Patents

Literature

701 results about "Aggregate (composite)" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Aggregate is the component of a composite material that resists compressive stress and provides bulk to the composite material. For efficient filling, aggregate should be much smaller than the finished item, but have a wide variety of sizes. For example, the particles of stone used to make concrete typically include both sand and gravel.

Nano-material composite concrete with super high performance

InactiveCN102199021AImprove mechanical propertiesIncreased durabilitySolid waste managementCarbon nanotubeAmmonium bromide

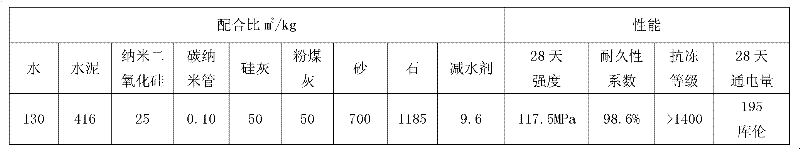

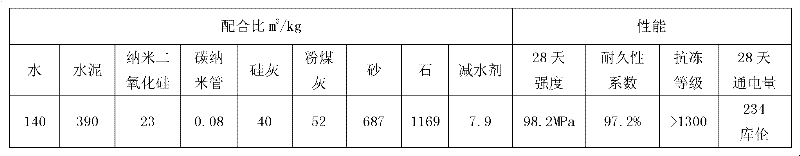

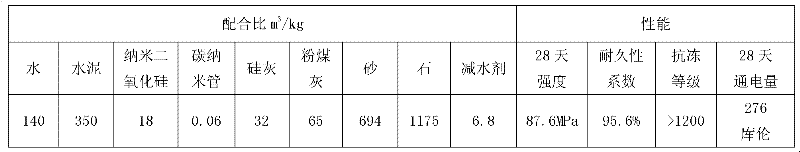

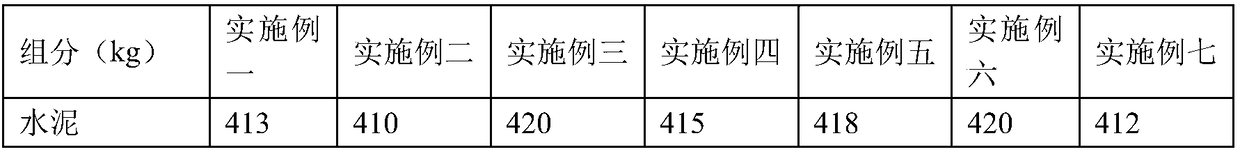

The invention relates to a preparation technology for concrete with super high performance, and belongs to the field of concrete technology in civil engineering. The invention is characterized in that: 1 m<3> of concrete contains 380 to 420 kg of cement, 680 to 740 kg of fine aggregate, 1120 to 1190 kg of coarse aggregate, 130 to 160 kg of water, 50 to 75 kg of fly ash, 25 to 64 kg of silica fume, 6.1 to 10.4 kg of a high performance water reducer, 0.05 to 0.25 kg of multi-walled carbon nanotubes and 15 to 25 kg of nanometer silica. The preparation technology is to carry out mechanical stirring for 180 to 240 seconds. The carbon nanotubes are added in the form of dispersion liquid, and a dispersant is cetyl trimethyl ammonium bromide (C16TAB), wherein the dispersion liquid is prepared according to the following portion MWNRs : C16TAB : water = 0.48 g : 4.1 g : 40 ml. The invention enables the super high performance concrete to have an enhanced mechanical property and lasting quality, a drastically increased service life, and capacity of being used in projects where requirements for the performance of concrete are high, for example, large-scale cross-sea bridges, super high buildings, and the like. The invention has a high utility value.

Owner:DALIAN UNIV OF TECH

Thermal-insulation loading recycled concrete

The invention relates to a concrete commonly used in building materials, and especially relates to a thermal-insulation loading recycled concrete. A technical problem to be solved is to provide a recycled concrete which is an integration of thermal insulation, loading, quake resisting, and energy saving and emission reduction. A technical scheme adopted is characterized in that a weight ratio (kg / m<3>) of a composite lightweight aggregate admixture: cement: recycled fine aggregate: sand: recycled coarse aggregate: cobblestone: ceramsite: coal ash: water: additives is (5-250):(200-800):(20-500):(5-800):(30-600):(5-1400):(50-800):(10-600):(50-500):(0.1-200); the composite lightweight aggregate admixture is a mixture of glazed hollow beads and an aerogel, and the weight part ratio of the glazed hollow beads to the aerogel is 1:(0.7-1.5); and the additives comprise the following components, by weight, 10-150 parts of silica fume, 4-40 parts of an air entraining agent, 5-30 parts of a foaming agent, 3-30 parts of a water reducing agent, 1-30 parts of a polypropylene fiber, and 10-150 parts of waste slag. The technical scheme is used for making the recycled concrete.

Owner:TAIYUAN UNIV OF TECH

Cement-based composite material used for 3D printing as well as preparation method and application thereof

ActiveCN105731942AGood lookingGreat tasteAdditive manufacturing apparatusSolid waste managementAggregate (composite)Alkali free

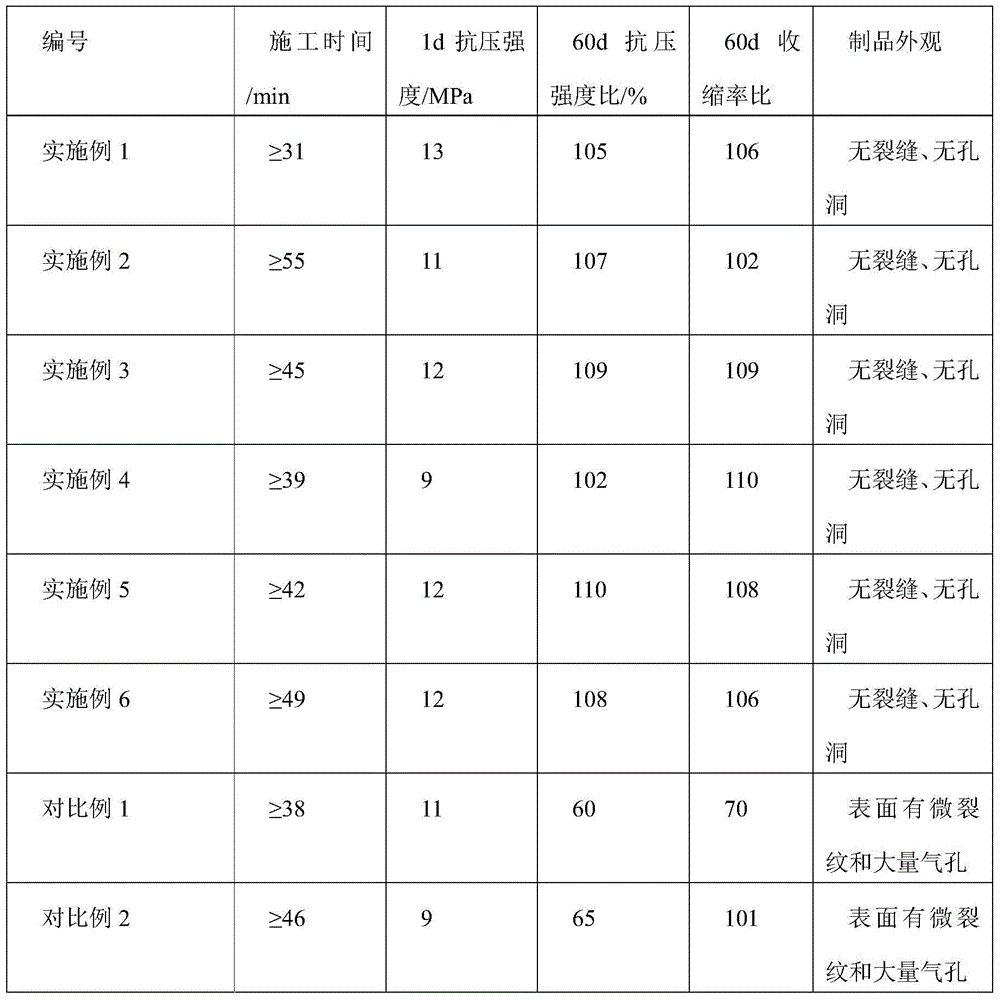

The invention discloses a cement-based composite material used for 3D printing as well as a preparation method and application thereof, and belongs to the field of building materials. The cemented-based composite material comprises the following components in percentage by weight: 19-25% of a composite gel material, 0.2-0.6% of a shrinkage inhibitor, 1-2% of an anti-carbonization agent, 57-66% of aggregates, 0.3-1.1% of fiber-reinforced materials, 0.9-1.8% of a liquid alkali-free accelerating agent, 0.8-1.7% of a retarder, 0.02-2% of a thickening agent, 0.2-0.4% of a plastic retaining agent, 0.04-0.09% of a defoaming agent, 0.04-0.2% of a water reducer and 5-14% of water. A cement product printed by the cement-based composite material has no holes and pitted surface in appearance.

Owner:CHINA BUILDING MATERIALS ACAD

Preparation technique of waste residue composite light-weight thermal-insulation wallboard

ActiveCN102863189ALow costCost enoughSolid waste managementCeramic shaping apparatusAggregate (composite)Engineering

The invention discloses a preparation technique of a waste residue composite light-weight thermal-insulation wallboard, which comprises the following steps: preparing a waste residue base material; preparing a composite admixture A; preparing waste residue light-weight aggregate; preparing a composite admixture B; preparing a wallboard blank material; preparing a wallboard blank; putting the wallboard blank in a curing chamber, and curing in a 75-80 DEG C saturated steam environment for 4-5 hours; and when the difference between inside temperature and outside temperature of the curing chamber is 25-40 DEG C, putting the wallboard blank outside the chamber, and demolding to obtain the waste residue composite light-weight thermal-insulation wallboard. According to the preparation method disclosed by the invention, the wallboard blank can be cured and demolded within 8.5-12 hours, and the demolded wallboard can be immediately put into engineering use, thereby shortening the processing cycle, and preparing the high-strength favorable-water-resistance light-weight wallboard under the conditions of changing wastes into valuable substances and using low production cost. The wallboard can be widely used in various types of construction engineering.

Owner:杜世永

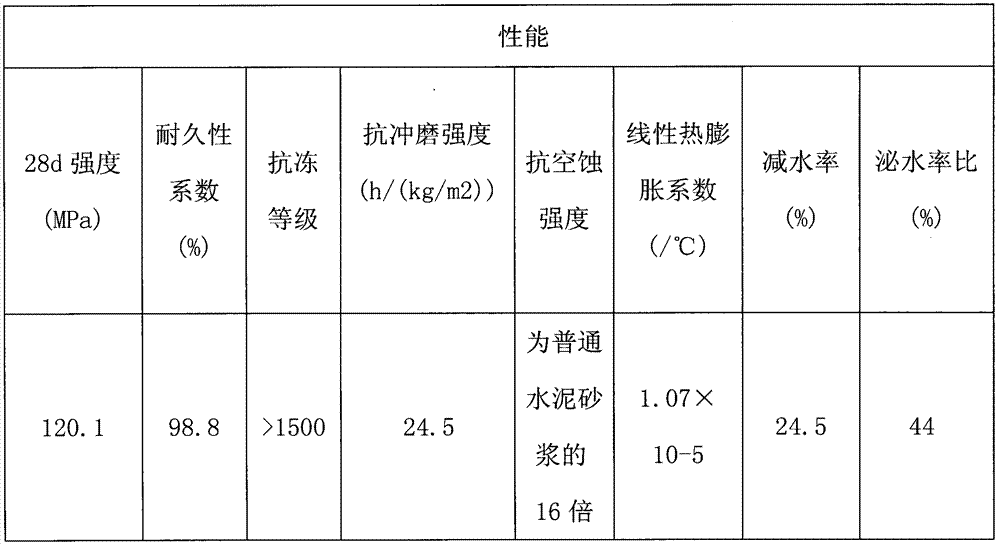

Cement-based composite material with high-temperature resistance and superhigh performance and preparation method thereof

InactiveCN102092996AReduce burstImprove compactnessSolid waste managementMetal fiberAggregate (composite)

The invention discloses a cement-based composite material with high-temperature resistance and superhigh performance and a preparation method thereof. The cement-based composite material comprises the raw materials of a gelled material, an aggregate, fibers, a water reducing agent and water, wherein the gelled material is a mixture of cement and active mineral admixture, the aggregate is yellow sand or a mixture of yellow sand and pebbles, and the fibers are organic fibers or mixtures of organic fibers and metal fibers. The cement-based composite material is produced through improvement on the basis of common concrete manufacturing, has the properties of superhigh mechanical property and high-temperature resistance, is applicable to high-temperature resistant engineering structures, and is favorable for preventing the collapse and the destruction of the construction structures in a fire disaster.

