Patents

Literature

720 results about "Clerestory" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

In architecture, a clerestory (/ˈklɪərstɔːri/ KLEER-stor-ee; lit. clear storey, also clearstory, clearstorey, or overstorey) is a high section of wall that contains windows above eye level. The purpose is to admit light, fresh air, or both.

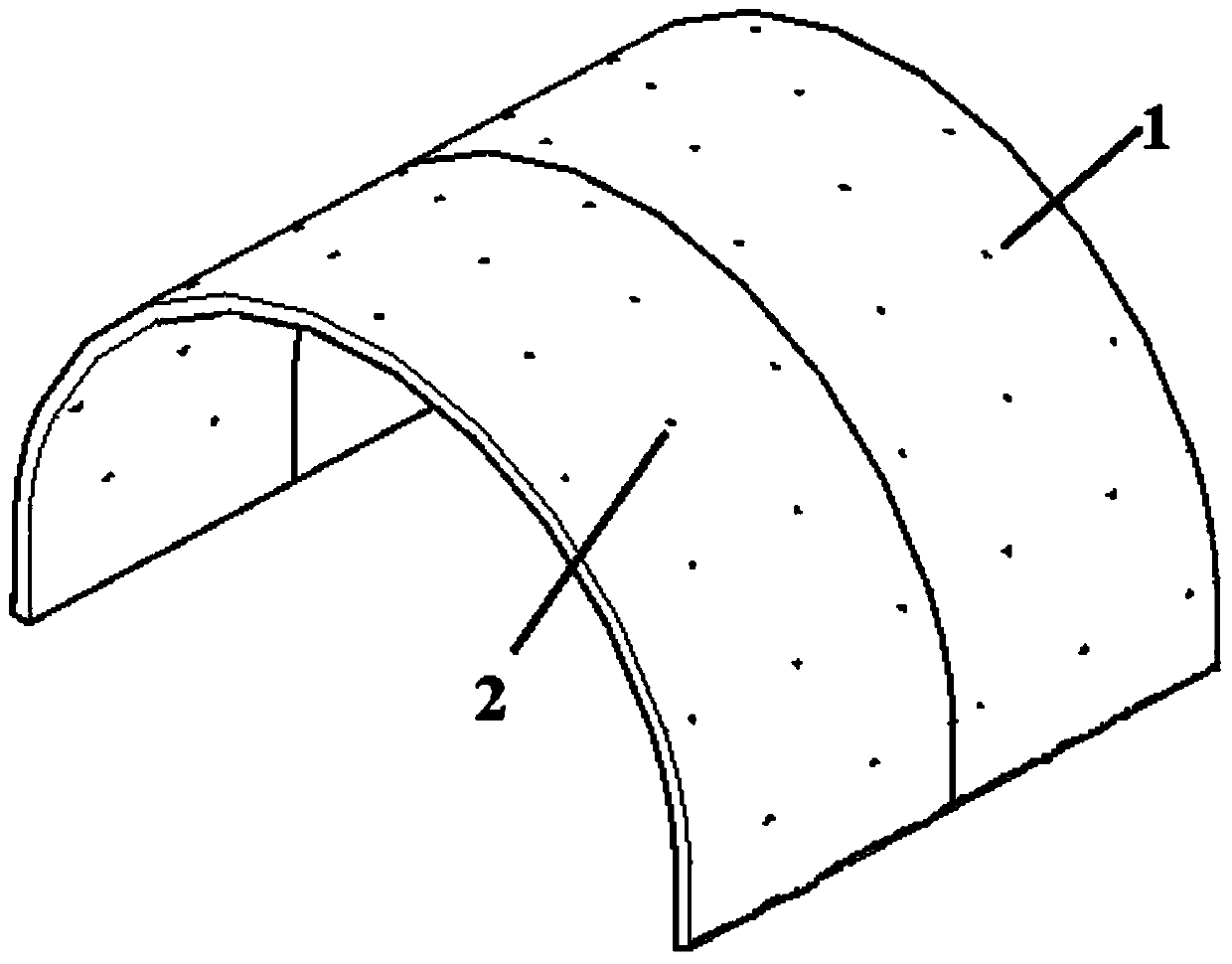

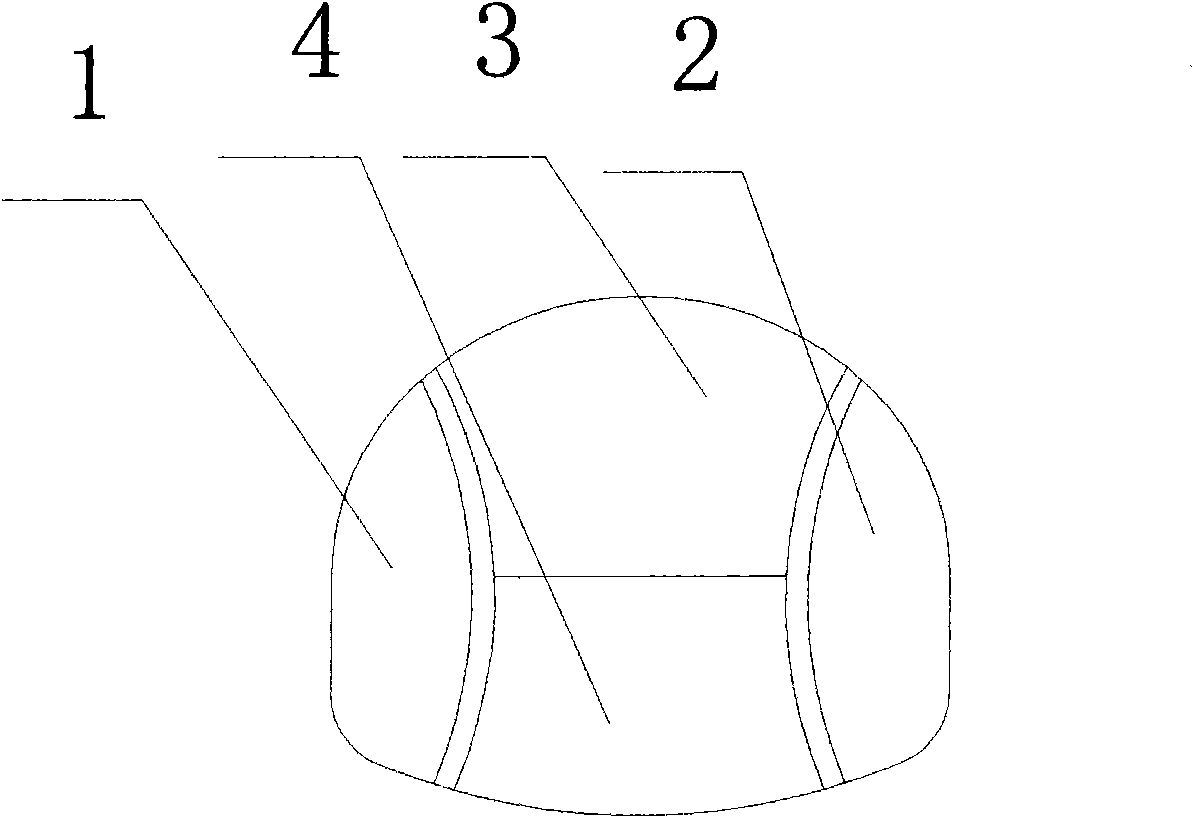

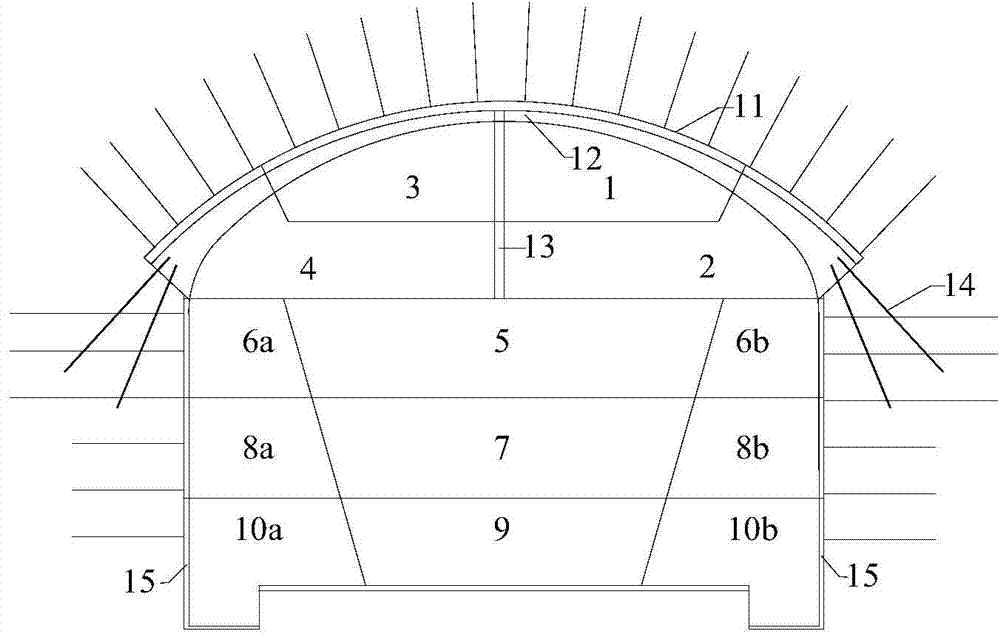

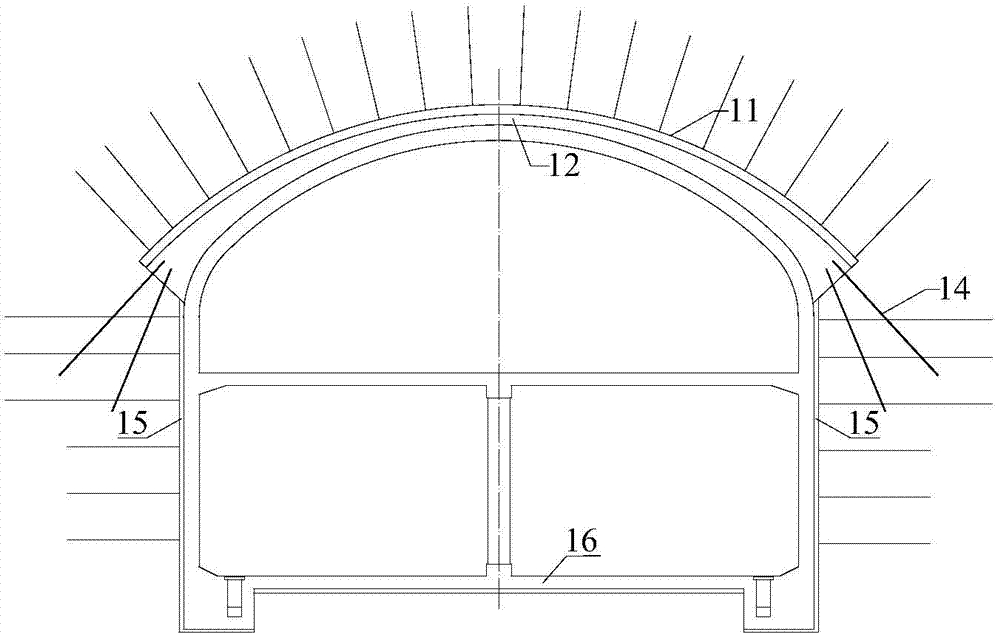

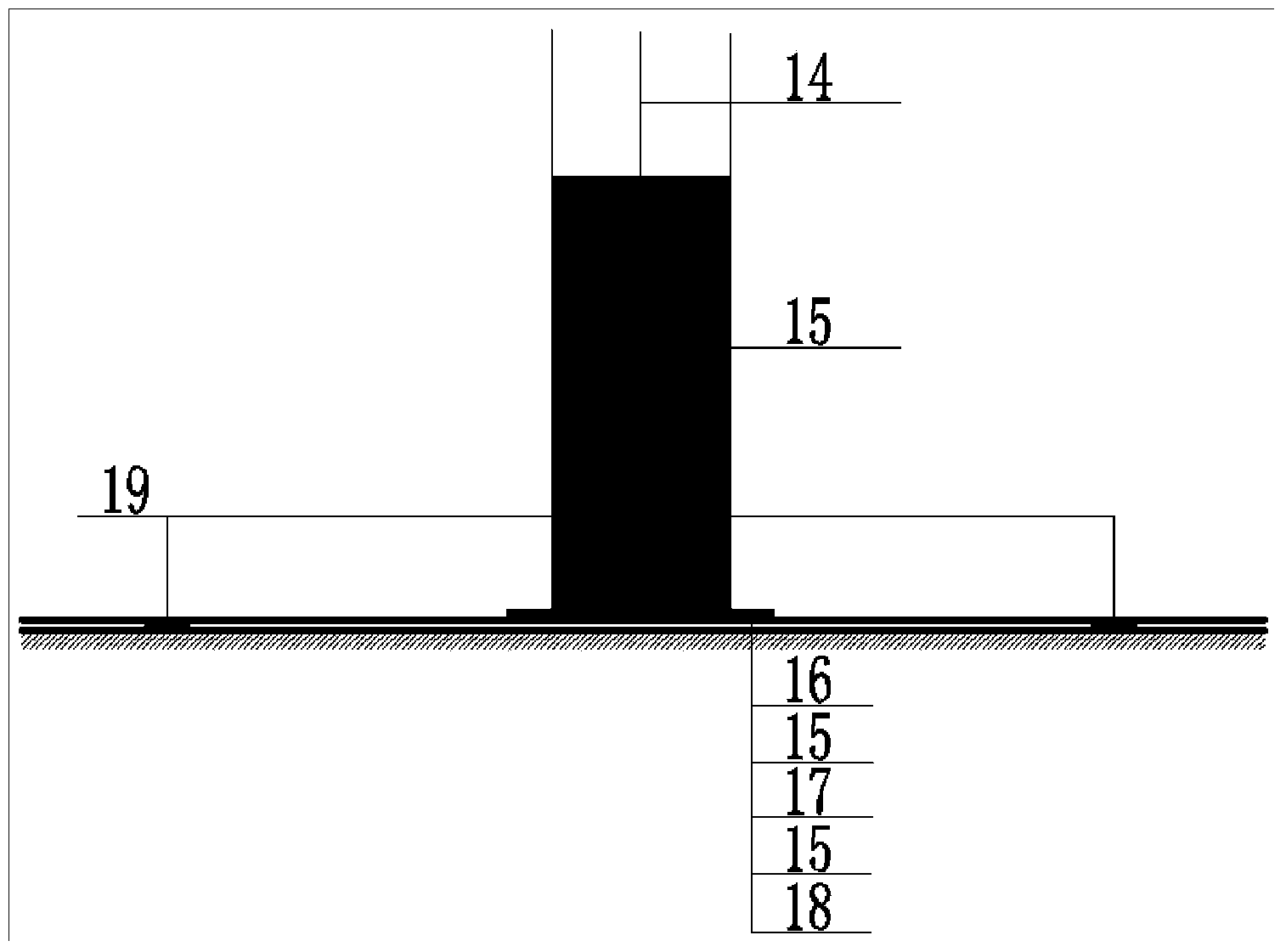

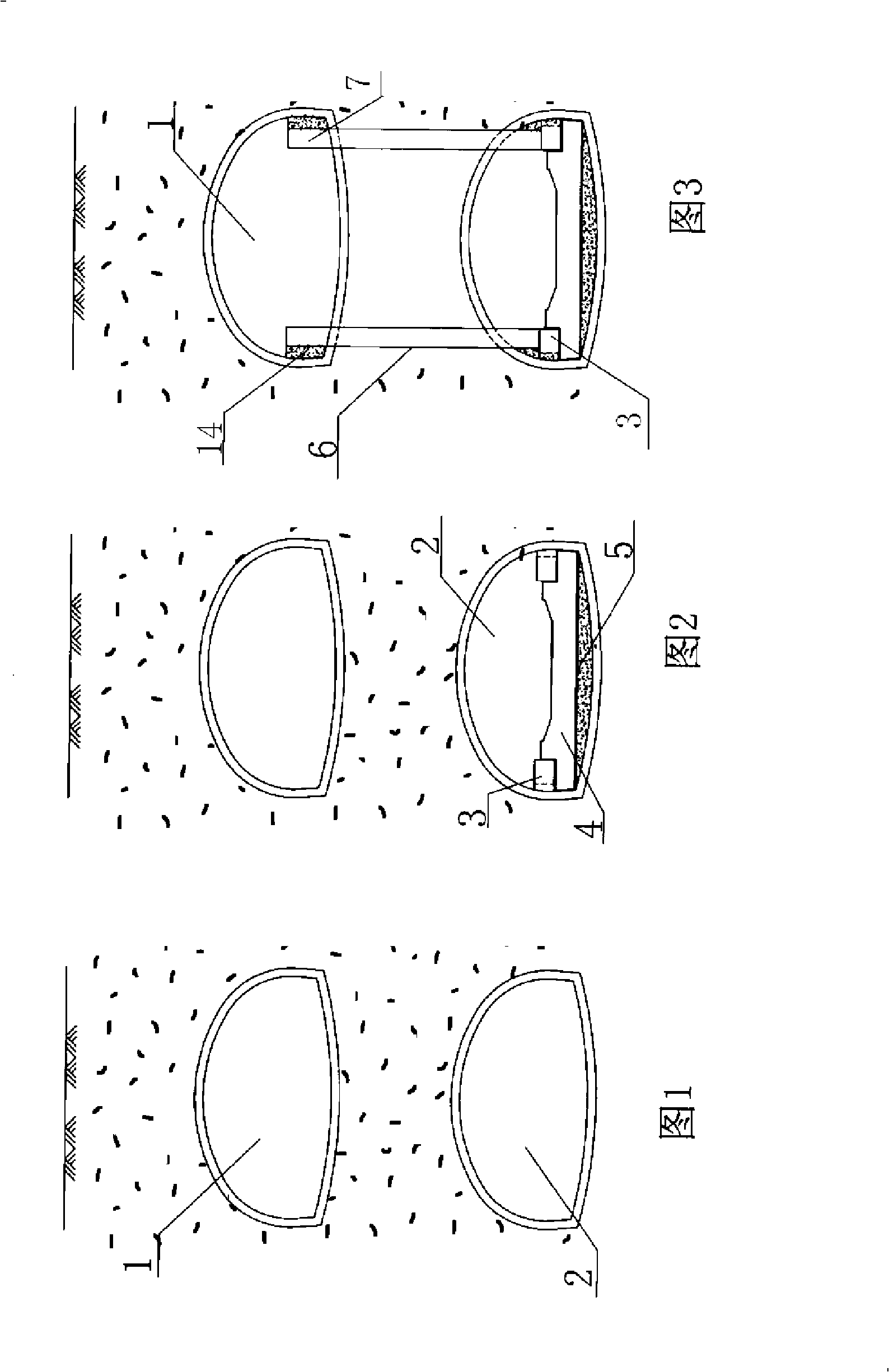

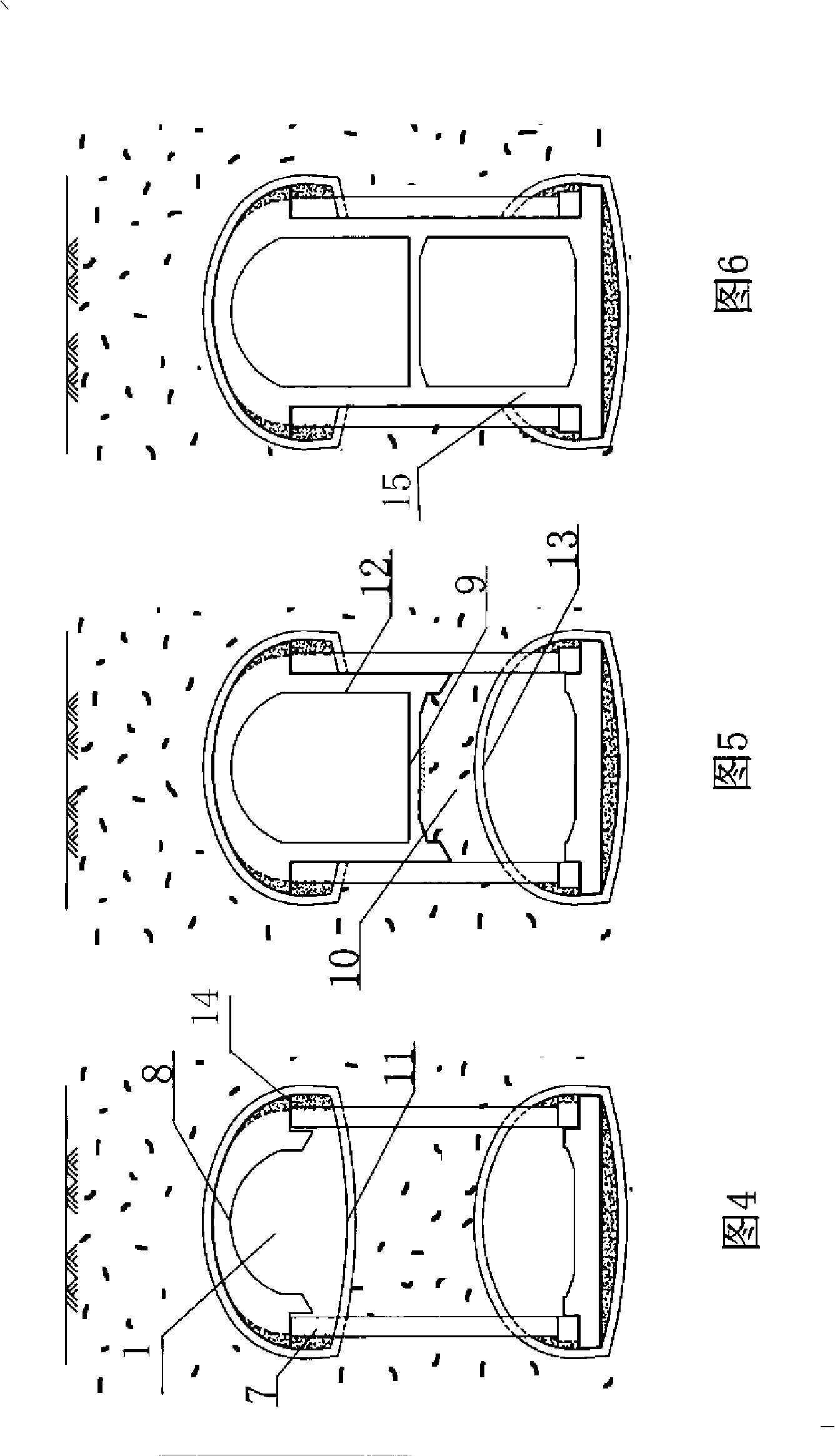

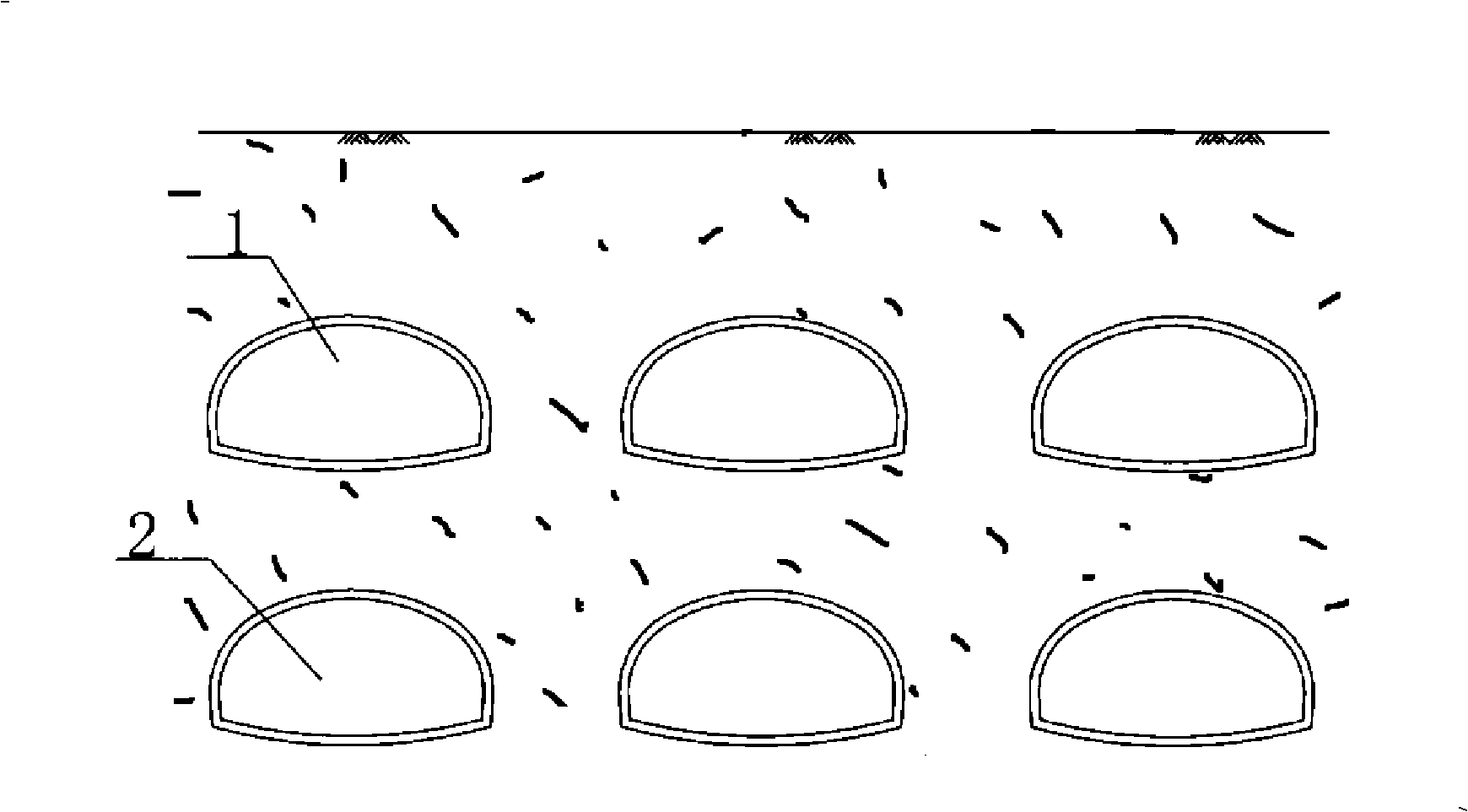

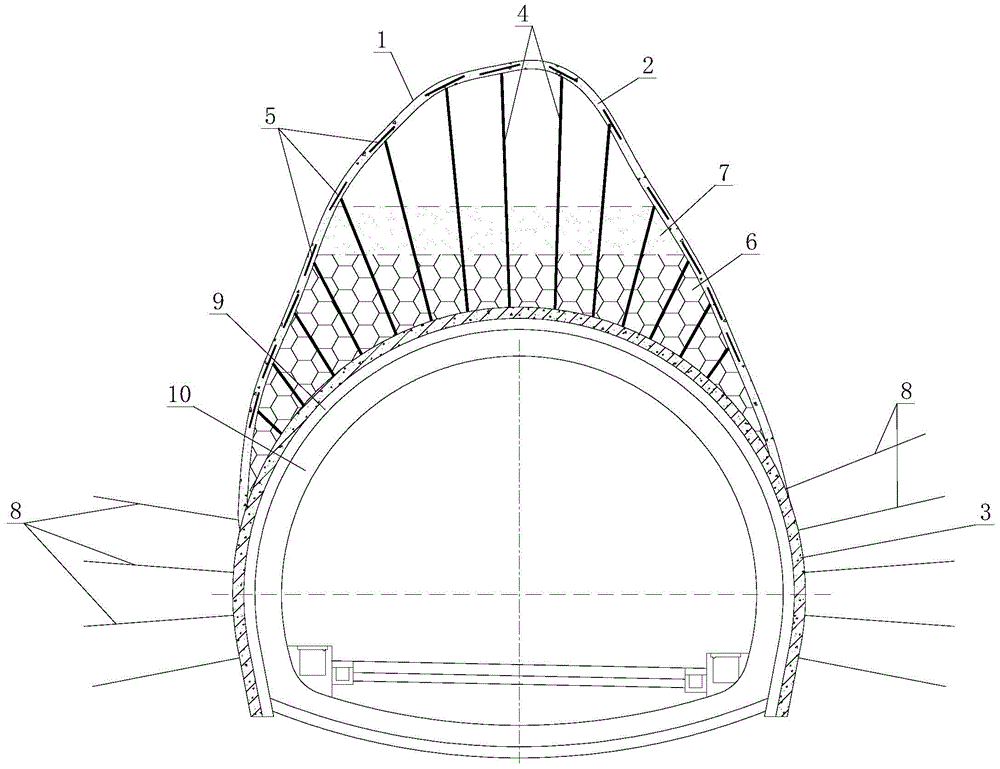

Construction method of pervious rib type arch beam tunnel

ActiveCN101324072AEasy constructionConstruction safetyArtificial islandsClimate change adaptationSupporting systemProcess safety

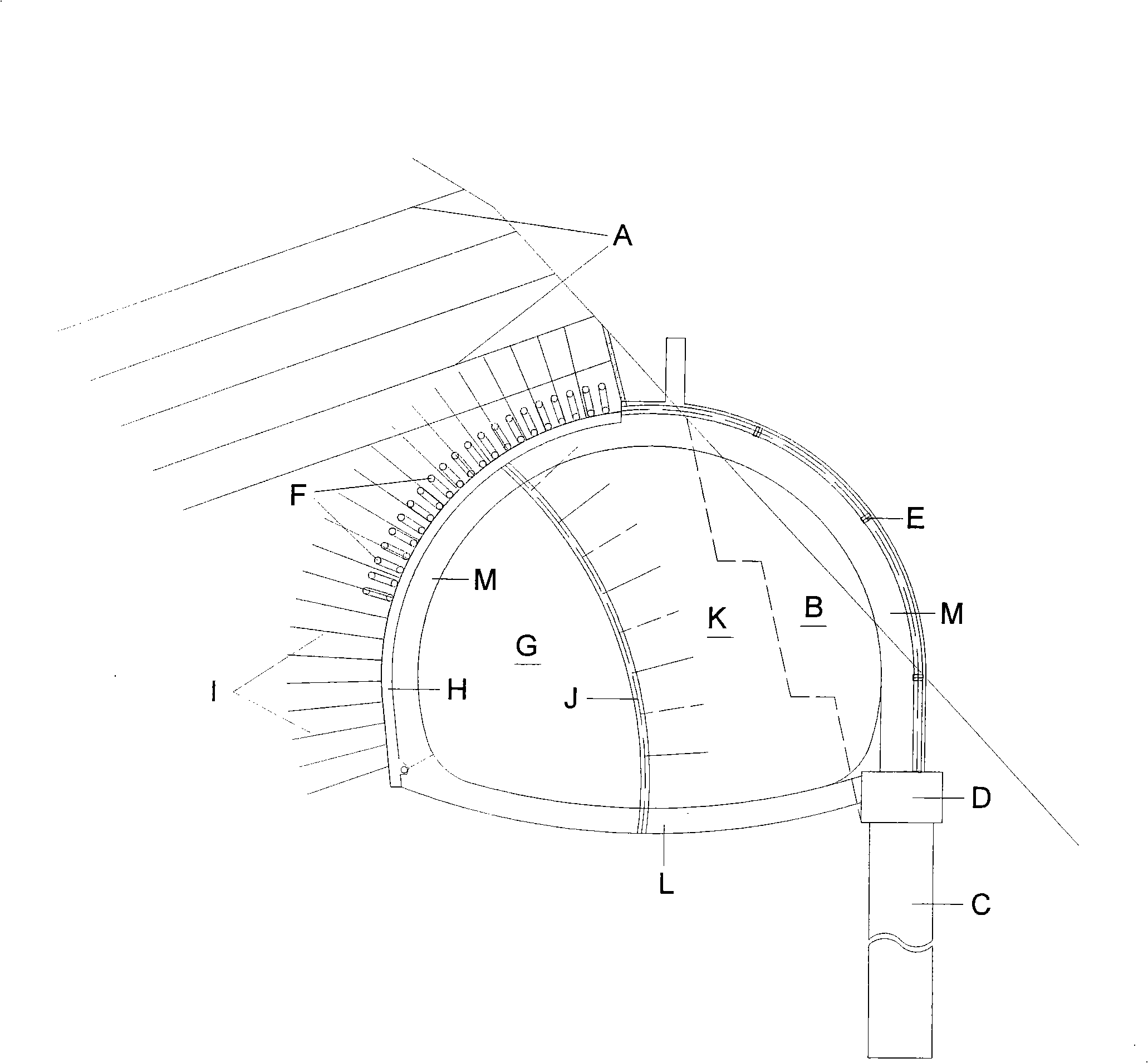

The invention discloses a through rib-typed arched girder tunnel construction method, comprising the steps as follows: before the excavation of the tunnel, the arch slope is reinforced by transverse pipe roof; the shaft excavation is carried out by a type of stepped excavation and reserving rock arch; after the wall rock deformation is basically stable, the internal side arch secondary lining, arch ground beam, the rock fall-proof retaining block, the rib-typed arched girder and the anti-collision wall are wholly constructed; the metering of each construction circulation excavation is 10-12m and the whole construction length is 6-8m. The invention is a set of whole construction method for the through rib-typed arched girder tunnel; the construction sequence and the supporting system are adaptable for the characteristics of the through rib-typed arched girder tunnel such as shallow burying, eccentric pressing and space forcing, effectively ensures the construction process safety and the stability of the tunnel structure, and provides a practically operatable construction technique for the generalization and application of the novel environmental-protective tunnel, namely, through rib-typed arched girder tunnel.

