Patents

Literature

422results about How to "Avoid hollowing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Heat preservation and energy saving type lightweight, gas filled wall bricks, and preparation method

This invention relates to a method for preparing heat-insulating and energy-saving lightweight aerated wall bricks, which are prepared from aggregate, gelation agent, aeration agent, heat-insulating material and water. The aggregate is composed of slag or river sand, glass microbeads, floating beads, closed perlite, and expanded perlite. The gelation agent is composed of cement, gypsum and lime. The aeration agent is Al powder. The fiber heat-insulating material is composed of high-Al powder, tripolite, ceramic fibers, mineral wool, sepiolite, expanded vermiculite, glass cotton and palygorskite. The wall bricks have such advantages as high compressive strength, low heat conductivity, high heat-insulating performance, high fireproof and damp-proof performances, rapid and convenient construction, and no need for composite heat-insulating layer.

Owner:徐振飞

Sulfur and phosphate cement insulation mortar or insulation board

The invention relates to a sulfur and a phosphate cement insulation mortar or an insulation board, the insulation mortar and the insulation board are prepared by uniformly mixing the following raw materials by weight: 9-36 parts of heavy roasted magnesium oxide, 9-32 parts of dihydric phosphate, 0.5-7 parts of thickening time control agent, 6-25 parts of light roasted magnesium oxide, 0.5-7 parts of sulfur-containing component, 1-25 parts of industrial waste residue powder, 0-25 parts of reinforced thickening agent, 1-20 parts of diatomite, 5-35 parts of expansion aggregate, 0-5 parts of polystyrene foam particles, 1-15 parts of dispersible latex powder and 0-0.2 parts of chopped fiber. The insulation board can be a solid board material or a hollow board material. The sulfur and phosphate cement insulation mortar or the insulation board enables simple technology, and is especially suitable for constructing in low temperature season, no hollowing crack phenomena can be generated after constructing, and the sulfur and phosphate cement insulation mortar or the insulation board is especially suitable for insulation heat insulation material of building walls.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS +1

Heat insulating mortar powder and its prepn process

The heat insulating mortar powder contains cementing material, foamed modified polystyrene grain, modified expanded pearlite, cementing material modifier and fiber. The foamed modified polystyrene grain contains foamed polystyrene grain, foamed polystyrene modifier and flyash; the modified expanded pearlite contains expanded pearlite, expanded pearlite modifier and sodium hydroxide; and the cementing material modifier contains polymer adhesive, air entraining and water reducing agent and flyash activator. The preparation process includes preparing foamed modified polystyrene grain, preparing modified expanded pearlite, preparing cementing material modifier, and mixing all the materials in certain proportion. The present invention has the advantages of small heat conducting coefficient, high compression strength, good construction performance, high adhering strength, etc.

Owner:爱福家居(江苏)有限公司

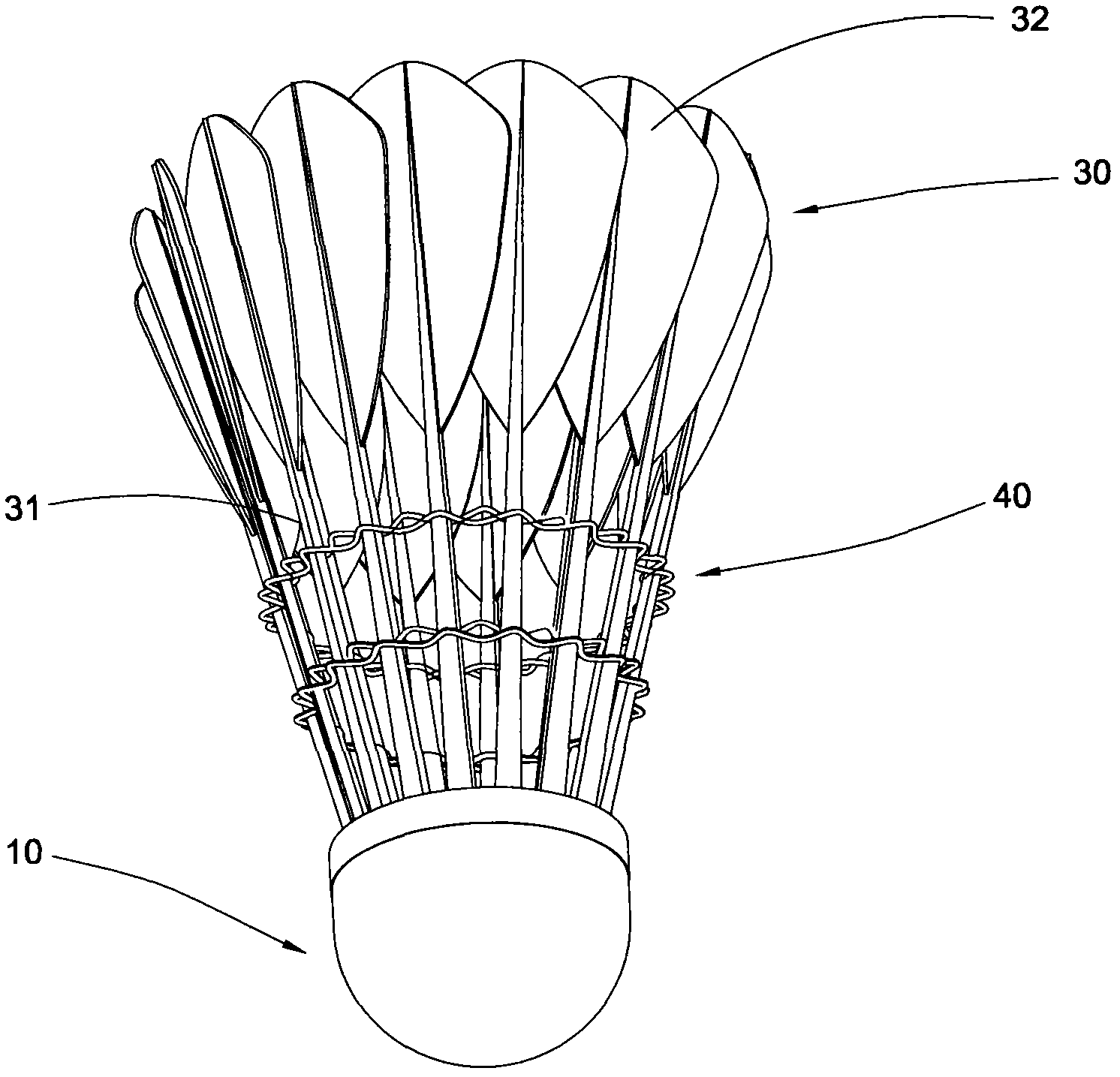

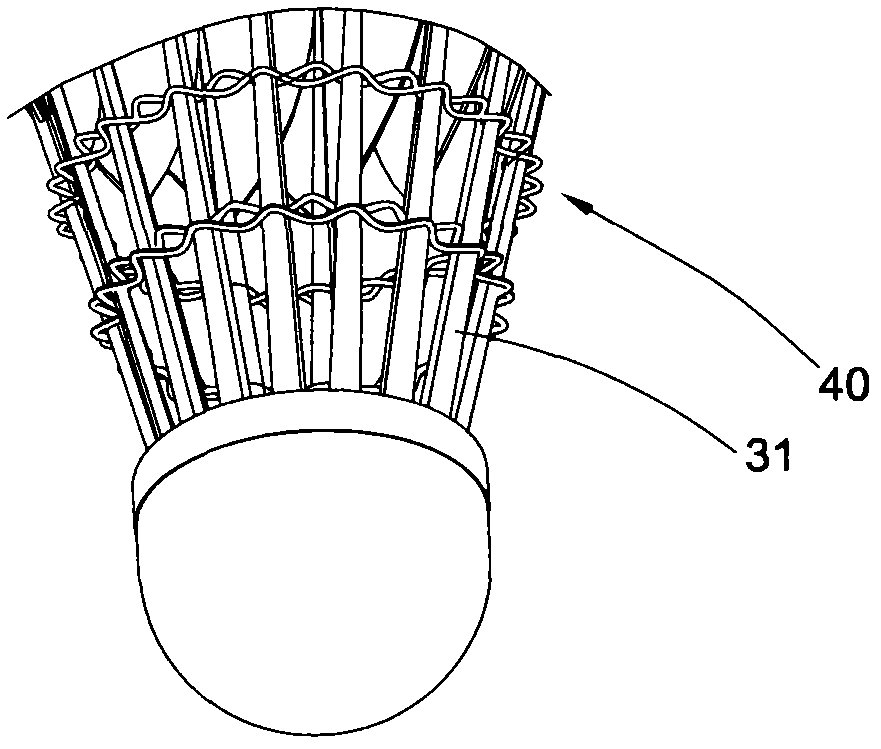

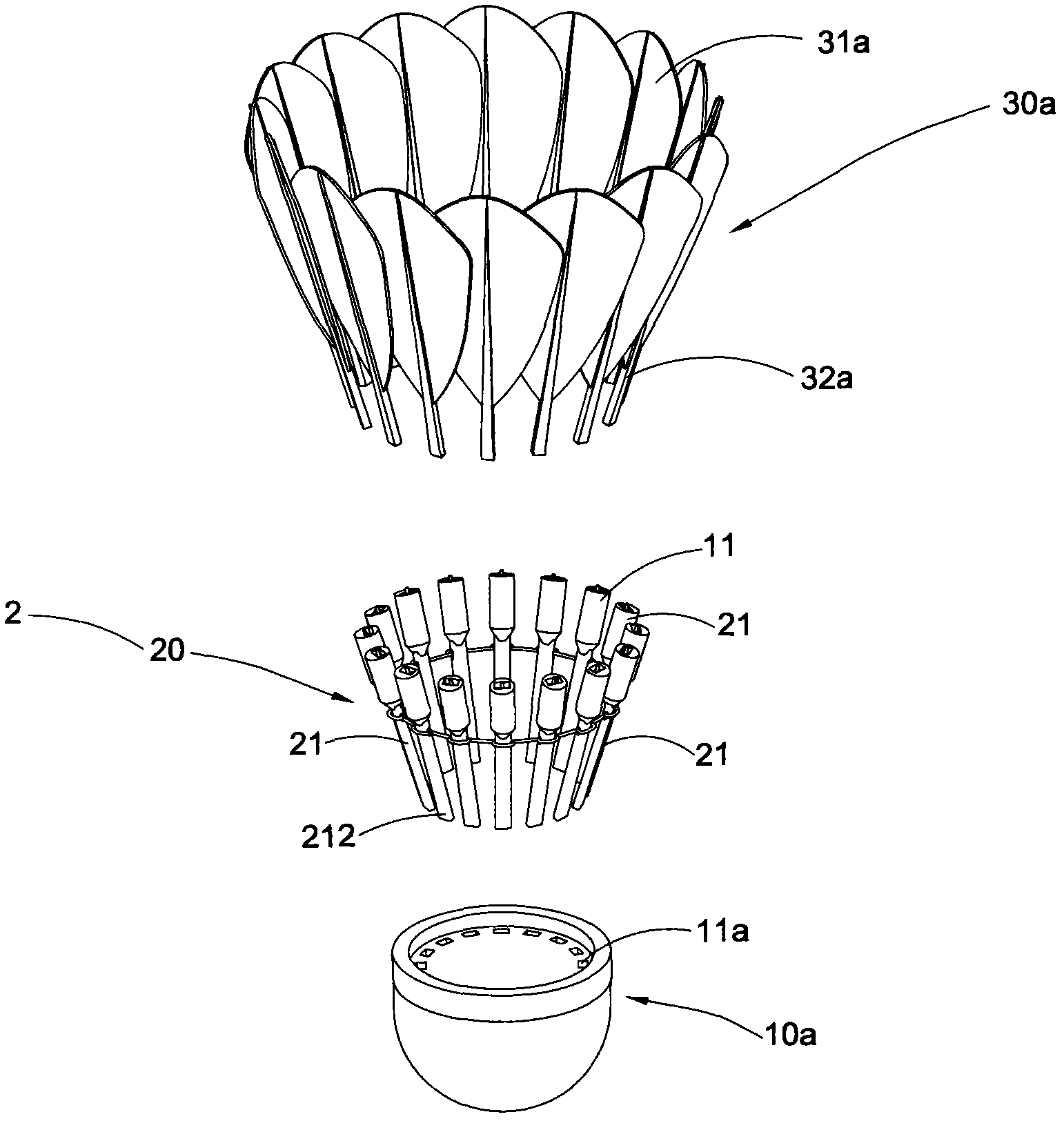

Shuttlecock and manufacturing method thereof

InactiveCN103127683AIncrease profitReduce dosageBall sportsRacket sportsEngineeringAgricultural engineering

