Patents

Literature

41results about How to "Increase the construction work area" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for constructing double-arch tunnel by rebuilding and expanding existing single-hole tunnel

InactiveCN101737061AIncrease the construction work areaImprove construction efficiency and construction safetyUnderground chambersTunnel liningSingle holeEngineering

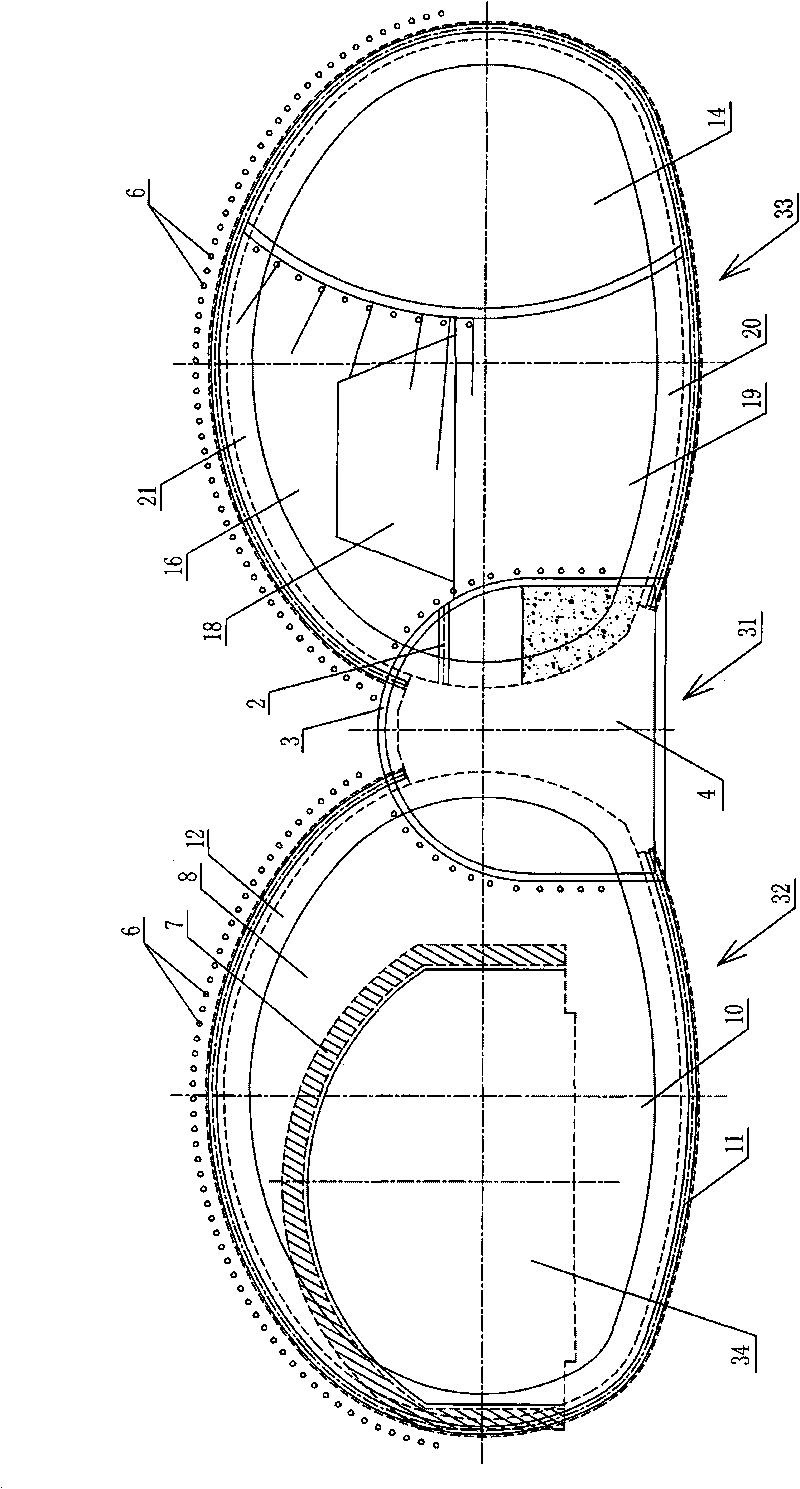

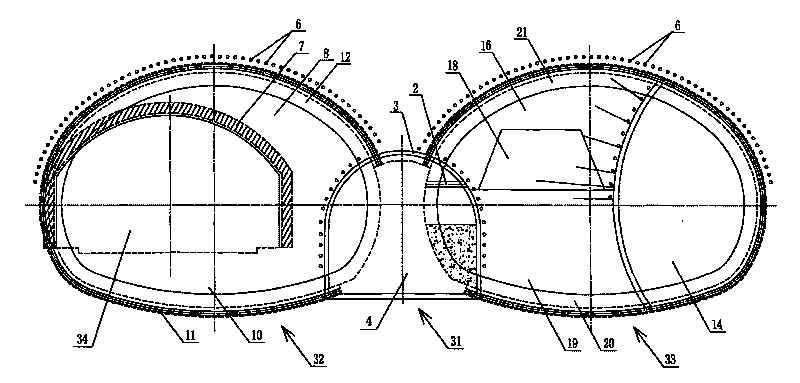

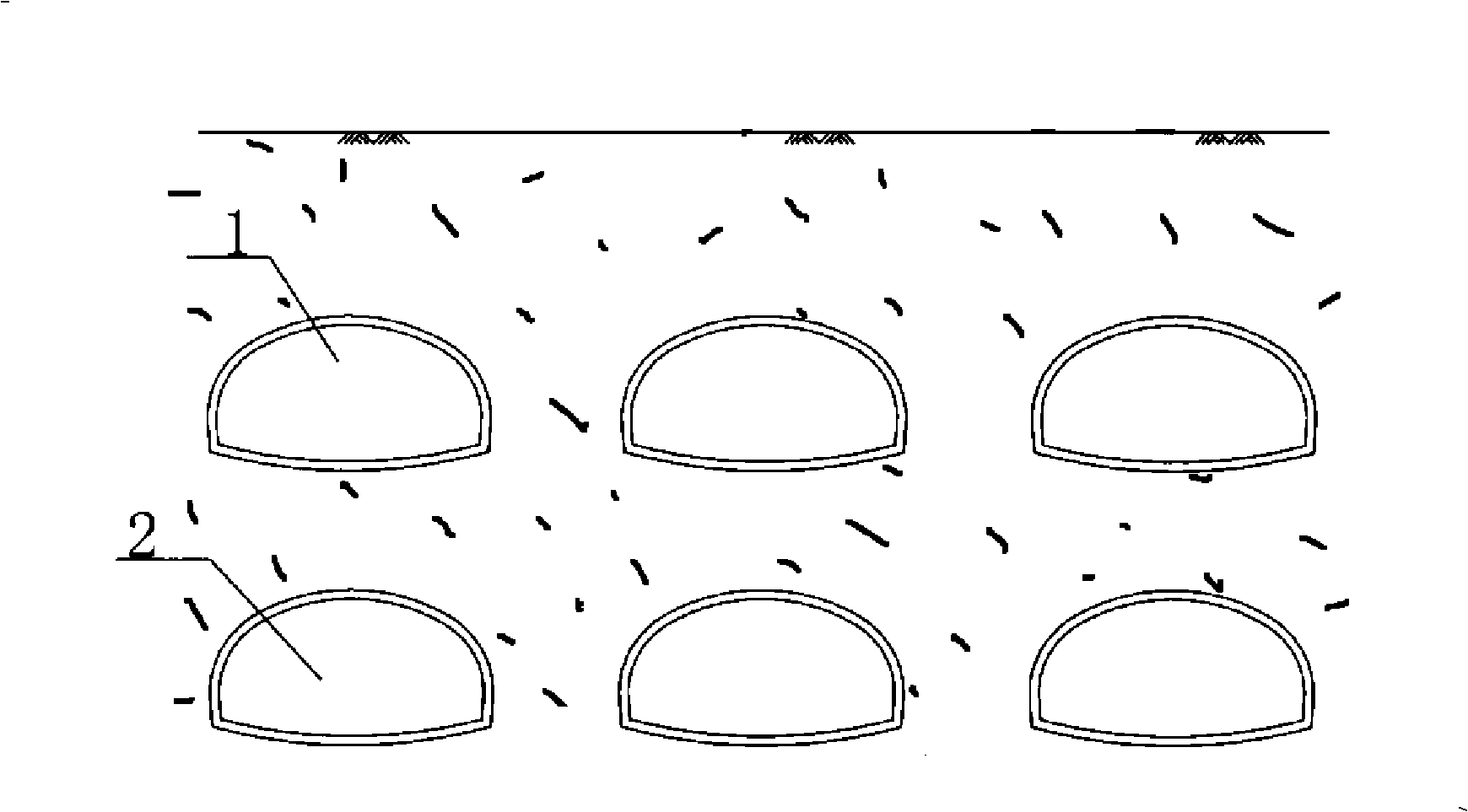

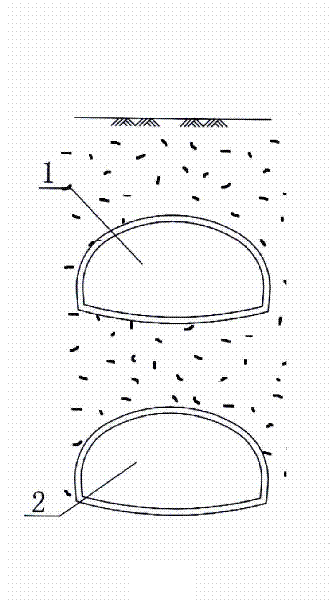

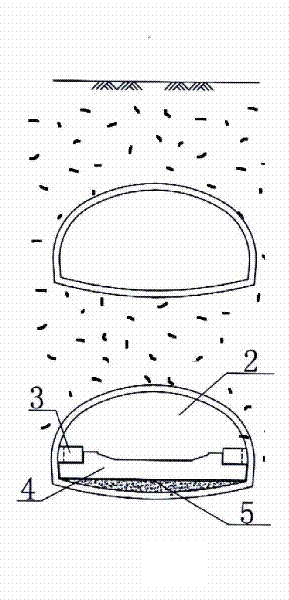

The invention relates to a method for constructing a double-arch tunnel by rebuilding and expanding an existing single-hole tunnel. The technical problem to be solved by the invention is to provide a method for constructing the double-arch tunnel by rebuilding and expanding the existing single-hole tunnel, which adopts a ' middle pilot hole, the existing tunnel and a right hole' three pilot pit construction scheme, enlarges construction face and reduce excavation face and surrounding rock disturbed zone. To solve the technical problem, the invention adopts a technical scheme that the method for constructing the double-arch tunnel by rebuilding and expanding the existing single-hole tunnel comprises the following steps: 1.1 constructing the middle pilot hole parallel to the existing single-hole tunnel on one side of the existing single-hole tunnel and completing supporting construction; 1.2, constructing a left hole by sequence and zone on the basis of the existing single-hole tunnel and communicating the left hole and the middle pilot hole; and 1.3, after excavating the left hole to a certain size, constructing the right hole by sequence and zone and communicating the right hole with the middle pilot hole. The method is mainly used in highway traffic engineering and municipal traffic engineering.

