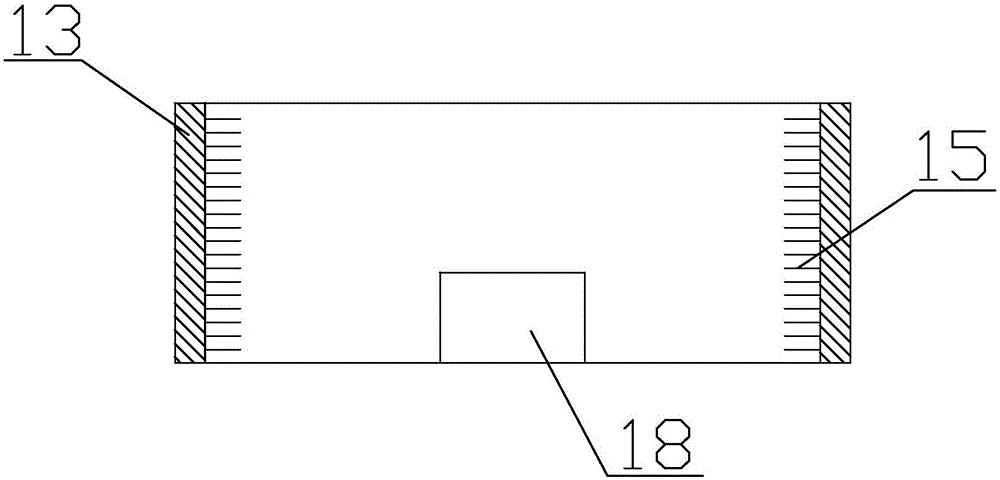

The invention discloses a green walnut peeling machine. The green walnut peeling machine comprises a cylindrical shell (1) and a supporting seat (2), wherein a cover plate (3) is arranged at the top of the cylindrical shell. The green walnut peeling machine is characterized in that a feed hopper (4) is arranged on the cover plate (3), the feed hopper (4) communicates with the cylindrical shell (1), and a first peeling mechanism and a second peeling mechanism are arranged in the cylindrical shell (1); a driving mechanism is arranged on the cylindrical shell (1); a water supply mechanism is arranged on the cylindrical shell (1); a walnut outlet (6) is formed in the cylindrical shell (1); net holes (7) are formed in the supporting seat (1); and a collecting pipe (8) is arranged under the supporting seat (2). The green walnut peeling machine provided by the invention comprises two peeling processes, and peeled walnuts are added with water for washing, so that the walnuts are thoroughly peeled, and complete walnuts after kernel removal are maintained.

Owner:张文凯

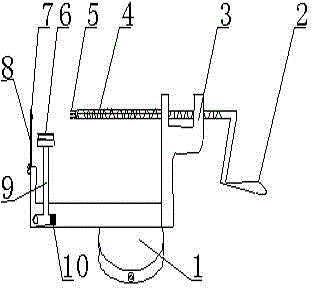

Novel fruit peeling machine

The invention discloses a novel peeling machine, which comprises a base 1, a crank handle 2, a bracket 3, a threaded rod 4, a three-fork knife 5, a peeling knife 6, a rotary knife 7, a rotary knife rest 8, a peeling knife rest 9 and a tension spring (10); the peeling machine is characterized in that the peeling knife 6 is arranged on a transverse rod at the bottom of the bracket 3 by virtue of the peeling knife rest 9; the peeling knife rest 9, by taking the bracket 3 as a pivot, can swing by a 20-degree angle by virtue of the tension spring 10; the rotary knife 7 is fixed to the leftmost end of the bracket 3 by virtue of the rotary knife rest 8; a thickness limiter is arranged on the peeling knife 6; and by adjusting the positions of a screw and a reset spring, a peeling thickness is controlled. The peeling machine is simple in structure; the peeling machine is capable of conducting peeling and slicing simultaneously; fruits can be cut into spiral forms, so as to facilitate direct eating; and the peeling machine is suitable for peeling off various fruits.

Owner:青岛时空机械科技有限公司

Chinese yam peeling machine

The invention discloses a Chinese yam peeling machine and belongs to the mechanical technology field. The Chinese yam peeling machine can solve the technical problem that Chinese yams are greatly wasted when a current Chinese yam peeling machine performs peeling. The Chinese yam peeling machine comprises a pedestal on which two installing bases are arranged at intervals, and bearings are respectively arranged on the installing bases; the Chinese yam peeling machine further comprises a roller and two mutual parallel sliding rails, both ends of the roller are respectively inserted in the bearings on the two installing bases, and one end of the roller is further connected with a first motor which is fixed on the pedestal; the length direction of each sliding rail is perpendicular to the special-shaped plane in the length direction of the roller; the sliding rail is connected with a sliding base in sliding, the sliding base between the sliding rails on two poles is connected through a fixing rod, a turntable is further arranged on the sliding base in a rotation way, and a positioning mechanism capable of fixing Chinese yams is arranged on the turntable. According to the Chinese yam peeling machine, the waste caused by peeling the Chinese yams can be reduced.

