Automatic peeling machine of potato

A peeling machine, automatic technology, applied in the peeling of vegetables or fruits, food science, application, etc., to achieve the effect of wide application range, high efficiency and obvious effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

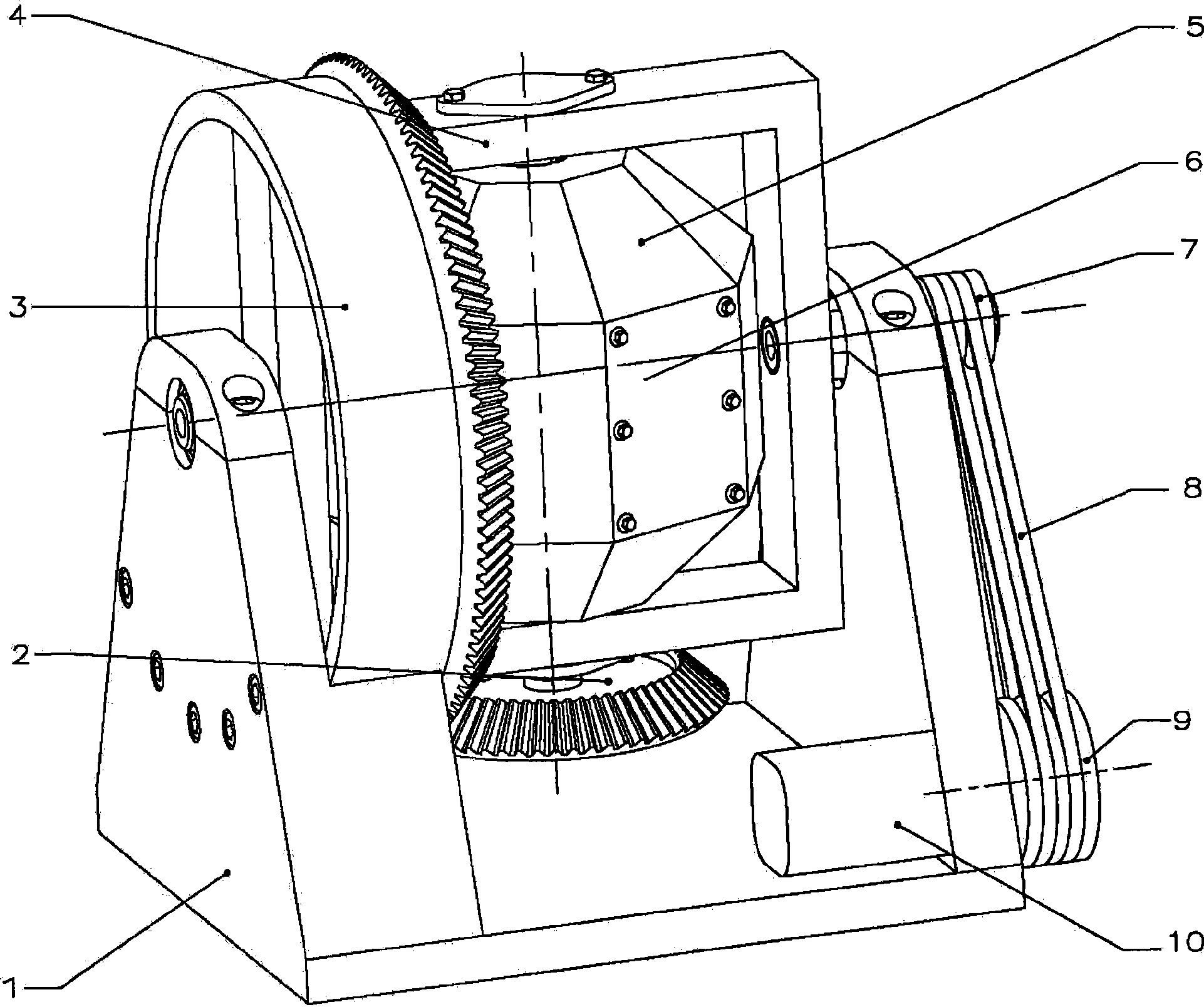

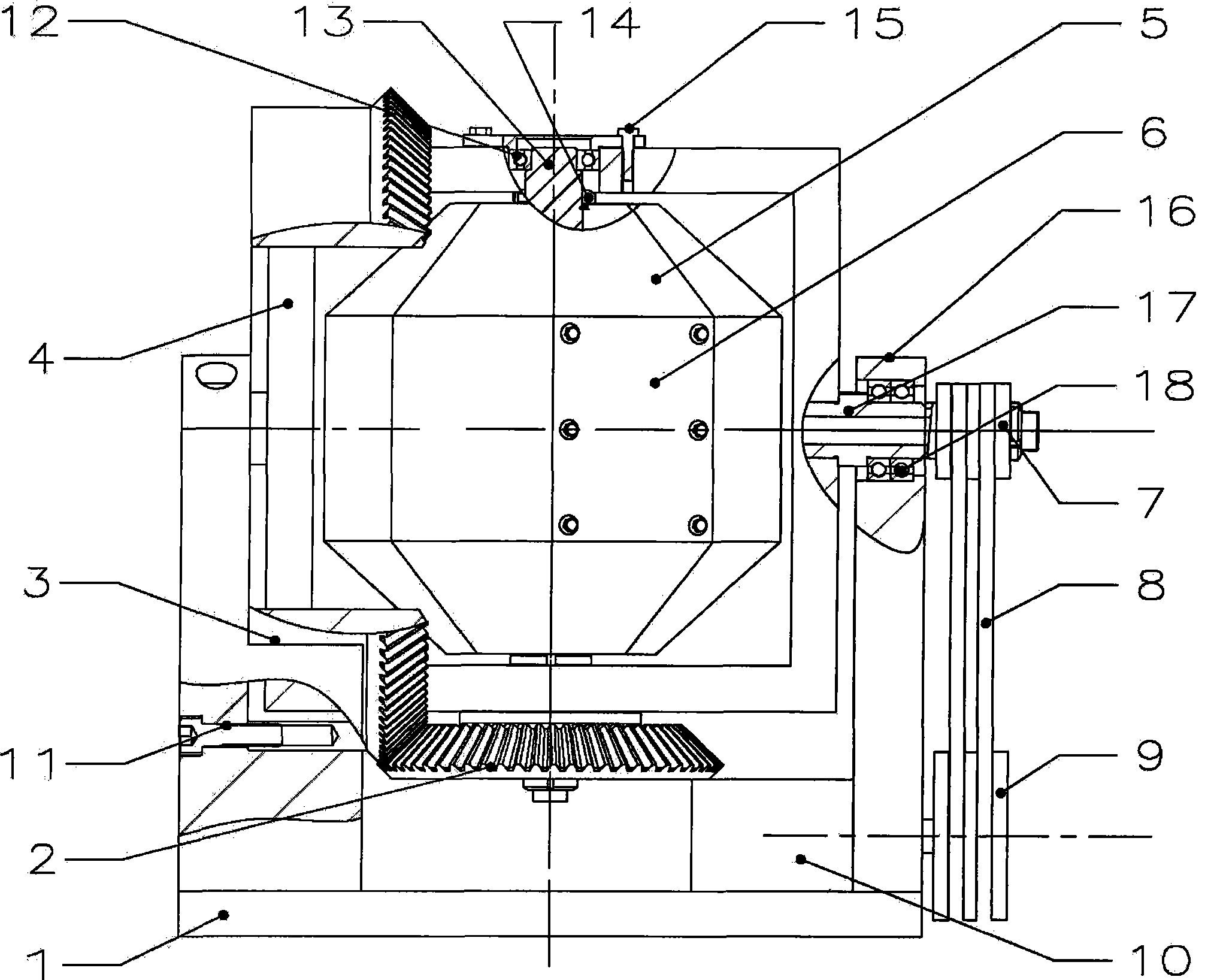

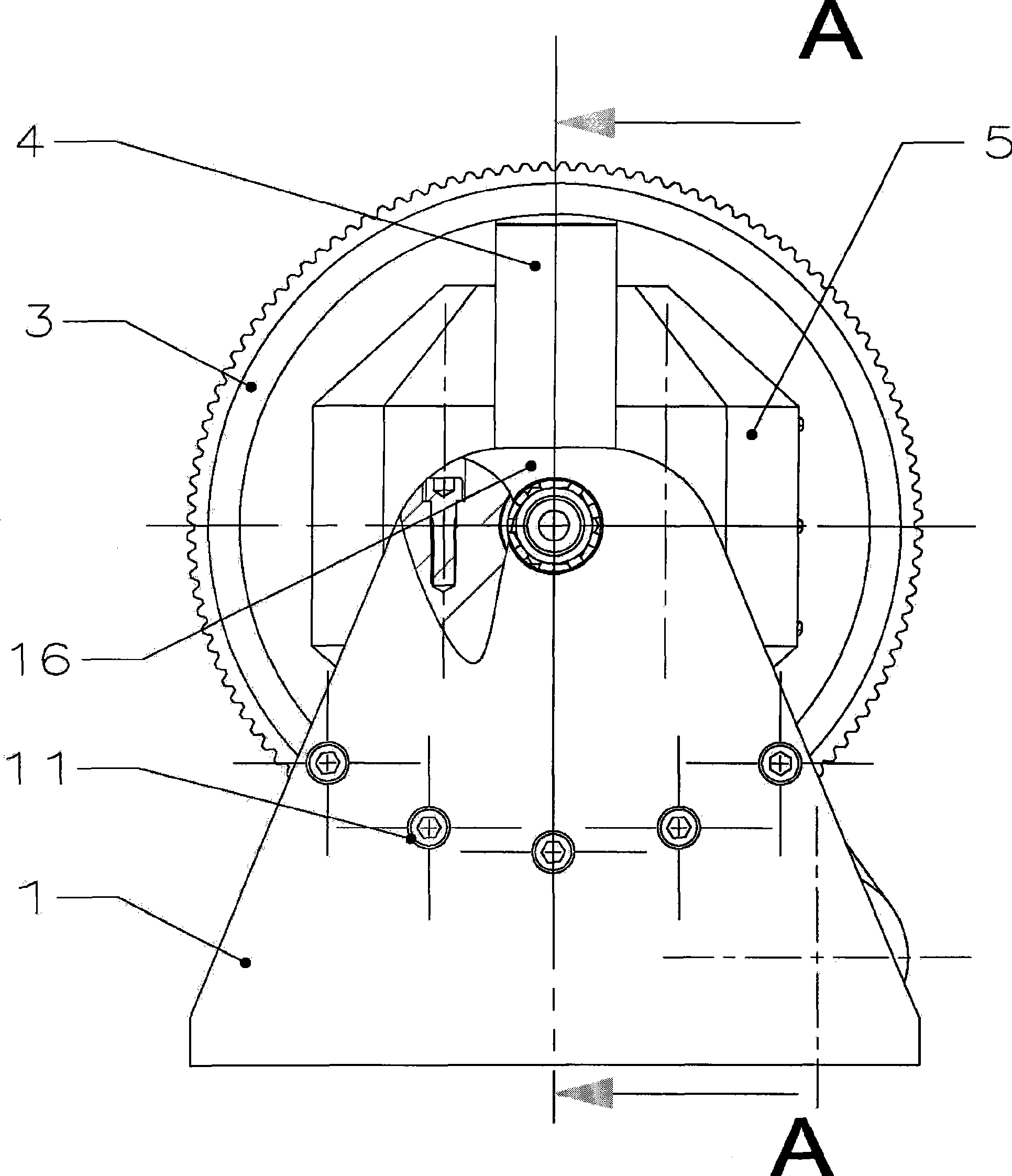

[0029] Example: figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 As shown, the present invention comprises base 1, and base 1 is the metal part that is " U " shape structure, and gear transmission mechanism and silo mechanism and belt transmission mechanism are fixedly arranged on base 1, and gear transmission mechanism is made of large bevel gear 3 Composed of meshing bevel gears 2, the belt transmission mechanism includes a motor 10, the motor 10 is connected to the large pulley, the large pulley 9 is connected to the small pulley 7 through the transmission belt 8, the motor 10 is fixed on the base 1, and the characteristic is that the silo mechanism is set In the middle of the base 1, the gear transmission mechanism and the belt transmission mechanism are arranged on both sides of the silo mechanism. The silo mechanism includes a support frame 4 and a silo 5. The long axis 13 is connected with the support frame 4, the bin mouth and the bin mouth cover 6 are set o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com