Patents

Literature

80 results about "Precipitation types" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

In meteorology, the various types of precipitation often include the character or phase of the precipitation which is falling to ground level. There are three distinct ways that precipitation can occur. Convective precipitation is generally more intense, and of shorter duration, than stratiform precipitation. Orographic precipitation occurs when moist air is forced upwards over rising terrain, such as a mountain.

Phosphorus-free corrosion and scale inhibitor

InactiveCN101607763AReduce dosagePlay a role in corrosion inhibitionTreatment using complexing/solubilising chemicalsChelationPrecipitation types

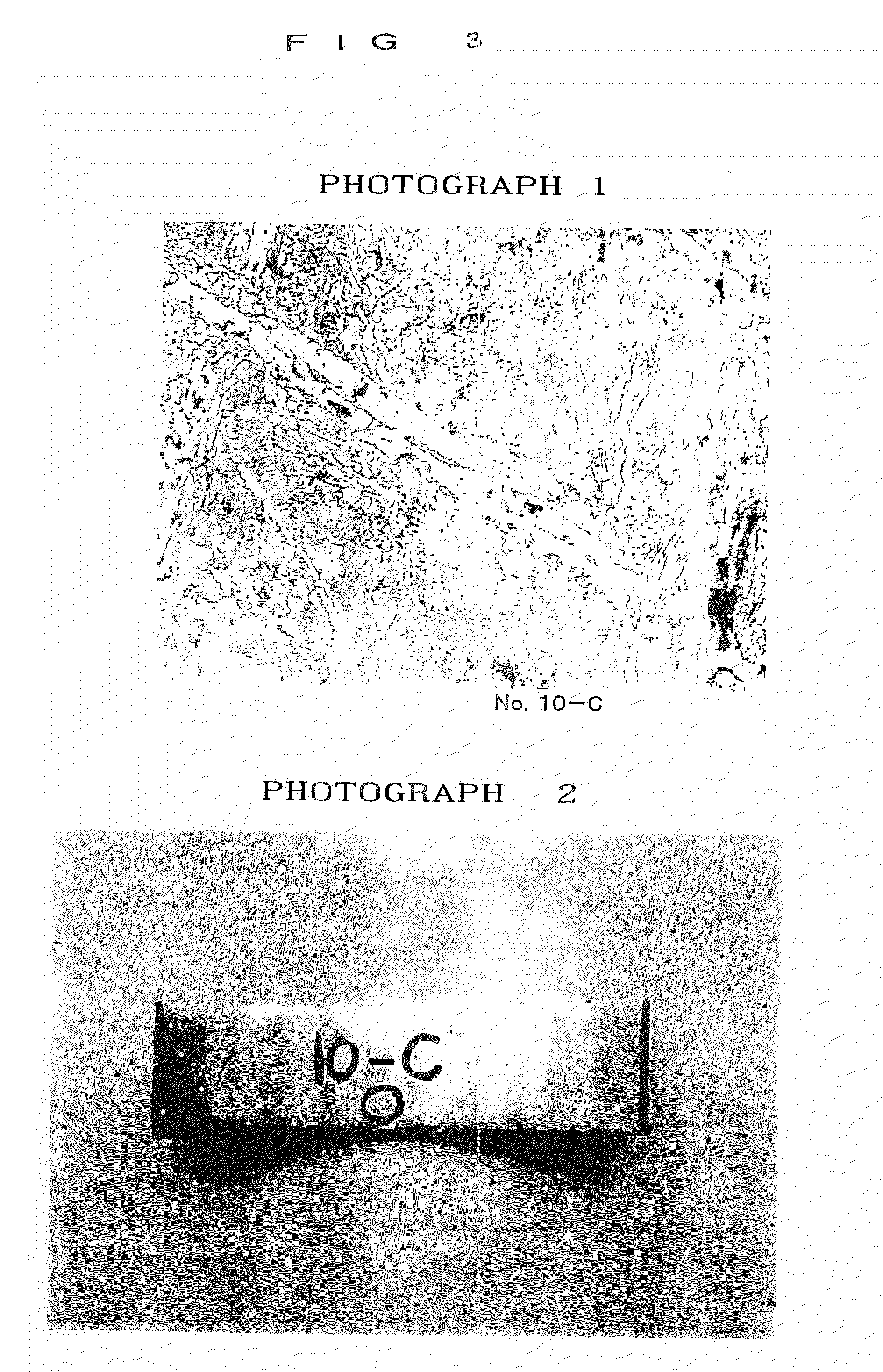

The invention relates to a phosphorus-free corrosion and scale inhibitor, which is prepared from sodium molybdate, zinc salt, citrate, triethanolamine, benzotriazole (BTA), polyaspartic acid (PASP), polyepoxysuccinic acid (PESA), AA / AMPS terpolymer, solid alkali and water. The phosphorus-free corrosion and scale inhibitor inhibits corrosion of metals by forming oxidization type and precipitation type films on the surfaces of the metals, has the effect of inhibiting scale through chelation and dispersive action on salts causing scale in cooling water, is non-toxic and phosphorus-free, has easily biodegradable major organic compositions, does not cause environmental pollution and is not limited by phosphorus in emission.

Owner:SHANGHAI WEILAI ENTERPRISE

Iron-based corrosion resistant wear resistant alloy and deposit welding material for obtaining the alloy

InactiveUS20100189588A1Efficient use of resourcesEffective utilization of rareWelding/cutting media/materialsSoldering mediaChromium carbideHigh carbon

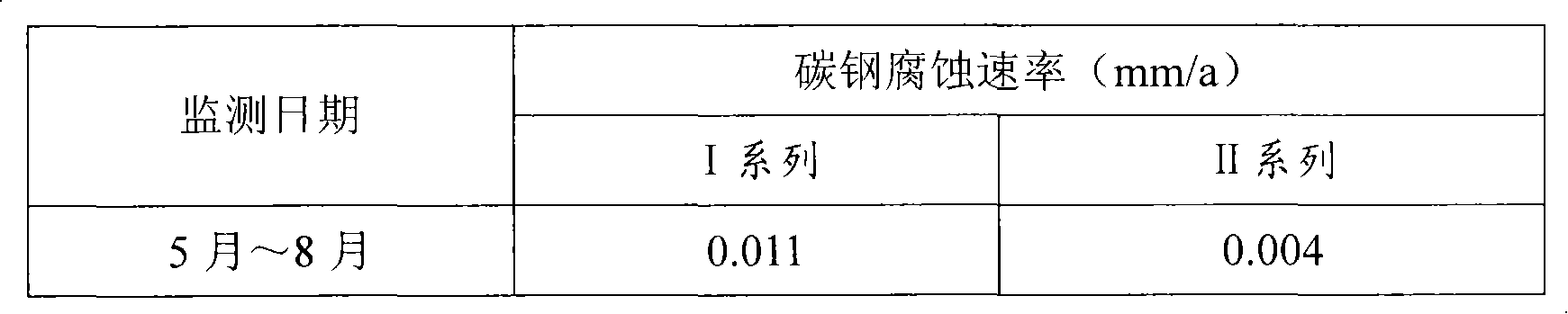

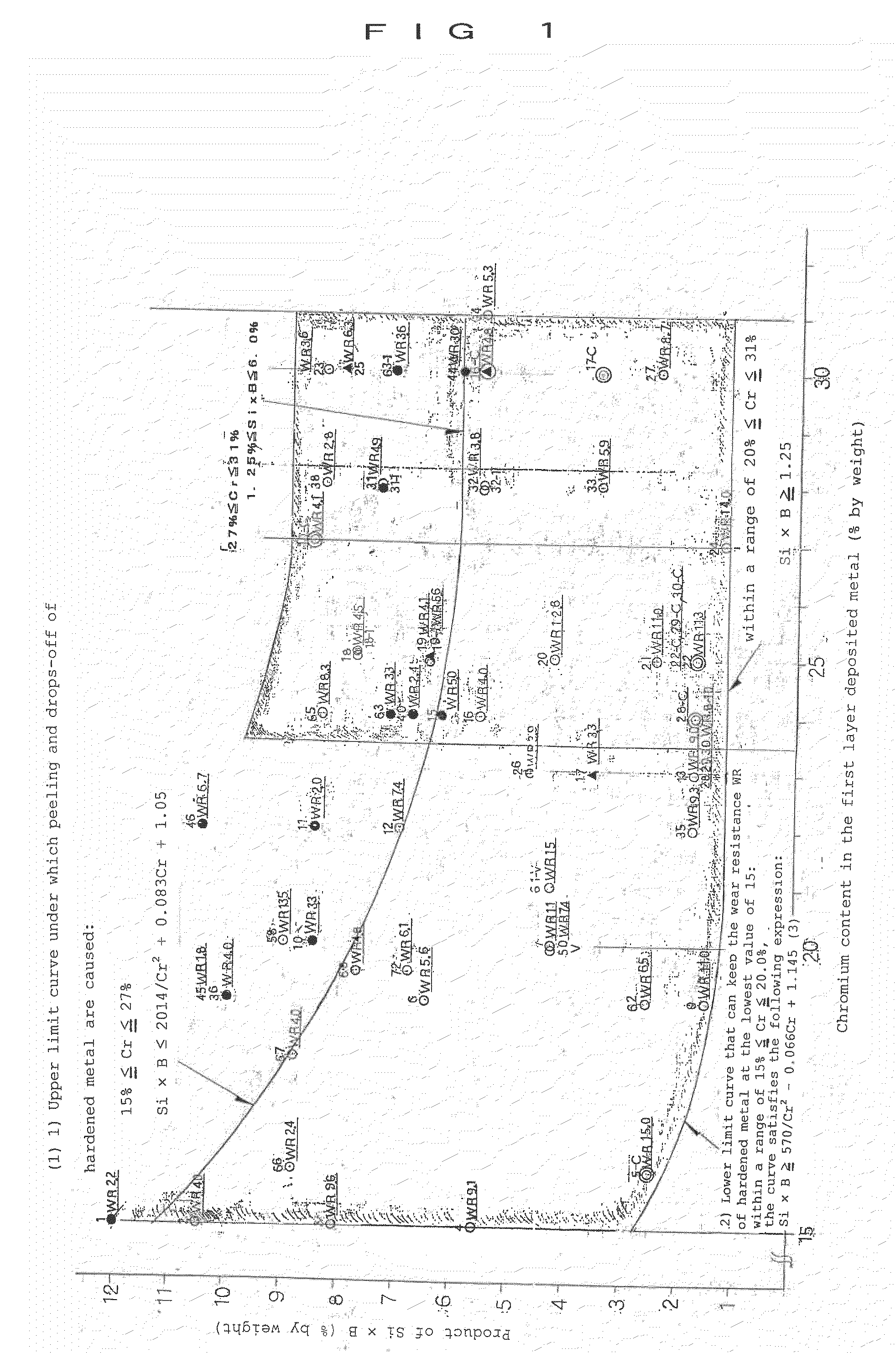

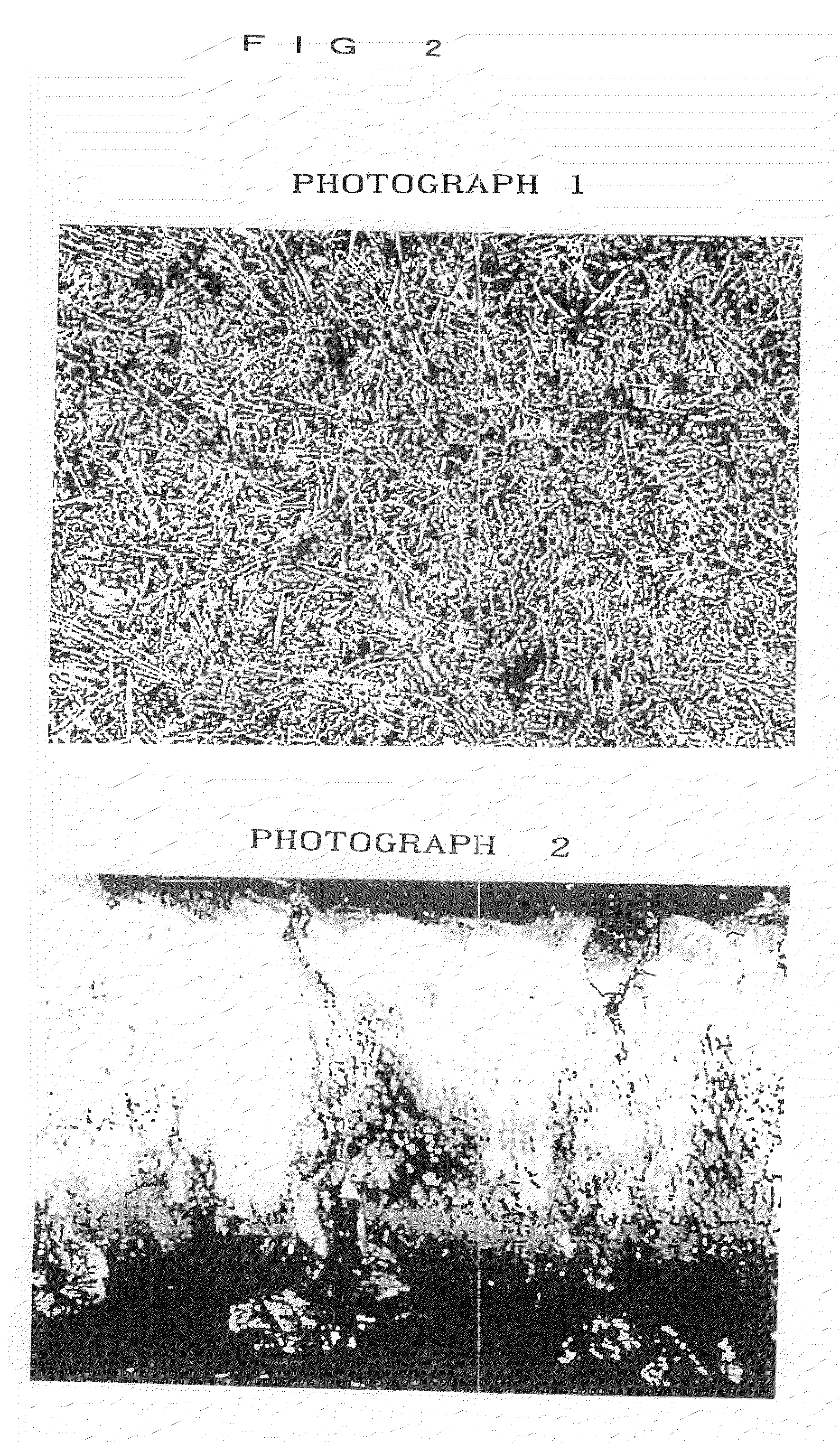

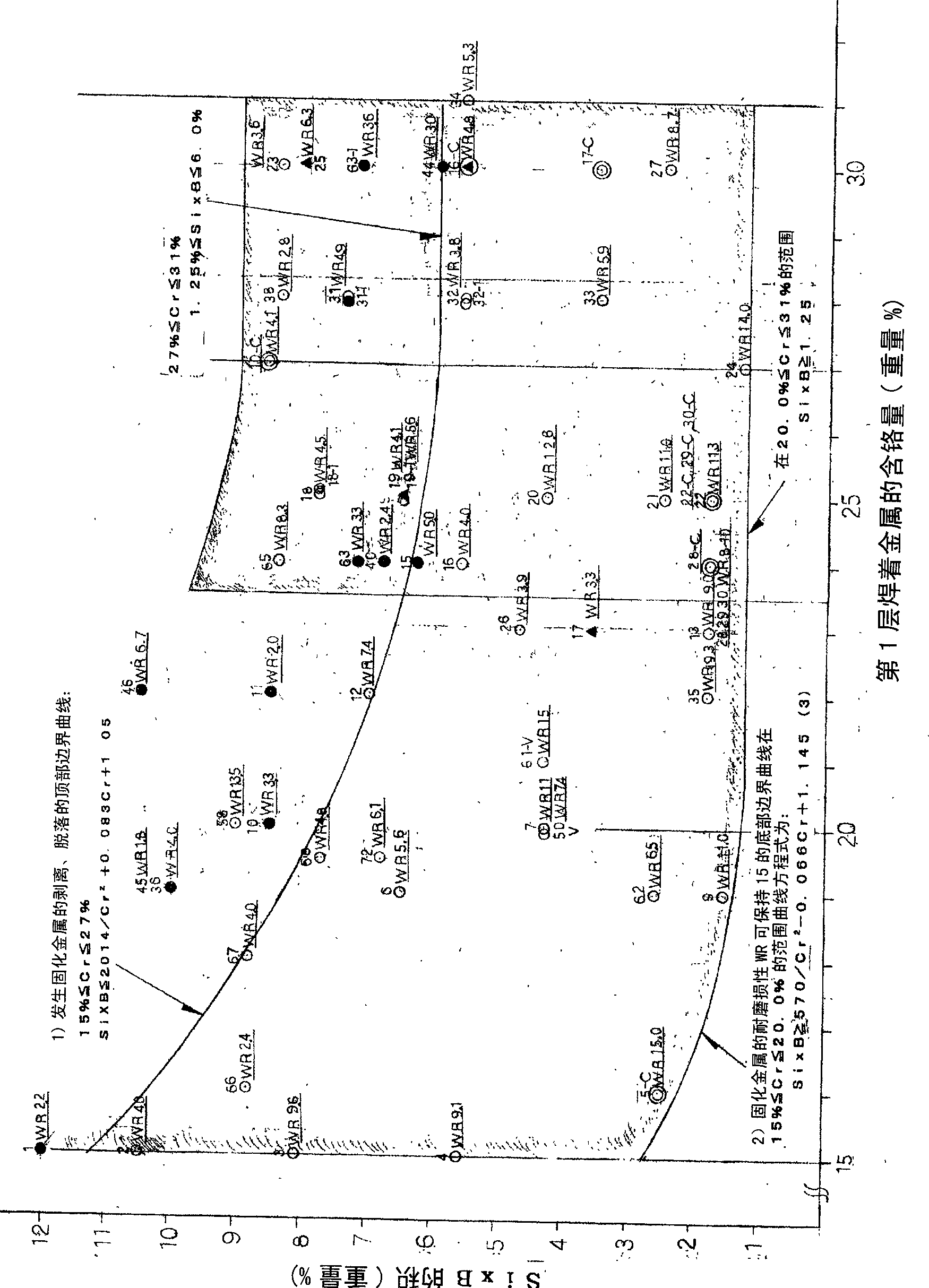

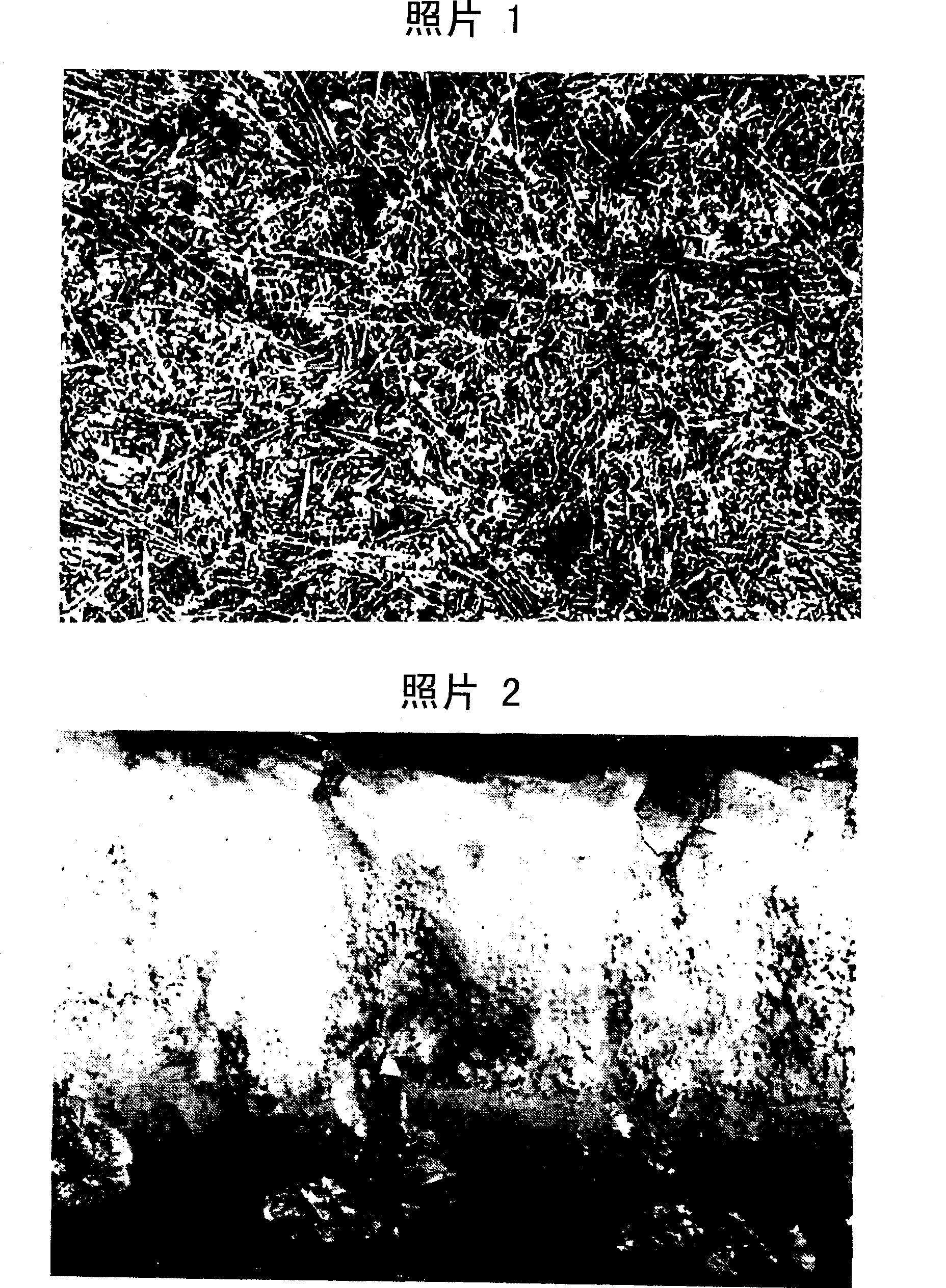

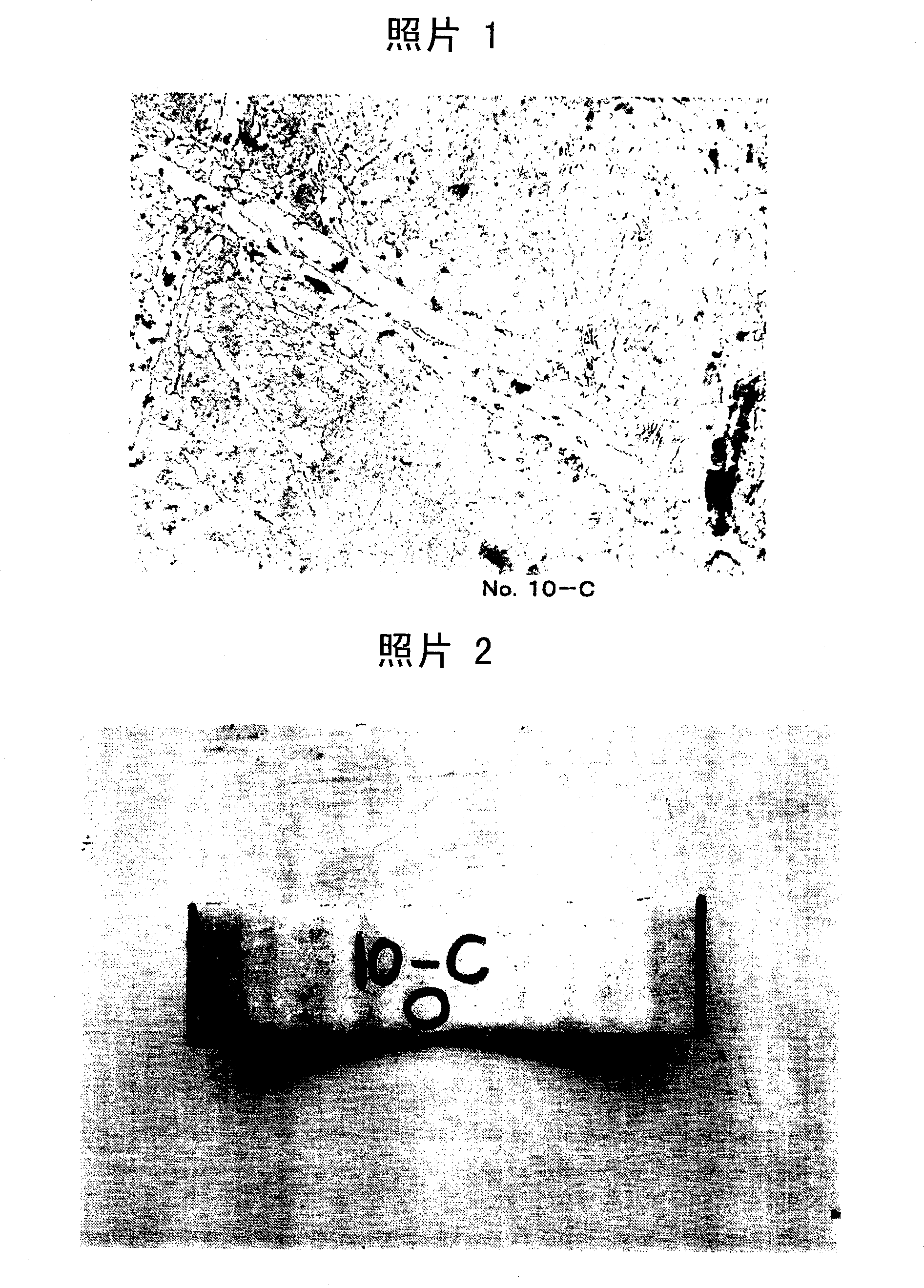

To provide a high-performance, inexpensive low C-high Si-high Cr—B—Nb type iron-based corrosion-resistant and wear-resistant alloy that is extremely superior in corrosion resistance and wear resistance to 304 stainless steel, high-chromium cast iron and high carbon-high chromium cast-iron-type materials, has a high corrosion-resistant property that would never be obtained from a high carbon-high chromium carbide precipitation-type iron-based wear-resistant alloy and at the same time, a wear-resistant property that is superior to these metals, and further hardly causes brittle peeling that is inherent to high Si—containing steel. This alloy contains, all percentages by weight, C: 0.5 to 2.5% by weight, Si: 2.5 to 4.5%, Mn: 0 to 10% or less, Cr: 15% to 31%, Ni: 0 to 16%, Cu: 7% or less, Mo: 10% or less, B: 0.5% to 3.5%, and 0≦Nb+V≦8%, and in this structure, within a range of 15% Cr≦Cr<27%, (Si×B)≦2014 / Cr2+0.083Cr+1.05 is satisfied, within a range of 27%≦Cr≦31%, 1.25%≦(Si×B) 6.0% is satisfied, within a range of 15%≦Cr<20%, (Si×B) 570 / Cr2−0.066Cr+1.145 is satisfied, and within a range of 20%≦Cr≦31%, (Si×B)≧1.25 is satisfied.

Owner:ING SHOJI

Iron-based corrosion resistant wear resistant alloy and deposit welding material for obtaining the alloy

InactiveCN101505910AOvercoming brittlenessOvercome vulnerabilityWelding/cutting media/materialsSoldering mediaChromium carbideWear resistant

To provide a high-performance, inexpensive low C-high Si-high Cr-B-Nb type iron-based corrosion-resistant and wear-resistant alloy that is extremely superior in corrosion resistance and wear resistance to 304 stainless steel, high-chromium cast iron and high carbon-high chromium cast-iron-type materials, has a high corrosion-resistant property that would never be obtained from a high carbon-high chromium carbide precipitation-type iron-based wear-resistant alloy and at the same time, a wear-resistant property that is superior to these metals, and further hardly causes brittle peeling that is inherent to high Si-containing steel. This alloy contains, all percentages by weight, C: 0.5 to 2.5% by weight, Si: 2.5 to 4.5%, Mn: 0 to 10% or less, Cr: 15% to 31%, Ni: 0 to 16%, Cu: 7% or less, Mo: 10% or less, B: 0.5% to 3.5%, and 0+0.083Cr+1.05 is satisfied, within a range of 27% / =570 / Cr-0.066Cr+1.145 is satisfied, and within a range of 20% / =1.25 is satisfied.

