Patents

Literature

688 results about "Composite girder" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Composite spars

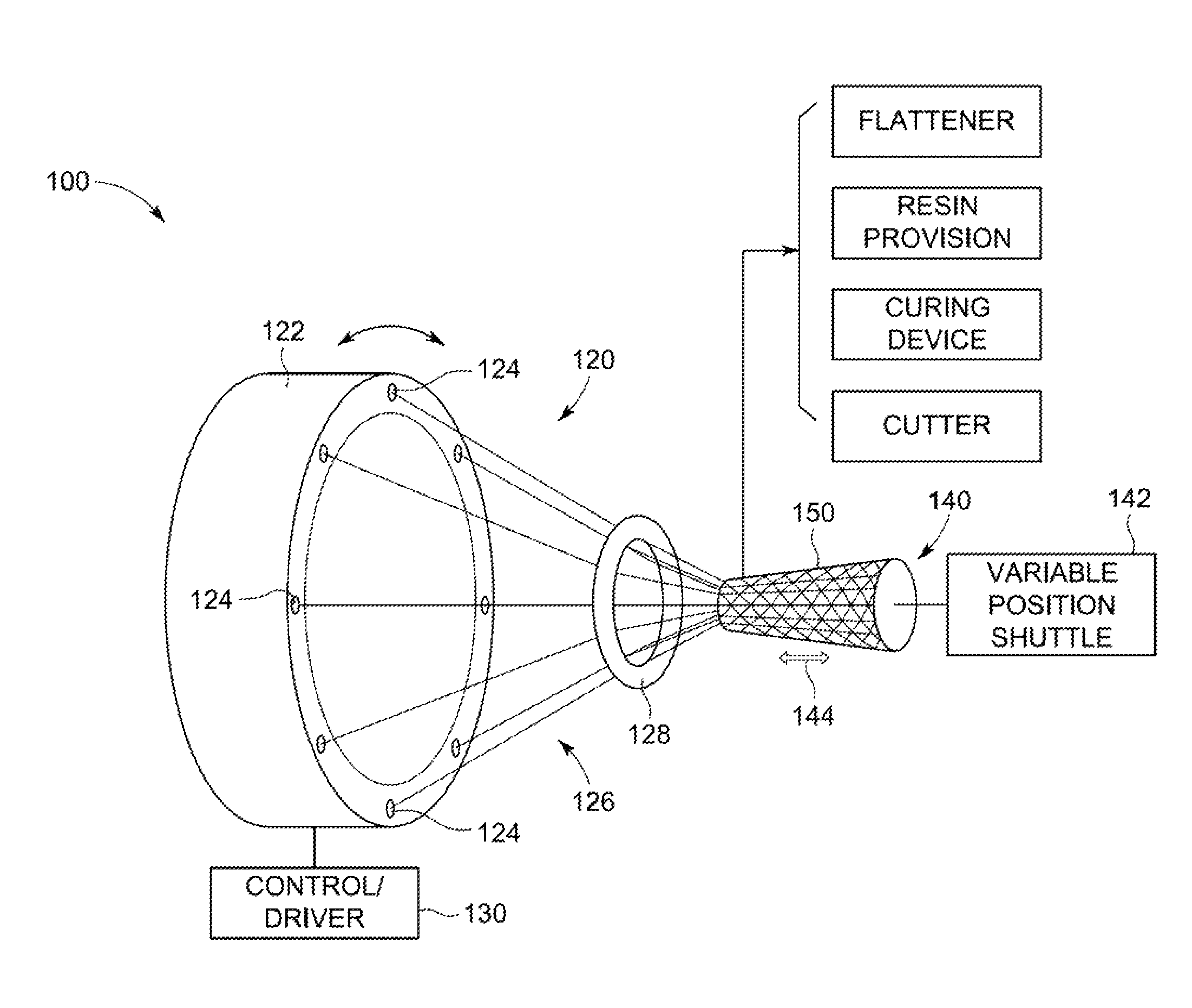

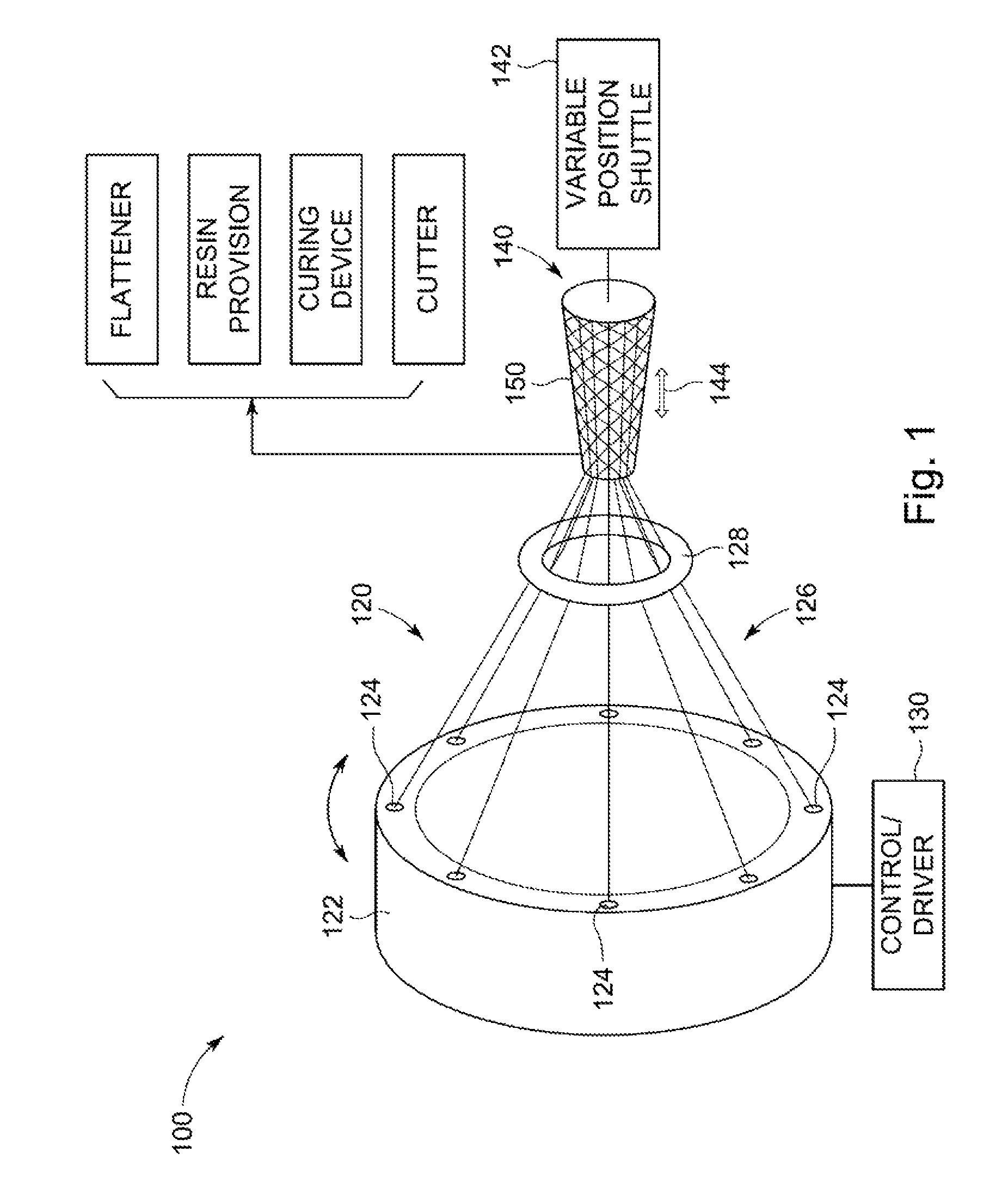

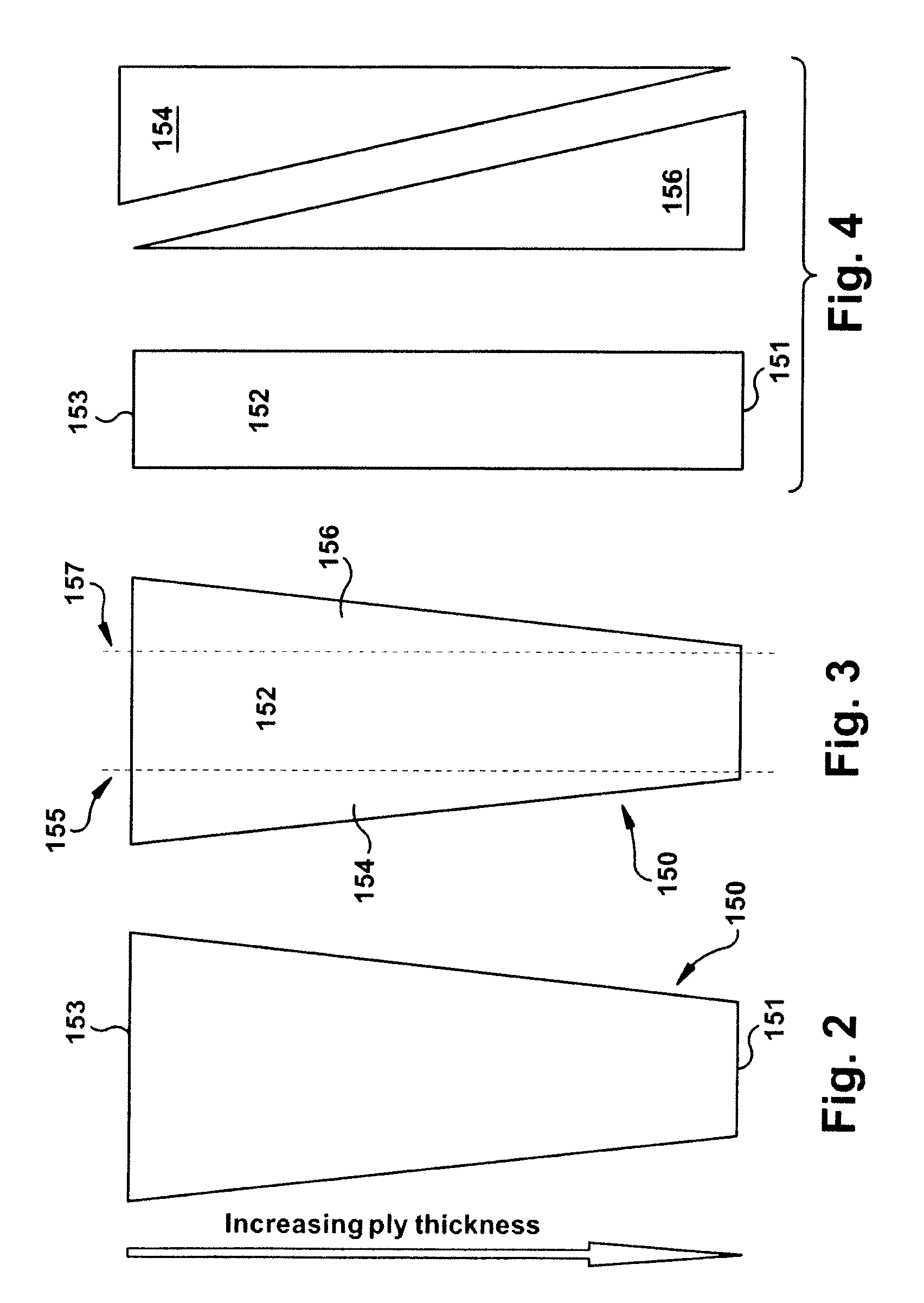

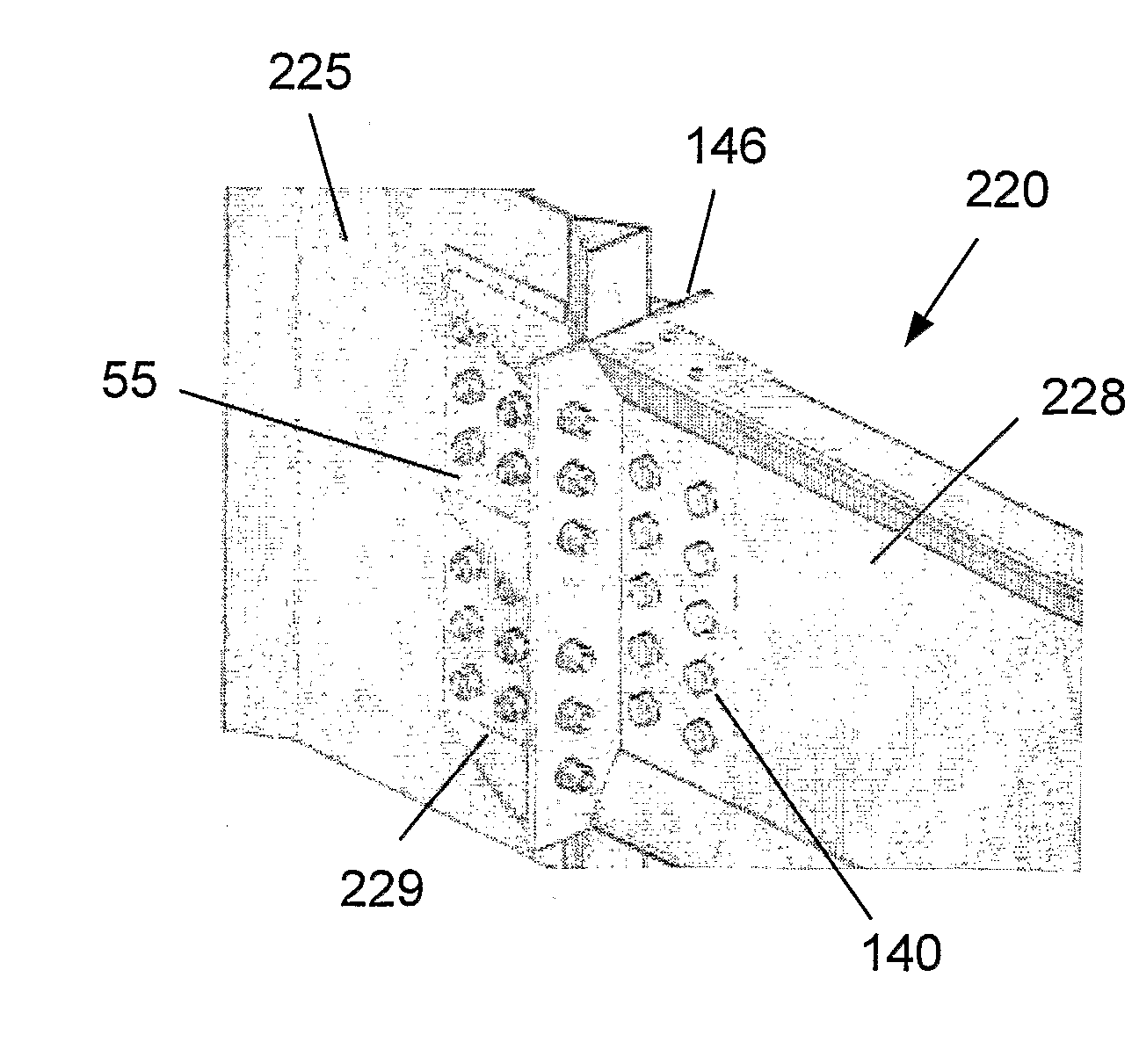

ActiveUS8061253B2Production is thereby speededOrnamental textile articlesEfficient propulsion technologiesFiberVariable thickness

According to one aspect, the present invention relates to a method of manufacturing at least one non-uniform thickness composite spar component. The method comprises braiding a plurality of fibers over a non-cylindrical mandrel to form a variable thickness shaped fiber preform, flattening the shaped fiber preform and cutting the flattened shaped fiber preform to obtain the at least one non-uniform thickness composite spar component. Spars made according to various embodiments of the present invention are faster and less expensive to manufacture than conventional composite spar components.

