Patents

Literature

1410results about How to "Preserve the flavor" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Compounded stabilizer, normal temperature yoghurt containing compounded stabilizer, and preparation method of yogurt

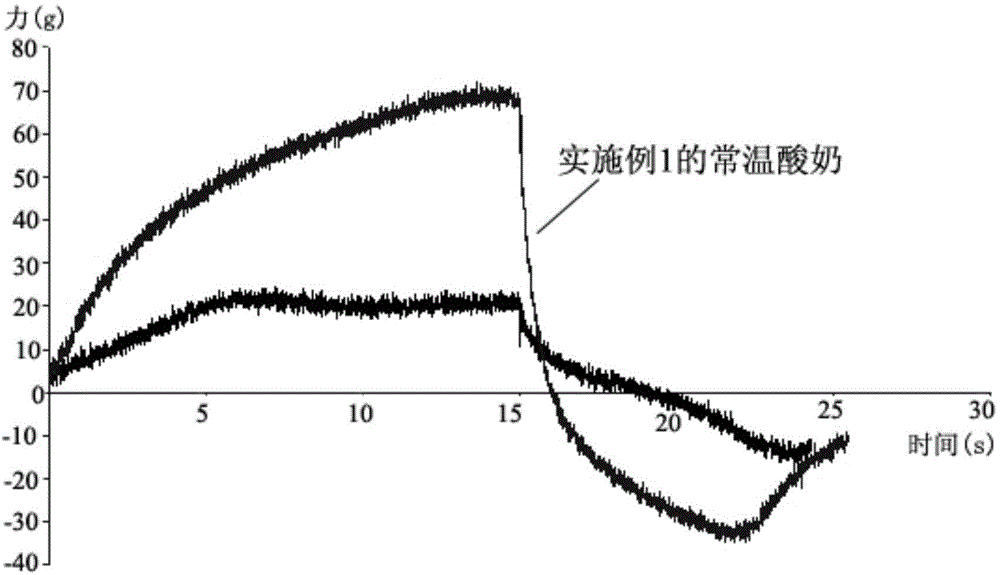

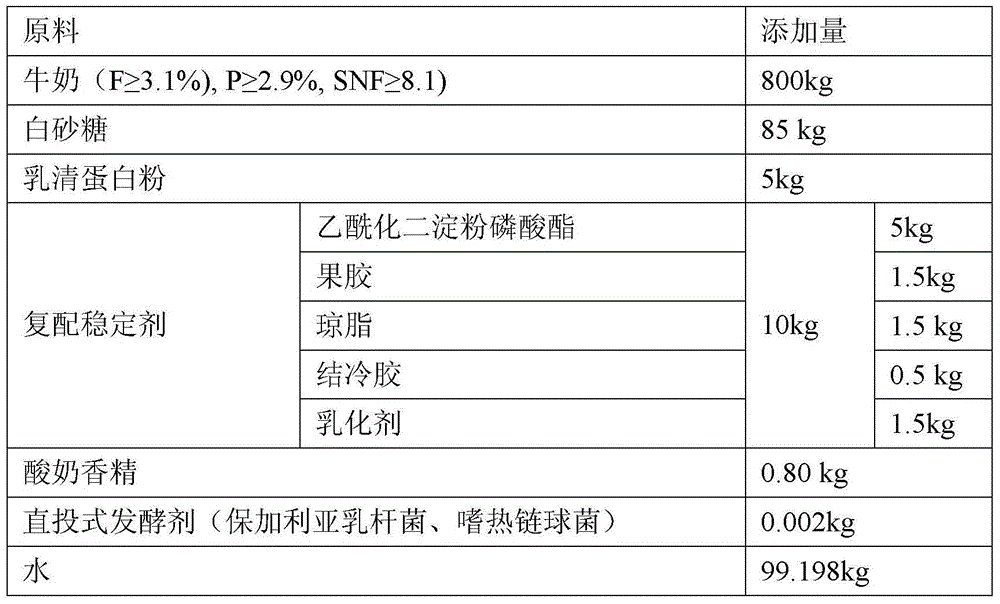

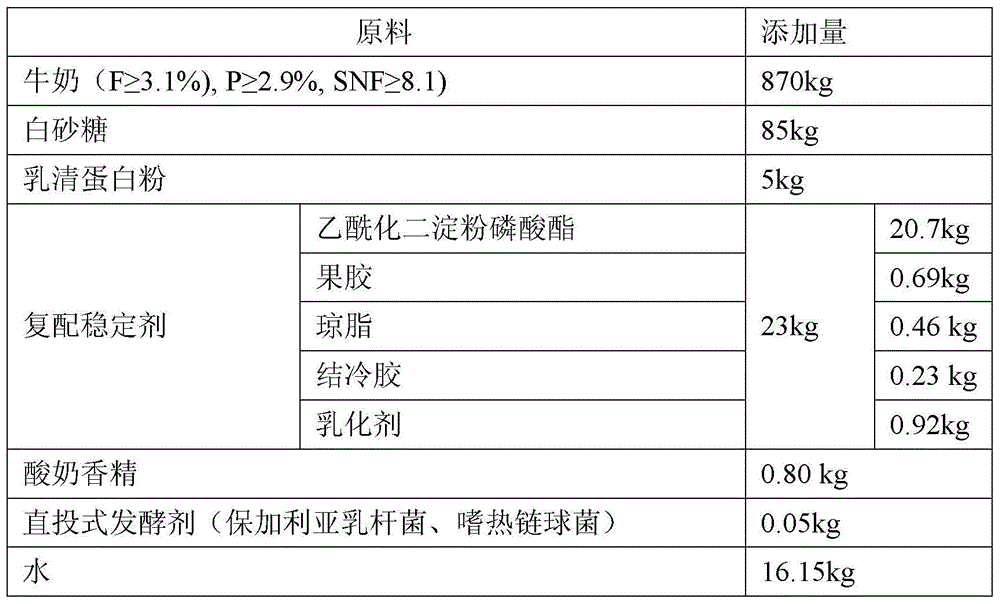

The invention relates to a compounded stabilizer, normal temperature yoghurt containing the compounded stabilizer, and a preparation method of the yogurt. The compounded stabilizer comprises, by mass, 50-90% of esterified modified starch, 3-15% of pectin, 2-15% of agar, 4-15% of an emulsifier and 1-5% of gellan gum. The invention also provides normal temperature yoghurt containing the compounded stabilizer, and a preparation method of the yogurt. The compounded stabilizer has good process tolerance, improves the viscosity stability of a technology processed normal temperature yoghurt system and the viscosity recovery stability of a subsequent product, and allows the viscosity of yogurt at normal temperature of 20-40DEG C to be similar or greater than the viscosity of yogurt refrigerated at normal temperature of 3500-5000cp. The normal temperature yogurt prepared in the invention can be stored at normal temperature of 20-40DEG C for 4-6 months, and allows high quality yogurt to be drunk in remote cold chain lacking places.

Owner:INNER MONGOLIA YILI INDUSTRIAL GROUP CO LTD

Method for preparing instant nutritious fruit and vegetable crisp tablet

InactiveCN1907105ARetain colorPreserve the flavorFood preparationPlant ingredientsFood flavorFruits and vegetables

The invention discloses a process for preparing instant nourishing fruit and vegetable crisp tablets, which consists of preserving color of fresh fruits and vegetables, beating, decocting, allocating, roller drying, comminuting and sieving. The original color, luster and flavor of the fruits and vegetables can be well preserved.

Owner:林玉惠

Eating five-element corn-vegetable-fruit health product

InactiveCN101971985AClear mechanismClarify the mechanism of health careFood preparationBiotechnologyUncooked Foods

The invention relates to an eating five-element corn-vegetable-fruit health product comprising more than 40 raw materials, such as naked oat flour, cichory flour, bitter almonds, coixseeds, white lablab seeds, burdocks, white turnips, white fungi, yam, ginkgo, coconuts, highland barley, brassica campestris, green tea powder, cowberries, green apples, peas, green beans, spinach, cacti, spirulina, Chinese goosebeeries, black tartary buckwheats, agaricus blazei murill, blackcurrant, mulberry powder, black kerneled rice, teata glycinis, niger seeds, dried purple seaweed, mushrooms, black fungi, Tibetan red beans, and the like, which is white, green, black, red or yellow corn-vegetable-fruit grains or integrative five-color corn-vegetable-fruit grains prepared by a specific technology. The eating five-element corn-vegetable-fruit health product is produced on the basis of a traditional Chinese medical five-element theory and a modern nutriology theory, has excellent raw materials, edible safety, pure taste and rich nutrition, is especially used for raw foods, provides complete, balanced and reasonably-matched nutrients for a human body, has obvious opsonization for sub-health physiques and various chronic diseases, is easy to industrially popularize and has positive social and economic benefits.

Owner:崔晓廷

Fermenting type apple vinegar beverage and preparation method thereof

ActiveCN102771864ARetain nutrientsPreserve the flavorVinegar preparationFood preparationFood flavorCulture fungus

The invention discloses a fermenting type apple vinegar beverage and a preparation method thereof. The fermenting type apple vinegar beverage is characterized by being prepared by preparing, filtering, sterilizing and filling the following raw materials by weight proportion: 50-70 parts of apple vinegar, 80-120 parts of concentrated apple juice, 2-8 parts of honey, 1-3 parts of aspartame and 799-867 parts of water. The fermenting type apple vinegar beverage has the advantages of well retaining the original nutrient substances and flavor of apple, having high acid production rate, being obviously shortened in fermenting time, further being capable of separating cured acetic bacteria cells and products easily and being used repeatedly, enabling strains to be efficient, greatly improving production efficiency, saving production cost and reducing pollution discharging.

Owner:YANTAI QIWEI WINE IND

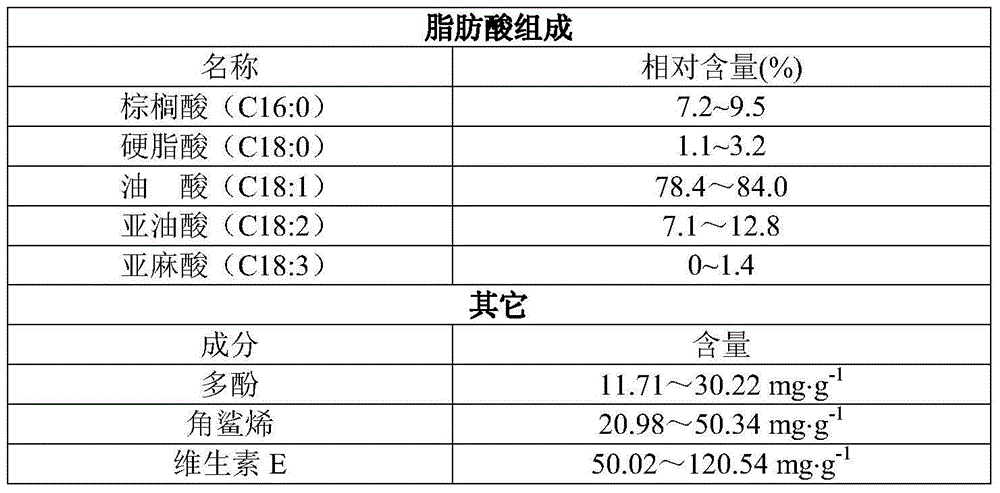

Process for preparing cold-pressed camellia oleosa seed oil by virtue of vacuum microwave enzyme method pretreatment

ActiveCN103981010AImprove qualityPreserve the flavorFatty-oils/fats productionVegetable oilMicrowave

The invention belongs to the field of vegetable oil processing, and particularly relates to a process for preparing cold-pressed camellia oleosa seed oil by virtue of vacuum microwave enzyme method pretreatment. The process comprises the following procedures: (1) picking fruits; (2) removing husks; (3) crushing; (4) adding enzymes; (5) carrying out staged vacuum microwave treatment; (6) carrying out physical cold pressing; (7) drying; (8) filtering. The process disclosed by the invention can be used for pretreating the camellia oleosa seeds by adopting a staged vacuum microwave enzyme method, is moderate in process condition and can be used for greatly enhancing the oil yield of subsequent cold pressing; the prepared camellia oleosa seed oil has good quality and can be used for better preserving the original nutrition and flavor of the camellia oleosa seed oil.

