Papaya crisp slices and preparation method thereof

A technology of papaya chips and crisps, applied in the field of papaya chips and its preparation, can solve the problems of adverse effects on the final puffing effect, long drying time, and low efficiency, and achieve shortened drying time, short production cycle, and good quality Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

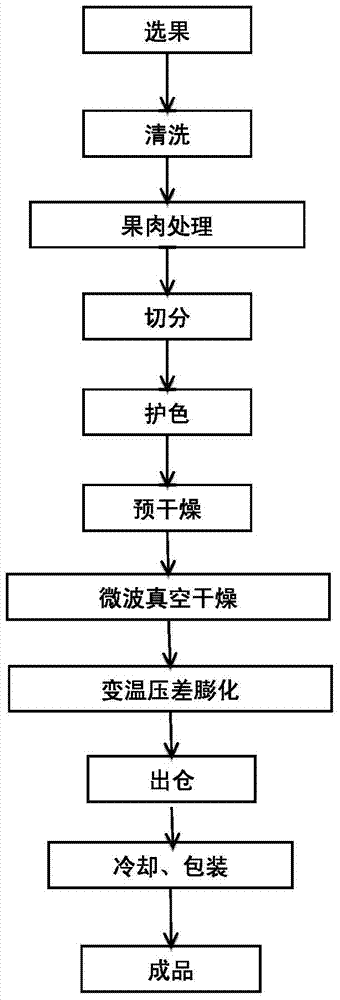

Method used

Image

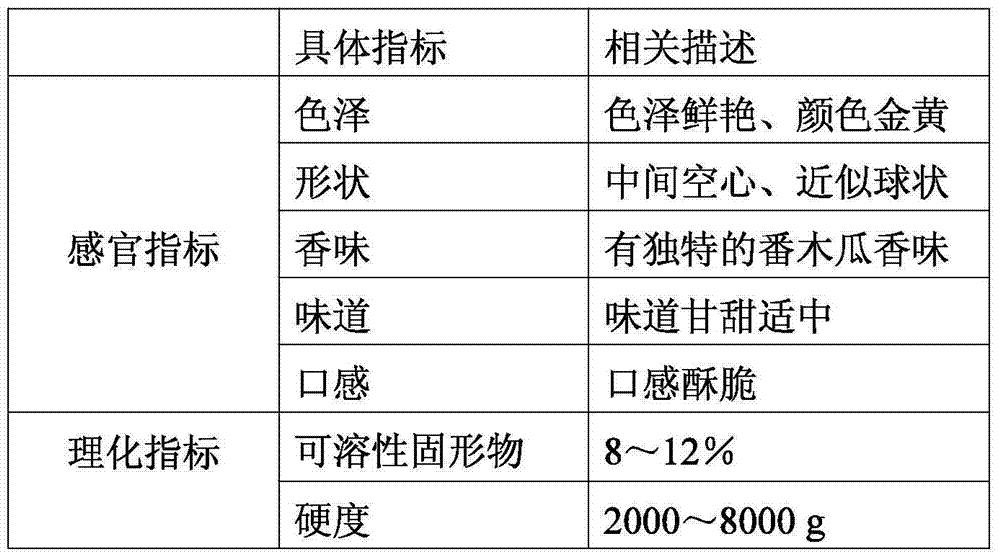

Examples

Embodiment 1

[0045] (1) Fruit selection: select fresh papaya fruits that are complete, uninjured, similar in size, and seven or eight mature;

[0046] (2) Cleaning: wash the papaya selected in step (1) with clear water;

[0047] (3) Pulp processing: remove the inedible part of the papaya after step (2) with a tool, including removing the skin, seeds and parts with higher hardness at both ends, to obtain papaya pulp;

[0048] (4) cutting: the papaya pulp of step (3) gained is cut into the papaya sheet that thickness is 8mm through slicer;

[0049] (5) color protection: put the papaya slices of step (4) gained into the color protection solution according to the ratio of material to liquid of 1:5 and soak for 30min. The color protection solution consists of 2% citric acid, 2% chlorine calcium chloride, 1% sodium sulfite (mass percent concentration);

[0050] (6) Pre-drying: hot-air drying the papaya slices after the color protection treatment in step (5), the wind speed is 2.5m / s, the dryin...

Embodiment 2

[0060] (1) Fruit selection: select fresh papaya fruits that are complete, uninjured, similar in size, and seven or eight mature;

[0061] (2) Cleaning: wash the papaya selected in step (1) with clear water;

[0062] (3) Pulp processing: remove the inedible part of the papaya after step (2) with a tool, including removing the skin, seeds and parts with higher hardness at both ends, to obtain papaya pulp;

[0063] (4) cutting: the papaya pulp of step (3) gained is cut into the papaya sheet that thickness is 6mm through slicer;

[0064] (5) color protection: put the papaya slices obtained in step (4) into the color protection solution according to the ratio of material to liquid of 1:5 and soak for 15min. The color protection solution consists of 3% citric acid, 2.5% chlorine Calcium chloride, 1.5% sodium sulfite (mass percentage concentration) composition;

[0065] (6) Pre-drying: hot-air drying the papaya slices after the color protection treatment in step (5), the wind speed...

Embodiment 3

[0075] (1) Fruit selection: select fresh papaya fruits that are complete, uninjured, similar in size, and seven or eight mature;

[0076] (2) Cleaning: wash the papaya selected in step (1) with clear water;

[0077] (3) Pulp processing: remove the inedible part of the papaya after step (2) with a tool, including removing the skin, seeds and parts with higher hardness at both ends, to obtain papaya pulp;

[0078] (4) cutting: the papaya pulp of step (3) gained is cut into the papaya sheet that thickness is 10mm through slicer;

[0079] (5) color protection: the papaya slices of step (4) gained are put into the color protection solution and soaked for 45min according to the ratio of material to liquid of 1:5, and the color protection solution consists of 1% citric acid, 1% chlorine Calcium chloride, 0.5% sodium sulfite (mass percentage concentration) composition;

[0080] (6) Pre-drying: Carry out hot-air drying to the papaya slices after step (5) color protection treatment, t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com