Patents

Literature

472 results about "Grain shape" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Preparation method of novel core-shell type cement-based high-strength lightweight aggregate

ActiveCN103496866AConducive to the protection of non-renewable resourcesSimple processSolid waste managementSpecific functionPollution

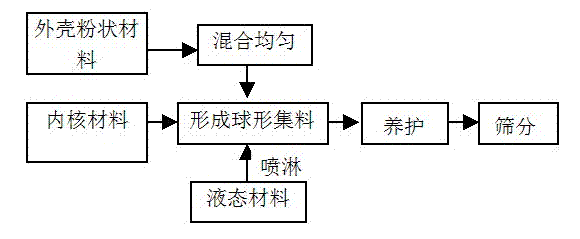

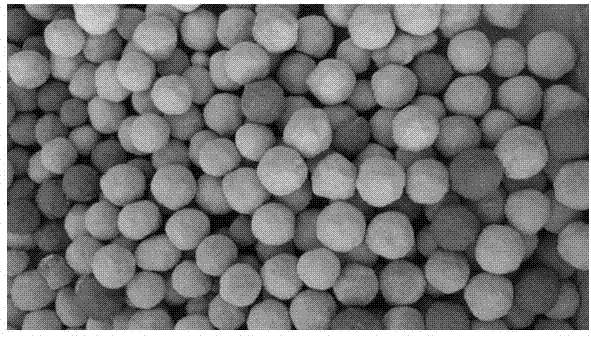

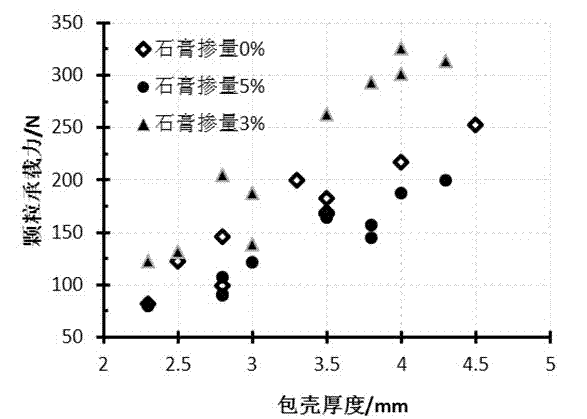

The invention provides a preparation method of novel core-shell type cement-based high-strength lightweight aggregate. A cement-based composite material (cement and an admixture) is used as a main cementing material of a shell material, a pelletizing process is adopted for surrounding a shell outside a lightweight core material, and the high-strength lightweight aggregate can be successfully prepared after curing is performed for a certain period of time. The prepared light aggregate has the advantages of high specific strength, good grain shape and good heat preservation and heat insulation, and can realize certain specific functions, such as heat storage, sound insulation and wave absorption. A production process of the high-strength light aggregate comprises the steps of mixing powder, uniformly stirring, spraying liquid to form pellets, curing (steam curing and moisturizing) and screening. According to the preparation method, the problems of great production energy consumption, complex process and serious pollution of the aggregate produced by a traditional sintering process or the problems of relatively large packing density, insufficiently high strength and insufficiently high product quality of unburned ceramsite products are solved.

Owner:SOUTHEAST UNIV

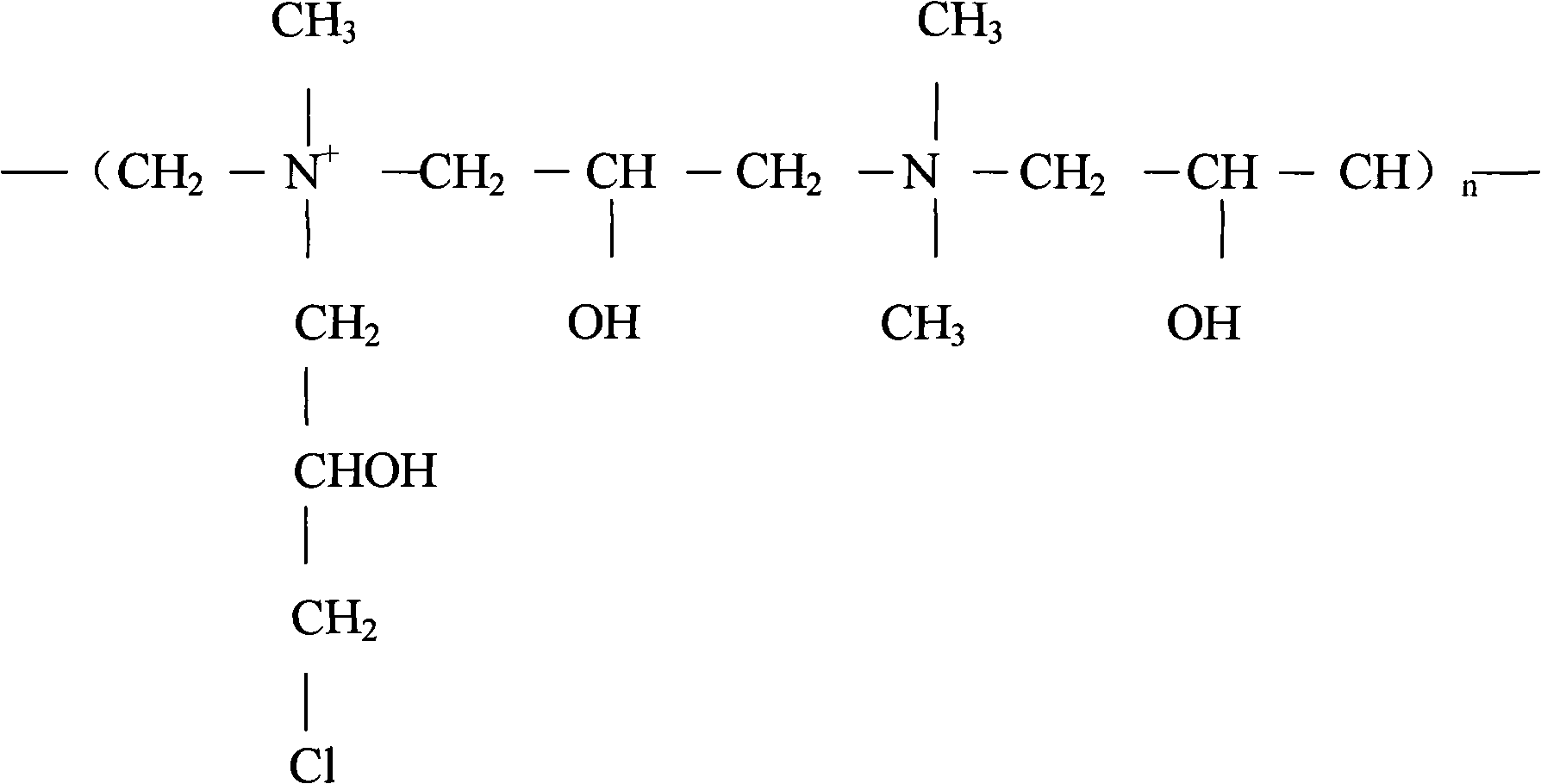

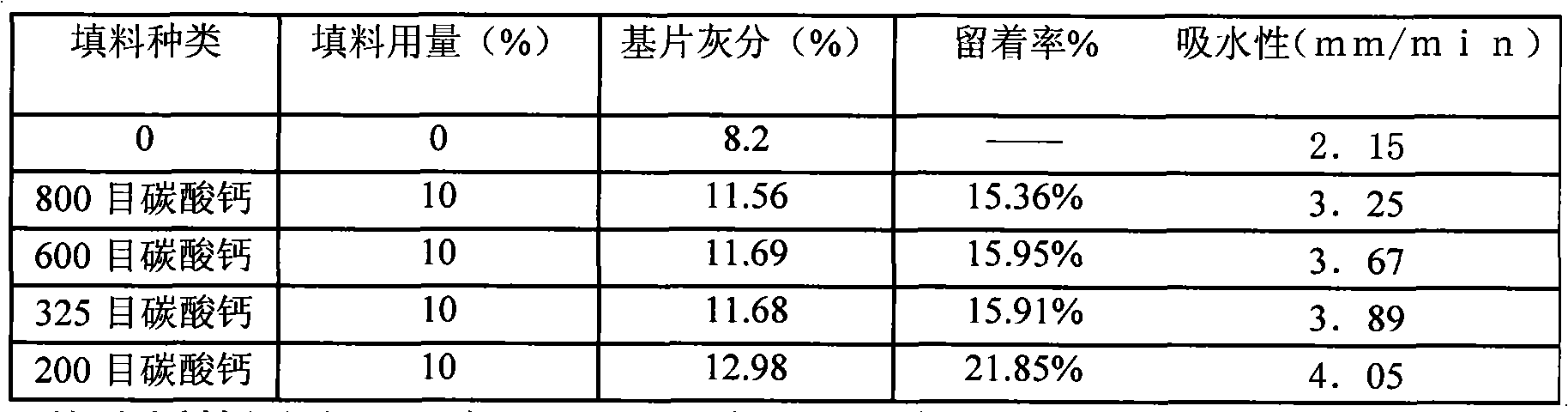

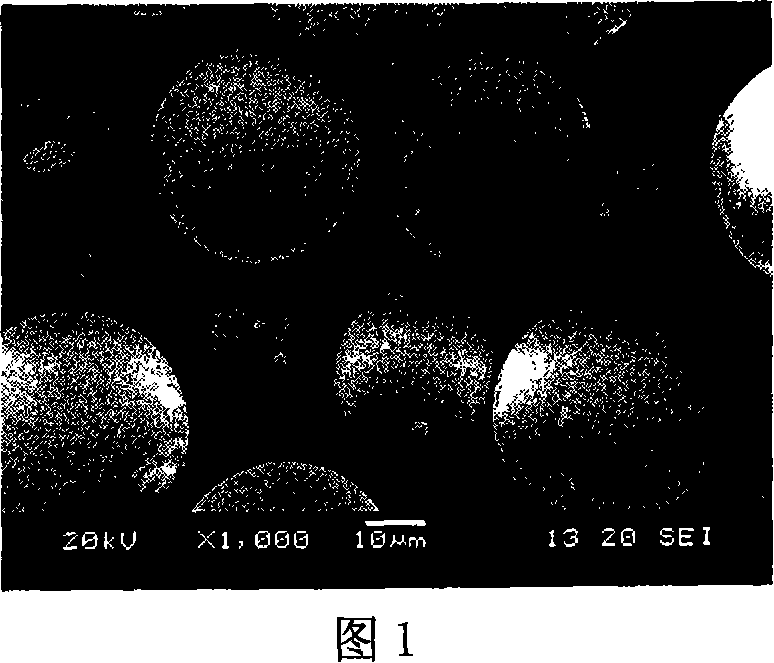

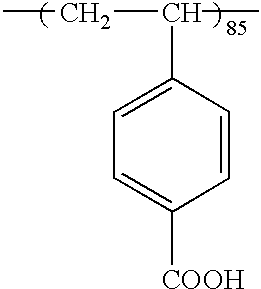

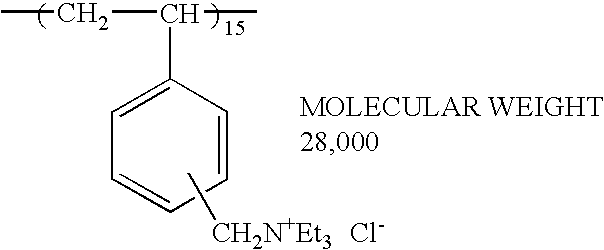

Method for improving sheet quality by increasing retention of filler calcium carbonate in sheet

InactiveCN101683180AImprove retentionQuality improvementTobacco preparationGranularityElectron microscope

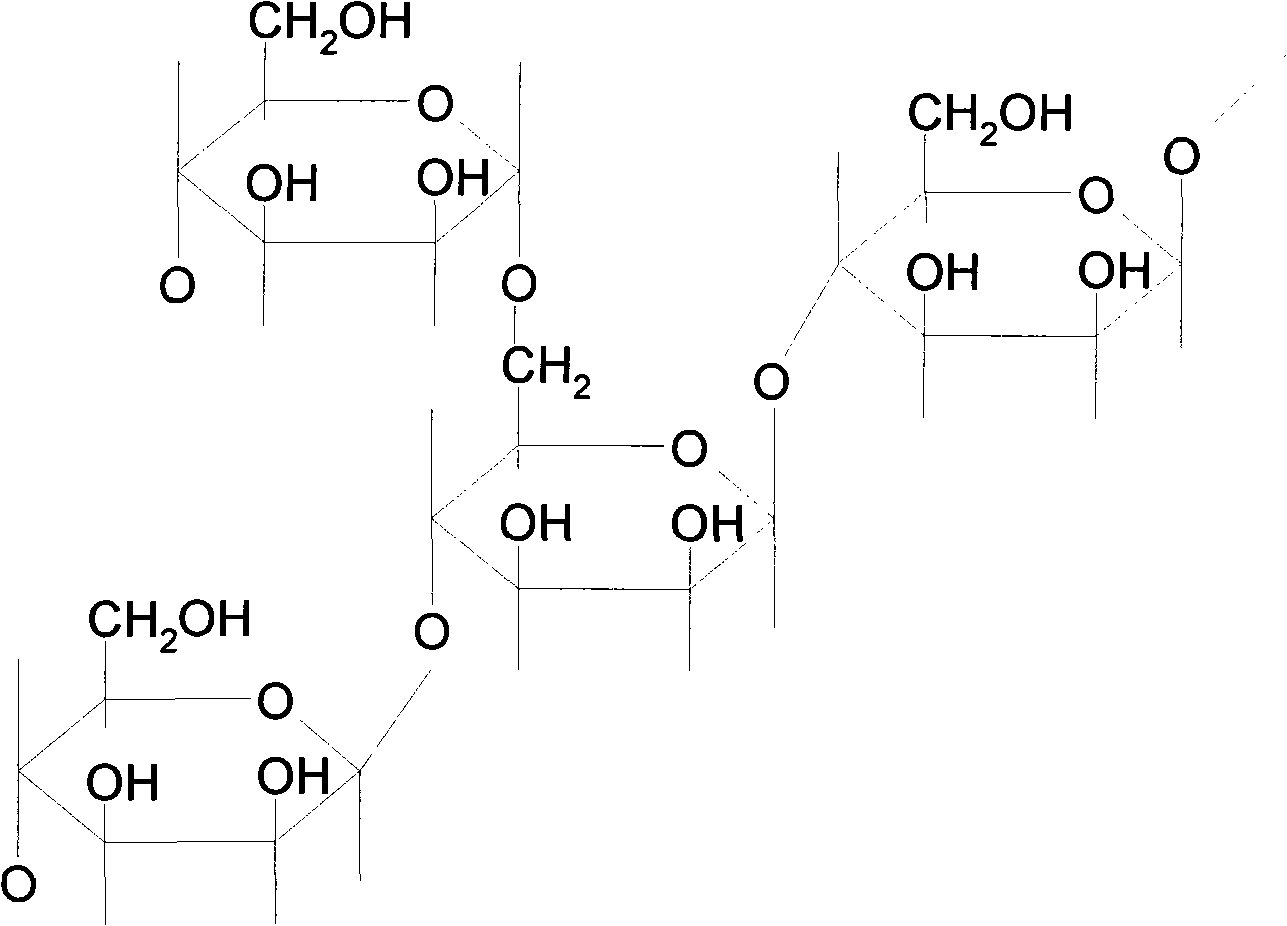

The invention discloses a method for improving sheet quality by increasing retention of a filler calcium carbonate in a sheet, belonging to the technical field of tobacco sheets. The method adopts thefollowing technical measures: (1) selecting nonsphericity as the grain shape of the calcium carbonate through an electron microscope; (2) controlling the granularity between 125 meshes and 400 meshes; (3) ensuring the addition of the filler calcium carbonate to be 7-12% of the total weight of mixed slurry; (4) adding guar gum accounting for 0.04-0.2% of the total weight of the mixed slurry into the slurry to serve as a retention aid; and (5) adding an anion catcher accounting for 0.1-0.8% of the total weight of the mixed slurry into the slurry. The method features effective measures and obvious generated technical effects, solves the technical problems and can improve the retention of the filler calcium carbonate in the sheet and the sheet quality.

Owner:HUBEI CHINA TOBACCO IND +1

Loading method of polyolefin catalyst

The invention belongs to the field of a polyolefin catalyst. The method comprises the steps: dissolving or suspending a carrier in an organic solvent; adding compounds of organic lithium, organic sodium or organic potassium or a format reagent to the obtained carrier liquor or suspending liquor at the temperature of -40 DEG C to 30 DEG C; reacting for 0.5 to 3 hours at the temperature of -20 DEG C to 10 DEG C after the adding step; raising the temperature to 30 DEG C to 80 DEG C; reacting for 0.5 to 3 hours; obtaining a mixture; filtering the mixture for washing and removing residual organic lithium, organic sodium, organic potassium or the format reagent; reacting with titanium, metallocene, non-metallocene, vanadium, rare earth metal or chromic halide in the organic solvent at the temperature of -40 DEG C to 30 DEG C; reacting for 0.5 to 3 hours at the temperature of -30 DEG C to 0 DEG C after the adding step; raising the temperature to 20 DEG C to 100 DEG C; reacting for 1 to 5 hours; removing the residual halide by filtering and washing; drying; and obtaining a solid catalyst. The catalyst has the advantages of good grain shape, high loading quantity and high activity, does not fall off the carrier and is suitable for vapor phase polymerization technology, slurry polymerization technology or combination polymerization technology.

Owner:BEIJING UNIV OF CHEM TECH

Prepn process of polyimide microsphere

The present invention relates to dispersive polymerization process of preparing polyimide microsphere in monomer solution. The process includes the following steps: dissolving monomer diamine and dispersant in organic solvent through stirring; stage adding monomer diamine and heating for polymerizing to prepare polyamic acid solution; adding catalyst and dewatering agent successively for chemical imination; dropping water solution of dispersant to separate out solid grains, centrifugally filtering, washing and stoving to obtain polyimide microsphere. Thus prepared polyimide microsphere has glass transition temperature Tg of 200-300 deg.c, and grain size of 0.1-100 micron. The process has high polyimide yield, low cost and controllable grain shape and size distribution.