Owner:GE AVIATION SYST LTD

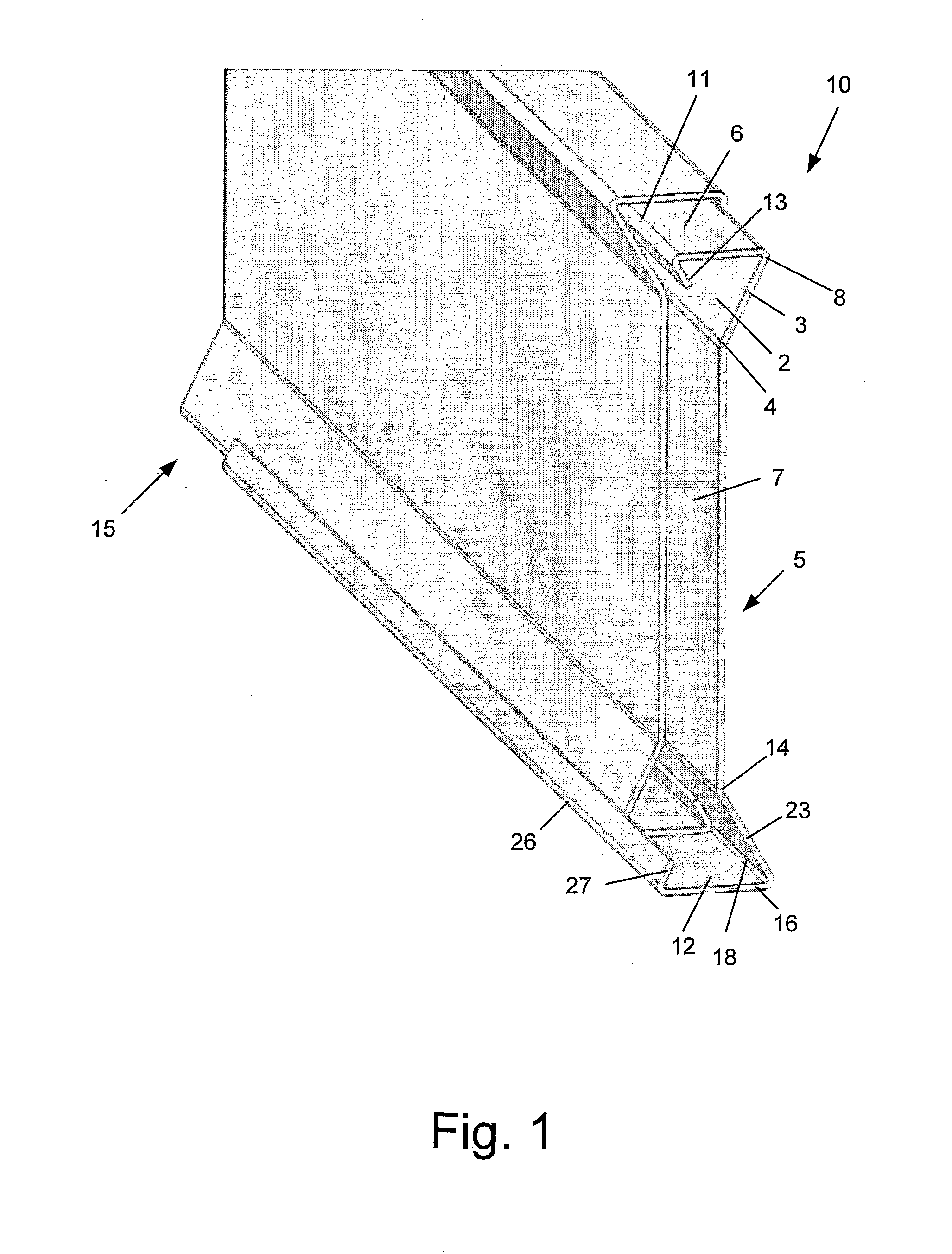

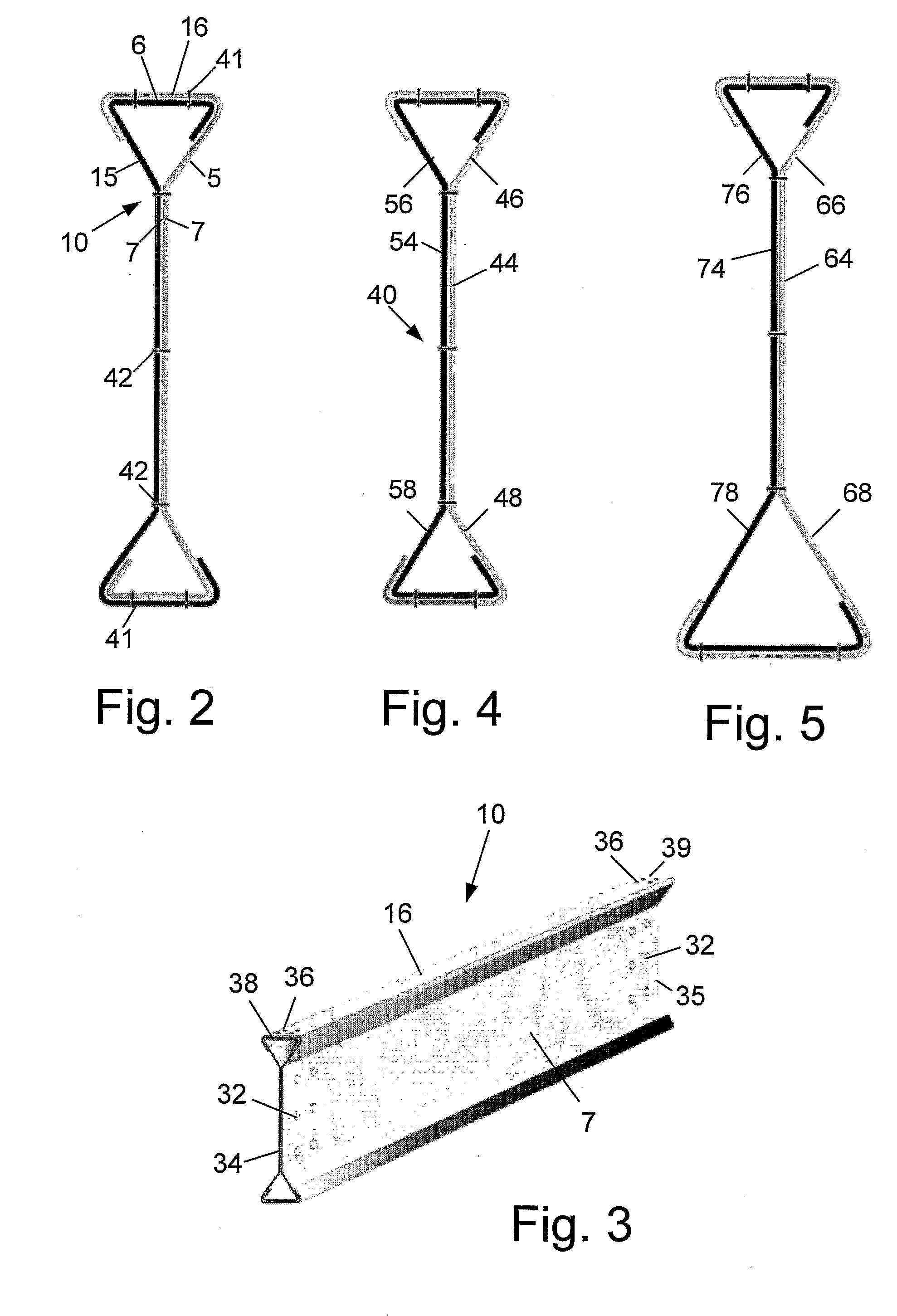

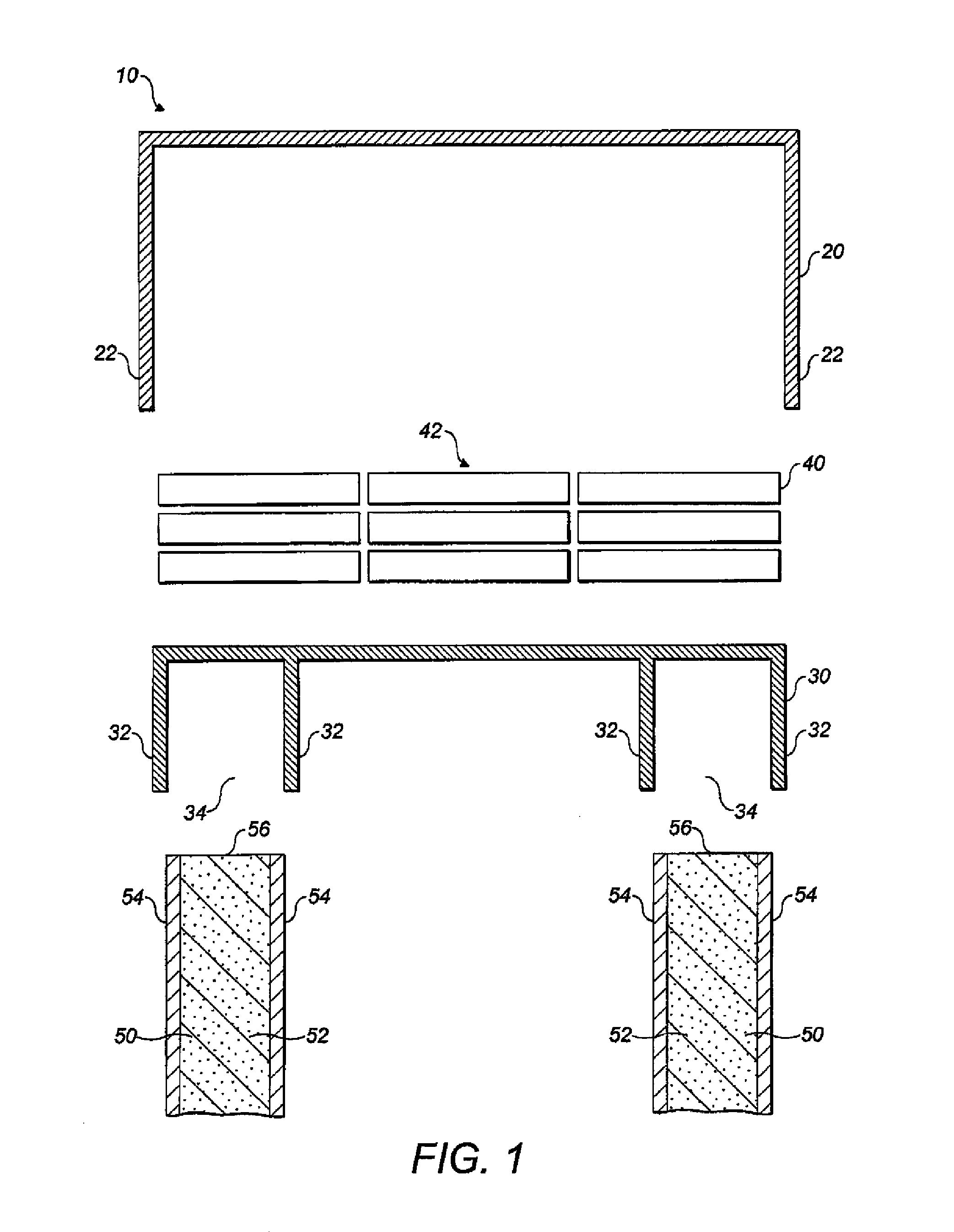

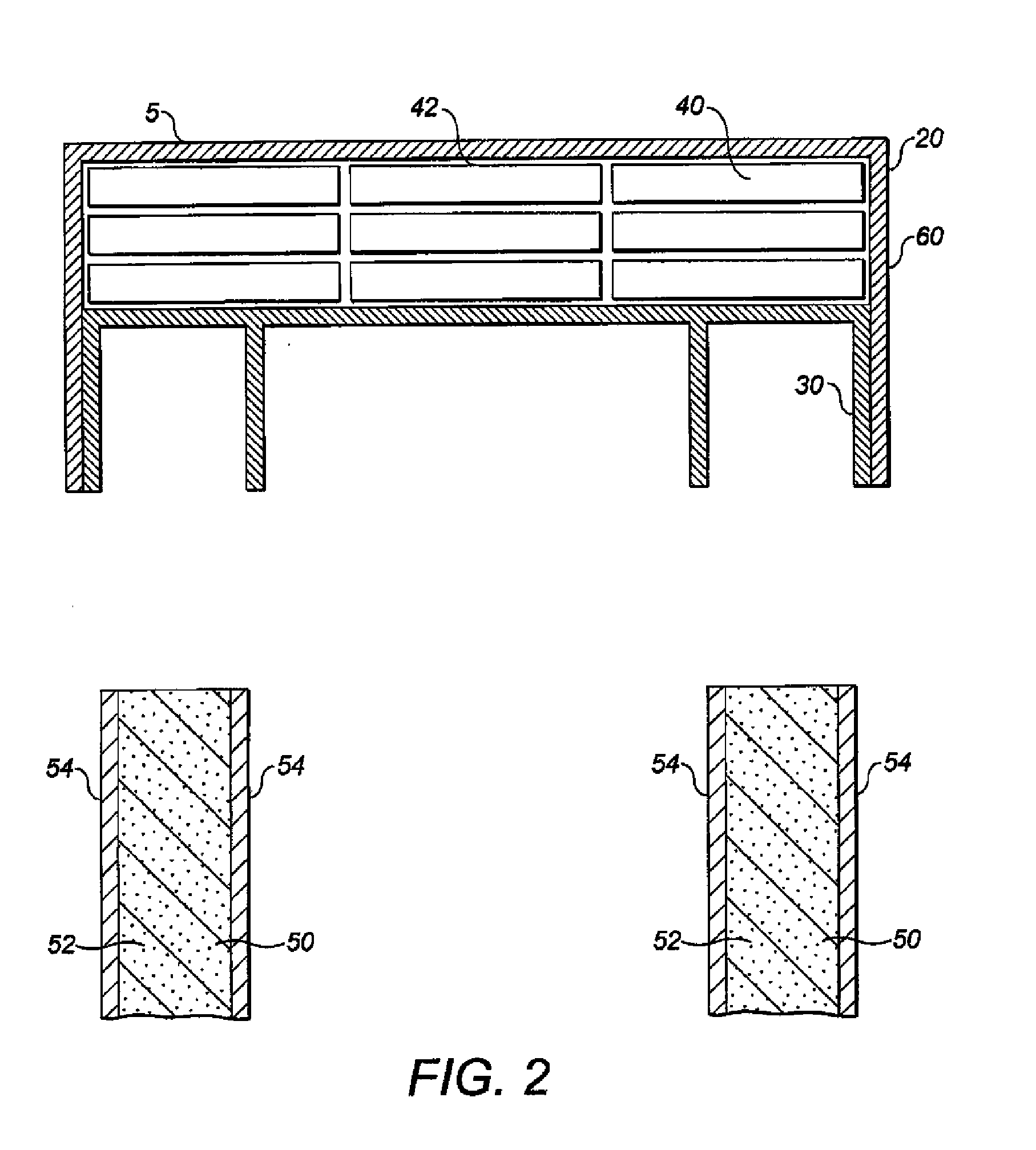

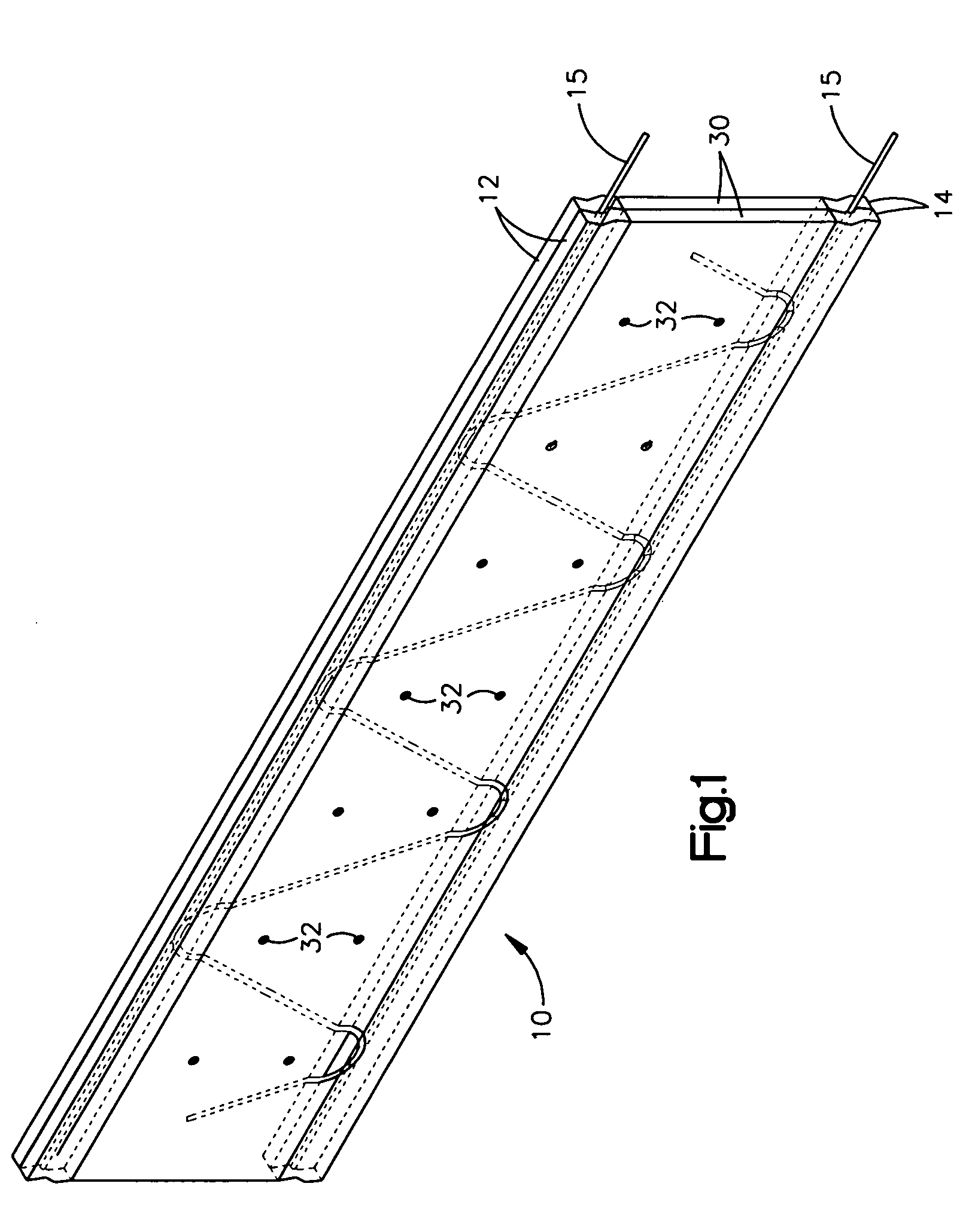

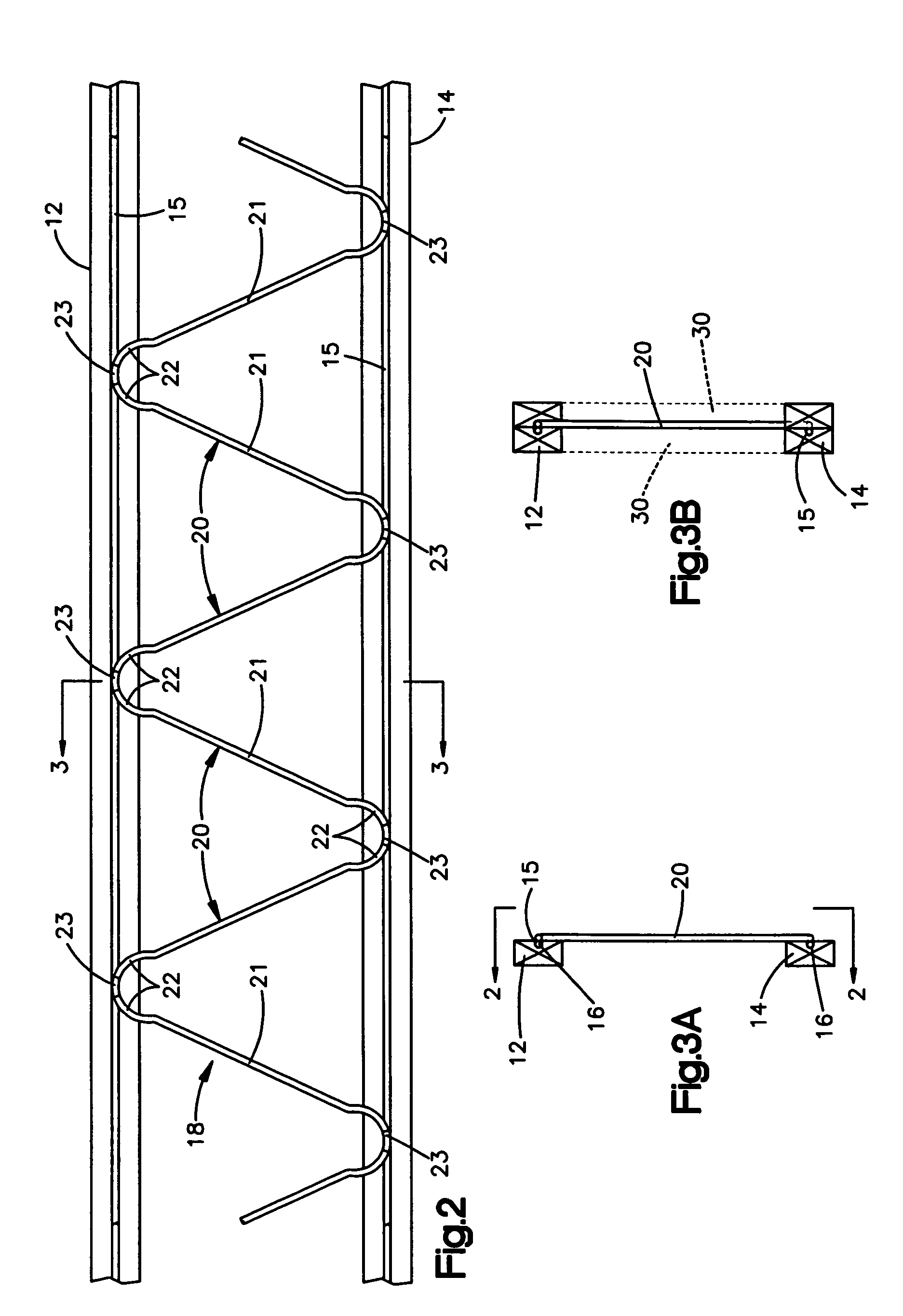

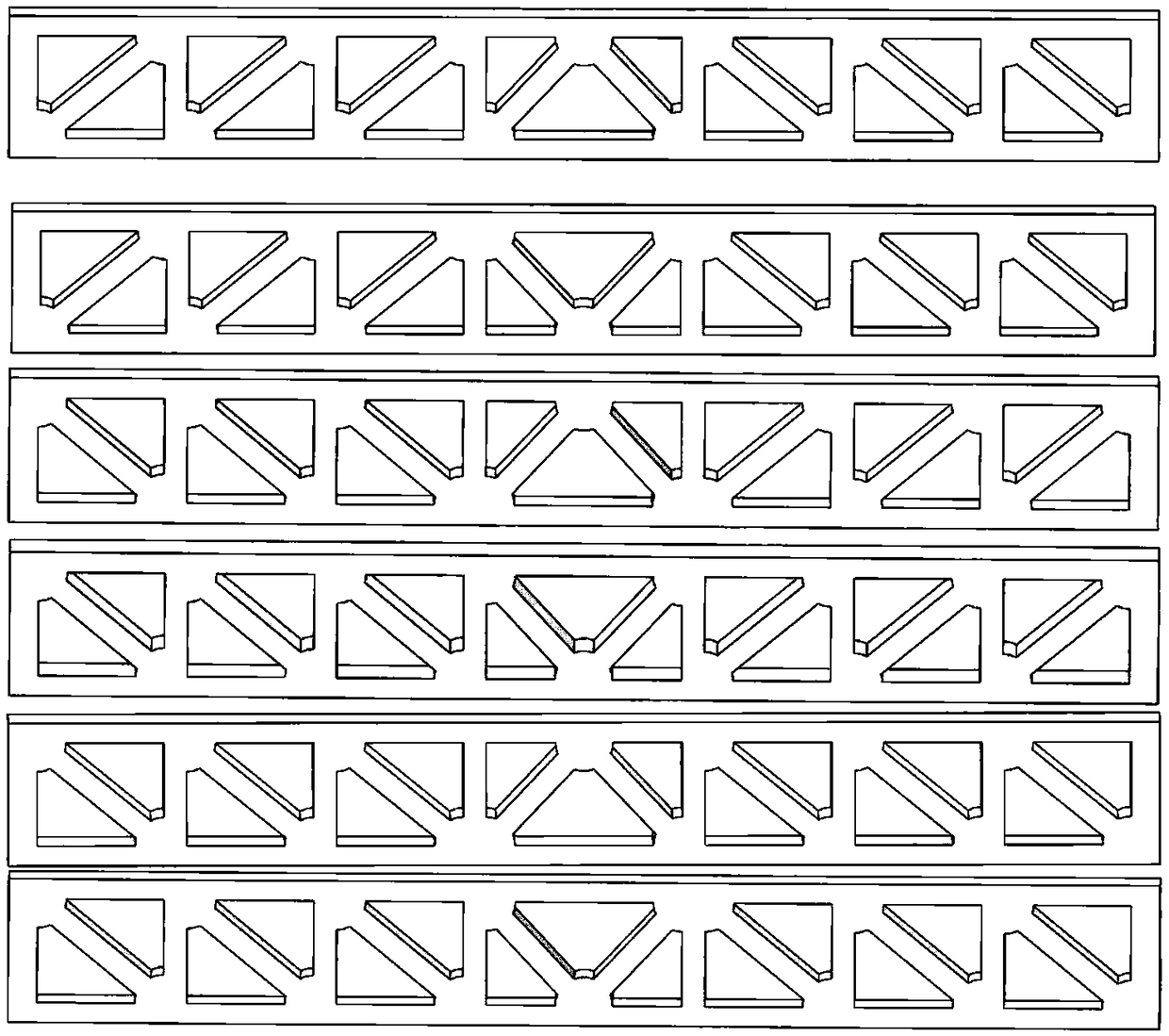

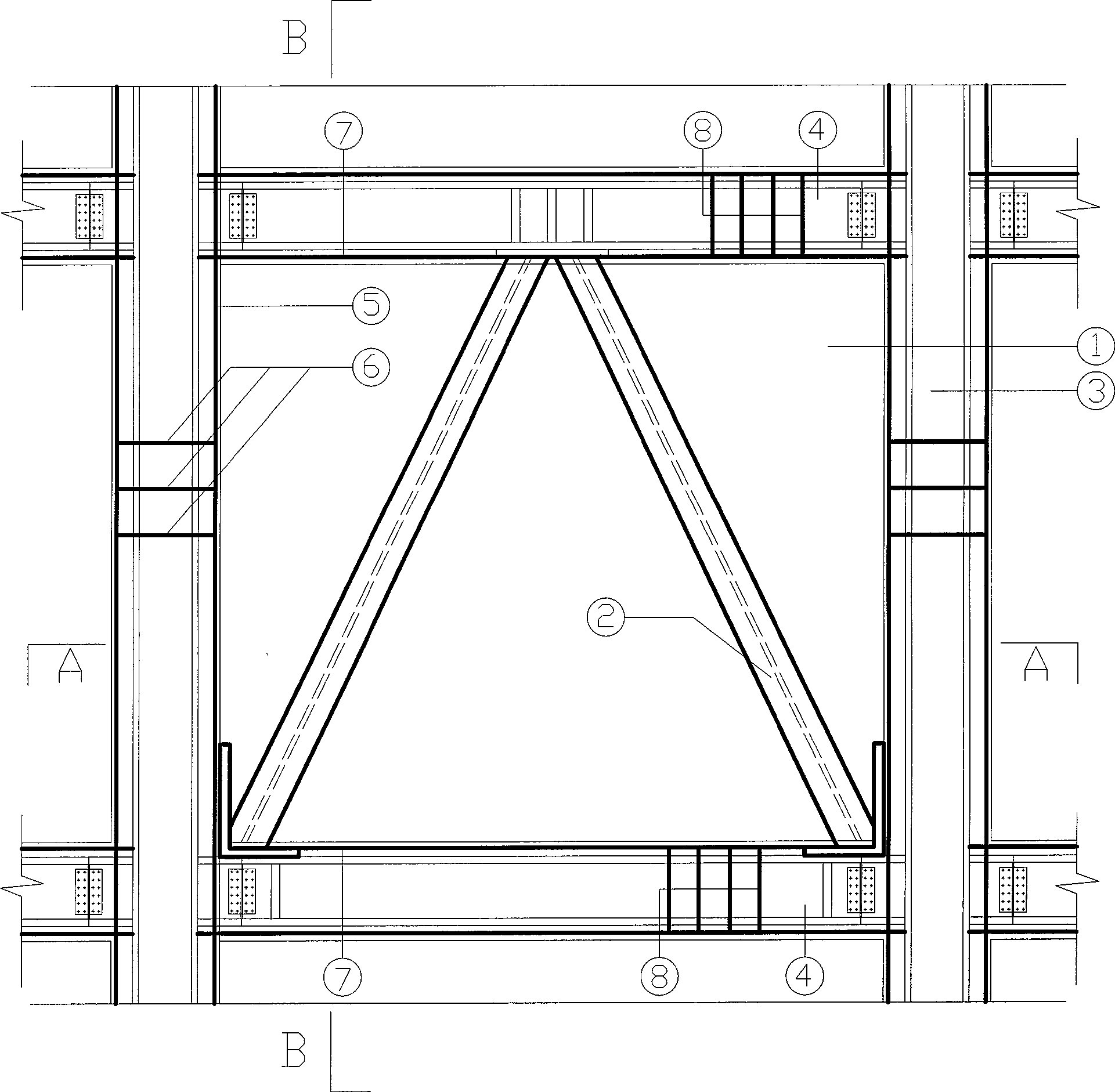

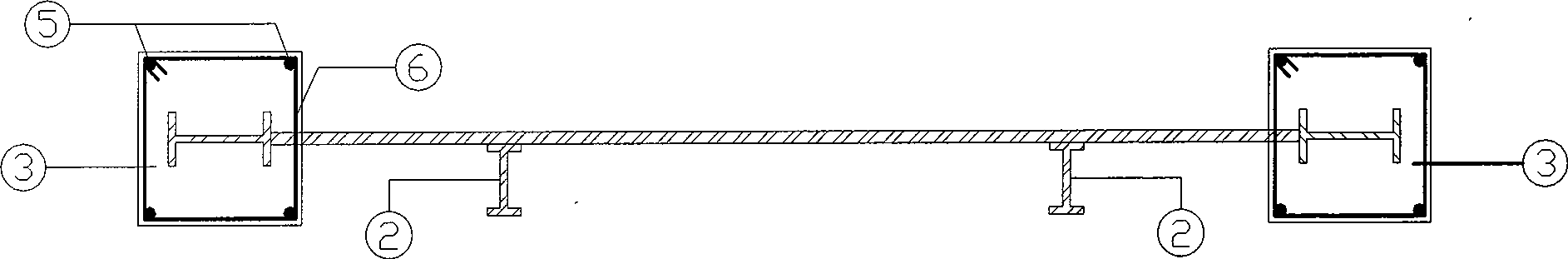

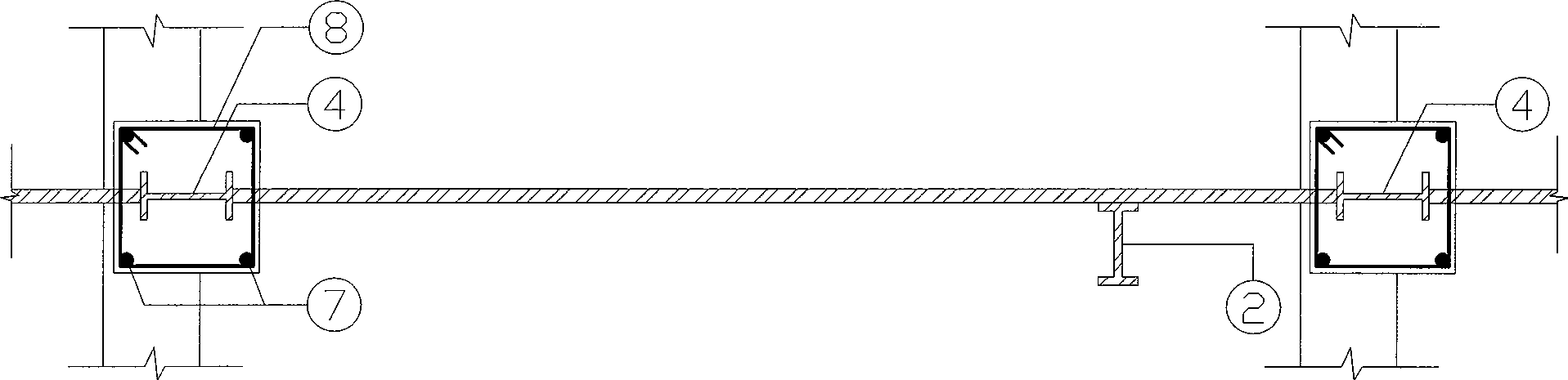

Modular Reinforced Structural Beam and Connecting Member System

InactiveUS20090007520A1Avoid displacementArched girdersBuilding roofsComposite beamsComposite girder

A modular reinforced structural beam and connecting member system that includes at least one composite beam having two oppositely oriented triangular closed head portions and a transversally extending web interposed between said two closed head portions, each of said beams consisting of two separate members arranged such that corresponding head portions of said two members are nested one within the other and adjacent elements of the two members are in mutual stabilizing contact. A plurality of connecting members are connected to, and are in force transmitting contact with, one of the composite beams and another structural element.

Owner:NAVON RAM

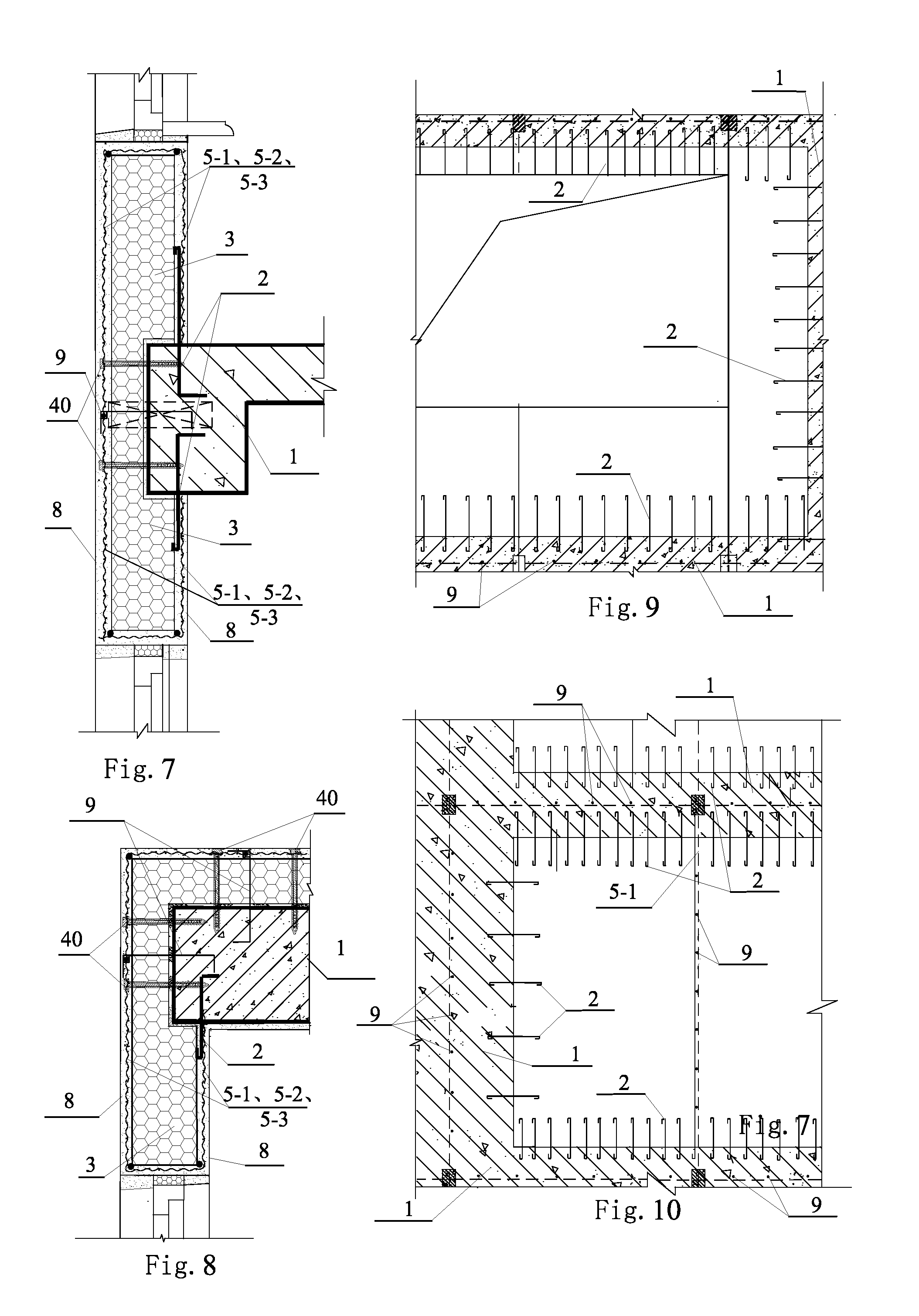

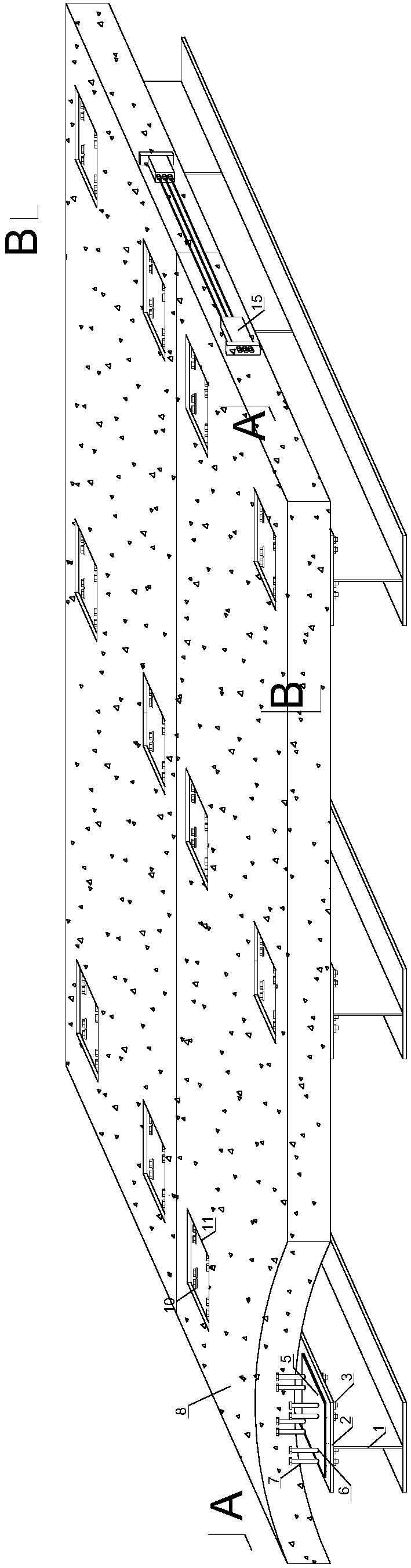

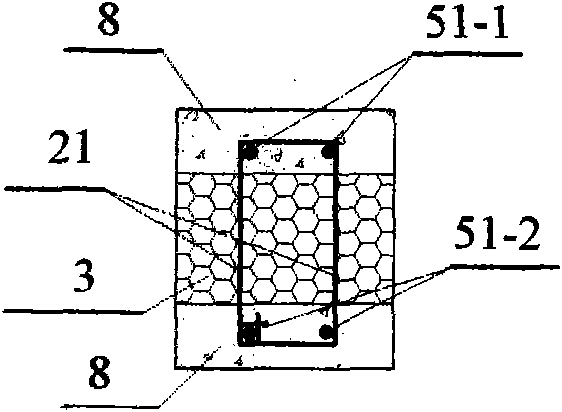

Composite Thermal Insulation Wall Body of a Building

InactiveUS20110258964A1Decreasing total construction weightImprove performanceWallsHeat proofingThermal insulationArchitectural engineering

A composite thermal insulation member of building is provided. It relates to the composite thermal insulation member of the building, especially the composite thermal insulation wall body and the composite roof aimed to solve the problem of high cost of the existing energy-saving wall body and the inconvenience of construction, the first structure is the core layer bonded inside the frame with the outer protecting layer provided on the surface of the core layer and the alkali-resistant netting fabric bonded to the outer protecting layer and the load-carrying component, the second structure is the core layer provided between the indoor and outdoor outer protecting layers and bonded each other, also the steel hoop fixed with the steel bars inside the indoor and outdoor outer protecting layers, the third structure is the outer protecting layer provided on two sides of the core layer and its upper side and bonded to it, also the core layer and the steel bars arranged inside the outer protecting layer as well as the outer protecting layer wrapped and surrounded by the alkali-resistant netting fabric, the fourth structure is the composite pillar anchored to the main structure and the core layer bonded to the main structure and the light composite pillar with the composite girder supported on the composite pillar and the plastered outer protecting layer on the composite pillar, composite girder and the outer side of the core layer, the fifth structure is the core layer provided between the upper and lower outer protecting layers with the lower outer protecting layer fixed to the girder or wall of the main structure, the invention has the advantages of low cost, convenience of construction etc. which is beneficial to the energy-saving of the construction and the reform of the wall body.

