Patents

Literature

838 results about "Ferric hydroxide" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

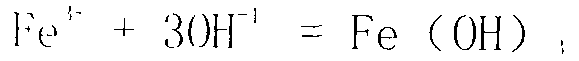

Ferric Hydroxide is usually prepared from a chemical reaction between ferric chloride and sodium hydroxide or it can also be obtained from oxidation of ferrous iron to ferric iron which further reacts with water to form iron hydroxide as a precipitate.

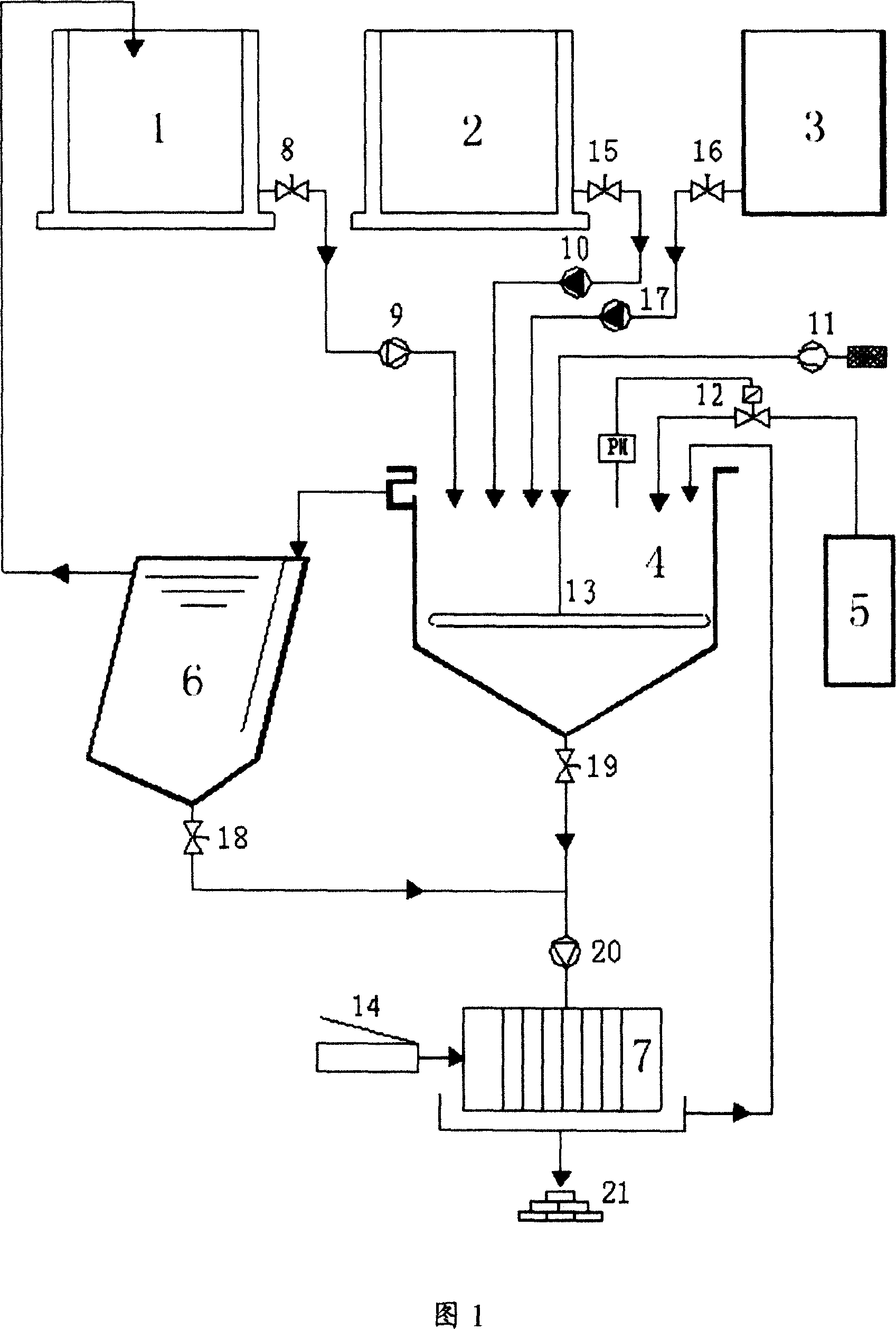

Multiple element composite metal oxidate arsenic removal settling agent and use method thereof

The invention belongs to the material field for removing the arsenic in water by settlement, more particularly relates to polyelement composite metal oxide arsenic removal settlement agent and an application method thereof based on iron oxide, manganese oxide, and aluminum oxide. The invention uses an ectopic preparation method or situ preparation method for preparing and obtaining polyelement composite metal oxide arsenic removal settlement agent which comprises hydrated iron oxide, hydroxyl-hydrated ferric hydroxide, hydrated aluminum oxide, hydroxyl-hydrated alumina, hydrated manganese oxide and the like. The polyelement composite metal oxide arsenic removal settlement agent can be used for removing the arsenic pollutants in water bodies such as lakes, reservoirs, rivers, groundwater, drinking water, industrial waste water, and the like; in addition, the settlement agent can also be used for removing the heavy metals such as copper, chromium, cadmium, lead, and the like, and the pollutants such as iron, manganese, phosphates, and the like in water by settlement.

Owner:RES CENT FOR ECO ENVIRONMENTAL SCI THE CHINESE ACAD OF SCI

Synthesis of high molecular weight iron-saccharidic complexes

A process for preparing parenteral iron-saccharidic complexes, and the complexes produced, comprising: (1) providing an aqueous solution or dispersion including (i) Fe(III) and (OH)− ions and (ii) at least one saccharide, to form a reaction mixture, where the molar ratio of (i): (ii) is about 30:1 to about 1:30; and the mixture temperature and pH are at or above the complex assembly point (CAP); and (2) maintaining temperature and pH at or above the CAP for a time sufficient to form an iron-saccharidic complex having a molecular weight of about 25,000 Daltons or more. Control of the temperature and pH efficiently produces a high molecular weight complex. The complex can be separated by precipitation, dialysis and / or column fractionation and, if desired, dried, e.g., lyophilized or spray dried. The process can controllably synthesize complexes of varying molecular weight and / or chemical composition, particularly sodium ferric gluconate and ferric hydroxide-sucrose.

Owner:CHROMACEUTICAL ADVANCED TECH

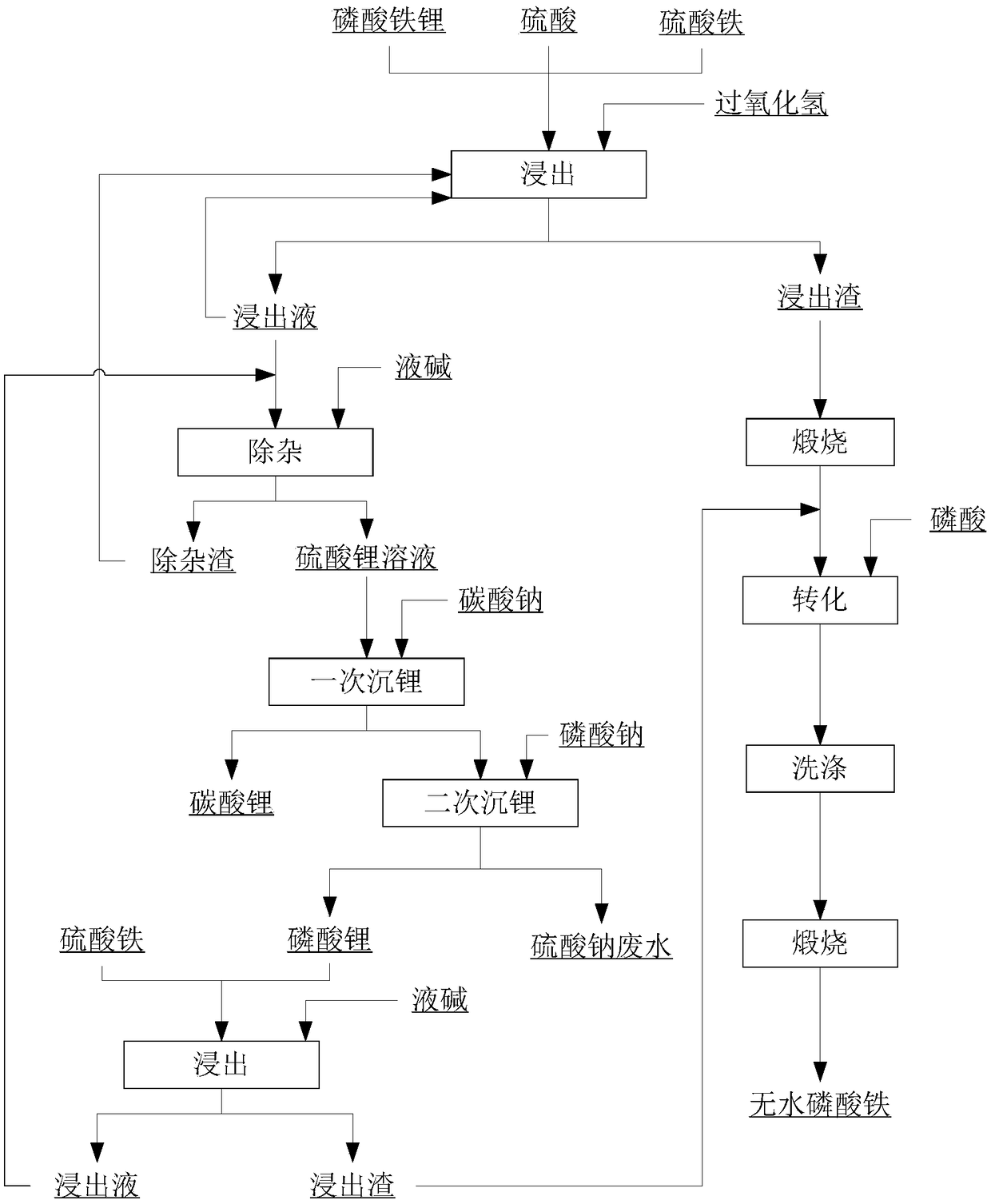

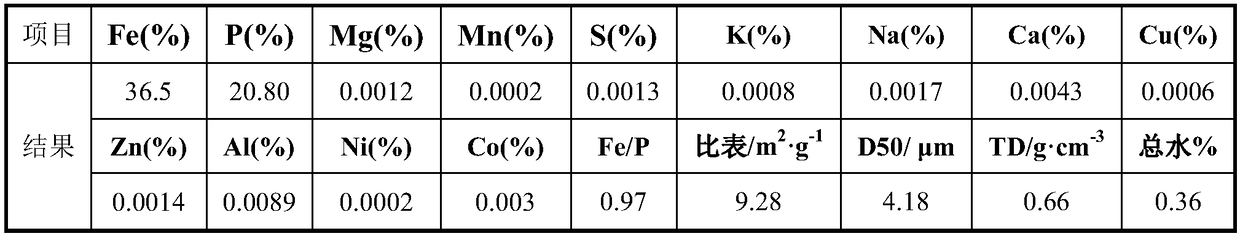

Method for recovering lithium from lithium iron phosphate

ActiveCN108899601ADoes not affect the leaching rateHigh purityWaste accumulators reclaimingProcess efficiency improvementFerric hydroxideIron sulphate

The invention discloses a method for recovering lithium from lithium iron phosphate. The method disclosed by the invention comprises the following steps: dissolving waste lithium iron phosphate slag with sulfuric acid and ferric sulfate, leaching iron, lithium and phosphorus, adding an oxidizing agent, reacting iron and phosphate radicals to produce an iron phosphate precipitate and a small amountof ferric hydroxide, converting lithium into a water-soluble lithium sulfate solution, filtering to obtain the lithium sulfate solution, adding sodium carbonate into the lithium sulfate solution to prepare a lithium carbonate product, and adding sodium phosphate or phosphoric acid to prepare lithium phosphate; dissolving the lithium phosphate with ferric sulfate again to obtain the lithium sulfate solution and a compound taking iron phosphate as a principle component, returning the lithium sulfate solution to the system to prepare lithium carbonate, and calcining the iron phosphate slag to remove organic matters and carbon in the slag; and slurrying to prepare cell grade iron phosphate. According to the method for recovering lithium from lithium iron phosphate disclosed by the invention,the lithium is totally converted into the product lithium carbonate in the method, the process flow is short, the cost is low, the lithium recovery rate is 97%, the metal lithium in the lithium iron phosphate can be effectively recovered, and all the slag is converted into the cell grade iron phosphate.

Owner:취저우화여우코발트뉴머터리얼컴퍼니리미티드 +1

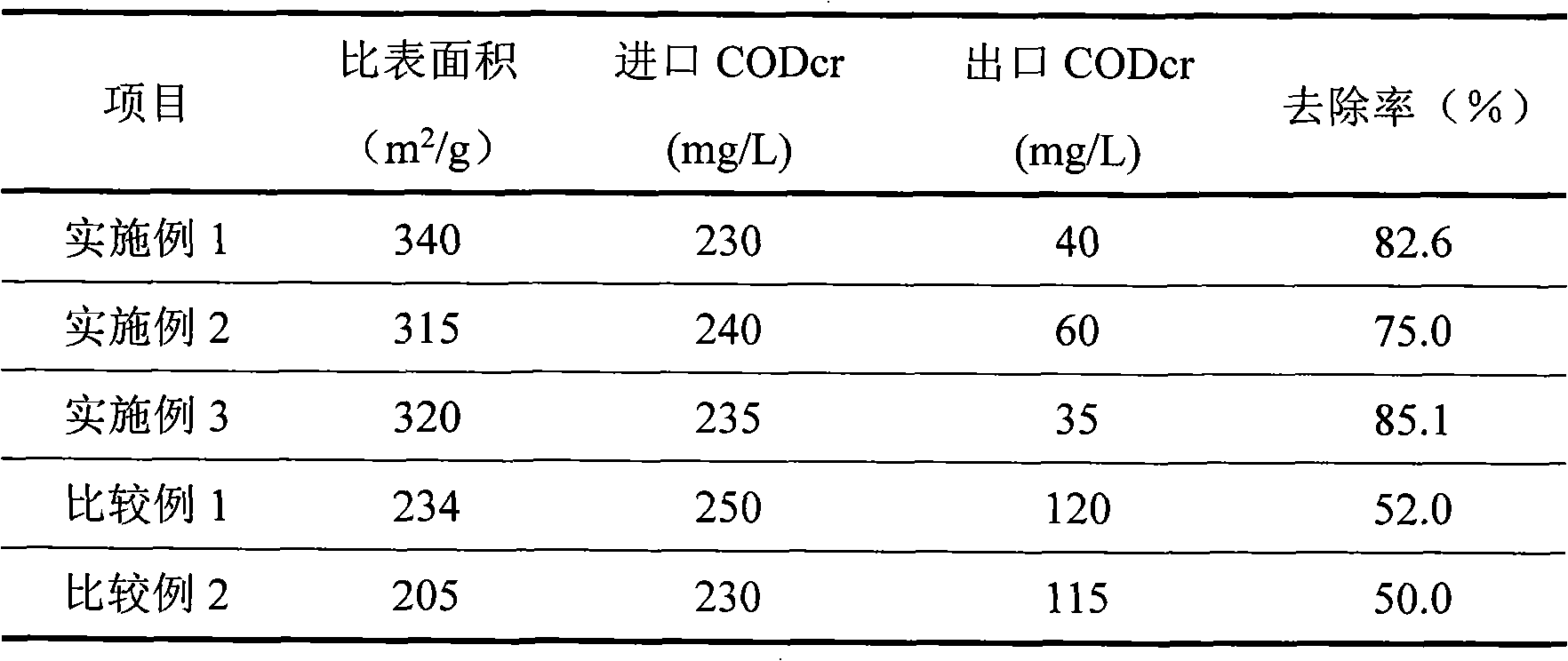

Preparation method of ozone catalytic oxidation catalyst used for treating oil refining waste water

ActiveCN101982237ASimple preparation stepsSuitable for industrial scale-upMetal/metal-oxides/metal-hydroxide catalystsWater/sewage treatment by oxidationParticulatesFerric hydroxide

The invention relates to a preparation method of ozone catalytic oxidation catalyst used for treating oil refining waste water. Amorphous aluminium oxide powder and ferric hydroxide powder are mixed by dry basis weight ratio of 100: 1-30, and rolling pelleting, maintaining, drying and roasting are carried out, thus obtaining the finished product catalyst. The method includes the following steps: (a) amorphous aluminium oxide and ferric hydroxide powder are mixed to be uniform; (b) the mixture is placed into a rotary pelleting machine, binder is sprayed, and rolling pelleting is carried out, the binder is sprayed in solution or colloid form in an atomizing way, and the amount of binder sprayed into the pelleting machine is 2-50% of total mass of amorphous aluminium oxide; and diameter of pelleting is controlled to be 1-8mm; (c) particle matter is maintained for 3-24 hours under the condition that temperature of water vapour is 100-110 DEG C; (d) catalyst is dried, drying temperature is 50-180 DEG C, drying time is 2-10 hours, and then roasting is carried out; and roasting temperature of catalyst is 400-600 DEG C, roasting time is 2-8 hours, and finished product catalyst is obtained.