Owner:NANJING UNIV OF TECH

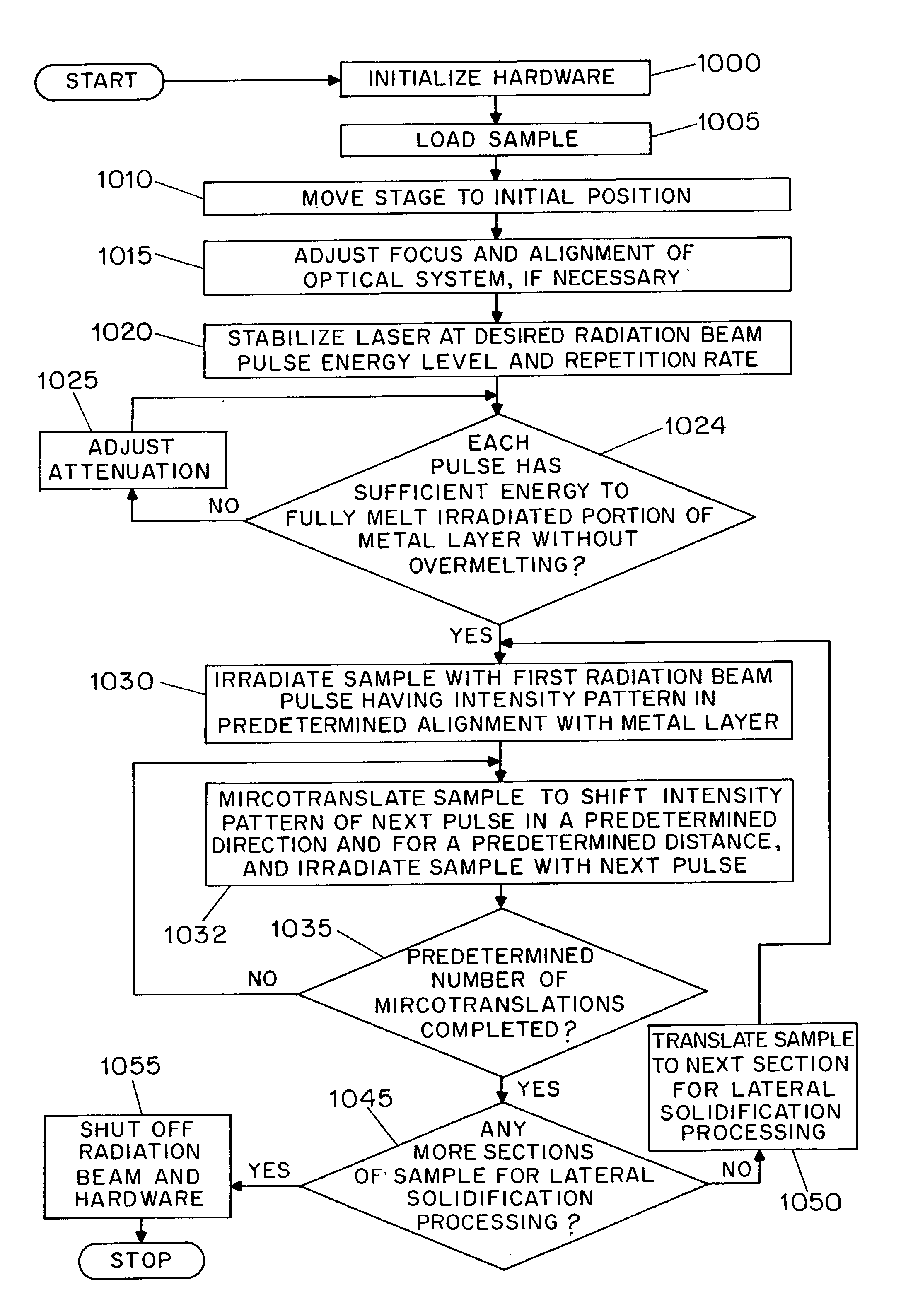

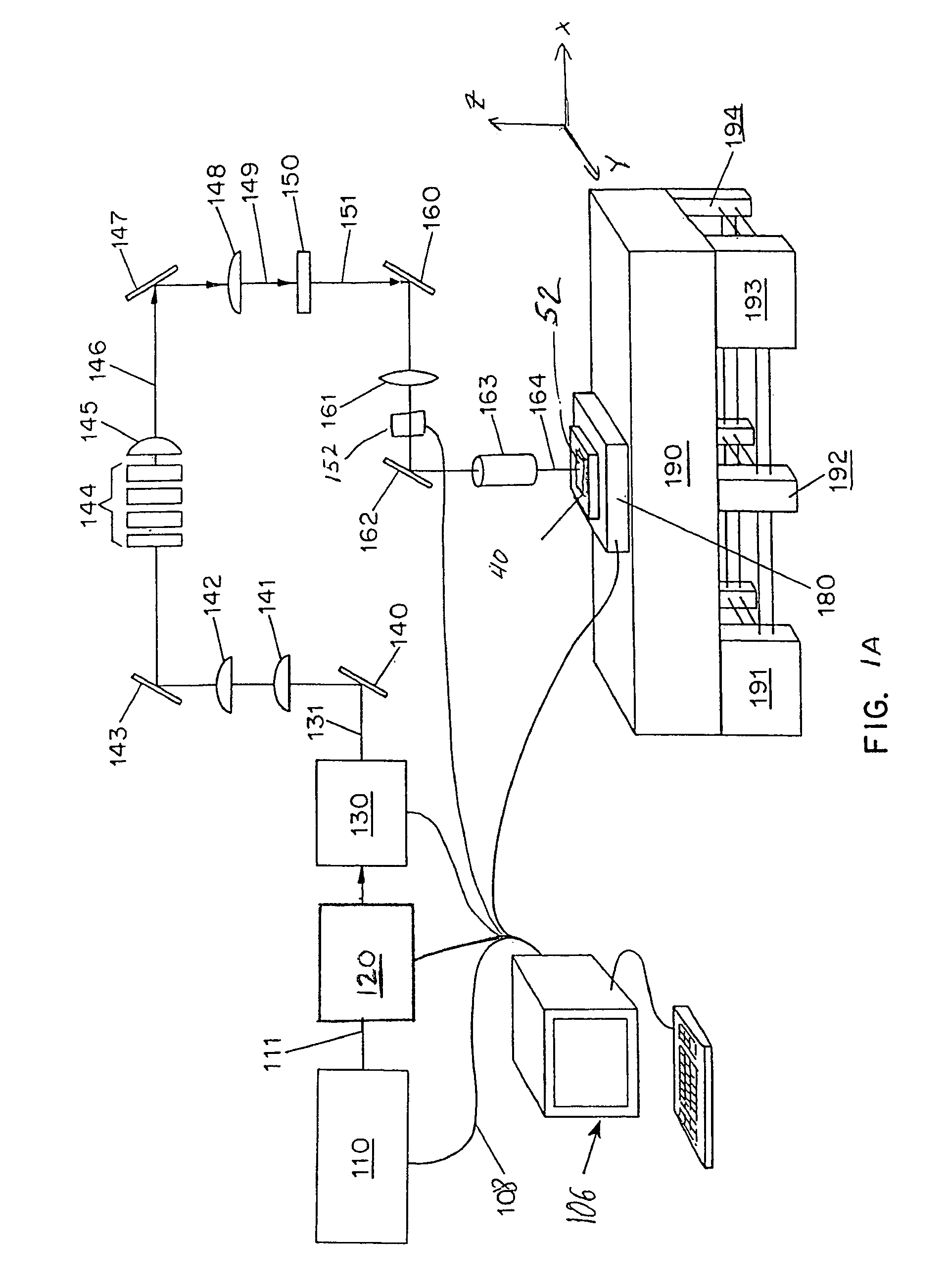

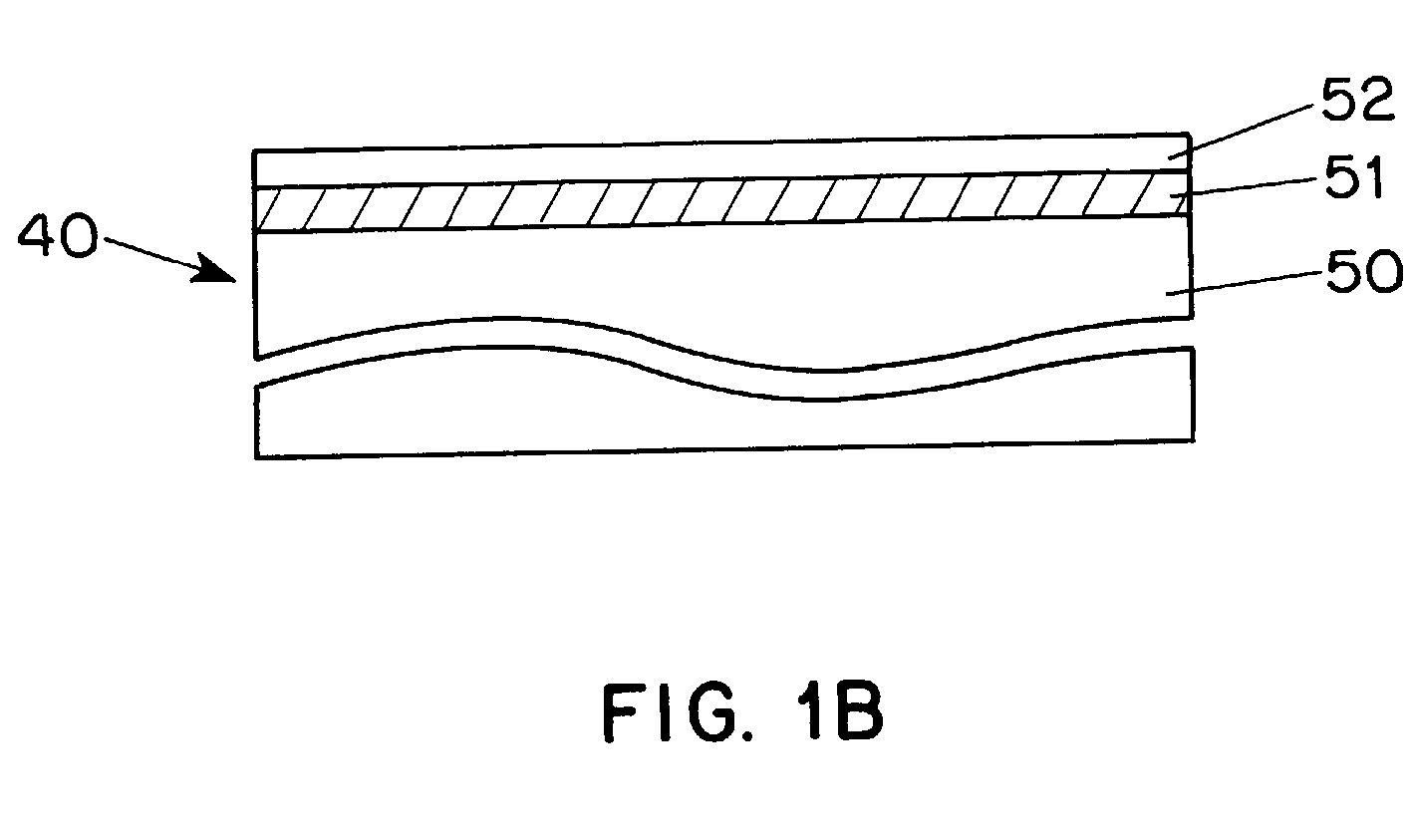

Method and apparatus for processing thin metal layers

InactiveUS7115503B2Small widthMetal-working apparatusSemiconductor/solid-state device manufacturingThin metalOptoelectronics

A method and apparatus for processing a thin metal layer on a substrate to control the grain size, grain shape, and grain boundary location and orientation in the metal layer by irradiating the metal layer with a first excimer laser pulse having an intensity pattern defined by a mask to have shadow regions and beamlets. Each region of the metal layer overlapped by a beamlet is melted throughout its entire thickness, and each region of the metal layer overlapped by a shadow region remains at least partially unmelted. Each at least partially unmelted region adjoins adjacent melted regions. After irradiation by the first excimer laser pulse, the melted regions of the metal layer are pemitted to resolidify. During resolidification, the at least partially unmelted regions seed growth of grains in adjoining melted regions to produce larger grains. After completion of resolidification of the melted regions following irradiation by the first excimer laser pulse, the metal layer is irradiated by a second excimer laser pulse having a shifted intensity pattern so that the shadow regions overlap regions of the metal layer having fewer and larger grains. Each region of the metal layer overlapped by one of the shifted beamlets is melted throughout its entire thickness, while each region of the metal layer overlapped by one of the shifted shadow regions remains at least partially unmelted. During resolidification of the melted regions after irradiation by the second radiation beam pulse, the larger grains in the at least partially unmelted regions seed growth of even larger grains in adjoining melted regions. The irradiation, resolidification and re-irradiation of the metal layer may be repeated, as needed, until a desired grain structure is obtained in the metal layer.

Owner:THE TRUSTEES OF COLUMBIA UNIV IN THE CITY OF NEW YORK

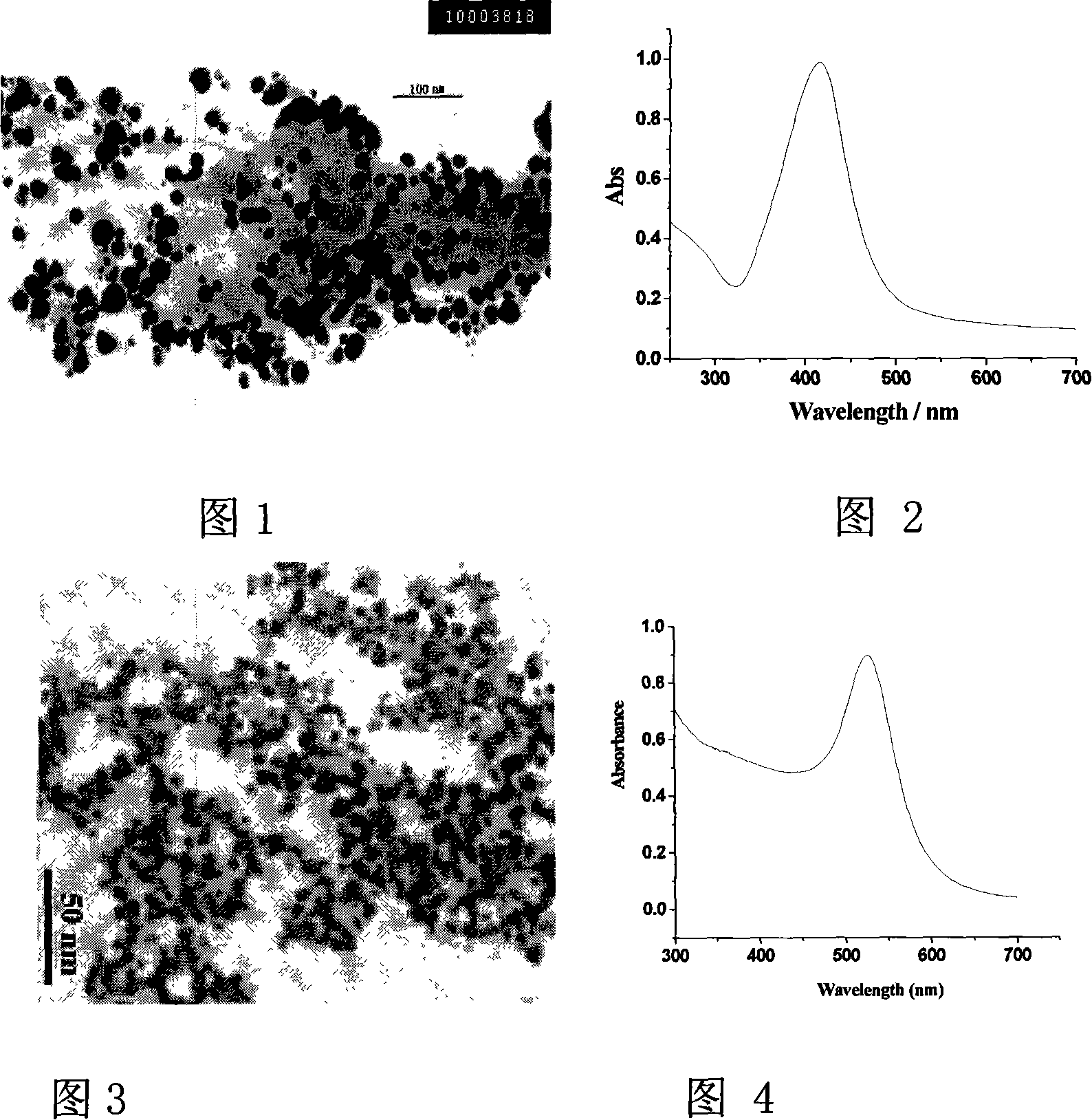

Microwave preparing method for nanometer silver or gold

The present invention discloses a microwave producing method for nano-silver or gold; the reactants are added into the reactor according to the proportion of 1 to 1; the reactants are silver nitrate or auric chloride acid and starch or sodium carboxymethyl cellulose; the reactor is put into a microwave oven; with a mixer of a rotation speed of 100 / min and the microwave power of 0.3 Kw, the reaction time of the reactant starch is one hour while the time of the reactant sodium carboxymethyl cellulose is seven hours; the solution is dried by air or vacuum freeze or spraying after the reaction is over to produce nano-silver or gold powder or concentrated to nano-silver or gold colloid of the needed consistency through vacuum concentration. The present invention discards the ordinary reducing agent in thermochemical synthesis and takes the microwave heating to replace the traditional local heating method and realize homogeneous growing of nano-silver or gold; the grain size distribution of the nano-silver and gold is narrow and the grain shapes are regular; the method is widely used in biochemical and antiseptic material field.

Owner:HUAIYIN INSTITUTE OF TECHNOLOGY

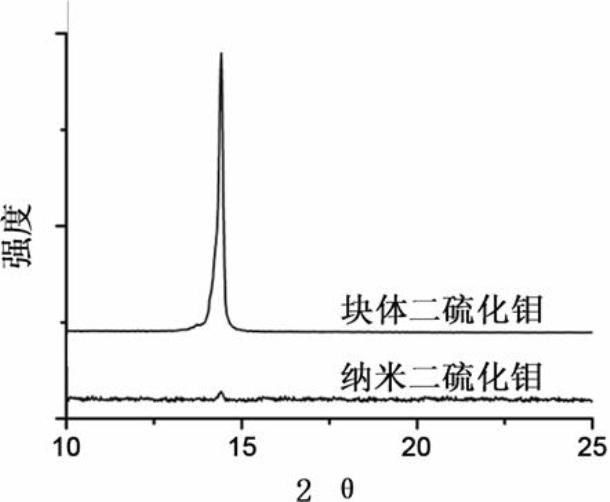

High-performance rechargeable magnesium battery and manufacturing method thereof

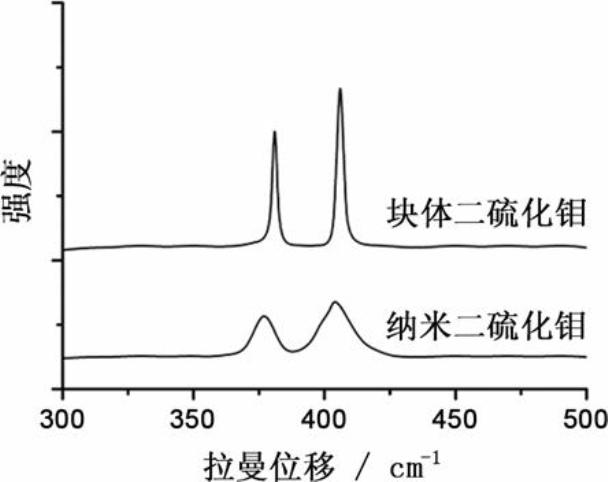

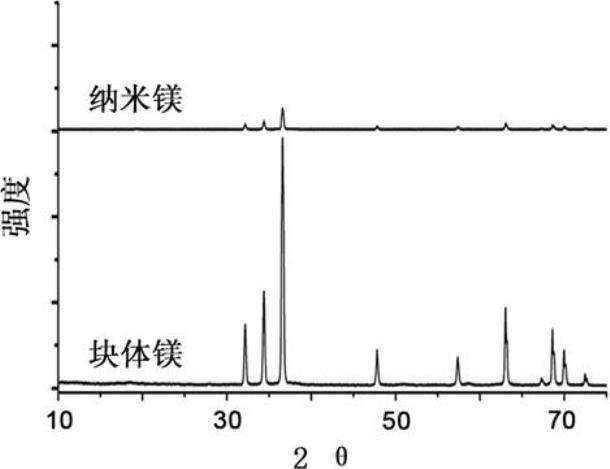

ActiveCN102024996AMild conditions for material preparationHigh specific capacityFinal product manufactureCell electrodesGrignard reagentPolypropylene

The invention discloses a high-performance rechargeable magnesium battery consisting of a positive plate, a negative plate, a diaphragm and an electrolyte. The positive plate is made from highly stripped nano-supramoly which is of highly erosive structure, wherein the average number of the layers of the nano-supramoly is not more than 4, and the average thickness is not more than 3nm. The negative plate is made from grain-shaped nanometer-level magnesium or nanometer-micrometer level composite magnesium, and the average grain diameter is 1-10nm. The diaphragm is a three-layer film made from polythene, polypropylene and polyethylene. The electrolyte is made from a tetrahydrofuran solution of Grignard reagent derivate. The invention has the advantages that: the rechargeable battery has gentler material preparation conditions (from the room temperature to 150 DEG C), larger specific capacity (170mAhg<-1>), higher operating voltage (1.8V), better circulation performance (still keeping 95%of initial capacity after circulating for 50 periods) and the like compared with the reported magnesium secondary battery system, and the rechargeable battery can be applied to the next generation large-scale energy storage batteries.

Owner:NANKAI UNIV

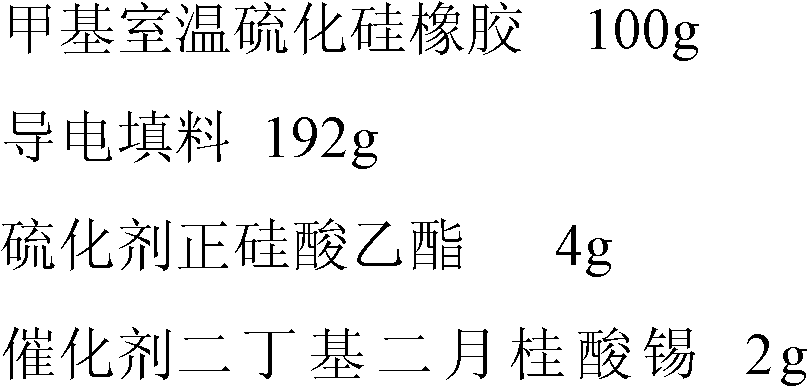

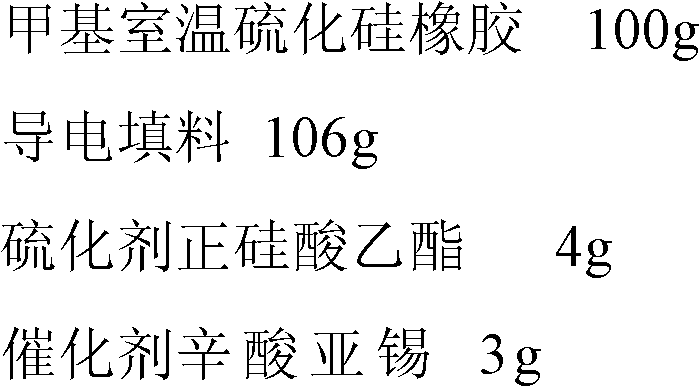

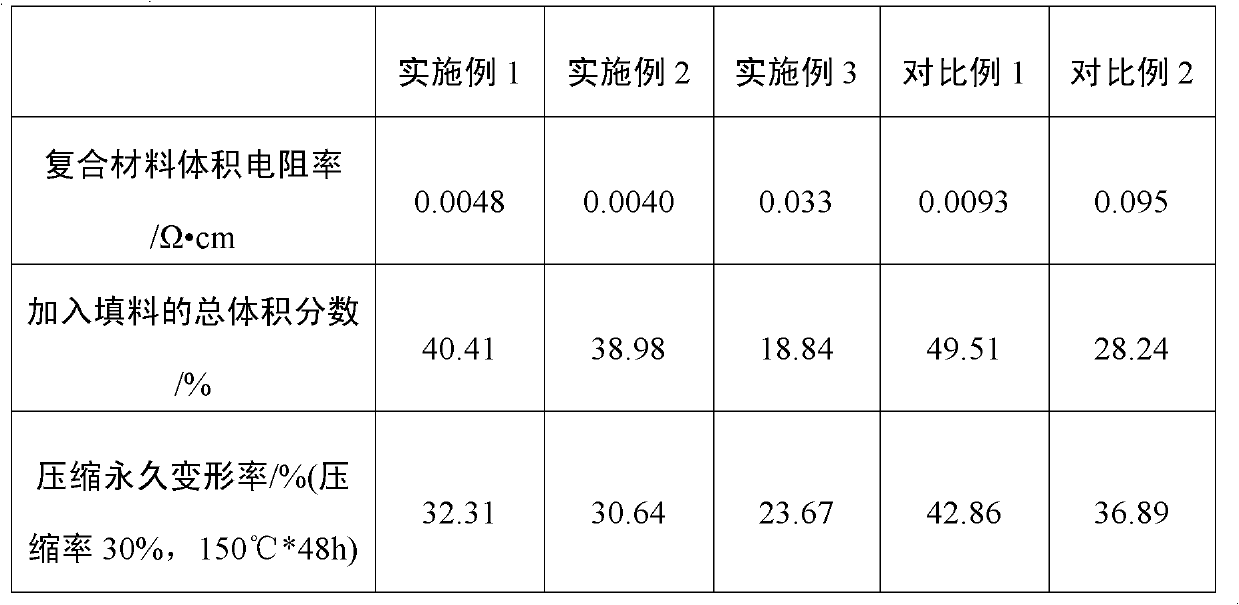

Low-compressive-deformation and high-conductivity rubber composite material and preparation method thereof

The invention relates to a low-compressive-deformation and high-conductivity rubber composite material and a preparation method thereof. The low-compressive-deformation and high-conductivity rubber composite material is prepared by the following steps of: taking silicon rubber as a base body and utilizing modified grain-shaped and fiber-shaped metal-plating conductive fillers containing a reactive double-bond silane coupling agent under a CO2 supercritical state to prepare low-compressive-deformation and high-conductivity rubber composite material. Under the condition of guaranteeing the high conductivity, the use amount of the conductive fillers is reduced and the composite material has low compressive deformation and high conductive property.

