Patents

Literature

53results about How to "Facilitate construction quality control" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

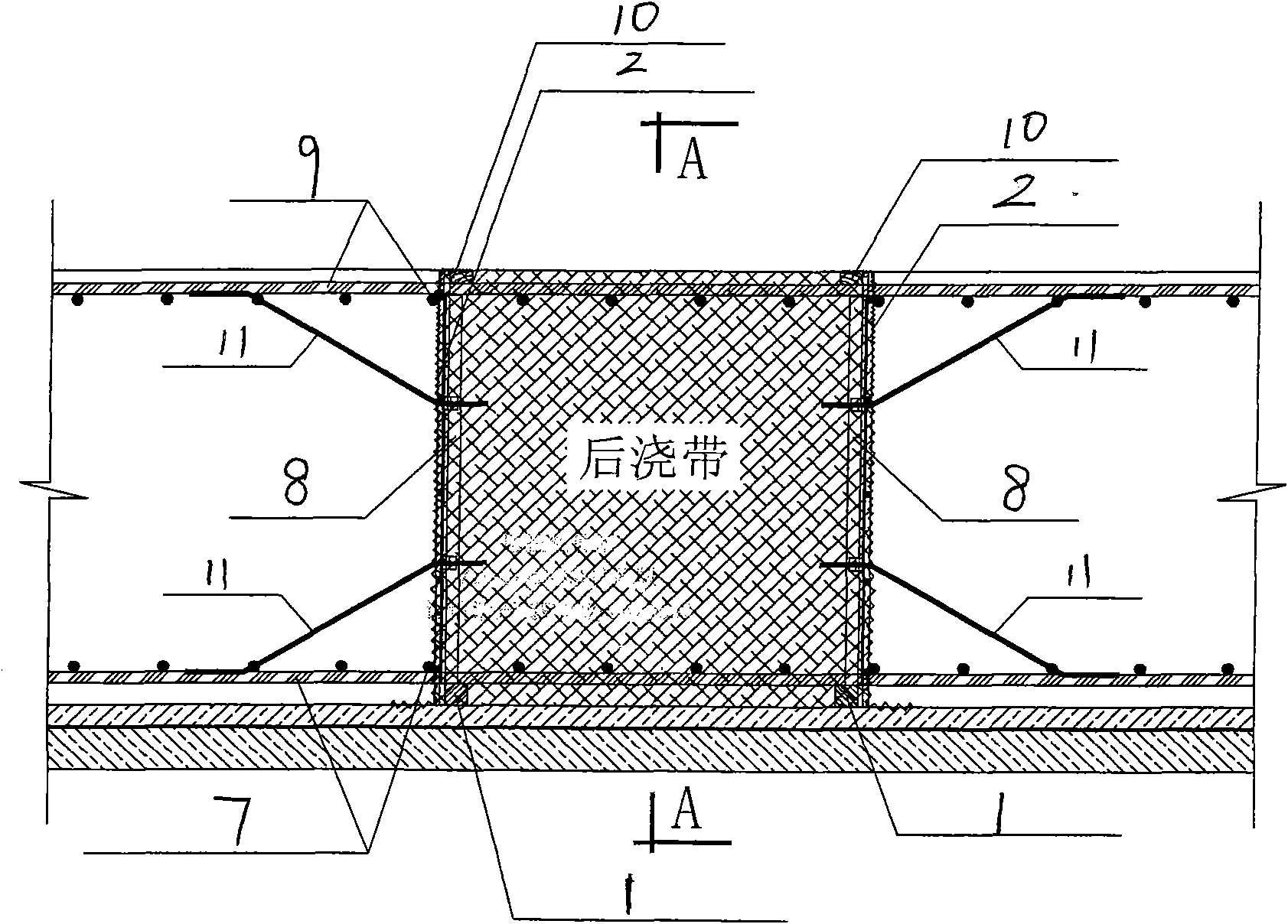

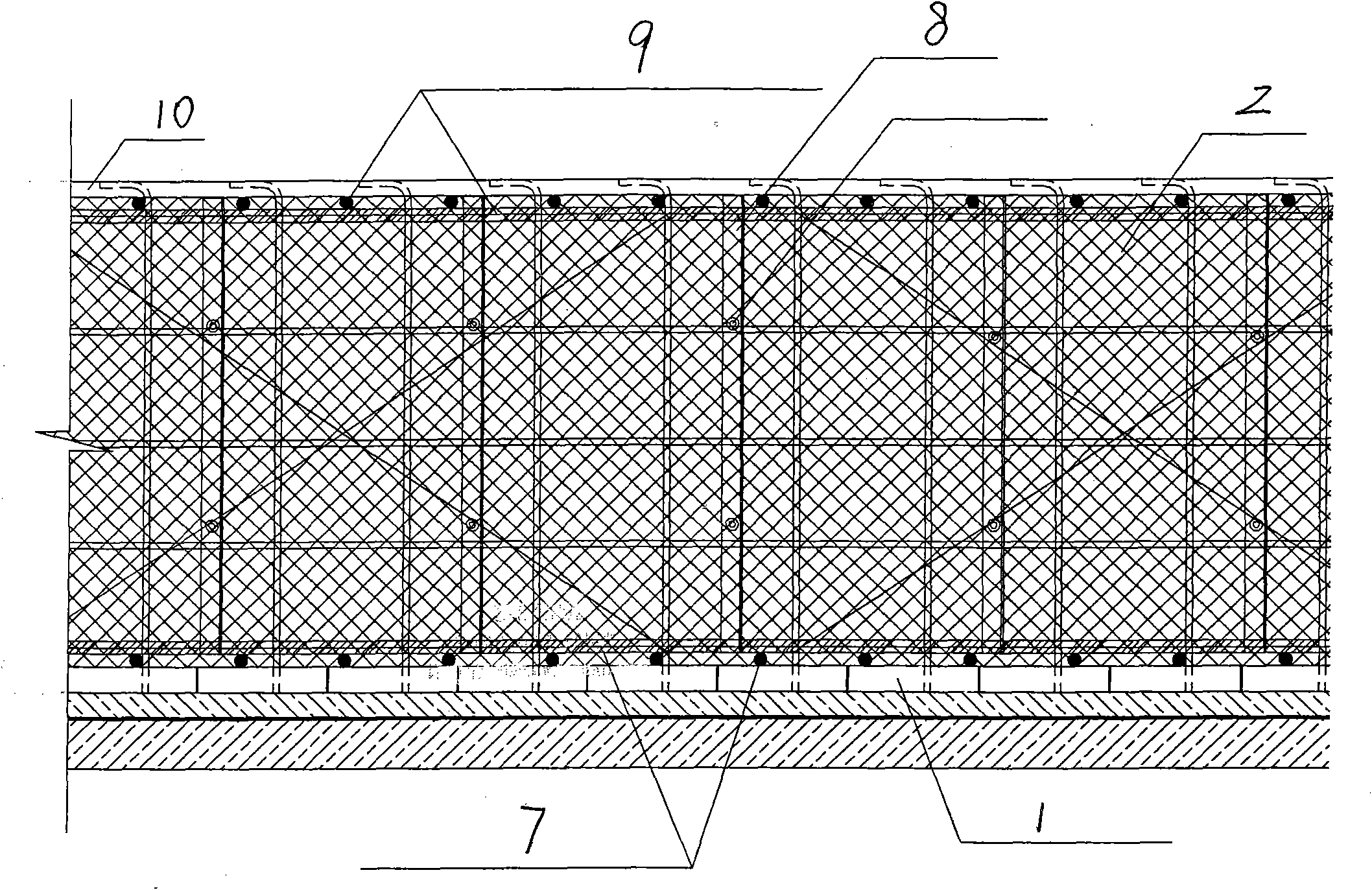

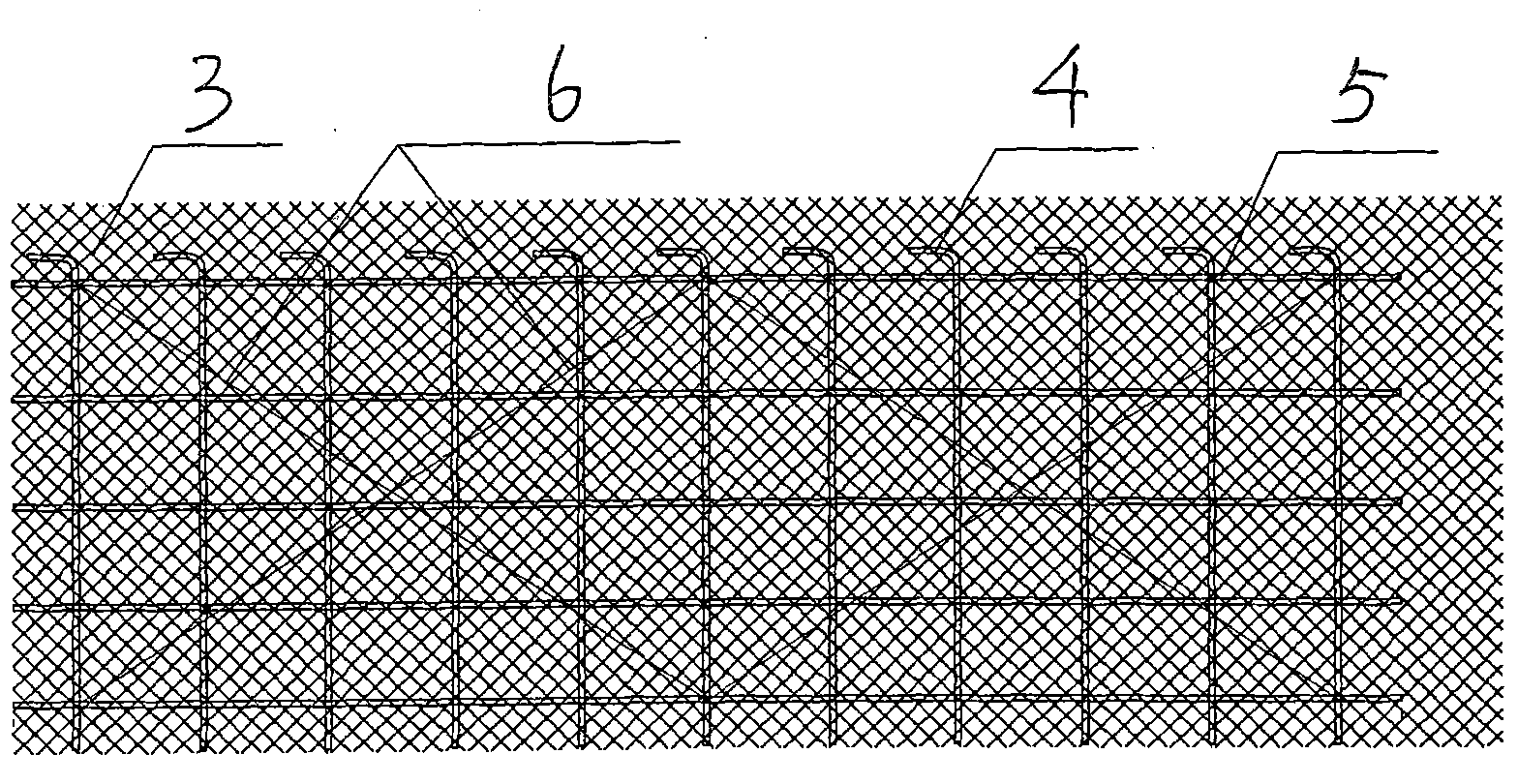

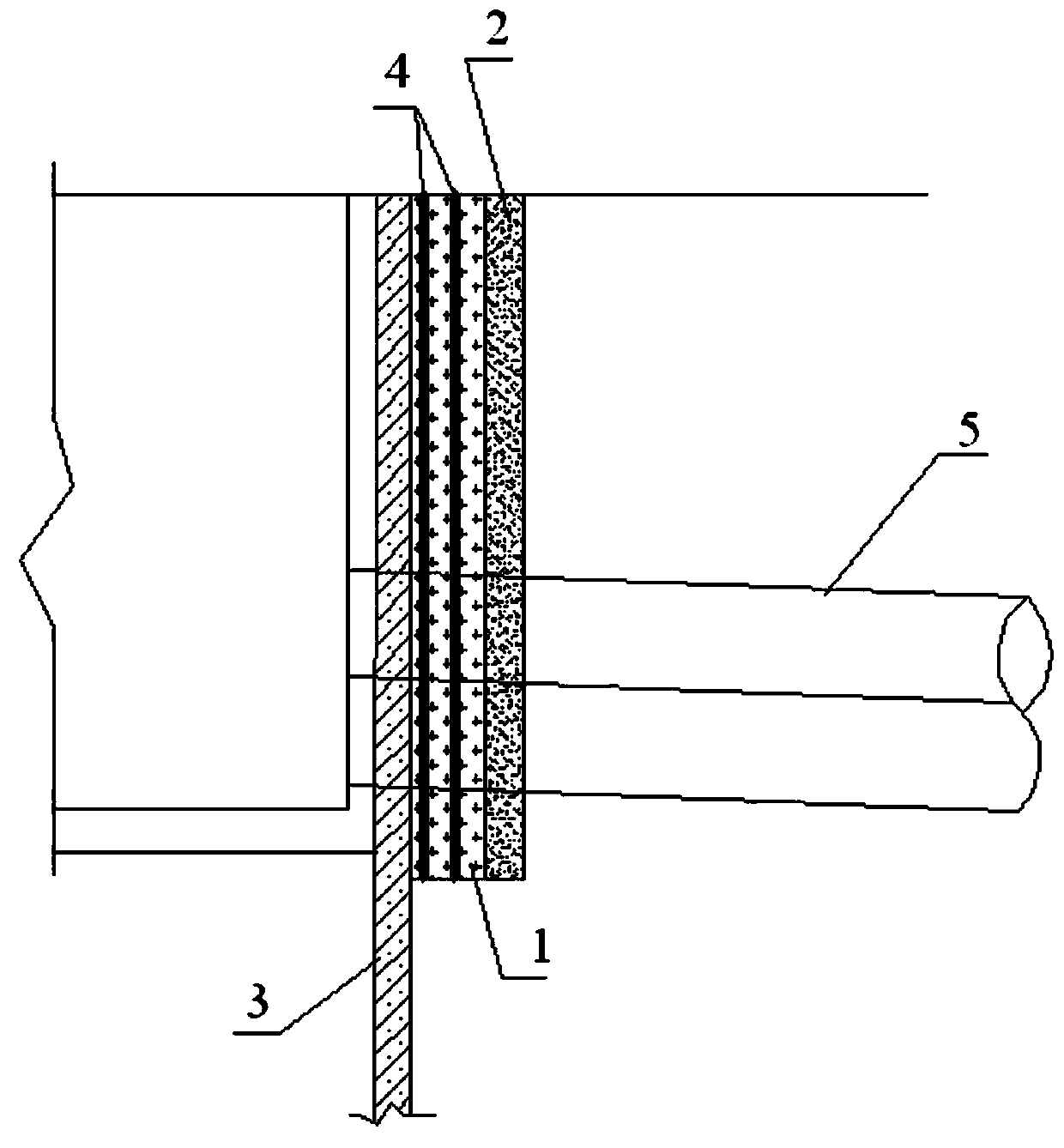

Construction method of sole plate post-poured strip form bracing system

ActiveCN101832026AGuarantee the construction qualityEasy constructionBuilding material handlingForm treatmentRebarSheet steel

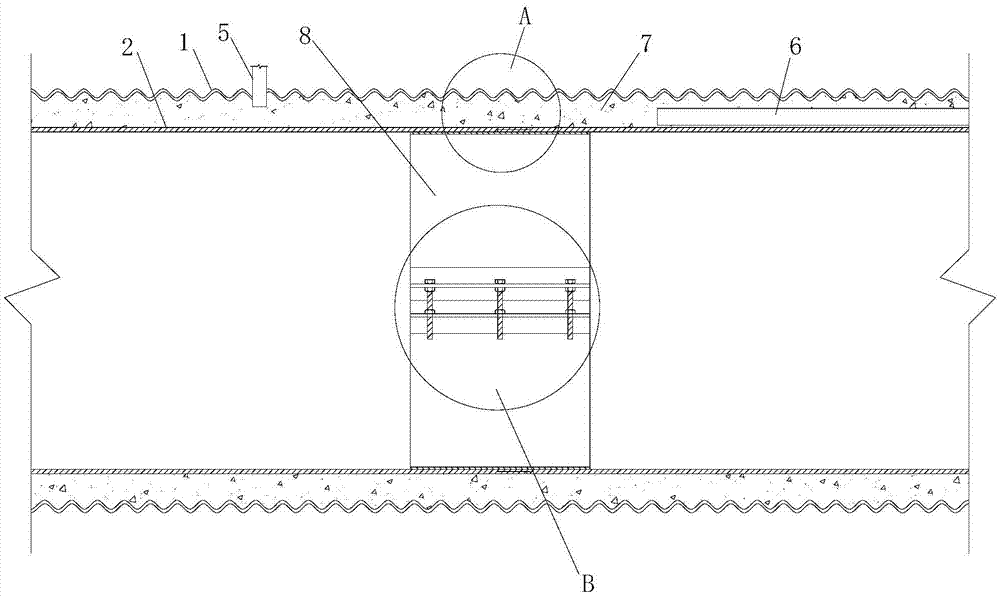

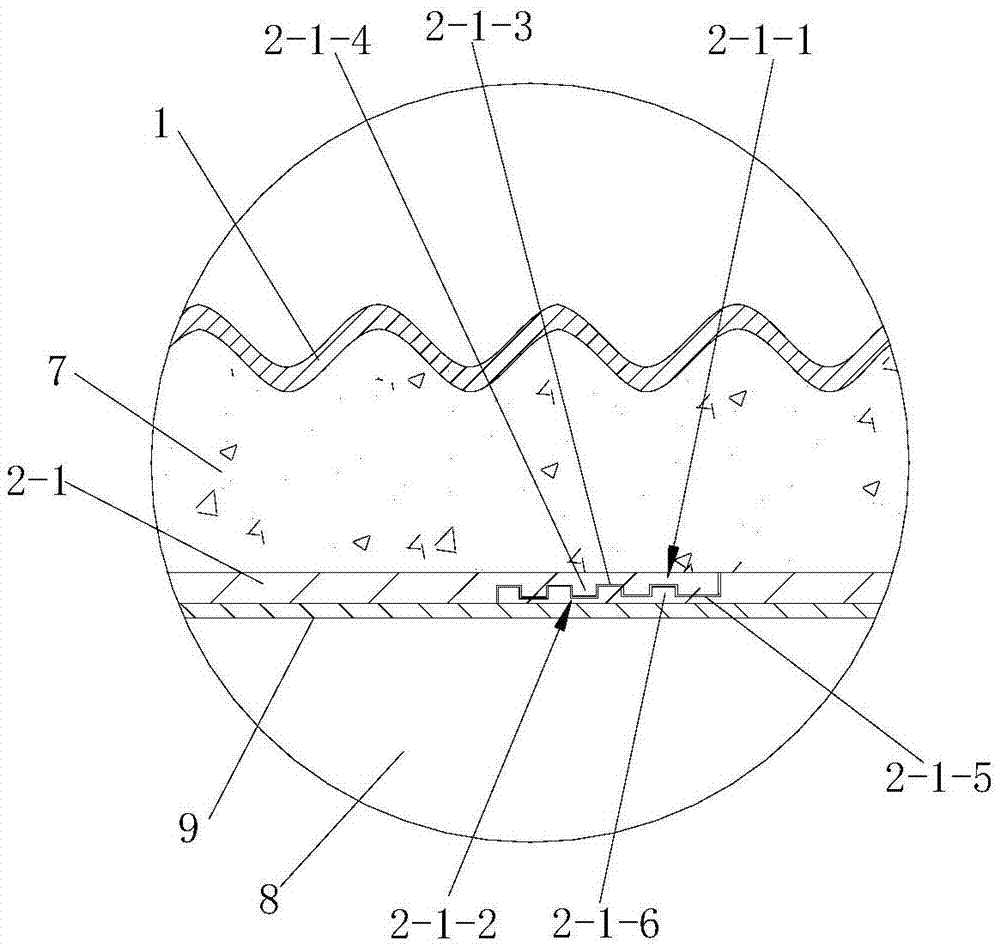

The invention discloses a sole plate post-poured strip form bracing system, applicable to sole plate post-poured strip form bracing of basement in constructional engineering. The form bracing system is mainly composed of components of a steel screen mould, a cable-stayed bolt and structural steel back plank, a precast slurry baffle concrete strick and a slurry baffle wood block. The invention utilizes a sole plate reinforcing mattress as a main bracing body, side pressure of concrete at the two sides of the post-poured strip can be effectively braced, the cavity of the formed post-poured strip is clean, tidy and clear and has no concrete pouring oozing or laitance pollution, most materials in the post-poured strip form bracing system are available and can be dismantled and recycled, and design function of post-poured strip can be effectively realized.