Owner:HUNAN XIANGCHUN AGRI TECH

A kind of processing method of jujube chips

The invention discloses a processing method of red jujube chips. After cleaning the red dates, remove the pits, slice them, and freeze them, then take out the frozen jujube slices and dry them under vacuum at 50-600Pa and 30-50°C for 1-2 hours. 3h, and finally sterilized under microwave and vacuum packed. The present invention adopts the combination method of freezing and vacuum drying to prepare red jujube chips, and while retaining the original flavor, color, nutrition and crispy taste of fruits and vegetables to the greatest extent, it also retains the original appearance and shape of jujube chips, making the product smooth , bright color, and has moisture absorption resistance, short production cycle, low energy consumption.

Owner:SHAANXI UNIV OF SCI & TECH

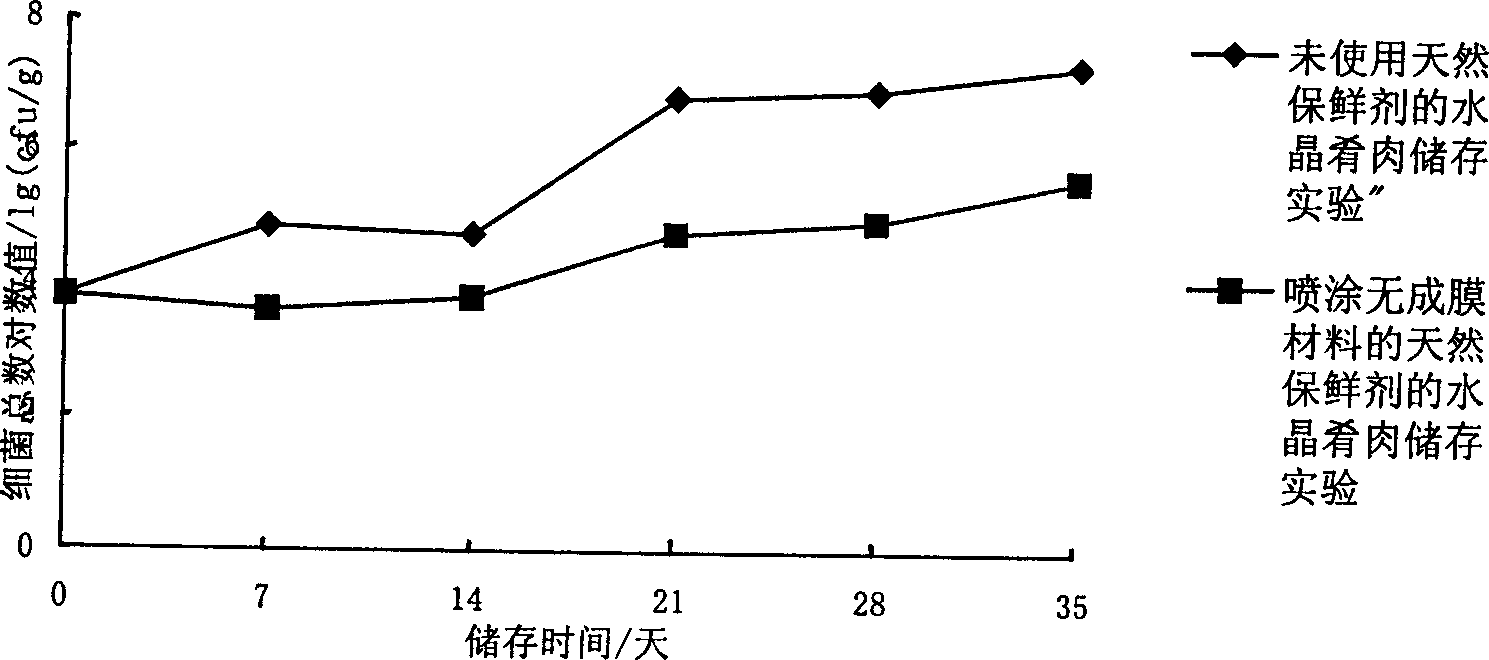

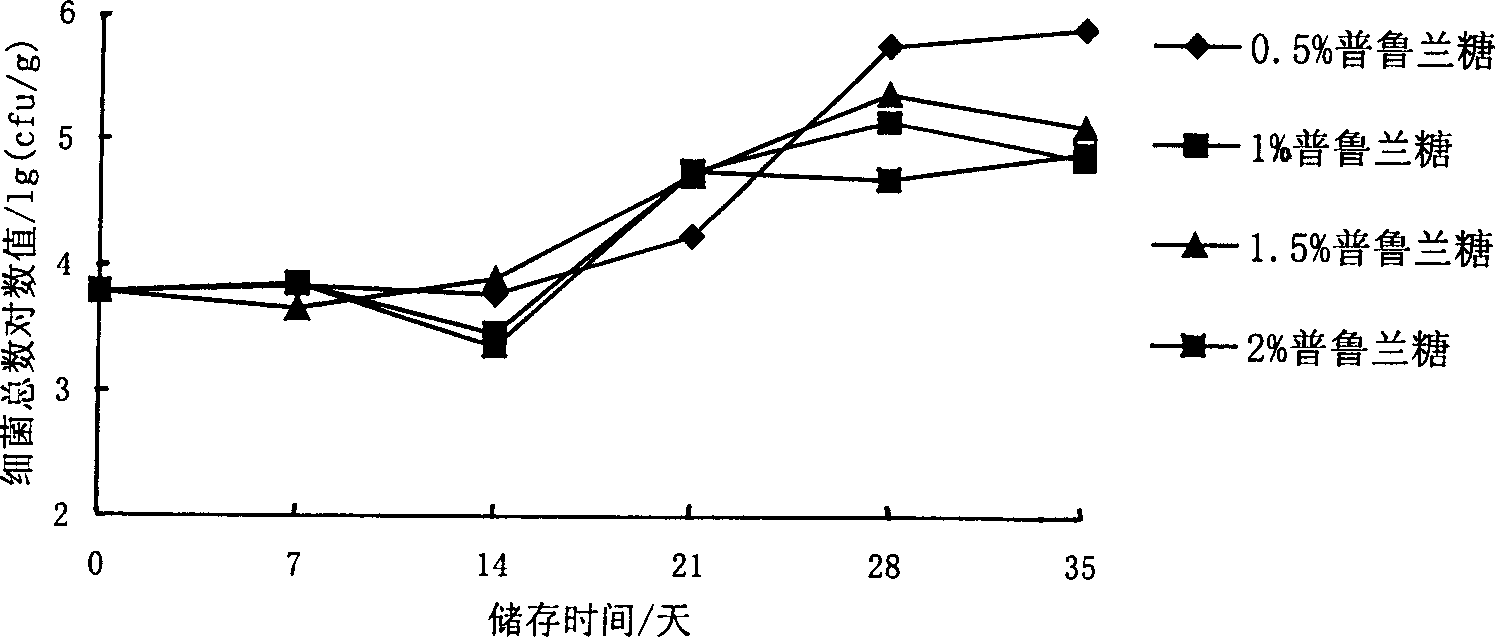

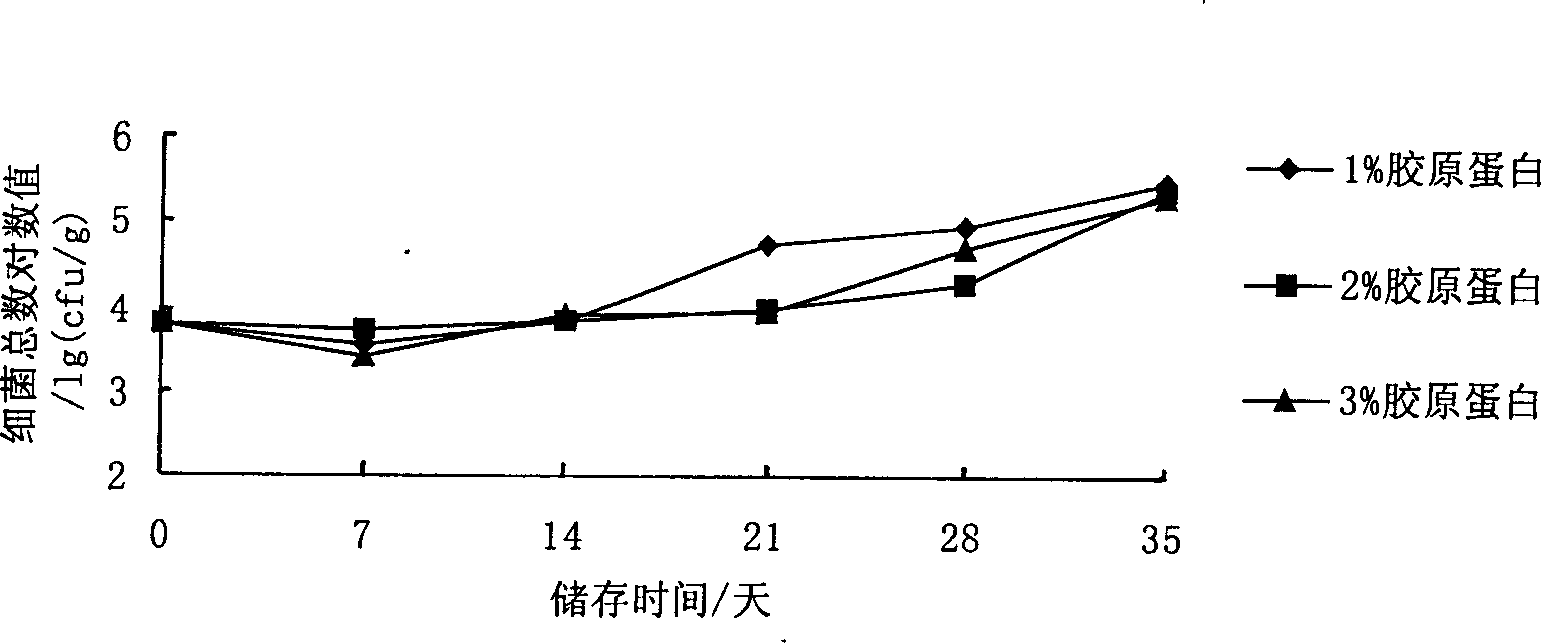

Natural membrane forming preservation agent used for crystal-like delicious meat

InactiveCN1723803AExtended shelf lifeLong shelf lifeFood preservationFood preparationAcetic acidFoaming agent

