Patents

Literature

608results about How to "Harden fast" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Methods of rapidly consolidating particulate materials in wells

The present invention provides improved methods of consolidating particulate material in a subterranean zone penetrated by a well bore. The methods basically comprise the steps of coating the particulate material with a hardenable resin composition and irradiating the hardenable resin composition coating on the particulate material with microwaves to thereby accelerate the hardening of the resin composition whereby the particulate material is rapidly consolidated into a stationary permeable mass.

Owner:HALLIBURTON ENERGY SERVICES INC

Injectable depot gel composition and method of preparing the composition

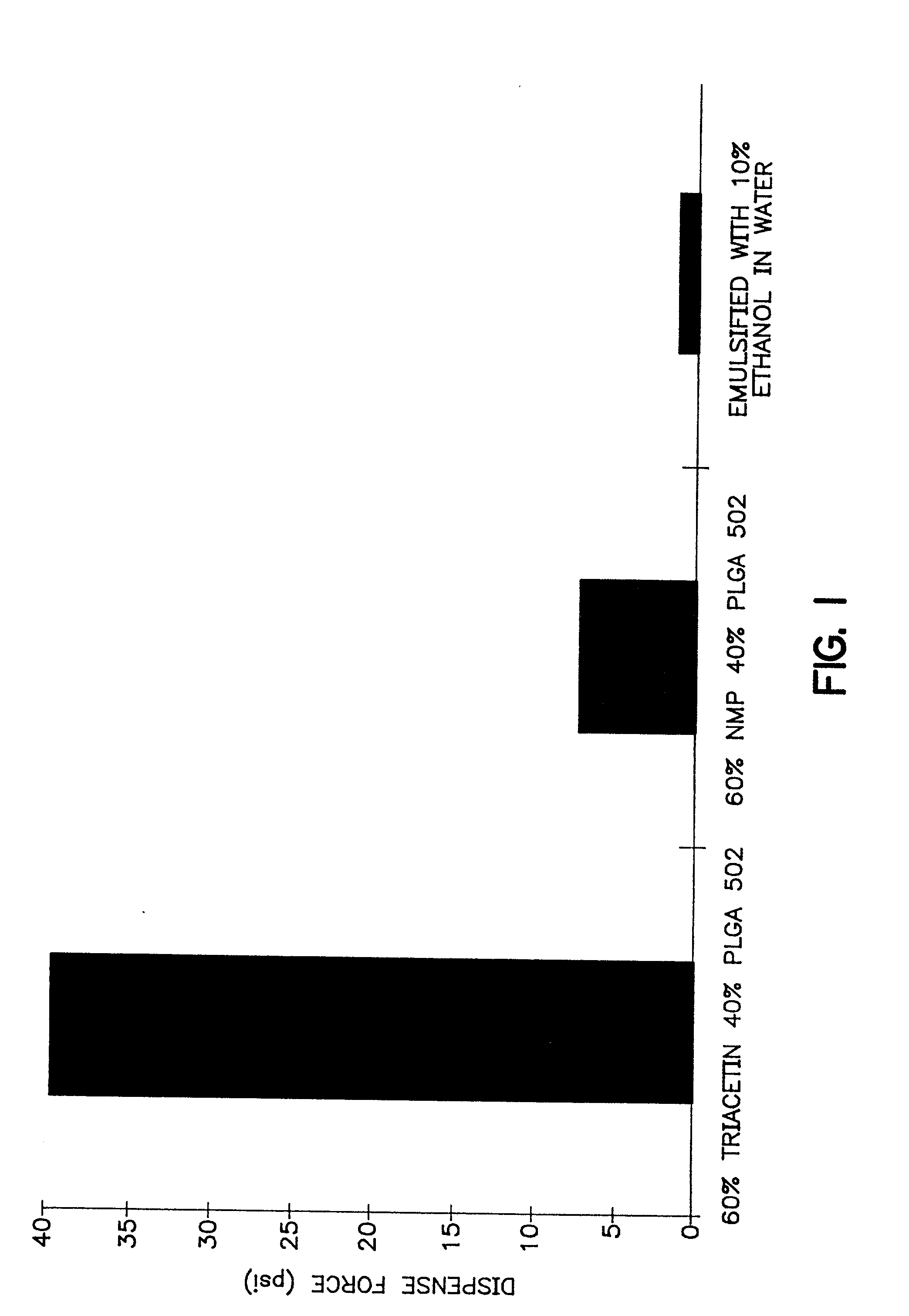

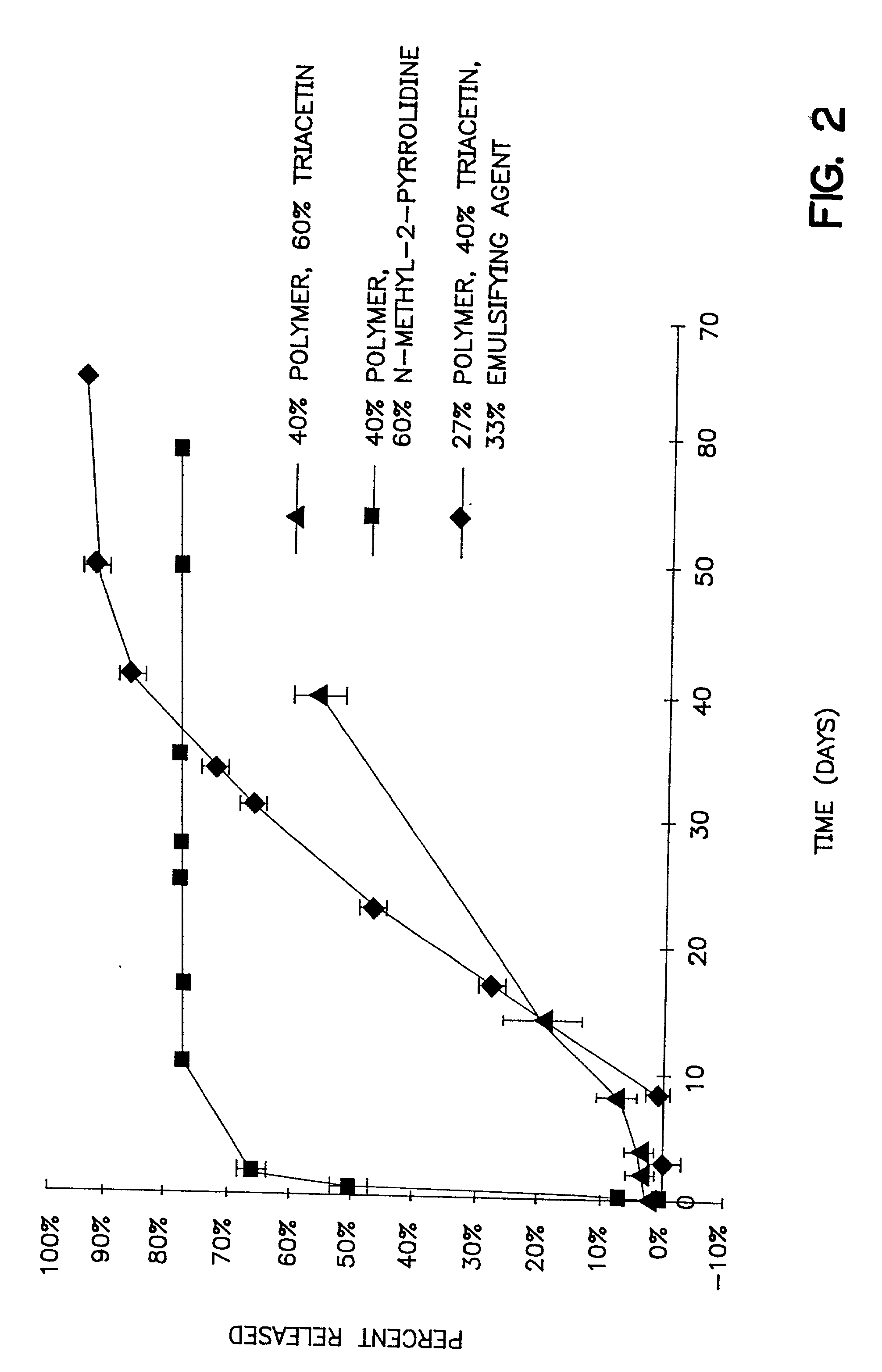

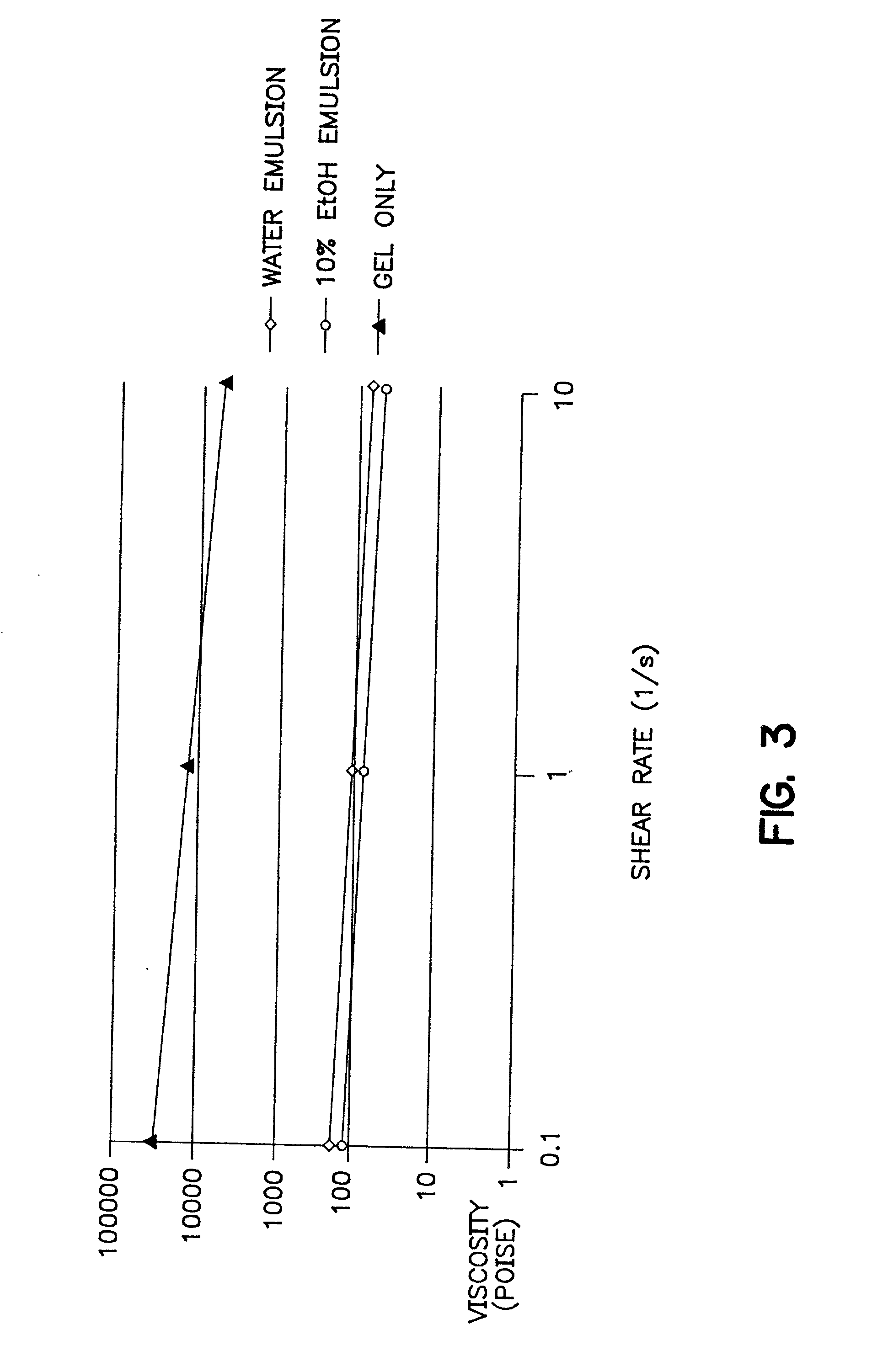

InactiveUS20020034532A1The process steps are simpleHarden fastPowder deliveryPeptide/protein ingredientsSolventPolymer chemistry

An injectable depot gel composition containing a polymer, a solvent that can dissolve the polymer and thereby form a viscous gel, a beneficial agent; and an emulsifying agent in the form of a dispersed droplet phase in the viscous gel. The injectable depot gel composition can be prepared by mixing the polymer and the solvent so that the solvent dissolves the polymer and forms a viscous gel. The beneficial agent is dissolved or dispersed in the viscous gel and the emulsifying agent is mixed with the beneficial agent containing viscous gel. The emulsifying agent forms a dispersed droplet phase in the viscous gel to provide the injectable depot gel composition. The injectable depot gel composition can deliver a beneficial agent to a human or animal with a desired release profile.