Owner:南通建工集团股份有限公司

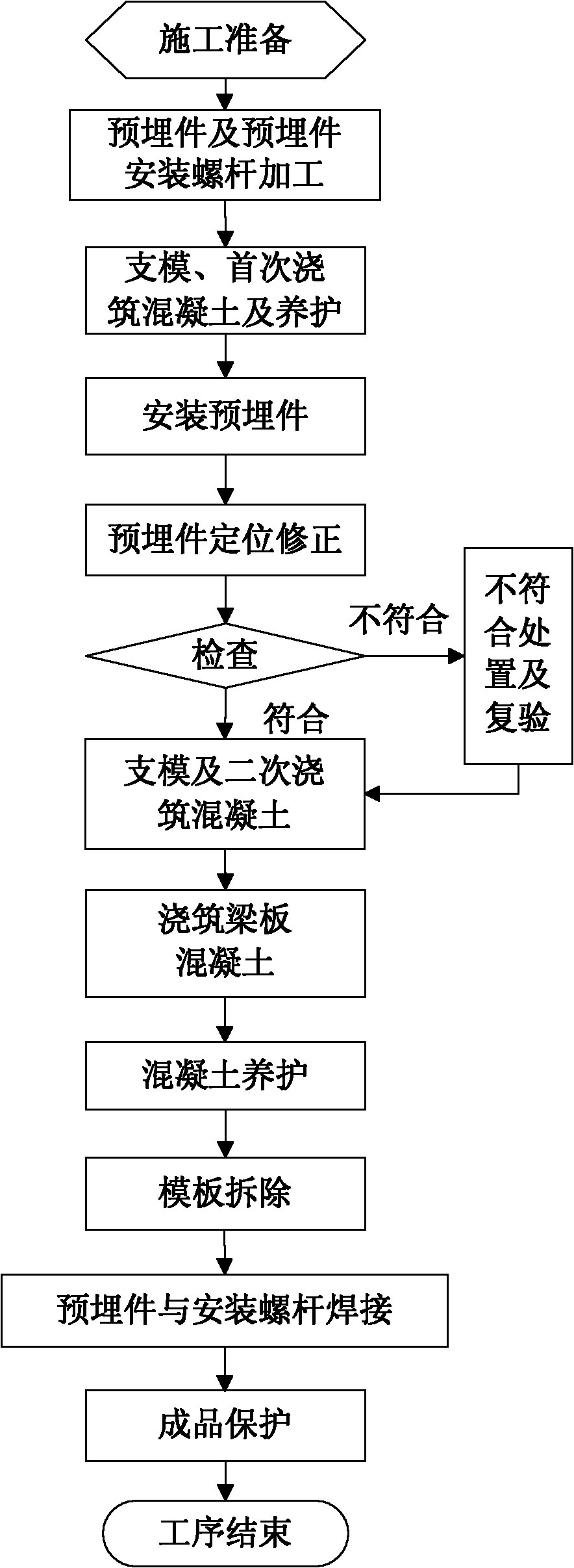

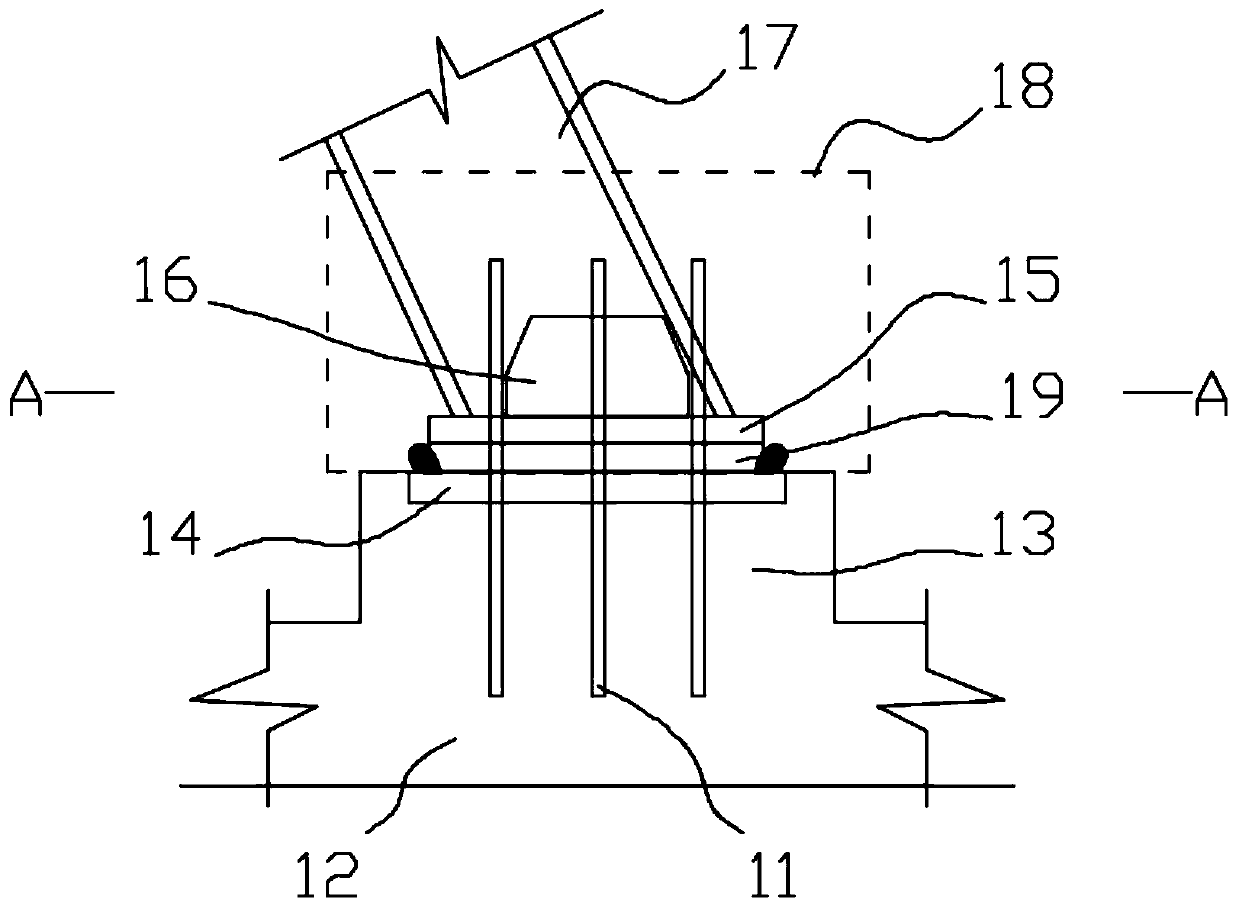

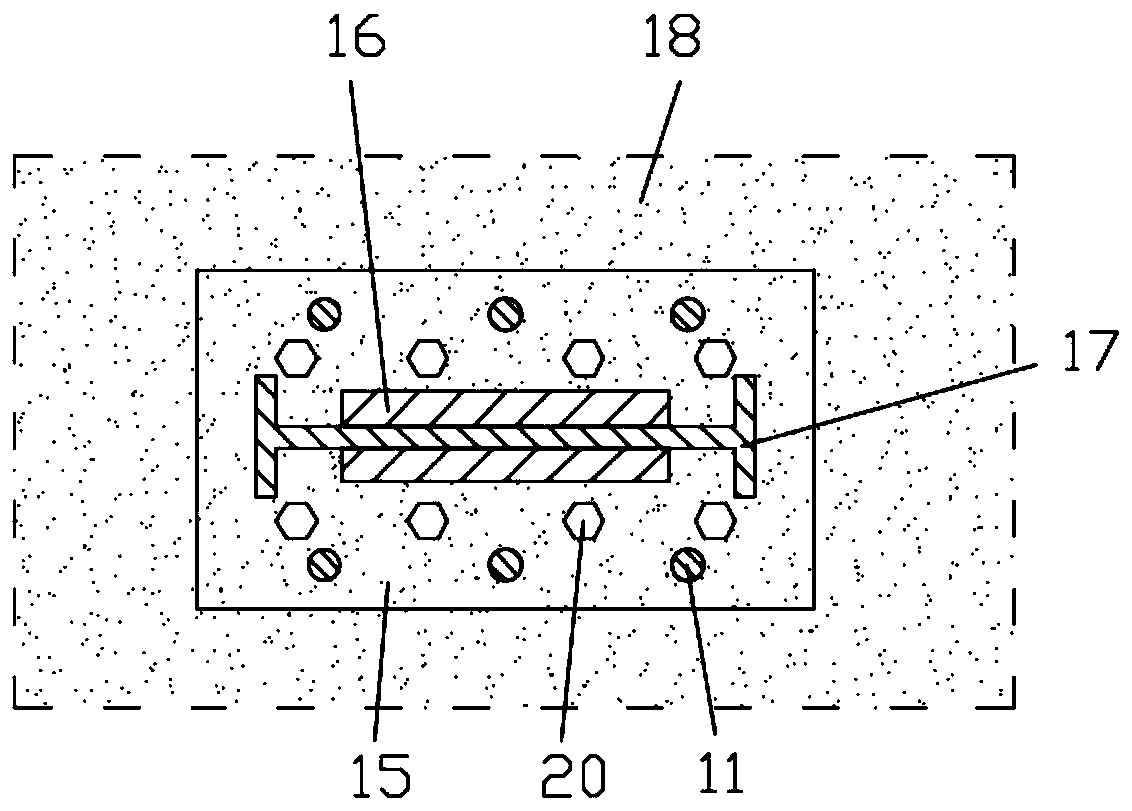

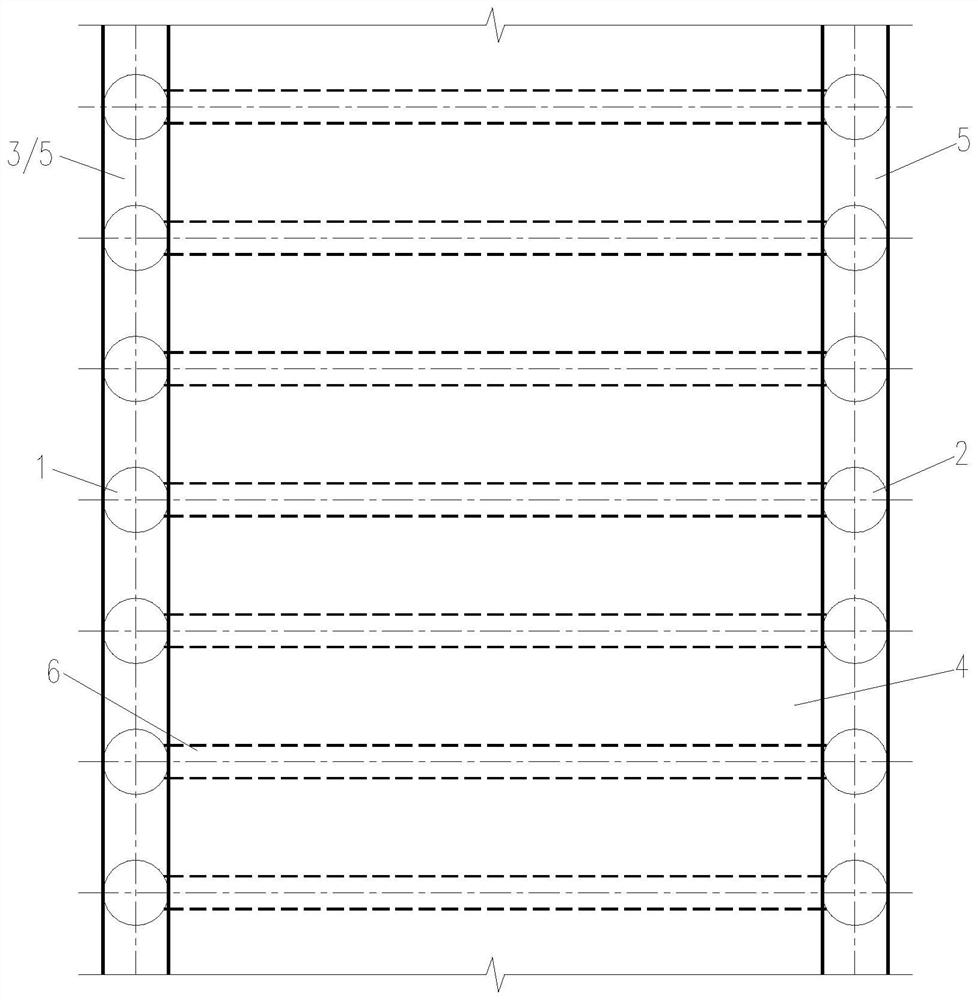

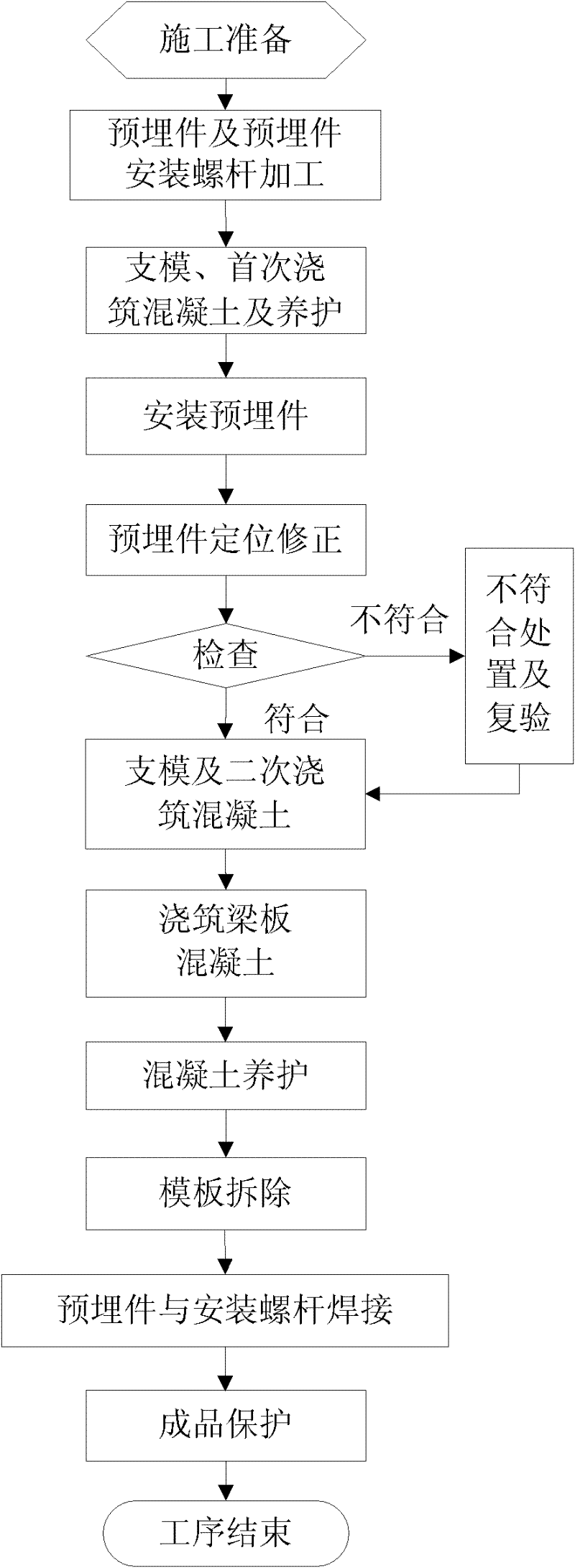

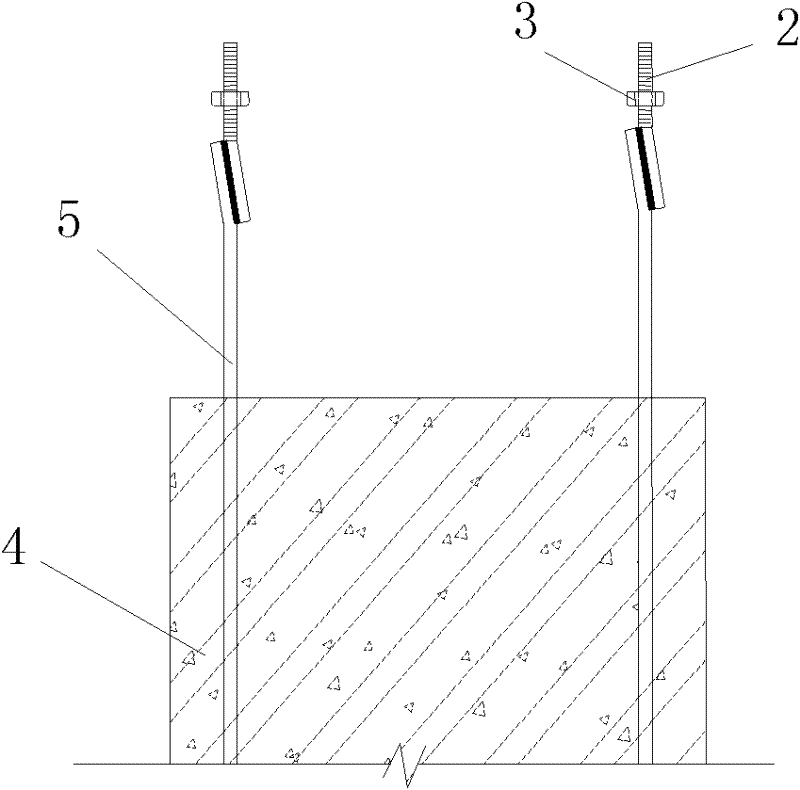

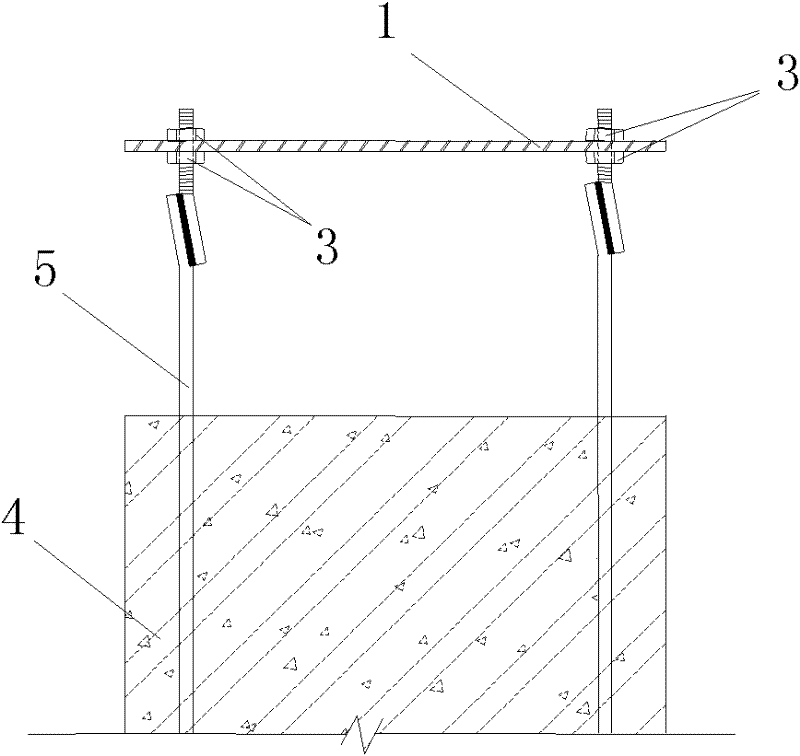

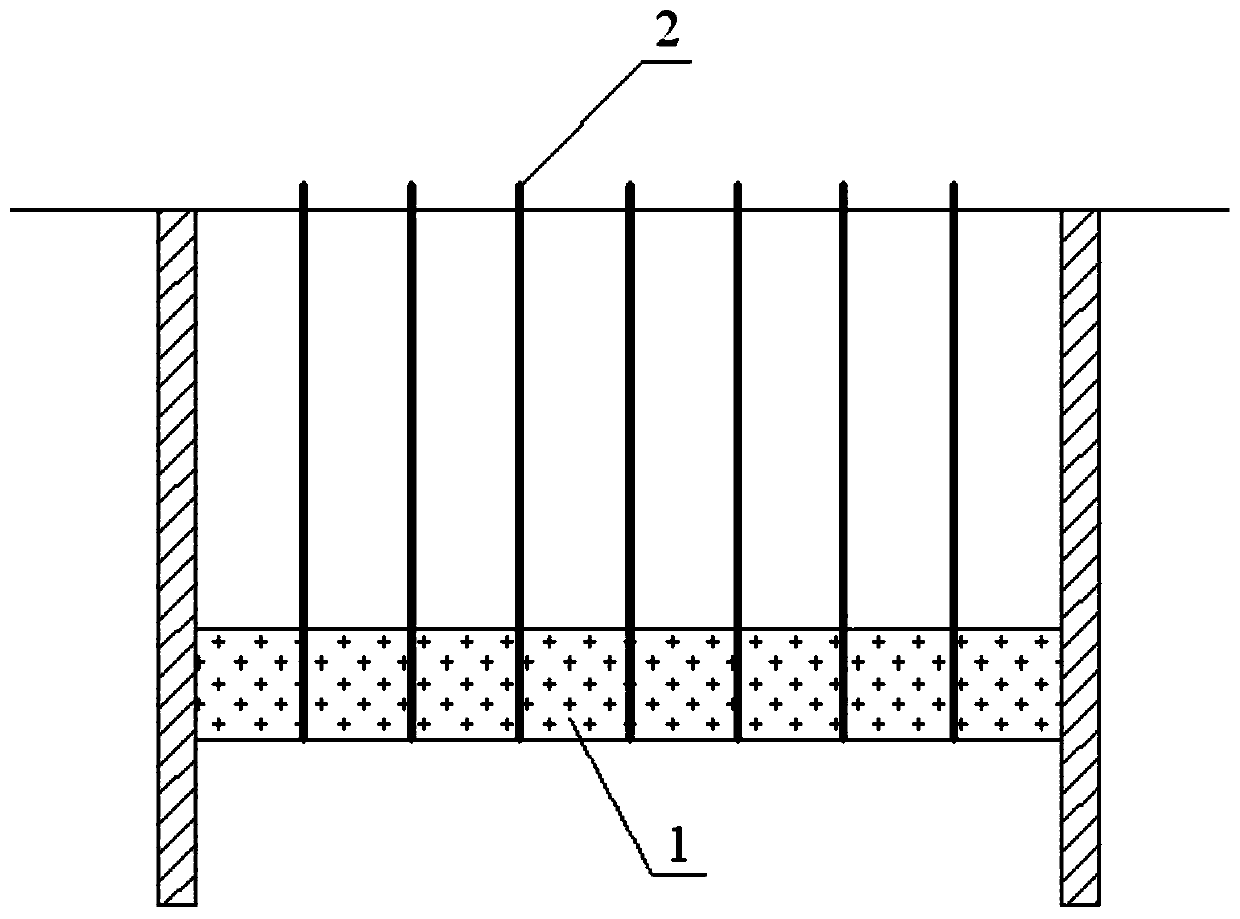

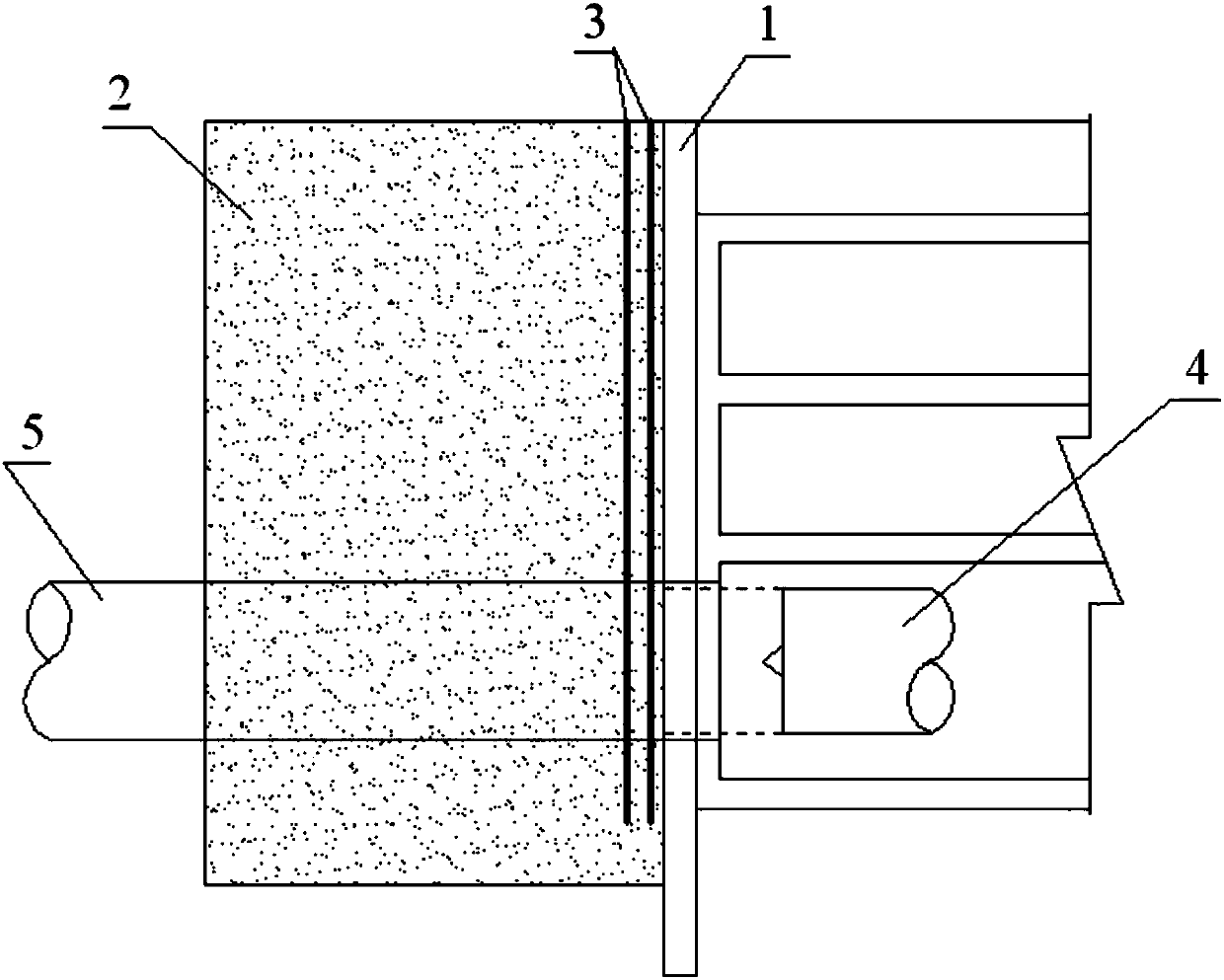

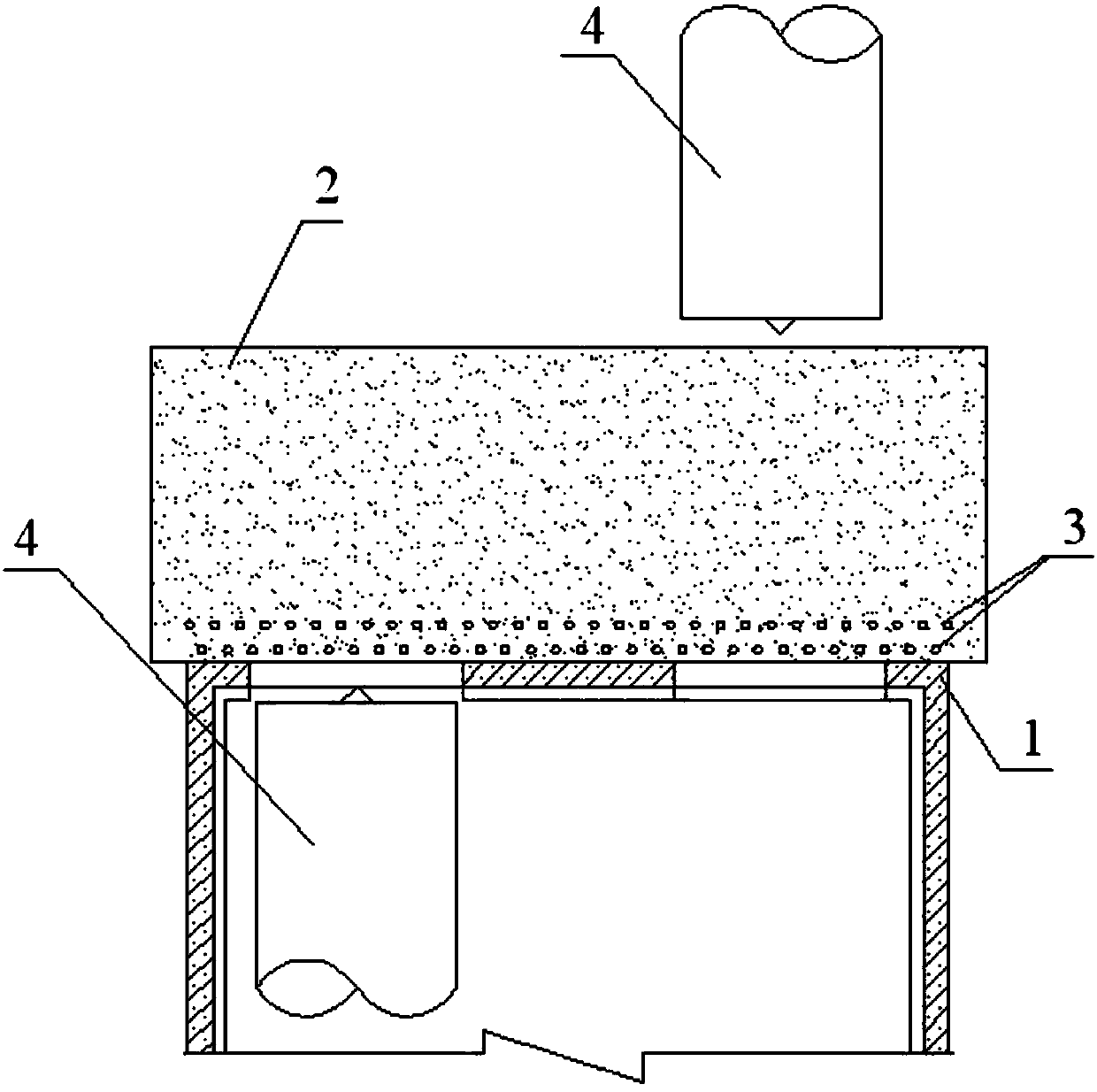

Embedding accuracy control construction method for embedded part of overlong equipment foundation platform

InactiveCN102134879AReasonable designSimple construction stepsFoundation engineeringBuilding constructionsRebarReinforced concrete

The invention discloses an embedding accuracy control construction method for an embedded part of an overlong equipment foundation platform, including the following steps: firstly, processing the embedded part and the installation screw of the embedded part; secondly, molding construction of the lower middle reinforced concrete structure of the foundation platform needing construction: a plurality of vertical reinforcing steel bars extend out from the top of the lower middle reinforced concrete structure under construction of molding and are arranged vertically; thirdly, installing the installation screw of the embedded part; fourthly, installing a nut at the bottom of the threaded section of the installation screw of the embedded part; fifthly, installing and positioning the embedded part; sixthly, installing a nut on top of the threaded section of the installation screw of the embedded par; seventhly, molding construction of the upper reinforced concrete structure of the foundation platform needing construction; and eighthly, subsequent construction treatment. The method has in design, simple construction steps, easy control of construction quality, high construction accuracy and good in use effect, and can solve the problems of the existing embedding construction method of embedding parts that the embedding accuracy is inconvenient to control, the embedding accuracy is low, the construction quality is poor, the investment cost is high, the construction period is long, and the like.