Owner:NANJING YURUN FOOD

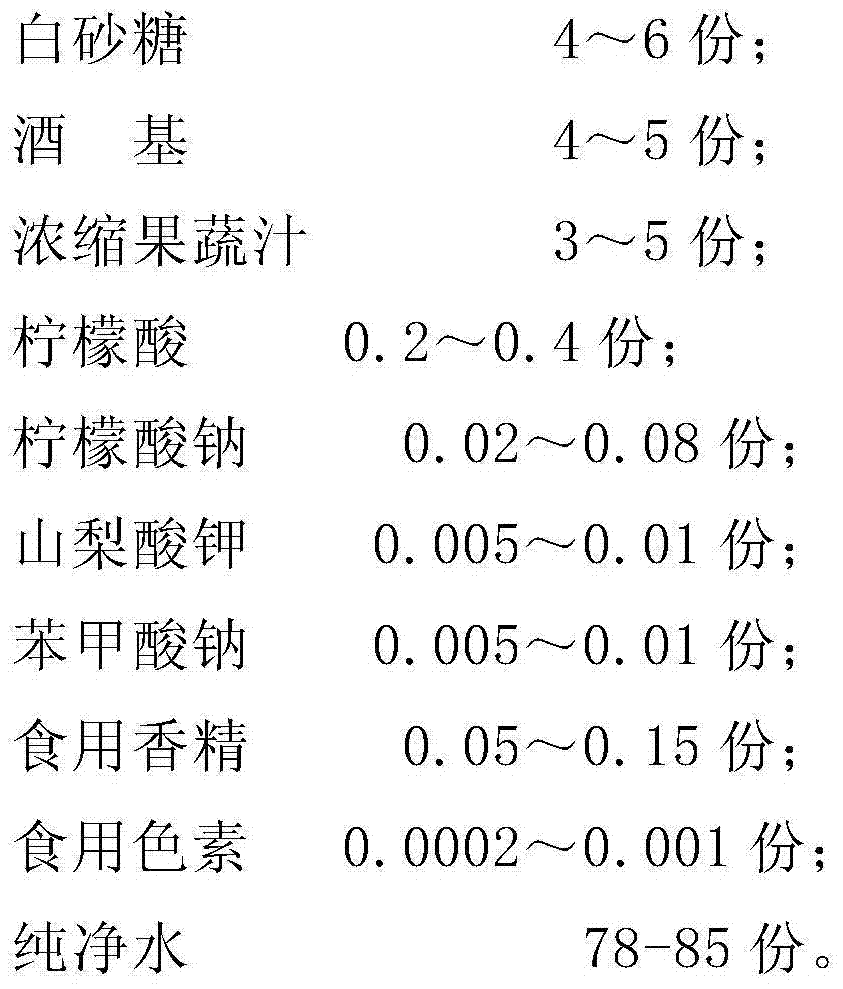

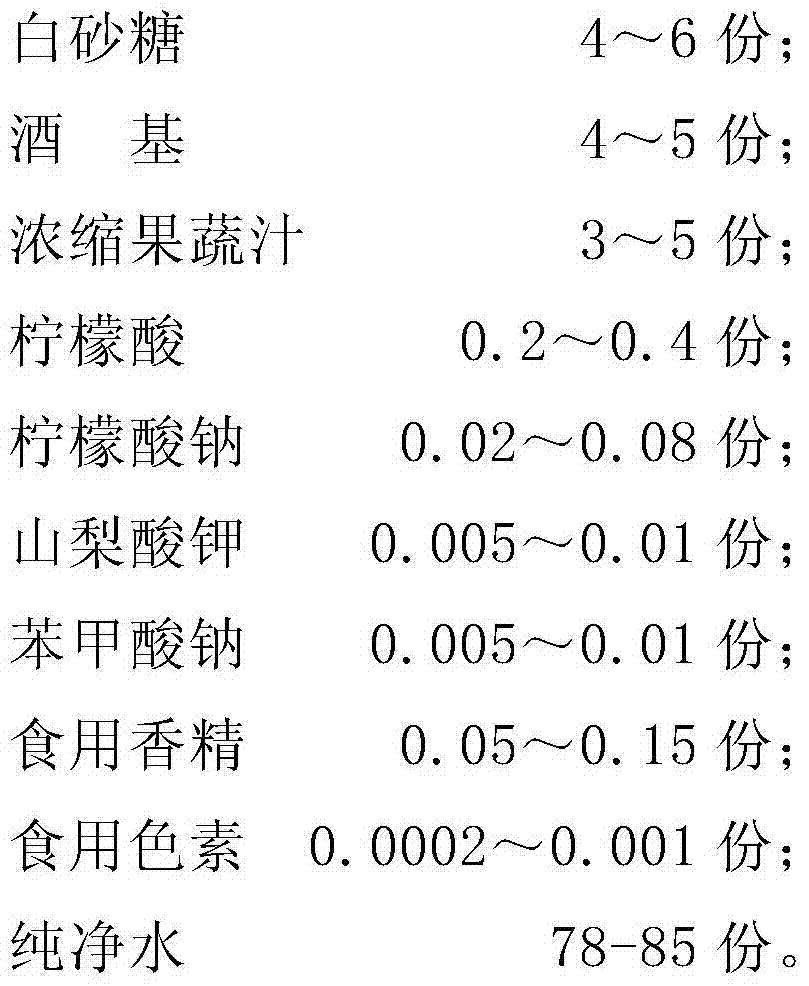

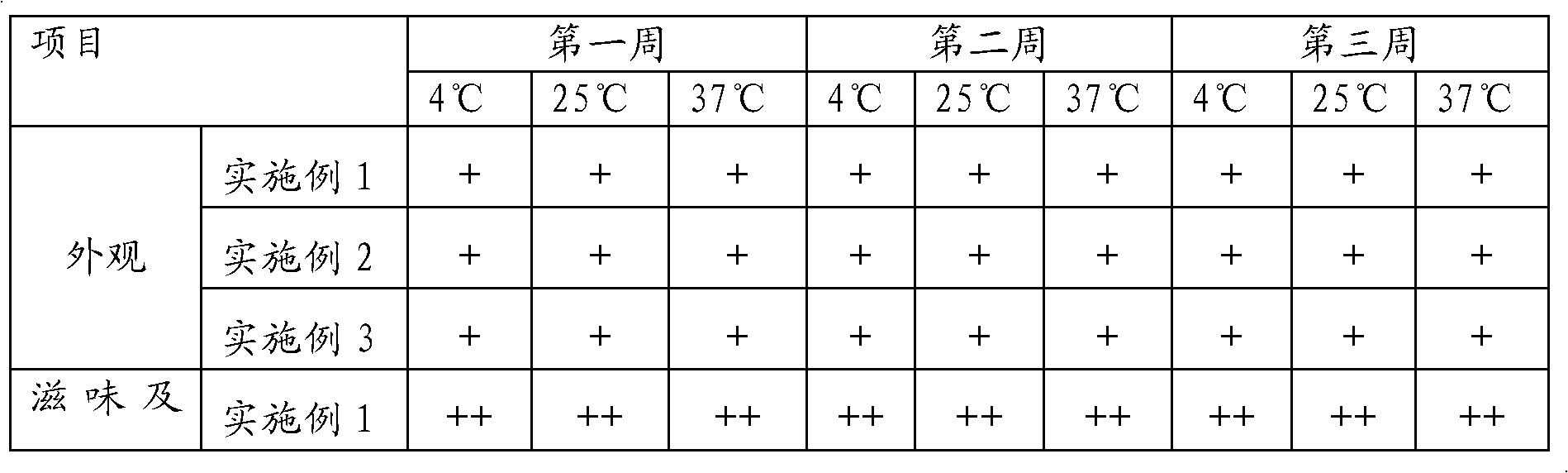

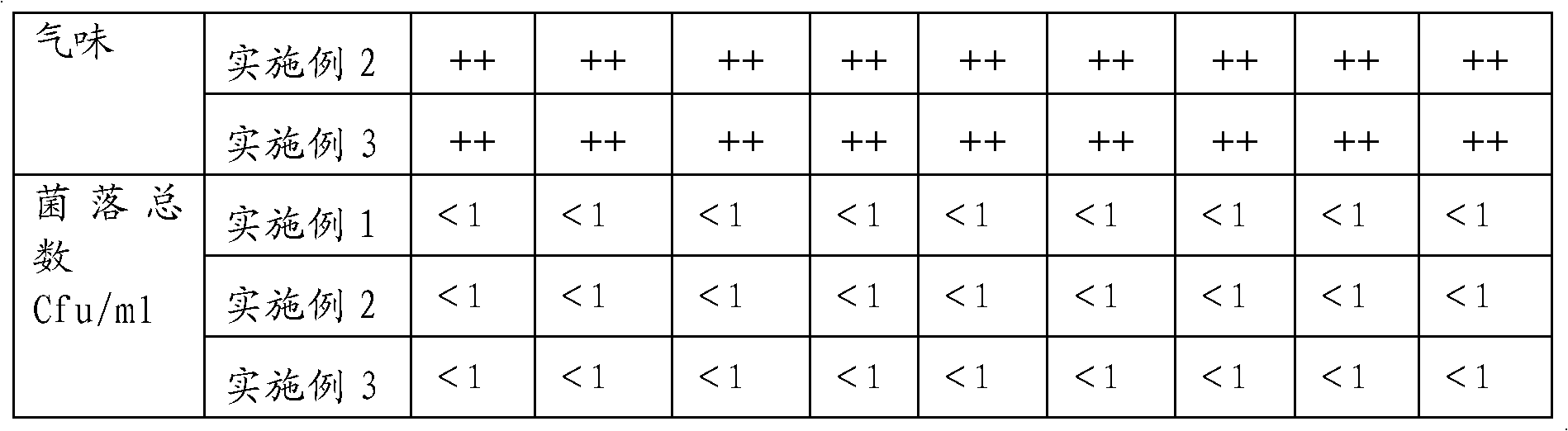

Cocktail and preparation method thereof

InactiveCN103571710ASatisfy the pursuit of slightly drunken stimulationKeep the tasteAlcoholic beverage preparationFlavorFruit juice

The invention discloses a cocktail, which is prepared from white granulated sugar, a wine base, concentrated fruit and vegetable juice, citric acid, malic acid, sodium citrate, potassium sorbate, sodium benzoate, an edible essence, an edible pigment and pure water. The invention also discloses a preparation method of cocktail. The cocktail disclosed by the invention is an industrialized cocktail product prepared by carbonating such distilled liquor as vodka, whiskey, brandy, rum, gin, tequila, grape wines and edible alcohol, as well as brewed wines and fruit and vegetable juice by using carbon dioxide and filling. The cocktail can satisfy the pursuit of people for the dazing stimulation of wines, and does not lose the taste of juice. Due to the perfect combination of wines and fruit juice, the cocktail retains the taste and flavor of cocktailed mixed in bars on the scene better and also solves the bottleneck of the storage life.

Owner:SHANGHAI BACCHUS LIQUOR

Processing method of vacuum refrigerating flavored prawn cake

The invention discloses a processing method of a vacuum refrigerating flavored prawn cake. The processing procedure comprises the following steps of: material selecting, pretreating, pulping, forming, steaming, cooling, traying, refrigerating fast, cutting, refrigerating fast, vacuum refrigerating and drying, sorting, metal detecting and packaging. The flavored prawn cake comprises the following raw materials in parts by weight: 70-80 parts of minced fillet, 20-30 parts of peeled prawns, 8-10 parts of soy protein isolate and 2-4 parts of prawn meat extract. The processing method of the vacuum refrigerating flavored prawn cake provided by the invention has the advantages that the product appearance is good in color, that the original rich nutrition ingredients and the special flavor and taste of the vacuum refrigerating flavored prawn cake are reserved, that other bad smell is not generated, and that the vacuum refrigerating flavored prawn cake can be stored for a long time even at normal temperature, has a shelf life as long as 12 months and is ready to eat.

