Node structure for combined beam and concrete column and construction thereof

A technology of concrete columns and joint structures, applied to truss structures, columns, joists, etc., can solve the problems of lack of research on beam-column joints, and achieve the effects of increased strength, uniform internal force transmission, and uniform internal force distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described in detail below in conjunction with the embodiments and the accompanying drawings, but the embodiments of the present invention are not limited thereto.

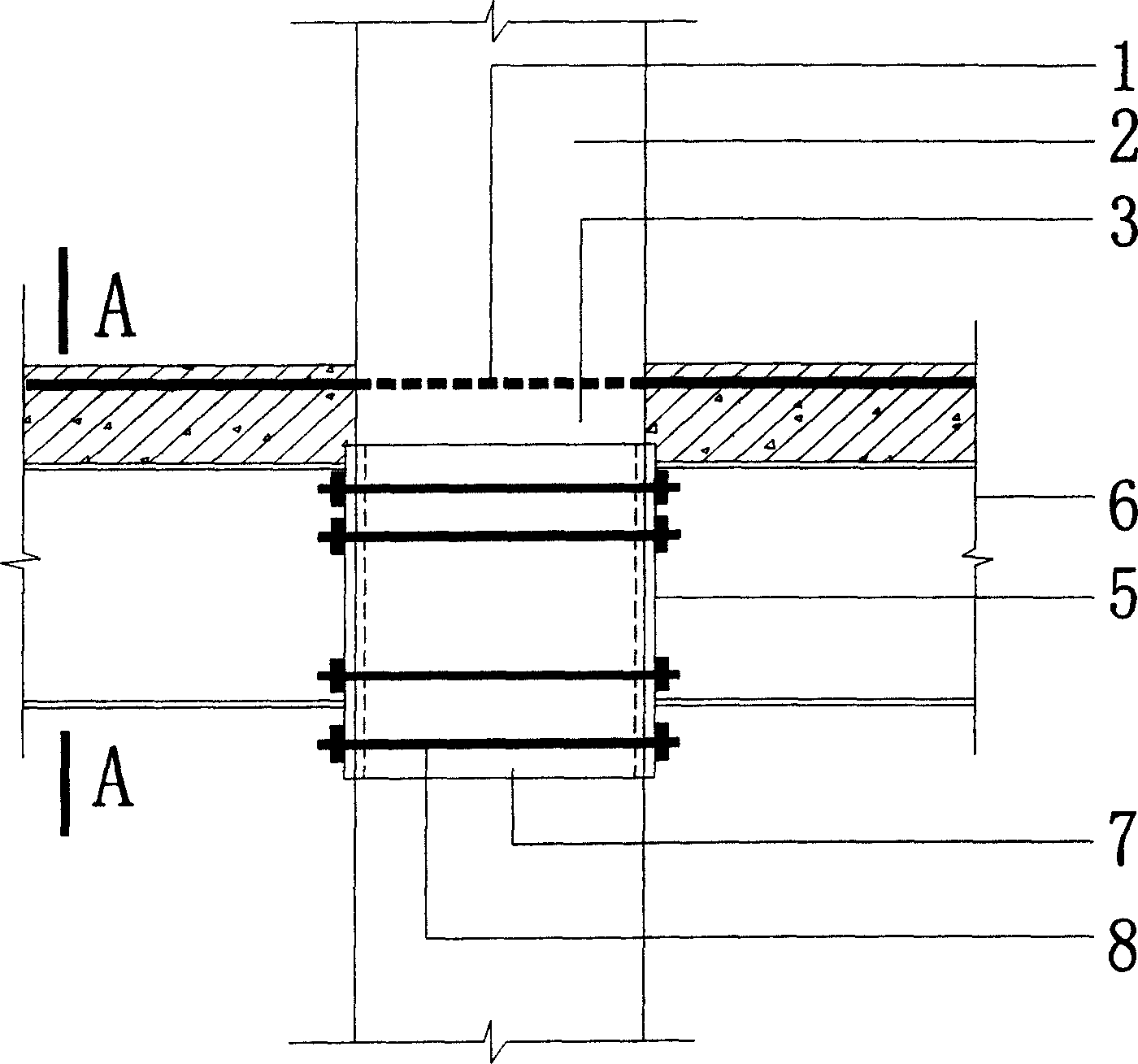

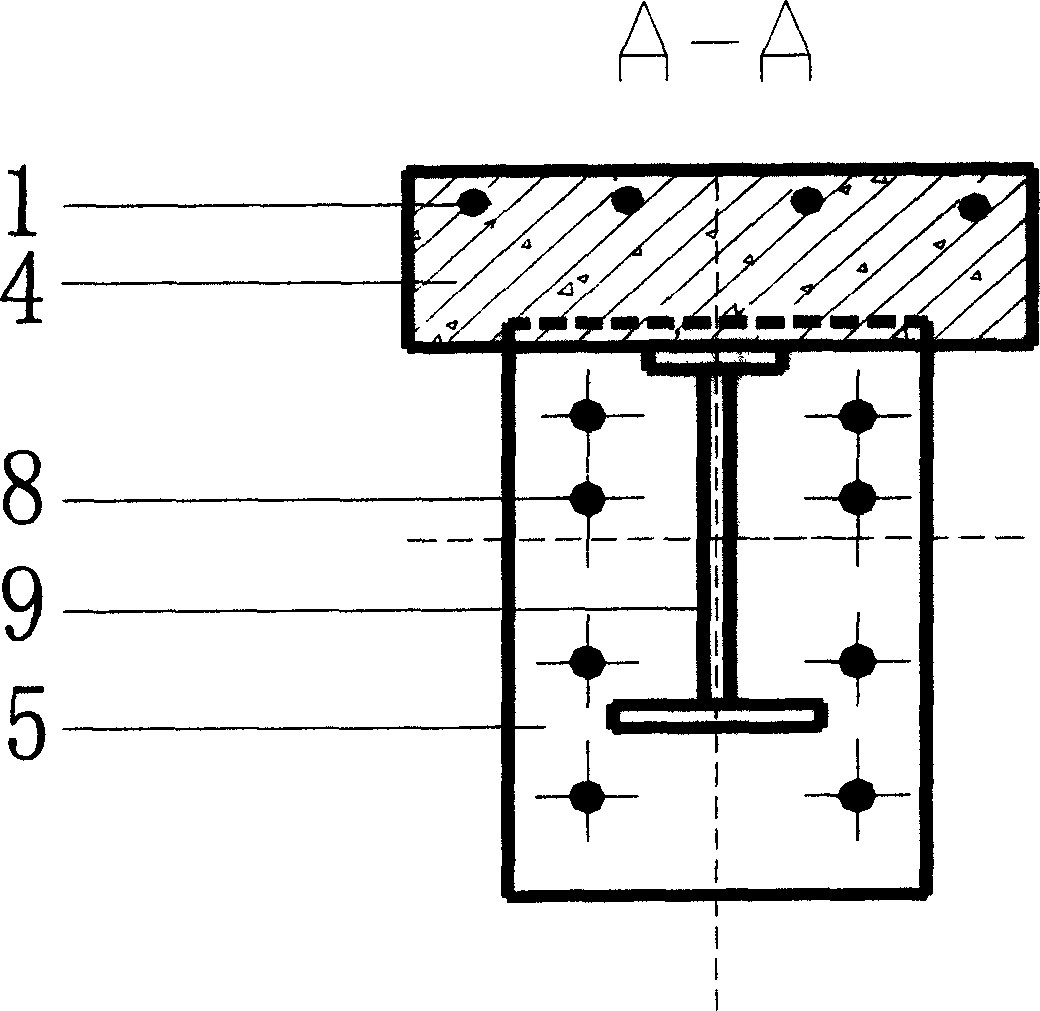

[0025] figure 1 The specific structure of the composite beam and concrete column joint structure is given, such as figure 1 As shown, the composite beam and concrete column joint structure includes the concrete 3 in the core area of the joint, the steel plate hoop 7, the overhanging end plate 5, the long rod bolt 8, and the negative steel bar 1 of the composite beam 6. The concrete 3 in the core area of the joint is a combination The concrete at the junction of the beam 6 and the concrete column 2, the steel plate hoop 7 is wrapped on the outer peripheral surface of the concrete 3 in the core area of the node, the steel plate hoop 7 and the overhanging end plate 5 are located under the negative steel bar 1, and the two overhanging end plates 5 pass through The lon...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com