Owner:SCEGC NO 6 CONSTR ENG GRP CO LTD

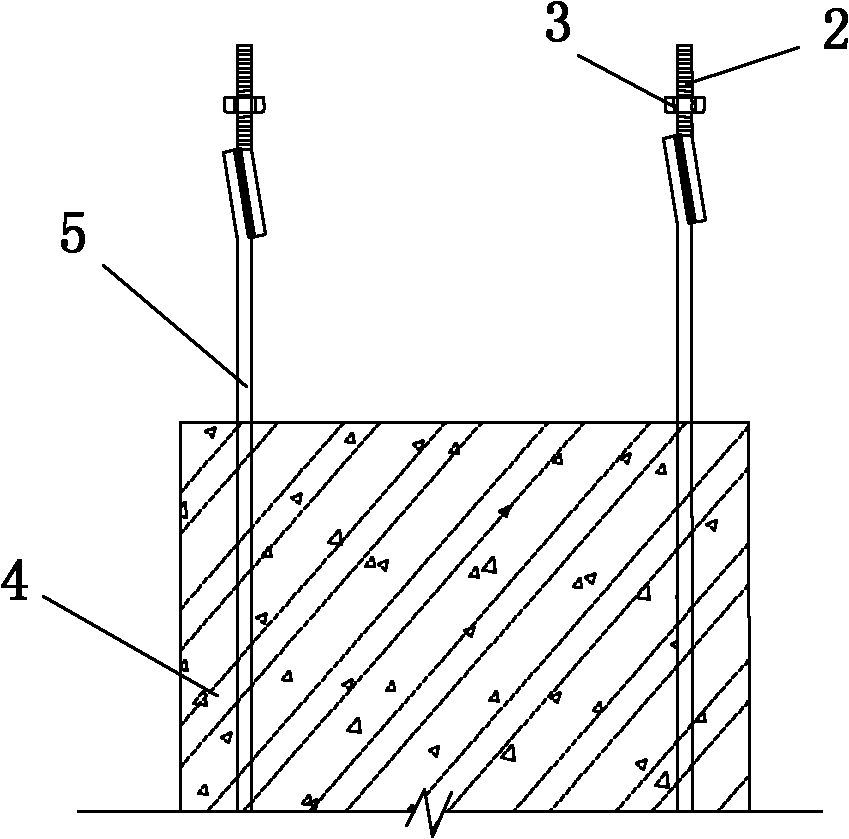

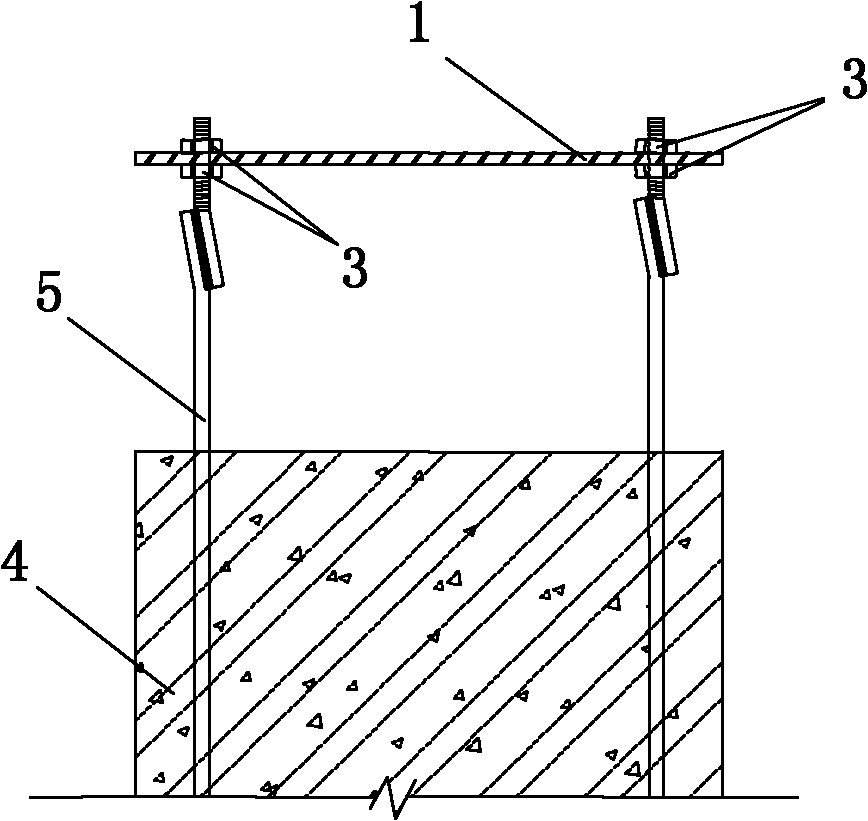

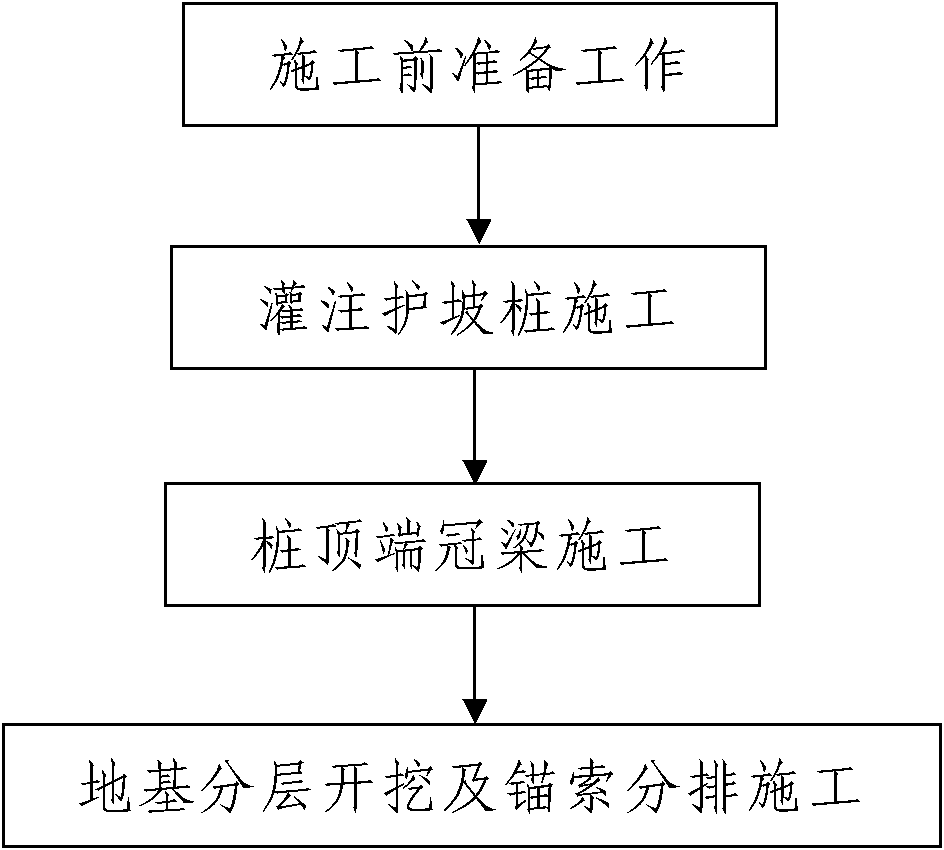

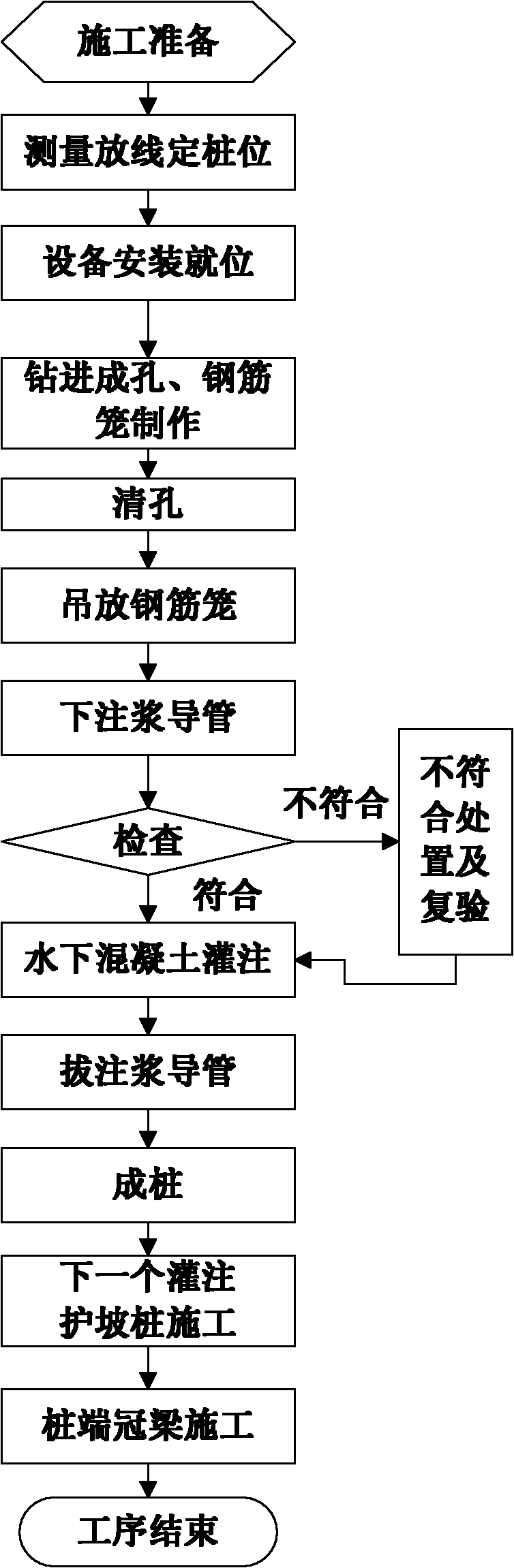

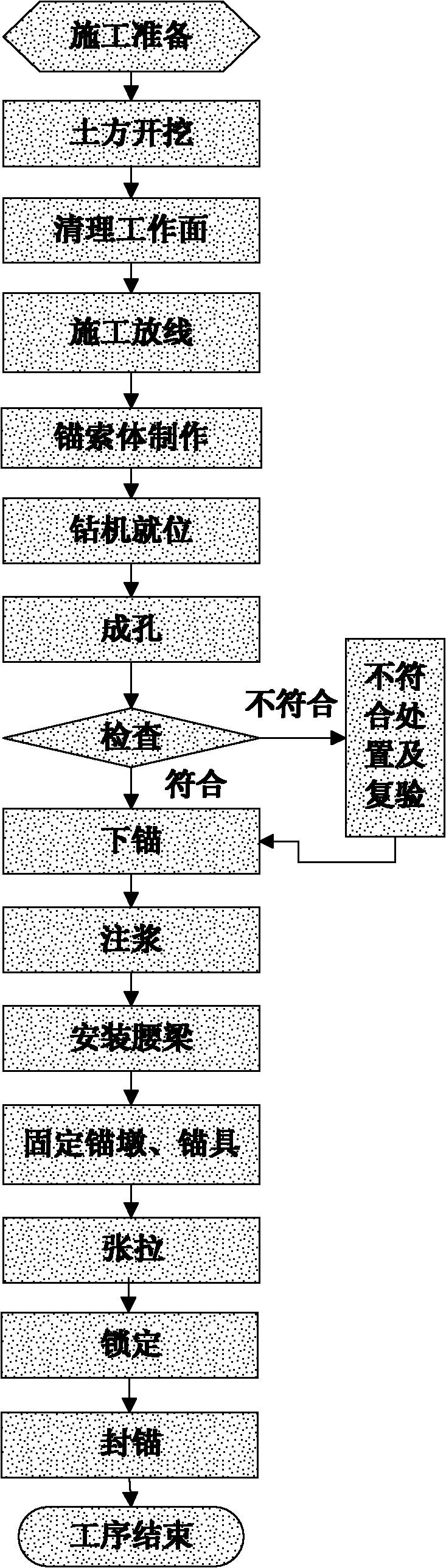

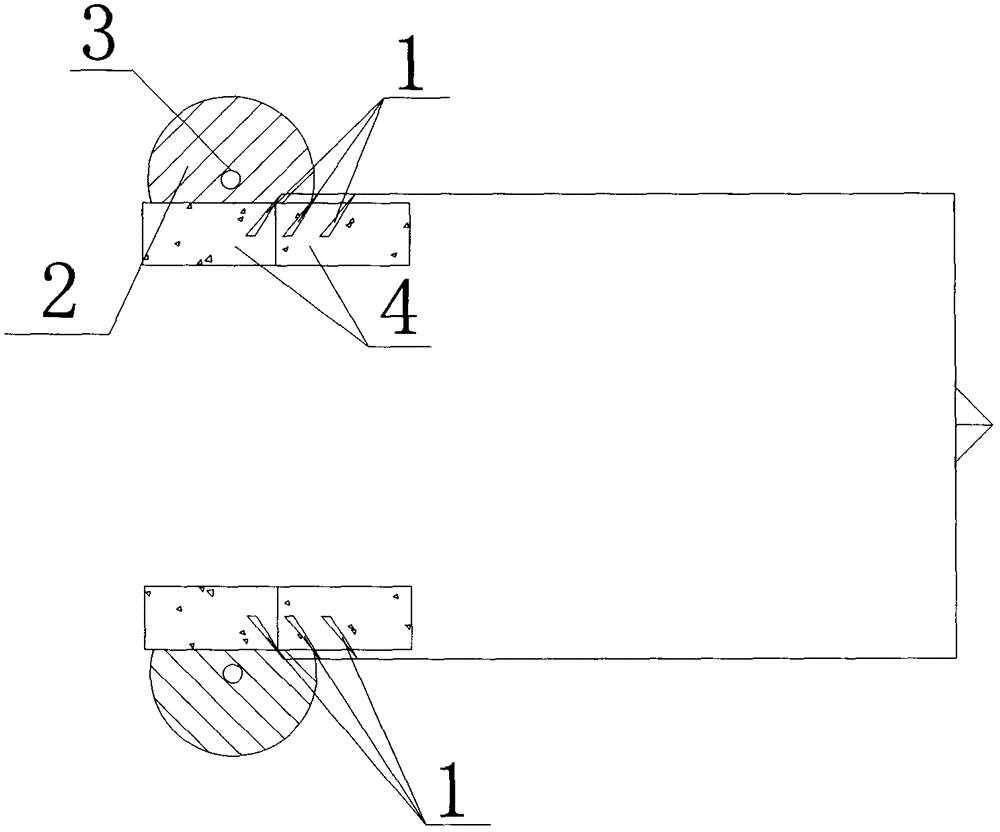

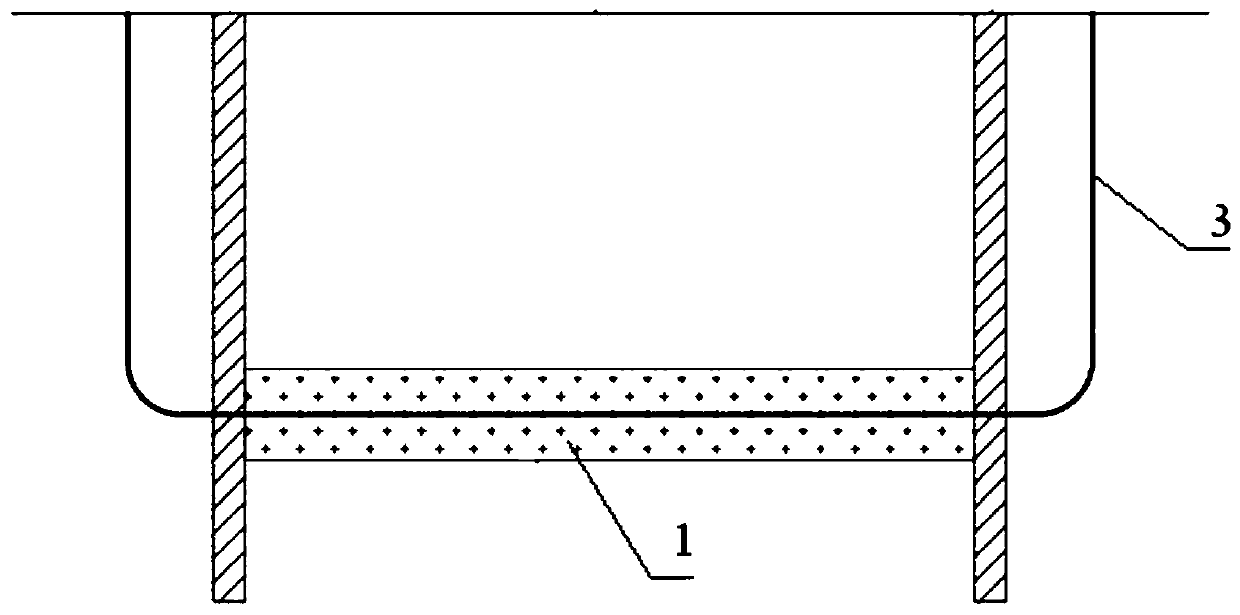

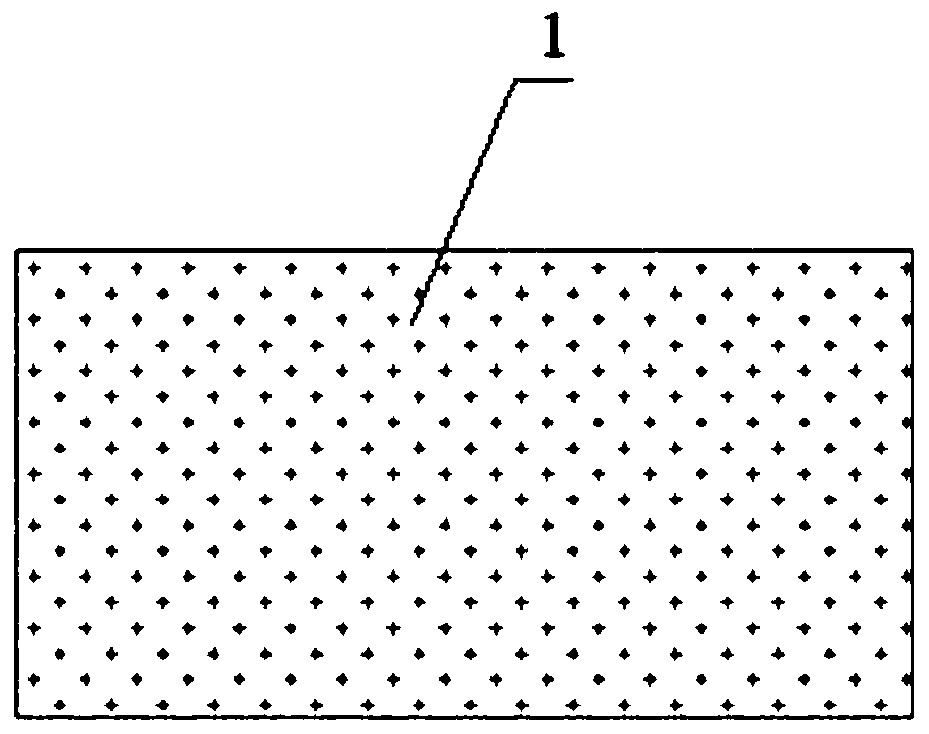

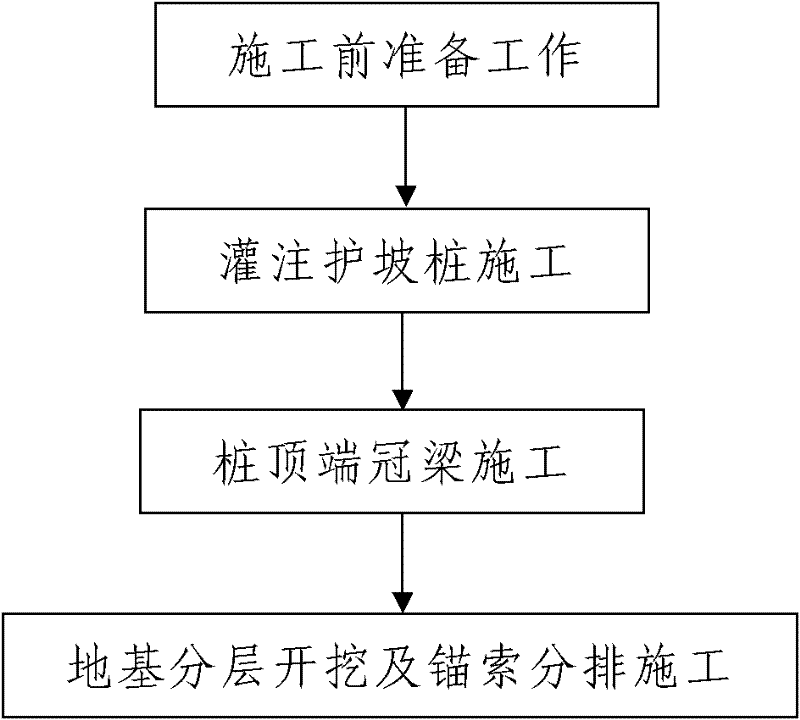

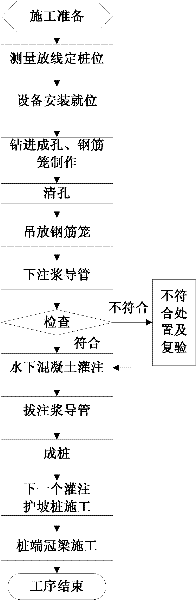

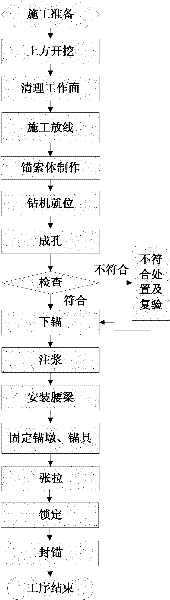

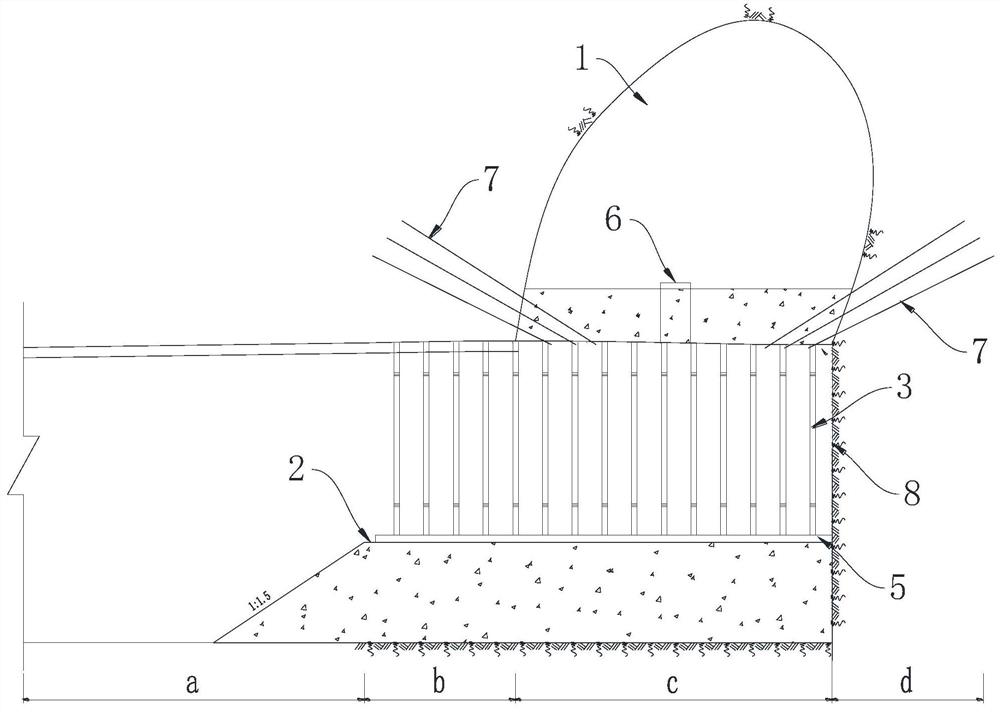

Slope protection pile pouring and cable bolting construction method for deep foundation pit

InactiveCN102031784ASimplify construction stepsFacilitate construction quality controlDrill bitsExcavationsLine tubingRebar

The invention discloses a slope protection pile pouring and cable bolting construction method for a deep foundation pit. The method comprises the following steps of: 1, making preparations before construction; 2, pouring a slope protection pile, namely measuring, paying off, molding and constructing the poured slope protection pile, punching holes on the poured slope protection pile, binding and hoisting a steel reinforcement cage for molding the slope protection pile, pouring concrete into the poured slope protection pile and constructing a crown beam at the top end of the pile; and 3, excavating a foundation in a layered form and constructing anchor ropes on different rows, namely excavating a first-layer foundation, arranging a first row of anchor ropes, arranging a steel waist rail, arranging anchor heads of the anchor ropes, tensioning the anchor ropes and finishing excavating processes of different layers of foundations and arranging different rows of anchor ropes. The method has a reasonable design, simple construction steps, low investment cost, large support depth and good using effect, and solves the problems of complicated construction steps, high construction cost, inconvenience in control, easy damage to surrounding pipelines, roads, buildings and the like, large construction space and the like existing in the conventional double-row pile supporting method can be solved.

