Method for stabilizing fly ash from refuse incineration by combination of complementary type medicaments

A technology for waste incineration fly ash and incineration fly ash, which is applied in the direction of solid waste removal, etc., can solve the problems of prolonged treatment time, increased consumption, complicated system, etc., and achieves flexible implementation, reduced treatment costs, and enhanced stabilization effect. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Embodiment 1: to the processing of the fly ash that dioxin content is lower than 3 μ g I-TEQ / kg, concrete steps are as follows:

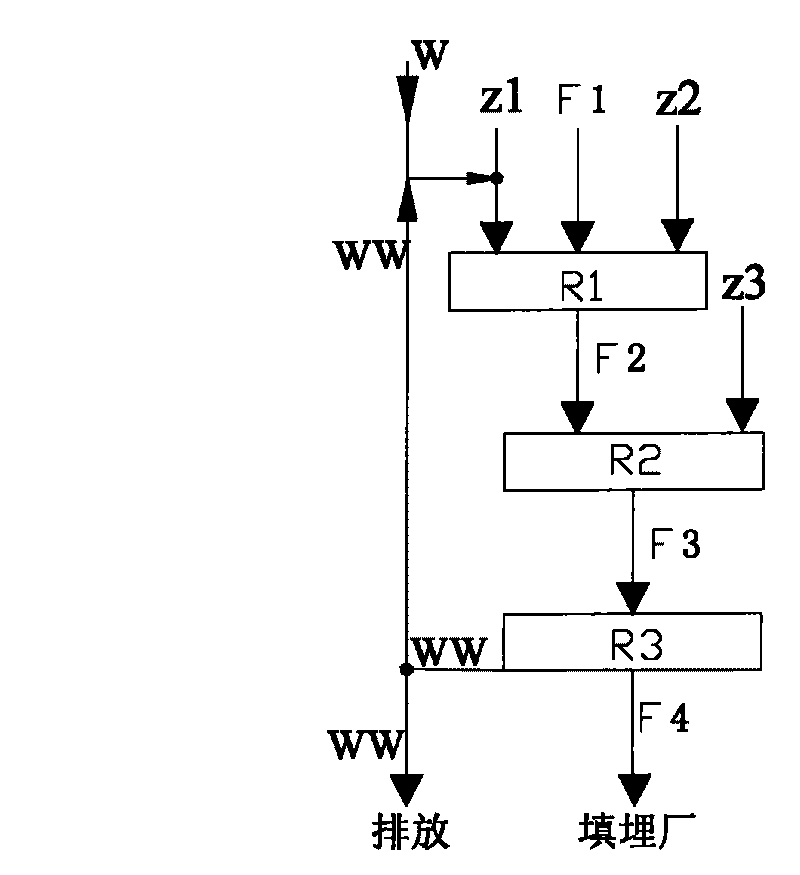

[0032] refer to figure 1 .

[0033] Step 1: Make a solution of a certain amount of class I agent z1 and water W, and mix it with fly ash F1; or mix F1, z1, and W directly. The mixture is opened to the air and stirred for a period of time, or the reactor R1 is blown into the air flow or the flue gas flow z2 for stirring to form the intermediate reactant F2.

[0034] z1 is ferrous salt or sulfide, or a mixture of iron powder and ferric oxygen salt; or a mixed agent that can rapidly produce ferrous ions in the liquid phase;

[0035] Step 2: Add the solution of Class II agent z3 continuously to the gray water mixture reactor R2 within 0.5-2h to mix with F2. R2 and R1 can be the same reactor or two separate reactors. Or R1 is the first half of the reactor and R2 is the second half of the reactor. z3 can be TMT, thiourea or other soluble organi...

Embodiment 2

[0043] Its technological process is as embodiment 1, and above-mentioned incineration fly ash of a certain incineration plant in East China, its dioxin content is 0.7 μ gI-TEQ / kg, detect heavy metal Pb according to leaching HJ / T299 leaching method, Cd exceeds toxicity leaching identification standard. Adopt method of the present invention here, the first step makes it mix with sodium sulfide solution, the consumption of sodium sulfide is 16.4kgS / ton 干灰 After vigorously stirring with air flow for 30 minutes, in the second step, add a solution made of TMT equivalent to 0.55% wt of fly ash, and mix evenly. The final liquid-solid ratio is 0.86:1, without liquid-solid separation. Curing and drying until the water content is below 30%, the leaching test is carried out according to the method of standard HJ / T 300, see Table 2, all indicators meet the requirements of GB16889-2008, and can be directly sent to the domestic waste landfill for separate landfill.

[0044] Table 2 Example ...