Owner:HUBEI XINMEIXIANG FOODS

Coconut-water beverage and preparation method thereof

The invention discloses a method for preparing a coconut-water beverage. The method comprises the following steps: (1) breaking coconuts and then getting coconut water, adding an ascorbic acid the weight of which accounts for 0.1-0.15% of that of the coconut water into the coconut water, then stirring the obtained mixture so as to dissolve the ascorbic acid; (2) adding water into the solution obtained in the step (1), then stirring the obtained mixture, wherein the weight ratio of the water to the coconut water is (0.5-1.2): (4-5); (3) adding cane sugars into the aqueous solution obtained in the step (2), adjusting the sugar degree of the obtained mixture to 7.0-8.00 Brix, then adding a citric acid into the obtained product, and adjusting the pH value of the obtained mixture to 4.6-4.8; and (4) carrying out membrane filtration sterilization and ultrahigh-pressure low-temperature sterilization on the aqueous solution obtained in the step (3) so as to obtain the coconut-water beverage. The invention also discloses a coconut-water beverage. The coconut-water beverage and preparation method thereof disclosed by the invention have the advantages that because of changing the traditional heat treatment technology for sterilization and adopting the combination of low temperature membrane filtration sterilization and high pressure low temperature sterilization, the purposes of sterilization and refreshment are achieved, the unique flavor, nutrition and functional components of the coconut water are effectively kept, and the quality guarantee period of the prepared coconut-water beverage is long; and through filtering large particles in the coconut water through centrifugal filtration and membrane filtration, the prepared coconut-water beverage is clear, soft, delicate, pure and fresh.

Owner:海南品香园食品有限公司

Low-temperature salting and multi-layer continuous fume smoking method for cured meat

InactiveCN101502329AShorten marinating timeIncrease product yieldFood preparationMeat/fish preservation by dryingNutrientClear Layer

The invention discloses a bacon low-temperature pickling and multi-layer continuous smoking method, belonging to the processing method of bacon. On the basis of traditional firewood bacon, the bacon is produced by combining the traditional processing technique and the current technique. The processing method comprises: pre-processing the fresh pork; pickling the pre-process pork at low-temperature; air-drying the pickled pork; multi-layer continuously smoking the air-dried pork; removing dust and testing the quality of the smoked pork; vacuum packaging the tested pork. The bacon has golden yellow color, dry and compact meat, clear layer, transparent fat lining, red lean meat, fresh taste, rich nutrient and long shelf-life of up to 10 months and so on. The human keeps fit and the life is prolonged after eating the bacon for a long time and the bacon is a common food for guest and a good gift for friend.

Owner:冯廷萃

Preparation method of asparagus whole powder and asparagus solid beverage

InactiveCN102266018AHigh nutritional valueRetain nutritionFood preparationAsparagus adscendensDrum drying

The invention discloses a preparation method of asparagus whole powder and asparagus solid beverage, which belongs to the technical field of food processing. A method for preparing whole asparagus powder, comprising the following steps: (1) selecting and cleaning raw materials; (2) cutting into pieces and blanching; (3) crushing and beating; (4) miniaturization treatment; (5) homogenizing; 6) Sterilization; (7) Drum drying; (8) Crushing and sieving. The first preparation method of the asparagus solid beverage is to use the above-mentioned asparagus whole powder as the main raw material, and mix it with other powdery raw materials evenly to obtain the asparagus solid beverage. The second preparation method of the asparagus solid beverage is to prepare the asparagus pulp before homogenization, so that the asparagus slurry and other powdery raw materials are evenly mixed, and other processes are similar to the preparation method of the whole asparagus powder. The production of asparagus products by the method of the invention has low cost, high production efficiency, continuous production can be realized, and the product has good quality, good brewability and rich nutritional value.

Owner:CHINA AGRI UNIV

Preparation method of frozen prepared chicken cutlet

The invention discloses a preparation method of frozen prepared chicken cutlet. The preparation method comprises the following steps: selecting materials, cutting into blocks, preparing a tumbling liquid, tumbling, curing for being tasty, adding cheese, preparing wrapping powder and wrapping pulp, coating the wrapping powder and the wrapping pulp, frying in advance, placing in a dish and quick-freezing, packing, performing metal detection and storing, wherein in the preparation process, the tumbling liquid is prepared from the following components: salt, white granulated sugar, monosodium glutamate, composite phosphate, white pepper powder, garlic powder, and water at the temperature of 0-5 DEG C; and the wrapping powder is prepared from 48-52 parts of wheat flour, 28-32 parts of cassava modified starch, 18-22 parts of sweet potato flour, 0.3-0.7 part of xanthan gum, 0.3-0.7 part of pyrophosphate. The preparation method is applied to processing of frozen prepared food, a product is attractive in appearance, rich in nutrition, delicious, and long in guarantee period, and has a good market development prospect.

Owner:SANTONG WANFU QINGDAO FOOD

Instant freeze dried hot and spicy food and its production process

InactiveCN101066144APreserve the flavorEasy to carryFood preparationMonosodium glutamateFreeze-drying

The instant freeze dried hot and spicy food consists of staple food and auxiliary food. The staple food is freeze dried and may be served simply after being scalded in hot water. The auxiliary food includes sauce and seasoning, the sauce is cooked with butter, Pixian County broad bean paste, beef, sesame and peanut paste, chili powder, ginger, garlic and prickleash; and the seasoning is mixture of salt, monosodium glutamate and chili powder. The staple food, the sauce and the seasoning in the weight ratio of 1 to 1-1.2 to 0.25-0.35 are packed separately and set inside one outer package. The instant freeze dried hot and spicy food is produced through an industrial process and convenient in eating.

Owner:NORTH GREEN FOOD

Pure walnut fermented milk and a production method thereof

The present invention discloses beverage processing technology, and especially relates to pure walnut fermented milk and a production method including the following steps: peeling-refining-sugar emulsifying-adjunct material emulsifying-mixing-homogenizing-pH adjusting-sterilizing-fermenting-after-ripening. The produced pure walnut fermented milk not only achieves good preservation and improvement in nutrition, but also does not need to add milk powder in the fermentation process. There is no need to activate strains or to degrease the walnut milk by using a directed vat set inoculation method. Through improving technology, raw material formula and strain ratio, fermented strains can grow well in high-fat pure walnut milk so that a mellow and nice taste of the walnut fermented beverage and an unique flavor of the walnuts are retained, and stability and taste of the pure walnut fermented milk are ensured, making the beverage homogeneous and stable in property, delicate, fragrant and sweet and refreshing and smooth in taste, prone to absorption, and nutritional and healthy in character.

Owner:HEBEI YANGYUAN ZHIHUI BEVERAGE

Method for preparing traditional Chinese medicine health-care liquor

InactiveCN101698819AAddress food securityAvoid pollutionMicroorganism based processesAlcoholic beverage preparationMedicinal herbsDissolution

The invention relates to a method for preparing traditional Chinese medicine health-care liquor, which belongs to the technical field of liquor brewing. The method is characterized by being carried out according to the following procedures: pulverizing medicinal materials, sieving, saccharifying starch, filtering or centrifugalizing to remove medicine residues, fermenting saccharification liquid to prepare alcohol and ethanol, separating double water phases of inorganic salt and collecting an upper phase, wherein the medicinal materials are peltate yam, ussuri fritillary, yam, radix puerariae, yam, ginseng and the like which are rich in starch, the starch in the medicinal materials is saccharified by a double-enzyme method, the saccharification liquid is inoculated with a strain which produces the ethanol to carry out alcohol fermentation, the inorganic salt is added into fermentation liquid after the fermentation is finished, the ethanol is replenished according to requirements to form the double water phases, and the upper phase is separated so as to obtain the health-care liquor. At different periods of saccharification or different periods of alcohol fermentation, the assistant materials of other medicinal materials are added for assisting or enhancing the health-care function of the health-care liquor. The invention overcomes the defects of long consumed time of production, incomplete dissolution of the traditional Chinese medicine effect components of the medicinal materials and the like of the traditional health-care liquor, omits a traditional distilling technology, saves energy resources and retains the natural and pure taste of the original liquor.

Owner:DALIAN UNIV OF TECH

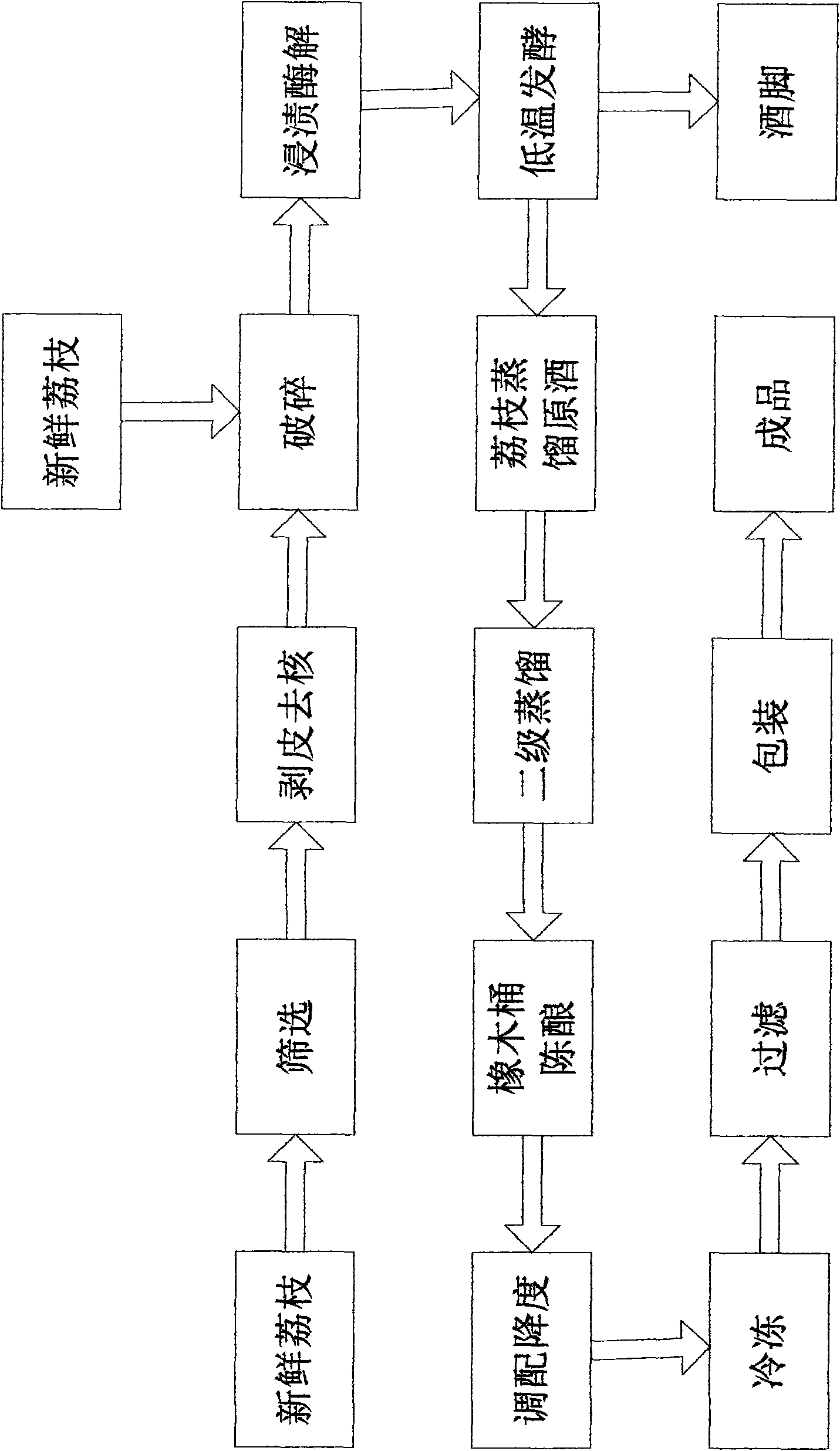

Processing technique of lichee brandy

InactiveCN101560452AInhibition of reproductive growthGrowth inhibitionAlcoholic beverage preparationMicroorganism based processesPectinaseAlcohol content

The invention relates to a processing technique of lichee brandy, including the steps as below: fresh lichee fruits are broken, and acid is added till 6.0g to 7.0 g / l during breaking; 30 to 120 mg / l of pectase and 250 to 500 mg / l of yeast are added to the fruit juices, the operation of starting fermentation is carried out during zymohydrolysis, and the operation of maceration and zymohydrolysis is carried out for 6 to 8 hours at the temperature between 12 and 20 DEG C; the mixture obtained is led into a fermentation cylinder to be fermented for 7 to 10 days at the temperature between 14 and 20 DEG C, and the operation of fermentation is stopped when the content of residual sugar is lower than 2g / l; the operation of twice distillation is carried out, head and last flows are cut down during first simple distillation, the alcohol content of the simple distillate is regulated to the degree of 29 percent Vol; and heads, first wine, second wine, feints and aromatic water are respectively cut down according to the alcohol content during secondary fine distillation. The processing technique has the advantages of favorable zymohydrolysis effect, high rate of juice yield and effective inhabitation of bacteria growth; the lower temperature fermentation and the grading wine cutting can keep the fragrance and the taste of wine, and the processing technique is suitable for preparing the lichee brandy.