Owner:SCEGC NO 6 CONSTR ENG GRP CO LTD

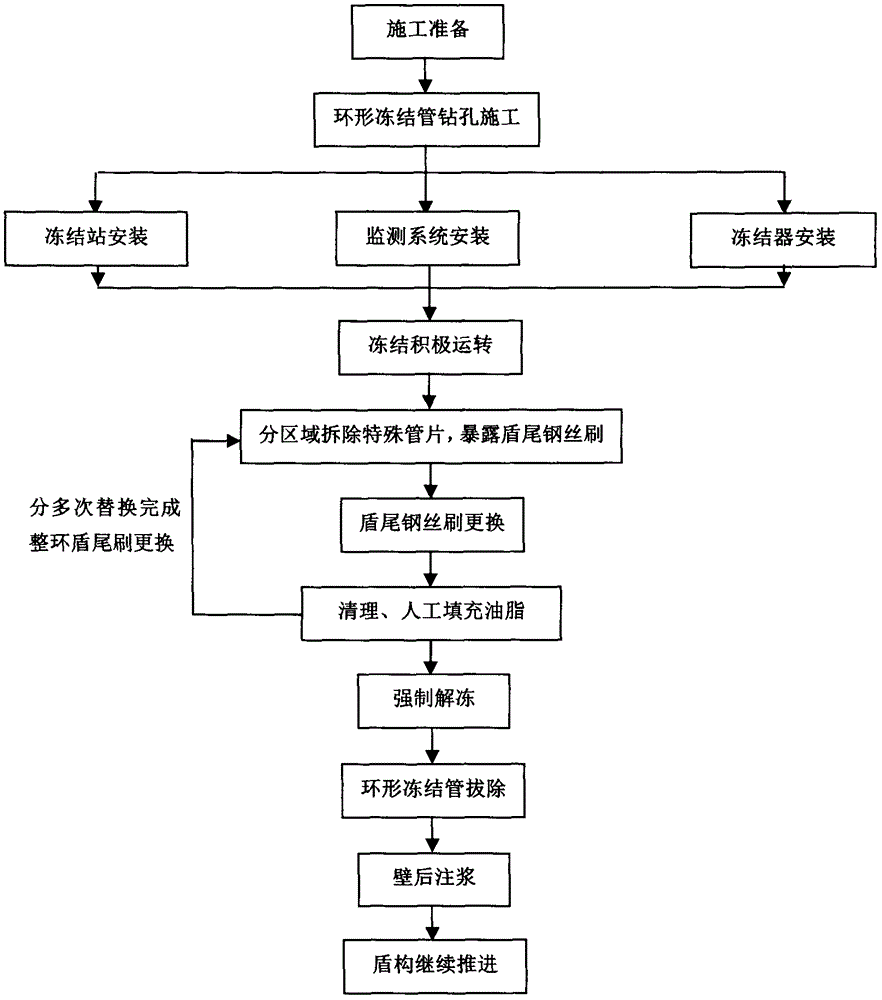

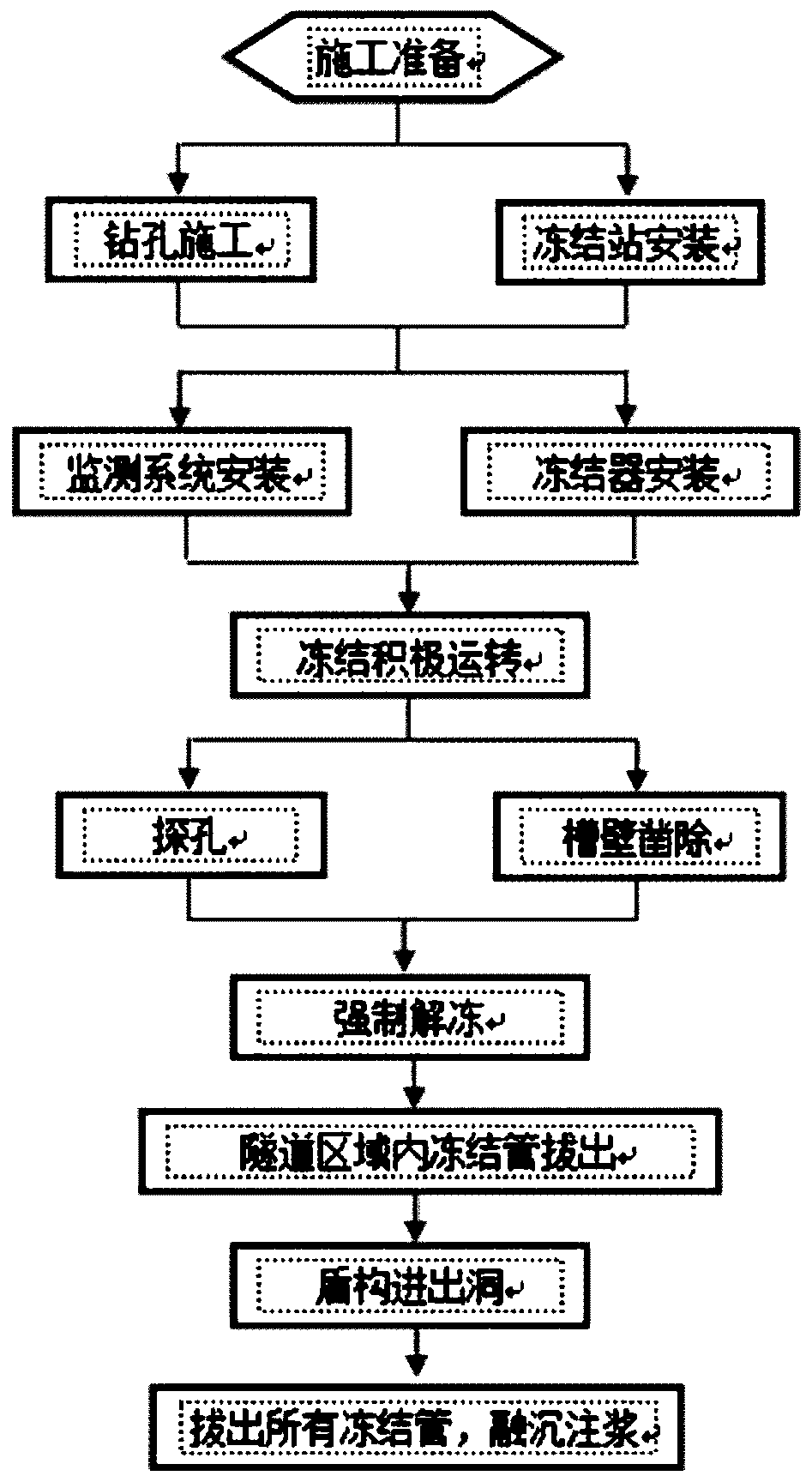

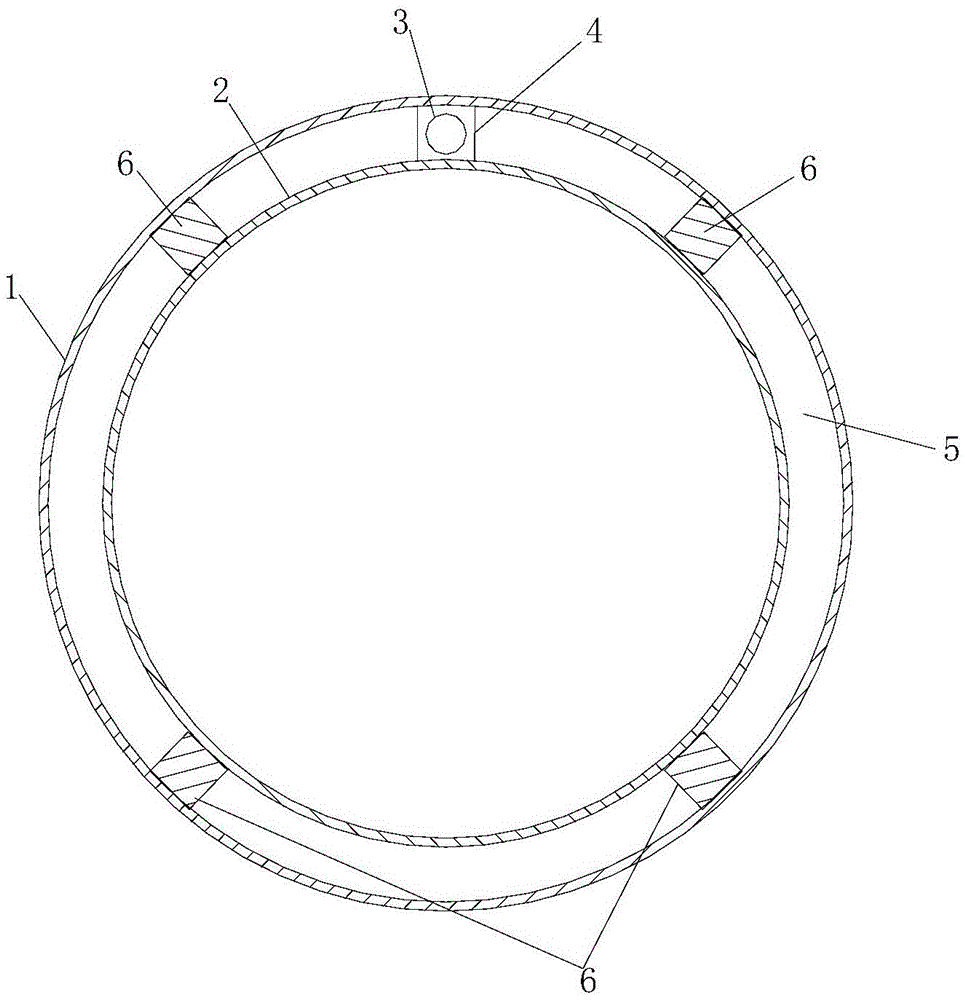

Shield tail brush replacement annular freezing reinforcing water seal structure and construction method thereof

ActiveCN105840202APerfect emergency planFlexible and diverse punching formsUnderground chambersTunnel liningTemperature measurementStructure of the Earth

The invention discloses a shield tail brush replacement annular freezing reinforcing water seal structure and a construction method thereof; the reinforcing water seal structure uses annular freezing pipe construction equipment to bury 1-2 annular freezing pipes in the soil body position needs to replace the shield tail brush, and uses an artificial freezing mode to enable the soil body around the annular freezing pipes to form a temporary annular frozen soil curtain reinforcing water seal structure; the specific technical process is listed as below: construction preparation-annular freezing pipe boring construction-freezing system and temperature measurement system installation-active freezing(temperature monitoring)-dismounting duct piece and replacing shield tail brush (freezing maintenance)-forced unfreezing-annular freezing pipe extraction (sealing hole)-back filled grouting-shield continue propulsion. The construction method is simple, easy to operate and realize, strong in construction practicality, convenient in construction quality control, good in reinforcing effect and water seal effect, outstanding in safety and reliability, and has very big application values.

Owner:CHINA RAILWAY TIMES BUILDING DESIGIN INST CO LTD

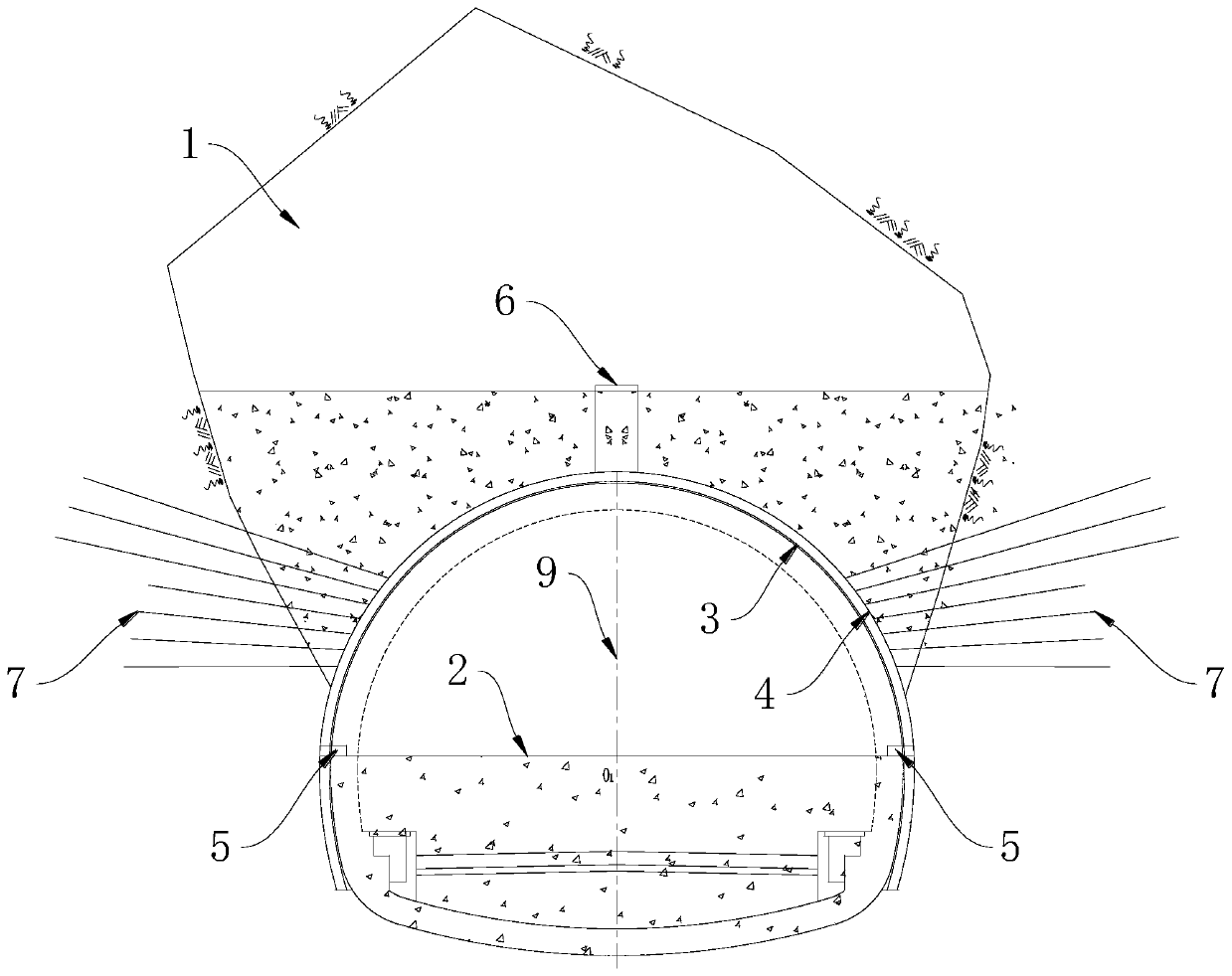

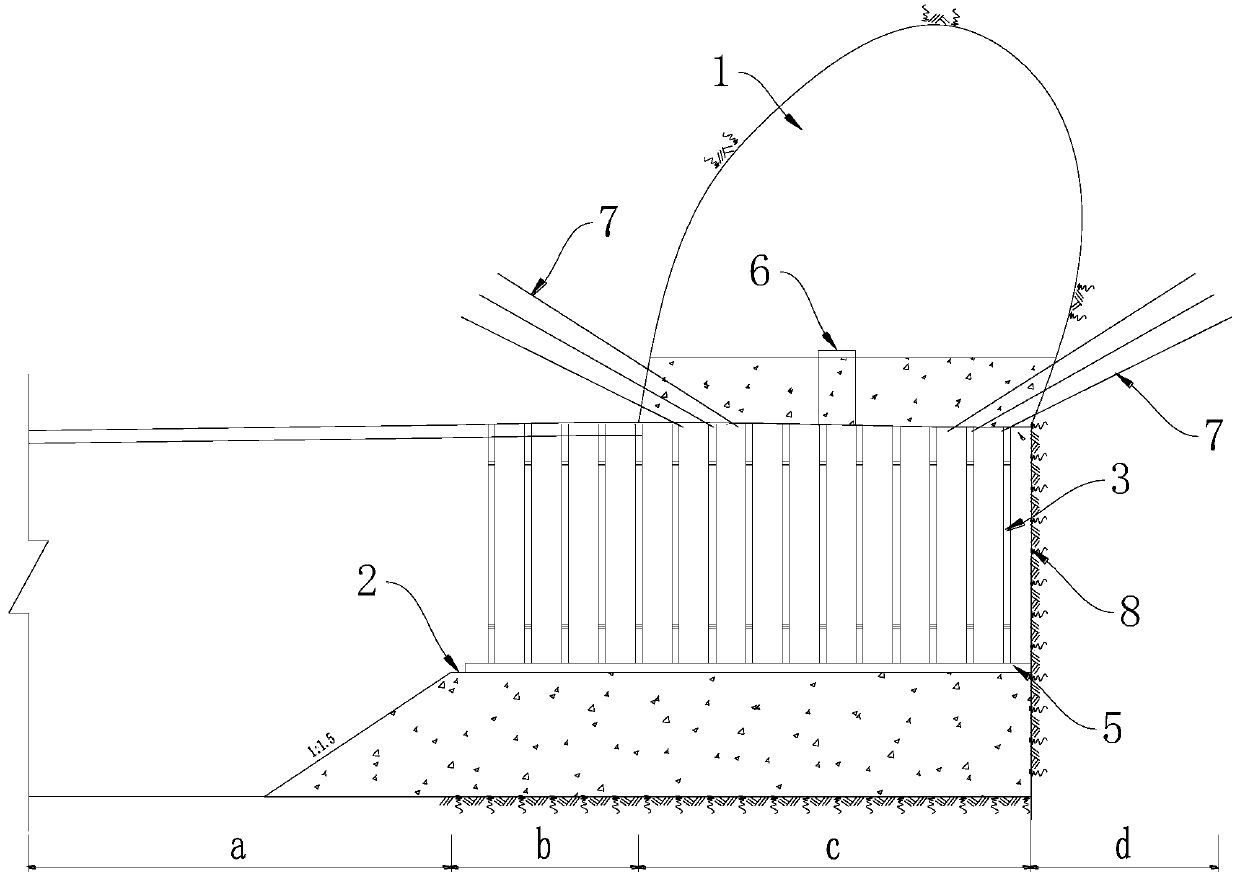

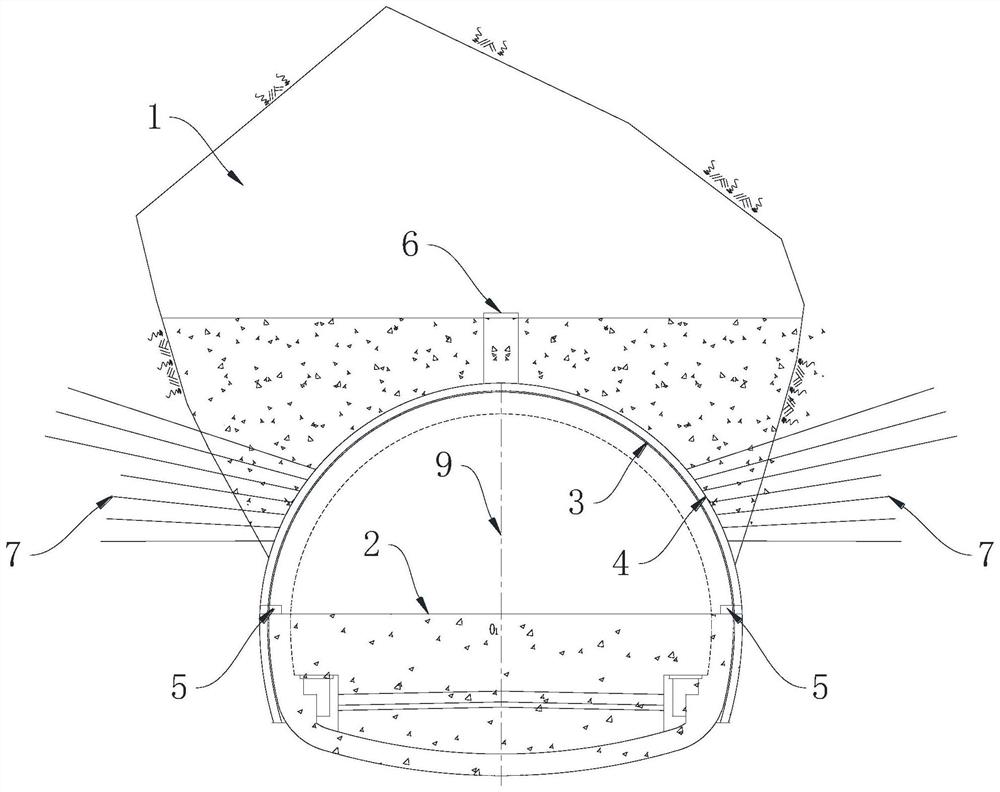

Tunnel collapse handling method for convergent collapse cavity

ActiveCN110656954AEasy to operateImprove project qualityUnderground chambersTunnel/mines ventillationCollapsed cavityLandslide

The invention discloses a tunnel collapse handling method for a convergent collapse cavity, and relates to the field of tunnel engineering. By the adoption of the tunnel collapse handling method for the convergent collapse cavity, the problem that an existing handling method lacks operability, can cause potential safety hazards, and is not economical is solved. According to the technical scheme, the tunnel collapse handling method for the convergent collapse cavity comprises the steps that first, after the tunnel collapse cavity is stabilized, a construction platform is formed by means of collapse residues; second, a landslide-affected section is divided into an excavated landslide-affected section and a non-excavated landslide-affected section which are separately reinforced; third, concrete is sprayed to support the collapse cavity; fourth, a temporary support and a formwork are constructed on a landslide section, a manhole is formed in the portion, in the middle of the landslide section, of a tunnel vault, the collapse cavity is backfilled with concrete, landslide anchoring rods are constructed, reinforcement of the temporary support and the landslide-affected section is removed, and the construction platform is removed through excavation; and finally, a tunnel drain pipe and a waterproof plate are constructed according to original design, and secondary lining concrete is constructed. The tunnel collapse handling method has high practical value in handling convergent tunnel collapse cavities.

Owner:POWERCHINA CHENGDU ENG

Dedicated gypsum based self-leveling mortar for floor heating backfill

InactiveCN109516755AReduce sensitivityFacilitate construction quality controlAluminum silicateMetakaolin

The invention belongs to the technical field of building materials and specifically discloses dedicated gypsum based self-leveling mortar for floor heating backfill. The dedicated gypsum based self-leveling mortar is prepared from water and powder, wherein the powder is prepared from the following ingredients in mass fraction: 5 to 30% of anhydrous fluorine gypsum, 5 to 30% of phosphorus buildinggypsum, 0.5 to 10% of alpha-high strength gypsum, 20 to 50% of fine sand, 5 to 20% of light calcium carbonate, 1 to 8% of cement, 0.01 to 1% of active roasted metakaolin, 0.1 to 2% of lime, 0.1 to 2%of lithium based bentonite, 0.1 to 1% of nano calcium sulfate whisker, 0.1 to 0.5% of magnesium aluminum silicate, 0.1 to 1% of sodium sulfate, 0.01 to 0.05% of hydroxypropyl starch ether, 0.1 to 0.5%of modified amino acid gypsum retarder and the like; the mass ratio of the water to the powder is (0.28 to 0.35) to 1. When the self-leveling mortar is prepared, a lot of solid waste can be consumed;furthermore, the ground construction efficiency and the ground flatness of buildings are improved.

Owner:HENAN QIANGNAI NEW MATERIALS CO LTD

Method of replacing shield tail brush of shield tunneling machine

InactiveCN107387101AImprove continuityImprove uniformityUnderground chambersTunnel liningEngineeringShield tunneling

The invention discloses a method of replacing a shield tail brush of a shield tunneling machine; the method comprises the steps of I, setting circular bamboo reinforcement grouting holes, and performing grouting construction; II, replacing the shield tail brush; III, mounting a segment; IV, taking protective measures after the replacement of the shield tail brush. The method of the invention has the advantages that directional localized grouting can be performed according to field actual conditions; the method has low manufacture cost, high construction practicability, zero tunnel space taken by reinforcing equipment, short construction period and the like; little influence is caused to structural durability of the segment, and no adverse influence is caused to the structural stability of a shield tunnel; the method is highly worthy of popularization and application.