Owner:ANHUI SANCAI SPORTS GOODS

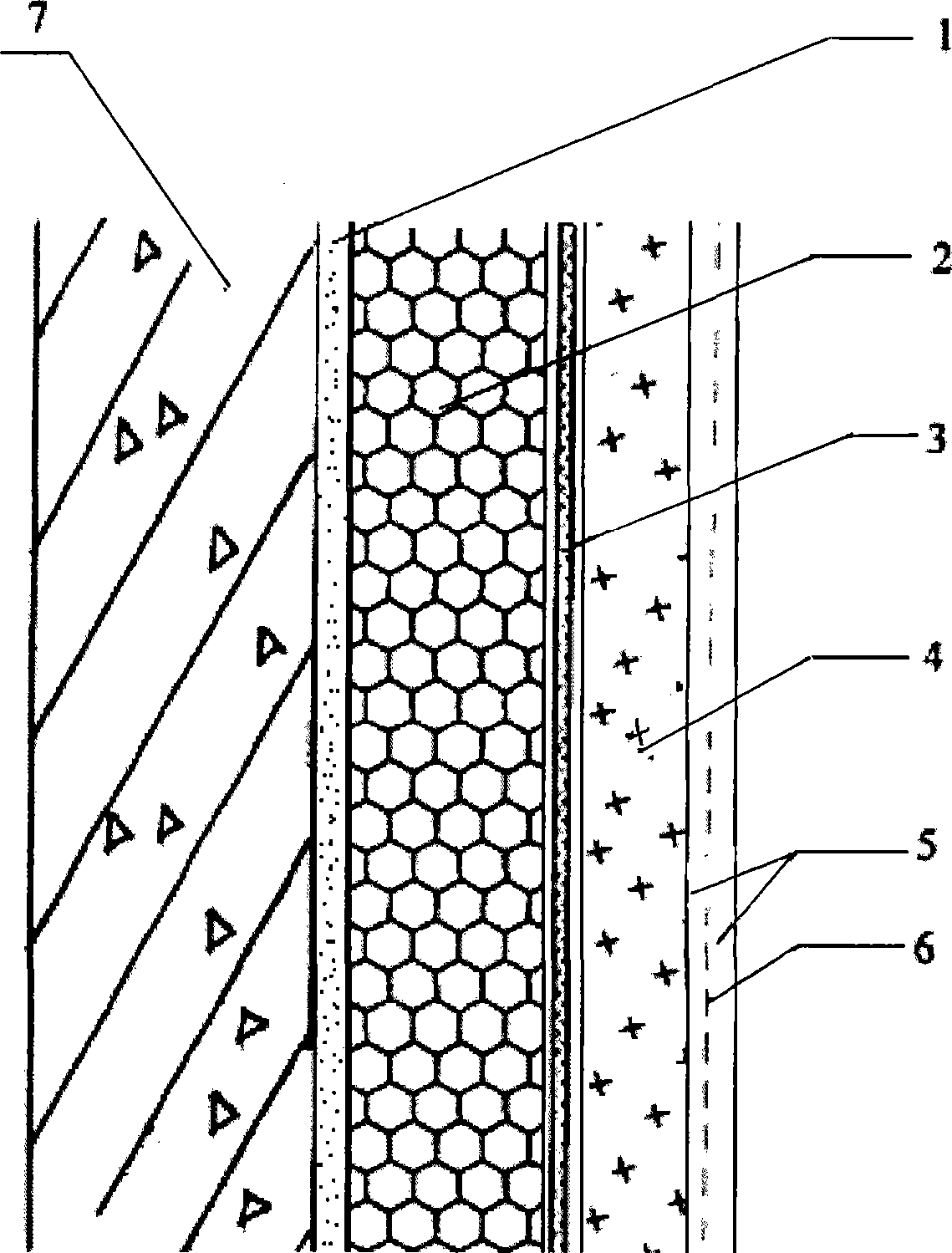

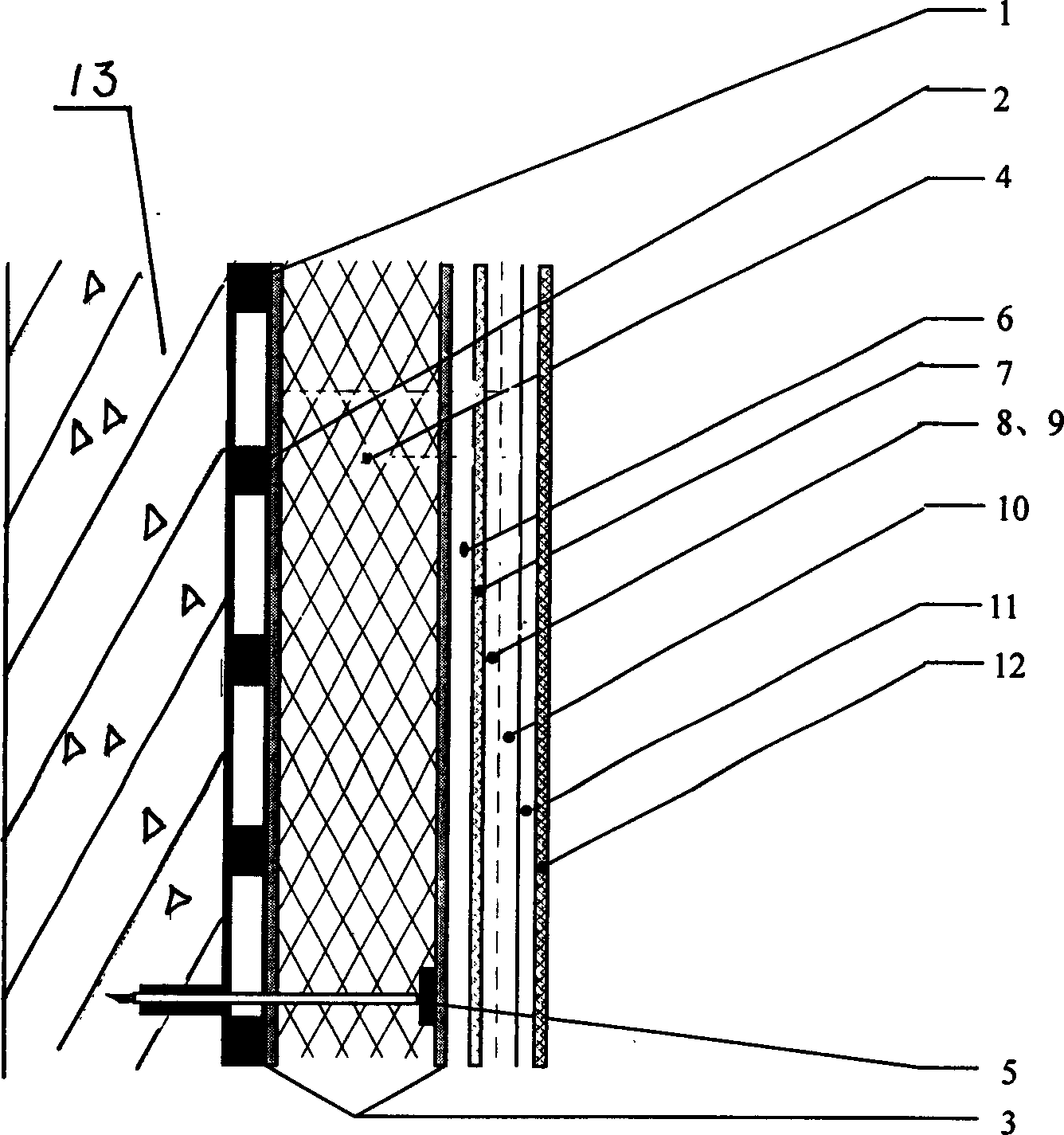

Exterior wall exterior heat preservation system for spray coating polyurethane rigid foam

InactiveCN101435254AAvoid hollowingWith fire-stop functionCovering/liningsHeat proofingSpray coatingEngineering

The invention relates to an outer heat insulation system for an outer wall sprayed with polyurethane hard bubble. The system is composed of moistureproof priming paint, polyurethane hard bubble, interface slurry, a levelling layer, alkali resistant grid cloth, plaster slurry, and a base wall, wherein the polyurethane hard bubble is directly arranged on the base wall surface coated with moistureproof priming paint, the outside of the polyurethane hard bubble is provided with the levelling layer, the interface slurry is disposed between the levelling layer and the polyurethane hard bubble, the outside of the levelling layer is provided with the alkali resistant grid cloth, and the outside of the alkali resistant grid cloth is provided with the plaster slurry. The system of the invention has simple structure and rapid construction, can effectively prevent the empty drum, crack, and water seepage of the wall surface, and has fireproof function.

