Patents

Literature

580 results about "Zinc hydroxide" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Zinc hydroxide Zn(OH)₂ is an inorganic chemical compound. It also occurs naturally as 3 rare minerals: wülfingite (orthorhombic), ashoverite and sweetite (both tetragonal). Like the hydroxides of other metals, such as lead, aluminium, beryllium, tin and chromium, zinc hydroxide (and zinc oxide), is amphoteric. Thus it will dissolve readily in a dilute solution of a strong acid, such as HCl, and also in a solution of an alkali such as sodium hydroxide.

Composition, method of making, and treatment of wood with an injectable wood preservative slurry having biocidal particles

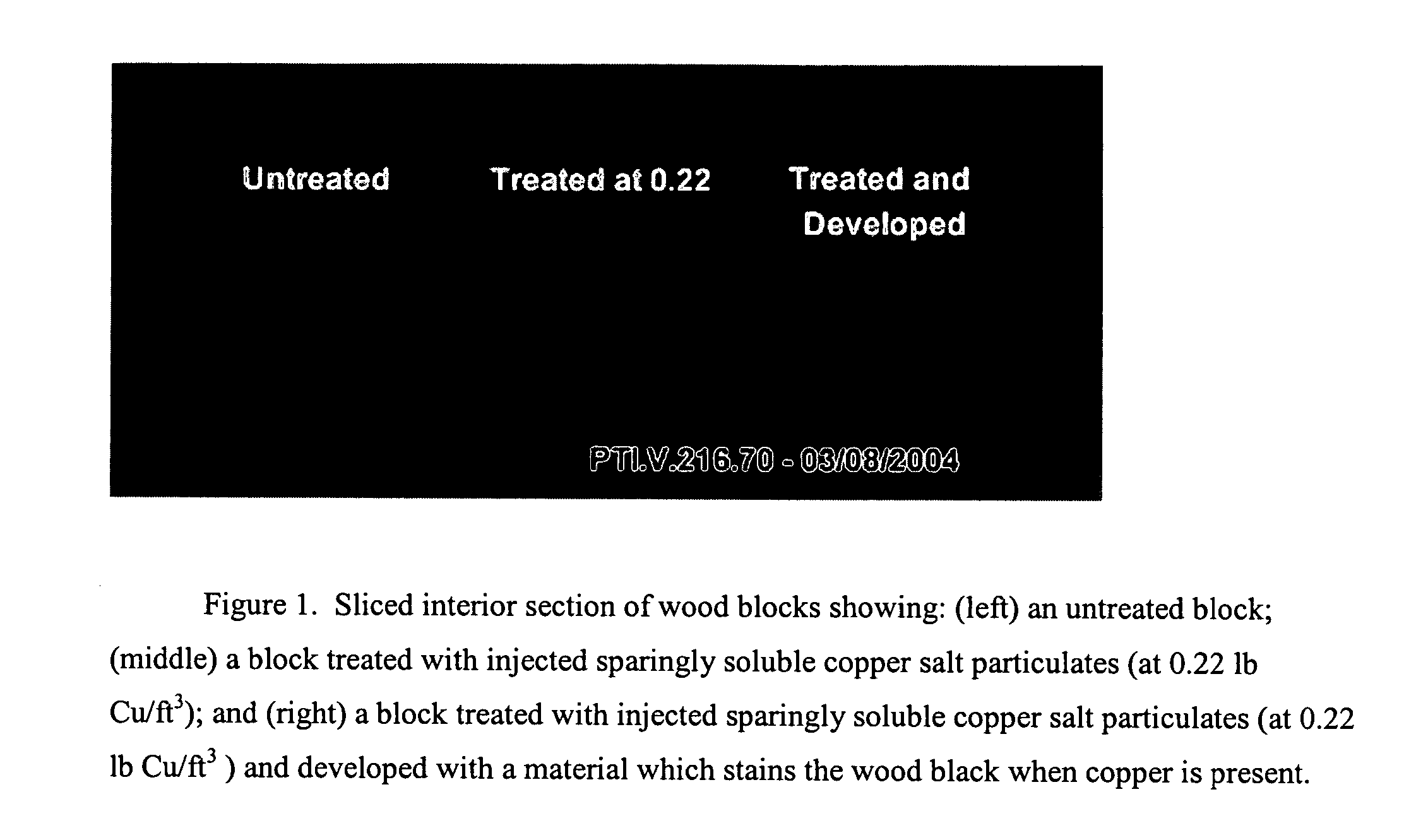

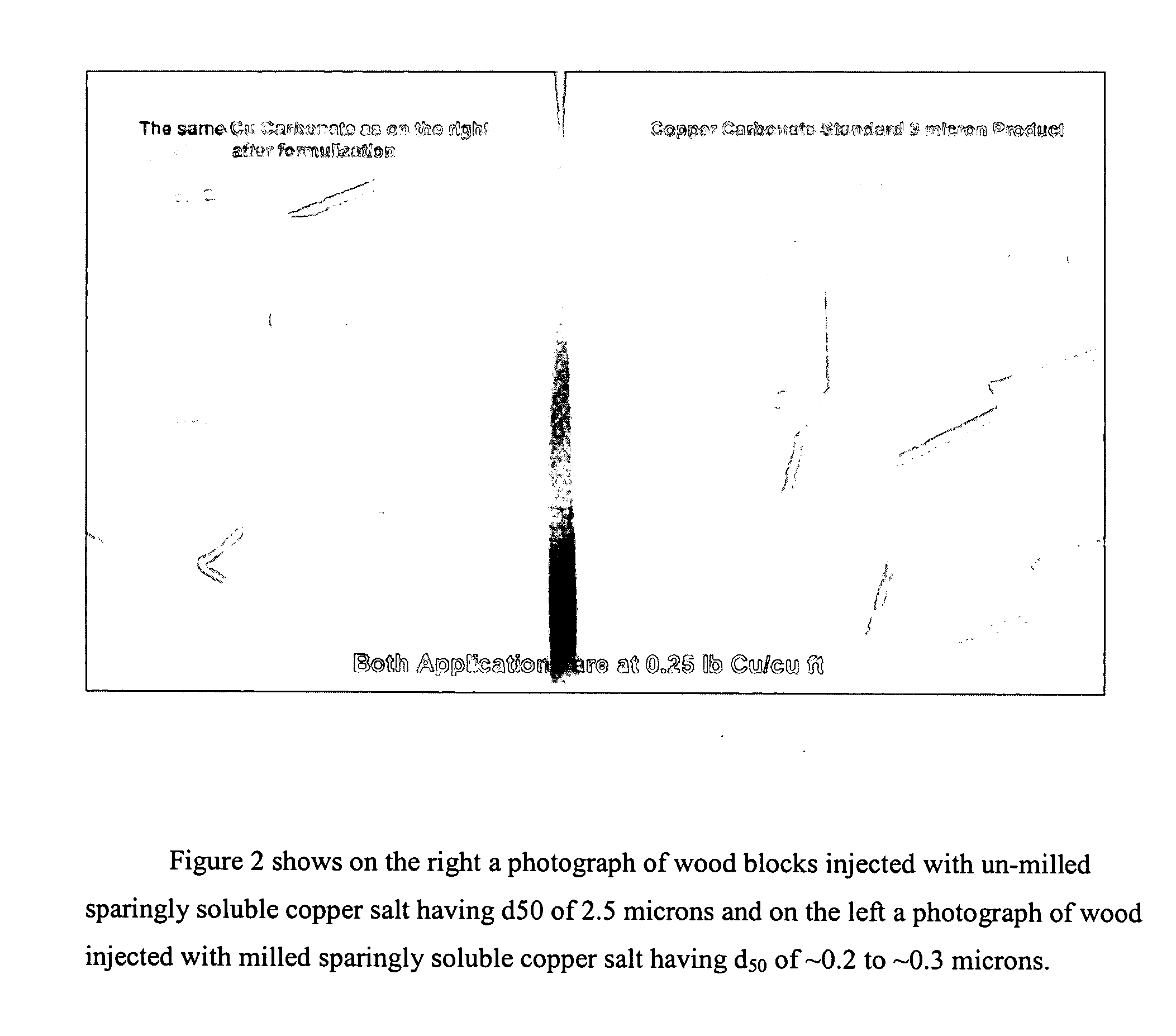

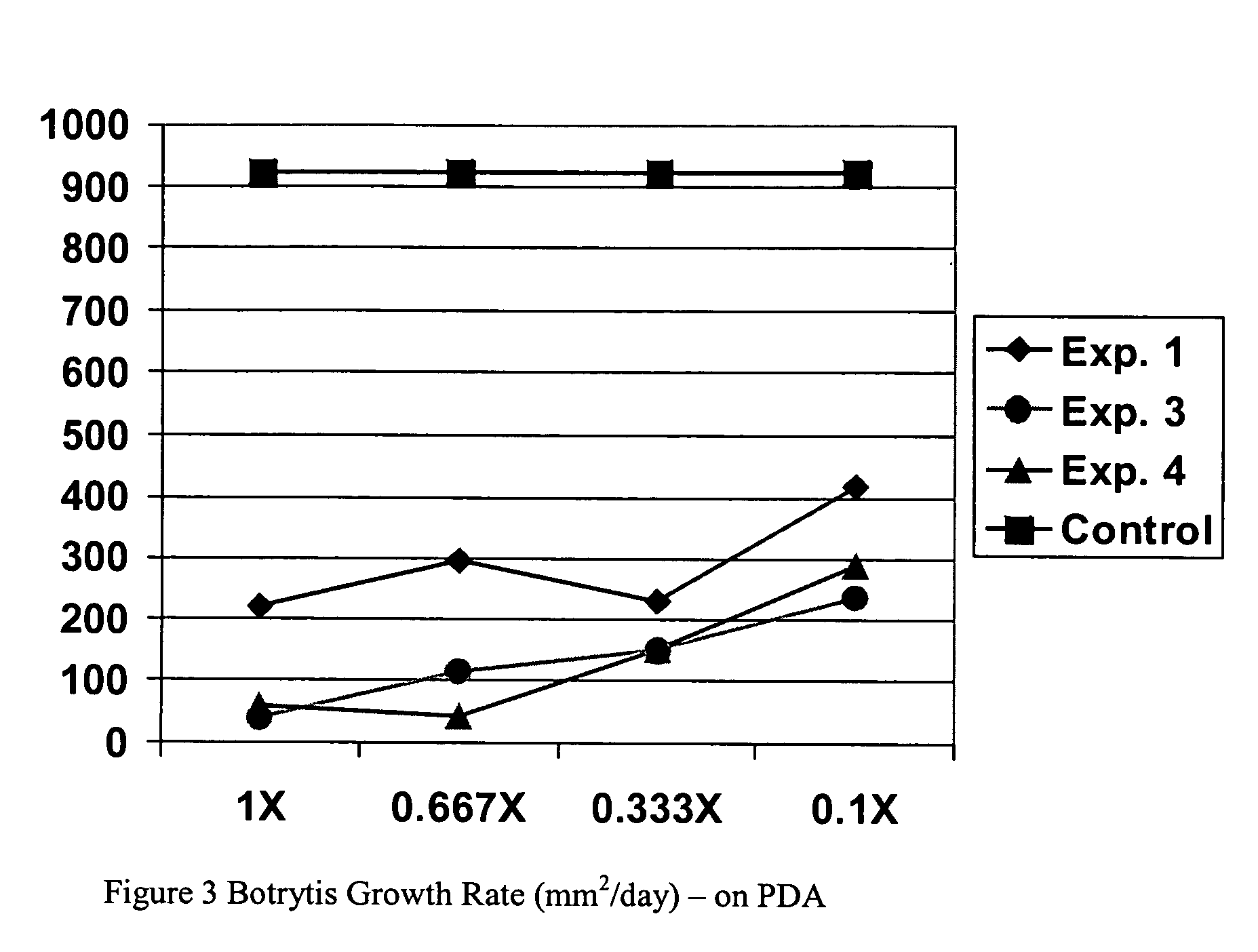

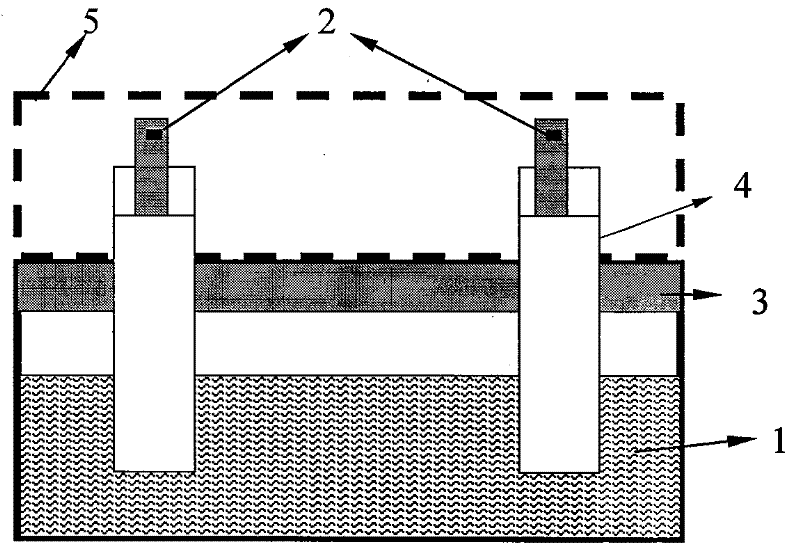

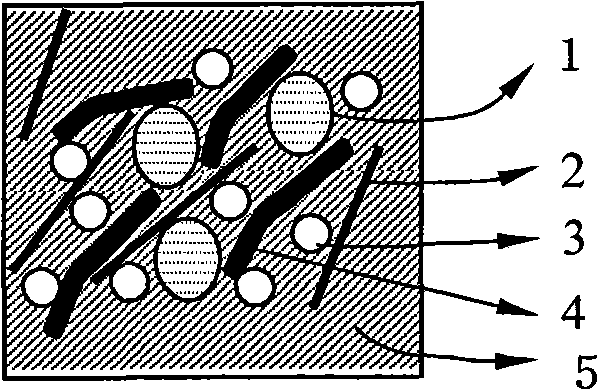

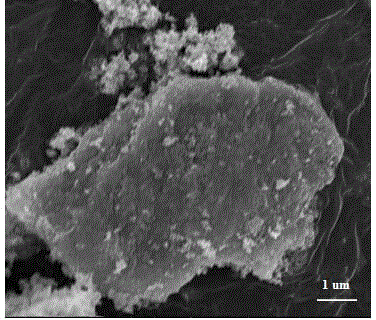

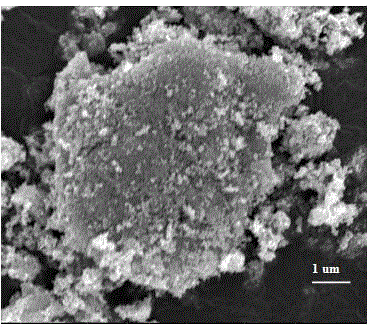

A method of preserving wood includes injecting into the wood an effective amount of a aqueous wood-injectable biocidal slurry, said a wood-injectable biocidal slurry containing dispersants and sub-micron biocidal particles selected from at least one of the following classes: 1) a plurality of particles containing at least 25% by weight of a solid phase of sparingly soluble salts selected from copper salts, nickel salts, tin salts, and / or zinc salts; 2) a plurality of particles containing at least 25% by weight of a solid phase of sparingly soluble metal hydroxides selected from copper hydroxide, nickel hydroxide, tin hydroxide, and / or zinc hydroxide; 3) a plurality of particles containing at least 25% by weight of a solid phase comprising a substantially-insoluble organic biocide selected from triazoles, chlorothalonil, iodo-propynyl butyl carbamate, copper-8-quinolate, fipronil, imidacloprid, bifenthrin, carbaryl, strobulurins, and indoxacarb; 4) a plurality of particles containing on the outer surface thereof a substantially-insoluble organic biocide; 5) a plurality of particles containing a solid phase of a biocidal, partially or fully glassified composition comprising at least one of Zn, B, Cu, and P. The particles may advantageously contain metallic copper, a leachability barrier, pigments, dyes, or other adjuvants disposed on the outer surface thereof.

Owner:OSMOSE

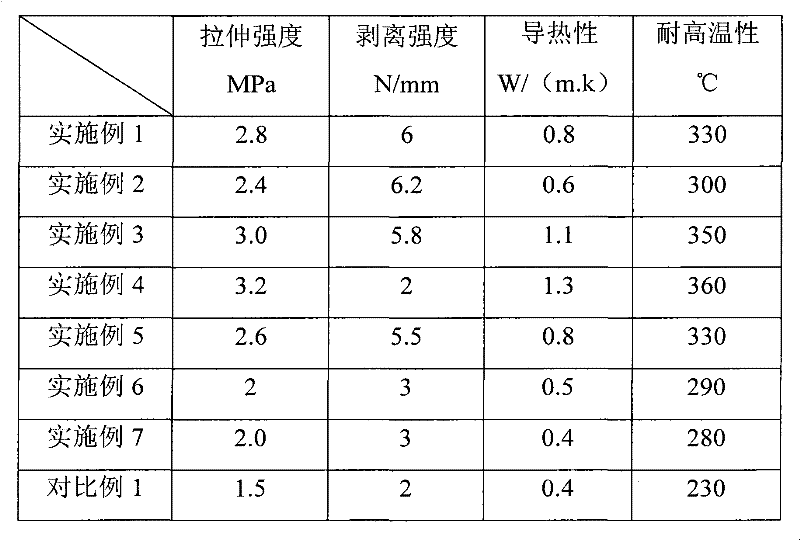

A high flame retardant high thermal conductivity composite material component and its manufacturing method

InactiveCN102260413AImprove thermal conductivityImprove flame retardant performancePolymer sciencePhenol formaldehyde resin

The invention relates to a high-molecular composite material having performances of high heat conduction and high flame retardation, the invention is characterized in that the composite material does not contain any halogen or a non environmentally-friendly heavy metal fire retardant, the flame resistance is capable of reaching a UL94 V0 standard, simultaneously, the composite material has good heat conducting performance, the heat conduction coefficient is more than 0.5 W / m. DEG C. The composite material provided in the invention has good injection moulding performance, extruding performance and hot pressing performance. The composite material comprises the following basic components: 1) one or a plurality of metal hydroxides, such as aluminum hydroxide, magnesium hydroxide, zinc hydroxide and the like, wherein the weight content is 10-70%, 2) about 0.2%-60% of the weight content of expandable graphite flaky powder, the lamina size is more than 10 um, and the expandable coefficient is more than or equal to 20 times; 3) 15%-70% of the weight content of matrix resins, such as epoxy resin, organic silicone resin, phenolic resin, thermosetting polyester resin and thermoplastic resins of nylon 6, nylon 66, PBT, PP, HDP and the like. The composite material component of the invention can be directly used for radiators such as LED, electric appliances and electronic components, the heat can be radiated into colder environment so that the operating temperature of the electronic device can be reduced.