Owner:WUYI UNIV

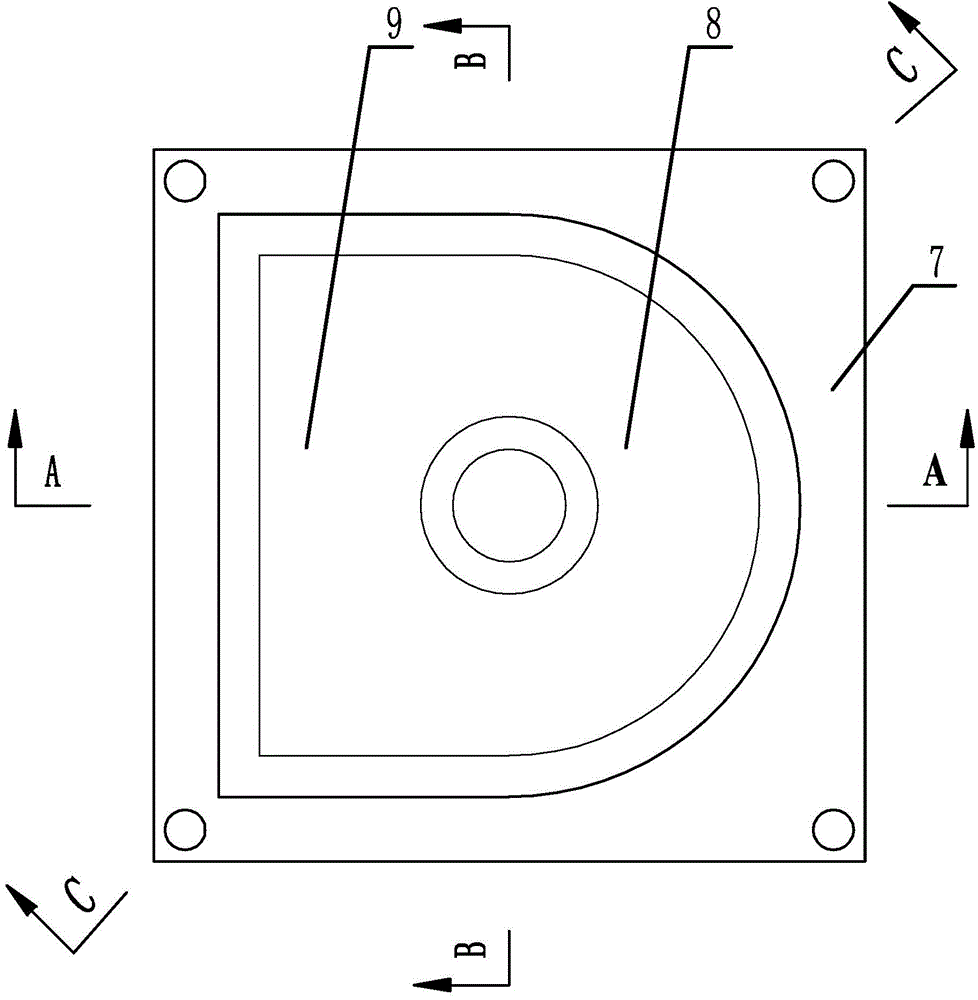

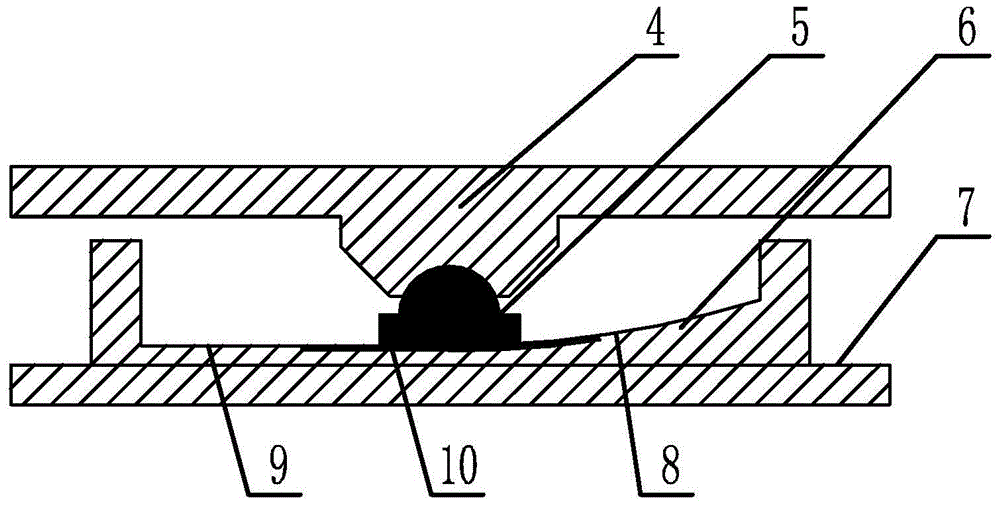

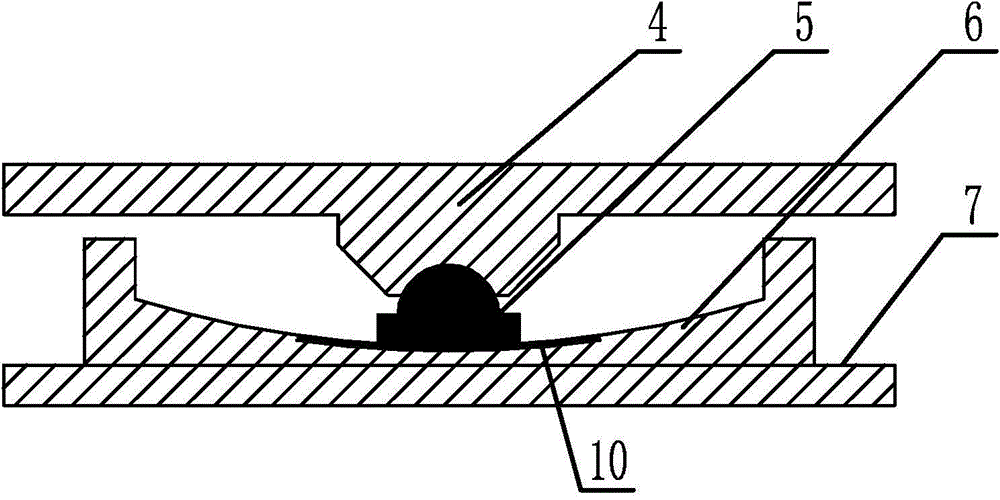

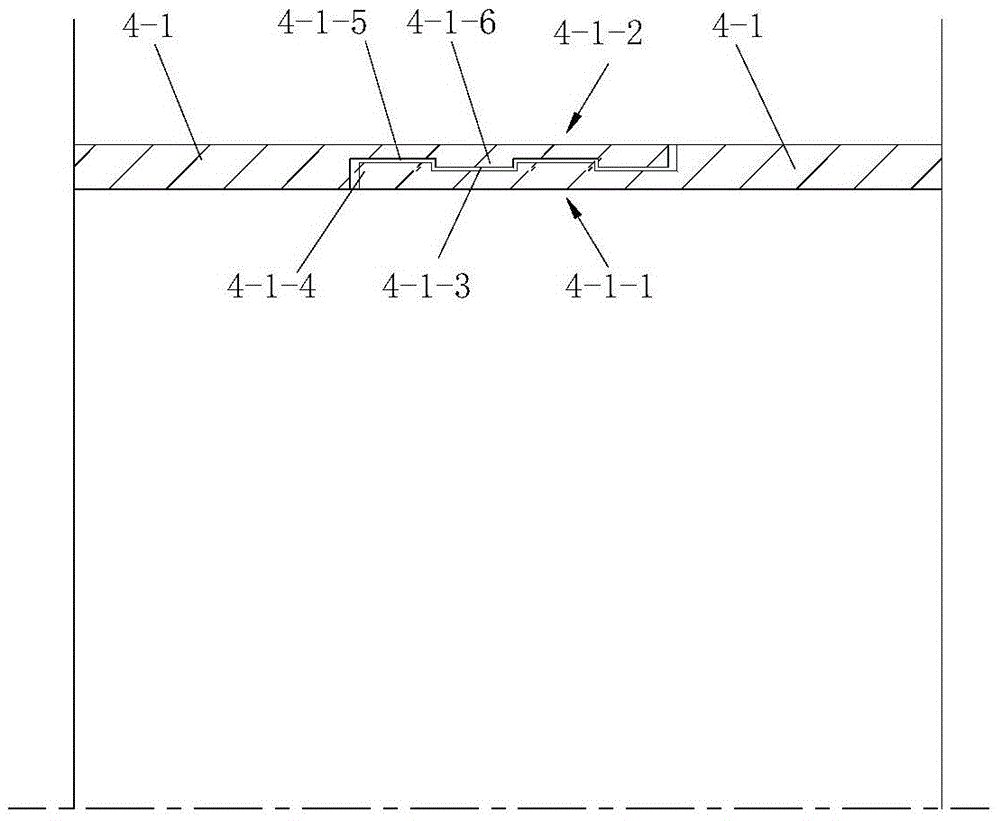

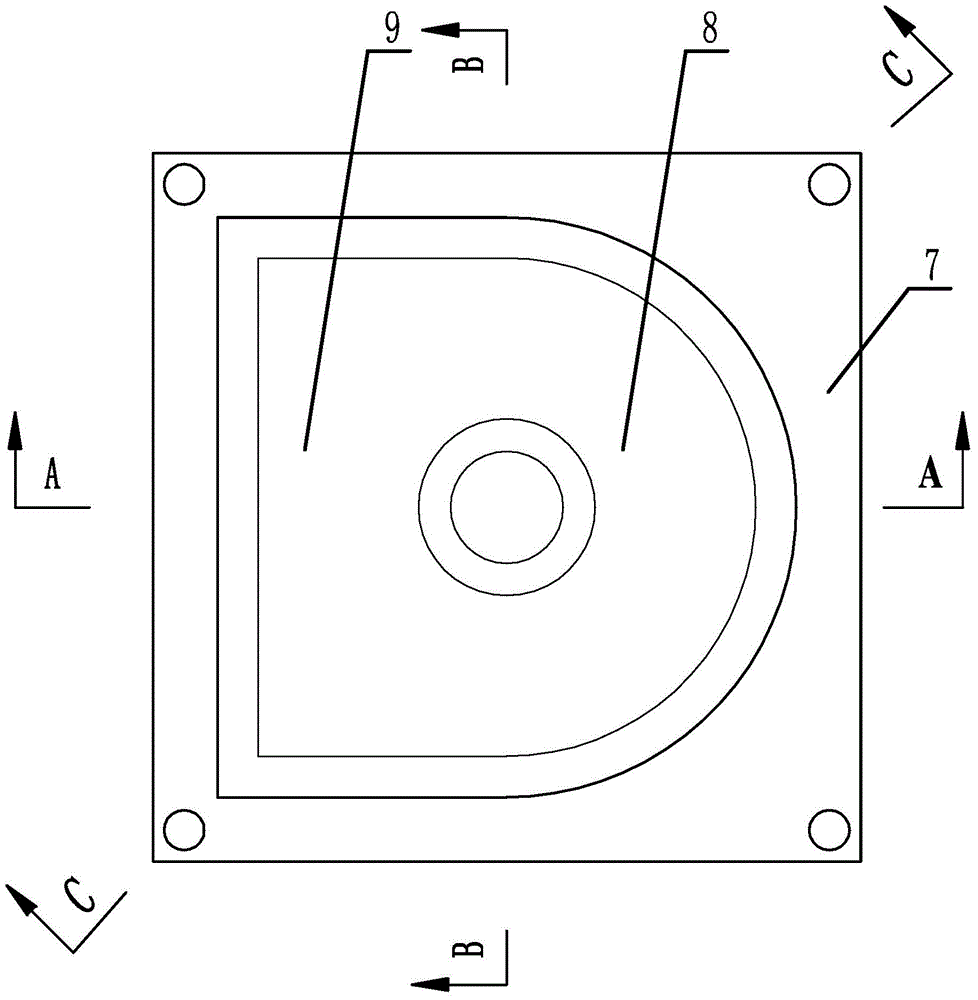

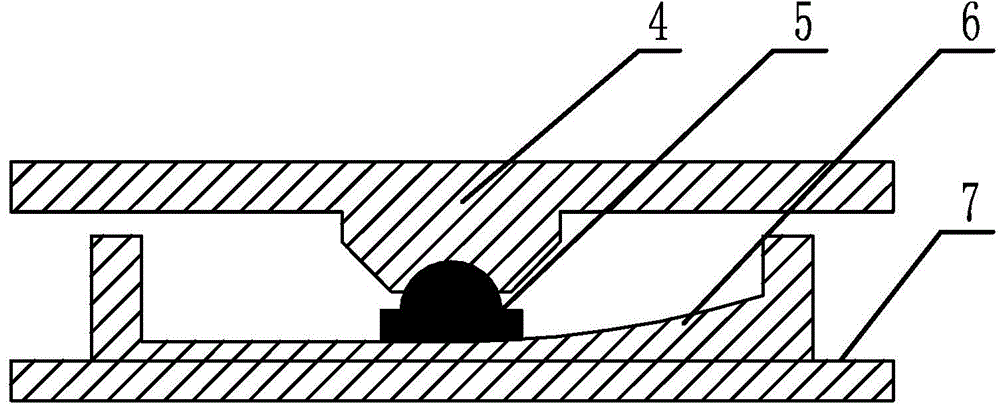

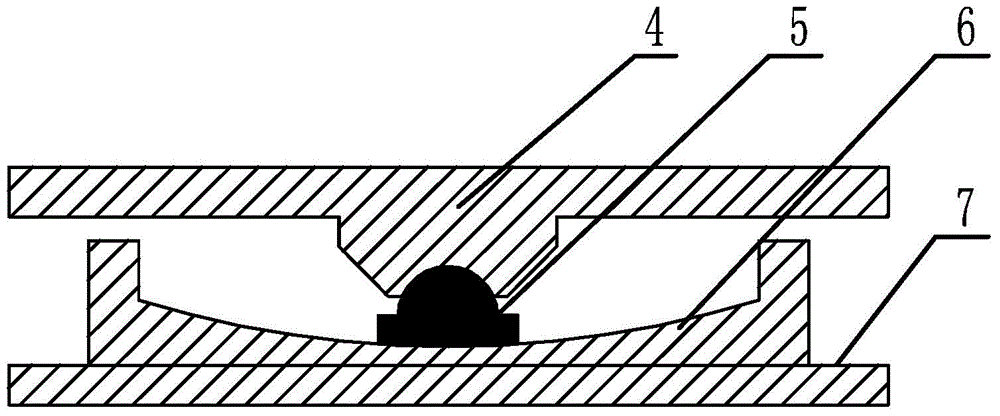

Variable friction-type spherical surface-cylindrical surface friction-type support

ActiveCN104912201AGood adaptive propertiesEnsure safetyBridge structural detailsShock proofingLeft halfResonance

A variable friction-type spherical surface-cylindrical surface friction-type support relates to a friction-type support, which is designed to solve the problems that resonance is produced by a structure and that structural seismic response is increased due to rigidity and constant damping of the existing friction pendulum support, wherein a slide groove is mounted on an upper end face of a connection steel plate; a slide block is located inside the slide groove; an upper portion of the slide block is a hemisphere shape; a hemisphere recess cooperated with the slide block is processed in the middle position of a lower end of an end cover; the end cover is supported on an upper end face of the slide groove through the slide block; an outline of the left half portion of the slide groove is shaped as a rectangle and the outline of the right half portion of the slide groove is shaped as a semicircle; a cylindrical groove is processed on the left half portion of the slide groove; a spherical recess is processed on the right half portion of the slide groove; a cambered surface radius of the cylindrical recess is set in a same way with the cambered surface radius of the spherical recess; the cylindrical recess and the spherical recess are connected in a smooth transitional way to form a complete slide surface; the upper end face of the slide groove is divided with at least two concentric circles in order from the center to the outside; and the friction coefficient at the concentric circle position from inside to outside is sequentially increased. The variable friction-type spherical surface-cylindrical surface friction-type support is used for vibration insulation for a large-span space structure.