Owner:POWERCHINA HUADONG ENG COPORATION LTD

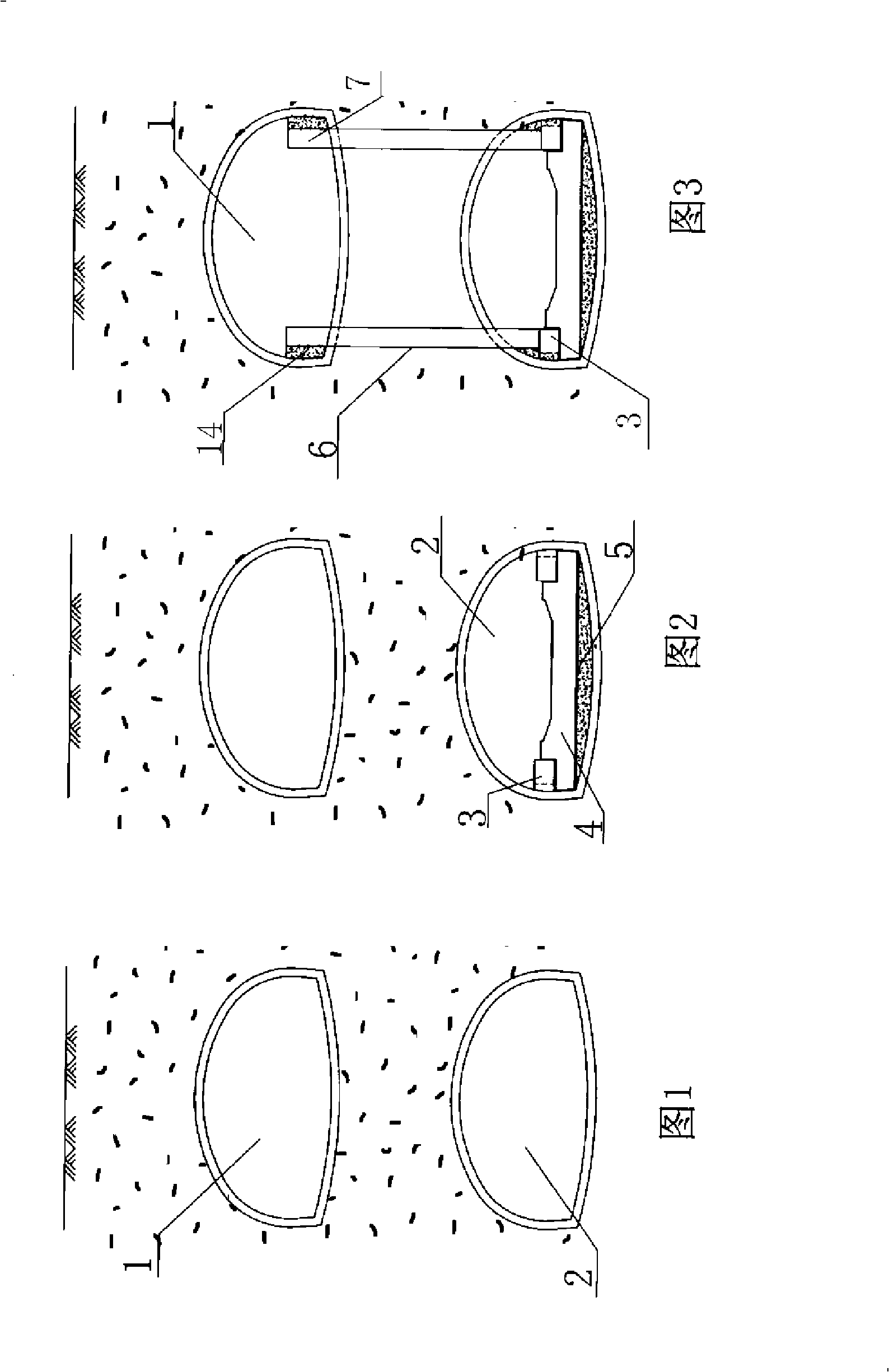

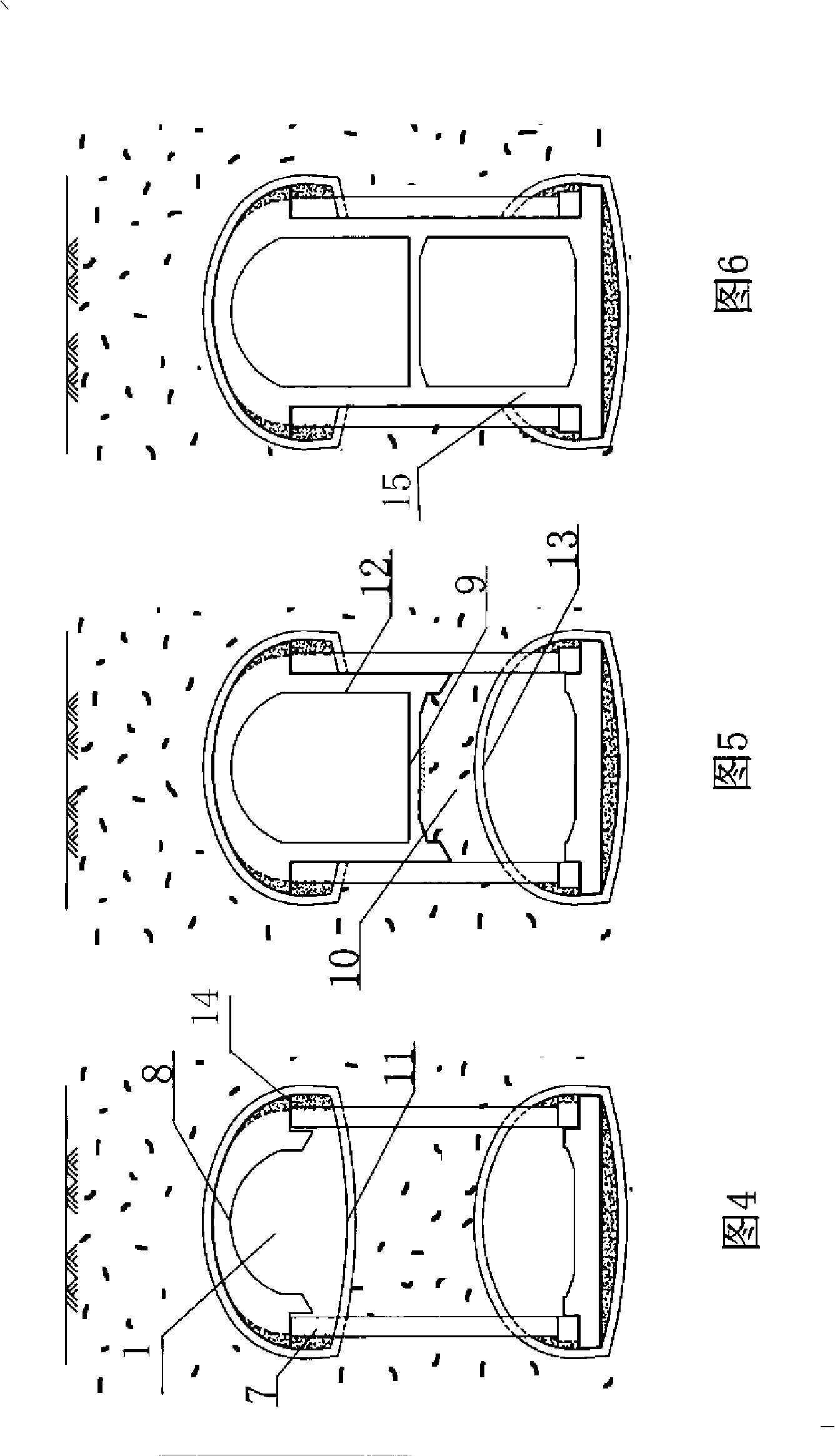

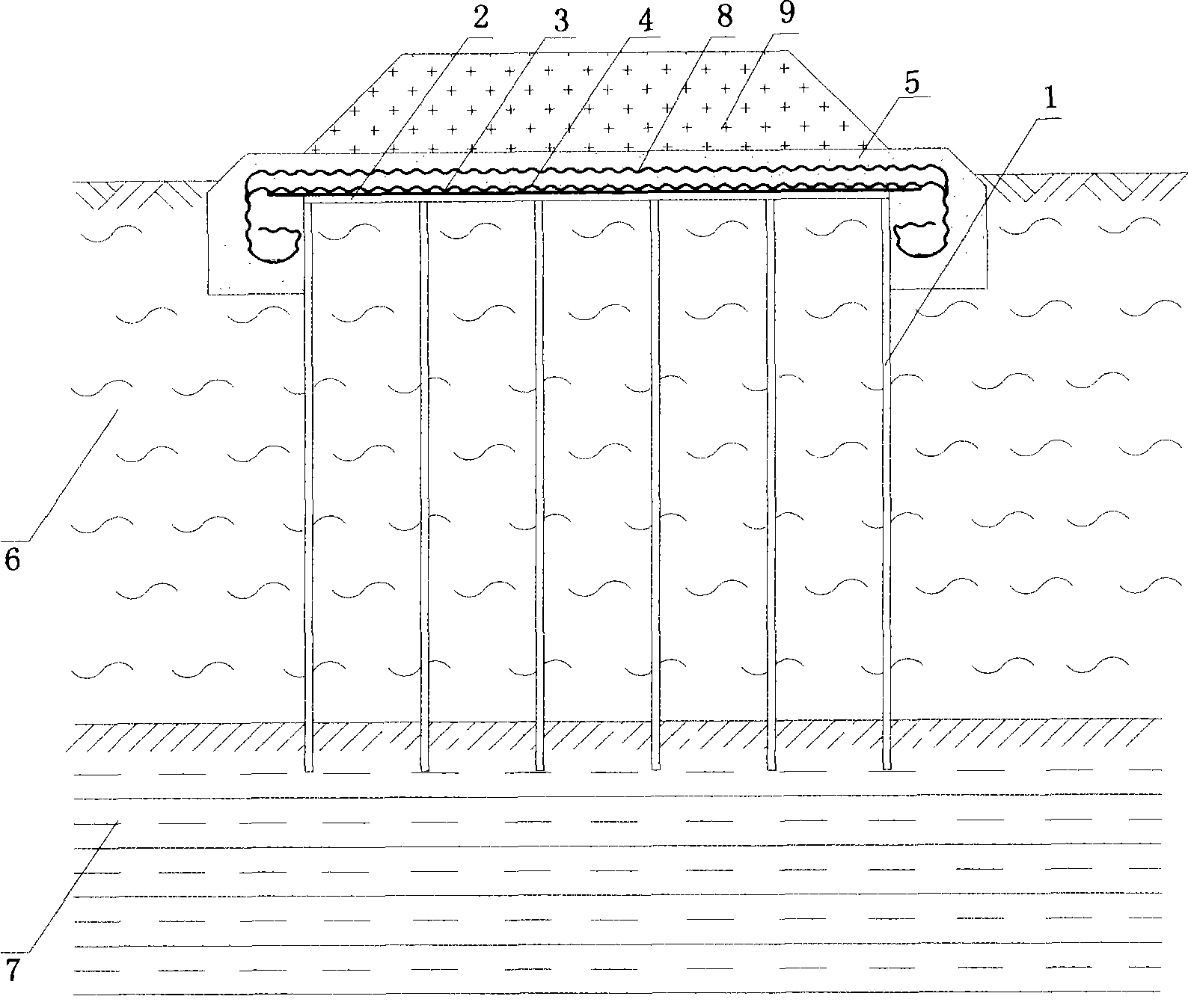

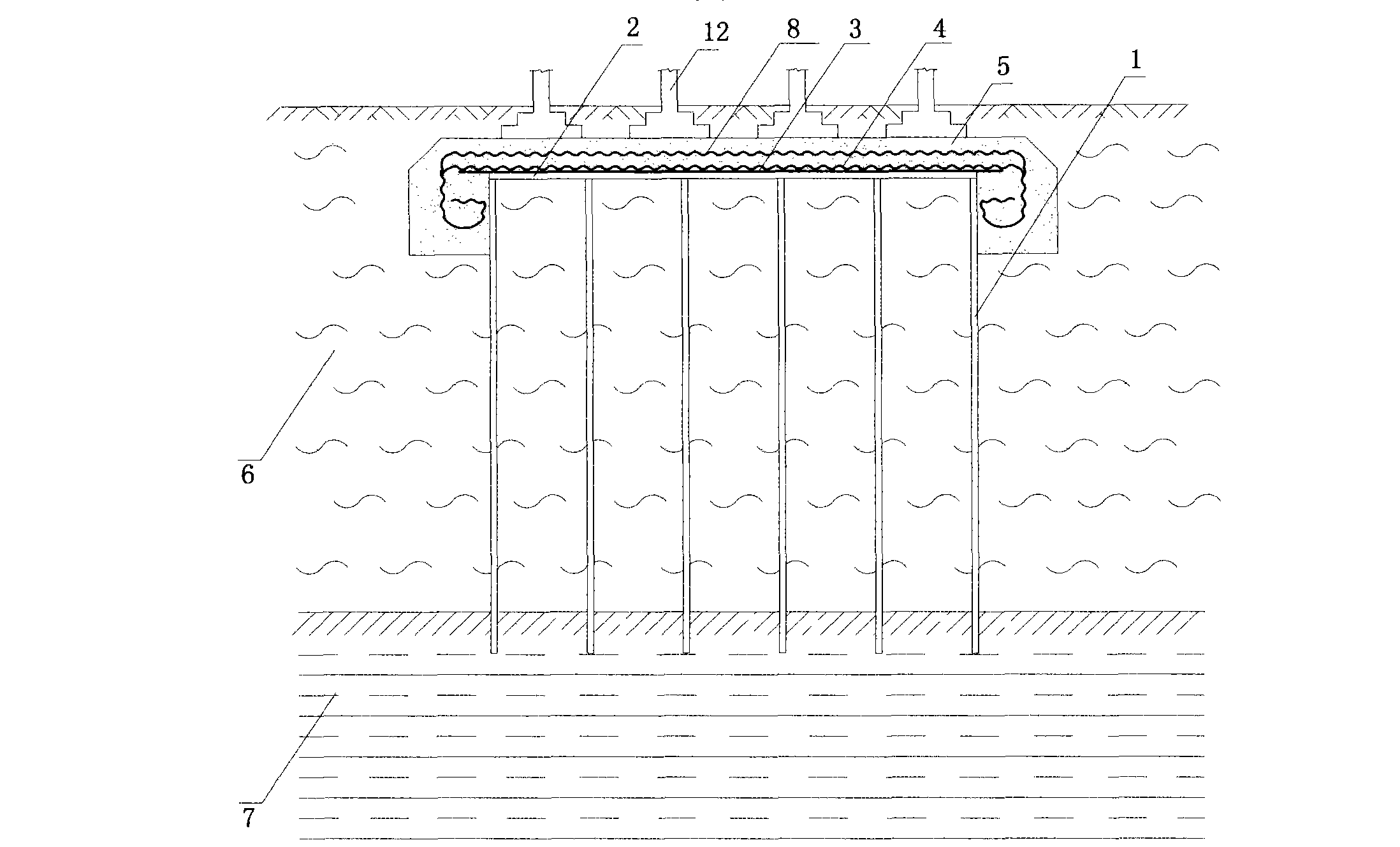

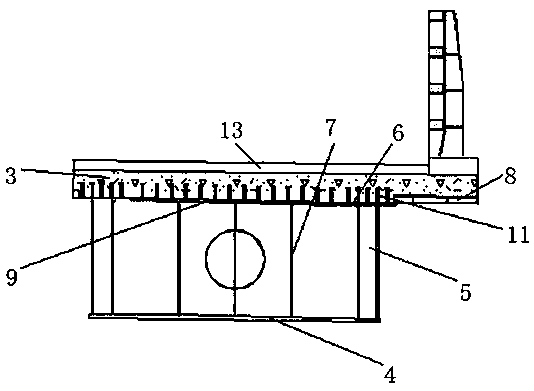

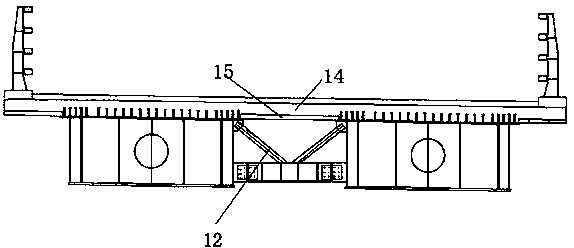

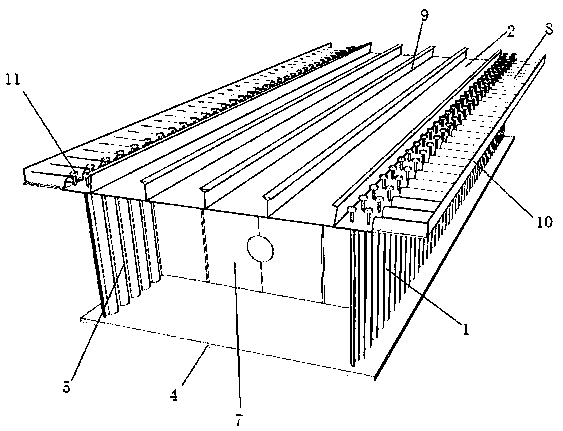

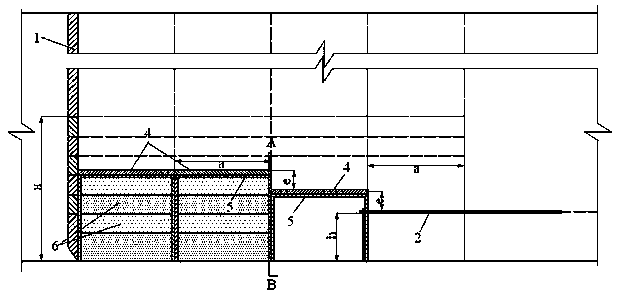

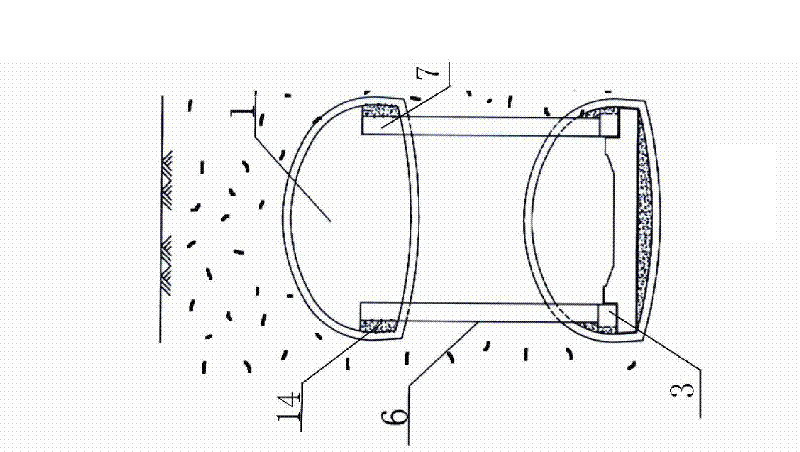

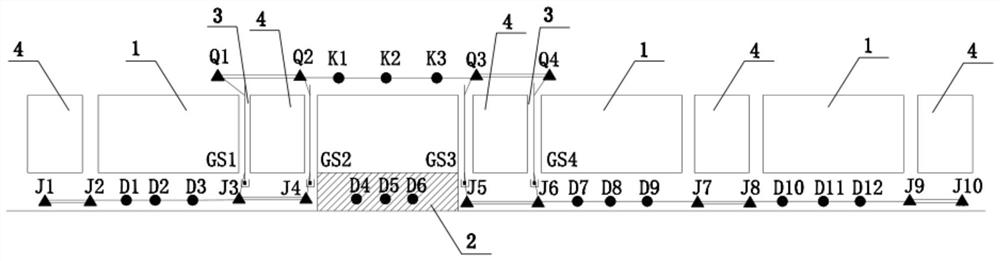

Supporting arch hidden digging top-down construction method

ActiveCN101338678AFew construction divisionsIncrease the construction work areaUnderground chambersTunnel liningClerestoryFloor slab

The present invention relates to a one time supporting arch subsurface excavation reversed construction method. The steps of the method are as follows: at least a pair of upper guide hole and lower guide hole are respectively excavated in a top body and a bottom body corresponding with an underground structure design space; each pair of guide holes forms one span; then the hole wall is processed for primary supporting; the bottom of the lower guide hole is laid with a waterproof layer; the waterproof layer is casted with an underlayer frame structure soleplate; a slope stake and a middle upright post are constructed from the upper guide hole; the arc top of the upper guide hole is laid with the waterproof layer, and an arc top permanent structure is cast; then a midspan soil body is excavated between two upper guide holes by a subsurface excavation method to form a midspan upper guide hole and to be constructed as a midspan upper guide hole arc top permanent structure; the primary support at the bottom of the upper guide hole is chiseled and removed; a soil body is excavated downwards, and a structure lateral wall and a middle floor slab are cast; the rest partial solid between the primary support at the top of the lower guide hole and the middle floor slab is excavated, at the same time, the primary support at the top of the lower guide hole is chiseled and removed, the rest lateral wall structure is cast, and an even span structure soleplate is closed. The method has small construction risk, large construction field and fast construction speed, uses few big guide holes and solves the technical problems of the large amount of the guide hole, the small size of the guide hole, small construction space, multiple times of structure stress conversions, the repeated perturbation of wall rock, etc of the traditional subsurface excavation method.

