Patents

Literature

1848results about "Mixing operation plant" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

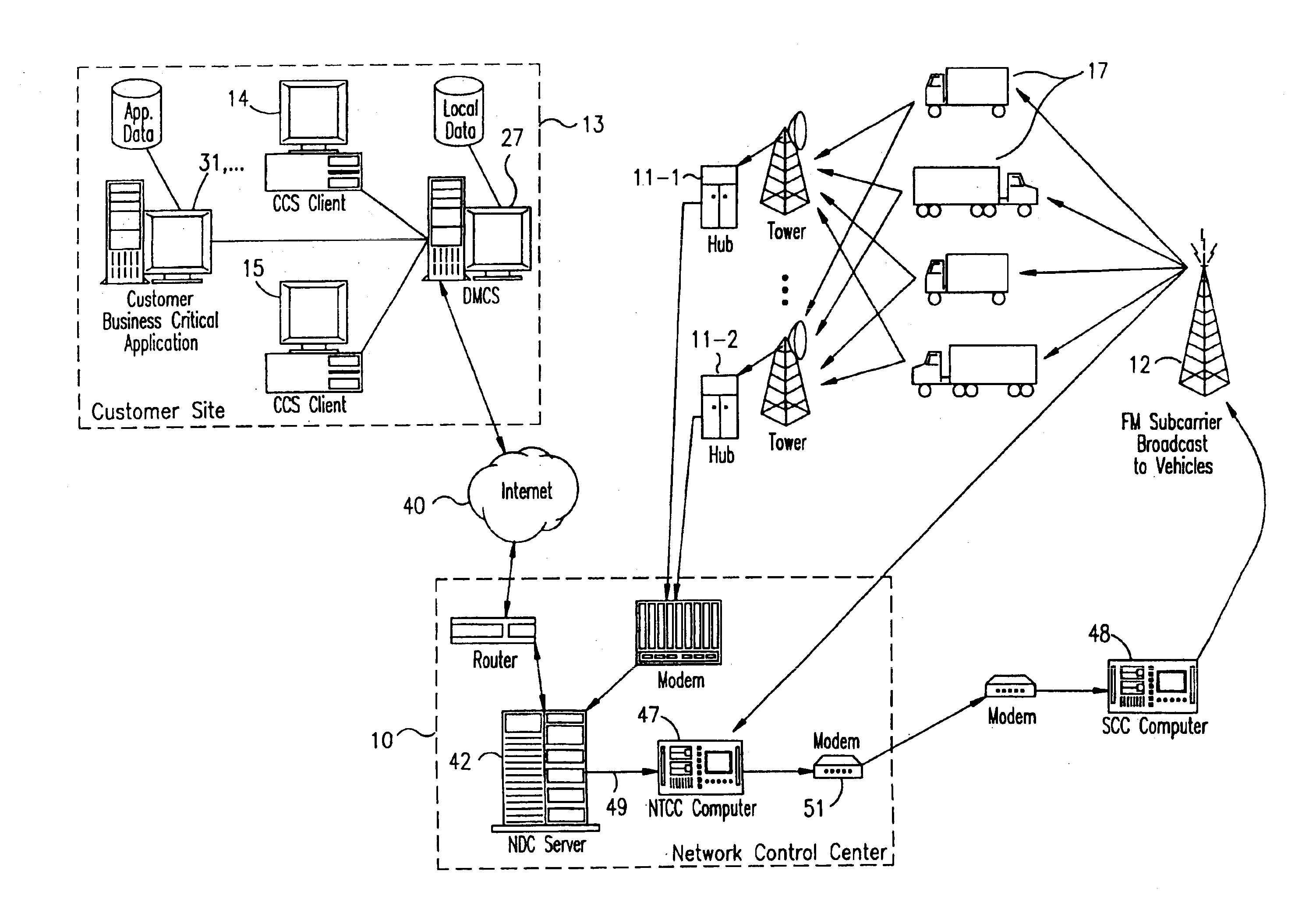

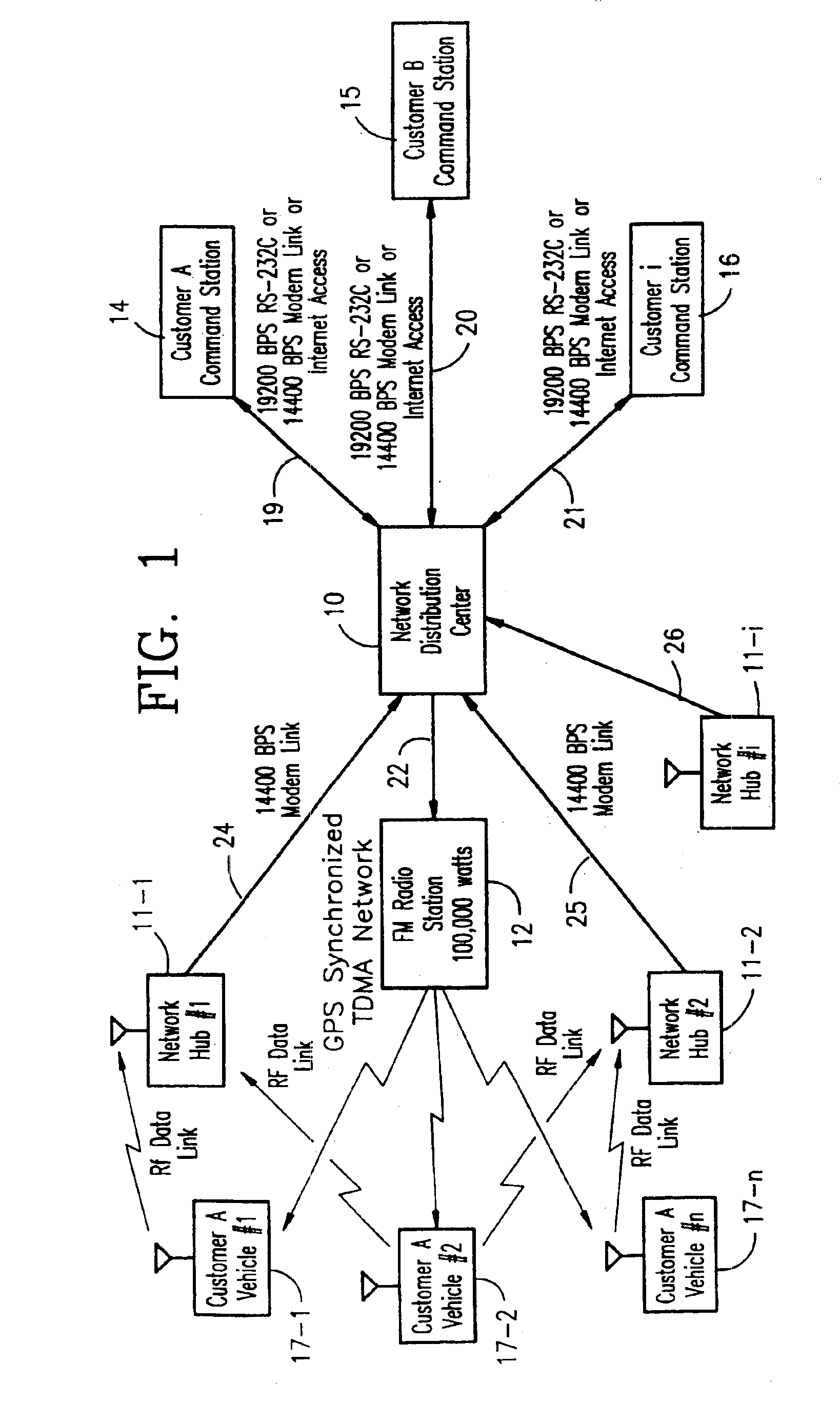

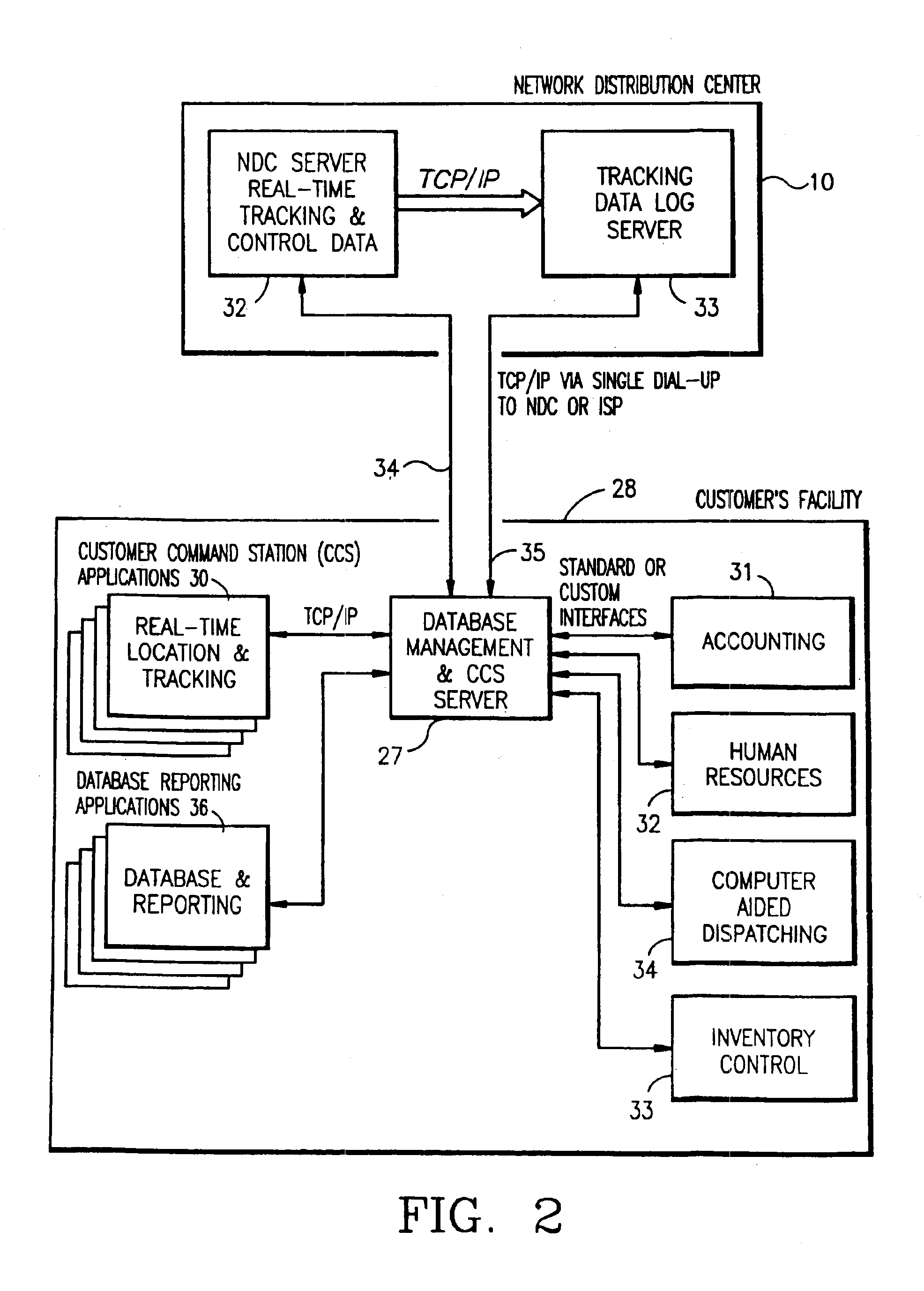

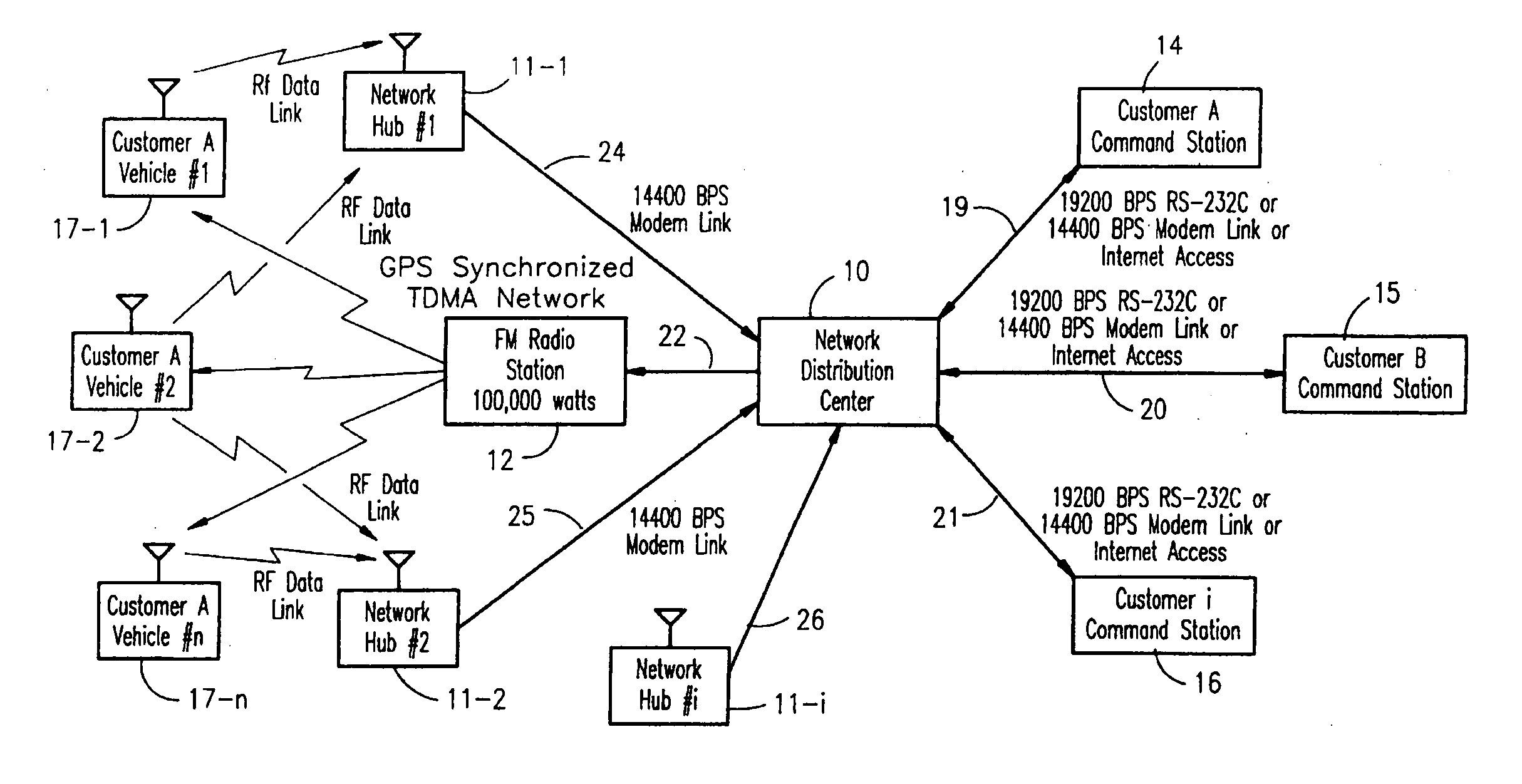

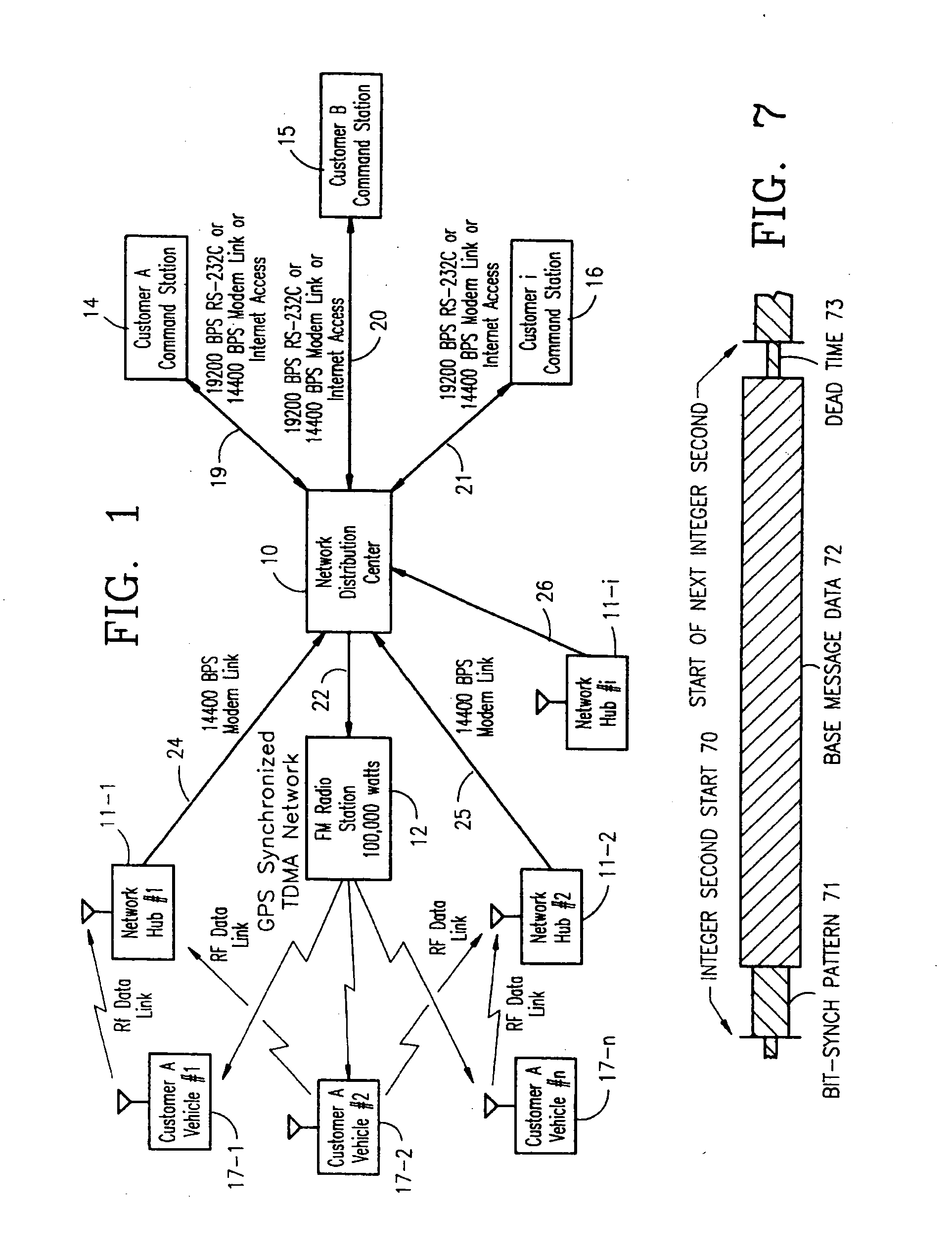

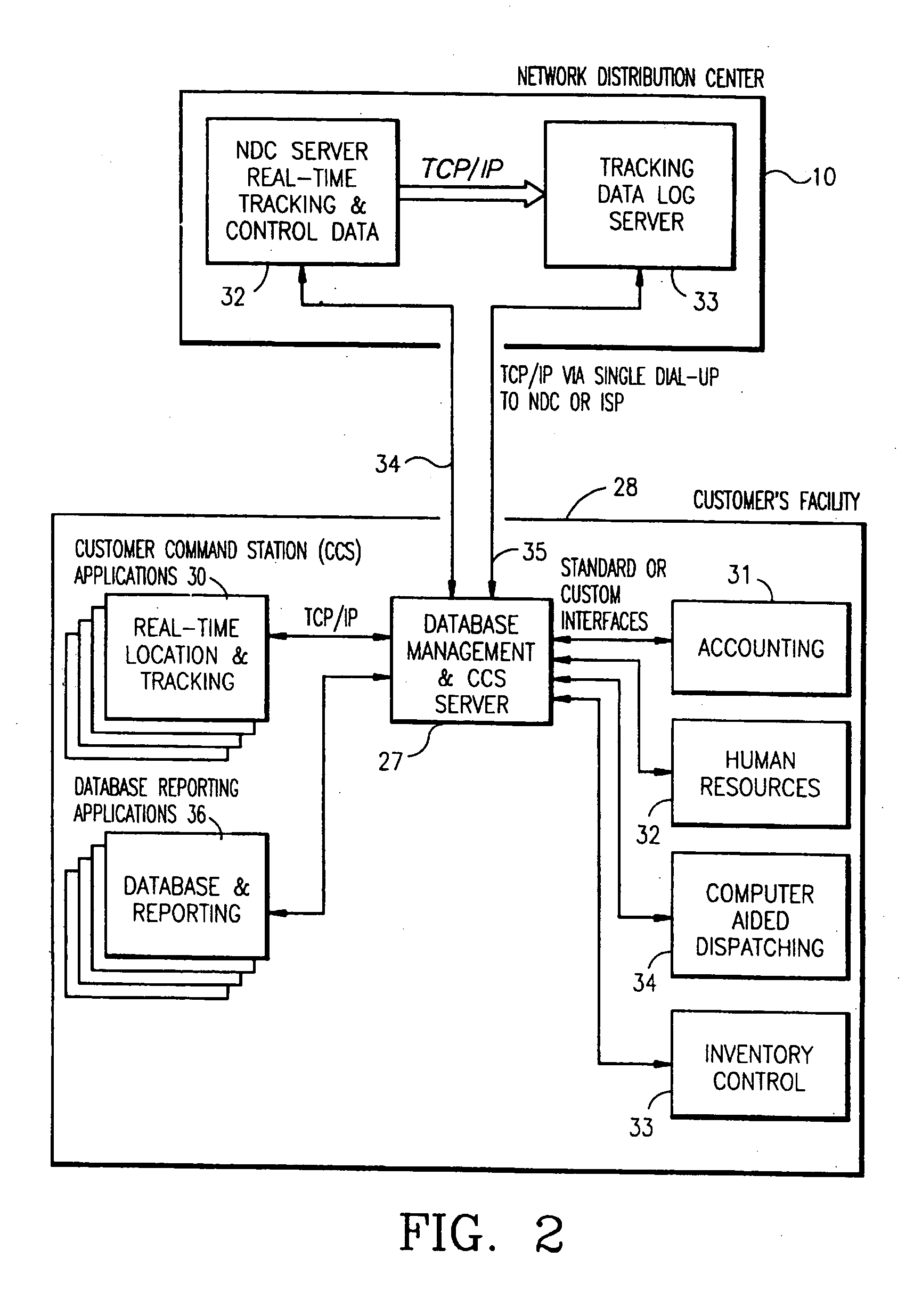

Vehicle tracking, communication and fleet management system

InactiveUS6892131B2Management moreEfficient and reliableVehicle testingRegistering/indicating working of vehiclesFleet managementTruck

A vehicle fleet management information system for identification of location and direction of movement of each vehicle in the fleet in real-time and automatic communication directly with management offices to report its location and heading, and status of predetermined events in which the vehicle may be engaged. One example is a cement delivery truck which monitors location, speed and status information such as start pour, pouring, end pour, wash and leave job, and automatically transmits this information with a management office without requiring affirmative action by the vehicle operator.

Owner:TRIMBLE NAVIGATION LTD

Vehicle tracking, communication and fleet management system

InactiveUS20060142913A1Management moreEfficient and reliableVehicle testingRegistering/indicating working of vehiclesFleet managementEngineering

A vehicle fleet management information system identifies location and direction of movement of each vehicle in a fleet in real-time, and automatically reports such information, as well as status of predetermined events in which the vehicle is engaged, directly to the fleet manager. Each fleet vehicle has an assigned time slot to transmit its reporting information over a communications network without interfering with transmissions from other vehicles in their own respective time slots. A timing control phase lock loop (PLL) provides precise time synchronization for timing corrections from a global positioning system (GPS) based time reference. A dual band full-duplex interface of the network has TDMA on one-half and broadcast on the other half. Microprocessor time processing units in components of the network perform precise clock synchronization. Space diversity performed on received vehicle transmitted messages avoids data corruption. Different vehicles have different periodic transmission intervals, by dynamically allocating the slots for various update rates. Auxiliary reporting slots enable prompt reporting of important data by the respective vehicle transmitters independent of the slower periodic transmission intervals.