Owner:BEIJING UNIV OF CHEM TECH +1

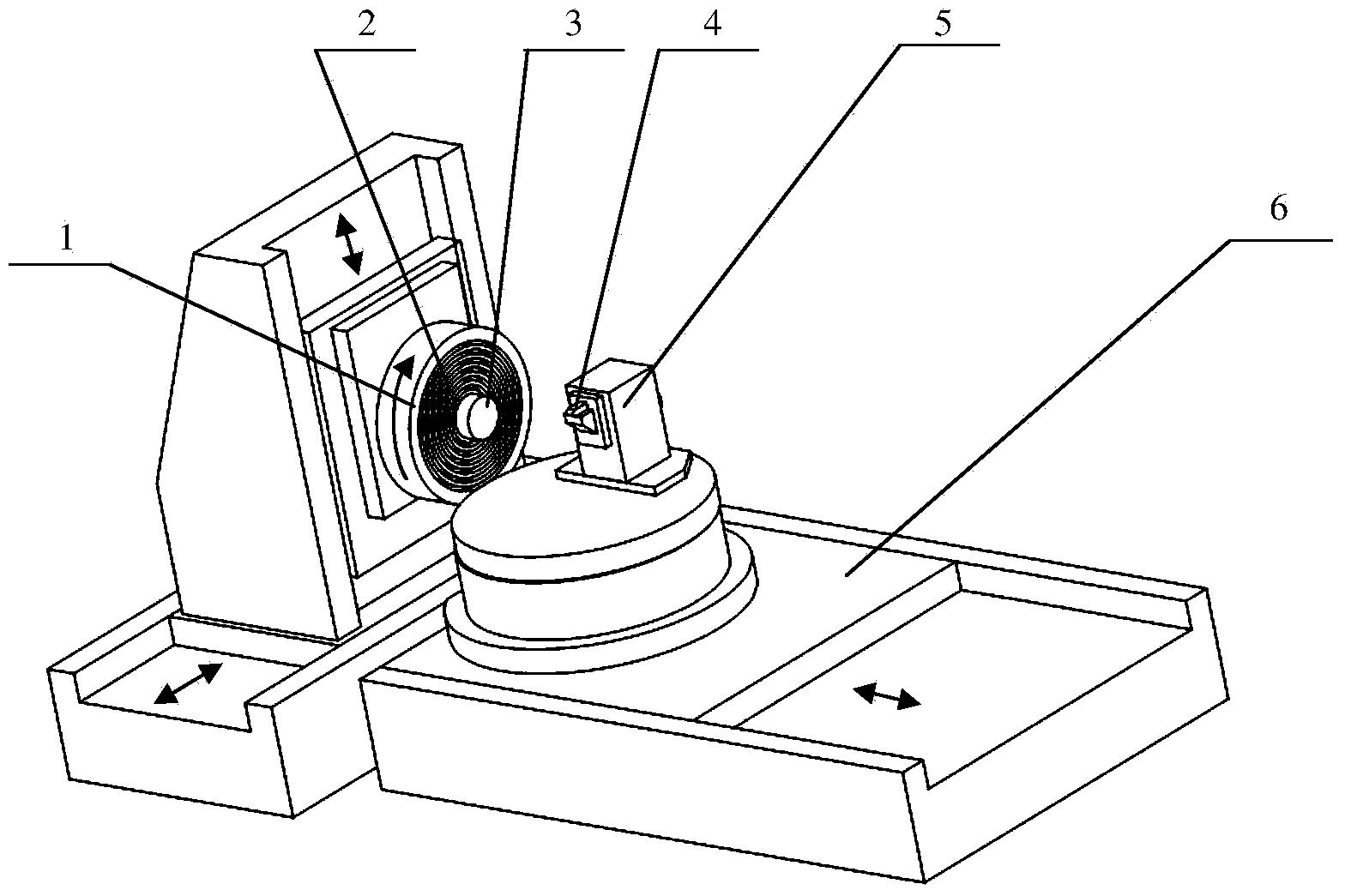

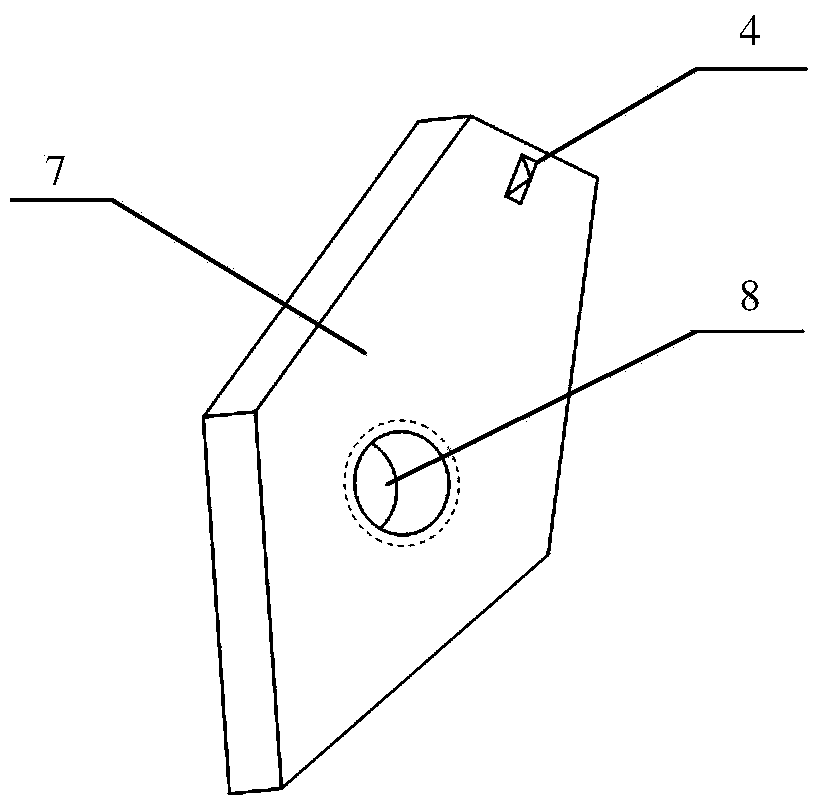

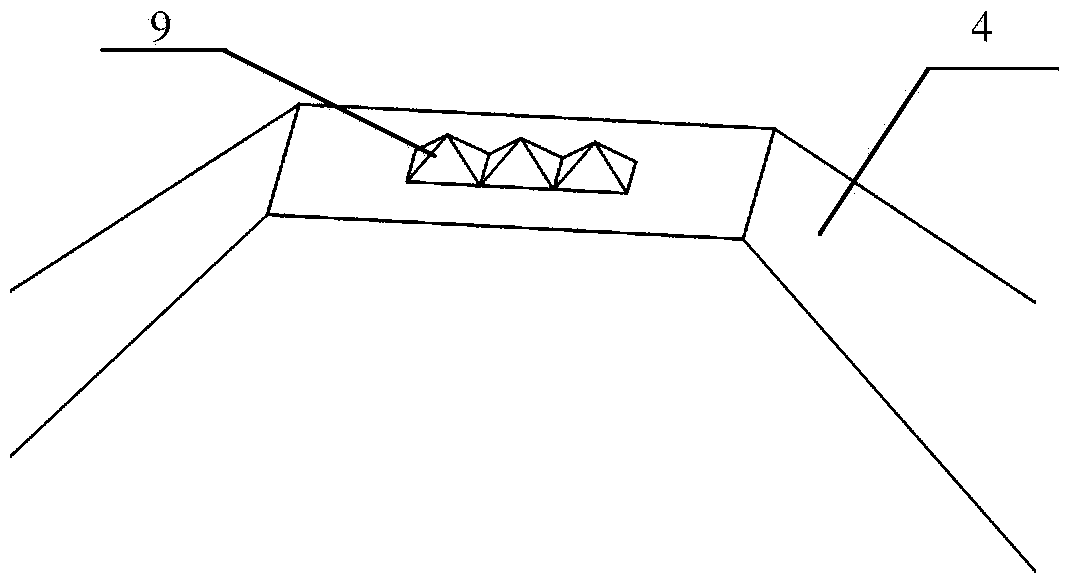

Method and device for determining grinding brittleness-ductility transformation critical cutting depth of hard and brittle material

InactiveCN103722467AImprove surface qualityHigh precisionGrinding feed controlGrinding machinesHigh surfaceRelative motion

The invention relates to the technical field of hard and brittle material ultra-precision machining. In order to achieve ductility domain grinding of the largest cutting depth, high surface quality of the hard and brittle material, and efficient and high-precision production machining, according to the technical scheme, a method and device for determining the grinding brittleness-ductility transformation critical cutting depth of the hard and brittle material comprises the following steps of (1) according to a grinding wheel used in ultra-precision grinding, determining the number, shape and distance of grains of a homemade multi-grain tool, (2) according to the grain shape, distance and front-angle parameters selected in the step (1), machining three or more grains on a grain base body, (3) controlling the multi-grain tool and a workpiece to generate relative motion, beginning to conduct scratching on the surface of the workpiece, meanwhile, controlling the multi-grain tool to conduct continuous feeding, enabling the depth of the scratch to continuously change, and observing and measuring the workpiece after scratching by utilizing a surface contourgraph and a confocal microscopy. The method is mainly applied to ultra-precision machining.

Owner:TIANJIN UNIV

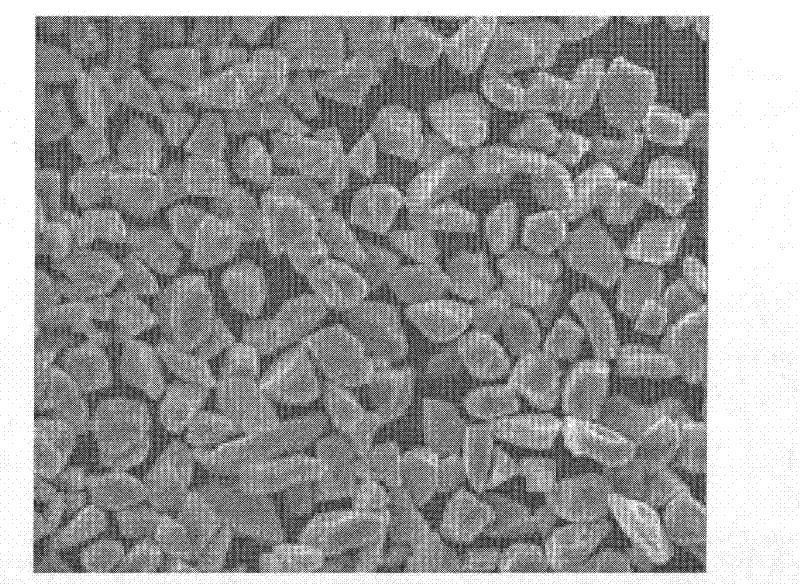

Support for lithographic printing plate and presensitized plate and method of producing lithographic printing plate

InactiveUS20030165768A1High sensitivityProlong lifePhotoprinting processesSurface reaction electrolytic coatingImage recordingEngineering

Disclosed is a support for a lithographic printing plate obtainable by performing at least graining treatment on an aluminum plate, having on its surface thereof, a grain shape with a structure in which a grained structure with medium undulation of 0.5 to 5 mum average aperture diameter and a grained structure with small undulation of 0.01 to 0.2 mum average aperture diameter are superimposed, and a presensitized plate provided with an image recording layer on the support for a lithographic printing plate. By using this presensitized plate, a balance between scum resistance and press life when a lithographic printing plate is produced therefrom, which has been in a trade-off relation in the past, can be maintained at a high level.