Owner:YUNFU HUANAN LIQUOR

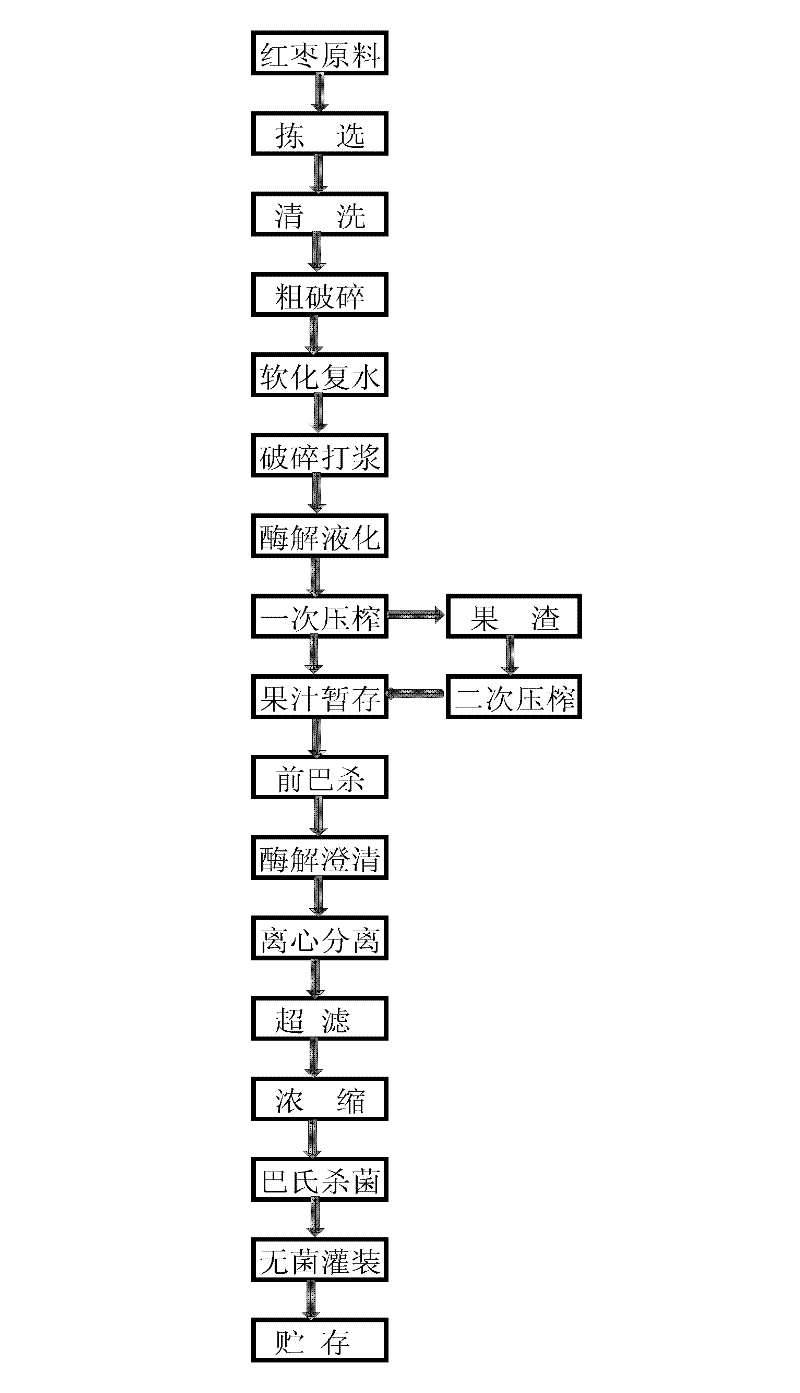

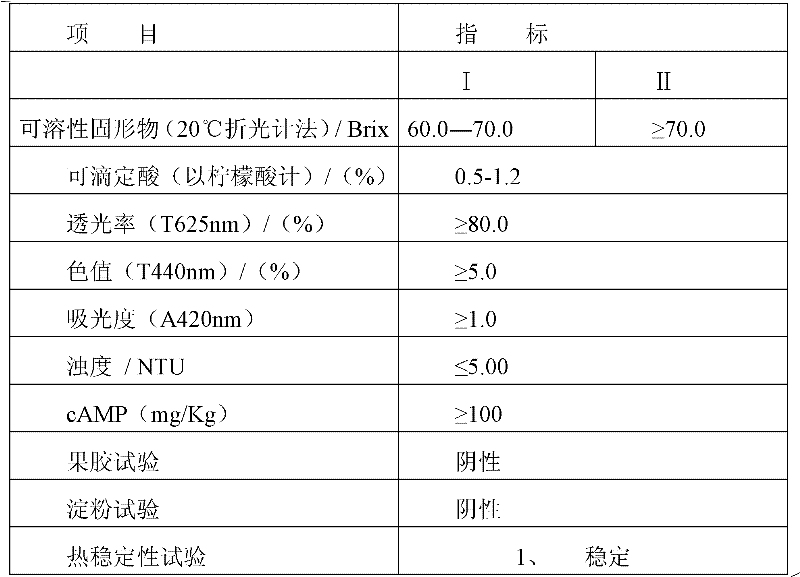

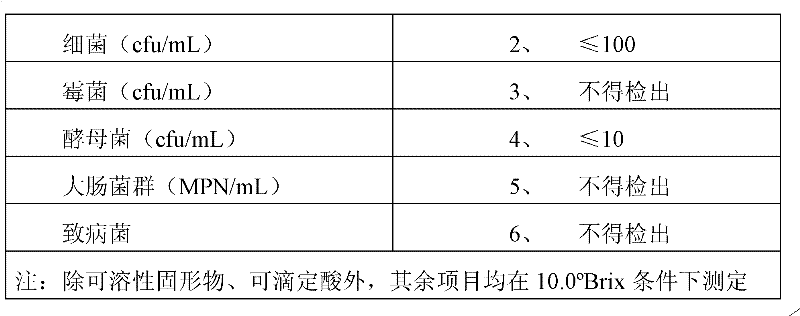

Method of preparing concentrated clear red jujube juice with high cAMP content

The invention discloses a method of preparing concentrated clear red jujube juice with high cAMP content, which comprises the following steps: taking out red jujube after rehydration, denucleating and then crushing pulp for preparing the red jujube thick liquid; conveying the red jujube after enzymolysis by pectinase into a juicer for squeezing, and filtering to obtain the red jujube juice; adding pectinase, amylase and cellulose into the red jujube juice for heat-preservation and enzymolysis for 60-90 minutes; and clearing, conducting concentration sterilization, and finally bulking. The concentrated clear red jujube juice prepared by the invention is clear and transparent, has the cAMP content being larger than or equal to 100 mg / Kg and soluble solid state material being larger than or equal to 60.0 Brix, is deposit-free and suspension-free, has brownish red color and does not have impurities which can be seen by naked eyes; and the concentrated juice is diluted to the soluble solidstate material being 60.0 Brix, and the juice has inherent fragrance and flavor of red jujubes and is free from extraneous odor.

Owner:LINGBAO BRANCH OF SHAANXI HAISHENG FRESH FRUIT JUICE CO LTD

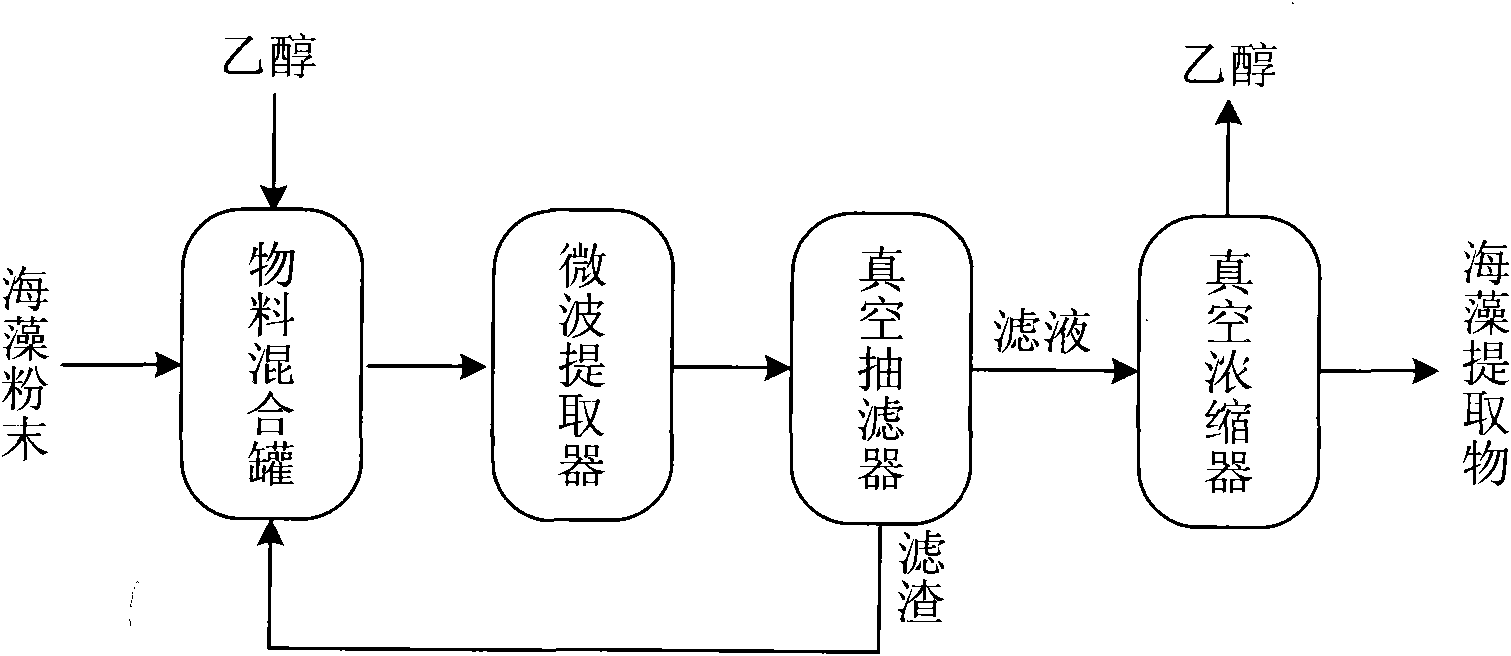

Seaweed flavor powder

The invention relates to edible seaweed, in particular to a seaweed flavor powder, and the flavor powder consists of 50 parts by weight of seaweed extract, 25-100 parts by weight of modified starch or / and dextrin and 1-5 parts by weight of emulsifier, wherein the emulsifier is glycerel monostearte or / and sucrose ester; the modified starch is crosslinked starch or / and gelatinized starch; and the seaweed extract is prepared by carrying out continuous microwave extraction on the edible seaweed by adopting 70-100% of ethanol. The seaweed flavor powder can retain aroma and taste of the seaweed and has the unique flavor of fresh, sweet, salty and fragrant. The seaweed flavor powder can be used as seaweed tea and seaweed soup, or be used on the surfaces of biscuits, cakes and bread or be added therein, or be added into dry noodles and instant noodles for producing foods with seaweed flavor.