Owner:JIAXING VOCATIONAL TECHN COLLEGE

Chinese yam peeling device

InactiveCN112273667APrevent sticky stickyThoroughly peeledVegetable peelingFood treatmentEngineeringMechanical engineering

The invention provides a Chinese yam peeling device, and relates to the technical field of Chinese yam processing. The Chinese yam peeling device comprises a base, a peeling mechanism, a fixing mechanism, a water tank and a filter plate, the peeling mechanism is arranged at the top end of the base, Chinese yams are peeled through the peeling mechanism, and in the peeling process of the Chinese yams, Chinese yam peels can be cleaned in the rotating peeling process of the peeling mechanism, and therefore, the Chinese yam peels are prevented from being accumulated in the peeling mechanism to influence the peeling effect. The bottom end of the peeling mechanism is fixedly connected with the top end of the base, a fixing mechanism is arranged in the peeling mechanism, the situation that the peeling effect is affected due to the fact that the Chinese yams rotate and break in the peeling process is prevented, and the fixing mechanism is fixedly connected with the peeling mechanism; and a water tank is arranged below the right side of the middle of the peeling mechanism, a filter plate is fixedly connected into the water tank, and the problem that in the peeling process of Chinese yams, due to the fact that the surfaces of the Chinese yams are uneven and have a certain radian, the Chinese yams are stressed unevenly, and consequently the Chinese yams are broken is solved.