Owner:CHINA NAT OFFSHORE OIL CORP +2

Method for simultaneously removing phosphorous and nitrogen through synergistic effect of nanoscale-iron and microbes

ActiveCN103803703AEnriched nanovoidsTreatment with anaerobic digestion processesParticulatesFerric hydroxide

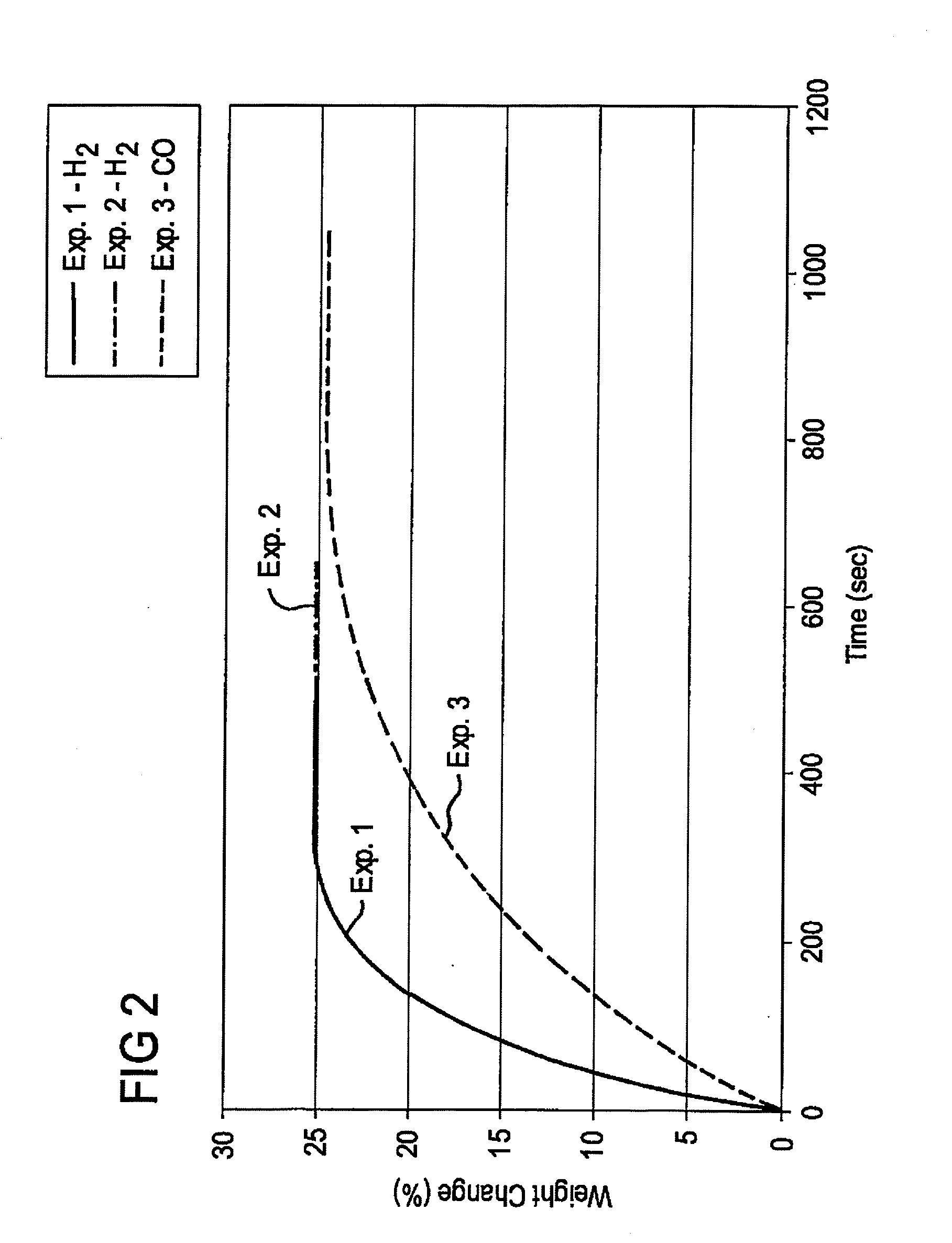

The invention provides a method for simultaneously removing phosphorous and nitrogen through the synergistic effect of nanoscale-iron and microbes. The method is characterized in that firstly limonite ore is broken and sieved so as to obtain particulate materials with the required particle size, the particulate materials mainly comprising nanoscale iron and having millimeter particle size and the porous structure characteristic are prepared through high temperature reduction under a hydrogen or carbon monoxide atmosphere, the nanoscale iron in the particulate materials slowly release nascent hydrogen atoms and hydrogen gas, and nitrate is chemically reduced; meanwhile, the particulate materials have relatively high void ratio, and abundant function anaerobic microbe denitrifying bacteria adhere to the inner parts and the outer surfaces of the particulate materials and reduce the nitrate by using hydrogen released through reaction between the nanoscale-iron and water as electron donors; adherent dependent nitrate iron-oxidizing bacteria also have the effect of reducing the nitrate; the nitrate in wastewater is removed under the chemical action of the nanoscale-iron and the synergistic effects of the anaerobic microbes; ferrous and ferric hydroxides are continuously formed on the inner surfaces and the outer surfaces of the porous particulate materials through the chemical reaction of the nanoscale-iron and water and the synergistic effect of the anaerobic microbes, so that the chemical adsorption of phosphorous in water is promoted, thus the effect of simultaneously removing phosphorous and nitrogen is achieved.

Owner:HEFEI UNIV OF TECH

Iron-dextran compound for use as a component in a therapeutical composition for prophylaxis or treatment of iron-deficiency

An iron-dextran compound for parenteral treatment of iron-deficiency anemia comprises hydrogenated dextran having a weight average molecular weight (Mw) between 700 and 1,400 Daltons, preferably approximately 1,000 Daltons, a number average molecular weight (Mn) of 400 to 1,400 Daltons and wherein 90% by weight of the dextran has molecular weights less than 2,700 Daltons and the Mw of the 10% by weight fraction of the dextran having the highest molecular weights is below 3,200 Daltons, said hydrogenated dextran having been subjected to purification by membrane processes having a cut-off value between 340 and 800 Daltons, in stable association with ferric oxyhydroxide. The compound is produced by using membrane processes to eliminate dextrans of higher molecular weights than approximately 2,700 Daltons and membrane processes to remove saccharides of molecular weights below approximately 340 Daltons from hydrogenated dextran before precipitating ferric hydroxide in the presence of said dextran followed by heat treatment and purification.

Owner:PHARMACOSMOS HLDG

Method of comprehensively utilizing serpentine

InactiveCN101235440ATake advantage ofFull controlSilicon oxidesProcess efficiency improvementFerric hydroxideSoluble glass

The invention relates to a method for comprehensively utilizing serendipities, which comprises: magnetically separating the serpentinites in a strong magnetic field, obtaining amorphous silica powder which contains silicon dioxide more than 90% through filtering acid dipping solution, dissolving the amorphous silica powder through using caustic soda under high temperature, which is used for manufacturing soluble glass with medium high modulus or taken as raw materials for producing white carbon black, then, mixing sulphuric acid and hydrochloric acid or nitric acid or mixing the sulphuric acid, the hydrochloric acid and nitric acid, adding acid dipping additive to carry out compound alternative and circulating acid dipping for ore powder which is magnetically separated and processed, fractionally depositing, filtering, and removing impurity for magnesium sulfate solution which is filtered through the acid dipping and contains the impurity, through adjusting the pH value, obtaining inorganic industrial dyes which mainly contain iron oxide yellow, ferric hydroxide and aluminum hydroxide, enriching the nickel, which is convenient for abstracting the nickel from the serpentinites, finally obtaining high purity magnesium oxide through refining refined magnesium sulfate solution whose impurity is removed after ammonium hydrogen carbonate and ammonial solution or sodium sulfide is used to deposit, and also obtaining ammonium sulfate or sodium sulfate which contains magnesium and calcium after liquid which is filtered is evaporated.