Owner:NANJING UNIV OF SCI & TECH

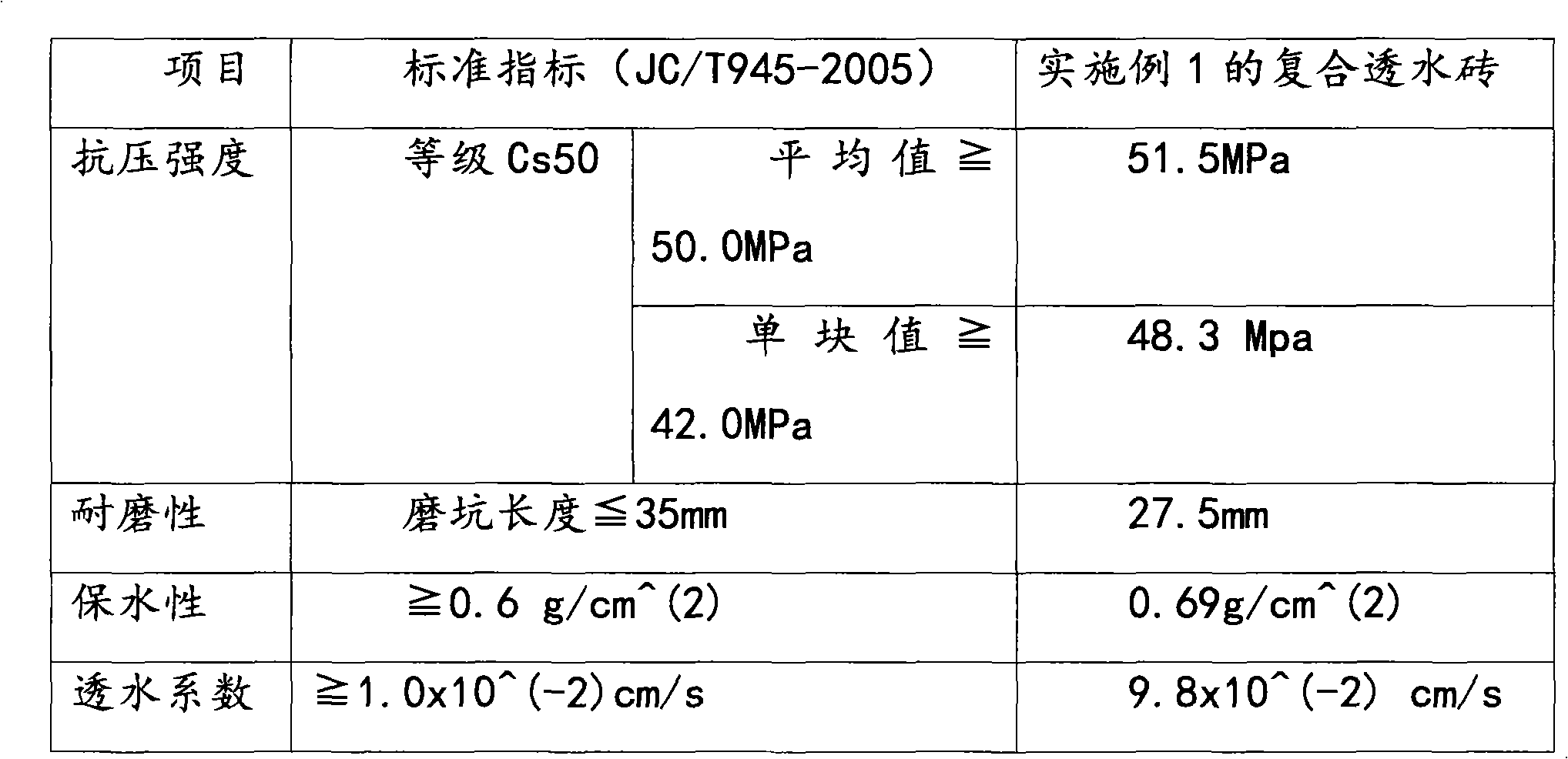

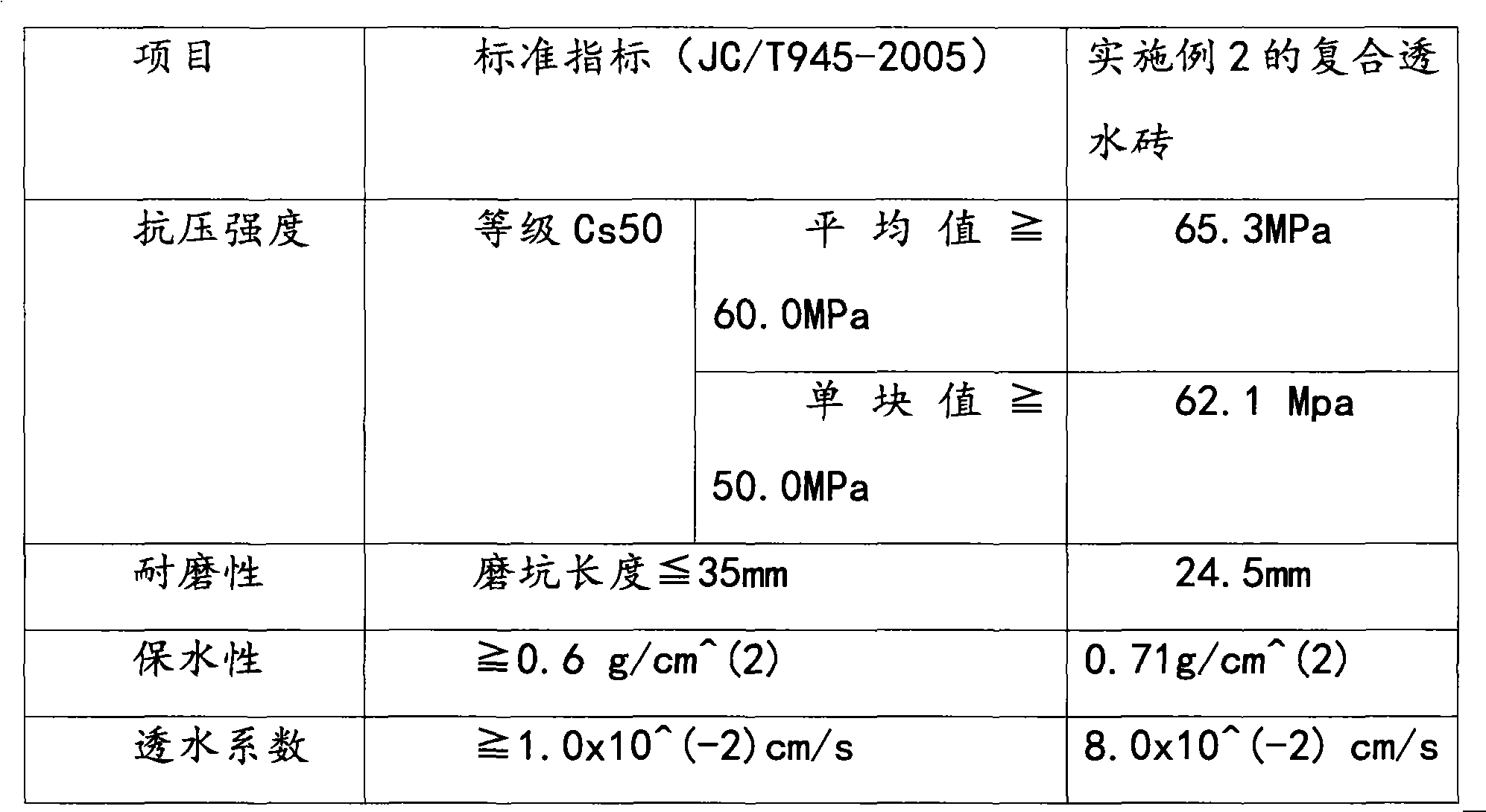

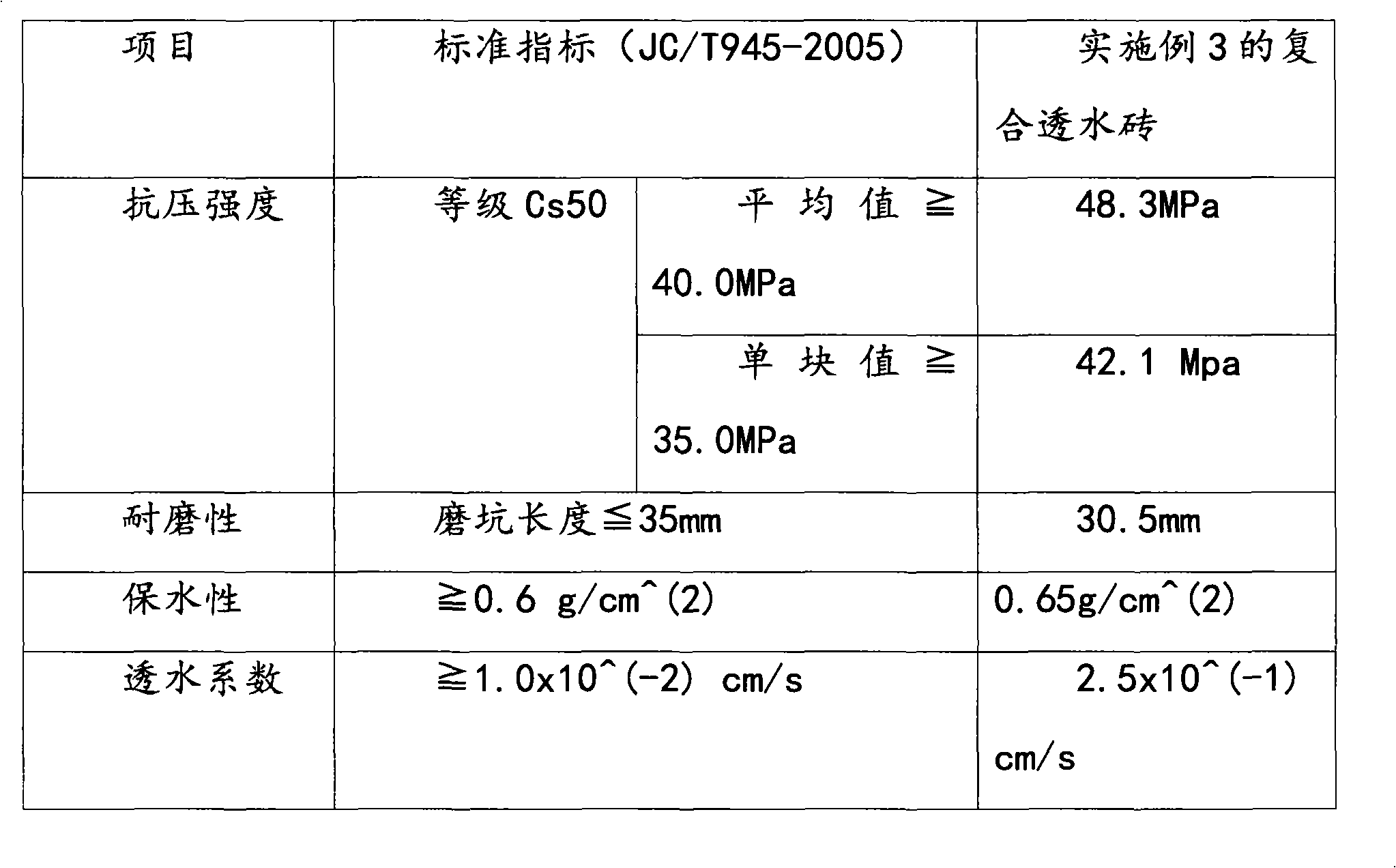

Pre-coated new sand, preparation method thereof and composite permeable brick

The invention provides pre-coated new sand, a preparation method thereof and a composite permeable brick. The pre-coated new sand comprises natural sand, pre-coated resin, a pre-coated curing agent, a coupling agent and a lubricating agent, wherein the pre-coated resin is weather-resistant alicyclic epoxy resin; the pre-coated curing agent is modified alicyclic amine. The composite permeable brick comprises a sandy surface layer and a concrete bottom layer, wherein the sandy surface layer contains pre-coated new sand and a fabric adhesive; the pre-coated new sand is the pre-coated new sand provided by the invention; the concrete bottom layer comprises a crushed stone aggregate, cement, coal ash, a water reducer and water. According to the pre-coated new sand provided by the invention, the composite permeable brick prepared by the pre-coated new sand has the characteristics of being high in strength and good in water permeability, and the composite permeable brick is simple in molding technology and low in cost.

Owner:李国辉

Concrete with electromagnetic wave radiation protection function and preparation method thereof

ActiveCN104628326AImprove the electromagnetic radiation protection functionImprove the protective effectSolid waste managementZinc oxides/hydroxidesAggregate (composite)Structural engineering

The invention relates to concrete with an electromagnetic wave radiation protection function and a preparation method of the concrete, and belongs to the field of construction materials. The concrete consists of water, dielectric loss type nano-composite wave-absorbing materials, magnetic loss type nano-composite wave-absorbing materials, a wave-absorbing base material, slag powder, cement, coal ash, fine aggregates, macadam and water reducing agents, and is prepared by mixing, stirring and pouring all components step by step. The concrete provided by the invention has high wide frequency wave-absorbing performance in 2-18 GHz, the bandwidth of less than -7dB optimally reaches 14.3 GHz and the bandwidth of less than -10dB reaches 10.6 GHz, and the concrete can be applied to electromagnetic wave of adjacent buildings such as radars, microwave base stations, high-power wireless communication launchers and the like, functional buildings in which a large quantity of precise electronic instruments are placed, critical buildings like national defense and administrative departments. The concrete has high scientific and technological contents, is high in innovativeness and wide in application prospect.

Owner:福建省盛威建设发展有限公司

Concrete material and preparation method thereof

The invention provides a concrete material, comprising the following components with corresponding proportions: cement, fine aggregate, coarse aggregate, fly ash, silica fume, carbon nanotube, nano silica, ceramsite, polyphenyl particles, steel fibers, nano kaolin particles, ultrafine natural zeolite powder, gypsum, polymer emulsion, a diol compound, modified lignosulfonate, a layered silicate mineral material, polysiloxane, oxalic acid, styrene acrylic emulsion, crystalline hydrated magnesium aluminum silicate minerals, water, a super plasticizer, a barium-containing naphthalene superplasticizer, an organic polymer plastic retaining agent, a composite retarder and an air entraining agent. The invention further relates to a preparation method of the concrete material. Compared with the existing concrete, various properties of the concrete material provided by the invention are greatly improved. The concrete material has a wide application range, a significant practical engineering value and remarkable technical and economic significance.

Owner:NORTH CHINA UNIV OF WATER RESOURCES & ELECTRIC POWER

High strength concrete and preparation method thereof

InactiveCN105367026AHigh strengthSolution to short lifeSolid waste managementHigh strength concreteAggregate (composite)

The invention discloses high strength concrete and its preparation method, and relates to the technical field of building materials. 1 m<3> of the high strength concrete comprises the following ingredients: 200-300 kg of ordinary Portland cement, 40-50 kg of mineral powder, 15-30 kg of rubber particles, 500-800 kg of fine aggregate, 600-900 kg of coarse aggregate, 20-60 kg of a concrete composite additive, 50-100 kg of polypropylene fiber, 100-200 kg of water, 45-90 kg of phosphorous slag powder, 2-3 kg of a corrosion inhibitor, 5-10 kg of a water reducing agent, and 10-20 kg of a reinforcing agent. According to the prepared concrete product, compressive strength is remarkably raised, cracks are minimized, and life of concrete structures is prolonged. In addition, the preparation method is simple, and production efficiency is high.

Owner:张进

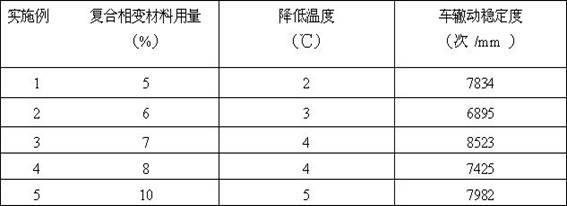

Composite phase transition cooling bituminous paving material

InactiveCN103508701AReduce the temperatureSmall temperature changeClimate change adaptationAggregate (composite)Urban heat island

The invention provides a composite phase transition cooling bituminous paving material, wherein the material can be used for preparing a set composite phase transition material from a phase transition material with an energy storage efficacy by a sol-gel method, drying, grinding and surface hydrophobic modification are carried out, the set composite phase transition particles are obtained after dried, the set composite phase transition particles after screened is used to replace an aggregate or a filling material with certain particle sizes in an asphalt mixture, and then the composite phase transition cooling bituminous paving material is obtained. The material has a good effect for reducing the bituminous paving temperature, can raise high temperature stability of the bituminous paving, and can simultaneously relieve urban heat island effect.