Owner:BEIJING URBAN CONSTR DESIGN & DEV GRP CO

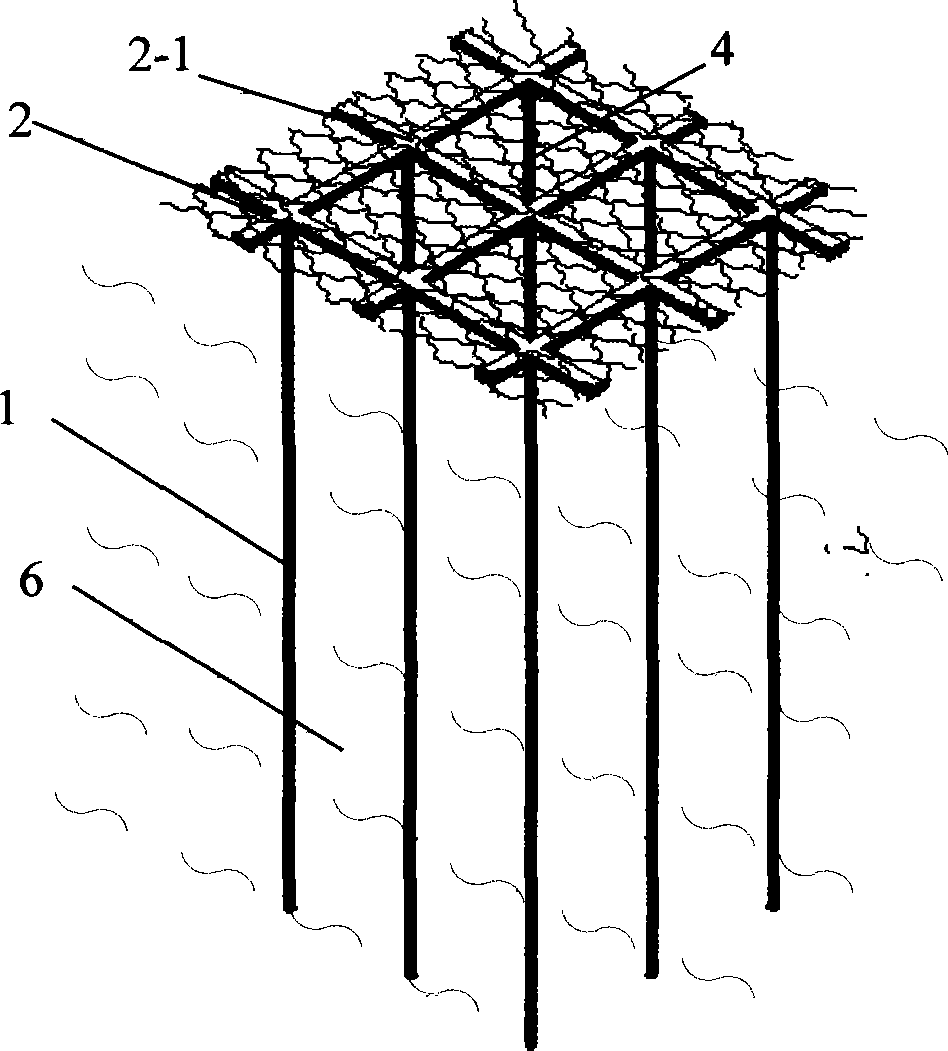

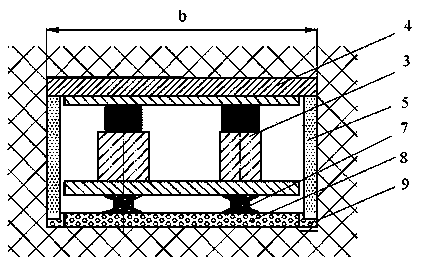

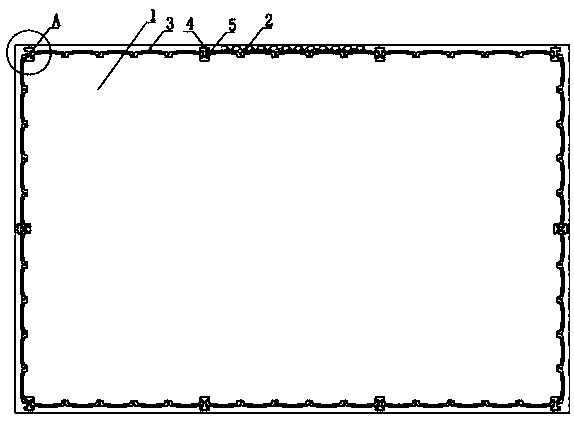

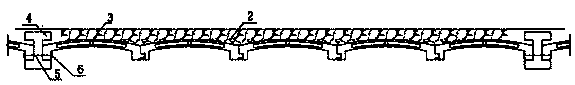

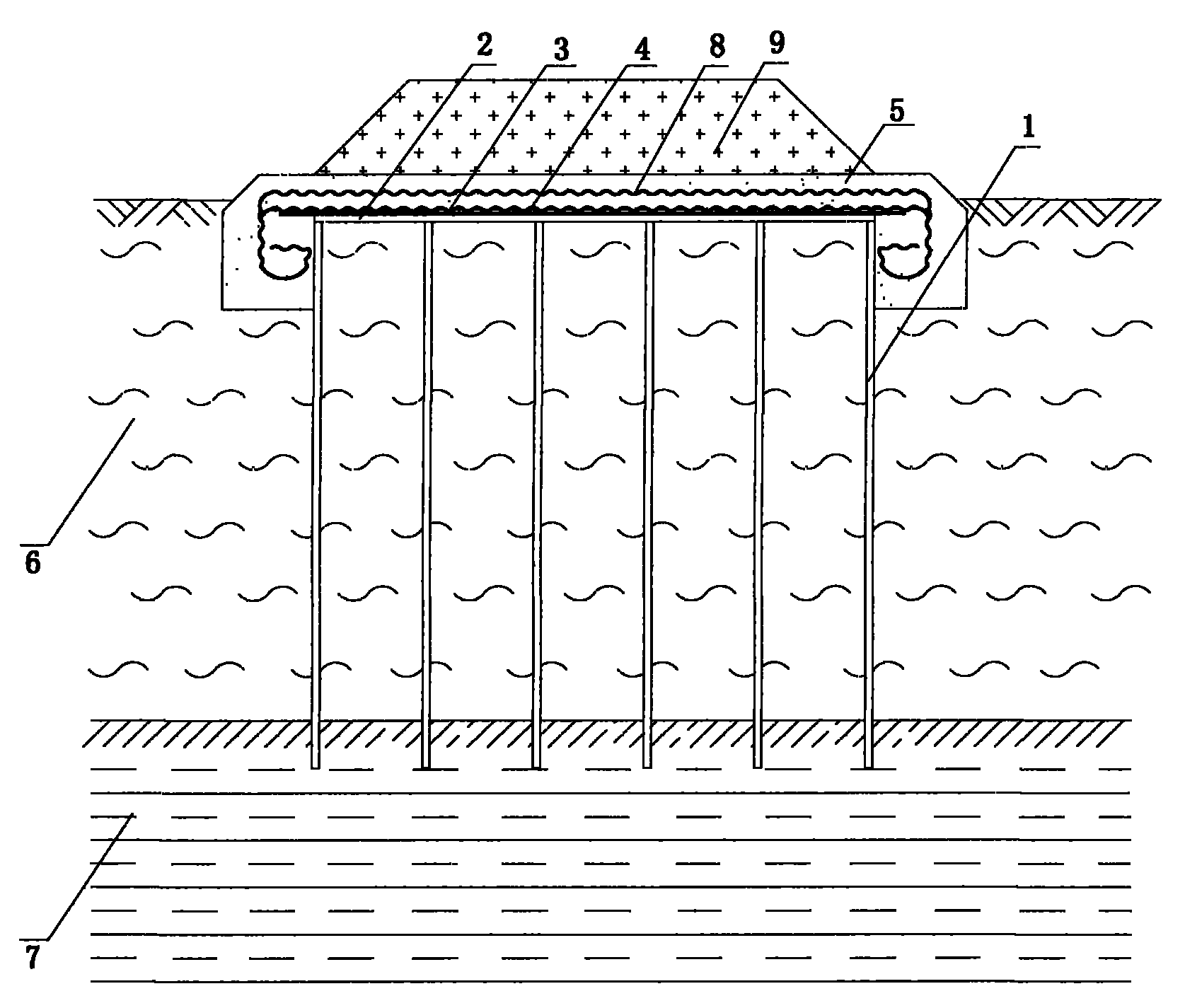

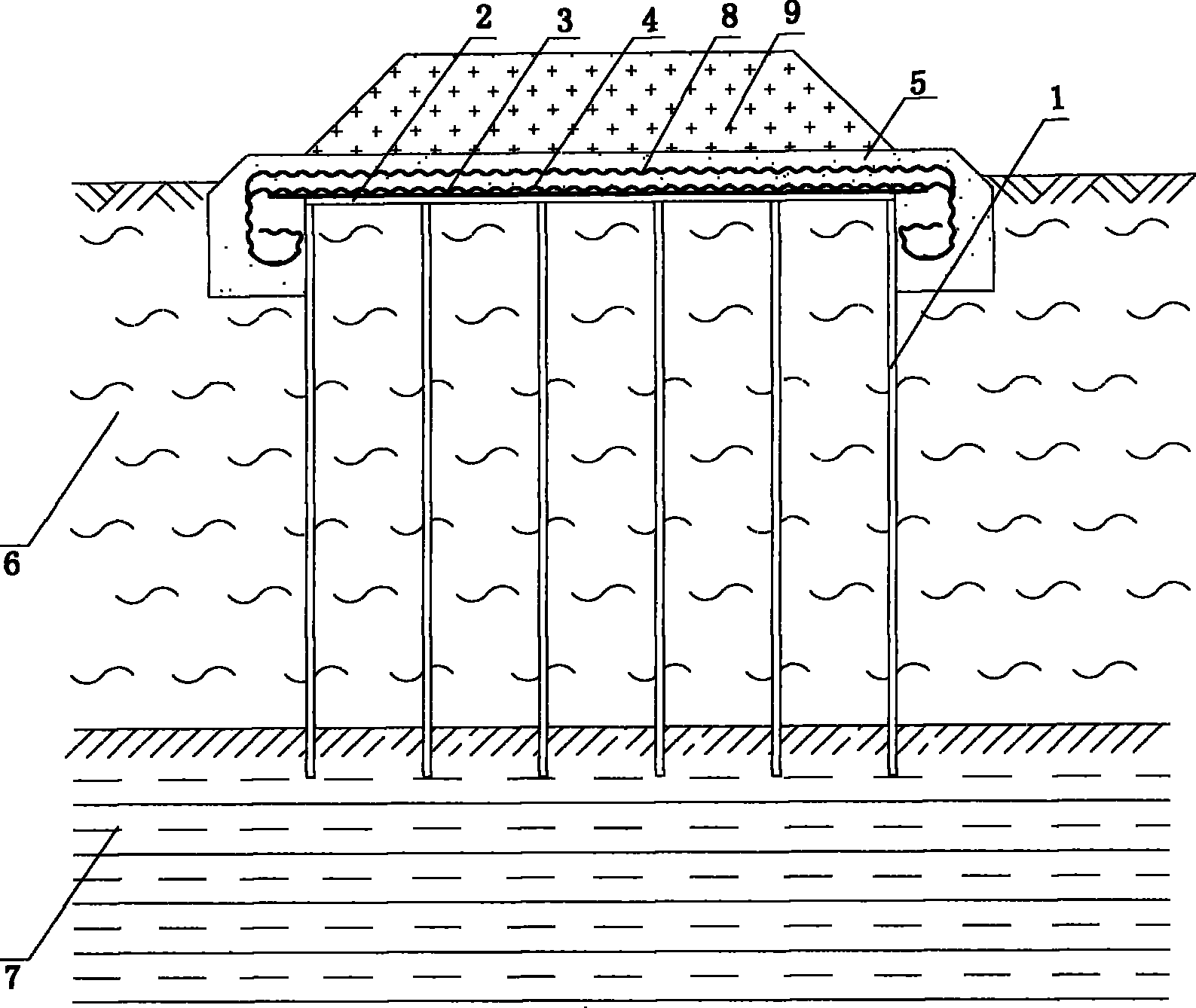

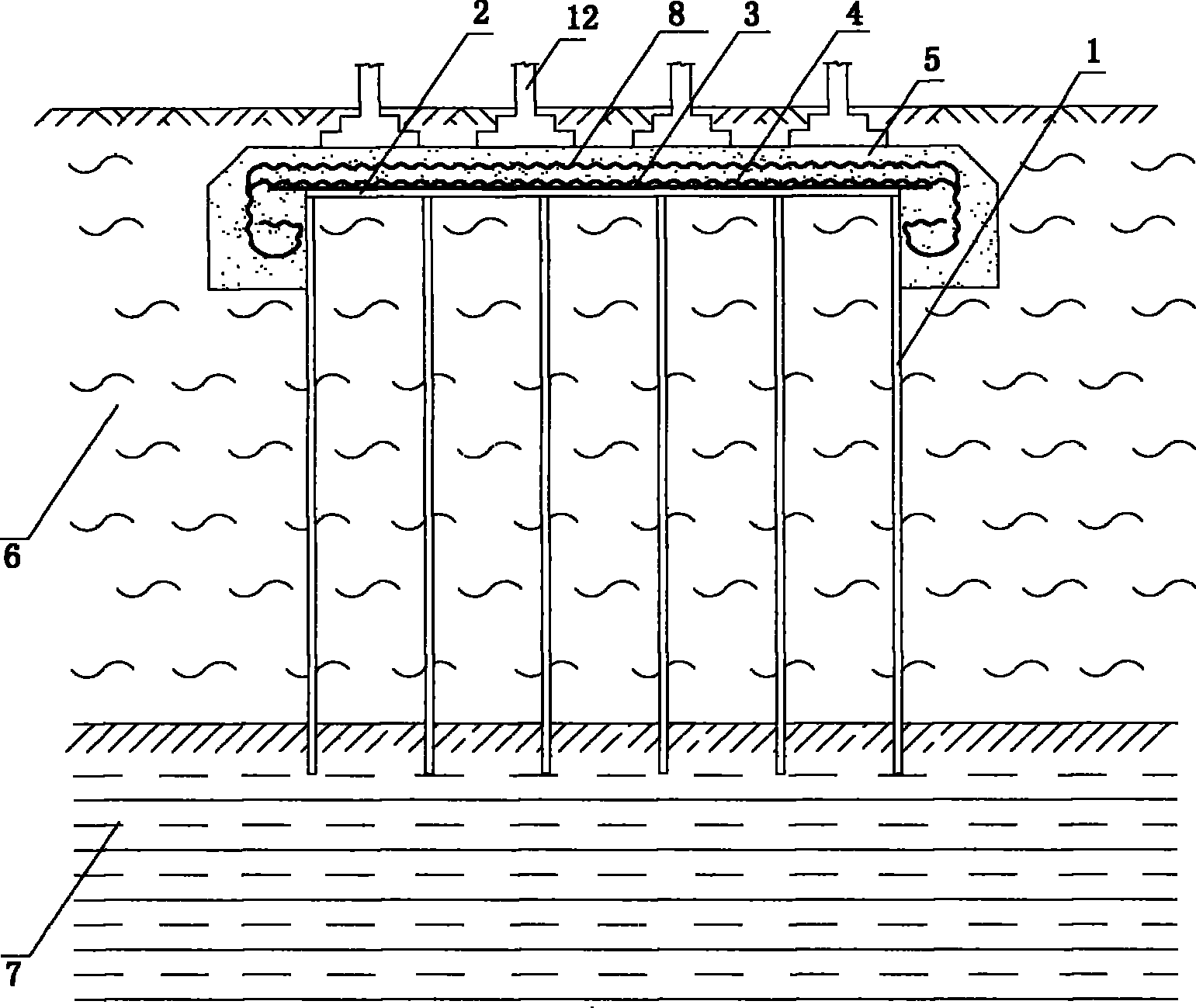

Rigid gridding and pile combined foundation and its use in soft soil foundation reinforcement

InactiveCN101476325AHigh strengthGood deformabilityBulkheads/pilesSoil preservationSurface layerStructural engineering

The invention discloses a rigid grid and pile composite foundation and a method applied to reinforcing soft soil foundation. The rigid grid and pile composite foundation comprises a precast pile or a cast-in-situ pile, a rigid grid structure, a tensioning net, tensioning ribs and a transitional underlayer; the precast pile or the cast-in-situ pile drives to a relatively hard ground layer from a foundation surface layer; the rigid grid structure is fixedly connected with the precast pile; the grid structure is paved with the tensioning net; the tensioning net is provided with the transitional underlayer; the transitional underlayer is tightly contacted with the foundation surface, and the thickness of the transitional underlayer is between 0.6 and 1.5 meters; and the transitional underlayer is sandy clay, gravel soil or plain concrete with crude particles. The invention organically combines the rigid grid and the pile structure, the transitional underlayer and a soft ground layer to construct a composite foundation, transfers the load to a deep layer soil body through the grid structure and a pile, can give a full play to the strength and the deformation performance of the deep layer soil body, thereby effectively improving the foundation strength and the deformation performance, and having good reinforcing effect.

Owner:SOUTH CHINA UNIV OF TECH

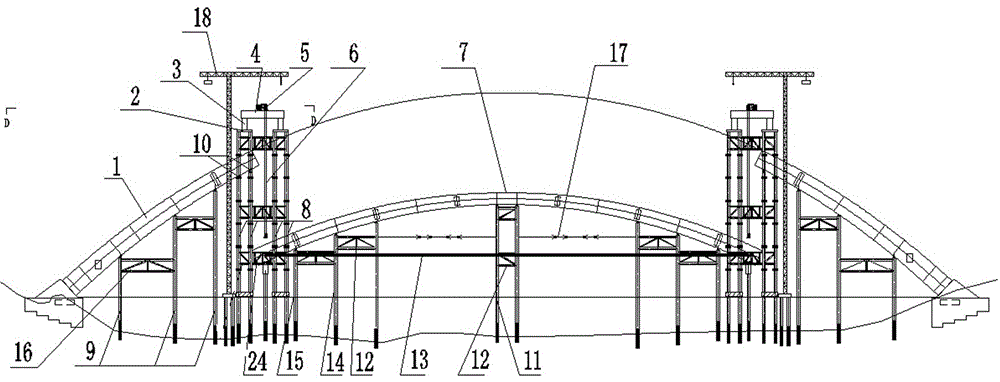

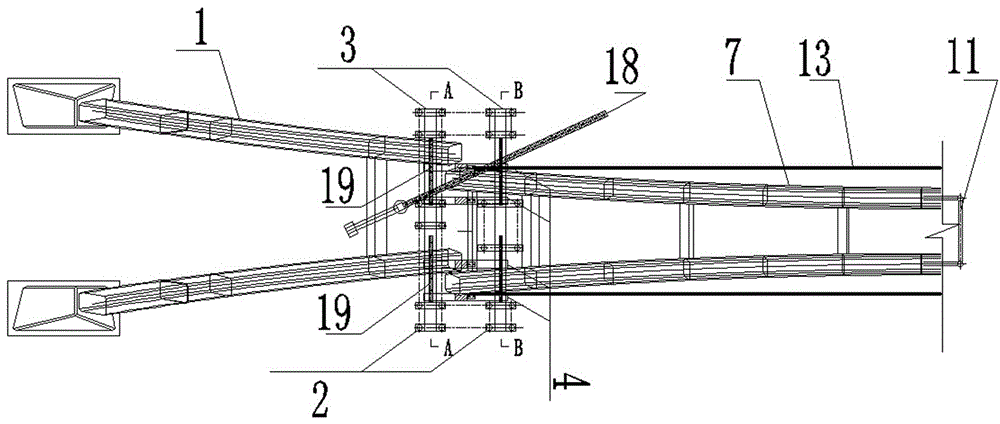

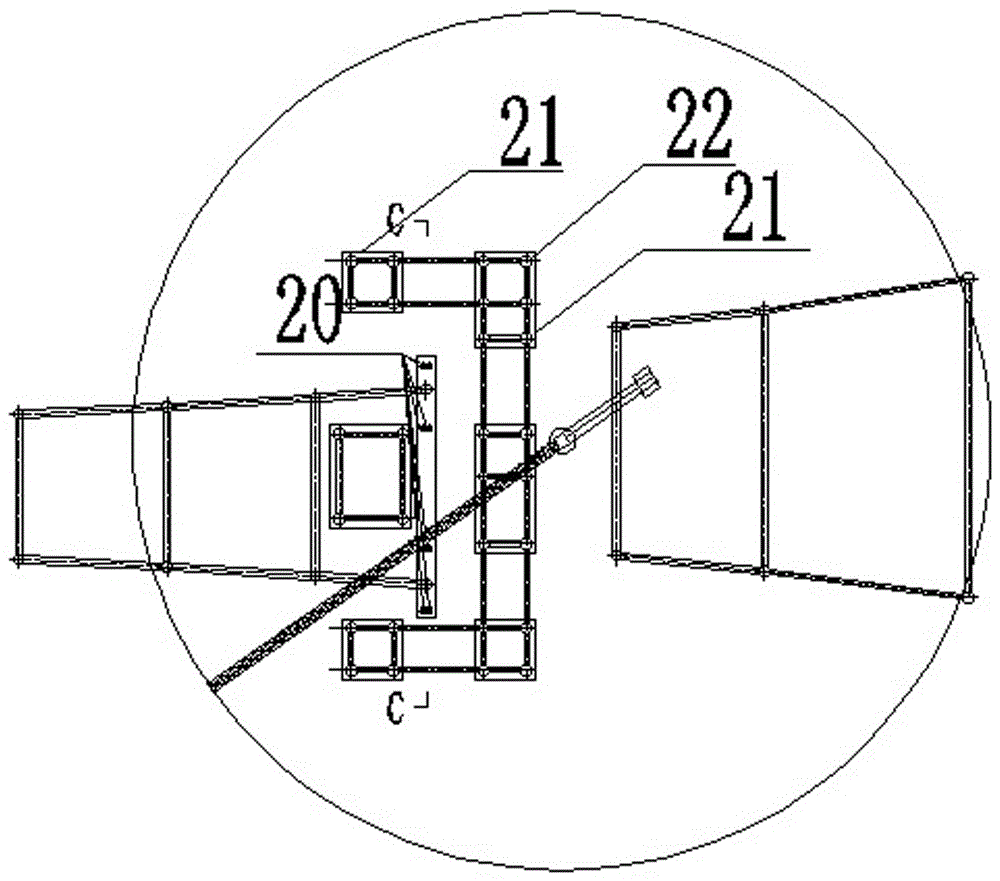

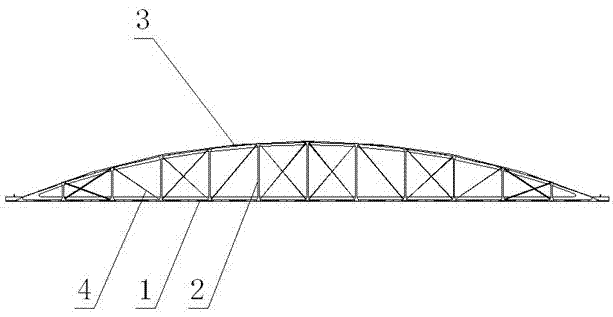

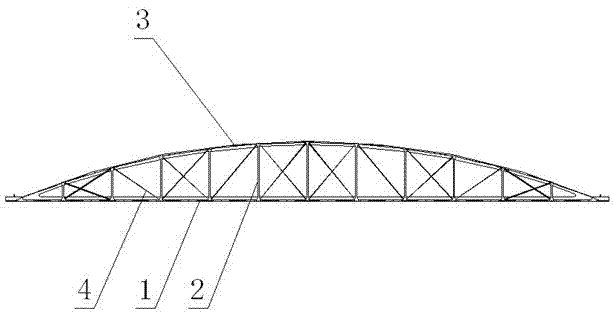

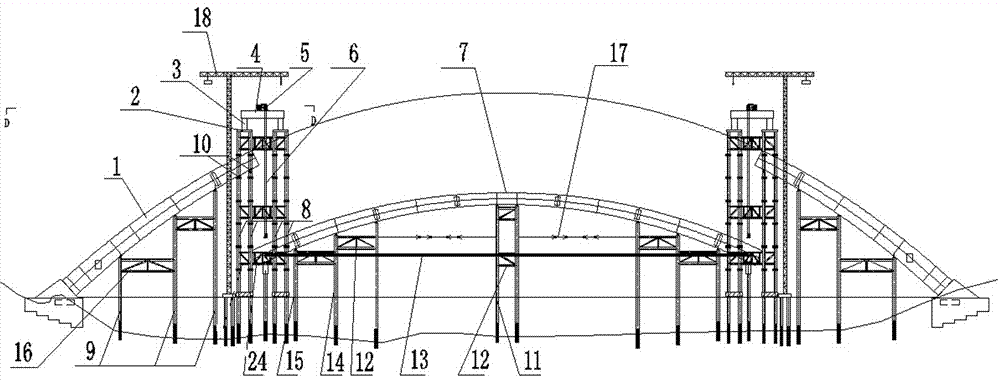

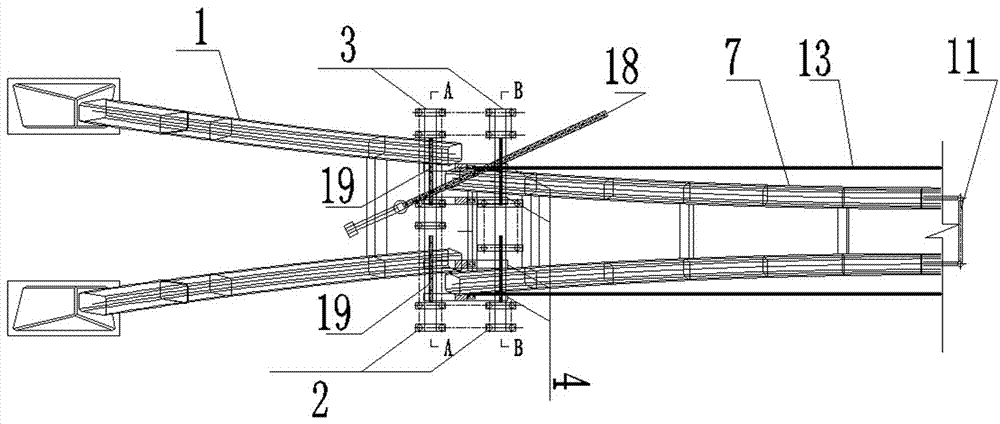

Method for lifting and installing whole bridge arch rib

ActiveCN106012864AGood stability against windReduce the difficulty of welding quality controlBridge erection/assemblySupporting systemManufacturing quality

The invention discloses a method for lifting and installing a whole bridge arch rib. The method includes the following steps of dividing the arch rib into two side arch rib bodies and a middle arch rib body, splicing the side arch rib bodies on a wharf, hoisting the side arch rib bodies to a set position through a floating hoist, erecting a side supporting system and a lifting portal, installing a lifting system, splicing a middle supporting system below the design position of the middle arch rib body, installing the middle arch rib on the upper face of the middle supporting system, arranging a temporary beam at the bottom of an arch foot of the middle arch rib body, arranging a temporary horizontal rope between the two ends of the arch foot, correspondingly connecting the lifting system with the temporary beam, and lifting, horizontally moving, putting down, putting in position, folding and installing the whole middle arch rib body. By means of the method, the requirements for installation quality and precision of the large-span arch rib bridge can be met, section lengths can be flexibly adjusted, section manufacturing quality is optimized, and section in-situ precision is improved.

Owner:SHANGHAI CIVIL ENG GRP FIFTH +1

Method for lifting whole steel structure to top of concrete cabin through slip form and low-altitude modular assembly

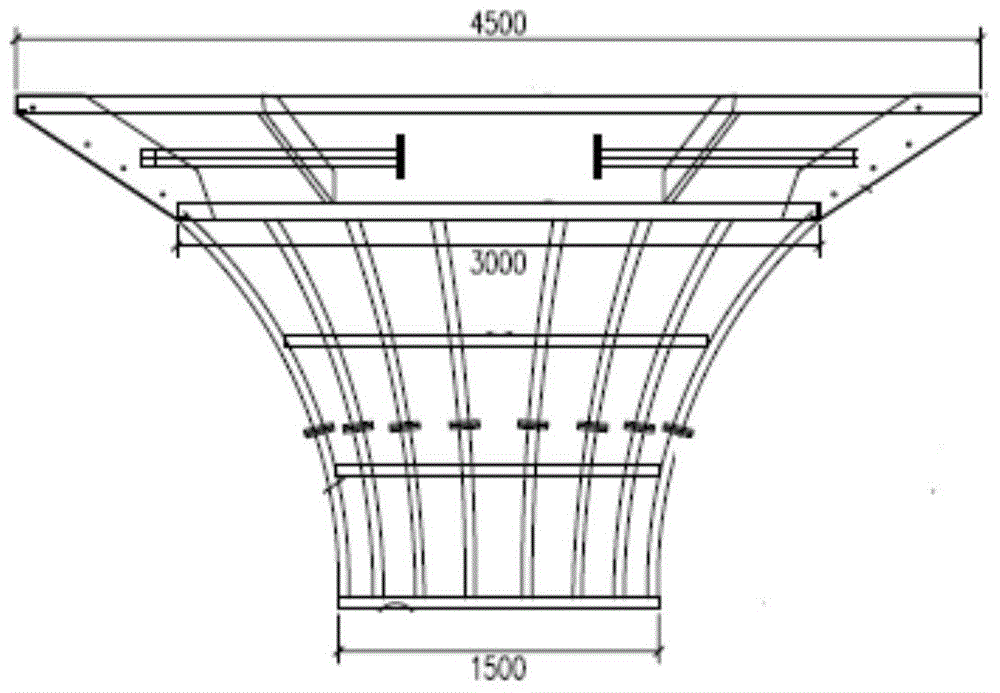

InactiveCN103510736AIncrease the construction work areaShorten assembly cycleBulk storage containerFalseworkEngineering

The invention discloses a method for lifting whole steel structure to the top of a concrete cabin through a slip form and low-altitude modular assembly. The method comprises the steps of assembling oblique beam units, assembling steel ring beams, assembling a slip form device, erecting a support ring beam scaffold platform, hoisting the steel ring beams, mounting the oblique steel beams, mounting a structure on a cabin top ring beam, hoisting the slip form system, and the like. As module units are assembled on the ground at the same time, the construction working area is increased, the assembling period is shortened, and the constriction duration is effectively shortened. Temperature and wind load influences when the unassembled large steel structure is assembled and measured at high altitude are reduced, the assembling precision is improved, and the engineering quality is ensured. As a great quantity of scaffolds are reduced duo to low-altitude assembling, and only a small quantity of simple scaffolds are needed to be erected, the mounting requirements can be met; meanwhile difficulty in high-altitude working, assembling and hoisting are reduced, and the security risk is effectively lowered.

Owner:成军

Construction method for reinforced concrete arched roof of grain store

InactiveCN102251667AReduce investmentReduce temporary land useBuilding material handlingFalseworkReinforced concrete

The invention discloses a construction method for a reinforced concrete arched roof of a grain store. The method comprises the following steps of: erecting a scaffold at the middle longitudinal part of a ring beam, and making a pedestal; paving lower chord prestressed steel bars, and performing prestressed tensioning; erecting a lower chord bottom die and a side die, installing a partition plate,and installing an upper chord arched bottom die and an upper chord arched side die at the top of the partition plate; paving upper chord steel bars; pouring concrete; stretching the prestressed steelbars when the strength of the concrete reaches over 85 percent, welding diagonal braces, and obtaining an arched plate after the diagonal braces are welded; and translating the arched plate, and welding and fixing the arched plate with an embedded steel plate. Because the construction mode of overhead prefabrication and integral translation is adopted, a large machine for hoisting is avoided, theconstruction progress is quickened, the safety risk is reduced, the cost is saved, the temporary site is reduced, and the construction efficiency is improved.

Owner:CHINA METALLURGICAL CONSTR ENG GRP

Construction method of main beam of steel-concrete composite beam cable-stayed bridge

ActiveCN109972517ASolve the lifting installationSolve walkingBridge erection/assemblyCable stayedEngineering

The invention discloses a construction method of a main beam of a steel-concrete composite beam cable-stayed bridge. The construction method comprises the steps: a wall-attached crane is mounted on acable tower, and initial section steel beams are hoisted by the wall-attached crane and fixed; the wall-attached crane hoists a first deck crane onto the initial section steel beams, unit splicing section steel beams are hoisted by the first deck crane and fixed to the two ends of the initial section steel beams, the first deck crane moves forwards onto the unit splicing section steel beams at oneends of the initial section steel beams, and the wall-attached crane hoists a second deck crane onto the unit splicing section steel beams at the other ends of the initial section steel beams; and the first deck crane and the second deck crane move forwards to splice the steel beams extending towards bridge side-span sections and the steel beams extending towards bridge mid-span sections and close the steel beams on the side-span sections and the steel beams on the mid-span sections. The construction method has the advantages of being high in operability, safe, reliable, controllable in quality, economical, efficient, capable of saving energy and protecting the environment and the like.