Owner:TRIMBLE NAVIGATION LTD

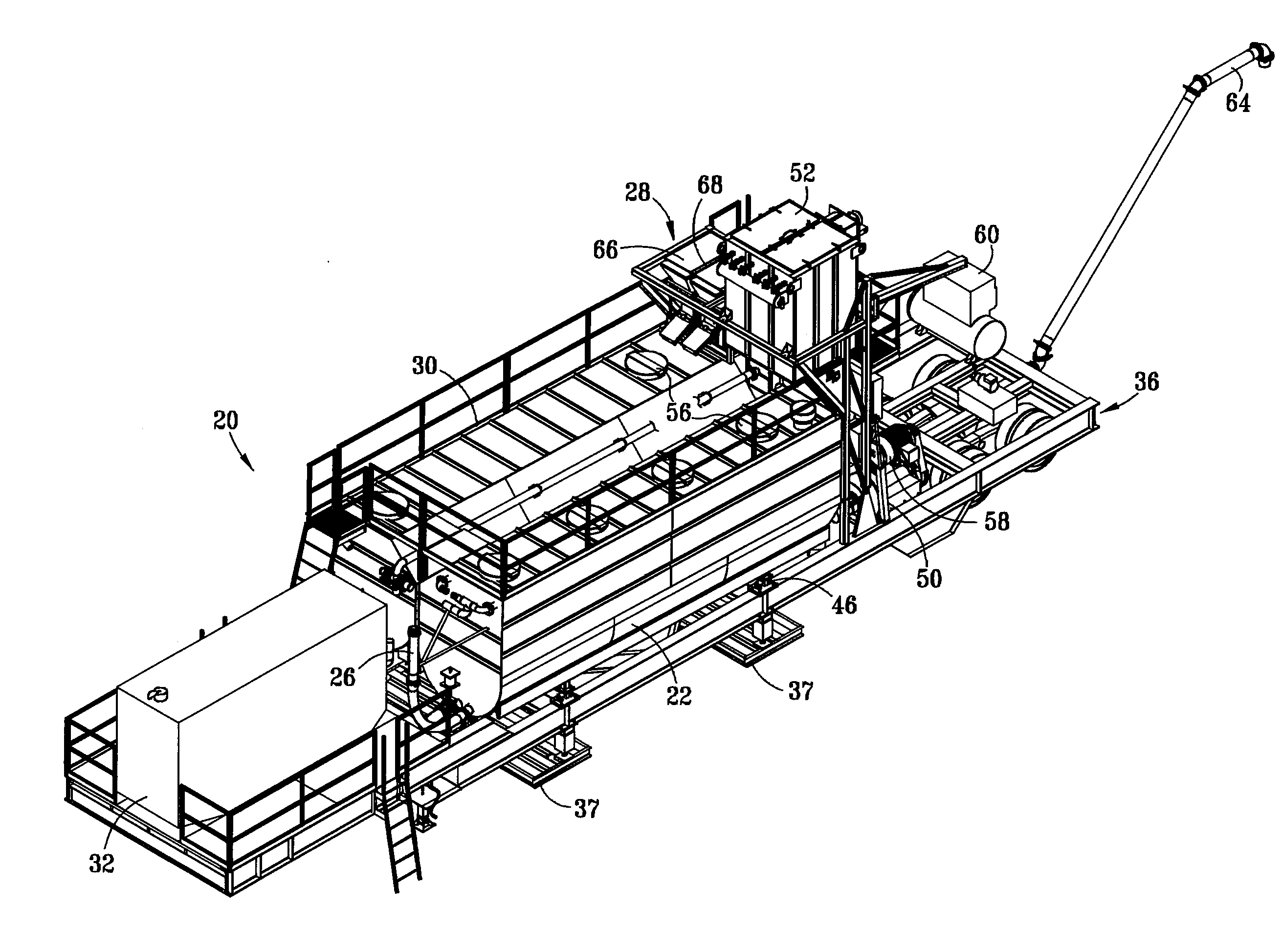

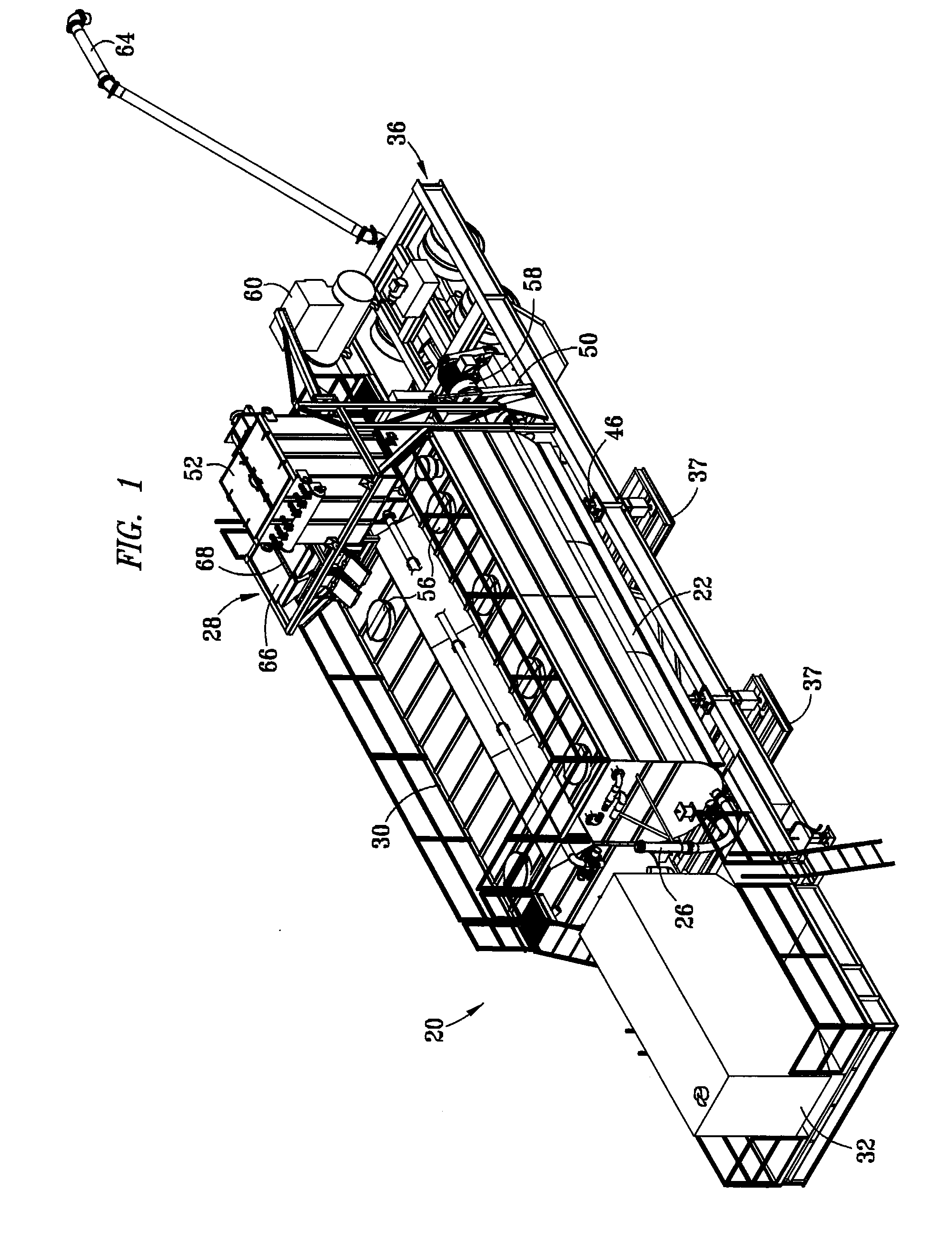

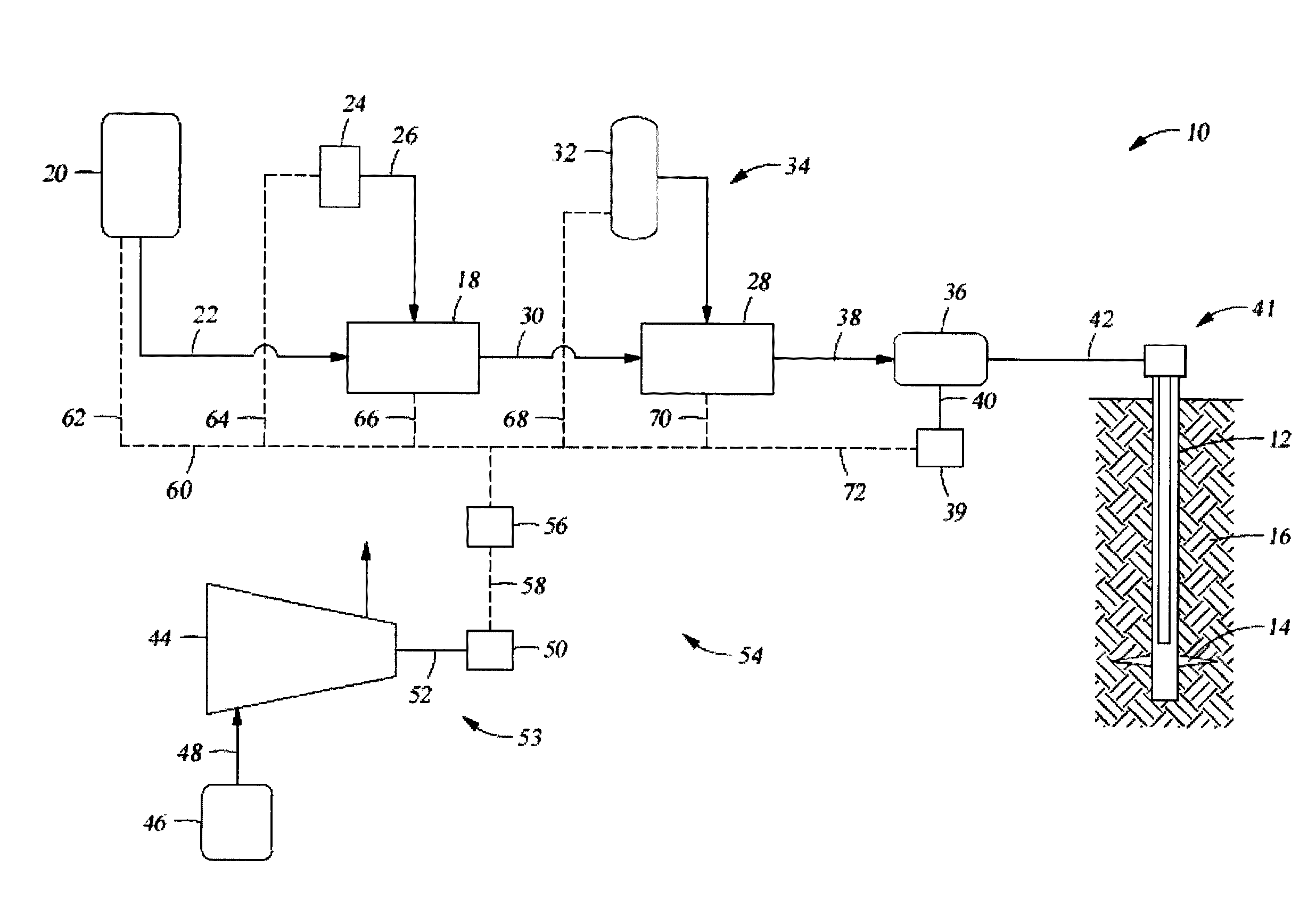

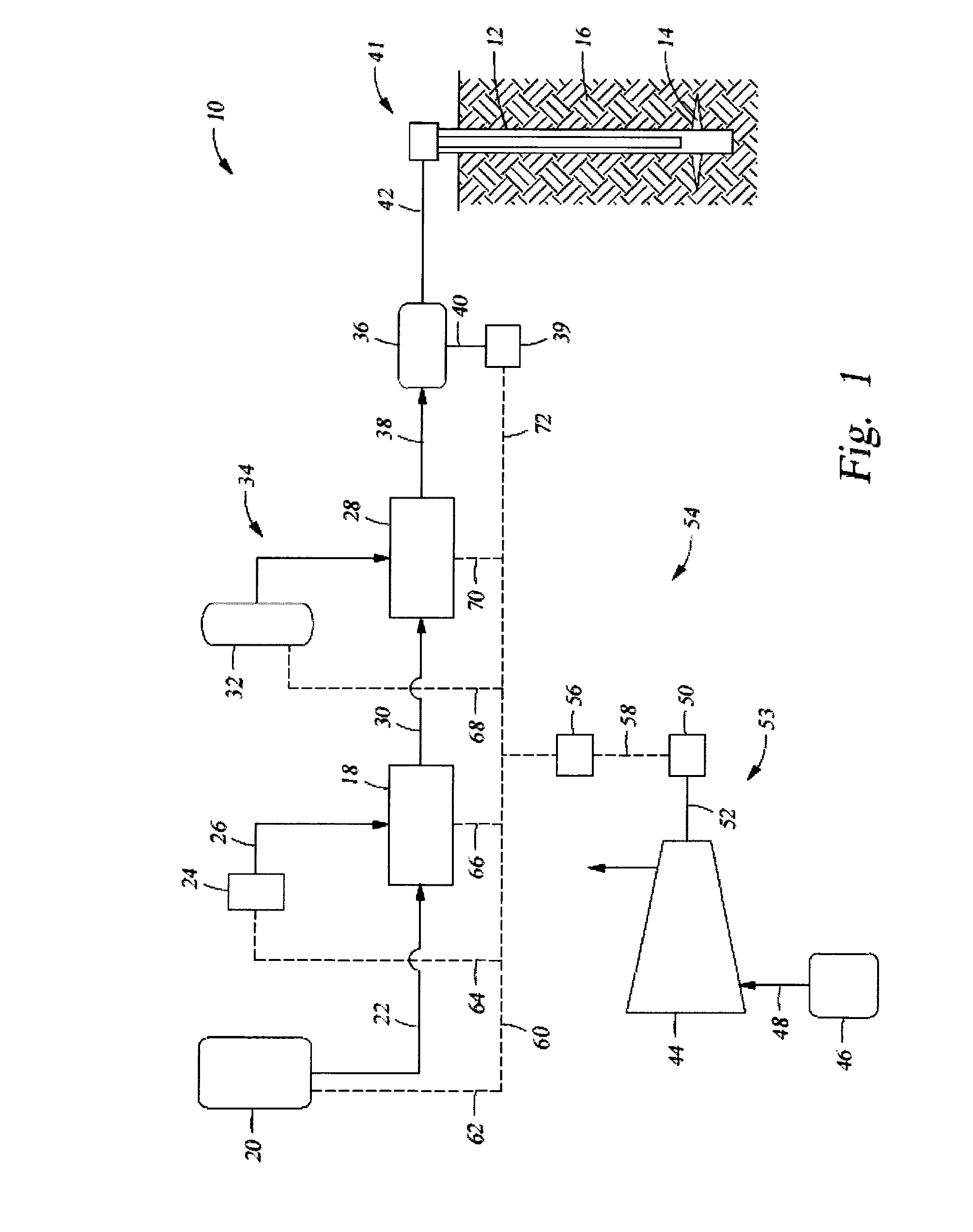

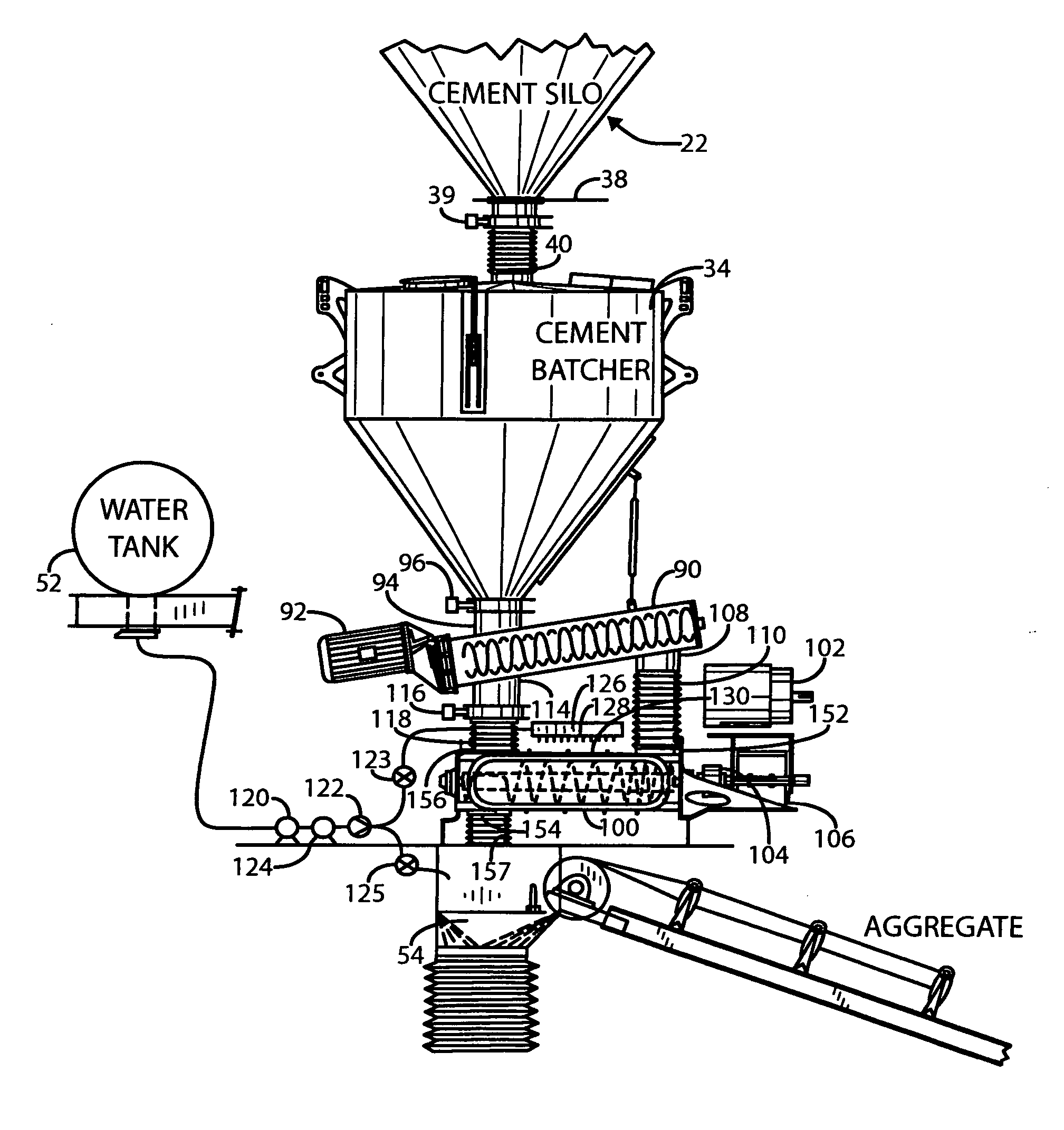

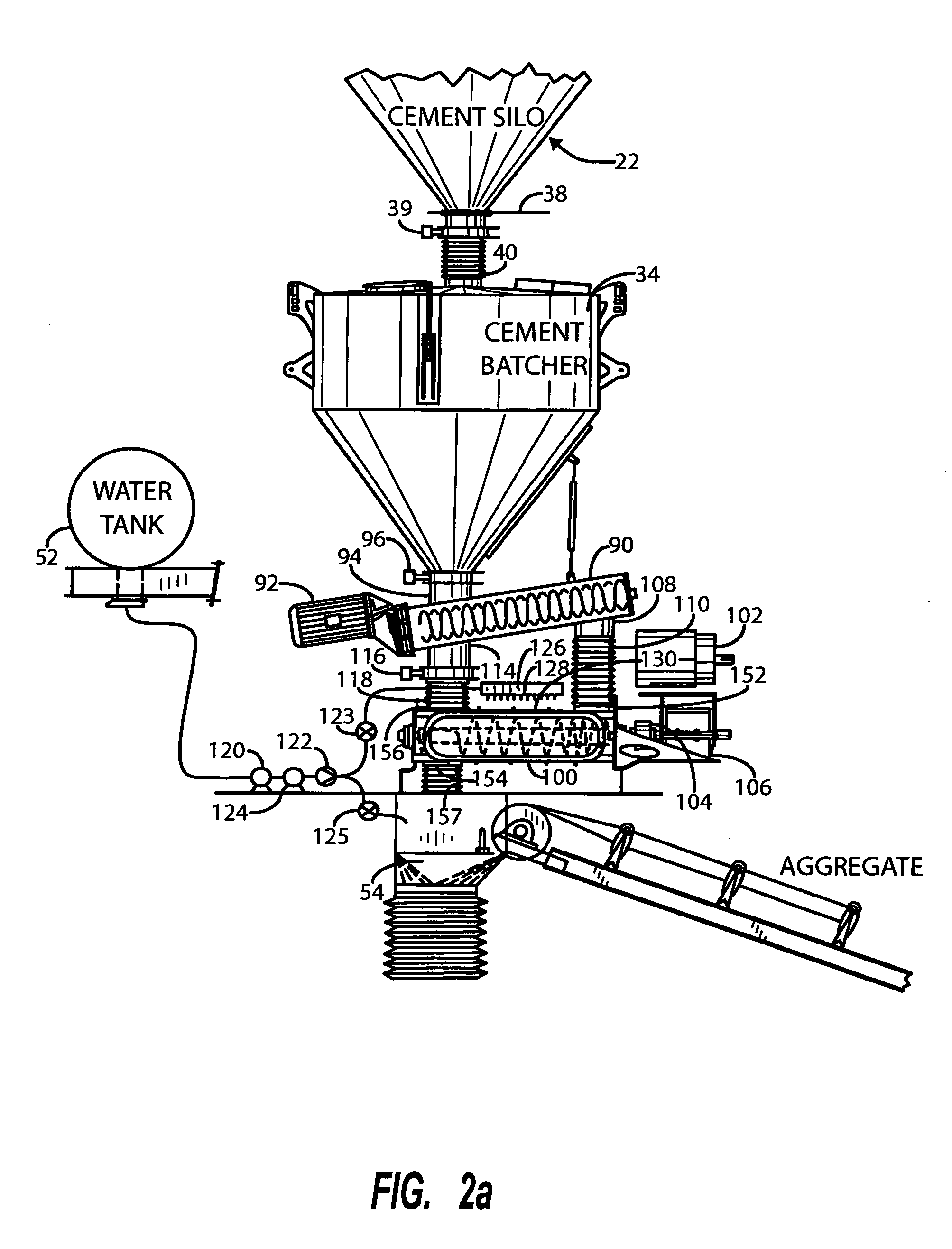

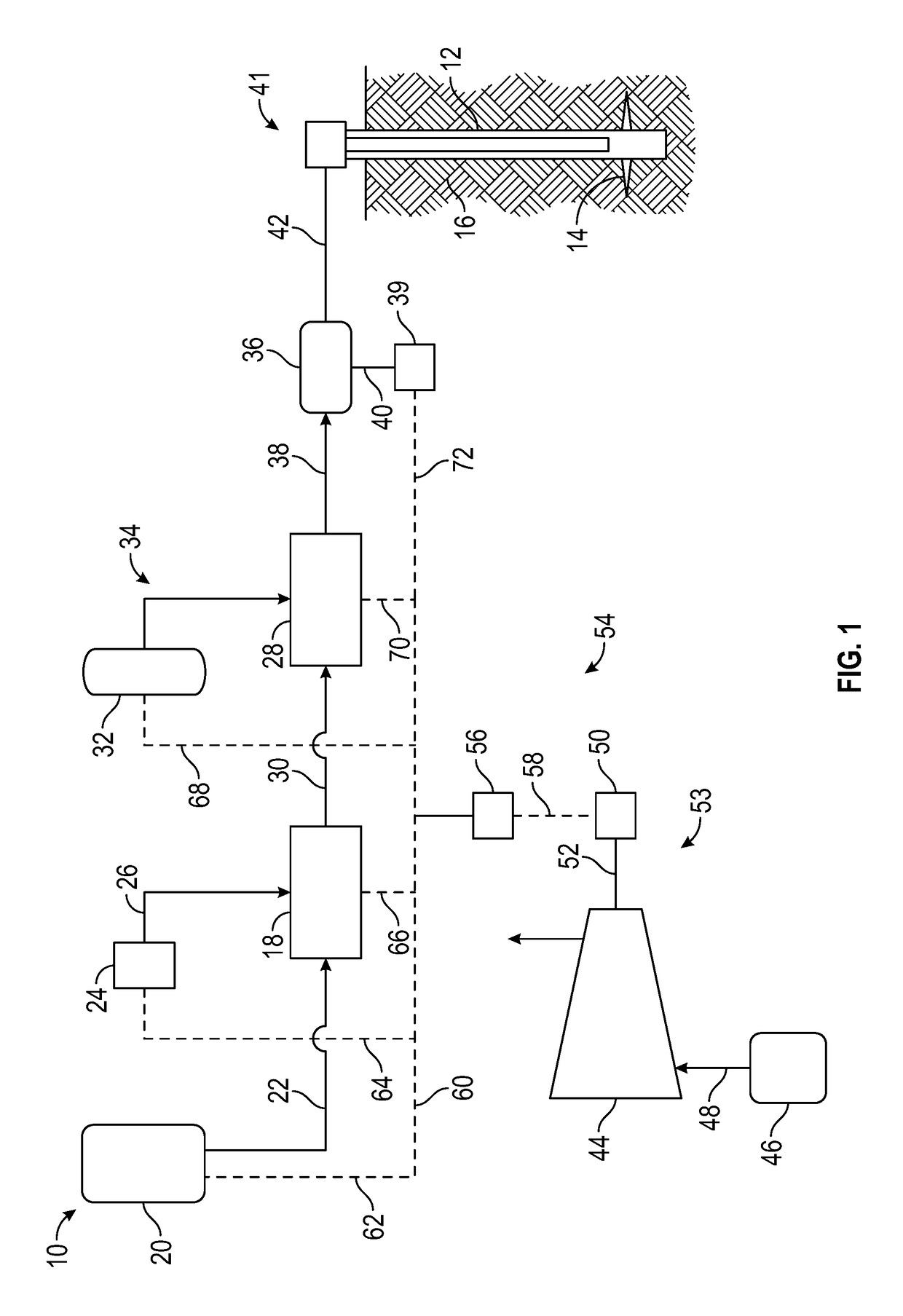

Cement Stabilization of Soils Using a Proportional Cement Slurry

ActiveUS20090044726A1Composition is stableAvoid settingSolid waste managementCement mixing apparatusChemical treatmentCellulose

A novel cement slurry composed of cement and water that can be used in cement stabilization applications. The cement slurry compound itself is chemically treated, by means of a cellulosic or other thixotropic thickening agent(s) to create a thixotropic system wherein the wetted cement remains in suspension and does not settle out prior to use even without further mixing. A chemical retarder / stabilizer is also used to prevent the slurry from prematurely setting during shipping. A novel apparatus and method for mixing the novel cement slurry is disclosed to insure the exact proportioning of all ingredients and the proper wetting of the cement.

Owner:TEXAS INDUSTRIES

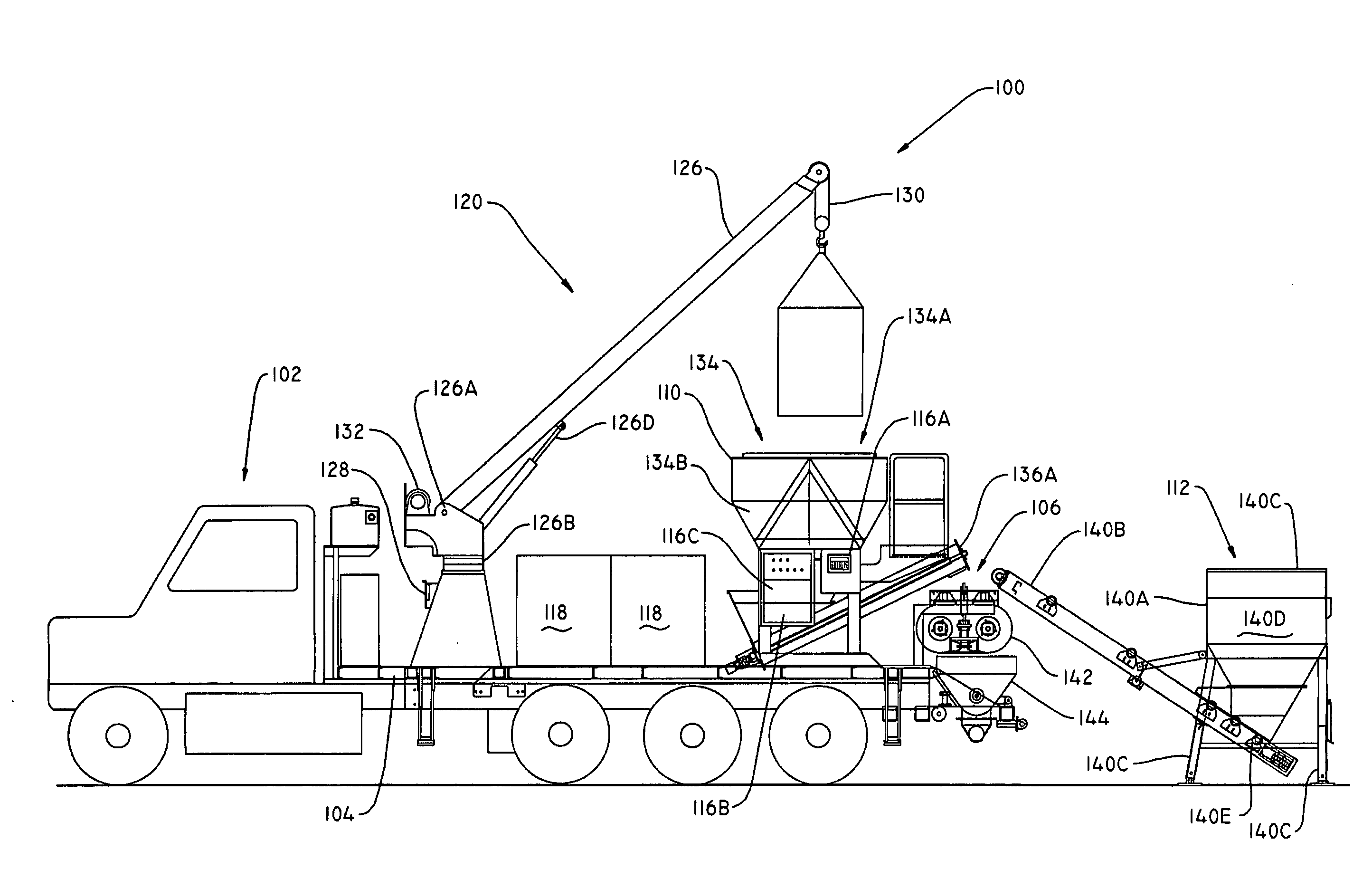

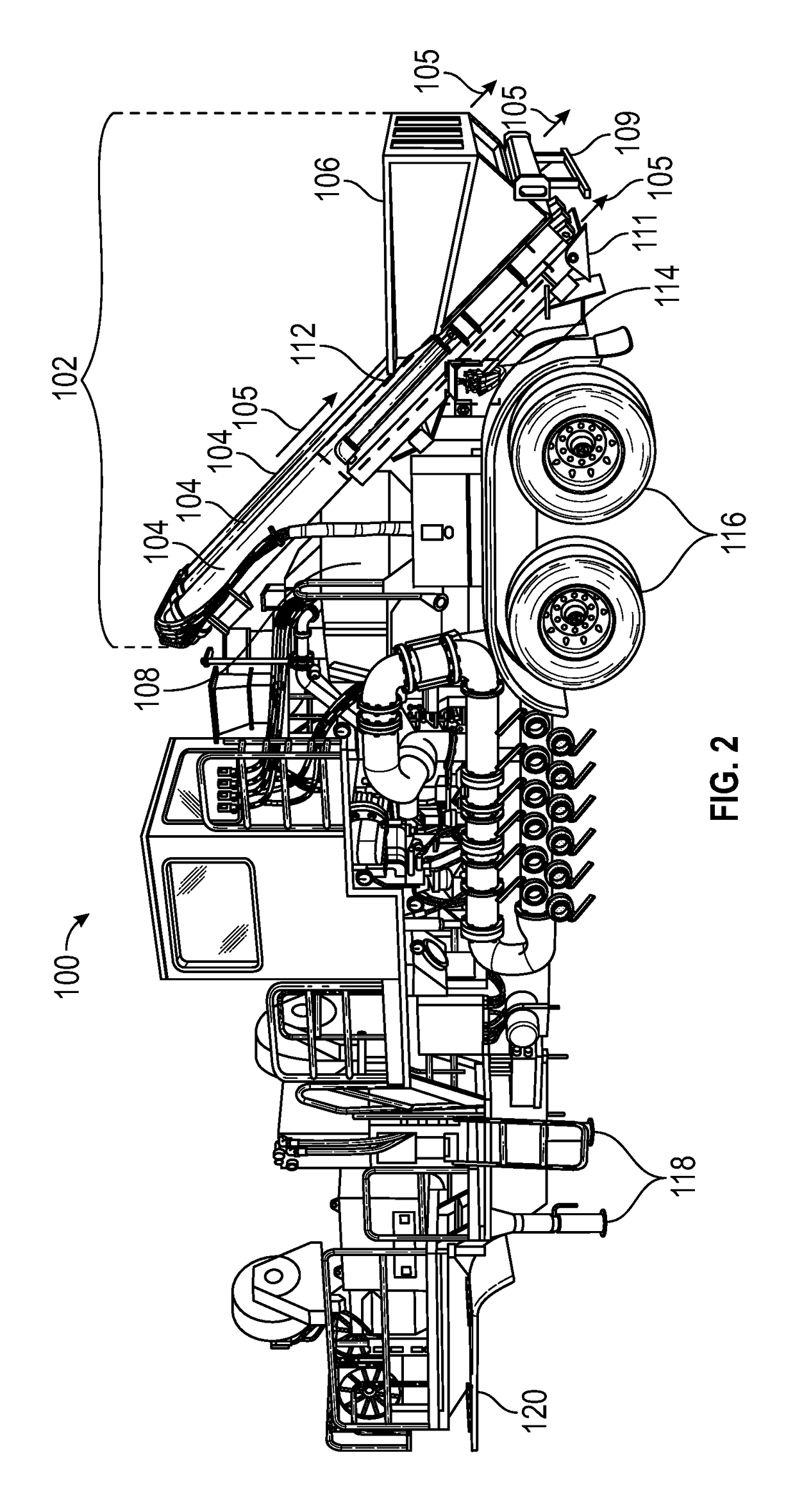

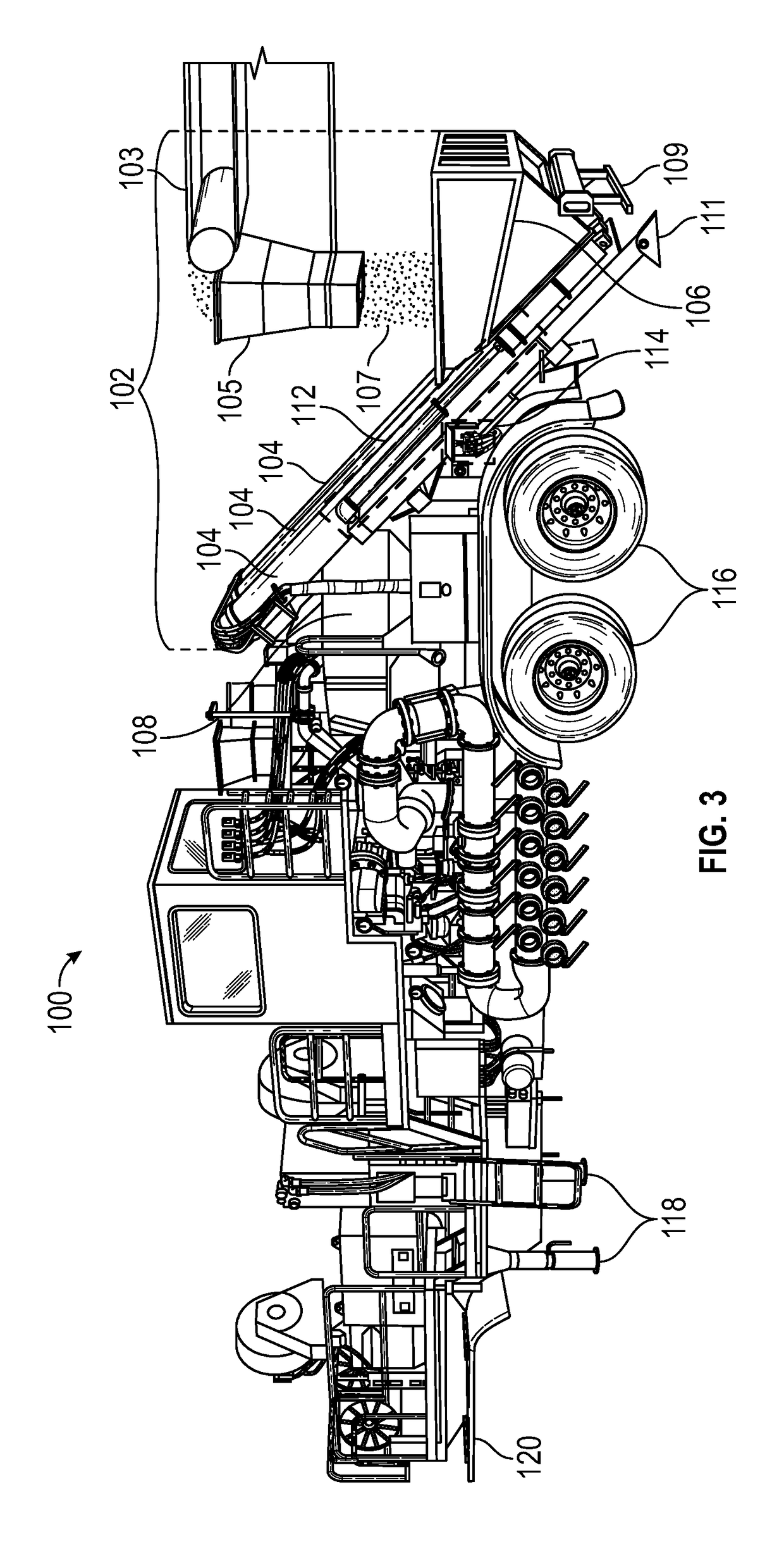

Independent control of auger and hopper assembly in electric blender system

Embodiments relate to a hydraulic fracturing system that includes a blender unit. The system includes an auger and hopper assembly to receive proppant from a proppant source and feed the proppant to the blender unit for mixing with a fluid. A first power source is used to power the blender unit in order to mix the proppant with the fluid and prepare a fracturing slurry. A second power source independently powers the auger and hopper assembly in order to align the hopper of the auger and hopper assembly with a proppant feed from the proppant source. Thus, the auger and hopper assembly can be stowed or deployed without use of the first power source, which is the main power supply to the blender unit.

Owner:US WELL SERVICS LLC

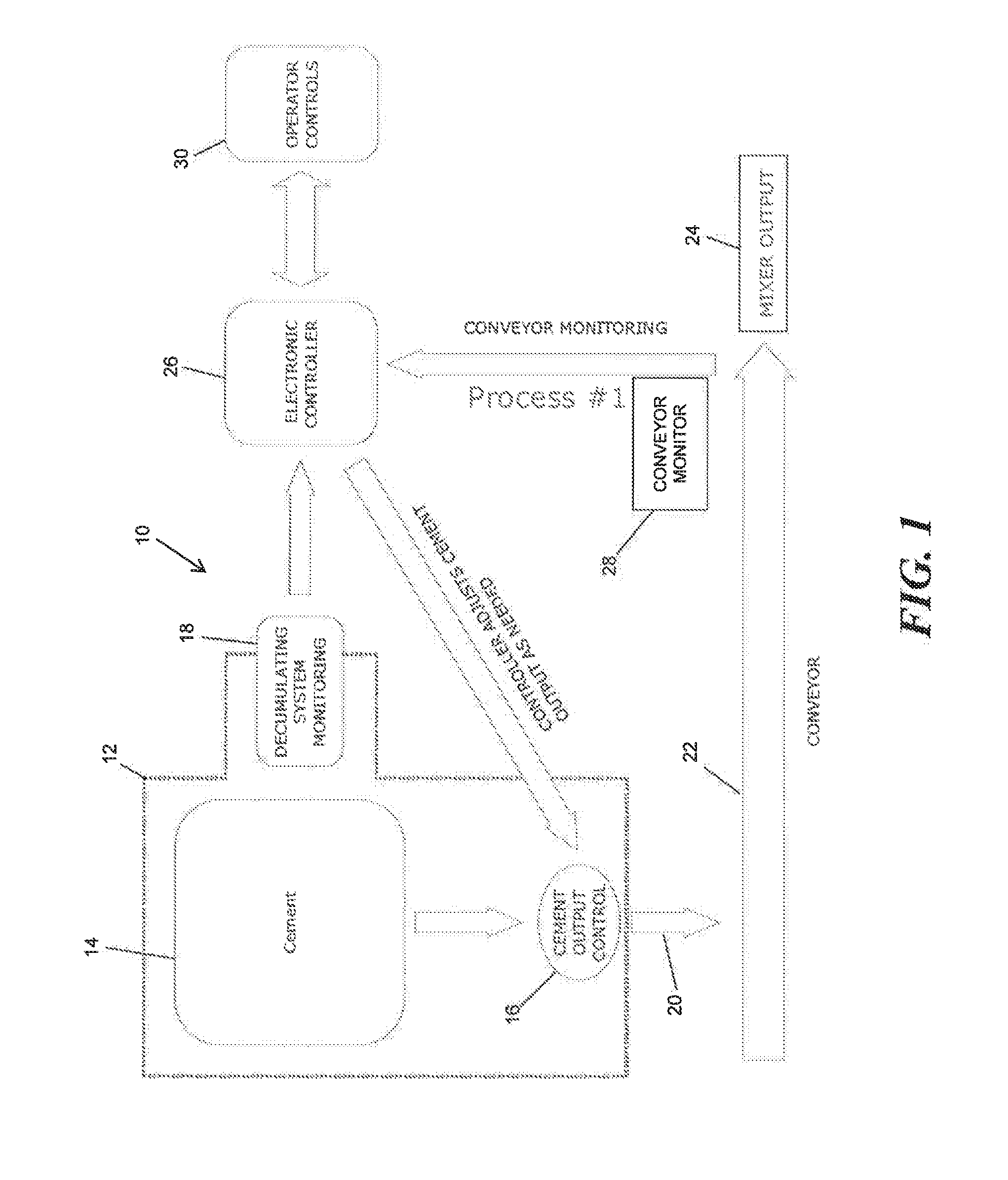

Volumetric mixer with monitoring system and control system

InactiveUS20160221220A1Uniform ratioEasy to controlIngredients proportioning apparatusCement mixing apparatusControl systemMonitoring system

A volumetric concrete mixer includes a monitoring and control system that assures a uniform amount of cement per unit of aggregate. A processor is in communication to receive an input of a weight of a cement bin from a cement bin load cell and in communication to receive an input of a number of rotations of a conveyor from an aggregate sensor. The processor is adapted to determine a rate of change of weight of the cement bin over a set number of rotations of the conveyor, and to instruct the cement dispenser to adjust the cement dispenser speed to maintain a constant rate of cement being dispensed from the dispenser bin to the mixing area per the set number of rotations of the conveyor.

