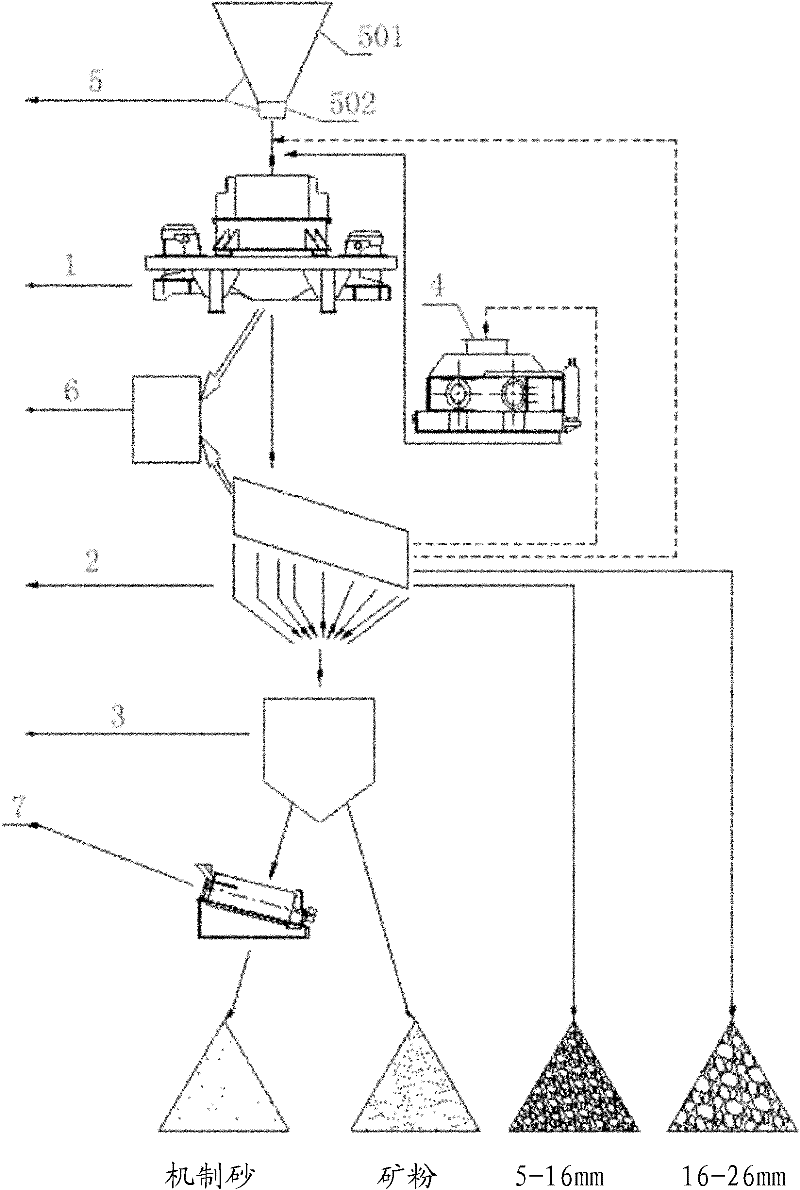

Fine aggregate processing production system

A production system and aggregate technology, applied in the direction of solid separation, mixing plant, and separation of solids from solids with air flow, etc., can solve the problems of low production efficiency, prolong the production process, reduce production efficiency, etc., and achieve the quality of the output The effect of improving, reducing costs and saving production time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