Owner:高玉国

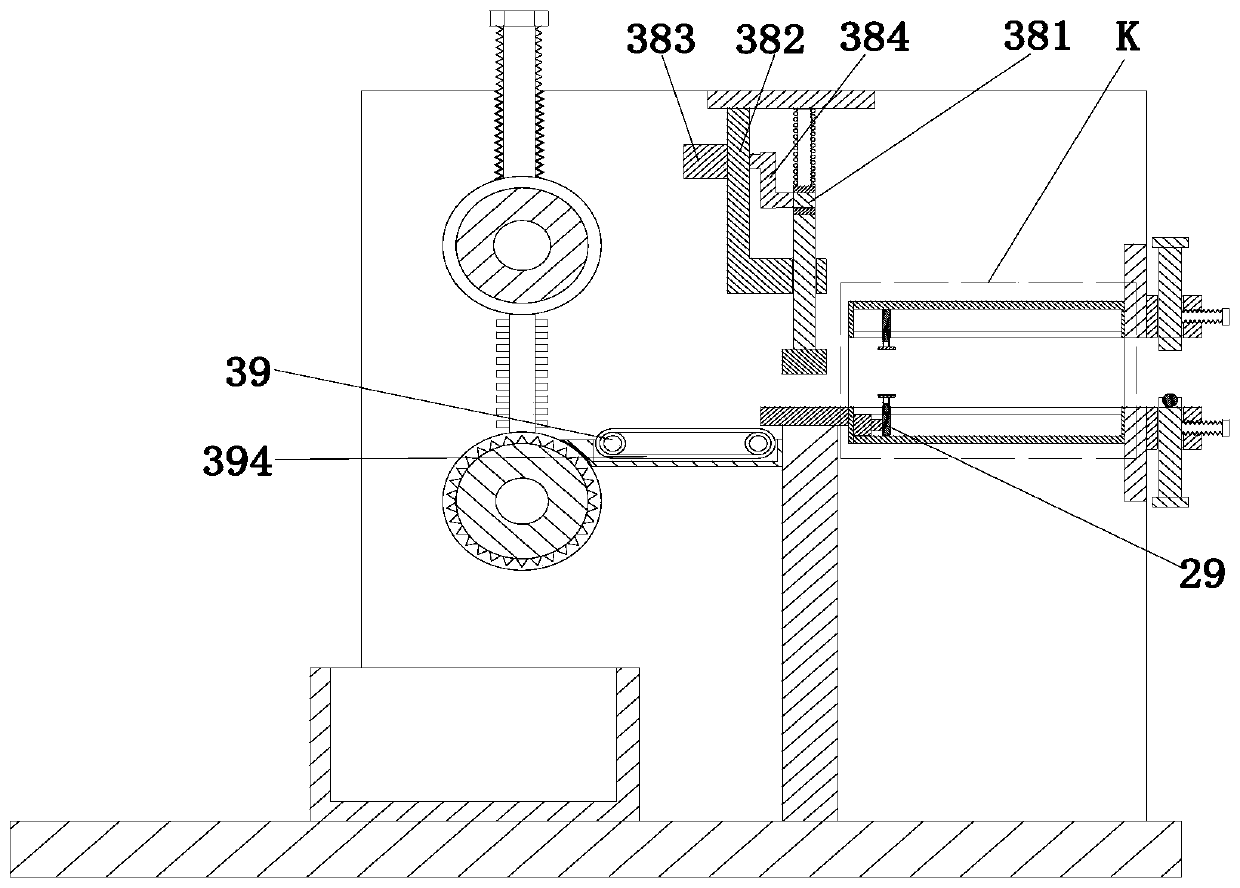

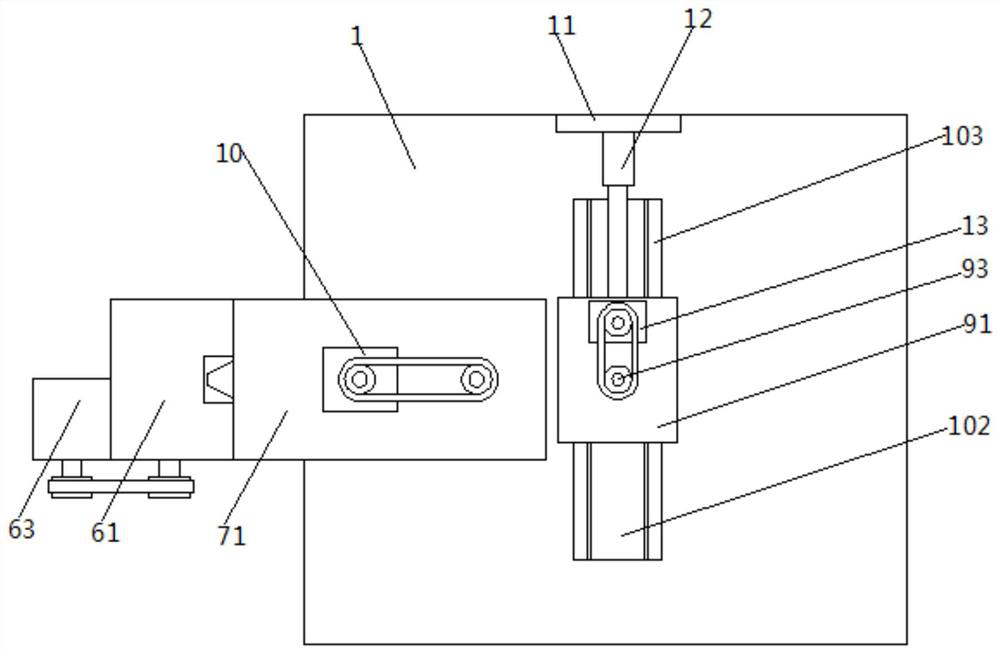

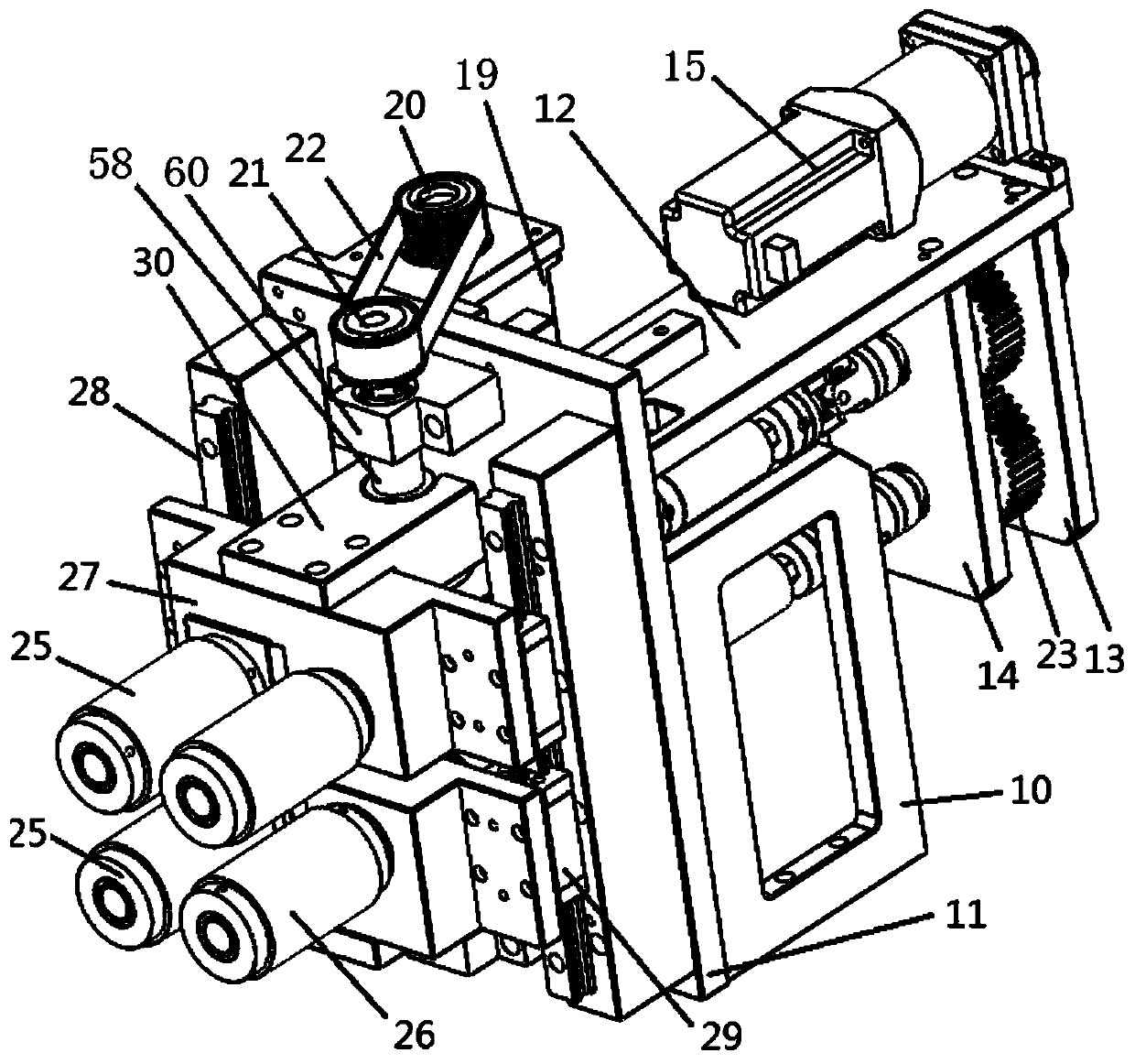

Power lead peeling device

ActiveCN110788924AEffective protectionAchieve productionMetal working apparatusApparatus for removing/armouring cablesGear wheelDrive by wire

The invention discloses a power lead peeling device. The power lead peeling device comprises a wire conveying device, a wire cutting device and a peeling device which are sequentially arranged from left to right, wherein the wire conveying device comprises a wire conveying support plate, a wire conveying motor mounting plate, a first isolation plate, a second isolation plate, a wire conveying driving motor, a first driving belt pulley, a first driven belt pulley, a first synchronous belt, a wire conveying motor, a second driving belt pulley, a second driven belt pulley, a second synchronous belt, a gear, a driving shaft, a driving roller, a fixed roller, a roller support seat, a vertical sliding chute seat, a sliding block, a lead screw nut seat and a side surface fixing plate. The power lead peeling device is designed for various cable varieties, adaptive processing of wire diameters is satisfied, automatic cutting of wire heads, wire middle parts and wire tails of cables is performed, cutting can be performed according to a fixed length, a copper core is effectively protected by twisting of a scissor hand through two vertical and horizontal peeling parts, unmanned assembly line production is achieved better, the power lead peeling device is high in reliability and thorough in peeling, and the yield of a product is improved.