Owner:OMEGA CM DELTA LLC

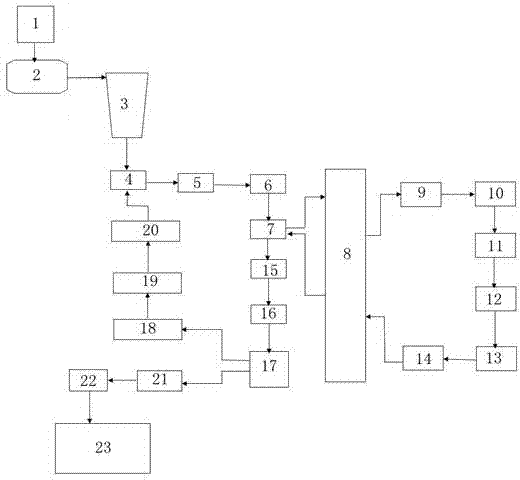

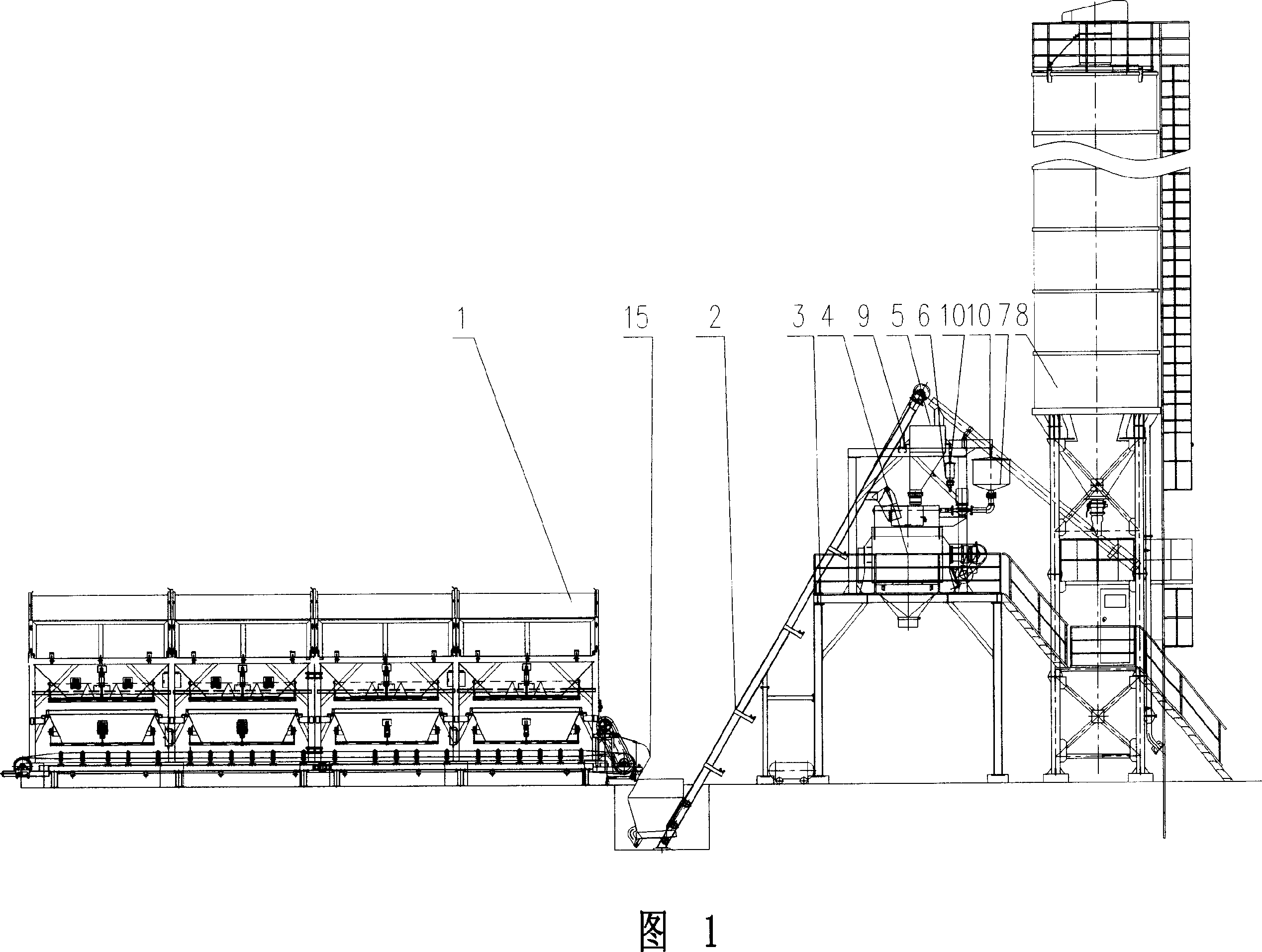

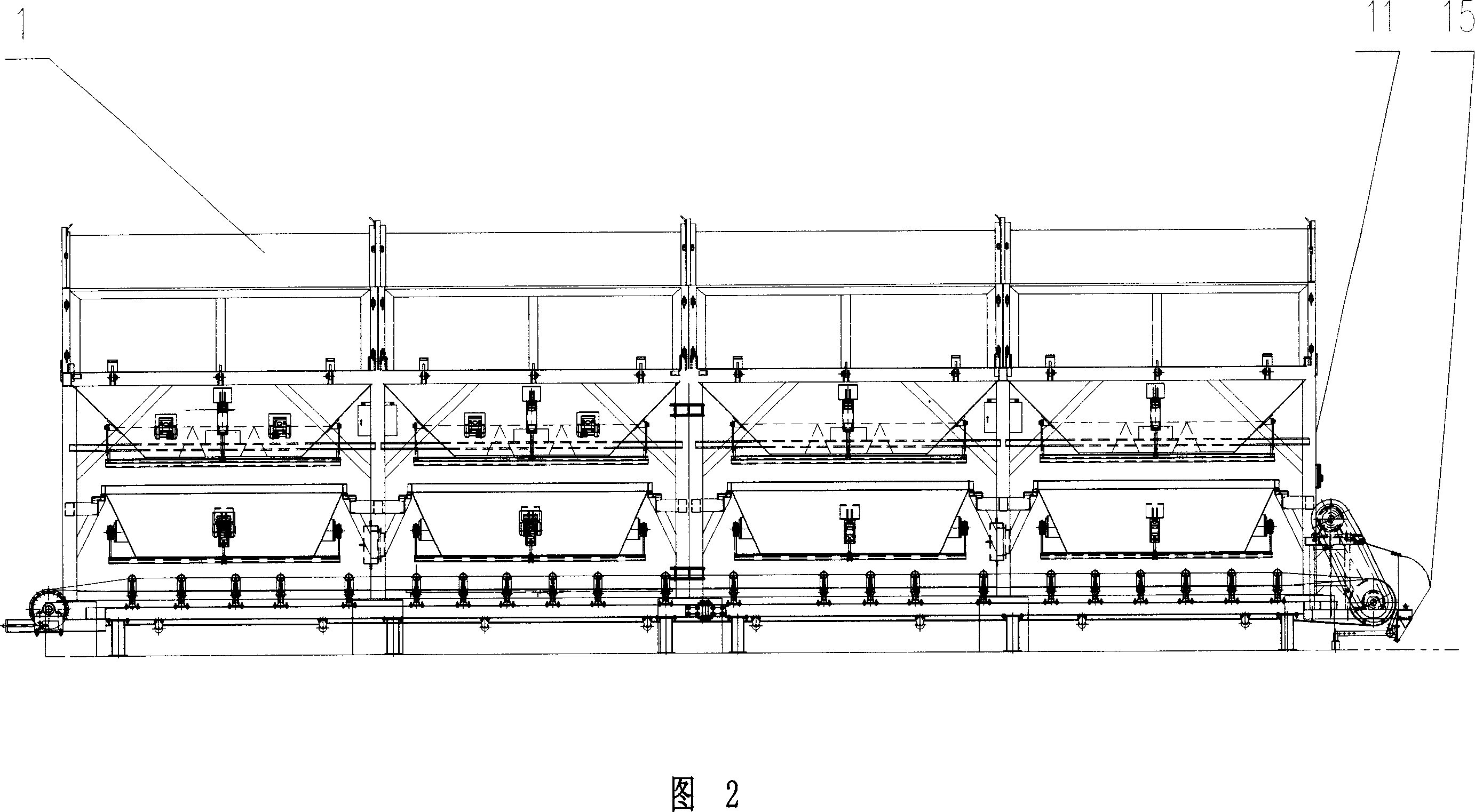

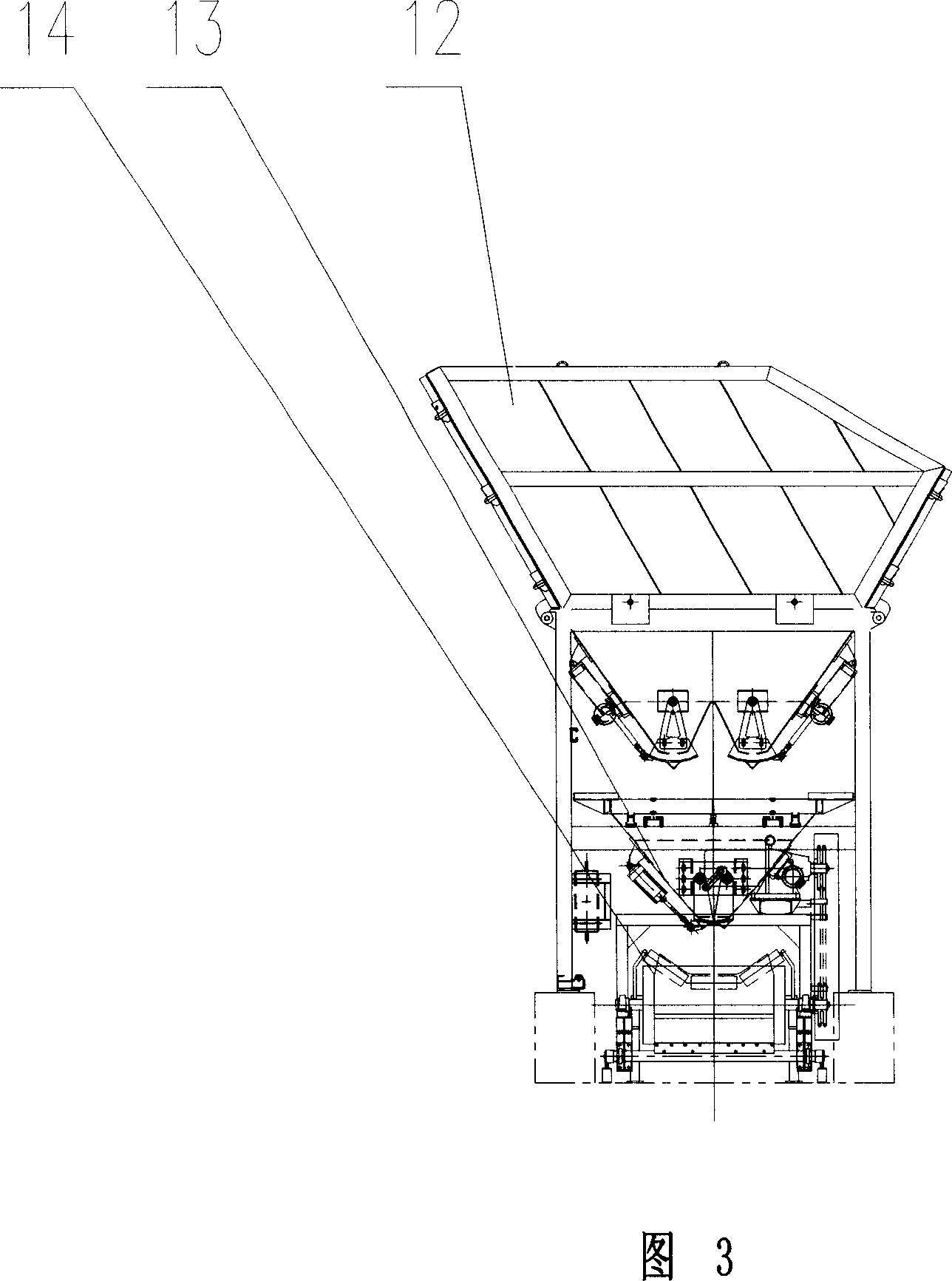

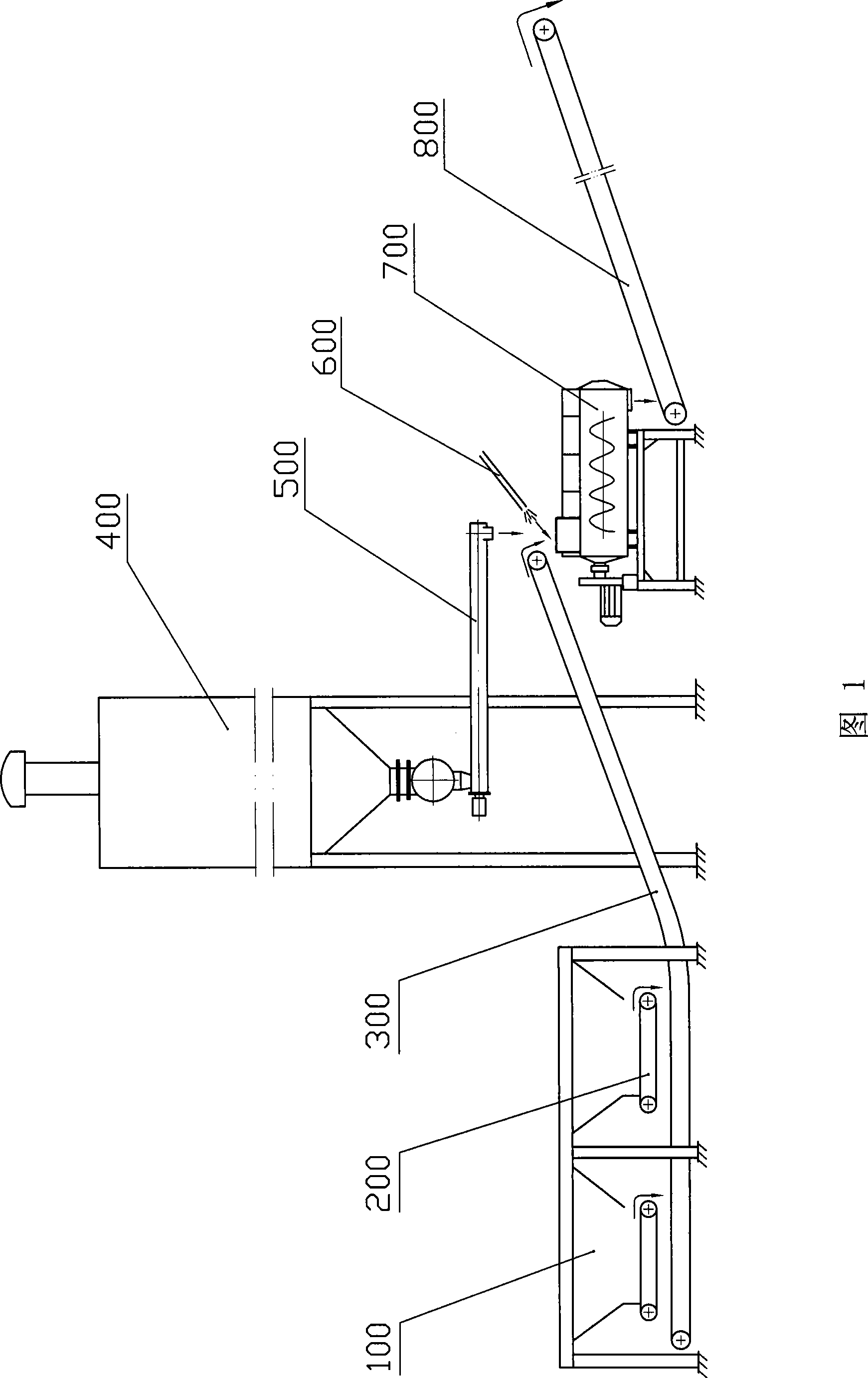

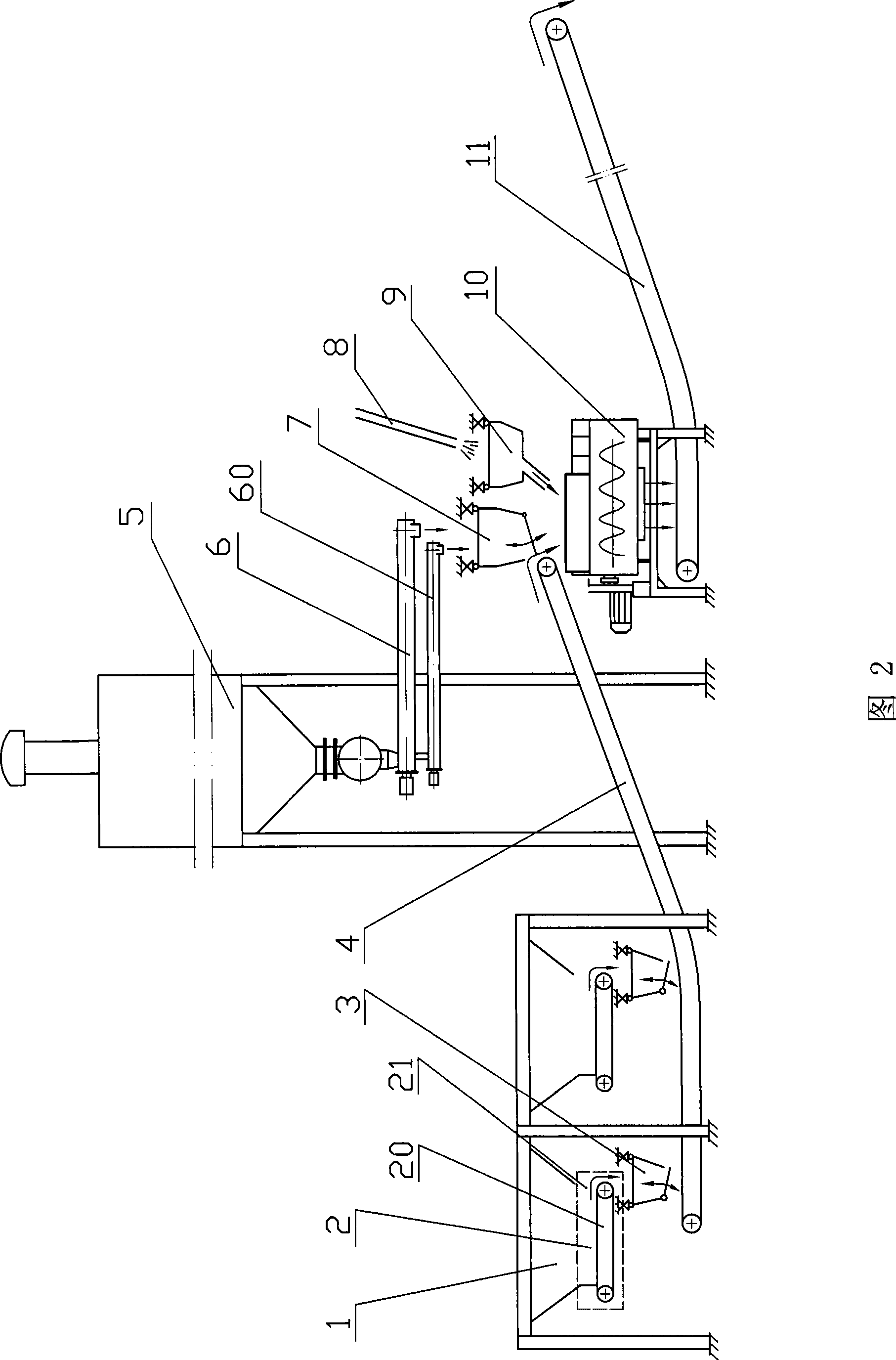

Dry-mixed mortar station

InactiveCN101462310AGood construction performanceQuality improvementMixing operation control apparatusSold ingredients supply apparatusDry sandDelivery system

The invention discloses a dry mortar mixing station, which consists of a sand conveying system, a drying system, a dust removing system, a dry sand hoisting-sieving and storing system, a powder storage system, a mixture metering and conveying system, a stirring system, and a finished product storing, conveying and packaging system. The dry mortar mixing station has good metering precision and efficient production capability; and the produced dry mixed mortar has superior construction performance and quality, is environment-friendly, can meet various construction works, and can adapt to different requirements of various novel building materials on mortar.

