Preparation method of Fe2O3/graphene composite material

A composite material and graphene technology, applied in the manufacture of hybrid/electric double layer capacitors, hybrid capacitor electrodes, etc., can solve the problems of affecting the electrochemical performance of materials, fast formation speed, and inability to obtain uniformly dispersed composite materials, etc., to achieve preparation The method is simple and easy to operate, good electrochemical performance, and obvious effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] 1) Prepare 30 mL of graphene oxide solution with a concentration of 0.5 g / mL, and ultrasonically treat it to obtain a uniform and transparent colloidal solution.

[0030] 2) Take 30mL of deionized water, heat it to boiling, add 2mL of saturated ferric chloride solution dropwise, keep boiling for 3min to prepare ferric hydroxide colloid, and then cool naturally.

[0031] 3) Take 2mL of ferric hydroxide colloid, slowly add the solution in 1) while stirring, and sonicate for 30min.

[0032] 4) The above solution was transferred into a 100 mL polytetrafluoroethylene-lined stainless steel hydrothermal kettle, and kept at a constant temperature of 180° C. for 12 hours.

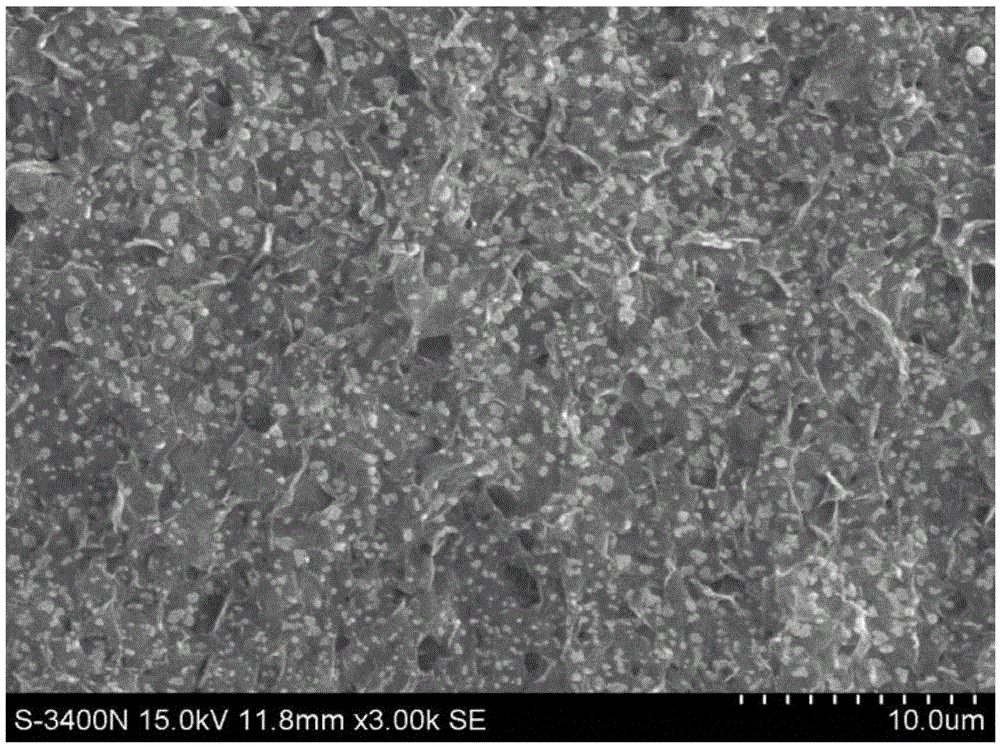

[0033] 5) After the hydrothermal kettle was naturally cooled, the obtained precipitate was washed three times with deionized water, and dried at 80°C. In the obtained composite material, Fe 2 o 3 The particle size is around 500nm. Its scanning electron microscope picture is as figure 1 shown.

[0034] T...

Embodiment 2

[0036] 1) Prepare 30 mL of graphene oxide solution with a concentration of 0.5 g / mL, and ultrasonically treat it to obtain a uniform and transparent colloidal solution.

[0037] 2) Transfer the solution in 1) to an ice bath, and wait for its temperature to drop to 0-5°C.

[0038] 3) Add 1 mL of saturated ferric chloride solution dropwise to the solution in 1), stir while adding, and sonicate for 30 minutes after completion.

[0039] 4) The above solution was transferred into a 100 mL polytetrafluoroethylene-lined stainless steel hydrothermal kettle, and kept at a constant temperature of 180° C. for 12 hours.

