Lightly calcined dolomite thermal insulation mortar

A technology for lightly burning dolomite and lightly burning dolomite powder, which is applied in the field of construction engineering, can solve the problems of easy cracking and durability of thermal insulation mortar, limited bonding ability of substrates, long construction period, etc., and achieves good thermal insulation performance and improved The effect of thermal insulation performance and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

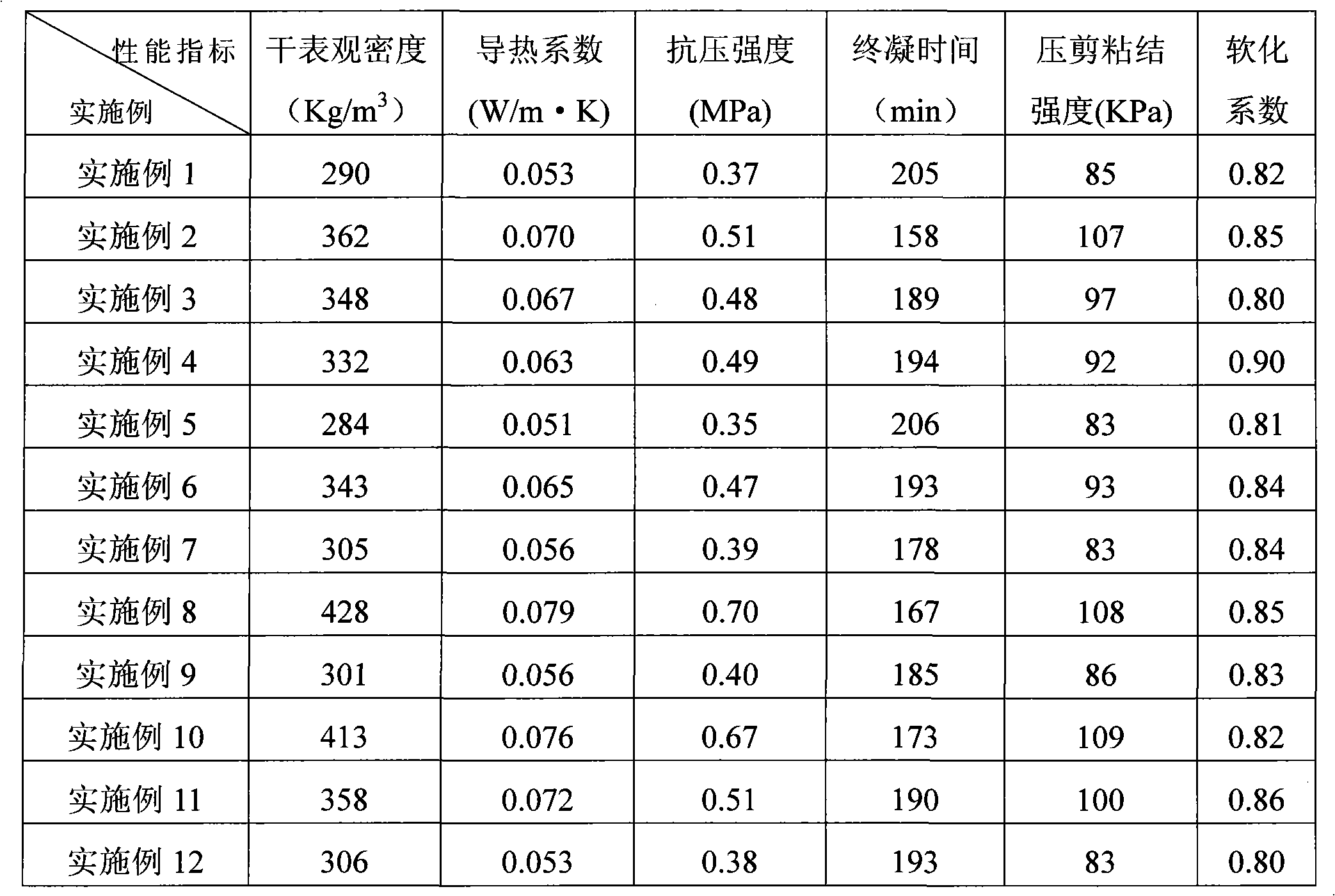

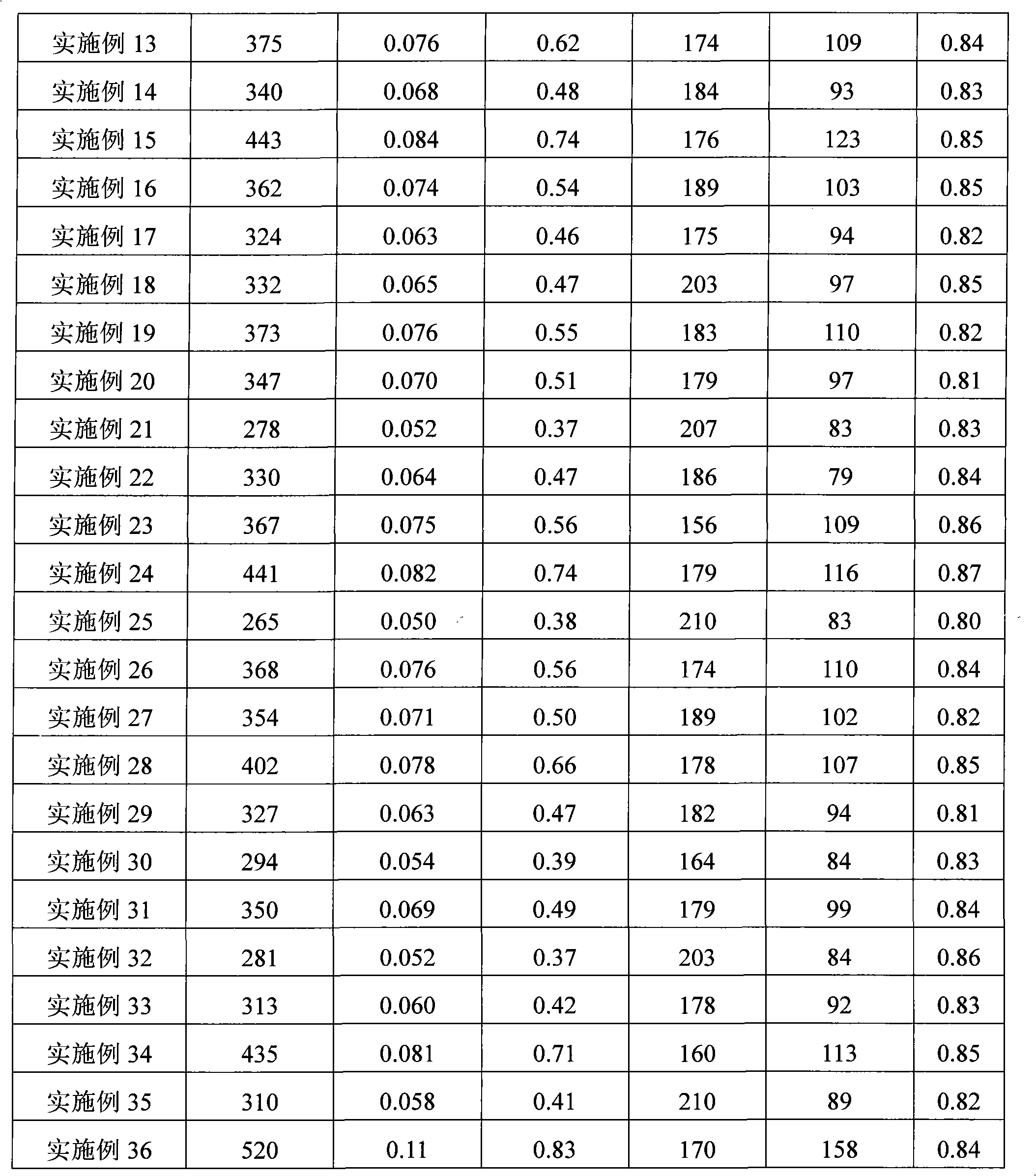

Embodiment 1

[0030] Embodiment 1: A kind of light-burned dolomite thermal insulation mortar is made up of the following components by weight:

[0031] 38 parts of lightly burned dolomite powder, 27 parts of coagulation regulator

[0032] 25 parts of expanded aggregate, 3 parts of water-resistant admixture.

[0033] Among them, the coagulation regulator is anhydrous magnesium chloride, the expansion aggregate is open-cell expanded perlite particles, and the anti-water additive is mixed with sodium phosphate, sodium metaphosphate and calcium dihydrogen phosphate in a ratio of 1:0.5:1.

Embodiment 2

[0034] Embodiment 2: A kind of light-burned dolomite thermal insulation mortar is made up of the following components by weight:

[0035] 45 parts of lightly burned dolomite powder, 31 parts of coagulation regulator

[0036] 32 parts of expansion aggregate, 2 parts of water-resistant admixture

[0037] 34 parts of fly ash.

[0038] Wherein, the coagulation regulator is formed by mixing anhydrous magnesium sulfate, magnesium sulfate monohydrate and magnesium sulfate trihydrate according to the ratio of 1:2:3. The expanded aggregate is closed-cell expanded perlite particles, and the anti-water additive is mixed with sodium phosphate and sodium dihydrogen phosphate in a ratio of 1:0.5.

Embodiment 3

[0039] Embodiment 3: a kind of light-burned dolomite thermal insulation mortar is made up of the following components by weight:

[0040] 40 parts of lightly burned dolomite powder, 24 parts of coagulation regulator

[0041] 25 parts of expanded aggregate, 1 part of water-resistant admixture

[0042] Enhance thickener 27 parts.

[0043] Among them, the coagulation regulator is anhydrous magnesium chloride and dihydrate magnesium chloride mixed according to the ratio of 0.5:1, the expansion aggregate is open-pore expanded perlite particles, and the water-resistant additives are sodium phosphate, sodium metaphosphate and calcium dihydrogen phosphate It is mixed according to the ratio of 1:2:4, and the thickening agent is magnesium oxide.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com