Owner:INST OF ROCK & SOIL MECHANICS CHINESE ACAD OF SCI +1

Construction method applicable to intersection between inclined shaft and slant hole of weak surrounding rock tunnel

The invention discloses a construction method applicable to an intersection between an inclined shaft and a slant hole of a weak surrounding rock tunnel, and the method comprises the following steps that (1) the inclined shaft is dug; (2) the arch part of an inclined shaft section is supported; (3) the vertical central line of a face at the intersection between the inclined shaft and the slant hole serves as a boundary, first a slant hole section on one side of the boundary is dug, and sectional digging is adopted on every side; an area which is enclosed by the arch top of the slant hole, the side walls of the slant hole on both sides and the extended surface of the ramp slope surface of the inclined shaft is a I part; an area which is enclosed by the plane of the intersection line of the ramp slope surface on an inclined shaft digging surface, the side walls of the slant hole on both sides and the extended surface of the ramp slope surface of the inclined shaft is a II part; and an area which is enclosed by the plane of the intersection line of the ramp slope surface on the inclined shaft digging surface, the side walls of the slant hole on both sides and the bottom of the slant hole is a III part; the slant hole section on the other side is dug in a sectional way; (4) supporting and reinforcement are carried out; and (5) inverted arch and lining construction are carried out. According to the method, the deformation of surrounding rock is reduced, some temporary supporting steps are saved on the premise of good safety, so that the procedures are simple, the construction cost is reduced, and the construction progress is improved.

Owner:中铁二十三局集团第四工程有限公司 +1

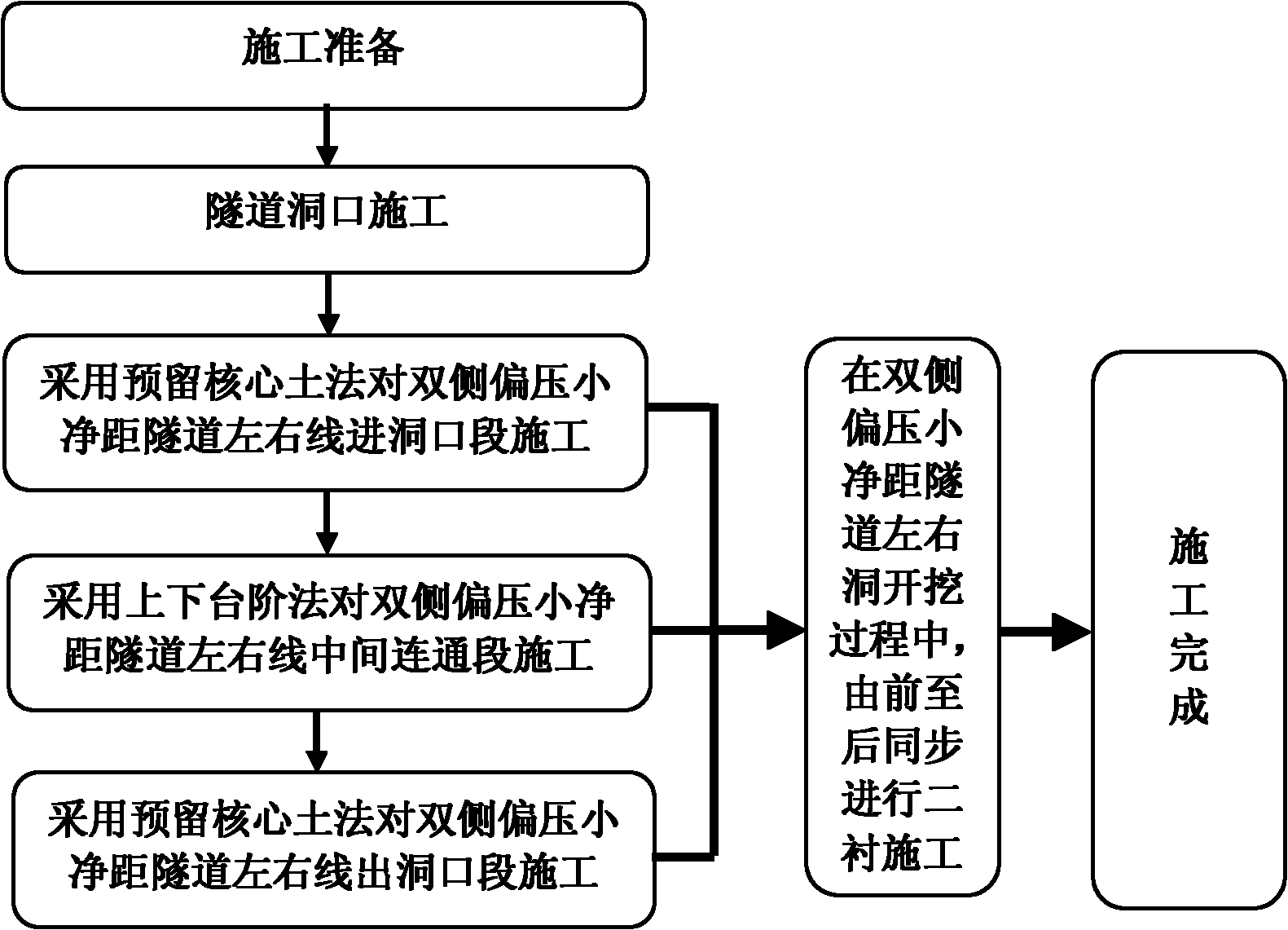

Construction method of bilateral biased small-clear distance tunnel

InactiveCN102128035AReasonable designThe construction steps are arranged compactlyUnderground chambersTunnel liningClerestoryEnvironmental geology

The invention discloses a construction method of a bilateral biased small-clear distance tunnel, which comprises the following steps of: 1) preparing for construction; 2) constructing a tunnel portal; 3) adopting a reserved core soil method to construct tunnel entry portal sections, wherein a biased deep-buried side master cave is firstly constructed, and then, a tunnel shallow-buried side mastercave is constructed; 4) adopting a bench cut method to excavate a middle communication section of the tunnel; and 5) adopting a reserved core soil method to construct tunnel exit portal sections, wherein the distance between heading faces of the left and right caves of the tunnel is controlled to be 20-30m in the construction process from the tunnel entry portal sections to the exit portal sections; and carrying out secondary lining construction on the left and right caves of the tunnel from front to back. The invention has the advantages of reasonable design, compact construction steps and convenient construction process, can effectively control the ground subsidence, the vault settlement of the left and right caves, the inter-cave border convergence and the deformation and stress of themiddle rock pillar, reduces the construction hazard, saves the project cost, ensures the stability of the wall rock of the tunnel and the middle rock pillar, and lowers the construction risk of the bilateral biased small-clear distance tunnel.

Owner:CHONGQING UNIV

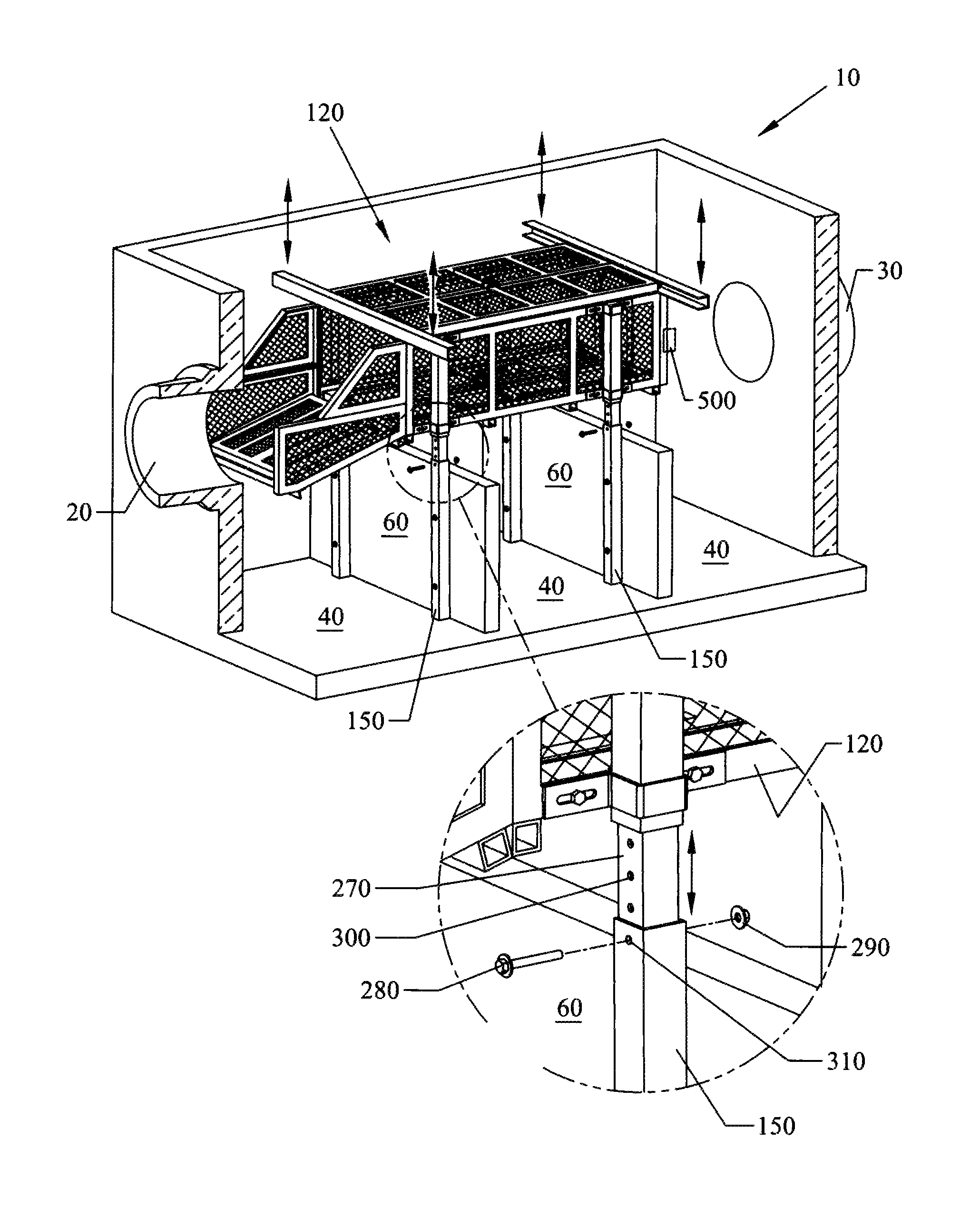

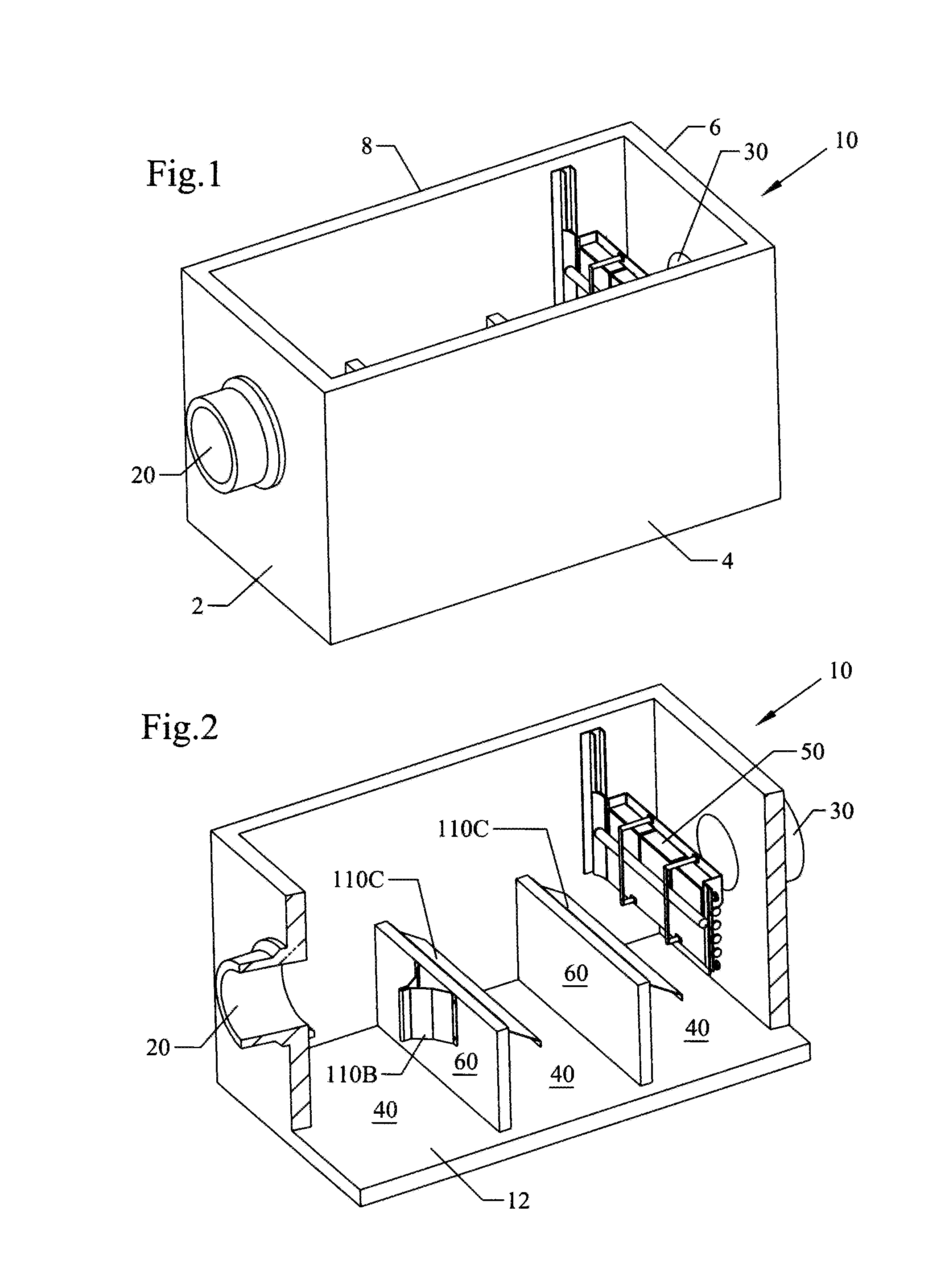

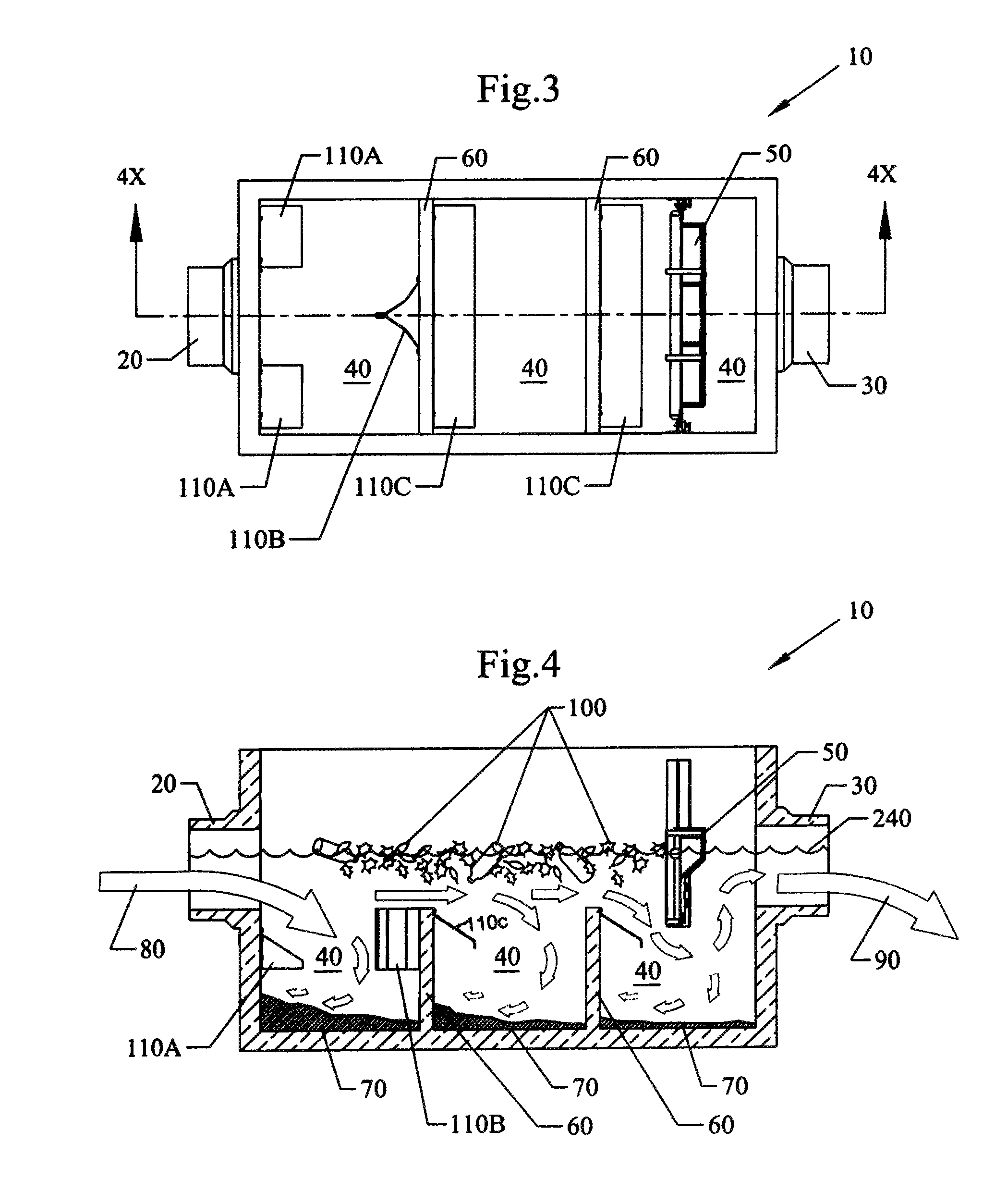

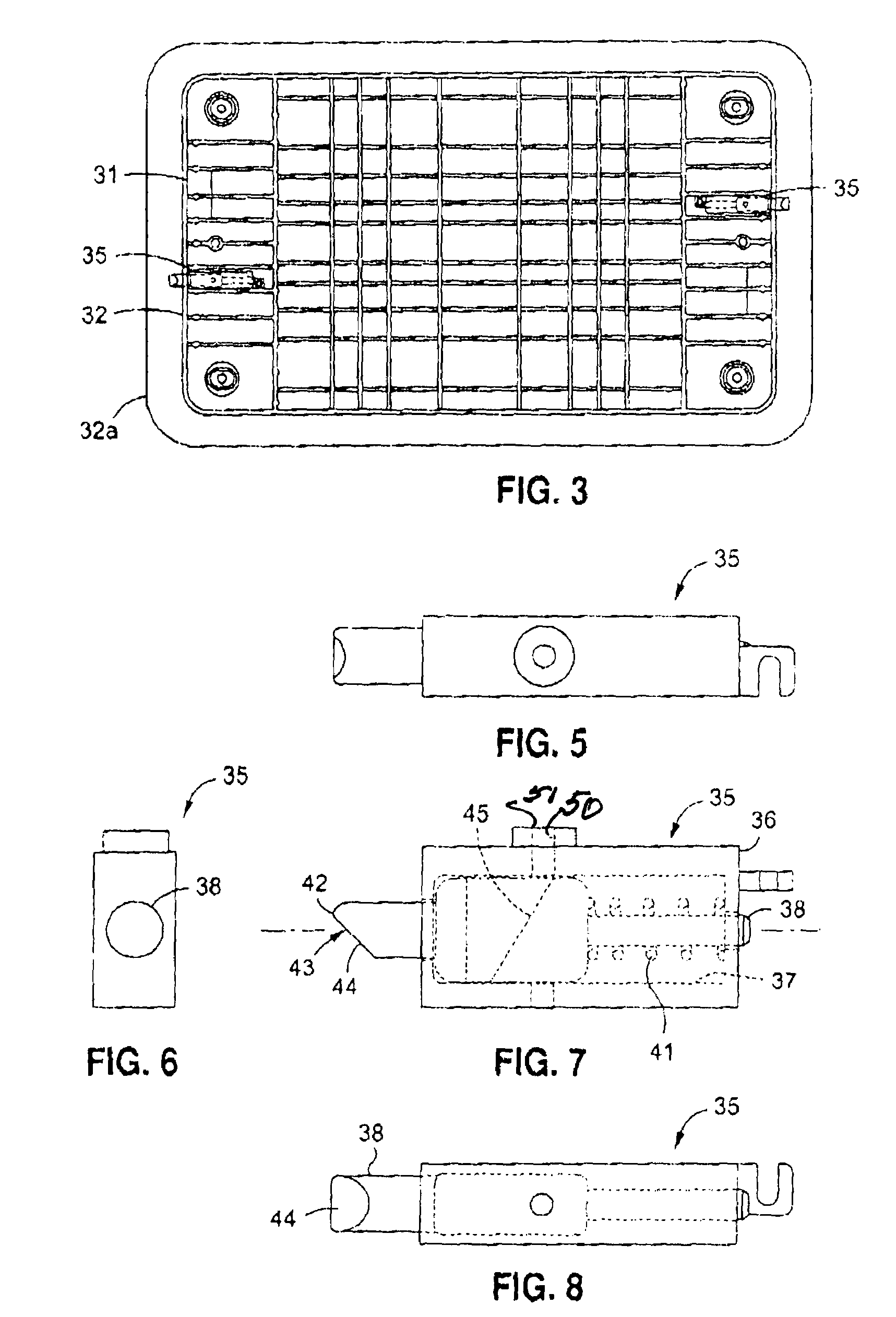

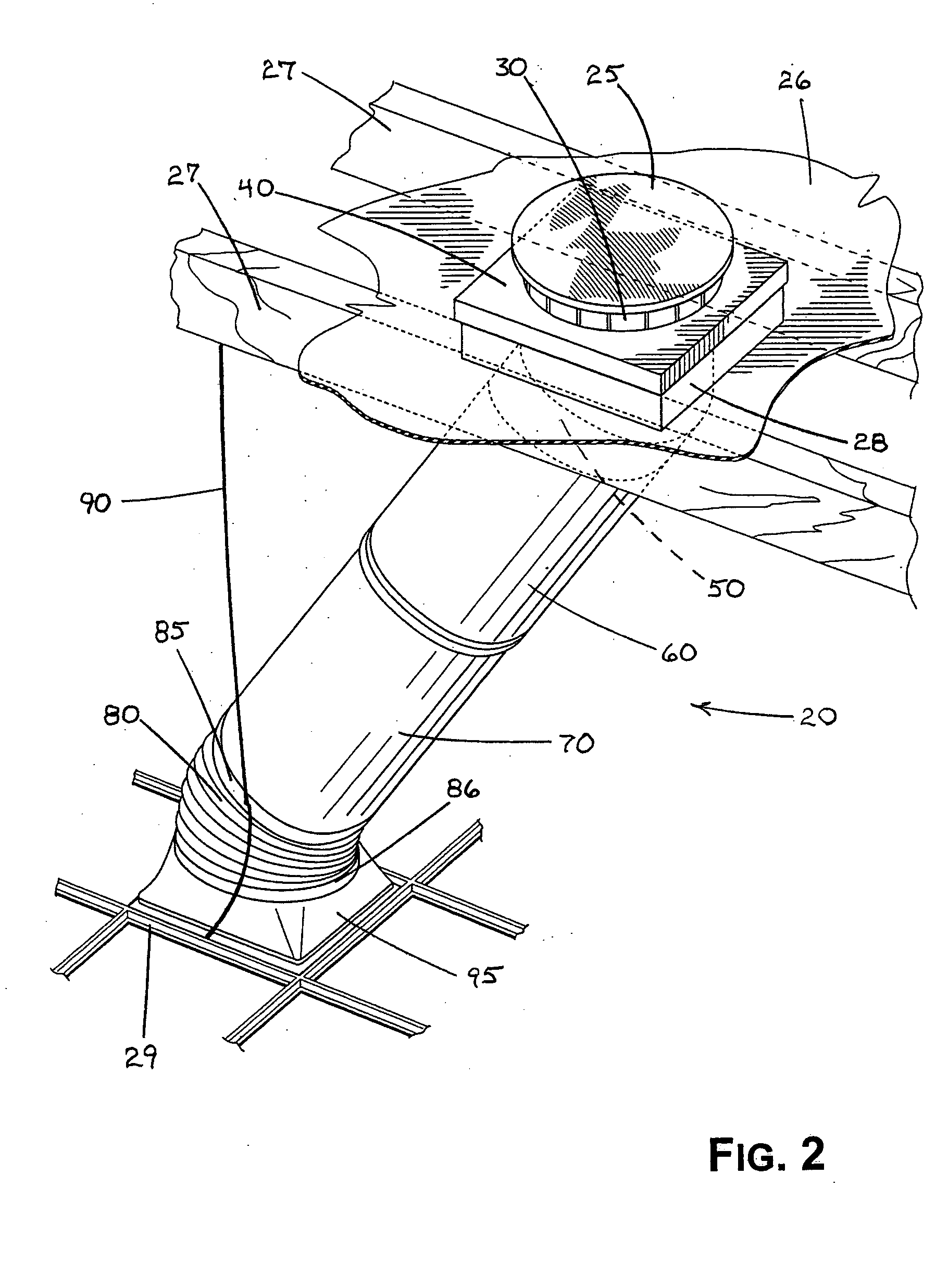

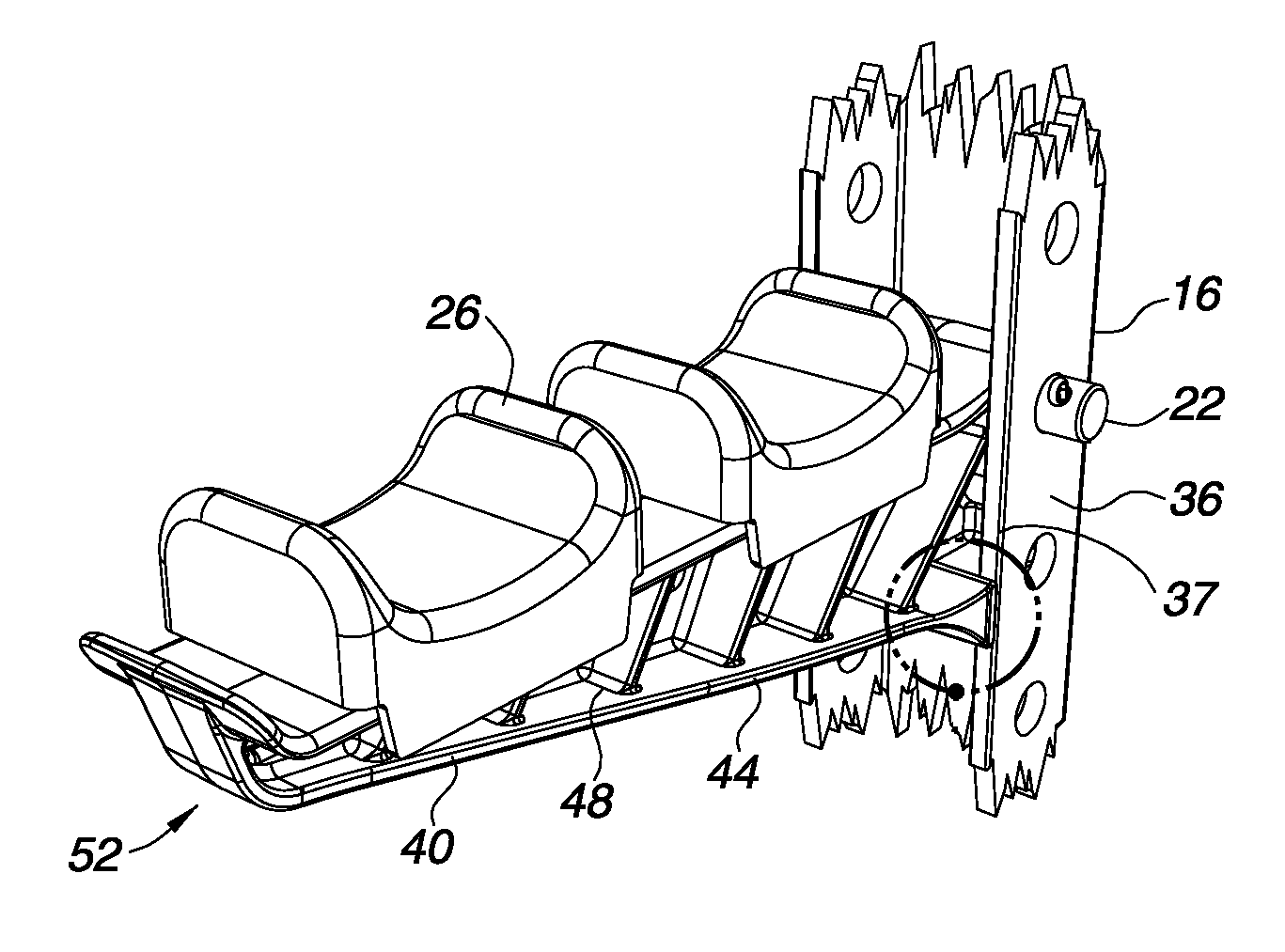

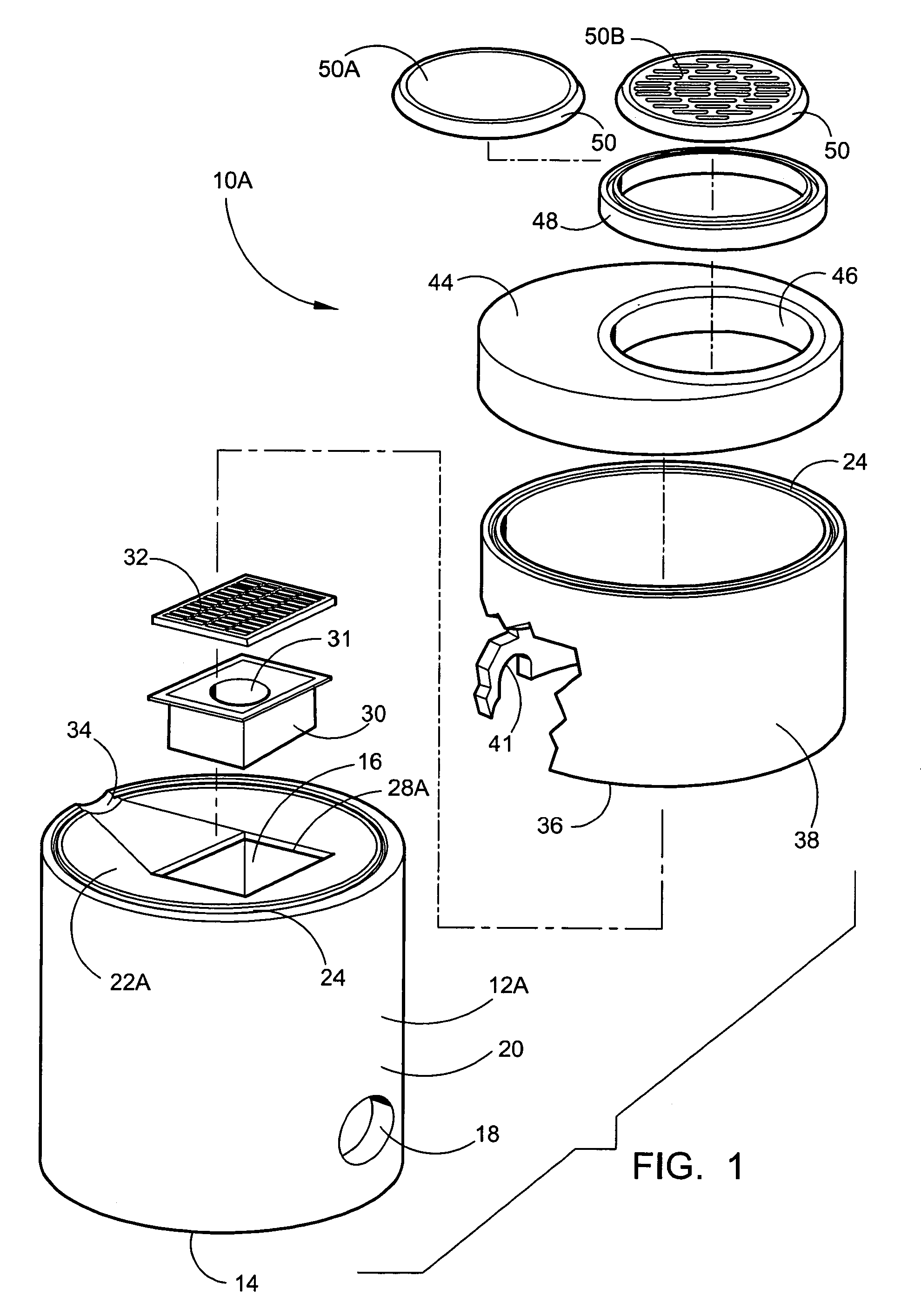

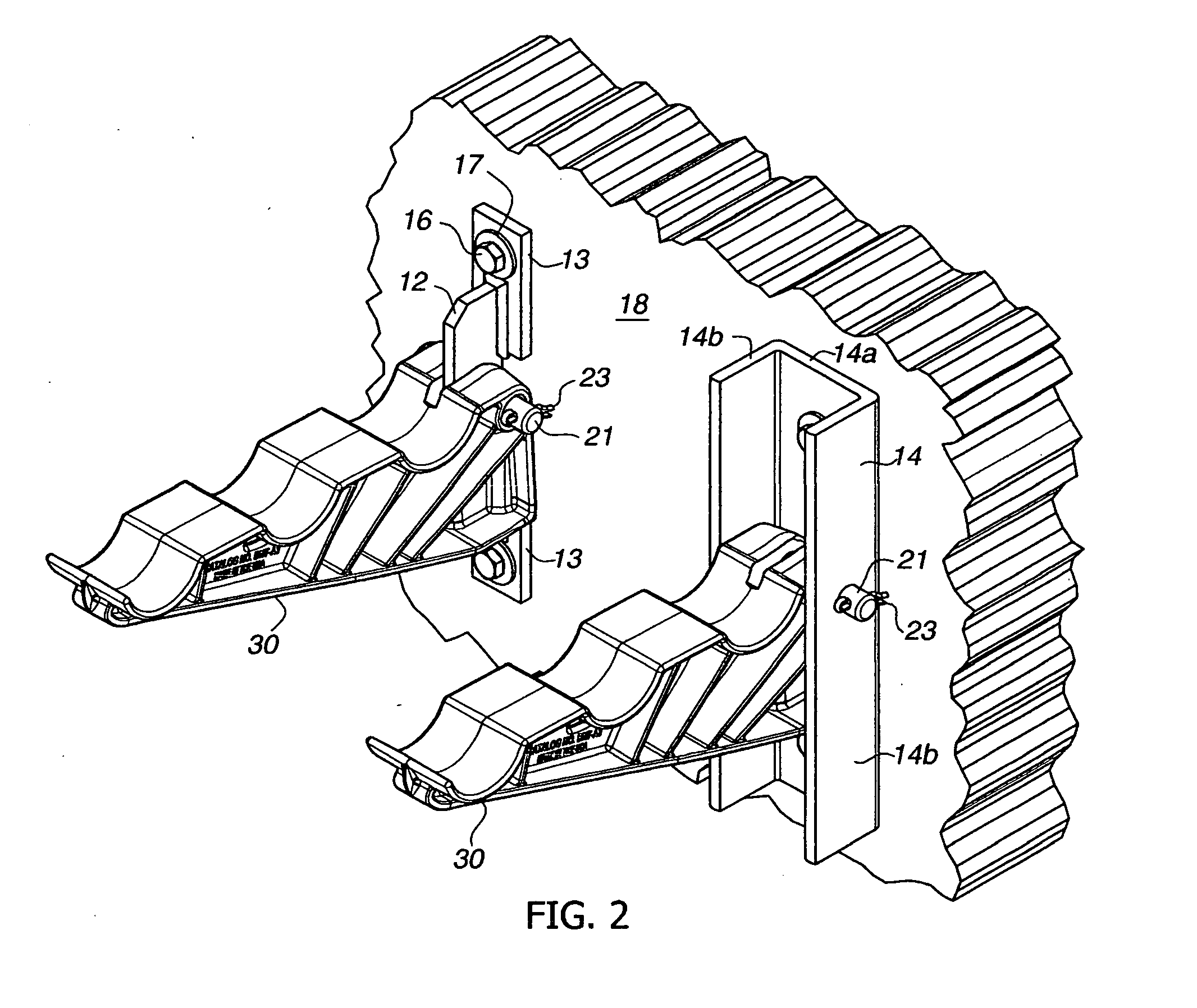

Telescoping post supports and sliding lid systems for filter baskets

Devices, apparatus, systems and methods of using an adjustable filter basket on telescoping post supports to raise and lower the filter basket so as to adjust the position of the inlet chute for different ground water levels in storm water treatment systems, along with horizontal slidable lids in tracks on the basket that allow access to the inside of the basket in vaults having ceilings close to the top of the baskets. A single winch point or floats can be used to raise and lower the filter basket on the telescopic post supports.