Owner:ING SHOJI

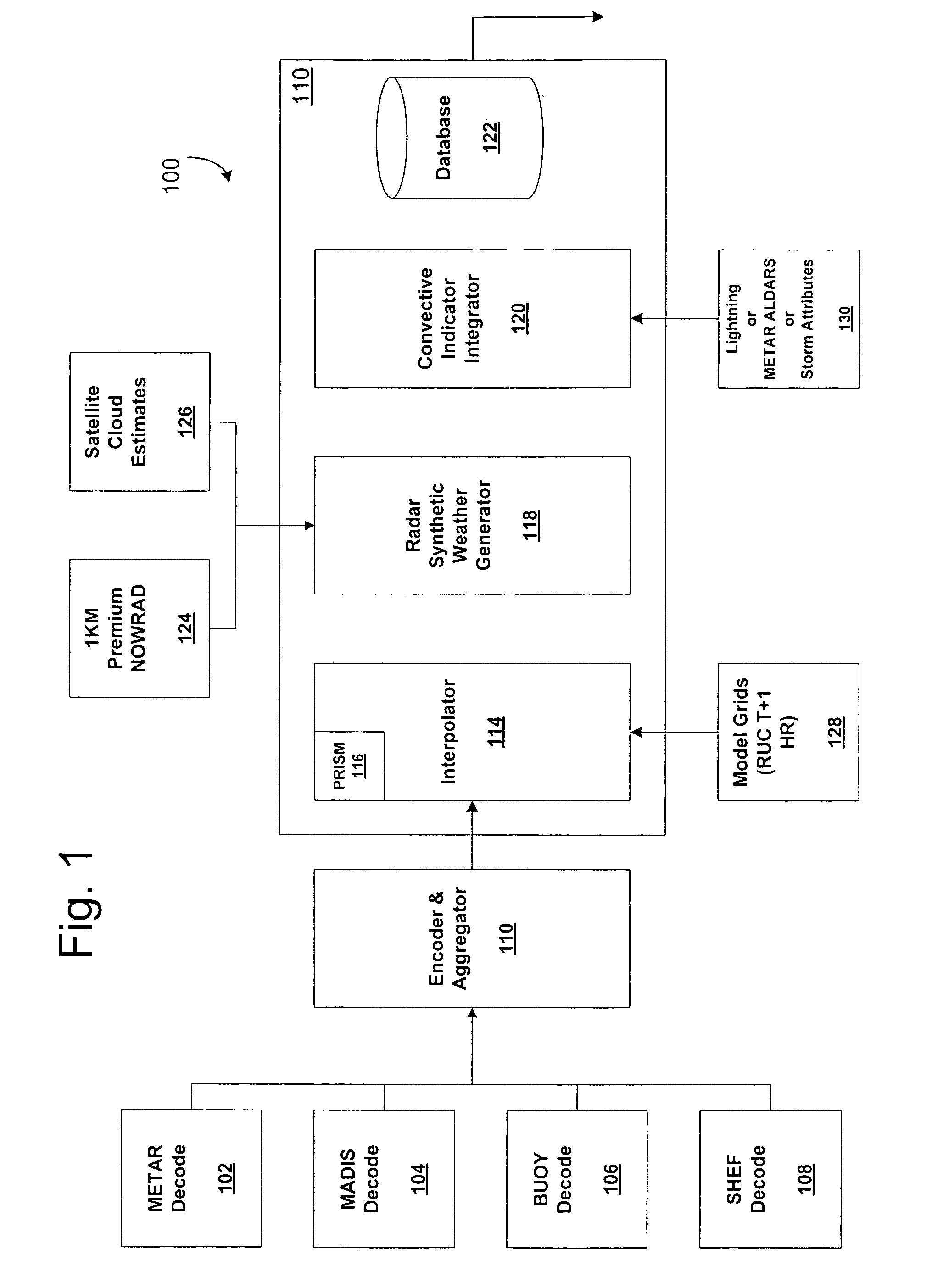

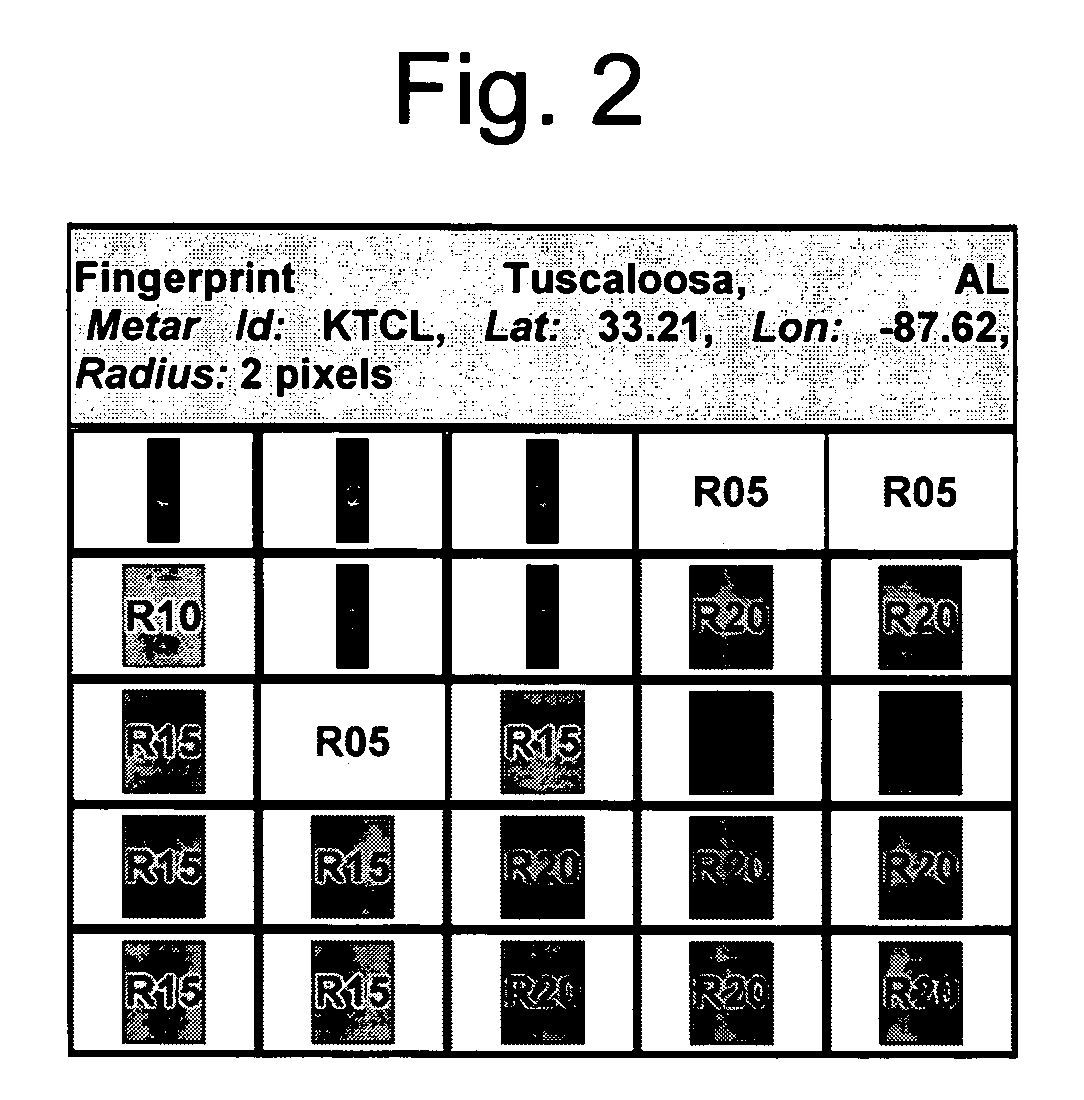

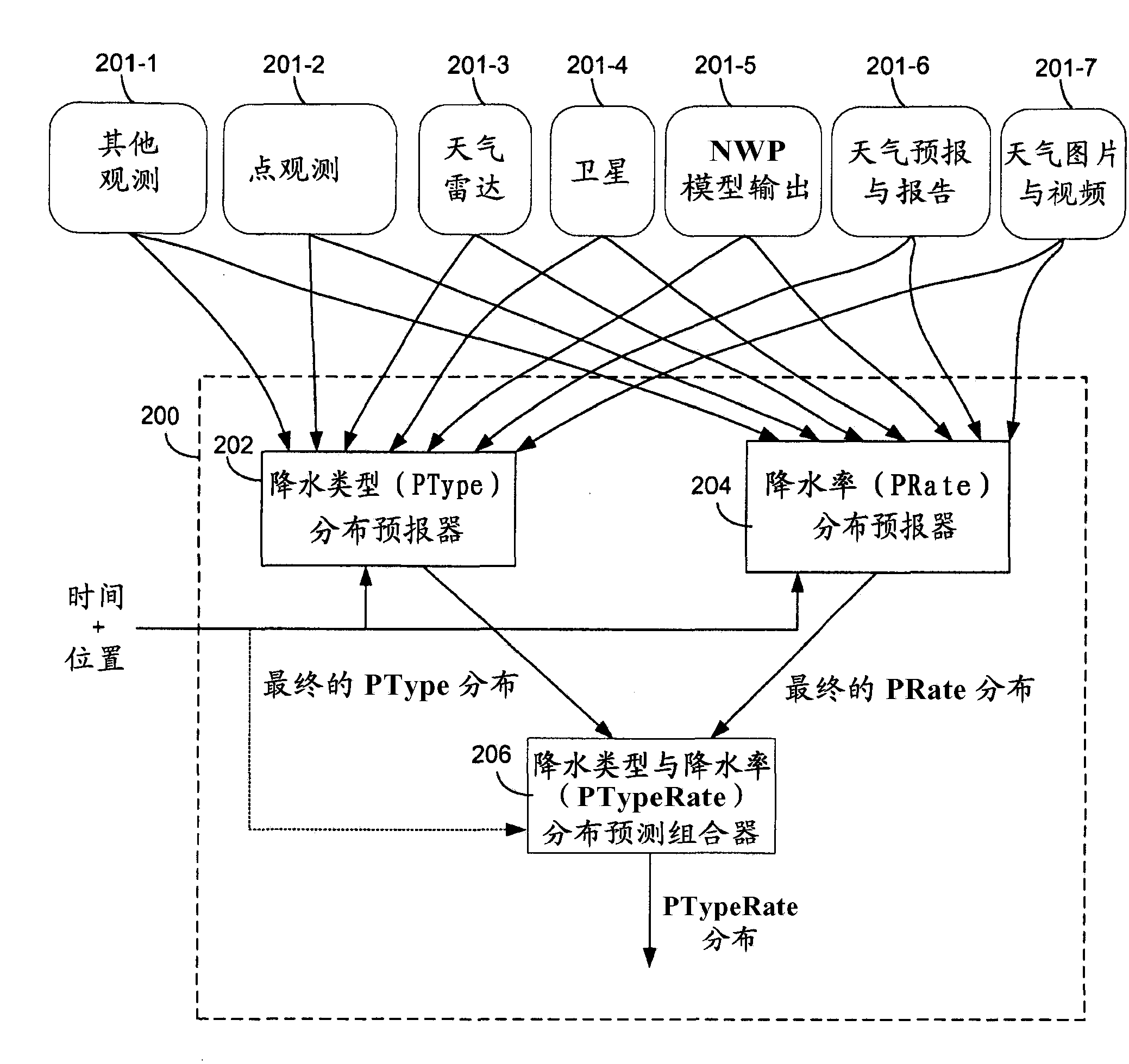

Producing high-resolution, real-time synthetic meteorological conditions from radar data

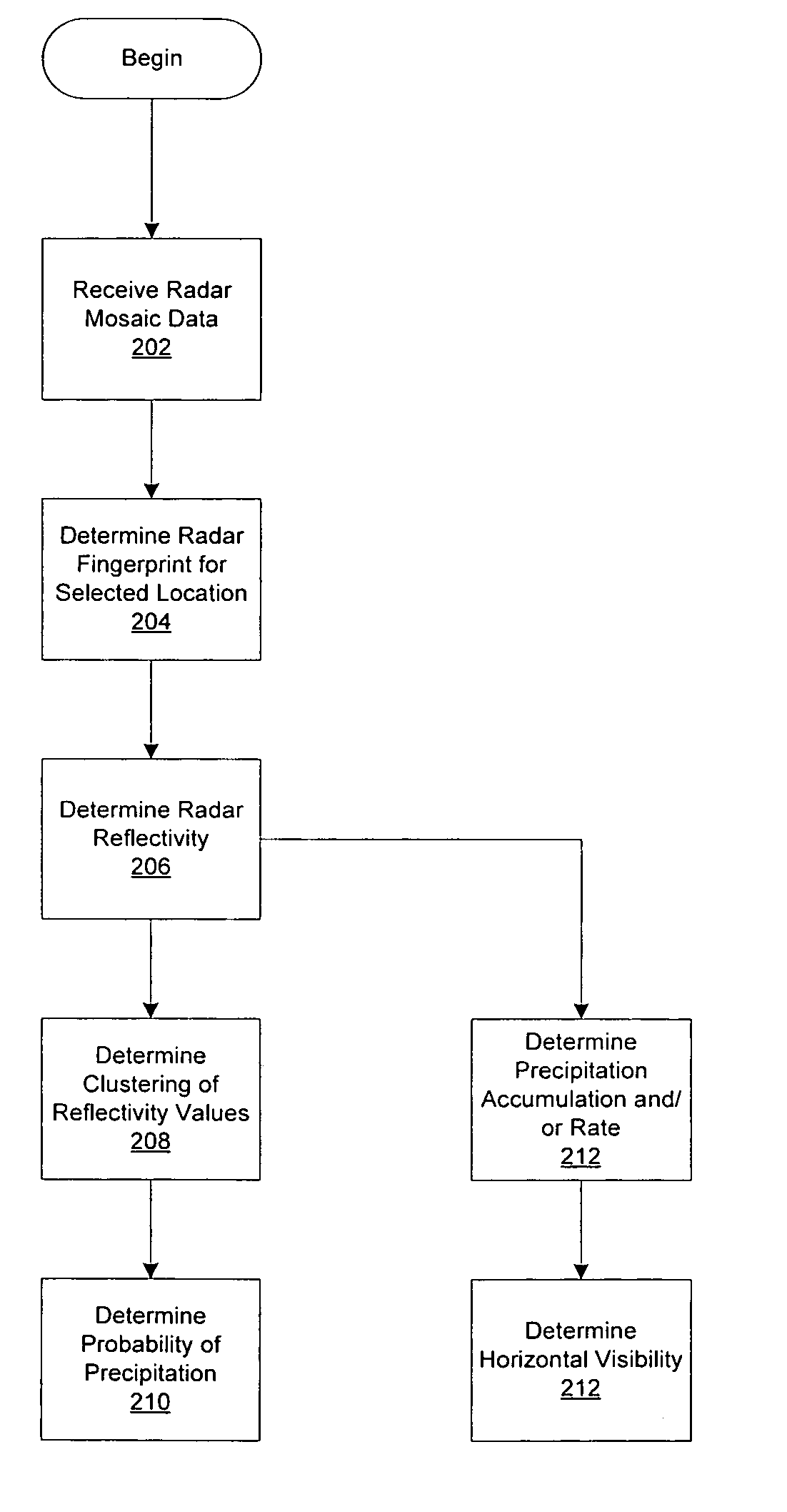

ActiveUS7231300B1Good estimateWeather condition predictionCryogenic temperature measurementVisibilityWeather radar

Methods and articles of manufacture for estimating or deriving weather observations for any given location. Using weather radar data, a correspondence between the weather radar coverage, intensity and the precipitation type may be monitored. From that, a measure of corroboration between the radar data and surface weather conditions may be established. Through radar calibration statistics and estimates of ground-based precipitation, the corroboration can be iteratively tuned, resulting in a final improved estimate of the present weather and associated meteorological fields. The associated meteorological fields may include at least one of a probability of precipitation, precipitation accumulation, precipitation rate, and horizontal visibility.

Owner:DTN LLC

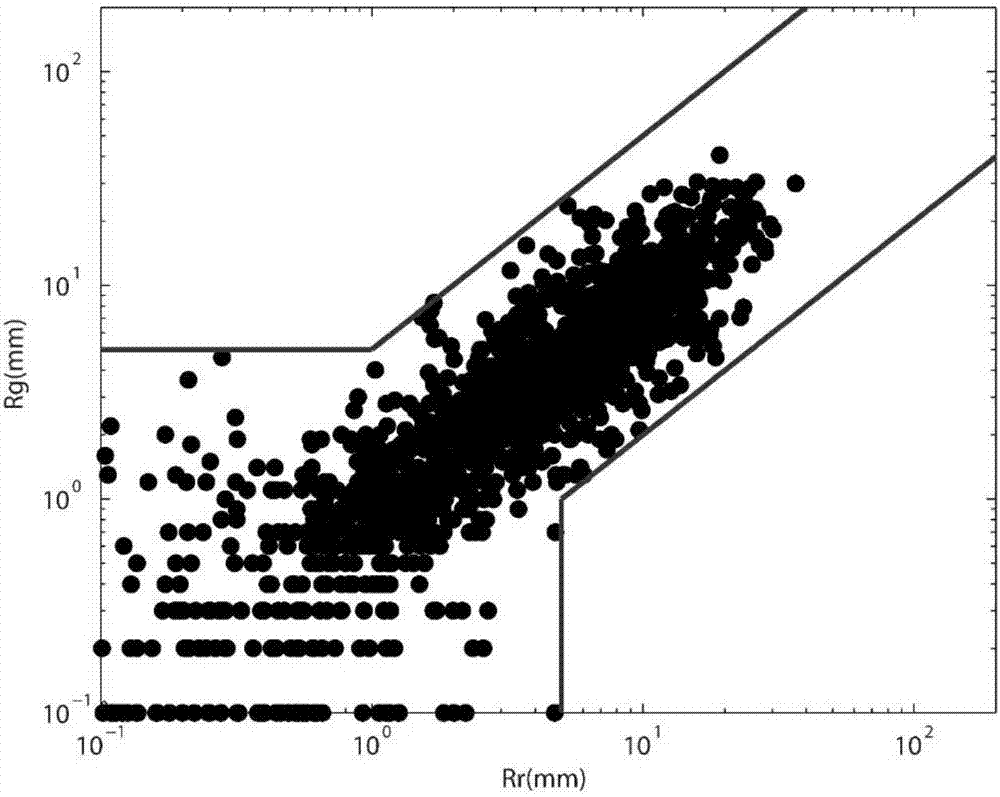

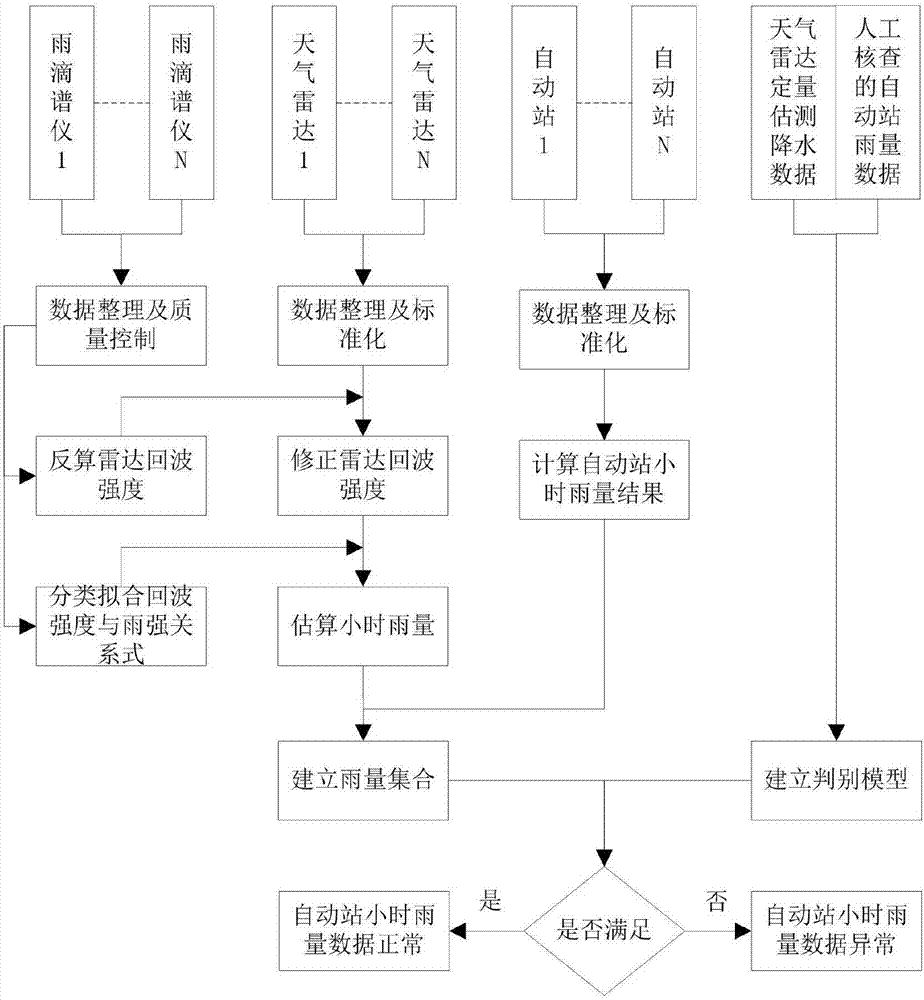

Regional automatic weather station hourly rainfall data quality control method

ActiveCN106950614AImproving Observational Data QualityRainfall/precipitation gaugesICT adaptationWeather radarRainfall estimation

The invention discloses a regional automatic weather station hourly rainfall data quality control method. The method comprises the steps that a discriminant model is established according to historical data; raindrop spectrometer data, weather radar data and automatic weather station rainfall data are collated in real time; the data of a number of raindrop spectrometers are used to evaluate and revise a radar echo intensity result; the relationship between the radar echo intensity and the rain intensity is fitted according to different precipitation types; the fitted relationship is substituted into a radar quantitative estimation precipitation module to realize radar quantitative rainfall estimation to acquire hourly rainfall; the set of weather radar estimated hourly rainfall and regional automatic weather station hourly rainfall is established; and comparing with the pre-established discriminant model is carried out to judge whether the regional automatic weather station hourly rainfall data are abnormal. The automatic weather station rainfall data are accurate and reliable. The observation data quality is improved. The method lays a good foundation for weather monitoring, early warning, forecasting and other businesses.

Owner:中船鹏力(南京)大气海洋信息系统有限公司

Bottom water plugging agent system and process for horizontal well

InactiveCN102876304AReasonable choiceEasy to combineDrilling compositionSealing/packingHigh intensityEnvironmental engineering

The invention discloses a bottom water plugging agent system and process for a horizontal well. The bottom water plugging agent system for the conventional horizontal well is characterized by comprising an inorganic precipitation type system and a polysilicon system or polymer gel system.The bottom water plugging agent system for the thermal-recovery horizontal well is characterized by comprising an inorganic precipitation type system and a N2 foam system or temperature-sensitive gel system. The bottom water plugging agent process for the horizontal well comprise the following steps: (1) injecting an annular chemical plugging device by using a mechanical packer plugging device on the basis of clarifying a water outlet point so as to ensure the selectivity of the injection; (2) selecting the bottom water plugging agent system according to the temperature, the heterogeneity and other parameters of the oil reservoir at the horizontal well; and (3) injecting the bottom water plugging agent system. The bottom water plugging agent system is selected reasonably and combined properly. The technology of the bottom water plugging agent process can be applied to the horizontal well with high or ultrahigh water content to achieve the purpose of deeply plugging more than 90% of bottom water at high strength, so that the water content of the horizontal well is reduced effectively, and the productivity of the oil well is improved.