Owner:徐州天地重型机械制造有限公司

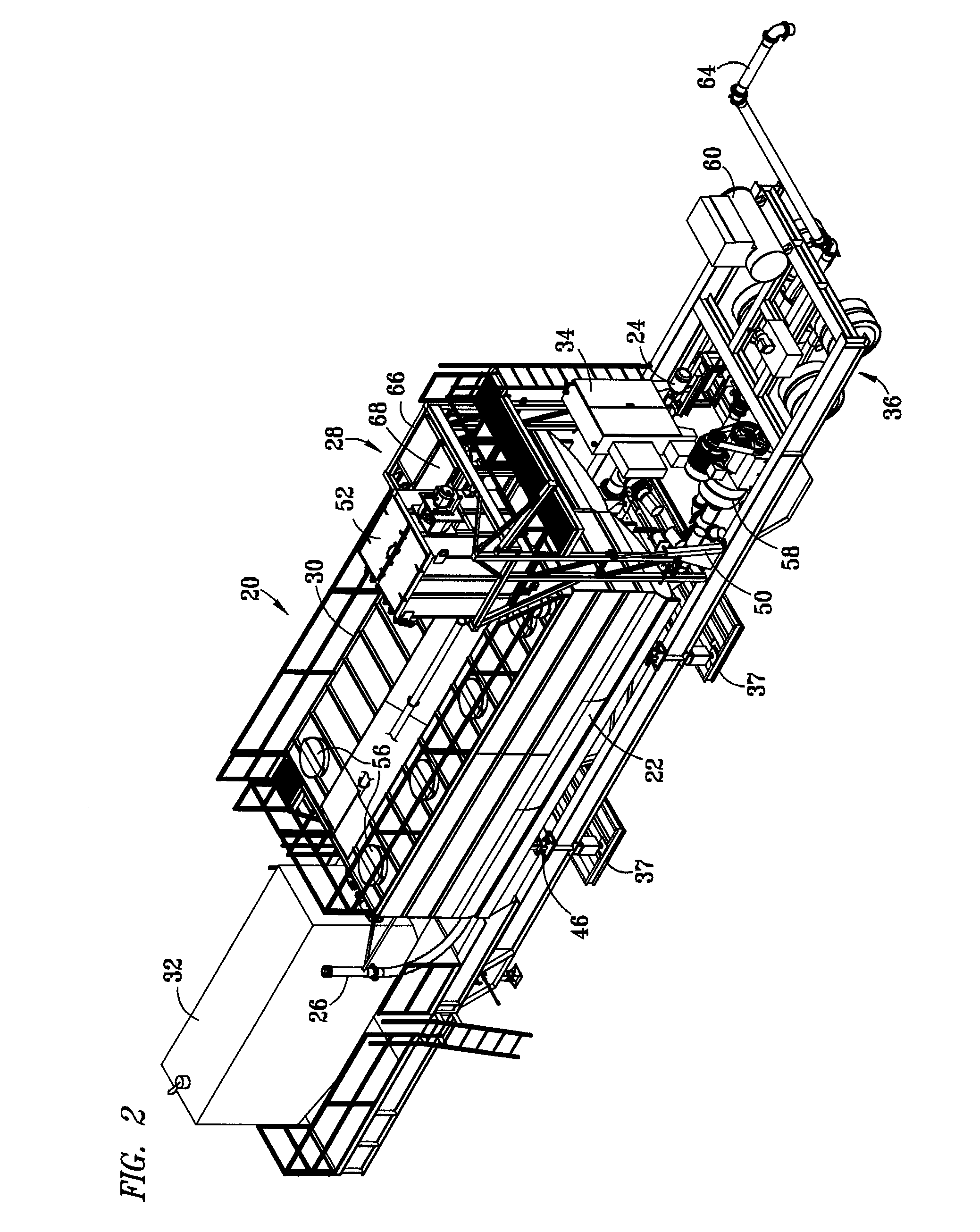

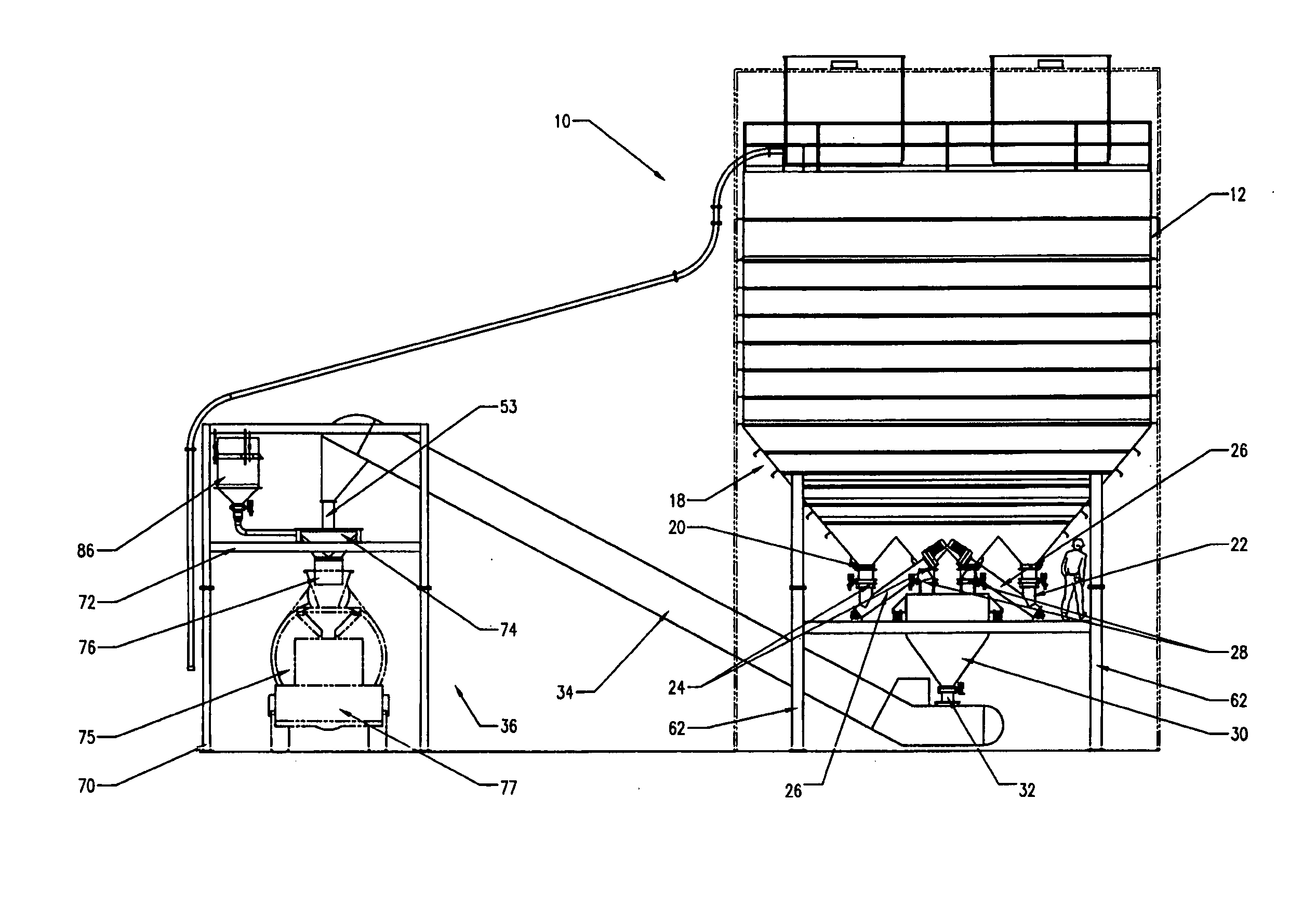

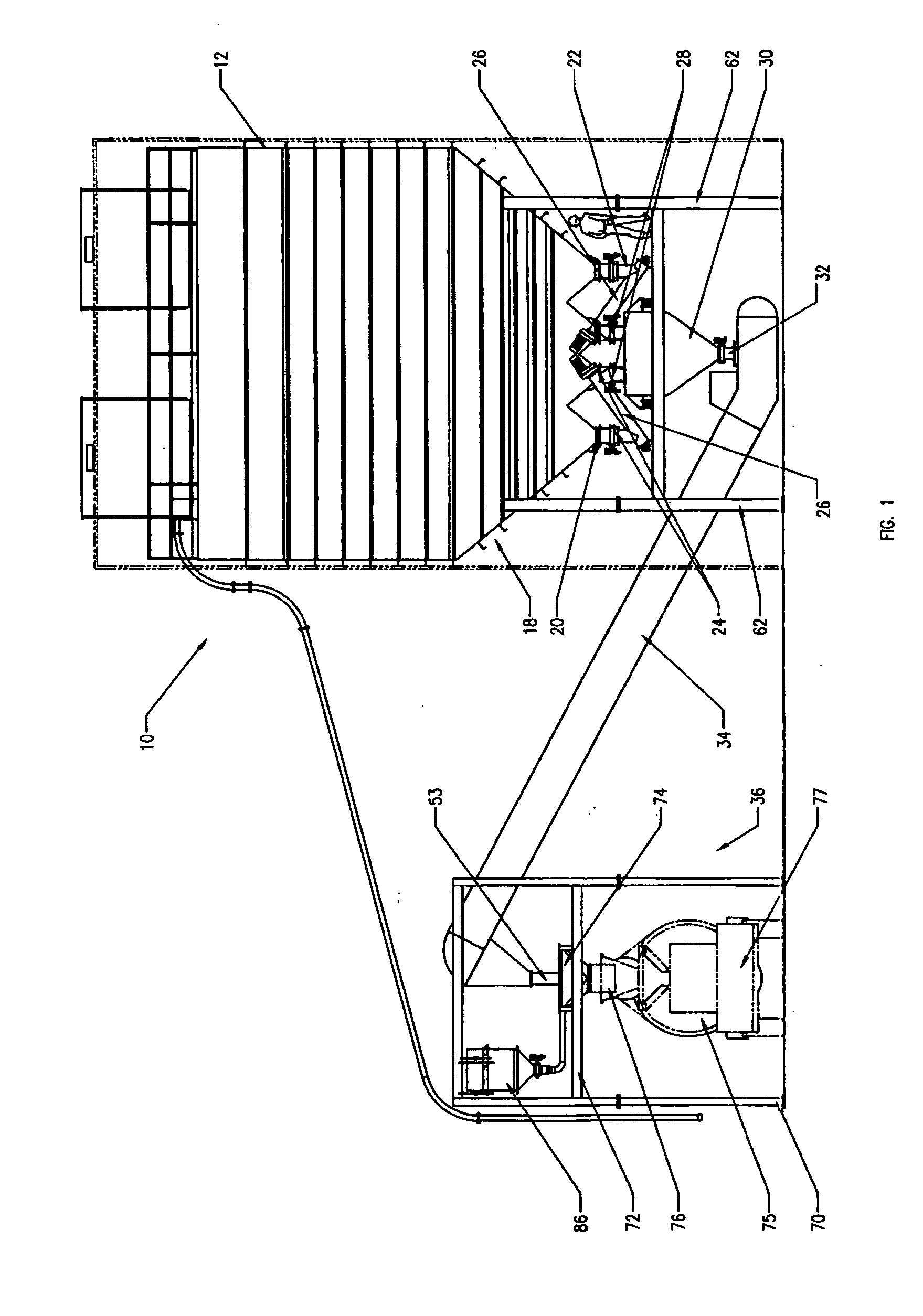

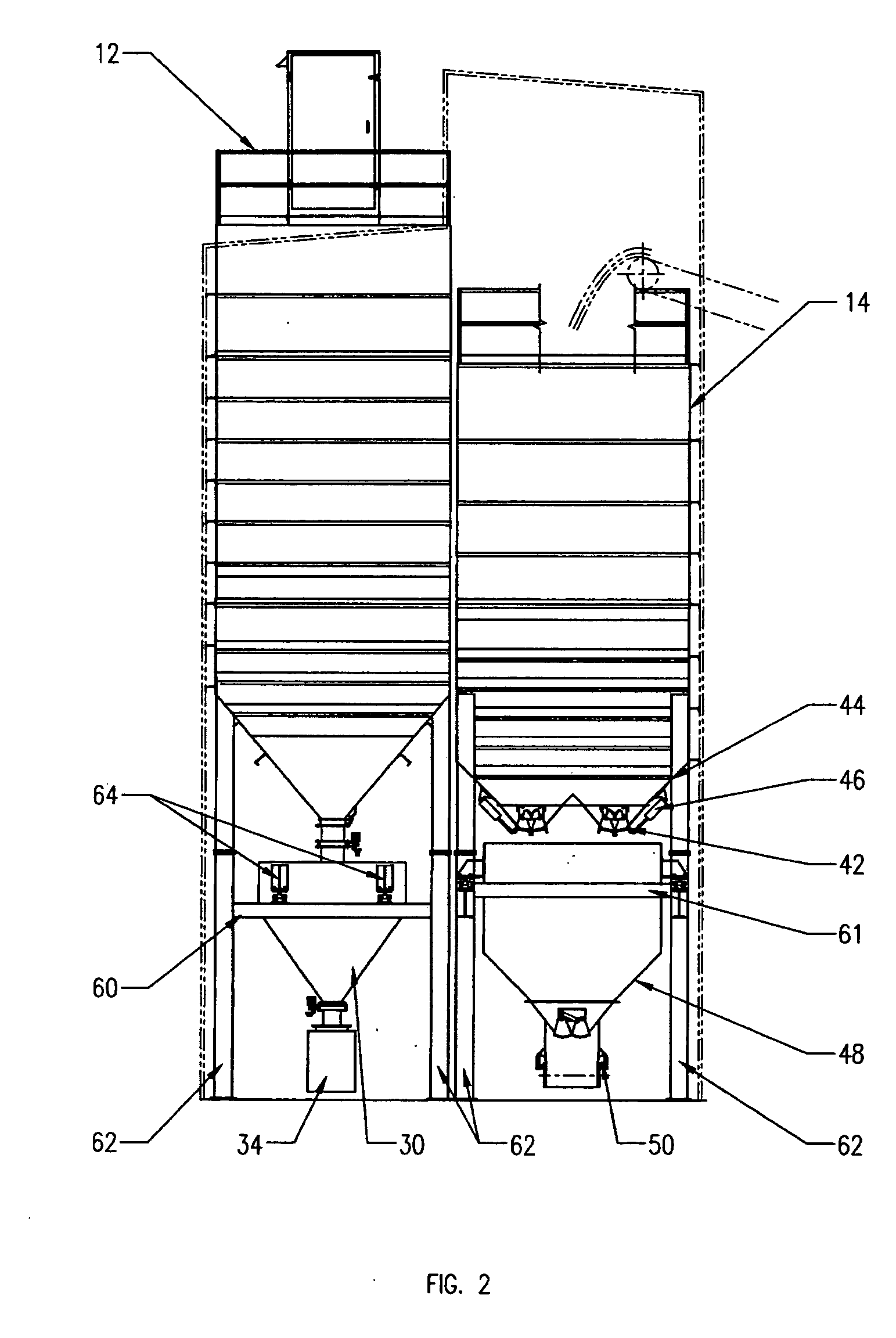

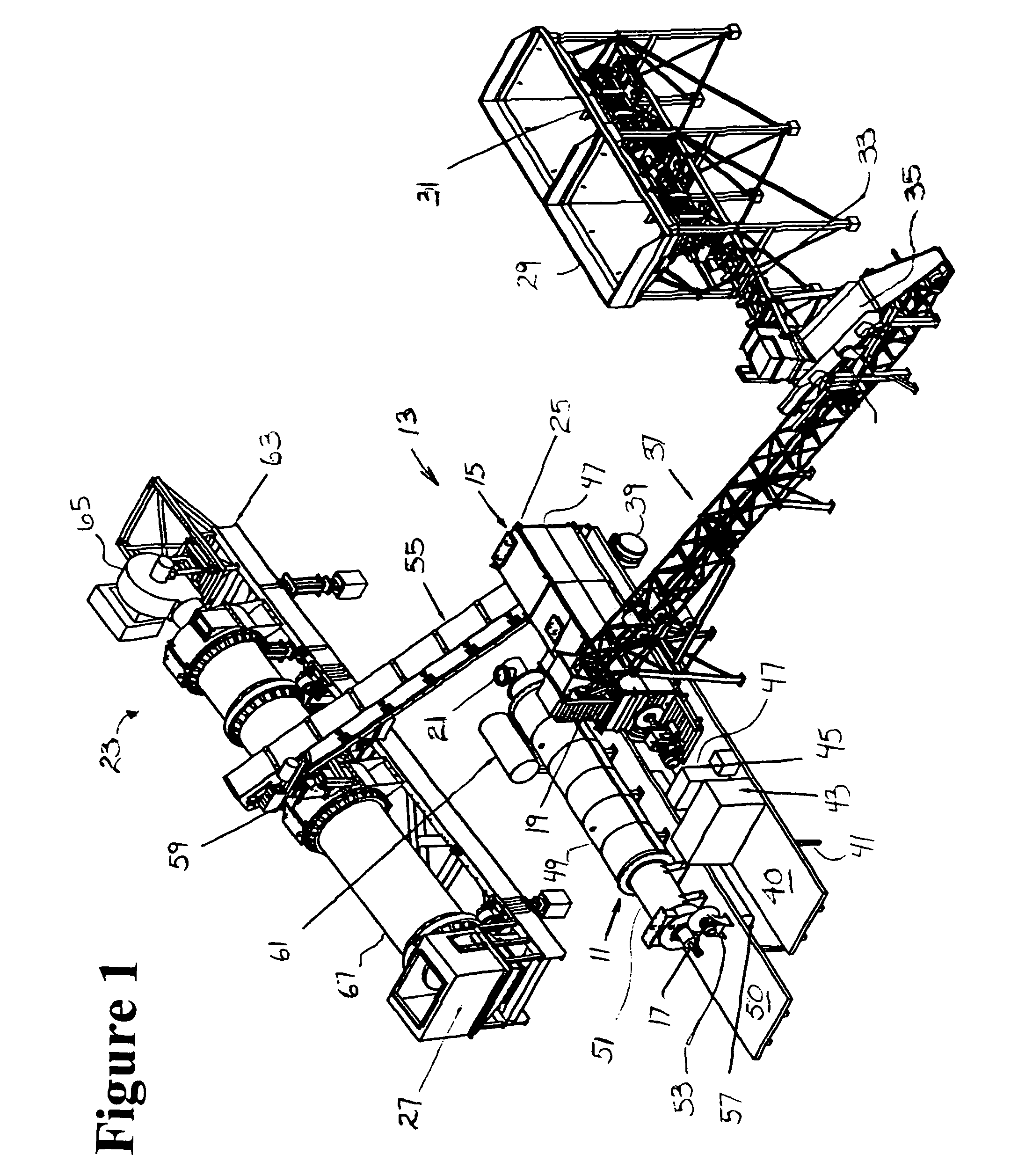

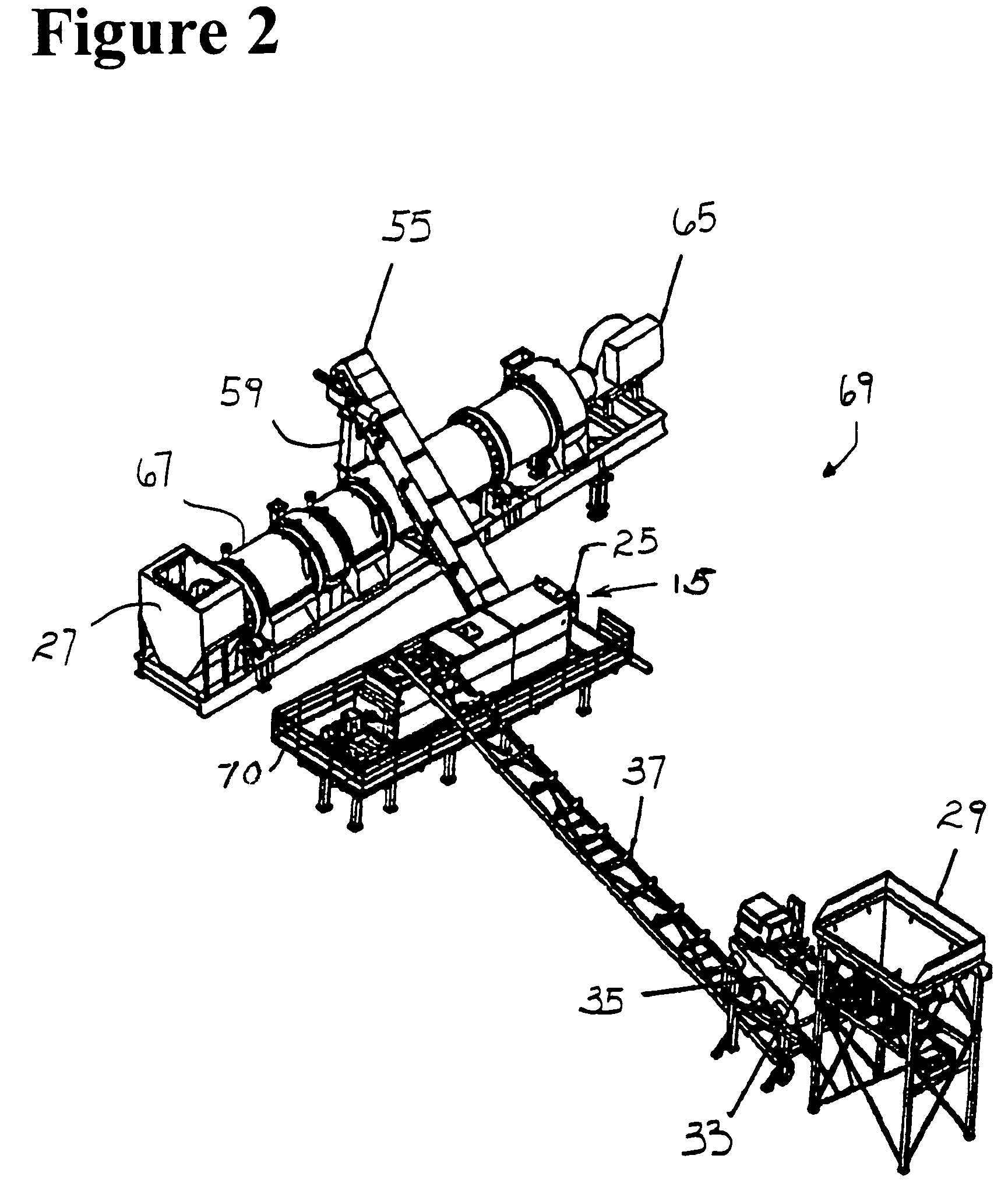

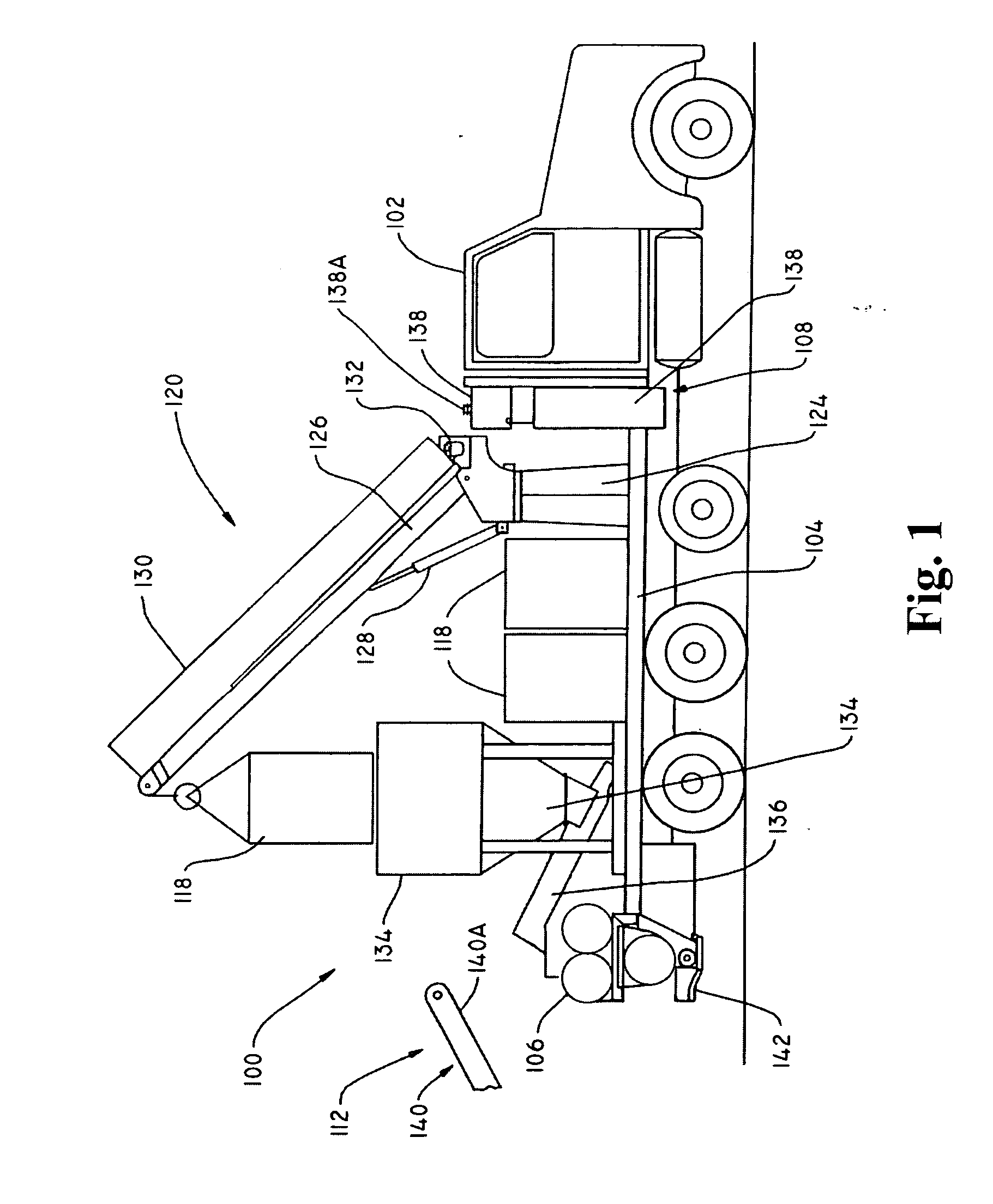

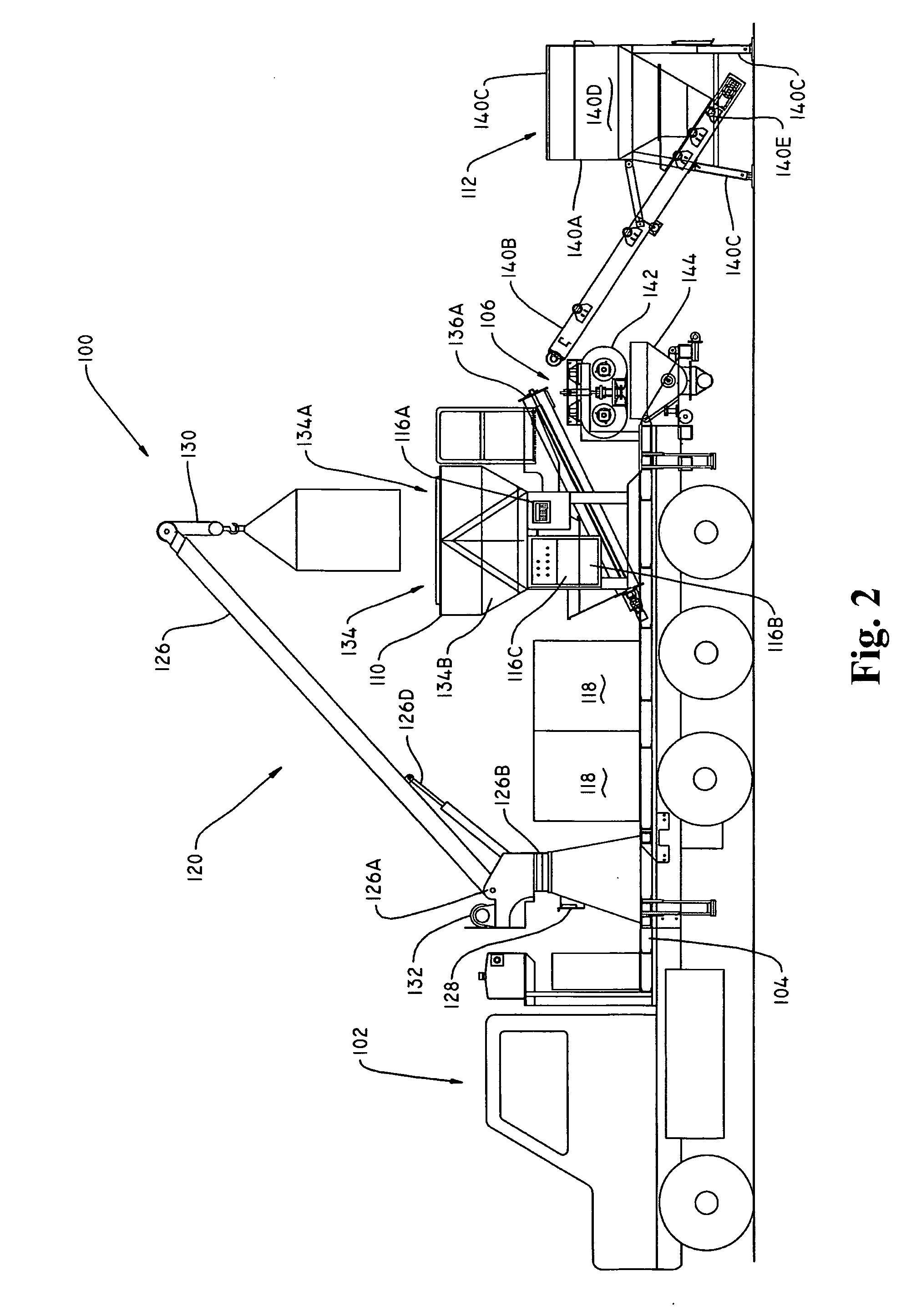

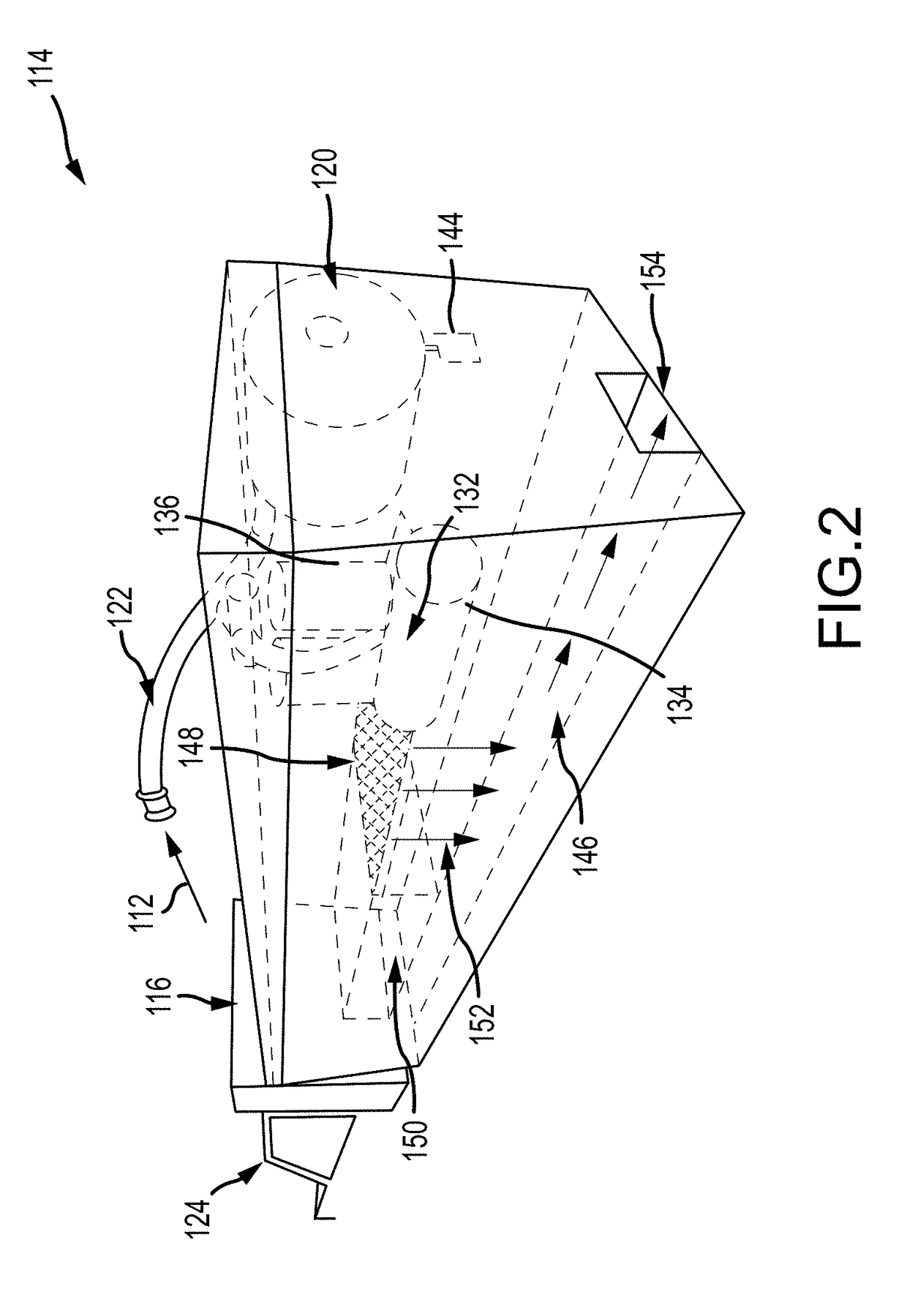

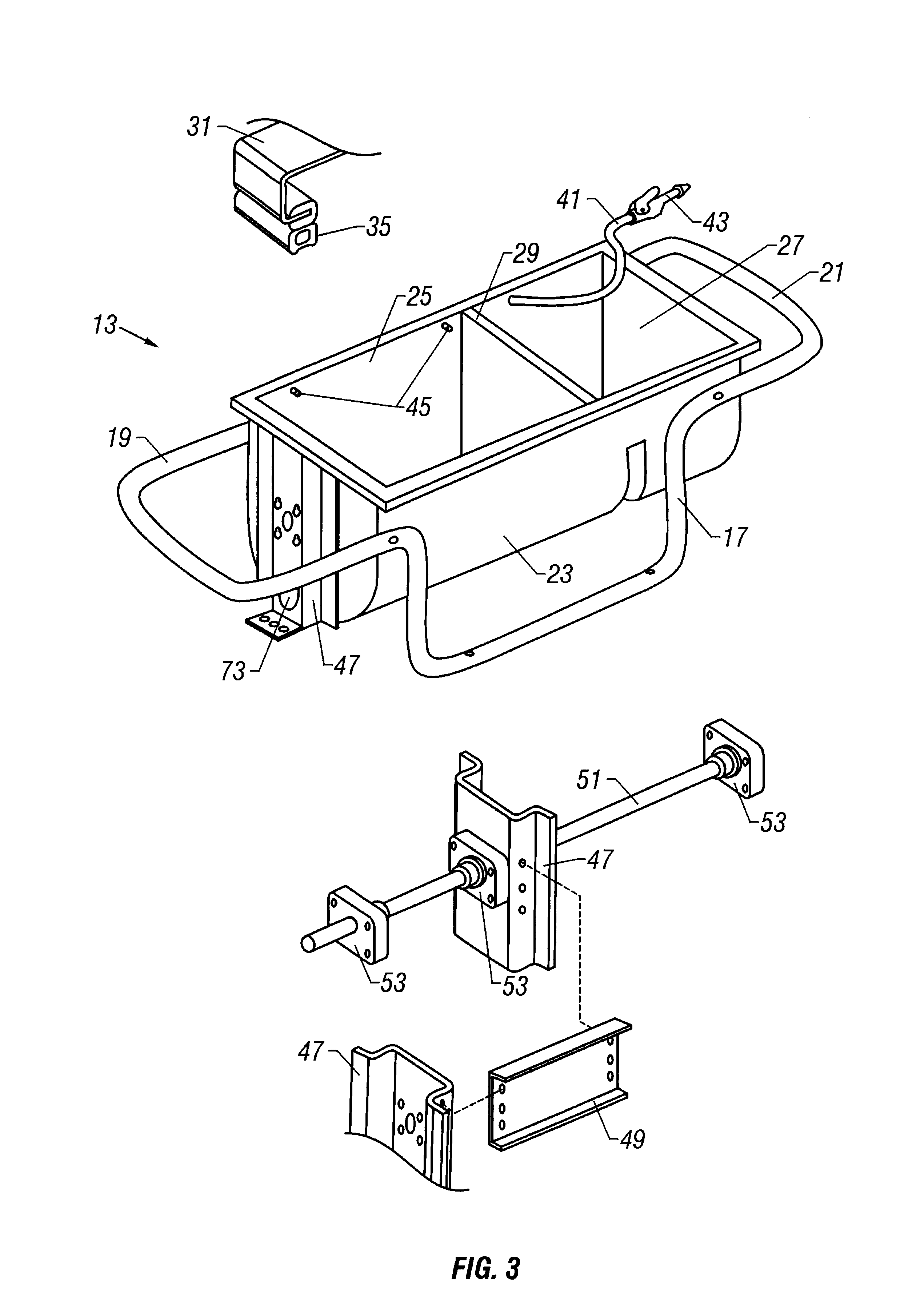

Low profile mixing plant for particulate materials

InactiveUS20050219942A1Mixing methodsMixing operation control apparatusParticulatesProcess engineering

A low profile particulate mixing plant is described. The plant is suitable for discharging the components of a particulate mixture. The plant includes a pair of storage receptacles located side-by-side. Each of the receptacles has a discharge adjacent an underside thereof to transfer a component of the particulate material mix within each receptacle to a respective conveyor at a height adjacent to ground level. The conveyor elevates the components from the discharges to a mixing station spaced from the receptacles. The plant is suitable for use as a concrete mixing plant.

Owner:WALLGREN KRIS

Recycled asphalt pavement (RAP) preparation system

InactiveUS7758235B1Reduces quick steam ventingLimit “ stripping activity ”Mixer accessoriesRoads maintainenceCombustorRoad surface

Thermal processing of recycled asphalt pavement (RAP), having up to approximately 8% or more moisture content, dries and preheats the material to enhance efficient recycling in a hot mix asphalt plant. A combustor and heat exchanger reheat circulating hot oil, which with hot gas, moves through a hollow auger and around the RAP counter to the flow of RAP. Moisture is forced outward from within the particles and is flashed away by the hot exhaust gas. A similar secondary heater heats the RAP to just below asphalt coking temperature before the hot dry RAP is added as an aggregate to the hot mix asphalt plant.

Owner:COLLETTE JERRY R

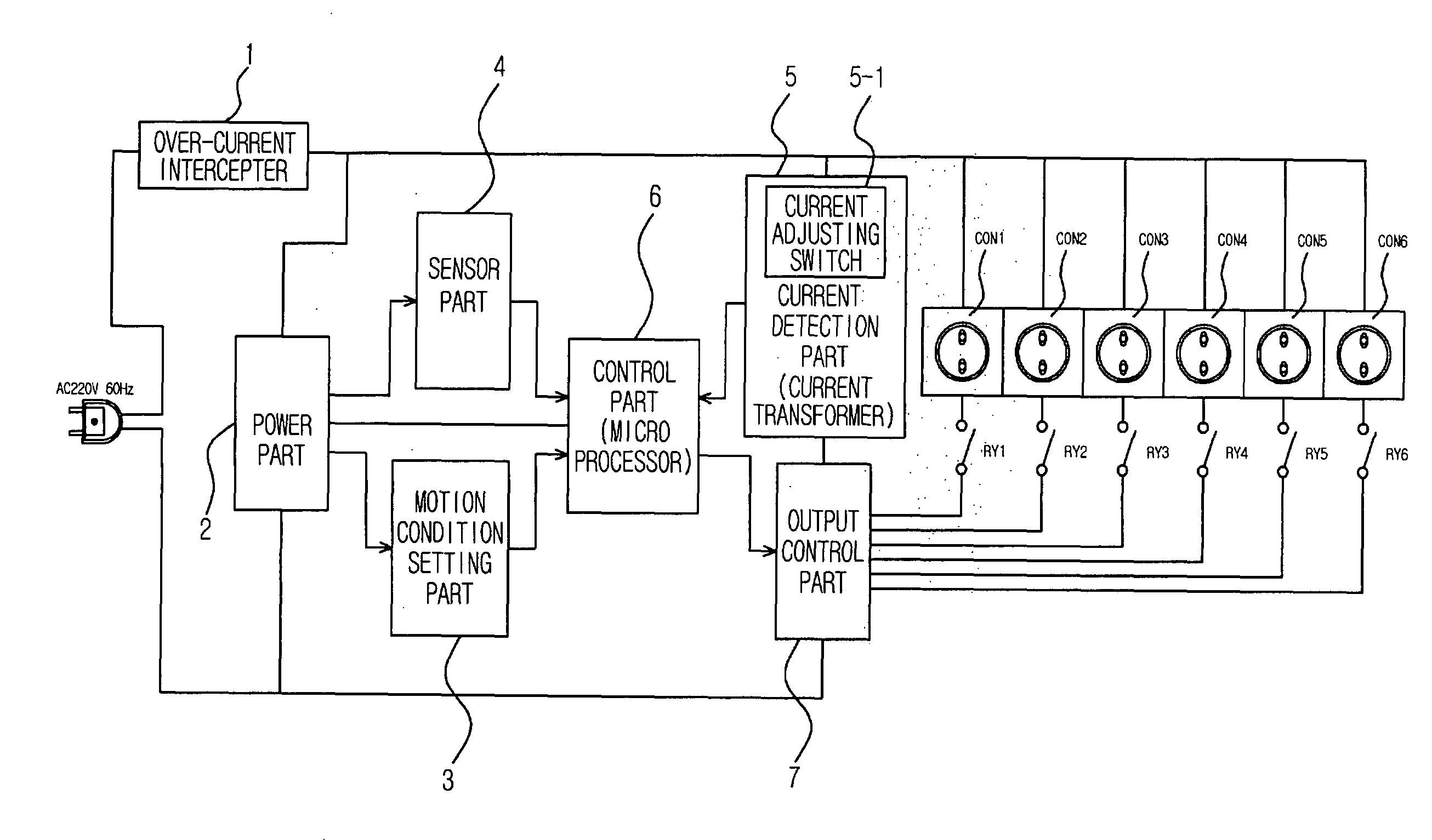

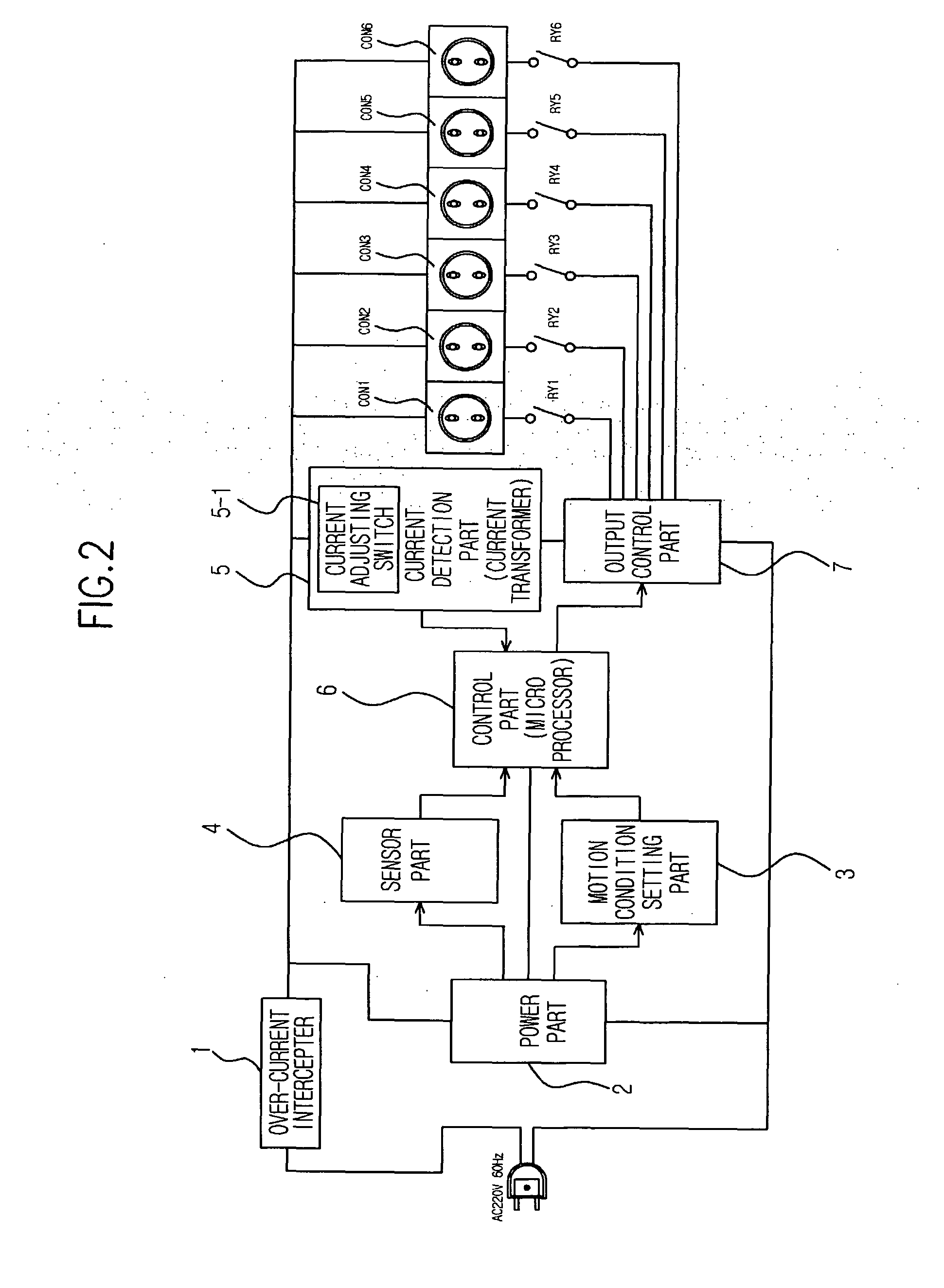

Multifunctional Multi-Outlet of Saving Electric Power and a Control Method Employing the Same

ActiveUS20070262646A1Prevent leakageAvoid fireSievingDc network circuit arrangementsIlluminanceEngineering

Owner:WELLBAS LTD

Concrete batching pre-mixer and method

InactiveUS20050219939A1Eliminate buildupWell mixedTransportation and packagingMixing operation control apparatusTruckMixed systems

A pre-mixer agglomerator and method of pre-mixing batching ingredients used to produce concrete mixes is disclosed. Specifically, this invention involves a pre-mix system which blends the wetting agents and the cementitious ingredients in relation to each other at any selected ratio in an adjustable and repeatable manner. The pre-mixer is a twin screw, preferably counter-rotating, pre-mixer agglomerator unit for pre-mixing these materials prior to combining them with aggregates in a drum of a transit mixer truck or other final mixing vessel.