Owner:STATE GRID ZHEJIANG JIASHAN POWER SUPPLY CO LTD +1

Peeling machine

The invention discloses a peeling machine. The peeling machine comprises a workbench, an arc-shaped pedestal, driving chain wheels, driven chain wheels, a chain, a first motor, a metal strip, a secondmotor, a peeling knife, a slide block, a limiting bump, a baffle ring, a first cylinder, a rotation cylinder, a third motor, a support plate and a threaded sleeve. A driving shaft and a driven shaftare arranged in the workbench. The two ends of the driving shaft and the driven shaft are rotatably connected to the corresponding two side inner walls of the workbench through bearings. The driving chain wheels symmetrically sleeve and are fixed to the outer side of the driving shaft. The driven chain wheels symmetrically sleeve and are fixed to the outer side of the driven shaft. The driven chain wheels are connected to the driving chain wheels through the chain in a transmission connection mode. One side of the workbench is fixed with the support plate. The operation of the device is safe,usage is convenient, the structure is simple, the machine is suitable for a plurality of different fruits, the plurality of fruits can be conveniently cut, the fruits are peeled cleanly with less losses, and labor efficiency is high.

Owner:山东爱樱维生态农业有限公司

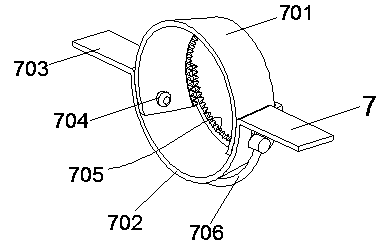

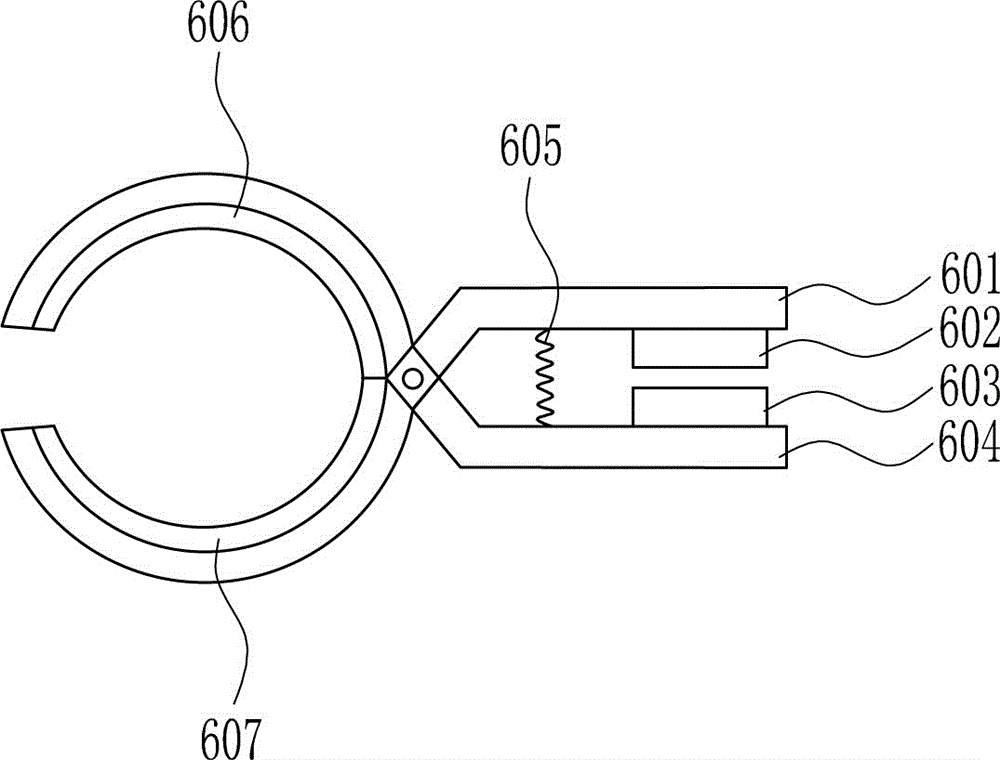

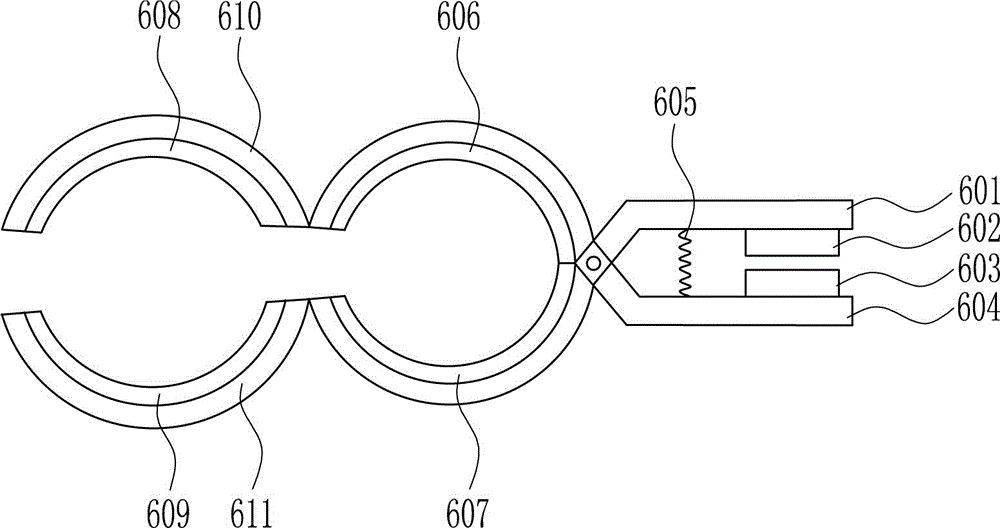

Electrified high-voltage cable hot-melt stripping machine

InactiveCN110474263AAutomatically adjust the arcLock lockApparatus for removing/armouring cablesHot meltHigh pressure