Owner:CHINA PETROLEUM & CHEM CORP +1

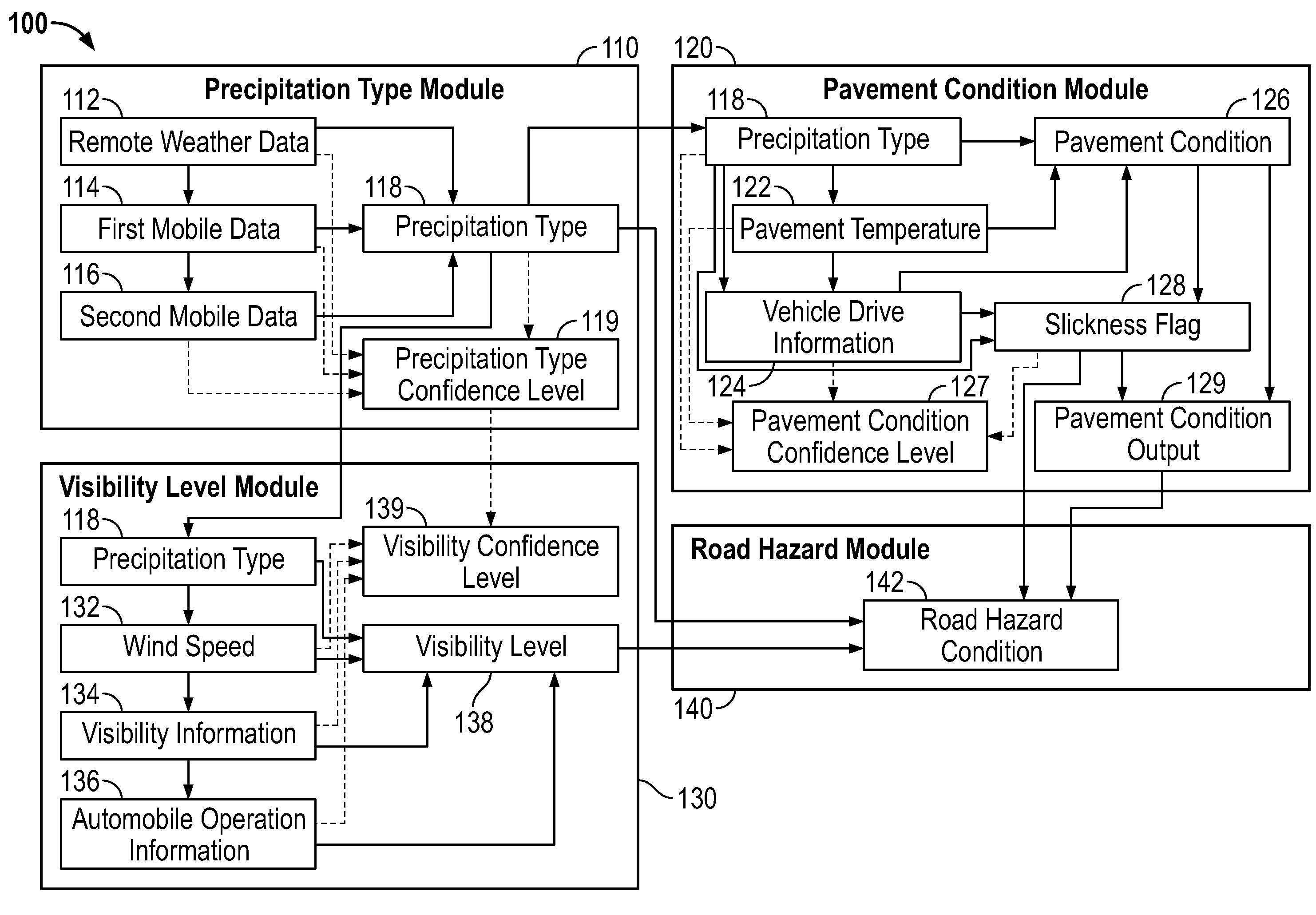

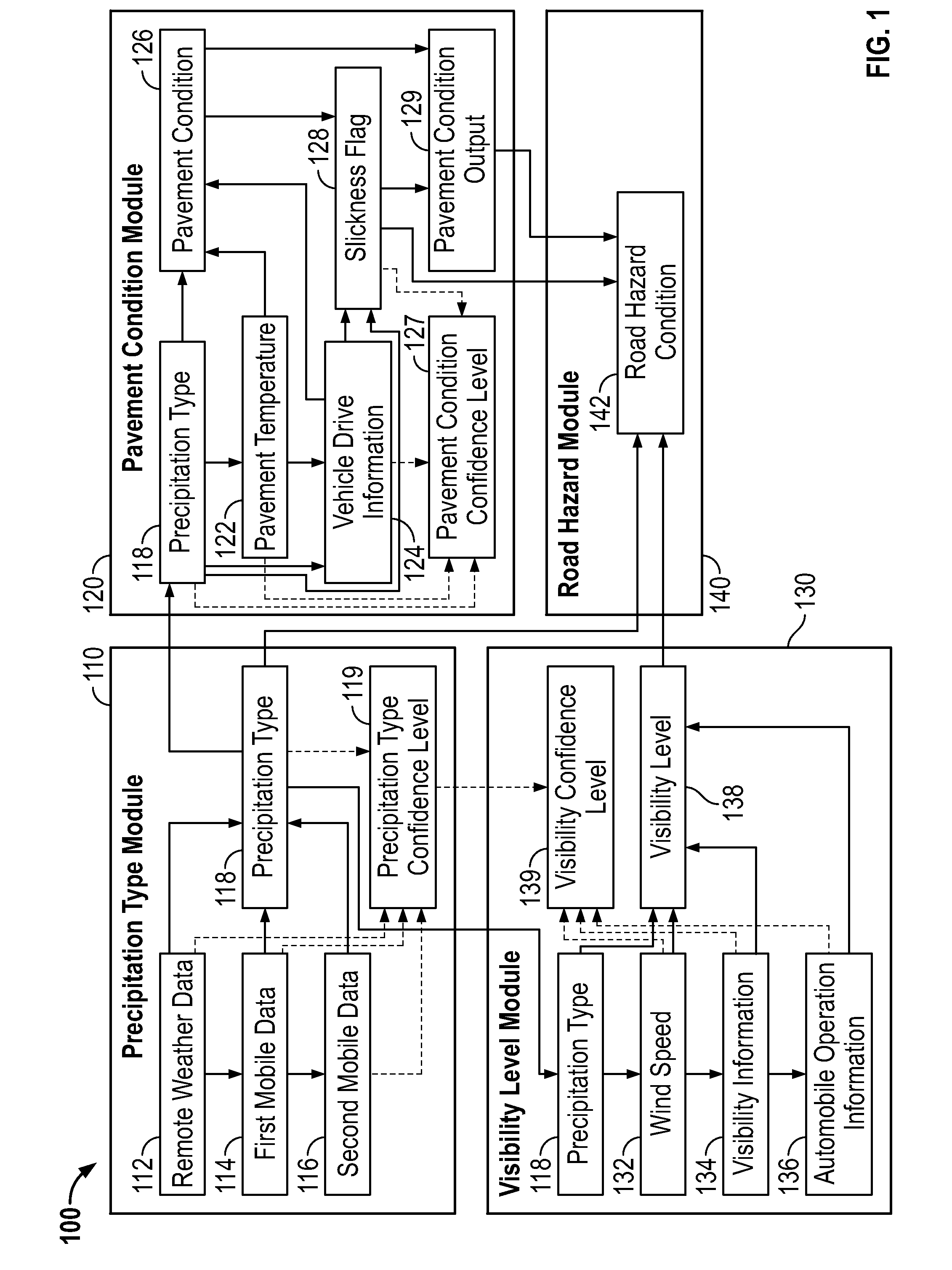

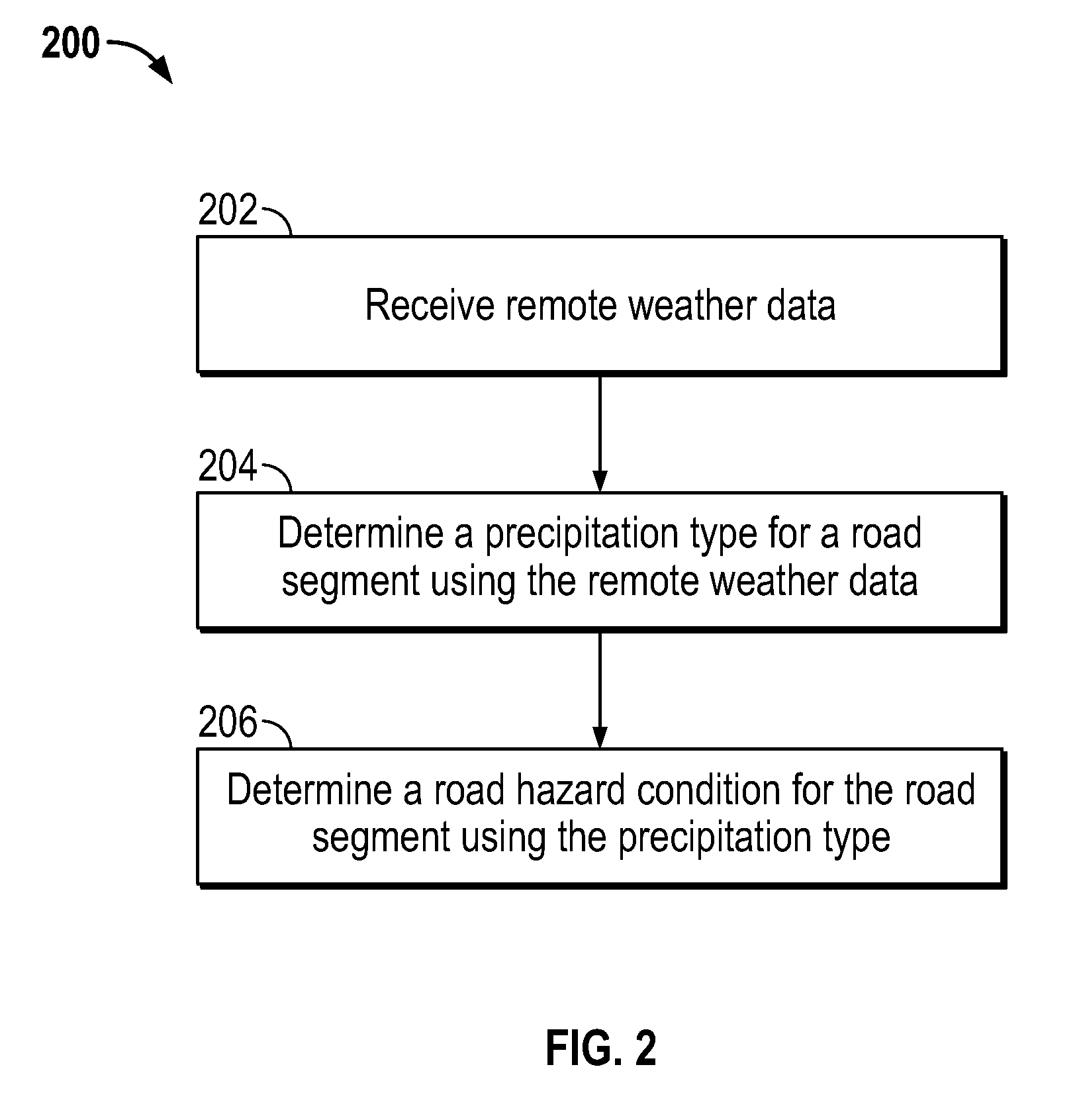

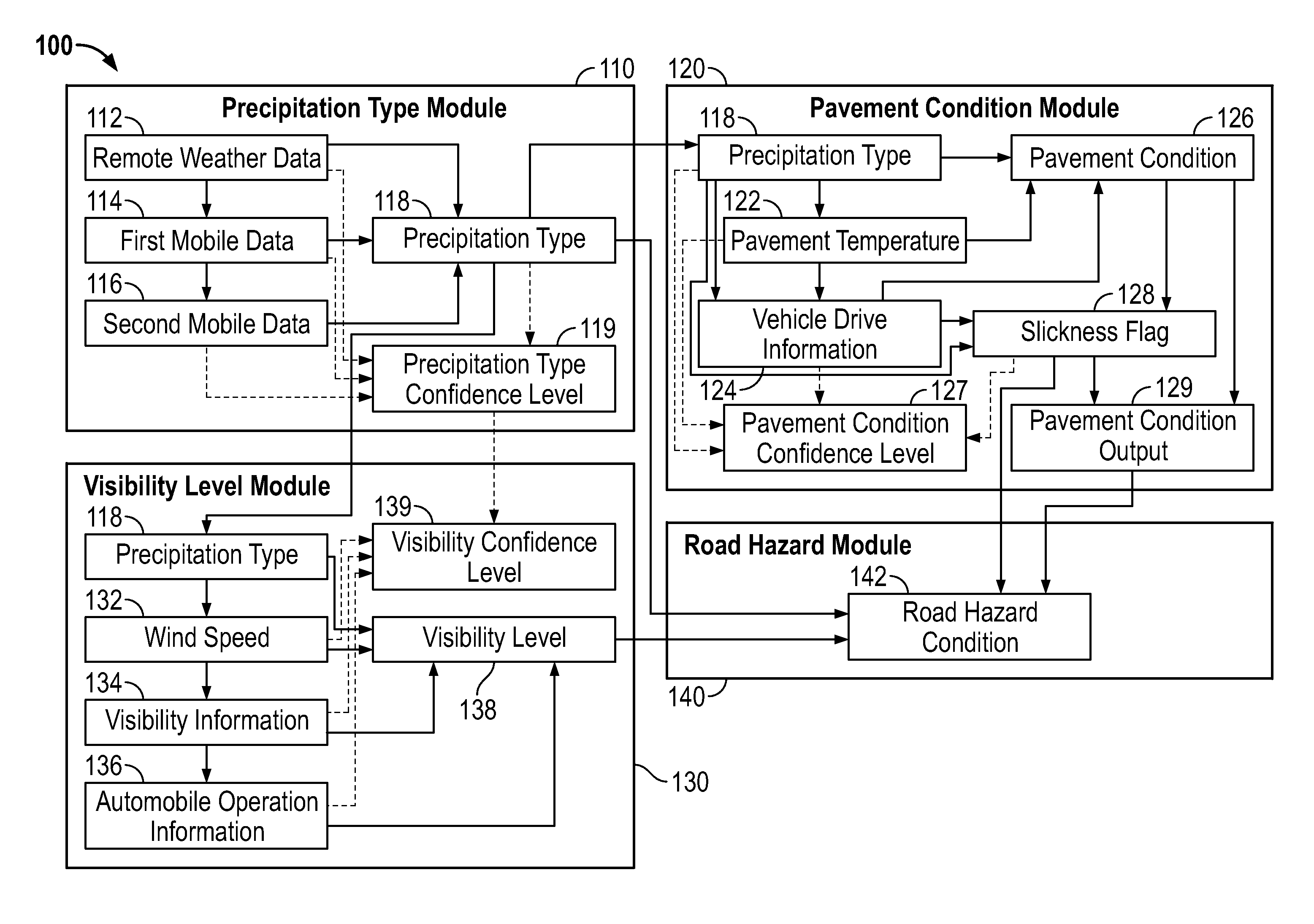

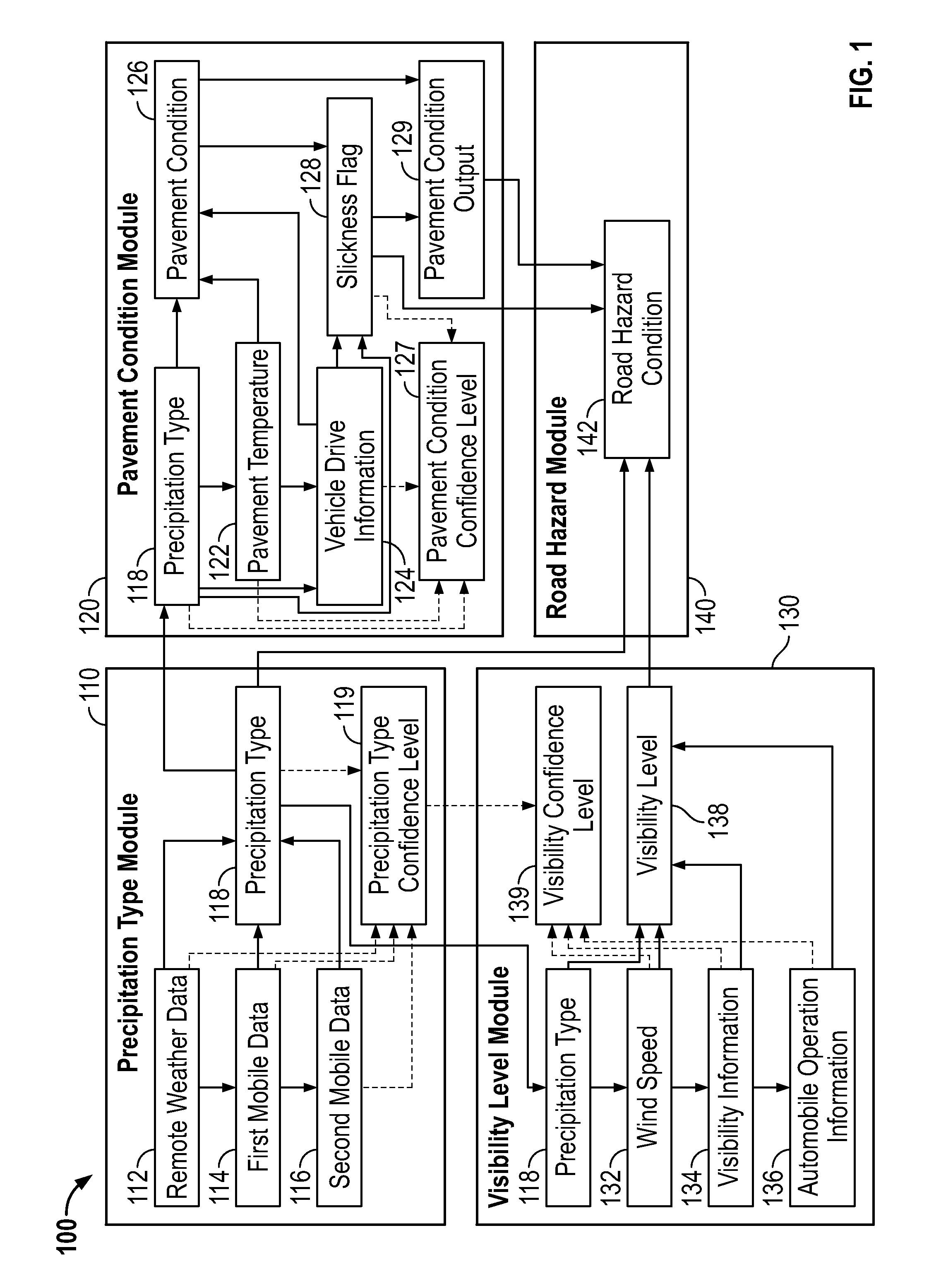

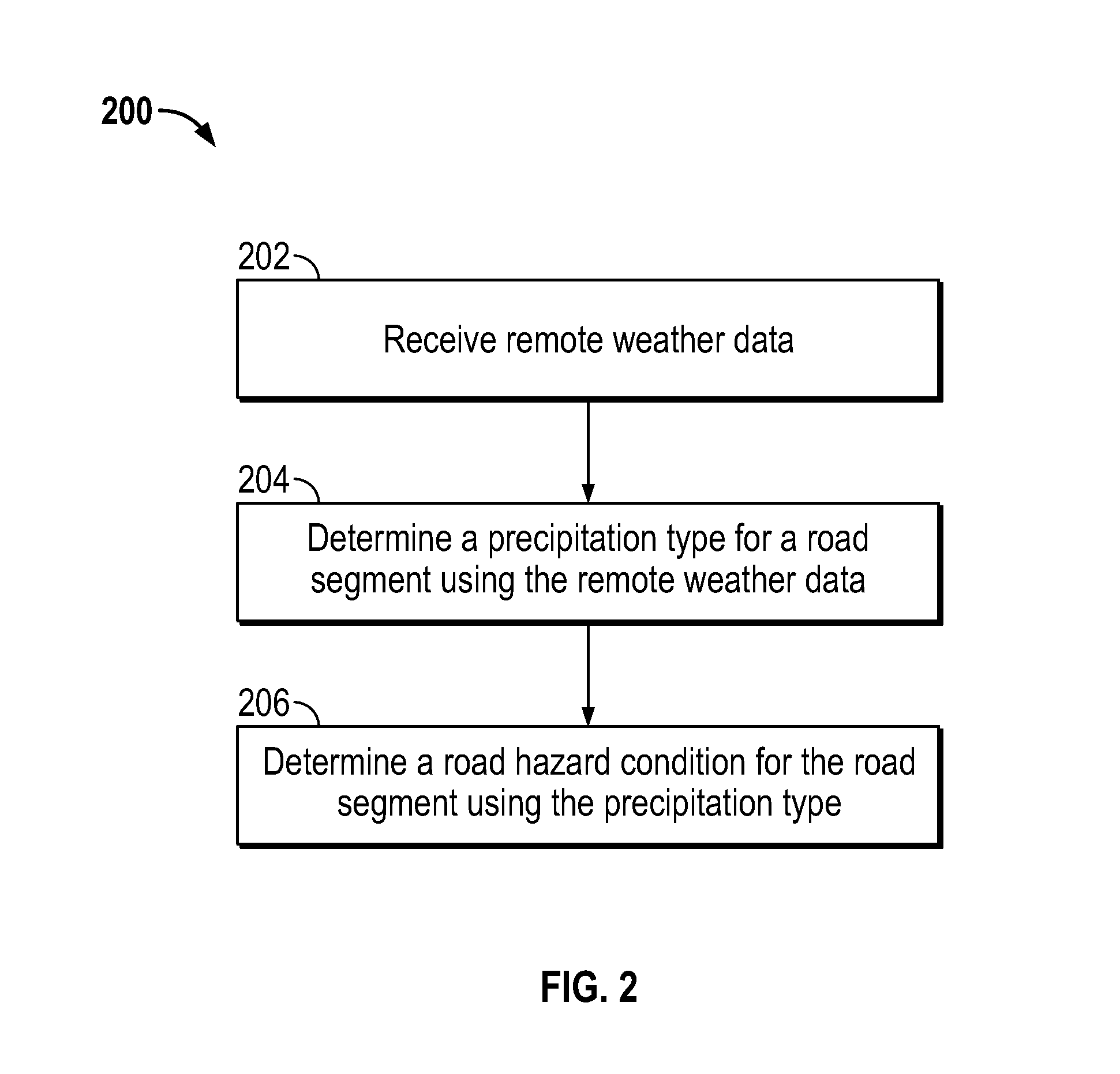

Road weather hazard system

ActiveUS20150109146A1Rainfall/precipitation gaugesArrangements for variable traffic instructionsAutomatic brakingRoad surface

A method and system for assessing road conditions is provided. The method includes determining a road hazard condition for a road segment that may include a precipitation type, a pavement condition, and a visibility level. The precipitation type may be determined using radar data, satellite cloud classification data, weather station air temperature data, wiper status, mobile air data, speed ratio, or headlight status. The pavement condition may be determined using pavement temperature, precipitation type, automatic brake system status, traction status or a stability control observation, and a yaw rate. The visibility level may be determined using wind speed, relative humidity, percentage of fog lights on, percentage of high beams on, speed ratio, station visibility, station-reported visibility type, wildfire existence, wind direction, a dust existence indicator.

Owner:UNIV FOR ATMOSPHERIC RES

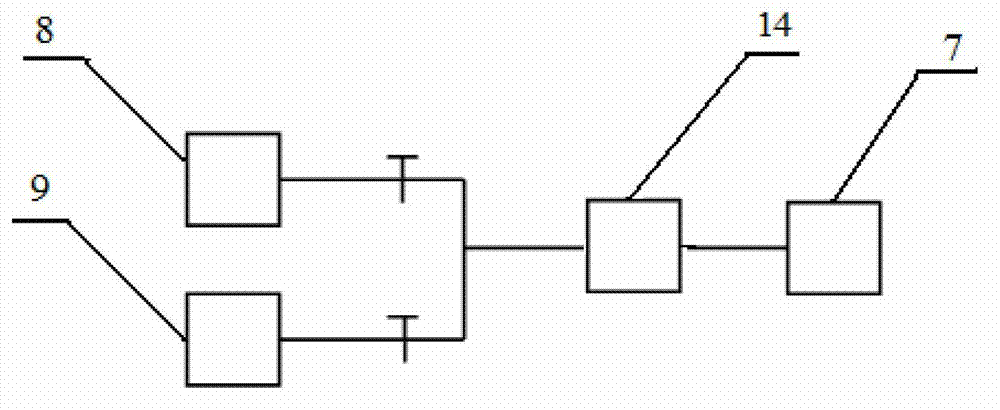

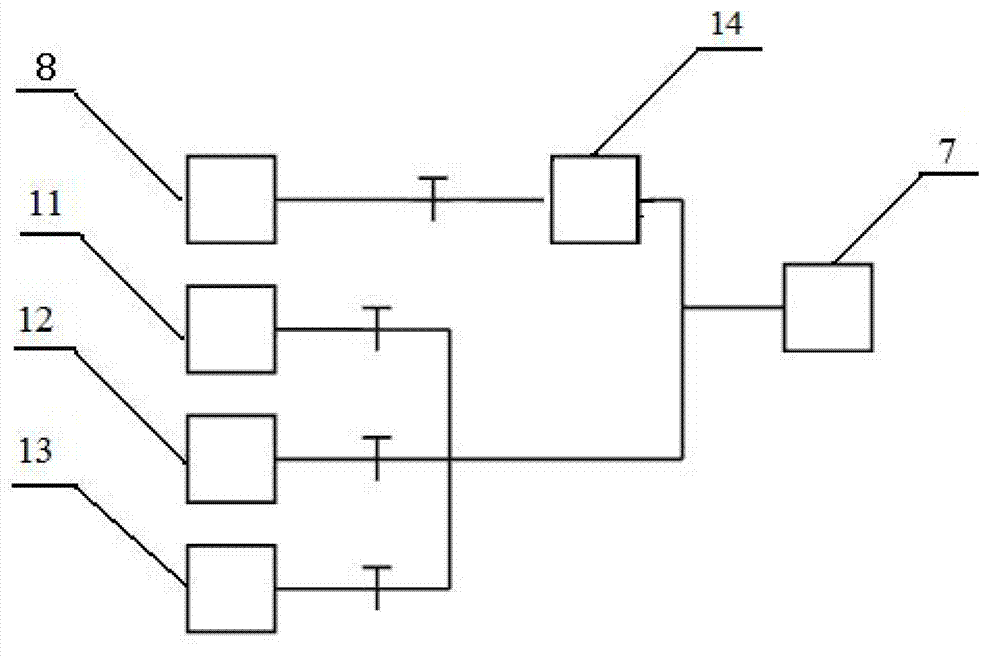

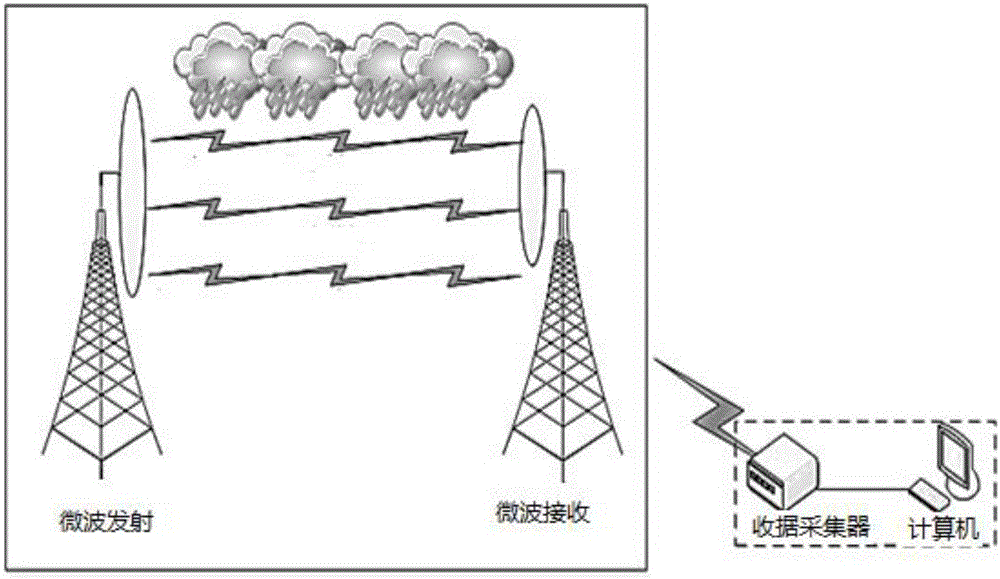

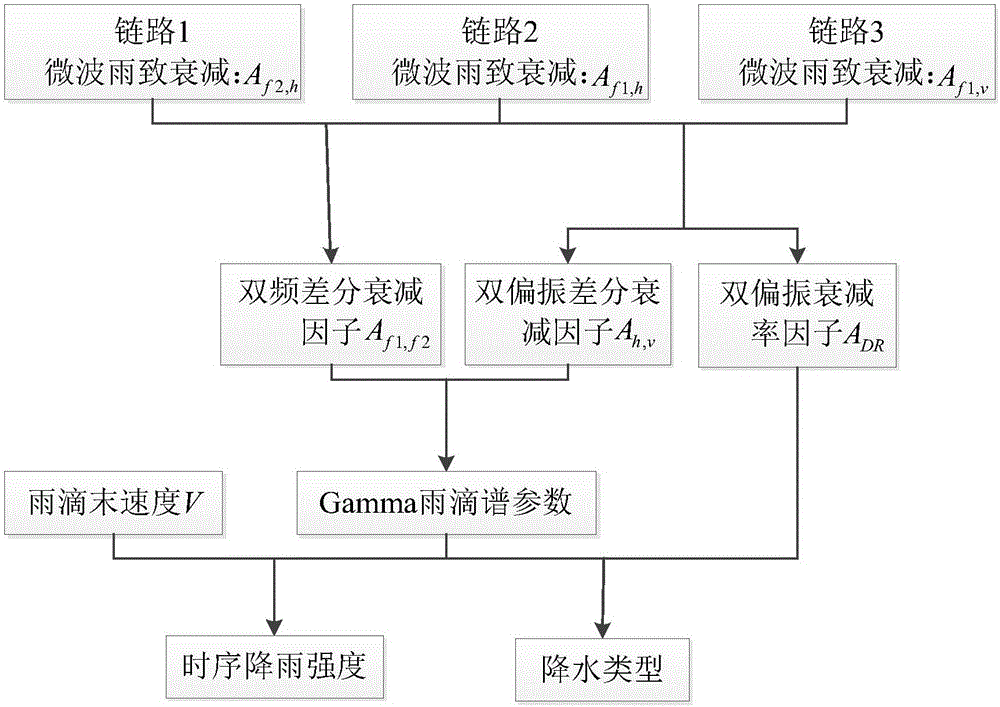

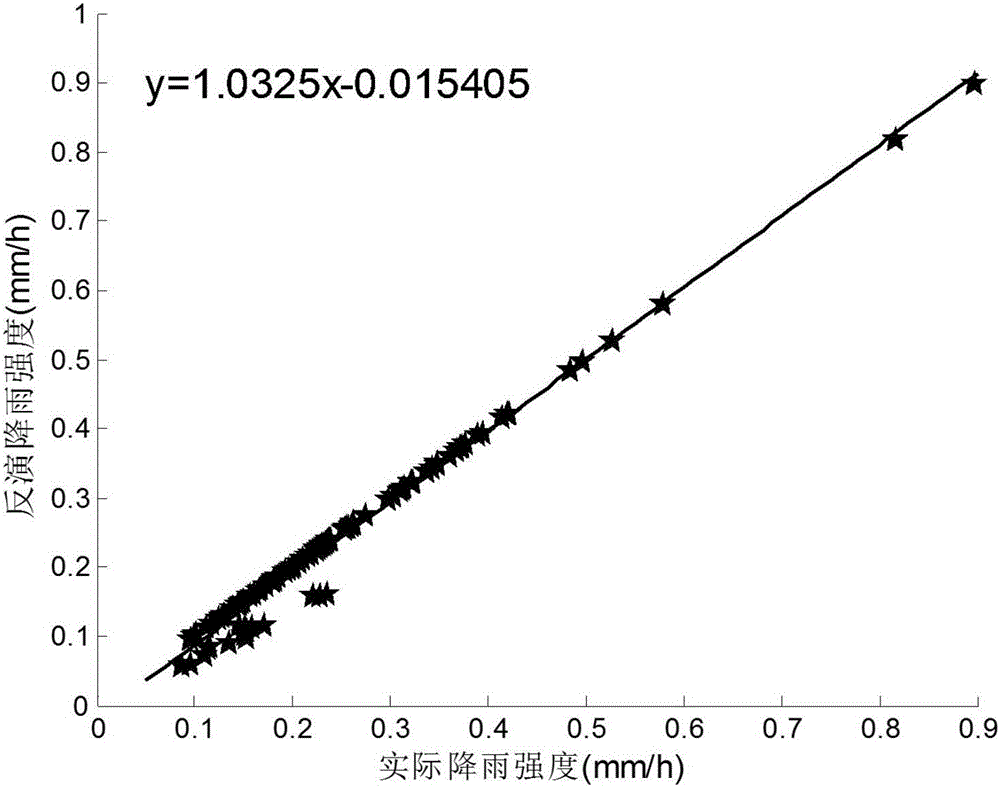

Dual-frequency dual-polarization microwave link joint raindrop spectrum inversion and precipitation type recognition method

ActiveCN106547037AFully excavatedExcellent spatio-temporal resolutionRainfall/precipitation gaugesDual frequencyUltrasound attenuation

The invention relates to a dual-frequency dual-polarization microwave link joint raindrop spectrum inversion and precipitation type recognition method, which comprises the steps of inversing the path average precipitation intensity based on rain attenuation information of a dual-frequency dual-polarization microwave link, firstly measuring rain attenuation intensities of different frequencies and different polarization directions by using a microwave transmitter and a receiver; then inversing path precipitation spectrum parameters by using the attenuation information; and finally calculating the path precipitation intensity by using the spectrum parameters, and performing precipitation recognition. The method provided by the invention fully exploits the microwave rain attenuation information, converts the rain attenuation information into precipitation information by the means of inversion, and has the characteristic of high temporal-spatial resolution. Meanwhile, influences of non precipitation factors are eliminated because of adoption of joint attenuation difference, and the inversion precision is improved. The method can be put into meteorological observation by acting as a new method for precipitation observation.

Owner:PLA UNIV OF SCI & TECH

Method for stabilizing fly ash from refuse incineration by combination of complementary type medicaments

InactiveCN101690934AReduce usageReduce processing costsSolid waste disposalFerric hydroxidePrecipitation types

The invention belongs to the technical field of the harmless treatment of dangerous solid waste and particularly relates to a method for stabilizing fly ash from refuse incineration by the combination of complementary type medicaments. The stabilizing method combines a reducing inorganic medicament (I type medicament) capable of precipitating and absorbing Pb, Zn, Cd, Hg, Cr, Cu and other heavy metals and an heavy metal ion precipitation type organic chelating agent (II type medicament). The method comprises the following steps: firstly mixing the I type medicament with the fly ash first in aqueous solution or in the presence of water for reaction to generate ferric hydroxide for absorbing and precipitating heavy metals or generating sulfides of the heavy metals to precipitate the heavy metals; and then adding the II type medicament in the system to allow the II type medicament to further generate precipitate type chelates with the residual heavy metals, particularly Pb, Cd, Hg and the like. The first step of the method is characterized in that reducing atmosphere still remains after the reaction. As a major part of heavy metals are stabilized by chalybeate or the chalybeate, so the dosage of the II type medicament is reduced considerably.