Owner:HARBIN INST OF TECH

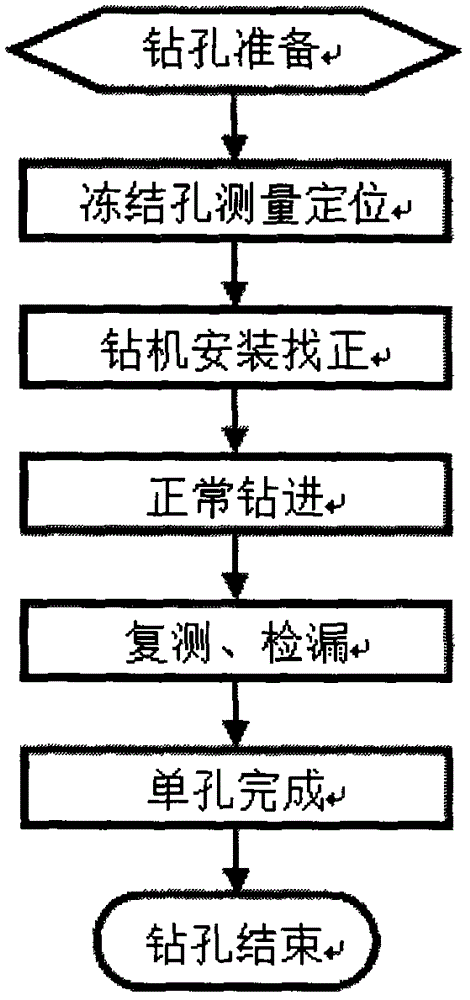

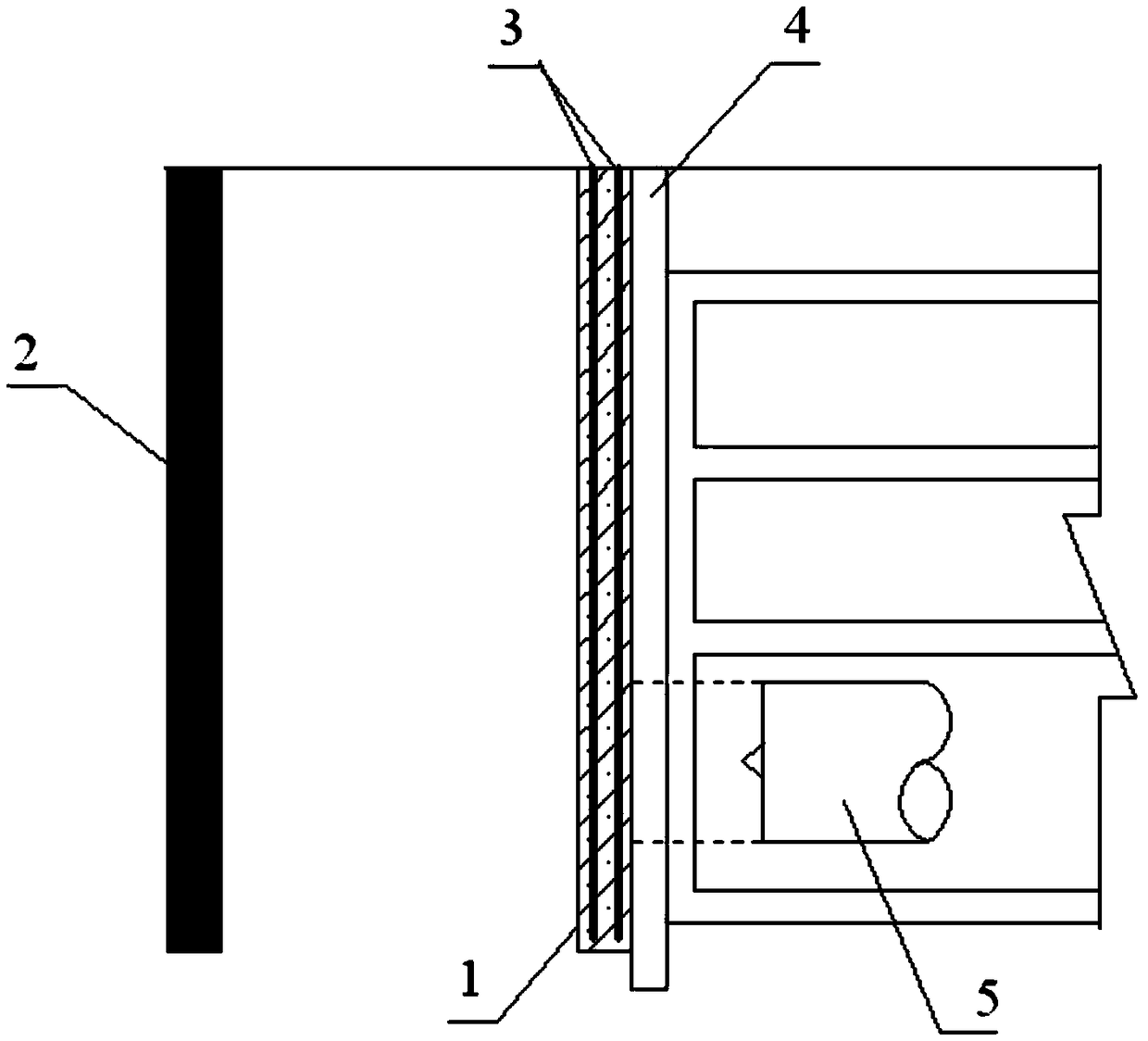

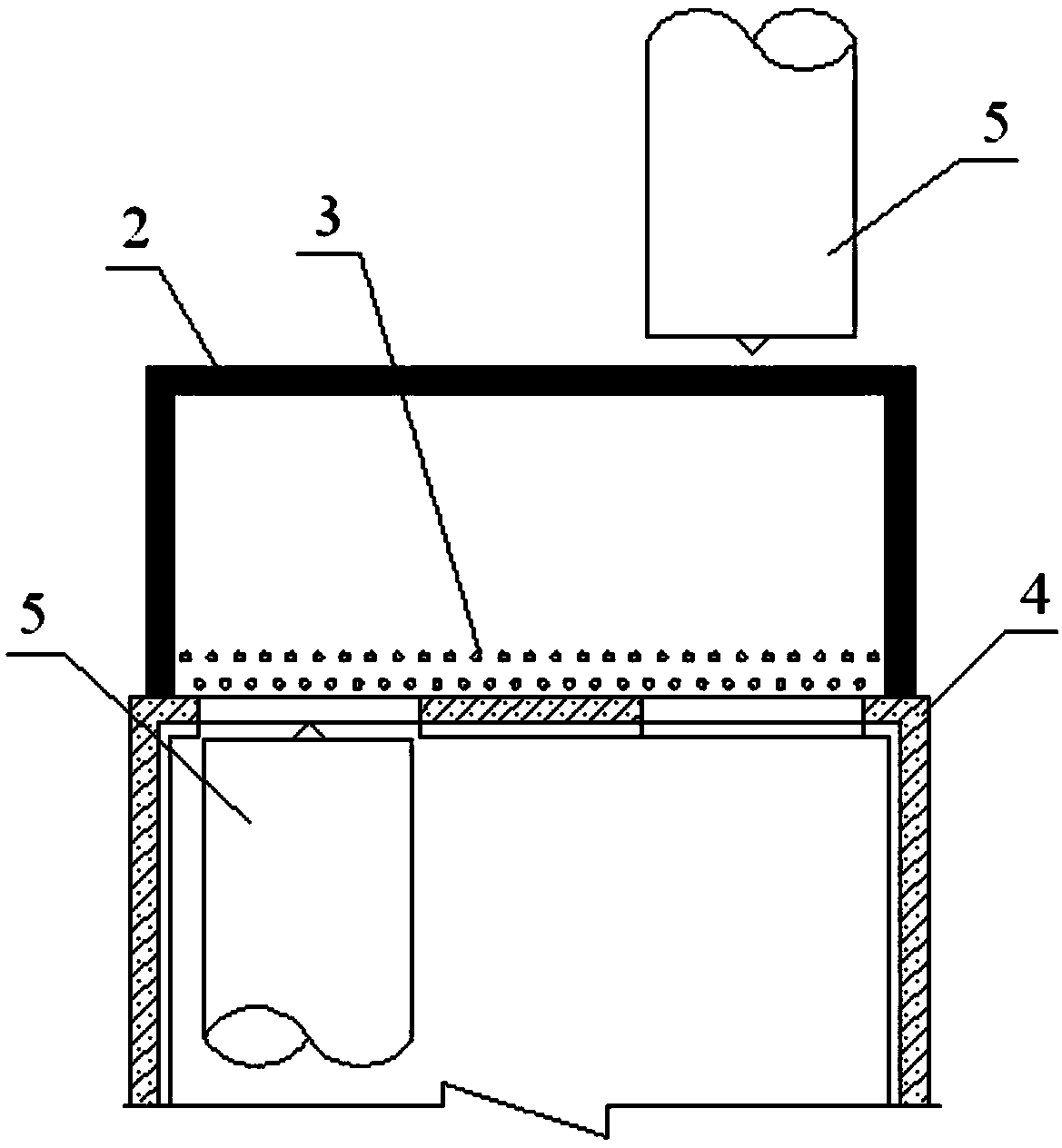

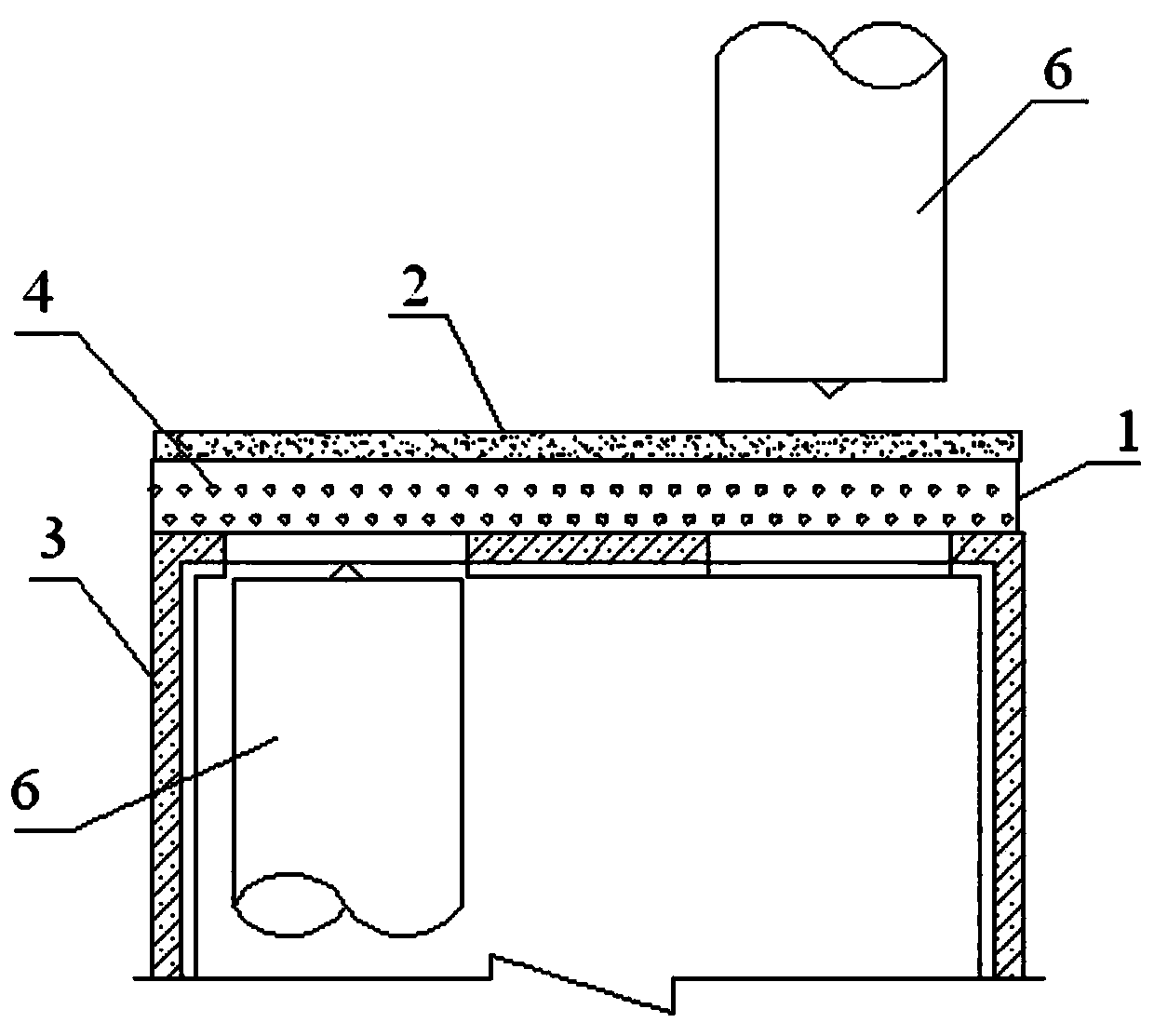

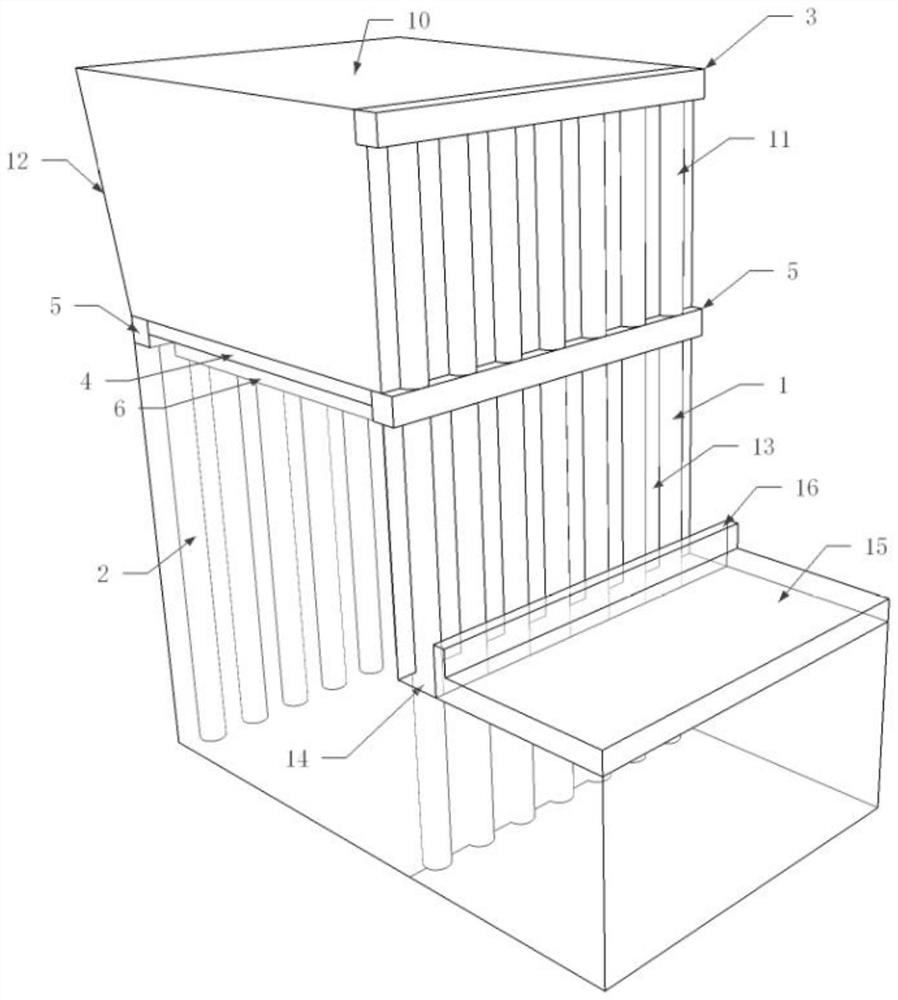

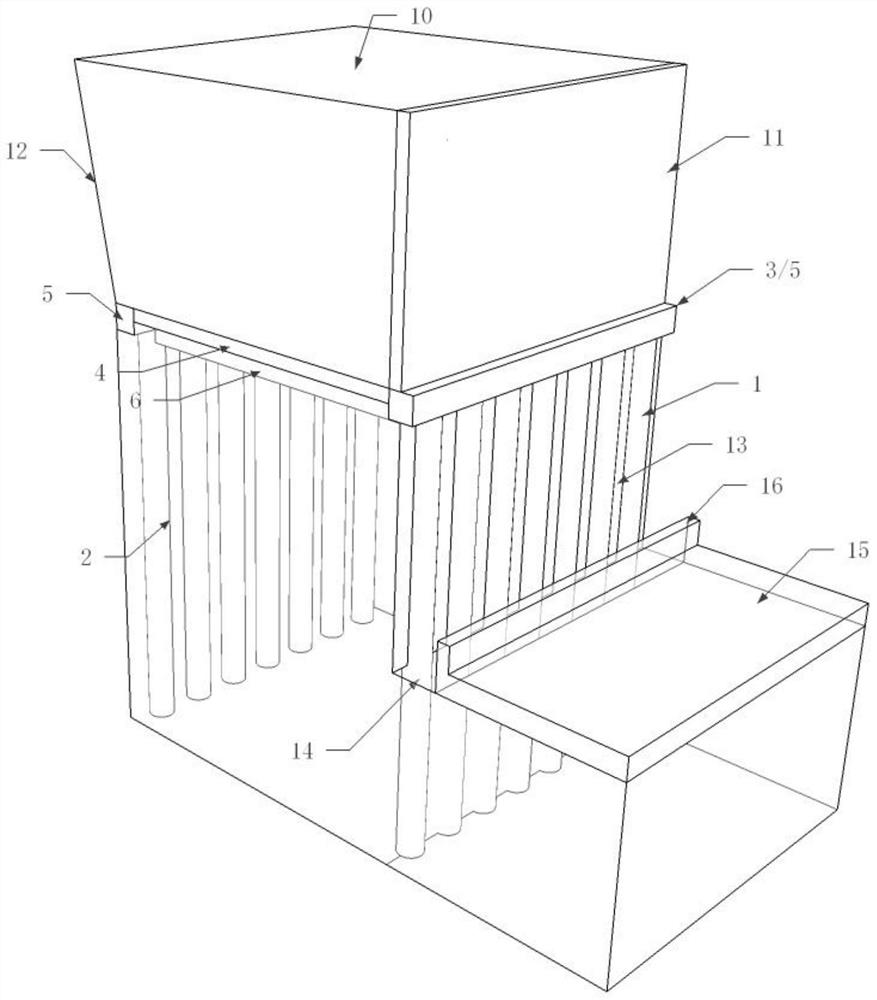

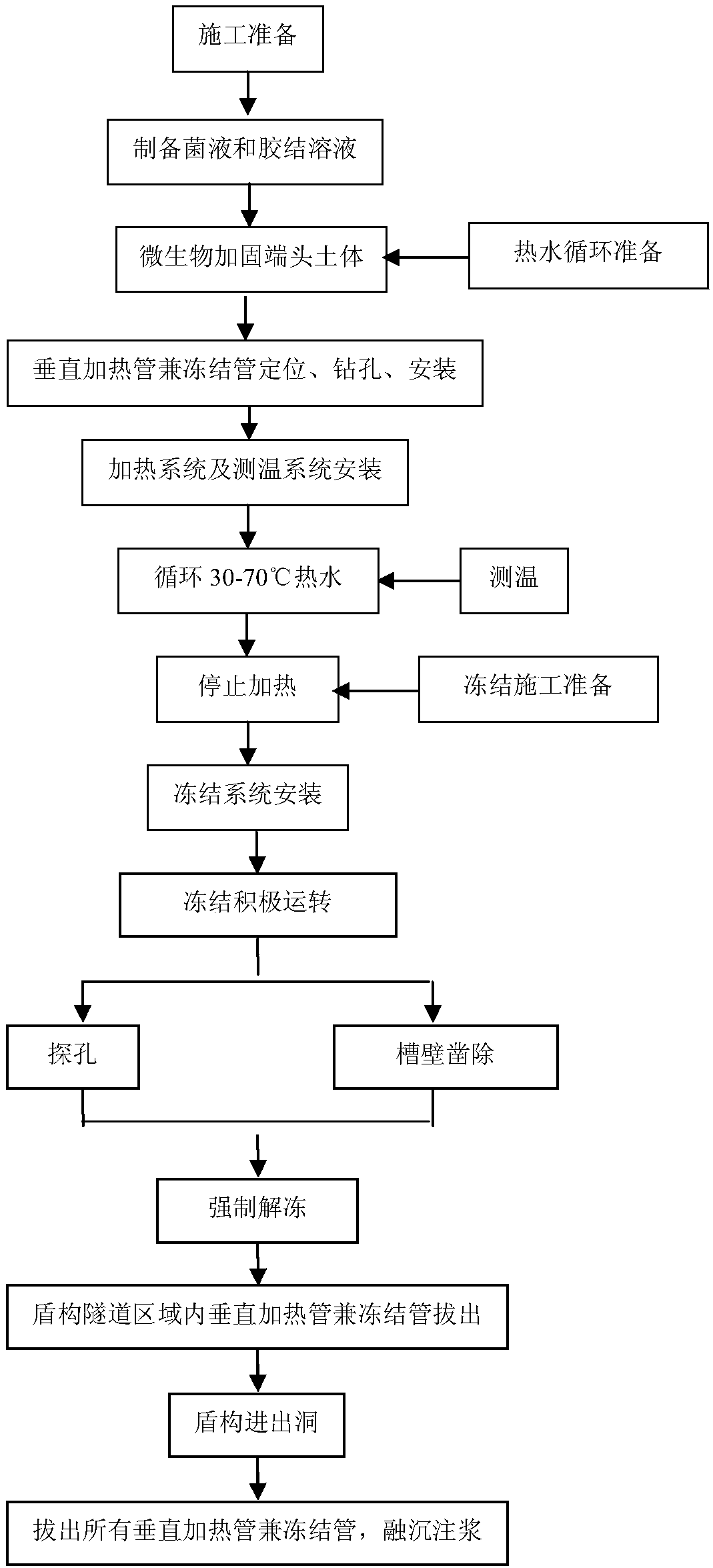

Joint reinforcement structure for shield tunnel end and a construction method

PendingCN109209396AGuaranteed accuracyImprove digging effectUnderground chambersTunnel liningSoil mixingEngineering

The invention discloses a joint reinforcement structure for a shield tunnel end and a construction method. The joint reinforcement structure is a rectangular box structure as a whole, and the rectangular box structure is formed by reinforcement structures surrounded on four sides. The reinforcement structure near a foundation pit is a frozen soil wall, and the reinforcement structures on the remaining three sides are cement soil continuous walls. The method includes a first step of construction of cement soil continuous walls by using a TRD method to construct continuous walls of cement soil with a three-cycle method; a second step of construction of vertical frozen soil wall by firstly, drilling of freezing holes, installing a freezing station at the same time; after confirming that the freezing meets the door chiseling condition, starting to break a hole wall, forcibly unfreezing before a shield main machine enters into the hole, pulling out a vertical freezing tube after the shieldmain machine completes entering and exiting the hole, and grouting. The joint reinforcement structure has the beneficial effects that strong construction practicability, convenient construction quality control and outstanding reinforcement effect. Compared with a traditional cement-soil mixing piles reinforcing method, the method saves cost and greater promotion and application value is ensured.

Owner:HAINAN UNIVERSITY

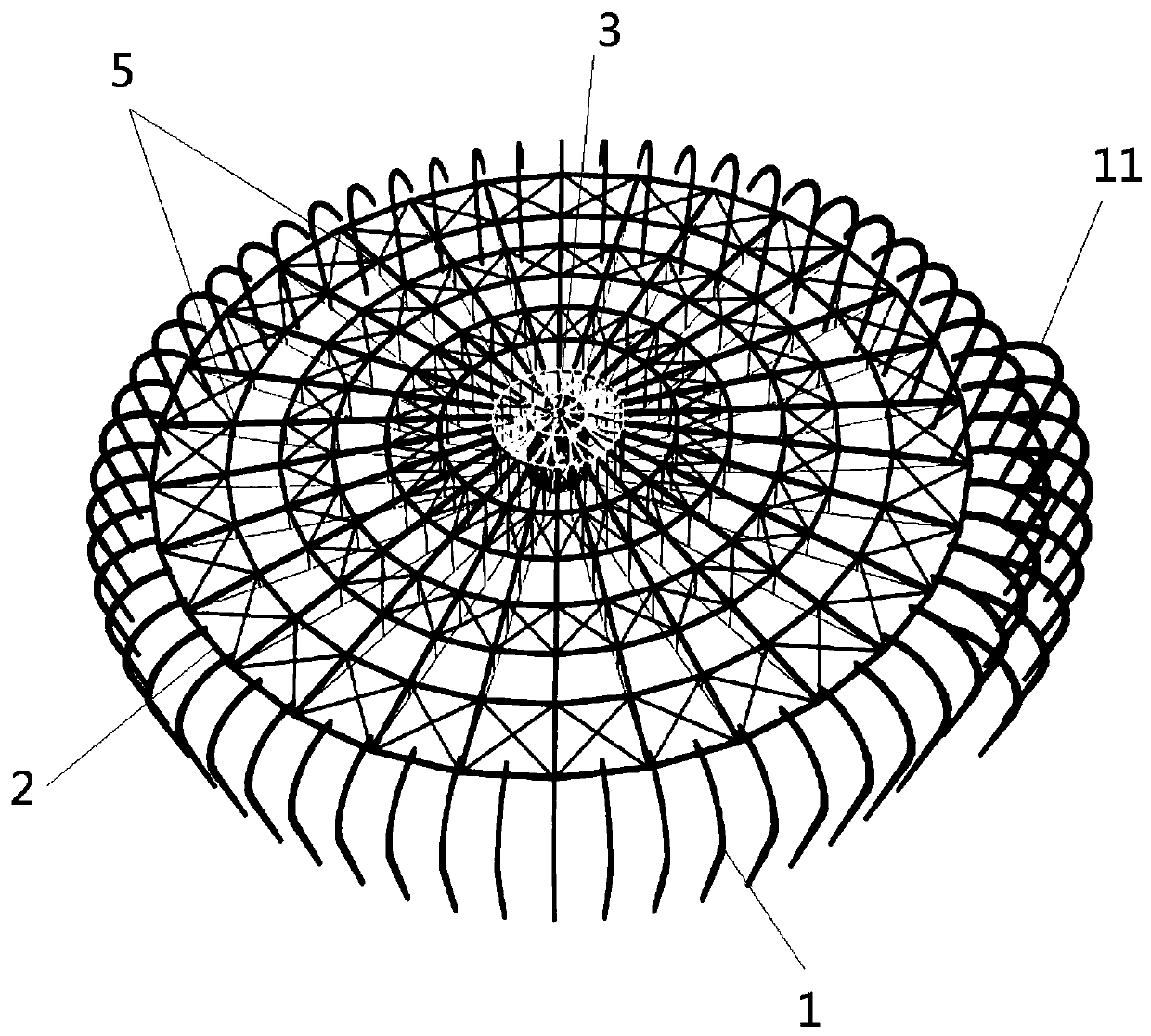

Steel structure tension beam roof construction method based on BIM technology

ActiveCN110886423AReduce investmentShorten the construction periodGeometric CADBuilding roofsPre stressConstruction engineering

The invention relates to a steel structure tension beam roof construction method based on a BIM technology, and belongs to the technical field of building construction. The BIM technology is applied in the construction process of a spoke-type string beam structure roof, a virtual spoke-type chord beam structure roof is established in advance through BIM, each lower chord beam is a pre-stressed cable, the cables are divided into three groups and two stages for circulation tension, the BIM technology is applied to perform simulation analysis of the whole process of the virtual cable tensioning construction, and the cable force and key point displacement of each lower chord beam in the tensioning process are dynamically tracked. According to the construction method, the BIM technology is applied to carry out three-dimensional dynamic simulation of the BIM in advance, and all the pre-stressed chord beams are subjected to three-batch two-stage cyclic tensioning; and on the premise of ensuring that the influence on the adjacent group of pre-stressed chord beams is minimal when the indifferent group of pre-stressed chord beams are inhaul cable tensioning construction, the construction period is reduced to the maximum extent. The required number of jacks is 1 / 3 that of the pre-stressed chord beams, and 2 / 3 of the original number of the jacks is decreased. The economic benefit is good,the construction quality control is good, mature operability is achieved, and the construction process safety is high.

Owner:成都容正软件有限公司

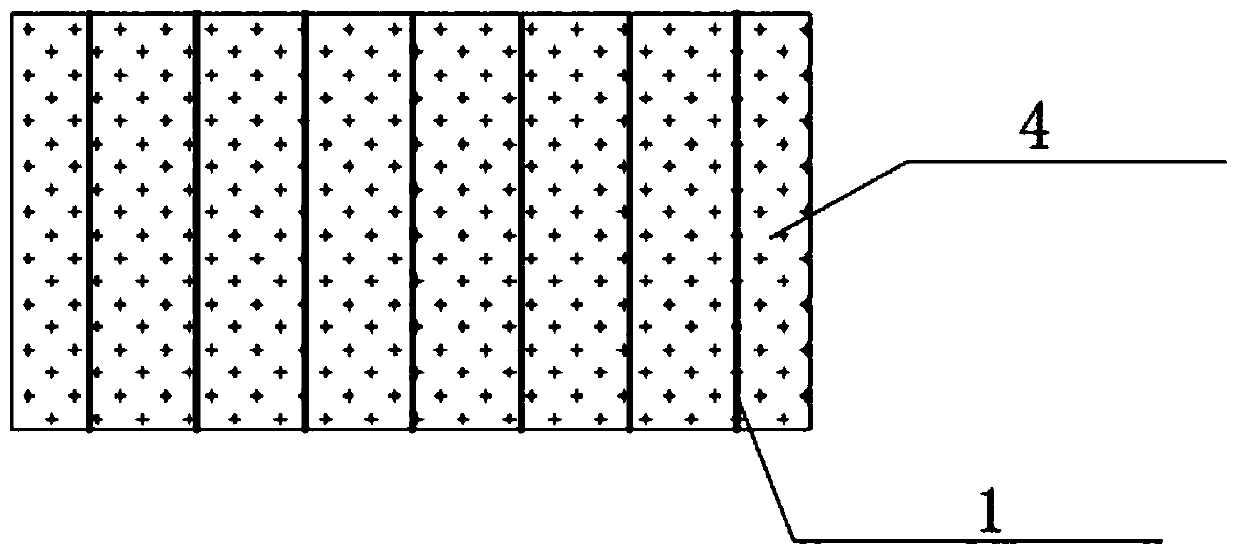

Shield tunnel end head frozen earth wall and even wall combined strengthening structure and construction method

PendingCN110173268ASmooth in and out of the holeStrong construction practicabilityTunnelsBulkheads/pilesShield tunnelingSlurry

The invention discloses a shield tunnel end head frozen earth wall and even wall combined strengthening structure and a construction method. The combined strengthening structure comprises a frozen earth wall and an even wall, wherein the frozen earth wall is arranged at the position next to an enclosure structure, and the even wall is arranged at the rear portion of the frozen earth wall. The construction method includes the steps that firstly, construction of the even wall is conducted, wherein the construction technology includes surveying and setting out, guide wall manufacturing, slurry mixing, even wall grooving and bottom clearing replacing, glass fiber reinforcement cage or bamboo reinforcement cage machining and lifting, concrete pouring, connector construction, connector pipe ejecting pulling and all-section construction complementation; and secondly, frozen earth wall construction is conducted, wherein according to the construction of the frozen earth wall, before shield tunneling, a manual refrigerating method is used for freezing a water-containing stratum in a working well end head area into a sealed and non-water-permeable curtain, and the frozen earth wall is formed.The shield tunnel end head frozen earth wall and even wall combined strengthening structure and the construction method have the beneficial effects that appropriate strengthening can be conducted onend head stratums rich in water sand layers in areas along seas, rivers, lakes and the like.

Owner:HAINAN UNIVERSITY

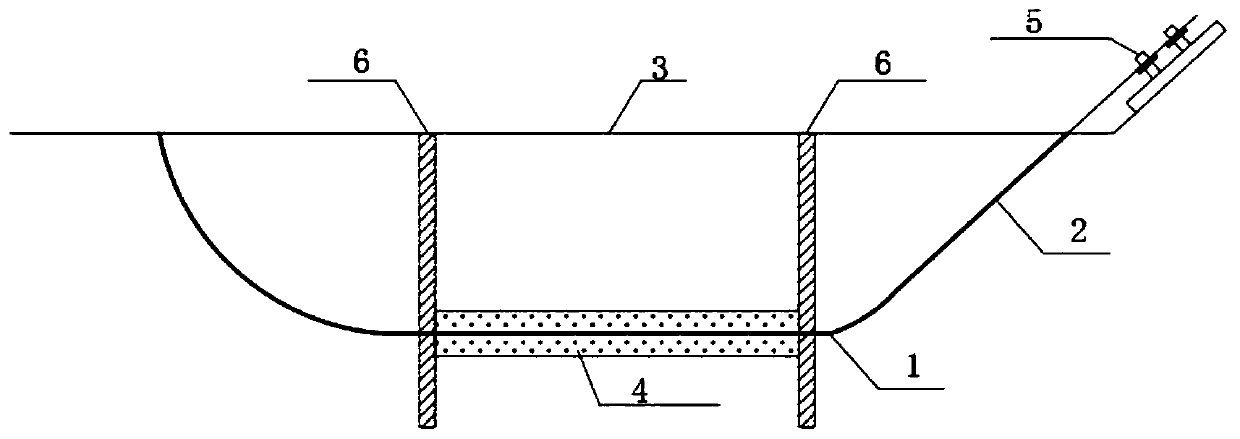

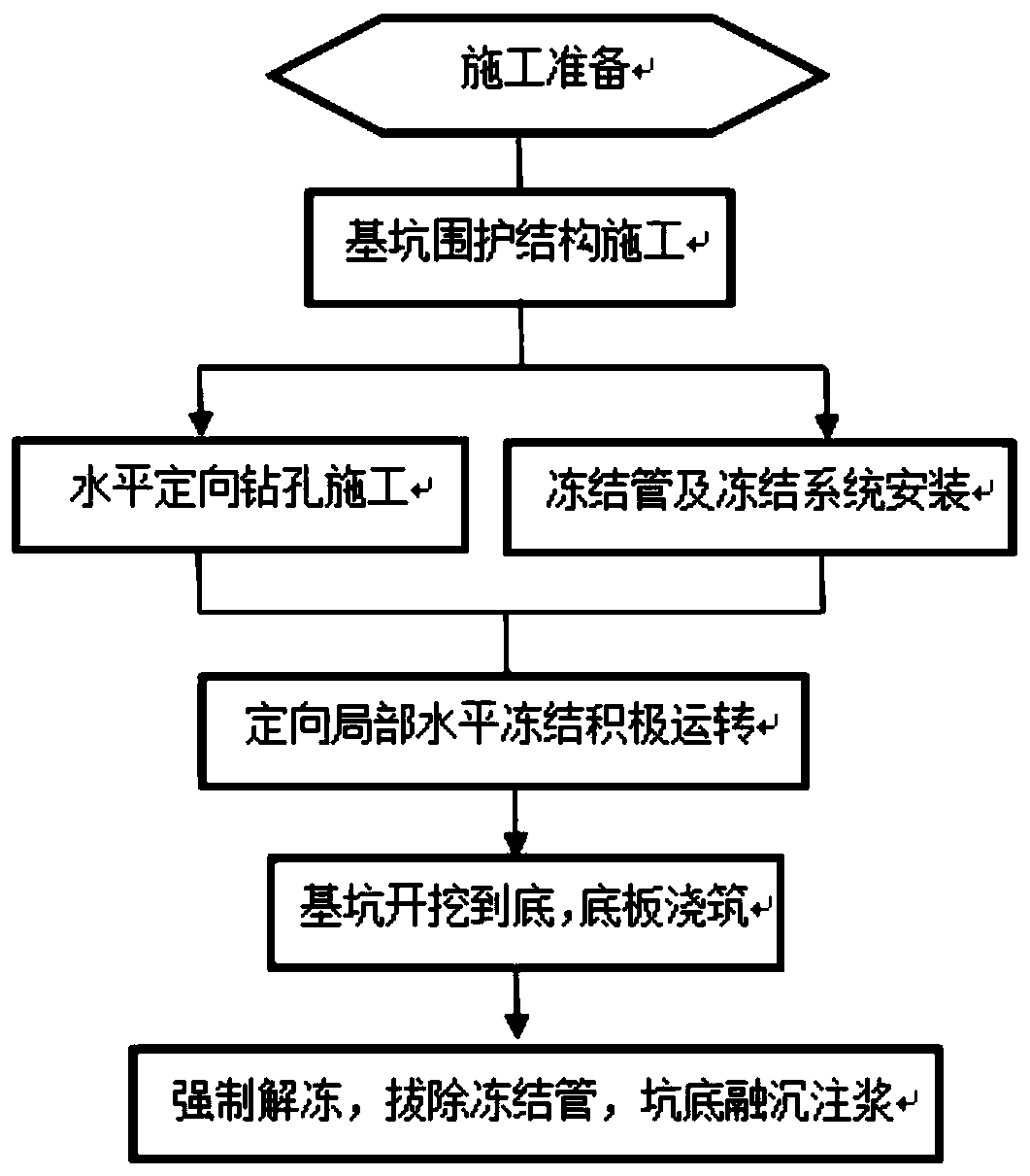

Foundation pit bottom horizontal freezing reinforcing structure and construction method

ActiveCN110080202AEnsure safetyEasy to controlSoil preservationDirectional drillingBuilding construction

The invention discloses a foundation pit bottom horizontal freezing reinforcing structure and a construction method. The reinforcing structure comprises a foundation pit, an enclosure structure, a horizontal freezing pipe and a freezing curtain. The horizontal freezing pipe penetrates through the enclosure structure in a horizontal directional drilling manner and is horizontally arranged at the bottom of the foundation pit; a plurality of horizontal freezing pipes are uniformly arranged in a soil layer at the bottom of the foundation pit along the horizontal direction, the horizontal freezingpipes freeze the soil layer at the bottom of the foundation pit to form the freezing curtain, and the foundation pit is excavated after the freezing curtain is formed and takes the top of the freezingcurtain as the bottom of the foundation pit. The construction method has the outstanding advantages of being high in construction practicability, convenient to control construction quality, good in reinforcing effect, particularly good in water stop effect, safe, reliable and the like, and the safety of deep soft soil engineering piles in the foundation pit in the excavation process can be guaranteed to the maximum extent.

Owner:王海霖

Light refractory castable material for heat insulation lining of cast steel plate (CPS) furnace roller

The invention discloses a light refractory castable material for a heat insulation lining of a cast steel plate (CPS) furnace roller. The light refractory castable material comprises the following components by weight percent: 40-50% of light mullite bone material, 5-8% of flint clay with a particle size of 0.1-1mm, 5-7% of kyanite powder, 6-9% of first-class bauxite chamotte with a particle size of less than or equal to 180 meshes, 7-9% of silicon micro powder, 5-8% of alpha-Al2O3 micro powder, 10-18% of bauxite cement, 1-4% of refractory fiber, 1-1.5% of spodumene, 0.05-0.154% of sodium hexametaphosphate, 0.05-0.15% of organic water reducing agent, 0.04-0.07% of organic silane coupling agent and 0.013-0.06% of defoaming agent. The refractory castable material has the characteristics of light volume weight, strong high temperature resistance, good mechanical property, good heat insulation property and excellent thermal shock stability performance.

Owner:武钢集团有限公司 +1

Evaluation method of mortar consistency of cement stabilized macadam permeable base

InactiveCN101799397AQuantitative evaluation of consistency rationalitySimple methodMaterial strength using tensile/compressive forcesPermeability/surface area analysisVoid ratioCrushed stone

The invention relates to an evaluation method of the mortar consistency of a cement stabilized macadam permeable base, which belongs to the field of urban construction, and aims to solve the problems that the existing evaluation method of mortar consistency has strong subjectivity and difficult quantification. The method comprises the following steps that: step 1, a leakage test is carried out for the mixed material of the cement stabilized macadam permeable base to be measured; step2, the mixed material of the cement stabilized macadam permeable base after the leakage forms at least two test pieces; step 3, one or more forming test pieces are uniformly divided into an upper part and a lower part, the voidage of the test pieces at the upper part and the lower part is measured, and whether the voidage of the test pieces at the upper part and the lower part is less than 5 percent is calculated; and step 4, a 7d unconfined compressive strength test is carried out for the remaining forming test pieces, and whether the compressive strength of the remaining forming test pieces is between 4.8MPa and 5MPa is tested; and when the two conditions of the step 3 and the step 4 are simultaneously met, the consistency of cement mortar is judged to meet the standard.

Owner:HARBIN INST OF TECH

Unloading type combined retaining structure and construction method thereof

PendingCN112323816AShorten the durationShort construction periodExcavationsBulkheads/pilesArchitectural engineeringRock bolt

The invention relates to an unloading type combined retaining structure and a construction method thereof. The unloading type combined retaining structure is divided into two types, wherein one type is a combined retaining structure jointly formed by supporting piles, unloading plate supporting piles, supporting pile top connecting beams, unloading plates, longitudinal connecting beams, transversesupporting beams, plate top backfill soil and other members; and the second structure is a combined retaining structure jointly formed by the supporting piles, the supporting pile top connecting beams, the unloading plates, the longitudinal connecting beams, ribbed beams or ribbed plates, the longitudinal supporting beams, reinforcing waist beams, the plate top backfill soil and other members. According to the unloading type combined retaining structure, the unloading effect of the unloading plates is fully utilized, the soil pressure acting on the supporting structure is effectively reduced,and the foundation pit supporting structure can be formed without occupying the space outside a red line, without implementing an anchor rod on the outer side of a foundation pit and without arranging a support inside the foundation pit. The unloading type combined retaining structure is clear and definite in stress, reliable in quality and high in construction speed, can greatly wide the application range of the supporting and retaining type supporting and retaining structure, and can replace an inner supporting and retaining structure under partial conditions.