Owner:上海英硕聚合材料股份有限公司

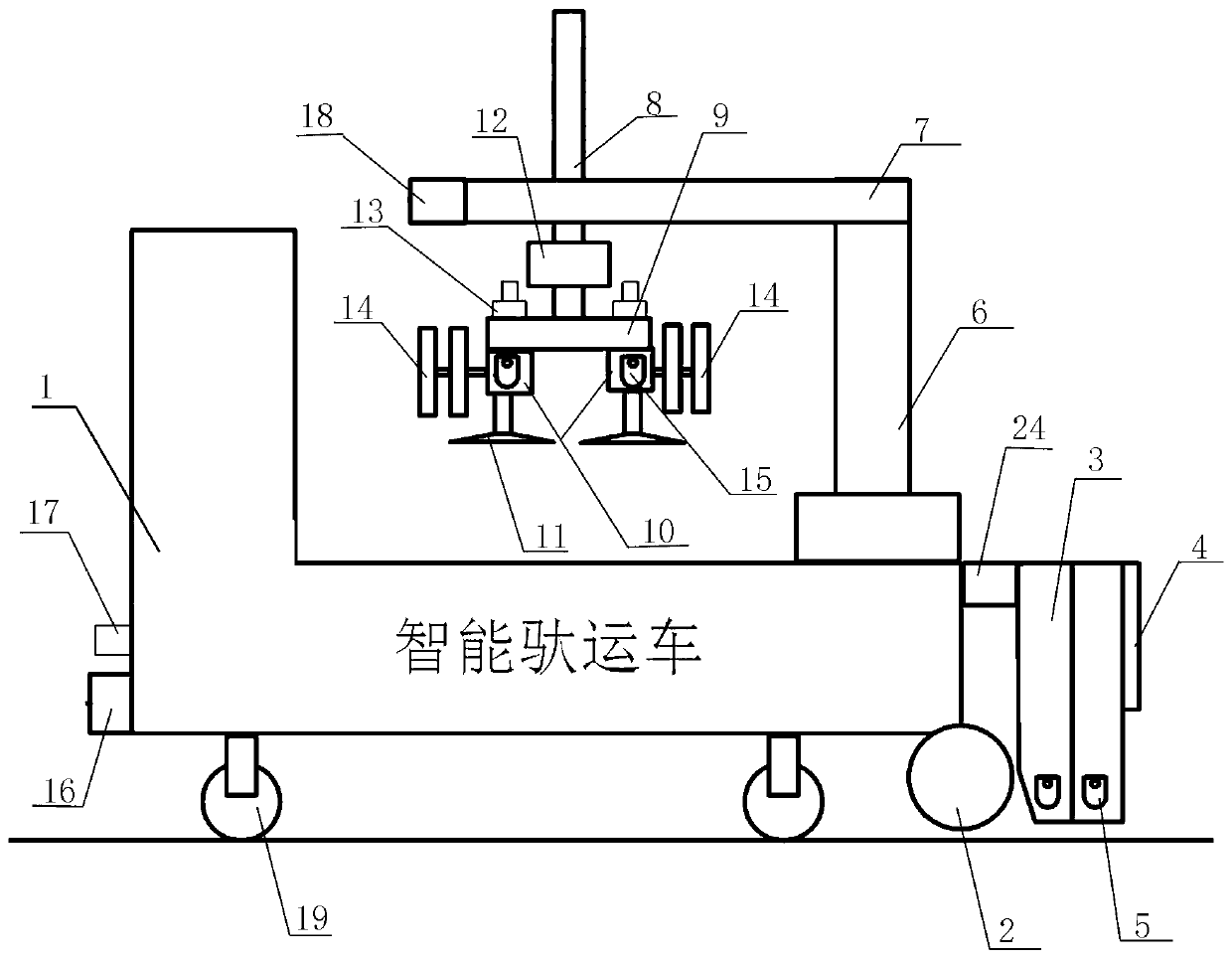

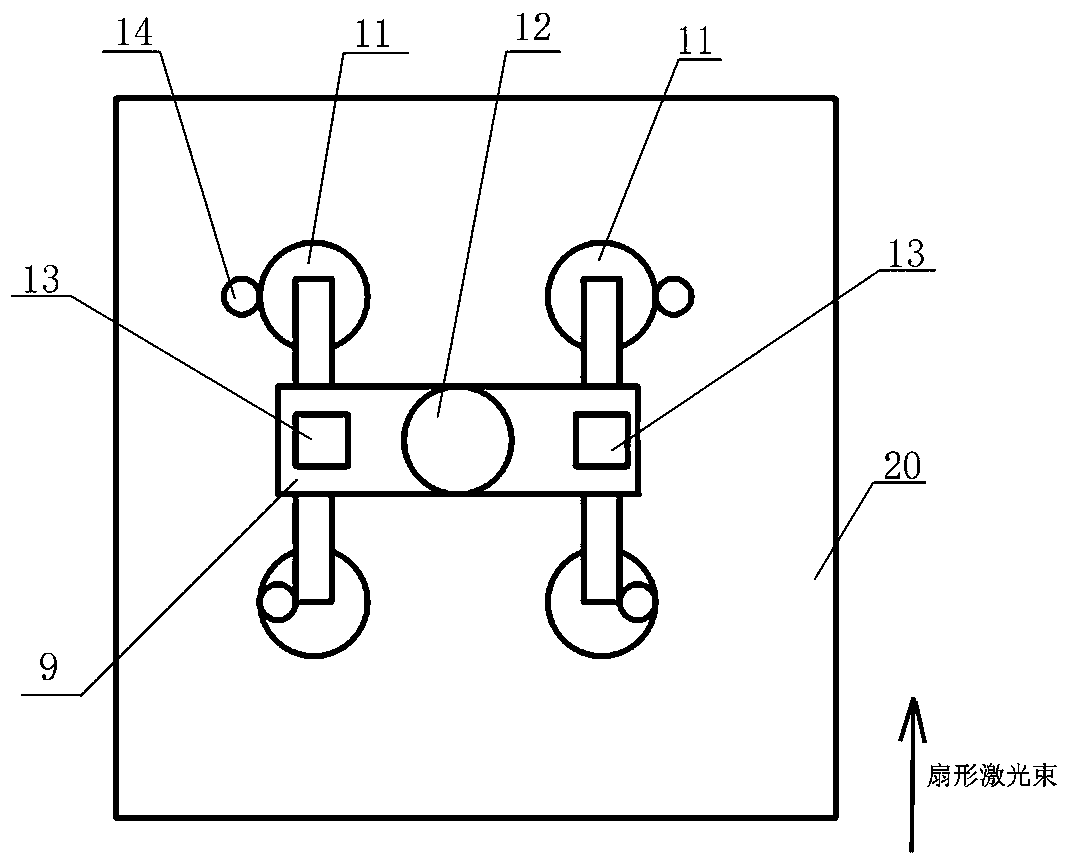

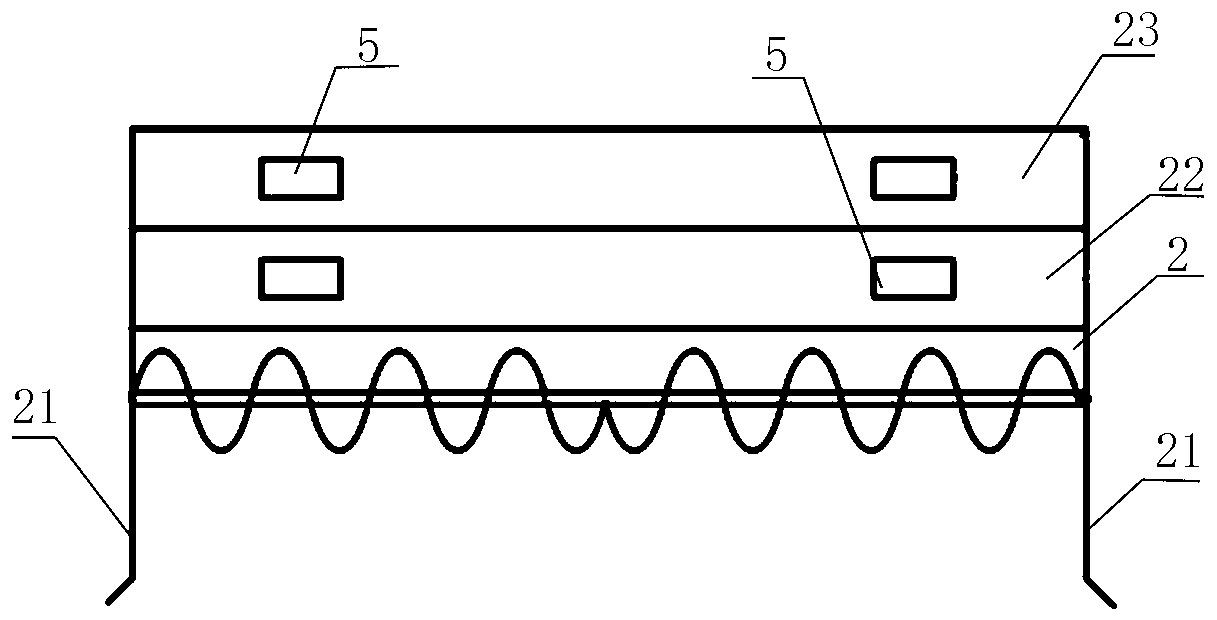

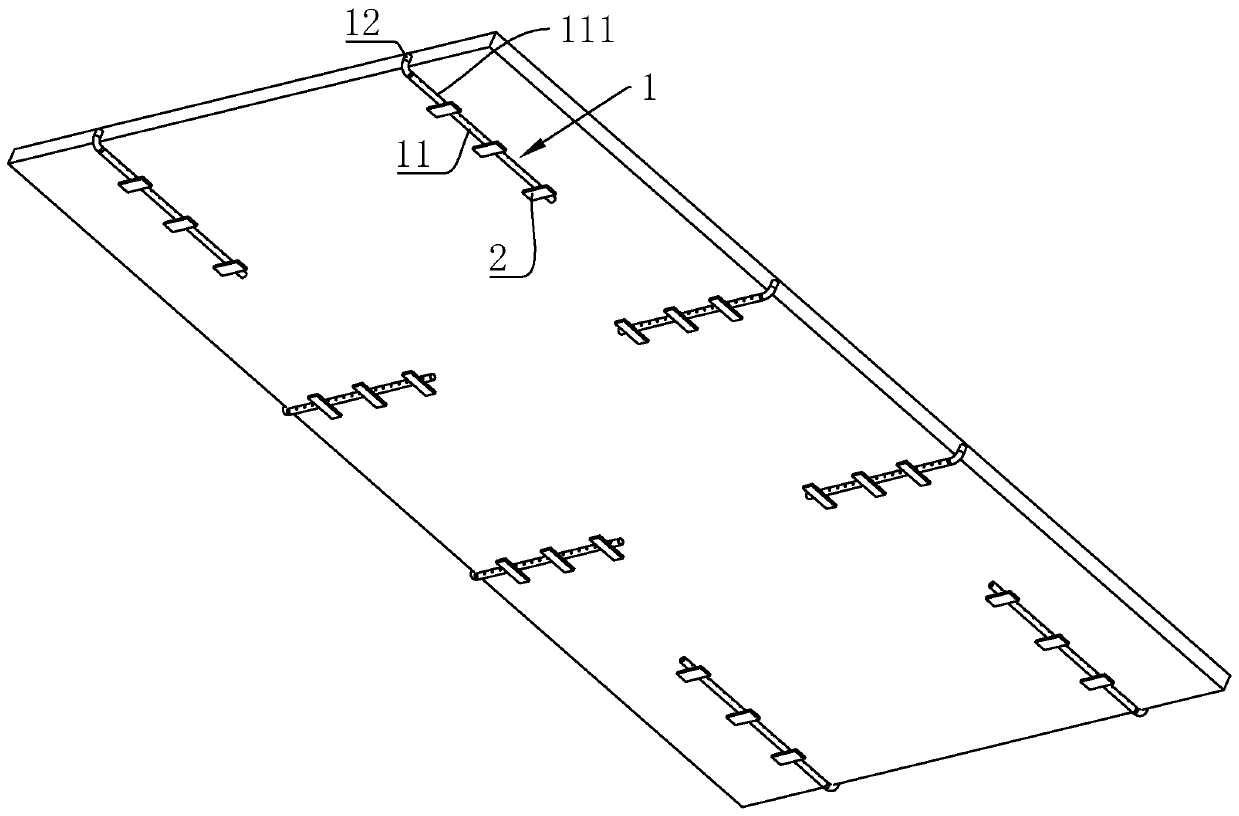

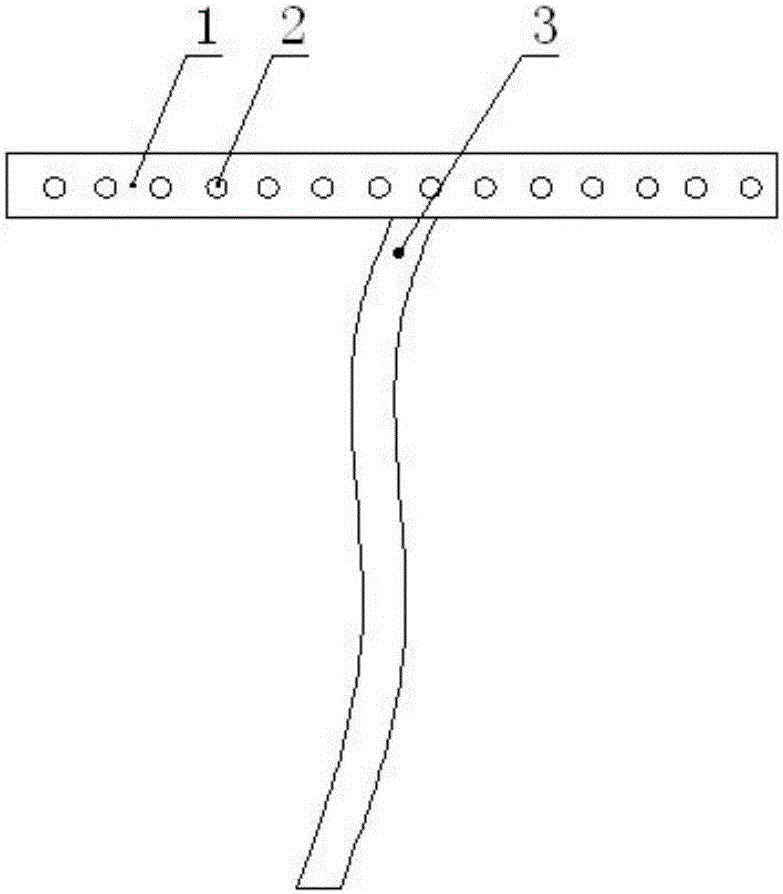

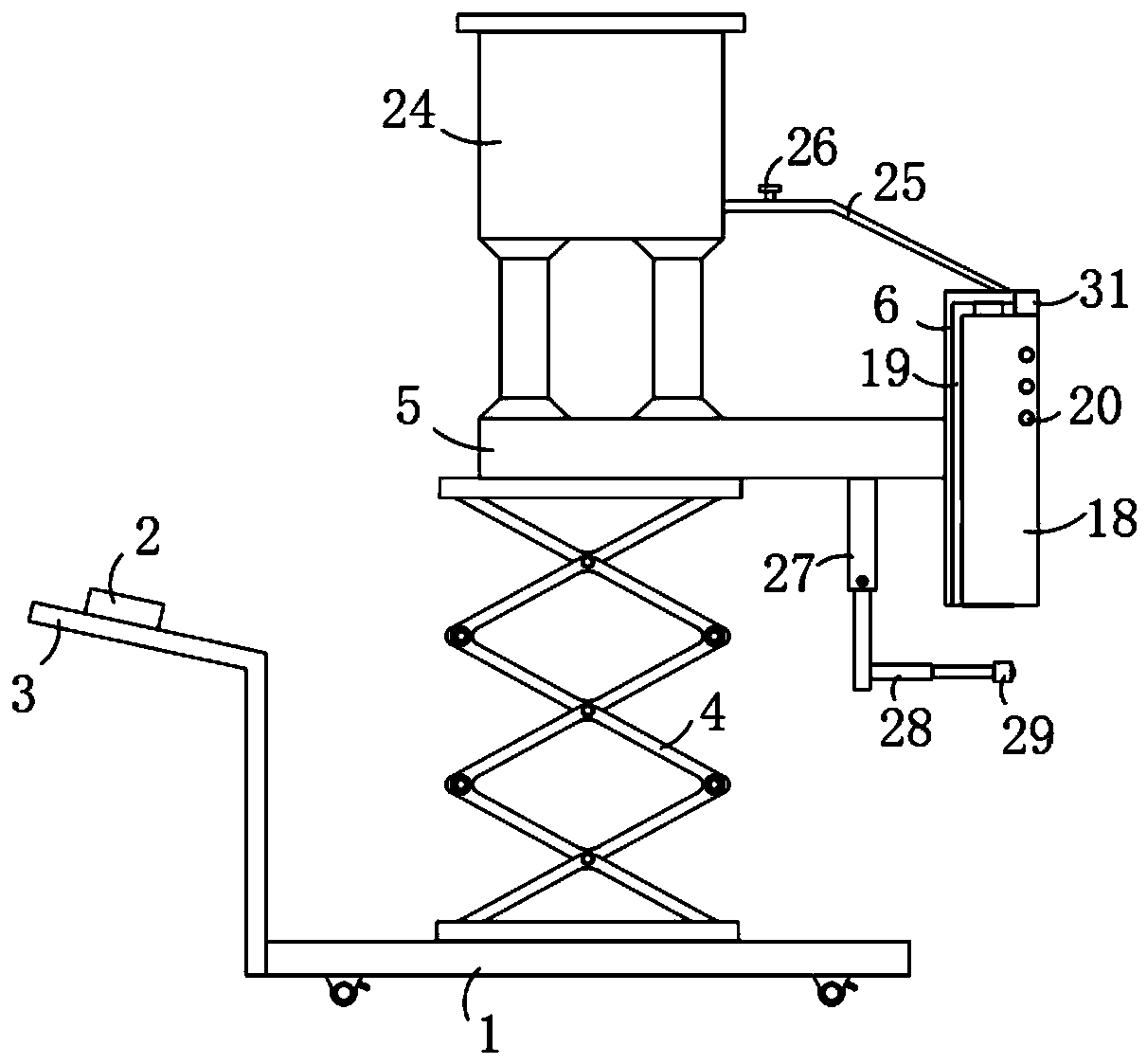

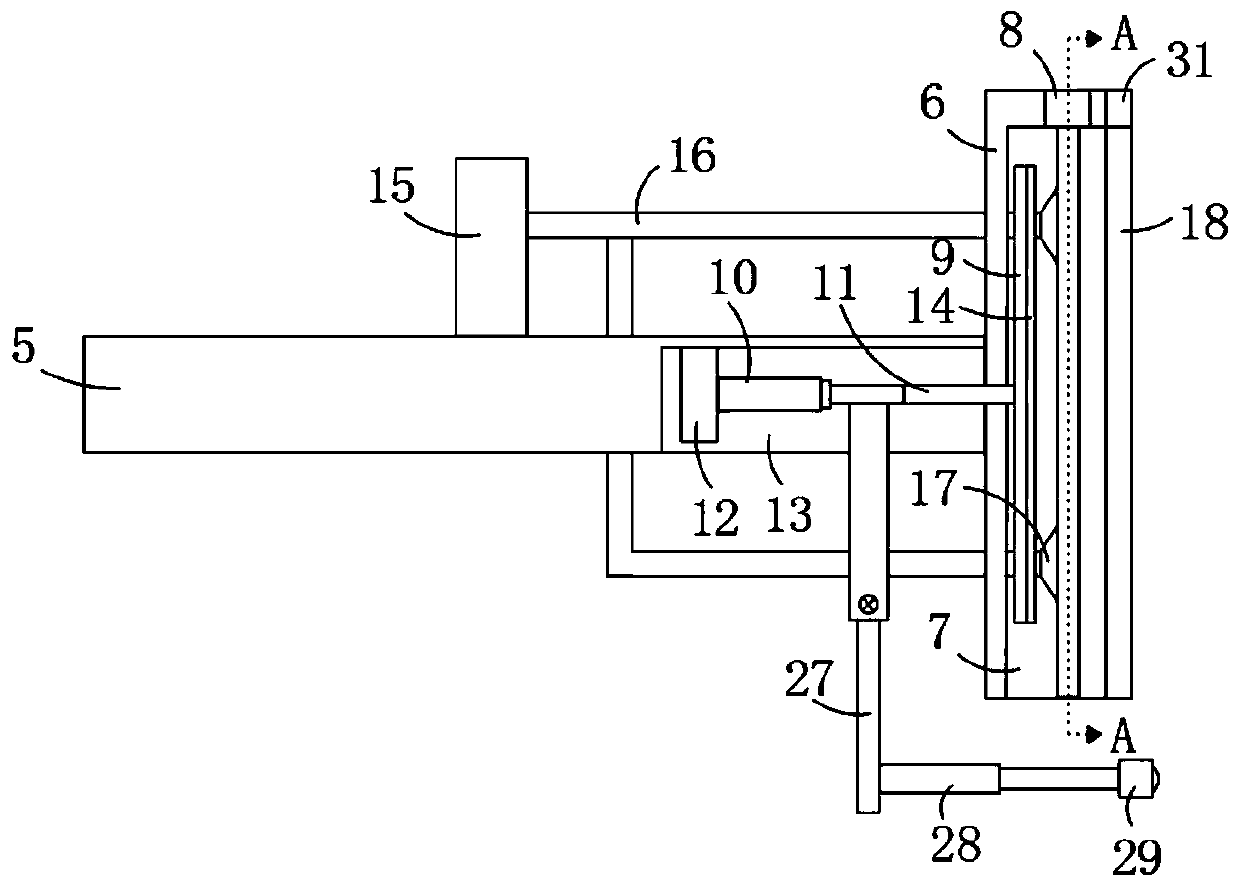

Full-automatic laying equipment and method for ceramic tiles

PendingCN109736554AAvoid hollowingImprove laying efficiencyBuilding constructionsMetallurgyDistributor

The invention discloses full-automatic laying equipment for ceramic tiles, comprising an intelligent carrying vehicle, a spiral distributor, a base material laying device, a ceramic tile grabbing device, a laser level and a visual detection device, the spiral distributor and the base material laying device are arranged behind the carrying vehicle, the laser level is used for forming a horizontal fan-shaped laser beam, and the visual detection device calibrates the driving direction of the intelligent carrying vehicle and the laying angle of ceramic tiles by collecting ground images. The tile laying method comprises the following steps: a) establishing a laser reference plane; B) controlling the carrying vehicle; C) laying a base material; D) detecting the height of the base material; E) carrying and transporting ceramic tiles; F) placing the ceramic tiles; and G)compacting the ceramic tiles. According to the full-automatic ceramic tile laying equipment and method, the hollowing phenomenon of laid ceramic tiles can be avoided, the technical problem that when the ceramic tiles are laid in a large area, the overall flatness is difficult to guarantee manually is solved, the labor intensity is reduced, and the laying efficiency of the ceramic tiles is improved.

Owner:SHANDONG JIAOTONG UNIV

Lightly calcined dolomite thermal insulation mortar

InactiveCN102070320ALow costIncrease the use of functionsSolid waste managementCeramicwareThermal insulationPolystyrene

The invention relates to lightly calcined dolomite thermal insulation mortar, which comprises the following components in part by weight: 20 to 60 parts of lightly calcined dolomite, 1 to 60 parts of flyash, 5 to 35 parts of retarding agent, 1 to 40 parts of strengthening and thickening agent, 1 to 20 parts of kieselguhr, 5 to 35 parts of expanded aggregate, 0.5 to 5 parts of polystyrene foam particle, 0.01 to 0.2 part of polypropylene fiber, 0.5 to 8 parts of water resistance additive, and 0.05 to 2 parts of water reducer. The thermal insulation mortar has the advantages of excellent thermal insulation property, good compression strength, freezing resistance and water resistance, good volume stability, low production cost, energy conservation, environmental friendliness and the like. The construction process is simple; and after construction, the lightly calcined dolomite thermal insulation mortar is not hollowed or cracked, and is particularly suitable for a thermal insulation material for building walls.