Owner:OLDCASTLE INFRASTRUCTURE INC

Treatment method for fault fracture zone collapse in tunnel construction process

InactiveCN104196546AReduce the risk of secondary landslidesLess investmentUnderground chambersTunnel liningShotcreteFracture zone

The invention discloses a treatment method for fault fracture zone collapse in the tunnel construction process. The method includes the steps that firstly, arch reinforcement is conducted on every two adjacent surrounding rocks in a collapse segment; secondly, a collapse body is removed, and concrete is jetted to the collapse tunnel face after the collapse body is removed to close the collapse segment; thirdly, a lifting jack acts on the four corners of each bottom of racks of formworks, the interval identical to the width of a steel arch is reserved between the formworks, formwork erection is conducted in time, and the formworks and the steel arch jointly form a supporting layer; fourthly, through holes reserved in the formworks in advance, an arch apex concrete layer is formed in a high-pressure grouting mode, and small grouting guide pipes are punched into arch springs and the side walls of the steel arch; fifthly, the front end of a bottom die composed of the formworks and the steel arch is grouted and reinforced through the small guide pipes, operation of the next construction circulation stage of the collapse segment is conducted, and the first step, the second step, the third step and the fourth step are specifically repeated; sixthly, after second circulation is finished, supports of arch protecting layer concrete are formed through conveying ports embedded through the second step.

Owner:SHANDONG UNIV

U-shaped steel composite support structure for deep dynamic pressure soft rock roadway and construction method of U-shaped steel composite support structure

InactiveCN106677797AConform to the law of deformationAvoid local damageUnderground chambersTunnel liningFiberPolyester

Owner:ANHUI UNIV OF SCI & TECH

Storm drain basin gate system

An automatically openable and closeable gate system that will find primary use with the street curb opening to a catch basin or vault of a storm drain system, and for other similar openings, the system having a gate which during dry and low-flow water drainage situations will be in a closed position such that items of trash, debris, litter, leaves and the like will be prevented from entering the basin, vault or system, yet in periods of heavy rainfall or other heavy water run-off situations will automatically open to allow free flow of water into the basis or vault to alleviate water accumulation in the adjacent street and other surrounding areas.

Owner:FLURY RONALD J

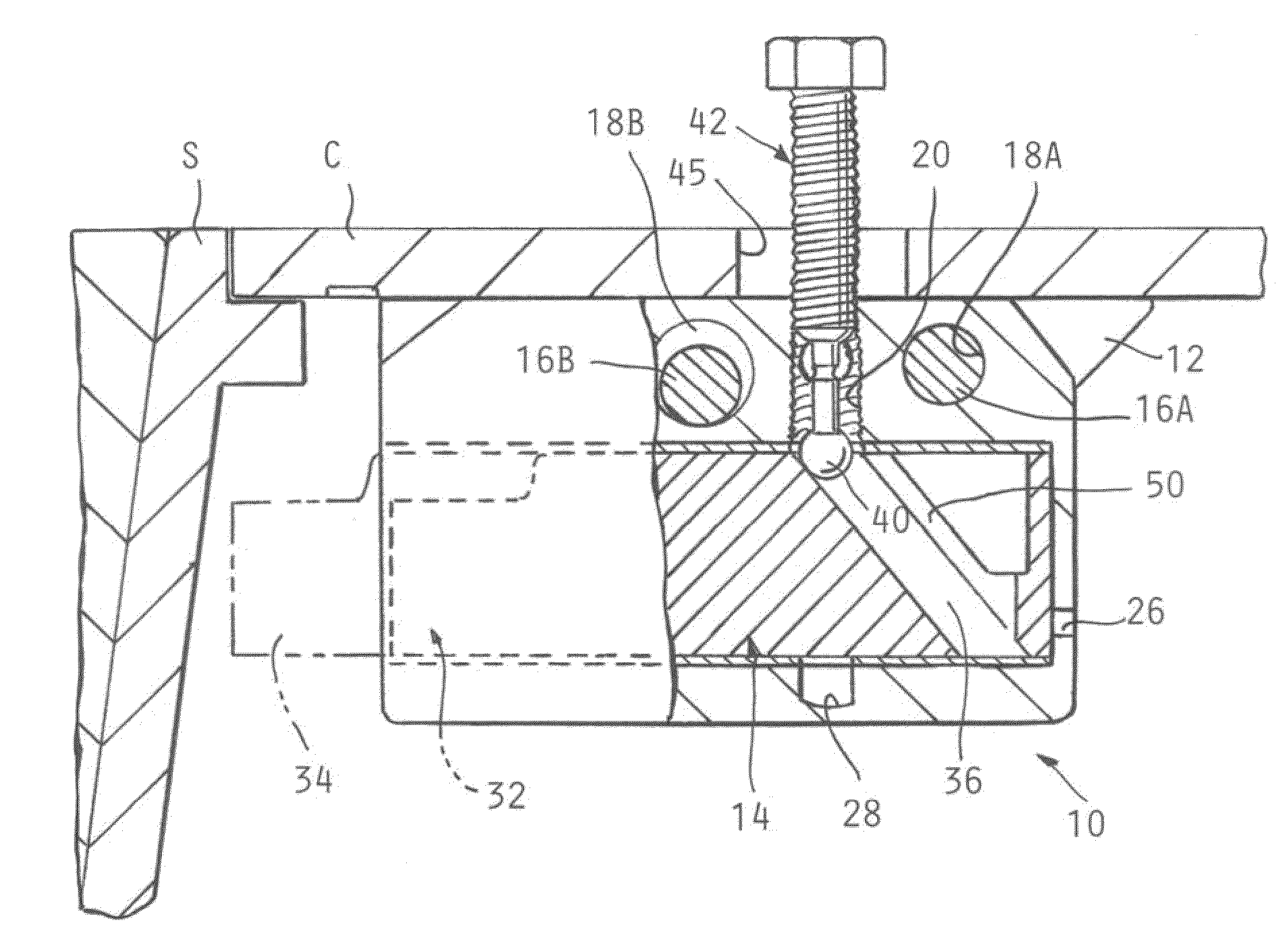

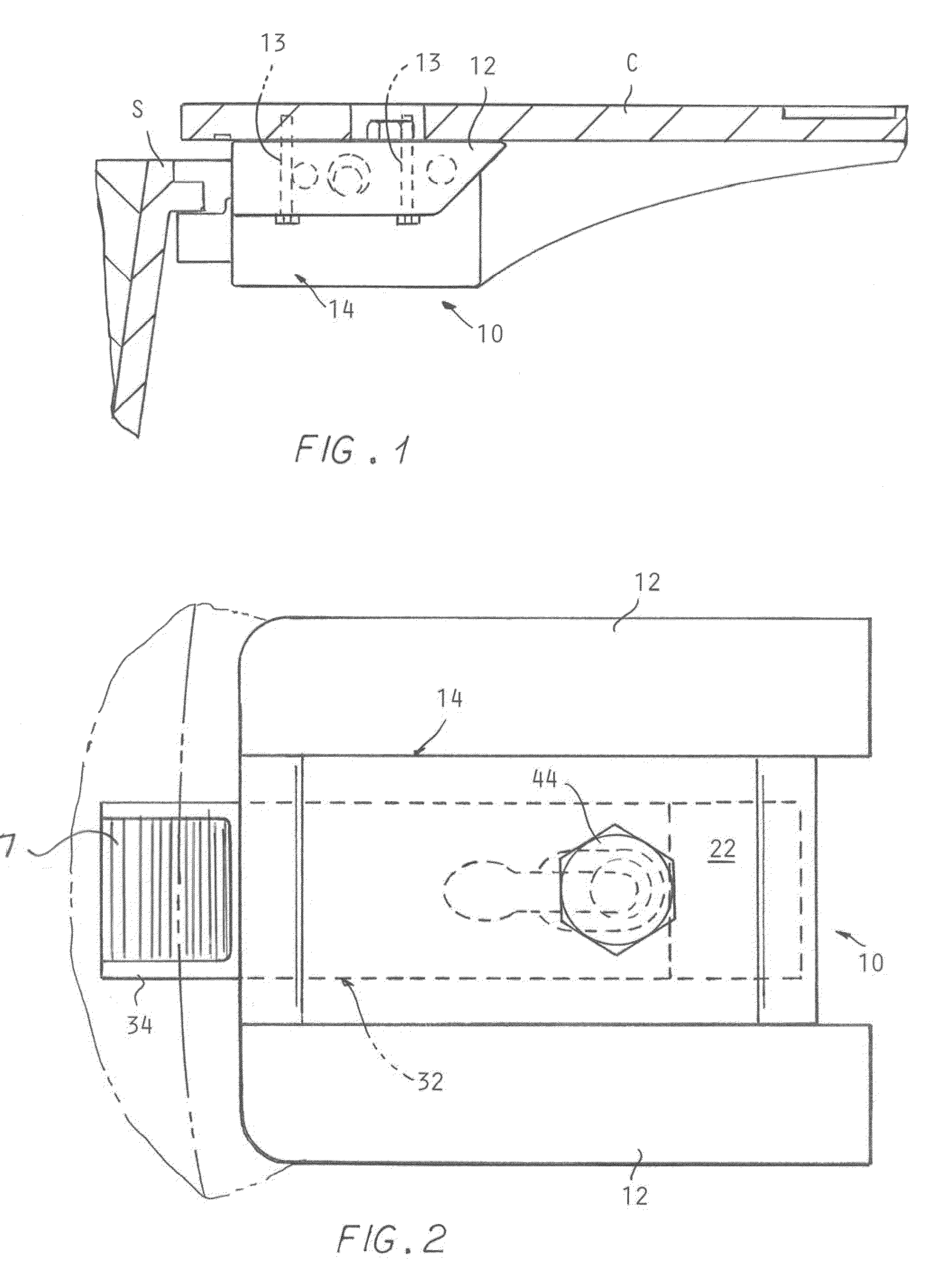

Manhole cover stop mechanism

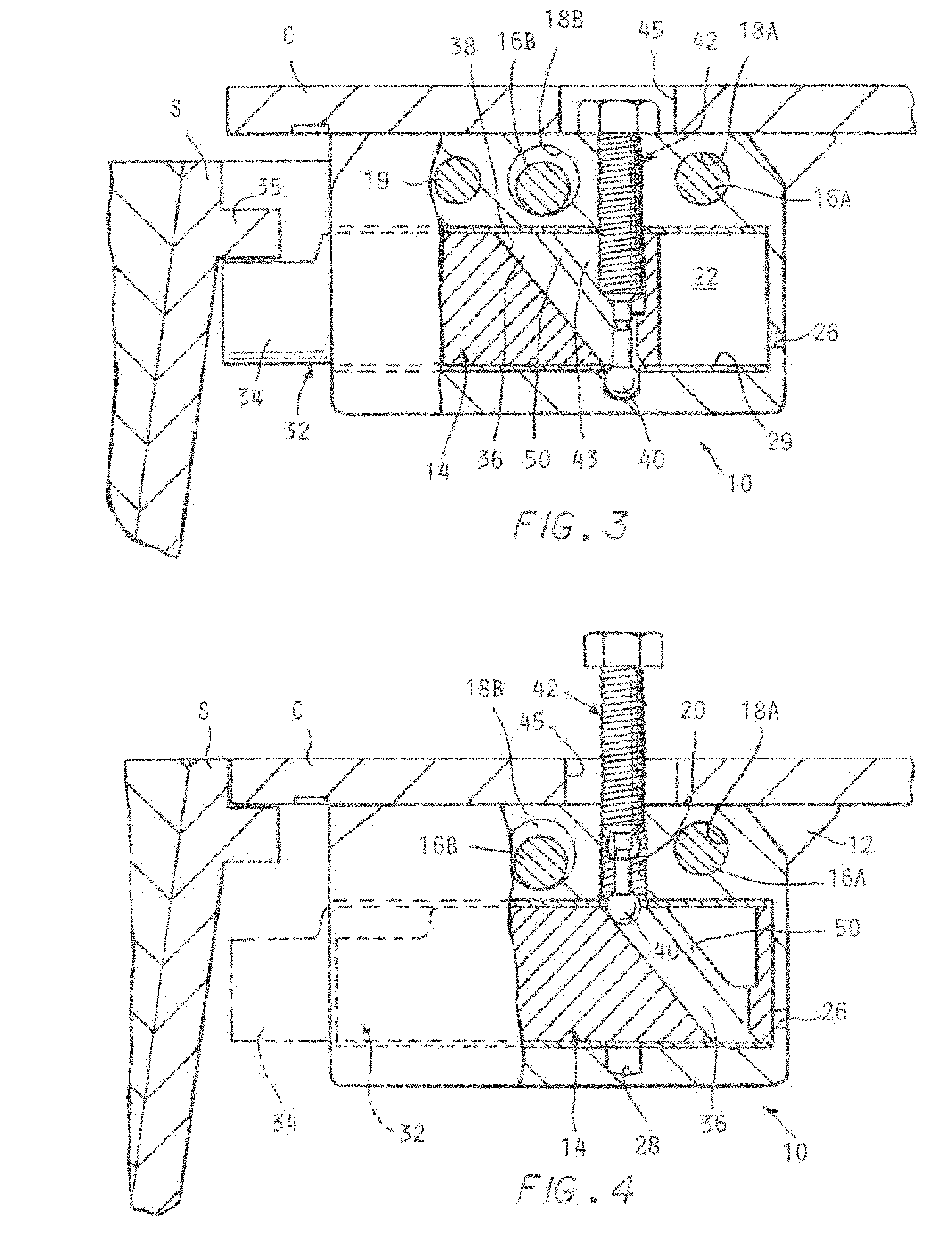

ActiveUS7891904B2Thorough removalComplete structureBuilding roofsArtificial islandsClerestoryElectrical and Electronics engineering

A stop mechanism advantageously combined with a manhole cover includes a holder body having a passage which slidably receives a stop member able to be cammed in and out upon advance or retraction of a threaded drive member having an enlarged tip engaged with a down sloping channel formed in the stop member. Upper sides of the channel engage the tip upon reversal of the drive member to cam the stop member back into the holder body. The stop member when extends prevents removal of the cover from being blown completely free of the manhole vault structure in the event of an explosion.

Owner:NEENAH FOUNDRY

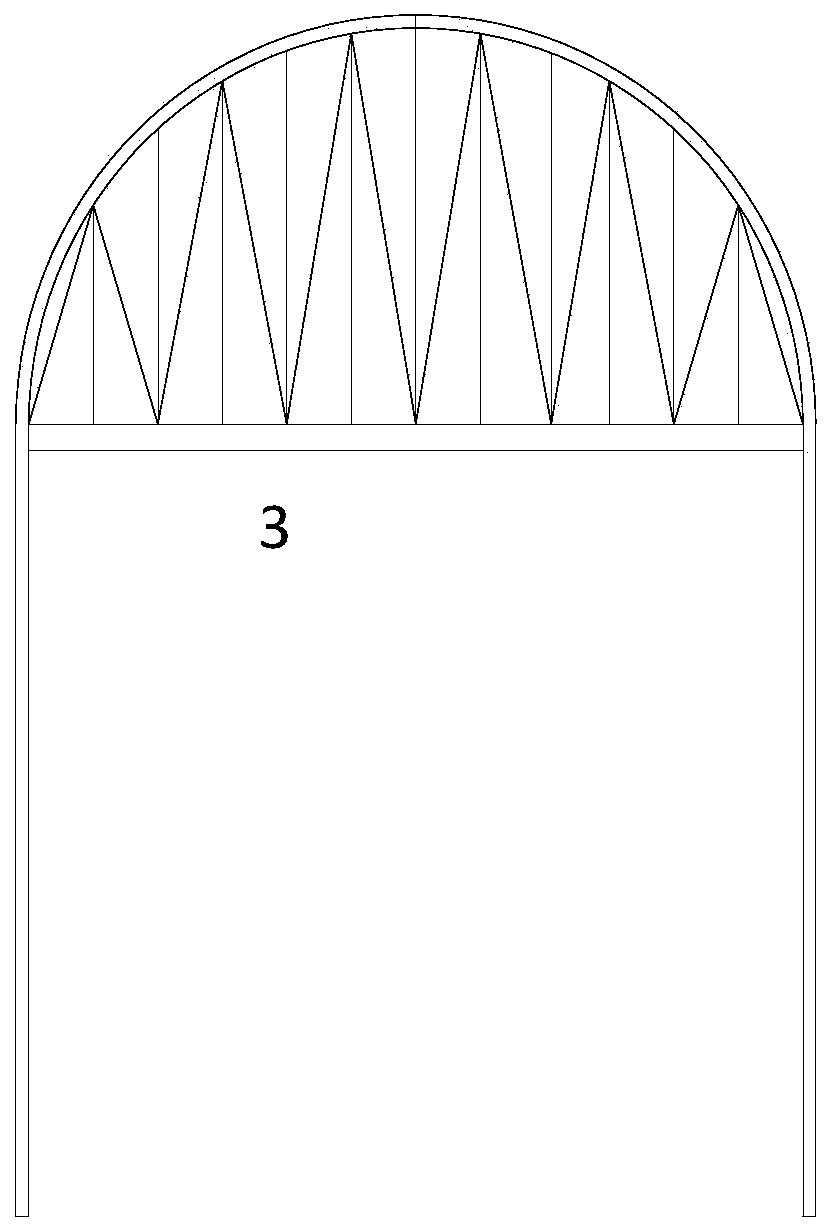

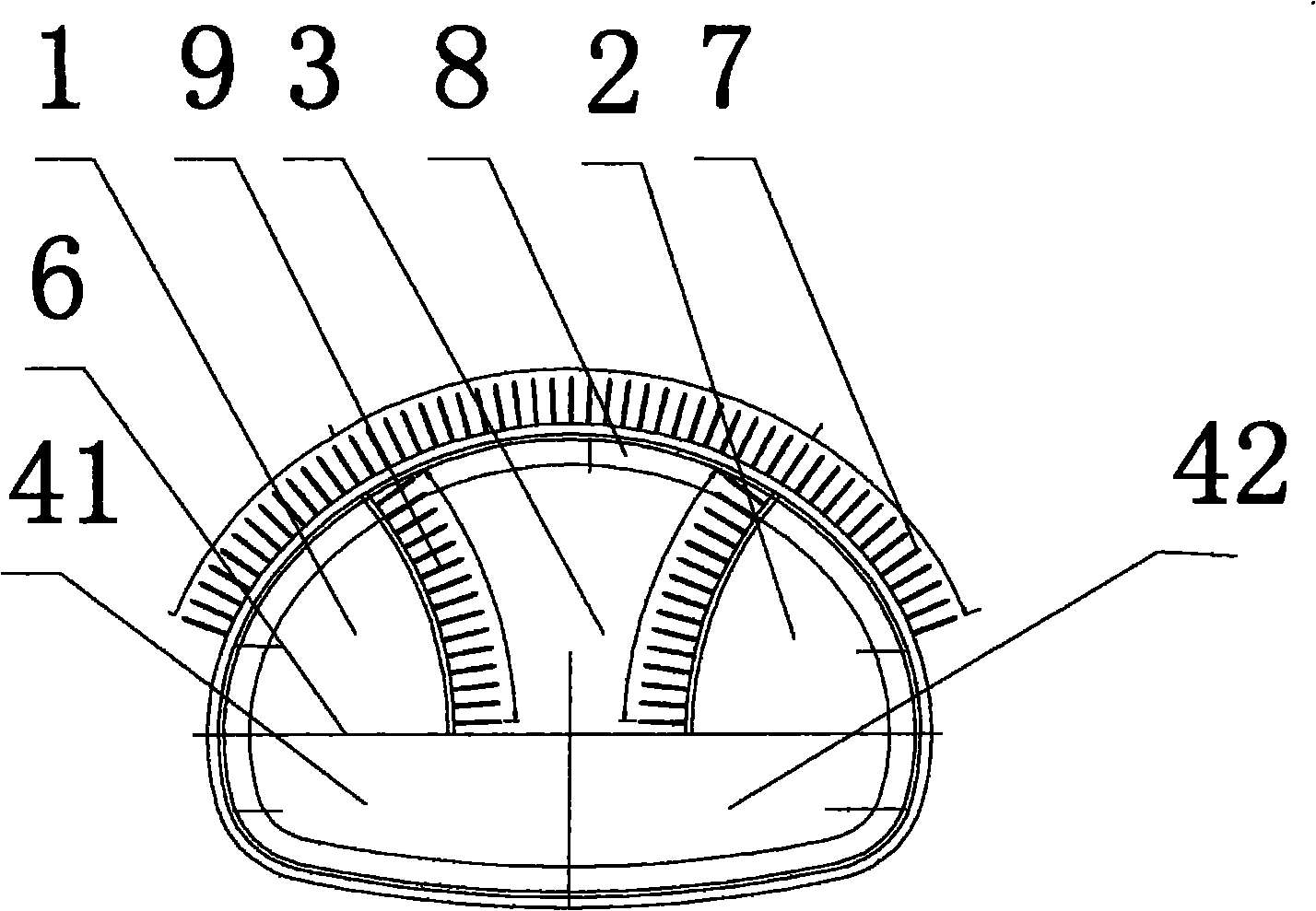

Tunnel double upper sidewall heading construction method

The invention provides a tunnel double upper sidewall heading construction method. When a tunnel is excavated, the cross section of the tunnel is divided into a first heading, a second heading and an upper core soil; a No.1 lower step and a No.2 lower step are excavated in different time; and a boundary of the first heading and the No.1 lower step, and a boundary of the second heading and the No.2 lower step are springing lines. The method has the advantages that: the cross section of the tunnel is divided into an upper part and a lower part by taking the springing line as a boundary, wherein the upper part is constructed by an improved double sidewall heading method; the tunnel with a large section is divided into a left heading and a right heading to be constructed one after another immediately, and the core soil is excavated by sloping, so that the excavation section span is reduced and the supporting effect of the core soil is achieved; and the lower part is divided into a left part and a right part to be constructed one after another; an invert arch and a filler course are constructed timely; and the secondary linings of an arch wall and an arch crown are constructed finally so as to enter a common working condition together with surrounding rock and primary supports.

Owner:SHENZHEN CONSTR GRP

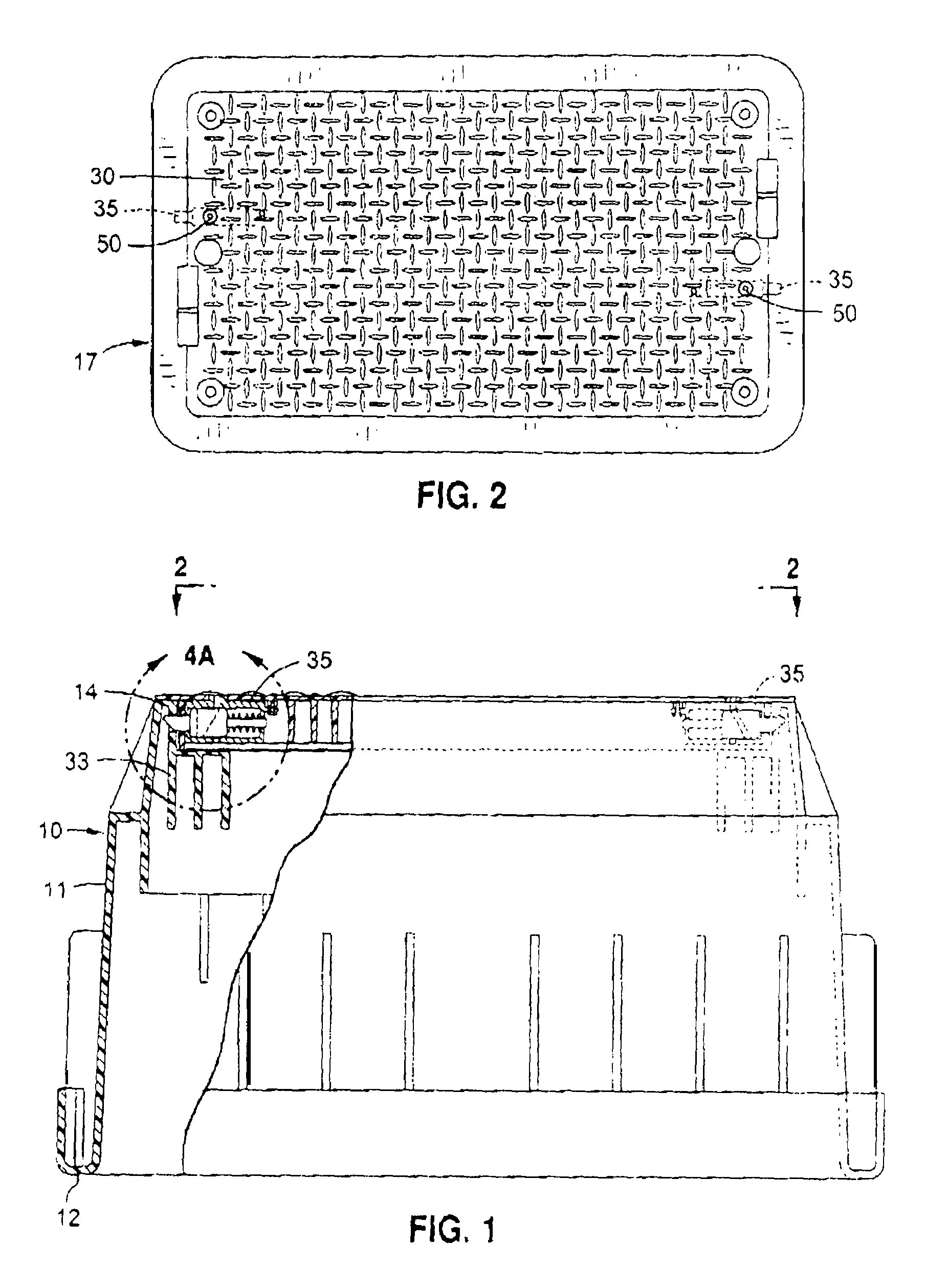

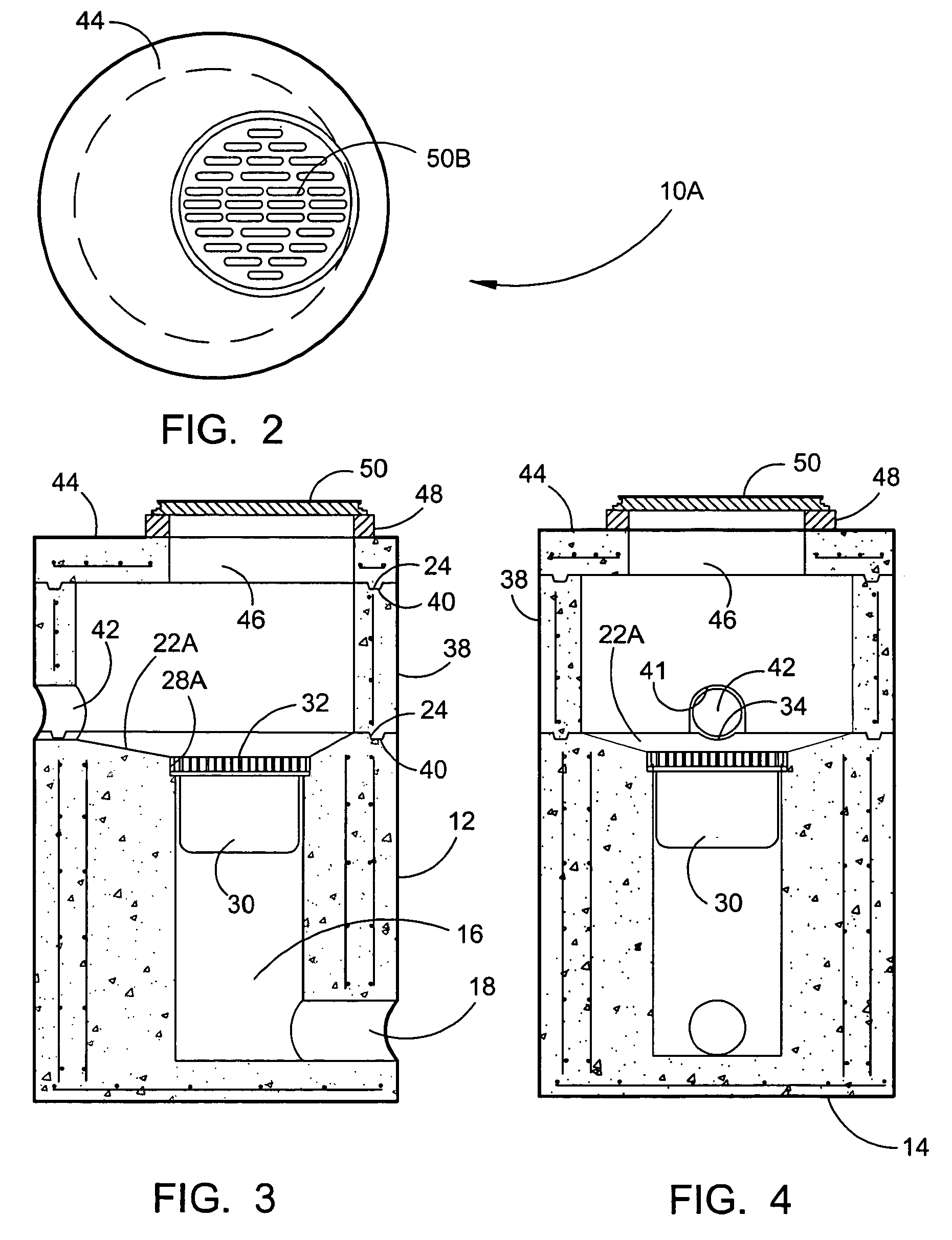

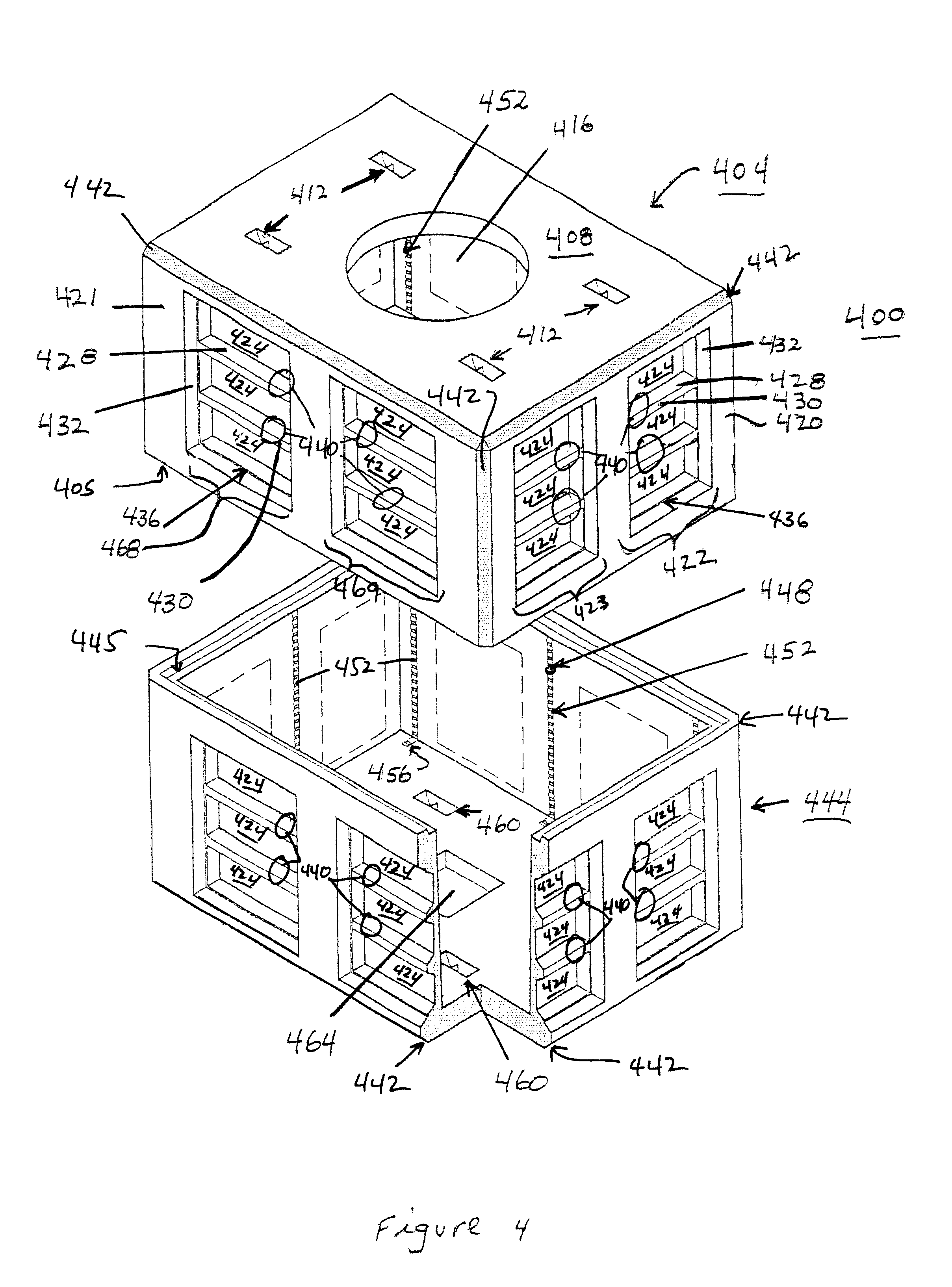

Method and apparatus for capturing, storing, and distributing storm water

A precast concrete storm water vault comprised of modular precast concrete components is provided. More specifically, a vault is provided that consists of a perimeter of footings with integral vertical walls extending therefrom that supports precast concrete roof panels that comprise the top horizontal structural for the placement of pavers, a fill, base, or a driving surface. The storm water vault disclosed may be combined with a filtration system and has easily removable roof panels that facilitates maintenance and cleaning.