Owner:WU SHUHUAN

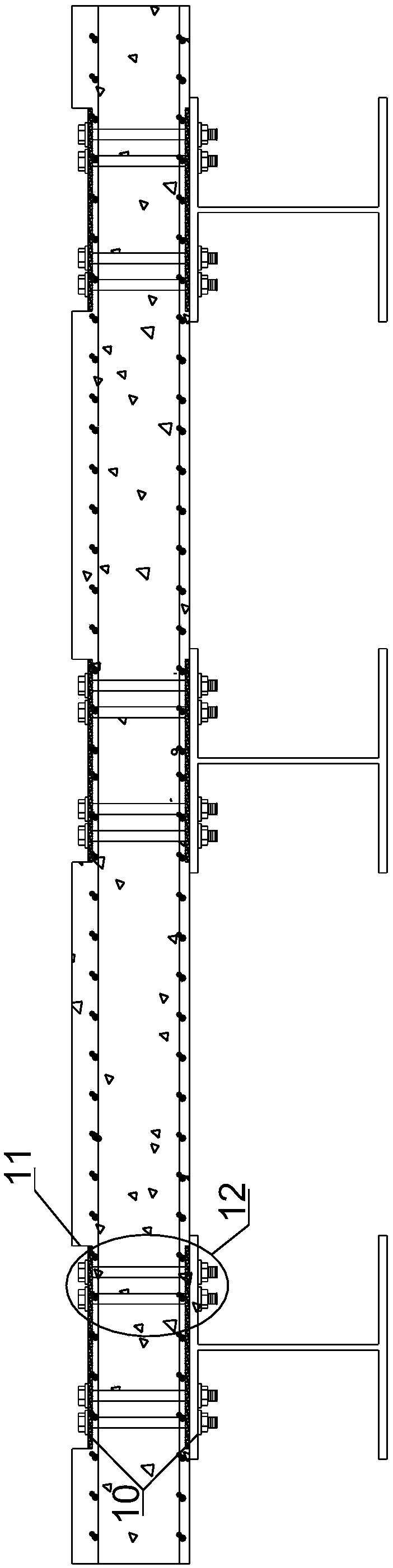

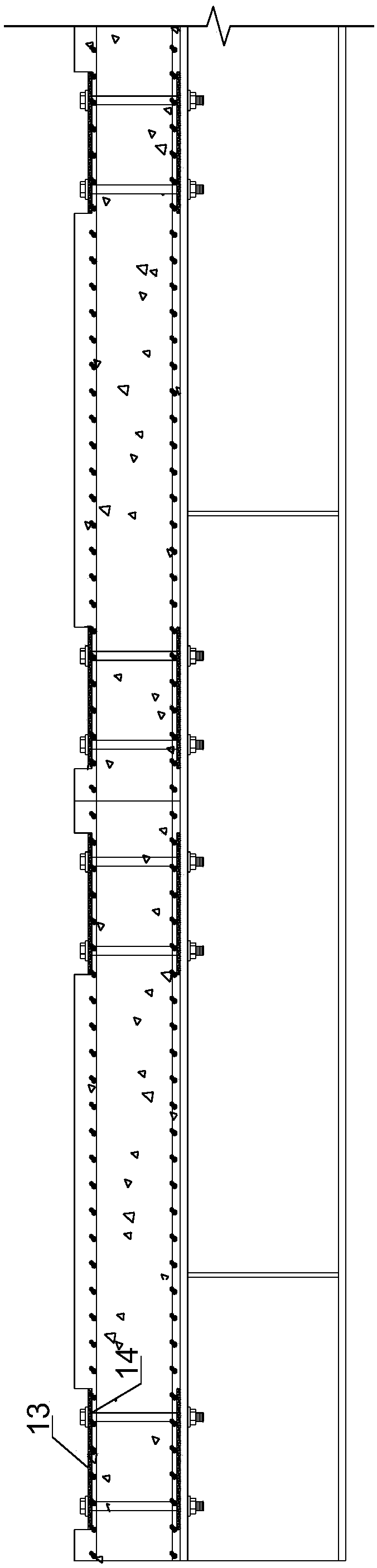

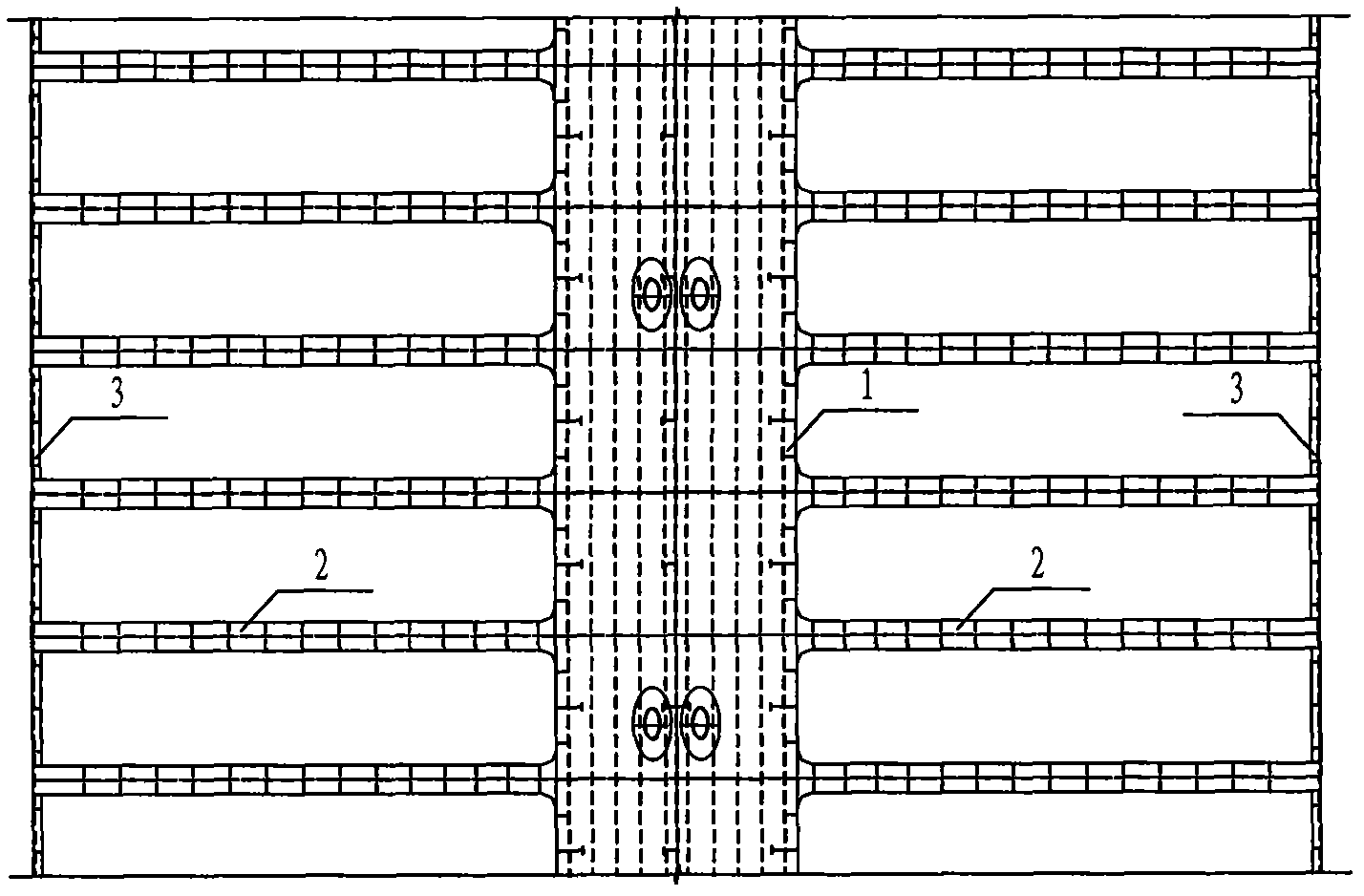

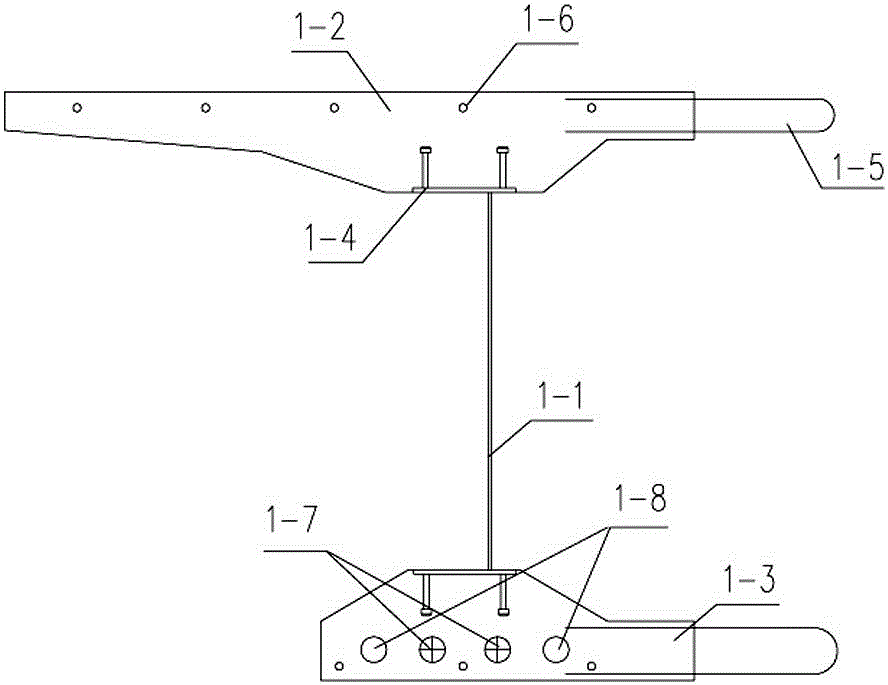

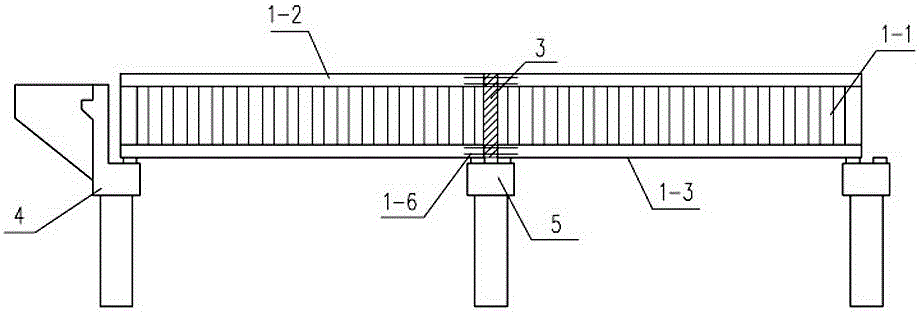

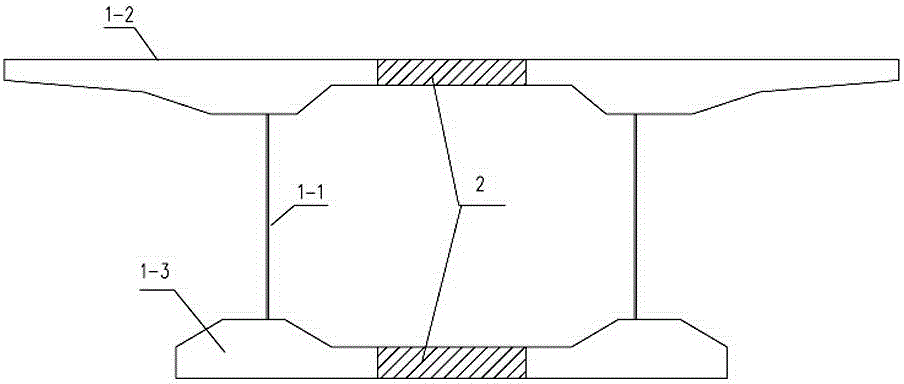

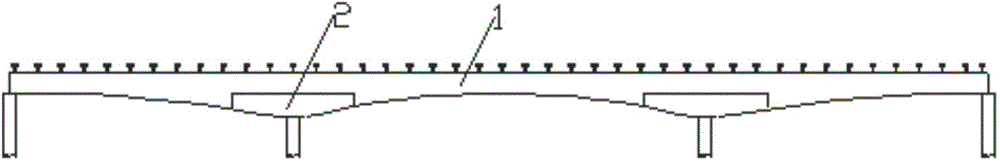

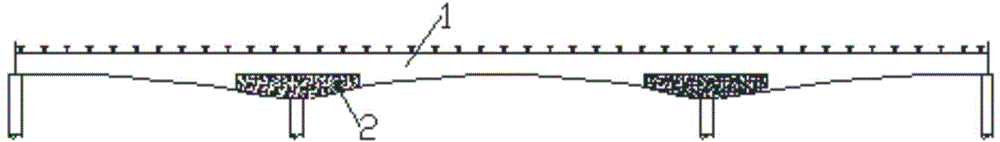

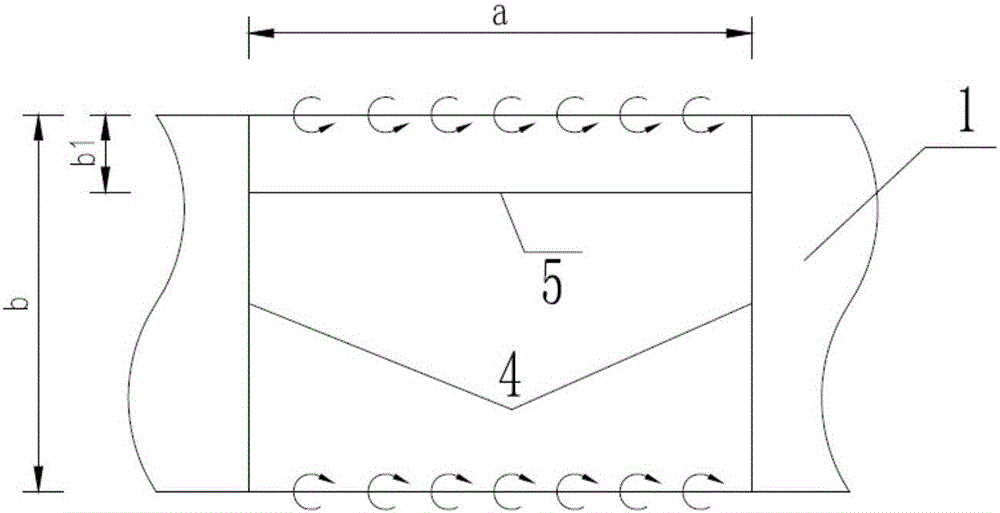

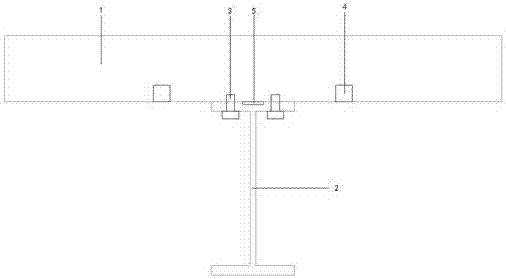

Replaceable prefabricated combined beam structure and manufacturing process

ActiveCN106835951AAvoid fatigue life reduction, residual stress and other problemsEasy constructionBridge structural detailsBridge erection/assemblyPre stressEngineering

The invention relates to a replaceable prefabricated combined beam structure which comprises a steel beam, prefabricated concrete plates and high strength bolt connectors. The prefabricated concrete plates are located on upper wing edge plates which are parallelly arranged on the steel beam, and adjacent prefabricated concrete plates in a span direction are connected through an external prestressing tendon; lower holes corresponding to the high strength bolt connectors are formed in the upper wing edge plates of the steel beam, reserved holes corresponding to the connectors are formed in the prefabricated concrete plate, and the high strength bolt connectors are connected through the reserved holes and the lower holes from top to bottom. The invention also provides a manufacturing process of the replaceable prefabricated combined beam structure. The invention provides the replaceable prefabricated combined beam structure which is simple to construct and relatively high in assembling efficiency, and the manufacturing process.

Owner:宁波联合龙门重工钢构有限公司

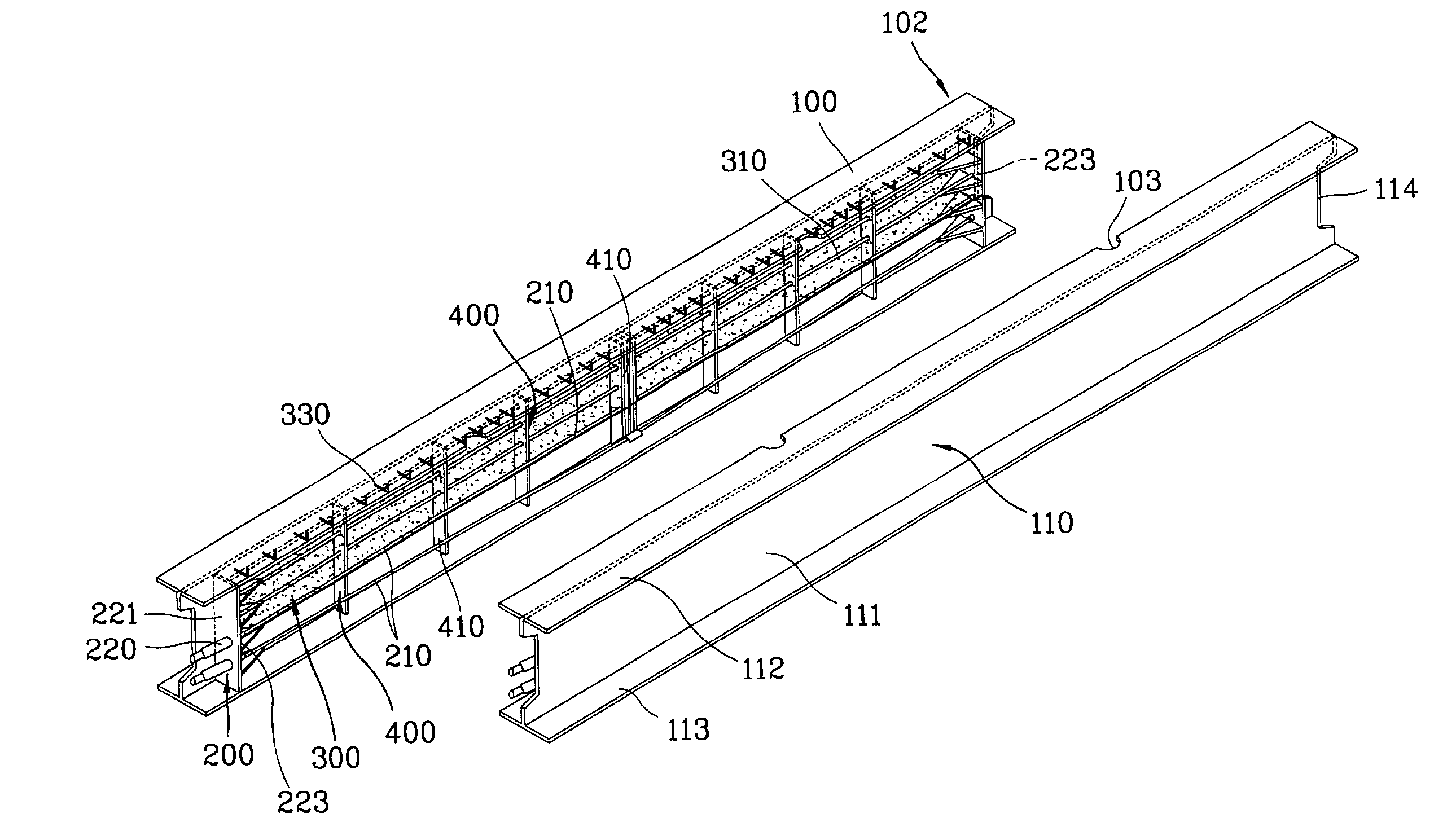

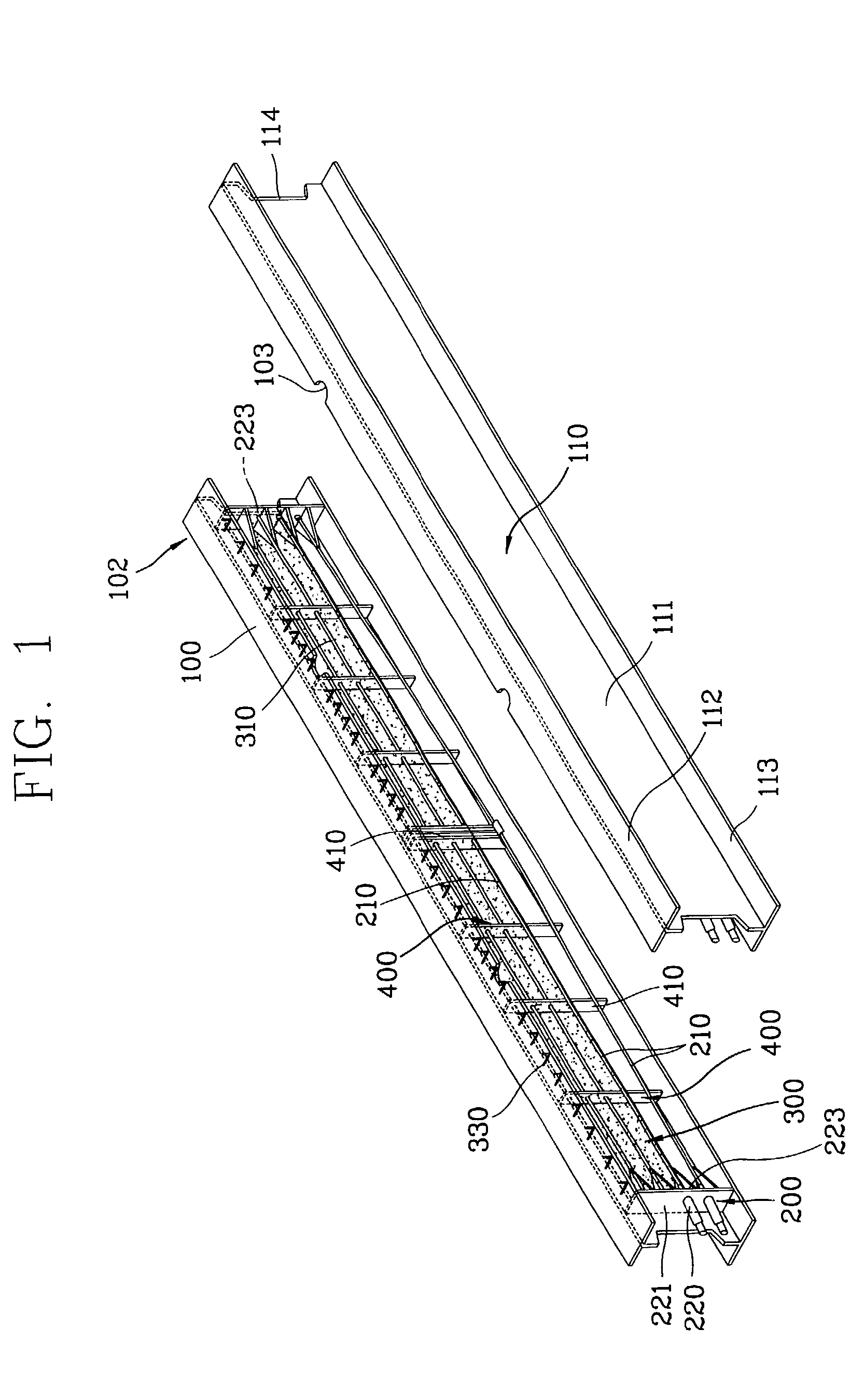

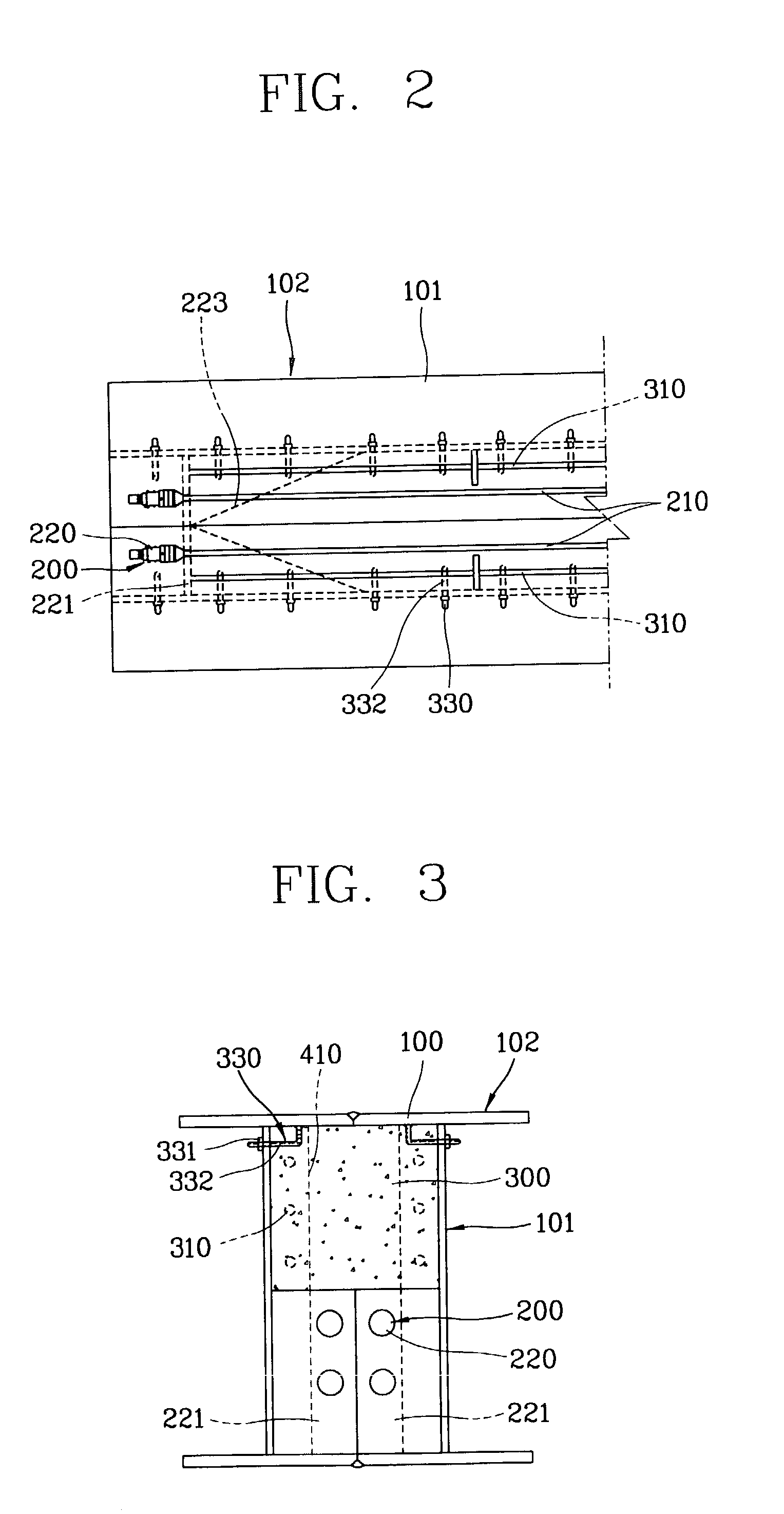

PSSC complex girder

Owner:PARK JAE MAN

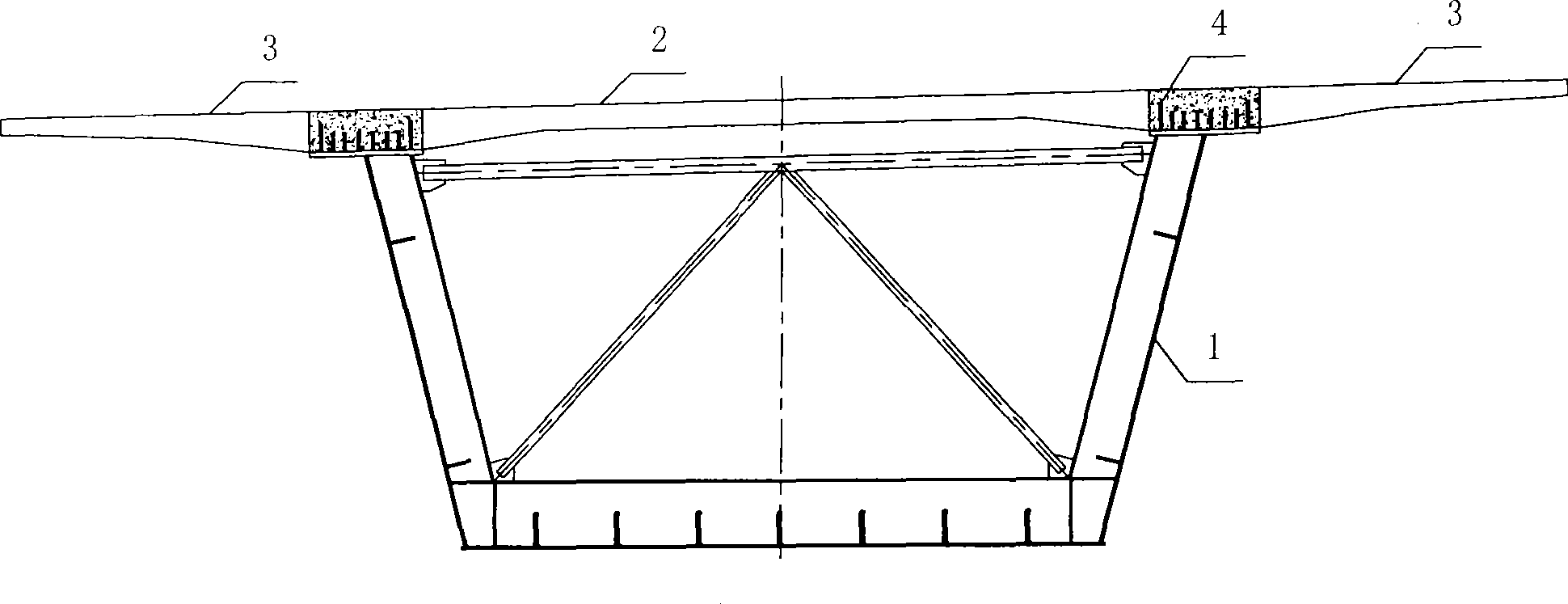

Main girder of steel box composite girder with long cantilever arms for single-plane cable stayed bridge

InactiveCN102094385AReduce horizontal sizeSolve the torsion problemCable-stayed bridgeBridge structural detailsCable stayedBridge deck

The invention relates to a main girder of a steel box composite girder with long cantilever arms for a single-plane cable stayed bridge. The two sides of a steel box girder in the middle of the main girder are respectively provided with a steel cantilever arm, and the steel box girder and the steel cantilever arms are connected by high strength bolts in bolting and welding modes; and the end part of each steel cantilever arm is provided with a longitudinal side beam, the tops of the steel box girder and the steel cantilever arms are paved with concrete bridge decks or cast-in-situ bridge decks, traffic lanes are arranged on the steel cantilever arms, the steel box girder is in a single-box single-chamber structure or multi-chamber structure, and a steel anchor box is arranged at the anchor point of a stayed cable. By adopting the steel box composite girder with long cantilever arms, the stress problems of the main girder, such as the torsion resistance and the like of the single-plane cable stayed bridge, are solved, and the horizontal dimension of the main girder is reduced; the main girder can be transported to the bridge location to carry out erection and installation, thereby solving the problem that the sectional dimension of the appearance is limited; and because most of the components of the main girder are prefabricated ones, the in-situ workload is reduced, and the construction quality and construction period can be effectively guaranteed. The main girder provided by the invention is specially adapted to the construction conditions in severe cold districts, for example, the main girder is applied to the construction of the Wusu Bridge in HeiXiazi Island of Heilongjiang Province, and achieves a good application effect.