Owner:HEFU NEW MATERIAL TECH WUXI

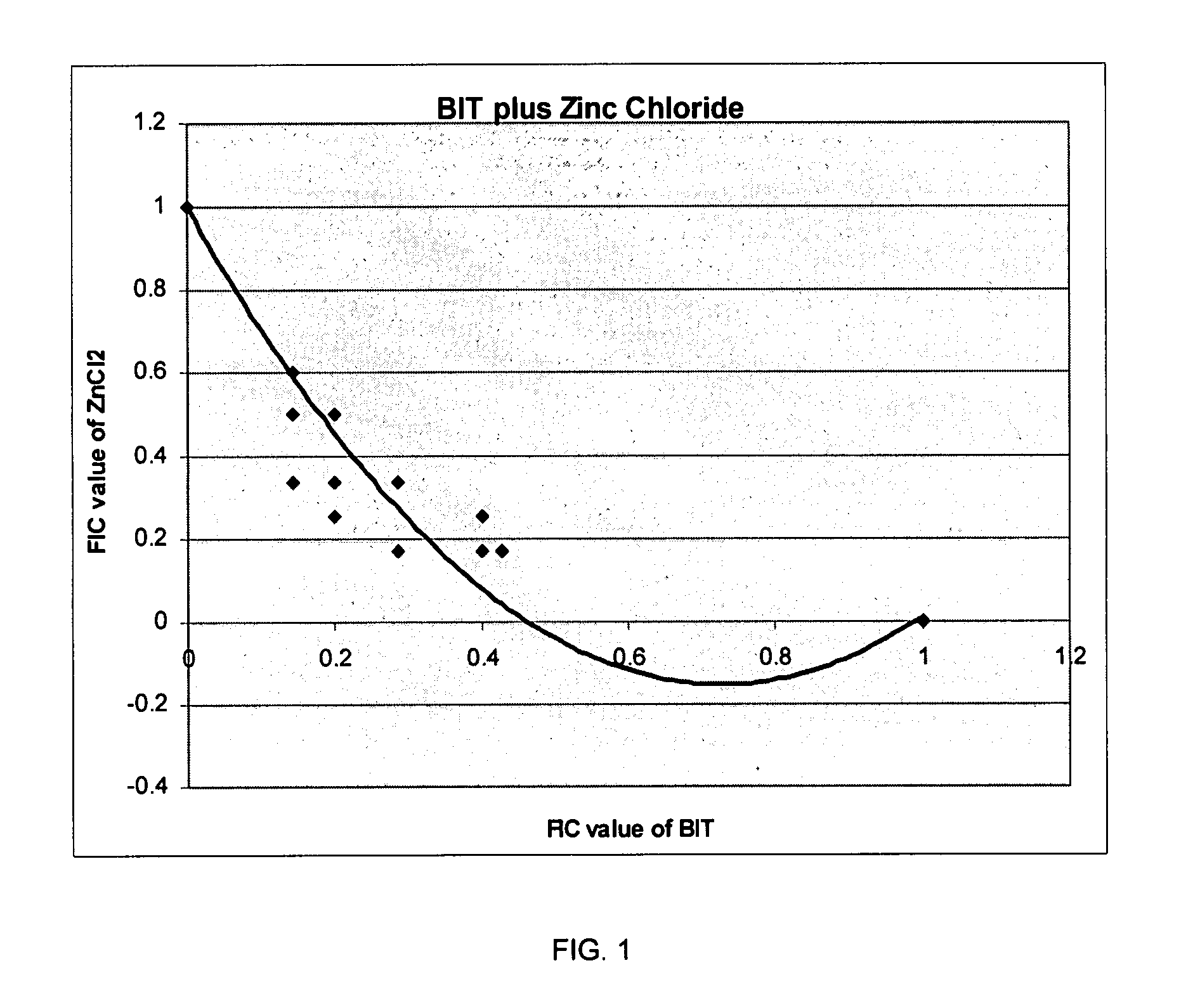

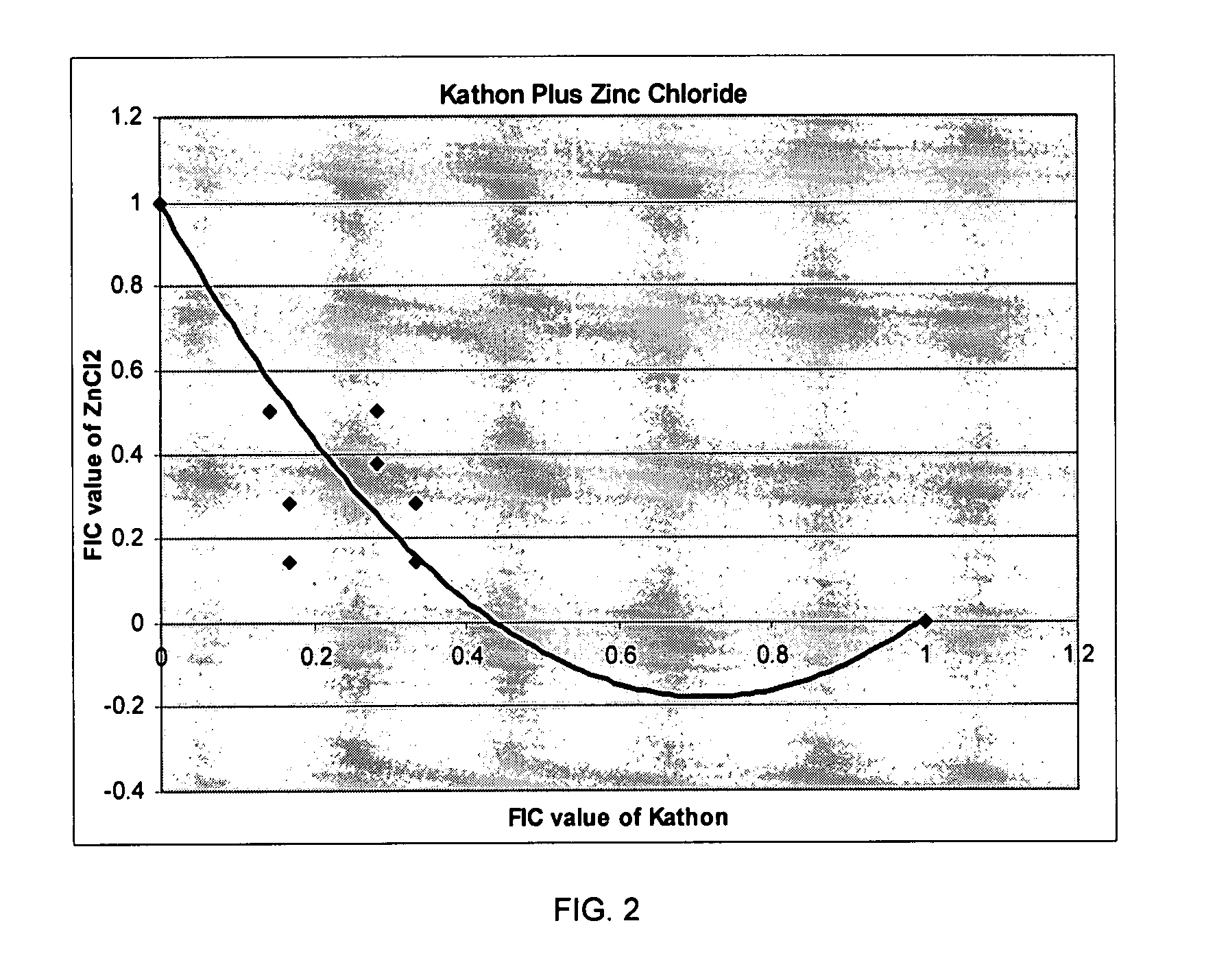

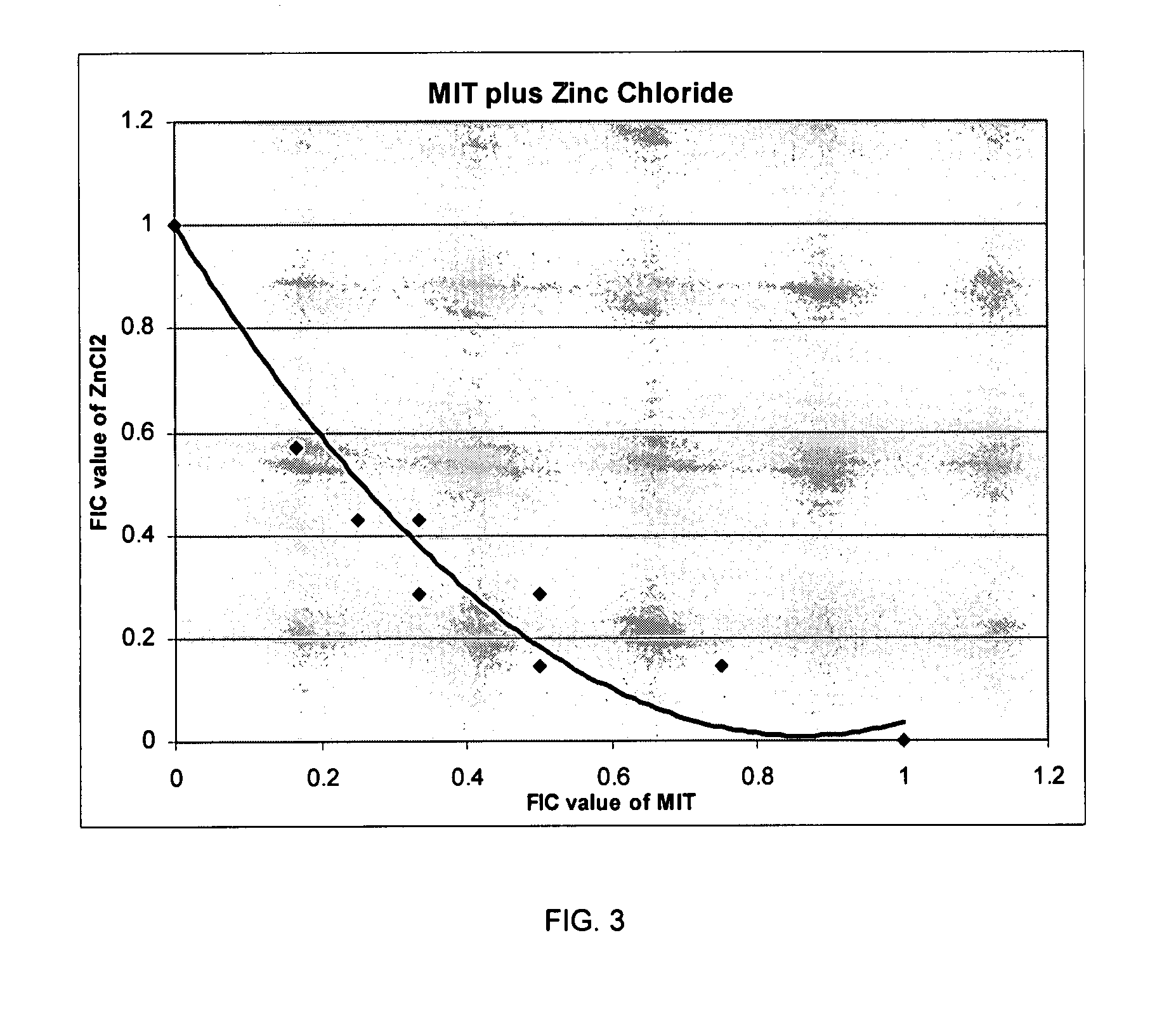

Isothiazolinone biocides enhanced by zinc ions

The present invention relates to an antimicrobial composition comprising an isothiazolinone, such as 1,2-benzisothiazolin-3-one, and a zinc compound selected from zinc salts, zinc oxides, zinc hydroxides or combinations thereof. Useful zinc salts include for example, oxides, sulfates, chlorides, and combinations thereof. In use, the zinc from the zinc compound enhances the antimicrobial activity to the isothiazolin-containing composition. This enhancement permits achieving the desired antimicrobial activity at a lower usage rate than is achieved using the isothiazolinone in the absence of the zinc compound. The antimicrobial composition can also contain co-biocides, such as pyrithiones, including zinc pyrithione or copper pyrithione.

Owner:ARCH CHEM INC

Negative electrode material for alkaline secondary zinc electrode

InactiveCN1595688AExtend your lifeImprove performanceAlkaline accumulatorsElectrode manufacturing processesZinc hydroxideManganese

The invention relates to negative electrode material for alkaline secondary zinc electrode , including calcium carbonate and millimicron oxide, the millimicron oxidation is transition metal or rare earth oxide. The mass percentage of calcium carbonate and millimicron oxide is: 80-98%, 2-20%, ratio of material is according to calcium carbonate [Ca(OH)2 .Zn(OH)2.XH2O(x=2,3)], in the condition of 150~500r / m and ratio of 3~20:1, by the protection of argon gas, calcium carbonate is formed by the mixture of calcium hydroxide(or calcium oxide), zinc hydroxide (or zinc oxide) and water after 5~25 hours. The invention has low cost, excellent property and no pollution, and multi-hole alkaline secondary zinc electrode made by mixture of calcium carbonate and millimicron oxide has better performance of discharge, suitable for various chargeable alkaline battery of Zn / Ni, Zn / Ag and Zn / Mn using Zn as negative electrode .

