Iron-based corrosion resistant wear resistant alloy and deposit welding material for obtaining the alloy

A wear-resistant, surfacing material technology, applied in welding/cutting media/materials, welding media, welding equipment, etc., can solve problems such as increased production costs, difficult welding and joining, and poor bending workability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

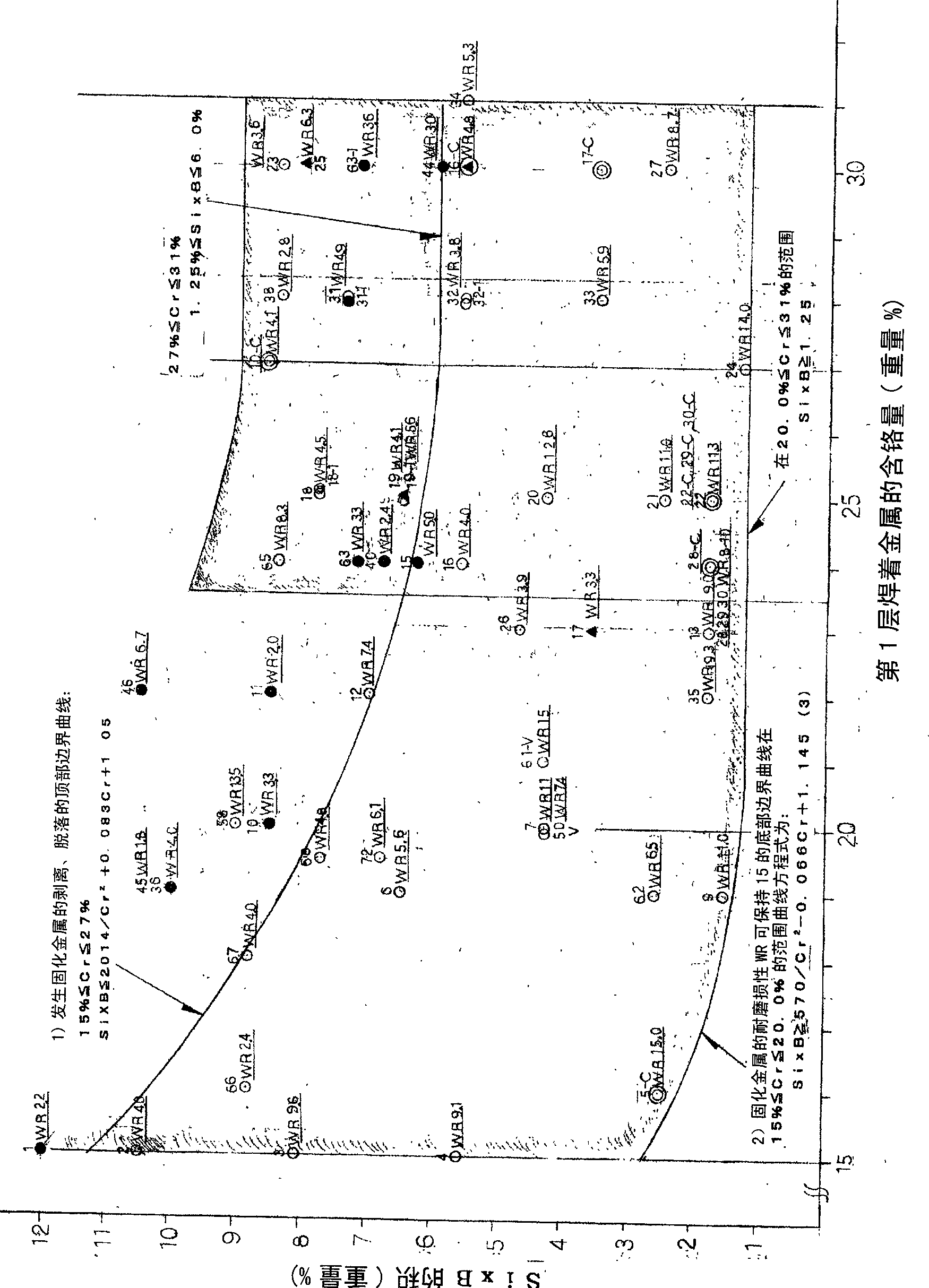

Method used

Image

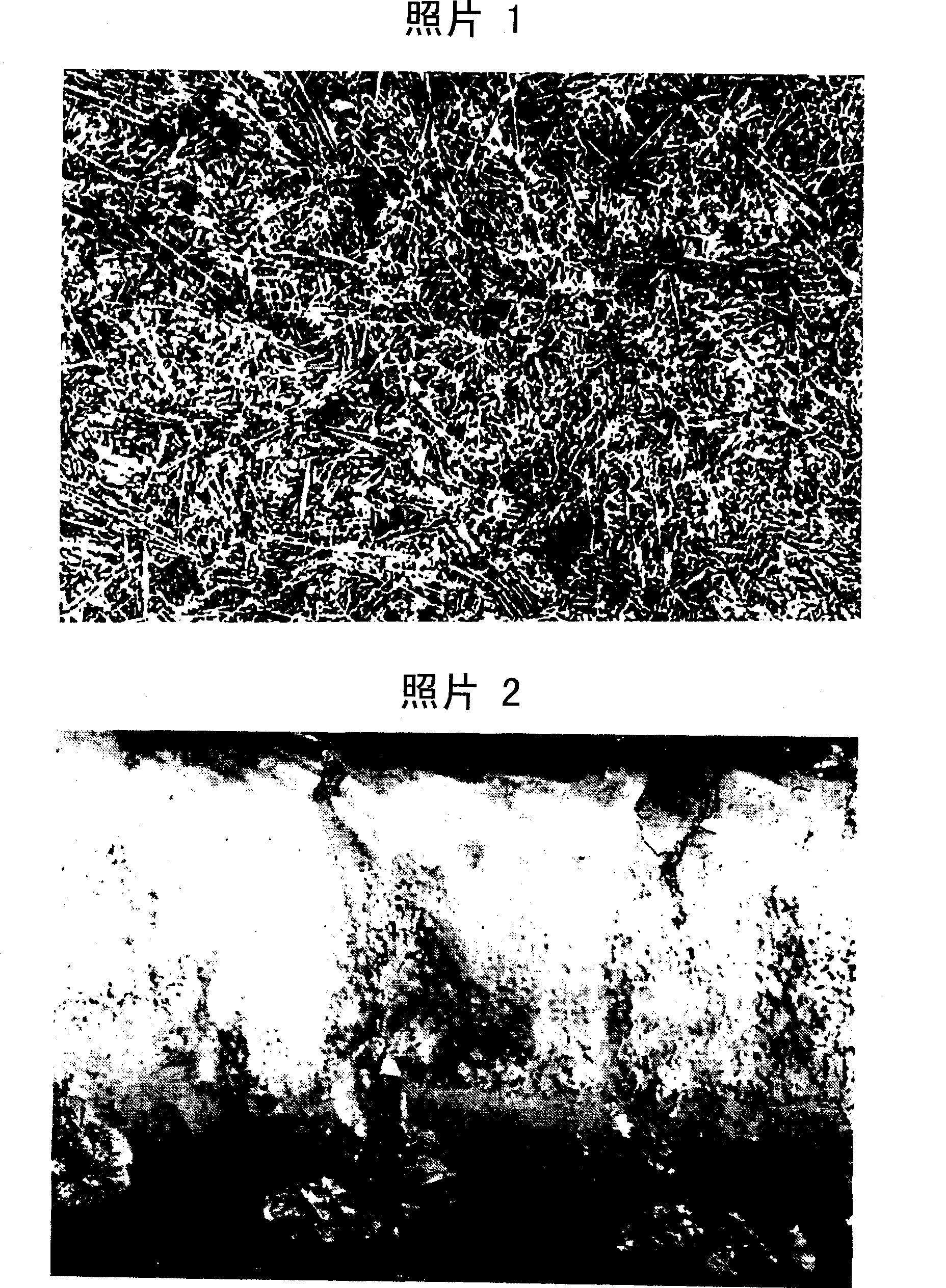

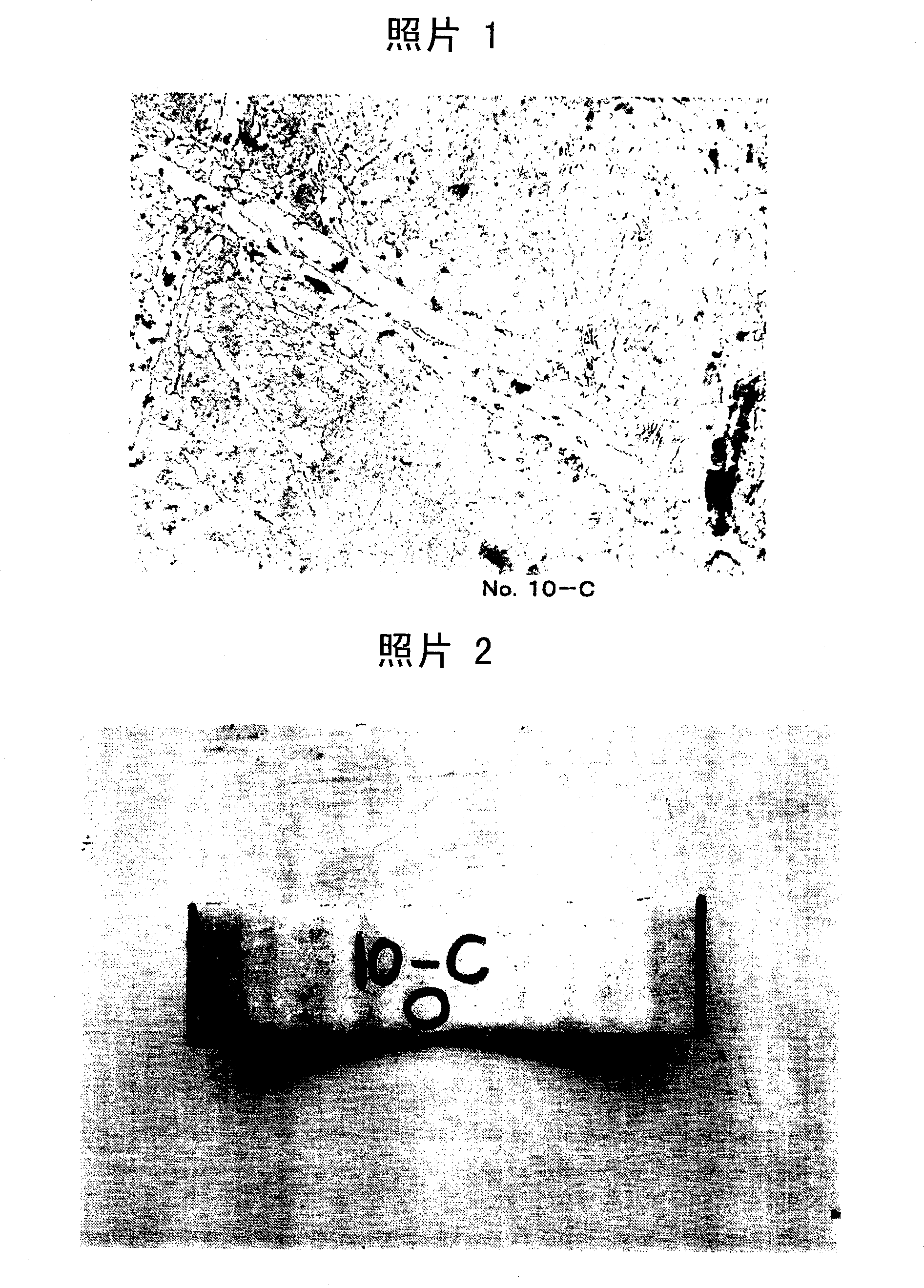

Examples

Embodiment

[0306] Next, the effects of the present invention will be demonstrated by showing examples and comparing with comparative examples. In recent years, the price of oil has soared, which has led to an increase in the cost of coal input. As a country with small resources, our country is suffering from soaring fuels. This is the current status quo. Especially in coal-fired power plants, iron factories, and cement plants that use a huge amount of coal, the use of high-priced good charcoal is reduced and mixed with cheap low-quality charcoal. Inferior charcoal also has coal with high sulfur content. If it is piled up in the open air in the stockyard, the moisture will increase due to rain, and the sulfur contained in the coal will react with water to form dilute sulfuric acid.

[0307] As an example, in the process of introducing coal to the pulverizer, although there is a trough conveyor, the floor bushing is constantly worn, so a wear-resistant steel plate made of high carbon-high ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com