Owner:OLDCASTLE PRECAST

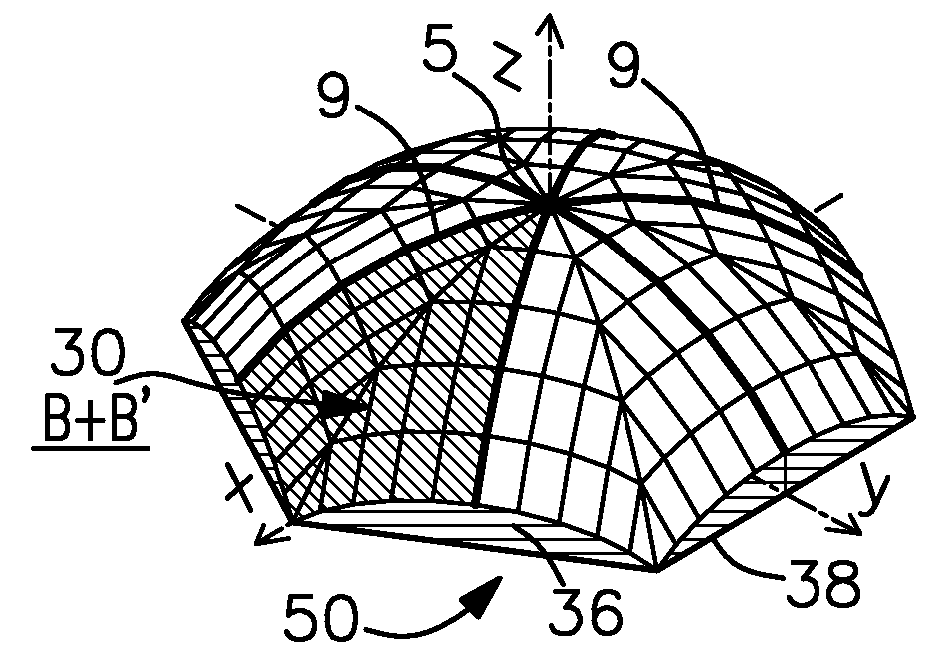

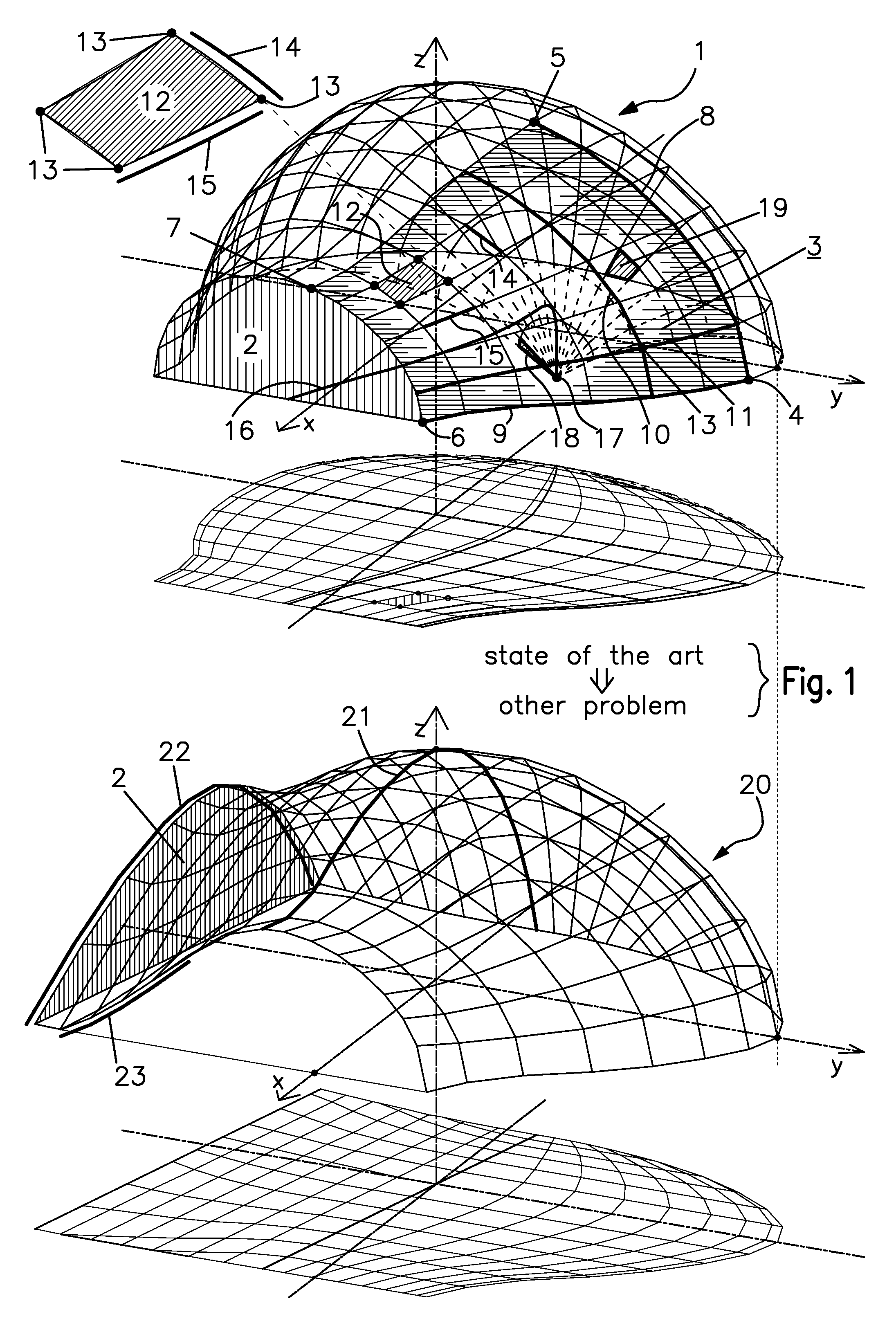

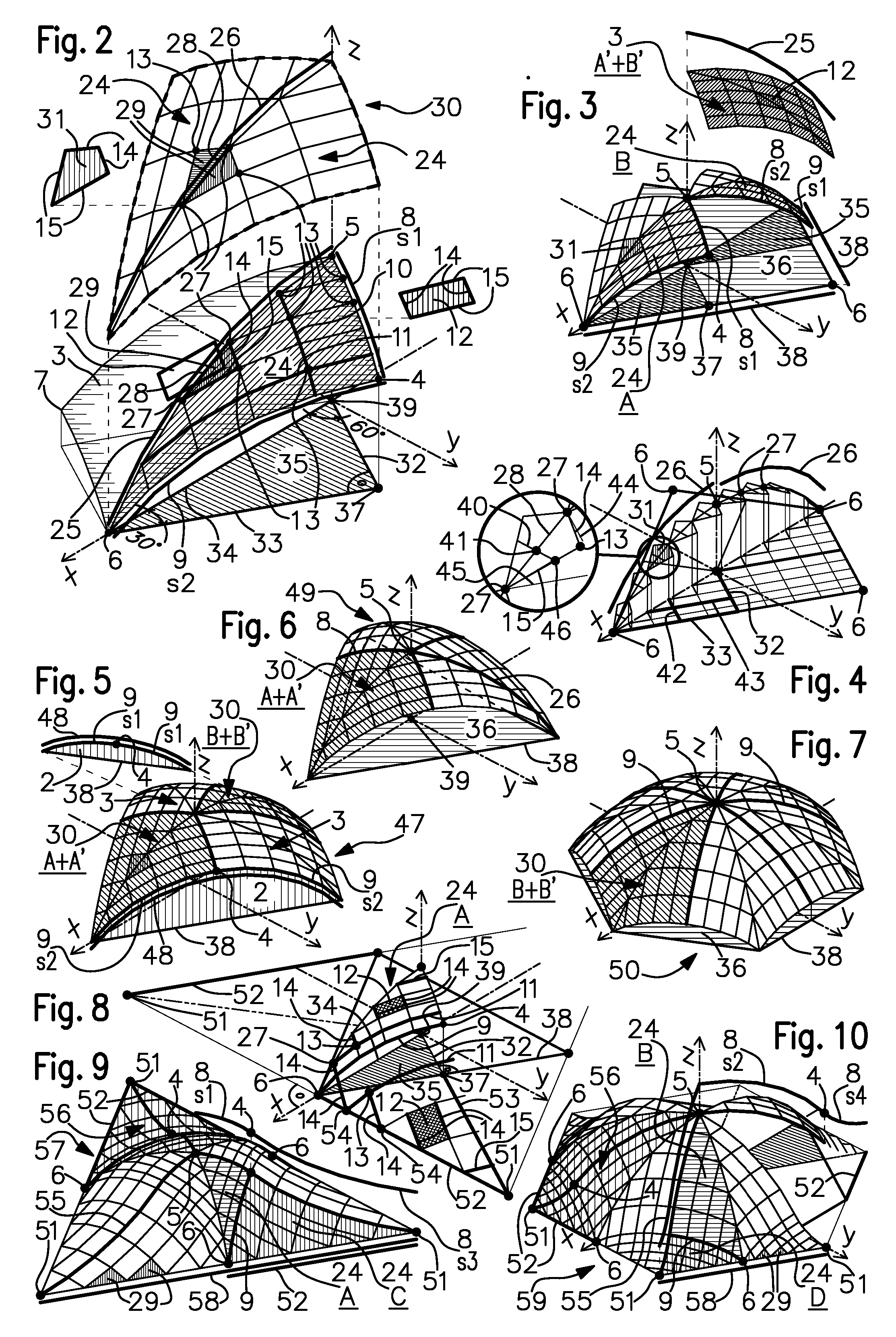

Double-curved shell

Owner:TUCZEK FLORIAN

Subgrade vault with latching cover

ActiveUS7501573B2Prevent upward movementPrecise alignmentInstallation of lighting conductorsInsulated cablesEngineeringWalling

A subgrade vault with a latching cover. The vault includes a peripheral wall with an open access port at the top. A peripheral ledge surrounds the access port. A cover to close the access port fits inside it, with a latch assembly inside it and a retractable latch pin disposed to fit in an aperture in the peripheral ledge. The latch pin is retractable by the stabbing motion of a tapered tool against a cam surface on the latch pin. The cover is locked in place merely by pressing down on it.

Owner:OLDCASTLE PRECAST

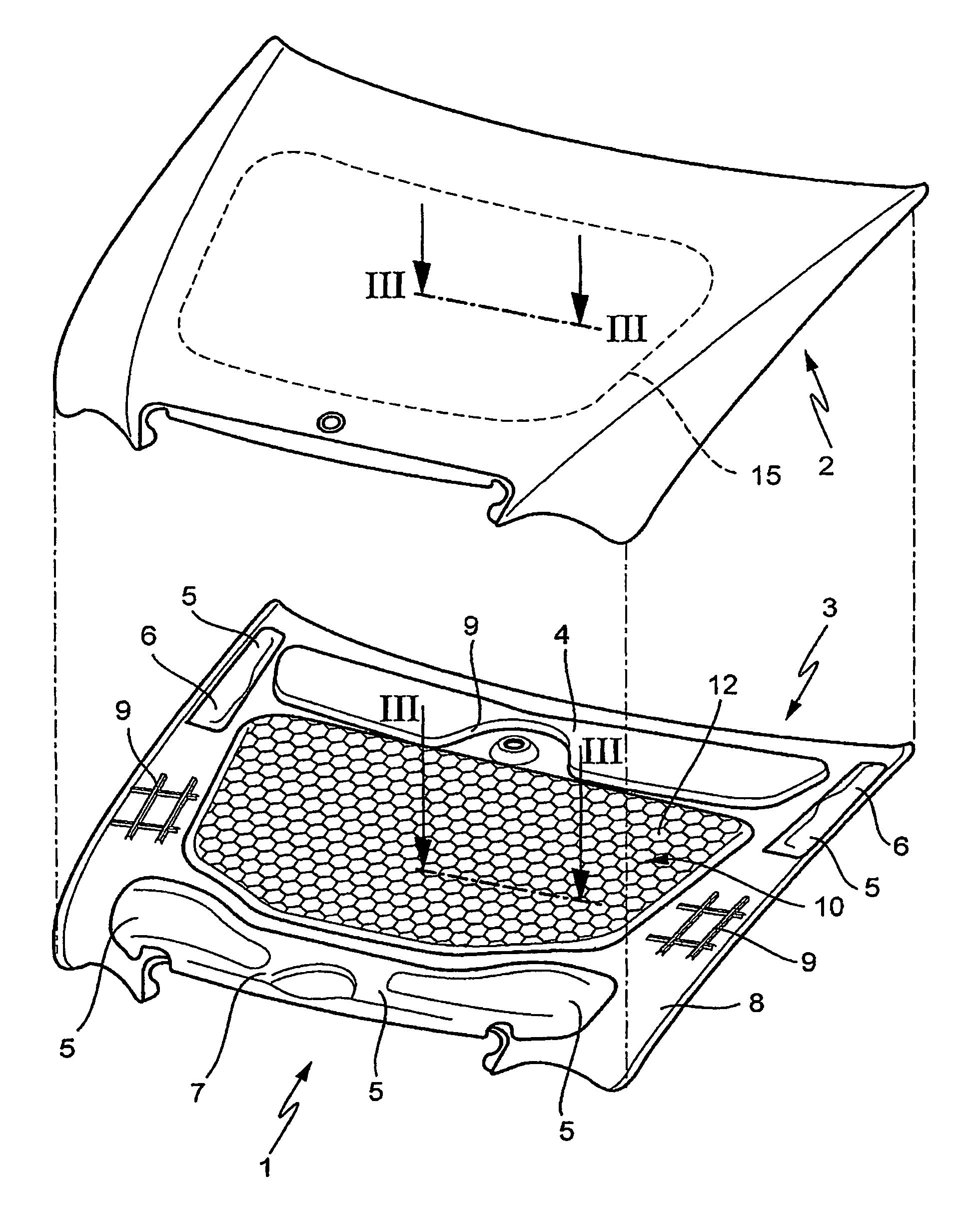

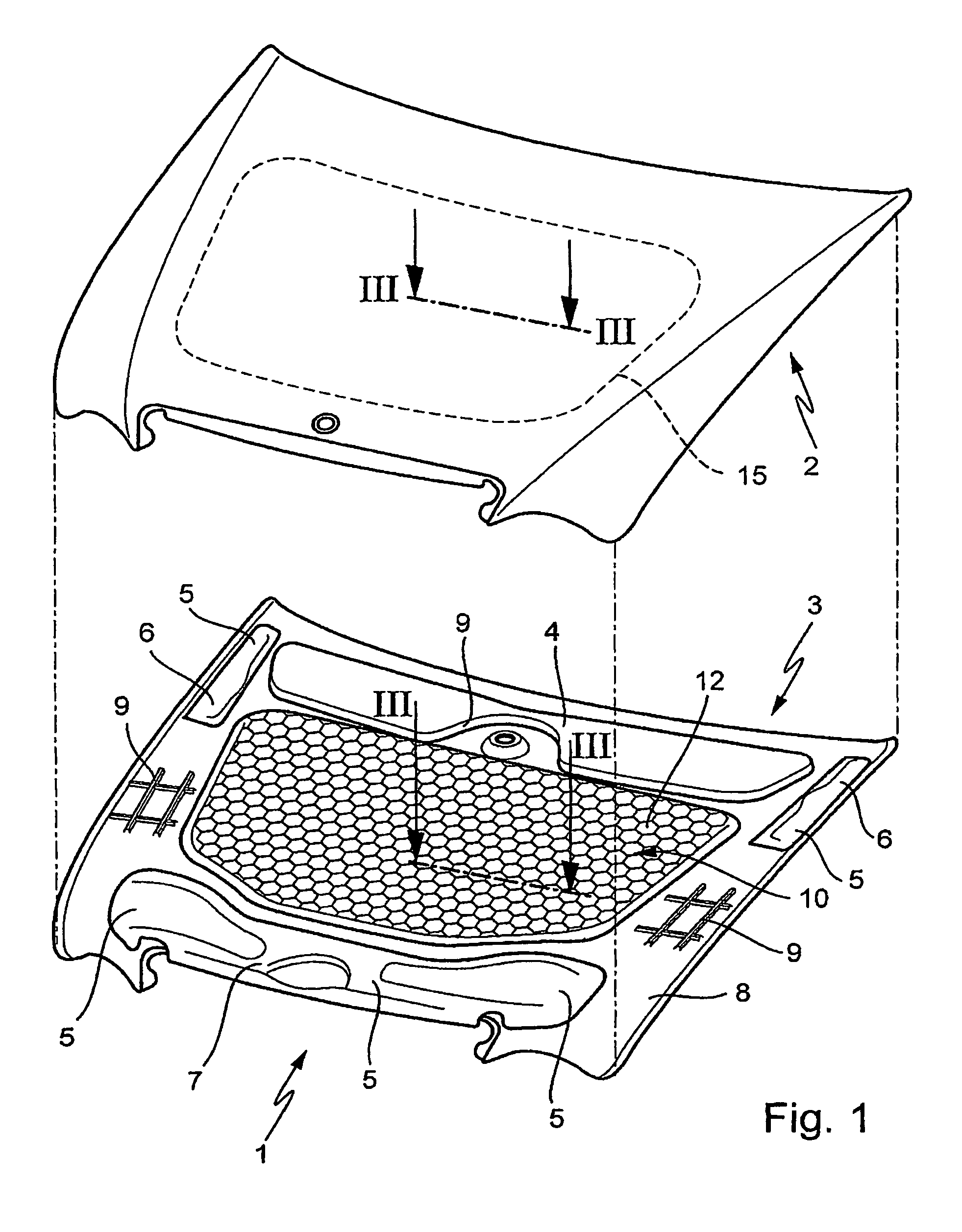

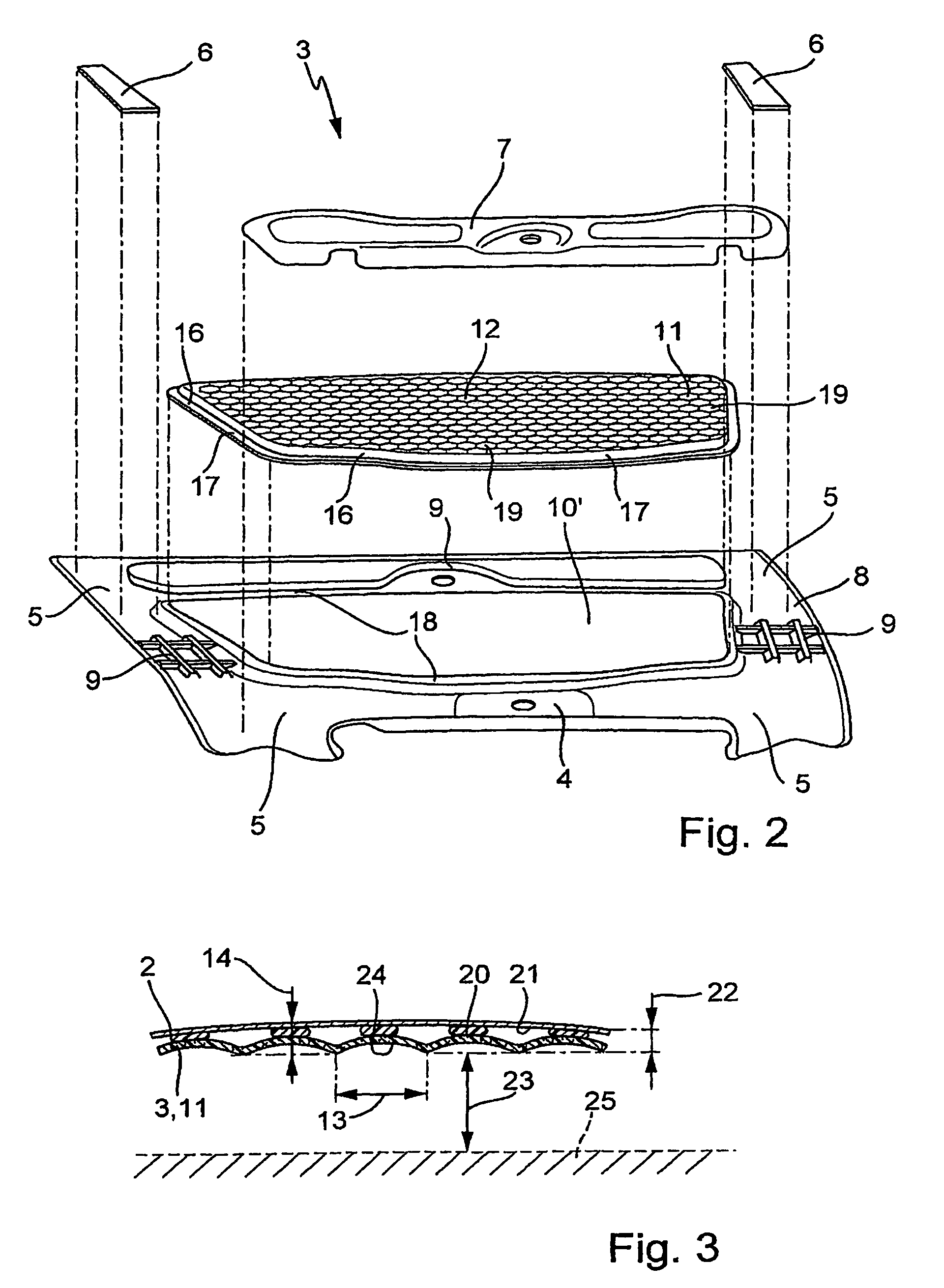

Engine hood comprising a protective device for pedestrians

InactiveUS7578548B2Reduce the overall heightLess spaceVehicle seatsPedestrian/occupant safety arrangementClerestoryEngineering

An engine hood for motor vehicles has a deformable head impact zone to protect pedestrians in the event of a collision with the motor vehicle. The engine hood comprises an outer shell, which is formed by the body paneling, and an inner shell which is arranged below the outer shell and is connected to the outer shell. The inner shell is provided with a vault-structured stiffening region in the region of the head impact zone.