Owner:内蒙古祥响新型建材开发有限责任公司 +2

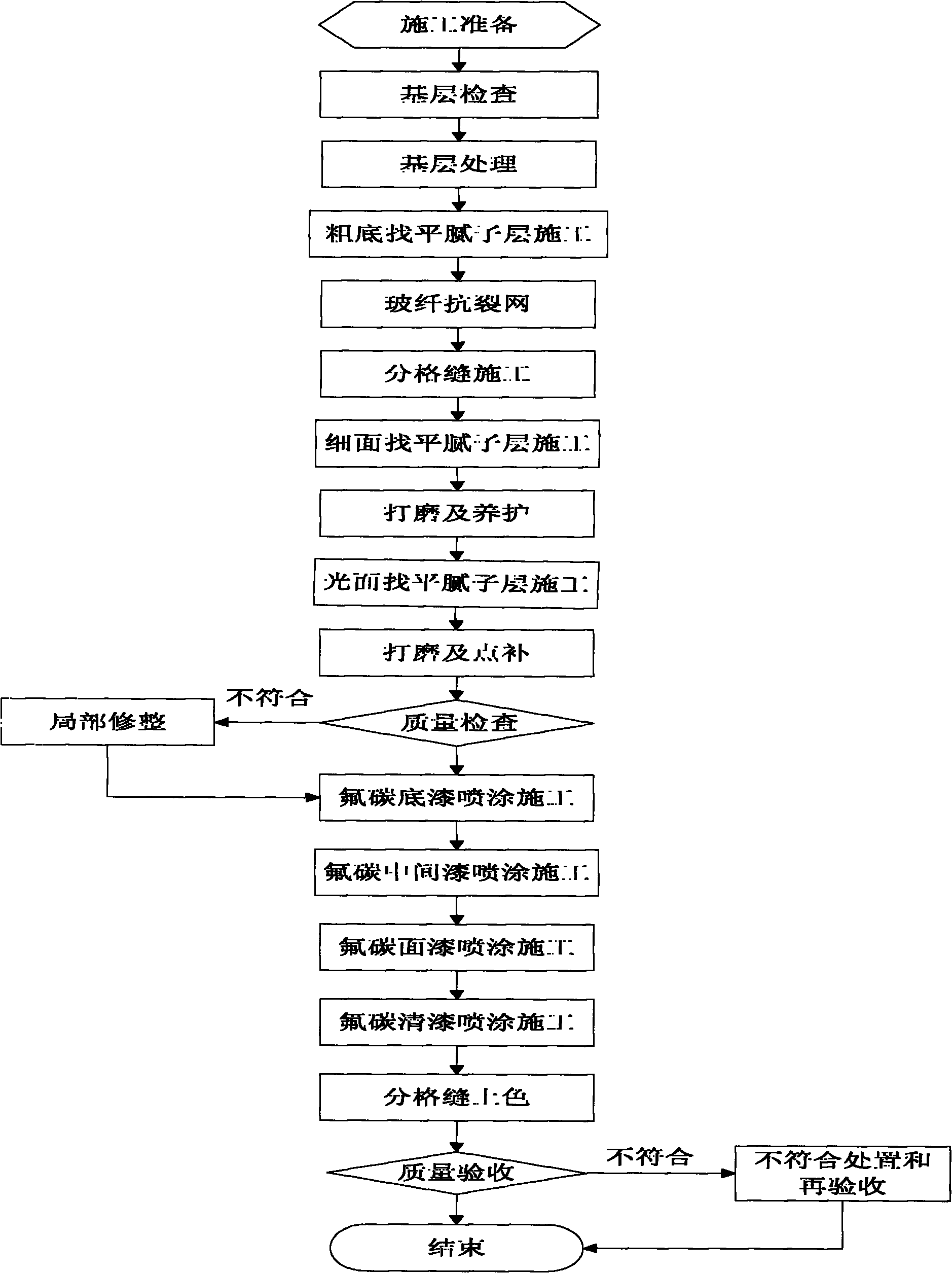

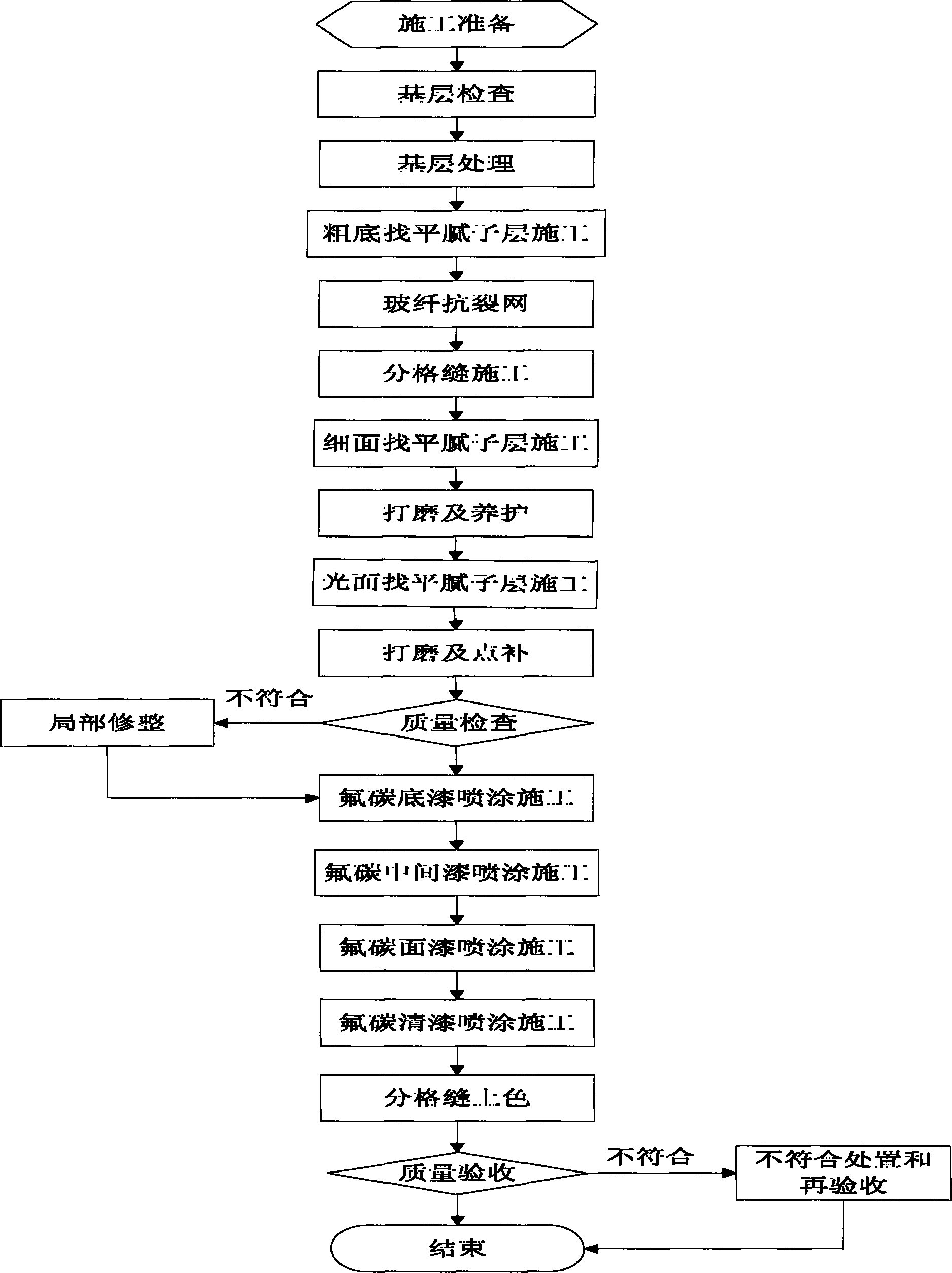

Construction process for outer wall metal fluorocarbon coating

InactiveCN101832015ASimplify construction stepsEasy to operateBuilding constructionsGlass fiberLacquer

The invention discloses a construction process for an outer wall metal fluorocarbon coating. The construction process comprises the following steps of: 1, checking a base layer; 2, treating the base layer; 3, performing coarse bottom leveling putty layer construction, wherein the used outer wall leveling coarse bottom putty is a finished putty special for the outer wall and a proper amount of quartz sand is added into the finished putty; 4, laying a glass fiber crack resistant net; 5, performing dividing joint construction; 6, performing fine surface leveling putty layer construction to ensure that the glass fiber crack resistant net is clamped between the coarse bottom leveling putty layer and the fine surface leveling putty layer; 7, polishing and maintaining; 8, performing polished side leveling putty layer construction; 9, performing fluorocarbon primer spraying construction; 10, performing fluorocarbon intermediate coating spraying construction; 11, performing fluorocarbon finish paint spraying construction; 12, performing fluorocarbon varnish spraying construction; and 13, coloring dividing joints. The construction process for the outer wall metal fluorocarbon coating has the advantages of simple construction steps, reasonable design, convenient operation, low construction cost, high construction quality, and excellent use efficiency, and can prevent the hollowness, delamination, crack and other quality defects on the surface of the outer wall metal fluorocarbon coating.

Owner:陕西建工第二建设集团有限公司

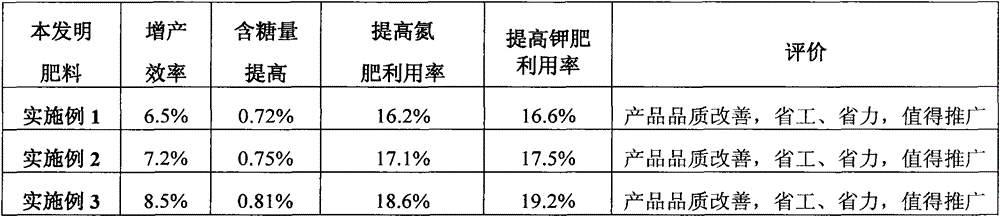

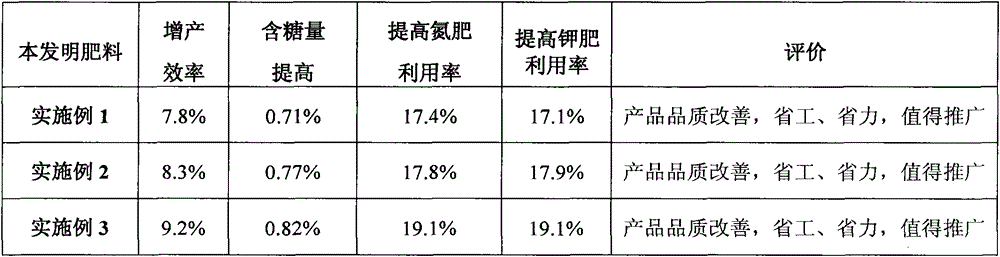

Special microbial fertilizer for pear and preparation method of microbial fertilizer

ActiveCN103332990AImprove fertilizer efficiencyImprove fat qualityBio-organic fraction processingOrganic fertiliser preparationBiotechnologyAmmonium sulfate

The invention discloses special microbial fertilizer for a pear and a preparation method of the microbial fertilizer. The special microbial fertilizer for the pear comprises the following ingredients in parts by weight: 5-10 parts of vinasse, 10-15 parts of soybean meal, 10-15 parts of aginomoto dreg, 15-17 parts of peanut cake, 18-22 parts of corn straw, 30-50 parts of chicken manure, 10-20 parts of chicken slaughter house waste, 2-4 parts of ammonium sulfate, 1-3 parts of diammonium phosphate, 1-3 parts of potassium sulfate, 3-5 parts of borax, 1-3 parts of potassium fulvic acid, 1-2 parts of bacillus mucilaginous, 0.8-1 part of aspergillus oryzae, 2-4 parts of plant lactobacillus, 1-3 parts of microzyme, 3-5 parts of hemicellulase, 3-5 parts of straw starter culture, and 3-5 parts of brown sugar. The special fertilizer for the pear can meet requirements of growth of the pear on various nutritional components, and is nontoxic, tasteless, safe, reliable, enduring in fertilizer efficiency, and harmless to a human body.

Owner:ZHENJIANG AGRI SCI INST JIANGSU HILLY AREAS

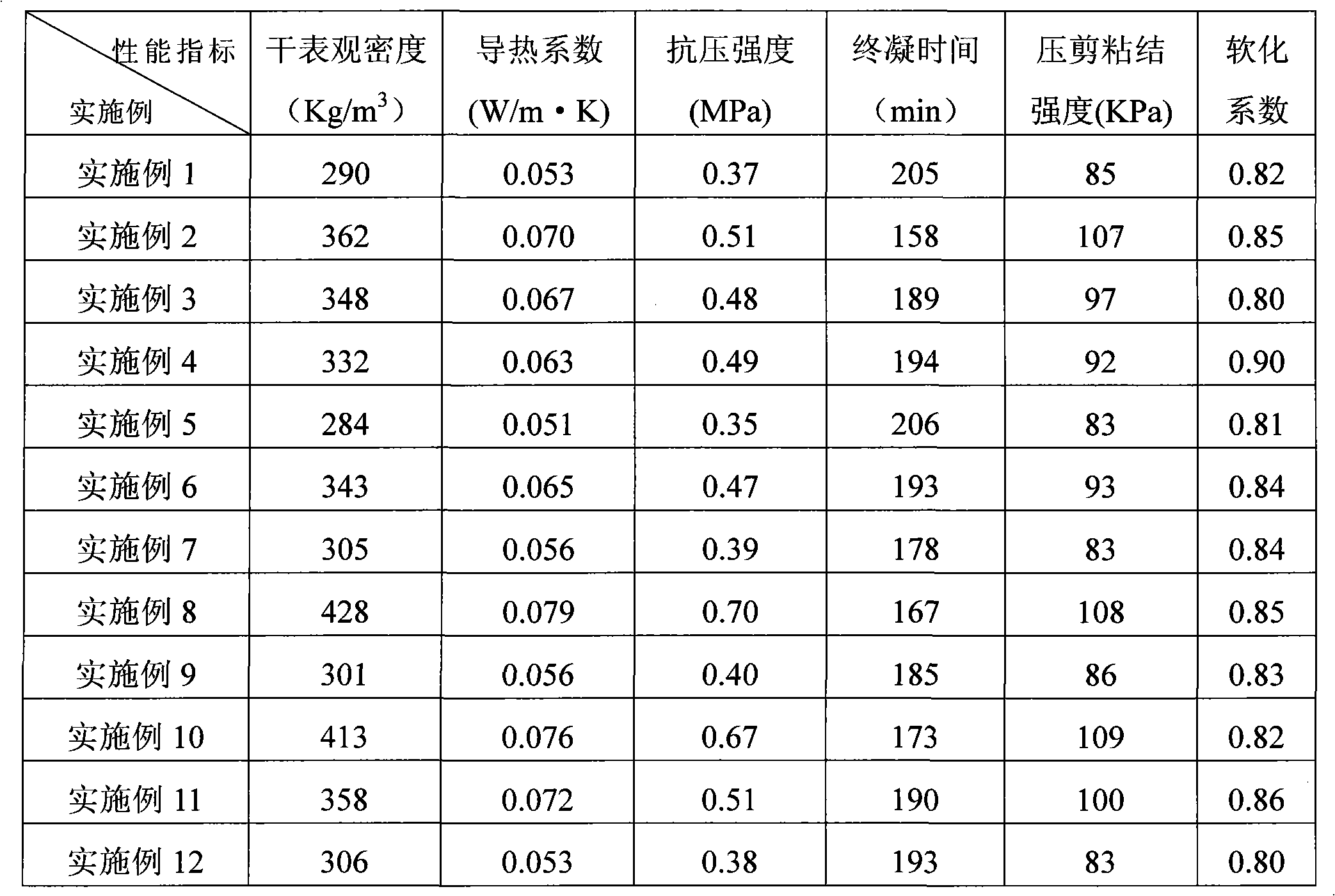

Hybrid high-efficiency thermal-insulation material and preparation method thereof

The invention relates to a hybrid high-efficiency thermal-insulation material and a preparation method thereof. The preparation method comprises the following steps: by using a pretreated light-weight porous material as aggregate, an inorganic active material as an initiator, reactive polymer powder and white cement as gelling materials and ash calcium and gypsum powder as propping materials, mixing with fibers, a water repellent, cellulose ether, a surfactant and the like, stirring and dispersing to obtain the hybrid high-efficiency thermal-insulation material. The hybrid high-efficiency thermal-insulation material is composed of the following components in parts by weight: 20-40 parts of aggregate, 10-15 parts of inorganic active material, 5-10 parts of reactive polymer powder, 20-35 parts of white cement, 15-20 parts of propping material, 5-15 parts of fiber, 1-5 parts of water repellent, 0.1-0.5 part of cellulose ether and 0.5-1 part of surfactant. A right amount of water can be added into the material and stirred to obtain a paste, and the paste is directly spread onto the basal plane of the wall. The product has the advantages of low heat conductivity coefficient, high compression strength, favorable binding strength, thermal insulation, water resistance, fire resistance, crack resistance, no toxicity, environment friendliness, low shrinkage, simple construction technique, low unit area cost and the like, and is suitable for thermal insulation of various building external walls.

