Patents

Literature

97results about How to "High oil absorption value" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Preparation method of high-quality white carbon black for rubber

The invention relates to a preparation method of high-quality white carbon black for rubber, which comprises the following steps: introducing CO2 gas into sodium silicate solution, heating up, stirring, and reacting till the pH value of solution is reduced to be 9-10.5, stopping carbonation, and conducting solid-liquid separation; conducting cocurrent and carbonation of residual liquid and the CO2 gas till the pH value of the solution is reduced to be 7-8, conducting solid-liquid separation, and obtaining the high-quality white carbon black for rubber by washing and drying solids; and soaking or heat cooking solid sediment separated in first carbonation with strong acid to remove impurities, and also obtaining the high-quality white carbon black for rubber by washing and drying. The white carbon black prepared by the method has high purity, fine and uniform granularity, good whiteness, and higher values of specific surface area and oil absorption of SiO2 particles, and can be directly used as high-quality white carbon black for rubber, with application performance meeting the performance index requirements of national standard white carbon black for rubber products.

Owner:CHINACOAL PINGSHUO GRP

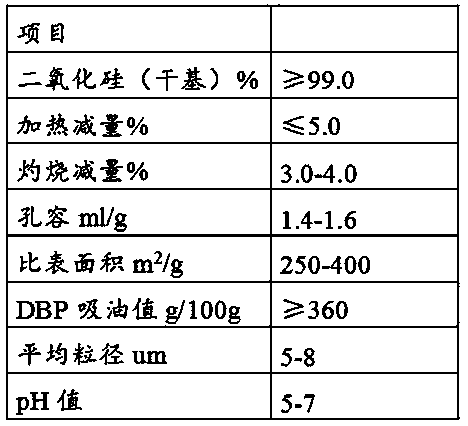

Preparation method of precipitated silica thickening agent for toothpaste

ActiveCN106185956ALarge specific surface areaHigh oil absorption valueCosmetic preparationsSilicaMicrometerToothpaste

The invention relates to a preparation method of a precipitated silica thickening agent for toothpaste. The raw materials include sodium silicate, dilute sulfuric acid and tap water, the synthesis process has no need of adding any structural control agent and electrolyte, and employs saturated steam for direct heating to lower the production cost. The synthesis process adopts three-section dilute sulfuric acid adding reaction, and ensures the particle uniformity and dispersion. The method is simple and easy to operate, and can guarantee the stability of product quality. The precipitated silica obtained by the method has the characteristics of large specific surface area and excellent thickening effect, and is suitable for use as a toothpaste thickening agent. The precipitated silica thickening agent for toothpaste provided by the invention has the characteristics of: a pH value of 5.5-7.5, a DBP oil absorption value of 250-300ml / 100g, a water absorption amount of 56-60ml / 20g, a BET specific surface area of 240-280m<2> / g, and an average particle size of 10-13 micrometers.

Owner:通化双龙化工股份有限公司

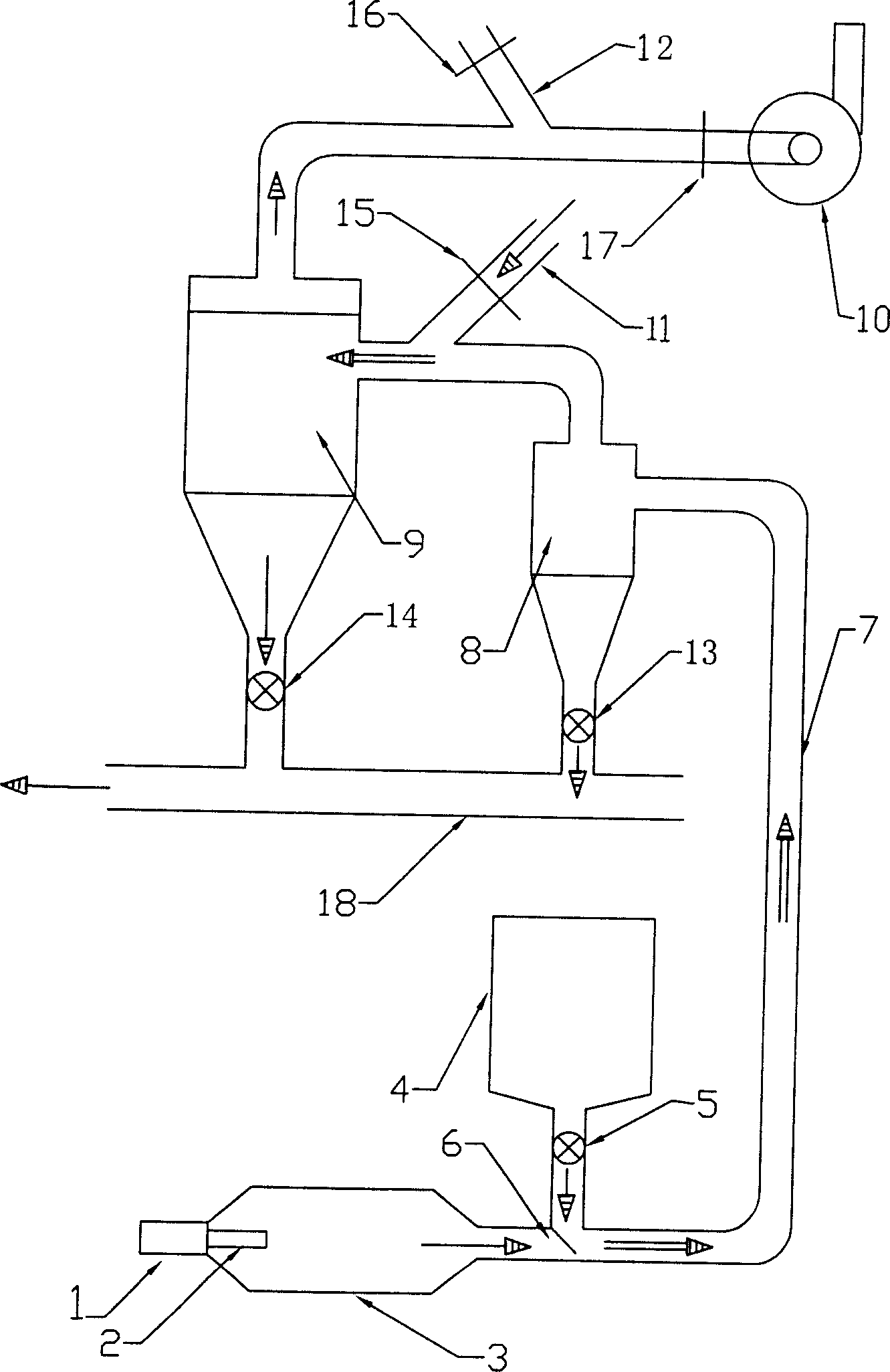

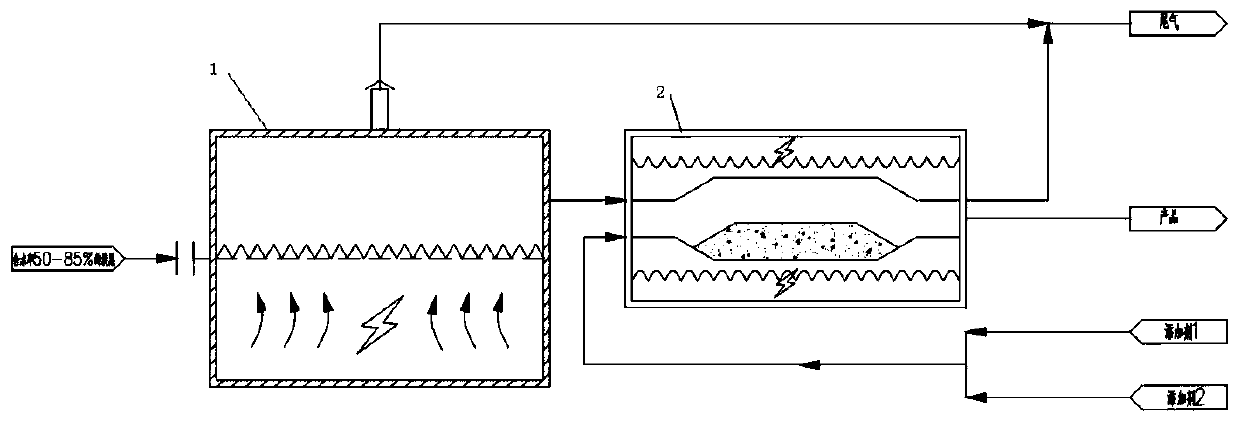

Technique of fluidized instant calcinations of kaolin in coal series

InactiveCN1915814AGood dispersionLarge gas-solid heat transfer areaPigmenting treatmentAluminium silicatesFlue gasEngineering

This invention relates to a fluid-state instantaneous calcining technique for calcining kaolin. The technique comprises a flue gas generating system, a loading system, a fluid-state calcining system, a gas-solid separating system and a post-calcining system. The material is loaded into the fluid-state calcining system by the loading system, where it is mixed with high-temperate flue gas flow generated by the flue gas generating system for instantaneous calcining. The calcined material is introduced into the gas-solid separating system, and the collected solid is then introduced to the post-calcining system for whitening treatment. The instantaneous calcining time is adjusted by the valve. The method can realize large-scale and continuous industrial manufacture, and can effectively reduce the time and energy consumption of post-calcining whitening treatment. The calcined kaolin product has improved oil-absorbency, hiding contrast rate and light extinction performance.

Owner:内蒙古蒙西高岭粉体股份有限公司

Preparation method of extinction powder special for elastic paint

InactiveCN108557828AHigh oil absorption valueGood matting effectSilicaPigment treatment with macromolecular organic compoundsChemistryAmmonium hydroxide

The invention relates to a preparation method of extinction powder special for elastic paint. In a reaction kettle, sodium silicate and water are added, the temperature is increased to 45 DEG C, in the stirring state, sulfuric acid with the concentration being 30% is added, the PH value is regulated to 6-6.5, ammonium hydroxide is added to regulate the PH value to 8.5-9.0, aging is performed for 50 min, then, the temperature is increased to 90 DEG C, meanwhile, sodium silicate and sulfuric acid of the certain concentration are added, aging is performed for 50 min, acid is added till the PH value is 4-5, and filtering, washing, drying and smashing and classification are performed to obtain finished extinction powder. The extinction powder has the advantages of being high in oil absorption value, good in dispersibility, fine in touch, high in transparency and the like, and is reasonable in technology and high in production efficiency.

Owner:山西天一纳米科技股份有限公司

Special scratch-resistant talcum powder for polypropylene and preparation method thereof

ActiveCN102127261ALow oil absorptionHigh oil absorption valuePigment treatment with macromolecular organic compoundsPigment treatment with organosilicon compoundsCouplingBiological activation

The invention relates totalcum powder and preparation method thereof, in particular to special scratch-resistant talcum powder for polypropylene and a preparation method thereof. The talcum powder comprises the following components in parts by weight: 0.1-0.5 part of titanate coupling agent, 0.1-0.5 part of silane coupling agent, 97-99 parts of superfine talcum powder and 0.1-0.5 part of high molecular weight siloxane copolymer. The invention has the following advantages and effects: the activation rate of the talcum powder provided by the invention is more than 99.0%, the oil adsorption value is less than 1.5mL / 100g, the product purity is high and the particle size is 1-50mu m. Through the inspections of the professional inspection institution, the scratch resistance of the polypropylene car bumper special material prepared from the talcum powder which is provided the invention satisfies the grade A of the multi-finger scratch test and the Delta L in the Erichsen cross test is less than 1.5.