Owner:CHONGQING JIAOTONG UNIVERSITY

Composite material toughened ceramisite concrete and preparation method thereof

ActiveCN105541212AImprove toughnessImprove isotropic performanceSolid waste managementFiberAggregate (composite)

The invention belongs to the field of preparation of concrete, and in particular relates to composite material toughened ceramisite concrete and a preparation method thereof. The composite material toughened ceramisite concrete comprises the following components in parts by weight: 320-360 parts of cement, 40-80 parts of lithium slagpowder, 20-40 parts of silica fume, 700-900 parts of recycled coarse aggregates, 500-800 parts of ceramisites, 3-4 parts of a water reducing agent, 100-200 parts of water, 10-20 parts of polyacrylate, 20-30 parts of a toughening composite material, 0.05-0.1 part of sodium gluconate, and 10-15 parts of triethanolamine, wherein the toughening composite material is prepared from the following raw materials in parts by weight: 1.2-1.8 parts of modified silicon dioxide nanotubes, 22-28 parts of a styrene-butadiene-styrene block copolymer, 46-50 parts of activated wood powder fibers, 3.5-5 parts of a silane coupling agent, 3.0-3.5 parts of a solubilizing agent, 4-6 parts of a filler and 180-220 parts of water. The concrete has good toughness, isotropy, fatigue resistance, compactness, crack resistance, shock resistance and permeability resistance, and is a high-performance concrete toughening material, and the 28-day compression strength of the prepared concrete can reach 30-60MPa, so that the concrete is suitable for building bearing structures.

Owner:福建省东霖建设工程有限公司

High-strength composite inorganic artificial stone and preparing method thereof

The invention discloses a high-strength composite inorganic artificial stone and a preparing method thereof; the inorganic artificial stone comprises the following components by the weight percentage: 30-65% of aggregates, 25-60% of cement, 1-10% of a composite modifying agent, 1-5% of a water reducing agent, 0-1.5% of a retarder, and 8-20% of water, wherein the particle sizes of the aggregates are graded according to the weight of the aggregates. The preparing method of the inorganic artificial stone comprises the steps: successively adding the aggregates with predetermined weight particle size graduation, the cement, the composite modifying agent and the water reducing agent into a stirrer successively, uniformly stirring, adding an appropriate weight of water, then uniformly stirring, distributing the material and pressing under a vacuum state, carrying out wet culture and curing, cutting, and polishing to obtain the product. The inorganic artificial stone has the advantages of high bending strength, environmental-protection production process, lower cost, high yield rate of the product, outstanding performance and the like.

Owner:WANFENG COMPOUND STONE TECH

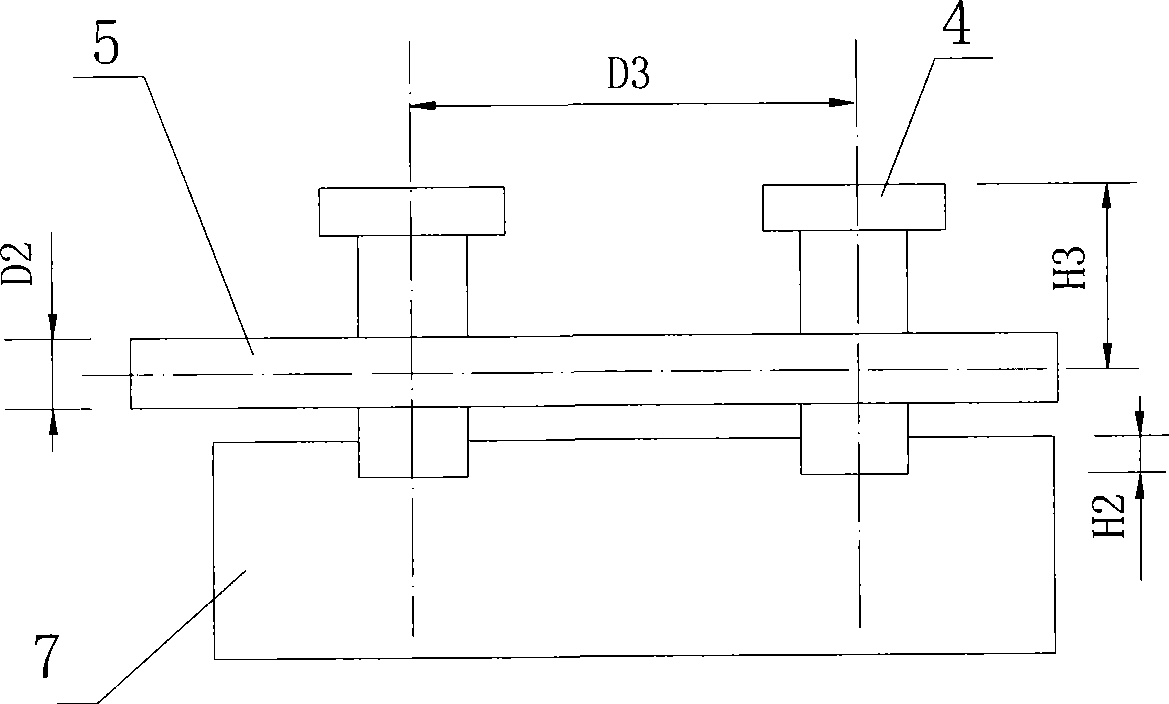

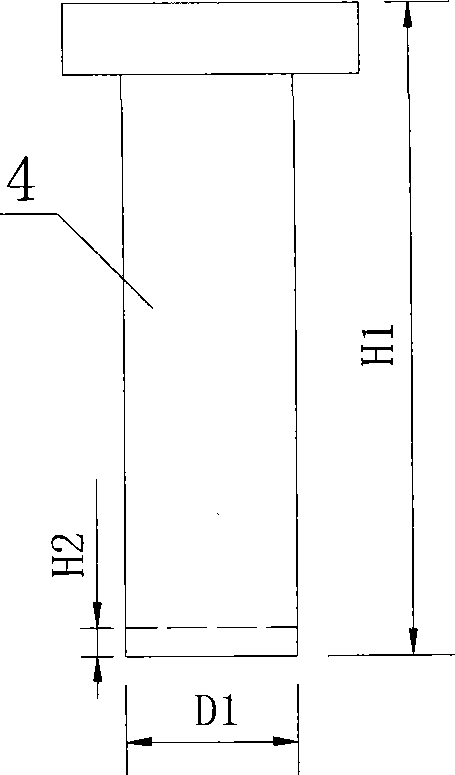

Heat-insulating integrated composite brick with alkaline structure and preparation method thereof

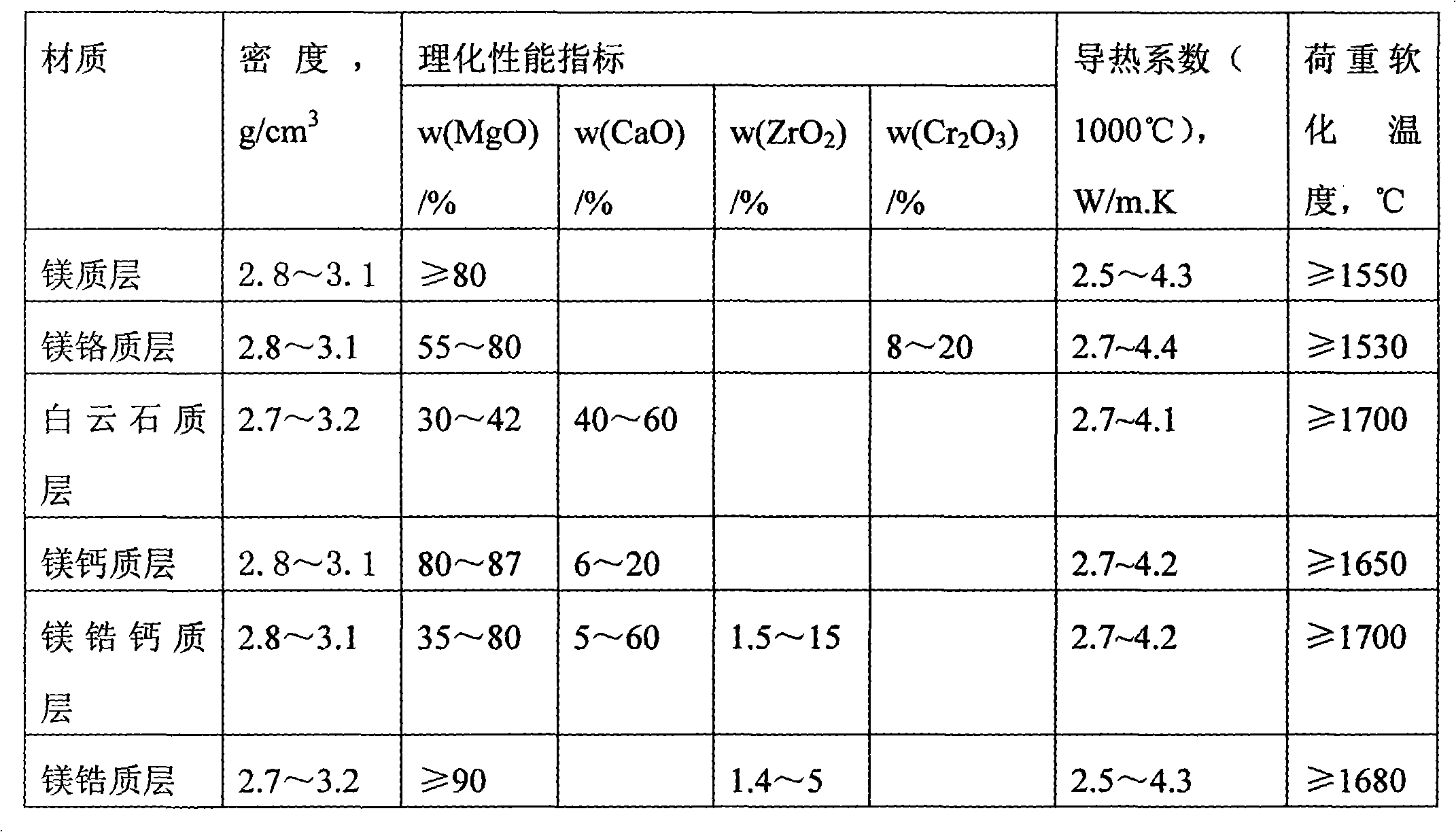

The invention discloses a heat-insulating integrated composite brick with an alkaline structure and a preparation method thereof, comprising a heavy-weight work layer and a light-weight heat-insulating layer, wherein the heavy-weight work layer takes compacted magnesium and compacted alkaline materials as the raw materials; the light-weight heat-insulating layer takes an alumina hollow ball or analuminum-magnesium hollow ball or a corundum hollow ball or the mixture of the three balls as the light-weight aggregate; the composite brick is composited by the heavy-weight work layer and the light-weight heat-insulating layer by vibration and pressurizing or mechanical-pressing moulding; and the proportion of the length dimension of the heavy-weight work layer and the light-weight heat-insulating layer is 1-5:2-1. The heat-insulating integrated composite brick overcomes the defect of big heat conductivity of the alkaline brick for a rotary kiln. The invention provides the heat-insulating integrated composite brick with good wear resistance, high refractoriness, good structural strength and good heat-preserving and heat-insulating performance.