Owner:DAIMLER AG

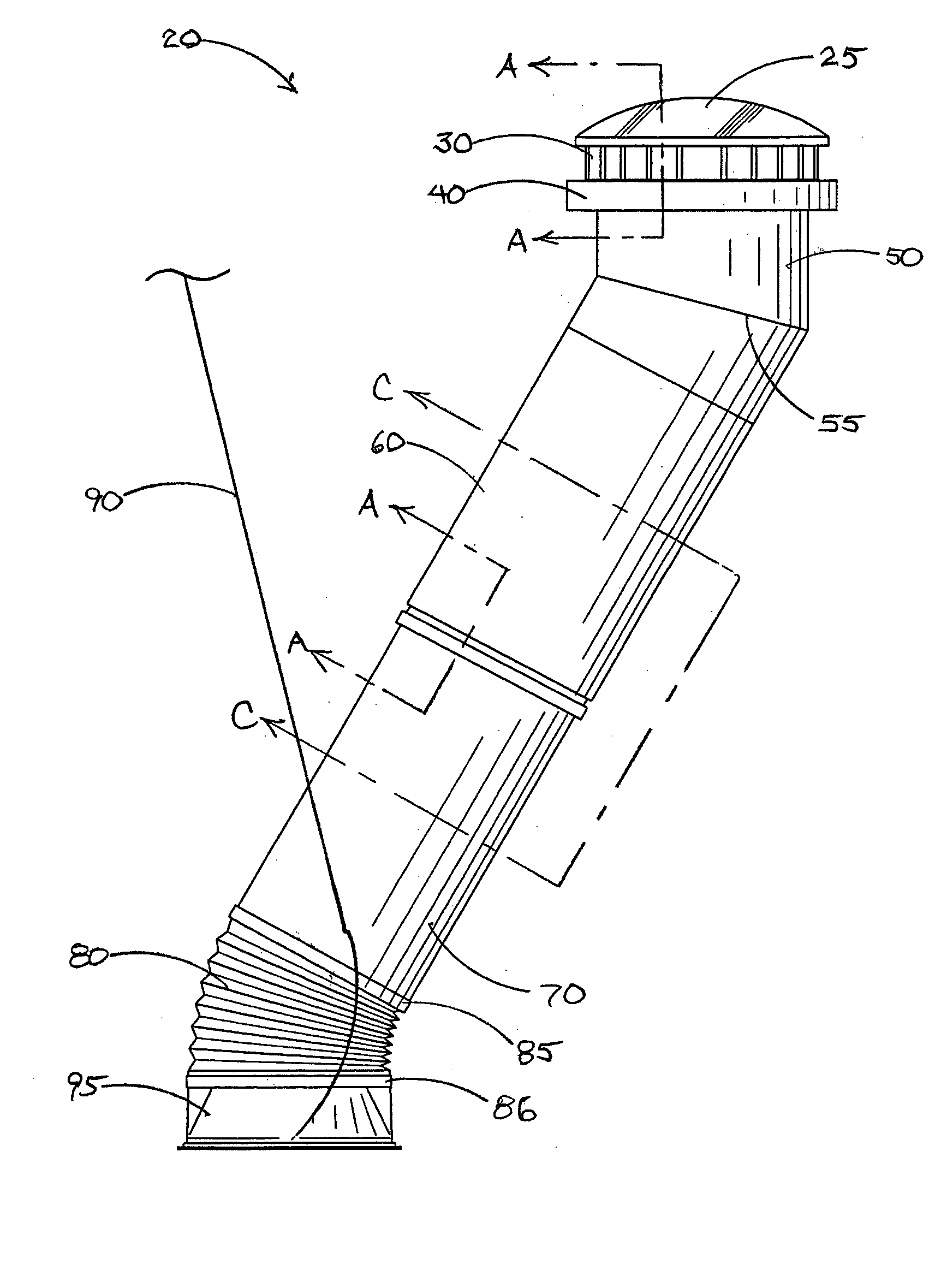

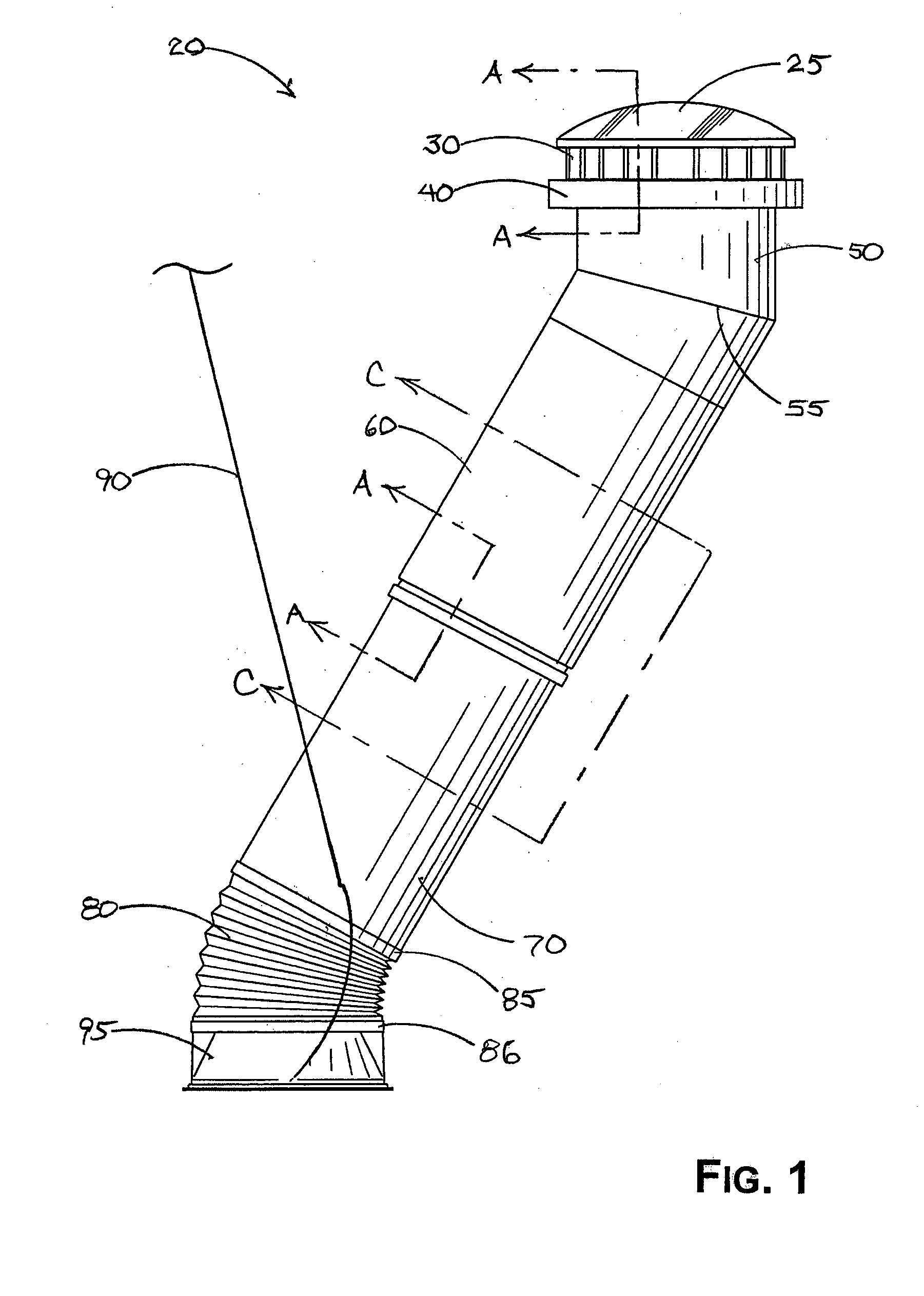

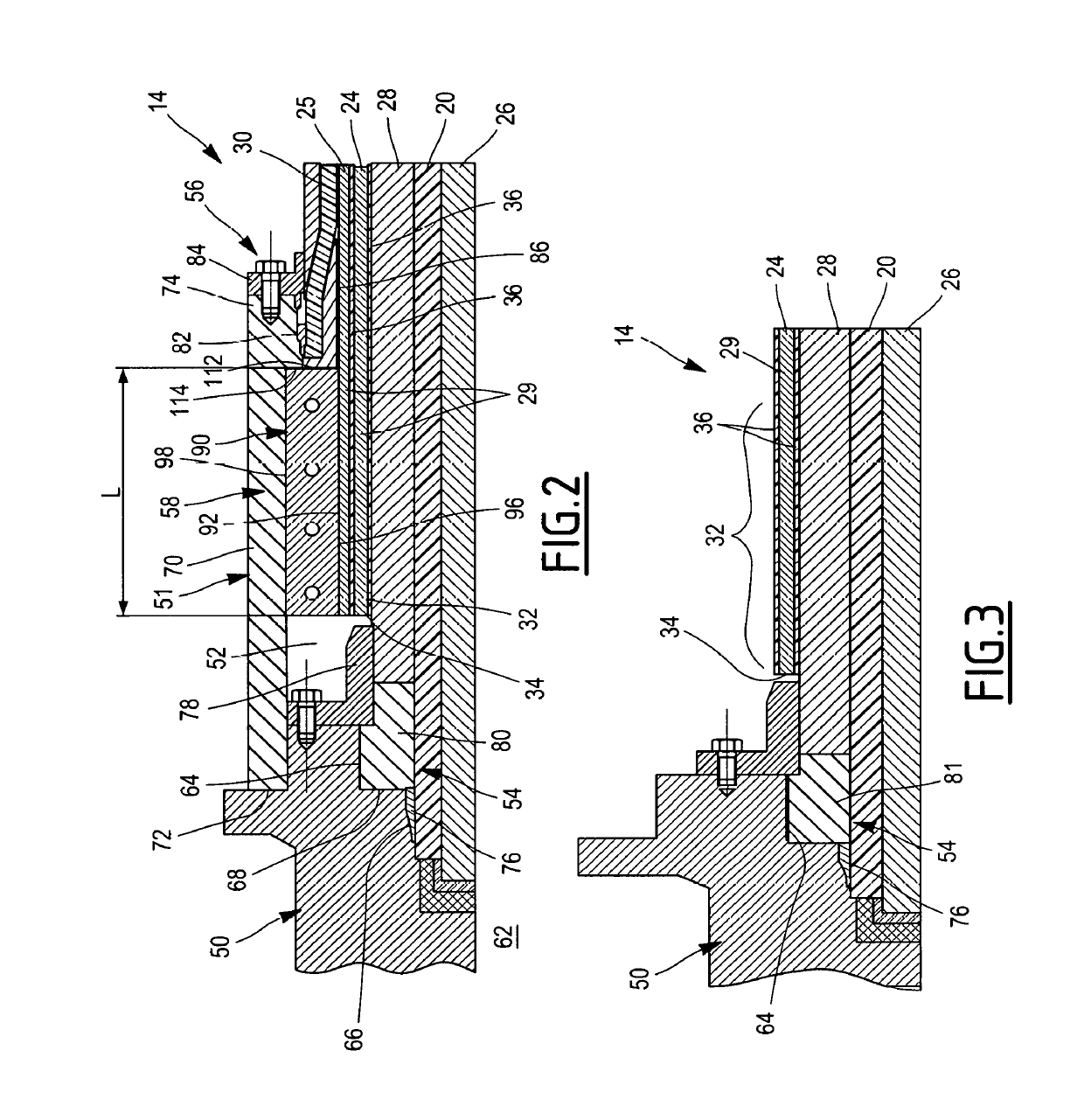

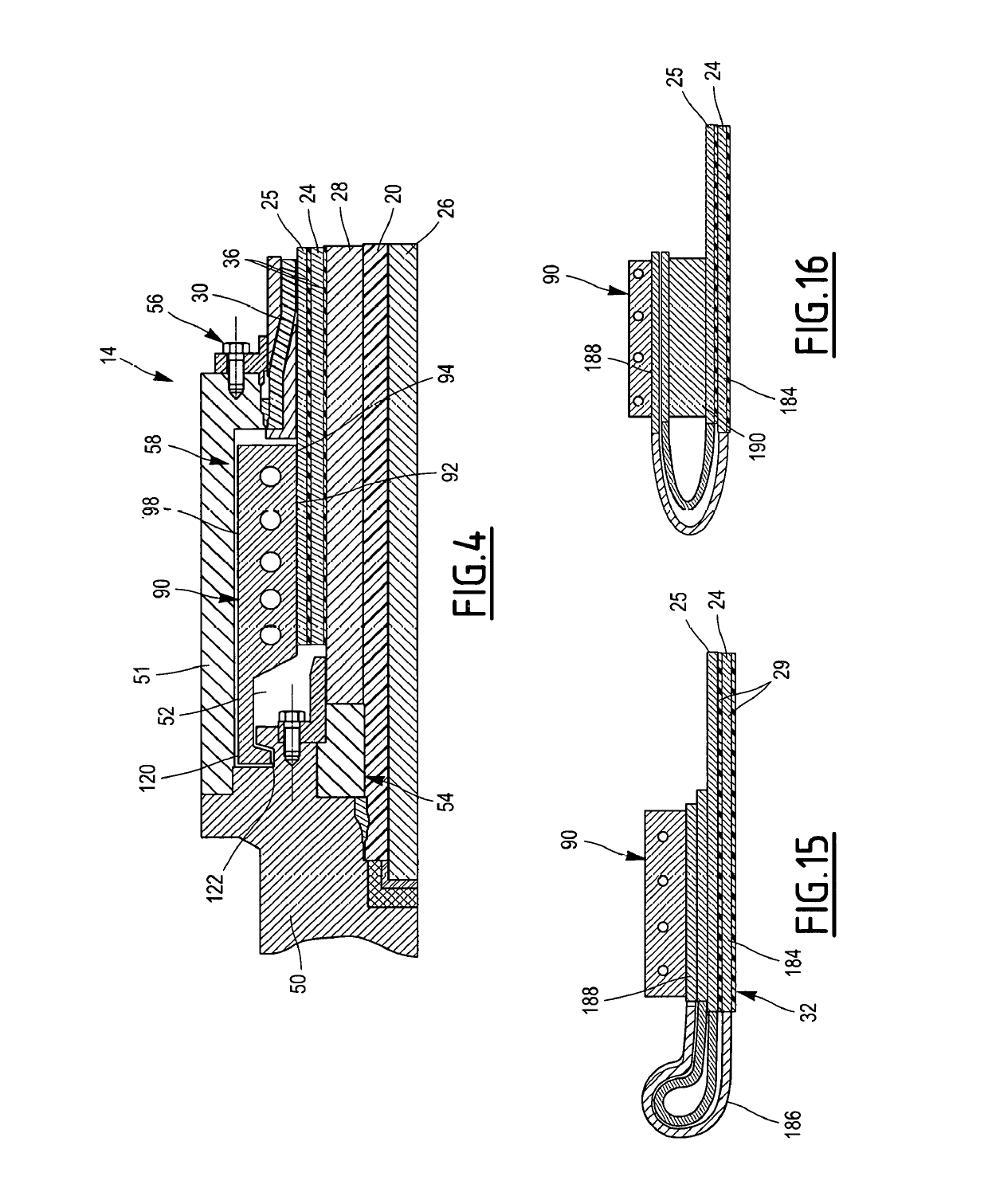

Skylight with displacement absorber and interlocking telescoping tubes

InactiveUS20050166490A1Easily and efficiently and distributedEasy and efficient to manufactureBuilding roofsCeilingsEngineeringThermal expansion

A skylight with displacement absorber and interlocking telescoping tubes is provided. The displacement absorber may be expandable, compressible, and bendable. The displacement absorber may absorb thermal expansion and contraction displacement between the skylight assembly relative to the building in which it is installed, as well as mechanical compression displacement from forces upon the building roof. The interlocking telescoping tubes may provide for telescopic adjustment of the length of the tube assembly. Also provided is a collar for securement to the building roof, the collar optionally including a condensation collection gutter. The skylight may also include a top elbow, adjustable for angular orientation of the light tubes depending from it. A lower adaptor box is also provided, for adapting from the cross-sectional geometry of the displacement absorber to desired cross-sectional geometries of interior ceiling diffusers.