Owner:TONGJI UNIV +1

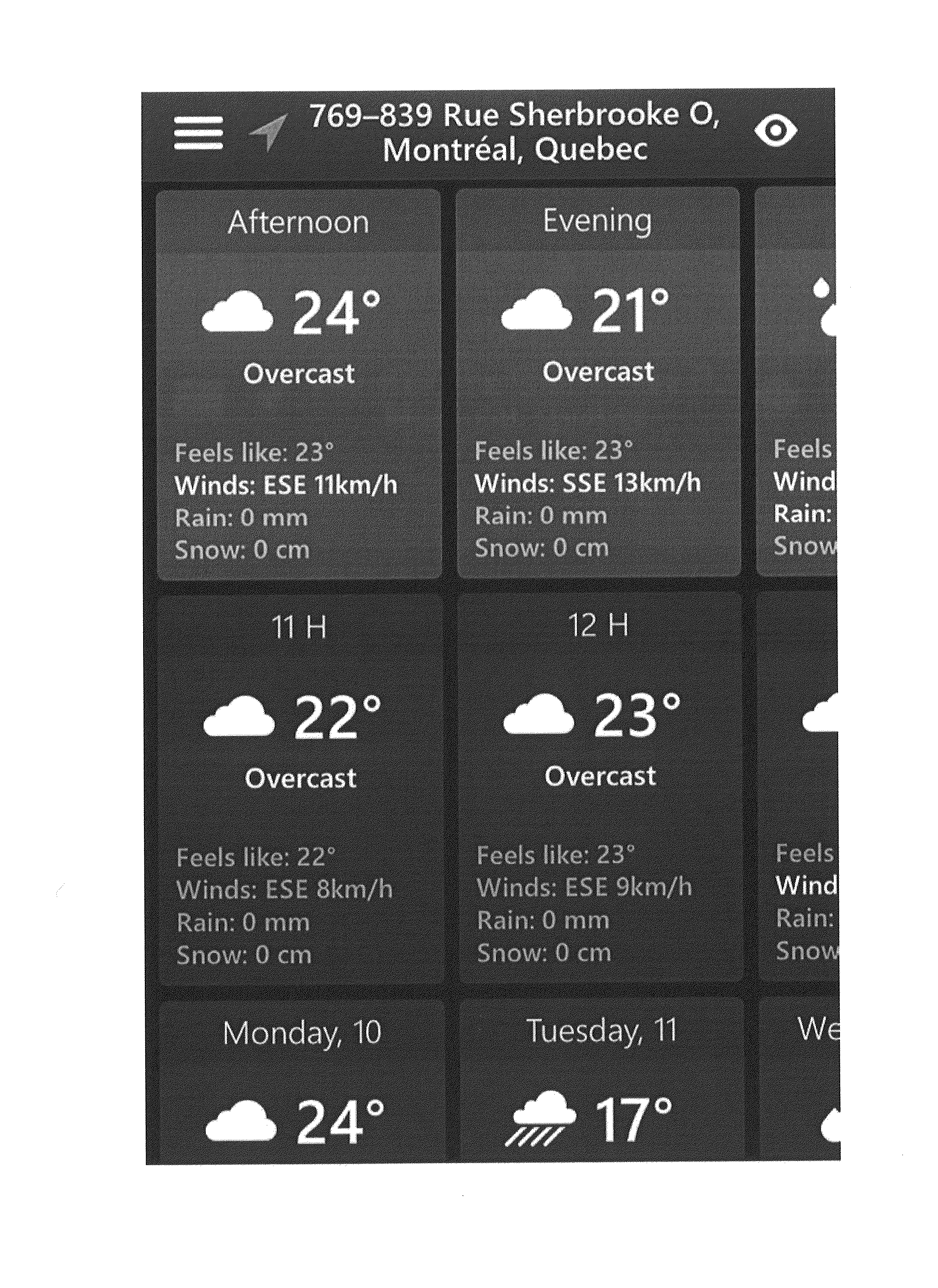

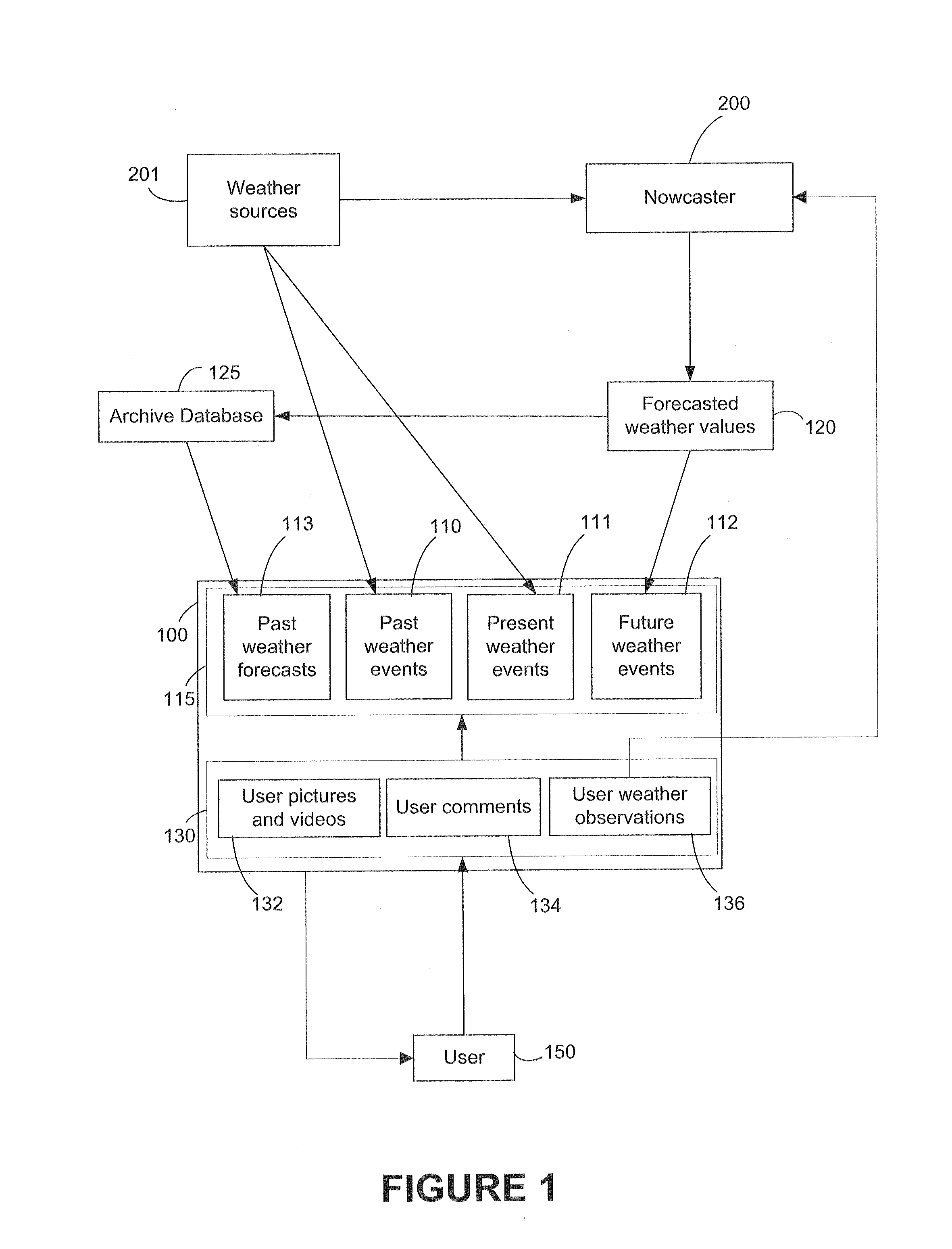

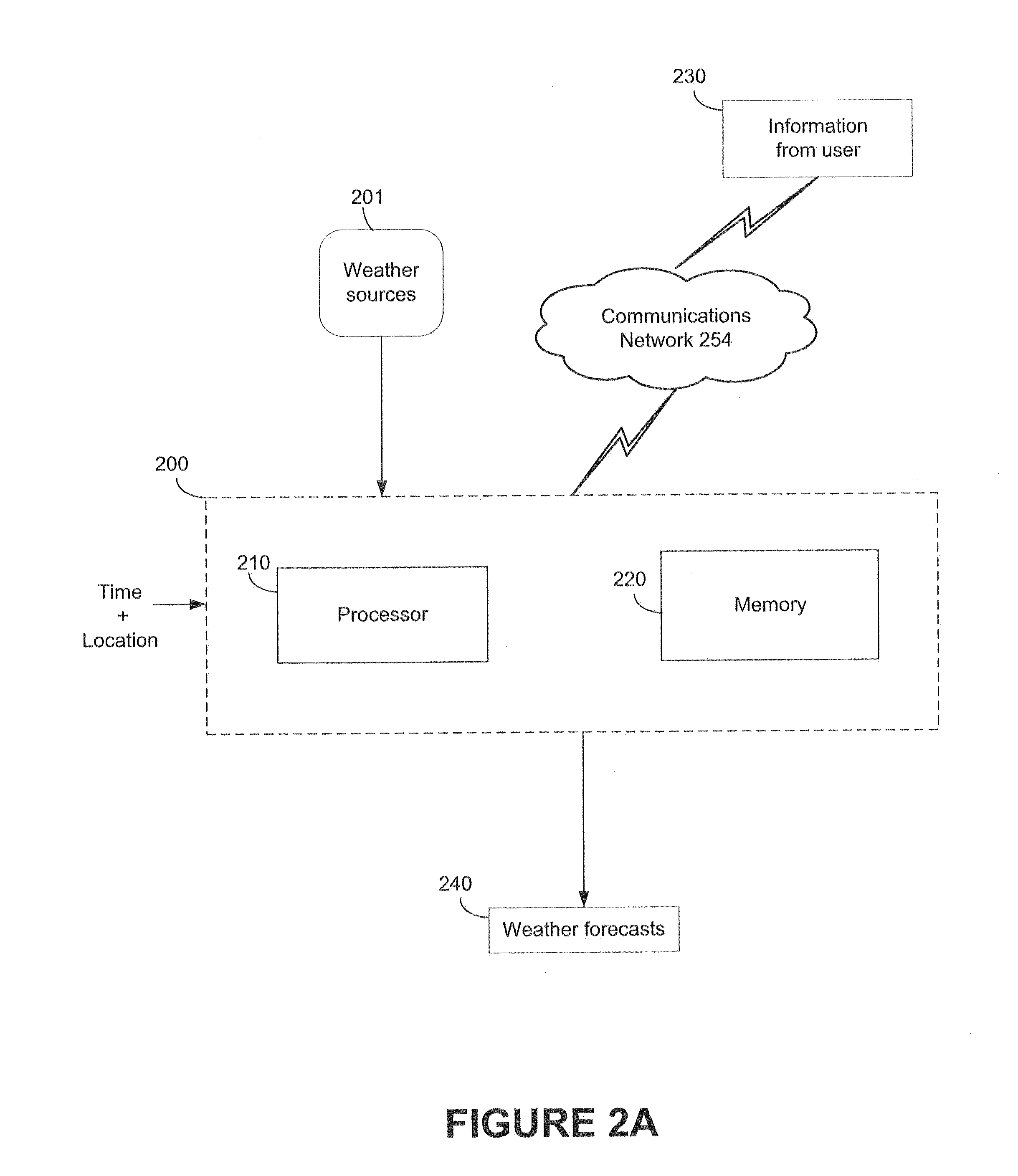

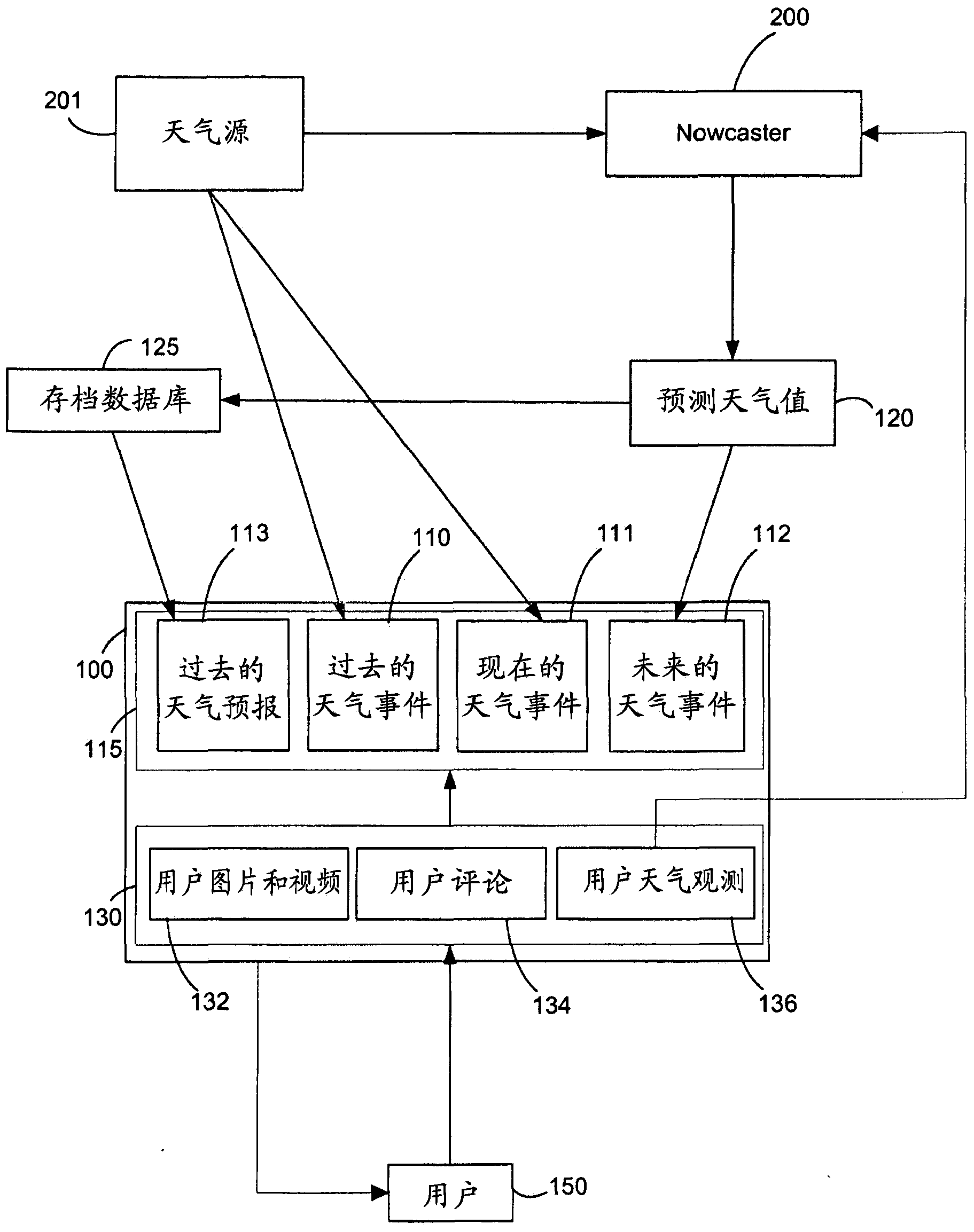

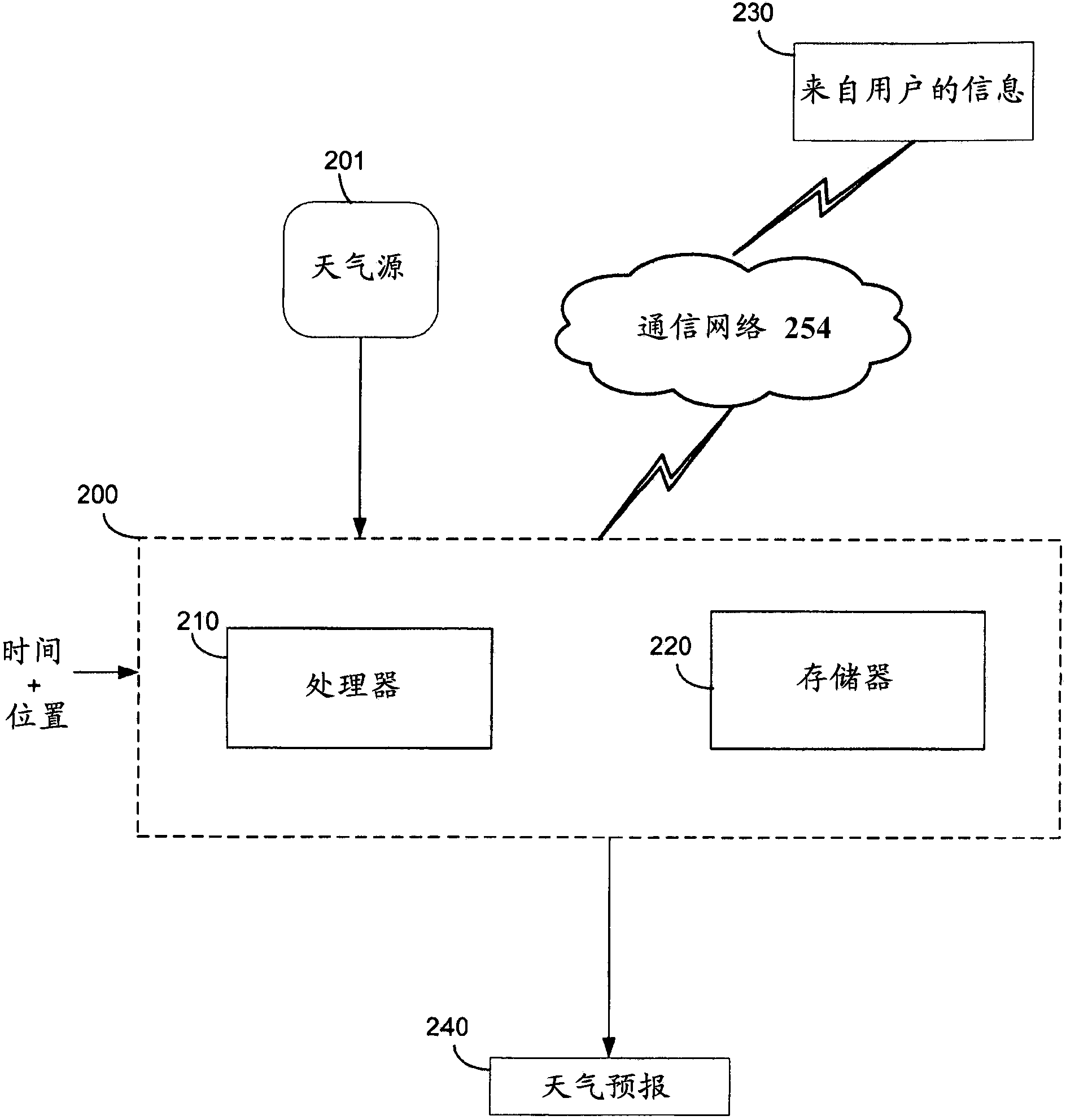

Method and system for displaying weather information on a timeline

ActiveUS20150006079A1Weather condition predictionSpecial data processing applicationsComputer sciencePrecipitation types

Provided are methods, devices, and non-transitory computer readable storage mediums to generate a weather timeline such as a succession of weather information on a continuous time scale. For example, a timeline may include first weather information associated with a first time in a first territorial location, second weather information associated with a second time, and third weather information associated with a third time. At least one of the first, second and third weather information may comprise a forecasted weather value indicative of a probability of having a specific type of precipitation at a specific intensity. A weather timeline may follow a specific location (e.g. city, town, any region with a definite boundary), a specific weather event (e.g. a specific precipitation type, a specific temperature level, a specific wind intensity), and / or a specific user. A timeline may include data created by an observer of the related weather information, where the data may be at least one of a picture, a video or a comment inputted by the observer about the related weather information.