Owner:ZHEJIANG UNIV

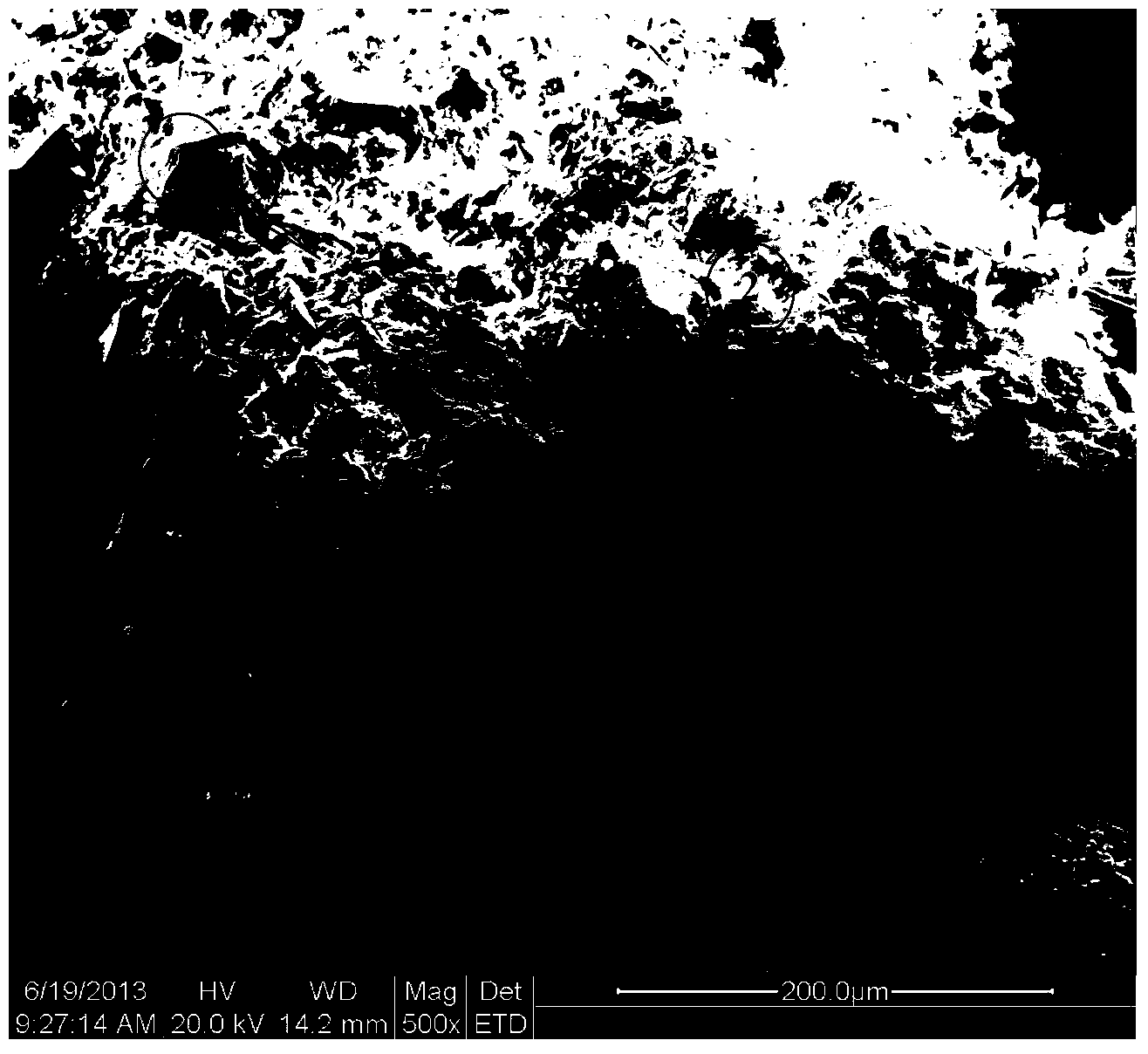

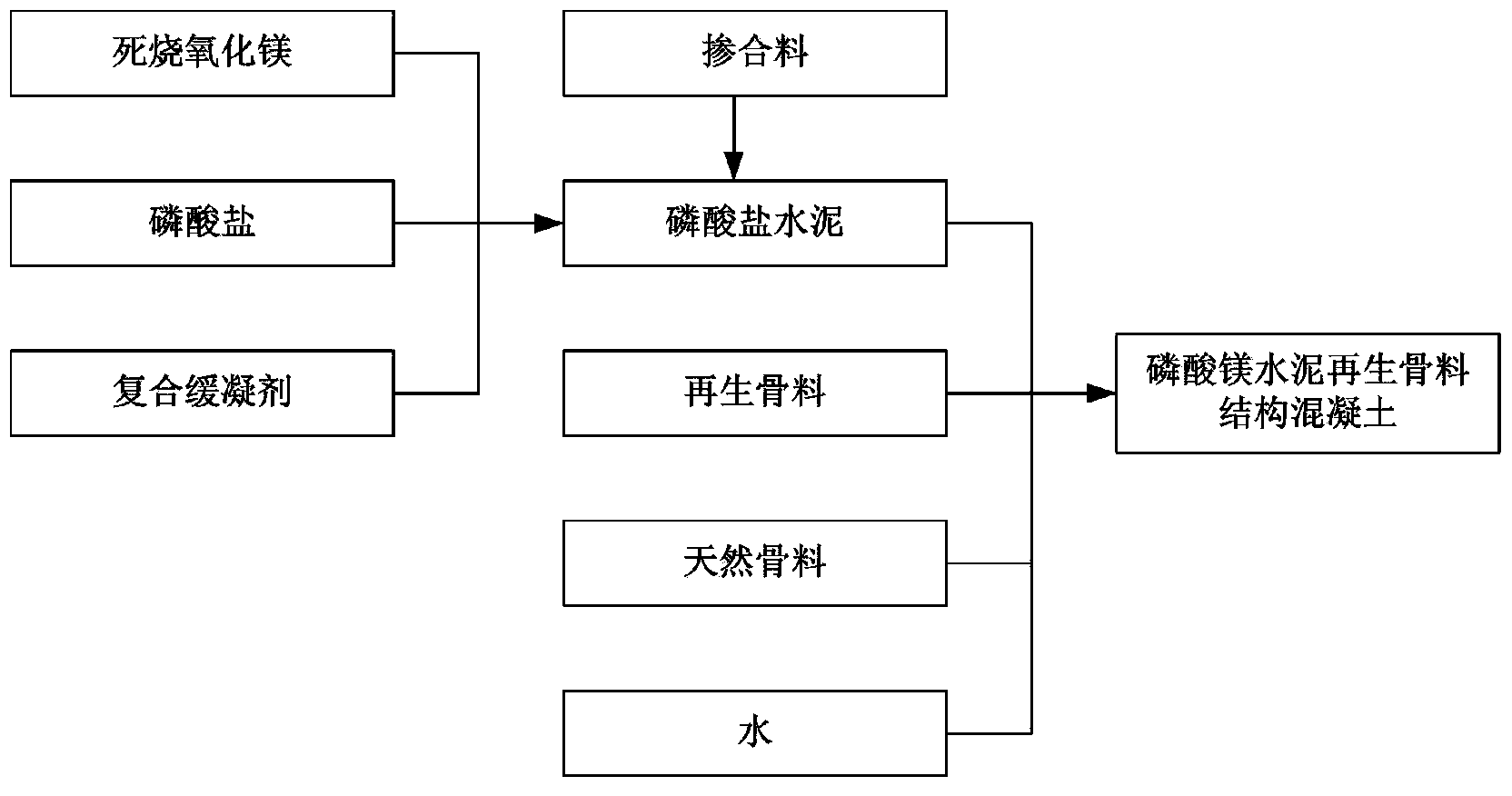

Magnesium phosphate cement recycled aggregate structure concrete and preparation method thereof

InactiveCN104072091AEarly hardening fastHigh strengthSolid waste managementAggregate (composite)Magnesium phosphate

The invention discloses magnesium phosphate cement recycled aggregate structure concrete and a preparation method thereof. The magnesium phosphate cement recycled aggregate structure concrete comprises the following components by weight percent: 12-30% of magnesium oxide, 8-20% of phosphate, 2-10% of composite retarder, 5-15% of admixture, 5-20% of recycled fine aggregate, 5-30% of recycled coarse aggregate, 0-10% of natural fine aggregate, 0-15% of natural coarse aggregate, and the balance being water. High early strength, small shrinkage rate, strong adhesive property and good corrosion resistance of the concrete are ensured by the magnesium phosphate cement; stable growth of the strength of the concrete is ensured by the admixture, and the durability and the volume stability are improved. The magnesium phosphate cement recycled aggregate structure concrete has the beneficial effects that the concrete material is applicable to the structure concrete and high-performance recycled aggregate concrete, can be applied to civil engineering in bad environments such as sulphate attack, marine corrosion, high-temperature environment and low-temperature environment, efficient utilization of the waste concrete is achieved, mining of natural gravel is reduced, the construction cost is reduced, and the targets of recycling wastes and protecting environment are achieved.

Owner:YANCHENG INST OF TECH

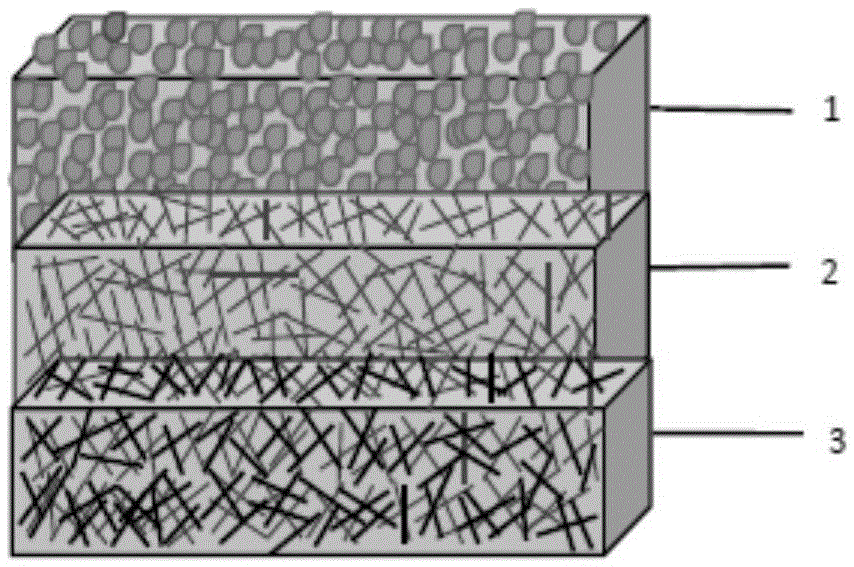

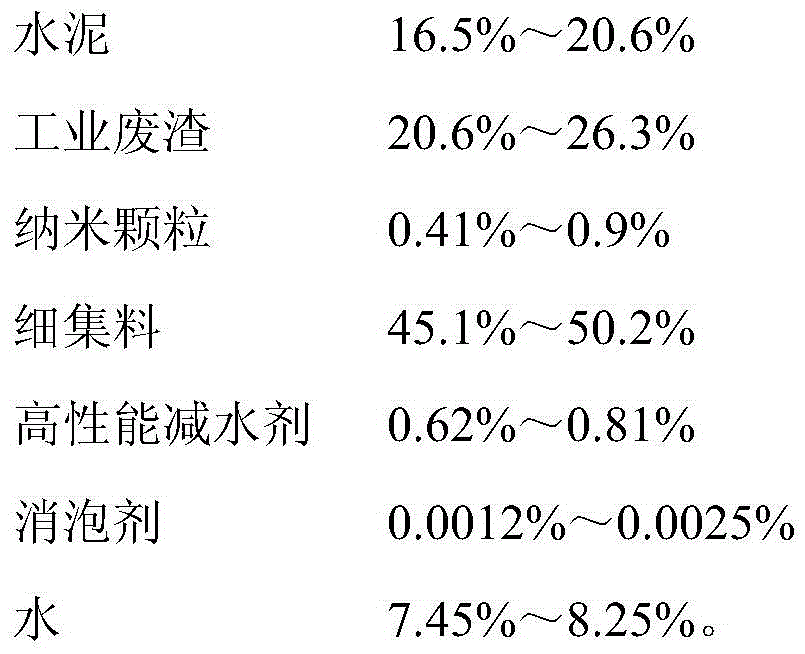

Anti-penetration and anti-explosion cement-based protective engineering material and preparation method thereof

ActiveCN105622018AWide variety of sourcesConducive to ecological sustainable developmentCrack resistanceCoupling

The invention discloses an anti-penetration and anti-explosion cement-based protective engineering material and a preparation method thereof. The protective engineering material is of a three-layer gradient structure made from very-high-performance mortar of the same proportioning ratio, a bottom layer is made from hybrid-fiber reinforced very-high-performance cement-based composite material, a middle layer is made from large-mixing-quantity steel-fiber reinforced very-high-performance cement-based composite material, a top layer is made from very-high-performance mortar-grouted high-strength coarse aggregate concrete, and the interfacial adhesivity is good. The very-high-performance mortar is prepared from cement, industrial residues, nanomaterials, fine aggregates, an antifoamer, a high-performance water reducing agent and water. According to the protective engineering material disclosed by the invention, hybrid fibers of the bottom layer can be used for improving the toughness and impact wave absorbing action of the structure and can also be used for improving crack resistance and high-temperature resistance; large-mixing-quantity steel fibers of the middle layer can be used for keeping the integrity of the structure and preventing bursting; high-strength coarse aggregates are added into the top layer, so that the penetration depth can be reduced, and the aim of anti-penetration and anti-explosion coupling action is achieved.