Owner:GUANGZHOU UNIVERSITY

Mesona chinensis benth series drinks and preparation method thereof

InactiveCN101703293ANo incompatibilitySimple ingredientsFood preparationHigh volume manufacturingAdditive ingredient

The invention discloses mesona chinensis benth series drinks and a preparation method thereof, wherein the method takes mesona chinensis benth as main material to prepare mesona chinensis benth herbal drink, mesona chinensis benth gelatine powder, hot grass jelly electuary and immortal grass tea with milk through the processes of boiling extraction, concentration and the like. Compared with the existing mesona chinensis benth drinks, the product has the effects of cooling, lowering fire and relieving restlessness, has simple and convenient carrying, convenient drinking, and simple ingredients without incompatibility, reduces precipitation and impurities, and retains the special flavour of vegetable material as much as possible, and also has lower cost, exact efficacy, simple production process and easy operation and control, thus ensuring the product quality and being applicable to large-scale production.

Owner:灵山县宇峰保健食品厂

All-shaddock fermentation drink and production method thereof

The invention discloses an all-shaddock fermentation drink and a production method thereof. The production method comprises the steps of separating the pulp and peels of shaddock, separately adding acid and enzyme for treatment, then adding sugar, heating for sterilizing, then leading into lactobacillus and active dry yeast, and fermenting to obtain fermentation liquor; mixing the pulp fermentation liquor and peel fermentation liquor, then adding gum, a sour agent, a sweetening agent, dietary fiber and vitamin C, and heating for sterilizing to obtain the all-shaddock fermentation drink. After being fermented by the lactobacillus and saccharomyces cerevisiae, the shaddock peel and pulp not only maintain the original flavor and effect of the shaddock, but also are endowed with the fermented flavor effect of the lactobacillus and saccharomyces cerevisiae. In addition, soluble dietary fiber is further added into the fermentation drink and plays roles in smoothing intestinal tract and detoxifying and the like. The all-shaddock fermentation drink is proper in sour taste, mellow and clear and sweet, has special aroma and mouthfeel, as well as the effects of wetting the throat and smoothing the intestinal tract.