Owner:MCNEILUS TRUCK & MFG INC

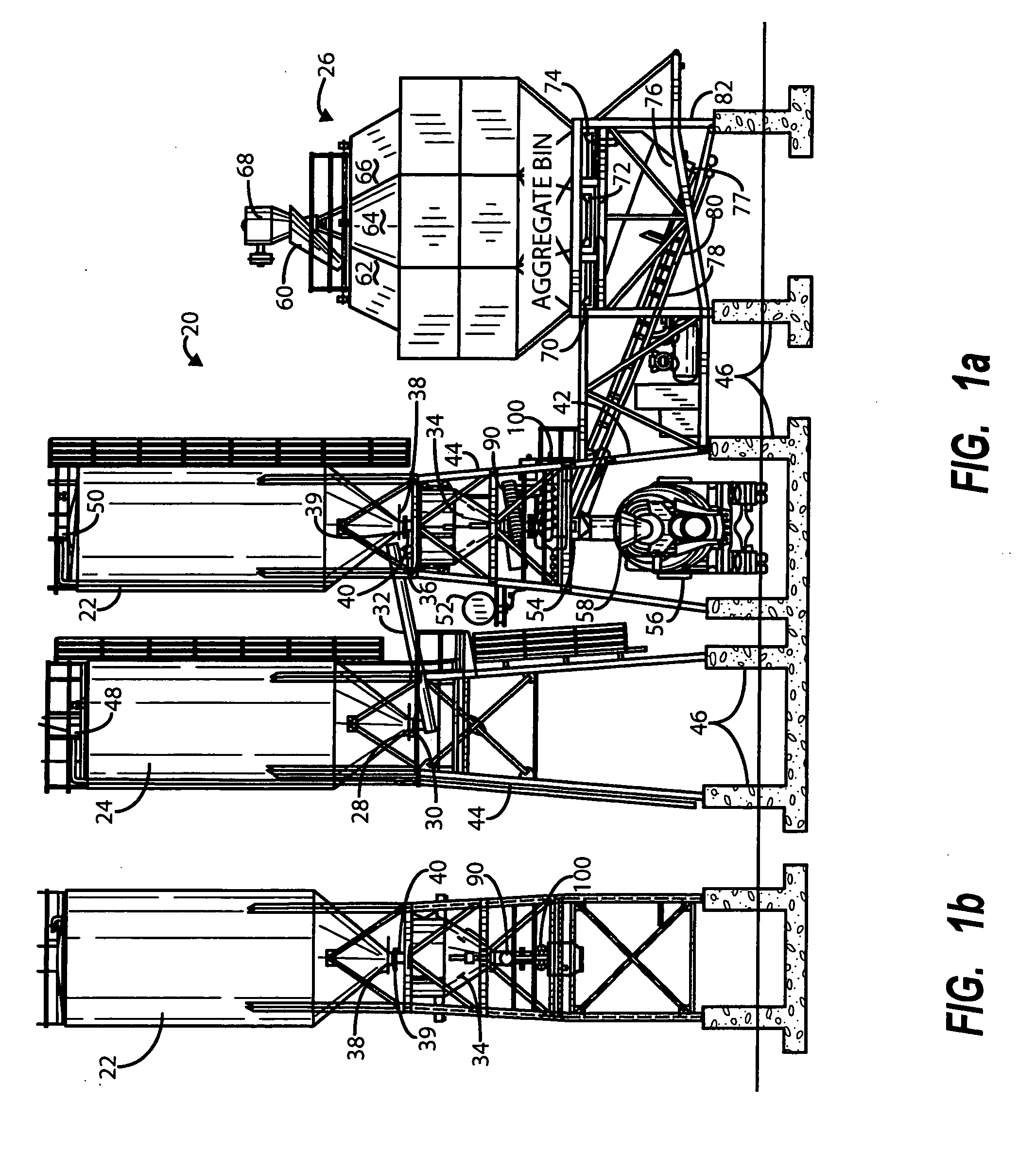

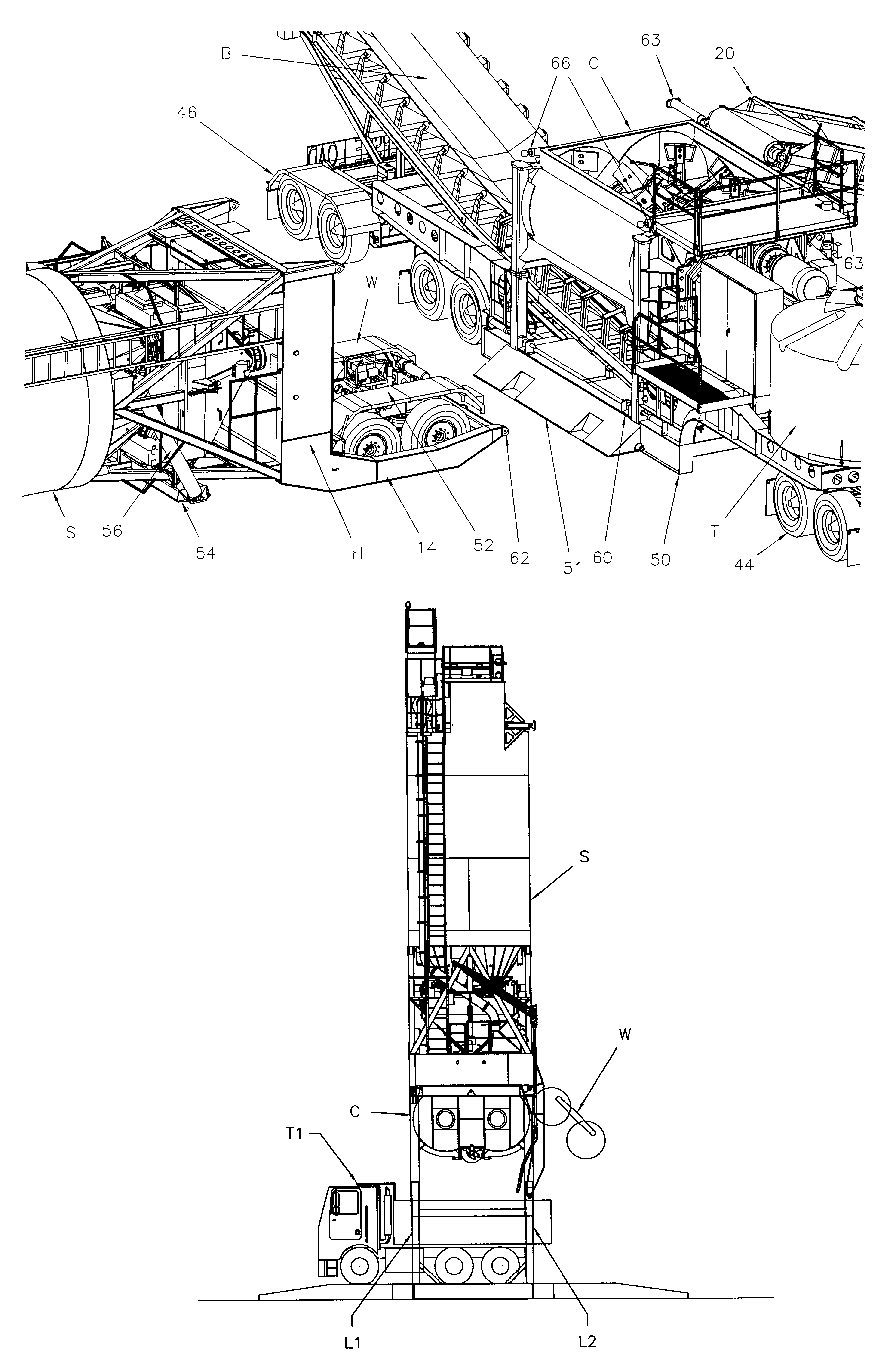

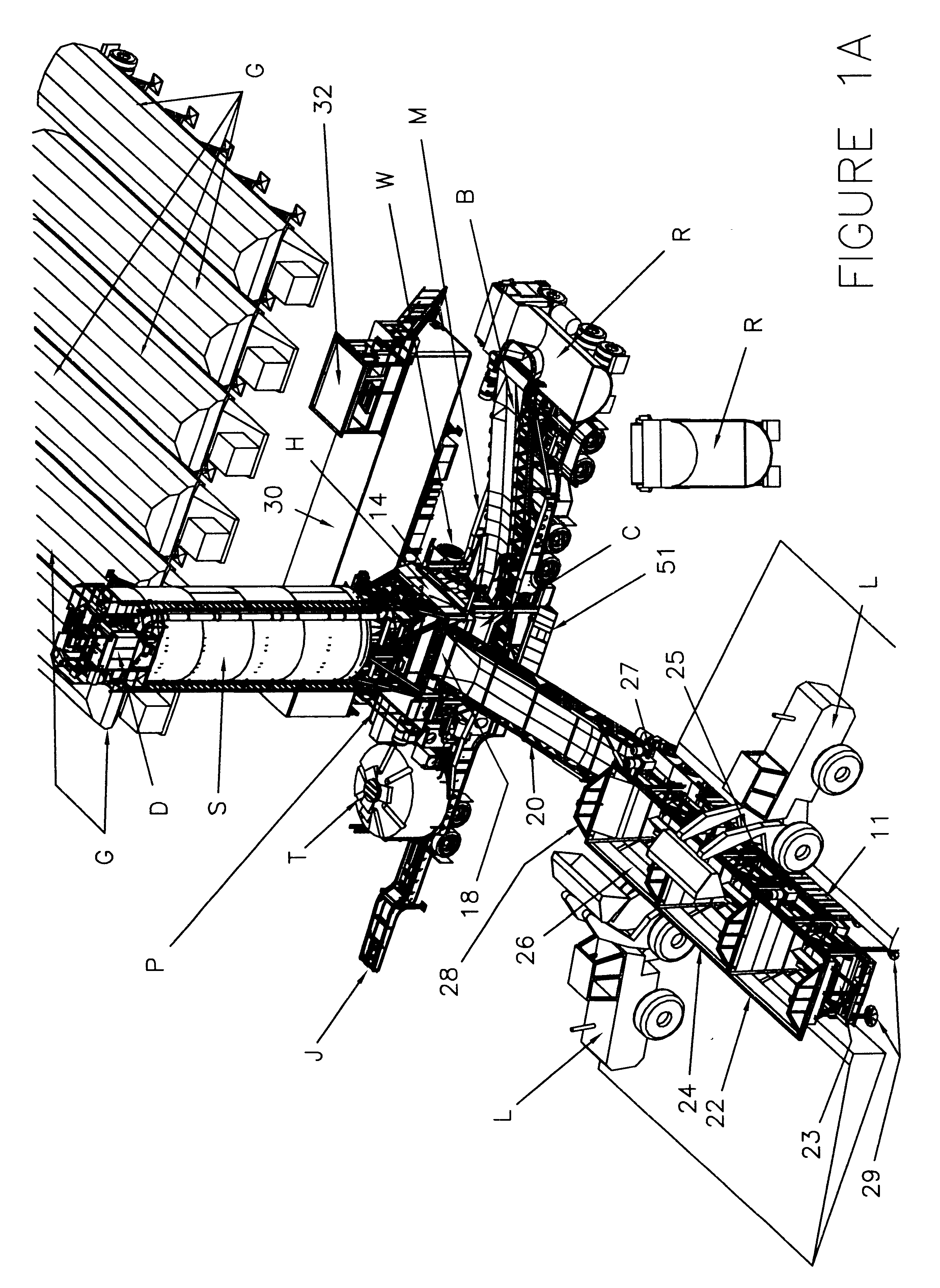

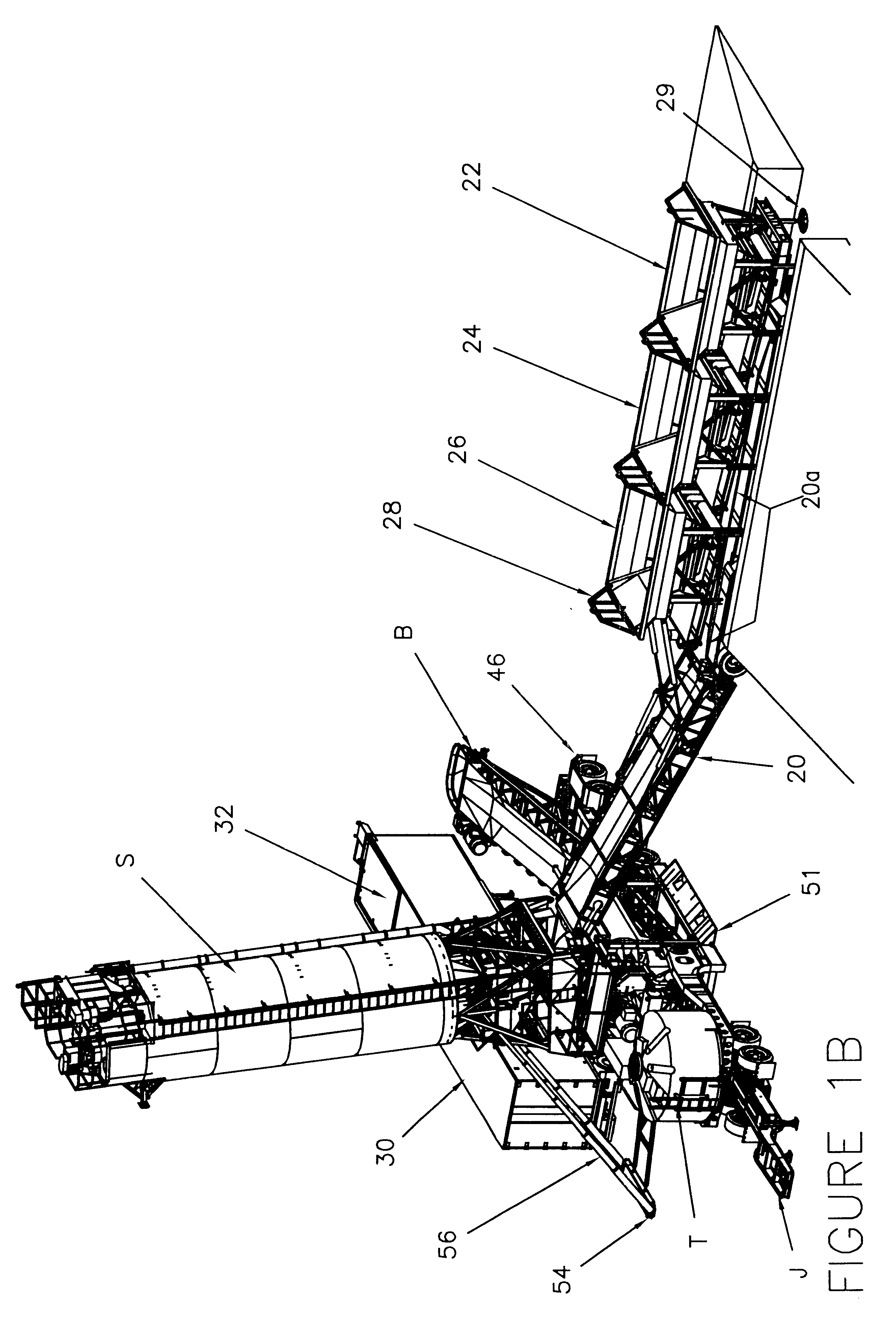

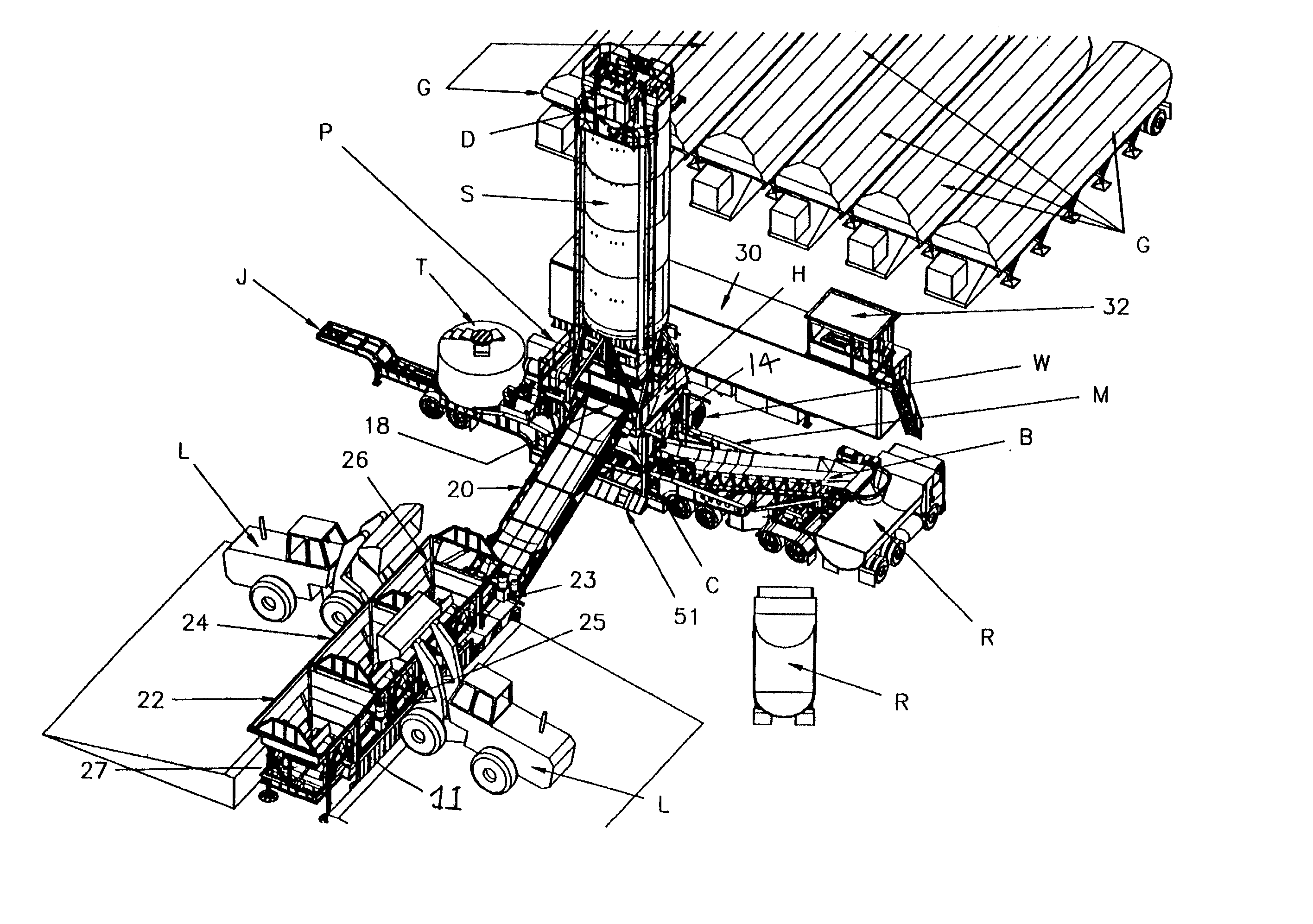

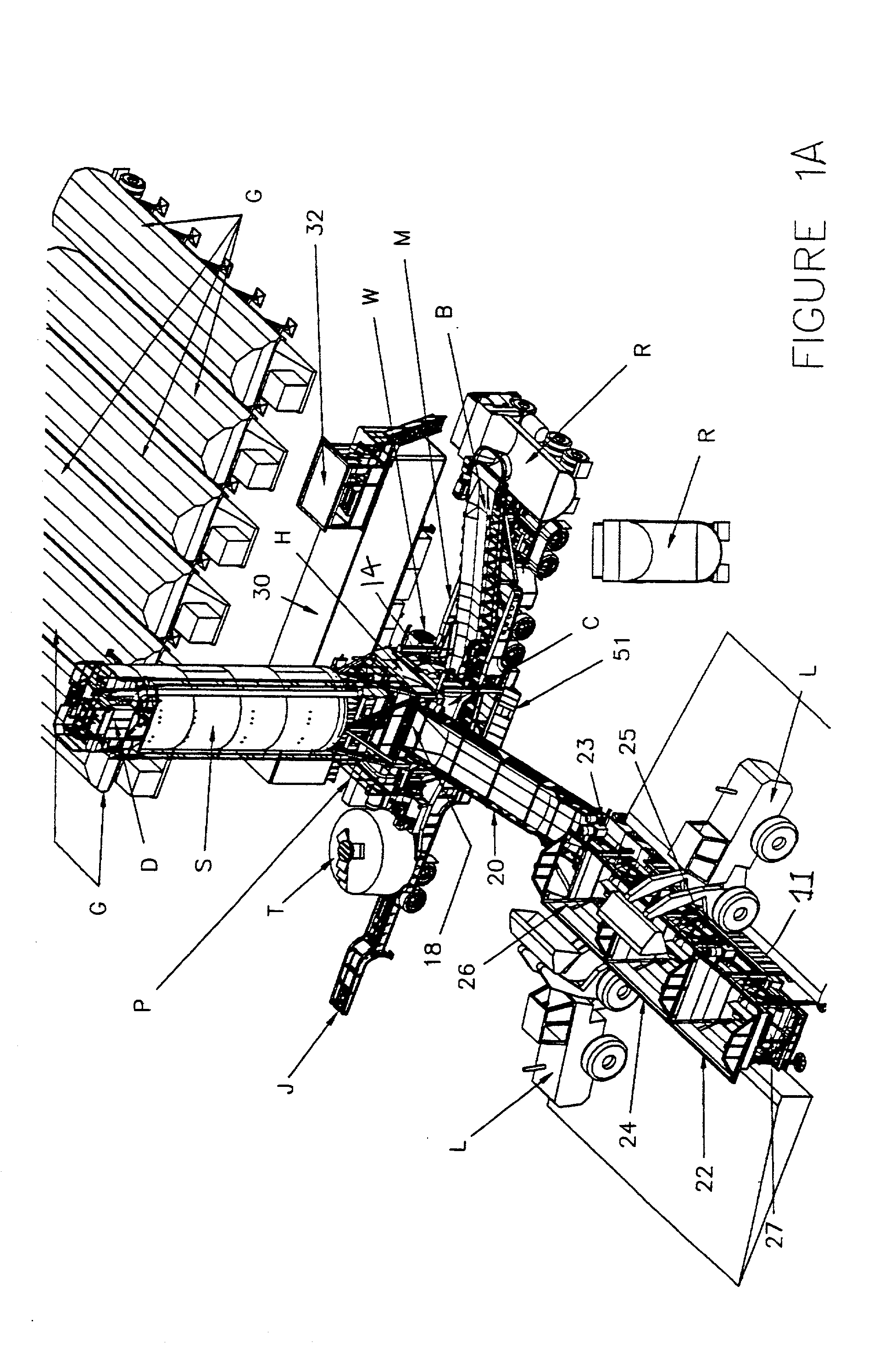

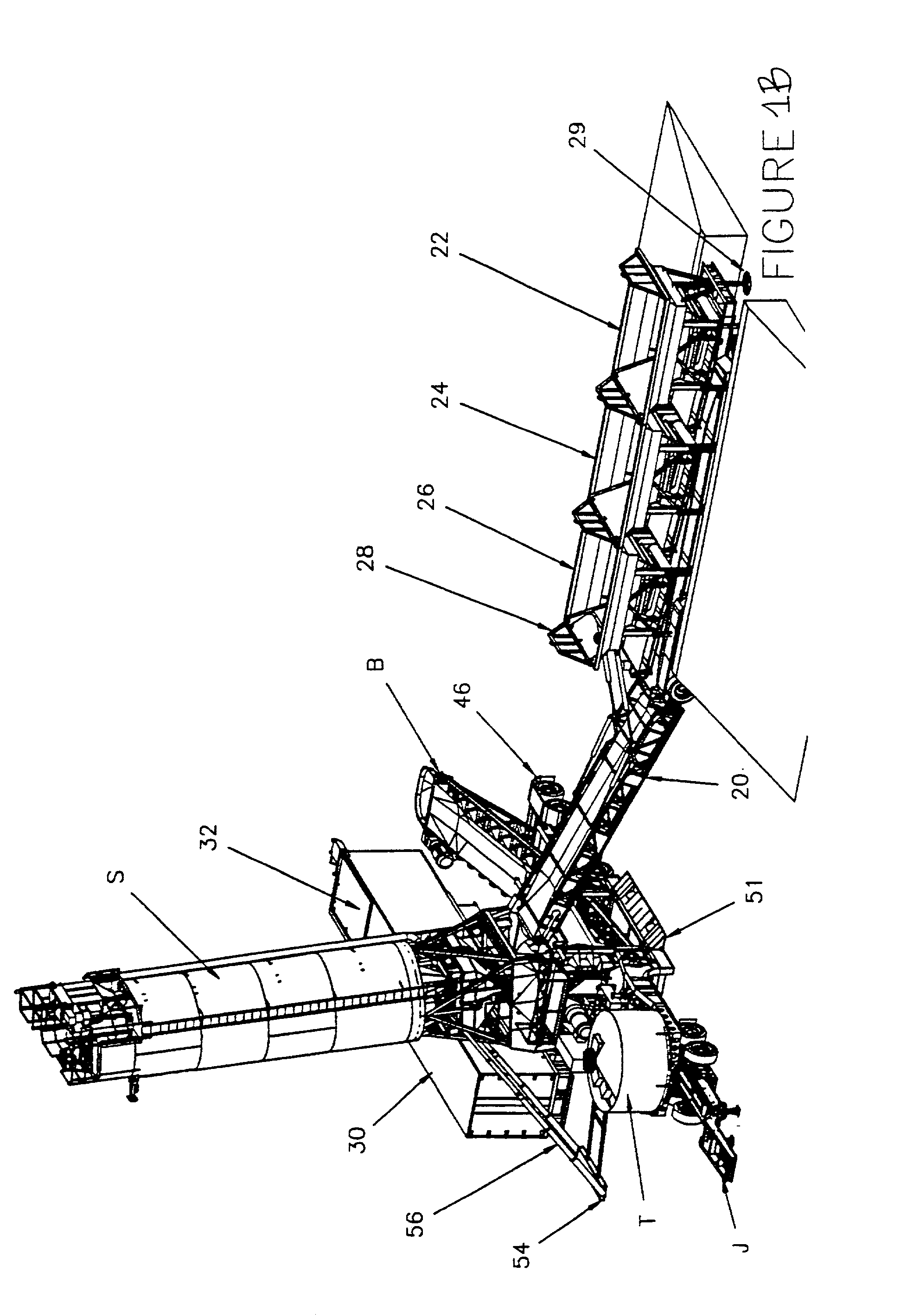

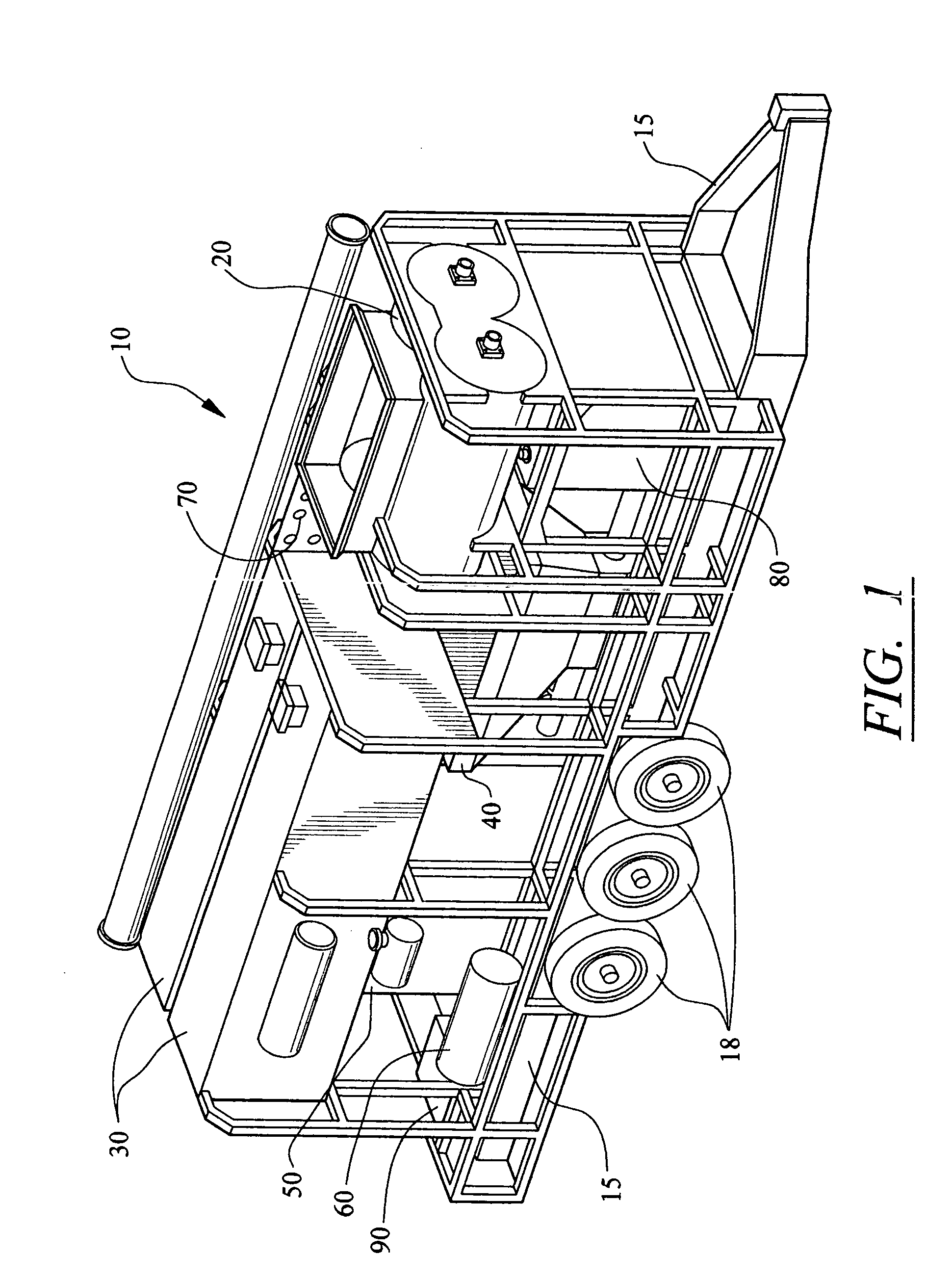

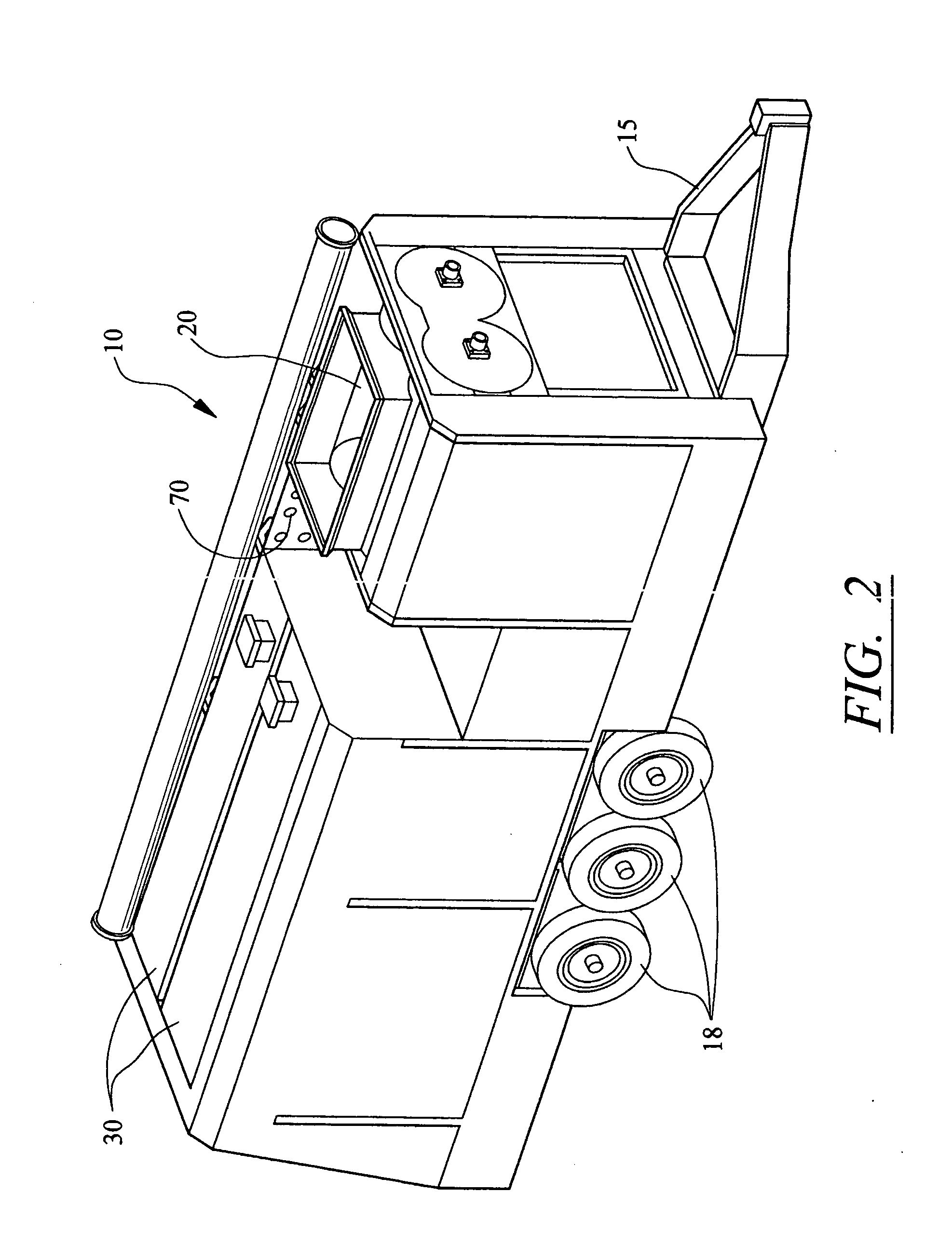

High volume portable concrete batching and mixing plant having compulsory mixer with overlying supported silo

A first mixer trailer forms the plant frame foundation around a twelve-yard compulsory mixer. The compulsory mixer is mounted for elevation relative to plant frame foundation by hydraulic lifting columns. In system erection, a cement silo trailer is first mounted to the top of the compulsory mixer when the compulsory mixer is at ground level. Thereafter, both the mounted silo and the compulsory mixer are raised and pinned in place by the hydraulic lifting columns so that gravitational discharge of mixed concrete can occur directly from the compulsory mixer to an underlying transporting apparatus, usually a truck.

Owner:GUNTERT & ZIMMERMAN CONSTR DIV

Portable cement mixing apparatus

InactiveUS20090177313A1Sampled-variable control systemsDigital data processing detailsAdditive ingredientEngineering

A portable cement mixing system uses ingredients such as cement, water and sand in predetermined quantities. A digital controller coordinates all of the operating elements of the apparatus for the entire mixing process and stores mixing programs relative to the mixing process for a variety of cements which includes the various ingredient quantities. Separate storage containers each coupled to a conveyors from the container extend to a mixer to transfer that quantity to the mixer for each cement ingredient. The conveyors are operated in sequence by the controller to load the mixer with a predetermined quantity of each of the required ingredients prior to mixing. The mixer and its contents are weighed before and during the transfer of each ingredient to precisely determine and transfer the required amount of each ingredient. After the mixer is loaded with all of the ingredients, the mixer is operated for a predetermined length of time.

Owner:SMART BATCH SYST

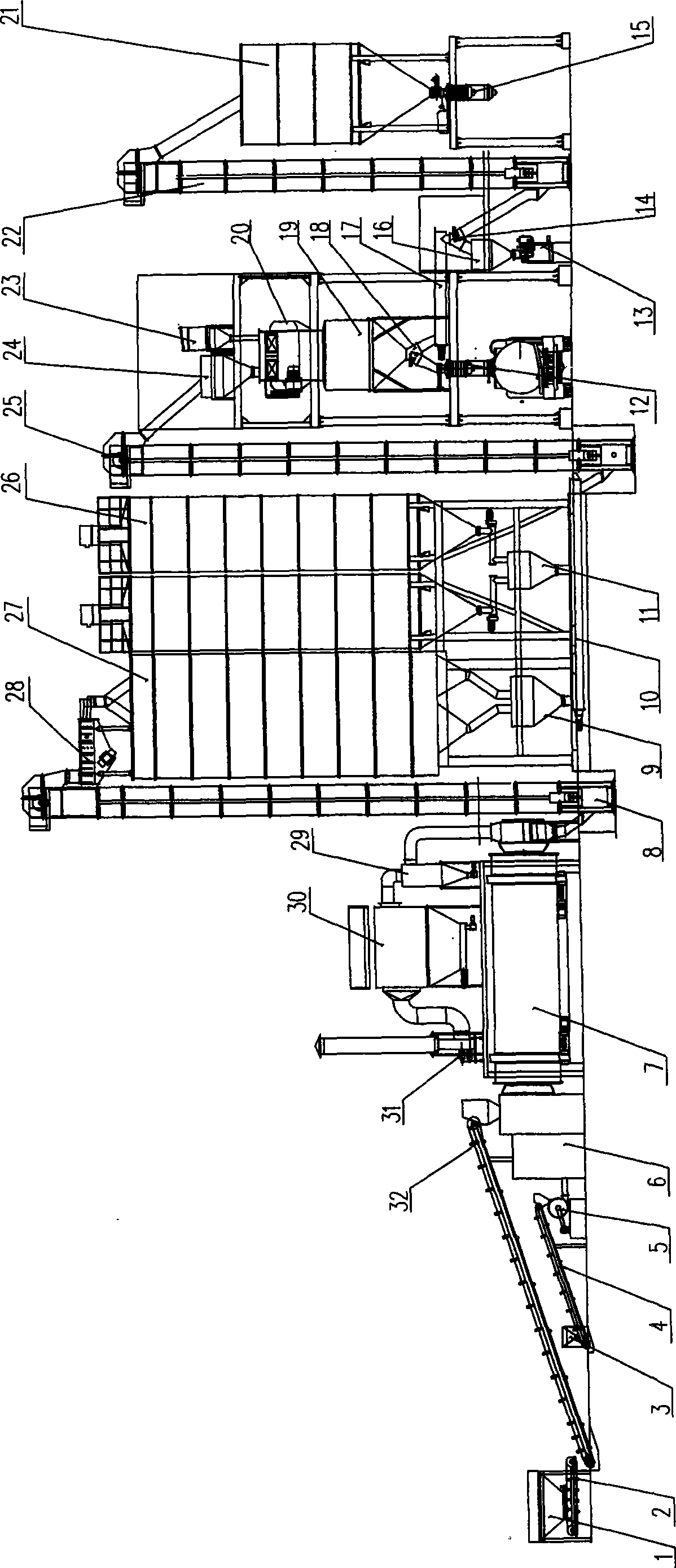

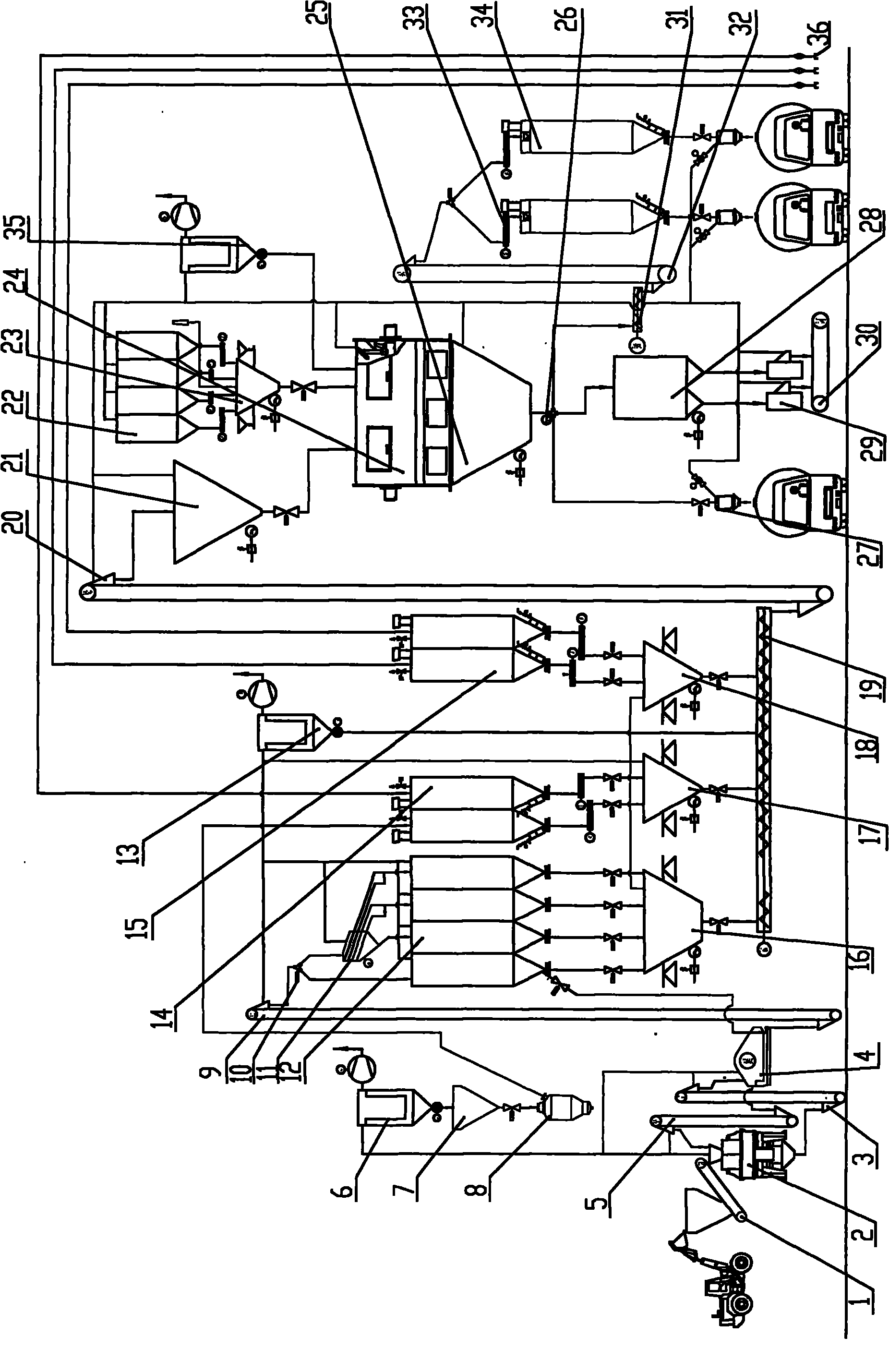

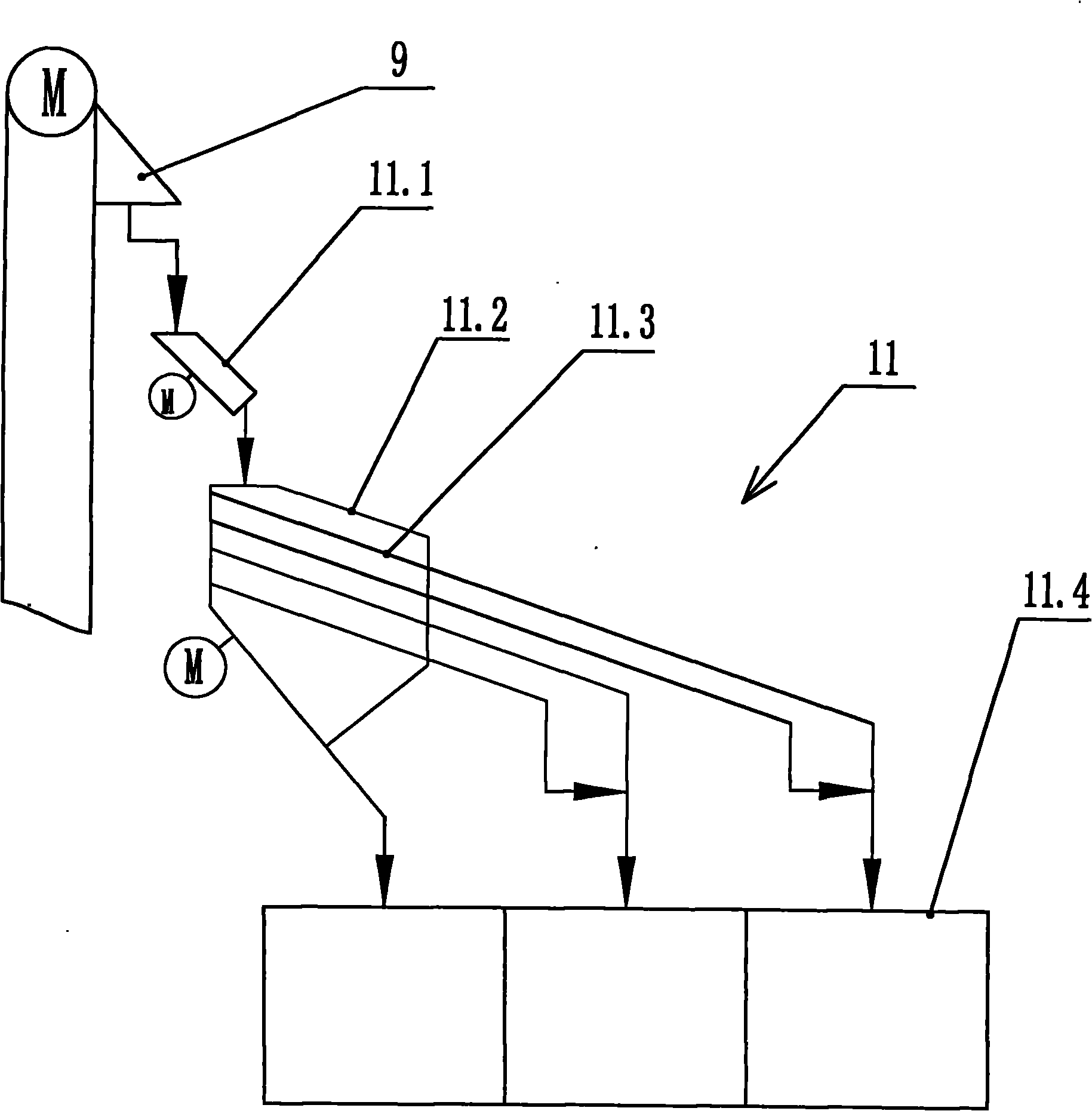

Drying-free dry-mixed mortar complete equipment

The invention relates to drying-free dry-mixed mortar complete equipment, comprising a charging belt conveyor (1), a crusher sand making machine (2), a discharging bucket elevator (3), a circulating vibration screen (4), a screening bucket elevator (9), a vibrating screen classifier (11), a classified sand warehouse (12), a return bucket elevator (5), a stone powder dust collector (6), a stone powder temporary storage bin (12), a stone powder delivery tank (8), a stone powder additive bin (14), a cement bin (15), a sand dispensing and metering device (16), an additive dispensing and metering device (17), a cement dispensing and metering device (18), a metering material spiral conveyer (19), a metering material bucket elevator (20), a metering material intermediate transition bin (21), an additive storage silo (22), an accurate dispensing and metering device (23), a mixer (24), a finished product material transition bin (25), a bulk head (27), a wrapping finished product bin (28), a sack filler (29), a package belt conveyer (30), a finished product material storage spiral conveyer (31), a finished product material storage bucket elevator (32), a dissociation-proof transport unloading device (33) and a finished product material bulk storage silo (34). The invention can omit drying and realizes drying-free effect.

Owner:WUXI JIANGJIA CONSTR MACHINERY

High volume portable concrete batching and mixing plant having compulsory mixer with overlying supported silo

A first mixer trailer forms the plant frame foundation around a twelve-yard compulsory mixer. The compulsory mixer is mounted for elevation relative to plant frame foundation by hydraulic lifting columns. In system erection, a cement silo trailer is first mounted to the top of the compulsory mixer when the compulsory mixer is at ground level. Thereafter, both the mounted silo and the compulsory mixer are raised and pinned in place by the hydraulic lifting columns so that gravitational discharge of mixed concrete can occur directly from the compulsory mixer to an underlying transporting apparatus, usually a truck.

Owner:GUNTERT & ZIMMERMAN CONSTR DIV

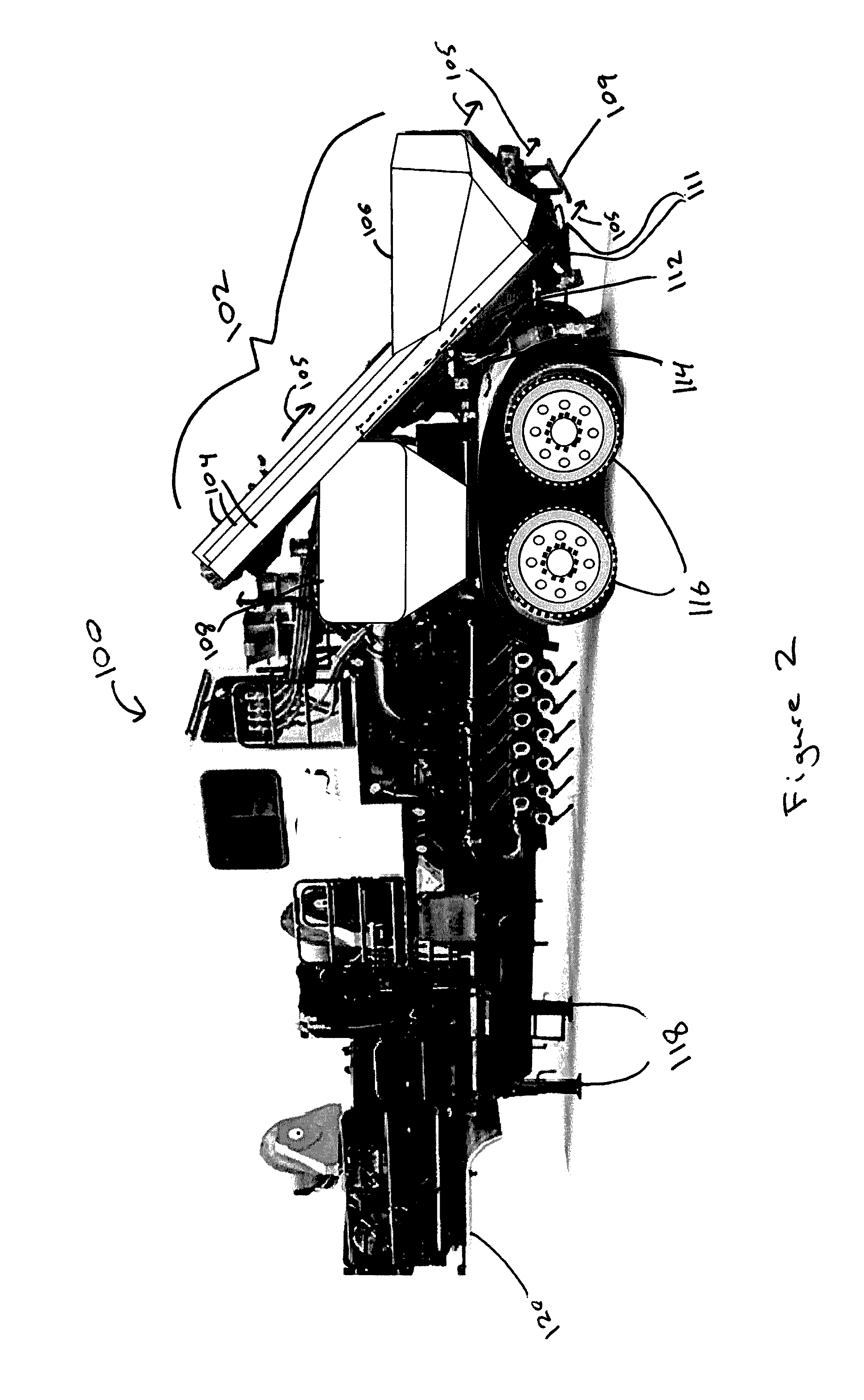

Independent control of auger and hopper assembly in electric blender system

Embodiments relate to a hydraulic fracturing system that includes a blender unit. The system includes an auger and hopper assembly to receive proppant from a proppant source and feed the proppant to the blender unit for mixing with a fluid. A first power source is used to power the blender unit in order to mix the proppant with the fluid and prepare a fracturing slurry. A second power source independently powers the auger and hopper assembly in order to align the hopper of the auger and hopper assembly with a proppant feed from the proppant source. Thus, the auger and hopper assembly can be stowed or deployed without use of the first power source, which is the main power supply to the blender unit.

Owner:US WELL SERVICS LLC

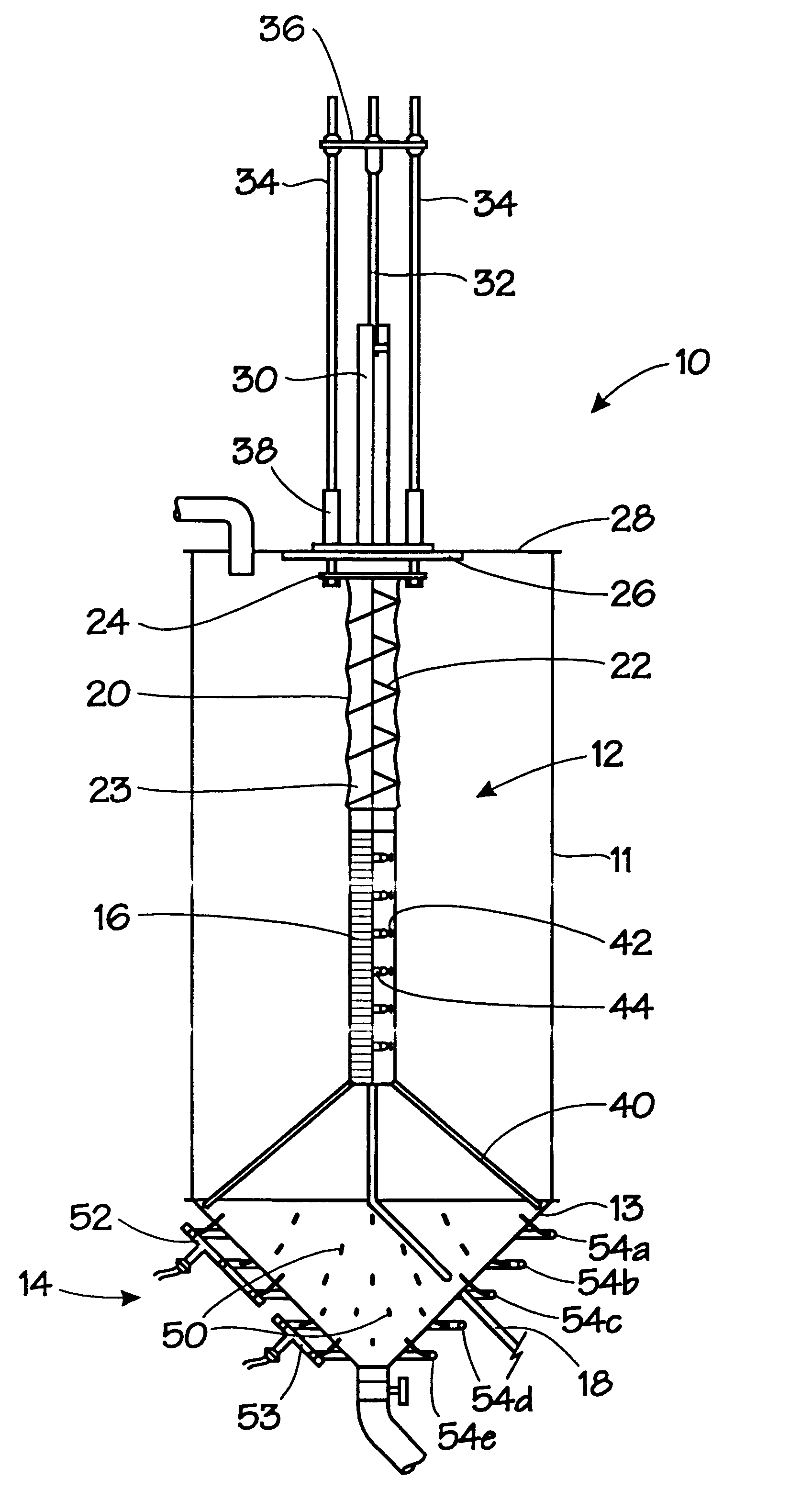

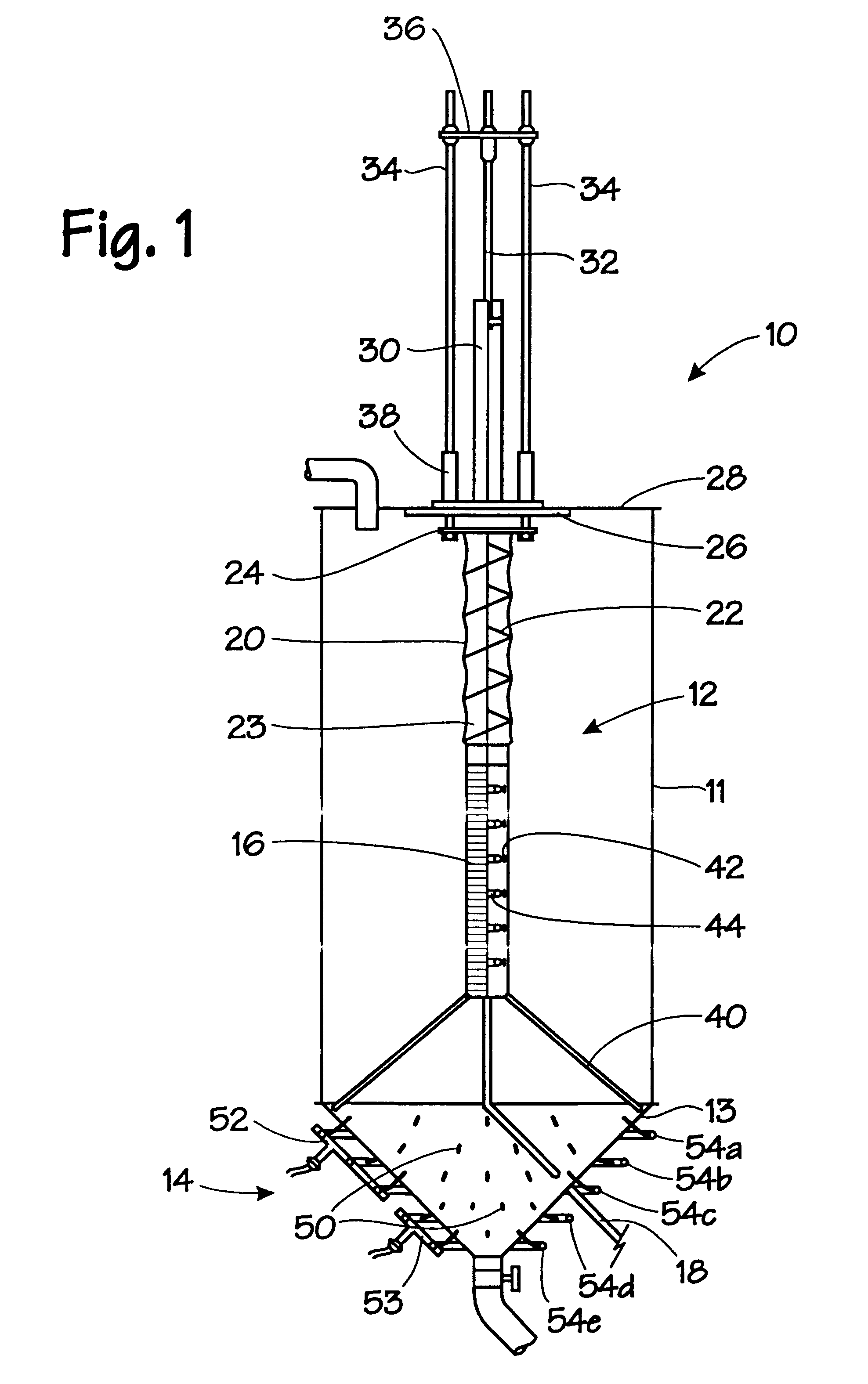

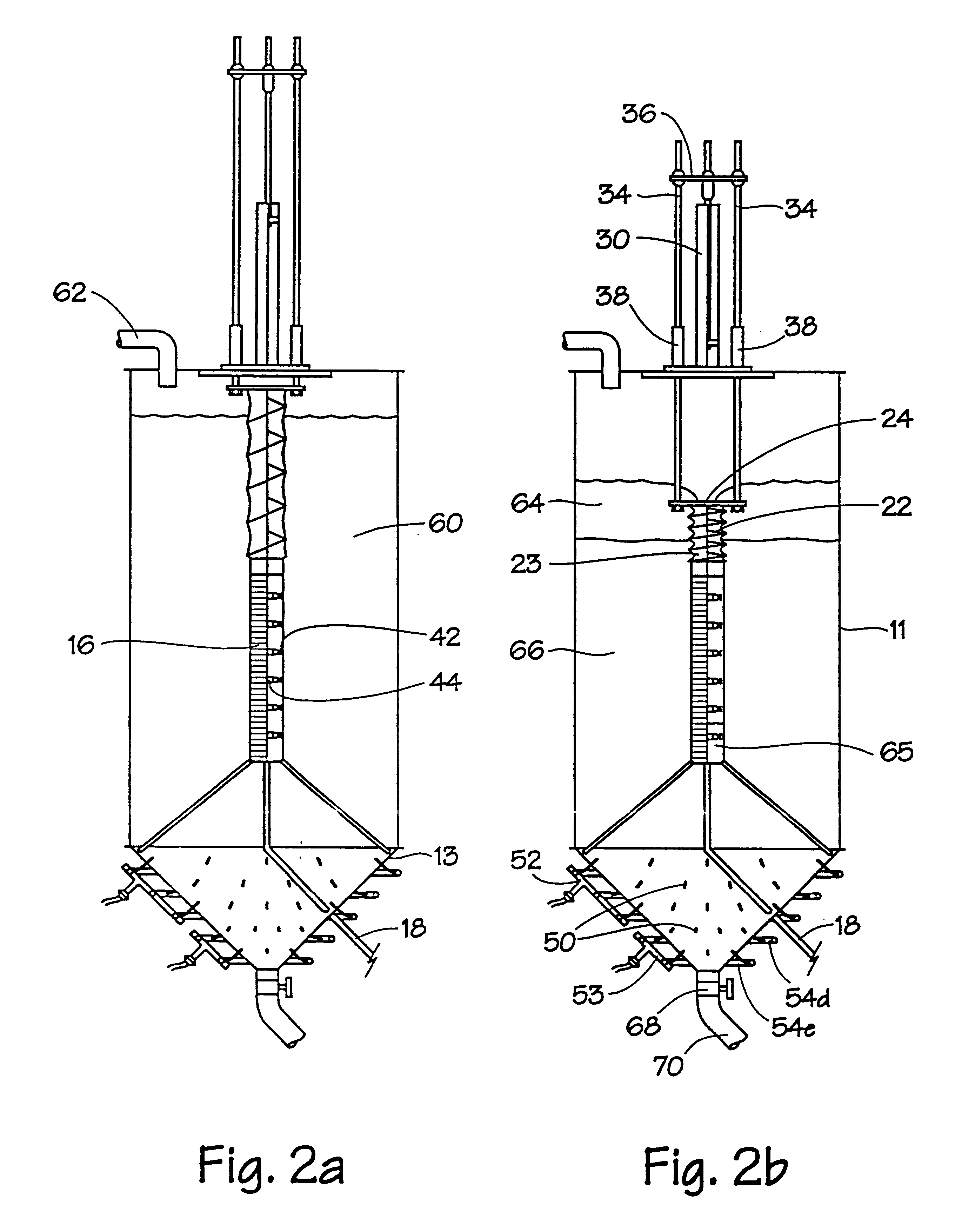

Apparatus for producing high density slurry and paste backfills

An apparatus for producing high density slurry and paste backfills for use, for example, in mining operations. The high density slurry or paste is produced from a mill tailings mixture in a silo which includes a percolation and decant apparatuses for percolating water out of the mill tailings mixture and for decanting clarified water from atop the settled tailings. While settling occurs, air is introduced from the bottom of the silo to agitate the mixture to ensure substantially homogeneous settlement of the solids. Once settled, the resultant high density slurry or paste is fluidized by air in order to give the paste more readily flowable characteristics.