Owner:FUJIFILM HLDG CORP +1

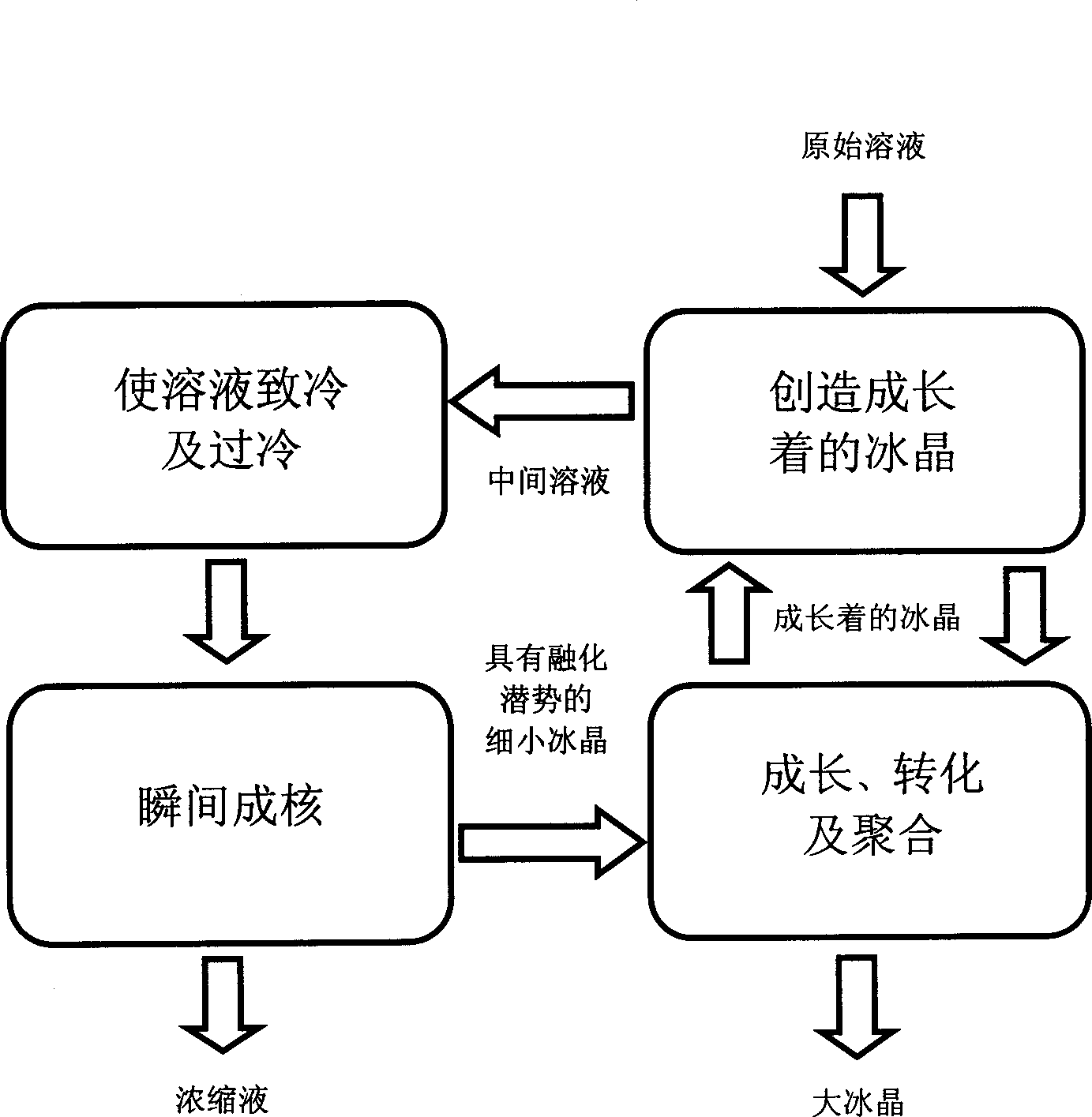

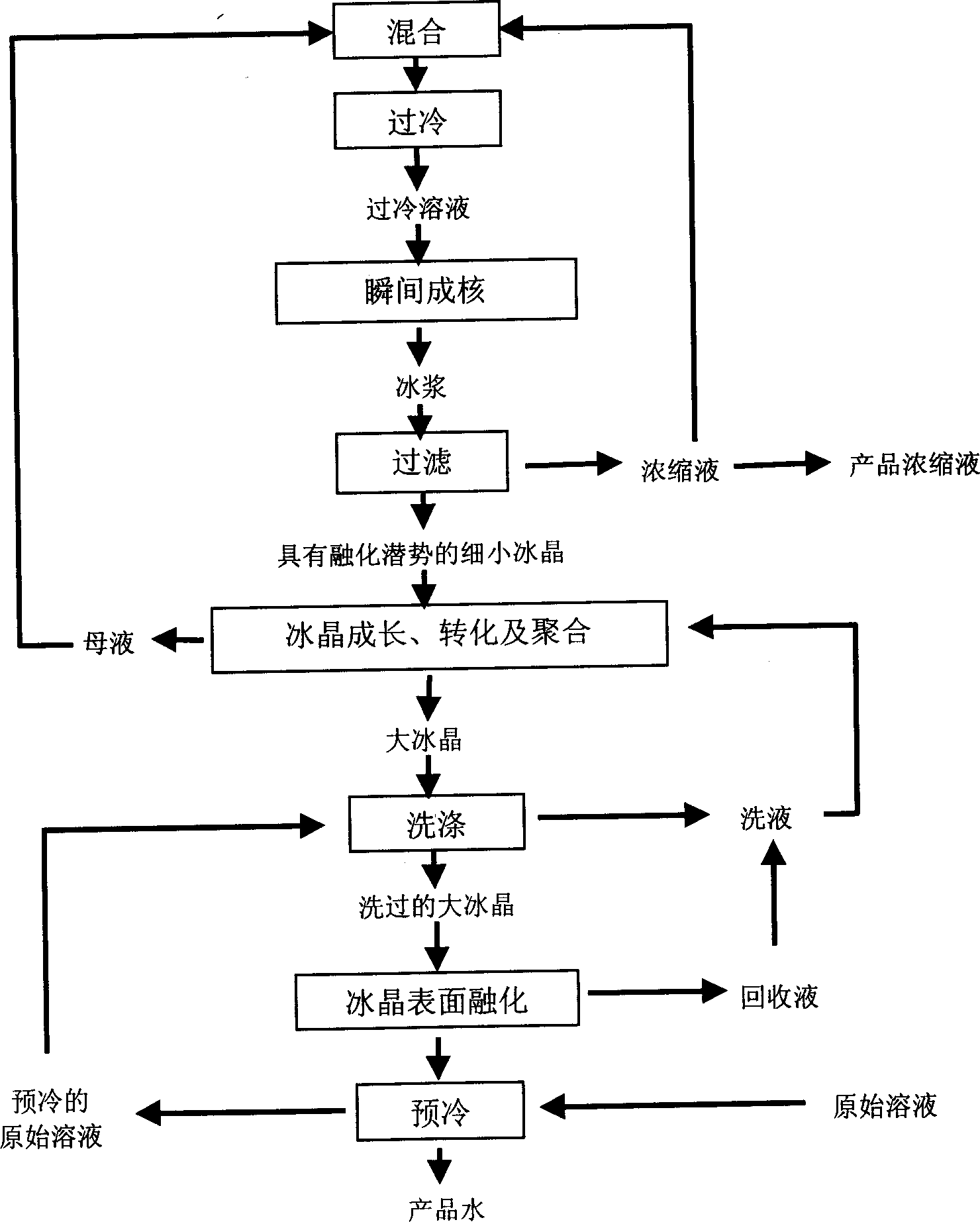

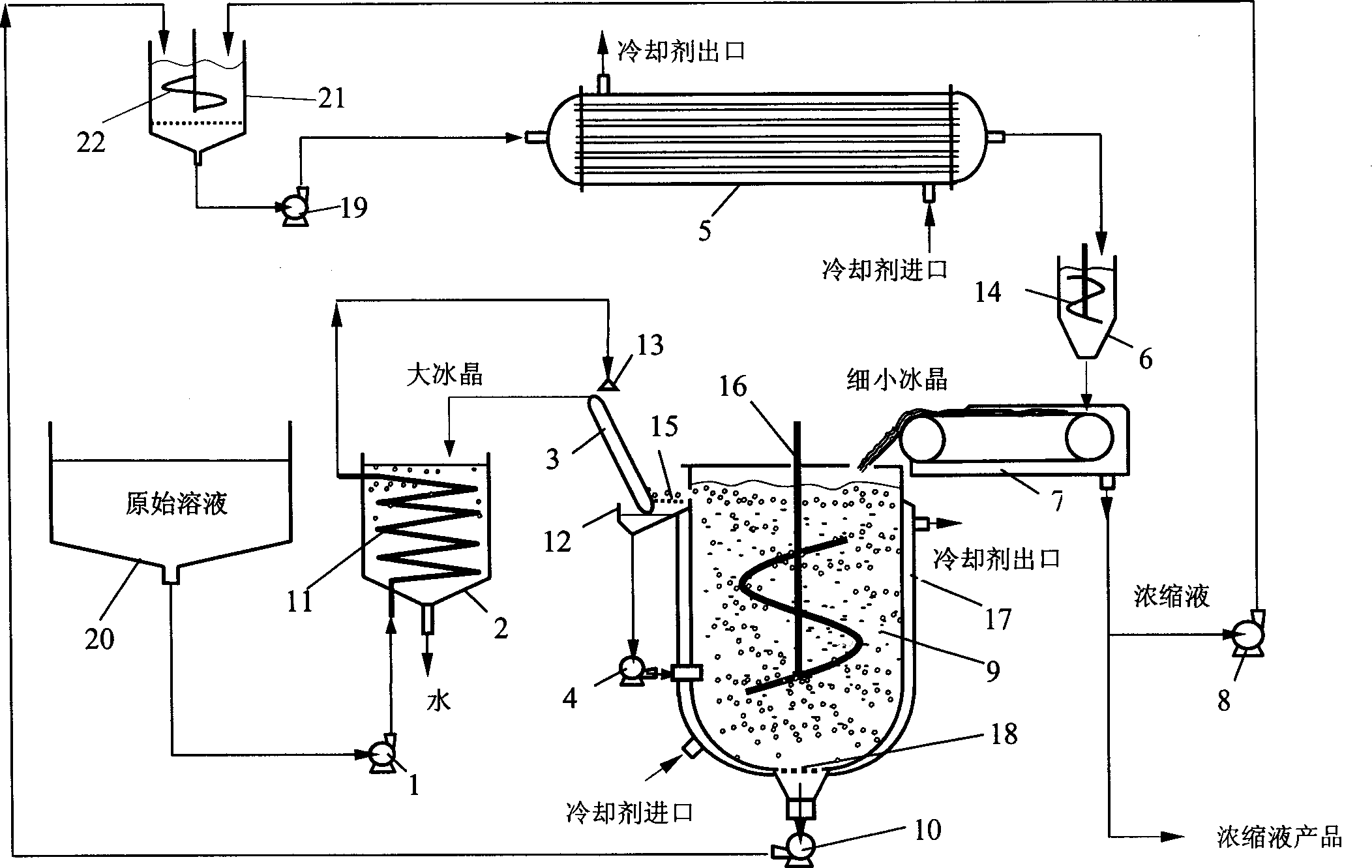

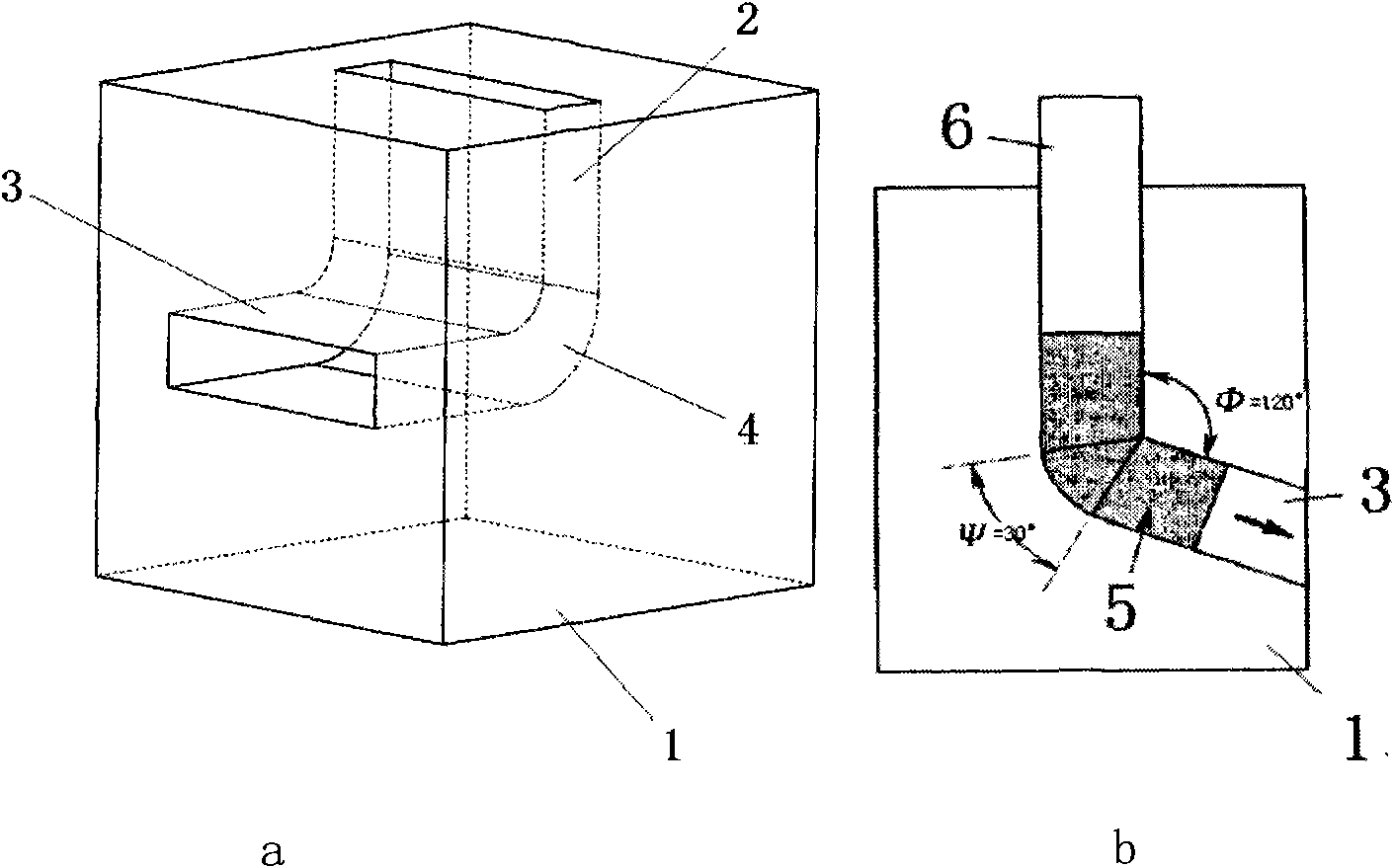

Freeze concentration for aqueous solutions

The invention is an efficient physical method of freezing and concentrating aqueous solutions based on the transformation of ice crystals. It results in a very high ice crystal growth rate, produces granular, aggregated large ice crystals without internal entrainment, and avoids scraping of ice crystals during freezing to save energy. The method mainly consists of the following processes: cooling the solution to a supercooled state without nucleation or ice formation on the heat transfer surface; instantly nucleating the supercooled solution to produce fine ice crystals and concentrating the solution; with the help of absorption-exotherm The growth, transformation and polymerization of ice crystals in a well-balanced and controlled environment produce large, granular or spherical ice crystals at high rates. Both single-stage and multi-stage operations can be used in this method and the main steps can be arranged flexibly. The equipment for implementing this method mainly includes refrigeration heat exchangers, nucleators, filters and multifunctional crystallizers, each of which has its own characteristics to meet the requirements of the method.

Owner:梁保民 +1

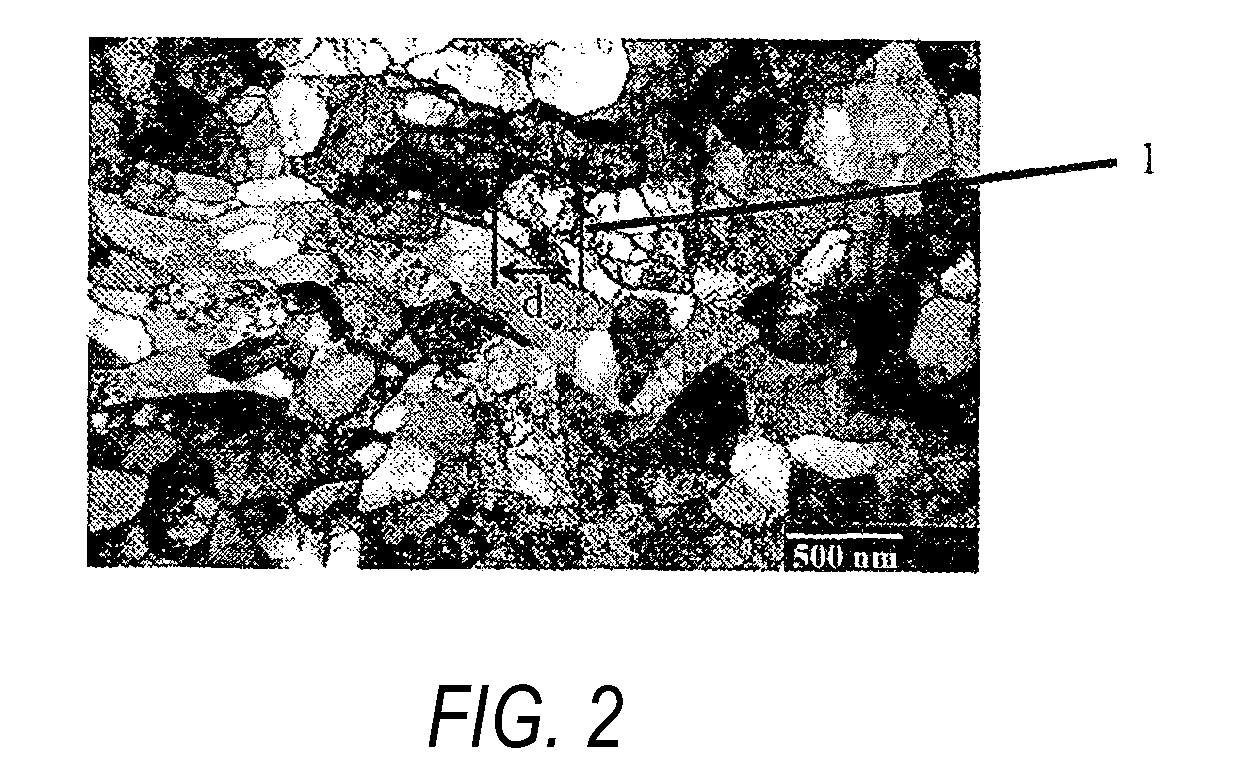

Nanostructured commercially pure titanium for biomedicine and a method for producing a rod therefrom

ActiveUS20110179848A1Improve failureImprove propertiesNanostructure manufactureMetal-working apparatusEqual channel angular extrusionCommercially pure titanium

Commercially pure titanium having UFG structure and enhanced mechanical and biomedical characteristics has nanocrystalline alpha-phase grains with a hexagonal close-packed lattice, in which the share of grains with a size of 0.1 . . . 0.5 μm and a grain shape coefficient of no more than 2 in the mutually perpendicular planes makes no less than 90%, over 60% of the grains having high-angle boundaries disoriented in relation to the adjacent grains by the angles from 15 to 90°.The method for making a rod of the material provides for equal-channel angular pressing of a billet at T≦450° C. with the total accumulated true strain e≧4 to effect severe plastic deformation of the billet and subsequent thermomechanical treatment with a gradual decrease of the temperature in the range of 450 . . . 350° C. and the strain rate of 10−2 . . . 10−4 s−1 with the strain degree from 40 to 80% to effect additional plastic deformation.

Owner:FSBFEI HPE USATU 50 +1

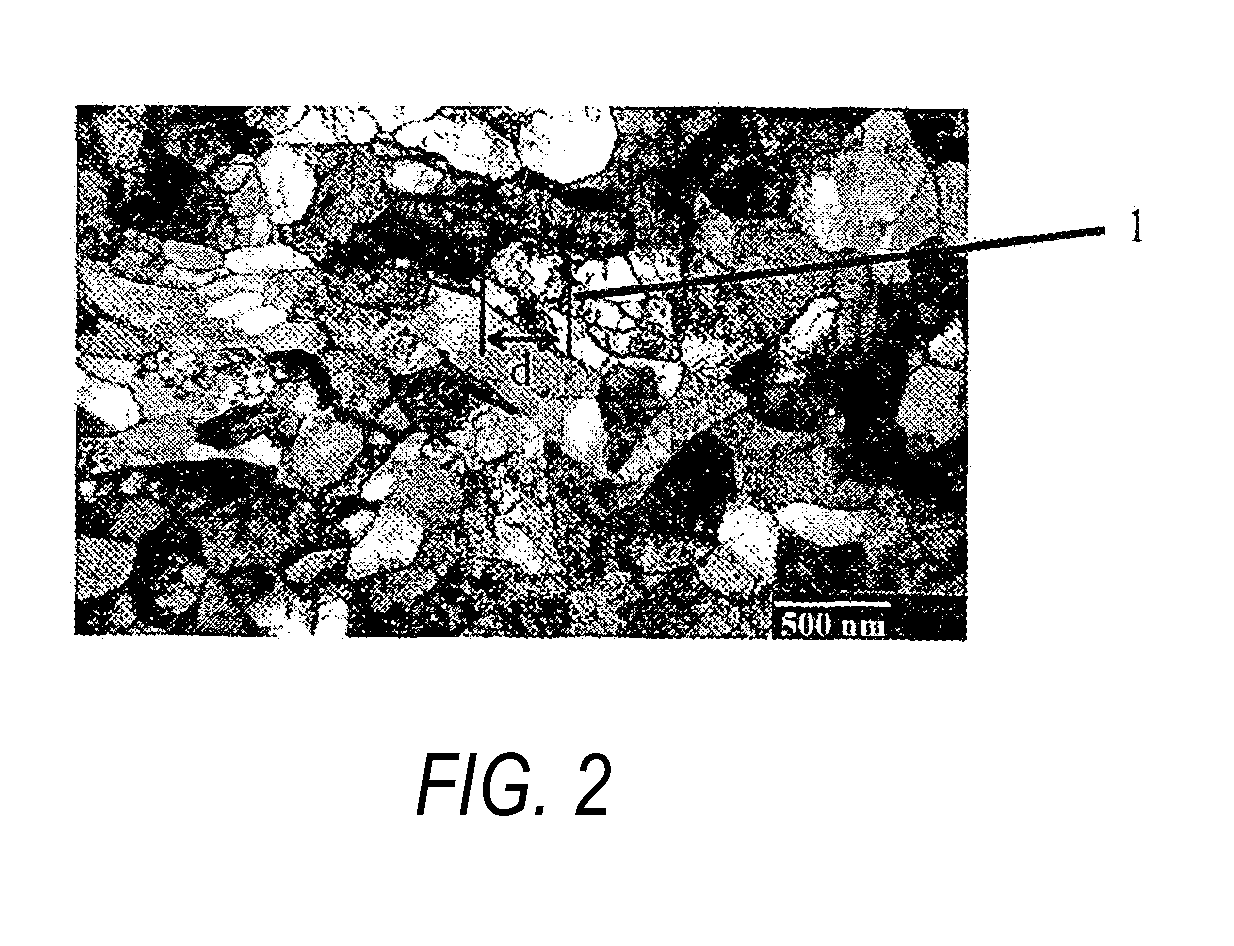

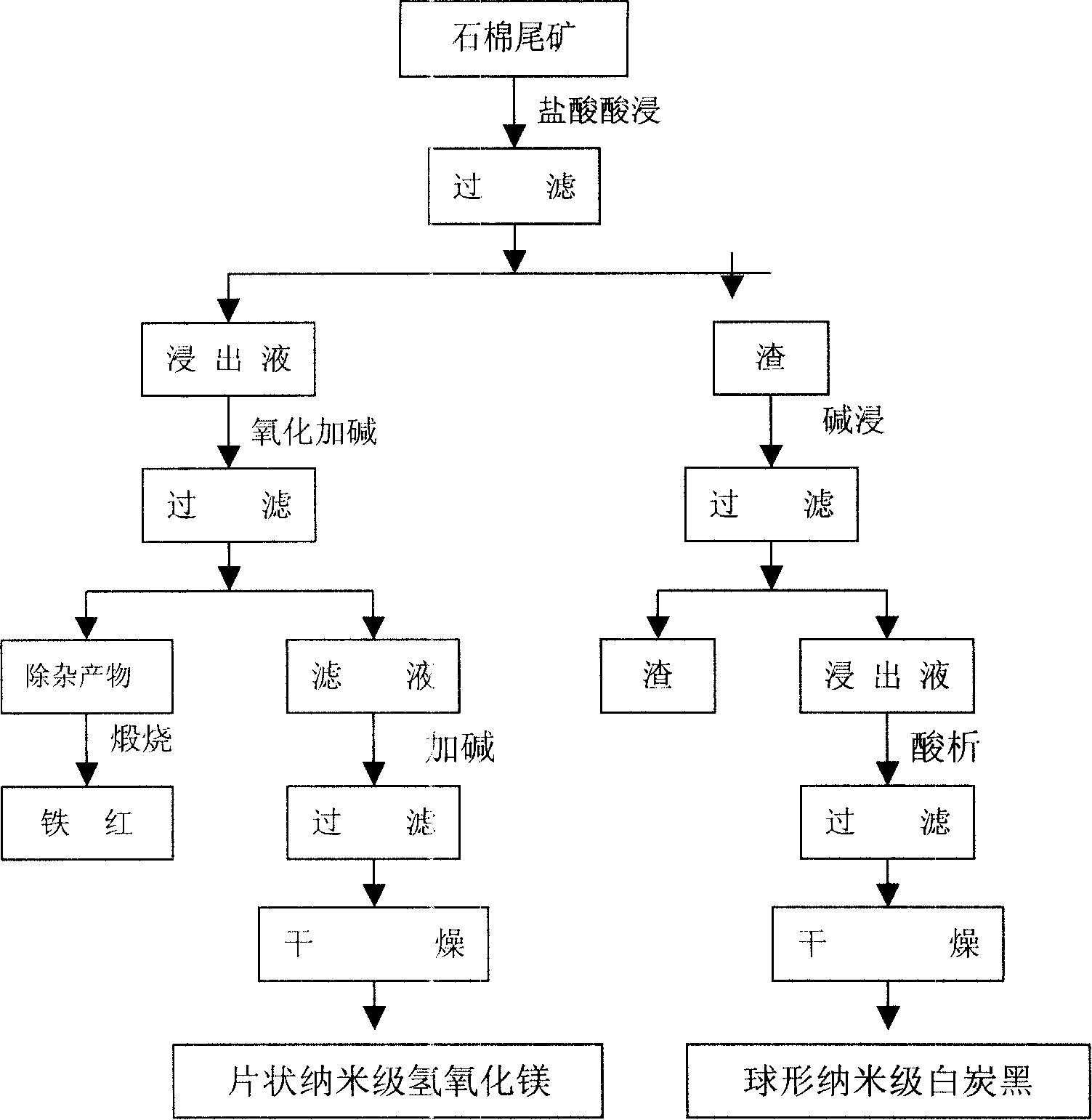

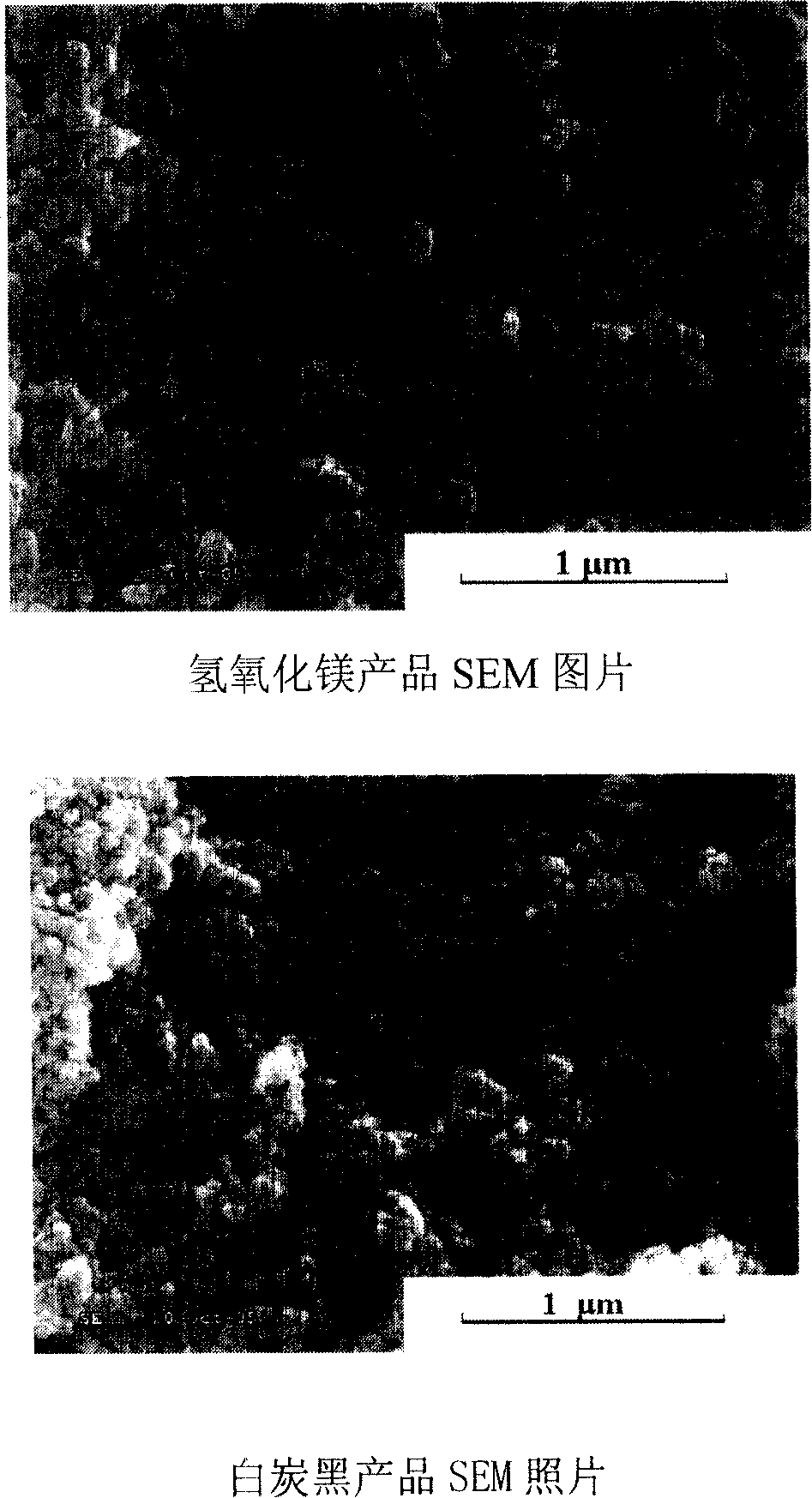

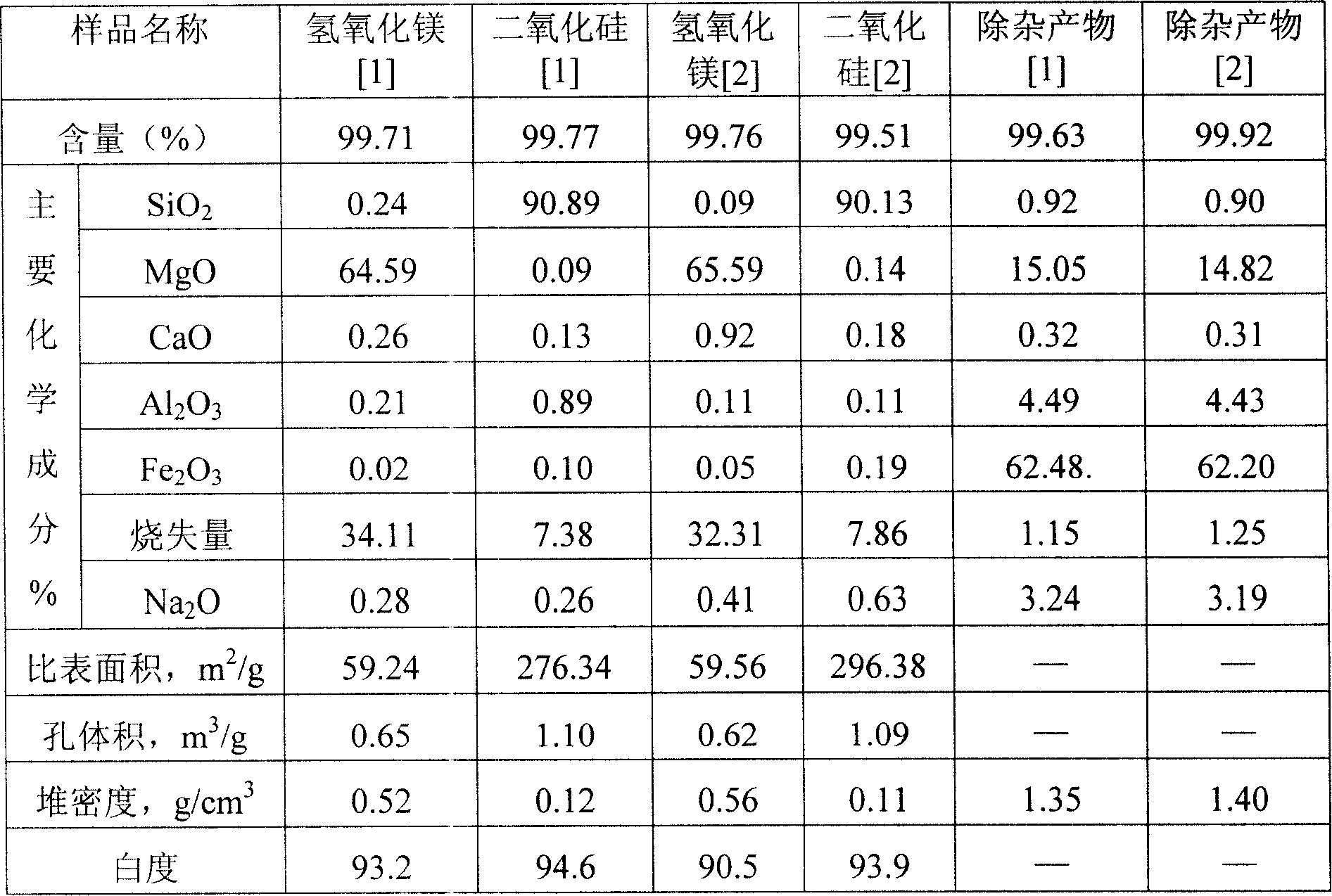

A method for preparing schistose nanometer magnesium hydroxide and sphericity nanometer white carbon black using zillerite gangue

InactiveCN101161591ASmall specific surface areaHigh puritySilicaMagnesium hydroxideSootSodium sulfate

The invention relates to a method of synthesis use of asbestos gangue, belonging to the mineral processing and environment protection field. The asbestos gangue powder and hydrochloric acid solution are conducted soaking reaction and separate solid and liquid component. The filtrate is added with oxidizer to oxidize Fe<2+> and added with alkali solution precipitate iron, aluminum and calcium filtrate components in the filter solution. Deposit is removed by filter and alkali is added for reaction. Right amount of particle separating dose is added at the same time. Magnesium hydroxide of nanometer grade and sheet shape grain shape is obtained. Reacted residue of asbestos gangue powder and hydrochloric acid and sodium hydroxide or sodium carbonate react in heating situation. The reacted product is filtered and the filter solution is added with little sodium sulfate and water to adjust thickness. Surface modifier or particle separating dose is added and acid is used to settle out. The settled out product is aged, filtered, washed and dried to get the round-shape nanometer grade white carbon soot. The impurity of the filter is removed by acid to get precipitation. The precipitation passes through drying and calcinations to get iron oxide, alumina and calcium oxide mixture (product of removing impurity).

