Modified sodium silicate binder for cold core box and preparation thereof

A technology of glass binder and modified water, applied in cores, manufacturing tools, casting and molding equipment, etc., can solve the problems of mixing resin sand core sand and water glass old sand, affecting the quality of old sand regeneration, etc. The effect of good collapsibility, improved working environment and less dosage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

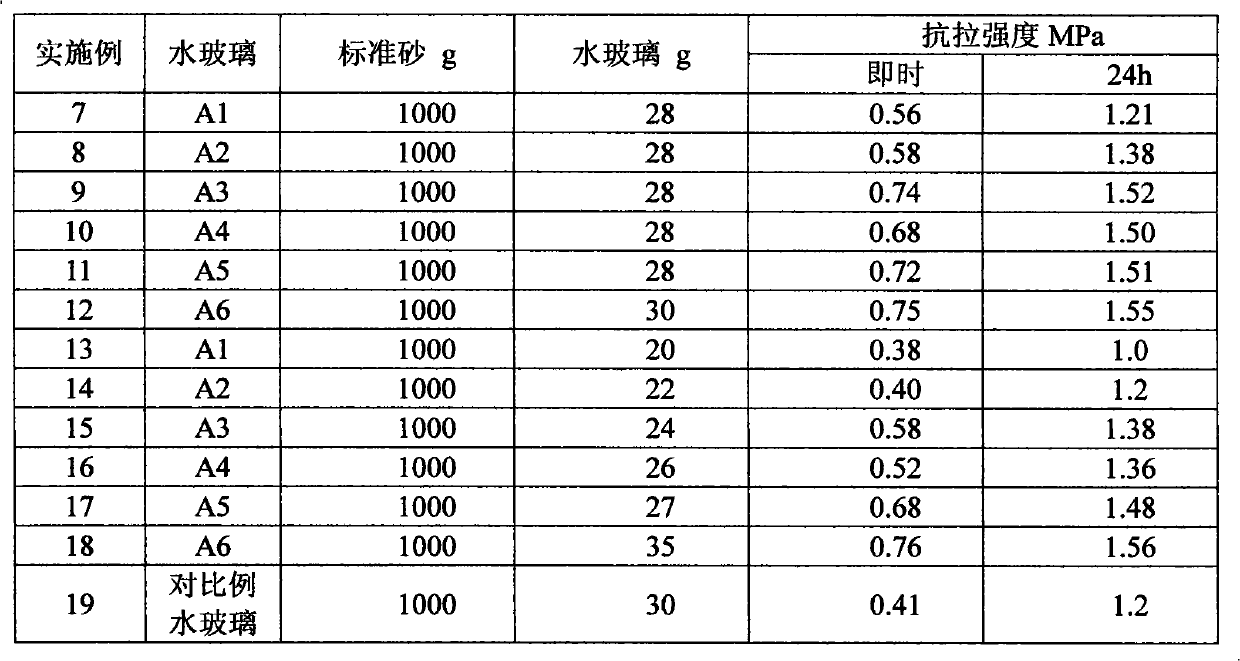

Embodiment 1

[0043]Dissolve 4g of industrial aluminum hydroxide and 4g of industrial zinc hydroxide into 10g of 40% sodium hydroxide aqueous solution to make an intermediate aqueous solution of modifier, industrial solid sodium silicate, solid-1 type 330g, and then industrial hydroxide Potassium 13g, industrial sodium hydroxide 54g, modifier intermediate aqueous solution 18g, tap water 350g, put into a 2L high-pressure reactor, cover and seal, start stirring, slowly heat up to 158°C, keep warm for 6h, naturally cool to room temperature, precipitate for 48h, Uncap to obtain water glass of the present invention, be denoted as A1, and list in Table 1.

Embodiment 2

[0045] Dissolve 2g of industrial aluminum hydroxide and 4g of industrial zinc hydroxide into 7g of 40% sodium hydroxide aqueous solution to make an intermediate aqueous solution of modifier, then industrial solid sodium silicate, 300g of solid-2 type, industrial hydroxide Potassium 55g, industrial sodium hydroxide 27g, sorbitol 4g, xylitol 10g, modifier intermediate aqueous solution 13g, tap water 398g, add to a 2L autoclave, cover and seal, start stirring, slowly heat up to 160°C, keep warm for 8h , naturally cooled to room temperature, precipitated for 72h, and opened the lid to obtain water glass of the present invention, which was recorded as A2 and listed in Table 1.

Embodiment 3

[0047] Dissolve 10g of industrial aluminum hydroxide and 20g of industrial zinc hydroxide into 33g of 40% sodium hydroxide aqueous solution to make an intermediate aqueous solution of the modifier, and then add industrial solid sodium silicate, solid-3 type 300g industrial solid silicic acid Potassium 34g, industrial potassium hydroxide 42g, industrial sodium hydroxide 15g, sorbitol 20g, xylitol 20g, glycerin 20g, modifier intermediate aqueous solution 63g, tap water 475g, add 2L autoclave, cover and seal, start stirring, Slowly raise the temperature to 165°C, keep it warm for 5 hours, cool naturally to room temperature, and precipitate for 48 hours. The water glass of the present invention is obtained after opening the lid, which is recorded as A3 and listed in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com