Owner:SKY MOTION RES ULC

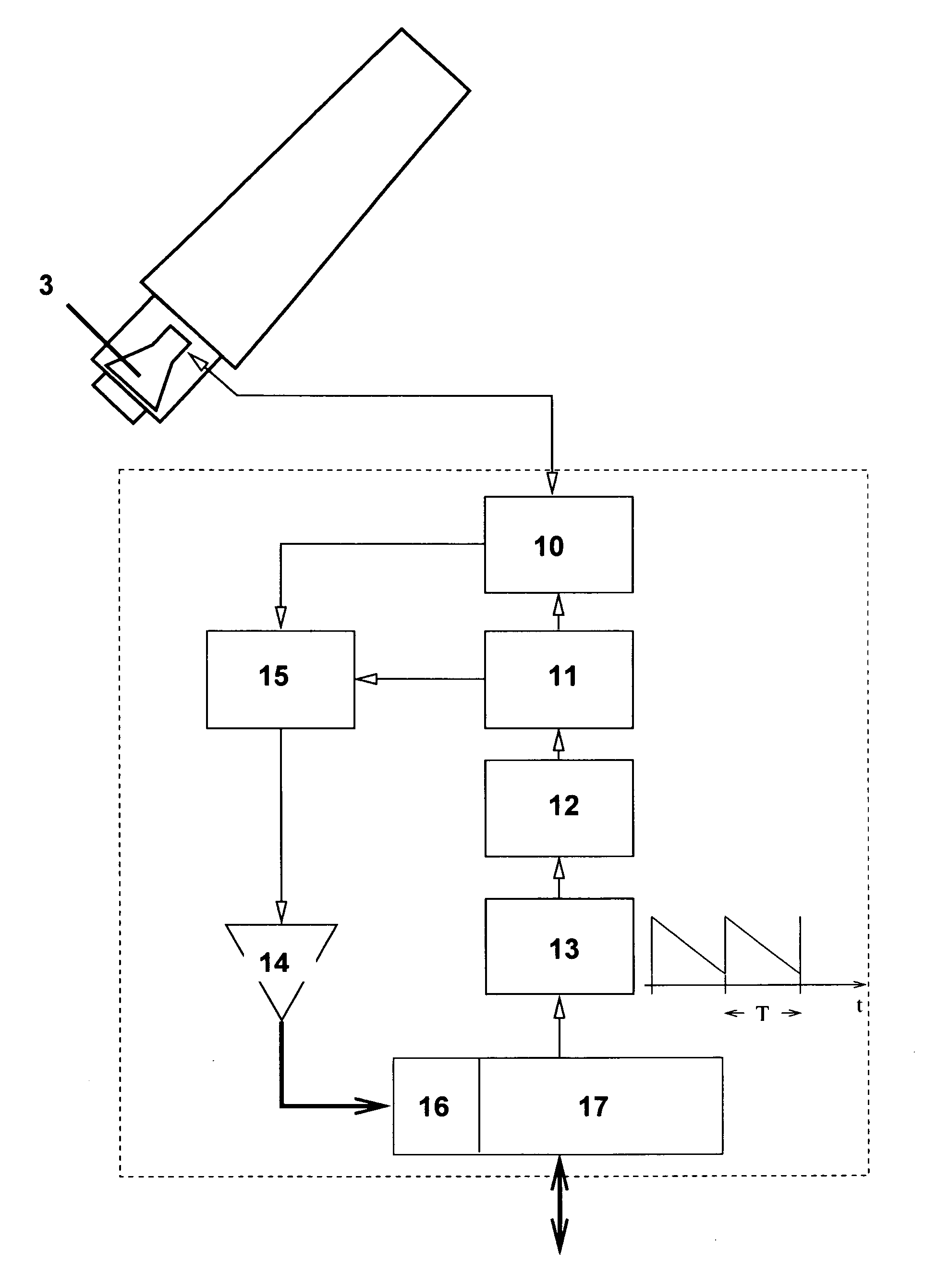

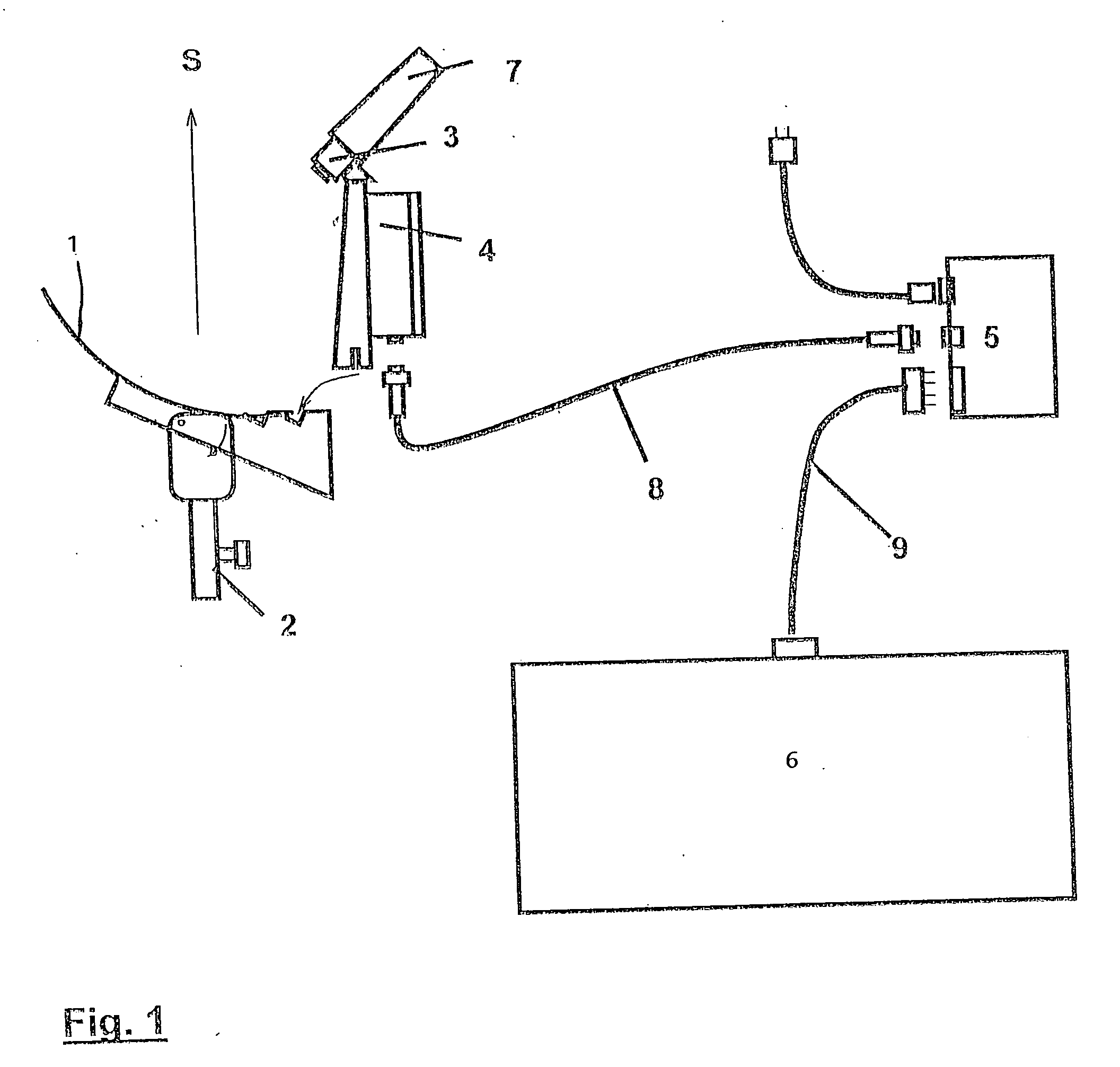

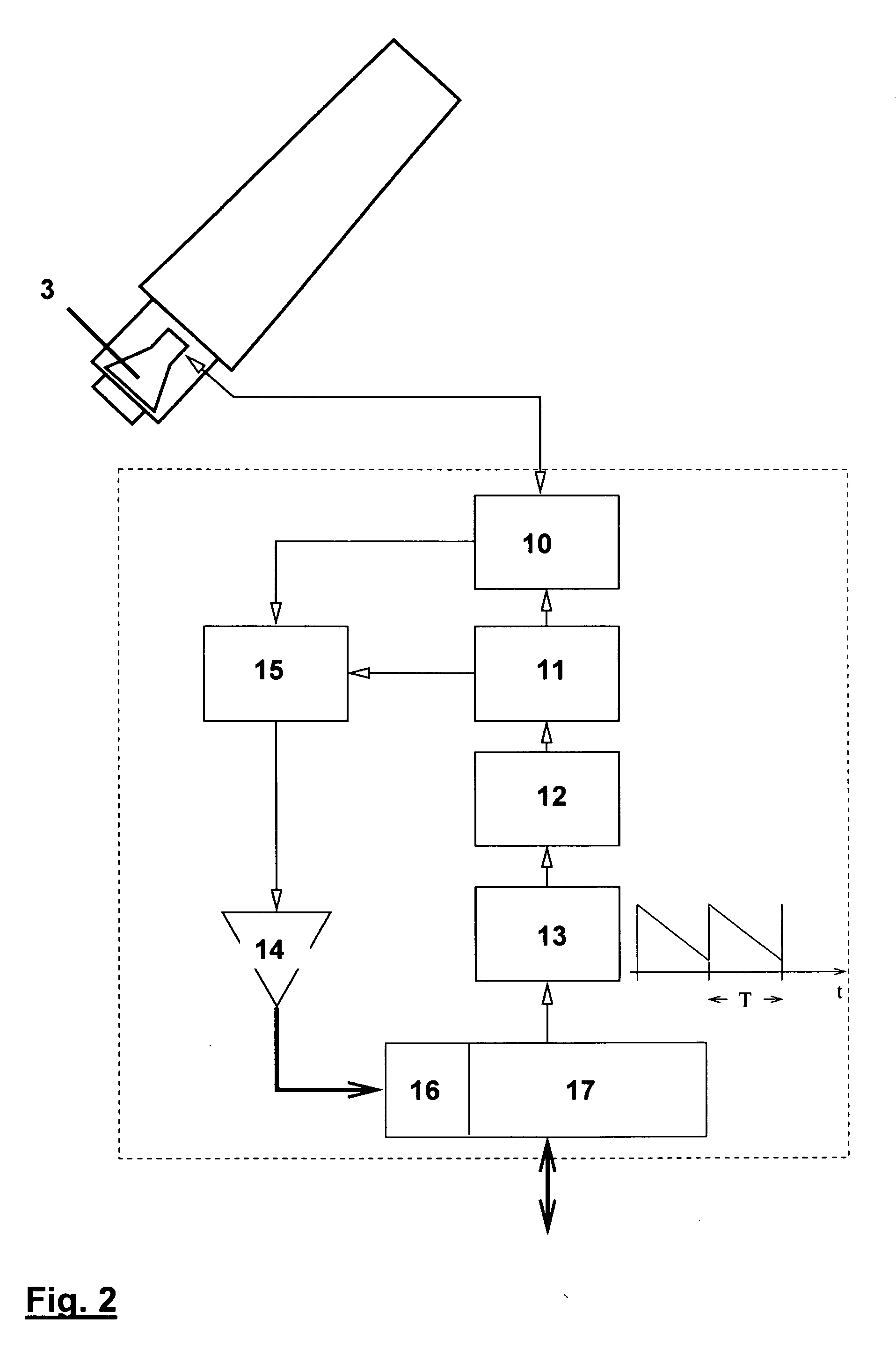

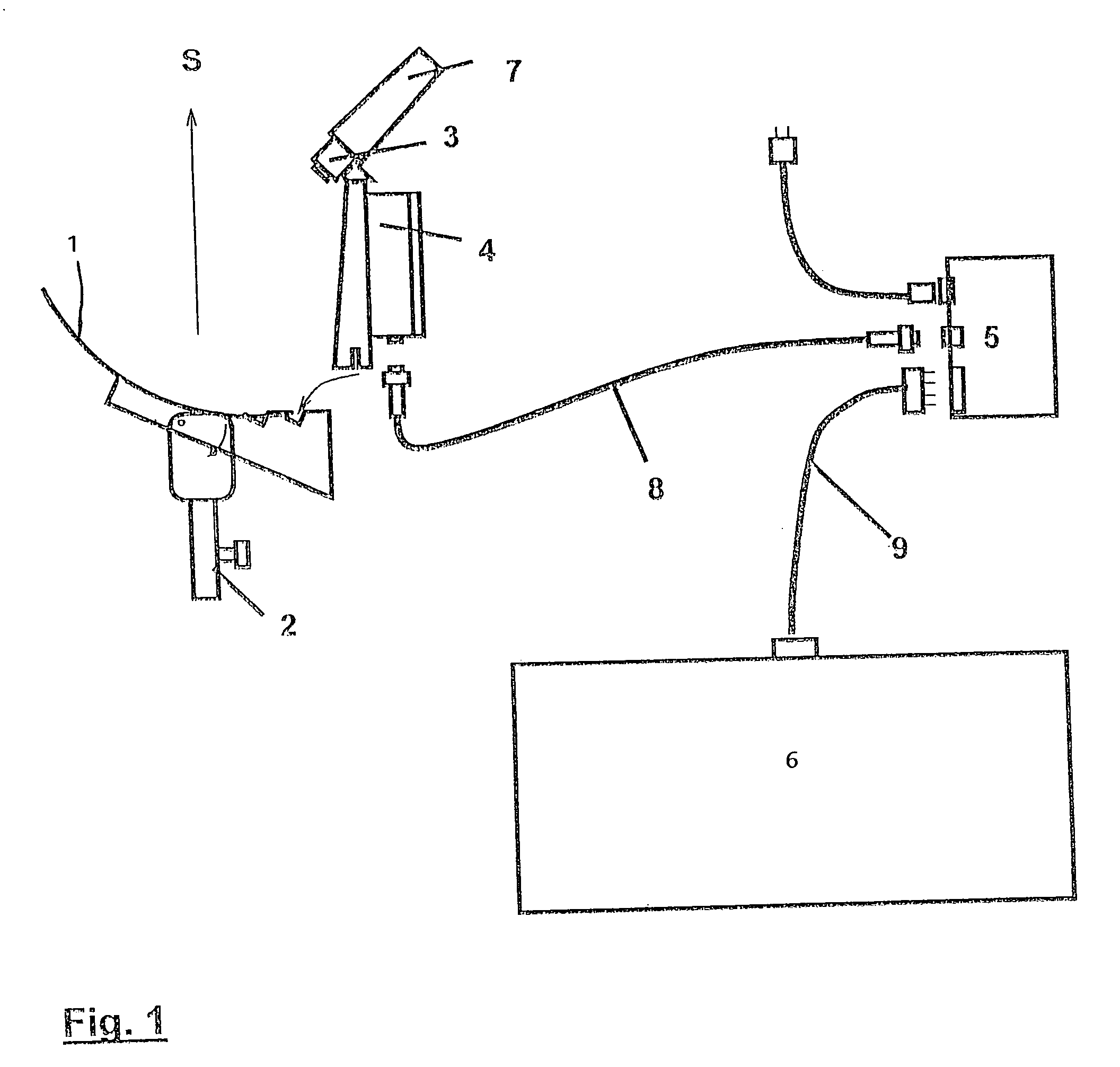

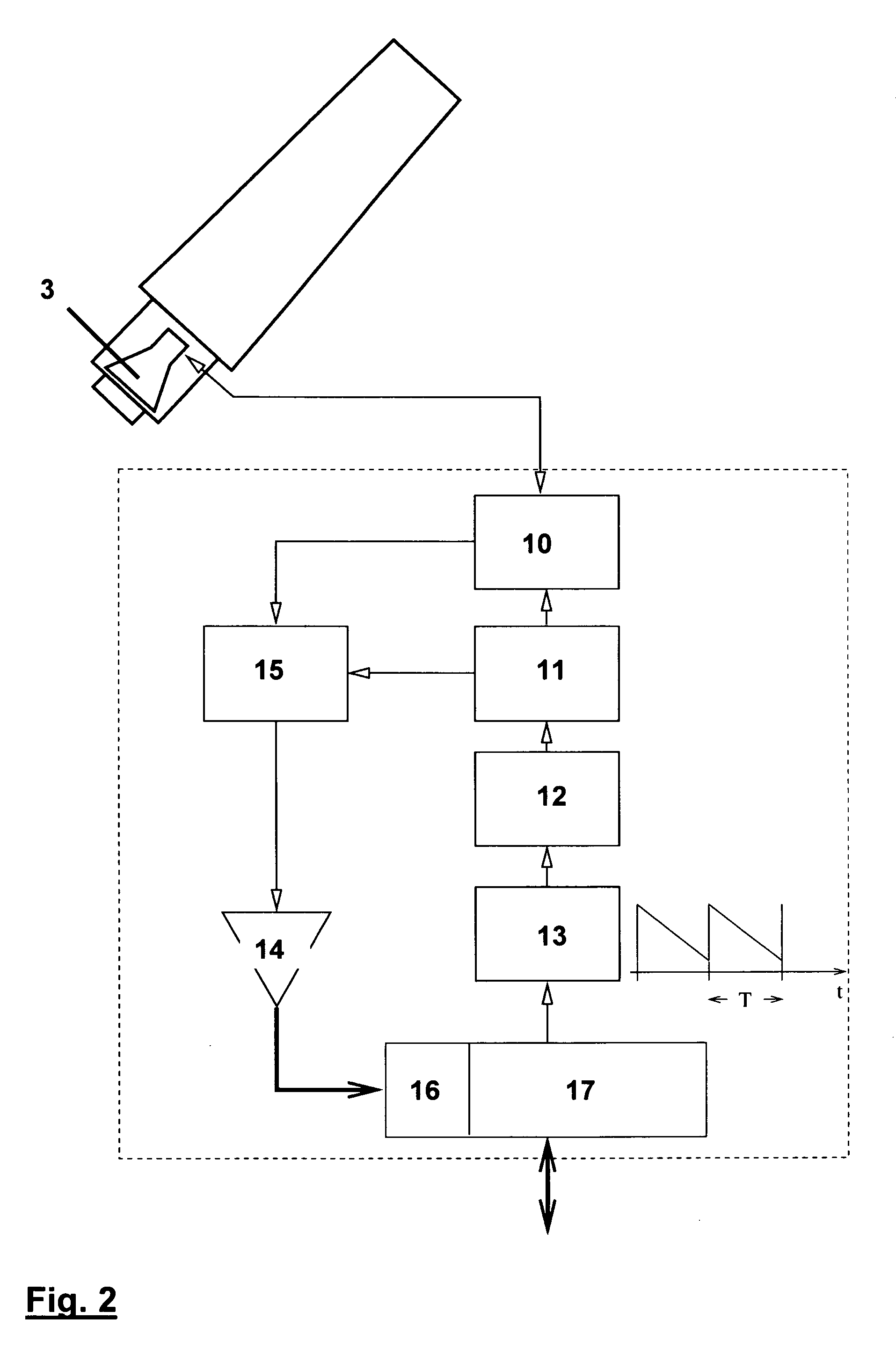

Method for determining types of precipitation in the atmosphere

ActiveUS20060097907A1ICT adaptationRadio wave reradiation/reflectionRadar signalsPrecipitation types

Owner:METEK

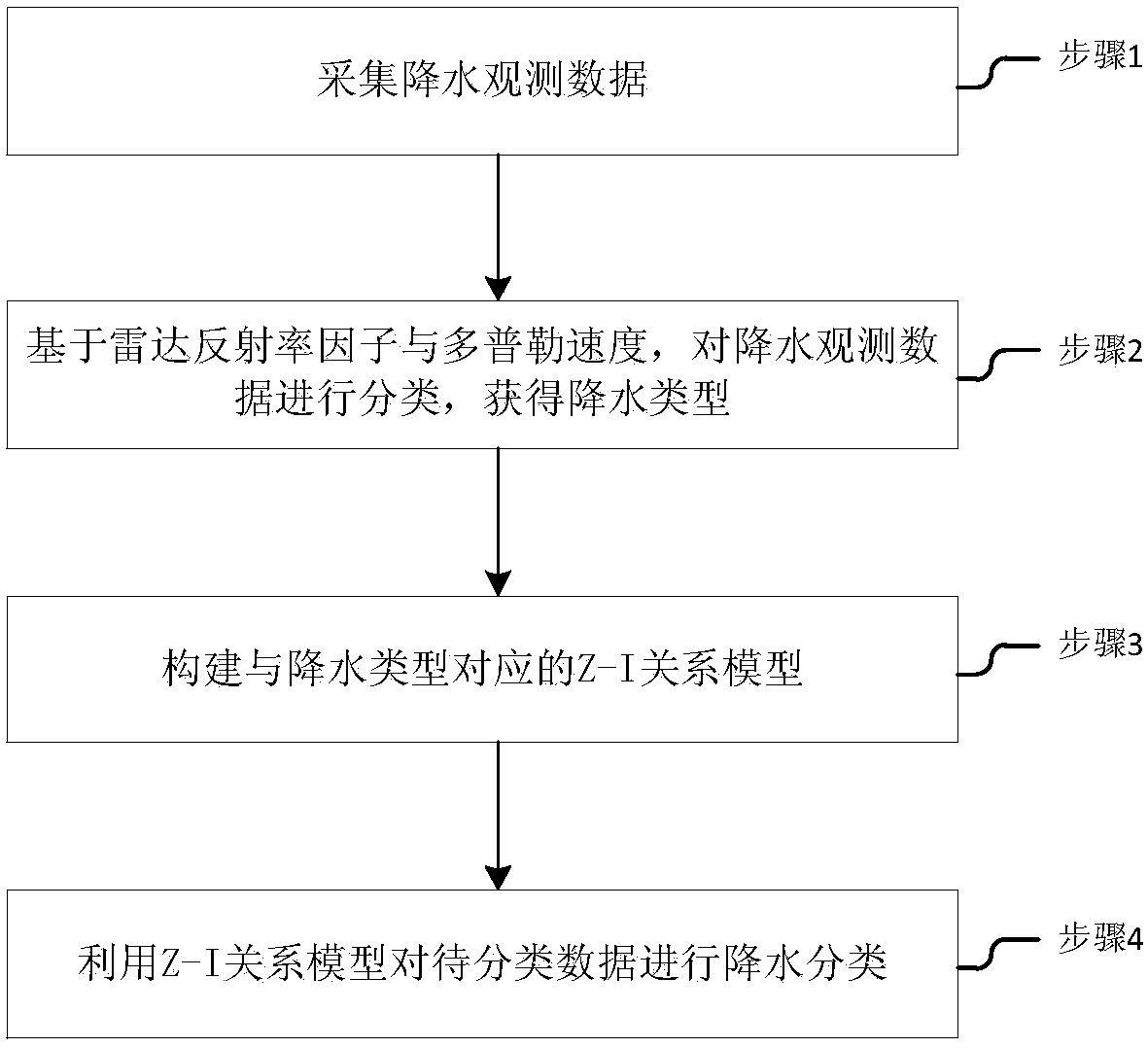

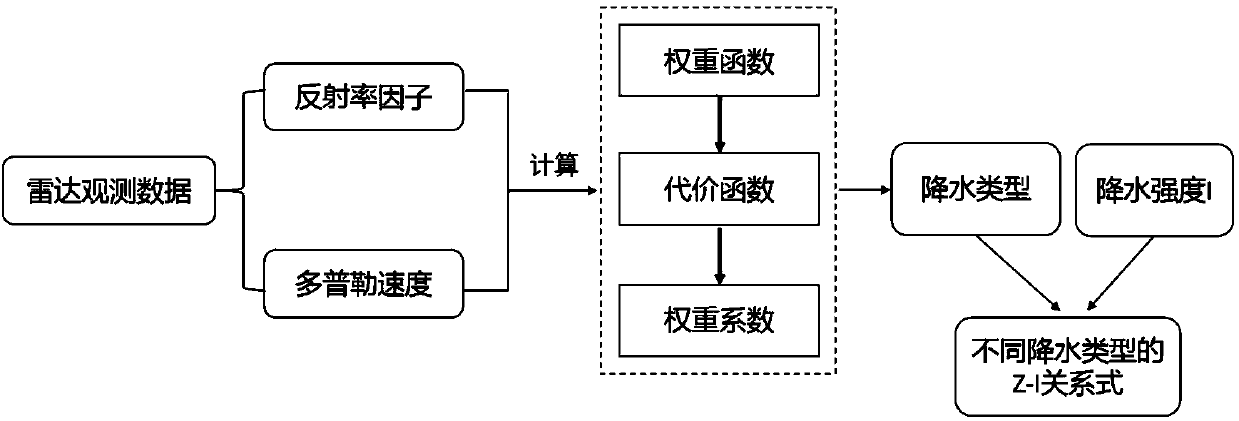

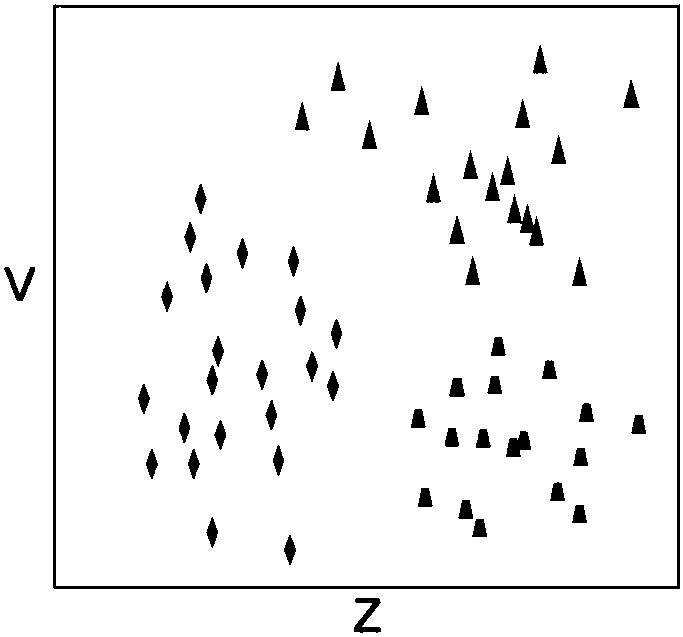

Precipitation classification method and system

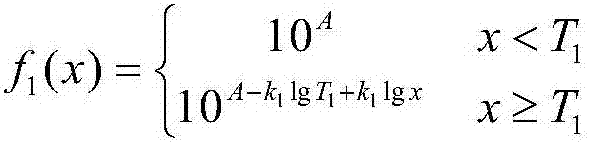

PendingCN107807907AImprove accuracyEfficiencyForecastingComplex mathematical operationsQuantitative precipitation estimationDoppler velocity

The invention relates to a precipitation classification method and system. The method comprises the steps that precipitation observation data is collected; based on radar reflectivity factors and Doppler velocities, the precipitation observation data is classified, and precipitation types are obtained; a Z-I relational model corresponding to the precipitation types is constructed, wherein Z refersto the radar reflectivity factors, and I refers to rainfall intensity; and the Z-I relational model is utilized to perform precipitation classification on to-be-classified data. Through the scheme, the precipitation types can be classified quickly through radar data, therefore, an accurate Z-I expression can be obtained, and the accuracy and efficiency of radar quantitative precipitation estimation are improved.