Owner:ZHONGTIE MAJOR BRIDGE RECONNAISSANCE & DESIGN INST

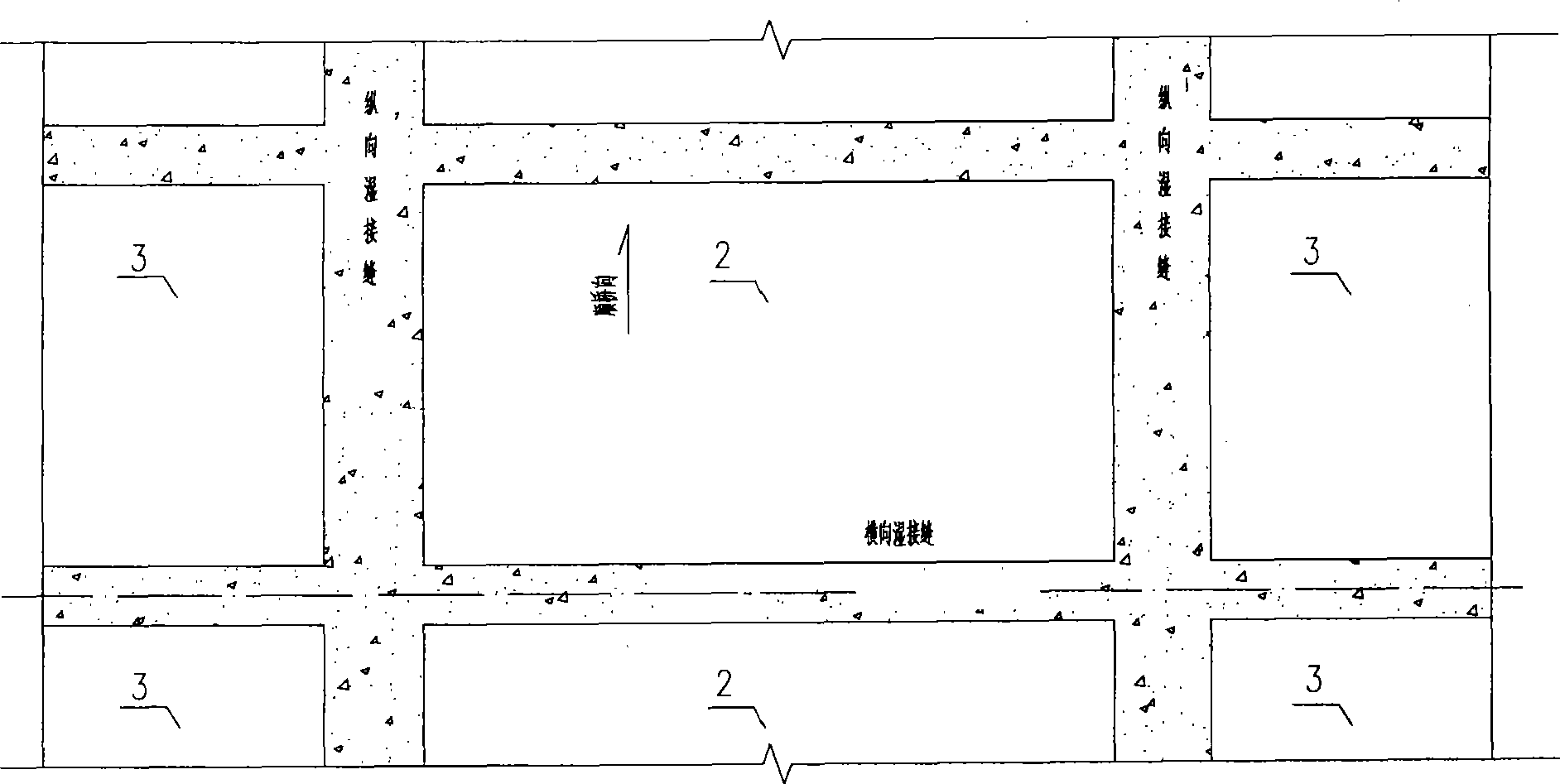

Secondary tensioning prestressed assembly-type corrugated steel web composite beam and construction method thereof

ActiveCN104988844AReduce back archImprove erection accuracyBridge structural detailsBridge erection/assemblyReinforced concretePre stress

The invention discloses a secondary tensioning prestressed assembly-type corrugated steel web composite beam. The composite beam comprises a composite beam unit which is formed in a way that a plurality of prefabricated corrugated steel web beam bodies are connected, each prefabricated corrugated steel web beam body comprises a corrugated steel web, a concrete top plate and a concrete base plate, the concrete top plate is connected with the corrugated steel web through an upper connecting piece, and the concrete base plate is connected with the corrugated steel web through a lower connecting piece; the transverse connecting end of each of the concrete top plate and the concrete base plate is provided with a transverse connecting steel bar, vertical connecting steel bars are arranged in the concrete top plate and the concrete base plate in balance, primary tensioning prestressed channels and secondary tensioning prestressed channels are arranged in the concrete base plate symmetrically, primary tensioning prestressed steel beams are arranged in the primary tensioning prestressed channels in a penetrating manner, and secondary tensioning prestressed steel beams are arranged in the secondary tensioning prestressed channels in a penetrating manner. The invention also provides a construction method of the composite beam. According to the invention, the prestressed steel beams are tensioned twice, inflected arch phenomena, of the prefabricated corrugated steel web beam bodies, caused by concrete shrinkage and creep can be reduced, the erection precision of the bridge is improved, and the usage performance of the prestressed assembly-type corrugated steel web composite beam can be improved.

Owner:HENAN PROVINCIAL COMM PLANNING & DESIGN INST CO LTD +1

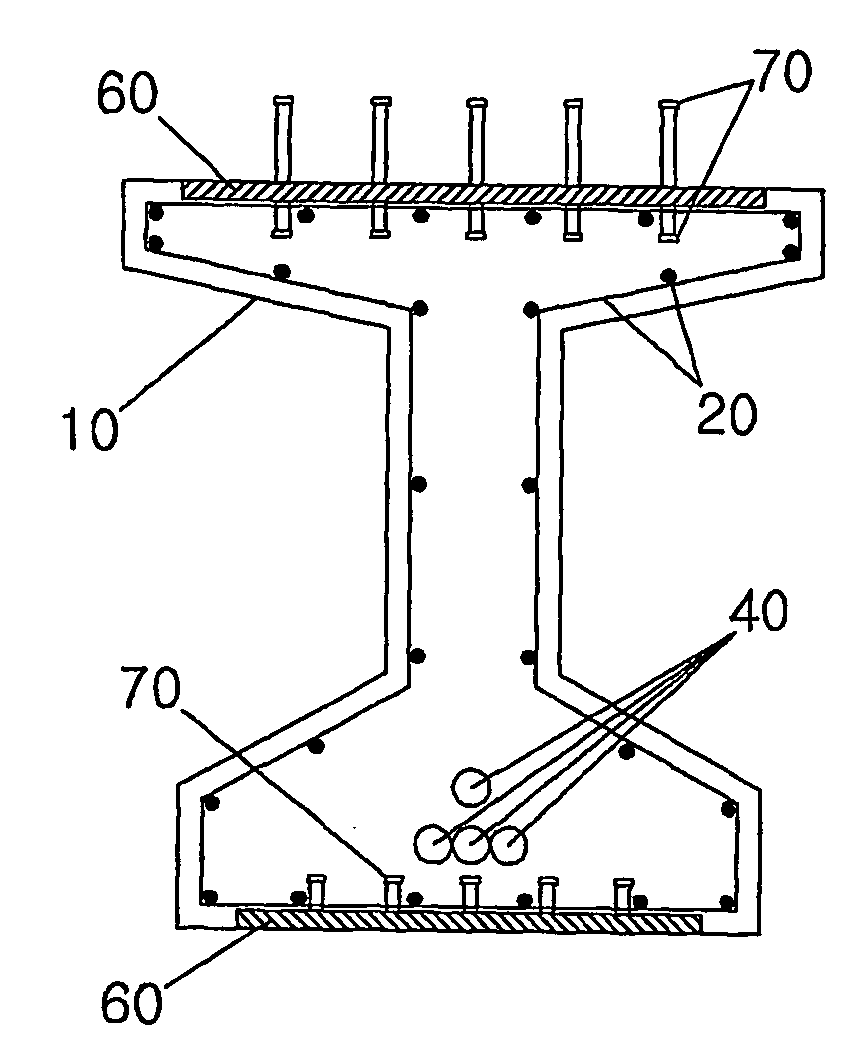

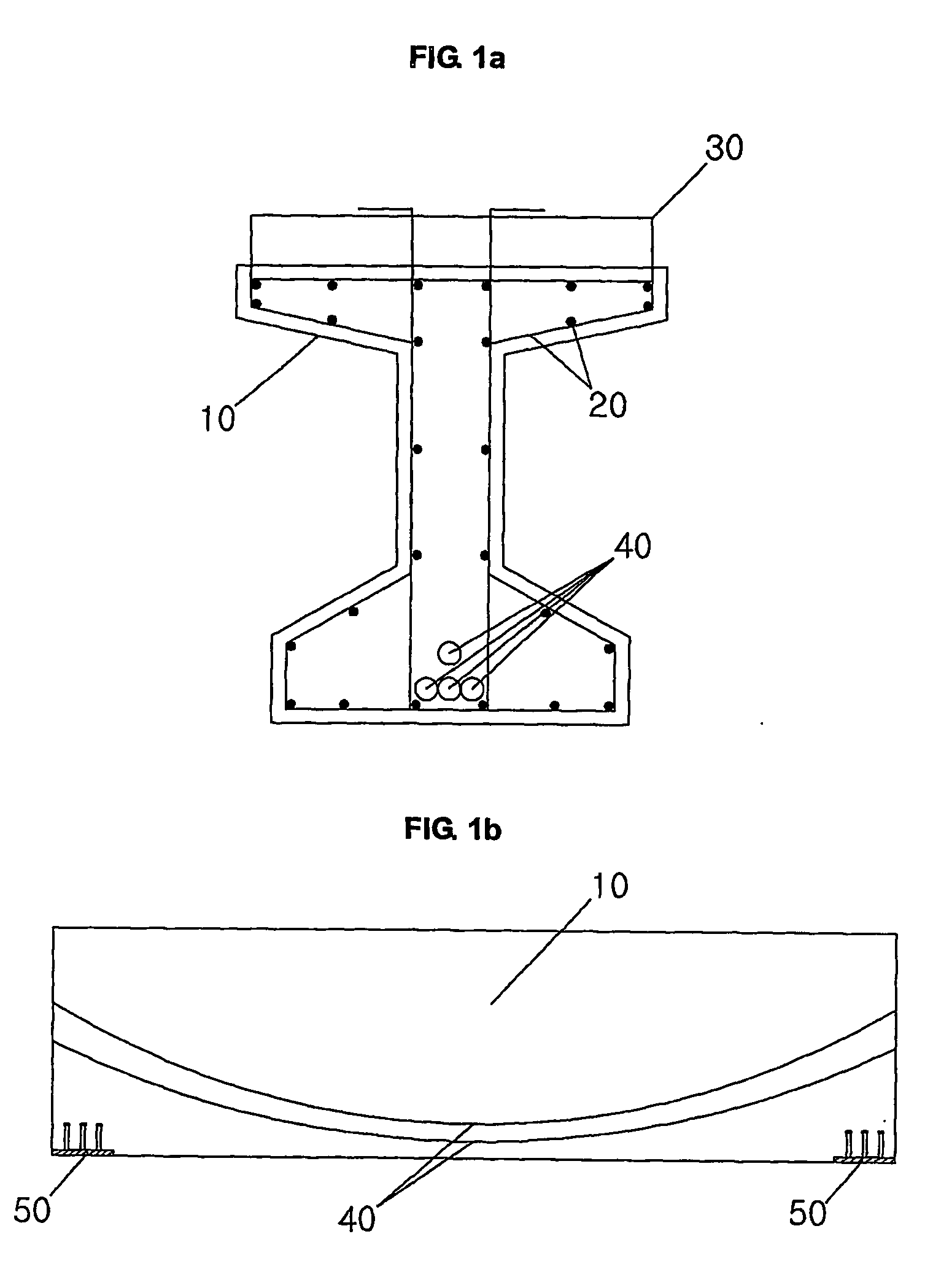

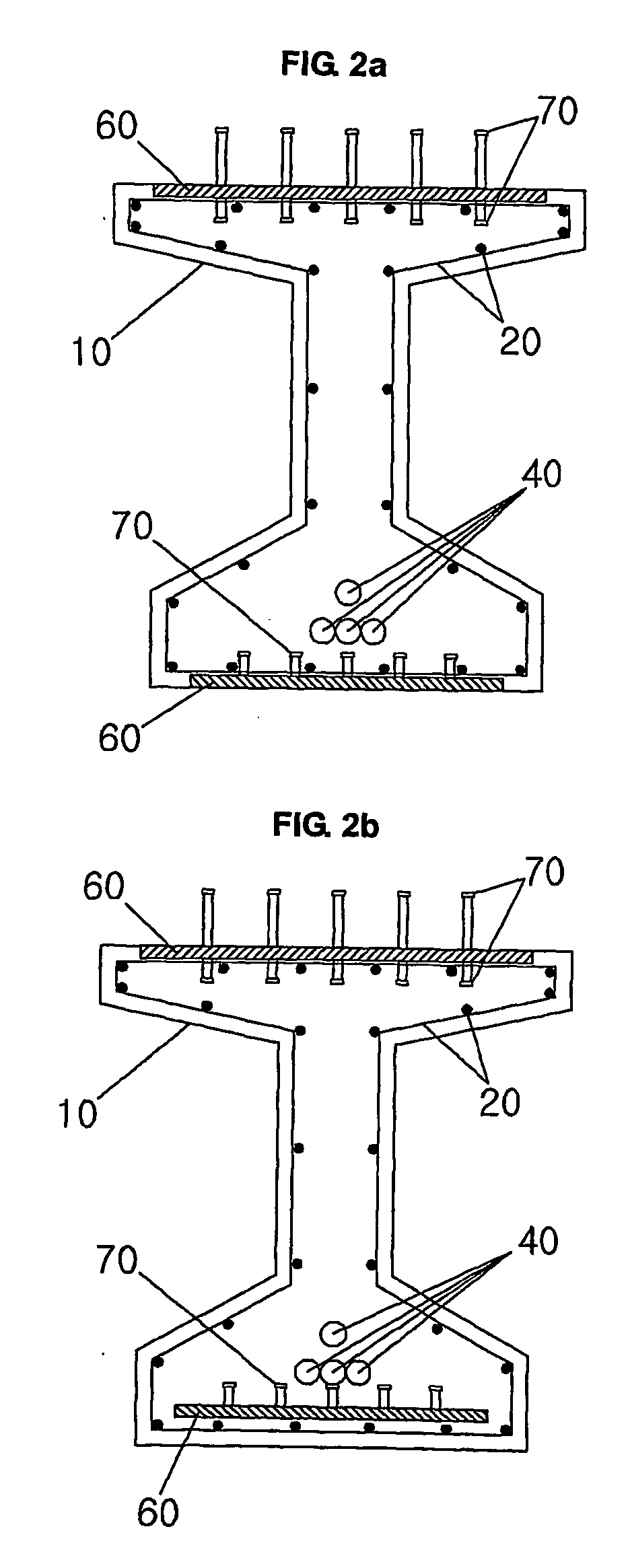

Prestressed composite girder, continuous prestressed composite girder structure and methods of fabricating and connecting the same

Disclosed herein are a prestressed composite girder with steel plates, a continuous prestressed composite girder structure with steel plates and methods of fabricating and connecting the same. The prestressed composite girder includes shear reinforcing bars and main reinforcing bars, sheaths, sole plates, and steel plates. The shear reinforcing bars and main reinforcing bars are arranged across the prestressed composite girder. The sheaths are adapted to contain steel wires arranged across the prestressed composite girder. The sole plates are placed at ends of the prestressed composite girder and provided with shear connecting members. The steel plates are placed in upper and lower flanges of the prestressed composite girder and provided with shear connecting members.

Owner:KOO MIN SE

Bridge deck and steel girder second combination method for whole arch precasted steel-concrete composite continuous box girder

InactiveCN101424073AAvoid crackingImprove the stress state of the structureBridge erection/assemblyBridge deckEngineering

The invention discloses a method for the secondary combination of a deck slab and a steel girder for an entire hole prefabricated steel-concrete combined continuous box girder, which comprises the following steps: firstly, performing the primary combination of the deck slab and the steel girder for the middle section of a composite girder in a precast field, wherein two ends of the composite girder are not combined with the deck slab; secondly, erecting the composite girder to the top of a bridge site pier through the transportation of a large floating crane, and finishing the concrete casting for a bottom plate of a dual-combination section between composite girder supporting point composite girders by a supporting point roof fall girder method after the composite girder is erected and simple beams are arranged continuously; and thirdly, performing the secondary combination of the deck slab and wet joint seam steel-concrete on the two ends of the composite girder to achieve the secondary combination of the deck slab and the steel girder. The method avoids limitations for the erection of the steel girder of the composite girder by adopting an incremental launching method to construct a large-span composite girder, reduces time-consuming, laborious and costly temporary rest piers to be constructed on a temporary support for segmental hoisting construction, and reduces the cumbersome segmental transportation of the steel girder.

Owner:CHINA MAJOR BRIDGE ENG

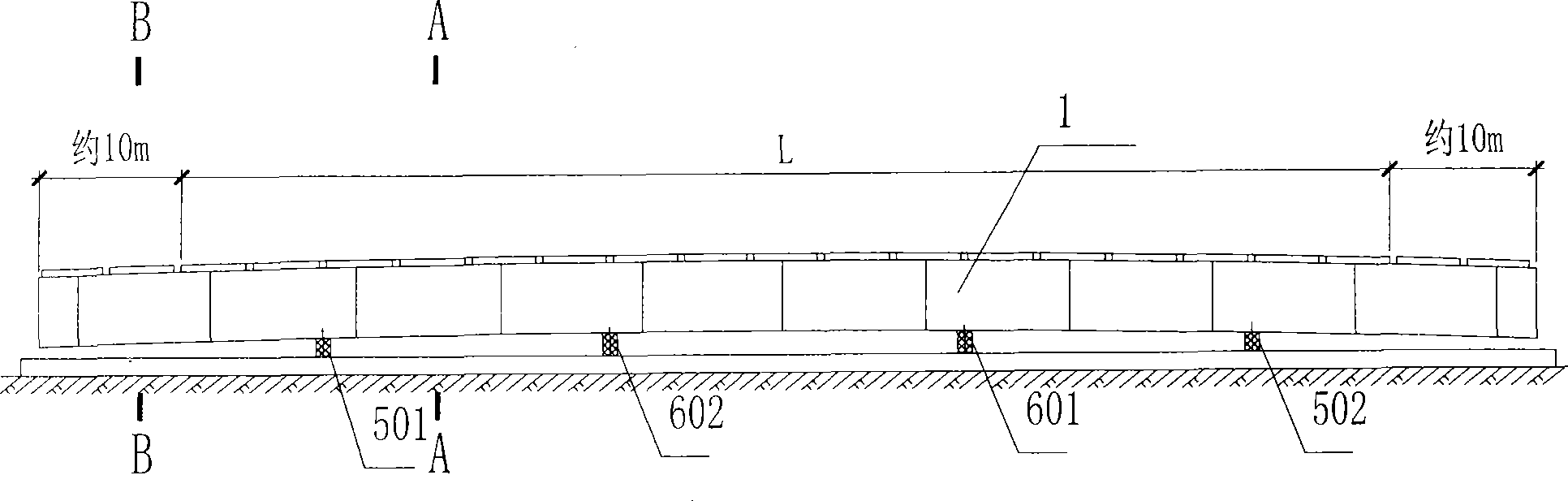

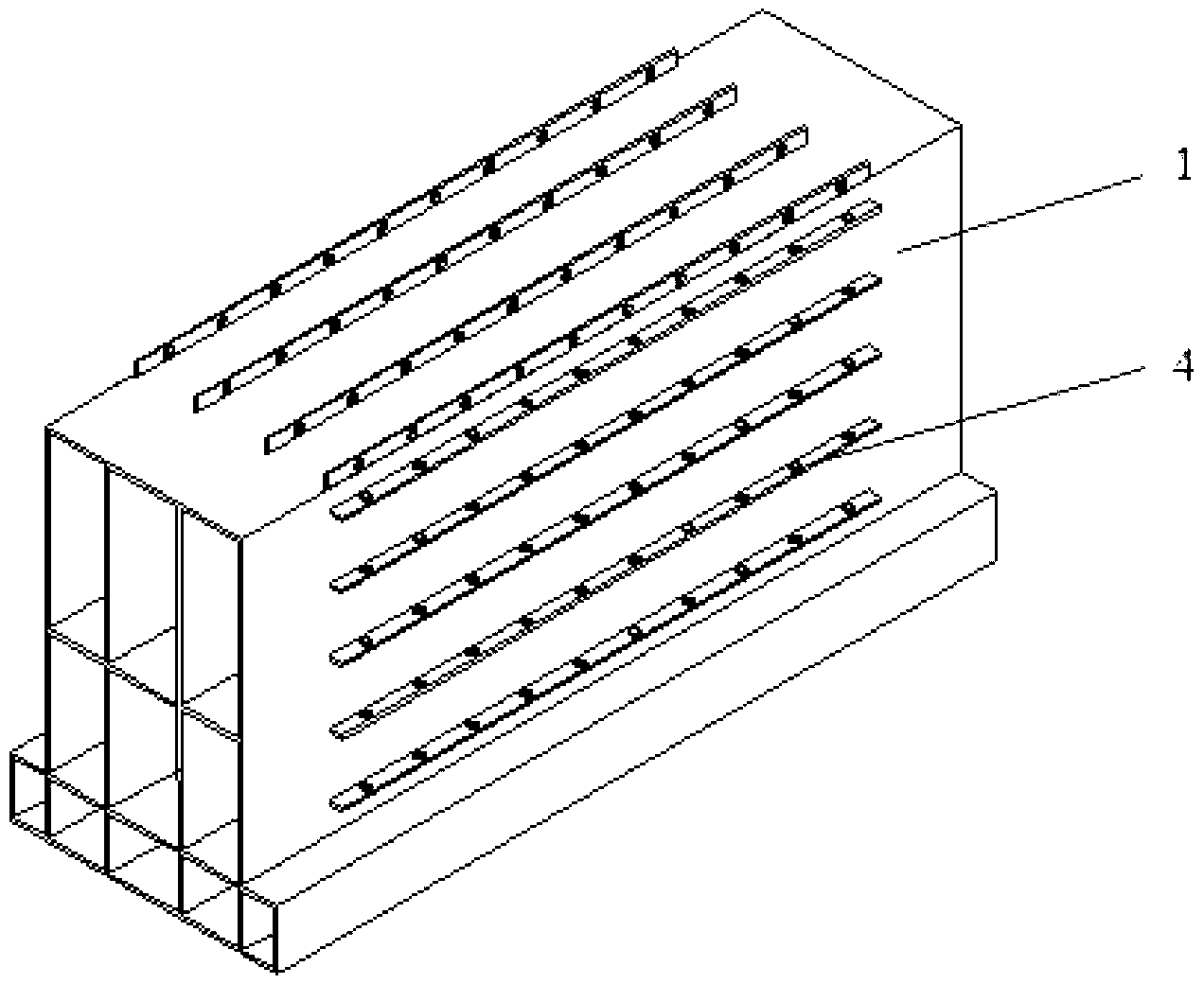

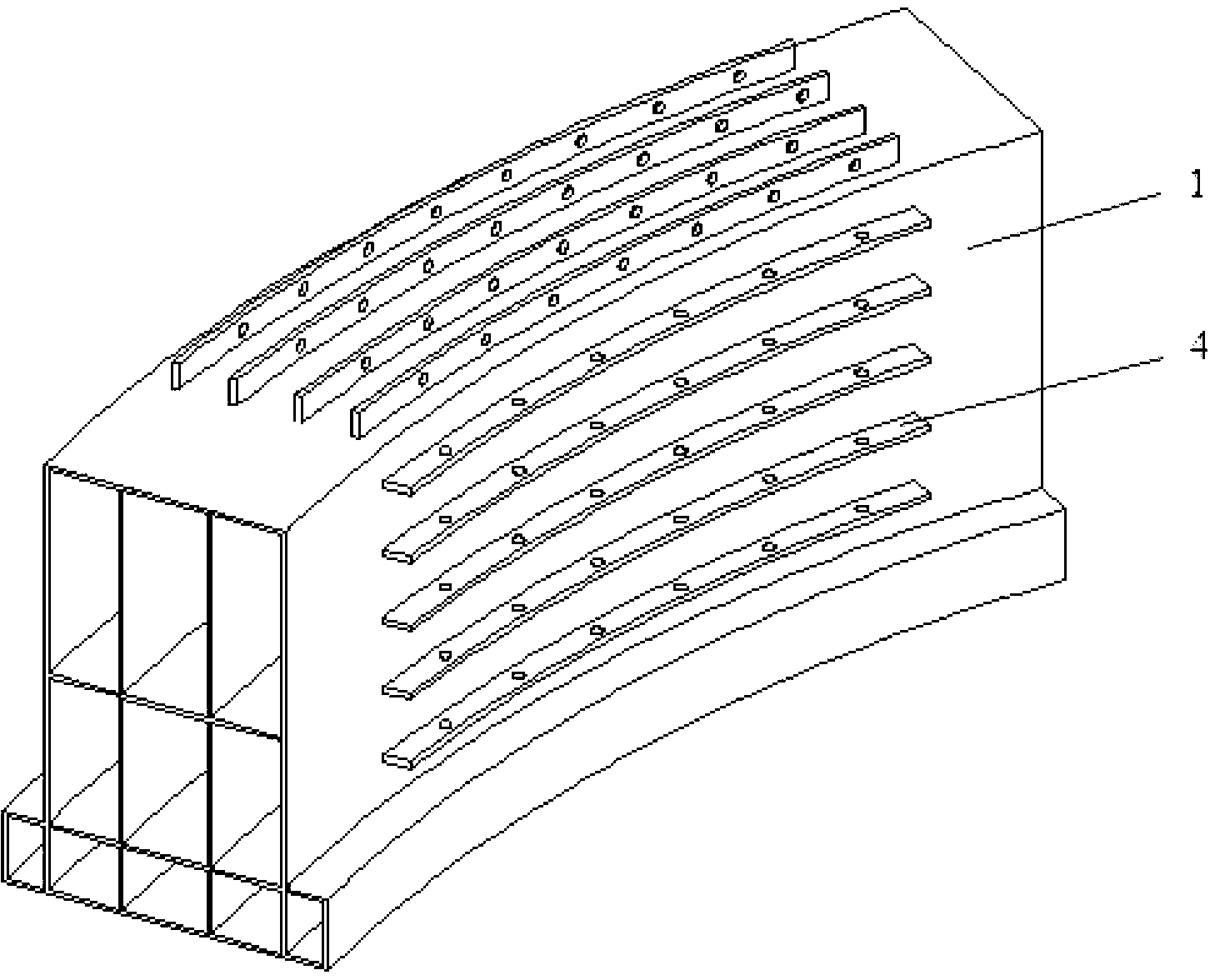

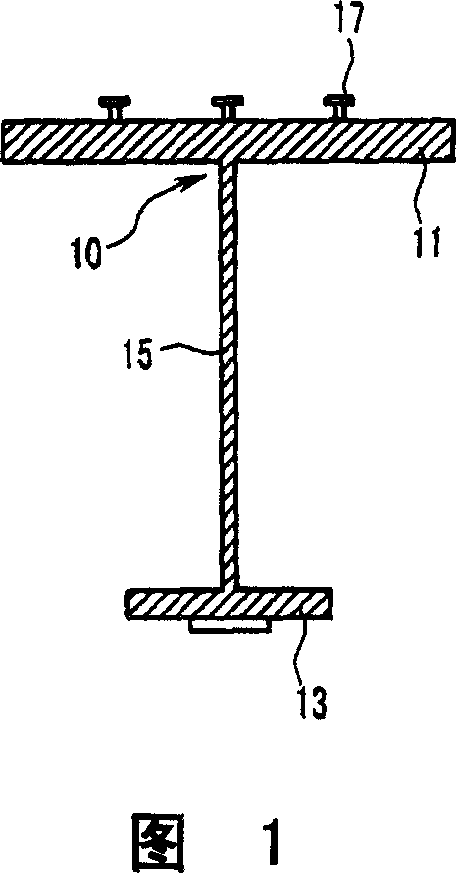

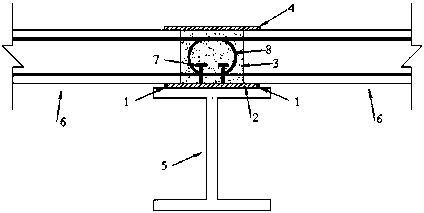

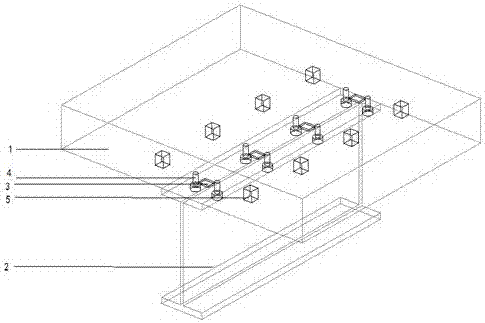

Pretensioned prestressing composite girder and method for producing the same

ActiveCN101418630ASmall beam heightReduce the overall heightLoad-supporting elementsBuilding material handlingShaped beamSheet steel