Owner:NANKAI UNIV

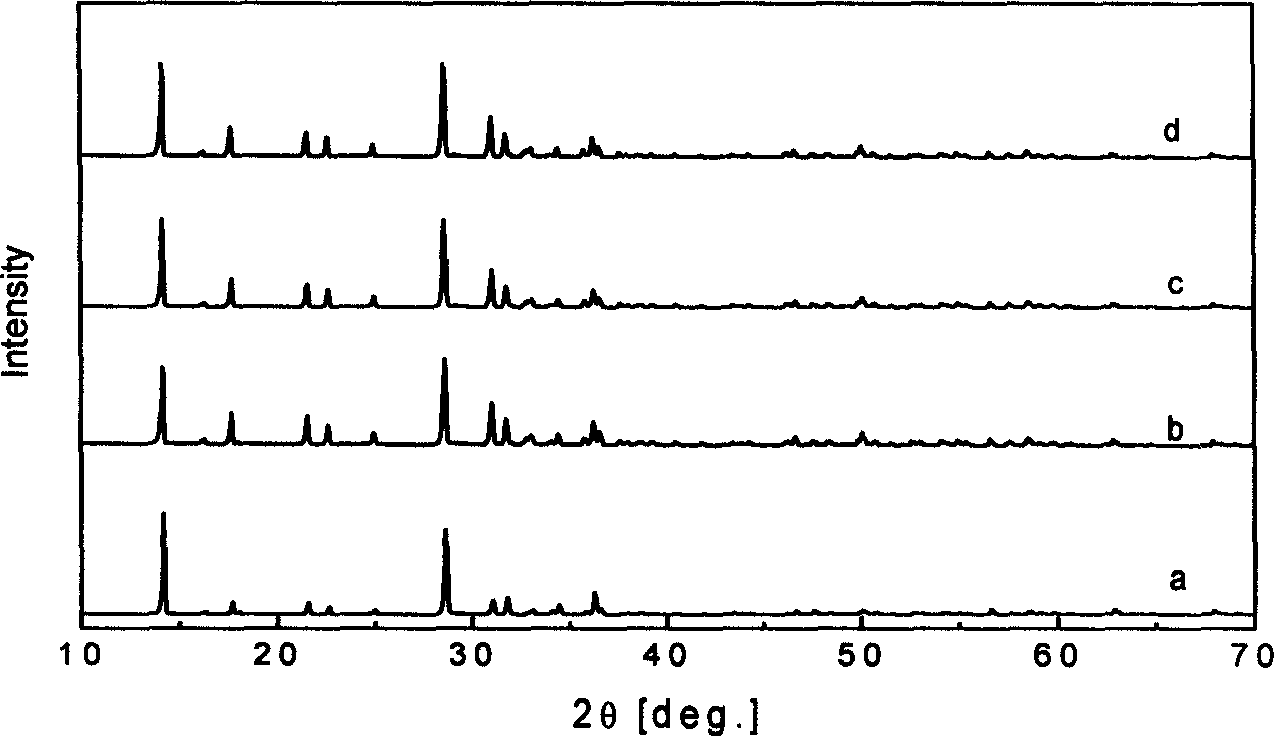

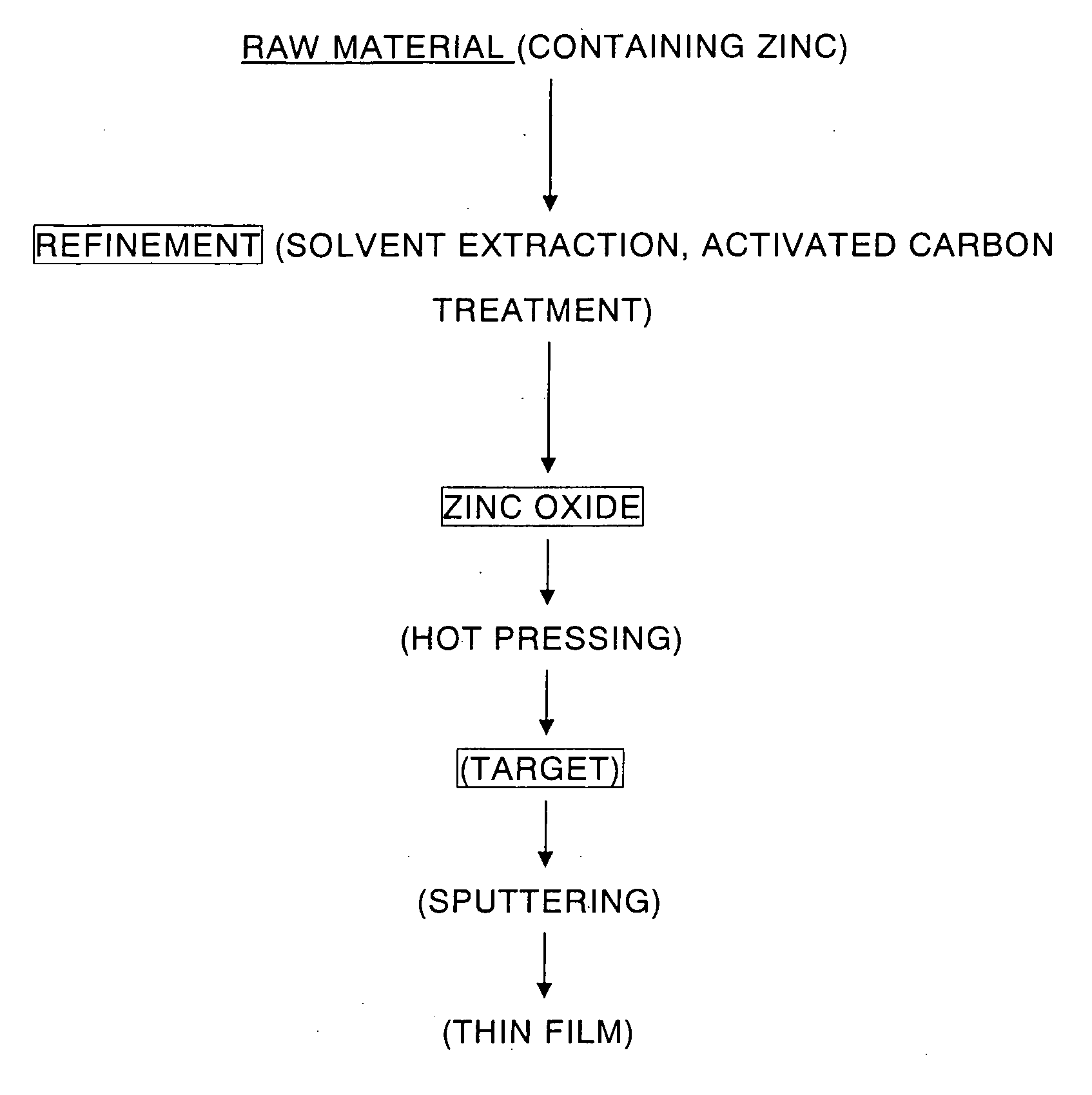

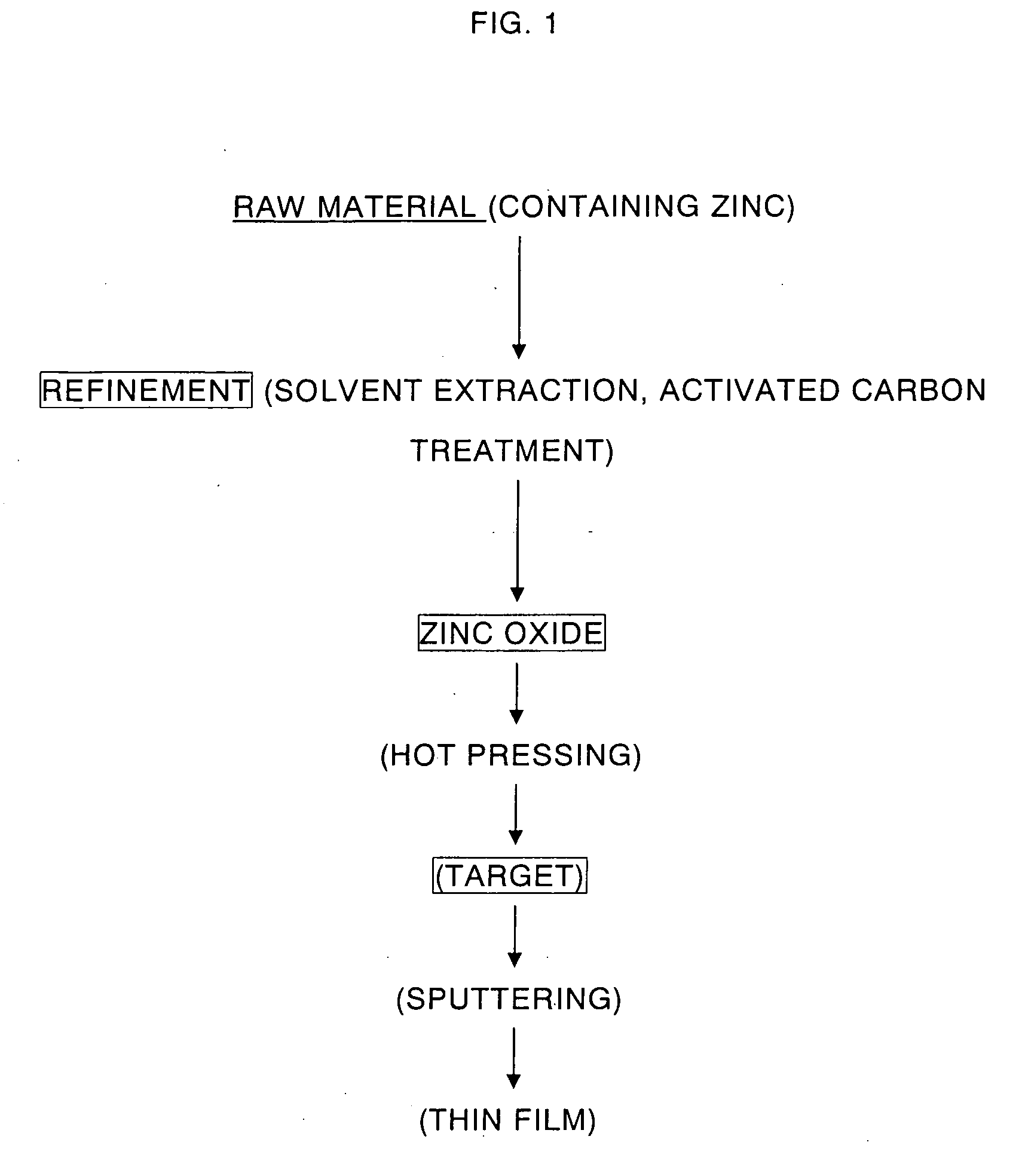

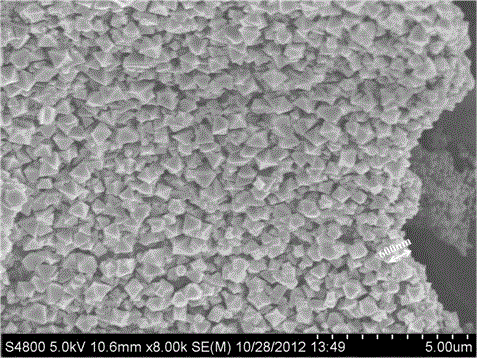

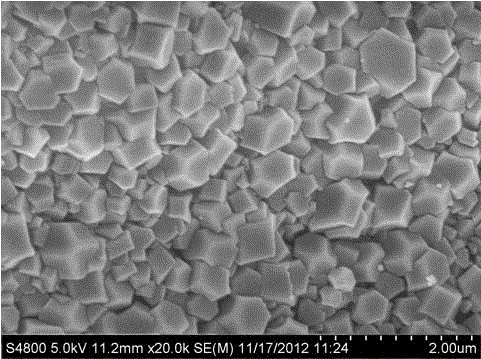

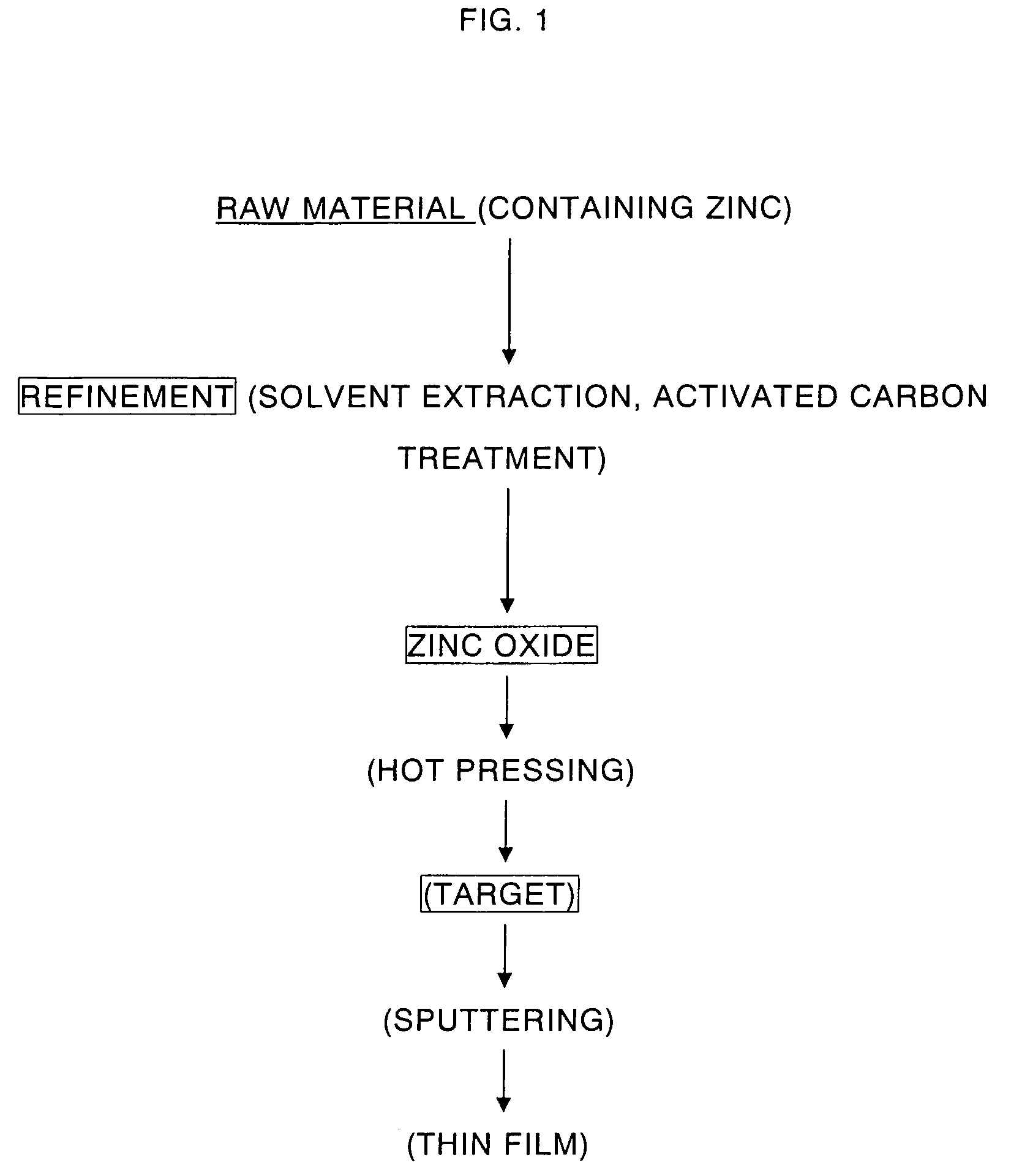

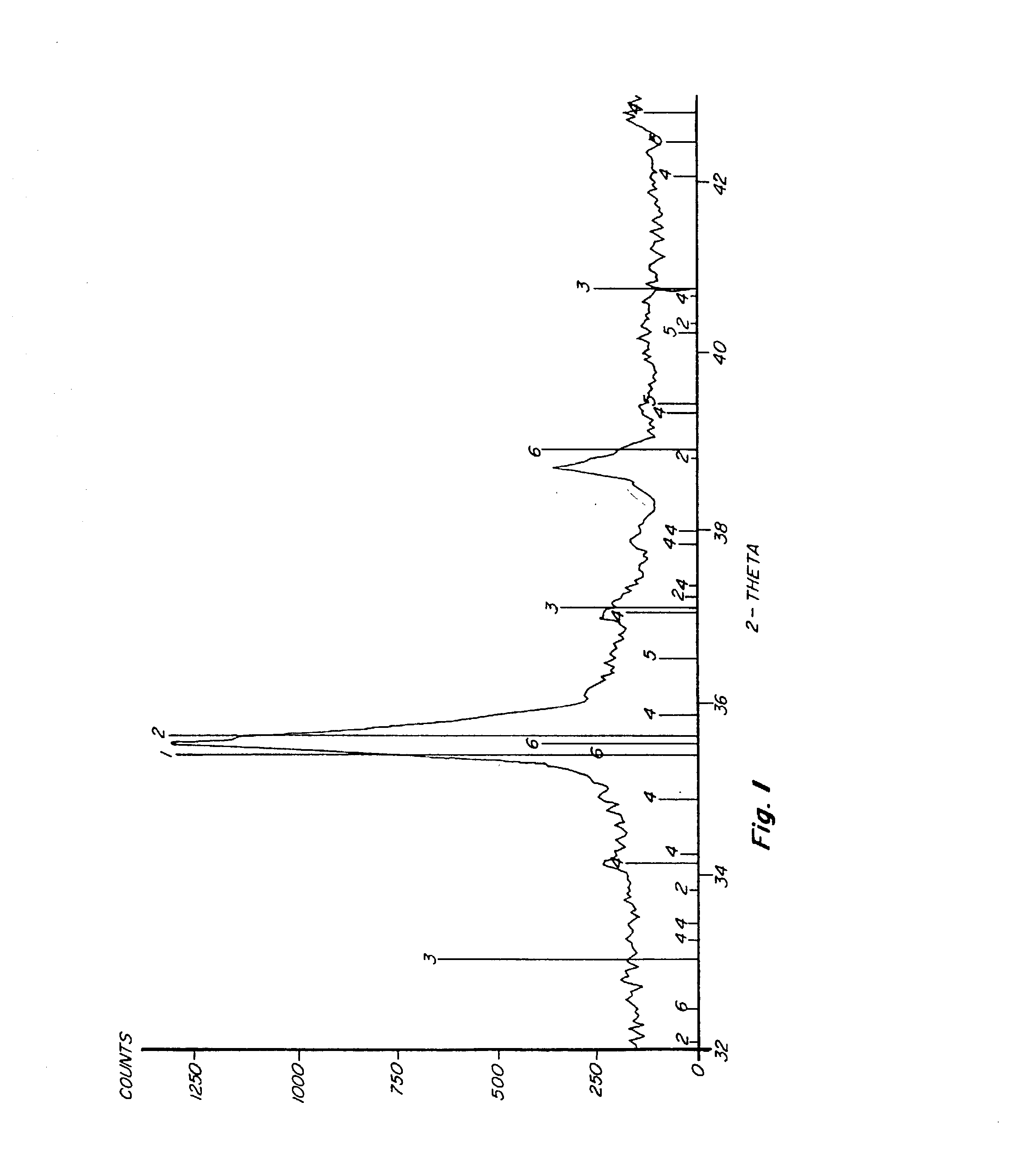

High purity zinc oxide powder and method for production thereof, and high purity zinc oxide target and thin film of high purity zinc oxide

InactiveUS20070098626A1High purityReduce manufacturing costCellsZinc halidesZinc hydroxideActivated carbon

Provided is a manufacturing method of high purity oxide powder including the steps of subjecting a raw material such as Zn-containing scrap to acid leaching or electrolytic extraction, thereafter performing solvent extraction and activated carbon treatment thereto in order to remove impurities, neutralizing the resultant solution freed of impurities with an alkaline solution to obtain zinc hydroxide, and firing the zinc hydroxide to obtain zinc oxide. Provided are high purity zinc oxide efficiently freed of impurities, in particular C, Cl, S and Pb impurities, at low cost and the manufacturing method thereof; a target manufactured by firing the high purity zinc oxide; and a high purity zinc oxide thin film obtained by the sputtering the target.

Owner:JX NIPPON MINING& METALS CORP

Preparation method of porous nano zinc oxide (ZnO)

InactiveCN102515246AZinc oxides/hydroxidesMetal/metal-oxides/metal-hydroxide catalystsZinc hydroxideDistillation

The invention discloses a preparation method of porous nano zinc oxide (ZnO). Zinc hydroxide gel is obtained through reaction and centrifugal separation with zinc salt, alkali and deionized water as raw materials according to the mass percent of zinc salt, alkali, sublimable compound template, amine chelant and deionized water of 0.001%-85%: 0.00001%-80%: 0.001%-65%: 0.001%-80%: 0.001%-95%. Wet zinc hydroxide products are obtained through processes of distilled water washing, ultrasonic dispersion, centrifugal separation and the like of zinc hydroxide gel, sublimable compound template, amine chelant and deionized water are added then, zinc hydroxide gel is dissolved to obtain solution through ultrasonic processing, and porous nano ZnO powder is obtained after processes of reduced pressure distillation of removal solvent and volatile constituent, drying, roasting, grinding and the like. The preparation method is simple and easy in process, small in investment and beneficial for popularization and application.

Owner:NANJING FORESTRY UNIV

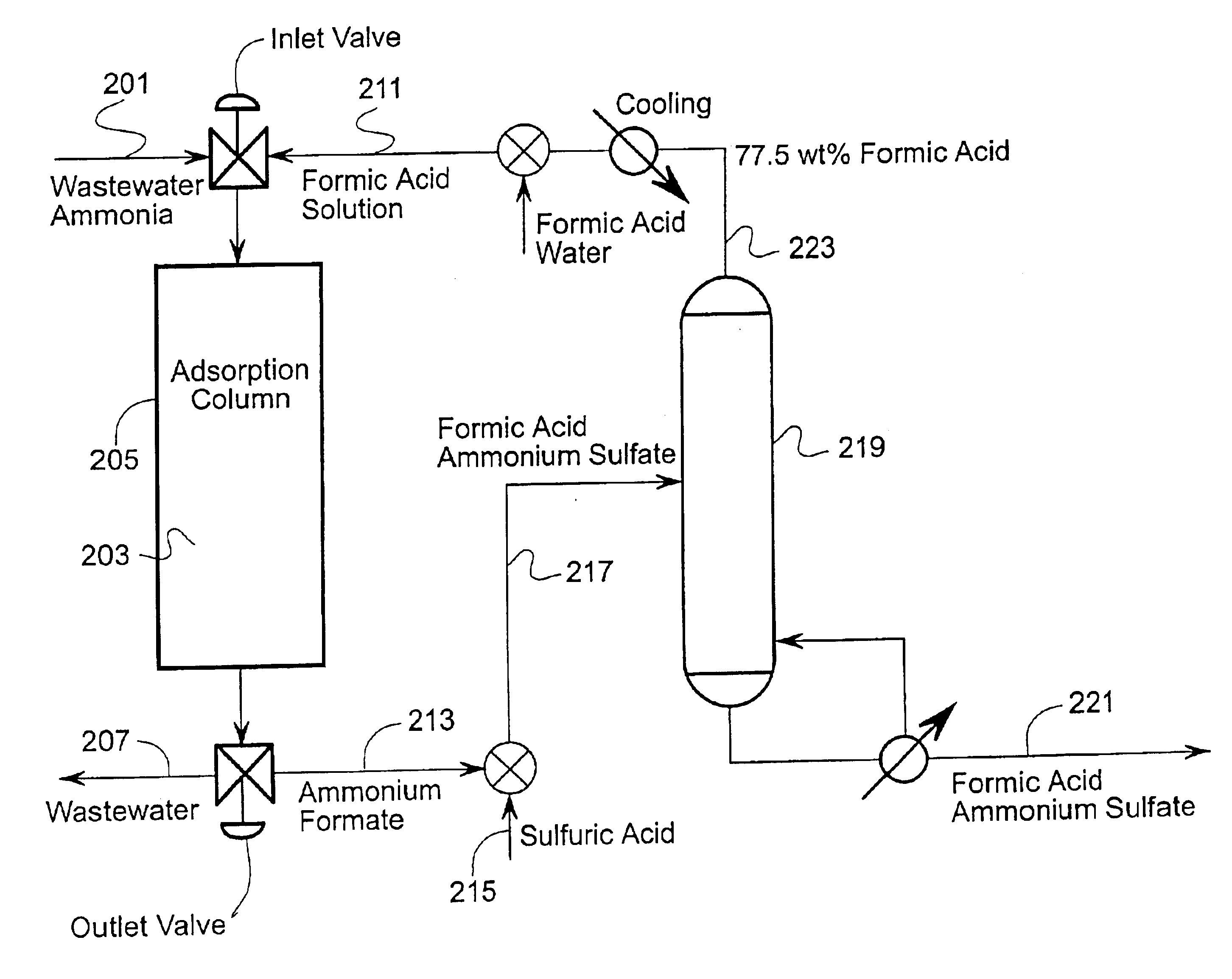

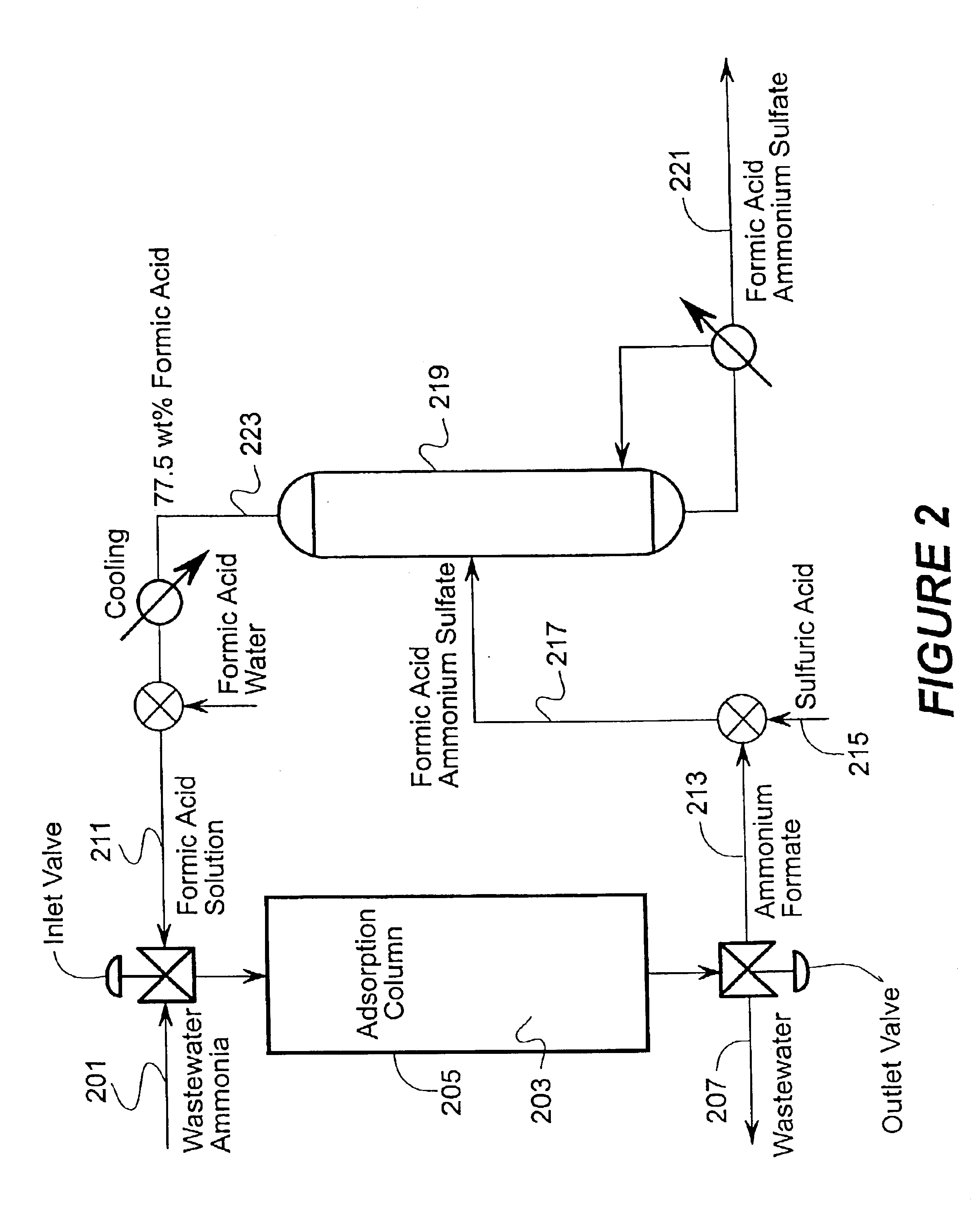

Apparatus and method for ammonia removal from waste streams

InactiveUS6838069B2Process economyCyanogen compoundsIon-exchanger regenerationZinc hydroxideDecomposition

Apparatus, materials, and methods for removing ammonia from fluid using metal hydroxides (e.g. zinc hydroxide) and metal cation loaded media (e.g. zinc loaded ion exchange resins); the metal hydroxides and metal cation loaded media may be regenerated with a weak acid (pKa between 3 and 7). Alternatively, ammonia is removed from fluids by using H2SO4 and ZnSO4 and metal cation loaded media; the metal cation loaded media may be regenerated with H2SO4 and ZnSO4; the ammonia containing H2SO4 and H2SO4 may be concentrated as necessary to form (NH4)2SO4.ZnSO4.6H2O (ammonium zinc sulfate hexahydrate) crystals. These crystals are removed from the mother liquor and heated to temperatures exceeding 200° C. releasing NH3 and H2O vapor upon the decomposition of the crystals.