Owner:LIAONING JINGHUA NEW MATERIAL CO LTD

Preparation method of graphene-rubber composite

The invention discloses a preparation method of a graphene-rubber composite. The method comprises the following steps: dispersing graphene in a dispersing agent to prepare a dispersion solution; adding latex into the dispersion solution to obtain a mixture; and drying the mixture. Mechanical mixing and ultrasonic agitation are utilized to prepare the graphene-latex mixture. The prepared high-adsorptivity graphene-rubber composite has communicating three-dimensional channels inside, thereby reducing the graphene interlaminar interaction force, and reducing the phenomenon of interlaminar superposition; and thus, the graphene is uniformly dispersed in the rubber without easily aggregating, and the graphene structure can not be destroyed, thereby maintaining the properties of the graphene material. The graphene-rubber composite has very high oil absorption number, and has the property of adsorbing heavy metal ions and organic pollutants in a water phase.

Owner:QINGDAO DT NANO TECH CO LTD

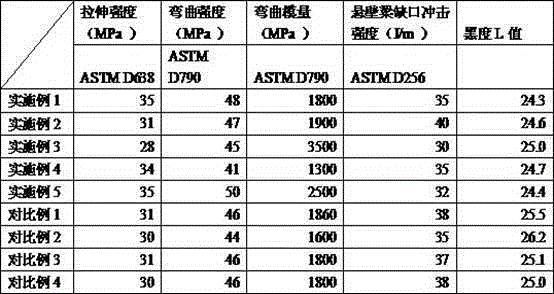

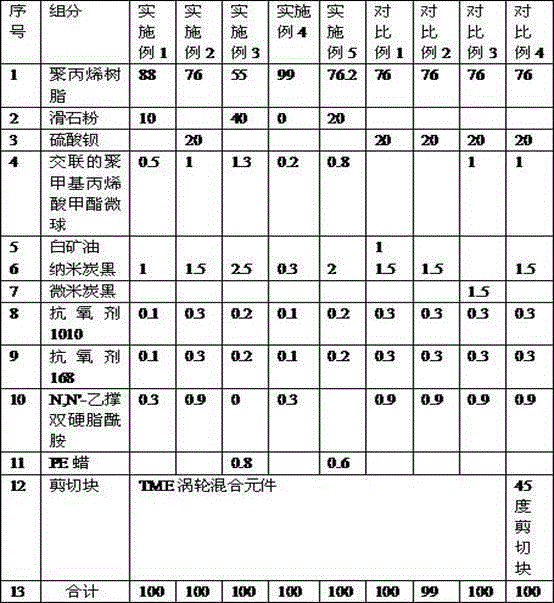

High-blackness polypropylene composition and preparation method thereof

The invention relates to the technical field of preparation of polypropylene and especially relates to a high-blackness polypropylene composition and a preparation method thereof. The high-blackness polypropylene composition is composed of following components, by weight, 55-99 parts of polypropylene resin, 0-40 parts of inorganic filling materials, 0.2-1.3 parts of crosslinked polymethyl methacrylate microspheres, 0.3-3 parts of nano carbon black and 0.4-1.5 parts of other additives. The preparation method includes the steps of feeding the polypropylene resin, the crosslinked polymethyl methacrylate microspheres and the nano carbon black into a high-speed stirrer, stirring the materials uniformly, adding other additives and filling materials, stirring the materials uniformly, and performing extrusion pelletization, melt extrusion and granulation to the uniformly-mixed materials through a double-screw extruder to prepare the high-blackness polypropylene composition. The composition is high in blackness and low in cost.

Owner:SILVER AGE ENG PLASTICS DONGGUAN

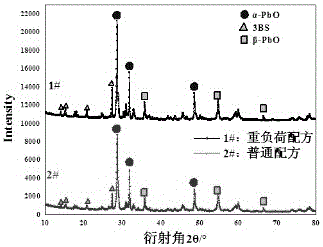

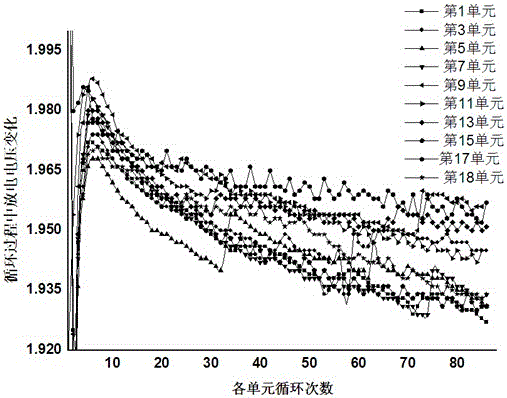

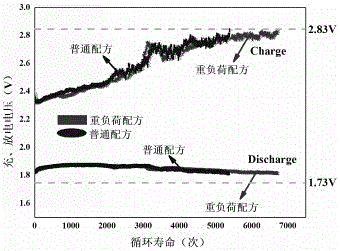

High-temperature heavy-load negative lead paste for start-stop battery and preparation method of negative lead paste

ActiveCN105702953AHigh mechanical strengthImprove bindingLead-acid accumulatorsCell electrodesPolyesterFiber

The invention relates to a high-temperature heavy-load negative lead paste for a start-stop battery and a preparation method of the negative lead paste, and belongs to the technical field of electrochemistry. The high-temperature heavy-load negative lead paste for the start-stop battery is prepared from the following components: dilute sulfuric acid with the density rho of 1.38g / mL, deionized water, a high-performance organic additive Expander 1, a high-performance organic additive Expander 2, a conductive polyester staple fiber, barium sulfate, a carbon material additive Carbon A and lead powder. The invention provides the high-temperature heavy-load negative lead paste for the start-stop battery with long service lifetime and deep discharge cycle performance under the partial state of charge and a preparation method of the negative lead paste. The negative electrode produced by the formula can significantly improve sulfation of the negative electrode under the partial state of charge, reduces the electrochemical polarization phenomenon of the battery in the high-temperature deep circulating charge and discharge processes, and improves the conductivity and the electrochemical property of the negative electrode and the thermodynamic structure stability, so that the high-temperature deep discharge cycle lifetime of the negative electrode under the partial state of charge is prolonged.