Owner:BRODBECK KEVIN J +1

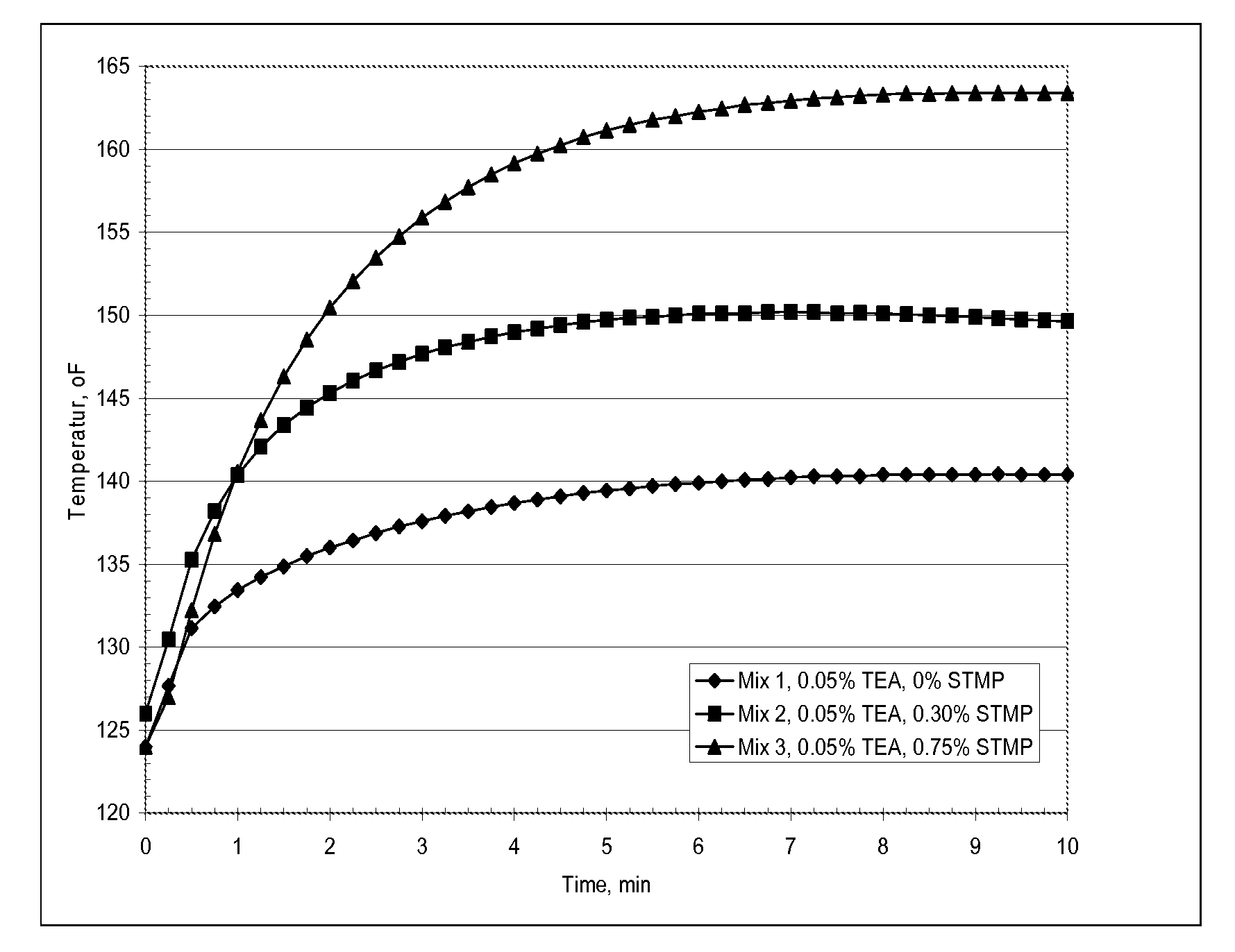

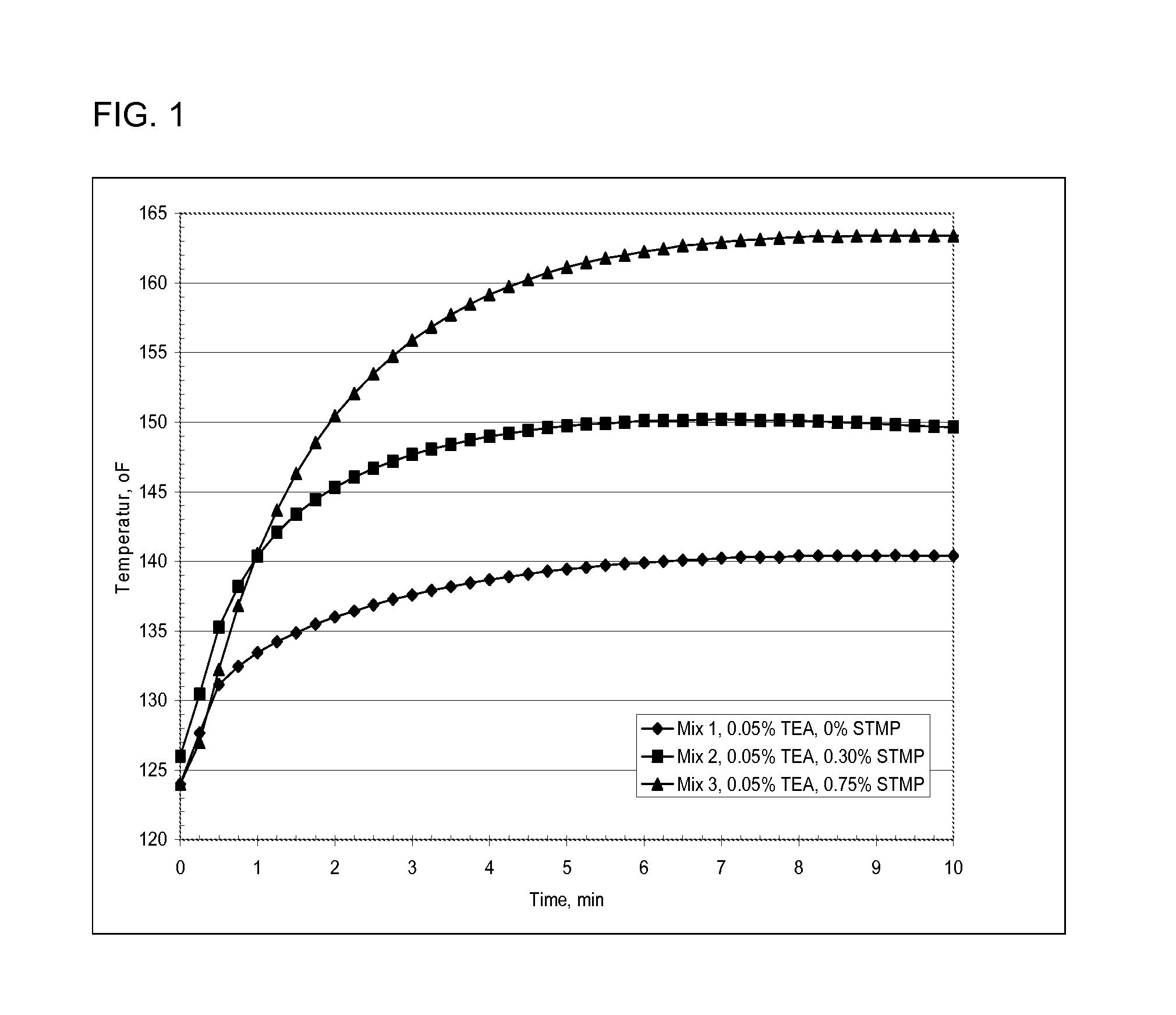

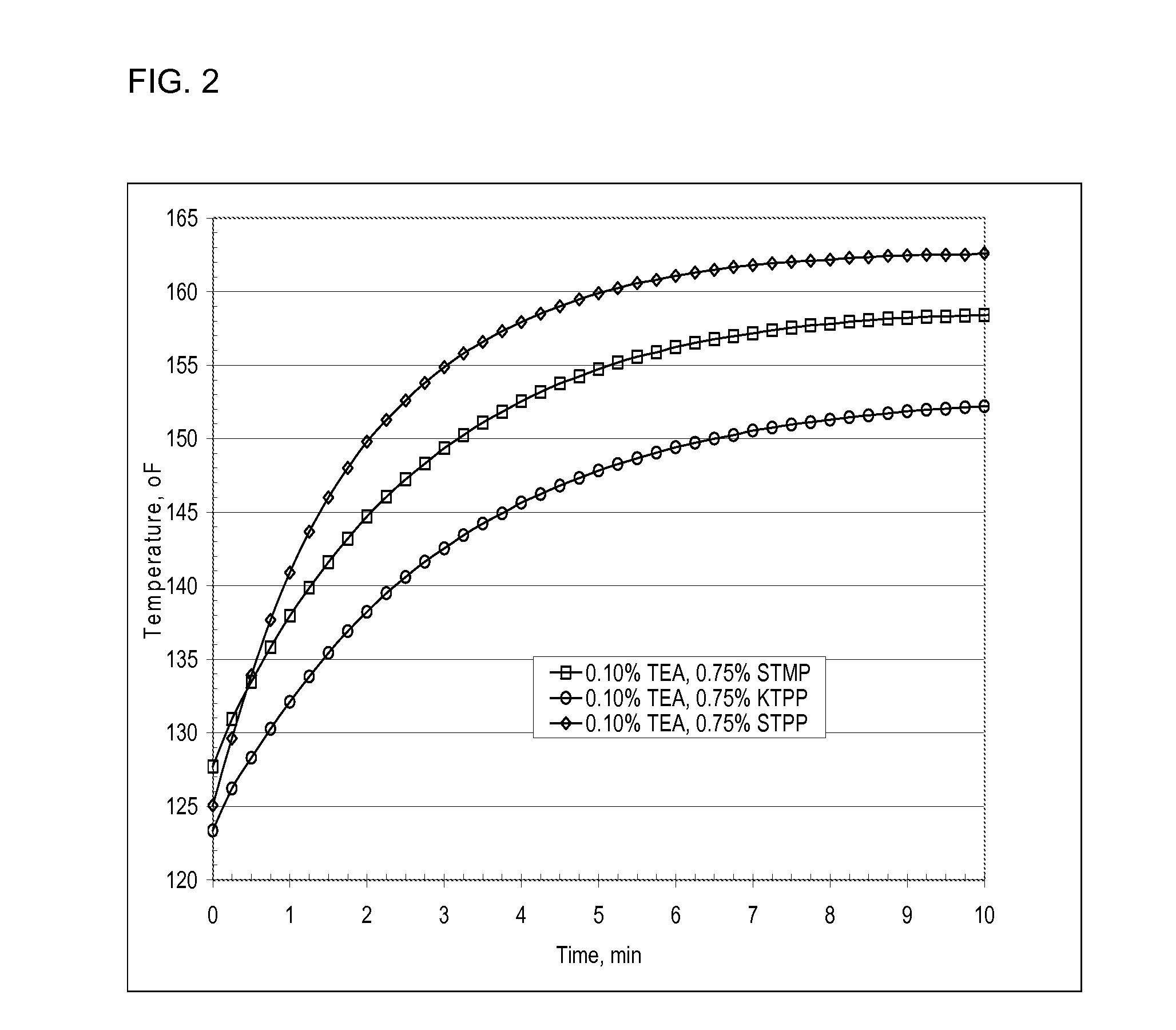

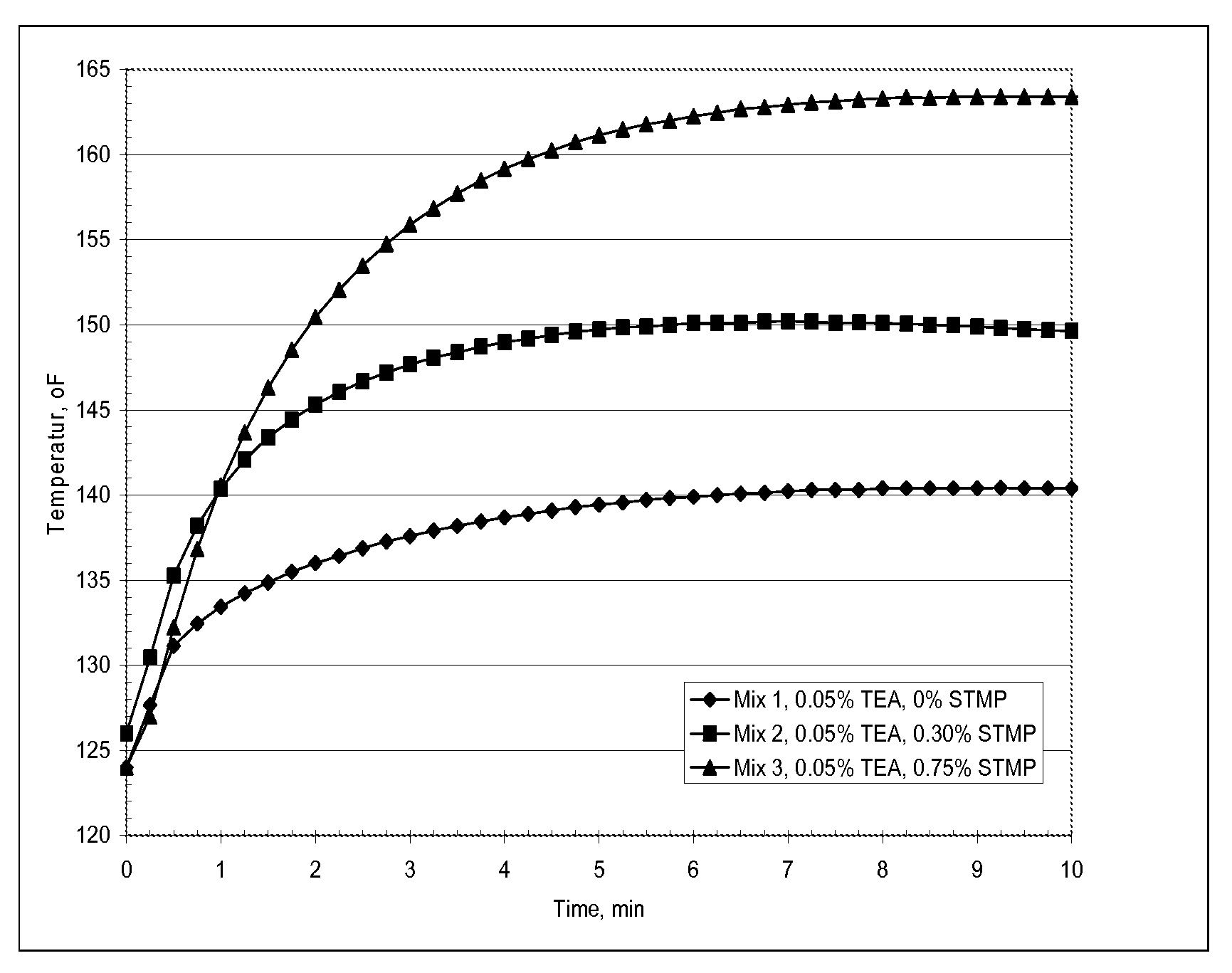

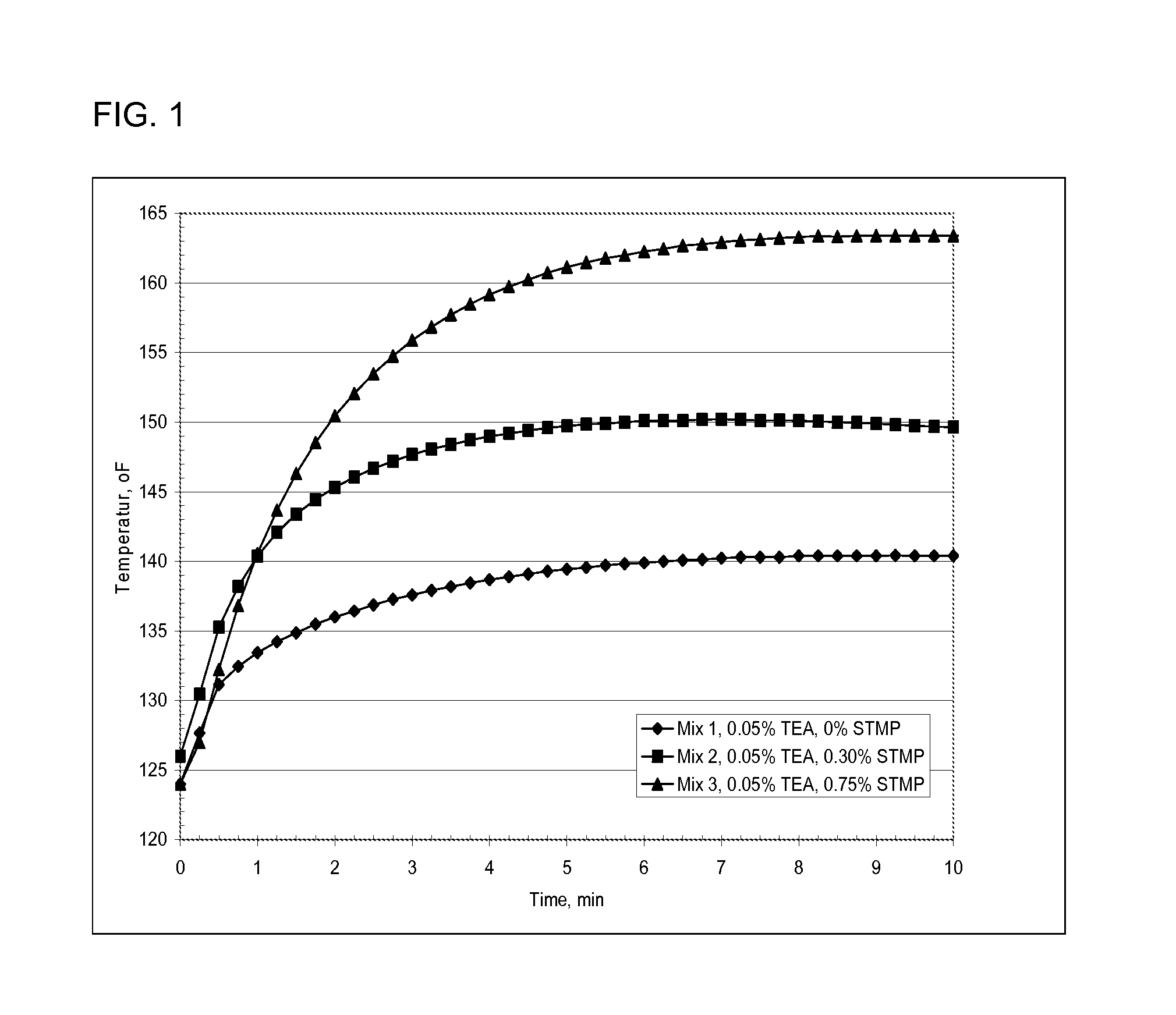

Very fast setting cementitious composition with high early-age compressive strength

ActiveUS7670427B2Addressing slow performanceHigh compressive strengthSolid waste managementPortland cementCement board

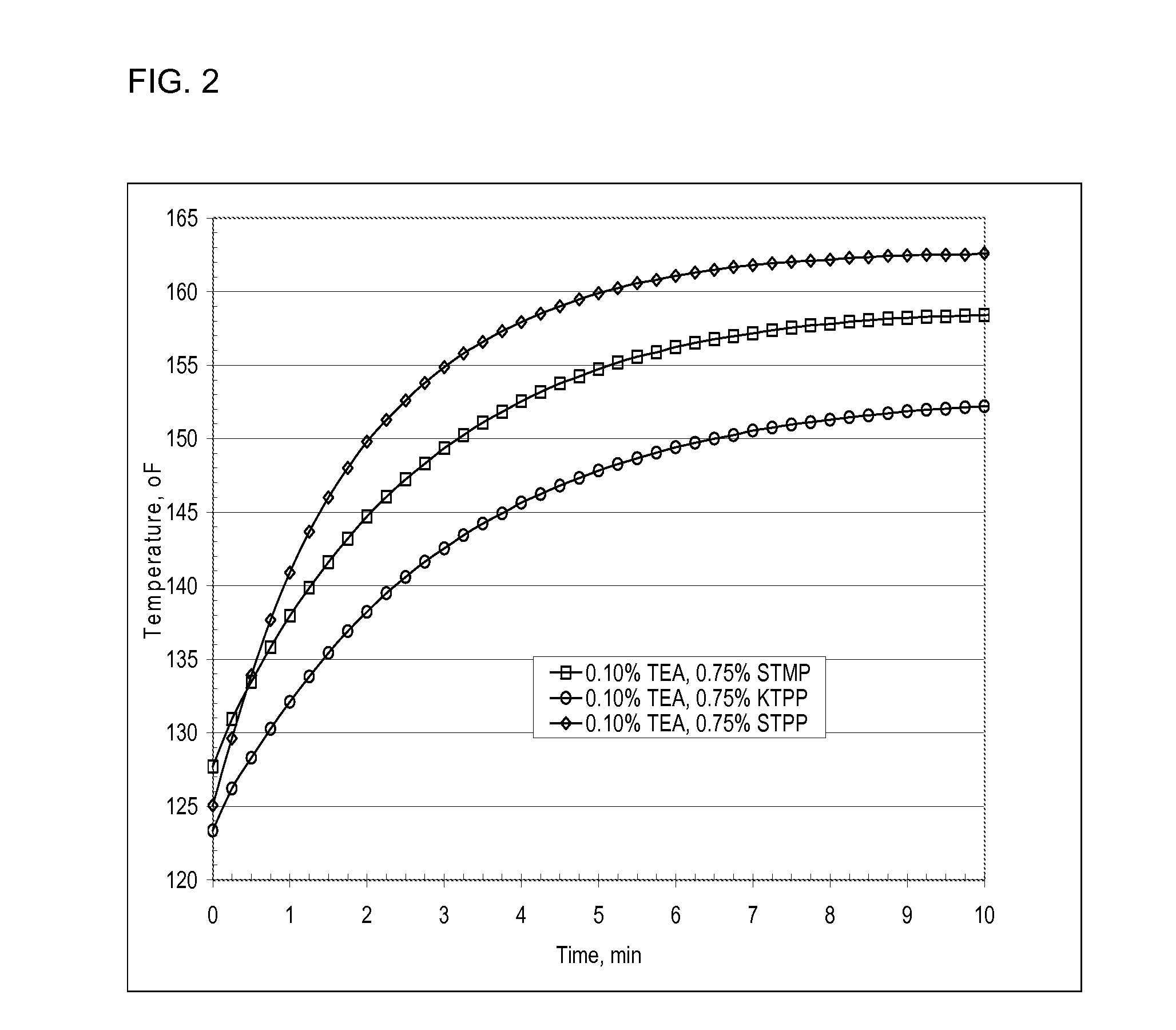

A method of making a rapid setting composition for cement boards is disclosed. Compositions including portland cement, fly ash, gypsum, alkanolamine and phosphate are disclosed. A synergistic interaction between the alkanolamine and phosphate increases the effectiveness of accelerating reactions thus allowing for quick setting and increased early-age compressive strength compositions.

Owner:UNITED STATES GYPSUM CO

Concrete super instant coagulant

The invention discloses a concrete early-strength agent, which is characterized in comprising the following components according to weight percentage: inorganic salt early-strength component 35-55 percent, organic early-strength component 5-10 percent, water reducing component 15-25 percent, wherein the inorganic salt early-strength component is prepared by at least two among sulfate, carbonate, nitrate, and nitrite; the organic early-strength component selects any one among calcium formate, sodium acetate, calcium oxalate, triethanolamine, tri-iso-propanolamine and carbamide; the water reducing component selects one among naphthalenesulfuric acid type, melamine type and polycarboxylate type. The invention makes the concrete be coagulated and hardened rapidly under the condition of low temperature, so that the early strength of the concrete is greatly improved as well as later strength is ensured.

Owner:ZHONGYIFENG CONSTR GRP +1

Very fast setting cementitious composition with high early-age compressive strength

ActiveUS20080302276A1Addressing slow performanceHigh compressive strengthSolid waste managementPortland cementCement board

A method of making a rapid setting composition for cement boards is disclosed. Compositions including portland cement, fly ash, gypsum, alkanolamine and phosphate are disclosed. A synergistic interaction between the alkanolamine and phosphate increases the effectiveness of accelerating reactions thus allowing for quick setting and increased early-age compressive strength compositions.

Owner:UNITED STATES GYPSUM CO

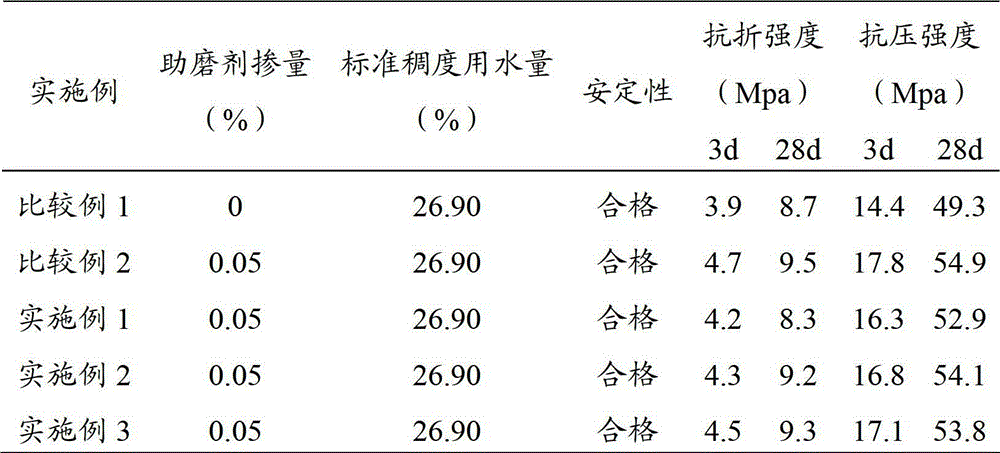

Grinding aid for slag cement

The invention provides a grinding aid for slag cement. The grinding aid provided by the invention comprises the following components by weight percent: 5-20wt% of alcohol amine compound, 0.1-5wt% of hydroxypropyl methyl cellulose, 5-30wt% of polyhydric alcohol compound, 0.5-10wt% of sodium hexametaphosphate, 1-10wt% of soluble sulfate, 1-8wt% of sodium dodecyl benzene sulfonate and the balance of water. In the grinding agent provided by the invention, the hydroxypropyl methyl cellulose is beneficial for stimulating the activity of the slag, forming stable hydrous products in the reaction process, improving the property of the cement, improving the strength of the cement and improving the stability of the liquid grinding aid at the same time. Experimental result shows that the grinding aid is capable of increasing the breaking strength of the cement to 9.5MPa and increasing the compressive strength to about 55MPa.