Owner:SOUTH CHINA UNIV OF TECH

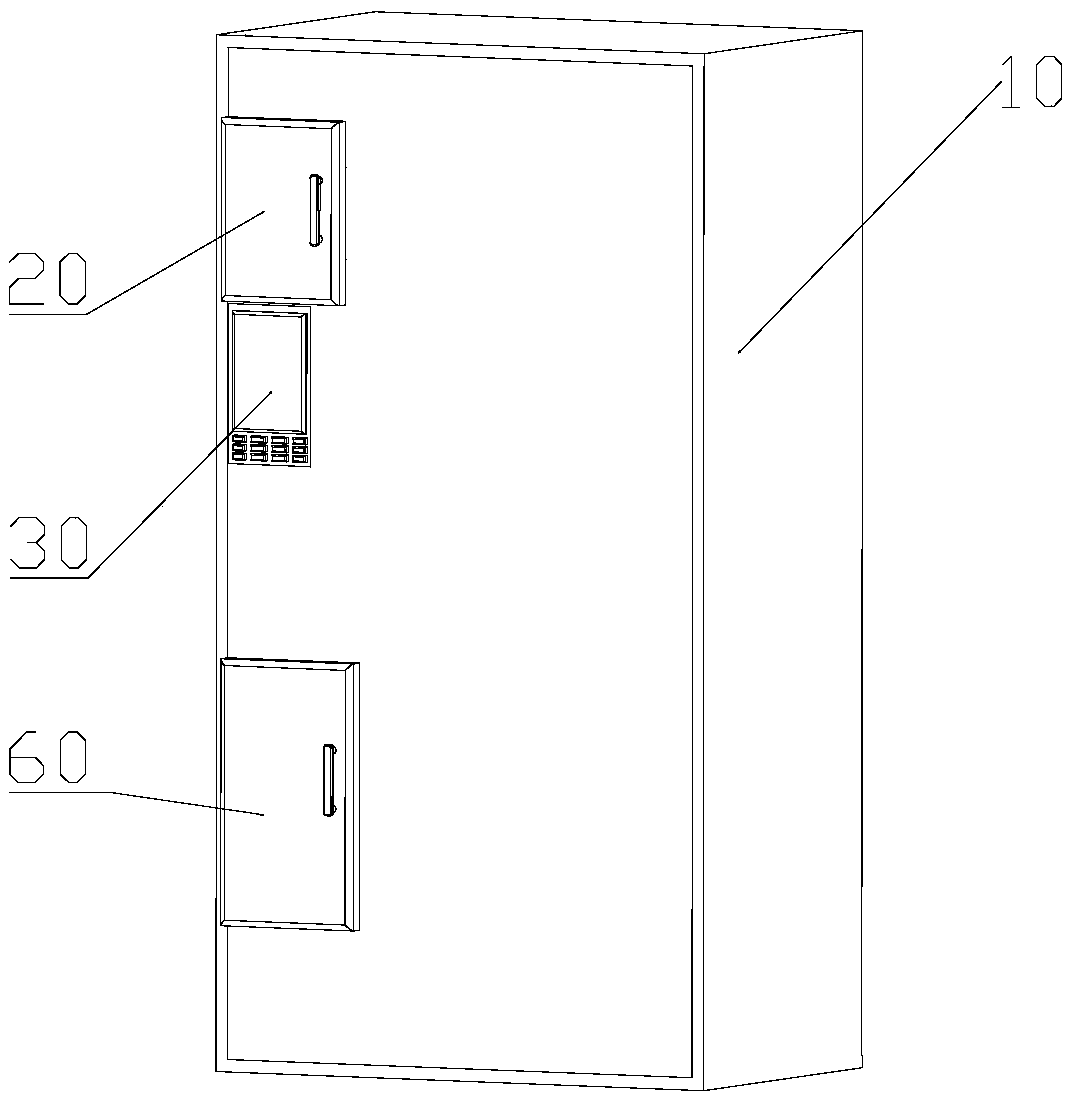

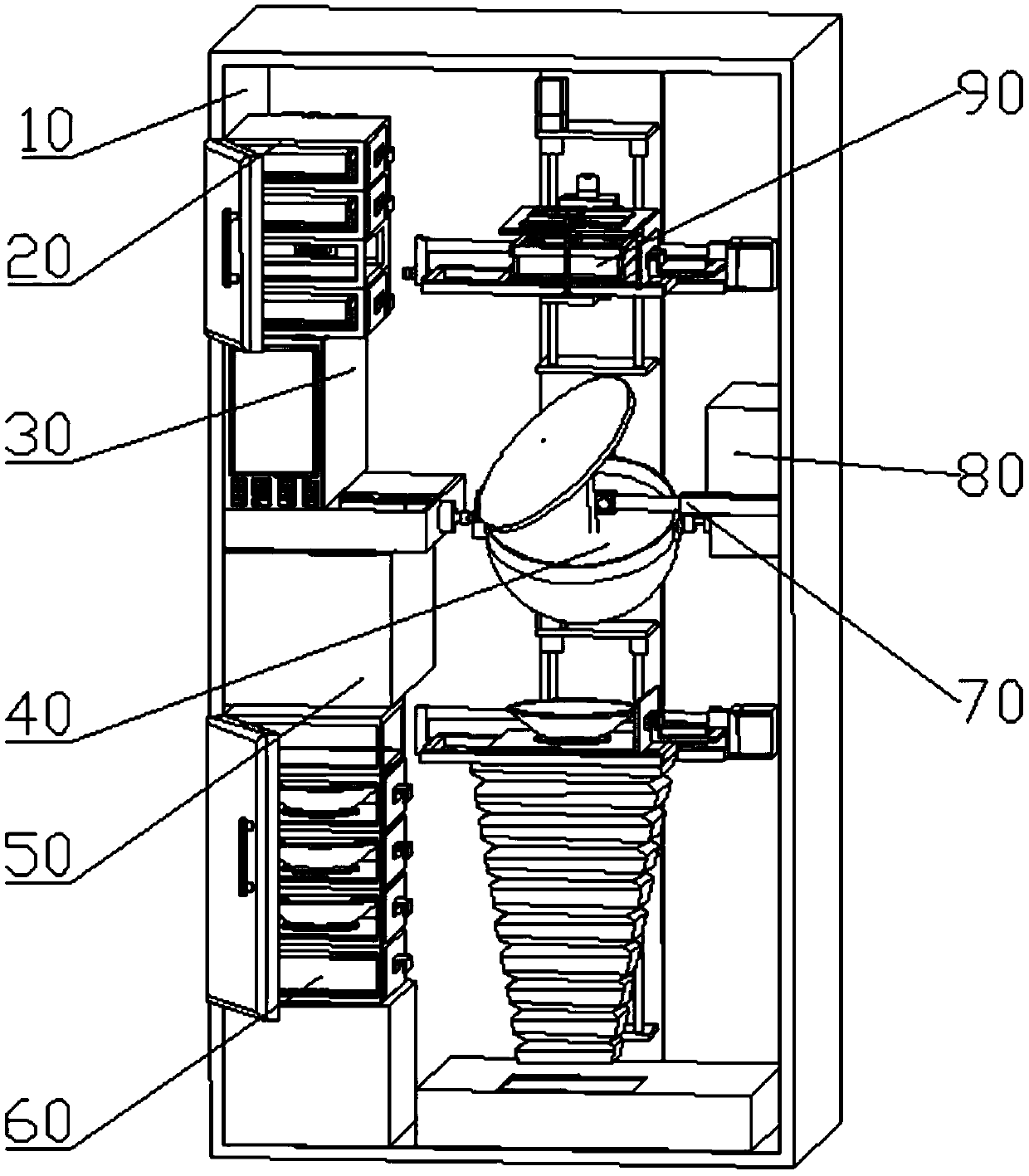

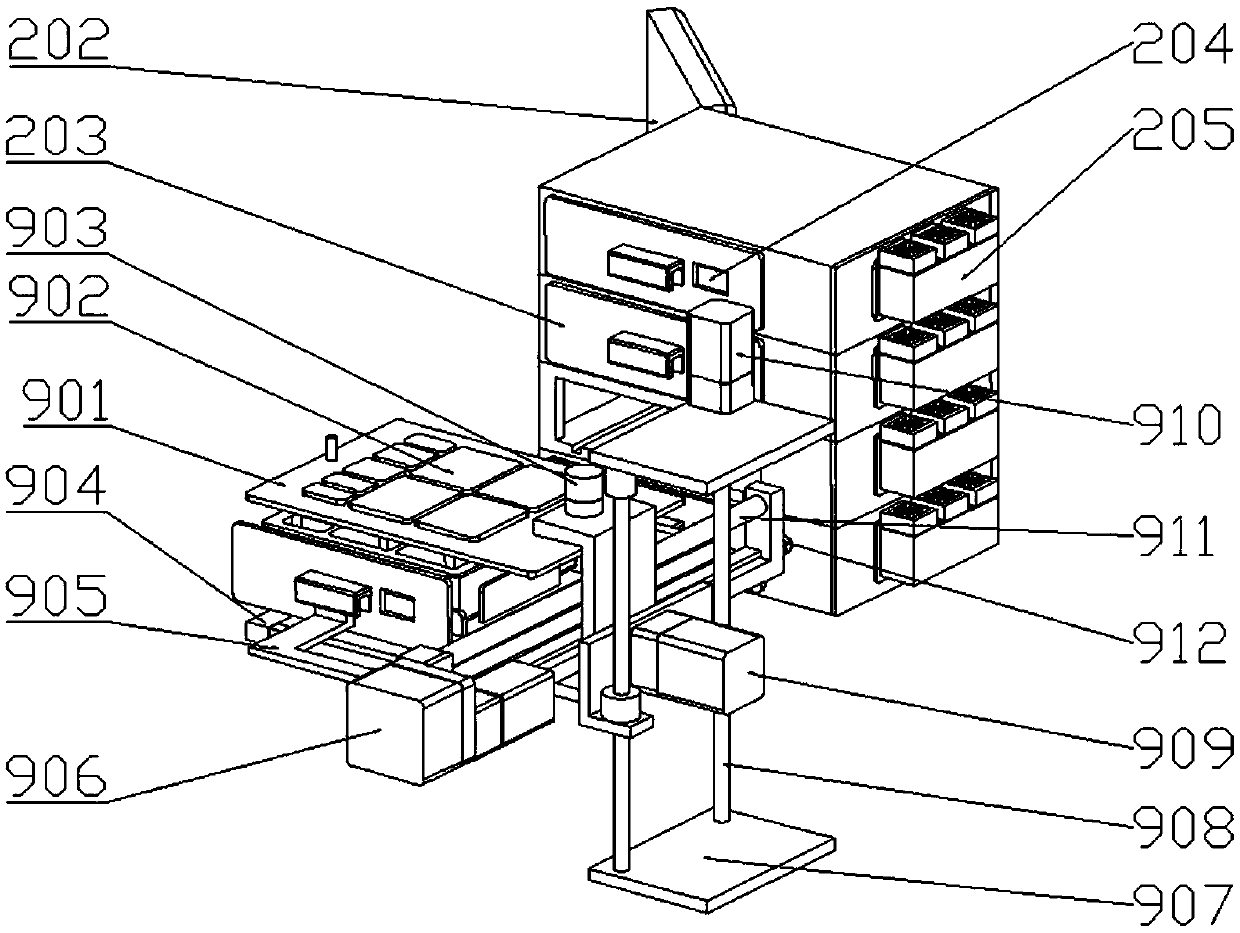

Automatic cooking machine and automatic cooking method

PendingCN109674337ACompact spaceMiniaturizationSteam cooking vesselsRoasters/grillsRoom temperatureGeneral family

The invention discloses an automatic cooking machine. The automatic cooking machine comprises an automatic feeding system, a food material dynamic processing system and a food material static processing system, wherein in the automatic cooking process, the automatic feeding system is used for putting food materials to be cooked in a food material box into a cooking container according to a presetcooking program; the food material dynamic processing system is used for dynamically processing the food materials according to the actions and time specified in the cooking program, and then dumpingthe food materials into a containing utensil, and conveying the containing utensil to the food material static processing system; and if the dynamic treatment is needed, the food materials placed in the food utensil are statically treated according to the heating process and time to which the cooking program corresponds, and if not required, the food materials in the food utensil are kept warm orstored at room temperature. The automatic cooking machine utilizes the transfer function of the cooking container and the heating and heat preservation and storage functions of the food material static processing system, has the advantages of multiple cooking modes, simple structure and tiny volume and can completely meet the daily cooking needs of ordinary families.

Owner:广州餐无忧科技有限公司

A kind of purple sweet potato cake and preparation method thereof

The invention discloses a purple sweet potato cake and a preparation method thereof, and aims to solve the defects of long time of preparation by conventional methods, excessively tedious operations, influence on the intrinsic color of purple sweet potatoes, and simultaneously, substantially hardened texture caused by starch aging during the storage of purple sweet potato cakes, as well as seriously affected mouthfeel in prior art. With purple sweet potatoes as the main raw materials, the method selects different excipients to season the purple sweet potato cake, and maintains the original flavor of purple sweet potatoes by changing the production process. Thus, the obtained purple sweet potato cake has bright color, long storage time and good mouthfeel.

Owner:SICHUAN ACAD OF AGRI SCI +2

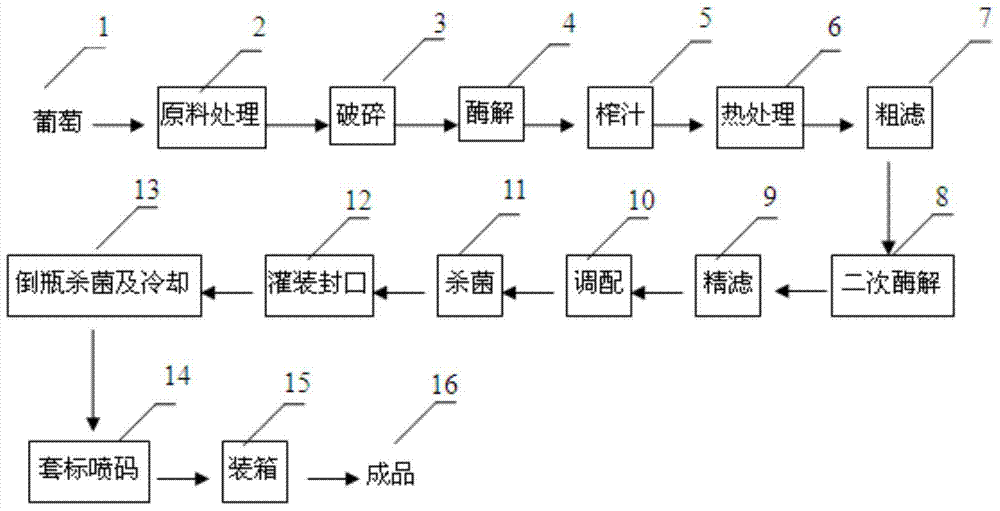

Pure grape juice beverage and production method thereof

InactiveCN103876226AFactors Inhibiting Quality DeteriorationPrevent precipitationFood sciencePurplish redBottle

The invention discloses a pure grape juice beverage and a production method thereof. The production method is characterized by taking fresh grape as raw material and comprising the following steps: processing the raw material, crushing, carrying out enzymolysis, juicing, heating, roughly filtering, carrying out secondary enzymolysis, finely filtering, mixing, sterilizing, filling and sealing, reversing bottle for sterilizing and cooling, putting on labels and spraying codes, and packing to produce a clear type pure grape juice beverage which is delicious and has the characteristics and taste of the grape. The method is capable of carrying out large-scale industrial production; the produced grape beverage is purplish red in color, clear and transparent, and long in quality guarantee period; the grape beverage is stored, circulated and sold at normal temperatures.

Owner:SICHUAN UNIV

Method for producing fermented fish paste

The invention discloses a method for producing fermented fish paste. The method for producing the fermented fish paste mainly comprises the steps of low-value fish raw materials, pretreatment (removal of scales, head, tails, internal organs and vertebras), soaking in salt vinegar water, draining, soaking in ozone water, draining, defibrination, salt addition, in-jar fermentation, seasoning, mixedhomogeneity and obtaining of finished products. The method adopts a salt vinegar water soaking method to remove fishy-smell substance, is scientific, easy to operate and good in effect. The salt vinegar water is used for soaking fish slices, and acetic acid promotes solubility of the fishy-smell substance (trimethylamine oxide and dimethylamine oxide) in water with the assist of the salt water and enables the fishy-smell substance to be solved in the water, thereby achieving the removal purpose. Ozone solution produced by an electrolysis type ozone generator is used for soaking and disinfection, sundry fungus pollution and usage of preservatives are reduced, and the requirement for green production is met. Self enzyme of fishes is utilized to perform natural fermentation, thereby ensuringgood taste and special flavor of the fish paste.

Owner:CHANGSHA UNIVERSITY OF SCIENCE AND TECHNOLOGY

Instant preserved meat ham food and processing process of instant preserved meat ham food

The invention relates to instant preserved meat ham food and a processing process of the instant preserved meat ham food and belongs to the technical field of instant food and a processing process of the instant food. Major ingredients of 13 to 18 parts of pork, 7 to 7.5 parts of pigskin, 13 to 15 parts of chicken, 7 to 8 parts of pig fat and 9 to 10.5 parts of diced preserved meat are adopted to be matched with auxiliary materials, and the instant preserved meat ham food is prepared. The instant preserved meat ham food solves the problems that in the prior art, the recipe of the preserved meat food is not reasonable, the flavor belongs to the western style flavor and cannot conform to the eating habits of most people, and the flavor cannot be similar to the flavor of the traditional preserved meat. The invention provides a recipe and a mixture ratio of the instant preserved meat ham food. The flavor is similar to the flavor of the traditional preserved meat. The processing process of the instant preserved meat ham food provided by the invention has the advantages that the flavor of the food prepared by using the recipe is more similar to the flavor of the traditional preserved meat, and in addition, the flavor can be maintained for a long time.

Owner:四川高金翔达食品有限公司

Fermented coconut cream/coconut pulp juice, coconut yogurt and preparation methods of fermented coconut cream/coconut pulp juice and coconut yogurt

The invention relates to the technical field of foods and relates to fermented coconut cream / coconut pulp juice, coconut yogurt and preparation methods of fermented coconut cream / coconut pulp juice and coconut yogurt. The preparation method of the fermented coconut cream / coconut pulp juice comprises the following steps: removing partial grease from coconut cream / coconut pulp juice, and carrying out sterilization and cooling, so as to obtain a fermented raw material; and adding a first fermentation strain into the fermented raw material, so as to obtain the fermented coconut cream / coconut pulp juice. The preparation method of the coconut yogurt comprises the following steps: respectively and independently fermenting the coconut cream / coconut pulp juice and a milk product, so as to obtain the fermented coconut cream / coconut pulp juice and fermented yogurt; and mixing the fermented coconut cream / coconut pulp juice with the fermented yogurt with the fermented yogurt in proportion, and carrying out blending and sterilization, so as to obtain the coconut yogurt. The products provided by the invention have special flavors of coconuts and yogurt, stable tissue state and fine and smooth taste and are rich in nutrition and easy to digest and absorb.

Owner:卞寿斌

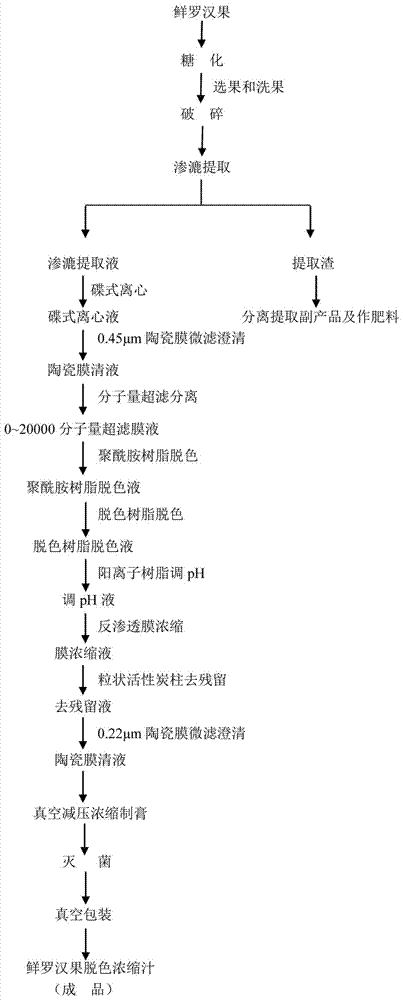

Process for preparing fresh momordica grosvenori decolored concentrated juice

The invention provides a process for preparing fresh momordica grosvenori decolored concentrated juice. The process comprises the following steps: saccharifying fresh momordica grosvenori, selecting and washing momordica grosvenori, crushing, performing percolation extraction, performing disc-type centrifugation, performing micro-filtration clarification with a ceramic membrane of 0.45mu m, performing molecular weight ultra-filtration separation, performing decoloring with a polyamide resin, performing decoloring with a decoloring resin, adjusting the pH value with a cationic resin, concentrating with a reverse osmosis membrane, removing residues with a granular activated carbon column, performing micro-filtration clarification with a ceramic membrane of 0.22mu m, performing vacuum concentration so as to obtain an ointment, sterilizing, and performing vacuum packaging, so as to obtain the fresh momordica grosvenori decolored concentrated juice. The flavor and the nutrient components of fresh momordica grosvenori of the fresh momordica grosvenori decolored concentrated juice produced by using the process are maintained, and the juice is nearly colorless and is clear and transparent, is very good in taste, free of after precipitate and high in quality, can be widely applied to food, drinks, medicines and healthcare products, and is simple in production process, advanced in technique, high in automation degree, high in efficiency, low in energy consumption, low in production cost, stable in product quality and high in quality.