Provided is a pre-tensioned prestressed composite beam, which is an I-shaped beam composed of H-shaped steel and concrete, the web plate of the H-shaped steel is provided with trapezoidal holes (14) at intervals, the upper flange and the lower flange of the H-shaped steel are welded with shearing nails, the outer periphery of the lower flange is enclosed with concrete to form a steel-concrete lower flange (4), and the inside of the steel-concrete lower flange is embedded with prestressed steel twisted wire by pretensioning method. The manufacturing method of the composite beam is that: a steel plate is cut into two tooth-shaped plates along tooth-shaped line to be respectively as the trapezoidal hole plates of the H-shaped steel flange, the trapezoidal hole plates are welded with steel plates to form the web plate, the web plate is welded with the upper flange and the lower flange to form the H-shaped steel (1) having trapezoidal holes, the H-shaped steel is put on a base surface with the lower flange downward, the two sides of the lower flange are provided with side molds, a stirrup (7) is arranged and steel twisted wires (3) are longitudinally fastened between the two side molds, the steel twisted wire is tensioned to tensioning state, the concrete for enclosing the H-shaped lower flange is poured and tamped between the two side molds, the steel-concrete lower flange (4) is formed after demolding, and the steel twisted wire at tensioning state is loosened after the concrete reached to predetermined strength and is cut off at predetermined position. The invention is suitable for beams of buildings.

Owner:杨峰

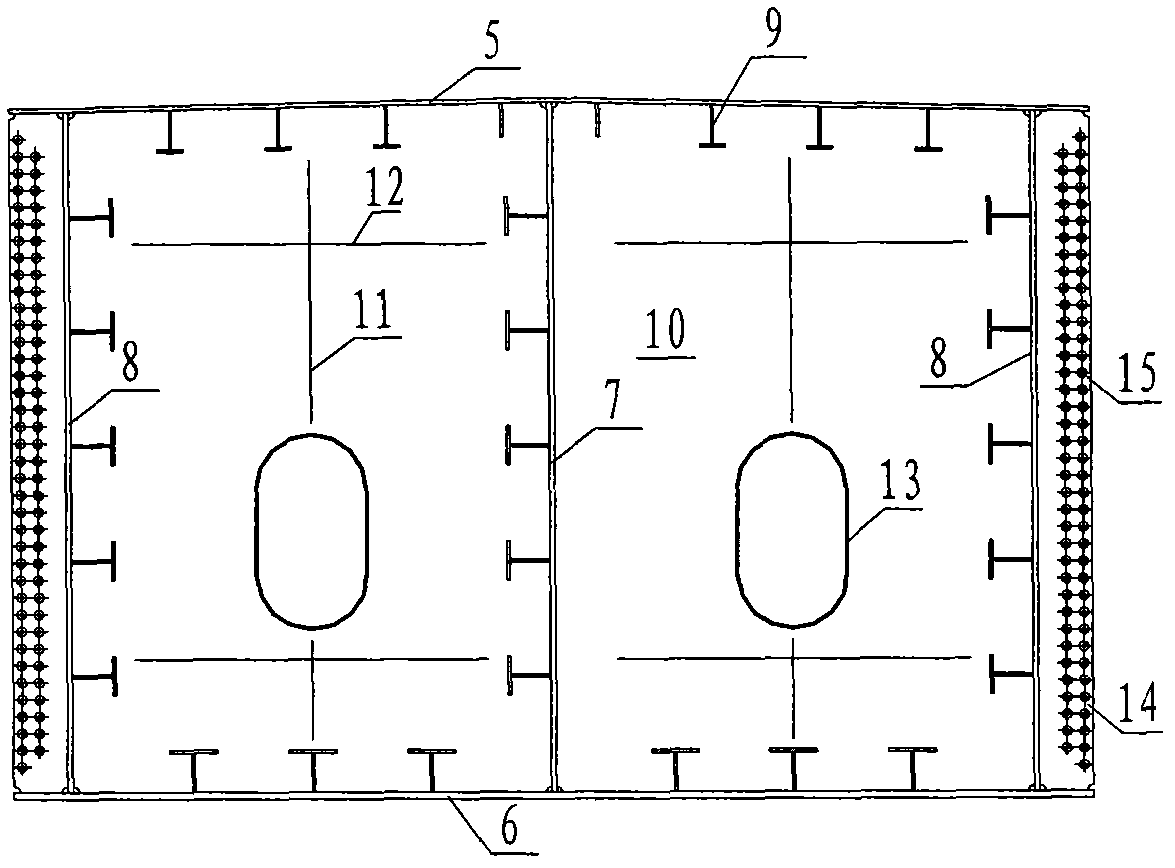

Novel short segment steel box-concrete combined beam

The invention relates to a novel short segment steel box-concrete combined beam, which belongs to the technical field of bridge engineering. The novel short segment steel box-concrete combined beam comprises a steel box beam, anti-shearing connecting elements (4) and three-side outer covering reinforced concrete structures, wherein the steel box beam is formed by short segment steel boxes (1) through split joint via split joint plates (2), the anti-shearing connecting elements (4) are arranged on the two side surfaces and the top surface of the steel box beam, the three-side outer covering reinforced concrete structures consist of concrete (3), vertical steel bars and transverse steel bars and are arranged on the two side surfaces and the top surface of the steel box beam. The novel short segment steel box-concrete combined beam has the beneficial effects that the steel box-concrete combined beam is adopted, the tensile performance of the steel boxes and the pressing resistance performance of the concrete are sufficiently utilized, the steel materials are saved, the cost is reduced, and the obvious economic performance is realized. The steel box beam adopts the segment split joint, the short segment steel boxes and the split joint plates can realize the mass production, the construction progress is fast, and the construction period is short. The combined beam adopts the three-side outer covering reinforced concrete, and adapts to the characteristic of variation of the straddle type monorail traffic rail beam line change, i.e. the three-side stress and line type variation requirement is met.

Owner:BEIJING JIAOTONG UNIV

Modular structural composite beam

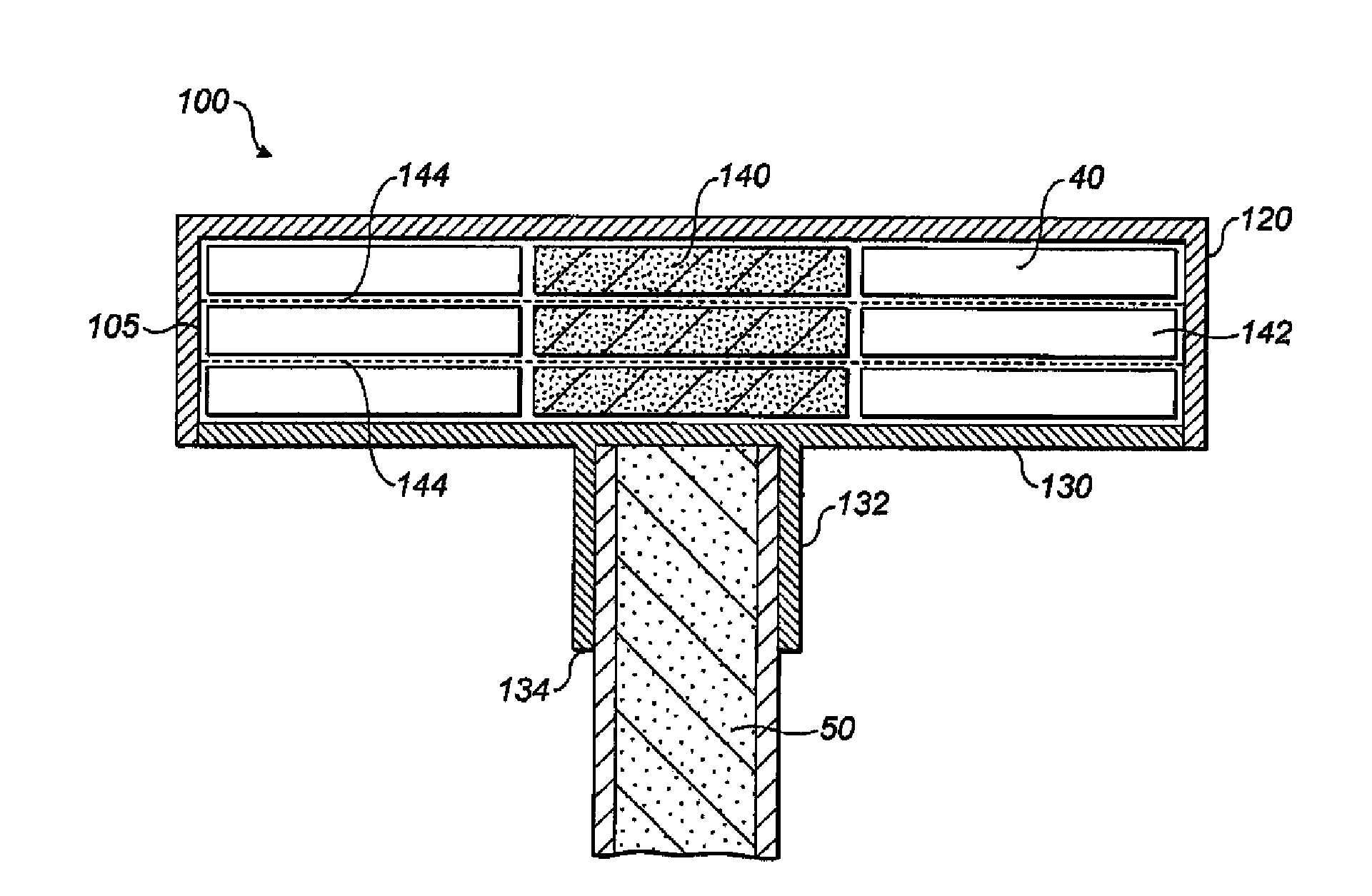

ActiveUS20130340385A1Increase flexibilityQuality improvementFinal product manufactureMachines/enginesFiberEngineering

A modular fibre reinforced plastic flange for a structural composite beam which comprises a body formed of a plurality of elongate elements arranged in an array, wherein the dimensions of the body are substantially determined by the number and arrangement of the elongate elements in the array, and a skin member at least partially surrounding the array. Also, a structural composite beam comprising the modular fibre reinforced plastic flange and a shear web connected to the skin member of the modular flange. A method of making the modular flange and beams, and a kit of parts for making the modular flange are also disclosed.

Owner:BLADE DYNAMICS LTD

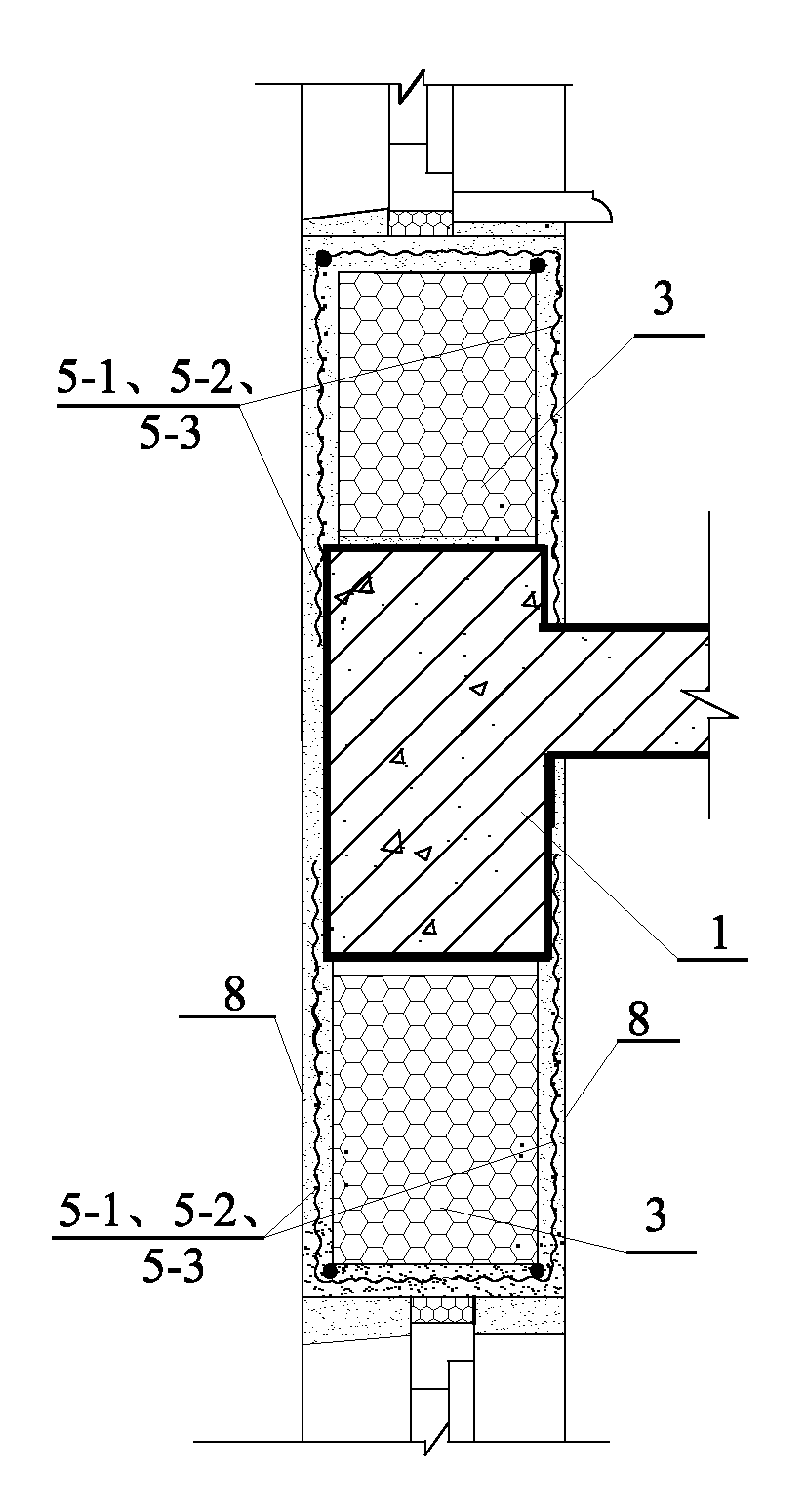

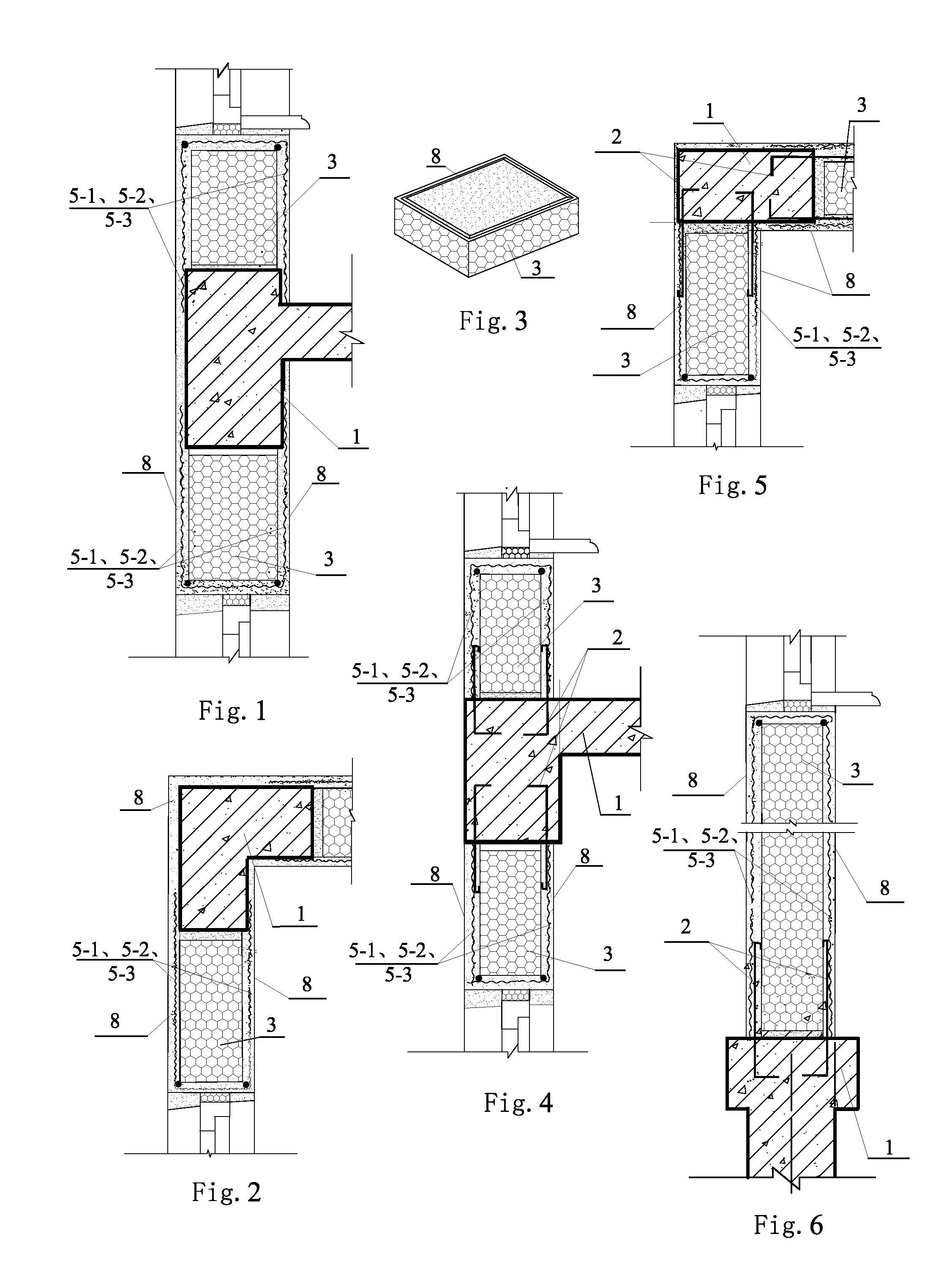

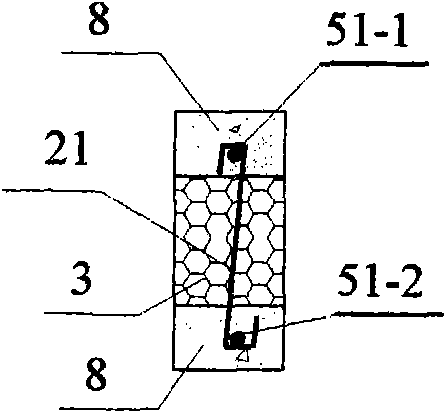

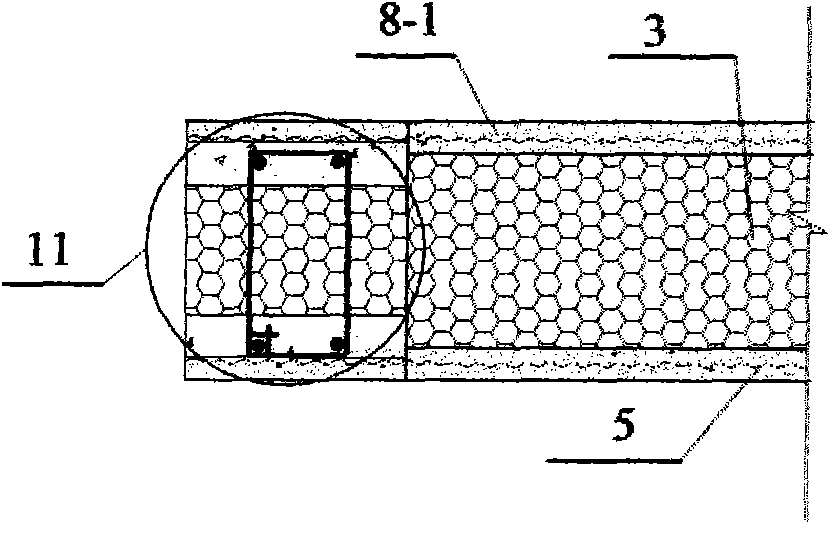

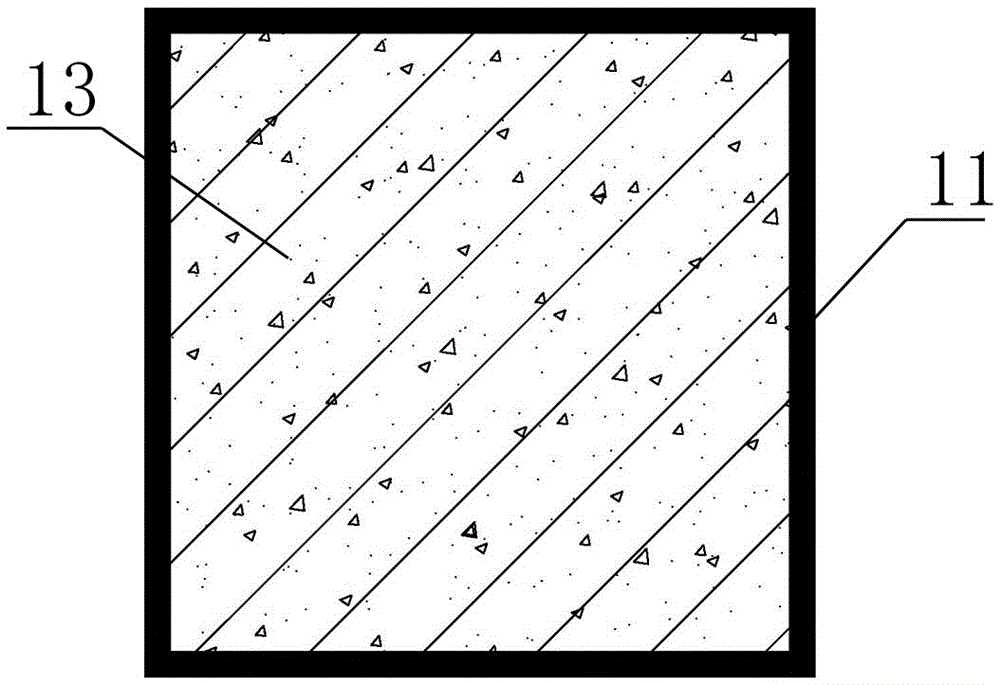

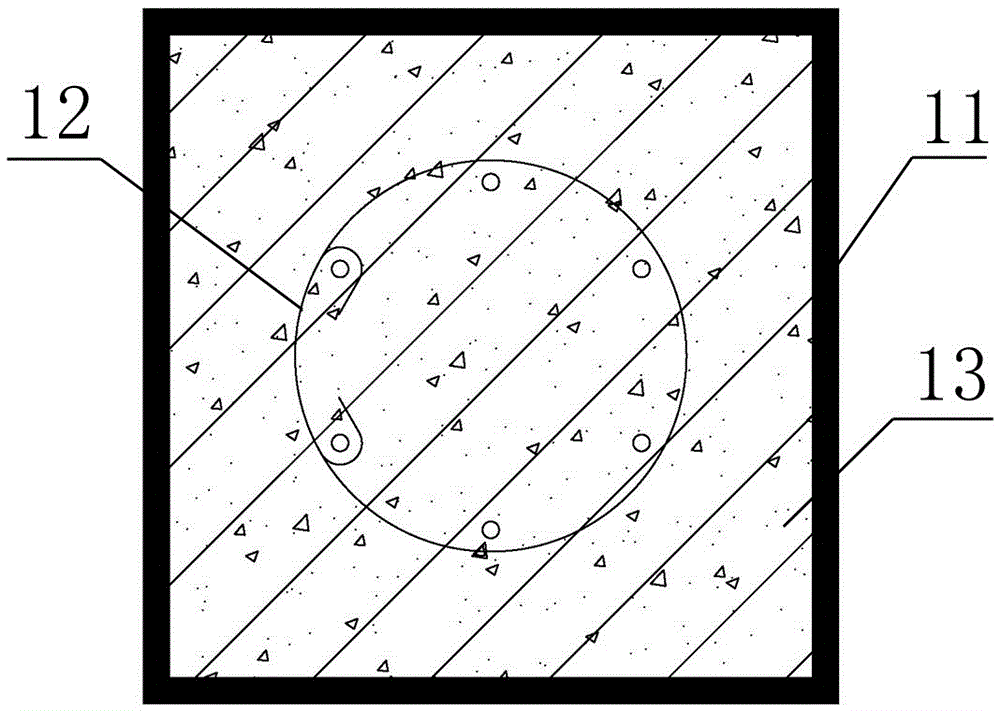

Lightweight composite column, lightweight composite beam and load bearing lightweight composite thermal-insulation wall body

The invention discloses a lightweight composite column, a lightweight composite beam and a lightweight composite thermal-insulation wall body. The invention relates to a composite thermal-insulation wall body for buildings. The purpose of the invention is to increase the bearing capacity of the lightweight composite thermal-insulation wall body and to cancel thermal bridges at openings. The lightweight composite column is formed by steel bars, a core layer, steel hoops and a protective layer, wherein the core layer is arranged between an internal protective layer and an external protective layer and is bonded with the internal protective layer and the external protective layer, the steel bars are arranged in the internal protective layer and the external protective layer and the steel hoops are tightly tied with the steel bars. The lightweight composite beam is formed by steel bars, a core layer, a protective layer and an alkali-resisting mesh, wherein the protective layer is arranged on the two sides and the upper part of the core layer and is bonded with the core layer; and the steel bars and the protective layer are wrapped and wound by the alkali-resisting mesh. The lightweight composite wall body is formed by beams or slabs of the main body structure of a building, lightweight composite columns, lightweight composite beams, lightweight boards and a leveling blanket, wherein the lightweight composite columns are anchored with the beams or slabs of the main body structure of the building, and the lightweight boards are arranged on the beams or slabs and are bonded with the columns; and the lightweight composite beams are arranged at openings and are connected with the lightweight composite columns. The composite wall body of the invention has the advantages that the thermal insulation performance is good, the manufacturing cost is low, the application scope is wide, the wall body reformation is promoted and the energy is saved.