Owner:SHANDONG HONGYI TECH +1

Hot cast high temperature wear resistant ceramic material

The present invention is hot cast high temperature wear resistant ceramic material is one anti-wear refractory material suitable for fast hot repair of tertiary air duct, high temperature air duct, high temperature dust collector, etc in cement producing apparatus as well as thermal apparatus in iron and steel works, power plant, etc. The hot cast high temperature wear resistant ceramic material is powder comprising high alumina anti-wear refractory material as the aggregate, phosphate, phosphoric acid and aluminum dihydrogen phosphate as the binding agent, and additive. It has convenient repair construction process, high flowability, high strength, high heat resistance, high wear resistance, and high heat shock resistance.

Owner:洛阳鹏飞耐磨材料股份有限公司

Composite bonding wear-resistant castable refractory

The invention relates to a composite bonding wear-resistant castable refractory, which can be used for high-temperature kiln engineering. The amorphous castable refractory which is normal in coagulation, quick in hardening, low in porosity, high in strength and high in abrasive resistance is prepared from silica sol serving as a bonding agent, aluminate cement serving as a curing agent, alumina micro powder and wollastonite which serve as a compact agent, heat resistant steel filters serving as a reinforcing agent and corundum and alumina which serve as an aggregate. The composite bonding wear-resistant castable refractory is suitable for positions such as air pipeline elbows for the cogeneration of cement kilns, cyclone cones and linings for triple air pipe gates which are easy to wear in high-temperature kilns.

Owner:ANHUI RUITAI NEW MATERIALS TECH

Thermal insulation mortar

InactiveCN102010174AGood volume stabilityStrong water resistanceSolid waste managementPolystyreneTime control

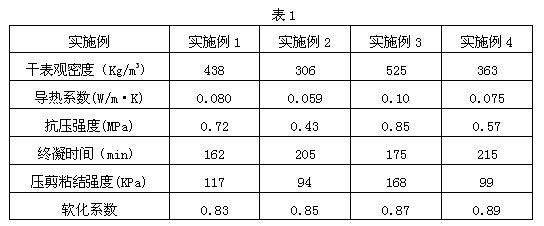

The invention discloses thermal insulation mortar which comprises the following components in percentage by weight: 20 to 60 percent of caustic calcined magnesia, 1 to 25 percent of fly ash, 5 to 35 percent of thickening time control agent, 0 to 40 percent of enhanced thickener, 1 to 20 percent of kieselguhr, 5 to 35 percent of expanded aggregate, 0 to 5 percent of polystyrene foam particles, 0 to 0.2 percent of polypropylene fiber, 0.5 to 8 percent of water-resisting admixture, and 0 to 2 percent of water reducing agent. The thermal insulation mortar has the characteristics of capability of coagulating and hardening quickly and having strong binding capacity with base materials, good volume stability, capability of producing volume micro-expansion in the process of coagulating and hardening, no crack, no splitting, strong water resistance, ageing resistance, long service life, light weight, and good heat preservation and heat insulation performance, wherein the coefficient of thermal conductivity is 0.05 to 0.30 W / m.k. The thermal insulation mortar has the advantages of no toxicity, odourlessness, zero radioactivity, no harm to human bodies, no pollution to environments, energy conservation, environmental friendliness and low production cost.

Owner:QINGHAI INST OF SALT LAKES OF CHINESE ACAD OF SCI +2

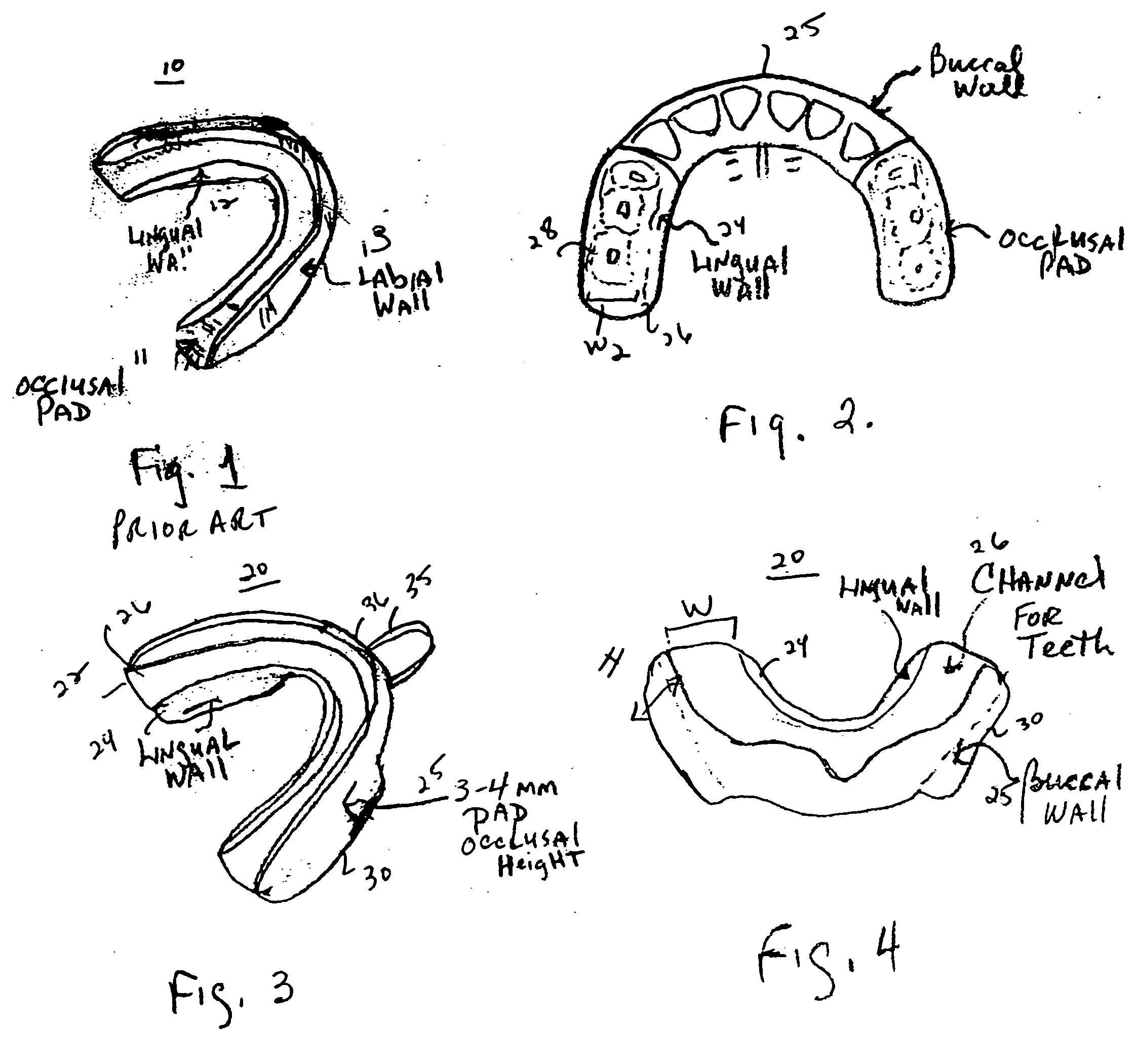

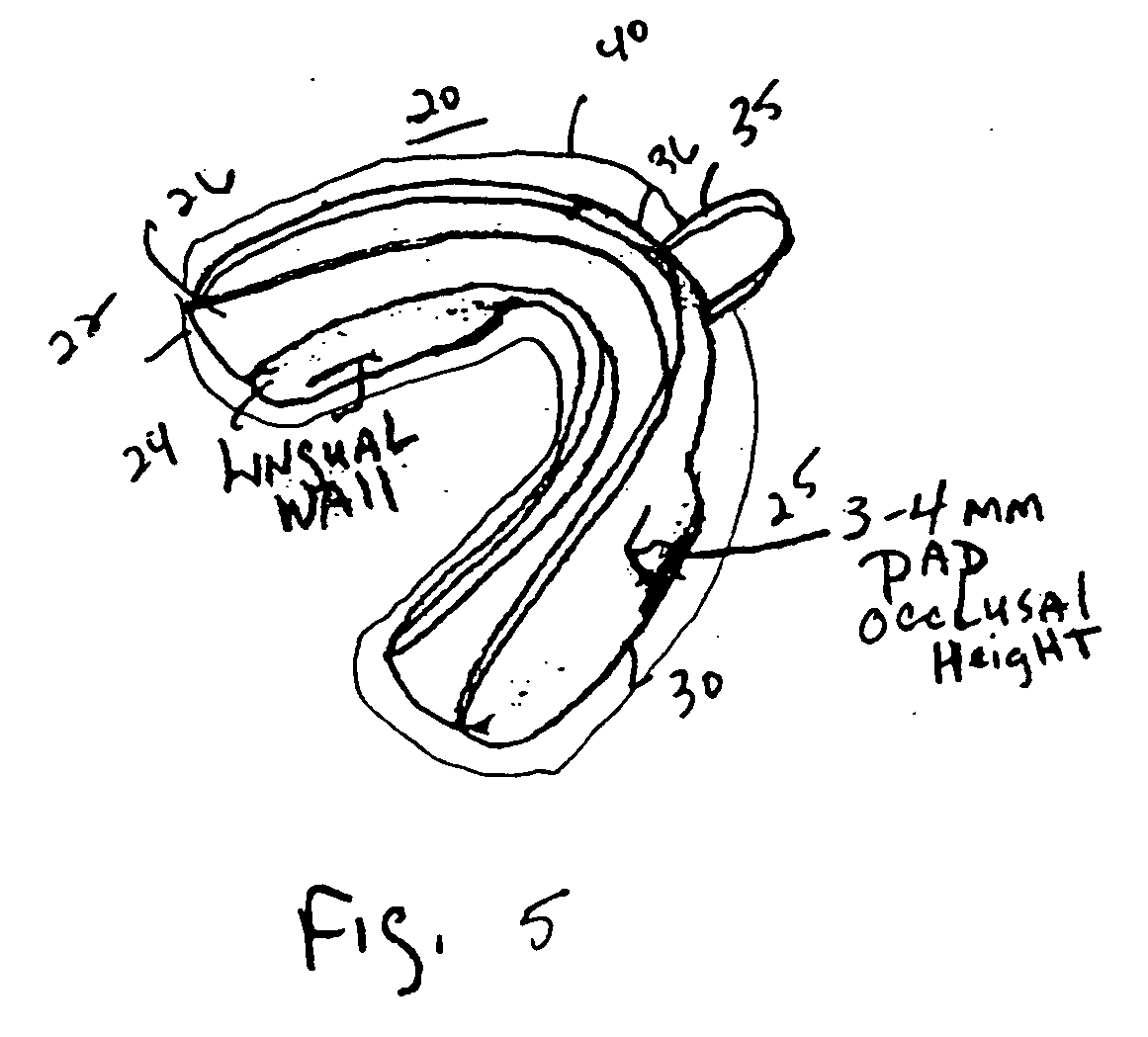

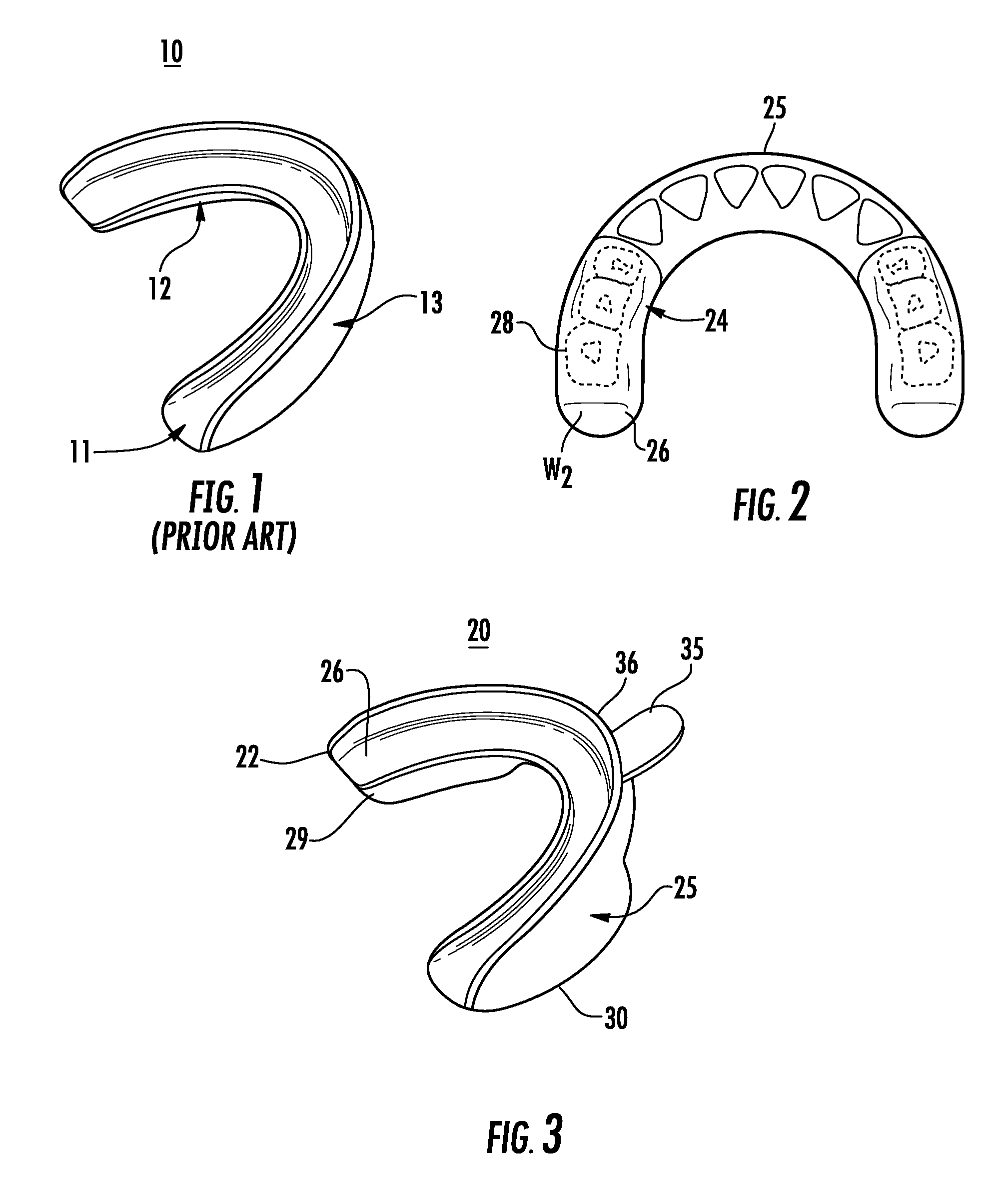

Dental appliance and mouthguard formed of polyolefin elastomer

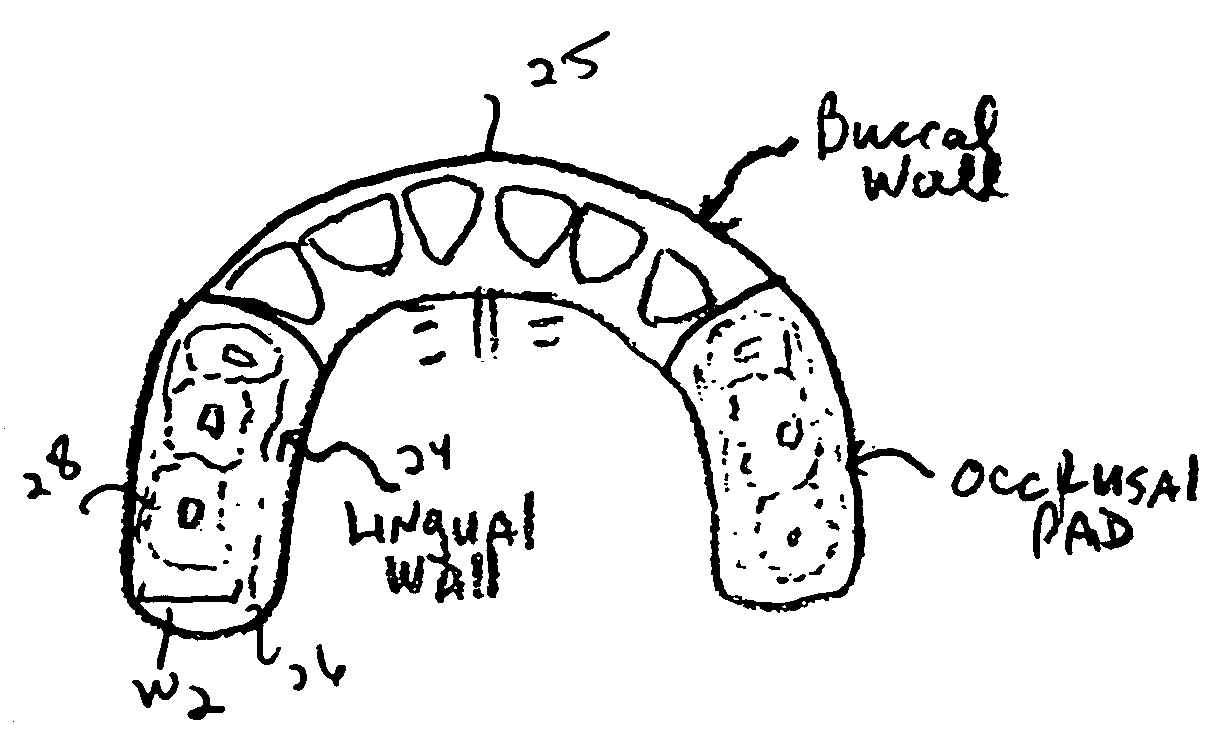

ActiveUS20050256276A1High materialIncrease in temperatureImpression capsTeeth fillingOlefin polymerizationPolypropylene

A self-customizable dental appliance adapted to lie within the mouth of a person including occlusal pads with a connecting arch or a u-shaped style base with upstanding labial and lingual walls. The appliance is formed of a semi-crystalline polyolefin polymer or crystallizable blend. In one embodiment, the appliance is formed of elastomeric propylene-ethylene polypropylene, optionally including high density polypropylene. An optional occlusal lifting pad can be used in the self-customizable dental appliance.

Owner:DENTAL CHOICE HLDG LLC

Desulfurization gypsum-based thermal insulation mortar and preparation method thereof

The invention relates to a desulfurization gypsum-based thermal insulation mortar and a preparation method of the mortar, belonging to the technical fields of solid waste comprehensive utilization and building material. The desulfurization gypsum-based thermal insulation mortar comprises the components in parts by weight: 1000 parts of desulfurization gypsum, 3-10 parts of white cement, 350-450 parts of glass beads, 5-15 parts of redispersible latex powder, 1-5 parts of wood fiber, 5-25 parts of sepiolite fiber, 1.5-5 parts of polypropylene (PP) fiber, 1-8 parts of polyvinyl alcohol, 1-5 parts of hydrophobic agent, 0.4-3 parts of retarder, 1-5 parts of water reducing agent and 2-6 parts of thickening agent. The desulfurization gypsum-based thermal insulation mortar is convenient to transport and has very strong thermal insulation performance and fireproof performance.