Owner:刘湘霖 +1

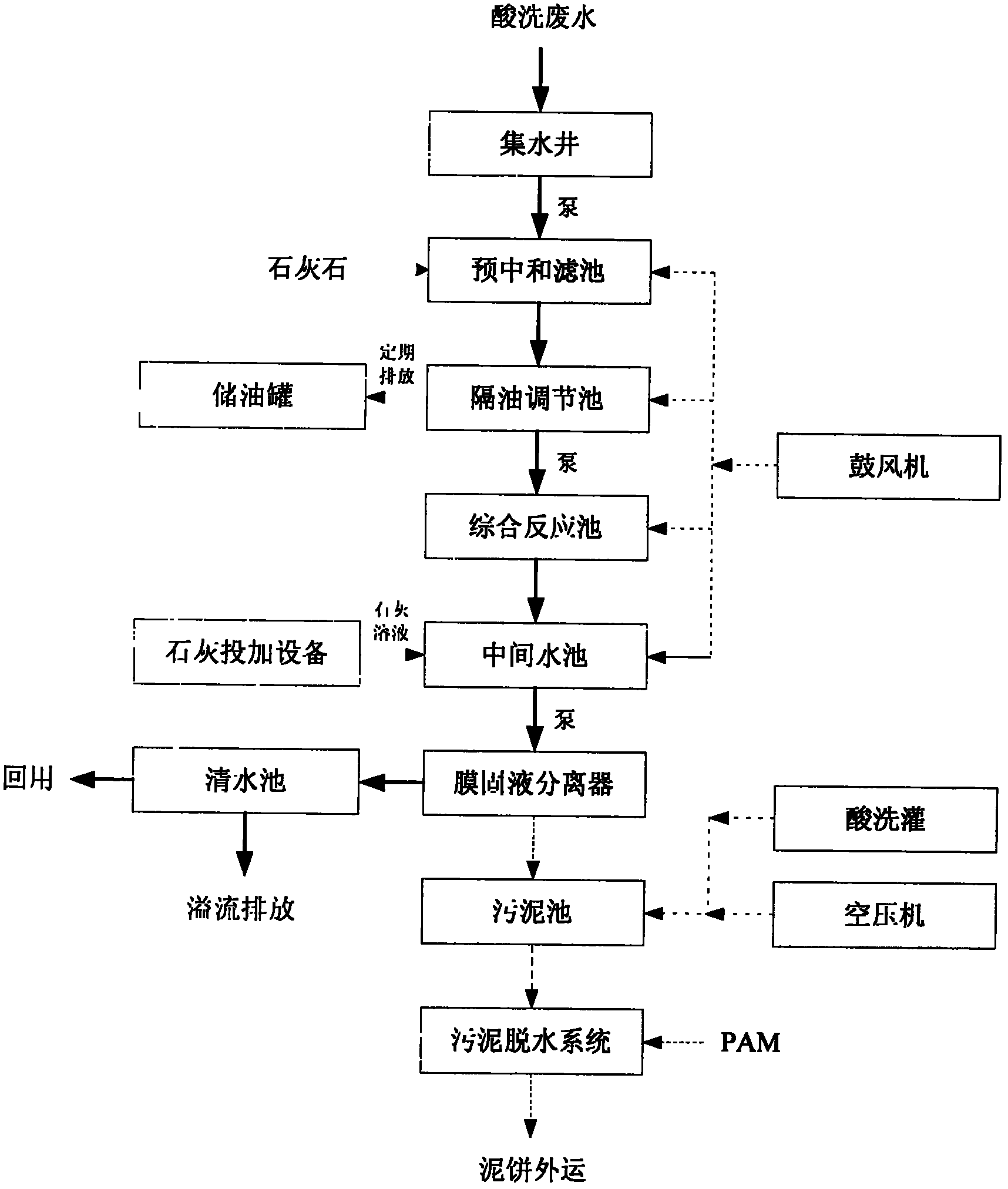

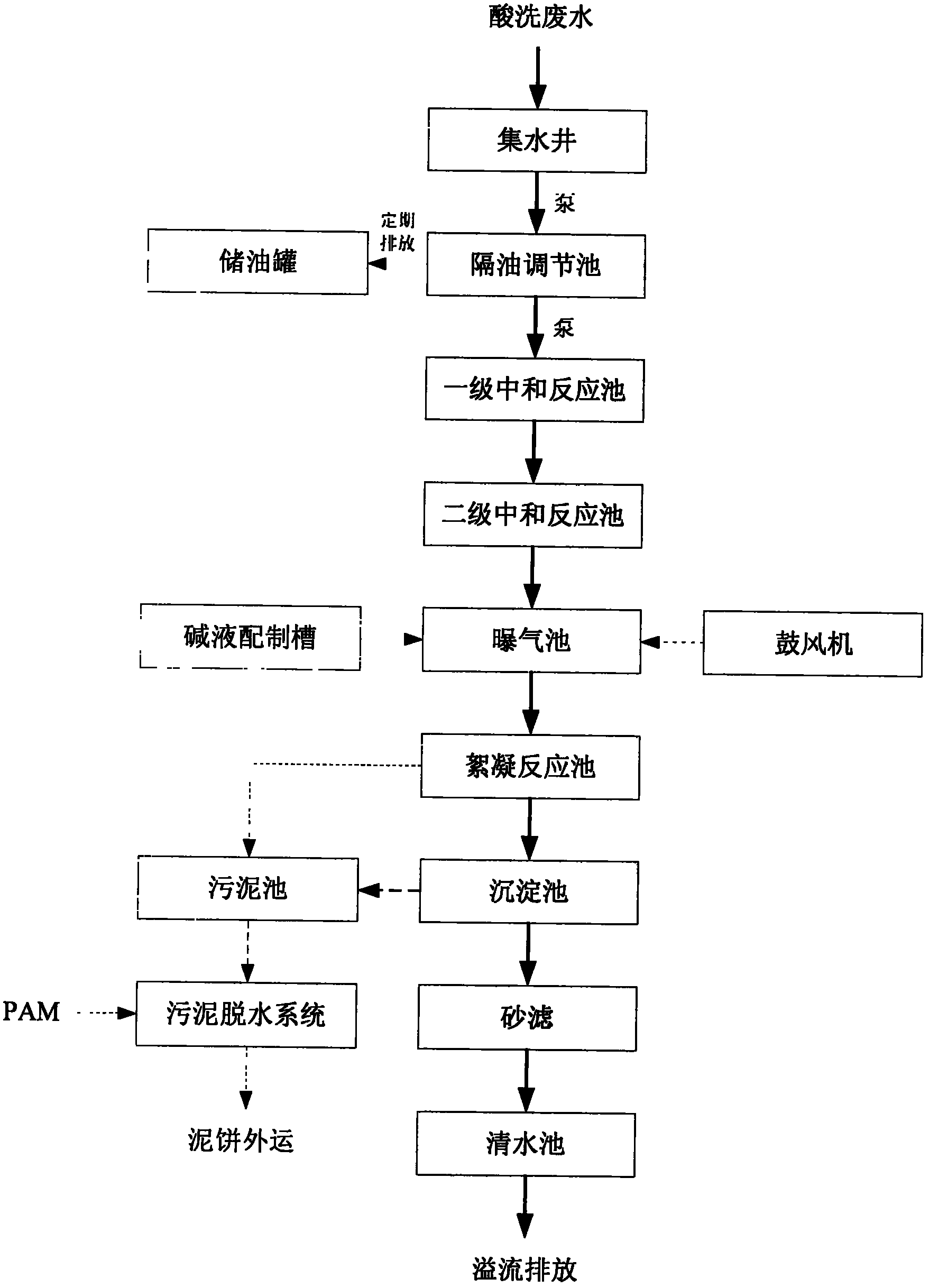

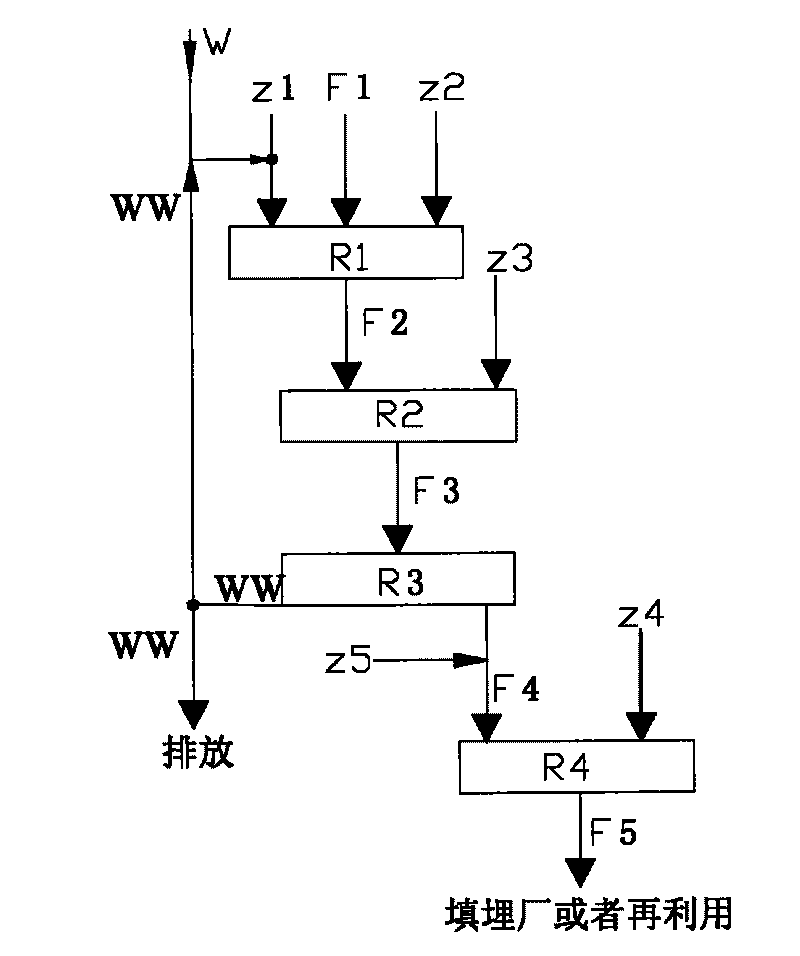

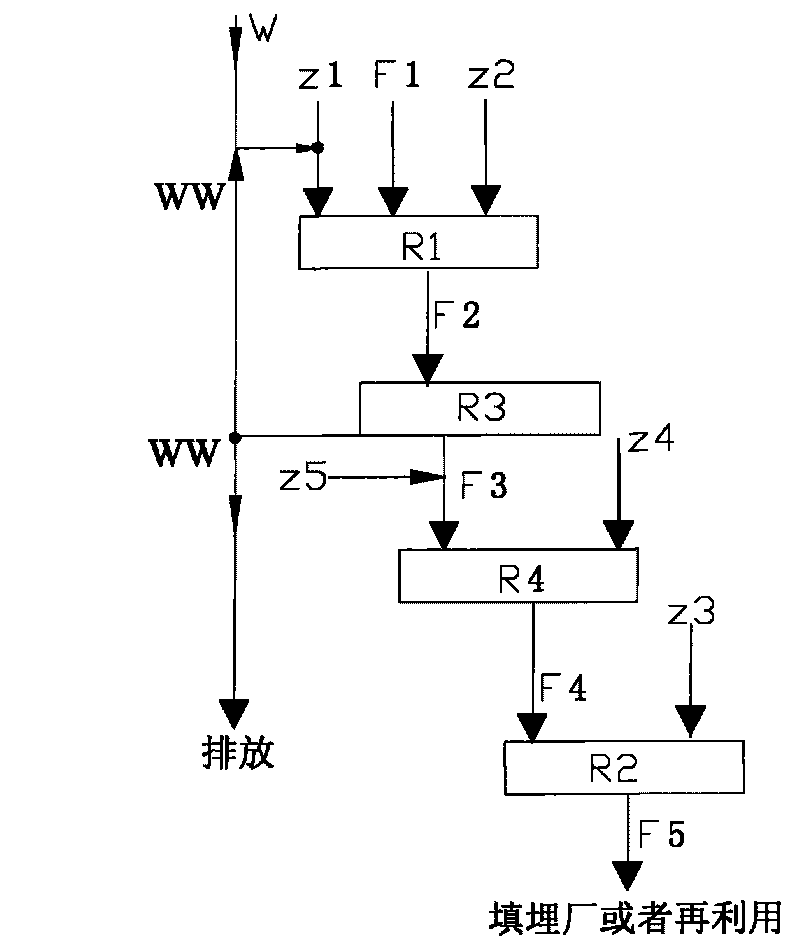

Method for treating acid-washing wastewater and metallic ions in iron and steel industry

InactiveCN102107963ALow running costGuaranteed uptimeWater contaminantsMultistage water/sewage treatmentFerric hydroxideZinc hydroxide

The invention provides a method for treating acid-washing wastewater and metallic ions in iron and steel industry, which comprises steps as follows: acid-washing wastewater naturally flows into a water collecting well and enters a preneutralization filter chamber under the elevation action of a pump, the preneutralization filter chamber is provided with 10-200mm limestone which is in a graded distribution mode, and after the acid-washing wastewater is preneutralized by the limestone, the pH value of the effluent water is controlled at 5-6, wherein the method provided by the invention greatly lowers the chemical expenses and operating cost as compared with the conventional method of directly adding an alkali solution; the acid-washing wastewater, which is subjected to initial pH value regulation, naturally flows into an oil separation regulating chamber, so that iron ions in the wastewater react with the alkali solution to form a precipitation mixture of ferric hydroxide, zinc hydroxide and the like; and the wastewater is elevated into a membrane solid-liquid separator to complete solid-liquid separation, so that the wastewater can be discharged after reaching the standard. The invention thoroughly solves the problems that the precipitate can not easily settle, the iron can not be easily removed, and the iron ions are dissolved out. The invention has the advantages of simple technique, high economy, low requirements for technical levels of workers, and high controllability, is reliable to operate, and has wide market prospects.

Owner:TIANJIN ACADEMY OF ENVIRONMENTAL SCI

Method for selective solvent extraction of heterogenite with full-wet-process

InactiveCN101509069ATake advantage ofProcess efficiency improvementFerric hydroxideReaction temperature

The invention relates to a method for selectively leaching heterogenite, which is based on the whole wet method and characterized in that the method comprises the following steps: ball-milling and pulping heterogenite minerals until the requirement that the particle size is smaller than 150 meshes is met; putting the heterogenite minerals into concentrated sulfuric acid, concentrated hydrochloric acid or a mixed solution of both the concentrated sulfuric acid and the concentrated hydrochloric acid; adding a reducing agent containing ferrous ions to carry out reduction reaction for 5 to 9 hours under the conditions that the pH value of the solution is 1.0 to 2.0 and the reaction temperature is 60 to 90 DEG C; sampling and detecting, and stopping adding the reducing agent when the content of Cobalt in the residue is lower than 0.5% and the content of the ferrous ions in the solution is lower than 2.0g / L; adding sodium chlorate or hydrogen peroxide as an oxidizing agent, or pumping air into the solution, to oxidize the residue ferrous iron into ferric iron; adding sodium carbonate to the solution to adjust the pH value of the solution to 2.5 to 4.5; reacting for 2 to 3 hours, to precipitate the ferric iron in the form of ferric hydroxide; and leaching the waste residue after the reaction. The invention has the advantages of low production cost and low environmental pollution level.

Owner:南通新玮镍钴科技发展有限公司

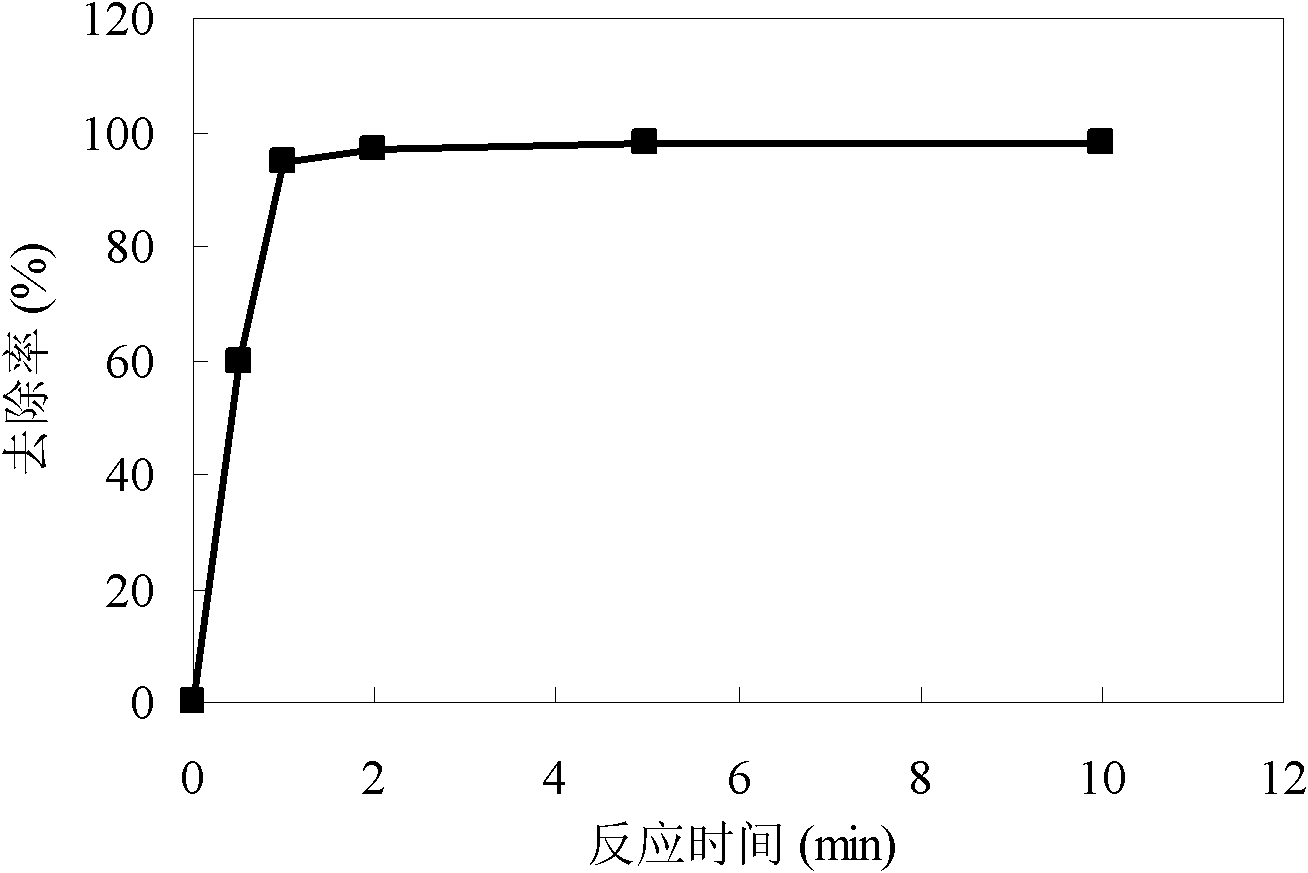

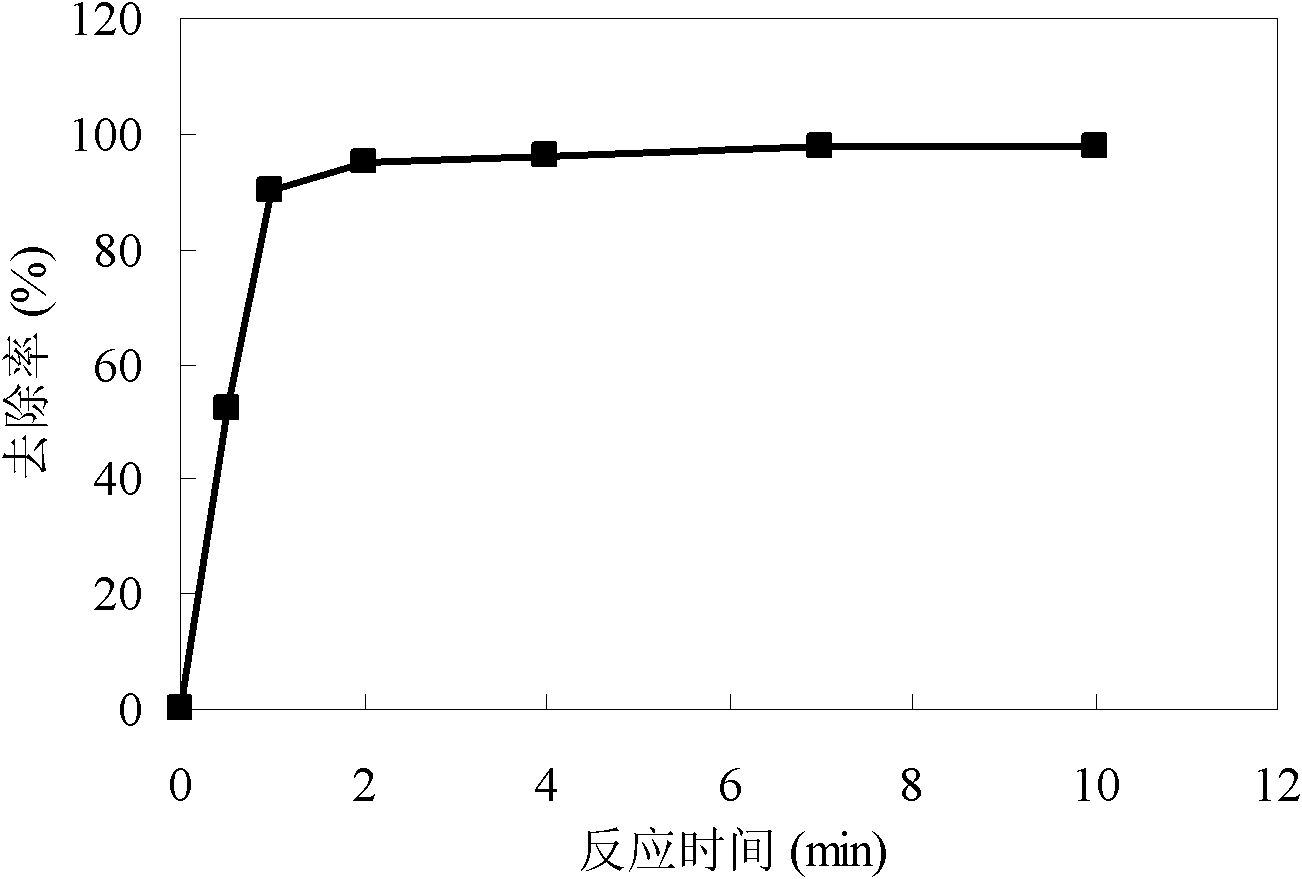

Water treatment method for removing Tl<+> and/or Cd2<+> by producing nanometer iron and manganese oxides in situ

ActiveCN102145947AHigh electronegativityLarge specific surface areaWater contaminantsMultistage water/sewage treatmentFerric hydroxideWater source

The invention discloses a water treatment method for removing Tl<+> and / or Cd2<+> by producing nanometer iron and manganese oxides in situ, relating to a water treatment method of thallium and / or cadmium-containing source water and solving the problems of complex process, high running cost and low removing efficiency of thallium and / or cadmium existing in the conventional water treatment technology specific to thallium and / or cadmium-polluted source water. The method comprises the following steps of: adding permanganate and ferrous salt into Tl<+> and / or Cd2<+>-containing water; stirring to obtain a mixed solution; adding a coagulant; and performing conventional water treatment. A nanometer ferric hydroxide-manganese dioxide oxide composite adsorbent which has a large specific surface area and high electronegativity and is easy for precipitation separation is produced in situ by making permanganate react with the ferrous salt, so that Tl<+> and / or Cd2<+> can be removed effectively andspecifications in the national Sanitary Standard for Drinking Water are met. The method has the advantages of high removing efficiency, simple process, flexibility and convenience for operation, no change of the original treatment process of a water plant, low running cost and the like, and can be applied to emergency treatment of a water pollution event.

Owner:HARBIN INST OF TECH

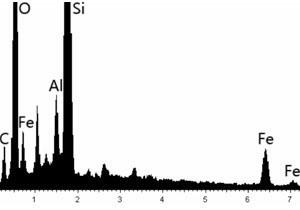

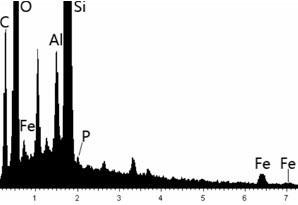

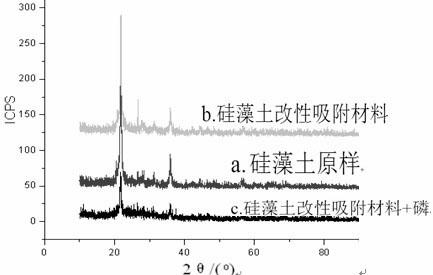

Kieselguhr modified adsorption material and preparation method and application thereof

InactiveCN102091591ASimple preparation processLow costOther chemical processesWater/sewage treatment by sorptionSolubilityFerric hydroxide

The invention discloses a kieselguhr modified adsorption material and a preparation method and application thereof. The kieselguhr modified adsorption material is formed by directly loading ferric hydroxide solution on the acid-washed pretreated raw kieselguhr and drying the kieselguhr. Through the kieselguhr modified adsorption material, the modified kieselguhr micropores and the surface roughness are obviously changed, the specific surface area is enlarged by 10 times, H<+> of ferric hydroxide loaded on the kieselguhr has extremely strong affinity with O<2-> in the structure in the solution of low pH value range, and Fe<3+> is released to the solution, so that the solubility of the adsorption material is increased, the adsorption capacity is enhanced, and the adsorption material is suitable for decontamination research of meta-acid water and has potential application value in the treatment of eutrophic water of Pearl River valley. The preparation method for the kieselguhr modified adsorption material is convenient for operation, simple in process and low in cost. The kieselguhr modified adsorption material is convenient and practical in application.

