Pure grape juice beverage and production method thereof

A production method and grape juice technology, applied in the field of food processing, can solve the problems of outdated processing technology and equipment, easy discoloration of grape beverages, and escape of aromatic substances, and achieve the effects of increasing juice yield, retaining flavor and characteristics, and extending shelf life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

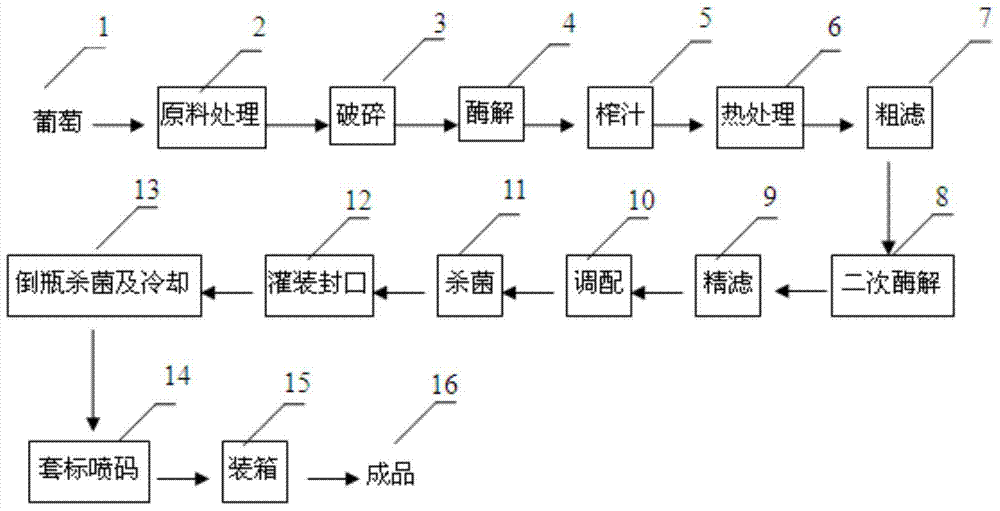

Method used

Image

Examples

Embodiment 1

[0053] Select fresh grapes, after manual selection and cleaning, send them to the crushing and destemming machine for fruit stem crushing and fruit separation; the grape jam body is pumped into a stainless steel enzymatic heat preservation tank; 0.5 parts of pectinase is added to 1000 parts of grape jam , at a speed of 20rpm, react at a temperature of 45°C for 3 hours; pump the enzymolyzed grape sauce into a juicer to extract grape juice; pump the grape juice into a heat exchanger, heat-treat at a temperature of 90°C for 15 seconds, cool to 45°C, pump Enter filter bag pore size and be 80 mesh duplex filters to filter; By weight: 0.02 parts of pectinase and 50 parts of gelatin solution with concentration of 1% are added in 1000 parts of grape crude filtrate, under the rotating speed of 10rpm, at temperature React at 45°C for 3 hours; then add 2 parts of diatomaceous earth, stir evenly and then let it stand for 8 hours; the secondary enzymolysis solution is first filtered through...

Embodiment 2

[0055] Select fresh grapes, after manual selection and cleaning, send them to the crushing and destemming machine for fruit stem crushing and fruit separation; the grape sauce body is pumped into the stainless steel enzymatic hydrolysis insulation tank; 0.1 part of pectinase is added to 1000 parts of the grape sauce body , at a speed of 50rpm, react at a temperature of 40°C for 2h; pump the enzymolyzed grape sauce into a juicer to extract grape juice; pump the grape juice into a heat exchanger, heat-treat at a temperature of 90°C for 20s, cool to 40°C, pump Enter the filter bag with a pore size of 40 mesh and filter through a double filter; add 0.08 parts of pectinase and 80 parts of gelatin solution with a concentration of 1% to 1000 parts of grape crude filtrate, and react at a temperature of 40 °C at a speed of 20 r / min 2h; then add 3 parts of diatomaceous earth, stir evenly and let it stand for 6h; the secondary enzymolysis solution is first filtered with a cloth bag filter...

Embodiment 3

[0057] Select fresh grapes, after manual selection and cleaning, send them to the crushing and destemming machine for fruit stem crushing and fruit separation; the grape sauce body is pumped into a stainless steel enzymatic heat preservation tank; 0.3 parts of pectinase are added to 1000 parts of the grape sauce body , at a speed of 35rpm, react at a temperature of 42°C for 2.5h; enzymatically hydrolyzed grape jam is pumped into a juicer to extract grape juice; grape juice is pumped into a heat exchanger, heat-treated at a temperature of 90°C for 17s, cooled to 42°C, Pump into the filter bag with a pore size of 60 mesh for filtration; add 0.05 parts of pectinase and 60 parts of gelatin solution with a concentration of 1% to 1000 parts of grape crude filtrate, and react at a temperature of 42 ° C for 2.5 at a speed of 15 rpm. h; then add 2.5 parts of diatomaceous earth, stir evenly and let stand for 7 hours; the secondary enzymolysis solution is first filtered with a 400-mesh cl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com