A construction method for the main girder of a steel-concrete composite girder cable-stayed bridge

A steel-concrete combination and construction method technology, applied in bridges, bridge construction, erection/assembly of bridges, etc., can solve problems such as the large influence of climate factors, the influence of the installation quality of the combined beam and the overall construction period, and the limitation of the scattered work surface.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0035] Such as figure 1 The construction method of the main girder of the steel-concrete composite beam cable-stayed bridge shown in -11, the steps are as follows:

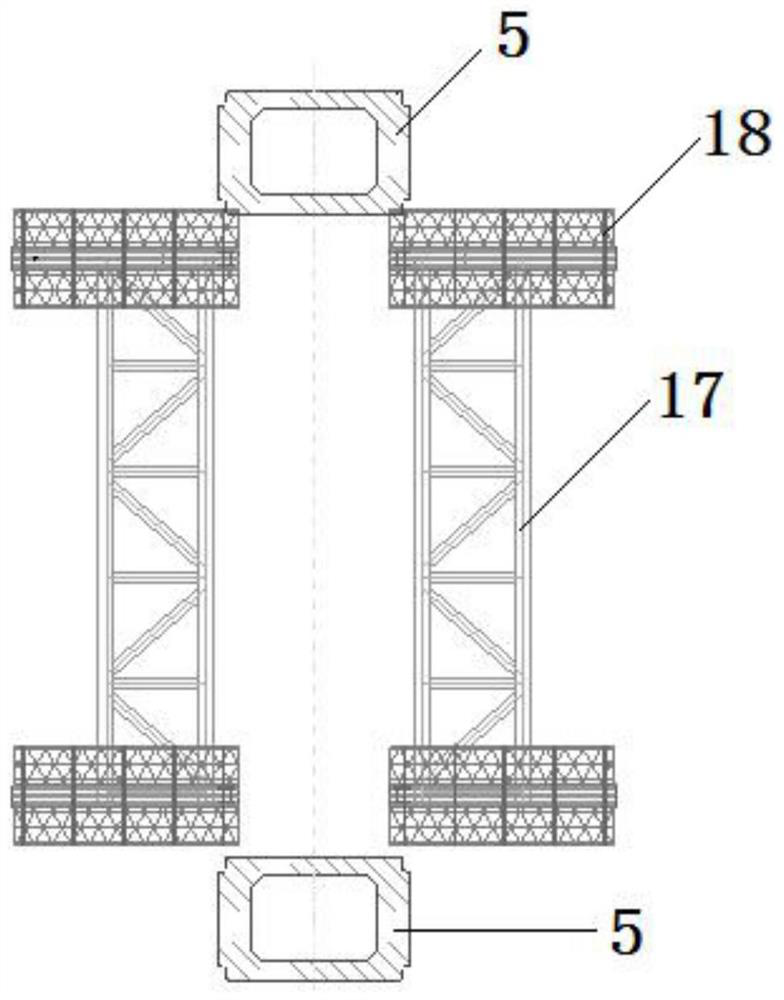

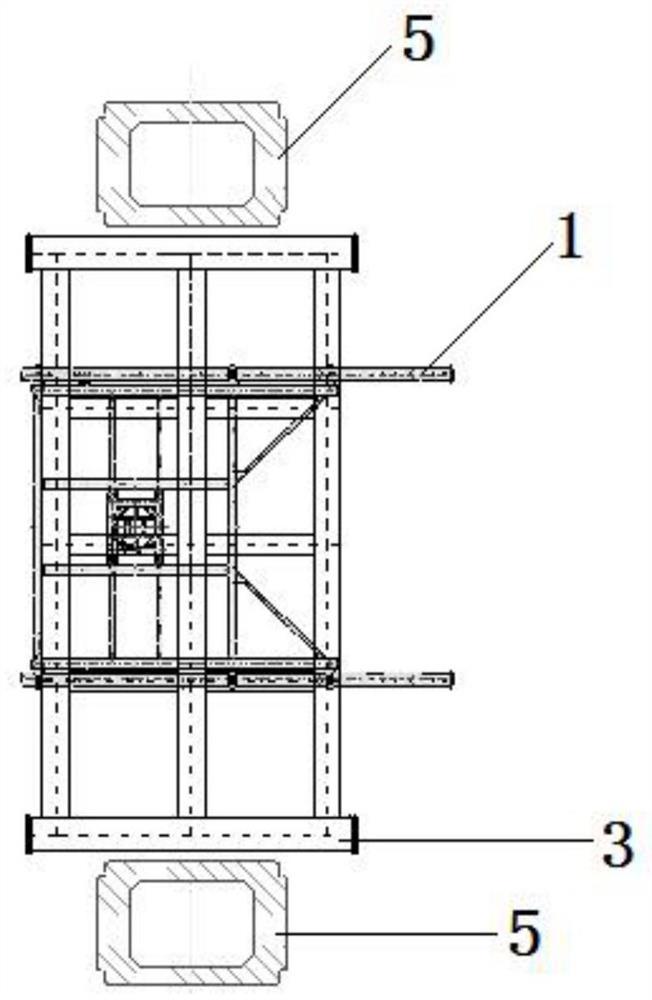

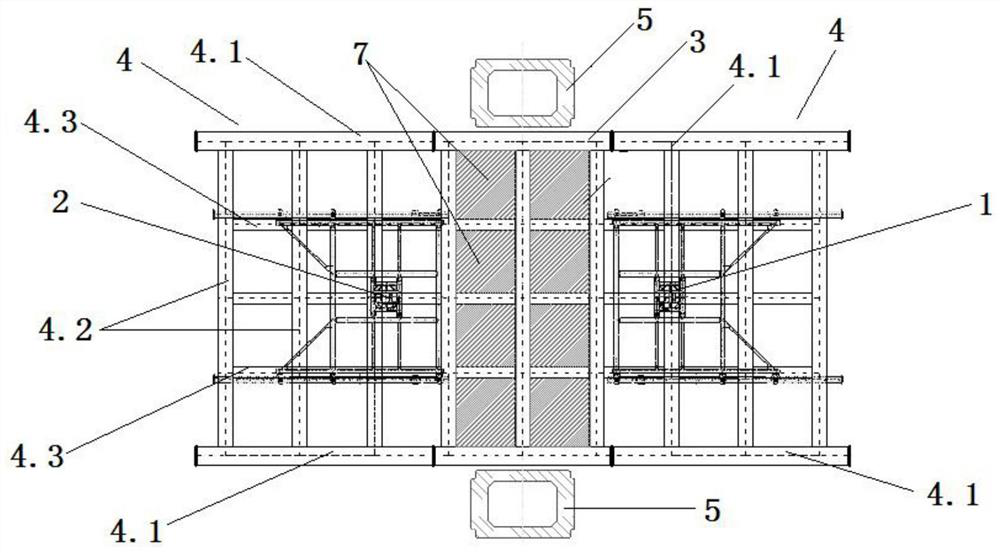

[0036]1) Install the wall-attached crane on the two cable towers 5, hoist the temporary consolidation 17 and the protection platform 18 on the wall-attached crane and install them on the cable tower 5, and erect the initial segmental steel beam on the temporary consolidation 17 3;

[0037] 2), hoist the first deck crane 1 to the steel girder 3 of the initial section by the wall-attached crane and fix it, and fix the steel beam 4 of the splicing section of the hoisting unit of the first deck crane 1 to the steel beam 3 of the initial section At both ends, the stay cables 6 of the steel beams 4 of the unit splicing section are installed and tensioned;

[0038] The fixing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com