Owner:GUANGDONG UNIV OF TECH

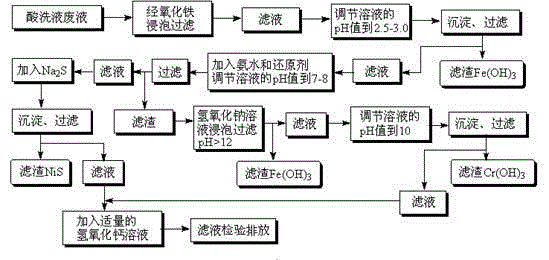

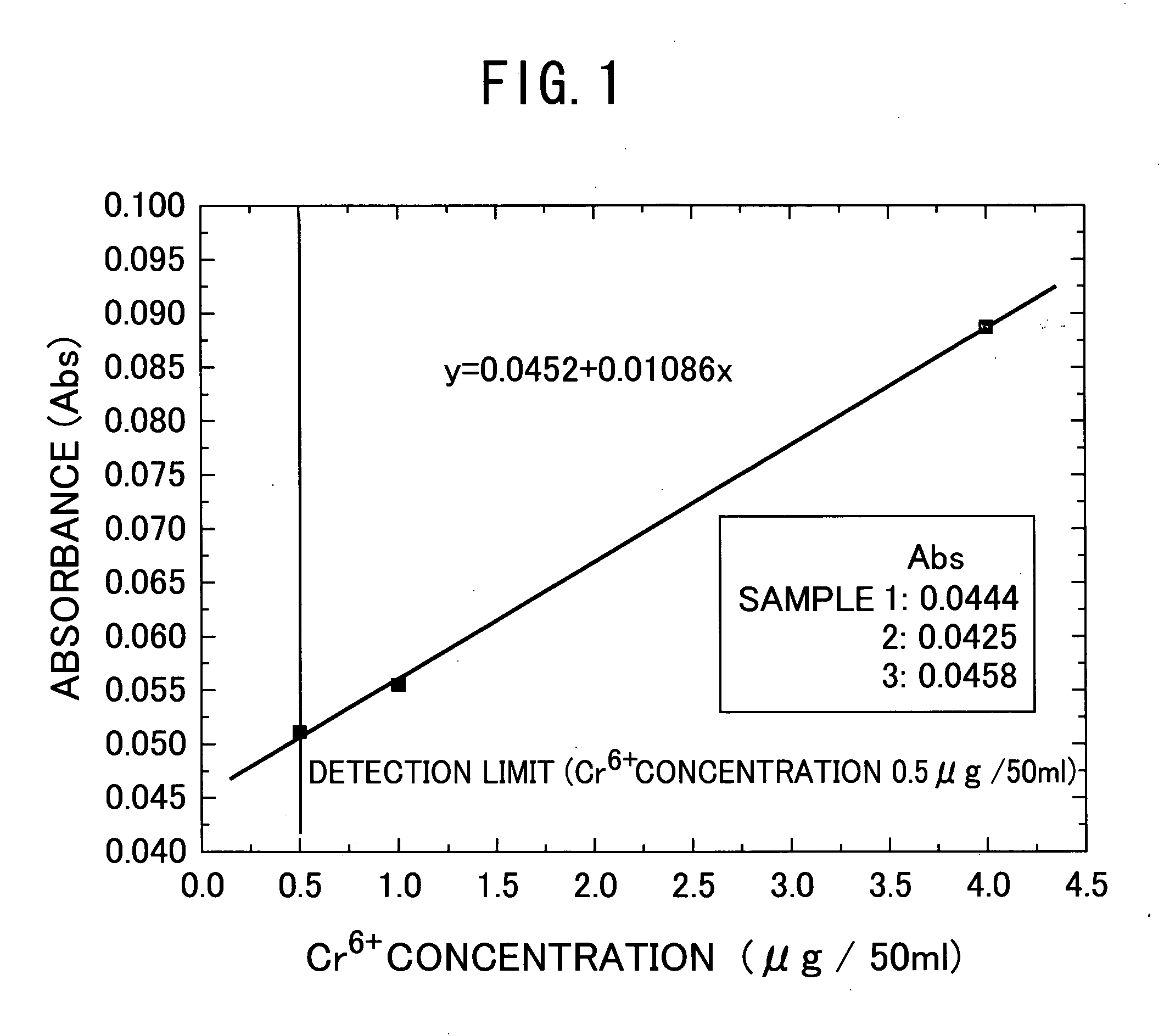

Method for treating stainless steel pickling waste liquor and recovering iron, chromium and nickel

InactiveCN104805291AHigh puritySolve processingWater contaminantsWaste water treatment from metallurgical processFerric hydroxideFractional Precipitation

The invention discloses a method for treating stainless steel pickling waste liquor and recovering iron, chromium and nickel. According to the method, a sodium hydroxide solution is adopted to control the pH of the stainless steel pickling waste liquor to achieve the purpose of recovery of iron, chromium and nickel through fractional precipitation. Because pH ranges of deposition of the iron, chromium and nickel elements are overlapped, part of iron oxide-hydroxide is precipitated firstly in a separation and recovery process, residual iron and chromium elements are co-precipitated out, and then chromium is precipitated and dissolved under the strong alkaline condition to realize final separation of iron and chromium. Due to presence of ammonia water and a reducing agent, the nickel element exists in the form of ions or a nickel ammine complex, is dissolved in the waste liquor, and finally reacts with a sulfide to precipitate NiS. The method has the characteristics of low cost, easiness in control, high separation and recovery rate of the iron, chromium and nickel elements and the like. The method can treat the stainless steel pickling waste liquor effectively, and the natural environment cannot be polluted after emission; the recovered metal elements have the recycling economic benefits, and the method has high application value and important technological innovation meaning.

Owner:NANYANG NORMAL UNIV

Preparation of high pure ferric phosphate

The invention discloses a preparation method of ferric orthophosphate which is characterized by oxidizing the ferrite solution into ferric salt solution by oxidant under acid condition, then reacting the phosphate or monohydric phosphate with the ferric salt to obtain basic ferric phosphate containing ferric hydroxide, treating the crude product of basic ferric phosphate using phosphoric acid with a concentration of 0.65 M so as to convert the ferric hydroxide thereof into ferric orthophosphate, then separating the solid and liquid of the product and washing, drying the product to obtain white product of ferric orthophosphate with a purity lager than 99%. The preparation method can be widely used in the preparation of paint, pigment, feed additive, catalyst and new battery materials, especially for the production of lithium iron phosphate for lithium ion battery anode material.

Owner:湖南海利锂电科技有限公司

A comprehensive utilization method of red mud

ActiveCN104340995AEfficient separationAchieve cycleChlorine/hydrogen-chlorideSolid waste disposalFerric hydroxideAluminium hydroxide

The invention relates to a comprehensive utilization method of bauxite and particularly relates to a comprehensive utilization method of red mud. The method includes: a step of mixing the red mud with hydrochloric acid, adding the mixture into a hydrochloric acid-resistant reactor, and reacting; a step of cooling after the reaction is finished, performing solid liquid separation and washing; a step of adding the obtained solution into a sodium hydroxide solution to obtain an aluminium hydroxide precipitate, an iron hydroxide precipitate and a sodium chloride solution, performing solid liquid separation, and washing; a step of preparing the aluminium hydroxide and iron hydroxide solid into metallurgy-level aluminum oxide and high-iron slag through a simple Bayer process; a step of subjecting the sodium chloride solution to electrolysis by an ionic exchange membrane electrolytic cell to obtain hydrogen, chlorine and a sodium hydroxide solution; a step of returning the sodium hydroxide solution discharged from an ionic membrane cathode zone and recycling; and a step of returning and recycling the obtained hydrogen and the obtained chlorine. The method is obvious in environment protection effects, effectively separates aluminum, iron and silicon in the red mud, and recovers the aluminum, the iron, sodium and other useful elements, thus achieving comprehensive utilization.

Owner:SHENYANG ALUMINIUM MAGNESIUM INSTITUTE

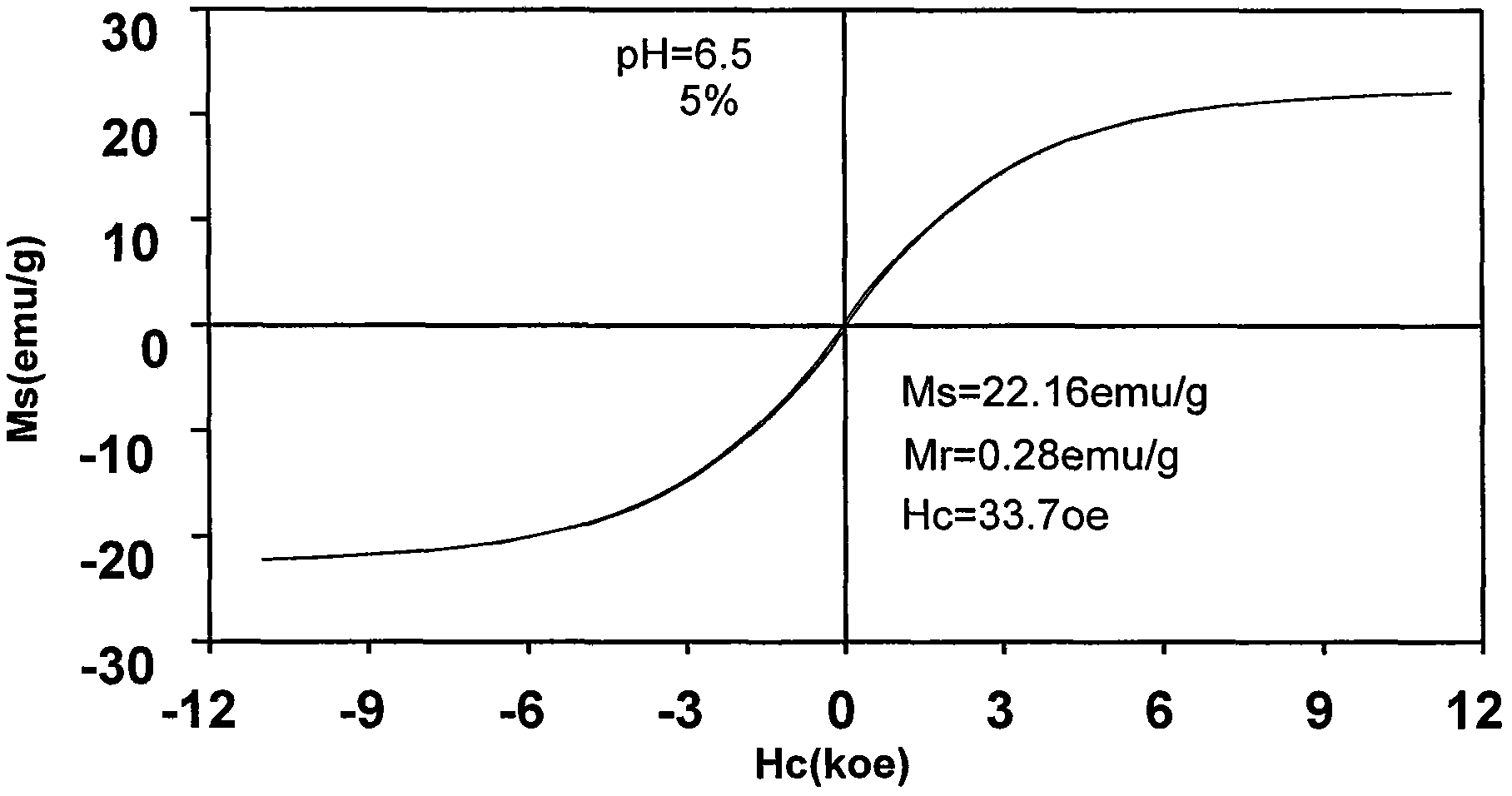

Macroscopic three-dimensional ultralight Fe3O4 doped graphene aerogel composite material and preparation method

The invention belongs to the technical field of functional materials and relates to a macroscopic three-dimensional ultralight Fe3O4 doped graphene aerogel composite material and a preparation method. According to the preparation method, firstly, expanded graphite powder is taken as a raw material, graphene oxide is prepared with an improved Hummers method, and ferric trichloride is thermally hydrolyzed to prepare ferric hydroxide colloid; secondly, the ferric hydroxide colloid is dropwise added into a graphene oxide solution, and a hydrothermal reduction reaction is performed to obtain Fe3O4 doped graphene aerogel; and finally, hydrothermal treatment by ammonia water and vacuum freeze-drying are performed to obtain the macroscopic three-dimensional ultralight Fe3O4 doped graphene aerogel composite material. In percentage by weight, the Fe3O4 content is 0-65% and the balance is graphene aerogel. The synthetic method for the Fe3O4 doped graphene aerogel composite material is simple, feasible, easy to control, small in specific gravity, large in surface area and outstanding in porous characteristic, and can be used in the fields of sewage treatment, stealth, biological medicines, new energy, electronic materials and the like.

Owner:ZHENGZHOU UNIV

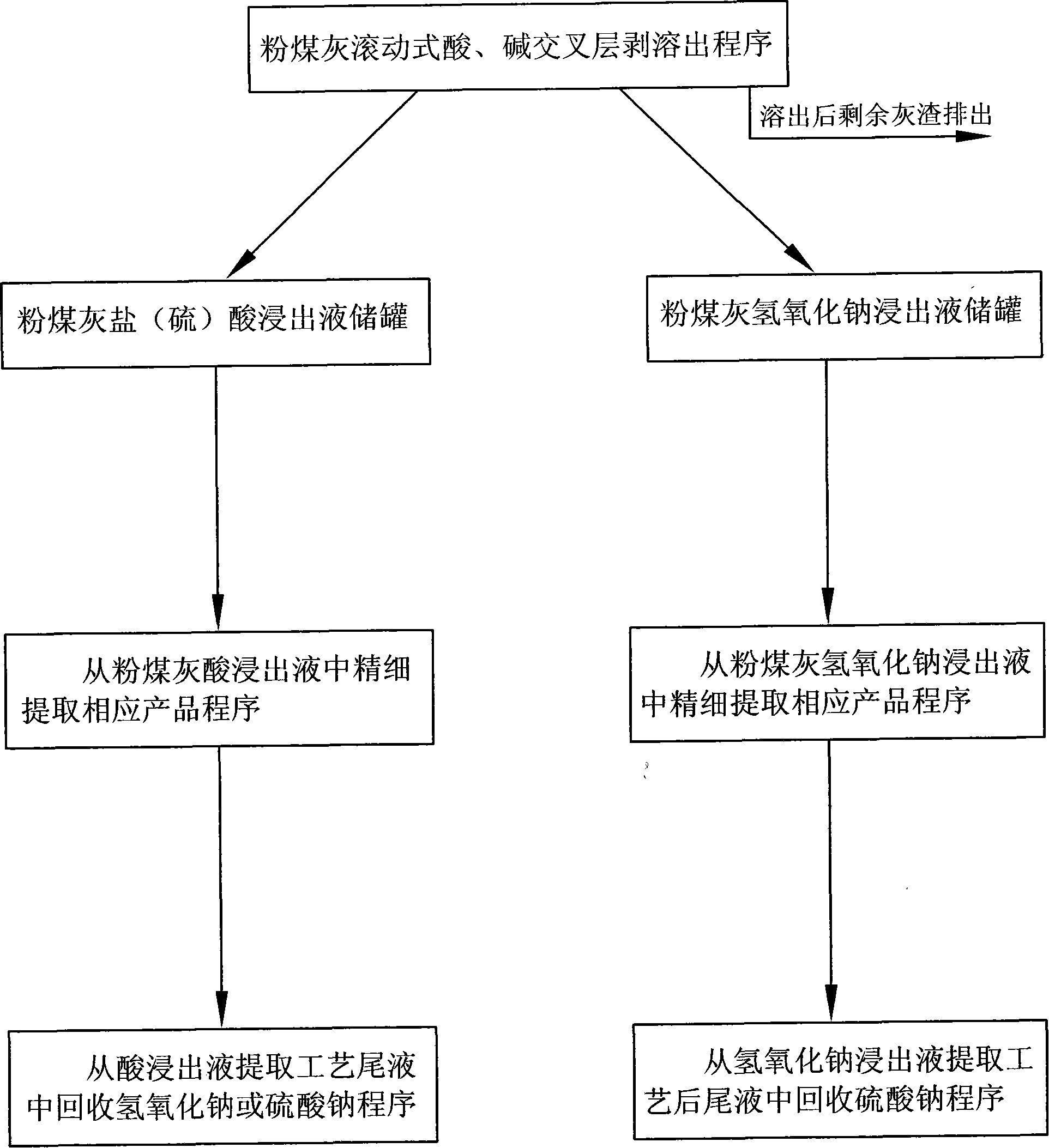

Coal ash roller type fine extractive technique

InactiveCN101200305ACompletely zero emissionsIron oxides/hydroxidesSolid waste disposalFerric hydroxideBrick

The invention relates to a powder coal ash rolling-type fine extraction method which can effectively peel and dissolve extractive, serially extract active silica, ferric hydroxide, iron oxide red, magnesium hydrate, calcium hydroxide, barium sulfate, lithium carbonate and lanthanide series and actinium series rare earth hydroxide with an enrichment amount >=0.01%, manganese, copper, zinc and gallium with an enrichment amount >=0.05%, and germanium dioxide, vanadium pentoxide, gold, silver, palladium and platinum metal with an enrichment amount >=0.0001% from the powder coal ash. The powder coal ash rolling-type fine extraction method has the advantages that the remainder ash of the powder coal ash after the treatment by the rolling-type fine extraction technique can be still comprehensively used for making brick and blending coagulation, thereby fully using the powder coal ash and realizing zero emission.