Owner:CHINA ELECTRIC POWER RES INST +2

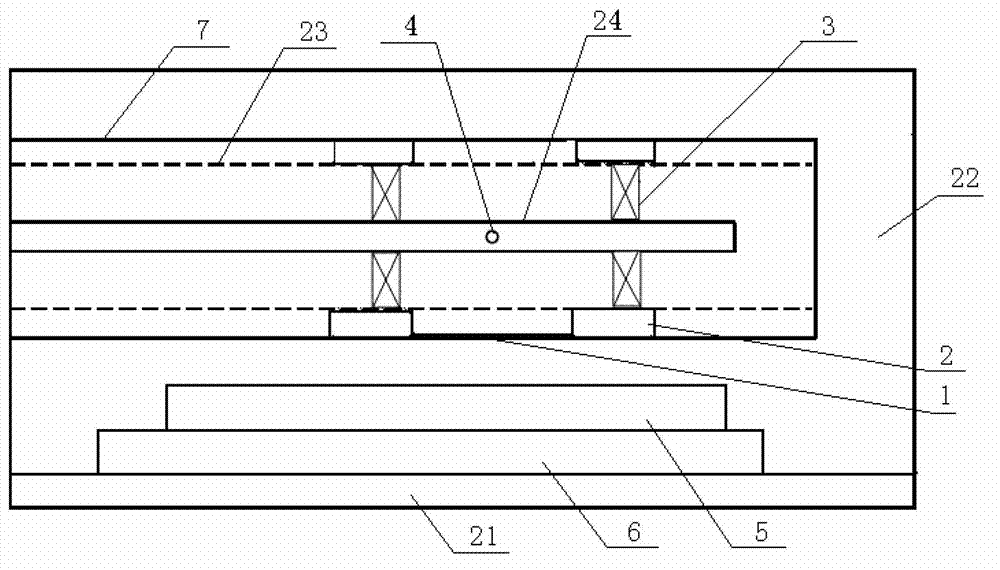

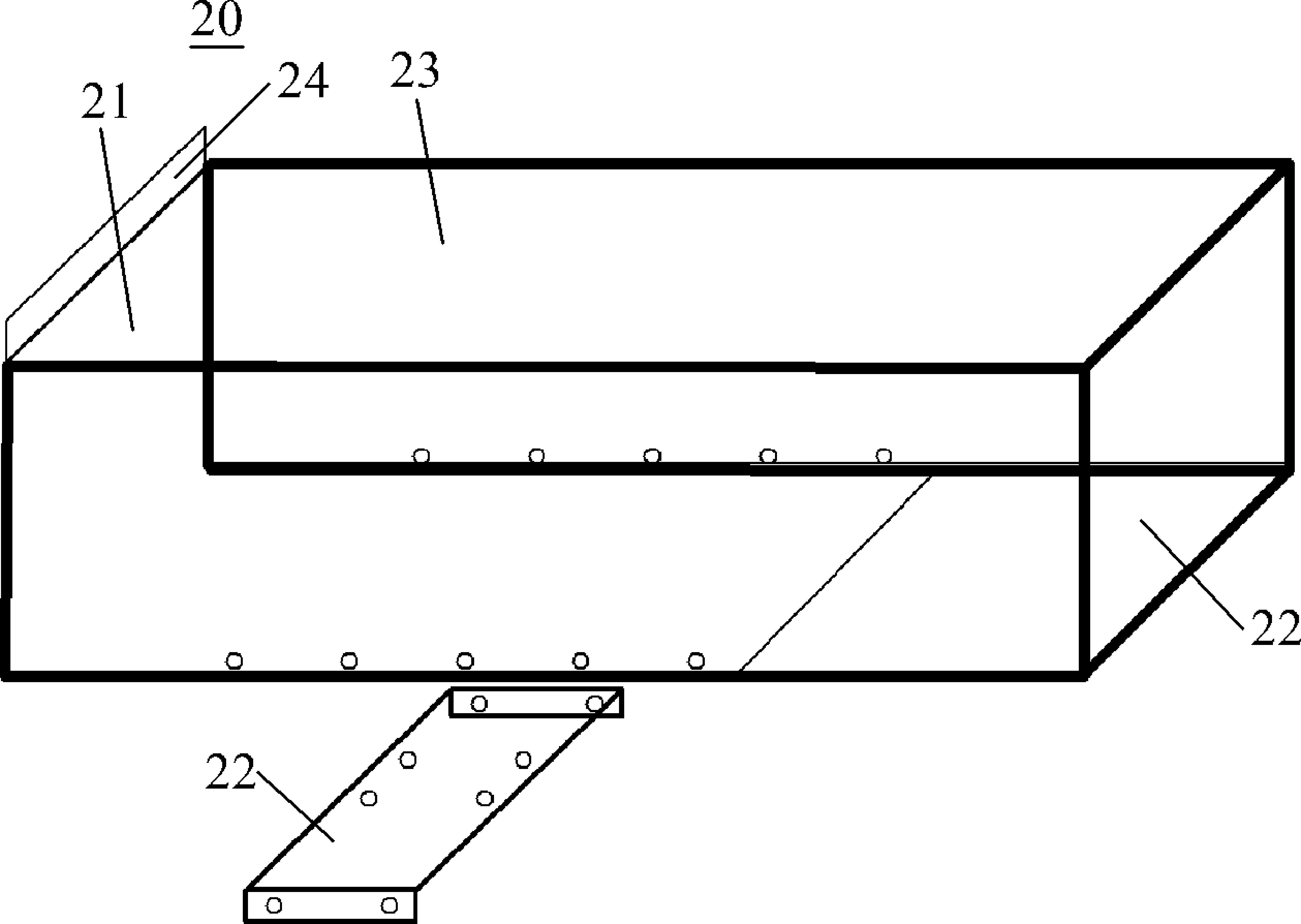

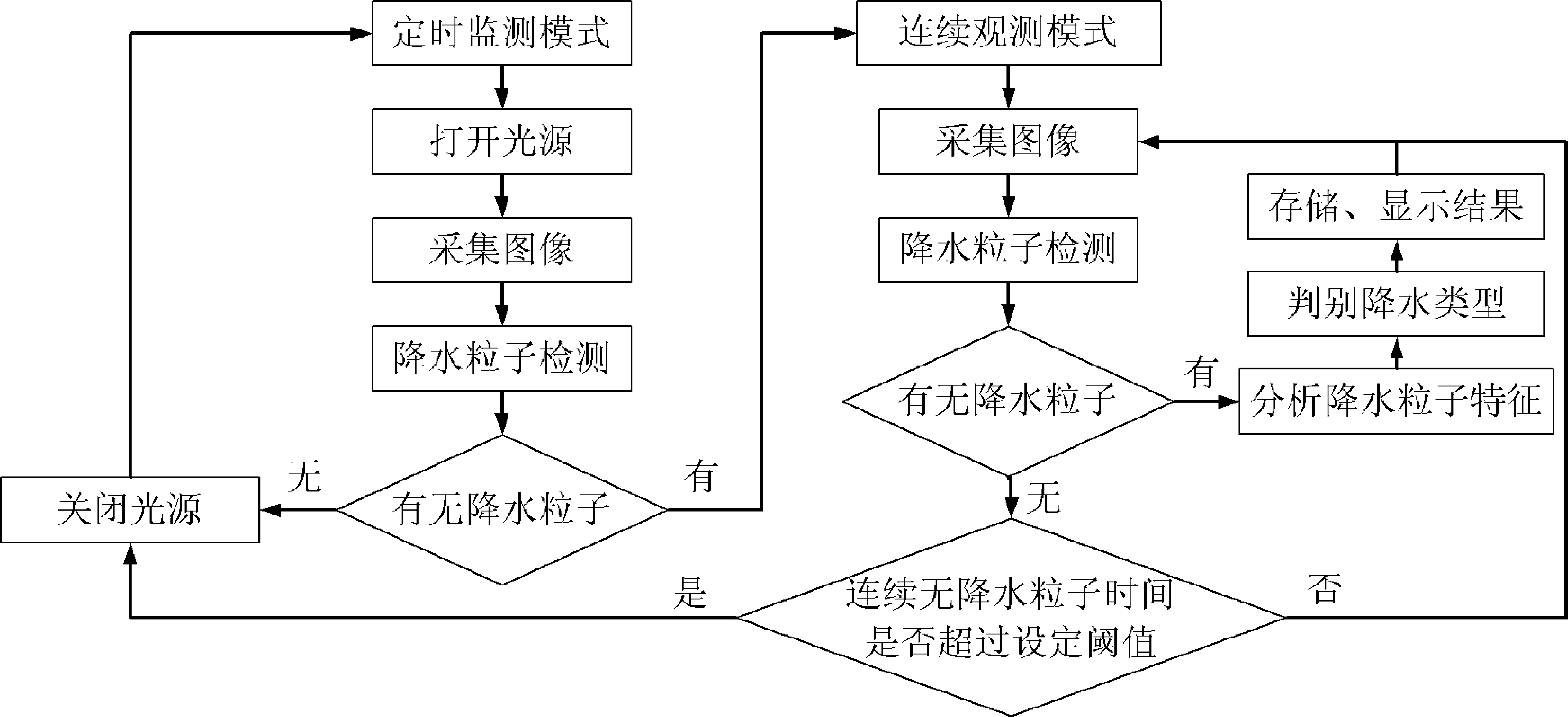

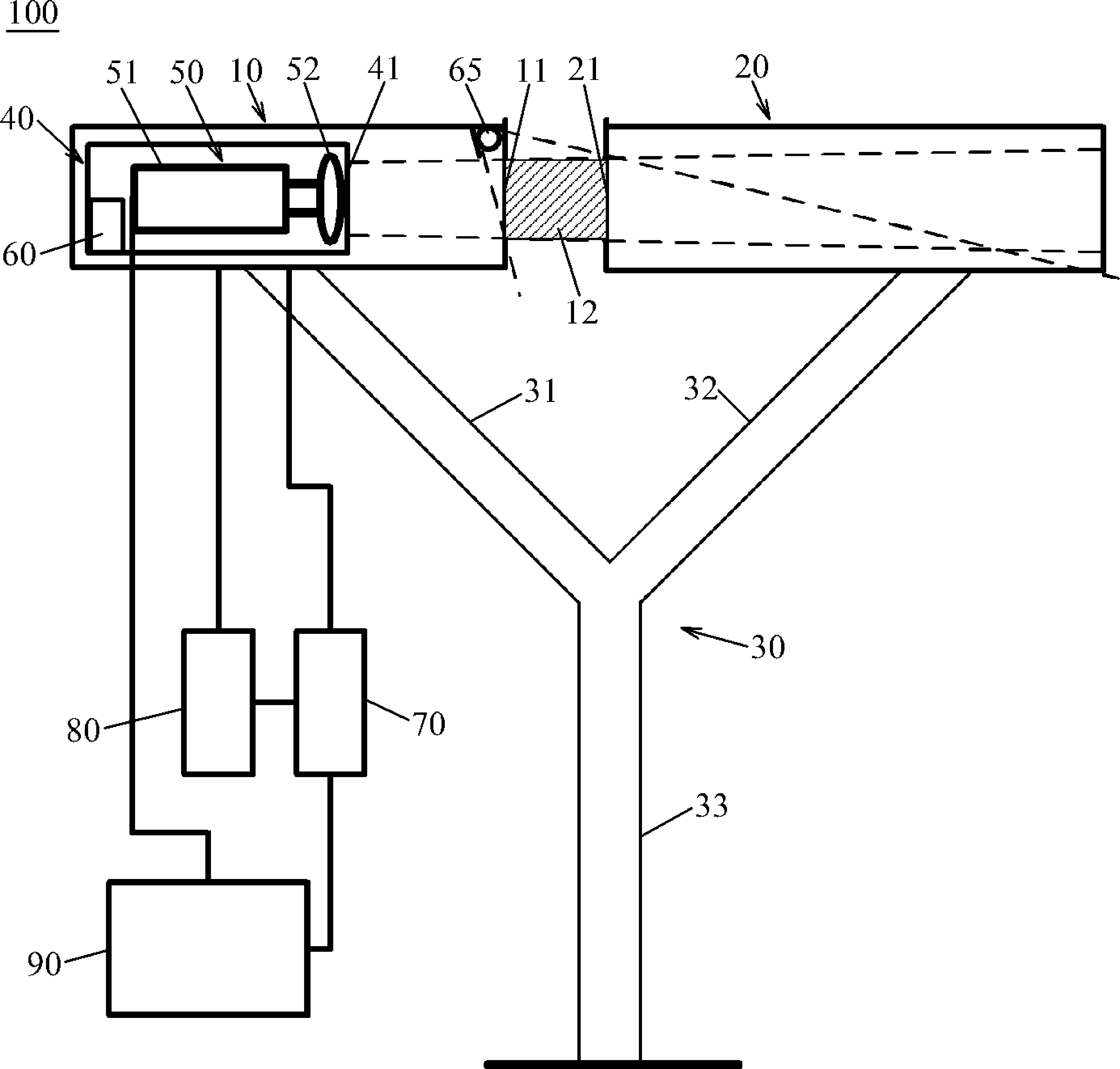

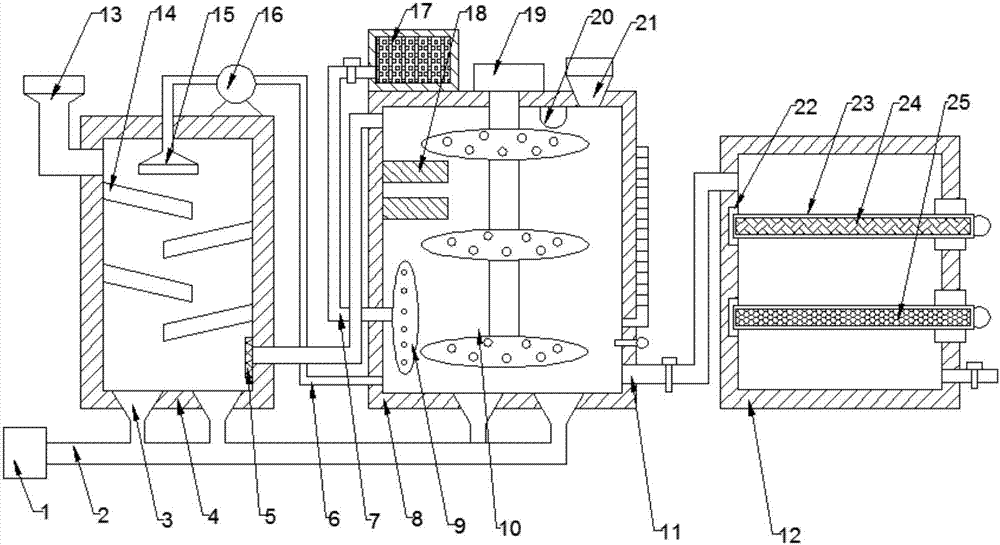

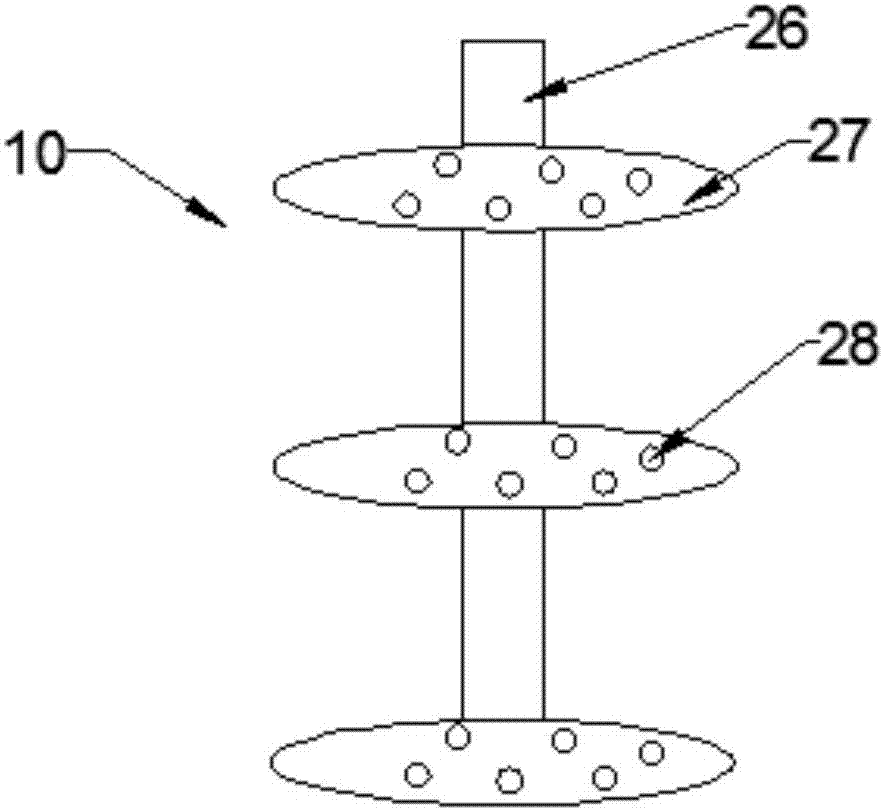

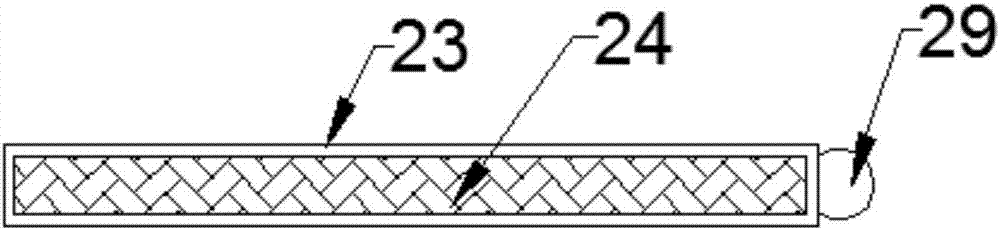

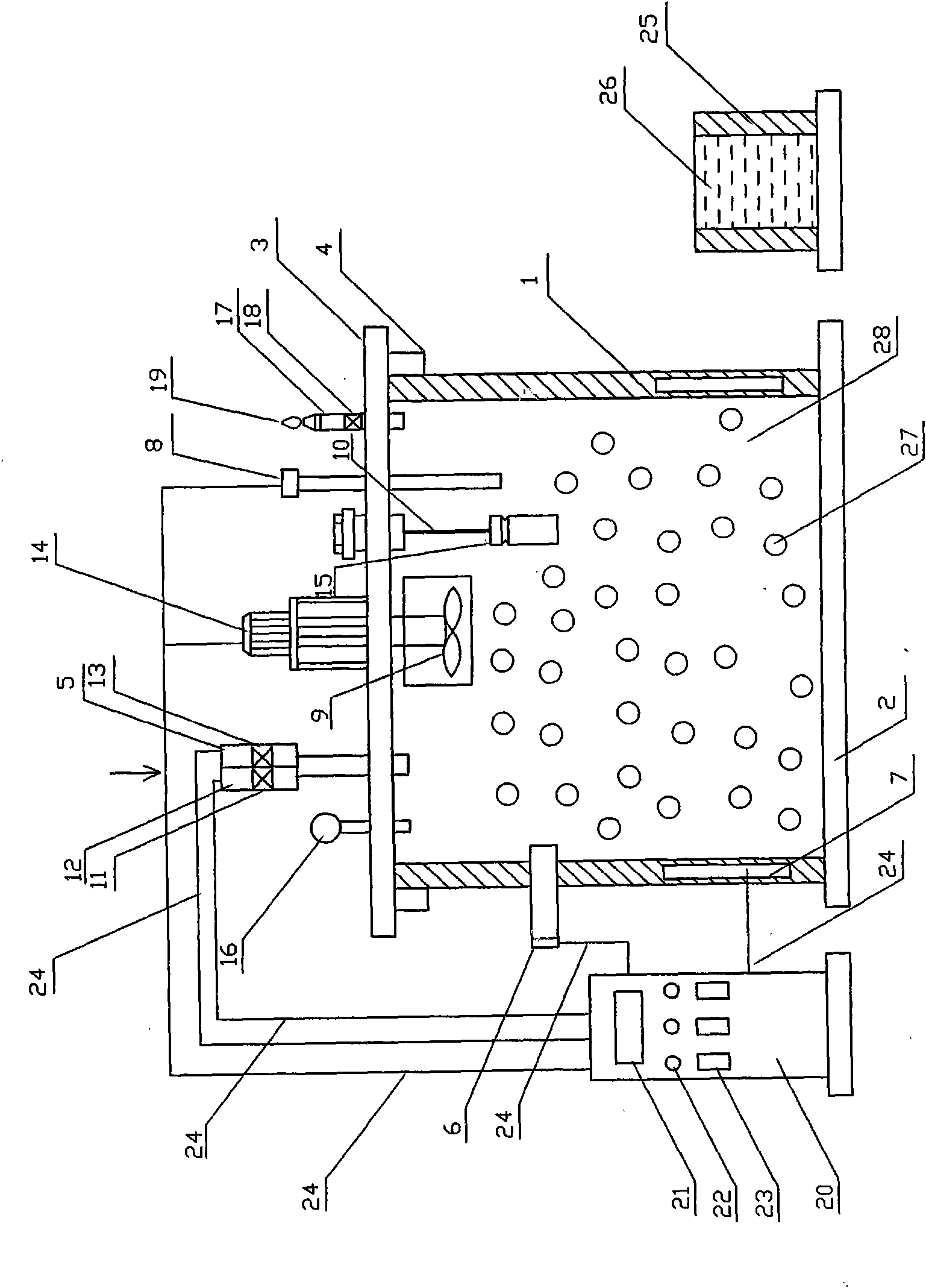

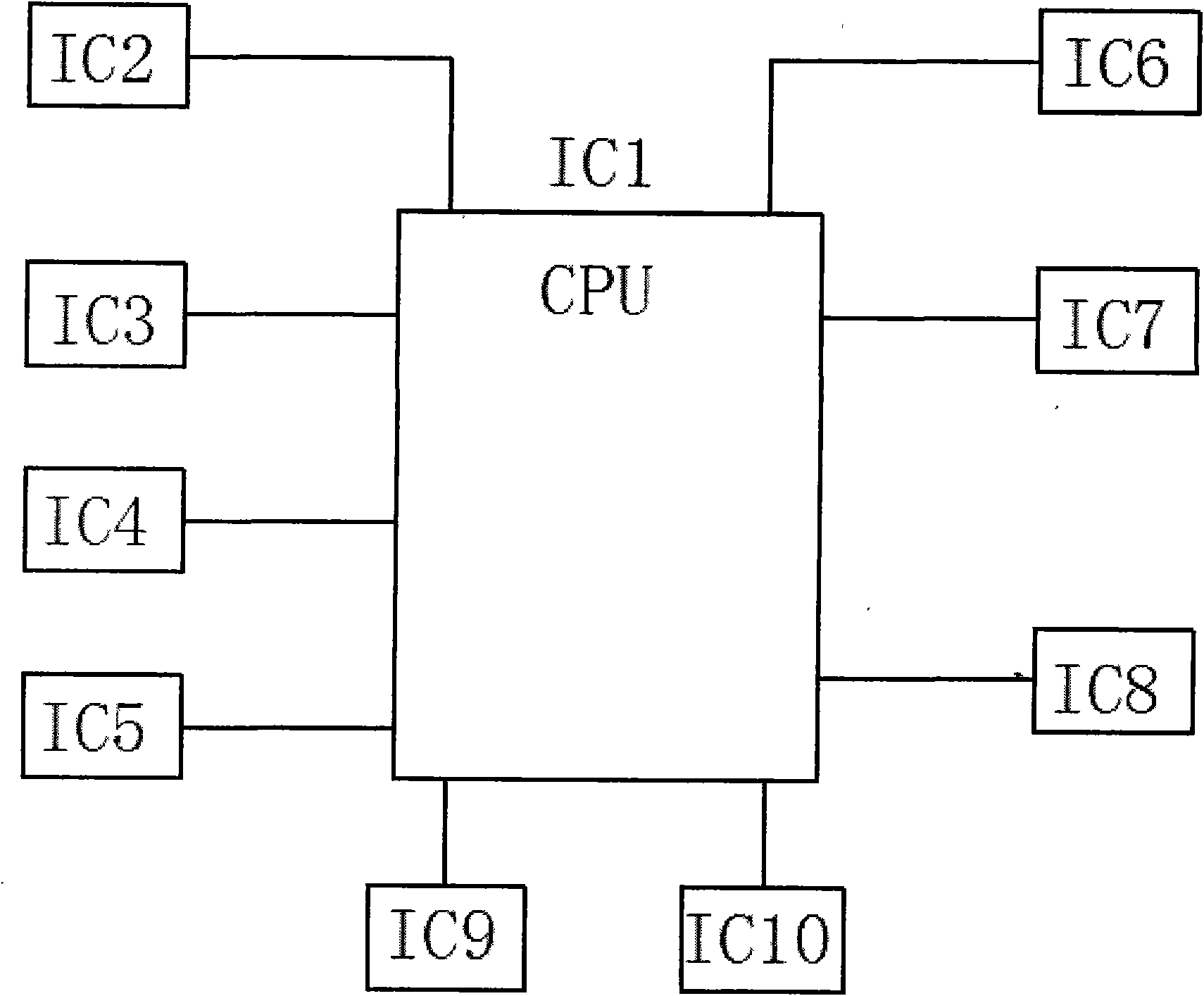

System for automatically observing precipitation phenomenon based on digital shooting

InactiveCN102183801AAutomate analysisRealize automatic discrimination of precipitation typeInstrumentsTemperature controlEngineering

The invention provides a system for automatically observing a precipitation phenomenon based on digital shooting, which comprises a shooting end box body with a shooting opening, a protective cover, a background box body with a background opening, a shooting device, a temperature control device, a light source, a control module, a power module and a computer, wherein the protective cover is arranged inside the shooting end box body, and the end of the protective cover, which is provided with a shooting window made of a transparent material, faces the shooting opening; the background opening is opposite to the shooting opening along the horizontal direction; the shooting device is arranged inside the protective cover and is used for controllably shooting images in a sampling area; the temperature control device is arranged inside the protective cover and is used for adjusting the ambient temperature in the protective cover; the light source is arranged inside the shooting end box body close to the shooting opening and is used for improving the brightness of the sampling area; the control module controls the work of the temperature control device and the light source; and the power module supplies power to the shooting device, the temperature control device, the light source and the control module. The system can acquire a clear digital image of precipitation particles in a natural motion state, analyze the image to obtain the size, shape and other characteristics of the precipitation particles and identify various precipitation types.

Owner:CHINESE ACAD OF METEOROLOGICAL SCI

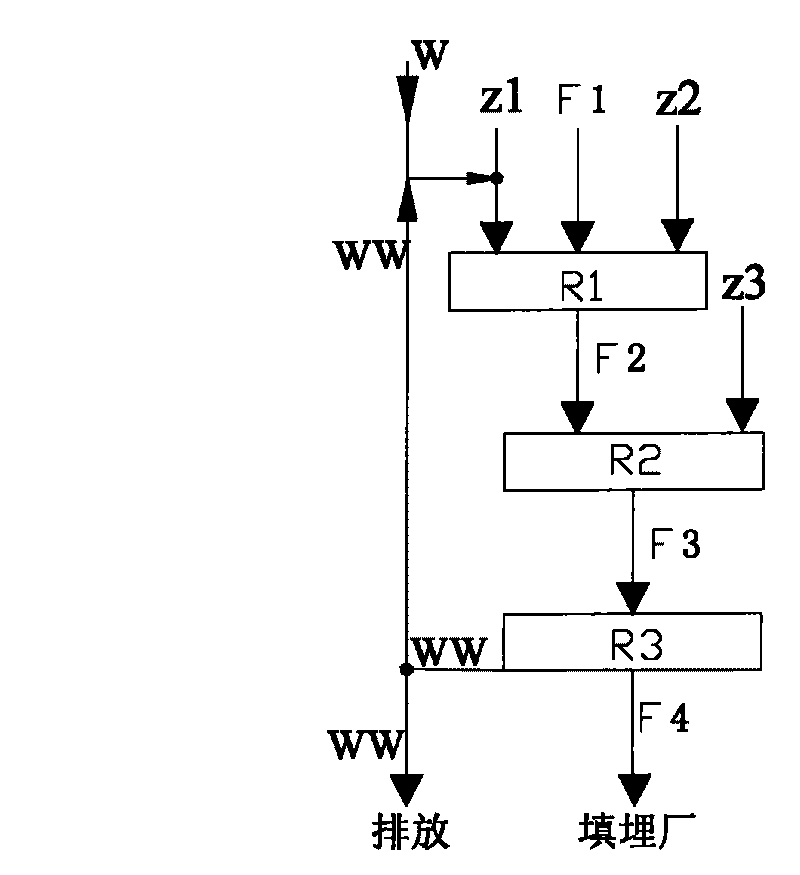

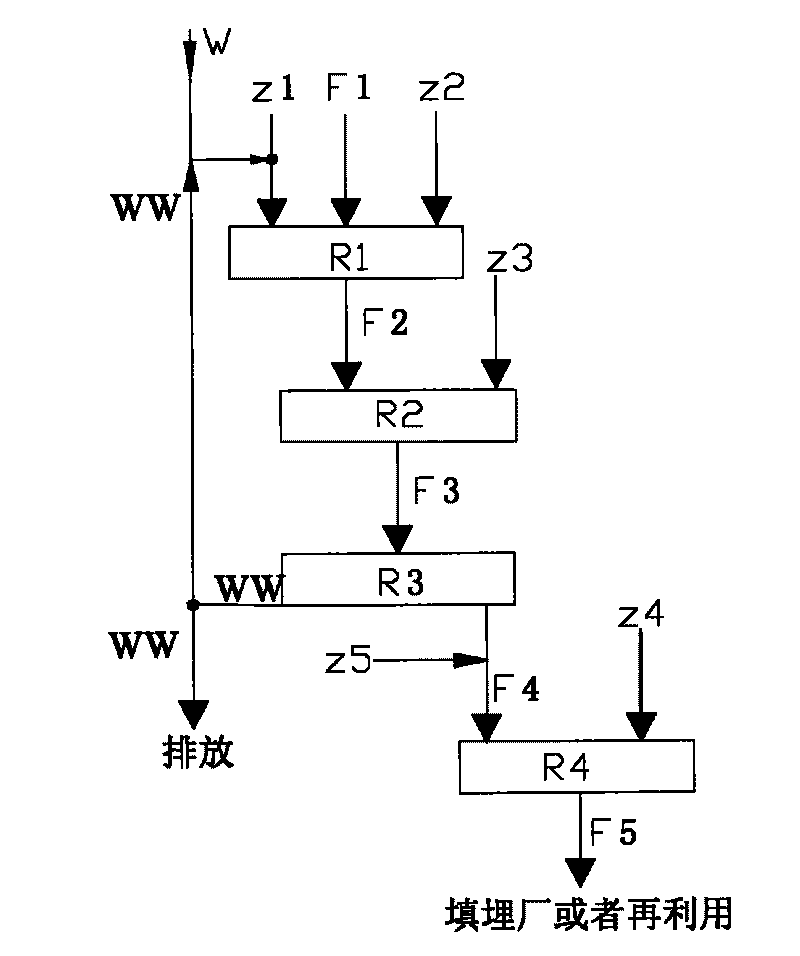

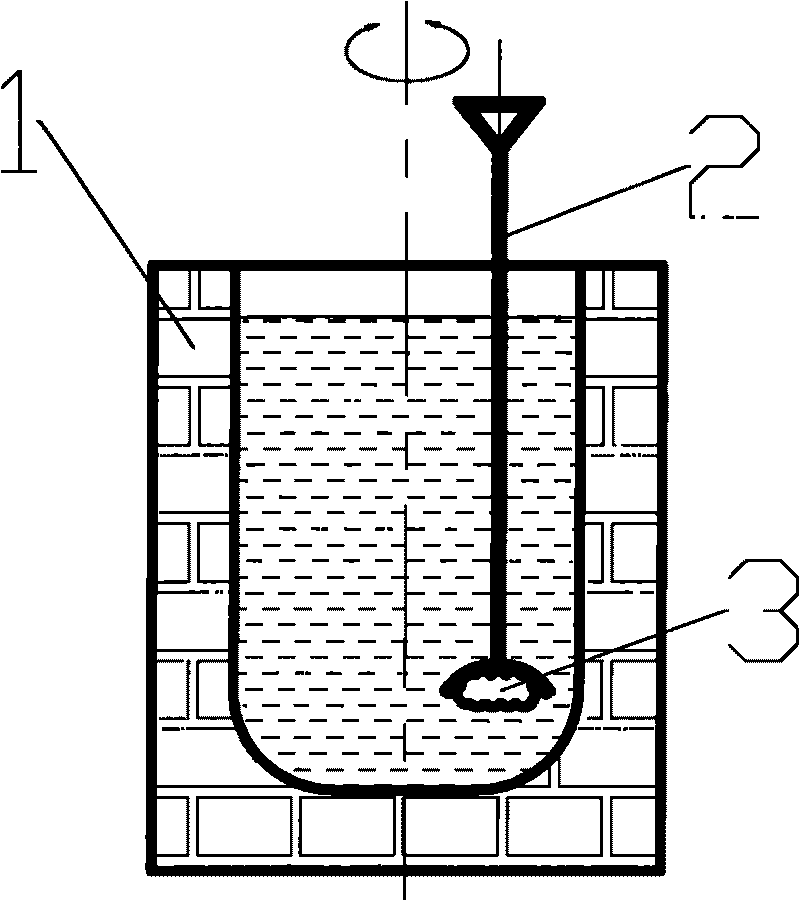

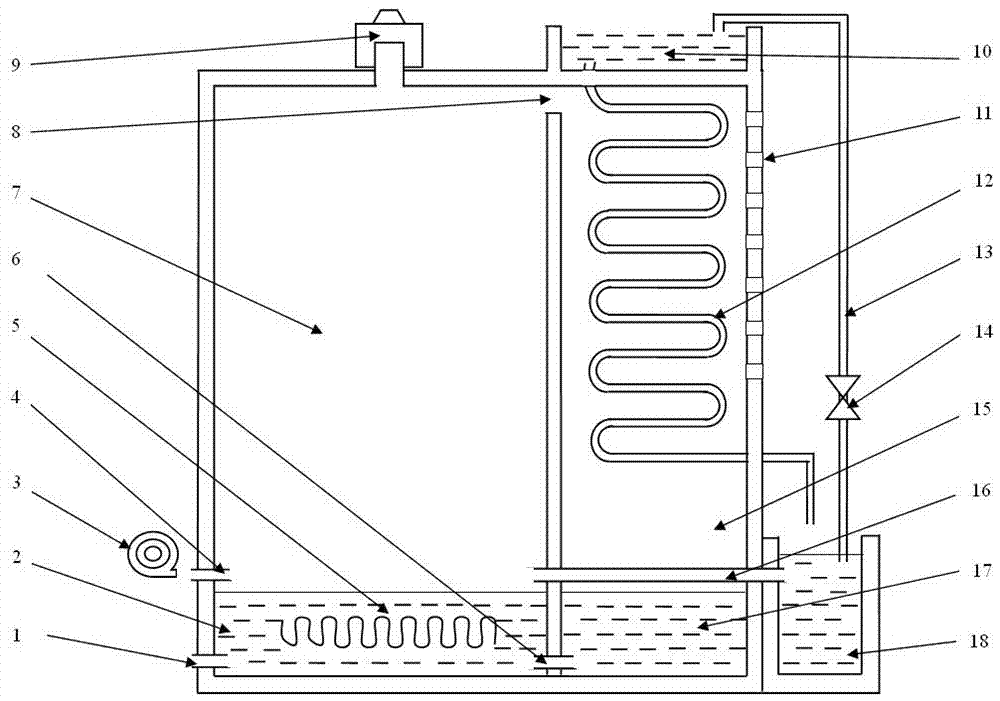

Secondary precipitation type sewage purification treatment device

InactiveCN107487919AAvoid breedingEasy to settleWater/sewage treatment by irradiationWater treatment compoundsActivated carbonSewage

The invention provides a secondary precipitation type sewage purification treatment device, which belongs to the technical field of sewage treatment. The deflectors are arranged alternately on both sides of the inner cavity of the first settling tank; the right end of the water suction pump passes through the water suction pipe and The second settling tank is connected, and the left end of the water suction pump is connected with the water outlet bucket through the water suction pipe; the lower end of the motor is provided with a disinfection device; the ozone generator is connected with the ventilation pipe through the gas delivery pipe; It is arranged at the upper end of the inner cavity of the second sedimentation tank; the activated carbon layer is arranged under the inner cavity of the purification tank; the device of the present invention is fixed with a disinfection sheet on the rotating shaft, and has rotating and stirring sewage and flocculants to facilitate precipitation and disinfection Ozone generator is welded and fixed on the upper left side of the second settling tank, which has the function of avoiding the growth of anaerobic bacteria and oxidizing domestic sewage at the same time; this device has simple manufacturing process, strong practicability and good decontamination effect specialty.

Owner:顾渠成

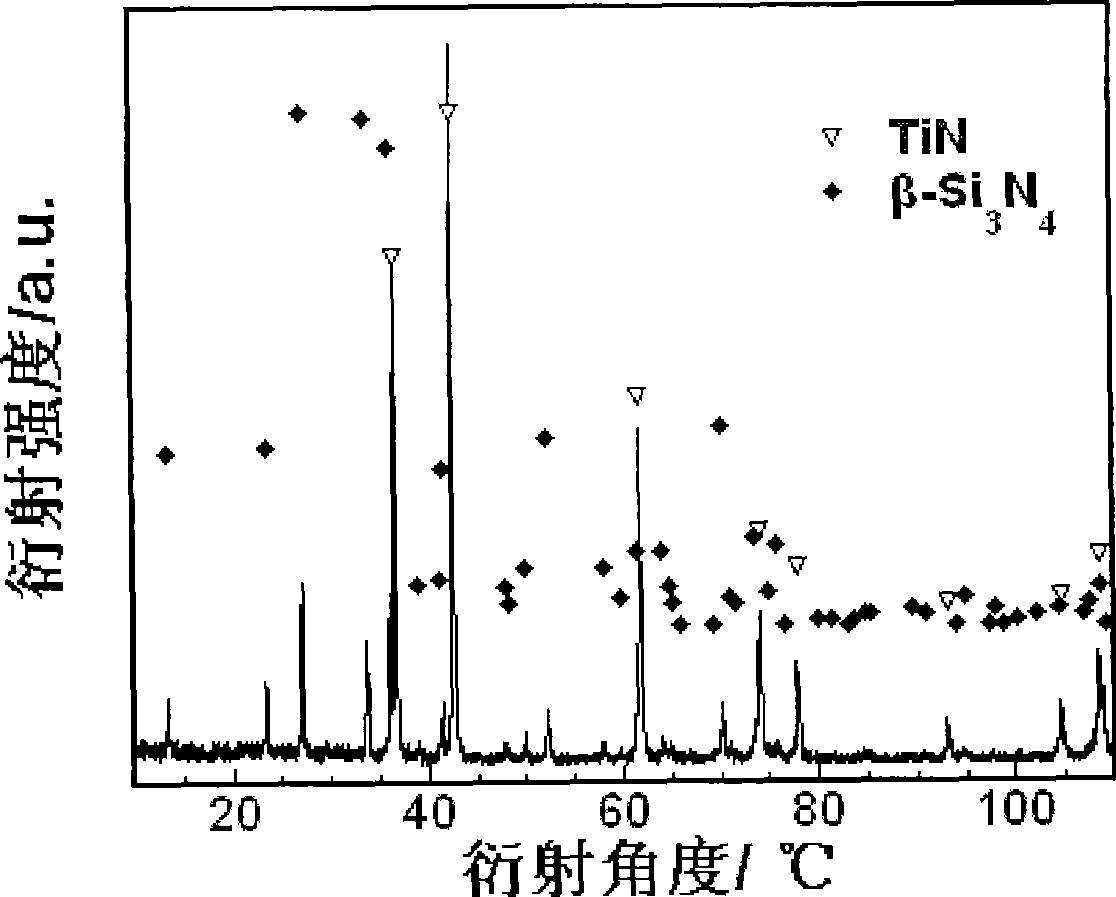

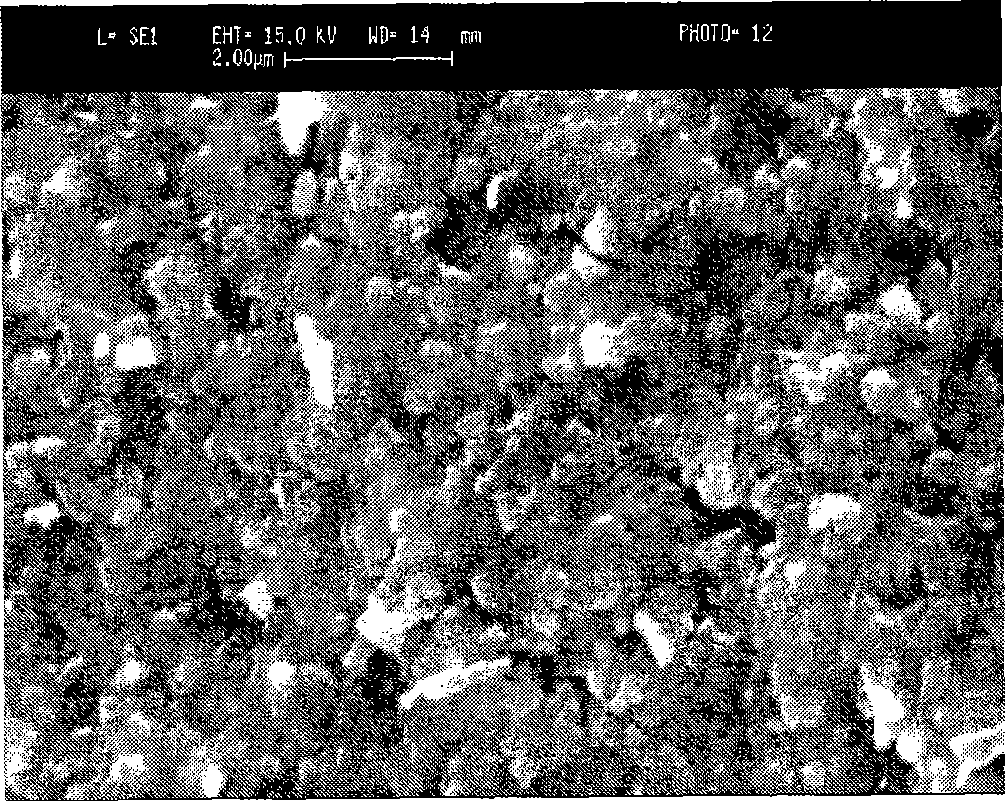

Preparation of conductive titanium nitride/silicon nitride nano composite material

InactiveCN101475151AImprove performanceReduce energy consumptionNitrogen compoundsTitanium nitrideTitanium tetrachloride

The invention belongs to the field of conductive composite ceramics, and relates to a method for preparing a conductive titanium nitride / silicon nitride nano composite material. The method is characterized by comprising the following steps: under the low-temperature liquid phase condition, simultaneously reducing TiCl4 and SiCl4 as raw materials at a temperature of between 50 DEG C below zero and 20 DEG C to directly obtain TiN / Si3N4 co-precipitation type composite powder; and directly preparing the composite powder co-coated by nano TiN and nano Si3N4, wherein the composite powder can form cores on the surface of silicon nitride micron or sub-micron particles. By controlling the content of TiN in the nano composite powder, the nano conductive composite material meeting electric spark processing (EDM) can be obtained. The titanium nitride / silicon nitride nano composite material has the advantages of even components, fine particles, simple and convenient process, low energy consumption, and popularization prospect.