Owner:上海复培新材料科技有限公司

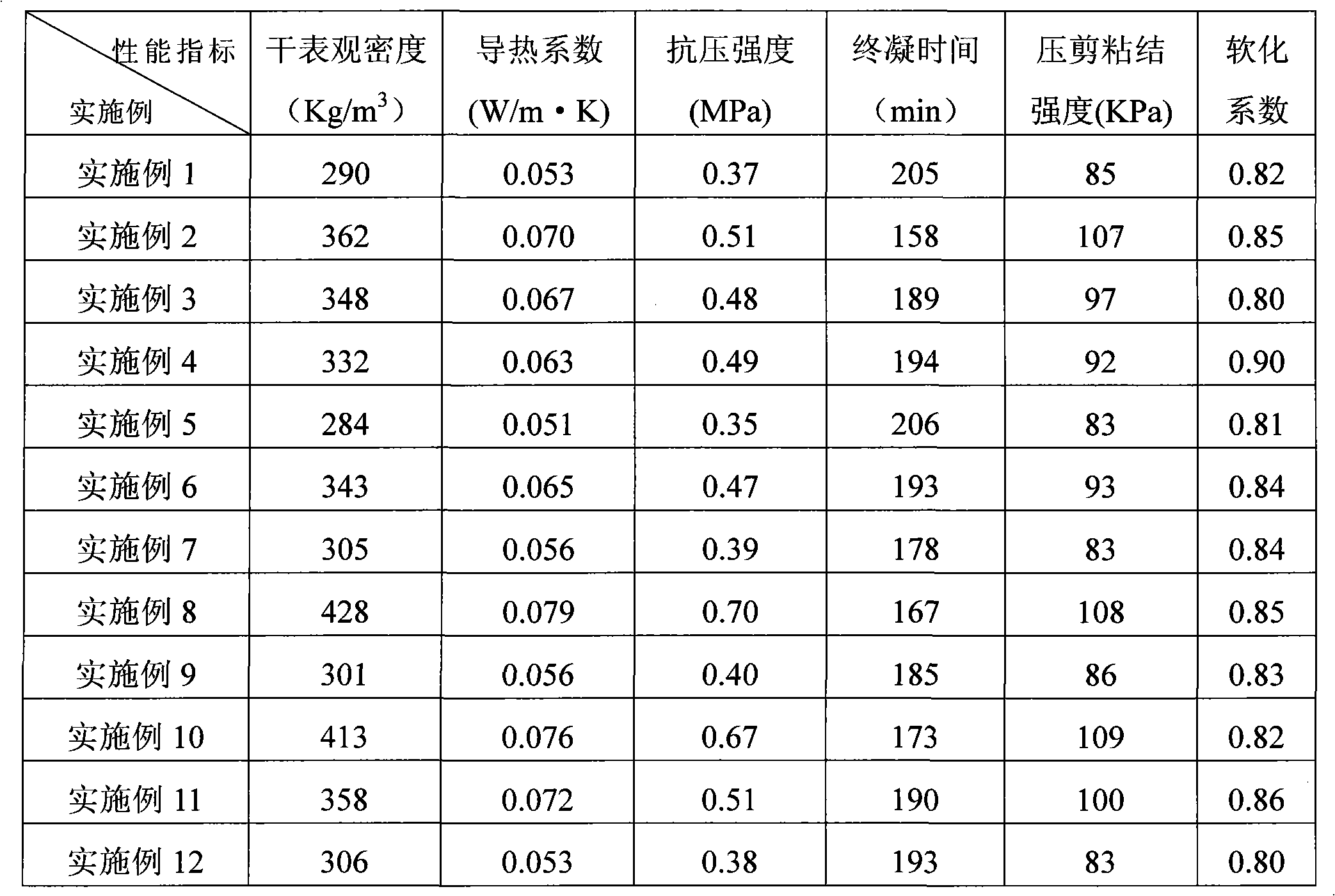

Metakaolin-based polymer foam concrete and preparation method thereof

The invention relates to metakaolin-based polymer foam concrete and a preparation method thereof. Metakaolin, coal ash and a coagulation accelerating agent are added into a mixing machine in proportion to be mixed to be uniform, an alkali excitant and water are added in proportion, and mixing is carried out to prepare slurry; while the slurry is prepared, a foaming agent is diluted with water in proportion of 1: 15, a high-speed mixing machine or a vacuum foaming machine is adopted for preparing fine and stable foam; and according to density design requirement, the prepared foam is blended into the uniformly mixed slurry in volume ratio to be mixed and foamed, wherein the volume ratio of the foam to the slurry is (1-4):1, and mixing is carried out for 2.5-3min until the foam is uniformly dispersed in the slurry, thus freshly blended metakaolin-based polymer foam concrete is prepared. Compared with the traditional cement-based foam concrete taking silicate cement as a main cementing material, the metakaolin-based polymer foam concrete has the characteristics of environmental friendliness, higher strength, low thermal conductivity, good heat insulating property and the like, and can be used for producing various foam concrete products.

Owner:CHONGQING UNIV

3D printing mortar and preparation method thereof

The invention relates to 3D printing mortar and a preparation method thereof and belongs to the field of building materials. The mortar is mainly composed of 70-90% of compound cement, 5-20% of quartz sand, 0.2-2% of lime, 1-5% of coagulant, 0-3% of water reducing agent, 0-3% of defoaming agent, 0-0.5% of thickener and 0.2-0.8% of fiber. The mortar can be quickly hardened and is good in thixotropy and flowability, initial setting time can be within 2 min at least, the requirement that the 3D printing mortar is quickly dried and hardened can be met, and later strength is high.

Owner:WUHAN UNIV OF TECH

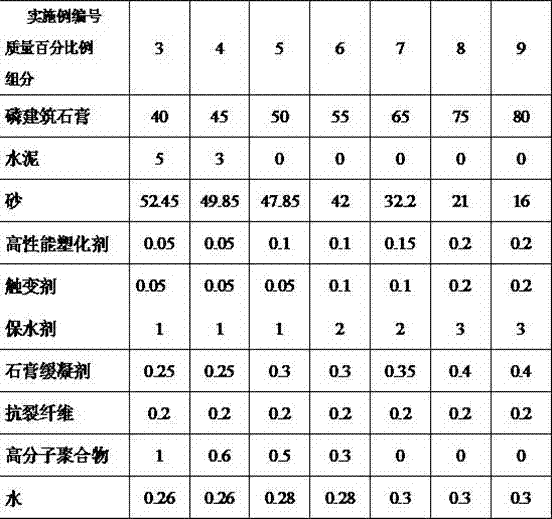

Preparation method of phosphogypsum-based anti-cracking mortar applied to interior insulation of external wall

The invention discloses a preparation method of phosphogypsum-based anti-cracking mortar applied to interior insulation of an external wall. The preparation method is characterized in that the anti-cracking mortar comprises the following components in percentage by mass: 40-80% of building phosphogypsum, 20-50% of dried sand, 0-20% of cement, 0-5% of fly ash, 0-0.2% of a high-performance plasticizer, 0-0.2% of a thixotropic agent, 0.1-0.3% of a water-retaining agent, 0.01-0.4% of a gypsum retarder, 0-3% of a micromolecular polymer and 0-0.25% of anti-cracking fiber. According to the preparation method, the building phosphogypsum prepared by washing and calcining industrial byproduct phosphogypsum is used as a cementing material, so that the problems that a cement-based material is easy to shrink, hollow and crack are solved; through full use of the characteristics of fast setting and hardening, good volume stability and low own ratio of compressive strength to flexural strength of a gypsum material, the anti-cracking mortar, of which the ratio of the compressive strength to the flexural strength is lower than 2.5, the operable time is 1-2h, the final setting time is shorter than 3h, the insulation board bonding strength is higher than 0.10MPa and breakage occurs inside an insulation board, is prepared. The anti-cracking mortar is applied to the interior insulation of the external wall and low in cost, reduces the environment pollution, and is simple in production process, low in energy consumption and good in product performance; compared with other insulation board crack resisting products, the anti-cracking mortar has higher market competitiveness and is strong in practicality.

Owner:四川华邦保和涂料有限公司

Modified sodium silicate binder for cold core box and preparation thereof

ActiveCN101947637AWide variety of sourcesImprove working environmentFoundry mouldsFoundry coresZinc hydroxideAluminium hydroxide

The invention aims to provide a modified sodium silicate binder for a cold core box and a preparation method thereof. The binder has the advantages of wide raw material sources, no toxicity or smell and good mechanical property and is applicable to mechanized core manufacture of the cold core box and manual core manufacture. The modified sodium silicate binder comprises the following chemical compositions in percentage by mass: 20 to 30 percent of SiO, 10 to 20 percent of Na2O, 0.5 to 19 percent of K2O, 1.0 to 20 percent of modifier and the balance of water, wherein the modifier can be aluminium hydroxide and / or zinc hydroxide, or one or more of amylin, sugar, molasses, polyacrylamide, sodium polyacrylate, sodium tripolyphosphate, cellulose, humic acid, sodium humate, sorbierite, xylitol and sodium silicate are added.

Owner:SHENYANG HYATON FOUNDRY MATERIAL

Liner making technique for casting lander of blast furnace with single iron notch, and free from baking casting material for iron notch

Owner:北京联合荣大工程材料股份有限公司

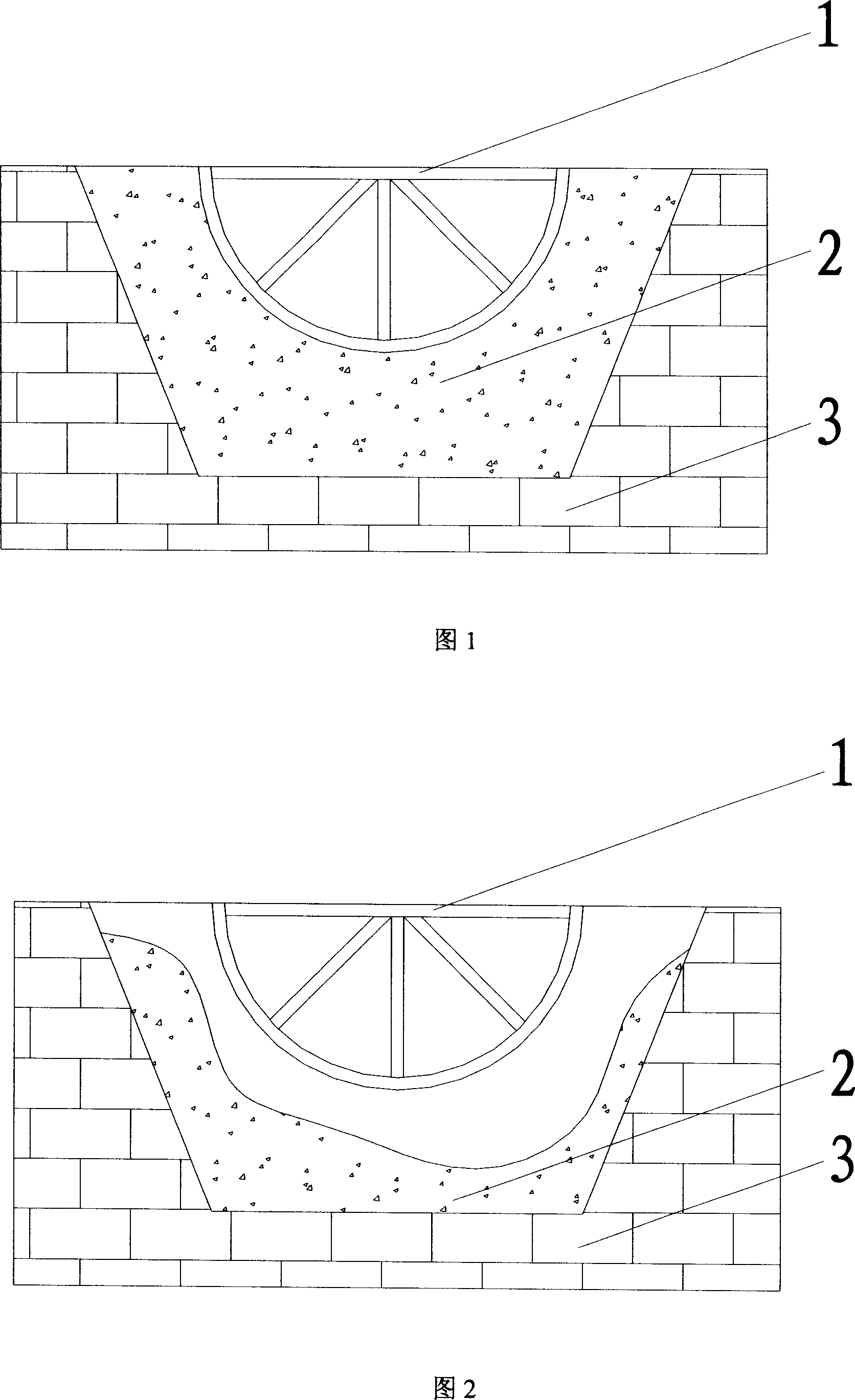

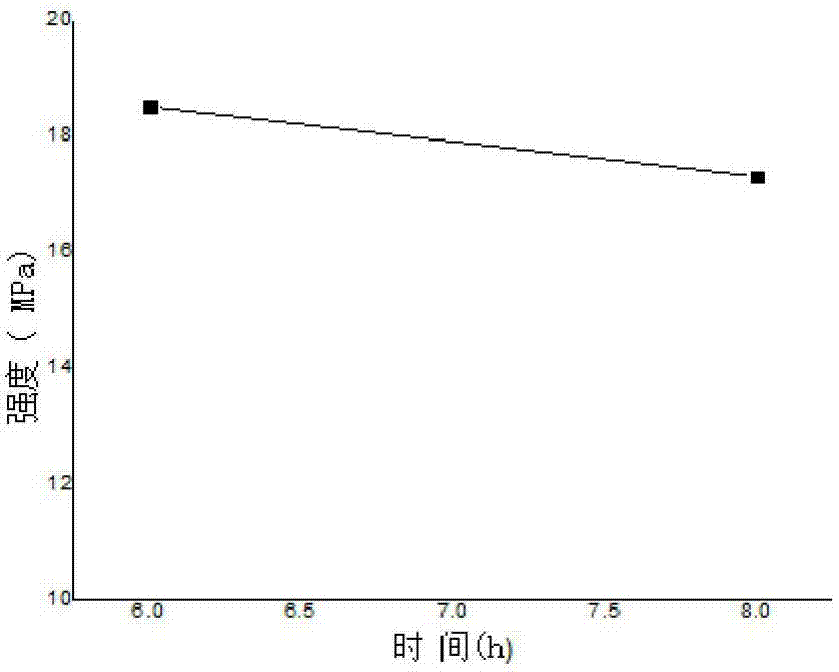

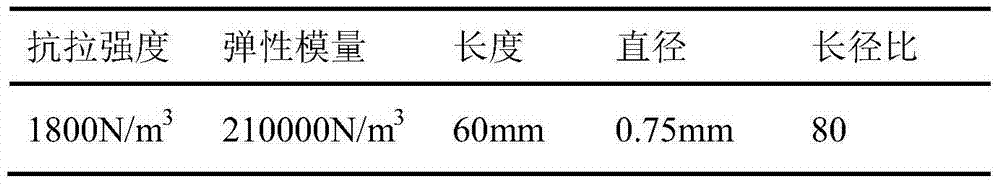

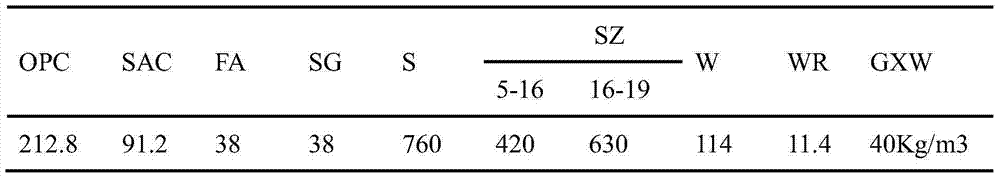

Steam-curing-free early-strength steel fiber concrete pipe segment and preparation method thereof

InactiveCN104773988AHarden fastSimplify maintenanceSolid waste managementFiberCALCIUM HYDROXIDE SOLUTION

The invention discloses a steam-curing-free early-strength steel fiber concrete pipe segment comprising ordinary Portland cement, early-strength sulphoaluminate cement, fly ash, slag, fine aggregate, coarse aggregate, water, a polycarboxylic acid type water reducer and end hook type steel fibers. The invention also discloses a preparation method of the steam-curing-free early-strength steel fiber concrete pipe segment. The steam-curing-free early-strength steel fiber concrete pipe segment is quick in coagulation and hardening and high in early strength, can reach the strength of 15MPa required by pipe segment demolding in 6-8 hours, and can be prepared into a concrete pipe segment for an underground structure by performing water curing in a 20 DEG C saturated calcium hydroxide solution for 24 hours and then performing natural curing for 28 days. The steam-curing-free early-strength steel fiber concrete pipe segment does not need steam curing, so that the curing mode of the pipe segment can be simplified, the curing time is shortened, a lot of manpower and resources are saved, and the popularization and application values are high.

Owner:SOUTHEAST UNIV +1

Method for producing architectural gypsum powder by using phosphogypsum

This invention relates to a method for producing construction gypsum powder from ardealite. The method comprises: (1) prehomogenizing ardealite waste residue, placing in a continuous high-efficiency calcining kiln, and calcining; (2) taking out and aging naturally for 7-15 d; (3) milling into 100-200 mesh powder. This invention uses a unique calcination technique to produce high performance construction gypsum from ardealite waste residue, and has such advantages as no secondary pollution and saved water resource.