Owner:CHINA UNIV OF MINING & TECH (BEIJING)

Pulse laser surface melting method for achieving grain shape regulation of titanium alloy surface

ActiveCN108754373AImprove mechanical propertiesAdditive manufacturing apparatusIncreasing energy efficiencyMelting tankTitanium alloy

The invention discloses a pulse laser surface melting method for achieving grain shape regulation of a titanium alloy surface. The method includes first preliminarily optimizing a laser surface melting process window and recording the fixed-point temperature change of the molten pool surface during the laser melting process under the optimized process window to obtain a fixed-point thermal cycle curve and the average cooling rate Xi at the molten pool center; When Xi<=2*10<3>DEG C / s and Xi / V2>=5*10<8>DEG Cs / m<2>, providing continuous laser for columnar crystal with the laser power of 400-900Wand the scanning speed of 6-10mm / s; when 2*10<3><= Xi <=10<5>DEG C / s and Xi / V2<=10<6>DEG Cs / m<2>, providing pulse laser with square waveform for isometric crystal with the laser power of 600-1000W andthe scanning speed of 4-8mm / s; finally obtaining the titanium alloy surface with the beta crystal form regulated. By means of the method, regulation of the beta crystal shape on the titanium alloy surface is achieved, and the mechanical property of a formed part can be effectively improved.

Owner:HUNAN UNIV

Preparation method of ultra-pure aluminum ultrafine grain sputtering target

InactiveCN101638760AIncrease the amount of deformationVacuum evaporation coatingSputtering coatingSputteringMaterials processing

The invention discloses a preparation method of ultra-pure aluminum ultrafine grain sputtering target, belonging to the technical field of metal material processing. The preparation method comprises:putting an ultra-pure aluminum board into an equal channel angular extruding module for extrusion for 3-15 passes; performing deep undercooled processing to extruded ultra-pure aluminum board in liquid nitrogen at the deep undercooled temperature of minus 80 to minus 10 DEG C; rolling the deep undercooled ultra-pure aluminum board for 3-15 passes. The invention combines equal channel pressing, deep undercooled processing and rolling to fully utilize the characteristic of large extruded deformation amount so as to greatly improve the deformation amount of the ultra-pure aluminum board. The invention utilizes dynamic recrystallization in the deep undercooled inhabitation rolling process and utilizes vertical rolling to change fibroid grain tissue produced by extrusion, and finally, grain shape changes to be even and small as well as easy to be equiaxial.

Owner:SHANGHAI JIAO TONG UNIV

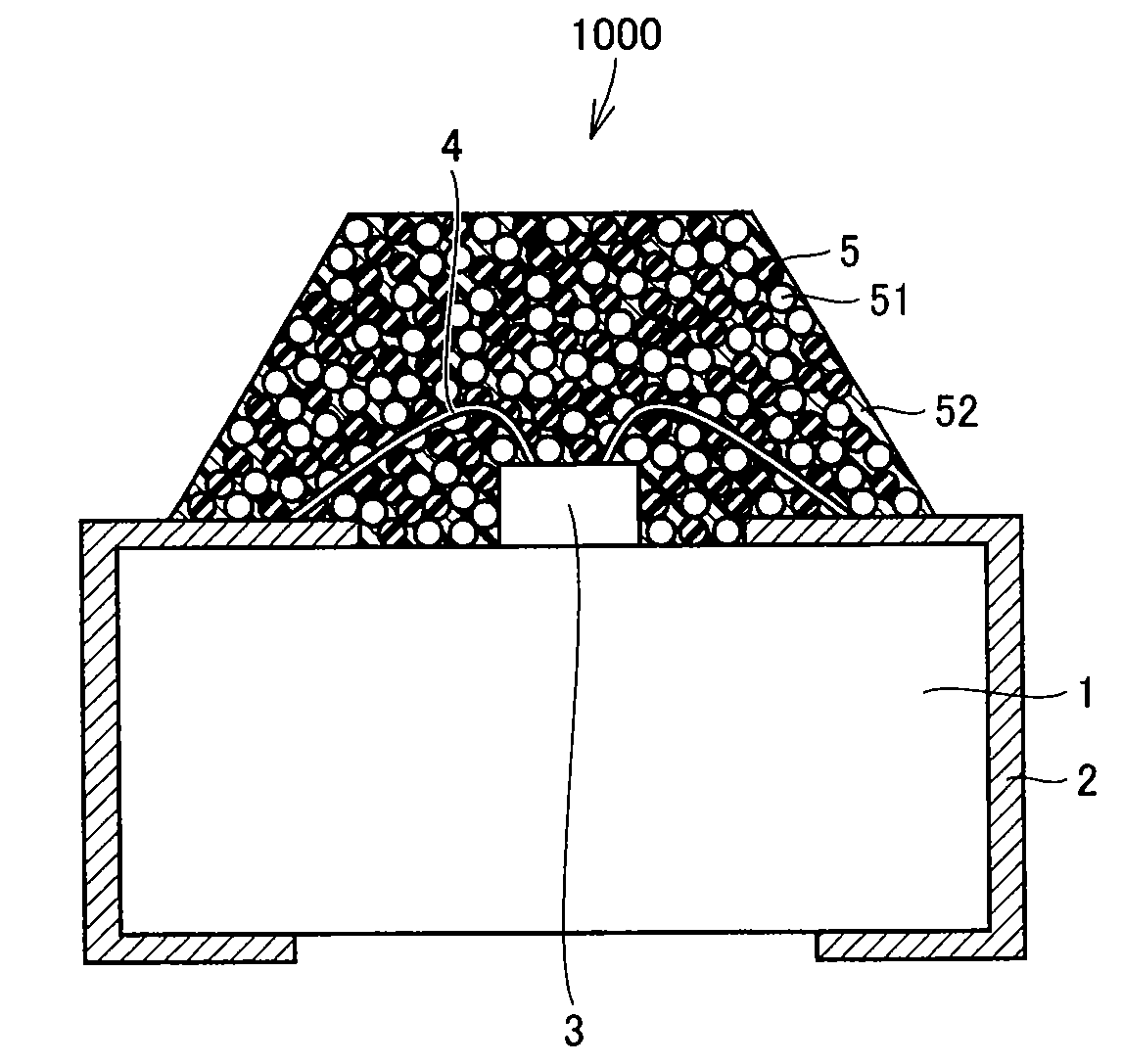

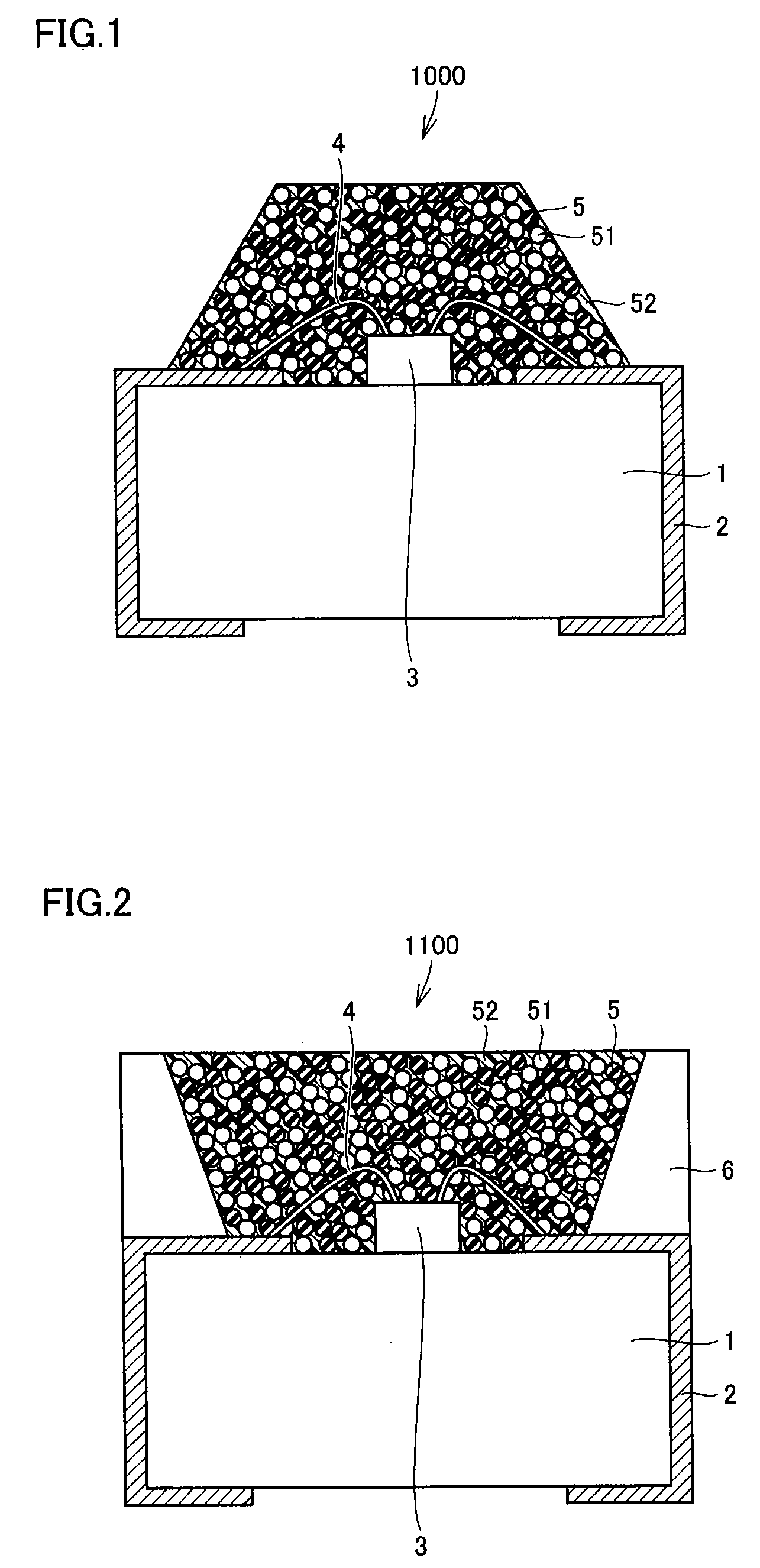

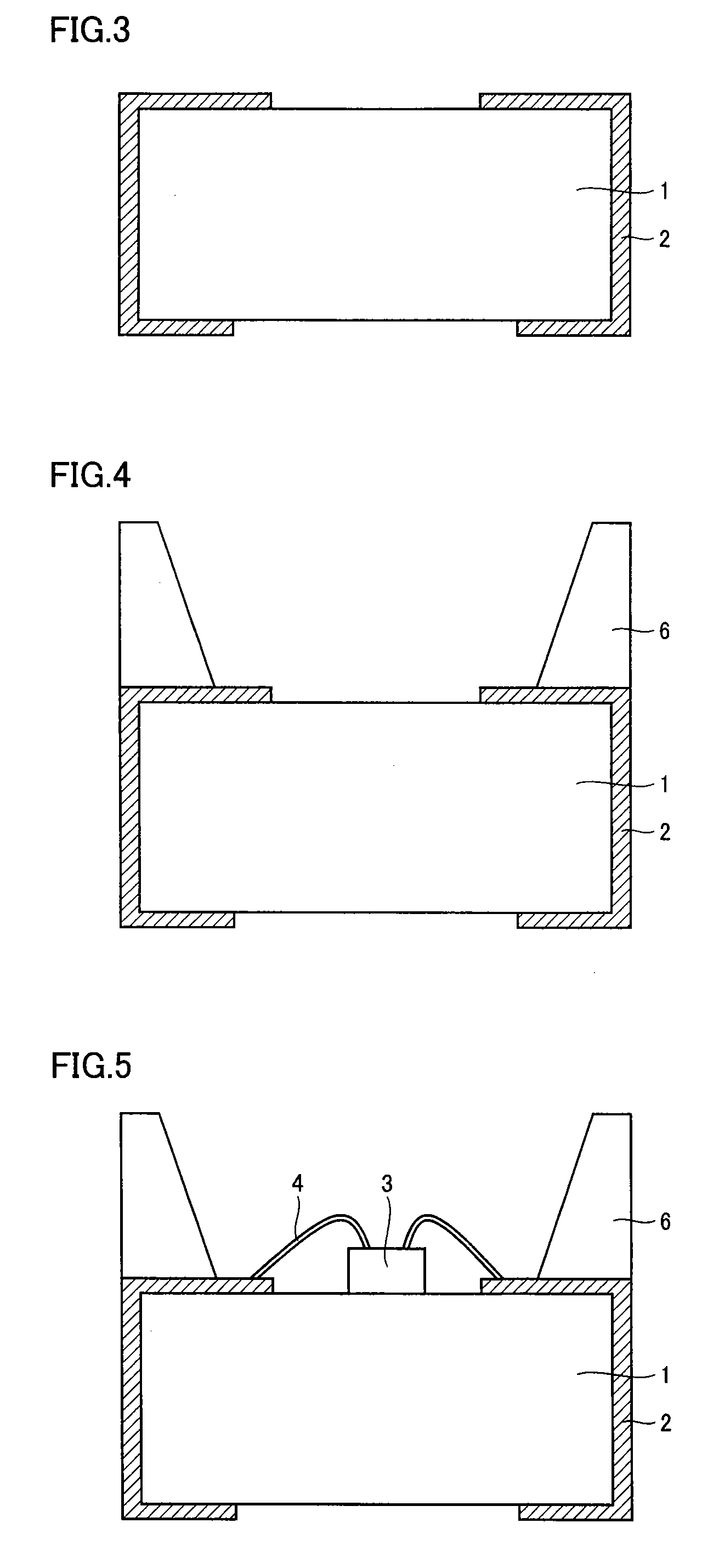

Light emitting device and method for manufacturing the same

InactiveUS20080299398A1Luminous overallGood colorDischarge tube luminescnet screensSynthetic resin layered productsPhosphorLength wave

In a light emitting device having a light emitting element, mounted on a substrate, at least one portion of which is coated with a mold component, the mold component is provided with resin particles and or inorganic material particles, phosphor particles and a sealing resin, and phosphor particles have a specific gravity different from that of resin particles and / or the inorganic material particles, and are made from a grain-shaped phosphor which, when irradiating with excited light, emits fluorescent light having a wavelength longer than that of the excited light, with resin particles and / or the inorganic material particles and the phosphor particles being dispersed in sealing resin; thus, the present invention relates to such a light emitting device and a method for manufacturing the same.

Owner:SHARP KK

Nanostructured commercially pure titanium for biomedicine and a method for producing a rod therefrom

ActiveUS8919168B2Improve failureImprove propertiesNanostructure manufacturePig casting plantsEqual channel angular extrusionCommercially pure titanium

Commercially pure titanium having UFG structure and enhanced mechanical and biomedical characteristics has nanocrystalline alpha-phase grains with a hexagonal close-packed lattice, in which the share of grains with a size of 0.1 . . . 0.5 μm and a grain shape coefficient of no more than 2 in the mutually perpendicular planes makes no less than 90%, over 60% of the grains having high-angle boundaries disoriented in relation to the adjacent grains by the angles from 15 to 90°.The method for making a rod of the material provides for equal-channel angular pressing of a billet at T≦450° C. with the total accumulated true strain e≧4 to effect severe plastic deformation of the billet and subsequent thermomechanical treatment with a gradual decrease of the temperature in the range of 450 . . . 350° C. and the strain rate of 10−2 . . . 10−4 s−1 with the strain degree from 40 to 80% to effect additional plastic deformation.

Owner:FSBFEI HPE USATU 50 +1

A kind of production method of silicon wafer cutting blade material

The invention relates to a production method of a silicon wafer cutting blade material. The production method of the silicon wafer cutting blade material uses high-purity green silicon carbide as the raw material and comprises the following steps: performing jaw crushing, screening, performing automatic circulation type wet ball milling and hydraulic cyclone classification, performing automatic overflow carbon removal, performing magnetic separation to automatically remove iron, performing alkali washing, cleaning, performing overflow classification under automatic control of a programmable logic controller (PLC), centrifuging to dewater, drying, mixing, performing fine screening and the like. The silicon carbide blade material prepared by the method has equiareal shape, sharp edges and high cutting capability; the blade material particles have large specific surface area and clean appearance and high suitability to cutting fluid such as polyethylene glycol; the product ground by automatic circulation type wet ball milling and cyclone classification has more equiareal shapes, good grain shape and high yield, and overgrinding can be avoided; and automatic magnetic separation is adopted to perform acid-free iron removal, thus the method has high efficiency, environmental friendliness and high degree of automation and is suitable for large-scale production. The product ground by the method has high particle size concentration degree and good grain shape, and better cutting effect can be realized.

Owner:JIANGSU TAYAL PHOTOVOLTAIC AUXILIARY MATERIAL

Special charcoal-base slow release fertilizer for peanut and preparation method thereof

InactiveCN101121619AHigh porosityPoor adsorption capacityAgriculture gas emission reductionAmmonium salt fertilisersPotassiumBorax

The present invention relates to a special fertilizer for a charry releasing earthpea, which is characterized in that: the fertilizer comprises earthpea core grain carbon grain, ammonium sulphate, ammonium phosphate, zinc sulfate, kalium sulphate, potassium chlordide and borax. The present invention also relates to the produce method for the special fertilizer for a charry releasing earthpea. The method is to use the character of the earthpea core grain carbon grain with multi-micro hole and strong absorbing ability combined with nitrogen, phosphor, kalium and the other nutrition components required by the growth of the earthpea, and then uses a moist soil or clay as the cement compound to prepare the grain-shaped special fertilizer for a charry releasing earthpea. The preparation process for the fertilizer is simple, economical and environment-protective with one-off use; the fertilizer can satisfy the requirement of the nutrient for the whole growth period for the earthpea effectively; the utilization ratio of the fertilizer is higher with saving the energy and the cost; the fertilizer is adaptable to be widely popularized in the large-scale production for the earthpea.