Owner:CCCC SECOND HARBOR ENG +1

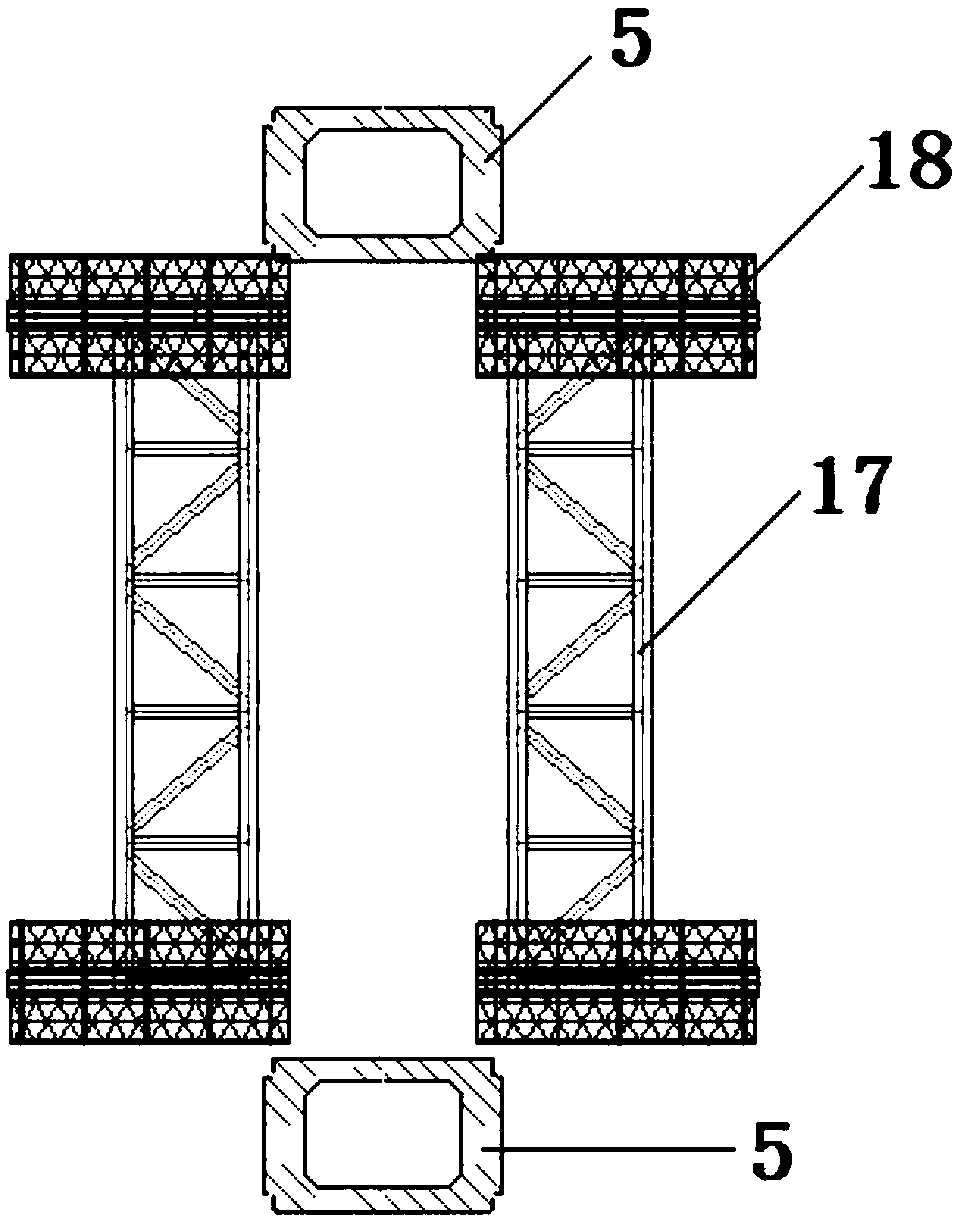

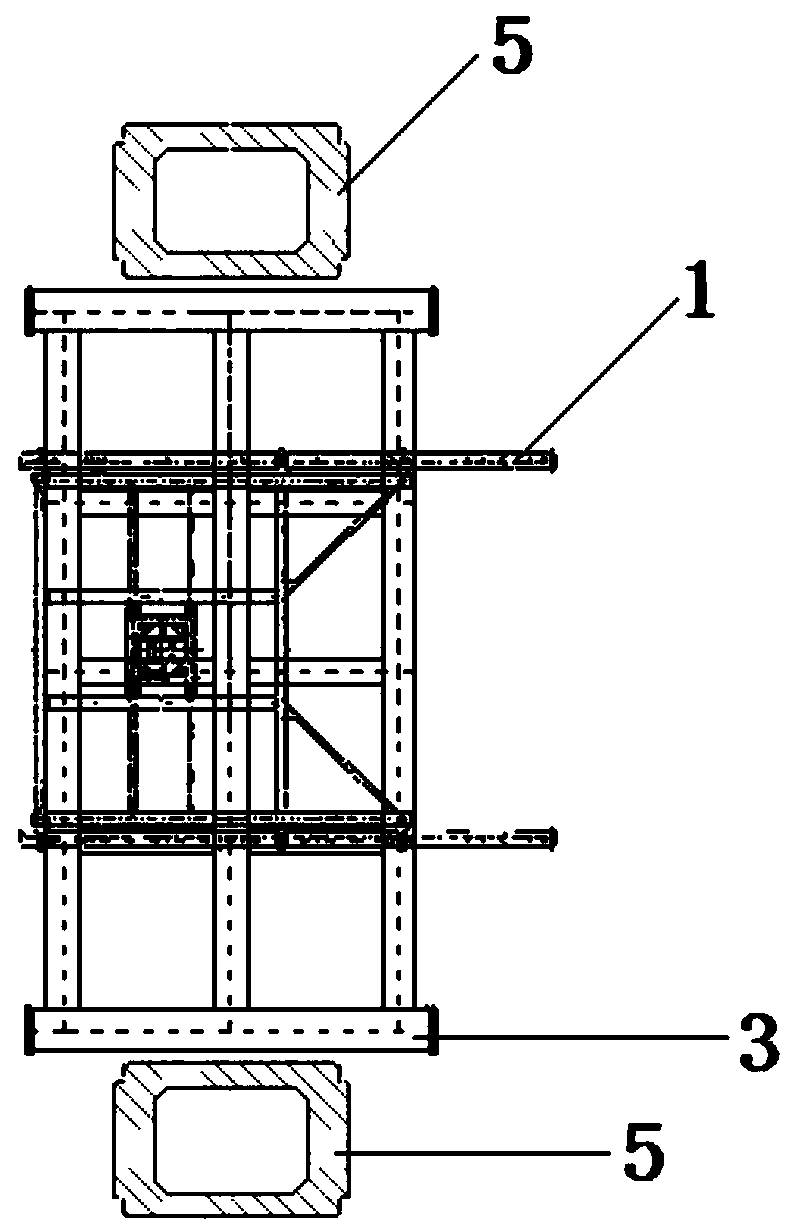

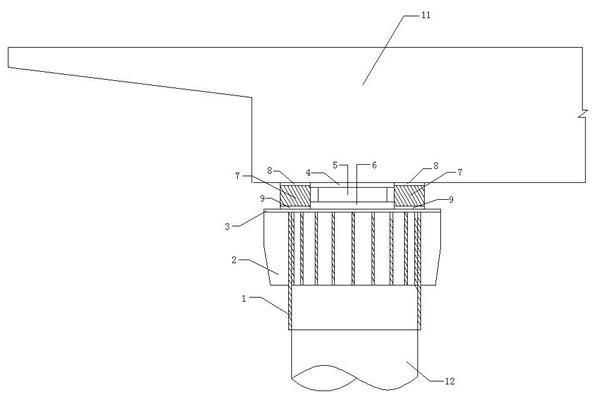

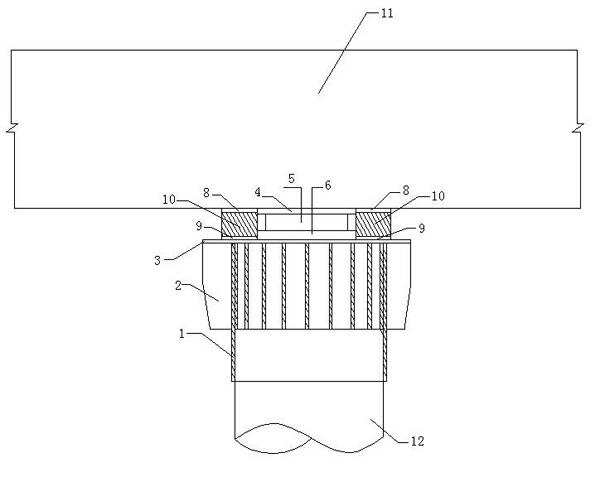

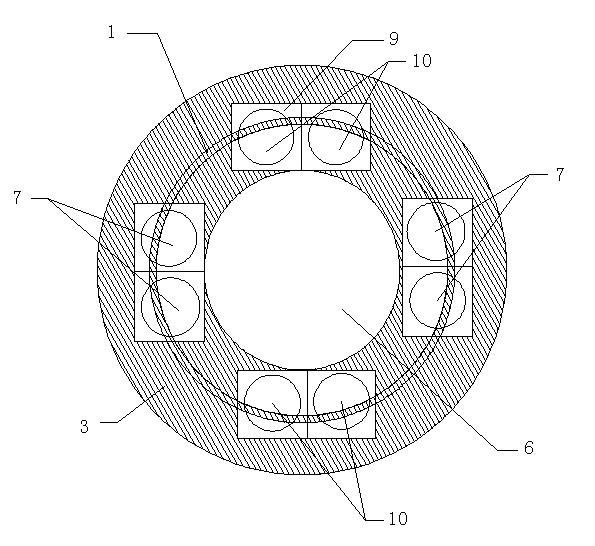

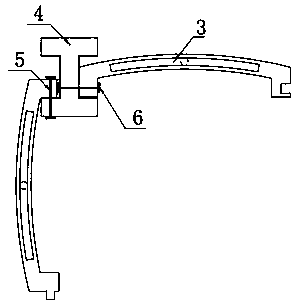

Operation platform for replacing support saddle of bridge

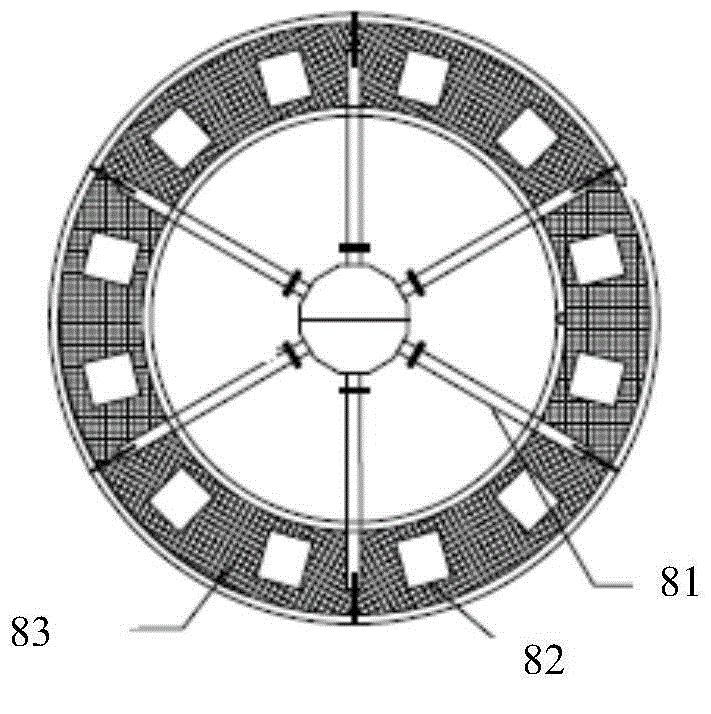

InactiveCN102518050AIncrease the construction work areaAvoid damageBridge erection/assemblyBridge strengtheningBuilding constructionEngineering

The invention discloses an operation platform for replacing a support saddle of a bridge, and is characterized in that the operation platform comprises a pier pillar hoop, a plurality of rib plates and a crown plate, wherein the pier pillar hoop is sleeved on the periphery at the upper end of the pier pillar; the crown plate adopts a circular structure and is arranged at the tops of both the pier pillar and the pier pillar hoop; the rib plates are uniformly distributed at the periphery of the pier pillar hoop; the upper parts of the rib plates are connected with the crown plate; and the pier pillar hoop, the rib plates and the crown plate are welded and fixed with each other. The platform is erected at the top of the pier pillar of the bridge to enlarge the area of the construction working face at the top of the pier pillar of the bridge; and serving as an operation platform for replacing the support saddle of the bridge or repairing padstone, the operation platform provided by the invention has the advantage that the reliability is high, and as processes such as building ribs in the pier pillar of the bridge are not required, damage on the pier pillar of the bridge is small.