Owner:宁夏建筑材料研究院(有限公司)

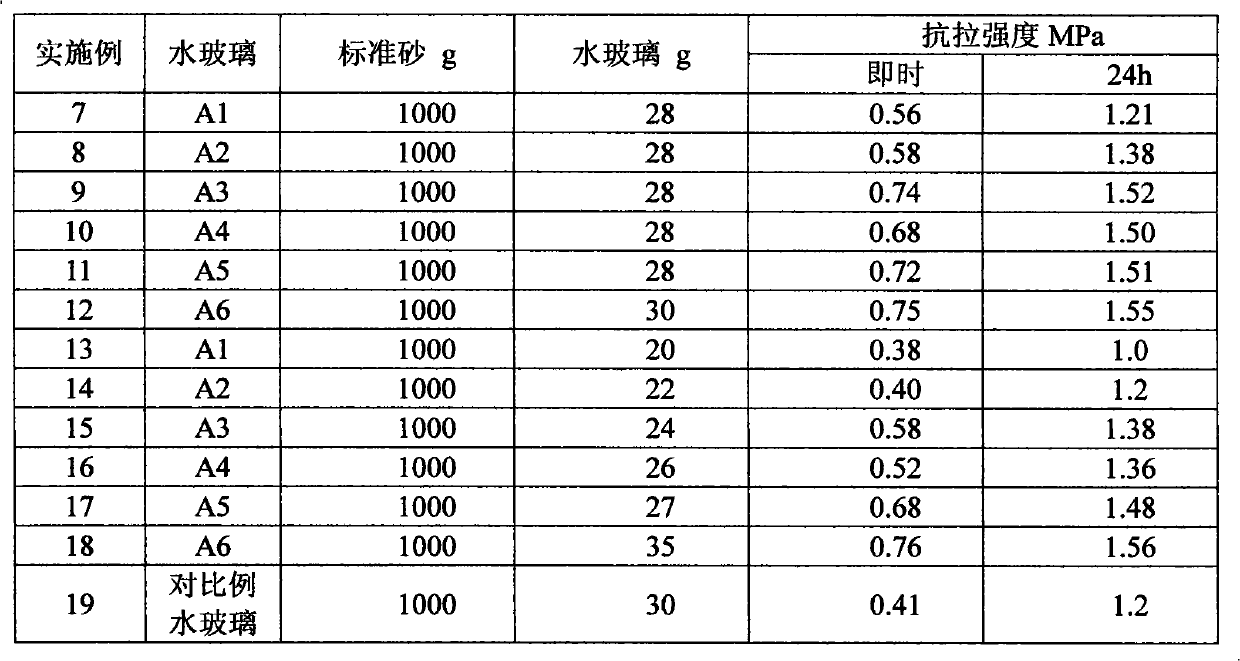

Alkaline phenol formaldehyde resin for 3D printing, and preparation method thereof

ActiveCN104817665AMeet the needs of useGet rid of the characteristic of high viscosityAdditive manufacturing apparatusFurfuryl alcoholHardness

The present invention relates to an alkaline phenol formaldehyde resin for 3D printing, and a preparation method thereof, wherein the alkaline phenol formaldehyde resin comprises cresol, phenol, furfuryl alcohol, formaldehyde, propylene glycol methyl ether, sodium hydroxide, a coupling agent, and a modifier. According to the present invention, the large viscosity characteristic of the conventional alkaline phenol formaldehyde resin is removed in the alkaline phenol formaldehyde resin of the present invention, wherein the resin viscosity is controlled to equal to or less than 20 mpa.s (25 DEG C); the process resin is added with the right amount of modifier, such that the free formaldehyde content and the free phenol content in the resin can be effectively reduced and can be reduced to equal to or less than 0.1% so as to provide the mild property for the on-site work environment and so as not to produce the adverse reaction for people; and with the special synthesis and reaction conditions of the process, the prepared resin can achieve rapid hardening, the mold sand usable time is less than 2 min (25 DEG C), the 24 h mold sand tensile strength is more than or equal to 1.2 MPa, the modeling can be performed on the high heat resistance and high hardness sand mold, and the use requirement of the 3D printing technology can be completely met.

Owner:NINGXIA KOCEL MOLD

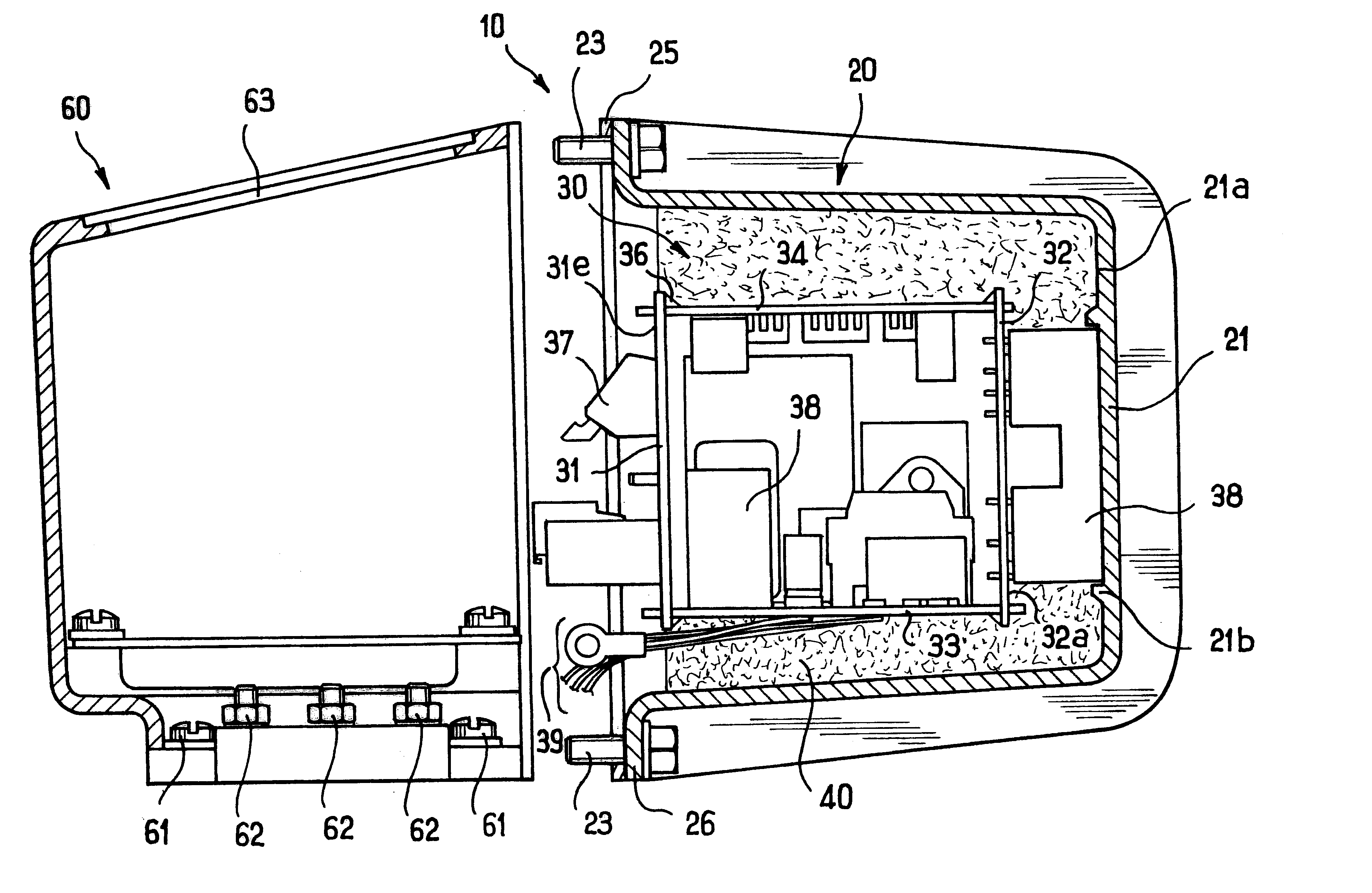

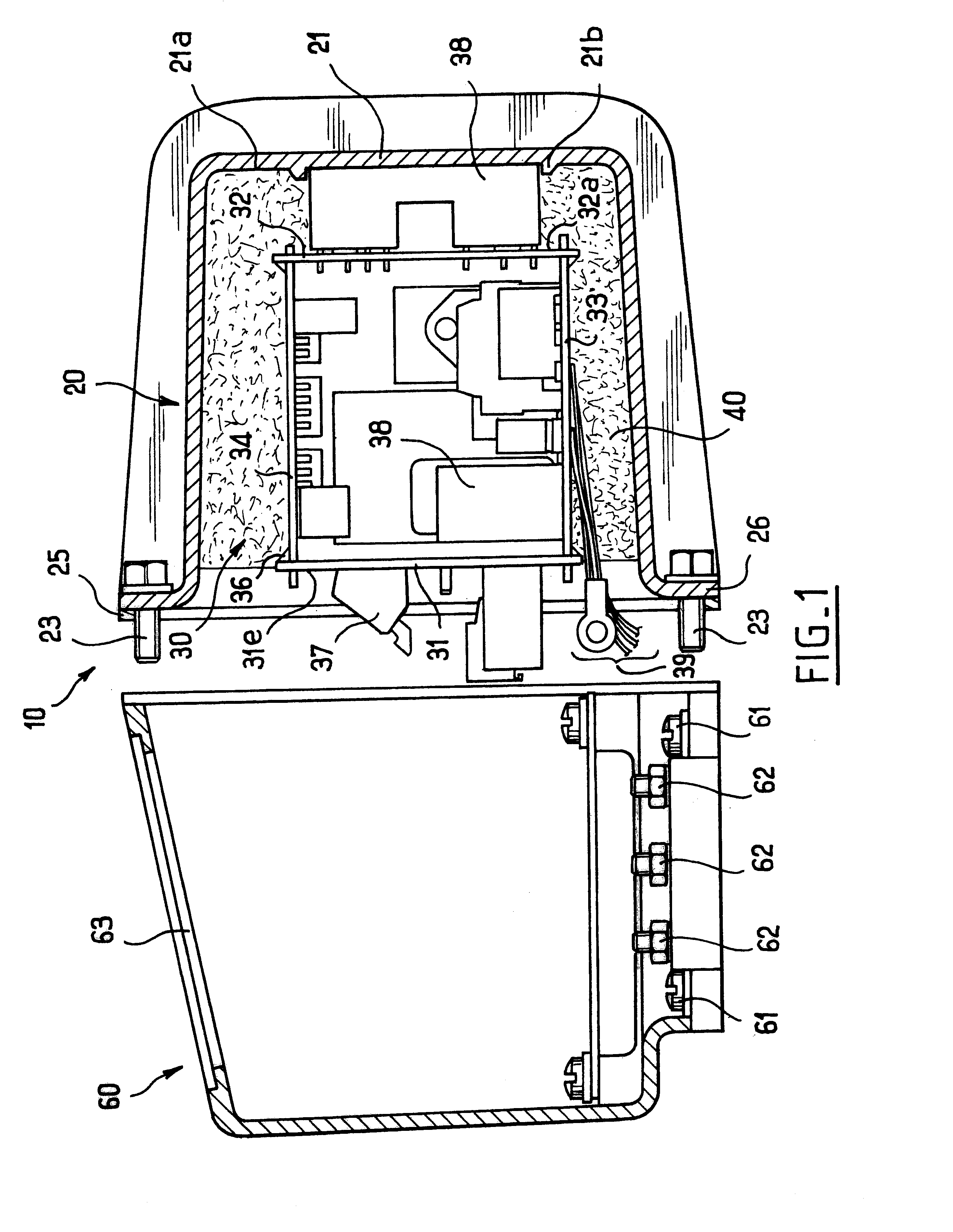

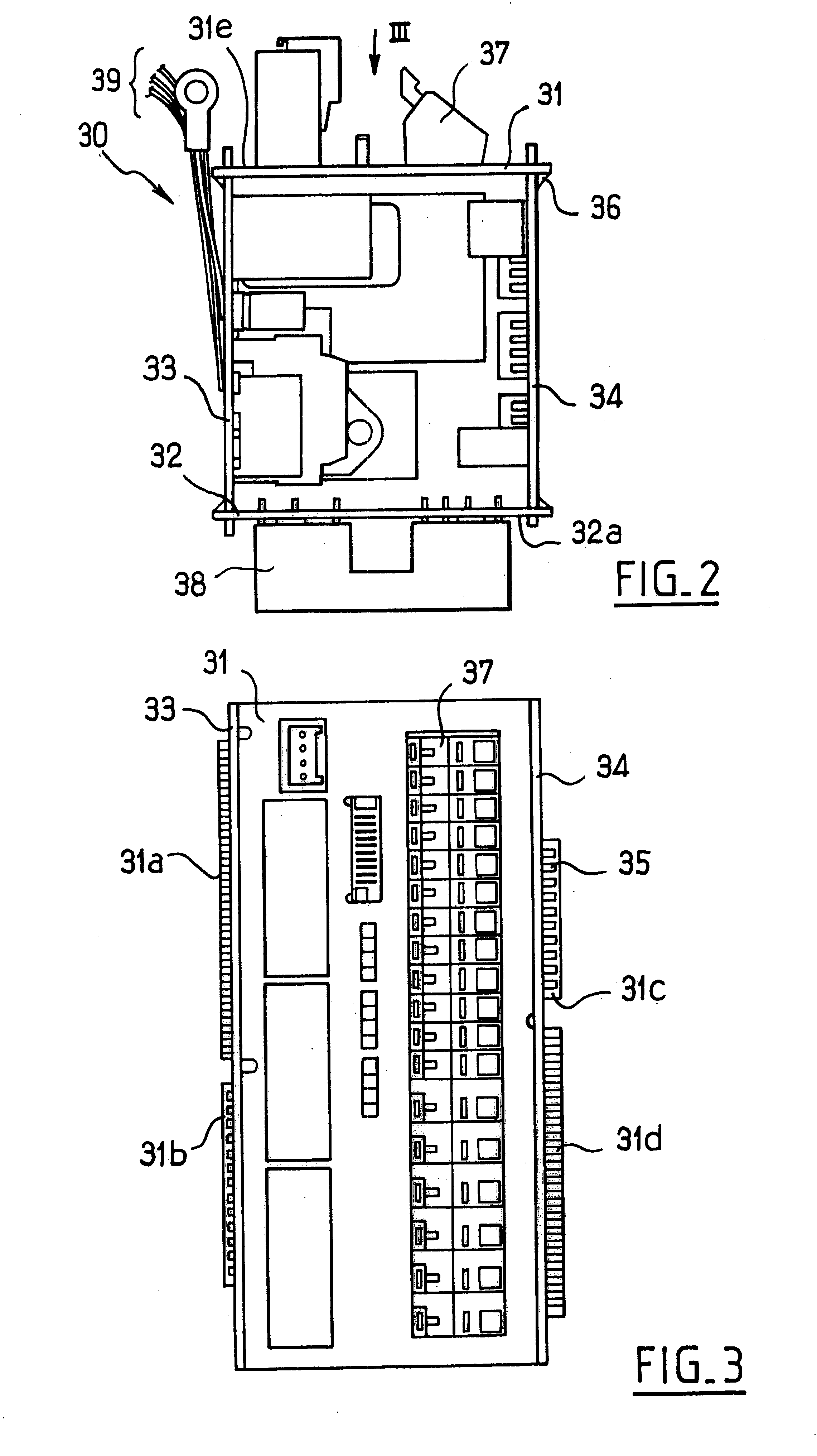

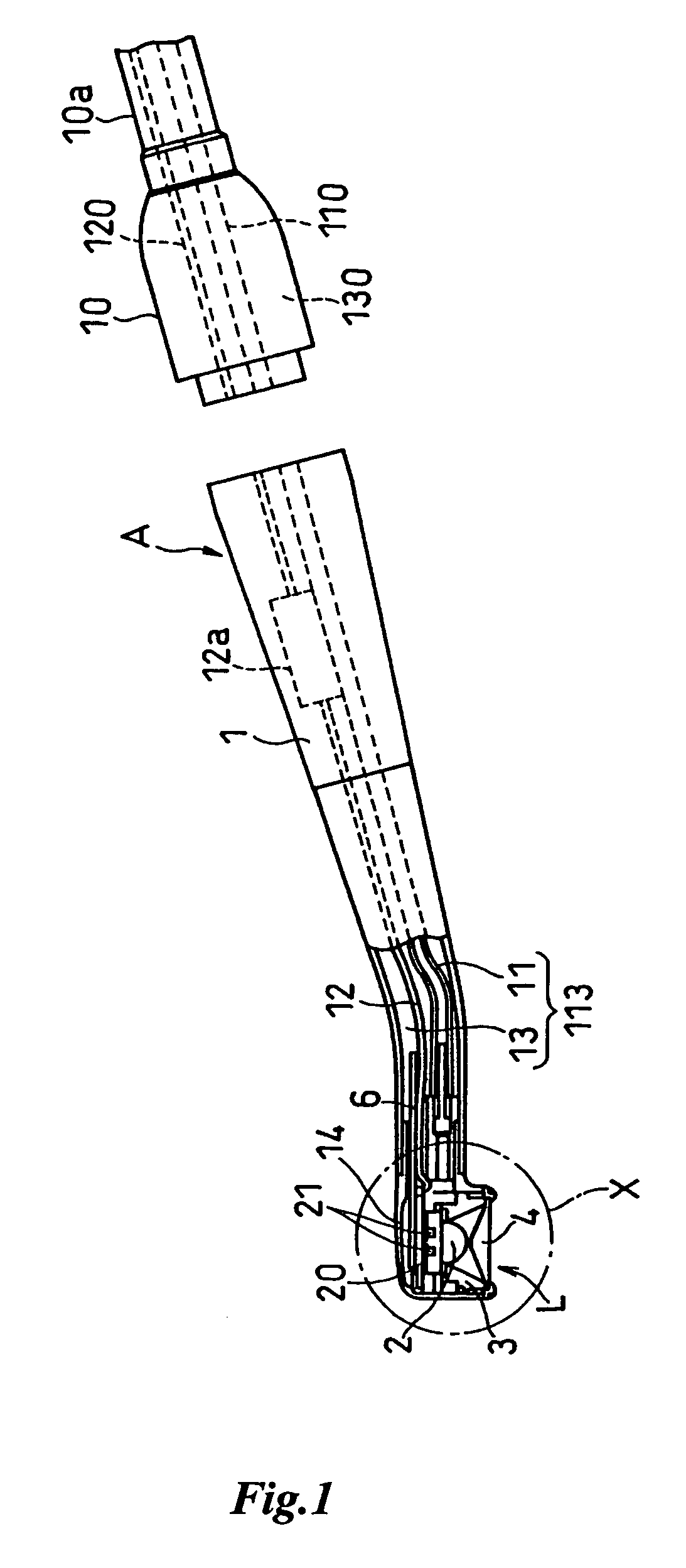

Modular converter

InactiveUS6472785B2Easy to replaceHarden fastAssociation with control/drive circuitsSupports/enclosures/casingsElectrical conductorTransformer

A converter for an electric motor or transformer, the converter being comprising a connection box having passages for electrical conductors and having a semiconductor electronic module removably fixed to the connection box. The electronic module has a radiator-forming box that is open at one end, at least one electronic card at least partially embedded in a resin cast inside said radiator-forming box, and at least one connector emerging from the resin. The opening of the radiator-forming box enables it to be fitted to the connection box. The connection box has at least one window giving access to the connector(s) of the electronic module.