Owner:NANJING UNIV OF SCI & TECH

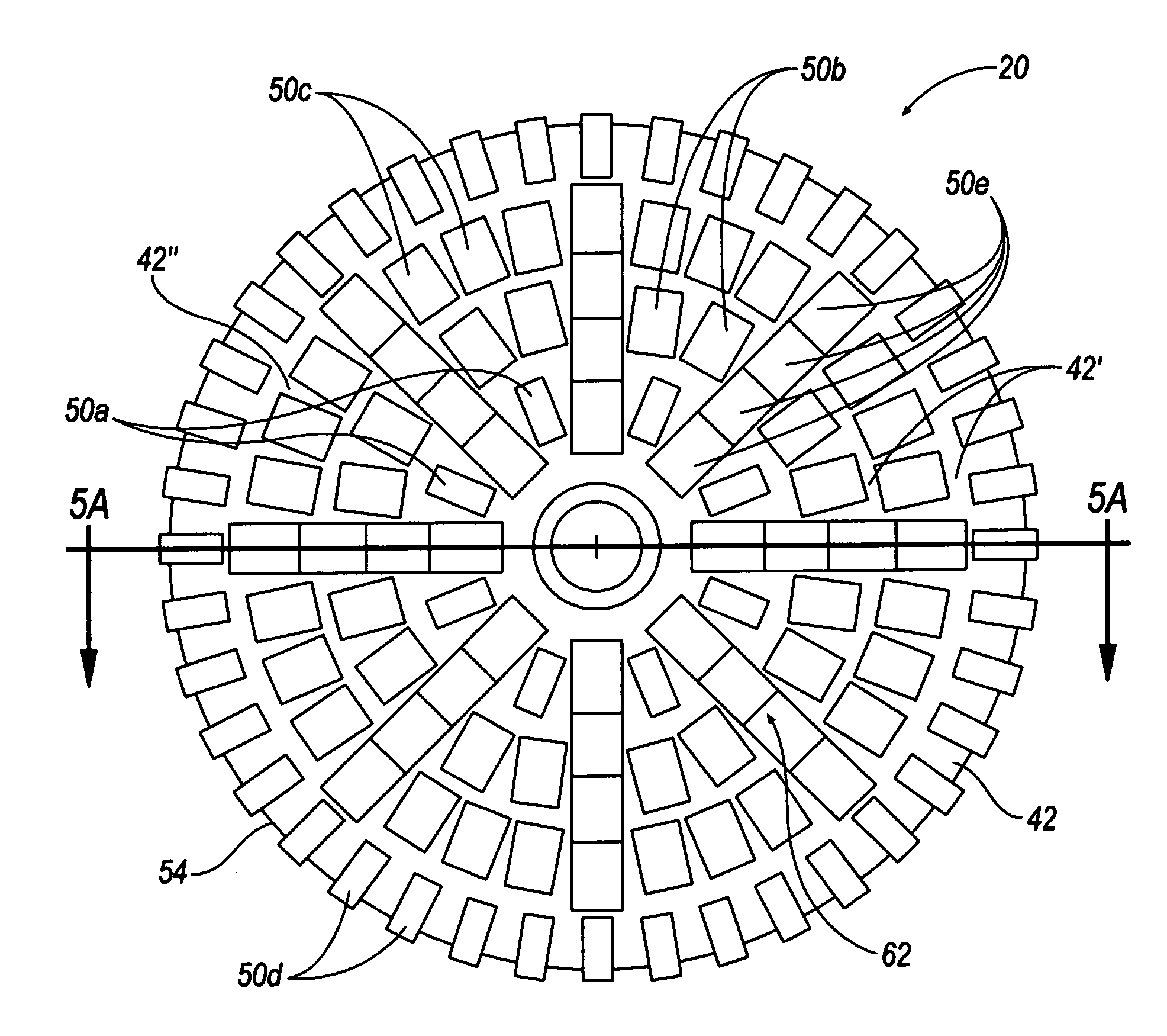

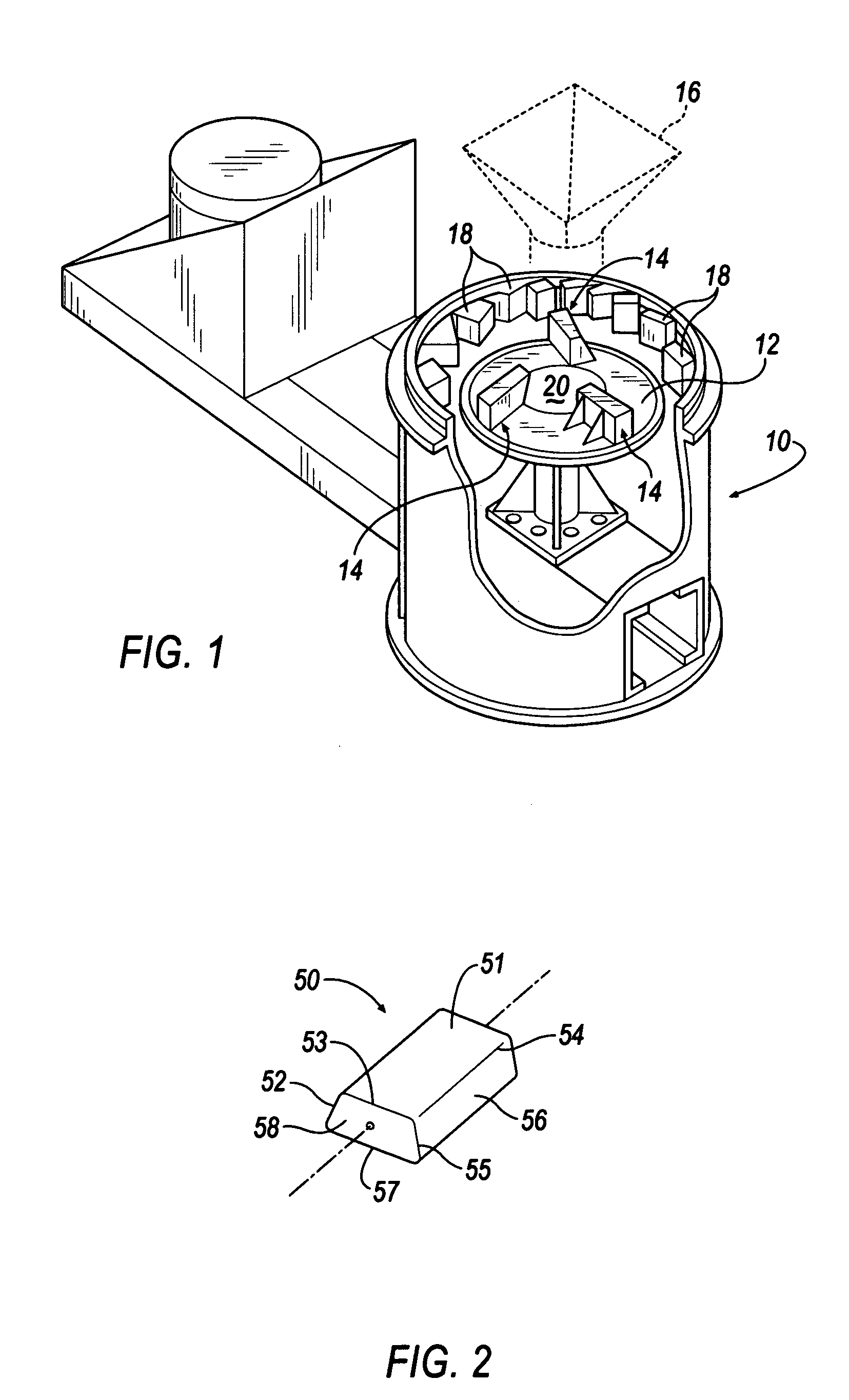

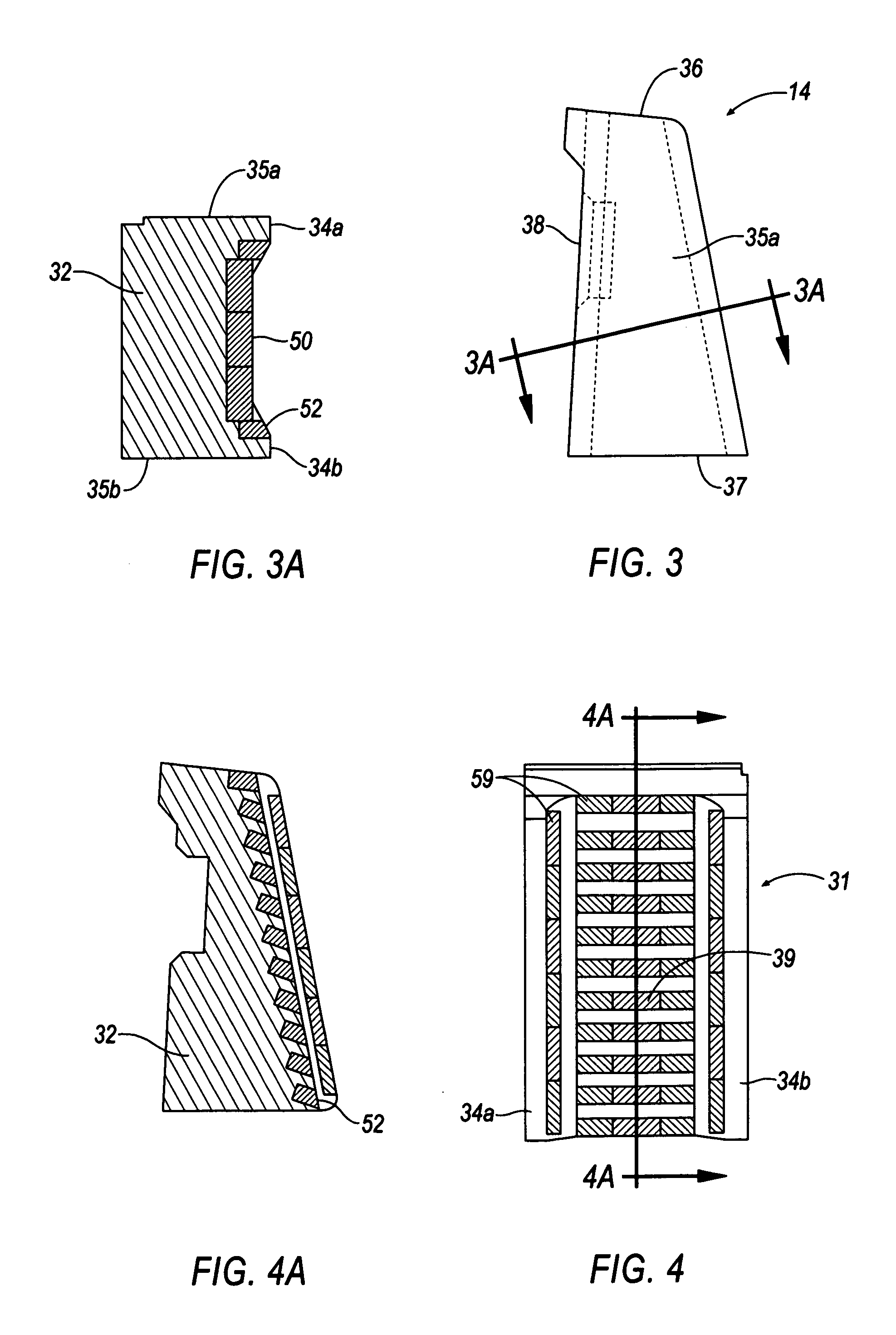

Wear bars for impellers

The present invention is particularly, but not exclusively, useful for reducing wear of component parts of impact-type rock-crushing machines caused by earth aggregate flows during operation of impact crushers. The present invention includes a central feed body and impeller shoe that has hard material insert bars fixed therein to reduce wear. The exposed top surface of the central feed body and front face of the impeller shoe are impregnated with a plurality of cemented carbide insert bars. The cemented carbide insert bars form an upper composite matrix that helps to reduce wear and the premature wash out of the hard material insert bars integrally cast within the central feed body.

Owner:KENNAMETAL INC

High-toughness inorganic material/polymer composite concrete and preparation method thereof

The invention discloses high-toughness inorganic material / polymer composite concrete and a preparation method thereof. The preparation method of the high-toughness inorganic material / polymer composite concrete comprises the following steps: modifying carbon nanometer tubes through a chemical reaction to obtain modified carbon nanometer tubes of which the surface is chemically grafted with high-substituted hydroxyproxyl cellulose, adding the modified carbon nanometer tubes in polyacrylate emulsion and stirring and mixing with water, a polyacrylate toughening emulsion, concrete, gravel, a fine aggregate, slag powder, fly ash and a water reducer as raw materials, thus obtaining the high-toughness inorganic material / polymer composite concrete. Through detection, the high-toughness concrete provided by the invention can show the significant strain hardening or deformation hardening characteristics under the action of a direct tensile load or a bending load, the bending strength can reach 19-29MPa, the tensile strength can reach 8-16MPa and the compressive strength can reach 78-95MPa. The high-toughness inorganic material / polymer composite concrete can be applied to fields such as bridge floor of large-span cross-sea / cross-river bridges, high-speed rail overhead viaducts and arch walls of various tunnels such as subway.

Owner:FUJIAN JUAN CONSTR ENG CO LTD

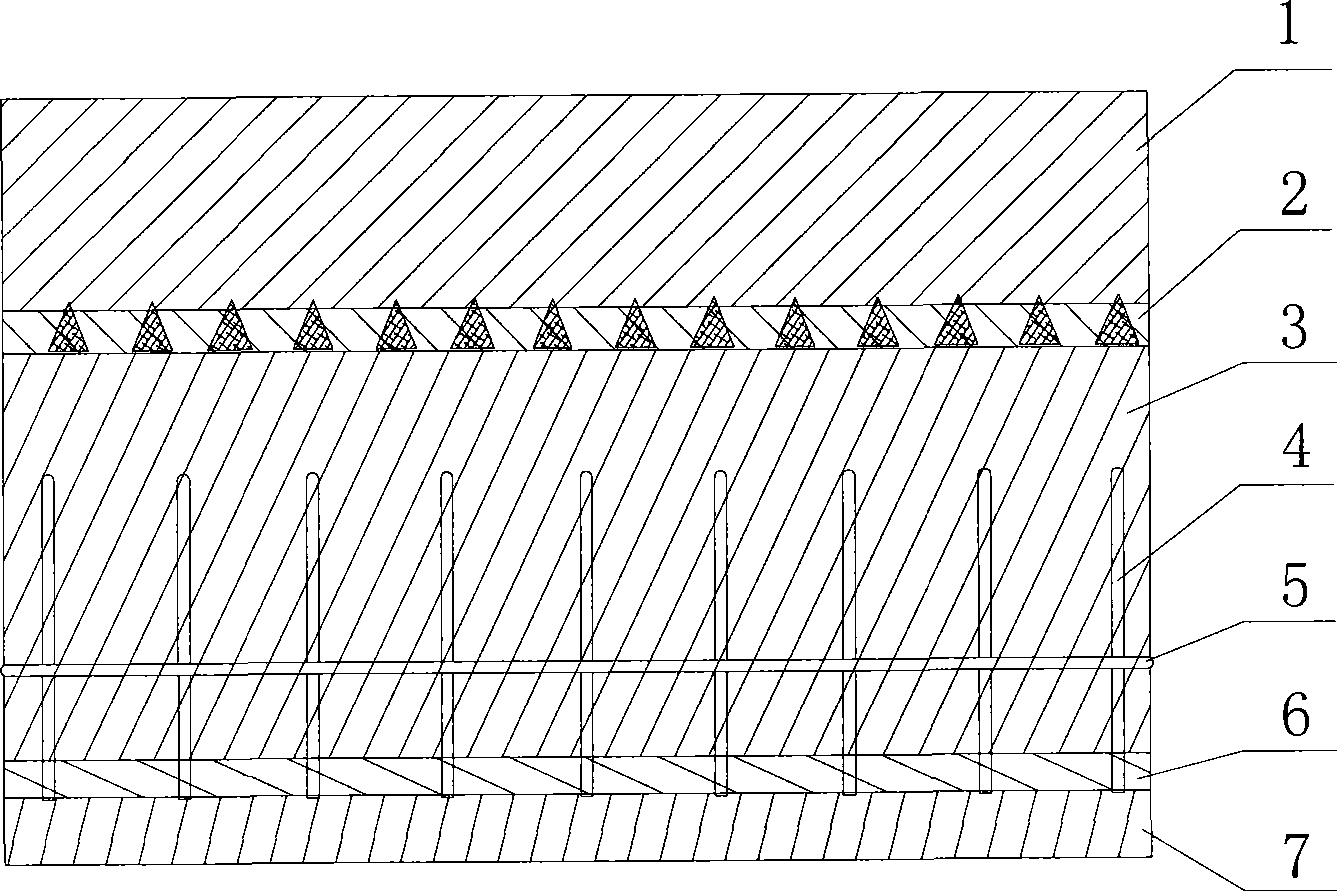

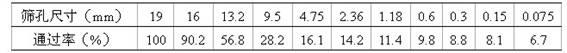

Pavement method for anti-movement composite structure of large-span steel box beam bridge deck

ActiveCN101368368AImprove bindingIncrease stiffnessIn situ pavingsBridge structural detailsSheet steelBridge deck

The invention relates to a method for paving combined anti-push structures on the surface of a large-span steel box girder bridge, including the following steps: 1) pretreating the armor plates of the large-span steel box girder bridge; 2), welding shear studs: welding shear studs on the armor plates of the large-span steel box girder bridge, with an interval at area of (35-45)cm X (35-45)cm between two shear studs; 3) colligating the reinforcement mats: fixing the reinforcement mats at specification of (95-105)cm X (95-105)cm on the shear studs; 4) mineral aggregate grading; 5)preparing and paving cast-type asphalt concrete; 6) paving a waterproof bond coat; and 7)paving anti-skid denoising wearing layer: paving a anti-skid denoising wearing layer at thickness of 3-5cm on the waterproof bond coat. The method has the advantages that cohesiveness at the interfaces is good, the paved layer and the armor plates are strong in coordinated deformability, and construction process is simple and convenient.

Owner:WUHAN MUNICIPAL CONSTR GROUP +1

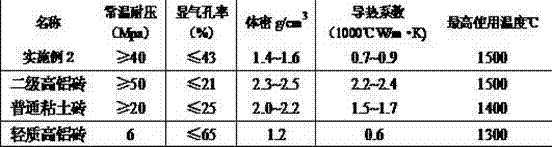

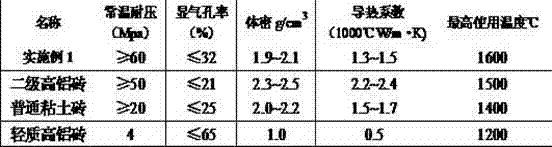

Novel lightweight mullite brick and fabrication method thereof

The invention discloses a novel lightweight mullite brick and a fabrication method thereof. According to the fabrication method, partial high-strength lightweight mullite aggregate, composite organic pore forming material and a high-polymer bonding agent are added to mullite which is used as a main raw material. The novel lightweight mullite brick has a lower heat conductivity coefficient, high compressive strength, high service temperature and certain erosion resistance, and can be extensively applied to parts of various sets of thermal equipment, which are not in direct contact with melt and materials. The novel lightweight mullite brick can replace a heavyweight high-alumina brick and a clay brick to be used as a working layer at some parts of various sets of thermal equipment, the deadweight of the thermal equipment can be reduced by more than 20%, and energy can be saved by above 25%.