Owner:吴淑环

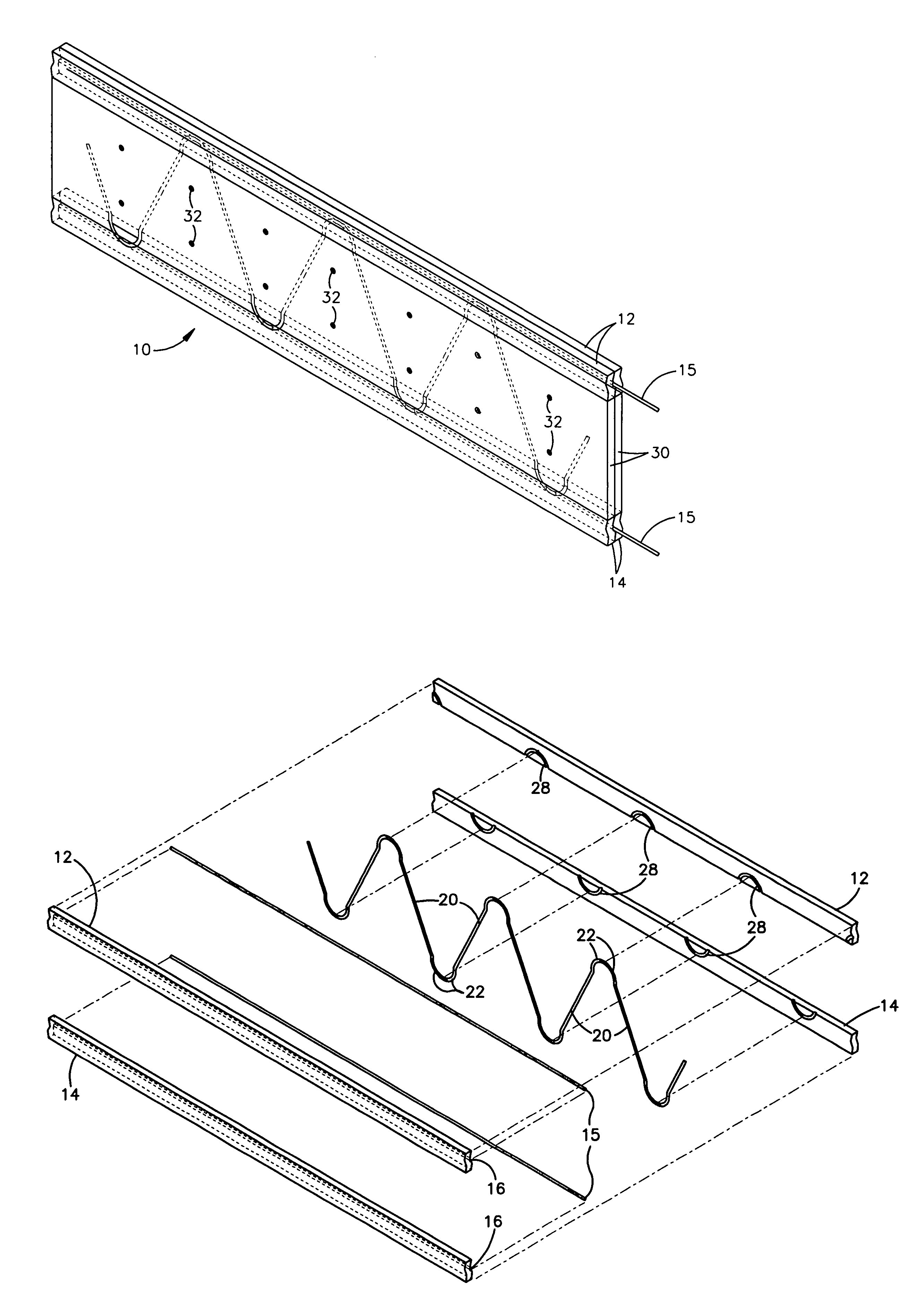

Composite beam

A composite beam is disclosed. The component has spaced pairs of elongate wood members, the members of each pair being in face to face mating orientation. A generally sinuous shaped spacer rod sub assembly having spacer portions connected at junctures is provided. The elongate member pairs each having mating faces including recesses contoured to receive one of the junctures and parts of connected spacer portions. The connected spacer portions each project angularly in opposed directions from their associated juncture and its recess in one of the pairs toward the other pair of members. Each of the junctures is disposed in an associated recess in the members whereby to provide a composite beam having the pairs of elongate members maintained in spaced relationship by the rod subassembly.

Owner:STEADMAN WILLIAM

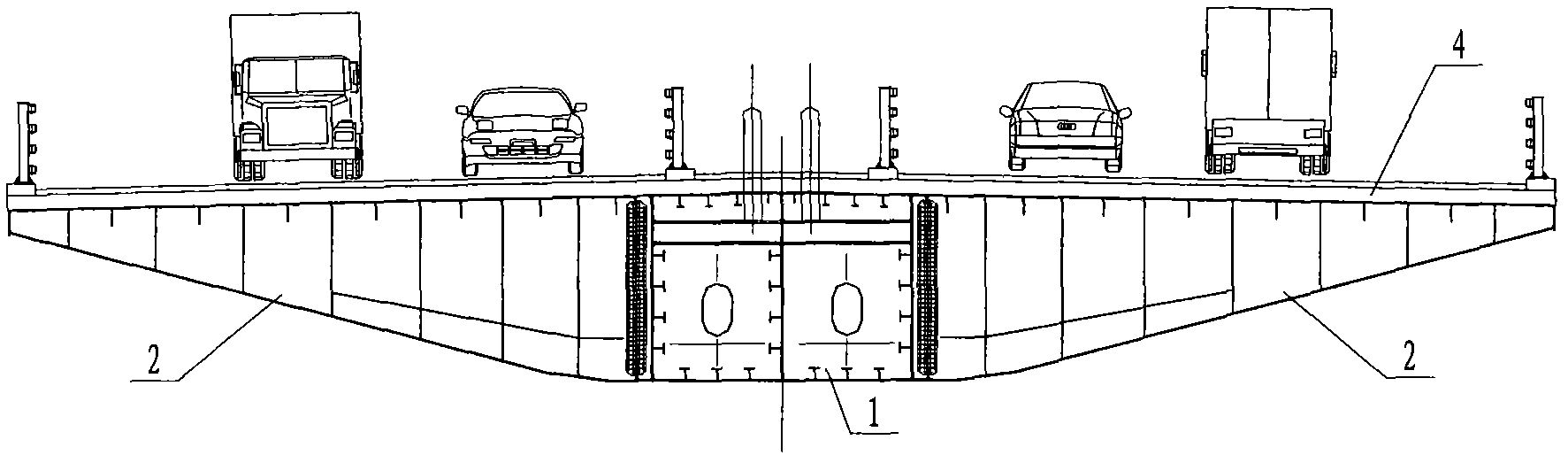

Partial filling type steel box concrete continuous composite girder bridge and construction method thereof

The invention relates to a partial filling type steel box concrete continuous composite girder bridge and a construction method thereof. The construction method comprises the following steps of (1) erecting steel box continuous girders; (2) filling concrete in a middle support area portion; (3) pouring a first reinforcement concrete bridge deck in a midspan area; and (4) pouring a second reinforcement concrete bridge deck in the middle support area. By the method, the deck of the bridge is subjected to section construction, so that the anti-cracking ability of the reinforcement concrete bridge deck of the middle support area is improved, the bridge deck of the midspan area is assembled after being subjected to a pouring procedure, tensile stress cannot be generated in the bridge deck of the middle support area which is subjected to the pouring procedure later by the weight of the bridge deck of the midspan area, and the anti-cracking ability of the reinforcement concrete bridge deck of the middle support area is improved.

Owner:GUILIN UNIVERSITY OF TECHNOLOGY

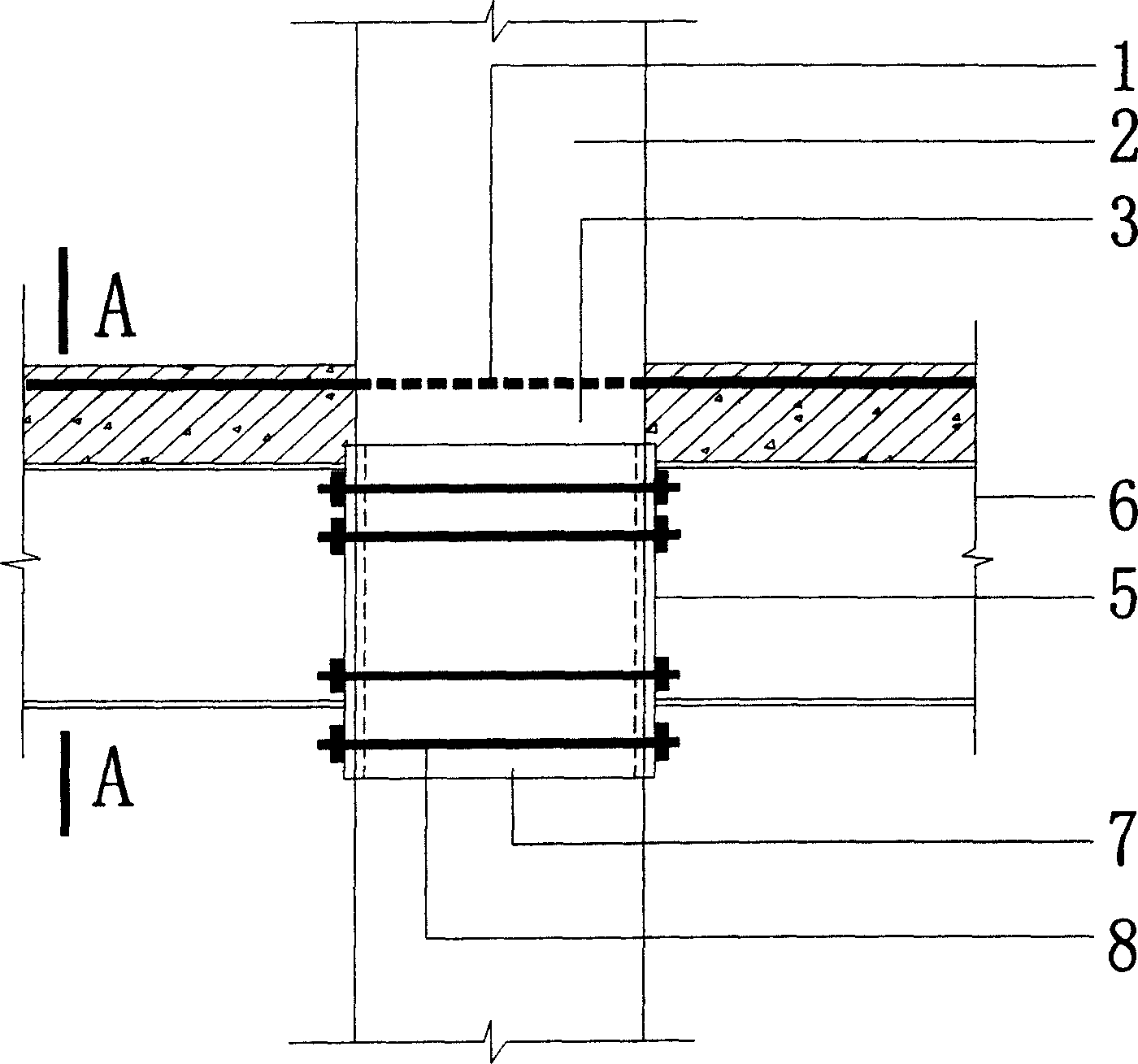

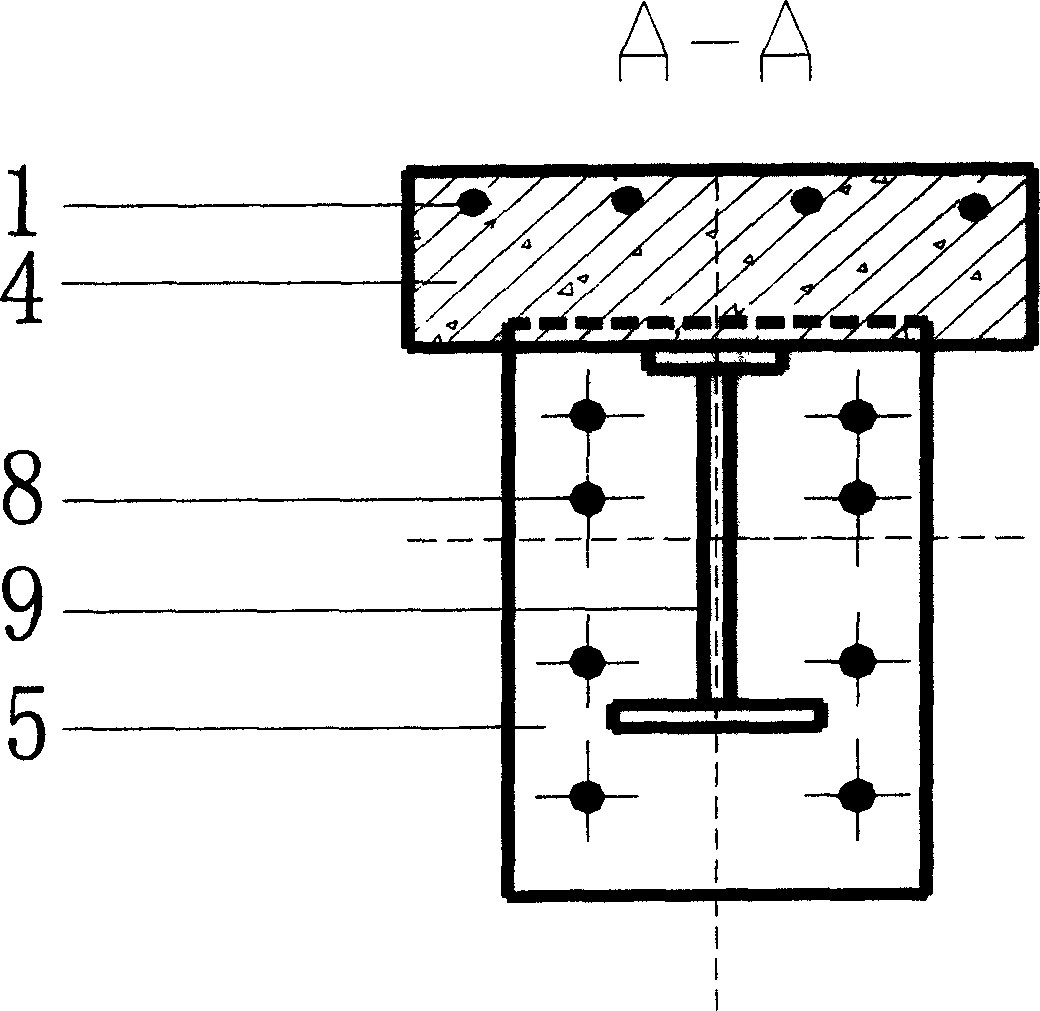

Node structure for combined beam and concrete column and construction thereof

InactiveCN1644827AGive full play to the shearing effectHigh strengthStrutsGirdersShaped beamSheet steel

A node structure for combined beam and concrete column is composed of the concrete in the core region of node, steel-plate hoop, extended plate, long screw bolt, and the negative reinforcement of combined beam. Its construction method includes such steps as calculating the stress of node, and the number and diameter of long screw bolts, determining the sizes of extended plate and steel-plate hoop and making them, welding the extended plates with I-shaped beam, installing all members, pouring concrete, and turning the long screw bolts for closing the extended plate to steel-plate hoop.

Owner:SOUTH CHINA UNIV OF TECH

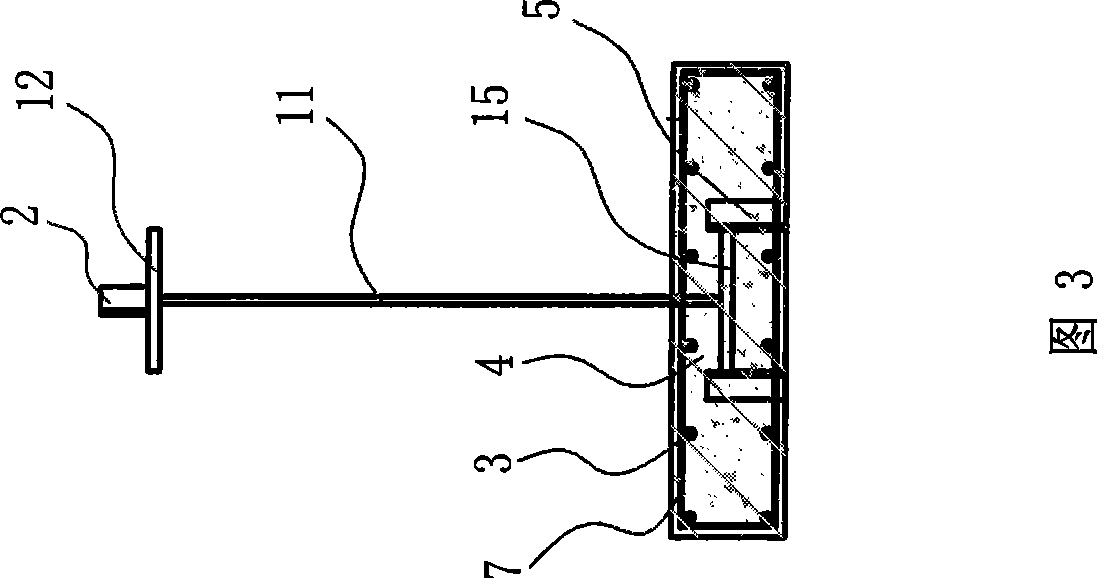

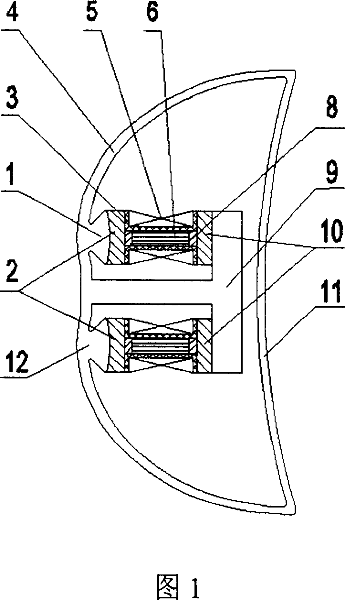

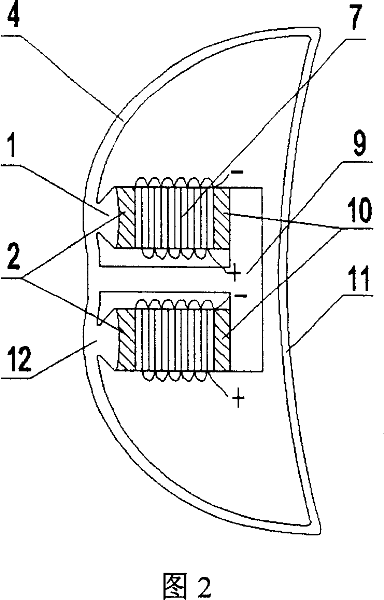

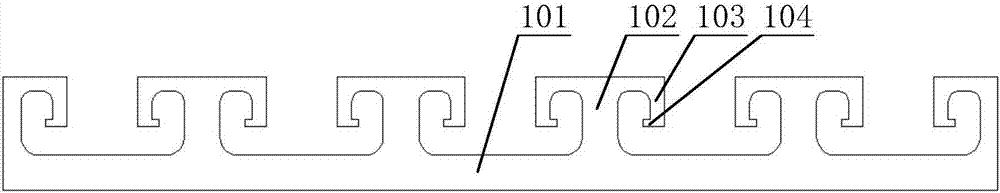

Ultra-low frequency underwater acoustic transducer

InactiveCN101038740AImprove Radiation PerformanceLower resonant frequencySound producing devicesTransducerEngineering

The invention relates to an ultra-low frequency acoustic transducer comprises a first grade bending girder, a second grade bending girder, a first projection, and a second projection, the first and the second projection are provided on an inner wall of the first grade bending girder, a T-shape quality yoke is arranged between the two projections and composes a composite girder bending-opening shell together with the first grade bending girder, a bow-shape closed curved face is composed by the first grade bending girder and the second grade bending girder and has a sturcture of symmetrical upper and lower portions, both two end faces of a translation body are not closed; a driving member, a first transition block and a second transition block compose an inner chamber assembling unit of the transducer, the size of the assembling unit in a length direction is larger than a distance between the projections and the T-shape quality yoke; the first transition block and the second transition block are arranged at two outer side of the driving members of each assembling unit, respectively, at least a driving member and the transition blocks arranged at left and right sides of the driving member are mounted between the first grade bending girder and the T-shape quality yoke. The transducer of the invention has a structure format which is better for realizing an ultra-low frequency and high power radiation.

Owner:INST OF ACOUSTICS CHINESE ACAD OF SCI

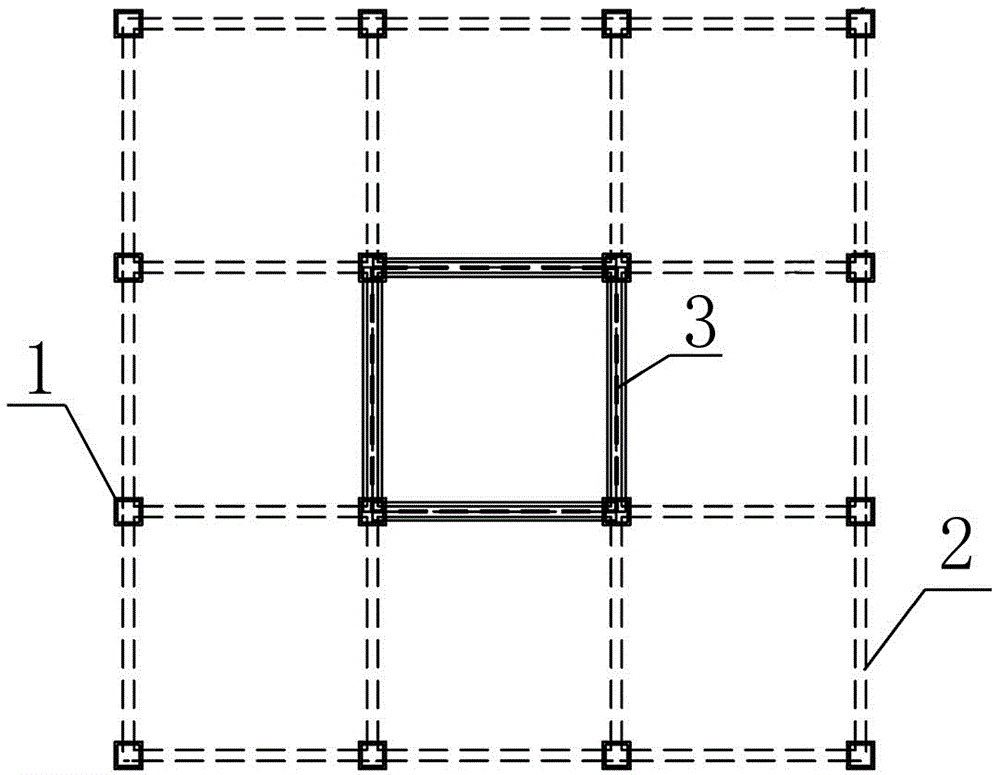

Prefabricated building main body structure

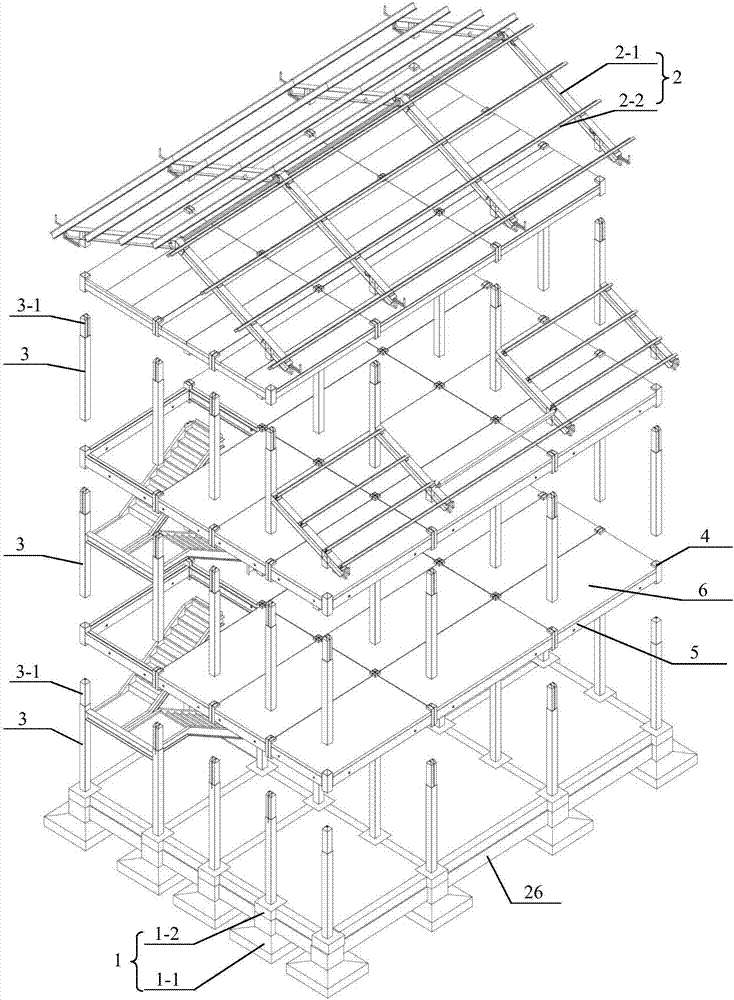

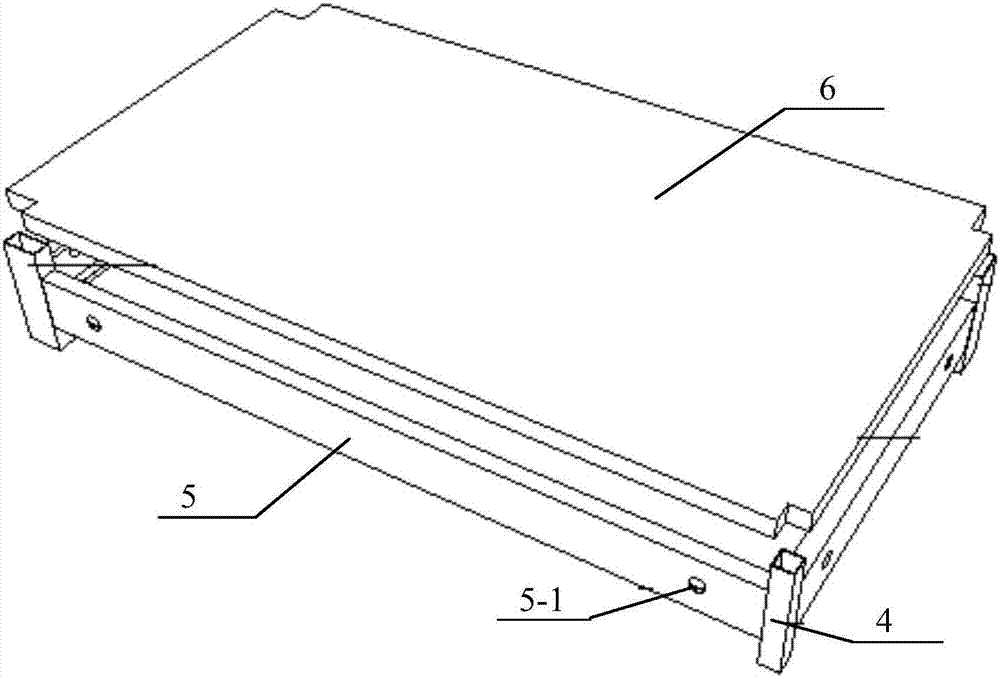

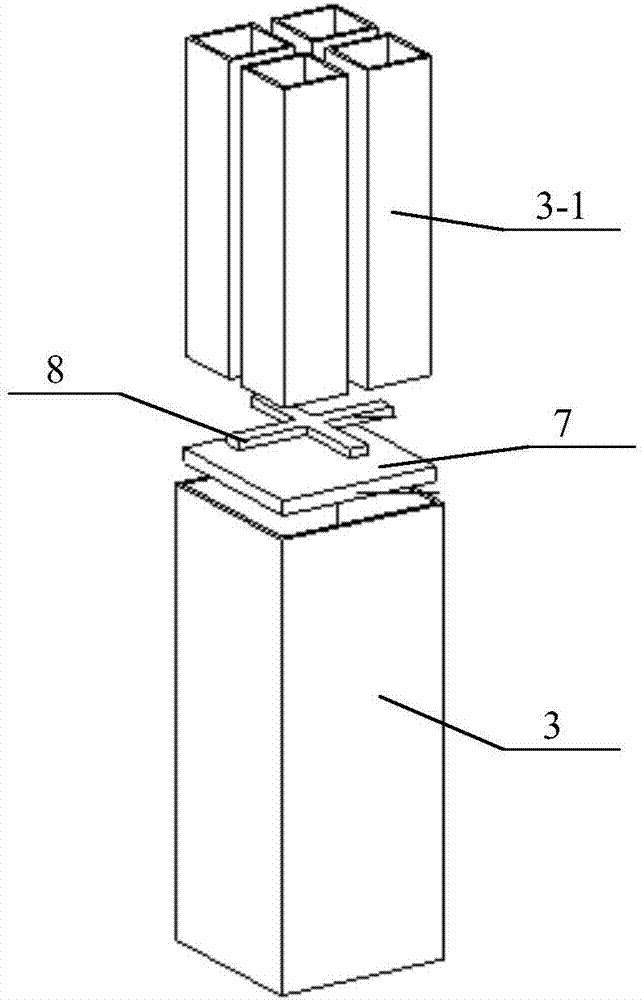

PendingCN107366356AReasonable connectionEasy to installBuilding constructionsFloor slabArchitectural engineering

The invention discloses a prefabricated building main body structure, and relates to the technical field of constructional engineering structures. The prefabricated building main body structure comprises an independent foundation; at least one layer of floor slabs is fixedly arranged above the independent foundation; a supporting structure is arranged under each layer of the floor slabs; a roof frame structure is fixedly arranged above the top layer of the floor slabs; the floor slabs comprise a plurality of combination beam plates; the supporting structure of each layer comprises a plurality of square pipe columns; tenon pipes connected with the combination beam plates in an inserting manner are arranged on the square pipe columns; a stairway is arranged between every two vertically adjacent layers of floor slabs; the combination beam plates comprise four-corner components; steel beams are fixedly connected between the adjacent four-corner components; the upper edges of the steel beams are spaced from the top ends of the four-corner components by a certain distance; concrete slabs are poured on the steel beams; reinforcement meshes are arranged in the concrete slabs; reserved pipeline holes are formed in the side surfaces of the steel beams; and the four-corner components are sleeves matched with the tenon pipes in an inserting manner. The beam and column connection is reasonable, the mounting is convenient and the flexural capacity is high.