Owner:JIANGXI ZHONGKEXIN NEW BUILDING MATERIALS

Polymer dry mixed mortar

The dry mixed polymer mortar consists of quartzite 60-65 wt%, cement 20-25 wt%, limestone powder 8-12 wt%, amylase 3-3.5 wt%, thixotropic bentonite lubricant 1-3 wt%, organic silicon compound 1.5-2.0wt%, hydrophobic agent 0.15-0.20 wt%, methyl cellulose 0.20-0.30 wt% and cellulose fiber 0.30-0.60 wt%. It is one kind of green furnishing and decorating material and has the features of light weight, high strength, high adhesion, being fireproof, etc.

Owner:王胜怀

Heat insulating system outside external wall

InactiveCN1811088AAvoid spreadingStop crackingHeat proofingBuilding reinforcementsEngineeringFire retardant

The heat insulating system outside external wall features that there are base layer with alkali resistant strengthening treating agent outer the concrete base wall and connected to the heat insulating board through silicon modified polymer mortar adhesive and plastic anchor part, alkali resistant netted cloth outside the heat insulating board, elastic anticracking silicon modified polymer putty and self-structured waterproof anticracking closing layer between the heat insulating board and the alkali resistant netted cloth, facing silicon modified polymer mortar outside the alkali resistant netted cloth, fire retardant paint around the window and silicon modified acrylate paint in the outmost layer. The present invention has the advantages of simple structure, low cost, easy construction, raised wall surface quality and fire retarding function.

Owner:上海英硕聚合材料股份有限公司

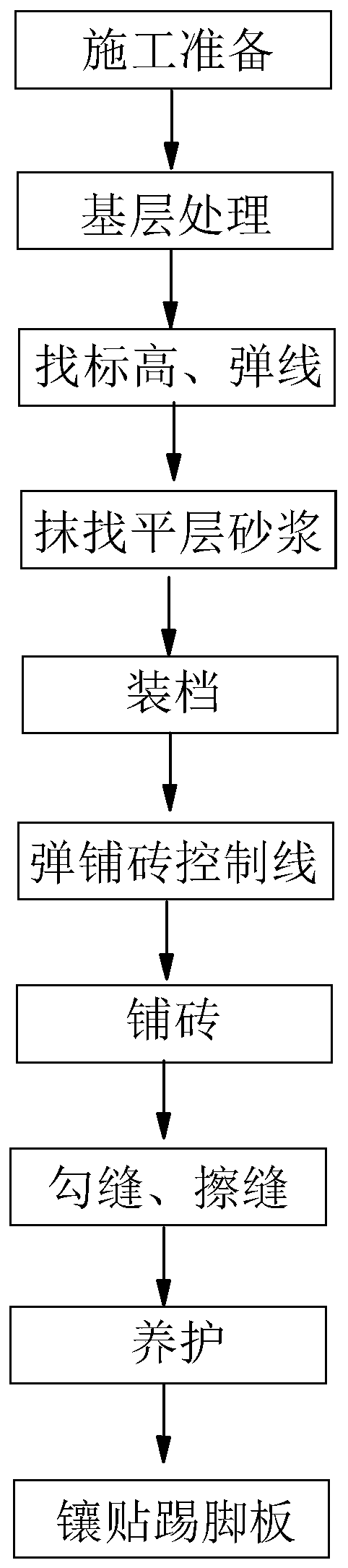

Floor tile floor paving construction method

The invention relates to a floor tile floor paving construction method. The floor tile floor paving construction method comprises the following steps that 1, construction preparation is carried out, specifically, a horizontal elevation line is first calibrated on an inner wall, and floor tiles are screened and selected through a prefabricated mould; 2, base layer treatment is carried out; 3, the elevation and elastic lines locating is carried out; 4, mortar plastering leveling layer is carried out; 5, positions between marking ribs are filled with cement mortar; 6, snapping a tile paving control line is carried out, specifically, a gap width of floor tile paving is determined according to the design requirements, when the compressive strength of the leveling layer mortar reaches 1.2 Mpa, the control line of tiles is snapped by a person; 7, the tiles are paved, specifically, paving according to the control line of the floor tiles is carried out; 8, joint pointing and scraping is carriedout; 9, the maintenance is carried out; and 10, skirting boards are inlaid, specifically, vertical joints of the skirting boards ought to be aligned with floor joints, during paving, a tile ought tobe inlaid at each internal corner of the two end heads of a room wall, the upper edge is served as a standard hanging line, and the paving is started. The floor tile floor paving construction method has the advantages that the construction requirements are met, the method is grasped by workers quickly and conveniently, and the construction effect is obvious.

Owner:北京金碧合力建筑设计工程有限公司

Special microbial fertilizer for watermelons and preparation method thereof

InactiveCN103274878ALong-lasting fertilizer effectImprove efficiencyBio-organic fraction processingOrganic fertiliser preparationFertilizerLeavening agent

The invention discloses a special microbial fertilizer for watermelons and a preparation method thereof. The special microbial fertilizer for the watermelons comprises components in a weight ratio as follows: 10-15 parts of furfural residues, 20-30 parts of soybean meal, 15-20 parts of peanut cake, 15-20 parts of corn straws, 10-20 parts of chicken slaughter-house waste, 2-4 parts of ferrous sulfate, 3-5 parts of borax, 1-3 parts of potassium humate, 1-2 parts of bacillus stearothermophilus, 0.8-1 part of mucor, 2-4 parts of plant lactobacillus, 1-3 parts of yeast, 3-5 parts of cellulose, 3-5 parts of a straw leavening agent and 3-5 parts of brown sugar. The special fertilizer for the watermelons can satisfy various nutritional ingredients required by watermelon growth, is nontoxic, flavorless, safe, reliable, lasting in fertilizing efficiency and harmless to human bodies.

Owner:SUZHOU RENCHENG BIO SCI & TECH

Dedicated gypsum based self-leveling mortar for floor heating backfill

InactiveCN109516755AReduce sensitivityFacilitate construction quality controlAluminum silicateMetakaolin

The invention belongs to the technical field of building materials and specifically discloses dedicated gypsum based self-leveling mortar for floor heating backfill. The dedicated gypsum based self-leveling mortar is prepared from water and powder, wherein the powder is prepared from the following ingredients in mass fraction: 5 to 30% of anhydrous fluorine gypsum, 5 to 30% of phosphorus buildinggypsum, 0.5 to 10% of alpha-high strength gypsum, 20 to 50% of fine sand, 5 to 20% of light calcium carbonate, 1 to 8% of cement, 0.01 to 1% of active roasted metakaolin, 0.1 to 2% of lime, 0.1 to 2%of lithium based bentonite, 0.1 to 1% of nano calcium sulfate whisker, 0.1 to 0.5% of magnesium aluminum silicate, 0.1 to 1% of sodium sulfate, 0.01 to 0.05% of hydroxypropyl starch ether, 0.1 to 0.5%of modified amino acid gypsum retarder and the like; the mass ratio of the water to the powder is (0.28 to 0.35) to 1. When the self-leveling mortar is prepared, a lot of solid waste can be consumed;furthermore, the ground construction efficiency and the ground flatness of buildings are improved.

Owner:HENAN QIANGNAI NEW MATERIALS CO LTD

Insulating system of external wall and its construction technology

InactiveCN1334389AHigh masonry strengthShorten drying timeWallsClimate change adaptationAdhesiveEngineering

An insulating system for external wall and its construction technology are disclosed. The system features that unique cement mate, insulating adhesive, alkali-resistant glass reinforced grid, special cutting tools, grinding tools and toothed plastering tool are used. Its advantages are high quality, short construction period, low cost and saving energy by more than 50%.

Owner:LIMEISHUN PAINT RESIN DALIAN

Preparation method and construction method of non-cured rubber asphalt paint and coil composite waterproof layer

ActiveCN103465540AEasy constructionQuality improvementLaminationLamination apparatusWater leakageAsphalt

The invention discloses a non-cured rubber asphalt paint composite waterproof layer. The composite waterproof layer is formed by bonding non-cured rubber asphalt paint and a waterproof coil which is dissolved with the non-cured rubber asphalt paint. The composite waterproof layer gives full play to respective technological advantages of the non-cured rubber asphalt paint and the waterproof coil and a full-interface closed seal structure is formed by bonding the non-cured rubber asphalt paint and the waterproof coil firmly, thus achieving the aims of repairing and sealing cracks of subbases and capillary interstices and effectively preventing water channelling and water leakage between the composite waterproof layer and subbases.

Owner:BEIJING ORIENTAL YUHONG WATERPROOF ENG

Interior wall plastering mortar and construction method thereof

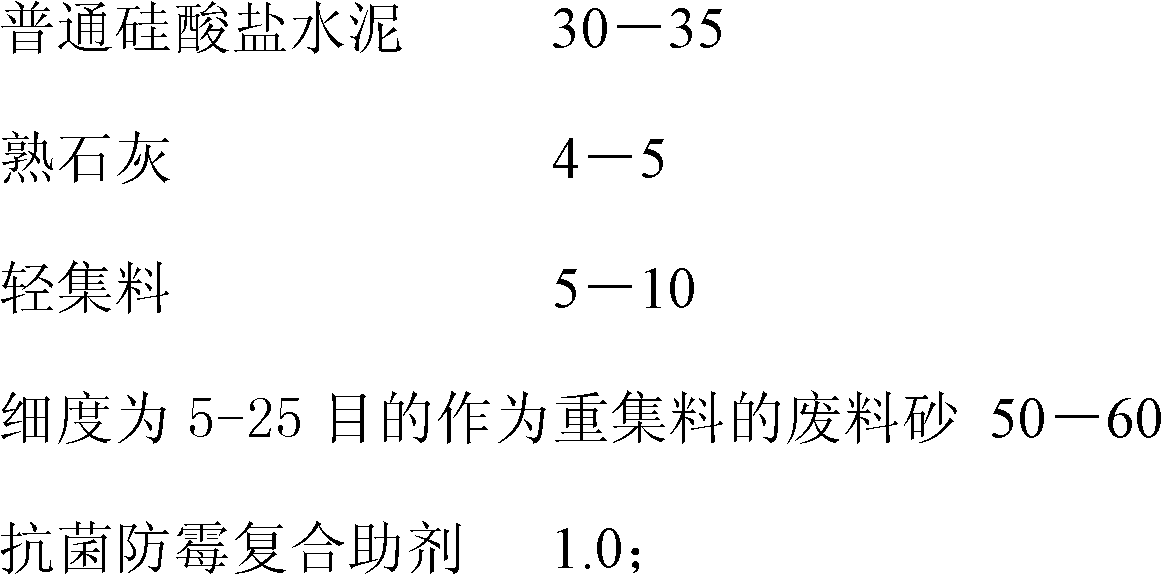

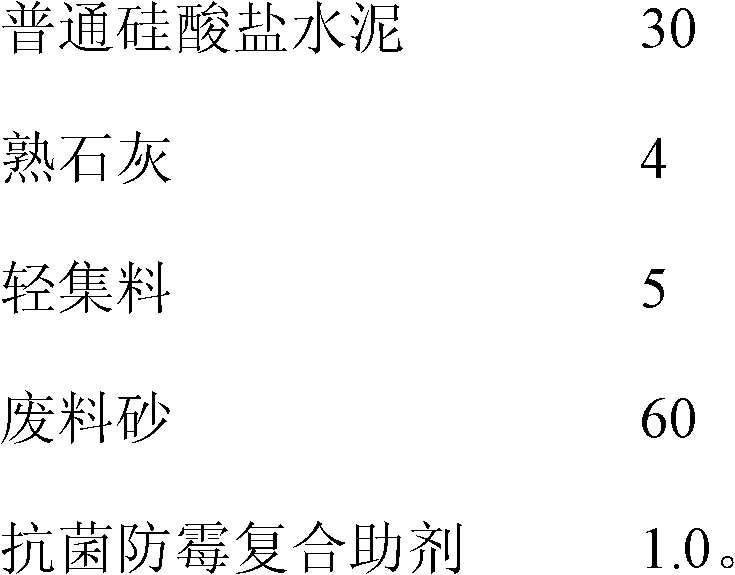

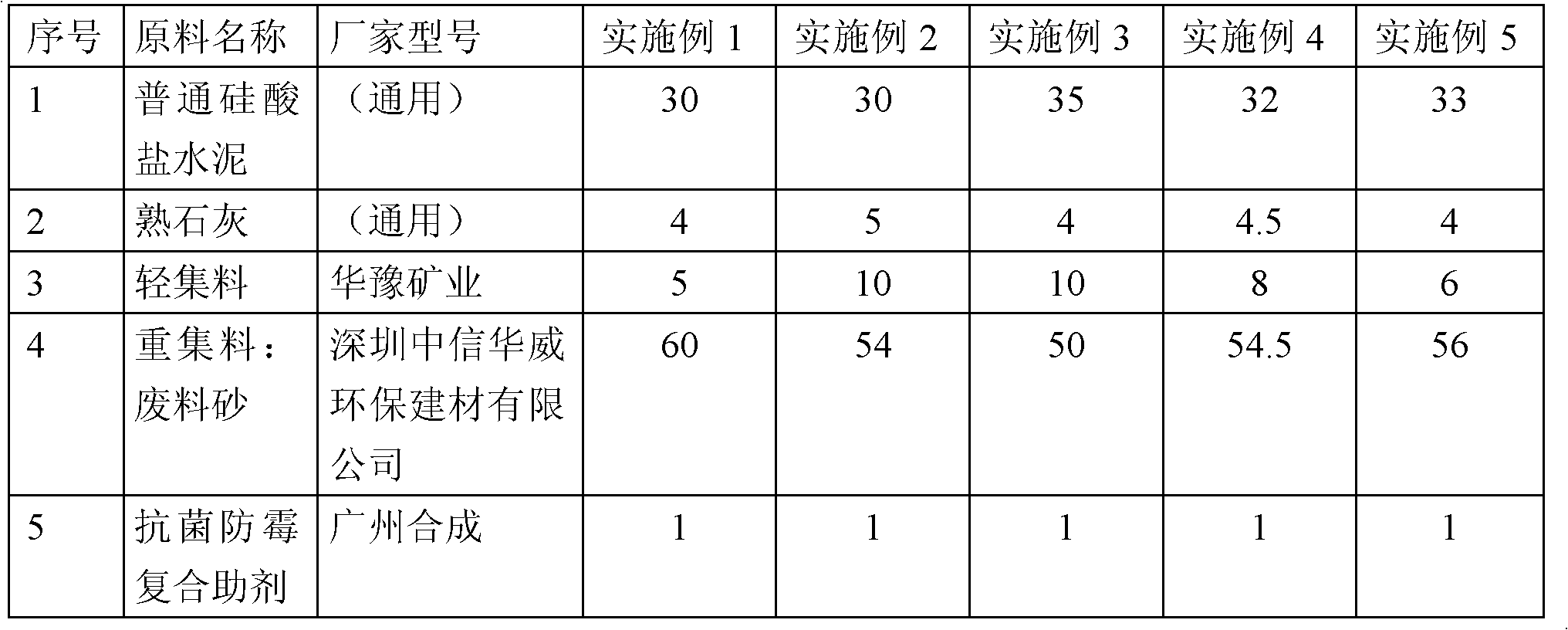

InactiveCN101712545AHigh tensile strengthReduce stretchCovering/liningsSolid waste managementRiver sandFineness