Owner:BATTELLE MEMORIAL INST

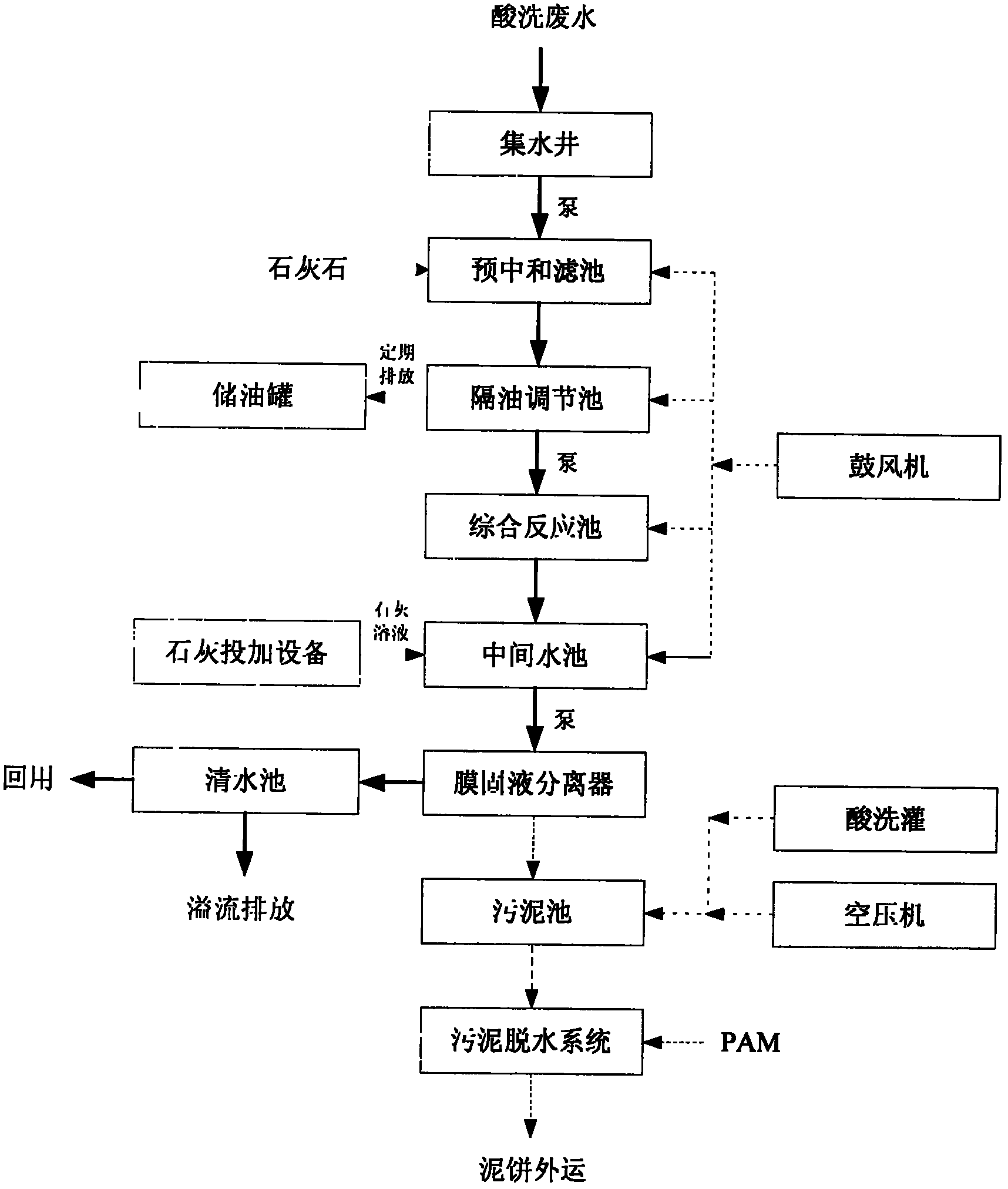

Method for treating acid-washing wastewater and metallic ions in iron and steel industry

InactiveCN102107963ALow running costGuaranteed uptimeWater contaminantsMultistage water/sewage treatmentFerric hydroxideZinc hydroxide

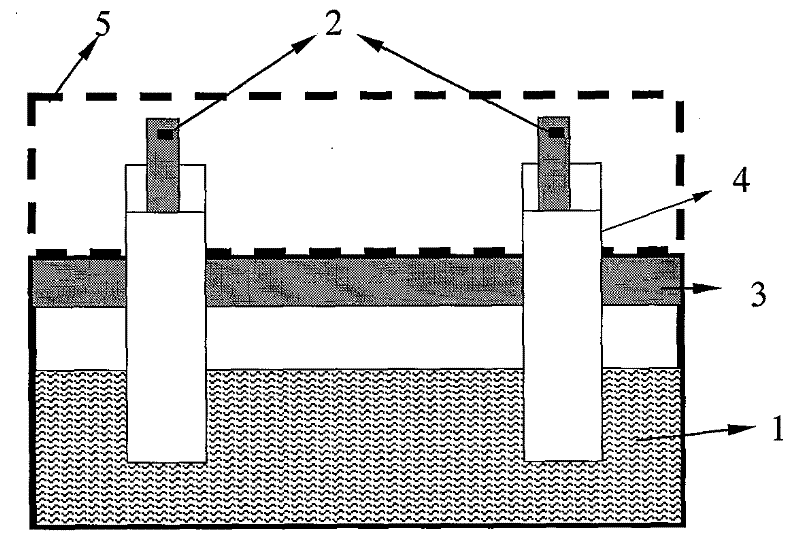

The invention provides a method for treating acid-washing wastewater and metallic ions in iron and steel industry, which comprises steps as follows: acid-washing wastewater naturally flows into a water collecting well and enters a preneutralization filter chamber under the elevation action of a pump, the preneutralization filter chamber is provided with 10-200mm limestone which is in a graded distribution mode, and after the acid-washing wastewater is preneutralized by the limestone, the pH value of the effluent water is controlled at 5-6, wherein the method provided by the invention greatly lowers the chemical expenses and operating cost as compared with the conventional method of directly adding an alkali solution; the acid-washing wastewater, which is subjected to initial pH value regulation, naturally flows into an oil separation regulating chamber, so that iron ions in the wastewater react with the alkali solution to form a precipitation mixture of ferric hydroxide, zinc hydroxide and the like; and the wastewater is elevated into a membrane solid-liquid separator to complete solid-liquid separation, so that the wastewater can be discharged after reaching the standard. The invention thoroughly solves the problems that the precipitate can not easily settle, the iron can not be easily removed, and the iron ions are dissolved out. The invention has the advantages of simple technique, high economy, low requirements for technical levels of workers, and high controllability, is reliable to operate, and has wide market prospects.

Owner:TIANJIN ACADEMY OF ENVIRONMENTAL SCI

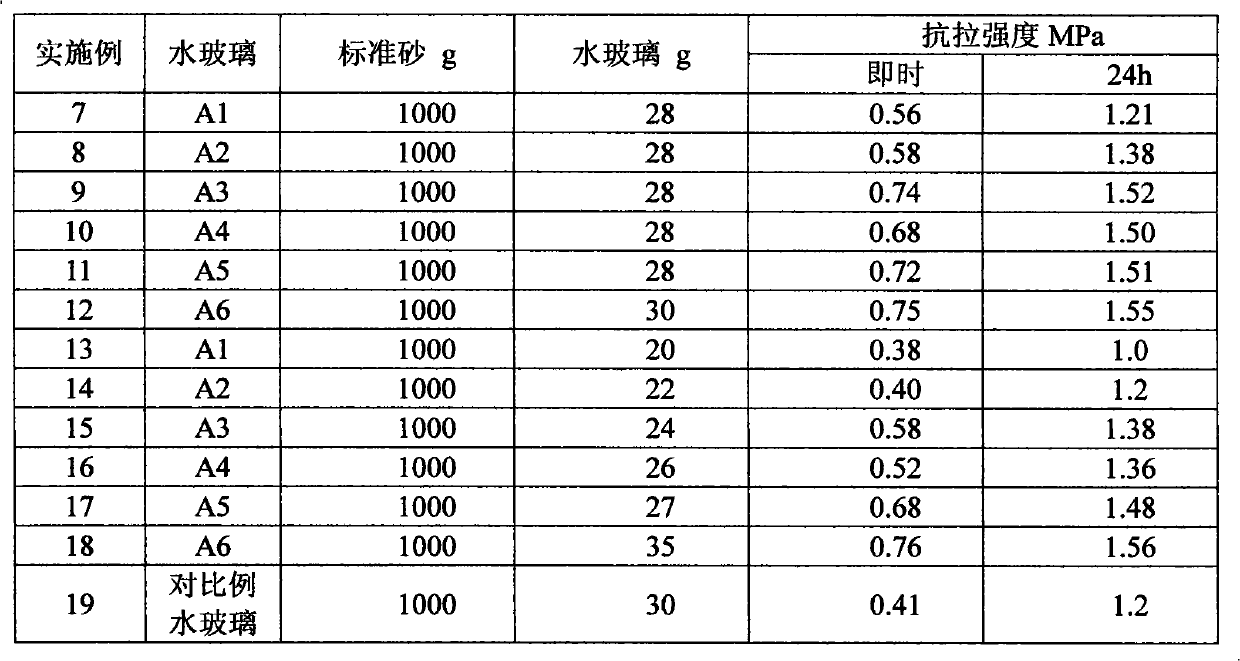

Modified sodium silicate binder for cold core box and preparation thereof

ActiveCN101947637AWide variety of sourcesImprove working environmentFoundry mouldsFoundry coresZinc hydroxideAluminium hydroxide

The invention aims to provide a modified sodium silicate binder for a cold core box and a preparation method thereof. The binder has the advantages of wide raw material sources, no toxicity or smell and good mechanical property and is applicable to mechanized core manufacture of the cold core box and manual core manufacture. The modified sodium silicate binder comprises the following chemical compositions in percentage by mass: 20 to 30 percent of SiO, 10 to 20 percent of Na2O, 0.5 to 19 percent of K2O, 1.0 to 20 percent of modifier and the balance of water, wherein the modifier can be aluminium hydroxide and / or zinc hydroxide, or one or more of amylin, sugar, molasses, polyacrylamide, sodium polyacrylate, sodium tripolyphosphate, cellulose, humic acid, sodium humate, sorbierite, xylitol and sodium silicate are added.

Owner:SHENYANG HYATON FOUNDRY MATERIAL

Method for recycling iron and zinc containing waste hydrochloric acid solution

ActiveCN105696010ATake advantage ofSolve the problem of no separation and recyclingProcess efficiency improvementZinc hydroxideChloride

The invention discloses a method for recycling an iron and zinc containing waste hydrochloric acid solution. The method specifically comprises the following steps that 1, acid consuming and reducing are carried out, acidity is made to meet the requirement, and ferric iron in waste acid is reduced into ferrous iron; 2, zinc and iron are extracted and separated, and a ferrous chloride solution is obtained; 3, an organic phase transfers zinc into a strip liquor through reverse extraction, and the organic phase is extracted for reuse; and 4, the strip liquor is subjected to subsection kalizing treatment, zinc hydroxide is obtained, and the strip liquor is reused. According to the method, iron and zinc are separated through different extracting capacities of N235 to the ferrous iron and zinc, and therefore pure ferrous chloride liquid and zinc hydroxide solids are obtained. Ferrous chloride can be oxidized into ferric trichloride, and ferrous chloride and ferric trichloride both can be used as a water treatment agent; and zinc hydroxide can be used as a raw material for preparing zinc oxide or zinc chloride.

Owner:3R ENVIRONMENTAL TECH CO LTD

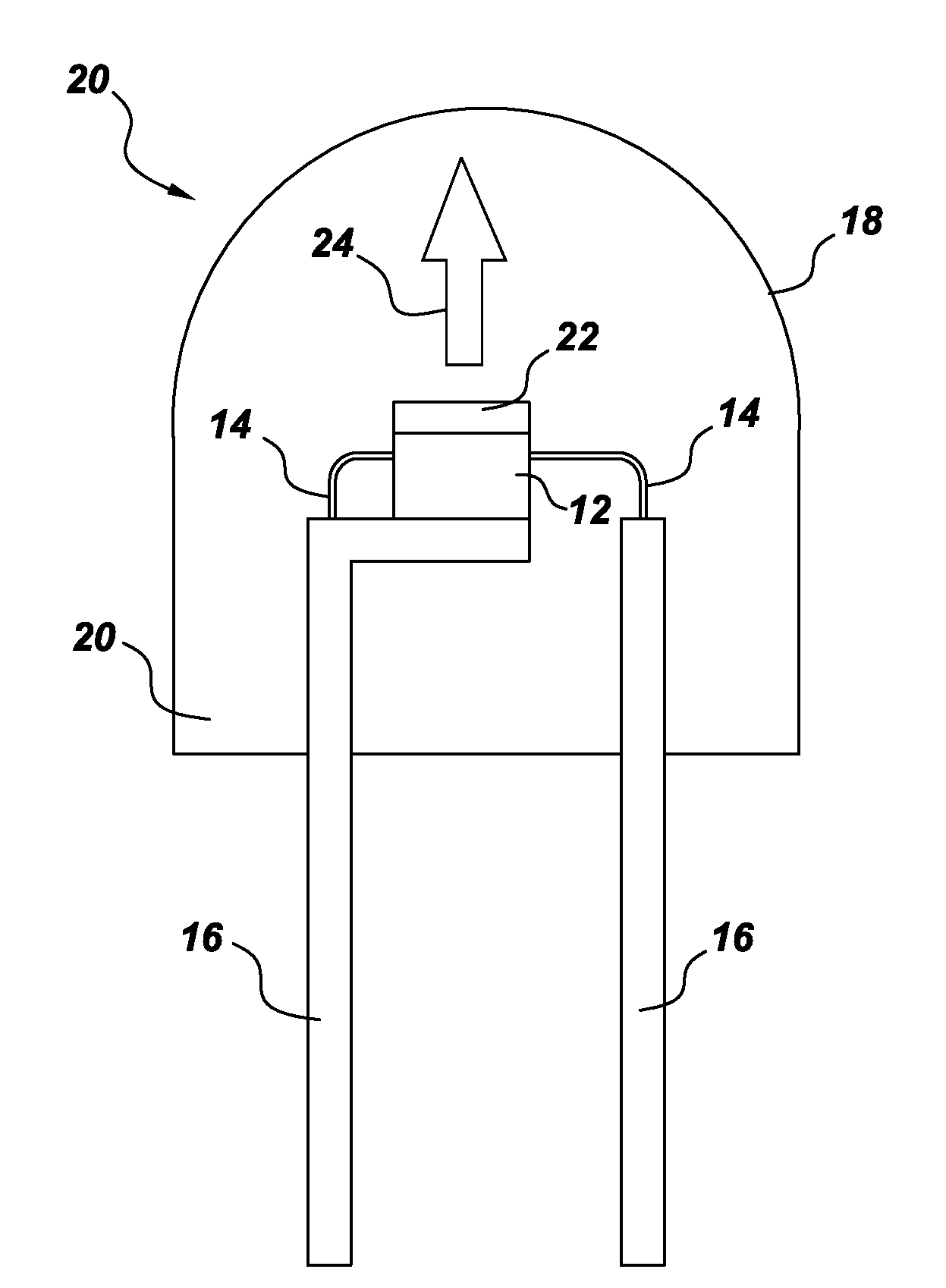

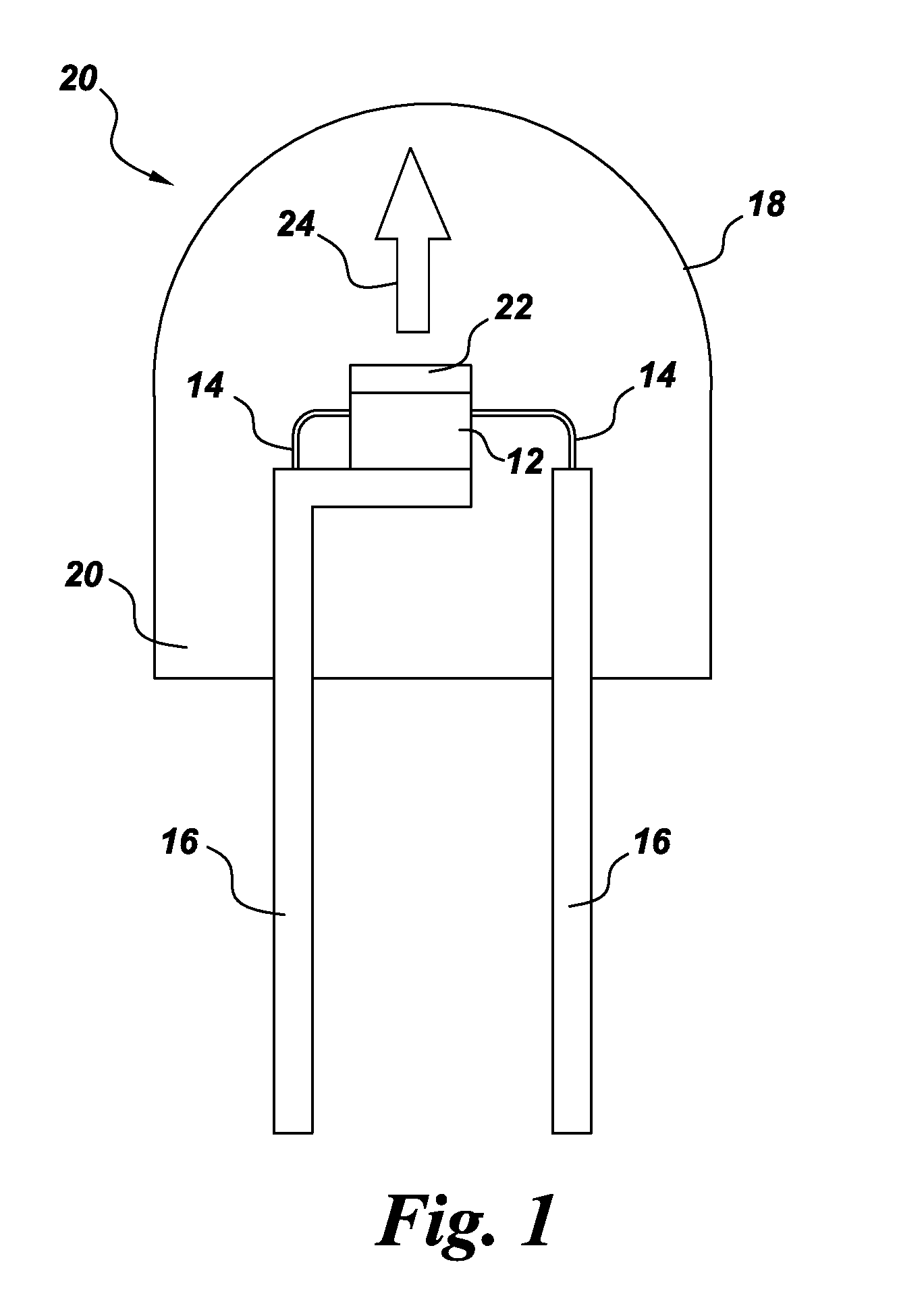

Color stable phosphors

ActiveUS20110279011A1Discharge tube luminescnet screensLamp detailsZinc hydroxideMagnesium phosphate

An LED lamp includes a light source configured to emit radiation with a peak intensity at a wavelength between about 250 nm and about 550 nm; and a phosphor composition configured to be radiationally coupled to the light source. The phosphor composition includes particles of a phosphor of formula I, said particles having a coating composition disposed on surfaces thereof;((Sr1−zMz)1−(x+w)AwCex)3(Al1−ySiy)O4+y+3(x−w)F1−y−3(x−w) Iwherein the coating composition comprises a material selected from aluminum oxide, magnesium oxide, calcium oxide, barium oxide, strontium oxide, zinc oxide, aluminum hydroxide, magnesium hydroxide, calcium hydroxide, barium hydroxide, strontium hydroxide, zinc hydroxide, aluminum phosphate, magnesium phosphate, calcium phosphate, barium phosphate, strontium phosphate, and combinations thereof; andA is Li, Na, K, or Rb, or a combination thereof;M is Ca, Ba, Mg, Zn, or a combination thereof; and0<x≦0.10, 0≦y≦0.5, 0≦z≦0.5, 0≦x≦x.