The invention relates to an electrified high-voltage cable hot-melting type stripping machine and belongs to the technical field of electrified high-voltage cable hot-melting type stripping machine structures. The device comprises two gear rings which synchronously rotate; the gear rings are driven by a gear mechanism meshed with the gear rings; shells are mounted on the exteriors of the two gearrings respectively; the shells are mounted on a cutter holder; a first rotating shaft is installed between the two gear rings; a row of blades of the same structure is installed along the length direction of the first rotating shaft; the lower surface of each blade is provided with an angle adjusting spring and an electromagnetic heating coil; one end of each angle adjusting spring is connected with the corresponding blade, and the other end of each angle adjusting spring is connected with the cutter holder; an adjustable clamp used for clamping a cable is installed between the two gear rings;and the edges of the blades contact with the sheath of the cable. The electrified high-voltage cable hot-melting type stripping machine has the advantages of low price, good stripping effect and simple and convenient operation.

Owner:QIXIA POWER SUPPLY CO STATE GRID SHANDONG ELECTRIC POWER CO

Drum sieve mango fire peeling device

The invention discloses a drum screen type fire peeling device for mangos. A long-paddle flame stirrer is arranged between a drum screen and combustor flame, wherein the drum screen, the long-paddle flame stirrer and a combustor form a firing and carbonizing part; the inclination angle and rotation speed of the drum screen are adjustable; a heat insulation and preservation layer which is thick enough is arranged in an external surrounding structure to form a baking chamber; a vibratory feeding hopper is arranged at the feeding end of the drum screen; the discharging end of the drum screen is connected with a brush stranding cage; a left section of the brush stranding cage is a parallel structure and comprises a coarse screen which is communicated with a buffering tank and a regeneration water sprayer through a water pump and a cyclone separator component; the regeneration water sprayer is used for spraying the left section of the brush stranding cage; a running water sprayer is arranged above the right section of the brush stranding cage and is used for spraying the right section of the brush stranding cage; the discharging end of the brush stranding cage is connected with a finished product tank. According to the drum screen type fire peeling device for mangos, the drum screen is used for conveying and stirring materials and cooperates with a powerful stirring manner to carry out fire peeling; no noxious residue is left after the mangos are washed; the drum screen type fire peeling device for mangos is capable of easily, thoroughly and uniformly peeling, conveniently adjusting the processing scale and continuously peeling.