Owner:JIAN YAN FOUND ENG

Embedding accuracy control construction method for embedded part of overlong equipment foundation platform

InactiveCN102134879BReasonable designSimplify construction stepsFoundation engineeringBuilding constructionsReinforced concreteRebar

The invention discloses an embedding accuracy control construction method for an embedded part of an overlong equipment foundation platform, including the following steps: firstly, processing the embedded part and the installation screw of the embedded part; secondly, molding construction of the lower middle reinforced concrete structure of the foundation platform needing construction: a plurality of vertical reinforcing steel bars extend out from the top of the lower middle reinforced concrete structure under construction of molding and are arranged vertically; thirdly, installing the installation screw of the embedded part; fourthly, installing a nut at the bottom of the threaded section of the installation screw of the embedded part; fifthly, installing and positioning the embedded part; sixthly, installing a nut on top of the threaded section of the installation screw of the embedded par; seventhly, molding construction of the upper reinforced concrete structure of the foundation platform needing construction; and eighthly, subsequent construction treatment. The method has in design, simple construction steps, easy control of construction quality, high construction accuracy and good in use effect, and can solve the problems of the existing embedding construction method of embedding parts that the embedding accuracy is inconvenient to control, the embedding accuracy is low,the construction quality is poor, the investment cost is high, the construction period is long, and the like.

Owner:SCEGC NO 6 CONSTR ENG GRP CO LTD

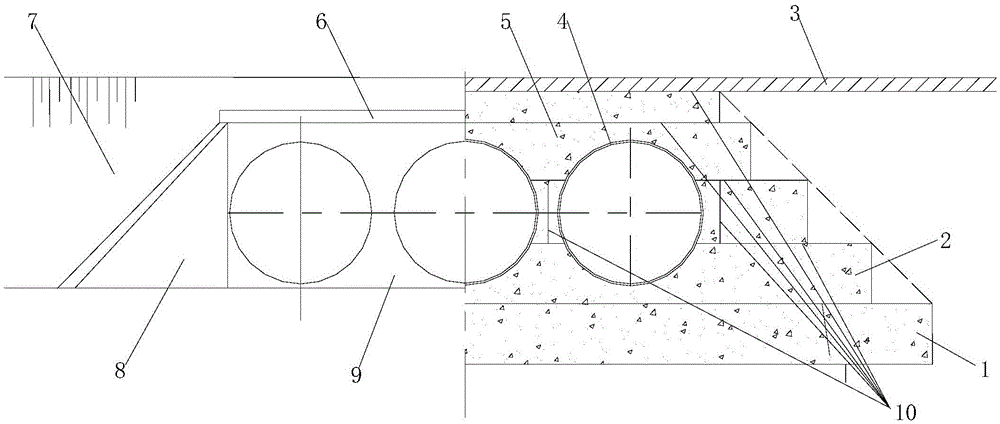

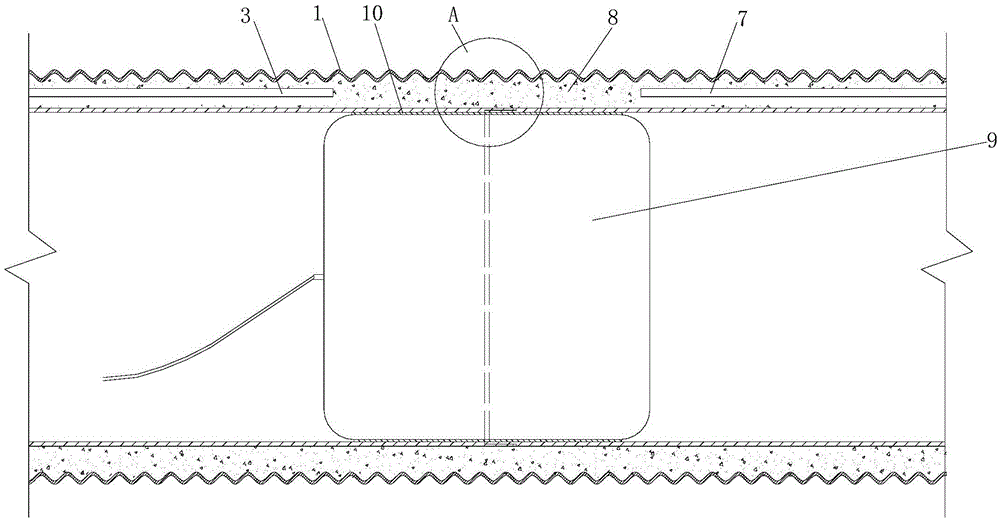

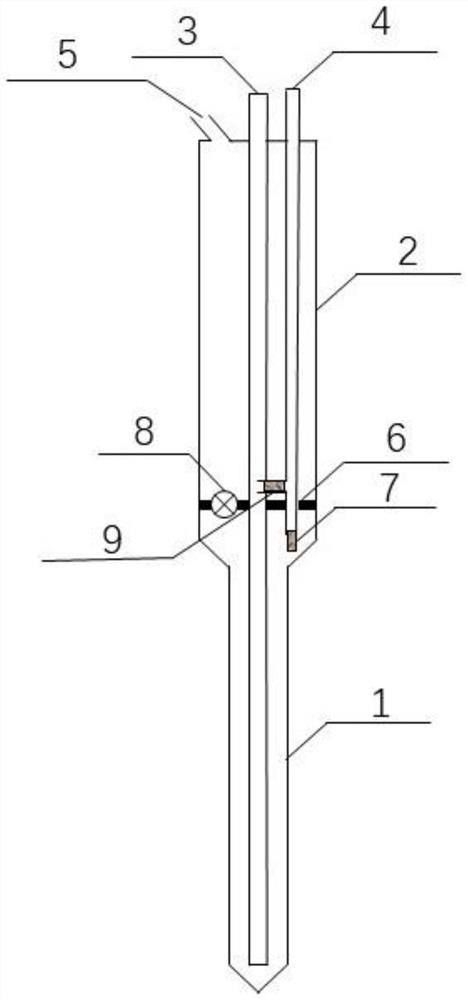

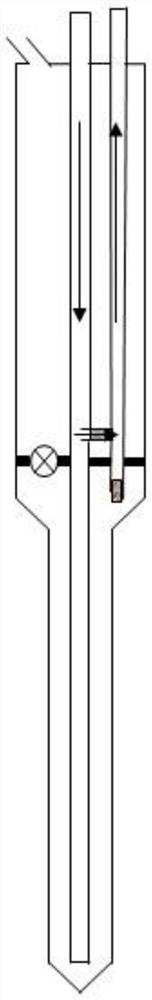

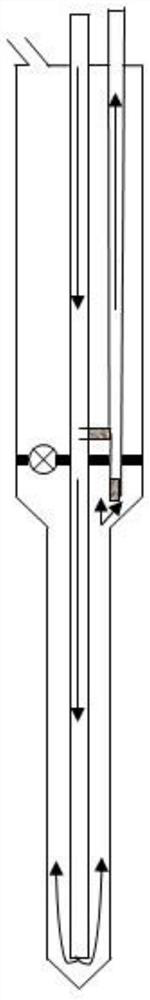

Culvert structure adopting high density polyethylene (HDPE) winding reinforcement pipes and foam concrete and construction method of culvert structure

ActiveCN105648934AFew jointsStrong ability to adapt to ground deformationGround-workFoundation repairFilling materialsClerestory

The invention discloses a culvert structure adopting high density polyethylene (HDPE) winding reinforcement pipes and foam concrete. The culvert structure comprises a culvert pipe foundation, culvert pipes and filling bodies located on the two sides and the upper portions of the culvert pipes. The filling bodies are foam concrete filling bodies. The culvert pipes comprise the multiple HDPE winding reinforcement pipes which are connected in an end-to-end mode in sequence. The inner side of the connecting position of every two adjacent HDPE winding reinforcement pipes is provided with an annular steel band in a winding mode. Seepage-proofing sealing structures are disposed between the annular steel bands and the HDPE winding reinforcement pipes. Sealing reinforcement devices are disposed on the annular steel bands. The culvert structure is small in self weight, low in requirement for foundation bearing capacity, capable of effectively solving the problems of differential settlement and cambering of the culvert pipes and suitable for the environment conditions of corrosion and abrasion. The invention discloses a construction method of the culvert structure. The construction method includes the steps of (1) culvert pipe foundation construction, (2) culvert pipe mounting, (3) construction of the filling bodies and (4) construction of a road surface. By means of the construction method, the foam concrete is used as a filling material, and the link of compacting the fillers on the arch apex and culvert sides is omitted.

Owner:CHANGAN UNIV

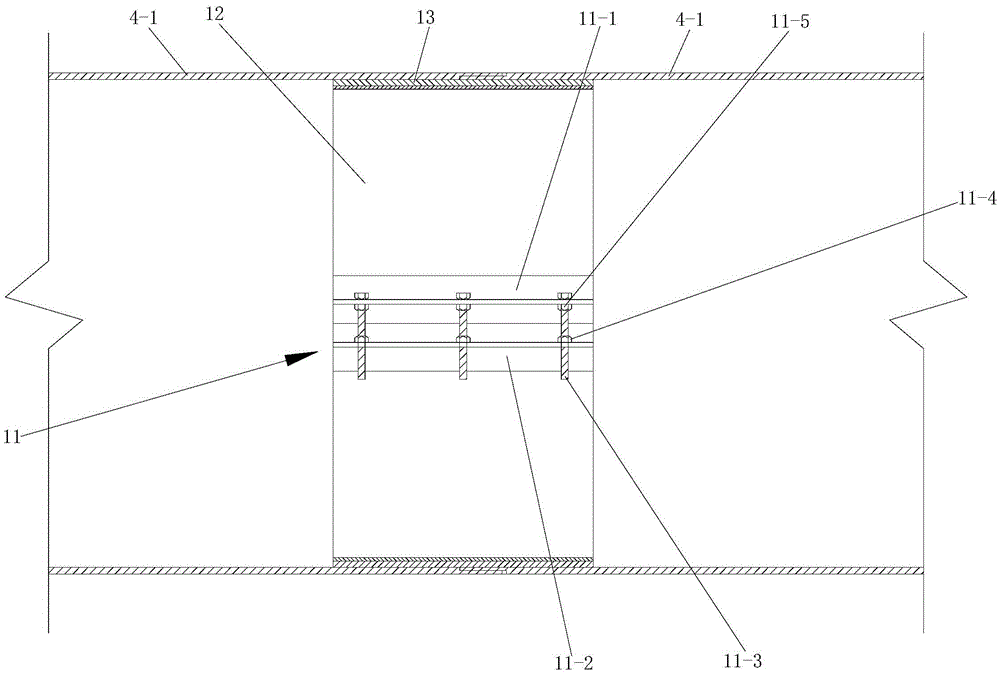

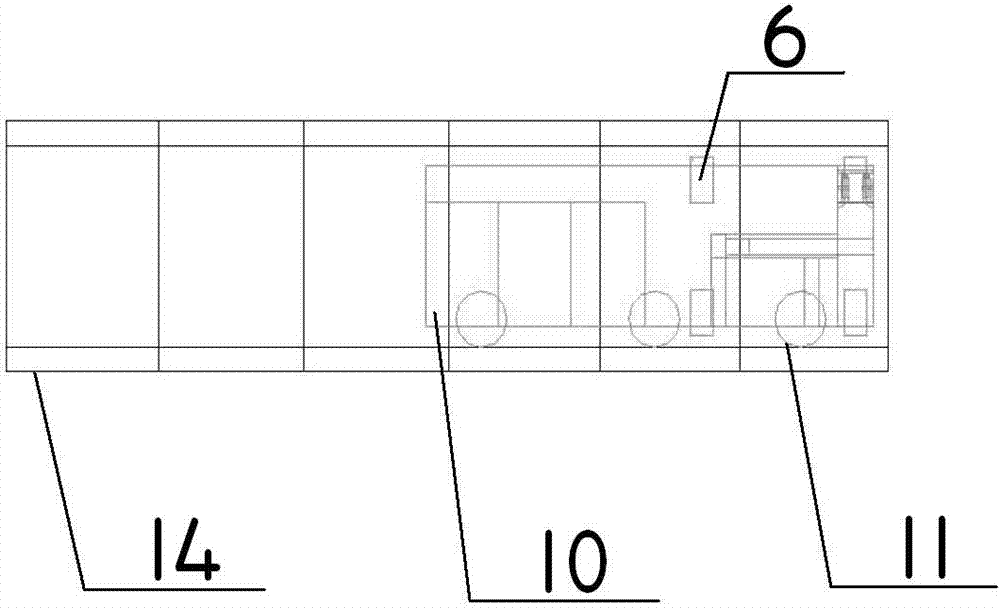

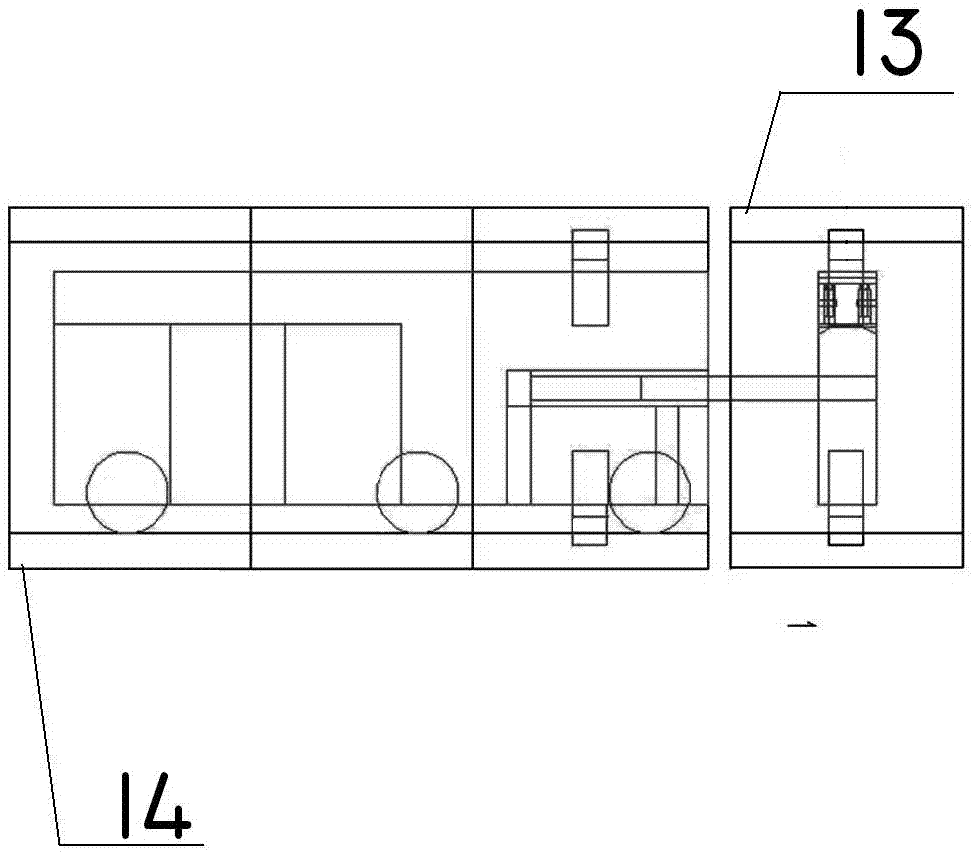

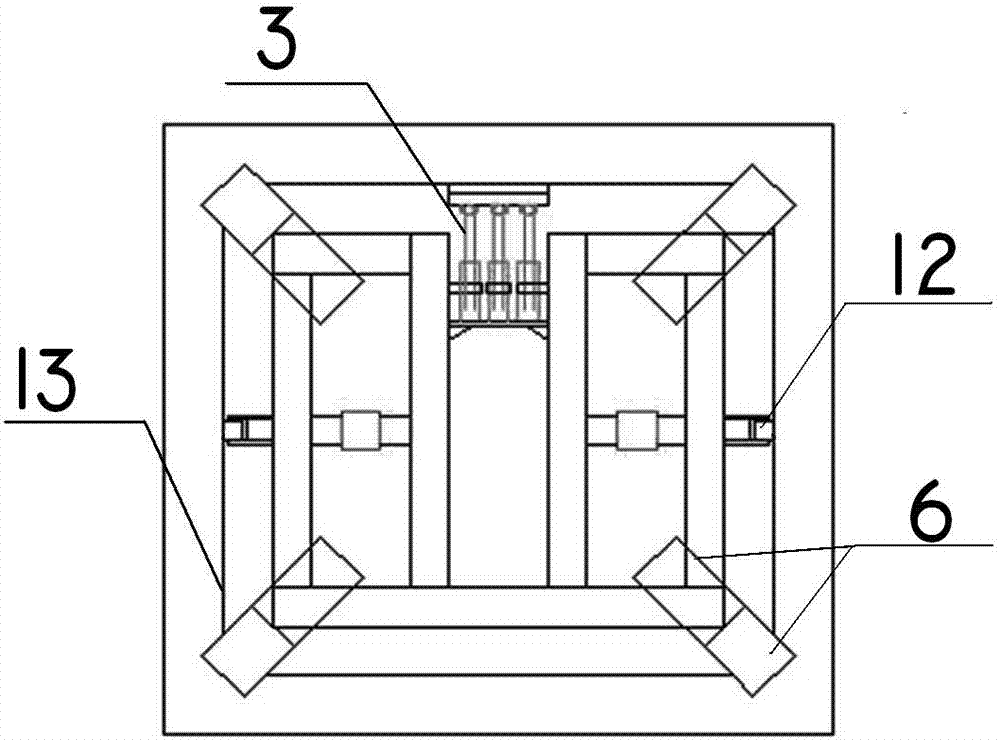

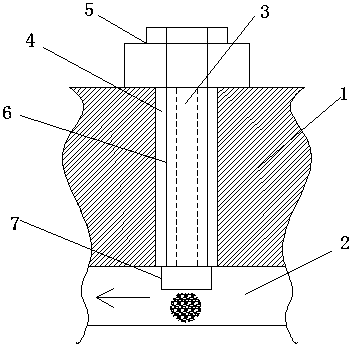

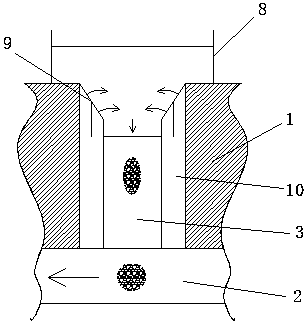

Prefabricated pipe joint assembly equipment and construction method thereof

ActiveCN107476334AReduce pollutionEasy to operateArtificial islandsHydro energy generationConstruction engineeringHydraulic pump

The invention discloses prefabricated pipe joint assembly equipment and a construction method thereof. The prefabricated pipe joint assembly equipment comprises a supporting-connecting mechanism, a positioning mechanism, a tensioning mechanism and a power system, wherein the supporting-connecting mechanism comprises a lifting device and a supporting-connecting frame; the lifting device comprises a lifting oil cylinder and a steel supporting plate; the positioning mechanism comprises a rectangular rear positioning frame, positioning oil cylinders and clamping parts; the positioning oil cylinders are correspondingly arranged on four corners of the rectangular rear positioning frame; the clamping parts are fixedly connected with the front ends of the piston rods of the positioning oil cylinder; the tensioning mechanism comprises telescopic oil cylinders and sliding guide rails; and the power system comprises a hydraulic pump, a control valve group and an oil tank. By adoption of the prefabricated pipe joint assembly equipment and the construction method, a one-step forming and assembly process of a prefabricated assembly-type comprehensive pipe rack can be achieved; the one-step forming and assembly process comprises the steps of pipe joint supporting and connection, adjusting and aligning, tensioning, and the like; and the operation is simple, the working efficiency is high, the working period is short, the degree of mechanization is high, the labor intensity is low, the labor cost is reduced, and the environmental pollution is reduced.

Owner:BCEG CIVIL ENG

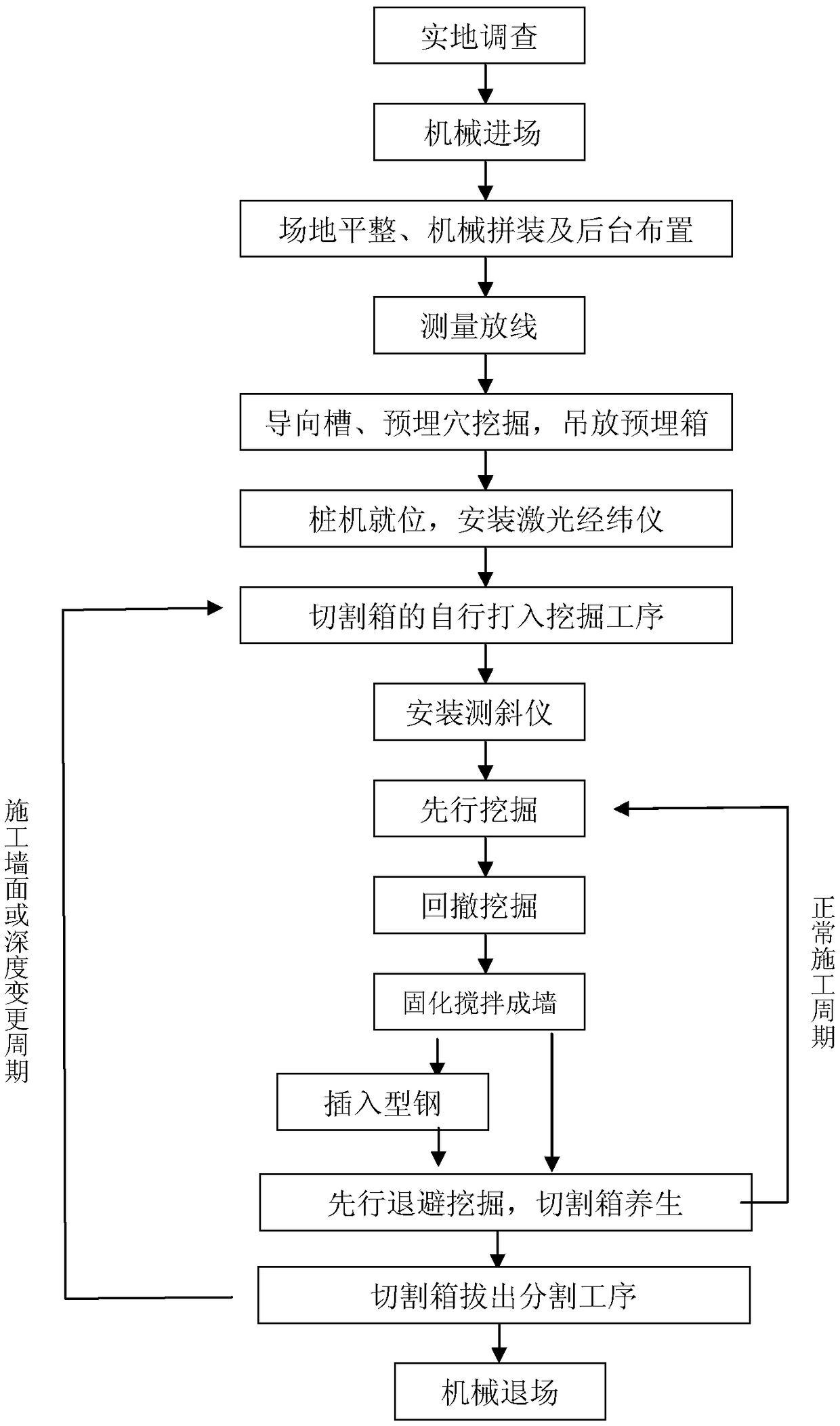

Embedded type shaft excavation construction technology

InactiveCN107905792AStrong construction adaptabilityHigh security and high efficiencyShaft sinkingPilot holeQuality control

The invention discloses an embedded type shaft excavation construction technology. The embedded type shaft excavation construction technology comprises the steps of construction of a pilot hole, expanding excavation of a shaft section and the like. The pilot hole is excavated from bottom to top, the shaft is subjected to expanding excavation from top to bottom, manual slagging off is conducted onthe top, and mechanical deslagging is conducted on the bottom. The embedded type shaft excavation construction technology has the advantages that the adaptive capacity to shaft construction with a complex site rock geological condition is high; the requirement for a site is not high, and the construction requirement of a narrow site can be met; the safety guarantee efficiency is high; quality control is convenient; and the speed is high, the construction period can be shortened, and the construction schedule can be accelerated.

Owner:XINJIANG NORTH CONSTR GRP CO LTD

Spherical surface and cylindrical surface friction type support

ActiveCN104929266AExtend your lifeExtend the natural vibration periodShock proofingLeft halfResonance

The invention provides a spherical surface and cylindrical surface friction type support and relates to a friction type support. The spherical surface and cylindrical surface friction type support solves the problems that an existing friction swing support is prone to generating resonance, a variable frequency swing support is in point and surface contact for a long time, and consequently the vibration isolation and reduction effect is poor. A sliding groove is formed in the upper end face of a collecting steel plate, a sliding block is located in the sliding groove, the upper half part of the sliding block is in a semispherical shape, a semispherical groove matched with the sliding block is machined in the center of the lower end of the cover plate, the cover plate is supported by the upper end face of the sliding groove through the sliding block, the contour of the left half part of the sliding groove is rectangular, the contour of the right half part of the sliding groove is semicircular, a cylindrical groove is machined in the left half part of the sliding groove, a spherical groove is machined in the right half part of the sliding groove, the radius of the arc surface of the cylindrical groove and the radius of the arc surface of the spherical groove are identical, and the cylindrical groove and the spherical groove are in smooth transition connection to form a complete smooth surface. The spherical surface and cylindrical surface friction type support is used for vibration isolation of a large-span space structure.

Owner:HARBIN INST OF TECH

Foundation pit bottom freezing reinforcing structure and construction method thereof

PendingCN109989391AGuaranteed stabilityStrong construction practicabilitySoil preservationGratingEdge type

The invention discloses a foundation pit bottom freezing reinforcing structure and a construction method thereof. The foundation pit bottom freezing reinforcing structure is formed by arranging a freezing reinforcing structure at a foundation pit bottom. The freezing reinforcing structure is of a full hall type or a grating type or a skirt edge type or a drawing strip type, and the freezing reinforcing structure is formed by freezing through a vertical freezing pipe or a horizontal freezing pipe. The construction method comprises the steps that 1, construction preparation is conducted; 2, a foundation pit support structure is constructed; 3, drilling construction and freezing system installation are conducted; 4, positive freezing is conducted to form the foundation pit bottom freezing reinforcing structure; 5, the freezing pipe is pulled out; and 6, a foundation pit is excavated to the bottom, and a bottom plate is poured. The invention has the beneficial effects that the foundation pit bottom freezing reinforcing structure has the advantages of being high in construction practicability, convenient for controlling construction quality, good in reinforcing effect, especially waterstop effect, safe, reliable and the like, and has large application and popularization value.