Owner:HER MAJESTY THE QUEEN & RIGHT OF CANADA REPRESENTED BY THE MIN OF NATURAL RESOURCES

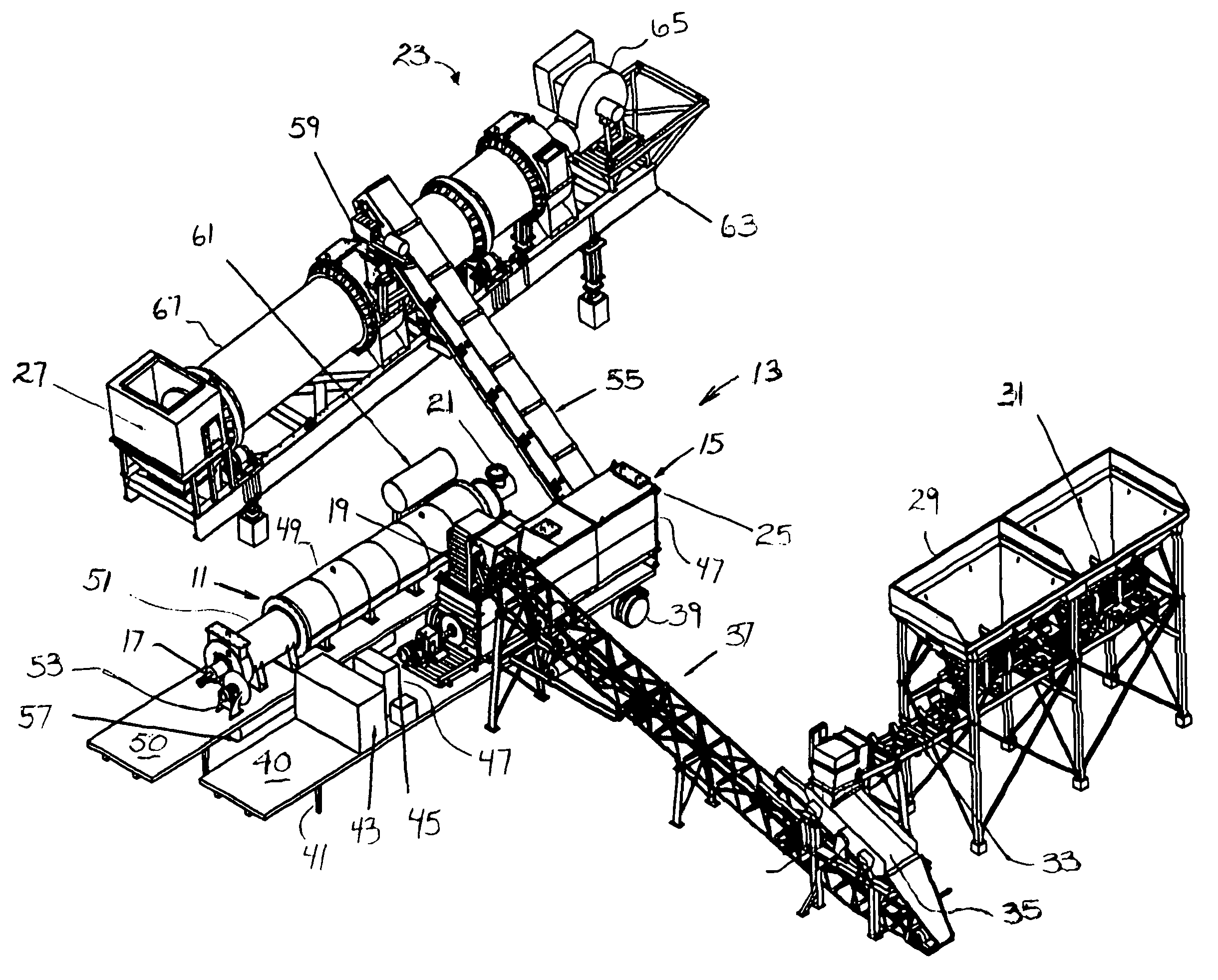

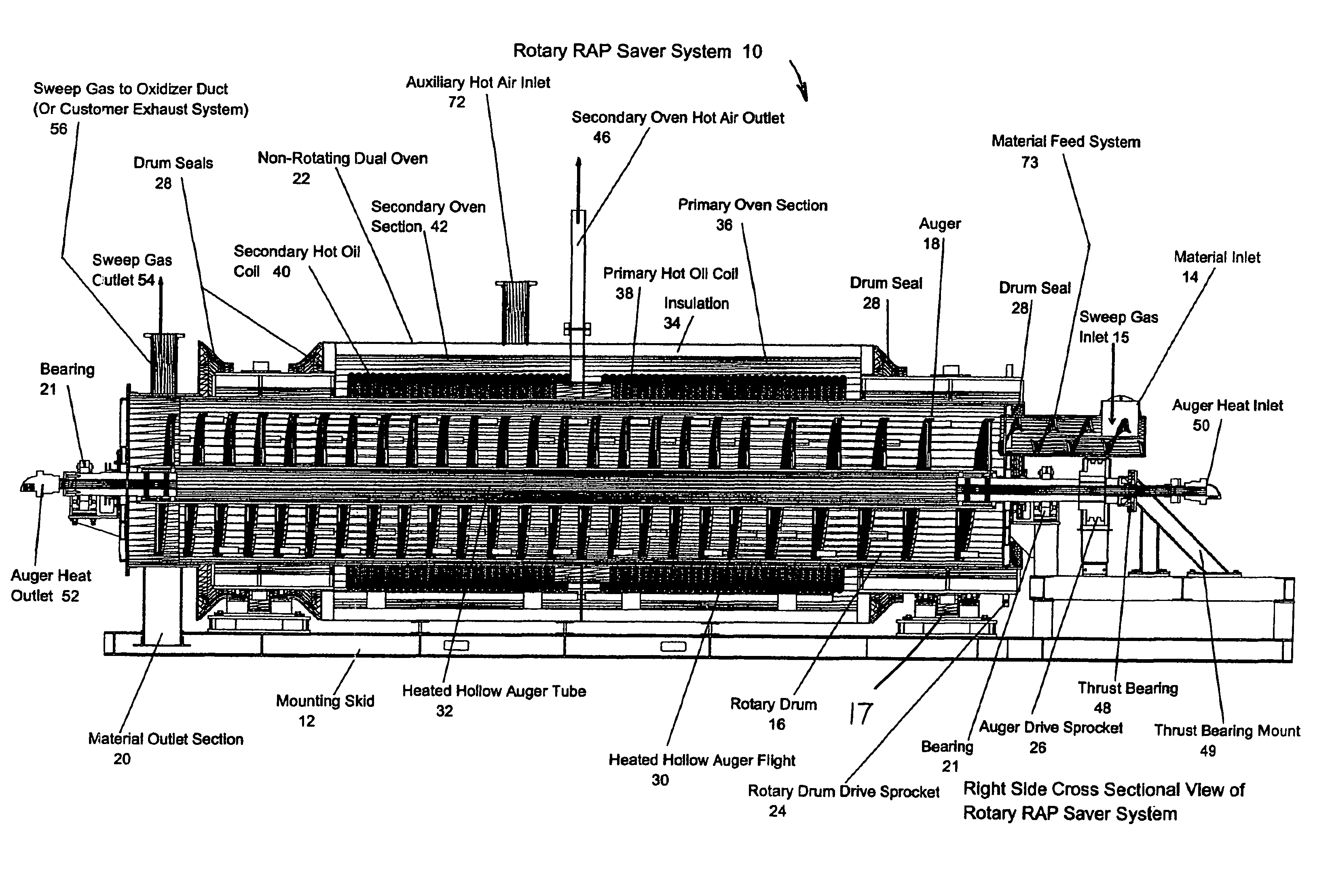

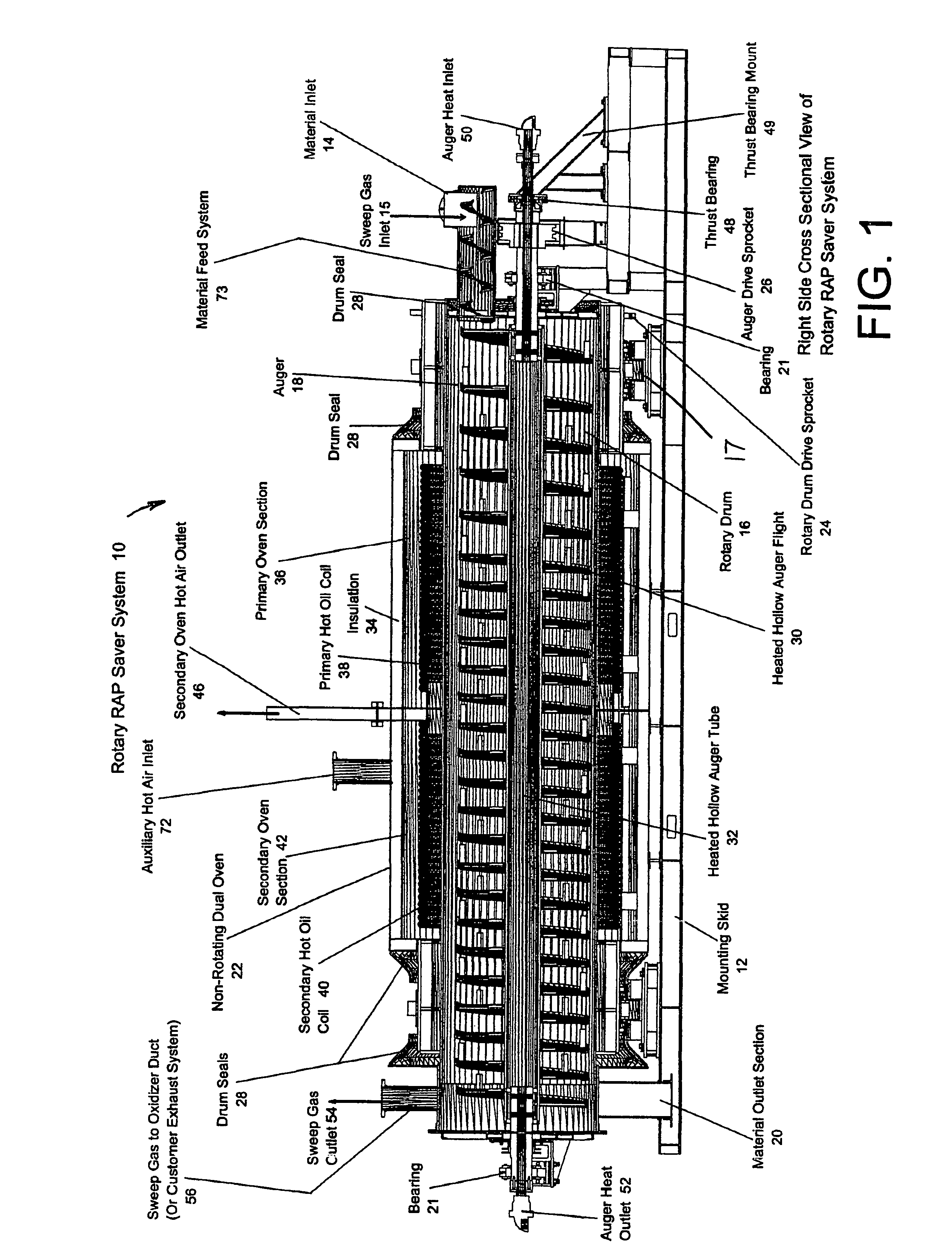

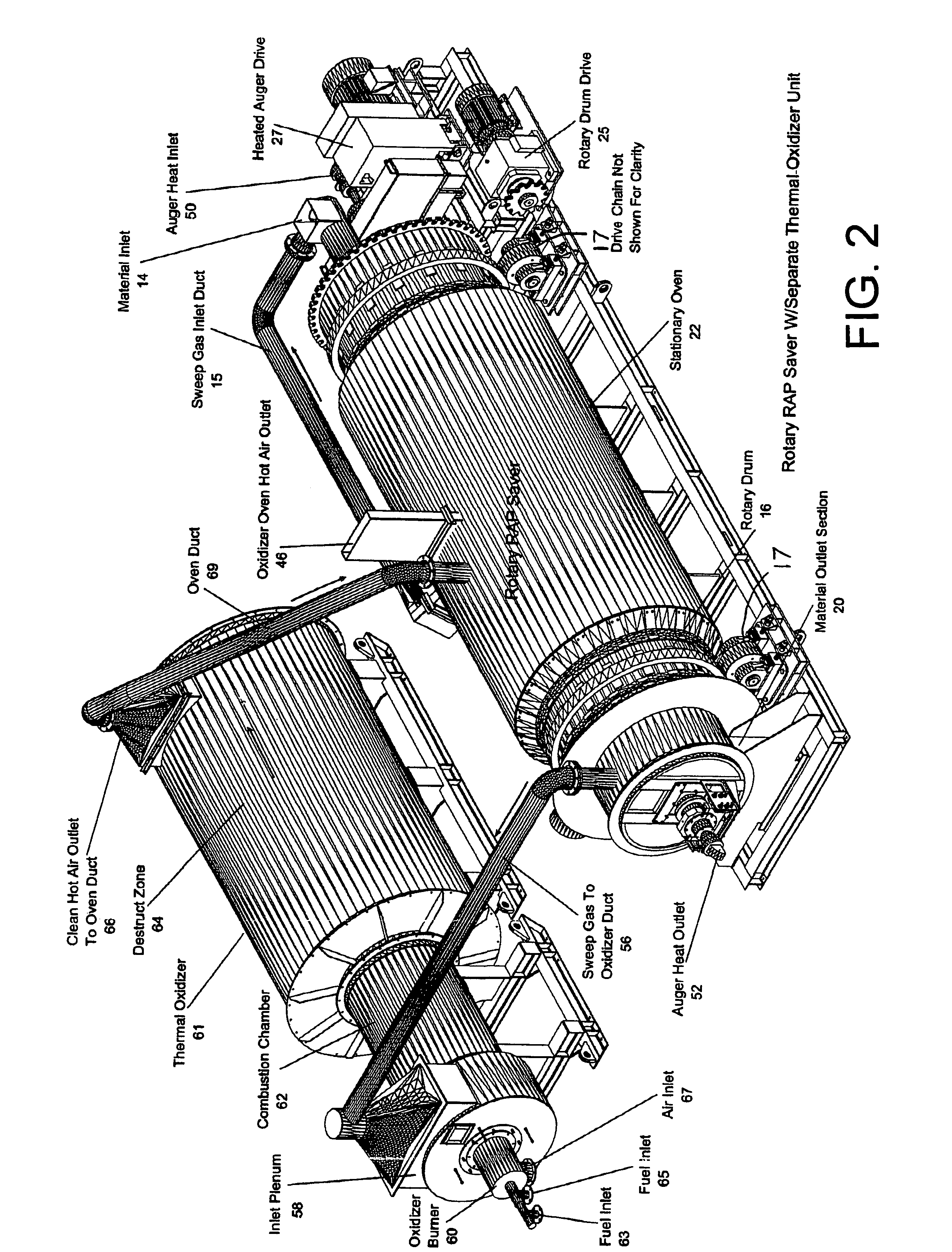

Rotary thermal recycling system

InactiveUS7993048B1Slow gradual elevationRotary drum furnacesCharge manipulationEngineeringMechanical engineering

A Rotary thermal processor for particulate materials has a rotating drum and a rotating hollow auger. A stationary cylindrical oven with stationary coils surrounds the rotating drum. Hot gas heats a first part of the oven, coil and drum. A rotating hollow auger is heated with hot fluid from the coils. Oven exhaust sweeps evaporated and volatized components of the treated materials to separators and a thermal oxidizer. Cleaned gas from the thermal oxidizer heats a second part of the oven coil and drum and exits a stack. The rotating drum and auger lifts and turns the treated material as it is advanced by the auger.

Owner:COLLETTE JERRY R +1

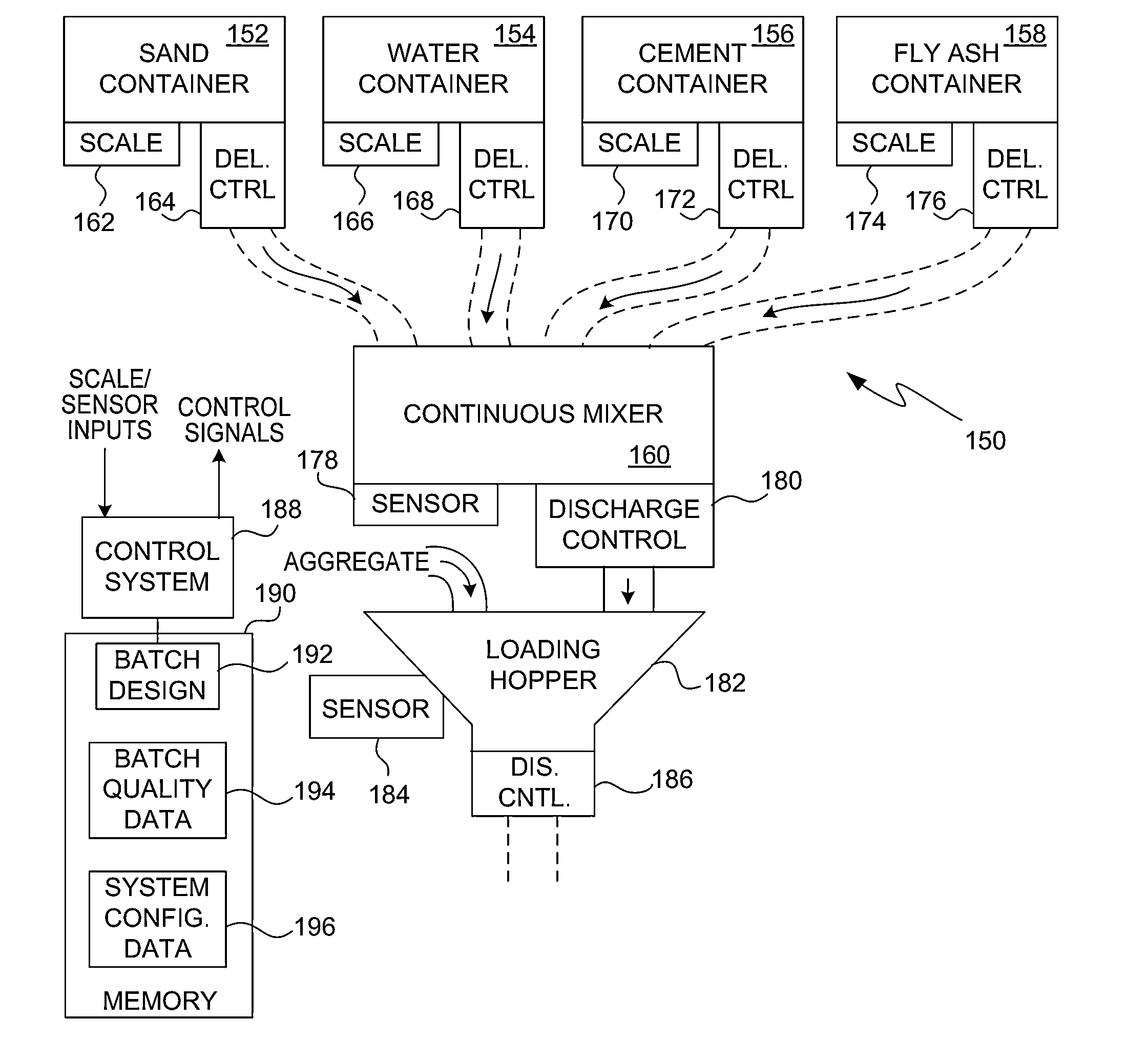

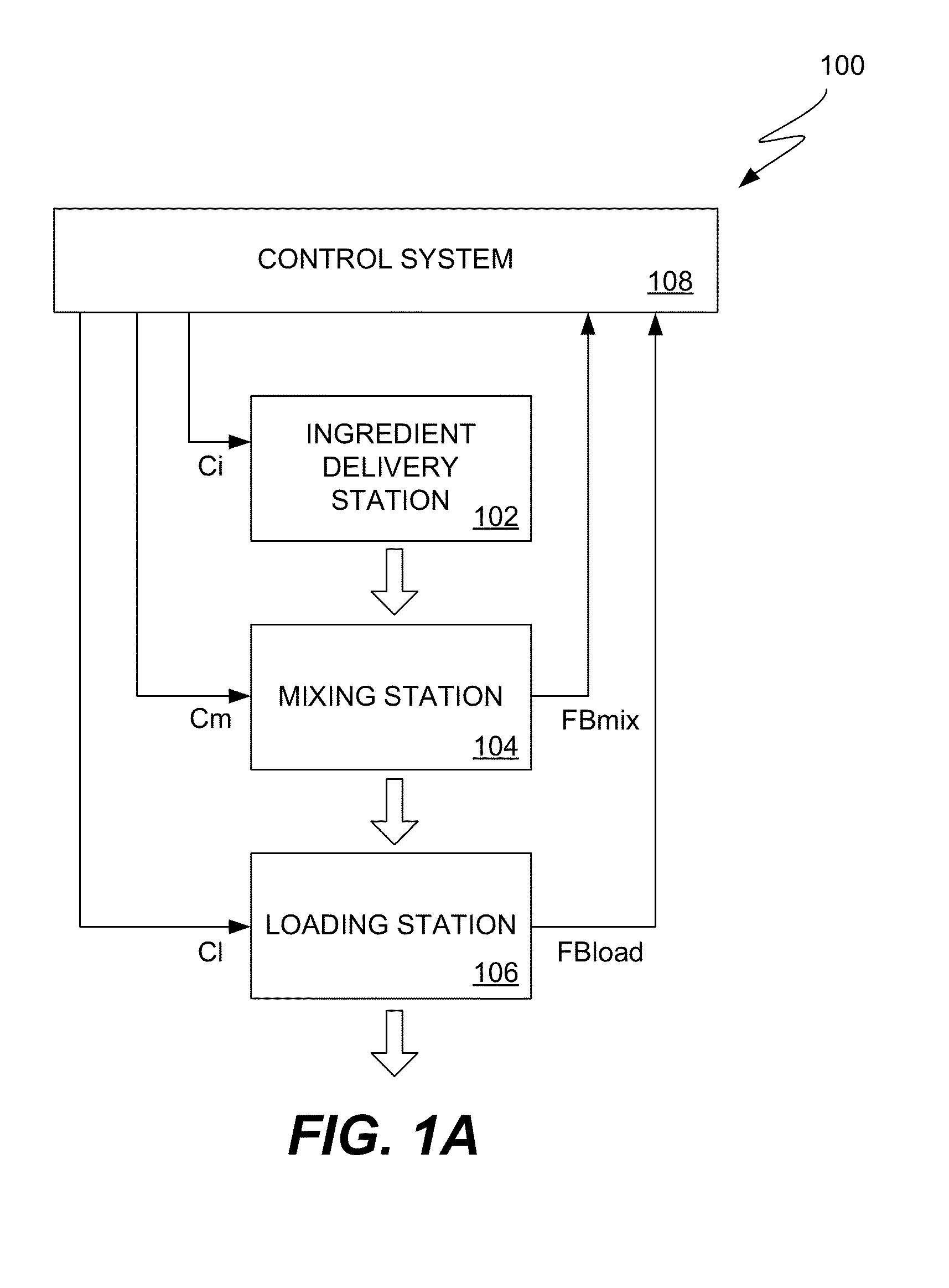

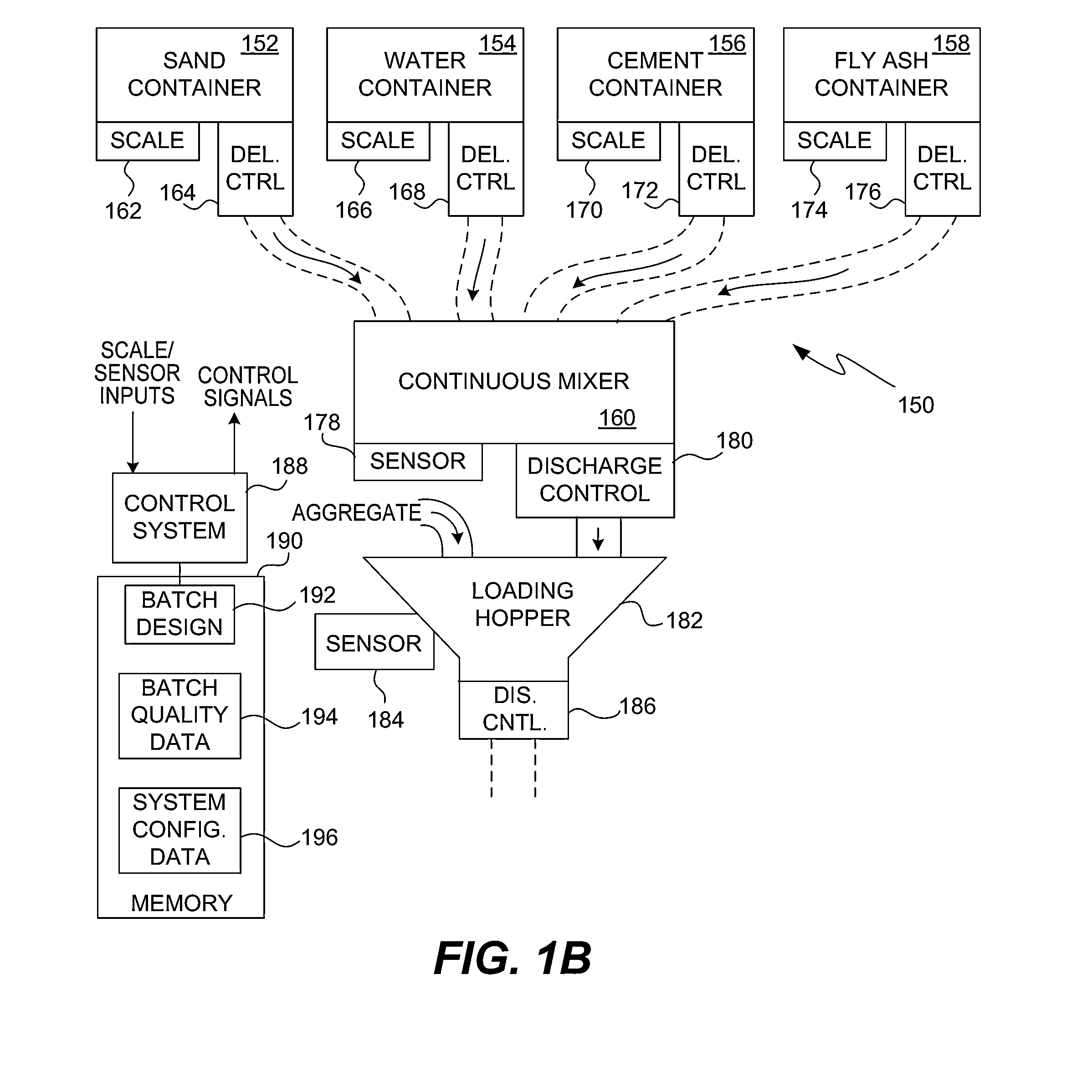

Feedback Controlled Concrete Production

ActiveUS20140355372A1Easy loadingEfficient productionRotary stirring mixersMixing operation control apparatusControl systemStructural engineering

Techniques or processes for efficiently producing concrete using dynamic feedback are disclosed. A concrete plant can use a control system to manage concrete production based on the dynamic feedback. The dynamic feedback can control mixing of concrete ingredients so as to yield uniform particle distribution for the concrete ingredients. The dynamic feedback can also avoid overflow situations as well as yield improved loading of the resulting concrete into a concrete transport vehicle (e.g., concrete truck).

Owner:BLACK MELVIN L +1

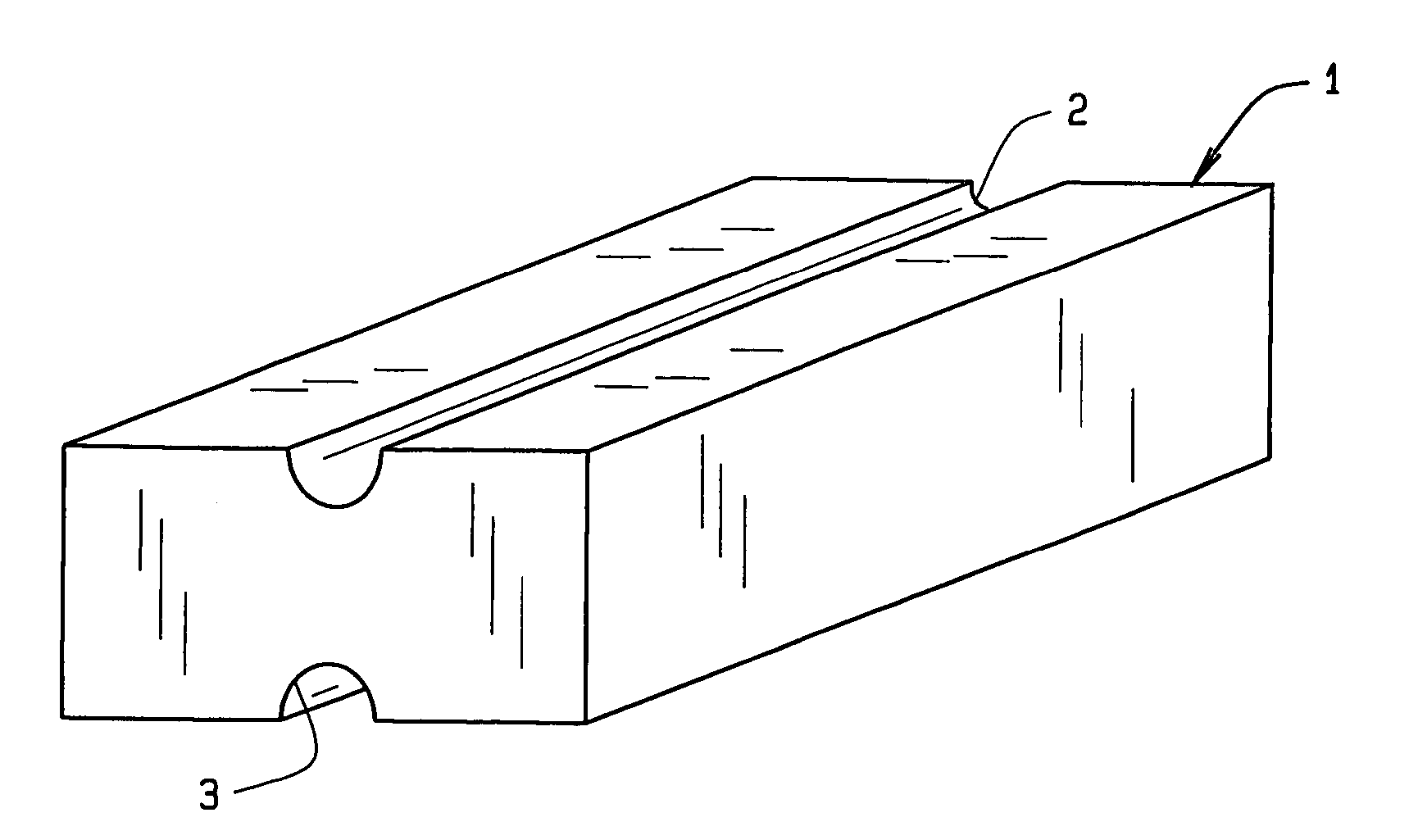

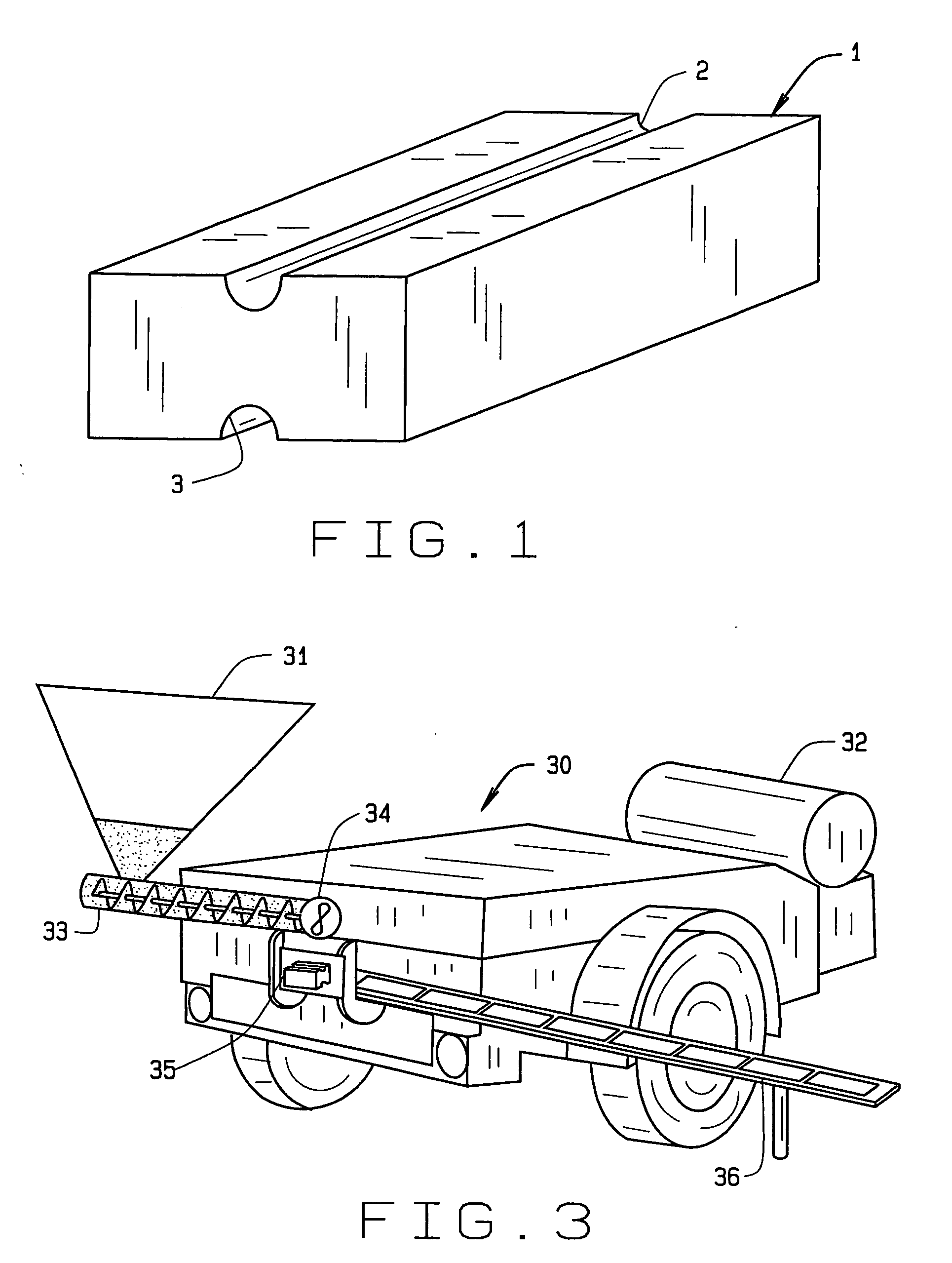

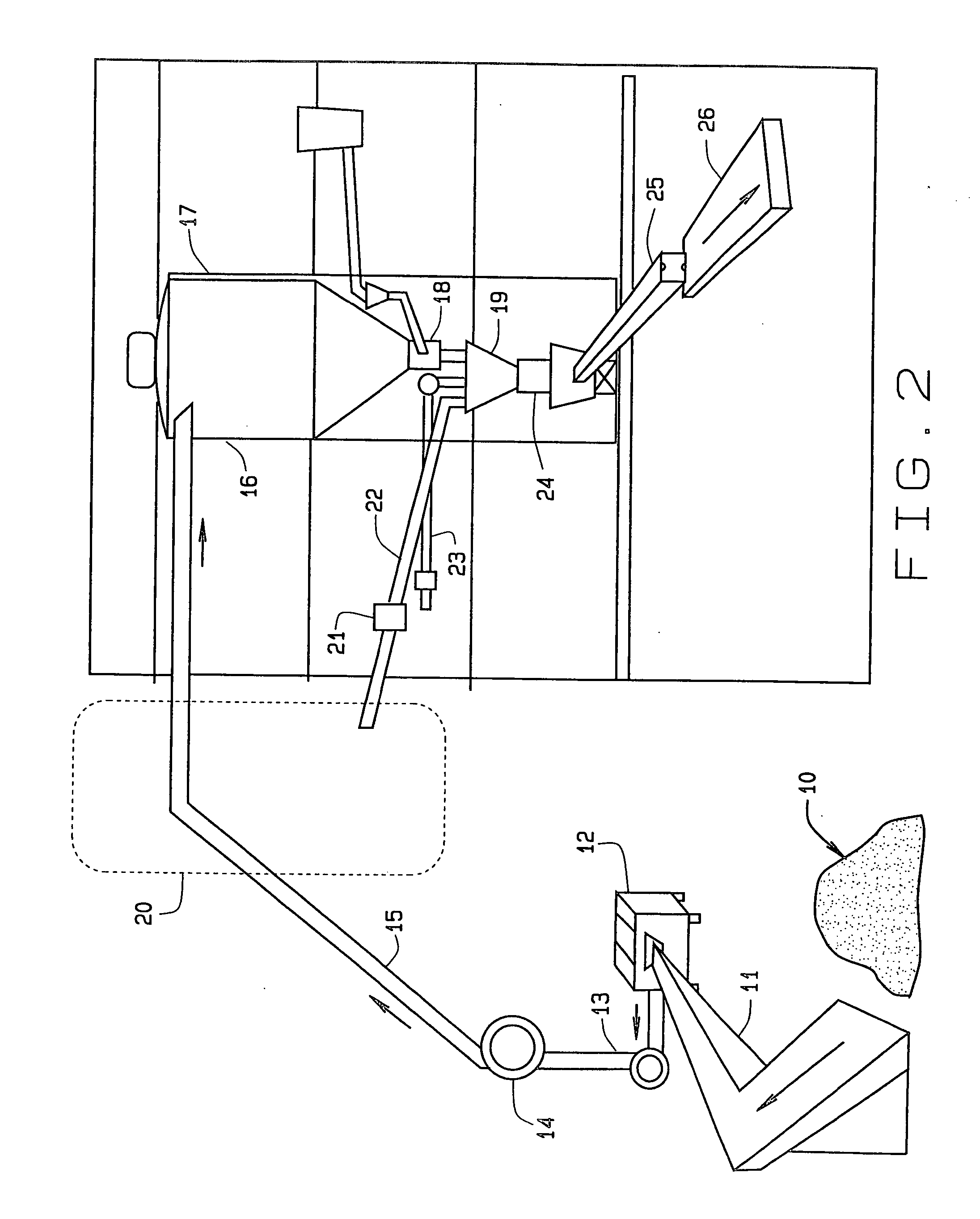

Building block and system for manufacture

InactiveUS20070277472A1High strengthConstruction materialSolid waste managementFly ashManufacturing systems

A compressed building block formed of a pre-mix of fly ash, Class C type, are combined with various aggregates either ground wood and / or chips, having maybe a small amount of Portland cement added thereto, moisturized, and then either molded, extruded or compressed in a press into the configuration of a block. Boron as a mold retardant and an insecticide, may be added to the composition, to provide the formed block with further beneficial attributes. The blocks may be formed by a system for extruding such blocks from the formulation, or they may be formed by means of a mold or hydraulic or other press and pressed into the configuration of the desired block, needed for the construction.