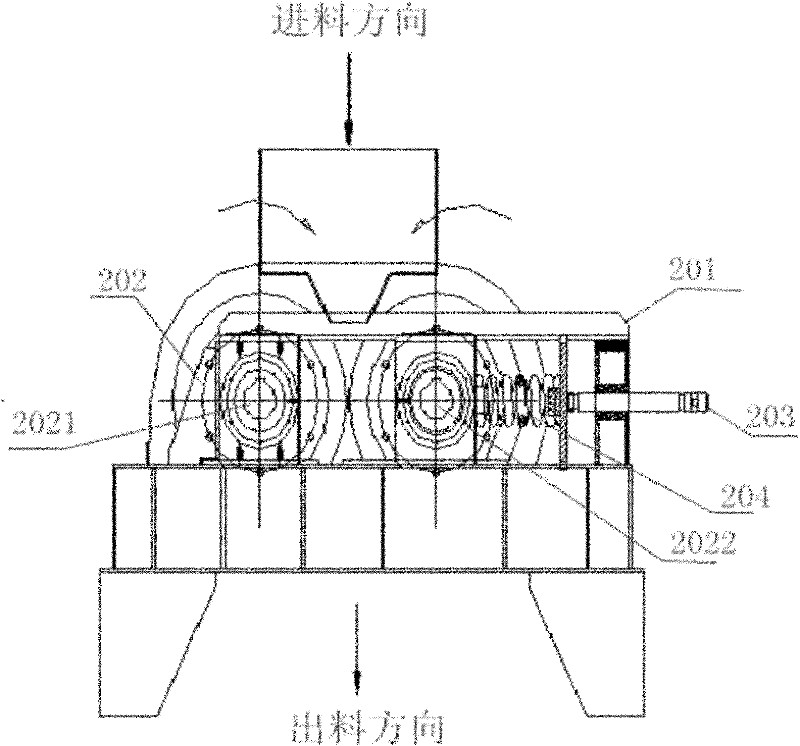

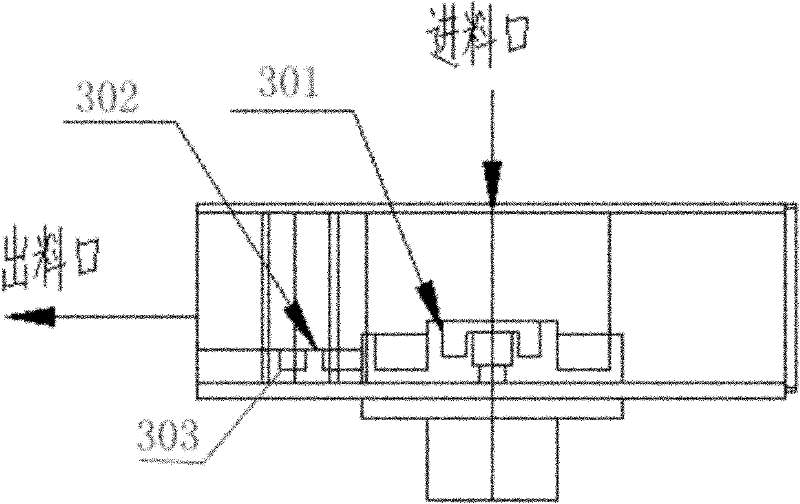

Method used

Image

Examples

Embodiment 1

[0054] V30 technical indicators: (annual output of 300,000 cubic meters of concrete)

[0055]

[0056] Occupation: less than 1000 square meters in plane, 200 square meters in three-dimensional

[0057] Production method: dry method

[0058] Environmental protection index: zero pollution, zero discharge

[0059] Capacity: 150 tons / hour, with an annual output of 600,000 tons (4,000 hours), which can meet 300,000 cubic meters of concrete

[0060] Product quality: adjustable sand Fm=2.5-3.0, no need to add fine sand, it can be used directly. No mud content, powder content 3% - 12% controllable, suitable for C20-C60.

[0061] Grain shape: cubic polyhedron, good bite, effectively improve the strength of concrete.

[0062] Important note: uniform particle size distribution, stable gradation, medium sand zone 2, 40% content below 0.63, 20% below 0.315. It solves the problem that 2.5-1.2mm crushed sand and coarse sand are too much in the past, and 0.6-0.3mm and 0.3-0.15mm sand ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com