Owner:VKR HLDG AS

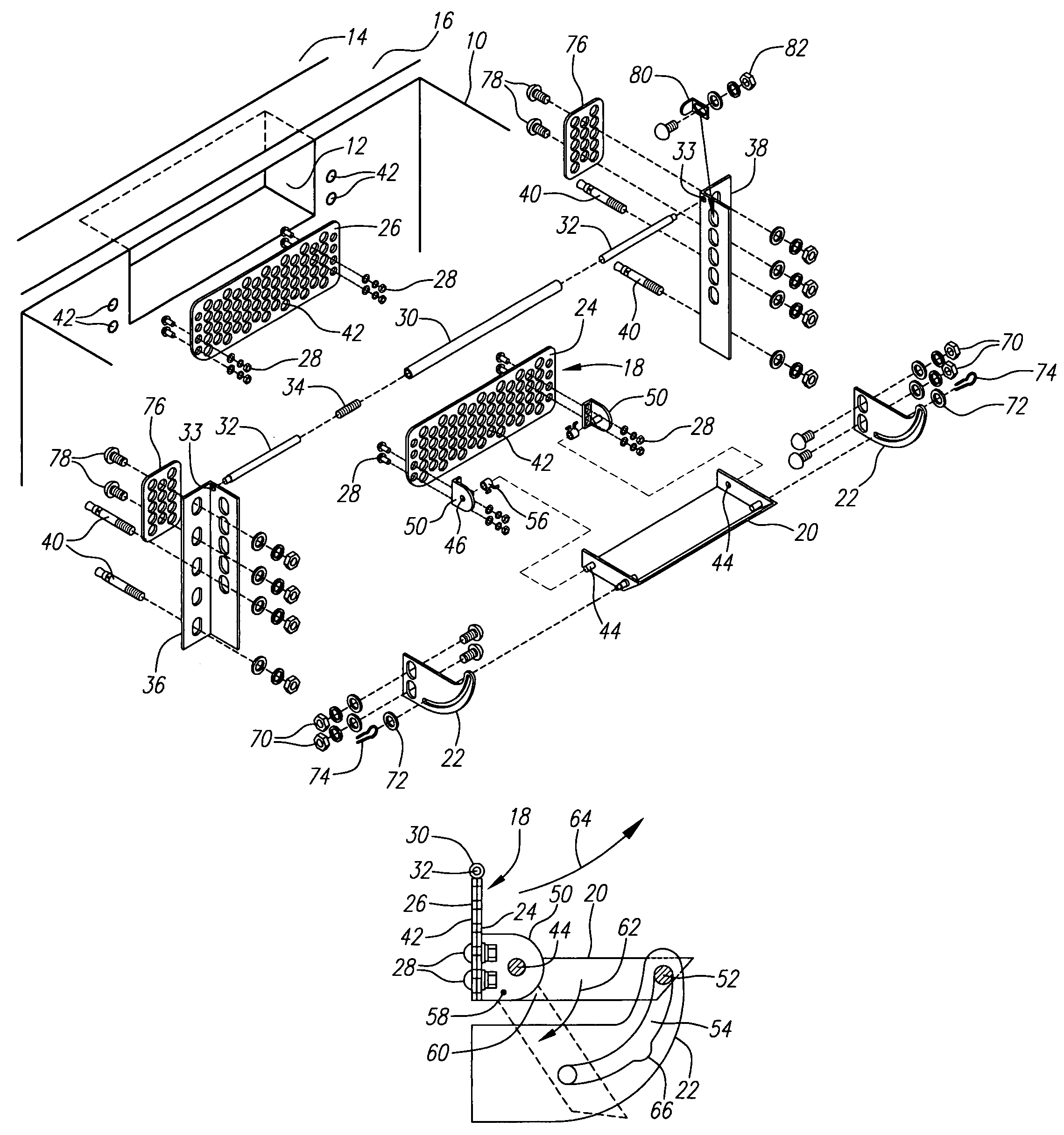

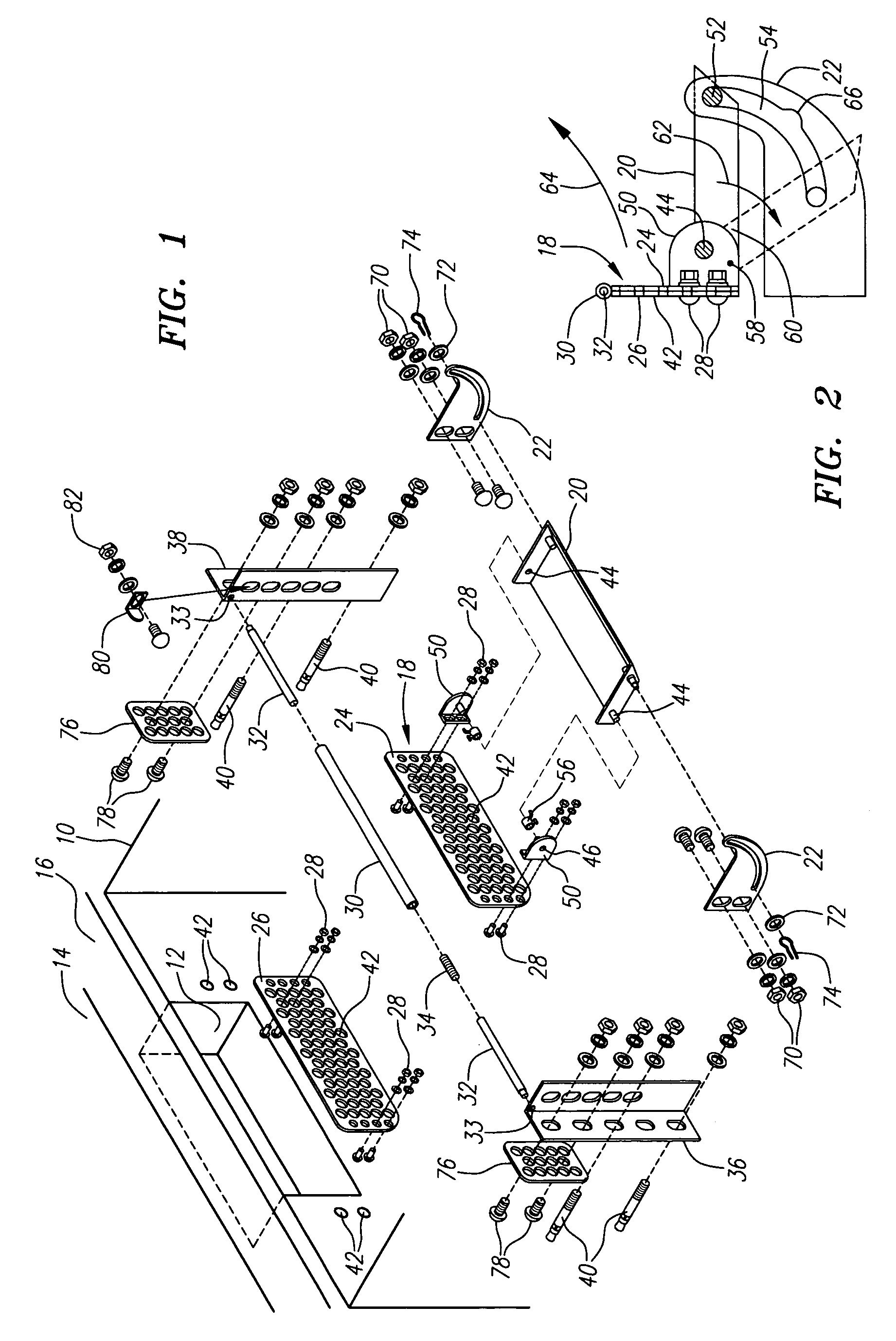

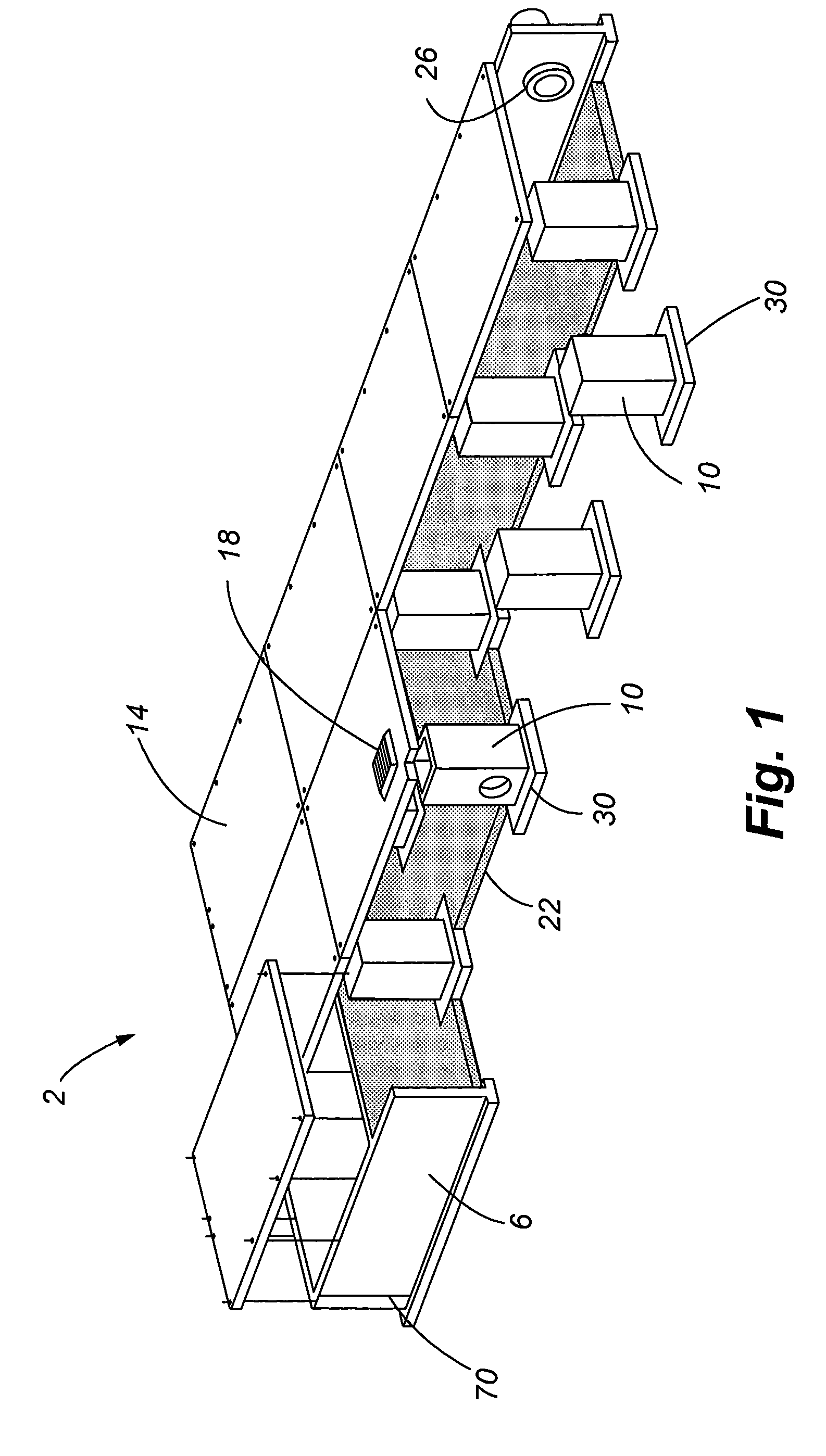

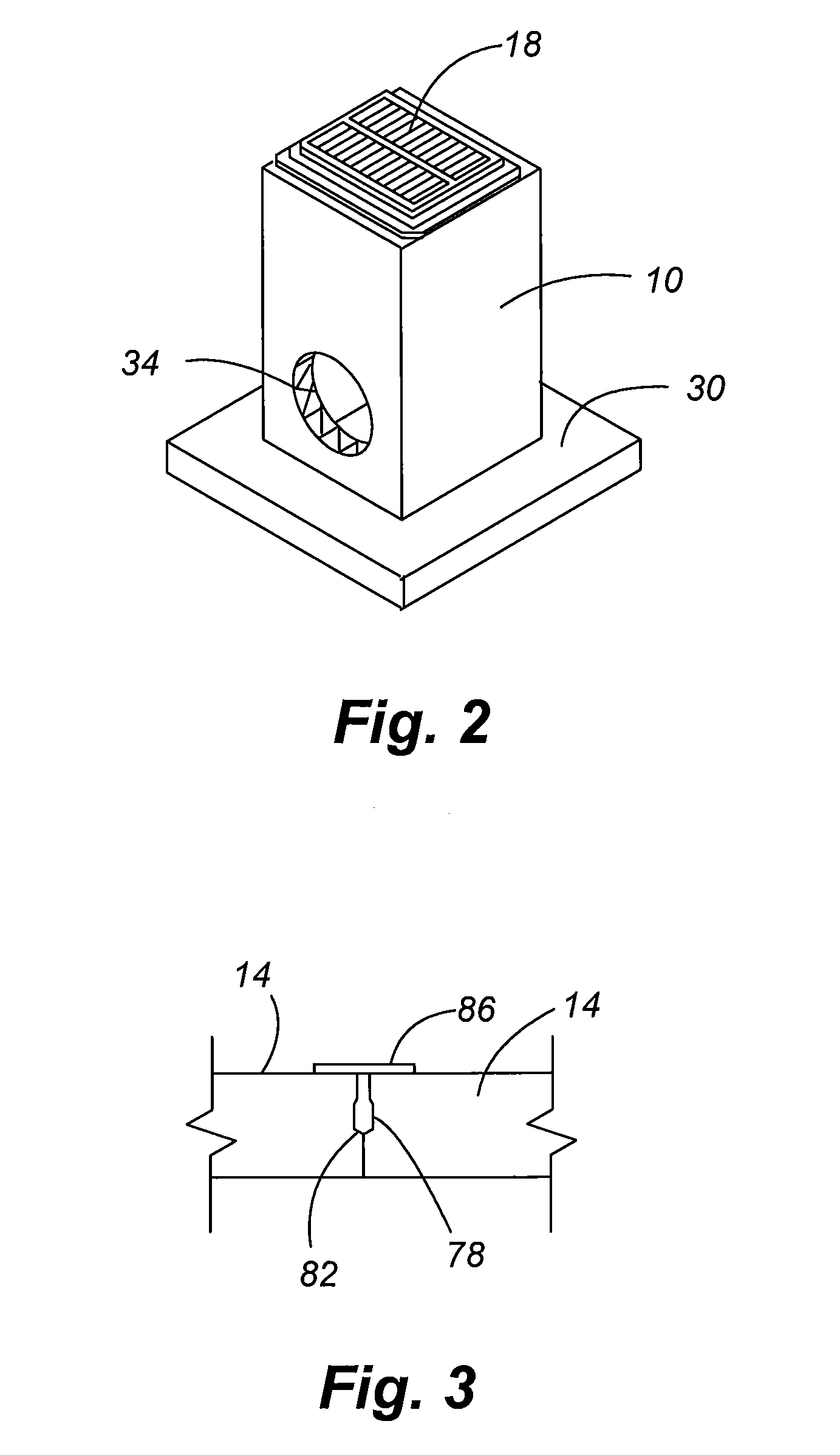

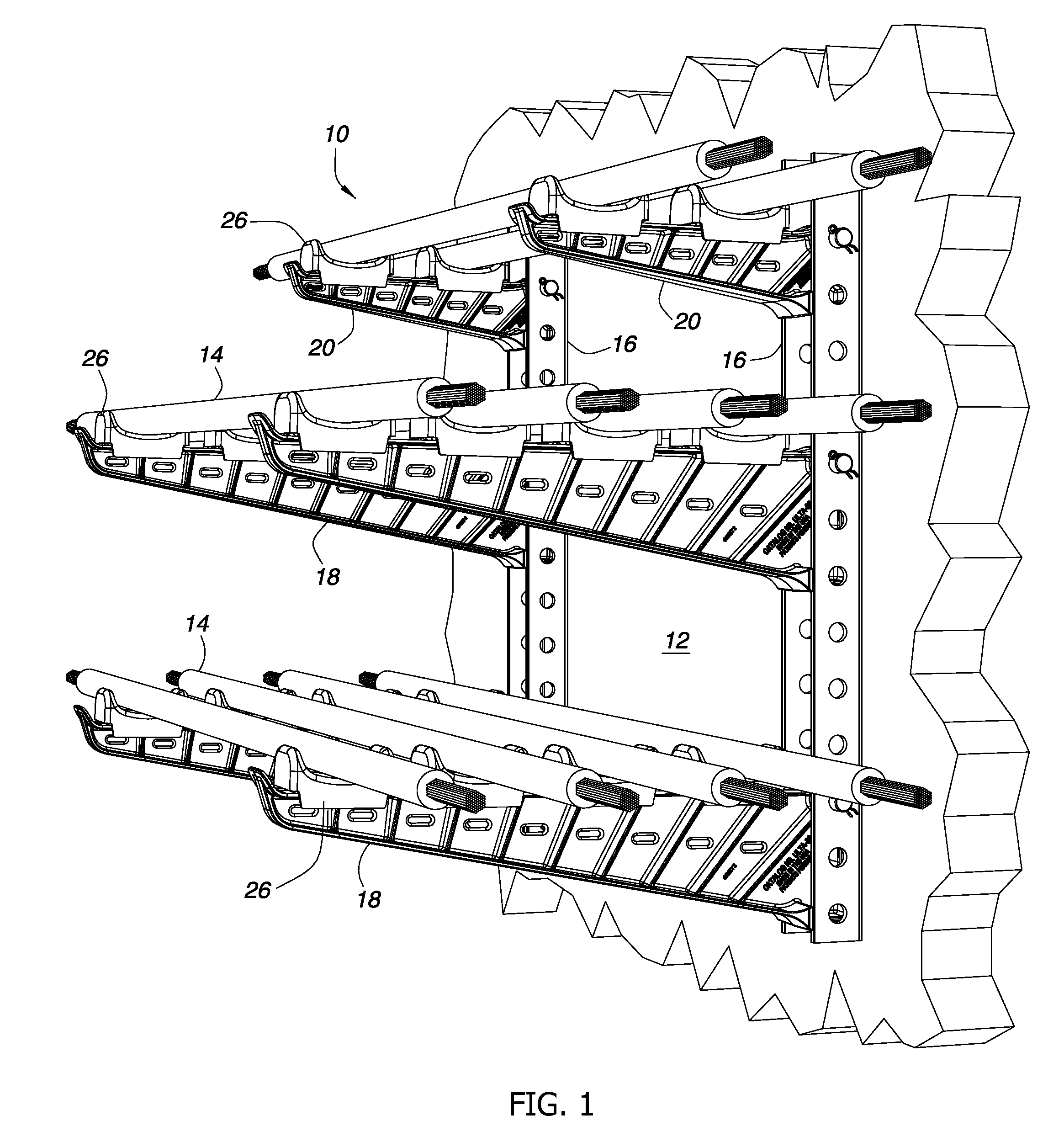

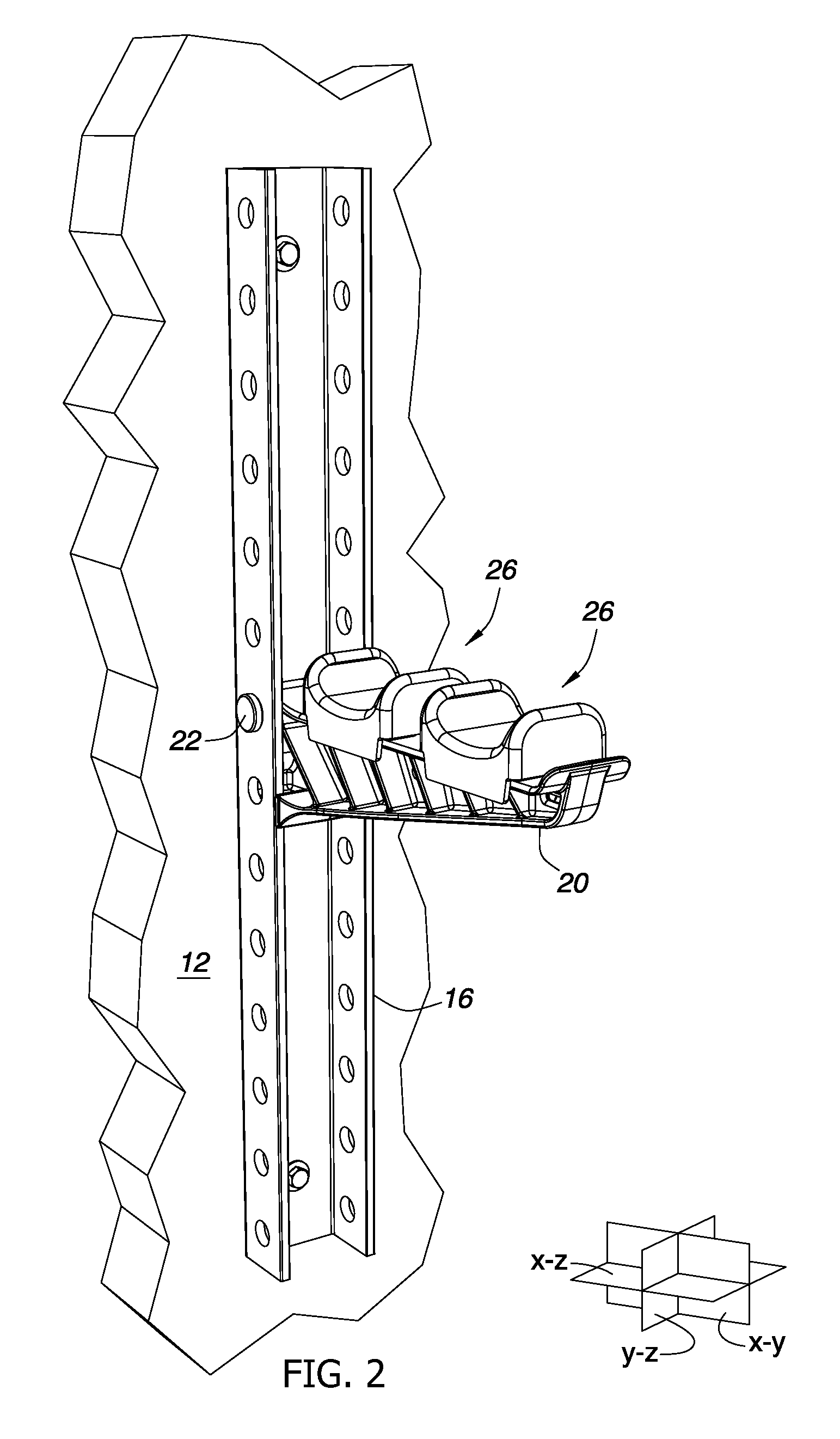

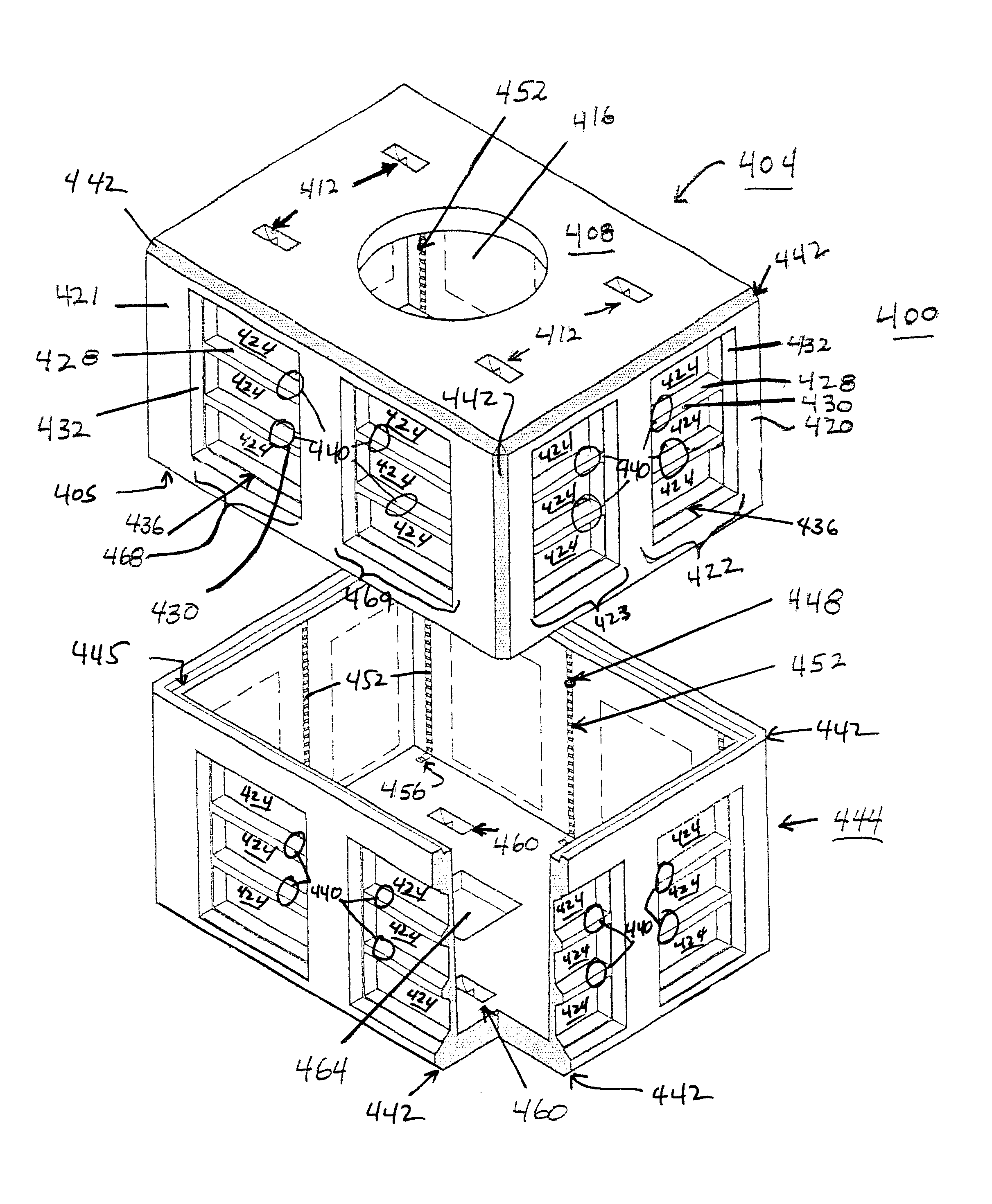

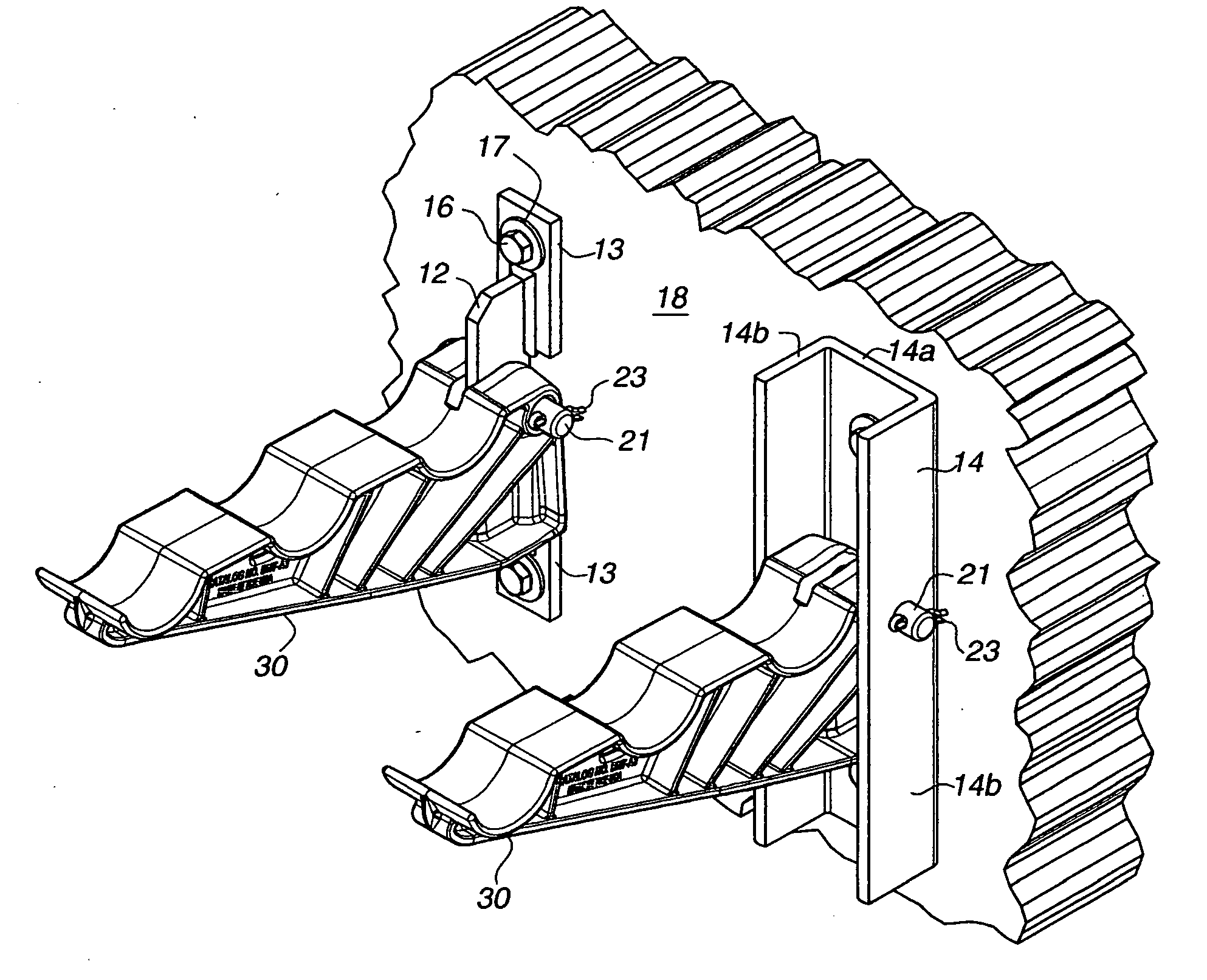

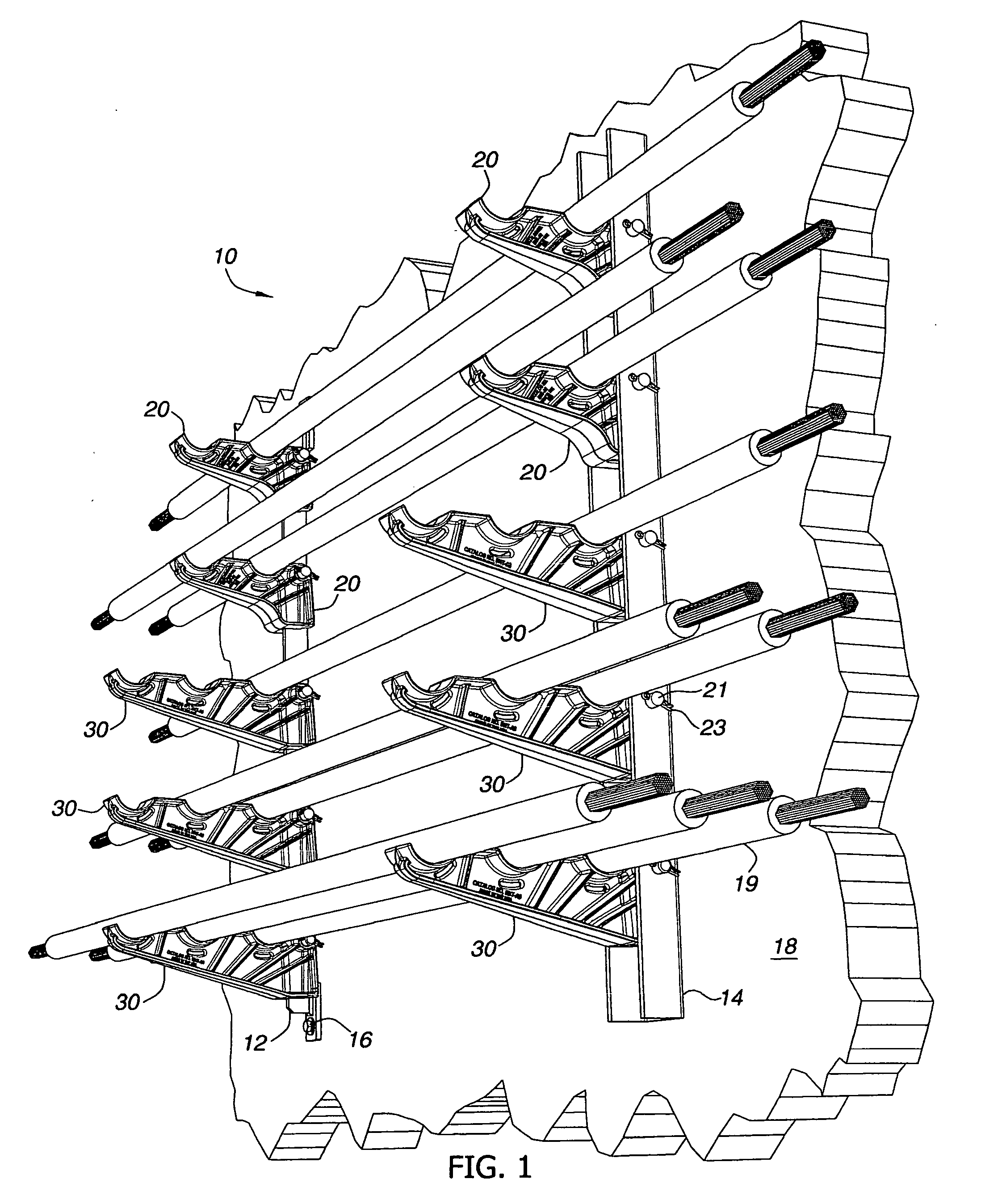

ULT cable support system with saddles

A cable rack arm and support system suitable for underground power and communication service is made from reinforced non-metallic polymers that will not rust or corrode. A cable rack arm up to thirty inches long may be compression molded with long glass fibers in a polyester or vinylester matrix. Each cable rack arm is securely mounted to a non-metallic stanchion that may be made from a reinforced, pultruded composite material. Nonmetallic pins may be used to secure the cable rack arms to the stanchions. Each cable rack arm then supports one or more cables in cable saddles that are snap-fit atop the arm, thus keeping the cables accessibly organized in a manhole, tunnel or vault. Each saddle may include elastomeric dampening material to reduce shock and vibration in the mechanical and electrical environment in underground tunnels, vaults and manholes.

Owner:UNDERGROUND DEVICES

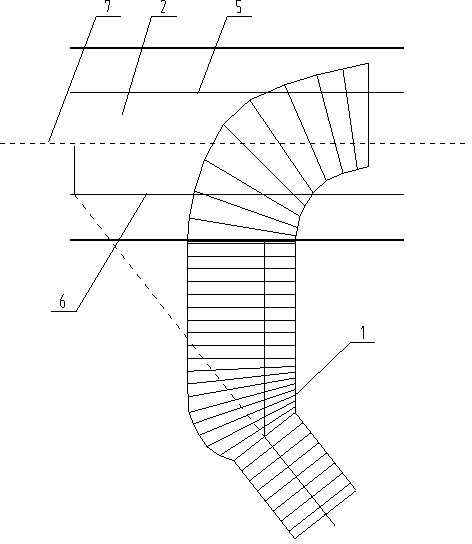

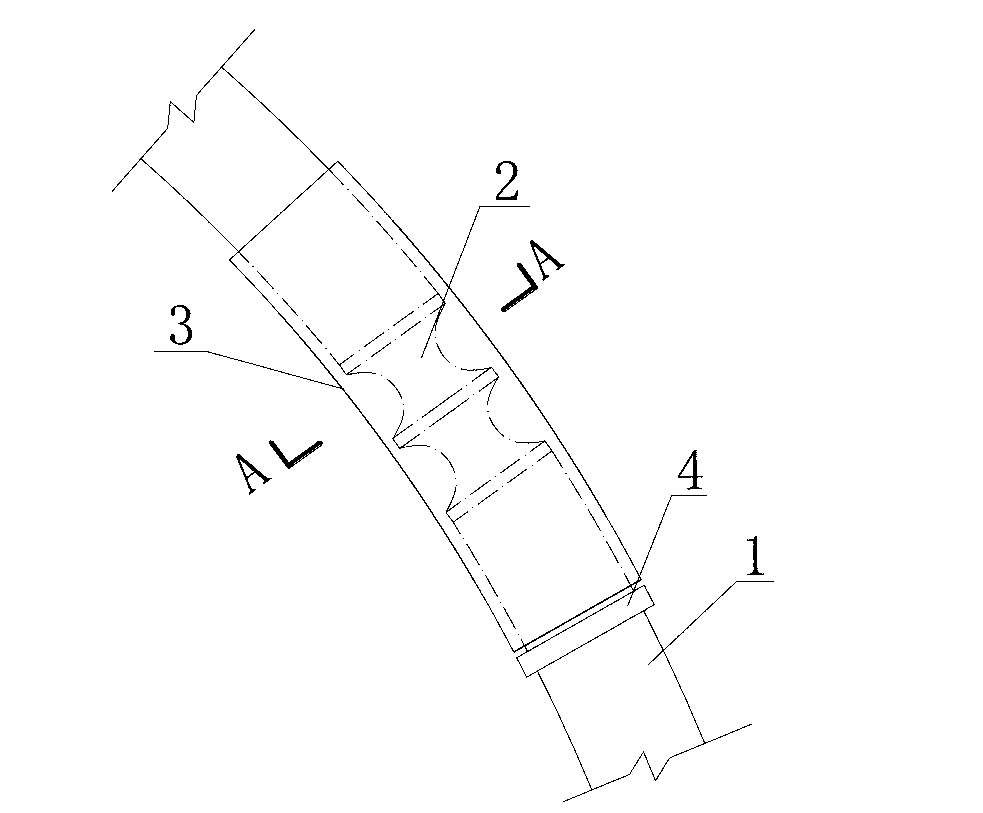

Oblique-crossing inclined shaft upper arc guide top brushing construction method for soft crushed rock layer

ActiveCN102587922AShorten the lengthOptimize the force structureUnderground chambersTunnel liningSteel frameEngineering

The invention relates to the field of inclined shaft top brushing, in particular to an oblique-crossing inclined shaft upper arc guide top brushing construction method for a soft crushed rock layer, and solves the problems of the existing inclined shaft top brushing construction adopting small pilot tunnel top brushing. The method comprises the following steps of: setting curve transition at the intersection of an inclined shaft and a front tunnel so that an inclined shaft mouth is orthogonal with the front tunnel; arranging a door-shaped steel frame support at the intersection, wherein a steel arch frame of the front tunnel is firmly connected with the door-shaped steel frame; arranging a cover arch support at the section close to the front tunnel and inclined shaft; additionally arranging an I-shaped steel cross arm on a bottom plate; performing top brushing by use of an upper arc guide within the front tunnel range, wherein the last arch frame of the upper arc guide is vertical to the line direction, and the arch top is level with the arch top of the front tunnel; performing expanded excavation along the cross section of the front tunnel, and constructing an upper guide primary support of the front tunnel; reversely dismantling the steel arch frame temporary supports of the upper arc guide one by one, and constructing an upper guide primary support of the front tunnel on the other side; and performing normal construction within the front tunnel range to finish the top brushing. Through the invention, the working efficiency is improved, the construction is accelerated, the safety risk is lowered, the inclined shaft top brushing construction is safely, quickly, perfectly and efficiently finished, and a good effect is obtained.

Owner:THE 2ND ENG OF THE 12TH BUREAU GROUP OF CHINA RAILWAY +1

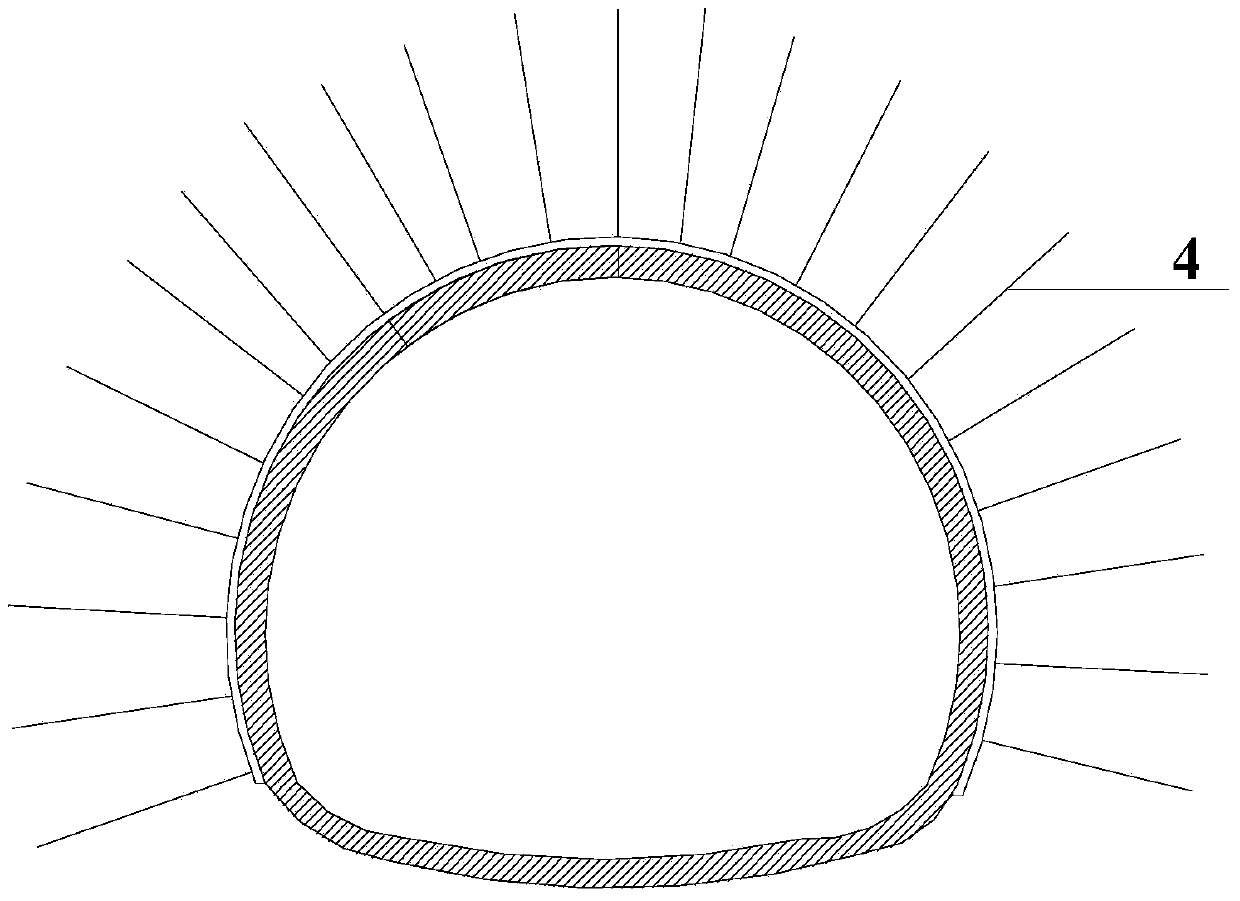

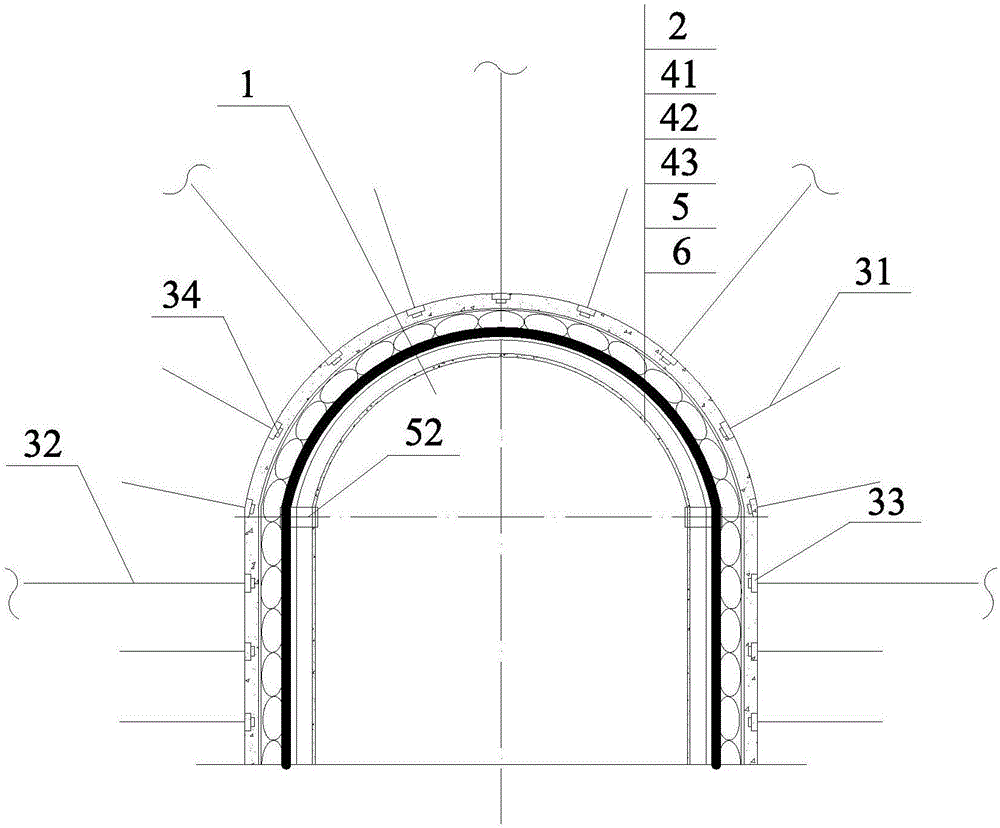

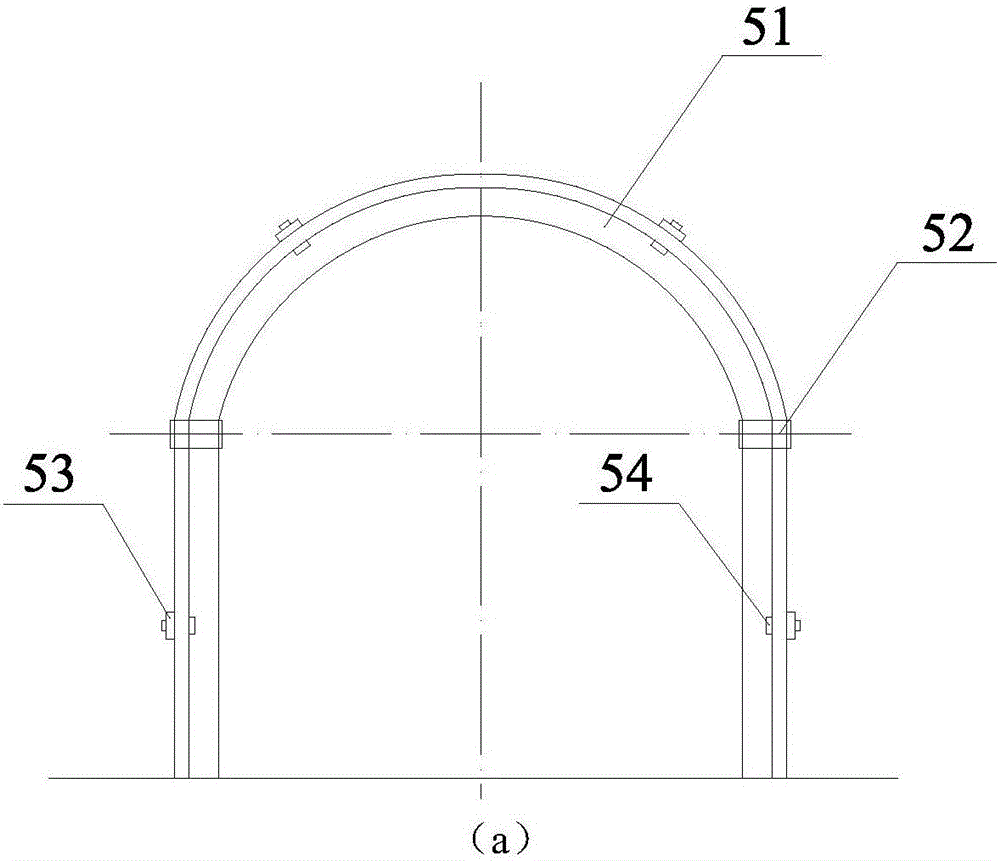

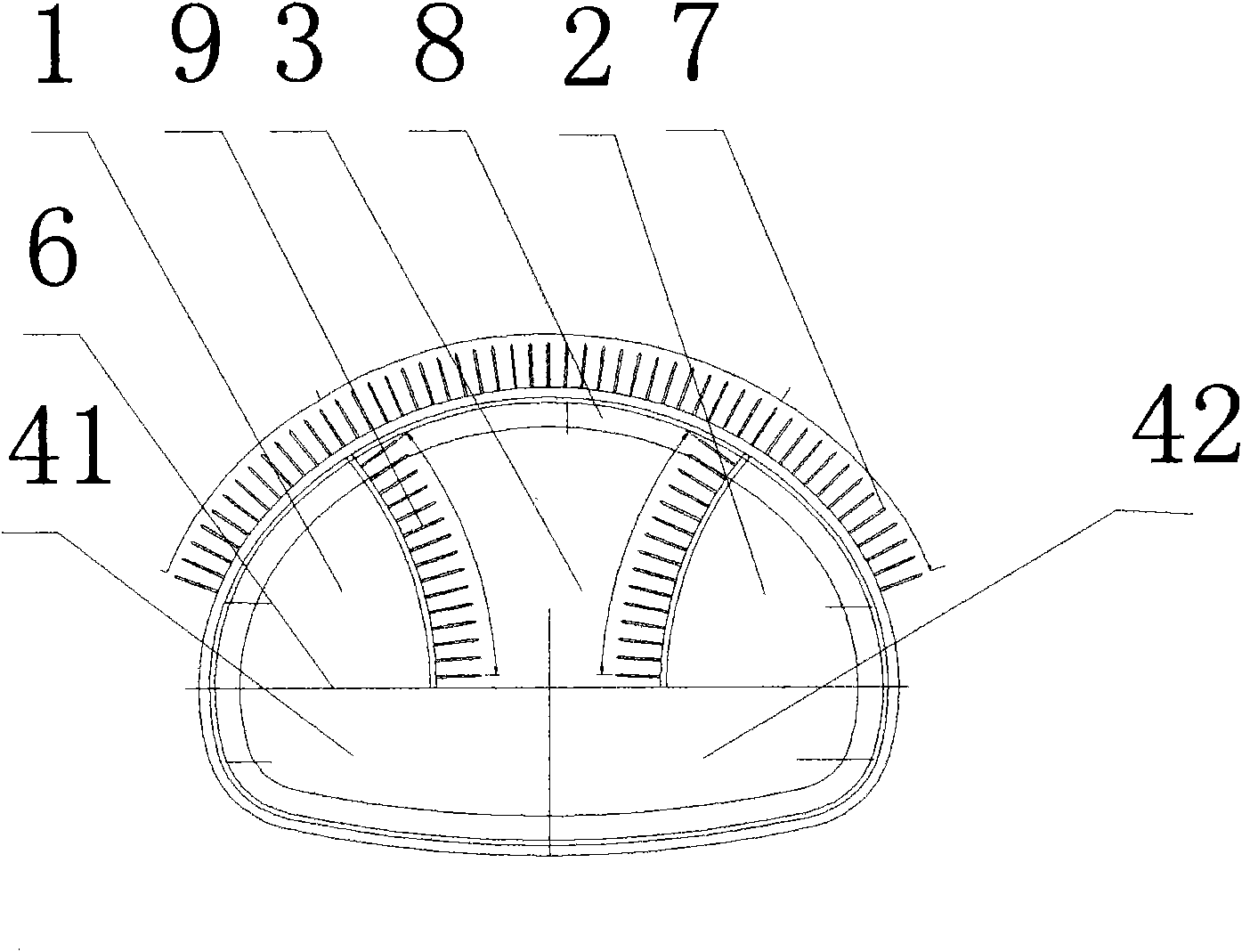

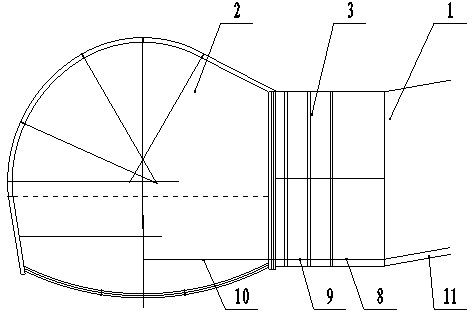

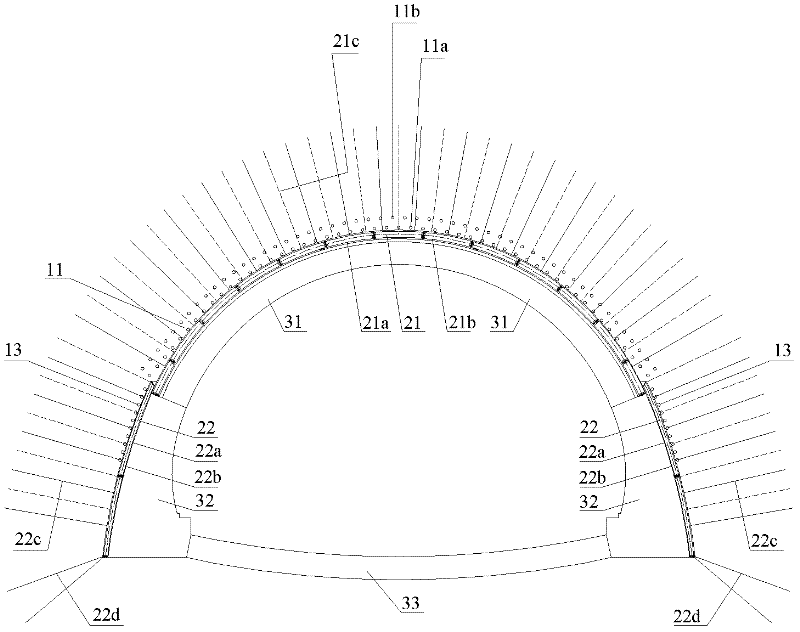

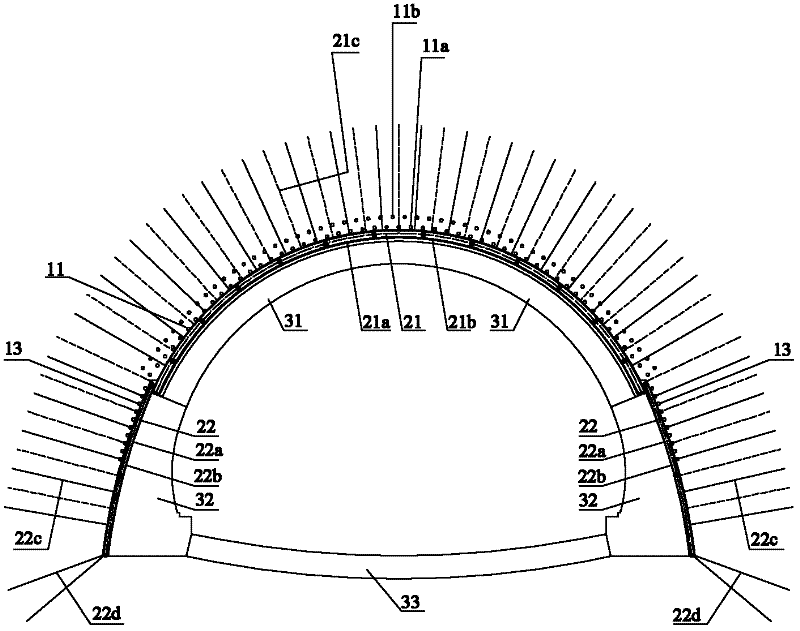

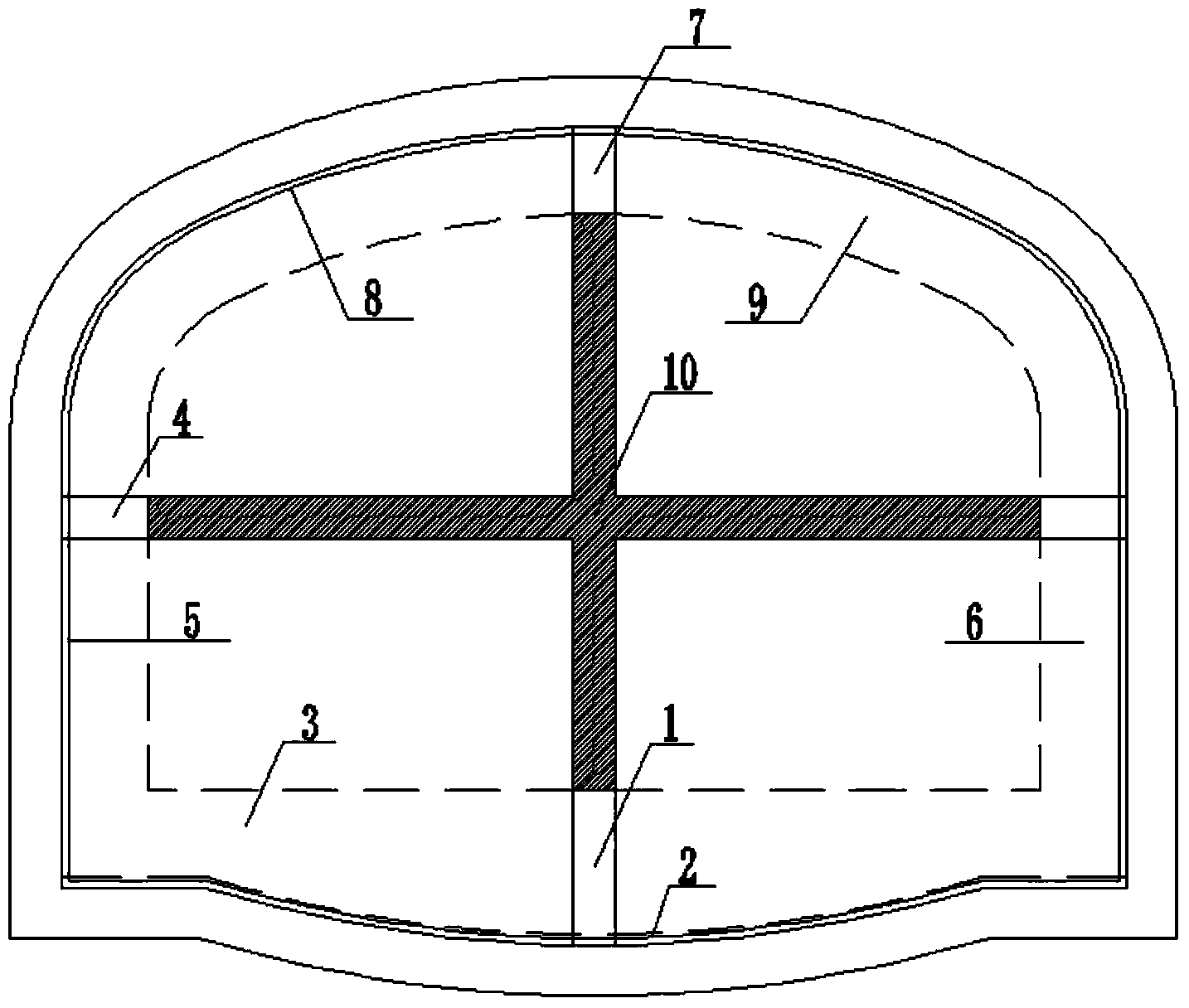

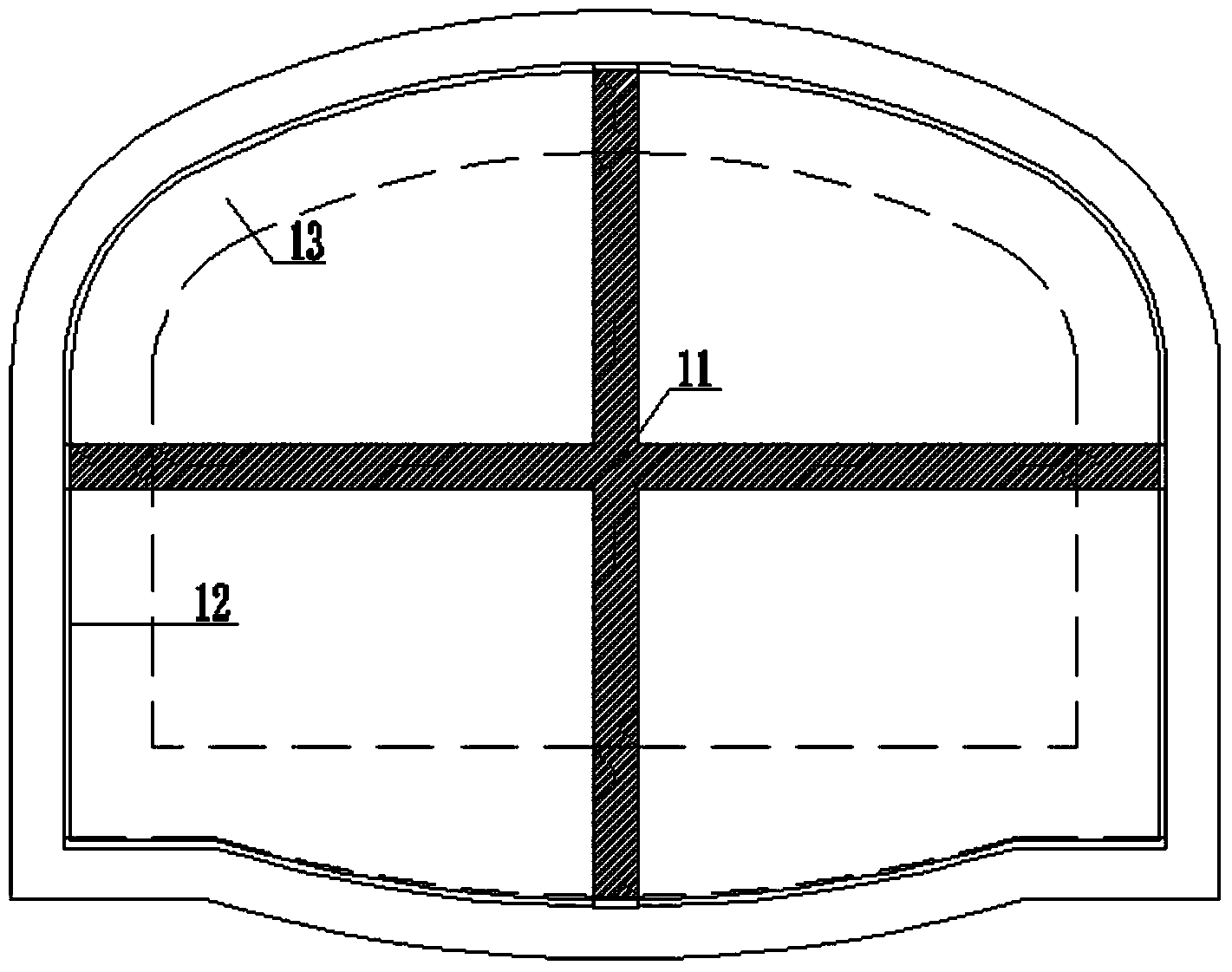

Composite liner structure of four-track large-span wall-foundation arched tunnel

InactiveCN102213099ASolve the problem of sinking deformationIncrease stiffnessUnderground chambersTunnel liningComposite linerSubsidence

The invention relates to a composite liner structure of a four-track large-span wall-foundation arched tunnel. According to the composite liner structure provided by the invention, subsidence of an arch crown of a four-track large-span tunnel can be effectively controlled, and crack of a liner, even a tunnel collapse accident caused by subsidence of an arch springing and deformation of the arch crown can be avoided so that the stability and the safety of tunnel construction and operation are ensured. The composite liner structure comprises a forepoling structure, a preliminary poling structure and a secondary liner structure which are arranged from inside to outside. The secondary liner structure comprises a secondary liner structure (31) at an arch part, wall-foundation structures (32) at two sides of a tunnel and an inverted arch; the forepoling structure comprises a forepoling structure (11) at the arch part and forepoling structures (12) on the side walls of a wall foundation; the preliminary poling structure comprises preliminary poling structures (21) at the arch part and preliminary poling structures (22) on the side walls of the wall foundation; and the lower ends of the preliminary poling structures (21) at the arch part and the secondary liner structure (31) at the arch part are respectively supported at the upper ends of the wall-foundation structures (32) at two sides of the tunnel.