Owner:ENCORE BUILDING SOLUTIONS

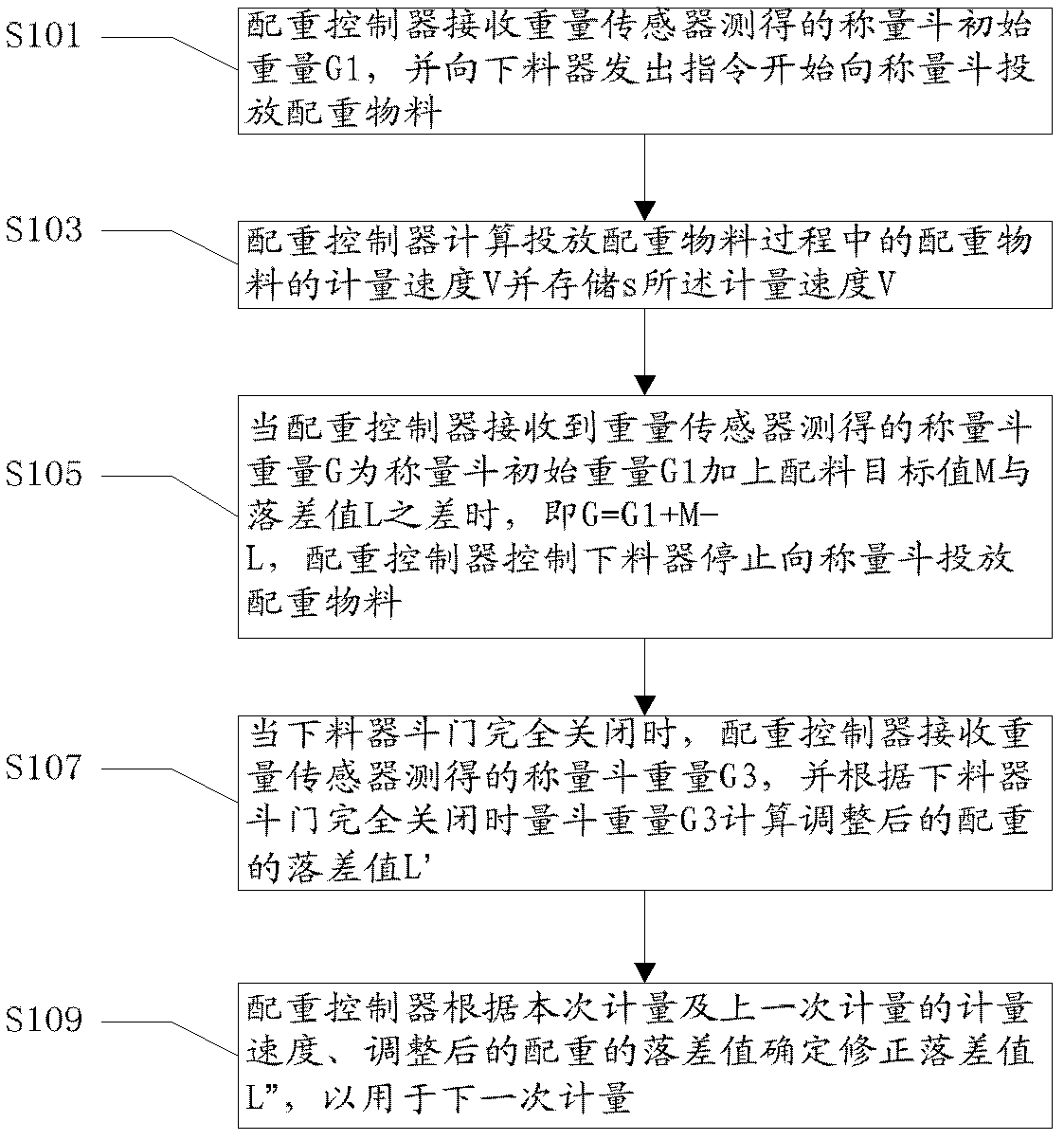

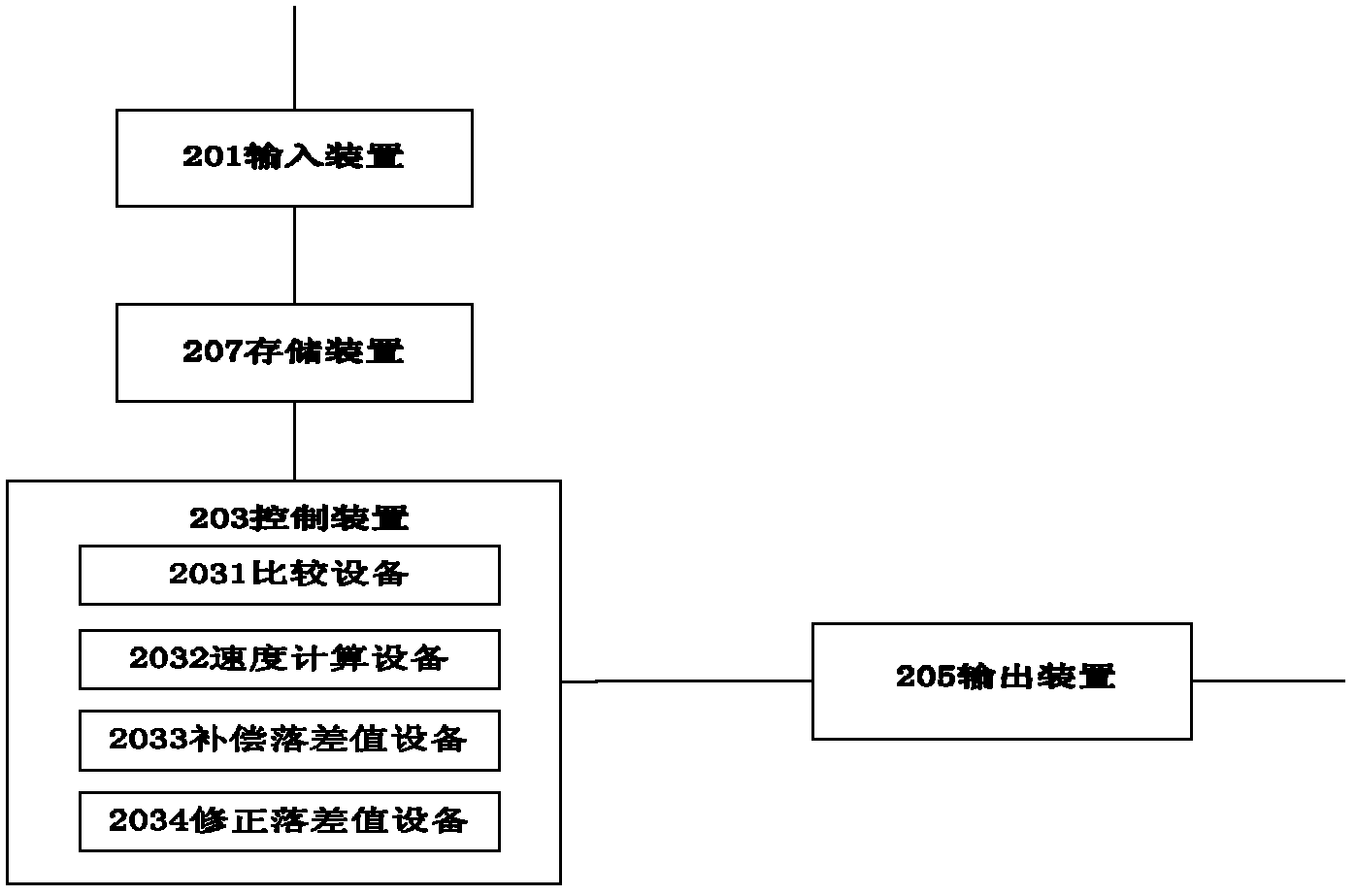

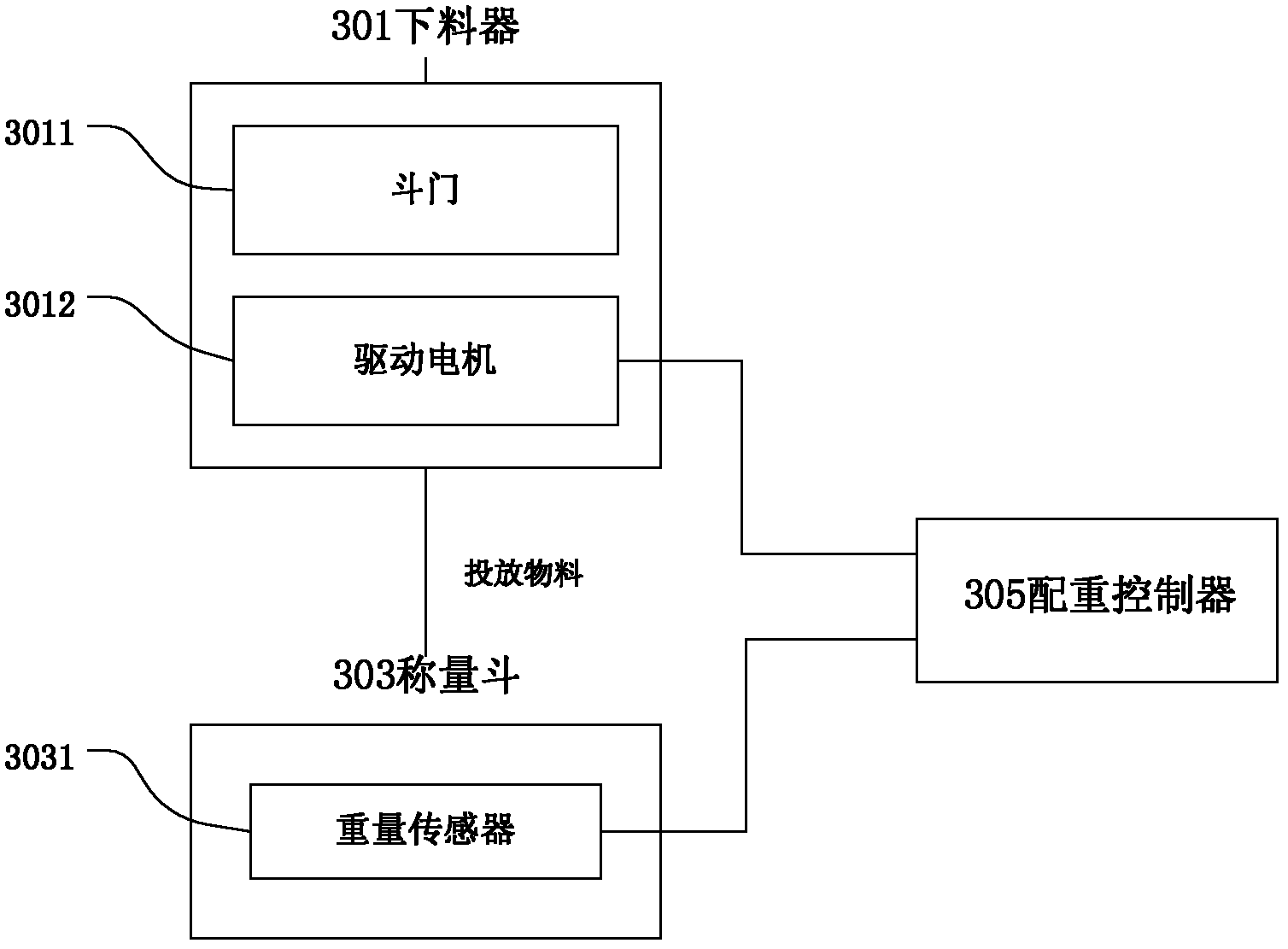

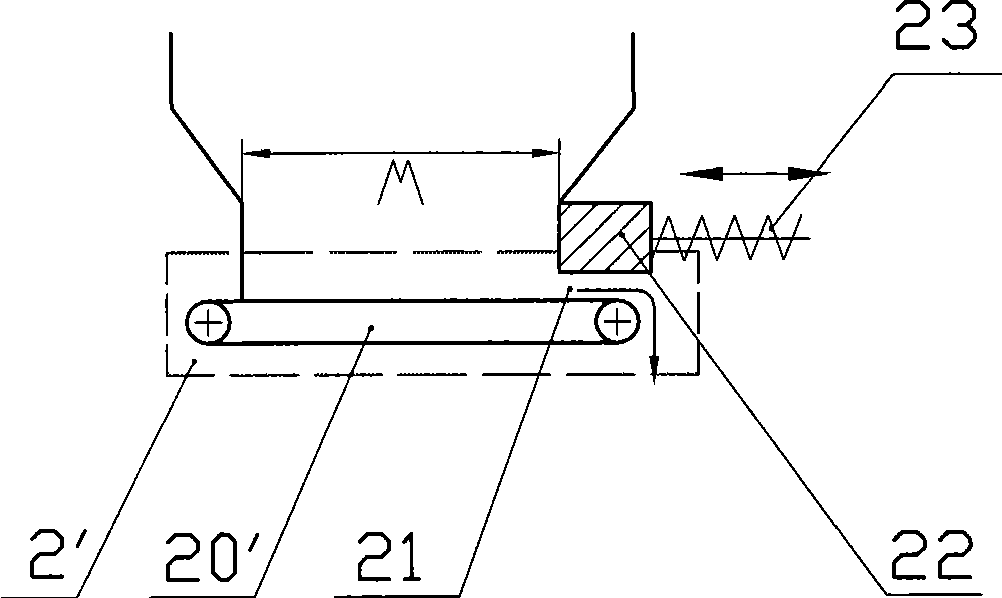

Proportioning material metering method, proportioning weight controller, system and concrete mixing plant

ActiveCN102615710AHigh precisionMixing operation control apparatusControl apparatusControl theoryCurrent time

The invention provides a proportioning material metering method, which comprises the following steps that: a proportioning weight controller receives weighing hopper initial weight G1 measured by a weight sensor and controls a feeder to start to feed proportioning materials into a weighing hopper; the proportioning weight controller calculates and stores metering speed V; when the weighing hopper weight G=G1+M-L measured by the weight sensor is received, the proportioning weight controller controls the feeder to stop feeding the proportioning materials into the weighing hopper; the proportioning weight controller receives the weighing hopper weight G3 measured by the weight sensor when the hopper door of the feeder is fully closed, and calculates a difference value L' of adjusted proportioning weight; and the proportioning weight controller determines a corrected difference value L'' which is used for the next time of metering according to the metering speed of the current time and the previous time and the difference value of the adjusted proportioning weight. Besides, the invention additionally provides the proportioning weight controller, a proportioning material metering system and a concrete mixing plant for realizing the method. The proportioning material metering method, the proportioning weight controller, the proportioning material metering system and the concrete mixing plant provided by the invention have the advantages that the deviation caused by external factors to metering results is avoided and the metering accuracy is improved.

Owner:ZOOMLION HEAVY IND CO LTD

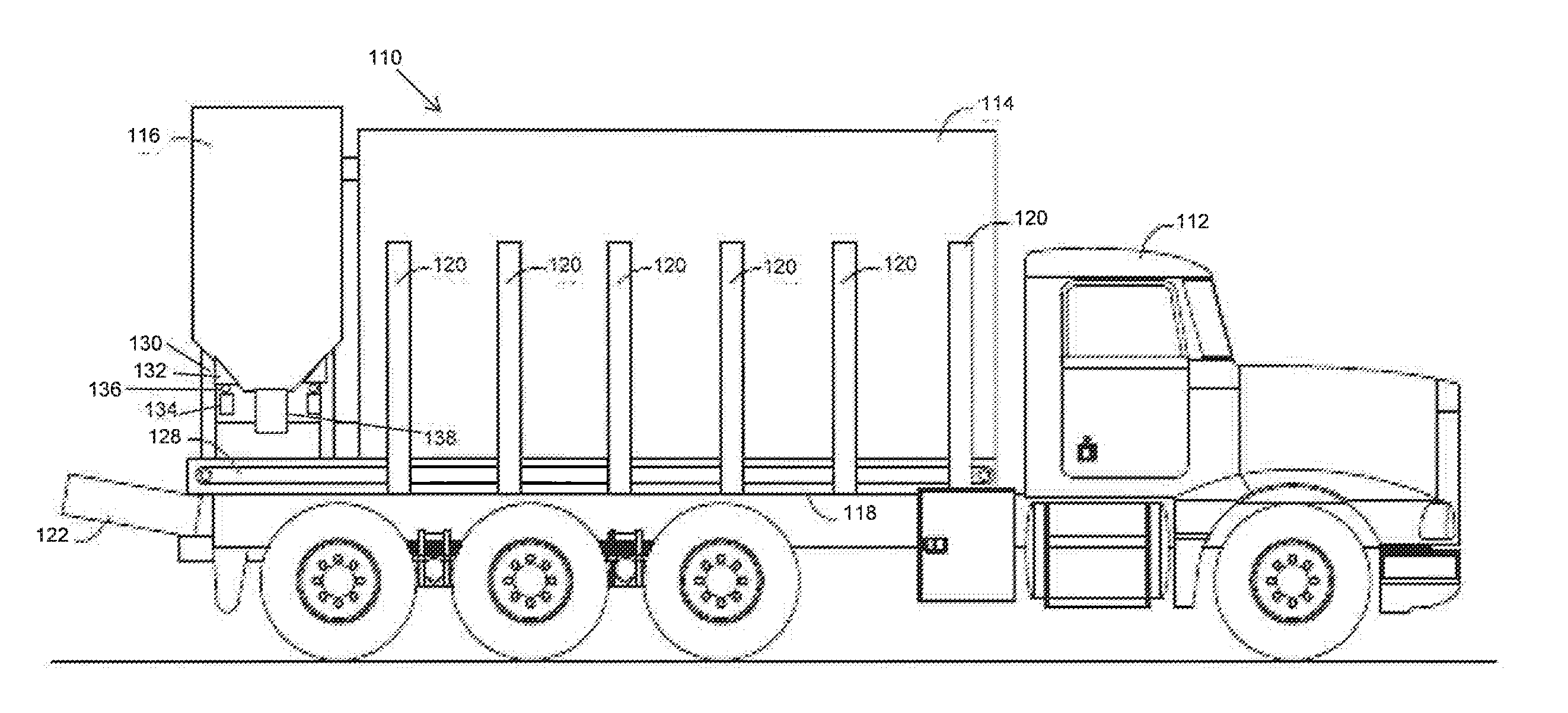

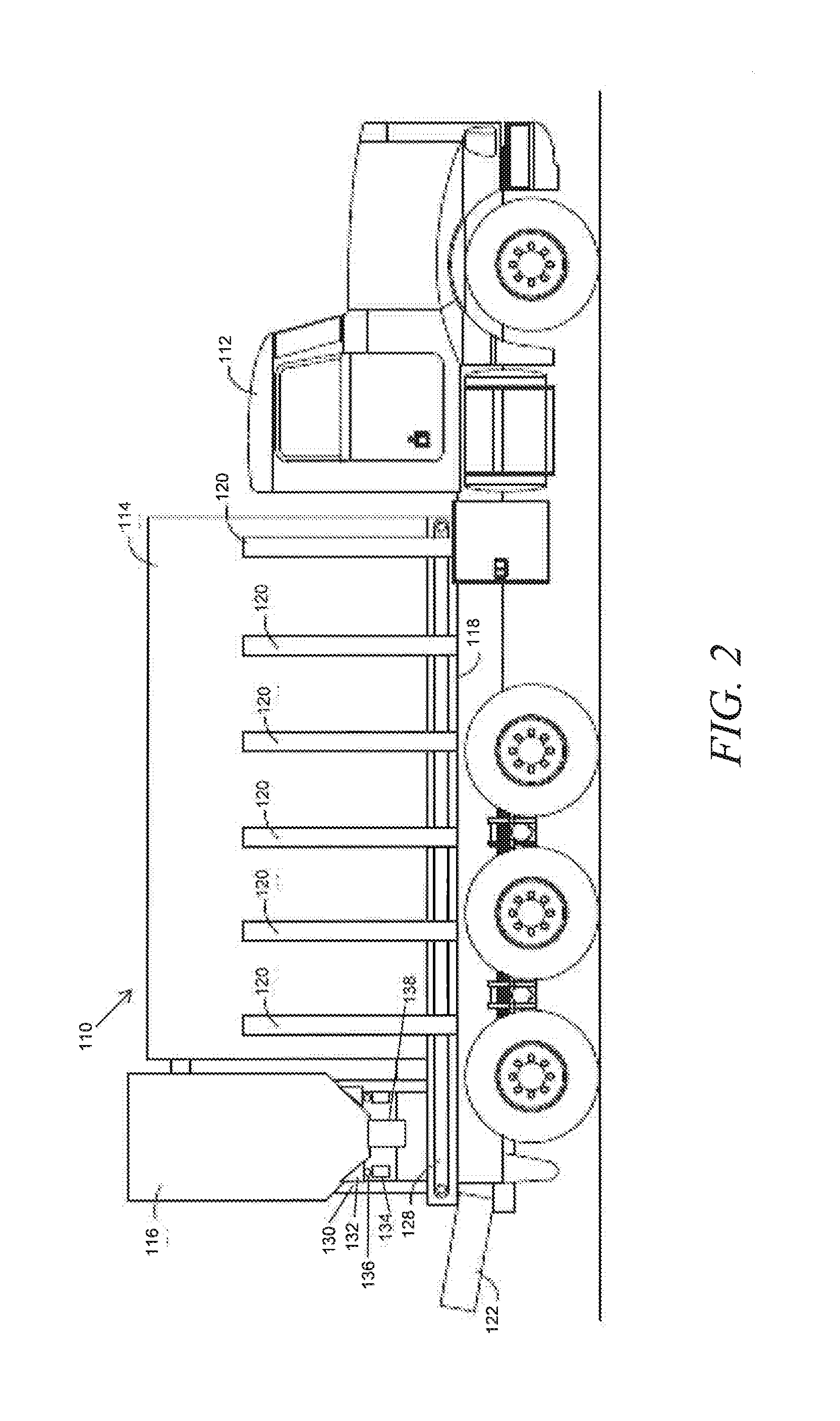

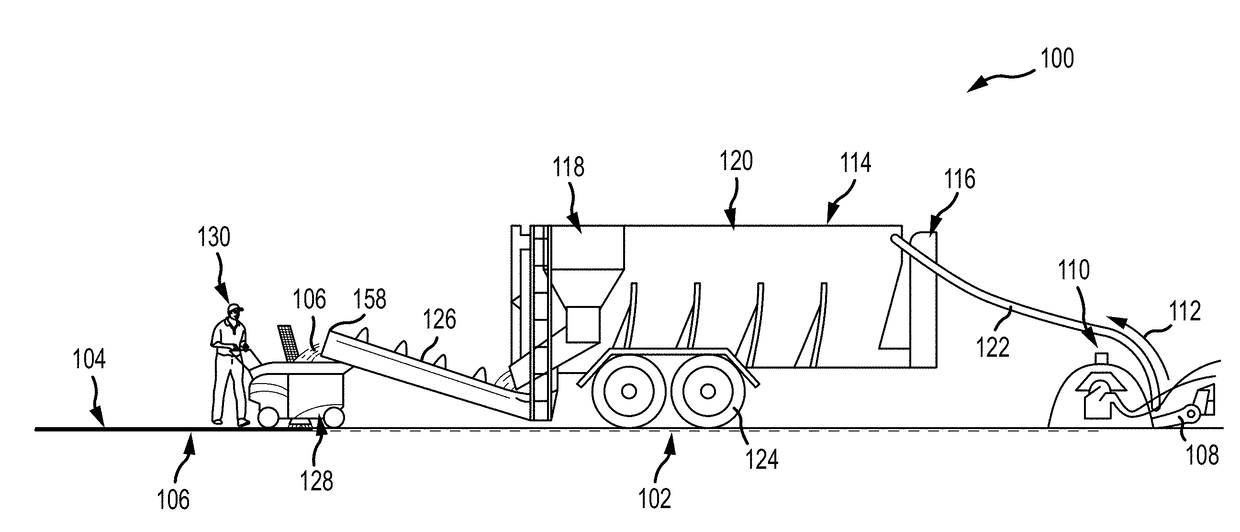

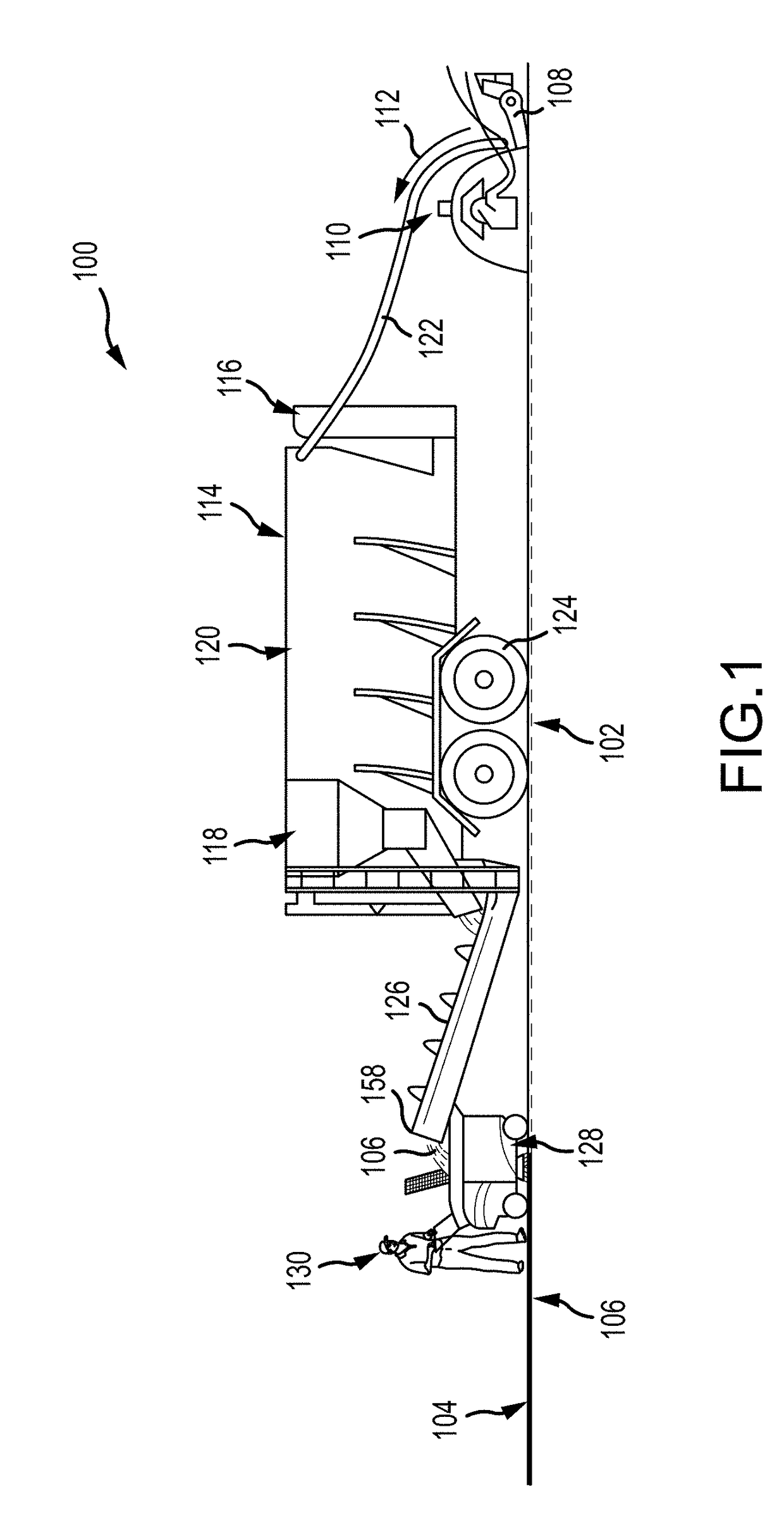

Volumetric concrete mixing system, equipment, and method

ActiveUS20180126592A1Easy to pourRotary stirring mixersTransportation and packagingWaste managementCement

A mobile volumetric concrete mixing system includes a suction system that vacuums up trench spoils while a trench is being cut. These trench spoils are then screened on-site for particle size to be reused and mixed with water, cement, and / or other admixtures at an auger mixer to form a backfill mixture. This backfill mixture may then be loaded into a hopper that continuously agitates the mixture so that the mixture does not harden before pouring. The agitating hopper is coupled to a discharge chute of the auger mixer and includes one or more augers disposed at various orientations that the backfill mixture is channeled through. From the agitating hopper, the backfill mixture is channeled to an applicator that moves along the trench and that enables the mixture to be quickly poured into the trench with little clean-up required.

Owner:J&P INVESCO LLC

Full-automatic composite self-insulation building block production method

InactiveCN103612318AIncrease profitImprove thermal insulation performanceMixing operation control apparatusCeramic shaping plantsSocial benefitsFoaming agent

The invention discloses a full-automatic composite self-insulation building block production method. The full-automatic composite self-insulation building block production method includes distributing, building block forming, maintenance, supporting plate returning and product conveying. Distributing includes shell material distribution and thermal insulation material distribution. Shell materials are made of 15% of cement, 50% of coal cinders, 18% of sand, 10% of rubble and 7% of water. Thermal insulation materials are made of, by mass, 54% of PO42.5 cement, 10% of fly ash, 0.5% of foam stabilizer and fortifiers, 31.5% of water and 4% of foaming agents. The stirred raw materials are conveyed into a forming machine (4) so that forming can be carried out; a formed building block shell is conveyed into a maintenance kiln (8) to be maintained four hours; filling cores are poured, and the building block shell is conveyed into the maintenance kiln again to be maintained five to eight hours; maintained building blocks are piled, packaged and stacked. All the steps of the production method are coordinated, automatic control is achieved, and production efficiency is improved; the full-automatic composite self-insulation building block production method has good ecological benefit and social benefit.

Owner:连太吉 +3

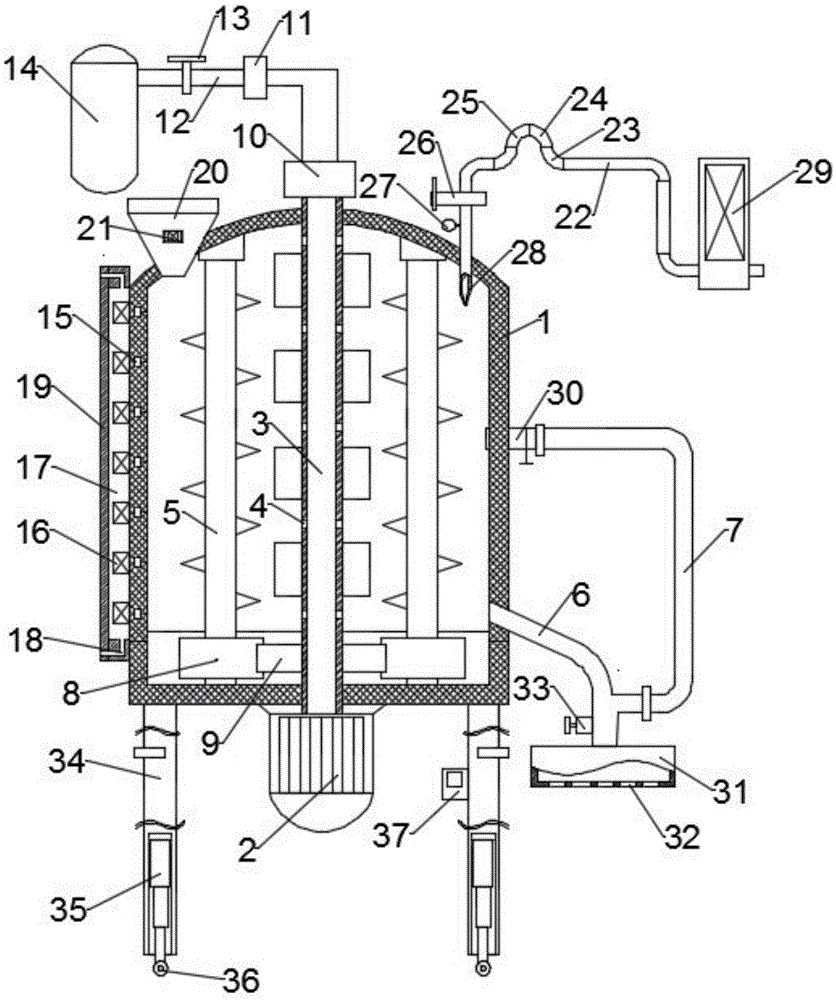

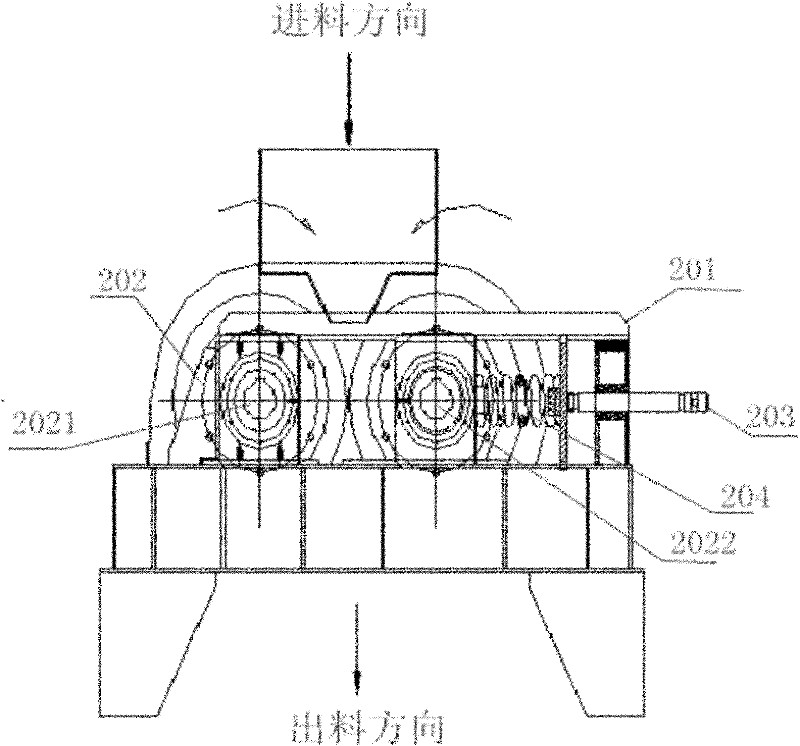

Temperature-controlled concrete stirring device

ActiveCN105643801AOvercome the problem of deviation in use effectImprove qualityDischarging apparatusMixing operation control apparatusTemperature controlStopped work

The invention discloses a temperature-controlled concrete stirring device comprising a stirring barrel body, wherein two sides of a first driving gear are meshed with second driven gears; the second driven gears are fixedly arranged on driven shafts; a plurality of temperature probes are arranged inside the left side wall of the stirring barrel body; a ceramic heating body is arranged inside a cavity; the bottom of the right side wall of the stirring barrel body is provided with a first discharging pipe; a second discharging pipe is connected with an auxiliary unloading hose; the top of the stirring barrel body is also provided with an additive introducing device; and a pipeline of a liquid control switch and an additive delivery pump is provided with a horizontal section pipeline, a first elbow pipeline, a second elbow pipeline and a third elbow pipeline. By using the temperature-controlled concrete stirring device, the temperature of inside concrete can be controlled, the automatic and quantitative addition of water is realized, the problem of deviation caused by different heights is overcome, and the retention phenomenon cannot be generated after the additive delivery pump stops working.