Owner:HAINAN UNIVERSITY

Slope protection pile pouring and cable bolting construction method for deep foundation pit

InactiveCN102031784BSimplify construction stepsFacilitate construction quality controlDrill bitsExcavationsLine tubingRebar

The invention discloses a slope protection pile pouring and cable bolting construction method for a deep foundation pit. The method comprises the following steps of: 1, making preparations before construction; 2, pouring a slope protection pile, namely measuring, paying off, molding and constructing the poured slope protection pile, punching holes on the poured slope protection pile, binding and hoisting a steel reinforcement cage for molding the slope protection pile, pouring concrete into the poured slope protection pile and constructing a crown beam at the top end of the pile; and 3, excavating a foundation in a layered form and constructing anchor ropes on different rows, namely excavating a first-layer foundation, arranging a first row of anchor ropes, arranging a steel waist rail, arranging anchor heads of the anchor ropes, tensioning the anchor ropes and finishing excavating processes of different layers of foundations and arranging different rows of anchor ropes. The method has a reasonable design, simple construction steps, low investment cost, large support depth and good using effect, and solves the problems of complicated construction steps, high construction cost, inconvenience in control, easy damage to surrounding pipelines, roads, buildings and the like, large construction space and the like existing in the conventional double-row pile supporting method can be solved.

Owner:SCEGC NO 6 CONSTR ENG GRP CO LTD

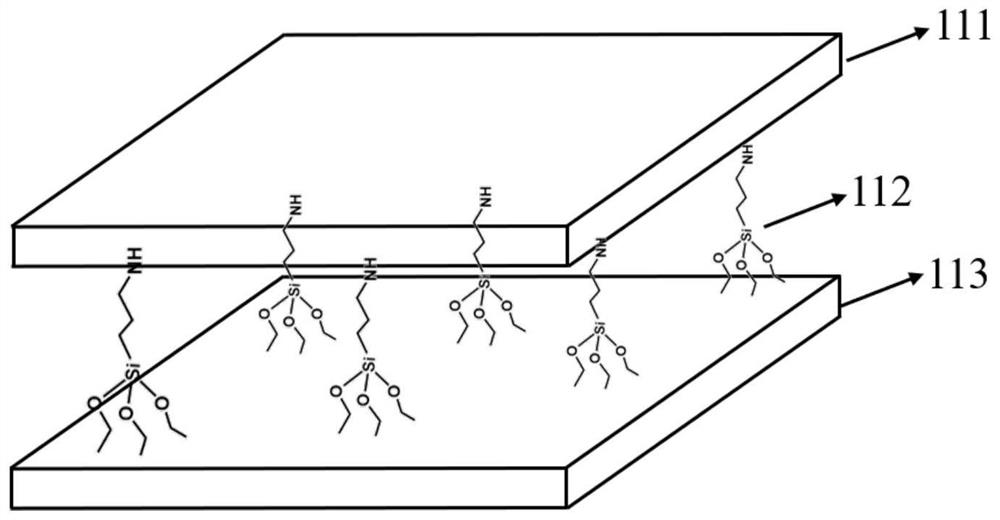

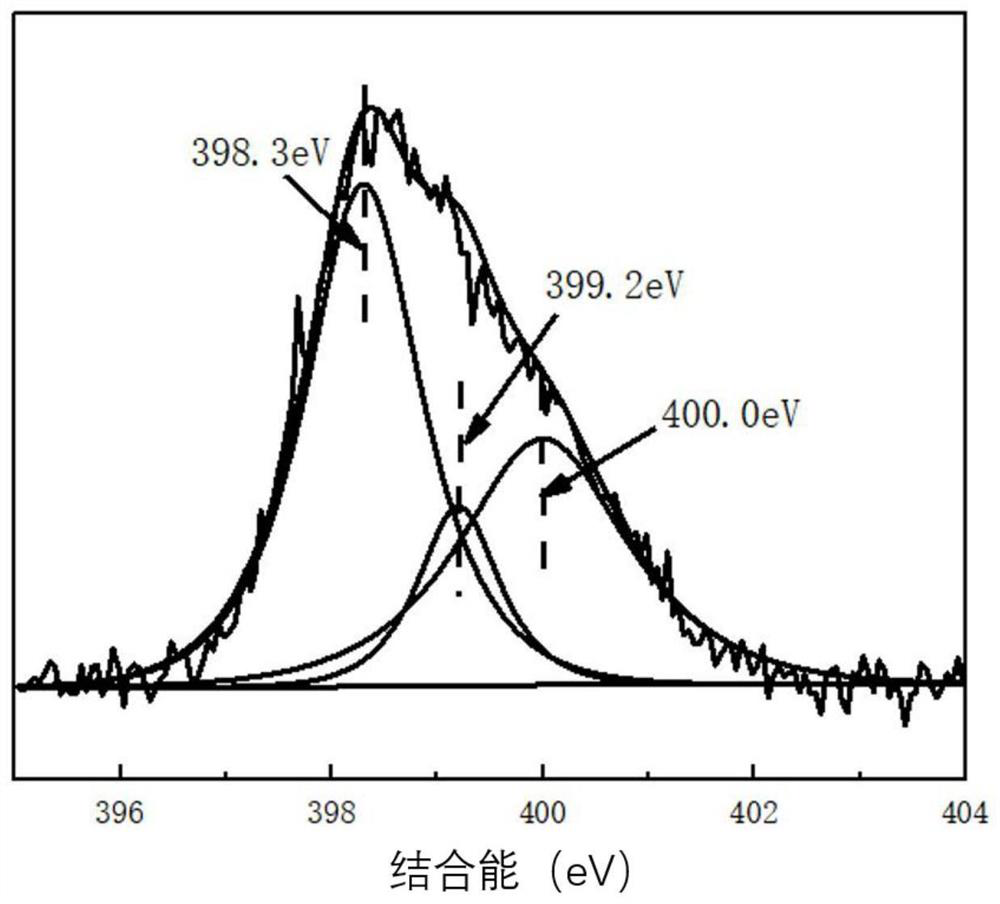

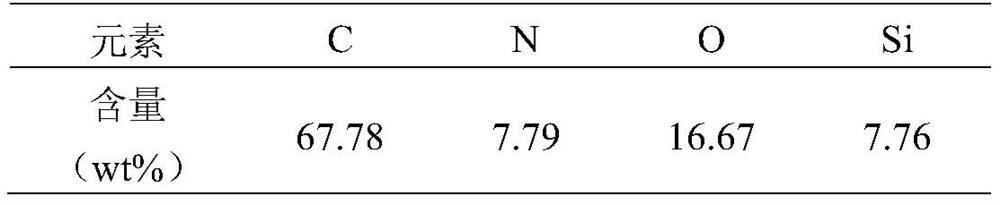

Preparation method of novel extruded polystyrene thermal insulation material/mortar covalent bonding system

ActiveCN113150353AAchieve covalent bondingHigh bonding strengthCoatingsTriethoxysilaneVinyltriethoxysilane

The invention relates to an extruded polystyrene (XPS) insulation board / mortar insulation system combined in a covalent bonding mode. The method comprises the following steps: activating an XPS plate by utilizing an ultraviolet-ozone radiation method; enabling organic functional groups in the silane coupling agent to react with the activated XPS surface, thereby achieving the coupling modification of XPS. And the selected silane coupling agent comprises gamma-aminopropyl triethoxy silane, gamma-mercaptopropyl trimethoxy silane, vinyl triethoxy silane and the like. Covalent bonding between the organic XPS board and the inorganic mortar is realized by utilizing the amphipathicity of the silane coupling agent. In one embodiment, the bond strength between the interface coupled XPS board and mortar is enhanced by 158.6%.

Owner:BEIJING UNIV OF TECH

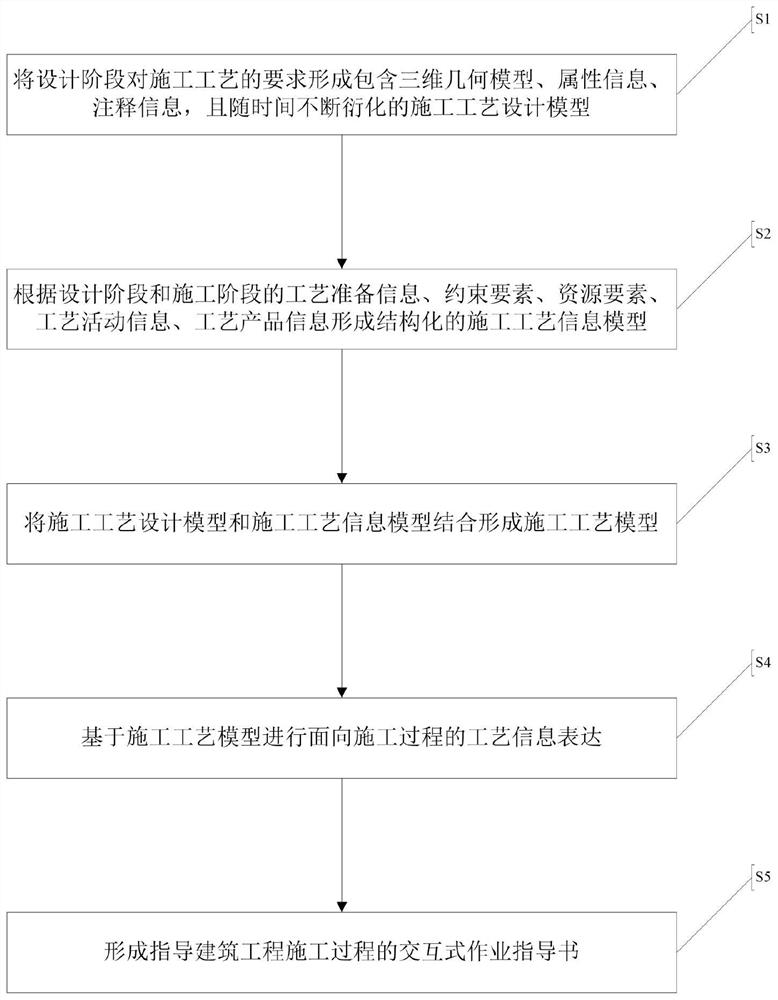

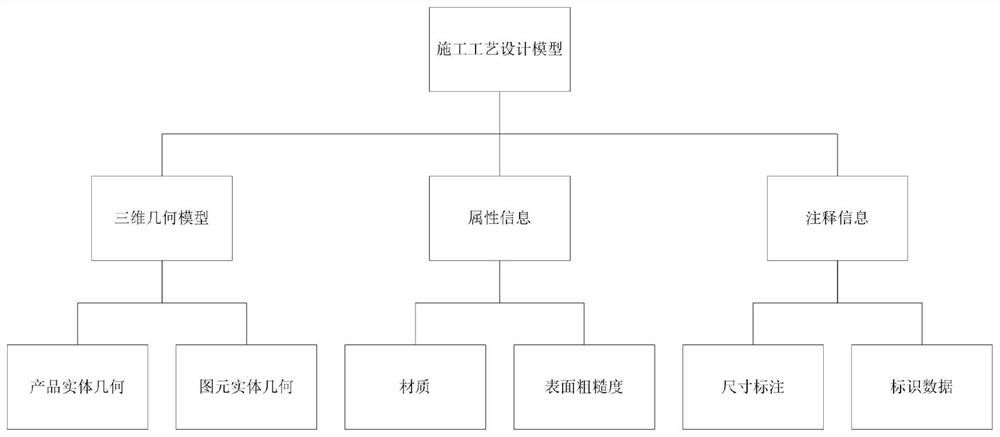

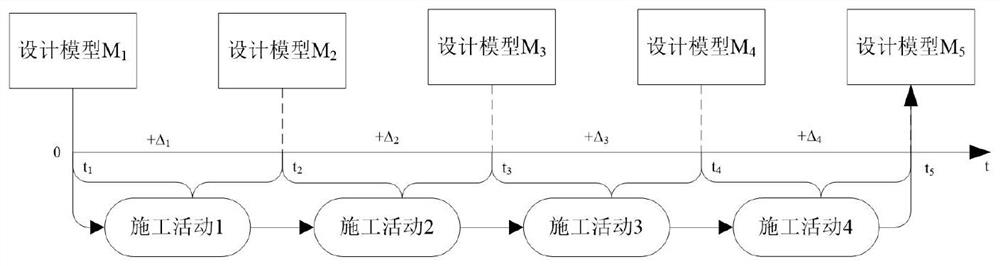

Technological process digitization method for intelligent construction

PendingCN114266145ASpread evenlyCoordinated and efficientDesign optimisation/simulation3D modellingProcess qualityDesign phase

The invention provides a technological process digitization method for intelligent construction. The method comprises the following steps of S1, forming a construction process design model which comprises a three-dimensional geometric model, attribute information and annotation information and is continuously derived along with time according to requirements of a design stage on a construction process; s2, forming a structured construction process information model according to the process preparation information, the constraint elements, the resource elements, the process activity information and the process product information of the design stage and the construction stage; s3, combining the construction process design model and the construction process information model to form a construction process model; s4, performing construction process-oriented process information expression based on the construction process model; and S5, forming an interactive construction operation instruction book for guiding the construction process of the building engineering. According to the method, the construction technological process in the construction process is standardized, a three-dimensional visualization technical form is adopted, the technological information in the construction process is visually displayed, and effective control over the construction quality and the technological quality of building engineering is achieved.

Owner:NANCHANG UNIV

Method for reinforcing circular pipe culvert by adopting HDPE winding reinforcing tubes and cement mortar

ActiveCN105672147AImprove bearing capacityIncrease the cross-sectional areaGround-workFoundation repairEngineeringCement mortar

Owner:CHANGAN UNIV +1

Tunnel Collapse Treatment Method for Convergent Cavity Collapse

ActiveCN110656954BEasy to operateImprove project qualityUnderground chambersTunnel/mines ventillationCollapsed cavityLandslide

The invention discloses a tunnel collapse handling method for a convergent collapse cavity, and relates to the field of tunnel engineering. By the adoption of the tunnel collapse handling method for the convergent collapse cavity, the problem that an existing handling method lacks operability, can cause potential safety hazards, and is not economical is solved. According to the technical scheme, the tunnel collapse handling method for the convergent collapse cavity comprises the steps that first, after the tunnel collapse cavity is stabilized, a construction platform is formed by means of collapse residues; second, a landslide-affected section is divided into an excavated landslide-affected section and a non-excavated landslide-affected section which are separately reinforced; third, concrete is sprayed to support the collapse cavity; fourth, a temporary support and a formwork are constructed on a landslide section, a manhole is formed in the portion, in the middle of the landslide section, of a tunnel vault, the collapse cavity is backfilled with concrete, landslide anchoring rods are constructed, reinforcement of the temporary support and the landslide-affected section is removed, and the construction platform is removed through excavation; and finally, a tunnel drain pipe and a waterproof plate are constructed according to original design, and secondary lining concrete is constructed. The tunnel collapse handling method has high practical value in handling convergent tunnel collapse cavities.

Owner:CHINA HYDROELECTRIC ENGINEERING CONSULTING GROUP CHENGDU RESEARCH HYDROELECTRIC INVESTIGATION DESIGN AND INSTITUTE

Local difference freezing pipe capable of controlling freezing section and applied to freezing construction

The invention relates to the technical field of artificial stratum freezing method construction of underground engineering, in particular to a local difference freezing pipe capable of controlling a freezing section and applied to freezing construction. The freezing pipe comprises an upper control freezing section, a lower control freezing section, a partition device, a liquid inlet pipe, a liquid return pipe and a control valve; and different valves are controlled, and the flowing path of low-temperature refrigerant in the freezing pipe is controlled. According to the local difference freezing pipe, selective freezing can be achieved, the defect that a traditional freezing pipe can only conduct whole-section freezing is overcome, controlled freezing of stratums with different layer depths can be achieved, the freezing efficiency of the freezing pipe is improved, a freezing area and the freezing section can be controlled, various construction requirements and engineering actual working condition requirements are met, and the working efficiency is improved. The local difference freezing pipe has the outstanding characteristics of being easy to operate, high in construction practicability, excellent in economical efficiency and the like, and has high application and popularization value.

Owner:ANHUI UNIV OF SCI & TECH

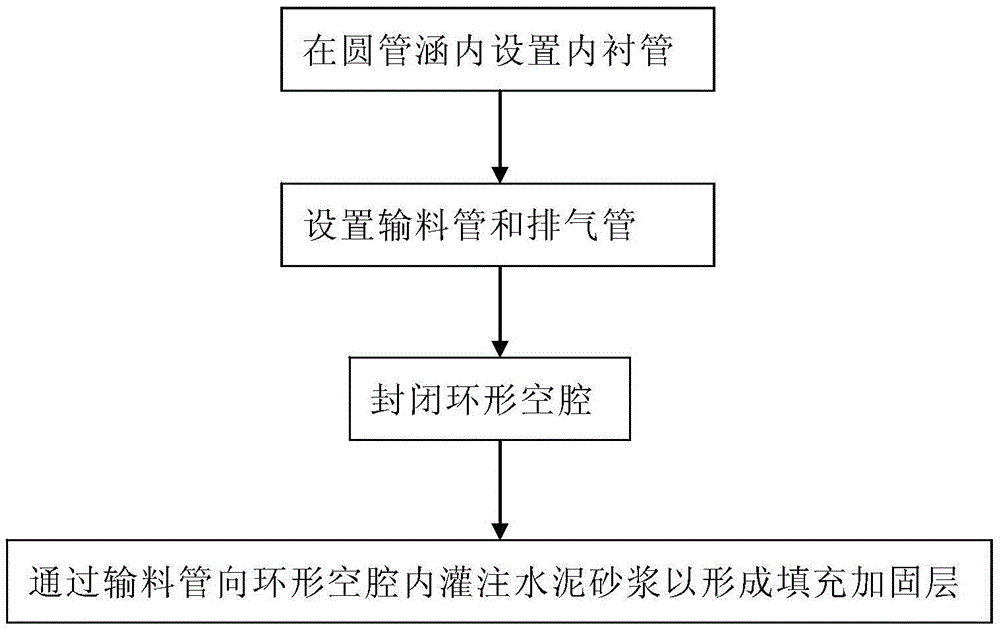

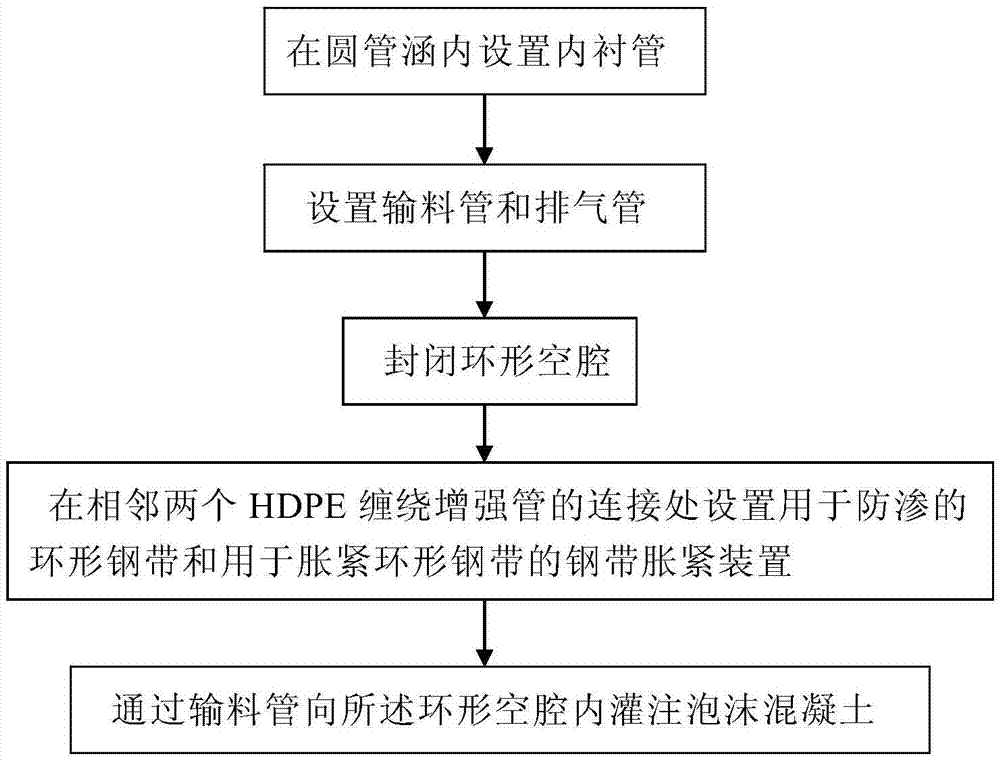

Reinforcing method of circular culvert

ActiveCN105442463APrevent leakageImprove anti-seepage performanceGround-workFoam concreteEngineering

The invention discloses a reinforcing method of a circular culvert. The method includes the following steps of arranging a lining pipe in the circular culvert, wherein a plurality of HDPE winding reinforcing pipes are sequentially connected and moved into the circular culvert to form the lining pipe, and an annular cavity is formed between the lining pipe and the circular culvert; arranging a material conveying pipe and an exhaust pipe, wherein the material conveying pipe and the exhaust pipe extend into the annular cavity; closing the annular cavity, wherein a first blocking end wall for closing one end of the annular cavity is constructed at the water inlet of the circular culvert, and a second blocking end wall for closing the other end of the annular cavity is constructed at the water outlet of the circular culvert; arranging an anti-leakage annular steel belt and a steel belt expansion device at the joint of every two adjacent HDPE winding reinforcing pipes, and filling the annular cavity with foamed concrete through the material conveying pipe to form a filling reinforcing layer. By means of the reinforcing method, durability repair of the circular culvert can be achieved; by enlarging the sectional area of a culvert bearing component, the culvert bearing capacity is improved.

Owner:CHANGAN UNIV

A microbial reinforcement structure at the end of a shield tunnel and its construction method

InactiveCN106285695BImprove reinforcement effectSmooth in and out of the holeTunnelsVertical tubeComing out

Owner:HAINAN UNIV

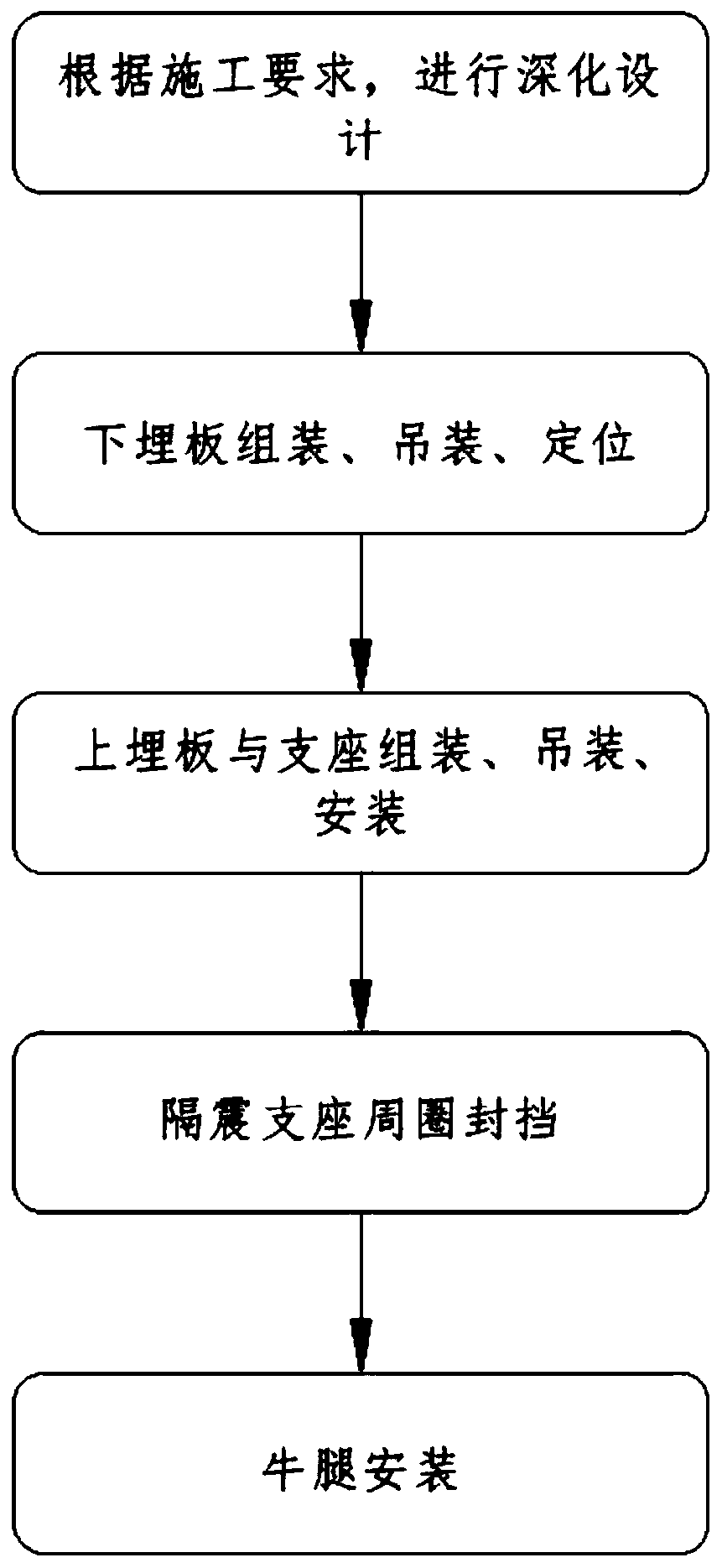

Earthquake-insulation construction process based on LRBLNR type support seat

InactiveCN111236464AImprove the success rate of an installationImprove compactnessProtective buildings/sheltersBuilding material handlingArchitectural engineeringMolten slag

The invention discloses an earthquake-insulation construction process based on an LRBLNR type support seat. The earthquake-insulation construction process comprises the steps that (1), deepening design is performed according to the construction requirements; (2), lower buried plate assembling, hoisting and positioning are performed; (3), upper buried plate and support seat assembling, hoisting andinstalling are performed; (4), earthquake-insulation support seat circumferential sealing blocking is performed; and (5), bracket installing is performed. By means of the earthquake-insulation construction process based on the LRBLNR type support seat, the primary installation success rate of the earthquake-insulation support seat is improved, errors in the installation procedure are reduced, theconstruction schedule is greatly accelerated, the concrete compactness in casting is greatly improved, and construction quality control is conveniently performed, convenience is provided for follow-up construction, influence of high temperature or molten slag on the support seat in the upper-portion steel structure welding process can be prevented, deface caused to the support seat in the upper-portion structural concrete pouring process is avoided, and the situation that concrete intrudes into a connecting plate to influence later-period replacement of the support seat further can be prevented.

Owner:CHINA RAILWAY CONSTR GRP BEIJING ENG CO LTD +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com