Owner:江苏华通工程技术有限公司

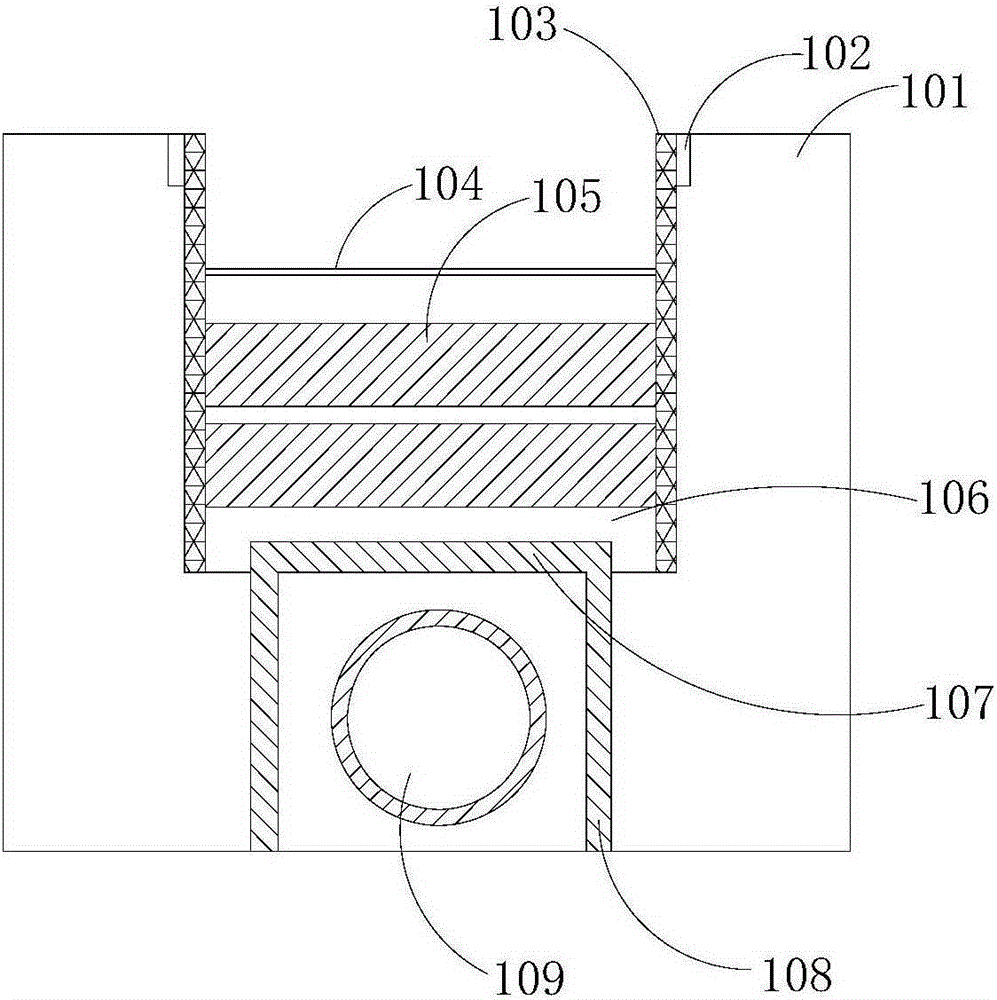

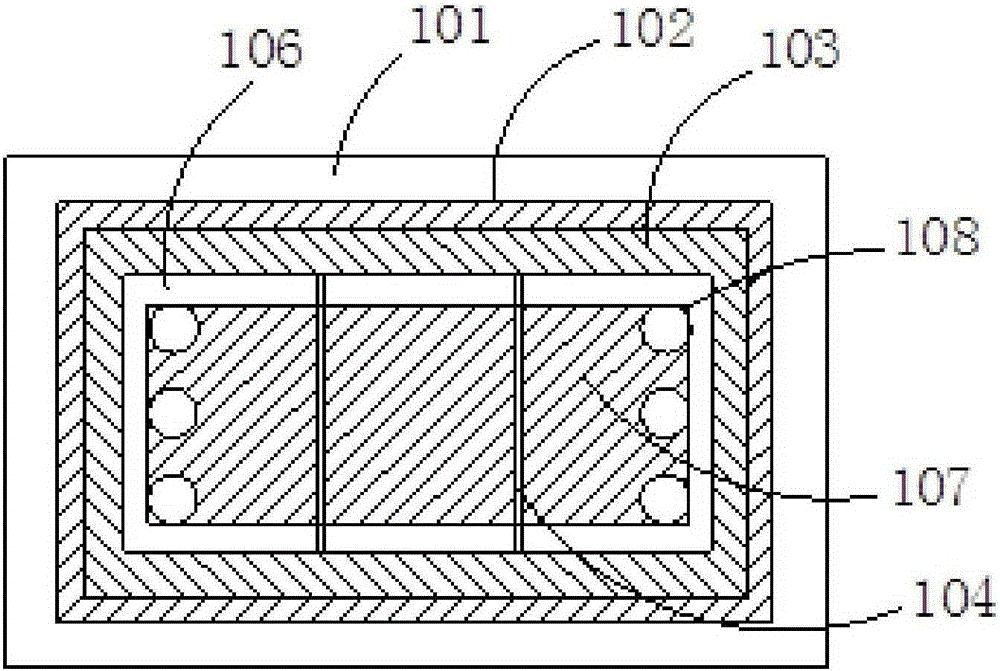

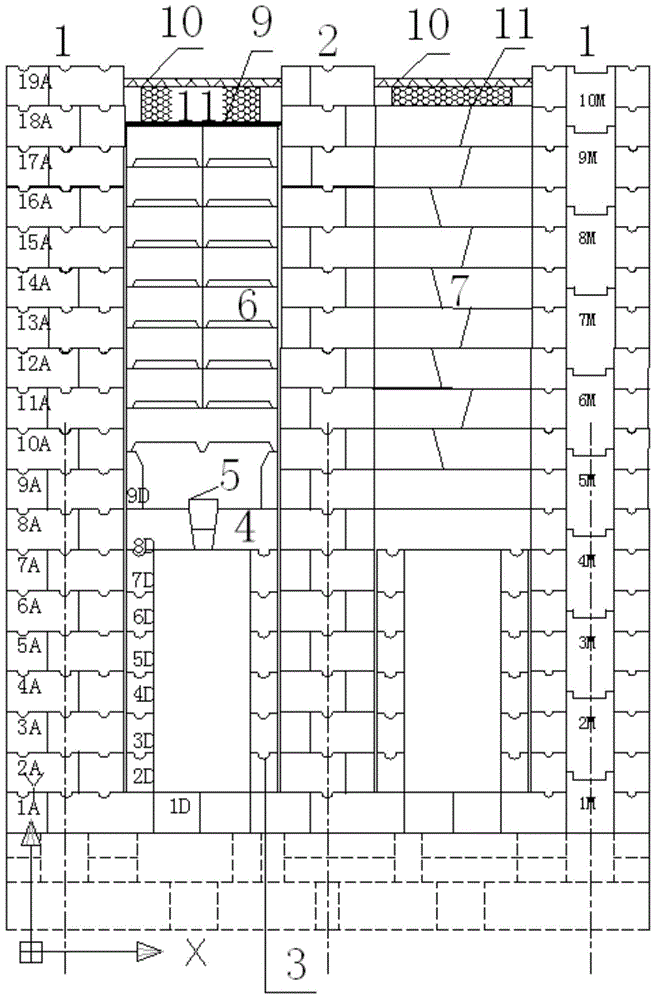

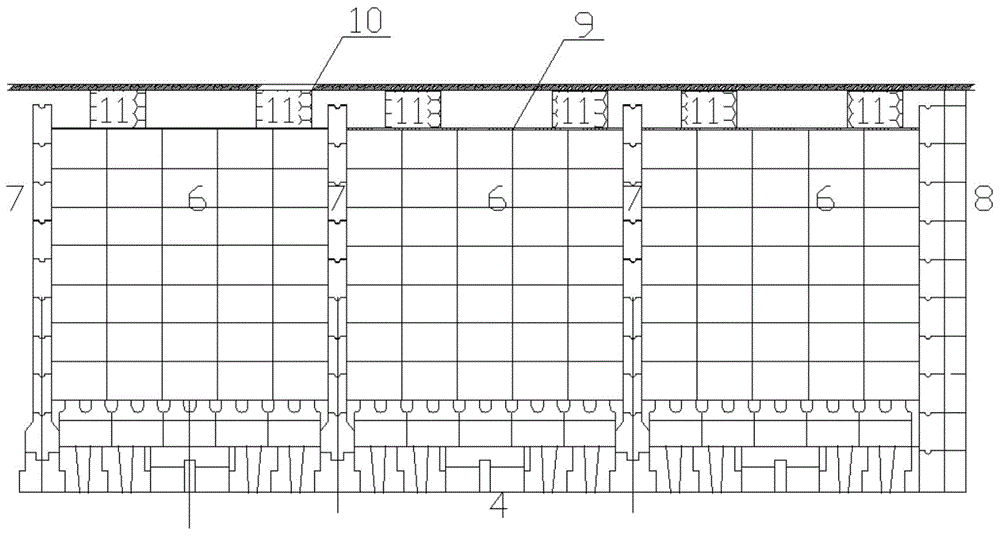

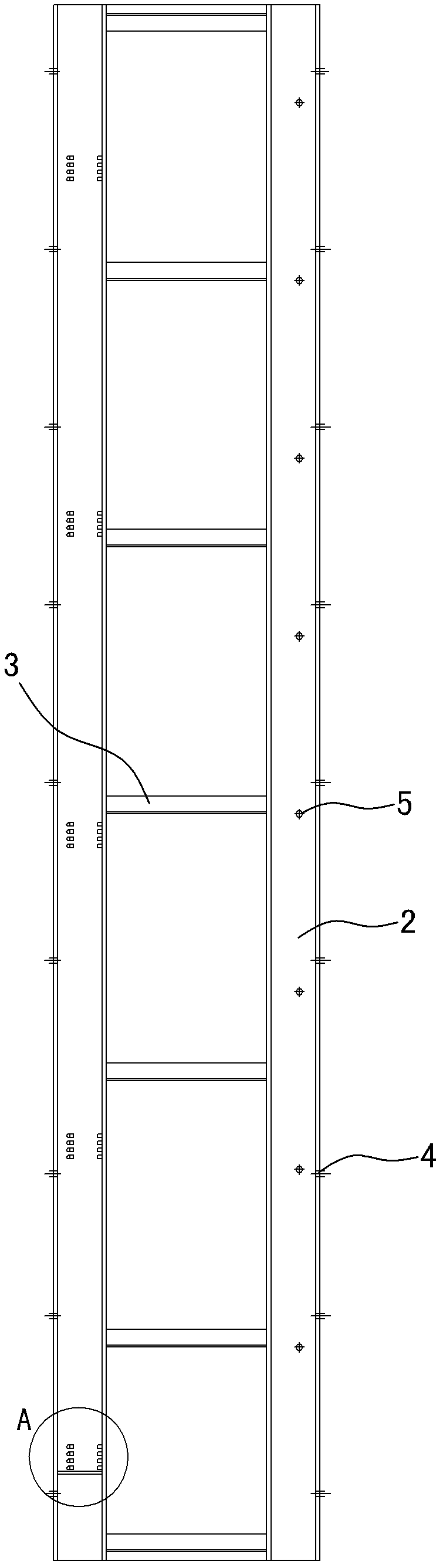

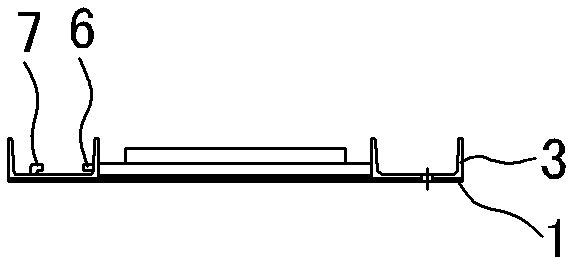

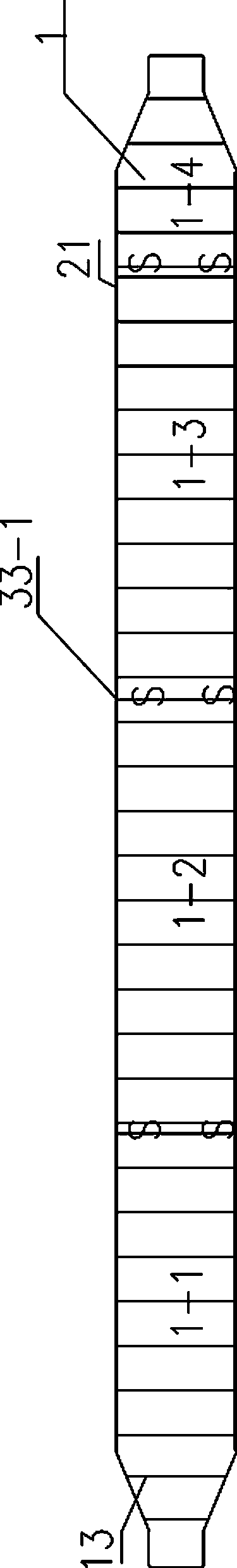

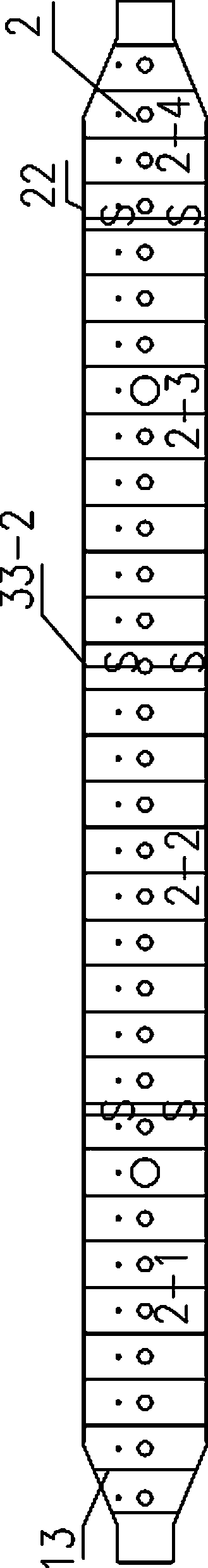

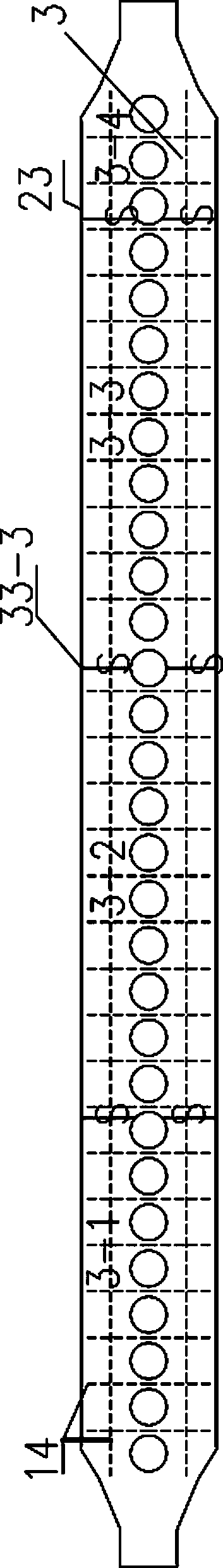

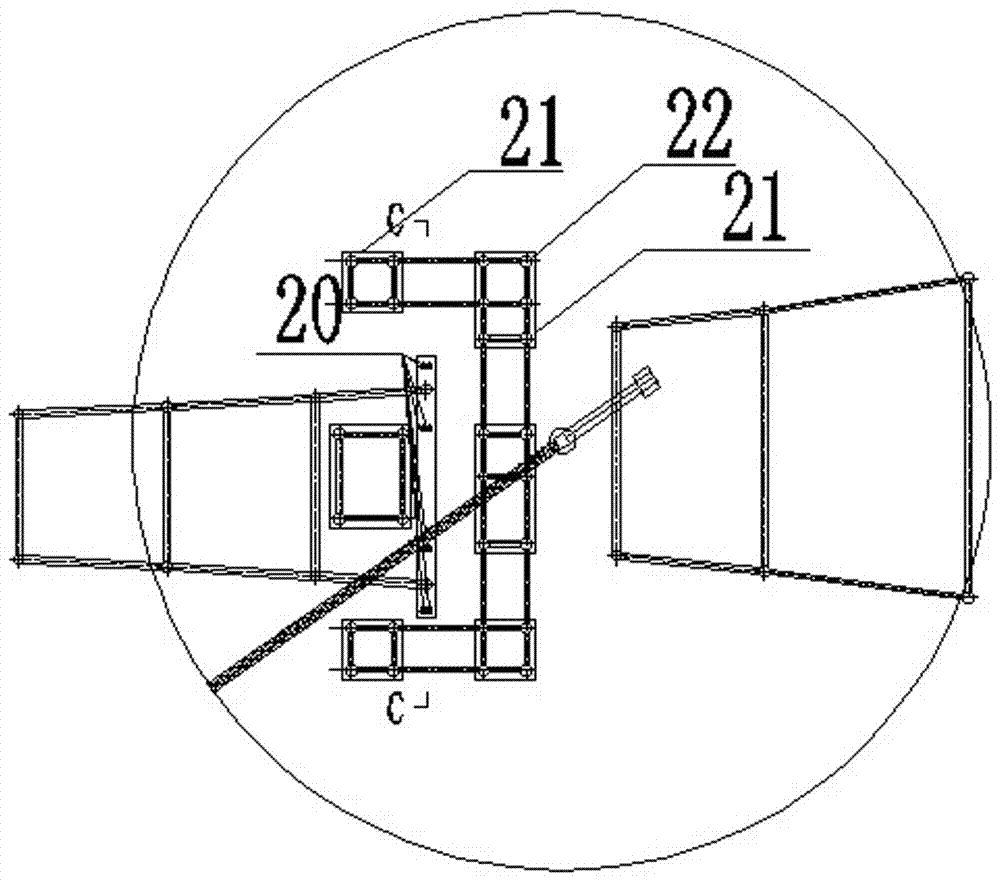

Vertical shaft construction device and method

The invention provides a vertical shaft construction device and a method, and belongs to the field of foundation engineering construction. The device comprises a ring beam, supports, a support system and floating prevention structures, wherein the ring beam is arranged in a soil body above a tunnel; the supports are applied to the side walls of a vertical shaft; the support system is a multilayer structure, and comprises a steel support structure and a middle separation plate structure arranged in the vertical direction; the support system is perpendicular to the length direction of the vertical shaft, and is fixedly connected with the supports at the two sides of the vertical shaft; and the floating prevention structures are positioned at the upper side and the left and right sides of the tunnel. The span of the vertical shaft is small, the device is provided with the multilayer support system, and the vertical shaft construction device is strong in structure, so that the pressure of soil bodies at the two sides of the tunnel can be preferably transferred, the interference on the soil bodies around the subway tunnel is little, and the swell quantity of the tunnel can be effectively controlled to satisfy the design requirement. In addition, the symmetric parallel operation can be adopted to synchronously construct and install the device on multiple working surfaces, so that the construction period is reduced.

Owner:CHINA RAILWAY SHANGHAI ENGINEERING BUREAU GROUP CO LTD +1

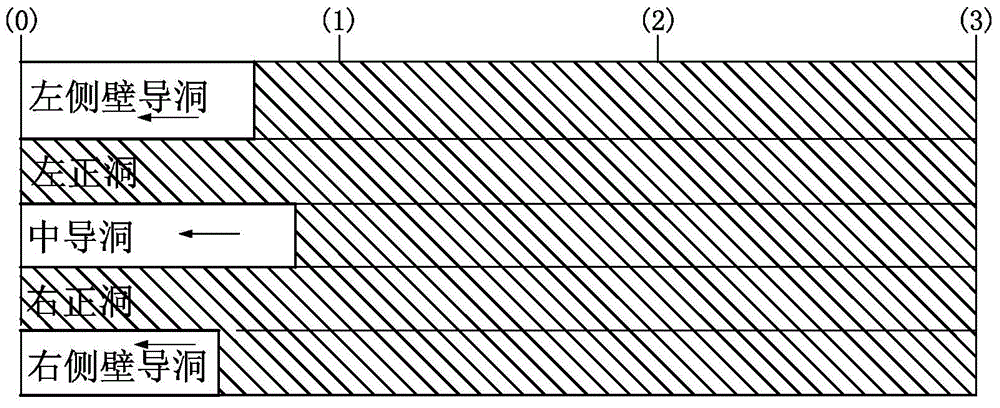

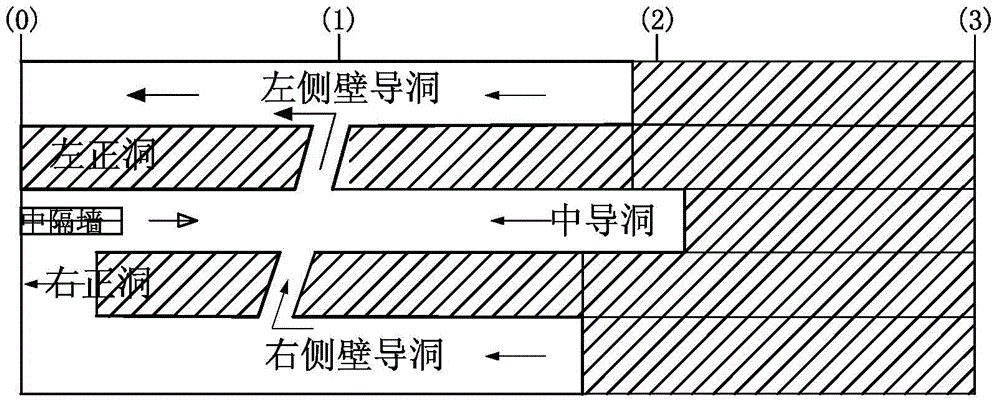

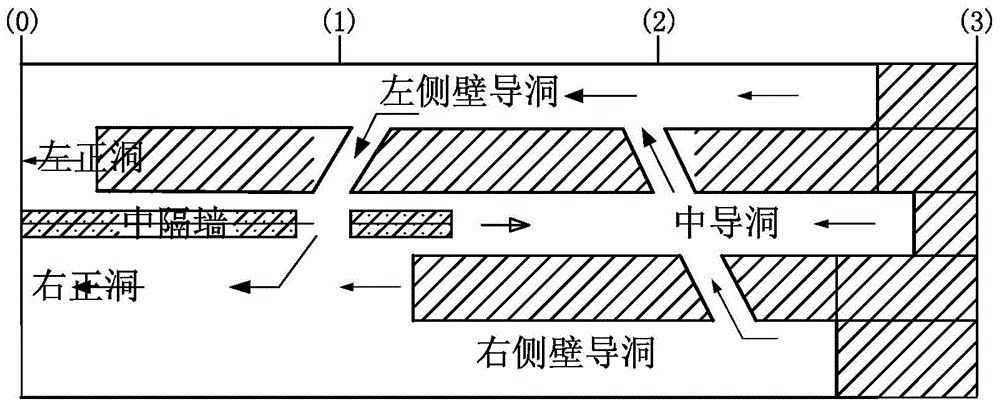

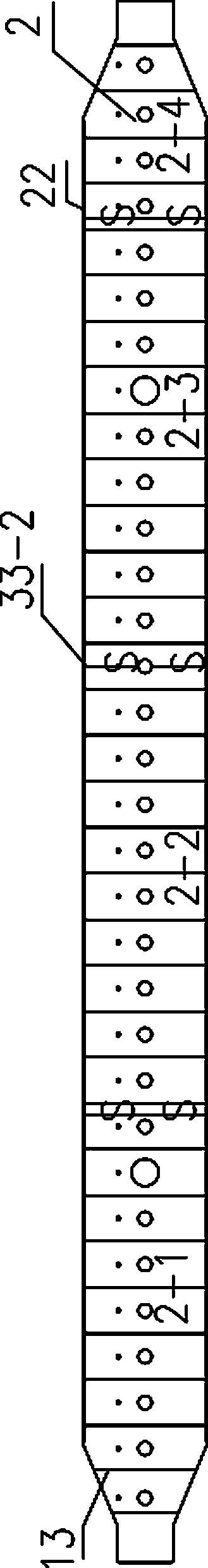

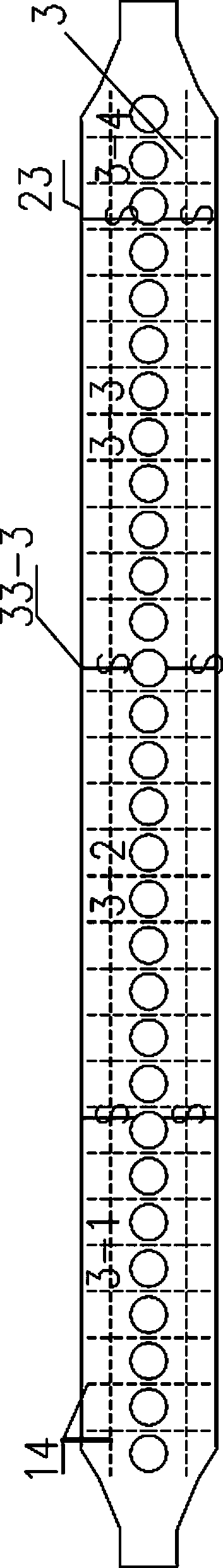

Rapid construction method for long and large double-multiple arch tunnel

ActiveCN104912559ASolve the problem that cannot be excavatedIncrease the construction work areaTunnelsRapid constructionTunnel construction

The invention discloses a rapid construction method for a long and large double-multiple arch tunnel. The tunnel is equally divided into 2n sections according to the length along the longitudinal direction; 0-n section of tunnel construction is used for illustration; n-2n section of tunnel construction and 0-n section of tunnel construction are symmetrically carried out at the same time. The method comprises the steps: step (1), 0-1 section is constructed in a hole, a mid-guiding hole is firstly excavated and supported, and a left side wall guiding hole and a right side wall guiding hole are excavated and supported in a way of lagging the mid-guiding hole for a certain safe distance; and step (2)-step (5), construction passages are alternately converted to continue carrying out a next period of construction; the phenomenon that mutual interference happens to construction of a middle wall, the left side wall guiding hole, the right side wall guiding hole, the mid-guiding hole, a left main hole and a right main hole; the middle wall at a (n-1)st contact channel is constructed after the construction of n-2 section-n-1 section of left main hole and n-1 section-n section of middle wall is completed; afterwards, the construction passages are converted again; and the left main hole and the right main hole are respectively used as respective construction passages to complete the construction of the rest n-1 section-n section of left main hole and right main hole.

Owner:江苏中车城市发展有限公司

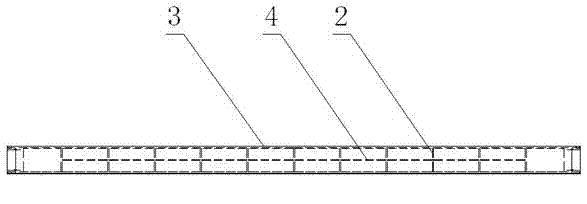

Assembly type corrugated steel web steel and concrete composite beam bridge and construction method

PendingCN110424242AAvoid fatigue damageLight weightBridge structural detailsBridge materialsBridge deckEngineering

The embodiment of the invention discloses an assembly type corrugated steel web steel and concrete composite beam bridge and a construction method. The assembly type corrugated steel web steel and concrete composite beam bridge comprises a steel box beam, a profiled steel plate arranged at the top of the steel box beam and a bridge deck slab arranged at the top of the profiled steel plate, whereinthe steel box beam comprises a steel bottom plate, corrugated steel webs, an upper wing plate and partition plates; the corrugated steel webs are welded on the steel bottom plate and are positioned on the two sides of the steel bottom plate; and the bottom edges of the partition plates are connected to the steel bottom plate, the two sides of the partition plates are connected with the corrugatedsteel web, and the upper wing plate is arranged at the top of the corrugated steel web plate. The assembly type corrugated steel web steel and concrete composite beam bridge is convenient to assembleand construct, and can guarantee the quality of bridge prefabricated members during transportation.

Owner:GANSU ROAD & BRIDGE CONSTR GROUP +2

Down-adjusted 7m coke oven regenerative chamber constructing method

InactiveCN104927882AImprove working environmentCreate pollutionCoke oven brickworkBrickArchitectural engineering

The invention discloses a down-adjusted 7m coke oven regenerative chamber constructing method. The method comprises the following steps: firstly, alternately constructing main wall, single wall, small flue lining bricks and grating bricks of a small flue construction section according to construction section and construction order; and then, alternately constructing main wall, single wall, down-adjusted hole adjusting bricks, checker bricks, partition and enclosing wall of a regenerative chamber construction section according to construction section and construction order until reaching the top of a regenerative chamber. Therefore, the constructing method can expand a construction working surface, guarantee constructing quality, facilitate quality inspection, improve working efficiency, improve the working environment of workers and avoid dust pollution to the environment.

Owner:MCC TIANGONG GROUP

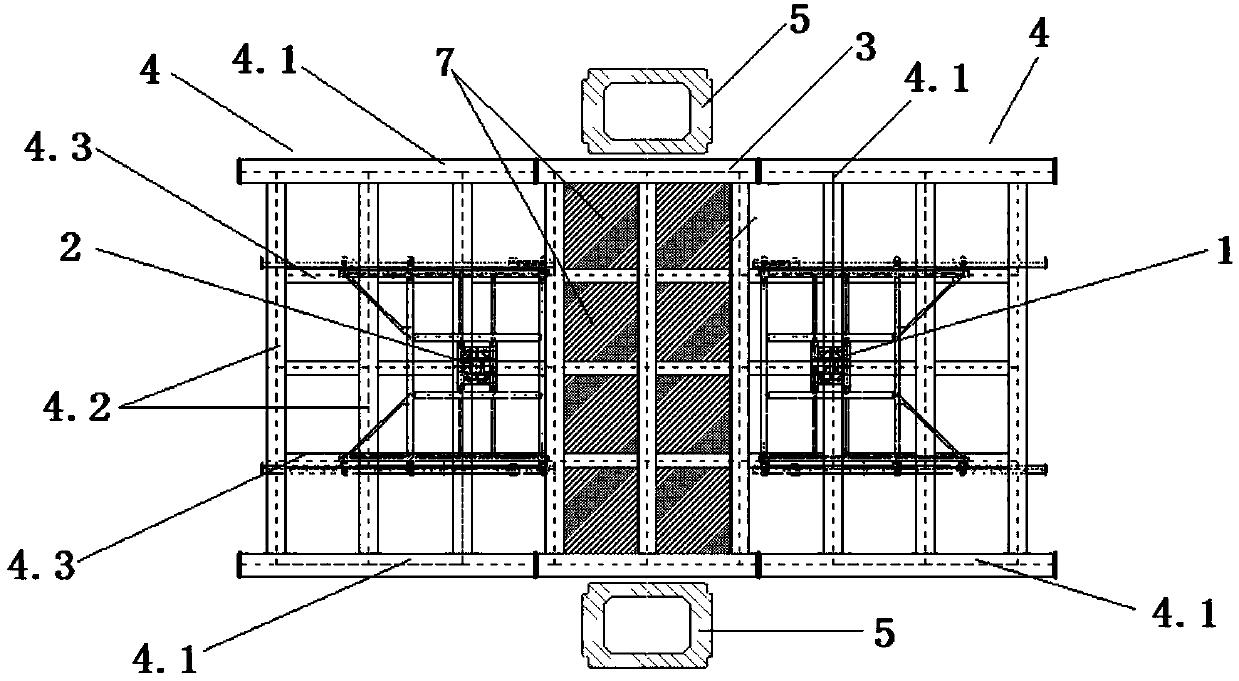

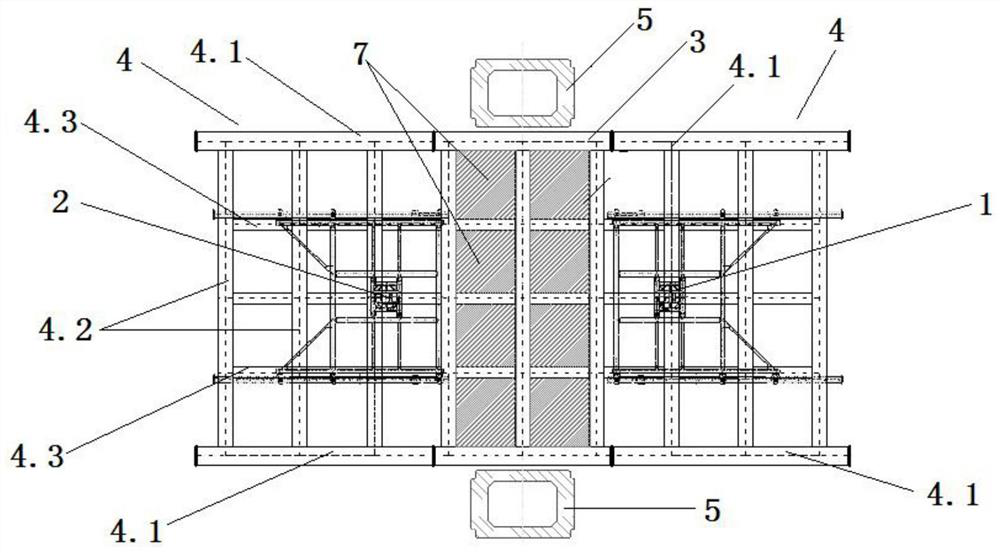

Pouring method of coupled shear wall structure

InactiveCN102587665AAchieve preparationEasy to assemble and disassembleBuilding material handlingEngineeringExpansion joint

The invention discloses a pouring method of a coupled shear wall structure. The pouring method comprises the following steps of: (1) splicing a left-side template, locating and then installing the left-side template; (2) installing a template supporting member on the left-side template; (3) regulating the left-side template and installing a split bolt; (4) splicing a right-side template, after completing, installing the right-side template, and enabling the left-side template and the right-side template to be arranged oppositely; (5) regulating the right-side template so that the channel steel of the left-side template is clamped in an opening of the angle steel of the right-side template; installing the template supporting member and the split bolt so that the left-side template and the right-side template are fastened through the split bolt and are supported through the template supporting member; (6) installing a common building template; (7) placing concrete grout between the left-side template and the common building template as well as between the right-side template and the common building template; (8) maintaining concrete; (9) dismantling the template supporting member and disassembling the left-side template, the right-side template and the common building template; and (10) completing construction. With the adoption of the pouring method, the preparation of an expansion joint coupled shear wall is realized, and the pouring method of the coupled shear wall structure has positive practical significance.