Owner:骆驼集团蓄电池研究院有限公司

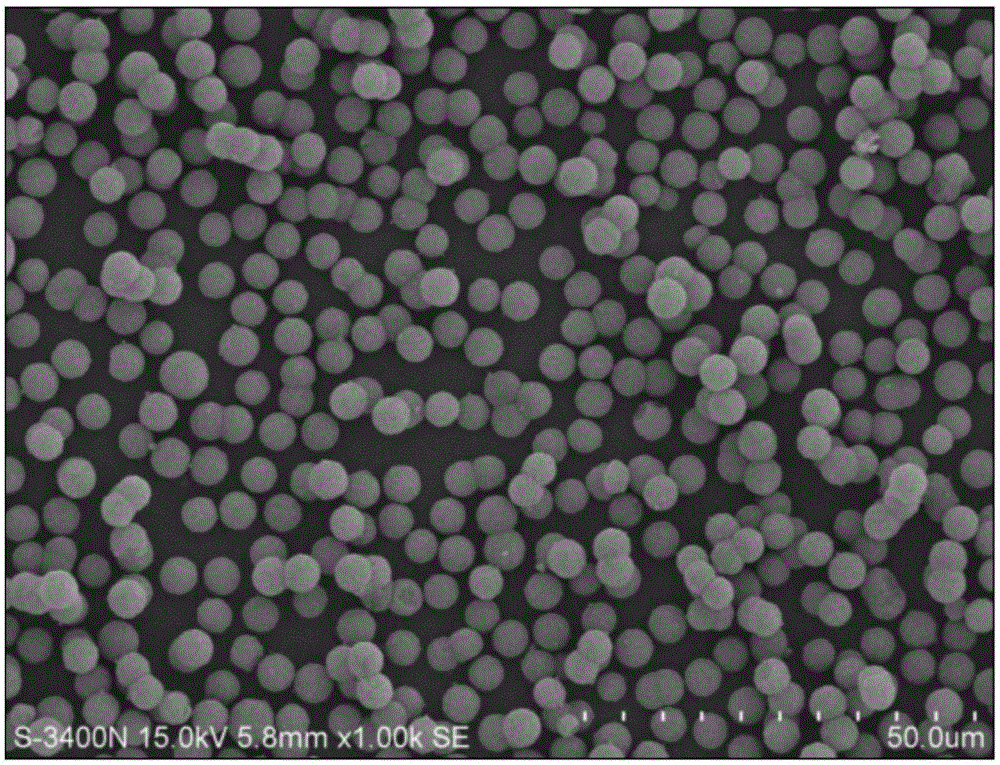

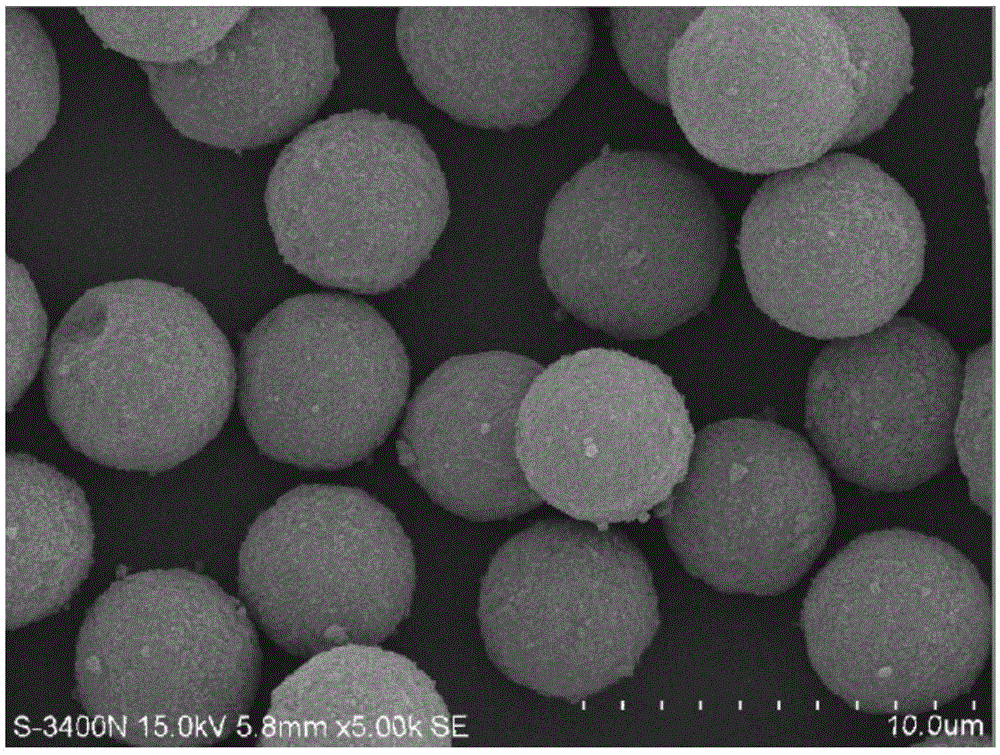

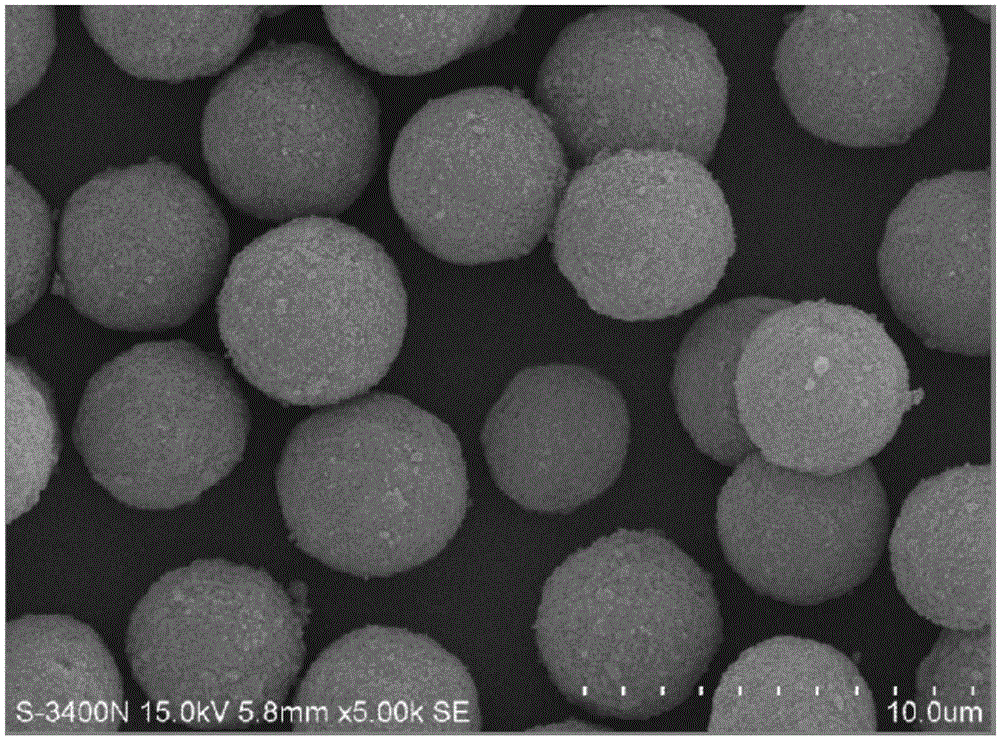

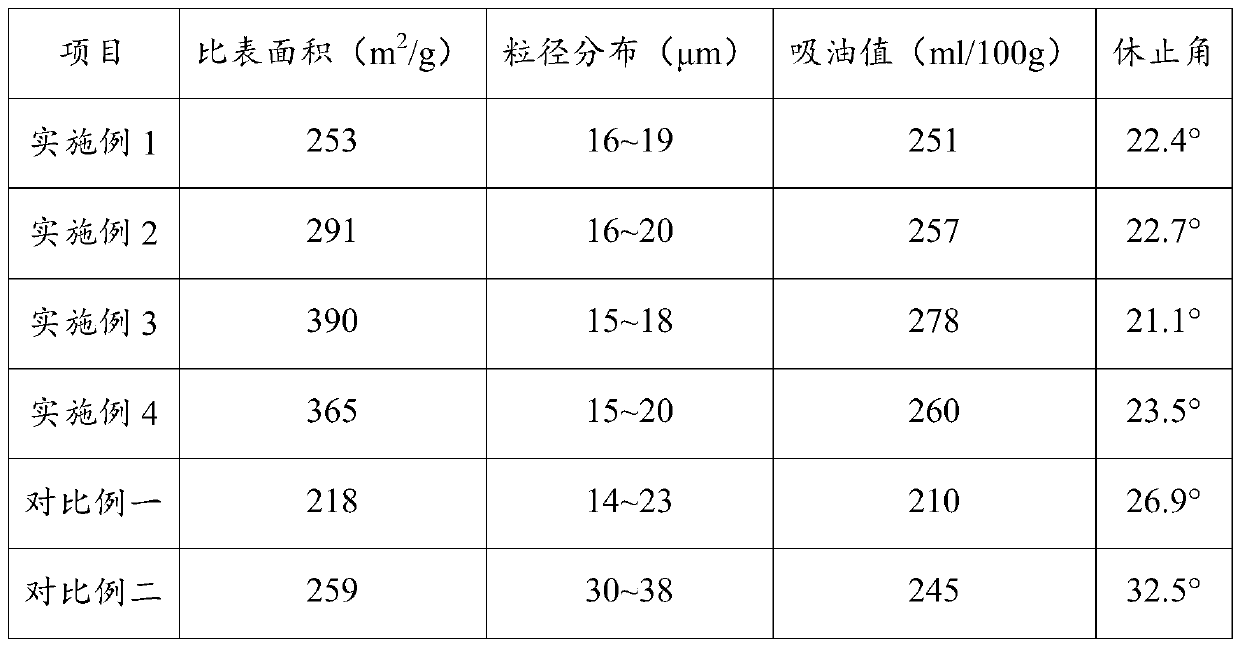

Monodisperse mesoporous silica microsphere powder and preparation method thereof

The invention discloses monodisperse mesoporous silica microsphere powder and a preparation method thereof. The method comprises the steps that a water-soluble macromolecule release agent is uniformly dispersed into deionized water to obtain a water-soluble polymer release agent pre-dispersing solution; a template agent is placed into the water-soluble polymer release agent pre-dispersing solution, a proper PH value is obtained through adjustment and then stirring and uniform dispersion are performed; then, tetraethoxysilane and the water-soluble polymer release agent dispersion solution are stirred and dispersed uniformly. The obtained tetraethoxysilane dispersion solution is added into the template agent dispersion solution, a sufficient reaction is performed by controlling the temperature, the stirring speed and the PH value, and monodisperse mesoporous silica microsphere powder is obtained through seasoning, centrifuging, drying and muffle furnace thermal treatment. The technology is simple, the condition controllability is high, the obtained monodisperse mesoporous silica microsphere powder is uniform in particle size, microspheres have the monodispersion and are free of stickiness, the oil absorption value is high, the spherical surface is smooth, smearing is light and smooth, and the monodisperse mesoporous silica microsphere powder is a good cosmetic additive raw material.

Owner:江西联锴新材料有限公司

Production method of food additive white carbon black

The invention relates to a production method of an inorganic powder material, in particular to a production method of food additive white carbon black. White carbon black precipitates for a synthetic reaction, wherein a certain quantity of prepared sodium silicate solution is put into a reaction kettle and serves as a backing material, then 5 m<3> of water is added, vapor is introduced, stirring starts when temperature is raised to 50-55 DEG C, temperature continues to be raised to 86-88 DEG C, reaction time is 40 min, and a pH value is controlled between 9 and 11; secondly, sodium silicate and dilute sulphuric acid are added into the reaction kettle according to the flow for synthesis reaction, reaction time is 50 min, reaction temperature is 86-88 DEG C, and a pH value is controlled between 10 and 11 during reaction; thirdly, dilute sulphuric acid continues to be added, a terminal point pH value is adjusted to be 4-5, stirring continues, and after aging is performed for 30 min, stirring stops. By optimizing technological parameters, the requirements of improving the porosity and enhancing the adsorption performance are met, and the defects that in a common precipitation method, the porosity of white carbon black is low, and the adsorption performance is poor are overcome.

Owner:通化双龙化工股份有限公司

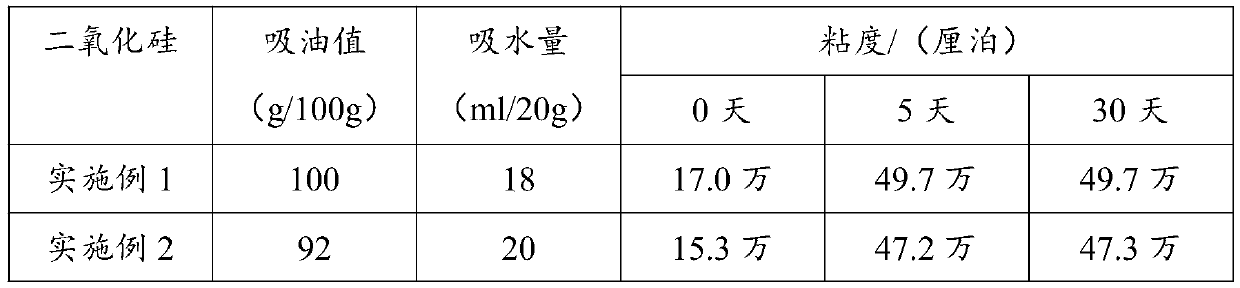

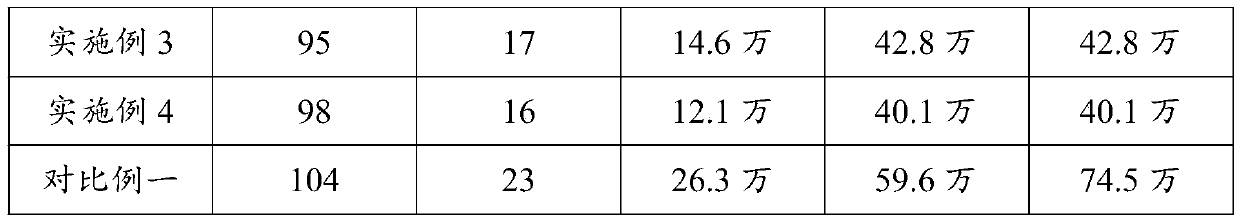

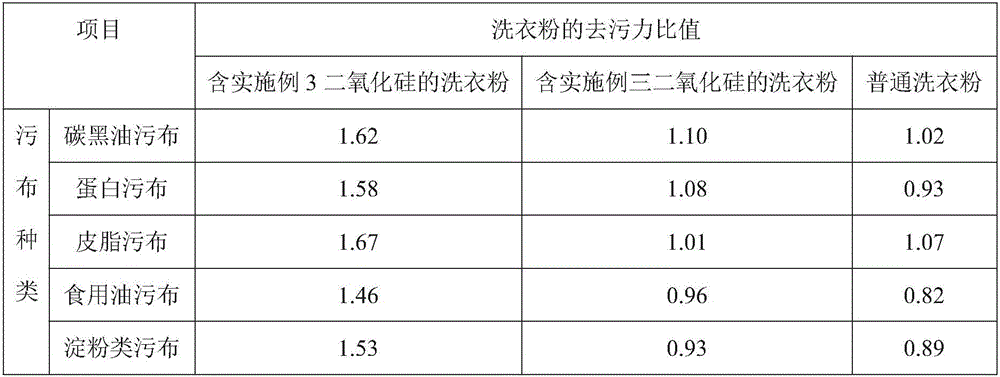

Silica with high fluidity and high oil absorption value for washing powder and preparation method thereof

ActiveCN110395740AHigh oil absorption valueUniform particle sizeInorganic/elemental detergent compounding agentsSilicaFiltrationSODIUM SILICATE SOLN

The invention belongs to the technical field of silica preparation, and particularly relates to silica with high fluidity and high oil absorption value for washing powder and a preparation method thereof. The preparation method of silica comprises the following steps: S1, adding water into a reaction kettle, adding a sulfuric acid solution under stirring, performing heating, dropwise adding a sodium silicate solution until a pH value is 3.5-4.5, then simultaneously dropwise adding the sodium silicate solution and the sulfuric acid solution to carry out a cocurrent neutralization reaction, controlling a pH value to be 3.0-5.0, simultaneously stopping addition of the sulfuric acid solution when drop addition of the sodium silicate solution is completed, and further performing stirring; S2, continuously adding the sodium silicate solution, stopping drop addition of the sodium silicate solution when a pH value is 7.0-8.0, and performing maturing; and S3, performing pressure filtration andwashing on the formed silica, and performing spray drying treatment to obtain the silica. The silica has uniform particle size distribution, large specific surface area, high oil absorption value andhigh fluidity, and has good application prospects in washing powder.