Owner:UNIV OF SCI & TECH BEIJING

Method for producing industrial precipitation-type nano calcium carbonate

InactiveCN104556184AReduce consumptionSolve pollutionCalcium/strontium/barium carbonatesMaterial nanotechnologyCALCIUM HYDROXIDE SOLUTIONFlue gas

Owner:安徽雪城超细碳酸钙有限公司

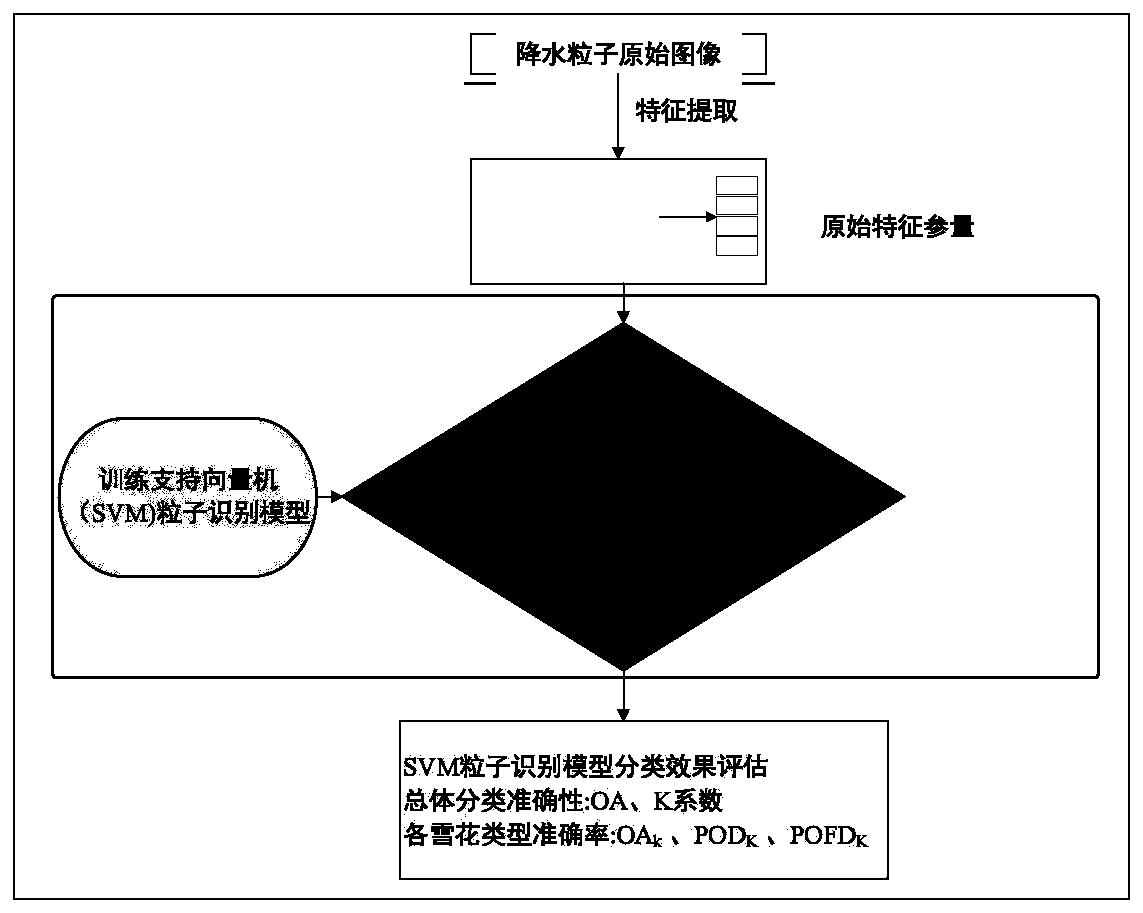

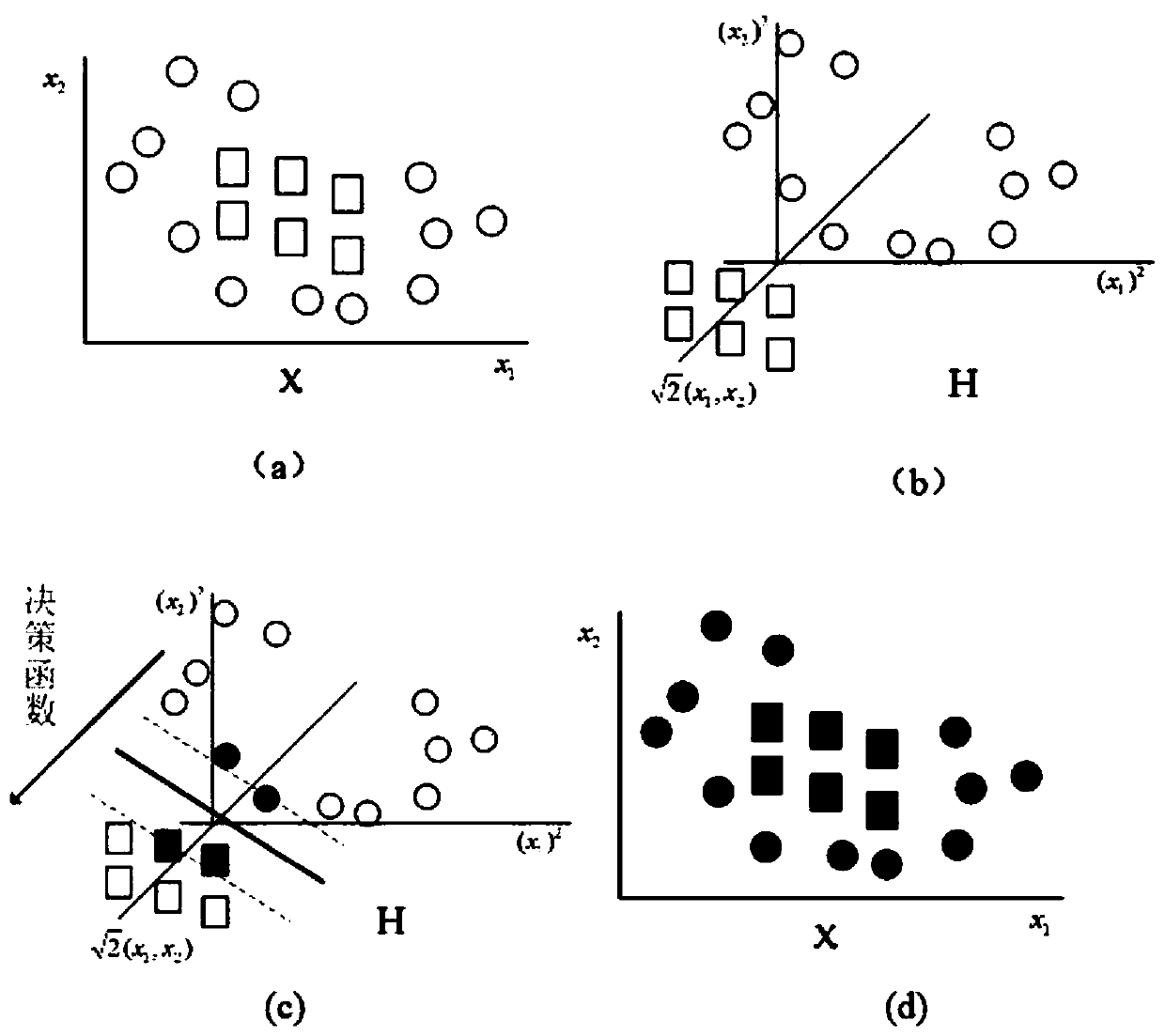

Precipitation type identification method based on precipitation particle multi-characteristic parameters

InactiveCN110059713AImprove the degree of refinementEasy inputCharacter and pattern recognitionFeature parameterPrecipitation particle

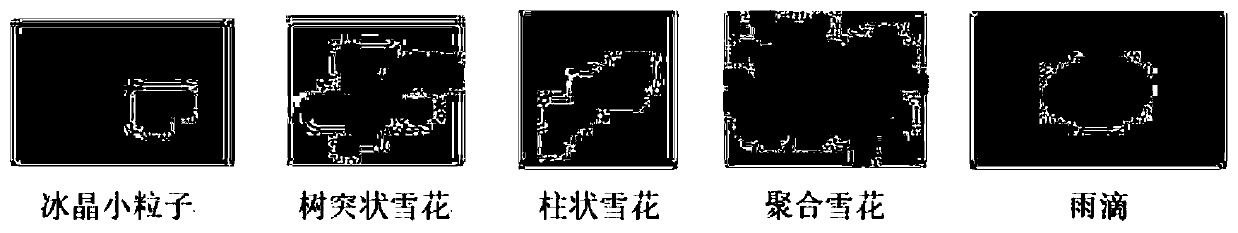

The invention discloses a rainfall type identification method using rainfall particle multi-characteristic parameters. The method comprises the following steps of: establishing a feature vector required by a precipitation particle recognition model by utilizing feature parameters such as precipitation particle geometric information, gray scale information and speed information measured by an observation instrument; according to the actual measurement particle image information, dividing the main rainfall particle types into ice crystal small particles, dendritic snowflakes, columnar snowflakes, aggregated snowflakes and raindrops; and using a support vector machine method to establish a rainfall particle type recognition model, and achieving fine recognition and classification of rainfalltypes. According to the invention, fine classification and identification of precipitation particles can be effectively realized. The measurement performance of the imaging raindrop spectrometer can be further exerted, and the fineness degree of rainfall type description is improved.

Owner:NAT UNIV OF DEFENSE TECH

Carbide precipitation type rare earth carburizing steel

InactiveCN101967605AHigh surface hardnessHigh strengthSolid state diffusion coatingMean diameterCarbon potential

The invention relates to carbide precipitation type rare earth carburizing steel, which is chromium-manganese-silicon-molybdenum rare earth alloy steel. The carbide precipitation type rare earth carburizing steel is used for carburization by a gas carburizing method comprising the following steps of: washing a chromium-manganese-silicon-molybdenum rare earth alloy steel test bar with kerosene, hoisting the washed test bar in a carburizing furnace, adding dropwise a carburizing agent isopropanol and a diluent methanol, dispersing and precipitating ultrafine granular alloy carbides with the mean diameter of 200nm from a carburized layer at the same time of internally diffusing carbon atoms from the surface under the conditions of the temperature of 920+ / -5 DEG C, the carbon potential Cp of 1.25+ / -0.05 percent and the heat preservation time of 420+ / -10min to make 1.6mm deep the carburized layer and 2 to 3 percent the carbon content of the surface layer, reducing the temperature to 840 to 850 DEG C, preserving the heat for 30min, performing impregnation and quenching by using 5 percent PAG aqueous solution and performing tempering at the low temperature of 180+ / -5 DEG C. The carburized layer of the chromium-manganese-silicon-molybdenum rare earth alloy has the hardness of HV0.11057 improved by 20 percent compared with that in the prior art, and the abrasive resistance improved by 60 percent, so that the hardness, strength and abrasive resistance of the surface of a work piece are greatly improved.

Owner:TAIYUAN UNIV OF TECH

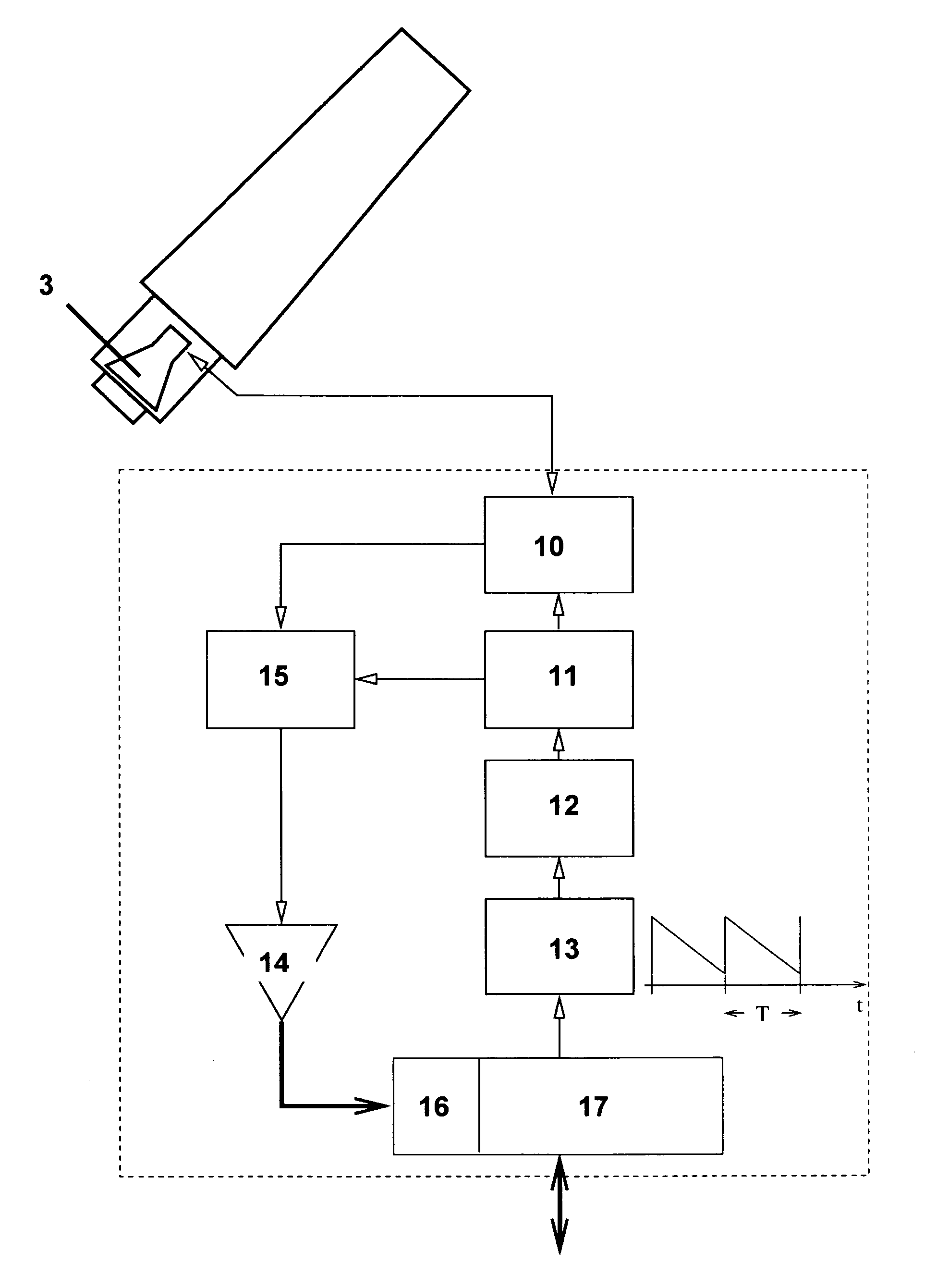

Method for determining types of precipitation in the atmosphere

ActiveUS7688249B2ICT adaptationRadio wave reradiation/reflectionFrequency spectrumPrecipitation particle

A method for determination of precipitation types in the atmosphere is described, wherein an output signal, in particular a radar signal, having a transmitting frequency spectrum is transmitted, reflection signals formed by reflection of the output signals at precipitation particles at at least two atmospheric levels and having a reflection spectrum are detected, and wherein finally the characteristics of the reflection signals are analyzed.The method according to the invention is characterized in that on analyzing characteristics of the reflection signals a course of a difference frequency spectrum formed by transmission frequency and reflection frequency spectrum is analyzed resolved by altitude levels.

Owner:METEK

Method and system for displaying weather information on a timeline

Provided are methods, devices, and non-transitory computer readable storage mediums to generate a weather timeline such as a succession of weather information on a continuous time scale. For example, a timeline may include first weather information associated with a first time in a first territorial location, second weather information associated with a second time, and third weather information associated with a third time. At least one of the first, second and third weather information may comprise a forecasted weather value indicative of a probability of having a specific type of precipitation at a specific intensity. A weather timeline may follow a specific location (e.g. city, town, any region with a definite boundary), a specific weather event (e.g. a specific precipitation type, a specific temperature level, a specific wind intensity), and / or a specific user. A timeline may include data created by an observer of the related weather information, where the data may be at least one of a picture, a video or a comment inputted by the observer about the related weather information.

Owner:SKY MOTION RES ULC

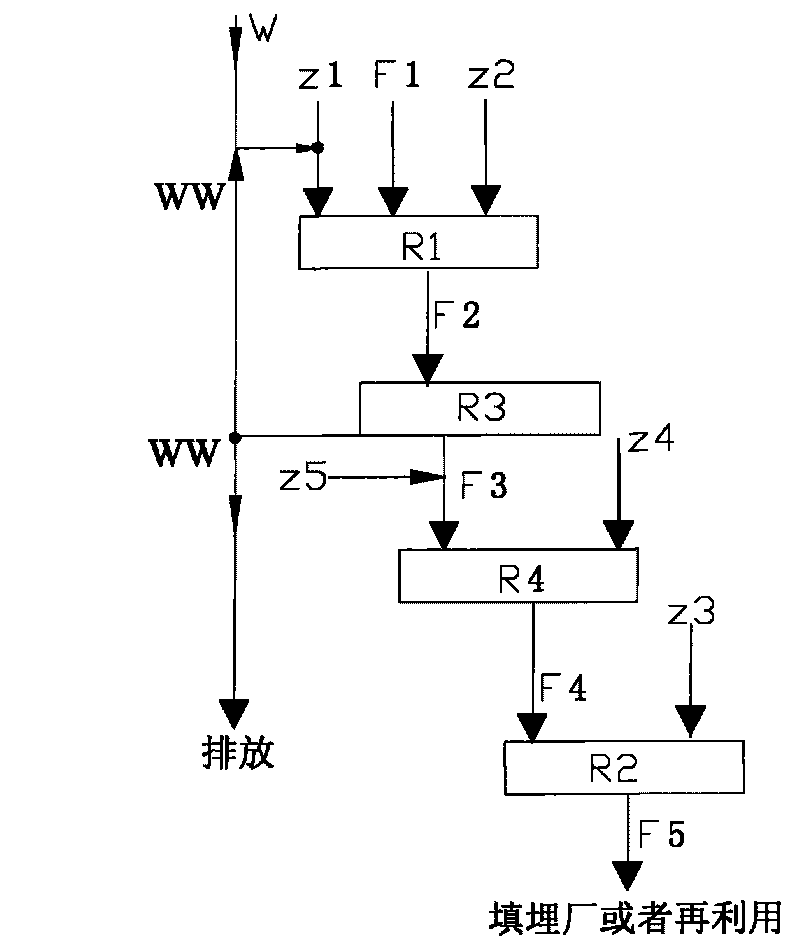

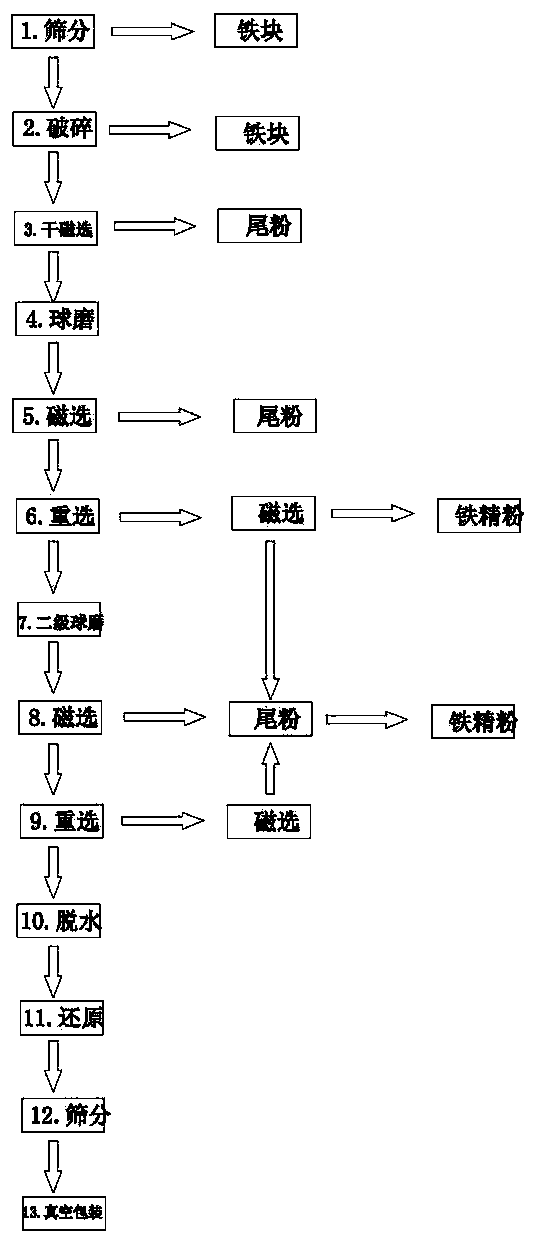

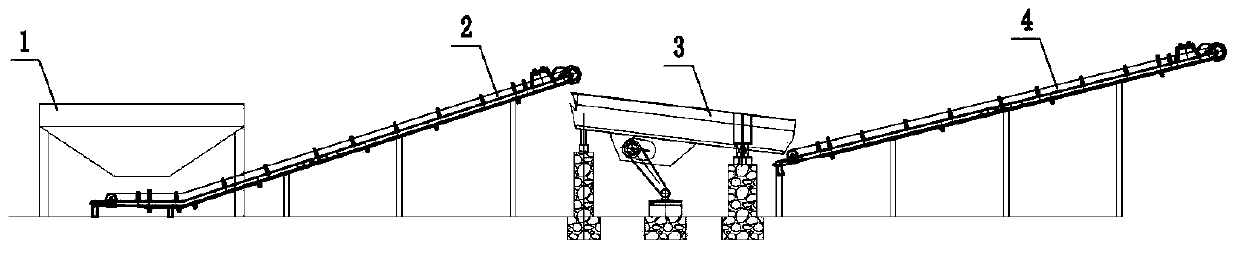

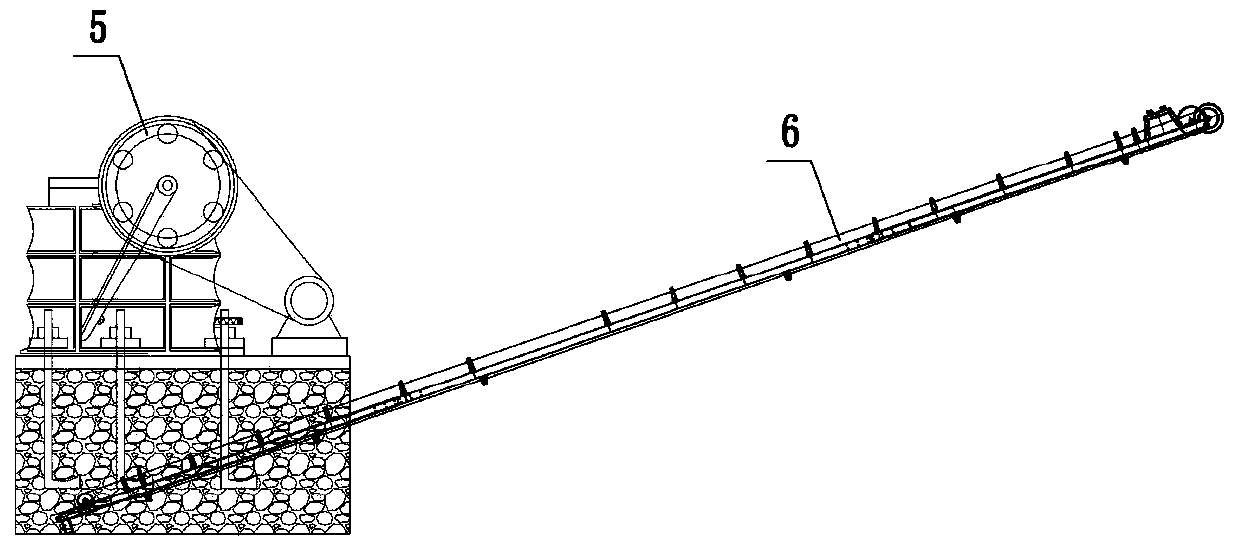

Comprehensive recycling process of second zinc oxide rotary kiln tailings and production line of comprehensive recycling process

InactiveCN104174861ASmall granularityEasy to chooseSolid waste disposalMagnetic separationEngineeringCrusher

The invention discloses a comprehensive recycling process of second zinc oxide rotary kiln tailings and a production line of the comprehensive recycling proces. The process comprises the following steps of screening, crushing, dry magnetic separation, ball milling, magnetic separation, reselection, ball milling, magnetic separation, reselection, dehydration, reduction, screening and packaging. The production line of the comprehensive recycling process of the second zinc oxide rotary kiln tailings comprises a discharge bin, a vibrating screen, a vertical hammer crusher, a magnetic separation belt, a first single-bin ball mill, a first wet type half counter-current magnetic separator, a first precipitation type classifier, a second single-bin ball mill, a second wet type half counter-current magnetic separator, a second precipitation type classifier, a vibrating dehydrator, a drying kiln, a rotary type hydrogen reducing furnace, a three-dimensional vibrating screen and another discharge bin, wherein the discharge bin, the vibrating screen, the vertical hammer crusher, the magnetic separation belt, the first single-bin ball mill, the first wet type half counter-current magnetic separator, the first precipitation type classifier, the second single-bin ball mill, the second wet type half counter-current magnetic separator, the second precipitation type classifier, the vibrating dehydrator, the drying kiln, the rotary type hydrogen reducing furnace, the three-dimensional vibrating screen and the other discharge bin are arranged in sequence. The comprehensive recycling process and the production line of the comprehensive recycling process have the advantages of energy conservation and emission reduction, resource recycling is realized, energy consumption and manpower are effectively reduced, and the product quality is increased.

Owner:邱建彪

Carbonate reservoir self-filtrate-reducing acid fracturing method

ActiveCN110439527AEasy to flow backReduce harmFluid removalFlushingAcid fracturingPrecipitation types

The invention relates to a carbonate reservoir self-filtrate-reducing acid fracturing method. The carbonate reservoir self-filtrate-reducing acid fracturing method comprises the steps that (1) fracture pressure and fracture extension pressure of a transformed reservoir are calculated; (2) an A agent is injected into a stratum under the condition of being higher than stratum fracture pressure, so that fractures are generated on the stratum; (3) a B agent is injected into the stratum under the condition of being higher than the stratum fracture pressure, and the B agent extends the fractures andcommunicates with a natural fracture net; (4) an acid liquor system C agent with the high etching power is pumped into the stratum under the condition of being higher than the extension pressure andlower than the fracture pressure, and the fracture conductivity is improved; (5) a D agent of displacing liquid is injected under the condition of being lower than the stratum fracture pressure, acidliquor in a well casing is jacked into the stratum; and (6) a well is shut down, and flow-back is carried out. The A agent is gel acid or VES acid, the B agent is self-filtrate-reducing gel acid or self-filtrate-reducing VES acid, the C agent is closed acid, and the D agent is the displacing liquid. Precipitation type solid filter cakes are formed on the wall surfaces of the fractures by utilizinga self-filtrate-reducing system, temporary blocking filtrate reducing is carried out, the technology is simple, injection is facilitated, filtrate-reducing agents are easy to disperse and flow back,and the method is safe and environment-friendly.