Owner:GE LIGHTING SOLUTIONS LLC

Preparation method for modified transparent nano-zinc oxide sol

InactiveCN103159251AHigh transparencyHigh purityZinc oxides/hydroxidesNanotechnologyZinc hydroxideFlocculation

The invention relates to a preparation method for modified transparent nano-zinc oxide sol. The method comprises the following steps: according a mol ratio of zinc to an alkali of 1: 1-2, directly mixing a zinc salt dissolved in polyol and the alkali dissolved in polyol for a reaction so as to produce a white zinc hydroxide flock mixed solution and heating and aging the obtained zinc hydroxide solution so as to obtain transparent sol; and using a surface modifier for surface modification of the nanometer zinc oxide sol in a polyol system, carrying out water flocculation, cleaning and separation to obtain a deposit and re-dispersing the deposit in a frequently used polar or non-polar organic solvent to form the transparent nano-zinc oxide with high purity. The method provided by the invention has the advantages of easiness, low energy consumption and convenient operation; the obtained crystalline zinc oxide sol has the characteristics of high transparency, high purity, a small particle size and good homogeneity; and large scale industrial production of the modified transparent nano-zinc oxide sol can be realized.

Owner:贵州省纳米材料工程中心

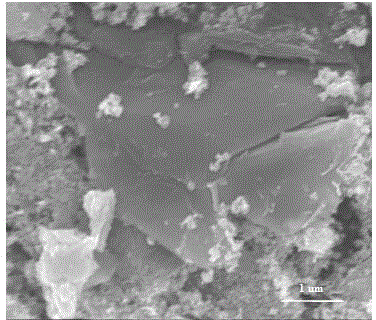

Preparation method for nano-zinc oxide modified graphene hybrid material

ActiveCN104098088ASimple processSynthetic conditions are mildMaterial nanotechnologyZinc oxides/hydroxidesZinc hydroxideVulcanization

The invention discloses a preparation method for a nano-zinc oxide modified graphene hybrid material. The method includes: preparing a graphene oxide suspension solution; dissolving a zinc salt in water, adding the solution into the graphene oxide suspension solution, conducting ultrasonic treatment, adding an alkali reagent dropwise to obtain a zinc hydroxide graphene oxide suspension solution; under ultraviolet light irradiation, performing static aging to obtain a zinc hydroxide-graphene oxide gel, adding an excessive reducing agent, carrying out reaction, using water and ethanol to conduct repeated washing, and performing drying to obtain a zinc hydroxide-graphene dry gel; placing the gel in a muffle furnace, and conducting treatment at high temperature to obtain the gray nano-zinc oxide modified graphene hybrid material. The nano-zinc oxide obtained by the invention has a large specific surface area, can effectively promote vulcanization crosslinking, greatly reduces the using amount of zinc oxide, and is of great importance to full utilization of zinc resources and ecological economy. At the same time, without affecting the performance of graphene, the method is in favor of further expanding the potential application scope of graphene.

Owner:SOUTH CHINA UNIV OF TECH

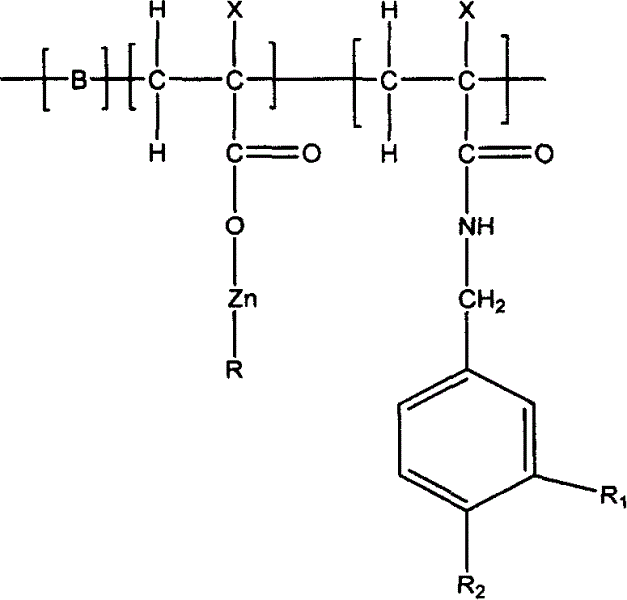

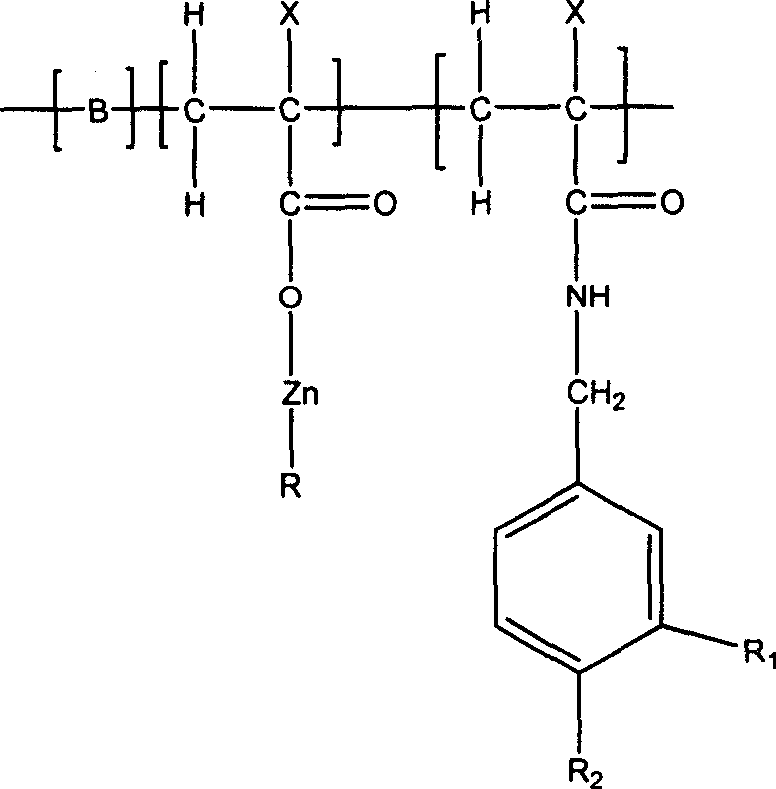

Resin of zinc acrylate or copper acrylate containing capsaicin function group, its preparation and use

This is a kind of acrylic zinc or cuprum resin containing capsaicin functional group and its preparation method. Its characteristics are: firstly synthesize monomer containing capsaicin functional group, then synthesize acrylic resin containing functional group and carboxyl, finally make the acrylic resin and zinc hydroxide or cuprum hydroxide react to obtain acrylic zinc or cuprum resin containing capsaicin functional group. The resin of the invention can be used for preparing sea antifouling dope. In the seawater, the organic zinc or cuprum acrylic ester on the polymer linear main chain of the coat surface hydrolyzes, and send out organic zinc or cuprum; the hydrolyzed polymer main chain contains capsaicin functional group with highly efficient antifouling activeness, which makes the hydrolyzed polymer main chain still has sterilization activeness. So the dope can effectively prevent halobios from clinging on the surface of fishing tools, ships and seacoast establishments, and has good antifouling performance.

Owner:OCEAN UNIV OF CHINA

Silicone rubber composition and preparation method of silicone rubber

The invention provides a silicone rubber composition comprising, a heat conductive composite material, a silane cross-linking agent, and polyether. The heat conductive composite material comprises a silane coupling agent, and titanium oxide coated with zinc hydroxide. The invention also relates to a preparation method of silicone rubber. The silicone rubber composition provided by the invention is easy to prepare and to store. Prepared silicone rubber has advantages of high-temperature resistance, high heat conductivity, stable performance, and good anti-yellowing performance. With the technical schemes provided by the invention, application environment of the silicone rubber composition is extended. Materials manufactured with the silicone rubber composition have good mechanical properties and improved mechanical strengths. With good adhesion of the silicone rubber, sealing performances of manufactured materials are improved. Comprehensive property of the silicone rubber is excellent. With the silicone rubber composition and the preparation method provided by the invention, a basis is established for further development of silicone rubber.

Owner:宁海县集美特电器有限公司

Method of Controlling Organoleptic Odors

InactiveUS20100189595A1Reduce odorMolecular sieve catalystsDeodrantsCalcium silicateSodium Bentonite

A method is taught for capturing organoleptic odor. Where a functional additive has odors from a plurality of organolepic sources, and is blended with an odor control agent and a resin to produce a blend, where the blend exhibits at least a 5% reduction in odor based on a standardized odor test SAE-J1351. The odor control agent is selected from the group but not limited to: nepheline syenite, silica gel, hydrogels, hard and soft clays, bentonite, clinoptilolite, hectorite, cationic exchanged clinoptilolites, cerium, cesium, chabazite, faujasite, gmelinite, brewsterite, calcium silicate, hydrotalcites, zinc or magnesium aluminum hydroxy carbonates, zinc oxide, zinc hydroxide, zinc carbonate, calcium oxide, calcium hydroxide, calcium carbonate, potassium meta phosphate, silver oxide, magnesium hydroxide, magnesium oxide, copper oxide, ferric and ferrous oxides, sorbitol, glucitol, mannitol, glucose, dextrose, dextrin, allophanes, silica, sodalite, silicon oxide, aluminum oxide, natural zeolites, manganese dioxide, nano zinc oxide and nano titanium and combination thereof.