Owner:MOTEURS LEROY SOMER

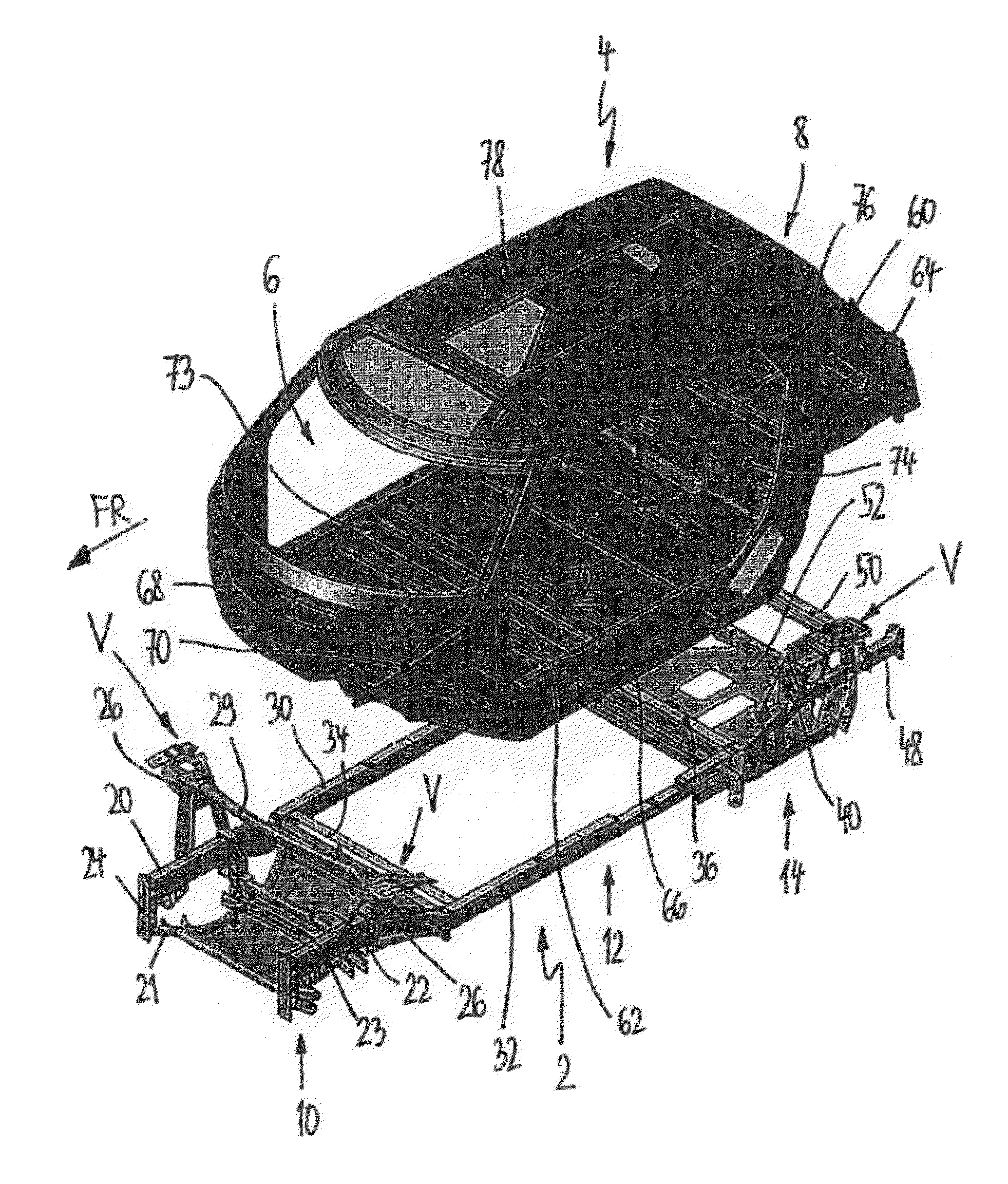

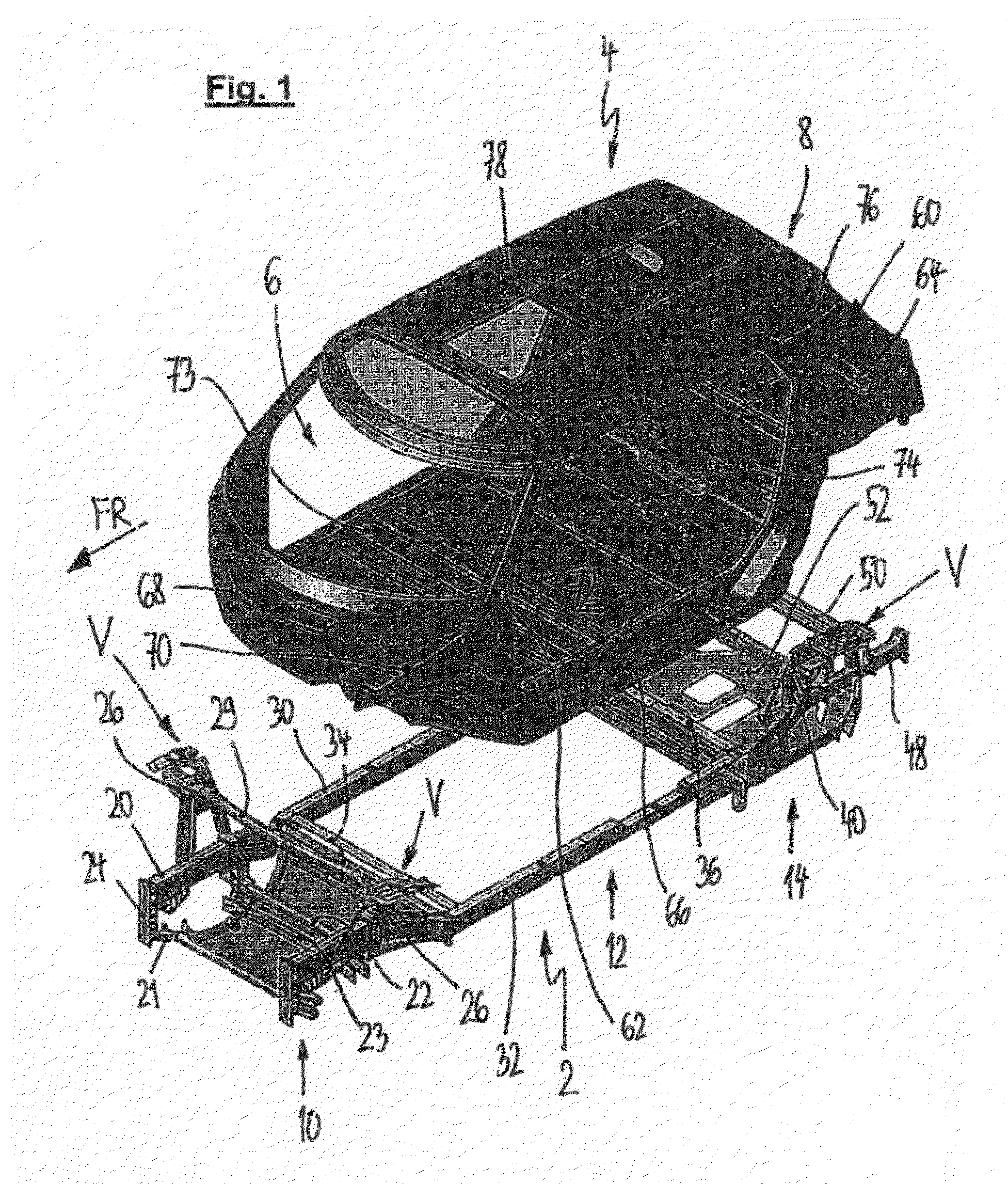

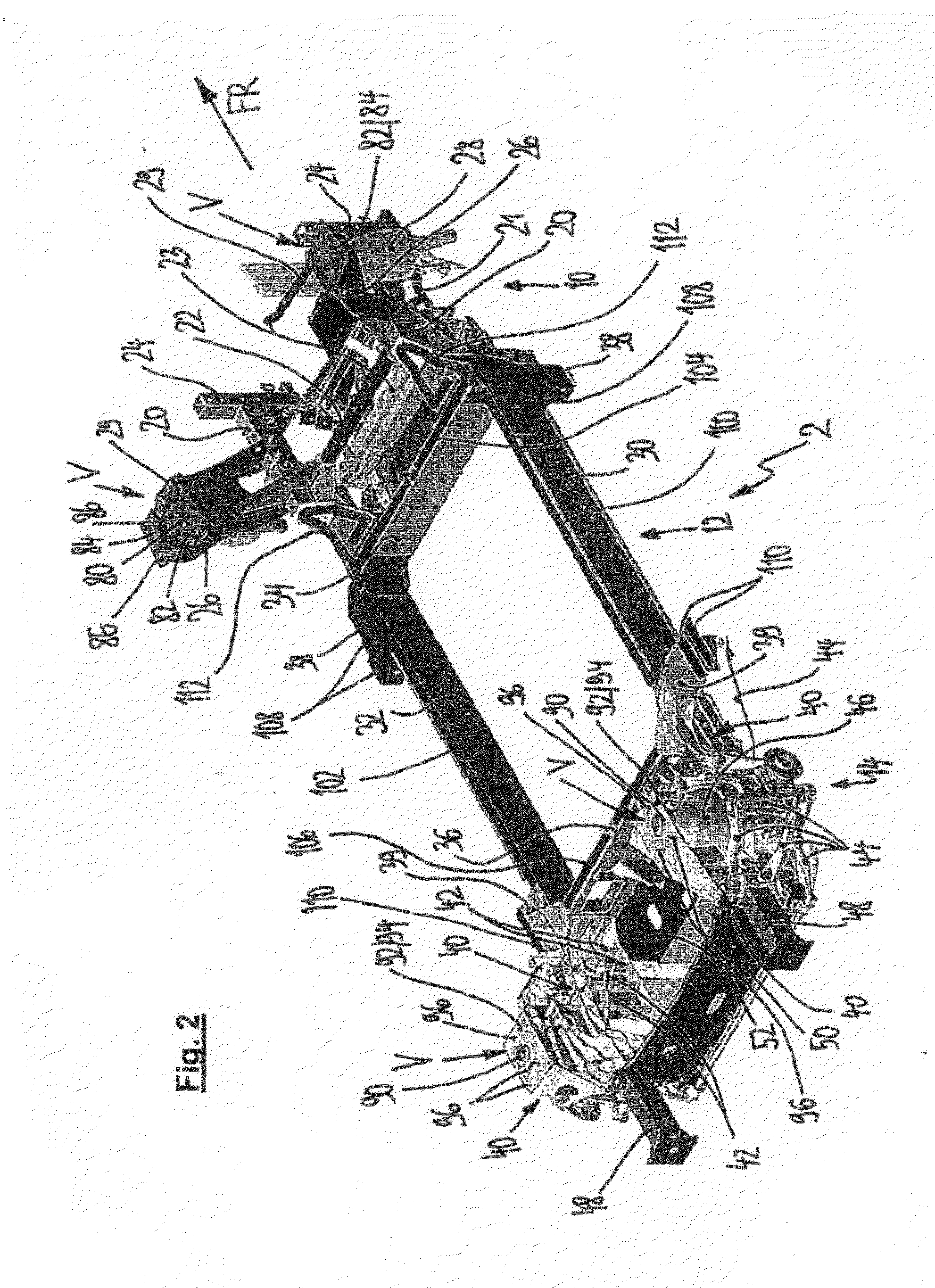

Motor Vehicle Having a Chassis Frame and a Vehicle Body

ActiveUS20130076069A1Reduce high energyHigh stiffnessVehicle body-frame connectionsUnderstructuresVehicle frameEngineering

Owner:BAYERISCHE MOTOREN WERKE AG

Reinforcing and repairing grouting material for construction in minus-temperature environment

The invention provides a reinforcing and repairing grouting material for construction in a minus-temperature environment in the technical field of construction materials, which comprises the following components in percentage by weight: 7 to 13 percent of magnesium oxide, 25 to 35 percent of potassium dihydrogen phosphate, 5 to 45 percent of quartz sand, 15 to 25 percent of fly ash, 1 to 2 percent of boric acid or borax or citric acid, and 1 to 2 percent of calcium lignosulfonate or sodium lignosulphonate. Compared with the prior art, the material has the characteristics of constructing and condensing to become hard to generate strength at the temperature of 18 DEG C below zero, along with high mobility, high early strength and the like.