Owner:GUANGZHOU FEIXUE MATERIAL TECH

Precipitated silica for low-viscosity toothpaste and preparation method of precipitated silica

ActiveCN110015667AImprove adsorption capacityLow initial viscosityCosmetic preparationsSilicaFiltrationToothpaste

The invention belongs to the technical field of silica preparation, and particularly relates to precipitated silica for low-viscosity toothpaste and a preparation method of the precipitated silica. The preparation method comprises the following steps: S1, adding a sodium sulfate solution to a reaction kettle, conducting stirring and heating, and then adding a sodium silicate solution to adjust thepH value; S2, simultaneously adding a sodium silicate solution and a sulfuric acid solution for reaction, and controlling the pH value of the reaction process to be 9-10, and after the sodium silicate solution is completely added, continuing adding the sulfuric acid solution until an end point pH value, and conducting stirring to obtain a preliminary product of silica; and S3, subjecting the preliminary product of silica to pressure filtration and washing by dilute sulfuric acid, and then conducting drying, and finally conducting crushing, so as to prepare the silica. The silica of the present invention can reduce the initial viscosity of the toothpaste and inhibit the viscosity of the toothpaste from growing, enables the toothpaste to maintain a proper viscosity, a good pseudoplasticityand thixotropy, and has a good application effect.

Owner:GUANGZHOU FEIXUE MATERIAL TECH

Method for increasing oil absorption value of calcined kaolin

ActiveCN101857740ANo adverse effect on whitenessWater Solubility No Adverse EffectsCoatingsPhotochemistryAnhydrous magnesium chloride

The invention relates to a method for increasing oil absorption value of calcined kaolin, which comprises the following steps of: mixing the calcined kaolin and anhydrous magnesium chloride in a weight ratio of 1:(0.001-0.1), stirring the mixture for 1 to 2 hours at the constant temperature of between 50 and 200 DEG C, and cooling the stirred mixture to obtain the calcined kaolin with high oil absorption value. The method has the advantages of simpleness, convenience, low cost, no pollution and capability of obviously increasing the oil absorption value of the calcined kaolin to between 72.50 and 102.60ml / 100g from 65 to 70ml / 100g.

Owner:CHINA UNIV OF GEOSCIENCES (WUHAN) +1

Preparation method of silicon dioxide with high oil absorption value and high water absorption capacity for washing powder

ActiveCN105858668AGenerate violentHigh oil absorption valueInorganic/elemental detergent compounding agentsSilicaSolubilityHydrogen peroxide

The invention belongs to the technical field of silicon dioxide, and in particular relates to a preparation method of silicon dioxide with high oil absorption value and high water absorption capacity for washing powder. The method comprises: S1, preparing S into a sodium silicate solution and a sodium hydrogen carbonate solution; S2, adding water into a reaction tank, performing heating, and simultaneously, dropwise adding the sodium silicate solution and the sodium hydrogen carbonate solution; S3, performing heating, continuously adding the sodium silicate solution, then dropwise adding the sodium hydrogen carbonate solution, performing titration of sulfuric acid until the end point, and performing aging to obtain a head product; S4, performing pressure filtration on the head product, then putting the head product into an agitator tank, adding a mixed solution of hydrogen peroxide and sulfuric acid, and performing agitation to obtain silicon dioxide; and S5, performing pressure filtration washing on the obtained silicon dioxide, and performing crushing to obtain a product. The silicon dioxide prepared by the method has high oil absorption value and high water absorption capacity, and can be used as a detergent assistant to enable the washing powder to have better solubility, dispersity, adsorbability and decontamination ability.

Owner:GUANGZHOU FEIXUE MATERIAL TECH

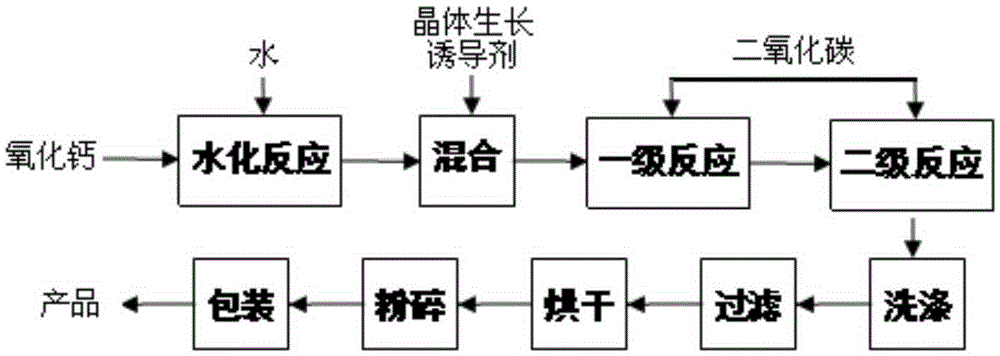

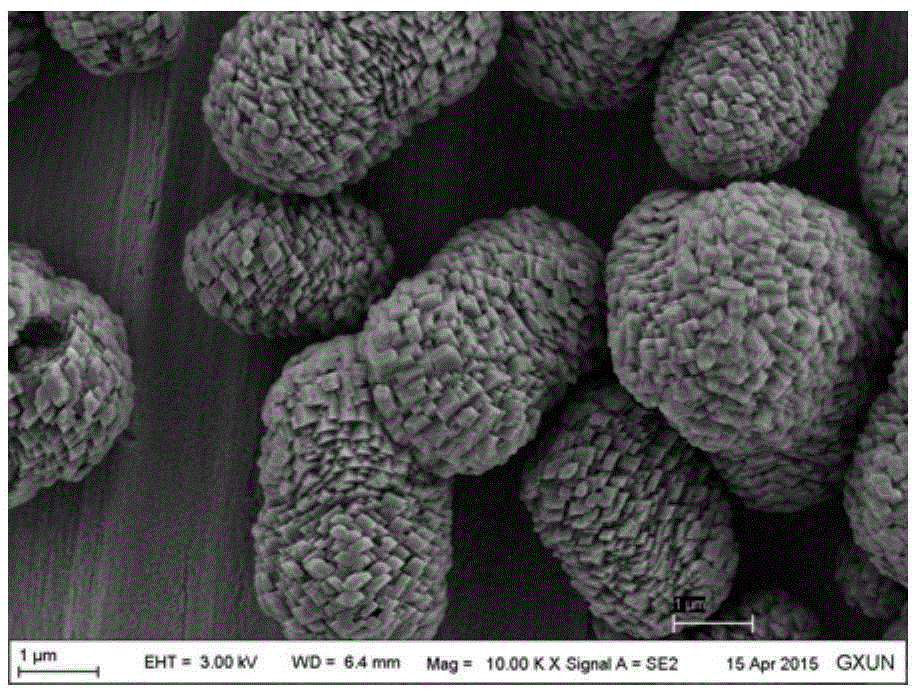

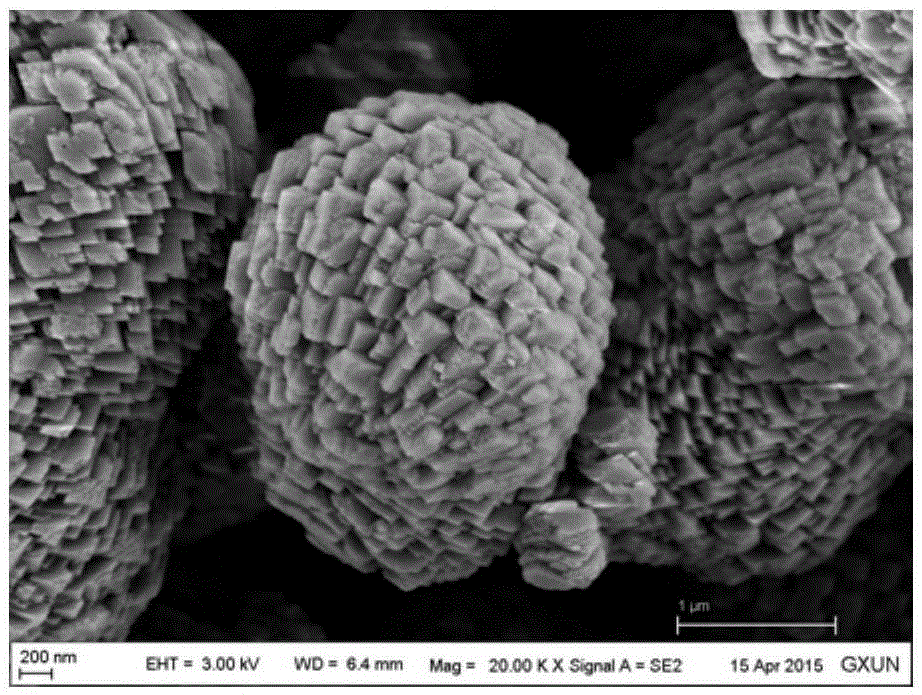

Preparation method of pine-cone-shaped calcite type micron-size calcium carbonate particles

InactiveCN105271344AGood application effectHigh oil absorption valueCalcium/strontium/barium carbonatesHydration reactionCalcite

The invention discloses a preparation method of pine-cone-shaped calcite type micron-size calcium carbonate particles. 60 parts by mass of calcium oxide is dissolved in water, a 5wt%-15wt% Ca(OH)2 suspension liquid is prepared through a conventional hydration reaction, a crystal growth compound control agent is added, CO2 is introduced to a carburizing reaction kettle at the temperature of 25 DEG C-95 DEG C, a first-level carburizing reaction is performed, a second-level carburizing reaction is performed when pH (potential of hydrogen) of a reaction liquid ranges from 8 to 9, introduction of CO2 is stopped when the pH is equal to 7-7.5, a carburizing reaction proceeds for 20 min, then conventional filtering, washing and hot-air drying are performed, and the pine-cone-shaped calcite type micron-size calcium carbonate particles are obtained. A pine-cone-shaped calcium carbonate product is obtained by changing a crystal growth control agent and performing the second-level carburizing reaction, the product has a low oil absorption value, the surface area is larger, the application effect of calcium carbonate is improved, reaction conditions are simple, the operation is easy, the product cost is low, and economic benefits, social benefits and ecological benefits are good.

