On-line production method and device of composite foamed slurry

A production method and technology of foamed slurry, which is applied in the direction of clay preparation equipment, chemical instruments and methods, and mixing operation control, etc., can solve problems such as inability to meet engineering needs, inability to guarantee slurry quality, and slurry foam breaking, and achieve improvement Production and construction efficiency, continuous processing and transportation, and the effect of less foam loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0068] On-line production of polystyrene cement composite foam slurry, 1m 3 The main materials based on foaming slurry are:

[0069] Polystyrene foam particles: 0.8 m 3 ;

[0070] Cement: 300kg;

[0071] Water: 200kg;

[0072] Cement foaming agent: 1kg;

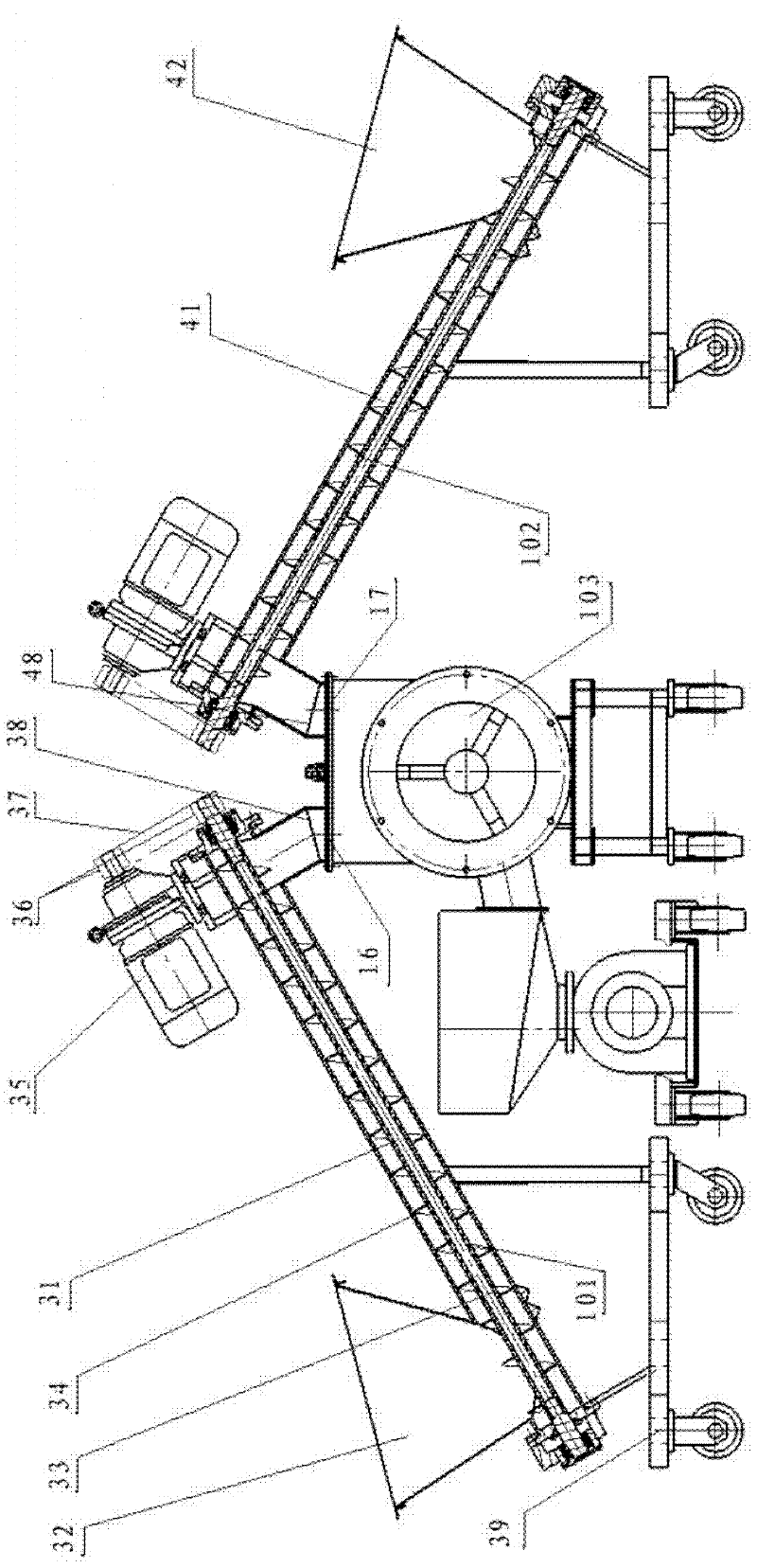

[0073] Such as Figure 7 As shown, the on-line production of polystyrene foam cement composite foam material includes the following steps:

[0074] Step 1: Loading

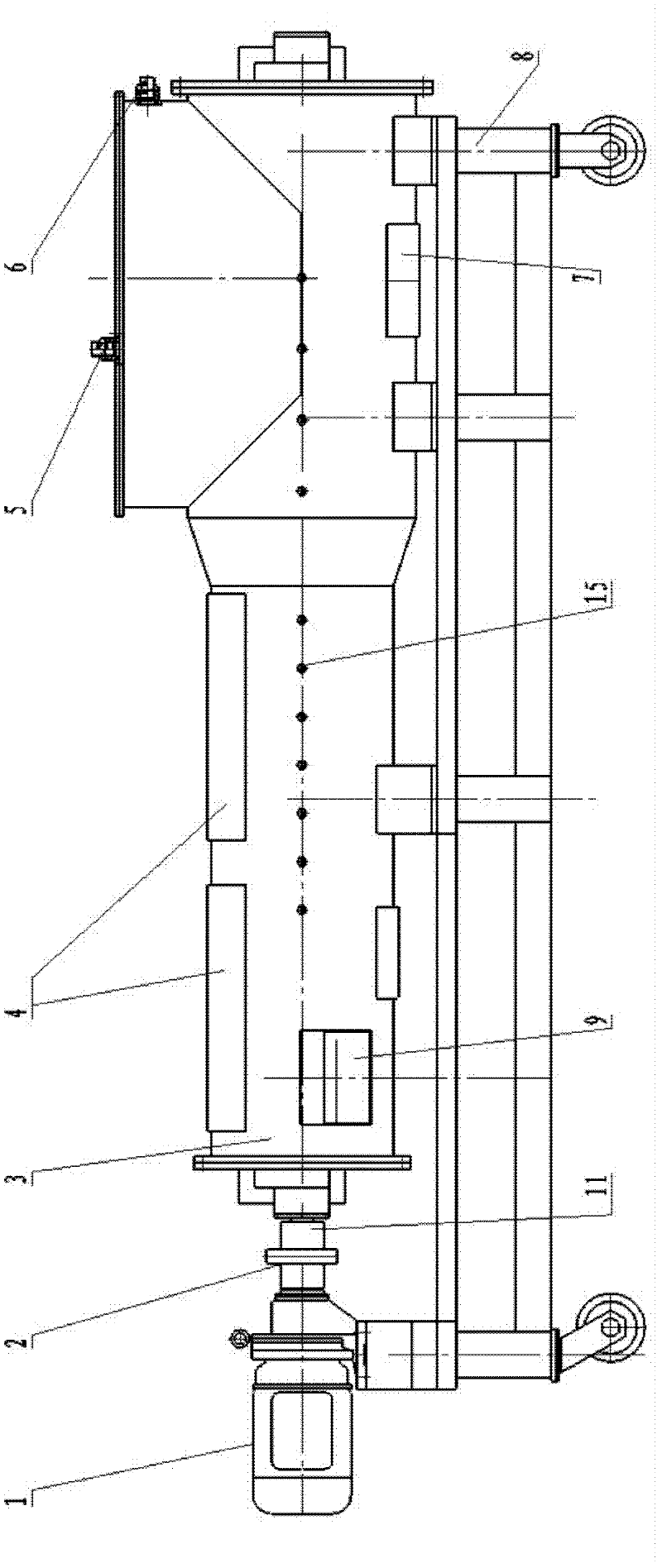

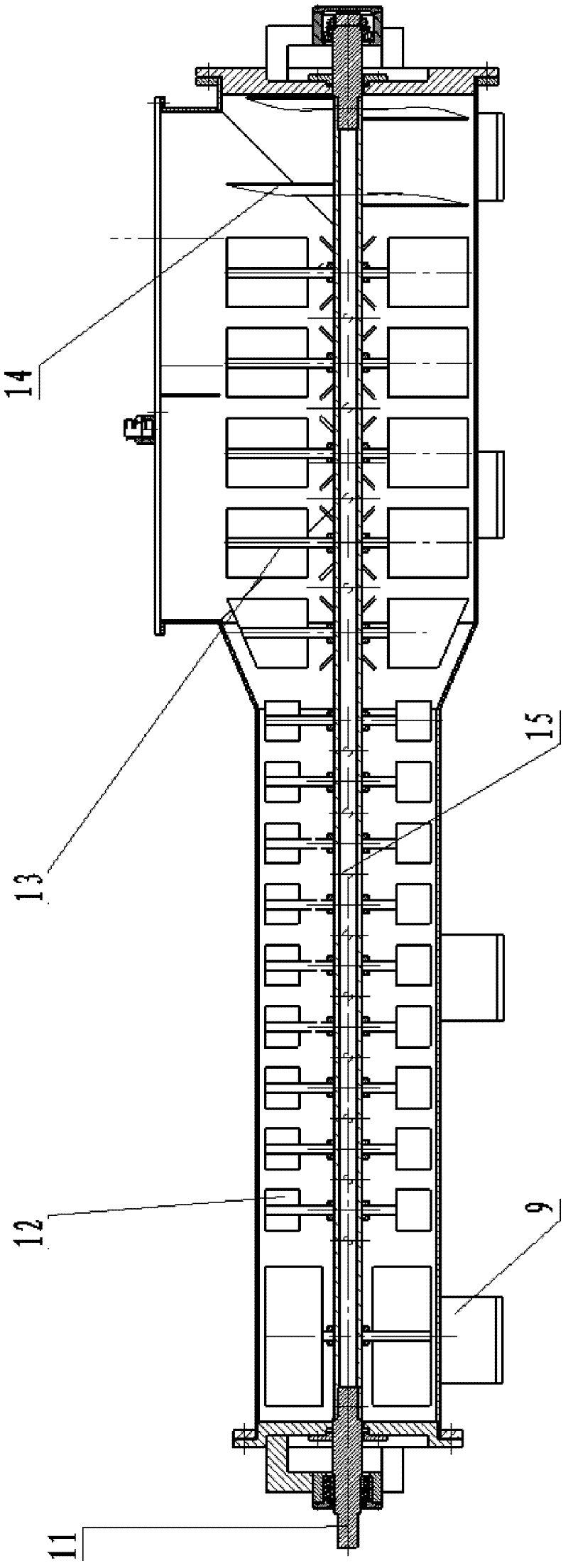

[0075] Add cement and polystyrene foamed particles into the cement silo 32 and the aggregate silo 42 respectively, and feed the dry material of cement and polystyrene foamed particles through the cement feeder 101 and the aggregate feeder 102 respectively. Be transported in the agitating conveyor 103, while the upper water pump injects water into the agitating conveyor 103 through the water injection port 6 of the agitating conveyor 103;

[0076] Step 2: Mixing

[0077] Stirring conveyor 103 initially mixes cement, water and polystyrene foam particles th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com