Owner:CHINA RAILWAY ERYUAN ENG GRP CO LTD

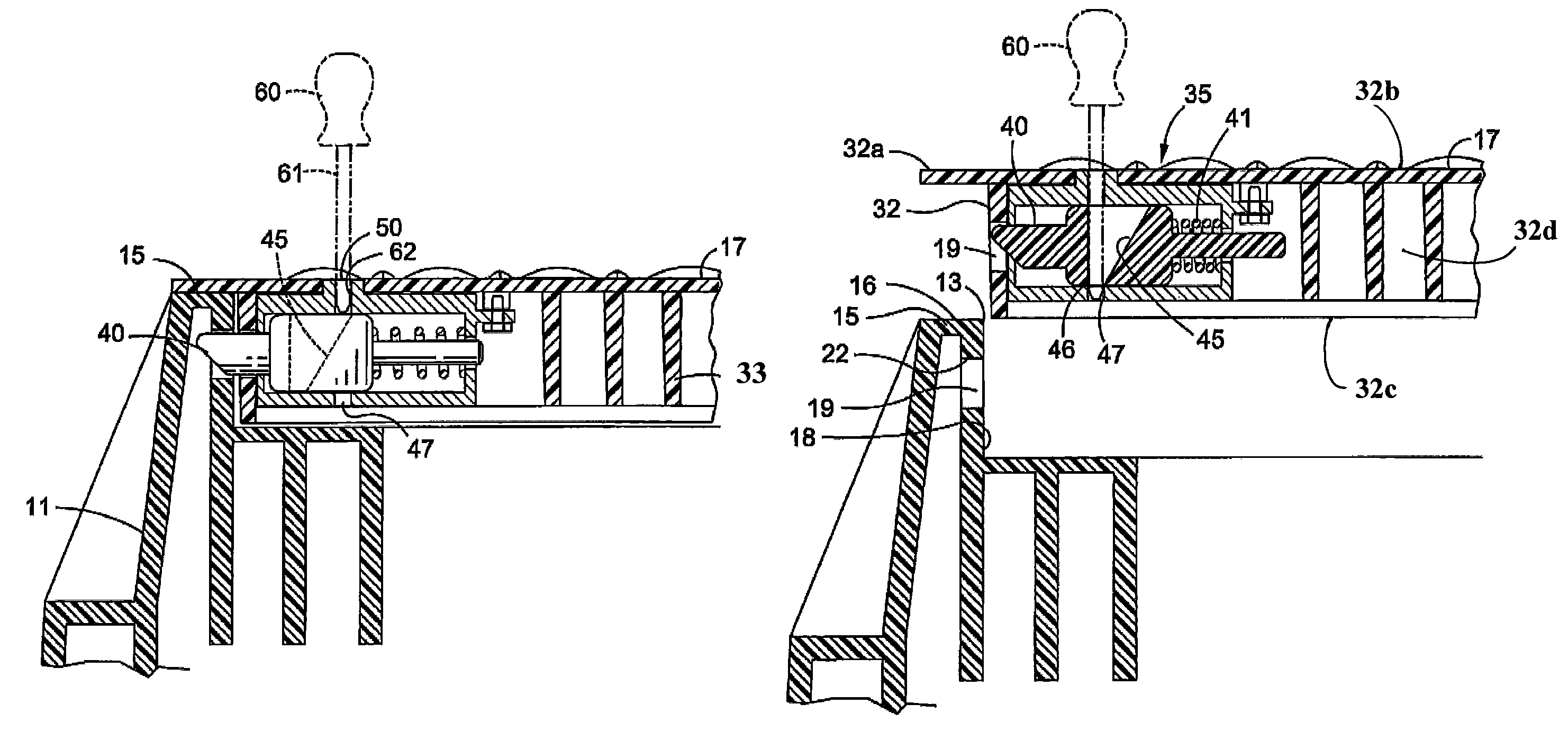

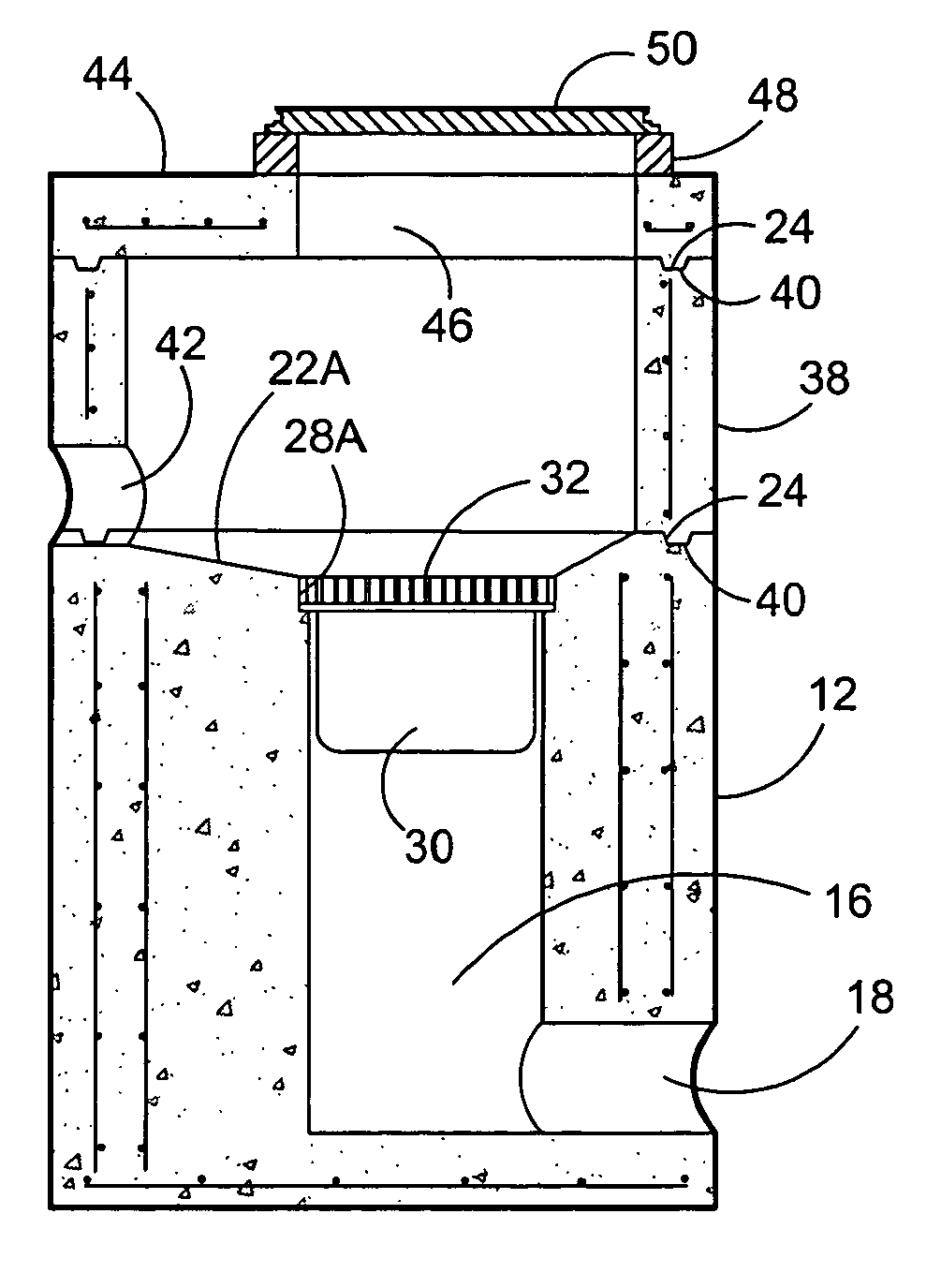

Integrated below-ground vault with a filtered catch basin

InactiveUS7163635B2Improve handlingImprove purification effectPaving gutters/kerbsLoose filtering material filtersFlood controlStreamflow

The invention relates to an integrated belowground vault with filter catch basin, that allows the runoff water to enter into a belowground two-part vault passing through a commercially available replaceable filter before being transferred out to the sewer, flood control system or out through a French drain consisting of a cavity below the device that is filled with drain gravel. A layer of filter cloth can optionally be placed over the drain gravel. This device will be manufactured in variety of sizes and shapes and made from several different materials. The device has the unique ability of being capable of filtering low flow water runoff while allowing high volume to pass through with the added benefit of not retaining water that can become a mosquito breeding ground.

Owner:FITZGERALD JAMES

Industrial vault

InactiveUS6401400B1Minimize potential for undesired leakingImprove sealingWallsTowersElectricityClerestory

This invention comprises reinforced industrial vaults with segmented knock-outs having a variety of shapes and orientations. The invention also comprises vaults having cast-in cable racks. The cable racks can be electrically connected to the reinforcing elements during manufacture, providing electrical grounding of electronic equipment placed in the vault. Cable channels can be installed at desired locations by selecting a knock-out, removing the knock-out and installing a terminator plate having cable conduits. Cable conduits can have diaphragms that can be removed to provide additional choices for locating cable channels. Cable channels can be provided in a vault in the field, even if the vault has been already installed.

Owner:NEEBASIS LLC +1

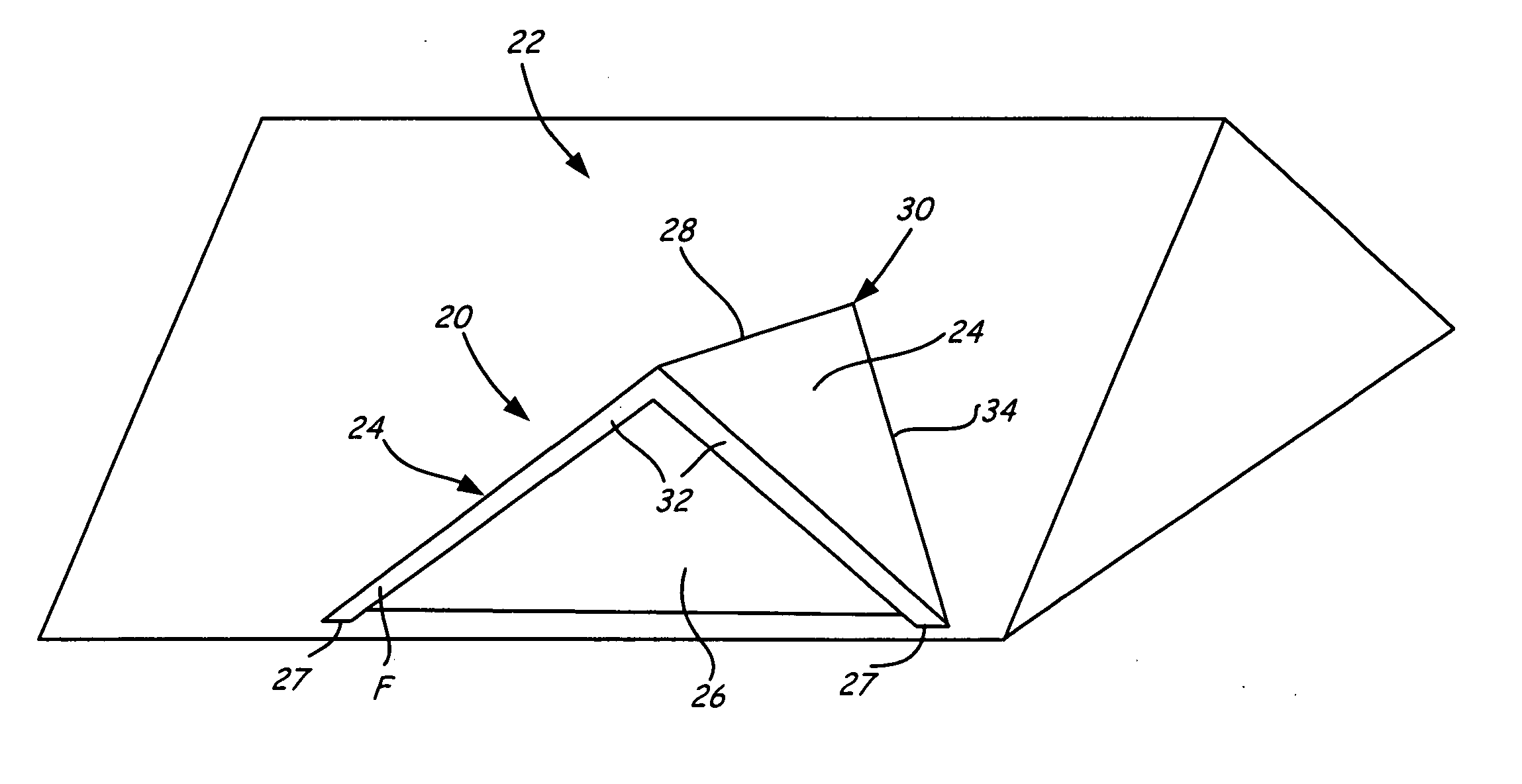

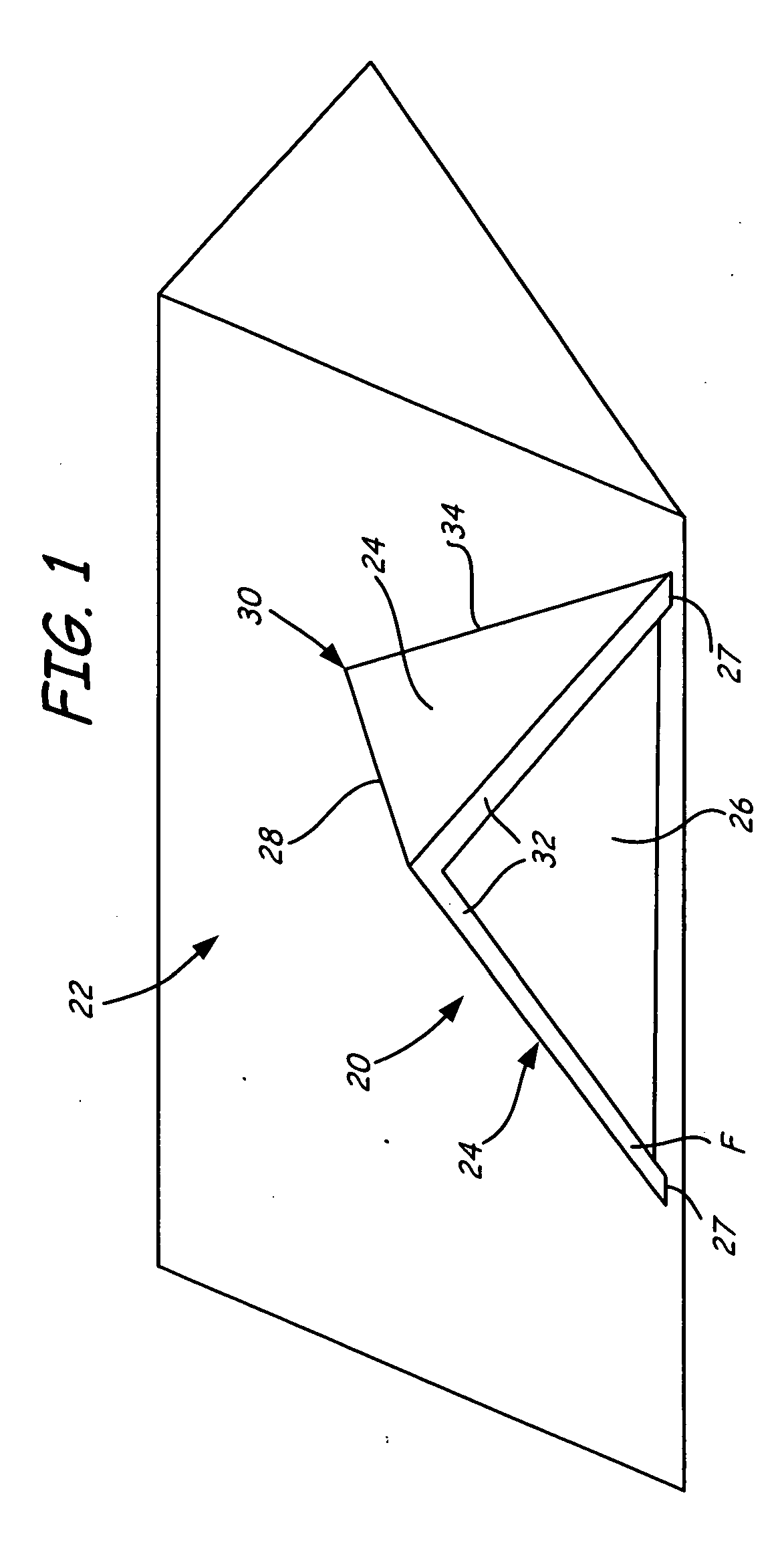

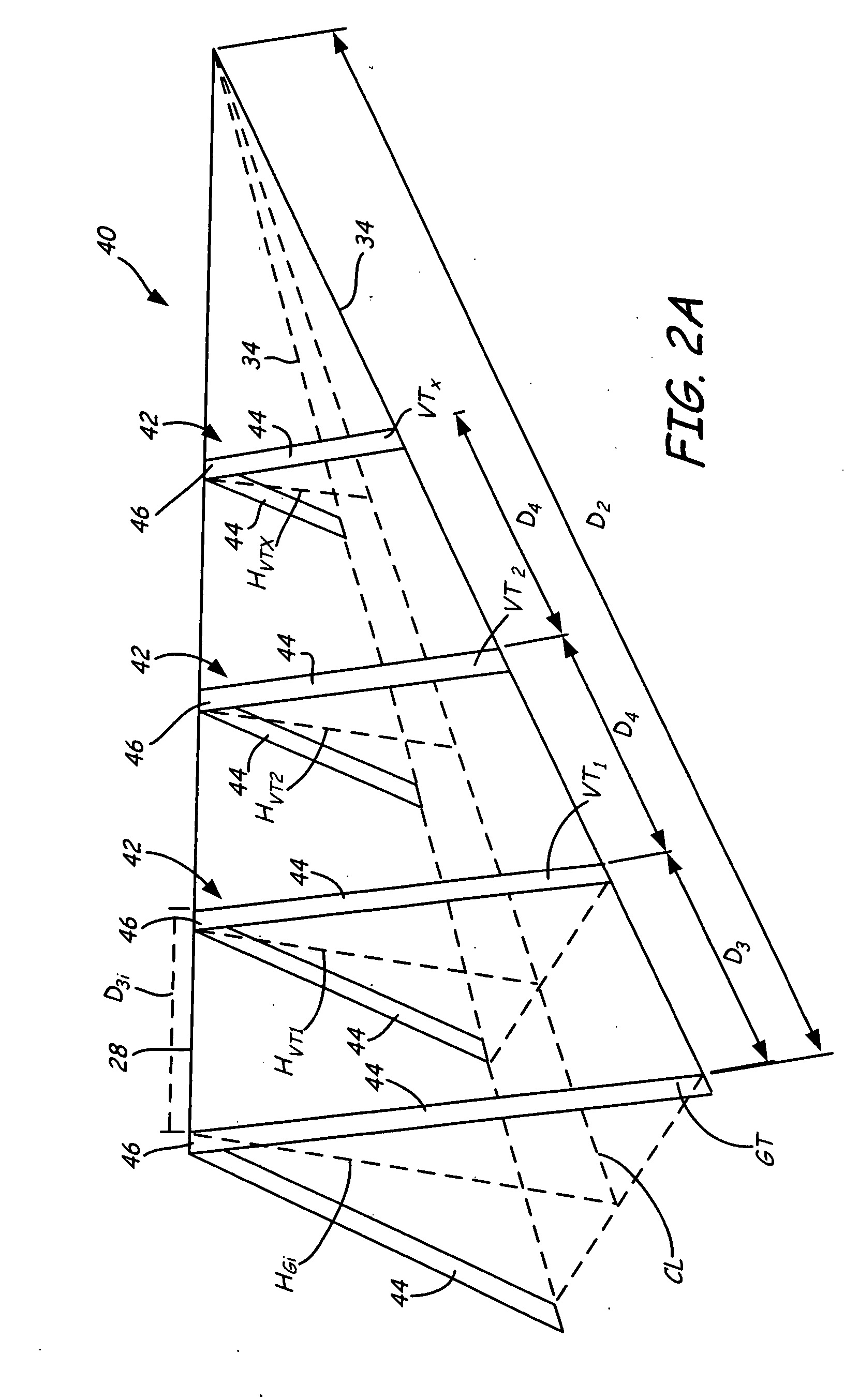

Dormer calculator

The present invention is a method for laying out a dormer that projects outward from a main roof and has a gable end and a dormer roof originating at a dormer point and terminating at an outer edge of the dormer roof near the gabled end. The dormer includes roof sheathing supported by dormer trusses. The dormer trusses include a gable truss and a plurality of valley trusses. The method of the present invention includes receiving a plurality of dormer inputs from a user. A plurality of layouts for the roof sheathing on the dormer roof are generated as a function of the dormer inputs. One or more layouts are then recommended to a user to reduce a quantity of roof sheathing waste.

Owner:ONCHUCK DEAN

Underground excavation construction method of large-span subway station in flexible-top and hard-bottom stratum

InactiveCN104763433AGuarantee the construction qualityUnderground chambersTunnel liningEngineeringSubway station

The invention provides an underground excavation construction method of a large-span subway station in a flexible-top and hard-bottom stratum, and aims at effectively reducing the construction risk and increasing the excavation construction efficiency. The method comprises the steps of constructing an arch part by the left part and the right part; constructing a temporary partition wall in the middle of the arch part constructing a first initial support for the arch part; removing the temporary partition wall in the middle within a short circulation after excavating the arch part; constructing a second initial support; gradually thickening from the top to the bottom of the arch to form a structural form that large arch feet are formed at the end parts; connecting the first initial support and the second initial support through reinforcing steel bars to form overlapped initial support arch covers; excavating the rest rock by a pulling trough step method under the protection of the double-layer overlapped initial support arch covers until reaching the bottom part of the tunnel; sequentially constructing a two-lining structure and the inner structure of the station from bottom to top.

Owner:CHINA RAILWAY ERYUAN ENG GRP CO LTD

CRD construction method tunnel waterproof construction method

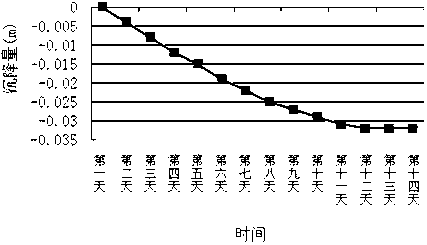

InactiveCN103643973ASolve the problem of large settlement deformationShorten the construction periodUnderground chambersTunnel liningSupporting systemDeformation monitoring

A CRD construction method tunnel waterproof construction method includes the following steps that after a primary support system is stabilized, deformation monitoring points are arranged on an arch crown and side walls; CRD I-steel is demounted every other within the range of a lining bottom plate and a lining top plate; the residual non-demounted I-steel is ground, and the periphery of the I-steel is floated with cement mortar and hardened; the non-demounted I-steel and the hardened base surface are coated with rubber bitumen and paved with waterproof plates, the surfaces of the waterproof plates on the periphery of the I-steel are coated with a layer of rubber bitumen, and eventually a water stop flange is welded to each I-steel, and grouting systems are arranged on the two sides of the I-steel; bottom plate lining construction and top plate lining construction are conducted, after the top plate lining construction is conducted, all residual temporary supports are demounted; temporary inverted arch concrete and the I-steel within the range of the bottom plate side walls are broken and demounted; bottom plate side wall ECB waterproof plate pavement and lining construction are conducted. The phenomenon of settlement deformation of primary supports in the lining process can be effectively controlled, the construction period is shortened, and construction investment is reduced.

Owner:CHINA RAILWAY CONSTR BRIDGE ENG BUREAU GRP

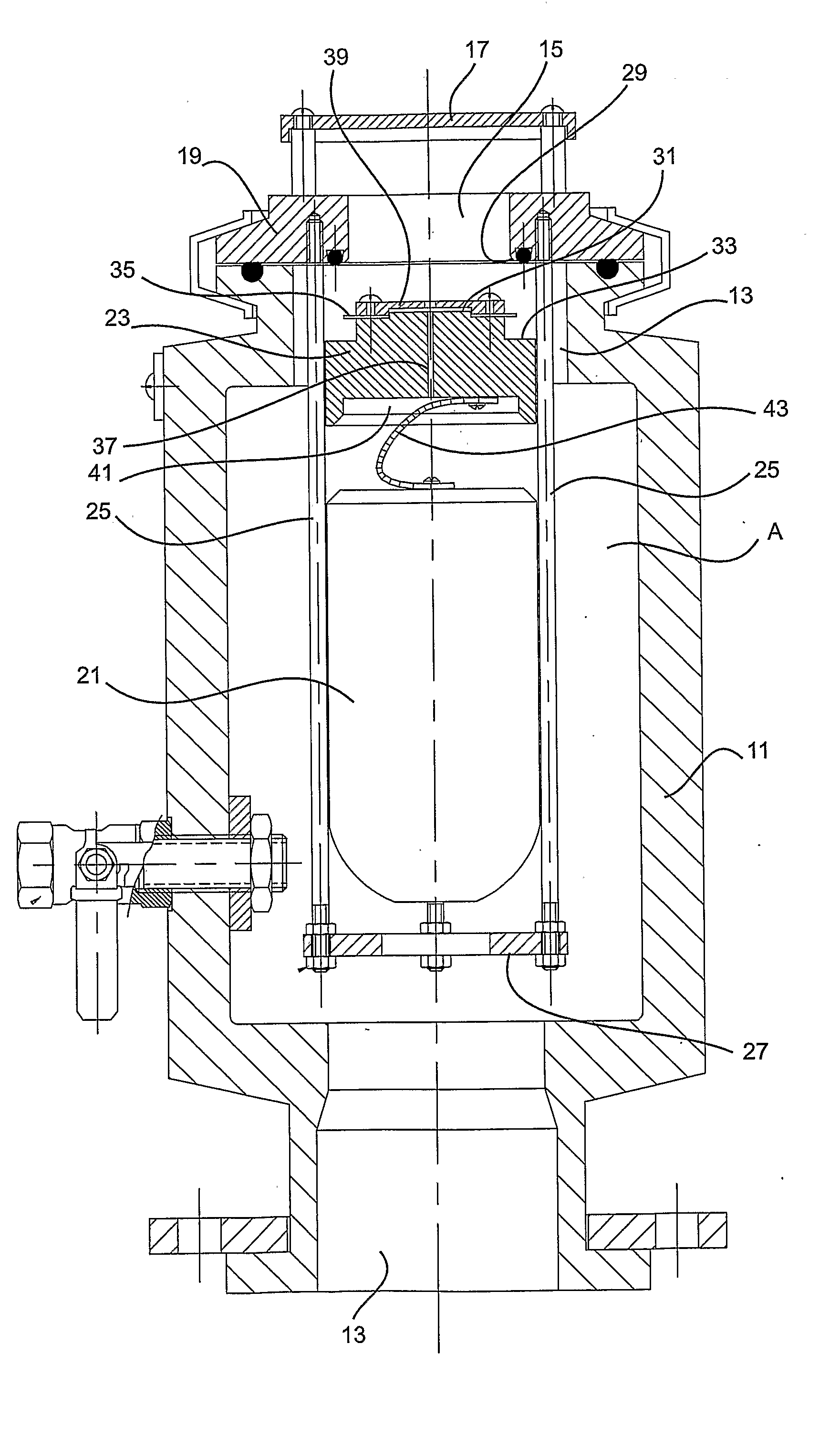

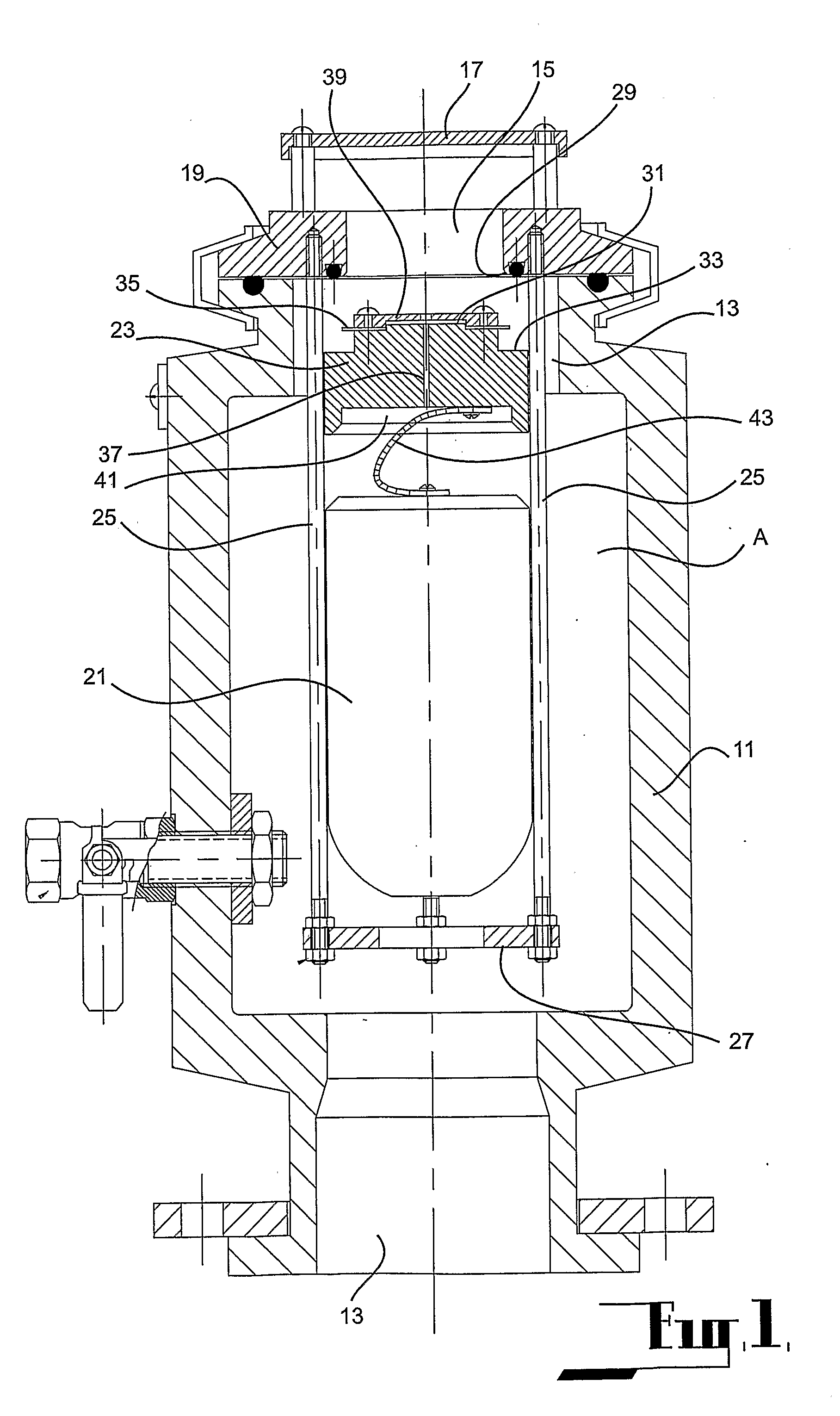

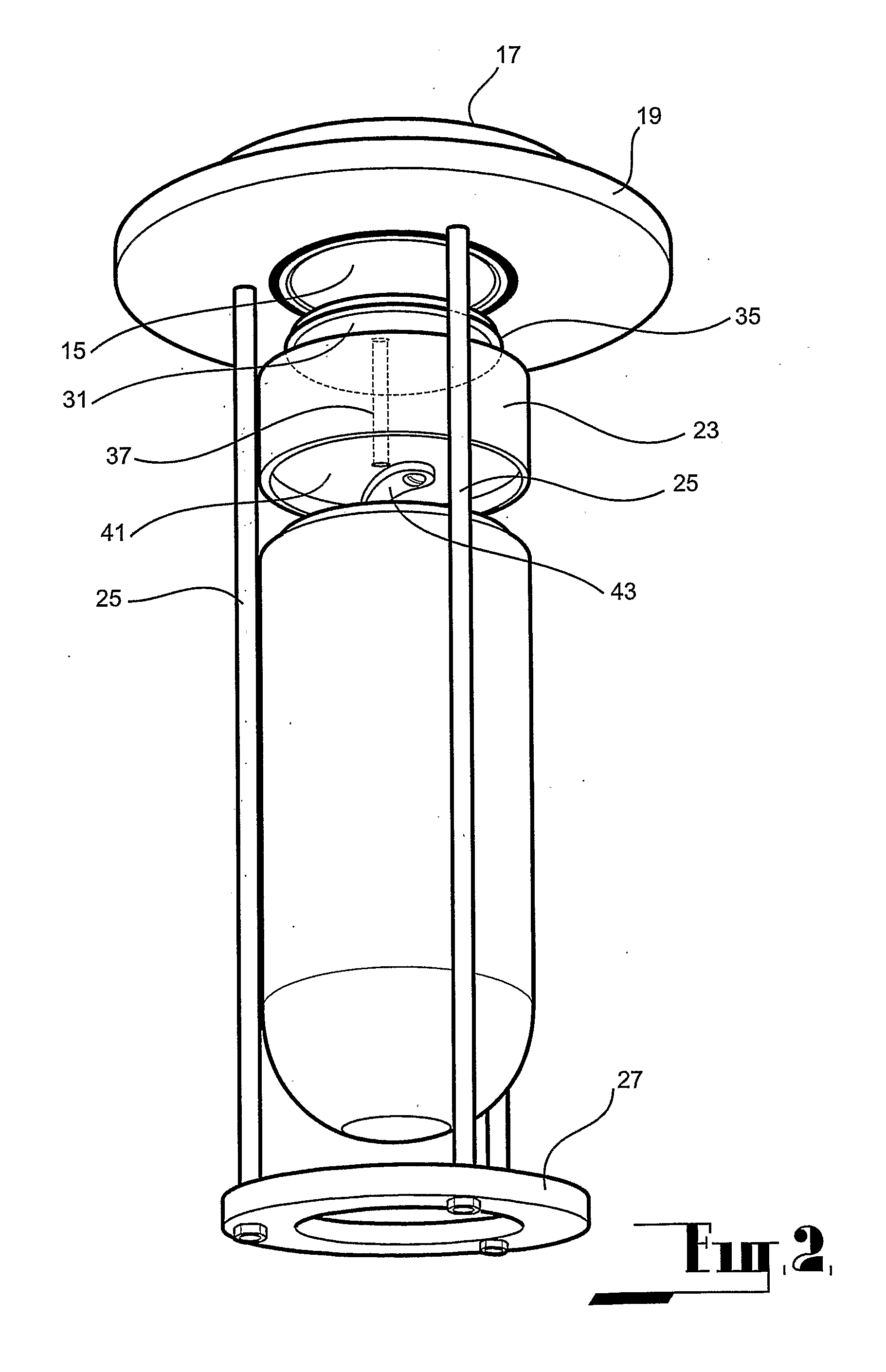

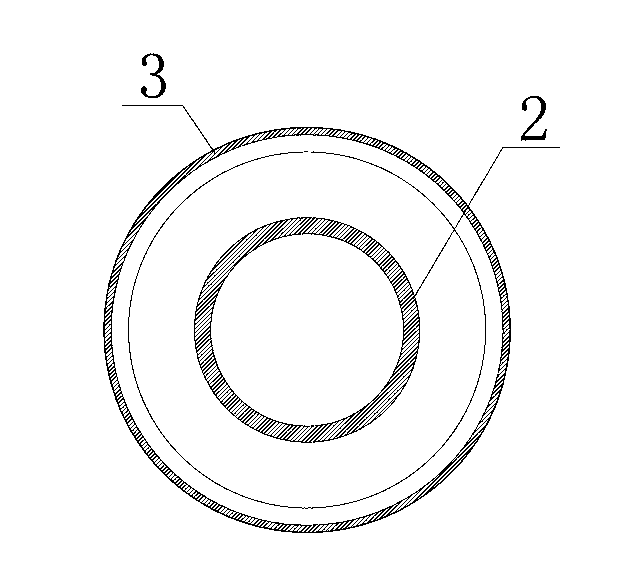

Vent valve

InactiveUS20090139581A1Operating means/releasing devices for valvesVenting valvesExhaust valveEngineering