Owner:HUNAN HUACHENG BIOTECH

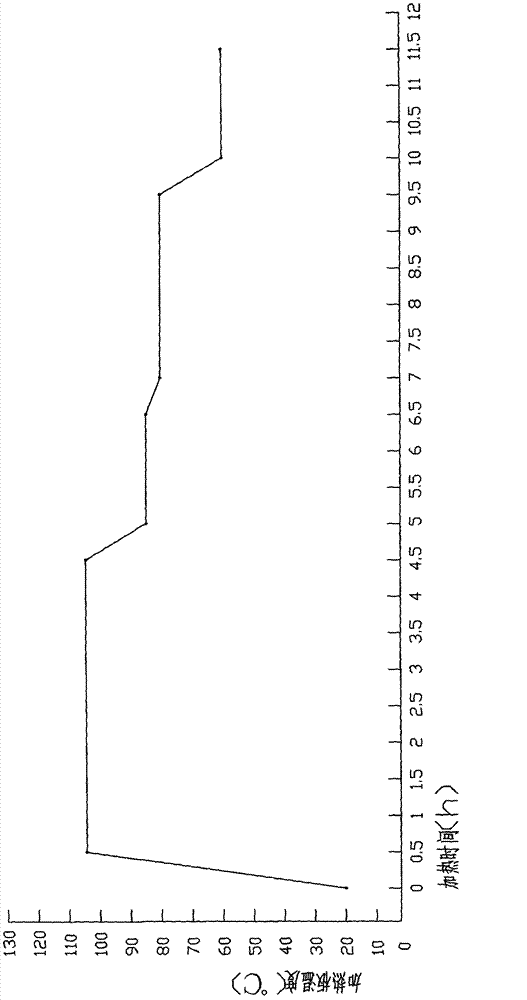

Method for preparing blowfish can

InactiveCN101301092AAccelerateHigh temperature control accuracyFish washing/descalingMeat/fish preservation by heatingNutrientPre treatment

The invention relates to a method for making globe fish can, including the following steps: material preprocessing, cutting, soup stock production, mixing, canning, pre-boiling, sealing, sterilization, cooling, casing. The key technology of the method is adopting the wave-type hot water injection of an automatic spraying sterilizer and the temperature rise regulating sterilization in multi-stage. The making method has a strict and general sterilization to the globe fish materials, makes use of the advanced processing devices, temperature rise regulating sterilization in multi-stage and reasonable making technology. The can products are not only safe, nutrient, but also maintain the natural taste of the globe fish.

Owner:刘烈

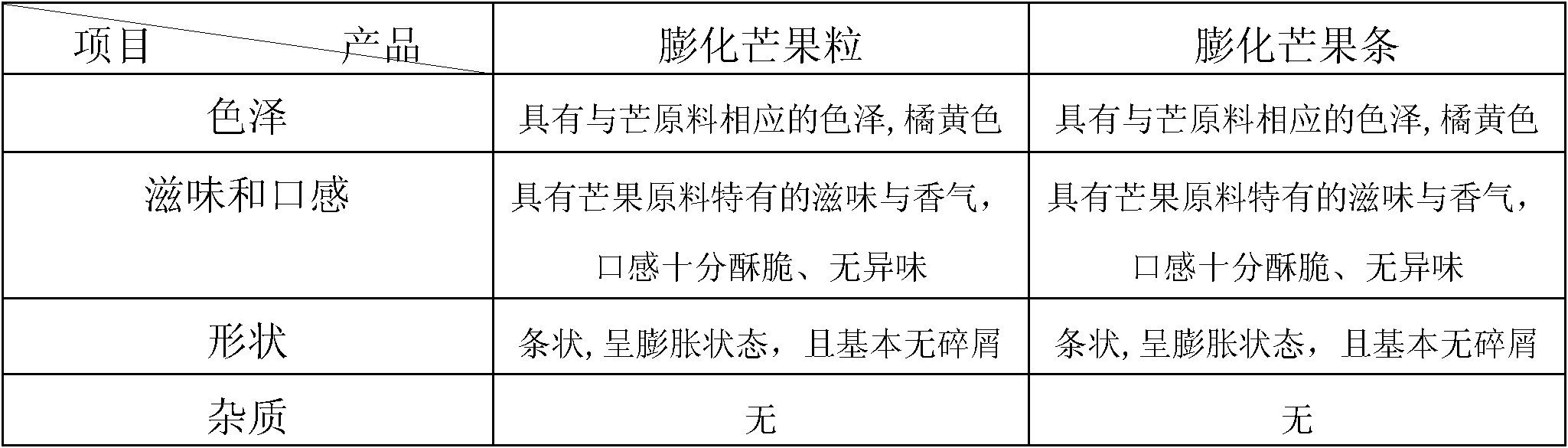

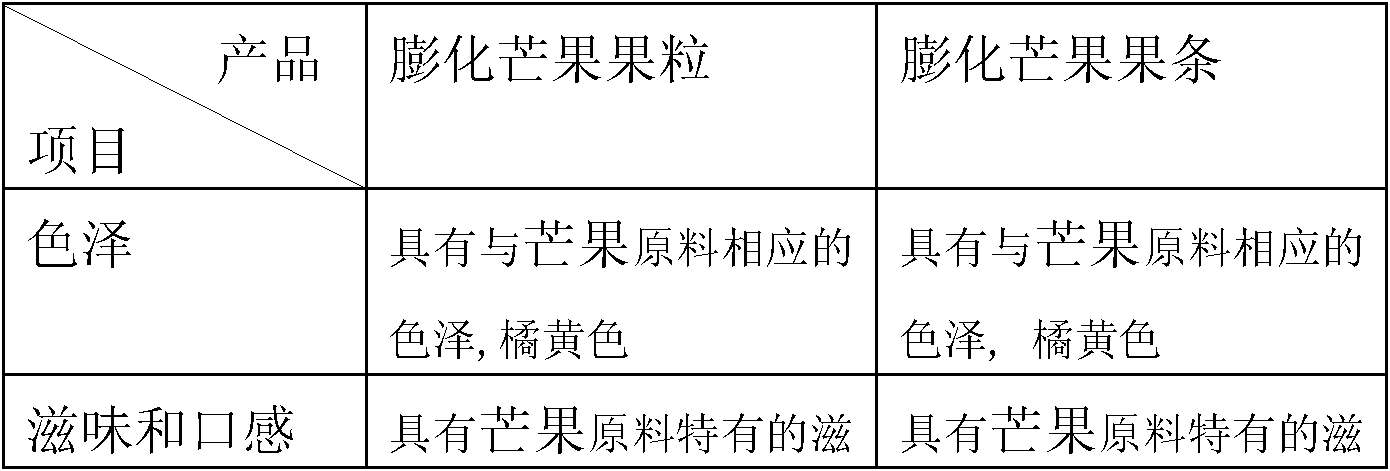

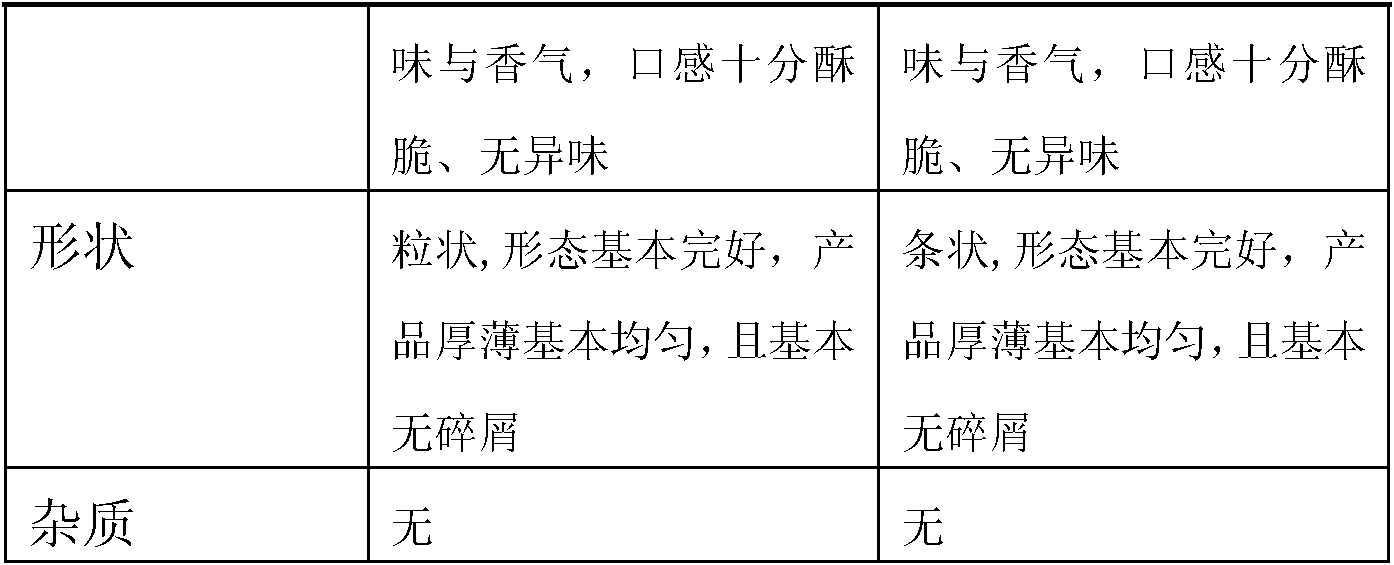

Puffed mango and preparation method thereof

The invention discloses a puffed mango and a preparation method thereof. The method comprises the following steps of putting the pulps of mango into a puffing tank; then carrying out variable-temperature and pressure-difference puffing on the pulps of mango; and the process of the variable-temperature and pressure-difference puffing comprises the following steps: 1) raising the temperature in thepuffing tank to 70-90 DEG C, raising the pressure in the puffing tank to a pressure 0.1-0.3 MPa higher than the atmospheric pressure outside the puffing tank, and keeping the temperature and the pressure, so that the surface temperature of a mango is consistent with the temperature in the puffing tank; 2) reducing the pressure in the puffing tank to a vacuum state, and reducing the temperature to60-80 DEG C under vacuum, then keeping the pressure and the temperature under vacuum, so that the moisture content of the pulps of mango is 3-5%; and 3) reducing the temperature in the puffing tank to 10-30 DEG C, and keeping the temperature 30-60 minutes under vacuum so as to obtain the puffed mango. The method is a new technique for processing vegetable slices; and by using the method disclosedby the invention, the nutrient compositions and flavors of raw materials can be kept furthest, no additive is used in the process of processing, and the defect that fried products contain a small amount of oils is avoided.

Owner:INST OF AGRO FOOD SCI & TECH CHINESE ACADEMY OF AGRI SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com