Embodiment 3

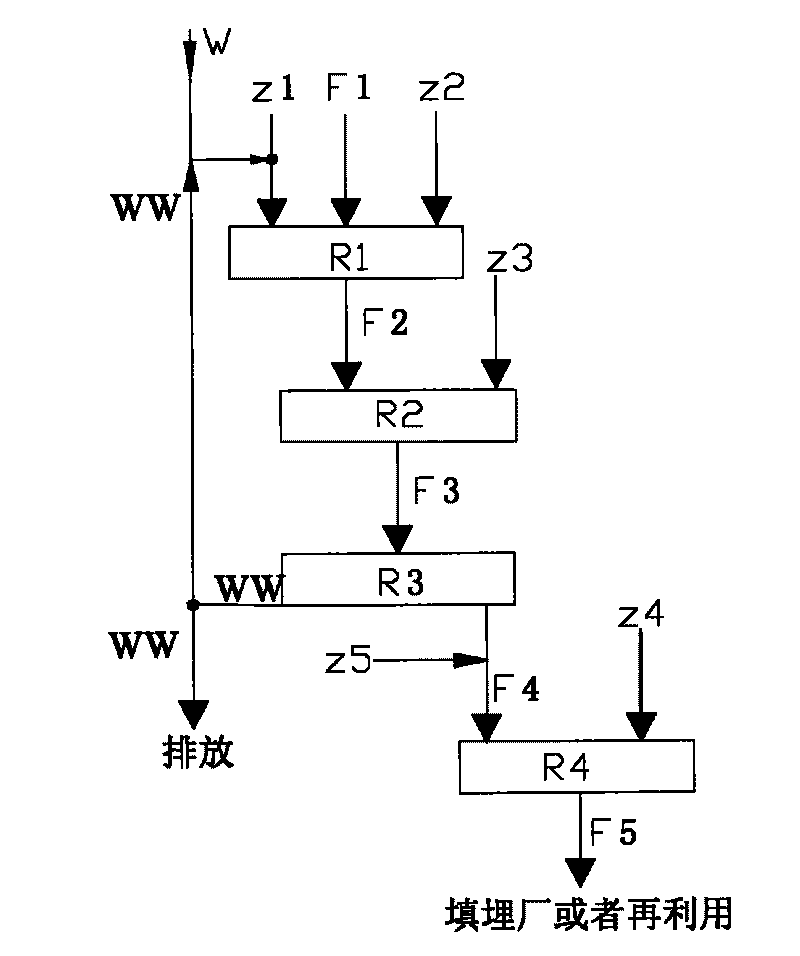

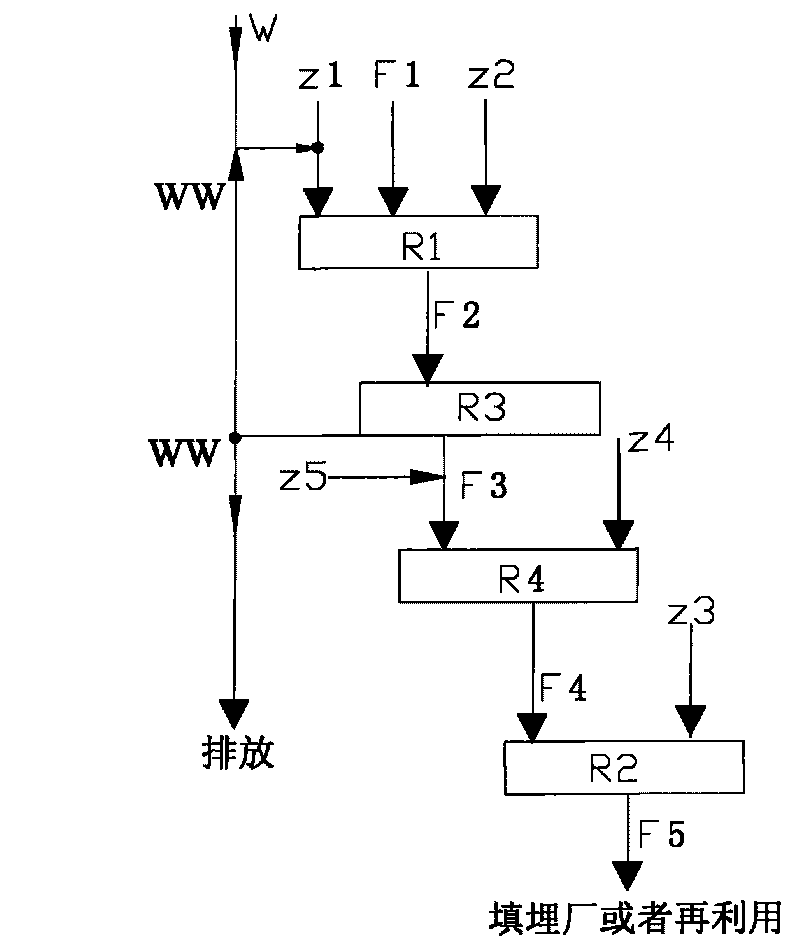

[0050] Its technological process is as embodiment 1, and above-mentioned incineration fly ash of a certain incineration plant in East China, its dioxin content is 0.7 μ gI-TEQ / kg, detect heavy metal Pb according to leaching HJ / T299 leaching method, Cd exceeds toxicity leaching identification standard. Adopt the method of the present invention, the first step makes it mix with iron powder and ferric sulfate solution that scrap iron is made, and the mol ratio of iron powder and ferric sulfate is 1.2: 1, the mixing of final iron powder and ferric sulfate makes total iron consumption 120kgFe / ton of fly ash, after vigorous stirring with air flow for 60min (pay attention to the timely discharge of gas and good ventilation during the process), the second step is to add a solution made of TMT equivalent to 0.1% wt of fly ash, and the final liquid-solid The ratio is 2.5:1, after stirring to make it evenly mixed; the third step is liquid-solid separation, and 2 / 3 of the separated process...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com