Processing technique of lichee brandy

A production process and brandy technology, applied in the field of lychee brandy production, can solve the problems of affecting the quality of secondary distillation, affecting the aroma and taste of fermented original wine, and making it difficult to brew original wine, so as to preserve the aroma and flavor, inhibit the growth of miscellaneous bacteria, and keep fresh Pleasant fruity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

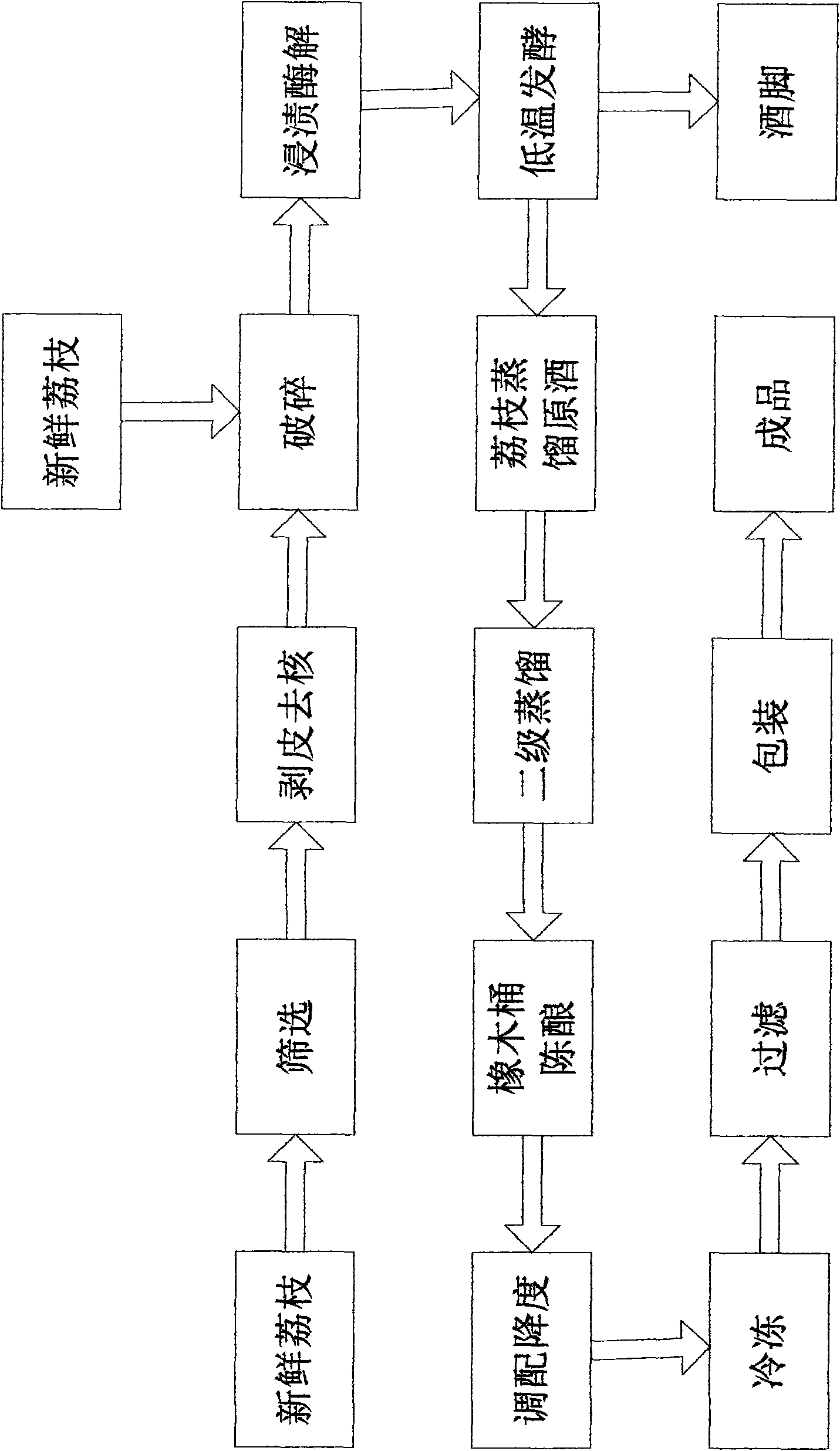

Image

Examples

Embodiment Construction

[0022] The fresh lychee fruit is screened first, and the sugar content of the fresh fruit is required to be around 120g / l-160g / l, and then cleaned, peeled and pitted in a special peeling and pitting machine for lychees, and the pulp is crushed. When crushing, add tartaric acid until the total acid content is 6.0g / l-7.0g / l.

[0023] Transport the crushed lychee pulp and juice to the dipping tank together, add 30mg~120mg of activated pectinase and 250mg~500mg of Saccharomyces cerevisiae to each liter of juice, start fermentation while enzymatic hydrolysis, and start the refrigerator Cool down the juice, keep the dipping enzymolysis temperature at 12° C. to 20° C., and the time for 6 hours to 8 hours to obtain fermented clear juice.

[0024] Pump the fermented clear juice into the fermenter, continue to ferment, control the temperature at a low temperature of 14°C to 20°C, and ferment for 7 to 10 days until the sugar content in the fermented liquid is lower than 2g / l. Settling, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com