Owner:北京善筑科技股份有限公司

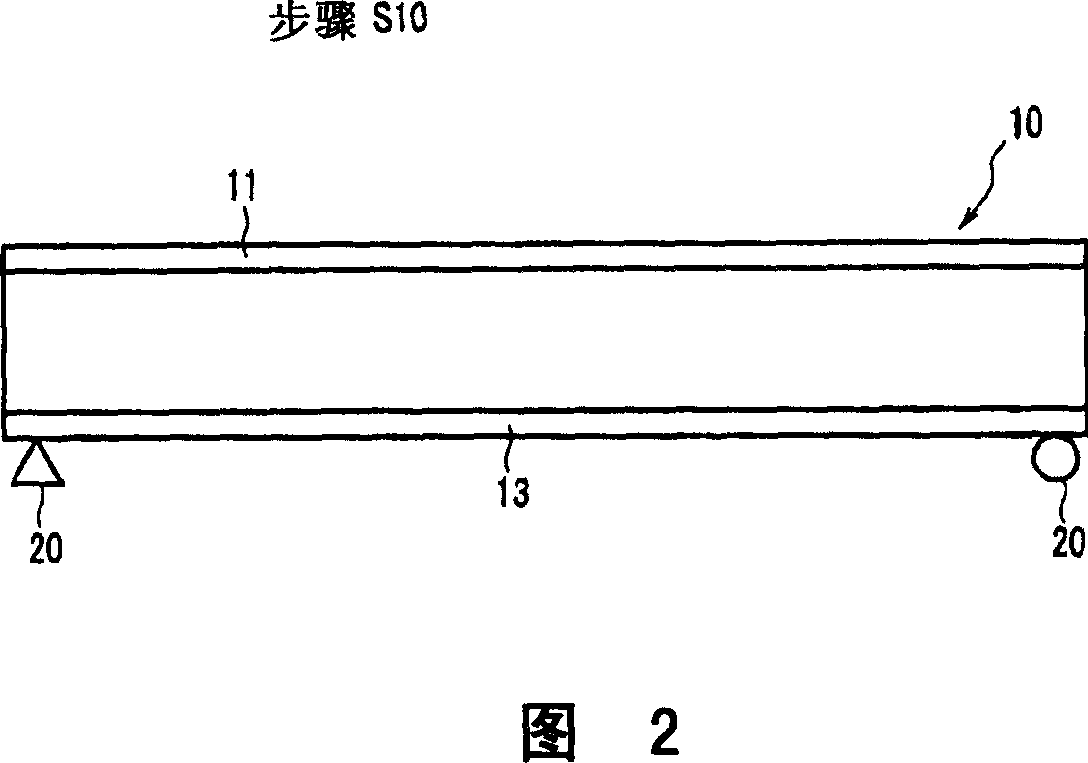

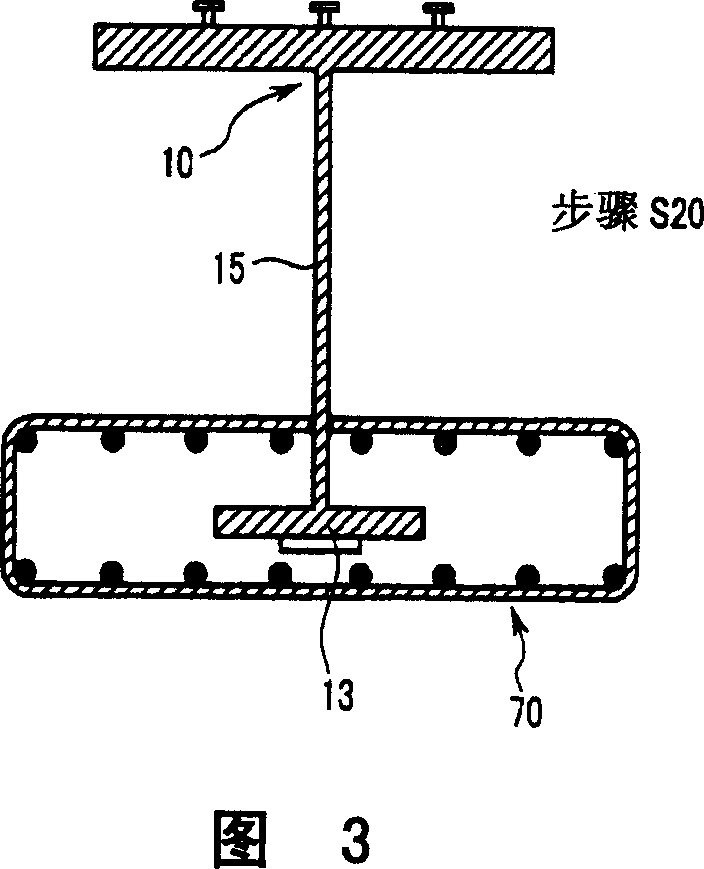

Manufacturing method for prestressed steel composite girder and prestressed steel composite girder thereby

ActiveCN101080534ANo tensile stressNo stress lossBridge erection/assemblyBridge materialsPre stressMaterials science

A prestressed steel composite girder and a method of manufacturing the prestressed steel composite girder are provided by using a steel beam and a concrete. The method includes steps of: placing the steel beam above the ground; installing a form, into which the concrete is to be inserted, to surround at least a portion of the steel beam, the form being suspended by the steel beam; inserting the concrete into an internal space of the form and curing it; and removing the form to compose the steel beam and the concrete. The prestressed steel composite girder includes a steel beam and a concrete composed to surround a portion of the steel beam so that stress caused by its self- weight can be applied on only the steel beam.

Owner:RES INST OF IND SCI & TECH +1

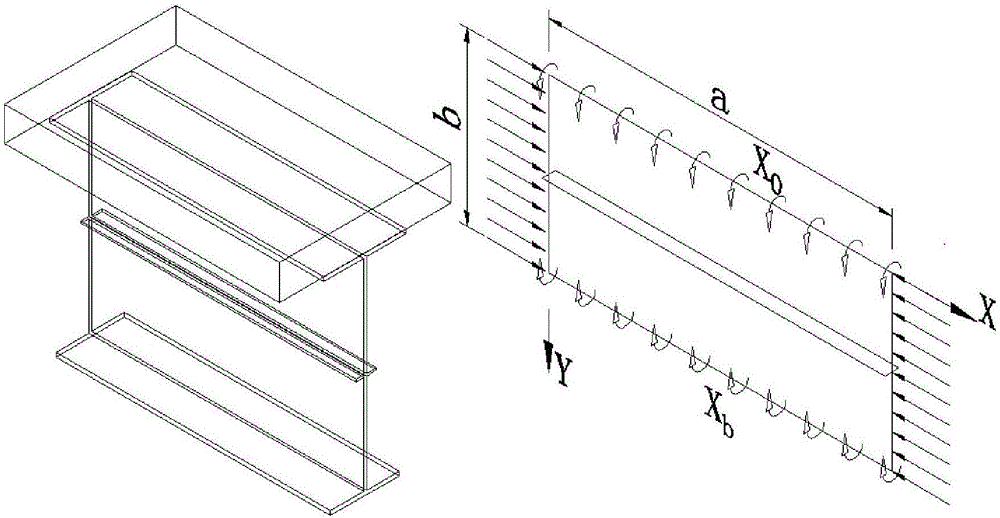

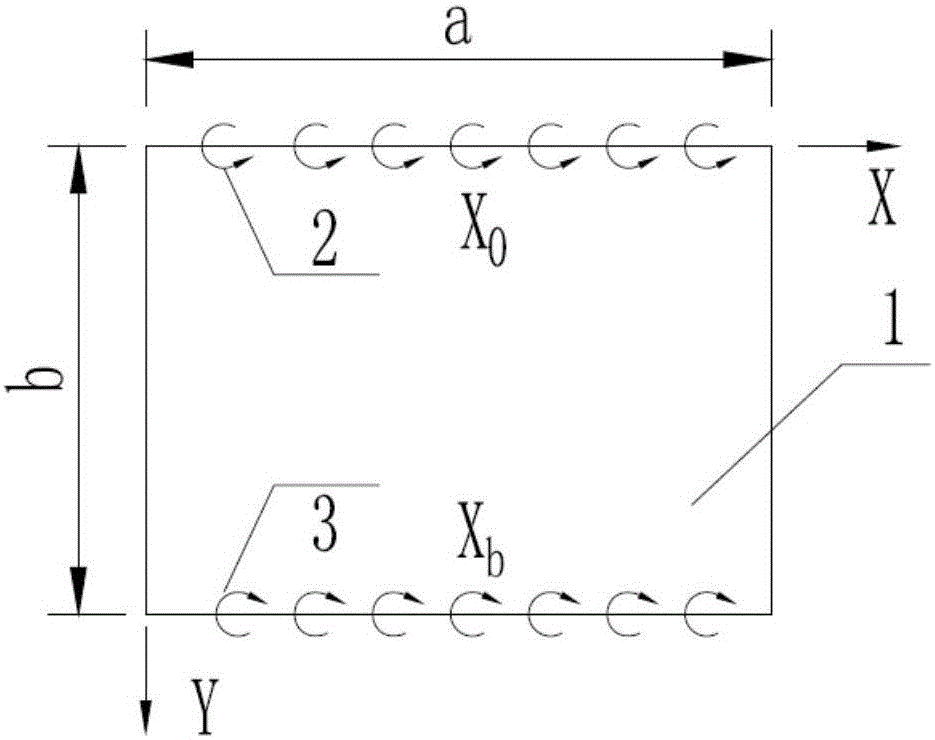

Method for setting longitudinal stiffening rib of high web of elastic rotation constrained boundary steel-concrete composite beam

ActiveCN106758738AAccurate calculation of critical buckling stressImprove rationalityBridge materialsEngineeringEnergy method

The invention relates to a method for setting a longitudinal stiffening rib of a high web of an elastic rotation constrained boundary steel-concrete composite beam. The method comprises the following steps: firstly building a displacement function equation with the elastic rotation constrained boundary and the boundary condition, deriving buckling stress calculation expression of the stiffening rib under two states of the rigid stiffening and flexible stiffening based on an energy method, and obtaining a calculation formula of the elastic rotation constrained boundary longitudinal stiffening rib critical rigidity; and then, considering external work and a minimum potential energy principle, presenting a critical buckling stress calculation formula of a non-uniform pressing plate under the elastic rotation constrained boundary; and finally, according to a buckling safety degree equal principle, obtaining the optical position of setting the longitudinal stiffening rib under the elastic rotation constrained boundary. The method is capable of, according to the actual stress situation, accurately setting the longitudinal stiffening rib of the high web of the steel-concrete composite beam, solving the problems of the current steel-concrete composite bridge bream stiffening rib that the design is conservative and the amount of the steel products is large, and remarkably improving the rationality and economy of the stiffening rib setting of the high web.

Owner:WUHAN UNIV OF TECH

Steel-concrete combined beam wet joint corrosion prevention construction method and application

The invention discloses a steel-concrete combined beam wet joint corrosion prevention construction method. The method is characterized by including three parts of prefabricated bridge deck slab and steel beam contact bottom face corrosion prevention, wet joint cast-in-place concrete corrosion prevention and wet joint concrete top corrosion prevention. By the adoption of the steel-concrete combinedbeam wet joint corrosion prevention construction method, the prefabricated bridge deck slab and steel beam contact bottom face corrosion prevention part uses high-elastic modulus corrosion preventionrubber strips and bottom face high-strength quick-solidifying epoxy corrosion prevention mortar and is characterized in that the high-elastic modulus rubber strips are stuck to the edges of an upperflange plate of a steel beam and the periphery of each shear pin in a wet joint and mainly achieve two effects that firstly, a corrosion channel through which an outer medium enters an interface froma contact joint of a prefabricated bridge deck slab and the steel beam is obstructed, and secondly, a pouring formwork is provided for the bottom face high-strength quick-solidifying epoxy mortar. Thesteel-concrete combined beam wet joint corrosion prevention construction method can be applied to wet joint corrosion prevention structural measures in the steel-concrete combined beam assembling construction process in coastal areas.

Owner:青海省高等级公路建设管理局 +2

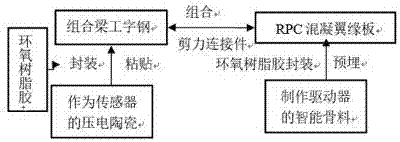

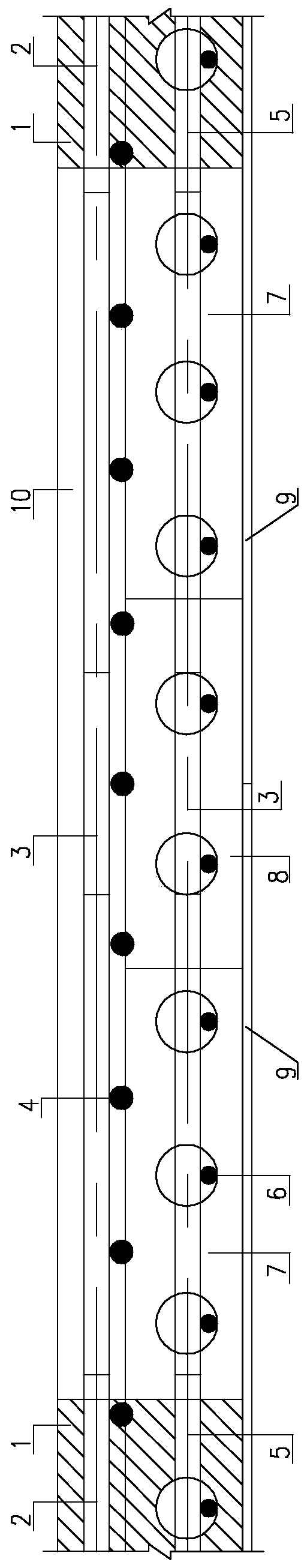

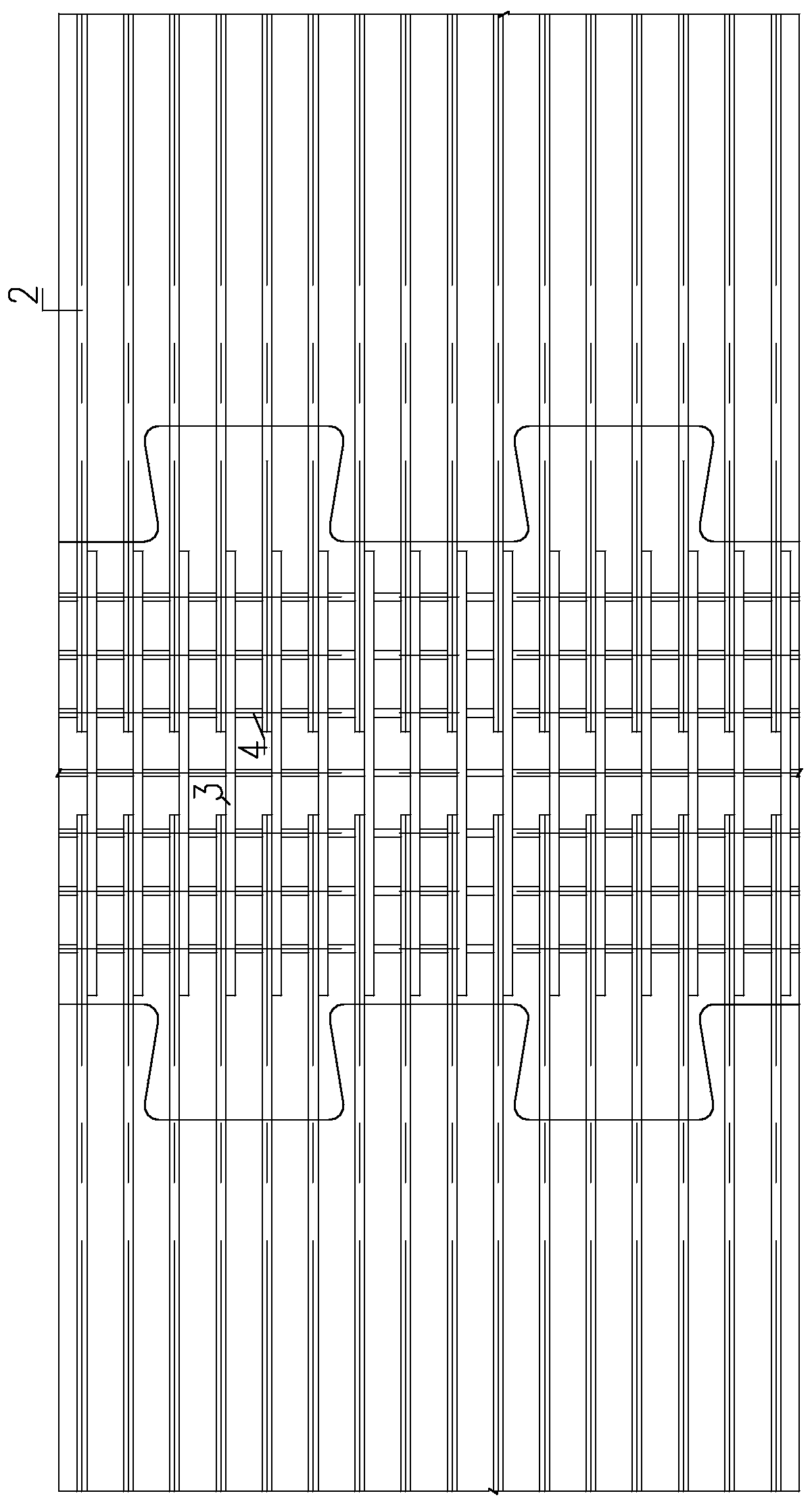

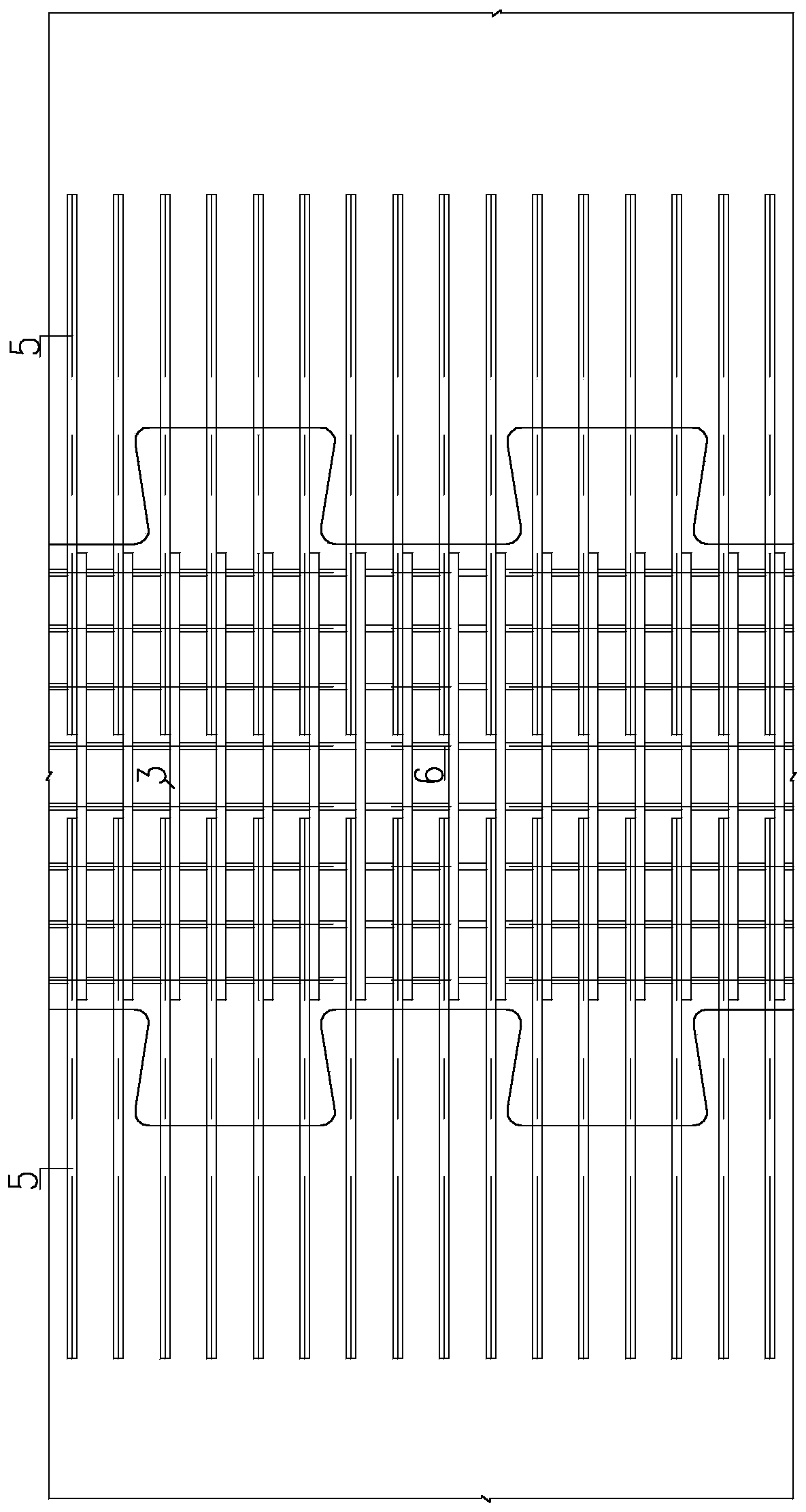

Manufacturing method for composite profile steel-concrete combined beam, combined beam and monitoring device

InactiveCN106948488AImprove ductilityLight weightPreparing sample for investigationBridge structural detailsEngineering structuresConstruction aggregate

The invention discloses a manufacturing method for a composite profile steel-concrete combined beam, the combined beam and a monitoring device. The composite profile steel-concrete combined beam comprises a reactive powder concrete (RPC) flange plate. The lower surface of the RPC flange plate is fixedly connected with an I-steel beam through shear connecting pieces. A plurality of grooves are formed in the central line of the upper surface of the upper flange of the I-steel beam in the span direction. A piezoelectric ceramic piece is fixed into each groove. Piezoelectric smart aggregate is embedded into the portions, on the two sides of the shear connecting pieces, of the RPC flange plate, and the lower surface of the aggregate smart aggregate is flush with the lower surface of the RPC flange plate. By adoption of the manufacturing method for the composite profile steel-concrete combined beam, the combined beam and the monitoring device, the span of the profile steel-concrete combined beam is increased, mechanical performance of the profile steel-concrete combined beam is improved, and therefore the profile steel-concrete combined beam can be used for the newly-built construction of a civil engineering structure. The monitoring device is high in sensitivity, rapid in response, easy and convenient to operate, low in price and capable of being applied to slipping monitoring of the composite profile steel-concrete combined beam.

Owner:CHANGSHA UNIVERSITY OF SCIENCE AND TECHNOLOGY

Ultra-high performance concrete composite beam bridge deck slab wet joint continuous structure with template

InactiveCN110952446AHigh tensile strengthHigh compressive strengthBridge structural detailsButt weldingArchitectural engineering

The invention discloses an ultra-high performance concrete composite beam bridge deck slab wet joint continuous structure with a template, which comprises a prefabricated section, a wet joint sectionand a steel bottom template; the prefabricated section bridge deck slab is made of an ultra-high performance concrete material; the steel bottom template is an extension section of the prefabricated section bridge deck slab bottom template, butt welding is conducted in the middle of the wet joint, and the steel bottom template serves as a bottom template of the wet joint section; the wet joint section is supported on the steel bottom template and connected with the steel bottom template and the prefabricated section in a pouring mode, the wet joint section is laid continuously, the thickness of the wet joint section is equal to that of the bridge deck slab, and the wet joint section is made of ultra-high performance concrete materials the same as those of the bridge deck slab. The wet joint is provided with the template, is high in tensile strength and compressive strength and good in durability, can effectively guarantee the performance continuity of the ultra-high performance concrete at the wet joint interface, has the advantages of being effective in steel bar connection, convenient to construct and easy to maintain, and can solve the problem of the connection quality of the ultra-high performance concrete wet joint.