Owner:JISHOU UNIVERSITY

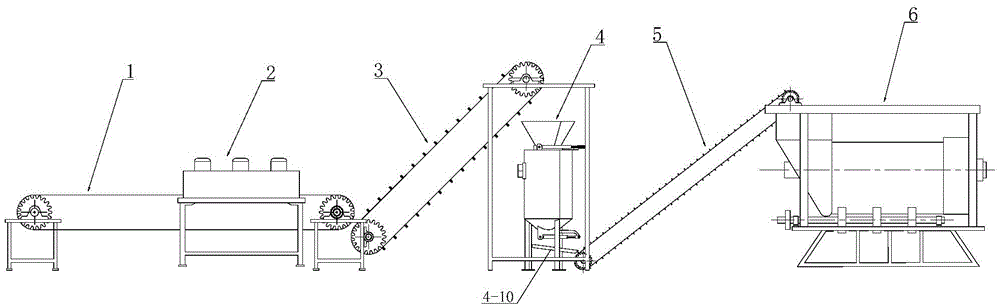

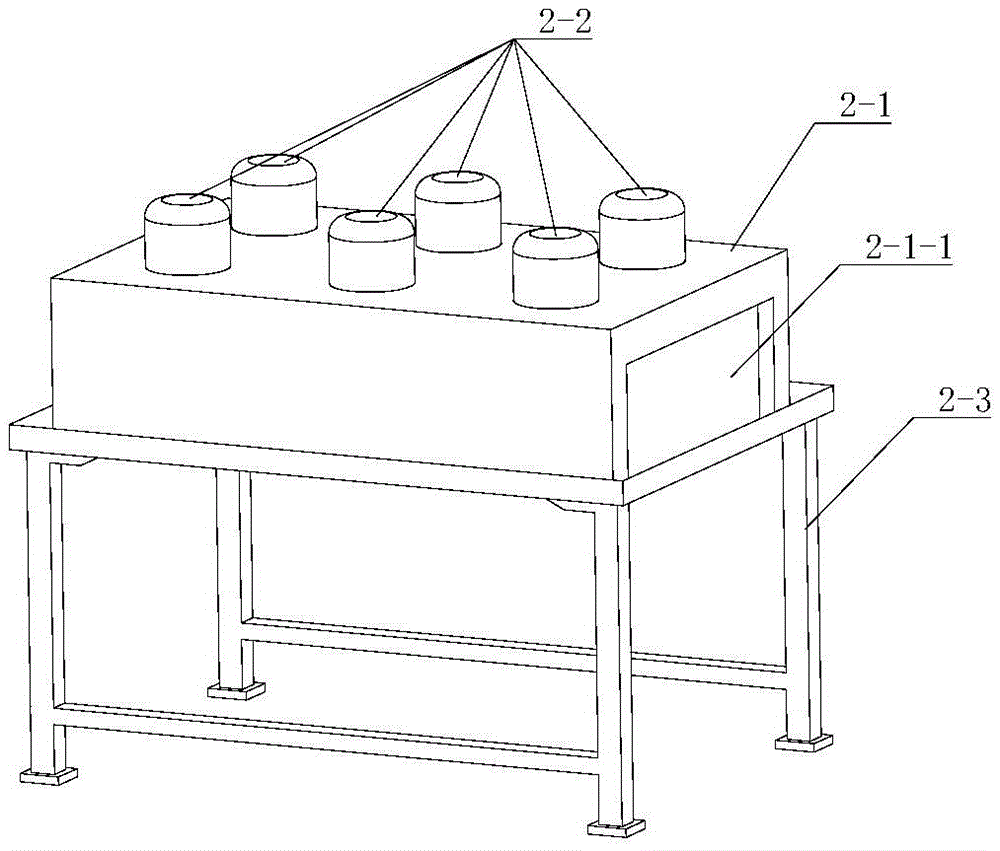

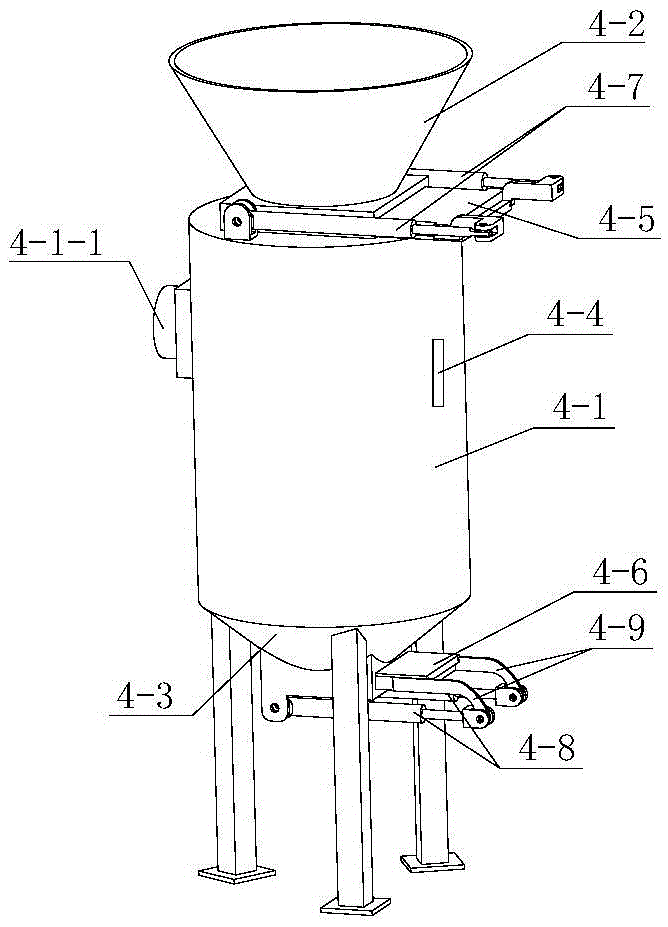

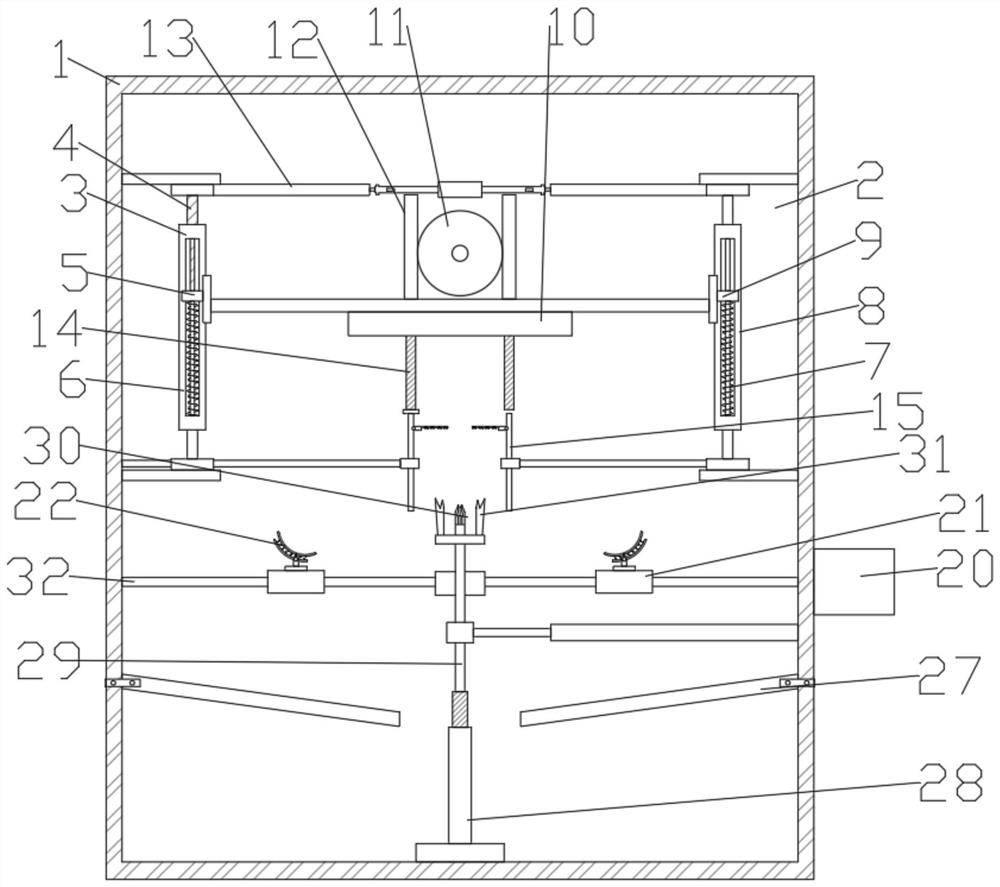

Full-automatic dry-type garlic peeling equipment

Full-automatic dry-type garlic peeling equipment is composed of a first-stage chain plate conveyor, a micro drying device, a second-stage chain plate conveyor, a pressurizing and depressurizing device, a third-stage chain plate conveyor and a pneumatic peeling device. According to a material conveying direction, a discharging end of the first-stage chain plate conveyor is connected with a feeding end of the second-stage chain plate conveyor, a discharging end of the second-stage chain plate conveyor is connected with a material inlet of the pressurizing and depressurizing device, a material outlet of the pressurizing and depressurizing device is connected with a feeding end of the third-stage chain plate conveyor, a discharging end of the third-stage chain plate conveyor is connected with a material inlet of the pneumatic peeling device, and an upward-moving conveying chain plate of the first-stage chain plate conveyor penetrates from a heating passage of a garlic drying box of the micro drying device. Binding force between garlic peels and garlic cloves is damaged through the micro drying device and the pressurizing and depressurizing device to separate the garlic peels from the garlic cloves, and then peeling is realized through high-pressure air, so that peeling efficiency is improved, good peeling effect is realized, and breakage rate of the garlic cloves is lowered substantially.