Owner:LEHIGH TECH INC

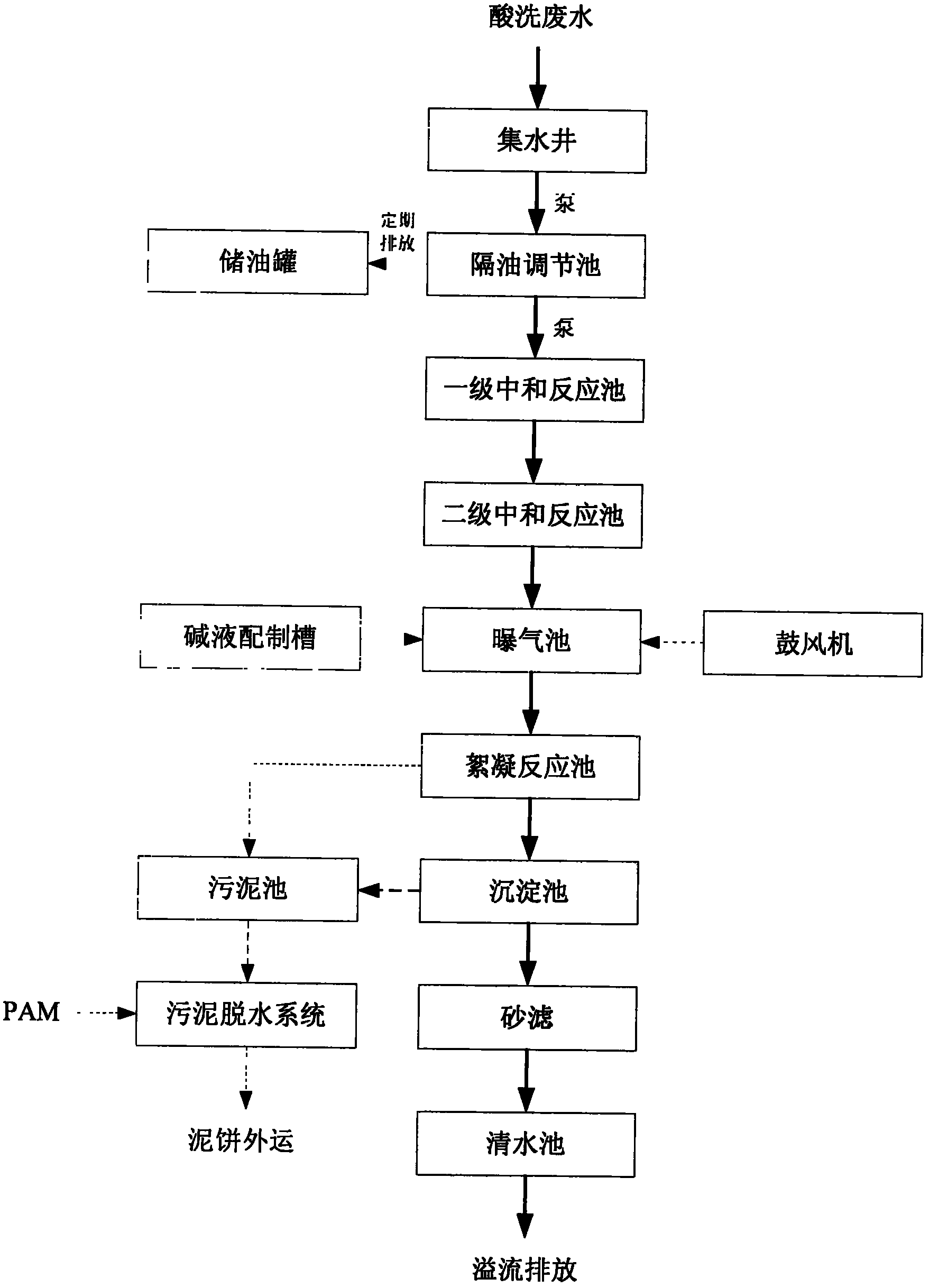

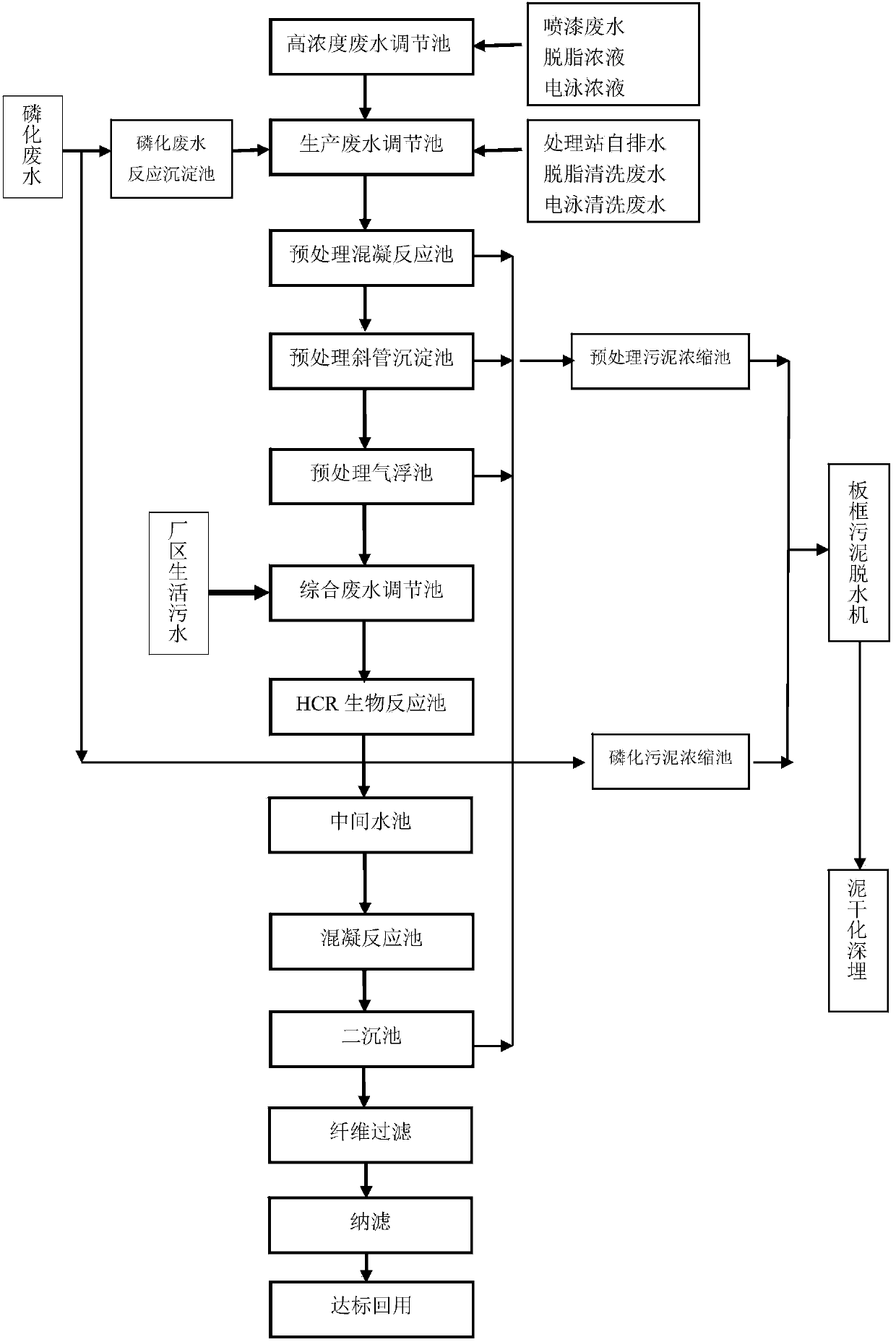

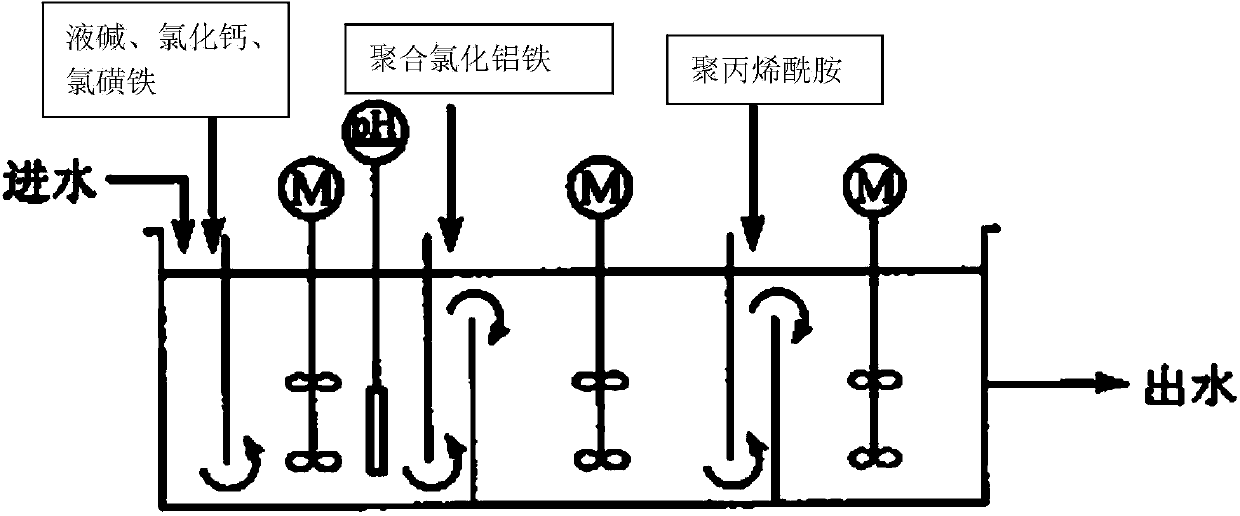

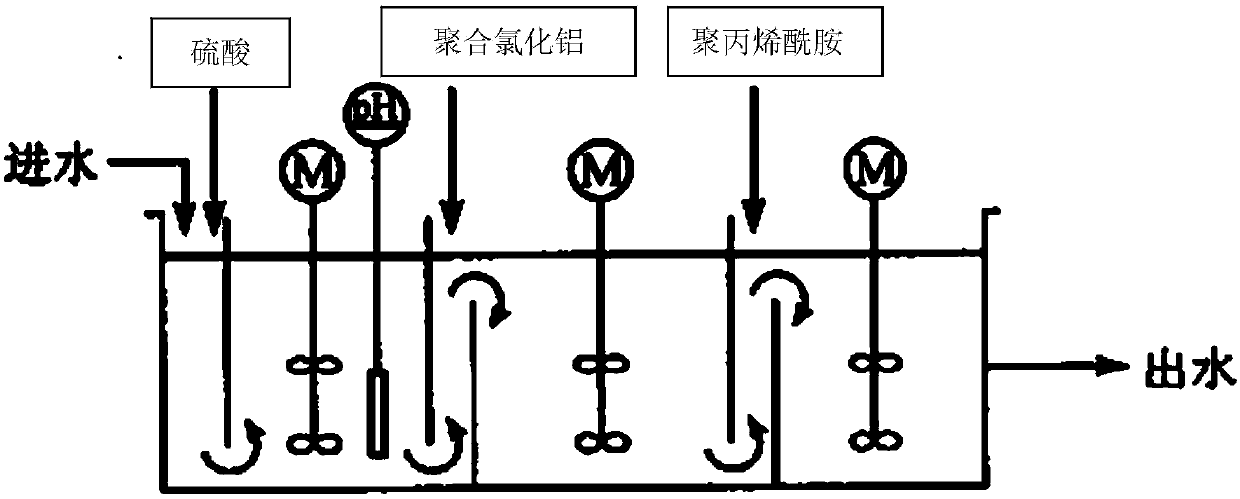

Recycling treatment method for automobile coating wastewater

The invention provides a recycling treatment method for automobile coating wastewater. The recycling treatment method comprises the following steps: adjusting wastewater, pre-treating, carrying out microbiological treatment, carrying out cohesion treatment, carrying out fiber filtering, carrying out nano filtering and carrying out sludge floating slag treatment; in a cohesion process, the pH (Potential of Hydrogen) value is controlled to 10.0-10.5 so that hydroxyapatite [Ca5(OH)(PO4)3] and zinc hydroxide sediment are generated by a phosphate radical and zinc ions. The pre-treating step adopts secondary coagulation treatment; solid-liquid separation after a cohesion reaction respectively adopts an inclined tube settler and an air floating tank, namely an inclined plate sedimentation basin is used for removing heavy metal compound sediment with the great specific gravity and the air floating tank is used for removing organic matters with the light specific gravity. The microbiological treatment adopts an HCR which is an efficient jet bioreactor so that the biological reaction efficiency in the reactor is greatly improved. Desalting treatment adopts a nano filtering device with a low operation cost to remove a lot of salts and fine impurities, so that output water can be recycled to afforest and irrigate.

Owner:新疆德安环保科技股份有限公司

Method for microwave synthesis of nano-ZnO assembled cotton fibers

The invention discloses a method for microwave synthesis of nano-ZnO assembled cotton fibers and in particular relates to a method for preparing cotton fibers which are assembled by nano ZnO, TiO2 and AG or compositions of the nano ZnO, TiO2 and AG and are favorable in antibiosis, ultraviolet resistance and water washing resistance. According to the method, a main raw material, namely zinc nitrate (zinc sulfate or zinc chloride), and NaOH react to generate zinc hydroxide precipitate, the zinc hydroxide precipitate is dissolved in an aqueous ammonia solution to form a zinc ammonia solution, the cotton fibers adsorbed with the zinc ammonia solution are assembled under a microwave heating condition, and nano zinc oxide small particles are formed in cavities and a network structure of the cotton fibers. By virtue of ZnO, TiO2 and Ag inorganic nanopowder, the pure cotton fibers have antibiosis, sterilization and ultraviolet resistance properties, and the application field of the cotton fibers is greatly broadened.

Owner:CIVIL AVIATION UNIV OF CHINA

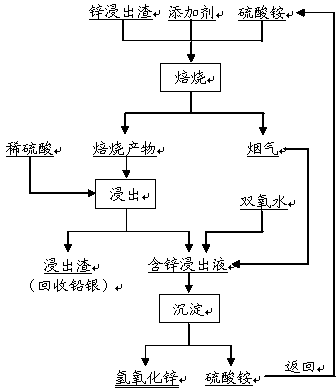

Method for separating zinc and iron from zinc leaching residues

InactiveCN104178642AAchieve regenerationIncrease incidenceProcess efficiency improvementZinc hydroxideSulfate zinc

The invention discloses a method for separating zinc and iron from zinc leaching residues. The method comprises the following steps: firstly, mixing the zinc leaching residues with ammonium sulfate and an additive, then performing roasting to ensure that zinc ferrite and the like in the zinc leaching residues are changed into soluble zinc sulfate and insoluble ferric oxide; secondly, directly leaching out a roasted product by using a dilute sulfuric acid solution; and finally, introducing fume which is produced during roasting and mainly contains ammonia gas into a zinc leaching solution to perform deposition so as to produce zinc hydroxide and an ammonium sulfate solution, and concentrating and crystallizing the ammonium sulfate solution to prepare ammonium sulfate which is returned to the ammonium sulfate roasting process. The ammonium sulfate roasting process in the method can ensure that a zinc ferrite phase in the zinc leaching residues is changed into soluble zinc sulfate, the leaching rate of zinc is more than 97%, and the leaching rate of iron is lower than 2%, so that the separation of zinc and iron is effectively realized; the ammonia gas produced in the ammonium sulfate roasting process is directly used for depositing zinc from the leaching solution, and the regeneration of ammonium sulfate can be realized while a zinc hydroxide product is generated; the comprehensive recovery rate of zinc is more than 96%; the method can realize closed-loop circulation and is relatively environment-friendly.

Owner:CENT SOUTH UNIV

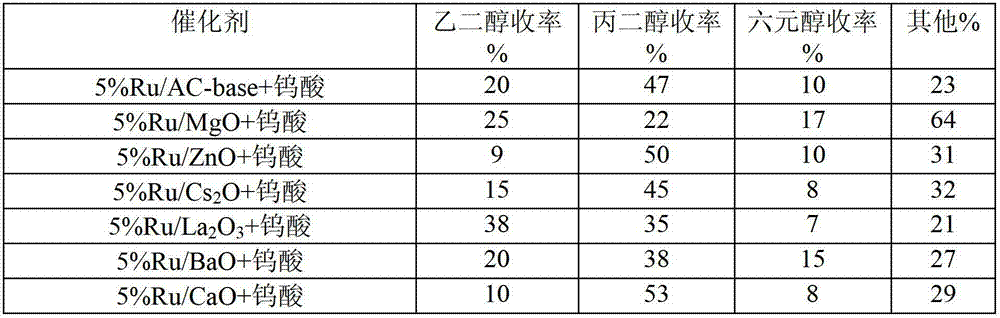

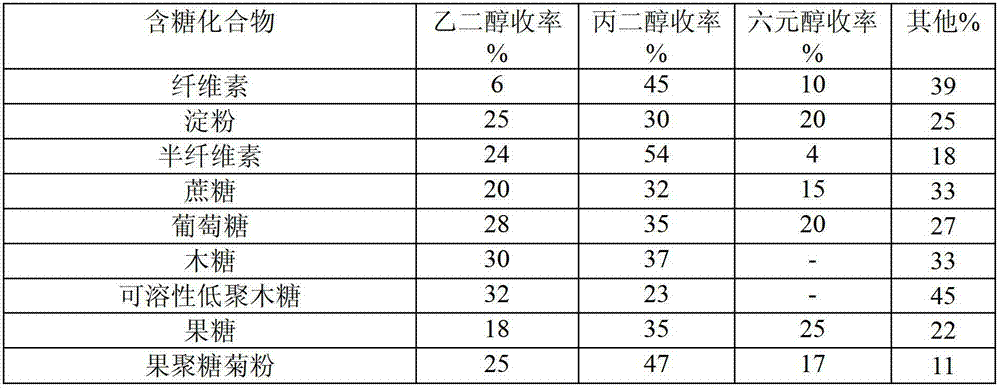

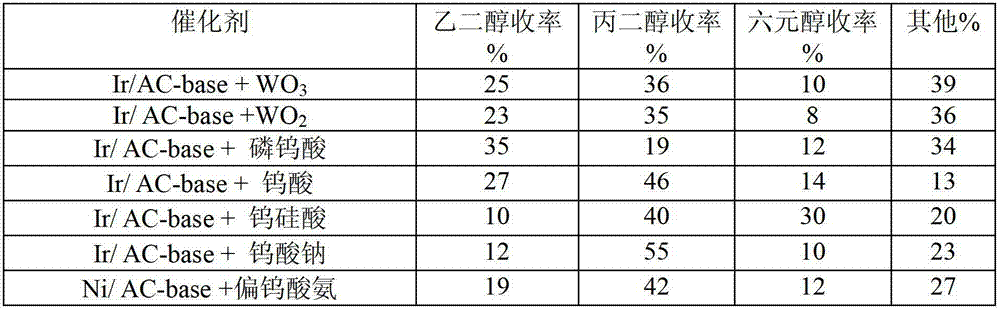

Method for selectively preparing propylene glycol from sugar-containing compound

ActiveCN102731257ARaw material resources are renewableMeet the requirements of sustainable developmentOrganic compound preparationHydroxy compound preparationAlkaline earth metalHydrogen pressure

The present invention provides a method for highly-selectively preparing propylene glycol from a sugar-containing compound, wherein the sugar-containing compound comprises cellulose, starch, hemicellulose, sucrose, glucose, fructose, fructosan, xylose, and soluble xylooligosaccharide. According to the method, the sugar-containing compound is adopted as a reaction raw material, a three-component composite catalyst is adopted, and a one-step catalytic conversion process is performed at a temperature of 120-300 DEG C under hydrogen pressure of 0.1-15 MPa to achieve high performance, high selectivity and high yield preparation of propylene glycol from the sugar-containing compound, wherein active components of the catalyst comprise one or more than two materials selected from 8, 9, and 10 group transition metals such as iron, cobalt, nickel, ruthenium, rhodium, palladium, iridium and platinum, one or more than two materials selected from an inorganic compound of tungsten, an organic compound of tungsten, a complex of tungsten and elementary tungsten, and one or more than two materials selected from an oxide of an alkali metal or an alkaline earth metal, a hydroxide of an alkali metal or an alkaline earth, an alkaline salt of an alkaline metal or an alkaline earth metal, aluminium hydroxide, zinc oxide, and zinc hydroxide.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

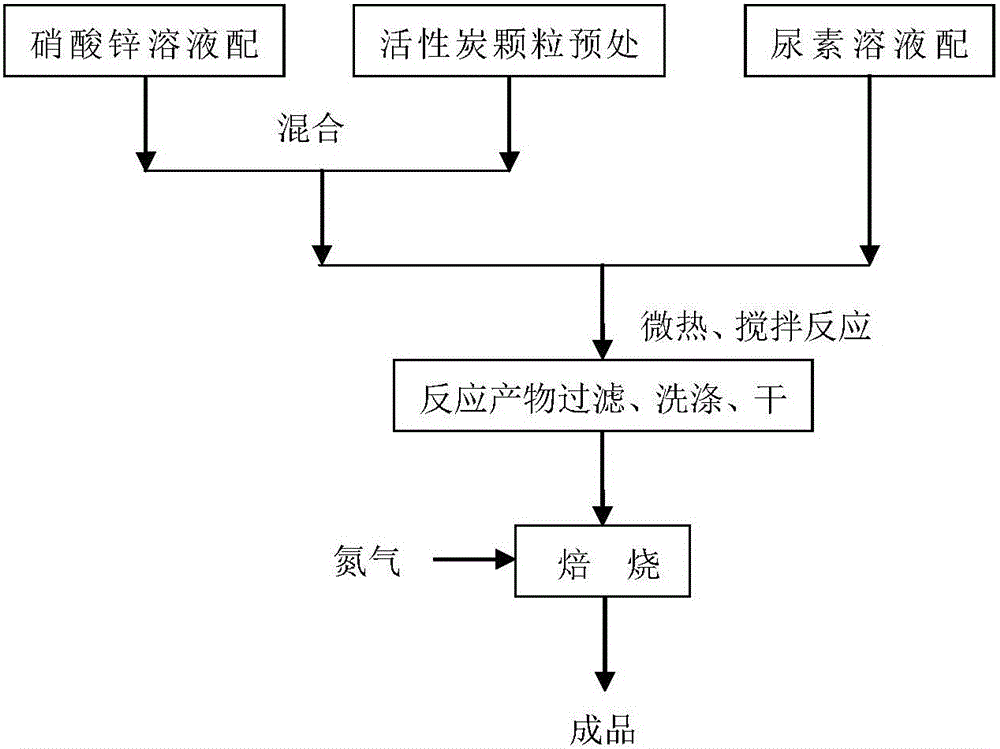

Activated carbon-loaded nano-zinc oxide ozonation catalyst and preparation and use thereof

InactiveCN106000380ARetention of adsorption propertiesImprove oxidation capacityOther chemical processesWater contaminantsZinc hydroxideZno nanoparticles

The invention relates to an activated carbon-loaded nano-zinc oxide ozonation catalyst and preparation and use thereof. The catalyst is prepared by loading nano-zinc oxide on the surface of modified activated carbon. The modified activated carbon carrier is prepared by cleaning activated carbon with a sodium hydroxide solution, then dipping with dilute nitric acid, cleaning with deionized water and then drying. According to the catalyst disclosed by the invention, active components are prepared by adopting a coprecipitation method and taking zinc nitrate as a precursor; zinc hydroxide precipitate is generated by using a saturated zinc nitrate solution and a saturated urine solution and is attached to the surface of the modified activated carbon, and then the activated carbon the surface of which is attached with the zinc hydroxide is dried and roasted to prepare the oxidization catalyst. That is, the adsorption property of the activated carbon is reserved, and nano-zinc oxide microparticles having ozone catalysis activity are loaded in the activated carbon. Under the synergistic effect of adsorption and activation, organic pollutants in water can be adsorbed at high efficiency, and meanwhile, ozone molecules can be catalyzed and activated to produce free radicals having high oxidizability, thereby obtaining a better catalytic ozonation effect.

Owner:天津大拇指环境工程有限公司

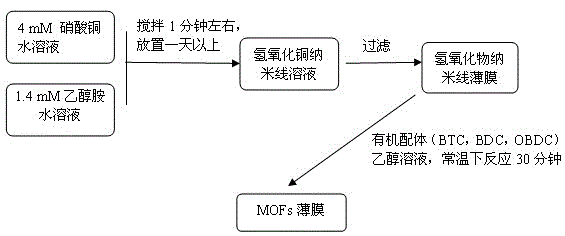

Method of rapidly preparing metal organic framework material thin-film from hydroxide nanowires and organic ligands under normal temperature

The invention discloses a method of rapidly preparing a metal organic framework material thin-film from hydroxide nanowires and organic ligands under a normal temperature. The method comprises (1) adding an ethanolamine aqueous solution into cupric nitrate, zinc nitrate or cadmium nitrate aqueous solution of a same volume under magnetic stirring, slowing down a stirring speed to obtain corresponding copper hydroxide, zinc hydroxide or cadmium hydroxide nanowire solution, and directly filtering the nanowire solution through a porous alumina film to form a nanowire layer; (2) adding the nanowire layer into an organic ligand solution with ethanol, octanol or N,N-dimethyl formamide as a solvent, and reacting for 30 minutes under the normal temperature to obtain the metal organic framework material thin-film. The method provided by the invention can directly prepare large-area compact thin-film on a porous substrate under the normal temperature, and the method is simple in operation steps, low in cost, and environmental-protective. Reaction residues can be easily recovered. The prepared thin-film can stably exist. The method expands an application range of the metal organic framework material thin-film.

Owner:ZHEJIANG UNIV

High purity zinc oxide powder and method for production thereof, and high purity zinc oxide target and thin film of high purity zinc oxide

Owner:JX NIPPON MINING & METALS CORP

Electroplating sludge resource recovery process

InactiveCN102786192AGood effectAvoid influenceSludge treatmentWaste water treatment from metallurgical processZinc hydroxideSludge

The invention discloses an electroplating sludge resource recovery process. After acid solution, purification, copper precipitation and purification, dezincification and nickel precipitation, Cu(OH)2, Zn(OH)2 and Ni(OH)2 are obtained. The application range of the zinc hydroxide and the nickel hydroxide produced by the process technology disclosed by the invention is wider, and therefore the electroplating sludge resource recovery process overcomes the defect that the application range of nickel sulfate is limited.

Owner:HENGFENG COUNTY YUANSHENG METAL RESOURCE RECYCLE

Process and composition for increasing the reactivity of sulfur scavenging oxides

InactiveUS20020182135A1Increase response rateRaise the potentialPhysical/chemical process catalystsOther chemical processesZinc hydroxideManganese oxide