Owner:李文志 +1

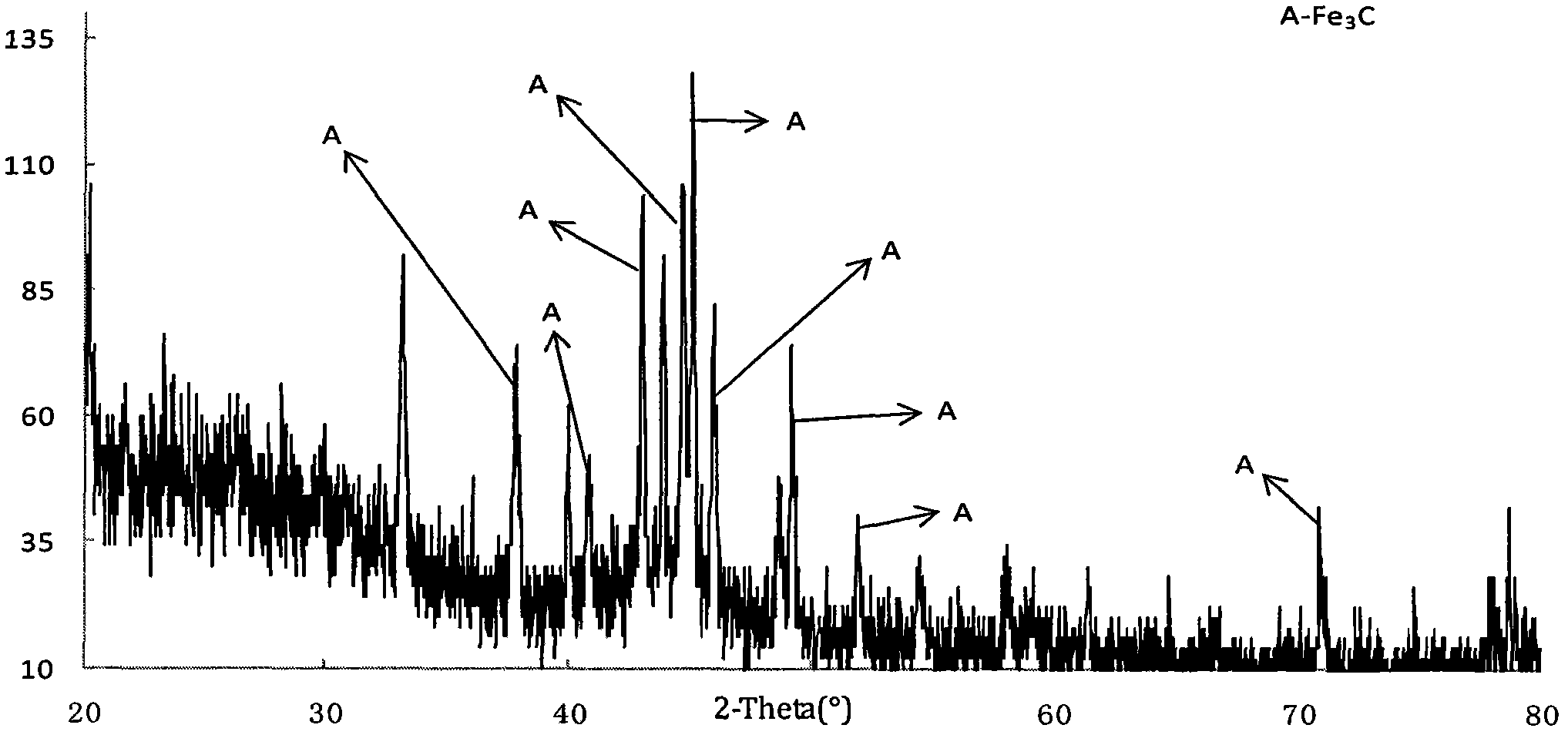

Preparation method of coal-based magnetic activated carbon and coal-based magnetic activated carbon

InactiveCN101972629AEasy to separate and recycleIncrease the areaOther chemical processesMagnetic materialsFerric hydroxideCarbonization

The invention relates to a preparation method of coal-based magnetic activated carbon and the coal-based magnetic activated carbon. The preparation method of the coal-based magnetic activated carbon comprises the following steps of: placing deashing coal dust and dodecyl sodium sulfate into a ferric chloride solution, sufficiently mixing, and then standing for adsorption; then adding ammonia water and a sodium hydroxide solution or a potassium hydroxide solution, sufficiently stirring, and then standing for transforming ferric chloride into ferric hydroxide; filtering and drying solid-phase materials to obtain a mixture of deashing coal and the ferric hydroxide, i.e. a precursor of the coal-based magnetic activated carbon; sufficiently mixing the precursor with activating agents, i.e. potassium hydroxide or sodium hydroxide, adding distilled water to stir into paste, and warming for carbonization under the protection of nitrogen; and heating and activating under the protection of the nitrogen. The obtained coal-based magnetic activated carbon has difficult blockage of pores because a magnet exists in a state of Fe3C, thereby having higher saturation and magnetization intensity and larger specific surface area. The invention has the advantages of extensive source of coal raw materials, low cost, simple preparation process and easy separation and recovery of the coal-based magnetic activated carbon.

Owner:CHONGQING UNIV

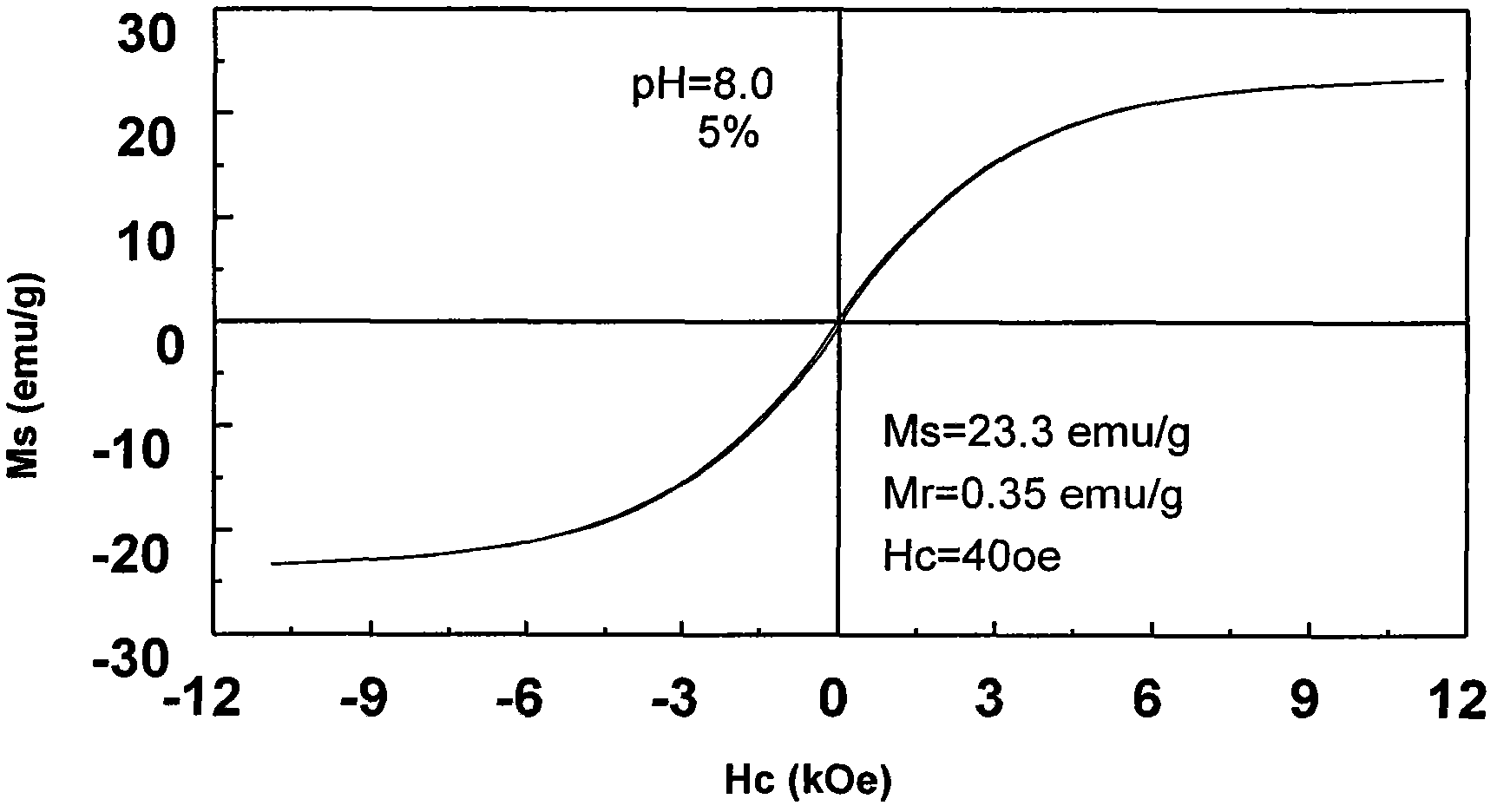

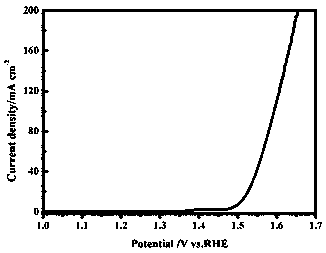

Ferronickel hydroxide/reduction-oxidation graphene electrochemical oxygen evolution catalyst with nickel foam as carrier and preparation method of ferronickel hydroxide/reduction-oxidation graphene electrochemical oxygen evolution catalyst

InactiveCN108707923AHigh activityImprove stabilityLiquid/solution decomposition chemical coatingElectrode shape/formsIron saltsNickel salt

The invention relates to a ferronickel hydroxide / reduction-oxidation graphene electrochemical oxygen evolution catalyst with nickel foam as a carrier and a preparation method of the ferronickel hydroxide / reduction-oxidation graphene electrochemical oxygen evolution catalyst. The nickel foam is used as the carrier of the catalyst, ferric hydroxide, nickel hydroxide or a compound of the ferric hydroxide and the nickel hydroxide is used as the active component of the catalyst, and reduction-oxidation graphene is used as the conductive material of the catalyst. The catalyst is prepared through a water heating and impregnation method. Firstly, the nickel foam is subjected to ultrasonic cleaning and drying; then, a certain amount of nickel salt and a certain amount of urea are weighed, dissolvedin deionized water and stirred to be evenly mixed at the room temperature; then, oxidized graphene is added, ultrasonic treatment is conducted, and evenly-dispersed mixed liquor is obtained; the nickel foam and the mixed liquor are transferred into a water heating kettle and react for 12 h to 24 h at the temperature being 120-200 DEG C; the nickel foam subjected to reaction is cleaned and dried;and finally, after the nickel foam is soaked in an iron salt solution with the concentration ranging from 5 mmol / L to 30 mmol / L for 0 h to 48 h, cleaning and drying are conducted, and the ferronickelhydroxide / reduction-oxidation graphene electrochemical oxygen evolution catalyst with the nickel foam as the carrier is obtained. The catalyst is good in catalysis activity and high in stability; andthe preparation method is simple and controllable, and industrial popularization is facilitated.

Owner:EAST CHINA UNIV OF SCI & TECH

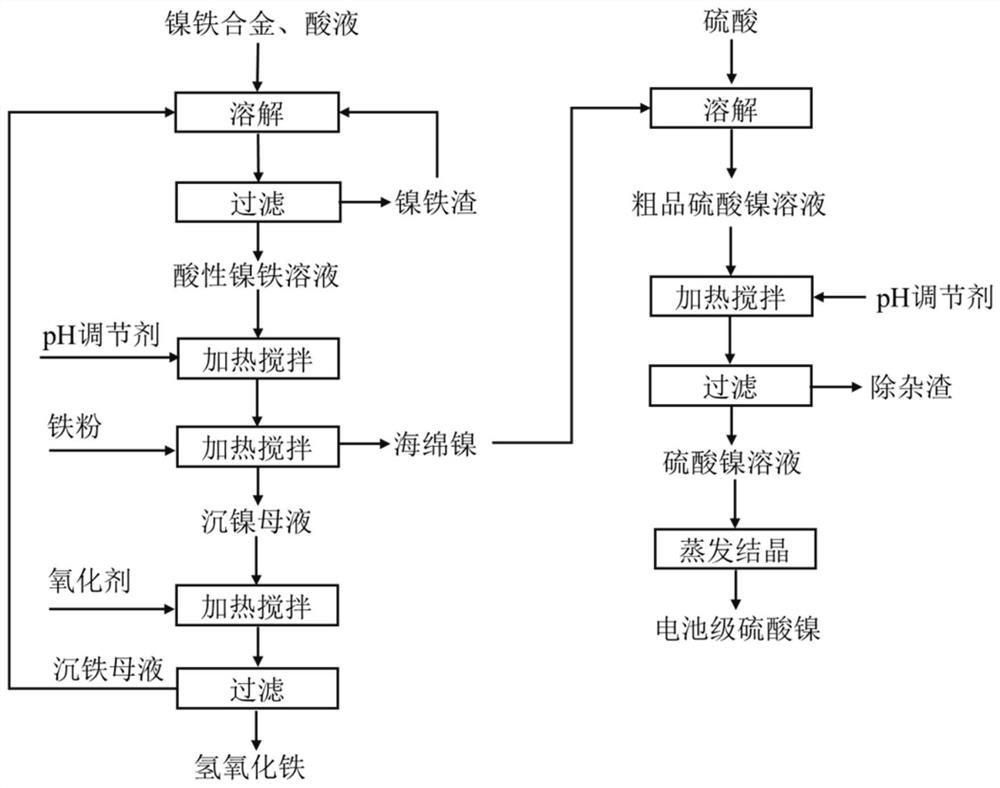

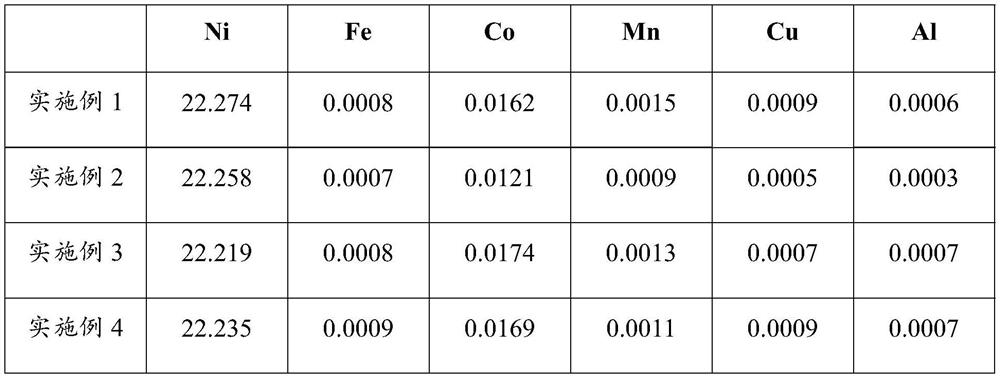

Method for separating nickel and iron from nickel-iron alloy and application

ActiveCN112941314AAchieve separationHas economic valueIron oxides/hydroxidesNickel sulfatesFerric hydroxideIron powder

The invention belongs to the field of hydrometallurgy, and discloses a method for separating nickel and iron from a nickel-iron alloy and application. The method comprises the following steps: dissolving the nickel-iron alloy in an acid solution, filtering, and taking filtrate to obtain an acidic nickel-iron solution; adjusting the pH value of the acidic nickel-iron solution, heating, stirring, adding iron powder, and continuously heating and stirring to obtain sponge nickel and nickel precipitation mother liquor; enabling the nickel precipitation mother liquor to be subjected to oxidation iron precipitation to obtain ferric hydroxide slag and iron precipitation mother liquor; and dissolving sponge nickel into sulfuric acid, filtering, collecting filtrate, heating, and adjusting the pH value to obtain a nickel sulfate solution; According to the method, after the nickel-iron alloy is dissolved by using the acid liquor, nickel in the solution is replaced by iron powder to obtain sponge nickel, the nickel precipitation mother liquor is oxidized to generate ferric hydroxide, the nickel content is lower than 0.4%, the iron precipitation mother liquor can be returned to a leaching section, and the sponge nickel is subjected to acid dissolution, impurity removal and evaporative crystallization to obtain a battery-grade nickel sulfate product.