Owner:HEBEI UNIV OF TECH

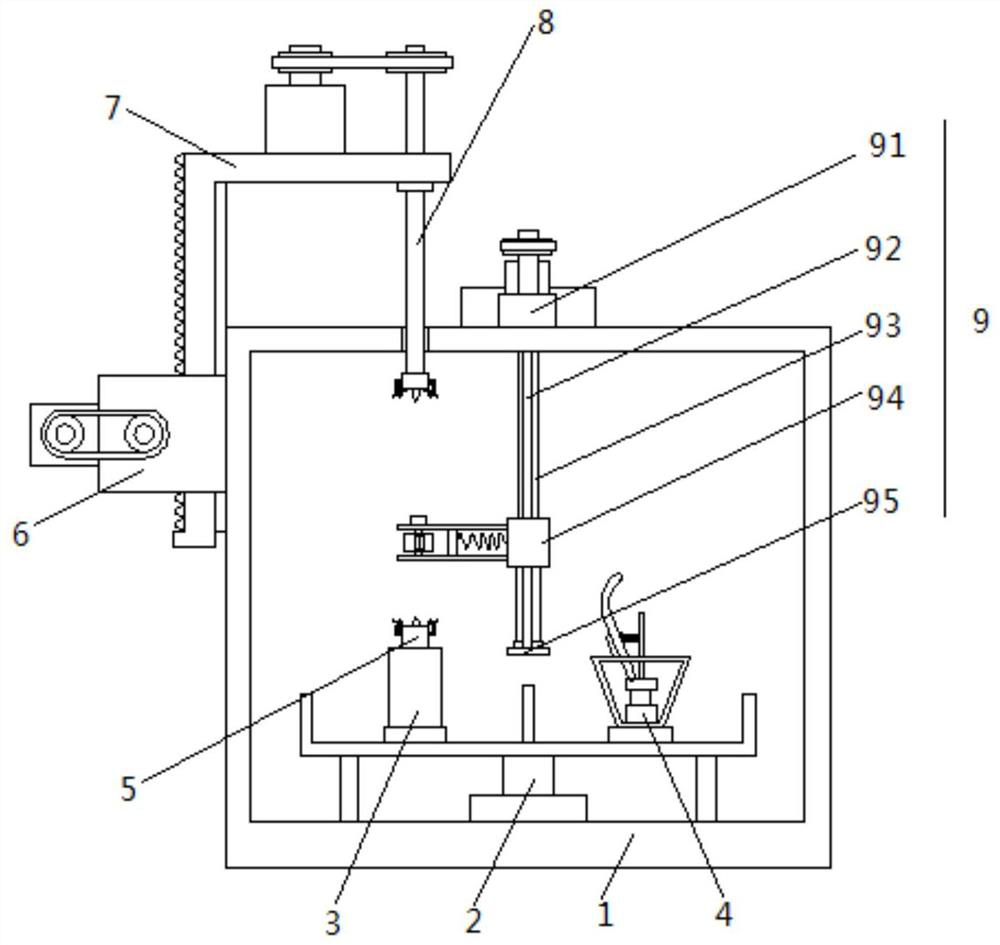

Adjustable stripping machine for cable processing

ActiveCN111697495AImprove peeling efficiencyThoroughly peeledApparatus for removing/armouring cablesPhysicsElectric cables

The invention discloses an adjustable stripping machine for cable processing, belongs to the technical field of cable processing, and solves a problem that an existing device cannot clamp and limit cables with different thicknesses, and the cables are easy to fall off. The stripping device is technically characterized in that the stripping device comprises a shell and a processing cavity, whereinthe processing cavity is formed in the shell, a stripping assembly used for stripping is arranged at the bottom of the processing cavity, a limiting mechanism is further arranged in the processing cavity, the limiting mechanism comprises an upper clamping assembly and a lower clamping assembly, and the upper clamping assembly is installed on a lifting base. The stripping device is advantaged in that the limiting mechanism is arranged, that the cable does not fall off when the cable is peeled can be ensured, the cable stripping device is suitable for clamping and limiting different types of cables, stripping efficiency is improved, and a main stripping knife and an auxiliary stripping knife are matched to work, so stripping is more thorough, and popularization and application are facilitated.