Owner:SHANGHAI JIAO TONG UNIV

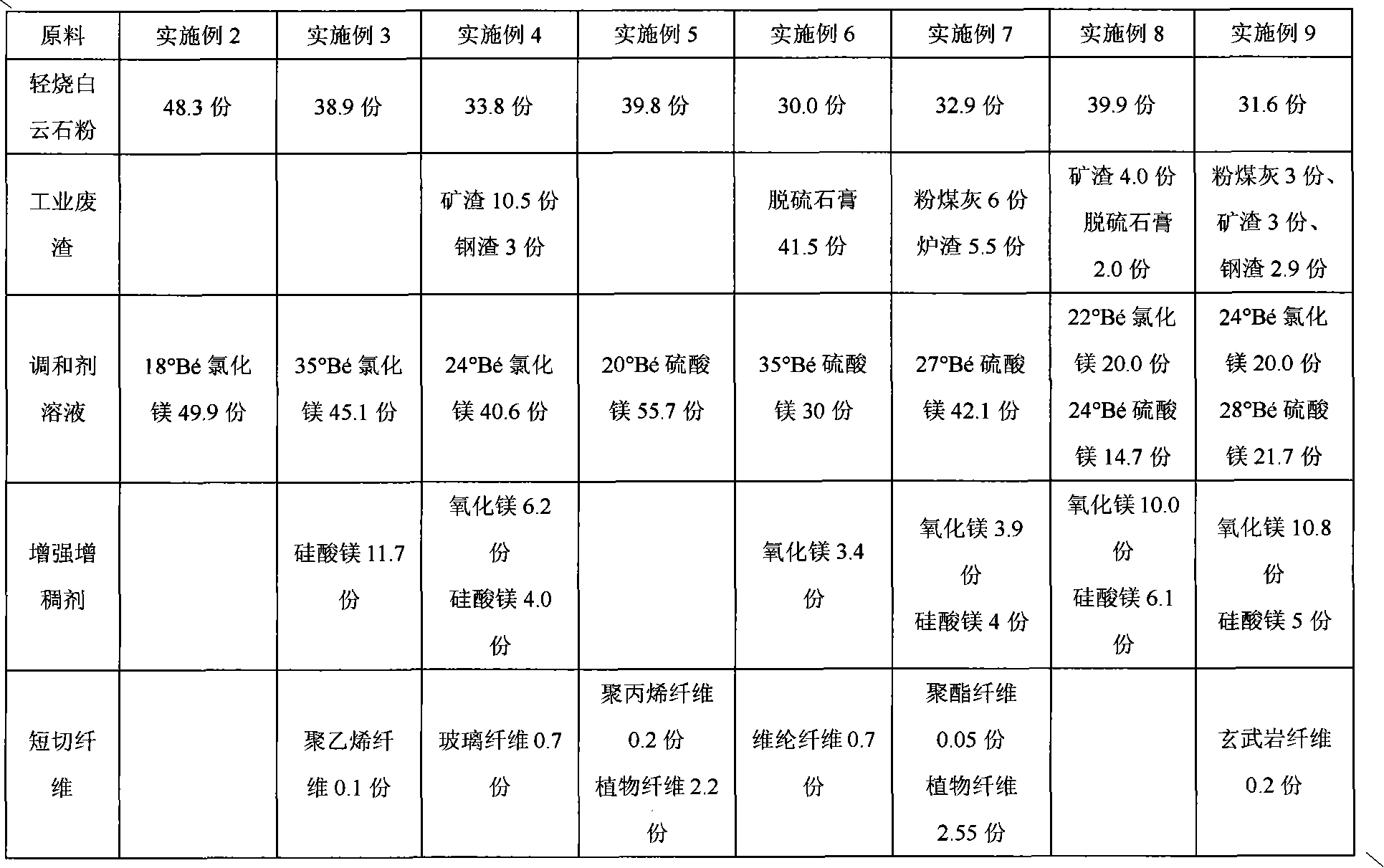

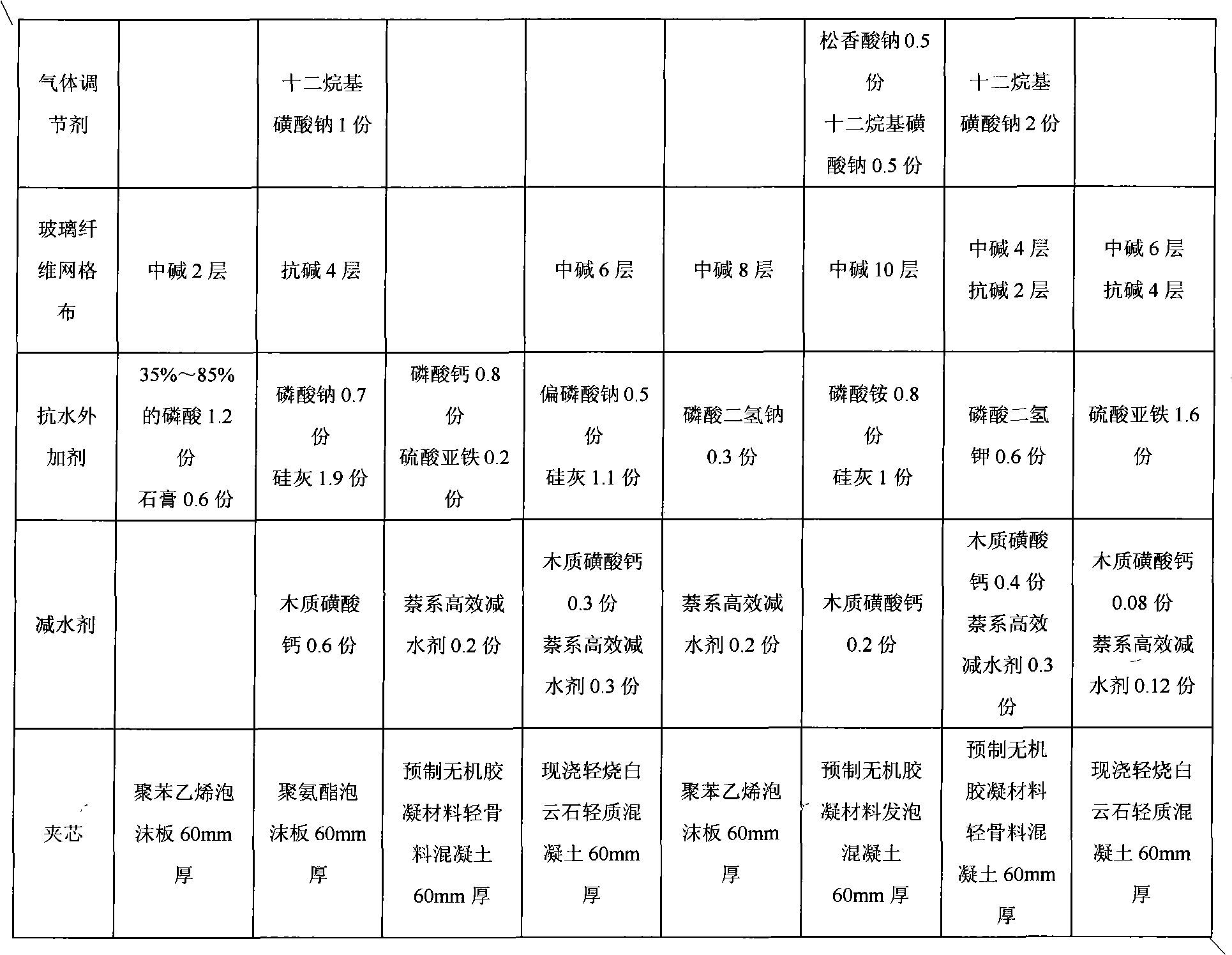

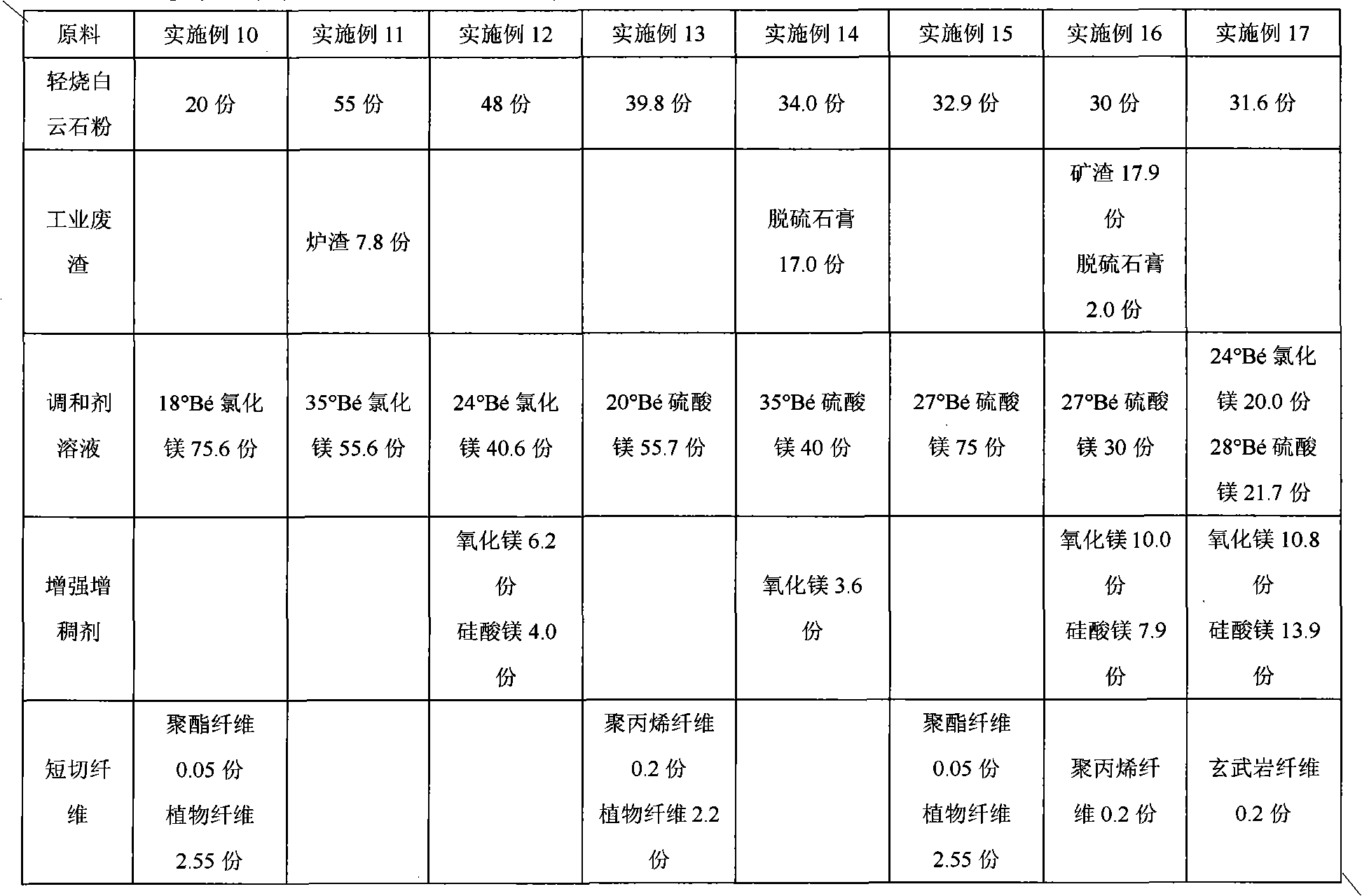

Lightly calcined dolomite thermal insulation mortar

InactiveCN102070320ALow costIncrease the use of functionsSolid waste managementCeramicwareThermal insulationPolystyrene

The invention relates to lightly calcined dolomite thermal insulation mortar, which comprises the following components in part by weight: 20 to 60 parts of lightly calcined dolomite, 1 to 60 parts of flyash, 5 to 35 parts of retarding agent, 1 to 40 parts of strengthening and thickening agent, 1 to 20 parts of kieselguhr, 5 to 35 parts of expanded aggregate, 0.5 to 5 parts of polystyrene foam particle, 0.01 to 0.2 part of polypropylene fiber, 0.5 to 8 parts of water resistance additive, and 0.05 to 2 parts of water reducer. The thermal insulation mortar has the advantages of excellent thermal insulation property, good compression strength, freezing resistance and water resistance, good volume stability, low production cost, energy conservation, environmental friendliness and the like. The construction process is simple; and after construction, the lightly calcined dolomite thermal insulation mortar is not hollowed or cracked, and is particularly suitable for a thermal insulation material for building walls.

Owner:内蒙古祥响新型建材开发有限责任公司 +2

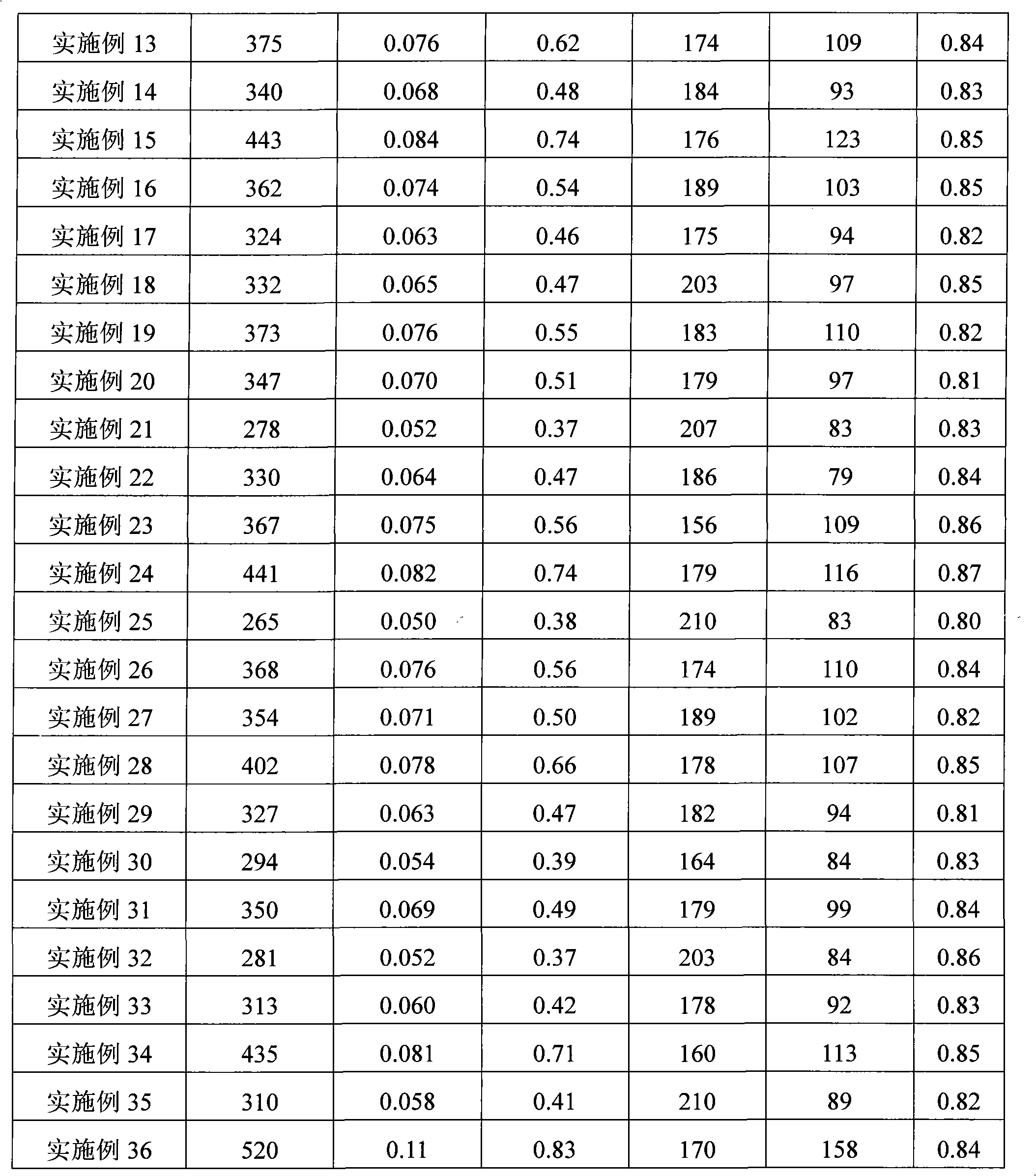

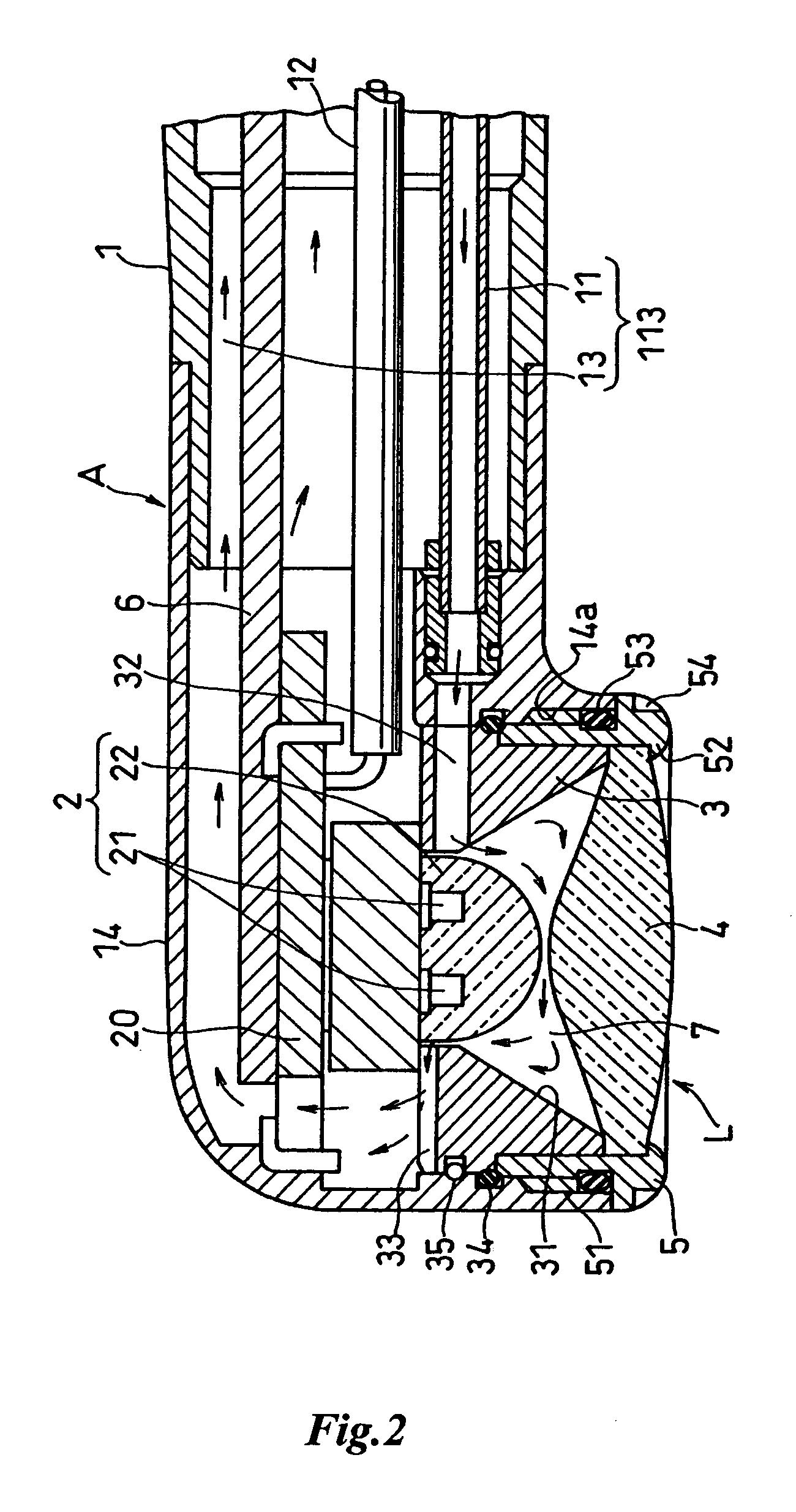

Medical irradiation apparatus

A medical irradiation apparatus comprising a main body, a luminous body comprised of a light emitting element provided in a light outlet of the main body, an annular reflective member with a reflective surface provided at the circumference of the luminous body, the reflective surface reflecting the light from the luminous body forward, and a lens member provided so as to cover a forward opening of the reflective member, the lens member refracting and transmitting the direct light from the luminous body and the light reflected from the reflective member. According to the apparatus, all the outgoing light from the lens member is emitted so as to direct into a specified irradiation area.

Owner:MORITA MFG CO LTD

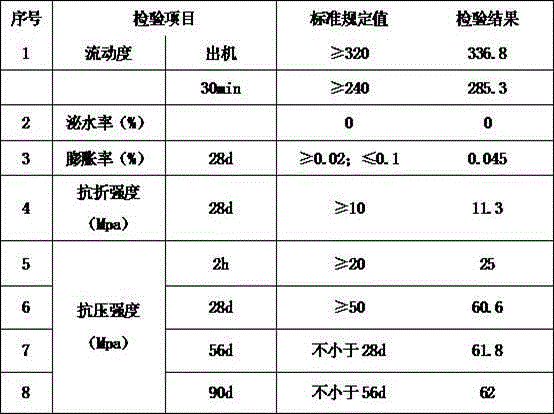

Bridge bearing mortar and production method thereof

The invention relates to a bridge bearing mortar and a production method thereof. The invention is characterized in that the bridge bearing mortar is prepared from the following raw materials in parts by weight: 45-60 parts of graded quartz sand, 30-40 parts of 42.5 sulfoaluminate cement, 5-15 parts of 42.5 Portland cement, 1-10 parts of U-shaped expanding agent, 0.1-1 part of water reducing agent, 0.1-0.5 part of water retention agent, 0.01-0.1 part of early-strength admixture, 0.2-1 part of retarder and 0.01-0.03 part of defoaming agent. The bridge bearing mortar has the characteristics of low cost, excellent performance, stable quality, high fluidity, short initial and final setting time, quick strength development and favorable micro-expansion, and can be widely used in the bridge bearing mortar for high-speed railways, highways, traffic bridges and other bridges and a production method thereof.

Owner:GUANGXI NANNING BAIRUITONG SYNTHESIS BUILDING MATERIALS TECH

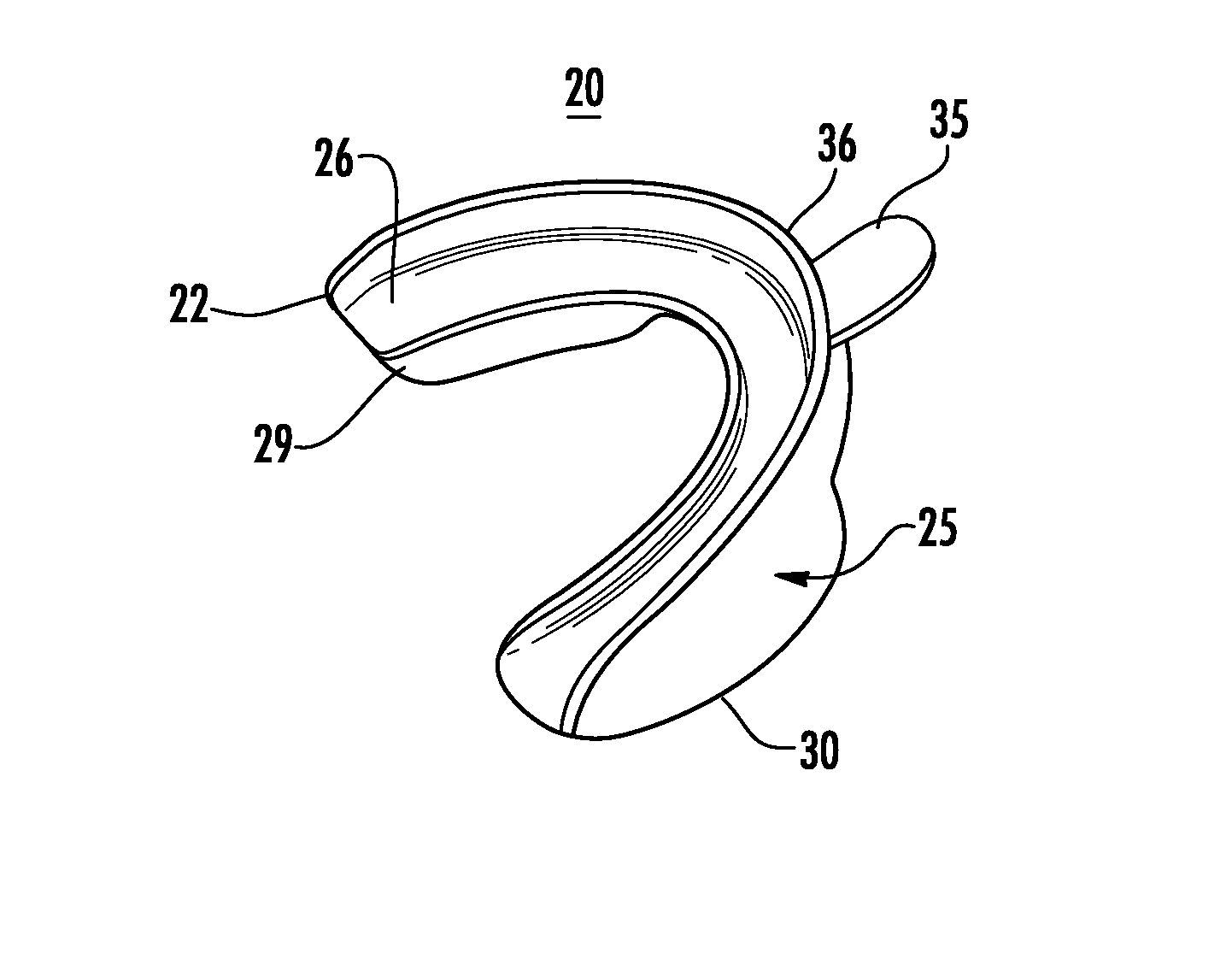

Mouthguard formed of propylene/alpha-olefin polymer elastomer

A self-customizable dental appliance adapted to lie within the mouth of a person with a connecting arch or a u-shaped style base with upstanding labial and lingual walls. The appliance is formed of a semi-crystalline polypropylene alpha-olefin copolymer containing stereoregular polymerized units of identical tacticity. In one embodiment, the appliance is formed of elastomeric propylene-ethylene copolymers.

Owner:DENTAL CHOICE HLDG LLC

Lightly-calcined-dolomite sandwich composite partition wall plate and manufacturing method thereof

InactiveCN102041871ACuring reaction at room temperatureHarden fastClimate change adaptationBuilding componentsGlass fiberFiberglass mesh

The invention relates to a lightly-calcined-dolomite sandwich composite partition wall plate and a manufacturing method thereof. The lightly-calcined-dolomite sandwich composite partition wall plate is of a composite structure comprising a shell and a core, wherein the core is a heat-insulating layer, and the shell is made of a fiberglass mesh enhanced lightly-calcined dolomite mixture. The manufacturing method comprises the following steps of: (1) preparing a lightly-calcined dolomite mixture; (2) pouring the lightly-calcined dolomite mixture 2-5 mm in thickness on the bottom surface of a mold; (3) spreading a fiberglass mesh; (4) pouring lightly-calcined dolomite mixture 2-5 mm in thickness; and (5) placing or pouring the heat-insulating core layer. The lightly-calcined-dolomite sandwich composite partition wall plate provided by the invention has the advantages of steam-free or autoclaving maintenance, quick normal-temperature reaction curing, high strength, good water resistance, no moisture absorption or helogenation, no efflorescence, frost resistance, sound insulation, heat insulation, flame retarding, utilization of a great amount of industrial solid wastes and agricultural wastes, resource and energy saving, no emission of three wastes and the like.