Owner:郑州瑞泰耐火科技有限公司

Composite concrete agent

The invention discloses a concrete complexing agent as additive in the architectural material technical domain, which comprises the following parts: 48-55% silica, 27.5-45% fluorite, 2.5-8% sodium cetylsulfate, 4-9% hydroxy carboxyl acid and 0.5-1% aliphatic hydroxy sulfonate high-effective dehydragent. The complexing agent improves particle bond of concrete aggregate, which saves cement quantity by 10-20%.

Owner:王衡

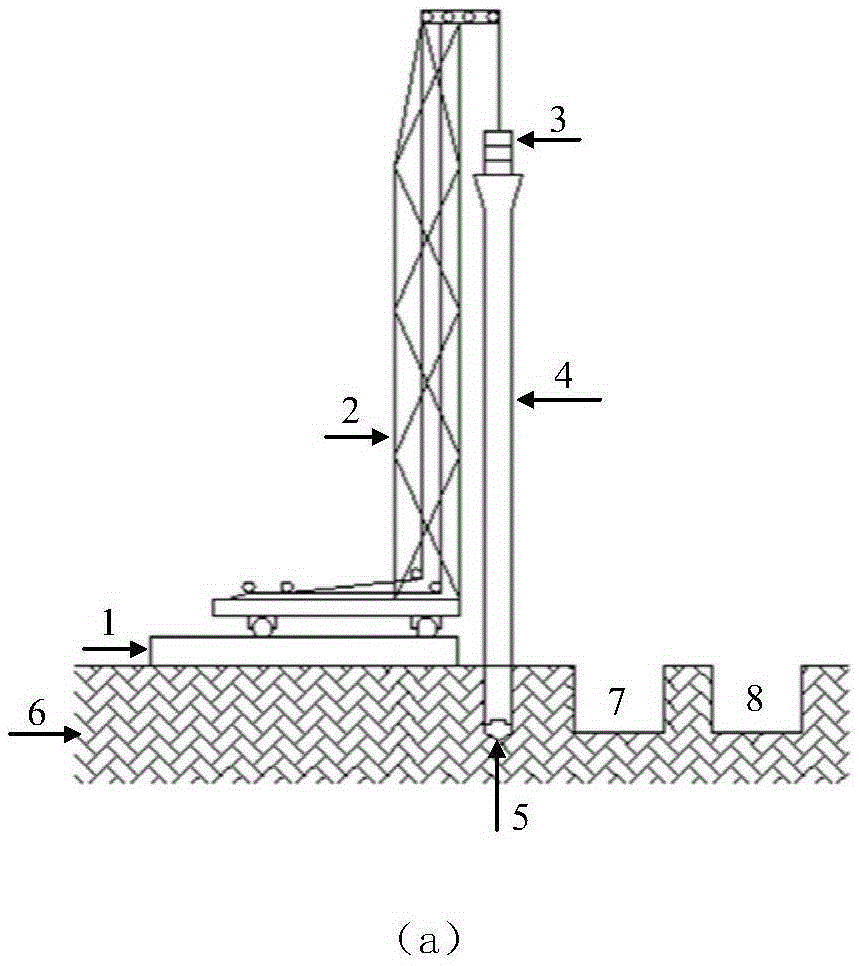

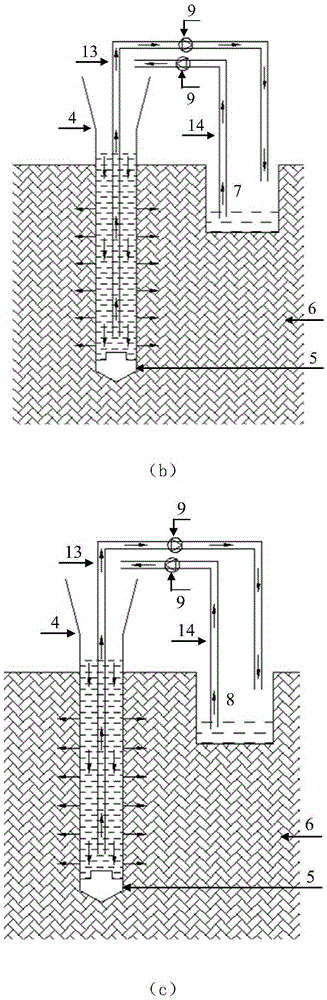

Microorganism soil-reinforcement cement fly-ash gravel (CFG) pile composite foundation and construction method

ActiveCN105386433AHigh strengthImprove bearing capacityBulkheads/pilesSoil preservationMicroorganismAggregate (composite)

The invention discloses a microorganism soil-reinforcement cement fly-ash gravel (CFG) pile composite foundation and a construction method. The construction method comprises the steps that a, a pile pipe is pressed into a foundation; b, microorganism bacterium liquid is injected into the pile pipe at the same time, and the microorganism bacterium liquid is made to diffuse towards the foundation around the pile pipe; c, the microorganism bacterium liquid is pumped out, and a cementing solution is injected into the pile pipe and made to diffuse to the foundation around the pile pipe and reacts with the microorganism bacterium liquid to generate calcium carbonate crystals, and incompact sandy soil or floury soil is cemented; d, the step b and the step c are executed repeatedly till the soil around the pile pipe meets the reinforcement requirement; e, pipe-drawing pile formation is conducted while cement-ash stabilized aggregates are poured; and f, a bed course is laid, so that the CFG pile composite foundation is formed. According to the microorganism soil-reinforcement CFG pile, the soil around the pile pipe is reinforced through calcium carbonate generated through reaction between the microorganism bacterium liquid and the cementing solution, so that the strength of the soil around the pile pipe is improved, and the quality problems of necking, pile breakage, soil carrying and the like in the pile forming process are solved; in addition, a reinforced soil body can be combined with a pile for bearing, and the bearing capacity of the single pile is effectively improved.

Owner:NANJING FORESTRY UNIV

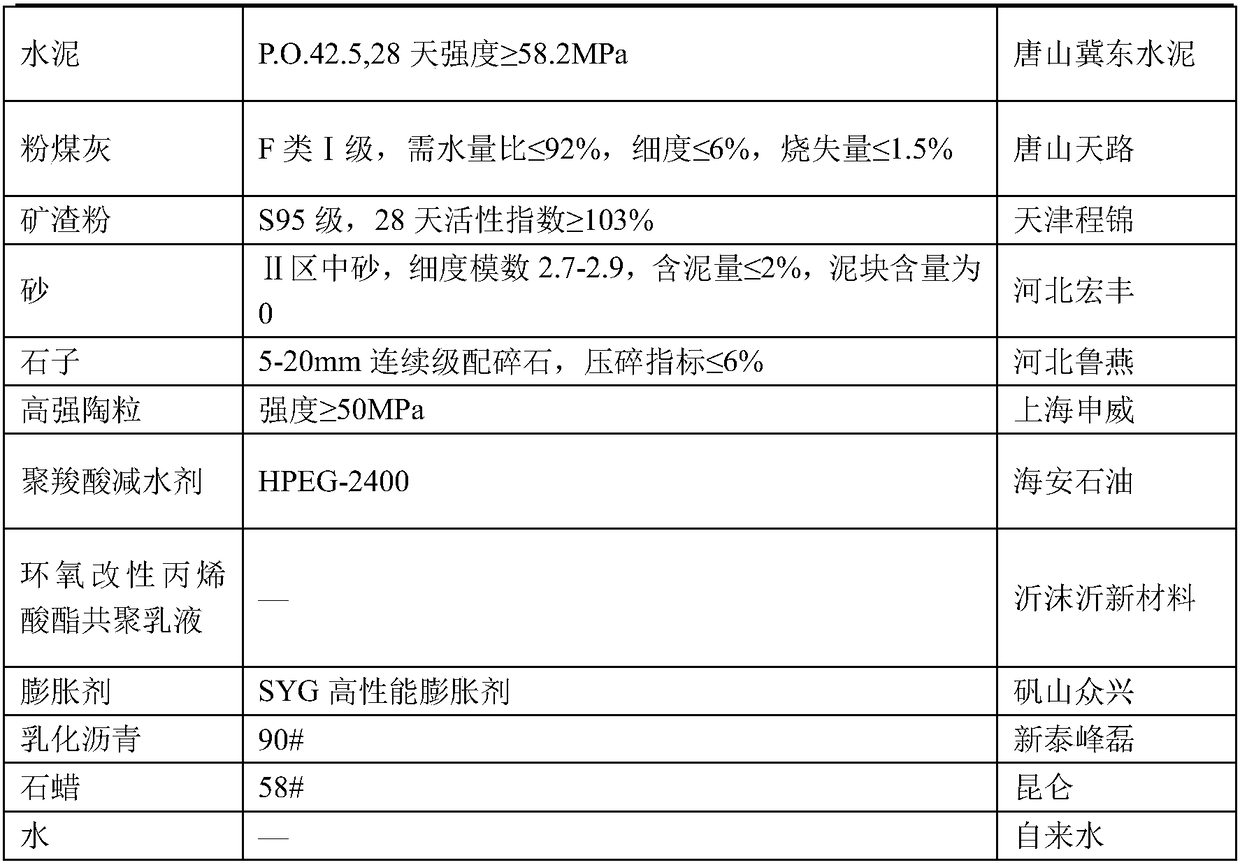

Phase change thermoregulation cement pitch composition concrete and preparation method thereof

The invention relates to phase change thermoregulation cement pitch composition concrete and a preparation method thereof. Cement mucilage mixed with phase change materials is filled into pitch concrete with big pores in self-leveling mode so as to guarantee that the pores are fully filled. Components of the pitch concrete with the big pores include: 88-90% of aggregate, 5-7% of mineral powder and 4-5% of modified pitch, wherein porosity of the pitch concrete ranges from 20% to 30%. Components of the cement mucilage mixed with the phase change materials include: 40-45% of cement, 15-20% of fine sand, 5-7% of coal ash, 25-30% of water, 0.6-1.5% of swelling agent, 5-10% of composite phase change materials and 0.3-0.5% of water reducer. The phase change thermoregulation cement pitch composition concrete and the preparation method of the phase change thermoregulation cement pitch composition concrete have the advantages of being simple in technology, low in cost, easy to implement and capable of enabling road surfaces to have strong capacity of resisting tracks, simultaneously having a function of lowering temperature of the road surfaces, and avoiding thermal damage on the phase change materials during a high temperature mixing and paving process in the traditional hot-mixed pitch concrete.

Owner:WUHAN UNIV OF TECH

Electromagnetic wave absorbing concrete and preparation method thereof

ActiveCN104649633AImprove electromagnetic wave absorption functionImprove the protective effectSolid waste managementAggregate (composite)Oxide composite

The invention relates to electromagnetic wave absorbing concrete and a preparation method of the concrete and belongs to the field of building materials. The concrete is prepared from a polymethylacrylic composite wave absorbing material containing nano LiFe5O8 / graphene oxide, a nano beta-MnO2 / graphene oxide composite wave absorbing material, water, cement, slag powder, coal ash, a water reducer, a fine aggregate and macadams by the steps of mixing, stirring and pouring. The concrete provided by the invention shows a good broadband microwave absorbing performance in a range of 2-18GHz, and the bandwidth of the concrete lower than -7dB is optimally 13.7GHz and the bandwidth of the concrete lower than -10dB is optimally 9.8GHz, so that the concrete can be applied to electromagnetic wave protection of critical buildings of military and administrative branches, functional building internally provided with a lot of precise electronic instruments, buildings adjacent to radar, microwave base stations, high power wireless communication transmitting stations and the like. The concrete provided by the invention is innovative, high in scientific content and broad in application prospect.

Owner:福建省盛威建设发展有限公司

Self-compacting concrete and preparation method thereof

The invention relates to a self-compacting concrete. The self-compacting concrete comprises, by weight, 410 to 420 parts of cement, 50 to 60 parts of fly ash, 30 to 35 parts of slag powder, 750 to 760parts of sand, 970 to 980 parts of coarse aggregate, 10 to 15 parts of an additive, 28 to 35 parts of an expanding agent and 150 to 160 parts of water, wherein the coarse aggregate comprises cobblestone and phase-change ceramsite in a weight ratio 5: 1, and the additive comprises a polycarboxylate superplasticizer and a binder in a mass ratio of 2: 1. According to the invention, the expanding agent and a composite phase-change material are added into the concrete, so gaps in the self-compacting concrete are filled, and internal cracks in the concrete are reduced.

Owner:北京中实上庄混凝土有限责任公司

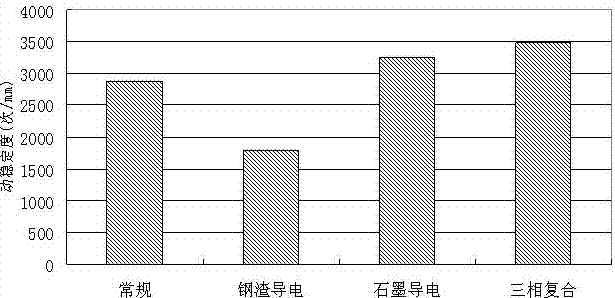

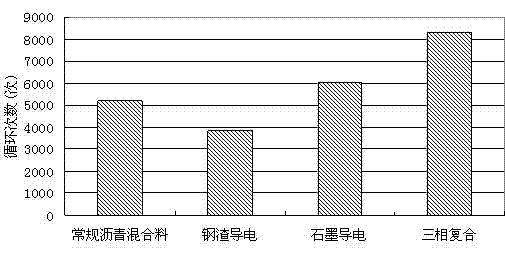

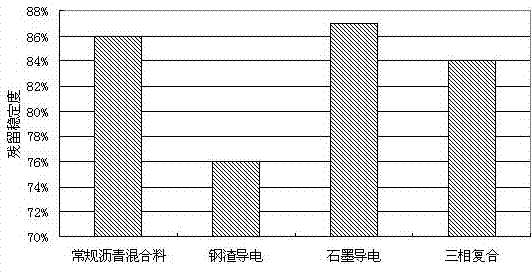

Three-phase composite conductive anti-freezing asphalt mixture and preparation method thereof

InactiveCN102329104AAchieve sustainable developmentImprove high temperature mechanical propertiesSolid waste managementFiberAggregate (composite)

The invention discloses a three-phase composite conductive anti-freezing asphalt mixture and a preparation method thereof. The three-phase composite conductive anti-freezing asphalt mixture comprises coarse aggregates, fine aggregates, mineral powder and asphalt, and is added with a conductive material which consists of 15-20 percent of graphite, 0.2-0.5 percent of carbon fibers and 15-55 percent of steel slag by weight percent. The preparation method comprises the steps of: screening, crushing and heating the aggregates to 180 DEG C plus or minus 5 DEG C, adding the steel slag and agitating for 85-95s; adding the carbon fibers and agitating for 80-90s; adding matrix asphalt and agitating for 85-95s at 165 DEG C plus or minus 5 DEG C; then adding the filler mineral powder and the graphite and agitating for 85-95s; and finally conducting heat preservation for 1-2h in a drying oven at the temperature being 140-145 DEG C to obtain the three-phase composite conductive anti-freezing asphalt mixture. Snow melting through electric conduction is realized. At the same time, the high-temperature mechanical property and the anti-fatigue durability of the pavement are improved.