Owner:辽宁金和福农业科技股份有限公司

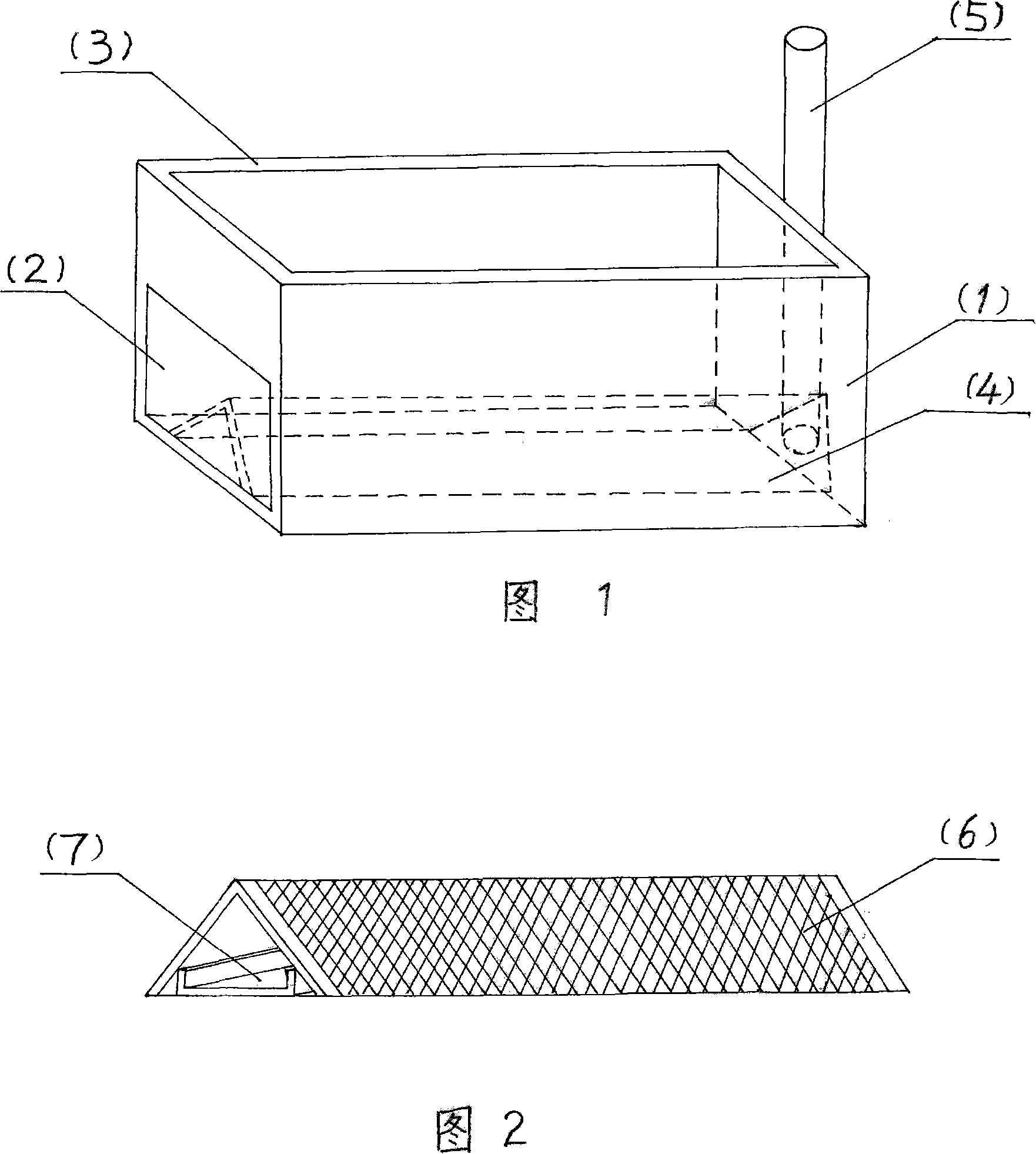

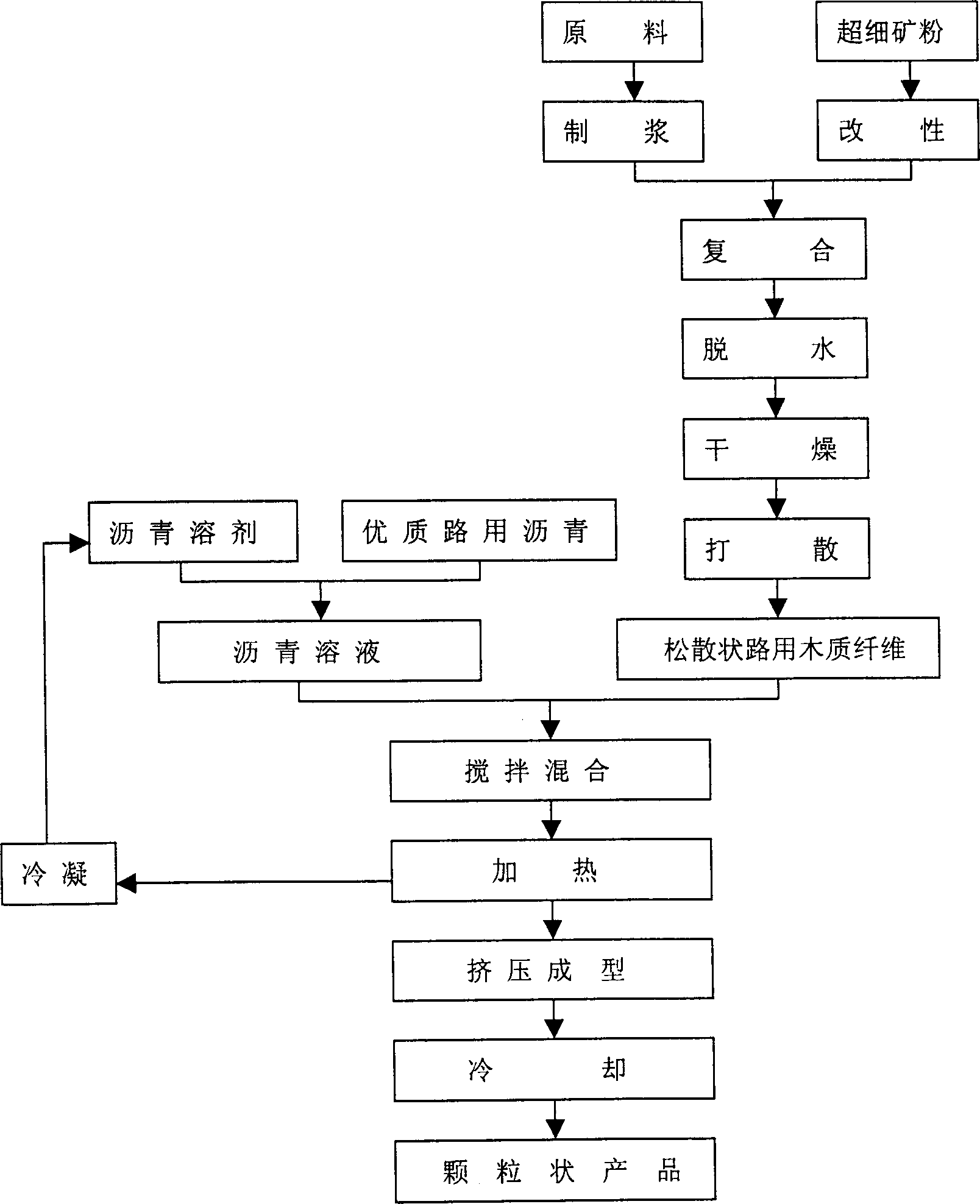

Method for preparing lignocellulose for road

InactiveCN1405372AHigh oil absorption valueLarge specific surface areaTextile disintegration and recoveryFibre disintegrationFiberRoad surface

Owner:NORTHEASTERN UNIV

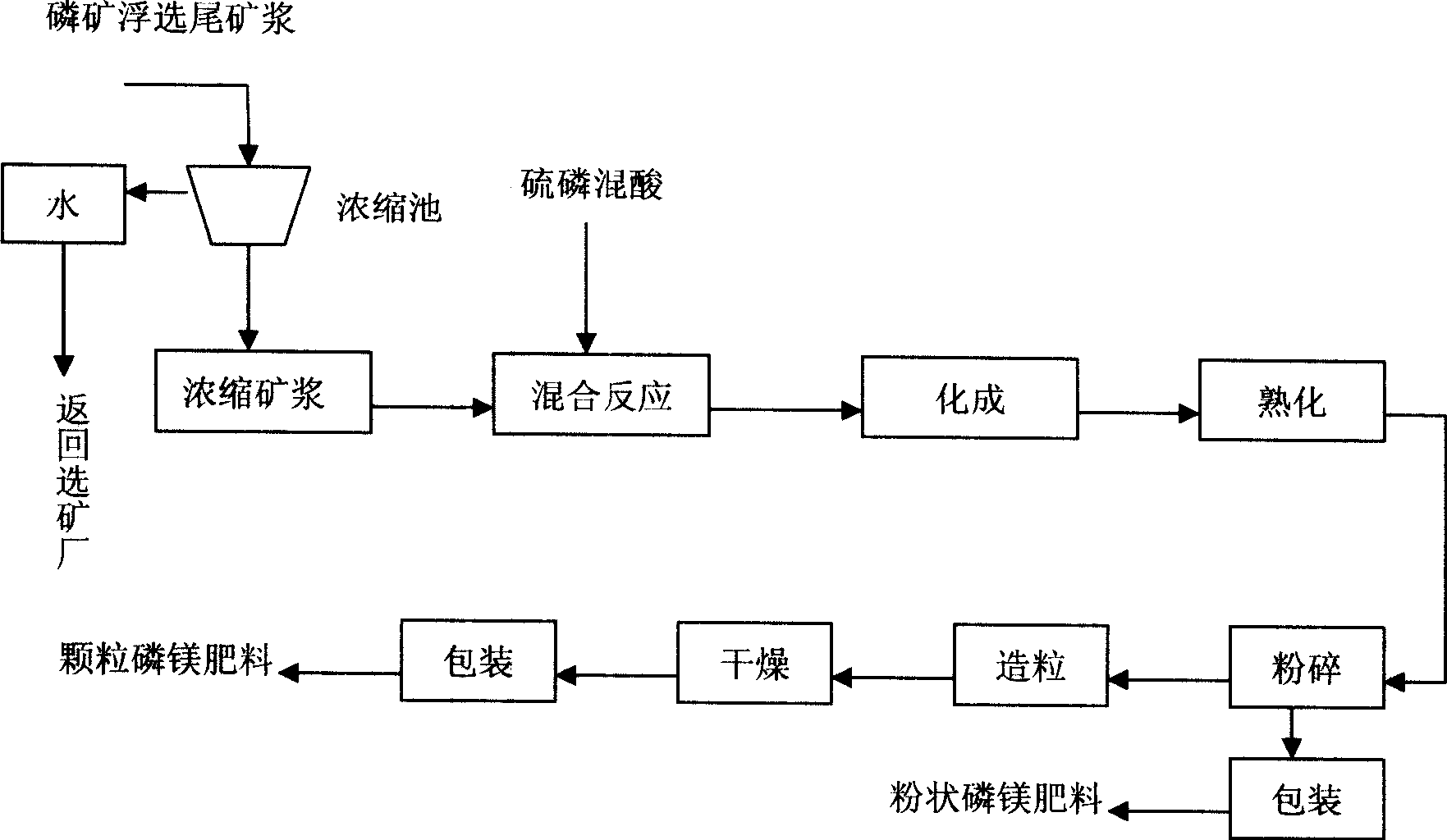

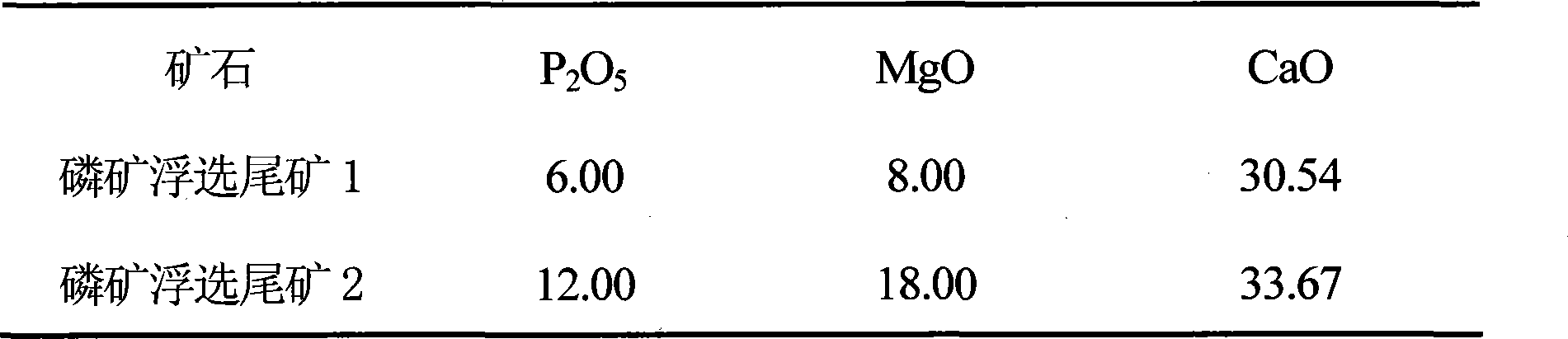

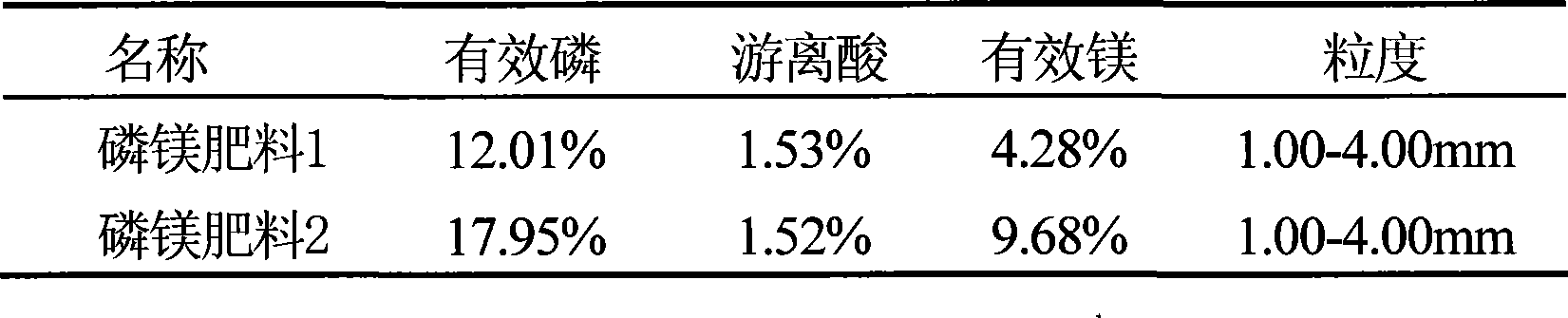

Method for directly preparing phosphor magnesium fertilizer with by-product mine tailing of phosphorus ore floatation

The invention relates to a preparation method of magnesium phosphate fertilizer, in particular to a method which takes phosphate flotation byproduct tailings in medium low-grade as raw materials to prepare industrial-grade magnesium phosphate fertilizer, and belongs to the field of chemical technology. The preparation method is characterized in that the preparation method comprises the following steps: first: taking flotation phosphate tailing slurry as the raw material, controlling the liquid water content to be between 40 percent and 45 percent; second: leading the tailing slurry in step (1) to a mixed reactor, starting a mixer, and controlling the rotate speed to be 400 r / min to 500 r / min; third: adding parathion mixed acid with a certain molar ratio into the reaction in the mixed reactor in step (2), carrying out chemical reaction when the mixed reactor warms up to a certain temperature, reaches a certain mixed reaction time and goes into a chemical chamber; fourth: delivering fresh magnesium phosphate fertilizer obtained from step (3) into a ripening warehouse for ripening; fifth: smashing the magnesium phosphate fertilizer obtained from step (4) to be directly packed to obtain power-shaped magnesium phosphate fertilizer products; sixth: smashing and delivering the magnesium phosphate fertilizer obtained from step (4) to a back pelletizer for pelleting to make grain-shaped magnesium phosphate fertilizer products.

Owner:YUNNAN CHEM RES INST

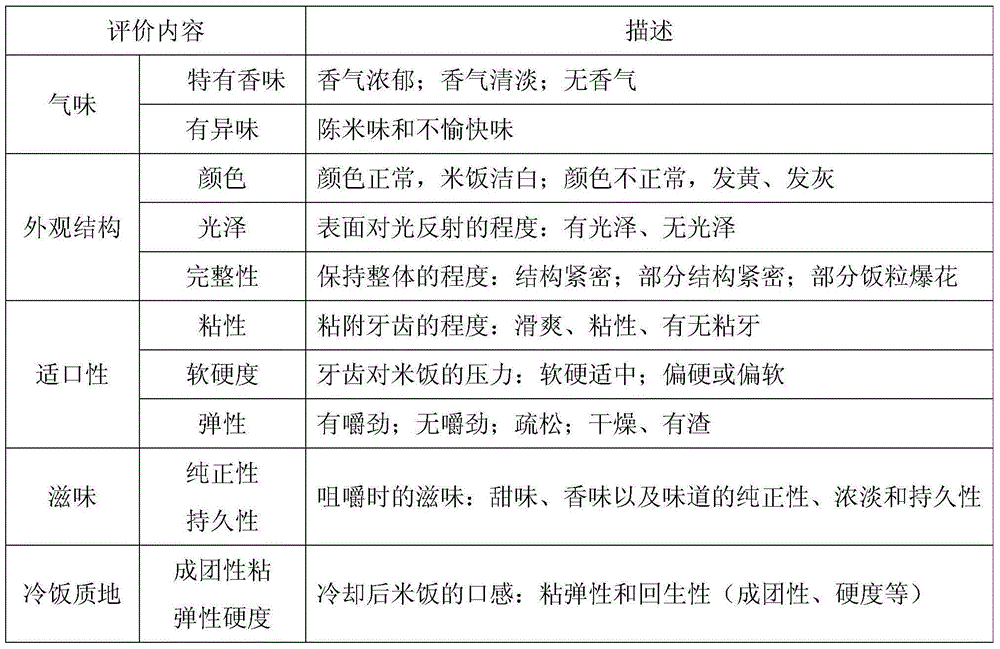

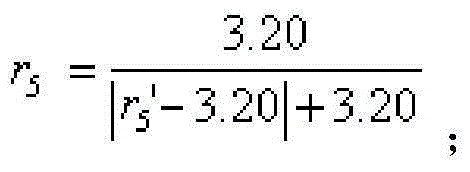

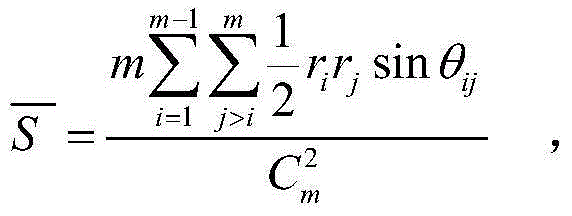

Method for determiningtaste quality of rice by using physical and chemical property indexes of rice quality

ActiveCN105067784AMake up for the shortcomings of the cumbersome sensory evaluation process for eating qualityFast processTesting starch susbtancesMaterial analysis by optical meansEvaluation resultFeature vector

The invention discloses a method for determining taste quality of rice by using physical and chemical property indexes of rice quality. The method comprises the following steps: respectively obtaining measured values of five physical and chemical indexes of rice to be determined: amylose, gel consistence, alkali spreading value, protein and grain shape; carrying out conversionof characteristic vectors forthe measured values of thefive physical and chemical indexes of rice; obtaining angles ofthefive physical and chemical indexes of rice; carrying out characteristic vector analyses of each index by means of radar map; carrying out a comprehensive evaluation analysis by means of radar map; carrying out a conversion of thecomprehensive evaluation result, and obtaining a rice taste value. The method provided by the invention can be used for rapidly determining taste quality of rice.

Owner:CHINA NAT RICE RES INST

Hydrogenation catalyst and preparation method thereof

ActiveCN102350351AShorten the production cycleIncrease productivityMetal/metal-oxides/metal-hydroxide catalystsHalogenated silanesSilicon alloyRare earth

The invention discloses a hydrogenation catalyst and a preparation method thereof. The catalyst is applied to a hydrogenation reaction for transforming trichlorosilane by using silicon tetrachloride. The catalyst takes copper-silicon alloy, copper-nickel-silicon alloy, copper-silicon-rare-earth alloy or copper-nickel-silicon-rare-earth alloy as an active ingredient and is powdered or grain-shaped. The preparation method of the catalyst comprises the main process steps of: smelting, atomizing, reducing and drying, and sieving to obtain a finished catalyst. The catalyst has the advantages of high transformation rate, good heat-resistant stability, high product purity and the like; and compared with a chemical method, no waste gas and waste acid are discharged in the production process, the production cycle is short and the production efficiency is high.