Owner:SOUTHWEST PETROLEUM UNIV

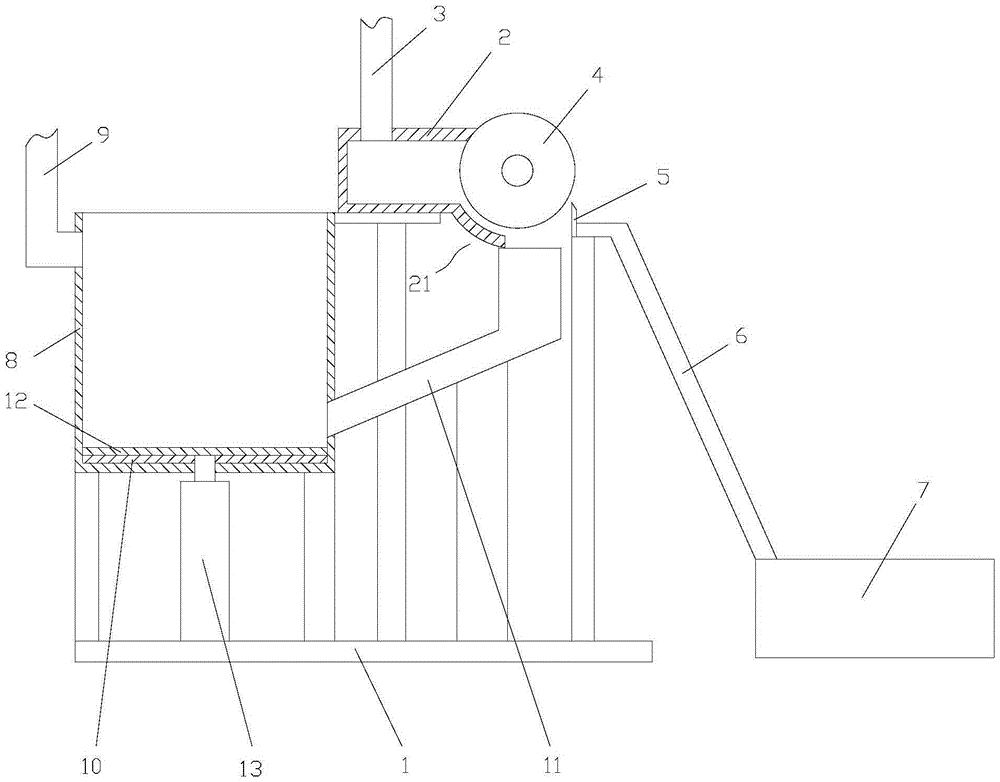

Combined type separation device for scrap iron in grinding fluid

InactiveCN105170315AReduce the content of iron filingsSimple structureMagnetic separationWet separationEngineeringSediment

The invention provides a combined type separation device for scrap iron in grinding fluid. The combined type separation device comprises a rack, a magnetic roller type separation device and a precipitation type separation device, wherein the magnetic roller type separation device comprises a grinding fluid groove, a magnetic roller, a scraping knife and a scrap iron conveying groove; the precipitation type separation device comprises a precipitation box and a magnetic plate; a transferring pipe for conveying the grinding fluid to the bottom of the precipitation box is arranged at the lower part of an outlet end of the grinding fluid groove. According to the combined type separation device for the scrap iron in the grinding fluid, provided by the invention, the scrap iron in the grinding fluid is firstly adsorbed by the magnetic roller and the separated scrap iron is scraped off from the magnetic roller by the scraping knife so as to be transferred into the scrap iron conveying groove to be discharged out; the precipitation box is used for carrying out precipitation separation on the scrap iron in the grinding fluid; the magnetic plate arranged at the bottom of the sediment box can accelerate a precipitation process so that the precipitation separation quality is improved, after double separation, the content of the scrap iron in the grinding fluid is lower and the separation effect is good; the separation device is simple in structure and low in manufacturing cost.

Owner:CHONGQING CHANGZHAN MACHINERY

Five process methods for reducing precipitation type pores of aluminum alloy die casting parts

The invention relates to an aluminum alloy die casting process method, in particular to the process method which is applicable to reducing the involvement type pores of aluminum alloy die casting parts. The process method can effectively reduce the production of the involvement type pores in the aluminum alloy die casting parts by combining with the experiences and problems of the existing degassing process method and respectively adopting the five process methods of process treatment of raw and auxiliary materials, treatment by a smelting device, refining and degassing process treatment, argon degassing process treatment and molten solution treatment.

Owner:WUJIANG TIANLONG MACHINERY

Road weather hazard system

ActiveUS9401089B2Rainfall/precipitation gaugesArrangements for variable traffic instructionsVisibilityRadar

A method and system for assessing road conditions is provided. The method includes determining a road hazard condition for a road segment that may include a precipitation type, a pavement condition, and a visibility level. The precipitation type may be determined using radar data, satellite cloud classification data, weather station air temperature data, wiper status, mobile air data, speed ratio, or headlight status. The pavement condition may be determined using pavement temperature, precipitation type, automatic brake system status, traction status or a stability control observation, and a yaw rate. The visibility level may be determined using wind speed, relative humidity, percentage of fog lights on, percentage of high beams on, speed ratio, station visibility, station-reported visibility type, wildfire existence, wind direction, a dust existence indicator.

Owner:UNIV FOR ATMOSPHERIC RES

Classification method and classification system of precipitation types based on typhoon climate precipitation rate

ActiveCN109087020ALowering the Precipitation Rate ThresholdResourcesLower limitClassification methods

A method for classifying precipitation types based on the climate precipitation rate of typhoon includes detecting the descending water type at a time, obtaining a plurality of continuous samples Ri-N-Ri+n of precipitation rate at the time and in time intervals before and after the time; according to the precipitation types, the climate and the precipitation history records, the lower threshold, the difference threshold and the upper threshold of precipitation being set; according to the lower threshold, the difference threshold and the upper threshold, it is judged that the precipitation is stratus precipitation, convective precipitation or mixed precipitation. The invention fully takes into account that the raindrop spectrum characteristics of the precipitation caused by the difference in the formation mechanism between the precipitation in the rain belt of the Taiwan and the precipitation in other weather systems are different, and the raindrop spectrum characteristics are embodiedin the observation of the raindrop spectrum instrument on the ground.

Owner:SHANGHAI TYPHOON INST CMA

Rice direct-seeding planting method applicable to coastal mud precipitation type silty saline and alkaline land

PendingCN110122229AIncrease suspension fusionImprove lodging resistanceSeed and root treatmentAgriculture gas emission reductionFresh water organismOrganic fertilizer

The invention discloses a rice direct-seeding planting method applicable to coastal mud precipitation type silty saline and alkaline land. The method comprises the steps as follows: step 1, ploughingand field soaking with freshwater to wash salt and reduce alkali; step 2, application of organic fertilizer and rice seed soaking for germination acceleration; step 3, seeding after rotary tillage andleveling; step 4, later field management. A tractor driven rotary cultivator and a tractor driven leveling machine are adopted, the suspension blending amount of mud precipitation type silt is increased through turning and rotating of the rotary cultivator, mud suspensions are treated and stirred by the leveling machine, and rapid separation of water from soil is prevented. Then, a tractor drivenseeding and fertilizer broadcasting integrated machine is adopted to seed germination accelerated rice seeds before separation of mud, the rice seeds are covered with suspended muddy soil, normal seedling erection after rice direct-seeding planting in the mud precipitation type silty saline and alkaline land is realized and the lodging resistance capability of rice seedlings is improved.

Owner:江苏省沿海开发(东台)有限公司

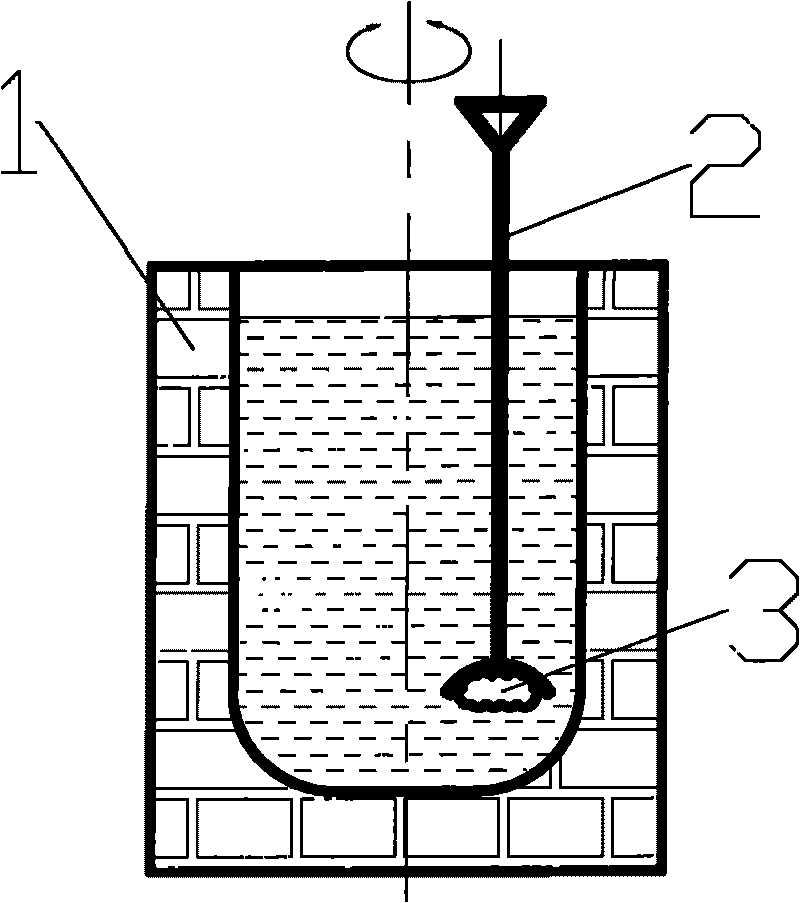

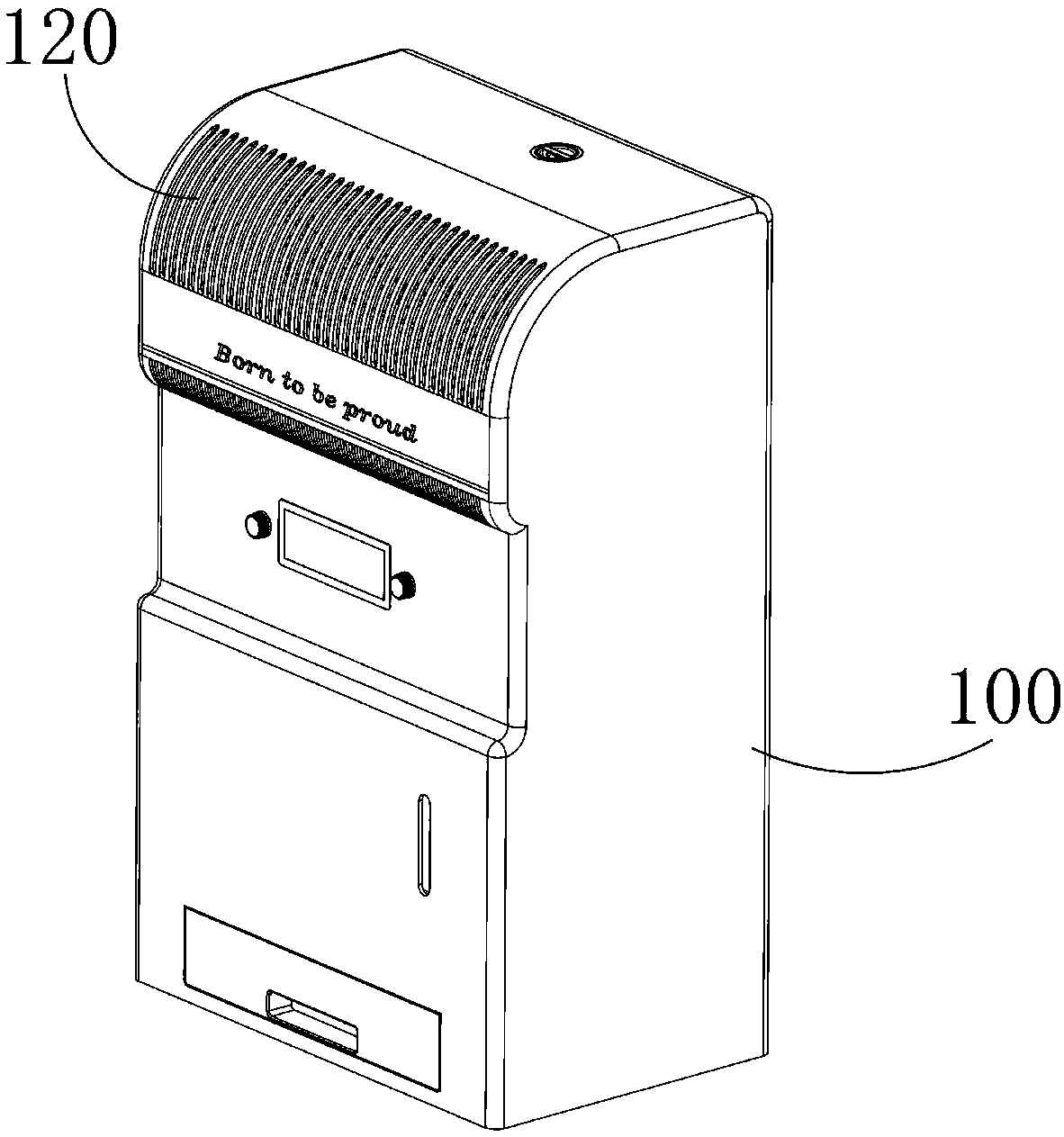

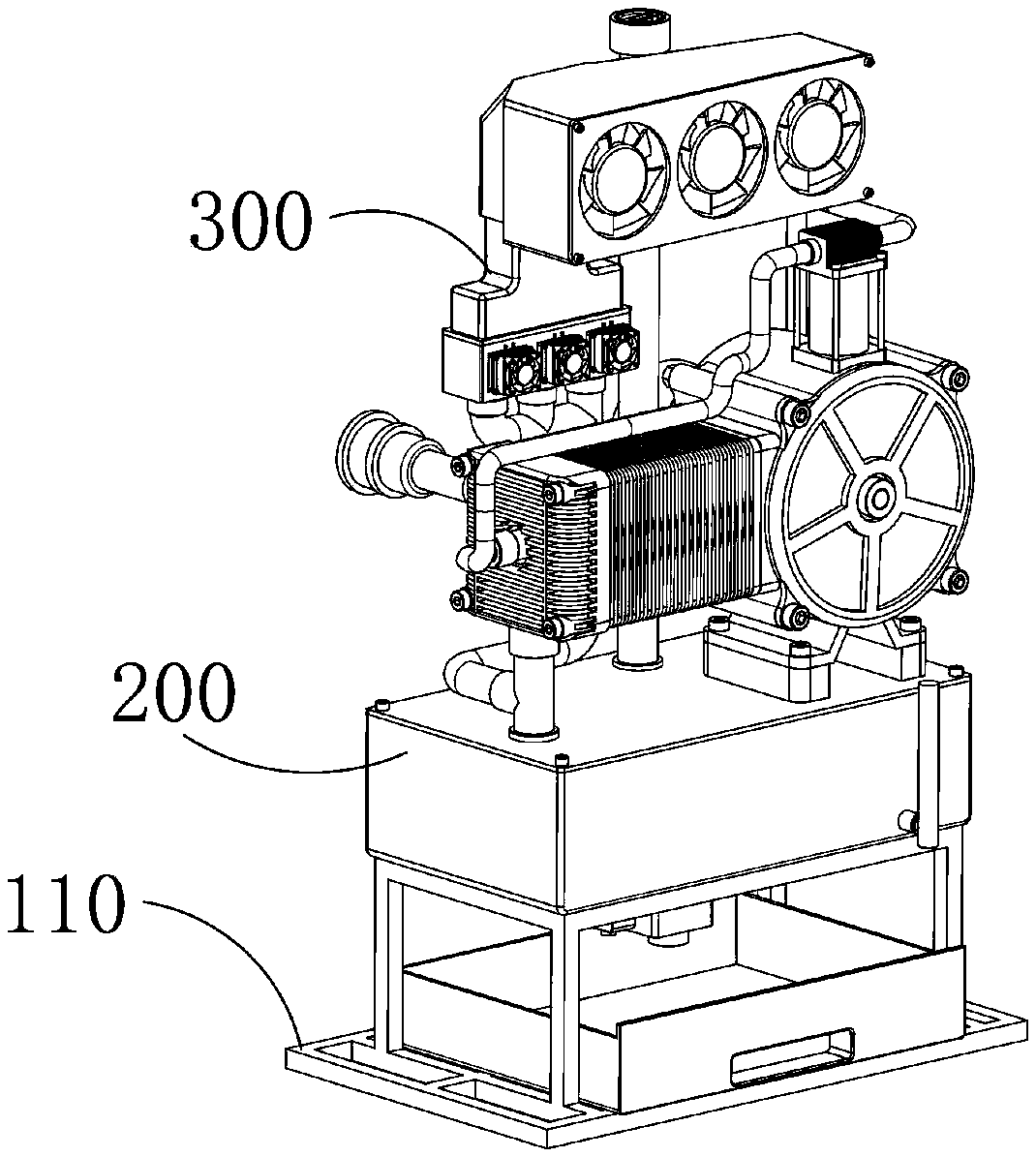

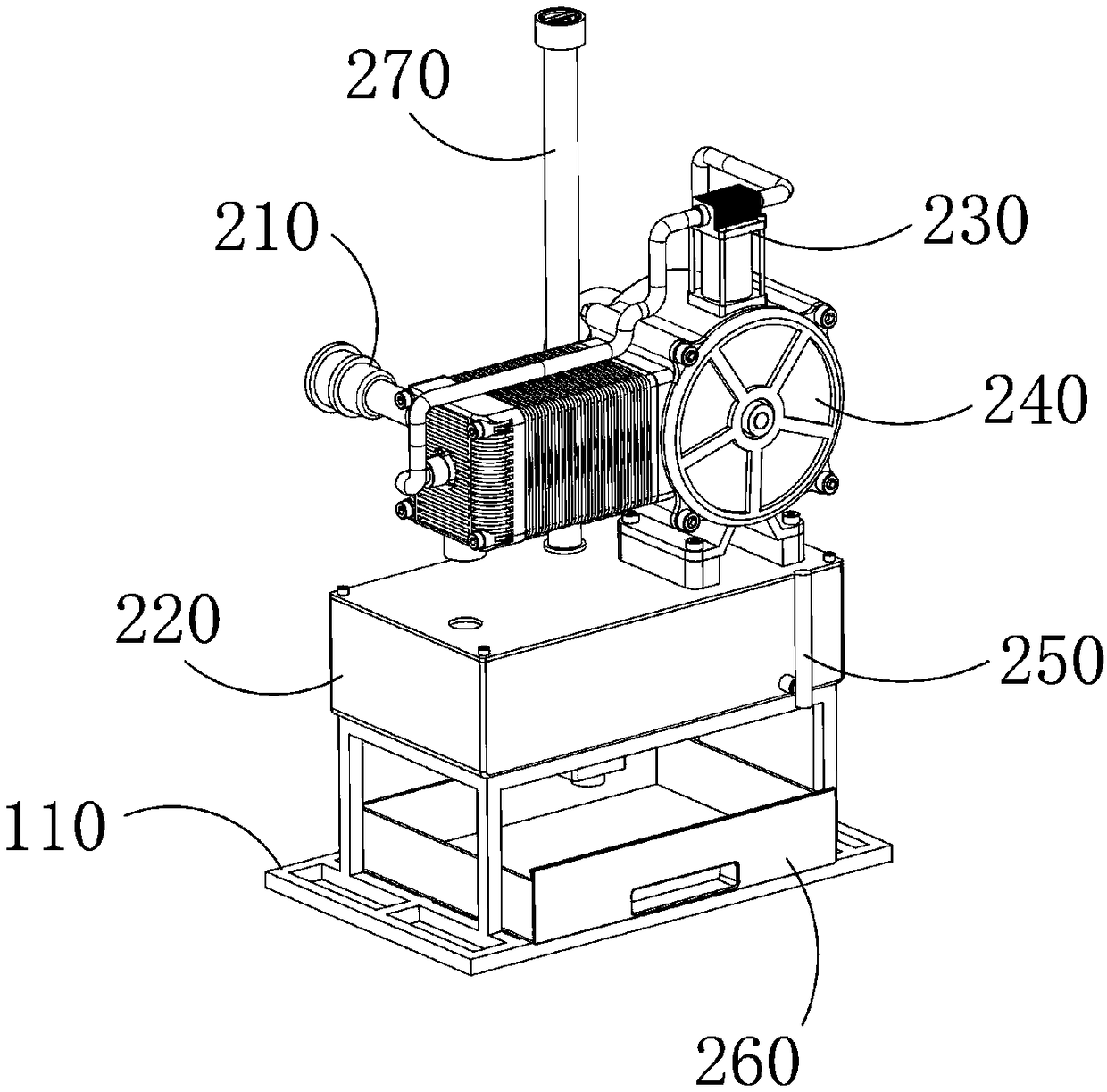

Artificial precipitation type air purifier

InactiveCN107029496AAchieve purificationReduce consumptionUsing liquid separation agentParticulatesAir purifiers

The invention relates to an air purifier, in particular to an artificial precipitation type air purifier which comprises a water vapor chamber and a condensation chamber, wherein the water vapor chamber is used for generating water vapor and forming haze, and the condensation chamber is used for condensing water vapor and forming rainfall. The water vapor chamber is provided with an air inlet and a water vapor port, the air inlet is used for inputting external air, the water vapor port is used for outputting water vapor, a hot water tank is arranged on the lower portion of the water vapor chamber, a heater is arranged in the hot water tank, the water vapor port of the water vapor chamber is communicated to the condensation chamber, namely, outputted water vapor enters the condensation chamber through the water vapor port, an air outlet for discharging purified air is formed in the upper portion of the condensation chamber, a condensation is arranged in the condensation chamber, a sewage tank is arranged on the lower portion of the condensation chamber, a sewage circulation channel is formed between the sewage tank and the hot water tank, and the hot water tank is provided with a sewage draining port for draining sewage. According to three elements of rainfall, as many particulates as possible in the air are absorbed by the aid of as less water consumption and energy consumption as possible, so that the air is purified.

Owner:JINHUA VOCATIONAL TECH COLLEGE

Water mist precipitation type method for purifying air in bedrooms of house

InactiveCN109011951APrevent moistureSimple and convenient replacement processUsing liquid separation agentWater storageWater storage tank

The invention discloses a water mist precipitation type method for purifying air in the bedrooms of a house. The method comprises following steps: operating a power mechanism to suck indoor air into apurifying zone of a cylinder; at the same time, pumping water, which has been filtered by a filter tip, in a water storage tank to a water storage zone of the cylinder; and keeping on operating the power mechanism to make water in the pump flow into the purifying zone of the cylinder. Pollutants in the air such as dust are precipitated by the water, at the same time, the power mechanism increasesthe pressure of the purifying zone, the mixture of water and air is discharged from a vent; the water-air mixture is discharged through an exhaust pipe network; the precipitates fall into the water storage tank through the vertical flow pipe of an exhaust T-branch pipe; purified air is rapidly distributed to the indoor space through a cooling mechanism and a blowing mechanism; a user opens an electromagnetic valve, sewage in the water storage tank is discharged into a sewage discharge box, then the sewage discharge box is taken out and inclined to discharge the sewage, and then new water is delivered to the water storage tank by a water inlet pipeline.

Owner:朱文祥

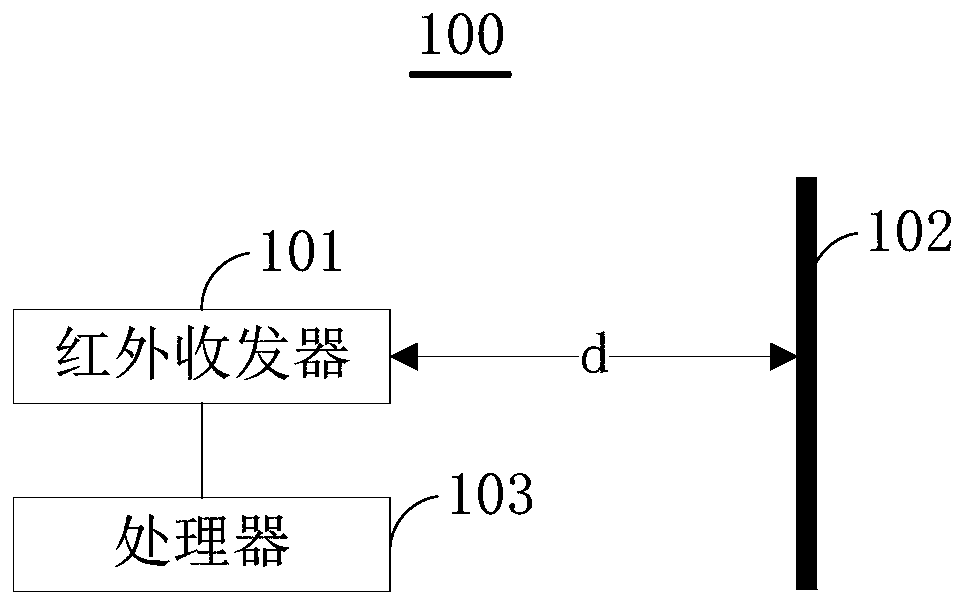

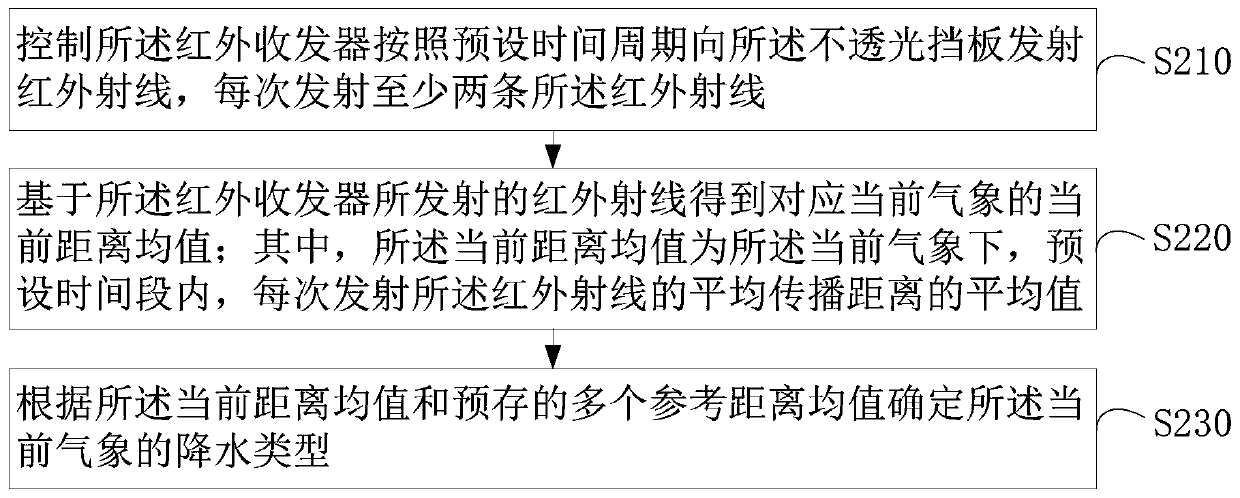

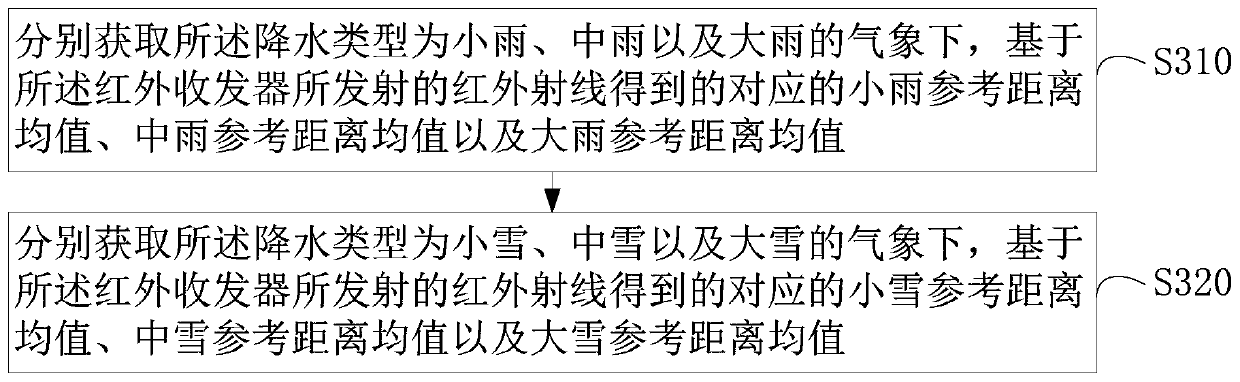

Rainfall type detection method, system and device, computer equipment and storage medium

InactiveCN111538112AReduce the difficulty of implementationShort detection cycleRainfall/precipitation gaugesTransceiverImage resolution

The invention relates to a rainfall type detection method, system and device, computer equipment and a storage medium. The method is applied to a rainfall type detection system, and the system comprises an infrared transceiver, a lightproof baffle and a processor. The method comprises the steps: controlling an infrared transceiver to emit infrared rays to a lightproof baffle according to a presettime period, and emitting at least two infrared rays every time; obtaining a current distance mean value corresponding to the current weather based on the infrared rays emitted by the infrared transceiver, wherein the current distance mean value is the mean value of the average propagation distances of the infrared rays emitted each time in a preset time period under the current weather; and determining the rainfall type of the current weather according to the current distance mean value and a plurality of pre-stored reference distance mean values. By adopting the method, the whole detection period can be shortened, the time resolution is high, the precipitation type detection method implementation difficulty is reduced, and the detection efficiency is improved.

Owner:上海眼控科技股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com