Owner:苏州第五建筑集团有限公司

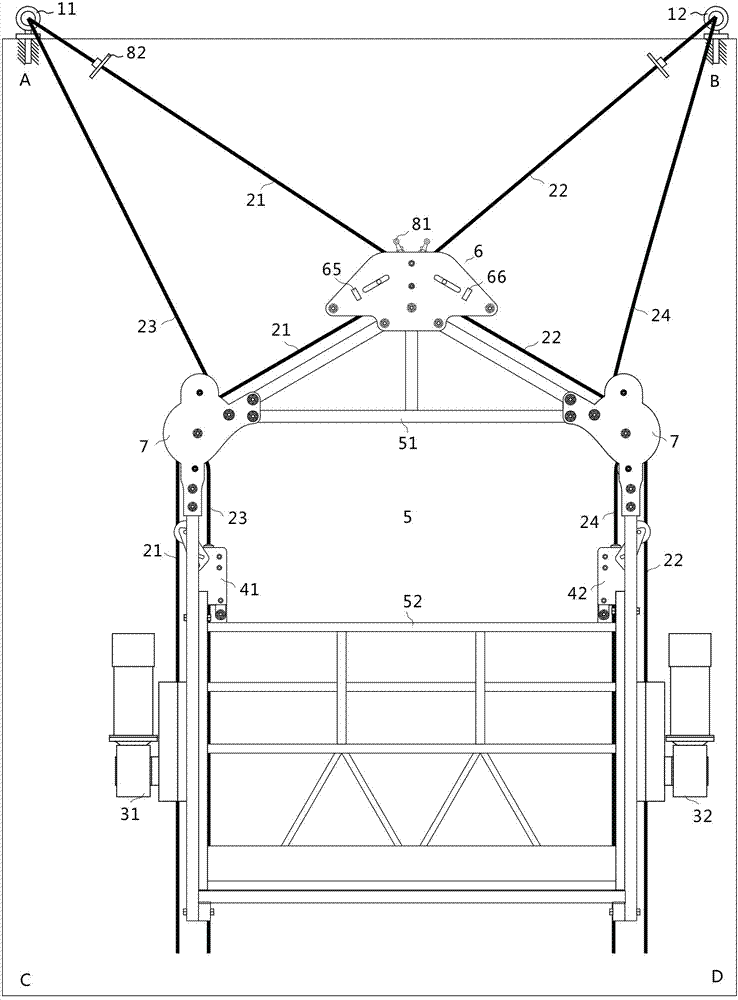

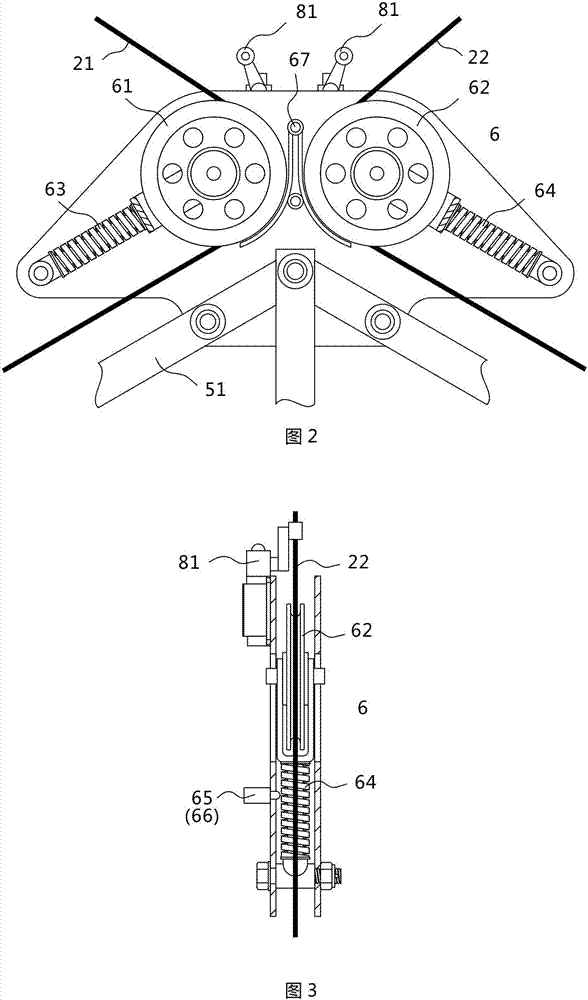

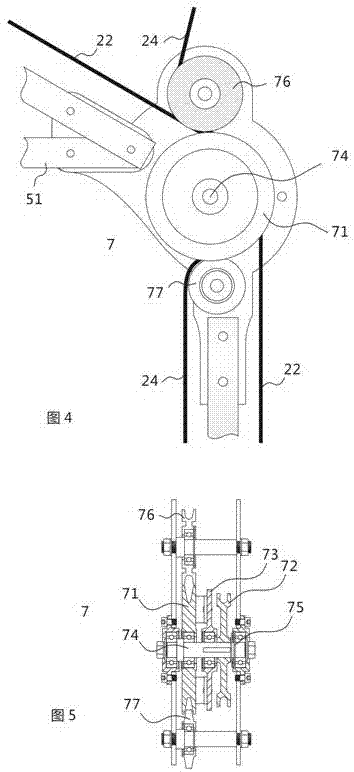

Inclined-hanging type hanging basket

InactiveCN107128853AObvious technical advantagesReduce equipmentSafety devices for lifting equipmentsBuilding liftsArchitectural engineeringHanging basket

The invention relates to an inclined-hanging type hanging basket and is the divisional application of a two-dimensional work hanging basket with the application number of 2014103589569. A left suspension mechanism and a right suspension mechanism are arranged on the left and right top points of the working surface of a building correspondingly. An isosceles triangle support is arranged on the top of a suspension platform. Guiding mechanisms are arranged at the top corner and two bottom corners of the support correspondingly. Facade distribution of steel wire ropes in the air is in the shape of a butterfly. During working, the suspension platform is obliquely hanged between the left suspension mechanism and the right suspension mechanism through the steel wire ropes. During operating, the action lengths of the left steel wire rope and the right steel wire rope are changed by operating a left elevator and a right elevator correspondingly; the suspension platform can be driven to operate in all directions on the working surface to arrive any required positions in the working scope. According to the hanging basket, the construction working surface of the suspension platform is widen by enlarging the intervals between hanging points of the suspension mechanisms, the working efficiency of the hanging basket is improved, the balance of the suspension platform is ensured through butterfly-shaped distribution of the steel wire ropes; an overload protection guiding mechanism at the top corner can prevent the steel wire ropes from overloading caused by oversized inclined angle; a frictional damping guiding mechanism at the left and right bottom corners can effectively damp inertia swinging of the suspension platform; and the stability and the reliability of the hanging basket construction are guaranteed.

Owner:温建

Excavation method of barrier lake aerial drainage tunnel

PendingCN110030004AReduce excavationSolve shipping problemsUnderground chambersMine roof capsSoil massGeomorphology

The invention provides an excavation method of a barrier lake aerial drainage tunnel. The excavation method of the barrier lake aerial drainage tunnel is characterized in that small space excavation is sectionally adopted, a large tunnel is formed by a manner of successive jacking in sections, at the same time, the top end and the two side ends of each section of the tunnel are continuously strengthened and supported according to successive jacking, and a steel body of each section of the tunnel is formed after strengthening and supporting; during aerial drainage, water constantly scours the bottom surface of soil mass, the bottom surface of the tunnel is hollowed out, the steel body of each section of the tunnel decreases continuously with the bottom surface of the soil mass, and the barrier lake aerial drainage height is further decreased; and the starting position of small space excavation is set in the unilateral direction or bilateral direction of a barrier lake or in a middle open caisson, construction of the open caisson is carried out in one-direction or two-direction manner, and a flow control device is arranged in the steel body of the aerial drainage tunnel or the open caisson. According to the excavation method of the barrier lake aerial drainage tunnel, the earth excavated volume is greatly decreased, the working face is increased by setting the open caisson on anexcavation line, the excavation length of each working face is greatly shortened, and it is conducive to start the aerial drainage and remove danger work in a very short time.

Owner:EAST CHINA UNIV OF TECH

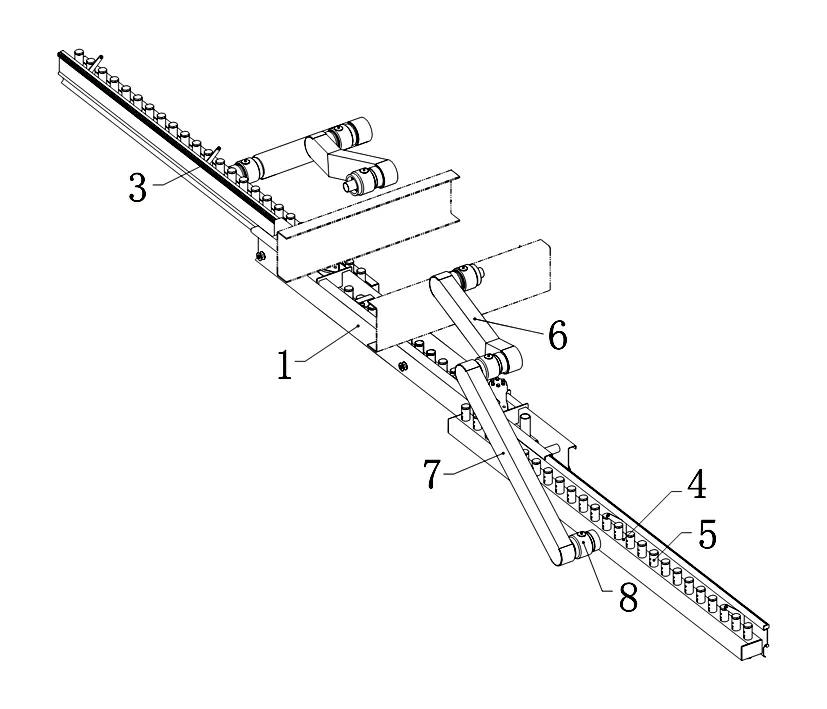

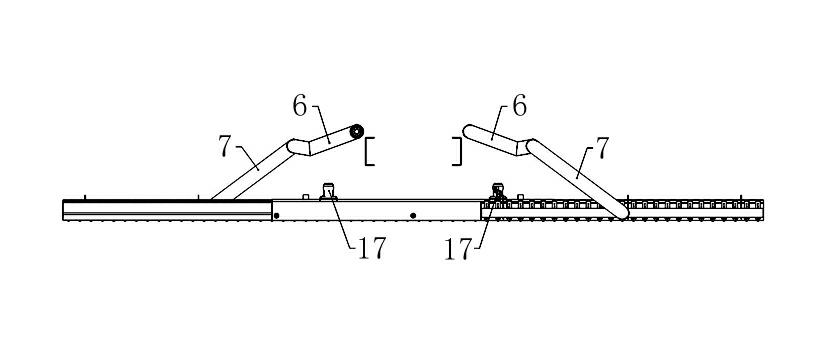

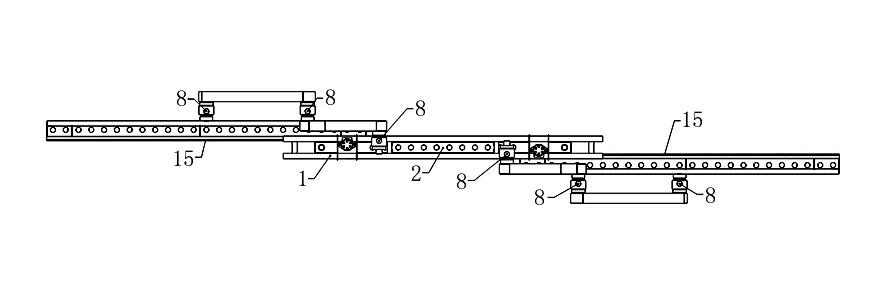

Inner double circulation runner type stretchable pitch sprinkling device

ActiveCN102644227ARealize the preheating function of circulating flowSolve the problem of poor seal and leakageRoads maintainenceHydraulic motorGear wheel

The invention relates to an inner double circulation runner type stretchable pitch sprinkling device which mainly comprises a support frame, a fixed sprinkling rod component, a left stretching sprinkling rod component and a right stretching sprinkling rod component which are the same in structure, and a pitch sprinkling valve, wherein the fixed sprinkling rod component is mounted on the support frame; each of the left stretching sprinkling rod component and the right stretching sprinkling rod component comprises a primary pitch pipeline, a secondary pitch pipeline, a rotating joint, a side sprinkling pipe and a pitch sprinkling valve; each primary pitch pipeline, each secondary pitch pipeline and each side sprinkling pipe are all divided into an oil inlet channel and an oil return channel by separating plates; an inner flowing pipe with smaller diameter is arranged in each rotating joint; and a transmission gear is driven by a hydraulic motor which is mounted on the support frame and a transmission rack fixedly arranged on the left stretching sprinkling rod component and the right stretching sprinkling rod component is driven to do linear motion, so that expansion and retraction of the left stretching sprinkling rod component and the right stretching sprinkling rod component are realized. Without using an externally connected pipeline, the inner double circulation runner type stretchable pitch sprinkling device can realize pitch circulation; the sprinkling distributing width is wide; and the structure is simple.

Owner:ZHEJIANG MEITONG ROAD CONSTR MACHINERY

Large-span underground space deep foundation pit support system and construction method

PendingCN110878555AIncrease lateral stiffnessReduced lateral support settingsExcavationsBulkheads/pilesSupporting systemArchitectural engineering

The invention discloses a large-span underground space deep foundation pit support system. The large-span underground space deep foundation pit support system comprises a deep foundation pit, multiplesupport units are continuously arranged on the inner wall of the periphery in the deep foundation pit, an I-shaped steel plate pile is formed between two adjacent support units, each support unit comprises upper, lower, left and right prefabricated support parts which are in abut joint and spliced, the prefabricated support parts on the left and right ends are fixedly connected to the I-shaped steel plate piles through bolts, and a whole support wall is formed on the periphery inner wall of the deep foundation pit. Waterproof plain concrete is poured into gaps between the support units and afoundation on the inner wall of the excavated deep foundation pit. The four corners are each provided with one I-shaped steel plate pile. Through the prefabricated support parts, splicing combinationof the periphery of the deep foundation pit in the horizontal and vertical direction is carried out, a combined structure is formed by the deep foundation pit and the I-shaped steel plate piles, arrangement of a transverse support and an even wall of the large-span deep foundation pit can be reduced or removed, and the problem that in the prior art, the work face construction cannot be performed in a large-area manner is solved. The system has the advantages of being reasonable in structure, capable of greatly simplifying construction, low in cost, green, environment-friendly, capable of saving investment, safe, portable and the like.

Owner:中国市政工程西北设计研究院有限公司

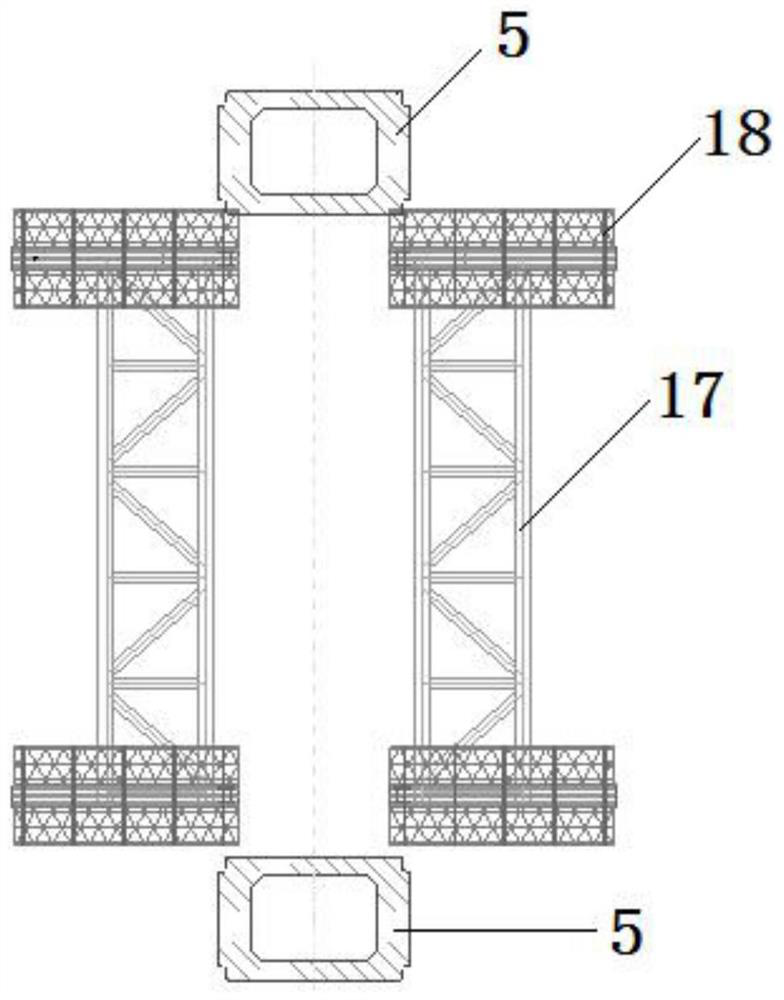

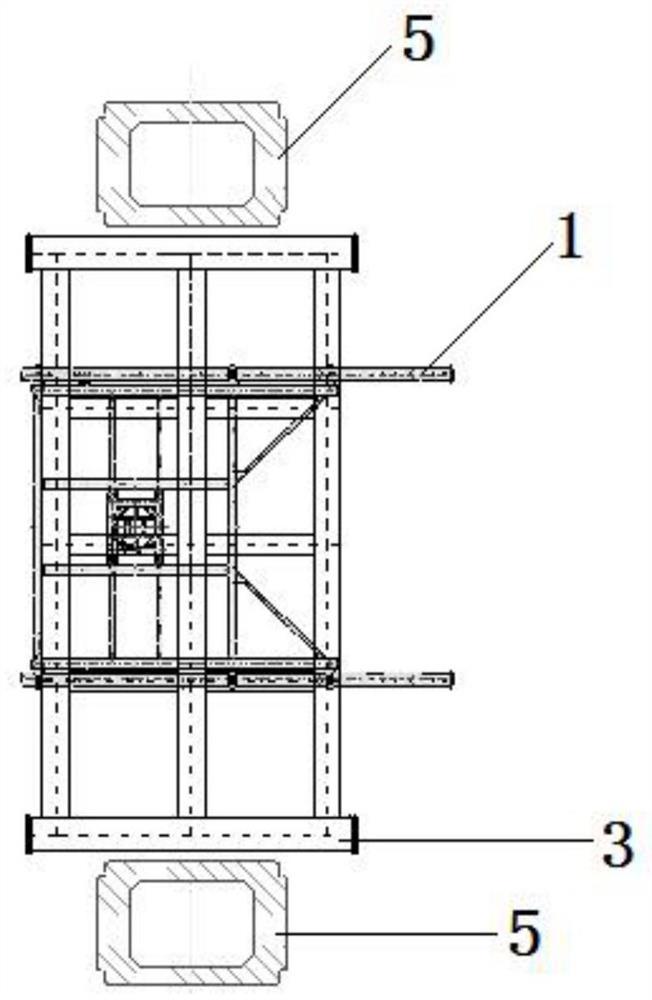

Construction method of large floating maintenance door

ActiveCN109967975AGuaranteed construction accuracyImprove precision controlReliability engineeringCorrosion

The invention discloses a construction method of a large floating maintenance door. The method comprises the following steps: (1) a first beam body, a second beam body, a third beam body, a fourth beam body, a fifth beam body and a sixth beam body are assembled; (2) a truss is assembled; (3) edge columns are assembled; (4) a maintenance door lower half body is manufactured; (5) a fender is assembled on the truss to manufacture a maintenance door middle body; (6) a maintenance door upper half body is manufactured; (7) a whole maintenance door is manufactured; (8) the edge columns are mounted onthe whole maintenance door; (9) the corrosion-resistance treatment is performed on the whole maintenance door; and (10) the construction of the large floating maintenance door is finished through assembly and welding. The construction method of the large floating maintenance door can solve the problems of assembly and corrosion resistance of the large floating maintenance door, is simple, feasible and convenient for corrosion-resistance construction, and greatly reduces the tonnage requirements on lifting equipment.