The invention provides interior wall plastering mortar, which is prepared by mixing the following components in part by weight: 30 to 35 parts of ordinary Portland cement, 4 to 5 parts of hydrated lime, 5 to 10 parts of light aggregate, 50 to 60 parts of heavy aggregate, and 1.0 part of C-type composite auxiliary, wherein the light aggregate is an inorganic vitrified hollow cellular material of which the fineness is lower than 100 meshes; the heavy aggregate is ordinary river sand; and the C-type composite auxiliary is sold by Guangzhou Hecheng Trading Company. The construction method for the interior wall plastering mortar comprises the following steps: diluting the light energy-saving interior wall plastering mortar with water accounting for 30 to 50 percent of the weight of the mortar; and mechanically or manually stirring the diluted mortar until the mortar is mixed uniformly to achieve the viscosity suitable for mechanical spraying or manual construction. Therefore, the mortar can be sprayed mechanically or constructed manually. The interior wall plastering mortar has light weight and energy conservation, can prevent hollowness, cracking and falling off by being matched with a light wall body, can effectively reduce cracking of the mortar, ensures the quality of construction work, has the advantages of heat insulation and noise reduction, low cost of unit area, good grain composition, good peaceability, mechanical construction contribution and simple process.

Owner:SHENZHEN GRANDLAND DECORATION GROUP

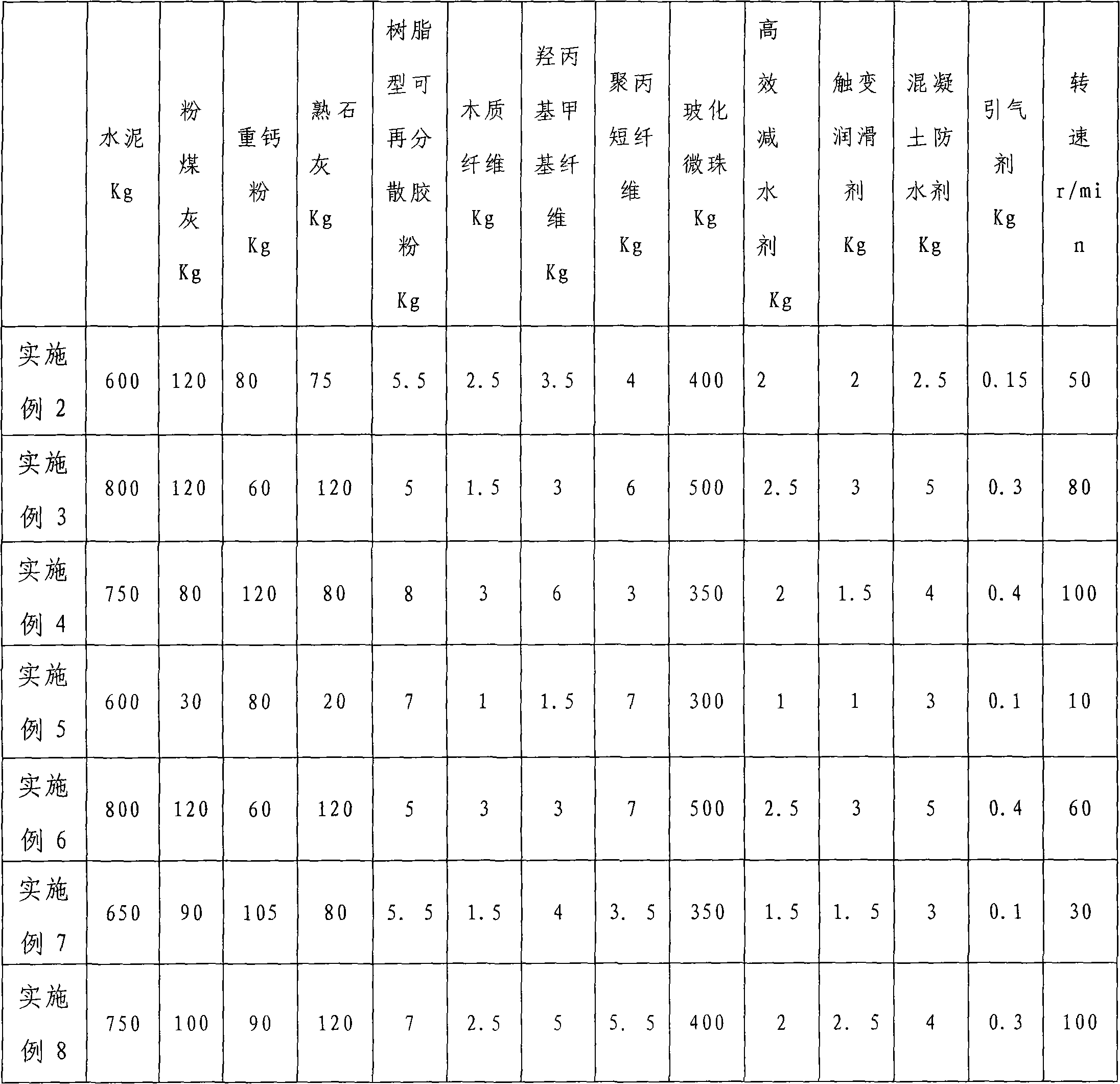

Fireproof lightweight composite thermal insulation mortar and its preparation method

The invention discloses a fireproof lightweight composite thermal insulation mortar. The mortar is prepared from the following raw materials, by weight, 5-8 parts of resin type re-dispersible latex powder, 1-3 parts of a wood fiber, 3-6 parts of a hydroxypropyl methyl fiber, 3-7 parts of a polypropylene short fiber, 80-120 parts of heavy calcium powder, 80-120 parts of slaked lime, 80-120 parts of coal ash, 600-800 parts of cement, 300-500 parts of a glass bead, 1-2.5 parts of a high-efficiency water reducer, 1-3 parts of a thixotroping lubricant, 3-5 pars of a concrete waterproof agent and 0.1-0.4 parts of an air entraining agent. The preparation method of the mortar comprises the following steps: adding the raw materials according to a certain order, and fully and uniformly mixing under normal temperature, normal pressure and a stirring speed of 10r / 100min. The mortar has the following advantages: a defect that the maintenances of common wall thermal insulation materials cannot be realized by themselves is solved, problems comprising cracking, hollowing, shedding and the like appearing after construction are solved because the needed balance of water absorption and water discharge is automatically reached, and small construction difficulty at normal temperature and according with energy saving and environmental protection requirements are realized because of no use of complicated operations comprising grid cloth use or the like.

Owner:康利生

Anti-yellowing interface agent

The invention relates to an interface agent, especially to an anti-yellowing interface agent. The anti-yellowing interface agent comprises components of hydroxyethyl cellulose, a dispersant, an antifoaming agent, a bactericide, an antifreeze agent, a conditioning agent, calcium carbonate, titanium dioxide, quartz sand, an acrylic acid emulsion and the like. The interface agent provided by the invention can effectively resist alkali releasing and yellowing of various wood-based panels, plasterboards, calcium silicate boards and the like with large water absorption and low surface strength, has good bidirectional softness, can be firmly combined with a putty layer, and can be used to prevent the putty layer from peeling, hollowing, cracking and the like.