Owner:HUNAN BRUNP RECYCLING TECH +2

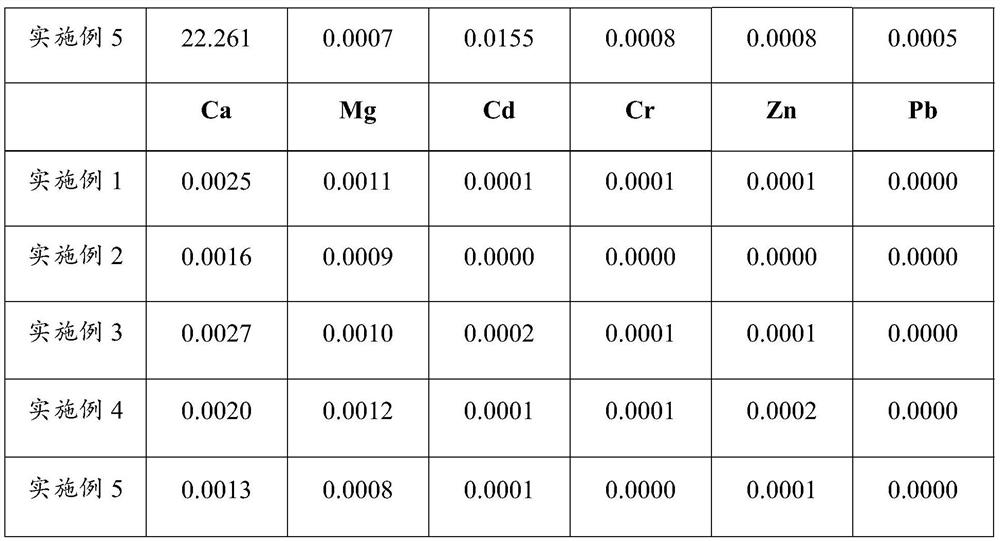

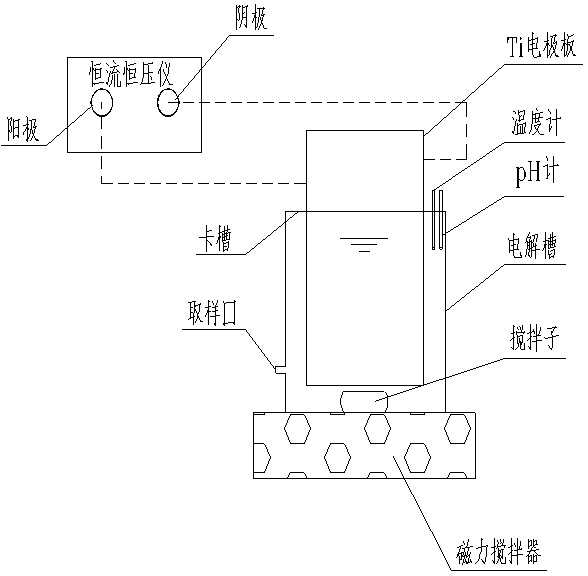

Method for removing harmful algae in water body by adopting electro-Fenton

InactiveCN101962216AStable in natureNo electrocoagulationWater/sewage treatment by oxidationFerric hydroxideElectrolysis

The invention belongs to the technical field of environmental protection and in particular relates to a method for removing harmful algae pollution in water body by adopting electro-Fenton. Hydrogen peroxide and ferrous ions in a reactor react to generate hydroxyl radicals, at the same time, the ferrous ions are regenerated from iron ions and iron hydroxide in the cathode region for electrolysis through reduction, thus continuously generating vast hydroxyl radicals, efficiently inactivating algae cells, simultaneously rapidly carrying out oxidation degradation on the microcystins and effectively avoiding secondary pollution. The body part of the reactor comprises a power source, electrodes, an electrolytic bath and a magnetic stirrer. After the algae liquid to be treated is introduced to the electrolytic bath, the magnetic stirrer at the bottom of the electrolytic bath is used for ensuring the algae liquid to be uniformly distributed in the whole reactor. Under the set process parameters, the method can realize rapid inactivation of the harmful algae and simultaneously realize efficient degradation of the microcystins.

Owner:FUDAN UNIV

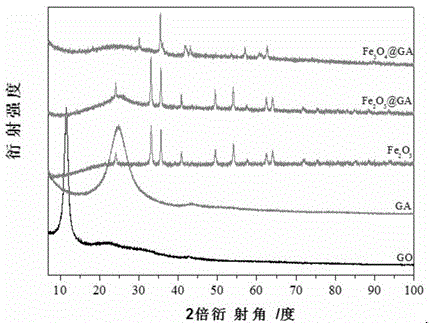

Preparation method of Fe2O3/graphene composite material

InactiveCN105489398AEasy to prepareThe particle size control effect is obviousHybrid capacitor electrodesHybrid/EDL manufactureFerric hydroxideNano composites

The invention belongs to the technical field of a supercapacitor nanometer composite material, and particularly to a preparation method of an Fe2O3 / graphene composite material. The preparation method of the Fe2O3 / graphene composite material comprises the steps of (1), preparing a graphene oxide colloidal solution; (2) mixing the graphene oxide colloidal solution and a ferric hydroxide colloid or a saturated ferric chloride solution, and performing ultrasonic treatment; and (3) placing the mixed solution after ultrasonic treatment into a hydrothermal reactor for reaction, and after reaction finishement, performing natural cooling, washing and drying for obtaining the Fe2O3 / graphene composite material. The preparation method has advantages of simple operation and environment-friendly process. Not only can size of Fe2O3 particle diameter be effectively controlled for obtaining Fe2O3 crystals with different particle diameters, but also the Fe2O3 is dispersed in the graphene in a more uniform manner. The Fe2O3 / graphene composite material represents an excellent electrochemical performance when used as a supercapacitor nanometer composite material. Furthermore the preparation method is a novel way for preparing a controllable metal oxide in a supercapacitor electrode material.

Owner:SHANGHAI INST OF TECH

Method for preparing magnetic ferric oxide nano particles

The invention discloses a preparation method for a magnetic iron oxide nanometer particle. The cleaned cellulose fibers are immersed in the 0.1-0.5mol / l ferric salt or ferrous salt solution; after the ferric ions in the ferric salt or ferrous salt solution are fully absorbed in the micro-pores of the cellulose fibers or on the surface of the cellulose fibers, the cellulose fibers are immersed in the 0.2-4mol / l NaOH solution; the ferric ions and the ferrous ions in the solution generate the ferric hydroxide precipitation or the ferrous hydroxide precipitation in the micro-pores of the cellulose fibers to constitute the cellulose composite fibers; the ferric oxide / cellulose composite fibers are obtained after the dehydration of the cellulose composite fibers; finally, the ferric oxide / cellulose composite fibers are ignited in the air atmosphere or the oxygen atmosphere at the temperature of 350-1000 Celsius system for 20-300 minutes, so that the magnetic iron oxide nanometer particles with high purity are obtained. The method has a simple operation and the low cost raw materials, the prepared iron oxide nanometer particles have the even diameter distribution with a certain magnetism.

Owner:WUHAN UNIV

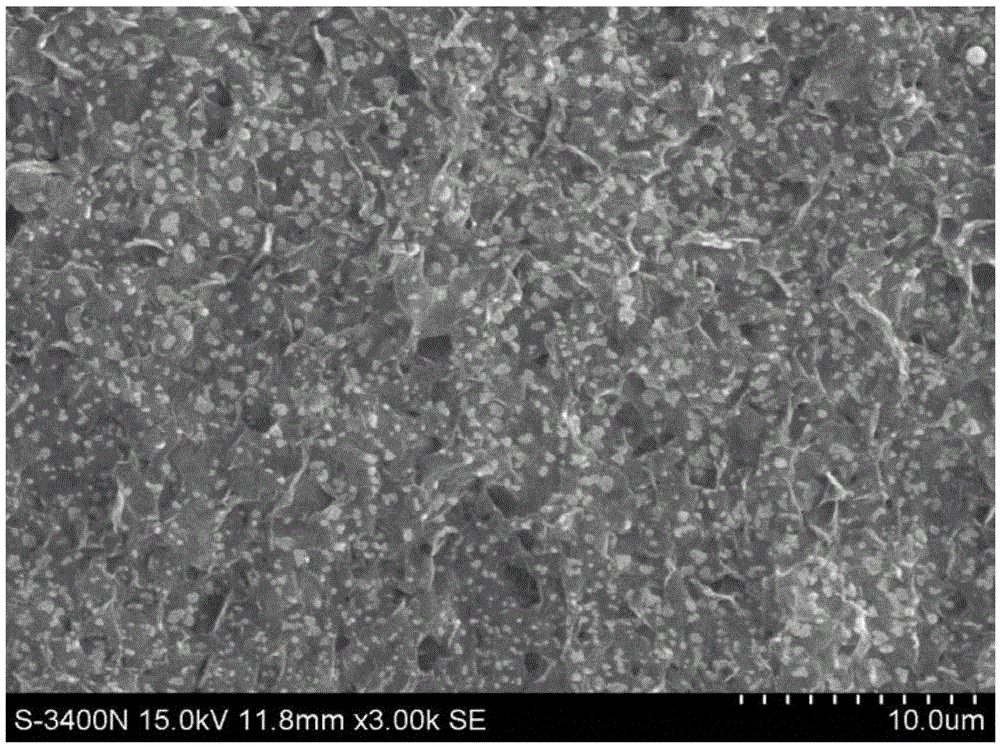

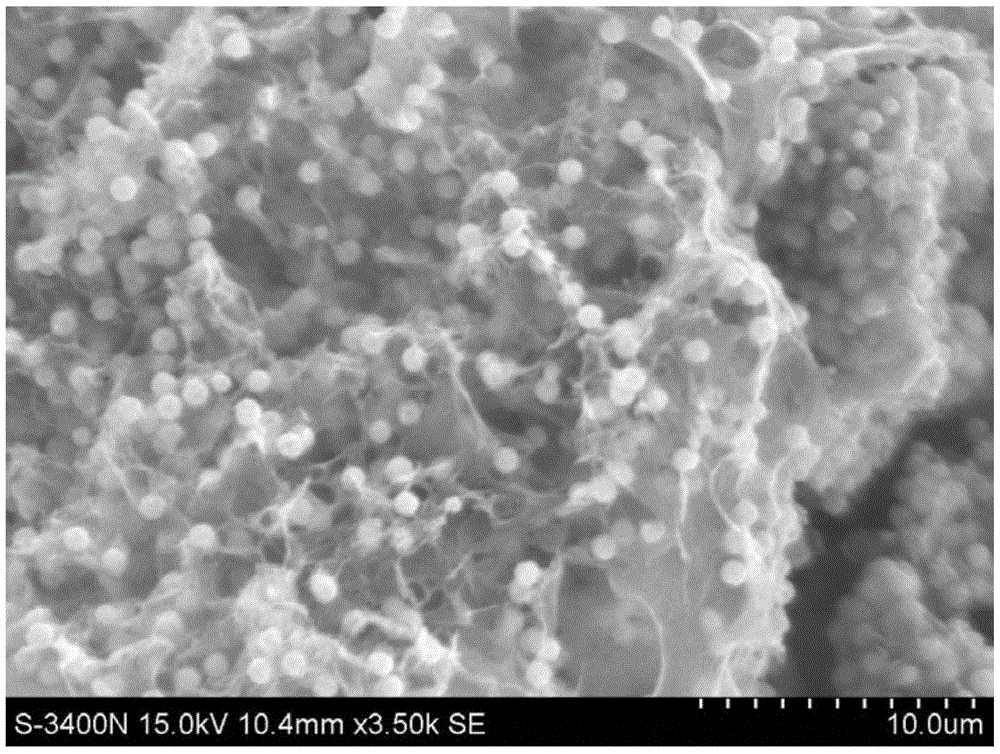

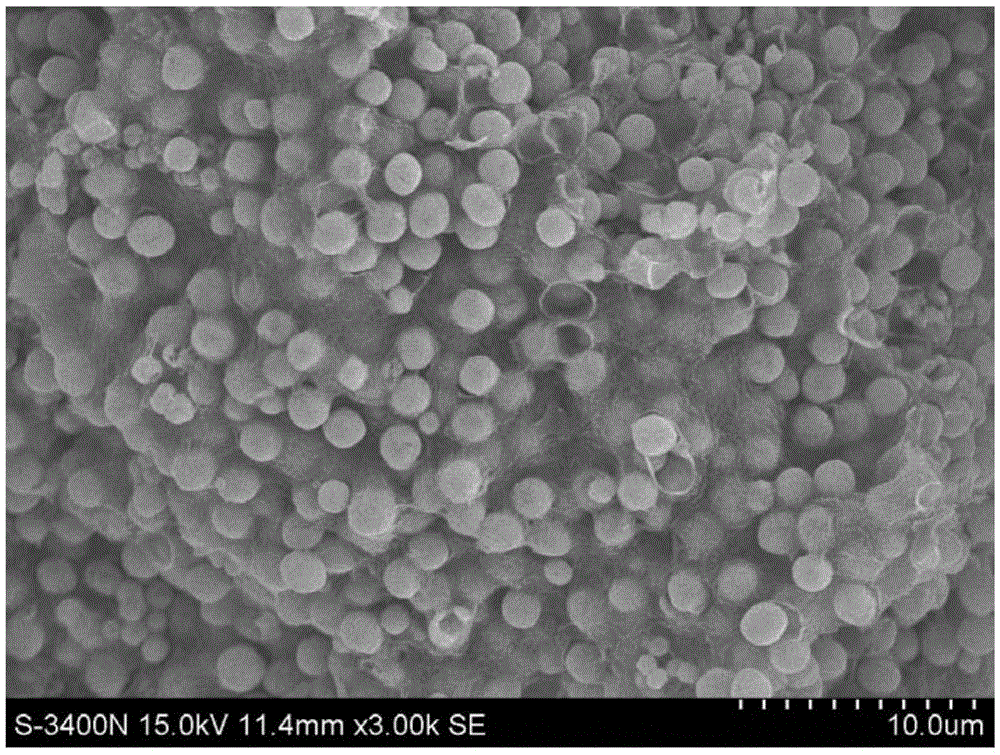

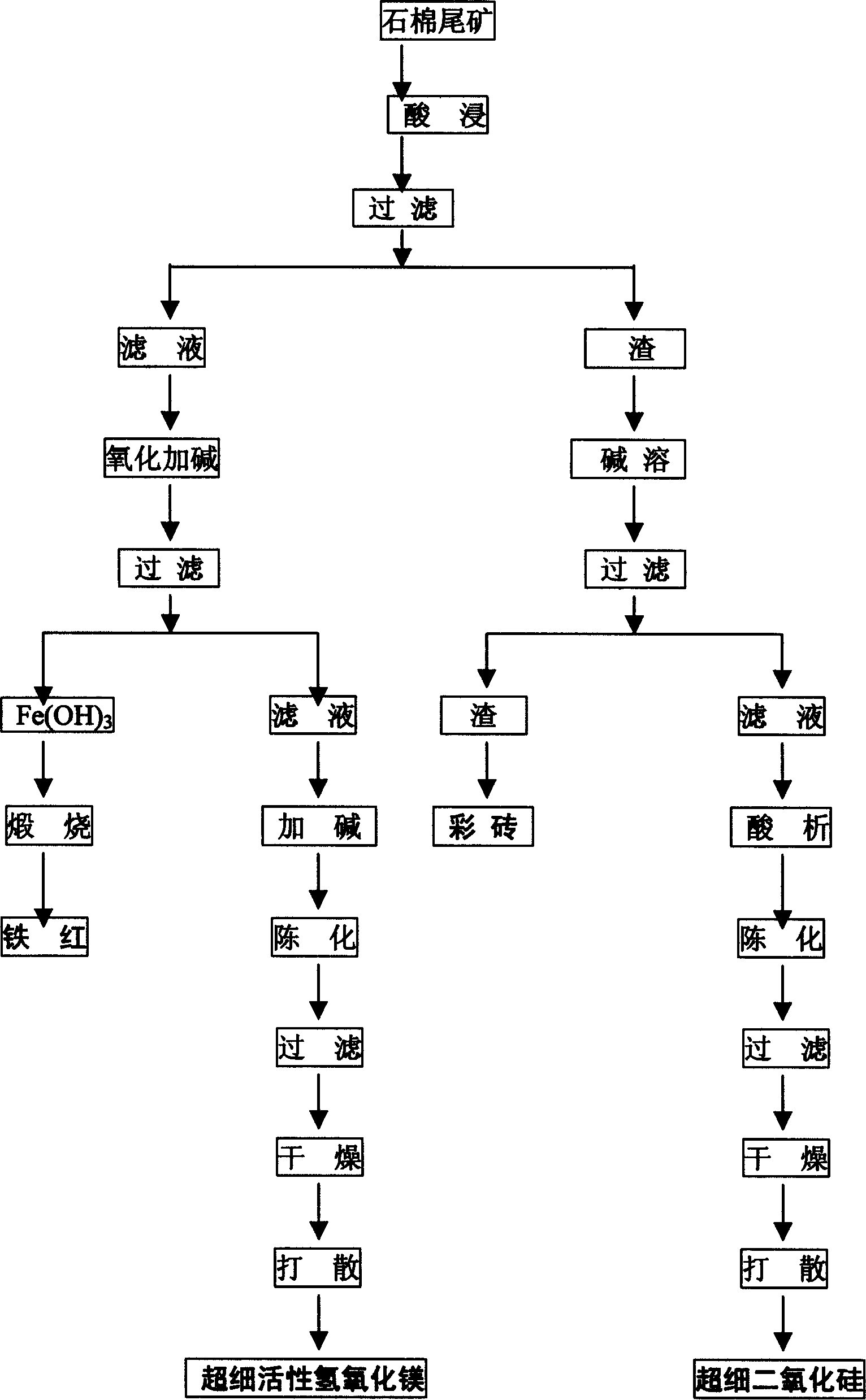

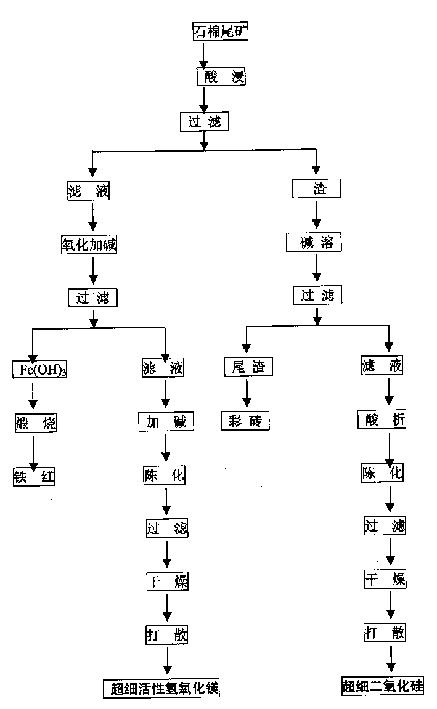

Comprehonsive utilization method of asbestos tail ore

A process for comprehensive utilization of asbestos tailings includes such steps as breaking, dissolving in acid, filtering, oxidizing filtrate, adding alkali, reaction, filtering to remove iron hydroxide, adding alkali and surface treating agent, reaction, filtering, drying, breaking to obtain superfine active magnesium hydroxide, dissolving dregs in alkaline solution, filtering, adding acid, depositing, adding isolating agent, agenig, filtering, washnig, drying, breaking to obtain superfine SiO2, calcining iron hydroxide to obtain iron oxide, mixing with mine tailings and assistant, and making color bricks.