Owner:河南国龙矿业建设有限公司

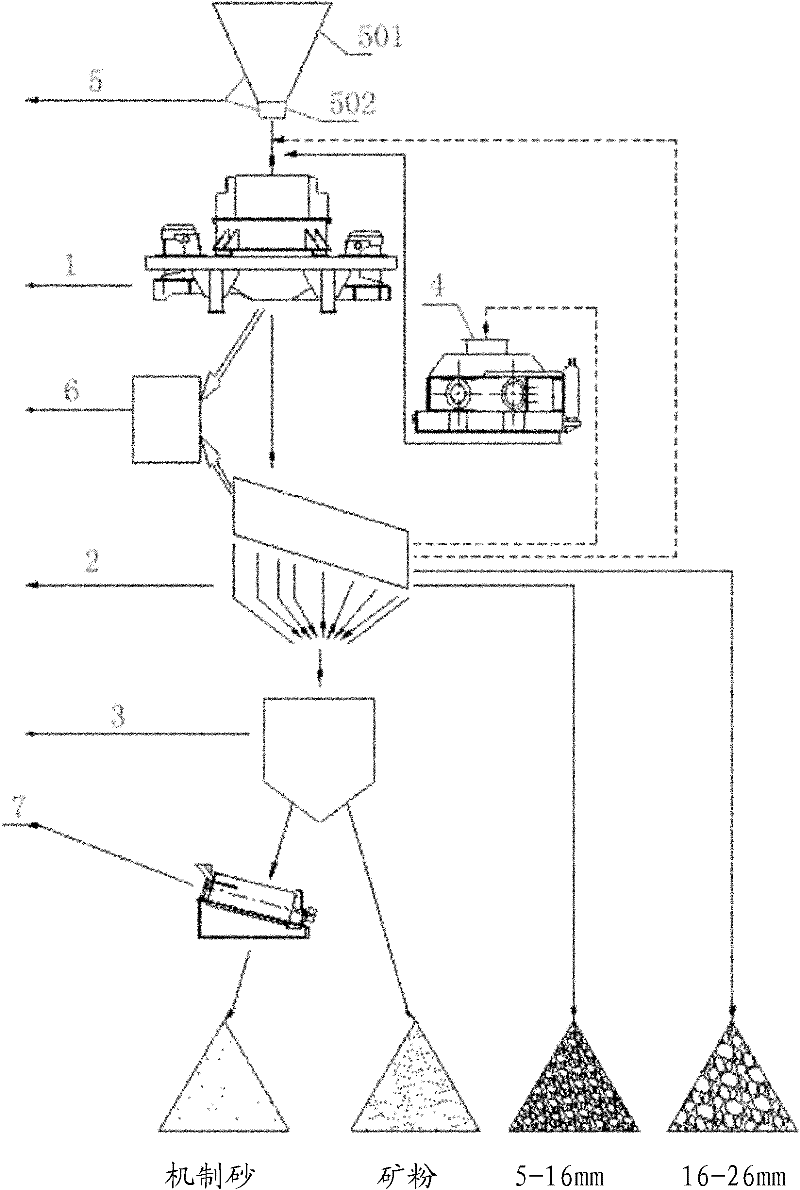

Fine aggregate processing production system

InactiveCN102528933ALow costImprove output qualityGas current separationGrain treatmentsElectric controlConstruction aggregate

The invention discloses a fine aggregate processing production system, which is characterized in that raw materials enter a sand making machine through a feeding device for sand crushing and making, obtained sand is conveyed to a screening screen for classification, wherein the sand with the particle size of 0-5mm is conveyed to a sand powder separation machine for sand separation; the sand with particle size larger than 5mm is classified into two categories, the sand with the particle size larger than 26mm is conveyed to the sand making machine for remaking, and the sand with the particle size of 5-16mm is conveyed to a grading adjustment machine connected with the screening screen for shaping and is returned to the sand making machine again for sand making. The fine aggregate processing production system adopts electric control centralized control, and grading adjustment is simultaneously performed during sand making so that production flow is shortened. The fine aggregate processing production system is provided with a dust removing and humidification device so as to achieve zero-emission production and save cost, and has huge economic value.

Owner:上海金路创展工程机械有限公司

Apparatus for automated finishing of interior surfaces

An automated interior finishing apparatus has an upper section for mixing material, and a lower section for conveying the material. The upper section has a mixing compartment and a separate washing / storage compartment. Each compartment has a hinged lid that forms an air-tight seal. The mixing compartment has a shaft with an auger for mixing compound with water. The lower section has a motor for driving a progressive cavity pump, which receives mixed material from the mixing compartment. The pump delivers a smooth and uniform supply of material through an external supply hose. The apparatus is used as one component of an overall automated interior finishing system and method for completing surface finishes. For example, one end of the supply hose is connected to the outlet end of the pump for delivering mixed material to a hand tool at the opposite end, such as a flat taper.

Owner:RENEGADE TOOL

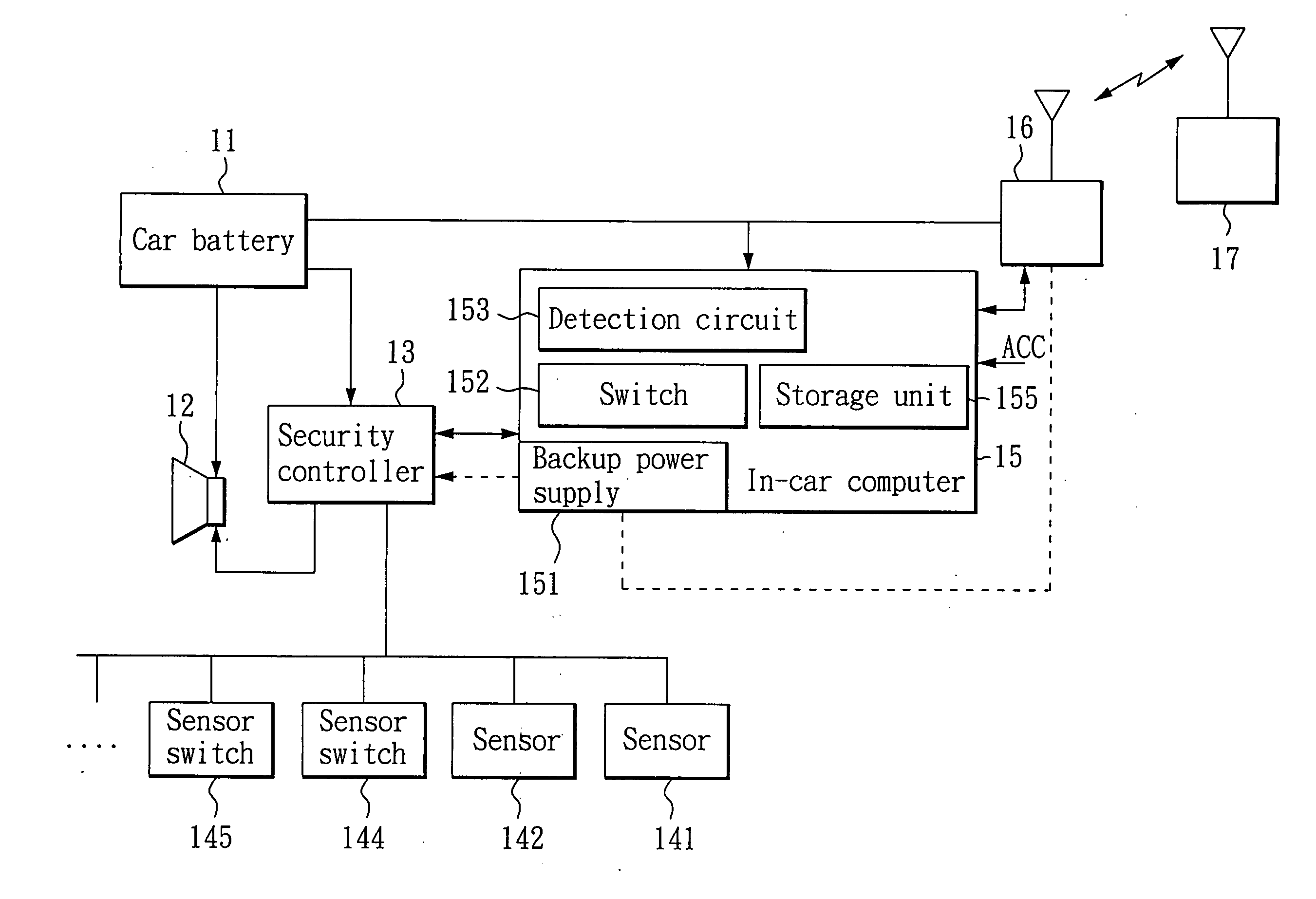

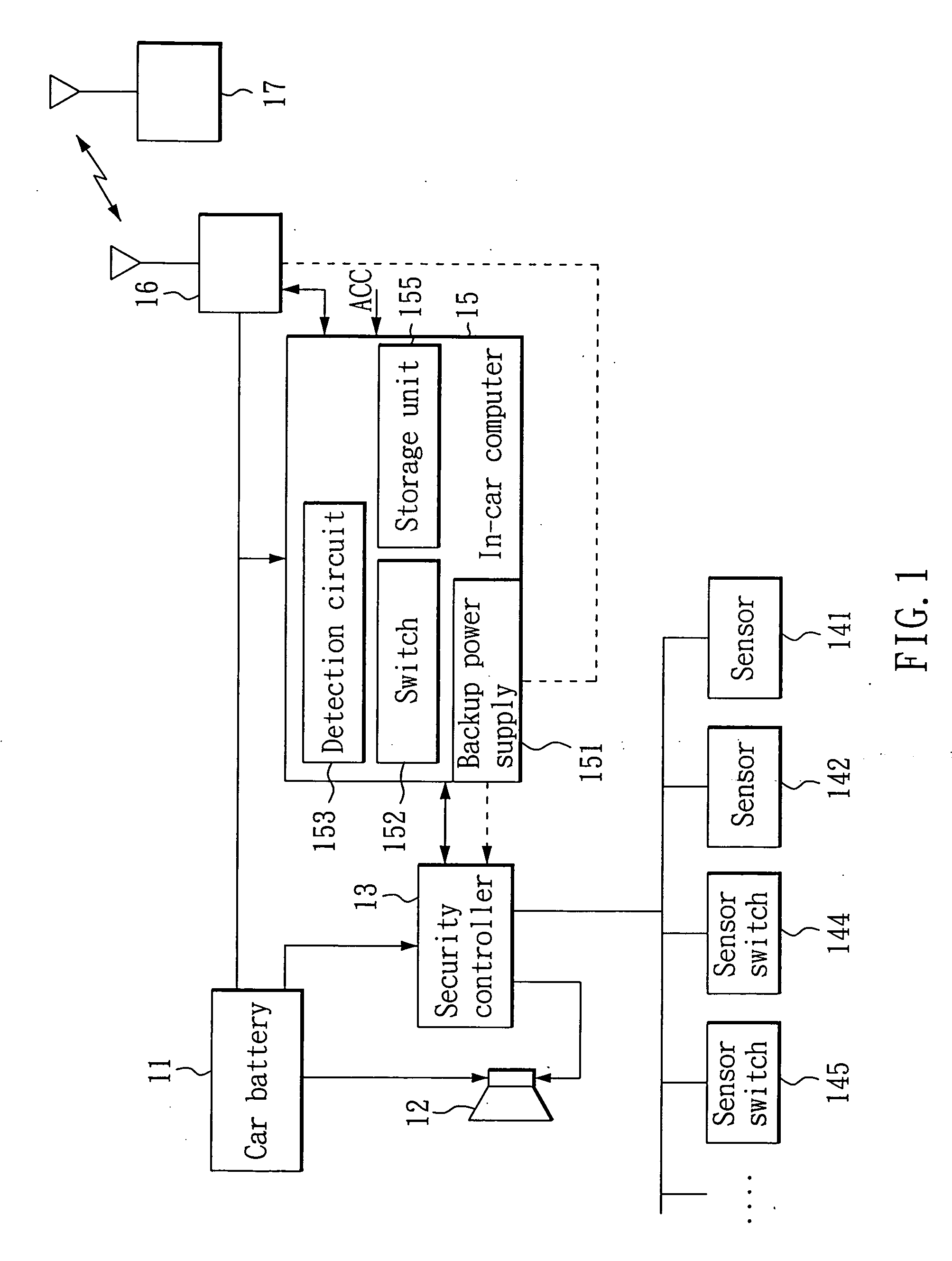

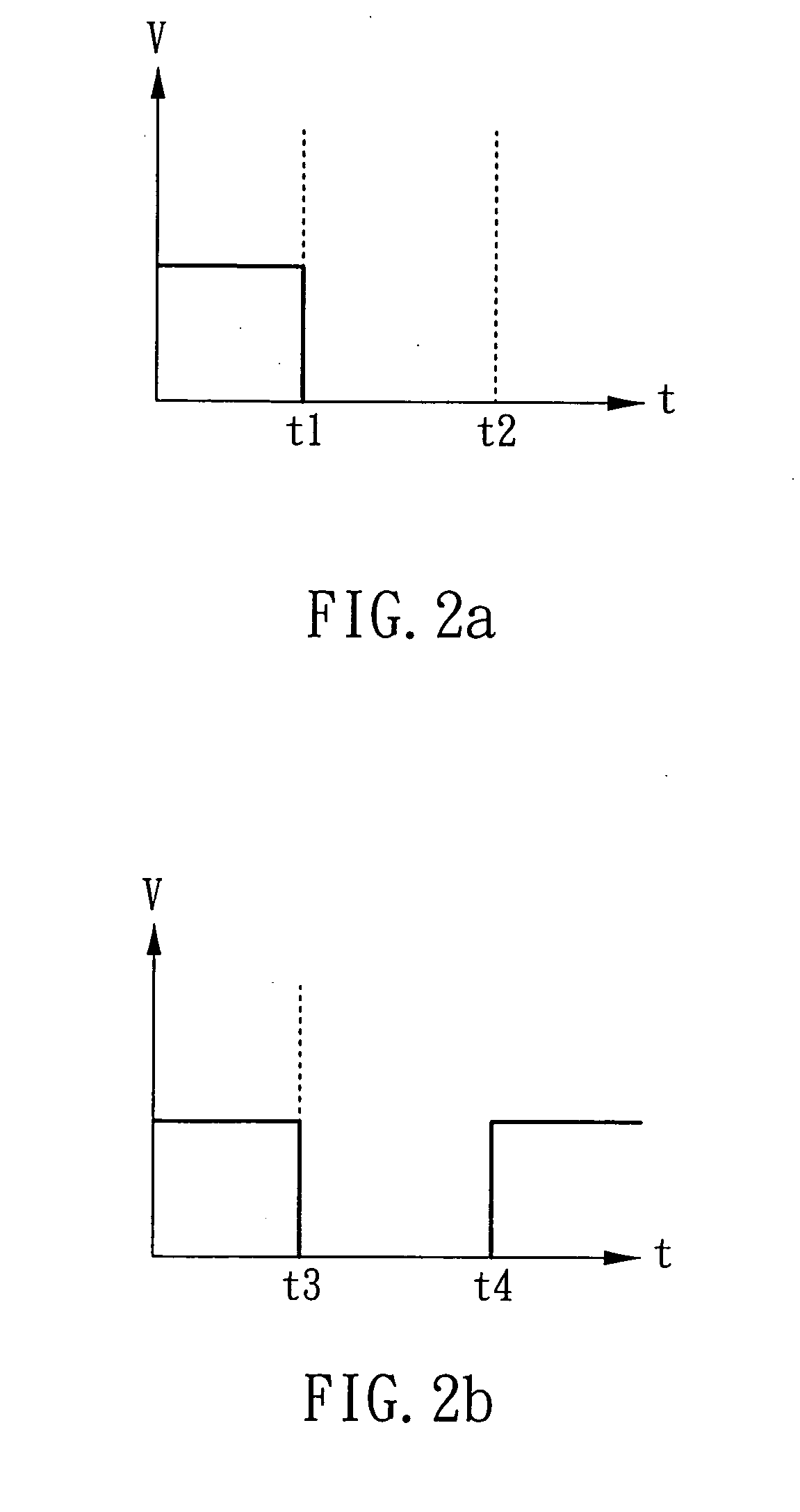

Vehicle security system

Disclosed is a vehicle security system, which uses a detection circuit to detect the supply of electric power from the car battery to the in-car computer and the status of the car ignition switch, and to start a backup power supply for the in-car computer, and drives the in-car computer to send an informing message to a remote receiver via a wireless communication module when the supply of electric power from the car battery to the in-car computer is terminated or when the car ignition switch is switched on during the alert mode of the vehicle security system.

Owner:XINGYI SCI & TECH

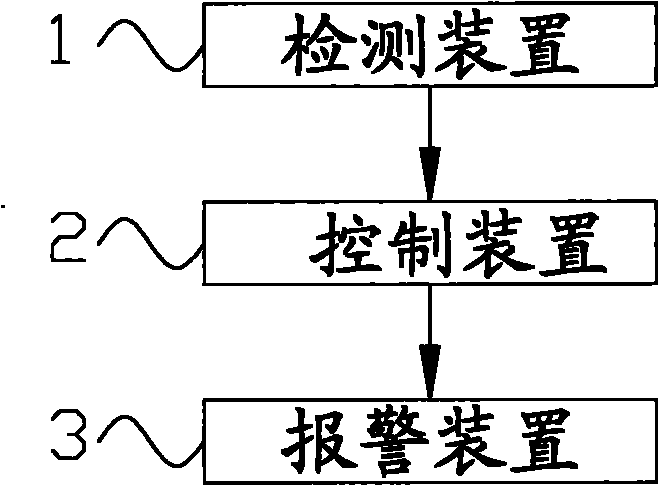

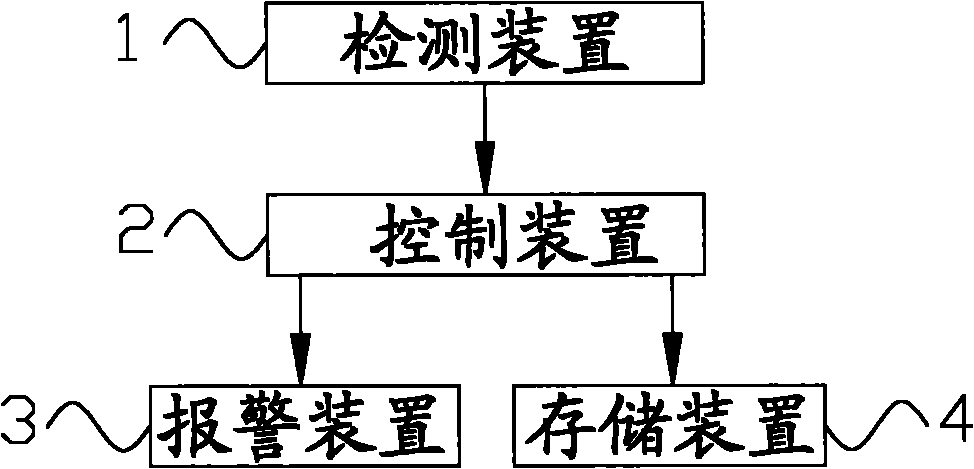

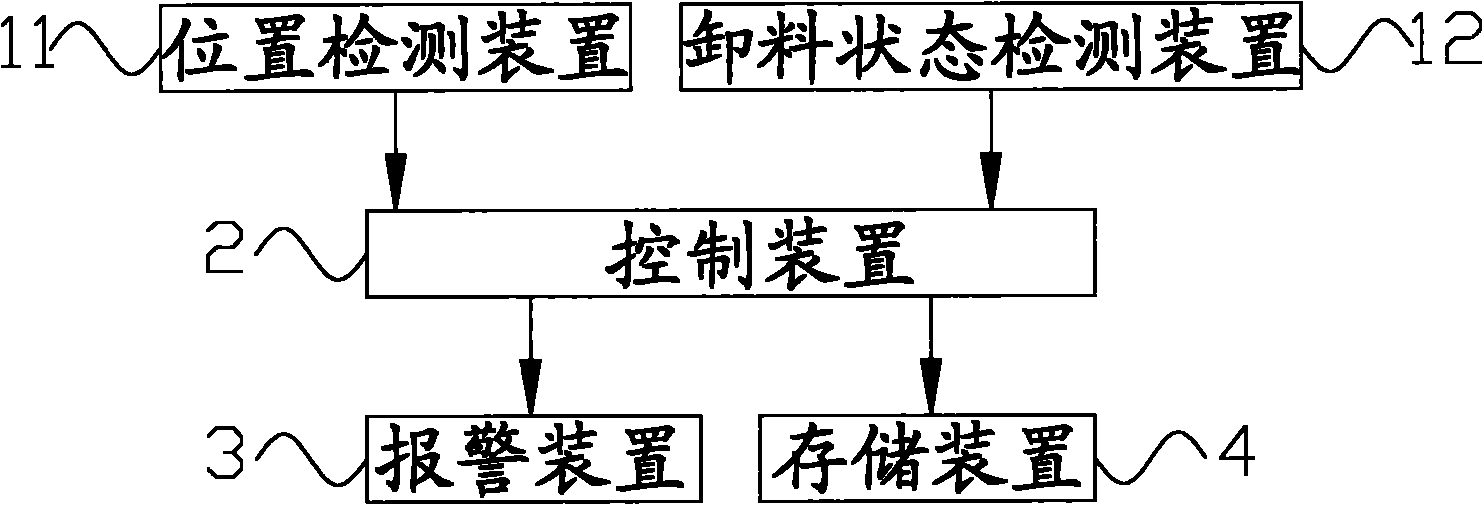

Mixing station and mixing vehicle state monitoring system and method thereof

The invention discloses a mixing vehicle state detecting system which comprises a detecting device (1), a control device (2) and an alarm device (3), wherein the detecting device (1) is mounted on a mixing vehicle and used for detecting the position and the unloading state of the mixing vehicle and obtaining a position signal and an unloading state signal; and the control device (2) is used for receiving the position signal and the unloading state signal and respectively comparing with a pre-stored target position signal and an unloading signal, when the position signal is different with the target position signal and the unloading state signal is the same with the unloading signal, the control device (2) is used for controlling the alarm device (3) to alarm. The mixing vehicle state monitoring system can monitor the position state and the unloading state of the mixing vehicle during the way of transporting concrete to a target site, effectively prevent the occurrence of phenomena of material stealing and the like and provide the guarantee to a third party with interest relationship. The invention further discloses the mixing vehicle including the mixing vehicle state monitoring system and a mixing vehicle state monitoring method.

Owner:SANY HEAVY IND CO LTD (CN)

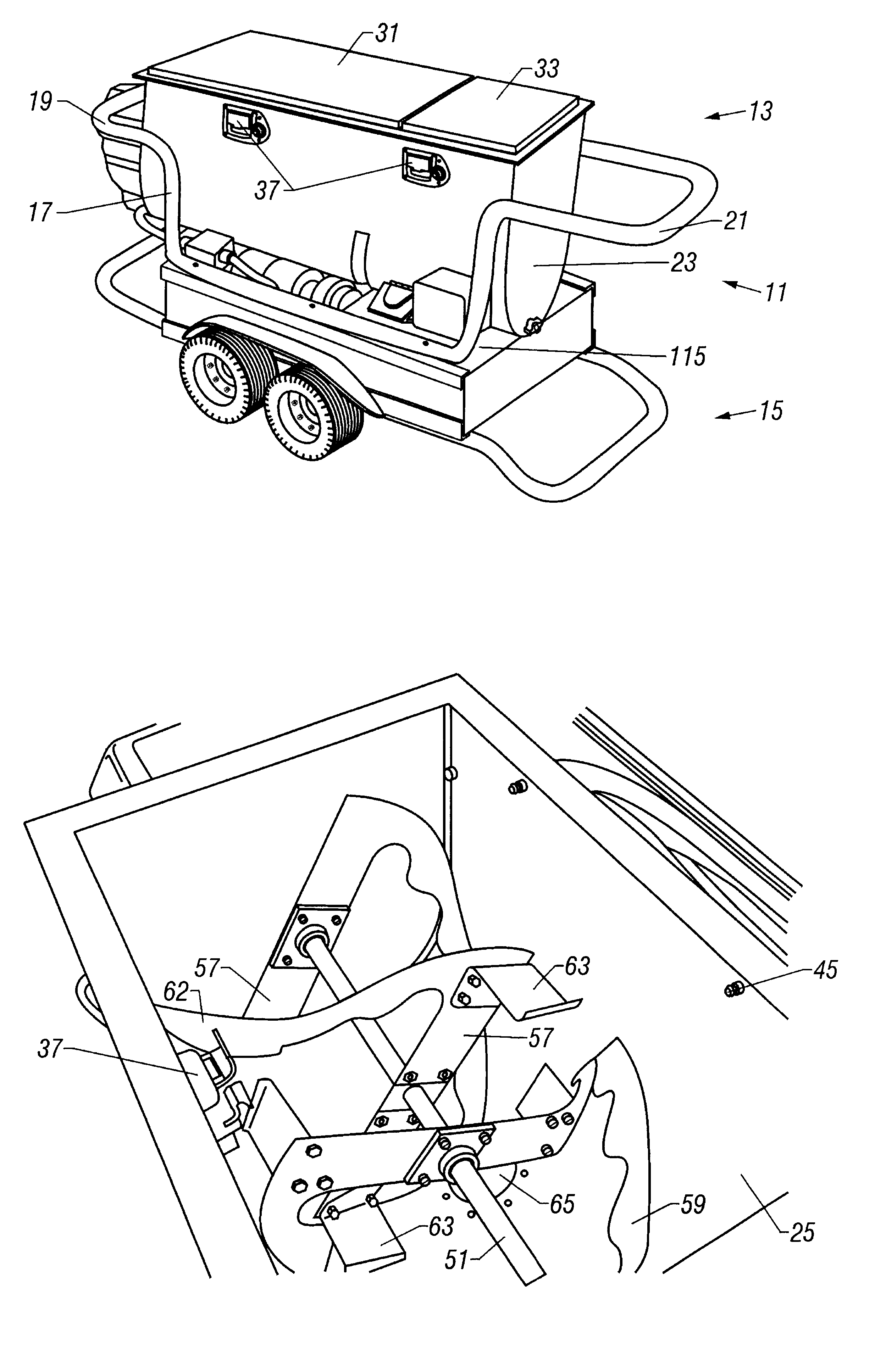

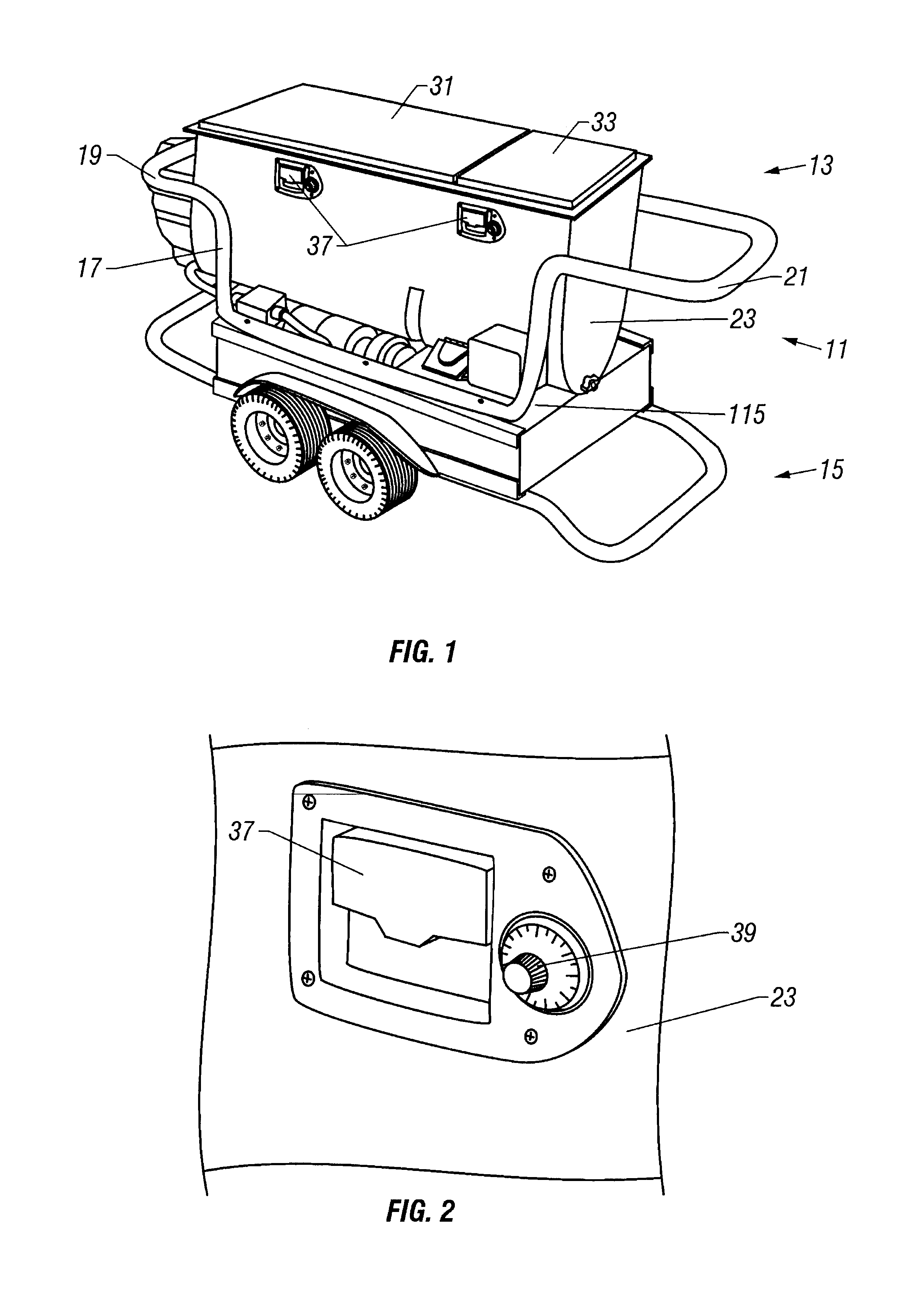

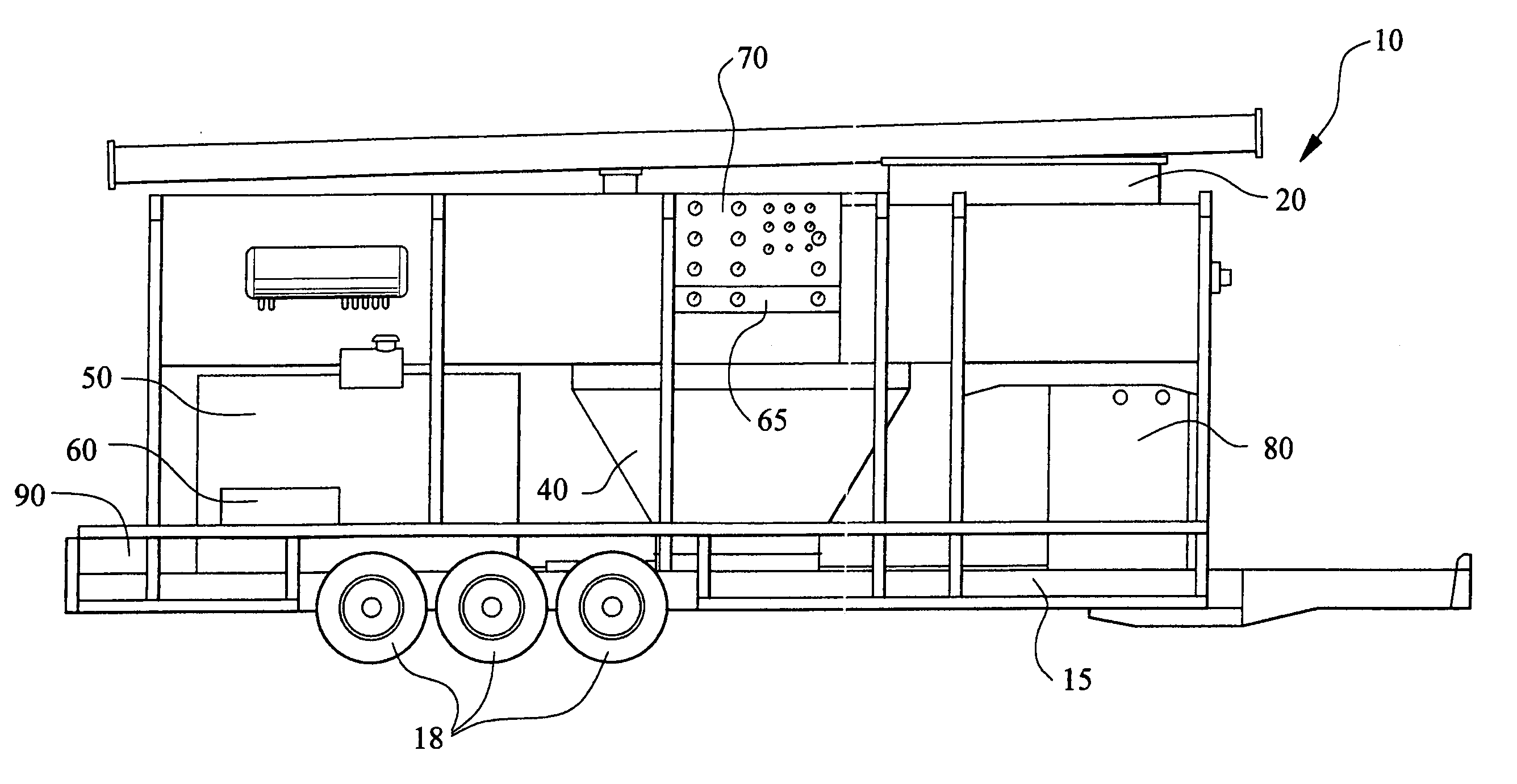

Lightweight concrete mixer

InactiveUS20050195681A1Discharging apparatusMixing operation control apparatusFoaming agentHydraulic pump

An apparatus for on-site manufacturing of lightweight concrete used for insulation in roof decks and roof systems of building structures. The apparatus is supported on a transportable trailer frame and includes a mixer, one or more tanks for holding water and chemical products, such as foaming agents, and a concrete pump. The chemical agents and water are forced through a foam generating carburetor with pressurized air to produce a foam product. Concrete and the foam product are combined in the mixer, in accordance with a predetermined mixture ratio, and released into the concrete pump for forced discharge from the apparatus and application to a roof structure. An internal combustion engine drives hydraulic pumps which operate several components of the apparatus. Controls are provided for operating the several components, functions and operations of the apparatus.

Owner:CONCRECEL USA

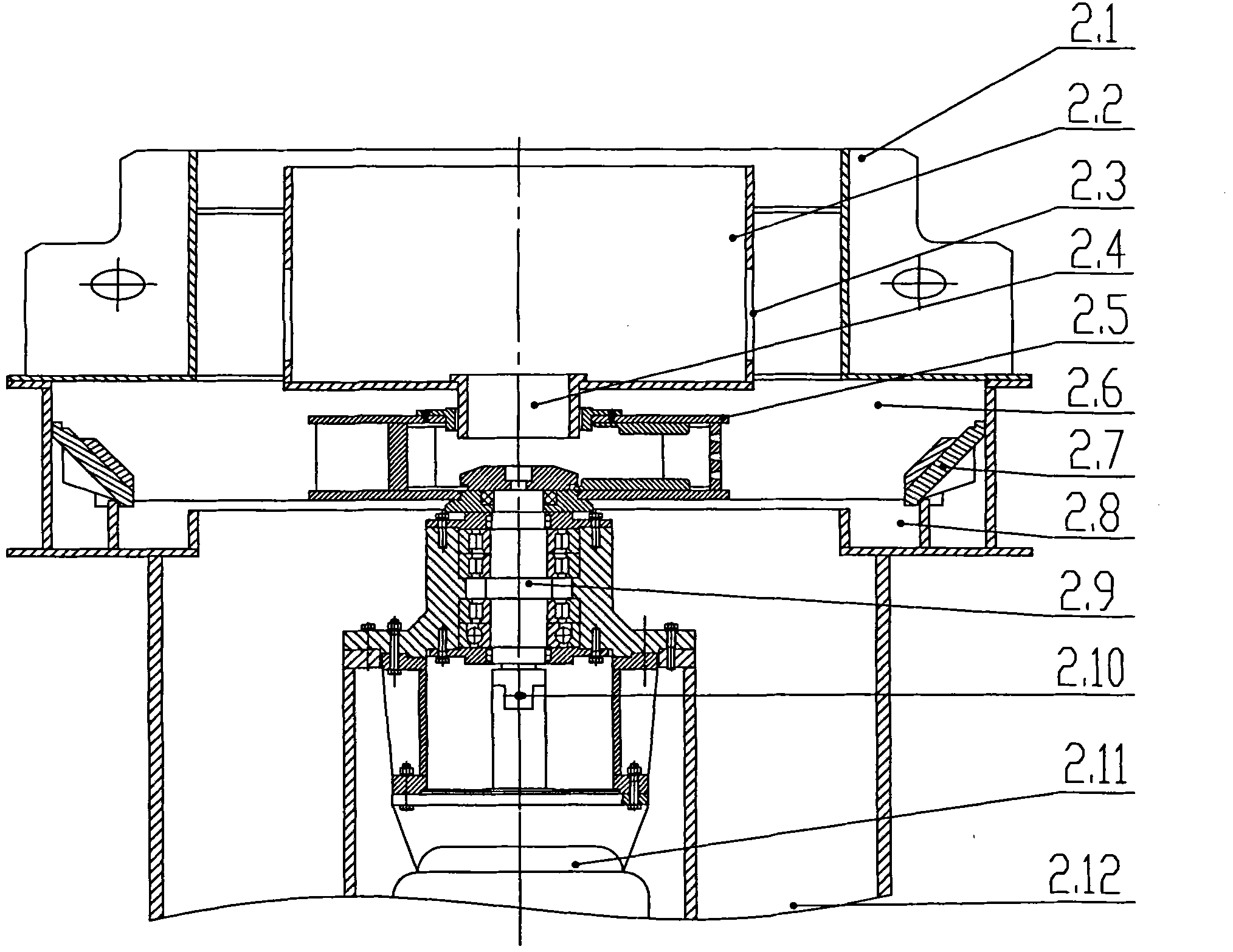

High-performance concrete mixing station

InactiveCN101011844ACompact structureHigh degree of modularityMixing operation control apparatusSold ingredients supply apparatusSmall footprintMaterials science

A high performance concrete mixer comprises the batching aggregate hoister, blender, powder weighting device, additive weighing device, water weighing device and powder storage, with one end of the aggregate hoister at the output of the batching machine, the other end above the inlet of the blender, and the weighing devices for additive, water and powder storage at the top of the inlet of the blender respectively. It is compact and simple in structure, high in modularization, small in land occupation, good in economical effect with energy saving effects.

Owner:SANY HEAVY IND CO LTD (CN)

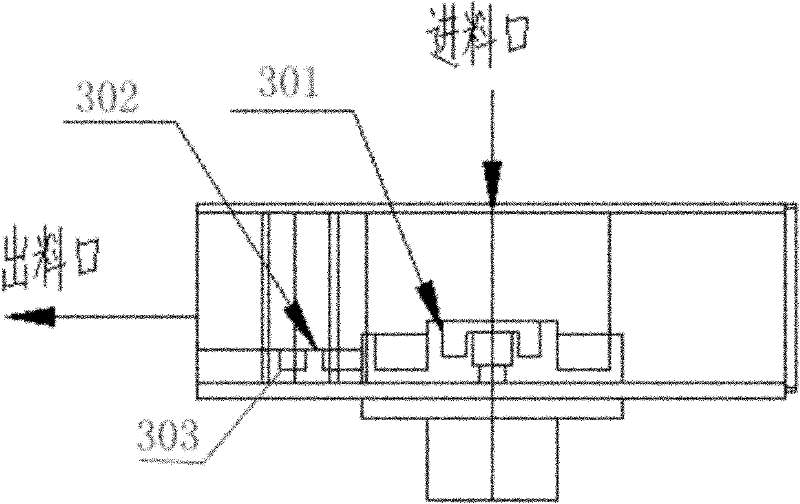

Novel stirring station

InactiveCN101456214AStir wellTwo machines in oneCement mixing apparatusControl apparatusEngineeringScrew conveyor

The invention relates to a novel stirring station, which comprises a skeletal material mixing cabin of which the bottom is provided with a material outlet, a material feeding system positioned below the skeletal material mixing cabin, a skeletal material weighting hopper positioned below the material feeding system, a material collecting belt conveyor positioned below the skeletal material weighting hopper, a stirring cylinder positioned below the material collecting belt conveyor, a cement storage bin, a cement spiral conveyor, a cement weighting hopper, a water pump and a water weighting hopper, wherein the stirring cylinder is simultaneously positioned below the cement weighting hopper and the water weighting hopper; the material feeding system is a variable material feeding system and comprises a variable feeding belt conveyor, a material outlet and a material door; and the structure of the stirring cylinder can be replaced according to different stirring materials.

Owner:陕西长大西筑路面机械科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com