A pipeline vent valve comprising a body (11) defining a chamber of clerestory configuration in which the upper portion (B) of the chamber is of reduced cross-sectional area, the chamber having an inlet (13) towards its lower end which is adapted to be connected to a pipeline and an outlet (15) in the upper portion, a valve body (23) supported in the upper portion of the chamber to be movable between a first position at which it is in sealing engagement with the outlet and a second position at which it is out of sealing engagement with the valve seat, said valve body being responsive to the level of liquid in the chamber in the chamber and being adapted to close on the liquid level in the chamber exceeding a predetermined level, said valve body having central passage (37) providing communication to each side of the valve body, a float member (21) supported within the chamber and adapted to cause said movement of said valve body between the first and second position as a result of the presence of liquid in the chamber, the float member being further adapted sealingly engage said central passage as the liquid in the chamber reaches the predetermined level and to and expose said passage on relative movement of the float member away from the valve body.

Owner:BWANOLAR

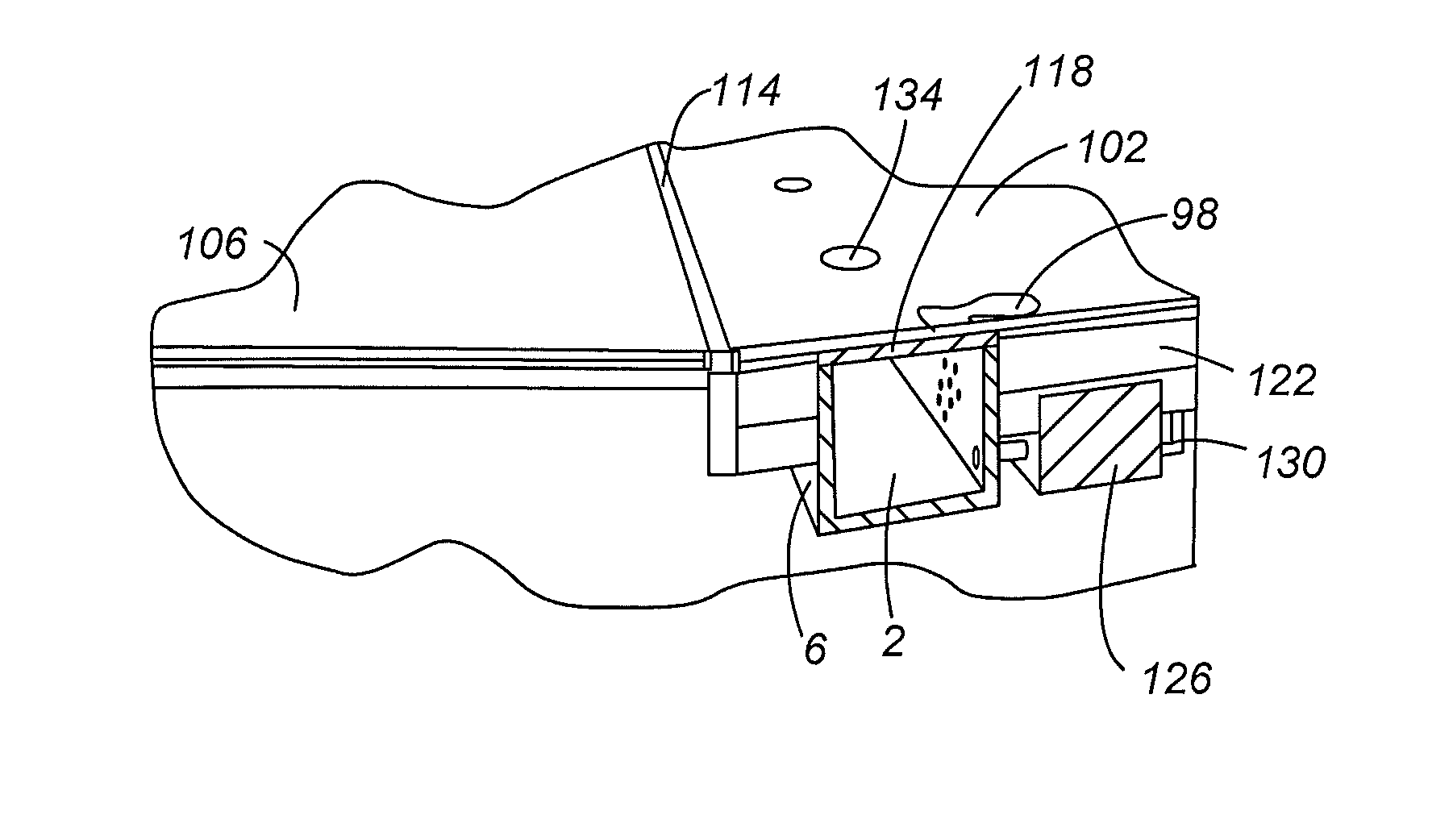

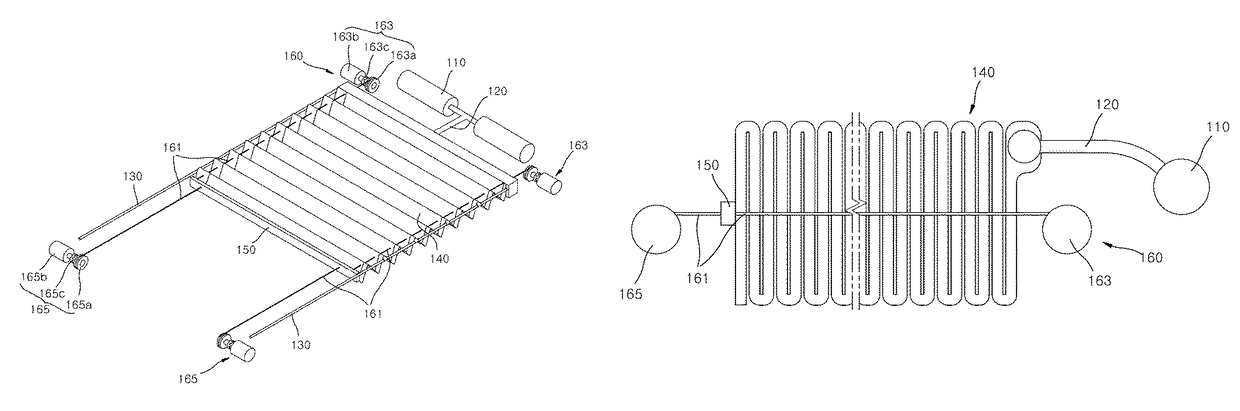

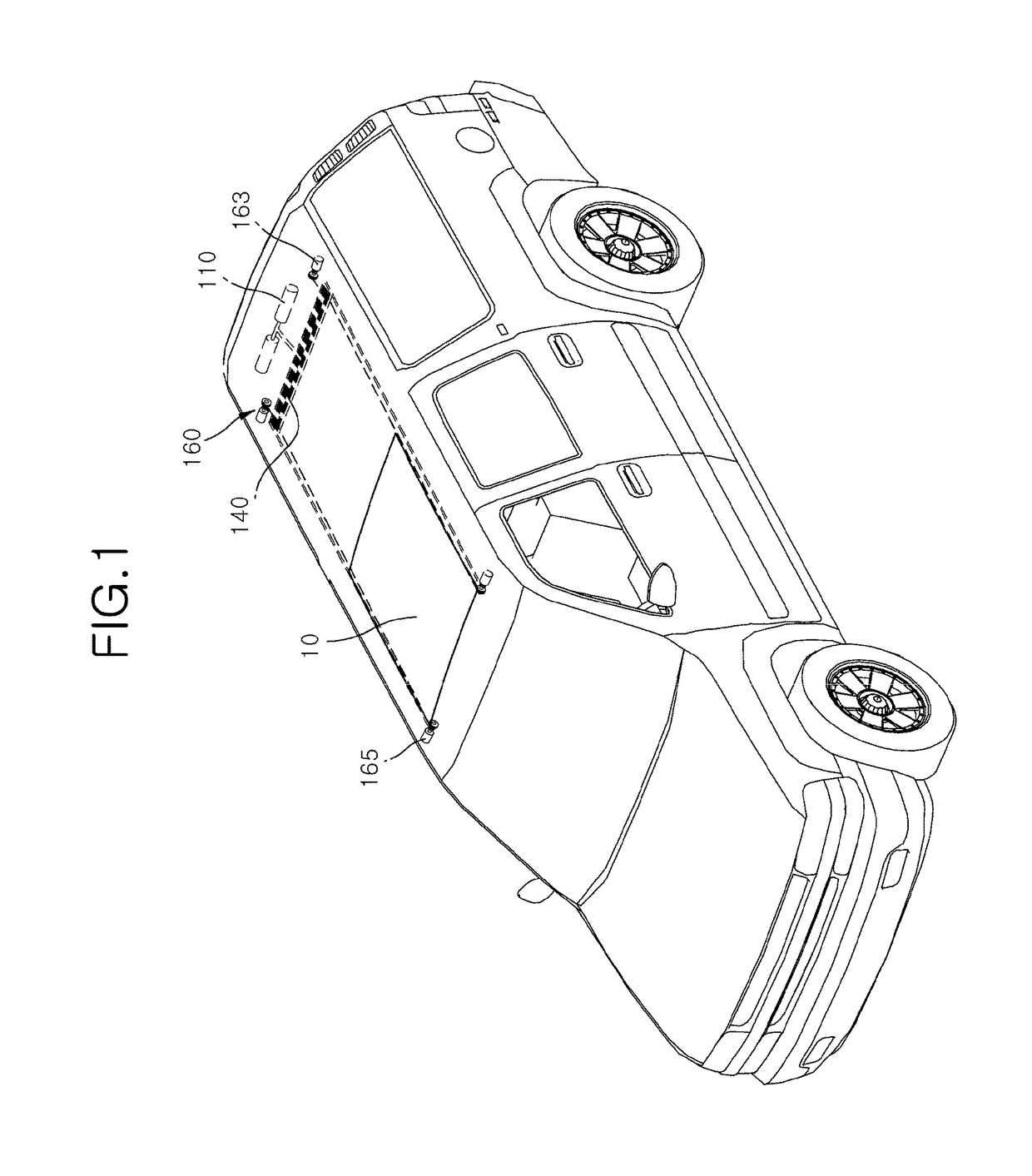

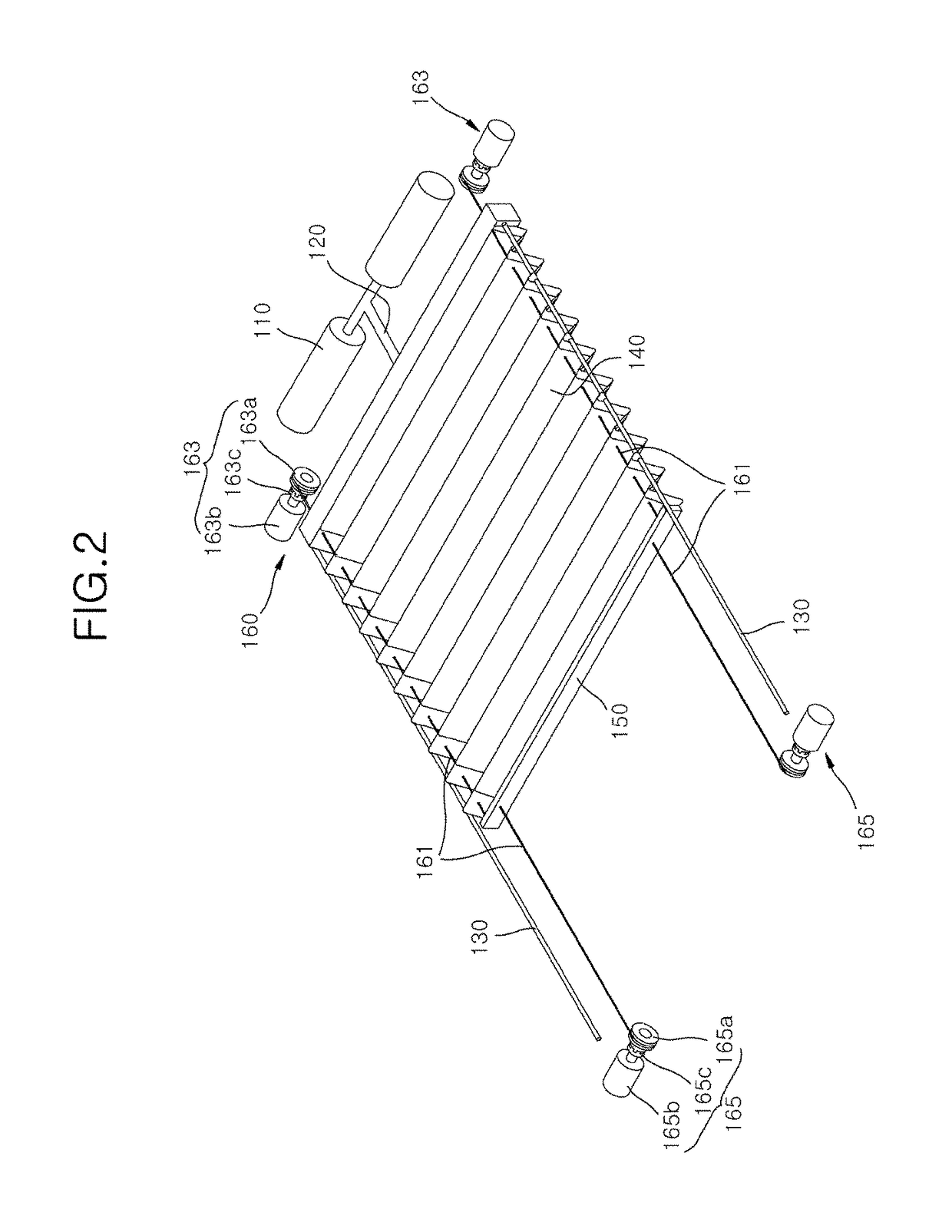

Airbag apparatus for panorama roof

ActiveUS9771048B2Improving airbag performanceAvoid separationPedestrian/occupant safety arrangementEngineeringAirbag

Owner:HYUNDAI MOBIS CO LTD

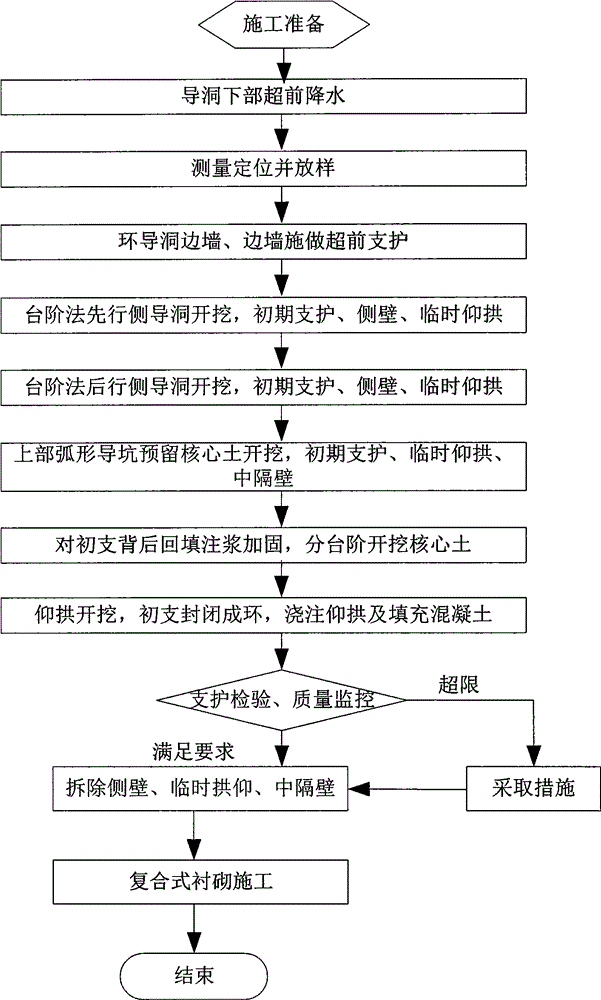

Advance precipitation construction method of oversized-section double-side lower pilot tunnels of water-rich tunnel

InactiveCN104373128AFast structure speedOne splicing construction deviation is smallTunnelsClerestoryPrecipitation

The invention relates to an advance precipitation construction method of oversized-section double-side lower pilot tunnels of a water-rich tunnel. Pilot tunnels on two side walls of a lower half section of a tunnel are adopted, and are partially closed to form rings; the advance precipitation is performed for the tunnel; the stability of arching legs of primary supports of the tunnel is guaranteed; the upper half section of the tunnel is dig by an arch pilot tunnel reserved core soil method; the arch part is dig in place once; the primary steel supports at the upper part of the tunnel are once spliced in place for closing to rings; the disturbance to surrounding rocks due to multiple splices is reduced; and the whole structure of the primary supports of the tunnel is quickly built. Compared with a traditional CD method, CRD method and double-side wall pilot tunnel method, the construction method is high in construction safety, quick in construction progress, short in construction period, low in part mechanical and labor resource configuration, low in once splicing construction deviation of the steel supports, high in construction quality of the primary supports, quick in building of the whole structure of the primary supports of the tunnel and low in vault crown settlement.

Owner:CHINA ROAD & BRIDGE

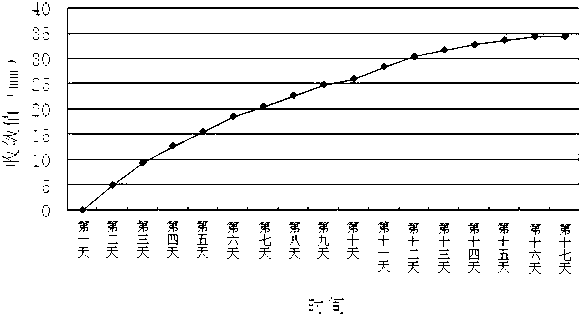

Supporting arch hidden digging top-down construction method

ActiveCN101338678AFew construction divisionsIncrease the construction work areaUnderground chambersTunnel liningClerestoryFloor slab

The present invention relates to a one time supporting arch subsurface excavation reversed construction method. The steps of the method are as follows: at least a pair of upper guide hole and lower guide hole are respectively excavated in a top body and a bottom body corresponding with an underground structure design space; each pair of guide holes forms one span; then the hole wall is processed for primary supporting; the bottom of the lower guide hole is laid with a waterproof layer; the waterproof layer is casted with an underlayer frame structure soleplate; a slope stake and a middle upright post are constructed from the upper guide hole; the arc top of the upper guide hole is laid with the waterproof layer, and an arc top permanent structure is cast; then a midspan soil body is excavated between two upper guide holes by a subsurface excavation method to form a midspan upper guide hole and to be constructed as a midspan upper guide hole arc top permanent structure; the primary support at the bottom of the upper guide hole is chiseled and removed; a soil body is excavated downwards, and a structure lateral wall and a middle floor slab are cast; the rest partial solid between the primary support at the top of the lower guide hole and the middle floor slab is excavated, at the same time, the primary support at the top of the lower guide hole is chiseled and removed, the rest lateral wall structure is cast, and an even span structure soleplate is closed. The method has small construction risk, large construction field and fast construction speed, uses few big guide holes and solves the technical problems of the large amount of the guide hole, the small size of the guide hole, small construction space, multiple times of structure stress conversions, the repeated perturbation of wall rock, etc of the traditional subsurface excavation method.

Owner:BEIJING URBAN CONSTR DESIGN & DEV GRP CO

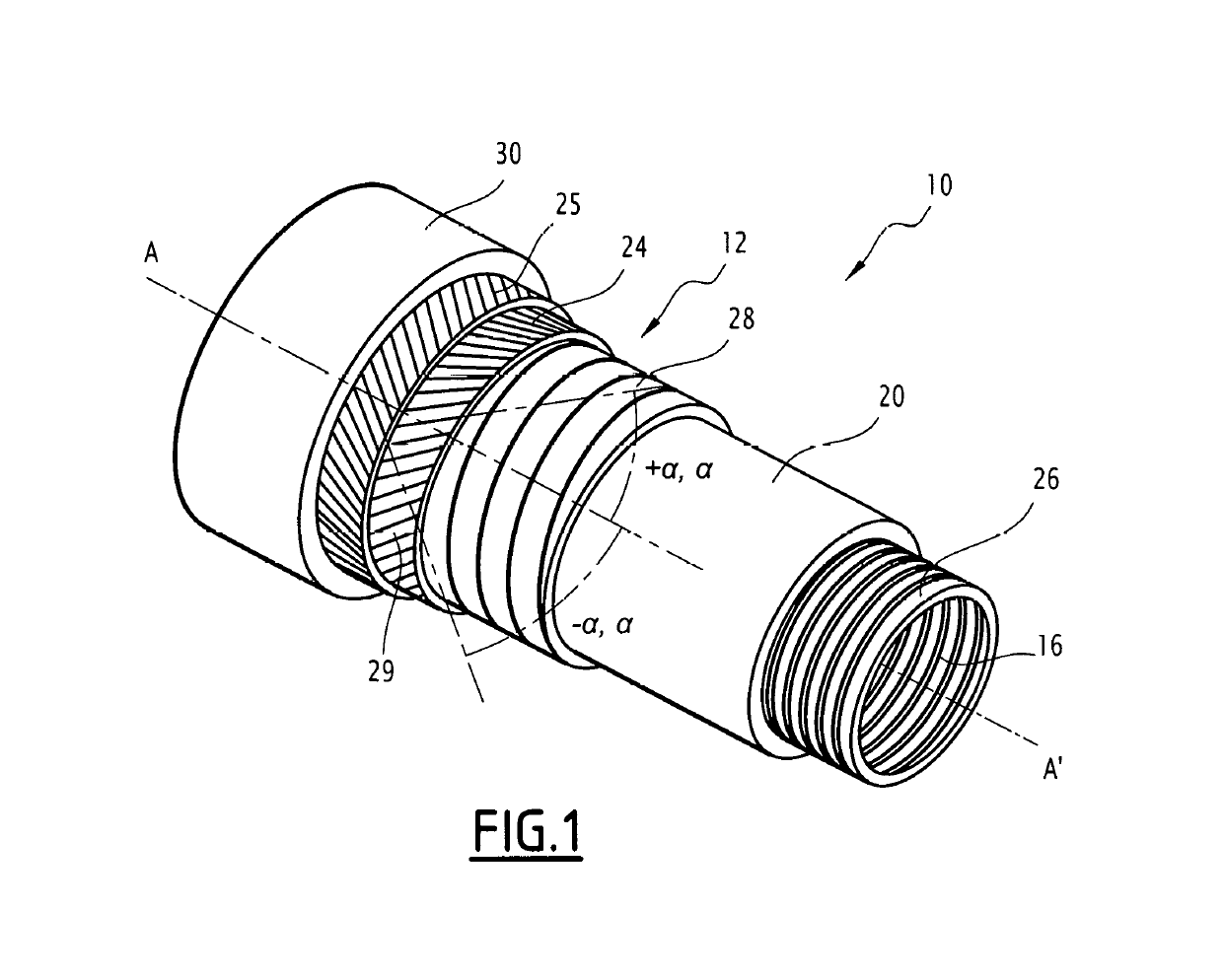

Connection end-piece of a flexible pipe for transporting fluid and associated method

ActiveUS10451206B2Effective absorptionSleeve/socket jointsFlexible pipesMechanical engineeringClerestory

A connection end-piece of a flexible pipe includes an end vault extending along a central axis; an outer cover fixed to the end vault and defining, with the end vault, a reception chamber for receiving an end section of the armor elements of the flexible pipe; at least one annular member applied externally to the armor elements of the flexible pipe, the annular member being at least partially accommodated in the reception chamber between the armor elements and the outer cover. The annular member applies a radial tightening pressure higher than 100 bars onto the armor elements toward the central axis of the flexible pipe.

Owner:TECH FRANCE SA

Non-metallic support stanchion

A cable rack arm and support system suitable for underground power and communication service is made from a non-metallic polymer that will not rust or corrode. The cable rack arm is adapted for mounting to existing underground stanchions or for stanchions of a more modern design. Each cable rack arm is securely mounted to the stanchion. Each cable rack arm then supports one or more cables in cable rests or saddles molded atop the arm, thus keeping the cables accessibly organized in a manhole, tunnel or vault. Plastic cable ties may be used to secure the cables to the cable rack arms. Nonmetallic pins may also be used to secure the cable rack arms to the stanchions. The stanchions may be made of nonmetallic composite material that includes a fiberglass cross-layered knitted apertured mat for increased strength.

Owner:UNDERGROUND DEVICES

Non-disturbance type supporting structure used for tunnel vault collapsed cavity processing

InactiveCN104975861AAdvanced conceptSimple and fast operationUnderground chambersTunnel liningCollapsed cavityEngineering

The invention discloses a non-disturbance type supporting structure used for tunnel vault collapsed cavity processing. The supporting structure comprises a concrete reinforcement net layer laid on a wall face of a collapsed cavity and a protection arc erected along the fracture surface of the collapsed cavity. The protection arc is arranged under the concrete reinforcement net layer. Multiple support pieces are arranged between the protection arc and the concrete reinforcement net layer. The space between the arc back of the protection arc and the inner wall of the concrete reinforcement net layer is filled by arch back backfill layers. Compared with the new Austrian tunneling method, the supporting idea is more advanced by following the principle that surrounding racks and lining structures bearing load together, so the lining structures are allowed to actively participate in load bearing to the greatest extent. The wall face of the collapsed cavity will not be nearly disturbed in the implementation process, so construction risks in the collapsed cavity processing process and potential operation risks are reduced.

Owner:CHINA MERCHANTS CHONGQING COMM RES & DESIGN INST

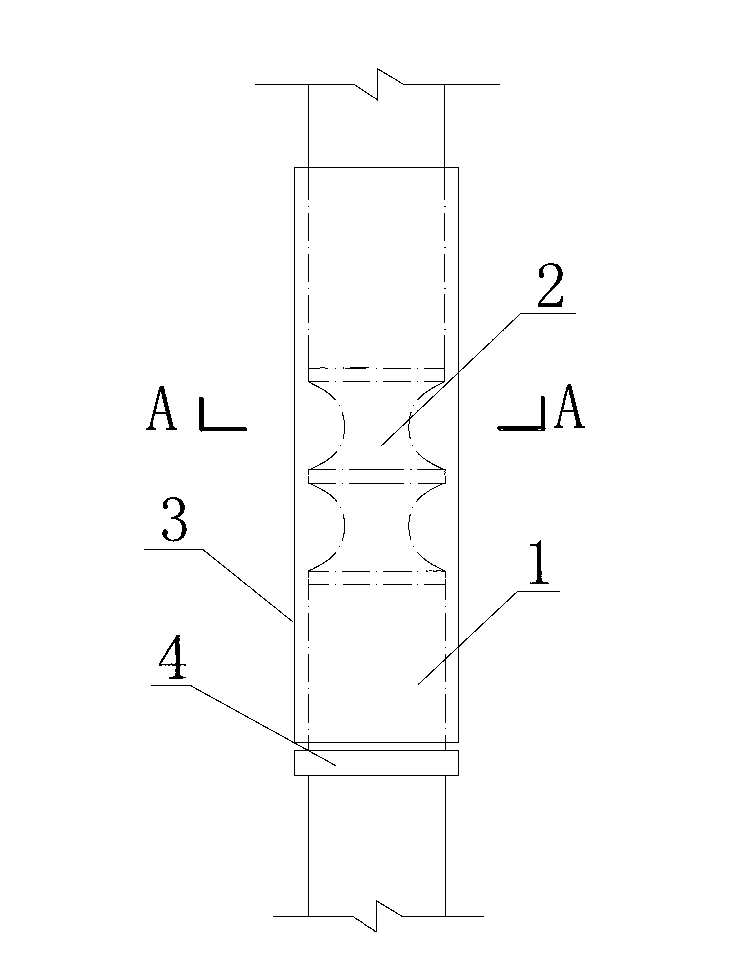

Quantitative yielding node applicable to underground engineering support lagging jack

ActiveCN102852534ASimple structureEasy to assembleUnderground chambersTunnel liningEngineeringEngineering support

The invention relates to a quantitative yielding node applicable to an underground engineering support lagging jack. The quantitative yielding node is formed by a lagging jack, a quantitative yielding device, a sleeve and a baffling ring; and the whole appearance shape of the quantitative yielding node is columnar or arc-shaped and the shape of the cross section is circular. The quantitative yielding node is mounted at a spandrel part, a vault part, a laneway side part or a bottom plate part of the lagging rack. The device is simple in structure and is convenient and flexible in installation; a yielding moment and a yielding amount are controllable and a plurality of yielding modes can be selected; the application range is wide; and with regard to various support lagging jacks with different shapes, sizes, cross section shapes and arc degrees, such as a mineral U-shaped steel lagging jack, circular steel pipe concrete lagging jacks with various section shapes and sizes and the like, the quantitative yielding node can be selected. The quantitative yielding node can be used for connecting the lagging jack for an underground engineering support and is particularly suitable for connecting a deep roadway support lagging jack.

Owner:SHANDONG UNIV +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com