Owner:CHINA UNIV OF MINING & TECH (BEIJING)

Method for preparing catalyst for catalyzing organic pollutants in wet oxidation water

InactiveCN103157501AImprove processing efficiencyMolecular sieve catalystsWater contaminantsFerric hydroxideMolecular sieve

The invention discloses a method for preparing a catalyst for catalyzing organic pollutants in wet oxidation water, and belongs to the field of water treatment technologies and environmental functional materials. When the method is used for preparing a meso-porous SBA-15 molecular sieve, a triblock copolymer EO20PO70EO20(P123) is used as a template, tetraethoxysilane (TEOS) is used as a silicon source, and hydrochloric acid is used as an acid source; and the meso-porous SBA-15 molecular sieve with good hydrothermal stability and large specific area is used as a carrier, CuO is used as an active ingredient, and ultrasonic waves are used for acting for a certain period of time in the preparation process to promote the dispersion of the active ingredient. Because ferric nitrate acts with sodium hydroxide to generate a deposit of ferric hydroxide in the method, Fe2O3 is obtained after the deposit is roasted, and a small amount of the Fe2O3 is used as an auxiliary agent to prevent the active ingredient from being sintered in the roasting process.

Owner:扬州鑫磊环境工程有限公司

Method for stabilizing fly ash from refuse incineration by combination of complementary type medicaments

InactiveCN101690934AReduce usageReduce processing costsSolid waste disposalFerric hydroxidePrecipitation types

The invention belongs to the technical field of the harmless treatment of dangerous solid waste and particularly relates to a method for stabilizing fly ash from refuse incineration by the combination of complementary type medicaments. The stabilizing method combines a reducing inorganic medicament (I type medicament) capable of precipitating and absorbing Pb, Zn, Cd, Hg, Cr, Cu and other heavy metals and an heavy metal ion precipitation type organic chelating agent (II type medicament). The method comprises the following steps: firstly mixing the I type medicament with the fly ash first in aqueous solution or in the presence of water for reaction to generate ferric hydroxide for absorbing and precipitating heavy metals or generating sulfides of the heavy metals to precipitate the heavy metals; and then adding the II type medicament in the system to allow the II type medicament to further generate precipitate type chelates with the residual heavy metals, particularly Pb, Cd, Hg and the like. The first step of the method is characterized in that reducing atmosphere still remains after the reaction. As a major part of heavy metals are stabilized by chalybeate or the chalybeate, so the dosage of the II type medicament is reduced considerably.

Owner:TONGJI UNIV +1

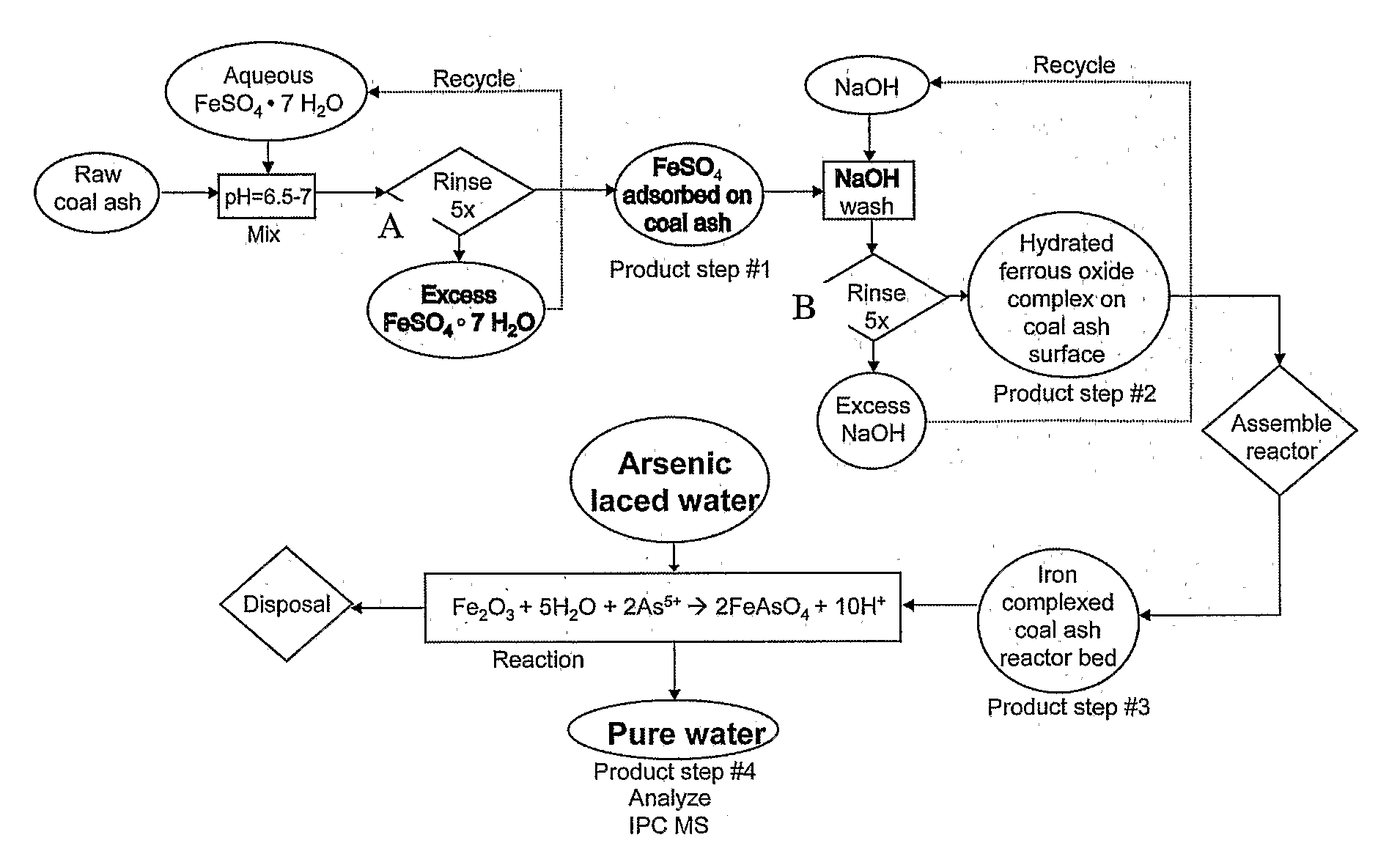

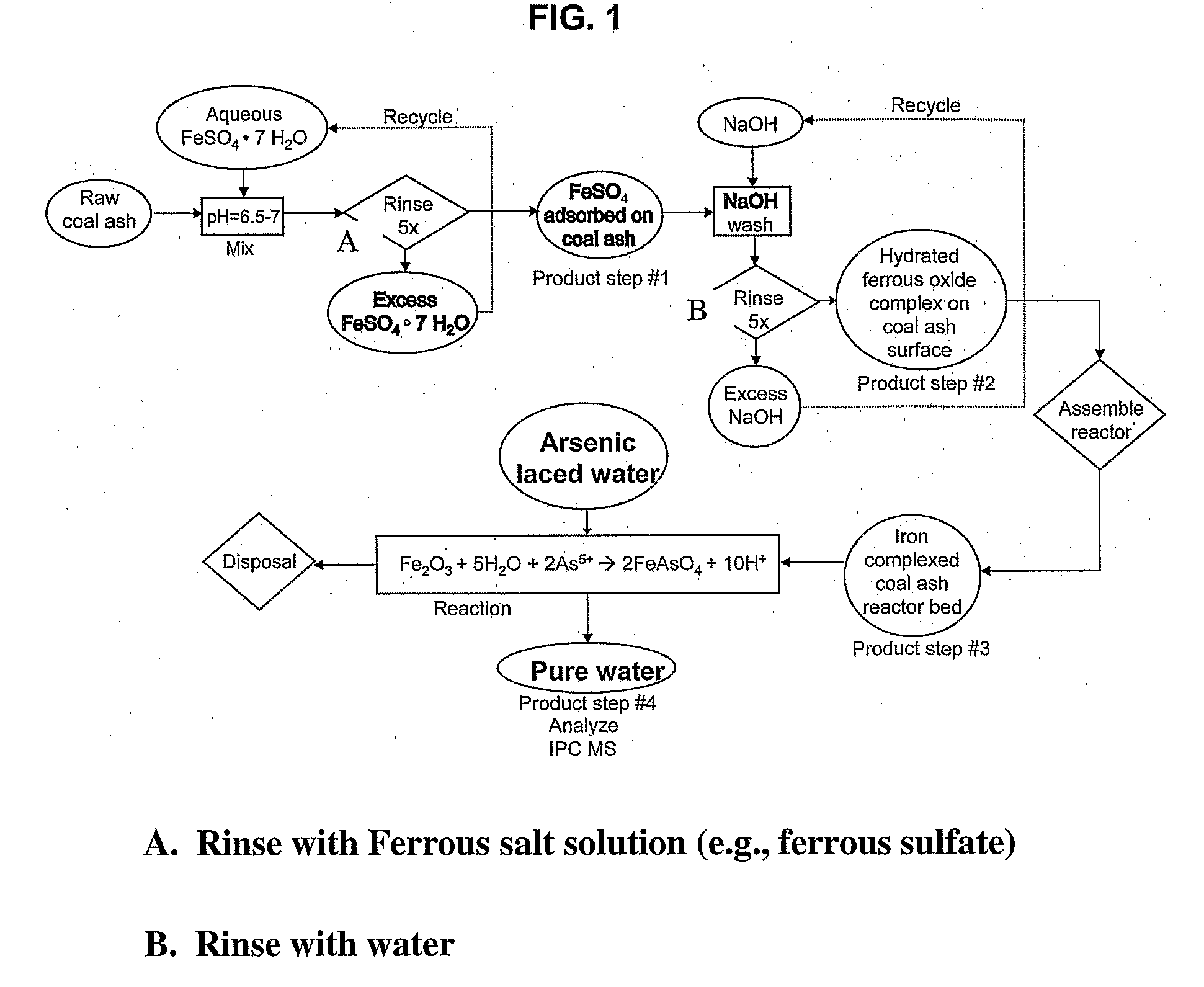

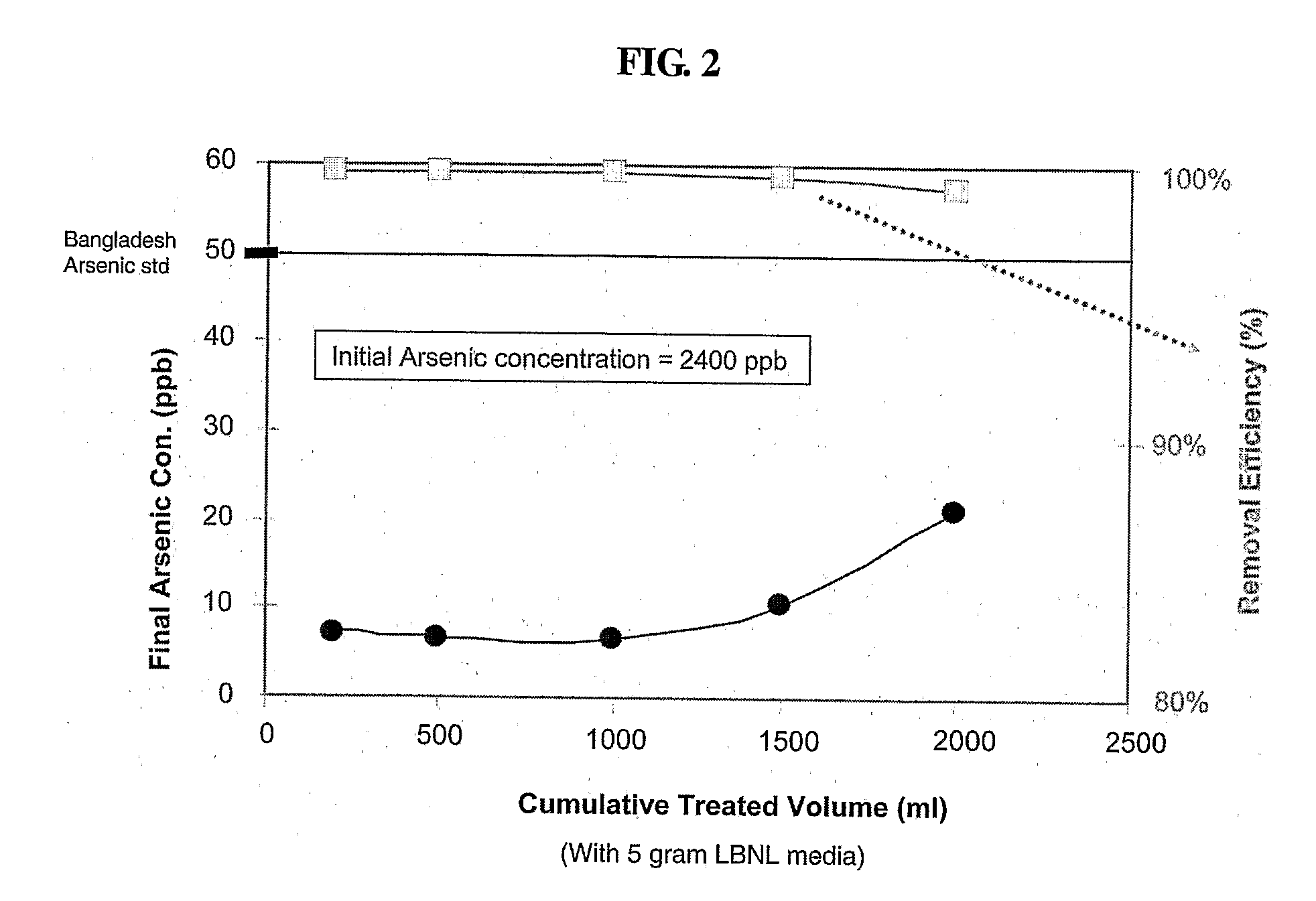

Compositions and Methods For Removing Arsenic in Water

InactiveUS20080197081A1Facilitates of oxidationEasy to doTreatment involving filtrationSolid sorbent liquid separationFerric hydroxideCadmium Cation

Compositions and methods and for contaminants from water are provided. The compositions comprise ferric hydroxide and ferric oxyhydride coated substrates for use in removing the contaminant from the water Contacting water bearing the contaminant with the substrates can substantially reduce contaminant levels therein. Methods of oxidizing the contaminants in water to facilitate their removal by the ferric hydroxide and ferric oxyhydride coated substrates are also provided. The contaminants include, but are not limited to, arsenic, selenium, uranium, lead, cadmium, nickel, copper, zinc, chromium and vanadium, their oxides and soluble salts thereof.

Owner:RGT UNIV OF CALIFORNIA

Comprehensive plating promoter treatment process and apparatus for hot galvanizing production line

InactiveCN1974834AReduce production processCompact structureHot-dipping/immersion processesControlling ratio of multiple fluid flowsFerric hydroxideProduction line

The present invention discloses comprehensive plating promoter treatment process and apparatus for hot galvanizing production line. The plating promoter in hot galvanizing production line is purified automatically and has its plating promoting components replenished with the waste from the hot galvanizing production process. The comprehensive plating promoter treatment process includes continuously pumping the solution from the plating promoting tank into the treating pot, pumping the solution from the dezincing tank and the smoke dust pot with a metering pump to the treating pot simultaneously, adding ammonia water under the control of a pH metering and controlling system, blasting air to oxidize the bivalent iron in the solution into trivalent iron with the oxygen in the air to form ferric hydroxide precipitate, separating in the sloping plate precipitator, eliminating the precipitate in a press filter, and returning the clear solution to the plating promoting tank.