Owner:厦门东顺涂料有限公司

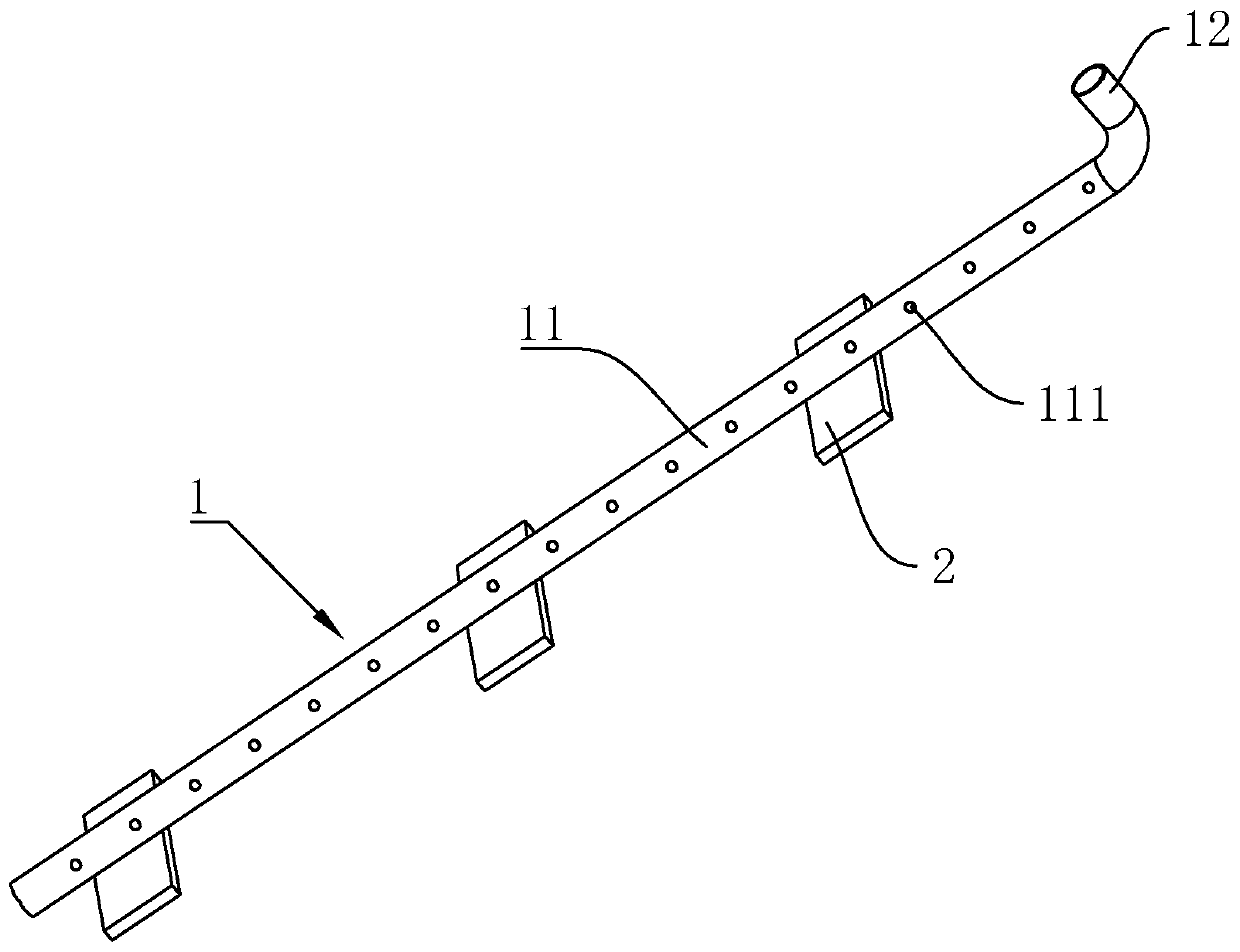

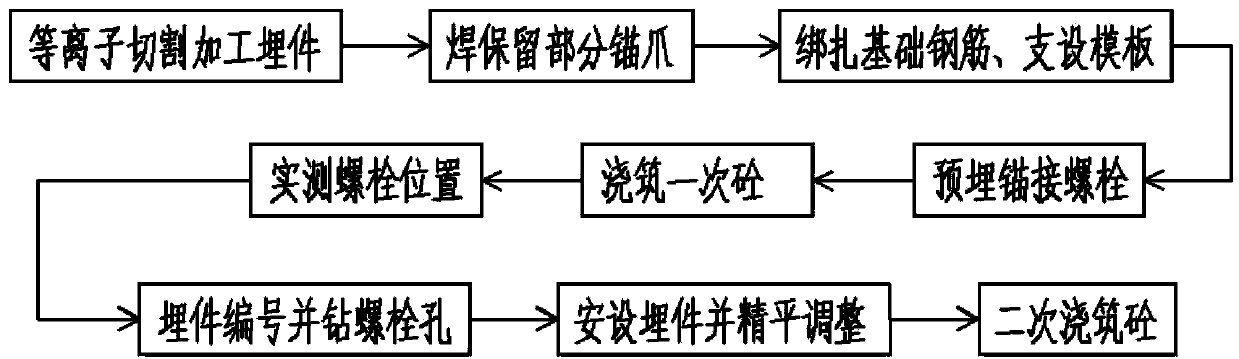

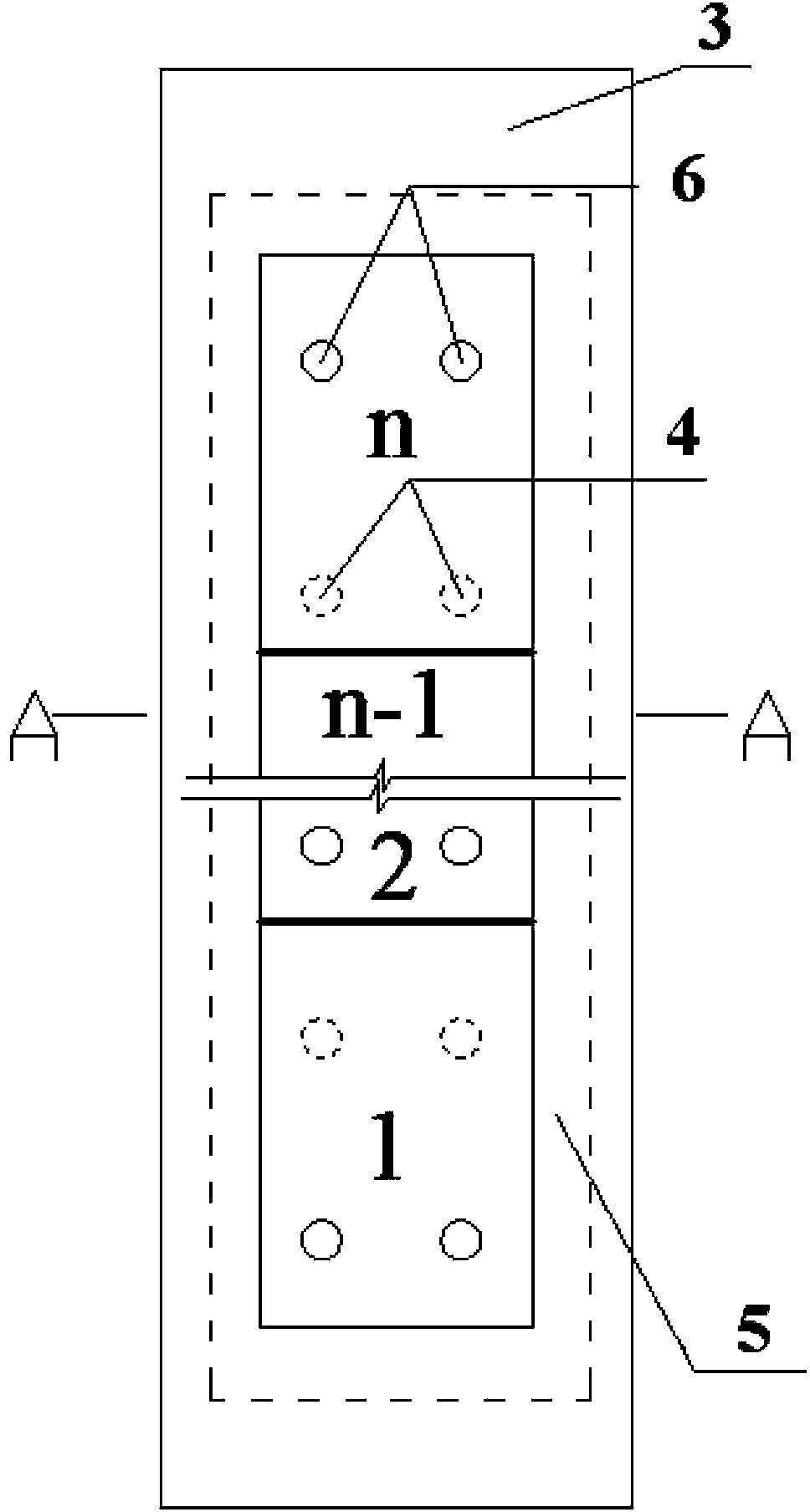

Super-long and large horizontal embedded part reverse construction method

InactiveCN103388343AReduce investmentImprove construction progressFoundation engineeringMaterials scienceCasting

The invention discloses a super-long and large horizontal embedded part reverse construction method. The method comprises the following steps: constructing a concrete equipment foundation; reserving an anchoring junction and a secondary casting layer in a corresponding range; embedding an embedded part; and performing secondary casting after leveling. According to the method, since repeated reinforcement, calibration and fixation work at the early stage are saved, the secondary casting can be performed by only arranging the embedded part after completion of primary casting; and thus, the investment in engineering resources such as labor and measure materials can be greatly saved, and the construction progress can be improved by 30-40 percent.

Owner:TIANJIN 20 CONSTR

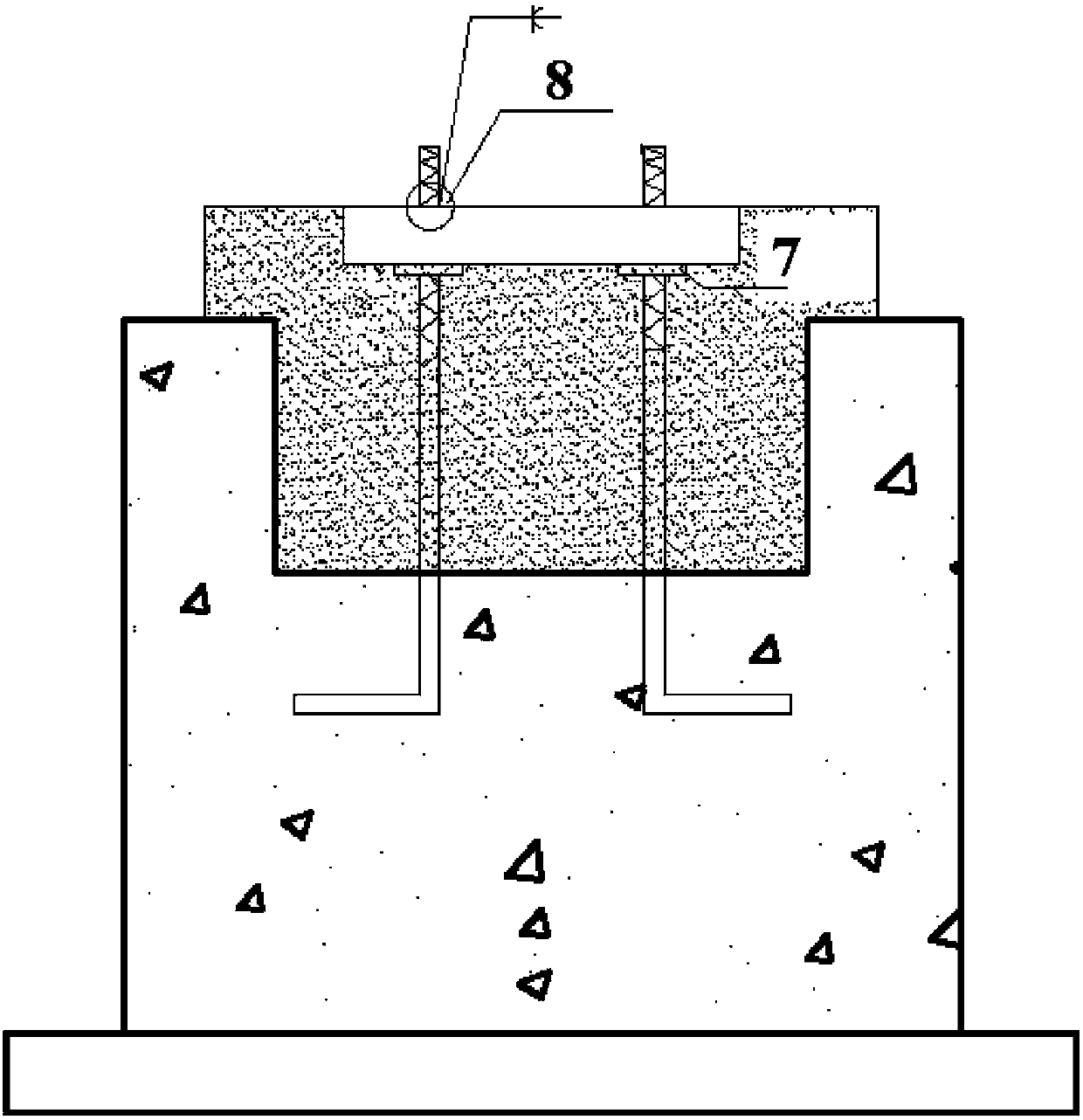

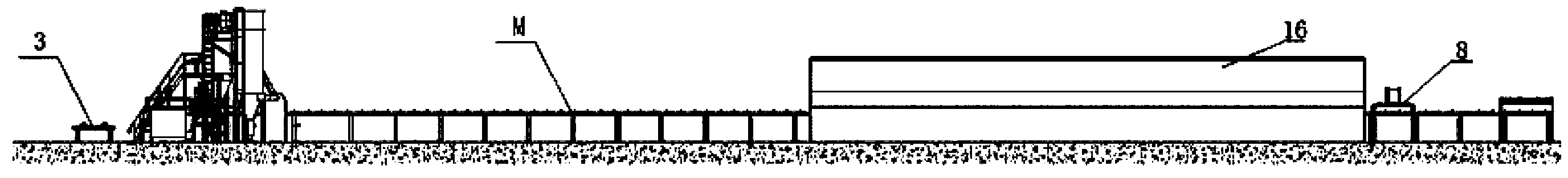

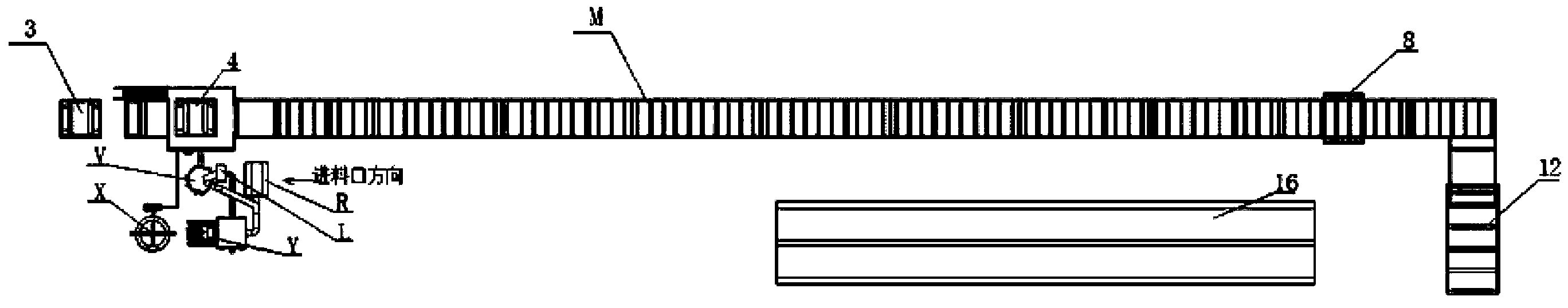

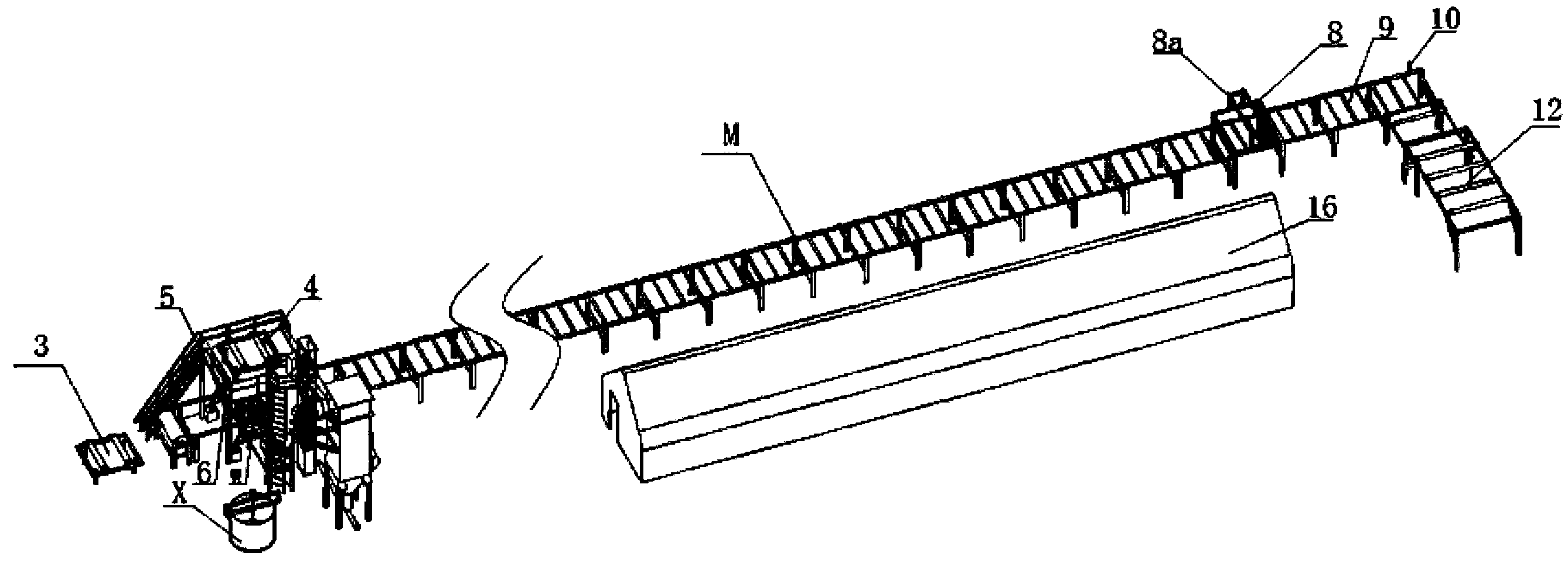

Reinforced glass fiber plasterboard automatic production line

InactiveCN103978548AImprove market competitivenessLower unit costCeramic shaping plantsFeeding arrangmentsGypsumTransmission system

The invention discloses a reinforced glass fiber plasterboard automatic production line which is provided with a plasterboard extrusion forming mechanism formed by an upper layer transmission system and a lower layer transmission system, a mesh cloth conveying system, a slurry supplying system, a plasterboard cutting system, a turning and clamping mechanism, a sucking disc device, a lifting transferring vehicle and a plasterboard drying system. The whole production line changes the traditional production technology of gypsum plasterboards, the plasterboard extrusion forming mechanism formed by the upper and lower layer transmission systems is used for processing the reinforced glass fiber plasterboard, the processing of the mesh cloth conveying system is finished on-line, the quality of the obtained reinforced glass fiber plasterboard is guaranteed, and the production cost has the great market competence.

Owner:SHANGHAI CHUNCUI DECORATION MATERIAL

Hollowing-resistant construction process of polished brick

The invention discloses a hollowing-resistant construction process of a polished brick. The hollowing-resistant construction process of the polished brick disclosed by the invention comprises the following steps of: (1), processing a basic layer: cleaning the surface of the basic layer; (2), snapping a control line; (3), brushing an interface agent: brushing an interface processing agent at the back of the polished brick, and naturally airing: (4), paving cement gum: uniformly smearing modified mortar or cement gum special for the polished brick on the surface of the basic layer so as to form an adhesive layer; (5), paving the brick: kneading the processed polished brick on the adhesive layer, and beating the surface of the polished brick by using a rubber hammer from top to bottom, so that the polished brick is stuck with the adhesive layer to the most extent; (6), adjusting, pointing and cleaning; and (7), maintaining: maintaining by watering after paving the polished brick for 24 h. According to the invention, the adhesive strength among various layers of materials can be increased; and the problems, such as hollowing and falling off of the surface layer, can be avoided.