Owner:GUANGXI UNIV FOR NATITIES

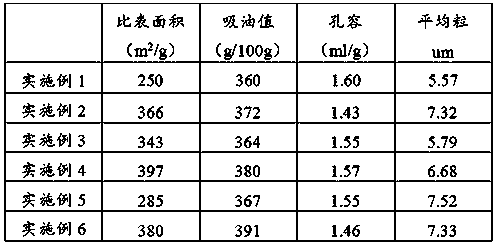

Preparation method of high-oil-absorption high-reinforcement silicon dioxide for rubber products

InactiveCN107021495AShorten vulcanization timeFast oil absorptionSilicon compoundsVulcanizationWarm water

The invention discloses a preparation method of high-oil-absorption high-reinforcement silicon dioxide for rubber products. The preparation method comprises the steps: firstly, accurately preparing water glass in a preparing tank; then, transferring processing hot water into a reactor from a warm water tank, transferring water glass into the reactor from a refining tank, heating the temperature to 60 DEG C; adding sulfuric acid and dilute water into the reactor while carrying out stirring, controlling pH to 6.5 to 7.0, then, stopping stirring, and carrying out aging for 30 minutes; starting to carry out stirring, meanwhile, heating the temperature to 85 DEG C, and starting to carry out flow merging; firstly, adding flow-merged water glass until the pH value is 9 to 10, then, adding sulfuric acid, and controlling the pH value to 9.5 to 10.5; carrying out stirring uninterruptedly after flow merging ends, adding the sulfuric acid and the dilute water for post-acidification, and controlling the pH value to 4.8 to 5.3 at an end; carrying out aging and stirring for 20 minutes, and ending the reaction. The silicon dioxide prepared by the preparation method has the characteristics of high specific surface area and high oil absorption and is low in loss on ignition and high in pH value, so that the vulcanization time of the rubber products is shortened by 50% or more, and the processing efficiency is greatly increased.

Owner:FUJIAN SANMING JUFENG CHEM

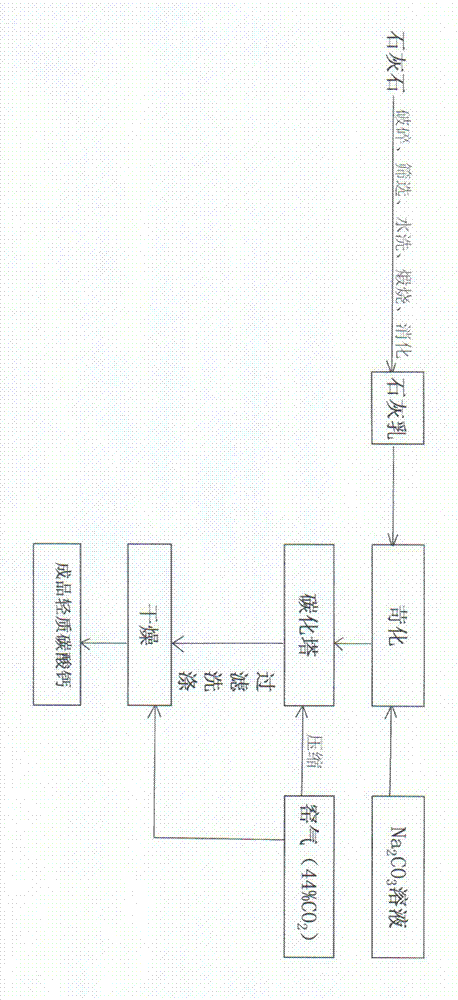

Preparation method of light calcium carbonate

InactiveCN104261452AImprove qualityHigh oil absorption valueCalcium/strontium/barium carbonatesCalcium carbonateCarbon dioxide

The invention discloses a preparation method of light calcium carbonate. The preparation method comprises the following steps: crushing a limestone raw material in a crusher; screening the crushed limestone, and washing the screened limestone by water; calcining the screened and washed limestone to generate quick lime (CaO) and carbon dioxide (CO2); digesting: adding the quick lime generated by calcining the limestone into hot water, and constantly stirring to generate lime milk; sieving the generated lime milk with a 120-mesh sieve, and concocting the lime milk by filtering till the effective CaO concentration is larger than 170g / L; transferring the lime milk at the concocted concentration into a stirring reactor, causticizing by adding a NA2CO3 solution; inflating kiln gas CO2 into a causticized CaCO3 solution for carbonizing in a carbonizing tower; filtering, washing, drying and grinding a carbonized CaCO3 slurry to obtain a light calcium carbonate product. The light calcium carbonate prepared by the preparation method is relatively high in quality.

Owner:山西玉竹活性石灰制造有限公司

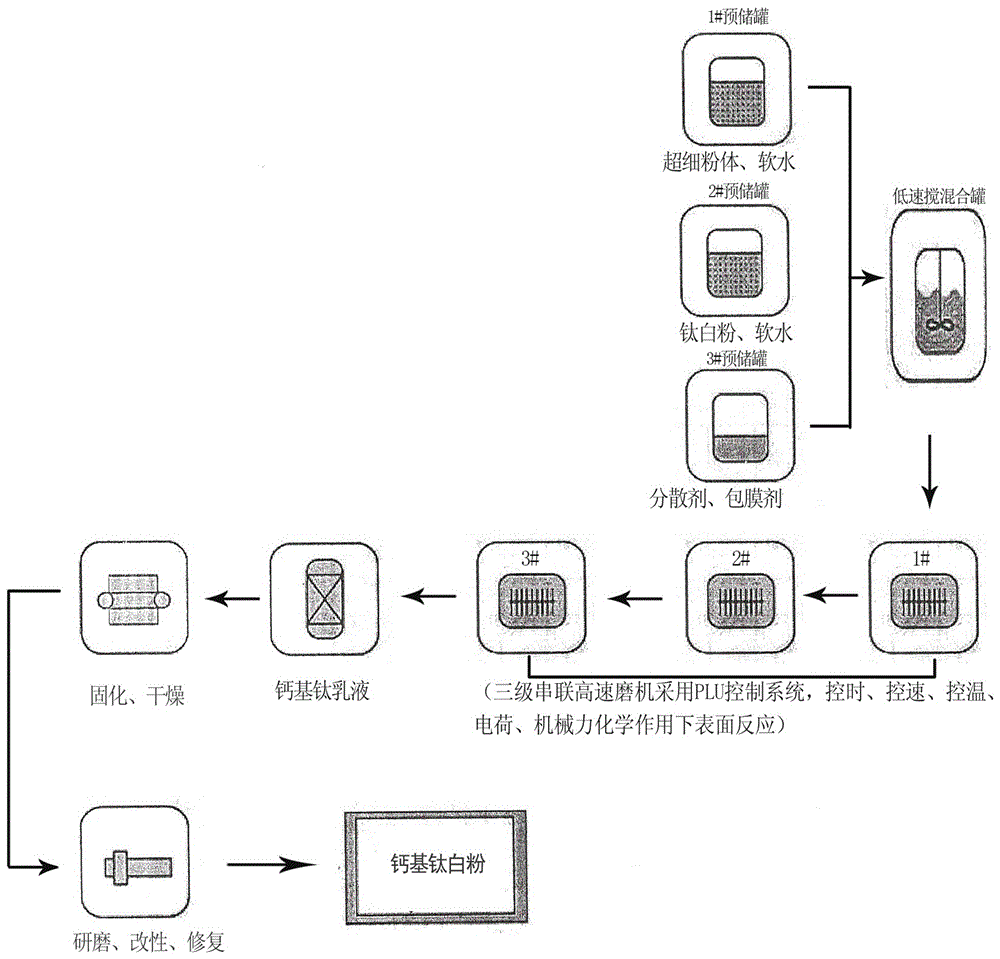

Calcium-based titanium dioxide and preparation process thereof

ActiveCN105754378AEffectively stay decentralizedCoated evenlyPigment treatment with macromolecular organic compoundsPigment treatment with organosilicon compoundsChemical reactionControl system

The invention discloses calcium-based titanium dioxide and a preparation process thereof. The calcium-based titanium dioxide is prepared from an outer membrane formed by coating a core substrate made of a 4,000-6,000-mesh superfine calcium carbonate inorganic powder material with titanium dioxide having the meshes of 10,000 or above. According to the preparation process, a uniformly mixed aqueous solution is prepared from superfine calcium carbonate, a uniformly mixed aqueous solution is prepared from titanium dioxide, a uniformly mixed aqueous solution is prepared from a dispersing agent and a coating agent, accordingly, the agglomeration phenomenon is effectively avoided, superfine calcium carbonate effectively keeps in a dispersed state, a PUC control system is used for controlling time, speeds, temperature and electric charge of a three-stage cascade high-speed mill as well as and mechanical chemical reactions, inorganic coating is performed according to the principles of kinetics and thermodynamics, and the outer membrane is uniform and compact in coating and firm in combination. Through drying, curing, homogenized powder and homogenization, modification and membrane repairing, the membrane is smoother, and the whiteness, the oil absorption value and the covering power of a product are effectively improved. Detection proves that the whiteness reaches 97%-99%, the oil absorption value is 29-35 g / 100 g, the covering power is higher than 35.4 g / m<2>, and the product indexes all reach or exceed the national standard.