Owner:QINGHAI INST OF SALT LAKES OF CHINESE ACAD OF SCI +2

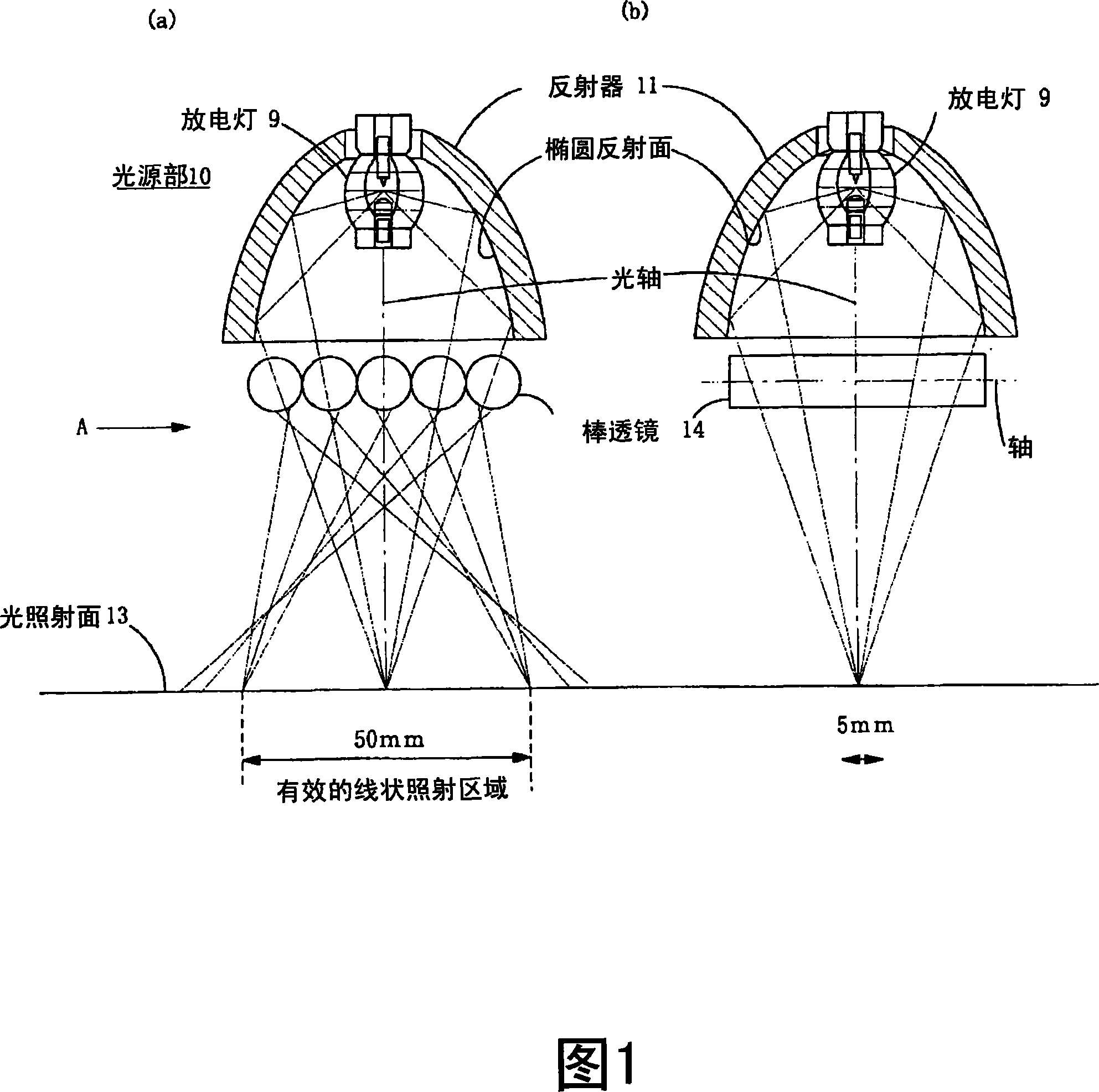

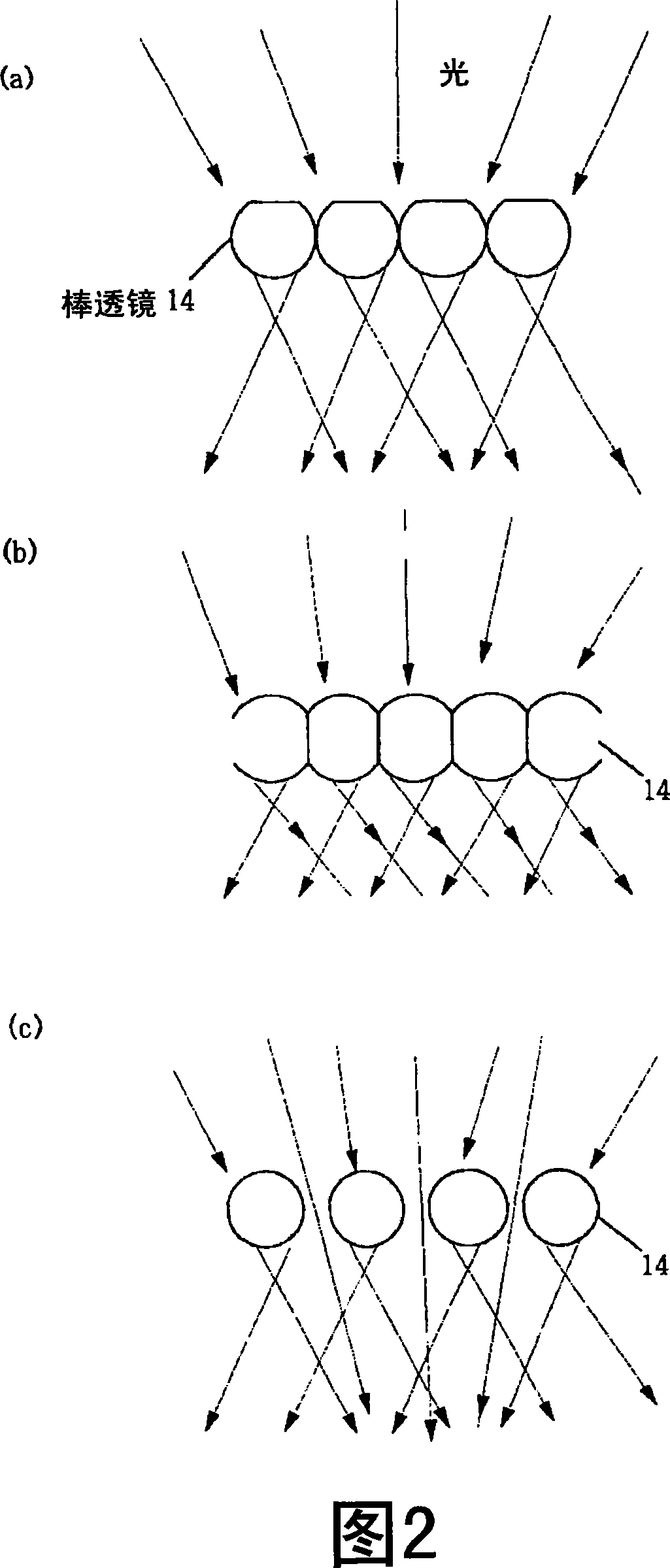

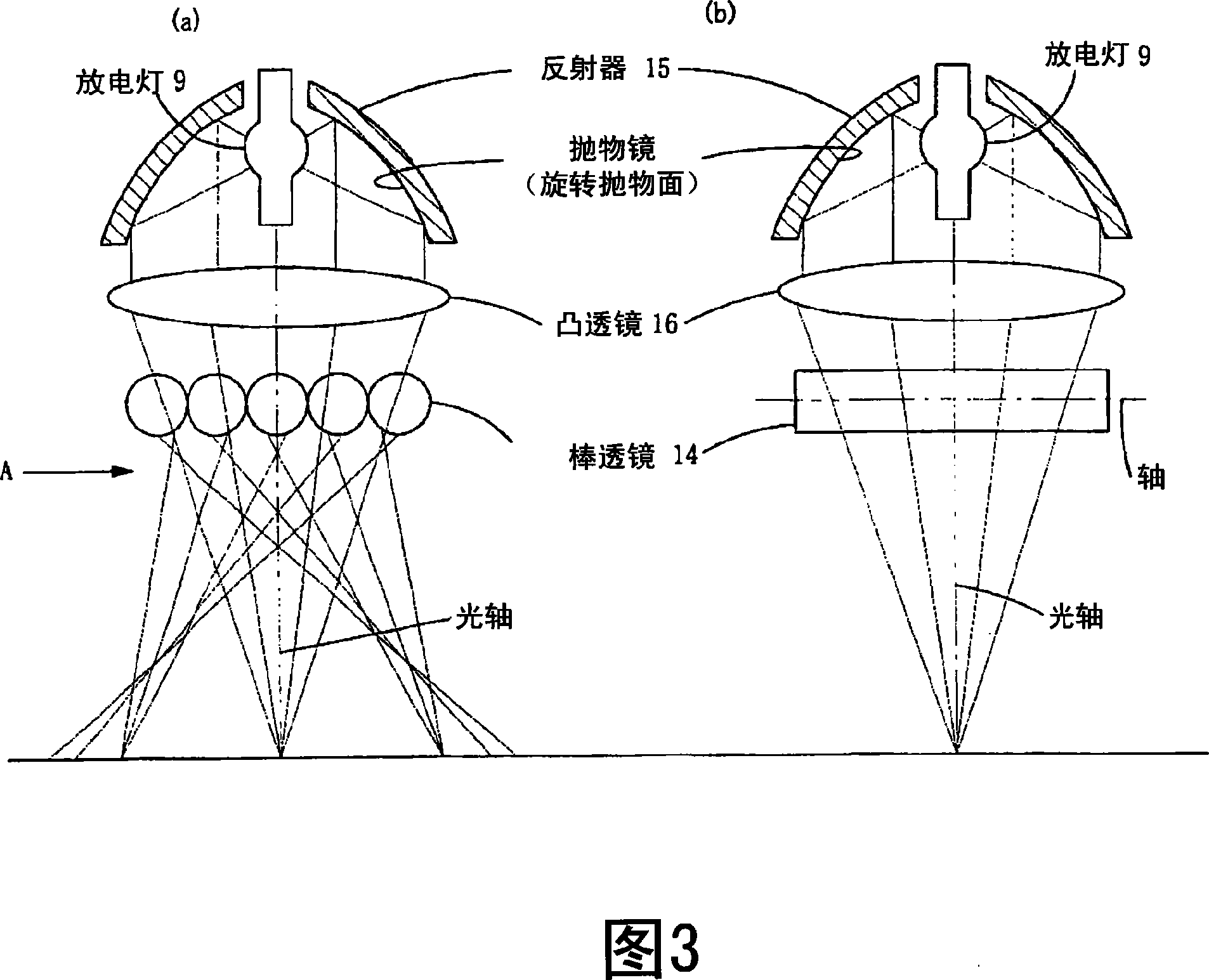

Light irradiation device and inkjet printer

ActiveCN101152784AAchieve smallAchieve lightweightPoint-like light sourceOther printing apparatusLight irradiationIlluminance

A light irradiation device that is capable of good irradiance uniformity in the lengthwise direction and that is applicable to an inkjet printer. A light-emitting portion of a short-arc type discharge lamp is positioned at the first focal point of a reflector that has a reflecting surface in the shape of an ellipsoid of revolution, and the light from the discharge lamp is reflected by the reflector and is focused at the second focal point; after which the light is incident on multiple, columnar rod lenses 14 . Of the light that is incident on the rod lenses, the light along the axial direction is focused at the second focal point of an elliptical reflector without being affected by the rod lenses, and the light along the direction perpendicular to the axial direction is focused by the rod lenses and then spreads and irradiates the light irradiation surface.

Owner:USHIO DENKI KK

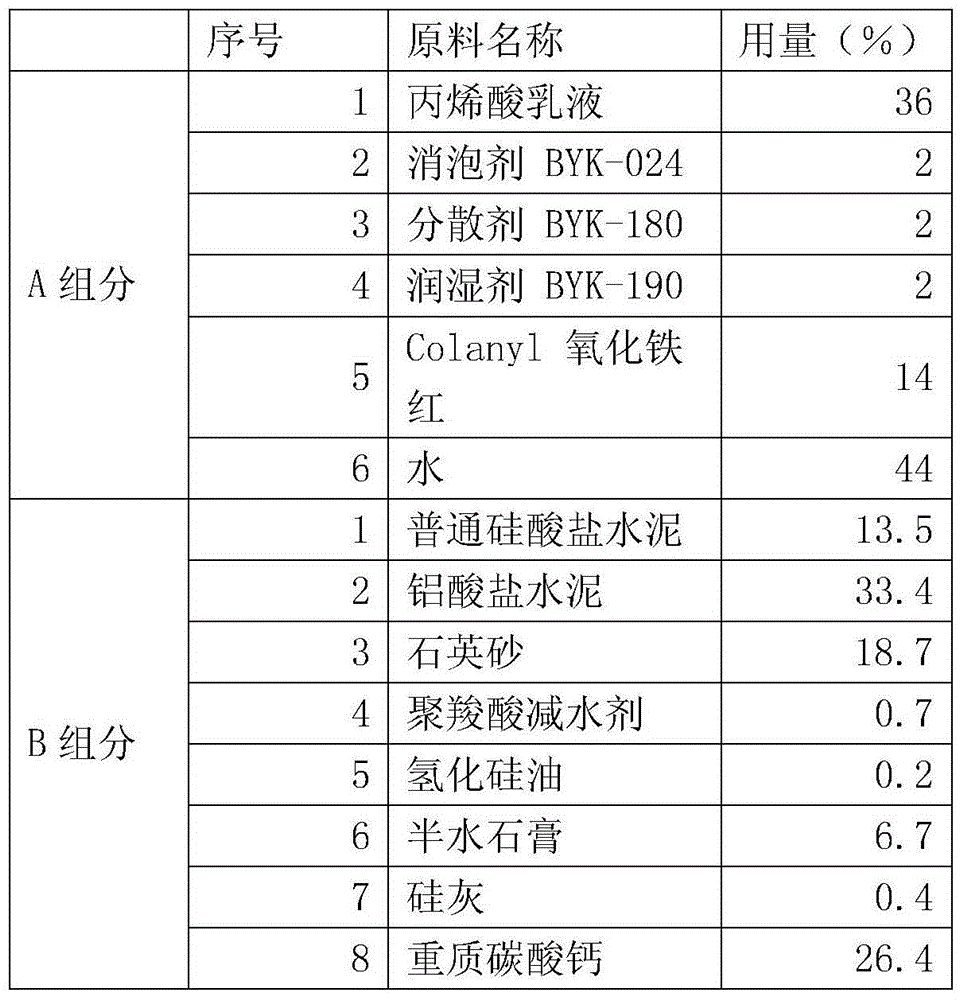

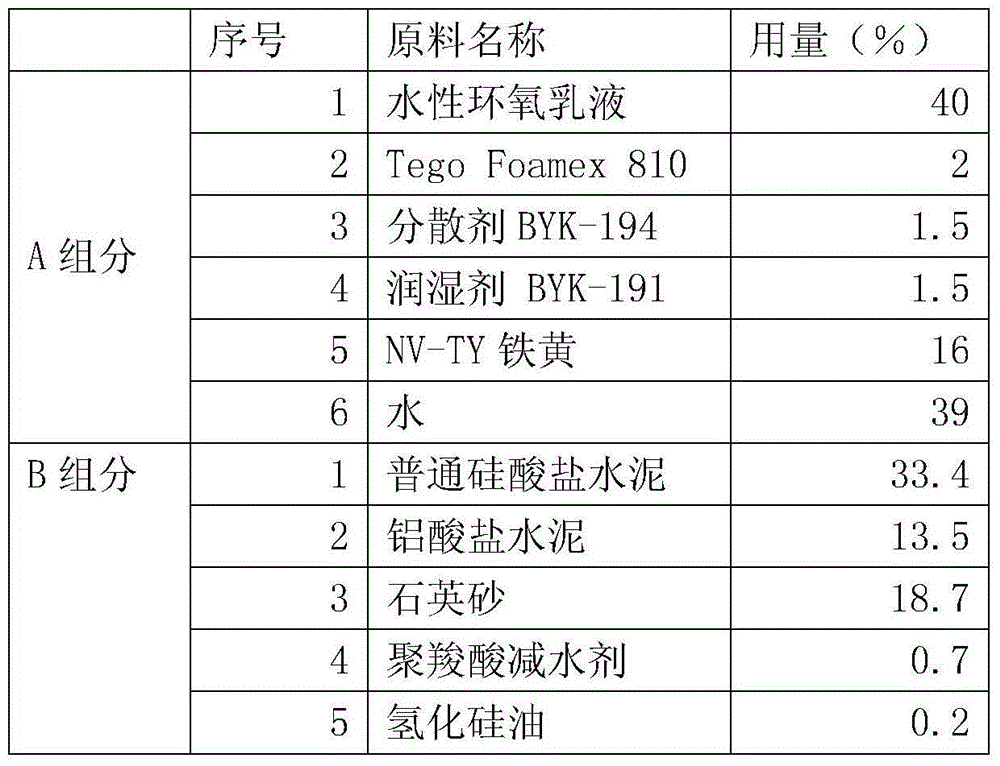

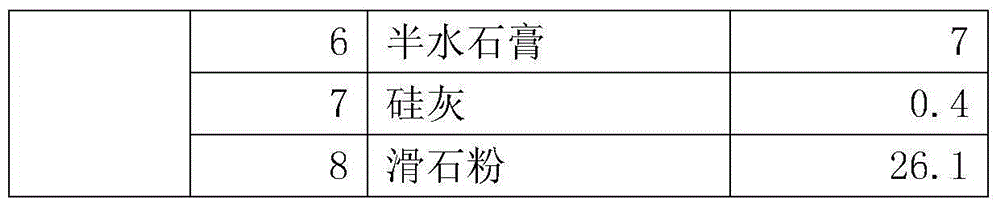

Color floor prepared by automatic leveling of color terrace coating mixed high-strength cement and construction method of color floor

ActiveCN104356811AHigh strengthDense microstructureConjugated diene hydrocarbon coatingsPolyurea/polyurethane coatingsAluminatePortland cement

The invention provides a color floor prepared by automatic leveling of color terrace coating mixed high-strength cement and a construction method of the color floor. The color floor is formed by mixing a component A with a component B, then paving the obtained mixture on the ground for automatically leveling, drying and polishing sequentially by using abrasive discs with different meshes until the ground is light, wherein the component A is color terrace coating which is formed by adding 20-75% of water-based emulsion, 1-10% of additives and10-30% of concentrated water-based color paste into 10-60% of water, and the component B consists of 10-45% of ordinary Portland cement, 10-45% of aluminate cement, 1-12% of semi-hydrated gypsum, 15-60% of quartz sand, 0.1-1% of a polycarboxylate water reducing agent, 0.1-1% of hydrogenated silicon oil, 0.1-3% of silica fume and 15-50% of fillers. The prepared color floor are fast in material setting and hardening, and is firm and wear-resistant; the floor is smooth and attractive and flat, natural and is soft and attractive in color, overload-resistant, highly pressure-resistant, and highly wear-resistant.

Owner:武汉菲凡士建材有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com