Owner:ZHEJIANG SHENMEI DECORATION ENG

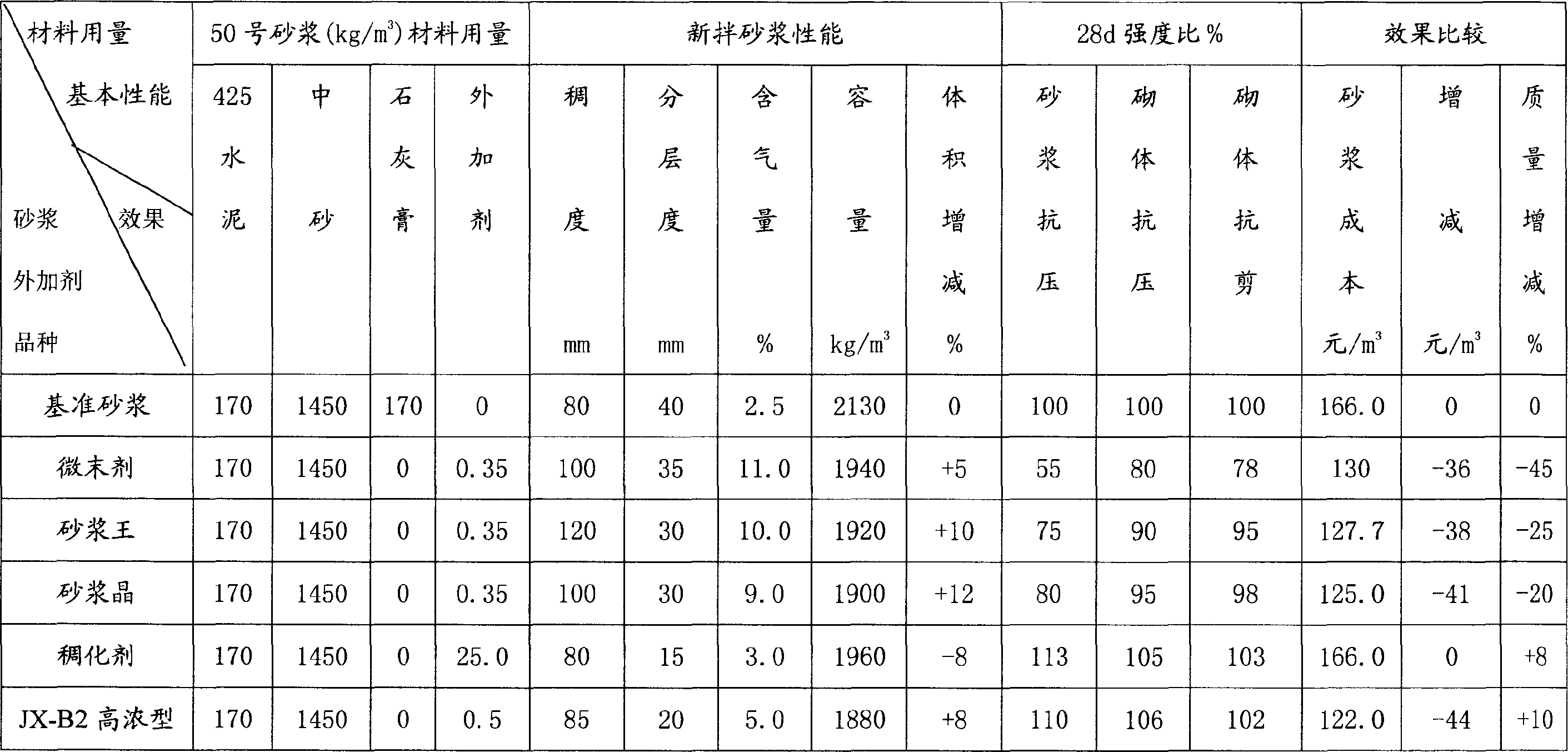

Efficient mortar plasticizer base material and its efficient mortar plasticizer composition

This invention relates to a basic material of a high efficient mortar DBP to be prepared by the following method: a, adding 11-14% rosin polymers into 45-55% water of 80-120deg.C slowly and mixing them in a kettle continuously to be solved fully, then adding 4-6% inorganic alkali and dissolving them completely under the 60-80deg.C constant to the complete reaction, b, adding 8-10% sulfosalt while mixing, 1-2% polyalcohol under 40-60 deg.C constant to the complete reaction, c, adding 10-11% DBP to be dissolved fully under 30-50 deg.C to be cooled to normal temperature, d, spraying and drying them to powder particles then to be matched with 3-5% DBP and 9-11% silicon powder to get the basic material of high efficient mortar DBP. This invention also relates to its compound.

Owner:四川铁科新型建材有限公司

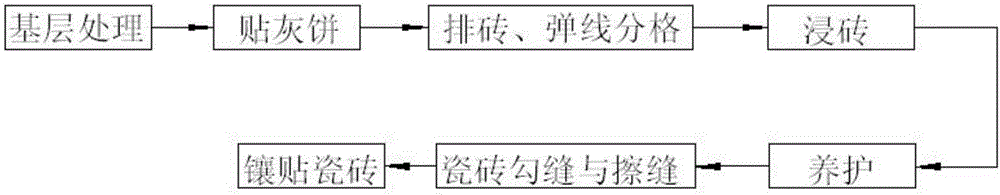

Wall tile hollowing-prevention inlaying construction method

The invention relates to a wall tile hollowing-prevention inlaying construction method. The method comprises the steps of substrate treatment, marl biscuit pasting, brick arranging, line snapping and mesh dividing, brick immersing, tile inlaying, tile jointing and wiping, maintenance and the like. The method is simple in construction, and according to tiles inlaid through the method, substrate crazing is avoided, so that the hollowing phenomenon is avoided; and by adopting the method, the tile are attractive in inlaying, and mesh joints are even. According to the method, the operation area of a watering tool is increased, so that the working efficiency is effectively improved. The method is simple and high in construction efficiency, tile pasting is attractive, and the hollowing phenomenon is avoided, so that the method has wide application and popularization value.

Owner:ZHONGTIAN CONSTR GROUP +1

Interface mortar with ardealite-based hydraulicity composite cementing material as cementing material

The invention belongs to the technical field of building materials and particularly relates to interface mortar with an ardealite-based hydraulicity composite cementing material as a cementing material. The interface mortar is composed of ardealite, a slag powder, coal ash, metakaolin, a copper tailing slag powder, red mud, ordinary Portland cement, aluminate cement, quartz sand, a quartz powder,chesterite, calcium bentonite, a polycarboxylate-type water reducing agent, cellulose ether and latex powder. By adopting the interface mortar, the binding property of a base wall and a heat preservation layer in a wall heat preservation system can be effectively improved, the peeling risk of the heat preservation layer of a building wall can be reduced, and environment security problems caused bypiling of industrial ardealite can be also solved. When the interface mortar is produced, a great amount of industrial solid wastes such as non-calcined ardealite, coal ash, copper tailing slag powder and red mud are used, so that the interface mortar has the outstanding advantages of being low in energy consumption, low in cost, low in emission, and the like. The interface mortar is applied to heat preservation systems of various building walls, and the like.

Owner:TONGJI UNIV

A kind of interior wall plastering mortar and its construction method

A mixed mix of a lightweight inner wall was mixed with the following weight ratio: 30-35 of ordinary silicate cement; 4-5 cooked lime; 5-10 light materials; 5--fineness is 5--The 25th purpose is 50-60 waste sand for heavy materials; 1.0 antibacterial and mold-proof composite agent provided by Guangzhou Synthetic Trade Company, 0.4 kg of antibacterial mold and mold per kilogram, 0.1 kg of water retention, 0.3 kg of diversified latex powder and diversified latex powder and diversified latex powder and 0.3 kg of diversified latex powder and diversified latex powder and 0.3 kg of diversified latex powder and diversified latex powder and 0.3 kg of diversified latex powder and diversified latex powder and 0.3 kg of diversified latex powder and diversified latex powder and 0.3 kg of diversified latex powder and diversified latex powder and 0.3 kg of diversified latex powder and divergent latex powder and 0.3 kg of divergent latex powder.The composition of the air induction agent is mixed with 0.2 kg; the light collection is the fine -grade -based inorganic vival and short -hole material below 100 destinations.The diluted weight ratio during construction is the inner wall plastering mortar: water = 100: 30-50.The mortar uses waste sand in the construction waste as the mortar. It uses materials to recycled, and the crack resistance is good.The adhesion intensity meets the requirements. It can be used with lightweight walls to prevent air drums, cracking, falling off, and ensuring the quality of the project; low unit area cost; can reduce mold and bacterial breeding.

Owner:SHENZHEN GRANDLAND DECORATION GROUP

Mechanical spraying plastering mortar

The invention provides a mechanical spraying plastering mortar and an additive. The mechanical spraying plastering mortar comprises: by weight, cement 10%-18%, fly ash 5%-10%, sand 75%-80%, and additive 0.5%. The additive comprises, by weight, cellulose ether 0.02%, montmorillonite powder 0.01%, starch ether 0.01%, water reducing agent 0.05%, air-entraining agent 0.0035%, and wood fibre 0.1%. The product optimizes the mix ratio of the plastering mortar, and mixes a certain ratio of additive, so that the plastering mortar has sag resistance, good lubricity, water-retaining property and fluidity, and strong binding power, and the performance requirements of mechanical pumping and spraying construction of the plastering mortar is realized. And thus, labor intensity is reduced, construction efficiency is enhanced, and the construction efficiency is more than two times of that of manual plastering. The wall plastering using mechanical spraying construction has high pressure and is uniform, avoids empty drum and crack of the plaster layer, and improves the engineering quality of the additive.

Owner:浙江正昶新型材料股份有限公司

Semi-automatic vertical type wall brick fitting device and construction method thereof

The invention discloses a semi-automatic vertical type wall brick fitting device which comprises a bottom plate and a controller, wherein the outer side wall of the bottom plate is fixedly connected with a lifting plate; the bottom of the controller is fixedly connected with the upper surface of the lifting plate; the upper surface of the bottom plate is fixedly connected with a lifting table; thelifting table is electrically connected with the controller; the top of the lifting table is fixedly connected with a mounting plate; one end of the mounting plate is fixedly connected with a baffleplate; one end, away from the mounting plate, of the baffle plate is equipped with a mounting slot; and a pushing device is arranged inside the mounting slot. According to the semi-automatic verticaltype wall brick fitting device disclosed by the invention, a wall brick is placed in the mounting device, the pushing device is utilized to further press the wall brick after a slurry unloading deviceis utilized to fill concrete between the wall brick and a wall surface, so that the problem that the back surface of the stuck wall brick is hollow as concrete on upper and lower parts of the same wall brick is uneven during manual fitting can be effectively avoided, and quality of the fitted wall brick is guaranteed.

Owner:山东恒远装饰设计工程有限公司

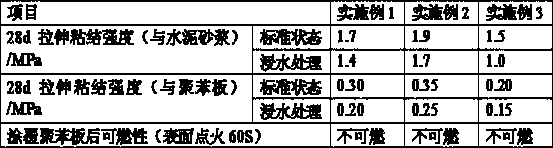

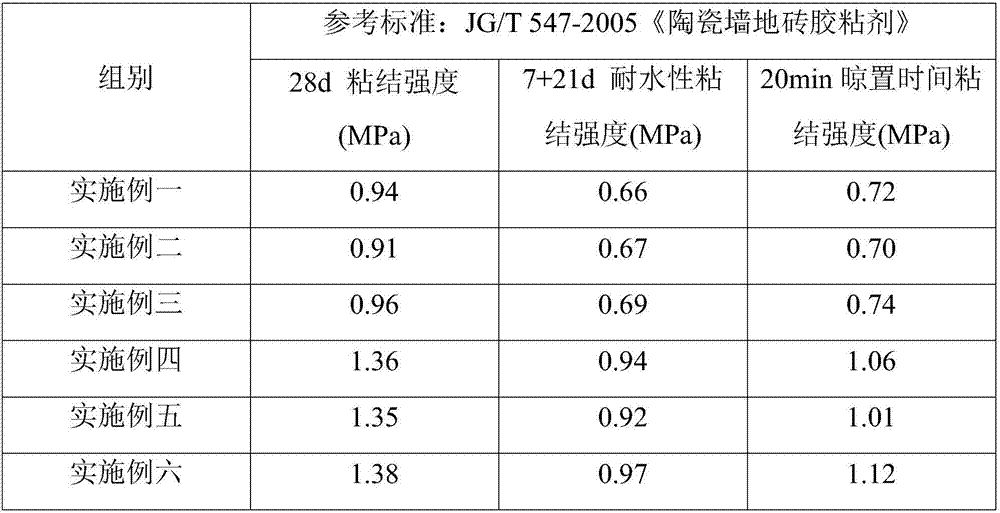

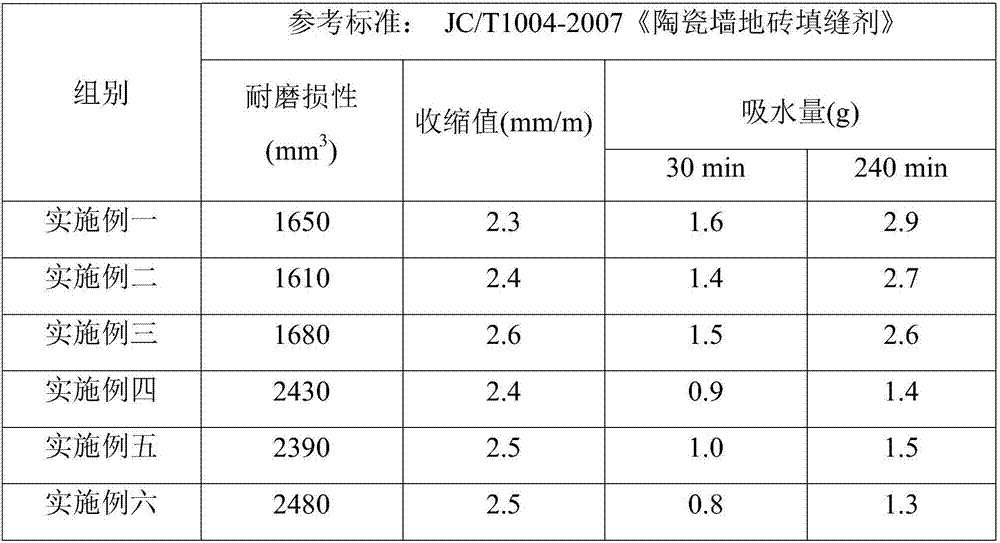

Bonding agent capable of preventing ceramic tile hollowing or falling, and preparation method and application thereof

ActiveCN107151541ADosage adjustmentHigh bonding strengthNon-macromolecular adhesive additivesMacromolecular adhesive additivesBrickWater resistant

The invention relates to a bonding agent capable of preventing ceramic tile hollowing or falling, and a preparation method and application thereof. The bonding agent is prepared from the following raw material ingredients in parts by weight: 80 to 100 weight parts of waterborne acrylate copolymer emulsion, 0.2 to 0.5 weight part of hydroxyethylcellulose ether, 0.5 to 1.5 weight parts of anionic surfactants, 1 to 3 weight parts of antifreezing solution, 1 to 3 weight parts of antifoaming agents, 1.5 to 2.5 weight parts of anti-foaming agents bactericide and 1 to 2 weight parts of thickening agents. The bonding agent provided by the invention has very good bonding intensity, high water resistant performance and low water absorption rate performance; shrinkage and cracking are avoided; the bonding agent can be applied to the pasting of ceramic tiles, vitrified bricks, polished tiles, glass mosaics and marble, building concrete plastering, surface repair and painting so as to prevent the hollowing and / or falling phenomenon.

Owner:吉林省沃豪斯建材科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com