Owner:南召县兴利达岗石有限公司 +1

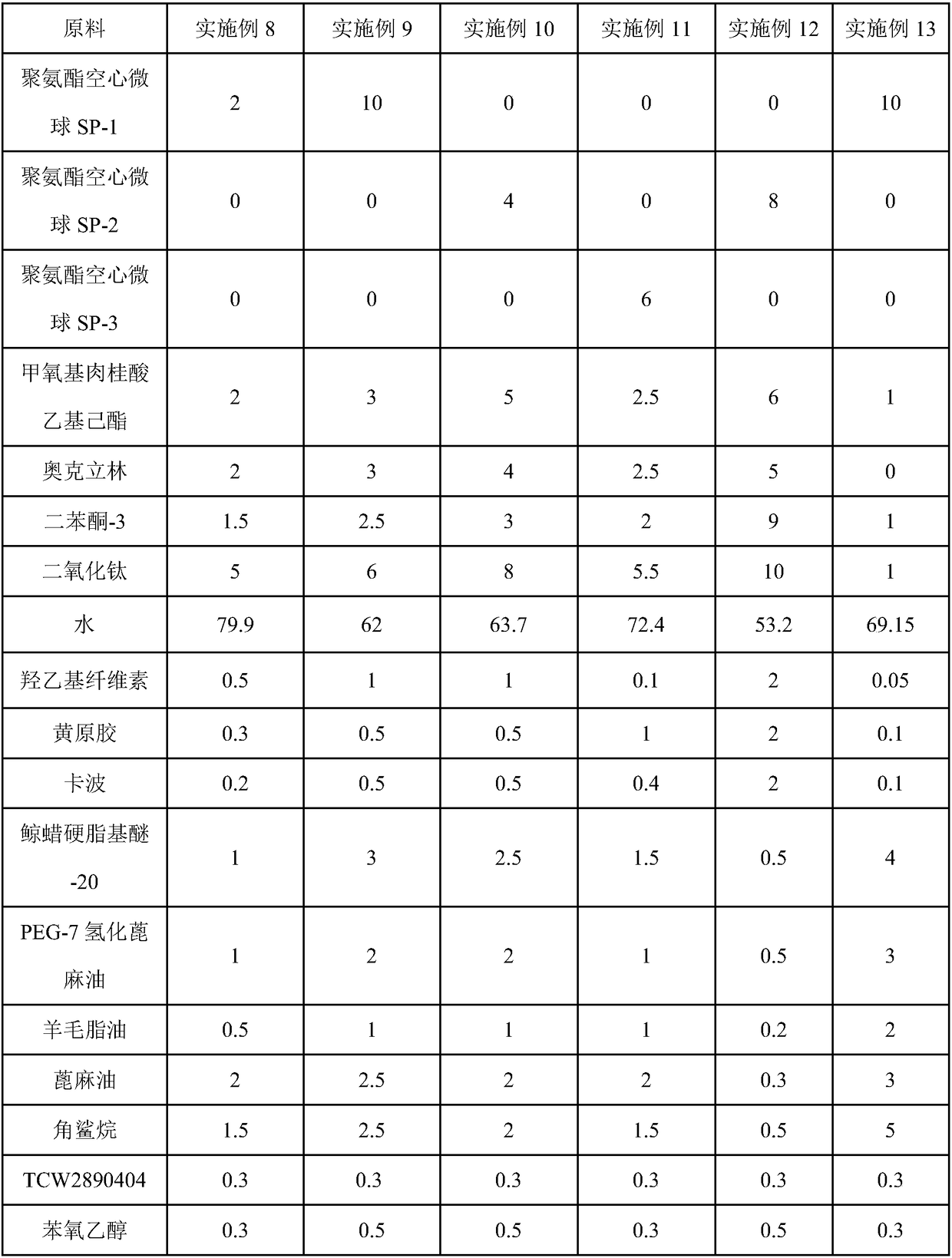

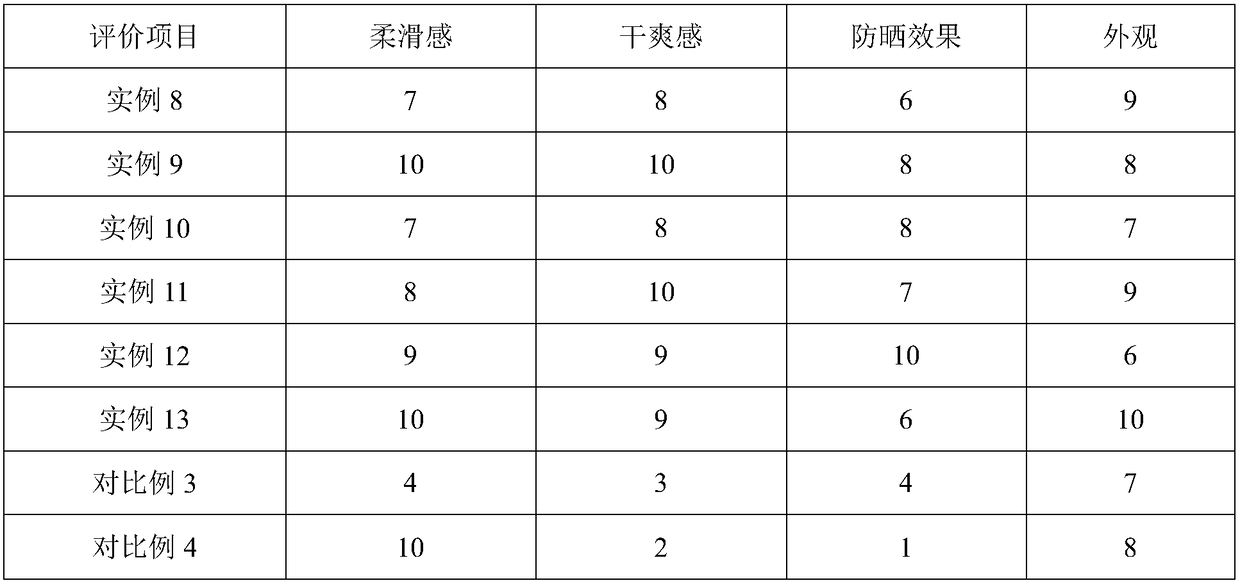

Preparation method of hollow polyurethane microspheres and photo-protection cosmetic composition containing hollow polyurethane microspheres

ActiveCN108175716ASoft skinSmooth and non-greasy skinCosmetic preparationsToilet preparationsHollow coreElastic skin

The invention relates to photo-protection cosmetic composition containing hollow polyurethane microspheres and a preparation method of the hollow polyurethane microspheres. Specifically, the composition has unique effects in aspects of high smooth and refreshing skin feelings while protecting skin against visible sunlight radiation. The hollow polyurethane microspheres are shells with specific optical performance and specific soft and elastic skin feelings, can bring smooth and refreshing skin feelings and the like to the photo-protection cosmetic composition and can effectively increase the SPF (sun protection factor) value of sun cream.

Owner:WANHUA CHEM GRP CO LTD +1

The method of improving the oil absorption value of white carbon black products

InactiveCN102295845AHigh oil absorption valueReduce the impactPigment physical treatmentFiltrationEconomic benefits

The invention discloses a method for improving an oil absorption value of a white carbon black product. In order to overcome the defects that after performing pressure filtration, white carbon black prepared by the existing gel method is pulped for 2-3 hours, and the oil absorption value of white carbon black is reduced because of destruction of a mechanical force to a secondary structure of white carbon black, and the like, the method disclosed by the invention shortens the dispersing time of white carbon black slurry by shortening the pulping time of white carbon black, and refines the pulped white carbon black by using a refining pump. The method is used for improving the oil absorption value of the white carbon black product; and by using the method, the oil absorption value of white carbon black is improved by 0.3-0.4, and simultaneously, power consumption can be saved by about 55 kilowatt-hours when each ton of white carbon black is produced. Thus, the method has obvious economic benefits.

Owner:台泥(怀化)水泥有限公司

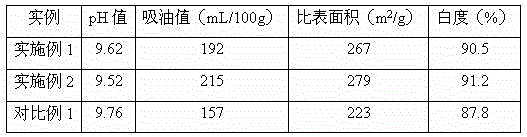

High-oil-absorption modified slag submicron powder and preparation method thereof

The invention discloses high-oil-absorption modified slag submicron powder and a preparation method thereof. The high-oil-absorption modified slag submicron powder is prepared from, by weight, 40-50%of slag, 0.4-1.2% of a slag grinding aid, 1.5-2.5% of a slag modification agent and 48-58% of absolute ethyl alcohol; the slag and the absolute ethyl alcohol are mixed and then ground at the rotationspeed of 600-1,000 r / min for 90-120 min, then the mixture is mixed with the absolute ethyl alcohol, the mixture is stirred at the rotation of 500-800 r / min at 20-35 DEG C for 60-100 min, then the mixture is mixed with the slag modification agent, the mixture is stirred at the rotation speed of 500-800 r / min at 60-80 DEG C for 60-100 min, through filtering and ultrasonic washing, the mixture is dried at 60-80 DEG C for 10-16 h, and the powder is obtained. According to the method, the slag is subjected to grinding assistance and modification treatment, so that the problems are solved that in theprior art, the slag is poor in grindability and compatibility and is difficultly ground; the oil absorption of the slag submicron powder is increased.

Owner:SHANGHAI BAOTIAN NOVEL BUILDING MATERIALS +2

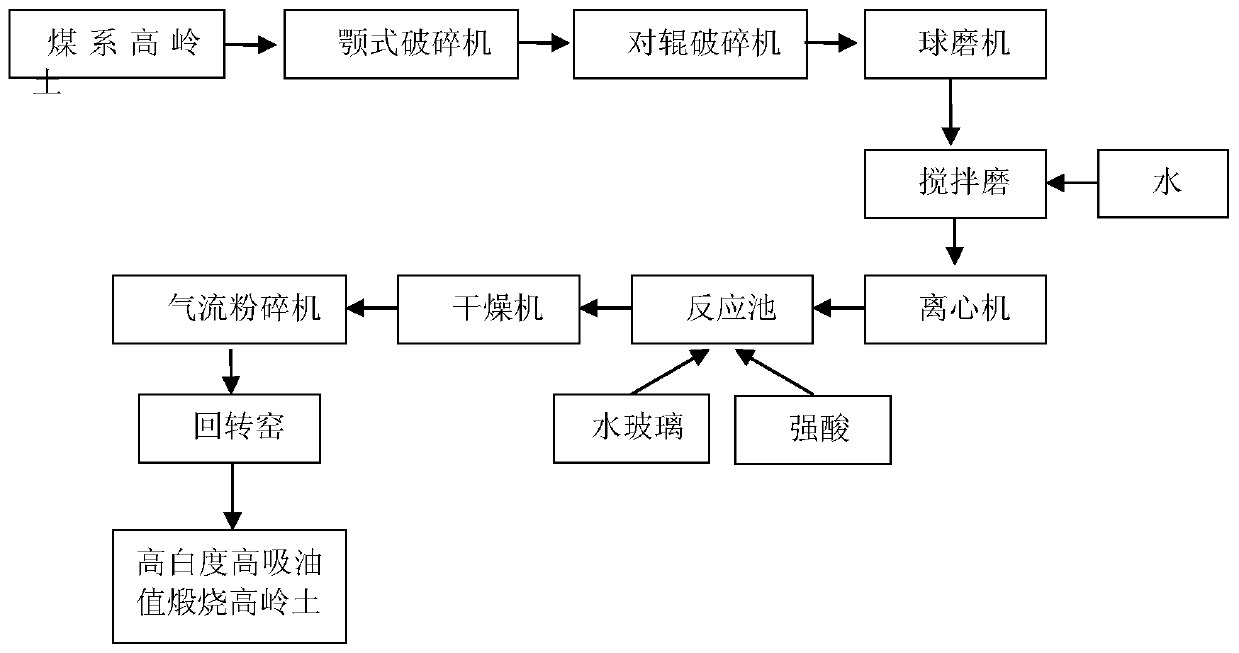

Calcined kaolin with high whiteness and high oil-absorbing value as well as preparation method thereof

ActiveCN109748286AHigh whiteness valueHigh oil absorption valueSilicon compoundsCarbon blackKaolin clay

The invention discloses calcined kaolin with high whiteness and high oil-absorbing value as well as a preparation method thereof. The calcined kaolin with high whiteness and high oil-absorbing value comprises calcined kaolin and white carbon black adsorbed on the surface of the calcined kaolin; and the white carbon black is 0.5 to 1.5 percent of the mass of the calcined kaolin. According to the calcined kaolin with high whiteness and high oil-absorbing value, the whiteness and the oil-absorbing value of the calcined kaolin are increased, and the calcined kaolin with high whiteness and high oil-absorbing value and capable of meeting the requirements of coating paper is produced.