Owner:CHINA GEZHOUBA GROUP MACHINERY & SHIP

Supporting arch hidden digging top-down construction method

ActiveCN101338678BReduce construction riskSave construction siteUnderground chambersTunnel liningFloor slabDesign space

Owner:BEIJING URBAN CONSTR DESIGN & DEV GRP CO

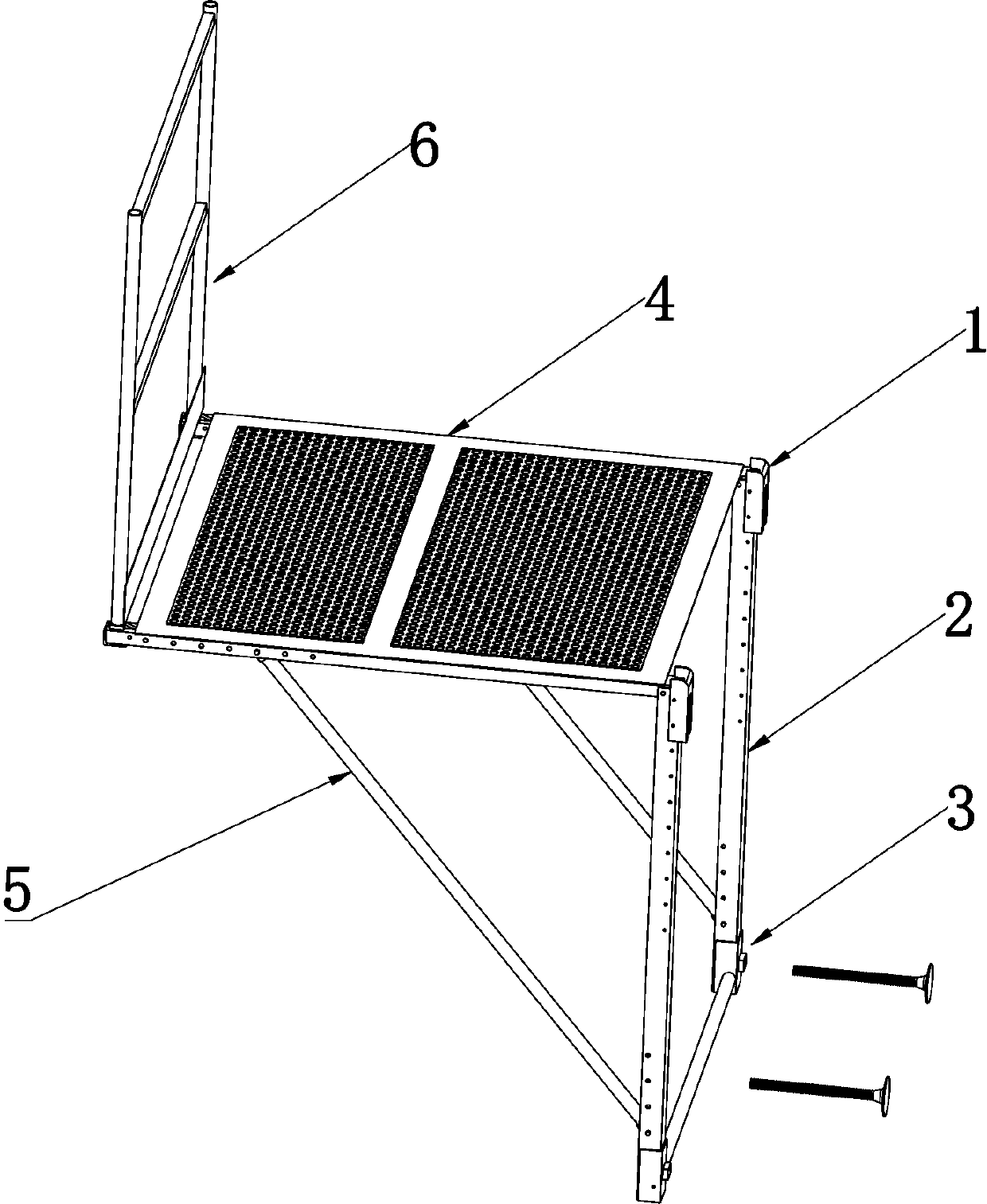

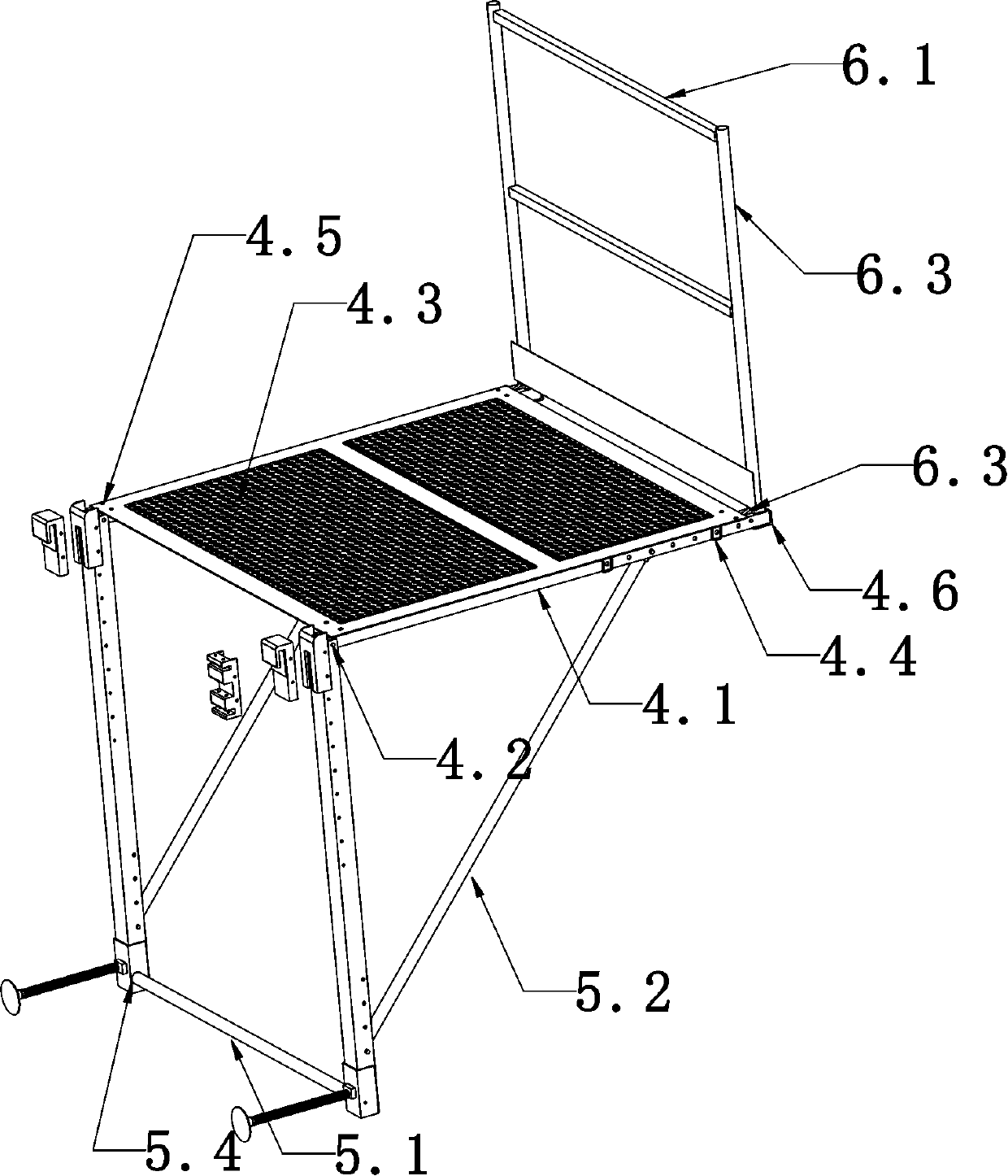

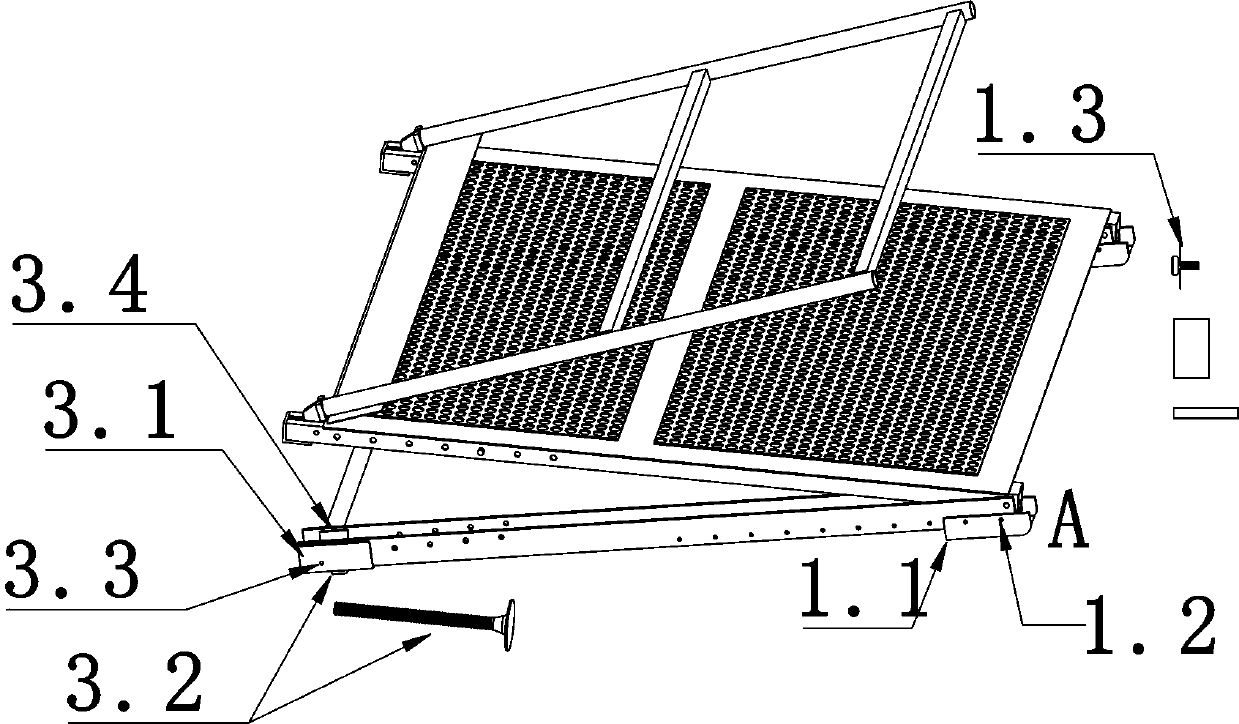

Multifunctional folding fabricated operating platform

PendingCN110453611AReduce erectionImprove securityBridge erection/assemblyBuilding support scaffoldsSocial benefitsButt joint

The invention discloses a multifunctional folding fabricated operating platform. The multifunctional folding fabricated operating platform is composed of hanging pedestals, bearing frames, connectingrods, adjustable supporting frames, a fence, an operating platform body, plugs and the like. During construction such as building construction, bridge pier stud construction, various kinds of cast-in-place construction, beam and slab prefabricated construction, steel and concrete superposed beam construction or construction of other cantilever structures, the folding fabricated operating platformis connected at a butt joint position through the different hanging pedestals, construction working faces are increased, the operation is facilitated, the construction speed is increased, the safety is good, transportation is convenient, the turnover performance is high, and economic benefits and social benefits are obvious.

Owner:四川路桥桥梁工程有限责任公司

A method for overall lifting and installation of bridge arch ribs

ActiveCN106012864BGood stability against windReduce the difficulty of welding quality controlBridge erection/assemblySupporting systemEngineering

The invention discloses a method for lifting and installing a whole bridge arch rib. The method includes the following steps of dividing the arch rib into two side arch rib bodies and a middle arch rib body, splicing the side arch rib bodies on a wharf, hoisting the side arch rib bodies to a set position through a floating hoist, erecting a side supporting system and a lifting portal, installing a lifting system, splicing a middle supporting system below the design position of the middle arch rib body, installing the middle arch rib on the upper face of the middle supporting system, arranging a temporary beam at the bottom of an arch foot of the middle arch rib body, arranging a temporary horizontal rope between the two ends of the arch foot, correspondingly connecting the lifting system with the temporary beam, and lifting, horizontally moving, putting down, putting in position, folding and installing the whole middle arch rib body. By means of the method, the requirements for installation quality and precision of the large-span arch rib bridge can be met, section lengths can be flexibly adjusted, section manufacturing quality is optimized, and section in-situ precision is improved.

Owner:SHANGHAI CIVIL ENG GRP FIFTH +1

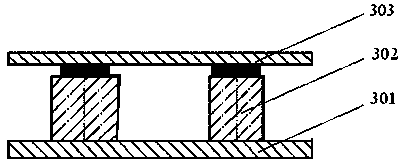

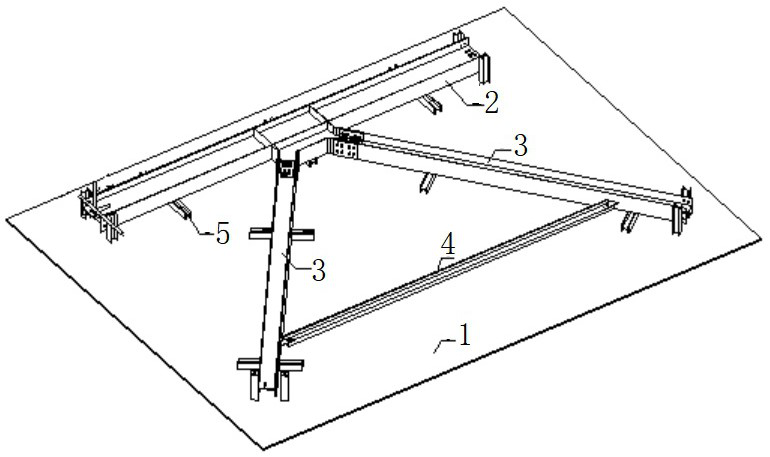

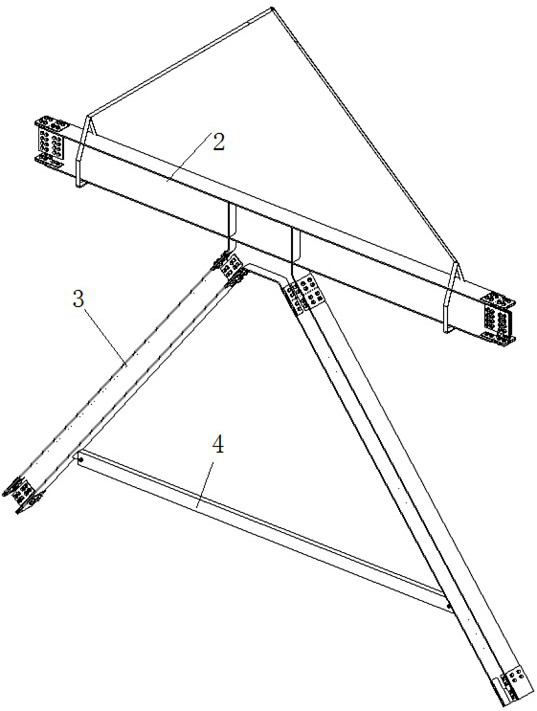

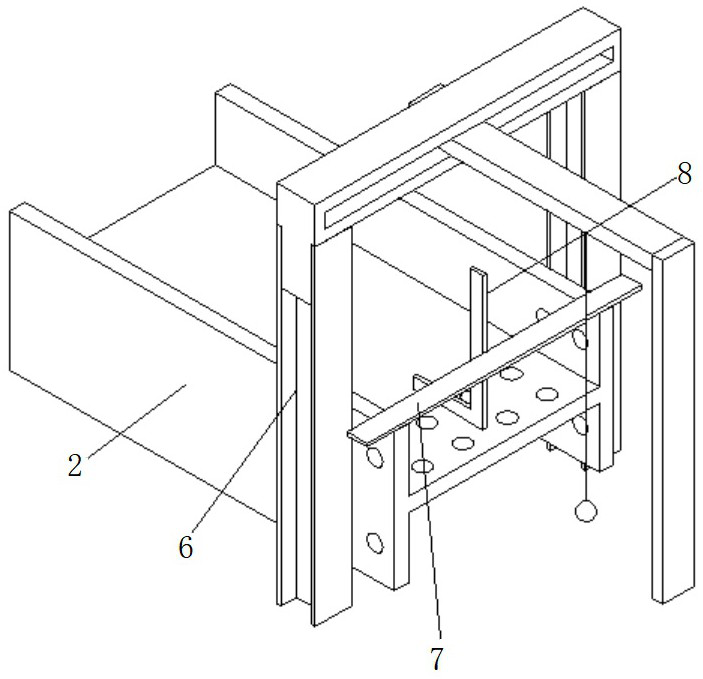

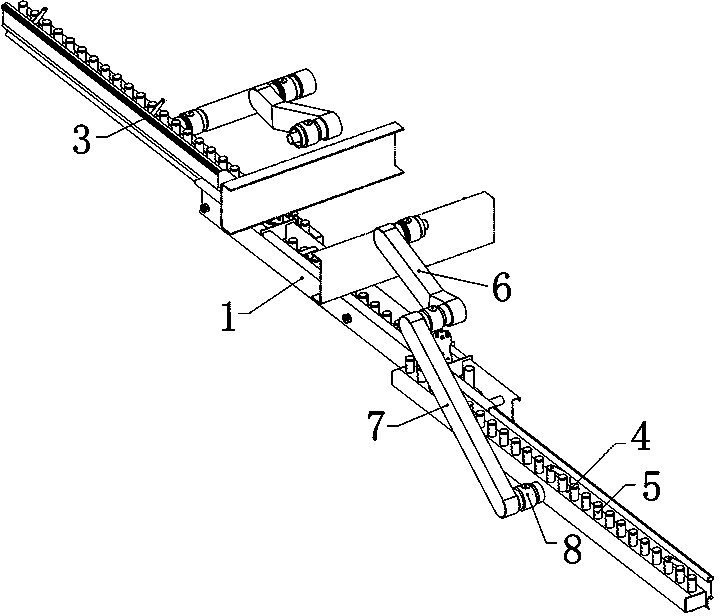

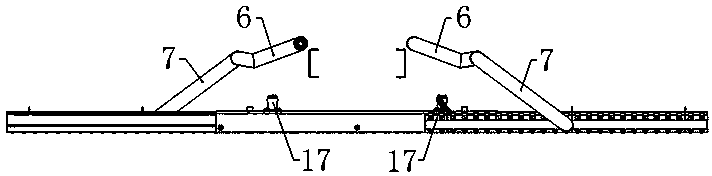

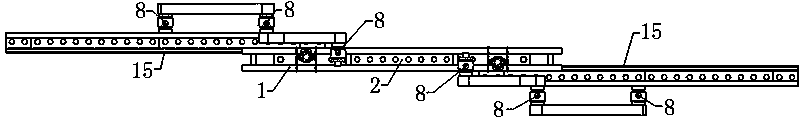

An integral installation method and assembly device for frame beams and herringbone braces

ActiveCN110485571BImprove assembly qualityGuaranteed installation qualityBuilding constructionsSocial benefitsStraightedge

The invention discloses an integral mounting method and assembly device of a frame beam and a herringbone diagonal brace, and belongs to the field of building construction. The integral assembly device for the frame beam and the herringbone diagonal brace comprises a bottom plate, a plurality of positioning blocks fixedly connected to the bottom plate and used for positioning the frame beam and the herringbone diagonal brace, a straightedge and an esquadro; and the straightedge and the esquadro cooperate with the positioning blocks in use and are used for the mounting and positioning of the frame beam. The integral mounting method for the frame beam and the herringbone diagonal brace adopts the assembly device for mounting, the simple assembly device is built at the position near the hoisting part of a construction site, and the frame beam and the herringbone diagonal brace are placed on the bottom plate. The working conditions of high-altitude hoisting are improved, the working risksof workers at high altitude are reduced and the working efficiency is improved. At the same time, a large number of tower crane working shifts are saved, a guarantee is provided for the smooth implementation of other processes, and the economic and social benefits are obvious.