Owner:聊城市宏伟电器有限公司

Rotating cylinder type ginger fire process peeling device

InactiveCN104783308AAvoid pollutionGood effectVegetable peelingShell and tube heat exchangerCombustion

The invention discloses a rotating cylinder type ginger fire process peeling device. A flame outlet of a combustion machine is connected with a rotating cylinder via a gas distribution cover, the rotating cylinder is obliquely arranged, and flame and ginger constitute reverse motion; a tail gas cover of the rotating cylinder is connected with a tube side of a shell-and-tube heat exchanger via an exhaust fan and a fan exhaust hole, then evacuation is performed, an upper shell side of the shell-and-tube heat exchanger is connected with the atmosphere, and a lower shell side is connected with the combustion machine; a movable joint is arranged at the discharge end of the rotating cylinder and connected with a rotating drum discharge valve, and a water tank is arranged at the lower end of the rotating drum discharge valve; and a movable joint is arranged at the feed end of the rotating cylinder and connected with a rotating drum feed valve, and a feed hopper is arranged above the rotating drum feed valve. According to the rotating cylinder type ginger fire process peeling device disclosed by the invention, a fire process is used for peeling, the operation is simple and ingenious, the effects are good, the operation is easy to implement, the fire process can become an optimal substitute for alkaline peeling, and chemical residues and emission of wastewater are avoided; and the rotating drum feed valve and the discharge valve ingeniously realize incoming and outgoing of materials and isolation of system gas. The rotating cylinder type ginger fire process peeling device disclosed by the invention is further convenient to realize continuous mechanical operation and low in energy consumption, and has better industrialization, large-scale implementation and standardized application prospects.

Owner:JISHOU UNIVERSITY

Vibrating screen type pyrogenic process-based yacon peeling device

The invention discloses a vibrating screen type pyrogenic process-based yacon peeling device. A long-paddle flame stirrer is arranged between the vibrating screen and the flame of a burner; the vibrating screen, the long-paddle flame stirrer and a burner form a burning carbonization part; the vibrating screen is adjustable in angle of inclination; a thermal insulating layer thick enough is arranged in an outer enclosure to form a baking chamber; a gas-collecting hood is arranged above the vibrating screen and connected to a cyclone dust collector via an exhaust fan; the cyclone dust collector is connected with the tube side of the tube type heat exchanger and then can be emptied; the shell side of the tube type heat exchanger is connected with a circulating pump, a heat exchanger in a drying room and a buffer tank to form a loop; a vibrating feeding hopper is arranged at the feeding end of the vibrating screen, and the discharge end is connected with a brush cleaning auger. According to the vibrating screen type pyrogenic process-based yacon peeling device, the vibrating screen is used for conveying and turning over materials to realize pyrogenic process-based peeling and has no any toxic residue after being cleaned, and thorough and even peeling can be achieved easily; the vibrating screen type pyrogenic process-based yacon peeling device is also convenient for adjusting the processing scale and realizing continuous peeling, and has complete dust removal and thermal recovery functions.

Owner:响水华清污水处理有限公司

Waste line peeling device for communication

InactiveCN112518845AExpand the range of peelingCost-effectiveFilament handlingCleaning using toolsElectric machineMechanical engineering

The invention discloses a waste line peeling device for communication, and belongs to the technical field of communication waste line recovery. The waste line peeling device for communication comprises a base, a first mounting plate is fixedly connected to a position, close to the right side, of the top of the base, a first motor is fixedly mounted on the front face of the first mounting plate, the output end of the first motor penetrates through the first mounting plate and is fixedly connected with a retention plate, the back face of the retention plate is fixedly connected with a rotating roller, inserting and fixing assemblies are arranged at the positions, close to the outer side, of the back face of the retention plate at equal intervals, the outer side of the rotating roller is movably connected with a line winding roller, and line fixing groove is formed in the position, close to the front face, of the outer side of line winding roller. According to the waste line peeling device for communication, a guide ring can carry out control on the winding direction of waste lines, so that the waste lines are wound more uniformly, the waste lines are prevented from being wound at thesame position all the time during winding, the waste lines are orderly wound on the line winding roller, the situation that the waste lines wound on the line winding roller are difficult to unwind isavoided, and the waste lines can be conveniently treated in the next step.

Owner:王洪明

Drum sieve type chufa pyrogenic peeling device

The invention discloses a drum sieve type chufa pyrogenic peeling device. A long oar flame stirrer is arranged between a drum sieve and a burner fire; a firing and carbonizing part is formed by the drum sieve, the long oar flame stirrer and the burner; the inclining angle and the rotary speed of the drum sieve can be adjusted; a baking chamber composed of a thermal insulation layer with enough thickness is arranged inside an outer envelope; a gas-collecting hood is arranged above the drum sieve and is connected with a cyclone dust collector through an exhaust fan; the cyclone dust collector is connected with a tube pass of a tube type heat exchanger and is evacuated; a loop is formed by the shell pass of the tube type heat exchanger, a circulating pump, a heat exchanger and a buffer tank in a drying room; a vibration feed hopper is arranged at the feed end of the drum sieve and a brush cleaning stranding cage is connected with the discharge end of the drum sieve. The materials are transported and turned by the drum sieve, peeled with pyrogenic process and washed without any toxic residue, and the peeling is complete and uniform. By adopting the drum sieve type chufa pyrogenic peeling device, the processing scale is conveniently adjusted, the continuous peeling is implemented and the perfect dedusting and heat recovery function is realized.

Owner:泰州市海通资产管理有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com