Owner:内蒙古超牌新材料股份有限公司

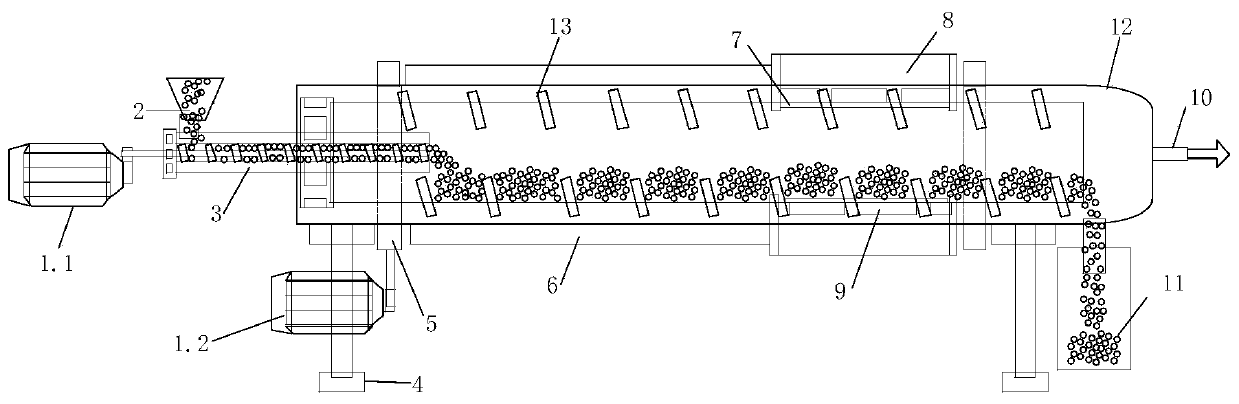

Waste tire cracking device and method based on combination of dividing wall heat exchange and microwave heating

InactiveCN111471476AReduce the temperatureSolve the problem of large thermal resistanceProductsReagentsElectric machineSpiral blade

The invention discloses a waste tire cracking device and method based on combination of dividing wall heat exchange and microwave heating. The main body of the cracking device is a horizontal cylindrical shell (12); a spiral conveying device (3) is arranged on the left side of the shell; the right half section of the spiral conveying device is positioned in the shell; a feeding opening (2) is arranged in the upper part of the left side of the spiral conveying device; the spiral conveying device is driven by a first speed regulating motor (1.1); a pyrolytic carbon black collecting box (11) is arranged at the lower end of the right side of the shell, an electric heating device (6) is installed on the front section outside the shell, a microwave heating device (9) of a microwave heating section is installed on the rear section outside the shell, four supporting frames (4) are arranged on the lower portion of the shell to support the whole device, and spiral blades (13) are arranged in theshell and penetrate through the shell from left to right. The spiral structure is used for conveying materials, so that the material adaptability of the reactor is improved; and the waste tire particles are slightly carbonized in the continuous temperature rising process of front-section electric heating, so that the wave absorbing property of the waste tire particles is greatly improved.

Owner:SOUTHEAST UNIV

Simple method for improving oil absorption value of calcined kaolin

The invention relates to a simple method for improving an oil absorption value of calcined kaolin. The simple method is characterized by comprising the following steps: stirring the calcined kaolin at room temperature; then adding sodium sulfide crystal particles, wherein the addition of the sodium sulfide crystal particles is 0.5wt%-4.0wt% of the calcined kaolin; and evenly stirring at room temperature, baking at the temperature of 25-150 DEG C, and then cooling so as to obtain the product. By using the method, the oil absorption value of the calcined kaolin is increased from 65-70ml / 100g to 72.50-102.00ml / 100g; and the method has the advantages of simple and convenient process, low cost, low requirement on equipment and suitability for industrial production.

Owner:CHINA UNIV OF GEOSCIENCES (WUHAN)

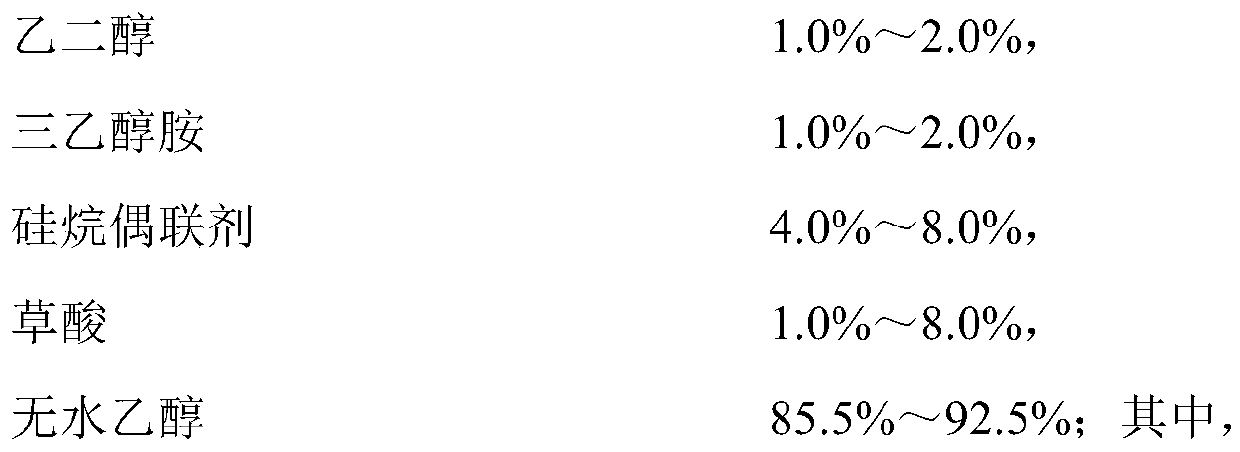

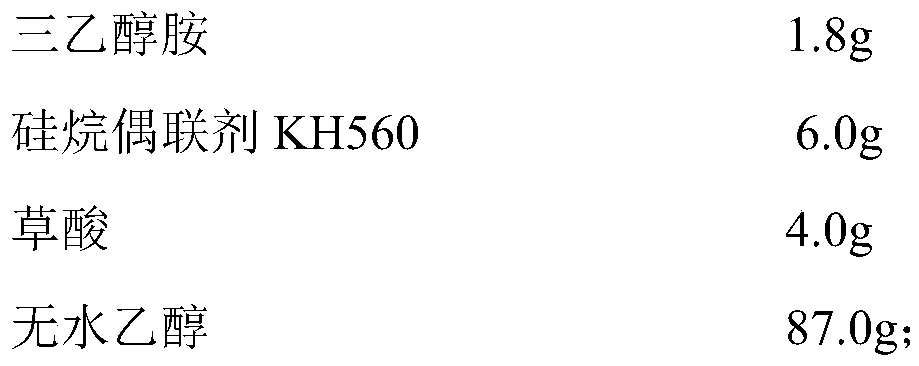

Aid-grinding and oil absorption steel slag composite modifier and preparation method thereof

ActiveCN109706276AImprove grinding effectGood compatibilityRecycling and recovery technologiesSlagUltra fine

The invention discloses an aid-grinding and oil absorption steel slag composite modifier and a preparation method thereof. The aid-grinding and oil absorption steel slag composite modifier is preparedfrom the following components in percentage by weight: 1.0%-2.0% of ethanediol, 1.0%-2.0% of triethanolamine, 4.0%-8.0% of silane coupling agent, 1.0%-8.0% of oxalic acid and 85.5%-92.5% of anhydrousethanol. Stirring is conducted for 50-100 min at 20-35 DEG C or below and at the rotating speed of 400-800 r / min, thus ethanediol and triethanolamine mixed liquid is obtained, stirring is conducted for 60-120 min at 20-35 DEG C or below and at the rotating speed of 600-1200 r / min, thus silane coupling agent and oxalic acid mixed liquid is obtained, the ethanediol and triethanolamine mixed liquidand the silane coupling agent and oxalic acid mixed liquid are mixed and then stirred for 10-20 min at 20-35 DEG C or below and at the rotating speed of 500-1000 r / min, and thus the aid-grinding and oil absorption steel slag composite modifier is obtained. The problems of poor grindability and poor compatibility of existing steel slag are solved, ultra-fine pulverization of the steel slag is improved, the oil absorption value of the steel slag is increased, and high value-added application of the steel slag is achieved.

Owner:SHANGHAI BAOTIAN NOVEL BUILDING MATERIALS +2

Preparation method of calcium silicate powder with low pH value, high oil absorption value and large specific surface area

ActiveCN105731475AHigh oil absorption valueIncrease the areaAlkaline-earth metal silicatesCalcium silicateCalcium hydroxide

The invention relates to a preparation method of calcium silicate powder with low pH value, high oil absorption value and large specific surface area. The preparation method comprises the following steps: (1) adding water into calcium hydroxide and performing shearing emulsification to obtain a calcium hydroxide suspension; (2) dropwise adding the calcium hydroxide suspension into a sodium silicate solution or an aluminum compound-containing sodium silicate solution to generate calcium silicate slurry; (3) performing suction filtration of the calcium silicate slurry, adding water into the obtained filter cake and performing shearing emulsification to obtain dealkalized calcium silicate slurry; and (4) dropwise adding acid silicic acid solution into the dealkalized calcium silicate slurry to form a calcium silicate suspension with pH value of 9-11; and washing and drying to obtain calcium silicate powder with low pH value. The powder has the characteristics of low pH value, high brightness, high oil absorption value, large specific surface area and the like and can be used as filler of the base materials such as rubber, plastic and paper so as to improve the mechanical properties of the base materials.