Owner:山东高速莱钢绿建发展有限公司

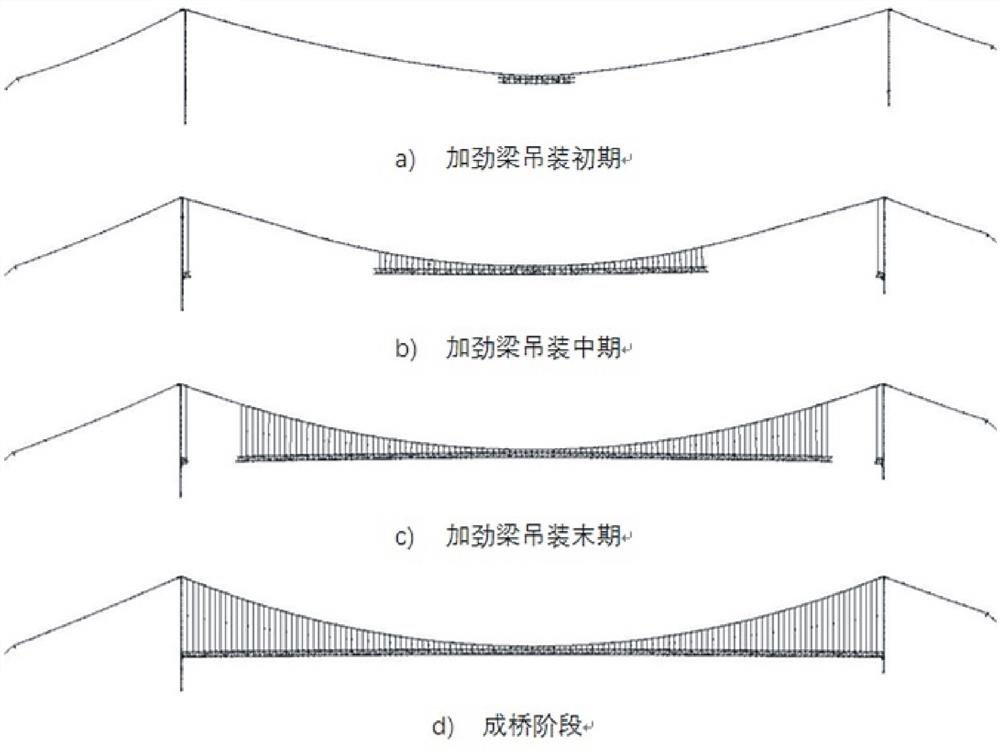

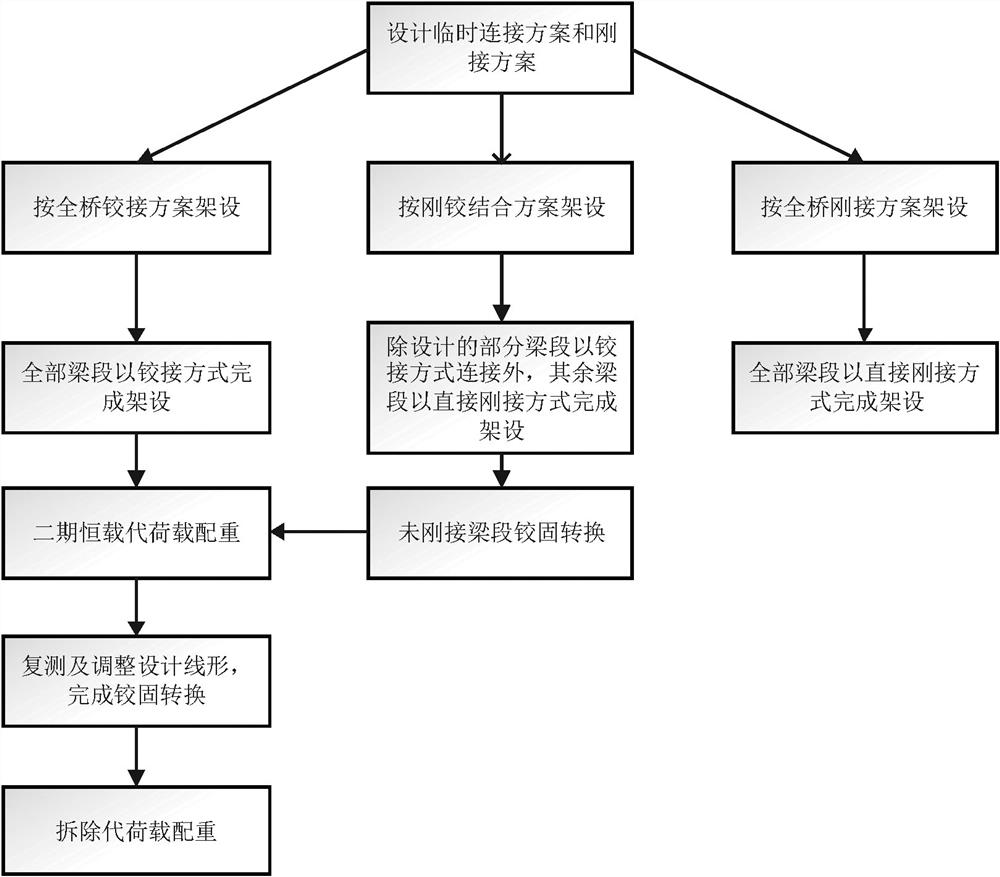

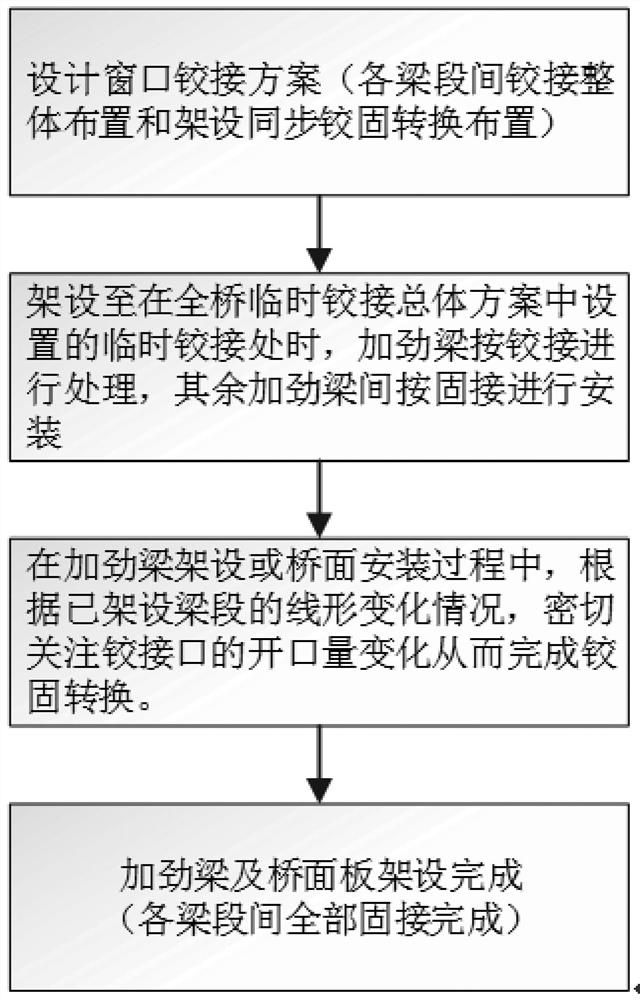

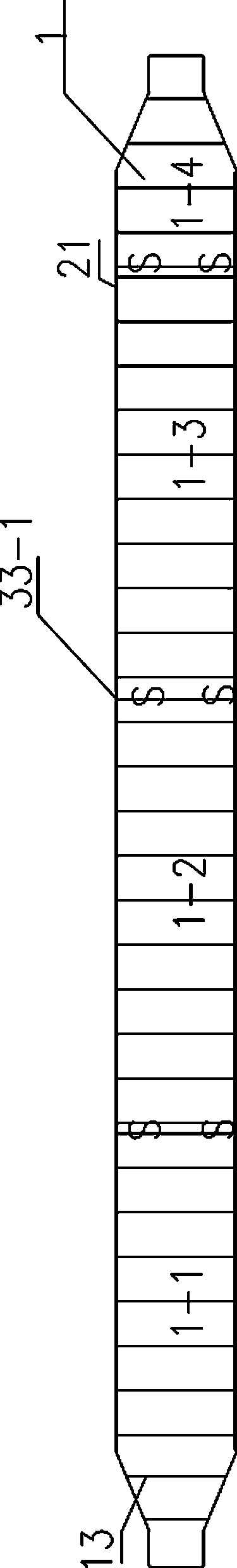

A Form-Finding Rigid Connection Method for Erecting Steel Truss Stiffeners of Suspension Bridges

ActiveCN111305075BIncrease the construction work areaSimple processSuspension bridgeBridge erection/assemblyArchitectural engineeringBridge deck

Owner:SOUTHWEST JIAOTONG UNIV +3

Method of construction of large floating inspection doors

ActiveCN109967975BGuaranteed construction accuracyImprove precision controlCorrosion preventionReliability engineering

The invention discloses a construction method of a large floating maintenance door. The method comprises the following steps: (1) a first beam body, a second beam body, a third beam body, a fourth beam body, a fifth beam body and a sixth beam body are assembled; (2) a truss is assembled; (3) edge columns are assembled; (4) a maintenance door lower half body is manufactured; (5) a fender is assembled on the truss to manufacture a maintenance door middle body; (6) a maintenance door upper half body is manufactured; (7) a whole maintenance door is manufactured; (8) the edge columns are mounted onthe whole maintenance door; (9) the corrosion-resistance treatment is performed on the whole maintenance door; and (10) the construction of the large floating maintenance door is finished through assembly and welding. The construction method of the large floating maintenance door can solve the problems of assembly and corrosion resistance of the large floating maintenance door, is simple, feasible and convenient for corrosion-resistance construction, and greatly reduces the tonnage requirements on lifting equipment.

Owner:CHINA GEZHOUBA GROUP MACHINERY & SHIP

Subway interval joint survey method based on reverse contact survey

ActiveCN114485584AMeet the precision requirementsAvoid constraintsSurveying instrumentsHydro energy generationReverse connectionControl theory

The invention relates to a subway interval joint measurement method based on reverse connection survey, which is used for joint measurement of control points between a cut-through interval and a non-cut-through interval in a joint measurement unit, and specifically comprises the following steps of: normally performing joint measurement on underground control points of a subway cut-through interval according to a mode from a station control edge to an interval lead point to the station control edge; two steel wires are hung on the non-through section part, the coordinate and the direction of an underground starting point of the through section are transmitted to a laid ground starting point in a reverse relation measurement mode to serve as ground starting data, and the ground part adjusts ground control points of the non-through section in an attached wire mode; and after the middle tunnel is communicated, the middle tunnel joint measurement data is incorporated into the whole network for data correction, and the overall joint measurement precision is ensured. The combined measurement method is reasonable in measurement method, high in measurement accuracy, high in operability and short in measurement period, and can better overcome the influence of the non-cut-through interval on the combined measurement work.

Owner:CHINA RAILWAY LIUYUAN GRP CO LTD

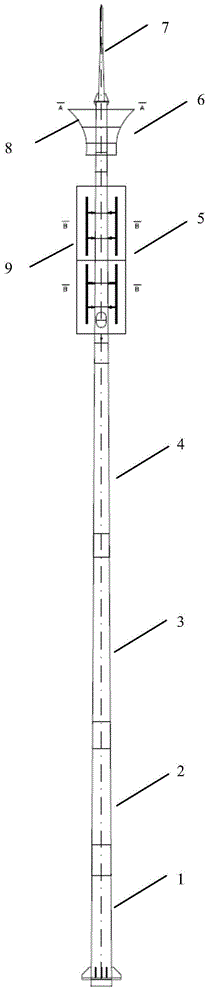

Inserting type beautifying tower

InactiveCN104963540AWithout destroying the basic landscapeAvoid disputesTowersTowerBuilding construction

The invention discloses an inserting type beautifying tower which comprises a first rod segment, a second rod segment, a third rod segment, a fourth rod segment, a fifth rod segment and a sixth rod segment. Adjacent rod segments are connected in an inserting mode. The beautifying tower is connected with a foundation through foundation bolts. The beautifying tower comprises a beautifying platform and a beautifying cover. The beautifying platform is arranged on the fifth segment, the beautifying cover is arranged on the sixth segment, and the beautifying cover covers an antenna. Compared with the prior art, the inserting type beautifying tower has the advantages that disputes and contradictions in construction are avoided, the construction speed is high, and the inserting type beautifying tower is safe to use.

Owner:TIANJIN FANGHUA COMM ENG

A construction method for the main girder of a steel-concrete composite girder cable-stayed bridge

ActiveCN109972517BSolve the lifting installationQuality assuranceBridge erection/assemblyArchitectural engineeringBridge deck

The invention discloses a construction method for the main girder of a steel-concrete composite girder cable-stayed bridge. The bridge deck crane is placed on the steel girder of the initial section, the hoisting unit of the first deck crane splices the steel beam of the section and is fixed on both ends of the steel beam of the initial section, and the first deck crane moves forward to one end of the steel beam of the initial section On the steel girder of the unit splicing section, the second deck crane is hoisted by the wall-attached crane to the steel girder of the unit splicing section at the other end of the initial section steel girder, and the first deck crane and the second deck crane respectively Move and complete the splicing construction of steel beams extending towards the side span of the bridge and the splicing construction of steel beams extending towards the middle span of the bridge, and complete the closing construction of the side span steel beams and the closing construction of the middle span steel beams. The invention has the advantages of strong operability, safety and reliability, controllable quality, high efficiency, energy saving and environmental protection.

Owner:CCCC SECOND HARBOR ENG +1

Inner double circulation runner type stretchable pitch sprinkling device

ActiveCN102644227BRealize the preheating function of circulating flowSolve the problem of poor seal and leakageRoads maintainenceHydraulic motorGear wheel

Owner:ZHEJIANG MEITONG ROAD CONSTR MACHINERY

Rigid gridding and pile combined foundation and its use in soft soil foundation reinforcement

InactiveCN101476325BHigh strengthGood deformabilityBulkheads/pilesSoil preservationSurface layerEngineering

The invention discloses a rigid grid and pile composite foundation and a method applied to reinforcing soft soil foundation. The rigid grid and pile composite foundation comprises a precast pile or a cast-in-situ pile, a rigid grid structure, a tensioning net, tensioning ribs and a transitional underlayer; the precast pile or the cast-in-situ pile drives to a relatively hard ground layer from a foundation surface layer; the rigid grid structure is fixedly connected with the precast pile; the grid structure is paved with the tensioning net; the tensioning net is provided with the transitional underlayer; the transitional underlayer is tightly contacted with the foundation surface, and the thickness of the transitional underlayer is between 0.6 and 1.5 meters; and the transitional underlayer is sandy clay, gravel soil or plain concrete with crude particles. The invention organically combines the rigid grid and the pile structure, the transitional underlayer and a soft ground layer to construct a composite foundation, transfers the load to a deep layer soil body through the grid structure and a pile, can give a full play to the strength and the deformation performance of the deep layer soil body, thereby effectively improving the foundation strength and the deformation performance, and having good reinforcing effect.

Owner:SOUTH CHINA UNIV OF TECH

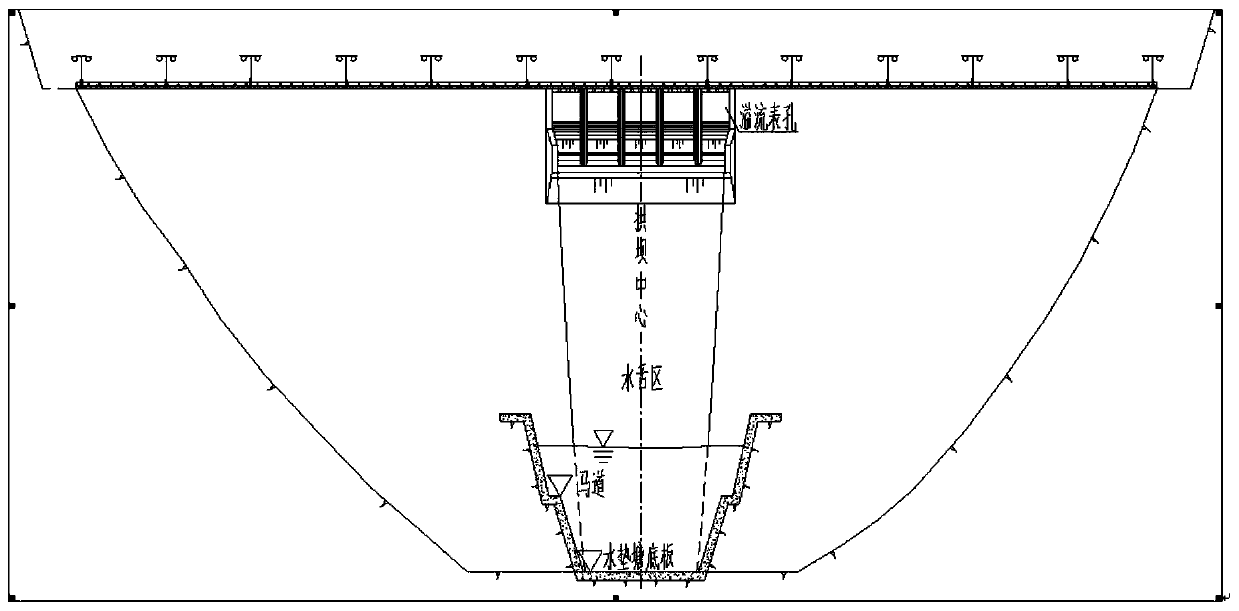

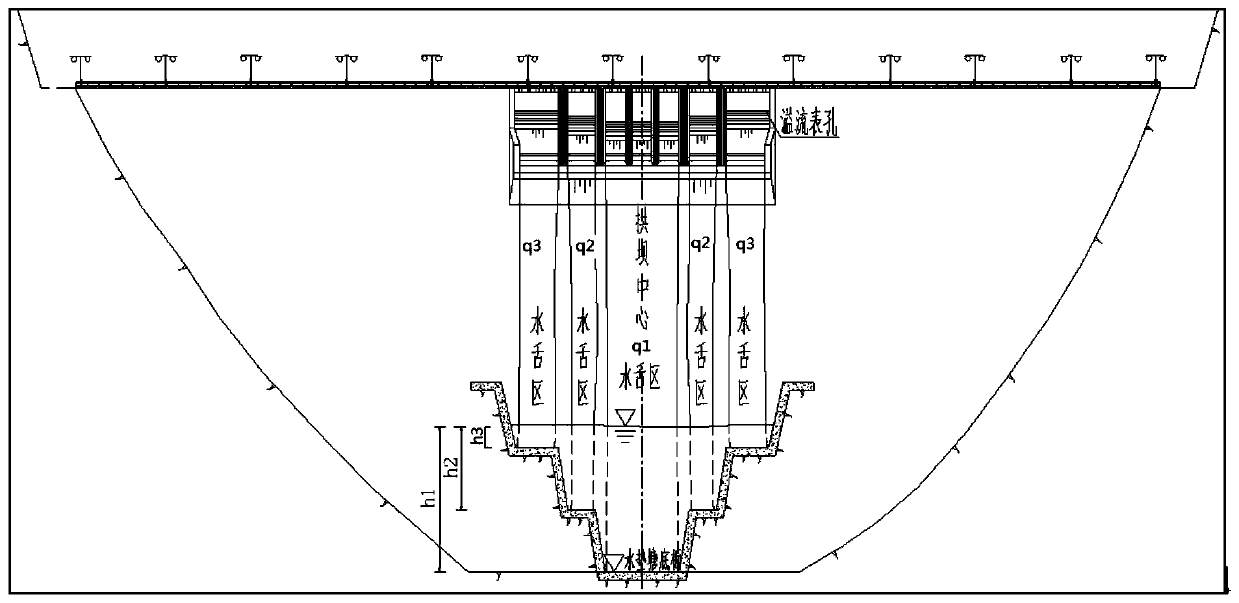

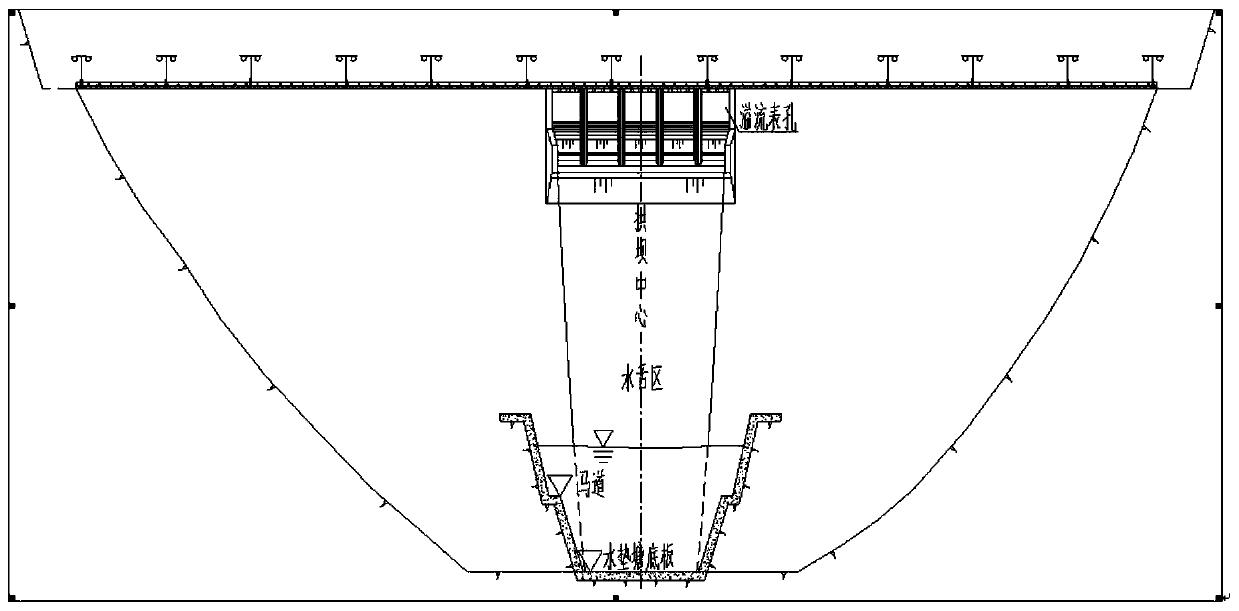

A high arch dam flood discharge and energy dissipation facility with the floor on both sides gradually raised

The invention discloses a high arch dam flood discharge and energy dissipation facility with gradually-elevated bottom plates on two sides. The facility comprises multiple overflow surfaces holes formed in an arch dam, and a plunge pool arranged on the downstream of the overflow surface holes and corresponding to the overflow surface holes. The overflow surface holes comprise low-position overflowsurface holes located in the middle, and high-position overflow surface holes located in the two sides, wherein the bottom elevation of the low-position overflow surface holes is low, and the bottomelevation of the high-position overflow surface holes is high. Among the overflow surface holes, with the high elevation, in the two sides, the bottom elevation of the overflow surface holes in the inner side is lower than the bottom elevation of the overflow surface holes in the outer side. The plunge pool is a compound fracture surface plunge pool. The pool bottom of the plunge pool comprises acenter bottom plate and step bottom plates which are located on the bank slopes of the two sides of the center bottom plate and are sequentially elevated step by step. The center bottom plate corresponds to water tongues jetted from the low-position overflow surface holes. The step bottom plates correspond to water tongues jetted from the high-position overflow surface holes. According to the facility, under the conditions of the same flow discharge amount and the stable and safe bank slopes of the plunge pool, the excavation amount of the plunge pool is reduced, and the project investment isreduced.

Owner:SICHUAN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com