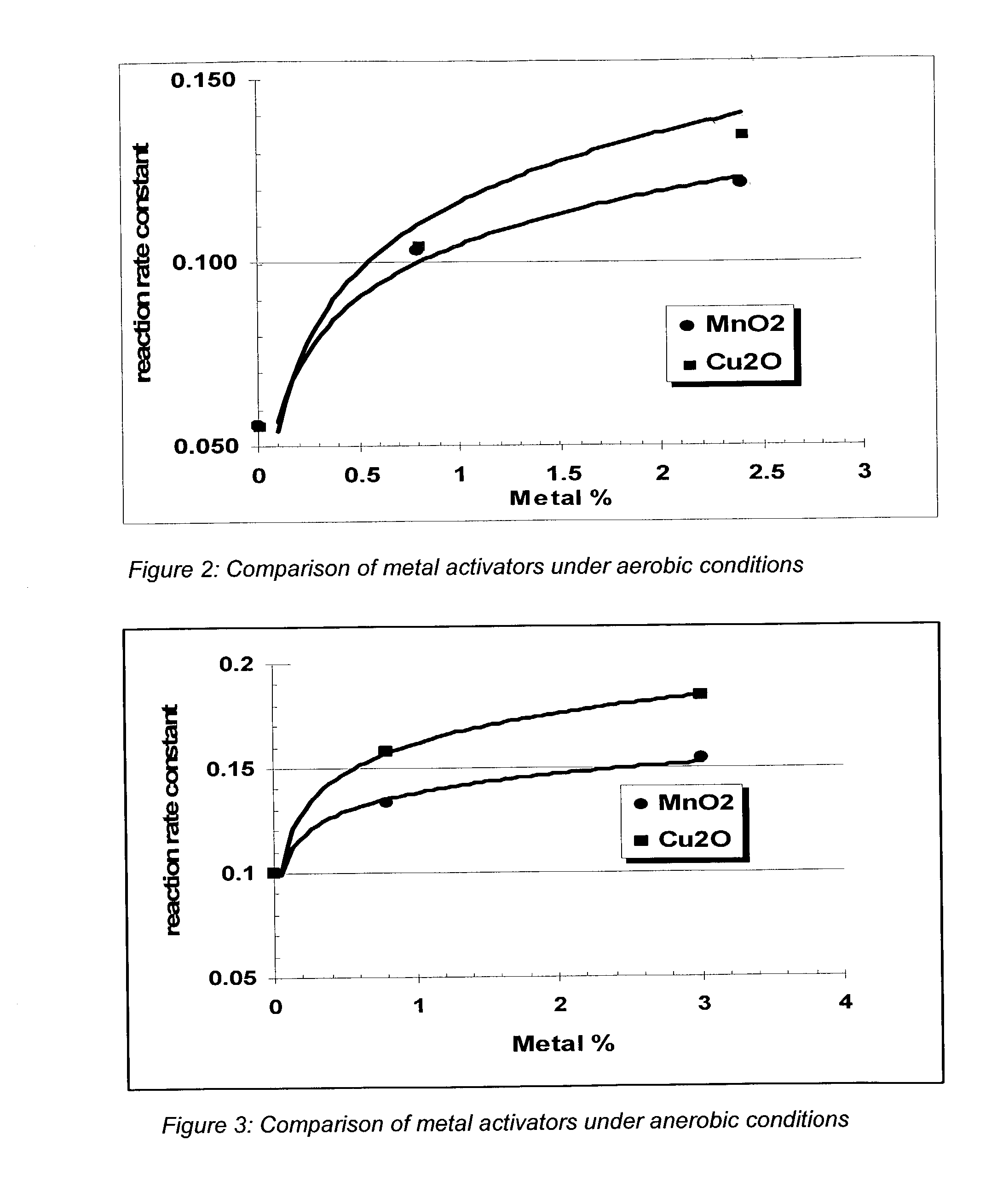

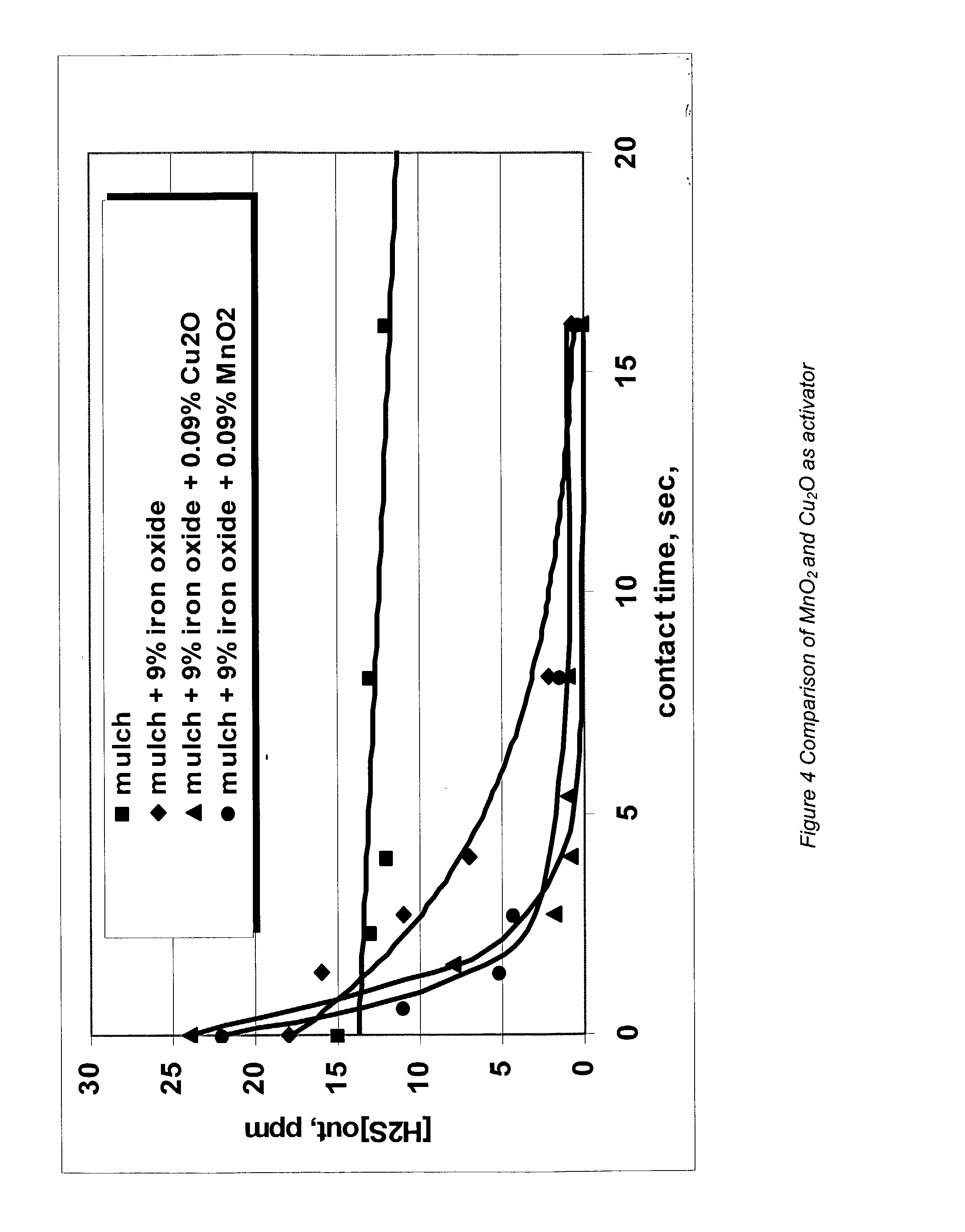

In ridding fluids, including hydrocarbon fluids, both gaseous and liquid, of sulfur compounds including hydrogen sulfide, oxides of sulfur, and thiols, the present invention uses a small quantity of an activator, generally a noble metal oxide, preferably a copper species and / or a manganese species, along with a known oxide product, such as iron oxide, iron hydroxide, zinc oxide, zinc hydroxide, manganese oxide, manganese hydroxide, or combinations thereof, to thoroughly remove sulfur contaminants in a short amount of time. The activator allows for the use of smaller reactor vessels and the production of hydrocarbon fluids substantially free of sulfur products.

Owner:MI

Antibacterial polymers and method for obtaining the same

ActiveUS20140296442A1Improve cleanlinessBiocideCell receptors/surface-antigens/surface-determinantsSodium PyrithioneZinc hydroxide

The invention relates to polymers selected from among polypropylene (PP), polycarbonate (PC), acrylonitrile-butadiene-styrene (ABS), polyvinylchloride (PVC) and polyethylene terephthalate (PET), nylon and polystyrene, having antibacterial properties, wherein the antibacterial effect is obtained by adding a zinc salt selected from among: zinc PCA, zinc oxide, zinc hydroxide, zinc pyrrolidone or zinc pyrithione during the process of polymerization of the monomers. The antibacterial polymers are used to prepare products intended to enter into contact with the skin.

Owner:PARX PLASTICS

Processing method for antibiotics bacterial slag containing zinc

InactiveCN1613534ALow toxicitySolve pollutionIon-exchange column/bed processesSolid waste disposalZinc hydroxideSlag

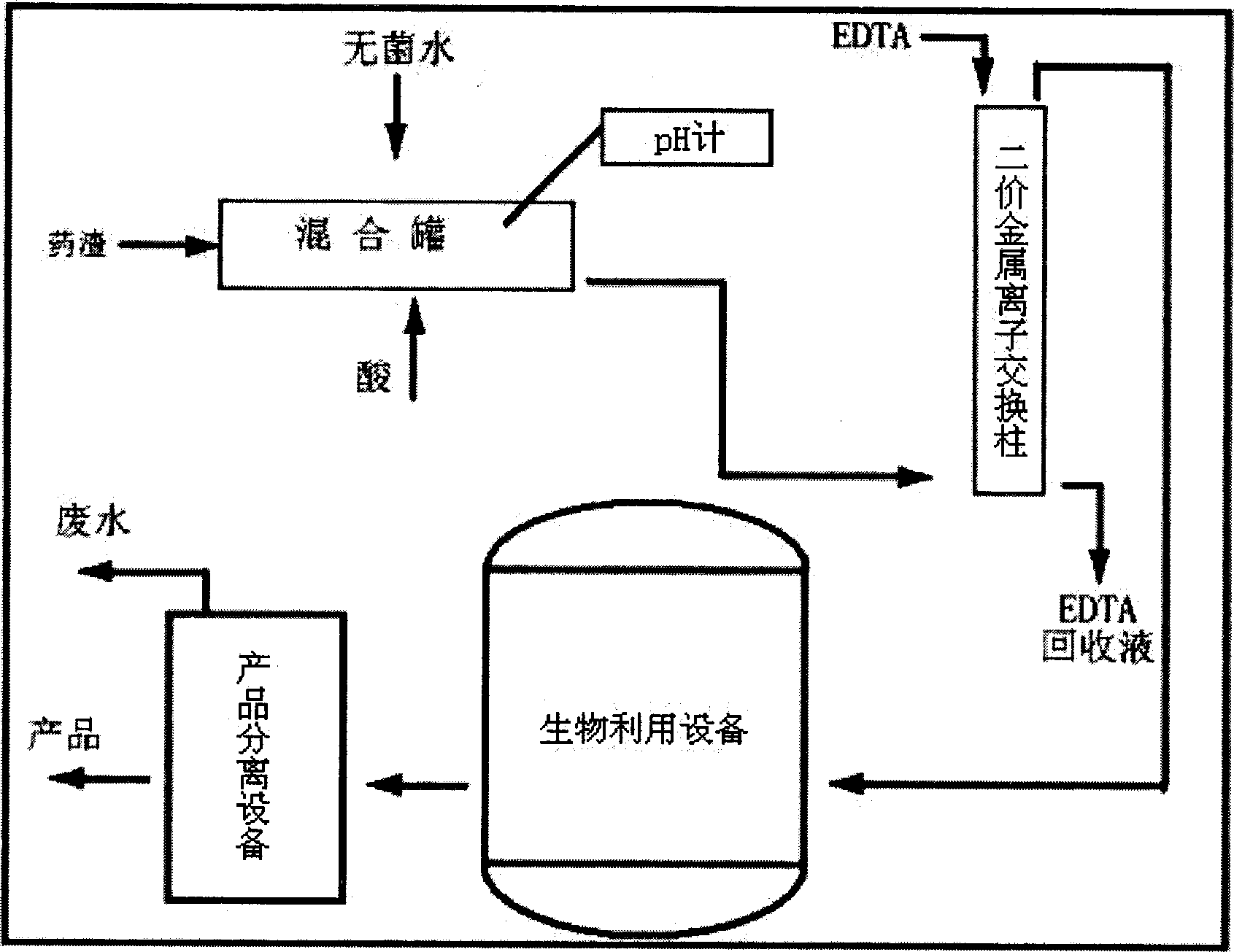

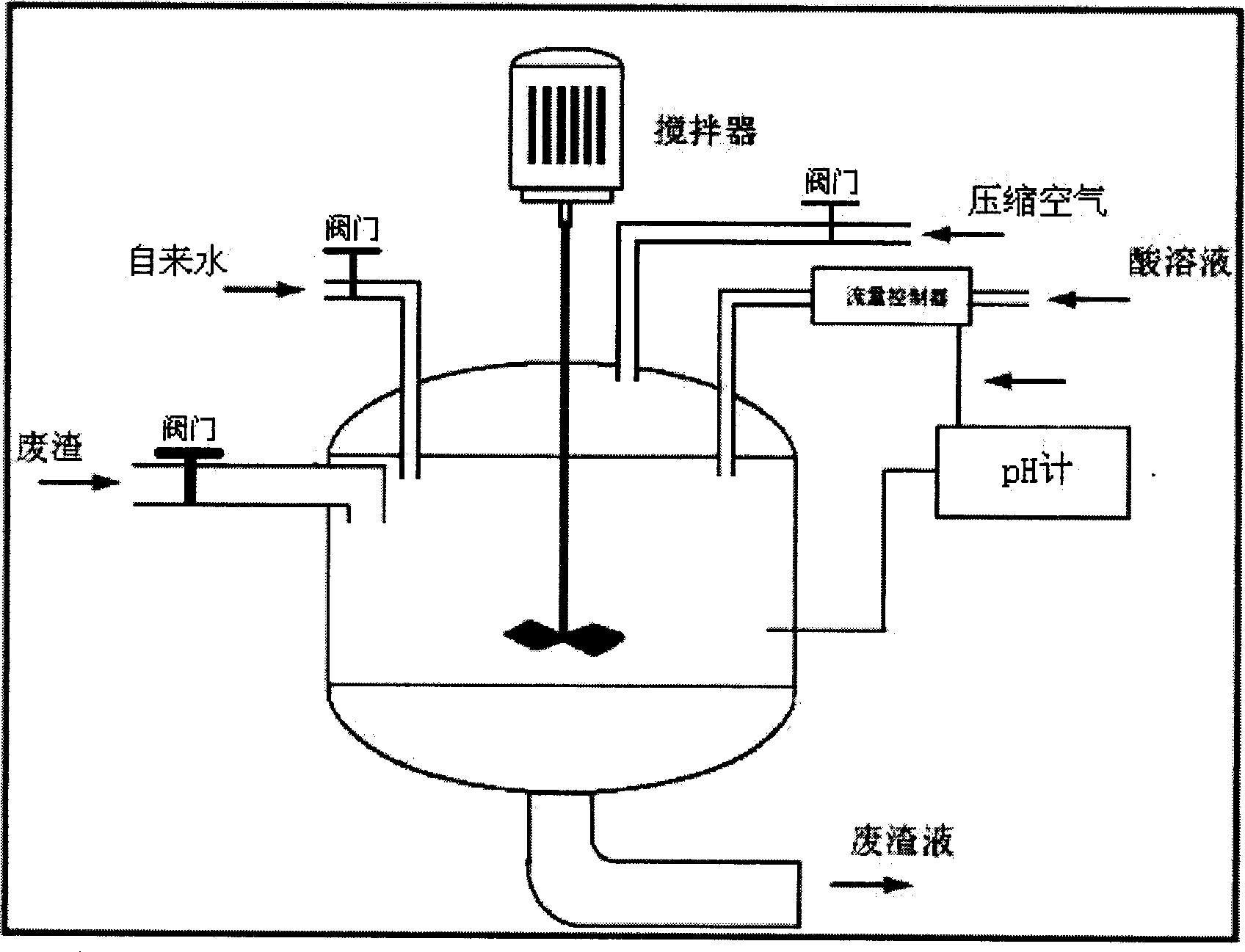

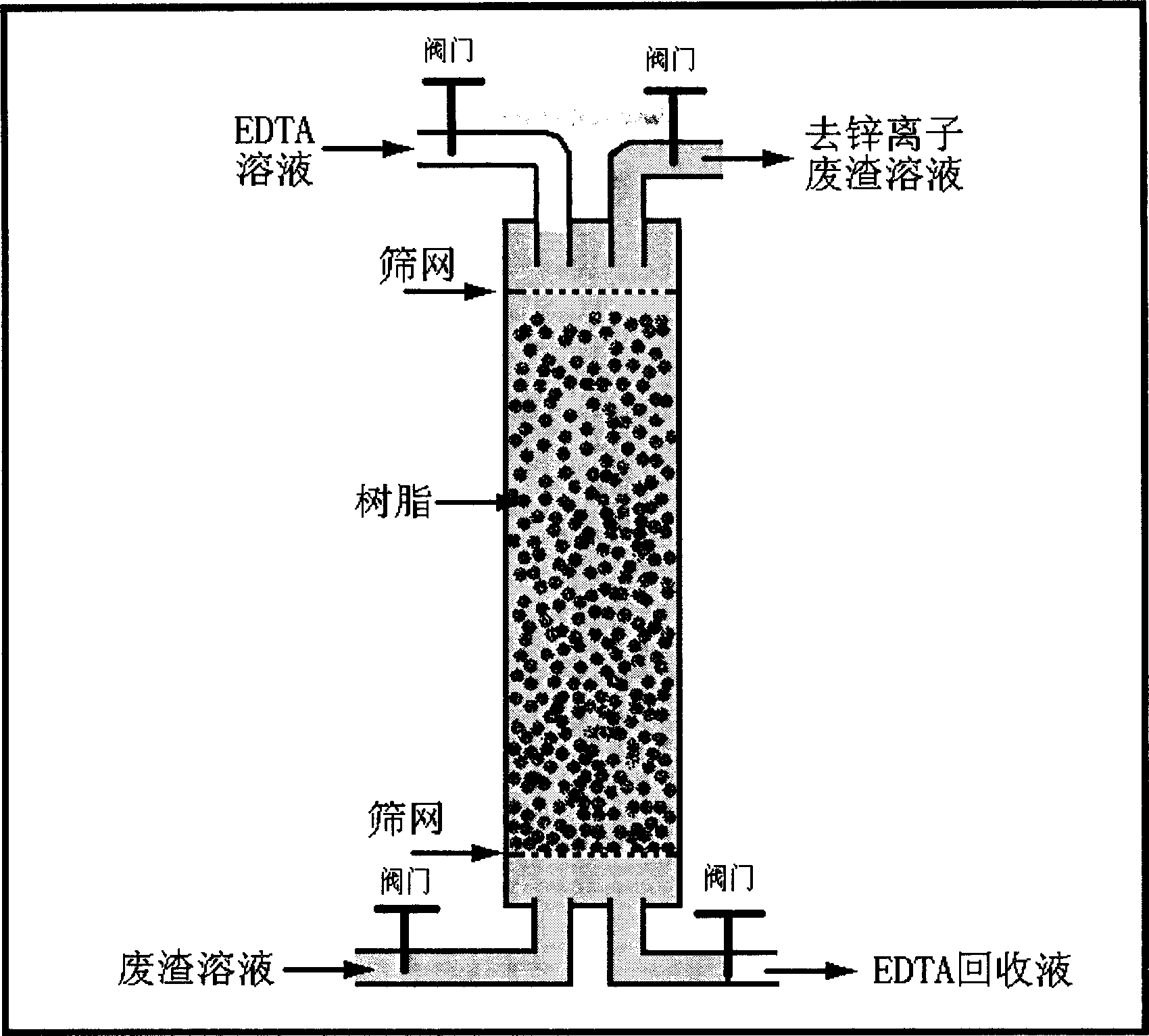

A process for treating the Zn-contained antibiotic bacteira dregs includes such steps as diluting it by water to obtain suspension, adding acid for regulating pH value and converting the Zn from zinc hydroxide to easily soluble Zn ions, flowing it through the 2-valence metal ion adsorption column to obtain Zn-removed dregs, and biologically using it.

