Preparation method of calcium silicate powder with low pH value, high oil absorption value and large specific surface area

A technology of calcium silicate powder and specific surface area, which is applied in the direction of silicate, alkaline earth metal silicate, etc., can solve the problems of high pH value and limited application, and achieve simple operation, improved mechanical properties, and increased oil absorption value Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

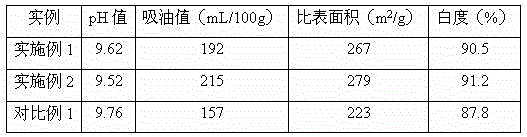

Examples

Embodiment 1

[0026] A preparation method of calcium silicate powder with low pH value, high oil absorption value and specific surface area, comprising the steps of:

[0027] (1) Synthesis of calcium silicate:

[0028] ① Disperse 16g of calcium hydroxide powder in 100g of water, shear and emulsify in a high-shear emulsifier at 25°C and 2000 rpm for 30 minutes to form a calcium hydroxide suspension, and set aside;

[0029] ②Dissolve 45.4g of sodium silicate in 200g of water (modulus 2.4), raise the temperature to 70°C, add dropwise the calcium hydroxide suspension obtained in ①, and complete the dropwise addition in 20 minutes; raise the temperature to 80°C, under the condition of 2000 rpm Shear emulsification reaction for 1 hour to obtain calcium silicate slurry;

[0030] (2) Suction filtration: suction filtration of calcium silicate slurry to obtain a filter cake, and the filtrate is recovered for the preparation of sodium silicate;

[0031] (3) Shear emulsification to form a slurry: add...

Embodiment 2

[0035] A preparation method of calcium silicate powder with low pH value, high oil absorption value and specific surface area, comprising the steps of:

[0036] (1) Synthesis of aluminum-containing calcium silicate:

[0037] ① Disperse 16g of calcium hydroxide powder in 100g of water, and shear and emulsify in a high-shear emulsifier for 30 minutes at 25°C and 2000 rpm to form a calcium hydroxide suspension for later use;

[0038] ②Dissolve 0.7g of aluminum sulfate octadecahydrate in 50g of water to form an aluminum sulfate solution;

[0039] ③Dissolve 45.4g of sodium silicate in 200g of water (modulus 2.4), raise the temperature to 70°C, add dropwise the aluminum sulfate solution in ②, and finish adding dropwise in 5 minutes, then add dropwise the calcium hydroxide suspension in ①, for 20 minutes The dropwise addition is completed; the temperature is raised to 80°C, and the shear emulsification reaction is carried out at 2000 rpm for 1 hour to obtain calcium silicate slurry;...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com