Owner:JIANGSU EASTTRANS INTELLIGENT CONTROL TECH GRP CO LTD

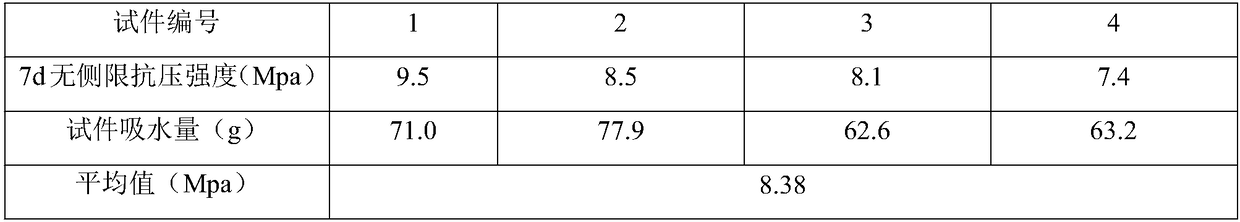

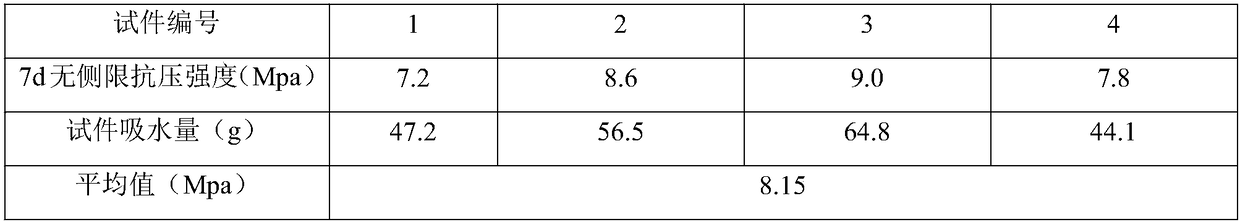

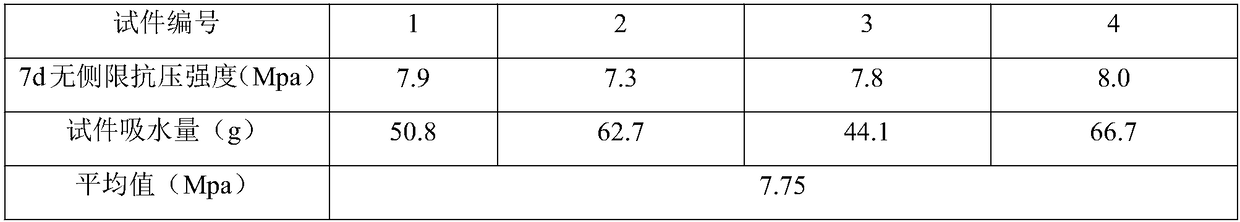

Phosphogypsum cement graded broken stone stable layer and preparation method thereof

The invention provides a phosphogypsum cement graded broken stone stable layer, which comprises aggregates and a phosphogypsum composite stable material. The aggregates comprise coarse aggregate and fine aggregate. The coarse aggregate comprises broken stones with three particle sizes: 15-25 parts of broken stones with particle size of 4.75-9.5 mm, 15-25 parts of broken stones with particle size of 9.5-19 mm and broken stones with particle size of 19-26.5 mm. the fine aggregate comprises 30-40 parts of stone chips with particle size of 0-4.75 mm. Addition amount of the phosphogypsum compositestable material is 15-20% of the amount of the aggregates. Water content of the graded broken stone stable layer is 7.0-8.1%. The invention has the following beneficial effects: a new approach of phosphogypsum utilization is provided, and the phosphogypsum accumulation problem can be effectively solved. The 7-day unconfined compressive strength of the graded broken stone stable layer is averagely8.1 Mpa. The 7-day unconfined compressive strength is raised by 7-9 Mpa, which is far higher than 5 Mpa of a cement-stabilized macadam stable layer. As slag of S95 and above is adopted for the gradedbroken stone stable layer, performance of the graded broken stone stable layer can be effectively raised and cost can be reduced, and environment pollution caused by slag will be avoided. The manufacturing method of the graded broken stone stable layer is simple, and the manufacturing can be realized without large quantities of professional equipment.

Owner:HUBEI CHANG YAOXIN MATERIALS LIMITED BY SHARE

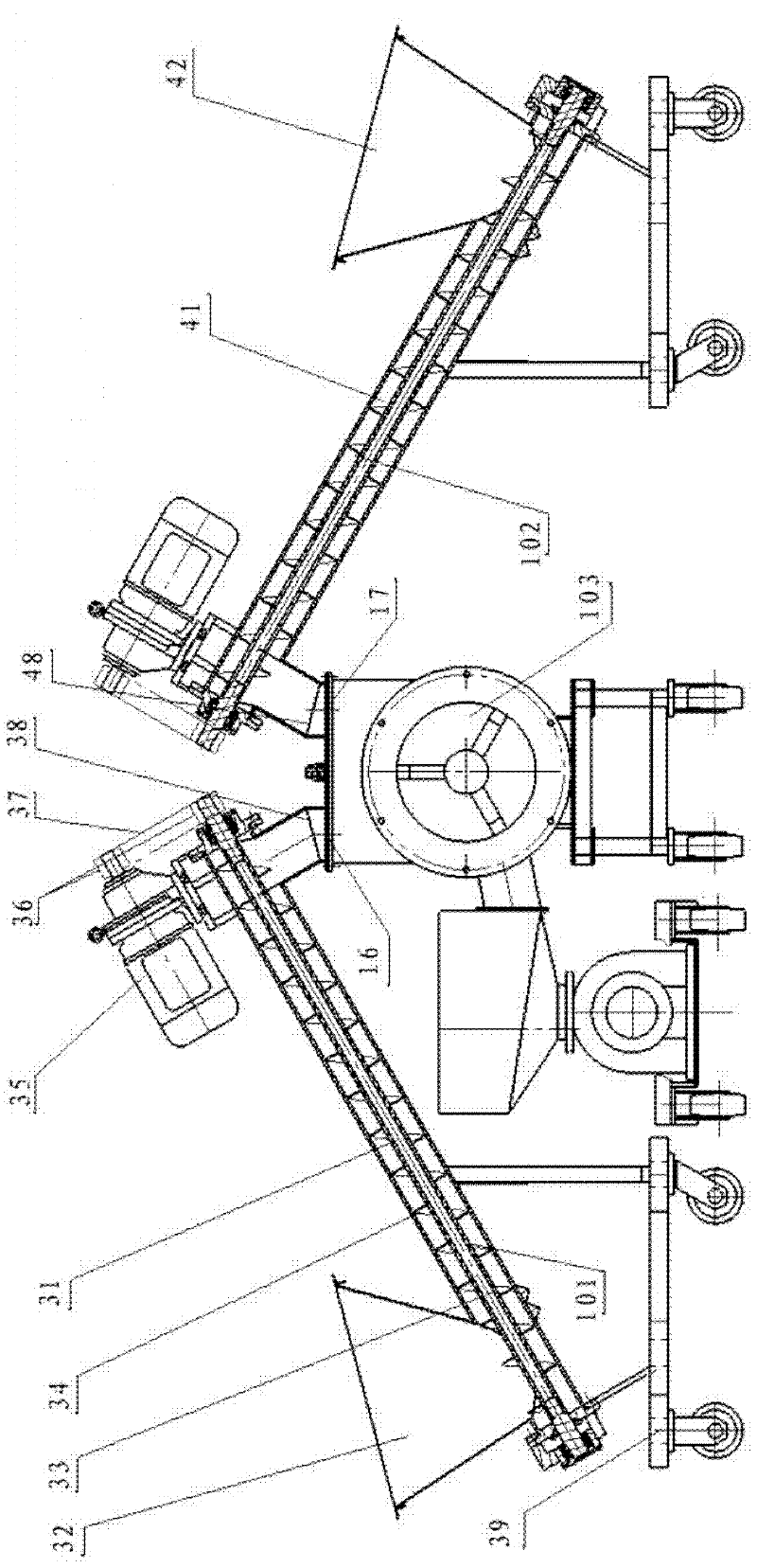

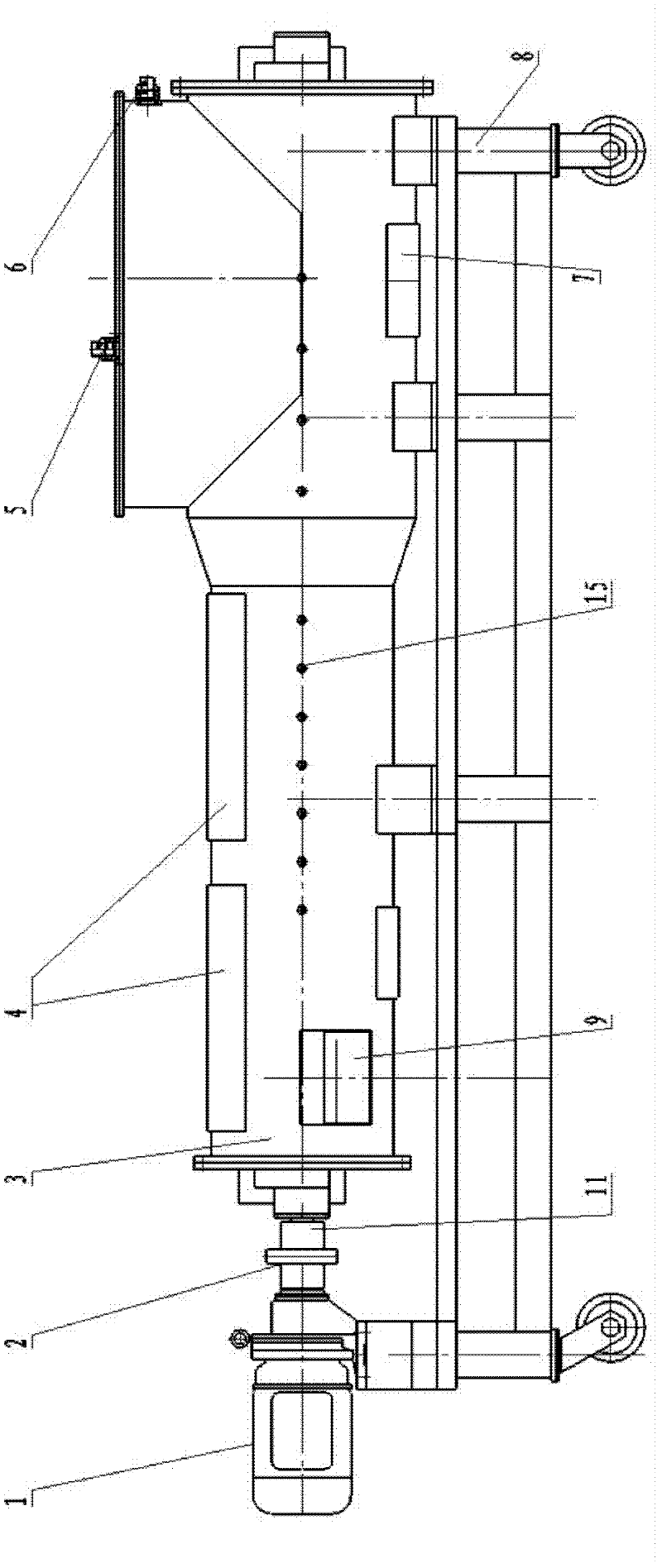

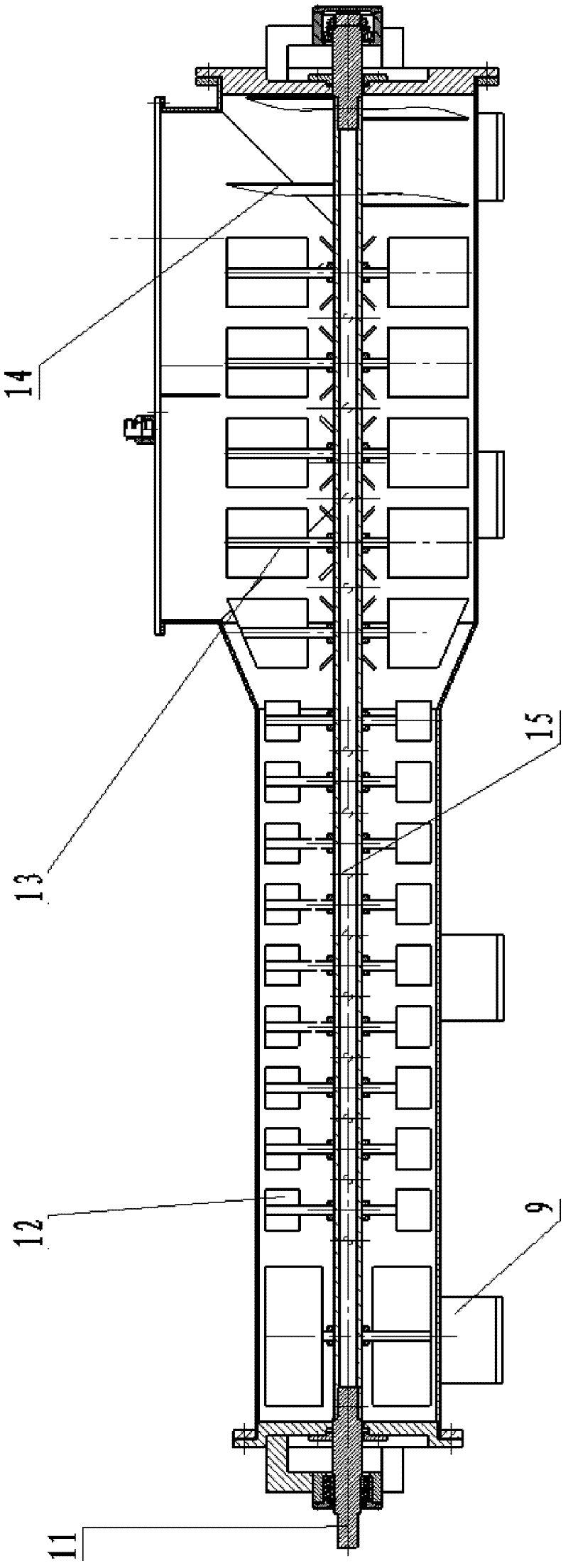

On-line production method and device of composite foamed slurry

InactiveCN102229206AReduce lossesImprove sound insulationMixing operation plantAggregate (composite)Fluid phase

The invention provides an on-line production method and an on-line production device of composite foamed slurry. The method comprises the steps of feeding, mixing, foaming, stirring and pumping. The device comprises a cement feeder, a polyphenyl granule feeder, an aggregate feeder, a water pump, a foaming machine, a stirring conveyer, a slurry storage tank, a concentrated slurry pump and an electric control device. According to the method and the device, effective recombination of organic light aggregate, inorganic heavy aggregate and foamed slurry is realized; the insulated, soundproof, anti-freezing, durable, light and high-strength composite foamed slurry with more optimized performance can be prepared and conveyed; the mixing proportion metering is more accurate compared with manual feeding, the stirring time is shorter compared with an intermittent stirring mode, the foam loss is lower, and solid-liquid phase separation of the slurry is avoided; and meanwhile, by continuous machining and conveying, the production and construction efficiency is improved.