Owner:GUANGDONG PROVINCE COMM PLANNING & DESIGN INST

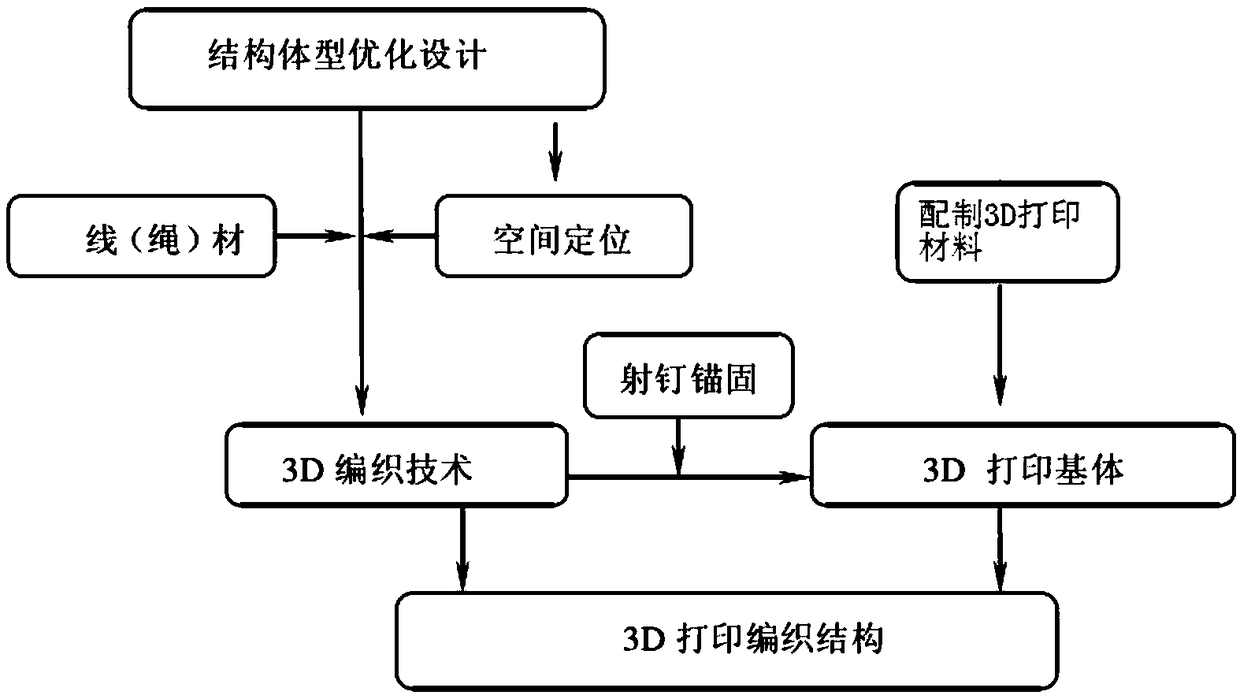

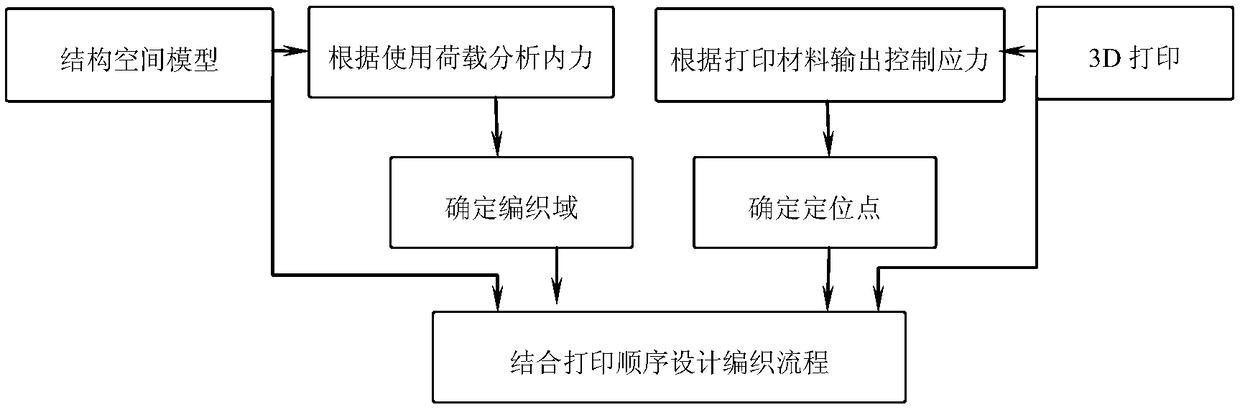

Construction method of composite beam integrally formed by 3D printing and knitting and composite beam

ActiveCN109129818ABeautify the facade of the structureReduce building construction proceduresAdditive manufacturing apparatusCeramic shaping plantsCrack resistanceForce analysis

The invention discloses a construction method of a composite beam integrally formed by 3D printing and knitting and the composite beam. The construction method comprises the steps that modeling is performed for force analysis, beam member spatial shape optimization is performed, and the shape and thickness of a composite beam member skeleton or a composite beam member external mold are determined;a knitting range, the knitting dosage and areas of encryption knitting and ordinary knitting of wires are determined; a knitting process is determined, and the knitting process is combined with a matrix printing process to be jointly designed to form a printing and knitting integrated process; 3D printing materials are prepared; and 3D printing of a matrix and knitting of the wires are performedto obtain the composite beam or a composite beam external mold. A beam member prepared by the construction method is the composite beam, the tensile resistance, shear resistance, abrasion resistance and crack resistance properties of a 3D printing member are effectively improved, the fracture toughness and impact resistance properties of the member are greatly enhanced, the fatigue performance anddurability of the beam member are improved, the space spanning capability is improved, construction is convenient, and quick application is achieved.

Owner:ZHEJIANG UNIV

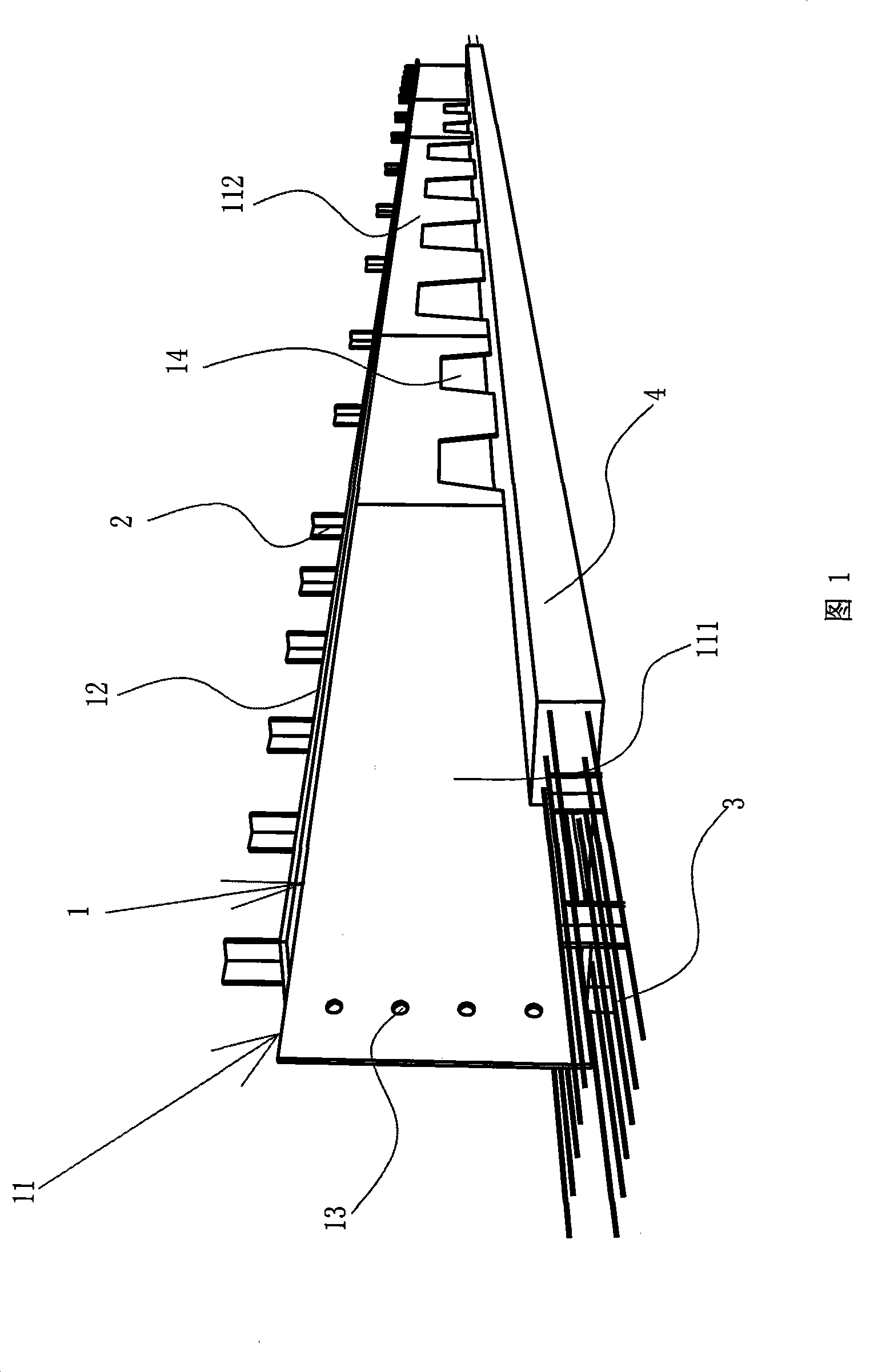

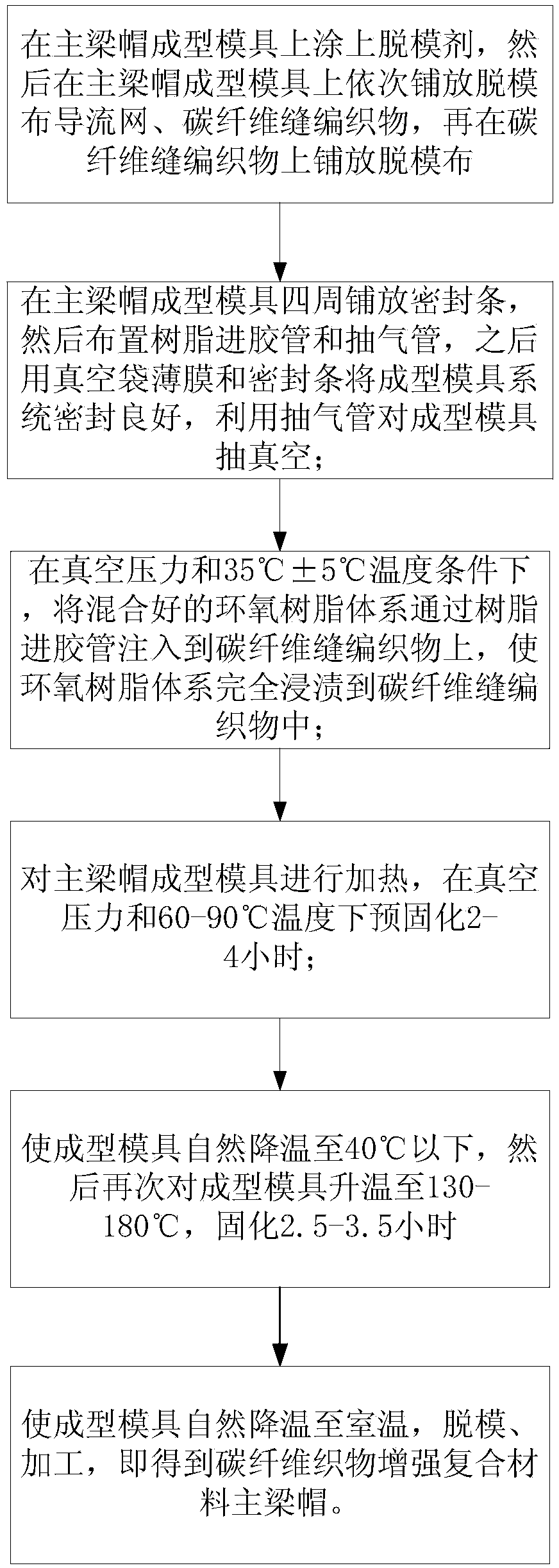

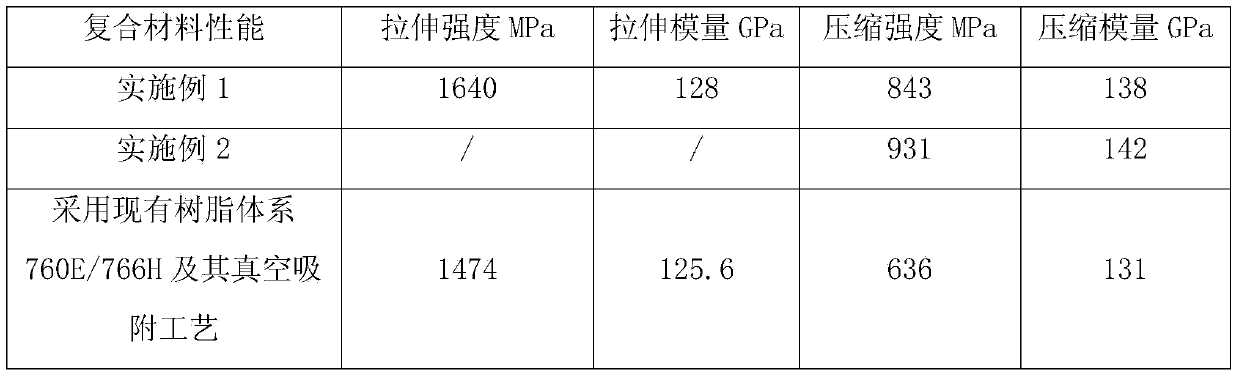

Carbon fiber fabric reinforced resin matrix composite girder cap and manufacturing method thereof

ActiveCN103994031ALow viscosityImprove structural strengthFinal product manufactureWind energy generationEpoxyCarbon fibers

The invention discloses a carbon fiber fabric reinforced resin matrix composite girder cap for a fan blade and a manufacturing method thereof. The carbon fiber fabric reinforced resin matrix composite girder cap is composed of a carbon fiber stitch-bonded fabric reinforcing material and a glycidyl ester epoxy resin system. The requirements for laying efficiency and pouring efficiency of a vacuum absorption process are met, the requirement of the girder cap for carbon fiber dynamic performance utilization is well taken into consideration, and mechanical performance of a carbon fiber stitch-bonded fabric composite and structural strength of the carbon fiber fabric reinforced resin matrix composite girder cap are remarkably improved. By means of the vacuum absorption process and a solidification rule that process auxiliary materials are removed after medium-and-low-temperature pre-solidification and then medium-and-high-temperature solidification is carried out, the hidden risk that the process auxiliary materials are not resistant to medium and high temperature is overcome, and structural mechanical performance of the girder cap is effectively guaranteed.

Owner:AEROSPACE RES INST OF MATERIAL & PROCESSING TECH +1

Hybrid industrialized architectural structural system and construction method thereof

InactiveCN106223461ANot easy to collapseImprove seismic performanceWallsGirdersReinforced concrete columnVariable stiffness

The invention discloses a hybrid industrialized architectural structural system and a construction method thereof. The hybrid industrialized architectural structural system comprises a structural system, wherein the structural system is formed by connecting structural columns, structural beams, shear walls and floors; the structural columns are steel columns or concrete filled steel tube columns or steel tube reinforced concrete columns; at least one of the structural beams is a prefabricated variable-stiffness hybrid combination beam; at least one of the shear beams is a prefabricated shear wall; the prefabricated shear wall is connected into a frame structure formed by being enclosed by the structural columns and the prefabricated variable-stiffness hybrid combination beam; the prefabricated variable-stiffness hybrid combination beam comprises a steel skeleton and reinforced concrete blocks arranged on two sides of a web plate of the steel skeleton. By using the hybrid industrialized architectural structural system and the construction method thereof, the technical problems that a conventional cast-in-place concrete structure is poor in shock resistance performance and long in construction time and a conventional steel structure is poor in fire resistance are solved.

Owner:姚攀峰

Steel truss-steel plate combined shear wall and method for producing the same

InactiveCN101457558AImprove ductilityImprove energy consumptionConstruction materialWallsUltrasound attenuationSheet steel

The invention relates to a shear wall, in particular to a steel truss-steel plate combined shear wall and a manufacturing method thereof. The shear wall comprises a frame beam, a frame pillar fixedly combined with the frame beam and a steel plate arranged between the frame beam and the frame pillar; wherein, the frame beam comprises a profile steel beam and concrete poured outside the profile steel beam to form a profile steel-concrete compound beam; the frame pillar is a profile steel-concrete pillar composed of the profile steel and the concrete poured outside the profile steel; the profile steel in the profile steel-concrete pillar is fixedly connected with the steel plate and the profile steel beam in the frame beam; a profile steel raking prop is fixedly combined on the plane of the steel plate along the oblique direction, and is distributed in a herringbone, an X shape or a reverse V shape. The profile steel beam, the profile steel-concrete pillar, the profile steel raking prop and the steel plate are combined with each other to form a steel truss-steel plate combined structure. Compared with the existing shear wall, the steel truss-steel plate combined shear wall has higher initial rigidity and carrying capacity, slower attenuation of carrying capacity and rigidity, better whole shakeproof and energy consumption performance as well as comparatively stable later period shakeproof performance, and can effectively relieve the damage caused by cutting and gliding at the bottom.

Owner:BEIJING UNIV OF TECH

Connecting part of combined structure of steel and concrete and combining beam consisting of same

The invention discloses a connecting part of a combined structure of steel and concrete. The connecting part comprises a bottom plate and reinforced steel positioning mechanisms, wherein the reinforced steel positioning mechanisms comprise webs, flange plates and reinforcing steel support blocks; the bottom plate is horizontally arranged; the webs are arranged vertically; the lower ends of the webs are fixed on the upper end surface of the bottom plate; the flange plates are arranged above the bottom plate and are parallel to the bottom plate; one end of each flange plate is fixedly connected to a side wall of each web; positioning notches are formed in the bottoms of the flange plates; the reinforcing steel support blocks are embedded into the positioning notches; one end of each reinforcing steel support block is fixedly connected with each flange plate; reinforcing steel embedding holes are formed between the other ends of the reinforcing steel support blocks and the side walls of the positioning notches; areas between the reinforcing steel support blocks and the bottom plate are first reinforcing steel holding areas; areas inside the positioning notches above the reinforcing steel support blocks are second reinforcing steel holding areas. The invention further discloses a combining beam consisting of the connecting part. By adopting the connecting part, reinforcing steel can be conveniently connected in lap joint, and the construction efficiency can be improved.

Owner:SICHUAN UNIV

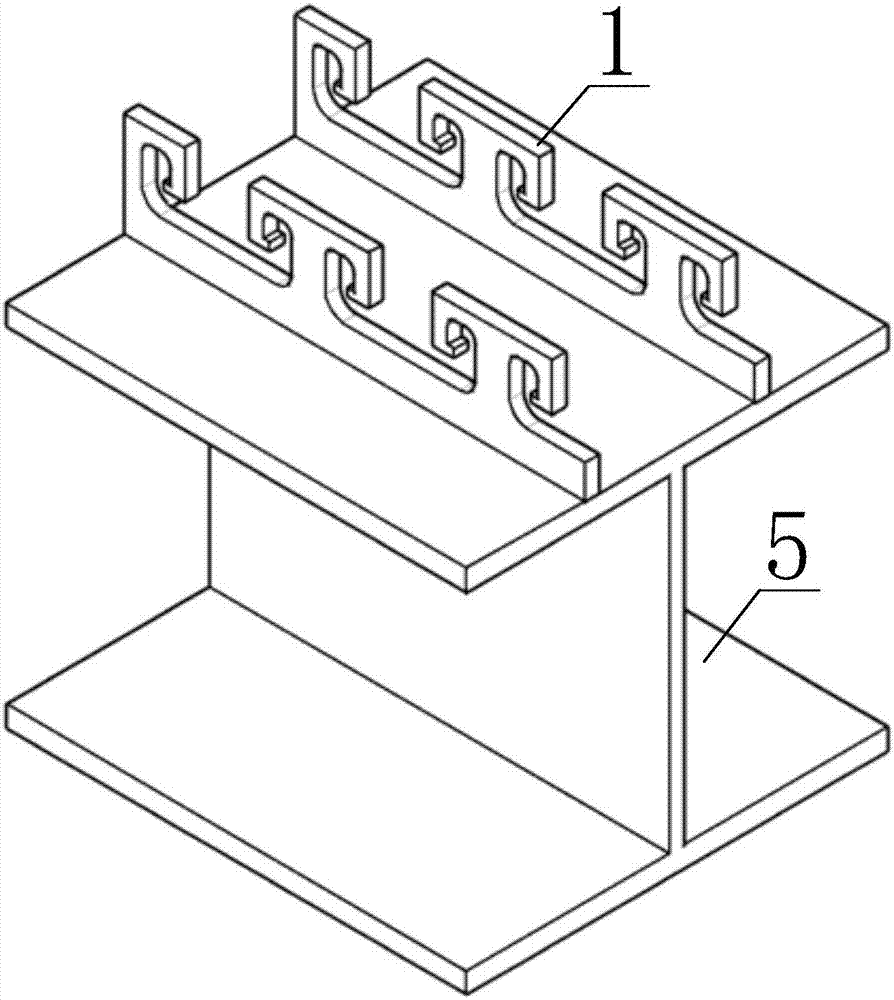

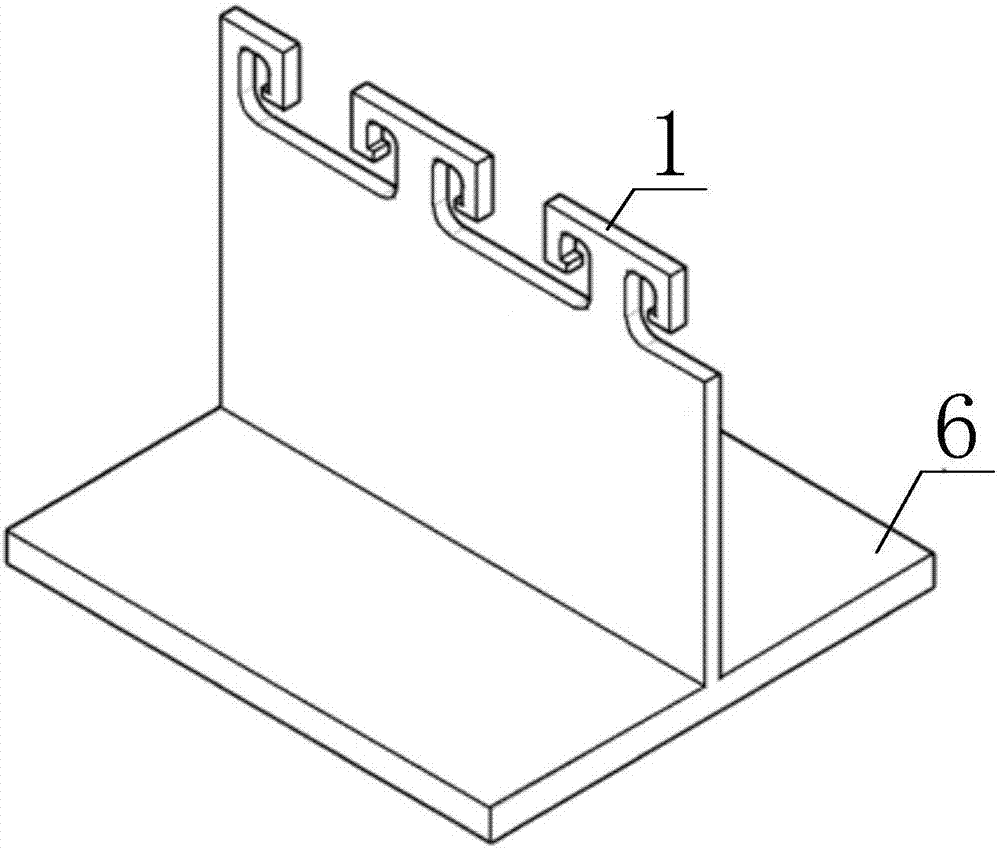

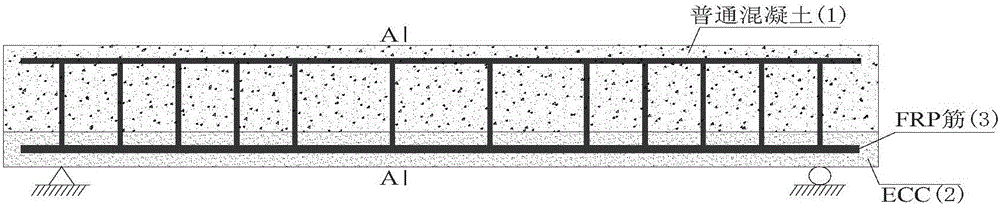

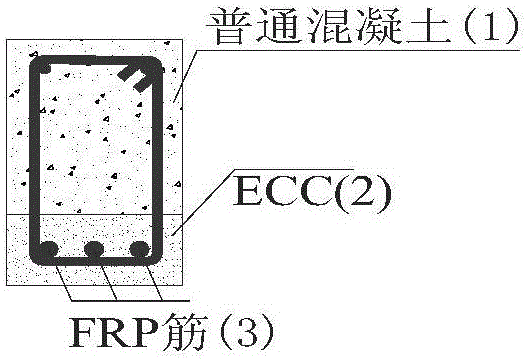

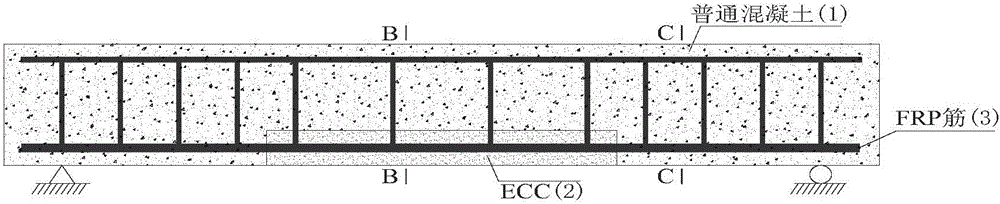

Fiber reinforced composite material rib and concrete composite beam

InactiveCN105888132AOvercoming softening propertiesSignificantly nonlinear deformationSolid waste managementClimate change adaptationFiber-reinforced compositeRebar

The invention discloses a fiber reinforced composite material rib and concrete composite beam which comprises fiber reinforced composite material ribs and concrete wrapping the peripheries of the fiber reinforced composite material ribs. The concrete wrapping the peripheries of the fiber reinforced composite material ribs in a composite beam stress area is an engineering cement-based composite. According to the composite beam, the reinforcing steel bar consumption is lowered, and the structural durability is high.

Owner:YANGZHOU UNIV

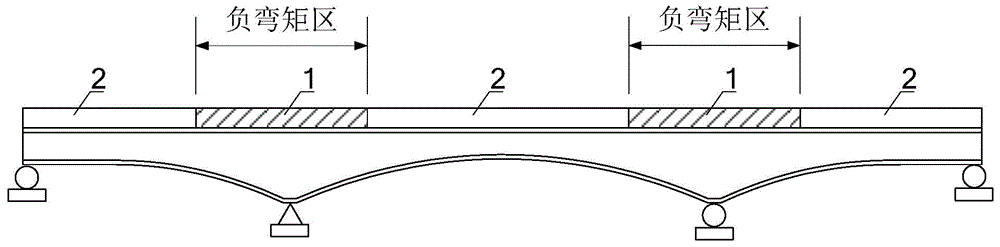

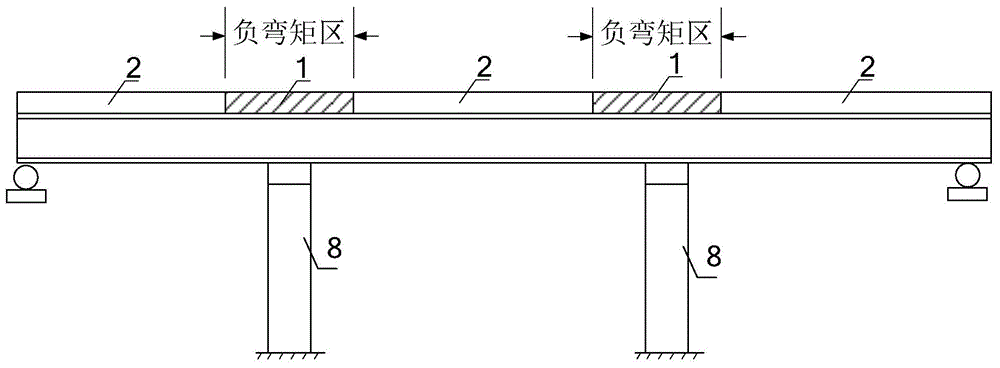

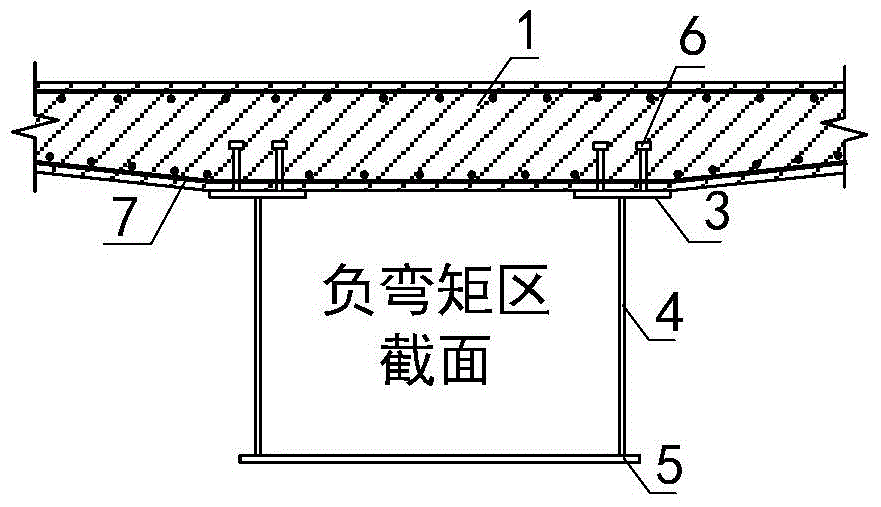

Bridge deck slab longitudinal unequal strength steel-concrete composite structure bridge and construction method thereof

InactiveCN104831627AImprove crack resistanceHigh strengthBridge structural detailsBridge materialsBridge deckEngineering

The invention relates to a bridge deck slab longitudinal unequal strength steel-concrete composite structure bridge and a construction method thereof and belongs to a novel bridge structural system applied to a continuous composite girder bridge or a composite rigid frame bridge. The bridge deck slab longitudinal unequal strength steel-concrete composite structure bridge of the invention is composed of super-high-performance concrete, ordinary concrete and steel beams. According to the ridge deck slab longitudinal unequal strength steel-concrete composite structure bridge of the invention, shear-resisting connection components and upper concrete plates are connected with each other so as to form an integrated body and work jointly, and therefore, the strength and rigidity of the bridge can be improved, and the quantity of steel consumption of the whole bridge can be decreased. The bridge deck slab longitudinal unequal strength steel-concrete composite structure bridge of the invention has respective advantages of an ordinary composite bridge deck system and super-high-performance concrete, and the advantages of high strength, high rigidity, excellent anti-cracking performance, high durability, easiness in construction and the like, and has a broad application prospect in composite structure bridges on which negative moment regions exist, such as a continuous girder bridge and a rigid frame bridge.

Owner:TSINGHUA UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com