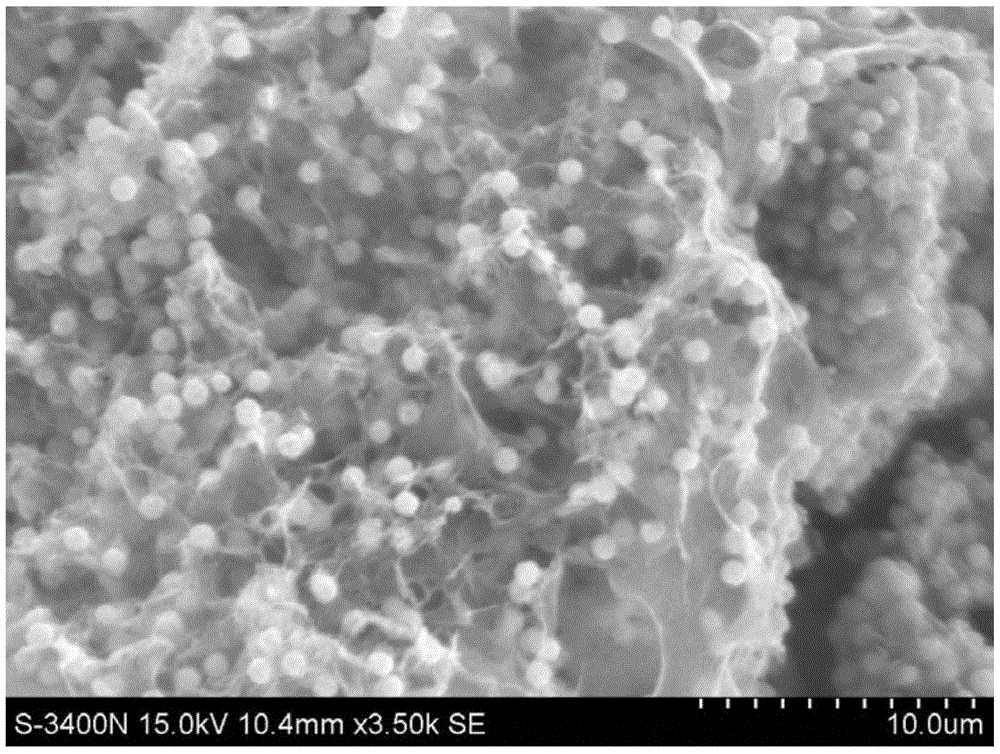

[0040] 5) After the hydrothermal kettle was naturally cooled, the obtained precipitate was washed three times with deionized water, and dried at 80°C. In the obtained composite material, Fe 2 o 3 The particle size is about 500nm, and its scanning electron microscope picture is as follows figure 2 shown.

[0041] cv curve such as Figure 4 As shown in a, the obvious...

Embodiment 3

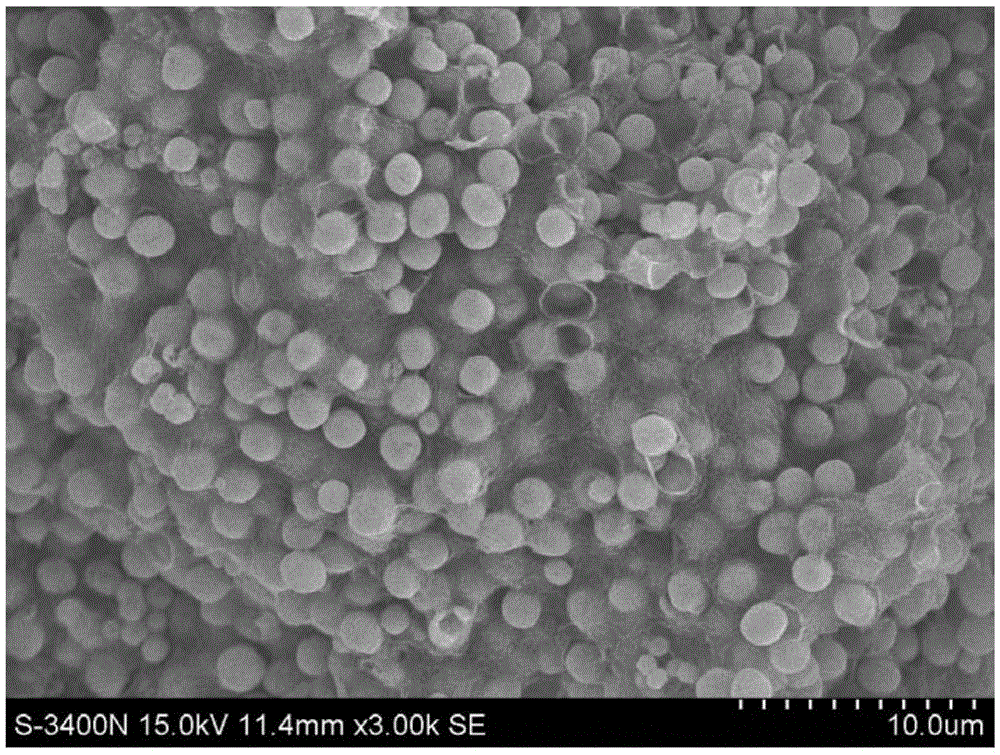

[0043] According to the method of embodiment 2, just do not add ice bath, directly add saturated ferric chloride solution in graphene oxide. The resulting composite material, Fe 2 o 3 The particle size is about 1.2 μm, and its scanning electron microscope picture is as follows image 3 shown.

[0044] cv curve such as Figure 4 As shown in a, the obvious redox peak indicates that the composite material exhibits good electrochemical behavior during cycling. The charge and discharge curve is as Figure 5As shown in a, at a current density of 2A / g, the capacitance reaches 297F / g.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com