Manufacturing method for composite profile steel-concrete combined beam, combined beam and monitoring device

A composite steel and concrete technology, applied in the direction of measuring devices, preparation of test samples, bridges, etc., can solve the problems of high price, complicated monitoring process, and high experience and technical requirements of monitoring personnel, and achieve simple operation, increased span, and low price Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

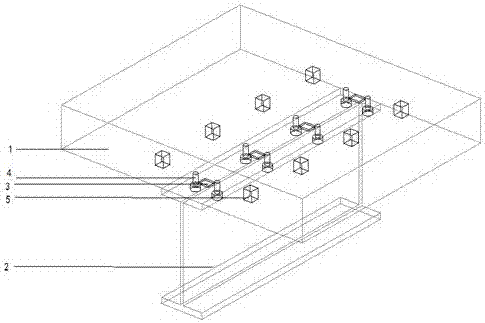

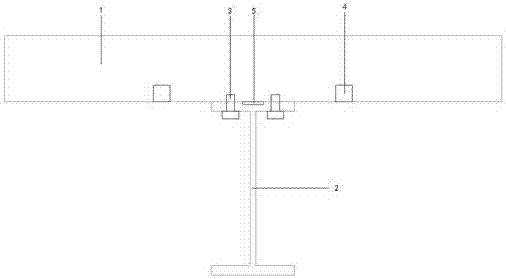

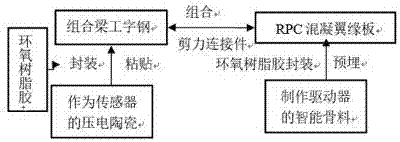

[0030] The preparation method of composite steel-concrete composite beam of the present invention is as follows:

[0031] 1) Clean the surface of the piezoelectric ceramic sheet PZT with anhydrous alcohol, let it stand still, and after the piezoelectric ceramic sheet is naturally dried, weld the wire on the piezoelectric ceramic sheet;

[0032] 2) A plurality of grooves are set along the span direction at the center line of the upper surface of the I-beam upper flange of the composite steel-concrete composite beam. The grooves match the size of the piezoelectric ceramic sheet PZT and are located on the steel-concrete composite beam. The position center of the medium shear connector;

[0033] 3) Paste the piezoelectric ceramic sheet PZT processed in step 2) along the span direction in the groove on the upper surface of the I-beam upper flange of the steel-concrete composite beam as a sensor, and encapsulate the piezoelectric ceramic sheet with a waterproof insulating material ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com