Owner:LUOHE HUATONG METALLURGICAL POWDER

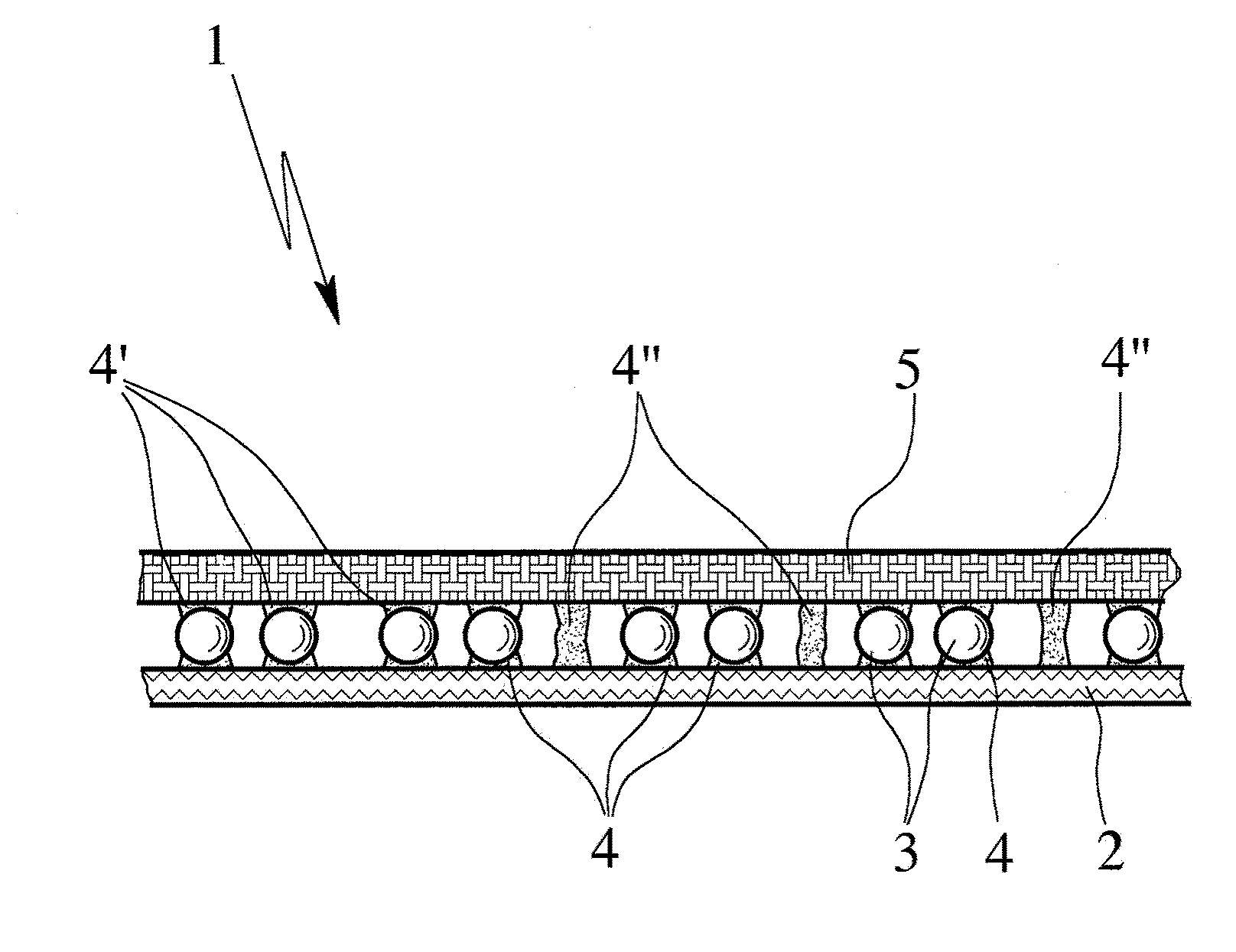

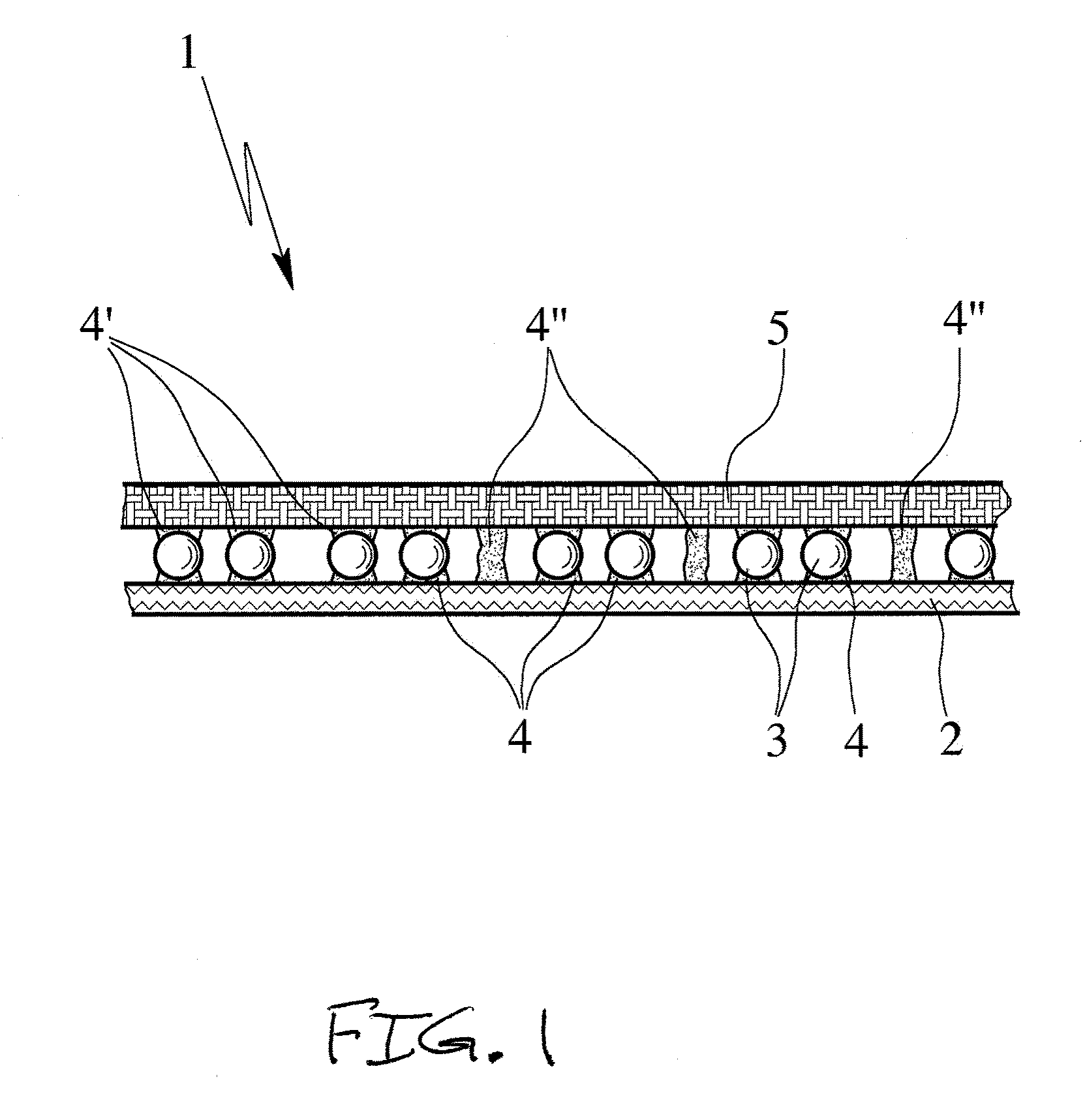

Adsorption filter material, particularly for producing abc protective clothing having improved wearing physiology

ActiveUS20100212071A1Improve protectionIncrease elasticityChemical protectionHeat protectionActivated carbonHazardous substance

Described is an adsorption filter material, in particular for NBC protective apparel, preferably for wearing next to the skin, in particular as an undergarment (underwear), wherein the adsorption filter material has a multilayered construction, wherein the multilayered construction comprises a first textile sheet material, a second textile sheet material and an adsorption layer disposed between the first and the second textile sheet materials, wherein the adsorption layer includes discrete, in particular grain-shaped, preferably sphere-shaped, sorbent particles, preferably based on activated carbon, adsorbing chemical and / or biological poison and noxiant materials, in particular warfare agents. The adsorption filter material is characterized in that the first textile sheet material and the second textile sheet material are each adapted to be elastic in at least one direction, preferably in both directions, and / or in that the first textile sheet material and the second textile sheet material have at least essentially the same elasticity properties. The adsorption material combines a high wearing comfort with excellent protection with regard to chemical poisons.

Owner:BLUCHER GMBH

High-content organic/inorganic compound fertilizer

InactiveCN101172900AMeet growth needsIncrease contentAnimal corpse fertilisersClimate change adaptationSesamum orientaleAlkali soil

The invention belongs to agricultural fertilizer, in particular to high content organic and non-organic composite fertilizer, which comprises the substances as follow counted in weight: 30 parts of furfural dregs, 10 parts of sheep droppings, 4 parts of plant ashes, 3 parts of bean cakes, 3 parts of sesame cakes, 5 parts of excrementum bombycises, 15 parts of sylvites, 10 parts of ammonium nitrates, 20 parts of powdered rock phosphates. The fertilizer has high nutrient content, with total nutrient of 50 percent. The fertilizer can be used as basic fertilizer or used for fertilizing. The fertilizer can satisfy the growth demand of various crops, and is particularly suitable to corns and beams planted in alkali soil northeast of china, without packaging with the soil and having protection function for the soil. The fertilizer takes a grain shape, thereby being used as the basic fertilizer together with seeds conveniently.

Owner:辽宁乌兰山生物技术有限公司

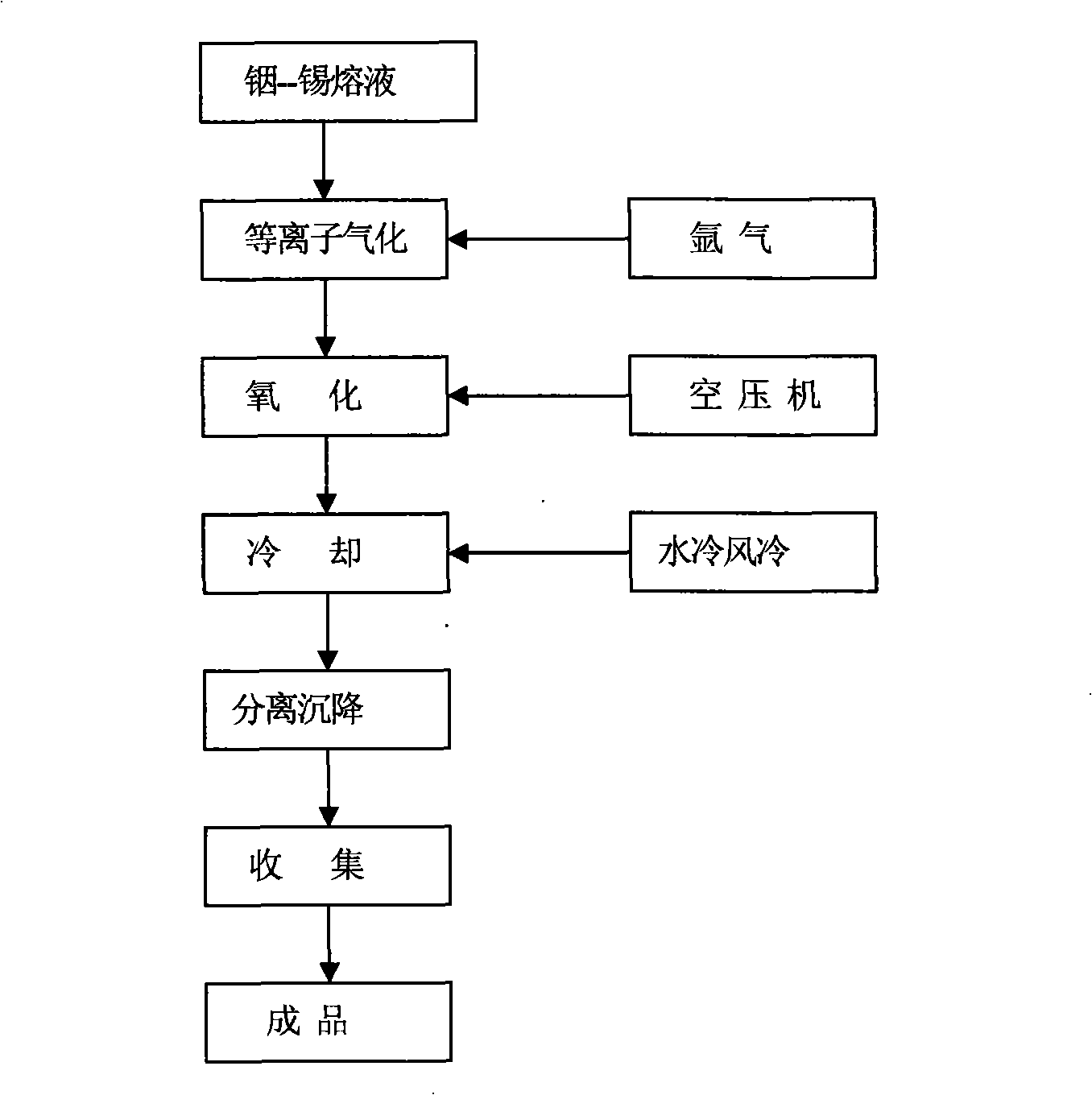

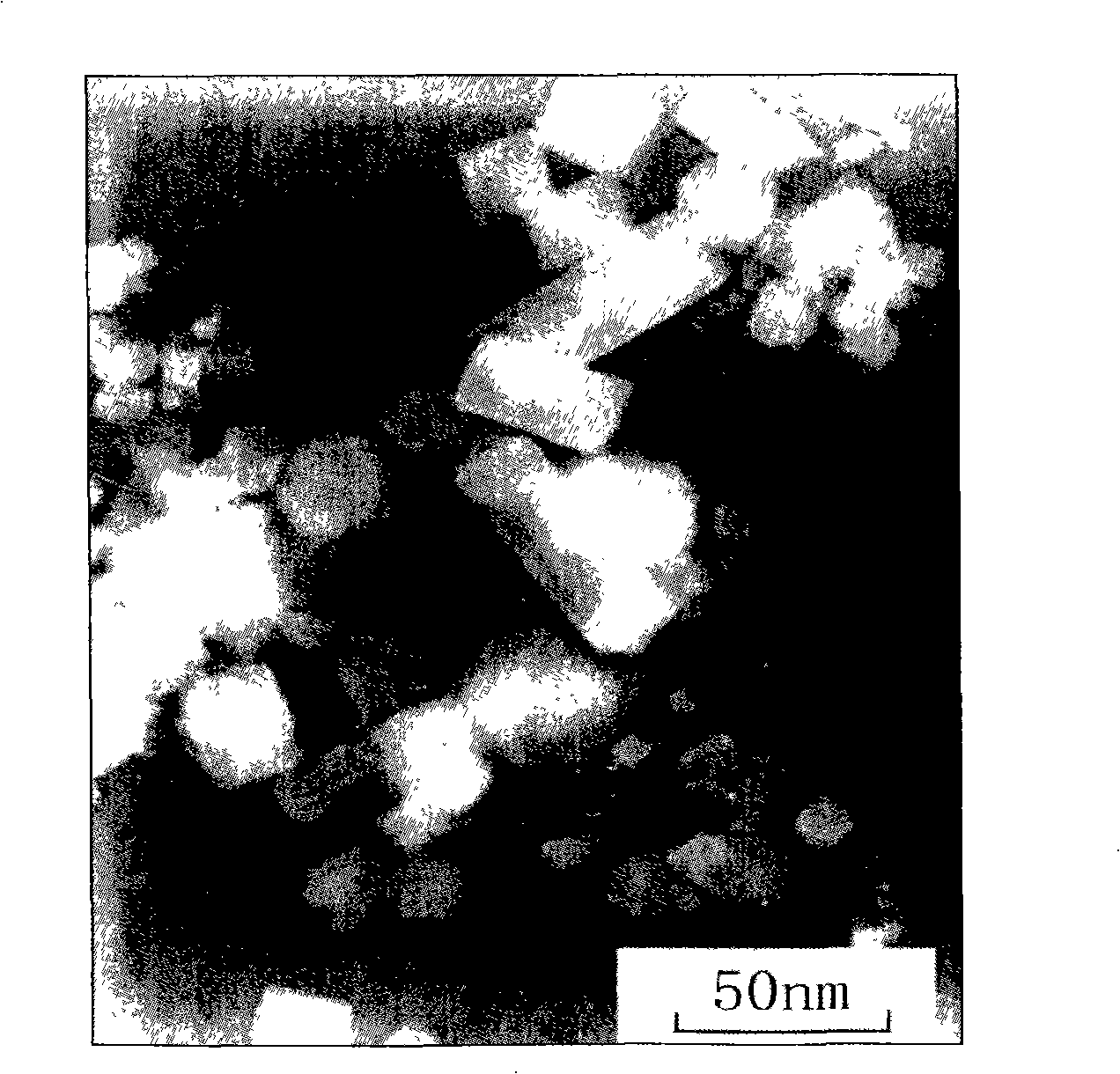

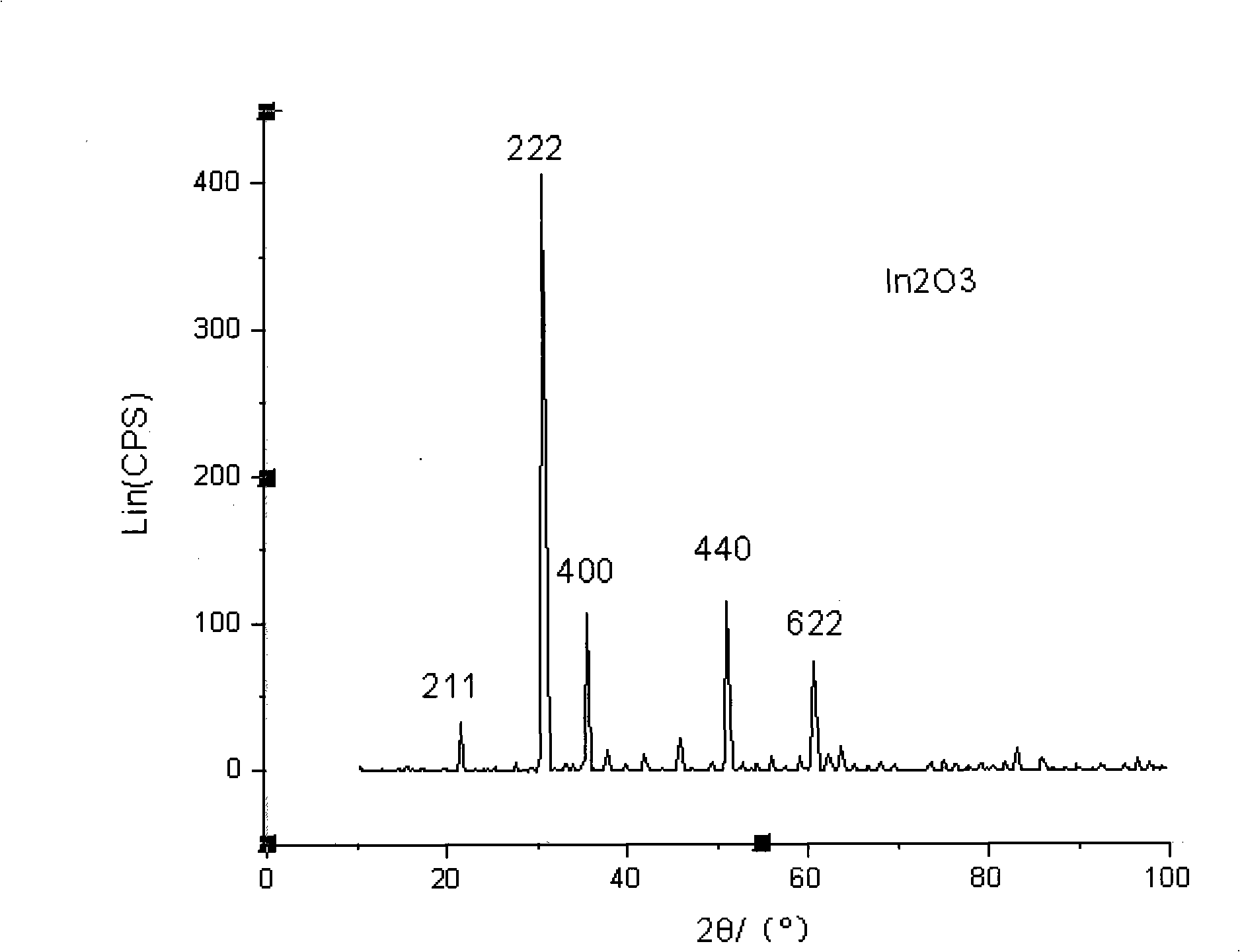

Method for producing nano-ITO powder with plasma electrical arc one-step method

InactiveCN101269834AGood dispersionGrowth inhibitionGallium/indium/thallium compoundsTin oxidesNano sizeGas phase

The invention relates to a method using a plasma arc one step method to prepare nano-size ITO powder. The method is characterized in that In-Sn alloy is continuously sent into a pot of a plasma reaction chamber by a feeding fixed point and fixed amount method, and the plasma reaction chamber uses Ar as a plasma gas, wherein, the working voltage ranges from 30 to 60 V, and the working current ranges from 100 to 400 A; alloyed material is used as a positive pole in the plasma reaction chamber, and a high igniter inflames between the positive pole and the negative pole of a nozzle to form an electric arc; inert gas around ionization forms stable plasma; raw materials are heated and melted by high temperature plasma to evaporate to form metal vapor which reacts with oxygen, and a great temperature grade is formed under the function of flowing water cooling of an inter layer of a reactor, thereby resulting in a high supersaturated zone in the metal vapor; through self nucleation, condensation and growth in a gas phase, nano-size to particle is formed. The nano-size ITO powder made by the method has the advantages of regular grain shape and high powder purity, and the method can realize continuous feeding, continuous reaction, and continuous milling. The efficiency is high, and compared with other methods, the method is easier to realize mass production.