Owner:SOUTH CHINA UNIV OF TECH

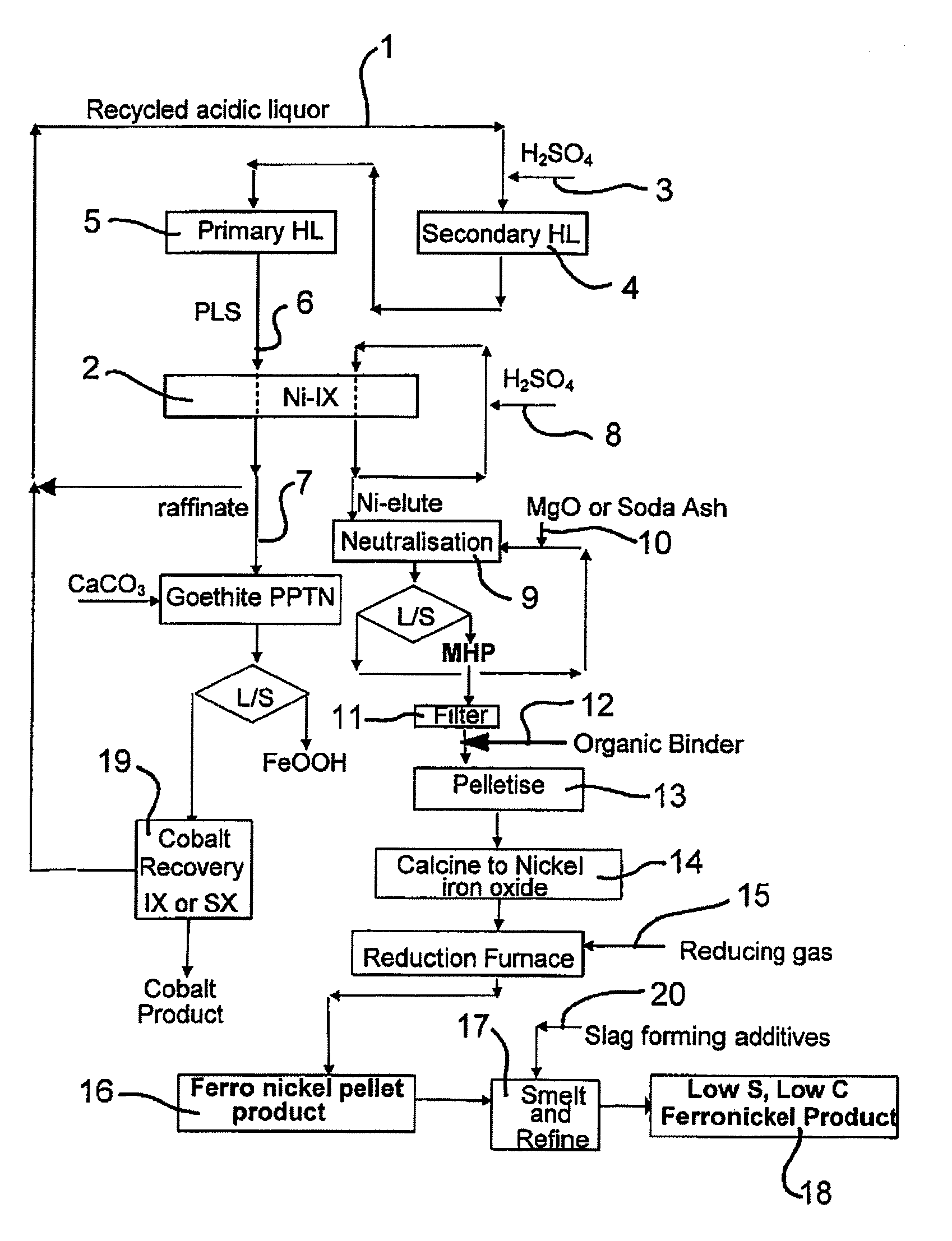

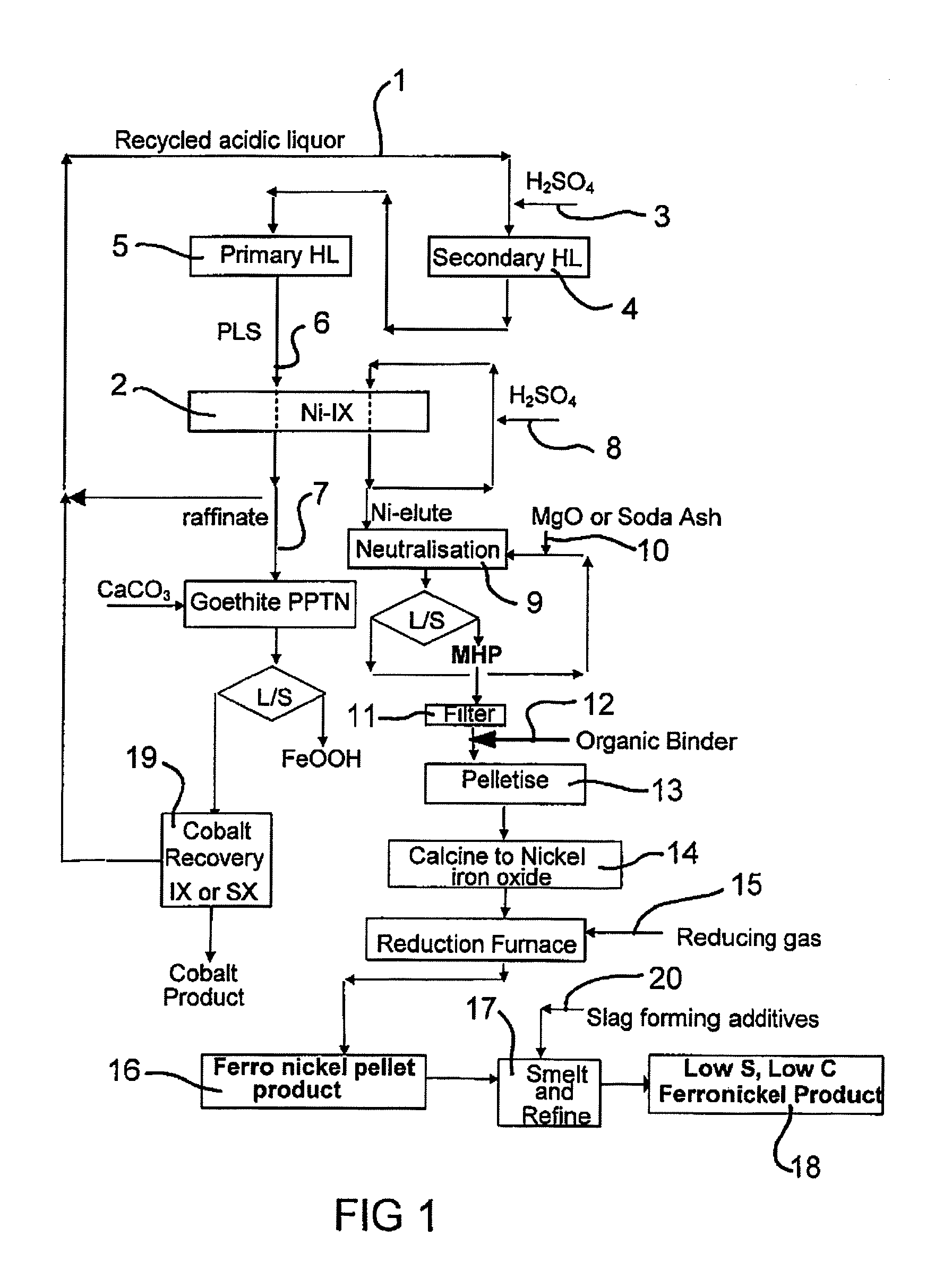

Production of Ferronickel

InactiveUS20080011126A1Low level of sulfurReduce sulfur contentProcess efficiency improvementFerric hydroxideMetallic Nickel

A process for producing a ferronickel product from a mixed nickel iron hydroxide product, said process including the steps of: providing a mixed nickel iron hydroxide product; pelletising the mixed nickel iron hydroxide product to produce nickel iron hydroxide pellets; calcining the nickel iron hydroxide pellets to produce mixed nickel iron oxide pellets; and reducing the nickel iron oxide pellets with one or more reducing gases at high temperatures to produce ferronickel pellets.

Owner:BHP BILLITON SSM TECH PTY LTD

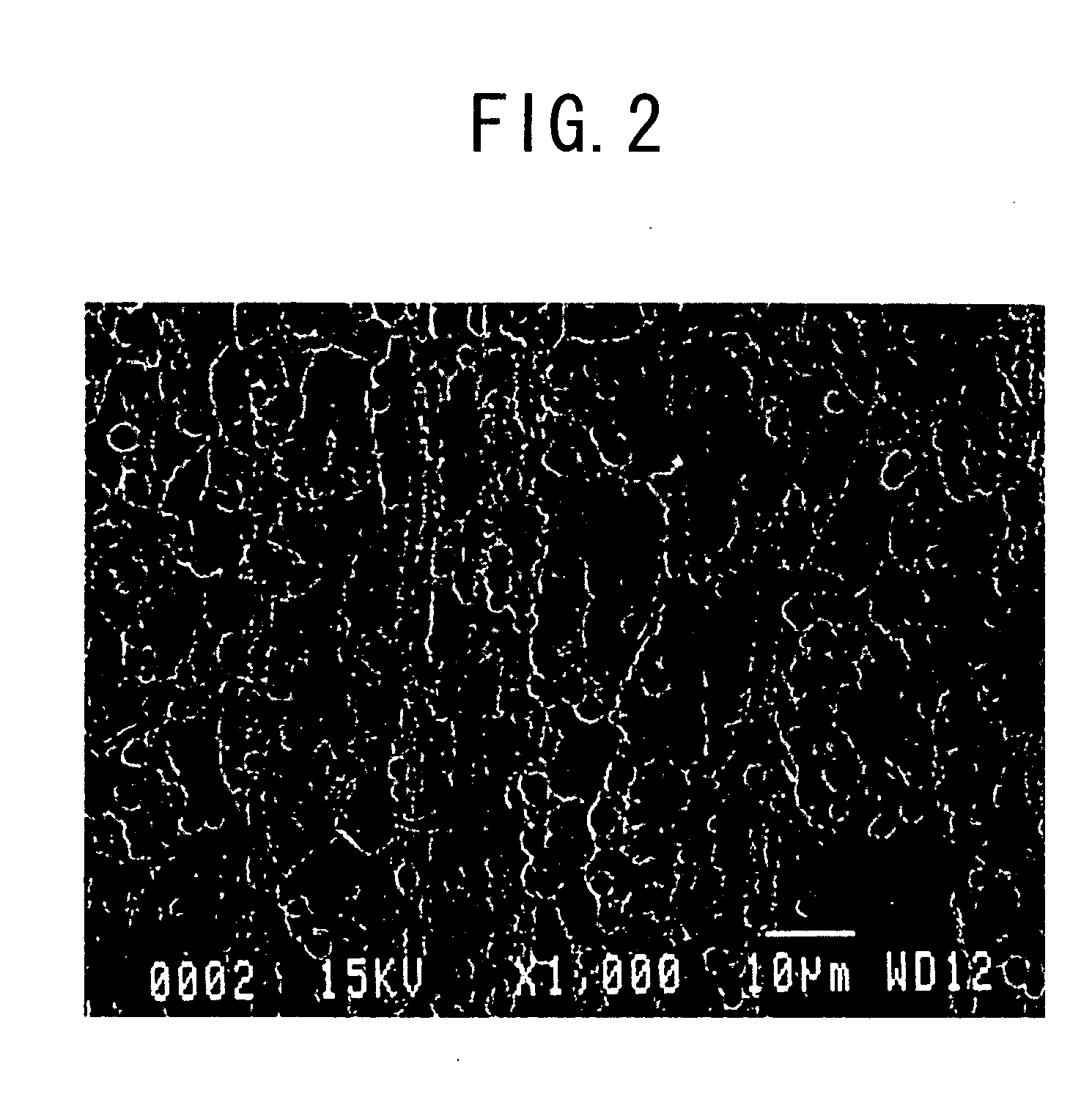

Stainless steel plate, method of manufacturing the same, and rubber-coated stainless steel plate gasket

InactiveUS20050057004A1Improve adhesionEfficient productionEngine sealsPhosphatisationCompound (substance)Hydroxide

This invention provides a rubber-coated stainless steel plate suitable as a gasket core material with excellent adhesion to the rubber layer, a method of manufacturing the same, and a gasket comprising the rubber-coated stainless steel plate. The following are provided by the present invention: a stainless steel plate having a roughened surface on which chrome hydroxide, chrome oxide, iron hydroxide, and iron oxide are deposited; a rubber-coated stainless steel plate formed by coating the surface of the stainless steel plate with a rubber layer; a gasket comprising the rubber-coated stainless steel plate; and a method of manufacturing the stainless steel plate, wherein the stainless steel plate is roughened with at least one of chemical roughening and electrochemical roughening and is then subjected to cathode electrolytic treatment in an alkaline solution.

Owner:NIPPON KINZOKU CO LTD +1

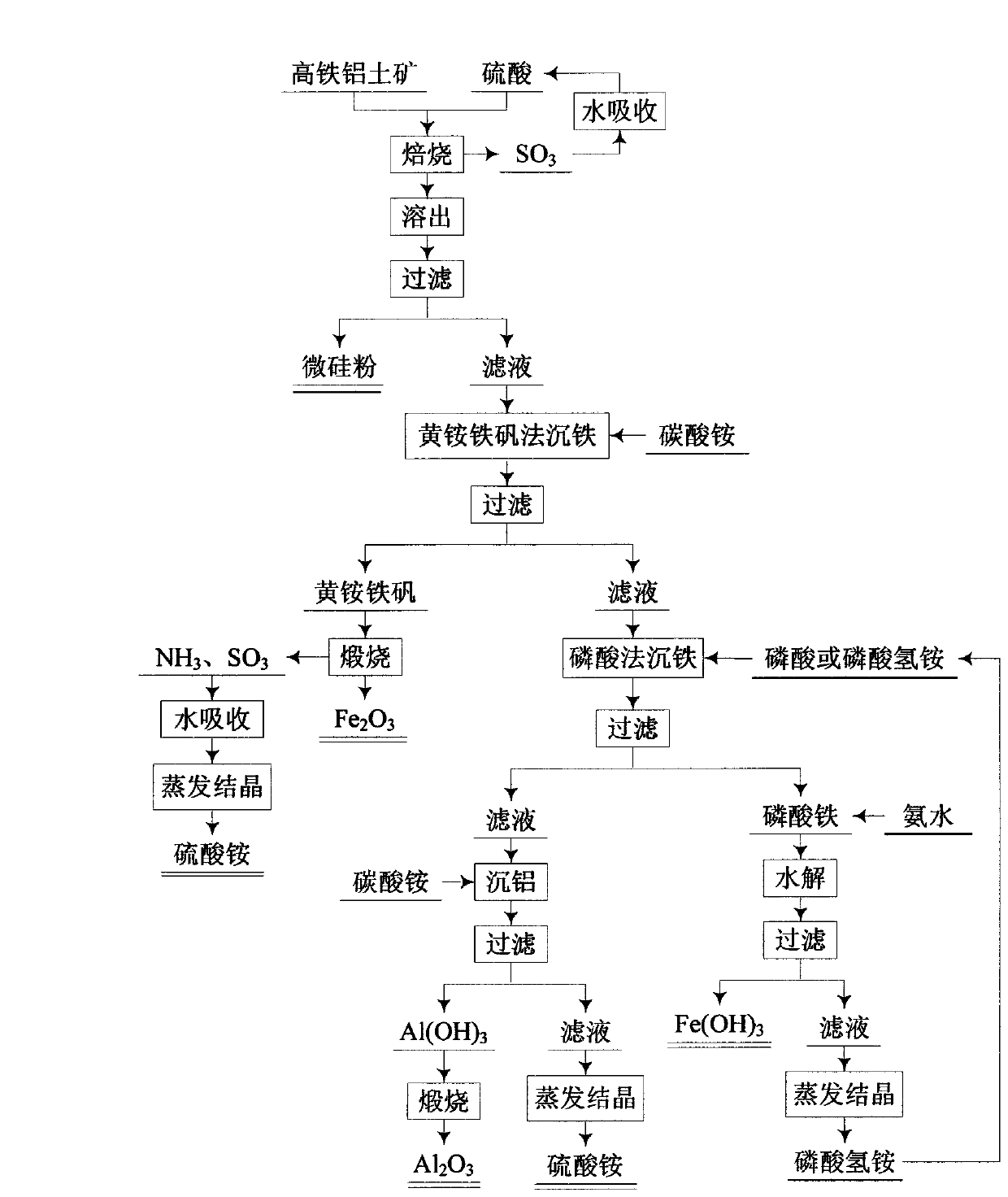

Method for integrally utilizing high-iron-content bauxite

The invention relates to a method for integrally utilizing high-iron-content bauxite, which comprises the following steps that: (1) the high-iron-content bauxite is crushed and finely ground and is then roasted with sulfuric acid; (2) roasted clinker is dissolved and filtered for obtaining coarse aluminum sulfate solution and extracted aluminum slag; (3) the coarse aluminum sulfate solution is subjected to iron settling by a metavoltaite method, then, the deep iron settling is carried out by phosphoric acid or ammonium phosphate, the obtained solution is subjected to aluminum settling, and aluminum hydroxide is obtained; (4) the aluminum hydroxide is calcined for preparing aluminum oxide; (5) ammoniojarosite is calcined for preparing ferric oxide; (6) iron phosphate is hydrolyzed for obtaining ferric hydroxide and ammonium phosphate; and (7) the extracted aluminum slag is directly used as silica fume.

Owner:NORTHEASTERN UNIV LIAONING

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com