Owner:沈阳金铠建筑科技股份有限公司

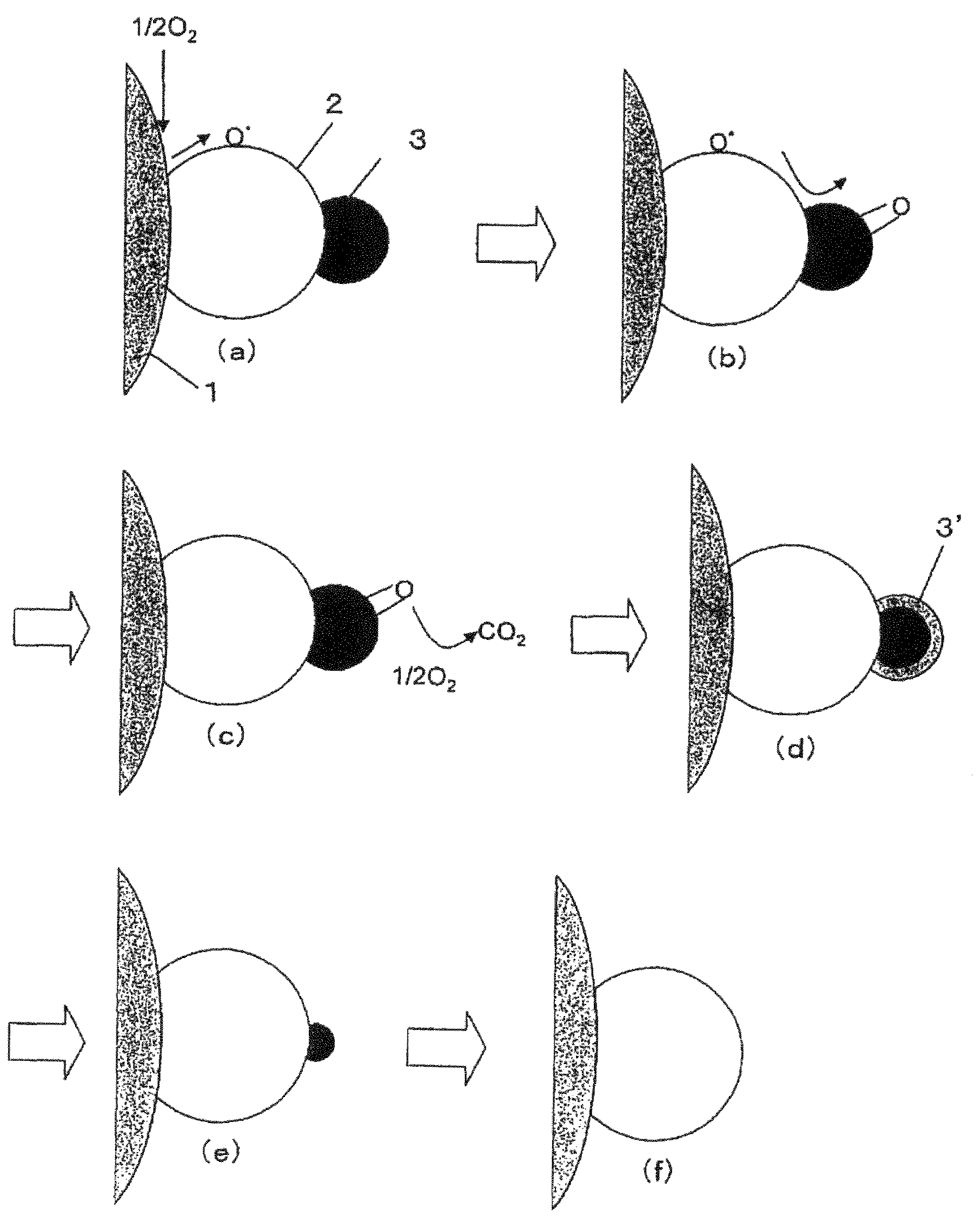

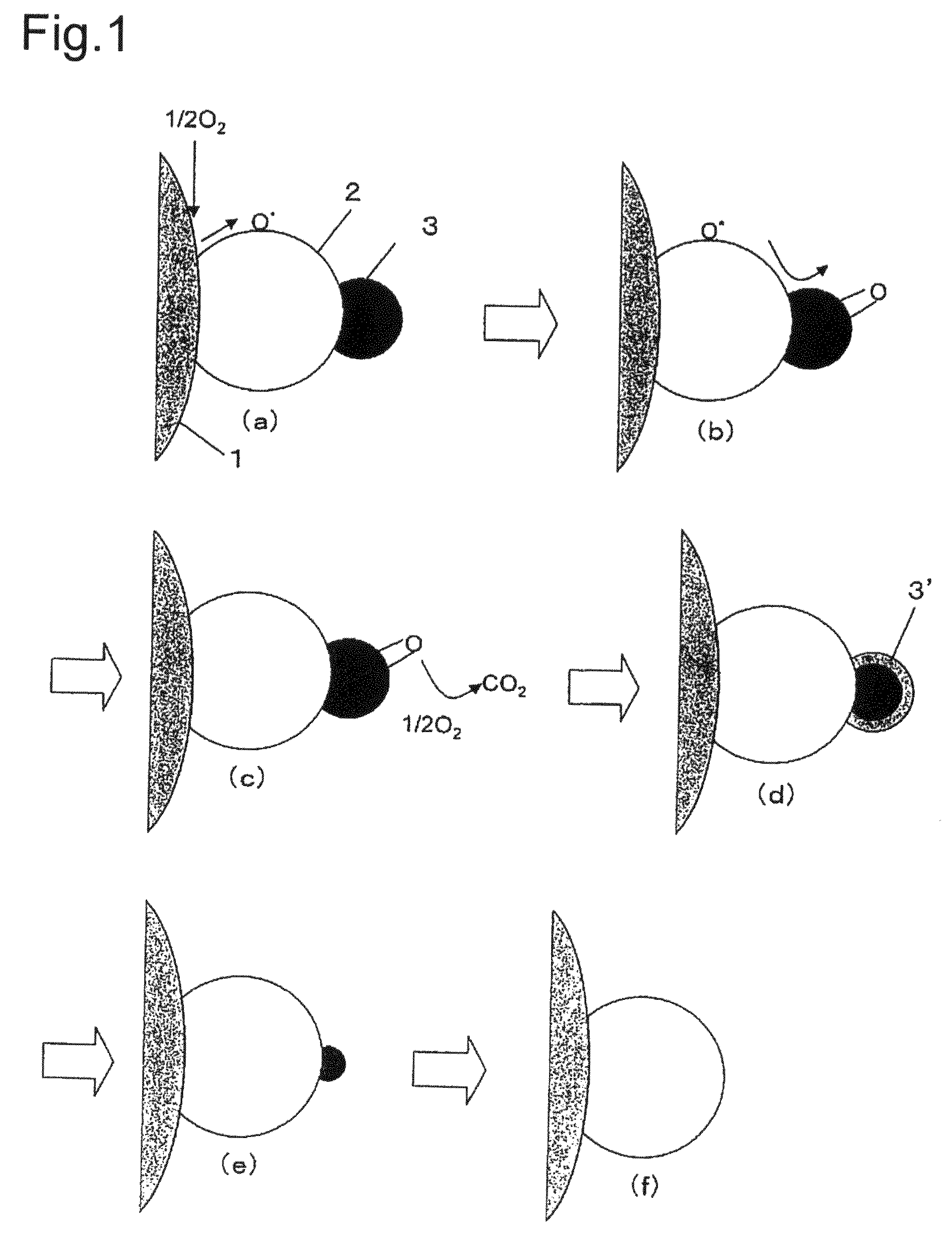

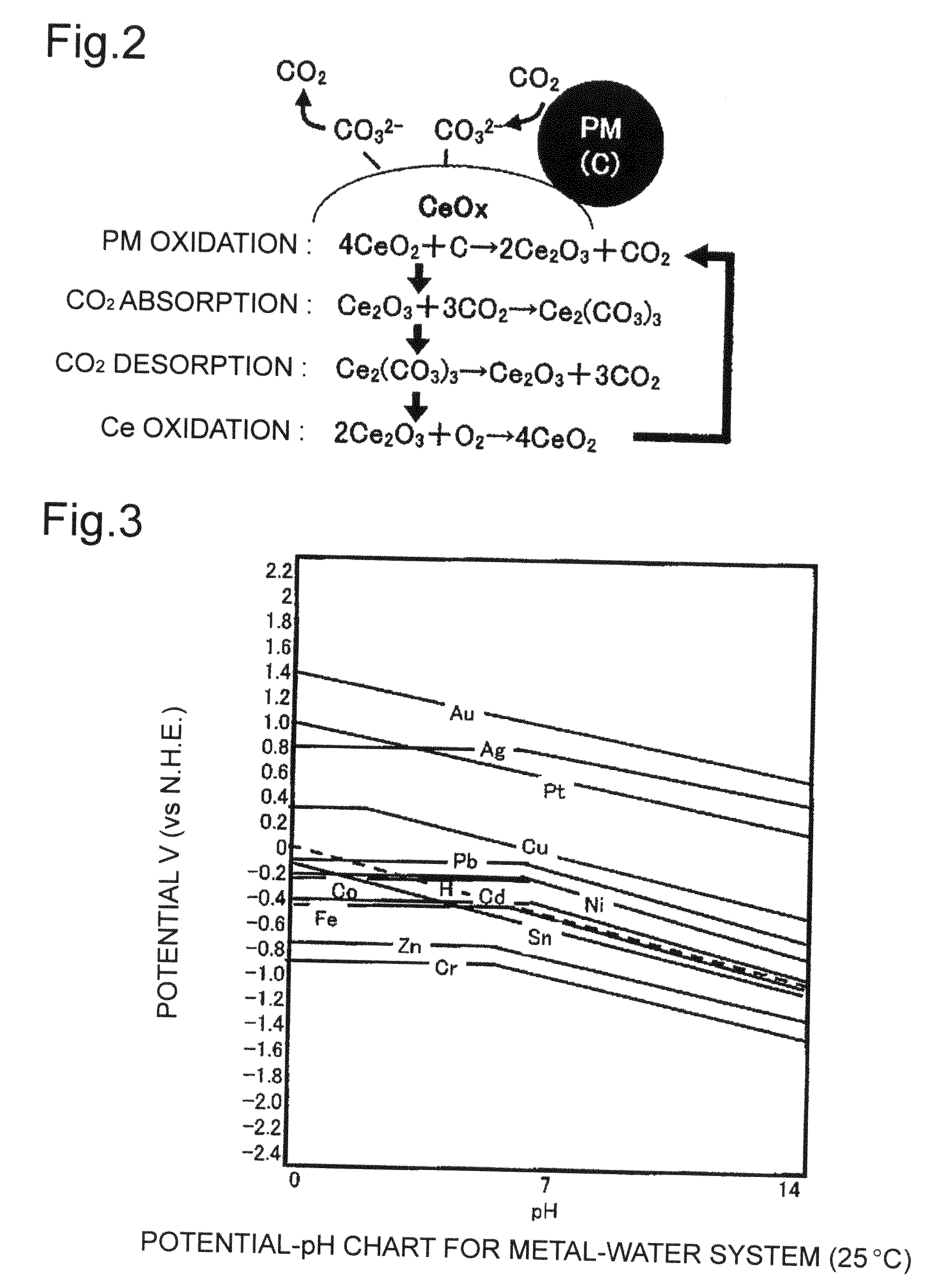

Composite material, composite material substrate, composite material dispersed fluid, and manufacturing methods thereof

InactiveUS20090209415A1Promote oxidation reactionIncrease surface densityMaterial nanotechnologyDispersed particle separationMetal particleMicroparticle

A composite material includes an aggregate which contains a first metal particle constituting a core and second metal oxide particulates surrounding the first metal particle and having an average primary particle diameter ranging from 1 to 100 nm.

Owner:TOYOTA CENT RES & DEV LAB INC

Ultra-viscous seal coat on bituminous pavement and construction method thereof

InactiveCN102425092AGood low temperature crack resistanceImprove water stabilityIn situ pavingsFiberLow noise

The invention relates to an ultra-viscous seal coat on the bituminous pavement and a construction method thereof. The ultra-viscous seal coat comprises a high performance modified emulsified bitumen bonding layer and an ultra-viscous cold-mixed material wearing layer which is obtained by cold-mixing aggregates, cement, water, composite modified emulsified bitumen, a fiber and a liquid additive. According to the construction method of the seal coat, the ultra-viscous cold-mixed material wearing layer mixing and lying and the high performance modified emulsified bitumen sprinkling are synchronously carried out. The seal coat has the characteristics of ultra bonding, high water resistance, high sliding resistance, low noise, crack resistance, low carbon, energy saving and environmental protection.

Owner:XIAN GUOLIN IND

Steel slag vegetation concrete

ActiveCN105294039AHigh compressive strengthIncreased durabilitySolid waste managementCeramicwareAggregate (composite)Slag

The invention provides steel slag vegetation concrete, which is prepared from the following components in parts by weight: 75 to 83 parts of steel slag aggregate, 15 to 24.5 parts of composite steel slag powder and 0.5 to 2 parts of strengthening agent. A preparation method comprises the steps of uniformly stirring and mixing the steel slag aggregate and the composite steel slag powder as well as the strengthening agent proportionally, and adding water to produce the steel slag vegetation concrete. The steel slag vegetation concrete prepared by utilizing steel slag is high in strength, large in porosity and an acid-base environment can meet the requirement of growth of plants.

Owner:宝武环科武汉金属资源有限责任公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com