Owner:HENAN WANGWU NANO TECH

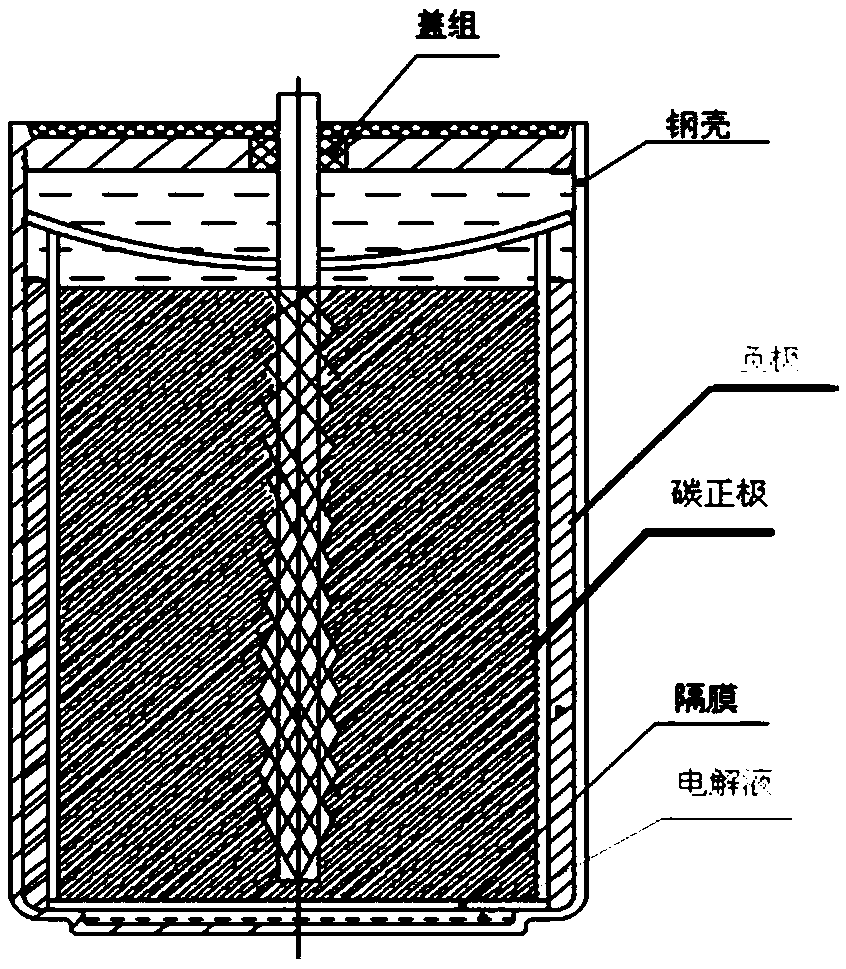

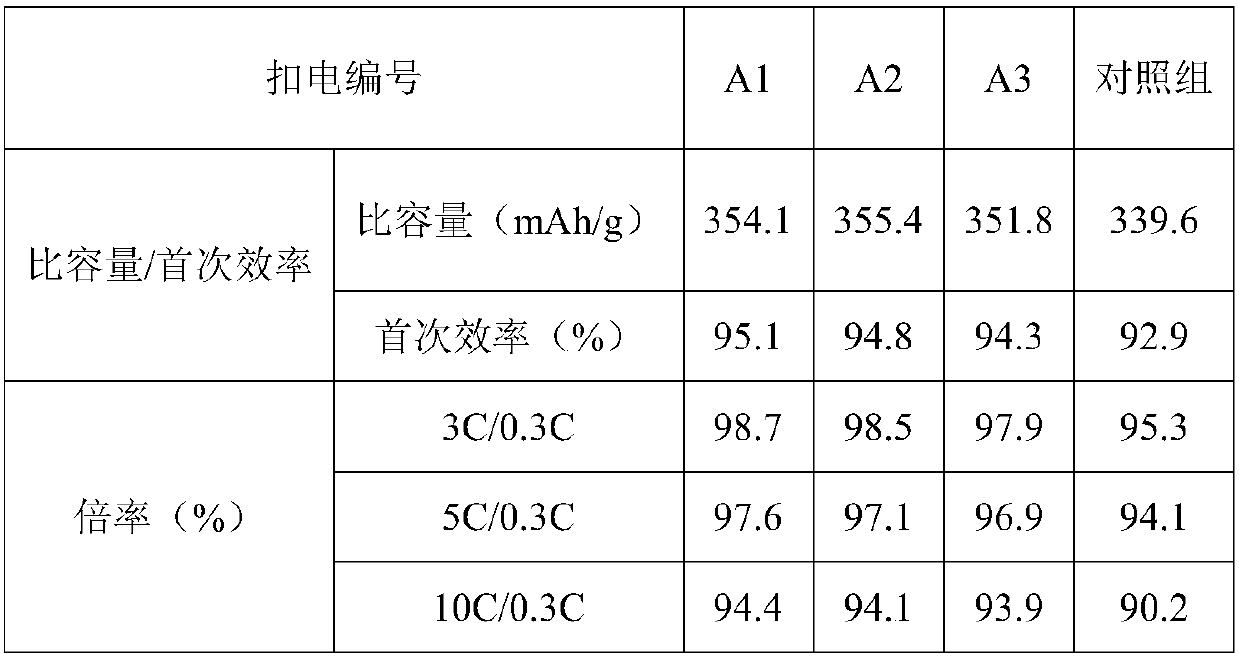

Positive electrode of lithium-thionyl chloride energy type battery and preparation method thereof and lithium-thionyl chloride energy type battery

ActiveCN109285990AHigh oil absorption valueImprove liquid absorption capacityNon-aqueous electrolyte cellsPrimary cell electrodesSolventPelletizing

The invention discloses a positive electrode of a lithium-thionyl chloride energy type battery, a preparation method thereof and the lithium-thionyl chloride energy type battery. The carbon positive electrode is composed of acetylene black, a polytetrafluoroethylene emulsion, a novel carbon material and a solvent, the mass ratio of the acetylene black to the polytetrafluoroethylene emulsion to thenovel carbon material to the solvent is 10: (1.8 to 2.1) ): (0.8-1.0): (45.5-48), and the carbon positive electrode is prepared by uniformly mixing the acetylene black, the polytetrafluoroethylene emulsion, the novel carbon material and the solvent through a low-speed and three-dimensional mixer by means of granulation and drying. The carbon positive electrode of the lithium-thionyl chloride energy type battery has improved liquid absorption capacity and liquid retention capacity, effectively solves the problem of capacity difference caused by the difference of electrolyte flow when the battery is arranged transversely and inverted, and improves the environmental adaptability of the battery.

Owner:武汉中原长江科技发展有限公司

Composite conductive agent and preparation method thereof, electrode plate and lithium ion battery

InactiveCN107910555AImprove conductivityImprove mechanical propertiesSecondary cellsNon-aqueous electrolyte accumulator electrodesThermal insulationCarbonization

The invention relates to a composite conductive agent and a preparation method thereof, an electrode plate and a lithium ion battery, and belongs to the preparation field of a lithium ion battery material. The preparation method comprises the following steps of performing mixing on a mixed solution A of a catalyst and citric acid, and carbon black, and next, performing soaking on the mixture at 25-200 DEG C at 1-10MPa for 2-48h to obtain a material B; performing heating on the material B to 600-1,200 DEG C and then performing thermal insulation at 600-1,200 DEG C for 2h, and pumping hydrogen for 10-350min, and then performing thermal insulation at 600-1,200 DEG C for 2h, and pumping a carbon source mixed gas for 10-300min, and performing cooling to obtain a composite material C; and enabling the composite material C and a graphene oxide solution to be reacted at a temperature of 150-200 DEG C for 1-12h, and performing drying, and next, performing carbonization at a temperature of 800-900 DEG C for 2-6h, and performing cooling. The obtained composite conductive agent is high in tap density and conductive performance and has high application prospect in the field of the lithium battery.

Owner:CHINA AVIATION LITHIUM BATTERY LUOYANG

Method for removing organic matters in byproduct carbon black of acetylene preparation through partial oxidation of natural gas

InactiveCN111574858AEfficient removalImprove qualityPigmenting treatmentPartial oxidationEnvironmental engineering

The invention belongs to the technical field of gas or steam separation by injecting a reactant, and particularly relates to a method for removing organic matters in a byproduct carbon black of acetylene preparation through partial oxidation of natural gas. The method comprises the following steps: A, drying: reducing the moisture content of carbon black to be less than or equal to 30%; and B, removal: putting the carbon black with the moisture content of less than or equal to 30% into an activation furnace, adding inert gas for a reaction, and adding a weak oxidant into the activation furnacefor an oxidation reaction after the reaction is finished. According to the method, the structure of the carbon black is well modified, organic matters in the carbon black can be effectively removed,and the quality of the carbon black is improved; and environmental pollution is reduced, carbon black is recycled, and a resource utilization rate is increased.

Owner:CHINA PETROLEUM & CHEM CORP +2

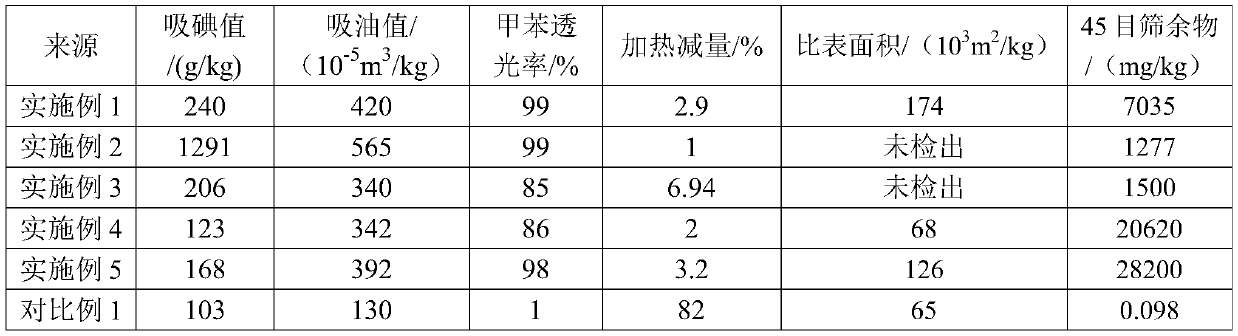

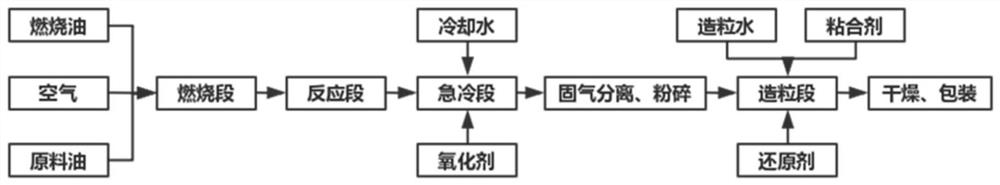

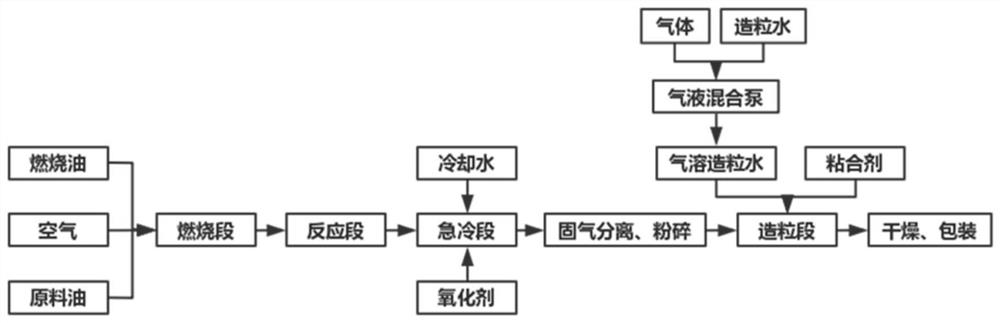

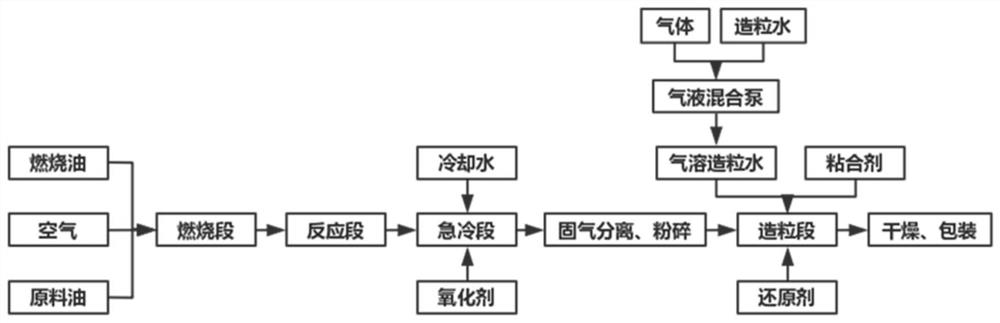

Carbon black as well as preparation method and application thereof

ActiveCN113122027AReduce crystal growth pointsParticle distance is smallPigmenting treatmentShielding materialsConductive materialsOrganic chemistry

The invention discloses carbon black as well as a preparation method and application thereof. According to the preparation method of the carbon black, the porosity of a carbon black product can be improved, and oxygen-containing functional groups on the surface of the carbon black product are reduced, so that the conductivity of the carbon black is improved. The prepared carbon black is high in specific surface area, large in oil absorption value, low in washing sieve residue, good in conductivity and very good in stability. A product with good conductivity can be obtained when the carbon black is applied to a conductive material.

Owner:MAOMING ROUND STAR CARBON BLACK COMPANY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com