Owner:KUNMING UNIV OF SCI & TECH

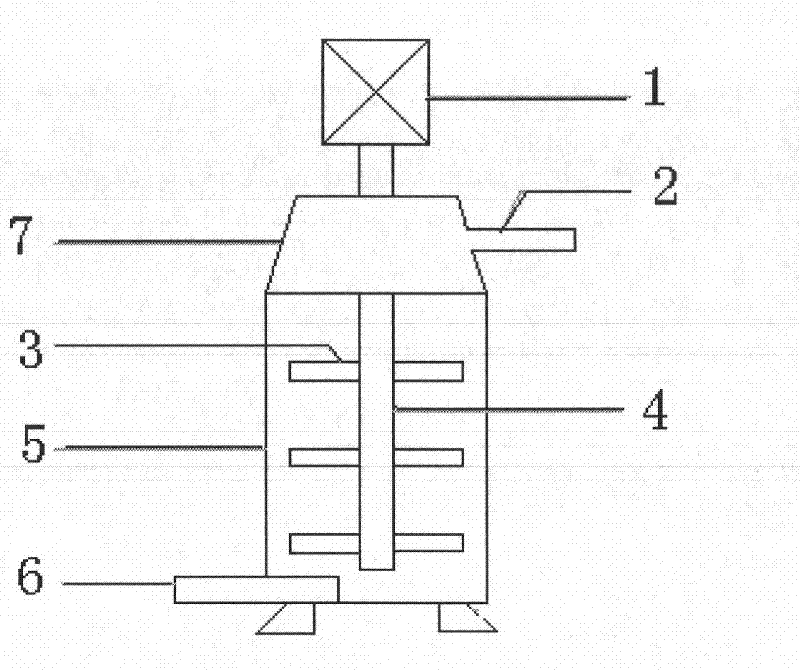

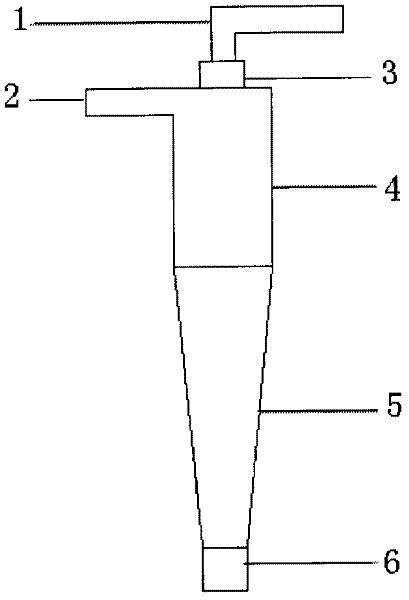

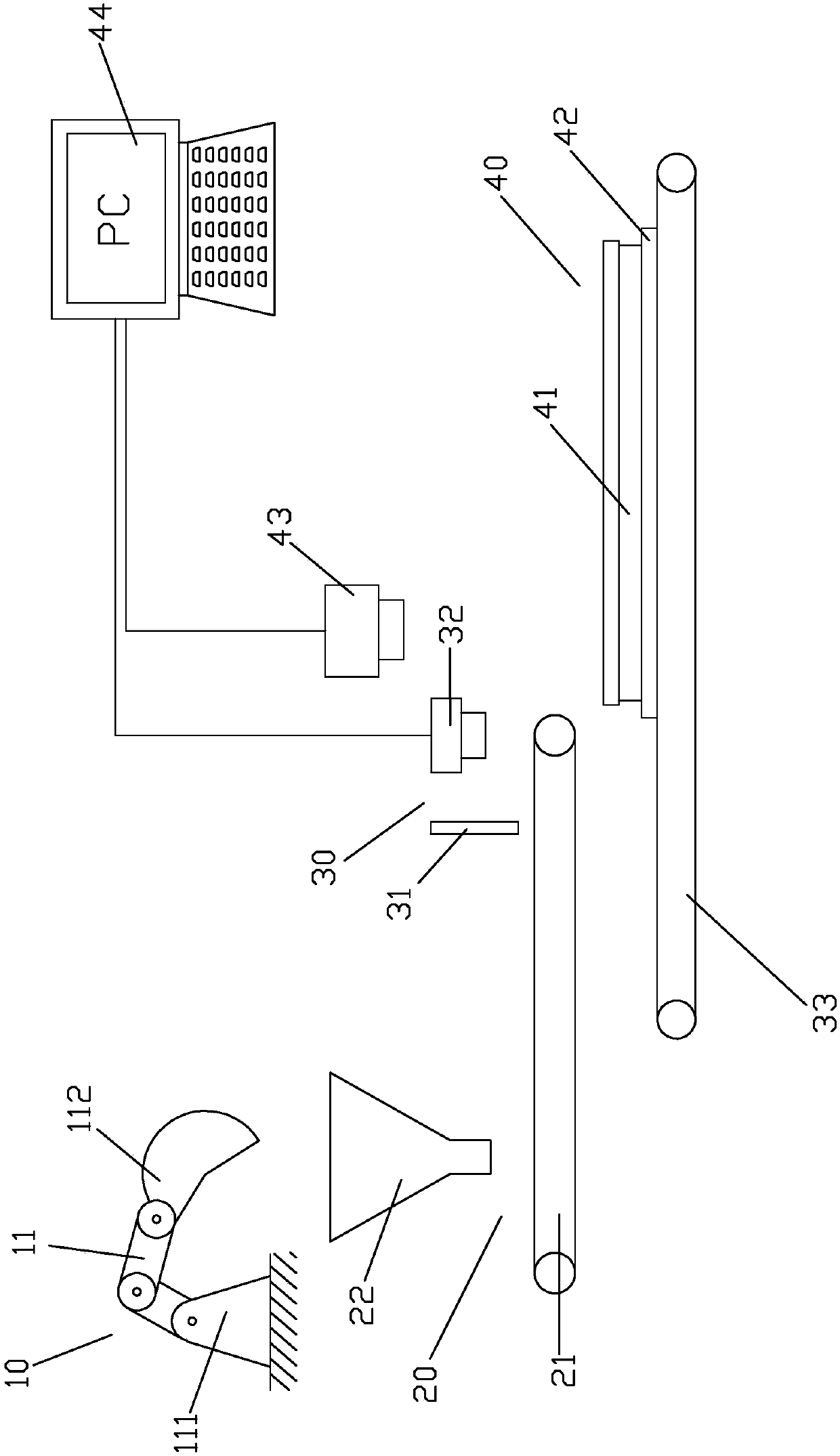

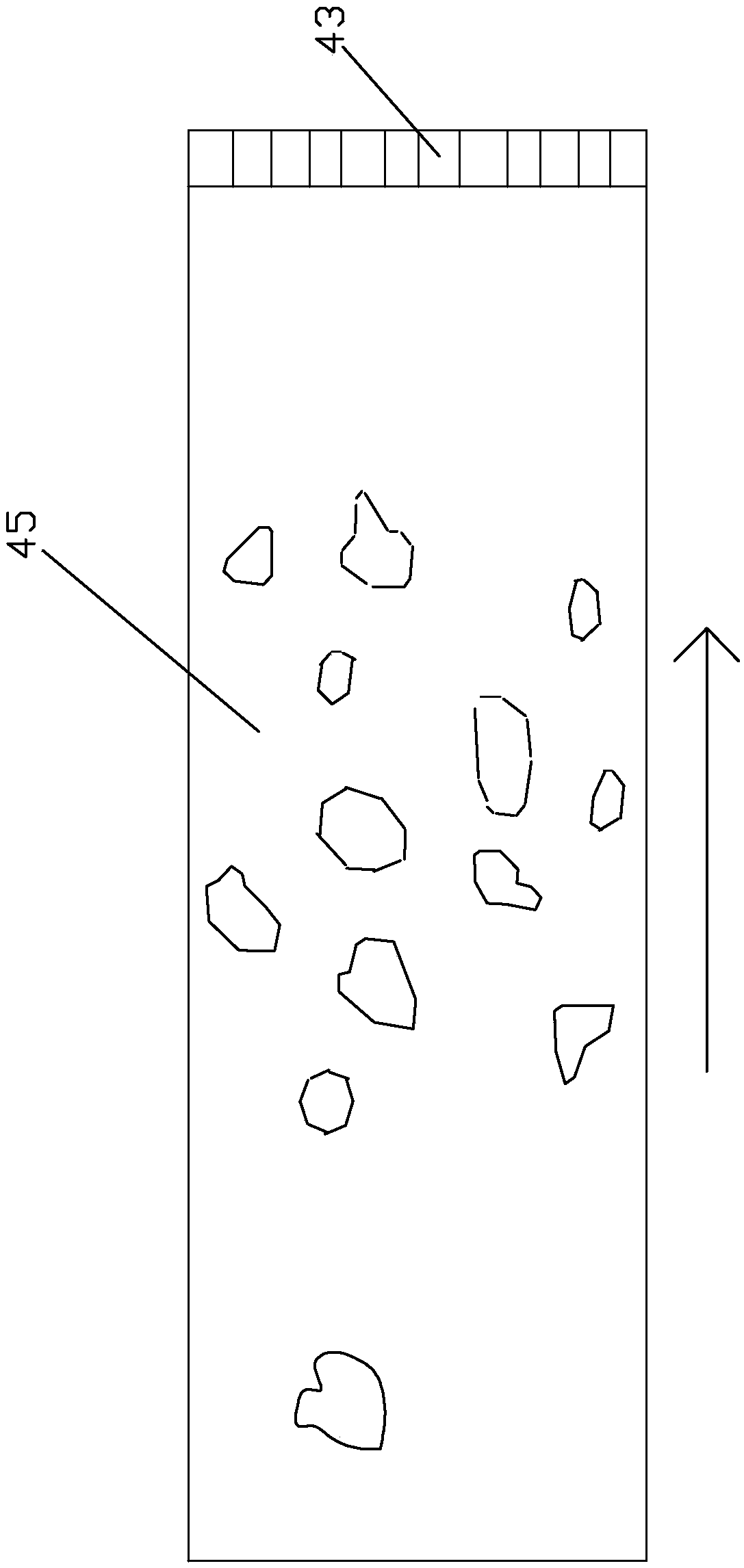

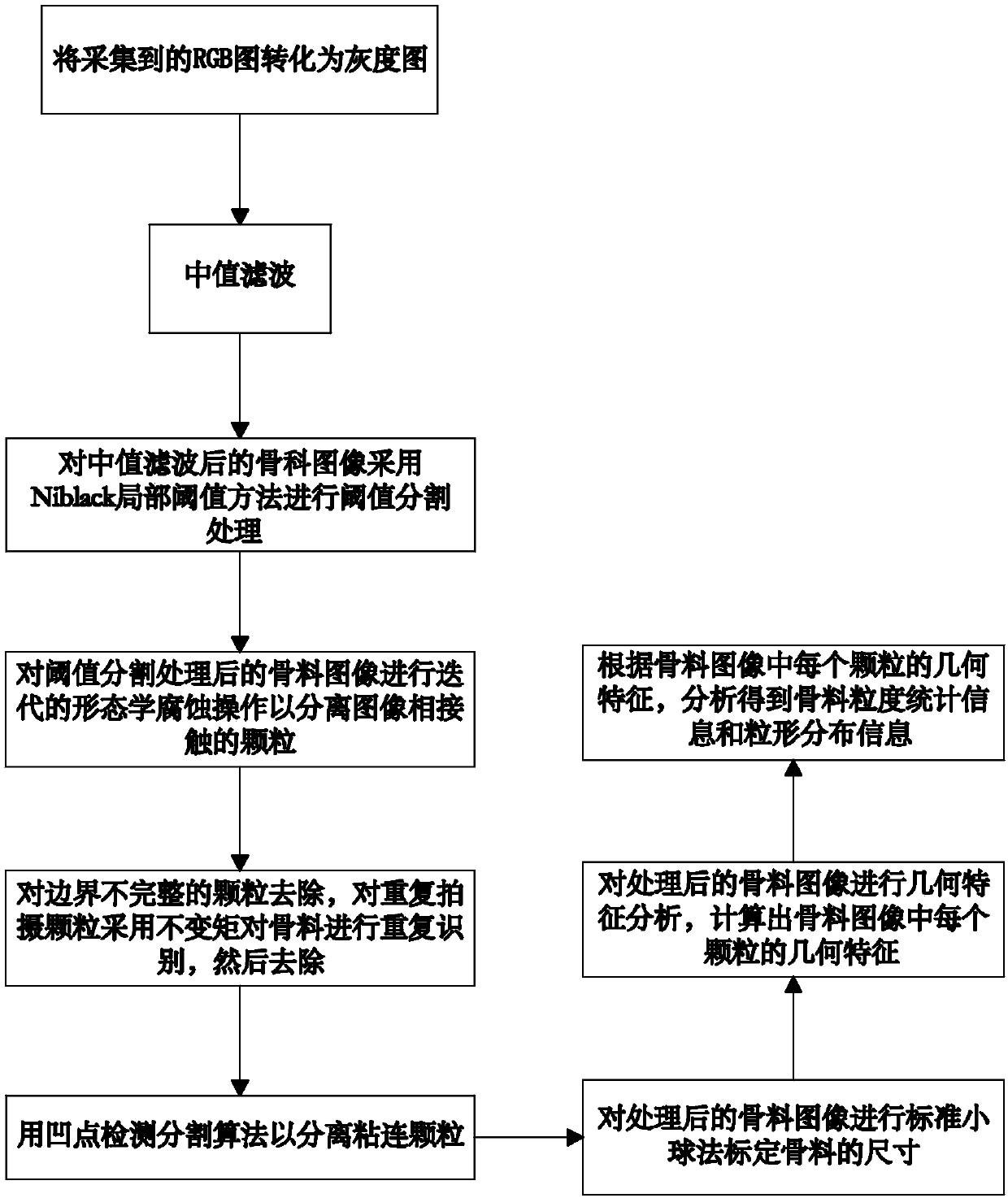

On-line aggregate monitoring device

PendingCN107621435AFast online detectionTimely reflection of aggregate gradingParticle size analysisProduction lineMachine vision

The invention belongs to an on-line aggregate monitoring device. The on-line aggregate monitoring device comprises a sampling module, a sample injection module, a dispersion module and an image acquisition and analysis module, wherein the sampling module is arranged on a feeding conveyor belt, performs sampling at a preset frequency and feeds samples to the sample injection module; the samples reach an image acquisition area of the image acquisition and analysis module through the dispersion module; and the image acquisition and analysis performs feature extraction on acquired images to obtainparameters of aggregate. The machine vision and digital image processing combined technology is adopted to realize rapid on-line detection of the granularity and the grain shape of aggregate, the aggregate grading situation of an aggregate production line can be reflected in time, and economic loss caused by unqualified granularity and quality of fine aggregate is avoided.

Owner:HUAQIAO UNIVERSITY

Method for preparing aluminum nitride ceramic substrate by adopting composite powder grain shape

The invention discloses a method for preparing an aluminum nitride ceramic substrate by adopting a composite powder grain shape. The method is innovatively characterized by comprising the following steps: calcining aluminum nitride and aluminum oxide composite powder through plasma activation, adding a sintering aid, an organic mixed solvent and other auxiliary solvents for performing ball-milling, performing vacuum defoaming, performing casting molding, performing pre-sintering and sintering on the casting green bodies to obtain the aluminum nitride ceramic substrate. The composite powder of aluminum oxide and aluminum nitride serves as a raw material, the surface state of the powder is changed through plasma calcining, the activity and diffusing capacity of atoms on the surface of the powder are improved, the sintering process is increased, and the sintering temperature is reduced. The powder is sintered in a reducing atmosphere in the sintering process, and novel ecological atoms are formed through a reduction reaction, so that the sintering process is improved, the production cost is saved, and the method is suitable for industrial production.

Owner:莱鼎电子材料科技有限公司

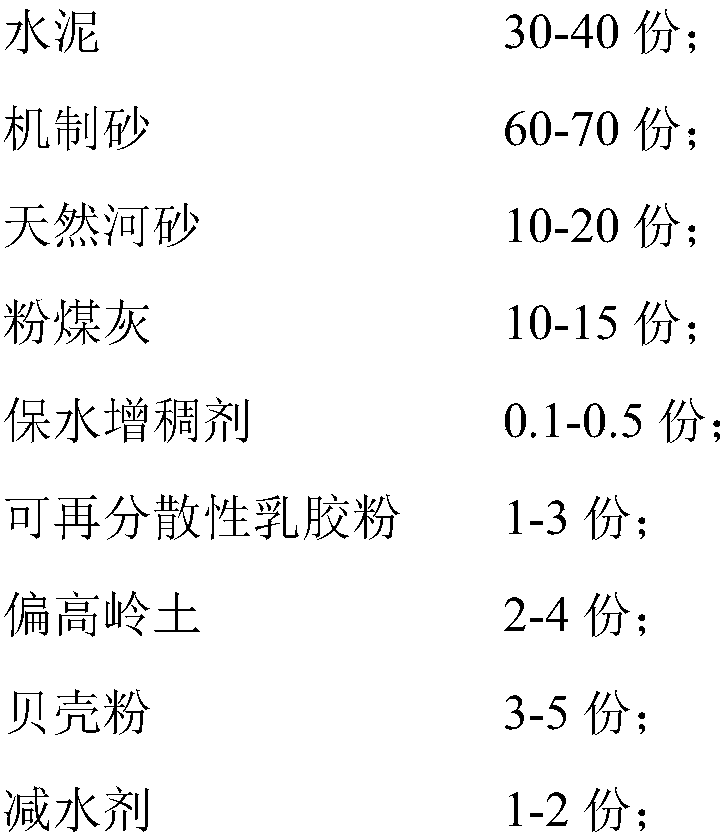

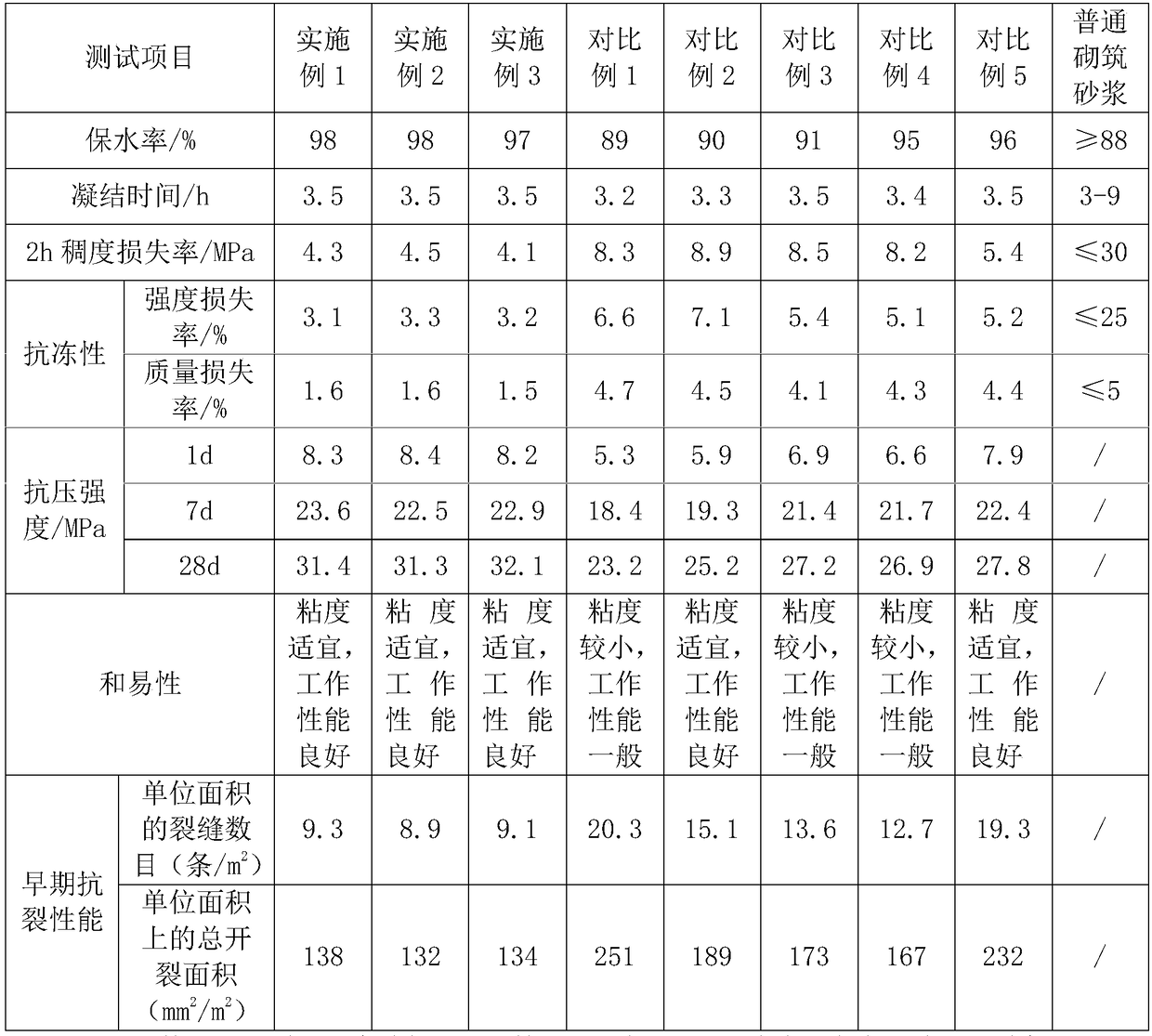

Mechanism sand dry-mixed mortar and preparation method thereof

The invention discloses a mechanism sand dry-mixed mortar and a preparation method thereof, belonging to the technical field of building materials. According main points in a technical scheme of the invention, the mechanism sand dry-mixed mortar comprises the following components: cement, tailing sand, natural river sand, fly ash, a water-retaining thickener, redispersible latex powder, metakaolin, shell powder and a polycarboxylic acid water reducer. According to the invention, the tailing sand widely available is used as a main fine aggregate, and the compounding of the natural river sand and mechanism sand can make up for the problems of poor grading characteristics and grain shape defects of the mechanism sand; by strictly controlling the content of stone powder in the tailing sand, the processing properties of drying and grading of the tailing sand are improved; gaps in the dry-mixed mortar are filled in by the metakaolin and shell powder, so the compactness and impermeability ofthe hardened mortar are enhanced; the water-retaining and thickening properties of the dry-mixed mortar is improved through the water-retaining thickener; and the raw materials of the dry-mixed mortarare improved in dispersion uniformity and workability is improved, and the adhesion between the raw materials of the dry-mixed mortar is enhanced.

Owner:北京建工新型建材有限责任公司

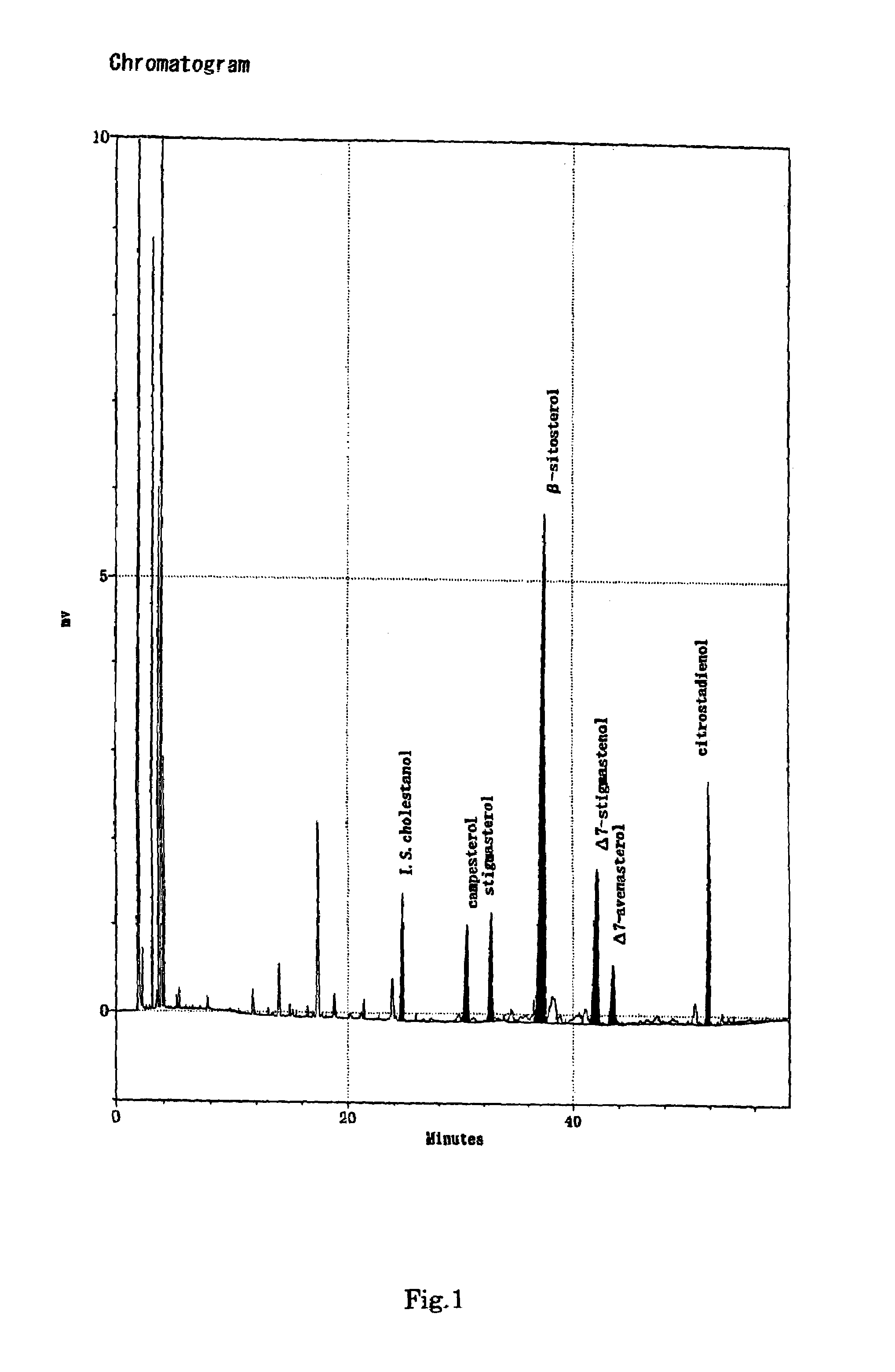

Soybean embryo fat/oil and process for producing soybean material with high embryo concentration

The purpose of the present invention is to extract oil from the soybean material containing soybean germ as a main component, and to utilize it.The present invention relates to a method for producing a soybean material, comprising crudely crushing selected soybeans into a size of less than ½, and separating and concentrating a soybean germ fraction by means of sieving, sorting with air, separation based on the grain shape and the like, to the soybean germ fraction produced by said method, to oil prepared from the soybean material containing soybean germ as a main component, to oil containing 0.8% by weight or more of sterols' content, and to foods containing said oil.

Owner:AJINOMOTO CO INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com