Owner:ZHEJIANG UNIV OF TECH

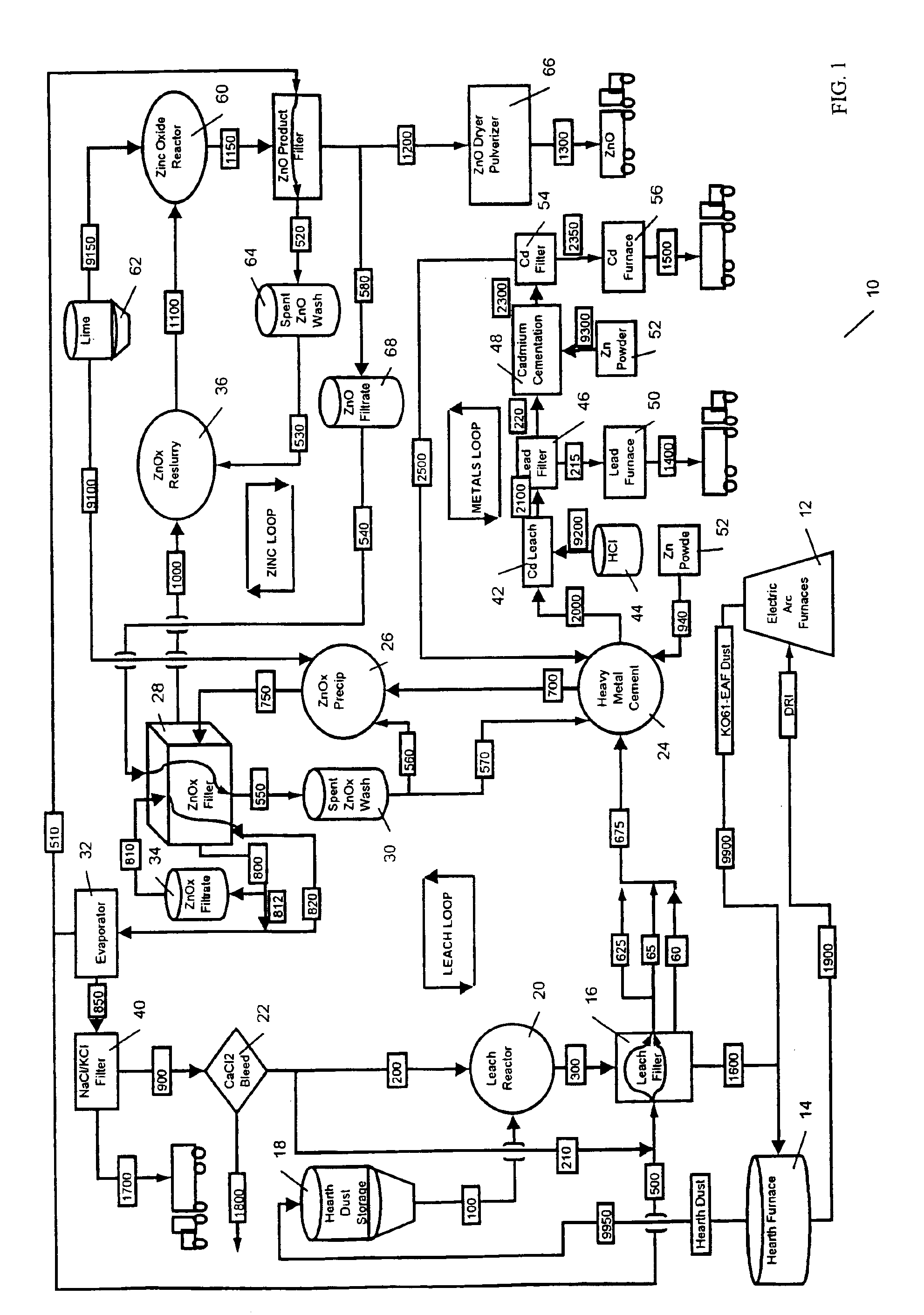

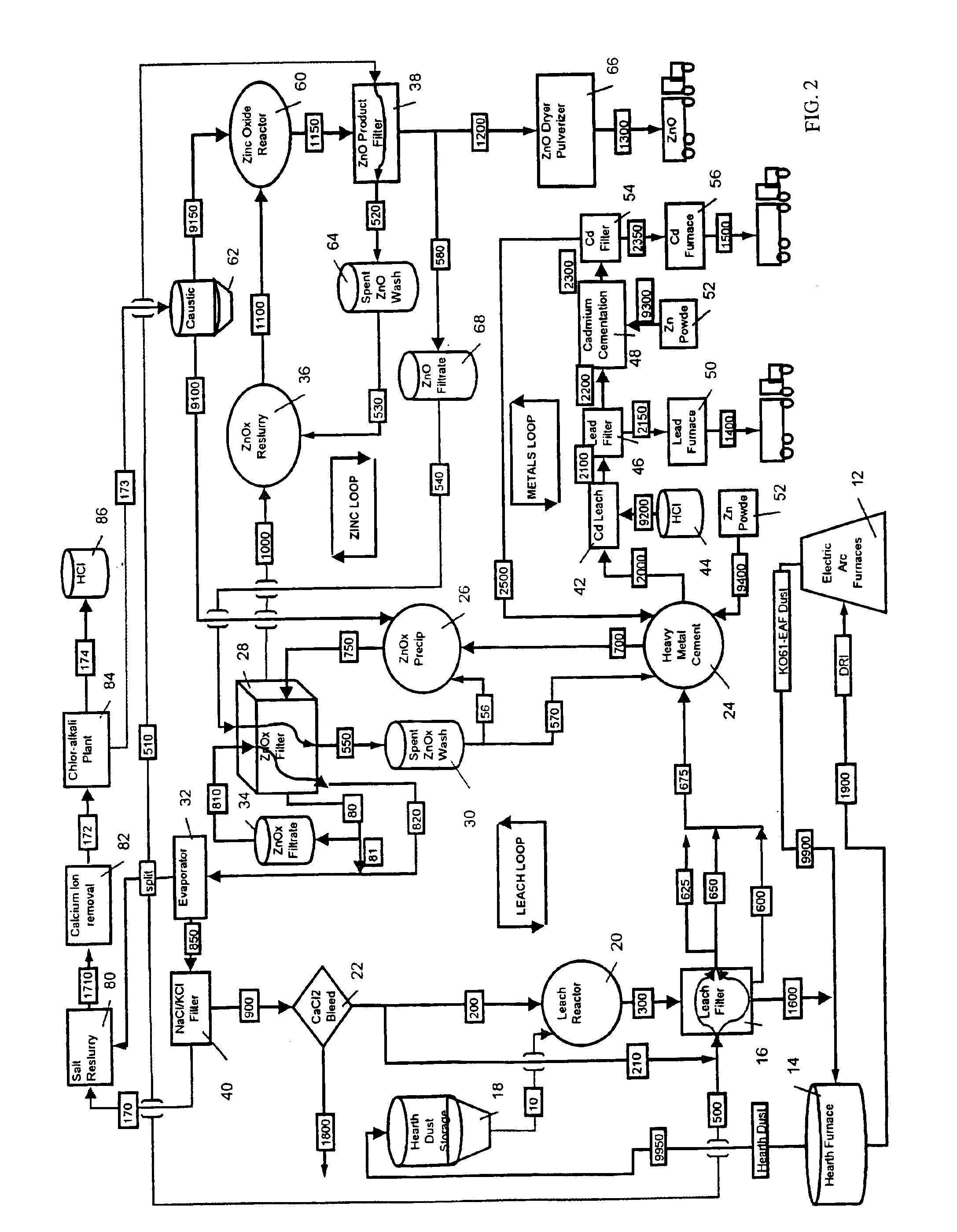

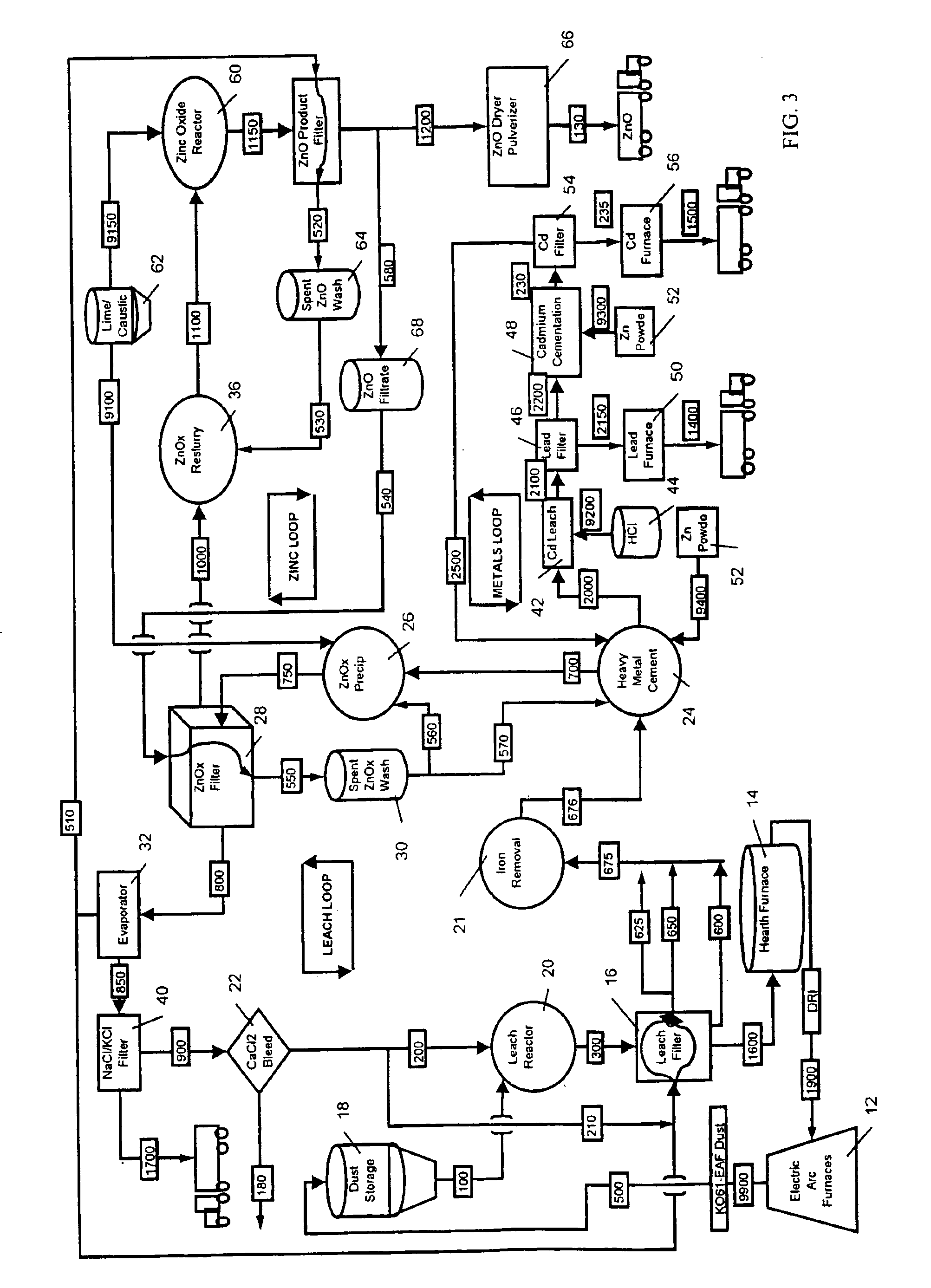

Process to produce simonkolleite, zinc oxide and zinc hydroxide

A hydrometallurgical process utilizing an atmospheric calcium chloride leach to selectively recover from various metal feed stocks (consisting of elemental metals, metal oxides, metal ferrite, metal hydroxide, metal carbonates, metal sulfate / sulfur compounds, and their hydrates, specifically including but not limited to EAF Dust K061) zinc, lead, cadmium, silver, copper and other valuable metals to the exclusion of iron, magnesium, halogen salts and other unwanted elements. The process solves the problem of iron and magnesium leach solution contamination because iron is unexpectedly converted to magnetite. The heavy metals are cemented out of solution using zinc or other selected dust at a pH of 6 or greater under unique and unexpected conditions, which do not require acid. Simonkolleite / zinc- oxychloride / zinc-hydroxide is produced from the purified zinc chloride complex pregnant leach solution and is converted directly to high purity active rubber grade 99+% zinc oxide having small particle size and high surface area. The products are metal concentrates suitable for: metal refiner / processors, production of elemental metal, or other conversion processes. The process removes Arsenic and Fluorides in the feed material. The process also solves the problem of chloride contamination in the zinc oxide and prevents heavy metal contaminants in the hydrometallurgically produced zinc oxide derived from feed stocks containing chlorides or when chlorides are used to leach the metal bearing feed stocks. In one embodiment, calcium and / or magnesium compounds are added to the iron bearing waste to increase the recovery of zinc and other non-ferrous metals and to produce an iron bearing flux. The process is environmentally friendly and fully recycles all streams.

Owner:WHITMAN CHESTER W

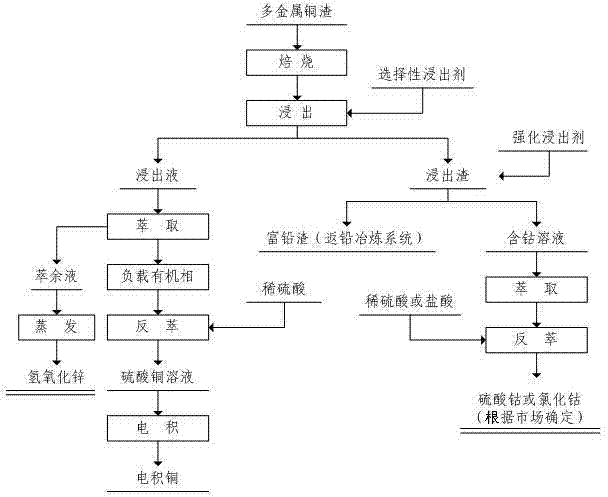

Method for producing electrodeposited copper from polymetallic copper slag

ActiveCN104846202AImprove leaching efficiencyHigh recovery ratePhotography auxillary processesProcess efficiency improvementZinc hydroxideLead smelting

The invention discloses a method for producing electrodeposited copper from polymetallic copper slag, which includes the following steps: the polymetallic copper slag is roasted to oxidize, so that the complex states of valuable metals in the polymetallic copper slag are transformed into oxides, changed into a state which can be selectively leached; leaching first adopts selective leaching agent to leach copper and zinc, the leachate is extracted, reextracted and electrodeposited, so that electrodeposited copper is obtained, and raffinate is vaporized and crystallized, so that zinc hydroxide is obtained; mechanical intensified leaching agent is then used for intensely leaching leaching residue, so that cobalt, nickel and the like in the leaching residue are leached, lead, iron and the like are enriched into the slag, the lead-rich slag is adopted as material for lead smelting, the leachate is extracted and reextracted, so that cobaltous sulfate or cobalt chloride is obtained, and if the nickel content in the leachate is overhigh, multi-stage extraction can be carried out to separate cobalt and nickel, so that nickel sulfate or nickel chloride is produced. The method can comprehensively recover a variety of metals, the leaching efficiency is high, the recovery rate is high, the method is environment-friendly, and is easy to implement, the method ensures that all the valuable metals in the polymetallic copper slag can be effectively separated and recycled, and the solid waste utilization rate can reach more than 99 percent.

Owner:NORTHWEST RES INST OF MINING & METALLURGY INST

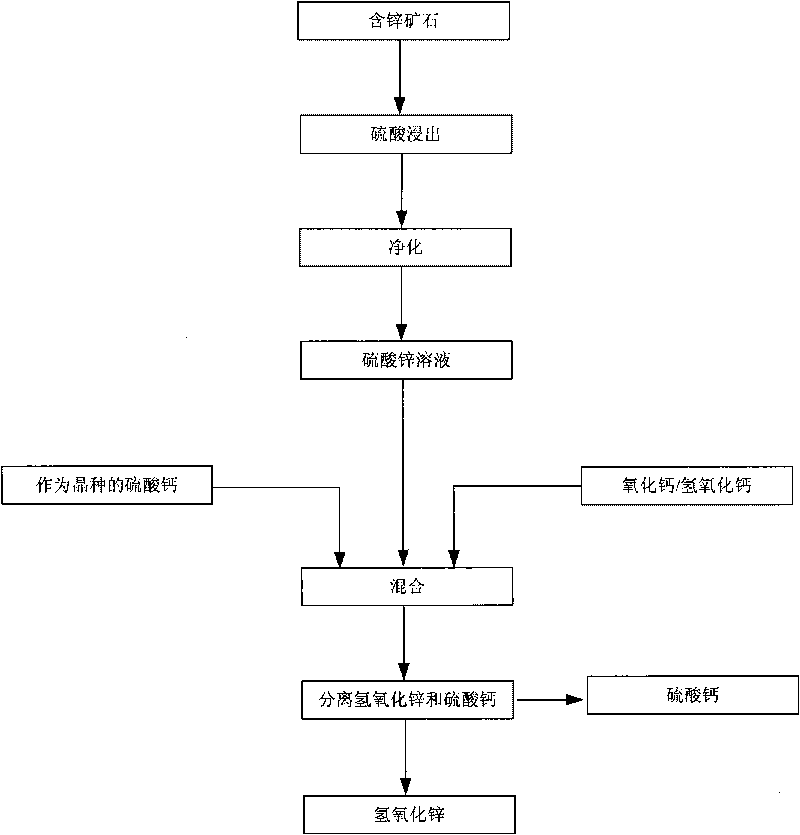

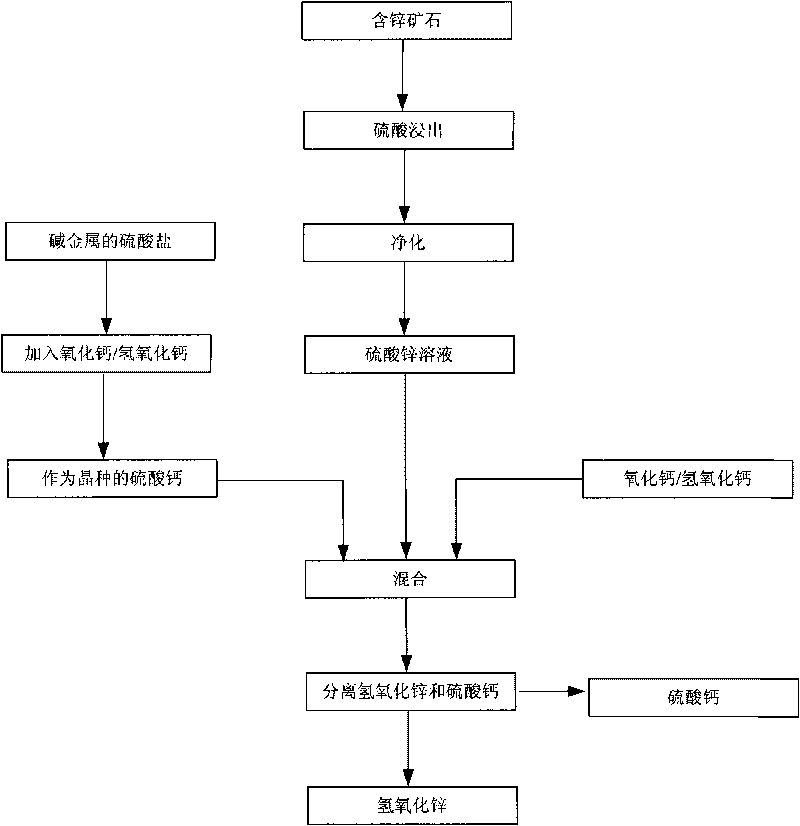

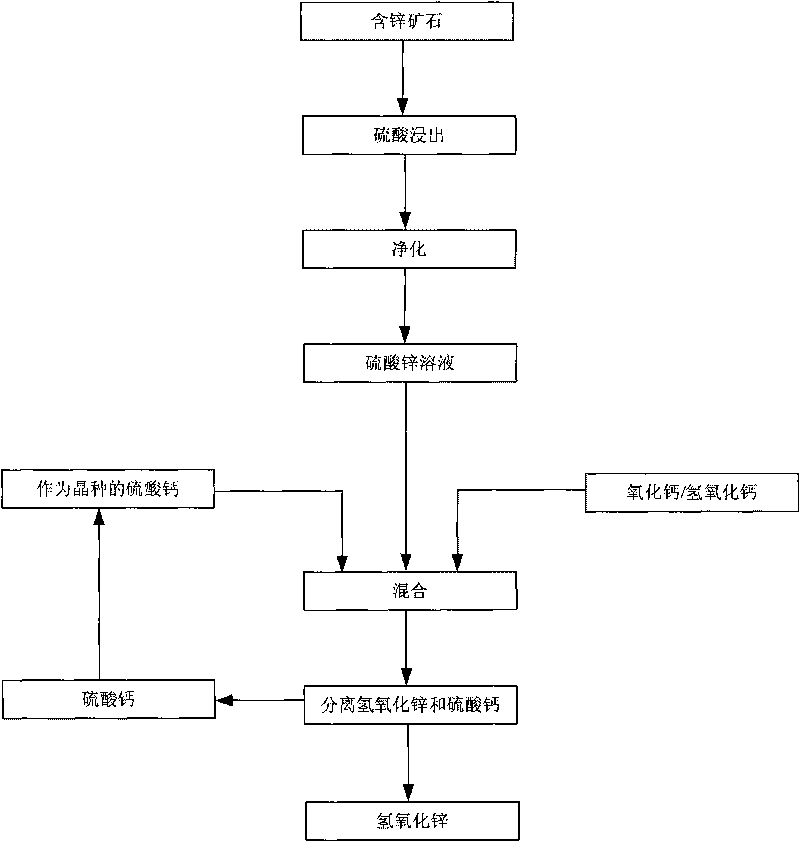

Method for leaching zinc-containing ores

ActiveCN101760613ALarge granularityReduce pollutionProcess efficiency improvementZinc hydroxidePregnant leach solution

The invention provides a method for leaching zinc-containing ores, comprising the following steps: A) mixing the zinc-containing ores with sulfuric acid solution to leach sulfuric acid so as to obtain leachate containing zinc sulfate; B) purifying the leachate to obtain zinc sulfate solution; C) mixing the zinc sulfate solution with calcium oxide and / or calcium hydroxide as well as calcium sulfate used as seed crystal to generate calcium sulfate precipitation and calcium hydroxide precipitation; and D) separating the calcium sulfate and the zinc hydroxide. The invention can recycle metallic elements from the zinc-containing ores with low cost and low pollution, recycle resources and additionally produce the calcium sulfate (gypsum), thereby reducing production cost and mitigating environmental pollution.

Owner:CHINA ENFI ENGINEERING CORPORATION

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com